Page 1

OPERATOR’S MANUAL

AUTOMATED HEMATOLOGY ANALYZER

SF-3000

SYSMEX CORPORATION

KOBE, JAPAN

Copyright © 1995 - 2001 by SYSMEX CORPORATION

All rights reserved. No part of this Operator’s Manual may be Code No. 461-2459-3

reproduced in any form or by any means whatsoever without PRINTED IN JAPAN

prior written permission of SYSMEX CORPORATION. Date of Last Revision: March 2001

SF-3000/06.95

Page 2

Sysmex is a registered trademark of SYSMEX CORPORATION.

CELLPACK, CELLCLEAN, STROMATOLYSER, SULFOLYSER, SF CHECK are

trademarks of SYSMEX CORPORATION.

Canon is a registered trademark of Canon, Inc.

Cubitainer is a registered trademark of Hedwin Corporation.

DeskJet and LaserJet are registered trademarks of Hewlett-Packard Corporation.

EPSON is a registered trademark of Seiko Epson Corporation.

SMI and SMI Micro/Pettor are registered trademarks of Scientific Manufacturing

Industries, Inc.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co., Inc.

VENOJECT is a registered trademark of Terumo Corporation.

OKI and MICROLINE are registered trademarks of Oki Electric Industry Co., Ltd.

Other trademarks referenced are property of their respective owners.

Patient names and doctor names are entered for information and illustration purposes

only, and do not imply real specific persons.

Revised September 1998

Page 3

RECEIVING INSTRUCTIONS

The SF-3000 has been thoroughly tested before shipment, and has been packaged

carefully to prevent damage from shipping and handling. Reagents and options have

also been sent and will arrive at approximately the same time as the analyzer. Follow

these guidelines when the system arrives:

• Check to see that the arrows on the sides of the packages are pointing up. If the

arrows do not point up, remark this information on the bill of lading.

• Visually inspect the outside of the package for rips, dents, or possible shipping

damage. Document any sign of damage on the bill of lading, regardless of how

insignificant it may appear. This is for your protection!

• Notify your service representative that the SF-3000 system and its components

have arrived.

• Wait for your service representative to unpack the system and open the packages.

• Follow the unpacking and storage instructions provided on the outside of the

package. Special requirements such as refrigeration are clearly marked on the

outside of the carton and will be included in the unpacking instructions and

package inserts.

WARRANTY INFORMATION

All instruments manufactured by Sysmex® are warranted against defective materials or

workmanship for a period of one year commencing on the installation date at the

customer's required location.

This Warranty does not cover any defect, malfunction, or damage due to:

1. Accident, neglect or willful mistreatment of the product

2. Failure to use, operate, service, or maintain the product in accordance with the

applicable Sysmex Operator's Manual

3. Failure to use the appropriate reagents or chemicals specified for the product

Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 4

SF-3000 OPERATOR'S MANUAL

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION

1. INTRODUCTION.................................................................................... 1-1

2. OPERATOR'S MANUAL ORGANIZATION........................................ 1-2

3. INFORMATIONAL HEADINGS ........................................................... 1-3

3.1 NOTE, CAUTION and WARNING ...................................... 1-3

3.2 Document Conventions .......................................................... 1-3

4. SYSTEM OVERVIEW............................................................................ 1-4

5. SYSTEM OPTIONS ................................................................................ 1-5

6. SAFETY................................................................................................... 1-6

6.1 General Safety ........................................................................ 1-6

6.2 Hazardous and Biohazardous Material................................... 1-6

6.3 Reagent Safety........................................................................ 1-6

6.4 Laser Safety............................................................................ 1-7

7. OPERATIONAL SUMMARY ................................................................ 1-8

8. ANALYSIS PARAMETERS................................................................... 1-9

9. DISPLAY SCREEN............................................................................... 1-10

9.1 LCD (Liquid Crystal Display) Screen.................................. 1-10

9.2 Root Menus .......................................................................... 1-14

9.3 Hard Copy ............................................................................ 1-16

10. PASSWORD .......................................................................................... 1-17

11. EMERGENCY SHUTDOWN PROCEDURE ...................................... 1-18

12. ALARMS ............................................................................................... 1-18

13. INSTALLATION REQUIREMENTS................................................... 1-19

13.1 Relocation Information......................................................... 1-19

13.2 Electrical Requirements ....................................................... 1-19

13.3 Space Requirements ............................................................. 1-20

13.4 Installation Environment ...................................................... 1-20

14. SYSTEM SPECIFICATIONS ............................................................... 1-21

CHAPTER 2: SAMPLE PROCESSING

1. INTRODUCTION.................................................................................... 2-1

1.1 Summary of Operation Mode ................................................ 2-1

1.2 Operational Procedures in Each Mode .................................. 2-2

2. START-UP PROCEDURE...................................................................... 2-3

2.1 Operator Checks .................................................................... 2-3

2.2 Turning On the Power ........................................................... 2-4

2.3 Self-Checks............................................................................ 2-4

2.4 Pressure Gauge Check ........................................................... 2-6

2.5 Auto Output Settings Check .................................................. 2-6

3. QUALITY CONTROL ANALYSIS........................................................ 2-7

3.1 QC Analysis : Manual Mode ................................................. 2-7

3.2 QC Analysis : Auto Mode ................................................... 2-12

3.3 QC Analysis : Manual Closed Mode................................... 2-13

3.4 QC Analysis : Manual CP Mode ......................................... 2-17

(To be continued)

Sysmex SF-3000 Operator's Manual -- Revised December 1995 i

Page 5

4. ANALYSIS MODE PROCEDURES....................................................2-18

4.1 Manual Mode ......................................................................2-18

4.2 Capillary Mode.................................................................... 2-23

4.3 Auto Mode...........................................................................2-29

4.4 Manual Closed Mode..........................................................2-37

4.5 Manual CP Mode.................................................................2-43

5. SHUTDOWN......................................................................................... 2-49

5.1 Shutdown Procedure............................................................2-49

6. TIMER MODE ......................................................................................2-51

6.1 Restarting the Pneumatic Unit.............................................2-51

CHAPTER 3: WORK LIST

1. INTRODUCTION ...................................................................................3-1

1.1 Order Inquiry Method........................................................... 3-1

2. EXECUTING A WORK LIST PROGRAM ...........................................3-2

2.1 Work List Display.................................................................3-2

2.2 Data Entry............................................................................. 3-3

3. DOWNLOAD LIST.................................................................................3-6

3.1 From Host Computer (HC)................................................... 3-6

3.2 From Floppy Disk (FD)........................................................3-8

4. DELETE.................................................................................................3-10

4.1 All Data...............................................................................3-10

4.2 Marked Data........................................................................3-11

4.3 Current Data........................................................................3-12

5. GP OUTPUT..........................................................................................3-13

6. BACKUP............................................................................................... 3-14

CHAPTER 4: RESULT INTERPRETATION/REPORTS

1. INTRODUCTION ................................................................................... 4-1

2. INTERPRETIVE (IP) MESSAGES........................................................4-2

3. LIST DISPLAY/STORED DATA...........................................................4-8

3.1 Sample Information Screen (Page 1)...................................4-10

3.2 CBC8 Screen (Page 2).........................................................4-13

3.3 WBC+5Diff# Screen (Page 3).............................................4-14

3.4 WBC+5Diff% Screen (Page 4)...........................................4-15

3.5 RBC/PLT Screen (Page 5) .................................................. 4-16

3.6 IP Messages Screen (Page 6)...............................................4-18

4. GRAPHIC DISPLAY............................................................................ 4-20

5. DATA VALIDATION...........................................................................4-24

6. MARK DATA........................................................................................4-25

7. SELECT DISPLAY...............................................................................4-26

7.1 Select By Flagging..............................................................4-27

7.2 Select By Date.....................................................................4-29

7.3 Select By No Output............................................................4-31

7.4 QC Data...............................................................................4-33

7.5 All Samples.........................................................................4-34

7.6 Read FD...............................................................................4-35

(To be continued)

ii Sysmex SF-3000 Operator's Manual -- Revised September 1995

Sysmex SF-3000 Operator's Manual -- Revised July 1996

Page 6

8. SEARCH STORED DATA.................................................................... 4-38

7.1 Top/Bottom.......................................................................... 4-38

7.2 By Sample No...................................................................... 4-39

7.3 Same Day............................................................................. 4-40

7.4 By Date ................................................................................ 4-41

9. SORT STORED DATA ......................................................................... 4-43

9.1 Sequence Order.................................................................... 4-43

9.2 Sample No. Order ................................................................ 4-45

10. EDIT SAMPLE INFORMATION ......................................................... 4-46

10.1 Sample No. .......................................................................... 4-47

10.2 ID Read Status ..................................................................... 4-48

10.3 POS to NEG......................................................................... 4-48

11. OUTPUT STORED DATA.................................................................... 4-49

11.1 Current Data......................................................................... 4-51

11.2 Marked Data ........................................................................ 4-52

11.3 All Data................................................................................ 4-52

11.4 Cancel .................................................................................. 4-53

11.5 Backup (FD) ........................................................................ 4-54

12. DELETE................................................................................................. 4-58

12.1 Current Data......................................................................... 4-59

12.2 Marked Data ........................................................................ 4-60

12.3 All Data................................................................................ 4-61

13. AUTO OUTPUT .................................................................................... 4-62

CHAPTER 5: MAINTENANCE AND SUPPLIES

1. INTRODUCTION .................................................................................... 5-1

2. SF-3000 MAINTENANCE CHECK LIST .............................................. 5-3

3. DAILY MAINTENANCE........................................................................ 5-4

3.1 Clean Detector Chamber and Manometer (Shutdown) ......... 5-4

3.2 Remove Fluid from Pneumatic Unit Trap Chamber.............. 5-6

4. WEEKLY MAINTENANCE ................................................................... 5-7

4.1 Clean SRV Tray..................................................................... 5-7

4.2 Execute Clean WBC Detector Sequence............................... 5-9

5. MONTHLY MAINTENANCE.............................................................. 5-14

5.1 Clean Orifice........................................................................ 5-14

5.2 Execute Clean Waste Chamber Sequence ........................... 5-16

5.3 Clean Sample Rotor Valve (SRV)....................................... 5-21

6. YEARLY MAINTENANCE.................................................................. 5-26

6.1 Visual Inspection for Laser Safety ...................................... 5-26

7. AS NEEDED MAINTENANCE............................................................ 5-29

7.1 Clean Manual Rinse Mechanism......................................... 5-29

7.2 Execute RBC Aperture Clog Removal Sequence................ 5-31

7.3 Execute Clean RBC Transducer Sequence.......................... 5-33

7.4 Clean RBC Detector Aperture............................................. 5-38

7.5 Execute Remove Flow Cell Air Bubbles Sequence ............ 5-41

7.6 Execute Replace Sheath Flow Reagent Sequence............... 5-43

7.7 Replace Waste Container (if used) ...................................... 5-45

(To be continued)

Sysmex SF-3000 Operator's Manual -- Revised September 1995 iii

Page 7

8. REPLACEMENTS................................................................................. 5-46

8.1 Replace Reagent .................................................................. 5-46

8.2 Replace the Piercer (Auto Sampler Unit) ............................ 5-51

8.3 Replace the Piercer (Manual CP Unit) ................................ 5-58

8.4 Replace the Hand Clipper.................................................... 5-62

8.5 Replace the Rubber Plate No. 39......................................... 5-63

8.6 Replace the Anti-Shock Rubber No. 49 .............................. 5-64

8.7 Replace the Fuses ................................................................ 5-65

8.8 Replace the Belt No. 6......................................................... 5-67

9. RESET THE COUNTER ....................................................................... 5-69

10. FORMAT FD.......................................................................................... 5-72

11. SUPPLIES AND REPLACEMENT PARTS LISTING......................... 5-74

CHAPTER 6: QUALITY CONTROL

1. INTRODUCTION.................................................................................... 6-1

1.1 Types of QC Method............................................................. 6-2

1.2 QC Parameters To Be Monitored.......................................... 6-2

2. DELETE FILE ......................................................................................... 6-3

3. SYSTEM SETTINGS .............................................................................. 6-5

4. QC PARAMETER SELECTION ............................................................ 6-7

4.1 Selecting QC Parameter ( X /L-J Control) ........................... 6-7

4.2 Selecting QC Parameter ( X M Control) .............................. 6-8

5. SETTING X M CONTROL ................................................................. 6-10

5.1 Executing the X M Control Settings Program ................... 6-10

6. TARGET/LIMIT.................................................................................... 6-13

6.1 Display................................................................................. 6-13

6.2 Read FD (Floppy Disk) ....................................................... 6-15

6.3 Help ..................................................................................... 6-19

6.4 Auto Setting......................................................................... 6-21

6.5 Manual Change.................................................................... 6-25

6.6 Lot Information ................................................................... 6-28

7. QC CHART............................................................................................ 6-31

7.1 Select File............................................................................ 6-33

7.2 Output QC Chart/Data......................................................... 6-34

7.3 Mean/SD (Calculation)........................................................ 6-36

7.4 Delete Plot ........................................................................... 6-38

7.5 Cal. History ......................................................................... 6-40

8. MANUAL QC ANALYSIS ................................................................... 6-41

9. SAMPLER QC ANALYSIS (L-J) ......................................................... 6-44

10. QC METHODS AND APPLICATIONS............................................... 6-47

10.1 X Control .......................................................................... 6-47

10.2 L-J Control .......................................................................... 6-47

10.3 X M Control....................................................................... 6-48

11. VARIABLE TARGET FUNCTION...................................................... 6-51

11.1 How Target Values Are Calculated..................................... 6-51

11.2 Variable Target Function and Erroneous Data.................... 6-52

12. CONTROL CHART DEFINITION....................................................... 6-53

iv Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 8

CHAPTER 7: CALIBRATION

1. INTRODUCTION.................................................................................... 7-1

1.1 Calibration Implementation Standards .................................. 7-1

1.2 Calibration Samples............................................................... 7-2

1.3 Reference Values................................................................... 7-2

2. HGB/HCT AUTO .................................................................................... 7-3

2.1 Overview of the HGB/HCT Auto Program........................... 7-3

2.2 Setting (Entering Reference Values) ..................................... 7-6

2.3 Analyze (Analyzing).............................................................. 7-8

2.4 Exclude (Excluding and Recovering Data) ......................... 7-10

2.5 Exe. Cal. (Calibrating)......................................................... 7-12

2.6 Graphic (Displaying Graphs)............................................... 7-14

3. HGB/HCT MANUAL............................................................................ 7-15

3.1 Calculating the Compensation Factor.................................. 7-15

3.2 Executing the HGB/HCT Manual Program......................... 7-16

4. CALIBRATION HISTORY................................................................... 7-18

4.1 Displaying the Cal. History ................................................. 7-18

4.2 Deleting the Cal. History ..................................................... 7-19

4.3 Outputting the Cal. History.................................................. 7-20

CHAPTER 8: TROUBLESHOOTING

1. INTRODUCTION.................................................................................... 8-1

2. TROUBLESHOOTING BY ERROR MESSAGES ................................ 8-2

2.1 Alphabetical Error Message Index ........................................ 8-2

2.2 Contents (Error Messages By Function)................................ 8-5

2.3 Troubleshooting Guide .......................................................... 8-9

3. TEST PROGRAMS ............................................................................... 8-59

3.1 Executing a Test Program.................................................... 8-59

3.2 Test SRV.............................................................................. 8-62

3.3 Test Motor ........................................................................... 8-63

3.4 Test PDA PCB..................................................................... 8-69

3.5 Test Laser Unit .................................................................... 8-70

3.6 Test Sampler ........................................................................ 8-71

3.7 Test Bar Code Reader.......................................................... 8-74

3.8 Test Memory........................................................................ 8-75

3.9 Test Floppy Disk.................................................................. 8-76

3.10 Test LCD Display................................................................ 8-78

3.11 Test Touch Panel ................................................................. 8-79

3.12 Test Output .......................................................................... 8-80

3.13 Version Check ..................................................................... 8-83

3.14 Service Data......................................................................... 8-85

4. STATUS DISPLAY............................................................................... 8-90

5. ERROR LOG ......................................................................................... 8-94

Sysmex SF-3000 Operator's Manual -- Revised September 1995 v

Page 9

CHAPTER 9: ADJUSTMENT

1. INTRODUCTION.................................................................................... 9-1

2. PRESSURE/VACUUM DISPLAY ......................................................... 9-1

2.1 Pneumatic Gauges .................................................................. 9-1

2.2 Displaying the Monitored Values on the LCD....................... 9-2

3. PNEUMATIC UNIT ADJUSTMENT..................................................... 9-3

3.1 Adjusting the 2.0 kg/cm

2

........................................................ 9-4

3.2 Adjusting the Vacuum............................................................ 9-5

4. MAIN UNIT ADJUSTMENT.................................................................. 9-5

4.1 Adjusting to 0.6 kg/cm

4.2 Adjusting to 0.5 kg/cm

2

......................................................... 9-6

2

......................................................... 9-7

4.3 Adjusting the 250 mmHg Vacuum......................................... 9-8

5. LCD CONTRAST ADJUSTMENT......................................................... 9-9

6. ID BAR CODE READER ADJUSTMENT (Option)............................ 9-10

CHAPTER 10: FUNCTIONAL DESCRIPTION

1. INTRODUCTION.................................................................................. 10-1

2. DETECTION PRINCIPLES .................................................................. 10-2

2.1 Flow Cytometry by Semiconductor Laser........................... 10-2

2.2 DC Detection Method.......................................................... 10-3

2.3 SLS-Hemoglobin ................................................................. 10-3

3. SAMPLE FLOW BLOCK DIAGRAM ................................................. 10-4

4. RBC/PLT/HGB ANALYSIS ................................................................. 10-5

4.1 RBC/PLT Analysis Flow..................................................... 10-5

4.2 HGB Analysis Flow............................................................. 10-6

4.3 Red Blood Cell (RBC) Indices ............................................ 10-7

5. WBC CLASSIFICATION ..................................................................... 10-8

5.1 4DIFF Analysis.................................................................... 10-8

5.2 WBC/BASO Analysis ......................................................... 10-9

6. WBC SCATTERGRAMS.................................................................... 10-10

7. RBC/PLT PARTICLE SIZE DISTRIBUTION ANALYSIS .............. 10-12

7.1 RBC Particle Size Distribution.......................................... 10-12

7.2 PLT Particle Size Distribution........................................... 10-13

7.3 Particle Size Distribution Representation.......................... 10-14

7.4 Histogram Flags................................................................. 10-15

8. MAIN UNIT ELECTRONIC SYSTEM .............................................. 10-16

9. MAIN UNIT COMPONENTS............................................................. 10-18

9.1 Front................................................................................... 10-18

9.2 Rear.................................................................................... 10-20

9.3 Right Side .......................................................................... 10-22

9.4 Left Side............................................................................. 10-24

9.5 Front Interior...................................................................... 10-25

9.6 Left Interior........................................................................ 10-26

9.7 Right Interior ..................................................................... 10-30

(To be continued)

vi Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 10

10. PNEUMATIC UNIT COMPONENTS................................................ 10-32

10.1 Front................................................................................... 10-32

10.2 Right Side .......................................................................... 10-33

10.3 Top Interior........................................................................ 10-34

10.4 Right Interior ..................................................................... 10-34

11. CAP PIERCING SAMPLER UNIT (OPTION) .................................. 10-35

11.1 Top..................................................................................... 10-35

11.2 Top Interior........................................................................ 10-36

12. MANUAL CP UNIT (OPTION).......................................................... 10-37

13. REAGENT SYSTEM........................................................................... 10-38

CHAPTER 11: SYSTEM SETUP

1. INTRODUCTION.................................................................................. 11-1

2. AUTO MANAGEMENT PROGRAMS................................................ 11-3

2.1 Auto Output Condition ........................................................ 11-6

2.2 Auto Output Mode (Data Specification).............................. 11-8

2.3 Auto Erase ........................................................................... 11-9

2.4 Auto Validation ................................................................. 11-11

3. DATA CRITERIA ............................................................................... 11-13

3.1 Mark Limits ....................................................................... 11-16

3.2 Critical Limits.................................................................... 11-18

3.3 Sampler Stop Limits .......................................................... 11-20

3.4 Sampler Stop Condition..................................................... 11-22

4. FLAG SYSTEM................................................................................... 11-24

4.1 WBC .................................................................................. 11-27

4.2 RBC ................................................................................... 11-29

4.3 PLT .................................................................................... 11-30

5. PERIPHERAL CONFIGURATION.................................................... 11-32

5.1 HC Setting (Host Computer) ............................................. 11-35

5.2 GP Setting (Graphic Printer) ............................................. 11-37

5.3 DP Setting (Data Printer)................................................... 11-38

6. GENERAL SET UP ............................................................................. 11-41

6.1 Date/Time .......................................................................... 11-44

6.2 Units................................................................................... 11-45

6.3 Password............................................................................ 11-47

6.4 Timer Mode ....................................................................... 11-48

6.5 Normal Range Display ...................................................... 11-49

6.6 Date Format ....................................................................... 11-51

6.7 ID Reader........................................................................... 11-52

6.8 Blood Sensor...................................................................... 11-54

6.9 Work List........................................................................... 11-56

7. OUTPUT SET VALUES ..................................................................... 11-57

7.1 Output to GP....................................................................... 11-57

7.2 Backup to FD...................................................................... 11-57

Sysmex SF-3000 Operator's Manual -- Revised March 1996 vii

Page 11

APPENDIX A: MENU TREE

APPENDIX B: INSTALLATION

1. PREINSTALLATION............................................................................. B-2

1.1 Unpacking Check List .......................................................... B-2

1.2 Supplementary Parts Information......................................... B-5

2. LAYOUT AND WORK SPACE ............................................................ B-6

3. REMOVING PACKING MATERIAL................................................... B-7

3.1 Front Cover........................................................................... B-7

3.2 Front Panel............................................................................ B-7

3.3 Main Unit Chassis................................................................. B-9

3.4 SRV..................................................................................... B-10

3.5 Rear Panel........................................................................... B-10

3.6 Pneumatic Unit ................................................................... B-11

4. TRAY .................................................................................................... B-11

5. BAR CODE ID READER (Optional)................................................... B-12

6. CP SAMPLER UNIT (Optional) .......................................................... B-13

6.1 Main Unit............................................................................ B-13

6.2 Sampler Unit....................................................................... B-14

6.3 Connection to Main Unit .................................................... B-15

7. MANUAL CP UNIT (Optional) ........................................................... B-17

7.1 Main Unit............................................................................ B-17

7.2 Manual CP Unit .................................................................. B-18

7.3 Connection to Main Unit .................................................... B-18

8. TUBE CONNECTION.......................................................................... B-22

8.1 Vacuum Line ...................................................................... B-22

8.2 Pressure Line ...................................................................... B-22

8.3 Reagent Container Preparation........................................... B-23

8.4 Reagent Lines ..................................................................... B-26

8.5 Waste Container.................................................................. B-27

9. BATTERY BACKUP ........................................................................... B-28

10. CABLE AND POWER CORD CONNECTIONS................................ B-29

10.1 Output Connections ............................................................ B-29

10.2 Pneumatic Cable Connections ............................................ B-30

10.3 Power Cord Connections .................................................... B-30

11. POWER ON AND SYSTEM SETUP................................................... B-31

11.1 Power On ............................................................................ B-31

11.2 System Setup ...................................................................... B-31

11.3 System Check ..................................................................... B-32

viii Sysmex SF-3000 Operator's Manual -- Revised December 1995

Page 12

APPENDIX C: TECHNICAL INFORMATION

1. SERIAL INTERFACE FOR HOST COMPUTER................................. C-2

1.1 Connection............................................................................ C-2

1.2 Input/Output Signals............................................................. C-2

1.3 Communication Format........................................................ C-2

1.4 Baud Rate/Character Structure ............................................. C-2

1.5 Signal Level.......................................................................... C-3

1.6 Interface Circuit.................................................................... C-3

1.7 Software................................................................................ C-4

2. TEXT FORMAT ..................................................................................... C-8

2.1 Sample Data Format ............................................................. C-8

2.2 Quality Control Data Format.............................................. C-12

2.3 Inquiry Data Format ........................................................... C-14

2.4 Order Information Data Format.......................................... C-15

3. ID BAR CODE...................................................................................... C-17

3.1 Applicable Bar Codes......................................................... C-17

3.2 Dimensions of Elements..................................................... C-18

3.3 Requirements on Wide/Narrow Ratio ................................ C-18

3.4 Optical Requirements ......................................................... C-18

3.5 Dimensions of Bar Code Label........................................... C-20

3.6 Check-Digit......................................................................... C-20

3.7 Applicable Characters......................................................... C-28

3.8 Effective Bar Code Length ................................................. C-28

Sysmex SF-3000 Operator's Manual -- Revised September1995 ix

Page 13

CHAPTER 1 INTRODUCTION

1. INTRODUCTION ............................................................... 1-1

2. OPERATOR'S MANUAL ORGANIZATION............................... 1-2

3. INFORMATIONAL HEADINGS ............................................. 1-3

3.1 NOTE, CAUTION and WARNING.................................... 1-3

3.2 Document Conventions ................................................... 1-3

4. SYSTEM OVERVIEW .......................................................... 1-4

5. SYSTEM OPTIONS............................................................. 1-5

6. SAFETY ........................................................................ 1-6

6.1 General Safety ............................................................. 1-6

6.2 Hazardous and Biohazardous Material................................. . 1-6

6.3 Reagent Safety ............................................................. 1-6

6.4 Laser Safety ................................................................ 1-7

7. OPERATIONAL SUMMARY.................................................. 1-8

8. ANALYSIS PARAMETERS ................................................... 1-9

9. DISPLAY SCREEN ........................................................... 1-10

9.1 LCD (Liquid Crystal Display) Screen................................. 1-10

9.2 Root Menus .............................................................. 1-14

9.3 Hard Copy................................................................ 1-16

10. PASSWORD.................................................................... 1-17

11. EMERGENCY SHUTDOWN PROCEDURE ............................. 1-18

12. ALARMS........................................................................ 1-18

13. INSTALLATION REQUIREMENTS....................................... 1-19

13.1 Relocation Information.................................................. 1-19

13.2 Electrical Requirements ................................................. 1-19

13.3 Space Requirements..................................................... 1-20

13.4 Installation Environment................................................ 1-20

14. SYSTEM SPECIFICATIONS................................................ 1-21

Revised September 1995

Page 14

INTRODUCTION

1. INTRODUCTION

The Sysmex® SF-3000 is a technically advanced, computerized, fully automated

hematology analyzer with many features, for in vitro diagnostic use in clinical

laboratories. The SF-3000 provides accurate screening for patients whose hematological

abnormalities indicate the need for further testing. In addition, it can contribute in the

diagnosis and therapeutic monitoring of patients.

The SF-3000 has the capability of analyzing up to 80 samples per hour, and display 4

different patterns -- WBC 5 differential, scattergrams for white blood cells and basophils,

and cell size distribution curves for red blood cells and platelets, as well as 23 analysis

data parameters on the color LCD (liquid crystal display) screen.

Chapter 1 is an introduction to this manual, major system components, system operation

and other general considerations. This chapter should be read before operating the

SF-3000. Chapter 1 contains the following subjects:

Manual Organization

A description of the Operator's Manual and explanation of important informational

headings.

System Overview

An introduction to the main elements of the SF-3000 analyzer, including a description of

the options available to enhance the instrument's operation.

Safety Summary

Covers major safety considerations when using and servicing the SF-3000.

Operational Summary

A summary of the operating procedures for each mode, the LCD screen display,

functions of touch panel, etc.

Installation Requirements

Includes space requirements, necessary equipment, installation environment and other

essential information to be reviewed before installation of the SF-3000.

Instrument Specifications

The instrument's specifications are given in a reference table.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-1

Page 15

INTRODUCTION

2. OPERATOR'S MANUAL ORGANIZATION

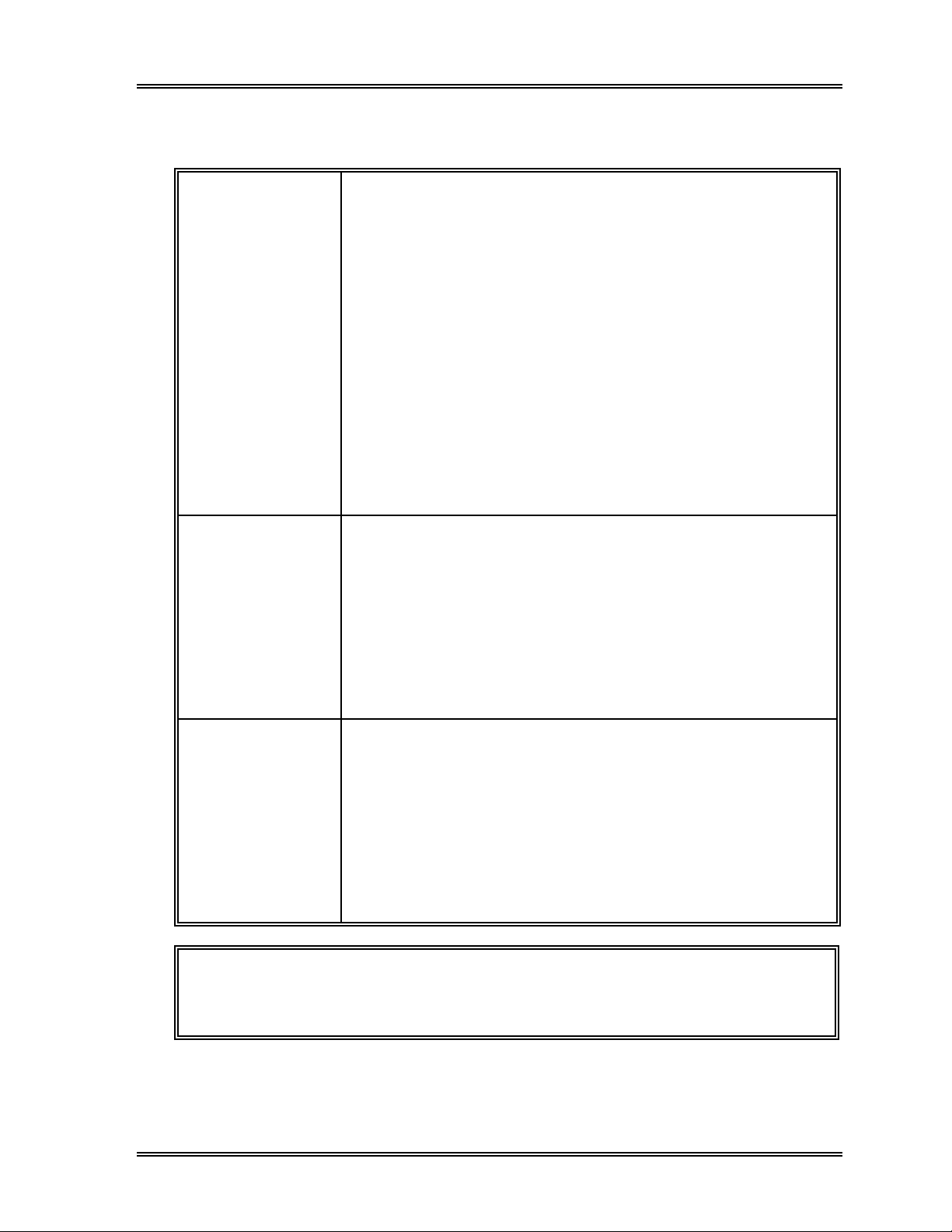

The SF-3000 Operator's Manual has been designed with the operator in mind. Each

chapter has its own table of contents and is designed to facilitate rapid location of

appropriate information.

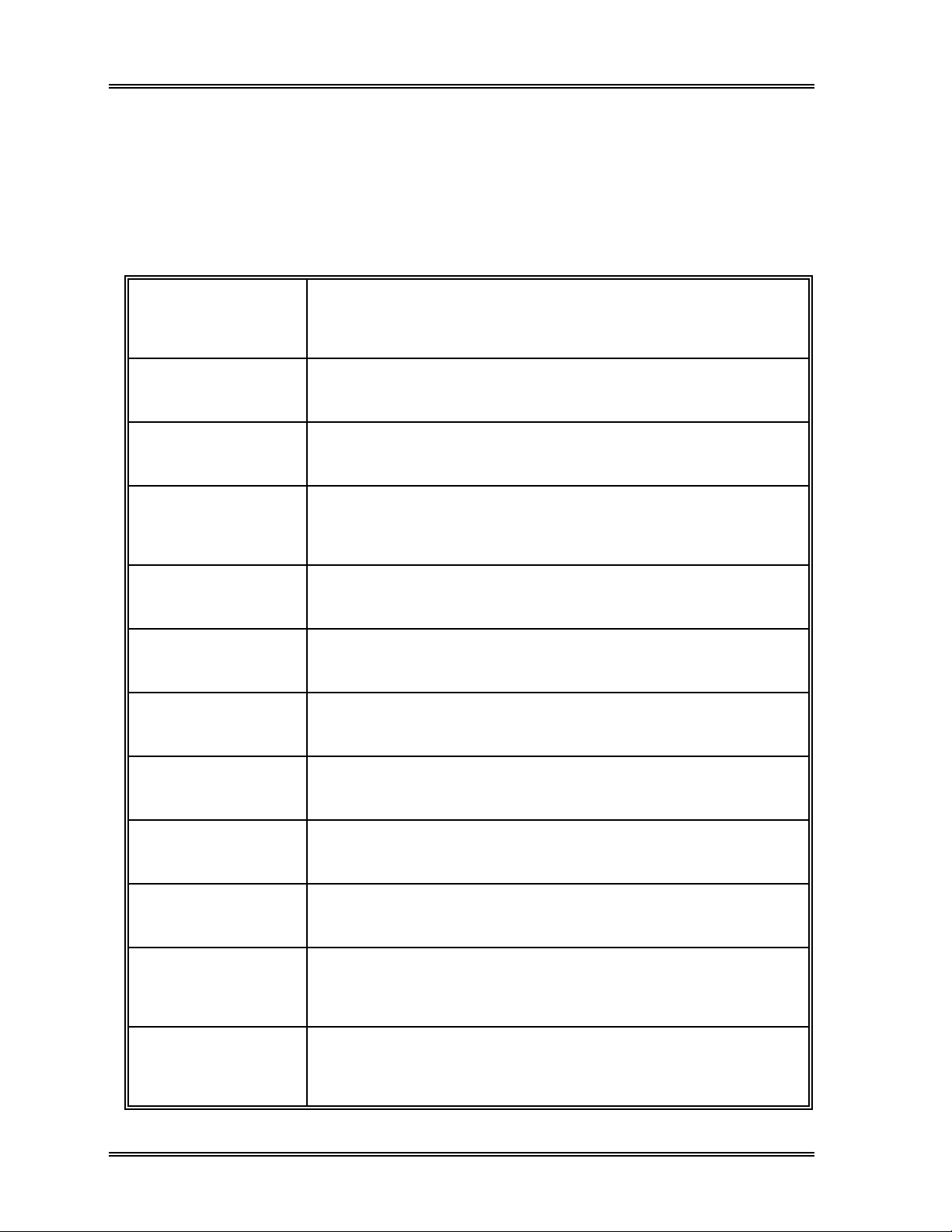

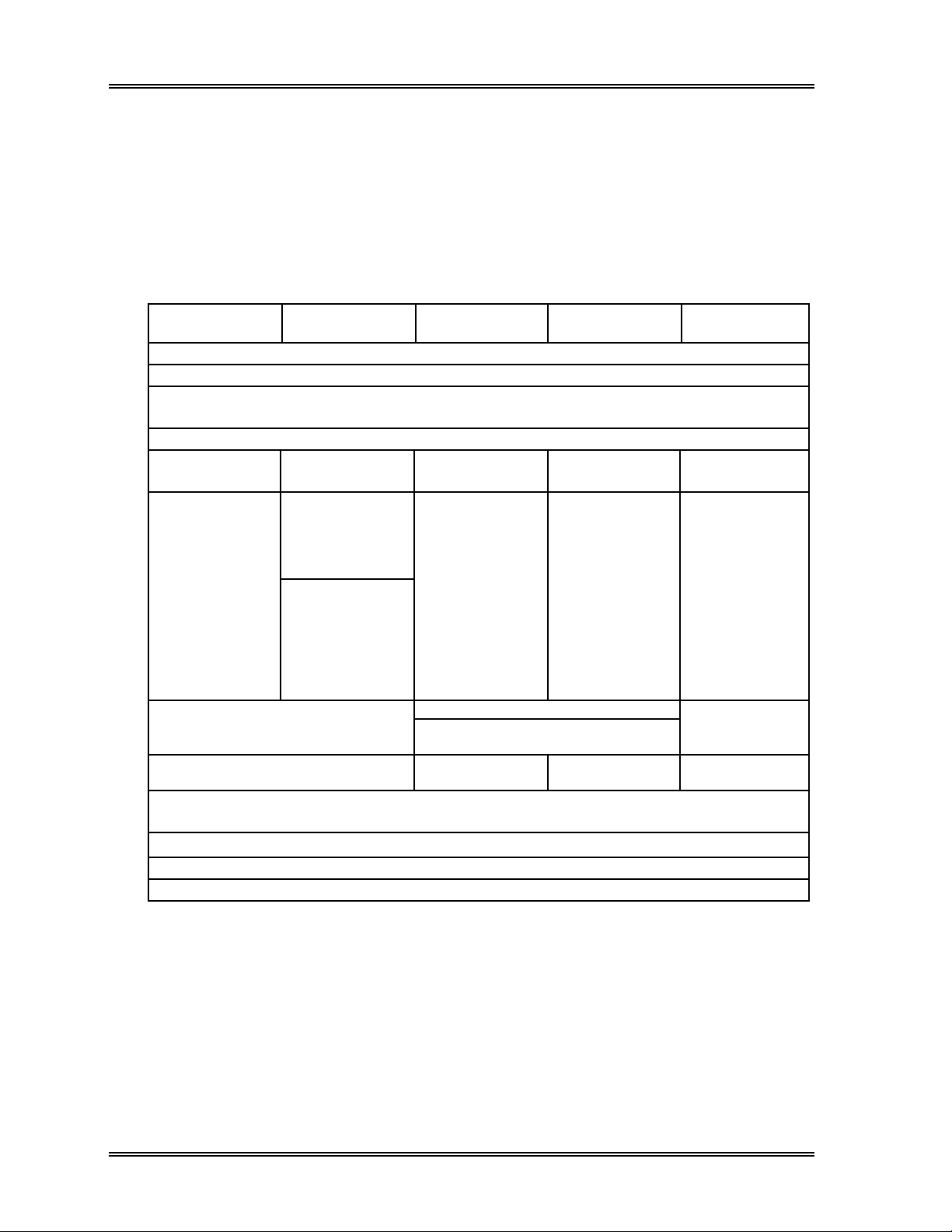

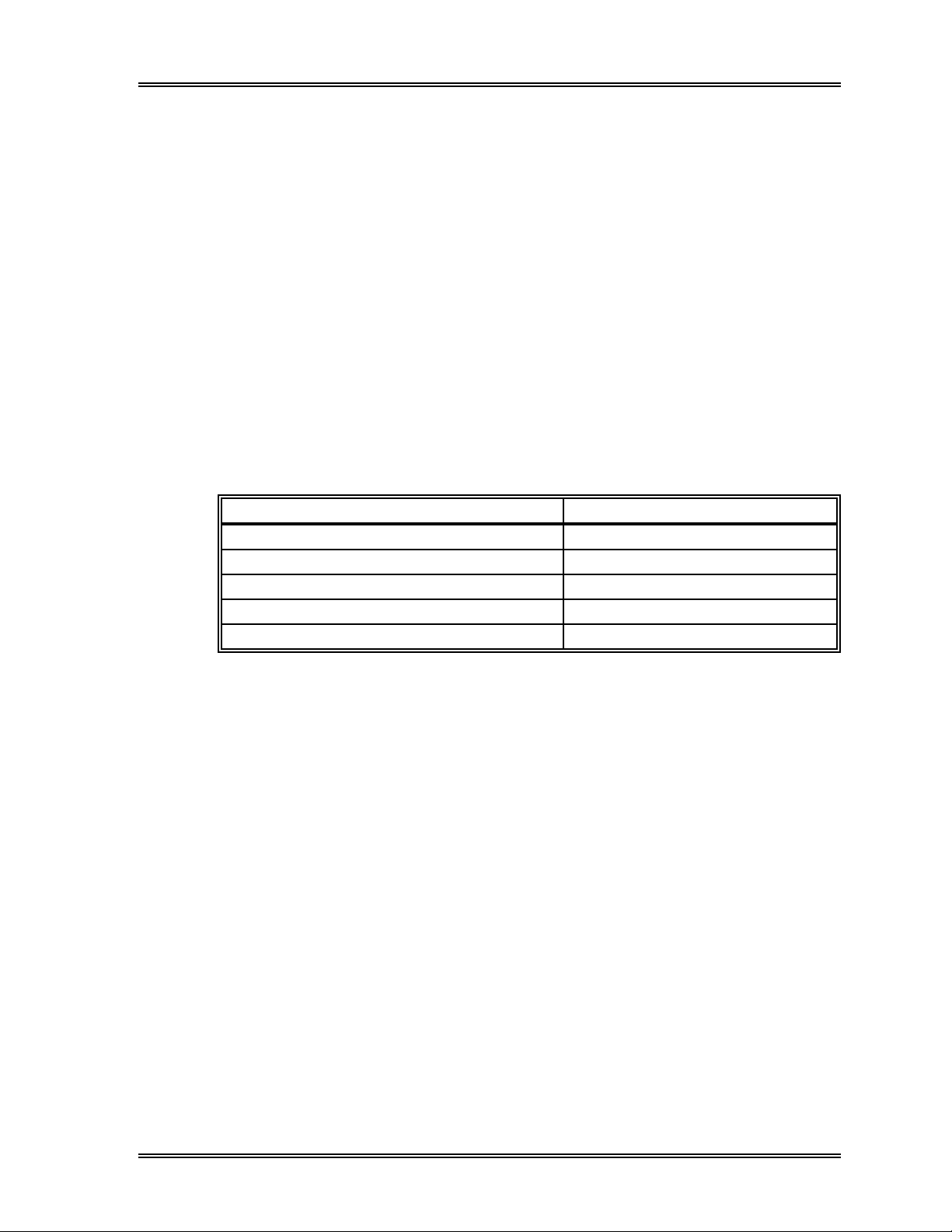

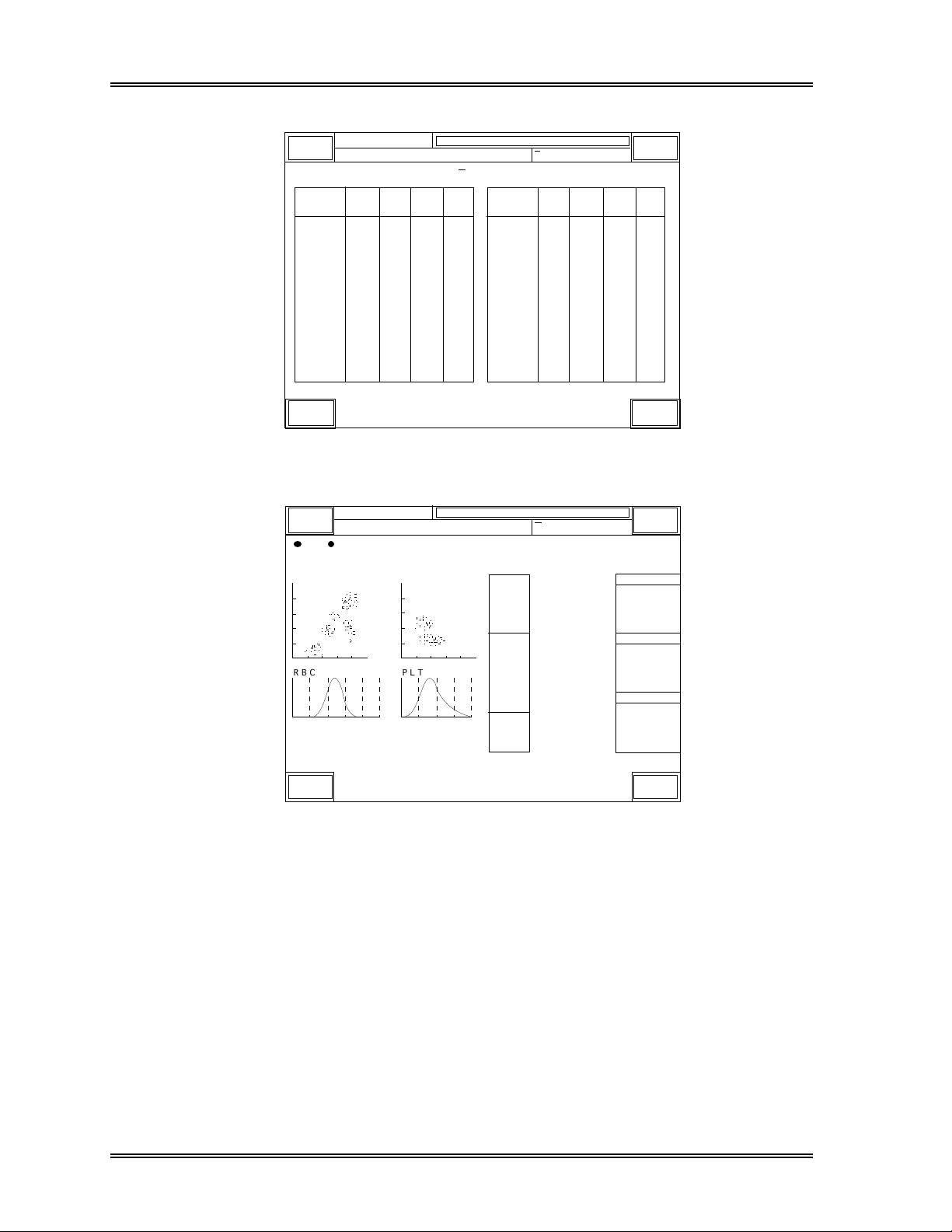

Table 1-1: Manual Organization

CHAPTER 1

Introduction

CHAPTER 2

Sample Processing

CHAPTER 3

Work List

CHAPTER 4

Result Interpretation/

Reports

CHAPTER 5

Maintenance and Supplies

CHAPTER 6

Quality Control

CHAPTER 7

Calibration

Contains basic information about the instrument; operating procedures,

screen displays, touch panel, installation and safety. This chapter must be

read prior to operating the Sysmex SF-3000.

Explains sampling procedure from start-up to shutdown. All sampling

operation procedures are contained in this chapter.

Explains how to enter order information with the display and management of

the records.

Explains procedures for displaying and processing Stored Data, and

procedures for analyzed result output. Also explains IP messages.

Explains periodic maintenance, and the procedures for replacing

consumables and reagents.

Explains how to run the Quality Control Program. Also explains, for your

reference, the quality control system used in this instrument.

Explains the procedures for auto-calibration and manual calibration.

CHAPTER 8

Troubleshooting

CHAPTER 9

Adjustments

CHAPTER 10

Functional Descriptions

CHAPTER 11

System Setup

APPENDICES A, B, C

Menu Tree, Installation

and Technical Information

Explains error messages and their troubleshooting. Also explains service

data and system test functions.

Explains how to adjust pressure and other adjustments.

Gives the main principles of analysis performed by the instrument. Also

contains system nomenclature.

Explains how to set date, time, units, sample analysis stop and other system

conditions. Also contains data analysis settings -- for abnormal data

judgments, etc.

Contains program menu tree, technical information including unpacking check

lists, installation procedures, bar-code labeling parameters and host

communication protocols.

1-2 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 16

INTRODUCTION

3. INFORMATIONAL HEADINGS

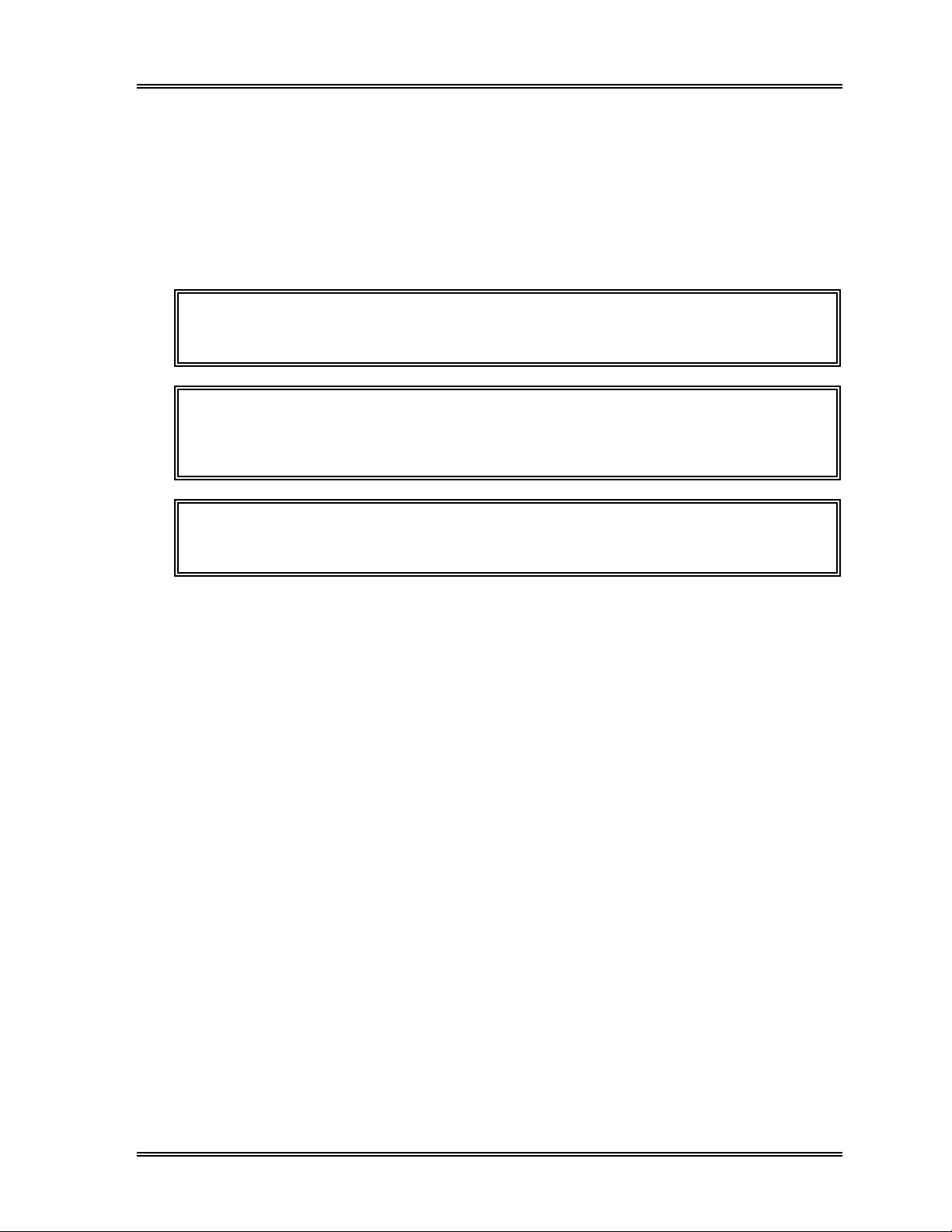

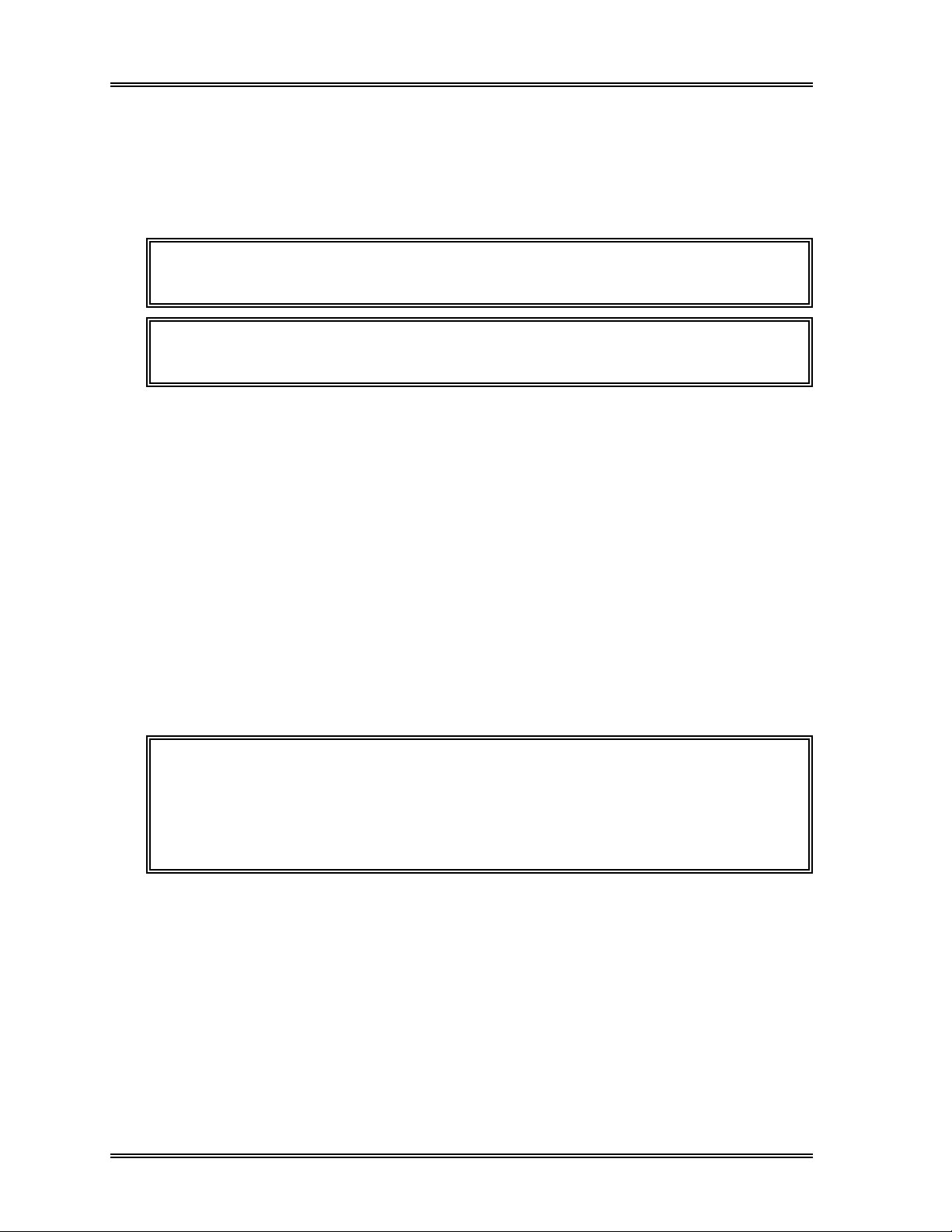

3.1 NOTE, CAUTION and WARNING

NOTE, CAUTION and WARNING boxes throughout this manual are meant to get to

attention to important safety and operational information. Always follow the instructions

contained in the boxes. Failure to do so may affect the safety or precision features of the

SF-3000 analyzer. The boxes are defined as follows:

NOTE: Highlights important facts, gives helpful information, and clarifies

procedures.

CAUTION: Provides information on the correct operation of the SF-3000 analyzer.

Information contained in CAUTION boxes is crucial to prevent damage

and to maintain performance of the analyzer.

WARNING! Indicates potentially hazardous situations that could result in serious

injury or infection to laboratory personnel.

3.2 Document Conventions

The SF-3000 Operator's Manual uses the following conventions:

"Quotations": Screen commands, messages, and status information that the SF3000 system displays appear within quotation marks. For example:

"All Samples", "Ready" or "Input Password"

[Square Brackets]: Names of function keys such as control or operational keys,

number keys, or arrow keys that you select on the SF-3000 appear within square

brackets. For example:

[Enter], [Sampler], [2] or [↑]

Italics: Application names and reference material appear in italic form. For

example:

Refer to Chapter 2: Sample Processing.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-3

Page 17

INTRODUCTION

4. SYSTEM OVERVIEW

The purpose of the SF-3000 is to provide accurate results on 23 parameters and to detect

abnormalities in the sample. To assist the laboratory in the screening of abnormalities,

the SF-3000 analyzes and processes the data obtained from the analyzer unit, and the

LCD displays and outputs either a POSITIVE or a NEGATIVE message for each sample.

A NEGATIVE message signifies that parameter values for the sample are within

acceptable limits and the sample does not require any additional verification of those

values. A POSITIVE message signifies that the sample is not within the acceptable limits

and requires further review and investigation. Proper use of the instrument requires each

laboratory to establish the acceptable limits for results.

The SF-3000 uses the optical detector block incorporating the semiconductor laser to

analyze the WBC population. In the DIFF channel, lymphocytes, monocytes,

eosinophils, and the group of neutrophils and basophils are analyzed to determine the

WBC 4-differentials using flow cytometry. Basophil determination and WBC number

counting are performed in the BASO channel. RBCs and PLTs are analyzed by the RBC

detector block using the DC detection method. HGB determination is performed using

the SLS hemoglobin detection method.

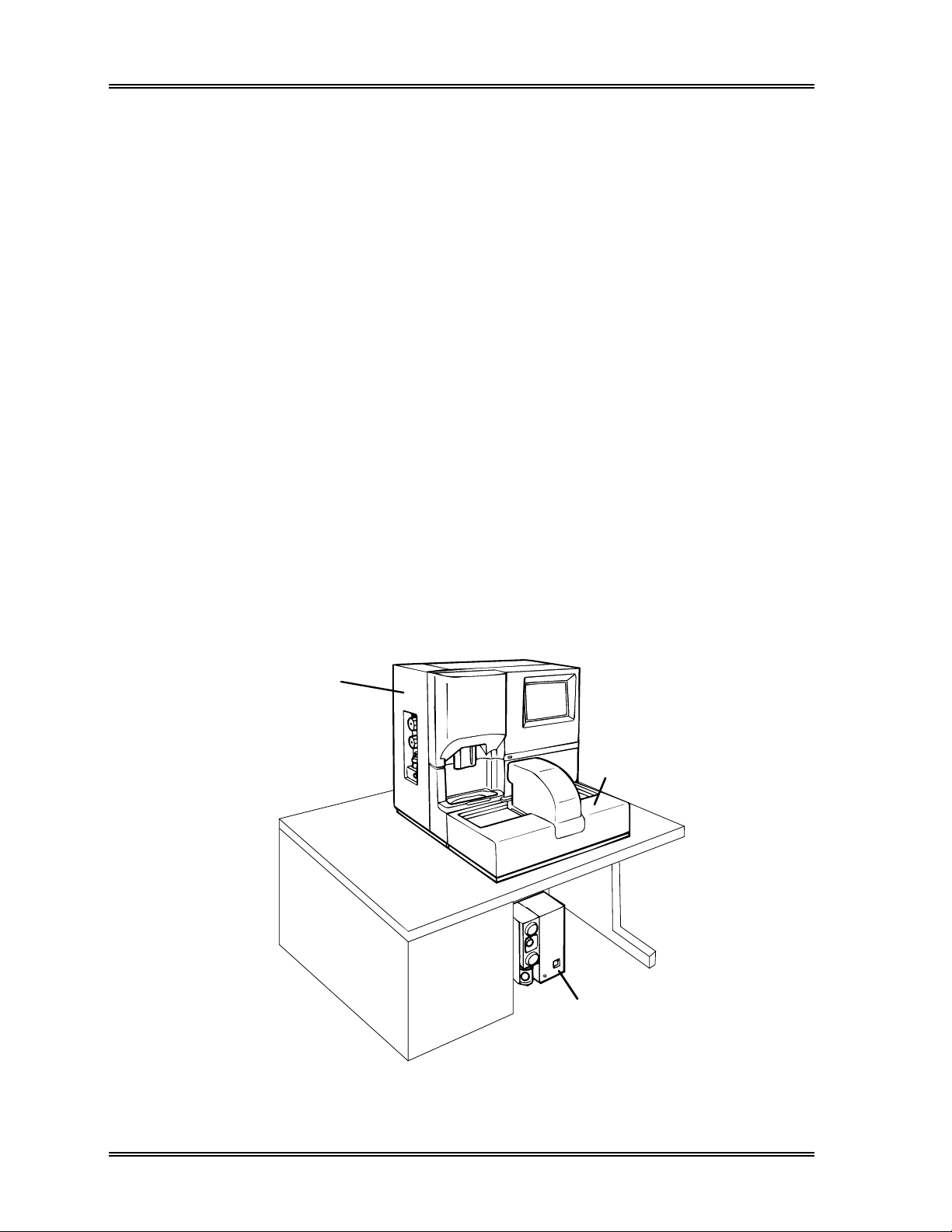

The SF-3000 consists of two major systems.

• Main Unit : Houses the hydraulic and electronic systems and their control

components. The unit analyzes, processes and displays the data

on the LCD screen.

• Pneumatic Unit : Supplies the required pressure and vacuum for analysis.

Main Unit

Sampler Unit

(Optional)

Pneumatic Unit

Figure 1-1: Sysmex SF-3000 Hematology Analyzer

1-4 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 18

INTRODUCTION

5. SYSTEM OPTIONS

Several options are available to enhance system efficiency. Available options for the

SF-3000 are:

• ID Bar Code Reader : Reads the ID numbers of bar code labeled samples,

and inputs the numbers automatically.

• Color Graphics Printer : Prints out analysis results (cell size distribution

or Page Printer graphs, scattergrams) and hard copies of screens in

color or black and white.

Printing can be done both in graphic and list format.

• Data Printer : Prints the analysis data in ticket format.

• (Cap Piercing) Sampler Unit : Consists of a mixer and a cap piercer unit, and loads

up to 5 sample racks (50 sample tubes) that enable an

automated closed sampling system.

• Manual CP Unit : Consists of a mixer and a cap piercer unit which

enables a manual closed sampling system.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-5

Page 19

INTRODUCTION

6. SAFETY

The operator must follow the instructions in this section. It contains important

information to operate the SF-3000 analyzer safely.

6.1 General Safety

While operating, maintaining, servicing or repairing the system, follow all procedures

contained in this manual. The operator must observe all NOTES, CAUTIONS and

WARNINGS posted anywhere on the instrument or given in this manual.

Do NOT touch the electrical circuits behind the enclosure panels of the SF-3000.

Touching the circuits is dangerous and may give you an electrical shock, especially if

your hands are wet.

Use only designated tools and parts for service and repair. Substitute parts should never

be used, and the SF-3000 should not be modified in any way.

Keep hair, clothing and fingers away from all moving parts.

Install the Sampler Unit on a table or work bench to prevent the system from accidentally

falling.

6.2 Hazardous and Biohazardous Material

All surfaces and components in contact or potentially in contact with patient blood

samples should be considered contaminated. Use of protective garments and gloves is

strongly recommended when operating, maintaining, or servicing the SF-3000.

Do not touch the waste when disposing of it or assembling/disassembling the associated

parts. If accidental contact with waste or any other potentially biohazardous material

occurs, flush the affected area immediately with water and follow your laboratory's

prescribed cleaning and decontamination procedures.

Consider all regulations applicable to your laboratory when operating the Sysmex

SF-3000 instrument.

6.3 Reagent Safety

If reagent comes into contact with skin or clothing, flush it with water. If eyes are

affected, flush with copious amounts of water and obtain medical advice if necessary.

1-6 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 20

INTRODUCTION, Safety

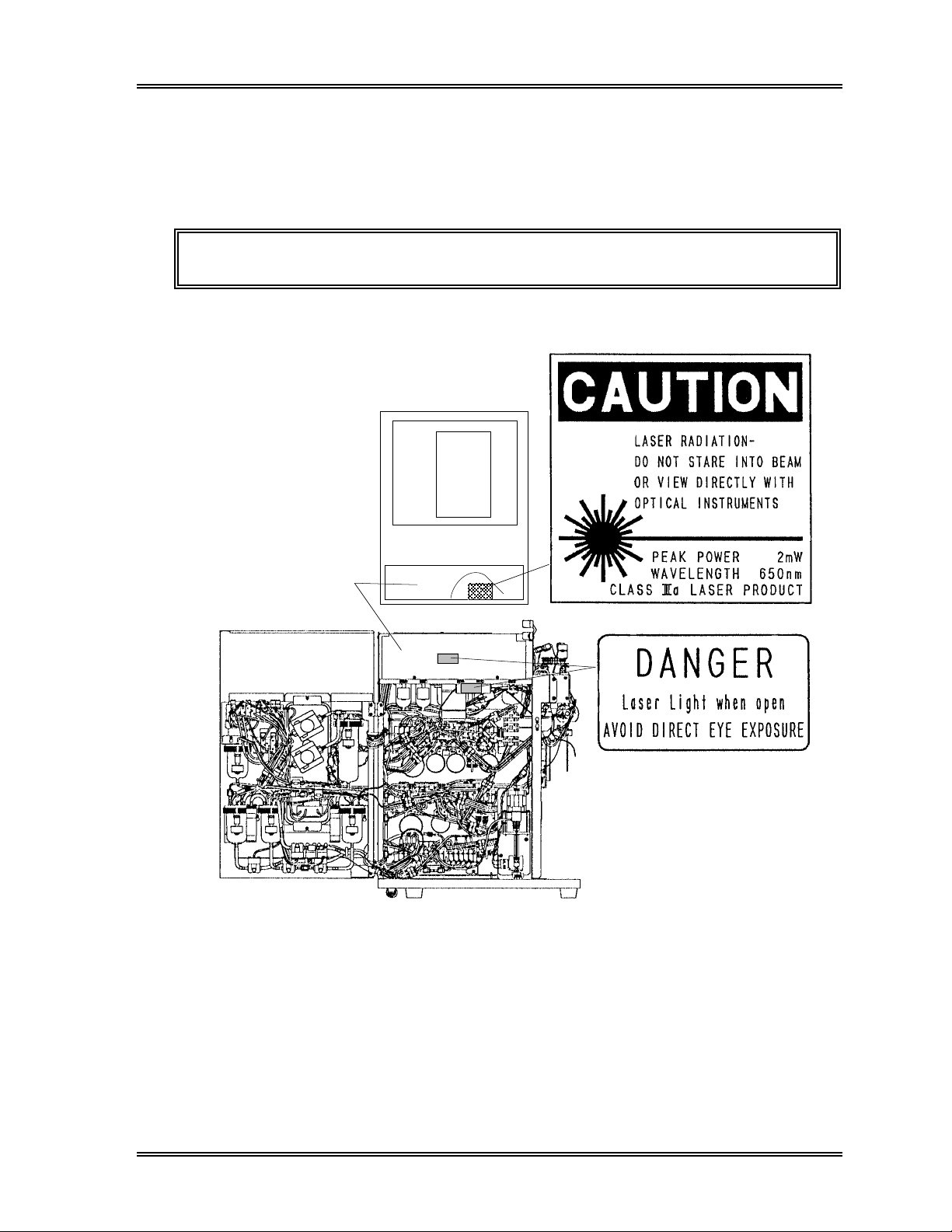

6.4 Laser Safety

The SF-3000 uses a semiconductor laser unit. Though this laser unit is placed in the

shield box, the operator must observe all NOTES, CAUTIONS and WARNINGS

concerning laser handling.

WARNING!: DO NOT remove the shield box cover of the Laser Unit.

NOTE: This caution label is located

inside the Laser Unit Cover.

< Top View >

Semiconductor Laser

Unit Cover

< Left Side View >

Figure 1-2: Location of Laser Unit and Labels

(Left Interior of the Main Unit)

Refer to Chapter 5, Section 6 for further information on laser handling.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-7

Page 21

INTRODUCTION

7. OPERATIONAL SUMMARY

The SF-3000 has two basic operating modes: the Manual Open Mode and Capillary

Mode. Additional three operating modes are available by means of optional units: the

Sampler Mode and Manual Closed Mode by means of Cap Piercing Sampler Unit, and

Manual CP Mode by means of Manual CP Unit.

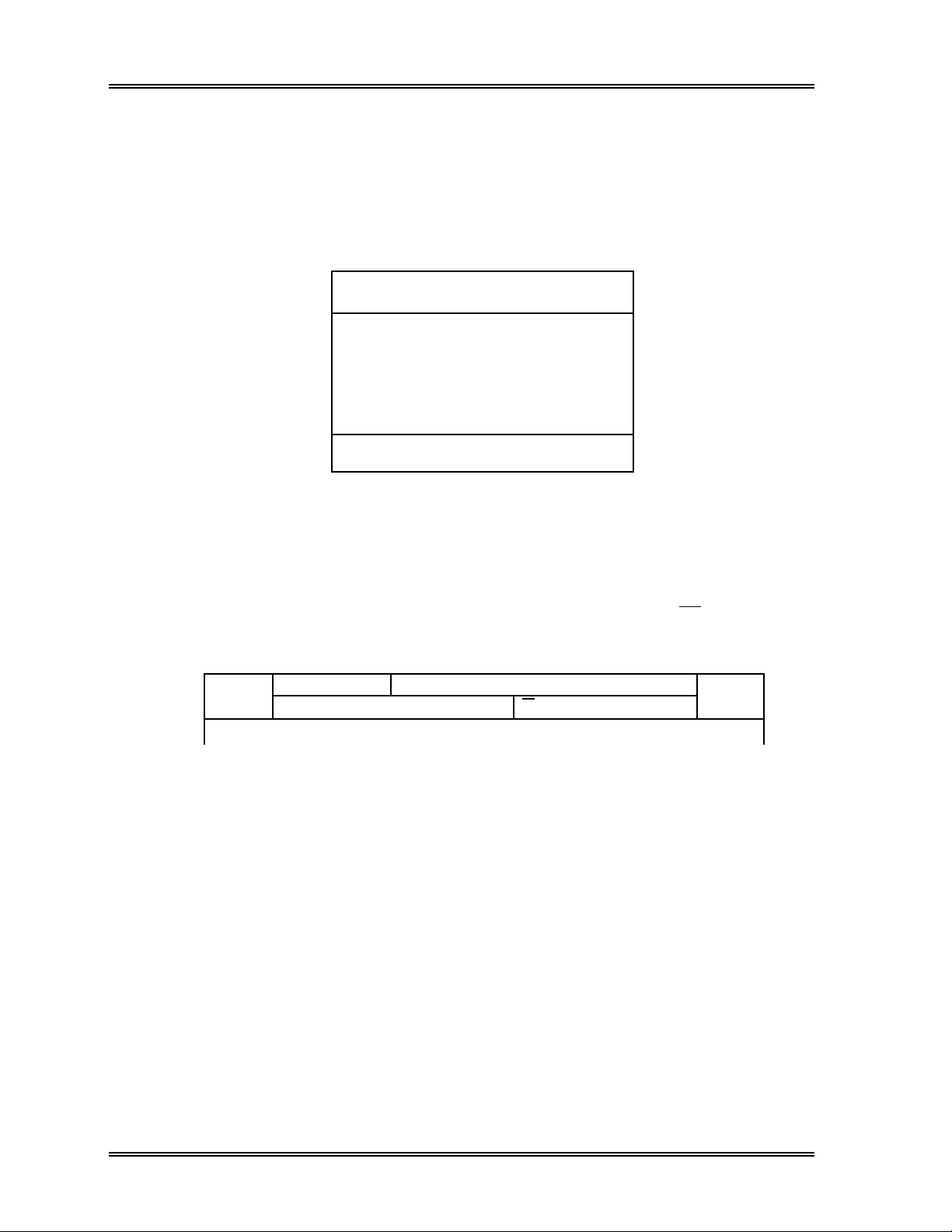

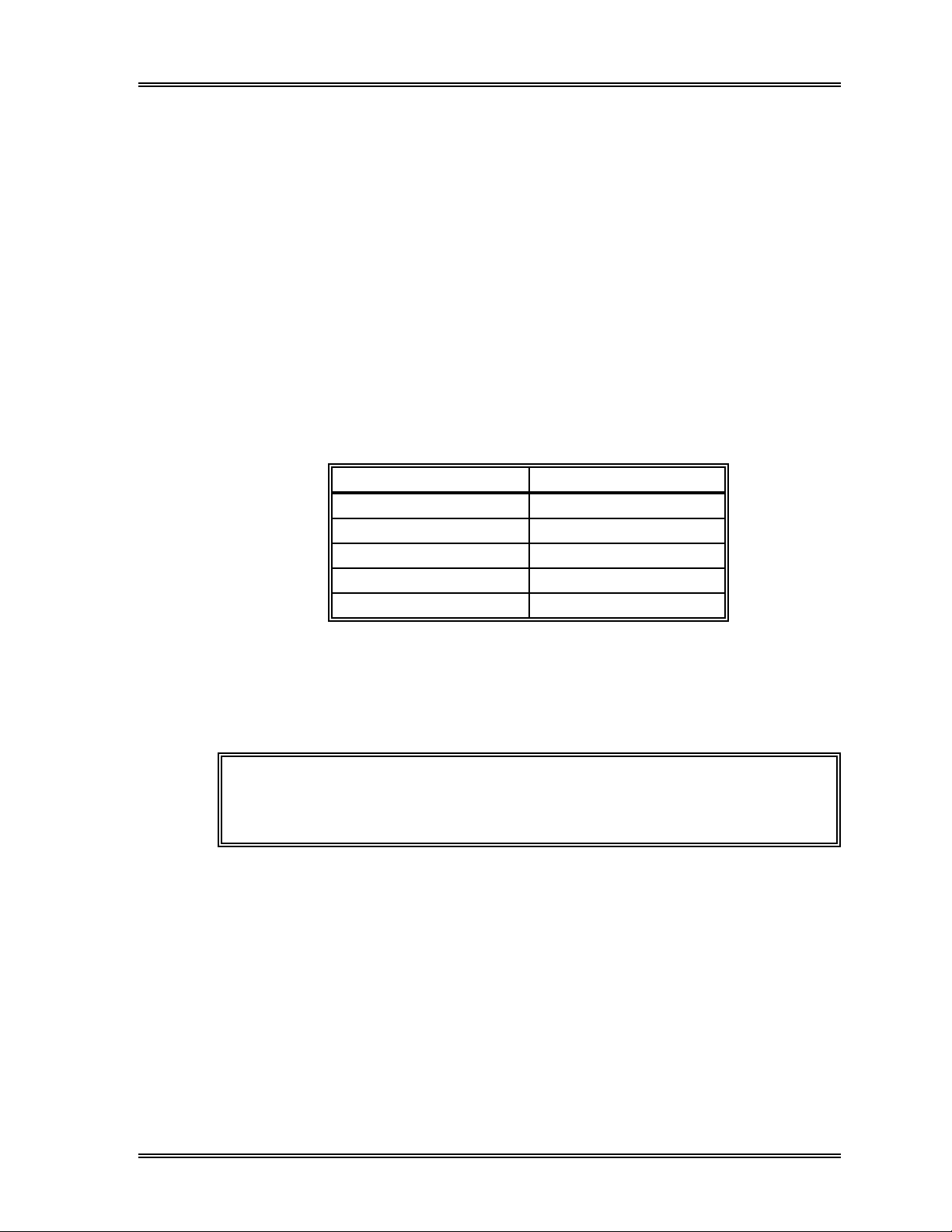

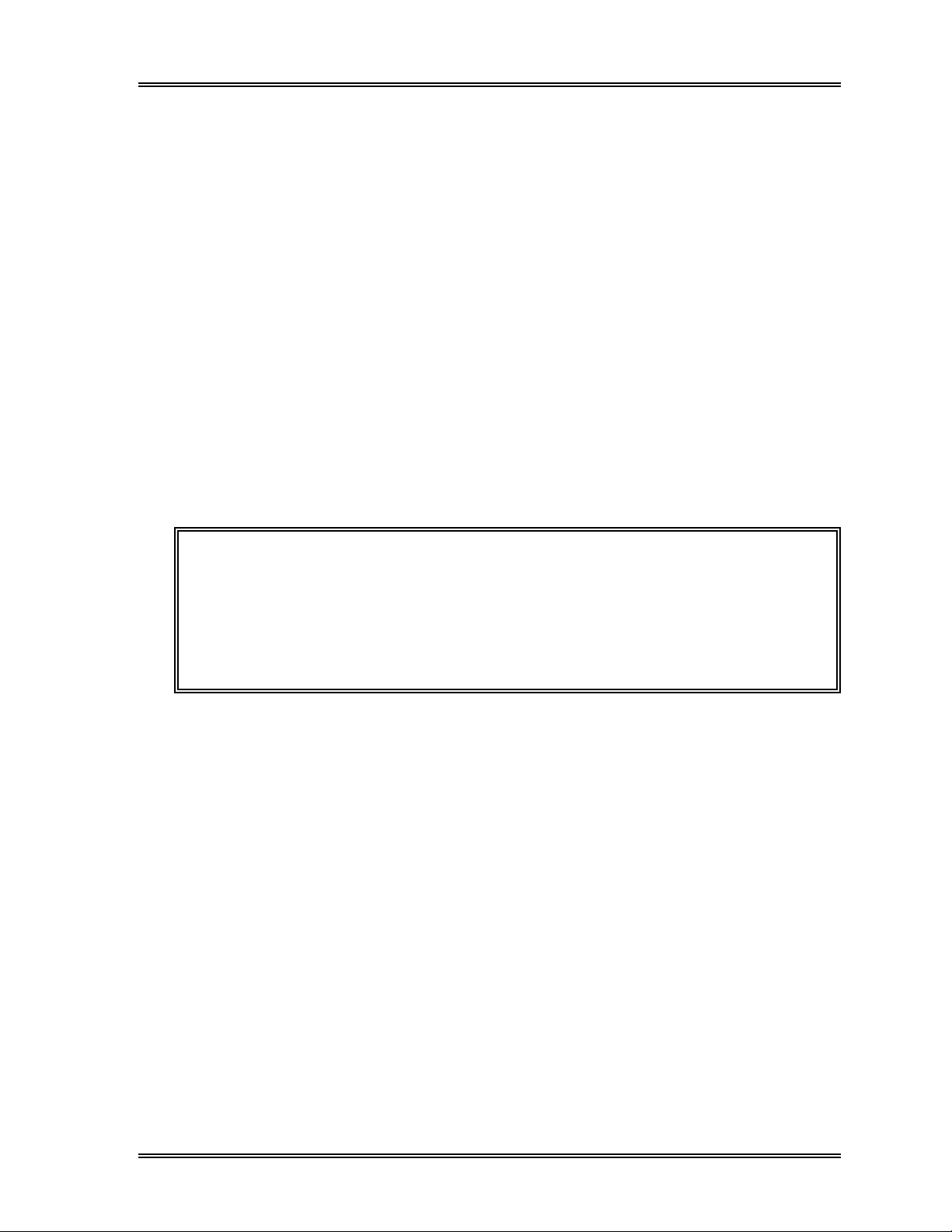

Table 1-2: Operation Modes

Manual Open

Mode

Select

manual mode

Set manual

sample ID

Set sample at manual Place sample in rack Place sample

aspiration pipette

Press the Start Switch

Capillary Mode Sampler Mode Manual Closed

Mode

Operator checks

Turn ON power

Self-check

Auto rinse

Ready

Select

capillary mode

Prepare

capillary

analysis

sample

(1:5 dilution)

Set capillary

sample ID

Analysis performed

Analysis complete

Post-analysis check

Perform shutdown

Press

[Sampler]

Set sample ID

(or read bar

code label)

Set rack No.

Set tube No.

Set rack on sampler in Manual CP

Press [Start] Press the

Power OFF

Select

closed mode

Set closed

sample ID

Start Switch

Manual CP

closed mode

Set closed

sample ID

Unit

Press the

Start Switch

Mode

Select

Operations performed by the operator are indicated in bold print.

Ready: READY LED turns on and "Ready" message is displayed on the LCD screen.

In this state, various operations can be performed, including analysis setting

and data processing.

1-8 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 22

INTRODUCTION

8. ANALYSIS PARAMETERS

The SF-3000 uses 4 detection methods and 5 types of reagents to analyze the following

23 parameters:

Table 1-3: Analysis Parameters

Parameter Acronym Detection Method

White Blood Cell Count WBC Flow Cytometry by Semiconductor Laser

Red Blood Cell Count RB C DC

Hemoglobin Concentration HGB SLS hemoglobin

Hematocrit (true relative percentage volume

of erythrocytes)

Mean Corpuscular (erythrocyte) Volume MCV Computed from RBC and HCT

Mean Corpuscular Hemoglobin MCH Computed from RBC and HGB

Mean Corpuscular Hemoglobin

Concentration

Platelet Count PLT DC

Neutrophil Percent NEUT%

Lymphocyte Percent LYMPH%

Monocyte Percent MONO% Flow Cytometry by Semiconductor Laser

Eosinophil Percent EO%

Basophil Percent BASO%

Neutrophil Count NEUT#

Lymphocyte Count LYMPH#

Monocyte Count MONO# Flow Cytometry by Semiconductor Laser

Eosinophil Count EO#

Basophil Count BASO#

RBC Distribution Width RDW-SD Computed

RBC Distribution Width RDW-CV Computed

Platelet Distribution Width PDW Computed

Mean Platelet Volume MPV Computed

Platelet Large Cell Ratio P-LCR Computed

H CT RBC Cumulative Pulse Height Detection

MCHC Computed from HCT and HGB

NOTE:

Customers in the United States:

Platelet Distribution Width (PDW) and

Platelet Large Cell Ratio (P-LCR) parameters have not been approved

for reporting by the Food & Drug Administration (FDA). The obtained

values should be excluded from all print forms until reporting approval has

been obtained. See

Chapter 11

for information on excluding these

values.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-9

Page 23

INTRODUCTION

9. DISPLAY SCREEN

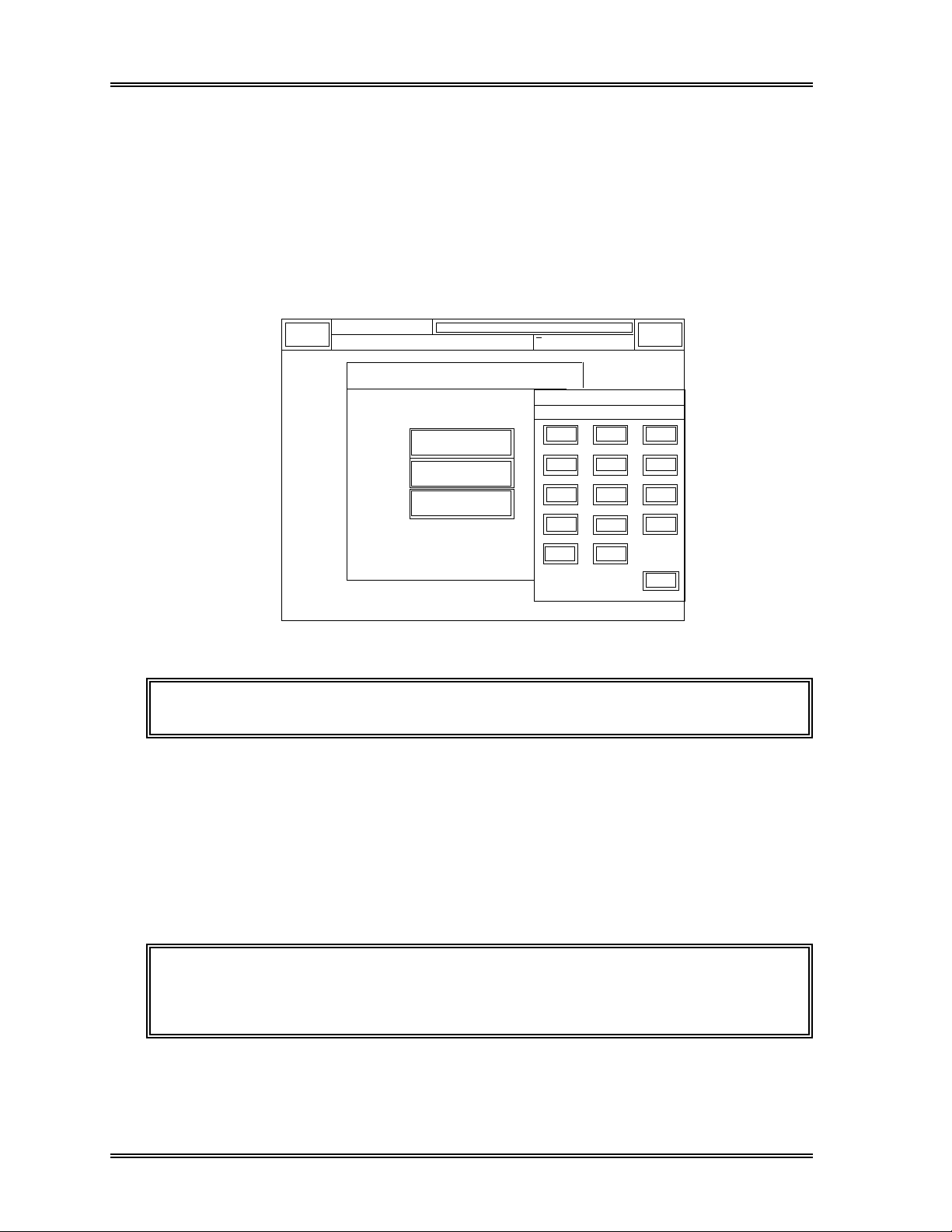

9.1 LCD (Liquid Crystal Display) Screen

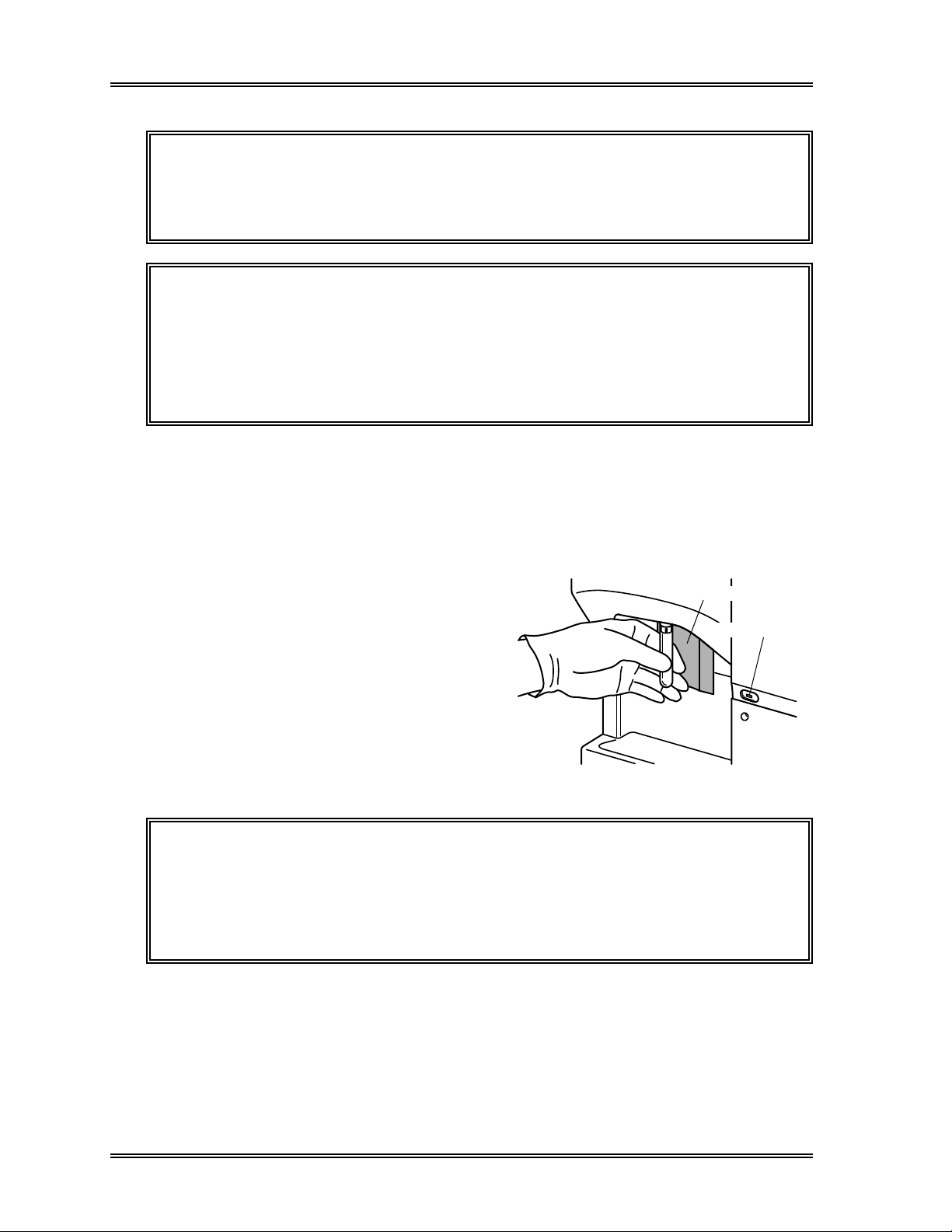

The LCD screen is divided into 3 parts: the System Status Area, the Data Processing

Area, and the Menu Area.

1. System Status Area

2. Data Processing Area

3. Menu Area

Figure 1-3: Display Screen

1 . System Status Area

The System Status Area appears as the top two lines of the screen (Figure 1-4).

This area displays Main Unit status information such as analysis status, errors, etc.

It also displays data processing status information such as Peripherals, X M, etc.

The [Sysmex] and [Sampler] function keys also appear in this area.

Sysmex

Ready Manual Mode

DP: 1234567890123 XM H C G P D P S U I D

Next No.1234567890123

Sampler

Figure 1-4: System Status Area

• Analysis Status

System status -- "Ready", "Not Ready", etc. is displayed to the left of the top line.

Analysis mode and the next sample ID number --

Analysis mode in which the system is set, and the next sample number to be

analyzed in the selected analysis mode are displayed.

Pressing this keypad displays the Sample No. Setting Screen for the Open

Sampling, Closed Sampling, or Capillary Sampling Manual mode. Using this

setting screen, the analysis mode, next sample ID number for the selected analysis

mode can be set up.

When the Capillary mode is selected, this area is displayed in yellow back-light.

1-10 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 24

INTRODUCTION, LCD Screen

NOTE: To set the next Sample ID No., Rack No. and Tube Position No. to be

analyzed in the auto mode by means of Sampler Unit, press [Sampler]

keypad to display the auto mode setting window.

The DP No. is displayed below the system status. If the Data Printer (DP) is the selected

output device, the DP No. displayed indicates the next sample data number to be printed

out.

Errors -- "2.0 kg/cm

2

Error", "Rack Move Error", etc. is displayed below the system

status, in place of the DP No. If 2 or more errors occur simultaneously, they are

displayed in order of importance. When an error is displayed, press [Sysmex] key to

display the action/help messages provided in the Error Log program. Refer to Chapter 8:

Troubleshooting for the action message display.

• Data Processing Status

X M : Indicates the status of X M control (one file of the QC program) in the

following way:

No indication : X M control is not in use (Stop).

X M :XM control is in use (Start).

X M (with red back-light) : X M Limit Error has occurred.

HC : Indicates transmission status of data to the Host Computer.

No indication : The Host Computer is set to "Not Connected".

HC : Ready for transmission to Host Computer.

HC (with green back-light) : Now transmitting to Host Computer.

HC (with red back-light) : Transmission to Host Computer not occurring

because of abnormality in Host Computer.

HC (with yellow back-light) : Error ("Not Transmissible", "No Ack" or "Ack

Code Err") has occurred between SF-3000 and

Host Computer.

GP : Indicates the status of the Graphic Printer (or Line Printer).

No indication : The Graphic Printer is set to "Not Connected".

GP : The Graphic Printer is ready.

GP (with green back-light) : Data being output to Graphic Printer.

GP (with red back-light) : Printing not possible because of abnormality in

Graphic Printer.

DP : Indicates the status of the Data Printer.

No indication : The Data Printer is set to "Not Connected".

DP : The Data Printer is ready.

DP (with green back-light) : Data being output to Data Printer.

DP (with red back-light) : Printing not possible because of abnormality in

Data Printer.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-11

Page 25

INTRODUCTION, LCD Screen

SU : Indicates the status of the Sampler Unit.

No indication : The Sampler Unit is not connected.

SU : Sampler Unit ready for sampler analysis.

SU (with red back-light) : Sampler not operational because of abnormality

in Sampler Unit.

CP : Indicates the status of the Manual Cap Piercing (CP) Unit.

No indication : The Manual CP Unit is not connected.

CP : Manual CP Unit ready for manual closed mode

analysis.

CP (with red back-light) : Manual closed mode not operational because of

abnormality in Manual CP Unit.

ID : Indicates the status of the ID Bar Code Reader.

No indication : The Bar Code Reader is set to "Not

Connected".

ID : The Bar Code Reader is ready.

ID (with red back-light) : "ID Unit Com. Error" has occurred between

SF-3000 and Bar Code Reader.

HD (with green backlight) : Appears when the system hard disk is being accessed.

• Function Keys

The [Sysmex] and [Sampler] keypads appear at each end of this area.

[Sysmex] -- Press this key to obtain the hard copy of screen and to access the Error Log.

Refer to Section 9.3 in this chapter for hard copy output. Refer to Chapter 8:

Troubleshooting for Error Log.

When an error occurs, this key changes to [Alarm Reset] with red backlight. Press to

stop the alarm.

[Sampler] -- Press to display the sampler start check window, where the Sample ID No.,

Rack No. and Tube Position No. for the next auto mode analysis can be set up. This

keypad changes to [Sampler Stop] during auto mode analysis.

2 . Data Processing Area

Analysis and sample information, including analysis data, scattergrams, cell size

distributions, QC menus, action messages, sub-program menu keypads, etc. are

displayed in the center area of the display screen.

1-12 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 26

INTRODUCTION, LCD Screen

3 . Menu Area

The available menu choices are displayed in the bottom line of the display screen. Touch

the desired keypad on the LCD to access and proceed for the program. In the Main

Screen, the Root Menus appear in this area. Refer to Section 9.2 in this chapter for the

root menus.

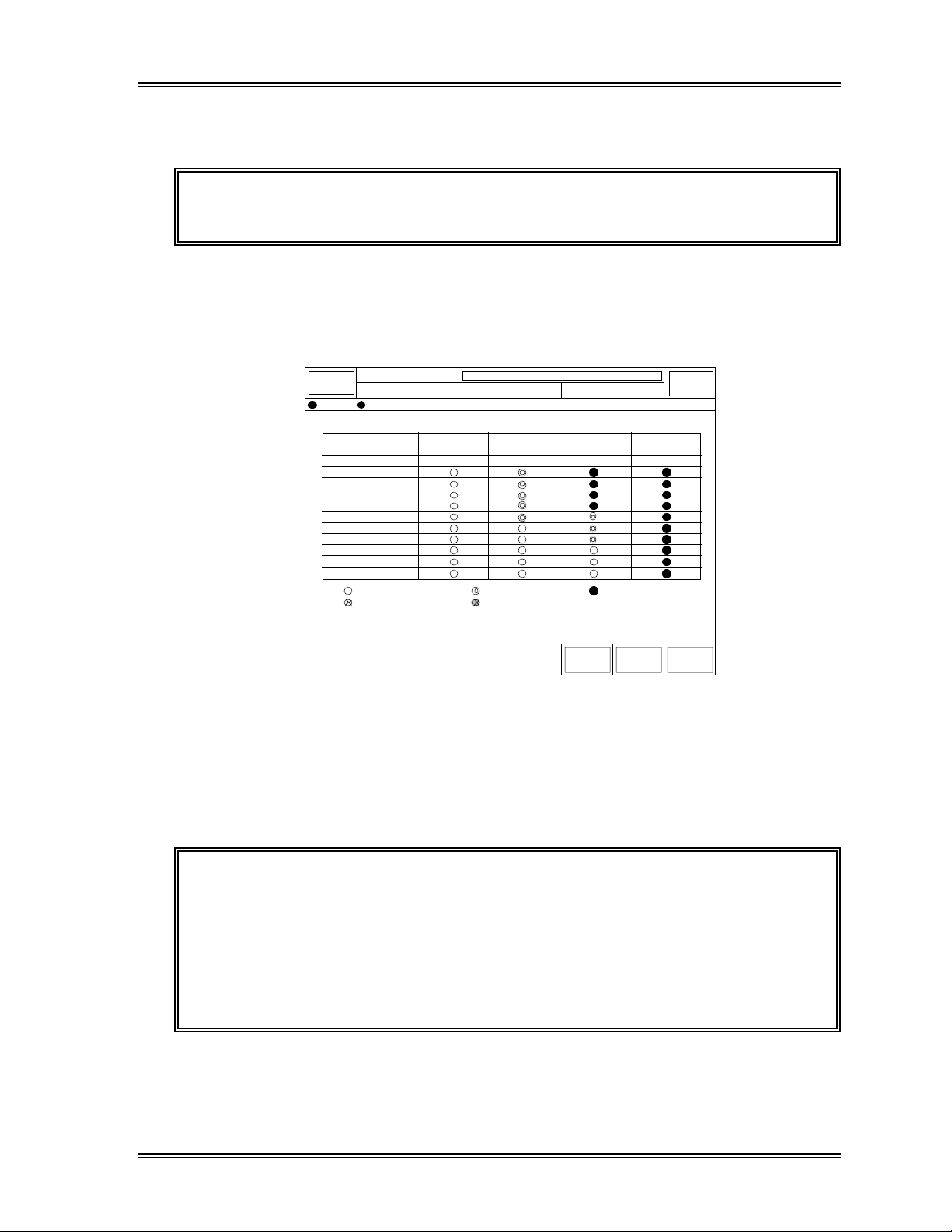

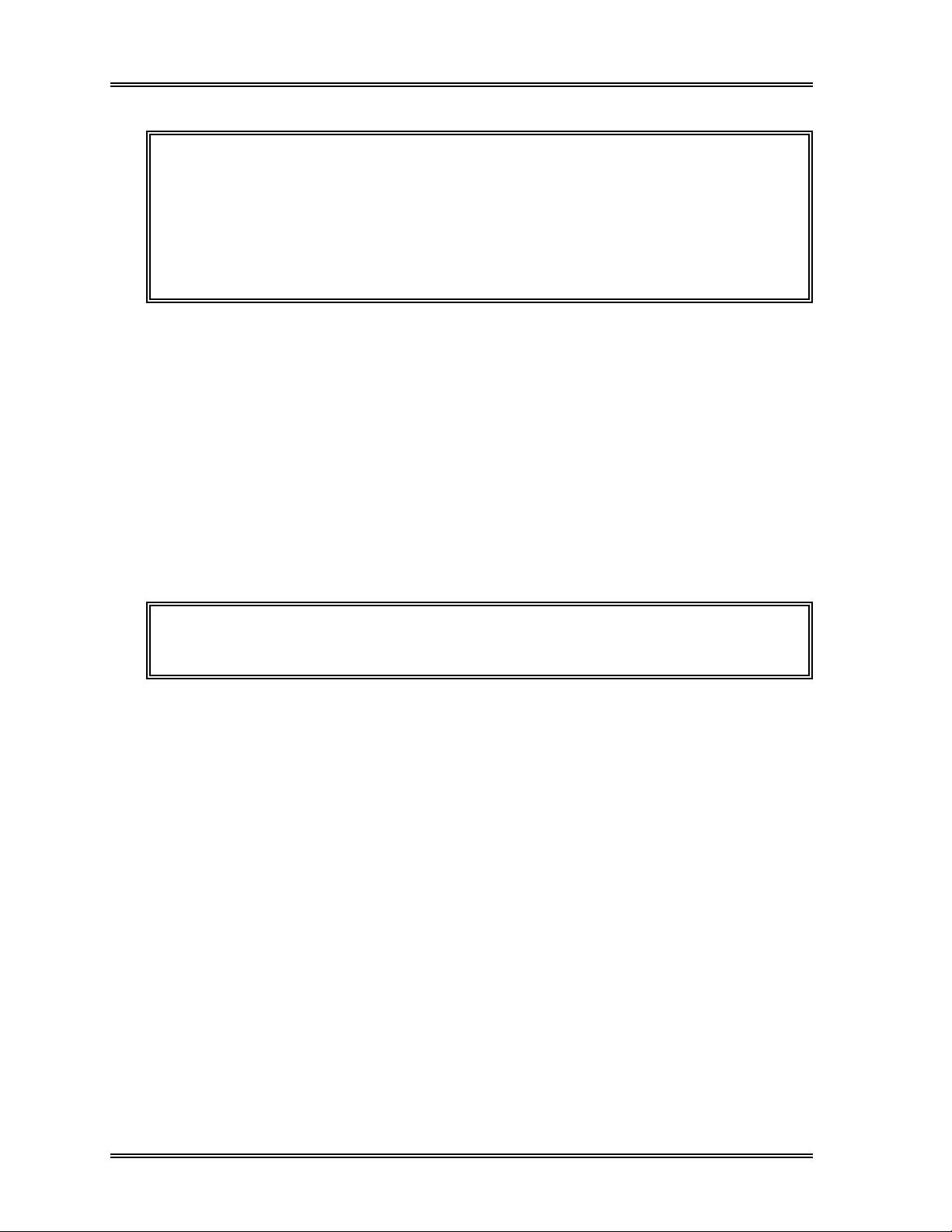

NOTE: The program keys masked as shown below do not function when

pressed.

Figure 1-5: Example of Masked Program Keys

4 . Power Saving Function

The LCD contrast will automatically decrease for the LCD power saving if the Main Unit

does not detect any key operation on the LCD for 5 minutes. Touch anywhere on the

LCD to exit the power saving mode.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-13

Page 27

INTRODUCTION

9.2 Root Menus

When the instrument power is ON, the Main Screen with the Root Menus is displayed as

the initial screen. By pressing the [Return] key on any screen, the visible display returns

to the previous screen, finally to the Main Screen.

The SF-3000 provides twelve Root Menus. The Main Screen displays seven Root

Menus on the menu line at a time. When you want to change a menu, press the [More]

key to alternate root menu.

The Root Menus is listed below. Each Root Menu consists a second menu(s) or menu

choices to proceed for the corresponding program.

[Status]

Use this menu to check the analyzer condition, analysis process, sensor status, etc. at

any time. (This menu does not display analysis errors.)

[Work List]

Use this menu to display, register, and process the analysis information, including

Sample No., Rack No., Tube Position, Order Information, etc. Refer to Chapter 3:

Work List for more information.

[Stored Data]

This menu provides options to display analysis results up to 1,000 samples stored in the

memory. The Stored Data List includes Date and Time analyzed, Sequential No.,

Sample No., Rack No., Tube Position, output status to the peripherals, flag information

and analysis results. Refer to Chapter 4: Result Interpretation/Reports for more

information.

[QC]

The SF-3000 quality control program provides X or L-J, and X M control

applications. The QC Root Menu performs QC analysis, displays and/or outputs the QC

Chart, establishes the QC settings, etc. Refer to Chapter 6: Quality Control for more

information.

[GP Print]

Use this menu to get options to output the data currently displayed on the screen to the

Graphic Printer.

[DP Print]

Use this menu to get options to output the data currently displayed on the screen to the

Data Printer.

[Replace Reagent]

Use this menu after replacing a reagent container to prime the reagent into internal

reservoir chamber.

1-14 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 28

INTRODUCTION, Root Menu

[Mainte.]

Use this menu to perform the customer maintenance programs, such as waste chamber

cleaning, clog removal, etc. and to perform the system test programs.

[Settings]

Use this menu to set the system parameters and conditions, such as date, time, units,

analysis stop condition, etc. Also this program contains data analysis settings to

establish certain standards for the SF-3000 system. System's operational parameters can

be set up to meet individual laboratory preferences to customize the operation of the

SF-3000. Refer to Chapter 11: System Setup for the setup procedure.

[Calib.]

Use this menu to calibrate the SF-3000 for specified parameter(s) automatically or

manually. Refer to Chapter 7: Calibration for the procedure.

[Shutdown]

Use this menu to clean the detector chambers and all hydraulic lines in the SF-3000

system with detergent.

[Auto Rinse]

Use this menu to rinse the hydraulic lines with the diluents, and check the background

values after rinsing. If the background values exceed the preset limit values, a

"Background Error" occurs.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-15

Page 29

INTRODUCTION

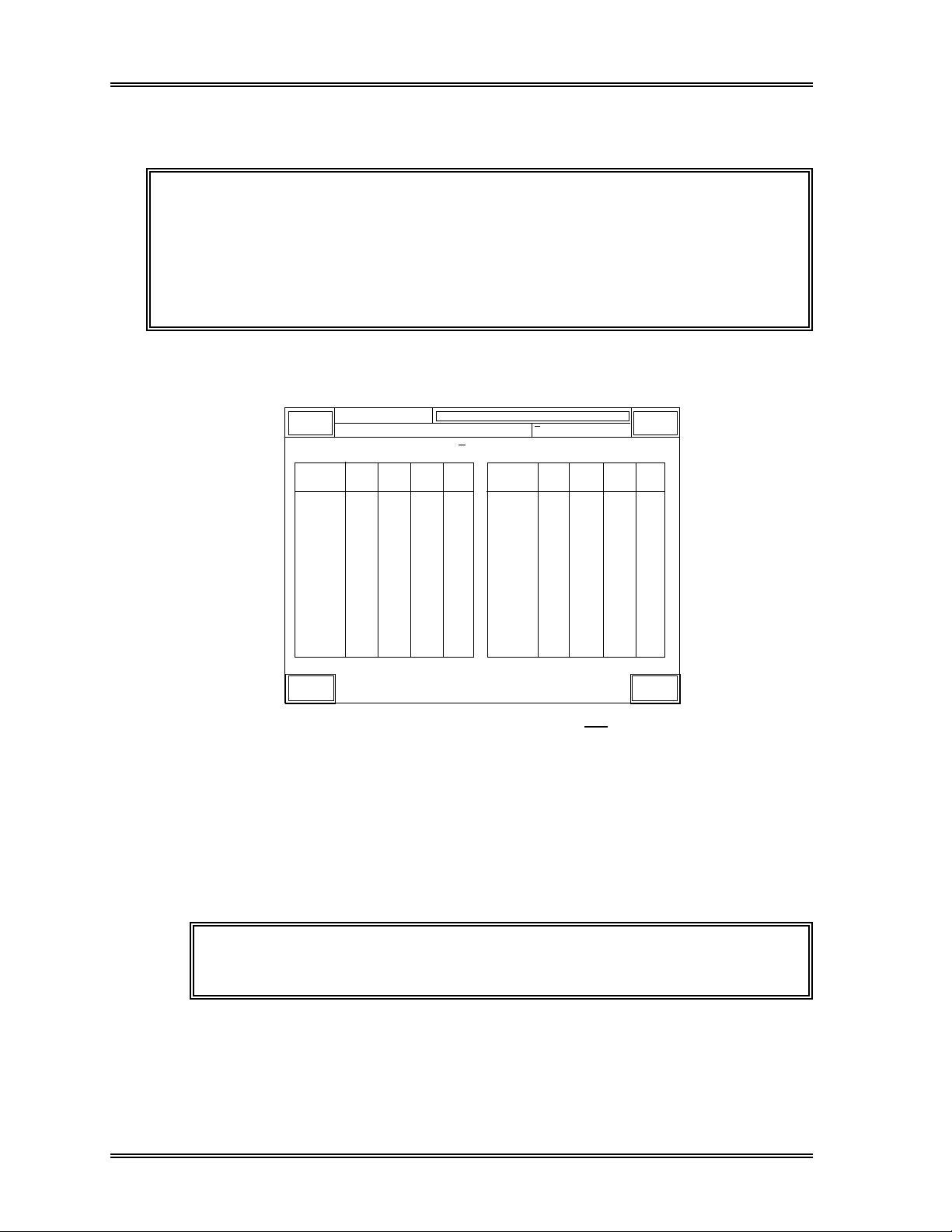

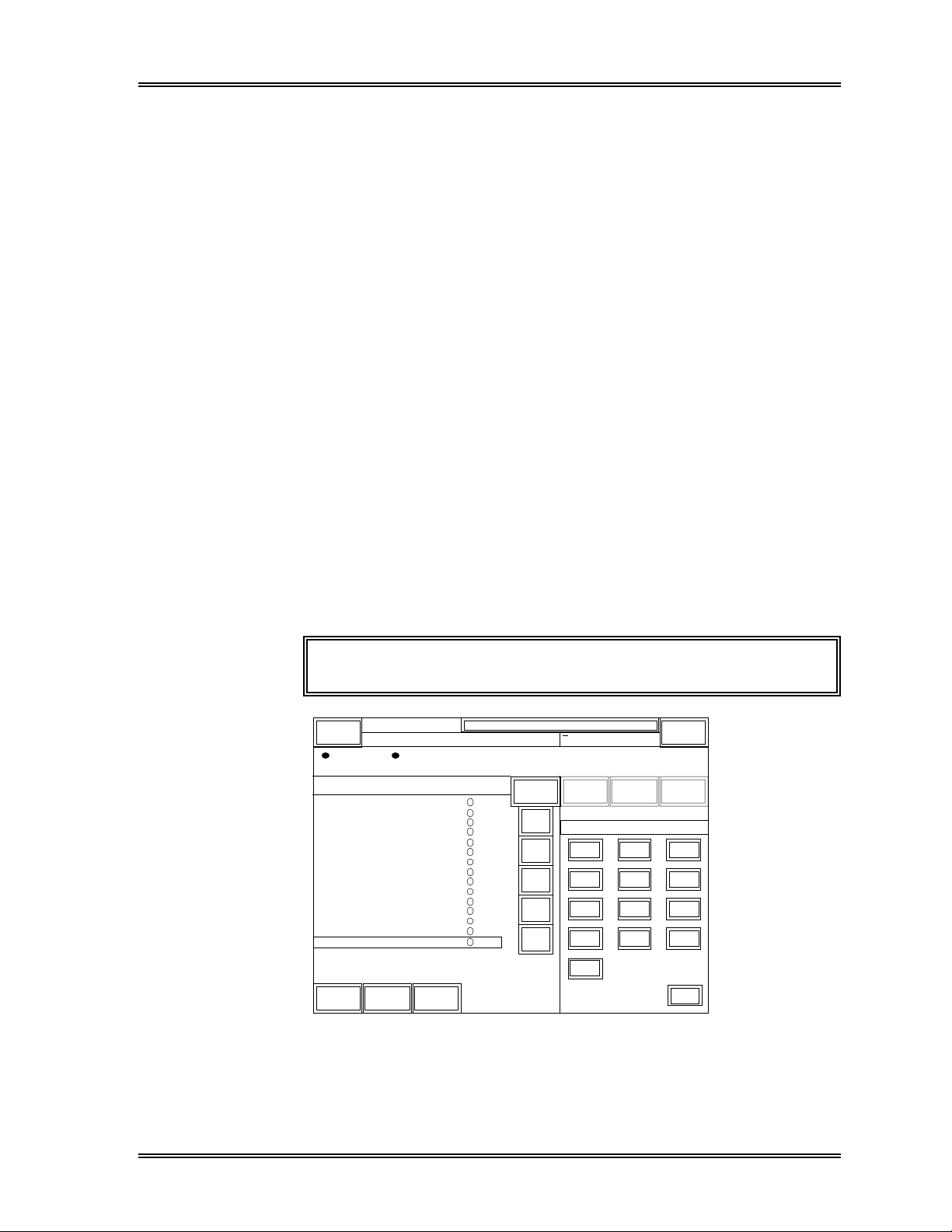

9. 3 Hard Copy

The [Sysmex] keypad always appears on the left of the top line of the screen.

Press this key to display the Sysmex submenu window as shown in Figure 1-6.

Sysmex

Status

Ready

DP:1234567890123

Hard

Copy

Error

Log

Cancel

Work

List

Manual Mode Next No.1234567890123

NO. R :

WBC

NEUT

LYMPH

MONO

EO

BASO

RBC

HGB

HCT

MCV

MCH

MCHC

RDW-SD

RDW-CV

PLT

PDW

MPV

P-LCR

Q C

G P

Print

Stored

Data

B A S O

40fL

XM HC GP DP SU

3

[x10 /uL]

6

[x10 /uL]

[g/dL]

[%]

[fL]

[pg]

[g/dL]

[fL]

[%]

3

[x10 /uL]

[fL]

[fL]

[%]

D P

Print

Replace

Reagent

[%]

[%]

[%]

[%]

[%]

Sampler

WBC Flag

RBC Flag

PLT Flag

More

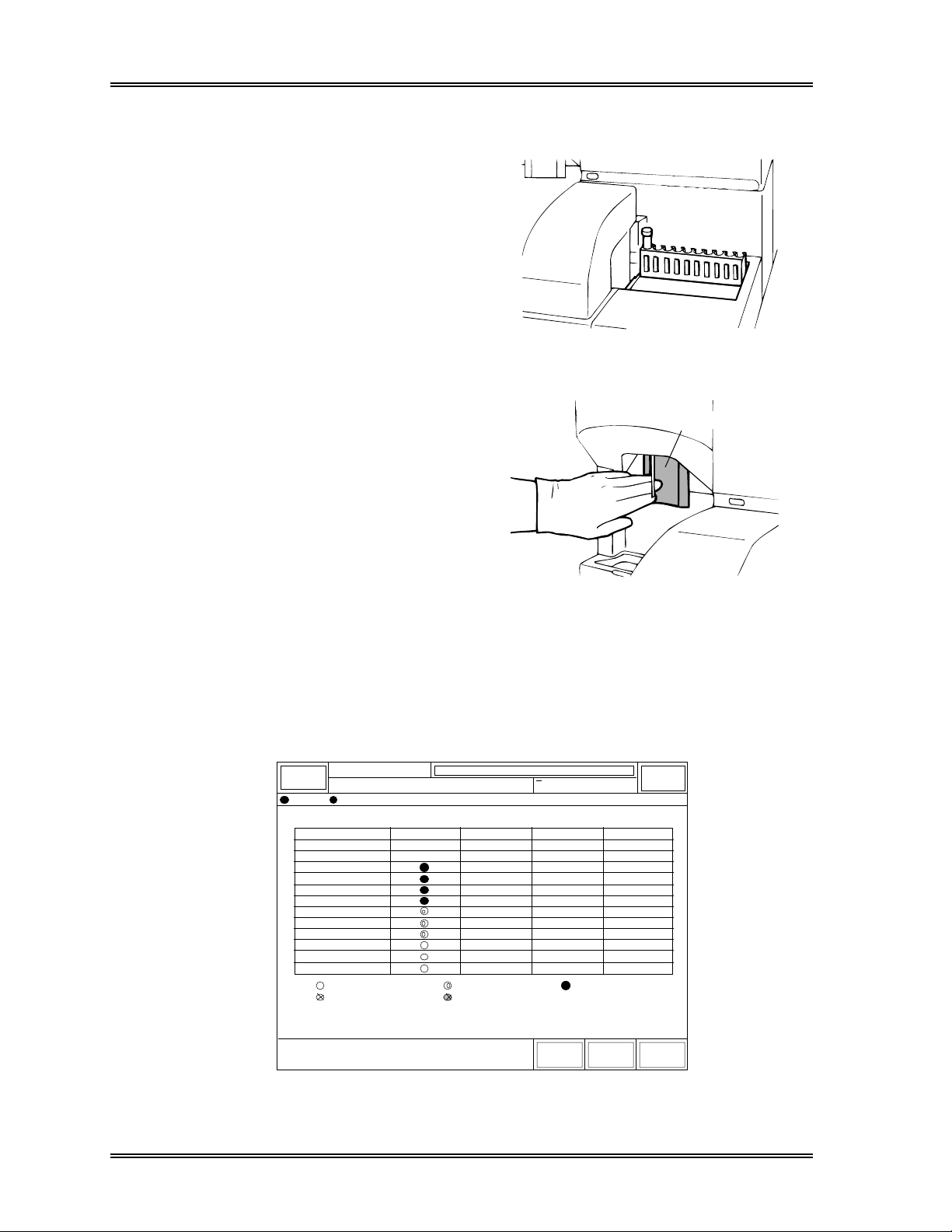

Figure 1-6: Sysmex Submenu Window

[Hard Copy]

Pressing this key outputs the hard copy of screen (screen shot), as displayed on the LCD

at the time of pressing the [Hard Copy] keypad, to the Graphic Printer. This function is

available in any status of instrument operation. The window will close automatically

after pressing this key.

[Error Log]

Pressing this key displays the error log and action/help messages for a specified error.

Refer to Chapter 8: Troubleshooting.

[Cancel]

Pressing this key closes the Sysmex submenu window.

1-16 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 30

INTRODUCTION

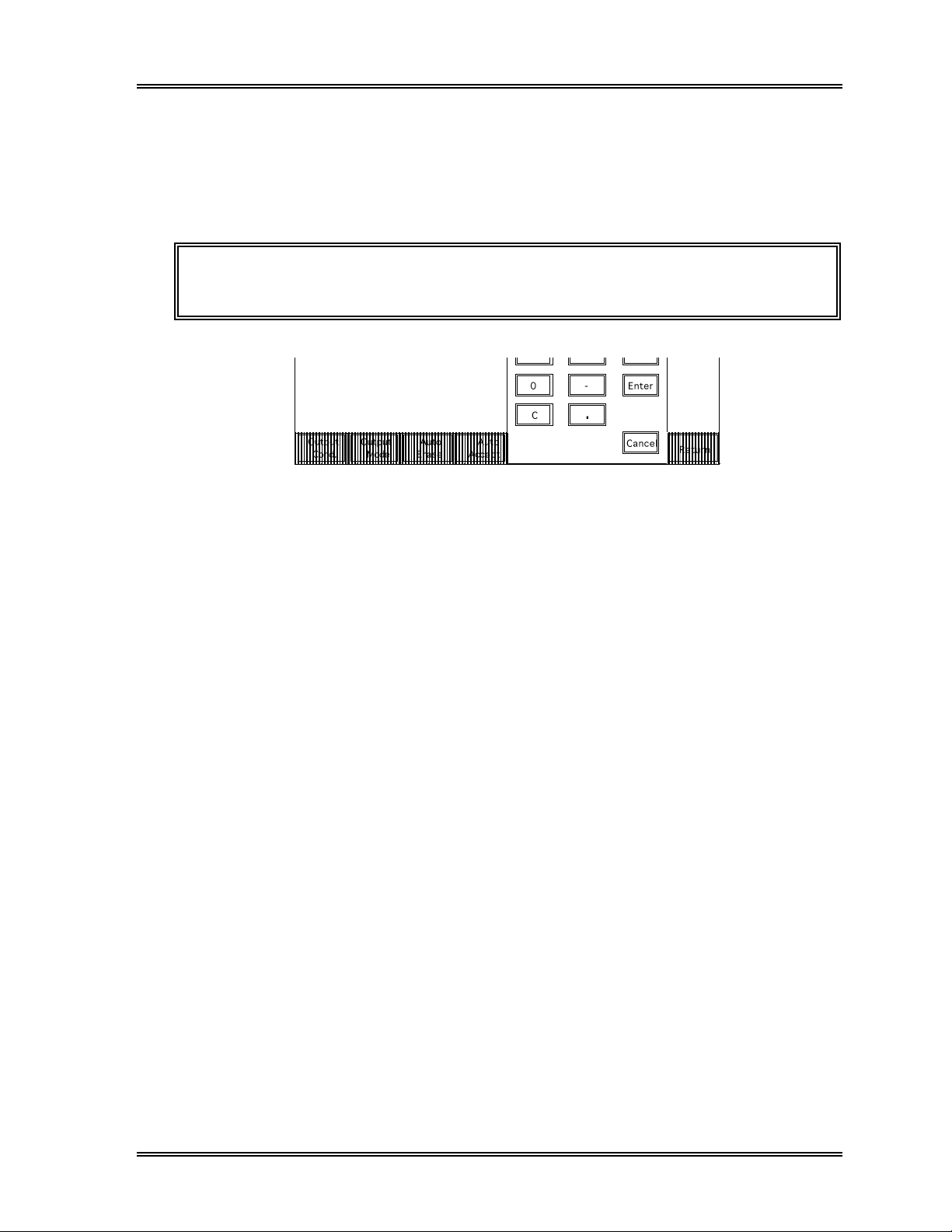

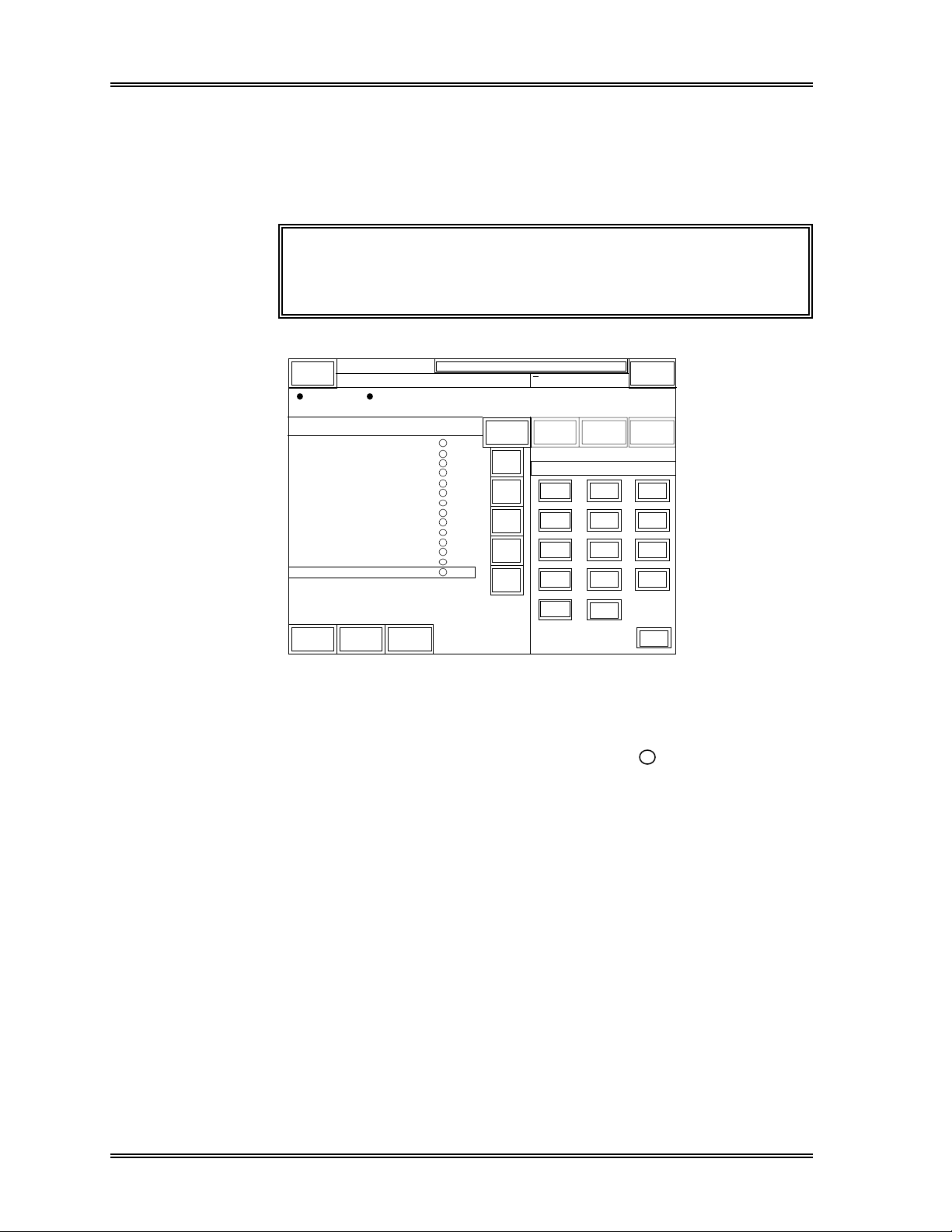

10. PASSWORD

Some programs in Q.C., Settings and Calibration require a password entry to prevent

unauthorized changes of the important settings and values. When such a program is

selected, the Password Input Screen appears with the message "Input Password". Enter

the registered password and press the [Enter] key. If the entered password is correct, the

program will be executed.

Sysmex

Ready

DP:1234567890123

Manual Mode Next No.1234567890123

XM HC GP DP SU

Input Password

Password

***

7 8

4

1 2 3

0 Ð Enter

C

.

Cancel

Sampler

9

65

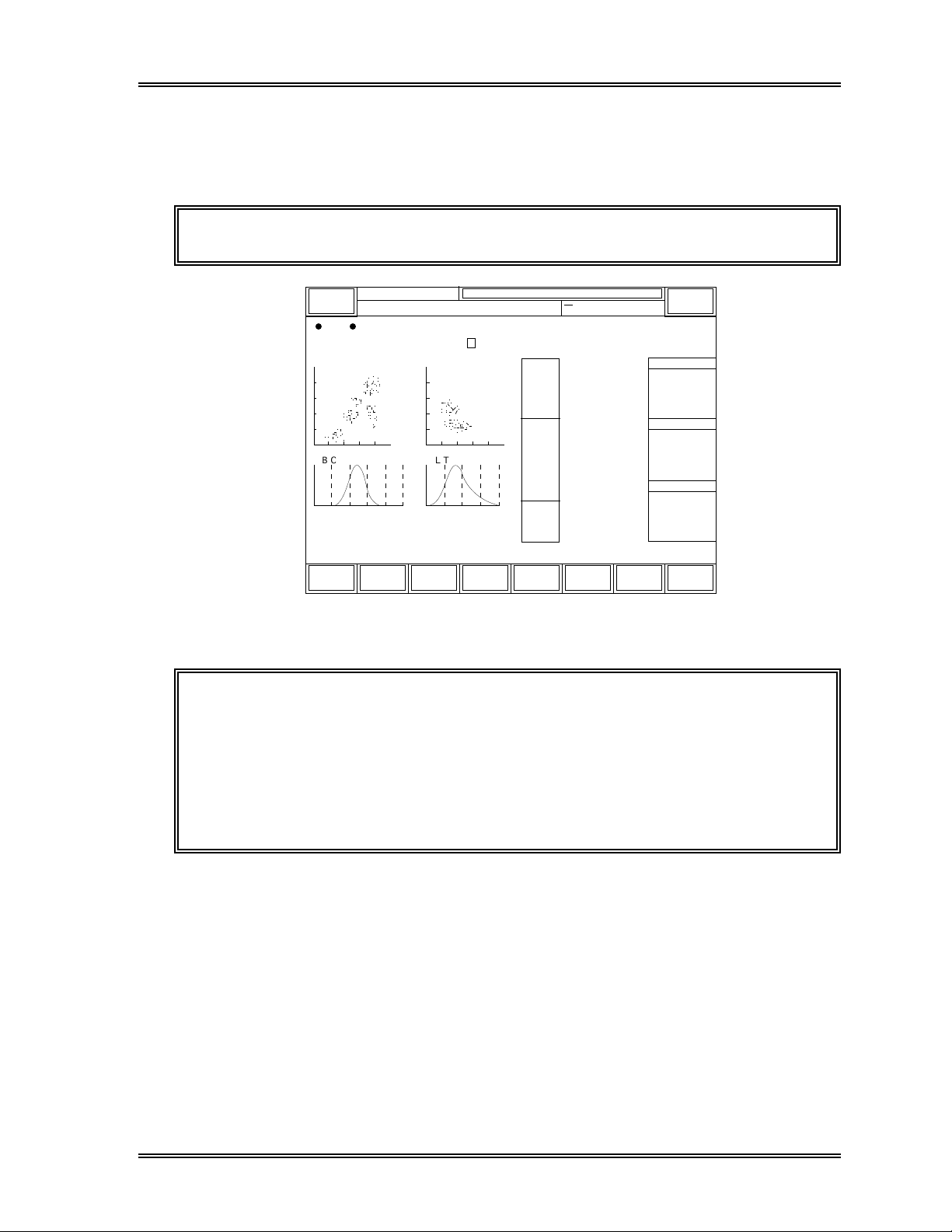

Figure 1-7: Password Entry Screen

The password is important for the management of the SF-3000, so be sure to memorize it

and/or have aids to help you remember it. Should you forget it, consult your Sysmex

service representative.

The password can consist of up to 12 digits. If you set the password to "0", no

password check will be performed, and the programs will be executed without the need

of password input.

For the procedures for setting and changing the password, refer to Chapter 11, "System

Setup".

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-17

Page 31

INTRODUCTION

11. EMERGENCY SHUTDOWN PROCEDURE

Should the analyzer need to be shut down in an emergency, such as a power failure in the

laboratory, turn OFF the power switches of the following major components before the

power is restored:

• Main Unit

• Pneumatic Unit

NOTE: If the Main Unit power is turned OFF during the system hard disk is

being accessed ("HD" indicator appears in the System Status Area),

the system memory check will be performed at next power ON. It will

take approx. 15 minutes to complete the memory check.

NOTE: When the system is restarted and becomes ready status, perform the

Waste Chambers and the WBC Detector cleaning sequences to

remove the potentially remained sample and reagent in the hydraulic

lines. Refer to

procedures.

Chapter 5: Maintenance and Supplies

for the

12. ALARMS

In the SF-3000, 3 types of alarm sounds are used to alert the operator:

1. Key Entry

A short beep (approx. 0.1 sec.) sounds every time a key is pressed on the LCD

touch panel keypad.

2. Operation Error

A long beep (approx. 1 sec.) sounds when a wrong key is pressed on the LCD touch

panel keypad.

3. Analysis Error

If any abnormality occurs in the Main Unit, a beep sounds and continues sounding

until the [Alarm Reset] keypad is pressed. This keypad appears at the top left corner

of the LCD instead of [Sysmex] keypad.

1-18 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 32

INTRODUCTION

13. INSTALLATION REQUIREMENTS

13.1 Relocation Information

The SF-3000 and associated equipment should only be installed by your Sysmex service

representative. Contact your Sysmex service representative if relocation of the system is

required after it has been installed.

NOTE: Problems resulting from the relocation of the SF-3000 by anyone other

than a Sysmex service representative are not covered by the

Warranty.

The service agreement covers moving the SF-3000 after the warranty period has expired.

13.2 Electrical Requirements

The SF-3000 comes equipped with a three-prong or two-prong plug power cord. The

type of cord and plug supplied depends on the source voltage for the system.

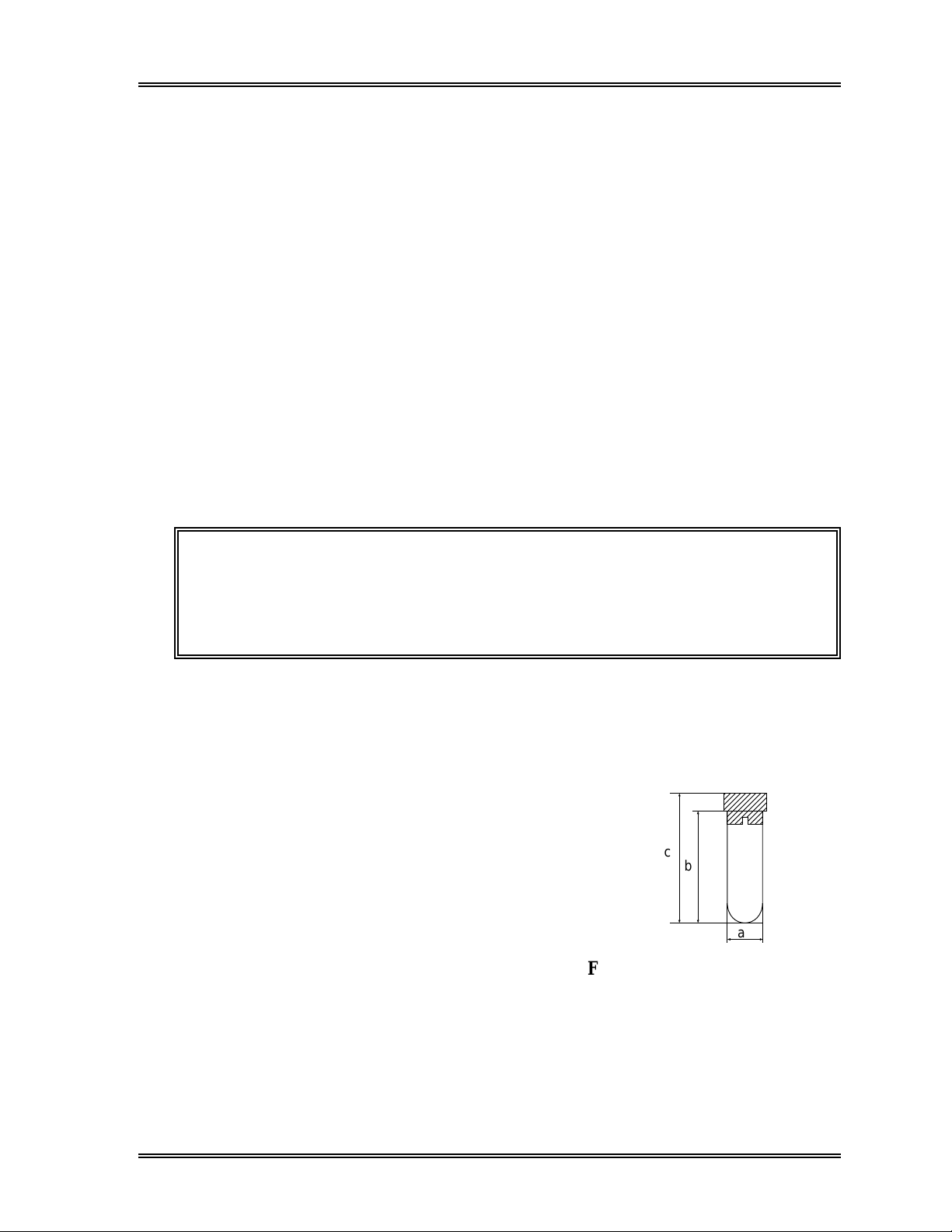

Figure 1-8: 117 VAC Plug Figure 1-9: 220 VAC Plug Figure 1-10: 240 VAC Plug

WARNING!: Proper use of the appropriate power cord assures adequate grounding

for the system. Failure to properly ground the SF-3000 bypasses

important safety features and may result in an electrical hazard.

The power source required for the SF-3000 system is: 117, 220 or 240 VAC ± 10%,

50/60 Hz.

The power consumption of the system, including the Pneumatic Unit and Sampler Unit,

is 600 VA or less.

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-19

Page 33

INTRODUCTION

13.3 Space Requirements

It is important to install the instrument in a suitable location. A poor location can

adversely affect its performance. Consider the following space requirements:

• Select a location near a power source and close to a suitable drain.

• Leave at least 0.5 m space on both sides, and at the rear and top of the system for

easy maintenance and servicing. A minimum of 0.2 m must be maintained between

the rear panel and the wall to allow for heat dissipation and tube clearance.

• Install the Pneumatic Unit, reagents and printers in suitable places that will make your

work easy.

WARNING!: Install the Sampler Unit on a table or work bench. If the Sampler Unit

is installed without supporting desktop under the unit, there is a

possibility that the SF-3000 system could accidentally fall.

13.4 Installation Environment

The environmental requirements are listed below:

• Operate the SF-3000 within a temperature range of 15 - 30°C (optimum temperature

25°C) and relative humidity of 30 - 85%.

• To compensate for heat generated by the system, approximately 430 kcal/hour (1705

BTU/hour) is required in an air-conditioned environment. (This figure does not

include additional cooling capacity required for the optional printers.)

• Avoid using the SF-3000 in areas of extreme temperature and direct sunlight.

• Place the SF-3000 in a well ventilated location.

• Avoid placing the SF-3000 near potentially interfering devices capable of emitting

radio frequencies such as a radio or television receiver.

1-20 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 34

14. SYSTEM SPECIFICATIONS

Table 1-4: System Specifications

INTRODUCTION

Parameters WBC, NEUT%, LYMPH%, MONO%, EO%, BASO%, NEUT#, LYMPH#,

Reagents Diluents : 1 (CELLPACK)

Aperture Diameter RBC, PLT 75 µm

Throughput Approximately 80 samples per hour

Principles WBC, LYMPH, MONO, NEUT, EO, BASO

MONO#, EO#, BASO#, RBC, HGB, HCT, MCV, MCH, MCHC, RDW-SD,

RDW-CV, PLT, PDW, MPV, P-LCR

WBC Reagents : 3 (STROMATOLYSER-FD (I),

STROMATOLYSER-FD (II),

STROMATOLYSER-FB)

HGB Reagent : 1 (SULFOLYSER)

Detergents : 1 (CELLCLEAN)

(Approx. 85 seconds per sample)

: Flow Cytometry with semiconductor laser beam

RBC, PLT : DC Detection Method

HGB : SLS Hemoglobin Method (at wavelength 555 nm)

HCT : Cumulative Pulse Height Detection Method

MC V : Calculated from RBC and HCT

MCH : Calculated from RBC and HGB

MCHC : Calculated from HCT and HGB

Sample Volume Required Sampler Mode : Approx. 270 µL

Data Storage Capacity Cell size distribution data (with graphs) : for 1,000 samples

Quality Control

Closed Mode : Approx. 270 µL

Manual Mode : Approx. 170 µL

Capillary Mode : Over 40 µL

Scattergrams : for 1,000 samples

Order information : for 50 samples

QC files : for 13 QC files

X

Control (or L-J Control) : 180 points x 12 files, 28 parameters

M Control : 180 points x 1 file, 28 parameters

X

Sysmex SF-3000 Operator's Manual -- Revised September 1995 1-21

Page 35

INTRODUCTION

Table 1-4: System Specifications (Continued)

Precision

for Closed and

Open mode

Precision Characteristics are determined during instrument evaluation using

one fresh normal whole blood sample analyzed ten times consecutively in

Closed Sampling Auto Mode or Open Sampling Manual Mode.

WB C CV 3.0% (when WBC ≥ 4.0 x 10

NEUT% CV 8.0% (when NEUT% ≥ 30.0% and WBC ≥ 4.0 x 10

LYMPH% CV 8.0% (when LYMPH% ≥ 15.0% and WBC ≥ 4.0 x 10

MONO% CV 20.0% (when MONO% ≥ 5.0% and WBC ≥ 4.0 x 10

EO% CV 25.0% or within ± 1.5 EO% (when WBC ≥ 4.0 x 10

BASO% CV 40.0% or within ± 1.0 BASO% (when WBC ≥ 4.0 x 10

NEUT# CV 8.0% (when NEUT# ≥ 1.20 x 10

LYMPH# CV 8.0% (when LYMPH# ≥ 0.60 x 10

MONO# CV 20.0% (when MONO# ≥ 0.20 x 10

EO# CV 25.0% or within ± 0.12 x 10

BASO# CV 40.0% or within ± 0.06 x 10

RB C CV 1.5% (when RBC ≥ 4.00 x 10

3

/µL)

3

/µL)

3

/µL)

3

/µL)

3

/µL

3

/µL

6

/µL)

3

3

/µL)

3

/µL)

3

/µL)

/µL)

3

/µL)

HGB CV 1.5%

HCT CV 1.5%

MCV CV 1.5%

MCH CV 1.5%

MCHC CV 2.0%

PLT CV 5.0% (when PLT ≥ 100 x 10

3

/µL)

RDW-CV CV 3.0%

RDW-SD CV 3.0%

PDW CV 10.0%

MPV CV 4.0%

P-LCR CV 18.0%

Precision

for Capillary mode

Accuracy

for Closed mode

for Open mode

Accuracy

for Capillary mode

Precision Characteristics are determined during instrument evaluation using

one fresh normal capillary blood sample analyzed ten times

consecutively in Open Sampling Manual Mode.

WB C CV 9.0% (when WBC ≥ 4.0 x 10

RB C CV 4.5% (when RBC ≥ 4.00 x 10

3

/µL)

6

/µL)

HGB CV 4.5%

HCT CV 4.5%

MCV CV 4.5%

MCH CV 4.5%

MCHC CV 6.0%

PLT CV 15.0% (when PLT ≥ 100 x 10

WBC within ± 3% or within 0.20 x 103/µL

RBC within ± 2% or within 0.03 x 10

PLT within ± 5% or within 10 x 10

3

6

/µL

3

/µL

/µL)

WBC within ± 10%

RBC within ± 8%

PLT within ± 12%

1-22 Sysmex SF-3000 Operator's Manual -- Revised September 1995

Page 36

Table 1-4: System Specifications (Continued)

INTRODUCTION

Differential Accuracy The instrument differential is compared by using 100 or more fresh samples

to the reference 400 cell manual differential (200 counts with 2 Lab. Techs.),

as per NCCLS H-20A. MONO% is compared by using the monoclonal

antibodies. Results are displayed as a range of values that are the mean

differences between the methods, expressed to a 95% confidence interval.