Page 1

OPERATOR’S MANUAL

Automated Blood Coagulation Analyzer

CA-50

CHAPTER 1: INTRODUCTION

CHAPTER 2: ANALYSIS PREPARATION

CHAPTER 3: SAMPLE ANALYSIS

CHAPTER 4: DISPLAY OF ANALYSIS RESULTS

CHAPTER 5: MAINTENANCE & SUPPLIES REPLACEMENT

CHAPTER 6: QUALITY CONTROL

CHAPTER 7: SETTING STANDARD CURVES

CHAPTER 8: TROUBLESHOOTING

CHAPTER 9: FUNCTIONAL DESCRIPTION

CHAPTER 10: INSTRUMENT SETUP

APPENDIX A: INSTALLATION

APPENDIX B: TECHNICAL INFORMATION

INDEX

SYSMEX CORPORATION

KOBE, JAPAN

Copyright 1999 - 2001 by SYSMEX CORPORATION

All rights reserved. No part of this Operator’s Manual may be Code No. 461-2035-2

reproduced in any form or by any means whatsoever without PRINTED IN JAPAN

prior written permission of SYSMEX CORPORATION. Date of Last Revision: February 2001

Page 2

• Sysmex is a registered trademark of SYSMEX CORPORATION.

• Dade is a registered trademark of Dade Behring Inc.

• Actin and Ci-Trol are registered trademarks of Dade International Inc.

• Eppendorf is a registered trademark of Eppendorf-Netherler-Hinz GmbH.

• Other trademarks referenced are property of their respective owners.

• It is prohibited to reproduce part or all of the contents of this Manual without permission.

• The display screens shown in this manual may differ slightly from the actual displays.

• As a result of product improvements, details described in this manual may differ slightly

from the actual product.

• Patient names and doctor names are entered for information and illustration purposes only,

and do not imply real specific persons.

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 3

I

RECEIVING INSTRUCTIONS

The CA-50 has been thoroughly tested before shipment, and has been packaged carefully

to prevent damage from shipping and handling. Reagents and options have also been sent

and will arrive accompanying the analyzer. Follow these guidelines when the system

arrives:

• Check to see that the arrows on the sides of the packages are pointing up. If the

arrows do not point up, record this information on the bill of lading.

• Visually inspect the outside of the package for rips, dents, or possible shipping

damage. Document any sign of damage on the bill of lading, regardless of how

insignificant it may appear. This is for your protection!

• Notify your service representative that the CA-50 system and its components have

arrived.

• Wait for your service representative to unpack the system and open the packages.

• Follow the unpacking and storage instructions provided on the outside of the

package. Special requirements such as refrigeration are clearly marked on the

outside of the carton and will be included in the unpacking instructions and package

inserts.

WARRANTY INFORMATION

All instruments manufactured by Sysmex® are warranted against defective materials or

workmanship for a period of one year commencing on the installation date at the

customer's required location.

This Warranty does not cover any defect, malfunction, or damage due to:

1. Accident, neglect or willful mistreatment of the product

2. Failure to use, operate, service, or maintain the product in accordance with the

applicable Sysmex Operator's Manual

3. Failure to use the appropriate reagents or chemicals specified for the product

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 4

I

ENSURE SAFE OPERATION OF THE INSTRUMENT

y

jury

y

y

g

Before operating this instrument, carefully read the "Ensure Safe Operation of the Instrument" and

OPERATOR’S MANUAL, and strictly follow the instructions given in them.

This manual carries a variety of illustrations to make sure that the product can be used safely and

correctly, thus preventing you and others from suffering injuries and damage to property.

The illustrations and meaning are described in the following.

Do understand what they mean before proceeding to the text of the MANUAL.

Meaning of Signs

WARNING

CAUTION

•If this sign is ignored and the instrument is operated incorrectly, there is

a potentiall

in

•If this sign is ignored and the instrument is operated incorrectly, there is

a potentiall

operator, adverse effect on output, or ma

Caution on Diagnosis

CAUTION

•This product is a clinical examination instrument for screening. In makin

clinical judgment based on analysis results, a physician is requested to

take clinical examination results and other test results into consideration.

hazardous situation which could result in death or serious

of an operator, or grave property damage.

hazardous situation which may result in injury of an

cause property damage.

I

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 5

I

WARNING

p

p

• In the event the instrument emits abnormal odor or any smoke, turn OFF the

ower immediately and disconnect the power plug from the wall socket.

If the instrument is used continuously in that state, there is a hazard that fire, electrical shock, or

injury may result.

Contact your Sysmex service representative for inspection.

• Take care not to spill blood or reagent, or drop wire staples or paper clips into the

instrument.

Those might cause short circuit or smoke emission. If such trouble should occur, turn OFF the

power immediately and disconnect the power plug from the wall socket. Then contact your Sysmex

service representative for inspection.

• Do not touch the electrical circuits inside the cover. Especially if your hands are

wet, there is a hazard that electrical shock may result.

• During an analysis, do not open the pipette guide and put in hands or fingers.

That could cause injury. When the pipette guide is opened during an analysis, an

alarm sounds and the operation stops.

• Always wear rubber gloves when performing maintenance work or inspection.

Use specified tools and parts.

After work is over, wash your hands with disinfectant.

There is a possibility that those areas of your hands which came in contact with blood could suffer

infection.

• Be careful when handling samples.

Always wear rubber gloves; otherwise infection by bacteria could result. If sample splash happened

to enter your eye or a cut, wash it off with plenty of water, and immediately see a physician.

When Handling Reagent

• If a reagent happens to enter your eye, wash it off immediately using plenty of

water, and take medical treatment at once.

• If you should swallow it inadvertently, call for a physician immediately, drink

lenty of water, and throw up.

• If it happens to adhere to your hands or skins, wash it off using plenty of water.

• When discarding used reaction tubes and instrument consumables, take proper

disposing steps as medical, infectious, and industrial wastes.

If they are contaminated with blood, infection of bacteria may result.

• Do not modify the instrument. Its modification is prohibited by Pharmaceutical

Affairs Law.

Sysmex CA-50 Operator’s Manual -- Revised July 1999

II

Page 6

I

WARNING

g

Power Supply, Connection, and Groundin

• Never put the power plug in any socket other than the AC 117, 220 or 240 V

socket.

Otherwise, fire or electrical shock will result.

• When installing the instrument, be sure to ground it.

Otherwise, fire or electrical shock will result.

Handling Power Supply Cord

• Take care not to damage the power cord, place a heavy device on it, or pull it

forcibly.

Otherwise, the wire may break causing fire or electrical shock.

• When connecting the instrument to a peripheral (host computer), be sure to

switch OFF the power beforehand.

Otherwise, electrical shock or instrument failure may result.

V

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 7

CAUTION

Use of Reagents

• After unpacking, be sure not to allow dust, dirt, or bacteria to come in touch with

the reagent.

• Do not use reagents which have expired.

• Handle a reagent gently to prevent formation of bubbles.

• Take care not to spill a reagent. If it spills, wipe it off immediately using a wet

cloth or the like.

• Follow other instructions described on the Package Insert in each reagent.

Use of Instrument

• When performing maintenance work or inspection, use specified tools and parts.

Do not use substitute parts, or modify the instrument. It is hazardous.

• Those who have no or only limited experience in using instrument are

recommended to have guidance or assistance of those with sufficient

experience.

• If the instrument has developed a trouble by any chance, a person in charge of it

should take steps within the range specified in the OPERATOR’S MANUAL. As to

troubles other than mentioned, contact your Sysmex service representative for

assistance or service.

• Unpacking, installation, and confirmation of initial setup must be done by your

Sysmex service representative.

Environment for Use

• Install the instrument in a place which is not subject to water splash.

• Install the instrument in a place which is not subject to adverse effects of high

temperature, high humidity, dust, direct sunlight, strong lighting, etc.

• Do not give the instrument a strong vibration or impact.

• Do not install the instrument near a chemical storage or a place where a gas is

generated.

Recommended Pipette and Pipette Chip

• We recommended that you use the following pipettes and pipette chips to add

plasma and dispense/add reagents.

• Pipette: Eppendorf reference 4910 (50 - 200 µL)

• Pipette Eppendorf 300 µL chip

For details on the usage of the pipette and pipette chip, refer to the instruction

manuals attached to them.

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Sysmex CA-50 Operator’s Manual -- Revised December 2000

V

Page 8

INTRODUCTION

Thank you for purchasing the Sysmex® Automated Blood Coagulation Analyzer CA-50.

Carefully read the OPERATOR’S MANUAL for correct use of the unit.

Keep this MANUAL in good condition after reading. It will continue to be of your help in finding

specific information about this instrument.

VI

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 9

CONTENTS OF THIS MANUAL

g

g

To make full use of the functions of this instrument, thoroughly read this manual and use the

instrument as directed. The Operator’s Manual is made up of the ten chapters and appendices listed

below.

Chapter 1: Introduction

Chapter 2: Analysis Preparation

Chapter 3: Sample Analysis

Chapter 4: Display of Analysis Results

Chapter 5: Maintenance & Supplies

Replacement

Chapter 6: Quality Control

Chapter 7: Setting Standard Curves

Chapter 8: Troubleshootin

Provides an overview of the instrument, explaining its

equipment, operating procedures, and messages as

well as points to be careful about during installation.

Explains how to prepare the instrument, reagents, and

samples before performing analyses.

Describes how to analyze samples and explains

registration procedures for sample ID numbers and

analysis parameters.

Explains the screen displays and the processing of

external output.

Explains the periodic maintenance procedures and how

to replace reagent and other supplies.

Explains how to perform quality control analyses and

how to print and store quality control data.

Explains how to prepare standard curves.

Explains the error messages and how to troubleshoot.

Chapter 9: Functional Description

Chapter 10: Instrument Setup

Appendix A: Installation

Appendix B: Technical Information

Explains the coagulation detection principles. Also lists

the names and functions of the each parts.

Explains how to preset the instrument's various

settings, such as the data measure settings (includin

limits that indicate abnormal data) and the test protocol

settings.

Explains how to install the CA-50.

Includes data output format for host computer and other

reference materials.

Sysmex CA-50 Operator’s Manual -- Revised July 1999

VII

Page 10

PREMISES FOR SIGNS

y

jury

y

y

g

y

Meaning of Signs

WARNING

CAUTION

CAUTION: •Indicates what we would like you to know to maintain instrument

NOTE: •Indicates information which will come handy in operating the instrument.

•If this sign is ignored and the instrument is operated incorrectly, there is

a potentiall

in

of an operator, or grave property damage.

•If this sign is ignored and the instrument is operated incorrectly, there is

a potentiall

operator, adverse effect on output, or ma

performance and prevent its dama

hazardous situation which could result in death or serious

hazardous situation which may result in injury of an

cause property damage.

e.

Document Conventions

In explaining operation, this manual uses the conventions as shown below.

• The keys on the panel keyboard are expressed within square brackets.

For example: [Start], [Print], [

]

• The display on LCD appears within quotation marks.

For example: "PT", "QC"

NOTE: • LCD and printing described in this manual may differ from those in

practice.

• As a result of product improvements, details described in this manual

ma

differ slightly from the actual product.

VIII

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 11

CA-50 OPERATOR’S MANUAL

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION

1. INTRODUCTION.........................................................................................1-1

2. INSTRUMENT OVERVIEW .......................................................................1-2

3. OUTLINE OF OPERATION ........................................................................1-3

4. ANALYSIS PARAMETERS AND CALCULATION PARAMETERS......1-4

5. LCD SCREEN AND INPUT KEYS.............................................................1-6

5.1 LCD Screen .........................................................................................1-6

5.2 Input Keys............................................................................................1-7

6. PASSWORDS ...............................................................................................1-8

7. ALARMS ...................................................................................................1-8

8. DETECTOR LED..........................................................................................1-9

9. PACKAGING................................................................................................1-9

10. INSTALLATION ENVIRONMENT..........................................................1-10

10.1 Installation and Relocation ................................................................1-10

10.2 Grounding..........................................................................................1-10

10.3 Installation Space...............................................................................1-11

10.4 Installation Environment ...................................................................1-11

11. INSTRUMENT SPECIFICATIONS...........................................................1-12

12. MENU TREE...............................................................................................1-16

13. MAIN MENU..............................................................................................1-17

CHAPTER 2: ANALYSIS PREPARATION

1. INTRODUCTION.........................................................................................2-1

2. BEFORE TURNING ON THE POWER ......................................................2-2

3. TURNING ON THE POWER.......................................................................2-2

4. REAGENT PREPARATION........................................................................2-4

4.1 Preparing the Reagents ........................................................................2-4

4.2 Setting the Reaction Tubes and Reagents............................................2-5

5. CHECKING THE STANDARD CURVES ..................................................2-6

6. QUALITY CONTROL..................................................................................2-7

7. SAMPLE PREPARATION...........................................................................2-8

CHAPTER 3: SAMPLE ANALYSIS

1. INTRODUCTION.........................................................................................3-1

2. WORK LIST..................................................................................................3-2

2.1 Selecting the Analysis Parameter ........................................................3-2

2.2 Registering the Sample ID Number.....................................................3-4

3. SAMPLE ANALYSIS...................................................................................3-6

3.1 Start of Analysis ..................................................................................3-7

3.2 Adding the Reagents............................................................................3-8

3.3 Registering and Analyzing the Next Sample.....................................3-11

4. SHUTDOWN ..............................................................................................3-12

Sysmex CA-50 Operator’s Manual -- Revised July 1999 i

Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 12

CHAPTER 4: DISPLAY OF ANALYSIS RESULTS

1. INTRODUCTION...................................................................4-1

2. DISPLAYING AND PRINTING OUT ANALYSIS RESULTS .............4-1

2.1 Displaying the Analysis Results ...........................................4-1

2.2 Printing Out the Analysis Results..........................................4-3

3. DISPLAYING DETAILED ANALYSIS RESULTS ..........................4-5

4. OUTPUTTING ANALYSIS RESULTS.........................................4-7

CHAPTER 5: MAINTENANCE & SUPPLIES REPLACEMENT

1. INTRODUCTION...................................................................5-1

2. CA-50 MAINTENANCE CHECKLIST .........................................5-2

3. DAILY MAINTENANCE AND INSPECTION................................5-3

3.1 Cleaning the Reaction Tube Holder, Incubator, and Pipette guide....5-3

4. WEEKLY MAINTENANCE AND INSPECTION ............................5-4

4.1 Cleaning the Instrument.....................................................5-4

4.2 Cleaning by Blower..........................................................5-5

5. REPLACING SUPPLIES ..........................................................5-6

5.1 Replacing Fuses ..............................................................5-6

5.2 Replacing Printer Paper .....................................................5-7

5.3 Supply Parts List .............................................................5-8

CHAPTER 6: QUALITY CONTROL

1. INTRODUCTION...................................................................6-1

1.1 Quality Control File..........................................................6-1

1.2 Quality Control Analysis....................................................6-1

1.3 QC Error Check ..............................................................6-2

2. QUALITY CONTROL MENU....................................................6-3

2.1 Displaying the QC Chart....................................................6-3

3. SELECTING THE QUALITY CONTROL FILE ..............................6-4

3.1 Selecting the Quality Control Parameter..................................6-4

3.2 Selecting the Quality Control File .........................................6-5

4. PRINTING OUT THE QC CHART..............................................6-6

5. DELETING THE QUALITY CONTROL DATA..............................6-7

5.1 Deleting the Data.............................................................6-7

5.2 Deleting the File..............................................................6-8

6. QUALITY CONTROL SETTINGS ..............................................6-9

ii Sysmex CA-50 Operator’s Manual -- Revised July 1999

Sysmex CA-50 Operator’s Manual -- Revised December 1999

Page 13

CHAPTER 7: SETTING STANDARD CURVES

1. INTRODUCTION.........................................................................................7-1

2. OBTAINING DATA FOR STANDARD CURVE.......................................7-1

3. STANDARD CURVE MENU ......................................................................7-4

4. PREPARING THE STANDARD CURVE...................................................7-6

4.1 Selecting the Analysis Parameter ........................................................7-6

4.2 Inputting the Standard Curve Data ......................................................7-7

5. PRINTING OUT THE STANDARD CURVE ...........................................7-10

6. SETTING THE CALCULATION PARAMETERS...................................7-11

6.1 Calculation Parameter Setting Menu.................................................7-11

6.2 Setting the Activity Percent and Concentration.................................7-12

6.3 Setting the Ratio ................................................................................7-14

6.4 Setting the INR ..................................................................................7-15

6.5 Setting the DFbg................................................................................7-16

6.6 Printing Out the Calculation Parameter Settings...............................7-17

7. DELETING THE STANDARD CURVE DATA .......................................7-18

CHAPTER 8: TROUBLESHOOTING

1. INTRODUCTION.........................................................................................8-1

2. WHEN YOU SUSPECT AN ERROR ..........................................................8-1

3. TROUBLESHOOTING BY ERROR MESSAGE........................................8-2

3.1 Troubleshooting Guide........................................................................8-2

3.2 Instrument Errors and Corrective Actions...........................................8-3

3.3 Analysis Data Errors and Corrective Actions......................................8-5

4. INSTRUMENT CHECK...............................................................................8-8

4.1 Test Program Menu .............................................................................8-8

4.2 Display of Temperatures......................................................................8-9

4.3 Sensor Test.........................................................................................8-10

4.4 Key Entry Test...................................................................................8-11

4.5 Built-in Printer Test...........................................................................8-11

4.6 Communication Test..........................................................................8-12

4.7 LCD Screen Test................................................................................8-12

CHAPTER 9: FUNCTIONAL DESCRIPTION

1. INTRODUCTION.........................................................................................9-1

2. DETECTION PRINCIPLES FOR COAGULATION METHOD ................9-2

2.1 Optical Detection Method (Scattered Light Detection Method) .........9-2

2.2 Blood Coagulation and Scattered Light Intensity................................9-3

2.3 Coagulation Point Detection Method

(Percentage Detection Method) ..........................................................9-4

2.4 Standard Curve for Coagulation Method.............................................9-5

2.5 Calculation of PT Ratio and INR Value..............................................9-5

2.6 Analysis Flow......................................................................................9-6

3. ANALYSIS MECHANISM........................................................................9-10

4. INSTRUMENT COMPONENTS AND FUNCTIONS ..............................9-11

4.1 Front, Top, and Right Side ................................................................9-11

4.2 Rear ..................................................................................................9-13

4.3 Bottom ...............................................................................................9-14

Sysmex CA-50 Operator’s Manual -- Revised July 1999 iii

Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 14

CHAPTER 10: INSTRUMENT SETUP

1. INTRODUCTION.................................................................10-1

2. SETTING MENU .................................................................10-2

3. MEASURE SETTINGS ..........................................................10-3

3.1 Measure Setting Menu.....................................................10-3

3.2 Test Protocol Settings .....................................................10-4

3.3 Data Check Parameter & Mark Limit Settings......................... 10-9

3.4 Report Limit Settings.....................................................10-13

3.5 Replication Difference Limit Settings..................................10-17

3.6 Measure Mode & Sample Incubation Ready Check Settings .......10-20

3.7 Conversion Settings.......................................................10-23

4. I/O SETTINGS ...................................................................10-26

4.1 I/O Setting Menu..........................................................10-26

4.2 Built-In Printer Settings..................................................10-26

4.3 Host Computer Settings..................................................10-28

4.4 Printing Out I/O Settings.................................................10-31

5. SYSTEM SETTINGS............................................................10-32

5.1 System Setting Menu.....................................................10-32

5.2 Date Settings...............................................................10-32

5.3 Time Settings ..............................................................10-33

5.4 Password Settings.........................................................10-34

6. PRINTING OUT ALL SETTINGS............................................10-36

APPENDIX A: INSTALLATION

1. INTRODUCTION..................................................................A-1

2. CHECK BEFORE INSTALLATION ........................................... A-1

3. INSTALLATION SPACE ........................................................A-2

4. CHANGING THE INSTALLATION DIRECTION OF PIPETTE

GUIDE............................................................................... A-3

5. INSTALLING THE FILTER ..................................................... A-5

6. CONNECTING THE POWER CORD AND CONNECTION CORD ..... A-5

6.1 Connecting the Power Cord ............................................... A-5

6.2 Connecting the Connection Cord ......................................... A-7

7. ADJUSTING THE LCD BRIGHTNESS .......................................A-8

8. SETTING A PRINTER PAPER.................................................. A-9

APPENDIX B: TECHNICAL INFORMATION

1. OUTPUT FORMAT FOR HOST COMPUTER...............................B-1

1.1 Hardware .....................................................................B-1

1.2 Software......................................................................B-2

1.3 Text Format..................................................................B-3

2. FACTORY DEFAULT SETTINGS.............................................B-7

2.1 QC Parameters and Factory Default Settings ...........................B-7

2.2 Standard Curve Data and Factory Default Settings.....................B-8

2.3 Standard Curve Calculation Parameters and

Factory Default Settings...................................................B-11

2.4 Instrument Setting Parameters and Factory Default Settings ........B-12

INDEX

iv Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 15

CHAPTER 1 INTRODUCTION

1. INTRODUCTION ................................................................................1-1

2. INSTRUMENT OVERVIEW ...................................................................1-2

3. OUTLINE OF OPERATION ....................................................................1-3

4. ANALYSIS PARAMETERS AND CALCULATION PARAMETERS....................1-4

5. LCD SCREEN AND INPUT KEYS ...........................................................1-6

5.1 LCD Screen .................................................................................1-6

5.2 Input Keys ..................................................................................1-7

6. PASSWORDS .....................................................................................1-8

7. ALARMS...........................................................................................1-8

8. DETECTOR LED .................................................................................1-9

9. PACKAGING.....................................................................................1-9

10. INSTALLATION ENVIRONMENT .........................................................1-10

10.1 Installation and Relocation .............................................................. 1-10

10.2 Grounding.................................................................................1-10

10.3 Installation Space .........................................................................1-11

10.4 Installation Environment................................................................. 1-11

11. INSTRUMENT SPECIFICATIONS.........................................................1-12

12. MENU TREE....................................................................................1-16

13. MAIN MENU ...................................................................................1-17

Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 16

INTRODUCTION

1 . INTRODUCTION

The Sysmex® CA-50 is an automated blood coagulation analyzer For In Vitro Diagnostic Use to

perform blood coagulation tests in clinical laboratories.

Chapter 1 provides an overview of the instrument and analysis procedures that should be read

before the CA-50 is used in a daily routine.

The major elements of Chapter 1 are listed below.

Instrument Overview

Provides an overview of the CA-50’s functions.

Analysis Procedure Overview

Provides an overview of the analysis procedure, LCD screen display, and key operation.

Installation Precautions

Explains matters that require confirmation before installing the instrument, such as the

installation space, required equipment, and environmental conditions.

Instrument Specifications

Provides the instrument specifications.

Menu Tree

Shows a menu tree of the CA-50.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-1

Page 17

INTRODUCTION

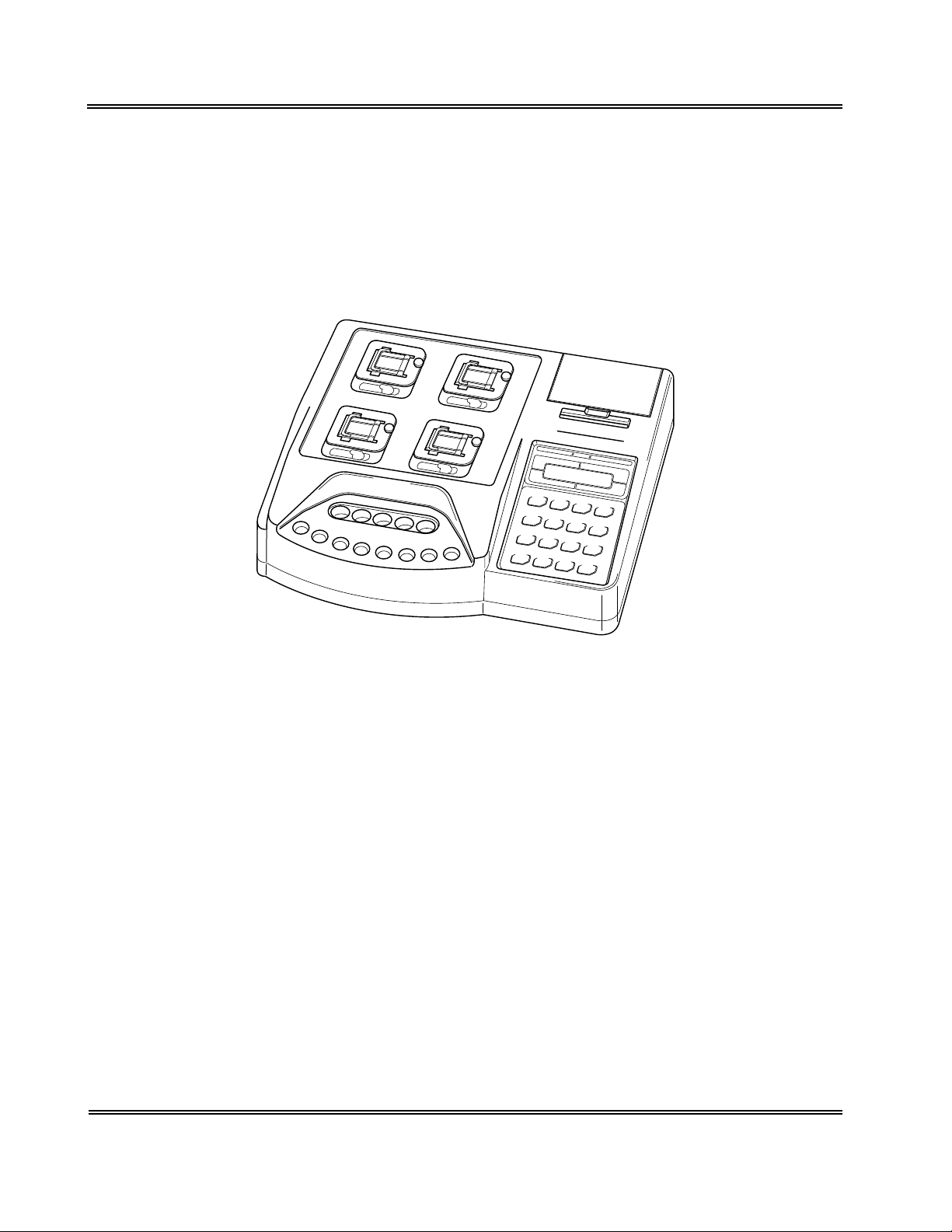

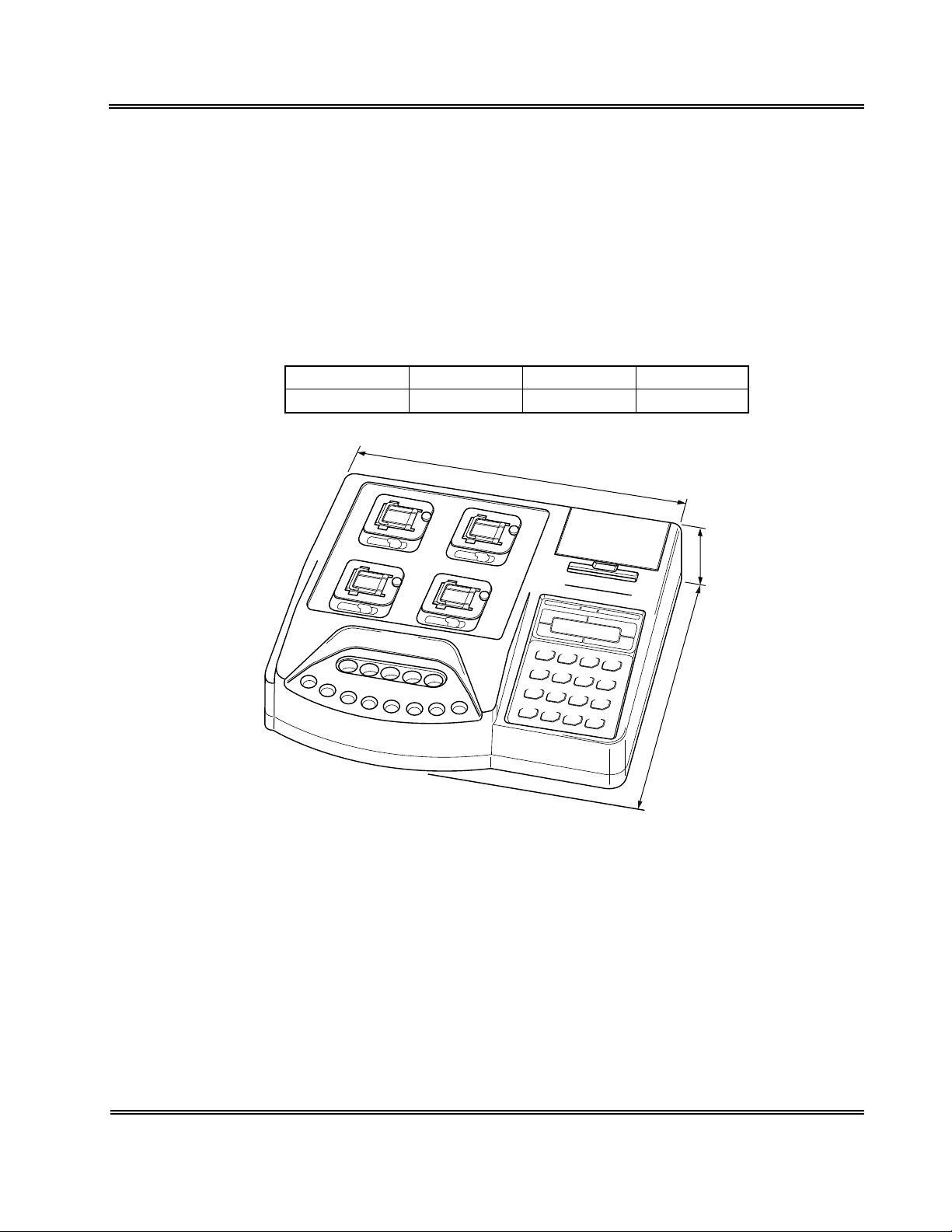

2 . INSTRUMENT OVERVIEW

The CA-50 is an automated blood coagulation analyzer that can quickly analyze samples with a

high degree of accuracy. The CA-50 can analyze samples using a Coagulation Method; and the

analyzed data can be displayed on its LCD screen and printed by the built-in printer. The CA-50

also has some supplemental functions including quality control.

Figure 1-1: Overview of CA-50

1-2 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 18

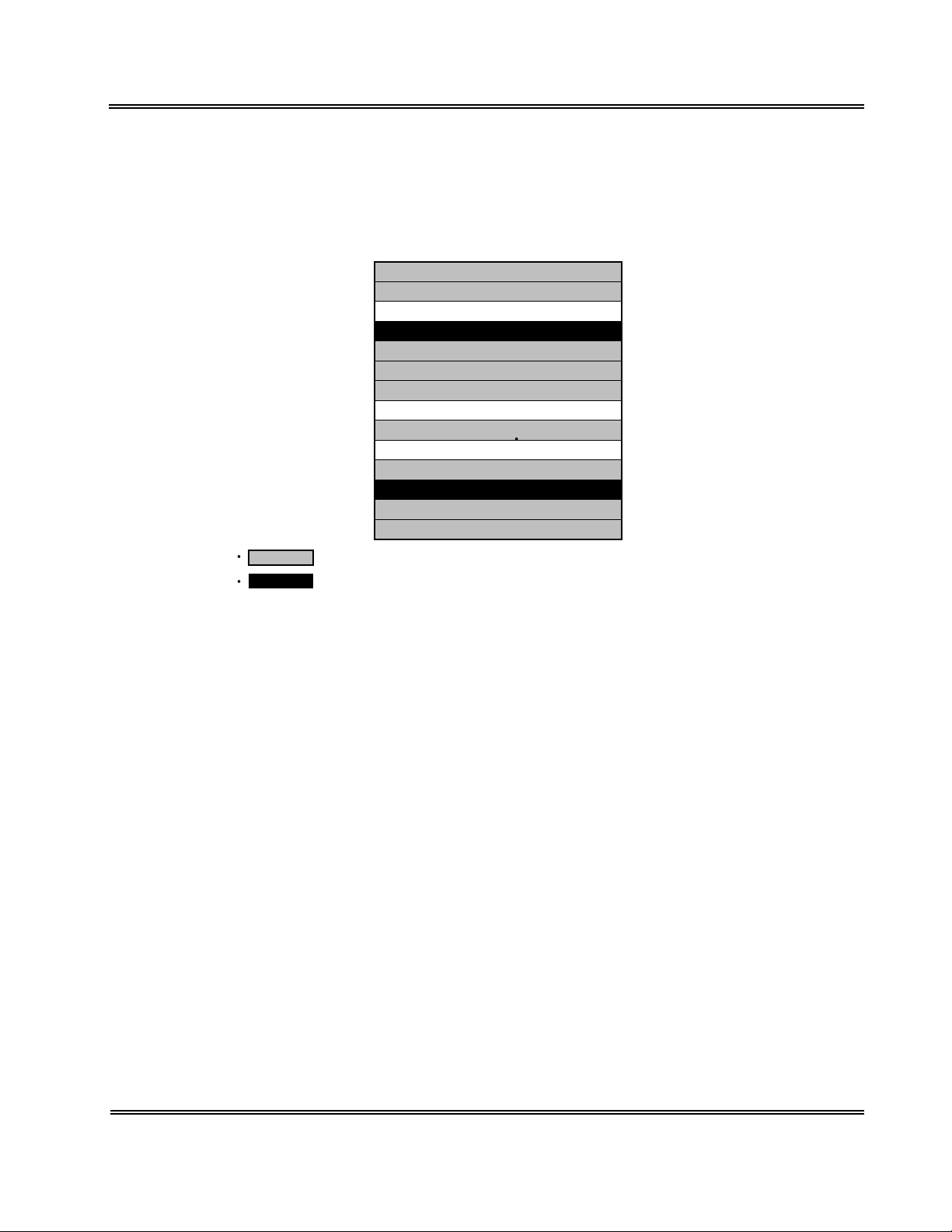

3 . OUTLINE OF OPERATION

g

The CA-50 performs an analysis by the following procedure.

Table 1-1: CA-50 Analysis Procedure

Check before turning ON power

Power ON

Self-check

Ready

Preparation for analysis

Work List

Press [START] key

Execution of sample incubation

Addition of reagents

Execution of analysis

Discard used reaction tubes

Ready

Power OFF

Operation after analysis completion

INTRODUCTION

Ready

:

Indicates actions performed by the operator.

:

Indicates that the instrument is in the ready status. At this time,

the detector LED of each channel will light up in green indicating

that you can perform operations such as analysis and settin

s.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-3

Page 19

INTRODUCTION

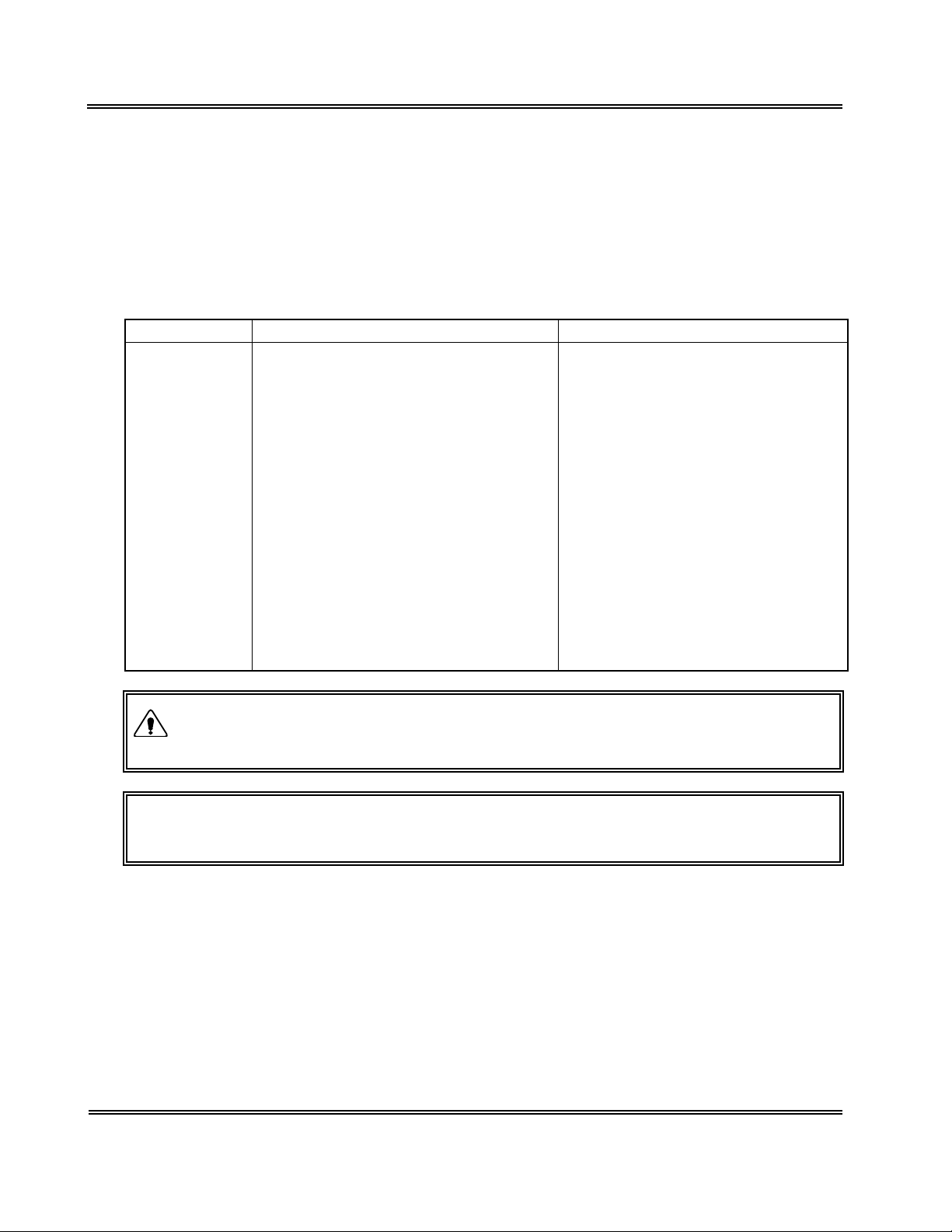

4 . ANALYSIS PARAMETERS AND CALCULATION PARAMETERS

The CA-50 can analyze and calculate the parameters shown below. Additional analysis and

calculation parameters can be registered as well.

The following list shows the analysis and calculation parameters that can be analyzed by the CA-

50.

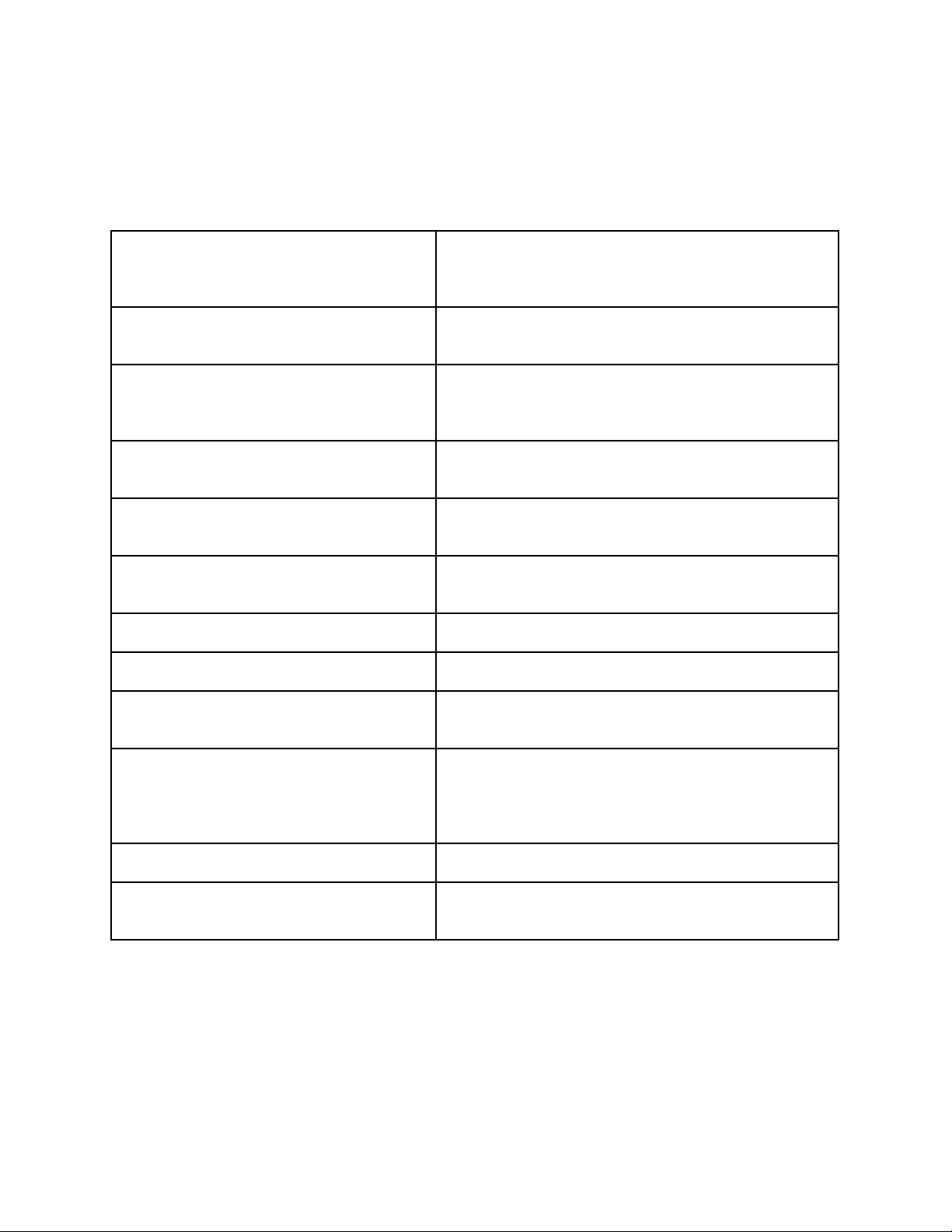

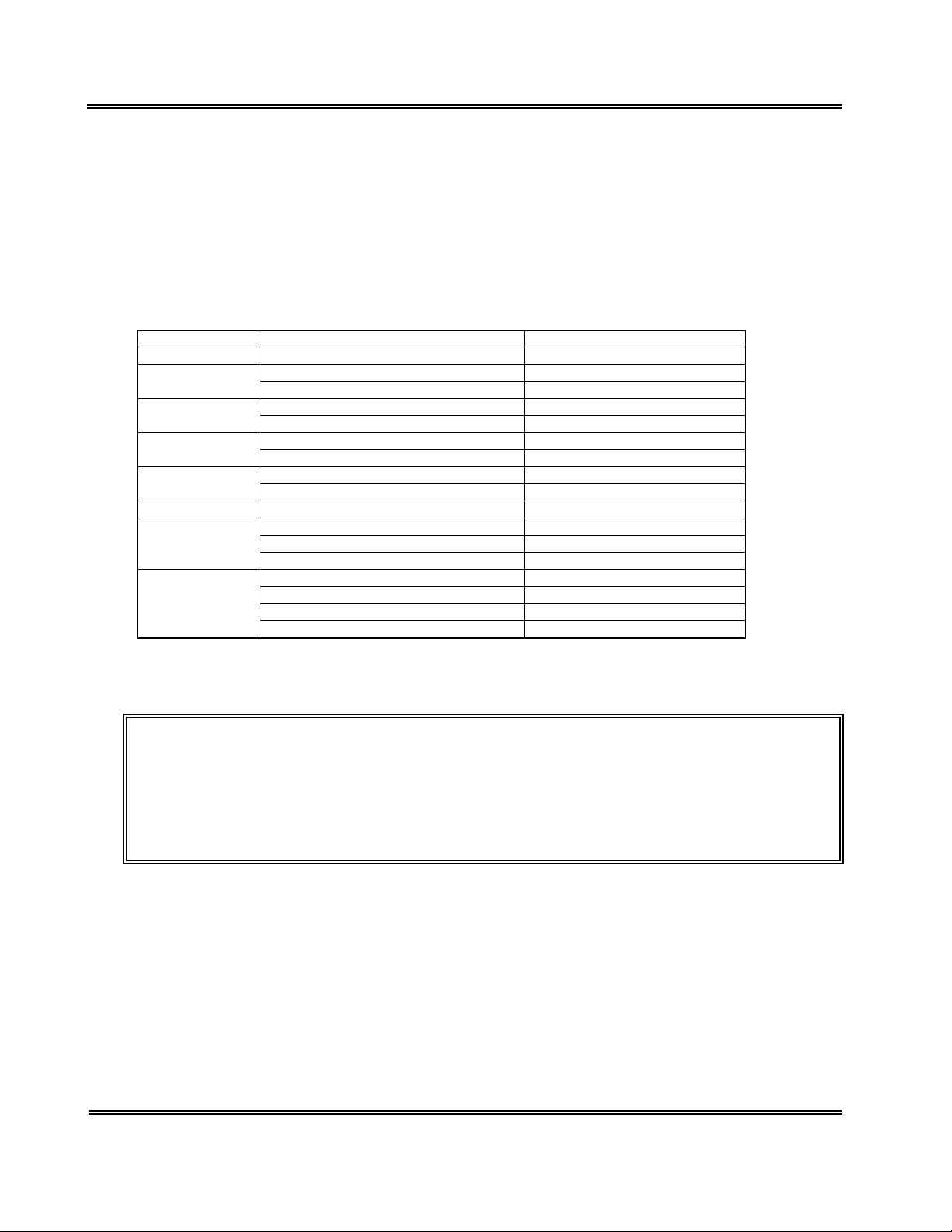

Table 1-2: CA-50 Analysis Parameters and Calculation Parameters

Method Analysis parameter Calculation parameter

Coagulation

Method

Prothrombin Time (PT)

Activated Partial Thromboplastin Time

(APTT)

Fibrinogen (Fbg)

Thrombotest (TTO)

Normotest (NT)

Thrombin Time (TT)

Extrinsic Factor Deficiency Assay

(II, V, VII, X)

Intrinsic Factor Deficiency Assay

(VIII, IX, XI, XII)

Prothrombin Activity Percent

Prothrombin Ratio

INR

Derived Fbg

Fibrinogen Concentration

Thrombotest Activity Percent

Normotest Activity Percent

Factor II Activity Percent

Factor V Activity Percent

Factor VII Activity Percent

Factor VIII Activity Percent

Factor IX Activity Percent

Factor X Activity Percent

Factor XI Activity Percent

Factor XII Activity Percent

CAUTION

• If you analyze with a wrong reagent, correct analysis results will not be

obtained.

NOTE: • You can set up to 3 types of calculation parameters each for an analysis

parameter.

1-4 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 20

INTRODUCTION

CAUTION

Interpretation of APTT Abnormal Early Reaction.

• APTT results less than or equal to 20.0 seconds, APTT results with NC

(No Coagulation), SC (Slight Coagulation) or CCE (Coag. Curve Error)

error messages, or abnormally short APTT results may be caused by an

abnormal early reaction.

APTT results with an abnormal early reaction can be identified in the

analysis data.

• If an APTT result less than or equal to 20.0 seconds is obtained, the

following steps should be taken:

1. Verify sample and reagent integrity along with maintenance procedures.

2. Print out the Analysis data.

See Chapter 4, Section 4: OUTPUTTING ANALYSIS RESULT and

Chapter 10, Section 4.2: Built-In Printer Settings.

Note that the stored analysis results will be deleted, when you start a

next analysis on the same channel or you turn OFF the power or so

on.

3. Observe time in the “2%” position.

4. If that time is equal to or less than 15 seconds, then an abnormal early

reaction may have occurred.

5. Re-analyze the sample.

6. If result is the same, it should not be reported.

7. Review the previous patient history to determine acceptability of

patient results. Results of the other parameters considered, then make

overall evaluation.

8. Follow your laboratory's alternate protocol.

• An error code may or may not be associated with this result.

• An abnormal early reaction rarely occurs.

• The CA-50 should be set up so that any APTT results of less than or

equal to 20.0 seconds will have a message of <20.1 seconds on the printout.

• To set up this function see Chapter 10, Section 3.4: Report Limit Settings

and enter 20.1 for the APTT lower limit.

• Remember to change the Built-in Printer Settings back to “List” after review

of the analysis data.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-5

Page 21

INTRODUCTION

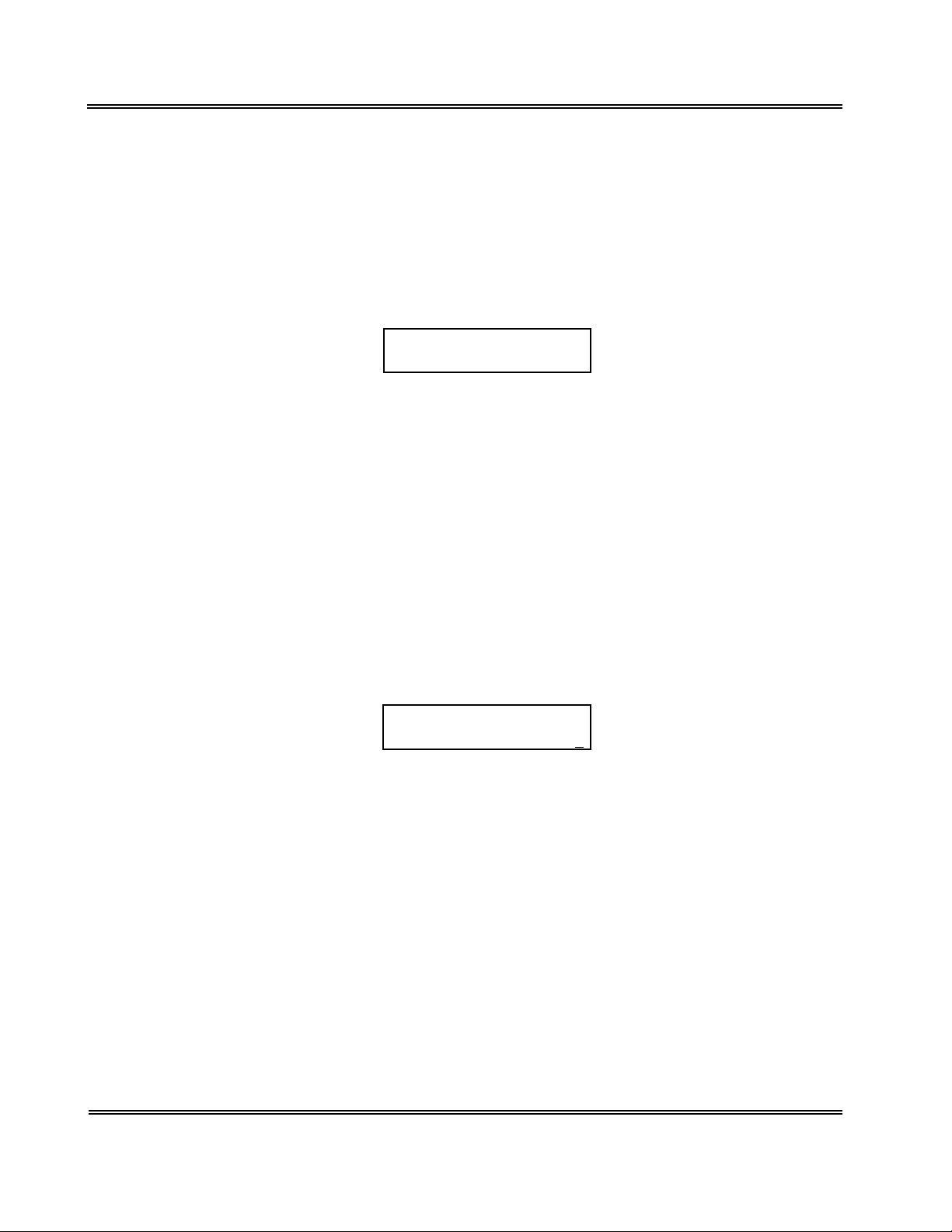

5 . LCD SCREEN AND INPUT KEYS

5. 1 LCD Screen

The instrument’s status, analysis results, and all other information are displayed on the CA-50’s

LCD screen. The screen is capable of displaying 16 characters by 2 lines maximum.

Display position of the each analysis channel on the screen

CH3 CH4

CH1 CH2

Figure 1-2: Display position of the each analysis channel on the screen

On the Analysis screen, the LCD screen is split into four parts to show the data of respective

channels from 1 to 4.

Analysis parameters are abbreviated into two characters as shown below:

• PT: PT • F5: Factor V

• AP: APTT • F7: Factor VII

• Fg: Fbg • F8: Factor VIII

• TO: TTO • F9: Factor IX

• NT: NT • 10: Factor X

• TT: TT • 11: Factor XI

• F2: Factor II • 12: Factor XII

Settings Screen

ID No. Entry

Select CH(1-4)?

1

Figure 1-3: Example of Settings Screen

On the Settings screen, parameters to be set or selected are displayed on the upper and lower

lines.

1-6 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 22

INTRODUCTION

5. 2 Input Keys

By using the input keys, you can perform each setting such as entering numerals and selecting

various parameters.

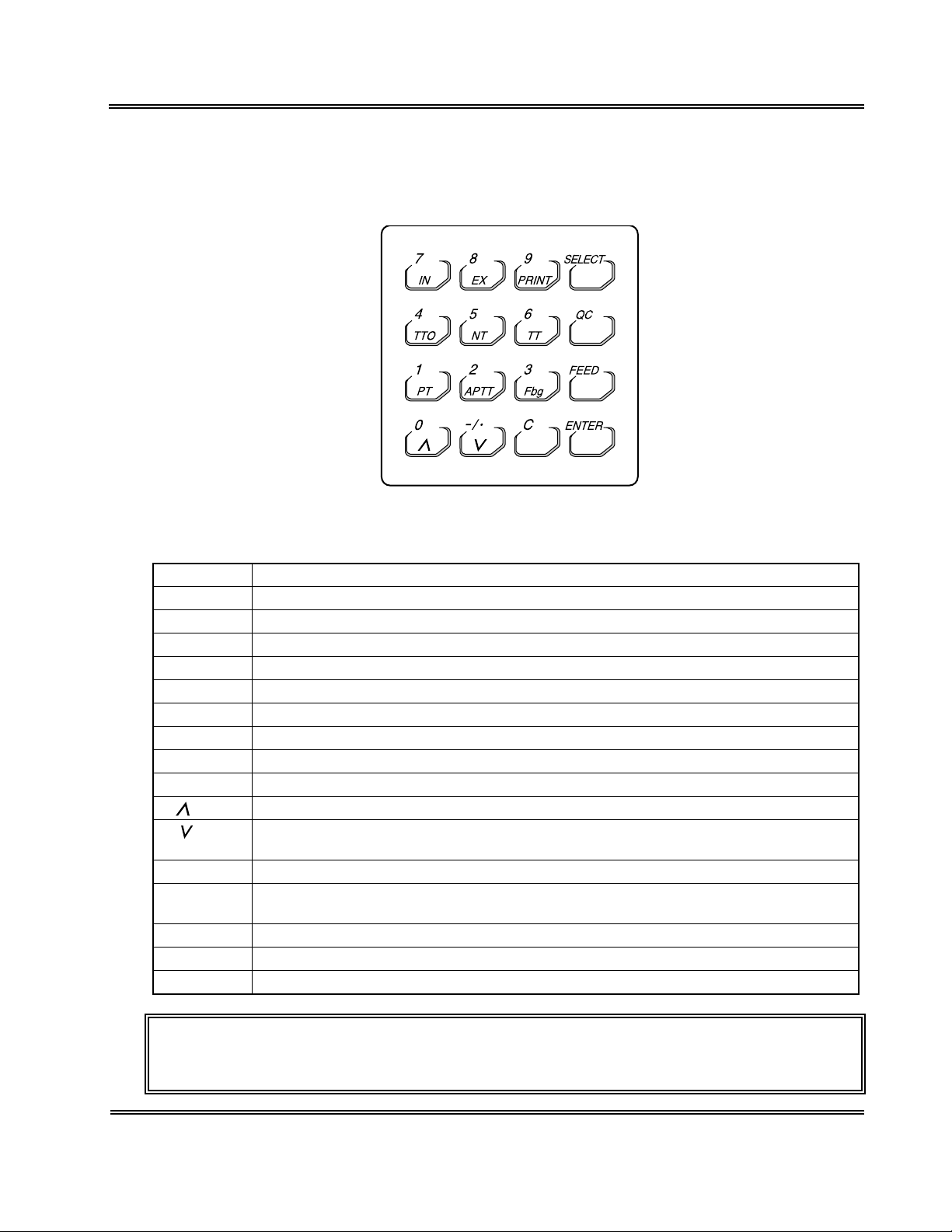

Figure 1-4: Input Keys

Table 1-3: Operation of Input Keys

Key Operation

1/PT Press to input the number "1" or select "PT".

2/APTT Press to input the number "2" or select "APTT".

3/Fbg Press to input the number "3" or select "Fbg".

4/TTO Press to input the number "4" or select "TTO".

5/NT Press to input the number "5" or select "NT".

6/TT Press to input the number "6" or select "TT".

7/IN Press to input the number "7" or select "intrinsic factor".

8/EX Press to input the number "8" or select "extrinsic factor".

9/PRINT Press to input the number "9" or print a menu.

0/ Press to input the number "0", scroll a menu up, or switch to the previous data.

-/./ Press to input a hyphen or a decimal point, scroll a menu down, or switch to the next

data.

C Press to clear inputted data or stop an error beep.

SELECT Press to switch between Menu and Ready, cancel updated data (when confirmed), or

return to the previous screen.

QC Press to input "QC" (when inputting an ID number).

FEED Press to feed paper.

ENTER Press to set inputted data or execute updated data (when confirmed).

CAUTION: • When a key has two or more functions, the function will be changed over

depending on the situation when the key is pressed.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-7

Page 23

INTRODUCTION

6 . PASSWORDS

Important programs are protected by a password so that the programs can be executed under the

control of a supervisor.

When a menu that is protected by a password is to be executed, a Password Entry window will

appear. To execute the menu, enter the preset password and press the [Enter] key.

For details on how to set the password, see Chapter 10, Section 5.4: Password Settings.

7 . ALARMS

The CA-50 makes three types of alarm sounds.

1. Key Entry

A short beep will sound each time an input key is pressed.

2. Reagent addition timing

Two short beeps followed by a long beep will sound to let you know the timing of adding

reagents.

The time allowed for reagent addition is preset at 10 seconds as default; 5 seconds before

and after the time of addition. If you wish to change the allowed time, see Chapter 10,

Section 3.2: Test Protocol Settings.

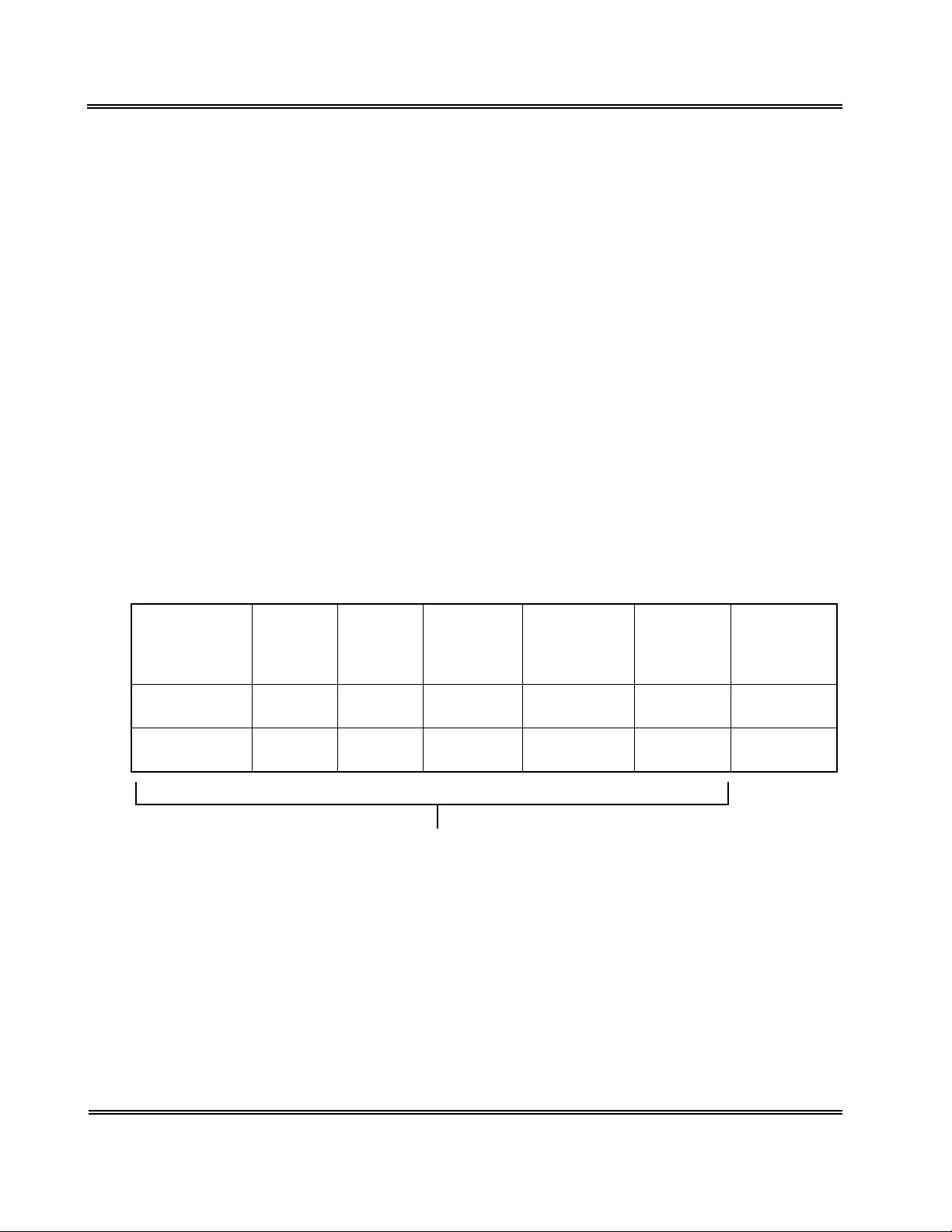

Table 1-4: Reagent Addition Timing Alarm

Reagent

addition allowed

time (start)

Two short

beeps

5 seconds

before

No sound A short

beep

• • •

A short beep A long beep A short beep A long beep

One beep

per second

Reagent

addition

For 0.5

seconds

Allowed time for reagent addition

3. Error

A long beep will sound when an error occurs on the instrument.

The beep will continue to sound until the [C] key is pressed.

• • •

One beep

per second

Reagent

addition

allowed time

(end)

An error beep

1-8 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 24

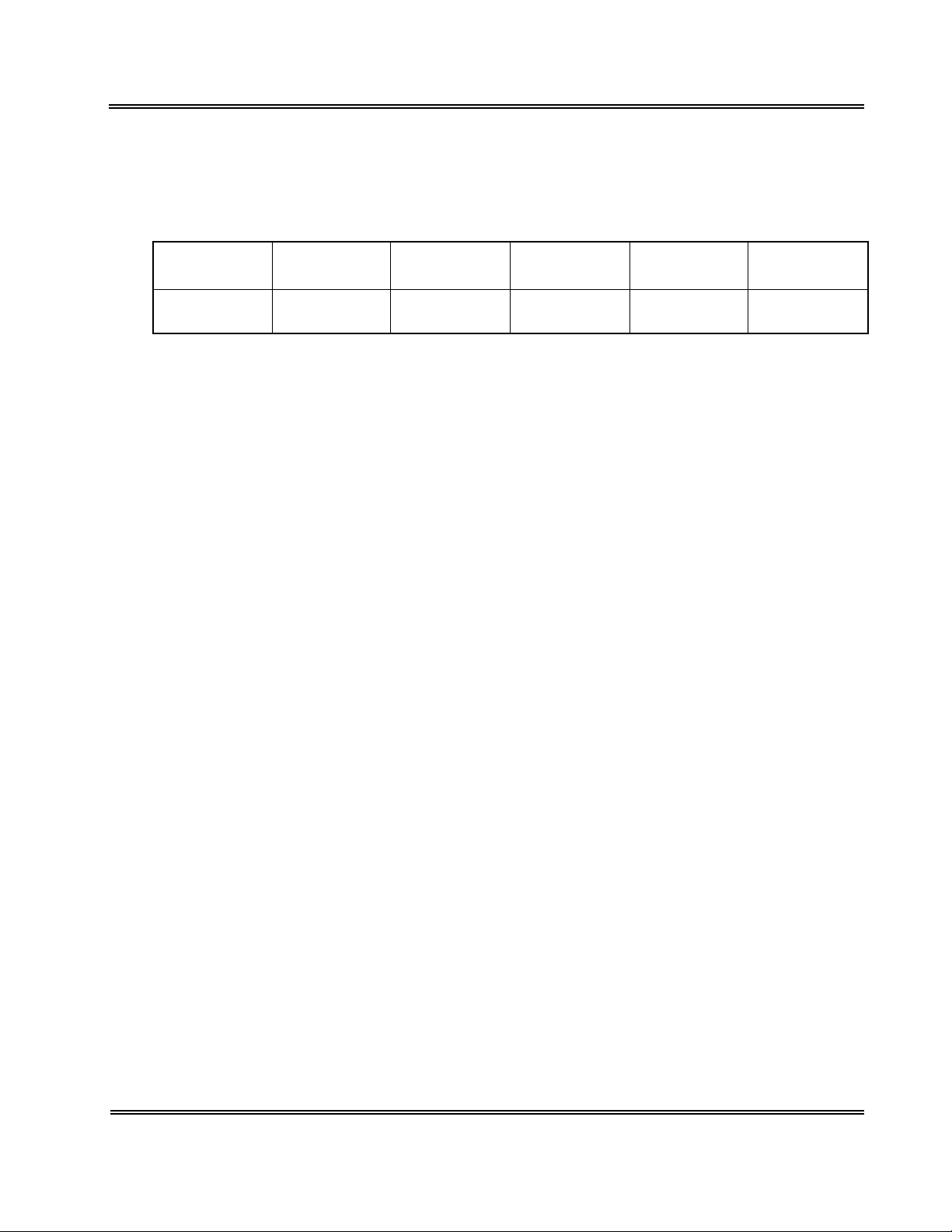

8 . DETECTOR LED

The detector LED of each channel indicates the status as shown in the table below.

Table 1-5: Operation of Detector LED

INTRODUCTION

During

warming-up

Turns off Lights up in

Ready During

green

Reagent

incubation

Blinks in red Blinks in green Lights up in red Lights up in

addition timing

During photo

detection

green

9 . PACKAGING

The CA-50 is thoroughly checked before it is shipped from the factory, and is carefully

packaged to withstand shocks during shipment.

After the CA-50 has been delivered, check the packaging. Make sure that the instrument is free

of exterior damage.

Your Sysmex service representative will unpack and install the instrument after delivery and will

also set the initial settings.

Ready

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-9

Page 25

INTRODUCTION

10. INSTALLATION ENVIRONMENT

10.1 Installation and Relocation

The CA-50 is installed by your Sysmex Service representative. In case relocation becomes

necessary after installation, see Appendix A: INSTALLATION to install the instrument

correctly.

WARNING

CAUTION

• When relocating the CA-50, be sure to wear rubber gloves. After the

relocation, wash your hands with disinfectant solution.

If your hands are contaminated with blood, infection by bacteria or the like

can occur.

• When relocating the CA-50, hold the instrument securely. If the instrument

falls, you can get injured or the instrument can be damaged.

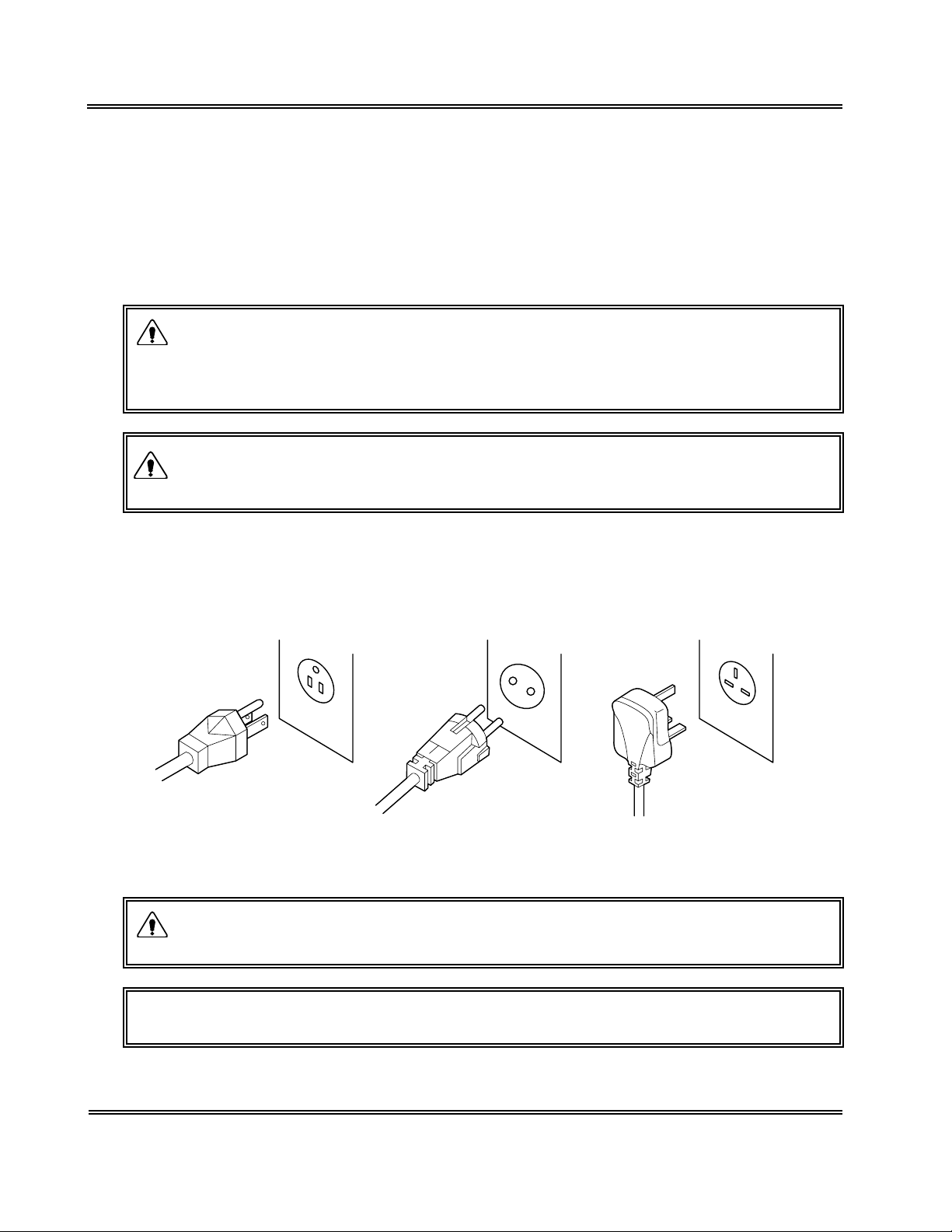

10.2 Grounding

The instrument power supply cord uses a 3-prong plug. When the power supply socket is 3prong (with grounded), simply plug it to the socket.

117 VAC Spec. 220 VAC Spec. 240 VAC Spec.

Figure 1-5: Plugs

WARNING

NOTE: • The number of power supply sockets required is 1.

• Make sure to ground the instrument. Inadequate grounding could cause

electrical shocks.

1-10 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 26

INTRODUCTION

10.3 Installation Space

To ensure that the instrument fulfills its function, it is important to install it in an appropriate

place:

• Select a place that is close to the power supply.

• Secure a place spacious enough for maintenance and service. Giving consideration to heat

radiation by the instrument, provide at least 10 cm distance from the wall to the rear panel.

The instrument dimensions are shown below. The power supply cord is 1.8 m long.

Table 1-6: Instrument Dimensions

Width (mm) Depth (mm) Height (mm) Weight (kg)

327 302 113 4.5

327 mm

113 mm

302 mm

Figure 1-6: Instrument Dimensions

10.4 Installation Environment

• Use the instrument at an ambient temperature of 15°C - 35°C (optimum: 23°C).

• Use it at a relative humidity range of 30% - 85%.

• Avoid a place that can become extremely hot or cold.

• Avoid a place that can be exposed to direct sunlight.

• Choose a well-ventilated place.

• Avoid a place close to a wireless telegraph or communication facility where high frequency

waves can be generated or radio interference can occur.

• Do not use in dusty areas.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-11

Page 27

INTRODUCTION

11 . INSTRUMENT SPECIFICATIONS

Analysis parameters/Calculation parameters

See Section 4: ANALYSIS PARAMETERS AND CALCULATION PARAMETERS in this

chapter.

Simultaneous Random Analysis of 4 Parameters

Random analysis is possible.

Required Sample

Prothrombin Time (PT): 50 µL

Activated Partial Thromboplastin Time (APTT): 50 µL

Fibrinogen (Fbg): 10 µL

Thrombotest (TTO): 20 µL

Normotest (NT): 10 µL

Thrombin Time (TT): 100 µL

Extrinsic Factor Deficiency Assay (II, V, VII, X): 5 µL

Intrinsic Factor Deficiency Assay (VIII, IX, XI, XII): 5 µL

Analysis Principles

Coagulation Method

1. Coagulation Reaction Detection Method (Scattered Light Detection Method)

Irradiates red light (660 nm) onto a mixture of blood plasma and reagent and detects the

change in turbidity (when the fibrin clots are formed) as the change in scattered light. And

measures the coagulation time.

2. Coagulation Point Detection Method (Percentage Detection Method)

Calculates the coagulation time as the time required to achieve the amount of scattered light

that is set for the coagulation detection point, using the amount of scattered light that is

present just after the start of detection as 0%, and the amount of scattered light that is

present at the completion of coagulation as 100%.

Range of Analysis

Fibrinogen Concentration

Can analyze from 50 mg/dL to 450 mg/dL.

Detection Time

Detects within the maximum detection time, and measures the result.

Typical maximum detection time: 100 seconds for PT and Fbg; 190 seconds for others.

Maximum detection time: 600 seconds for each parameter

1-12 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 28

INTRODUCTION

Reproducibility

Prothrombin Time (PT): C.V. 2% or less

Activated Partial Thromboplastin Time (APTT): C.V. 2% or less

Fibrinogen (Fbg): C.V. 4% or less

Thrombotest (TTO): C.V. 4% or less

Normotest (NT): C.V. 4% or less

Thrombin Time (TT): C.V. 10% or less

Extrinsic Factor Deficiency Assay (II, V, VII, X): C.V. 5% or less

Intrinsic Factor Deficiency Assay (VIII, IX, XI, XII): C.V. 5% or less

* The data above are variation coefficients for coagulation times (in seconds) or for the amount

of change in activity% taken from 10 analyses of Dade Behring Ci-Trol Level 1 (control

plasma), with the reagents below used.

Thromboplastin•C plus

Dade Behring Actin Activated Cephaloplastin Reagent

20 mM Calcium Chloride Solution

Dade Behring Fibrinogen Determination Reagents

Owren's Veronal Buffer

CA Series Complex Factor TTO

CA Series Complex Factor HPT

Dade Behring Factor-deficient Plasma

Display

Displays characters on a liquid crystal display (LCD).

Printing

Permits graphic printing through a built-in printer. (Printer paper specification: F1-1, width: 58

mm)

External Input/Output

Equipped with an RS-232C serial port (bit serial voltage signal).

Detector

Detector: 4 wells (Scattered light detector)

Incubator

Incubator: 5 wells

Reaction Tube Holder

Reaction tube holder: 8 wells

Temperature Control

Detector: 37°C±0.5°C

Incubator: 37°C±1°C

Applies when room temperature is within 15°C - 35°C.

Time to Reach Temperature Setting

Reaches preset temperature within 30 minutes after power is turned ON (when the room

temperature is within the specified range).

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-13

Page 29

INTRODUCTION

Quality Control

control (L-J control): 50 points × 3 files, 14 parameters

X

Standard Curve

6 points, 14 parameters

Power

Rated voltage: 117 VAC±10%, 230 VAC±15%

Frequency: 50 Hz or 60 Hz

Power consumption: 90 VA or less

Temperature Compensation Required: Approx. 307 BTU/h (77 kcal/h)

Environmental Requirements

15°C - 35°C

Dimensions/Weight

Main Unit: 327 (W) × 302 (D) × 113 (H) mm; approx. 4.5 kg

1-14 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 30

INTRODUCTION

CAUTION

Interpretation of APTT Abnormal Early Reaction.

• APTT results less than or equal to 20.0 seconds, APTT results with NC

(No Coagulation), SC (Slight Coagulation) or CCE (Coag. Curve Error)

error messages, or abnormally short APTT results may be caused by an

abnormal early reaction.

APTT results with an abnormal early reaction can be identified in the

analysis data.

• If an APTT result less than or equal to 20.0 seconds is obtained, the

following steps should be taken:

1. Verify sample and reagent integrity along with maintenance procedures.

2. Print out the Analysis data.

See Chapter 4, Section 4: OUTPUTTING ANALYSIS RESULT and

Chapter 10, Section 4.2: Built-In Printer Settings.

Note that the stored analysis results will be deleted, when you start a

next analysis on the same channel or you turn OFF the power or so

on.

3. Observe time in the “2%” position.

4. If that time is equal to or less than 15 seconds, then an abnormal early

reaction may have occurred.

5. Re-analyze the sample.

6. If result is the same, it should not be reported.

7. Review the previous patient history to determine acceptability of

patient results. Results of the other parameters considered, then make

overall evaluation.

8. Follow your laboratory's alternate protocol.

• An error code may or may not be associated with this result.

• An abnormal early reaction rarely occurs.

• The CA-50 should be set up so that any APTT results of less than or

equal to 20.0 seconds will have a message of <20.1 seconds on the printout.

• To set up this function see Chapter 10, Section 3.4: Report Limit Settings

and enter 20.1 for the APTT lower limit.

• Remember to change the Built-in Printer Settings back to “List” after review

of the analysis data.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-15

Page 31

INTRODUCTION

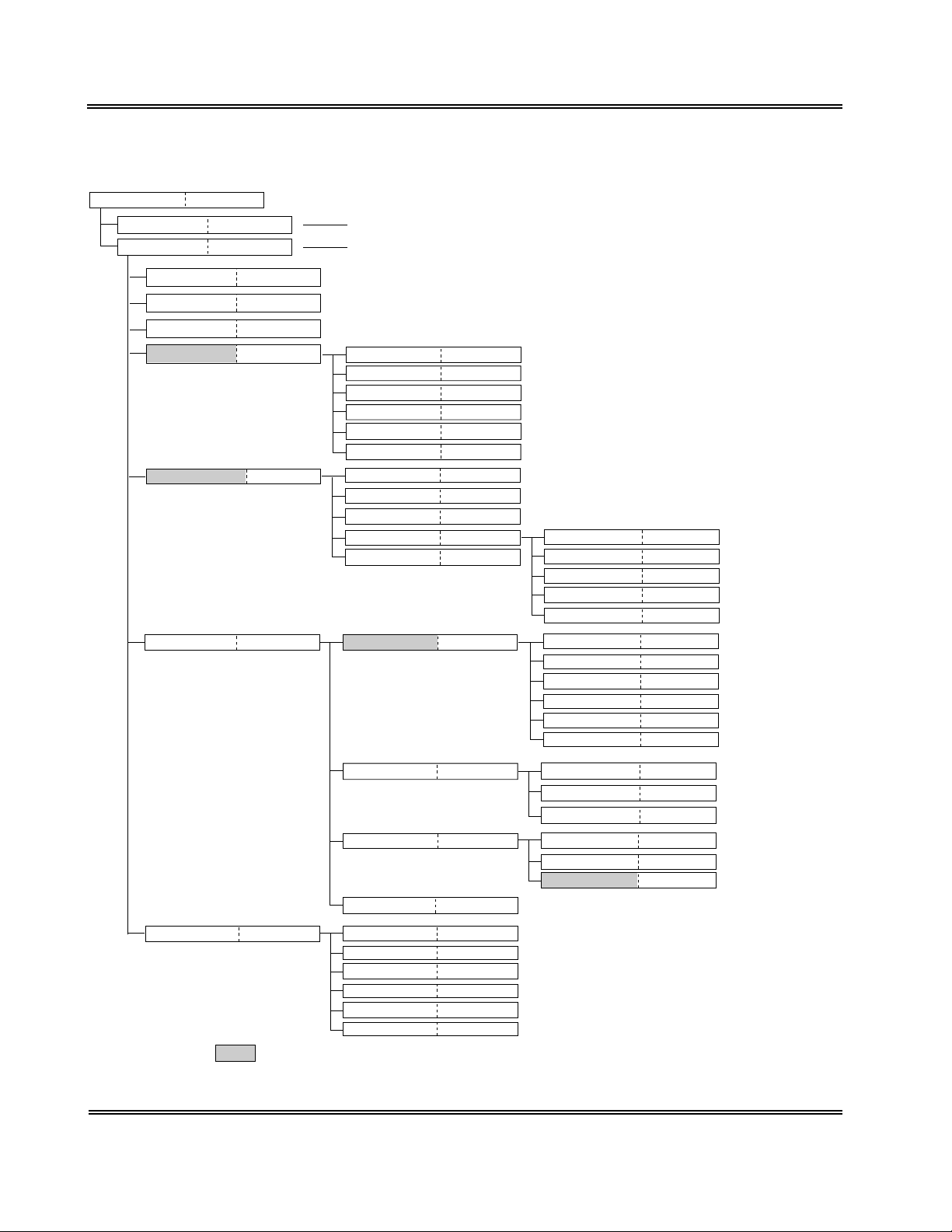

12 . MENU TREE

Ready

Analysis Start

MAIN MENU

Chapter 2, 3

Chapter 3, 3.1

Chapter 1, B

1. Select Test

2. ID No. Entry

3. Display Data

4. QC

5. Standard Curve

6. Settings

Chapter 3, 2.1

Chapter 3, 2.2

Chapter 4, 3

Chapter 6, 2

Chapter 7, 3

Chapter 10, 2

Press the [Start] switch.

Press the [SELECT] key.

1. Select Test

2. Select File

3. Print

4. Delete a Point

5. Settings

6. Clear a File

1. Select Test

2. Input

3. Print

4. Settings

5. Clear

1. Meas. Settings

Chapter 6, 3.1

Chapter 6, 3.2

Chapter 6, 4

Chapter 6, 5.1

Chapter 6, 6

Chapter 6, 5.2

Chapter 7, 4.1

Chapter 7, 4.2

Chapter 7, 5

Chapter 7, 6.1

Chapter 7, 7

Chapter 10, 3.1

1. Activity/Conc.

2. Ratio

3. INR

4. Dfbg

5. Print Settings

1. Test Protocol

2. Mark Limits

3. Report Limits

4. Diff. Check

5. Measure Mode

6. Conversion

Chapter 7, 6.2

Chapter 7, 6.3

Chapter 7, 6.4

Chapter 7, 6.5

Chapter 7, 6.6

Chapter 10, 3.2

Chapter 10, 3.3

Chapter 10, 3.4

Chapter 10, 3.5

Chapter 10, 3.6

Chapter 10, 3.7

Chapter 10, 4.2

Chapter 10, 4.3

Chapter 10, 4.4

Chapter 10, 5.2

Chapter 10, 5.3

Chapter 10, 5.4

7. Test Programs

2. I/O Settings

3. System Setting

4. Print Settings

Chapter 8, 4.1

: The password has to be entered if it is set.

1. Temperature

2. Sensor

3. Key

4. Printer

5. Host Computer

6. LCD

Chapter 10, 4.1

Chapter 10, 5.1

Chapter 10, 6

Chapter 8, 4.2

Chapter 8, 4.3

Chapter 8, 4.4

Chapter 8, 4.5

Chapter 8, 4.6

Chapter 8, 4.7

1. Printer

2. Host Computer

3. Print Settings

1. Date

2. Time

3. Password

1-16 Sysmex CA-50 Operator’s Manual -- Revised December 2000

Page 32

INTRODUCTION

13 . MAIN MENU

The Main Menu screen shows the menu for selecting and utilizing the functions provided with

the CA-50.

When you press the [SELECT] key on the Ready screen, the Main Menu screen will appear. For

details on the Ready screen, see Chapter 2, Section 3: TURNING ON THE POWER.

You can scroll the menu up and down by using the [ ] and [ ] keys.

MAIN MENU

1.Select Test

2.ID No. Entry

3.Display Data

4.QC

5.Standard Curve

6.Settings

7.Test Programs

Figure 1-7: Main Menu Screen

Pressing the following key will select each menu function.

[1] key: Moves the screen to the selection of analysis parameters (Select Test).

[2] key: Moves the screen to the entry of ID numbers (ID No. Entry).

[3] key: Moves the screen to the display of detailed analysis results (Display Data).

[4] key: Displays the quality control menu (QC).

[5] key: Displays the standard curve menu (Standard Curve).

[6] key: Displays the setting menu (Settings).

[7] key: Displays the test program menu (Test Programs).

[PRINT] key: Prints out the main menu.

[SELECT] key: Returns the screen to the Ready screen.

Sysmex CA-50 Operator’s Manual -- Revised December 2000 1-17

Page 33

CHAPTER 2 ANALYSIS PREPARATION

1. INTRODUCTION ................................................................................2-1

2. BEFORE TURNING ON THE POWER ......................................................2-2

3. TURNING ON THE POWER ..................................................................2-2

4. REAGENT PREPARATION....................................................................2-4

4.1 Preparing the Reagents ....................................................................2-4

4.2 Setting the Reaction Tubes and Reagents................................................2-5

5. CHECKING THE STANDARD CURVES ...................................................2-6

6. QUALITY CONTROL ...........................................................................2-7

7. SAMPLE PREPARATION......................................................................2-8

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 34

ANALYSIS PREPARATION

1. INTRODUCTION

Before beginning analysis, it is necessary to prepare the instrument, reagents, and samples.

Prepare for analysis by following the steps described below.

Table 2-1: Analysis Flow Chart

Check visually before

Turning ON the Power

Turn ON the Power

Prepare Reagents

Set Reaction Tubes and Reagents

Check Standard Curves

Run Quality Control

Prepare Samples

Make Work List

Analyze Samples

Start an Analysis

Add Reagents

All are explained in this chapter.

Refer to

Chapter 3: SAMPLE

ANALYSIS.

Shutdown

Sysmex CA-50 Operator’s Manual -- Revised July 1999 2-1

Page 35

ANALYSIS PREPARATION

y

2 . BEFORE TURNING ON THE POWER

Before turning ON the power to the instrument, check the following items:

1 . CA-50 Instrument Visual Check

Make sure that the power cord is securely plugged into the AC outlet.

Also, check whether the used reaction tube is not left in the detector.

2 . Printer Paper

If a printer is provided, make sure that it contains the amount of paper necessary for the

number of samples to be processed that day. Prepare extra paper when the remains of

paper run short.

3 . TURNING ON THE POWER

When you turn ON the power switch that is located on the right side, the instrument will

automatically perform a self-check.

(1) Turn ON the power switch.

A self-check will automatically be performed. When the self-check is completed without

finding any error, "OK" will be displayed on the screen and the built-in printer will output

a test print.

If an error occurs during the self-check, see Chapter 8: TROUBLESHOOTING.

Sysmex CA-50

Self Test OK

Figure 2-1: Self-Check Screen

15/06/1999 09:00

This is CA-50.

Blood Coagulation Analyzer

Produced by Sysmex

Figure 2-2: Example of Test Print

When the self-check is completed, the detector and the incubator will be warmed up.

During the warming-up, "warm" will be displayed on each channel of the screen.

NOTE: • The analysis parameter that was used in the previous analysis is

displa

ed on each channel.

2-2 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Sysmex CA-50 Operator’s Manual -- Revised August 1999

Page 36

ANALYSIS PREPARATION

Fg warm AP warm

PT warm AP warm

Figure 2-3: Warming-Up Screen

The "warm" will disappear and the detector LED will light up in green one by one as soon as

each channel completes the warming-up. It takes about 5 minutes to 30 minutes until the "warm"

disappears.

This status is called "Ready." You can perform various operations such as analysis and settings

on the channel that has entered the "Ready" status.

Fg AP

PT AP

Figure 2-4: Ready Screen

If you press the [SELECT] key on this screen, the Main Menu screen will appear. For details on

the Main Menu screen, see Chapter 1, Section 13: MAIN MENU.

Sysmex CA-50 Operator’s Manual -- Revised July 1999 2-3

Page 37

ANALYSIS PREPARATION

g

(

)

g

4. REAGENT PREPARATION

4.1 Preparing the Reagents

Prepare the required volume of coagulation reagents and Owren’s Veronal buffer for the

anticipated work load.

Table 2-2: Reagent Preparation

Parameter Reagent Consumption/Test

PT PT Reagent 100 µL

APTT APTT Reagent 50 µL

Calcium Chloride Solution 50 µL

Fbg Thrombin Reagent 50 µL

Owren's Veronal Buffer 90 µL

TTO Thrombotest Reagent 125 µL

Owren's Veronal Buffer 30 µL

NT Normotest Reagent 125 µL

Owren's Veronal Buffer 40 µL

TT Thrombin Time Reagent 50 µL

Extrinsic Factor PT Reagent 100 µL

Deficient Factor-deficient Plasma 50 µL

Assay Owren's Veronal Buffer 45 µL

Intrinsic Factor APTT Reagent 50 µL

Deficient Calcium Chloride Solution 50 µL

Assay Factor-deficient Plasma 50 µL

Owren's Veronal Buffer 45 µL

When you prepare reagents, take into account the analysis parameters and the number of

samples to be analyzed.

CAUTION: • We recommend that you use the following pipettes and pipette chips to

add plasma and dispense/add rea

• Pipette: Eppendorf reference 4910

• Pipette chip: Eppendorf 300 µL chip

For details on the usa

e of the pipette and pipette chip, refer to the

instruction manuals attached to them.

ents.

50 - 200 µL

2-4 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 38

ANALYSIS PREPARATION

4.2 Setting the Reaction Tubes and Reagents

Set reaction tubes and reagents into the instrument.

(1) Set reaction tubes into the reaction tube holder. Prepare a sufficient number of reaction

tubes beforehand.

Reaction tube

Reaction tube holder

Figure 2-5: Setting the Reaction Tubes

CAUTION: • Be sure to use the specified reaction tube (SU-40).

(2) Dispense the reagents to be used into the sample cups, and set them into the incubator.

Incubator

Sample cup

Figure 2-6: Setting the Reagents

Sysmex CA-50 Operator’s Manual -- Revised July 1999 2-5

Page 39

ANALYSIS PREPARATION

(

q

WARNING

CAUTION: • Do not set the reagent of 2 mL or more in the incubator. The reagent will not

• Cap the sample cups that are set in the incubator if they are not used. If

contaminants or dusts get in the reagent, or if the reagent evaporates,

correct analysis results will not be obtained.

• Let the incubator incubate the reagents more than 10 minutes. If the

incubation is insufficient, correct analysis results may not be obtained.

As the reagent may deteriorate, do not use the APTT reagent incubated

for 20 minutes or more and the other reagents incubated for 40 minutes or

more.

• Do not replenish reagents. Correct analysis results may not be obtained.

reach the desired temperature.

• Be sure to use the specified sample cup

e

uivalent).

Uniflex Conical 4 mL or the

5 . CHECKING THE STANDARD CURVES

Before performing an analysis, print out standard curves and make sure that they are correctly

set.

For the procedure to print out standard curves, see Chapter 7, Section 5: PRINTING OUT THE

STANDARD CURVE.

CAUTION: • If the standard curve is not set correctly, it is not possible to calculate the

calculation parameters such as the PT %.

If the settings are incorrect, set them correctly referring to Chapter 7: SETTING STANDARD

CURVES.

2-6 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 40

ANALYSIS PREPARATION

6. QUALITY CONTROL

To maintain reliable analysis data, it is necessary to implement quality control. With the CA-50,

a quality control file number (QC1 - QC3) can be registered as a sample ID number, the control

material (control plasma) is analyzed, and the analysis data is stored in a quality control file. This

data and a quality control program are used to monitor changes in the instrument and reagent

system that take place over time (day-to-day or hour-to-hour).

For details on quality control, see Chapter 6: QUALITY CONTROL.

Implementing Quality Control

When performing a quality control analysis, dispense control material into a reaction tube.

The procedure for a quality control analysis is the same as that for a sample analysis. For details,

see Chapter 3: SAMPLE ANALYSIS.

(1) Register the analysis parameter in the channel used for the analysis.

(2) Press the [QC] key on the ID No. Entry screen, and input the ID number for quality

control (any number from 1 to 3).

(3) Dispense control material into a reaction tube and set it into the detector.

(4) Press the [Start] switch.

(5) Add a reagent at the indicated timing, and close the pipette guide.

The analysis will be performed, and the analysis data will be stored in a quality control

file.

(6) Print out a QC chart and check the status of analysis data.

Sysmex CA-50 Operator’s Manual -- Revised July 1999 2-7

Page 41

ANALYSIS PREPARATION

y

y

y

y

7. SAMPLE PREPARATION

Prepare sample tubes containing plasma.

NOTE: • When handling the sample, be sure to wear rubber gloves. After the

operation is completed, wash

Failure to do so can cause infection b

(1) Add 1 part of 3.8%, 3.2% or 3.13% sodium citrate solution as anticoagulant to 9 parts of

venous blood, and mix the contents thoroughly.

(2) Centrifuge the mixture at 3000 rpm for 15 minutes to separate plasma components from

blood-cell components.

(3) Put only the centrifuged plasma into another test tube.

our hands with disinfectant solution.

bacteria.

CAUTION

Precautions when handling plasma:

• Containers should be plastic or silicone-coated glass tube.

• As anticoagulant, use 3.8%, 3.2% or 3.13% sodium citrate solution.

When any other anticoagulant is used, sedimentation may occur and

correct analysis result may not be obtained.

• Mix blood and sodium citrate solution in an accurate ratio of 9 parts to 1

part, respectively.

When the mixing ratio varies, coagulation time varies, occasionally

leading to incorrect analysis result.

• Store samples in the refrigerator and analyze within 4 hours of

collecting.

After 4 hours, or if the

ma

not be obtained.

are stored improperly, correct analysis results

2-8 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Sysmex CA-50 Operator’s Manual -- Revised December 1999

Page 42

CHAPTER 3 SAMPLE ANALYSIS

1. INTRODUCTION................................................................................ 3-1

2. WORK LIST...................................................................................... 3-2

2.1 Selecting the Analysis Parameter.........................................................3-2

2.2 Registering the Sample ID Number......................................................3-4

3. SAMPLE ANALYSIS ...........................................................................3-6

3.1 Start of Analysis ........................................................................... 3-7

3.2 Adding the Reagents.......................................................................3-8

3.3 Registering and Analyzing the Next Sample...........................................3-11

4. SHUTDOWN ....................................................................................3-12

Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 43

SAMPLE ANALYSIS

1. INTRODUCTION

This chapter will explain the operating procedures for the order information registration and from

the start of analysis to shutdown.

Table 3-1: Analysis Flow Chart

Check visually before

Turning ON the Power

Turn ON the Power

Prepare Reagents

Set Reaction Tubes and Reagnets

Check Standard Curves

Run Quality Control

Prepare Samples

Make Work List

Analyze Samples

Start an analysis

Add Reagents

Shutdown

Refer to

PREPARATION.

All are explained in this chapter.

Chapter 2:

ANALYSIS

Sysmex CA-50 Operator’s Manual -- Revised July 1999 3-1

Page 44

SAMPLE ANALYSIS

p

2 . WORK LIST

Register the analysis parameter and the sample ID number of each channel.

2.1 Selecting the Analysis Parameter

NOTE: • When the power is turned ON, the analysis parameter used in the

revious analysis is displayed on each channel.

(1) Press the [SELECT] key to enter the Main Menu screen.

MAIN MENU

1.Select Test

2.ID No. Entry

3.Display Data

4.QC

5.Standard Curve

6.Settings

7.Test Programs

Figure 3-1: Main Menu Screen

(2) Press the [1] key on the Main Menu screen.

The Channel Selection screen will appear.

Select Test

Select CH(1-4)?1

Figure 3-2: Channel Selection Screen

If you press the [SELECT] key, the display will return to the Main Menu screen (Figure 3-

1).

3-2 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 45

SAMPLE ANALYSIS

(3) Input the channel number (any number from 1 to 4) on which you wish to select the

analysis parameter, and press the [ENTER] key. However, when the replication measure

mode is set (See Chapter 10, Section 3.6: Measure Mode & Sample Incubation Ready

Check Settings.), select the channel number either 1 or 3.

The Analysis Parameter Selection screen will appear. (The parameter set in the previous

analysis is displayed.)

Select Test CH2

Test(PT-EX)? PT

Figure 3-3: Analysis Parameter Selection Screen

If you press the [SELECT] key, the display will return to the Channel Selection screen

(Figure 3-2).

(4) Press the key for the desired parameter, and press the [ENTER] key.

In the case of an intrinsic factor assay (8, 9, 11, or 12), press the [IN] key.

In the case of an extrinsic factor assay (2, 5, 7, or 10), press the [EX] key.

When you press the [IN] or [EX] key, the Factor Number Entry screen will appear.

When you press any of the other keys, the display will return to the Channel Selection

screen (Figure 3-2). Set the analysis parameter of the other channels in the same manner.

Select Test CH2

IN(8,9,11,12)? 8

Figure 3-4: Factor Number Entry Screen

If you press the [SELECT] key, the display will return to the Channel Selection screen

(Figure 3-2).

(5) In the case of an intrinsic factor assay, input any of 8, 9, 11, and 12.

In the case of an extrinsic factor assay, input any of 2, 5, 7, and 10.

Then press the [ENTER] key.

The display will return to the Channel Selection screen (Figure 3-2). Set the analysis

parameter of the other channels in the same manner.

Sysmex CA-50 Operator’s Manual -- Revised July 1999 3-3

Page 46

SAMPLE ANALYSIS

2.2 Registering the Sample ID Number

(1) Press the [SELECT] key to enter the Main Menu screen.

MAIN MENU

1.Select Test

2.ID No. Entry

3.Display Data

4.QC

5.Standard Curve

6.Settings

7.Test Programs

Figure 3-5: Main Menu Screen

(2) Press the [2] key on the Main Menu screen.

The Channel Selection screen will appear.

ID No. Entry

Select CH(1-4)?

Figure 3-6: Channel Selection Screen

If you press the [SELECT] key, the display will return to the Main Menu screen (Figure 3-

5).

(3) Input the channel number (any number from 1 to 4) on which you wish to register the

sample ID number, and press the [ENTER] key.

The ID No. Entry screen will appear.

ID No. Entry CH2

123-456

Figure 3-7: ID No. Entry Screen

If you press the [SELECT] key, the display will return to the Channel Selection screen

(Figure 3-6).

3-4 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 47

SAMPLE ANALYSIS

q

g

p

p

p

yp

g

p

p

p

y

(4) Input the ID number, and press the [ENTER] key.

The display will return to the Channel Selection screen (Figure 3-6). The sample ID

number can be registered with up to 15 digits consisting of numerals and hyphens (-). The

hyphens, however, cannot be used consecutively or as the first or last digits of the sample

ID number.

When a quality control analysis is performed, press the [QC] key and input any number

from 1 to 3.

NOTE: • If you do not input a sample ID number after the power is turned ON, the

number will be se

re

ardless of the channel or the analysis parameter.

• If a sam

from the ID number in

arameter.

• When a h

automatic increment will be the di

For exam

will be "990601-00."

• If "0" is in

And, if "0", "QC1", "QC2", or "QC3" is in

onl

le ID number is input, the number will be sequentially incremented

hen is used in the sample ID number, the subject of the

le, when the sample ID number is "990601-99", the next number

ut to the ID number, an external output will not be carried out.

one time at the input without automatic incrementing.

uentially incremented from "1" in each analysis

ut last regardless of the channel or the analysis

its after the hyphen.

ut, the ID number will become

Sysmex CA-50 Operator’s Manual -- Revised July 1999 3-5

Page 48

SAMPLE ANALYSIS

p

y

g

y

g

g

m

g

g

y

y

pip

y

p

g

y

3. SAMPLE ANALYSIS

When the detector LED is lit in green, you can perform an analysis on this channel. It is possible

to perform analyses on multiple channels simultaneously.

The CA-50 has a function to turn off the detector LED indicating the Ready status and prevent an

analysis from being started when the timings of reagent addition are expected to overlap one

another.

WARNING

CAUTION

• Be sure to wear rubber gloves during the analysis. After the operation is

com

leted, wash your hands with disinfectant solution. Failure to do so can

cause infection b

• Handle reaction tubes containin

an

infection by bacteria.

When discardin

medical and infectious wastes.

• The total volume of blood and rea

L. If the volume exceeds this range, sample may spill out of the reaction

tube when bein

• Be careful not to spill blood or reagents into the detector. This may damage

the instrument.

• Use the correct volume of blood and rea

correct anal

not be detected. For the specific volume required for each analysis, see

Chapter 9, Section 2.6: Analysis Flow

• Use a new

one even when

contaminated with the other sam

not be obtained.

• Be careful so that rea

Correct anal

bacteria.

sample with extreme care in order to avoid

used reaction tubes, take proper disposing steps as

ents must be in the range of 150 to 200

mixed, resulting in infection by bacteria.

ents. If the volume is improper,

sis results may not be obtained, or addition of reagents ma

.

ette chip each time. Replace the pipette chip with a new

ou add the same reagent consecutively. If sample is

le or reagent, correct analysis results will

ents or contaminants will not get in the reaction tube.

sis results will not be obtained.

3-6 Sysmex CA-50 Operator’s Manual -- Revised July 1999

Page 49

3.1 Start of Analysis

y

p

(1) Pipette plasma into a reaction tube and set it into the detector.

At this time, push it into the bottom of the detector firmly.

SAMPLE ANALYSIS

Reaction tube

Detector

Figure 3-8: Setting Plasma

(2) Press the [Start] switch.

Incubation of plasma will start. The reagent to be added and the countdown of the

remaining time before the reagent addition timing will be displayed on the screen. The

detector LED will blink in red.

PT Fg

AP PT 179

Figure 3-9: Display of Countdown

CAUTION: • When you press the [Start] switch by mistake, you can cancel the

anal

sis by pressing the [Start] switch again. However, the alarm sounds

in this case, and sto

s the alarm by pressing the [C] key.

Sysmex CA-50 Operator’s Manual -- Revised July 1999 3-7

Page 50

SAMPLE ANALYSIS

)

(

)

p

p

p

p

p

p

p

p

y

g

g

y

g

g

p

g

y

g

g

p

3.2 Adding the Reagents

When a reagent addition timing comes, an alarm will begin to sound and the detector LED will

blink in green. The detailed operations of the alarm and the detector LED are as shown below:

Table 3-2: Reagent Addition Timing Alarm

Reagent

addition allowed

time (start

Two short

beeps

5 seconds

before

No sound A short

bee

· · ·

A short beepA long bee

One bee

er second

Reagent

addition

For 0.5

seconds

· · ·

A short beepA long bee

One bee

er second

Reagent

addition

allowed time

end

An error bee

Allowed time for reagent addition

The time allowed for reagent addition is preset at 10 seconds as default; 5 seconds before and

after the time of addition. If you wish to change the allowed time, see Chapter 10, Section 3.2:

Test Protocol Settings.

Table 3-3: Operation of Detector LED

During warming-upRead

Turns off Lights up in

reen

Durin

incubation

Blinks in red Blinks in green Lights up in red Lights up in

Reagent addition

timin

During photo

detection

Read

reen

(1) When the alarm begins to sound, take the reagent to be added with a pipette.

CAUTION

• When two or more reagents are set in the incubator, be careful not to mix

u

them. If an incorrect reagent is used, correct analysis results will not be

obtained.

• Use the rea

insufficient, correct anal

Also, as the rea

incubated for 20 minutes or more and the other rea