Page 1

FOREWORD

http://www.motorcycle.in.th

This manual con tains an intro ducto ry de scri ption o n

the SUZUKI UY125/S and procedures for its inspection/service and ov erhau l of its main com pon ents.

Other info rm ation co ns ider ed as ge ner ally kno wn is

not included.

Read the GENERAL INFORMATION section to

familiarize yourse lf with t he motorcycl e and its m aintenance. U se this s ection a s well as o ther sectio ns

to use as a guide for proper inspection and service.

This manua l will hel p you kn ow the motor cycle better so that you can assure your customers of fast

and reliable service.

GROUP INDEX

GENERAL INFORMATION

PERIODIC MAINTENANCE

ENGINE

1

2

3

* This manual has been p repared on the ba sis

of the latest specifications at the time of publication. If modifications have been made since

then, differen ces may exi st betwe en the c ontent of this manual and the actual motorcycle.

* Illustrations i n this manu al are used to show

the basic principles of operation and work

procedures. They may not represent the

actual motorcycle exactly in detail.

* This manual is wr itten for persons who h ave

enough know ledg e, s kills a nd tools, i nclud in g

special tools, for se rvicing SUZUKI motorcy cles. If you do not ha ve the proper knowledge

and tools, ask your authorized SUZUKI

motorcycle dealer to help you.

!

Inexperienced mechanics or mechanics

without the proper tools and equipment

may not be able to properly perform the

services described in this manual.

Imprope r repair may result in in jury to the

mechanic and may render the motorcycle

unsafe for th e rider and passenger.

FUEL AND LUBRICATION

SYSTEM

CHASSIS

ELECTRICAL SYSTEM

SERVICING INFORMATION

4

5

6

7

© COPYRIGHT THAI SUZUKI MOTOR CO., LTD. 2005

THAI SUZUKI MOTOR CO., LTD.

Page 2

HOW TO USE THIS MANUAL

http://www.motorcycle.in.th

TO LOCATE WHAT YOU ARE LOOKING FOR:

1. The text of this manual is divided into sections.

2. The section titles are listed in the GROUP INDEX.

3. Holding the manual as shown at the right will allow you to find

the first page of the secti on easily.

4. The contents are listed on the first page of each section to

help you find the item and page you need.

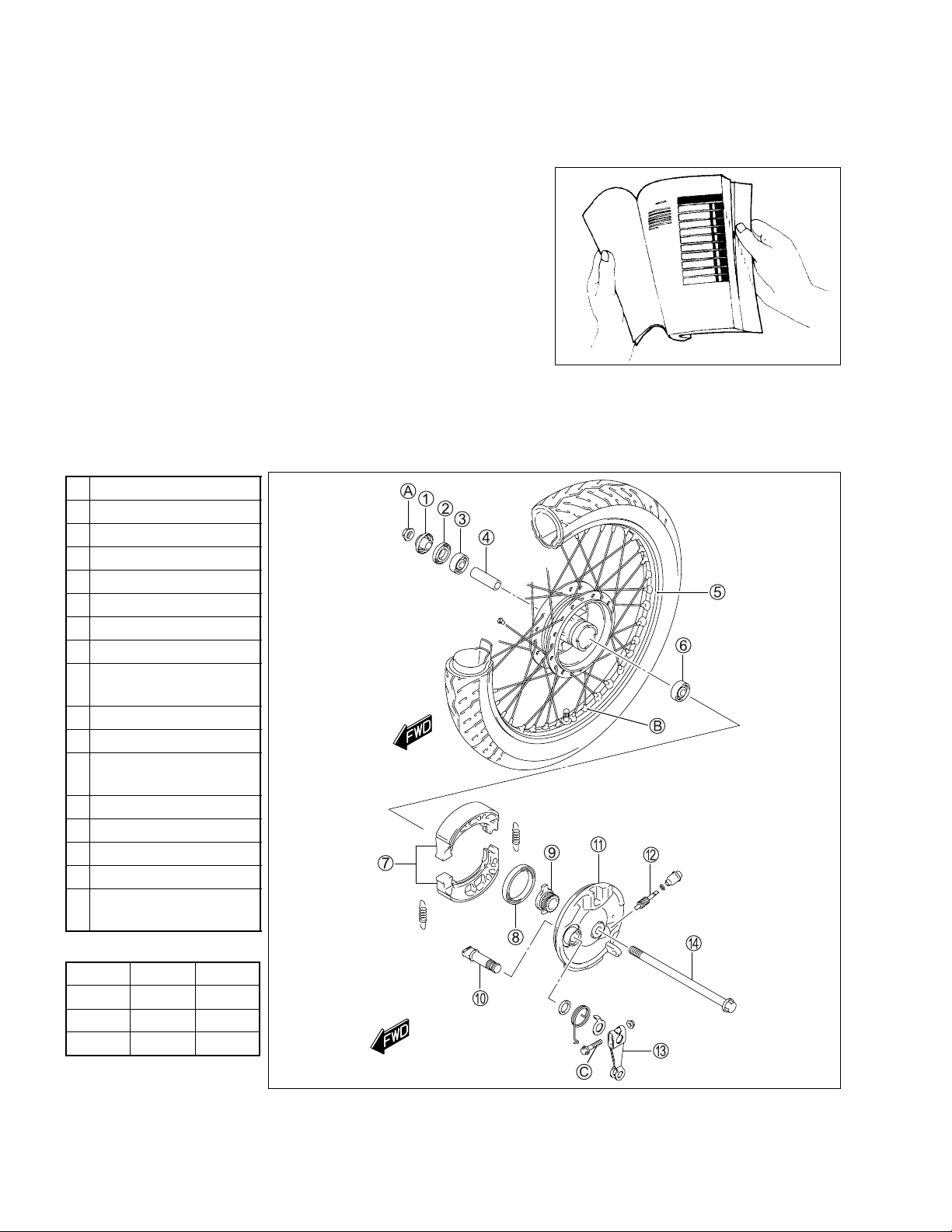

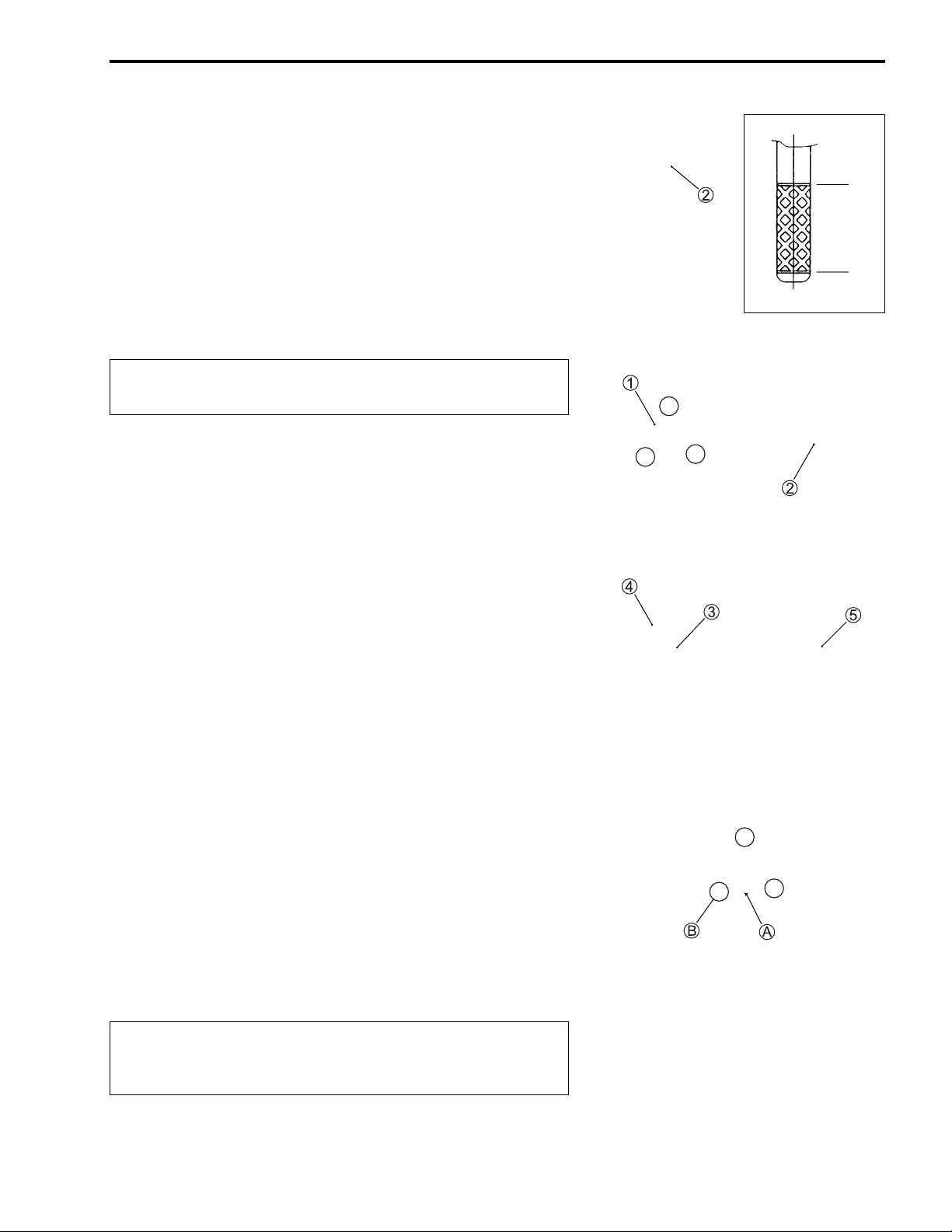

COMPONENT PARTS AND WORK TO BE DONE

Under the name of each system or unit, is its exploded view. Work instructions and other service information

such as the tightening tor que, lubricating points and locking agent points, are provided.

Example: Front wheel

1 Spacer

2 Dust seal

3 Bearing

4 Front wheel spacer

5 Front wheel

6 Bearing

7 Front brake shoe

8 Dust seal

Speedometer drive

9

gear

0 Front brake camshaft

A Front brake panel

Speedometer driven

B

gear

C Front brake cam lever

D Front axle

A Front axle nut

B Spoke nipple

Front brake cam lever

C

bolt

"

ITEM N·m kgf-m

A 42 4.2

B 4.5 0.45

C 80.8

Page 3

SYMBOL

http://www.motorcycle.in.th

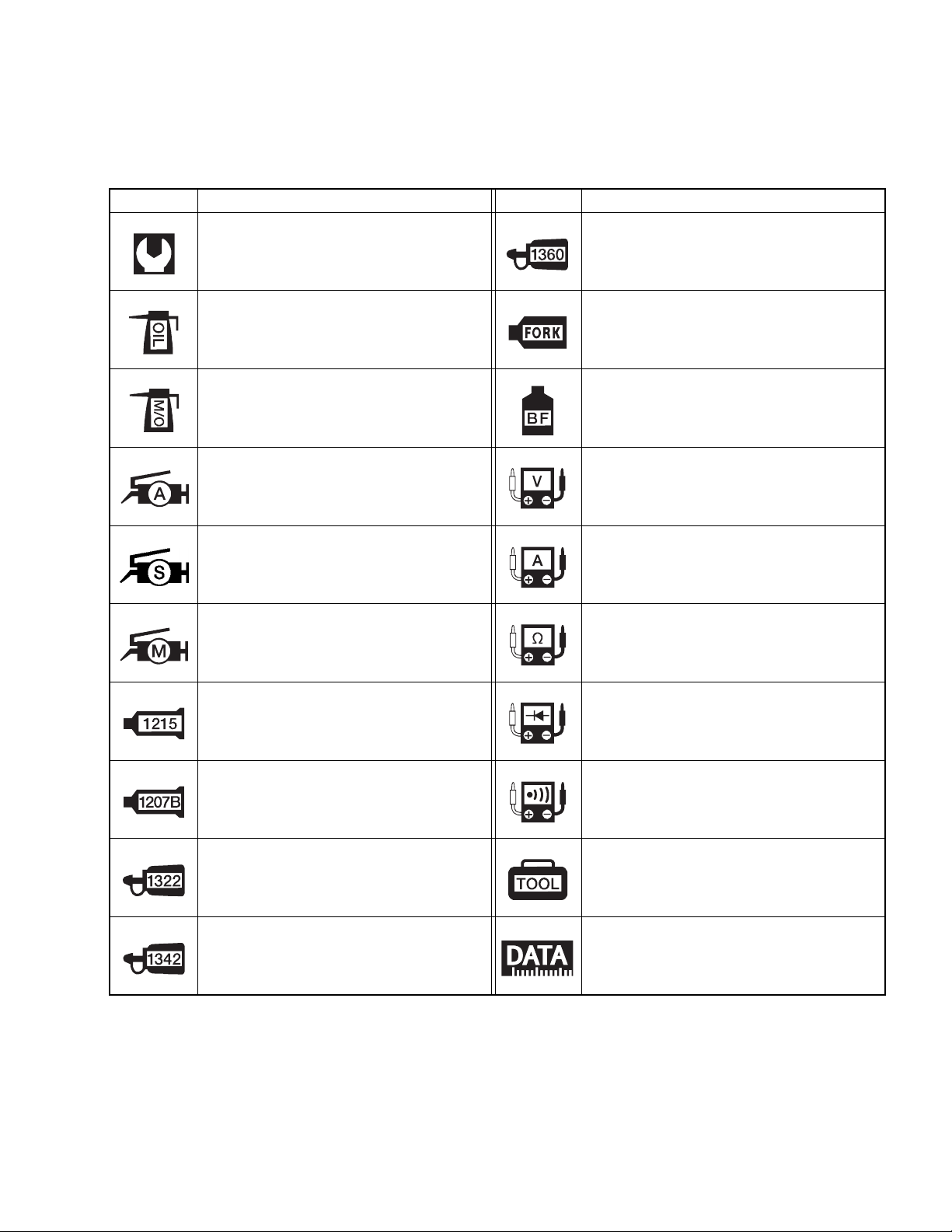

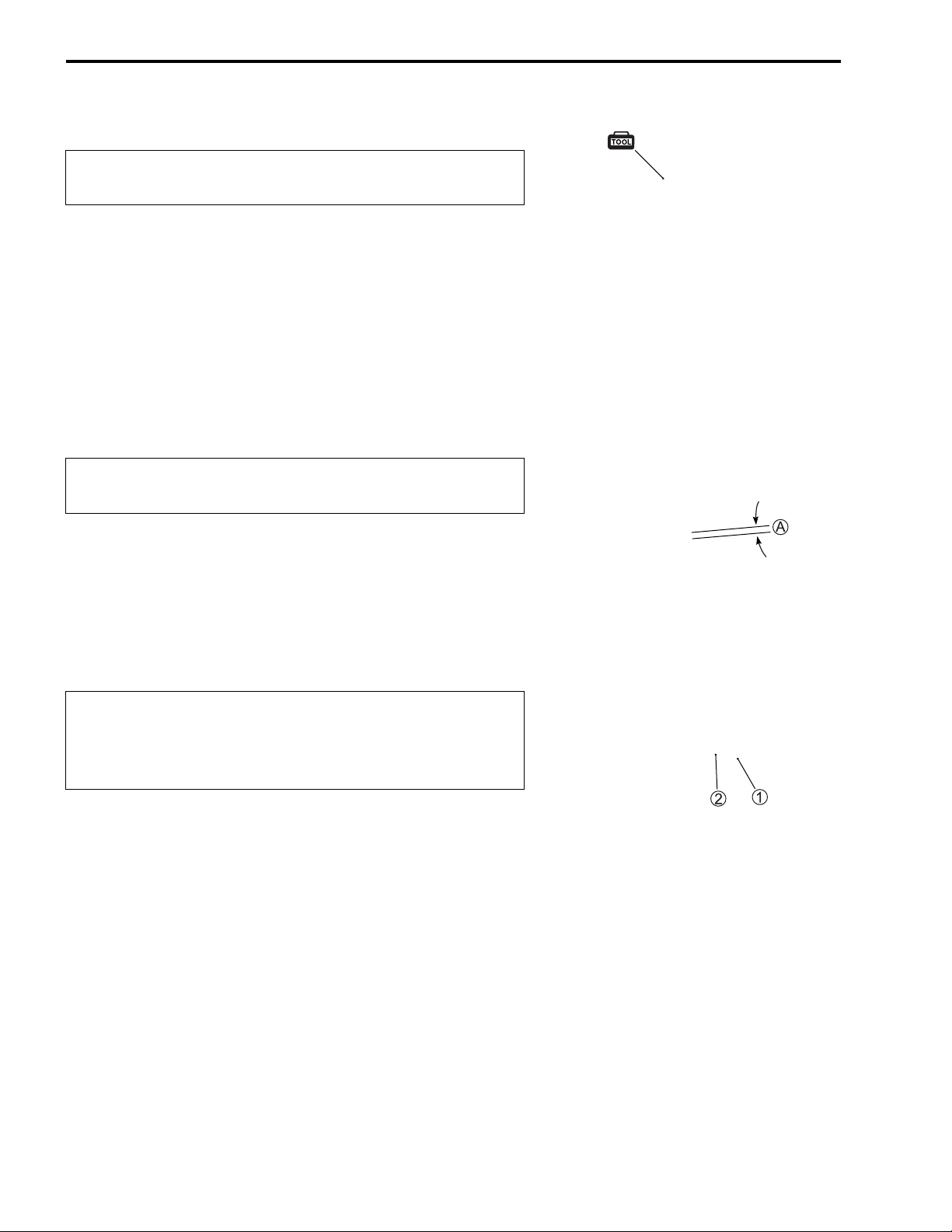

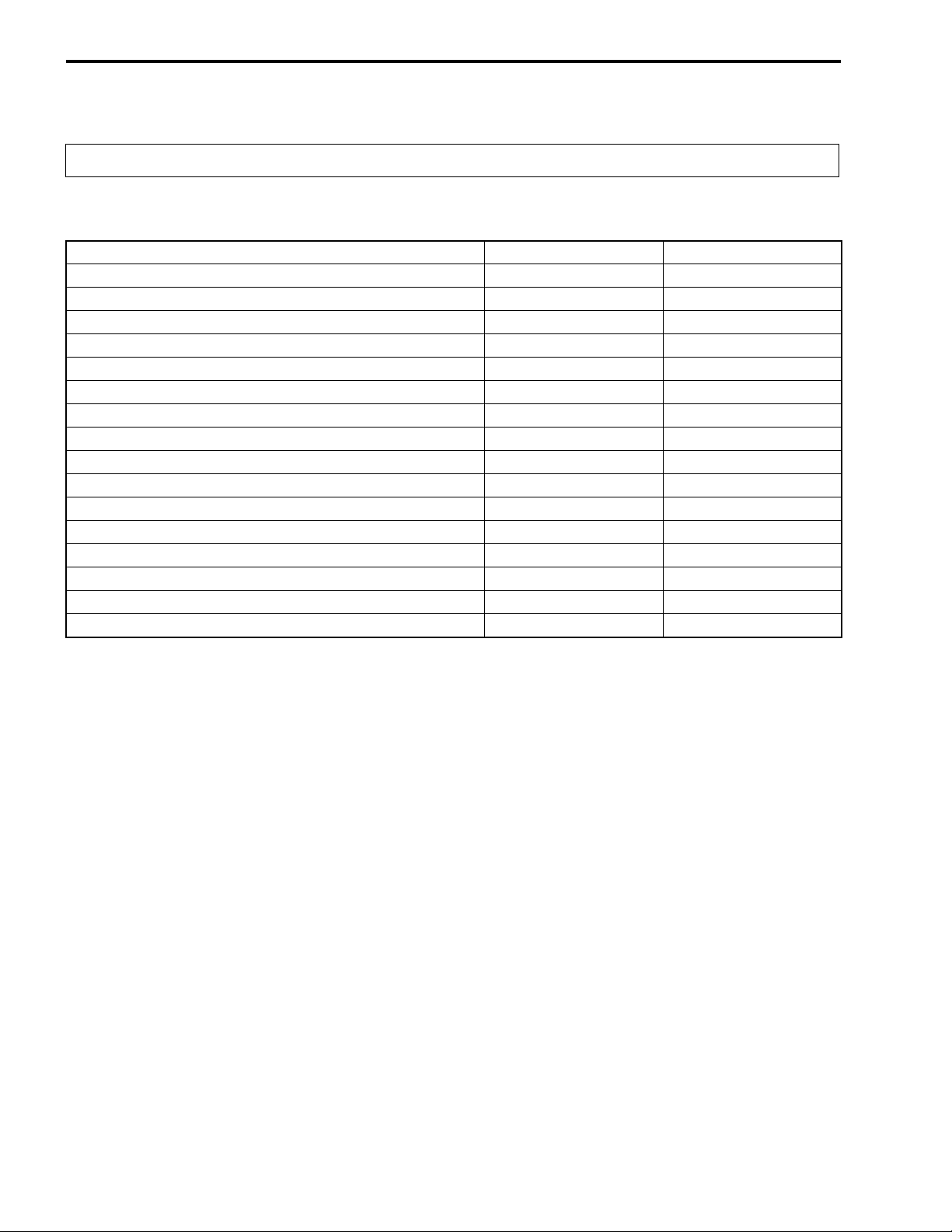

Listed in th e t able b elow ar e th e sy m bols i ndic ating ins truc tions a nd othe r in for matio n ne c essar y for ser vicing. The meaning of each symbol is also included in the table.

SYMBOL DEFINITION SYMBOL DEFINITION

Torqu e control requir ed.

Data beside it indicates specified

torque.

Apply oil. Use engine oil unless otherwise specified.

Apply molybdenum oil solution.

(Mixture of engine oil and SUZUKI

MOLY PASTE in a ratio of 1:1)

Apply SUZUKI SUPER GREASE “A”.

99000-25010

Apply SUZUKI SILICONE GREASE.

99000-25100

Apply SUZUKI MOLY PASTE.

99000-25140

Apply THREAD LOCK SUPER “1360”.

99000-32130

Use fork oil.

99000-99044-10G

Apply or use brake fluid.

Measure in voltage range.

Measure in current range.

Measure in resistance range.

Apply SUZUKI BOND “1215”.

99000-31110

Apply SUZUKI BOND “1207B”.

99000-31140

Apply THREAD LOCK SUPER “1322”.

99000-32110

Apply THREAD LOCK “1342”.

99000-32050

Measure in diode test range.

Measure in continuity test range.

Use special tool.

Indication of service data.

Page 4

White Page

http://www.motorcycle.in.th

Page 5

GENERAL INFO RMATION 1-1

http://www.motorcycle.in.th

GENERAL INFORMATION

CONTENTS

WARNING/CAUTION/NOTE.... ............... ............... .............. ............... ......... 1- 2

GENERAL PRECAUTIONS......................................................................... 1- 2

SUZUKI UY125K6/SK6 (’06-MODEL)......................................................... 1- 4

SERIAL NUMBER LOCATION................... .............. ............... ............... ..... 1- 4

FUEL AND OIL RECOMMENDATION ........................................................ 1- 5

FUEL.................... .............. ............... ............... .............. ............... ......... 1- 5

ENGINE OIL .......................................................................................... 1- 5

REDUCTION GEAR OIL ....................................................................... 1- 5

BRAKE FLUID (UY125S).. ............... ............... .............. ............... ......... 1- 5

FRONT FORK OIL................................................................................. 1- 5

BREAK-IN PROCEDURES.......................................................................... 1- 5

SPECIFICATIONS.................... ............... ............... .............. ............... ......... 1- 6

1

COUNTRY AND AREA CODES

The following codes stand for the applicable country(-ies) and area(-s).

CODE COUNTRY or AREA EFFECTIVE FRAME NO.

P-14 (UY125)

P-14 (UY125S)

Thailand

Thailand

CF48A-TH

CF48B-TH

!!!!!!

!!!!!!

–

–

Page 6

1-2 GENERAL INFORMATION

http://www.motorcycle.in.th

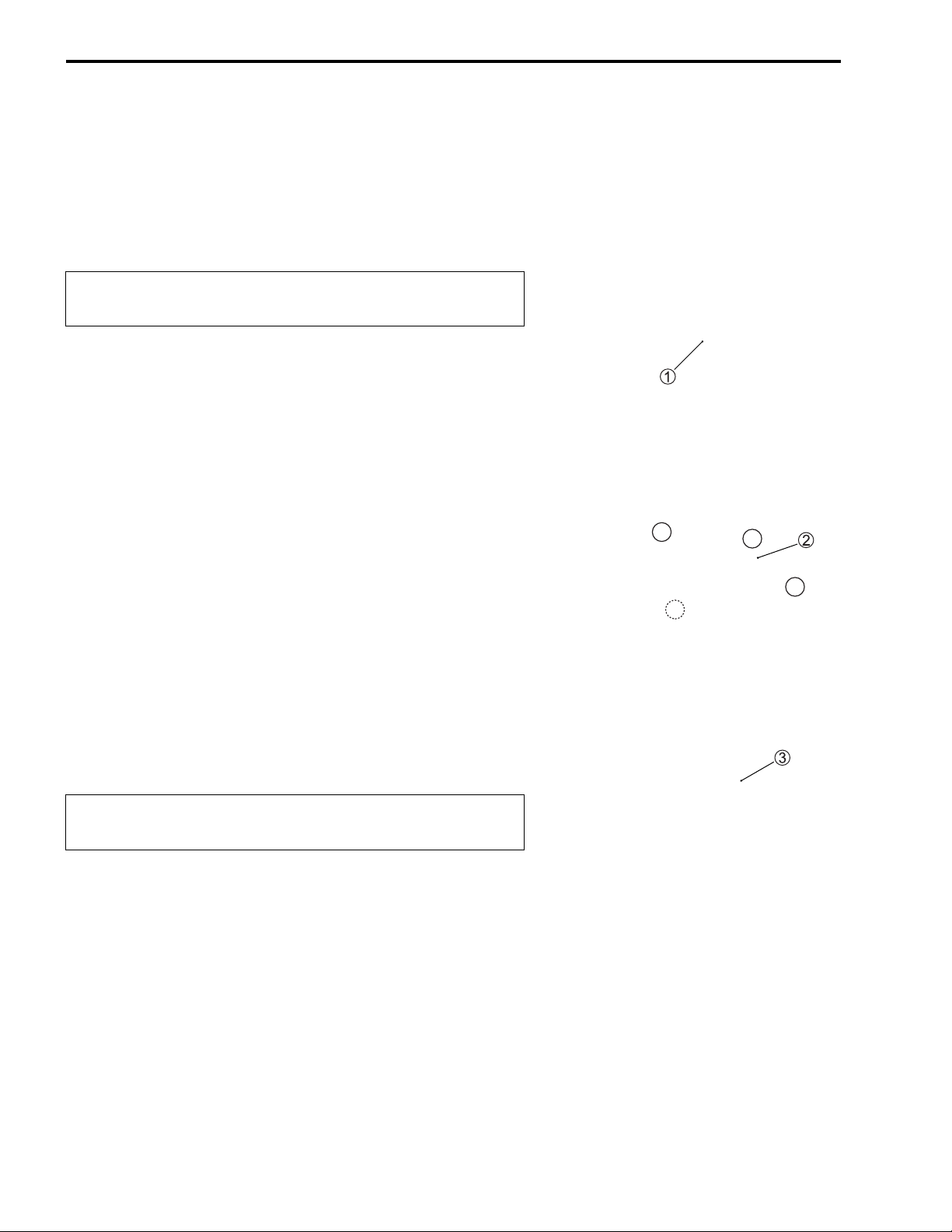

WARNING/CAUTION/NOTE

Please read thi s manua l and follow its instruc tions carefu lly. To em phasize s pecial info rmation, the symb ol

and the words WARNIN G, CA UTION and NOTE have speci al meanings . Pay sp ecial attent ion to the m essages highlighted by these signal words.

!

Indicates a potential hazard that could result in death or injury.

"

Indicates a potential hazard that could result in motorcycle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

Please note , howev er, that the warnings and cauti ons contained in this manual c annot possibly cover all

potential h azards re lating to the servic ing, or lac k of servici ng, of th e motorc ycle. In ad dition to the WARN INGS and C AU TI ONS st ated , you mu s t use goo d judg em ent and bas ic mechanical sa fety p rinc iples . If you

are unsure about how to perform a particular service operation, ask a more experienced mechanic for

advice.

GENERAL PRECAUTIONS

!

* Proper service and repair procedures are important for the safety of the service mechanic and

the safety and reliability of the motorcycle.

* When 2 or more persons work together, pay attention to the safety of each other.

* When it is necessary to run the engine indoors , make sure that exhaust gas is fo rced out-

doors.

* When workin g w ith to xic o r flam ma ble m aterial s, m ak e s ure that the area you wo rk in is well-

ventilated and that you follow all of the material manufacturer’s instructions.

* Never use gasoline as a cleaning solven t.

* To avoid getting burned, do not touch the engine, engine oil, radiato r and exhaust system

until they have cooled.

After servicing the fuel, oil, water, exhaust or brake systems, check all lines and fittings related

to the system for leaks.

Page 7

GENERAL INFO RMATION 1-3

http://www.motorcycle.in.th

"

* If parts replacement is necessary, replace the parts with Suzuki Genuine Parts or their equiva-

lent.

* When removin g pa rts th at are t o be reused , k eep t hem a rrang ed in an orderl y man n er so that

they may be reinstalled in the proper order and orientation.

* Be sure to use special tools when instructed.

* Make sure th at all parts used in reassembly are clean. Lubricate them when specified.

* Use the specified lubricant, bond, or sealant.

* When removing the battery, disconnect the negative cable first and then the positive cable.

* When recon necting the b attery, conn ect the posi tive cable first and then the negative ca ble,

and replace the terminal cover on the positive terminal.

* When performing service to electrical parts, if the service procedures do not require use of

battery power, disconnect the negative cable from the battery.

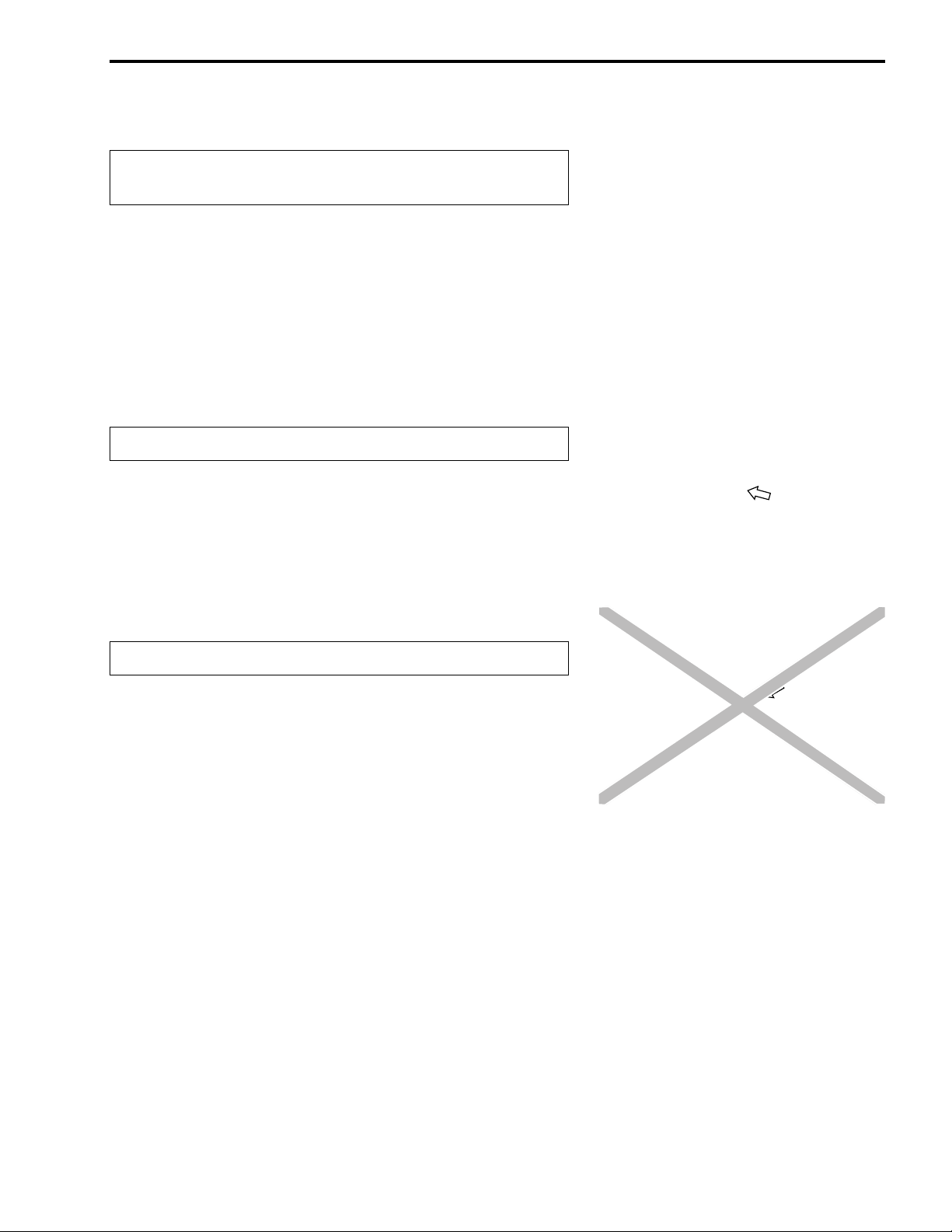

* When tightening the cylinder head or case bolts and nuts, tighten the larger sizes first.

Always tighten the bolts and nuts diagonally from the inside toward outside and to the speci-

fied tightening torque.

* Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, self-locking

nuts, cotter p ins, circlips and certain other pa rts as specified, be sure to repl ace them with

new ones. Als o, before installing these new parts, be sure to remove an y left over material

from the mating surfaces.

* Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger

than required to slip the circlip over the shaft. After installing a circlip, always ensure that it is

completely seated in its g roove and securely fitted.

* Use a torque wrench to tight en fast eners to t he spec ified torq ue. W ipe off g rease a nd oil if a

thread is smeared with them.

* After reassembling, check parts for tightness and proper operation.

* To protect the environment, do not unlawfully dispose of used motor oil and other fluids: bat-

teries and tires.

* To protect Earth’s natural resources, properly dispose of used motorcycle and parts.

Page 8

1-4 GENERAL INFORMATION

http://www.motorcycle.in.th

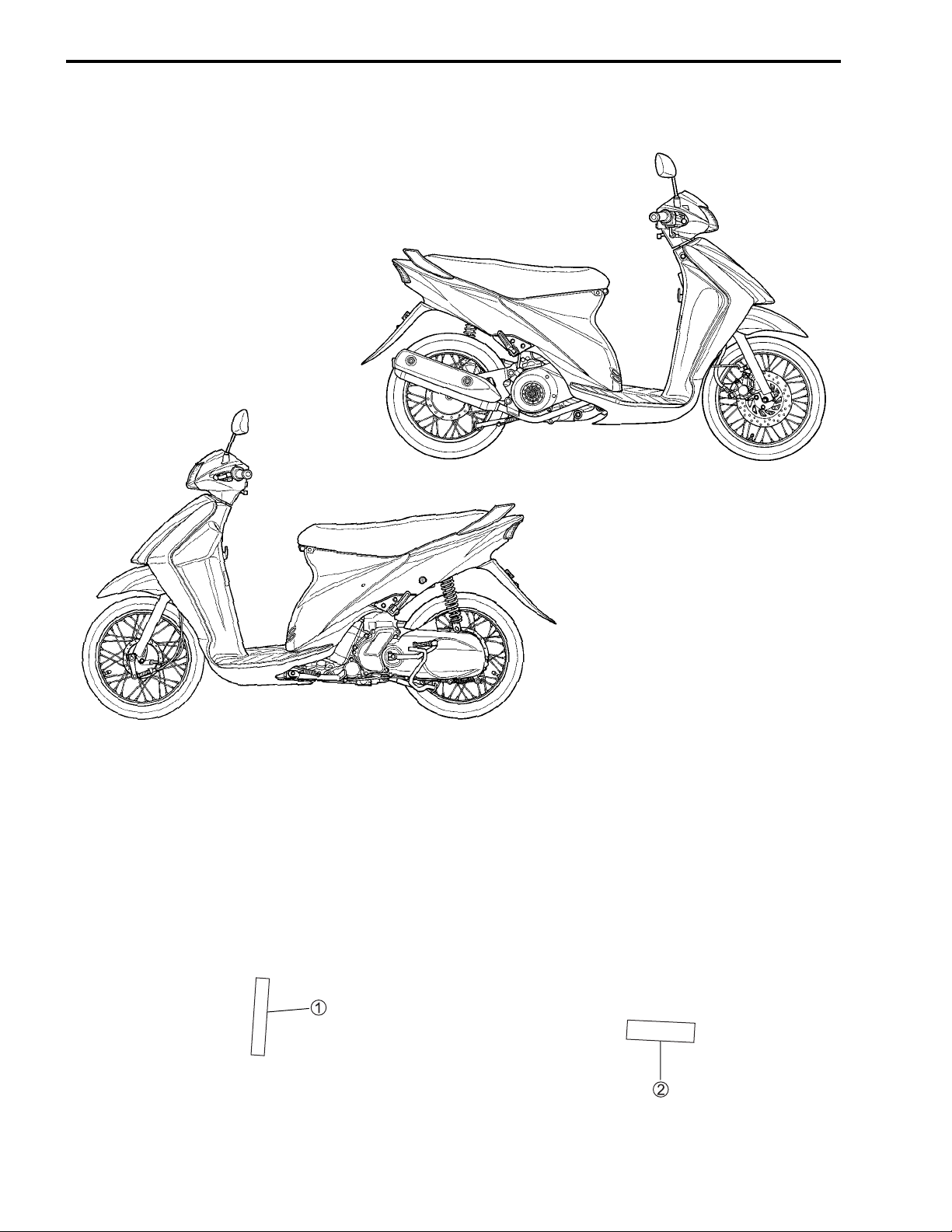

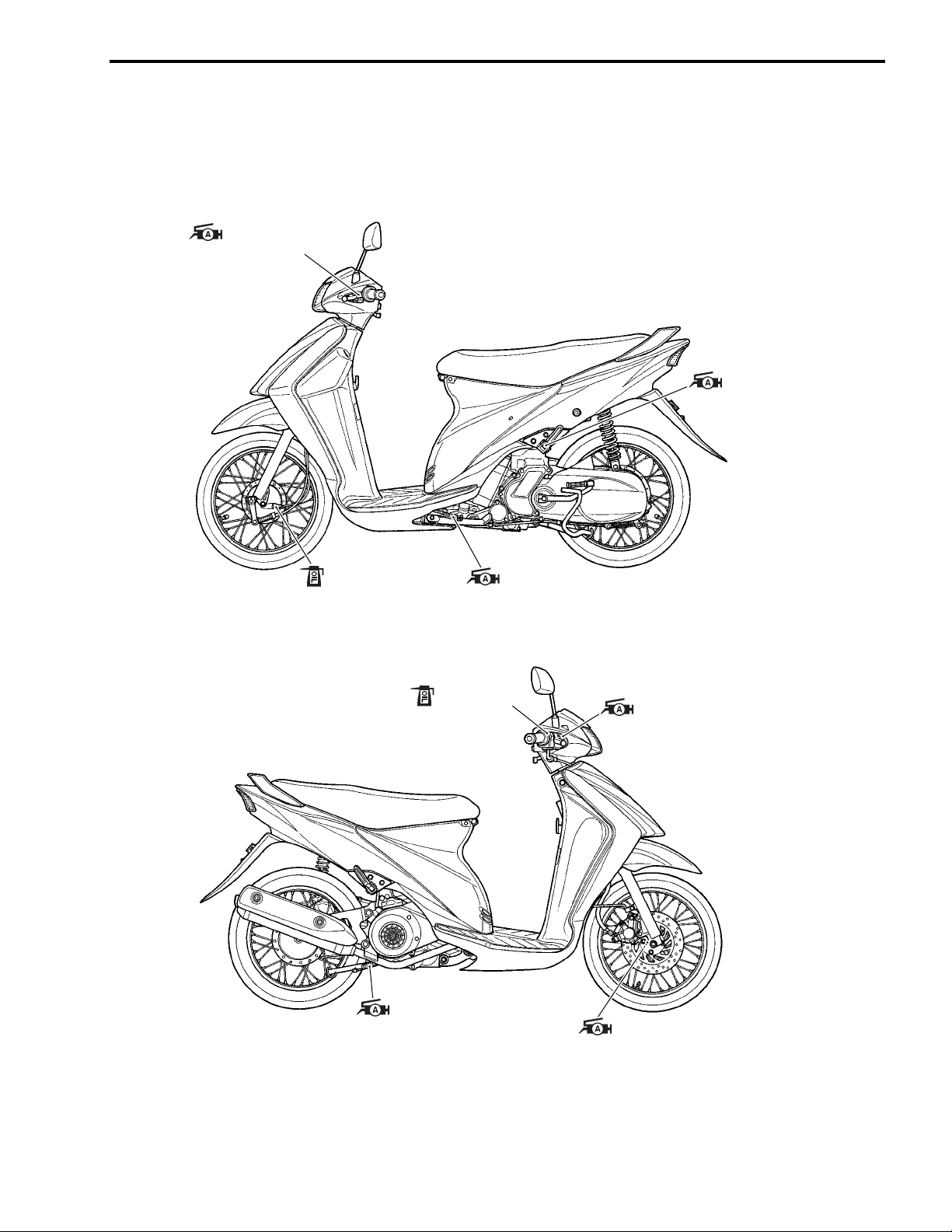

SUZUKI UY125K6/SK 6 (’06-M OD EL)

RIGHT SIDE (UY125S)

LEFT SIDE (UY125)

SERIAL NUMBER LOCATION

The frame s erial number or V.I.N. (Vehicle Identification Number) 1 is stamped on the left si de of the steering head pipe. The engine serial number 2 is loc ated on the left s ide of the crankc ase . The se num ber s are

required especially for registering the machine and ordering spare parts.

Page 9

GENERAL INFO RMATION 1-5

http://www.motorcycle.in.th

FUEL AND OIL RECOMMENDATION

FUEL

Gasoline used should be graded 91 octane (Research Method) or higher. Unleaded gasoline is recommended.

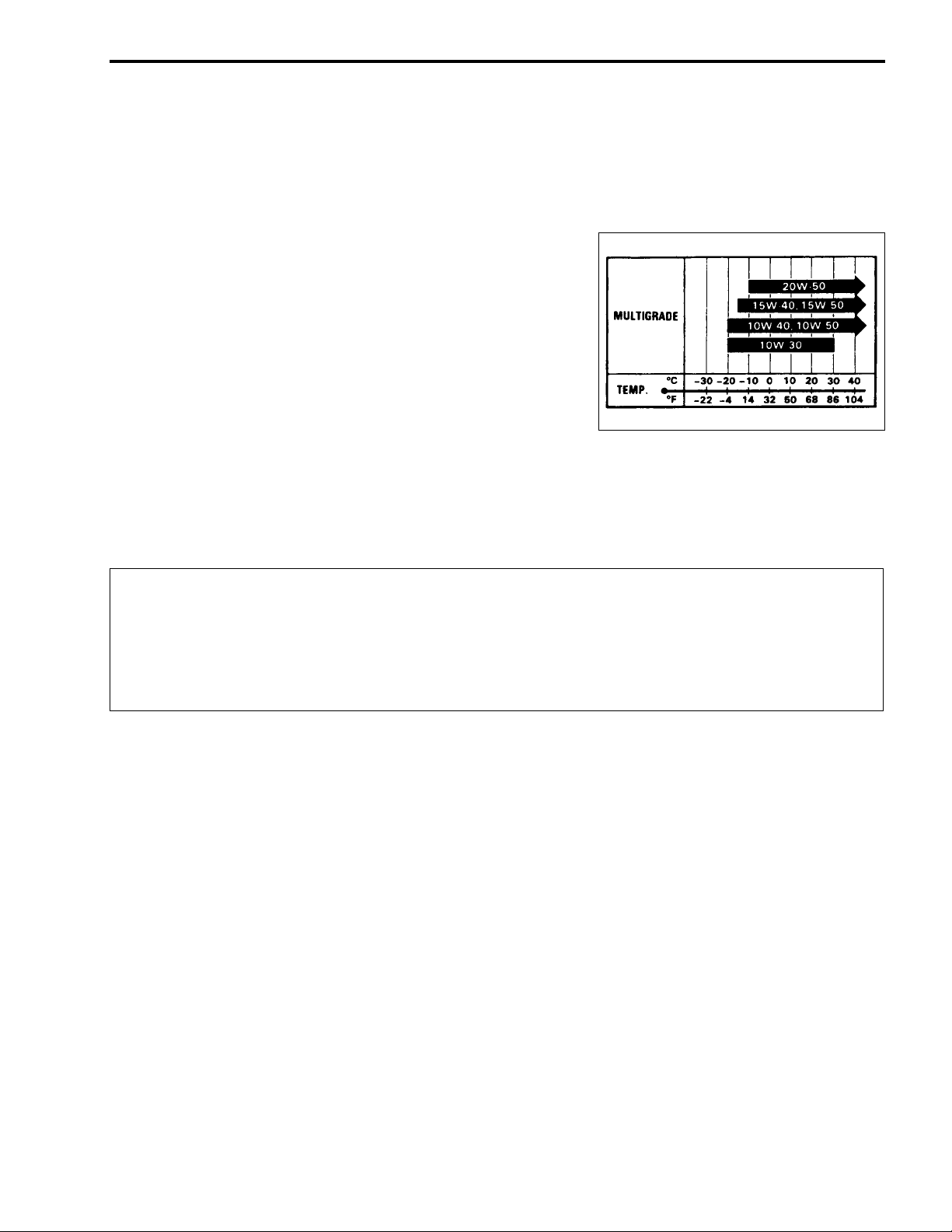

ENGINE OIL

Oil quality is a major contributor to your engine’s performance

and life . A lways sele ct g ood q uali ty e ngine o il. Us e o f SF/SG or

SH/SJ in API with MA in JASO.

Suzuki recommends the use of SAE 10W-40 engine oil. If SAE

10W-40 en gine oil is not ava ilable, sele ct an alternat ive acco rding to the right chart.

REDUCTION GEAR OIL

Use a good quality SAE 10W-40 multi-grade motor oil.

BRAKE FLUID (UY125S)

Specificat ion an d classifica tion : DOT 4

!

Since the brake system of this motorcycle is filled with a glyco l-based brake fluid by the manufacturer, do not use or mix different types of fluid such as silicone-based and petroleum-based

fluid for refilling the system, otherwise serious damage will result.

Do not use any brake fluid taken from old or used or unsealed containers.

Never re-use brake fluid left over from a previous se rvicing, which ha s been stored for a lo ng

period.

FRONT FOR K OIL

Use SUZUKI FORK OIL G10 (#10) or an equivalent fork oil.

BREAK-IN PROCEDURES

During m anu facture onl y th e be st po ssibl e mat erials a re used and all ma chined pa rts a re finis hed to a v ery

high standard but it is still necessary to allow the moving parts to “BREAK-IN” before subjecting the engine

to maximum stresses. The future performance and reliability of the engine depends on the care and restraint

exercised during its early life. Refer to the following throttle position recommendations.

• Keep to these break-in throttle positions:

Initial 800 km: Less than 1/2 throttle

Up to 1 600 km: Less than 3/4 throttle

• Upon reaching an odometer reading of 1 600 km you can subject the motorcycle to full throttle operation

for short periods of time.

Page 10

1-6 GENERAL INFORMATION

http://www.motorcycle.in.th

SPECIFICATIONS

DIMENSIONS AND DRY MASS

Overall length.......................................................................... 1 859 mm

Overall width........................................................................... 654 mm

Overall height .......................................................................... 1 046 mm

Wheelba se.............................................................................. 1 244 mm

Ground clearance ................................................................... 145 mm

Dry mass................................................................................. 94.2 kg .......... UY125

95.5 kg .......... UY125S

ENGINE

Type........................................................................................ Four stroke, forced air-cooled, OHC

Number of cylinders................................................................ 1

Bore ............................................ ............................................ 53.5 mm

Stroke...................................................................................... 55.2 mm

Displacement........................ .................................................. 124 cm³

Compression ratio................................................................... 9.6 : 1

Carburetor............................................................................... MIKUNI BS26

Air cleaner.......... ....... ............ ...... ....... ...... ...... ...... ...... ....... ...... Paper element

Starter system......................................................................... Electric and kick

Lubrication system...................... ....... ...... ...... ...... ...... ....... ...... Wet su mp

Idle speed............................................................................... 1 600 ± 100 rpm

TRANSMISSION

Clutch...................................................................................... Dry shoe, automatic, centrifugal type

Reductio n ratio........................................................................ Variable change (2.700 – 0.825)

Final reduction ratio ................................................................ 9.264 (49/17 × 45/14)

Drive system........................................................................... V-be lt drive

CHASSIS

Front suspension .................................................................... Teles copic, coil spring, oil damped

Rear suspension.................................................. ................... Swingarm type, coil spring, oil damped

Front fork stroke...................................................................... 85 mm

Rear wheel travel................................................. ................... 80 mm

Steering angle......................................................................... 45° (right and left)

Caster ..................................................................................... 25.6°

Trail......................................................................................... 100 mm

Turning radius......................................................................... 1.9 m

Front brake................................................................. ............. Drum brake.......... UY125

Disc brake............ UY125S

Rear brake .............................................................................. Drum brake

Front tire size.......................................................................... 70/90-14 M/C (34 P), tube type

Rear tire size........................................................................... 80/90-14 M/C (40 P), tube type

Page 11

GENERAL INFO RMATION 1-7

http://www.motorcycle.in.th

ELECTRICAL

Ignition t ype............................................................................. Electronic ignition (CDI)

Ignition t iming.......................................................................... 10° B.T.D.C.at 1 600 rpm

Spark plug ............. .................................................................. NGK CR6HSA or DENSO U20FSR-U

Battery..................................................................................... 12 V 12.6 k C (3.5 Ah)/10 HR

Generator................................................................................ Single-phase A.C. generator

Fuse ......... ....... ...... ...... ...... ....... ...... ...... ............ ....... ...... ...... .... 10 A

Headlight........................................ ......................................... 12 V 30/30 W

Turn signal light.................................... ................................... 12 V 10 W

Brake light/T aillight............................... ...... ...... ....... ...... ...... .... 12 V 18/5 W

Speedometer light................................................................... 12 V 3.4 W

High beam indicator light......................................................... 12 V 1.7 W

Turn signal indicator light ........................................................ 12 V 1.7 W

CAPACITIES

Fuel tank ................................................................................. 3.7 L

Engine oil, oil change ............................................................. 950 ml

with filter change................................................... 1 050 ml

overhaul................................................................ 1 100 ml

Reductio n gear oil, oil change................................................ 100 ml

overhaul .................................................. 110 ml

These specifications are subject to change without notice.

Page 12

White Page

http://www.motorcycle.in.th

Page 13

PERIODIC MAINTENANCE 2-1

http://www.motorcycle.in.th

PERIODIC MAINTENANCE

CONTENTS

PERIODIC MAINTENANCE SCHEDULE ................ ... .......................... ......... 2- 2

PERIODIC MAINTENANCE CHART .......... .......................... .............. .. 2- 2

LUBRICATION POINTS ....... ............... .............. ............... ............... ..... 2- 3

MAINTENANCE AND TUNE-UP PROCEDURES ......................................... 2- 4

AIR CLEANER ...................................................................................... 2- 4

EXHAUST PIPE BOLT AND MUFFLER MOUNTING NUT ................. 2- 5

COOLING FAN FILTER ....................................................................... 2- 5

VALVE CLEARANCE ........................................................................... 2- 6

SPARK PLUG ..... .............. ............... ............... .............. ............... ......... 2- 7

FUEL LINE ............................................................................................ 2- 8

ENGINE OIL AND OIL FILTER ............................................................ 2- 8

ENGINE IDLE SPEED .......................................................................... 2-10

THROTTLE CABLE PLAY ................................................................... 2-10

DRIVE BELT ......................................................................................... 2-11

REDUCTION GEAR BOX OIL .............................................................. 2-11

BRAKE ................................................................................................. 2-12

BRAKE HOSE AND BRAKE FLUID (UY125S) ................................... 2-13

TIRE AND WHEELS .......................................... ............... ............... ..... 2-15

STEERING ............................................................................................ 2 -17

FRONT FORK ....................................................................................... 2-17

REAR SUSPENSION ........................................................................... 2-17

CHASSIS BOLTS AND NUTS .............................. .......................... ..... 2-18

COMPRESSION PRESSURE CHECK ........................... .......................... ..... 2-20

COMPRESSION TEST PROCEDURE ............................. .................... 2-20

OIL PRESSURE CHECK ...................... ............... ............... .............. ............. 2-21

OIL PRESSURE TEST PROCEDURE ................................................. 2-21

AUTOMATIC CLUTCH INSPECTION ............................ ............... .............. .. 2-22

1. INITIAL ENGAGEMENT INSPECTION ............................................ 2-22

2. CLUTCH “LOCK-UP” INSPECTION ............................................... 2-22

2

6

Page 14

2-2 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

PERIODIC MAINTENANCE SCHEDULE

The chart below lists the recommended intervals for all the required periodic service work necessary to keep

the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilometer

and time for your convenience.

NOTE:

More frequent servicing may be performed on motorcycles that are used under severe conditions.

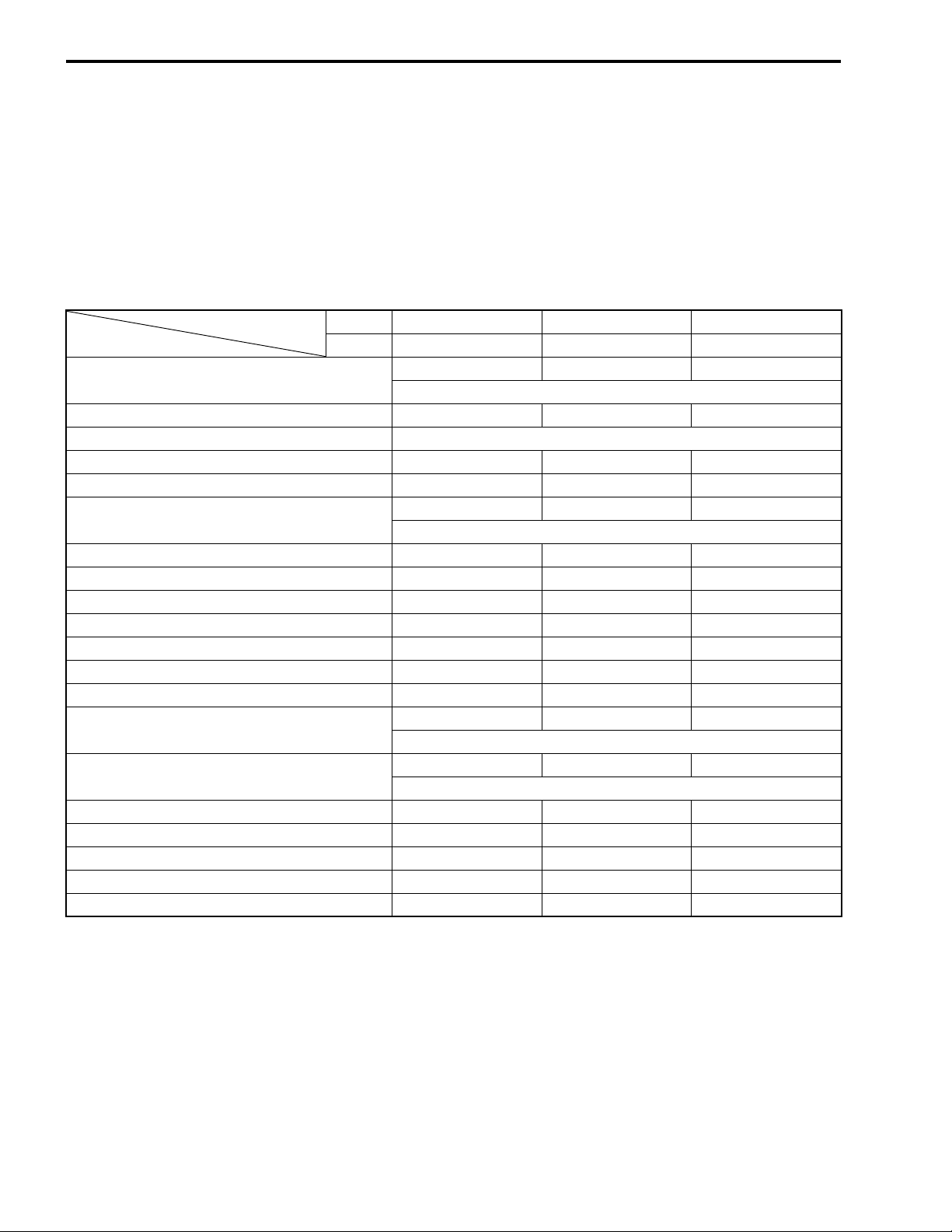

PERIODIC MAINTENANCE CHART

Interval

Item

Air cleaner

Exhaust pipe bolt and muffler bolt T — T

Cooling fan filter Clean every 3 000 km.

Valve clearance I I I

Spark plug — I R

Fuel line

Engine oil R R R

Engine oil filter R — R

Idle rpm I I I

Throttle cable play I I I

Drive belt — I I

Final reduction gear box oil — — I

Brake I I I

Brake hose (UY125S)

Brake fluid (UY125S)

Tire and wheels — I I

Steering I — I

Front fork — — I

Rear suspension — — I

Chassis bolt and nut T T T

km 1 000 4 000 8 000

months 5 20 40

—I I

Replace every 12 000 km.

—I I

Replace every four years.

—I I

Replace every four years.

—I I

Replace every two years.

NOTE:

I = Inspect and adjust, clean, lubricate or replace as necessary

R = Replace

T = Tighten

Page 15

PERIODIC MAINTENANCE 2-3

http://www.motorcycle.in.th

LUBRICATION POINTS

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle.

Major lubrication points are indicated below.

Rear brake

lever holder

Footrest pivot

Speedometer

cable

Center stand pivot

and spring hook

Side-stand pivot

and spring hook

Throttle cable

Front brake

lever holder

Speedometer

gearbox

NOTE:

* Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or grime.

* Lubricate exposed parts which are subject to rust, with a rust preventative spray whenever the motorcycle

has been operated under wet or rainy conditions.

Page 16

2-4 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

MAINTENANCE AND TUNE-UP

PROCEDURES

This section describes the servicing procedures for each item of

the Periodic Maintenance requirements.

AIR CLEANER

Inspect every 4 000 km (20 m ont hs) and rep lac e every

12 000 km thereafter.

• Place the motorcycle on the side stand.

• Remove the frame cover (left and right). (!5-10)

• Remove the hook 1.

• Remove the air cl eaner element bo x cap 2 b y removing th e

screws.

• Remove the air cleaner element 3.

• Inspect the air cleaner element for clogging.

If the a ir cleaner eleme nt is clo gge d wi th dust, r eplace th e a ir

cleaner element with a new one.

"

Do not blow the a ir cleaner el ement with com pressed

air.

NOTE:

If driving u nder dusty conditions, replace the air cleaner element

more frequently. Make sure that the air cleaner is in good condition at all times. The l ife of the e ngine depends largely on thi s

component.

• Install a new air cleaner element in the reverse order of

removal.

Page 17

• Remove the drain plug from the air cl eaner box to allow any

http://www.motorcycle.in.th

water to drain out.

EXHAUST PIPE BOLT AND MUFFLER

MOUNTING NUT

Tighten initially at 1 000 km (5 m onths) and every

8 000 km (40 months) thereafter.

• Tighten th e exhaust pipe bolts 1 and muffler mounting bolts

2.

PERIODIC MAINTENANCE 2-5

COOLING FAN FILTER

Clean every 3 000 km.

• Remove the cooling fan cover 1.

• Remove the holder 2 and cooling fan filter 3.

• Clean th e fa n f ilter in the s am e man ner o f th e a ir cl ea ner el ement.

• Reinstall the cleaned or new filter in the reverse order of

removal.

"

Do not apply engine oil to the filter after cleaning it.

Page 18

2-6 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

VALVE CLEARANCE

Inspect initially at 1 000 km (5 months) and every

4 000 km (20 month s) thereafter.

REMOVAL

• Remove the frame front cover. (!5-8)

• Remove the spark plug. (!2-7)

• Disconnect the breather hoses 1 and remove the head cover

2.

INSPECTION

The valve clearance specification is s ame for both valves. Valve

clearance adjustment must be checked and adjust ed, 1) at the

time of periodic inspection, 2) when the valve mechanism is serviced, and 3) wh en the camshaft is distur bed by removin g it for

servicing.

NOTE:

* The piston must be at (TDC) on the compression stroke in

order to check the valve clearance or to adjust valve clear-

ance.

* The clearance specification is for COLD state.

* To turn the crankshaft for clearance checking, rotate in the nor-

mal running direction. The spark plug should be removed.

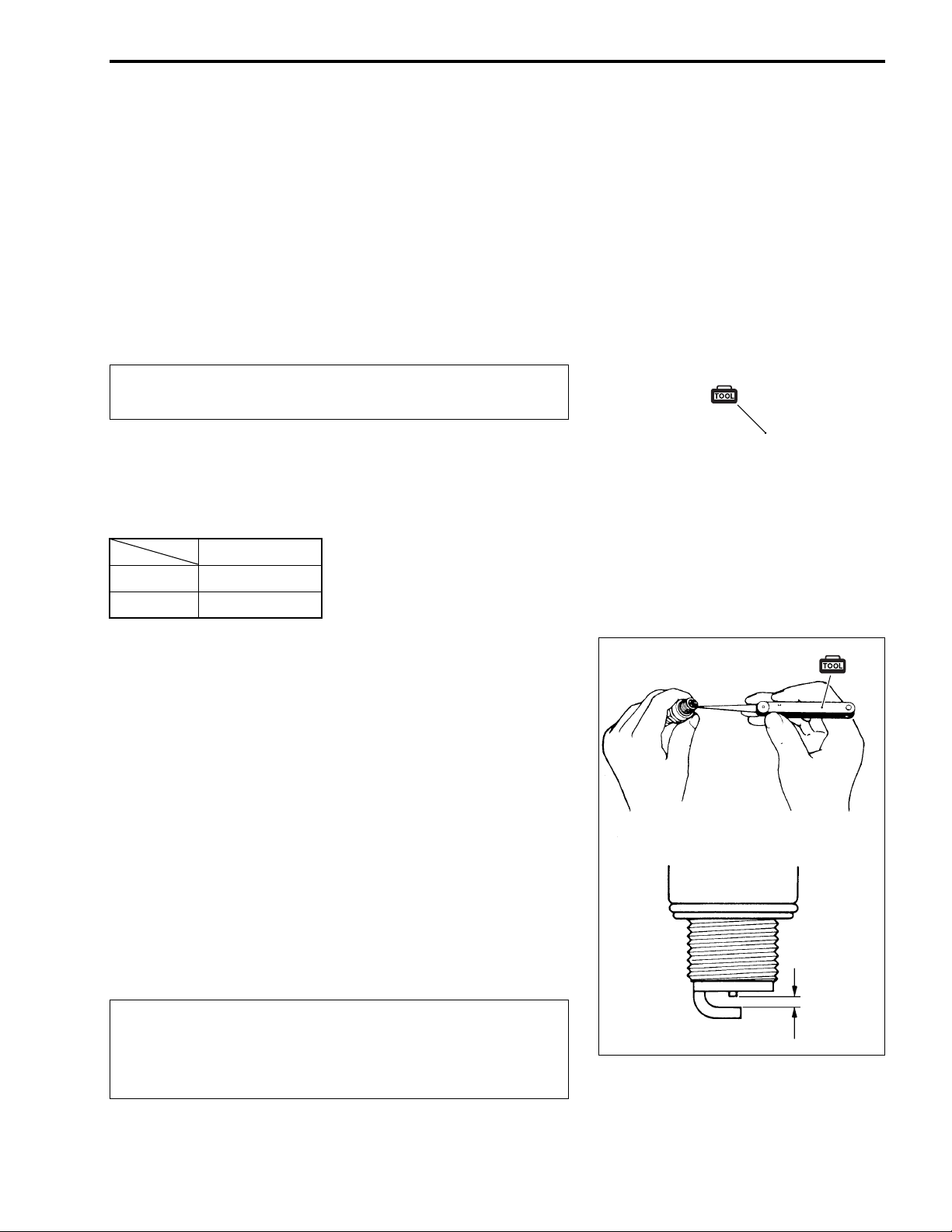

• Turn crankshaft to brin g the “TD C” mark A on the cooling fan

to the index mark B on the crankcase.

• Insert a thickness gau ge betw ee n the valve stem end and the

adjusting screw on the rocker arm.

If the clear ance is out of specifi cation, bring i t into the spe cified range.

# Valve clearance (when cold):

IN.: 0.04 – 0.07 mm

EX.: 0.10 – 0.15 mm

$ 09900-20803: Thickness gauge

09917-13210: Valve adjusting driver

Adjuster

Lock-nut

Page 19

• After finishing the valve clearance adjustment, reinstall the fol-

http://www.motorcycle.in.th

lowing items.

* Cylinder head cover (!3-11)

* Spark plug and plug cap (!2-7)

* Frame front cover (!5-8)

SPARK PLUG

Inspect at 4 000 km (20 months) and replace every

8 000 km (40 months) thereafter.

REMOVAL

• Remove the frame front cover. (!5-8)

• Disconnect the spark plug cap and remove the spark plug.

PERIODIC MAINTENANCE 2-7

$ 09930-10121: Spark plug socket wrench set

Standard

NGK CR6HSA

DENSO U20FSR-U

CARBON DEPOSIT

Check to see the carbon deposit on the plug.

If the carbon is deposite d, remove it with a spark plug cle aner

machine or carefully using a tool with a pointed end.

SPARK PLUG GAP

Measure th e plug gap with a thickness gauge if it is correct. If

not, adjust it to the following gap.

# Spark plug gap:

Standard: 0.6 – 0.7 mm

$ 09900-20803: Thickness gauge

ELECTRODE’S CONDITION

Check to see the worn or burnt condition of the electrodes. If it is

extremely worn or burnt, r eplace the plug . And als o repl ace the

plug if it has a broken insulator, damage d thread, etc.

"

Confirm the thread s ize and reac h when re placing the

plug. If the r eac h is too s hort , carb on wil l be depo sit ed

on the screw portion of the plug hole and engine damage may result.

0.6 – 0.7 mm

Page 20

2-8 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

INSTALLATION

"

Before using a spark plug wren ch, carefully turn the

spark plug by finger into the threads of the cylinder

head to prevent damage the aluminum threads.

• Install the spa rk pl ug to the cylinde r hea d by finge r tight, and

then tighten it to the specified torque.

% Spark plug: 11 N·m (1.1 kgf-m)

$ 09930-10121: Spark plug wrench set

FUEL LINE

Inspect every 4 000 km (20 months) thereafter.

Replace every 4 years.

Inspect the fuel hoses for damage and fuel leakage. If any

defects a re found, the fuel hoses must be replaced.

ENGINE OIL AND OIL FILTER

ENGINE OIL REPL ACEMENT

Replace initially at 1 000 km (5 months) and every

4 000 km (20 months) thereafter.

• Ke ep the motorcycle upright.

• Place an oil pan bel ow the engine. Drain oil by rem oving the

engine oil drain plug 1.

• Remove the oil filler cap 2.

• Tighten the engine oil drain plug 1 to the specified torque.

Pour new oil through the oil filler hole. When performing an oil

change (without oil filter replacement), the engine will hold

about 950 ml of oil. Us e an eng ine oil tha t meets AP I service

classifications SF or SG and that has a viscosity rating of SAE

10W-40.

% Engine oil drain plug 1: 18 N·m (1.8 kgf-m)

• Make sure that the engine is cooled.

• Place the motorcycle on level ground and hold it vertically.

• Install the oil filler cap 2.

• Start the engine and allow it to run for a few minu tes at idling

speed.

Page 21

• Turn off the en gine and wait minute, then check the oil level

http://www.motorcycle.in.th

by removing the filler cap 2. If the level is below mark “L”,

add oil to “F” level. (off the center stand, do not screw the filler

cap.)

If the level is above mark “F”, drain oil to “F” level.

OIL FILTER REPLACEMENT

Replace initially at 1 000 km (5 months) and every

8 000 km (40 months) thereafter.

• Drain engine oil as described in the engine oil replacement

procedure.

• Remove the oil filter cap 1 and oil filter 2.

• Replace the oil filter with a new one.

PERIODIC MAINTENANCE 2-9

F

L

• Install the spring 3 correctly.

• Apply engine oil lightly to the O-rings 4 and 5.

• Install the oil filter cap and tighten the bolts securely.

% Oil filter ca p bolt: 10 N·m (1.0 kgf-m)

NOTE:

* Before instal ling the new oil filter a nd oil filte r cap, make sure

that the spring 3 and new O-rings 4, 5 are installed correctly.

* The arrow mark A on the oil filter cap should be positione d

down.

* Fit the clamp to the bolt B.

• Add new engine oil and c heck the oil level as described in the

engine oil replacement procedure.

# Oil viscosity and classification:

10W-40 (SAE)/SF or SG (API)

# NECESSARY AMOUNT OF ENGIN E OIL

Oil change : 950 ml

Oil and filter change : 1 050 ml

Engine overhaul : 1 100 ml

"

Make sure t hat the o il filter i s install ed prop erly. If th e

filter is installed improperly, serious engine damage

may result.

OIL SUMP FILTER CLEANING (!3-19 and -57)

Page 22

2-10 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

ENGINE IDLE SPEED

Inspect initially at 1 000 km (5 months) and every

4 000 km (20 month s) thereafter.

NOTE:

Make this adjustment when the engine is hot.

• Connect an electric tachometer.

• Start up the en gine and set its sp eed at anywhere between

1 500 and 1 700 rpm by turning throttle stop screw.

Engine idle speed: 1 600 ± 100 rpm

$ 09900-26006: Tachometer

THROTTLE CABLE PLAY

Inspect initially at 1 000 km (5 months) and every

4 000 km (20 month s) thereafter.

Adjust the throttle cable play A with the following proced ure s.

• Loosen the l ock-nut 1 of the throttle cable.

• Turn the adjus ter 2 in or out until the throttle cable play A

should b e 2.0 – 4.0 mm at the throttle grip.

• Tighten the lock-nut 1 while holding the adjuster 2.

Throttle cable play A: 2.0 – 4.0 mm

&

After the a djustmen t is co mpleted , chec k that h andlebar movement does not raise the engine idle speed

and that the throttle grip returns smoothly and automatically.

NOTE:

Major adjus tment can be made by the carburetor side adjuster.

Page 23

DRIVE BELT

http://www.motorcycle.in.th

Inspect every 4 000 km (20 months) thereafter.

• Keep the motorcycle upright.

• Remove the clutch cover. (!3-10)

• Check the c on tact sur face f or cr ack or othe r d ama ge. If crack

or other damage exists, replace the b elt with a new one.

"

If grease or oil is p rese nt on the surfa ce, d ec reas e the

belt thoroughly.

• Install the clutch cover. (!3-72)

NOTE:

Drain water from the clutch cover by removing the drain bolt A.

PERIODIC MAINTENANCE 2-11

REDUCTION GEAR BOX OIL

Inspect every 8 000 km (40 months) thereafter.

• Keep the motorcycle upright.

• Place an oil pan bel ow the ge ar case , and drain oil by r emo ving the oil drain plug 1 and fil ler cap 2.

• Tighten the drain plug 1, and pour fresh oil through the o il

filler.

Oil viscosity and classific ation: SAE 10 W-40 with SF or SG

NECESSARY AMOUNT OF REDUCTION GEAR OIL

Oil change: 100 ml

Overhaul: 110 ml

Page 24

2-12 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

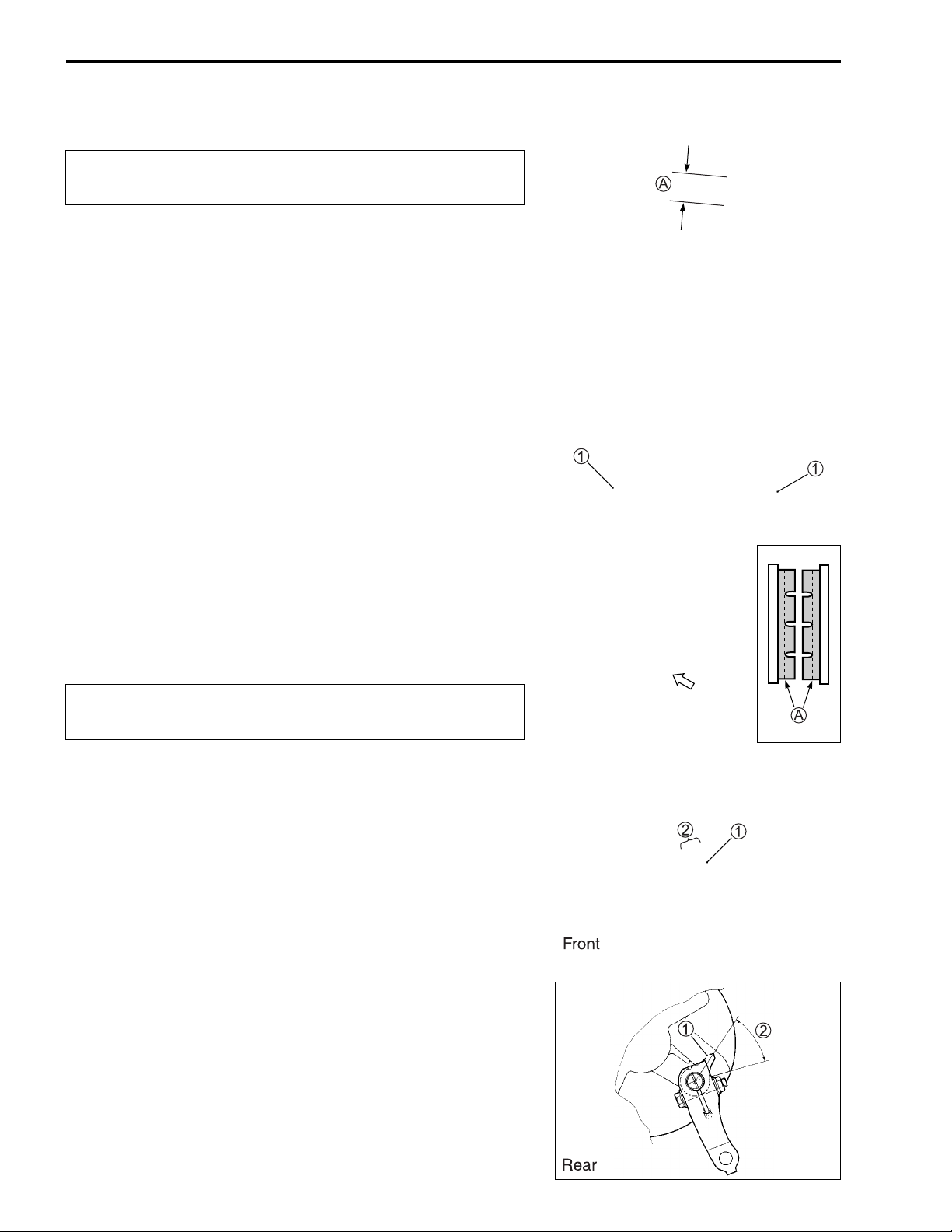

BRAKE

Inspect initially at 1 000 km (5 months) and every

4 000 km (20 month s) thereafter.

BRAKE LEVER PLAY

• Adjust the brake lever play by turning the adjusting nut 1 so

that the play A is 15 – 25 mm as shown.

# Brake lever play A: 15 – 25 mm

FRONT BRAKE PADS (UY125S)

The extent o f brake pad wear can be checke d by obse rving the

grooved limit line A on the brake pad . When t he wear ex ceeds

the grooved limit line, replace the pads with new ones.

(!5-25)

"

Replace the brake pads as a set, otherwise braking

performance will be adversely affected.

BRAKE SHOW WEAR

This motorcycle is equipped with the brake lining wear limit indicator on the brake.

To check wear of the brake lining, perform the following steps:

• First, check if the brake system is properly adjusted.

• While operating the brake, check to see tha t the tip of indic ator 1 is within the range 2 on the brake panel.

• If the tip of indicator 1 is beyond the ran ge, the brake shoe

assembly should be replaced with a new set of shoe.

(!5-13 and -49)

Page 25

BRAKE HOSE AND BRAKE FLUID (UY125S)

http://www.motorcycle.in.th

Inspect every 4 000 km (20 months).

Replace hoses every 4 years. Replace fluid every 2

years.

BRAKE HOSE

Check the brake hose for leakage, cracks, wear and damage. If

any damages are found, replace the brake hose with a new one.

PERIODIC MAINTENANCE 2-13

BRAKE FLUID LEVEL CHECK

• Keep the motorcycle upright and place the handlebars

straight.

• Check the brake flu id level relativ e to the low er limit li nes on

the front brake fluid reservoirs.

• When the level is below the lower limit line, replenish with

brake fluid that meets the following specification.

' Specification and classification: DOT 4

&

* The brake sys tem of this motorcyc le is filled with a

glycol-based brake fluid. Do not use or mix different

types of fluid such as silicone-based and petroleum-based fluids. Do not use any brake fluid taken

from old, used or unsealed containers. Never re-use

brake fluid left over from the last servicing or stored

for a long period of time.

* Brake fluid, if it leaks, will int erfere with safe runn ing

and immediately discolor painted surfaces. Check

the brake ho ses and h ose joi nts for crac ks and f luid

leakage before riding.

Page 26

2-14 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

FRONT BRAKE FLUID REPLACEMENT

• Remove the handlebar cover . (!5-5)

• Place the motorcycle on a level surface and keep the handlebar st ra ig h t.

• Remove the front master cylinder reservoir cap and diaphragm.

• Suck up the old brake fluid as much as possible.

• Fill the reservoir with new brake fluid.

' Specification and classification: DOT 4

• Connect a clear hose 1 to the air bleeder valve and insert the

other end of the hose into a receptacle.

• Loosen the a ir bleeder valve and pump the brake lever unt il

the old brake fluid is compl etely out of the brake system.

• Close the air bleeder valve and disconnect the clear hose. Fill

the reservoir with new brake fluid to the upper end of the

inspection window.

% Air bleeder valve: 7.5 N·m (0.75 kgf-m)

AIR BLEEDING FOR THE FRONT BRAKE FLUID CIRCUIT

Air trapped in the fluid circuit acts like a cushion to absorb a

large proport ion of the pressu re developed by the master cylinder and thus inte rferes with the full brak ing performance of th e

brake calipe r. The presence of air is indicated b y “sponginess”

of the brake lever and also by lack of brak ing for ce. Con s iderin g

the dange r to whic h such trapped a ir exp oses the m achine and

rider, it is es sential that , after remou nting the br ake and resto ring the brake system to the normal condition, the brake fluid circuit be purged of air in the following manner:

• Fill up the master cylinder reservoir to the “UPPER” line.

Place the reservoir cap to prevent entry of dirt.

• Connect a clear hos e 1 to the air bleeder valv e, and insert

the free end of the pipe into a receptacle.

• Front brake: Bleed the air from the air bleeder valve.

Page 27

• Squeeze an d release the brake lever sever al times in rapid

http://www.motorcycle.in.th

succession and squeeze the lever fully without releasing it.

Loosen the bleeder valve by turning it a quar ter of a turn so

that the brake fluid runs into the receptac le; this will remove

the tension o f the brake l ever causing it to touch th e handlebar grip. Th en, close th e valve, pu mp and s queeze the lever,

and open the valve.

Repeat this pr ocess unti l the fluid flow ing into the recepta cle no

longer contains air bubbles.

NOTE:

Replenish the brake fluid in the reservoir as necessary while

bleeding the brake system. Make sure that there is alw ays some

fluid visible in the reservoir.

• Close the bleeder valve, and disconnect the clear hos e.

% Air bleeder valve: 7.5 N·m (0.75 kgf-m)

Fill the reservoir with brake fluid to the “UPPER” line.

PERIODIC MAINTENANCE 2-15

"

Handle brake fluid with care: the fluid reacts chemically with paint, plastics, rubber materials and so on.

TIRE AND WHEELS

TIRE TREAD CONDITION

Inspect every 4 000 km (20 months).

Operating the motorcycle with excessively worn tires will

decrease riding stability and consequently invite a dangerous

situation. It is highly recommended to replace a tire when the

remaining depth of the tire tread reaches the following specification.

$ 09900-20805: Tire depth gauge

# Tire tread depth:

Service Limit: FRONT:1.6 mm

R EAR: 1.6 mm

Page 28

2-16 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

TIRE PRESSURE

If the tire pressure is too high or too low, steering will be

adversely aff ected and tire we ar will incre ase. Therefore , maintain the correct tire pressure for good ro adability and a longer

tire life. Co ld inflation tire pressure is as follows.

COLD INFLATION

TIRE PRESSURE

kPa kgf/cm

2

FRONT 175 1.75

REAR 225 2.25

"

The standard tire fitted on this motorcycle is a 70/

90-14M/C 34 P for the front and a 80/90-14M/C 4 0P for

the rear. The use of tires other than those specified

may cause instability. It is highly r ecommended to use

the specified tires.

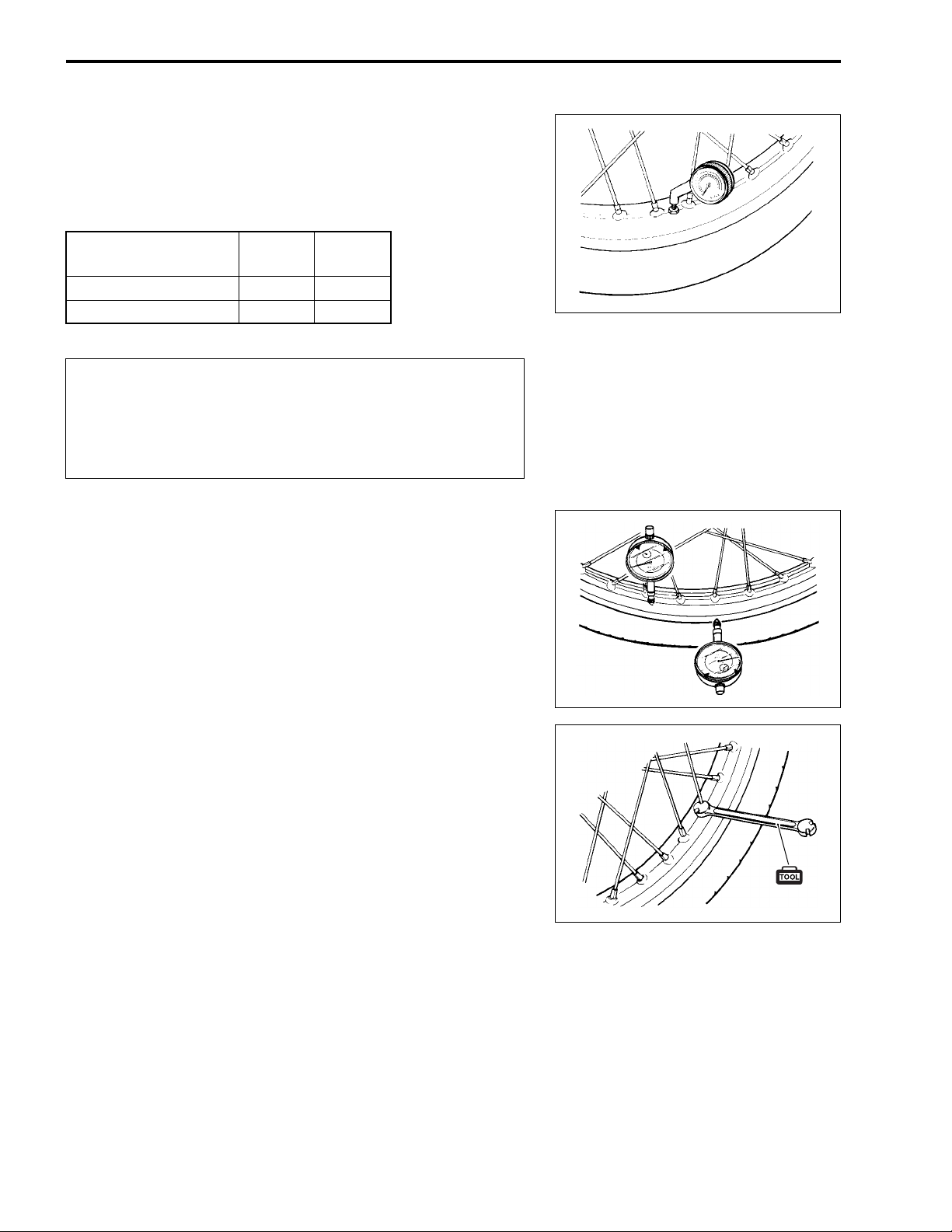

WHEEL

Make sure that the wheel runout (axial and radial) does not

exceed the service limit when checked as shown. An excessive

amount of runout is usually due to worn or loose wheel bearings

and can be corrected by replacing the bearings. If bearing

replacement fails to reduce the runout, replace the wheel.

# Wheel runout

Service Limit (axial and radial): 2.0 mm

SPOKE NIPPLES

Make sure t hat the nippl es are tight . If necess ary, tighten them

with a spoke nipple wrench.

% Spoke nipple: 4.5 N·m (0.45 kgf-m)

$ 09940-60113: Spoke nipple wrench

Page 29

STEERING

http://www.motorcycle.in.th

Inspect initially at 1 000 km (5 months) and every

8 000 km (40 month s) thereafter.

The steerin g should be adjusted pr operly for smooth tu rning of

handlebars and safe operation. Overtight steering prevents

smooth turning of the handlebars and too loose steering will

cause poor stability. Check that there is no play in the front fork.

Support th e mo torc ycle so that the fr on t wh eel i s off the gr oun d.

With the whee l fa cing st raigh t ahe ad, grasp the low er fork tu bes

near the axle and pull forward. If play is found, readjust the

steering. (!5-46)

FRONT FOR K

Inspect every 8 000 km (40 months).

Inspect the front forks for oil leakage, scoring or scratches on

the outer surface of the inner tubes. Replace any defective

parts, if necessary. (!5-34)

PERIODIC MAINTENANCE 2-17

REAR SUSPENSION

Inspect every 8 000 km (40 months).

Inspect the rear shock absorber for oil leakage and mounting

rubbers including engine mounting for wear and damage.

Replace any defective parts, if necessary. (!5-53)

Page 30

2-18 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

CHASSIS BOLTS AND NUTS

Tighten in itially at 1 000 km (5 months) and every 4 000 km (20 months) thereafter.

Check that all chassis bolts and nuts are tightened to their specified torque. (Refer to page 2-19 for the locations of the following bolts and nuts on the motorcycle.)

ITEM N·m kgf-m

1 Handlebar clamp bolt 60 6.0

2 Steering stem lock-nut 90 9.0

3 Front fork clamp bolt 28 2.8

4 Front fork cap bolt 33 3.3

5 Front axle nut 42 4.2

6 Engine mounting nut 85 8.5

7 Rear axle nut 120 12.0

8 Front brake caliper mounting bolt (UY 125 S) 25 2.5

9 Front brake hose union bolt (UY125S) 23 2.3

0 Front brake disc bolt (UY125S) 23 2.3

A Air breeder valve (UY125S) 7.5 0.75

B Front brake master cylinder bolt (UY125S) 10 1.0

C Rear shock absorber mounting nut (Upper & Lower) 29 2.9

D Front brake cam lever nut (UY125) 8 0.8

E Rear brake cam lever nut 11 1.1

F Spoke nipple 4.5 0.45

Page 31

PERIODIC MAINTENANCE 2-19

http://www.motorcycle.in.th

Page 32

2-20 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

COMPRESSION PRESSURE CHECK

The compression pressure reading of a cylinder is a good indicator of its internal condition.

The decis ion to o verhau l the c ylinder i s often b ased on th e results o f a c ompre ssion te st. Period ic mai ntenance records kept at your dealership should include compression readings for each maintenance service.

COMPRESSION PRESSURE SPECIFICATION

Standard Limit

750 – 1 200 kPa

(7.5 – 12 kgf/cm²)

Low compression pressure can indicate any of the following conditions:

* Excessively worn cylinder walls

* Worn piston or piston rings

* Piston rings stuck in grooves

* Poor valve seating

* Ruptured or otherw ise defective cylinder head gasket

NOTE:

When the compression pressure goes below specification, check the engine for conditions listed above.

650 kPa

(6.5 kgf/cm²)

COMPRESSION TEST PROCEDURE

NOTE:

* Before testing the engine for compression pressure, make

sure that the cylinde r head nuts are tightened to the sp ecified

torque values and the valves are prope rly adjusted.

* Warm up the engine before testing.

* Make sure that the battery is fully-charged.

Remove th e relate d parts a nd test t he compr ession pressure in

the following manner:

• Remove the spark plug. (!2-7)

• Install the compression gauge and adap tor in th e spark p lug

hole. Make sure that the connection is ti ght.

• Keep the throttle grip in the fully opened position.

• Press the starter button and crank th e engine for a fe w seconds. Record the maximum gauge reading as the cylinder

compression.

$ 09915-64512: Compression gauge

09915-63311: Adaptor

Page 33

PERIODIC MAINTENANCE 2-21

http://www.motorcycle.in.th

OIL PRESSURE CHECK

Check the oil pressure periodically. This will give a good indication of the condition of the moving parts.

OIL PRESSURE SPECISFICATION

18 – 40 kPa (0.18 – 0.40 kgf/cm²) at 3 000 rpm, Oil temp. at 60 °C.

If the oil pressure is lower or higher than specification, the following causes may be considered.

LOW OIL PRESSURE

* Clogged oil filter

* Oil leakage from the oil passage

* Damaged O-ring

* Defective oil pump

* Combination of the above items

HIGH OIL PRESSURE

* Engine oil viscos ity is too high

* Clogged oil passage

* Combination of the above items

OIL PRESSURE TEST PROCEDURE

• Connect a tachometer to the high-tension cord.

• Remove the main oil gallery plug 1.

• Install the oil pressure gauge and adaptor into the main oil

gallery.

• Warm u p the engine as follows:

Summer:10 minutes at 2 000 rpm

Winter: 20 minutes at 2 000 rpm

• After warming up the engine, increase the engine speed to

3 000 rpm (observe the tachometer), and read the oil pressure gauge.

$ 09915-74511: Oil pressure gauge

09915-74531: Adaptor

09900-26006: Tachometer

% Main gallery plug: 12 N·m (1.2 kgf-m)

Page 34

2-22 PERIODIC MAINTENANCE

http://www.motorcycle.in.th

AUTOMATIC CLUTCH INSPECTION

This motor cycle is equipped w ith an automatic cl utch and variable ratio be lt dr ive trans miss ion. T he en gage me nt of the c lutc h

is governed by engine RPMs and centrifugal mechanism located

in the clutch.

To insure prop er performance and lo nger lifetime of the clutch

assembly it is essential tha t the clutch engages smoothly and

gradually. The following inspections must be performed:

1. INITIAL ENGAGEMENT INSPECTION

• Warm up the engine to normal operating temperature.

• Remove the front frame cover. (!5-8)

• Connect an electric tachometer to the high-tens ion cord.

• Seated on the motorcycle with the motorcycle on level

ground, increase the engine RPM slowly and note the RPM at

which the motorcycle begins to move forward.

$ 09900-26006: Tachometer

Engagement rpm: 2 900 – 3 500 rpm

2. CLUTCH “LOCK-UP” INSPECTION

Perform this inspection to determine if the clutch is engaging

fully and not slipping.

• Apply the front and rear brakes as firm as possible.

• Briefly open the throttle fully and note the maximum engine

RPMs sustained during the test cycle.

"

Do not apply full power for more than x seconds or

damage to the clutch or engine may occur.

Lock-up rpm: 4 500 – 5 500 rpm

Page 35

ENGINE

http://www.motorcycle.in.th

CONTENTS

ENGINE C OMPONENT S REMOVA B L E W I T H THE ENGINE I N PL A C E .. 3- 2

ENGINE REMOVAL AND INSTALLATION................................................. 3- 4

ENGINE REMOVAL............................................................................... 3- 4

ENGINE REMOUNTING........................................................................ 3- 8

ENGINE DISASSEMBLY............................................................................. 3-10

ENGINE COMPONENT INSPECTION AND SERVICE............................... 3-20

CYLINDER HEAD COVER.................................................................... 3-20

CYLINDER HEAD.................................................................................. 3 -21

CYLINDER............................................................................................. 3-33

PISTON.................................................................................................. 3-34

CRANKSHAFT ...................................................................................... 3-36

OIL PUMP................ .............. ............... ............... .............. ............... ..... 3-37

MOVABLE DRIVE FACE....................................................................... 3-37

CLUTCH SHOE/MOVABLE DRIVEN FACE......................................... 3 -39

DRIVE BELT.......................................................................................... 3 -44

DRIVE BELT FILTER ............................................................................ 3 -44

STARTER CLUTCH............................................................................... 3-45

MAGNETO COVER ............................................................................... 3-46

KICK STARTER..................................................................................... 3-47

REDUCTION GEAR............................................................................... 3-49

BEARING INSPECTION........................................................................ 3-51

RIGHT CRANKCASE ........................... ............... .............. ............... ..... 3-51

ENGINE MOUNTING BUSHING ......................... .............. ............... ..... 3-51

LEFT CRANKCASE ......................... ............... ............... .............. ......... 3-52

ENGINE MOUNTING BUSHINGS ........ ............... .............. ............... ..... 3-54

CRANKSHAFT SHIM SELECTION....................................................... 3-55

ENGINE REASSEMBLY.............................................................................. 3-56

PAIR (AIR SUPPLY) SYSTEM..................................................................... 3-73

PAIR HOSES INSPECTION ............................ ............... .............. ......... 3-73

PAIR REED VALVE INSPECTION ........................................................ 3-73

PAIR CONTROL VALVE INSPECTION............................ ............... ..... 3-73

ENGIN E 3-1

3

Page 36

3-2 ENGINE

http://www.motorcycle.in.th

ENGINE COMPONENTS REMOVABLE WITH THE ENGINE IN PLACE

The parts listed below can be removed and reinstalled without removing the engine fro m the frame. Refer to

page listed in each section for removal and reinstallation instructions.

ENGINE CENTER

PARTS REMOVAL INSTALLATION

Starter motor !3-10 !3-71

Cylinder head cover !3-11 !3-70

Camshaft !3-22 !3-32

Camshaft sprocket !3-12 !3-68

Carburetor !3-4 !4-8

Cam chain tension adjuster !3-12 !3-69

PAIR cut valve !3-11 !3-71

Cylinder head !3-12 !3-67

Cylinder !3-12 !3-67

Piston !3-13 !3-66

Intake pipe !3-11 !3-71

Crankcase tube grommet !3-10 !3-72

ENGINE LEFT SIDE

PARTS REMOVAL INSTALLATION

Fixed drive face !3-17 !3-61

Movable drive face assembly !3-17 !3-60

Clutch housing !3-17 !3-60

Clutch shoe/movable driven face assembly !3-17 !3-60

Drive belt !3-17 !3-60

Reduction gear cover !3-18 !3-59

Oil sump filter !3-19 !3-57

Drive shaft !3-49 !3-59

Air cleaner box !3-5 —

Spark plug !3-11 !2-7

Oil filter !3-18 !3-58

Kick starter lever !3-10 !3-72

Cooling belt cover and duct !3-44 !3-45

Clu tc h cove r !3-10 !3-72

Cylinder cowling left cover !3-11 !3-71

Idle driven gear !3-18 !3-59

Clutch upper cover and crankcase tube !3-6 —

Page 37

ENGIN E 3-3

http://www.motorcycle.in.th

ENGINE RIGHT SIDE

PARTS REMOVAL INSTALLATION

Muffler ! 3-5 !3-9

Fan cowling cover !3-11 !3-71

Cooling fan !3-13 !3-65

Starter idle gear !3-15 !3-63

Magneto cover !3-14 !3-63

Magnetorotor !3-15 !3-62

Oil pump !3-16 !3-61

Cylinder cowling right cover !3-11 !3-71

Page 38

3-4 ENGINE

http://www.motorcycle.in.th

ENGINE REMOVAL AND INSTALLATION

ENGINE REMOVAL

Before taking the engine out of the frame, wash the engine

using a steam cleaner. Engine removal is sequentially explained

in the following steps. Reinstall the engine by reversing the

removal procedure.

• Remove the front frame cover. (!5-8)

• Remove the luggage box. (!5-9)

• Remove the frame covers (left and right). (!5-10)

• Disconnect the battery - le ad wire.

• Remove the fuel tank. (!4-2)

• Drain engine oil. (!2-8)

• Disconnect the starter motor lead wire.

• Remove the carburetor 1. (!4-8)

• Disconnect th e head cov er breathe r hose 2 and PAIR ho se

3.

Page 39

• Remove the air cleaner box.

http://www.motorcycle.in.th

• Disconne ct the ma gne to lead wire coupl er 4 an d pick-up co il

lead wire coupler 5.

ENGIN E 3-5

• Remove the engine ground bolt.

• Disconnect the spark plug cap 6.

• Remove the exhaust pipe bolts.

Page 40

3-6 ENGINE

http://www.motorcycle.in.th

• Remove the muffler mounting bolts and then remove the muffler 7.

• Remove the rear brake cable clamp bracket 8.

• Remove the rea r brake cable adjuster nut 9, spring 0 and

pin A.

• Remove the rear brake cable clamp.

• Remove the clutch upper c over B.

• Remove the crankcase tube C.

Page 41

• Support the engine using a jack.

http://www.motorcycle.in.th

• Remove the rear shock absorber lower mounting bolt.

• Remove the engine mounting bolt and nut.

NOTE:

Never remove the crankcase bracket D from the frame.

ENGIN E 3-7

• Remove the engine from the frame.

Page 42

3-8 ENGINE

http://www.motorcycle.in.th

ENGINE REMOUNTING

Remount the e ngi ne in the rev ers e o rder of remo v al. Pa y at tention to the following points:

• Install the crankcase bracket 1 to the frame and insert the

crankcase bracket mounting shaft.

• Push up on the rear part of the crankcase bracket 1 and

have the damper B to uch the stopper A. While hol ding the

damper, tighten the engine mounting bracket nut 2 to the

specified torque.

" Crankcase bracket nut: 102 N·m (10.2 kgf-m)

• Install the engine an d tighten the engine mou nting nut 3 to

the specified torque.

" Engine mounting nut: 85 N·m (8.5 kgf-m)

NOTE:

When tighte ning the engine mounting nut, make sure that the

front wheel is elevated.

• Tighten the rear shock abs orber lowe r mounting nu t 4 to th e

specified torque.

" Rear shock absorber mounting bolt: 29 N·m (2.9 kgf-m)

NOTE:

* Place 65 kg on the seat, after installing the engine.

* Check that clearance C and D are equal. If clearances C and

D are not equal, repeat the engine installation procedures.

• Install the crank case tube 5.

NOTE:

Set the crankcase tube E to the crankcase tube grommet F.

(!7-23)

Page 43

• Install the muffler.

http://www.motorcycle.in.th

#

Replace the gasket with new one.

ENGIN E 3-9

• After installing the engine, properly route the wire harness,

cables, a nd hoses. Refer to the wire and ca ble routing sections. (!7-12 to -19)

• Refer to the follow ing sections to adjust the res pective items

to specification.

* ENGINE OIL (!2-8)

* REDUCTION GEAR OIL (!2-11)

* THROTTLE CABLE PLAY (!2-10)

* ENGINE IDLE SPEED (!2-10)

* REAR BRAKE CABLE ADJUSTMENT (!2-12)

• Check for leakage of the engine oil and r eduction gear oil.

Page 44

3-10 ENGINE

http://www.motorcycle.in.th

ENGINE DISASSEMBLY

#

Identify the position of each removed part. Organize

the parts i n thei r r espe cti v e gr oups s o t hat th ey c an be

reinstalled in their original positions.

CLUTCH COVER

• Remove the kick starter lever.

• Remove the clutch cover assembly 1.

CRANKCASE TUBE GROMMET

• Remove the crankcase tube grommet No.1 1 and No.2 2.

STARTER MOTOR

• Remove the starter motor 1.

Page 45

PAIR CUT VALVE

http://www.motorcycle.in.th

• Disconnect the PAIR hose 1 and vacuum hose 2.

• Remove the PAIR cut valve 3.

FAN COWLING COVER/CYLINDER COWLING/INTAKE PIPE

• Remove the fan cowling cover 1 and cylinder cowling right

cover 2.

ENGINE 3-11

• Remove the intake pipe 3 and cylinder cowling left cover 4.

SPARK PLUG

• Remove the spark plug.

CYLINDER HEAD COVER

• Remove the cylinder head cover 1 and gasket.

Page 46

3-12 ENGINE

http://www.motorcycle.in.th

• Turn the crankshaft clockwise with a box wrench and align the

“Top” mark A on the cooling fan with the index mark B on the

magneto cov er.

NOTE:

The piston must be at TDC on the compression stroke.

CAM CHAIN TENSION ADJUSTER

• Remove the cam chain tension adjuster 1 and gasket.

CAMSHAFT SPROCKET

• R emove the decompression cam assembly 1 and camsha ft

sprocket 2.

CYLINDER HEAD

• Remove the cylinder head side nuts 1 and cylinder head nuts

2.

• Remove the cylinder head.

NOTE:

* W hen loosen ing the cyl inder head n uts, loosen e ach nut littl e

by little diagonally.

* If the cylinder head does not come off, lightly tap on the finless

portion of it with a plastic hammer.

CYLINDER

• Remove the dowel pins 1, gaske t 2 and cam chain guide 3.

• Remove the cylinder.

NOTE:

If the cylinder does not come off, lightly tap on the finless portion

of it with a plastic hammer.

Page 47

• Remove the dowel pins 4 and gasket 5.

http://www.motorcycle.in.th

PISTON

• Remove the piston pin circlip.

• Remove the pisto n by driving out the pist on pin.

NOTE:

Place a cle an rag over the cyl inder base so as n ot to drop the

piston pin circlip into the crankcase.

ENGINE 3-13

COOLING FAN

• Remove the cooling fan 1.

• Remove the cooling fan holder nut with the special tool.

$ 09930-40113: Rotor holder

• Remove the washer 2 and cooling fan holder 3.

Page 48

3-14 ENGINE

http://www.motorcycle.in.th

REAR WHEEL/REAR BRAKE

• Remove the rear wheel.

• Remove the brake shoes.

CENTER STAND

• Remove the center stand spring 1.

• Remove the cotter pin 2, washer 3, shaft 4 and center

stand 5.

MAGNETO COVER

• Remove the magneto cover 1.

Page 49

• Remove the dowel pins 2 and gasket 3.

http://www.motorcycle.in.th

STARTER IDLE GEAR

• Remove the starter idle gear 1 and shaft 2.

ENGINE 3-15

MAGNETOROTOR

• Hold the fixed drive face with the special tool.

$ 09930-40113: Rotor holder

• Remove the magnetorotor nut.

• Remove the magnetorotor 1 with the special tool.

$ 09930-34980: Rotor remover

• Remove the starter clutch 2.

Page 50

3-16 ENGINE

http://www.motorcycle.in.th

• Remove the key 3.

OIL PUMP

• Remove the oil pump cover 1.

• Turn the oil pump sprocket and align the oil pump sprocket

hole on the oil pump mounting screw 2.

• Remove the oil pump screw 2.

• Remove the oil pump assembly 3 along with the chain 4.

NOTE:

The oil pump assembly is a non-disassemblable type.

• Remove the cam chain 5.

Page 51

FIXED DRIVE FACE

http://www.motorcycle.in.th

• Remove the fixed drive face nut with the special tool.

$ 09930-40113: Rotor holder

• Remove the washer 1, kick starter 2 and fixed drive face 3.

ENGINE 3-17

MOVABLE DRIVEN FACE/CLUTCH HOUSING

• Remove the clutch housing nut with the special tool.

$ 09930-40113: Rotor holder

• Remove the clutch hosing 1.

• Remove the clutch shoe/movable driven face assembly 2

along with the drive belt 3.

• Remove the movable drive face assembly 4 and spacer 5.

Page 52

3-18 ENGINE

http://www.motorcycle.in.th

REDUCTION GEAR

• Drain the reduction gear oil. (!2-11)

• Remove the reduction gear cover 1.

• Remove the gasket 2 and dowel pins 3.

• Remove the washer 4, idle driven gear 5 and rear axle shaft

6.

OIL FILTER

• Remove the oil filter cap 1.

• Remove the oil filter 2 and O-ring 3.

Page 53

OIL SUMP FILTER

http://www.motorcycle.in.th

• Remove the oil sump filter cap 1 and oil sump filter 2.

BRAKE CAM LEVER

• Remove the rear brake cam lever 1, brake l i ning wear in di c a tor 2 and brake cam 3.

ENGINE 3-19

CRANKCASE

• Remove the crankcase bolts.

• Separator the crankcase into 2 parts, right an d left with the

crankcase separating tool.

$ 09920-13120: Crankcase separating tool

NOTE:

* Fit the crankcase s eparating tool, so th at the tool arms are in

parallel with the side of crankcase.

* The crankshaft component should remain in the left crankcase

half.

CRANKSHAFT

• Remove the crankshaft with the special tool.

$ 09920-13120: Crankcase separating tool

Page 54

3-20 ENGINE

http://www.motorcycle.in.th

ENGINE COMPONENT INSPECTION

AND SERVICE

CYLINDER HEAD COVER

DISASSEMBLY

• Remove the PA IR reed valv e cover 1 and PA IR reed valve

2.

• Remove the breather cover 3, oil separator 4 and gasket 5.

INSPECTION

REED VALVE

• Inspect the reed valve for the carbon deposit.

• If the carbon deposit is found in the reed valve, rep lace the

PAIR reed valve with a new one.

OIL SEPARATOR

• Check the oil separator for any damage or clogs.

• If they are clogged, clean the oil separator with a compressed

air or replace.

Page 55

REASSEMBLY

http://www.motorcycle.in.th

• Reassembly the cylinder head cover in the reverse order of

disassembly. Pay attention to the following points:

• Install the breather cover gasket 1.

#

Replace the removed breather gasket with a new one.

• Tighten t he breather cover bolts to the specified torque.

" Breater cover bolt: 10 N·m (1.0 kgf-m)

• Apply THREAD LOCK to the PAIR reed valve cover bolts and

tighten them.

% 99000-32050: THREAD LOCK “1342”

ENGINE 3-21

CYLINDER HEAD

#

Identify the position of each removed part. Organize

the parts in their respective groups (i.e., intake or

exhaust) so that they can be ins talled in their origin al

locations.

DISASSEMBLY

• Remove the cam chain tensioner 1.

• Remove the camshaft retainer 2.

Page 56

3-22 ENGINE

http://www.motorcycle.in.th

• Pull out the intake and exhaust rock er arm shaf ts 3 by us ing

an 8-mm thread bolt.

• Remove the intake and exhaust rocker arms 4.

• Remove the camshaft 5.

• Compress the valve spring with the valve spring compressor.

• Remove the valve cotters from the valve stem.

$ 09916-14510: Valve spring compressor

09916-14521: Attachment

09916-84511: Tweezers

• Remove the valve spring retainer 6 and valve spring 7.

• Remove the valve 8 from the combustion chamber side.

Page 57

• Remove the valve stem seal 9 and valve spring seat 0.

http://www.motorcycle.in.th

ROCKE R ARM SHA F T O.D.

Measure the diameter of rocker arm shaft.

& Rocker arm shaft O.D. (IN. & EX.)

Standard: 9.981 – 9.990 mm

$ 09900-20205: Micrometer (0 – 25 mm)

ENGINE 3-23

ROCKER ARM I.D.

When chec king the valv e rocker a rm, the insi de diamete r of the

valve rocker arm and wear of t he camshaft contac ting surface

should be checked.

& Rocker arm I.D. (IN. & EX.)

Standard: 10.003 – 10.018 mm

$ 09900-20605: Dial calipers

CYLINDER HEAD DISTORTION

Decarbon the combustion chamber.

Check the ga sketed su rfaced of the cyl inder head for distortion

with a straightedge and thickness gauge, taking a clearance

reading at sev eral places as indicated . If the largest readin g at

any position o f the straightedge exceeds the limit, replace the

cylinder head.

& Cylinder head distortion

Service Limit: 0.05 mm

$ 09900-20803: Thickness gauge

Page 58

3-24 ENGINE

http://www.motorcycle.in.th

VALVE FACE WEAR

The thickness of the valve face decreases as the face wears.

Visually ins pe ct e ach v alve fa ce for w ear a nd repl ace any v alv e

with an abnormally worn face. Measure the valve face thickness

T, if it is out of specification, replace the valve with a new one.

& Valve head thickness (IN. & EX.)

Service Limit T: 0.5 mm

$ 09900-20101: Venier calipers

VALVE STEM RUNOUT

Support the valve using V-blocks, as shown, and measure its

runout with the dial gauge. If the runout exceeds the limit,

replace the valve.

& Valve stem runout (IN. & EX.)

Service Limit: 0.05 mm

$ 09900-20701: Magnetic stand

09900-20607: Dial gauge (1/100 mm)

09900-21304: V-block (100 mm )

VALVE HEAD RADIAL RUNOUT

Place the dial gauge at right angles to the valve head, and measure the valve head radial runout.

If it measures more than limit, replace the valve.

& Valve head radial runout (IN. & EX.)

Service Limit: 0.03 mm

$ 09900-20607: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

09900-21304: V-block (100 mm )

VALVE STEM DEFLECTION

Lift the valve about 10 mm from the valve seat. Measure the

valve stem def lect ion in tw o d irecti on s, “ X” and “ Y”, perp endic ular to each other , by pos itioning the dial g auge a s show n. If th e

deflection measured exceeds th e limit, the n determ ine whether

the valve or the guide should be replaced with a new one.

& Valve stem deflec tion

Service Limit (IN. & EX.): 0.35 mm

$ 09900-20607: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

Page 59

VALVE STEM WEAR

http://www.motorcycle.in.th

If the valve stem is worn down to the limit , when measu red with

a micromete r, and the clearanc e is foun d to be in ex cess of th e

limit indicated previously, replace the valve, if the stem is within

the limit, the n replace the gu ide. After rep lacing valve or guide,

be sure to re-check the clearance.

& Valve stem O.D.

Standard (IN.) : 4.975 – 4.990 mm

(EX.): 4.955 – 4.970 mm

$ 09900-20205: Micrometer (0 – 25 mm)

VALVE GUIDE SERVICE

• Remove the valve guide with the valve guide remover.

$ 09916-44310: Valve guide remover

ENGINE 3-25

• Re-finish the v alve guid e holes in cyli nder head wi th the handle and reamer.

$ 09916-34542: Handle

09916-34580: Valve guide reamer (10.8 mm)

• Fit a ring to each valve guide.

• Lubricate ea ch valve guide with oil, and drive the guide into

the guide hole with the special tool.

$ 09916-44310: Valve guide installer

NOTE:

Install the valve guid e un ti l the ri ng A co ntac ts w ith t he c yli nder

head.

#

Be sure to use new ring and valve guide.

Page 60

3-26 ENGINE

http://www.motorcycle.in.th

• After fitting th e v alve g ui des, re -fin ish the i r gui ding b ore s w ith

the hand le and reamer. Be sure to clean and oi l the guides

after reaming.

$ 09916-34542: Handle

09916-34570: Valve guide reamer (5.0 mm)

VALVE SEAT WIDTH INSPECTION

Visually check for valve seat width on each valve face.

If the valve face has worn abnormally, replace the valve.

Coat the valve seat with Prussian Blue and set the valve in

place.

Rotate th e valve with light press ure. Chec k that the t ransferred

blue on the va lve face is unif orm all arou nd and in cente r of the

valve face.

If the seat w idth W measured excee ds the standard value, or

seat width is not uniform reface the seat using the seat cutter.

& Valve seat width W

Standard (IN.) : 0.90 – 1.10 mm

(EX.): 0.92 – 1.12 mm

Service Limit: Reface if measurement does not agree

with standard valve.

$ 09916-10911: Valve lapper set

• If either requirement is not met, correct the seat by servicing it

as follows.

Page 61

VALVE SEAT SERVICE

http://www.motorcycle.in.th

The valve seats 1 for both the intake and exha ust valves are

machined to four different angles. The seat conta ct surface is

cut at 45°.

INTAKE SIDE EXHAUST SIDE

45° N-122 N-122

15° N-121

30° N-126

$ 09916-21111: Valve seat cutter set

09916-20610: Valve seat cutter (N-121)

09916-20620: Valve seat cutter (N-122)

09916-20630: Valve seat cutter (N-126)

09916-24311: Solid pilot (N-100-5.0)

NOTE:

Use the solid pi lot (N-100-5.0) along with th e valve seat cutter

(N-121, -122 and -126).

ENGINE 3-27

For intake

For exhaust

#

The valve seat contact area must be inspected after

each cut.

15˚ 30˚ 45˚

• When installing the solid pilot 2, rotate it slightly.

Page 62

3-28 ENGINE

http://www.motorcycle.in.th

• Seat the pilot snugly. Install the 45° cutter 3, attachment and

T-handle 4.

INITIAL SEAT CUT

• Using the 45° cutt er, descale and clean up the seat. Rotate

the cutter one or two turns.

• Measure the valve seat width W after ever y cut.

• If the valve seat is p itted or bu rned, us e the 45° c ut ter to condition the seat some more.

NOTE:

Cut only the minimum amou nt necessary fr om the seat to prevent the possibi lity of the valve stem becoming too c lose to the

rocker arm for correct valve contact angle.

TOP NARROWING CUT

• If the contact area W is too high on the valve, or if it is too

wide, use the 15° (for exhaust side) and the 30° (for the intake

side) to lower and narrow the contact area.

45˚

15˚: For exhaust

30˚: For intake

Page 63

FINAL SEAT CUT

http://www.motorcycle.in.th

• If the contact area W is too low or too narrow, use the 45° cutter to raise and widen the contact area.

NOTE:

After cutting th e 1 5° an d 3 0° angles, it is possible that the valve

seat (45°) is too narrow. If so, re-cut the valve seat to the correct

width.

• After the desir ed seat pos ition and wi dth is achiev ed, use the

45° cutter very lightly to clean up any burrs caused by the previous cutting opera tions.

#

Do not use lapping compound after the final cut is

made. The finished valve seat should have a velvety

smooth finish but not a highly polished or shiny finish. This wil l provide a soft surface f or the final seating of t he valve whic h will occur du ring the first few

seconds of engine operation.

NOTE:

After servicing the valve seats, be sure to check the valve clearance after the cylinder head has been rei nstalled. (!2-6)

ENGINE 3-29

45˚

• Clean and ass emble the hea d an d valv e com pon ents. F il l the

intake an d exhaust ports with gasoline to check for lea ks. If

any leaks occur, inspect the valve seat and face for burrs or

other things that could prevent the valve from sealing.

'

Always use extreme caution when handling gasoline.

VALVE STEM END CONDITION

Inspect th e valv e ste m e nd fa c e for pi ttin g an d w ear. If p it ting or

wear is p resent, resur face the valve s tem end. M ake sure that

the length A is not less than 2.2 mm. If this length becomes less

than 2.2 mm, replace the valve.

& Valve stem end length

Service Limit: 2.2 mm

Page 64

3-30 ENGINE

http://www.motorcycle.in.th

VALVE SPRING INSPECTION

The force of t he coil spr ing keeps th e valve sea t tight. A wea kened spring results in reduced engine power output and often

accounts fo r t he ch atter ing nois e com i ng from the v alve m ec hanism.

Check the valv e springs for proper strength by measuring their

free length and also by the force requ ired to co mpress them. If

the spring length is less than the service limit or if the force

required to compress the spring does not fall within the specif ied

range, replace both the inner and outer springs as a set.

& Valve spring free length (IN. & EX.)

Service Limit: 32.9 mm

$ 09900-20102: Vernier calipers

& Valve spring tens ion (IN. & EX.)

Standard: 118 N (12.0 kgf)/26.8mm

CAMSHA F T CA M WE AR

Check for ab normal surface dam age or wear on the cam face.

Measure the cam height H with a micrometer.

Replace the camshaft if found worn dow n to the service limit.

& Cam height H

Service Limit(IN.) : 27.62 mm

(EX.): 27.47 mm

$ 09900-20202: Micrometer (25 – 50 mm)

CAMSHA F T BEA R ING

Rotate the camshaft bearing out er race by finger to i nspect for

abnormal play, noise and smooth rotation.

Replace the bearing in the follow ing procedure if th ere is anything unusual.

118 N (12.0 kgf)

26.8 mm

Page 65

• Remove the bearings and cam sprocket flange with a bearin g

http://www.motorcycle.in.th

puller.

$ 09913-60910: Bearing & gear puller

NOTE:

Avoid remov ing the cam sproc ket flan ge and bearing from th e

camshaft unless it is really necessary to do so, for example,

removing the damaged bearing.

#

The removed bearing should be replaced with a new

one.

• Press in the bearings to the camshaft with a bearing installer.

$ 09951-16080: Bearing installer ((49 mm)

09913-70210: Bearing installer ((32 mm)

ENGINE 3-31

CAM CHAIN TENSIONER

Inspect t he ca m ch ai n te nsione r f or dam age . If any dam age are

found, replace the cam chain tensioner with a new one.

REASSEMBLY

• Insert the valves, with their stems coated with molybdenum oil

solution a ll around a nd al ong the full stem length wi thout any

break.

Similarly oil the lip of the stem seal.

) MOLYBDNUM OIL SOLUTION

#

When inserting each valve, take care not to damage

the lip of the stem seal.

Page 66

3-32 ENGINE

http://www.motorcycle.in.th

• Install the valve sp ring, making sure that the close-pitch end

A of each spring goes in first to rest on the head . The coil

pitch of spring vary: the p itch decreas es from top to bottom,

as shown in the illustration.

• Put on the valve spring retainer, and using the valve lifter,

press down the spr ing, fit the cotter halves to the stem end,

and release the lifter to allow the cotter 1 to wedge in

between retai ner and ste m. Be sure that th e round ed l ip B of

the cotter fits snugly into the groove C in the stem end.

Towards

Head

$ 09916-14510: Valve lifter

09916-14521: Valve lifter attachment

09916-84511: Tweezers

#

Be sure to restore each spring and valve to their original positions.

NOTE:

Just before insta lling the cams haft into the c ylinder h ead, a pply

molybdenum oil solution to the cam faces.

) MOLYBDNUM OIL SOLUTION

• Apply engine oil to the rocker arm shafts, rocker arms and

install them.

Page 67

CAM CHAIN TENSIONER

http://www.motorcycle.in.th