Page 1

TimeHub 5500

User’s Guide

Issue 8 – February 2005

Part Number 097-55501-01

Page 2

Symmetricom, Inc.

2300 Orchard Parkway

San Jose, CA 95131-1017

U.S.A.

http://www.symmetricom.com

Copyright © 2003–2005 Symmetricom, Inc.

All rights reserved. Printed in U.S.A.

All product names, service marks, trademarks, and registered trademarks

used in this document are the property of their respective owners.

Page 3

Table of Contents

Contents

How to Use This Guide

Purpose of This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Who Should Read This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Structure of This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Conventions Used in This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Warnings, Cautions, Recommendations, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Related Documents and Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Where to Find Answers to Product and Document Questions. . . . . . . . . . . . . . . . . xviii

What’s New In This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Chapter 1 Description

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Physical Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Communication Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Input/Alarm Connector Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Clock Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Management Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Output Driver Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Output Connector Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connection Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarm Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Synchronization Status Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Input SSMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Automatic Reference Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Output SSMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Passthrough Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Passthrough Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Firmware Versions and Passthrough Operation . . . . . . . . . . . . . . . . . . . . . . . . 31

Master/Remote Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Remote Shelf Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SSMs in a Remote Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Expansion Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Output Driver Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Rear Panel of the Expansion Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Expansion Output Connector Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Output Driver Cards and Output Connector Modules . . . . . . . . . . . . . . . . . . . . 38

Redundancy Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Communicating With the Expansion Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

TimeScan THC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide iii

Page 4

Table of Contents

Chapter 2 Engineering & Ordering Information

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Wire-wrap Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Card Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Clock Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Management Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Output Driver Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Input/Alarm Connector Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Output Connector Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Ordering and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

User-Supplied Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 3 Installing the TimeHub

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Site Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Preliminary Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Installation Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Electromagnetic Interference (EMI) Considerations . . . . . . . . . . . . . . . . . . . . . 65

Ventilation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Unpacking the TimeHub 5500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Rack Mounting the TimeHub 5500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Mounting the Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Installing the Wire-wrap Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring the Shelf as a Master or Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Making Ground and Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Grounding the Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Grounding the Wire-wrap Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Making Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Testing Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Installing Modules into the Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installing Rear Panel Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installing the Input/Alarm Connector Module . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installing Output Connector Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Installing Blank Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Making Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Making Shelf–to–Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Connecting Timing Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Making Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Connecting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

GPS Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Installing the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

iv TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 5

Table of Contents

Installing Expansion Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Installing the Shelf in the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Making Ground and Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Setting the Expansion Shelf Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Installing Output Connector Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Making Expansion Shelf Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Chapter 4 Testing and Configuring the TimeHub

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Installing Cards into the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Installing the Management Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Installing the Clock Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Confirming the Master or Remote Shelf Setting . . . . . . . . . . . . . . . . . . . . . . . 106

Installing Output Driver Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Installing Cards into the Expansion Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Installing Expansion Controller Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Installing Output Driver Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Establishing a Connection to the TimeHub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Communicating by Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Communicating by Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Provisioning Master Shelf Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setting the System ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Setting the Target ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Verifying the Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Provisioning Inputs on a Master Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Provisioning Inputs on a Remote Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Testing the Clock Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Provisioning the Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Securing Cards in the Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Configuring CC Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Phase Aligning CC Input and CC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Setting the Delay on CC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Checking System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Enabling Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Managing the User List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Setting the Configuration to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Chapter 5 Maintaining the TimeHub 5500

Clearing Output Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

False Reporting of Output Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Clearing False Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide v

Page 6

Table of Contents

Testing the Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Reference Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Removing a Clock Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting the TimeHub 5500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting the Clock Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Troubleshooting the Output Driver Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Reading the Output Driver Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . 166

Troubleshooting the Management Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Troubleshooting the Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . 174

Replacing Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Replacing the Clock Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Replacing the Output Driver Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Replacing the Management Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Replacing the Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Replacing the Fuse in the Clock Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Replacing the Fuse on the Management Card . . . . . . . . . . . . . . . . . . . . . . . . 181

Replacing the Fuse in the Output Driver Card . . . . . . . . . . . . . . . . . . . . . . . . 182

Replacing the Fuse on the EC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Repair and Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Sales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

User Manual Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Chapter 6 Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Local Communication Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

LAN Communication Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Remote Communication Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

GPS Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Expansion Link 1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Expansion Link 2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

DS1 Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

PRS Reference Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Composite Clock Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

DS1 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Composite Clock Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Output Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Input Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Shelf Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Wire-wrap Panel Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Shelf and Wire-wrap Panel Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

vi TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 7

Table of Contents

Factory Default Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Management Card Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Clock Card Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Output Driver Card Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

User Changes to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Index

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide vii

Page 8

Table of Contents

viii TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 9

Table of Contents

Figures

1-1 The TimeHub 5500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-2 TimeHub 5500 Shelf and Connection Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-3 Block Diagram of the TimeHub 5500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-4 TimeHub 5500 Expansion Shelf – Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-1 Front and Rear of the High-Density Wire-wrap Adapter Panel . . . . . . . . . . . . . . . 42

2-2 Front Panel of the ST2-Rb Clock Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2-3 Front Panel of the Management Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-4 Front Panel of the Output Driver Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2-5 Front Panel of the Input/Alarm Connector Module . . . . . . . . . . . . . . . . . . . . . . . . 53

2-6 Output Connector Modules for the Master/Remote Shelf: DS1 (left) and

CC (right). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2-7 Output Connector Modules for the Expansion Shelf: DS1 (left) and CC (right) . . 56

2-8 Front Panel of the Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3-1 Mounting Options for the Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3-2 High-Density Wire-wrap Panel (Front and Rear) . . . . . . . . . . . . . . . . . . . . . . . . . 69

3-3 Assembling the Rack Extenders for a 23-inch Shelf. . . . . . . . . . . . . . . . . . . . . . . 69

3-4 Sample Rack Installation of a Master Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3-5 Sample Rack Installation of a Master and Expansion Shelf . . . . . . . . . . . . . . . . . 71

3-6 Master/Remote Rotary Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3-7 Connectors on the Rear Panel of the Master Shelf. . . . . . . . . . . . . . . . . . . . . . . . 74

3-8 Wire-wrap Panel Ground Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3-9 Power and Ground Connections on the Master Shelf. . . . . . . . . . . . . . . . . . . . . . 76

3-10 Location of Output Connector Modules on the Rear Panel of the

Master/Remote Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3-11 Location of Output Connector Modules on the Rear Panel of the Expansion

Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3-12 Rear Panel Connectors on the Main Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3-13 Connecting Outputs to the High-Density Wire-wrap Panel . . . . . . . . . . . . . . . . . . 83

3-14 Connecting Outputs to Existing Wire-wrap Panels . . . . . . . . . . . . . . . . . . . . . . . . 84

3-15 Connecting A-D Outputs of the Expansion Shelf to the High-Density

Wire-wrap Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3-16 Connecting E-H Outputs of the Expansion Shelf to the High-Density

Wire-wrap Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3-17 Input/Alarm Connector Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3-18 Power and Ground Connections on the Expansion Shelf . . . . . . . . . . . . . . . . . . . 92

3-19 Address Switch SW1 on the Expansion Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3-20 Location of Output Connector Modules on the Rear Panel of the

Master/Remote Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3-21 Connecting a Single Expansion Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3-22 Connecting Multiple Expansion Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4-1 Front Panel of the TimeHub 5500 Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4-2 Location of Switch S1 on the Management Card . . . . . . . . . . . . . . . . . . . . . . . . 102

4-3 Front Panel of the Management Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4-4 Front Panel of the Clock Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide

ix

Page 10

Table of Contents

4-5 Clock Card Switch S1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4-6 The TimeHub TimeScan THC Window in Serial Mode . . . . . . . . . . . . . . . . . . . . 111

4-7 The TCP/IP Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

4-8 Network Parameters Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

4-9 Set TimeHub Date and Time Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4-10 Set TimeHub System ID Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

4-11 Set TimeHub Target ID Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4-12 The TimeScan THC Input Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

4-13 The Remote Input Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4-14 Configuring Outputs Using TimeScan THC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

4-15 DS1 Output Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4-16 CC Output Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4-17 The Configuration Output Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4-18 Enabling Ports for CC Cable Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4-19 The User Administration Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

5-1 The Configuration Output Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5-2 Attempt to Clear Port Alarm Query Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5-3 Active DS1 Input Signal Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

5-4 Front Panel of the Clock Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

5-5 Front Panel of the Output Driver Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

5-6 Front Panel of the Management Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

5-7 Front Panel of the Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . 174

5-8 Location of Fuse XF1 on the Clock Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

5-9 Location of Fuse F1 on the Management Card and the Output Driver Card . . . 181

5-10 Location of Fuse F1 on the EC Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

x TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 11

Table of Contents

Tab les

1-1 SSM Quality Level and Meaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-2 SSM Source Determination for Remote Shelf. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-1 Wire-Wrap Panels Available for the TimeHub 5500 . . . . . . . . . . . . . . . . . . . . . . . 43

2-2 Wire-Wrap Connection Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2-3 Cable Management Panels Available for the TimeHub 5500 . . . . . . . . . . . . . . . . 43

2-4 Accessories for Adapter Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2-5 Clock Card Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2-6 Management Card Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2-7 Output Driver Card Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2-8 Expansion Controller Card Front Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . 58

2-9 Master and Remote Shelf Basic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2-10 Expansion Shelf Basic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2-11 Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-1 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-2 Master/Remote Rotary Switch Settings and Functions. . . . . . . . . . . . . . . . . . . . . 73

3-3 LAN Connector Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3-4 Pinout of Local Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3-5 Expansion Shelf Rotary Switch Settings and Functions . . . . . . . . . . . . . . . . . . . . 93

4-1 Management Card S1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4-2 Clock Card S1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4-3 Communications Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4-4 Typical Oscilloscope Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4-5 User Level and Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

4-6 Command Level and Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

5-1 Troubleshooting the Clock Card Front Using the LEDs . . . . . . . . . . . . . . . . . . . 157

5-2 Troubleshooting the Output Driver Card Using Front Panel LEDs . . . . . . . . . . . 163

5-3 Management Card Front Panel Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

5-4 Troubleshooting the Expansion Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . 175

6-1 Management Card Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

6-2 Clock Card Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

6-3 DS1 and E1 Output Module Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

6-4 User Changes to Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide

xi

Page 12

Table of Contents

xii TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 13

How to Use This Guide

This section describes the format, layout, and purpose of this guide.

In This Preface

Purpose of This Guide

Who Should Read This Guide

Structure of This Guide

Conventions Used in This Guide

Warnings, Cautions, Recommendations, and Notes

Related Documents and Information

Where to Find Answers to Product and Document Questions

What’s New In This Guide

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide

Page 14

How to Use This Guide

Purpose of This Guide

Purpose of This Guide

The TimeHub 5500 User’s Guide describes the procedures for unpacking, installing,

using, maintaining, and troubleshooting the Symmetricom TimeHub 5500. It also

includes appendixes that describe alarms and events, the languages that you use to

communicate with the TimeHub 5500, default values, and other information.

Who Should Read This Guide

Chapter 1, Description, is written for non-technical audiences who need general

information about the product. Chapter 2, Engineering & Ordering Information, and

subsequent chapters contain technical information about the product. Other

chapters and appendixes describe installation, maintenance, and configuration

instructions or details primarily intended for qualified maintenance personnel.

This User Guide is designed for the following categories of users:

Systems Engineers – Chapter 1 provides an introduction to the TimeHub 5500,

Cross-references in this chapter direct you to detailed system information in other

chapters as appropriate.

Installation Engineers – Chapter 2 through Chapter 6 and the Appendices

provide detailed information and procedures to ensure proper installation,

turn-up, operation, configuration, and testing of the TimeHub 5500.

Maintenance Engineers – Chapter 5 and the Appendices provide preventive

and corrective maintenance guidelines, as well as procedures for diagnosing and

troubleshooting fault indications and alarms.

While Chapter 1 is written for non-technical audiences who need information about

the TimeHub 5500 system, others, such as Chapter 2 through Chapter 6 contain

detailed information and instructions which are intended to be performed by

qualified personnel only.

xiv TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 15

How to Use This Guide

Structure of This Guide

Structure of This Guide

This guide contains the following sections and appendixes:

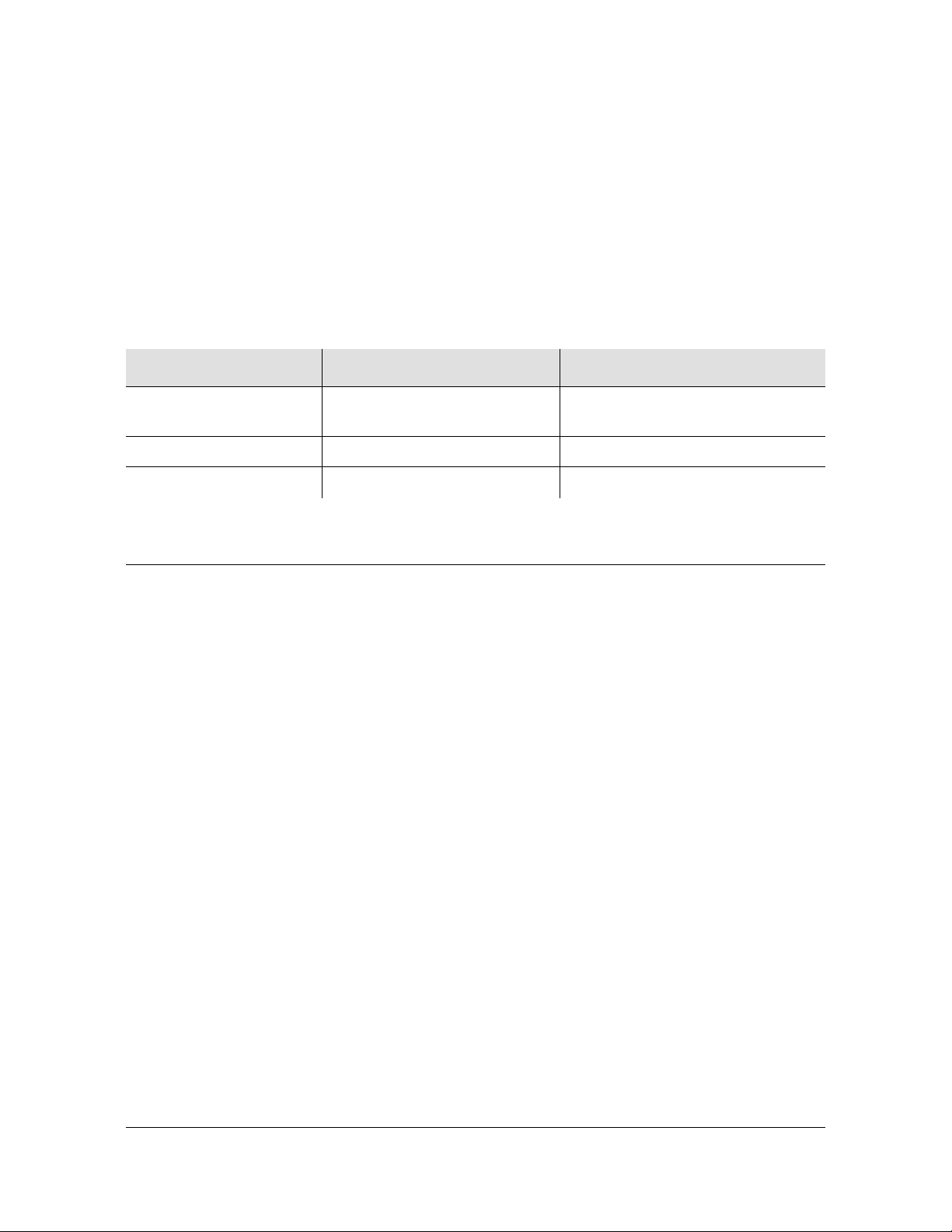

Chapter, Title Description

Chapter 1, Description Provides an overview of the product, describes the major

hardware and software features, and lists the system

specifications.

Chapter 2, Engineering &

Ordering Information

Chapter 3, Installing the

TimeHub

Chapter 4, Testing and

Configuring the TimeHub

Chapter 5, Maintaining the

TimeHub 5500

Chapter 6, Specifications Lists the specifications for the TimeHub 5500.

Index

Describes the modules and cards available with the TimeHub

and provides the part numbers for the parts and accessories.

Contains procedures for unpacking and installing the product,

and for powering up the unit.

Provides checklist-based commissioning tests that should be

performed after completing turn-up and software configuration to

ensure the system is ready for normal operation.

Describes

SSU-2000 after installing the unit.

Contains preventive and corrective maintenance, and

troubleshooting procedures for the product.

Provides references to individual topics within this guide.

the ICS and TL1 commands required to provision the

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide xv

Page 16

How to Use This Guide

Conventions Used in This Guide

Conventions Used in This Guide

This guide uses the following conventions:

Acronyms and Abbreviations – Terms are spelled out the first time they appear

in text. Thereafter, only the acronym or abbreviation is used.

Revision Control – The title page lists the printing date and versions of the

product this guide describes.

Typographical Conventions – This guide uses the typographical conventions

described in the table below.

When text appears

this way...

... it means:

TimeHub 5500 User’s Guide The title of a document.

SSU

An operating mode, alarm state, status, or chassis label.

CRITICAL

IOC1

Select File, Open... Click the Open option on the File menu.

Press Enter

Press ;

A named keyboard key.

The key name is shown as it appears on the keyboard.

An explanation of the key’s acronym or function

immediately follows the first reference to the key, if

required.

SSU

Username:

PING

STATUS

Text in a source file or a system prompt or other text that

appears on a screen.

A command you enter at a system prompt or text you

enter in response to a program prompt. You must enter

commands for case-sensitive operating systems exactly

as shown.

A re-timing application A word or term being emphasized.

Symmetricom does not

A word or term given special emphasis.

recommend...

xvi TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 17

Warnings, Cautions, Recommendations, and Notes

How to Use This Guide

Warnings, Cautions, Recommendations, and Notes

Warnings, Cautions, Recommendations, and Notes attract attention to essential or

critical information in this guide. The types of information included in each are

explained in the following examples.

Warning: To avoid serious personal injury or death, do not disregard

warnings. All warnings use this symbol. Warnings are installation,

operation, or maintenance procedures, practices, or statements, that

if not strictly observed, may result in serious personal injury or even

death.

Caution: To avoid personal injury, do not disregard cautions. All

cautions use this symbol. Cautions are installation, operation, or

maintenance procedures, practices, conditions, or statements, that if

not strictly observed, may result in damage to, or destruction of, the

equipment. Cautions are also used to indicate a long-term health

hazard.

ESD Caution: To avoid personal injury and electrostatic discharge

(ESD) damage to equipment, do not disregard ESD cautions. All ESD

cautions use this symbol. ESD cautions are installation, operation, or

maintenance procedures, practices, conditions, or statements that if

not strictly observed, may result in possible personal injury,

electrostatic discharge damage to, or destruction of, static-sensitive

components of the equipment.

Electrical Shock Caution: To avoid electrical shock and possible

personal injury, do not disregard electrical shock cautions. All

electrical shock cautions use this symbol. Electrical shock cautions

are practices, procedures, or statements, that if not strictly observed,

may result in possible personal injury, electrical shock damage to, or

destruction of components of the equipment.

Recommendation: All recommendations use this symbol.

Recommendations indicate manufacturer-tested methods or known

functionality. Recommendations contain installation, operation, or

maintenance procedures, practices, conditions, or statements, that

provide important information for optimum performance results.

Note: All notes use this symbol. Notes contain installation, operation,

or maintenance procedures, practices, conditions, or statements, that

alert you to important information, which may make your task easier

or increase your understanding.

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide xvii

Page 18

How to Use This Guide

Related Documents and Information

Related Documents and Information

Other helpful documents and software tools are listed below. See your

Symmetricom representative or sales office for a complete list of available

documentation.

TimeHub 5500 TL-1 Reference Guide 097-55501-01

TimeScan THC management software

Note: Symmetricom offers training courses designed to enhance your

knowledge of the TimeHub 5500. Contact your local representative or

sales office for a complete list of courses and outlines.

Where to Find Answers to Product and Document

Questions

For additional information about the products described in this guide, please contact

your Symmetricom representative or your local sales office. You can also contact us

on the web at www.symmetricom.com.

What’s New In This Guide

Issue 8 of this guide contains the following new information:

New format and typography to make the text easier to read

Procedures use TimeScan THC craft software version 3.2 and TL1 commands

Expanded Index

xviii TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 19

Chapter 1 Description

This chapter describes the TimeHub 5500, and includes the following topics:

Overview

Physical Description

Functional Description

Alarms

Synchronization Status Messaging

Passthrough Mode

Master/Remote Shelf

Expansion Shelf

TimeScan THC Software

Chapter

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 19

Page 20

Chapter 1 Description

Overview

Overview

The TimeHub 5500, shown in Figure 1-1, is a building integrated timing supply

(BITS) redundant timing distribution system for 1.544 Mb/s primary rate networks.

The system tracks incoming timing references, qualifies the signals against network

timing standards, then filters and distributes up to 140 precise timing signals.

The TimeHub 5500 clock uses precision timing references such as Primary

Reference Clocks (PRCs) (cesium frequency standards), GPS Primary Reference

Source (PRS) receivers, and DS1 input references from other nodes to generate

synchronized composite clock (CC) (64 kb/s) and DS1 (1.544 Mb/s) timing output

signals. These signals provide timing synchronization inputs to various network

elements. If a reference input is lost, the TimeHub 5500 provides SmartClock

holdover that exceeds Stratum 2 accuracy.

TimeHub 5500 applications include providing timing synchronization for ATM,

SONET, and digital wireless networks.

The TimeHub 5500 supports up to four optional Expansion shelves. Each

Expansion shelf provides up to 320 additional output signals, for a maximum of

1420 outputs in a full system.

Figure 1-1. The TimeHub 5500

20 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 21

Physical Description

The TimeHub 5500 consists of a shelf, wire-wrap panel(s), plug-in cards, connector

modules, cables, hardware, and software. As an option, you can install Clock cards

with four additional DS1 inputs for a total of nine inputs. The shelf contains slots for

a Management card, two Clock cards, and up to eight Output Driver cards.

The shelf and the connection panel(s) can be mounted in a 19-inch or a 23-inch rack,

as shown in

panel(s), except for a communications connector on the Management card.

Figure 1-2

Chapter 1 Description

Physical Description

. All connectors are at the rear of the shelf and connection

Figure 1-2. TimeHub 5500 Shelf and Connection Panels

Functional Description

The TimeHub 5500 accepts up to five incoming signals and selects one of the

qualified references (inputs 0–4) as the active tracked reference using criteria

programmed by a system administrator. The TimeHub then filters and distributes

precise timing signals to the office equipment. Inputs 5–8 on an optional Clock card

can be monitored for performance but none can be selected as the active reference

that drives the outputs.

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 21

Page 22

Chapter 1 Description

Functional Description

Figure 1-3 shows a block diagram of a TimeHub 5500 with redundant Clock cards

and 140 protected outputs. The outputs of each Clock card and the Management

card are connected to all Output Driver cards. Expansion shelves are capable of

providing 320 protected outputs.

Figure 1-3. Block Diagram of the TimeHub 5500

If all reference inputs fail, the system continues to provide timing by using its own

internal reference as a source (holdover).

If both Clock cards are removed, the Management card provides an unfiltered

version of an input to the output cards (passthrough). This feature is available on

Master or Remote Master shelves with Clock and IMC cards equipped with

hardware version “B” or higher and firmware version R4315C or higher. For more

information on passthrough, see Passthrough Mode, on page 29.

Communication Ports

LAN

The LAN connection allows you to connect the TimeHub 5500 to an Ethernet

network for monitoring and provisioning. You configure network parameters using

TL1 commands. The TimeHub 5500 can support up to 10 simultaneous network

sessions. The TL1 commands are described in detail in the TL1 Reference Guide.

22 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 23

Chapter 1 Description

Functional Description

Local

There are two Local port connections: one on the rear panel of the shelf and one on

the Management card. Dual connections are provided for access convenience and

both are physically connected to the same serial port. These ports provide a means

for TL1 command access to the TimeHub 5500.

Note: Communication cannot be established to both of the Local

ports simultaneously; only one port can be used at a time.

Power Supply

Each card is provided with its individual power supply unit. Two external power

inputs supply the voltage to each card on the shelf.

Input/Alarm Connector Module

The Input/Alarm Connector module provides the connections for input reference

signals to the shelf and for the alarm outputs. There are five timing inputs: one PRS

input and four DS1 inputs. The PRS input can be either 5 MHz or 10 MHz.

Depending on the type of Clock card used, four additional DS1 timing inputs can be

used for monitoring only.

DS1 inputs 1–4 can be used as a reference or for monitoring. (DS1 inputs 5–8 can

only be monitored.) If used as a reference, the input may be used for tracking and

can cause events or alarms if not qualified. Performance monitoring is also

available for inputs used as references. If monitored only, the input is monitored

without being used for tracking and no alarms occur, but the signal status is

reported via the TL1 interface.

You make the alarm connections on the Input/Alarm Connector module as

described in Alarm Connections, on page 26.

Clock Cards

Clock cards provide input monitoring, selection, and holdover. Two types of Clock

cards are available for the TimeHub 5500:

Standard Clock cards: These cards are equipped with five inputs (four DS1 and

one 5/10 MHz) and do not support Expansion shelves.

– Five-input with an ST2E rubidium oscillator (090-55513-01)

– Five-input with an ST3E quartz oscillator (090-55511-01)

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 23

Page 24

Chapter 1 Description

Functional Description

Extended-capacity Clock cards: These cards are equipped with nine inputs (four

DS1, four monitoring inputs, and one 5/10 MHz) and support Expansion shelves.

If you plan to use an Expansion shelf (or shelves) attached to a Master shelf, you

must use extended-capacity Clock cards.

– Nine-input with an ST2E rubidium oscillator (090-55514-02)

– Nine-input with an ST3E quartz oscillator (090-55512-02)

Two Clock cards are required for redundancy; oscillator types can be mixed.

Each Clock card receives the input reference signals from the Input/Alarm

Connector card, determines their quality for use by the system, and selects the most

appropriate input signal to use as the active reference. During normal operation, the

active clock tracks the active input signal, and produces a precise frequency for the

Output Driver cards based on the input reference. The standby clock does the same

thing except its output is not used by the Output Driver cards. The standby clock

backs up the active clock, ready to become active when necessary.

If the input reference is disqualified, the Clock card selects another qualified input

signal as the reference. If no input references are qualified, the Clock card goes into

holdover, using its own oscillator as the system reference.

For detailed information on Clock cards, see Clock Cards, on page 44.

Management Card

The Management card manages alarms to and from the TimeHub 5500, and

provides local and Ethernet LAN communication interfaces. The TimeHub can

operate without a Management card installed, but you will lose any communications

abilities, alarms, and the Passthrough feature.

If an alarm condition occurs, the Management card determines whether the alarm

state is critical, major, or minor, actuates the corresponding alarm relays, causes the

appropriate LEDs to light, and generates TL1 alarm message(s) via the local or LAN

communication interface. For more detailed information on the Management card,

see Management Card, on page 48.

Output Driver Cards

Output Driver cards provide non-protected or protected DS1 or CC outputs. A single

Output Driver card provides 40 non-protected outputs. Two Output Driver cards

functioning as a pair provide 40 protected outputs. An Output Driver card can

provide either 20 DS1 and 20 CC outputs or 40 of either type. The Output

Connector modules installed on the rear panel of the shelf determine the type of

output signal. Output Driver Cards, on page 50, describes the Output Driver cards in

more detail.

24 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 25

Chapter 1 Description

Alarms

Specific capabilities of the Output Driver card include:

Drive up to 40 outputs (40 DS1, 40 CC, or 20 CC and 20 DS1)

DS1 framable D4 or ESF, with full SSM support for ESF

Selective enable for every port

Controllable CC cable delay compensation. Each port can have delay

compensation enabled or not. Each group of 20 ports (1-20 and 21-40) can have

a specific delay amount applied.

Output Connector Modules

There are two types of Output Connector modules: DS1 and CC Output Connector

modules. Each module contains the hardware required to interface with the output

type (DS1 or CC). The Output Driver card reads the Output Connector module to

determine the appropriate voltage levels, frequency, and format for the

corresponding output type. See Output Connector Modules, on page 54, for more

information on Output Connector modules.

Connection Panels

Timing output connections between the TimeHub 5500 and network elements are

made at the wire-wrap connection panel. Each high-density wire-wrap connection

panel can accommodate up to 160 outputs.

Alarms

Alarms are indicated by shelf and card status LEDs, and TL1 messages are

reported via the local or LAN communication interface. In addition, contact closures

provide for remote indication of alarms on the shelf.

There are two types of alarms associated with the TimeHub 5500: shelf and system.

A shelf alarm is one that occurs from within the TimeHub shelf, and a system alarm

is one that is sensed via one of the external alarm wire-wrap inputs on the input/

alarm card. If an alarm is sensed on any of these 10 external alarm inputs, it

appears as a “System” alarm on the Management card front panel.

If simultaneous alarms occur with different severity levels, the front panel LEDs

indicate only the one with the highest severity. For example, if both MAJOR and

MINOR shelf alarms are present, only the MAJOR alarm LED is lit in the “Shelf”

alarm row. In this case, if the MAJOR alarm ends, then the MINOR alarm LED lights

(assuming that the source of that alarm is still present) since this is now the highest

severity shelf alarm.

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 25

Page 26

Chapter 1 Description

Synchronization Status Messaging

If there is a MAJOR shelf alarm and a MINOR system alarm (any of the external alarms

in 7 to 10 range) then the MAJOR LED is lit for the shelf alarm row and the MINOR LED

is lit for the system alarm row. In other words, it is possible to have alarm LEDs of

different severity illuminated if one is a shelf alarm and the other a system alarm.

In all cases, all current alarms are reported via the TL1 command interfaces (serial

and network) and can be retrieved at any time using the RTRV-ALM query (see the

TL1 Reference Guide). If there are multiple alarms of the same and different

severity, all are included in the RTRV-ALM response.

Alarm Connections

You make all alarm connections on the Input/Alarm Connector module at the rear

panel of the shelf.

Contact Closure Inputs

Ten sets of contact closure inputs are provided to connect to relay outputs of

equipment external to the shelf. Four of these input sets are Universal, and six are

contact closure only.

Contact Closure Outputs

Contact closure outputs are provided to actuate visible and/or audible alarm

indicators to inform the office of an alarm condition within the shelf.

Note: Contact closure outputs are generated by the Management

card. The Management card must be installed in order to generate

contact closure alarms or TL1 messages.

There are two sets of wire-wrap pins for Audible and Visual alarms; each set allows

you to make connections for Minor, Major, and Critical alarms. For more information

on the Input Connector card, see Installing the Input/Alarm Connector Module, on

page 78.

Synchronization Status Messaging

The TimeHub 5500 supports input and output SSM (Synchronization Status

Messaging). SSM provides a method for providing clock quality information to any

equipment that uses synchronization inputs. For DS1 signals, SSM information can

be encoded on ESF (Extended Super Frame) signals. D4 (also known as SF) DS1

signals are not capable of transporting SSM. You can use SSMs to automatically

switch the input reference to the next-best available signal if the current input

reference becomes unavailable.

26 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 27

Synchronization Status Messaging

Chapter 1 Description

The relationship between SSM quality level and the meaning attached to each level

is listed in Table 1-1.

Table 1-1. SSM Quality Level and Meaning

Description Quality Level Abbreviation

Stratum 1 Traceable 1 PRS

Synchronized – Traceability Unknown 2 STU

Stratum 2 Traceable 3 ST2

Transit Node Traceable 4 TNC

Stratum 3E Traceable 5 ST3E

Stratum 3 Traceable 6 ST3

SONET Minimum Clock Traceable (20 ppm clock) 7 SMC

Stratum 4 Traceable 8 ST4

DO NOT USE for synchronization 9 DUS

Reserved 10 RES

Input SSMs

The TimeHub 5500 provides several input-related SSM capabilities. You can

provision the TimeHub 5500 to read the SSM value associated with any input. You

can then use that value to determine which input becomes the active reference

signal. If an input does not have an SSM value associated with it (such as a D4framed DS1 input or a 5/10 MHz input), you can assign an SSM value to the input.

The TimeHub can extract and report the encoded SSM value on any of the timing

inputs using the TL1 keyword CURRSSM. This keyword allows you to retrieve the

SSM value currently associated with a selected input. The value returned is the

Quality Level in Table 1-1. For detailed syntax, see the description of this keyword in

the TimeHub 5500 TL1 Reference Manual.

If the input does not support SSMs (for example, D4 framed DS1 and 5/10 MHz

inputs), you can assign an assumed SSM value to the input using the TL1 keyword

QLEVEL. Assigning an SSM allows an input to be automatically selected when the

synchronization mode is set to SSM.

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 27

Page 28

Chapter 1 Description

Synchronization Status Messaging

Automatic Reference Switching

You can use the SSM values on the input signal to determine which input is selected

as the active timing reference. The TL1 keyword SYNCMDE provides this control.

SSM is one of the four possible SYNCMODE setting; when SSM is selected, the

CURRSSM value is the primary factor for selecting which input becomes the active

reference (the input must be otherwise qualified for use to be selected). For more

details on setting the sync mode, see Provisioning Inputs on a Master Shelf, on

page 121.

Three factors determine how the TimeHub selects the active timing reference from

the available qualified input signals:

1. Quality Level, which is either read directly from the SSM on the input signal, or is

assigned using the TL1 keyword QLEVEL. There is no preference given to an

input that is actually extracting SSM values (requires enabling SSMENB)

compared with one that is using an assumed SSM quality level (SSMENB

disabled).

2. SSM Priority level, which you assign to each input using the TL1 keyword

SSMPRI. For information on using these keywords and the syntax, see the TL1

Reference Guide.

3. The location of the reference signal on the Input panel; inputs on lower-numbered

inputs have higher priority when the other two factors have the same value.

If the CURRSSM quality value for an otherwise qualified input is numerically higher

than the quality level of the internal reference oscillator in the Clock card, that input

will be disqualified and hence cannot be selected as the active timing reference.

The rationale for this is that the internal reference oscillator will provide a better

timing reference than any input with a lower quality level. The quality levels for

TimeHub 5500 internal oscillators are 3 for any rubidium type clock (090-55513-01

and 090-55514-02) (Stratum 2 traceable) and 5 for any quartz type clock

(090-55511-01 and 090-55512-02) (Stratum 3E traceable). The QCUTOFF keyword

can be used to set an additional quality value that will disqualify any input whose

CURRSSM value is higher than the selected QCUTOFF value.

Output SSMs

SSMs are automatically encoded onto any DS1 output set for ESF framing. Normal

operation automatically encodes an appropriate SSM quality level on such outputs;

you can override the automatic setting and manually set the quality level to be

encoded on DS1 ESF outputs. Here are some details regarding how the SSM

quality level is set for ESF outputs:

28 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 29

Chapter 1 Description

Passthrough Mode

During normal operation, where a qualified input is being used as the active timing

reference, the SSM quality level of that input is included on all DS1 ESF outputs.

This quality level can be read by retrieving the CURRSSM value for the currently

active timing reference. If the active reference changes to a different input, the SSM

output changes to that of the newly selected input. Note that the SSM value is

output on DS1 ESF outputs regardless of the selected synchronization mode (see

SYNCMDE discussion above). It isn't necessary for SYNCMDE to be set to “SSM”

for outputs to encode SSM information.

When the TimeHub 5500 is using an internal oscillator as the timing reference

source, the output SSM quality level is the quality level associated with the

performance level for that internal oscillator. For the rubidium clocks (090-55513-01

and 090-55514-02) (Stratum 2 traceable), the quality level is 3. For the quartz clocks

(090-55511-01 and 090-55512-02) (Stratum 3E traceable), the quality level is 5.

The TimeHub uses the quality level associated with the Clock card in the following

situations:

After warming up, the Clock card enters the Freerun mode (indicated by an LED

on the front panel) while input references are being qualified. During this time the

internal oscillator on the active Clock card is the active timing reference.

If for some reason all external timing references become disqualified (for

example, signal is lost), the TimeHub 5500 enters either Freerun or Holdover

mode (indicated by an LED on the front panel). In either mode, the active Clock

card becomes the active timing reference. If external timing references later

become re-qualified, the TimeHub 5500 returns to normal operation and the

output SSM quality level changes to match that of the selected input.

You can manually set the output SSM quality level on DS1 ESF outputs using the

OMANSSM (Output Manual SSM) keyword. This allows you to select a specific SSM

quality level to be output on all channels in an Output card. By enabling OMANSSM

(set to “Y”) for a particular output card, any DS1 ESF outputs associated with that

card outputs the quality level set via the OQLEVEL (Output Quality Level) keyword.

A primary reason for providing this capability is to allow information such as “DON'T

USE for synchronization” (quality level 8) to be sent to downstream equipment during

maintenance operations. Using a signal marked DUS for timing purposes is a

violation of the BITS concept and Telcordia general requirements.

Passthrough Mode

The TimeHub 5500 can provide a usable clock in a situation where both Clock cards

are removed from the shelf. The capability is called Passthrough and resides on the

TimeHub Management card. The Management card has a connection to the timing

inputs, which it continually monitors for signal presence. An LED on the

Management card indicates when the Passthrough mode is active. An automatic

TL1 message is also provided on both communication ports whenever Passthrough

operation begins or ends.

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 29

Page 30

Chapter 1 Description

Passthrough Mode

Passthrough is available only when a Clock card has qualified at least one input

since power was applied to the Management card. The Management card monitors

the Clock cards for qualified inputs; if no qualified input has been detected,

Passthrough will not enable upon removal of Clock cards. When the Management

card has determined that Passthrough is ready, an automatic message, PTAVAIL, is

issued. You can check if Passthrough is available by using the TL1 keyword

RTRV-COND. See the TL1 Reference Guide for more information.

When Passthrough mode is activated, the following hierarchy determines which

input is selected as the reference:

The first choice is the most recently selected input reference prior to removal of

the Clock card.

If the first choice is not available (due to loss of signal), Passthrough is then

selected from the inputs previously qualified by the Clock card prior to its

removal. The attempt begins with the lowest numbered input.

If no recently qualified input is available, Passthrough is selected from any other

input that is providing a signal. The selection attempt starts with the lowest

numbered input.

For example, if inputs 1, 3, and 4 had been qualified by the active Clock card and

input 3 was the active reference just prior to removal of the Clock card:

Input 3 is the first choice; if it is not providing a signal, then

Input 1 is the next choice since it had been qualified by the clock and it is the

lowest numbered such input. If it is not providing a signal, then

Input 4 is the next choice since it had been qualified and is the next lowest

numbered such input. If Input 4 was selected and it goes away, Passthrough

cycles through the set of previously qualified inputs, in case one has returned.

If none of the qualified inputs are available, Passthrough searches the remaining

inputs for a signal. In this example, the only remaining inputs are 0 (the 5/10 MHz

input) and 2 (DS1 input). Starting with 0, if an input is detected, it is selected as

the active reference.

If no timing input is providing a signal while in Passthrough, the outputs are disabled

and Passthrough mode ends. Unlike Clock cards, which have the ability to provide

holdover capability when all timing inputs are removed (and thus maintain output

timing), the Management card cannot provide holdover. Therefore, outputs are

disabled if there is no timing input when in Passthrough mode.

30 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 31

Chapter 1 Description

Passthrough Mode

Passthrough Considerations

There are several restrictions and special considerations that apply to Passthrough

operation:

Brief phase hits on the outputs are likely when entering and exiting Passthrough

mode

You cannot configure the Clock or outputs while in Passthrough mode

Passthrough does not have the capability to reject inputs with excessive jitter or

that are significantly off frequency.

Passthrough does not filter input-to-output in the same way as a Clock card, so

out-of-mask timing (for example, TDEV and MTIE) is possible.

Firmware Versions and Passthrough Operation

Details of the Passthrough capability depend upon the firmware and hardware

versions of the Management (090-55542-01), Clock (090-5551x-xx), and Expansion

Controller (090-55545-01) cards. See the note at end of this section for how to

check firmware and hardware versions.

If either the Management or Clock cards contain firmware prior to 4315B or have

hardware version A, then the passthrough capability is as follows:

Passthrough functions only if the shelf is configured as a master system.

Passthrough will not function if the shelf is configured as a remote system.

There are likely to be brief phase-hits on the outputs when entering and exiting

Passthrough mode.

If an Expansion shelf is connected to the Master it also will operate in

Passthrough mode.

If the Management and Clock cards contain firmware version 4315B or later AND

have hardware revision B or later, then the Passthrough capability is as follows:

Passthrough functions when the shelf is configured as either master or remote.

As should be expected, for a remote shelf the timing references must be CC1

inputs. For a master shelf the timing references must be DS1 or 5/10 MHz inputs.

Phase-alignment between input and output is maintained during the transition

into Passthrough from normal operation, while in Passthrough, and during the

exit from Passthrough back to normal operation.

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 31

Page 32

Chapter 1 Description

Master/Remote Shelf

While this feature applies to both Master and Remote shelves, the easiest way to

understand it is to consider a Remote shelf that is timing a CC input prior to entering

Passthrough mode. Prior to Passthrough mode, the alignment of the active CC

input and any output CC will be nearly perfect. If you observed the positive bi-polar

violations on the input and any CC output on an oscilloscope, you would see that

they are completely aligned. The Passthrough feature maintains this alignment

while entering into Passthrough, while in Passthrough, and when exiting from

Passthrough back to normal operation (which would occur when a Clock card is

re-inserted). Thus, the phase alignment between input and output is never lost

during the entire Passthrough episode.

If an Expansion shelf is connected, it also operates in Passthrough mode, but its

behavior depends on the firmware revision of the Expansion Controller cards:

If an Expansion Controller card contains version A firmware, outputs from that

Expansion shelf do not maintain the pre-Passthrough phase-alignment while in

Passthrough mode of operation.

If an Expansion Controller card contains version B (or later) firmware, outputs

from that Expansion shelf will maintain pre-Passthrough phase-alignment while

in Passthrough mode of operation.

Note: Since Passthrough is not a normal operating mode, it should

not be routinely used. It is intended to provide a mechanism to “keep

alive” the outputs in a situation when both Clock cards are

inadvertently removed. The timing performance when in Passthrough

mode cannot be assured.

Master/Remote Shelf

The TimeHub 5500 can be configured for use as a Master shelf or as a Remote

shelf. The essential difference between these configurations is that a Master shelf

accepts PRS (5 or 10 MHz) and DS1 inputs as timing references while a Remote

shelf accepts Composite Clock (CC) inputs as the timing reference(s). Typically, a

Remote shelf takes its CC timing inputs from a TimeHub or DCD master shelf, both

which are capable of providing CC outputs.

The Remote shelf provides the same output distribution capability that is provided

by a Master shelf. The Passthrough capability is available in the Remote shelf with

R4315B or later firmware.

For information on configuring a shelf as a Master or Remote, see Configuring the

Shelf as a Master or Remote, on page 72.

32 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 33

Chapter 1 Description

Master/Remote Shelf

Remote Shelf Capability

The TimeHub Remote shelf can be located up to 3000 feet (1093 m) from the

Master shelf that provides the CC timing inputs. The Clock cards in the Remote

shelf closely follow the input CC signals; this maintains phase alignment between

the CC inputs and CC outputs. Unlike a Master shelf, which provides significant

filtering of the input timing references (PRS or DS1 signals), the Remote shelf

adjusts its outputs very quickly as changes occur on the CC inputs. Since the input

CCs are being distributed from a Master shelf that has already performed the

desired filtering on its inputs, only small timing variations are expected at the

Remote shelf inputs.

The Remote shelf does not provide performance monitoring data, which is available

for the PRS and all DS1 inputs on a Master shelf. For more information on

performance monitoring, see the TL1 Reference Guide (097-55501-02).

In addition to accepting up to two CC signals as timing references, the Remote shelf

can accept up to two DS1 inputs which are used to extract SSM information only.

Note: The DS1 lines extract only the SSM messages and do not

extract synchronization signals.

A typical setup for a Master/Remote shelf combination includes:

Two CC outputs are taken from a Master shelf connected as CC inputs to the

Remote shelf. Two outputs are used for redundancy; to isolate the signal paths

as much as possible, you can take each CC signal from a different output group

on the Master shelf (for example, one from the “C” group and another from the

“D” group). You compensate for the delay due to the cable length from the Master

shelf using the CCDEL and CCDENB keywords. The preferred method is to

compensate for the delay at the Master shelf.

Two ESF-framed DS1 outputs from different output groups on the Master shelf

are connected to the first two DS1 inputs on the Remote shelf. This provides a

redundant method for the remote shelf to receive SSM information from the

Master shelf.

Operational Specifics

This section describes the capabilities of the Remote shelf that are not available on a

Master shelf. The TimeHub Clock cards are designed to operate in either a Master or

Remote shelf configuration. When configured for Remote operation, the Input LEDs

on the front panel of the Clock card display information for the inputs. See

Figure 2-2

which shows the front panel of the Clock card. The relevant LEDs are CC 1 and 2 and

DS1 1 and 2.

,

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 33

Page 34

Chapter 1 Description

Master/Remote Shelf

CC Timing Inputs

Timing references for the Remote shelf are connected at the Input/Alarm Connector

module, located on the rear panel of the shelf (refer to Figure 3-17). This module

supports both Master and Remote operation. For Remote operation, the available

timing inputs are labeled CC IN 1 and CC IN 2. Typically a TimeHub or DCD master

shelf provides these signals.

DS1 SSM Inputs

Composite Clock input signals do not provide SSM information that can be included

on Remote output signals. You can connect ESF-framed DS1 inputs to a Remote

shelf in order to receive encoded SSM information from the Master shelf. The

Remote shelf then passes the SSM information on to the outputs. The sole function

of these DS1 inputs is for SSM decoding; they are not used as timing references.

SSMs in a Remote Shelf

Table 1-2 describes how the source of SSM is determined in a Remote shelf for a

variety of conditions. Other than the special case where the OMANSSM keyword is

used to manually set the output SSM value (see TimeHub TL1 Reference Guide for

details), the SSM source determines the SSM that is encoded on each ESF-framed

DS1 output generated on the Remote shelf.

Table 1-2. SSM Source Determination for Remote Shelf

Condition SSM Source

Shelf has no active timing reference (“A” is not

lit in either CC1 or CC2 row).

Shelf has at least one active timing reference

("A" is lit in either CC1 or CC2 row).

There are no valid SSM inputs. (No signal/or

non-decodable signal connected to DS1-1 and

DS1-2) OR neither SSM input is enabled ("E"

LED not lit in both DS1-1 and DS1-2 rows).

Shelf has at least one active timing reference

("A" is lit in either CC1 or CC2 row)

There is a single valid SSM input (“E”, “Q”,

and “A” lit on one DS1 input, Q is not lit on the

other one)

Shelf has at least one active timing reference

("A" is lit in either CC1 or CC2 row)

Both DS1-1 and DS1-2 are decoding valid

SSM information ("E" and "Q" are lit for both

DS1-1 and DS1-2 rows). Only one of these

rows can indicate "A".

The SSM value is that of the internal oscillator in

the active Clock card (see HFQLEVL keyword in

the

TL1 Reference Guide

The SSM value is taken from the “assumed” SSM

value (see QLEVEL keyword in the TL1 Reference

Guide) associated with the active timing reference.

For example, if CC2 is the active timing reference,

the SSM is taken from QLEVEL setting for channel

11 (Channel 11 is the TL1 reference to CC2).

The SSM value is being decoded from the DS1

input that is showing “E”, “Q”, and “A”.

The SSM value is taken from the DS1 input that

has the higher PRIORITY (lower numerical value)

setting. This is the one that has “A” lit. See the TL1

Reference Guide for details on PRIORITY

keyword.

).

34 TimeHub 5500 User’s Guide 097-55501-02 Issue 8 – February 2005

Page 35

Expansion Shelf

For situations requiring more outputs than can be provided by a Master shelf, the

TimeHub 5500 supports one to four Expansion shelves. Each Expansion shelf

provides up to 320 protected inputs; using four expansion shelves, a TimeHub

system can provide a total of 1420 outputs.

Note: In order to support Expansion shelves, the Master shelf must

be equipped with Extended-Capacity Clock cards, as described in

Clock Cards, on page 23. Standard Clock cards do not support

Expansion shelves.

Figure 1-4 illustrates the Expansion shelf. There are two types of plug-in cards used

with an Expansion shelf: Output Driver cards (p/n 090-55581-01) and Expansion

Controller cards (p/n 090-55545-01). Two types of Output Connector modules

provide DS1 or CC outputs.

Chapter 1 Description

Expansion Shelf

Figure 1-4. TimeHub 5500 Expansion Shelf – Front View

097-55501-02 Issue 8 – February 2005 TimeHub 5500 User’s Guide 35

Page 36

Chapter 1 Description

Expansion Shelf

Output Driver Cards

The Expansion shelf uses the same Output Driver cards used on the Master shelf

(see the following Note). Each Output Driver card provides 40 outputs, which can be

provisioned as all DS1, all Composite Clock (CC), or 20 outputs of each type. The

front-panel LEDs indicate the actual provisioning. The Output Connector modules