Page 1

LS 3070

Product Reference Guide

Click on red text at any location in the manual to jump to the

specified chapter, topic, or reference.

About This Manual

Table of Contents

Copyright

Feedback

Index

70-10294-02

Revision B

February 1998

Page 2

©

1997 SYMBOL TECHNOLOGIES, INC.

No part of this publication may be reproduced or used in any form, or by any

electrical or mechanical means, without permission in writing from the publisher.

This includes electronic or mechanical means, such as photocopying, recording,

or information storage and retrieval systems. The material in this manual is for

informational purposes and is subject to change without notice.

Symbol reserves the right to make changes to any product to improve reliability,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with,

the application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise

under any patent right or patent, covering or relating to any combination, system,

apparatus, machine, material, method, or process in which Symbol products might

be used. An implied license only exists for equipment, circuits, and subsystems

contained in Symbol products.

Symbol is a registered trademark of Symbol Technologies, Inc. Other product

names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

All rights reserved.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, N.Y. 11742-1300

http://www.symbol.com

Page 3

Contents

About This Manual

Notational Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . About-i

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . About-i

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . About-i

Symbol Support Center. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .About-ii

Chapter 1. The LS 3070 Cordless Scanner

The Freedom of Cordless Scanning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

The LS 3070 Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Rechargeable Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

The Base/Charger Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2. Setup

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Connecting the Cable to the Base/Charger Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Tip — Optimizing RF Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Inserting the Scanner Into and Removing Scanner from Base/Charger. . . . . . . . . . . . . . . . . . . 2-2

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Pairing the Scanner with the Base/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Assigning Address to Base/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Pairing Scanner with Base/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting Transmission Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Installing a Magstripe Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Chapter 3. Scanning with the LS 3070

1. Ready . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3. Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Hold at an Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Scan the Entire Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using a Long Range or High Visibility Scanner? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Scanning Transmission Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

RF Communication Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Restoring Normal RF Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

What If .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Decode Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

LS 3070 Standard Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

LS 3070LR Long Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

LS 3070ALR Advanced Long Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

i

Page 4

LS 3070XLR Extra Long Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

LS 3070HV High Visibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Chapter 4. Maintenance and Specifications

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recharging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Changing Battery Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Charge Status LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

LS 3070 Standard Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

LS 3070LR Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

LS 3070ALR Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

LS 3070XLR Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

LS 3070HV Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Chapter 5. Interface Guide

Connecting to a Host Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Connecting Base Station to a Host. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

OCIA and OCR Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

RS-232C Single Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

RS-232C Dual Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

IBM 4683/4684/4693/4694. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Connecting Keyboard Wedges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

PC Keyboards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Terminal Keyboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

IBM 3683/3684 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

IBM 3653 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

NCR 280 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

NCR 2151 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

NCR 2152 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

NCR 2154/2155 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

NCR 7052 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Fujitsu 9000 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Chapter 6. Programming

Programming Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

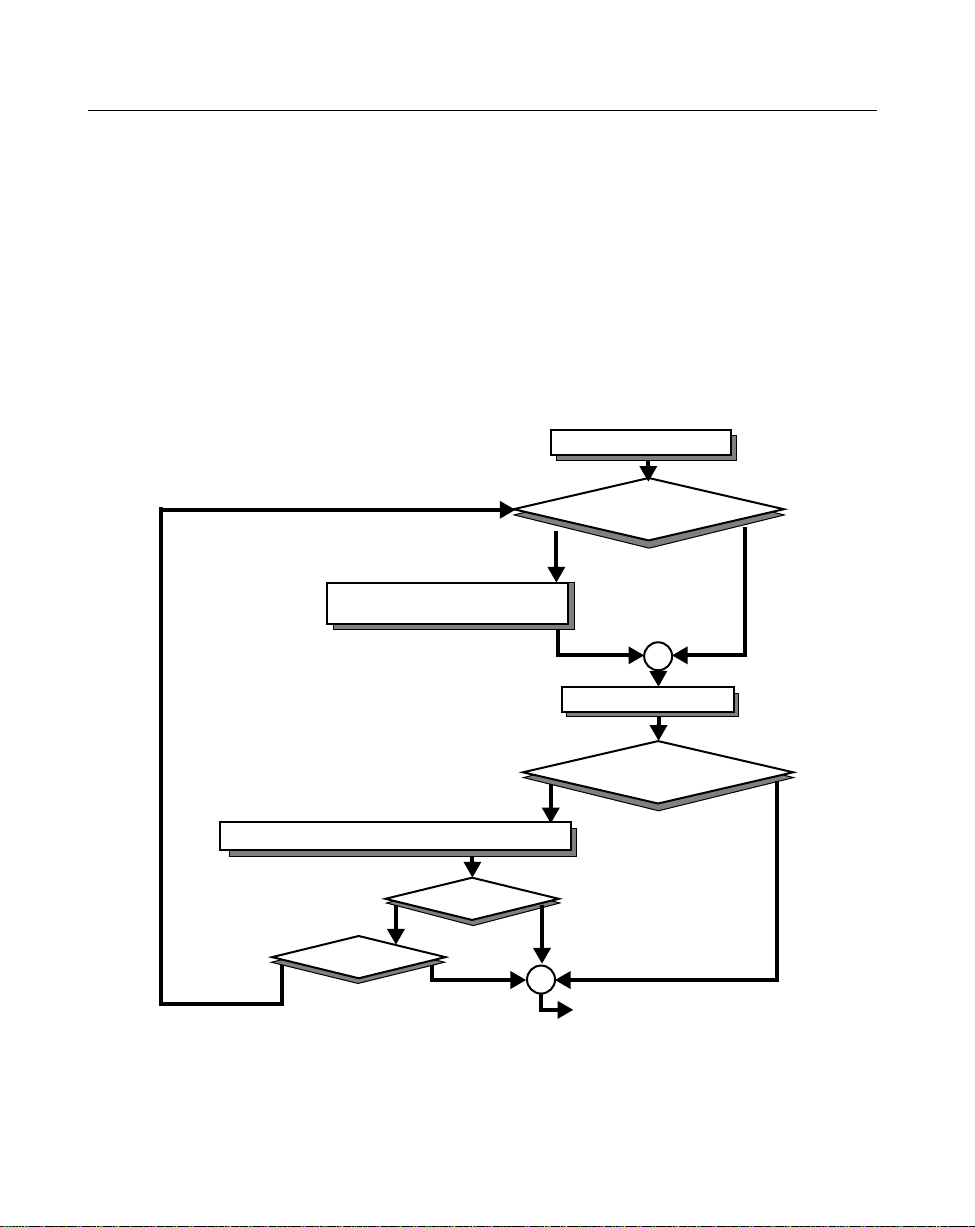

Scanning Sequence Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Errors While Scanning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Parameter Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Set Parameter Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Host Interface Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

ii

Page 5

Code Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Code Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Code 39 Full ASCII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Decode Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

UPC-A and -E Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Pause Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Prefix/Suffix Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Data Transmission Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Laser Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

RS-232C Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Intercharacter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Transmit Code ID Character . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Transmit AIM ID Character . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Ignore Unknown Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

OCIA Clock Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

OCIA Transmit Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

NCR 2152 Fast Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

IBM 4683/93 Magstripe Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

International Keypad Emulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

International Keypad Emulation Fast Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

National Keyboard Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Set Transmission Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Wait for Host Interface Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Parameter Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Beeper Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Standard Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Parameter Menu Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Code 39 Scan And Store . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Code 39 Buffering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Buffer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Clear Transmission Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Transmit Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Overfilling Transmission Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Attempt to Transmit an Empty Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Default Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Terminal Specific RS-232C Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Chapter 7. Parameter Menus

Set Default Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Code Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Code Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Decode Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

iii

Page 6

UPC-A Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

UPC-E Preamble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Pause Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Prefix/Suffix Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Data Transmission Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Magstripe Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Laser Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58

Check Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Hardware Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

Software Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

Serial Response Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Stop Bit Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-65

ASCII Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

RTS Line State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-67

Intercharacter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-68

Transmit Code ID Character . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

Transmit AIM Code ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-72

Ignore Unknown Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-73

OCIA Clock Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-74

OCIA Transmit Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-75

NCR 2152 Fast Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-78

IBM 4683 Magstripe Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-79

International Keypad Emulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-80

International Keypad Emulation Fast Transmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-81

National Keyboard Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-82

Set Transmission Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-84

All Countries Except France. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-84

France. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-84

Wait for Host Interface Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-87

Reserved For Future Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-90

Pairing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-97

Chapter 8. Keyboard Maps

ASCII Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Keyboard Identifier Maps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Index

iv

Page 7

About This Manual

The

LS 3070 Product Reference Guide

operation, troubleshooting, maintenance, and programming.

Notational Conventions

The following conventions are used in this document:

•

Bullets (•) indicate:

- action items

- lists of alternatives

- lists of required steps that are not necessarily sequential

•

Sequential lists (e.g., those that describe step-by-step procedures) appear

as numbered lists.

Related Publications

•

LS 3070 Quick Reference Guide

Service Information

provides general instructions for setup,

70-19993-0X

If you have a problem with your equipment, contact the Symbol Support

Center. Before calling, have the model number, serial number, and several of

your bar code symbols at hand.

Call the Support Center from a phone near the scanning equipment so that the

service person can try to talk you through your problem. If the equipment is

found to be working properly and the problem is symbol readability, the

Support Center will request samples of your bar codes for analysis at our plant.

If your problem cannot be solved over the phone, you may need to return your

equipment for servicing. If that is necessary, you will be given specific

directions.

About-i

Page 8

LS 3070 Product Reference Guide: About This Manual

Note

: Symbol Technologies is not responsible for any damages incurred during shipment if the approved shipping container is not used. Shipping the

units improperly can possibly void the warranty. If the original shipping container was not kept, contact Symbol to have another sent to you.

Symbol Support Center

In the U.S.A, for service information, warranty information or technical

assistance, call:

SYMBOL SUPPORT CENTER

1-800-653-5350

If you purchased your Symbol product from a Symbol Business Partner,

contact that Business Partner for service.

Canada

Mississauga, Ontario

Canadian Headquarters

(905) 629-7226

Europe

Wokingham, England

European Headquarters

0734-771-222 (Inside UK)

+441-734-771222 (Outside UK)

Asia

Singapore

Symbol Technologies Asia, Inc.

337-6588 (Inside Singapore)

+65-337-6588 (Outside Singapore)

About-ii

Page 9

Chapter 1 The LS 3070 Cordless Scanner

The Freedom of Cordless Scanning

The LS 3070 is a revolutionary, cordless approach to capturing bar coded data.

The scanner communicates with your host computer through a low-power

radio transmission instead of through a cable. W ith the LS 3070, you are fr ee to

scan and transmit without a physical cable to limit your movement, from as far

away as 30 - 50 feet (9 - 15 meters), depending on your environment. This lets

you take the scanner to where the work is, whether on the loading dock, the

plant floor, the warehouse, or the POS checkout area.

The scanning system has three main components: the cordless scanner, the

base/charger interface unit, and a cable to interface with the host device.

Figure 1-1. The LS 3070 Cordless Scanner

1-1

Page 10

LS 3070 Product Reference Guide: The LS 3070 Cordless Scanner

The LS 3070 Scanner

Housed in rugged, durable plastic, the LS 3070 scanner combines accurate,

aggressive bar code scanning with solid state dependability. Its ergonomic

design ensures comfortable use for extended periods of time.

This scanner combines premium visible laser diode (VLD) scanning

performance, reading color bar codes and symbols printed on all substrates,

with advanced decode and RF transceiver capabilities.

The scanning element can be any of a wide variety of configurations:

•

Standard - for most Class II scanning applications, in which symbol

density (5 to 55 mil) and range (0 - 35 in.) fall within relatively normal

ranges.

•

Long Range (LR) - for Class II applications with short range reading on

medium density symbols and long range reading on low density

symbols.

•

Advanced Long Range (ALR) - for long range reading on medium and

low-density symbols, optimized by the increased power of the Class IIIA

laser .

•

Extra Long Range (XLR) - for scanning ranges of up to 180 inches (457 cm)

on 55 mil symbols, also using a Class IIIA laser.

High Visibility (HV) - for scanning ranges up to 33 inches (86 cm) on 55

•

mil symbols, and ambient sunlight up to 10,000 ft. candles, using a Class

IIIA laser.

1-2

Page 11

LS 3070 Product Reference Guide: The LS 3070 Cordless Scanner

Rechargeable Battery Pack

In the handle of the scanner, there is a rechargeable NiCad battery pack. This

provides all power to the scanner during normal operation. It provides 360 mA

hours, which is sufficient for normal operation during an 8-hour shift.

When fully depleted, the battery module can be recharged to full charge within

two hours, with the LS 3070 inserted into the RL 470 base/charger unit.

Alternatively, the battery module can be recharged in the Universal Four-Slot

Charger/Recharger within 8 hours.

Ni-Cd

Nickel-cadmium rechargeable

battery. Must be recycled or

disposed of properly.

Figure 1-2. The LS 3070 Rechargeable Battery Pack

1-3

Page 12

LS 3070 Product Reference Guide: The LS 3070 Cordless Scanner

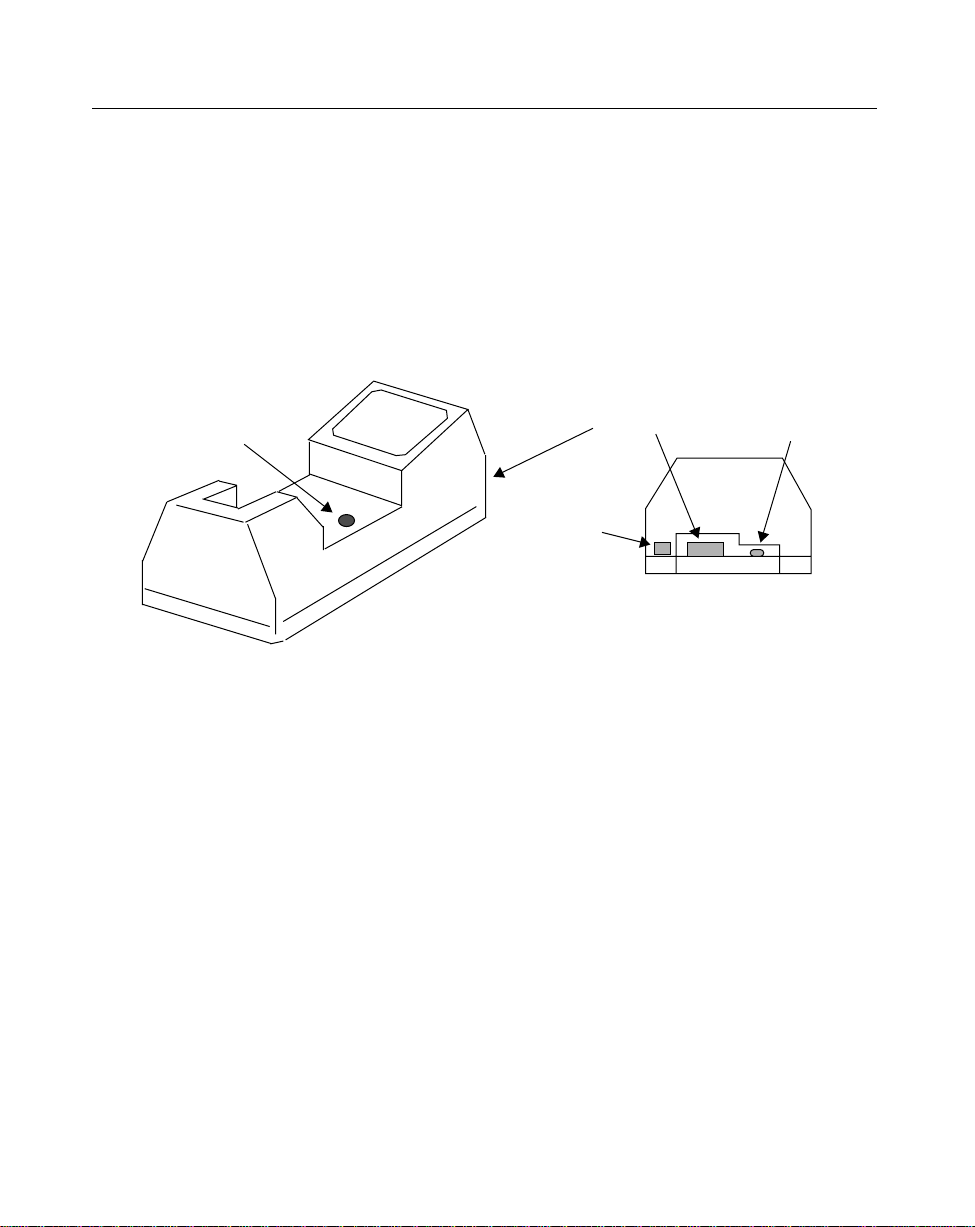

The Base/Charger Unit

The base/charger unit has two primary functions. First, it is the

base station

interface that manages the flow of information from the scanner to the host

device. Second, it is a

charging stand

which charges the scanner’s battery

module (located in the handle) and also holds the scanner securely when it is

not in use. An LED indicates the status of battery charging.

Host Cable

Connection

Charge

Status LED

Power Supply

Connection Port

Magstripe

Reader

Connection

Port

Figure 1-3. RL 470 Base/Charger Unit

The base/charger unit communicates via radio transmission with the scanner

to receive bar code data from the scanner, confirm receipt of data back to the

scanner, and exchange configuration information. The base/charger unit also

formats the scanned bar code data as required and then transmits it to the host

system through the attached cable.

1-4

Page 13

Chapter 2 Setup

Unpacking

Remove the LS 3070, the RL 470 base/charger unit, and the host interface cable

from its packing and inspect each for evidence of physical damage. If any

equipment was damaged in transit, call the Symbol Support Center at the

number in the front matter.

KEEP THE PACKING

used if you ever need to return your equipment for servicing.

. It is the approved shipping container and should be

Connecting the Cable to the Base/Charger Unit

The cable connects to the base/charger in the same way but to each host

terminal differently. For complete details per terminal type, refer to the RL 470

Base Station Interface Guide

.

Installation Tip — Optimizing RF Performance

The LS 3070 scanning system is equipped with a low power 2.4 Ghz radio.

Depending on environmental conditions, the LS 3070 can have an RF

transmission range of 30 - 50 feet (9 - 15 meters).

Where environmental objects affect RF range and performance, do the

following when you install the LS 3070 scanning system. This will help assure

peak performance.

2-1

Page 14

LS 3070 Product Reference Guide: Setup

The RL 470 base station is a charger, host interface, and — significantly —

receiving station for RF transmission. Therefore, do not install the RL 470

inaccessibly under a table or buried in a desk drawer. At a minimum, mount

the RL 470 on a table or desk top. For optimum RF performance, especially in

difficult environments, mount the RL 470 on a wall as high as possible. But

keep in mind the limits of interface cable length and charging accessibility.

Proper base positioning gives you the best possible range and coverage

performance from the LS 3070 cordless scanning system.

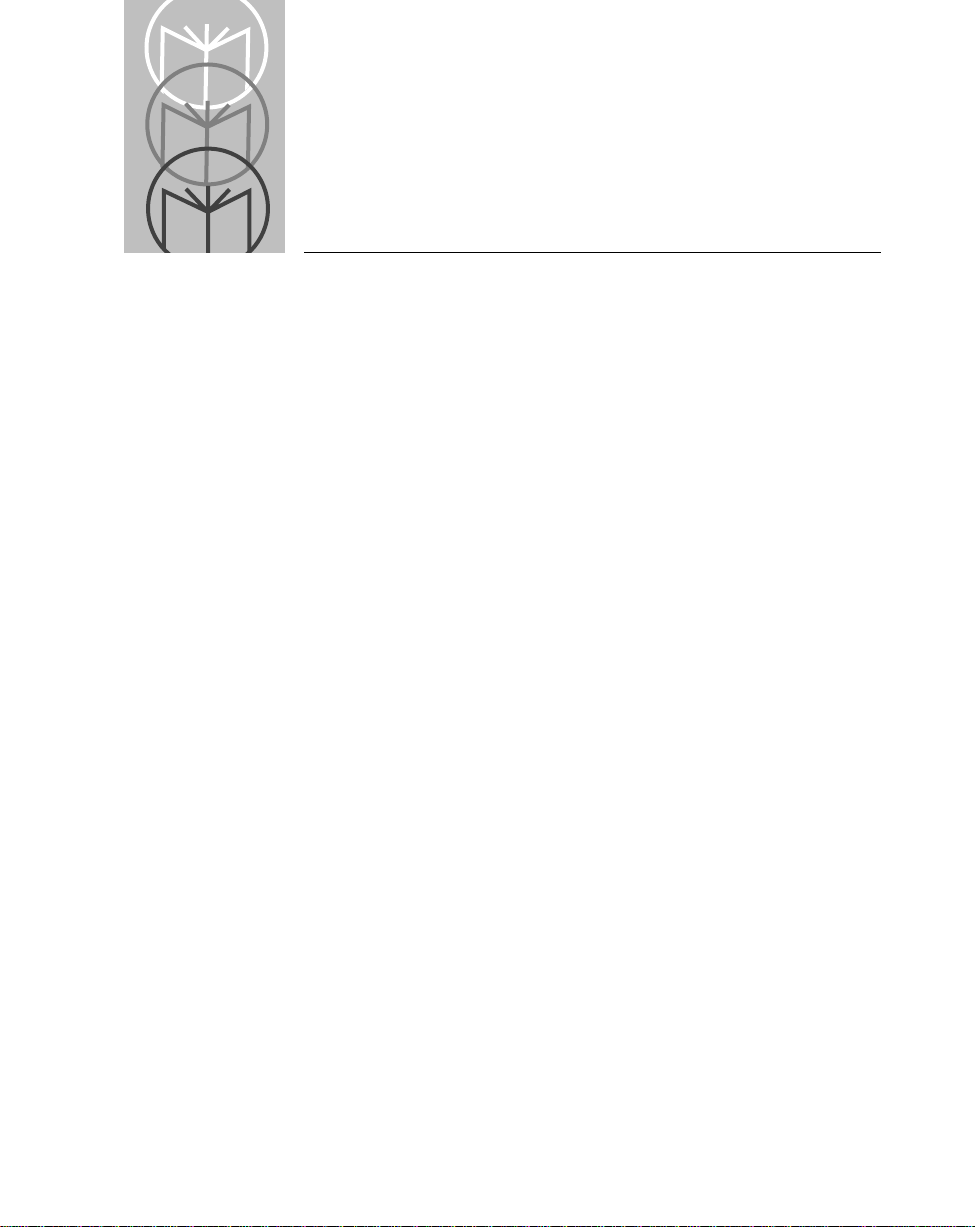

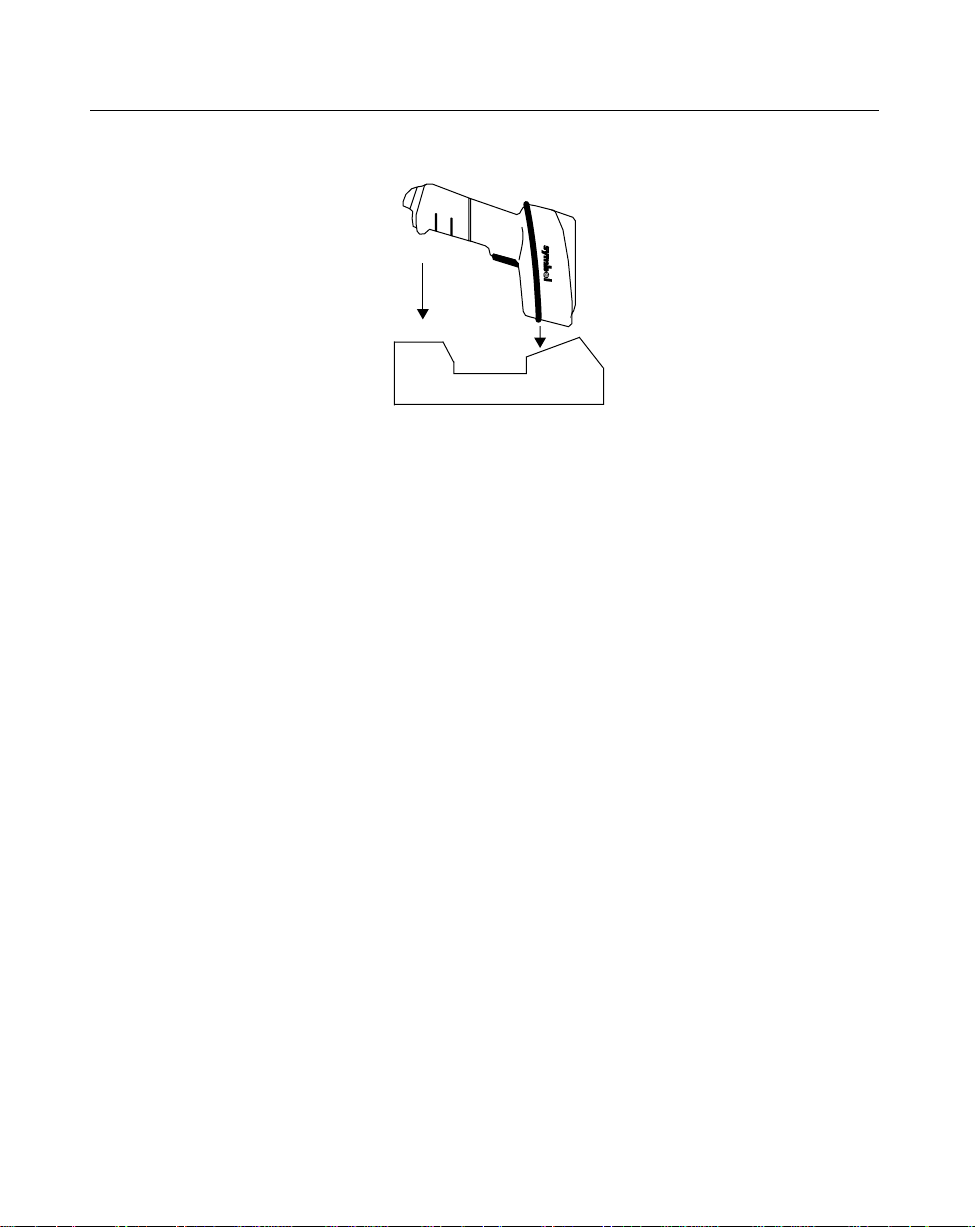

Inserting the Scanner Into and Removing Scanner from Base/Charger

To insert the scanner into the base/charger:

1. First, place the nose to the scanner into the large rectangular receptacle of

the base/charger.

2. Then place the scanner handle into the opening of the smaller, latched

receptacle and press down firmly until the bottom of the handle seats

snugly into the receptacle and engages the latch.

Caution

Use of excessive force in placing the scanner into the base can

damage the charging contacts on the shoe of the scanner or in the

receptacle of the base. Such damage can interfere with or prevent

charging of the scanner’s batteries by the base

3. To remove the scanner from the base/charger, grasp the handle of the

scanner and lift the bottom of the handle out of the latched receptacle,

thereby freeing the scanner from the base.

.

Caution

It is important to remove the scanner

move the scanner nose-first can break latch in the base receptacle

2-2

handle-first

. Trying to re-

.

Page 15

LS 3070 Product Reference Guide: Setup

Charging the Battery

Before its first use, the LS 3070 batteries must be charged. To do so:

Connect the power supply to the power input port on the front panel of

•

the RL 470 base/charger, shown in

page 1-4.

Connect the power supply to a receptacle supplying AC power of the

•

proper voltage level.

•

Then insert the scanner into the base/charger cradle, so that the nose of

the scanner and tip of the handle fit snugly into the receptacles. Check the

charge status indicator (blinking = fully charged) for full charge, which

occurs within two hours. When fully charged, proceed with pairing.

Figure 1-3: RL 470 Base/Charger Unit

on

Pairing the Scanner with the Base/Charger

The wireless “connection” between the two is the low power radio

transmission through RF transceivers in the both the scanner and base/

charger. The actual communication consists of bidirectional message packets.

However,

to work between the two devices.

Assigning Address to Base/Charger

First, the base/charger must be assigned an address, with a value between 01

and 7E.

the scanner and base/charger must be paired

Each base station must have a unique address

2-3

for this communication

.

Page 16

LS 3070 Product Reference Guide: Setup

Note:

When setting the address of the base, you

automatically set the initial frequency on which the

base and the scanner communicate. In order to

minimize possible interference between systems,

bases which are close to each other should be

assigned sequential addresses.

Set the address through setting two rotary dials, located by opening a panel on

the base/charger’s underside. Turn the base/charger upside down, open the

panel, and notice two rotary dials.

Insert Screwdriver in Slot

Switch

Panel

Base/Charger Underside

0

High Order Low Order

10 Position

Rotary Switches

0

16 Position

The first is a 10-position (0 to 9, high order address digit) and the second a 16position (0 to F , low order address digit). Digits ar e printed sequentially around

each circle.

Do not use positions 8 and 9. Setting the 10-position switch to 8 or 9 will

result in an error beep (5 long low tones) during pairing.

Set the desired address with a small screwdriver; possible addr esses ar e listed

on the next page. Note that too large a screwdriver can damage the dials. When

the address is set, close the panel, turn the base/charger rightside up again.

2-4

Page 17

LS 3070 Product Reference Guide: Setup

Possible Base/Charger Addresses

01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

20 21 22 23 24 25 26 27 28 29 2A 2B 2C 2D 2E 2F

30 31 32 33 34 35 36 37 38 39 3A 3B 3C 3D 3E 3F

40 41 42 43 44 45 46 47 48 49 4A 4B 4C 4D 4E 4F

50 51 52 53 54 55 56 57 58 59 5A 5B 5C 5D 5E 5F

60 61 62 63 64 65 66 67 68 69 6A 6B 6C 6D 6E 6F

70 71 72 73 74 75 76 77 78 79 7A 7B 7C 7D 7E

Note: Each base station must have a unique address.

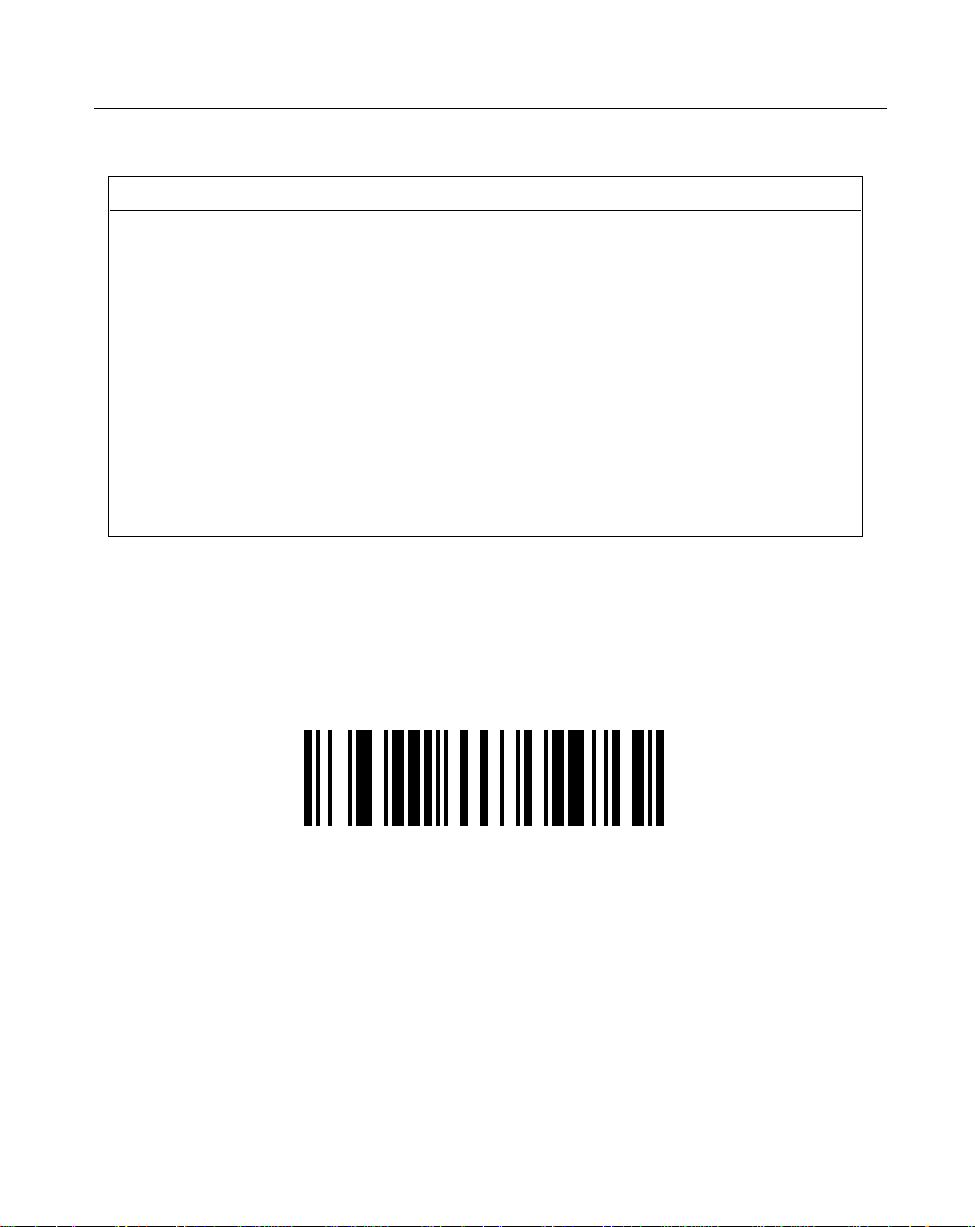

Pairing Scanner with Base/Charger

To pair the scanner with the base/charger:

•

Scan the

•

Then insert the scanner into the base/charger’s cradle. You have 15

PAIRING

bar code below or the bar code on the RL 470 base.

PAIRING

seconds to do this, or there will be error beeps (4 beeps = unsuccessful

pairing or base not powered). Note that you cannot scan data until this

pairing is complete.

2-5

Page 18

LS 3070 Product Reference Guide: Setup

At that time, through the scanner’s contact shoe, there is an exchange of

•

information (addressing, RF channels, etc.) between the scanner and the

base/charger’s cradle. This occurs in less than a second.

After that exchange, the scanner and base/charger are paired. Successful

•

pairing is indicated by a

indicated by a

Lo Lo Lo Lo

warble

beep.

beep; failure, or unsuccessful link, is

Setting T ransmission Frequency

Each scanner/base pair communicates on one of a number of channel

frequencies, which varies by country. In most countries, there are 80 available

channels (numbered 2 through 81); in France, there are only 9 channeles

(numbered 46 through 54).

The initial transmission frequency is determined by the base’s unique address,

so neighboring LS 3070 systems operate on different channels. This allows

them to transmit simultaneously without interfering with each other . Channel

separation is optimal between sequential base addresses, so base units closest

to each other should be assigned sequential base addresses if possible. (Note

that data is transmitted between a scanner and base so quickly that a number

of different LS 3070 systems can normally operate on the same channel without

noticeable interference.)

2-6

Page 19

LS 3070 Product Reference Guide: Setup

Occasionally, there can be excessive interference on a channel from some other

source of radio transmissions. In this case, the default channel of a system can

be changed using the parameter codes for

Set Transmission Frequency. If you

find a particular scanner/base pair has trouble communicating over a normal

operating distance, try setting different transmission frequencies to see if

performance improves. (The LS 3070 system changes channels automatically if

it encounters interference as much as 80% of the time over a continuous 5minute period.)

Note: To set trasmission frequency correctly, be sure to

use the correct Select Channel Number bar code for

your country, and to set a channel within the

allowable range.

Installing a Magstripe Reader

If desired, install a magstripe reader. This may be done before or after pairing.

1. Remove the blank plug in the magstripe connection port on the base/

charger, and then plug the magstripe reader’s cable into this port, as

illustrated below.

2. The purpose of the blank plug is to protect the base/charger from

accidental damage that can be caused by static electrical discharge into the

magstripe connection port. Keep this plug in the port whenever the magstripe

reader is not connected.

Magstripe

Reader

Connection

Port

2-7

Page 20

Chapter 3 Scanning with the LS 3070

1. Ready

Before starting to scan bar codes for data collection, make sure:

• The base station is connected to the host device.

• The battery has been charged.

• The scanner is paired with the base/charger.

2. Test

Aim the scanner toward a bar code and press the trigger. When you press the

trigger, the scanning beam is energized.

3. Scan

Make sure the symbol you want to scan is within the proper scanning range.

(See Decode Zones beginning on page 3-6.)

Aim and press the trigger.

• The scan beam and red SCAN LED will light for about 3 seconds, or until

a successful decode.

The scanner has read the symbol when:

• You hear a beep.

• The green DECODE LED lights.

The LED stays green for up to one second if the trigger is down or disappears

if you release the trigger. The scanner powers down after a successful decode.

3-1

Page 21

LS 3070 Product Reference Guide: Scanning with the LS 3070

If the scanning attempt ends in 4 error beeps, any of these may be true:

• Scanner is out of transmission range

• Scanner and base/charger are not paired

• Base/charger is not powered.

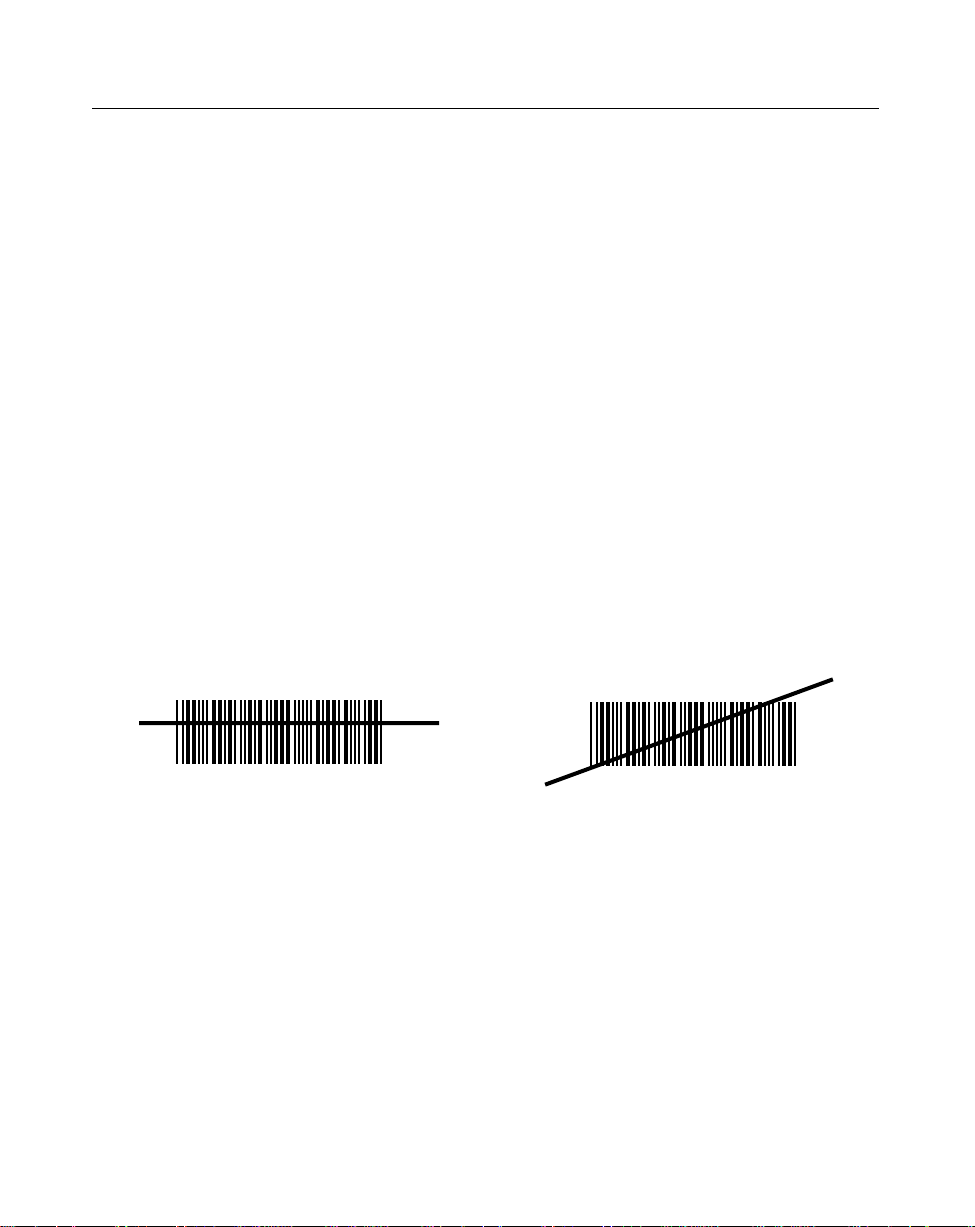

Hold at an Angle

Do not hold the scanner directly over the bar code. In this position, light can

bounce back into the scanner's exit window and prevent a successful decode.

Scan the Entire Symbol

• Your scan beam must cross every bar and space on the symbol.

• The larger the symbol, the farther away you should hold the scanner.

• Hold the scanner closer for symbols with bars that are close together.

• A short high-tone beep indicates a good decode.

RIGHT

012345

WRONG

012345

3-2

Page 22

LS 3070 Product Reference Guide: Scanning with the LS 3070

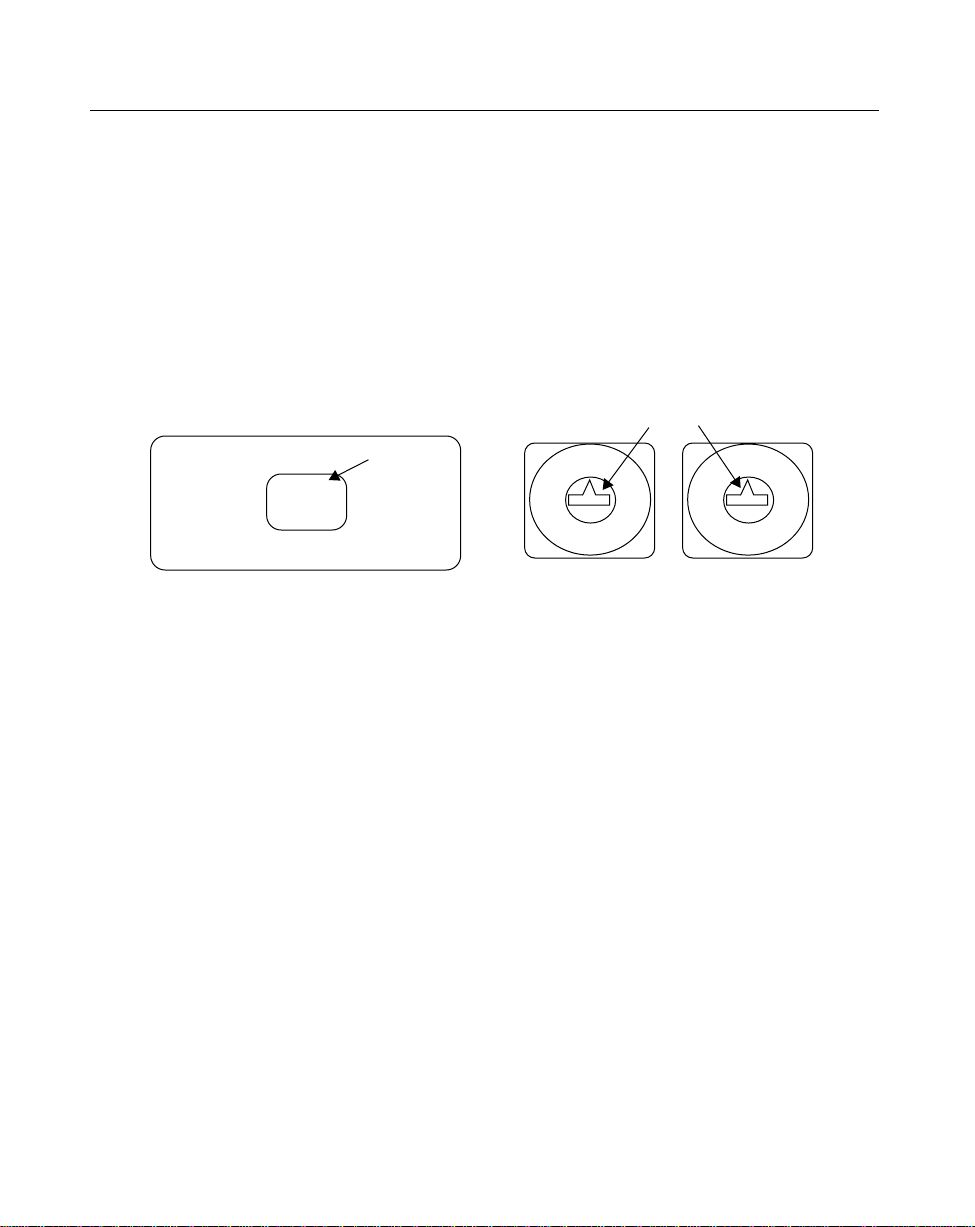

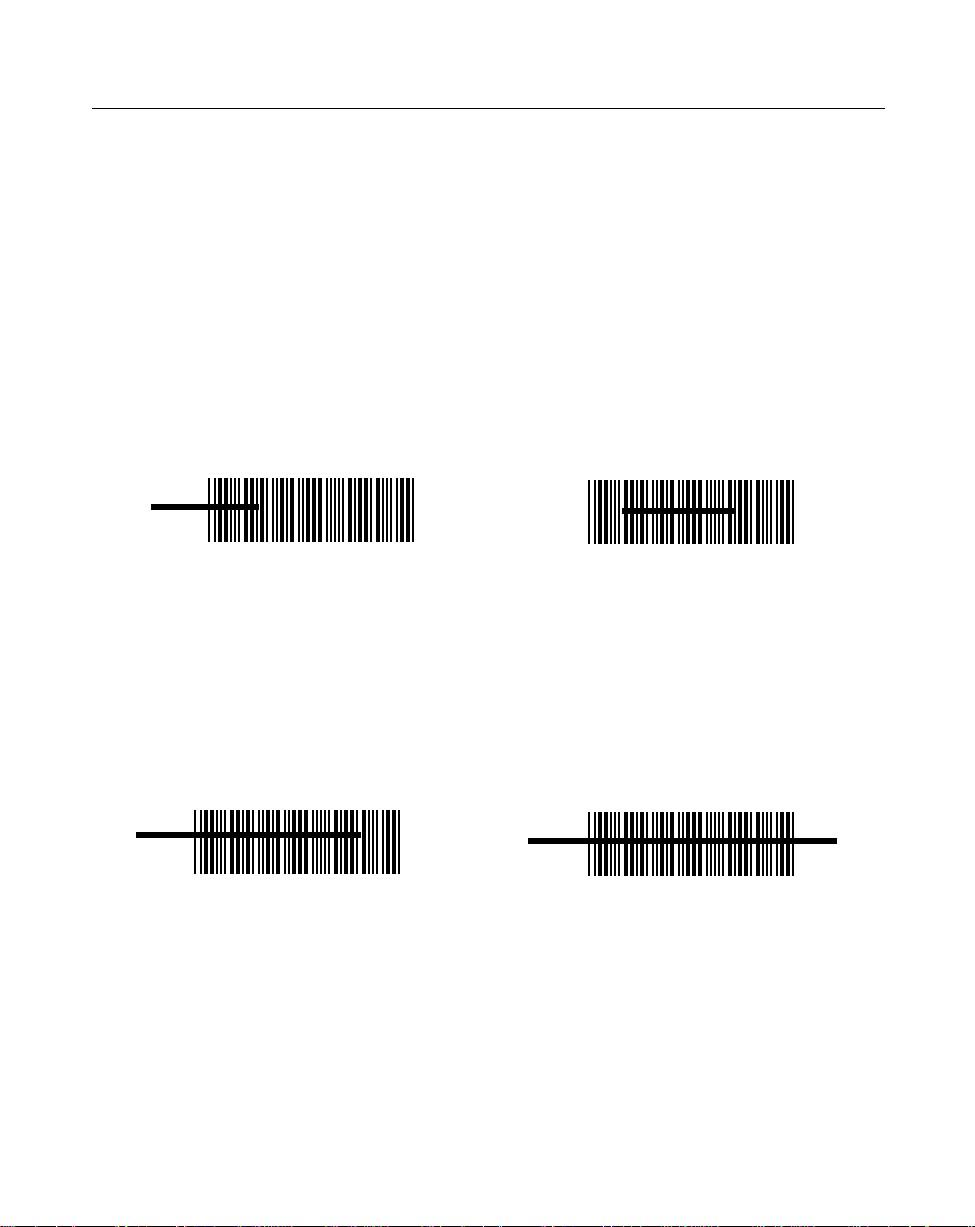

Using a Long Range or High Visibility Scanner?

These scanners have two-position triggers. Press the trigger to the first detent

and center the “collapsed” aiming beam on the target bar code, as illustrated

below. The collapsed beam helps to establish the correct scanning position.

Press the trigger to the second detent, and a scan beam crosses all the bars and

spaces on the bar code.

FIRST TRIGGER POSITION

WRONG

SECOND TRIGGER POSITION

WRONG

RIGHT

RIGHT

3-3

Page 23

LS 3070 Product Reference Guide: Scanning with the LS 3070

Scanning Transmission Range

RF Communication Errors

RF communication errors occur when the scanner is out of range from the base

during a scan data transmission attempt. An error is indicated by 6 beeps after

a bar code is scanned, although the bar code data appears on the host display.

This happens when the base receives the bar code data but the scanner did

NOT get the HIF response from the base, and therefore timed out.

The base reported an RF communication error because the NOMAD protocol

was not completed before timeout, however, transmitted the bar code data to

the host. Since the data has been sent, normal communications must be reestablished.

Restoring Normal RF Communications

Move the scanner closer to the base station so the transceivers can

communicate with each other better. Then re-scan the bar code. The scanner

sounds a good decode beep but the base does not display the bar code data,

because the data was already transmitted on the previous scan.

Resume normal scanning.

3-4

Page 24

LS 3070 Product Reference Guide: Scanning with the LS 3070

What If ...

Nothing happens when you follow the operating

instructions?

You should

• Check that the power supply is attached to the base/charger.

• Check for loose cable connections at the base/charger and host device.

• Check the scanner’s battery pack.

• Make sure the device is programmed to read the type of bar code you

want to scan.

• Check the symbol to make sure it is not defaced.

• Try scanning similar symbols of the same code type.

• Check that the gas tank is not exhausted.*

• Make sure the scanner and base/charger have been successfully paired.

• Be sure you’re within the proper scanning and transmission range.

If you get frequent Transmit Errors (error beeps after decode):

• Check that you are within scanning transmit range. (See Scanning

Transmission Range on page 3-4.)

• Check that the scanner is successfully paired with the base/charger.

• Check that the base/charger is powered up and that its cable connections

are secure.

Note: If after performing these checks the symbol still

does not scan, contact your distributor or call the

Symbol Support Center . See Symbol Support Center

on page About-ii for the telephone number.

* The gas tank limits the amount of time the laser remains on within a given

period to conform to the requirements of specific laser output classifications.

3-5

Page 25

LS 3070 Product Reference Guide: Scanning with the LS 3070

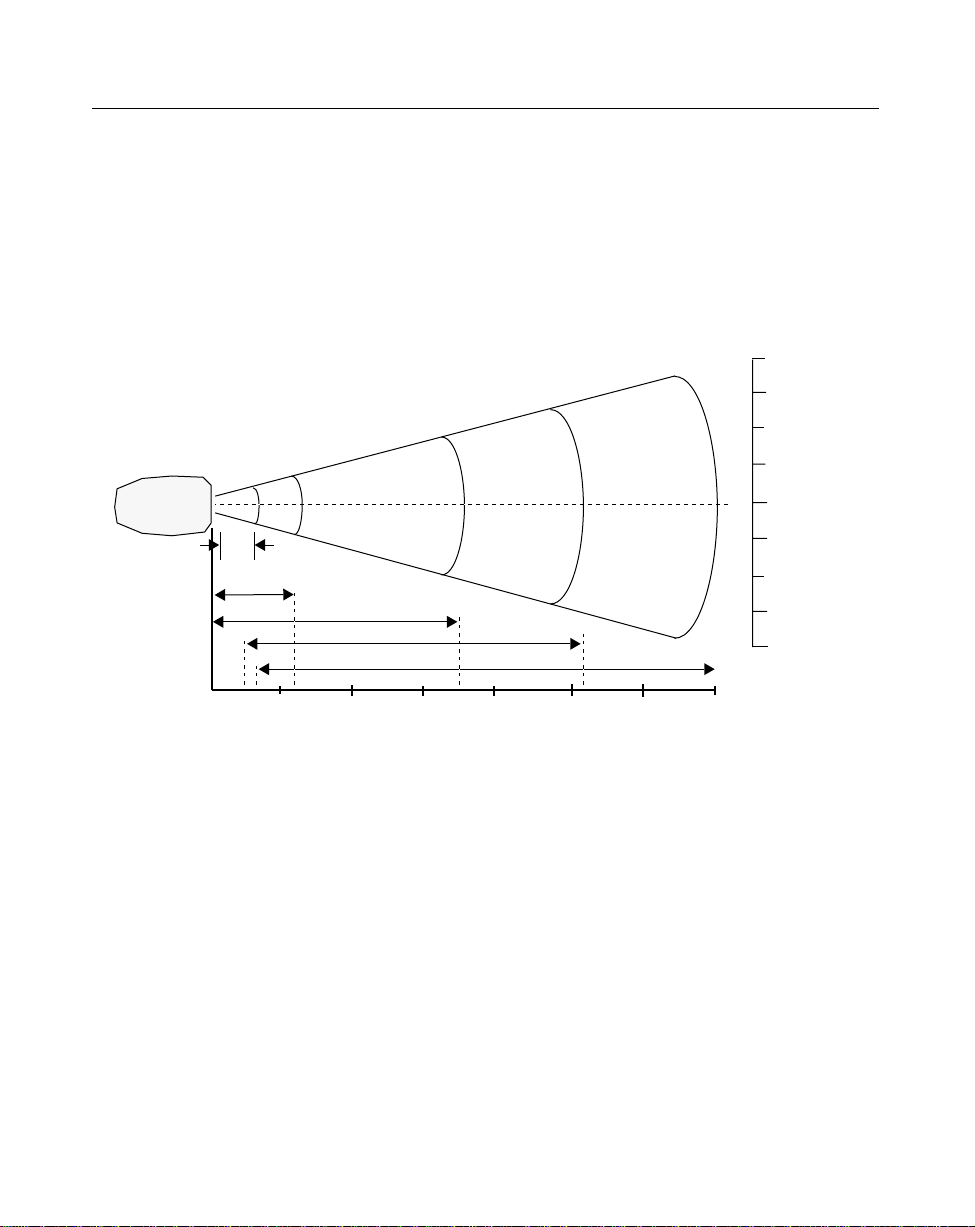

Decode Zones

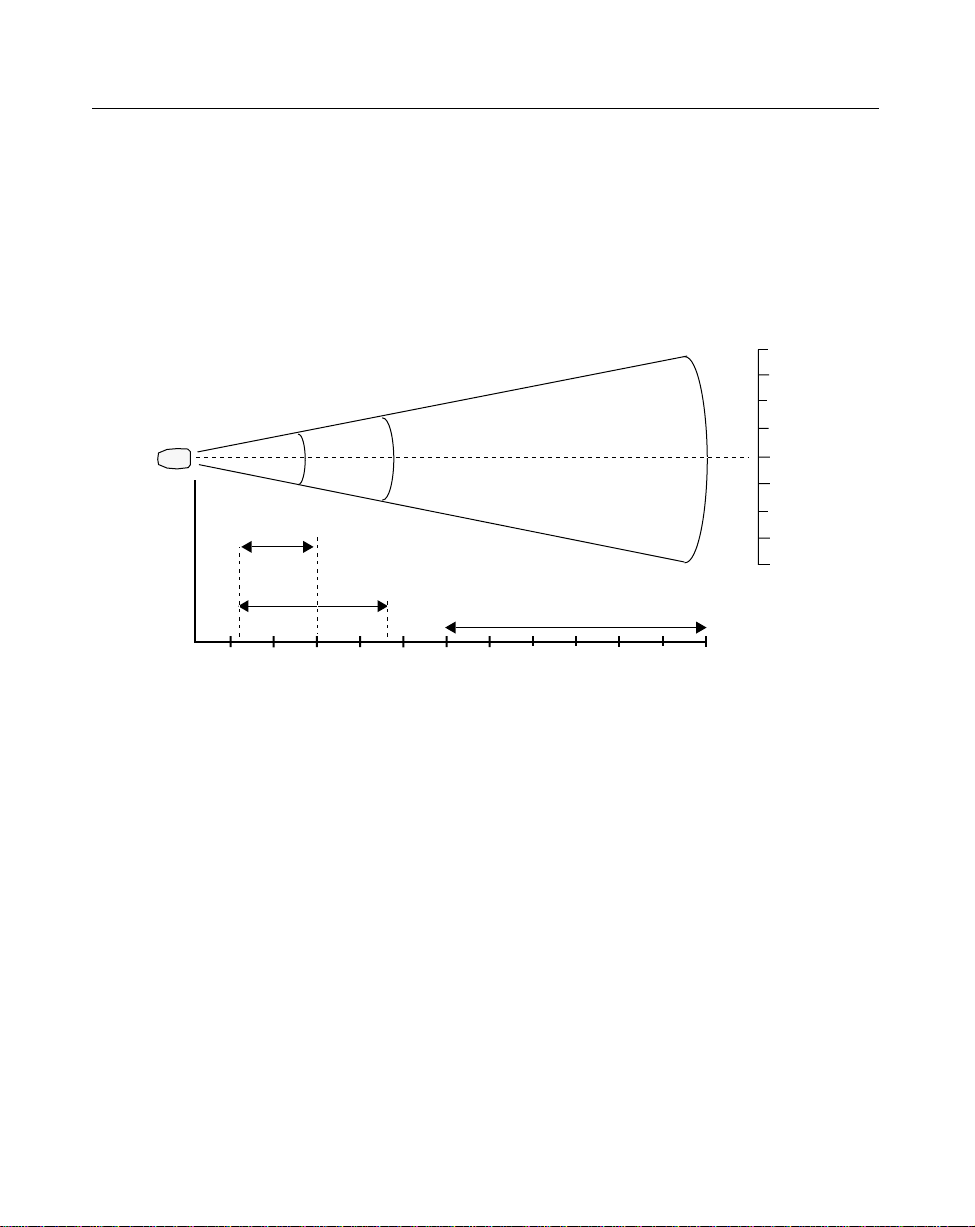

LS 3070 Standard Range

NOTE: Typical performance at 23o C (75o F) on high quality symbols.

Front of the

Scanner

10

5

0

25.4

12.7

0

.0055 In.

.0075 In.

.020 In. Minimum Element Width

.040 In. Minimum Element Width

.055 In. Minimum Element Width

5 10

12.7 25.4

15

38.1

20 250

50.8 63.50 76.2 88.9

30 35

Distance from Front of Scanner

Figure 3-1. LS 3070 Decode Zone:

Depth of field as a function of minimum element width.

5

10

In.

Inches

Cm.

12.7

25.4

Cm.

Width of Field

3-6

Page 26

LS 3070 Product Reference Guide: Scanning with the LS 3070

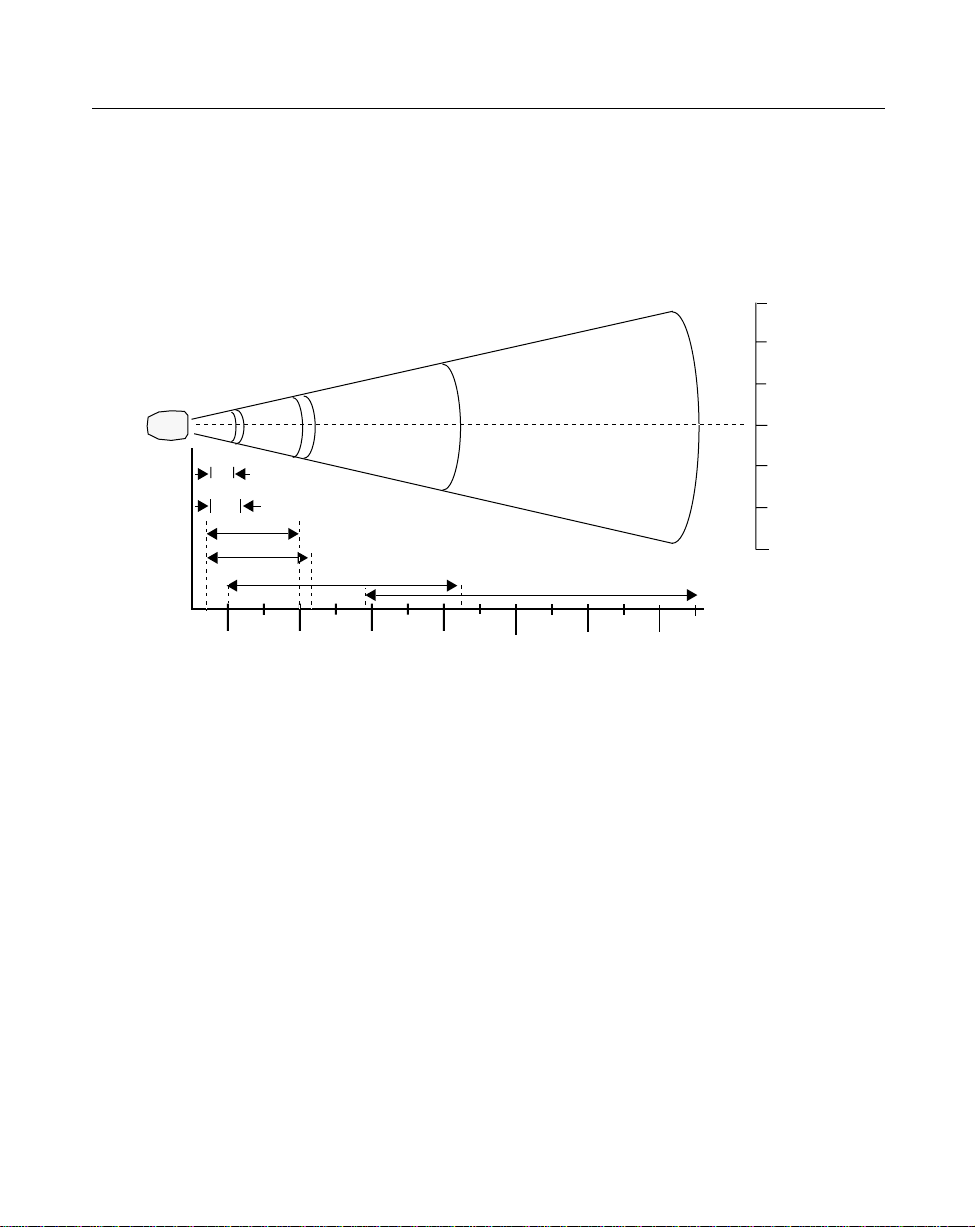

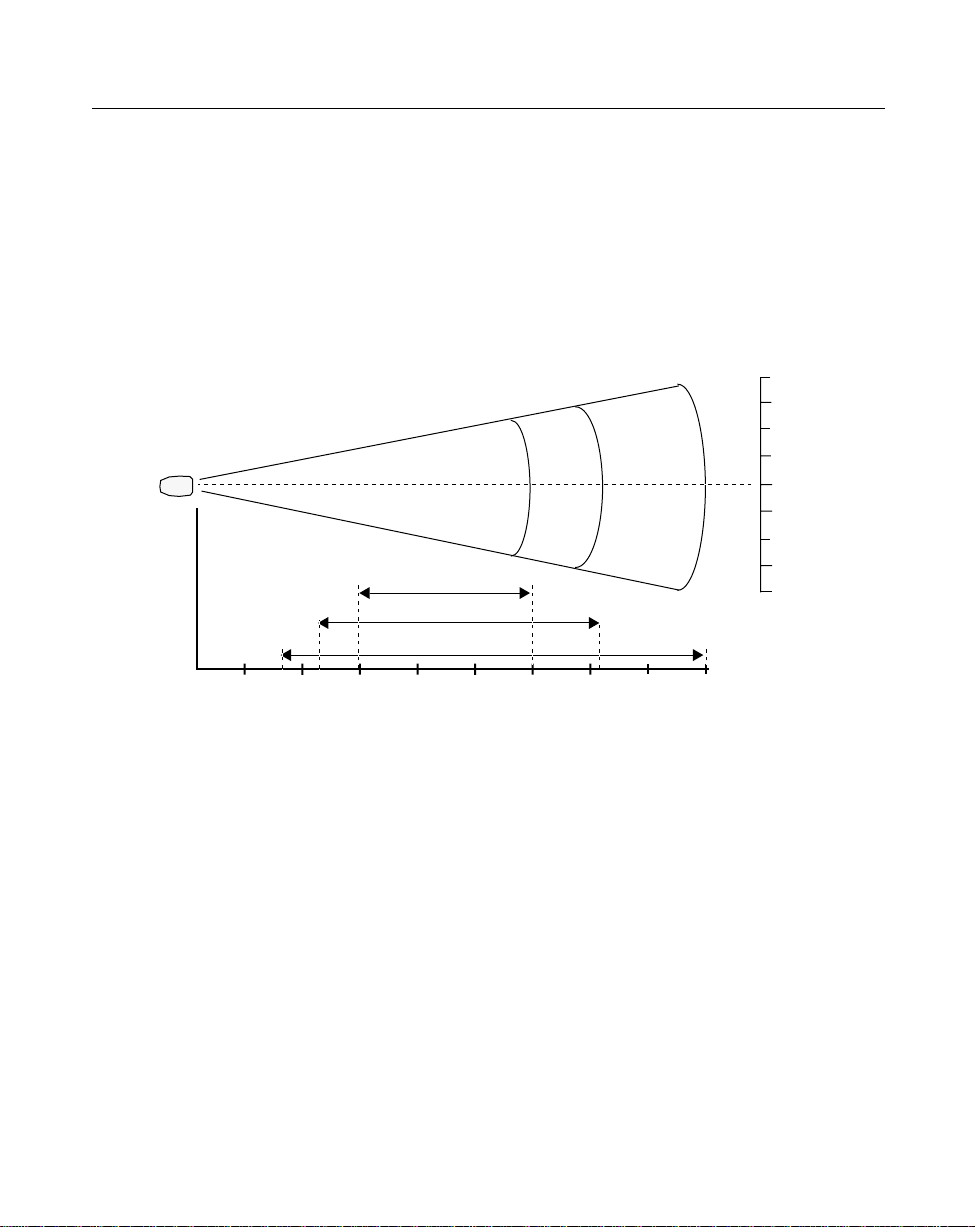

LS 3070LR Long Range

NOTE: Typical performance at 23o C (75o F) on high quality symbols.

30

20

76

51

Front of the

Scanner

7.5 Mil

10 Mil

15 Mil

20 Mil

10

25

20

51

30

76

40 Mil

40

102

50

127

60

152

70

178

70 Mil Reflective

800

2030 305 366

90

229

100

254

120 144

110 130

280 330

Distance from Front of Scanner

Figure 3-2. LS 3070LR Decode Zone:

Depth of field as a function of minimum element width.

10

0

10

20

30

In.

Inches

Cm

25.4

0

25.4

Width of Field

51

76

Cm.

3-7

Page 27

LS 3070 Product Reference Guide: Scanning with the LS 3070

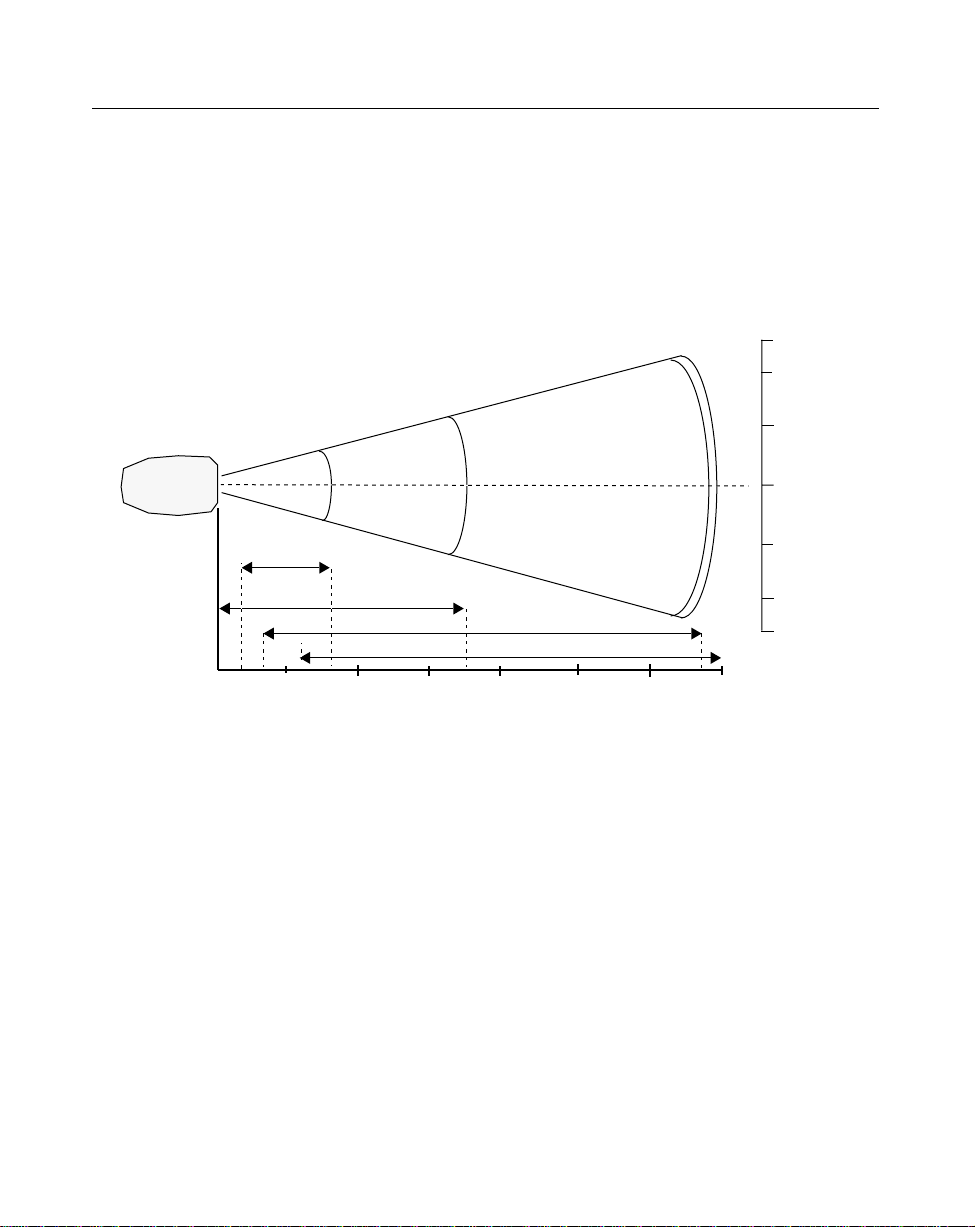

LS 3070ALR Advanced Long Range

NOTE: Typical performance at 23o C (75o F) on high quality symbols.

Front of the

Scanner

15 Mil

40 Mil

70 Mil Reflective

20

10

0

10

20

In.

51

25.4

0

25.4

51

Cm.

Width of Field

40 60 80 140 1600

20 Inches

102 152 203 356 4060 508 61051

100 120 180 220

254 305 457 556

200 240

Distance from Front of Scanner

Figure 3-3. LS 3070ALR Decode Zone:

Depth of field as a function of minimum element width.

3-8

Cm

Page 28

LS 3070 Product Reference Guide: Scanning with the LS 3070

LS 3070XLR Extra Long Range

NOTE: Typical performance at 23o C (75o F) on high quality symbols.

Front of the

Scanner

20

10

0

10

51

25.4

0

25.4

Width of Field

30 Mil

40 Mil

55 Mil

0

20 Inches

0 51

40

102

60

152

80

203

100

254

120

305

140

356

160

406

180

457

Distance from Front of Scanner

Figure 3-4. LS 3070XLR Decode Zone:

Depth of field as a function of minimum element width.

3-9

Cm

20

In.

51

Cm.

Page 29

LS 3070 Product Reference Guide: Scanning with the LS 3070

LS 3070HV High Visibility

NOTE: Typical performance at 23o C (75o F) on high quality symbols.

13

10

33

25.4

Front of the

Scanner

.0075 In.

.020 In. Minimum Element Width

.040 In. Minimum Element Width

.055 In. Minimum Element Width

5 10

12.7 25.4

15

38.1

20 250

50.8 63.50 76.2 86.4

Distance from Front of Scanner

Figure 3-5. LS 3070HV Decode Zone:

Depth of field as a function of minimum element width.

30 34

5

0

5

10

13

In.

Inches

Cm.

12.7

0

12.7

25.4

33

Cm.

Width of Field

3-10

Page 30

Chapter 4 Maintenance and

Specifications

Maintenance

Cleaning the exit window is the only maintenance required. A dirty window

may affect scanning accuracy.

• Do not allow any abrasive material to touch the window.

• Remove any dirt particles with a damp cloth.

• Wipe the window using a tissue moistened with ammonia/water.

• Do not spray water or other cleaning liquids directly into the window.

Recharging the Battery

As a charging stand, the base/charger rechar ges batteries in the scanner when

the scanner is in the cradle. The status of the scanner battery module

determines the charge rate. If the battery module is at full charge, the base/

charger supplies a trickle charge. If the battery module is at less than full

charge, there is a programmed charge. Note that the scanner can be removed

from the base/charger at any time.

When necessary, recharge the batteries. To do so:

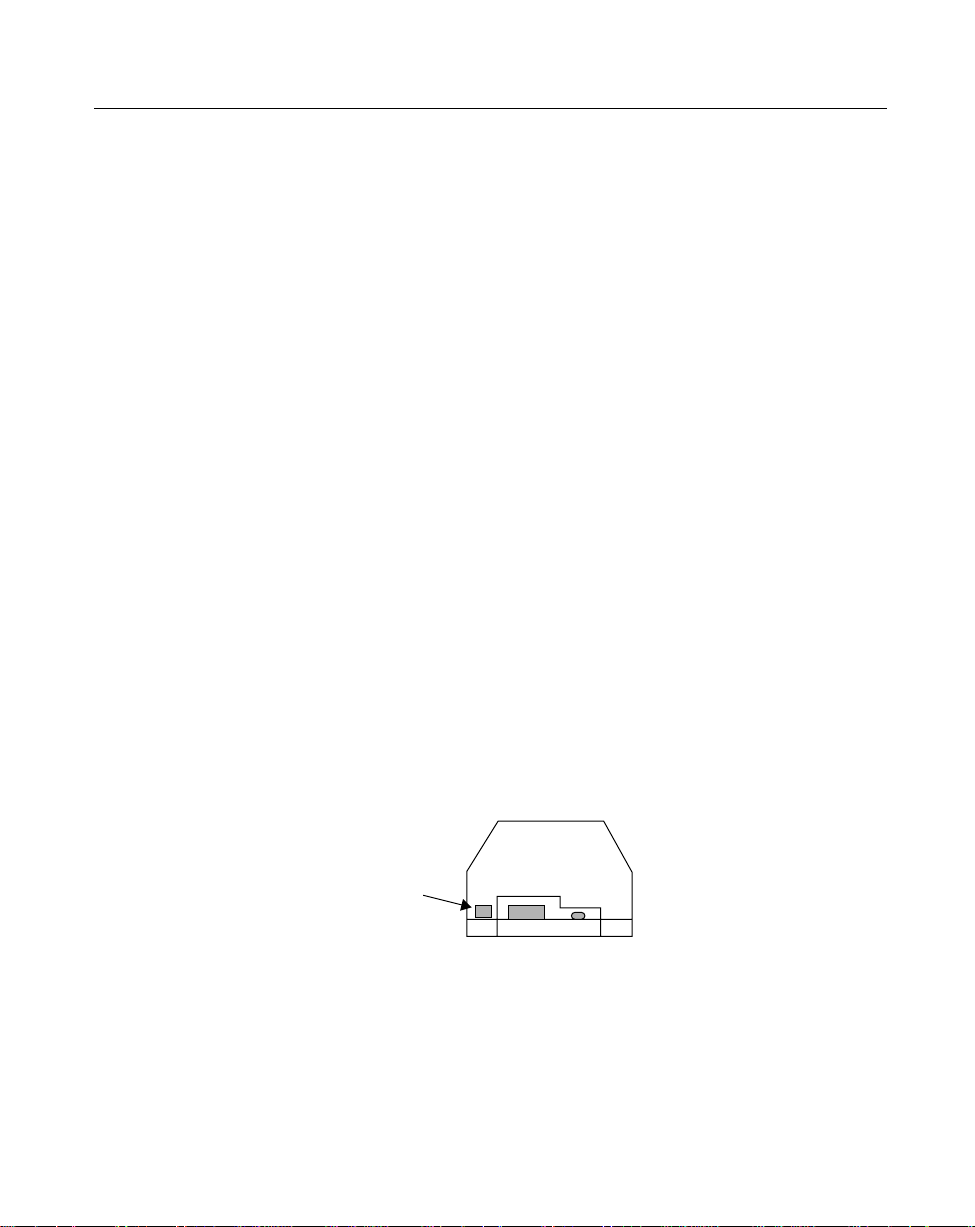

• Connect the power supply to the power input port on the front panel of

the RL 470 base/charger, as illustrated below.

• Connect the power supply to a receptacle supplying AC power of the

proper voltage level.

• Then place the scanner into the base/charger cradle, so that the nose of

the scanner and tip of the handle fit snugly into the receptacles. Check the

charge status indicator (blinking = fully charged) for full charge, which

occurs within two hours. However, the scanner can be used on less than

full charge.

4-1

Page 31

LS 3070 Product Reference Guide: Maintenance and Specifications

Power Supply

Connection Port

Figure 4-1. Recharging the LS 3070

Changing Battery Packs

You can charge battery packs on the Universal Four Slot Battery Charger so

that a charged battery pack is available when needed. In this case, simply

remove the depleted battery pack and replace it with a freshly charged one.

User instructions are in the Universal Four-Slot Battery Charger Quick Reference

Guide.

4-2

Page 32

LS 3070 Product Reference Guide: Maintenance and Specifications

1. Remove Lower Handle from Scanner.

Using a probe, press in the release button on the handle, as indicated at the

right. With button pressed in below the outer housing, slide the battery pack

out from the handle.

Release

Button

LS 3070 Battery Pack

Four Slot Charger with Charging Adapter

Figure 4-2. Changing LS 3070 Battery Packs

2. Insert Charged Battery Pack in Handle.

With release button down, slide charged battery pack up into handle until it

locks into place and the release button pops up into place as well.

4-3

Page 33

LS 3070 Product Reference Guide: Maintenance and Specifications

Charge Status LED Indications

On the base/charger , ther e is a red LED indicator which uses flashing patterns

to indicate the current charger status. The red Char ge Status LED indicates the

following conditions:

• RED LED OFF — The scanner is not properly inserted or the battery is

not functioning properly.

• RED LED blinking slowly (1/8 sec. ON, 3/8 sec. OFF) — Battery charge

is pending. This can occur if the batttery temperature is too high or low

or if the battery is deeply discharged. After several minutes, normal

charging should begin.

• RED LED ON — The battery is actively char ging. Charging will complete

in less than 2 hours.

• RED LED blinking rapidly (1/8 sec. ON, 1/8 sec. OFF) — Battery

charging is complete.

4-4

Page 34

LS 3070 Product Reference Guide: Maintenance and Specifications

Accessories

Standard Accessories

Part Number Description

RL 470 Base/interface charger

Base/Charger Cable: Cables are available for most applications.

See the Electronic ProductOrdering Guide for

more information.

70-10294-01 LS 3070 Product Reference Guide

70-10538-01 LS 3070 Advanced Programmer’s Guide

70-10294-01Q LS 3070 Series Quick Reference Guide

50-04000-041 117 V Power Supply

50-04000-040 220 V Power Supply

50-04000-037 100 V Power Supply

Optional Accessories

Optional accessories, listed in the Electronic Product Ordering Guide, include

various rechargers, magstripe readers, stands, and holders, which ar e supplied

at extra cost. Additional units of standard accessories listed above may also be

purchased at extra cost.

4-5

Page 35

LS 3070 Product Reference Guide: Maintenance and Specifications

LS 3070 Standard Technical Specifications

ITEM DESCRIPTION

Power Requirements:

Scanner 4.75 to 14 VDC; 210 mA @ 5 VDC Typical.

Base/Charger 5 VDC ± 10% @ 190 mA Typical.

12 VDC ± 10% @ 400 mA Typical.

Scan Repetition Rate Approximately 36 (± 3) scans/sec

(bidirectional)

Start-up Time <50 msec. from scan enable

Data Acquisition Time <110 msec. from scan enable

Skew Tolerance ± 65° from normal

Pitch Angle ± 55° from normal

Decode Depth of Field See LS 3070 Standard Range on page 3-6

Minimum Element Width 0.005 in. .127 mm

Maximum Element Width 0.2 in. 5.08 mm

Print Contrast Minimum 20% absolute dark/light reflectance

differential, measured at 675 nm.

Ambient Light Immunity

Artificial Lighting 450 ft. candles 4844 lux

Sunlight 8000 ft. candles 86112 lux (@8 in. on low

density bar codes)

Durability 6-ft. drop to concrete

Operating Temperature 0° to 40°C 32° to 104°F

Storage Temperature -40° to 60°C -40° to 140°F

Humidity 5% to 95% (non-condensing)

Height 6.3 in. 16 cm

Length 5 in. 12.7 cm

Width 2.8 in. 7.1 cm

CDRH Class I, II

4-6

Page 36

LS 3070 Product Reference Guide: Maintenance and Specifications

LS 3070LR Technical Specifications

ITEM DESCRIPTION

Power Requirements:

Scanner 4.75 to 14 VDC; 210 mA @ 5 VDC Typical.

Base/Charger 5 VDC ± 10% @ 190 mA Typical.

12 VDC ± 10% @ 400 mA Typical.

Scan Repetition Rate Approximately 36 (± 3) scans/sec

(bidirectional)

Start-up Time <50 msec. from scan enable

Data Acquisition Time <110 msec. from scan enable

Skew Tolerance ± 60° from normal

Pitch Angle ± 45° from normal

Decode Depth of Field See LS 3070LR Long Range on page 3-7

Minimum Element Width 0.007 in. .178 mm

Maximum Element Width 0.2 in. 5.08 mm

Print Contrast Minimum 50% absolute dark/light reflectance

differential, measured at 675 nm.

Ambient Light Immunity

Incandescent 450 ft. candles 4844 lux

Fluorescent 450 ft. candles 4844 lux

Sodium Vapor 450 ft. candles 4844 lux

Mercury Vapor 450 ft. candles 4844 lux

Sunlight 8000 ft. candles 86112 lux

Durability 6-ft. drop to concrete

Operating Temperature 0° to 40°C 32° to 104°F

Storage Temperature -40° to 60°C -40° to 140°F

Humidity 5% to 95% (non-condensing)

Height 6.3 in. 16 cm

Length 5 in. 12.7 cm

Width 2.8 in. 7.1 cm

CDRH Class II

4-7

Page 37

LS 3070 Product Reference Guide: Maintenance and Specifications

LS 3070ALR Technical Specifications

ITEM DESCRIPTION

Power Requirements:

Scanner 4.75 to 14 VDC; 210 mA @ 5 VDC Typical.

Base/Charger 5 VDC ± 10% @ 190 mA Typical.

12 VDC ± 10% @ 400 mA Typical.

Scan Repetition Rate Approximately 36 (± 3) scans/sec (bidirectional)

Start-up Time <50 msec. from scan enable

Data Acquisition Time <110 msec. from scan enable

Skew Tolerance ± 60° from normal

Pitch Angle ± 45° from normal

Decode Depth of Field See LS 3070ALR Advanced Long Range on page 3-8

Minimum Element Width 0.015 in. .380 mm

Maximum Element Width 0.1 in. 2.54 mm

Print Contrast Minimum 50% absolute dark/light reflectance differential,

measured at 675 nm.

Ambient Light Immunity

Incandescent 450 ft. candles 4844 lux

Fluorescent 450 ft. candles 4844 lux

Sodium Vapor 450 ft. candles 4844 lux

Mercury Vapor 450 ft. candles 4844 lux

Sunlight 8000 ft. candles 86112 lux

Durability 6-ft. drop to concrete

Operating Temperature 0° to 40°C 32° to 104°F

Storage Temperature -40° to 60°C -40° to 140°F

Humidity 5% to 95% (non-condensing)

Height 6.3 in. 16 cm

Length 5 in. 12.7 cm

Width 2.8 in. 7.1 cm

CDRH Class IIIA

4-8

Page 38

LS 3070 Product Reference Guide: Maintenance and Specifications

LS 3070XLR Technical Specifications

ITEM DESCRIPTION

Power Requirements:

Scanner 4.75 to 14 VDC; 210 mA @ 5 VDC Typical.

Base/Charger 5 VDC ± 10% @ 190 mA Typical.

12 VDC ± 10% @ 400 mA Typical.

Scan Repetition Rate Approximately 36 (± 3) scans/sec

(bidirectional)

Start-up Time <50 msec. from scan enable

Data Acquisition Time <110 msec. from scan enable

Skew Tolerance ± 60° from normal

Pitch Angle ± 45° from normal

Decode Depth of Field See LS 3070XLR Extra Long Range on page 3-9

Minimum Element Width 0.030 in. .762 mm

Maximum Element Width 0.1 in. 2.54 mm

Print Contrast Minimum 50% absolute dark/light reflectance

differential, measured at 675 nm.

Ambient Light Immunity

Incandescent 100 ft. candles 1076.4 lux

Fluorescent 450 ft. candles 4844 lux

Sodium Vapor 450 ft. candles 4844 lux

Mercury Vapor 450 ft. candles 4844 lux

Durability 6-ft. drop to concrete

Operating Temperature 0° to 40°C 32° to 104°F

Storage Temperature -40° to 60°C -40° to 140°F

Humidity 5% to 95% (non-condensing)

Height 6.3 in. 16 cm

Length 5 in. 12.7 cm

Width 2.8 in. 7.1 cm

CDRH Class IIIA

4-9

Page 39

LS 3070 Product Reference Guide: Maintenance and Specifications

LS 3070HV Technical Specifications

ITEM DESCRIPTION

Power Requirements:

Scanner 4.75 to 14 VDC; 210 mA @ 5 VDC Typical.

Base/Charger 5 VDC ± 10% @ 190 mA Typical.

12 VDC ± 10% @ 400 mA Typical.

Scan Repetition Rate Approximately 36 (± 3) scans/sec

(bidirectional)

Start-up Time <50 msec. from scan enable

Data Acquisition Time <110 msec. from scan enable

Skew Tolerance ± 60° from normal

Pitch Angle ± 45° from normal

Decode Depth of Field See LS 3070HV High Visibility on page 3-10

Minimum Element Width 0.0075 in. .190 mm

Maximum Element Width 0.1 in. 2.54 mm

Print Contrast Minimum 25% absolute dark/light reflectance

differential, measured at 675 nm.

Ambient Light Immunity

Incandescent 400 ft. candles 4305 lux

Fluorescent 450 ft. candles 4844 lux

Sodium Vapor 450 ft. candles 4844 lux

Mercury Vapor 450 ft. candles 4844 lux

Sunlight 10,000 ft. candles 107640 lux

Durability 6-ft. drop to concrete

Operating Temperature 0° to 40°C 32° to 104°F

Storage Temperature -40° to 60°C -40° to 140°F

Humidity 5% to 95% (non-condensing)

Height 6.3 in. 16 cm

Length 5 in. 12.7 cm

Width 2.8 in. 7.1 cm

CDRH Class IIIA

4-10

Page 40

Chapter 5 Interface Guide

Connecting to a Host Device

In most cases, connecting your LS 3070’s base station to your host terminal is a

very simple operation. You need only plug the cable into your host. Typical

configurations are shown on the following pages. Some POS keyboards requir e

more intricate installation instructions. Those begin on page 5-6.

We recommend that you disconnect the power supply from the base station

prior to connecting or disconnecting cables.

Refer to Interfaces beginning on page 5-23 for the proper interface cable

assembly.

After you've connected your base station to your host terminal, refer to Chapter

6: Programming for programming instructions.

5-1

Page 41

LS 3070 Product Reference Guide: Interface Guide

Connecting Base Station to a Host

OCIA and OCR Terminals

The OCIA or OCR port must be activated and referenced by the POS system,

or no communications will take place.

POS Terminal

Base Station

Figure 5-1. Connecting Base Station to OCIA/OCR Terminals

These include:

OCR

IBM 3653/3683/3684, Fujitsu 7770/7880/7990/8770/9000.

OCIA

NCR 2151/2152/2154/2155/2157/2126/2126-1120/2950/7050/7052,

Nixdorf 8812, ICL 9505/9507/9518.

The OCIA port on some terminals, specifically the NCR 2950, 2152 and 2257,

may not be accessible from the exterior of the unit. These terminals must be

opened and the base station cable connected to the OCIA port on the main

processor board.

Note: Some of the above terminals may also be connected as POS keyboard

wedges. See specific installation instructions beginning on page 5-6.

5-2

Page 42

LS 3070 Product Reference Guide: Interface Guide

RS-232C Single Port

RS-232C Device

Base Station

Figure 5-2. Connecting Base Station to RS-232C Single-Port Host

Any of the following RS-232C (DB 25) connectors are supported: Male, TxD on

pin 2 or TxD on pin 3. Female, TxD on Pin 2 or Pin 3. For other pinouts and

cable types, contact the Symbol Support Center at 1-800-653-5350.

RS-232C Dual Port

Host

System

(Port 1)

RS-232C Auxiliary

Device (Port 2)

Base

Station

Figure 5-3. RS-232C Dual-Port Mode

This interface involves connecting a Y-cable, for which the male connector is

Port 1 and the female connector is Port 2. For IK-1500, male = TxD on Pin 2 and

female = TxD on Pin 3. For IK-1501, male = TxD on Pin 3 and female = TxD on

Pin 2

5-3

Page 43

LS 3070 Product Reference Guide: Interface Guide

IBM 4683/4684/4693/4694

IBM 4683/4 5B, 9B, 17

IBM 4693 5B, 9B, 9C«

IBM 4694 9E

IBM 4683/84; 4693/94

Base Station

Figure 5-4. Connecting Base Station to IBM 4683/4684/4693/4694

T o connect the base station, plug the cable into the appr opriate port on the rear

of the IBM 4683/84, 4693/94.

For the IBM 4693, port 9C (which replaces port 17 on the 4683/84) is the

appropriate port for connecting the base station. Note that port 9C is

compatible with ports 9A and 9B, which have identical assignments of

connector pins.

For the IBM 4694, there is one single scanner attachment port, 9E, which is

equivalent in pin assignments to ports 9A, 9B, and 9C on the IBM 4693.

Note that this variation of port assignments over this range of models

represents electrical and mechanical changes only. For the IBM 4683/84 and

4693/94, communications between the attached scanning system and the

terminal’s operating system device driver programs remain the same.

5-4

Page 44

LS 3070 Product Reference Guide: Interface Guide

Connecting Keyboard Wedges

Terminal

Keyboard

Figure 5-5. Connecting Base Station to Keyboard Wedge

These include:

PC Keyboards

Base Station

IBM PC/AT/XT, PS2-30/50/55SX/60/70 and clones.

Terminal Keyboards

DEC VT2XX/VT3XX/4XX; HP 700/92, 2392; IBM 3178/3278/3151/316X/

3179/3180/319X, 3278, 347X; Telex-Memorex 88, 122; Wyse 50/60/85/185/

150.

T o connect the base station as a keyboard wedge, disconnect the keyboard fr om

the terminal, plug the keyboard connector into the base station cable, and plug

the other end of the cable into the terminal.

5-5

Page 45

LS 3070 Product Reference Guide: Interface Guide

IBM 3683/3684 Installation

Caution

Install cables as described below. Failure to do so may result in hardware damage.

There are four basic steps to this installation:

1. Remove the IBM 3683/84 top cover.

2. Remove the keyboard.

3. Install the cable internally or externally.

4. Replace the keyboard and top cover.

First: Remove the IBM 3683/84 Top Cover

1. Set ON/OFF switch to OFF.

2. If display is integrated, disconnect the display cable).

3. Release the front cover latches. See Figure 5-6.

• Insert a spring hook through the gap between the top cover and base at

the side of the cash register near ON/OFF switch.

• Hook the spring latch and pull it outward to release.

• Lift the cover slightly at this corner and maintain it in lifted position to

prevent it from relatching.

• Repeat this procedure and release spring latch at opposite side of the

machine.

4. Holding the cover near the front on both sides, lift front, then push toward

rear of the machine to release it from the retaining tabs.

5. Disconnect cable from connector on the right side. See Figure 5-7.

6. Remove by lifting the entire cover straight up.

Second: Remove the Keyboard

Remove the keyboard by lifting it straight up through the retaining guides.

5-6

Page 46

LS 3070 Product Reference Guide: Interface Guide

Third: Install the Cable Internally

The base station cable is installed internal to the IBM 3683/84 with the cable

exiting the rear of the terminal.

1. Remove the printer assembly as follows:

• Disconnect the printer ground strap (slide on connector) from the right

side of the printer, as shown in Figure 5-7).

• Slide the two printer locking tabs (black plastic) toward the front of the

register while pressing downward, as shown in Figure 5-8.

• Lift the printer up and out.

2. The cable to be installed is illustrated in Figure 5-9.

3. Mark an X on the side of J16 that faces the front of the terminal. Remove the

J16 connector from the keyboard connector bracket. Slide the J16 connector

under the printer mounting plate. See Figure 5-10.

4. Using a small screwdriver, remove the cable access door from the rear of

the register. Position the cable to connect J2 to J16 using the jumper PCB.

Make sure J2 and J16 are positioned so that the X and • align. (Some cables

are marked with TERM rather than •.) Use the tie wraps provided to secure

the connection. See Figure 5-11.

5. Slide J1 under the printer mounting plate to the keyboard access opening.

Pull it through the opening and secure it with the retaining clips (wher e J16

originally was). See Figure 5-12. (Some cables are marked with KBD or

Keyboard rather than •.)

6. Push the J2/J16 connection under the printer mounting plate. Replace the

cable access door at the rear of the register.

7. Replace the printer assembly as follows:

• Attach the ground strap to the right side of the assembly.

• Fasten the locking tabs by sliding them toward the rear of the register.

5-7

Page 47

LS 3070 Product Reference Guide: Interface Guide

Fourth: Replace the Keyboard and Top Cover

1. Replace the keyboard down into the retaining glides.

2. Replace the top cover as follows:

• Replace the display cable if display is integrated.

• Hold the cover so that rear slots fit into retaining tabs.

• Lower the cover at front to engage the front side latches.

You can now attach your scanner and peripheral devices.

Figure 5-6. Releasing the Front Cover Latches

5-8

Page 48

LS 3070 Product Reference Guide: Interface Guide

Figure 5-7. Disconnecting Cable from Connector

Connector

Printer Ground Strap

Figure 5-8. Sliding Printer Locking Tabs

5-9

Locking T ab

Page 49

LS 3070 Product Reference Guide: Interface Guide

Figure 5-9. Cable

Figure 5-10. J16 Connector

5-10

Page 50

LS 3070 Product Reference Guide: Interface Guide

Figure 5-11. Connecting J2 to J16

Figure 5-12. Securing J1

5-11

Page 51

LS 3070 Product Reference Guide: Interface Guide

IBM 3653 Installation

1. Be sure the IBM 3653 terminal is powered-down. Open the door over the

ribbon cartridge as shown in Figure 5-13.

2. Loosen the right side panel screw (see Figure 5-13). Grasp the right panel

at top of the rear corner; pull out to the side and push back to remove the

panel.

3. Loosen the two screws behind the top of the keyboard cover. Lift and

remove the keyboard cover. See Figure 5-14.

4. From the bottom of the register, slide the cable retaining clips until the

cables are free. From inside the register, pass the base station cable (single

end) through the power cable hole. See Figure 5-15.

Caution

Use extreme care to avoid damaging the connector pins.

5. Loosen the screw on the base of the cash register near the bottom left side

of the card cage. Swing the card cage open by pulling on the left side. See

Figure 5-16.

6. Locate the keyboard connector to check for 5 volts DC. Using a DVM,

connect the GND (-) probe to the screw that holds the keyboard to the

chassis, and connect the POS (+) probe to the 5-volt lead on the TOP ROW

of the keyboard connector , second fr om right (see Figur e 5-17). Turn on the

cash register . If the voltage is less than 5 volts, locate the voltage adjustment

hole on the power supply case behind the card cage (see Figure 5-18). Using

a flexible screw driver, adjust the potentiometer until the voltage is 5.0 to

5.1 volts. Turn off the register and remove the DVM.

7. Route cable under card cage to the front of the register.

8. Locate the keyboard connector on the keyboard and observe its orientation

while removing the connector.

9. Place shrink sleeve over the cable assembly (heat with blow dryer or heat

gun to shrink the sleeving if possible).

10. Insert the polarizing key into the top right corner socket. The polarizing

key is found in the bag containing the tie wrap.

5-12

Page 52

LS 3070 Product Reference Guide: Interface Guide

11. Remove the protective foam from the register end of the base station Ycable, and insert into the cable assembly. Place the assembly near the

bottom of the register behind the keyboard.

12. Install the keyboard connector , as shown in Figur e 5-19. Secure with the tie

wrap that doesn't have a mounting hole.

13. Locate the brass plate behind the card cage and remove the front left scr ew.

Install tie wrap between the screw and plate. Replace the screw and

tighten.

14. Loop tie wrap around the cable. Insert in slot and pull tight.

15. Close the card cage and tighten the screws.

16. Replace the keyboard cover and side panel, then tighten the screws.

You can now attach your scanner and peripheral devices.

Figure 5-13. Removing Panel

5-13

Page 53

LS 3070 Product Reference Guide: Interface Guide

Screws

Figure 5-14. Removing Keyboard Cover

Figure 5-15. Sliding Base Station Cable Through Hole

5-14

Page 54

LS 3070 Product Reference Guide: Interface Guide

Figure 5-16. Opening Card Cage

Figure 5-17. Connecting Probes

5-15

Page 55

LS 3070 Product Reference Guide: Interface Guide

Figure 5-18. Voltage Adjustment Hole

Figure 5-19. Installing Keyboard Connector

5-16

Page 56

LS 3070 Product Reference Guide: Interface Guide

NCR 280 Installation

1. Ensure that the NCR 280 is powered down and unplugged. Open the door

on the top, left-hand side and remove the two screws which fasten the steel

plate to the terminal cover. Slide the steel plate to the left to remove.

2. Remove the two round head screws from the back of the terminal. Be sur e

the doors on the left and right side of the terminal are open and that there

are no keys inserted in the locks on the front. Lift off the terminal cover.

3. Locate the card edge connector to the left of the keyboard. Mark the top

side of the connector before removing it from the keyboard.

4. Remove the four “C” clips that hold the keyboard in place. Remove the

keyboard.

5. Feed the end of the RL 470 base station cable with the 2x8 header connector

under the large capacitor mounted horizontally in the terminal power

supply. Next feed the cable between the two large vertically-mounted

capacitors then through the hole in the plate adjacent to these two

capacitors. Feed through enough cable so that the cable reaches the

terminal keyboard.

6. Mate the 2x8 header connector to the connector on the interface board.

Note that pin 10 is keyed.

7. With the component side up on the interface board, connect the card edge

connector on the interface board to the card edge on the keyboard. The

interface board will be mounted under the keyboard PC board.

8. Connect the card edge connector , removed earlier from the keyboar d, to the

interface board, with the marked side facing down.

9. Replace the keyboard with the interface board attached. Be sure the

interface board is installed so that it doesn't interfere with any cable

assemblies. Replace the “C” clips.

10. Remove any slack in the RL 470 base station cable by gently pulling it back

through the terminal power supply.

11. Using the cable tie provided, secure the base station cable to the cable

bundle near the capacitor , which is mounted horizontally appr oximately 6

1/2 in. from the rear of the terminal.

5-17

Page 57

LS 3070 Product Reference Guide: Interface Guide

12. Cut a 1-in. diameter semicircle at the bottom left of the terminal cover,

approximately 6 1/2 in. from the back of the unit, so that when the cover is

replaced, this opening fits over the cable. Be sure to file down all sharp

edges.

13. Replace the terminal cover making sure that cable fits into the opening;

secure the two screws at the back of the terminal. Replace the steel plate to

the terminal cover and secure.

You can now attach your scanner and peripheral devices.

NCR 2151 Installation

1. Be sure the NCR 2151 terminal is powered-down. Remove the terminal's

front grille by loosening the two (2) screws (turn clockwise) that fasten the

grille down to the front of the terminal. Fully extend the card slide

assembly. Disengage the catches holding the board assemblies in place.

Then gently pull out the processor board (top board) until the connectors

at the rear of the board become visible. To prevent the board from falling

through the card slide assembly, it may be necessary to support the board

assembly during this phase.

2. Locate the integrated circuit designated U109 on the processor board. Note

U109's orientation by locating its pin 1; this is crucial for the replacement

that follows.

Note: U109 is socketed. Using a small screwdriver,

remove U109 from its mating socket. Replace the

part with the Terminal Retrofit Circuit provided

with the installation kit. Be sure that the

replacement part is oriented in the same direction

as the part it replaces.

3. On the far left side of the processor board, carefully remove the connector

marked I/O P7 from its mate (J7). Take the K8 T-board connector (p/n 2102977-01) from the shipping container , and connect J1 to J7 on the processor

board. This connection mates in one direction only. As the connectors are

not keyed, be sure the connecting pair is properly aligned.

4. Locate the J3 connector on the rear right side of the processor board. If a

cable mates to J3, remove it and note its orientation, as it must be returned

to the same position later.

5-18

Page 58

LS 3070 Product Reference Guide: Interface Guide

5. Locate the end of the RL 470 base station cable that branches into a “Y”.

Slide that end under the board assembly inside the register. Leave enough

slack to make the connection required in the next few steps.

6. Mate the RL 470 base station cable “Y” branch ending in a 2 x13 female boxtype connector to P1 on the K8 T-board. Connector P1 is the middle

connector on the T-Board.

Note: Connector position 1 of the mating pair is keyed.

7. Locate connector P2 on the K8 T-boar d; it is the top connector on the board.

Mate P2 with the ribbon connector marked I/O P7. Be sure the ribbon

connector label I/O P7 faces up. Also be sure the left and right edges of the

two connectors line up. This check is very important, as the connectors are

not keyed.

8. Mate the RL 470 base station cable “Y” branch ending in a 2X6 female boxtype connector to P1 on the T-boar d (p/n 21-03428-01). Connector P1 is the

middle connector on the T-board.

Note: The connector position 1 of the mating pair is

keyed.

9. If J3 on the processor board had a cable mating to it, that cable must now

mate with connector P2 on the T-board (p/n 21-03428-01).

Note: The cable must have the same orientation it had

when removed from J3 on the processor board. If

no cable was mating with J3, then P2 on the

T-board (p/n 21-03428-01) is left unconnected.

10. Carefully slide the board assembly to its original position in the card slide.

Then return the card slide to its retracted position. Check that all cables

mating to the board assemblies are still firmly seated in position.

11. Locate the supplied cable fastener hardware. Using the hardware, secure

the RL 470 base station cable to one of the cable fastening posts located at

the bottom front edge of the terminal housing. Replace the grille removed