Page 1

TimeSource 3600

GPS Primary Reference Source

097-72060-01

Issue 2

Page 2

FCC Regulatory Notice

Warning: This equipment generates, uses, and can radiate radio

frequency energy, and if not used in accordance with the instruction

manual, may cause interference to radio communications. It has

been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart B of Part 15 of FCC rules,

which are designed to provide reasonable protection against such

interference when operated in a commercial environment. Operation

of this equipment in a residential area is likely to cause interference

in which case the user at his own expense will be required to take

whatever measures may be required to correct the interference.

Symmetricom, Inc.

2300 Orchard Parkway

San Jose, CA 95131-1017

http://www.symmetricom.com

Copyright © 1999–2001 Symmetricom, Inc.

All rights reserved. Printed in U.S.A.

Symmetricom is a registered trademark of Symmetricom, Inc. BesTime, DCD, and TimeSource are

trademarks of Symmetricom, Inc. All other product names, service marks, trademarks, and registered

trademarks used in this document are the proper ty of their respective owners.

2

TimeSource 3600

Page 3

Acronyms and Abbreviations

AIS alarm indication signal

E1 digital transmission (2.048 Mb/s)

ESD electrostatic discharge

ESF extended superframe

GPS Global Positioning System

LOS loss of signal

MDEV mean time deviation

pps pulse per second

PRS primary reference source

RO remote oscillator

SSM synchronization status messaging

TDEV time deviation

TOD time of day

UTC Universal Coordinated Time

Contents

3

Page 4

This page intentionally left blank.

4

TimeSource 3600

Page 5

Description

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Global Positioning System . . . . . . . . . . . . 19

Physical Description . . . . . . . . . . . . . . . . . 20

Roof Antenna . . . . . . . . . . . . . . . . . . . 22

Mechanical Window Antenna . . . . . . 23

Self-Adhesive Window Antenna . . . . 24

Wall Antenna . . . . . . . . . . . . . . . . . . . . 25

Functional Description . . . . . . . . . . . . . . . 26

Overview . . . . . . . . . . . . . . . . . . . . . . . 26

Antenna . . . . . . . . . . . . . . . . . . . . . . . . 28

IF Interface . . . . . . . . . . . . . . . . . . . . . . 28

GPS Receiver . . . . . . . . . . . . . . . . . . . . 28

Local Oscillator . . . . . . . . . . . . . . . . . . 28

Clock Extractors . . . . . . . . . . . . . . . . . 29

Power Supply . . . . . . . . . . . . . . . . . . . . 29

BesTime Ensemble Timing Generator 29

E1 or Analog Outputs . . . . . . . . . . . . 29

Eight Additional E1 or Analog Outputs

(990-72060-02 Systems Only) . . . 30

TOD Output . . . . . . . . . . . . . . . . . . . . 30

IRIG-B TOD Outputs

(990-72060-05 Systems Only) . . . 30

1 PPS Output . . . . . . . . . . . . . . . . . . . 30

Contents

5

Page 6

Description

Chapter 1

(cont’d)

10 MHz Output . . . . . . . . . . . . . . . . . 31

Two ESCIU Por ts

(990-72060-04 Systems Only) . . . 31

Alarm Interface . . . . . . . . . . . . . . . . . . 32

Communication Ports . . . . . . . . . . . . 32

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . 32

Engineering &

Ordering

Chapter 2

Antenna Guidelines . . . . . . . . . . . . . . . . . 36

Roof Antenna Location and

Cabling Guidelines . . . . . . . . . . . . . 38

Roof Antenna Earth Ground Location

Guidelines . . . . . . . . . . . . . . . . . . . . 42

Roof Antenna Cable Choices . . . . . . 43

Window and Wall Antenna

Location Guidelines . . . . . . . . . . . . 45

Window and Wall Antenna

Cable Choices . . . . . . . . . . . . . . . . 47

IRIG-B TOD

(990-72060-05 System Only) . . . 48

RJ-422–to–RS-232 TOD Converter . 48

Shelf Considerations . . . . . . . . . . . . . . . . 49

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Standard System (Two T1 Outputs) 50

With Eight Additional E1 or

2.048 MHz Outputs . . . . . . . . . . . 51

6

TimeSource 3600

Page 7

Engineering &

Ordering

Chapter 2

(cont’d)

With Two E1 Synchronization

Insertion (ESCIU) Ports . . . . . . . . 51

With Four IRIG-B TOD Outputs . . . 52

Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Roof Antenna . . . . . . . . . . . . . . . . . . . 53

Mechanical Window Antenna . . . . . . 53

Self-Adhesive Window Antenna . . . . 54

Wall Antenna . . . . . . . . . . . . . . . . . . . . 54

User-Supplied Tools and Materials . . . . . 55

For Roof Antenna Installation . . . . . . 55

For Mechanical Window Antenna

Installation . . . . . . . . . . . . . . . . . . . . 56

For Self-Adhesive Window Antenna

Installation . . . . . . . . . . . . . . . . . . . . 56

For Wall Antenna Installation . . . . . . 56

For Shelf Installation . . . . . . . . . . . . . . 57

Installation

Chapter 3

Outputs, Power, and Miscellaneous . 58

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . 60

Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Roof Antenna . . . . . . . . . . . . . . . . . . . 61

Mechanical Window Antenna . . . . . . 67

Self-Adhesive Window Antenna . . . . 70

Wall Antenna . . . . . . . . . . . . . . . . . . . . 73

Contents

7

Page 8

Installation

Chapter 3

(cont’d)

Rack Mounting . . . . . . . . . . . . . . . . . . . . . 77

Output Module Installation . . . . . . . . . . . 78

Power and Signal Cabling . . . . . . . . . . . . 80

Frame Ground . . . . . . . . . . . . . . . . . . . 82

Power . . . . . . . . . . . . . . . . . . . . . . . . . . 84

GPS Antenna . . . . . . . . . . . . . . . . . . . . 85

10 MHz Output . . . . . . . . . . . . . . . . . 85

E1 or Analog Synchronization

Outputs . . . . . . . . . . . . . . . . . . . . . . 86

Expansion Bus . . . . . . . . . . . . . . . . . . . 87

1 PPS Output . . . . . . . . . . . . . . . . . . . 87

E1 or Analog Reference Inputs . . . . . 88

Module for Additional E1 or

Analog Outputs

(990-72060-02 System Only) . . . 89

Module for IRIG-B TOD Outputs

(990-72060-05 System Only) . . . 90

Module for ESCIU Ports

(990-72060-04 System Only) . . . 91

Cutover Procedures for

Out-of-Service Equipment . . . 92

Cutover Procedures for

In-Service Equipment . . . . . . . . 94

Time of Day Output . . . . . . . . . . . . . 96

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . 99

8

TimeSource 3600

Page 9

Installation

Chapter 3

(cont’d)

Communication Port 1 . . . . . . . . . . . 100

Communication Port 2 . . . . . . . . . . . 101

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . 102

Craft Port . . . . . . . . . . . . . . . . . . . . . . . 103

Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Factory-Set Values . . . . . . . . . . . . . . . . . . 118

TL1 Reference

Chapter 4

Conventions . . . . . . . . . . . . . . . . . . . . . . . 122

Command Format . . . . . . . . . . . . . . . . . . 124

Response Format . . . . . . . . . . . . . . . . . . . 125

Parameters . . . . . . . . . . . . . . . . . . . . . . . . 127

Autonomous Messages . . . . . . . . . . . . . . 131

Report Alarm . . . . . . . . . . . . . . . . . . . 132

Report Event . . . . . . . . . . . . . . . . . . . . 133

Tasks/Commands . . . . . . . . . . . . . . . . . . . 134

Commands . . . . . . . . . . . . . . . . . . . . . . . . 136

Activate User . . . . . . . . . . . . . . . . . . . . 137

Cancel User . . . . . . . . . . . . . . . . . . . . . 138

Copy Memory . . . . . . . . . . . . . . . . . . . 139

Delete Equipment . . . . . . . . . . . . . . . . 142

Delete User Security . . . . . . . . . . . . . 143

Edit Communication . . . . . . . . . . . . . . 144

Edit Date . . . . . . . . . . . . . . . . . . . . . . . 148

Contents

9

Page 10

TL1 Reference

Chapter 4

(cont’d)

Edit Equipment . . . . . . . . . . . . . . . . . . 150

Enter Equipment . . . . . . . . . . . . . . . . . 158

Enter User Security . . . . . . . . . . . . . . . 160

Initialize Register . . . . . . . . . . . . . . . . . 161

Initialize System . . . . . . . . . . . . . . . . . . 162

Operate Alarm Cutoff All . . . . . . . . . 163

Retrieve Alarm All . . . . . . . . . . . . . . . 164

Retrieve Alarm Equipment . . . . . . . . 165

Retrieve Communication . . . . . . . . . . 167

Retrieve Condition All . . . . . . . . . . . . 170

Retrieve Condition Equipment . . . . . 171

Retrieve Equipment . . . . . . . . . . . . . . 173

Retrieve GPS Status . . . . . . . . . . . . . . 180

Retrieve Inventory . . . . . . . . . . . . . . . 182

Retrieve Performance Monitoring . . 184

Troubleshooting

Chapter 5

10

TimeSource 3600

Retrieve User Security . . . . . . . . . . . . 200

Set Source Identifier . . . . . . . . . . . . . . 201

Troubleshooting with Front Panel Items 204

Troubleshooting with Error Messages . . 209

Card Replacement . . . . . . . . . . . . . . . . . . 216

Repair and Return . . . . . . . . . . . . . . . . . . 218

Technical Assistance . . . . . . . . . . . . . . . . . 220

Page 11

Troubleshooting

Chapter 5

(cont’d)

Sales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Manual Updates . . . . . . . . . . . . . . . . . . . . 222

Specifications

Chapter 6

Antenna . . . . . . . . . . . . . . . . . . . . . . . . 224

Roof Antenna . . . . . . . . . . . . . . . . . 224

Mechanical Window Antenna . . . 224

Wall Antenna . . . . . . . . . . . . . . . . . 225

Self-Adhesive Antenna . . . . . . . . . 225

Communication Ports . . . . . . . . . . . . 226

Port 1 . . . . . . . . . . . . . . . . . . . . . . . 226

Port 2 . . . . . . . . . . . . . . . . . . . . . . . 227

Craft Port . . . . . . . . . . . . . . . . . . . . 228

Ethernet Port . . . . . . . . . . . . . . . . . . . . 229

Time of Day Outputs . . . . . . . . . . . . . 230

Network Time Protocol (NTP),vt

Type 4, Format 2 Driver Format 230

Cisco Systems Format . . . . . . . . . . 231

IRIG-B TOD Outputs

(990-72060-05 System Only) . 232

E1 Inputs . . . . . . . . . . . . . . . . . . . . . . . 233

Analog 2.048 MHz Inputs . . . . . . . . . 234

1 PPS Output . . . . . . . . . . . . . . . . . . . 235

E1 Outputs . . . . . . . . . . . . . . . . . . . . . 236

Standard . . . . . . . . . . . . . . . . . . . . . 236

Contents

11

Page 12

Specifications

Chapter 6

(cont’d)

Additional E1 Outputs

(990-72060-02 System Only) . 238

Analog 2.048 MHz Outputs . . . . . . . 240

Standard . . . . . . . . . . . . . . . . . . . . . 240

Additional Analog Outputs

(990-72060-02 System Only) . 241

10 MHz Output . . . . . . . . . . . . . . . . . 242

ESCIU Ports

(990-72060-04 System Only) . . . 243

Office Alarms . . . . . . . . . . . . . . . . . . . . 244

Connector Panel Contacts . . . . . . 244

Front Panel Lamps . . . . . . . . . . . . . 244

Front Panel Control . . . . . . . . . . . . 244

Power . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Shelf Mechanical . . . . . . . . . . . . . . . . . 245

Shelf Environmental . . . . . . . . . . . . . . 246

Index

Figures

12

TimeSource 3600

1. Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2. Roof Antenna . . . . . . . . . . . . . . . . . . . . 22

3. Mechanical Window Antenna . . . . . . 23

4. Self-Adhesive Window Antenna . . . . 24

5. Wall Antenna . . . . . . . . . . . . . . . . . . . . 25

Page 13

Figures

(cont’d)

6. Block Diagram . . . . . . . . . . . . . . . . . . . 27

7. ESCIU Signals . . . . . . . . . . . . . . . . . . . . 32

8. Antenna Field of View . . . . . . . . . . . . . 39

9. Antenna Location Examples . . . . . . . . 40

10. Sample Rooftop Antenna Mount . . 42

11. Antenna Mask Angle . . . . . . . . . . . . . 46

12. Rack Mounting Options . . . . . . . . . . 49

13. Roof Antenna-to-Shelf Cabling . . . . 62

14. Mechanical Window Antenna-to-Shelf

Cabling . . . . . . . . . . . . . . . . . . . . . . . . 67

15. Attaching the Mechanical Window

Antenna . . . . . . . . . . . . . . . . . . . . . . . 69

16. Mechanical Window Antenna Pivot

Screw . . . . . . . . . . . . . . . . . . . . . . . . . 69

17. Self-Adhesive Window Antenna-to-Shelf

Cabling . . . . . . . . . . . . . . . . . . . . . . . . 70

18. Attaching the IF Converter . . . . . . . 72

19. Wall Antenna-to-Shelf Cabling . . . . . 73

20. Hole Spacing . . . . . . . . . . . . . . . . . . . . 75

21. Wall Antenna Mounting . . . . . . . . . . 76

22. Rack Mounting Options . . . . . . . . . . 77

23. Options I/O Connector . . . . . . . . . . 79

24. Connector Panel and Front Panel

Connectors . . . . . . . . . . . . . . . . . . . . 81

Contents

13

Page 14

Figures

(cont’d)

25. Connector Panel Terminal Block

Connections . . . . . . . . . . . . . . . . . . . 82

26. E1 or Analog Output Wire-Wrap

Connections . . . . . . . . . . . . . . . . . . . 86

27. E1 or Analog Input Wire-Wrap

Connections . . . . . . . . . . . . . . . . . . . 88

28. Eight E1 or Analog Outputs

Connections . . . . . . . . . . . . . . . . . . . 89

29. IRIG-B TOD Output Connections . 90

30. Connector Layout of ESCIU Modules 91

31. ESCIU Cutover without Jacks

(Out-of-Service) . . . . . . . . . . . . . . . 93

32. ESCIU Cutover with Jacks

(In-Service) . . . . . . . . . . . . . . . . . . . . 95

33. RS-422–to–RS-232 TOD Converter

Mounting Plate . . . . . . . . . . . . . . . . . 97

34. RS-422–to–RS-232 TOD Converter

Connections . . . . . . . . . . . . . . . . . . . 98

14

35. Alarm Connections . . . . . . . . . . . . . . 102

36. Command Format . . . . . . . . . . . . . . . 124

37. Completed Response Format . . . . . 125

38. Deny Response Format . . . . . . . . . . 126

39. Controls and Indicators . . . . . . . . . . 205

40. Front of Shelf . . . . . . . . . . . . . . . . . . . 217

TimeSource 3600

Page 15

Ta b l e s

A. Timing Source Characteristics . . . . . . 27

B. TOD Connector Pinouts . . . . . . . . . . 96

C. Converter DB-25 Connector Pinouts 98

D. Ethernet 10base-T RJ-45 Connector

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . 99

E. COM1 Connector Pinouts . . . . . . . . . 100

F. COM2 Connector Pinouts . . . . . . . . . 101

G. Craft Terminal Connector Pinouts . . 103

H. Parameter Factor y Settings . . . . . . . . 118

I. Parameter Definitions . . . . . . . . . . . . . . 127

J. Commands for Tasks . . . . . . . . . . . . . . . 134

K. Front Panel Items . . . . . . . . . . . . . . . . . 206

L. Message Troubleshooting . . . . . . . . . . 209

Contents

15

Page 16

This page intentionally left blank.

16

TimeSource 3600

Page 17

Description

This chapter provides an overview of the

global positioning system, and a physical

and functional description.

Chapter

Chapter

1

Page 18

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Overview

The TimeSource 3600 is a Primary Reference Source (PRS) that

receives and processes signals from GPS satellites, and outputs

Stratum 1 synchronization signals traceable to UTC. TimeSource

3600 applications include synchronization for central offices,

wireless base stations, transmission nodes, and other cases where

a primary reference source can improve the performance of a

telecommunications network infrastructure.

The TimeSource 3600 is also ideal for installation in environments

where receiving GPS signals is difficult. Examples of environments

hostile to GPS signals include urban canyons which have a very

limited view of the sky because of blockage from nearby buildings,

and high interference zones where GPS signals are jammed by

competing over-the-air signals.

The TimeSource 3600 creates timing outputs by ensembling

signals from several sources. The sources include GPS signals, an

onboard rubidium local oscillator, and optional E1 or analog.

Timing outputs created from the ensemble are composed of the

most stable and least noisy parts of each input. The performance

of the E1 sources can be monitored and classified using standard

measures. Synchronization outputs are delivered in a framed, allones, E1 format or 2.048 MHz analog signal, a 10 MHz signal, a 1

pps signal, and a choice of time of day (TOD) formats.

18

The TimeSource 3600 minimizes timing impairments, such as

jitter and wander, that are created by network and transmission

systems. The synchronization timing is traceable to the GPS,

which provides the highest level of synchronization for telephony

networks. The TimeSource 3600 with its GPS input is a standalone office PRS. With the optional inputs ensembled, holdover is

extended if GPS signals are disrupted.

TimeSource 3600

Page 19

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Global Positioning System

The United States Government developed the GPS navigation

system. It is a satellite-based, radio navigation aid designed to

provide global, all-weather, precise navigation and timing

capability to users 24 hours a day.

The satellites, circling the earth at approximately 20,197 km, are

arranged in 6 orbits with 4 operational satellites in each orbit.

Each satellite has an orbital period of approximately 12 hours.

This configuration assures that a minimum of 4 satellites, and as

many as 12, are in view anywhere in the world at all times.

The TimeSource 3600 tracks all satellites within its field of view.

The performance of each tracked satellite is observed and

compared to the others, and available for use in the timing

solution. A satellite with unacceptable performance data is

dropped from the timing solution.

GPS antennas must have line-of-sight access to the transmitting

satellites. Any structure that interferes with, or blocks, the view of

the satellites disrupts the reception of the signals, and can

adversely impact the timing performance of a receiver.

The TimeSource 3600 bridges frequent GPS outage periods with

BesTime algorithms, its ultra-stable Rubidium local oscillator and

advanced holdover technology. The technology anticipates the

outages and uses BesTime-generated predictor values to optimize

the performance of timing without direct satellite input.

1

2

3

4

Description

5

19

Page 20

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Physical Description

The TimeSource 3600 consists of a shelf, plug-in card, antenna,

cables, hardware, and software. Optional system configurations

include eight additional E1 or analog outputs, two E1

synchronous clock insertion unit (ESCIU) ports, or four IRIG-B

TOD timing outputs.

The shelf (Figure 1) can be mounted in a 48 cm rack or an ETSI

53.5 cm rack. Other than a communications connector on the

front panel, all connectors are at the connector panel.

Four types of antennas are available:

• roof antenna for installation outdoors, usually on a roof

• mechanical antenna for installation indoors, mounted on a

window sill or wall for reception through a window

• self-adhesive antenna for installation indoors, adhered directly

to a window

20

• wall antenna for installation outdoors, through a hole in the wall

TimeSource 3600

Page 21

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 1. Shelf

22 cm

43.8 cm

990-72060-01, -02, -05 Systems

1

2

8.2 cm

3

22 cm

43.8 cm

990-72060-04 Systems

Description

4

8.2 cm

5

21

Page 22

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Roof Antenna

The roof antenna (Figure 2) is encased in weather-resistant plastic

housing for outdoor installation, usually on a roof. A single coaxial

cable carries signals and power between the antenna and the

shelf.

Figure 2. Roof Antenna

31.4 cm

22

4.4

cm

TimeSource 3600

Page 23

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Mechanical Window Antenna

The mechanical window antenna (Figure 3) may be attached to a

window sill or wall, in any position that allows the antenna to be

moved flush against the window. The antenna can be swung away

from the window for window maintenance, and returned to its

original position.

A single length of coaxial cable carries signals and power between

the antenna assembly and the shelf.

Figure 3. Mechanical Window Antenna

Coaxial Cable

Mounting Assembly

IF Converter

1

2

Antenna

3

43 cm

4

to TimeSource 3600 Shelf

Coaxial Cable

(not included with

antenna assembly)

Description

5

23

Page 24

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Self-Adhesive Window Antenna

The self-adhesive window antenna assembly (Figure 4) consists of

the antenna and two pieces of self-stick hook-and-loop fabric

fasteners (Velcro brand or equivalent). The hook-and-loop fabric

attaches directly to a window. Coaxial cables carry signals and

power between the antenna and the IF converter, and between the

IF converter and the shelf.

Figure 4. Self-Adhesive Window Antenna

GPS WINDOW

ANTENNA

24

TimeSource 3600

Page 25

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Wall Antenna

The wall antenna (Figure 5) is mounted on the outside of a

building wall. The antenna attaches magnetically to the mounting

bracket. The cable from the antenna is routed through a hole

drilled in the wall. Coaxial cables carry signals and power between

the antenna and the IF converter, and between the IF converter

and the shelf.

Figure 5. Wall Antenna

7.5 cm

1

2

Antenna Mounting Bracket

Antenna

3

Coaxial Cable

Description

4

5

25

Page 26

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Functional Description

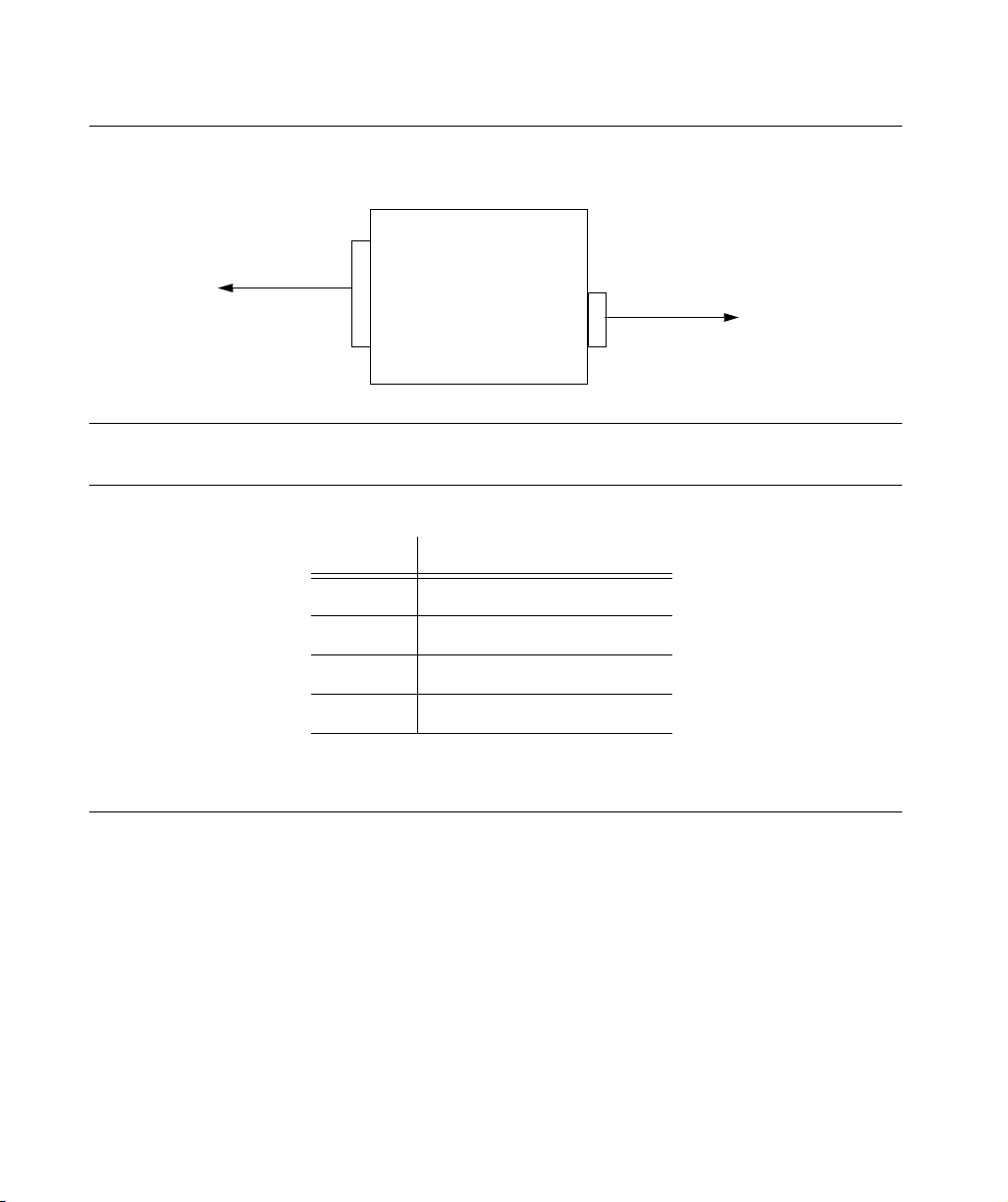

Overview

Figure 6 shows the main functions of the TimeSource 3600. The

center of the TimeSource 3600 is the BesTime Ensemble Timing

Generator, which uses the BesTime algorithm to analyze the phase

and frequency relationships, individually and collectively, of the

timing sources. Each type of timing source has a particular

characteristic that gives it an advantage over other sources, as

listed in Table A.

The BesTime algorithm uses the best characteristic of each source

to produce an output signal with greater overall accuracy and

stability than any single source. The contribution of a source is

based on its deviation from the weighted average of all the

sources. The more accurate a source, the more weight it has in the

final output. Every source is under constant evaluation and its

contribution subject to periodic adjustment. The output is

essentially the best performance of the best source.

26

TimeSource 3600

Page 27

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Al

Figure 6. Block Diagram

arm

Interface

Alarms

1

Clock input & dc

power to antenna

Antenna

input

Optional source s

E1 Span

Input #1

E1 Span

Input #2

–48 V A

–48 V B

IF

Interface

Local

Oscillator

Clock

Extractor

Clock

Extractor

Power

Supply

Power to

shelf

Micro-

processor

BesTime

Ensemble

Timing

Generator

COM ports

Ethernet port

Status lamps

E1/analog output A

E1/analog output B

1 pps output

TOD output

10 MHz output

8 E1/analog

outputs

4 IRIG-B

TOD outputs

2 ESCIU ports

Optional ports

2

3

4

Table A. Timing Source Characteristics

Source Characteristic

Local Oscillator Short term stability

E1 Line Intermediate term stability

GPS Signal Long term stability

Description

5

27

Page 28

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Antenna

The antenna types include a roof antenna, mechanical window

antenna, self-adhesive window antenna, or wall antenna. All

antennas include a GPS receiver, amplifier, and intermediatefrequency (IF) downconverter.

The GPS Receiver extracts a clock signal from the GPS satellite

signals. The receiver can process the signals from all satellites in

view, while simultaneously using the Earth location of the receiver

and other factors to determine an accurate clock signal.

The downconverter converts the L1-band GPS signal to IF for

long-distance transport on the coaxial antenna cable. The antenna

cable provides current from the shelf to the antenna, and

transports GPS satellite IF signals from the antenna to the shelf.

IF Interface

An IF interface accepts the signals from the antenna/IF converter,

and provides the clock information to the BesTime Ensemble

Timing Generator.

28

GPS Receiver

The GPS Receiver continuously tracks up to eight satellites, using both

carrier and code lock. The recovered pseudo-range measurement data

is processed to determine precise time and frequency state estimates

for the local oscillator. The receiver software is optimized to track and

update state estimates, when as few as one satellite is in view.

Local Oscillator

A rubidium oscillator, based on a digitally controlled servo-loop,

provides an ultra-stable local oscillator signal, which is sent to the

BesTime Ensemble Timing Generator.

TimeSource 3600

Page 29

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Clock Extractors

A clock extractor circuit extracts a timing signal from each

external reference source. (External sources, other than the GPS

antenna, are optional.) The extracted timing signal is sent to the

BesTime Ensemble Timing Generator.

Power Supply

A power converter filters and converts –48 volts dc power supplied

to the shelf into the voltages required by the circuitry.

BesTime Ensemble Timing Generator

Clock signals from the GPS antenna (via the IF interface), local

oscillator, and two optional E1 span lines are used as sources by

the BesTime algorithms in the BesTime Ensemble Timing

Generator. The signals are analyzed for MDEV, TDEV, and other

phase and frequency characteristics.

The BesTime Ensemble Timing Generator uses mathematical

models to analyze each clock. The ensemble algorithms use the

comparisons and analyses to generate a highly stable timing

signal, which uses the best qualities of all inputs.

1

2

3

4

E1 or Analog Outputs

The BesTime Ensemble Timing Generator provides the timing for

the E1 or analog (2.048 MHz) timing signal available at the E1

OUT A and B connectors. E1 is provided in a framed, all-ones

format, which can be set to CAS, CAS4, CCS, or CCS4 framing.

2.048 MHz is provided in accordance with G.703/10.

Description

5

29

Page 30

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Eight Additional E1 or Analog Outputs (990-72060-02 Systems Only)

This option provides a module for eight additional E1 or analog

(2.048 MHz) outputs. The module mounts in the OP TIONS I/O

mountings on the connector panel. These outputs function the

same as the standard E1 outputs.

TOD Output

The BesTime Ensemble Timing Generator provides the timing for

the TOD timing signal available at the RJ-45 connector, which

provides time code to devices compatible with NTP Type 4 or Cisco

format.

IRIG-B TOD Outputs (990-72060-05 Systems Only)

This option provides a module for four additional TOD outputs in

IRIG-B format. The module mounts in the OPTIONS I/O

mountings on the connector panel.

30

The BesTime Ensemble Timing Generator provides the timing for

the TOD timing signal, which provides timing code to devices

compatible with IRIG-B.

1 PPS Output

The BesTime Ensemble Timing Generator provides the timing for

the 1 pulse-per-second timing signal available at the 1 PPS

connector, which can be used for application-specific

requirements. This signal is not squelched during an alarm.

TimeSource 3600

Page 31

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

10 MHz Output

The BesTime Ensemble Timing Generator provides timing for the

10 MHz timing signal available at the 10 MHZ connector, which

can be used for local cellular frequency or testing purposes. This

signal is not squelched during an alarm.

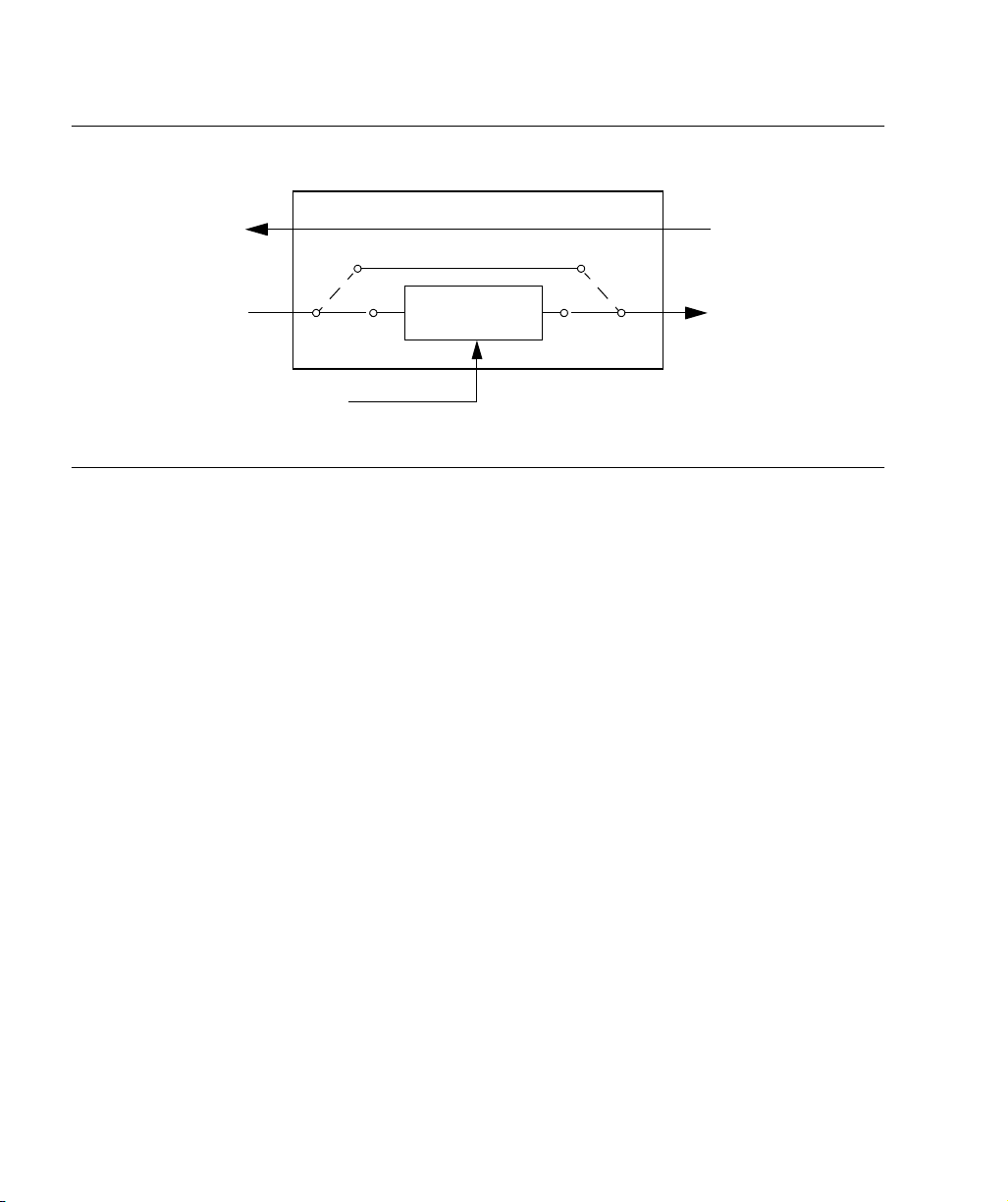

Tw o E S C I U Po r t s (990-72060-04 Systems Only)

This option provides a module for two E1 ports. The module

mounts in the OPTIONS I/O mountings on the connector panel.

E1 traffic-carrying signals are synchronized using the Bestime

ensemble timing generator. Jitter and wander are also removed

before sending the E1 signals to network elements.

If an alarm condition or power failure occurs, relays allow the E1

signals to bypass the system. (See Figure 7.)

1

2

3

Description

4

5

31

Page 32

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 7. ESCIU Signals

ESCIU

Pass-through in Return Direction

Relay Bypass Path

Datastream

Synchronizer

BesTime Ensemble

Timing Generator

Synchronizing signal

Alarm Interface

The microprocessor delivers alarms to normally open dry-contact

type connections. Alarms are also indicated by the front-panel

status lamps.

32

Communication Ports

Three serial communication ports carry TL1 commands,

responses, and autonomous messages between the TimeSource

3600 and an external terminal.

Ethernet

The TimeSource 3600 has six Ethernet ports to carry TL1

commands, responses, and autonomous messages between the

TimeSource 3600 and an external terminal, or an Element

Manager, or both. The user can configure the IP address, subnet

mask, and gateway address for the Ethernet ports.

TimeSource 3600

Page 33

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Four ports (5001, 5002, 5003, and 5004) are configured to act as

though a serial-port communication terminal were connected to

them. These ports communicate TL1 commands, responses and

autonomous messages.

Two additional ports communicate with Element Managers, which

may have NMS, OSMF, or similar software. An Element Manager

establishes a connection with one port (5551) for TL1 commands

and responses. Another port (5550) establishes a connection to an

Element Manager, sends autonomous messages, and closes the

connection when finished.

1

2

3

Description

4

5

33

Page 34

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

This page intentionally left blank.

34

TimeSource 3600

Page 35

Engineering & Ordering

This chapter provides information to assist

in planning the installation and ordering a

system appropriate for a specific site.

Chapter

2

Page 36

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Antenna Guidelines

Perform a site survey as described in Procedure A before ordering

the system. Use the guidelines and considerations in the Roof

Antenna Location and Cabling Guidelines section and the Shelf

Considerations section.

36

TimeSource 3600

Page 37

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure A. Site Survey

Step Action

1

Determine the shelf location.

2 Determine the best location for mounting the antenna (less than 330 m of cable

from the shelf). Use the guidelines and considerations in the Roof Antenna Location

and Cabling Guidelines section.

3 If a roof-mounted antenna is installed, determine the location of the grounding point

for the lightning suppressor, then determine the location of the lightning suppressor.

The cable length between the lightning suppressor and the grounding point must be

less than 4.6 m. If the grounding point is inside the building, the cable length between

the grounding point and the cable entry must be less than 15 m. Valid lightning

suppressor grounding points are:

• Valid ring ground system (usually for roof-mounted lightning suppressors)

• Structural steel of building (for interior-mounted or exterior-mounted lightning

suppressors, attach with a cad weld)

• Central Office ground plate (usually for interior-mounted lightning suppressors)

4 If a roof-mounted antenna is installed, two lengths of cable are required. Plan the

cable route and measure the length of cable required between the antenna and the

lightning suppressor, and between the lightning suppressor and the shelf.

2

2

3

5 If a window or wall-mounted antenna is installed, plan the cable route and measure

the length of cable required between the antenna and the shelf.

6 Determine the two separate –48 V power sources for the shelf. If only one –48 V

power source is available, it must be cabled to both TimeSource 3600 power inputs.

End of Procedure

Engineering & Ordering

4

5

37

Page 38

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Roof Antenna Location and Cabling Guidelines

DANGER:

electrical or physical hazard to work persons or equipment.

Avoid proximity to all high-voltage sources. Mount in an

easily maintainable location.

The ideal roof antenna location provides a clear, unobstructed

view of the sky from the zenith to the horizon line, and 360

degrees around the horizon.

A compromise often must be made between location and satellite field

of view. With a smaller the field of view, the TimeSource 3600 can use

fewer satellites in the solution for GPS derived time. The TimeSource

3600 will operate with an average of one satellite in view for 40% of the

time in a day.

Signals closer to the horizon are often subject to multipath effects,

which degrade the timing solution. The TimeSource 3600 can be

set to ignore, or mask, all signals from the horizon up to a chosen

angle of elevation (mask angle). (See Figure 8.)

Do not select an antenna location that could be an

38

TimeSource 3600

Page 39

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

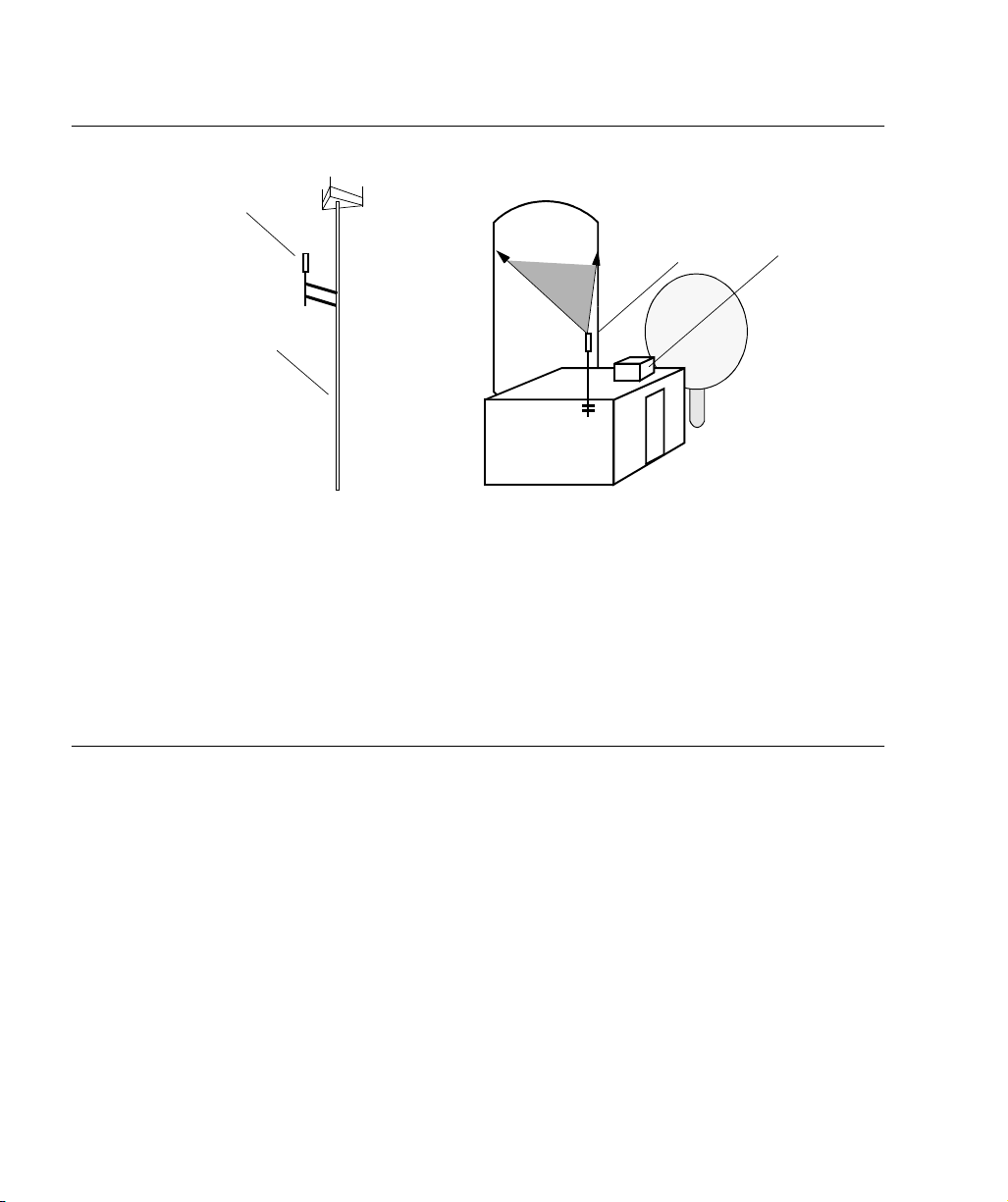

Figure 8. Antenna Field of View

Antenna position

Antenna

field of view

10°

Mask angle*

Horizon

Equator

* An angle of 10° masks objects up to about 1 m above the

horizon at 6 m from the antenna (illustration at right.)

Due to the geometry of the GPS satellite orbits, more satellites are

visible in the direction of the equator than the poles. If possible, place

the antenna so that the antenna has a clear view toward the equator

(toward the south in the northern hemisphere, or toward the north in

the southern hemisphere). Up to 60 degrees of arc, centered at the

pole, may be blocked with little effect in the temperate latitudes. This

note is less applicable in latitudes nearer the equator.

Obstructions

toward the pole

if possible

10°

Mask angle*

10°

6 m

Pole

1 m

2

2

3

4

The total of obstructions above the mask angle should not obscure

more than 25 percent of the total field of view (90 degrees of

azimuth) (Figure 9).

Engineering & Ordering

39

5

Page 40

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 9. Antenna Location Examples

Antenna tower

antenna

location

(Note 1)

Antenna

tower

Location A Location B

Notes:

1. Place the antenna high enough on the tower that obstructions are below the mask angle;

mount the antenna more than 1 meter away from the tower, and far below the interference

of the antennas at the top of the tower. Tower mounting is the least desirable location because of the potential for severe multipath, and difficulty in troubleshooting and maintenance.

2. Place the antenna high enough that the roof structure and tree are below the mask angle,

and the water tower does not block a large portion of the sky.

Water

tower

Building

antenna

location

(Note 2)

Tree

Roof

structure

40

No single obstruction should block a large portion (45 degrees of

azimuth) of the view.

The most important obstructions are within 400 meters of the

antenna. Obstructions may include, but are not limited to, towers,

buildings, other construction, trees, and high-voltage power lines.

Attempt to avoid locating the antenna within 30 degrees azimuth

of the transmission direction of any transmitting antenna in the

area, even if the transmitting antenna operates at a different

frequency. A transmitting antenna may cause the GPS antenna to

become overloaded and reduce its reception capabilities.

TimeSource 3600

Page 41

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

The minimum horizontal distance from other receiving antennas is

1 meter.

To reduce multipath signal distortions, the minimum horizontal

distance from vertical reflective structures (e.g., heating ducts,

equipment housings, etc.) is twice the height of the structure, and

no less than 3 meters (Figure 10).

Do not locate the antenna underneath high power lines. If this

cannot be avoided, ensure the antenna is placed at least twice as

far from the power line as the power line is high (to avoid danger

to personnel and multipath effects).

Cables must be run as straight as possible. All cables should be

routed in accordance with local company practices.

2

2

Note:

routed in accordance with local company practices.

Observe the following guidelines during the placement and

installation of the cables:

Warning:

Keep all impedances as low as possible. All cables should be

• Route cables as straight as possible (bends in the cable

increase impedance at lightning frequencies), in accordance

with local company practices.

• Any opening where conduit enters the building must be

waterproofed per local company practices.

• Treat all exposed connections with an electrically conductive

anti-corrosion compound (Kopr-Shield or equivalent).

Avoid small-radius turns and unnecessary turns.

3

4

5

Engineering & Ordering

41

Page 42

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 10. Sample Rooftop Antenna Mount

At or above the

level of the

Reflective

surface

reflective surface

Cable

conduit

2.4 m

Rooftop

Heating

Ducts

(twice the 2.4 m height)

4.8 m

(3 m minimum)

Cable entry

into building

Note: This is an example only. Not all parts are available from Symmetricom.

Antenna

Mounting

Bracket

Mounting Pipe

Pipe clamped

to wall

Building Wall

42

Roof Antenna Earth Ground Location Guidelines

The roof ring ground system, a Central Office grounding plate, and

building structural steel are examples of valid earth ground

points. If the mounting plate cannot be bolted to a valid earth

ground, or if the mounting plate is to be installed in a nonmetallic

junction box, bolt the mounting plate to a point within 4.6 meters

of the valid earth ground.

TimeSource 3600

Page 43

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Roof Antenna Cable Choices

The antenna assembly uses the same coaxial cable for power and

antenna signals. The length of cable is determined by

circumstances of the installation and site.

Symmetricom offers RG-59/U plenum-rated coaxial cable (0.812

mm [20 AWG], 75 ohm coaxial) with male TNC connectors

attached, in the following lengths:

• 3 m cable (060-72010-01)

• 6 m cable (060-72010-02)

• 15 m cable (060-72010-05)

• 30 m cable (060-72010-10)

• 61 m cable (060-72010-20)

• 91 m cable (060-72010-30)

• 152 m cable (060-72010-50)

• 182 m cable (060-72010-60)

• 243 m cable (060-72010-80)

• 305 m cable (060-72010-99)

Two cables are required: one to connect the antenna to the

lightning suppressor, and another to connect the lightning

suppressor to the TimeSource 3600 Shelf.

Optionally, one length of coaxial cable may be ordered, which

must be cut and prepared with end-connectors at the point where

the suppressor is located.

2

2

3

4

Engineering & Ordering

5

43

Page 44

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

The following items, which must be ordered separately, are

available for this type of installation:

• TNC connector kit (093-72010-98) includes:

- TNC connectors for RG-59/U cables (8)

- Rubber boots (8)

- TNC adapter connectors (2)

• TNC crimp tool (154-00023-01)

44

TimeSource 3600

Page 45

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Window and Wall Antenna Location Guidelines

When selecting a window or wall in which to install the antenna,

select the window or wall which has the maximum unobstructed

view of the sky. Do not select a window or wall which has the view

of the sky obstructed by trees, buildings, or towers. The smaller

the field of view, the fewer the number of satellites that can be

used in the timing solution for GPS derived time. The consequence

of this is that the timing generator may experience holdover more

often and may eventually go into alarm.

Due to the geometry of the GPS satellite orbits, more satellites are

visible in the direction of the equator than the poles. If possible,

select a window or wall which has a clear view toward the equator

(toward the south in the northern hemisphere, or toward the north

in the southern hemisphere). This guideline is less applicable in

latitudes nearer the equator and more important nearer the poles.

2

2

Certain parts of the sky are blocked from view. These obstructions

usually exist from the horizon line and up, for example, a building

or mountain. The processor inside the GPS receiver possesses

every piece of the sky, whether it is blocked or not. If unproductive

parts of the sky are masked from the processor’s view, the

processing time is reduced, and the timing solution can be

achieved more quickly.

Note:

view of the sky begins is called a mask angle. The mask angle typically should not exceed 10 degrees (if the mask angle is set too

high, too little of the sky is available to the receiver). Determine the

mask angle for the selected antenna location (Figure 11) and make

a note of it. The mask angle, in degrees, will be entered during the

initial setup.

A band of the sky from the horizon up to a point where a

Engineering & Ordering

45

3

4

5

Page 46

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 11. Antenna Mask Angle

TimeSource 3600

Antenna

1 m

6 m

Note: TimeSource 3600 does

not detect satellites in the

masked area.

*An angle of 10° masks objects up to about 1 m above the horizon at

6 m from the antenna.

10° mask angle*

46

TimeSource 3600

Page 47

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Window and Wall Antenna Cable Choices

A window or wall antenna includes an attached coaxial cable

terminating in a male SMA connector.

A separate cable is required to connect the IF converter to the

TimeSource 3600 shelf. Two types of plenum-rated cable are available.

The cables with longer length capabilities (060-72010-xx) are

RG-59/U (0.812 mm [20 AWG], 75 ohm coaxial) with male TNC

connectors attached to each end. Assembled cables are available

in the following lengths:

• 3 m cable (060-72010-01)

• 6 m cable (060-72010-02)

• 15 m cable (060-72010-05)

• 30 m cable (060-72010-10)

• 61 m cable (060-72010-20)

• 91 m cable (060-72010-30)

2

2

3

• 152 m cable (060-72010-50)

• 182 m cable (060-72010-60)

• 243 m cable (060-72010-80)

• 305 m cable (060-72010-99)

The more flexible cables (060-72050-xx) are Mini RG-59/U

(0.812 mm [20 AWG], 75 ohm coaxial) with male TNC connectors

attached to each end. Assembled cables are available in the

following lengths:

• 15 m (060-72050-05)

• 30 m (060-72050-10)

• 61 m (060-72050-20)

• 152 m cable (060-72010-50)

Engineering & Ordering

47

4

5

Page 48

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

IRIG-B TOD (990-72060-05 System Only)

If using the IRIG-B TOD outputs (990-72060-05 TimeSource 3600

System), right-angle BNC connectors are provided to prevent small

radius turns in the IRIG-B TOD cables. The right-angle BNC

connectors may be attached to the IRIG-B BNC adapter (also

provided) BNC connectors, to direct the cables from the shelf as

desired.

For each IRIG-B TOD output, a user-supplied cable with BNC

connectors on each end is installed between the adapter and the

network elements requiring IRIG-B TOD timing.

RJ-422–to–RS-232 TOD Converter

If using time-of-day (TOD), and the device receiving the time code

accepts an RS-232 signal instead of an RS-422 signal (for

example, a Cisco router), an RJ-422–to–RJ-232 TOD Converter Kit

is required (ordered separately, part number 093-72000-98).

The RJ-422–to–RJ-232 TOD Converter Kit consists of a mounting

plate with a female RJ-45 connector, a female DB-25 connector, a

TOD converter, and two screws.

48

Install the converter anywhere (for example, on unused space on a

rack) within 305 cable meters of the TimeSource 3600 shelf, and

within 15 cable meters of the device receiving the time code.

The user must supply two cables. One cable is a Category 5 fourpair RS-422 cable, 305 meter maximum, with RJ-45 connectors

on each end. Route this cable between the TimeSource 3600 Shelf

and the converter.

The other cable is an RS-232 data communications cable, 15

meters maximum, with a 25-pin male D-type connector and

another connector determined by the device receiving the time

code. Route this cable between the converter and the device

receiving the time code.

TimeSource 3600

Page 49

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

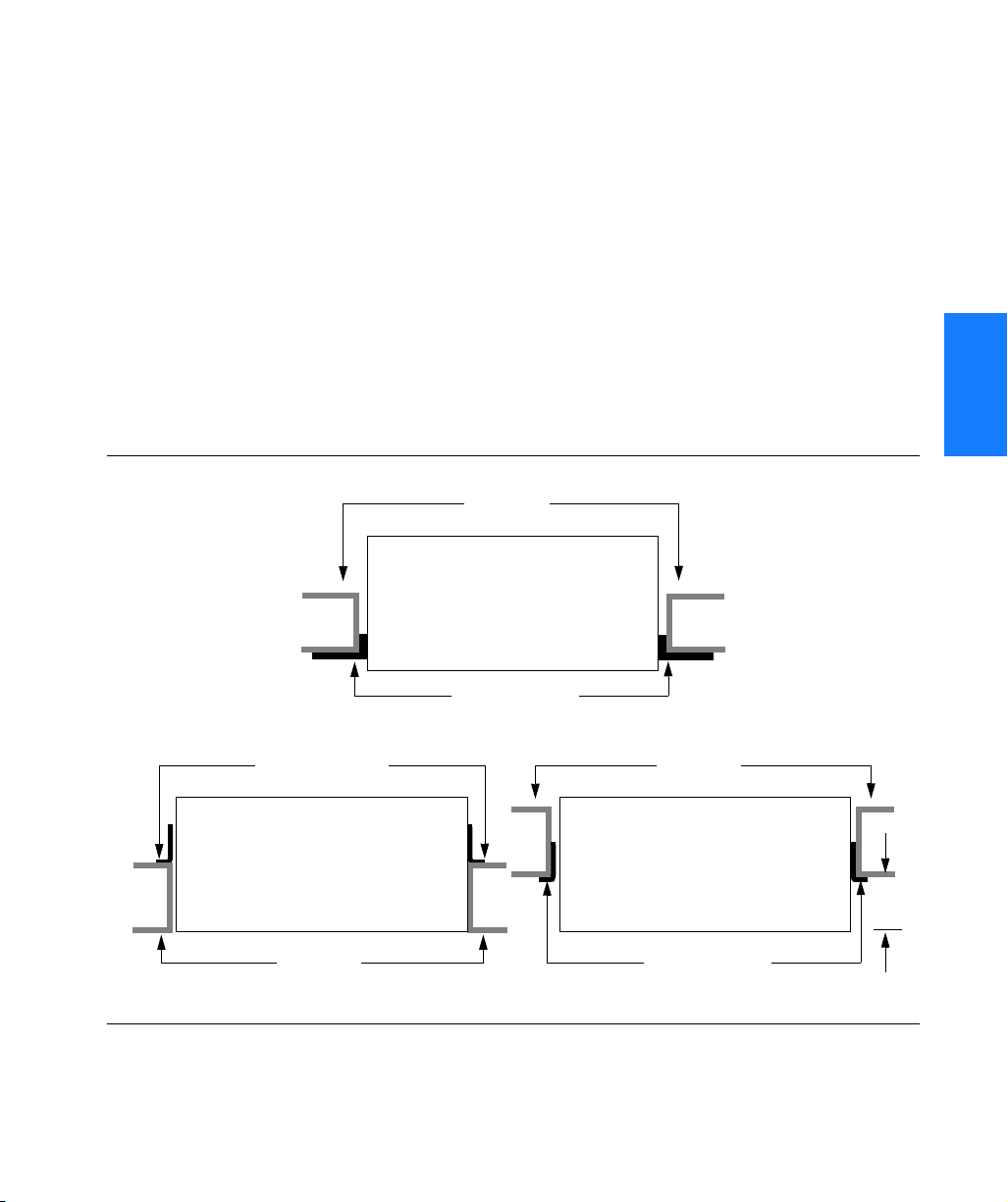

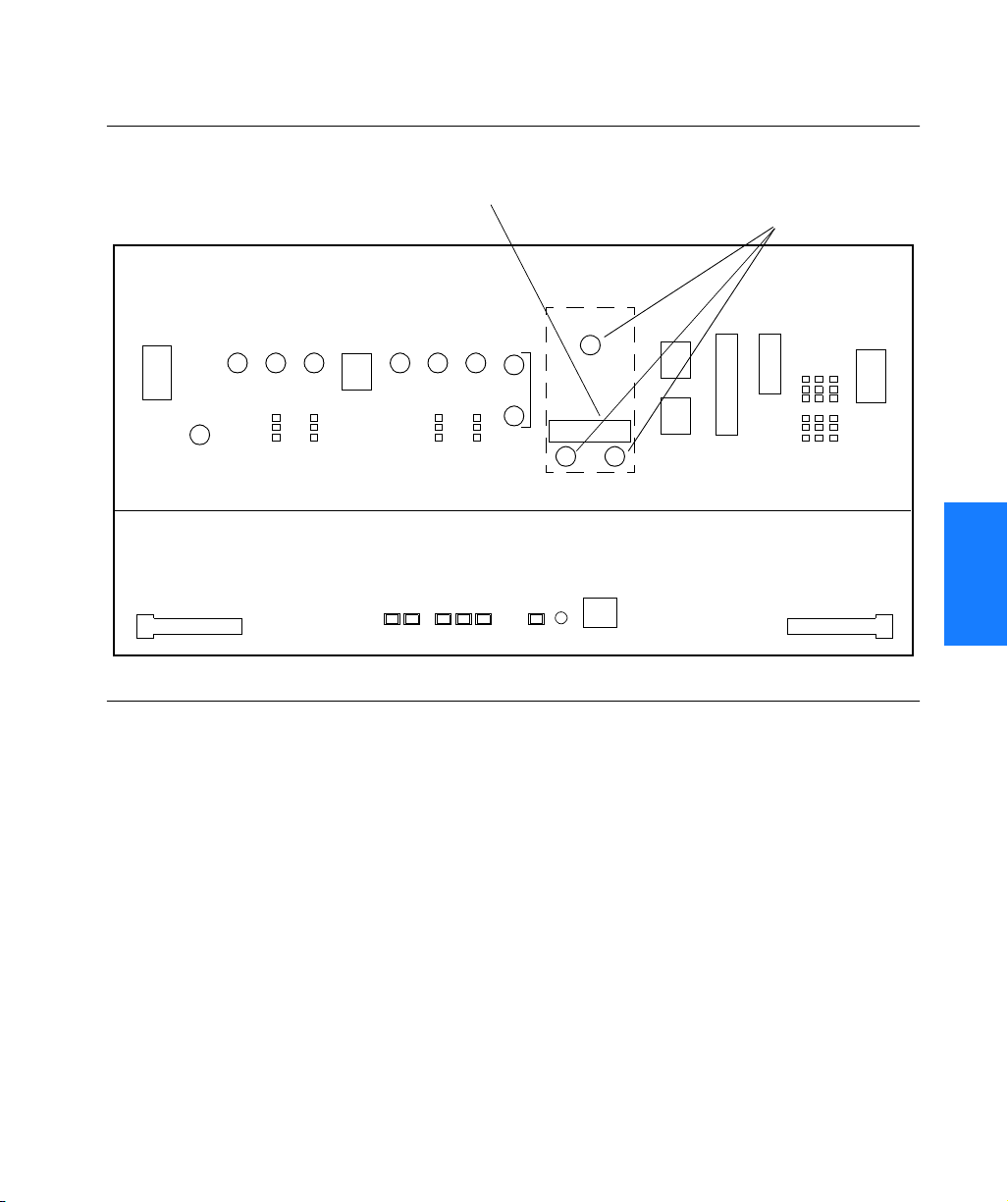

Shelf Considerations

The TimeSource 3600 Shelf can be mounted in an ETSI 53.5 cm

rack or a 48 cm rack. The shelf is shipped with supplied mounting

ears positioned for flush mounting on an ETSI 53.5 cm rack.

Attach the mounting ears, as shown in Figure 12, for flush

mounting or 12.7 cm offset mounting. Attach the long side of the

mounting ear to the shelf for an ETSI 53.5 cm rack, and attach

the short side of a mounting ear to the shelf for a 48 cm rack.

Mount the shelf in the rack according to standard company

practices.

Figure 12. Rack Mounting Options

Rack rails

Rear of rack

Top of shelf

2

2

3

A. ETSI – 53.5 cm rack

Mounting ears

Rear of rack

Top of shelf

Top of shelf

Rack rails Mounting ears

B. Flush mounting – 48 cm rack

Mounting ears

Rack rails

Rear of rack

Top of shelf

Top of shelf

C. 12.7 cm offset – 48 cm rack

Engineering & Ordering

4

12.7

cm

5

49

Page 50

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Systems

The TimeSource 3600 Systems available are listed below. The

antenna must be ordered separately.

Standard System (Two E1 Outputs)

This system (990-72060-01) includes:

• TimeSource 3100 Shelf (090-72000-11)

• TimeSource 3600 card (090-72060-01)

• Hardware kit (093-72060-87)

• System software compact disc (CD) (992-72060-xx) Version

1.04.02 or higher

• TimeScan Craft software compact disc (CD) (992-46750-xx)

Version 7.0.1 or higher

• TimeScan Craft connection key (020-46700-001)

50

TimeSource 3600

Page 51

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

With Eight Additional E1 or 2.048 MHz Outputs

This system (990-72060-02) includes:

• TimeSource 3100 Shelf (090-72000-11)

• TimeSource 3600 card with additional E1 or 2.048 MHz

outputs (090-72060-02)

• Hardware kit (093-72060-87)

• System software compact disc (CD) (992-72060-xx) Version

1.04.02 or higher

• TimeScan Craft software compact disc (CD) (992-46750-xx)

Version 7.0.1 or higher

• TimeScan Craft connection key (020-46700-001)

With Two E1 Synchronization Insertion (ESCIU) Ports

This system (990-72060-04) includes:

• TimeSource 3100 Shelf (090-72000-11)

2

2

3

• TimeSource 3600 card with ESCIU ports (090-72060-04)

• Hardware kit (093-72060-87)

• System software compact disc (CD) (992-72060-xx) Version

1.04.02 or higher

• TimeScan Craft software compact disc (CD) (992-46750-xx)

Version 7.0.1 or higher

• TimeScan Craft connection key (020-46700-001)

Engineering & Ordering

4

5

51

Page 52

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

With Four IRIG-B TOD Outputs

This system (990-72060-05) includes:

• TimeSource 3100 Shelf (090-72000-11)

• TimeSource 3600 card with IRIG-B TOD outputs (090-72060-

05)

• Hardware kit (093-72060-87)

• System software compact disc (CD) (992-72060-xx) Version

1.04.02 or higher

• TimeScan Craft software compact disc (CD) (992-46750-xx)

Version 7.0.1 or higher

• TimeScan Craft connection key (020-46700-001)

52

TimeSource 3600

Page 53

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Antennas

The antennas available are listed below. A TimeSource 3600

System must be ordered separately.

Roof Antenna

This antenna kit (990-72050-96) includes:

• IF antenna assembly (090-72010-97)

• Rooftop antenna installation kit (093-72050-96) includes:

- Antenna cable bracket kit (093-00001-01)

- Mounting bracket for surge suppressor (070-00300-02)

- Surge suppressor (143-00018-01)

- Miscellaneous installation parts

Mechanical Window Antenna

This antenna kit (990-72050-97) comes as a fully assembled

antenna with the following major components:

• Antenna, with cable and SMA connector attached (09072050-90)

• IF converter (090-72050-97)

• Mechanical chassis (074-72050-97)

2

2

3

4

Engineering & Ordering

5

53

Page 54

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Self-Adhesive Window Antenna

This antenna kit (990-72050-98) includes:

• Antenna (090-72010-87)

• IF converter (090-72050-97)

• Self-adhesive window antenna installation kit (093-72050-98)

includes:

- RG316 cable, 3 m (060-00062-01)

- Cable tie mounts (128-00302-02) and

cable ties (128-00500-05)

Wall Antenna

This antenna kit (990-72050-99) includes:

• IF converter (090-72050-97)

54

• Wall antenna kit (093-72050-99) includes:

- Antenna, with 5.8 m of cable and SMA connector attached

(112-00013-01)

- Antenna mounting bracket (070-00413-01)

- Cable tie mounts (128-00302-02) and

cable ties (128-00500-05)

TimeSource 3600

Page 55

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

User-Supplied Tools and Materials

Ensure that the user-supplied tools and materials listed below are

on hand for installation, as applicable.

For Roof Antenna Installation

• 2.5 cm diameter galvanized metal pipe, used as a mast to

mount the antenna. Mast should be long enough to position

the antenna above any metal object on the roof

• Screws to attach the lightning suppressor mounting plate

• Plumb line or bubble level

• Nonmetallic junction box for lightning suppressor (optional if

lightning suppressor mounted indoors)

2

2

• 2.5 cm diameter PVC pipe as conduit for outdoor cables

• PVC fittings appropriate to the installation and cable route

• Appropriate tools and materials for cutting, shaping, and

connecting PVC pipe

• 4.115 mm (6 AWG) ground wire

• Spade lugs for 4.115 mm (6 AWG) ground wire

• Crimp tool for 4.115 mm (6 AWG) spade lugs

• Hardware to attach the ground wire to a valid earth ground

• Fire-stopping material to seal conduit hole in roof or wall

• Electrically conductive antioxidant compound (Kopr -Shield or

equivalent) to coat exposed connections to prevent oxidation

• Tool to cut cable, if installation requires custom lengths of cable

Engineering & Ordering

55

3

4

5

Page 56

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

For Mechanical Window Antenna Installation

• Drill with bit of appropriate size and type to make pilot holes

for the mounting screws

• 2 screws of appropriate size and type to attach the foot of the

mechanical chassis to a window sill or wall near a window.

• Screwdriver

• Cable ties or other method of securing cable

• GPS handheld receiver, personal computer with GPS location

software, or other method of determining latitude, longitude,

and altitude

For Self-Adhesive Window Antenna Installation

• Drill with bit of appropriate size and type to make pilot holes

for the mounting screws

• 4 screws of appropriate size and type to attach the IF

converter to a wall or other mounting surface.

56

• Screwdriver

• GPS handheld receiver, personal computer with GPS location

software, or other method of determining latitude, longitude,

and altitude

For Wall Antenna Installation

• Ladder, or safe method of reaching the antenna location on

the exterior wall

• Drill with bits of appropriate size and type to make pilot holes

for the antenna mounting bracket screws, and to make a

hole through the wall for the antenna cable

TimeSource 3600

Page 57

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

• 2 screws of appropriate size and type to attach the antenna

mounting bracket to an exterior wall.

• Screwdriver

• Electrically conductive antioxidant compound (Kopr-Shield

or equivalent) to coat exposed connections to prevent

oxidation

• Fire stopping material to seal the hole in the wall

• GPS handheld receiver, personal computer with GPS location

software, or other method of determining latitude, longitude,

and altitude

For Shelf Installation

• A Phillips-head screwdriver for installing the TimeSource

3600 Shelf in a rack

• Four screws to mount the shelf in a rack

2

2

3

Engineering & Ordering

4

5

57

Page 58

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Outputs, Power, and Miscellaneous

• RG-58 coaxial cable for 1 PPS, 10 MHZ outputs

• Ethernet 10BaseT cable for Ethernet port

• Category 5 four-pair RS-422 cable, with RJ-45 connector for

the TOD output, RS-422–to–RS-232 TOD converter

• RS-232 cable with DB-25 connector for the RS-422–to–

RS-232 TOD converter

• RS-232 cable with DB-9 connector for COM2 port

• 4.115 mm (6 AWG) ground wire

• 1.47 mm (16 AWG) green insulated ground wire

• 1.47 mm (16 AWG) red insulated wire

• 1.47 mm (16 AWG) black insulated wire

58

TimeSource 3600

Page 59

Installation

This chapter is the sequential order of

procedures for installation and power-up.

Chapter

3

Page 60

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Unpacking

Use the procedures in the order they appear in this chapter to

install the TimeSource 3600. If any difficulties are encountered

during the installation process, contact Symmetricom’s Customer

Technical Assistance Center (CTAC). Refer to the Technical

Assistance section of the Troubleshooting chapter for telephone

numbers.

CTAC includes Product Technical Support for technical

information, and Customer Service for information about an order,

RMAs, and other information.

Warning:

procedures regarding electrostatic discharge (ESD), including:

•Use grounded wrist straps connected to equipment frame

•Store cards only in antistatic packaging provided by the

Note:

packed in the original packing material. Contact Customer Service

if additional packaging is needed.

Unpack equipment carefully; check for completeness against the

purchase order. Notify Symmetricom if items are missing.

Inspect equipment for shipping damage, including bent or loose

hardware, and broken connectors.

If equipment was damaged in transit, contact Customer Service to

request an RMA, and notify the carrier.

When handling electronic equipment, use local office

ground when handling cards.

factory.

Save packing material. All equipment returned must be

60

TimeSource 3600

Page 61

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Antenna

Roof Antenna

Installation procedures are to follow local company procedures

and the Installation Job Specification.

Prior to installing the antenna, the site, antenna location,

lightning suppressor location, lightning suppressor grounding

point, cable route, and all other details should have been planned.

To install the antenna, refer to Figure 13 and perform

Procedure B. Ensure all user -supplied materials are available.

Warning:

from electrical devices or cabling that may induce arcing.

Notes:

1. Recommended grounding points:

a. Valid roof ring ground system.

b. Cad weld to building structural steel.

c. Central office ground plate within 15 m of antenna cable

2. Order two cables or a single cable run can be made from the

antenna to the TimeSource Shelf. The cable can then be cut at the

lightning suppressor location, and TNC connectors attached to the

cut ends of the cable. The “xx” in the part number indicates the

cable length.

Ensure that the lightning suppressor is placed away

entrance into building.

3

3

4

5

Installation

61

Page 62

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 13. Roof Antenna-to-Shelf Cabling

Antenna

090-72010-97

Antenna Mounting

Hardware

(070-00377-01)

RG-59/U Cable

(060-72010-xx)

(See Note 2)

Lightning Suppressor

(143-00018-01)

and Mounting Bracket

(070-00300-02)

Valid earth ground

(See Note 1)

RG-59/U Cable

(060-72010-xx)

(See Note 2)

TNC Connector

(on shelf)

TNC Connector

(Attached

to cable)

TNC Connector

(Attached

to cable)

TNC Connector

(Attached

to cable)

TNC Connector

(Attached

to cable)

TimeSource 3600 Shelf

62

TimeSource 3600

Page 63

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure B. Roof Antenna Mounting and Cable Connection

Step Procedure

1 Attach the antenna mounting bracket to a pipe (2.5 cm diameter) or a wood post.

• If mounting the bracket to a pipe, slide the two V-bolts over the pipe, and

through the mounting bracket slots; then place the provided four washers

and four nuts over the V-bolts, against the mounting bracket. Leave the

V-bolts loose enough to allow for final adjustments.

Mounting

Bracket

Washers (4)

Nuts (4)

Pipe

• If mounting the bracket to a wood post, use the provided two self-tapping

screws in two diagonally positioned mounting bracket slots, and attach to the

post.

Screws (2)

V-Bolts (2)

Mounting

Bracket

Post

3

3

4

5

Installation

63

Page 64

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure B. Roof Antenna Mounting and Cable Connection (cont’d)

Step Procedure

2 Slide the antenna bolts through the holes in the mounting bracket, then attach the

antenna to the bracket, using the provided three nuts and three lockwashers.

Antenna

(±5° of vertical)

090-72010-97

Antenna Bolts (3)

Lock washers (3)

Mounting

Bracket

Nuts (3)

3 Using a plumb line or bubble level, ensure the antenna is within 5° of vertical

(perpendicular to the horizon), and tighten the mounting bracket bolts.

4 Bolt the lightning suppressor mounting plate to a flange that is attached to a valid

earth ground. The roof ring ground system, a Central Office grounding plate, and

building structural steel are examples of valid earth ground points. If the mounting

plate cannot be bolted to a valid earth ground, bolt the mounting plate to a point

within 4.6 m of the chosen valid earth ground. If the mounting plate is to be installed

in a nonmetallic junction box, perform the installation, and bolt the assembly near the

chosen valid earth ground.

64

TimeSource 3600

Page 65

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure B. Roof Antenna Mounting and Cable Connection (cont’d)

Step Procedure

5 Slide the longer bolt of the lightning suppressor through the D-hole, and attach with a

nut and a washer (provided).

KEPS nut (2)

4.115 mm (6 AWG)

ground wire

D-hole

Nut

Washer

Lightningsuppressor

Cable connector (2)

6 Install 2.5 cm nonmetallic conduit from the antenna to the lightning suppressor, and

from the lightning suppressor to the cable entrance into the building.

7 Install a user-supplied bracket, preferably non-metallic, to support the vertical section

of conduit to the antenna.

8 Connect a cable to the antenna, route the cable through the conduit, and connect

the cable to the lightning suppressor.

9 Connect a cable to the lightning suppressor, route the cable through the conduit into

the building, and route the cable through the building to the TimeSource 3600 Shelf

location.

10 If the lightning suppressor was not mounted directly to a valid earth ground, crimp a

length of 4.115 mm (6 AWG) ground cable to the two-hole terminal, slide the

terminal over two of the three threaded posts on the lightning suppressor mounting

plate, and attach the terminal to the mounting plate with two KEPS nuts. Use the two

posts that allow the least bending of the 4.115 mm (6 AWG) ground cable.

Mounting plate

Hole for mounting bolt (2)

Threaded posts (3)

(use any 2)

3

3

4

5

Installation

65

Page 66

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure B. Roof Antenna Mounting and Cable Connection (cont’d)

Step Procedure

11 Attach the other end of the cable to a valid earth ground.

12 Install fire-stopping material in all holes opened in the roof and/or walls during this

procedure.

13 Check all connections for tightness to prevent arcing and intermittent operation.

14 Coat all exposed connectors with an electrically conductive antioxidant compound

(e.g., Kopr-Shield spray).

End of Procedure

66

TimeSource 3600

Page 67

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Mechanical Window Antenna

Installation procedures are to follow local company procedures

and the Installation Job Specification.

Prior to installing the antenna, the site, antenna location, cable

route, and all other details should have been planned.

For best results, choose a window facing the equator (facing south

in the northern hemisphere, facing north in the southern

hemisphere), and with the fewest obstructions of the sky.

To install the antenna, refer to Figure 14 and perform

Procedure C.

Figure 14. Mechanical Window Antenna-to-Shelf Cabling

Components of

990-72050-97

antenna

assembly

(Attached to cable, and on shelf)

Antenna-to-IF cable

TNC Connector

(on IF converter)

TNC Connector

(Attached to cable)

TNC Connector

Antenna

IF Converter

Antenna Assembly

990-72050-97

TimeSource 3600 Shelf

IF-to-shelf cable

RG-59/U Cable

060-72010-xx

(3 m to 305 m) or

Mini RG-59 Cable

060-72050-xx

(15 m to 152 m)

Installation

67

3

3

4

5

Page 68

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure C. Mechanical Window Antenna Mounting and Cable Connection

Step Procedure

Prerequisite:

Observe all guidelines, considerations, Dangers, Warnings, Cautions, and Notes in the

Engineering and Ordering chapter.

Symmetricom Parts

• Mechanical Window Antenna (990-72050-97)

• A length of RG-59/U plenum-rated coaxial cable (060-72010-xx), or

• A length of Mini RG-59/U plenum-rated coaxial cable (060-72050-xx)

User-Supplied Materials:

For Mechanical Window Antenna Installation

• Drill with bit of appropriate size and type to make pilot holes for the mounting screws

• 2 screws of appropriate size and type to attach the foot of the mechanical chassis to a

window sill or wall near a window.

• Screwdriver

• Cable ties or other method of securing cable

• GPS handheld receiver, personal computer with GPS location software, or other method

of determining latitude, longitude, and altitude

1 At the window chosen in Chapter 2, Engineering and Ordering, attach the base of the

mechanical window antenna to the chosen location (sill, wall, etc.) using user-supplied

screws (Figure 15).

2 Use the pivots on the mechanical window antenna to place the antenna section flat

against the window.

3 Tighten the pivot screws to secure the antenna (Figure 16).

4 Connect the antenna cable to the IF downconverter on the mechanical window

antenna assembly and route the cable to the TimeSource 3600 Shelf location.

5 Secure the cable using local company procedures.

6 Check all connections for tightness to prevent intermittent operation.

End of Procedure

68

TimeSource 3600

Page 69

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Figure 15. Attaching the Mechanical Window Antenna

Use 2 user-supplied

screws to attach to wall

or window sill

Figure 16. Mechanical Window Antenna Pivot Screws

Place the antenna

against the window by

moving the chassis on

these pivots.

Tighten these pivot screws

to lock antenna posit ion.

3

3

4

Installation

5

69

Page 70

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Self-Adhesive Window Antenna

Prior to installing the antenna, the site, antenna location, cable

route, and all other details should have been planned.

Installation procedures are to follow local company procedures

and the Installation Job Specification.

For best results, choose a window facing the equator (facing south

in the northern hemisphere, facing north in the southern

hemisphere), and with the fewest obstructions of the sky.

To install the antenna, refer to Figure 17 and perform

Procedure D.

Figure 17. Self-Adhesive Window Antenna-to-Shelf Cabling

Antenna

090-72010-87

Antenna-to-IF cable (10 ft)

060-00062-01

SMA connector

(Attached to cable,

and on IF converter)

IF converter

090-72050-97

and Mounting Kit

TNC connector

(Attached to cable,

and on IF converter)

TNC Connector

(Attached to cable, and on shelf)

Antenna kit

990-72050-98

IF-to-shelf cable

RG-59/U Cable

060-72010-xx

(3 m to 305 m) or

Mini RG-59 Cable

060-72050-xx

(15 m to 152 m)

70

TimeSource 3600 Shelf

TimeSource 3600

Page 71

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure D. Self-Adhesive Window Antenna Mounting and Cable Connection

Step Procedure

Prerequisite:

Observe all guidelines, considerations, Dangers, Warnings, Cautions, and Notes in the

Engineering and Ordering chapter.

Symmetricom Parts:

• Self-Adhesive Window Antenna Kit (990-72050-98)

• A length of RG-59/U plenum-rated coaxial cable (060-72010-xx), or

• A length of Mini RG-59/U plenum-rated coaxial cable (060-72050-xx)

For Self-Adhesive Window Antenna Installation

• Drill with bit of appropriate size and type to make pilot holes for the mounting screws

• 4 screws of appropriate size and type to attach the IF converter to a wall or other

mounting surface.

• Screwdriver

• GPS handheld receiver, personal computer with GPS location software, or other method

of determining latitude, longitude, and altitude

1 Peel off the backing of one of the self-adhesive hook-and-loop strips and stick the

strip to the antenna.

3

3

2 Attach the hook-and-loop side of the other strip to the hook-and-loop side of the

strip on the antenna.

3 Peel off the backing and stick the antenna to the position on the window selected in

Chapter 2, Engineering & Ordering.

4 Use user-supplied screws to mount the IF downconverter to a suitable wall or other

structure (Figure 18). Be sure the distance along the cable route between the IF

downconverter and the antenna is no more than 3 m.

5 Route and connect the antenna cable to the antenna side of the IF downconverter.

6 Connect a cable to the TimeSource 3600 shelf side of the IF downconverter and

route the cable to the shelf location.

7 Secure the cable using local company procedures.

Installation

71

4

5

Page 72

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure D. Self-Adhesive Window Antenna Mounting and Cable Connection (cont’d)

Step Procedure

8 Check all connections for tightness to prevent intermittent operation.

End of Procedure

Figure 18. Attaching the IF Converter

Use 4 user-supplied

screws to attach to a

wall or other stru c ture.

72

TimeSource 3600

Page 73

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Wall Antenna

Prior to installing the antenna, the site, antenna location, cable

route, and all other details should have been planned.

Installation procedures are to follow local company procedures

and the Installation Job Specification.

For best results, choose a wall facing the equator (facing south in

the northern hemisphere, facing north in the southern

hemisphere), and with the fewest obstructions of the sky.

To mount the antenna through the wall, refer to Figure 19

and follow Procedure E.

Figure 19. Wall Antenna-to-Shelf Cabling

Antenna Mounting Bracket

070-00413-01

Antenna

112-0013-01

SMA connector

(Attached to cable,

and on IF converter)

IF converter

090-72050-97

and Mounting Kit

TNC connector

(Attached to cable,

and on IF converter)

TNC Connector

(Attached to cable, and on shelf)

Antenna kit

990-72050-99

IF-to-shelf cable

RG-59/U Cable

060-72010-xx

(3 m to 305 m) or

Mini RG-59 Cable

060-72050-xx

(15 m to 152 m)

3

3

4

TimeSource 36 00 She lf

Installation

5

73

Page 74

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure E. Wall Antenna Installation

Step Action

Prerequisite:

Observe all guidelines, considerations, Dangers, Warnings, Cautions, and Notes in the

Engineering and Ordering chapter.

Symmetricom Parts:

• Wall Antenna Kit (990-72050-99)

• A length of RG-59/U plenum-rated coaxial cable (060-72010-xx), or

• A length of Mini RG-59/U plenum-rated coaxial cable (060-72050-xx)

User-Supplied Materials:

• Ladder, or safe method of reaching the antenna location on the exterior wall

• Drill with bits of appropriate size and type to make pilot holes for the antenna mounting

bracket screws, and to make a hole through the wall for the antenna cable

• Two screws of appropriate size and type to attach the antenna mounting bracket to an

exterior wall

• Screwdriver

• Electrically conductive antioxidant compound (Kopr-Shield or equivalent) to coat exposed

connections to prevent oxidation

• Fire stopping material to seal the hole in the wall

• GPS handheld receiver, personal computer with GPS location software, or other method

of determining latitude, longitude, and altitude

1 Attach the IF downconverter (Figure 18) inside the building to a suitable wall or

other structure. Be sure the distance along the cable route between the IF converter

and the antenna is no more than 5.8 m. Include allowances for the drip loop and local

company procedures for cable routing.

2 Use Figure 20 to determine the spacing of the 2 holes for mounting the bracket, and

the distance to the hole for passing the cable into the building.

3 Drill a 10-mm diameter hole through the wall for the antenna cable. The diameter of

the hole should be larger than the outer diameter of the SMA connector on the

antenna cable, which will pass through the hole from the antenna to the inside of the

building.

4 Drill two pilot holes for the user-supplied screws or bolts that attach the mounting

bracket to the outside wall.

5 Using two screws or bolts, mount the antenna bracket assembly to the outside wall.

74

TimeSource 3600

Page 75

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

Procedure E. Wall Antenna Installation (cont’d)

Step Action

6 Place the magnetic side of the antenna on the outside of the mounting bracket.

7 Push the SMA connector of the antenna cable through the hole drilled in the wall in

Step 3. Be sure the antenna cable forms a drip loop between the antenna and the

cable entry into the building (Figure 21).

8 Route the antenna cable to the antenna side of the IF converter and connect the

cable.

9 Connect a cable to the TimeSource 3600 shelf side of the IF downconverter and

route the cable to the shelf location.

10 Secure the cable using local company procedures.

11 Install fire-stopping material in all holes opened in the roof and/or walls during this

procedure.

12 Check all connections for tightness to prevent intermittent operation.

13 Coat all exposed connectors with an electrically conductive antioxidant compound

(e.g., Kopr-Shield spray).

3

3

Figure 20. Hole Spacing

8.6 cm

End of Procedure

5 cm

2.5 cm

Bracket mounting hole (2)

Antenna Cable hole

Installation

4

5

75

Page 76

SSSSSSSSSSSS SSSSSSSSSS SSSSSSS

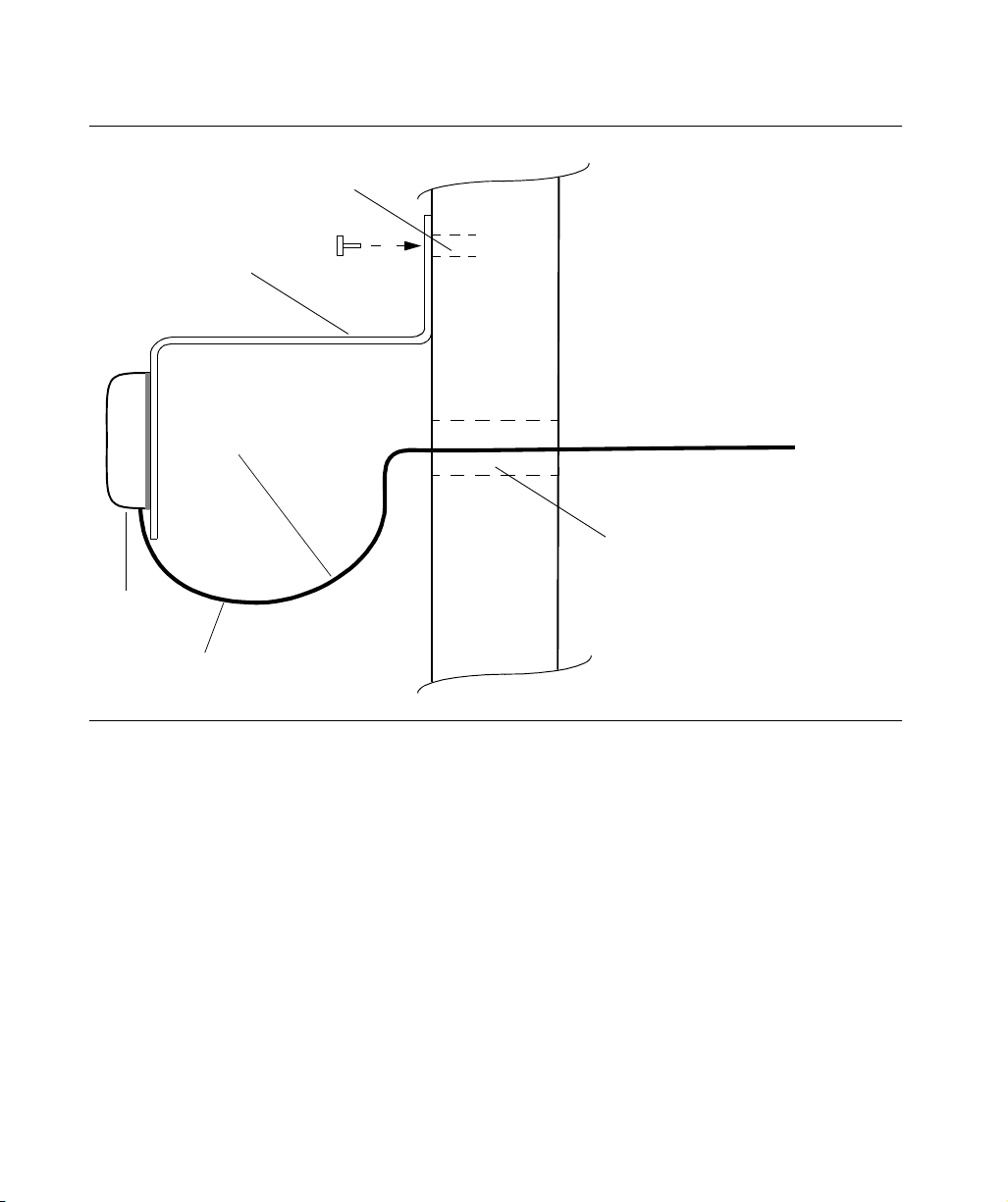

Figure 21. Wall Antenna Mounting

Holes for

bolts/screws

Mounting

bracket

Antenna

cable

Antenna

Wall