Page 1

Temperature Controller

Model No. 31095 and 31097

Instruction manual

PN 31095

PN 31097

Super System inc.

7205 Edington Drive

Cincinnati, Ohio 45249

United States

Phone: 513-772-0060

Toll free: 800-666-4330

Fax: 513-772-9466

www.supersystem.com

I 1 I 2 I 3

45.80

50

45.80

Page 2

Information

2

cc

NOTES

ON ELECTRIC

SAFETY AND

ELECTROMAGNETIC

COMPATIBILITY

Please read these instructions carefully before proceeding with the installation of the

controller.

Class II instrument (for indoor use only).

This controller has been designed in compliance with:

Regulations on electrical apparatus (appliance, systems and installations) according to

the European Community directive no. 73/23/EEC amended by the European Comunity directive no. 93/68/EEC and the Regulations on the essential protection requirements in electrical apparatus EN61010-1 : 93 + A2:95.

Regulations on Electromagnetic Compatibility according to the European Community

directive no. 89/336/EEC, amended by the European Community directive no. 92/31/EEC,

93/68/EEC, 98/13/EEC and the following regulations:

Regulations on RF emissions

EN61000-6-3 : 2001 residential environments

EN61000-6-4 : 2001 industrial environments

Regulation on RF immunity

EN61000-6-2 : 2001 industrial equipment and system

It is the responsibility of the installer to ensure compliance with regulations on safety requirements and EMC.

The device has no user serviceable parts. Please contact your nearest agent for repair services.

All information and warnings about safety and electromagnetic compatibility are marked

with the

B symbol.

Page 3

TABLE OF CONTENTS

Table of contents

1 INTRODUCTION.............................................................................................................page 4

1.1 P

RODUCT CODING..........................................................................................page 5

2 INSTALLATION .................................................................................................................page 6

2.1 DESCRIPTION.........................................................................................................page 6

2.2 ENVIRONMENTAL RATINGS.....................................................................page 8

2.3 PANEL MOUNTING ............................................................................................page 9

3 ELECTRICAL CONNECTIONS................................................................page 10

3.1 TERMINATION BLOCK ...................................................................................page 10

3.2 SUGGESTED WIRES ROUTING ..............................................................page 11

3.3 EXAMPLE OF WIRING DIAGRAM ........................................................page 12

4 OPERATIONS......................................................................................................................page 22

4.1 KEYS FUNCTIONS AND DISPLAY IN

OPERATOR MODE...............................................................................................page 22

4.2 PARAMETER SETTING...................................................................................page 24

4.3 C

ONFIGURATION PROCEDURE............................................................page 25

4.4 PARAMETERISATION - MAIN MENU ...............................................page 34

4.5 PARAMETERS.........................................................................................................page 46

4.6 PARAMETERISATION - ACCESS LEVELS ..................................page 50

5 DISPLAYS..................................................................................................................................page 57

5.1 S

TANDARD DISPLAY.......................................................................................page 57

5.2 FAST ACCESS .........................................................................................................page 57

6 COMMANDS ........................................................................................................................page 58

6.1 KEYPAD COMMANDS ...................................................................................page 59

6.2 DIGITAL INPUTS COMMANDS ............................................................page 58

6.3 COMMANDS FROM SERIAL COMMUNICATION

(PLEASE, REFER TO THE SERIAL COMMUNICATIONS MANUAL)

7 TECHNICAL SPECIFICATIONS.............................................................page 63

3

Page 4

1 - Introduction

1 INTRODUCTION

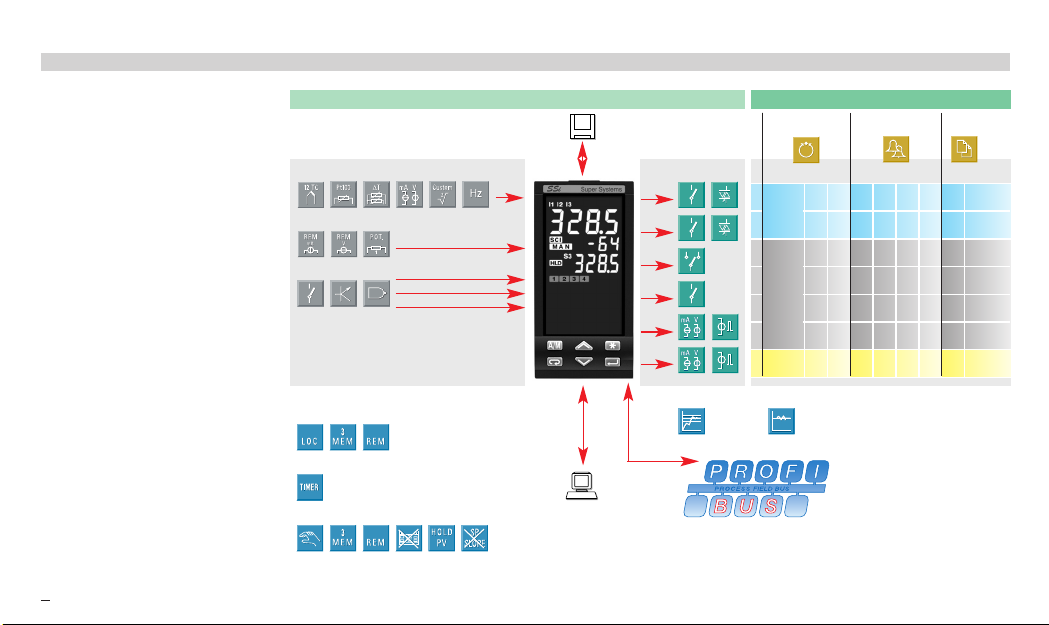

The 31095 has been designed

for use in industrial

environments. The 31095 is a

universal controller with many

standard features.

4

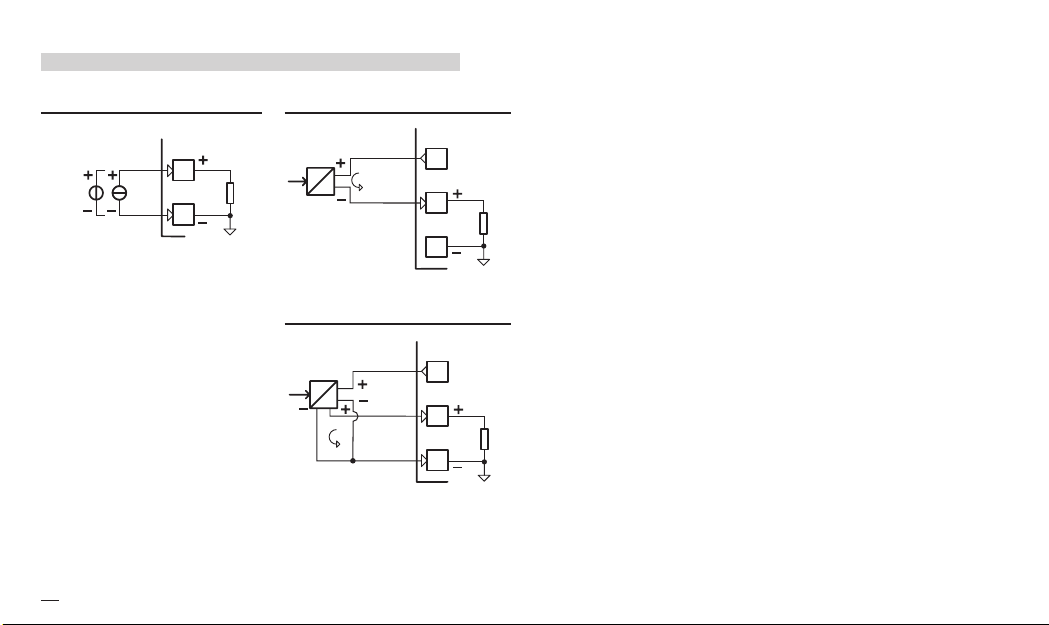

Main universal input

Auxiliary input

Digital input

Setpoint

Special function

Digital inputs (IL1,IL2 or IL3) functions

(option)

Resources

PV

AUX

IL1

IL2

IL3

Memory Chip

Data copy/Data store

(option)

Modbus

RS485 Slave

OP1

OP2

OP3

OP4

OP5

OP6

(option)

Fuzzy tuning

(opt.)

Operating mode

Control Alarms

1 OP1 OP2 OP3 OP4 OP5 OP6

Single

action

2 OP5 OP1 OP2 OP3 OP4 OP6

3 OP1 OP2 OP3 OP4 OP5 OP6

4 OP1 OP5 OP2 OP3 OP4 OP6

Double

action

5 OP5 OP2 OP1 OP3 OP4 OP6

6 OP5 OP6 OP1 OP2 OP3 OP4

Valve

7

OP1 OP2 OP3 OP4 OP5 OP6

with automatic selection

One shot

Auto tuning

One shot

Natural Frequency

Retransmission

PV/SP/MV

Page 5

PN

MN

SN

V

~(L-N)

: 31095

: X5-3150-0300

: A0A-0819/1208

: 100÷240V 50/60 Hz - 5W

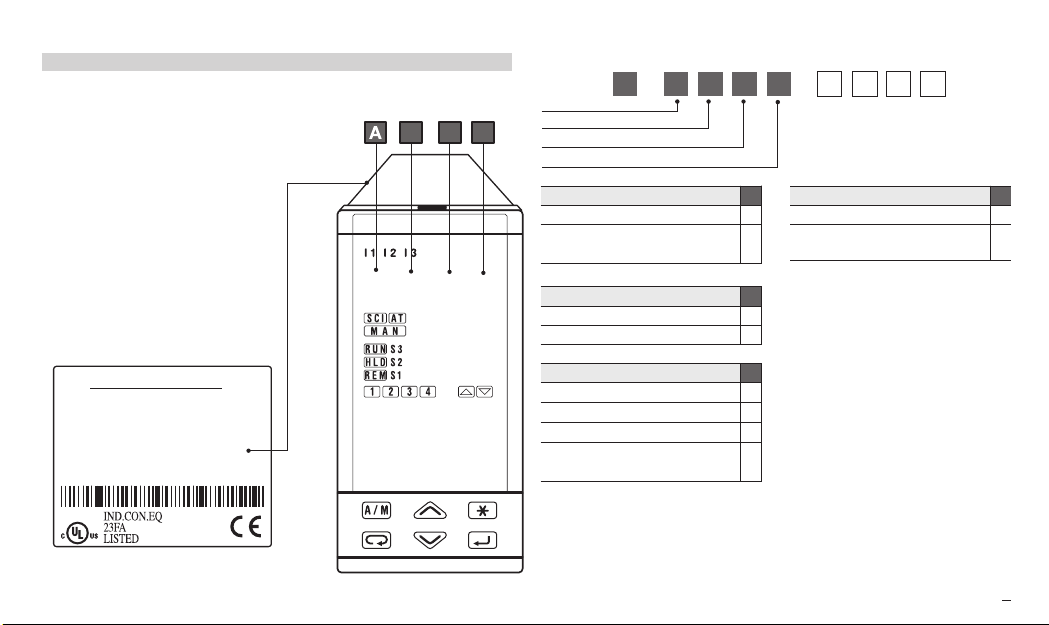

1.1 MODEL CODE

0

Model:

Power Supply

Outputs

Serial

Options

––

Line Basic Accessories

0X5 A B C D 3 0

1 - Introduction

The complete code is displayed

on the instrument side label.

The information about product

coding is accessible from the

front panel by means of a

particular procedure described

in section 5.1 page 53.

Instrument label

www.supersystem.com

Cincinnati, Ohio USA

Basic product code

B C D

Power supply A

X5

I 1 I 2 I 3

45.80

50

45.80

100...240Vac (- 15% + 10%)

24Vac (-25...+12%) or

24Vdc (-15... +25%)

Outputs OP1 - OP2 B

Relay - Relay

Triac - Triac

Serial Communications C

None

RS485 Modbus/Jbus SLAVE

PROFIBUS DP SLAVE

RS485 Modbus/Jbus SLAVE

+ PROFIBUS

Options D

None

3

2ndSSR drive/analog

5

output (OP6)

1

5

0

5

7

8

0

4

5

Page 6

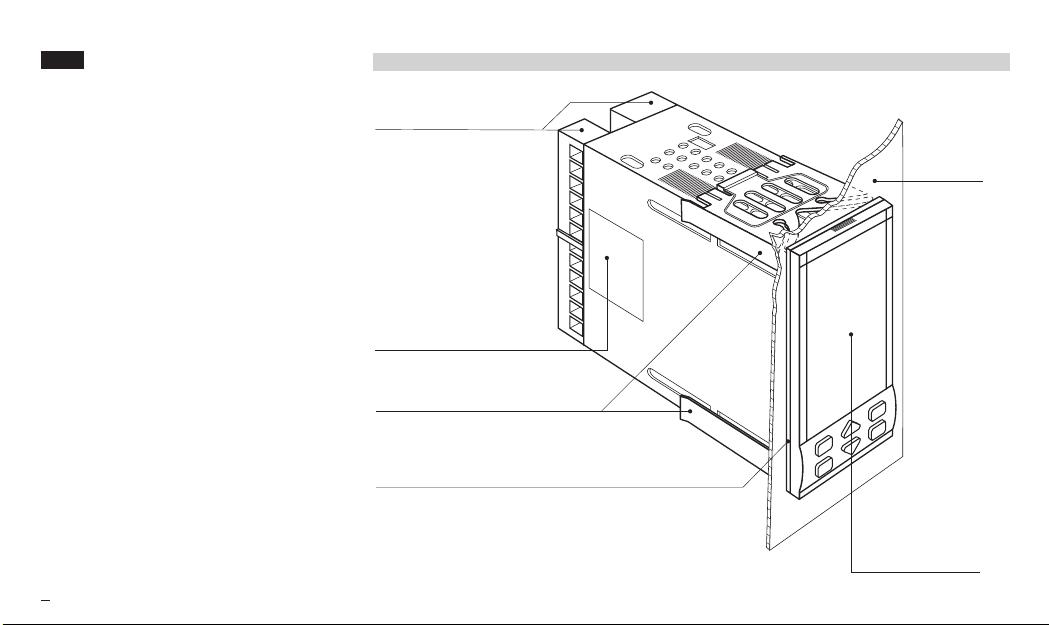

2 - Installation

IP 20 Terminal Block

EN61010 - 1 (IEC1010 - 1)

Product code label

Front panel gasket

Mounting clamps

Front panel

IP65 protection

EN 650529 (IEC 529)

Panel

surface

2 INSTALLATION

Installation must be carried out by

qualified personnel.

Before proceeding with the installation of

this controller, read the instructions in this

manual. Pay particular attention to

precautions marked with the B

symbol, related to the European

Community directive on electrical

protection and electromagnetic

compatibility.

B

To prevent contact with electronically live

components, the controller must be

installed in an enclosure or panel.

6

2.1 GENERAL DESCRIPTION

Page 7

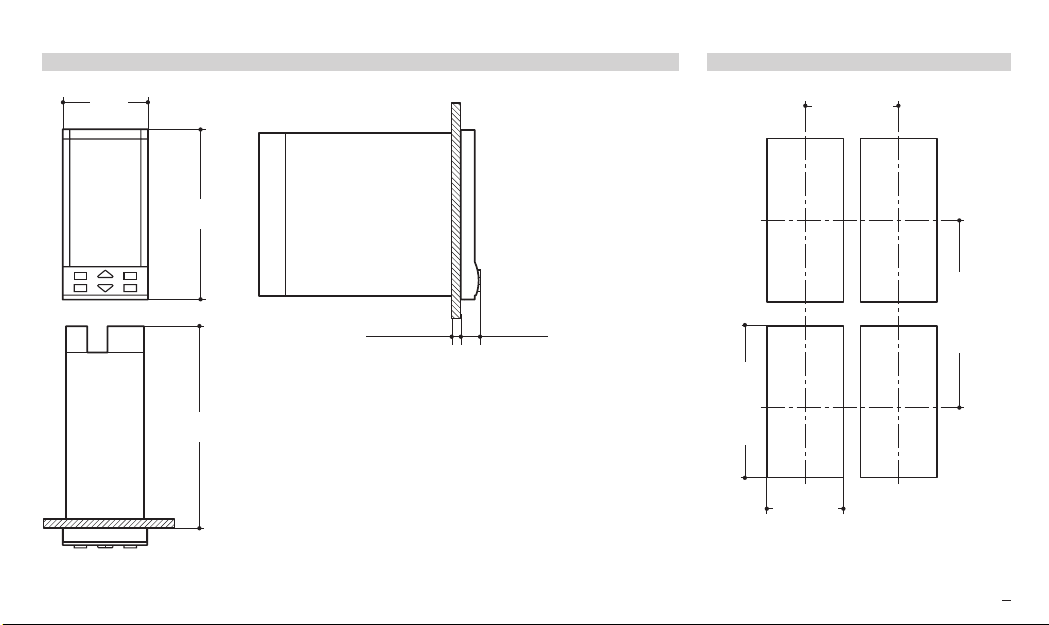

2.1.1 DIMENSIONAL DETAILS 2.1.2 PANEL CUT-OUT

96 mm

3.78 in

110 mm

4.33 in

48 mm

1.89 in

10 mm max.

0.39 in max.

10 mm max.

0.39 in max.

65 mm min

2.56 in min

45

+0.6

mm

1.78

+0.023

in

92

+0.8

mm

3.62

+0.031

in

113 mm min

4.45 in min

2 - Installation

7

Page 8

2 - Installation

2.2 ENVIRONMENTAL RATINGS

B

Operating conditions

UL notes

[1] Operating surrounding temperature

0…50°C

8

M

T

%Rh

Special conditions

M

T

%Rh

P

Prohibited Conditions

C

E

Altitude: up to 2,000 m

Temperature: 0…50°C [1]

Relative humidity: 5…95 % non-condensing

Altitude: > 2,000 m

Temperature: >50°C

Humidity: > 95 %

Conducting atmosphere

Corrosive atmosphere

Explosive atmosphere

Suggestions

Use 24Vac supply version

Use forced air ventilation

Warm up

Use filter

D

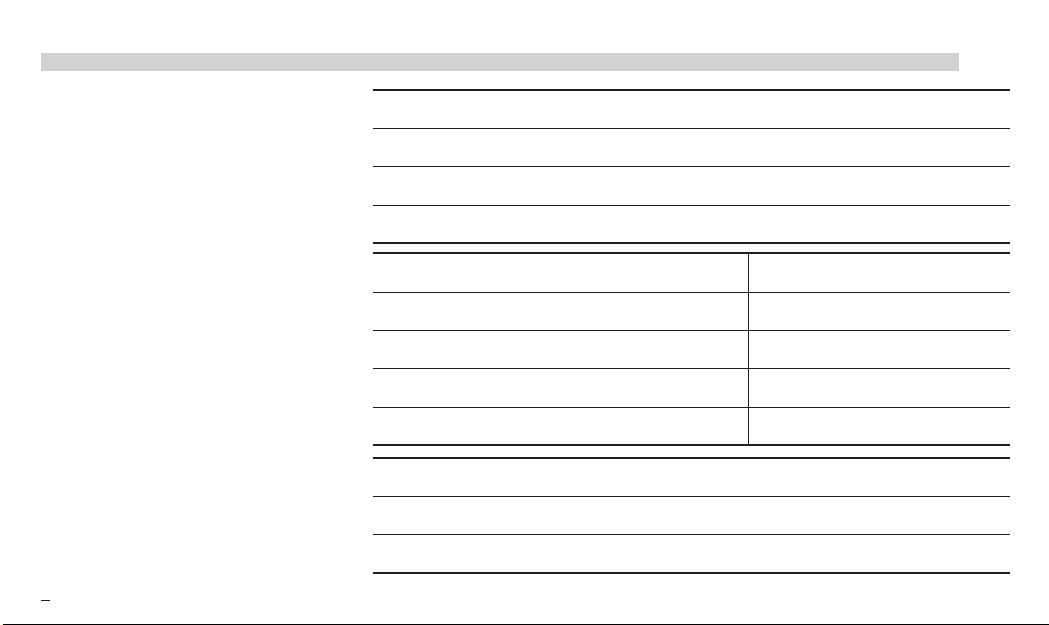

Page 9

1

3

2

1

2

1MΩ

1

2

1

2.3 PANEL MOUNTING [1]

2

1

1

2 - Installation

2.3.1 INSERT

THE INSTRUMENT

1 Prepare panel cut-out;

2 Check front panel gasket

position;

3 Insert the instrument through

the cut-out.

UL note

[1] For Use on a Flat Surface of a Type 2 and Type 3 ‘raintight’ Enclosure

2.3.2 INSTALLATION

SECURING

1 Fit the mounting clamps;

2 Push the mounting clamps

towards the panel surface to

secure the instrument.

2.3.3 CLAMP

REMOVAL

1 Insert the screwdriver in the

clips of the clamps;

2 Rotate the screwdriver.

.

2.3.4 INSTRUMENT

REMOVAL

1 Push and

2 Pull to remove the instrument.

Electrostatic discharges can

damage the instrument.

Before removing the instrument

the operator must discharge

himself to ground.

B

9

Page 10

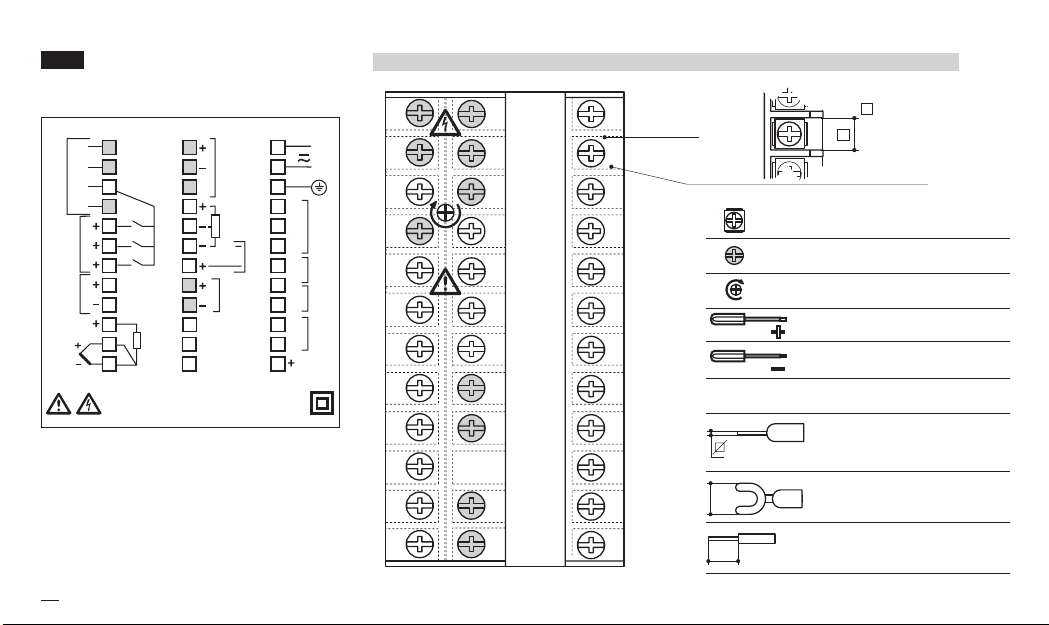

6

5

4

3

2

1

28

27

30

29

26

25

7

19

31

8

20

32

9

33

10

34

11

23

35

12

24

36

0,5

Nm

16

15

18

17

14

13

21

Rear

terminal

cover

Cable size

1 mm

2

[2]

5.7 mm

0.22 in

3 - Electrical Connections

C

N

L

1

2

3

4

5

6

7

8

9

10

11

12

19

20

23

24

25

26

27

28

29

30

31

32

33

34

35

36

TC

mV/V/mA

NC

CNOOP3

NO

C

NO

OP1

OP2

OP4

DG

OP6

(option)

24V—

OUT

1

2

3

A

b

B

RTD

13

14

15

16

17

18

21

22

N/C

LOGIC

INPUT

Profibus

VP

DP

DN

OP5

IN1

C

RS485

(Slave)

POT

0%

REM

NO

C

Ø

L

3 ELECTRICAL

CONNECTIONS

3.1 TERMINAL BLOCK [1]

B

UL notes

[1] Use 60/70 °C copper (Cu) conductor only.

[2] Wire size 1 mm

10

2

(18 AWG Solid/Stranded)

Terminals

35 screw terminals M3

Option terminals

Holding screw 0.5 Nm

Phillips screwdriver PH1

Flat blade screwdriver

0.8 x 4 mm

Pin connector

q 1.4 mm - 0.055 in max.

Fork-shape AMP 165004

Ø 5.5 mm - 0.21 in

Stripped wire

L 5.5 mm - 0.21 in

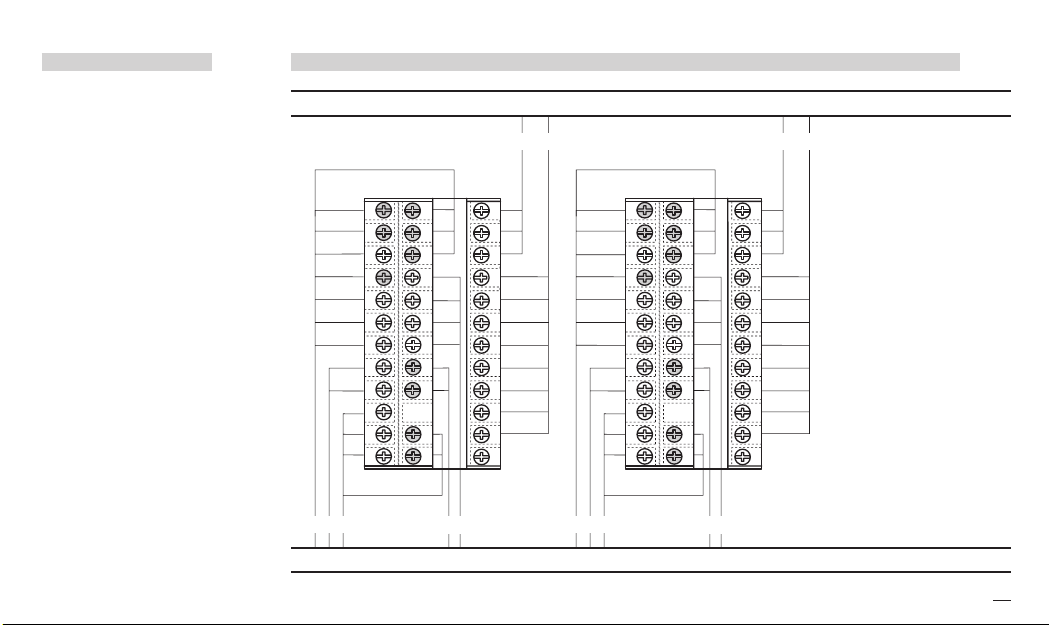

Page 11

6

5

4

3

2

1

28

27

30

29

26

25

7

19

31

8

20

32

9

33

10

34

11

23

35

12

24

36

16

15

18

17

14

13

21

6

5

4

3

2

1

28

27

30

29

26

25

7

19

31

8

20

32

9

33

10

34

11

23

35

12

24

36

16

15

18

17

14

13

21

A B

E C D CD

A B

E C D CD

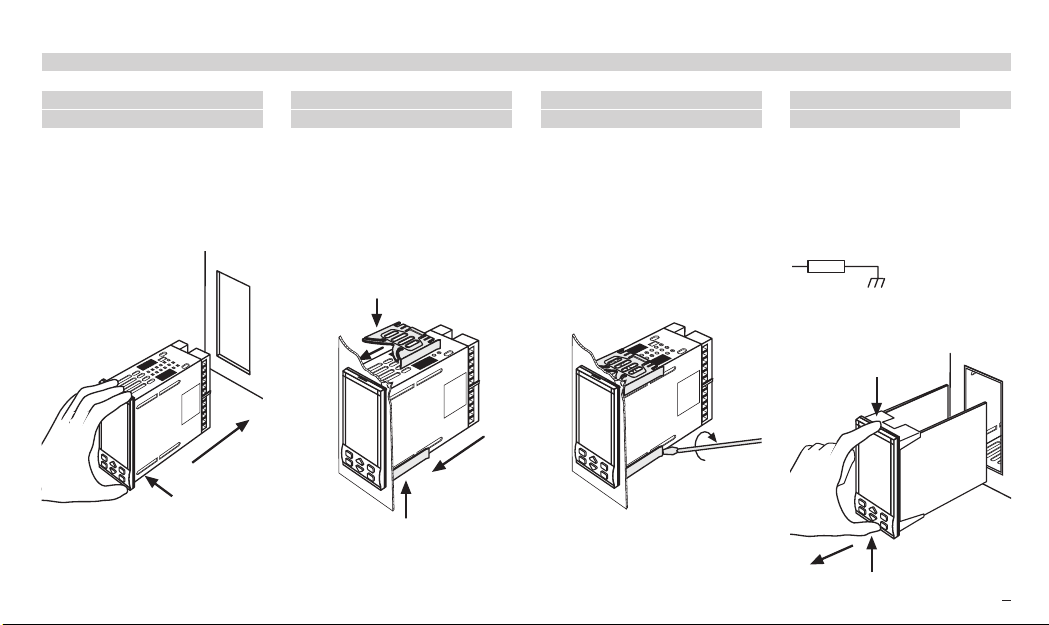

PRECAUTIONS

The instrument has been

designed to work in an harsh

and noisy environmental (level IV

of the industrial standard IEC

801-4). It is recommended to

follow the following suggestions.

A

All the wiring must comply

with the local regulations.

The supply wiring should be

routed away from the power

cables. Avoid to place electromagnetic contactors, power

relays and high power motors

nearby. Avoid power units in

close proximity, especially if

controlled in phase angle mode.

Keep the low level sensor

input wires away from the

power lines and the output

wiring. If this is not achievable, use shielded cables on

the sensor input, with the

shield connected to ground.

B

3.2 SUGGESTED WIRES ROUTING

3 - Electrical Connections

B

Conduit for supply and output cables

A = Supply

B = Outputs

C = Analog inputs

D = Analog output

E = Digital input

Serial Comm.s

Conduit for low level sensor cables

11

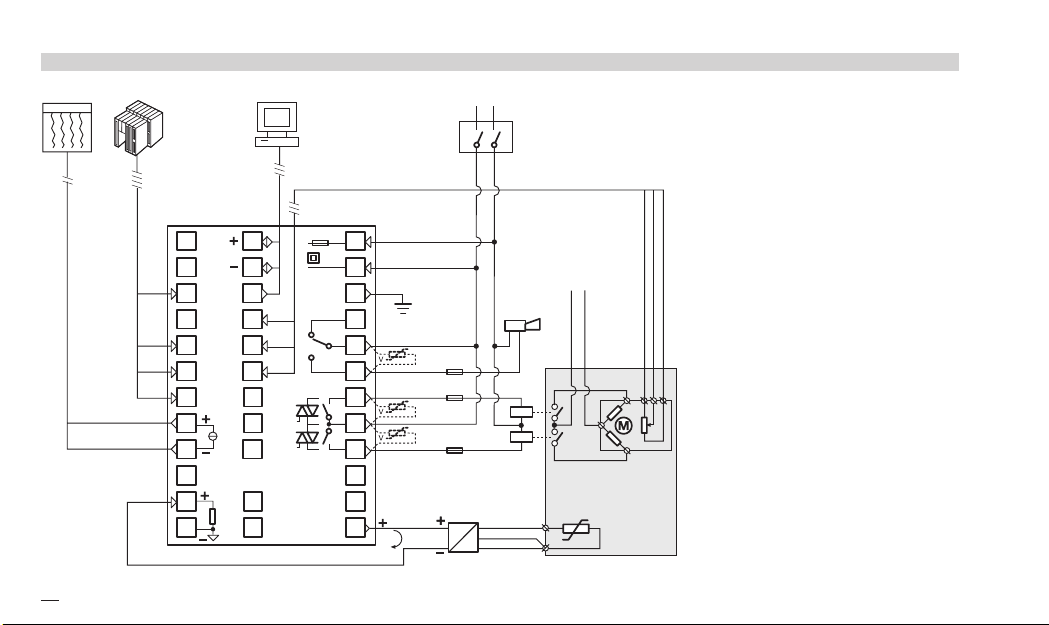

Page 12

3 - Electrical Connections

SupervisoryCommands

RS485

Power

supply

switch

Alarm

V

~

[3]

C

IL1

IL2

IL3

[6]

[6]

[5]

[5]

[5]

OP3

OP1

OP2

°C

C

Retransm.

I

Pt100

[6]

Transmitter

4…20mA

24V

V ~

Servomotor

Rj

PTC

12

11

10

9

8

7

6

5

4

3

2

1

24

23

20

19

36

35

34

33

32

31

30

29

28

27

26

25

18

17

16

15

14

13

21

3.3 EXAMPLE OF WIRING DIAGRAM (VALVE CONTROL)

12

B

Notes:

1] Ensure that the power supply voltage is

the same as that on the instrument label.

2] Switch ON the power supply only after

all electrical connections have been

completed.

3] In accordance with electrical safety reg-

ulations, there must be an easly identifiable and accessable power disconnect.

4] The instrument is PTC protected.

In case of failure, return the instrument to

the manufacturer for repair.

5] To protect internal circuits use:

- 2 A

~ T fuse for Relay outputs (220 Vac)

- 4 A~ T fuse for Relay outputs (110 Vac)

- 1 A~ T fuse for Triac outputs

6] Relay contacts are protected with varis-

tors.

In case of 24 Vac inductive loads, use

model A51-065-30D7 varistors (on

request).

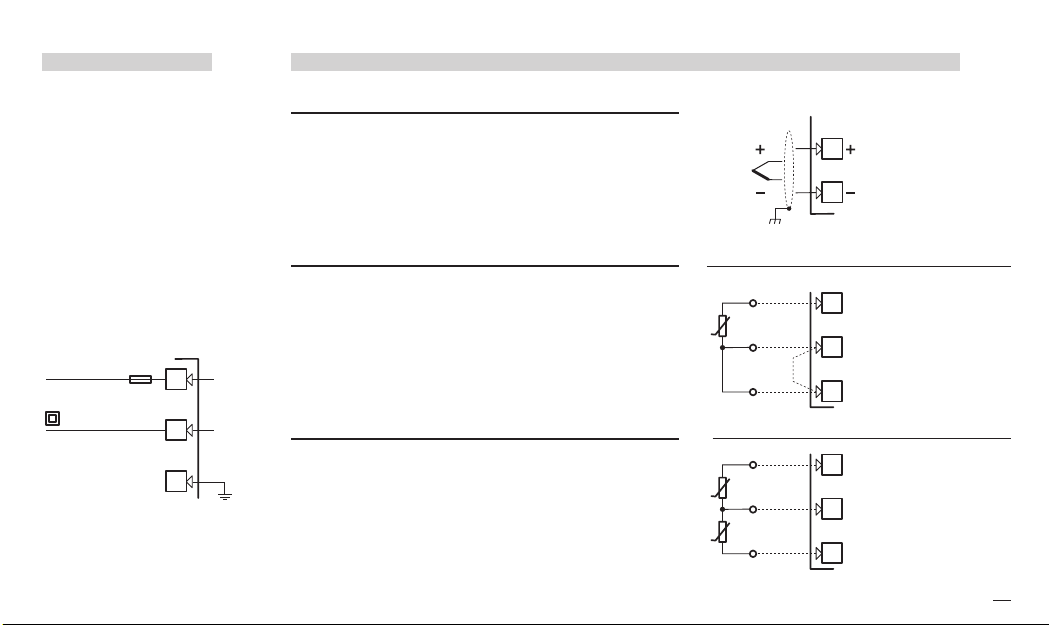

Page 13

3.3.1 POWER SUPPLY

L

N

25

26

PTC

included

Supply

27

10

11

12

A

B

A

R2

R1

10

11

12

A

b

B

11

12

B

3.3.2 PV CONTROL INPUT

3 - Electrical Connections

B

Switching power supply with multiple isolation and PTC protection.

• Standard version:

Nominal voltage:

100... 240Vac (-15...+10%);

Frequency 50/60Hz.

• Low Voltage version:

Nominal voltage:

24Vac (-25...+12%);

Frequency 50/60Hz

or 24Vdc (-15...+25%);

Power consumption 5W max.

A L-J-K-S-R-T-B-N-E-W thermocouple type

• Connect wires with the polarity as shown;

• Always use compensation cable of the correct type

for the thermocouple used;

• The shield, if present, must be connected to ground.

B For Pt100 resistance thermometer

• If a 3 wires system is used, always use cables of the

same section (1mm2min.), maximum line resistance

20 Ω/line.

• When using a 2 wires system, always use cables of the

same section (1.5mm2min.) and put a jumper between

terminals 11 and 12

C For ∆T (2x RTD Pt100) Special

A When the distance between the controller and the

sensor is 15m, using a cable of 1.5mm2 section, produces an error on the measure of 1°C.

R1 + R2 must be <320Ω

Wire resistance

150Ω max.

Only for two wires

system, put a

jumper between terminals 11 and 12.

Use wires of the

same length and 1.5

2

mm

size.

Maximum line resistance 20 Ω/line.

13

Page 14

3 - Electrical Connections

Rj

V,mV

mA

11

12

Rj

24V–

4…20mA

Transmitters

PV

36

11

12

[1]

mA

Rj

24V–

4…20mA

Transmitters

PV

36

11

12

[1]

mA

3.3.2 PV CONTROL INPUT

B

C For mA, mV

Input resistance = 30Ω per mA;

Input resistance > 10MΩ per mV;

Input resistance = 10kΩ per Volt;

14

C1 With 2 wires transducer

C2 With 3 wires transducer

[1] Auxiliary power supply for exter-

nal transmitter 24Vdc ±20%/30mA

max without short circuit protection.

Page 15

3.3.4 AUXILIARY INPUT

19

18

mAmV-V

Rj

Operating

travel

distance

pot.h

pot.I

Total

travel

distance

18

17

16

100%

0%

3

7

6

TTL

o.c.

Isolated

contact

Com.

IL 3

IL 2

C2

C3

5

NPN

o.c.

IL 1

C1

A - From Remote Setpoint

Current 0/4…20mA;

Input resistance = 30Ω.

Voltage 1…5V, 0…5V, 0…10V;

Input resistance = 300kΩ.

B

B - From Potentiometer

For the measure of the position of the motor or the valve.

3.3.5 DIGITAL INPUT

• The input is active when

the logic state is ON,

corresponding to the

contact closed.

• The input is inactive

when the logic state is OFF,

corresponding to the

contact open.

3 - Electrical Connections

B

15

Page 16

3 - Electrical Connections

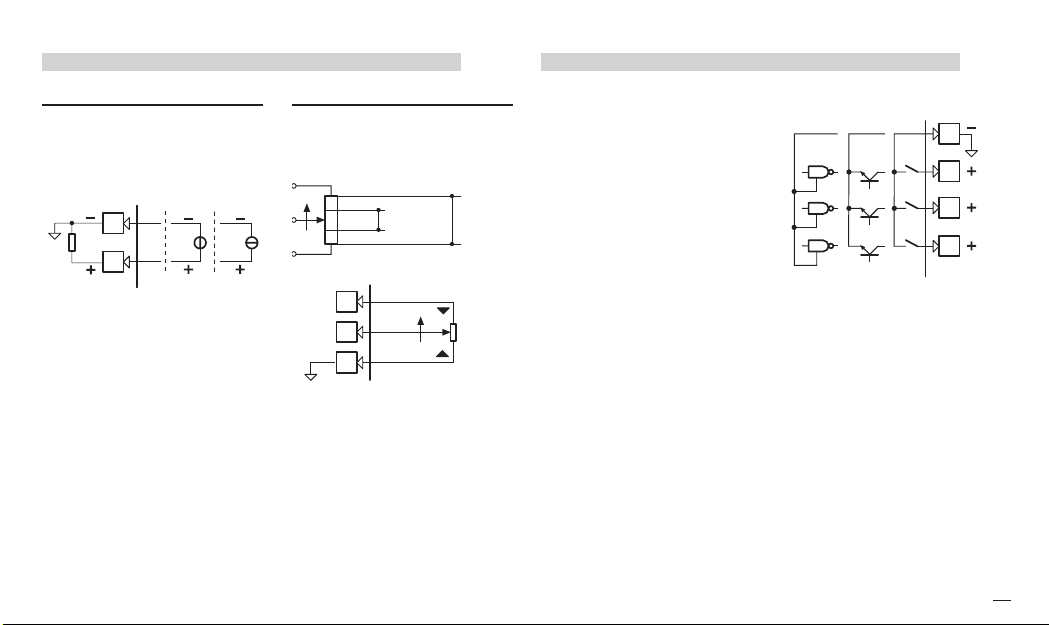

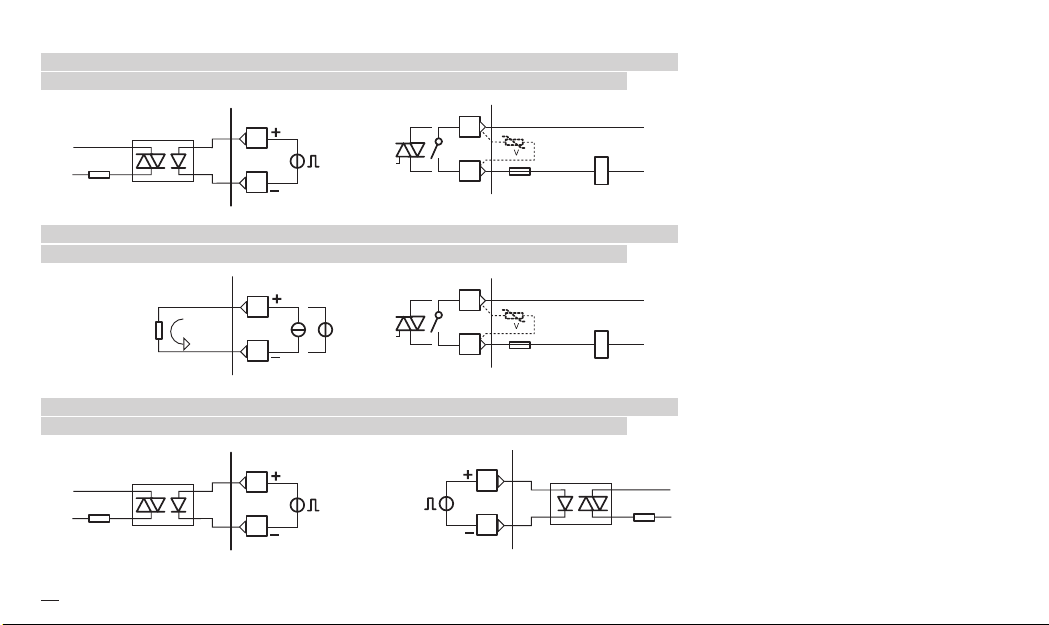

3.3.6 OP1 - OP2 - OP3 - OP4 - OP5 - OP6 OUTPUTS (OPTION)

The functionality associated to each of OP1, OP2, OP4, OP5 and OP6 is defined during the configuration of the instrument.

The allowed combinations are:

Control outputs Alarms Retransmission

A

B

D

E

F

G

L

where:

Single

action

Double

action

Valve drive

Main (Heat) Secondary (Cool) AL1 AL2 AL3 PV / SP / MV

OP1

OP5

OP1 OP2

OP1 OP5

OP5 OP2

OP5 OP6

OP1

s

OP2

OP1 OP2 OP3

OP1 OP3

t

OP2 OP3 OP5

OP3 OP5

OP2 OP3

OP2 OP3

OP3 OP5OP4

AL4

OP4

OP4

OP4

OP4

OP4

OP4

OP6

OP6

OP6

OP6

OP6

OP6

B

OP1 - OP2

OP3 - OP4

OP5 - OP6

16

Relay or Triac output

Relay outputs

Analog control or retransmission outputs

Page 17

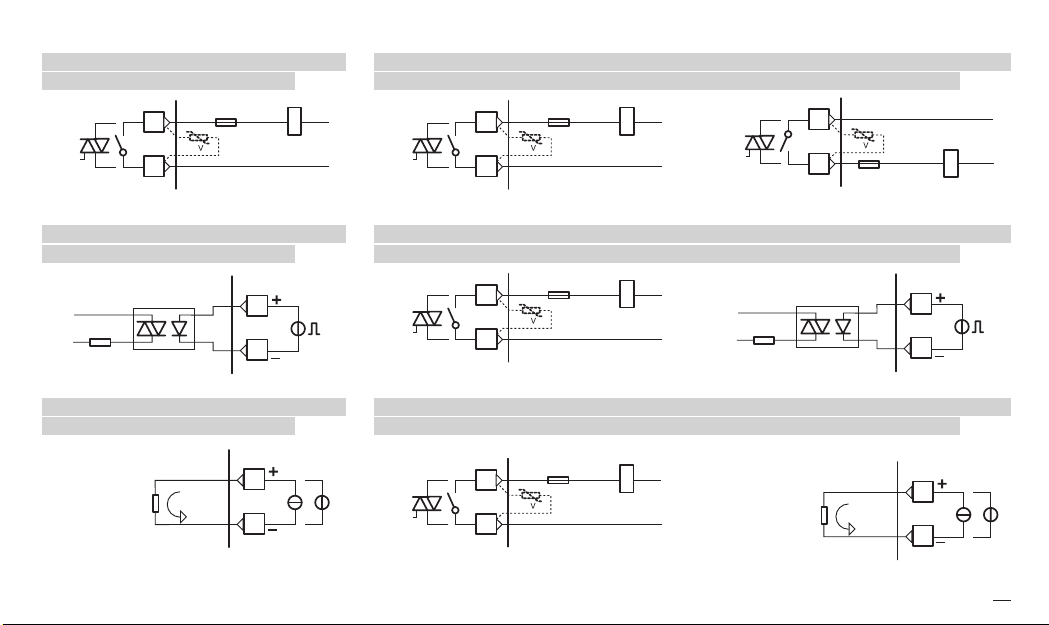

3.3.6-A SINGLE ACTION RELAY

Fuse

Coil of the heat

load contactor

31

32

OP1

[1]

Fuse

Coil of the heat

load contactor

31

32

OP1

[1]

Fuse

Coil of the cool

load contactor

32

33

OP2

[1]

Fuse

Coil of the heat

load contactor

31

32

OP1

[1]

Heat

load

Static

Relay

8

9

OP5

Cool

load

Static

Relay

8

9

OP5

8

9

OP5

Heat

load

mA mV,V

Fuse

Coil of the heat

load contactor

31

32

OP1

[1]

8

9

OP5

Cool

load

mA mV,V

(TRIAC) CONTROL OUTPUT

B

3.3.6-C DOUBLE ACTION

RELAY (TRIAC)/RELAY (TRIAC) CONTROL OUTPUT

3 - Electrical Connections

B

3.3.6-B1 SINGLE ACTION LOGIC

CONTROL OUTPUT

3.3.6-B2 SINGLE ACTION

ANALOG OUTPUT

B

B

3.3.6-D1 DOUBLE ACTION

RELAY (TRIAC)/LOGIC CONTROL OUTPUT

3.3.6-D2 DOUBLE ACTION CONTROL OUTPUT

RELAY (TRIAC)/ANALOG CONTROL OUTPUT

B

B

17

Page 18

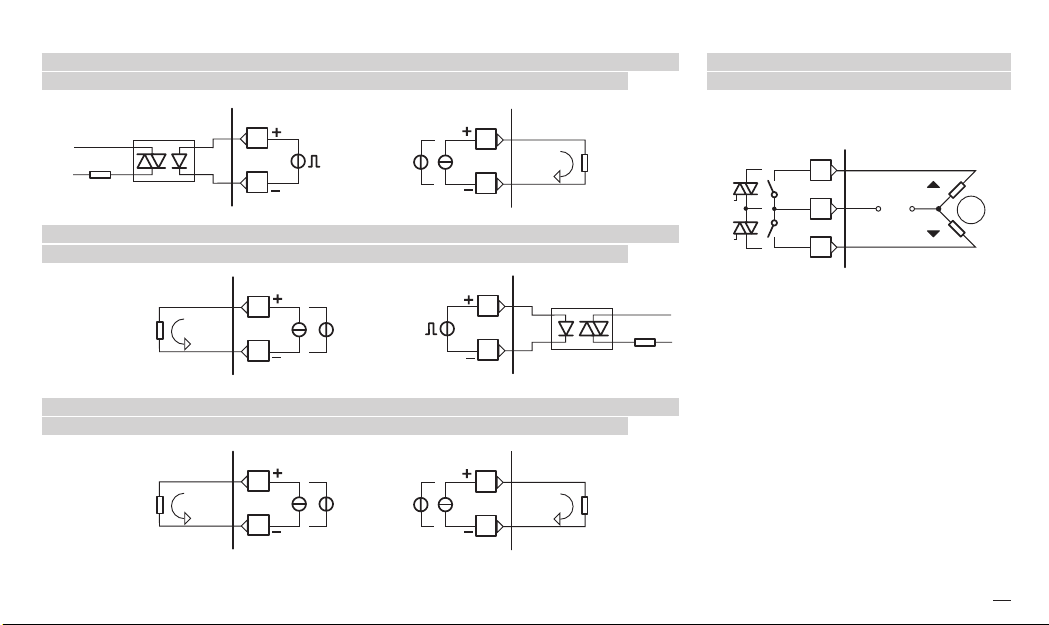

3 - Electrical Connections

Cool

load

Static

Relay

20

21

OP6

8

9

OP5

Heat

load

mA mV,V

Heat

load

Static

Relay

8

9

OP5

Fuse

Coil of the cool

load contactor

32

33

OP2

[1]

Fuse

Coil of the cool

load contactor

32

33

OP2

[1]

Heat

load

Static

Relay

8

9

OP5

3.3.6-E1 DOUBLE ACTION

DIGITAL/RELAY (TRIAC) CONTROL OUTPUT

3.3.6-E2 DOUBLE ACTION

ANALOG/RELAY(TRIAC) CONTROL OUTPUT

B

B

Notes for pages 17 - 18 - 19

OP1 - OP2 Relay output

• SPST Relay N.O., 2A/250 Vac

(4A/120Vac)

for resistive load,

• Fuse 2A ac T at 250V, 4A ac T at 110V.

OP1 - OP2 Triac output

• N.O. contact for resistive load of up to

1A/250 Vac max.

• Fuse 1A ac T

Isolated digital outputs OP5-OP6

• 0…24Vdc, ±20%, 30 mA max.

Isolated analog outputs OP5-OP6

• 0/4…20mA, 750Ω / 15V max.

0/1…5V, 0…10V, 500Ω / 20mA max.

[1] Varistor for inductive load 24Vac only

3.3.6-F1 DOUBLE ACTION

DIGITAL/DIGITAL CONTROL OUTPUT

18

B

Page 19

OP1

33

32

31

OP2

V~

Lower

Raise

M

~

20

21

OP6

Cool

load

mAV,mV

3.3.6-F2 DOUBLE ACTION CONTROL OUTPUT

8

9

OP5

Heat

load

mA mV,V

8

9

OP5

Heat

load

mA mV,V

Cool

load

Static

Relay

20

21

OP6

20

21

OP6

Cool

load

mAV,mV

Heat

load

Static

Relay

8

9

OP5

DIGITAL/ANALOG

B

3 - Electrical Connections

3.3.6-G MOTOR POSITIONER OUTPUT

RELAY (TRIAC) / RELAY (TRIAC)

Valve drive PID without potentiometer 3 pole

output with N.O. contacts (raise, lower, stop)

3.3.6-F3 DOUBLE ACTION CONTROL OUTPUT

ANALOG/DIGITAL

3.3.6-F4 DOUBLE ACTION CONTROL OUTPUT OR SPLIT RANGE

ANALOG/ANALOG

B

B

19

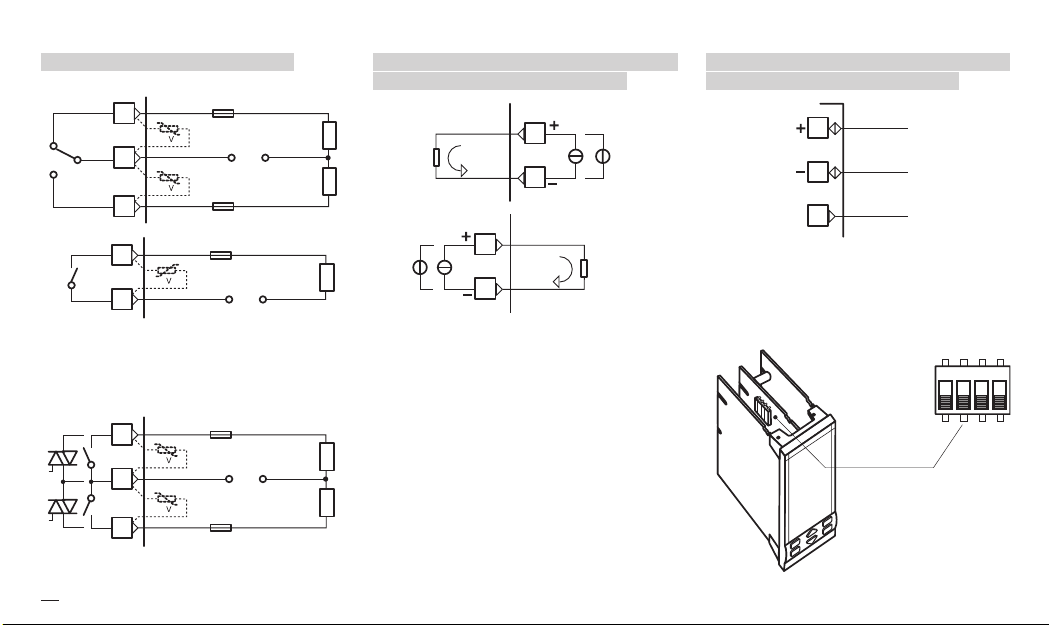

Page 20

3 - Electrical Connections

Fuse

AL3 load

28

29

OP3

[1]

30

[1]

AL3 load

V

~

Fuse

NC

C

NO

Fuse

AL1 load

31

32

OP1

[1]

33

OP2

[1]

AL2 load

V

~

Fuse

Fuse

AL4 load

34

35

OP4

[1]

V~

C

SLAVE

13

14

15

20

21

OP6

Cool

load

mAV,mV

8

9

OP5

Heat

load

mA mV,V

1234

SLAVE

3.3.7 OP1-2-3-4 ALARM OUTPUTS

e The relay/triac output OP1/OP2, can be used

as alarm outputs only if they are not used

as control outputs.

20

B

3.3.8 OP5 AND OP6 (OPTION)

ANALOG CONTROL OUTPUTS

B

OP5 and OP6 can be configured for control

action or PV/SP/MV retransmission:

• Galvanic isolation 500Vac/1 min:

• 0/4…20mA, 750Ω / 15Vdc max.

0/1…5V, 0…10V, 500Ω / 20mA max..

Notes:

[1] Varistor for inductive load 24Vac only

[2]

A Please, read the user manual:

“Serial communications and configuration software”.

3.3.9 SERIAL COMMUNICATIONS

(OPTION) [2]

• Galvanic isolation 500Vac/1 min;

Compliance to the EIA RS485 standard

for Modbus/Jbus;

• Termination setting dip switches.

B

Page 21

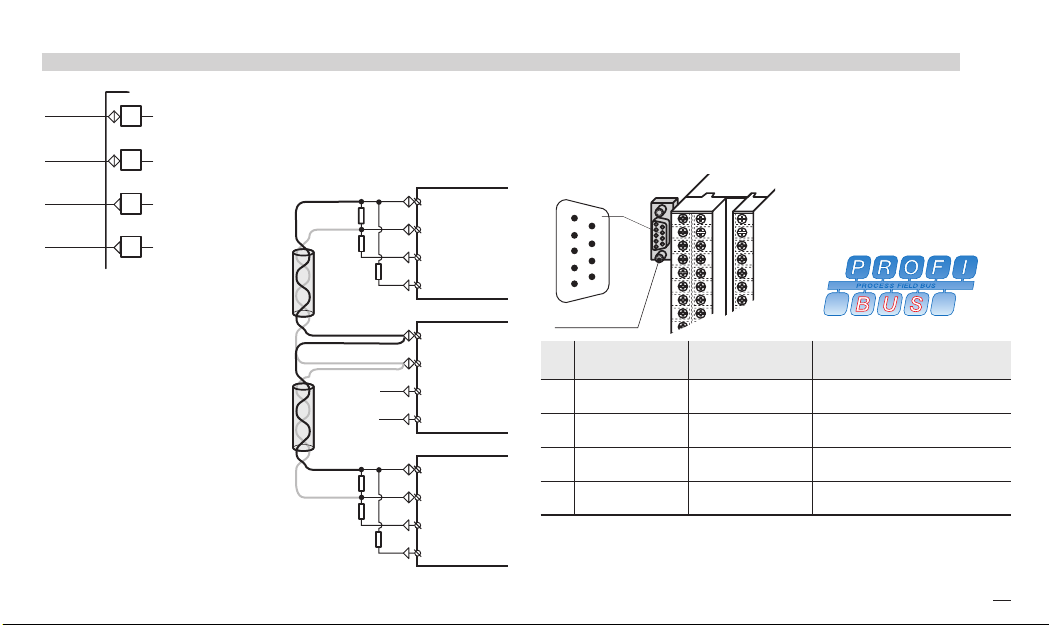

3.3.10 PROFIBUS DP (OPTION)

DP

DN

DG

VP

1

2

3

4

DP

DN

DG

VP

Initial

PROFIBUS

station

DP

DN

DG

VP

Other

PROFIBUS

stations

DP

DN

DG

VP

Ending

PROFIBUS

station

220Ω

390Ω

390Ω

220Ω

390Ω

390Ω

33

4-40UNC-2B

5

9

6

1

3 - Electrical Connections

B

•

Galvanic isolation 500 Vac/1 min

• Compliance to the EIA RS485

standard for PROFIBUS DP;

• Connecting cable: twisted

pair cable as per PROFIBUS

specifications (e.g. Belden

B3079A);

• Max. lenght: 100 m at 12 Mb/s

Termination resistors 220Ω and

390Ω (1/4W, ±5%) for external

mounting on the first and ending PROFIBUS stations only.

To make the connections easier, a D-Sub type (9 poles)

connector, model AP-ADP-PRESA-DSUB/9P is provided

Must be used with a 9PIN male ERNI type part no. 103648 or similar connector.

X5 D-SUB 9 poles Signal

1 3 RxD/TxD-P (DP)

2 8 RxD/TxD-N (DN)

3 5 DGND (DG)

4

6

VP (VP)

Description according to

PROFIBUS specifications

Receive data/transmission

data plus

Receive data/transmission

data negative

Data transmission potential

(ground to 5V)

Supply voltage of the terminating resistance-P, (P5V)

Detailed information concerning wiring and cables can be found on

the PROFIBUS Product Guide on Internet at:

http://www.profibus.com/online/list

21

Page 22

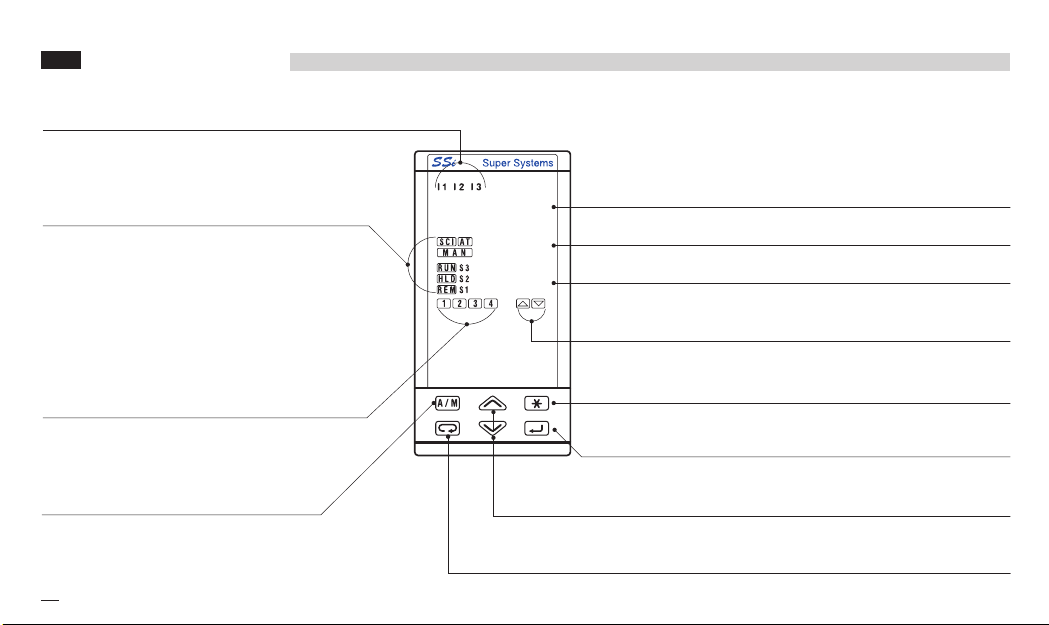

I 1 I 2 I 3

45.80

45.80

50

4 - Operation

4 OPERATION

4.1.1 KEY FUNCTIONS AND DISPLAYS IN OPERATOR MODE

Digital input status LEDs (yellows)

ó - IL1 active

ò - IL2 active

ô - IL3 active

Status LEDs (greens)

} Communications running

(serial communications interface)

Ä Tuning running

{ Manual operating mode

Ö Timer

á Program Waiting

Ü Remote Setpoint active

ú First stored Setpoint active

ù Second stored Setpoint active

û Third stored Setpoint active

Alarm status LEDs (reds)

Å AL1 ON

Ç AL2 ON

É AL3 ON

Ñ AL4 ON

Auto/Man

22

Over range Under range

8888____ 8888----

PV control input in engineering units

% Control output

or Program status (see page 64)

SP operating Setpoint

(Local/Remote or Stored)

Control output LEDs (red)

å OP1/OP4 ON - ç OP2/OP4 OFF

Run/stop Timer or a program

Entry key for selection and value setting confirmation

Setpoint setting

Menu access

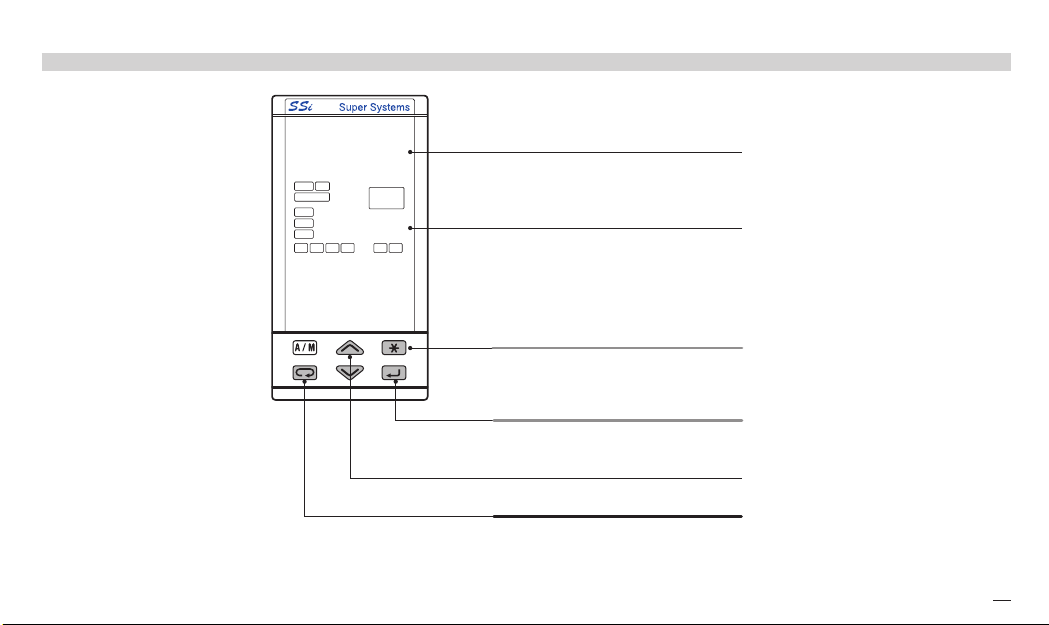

Page 23

4.1.2 KEY FUNCTIONS AND DISPLAY IN PROGRAMMING MODE

35.0

P.b.

4 - Operation

The parameter setting proce-

A

dure has a timeout. If no keys

are pressed for, at least 30

seconds, the controller automatically switches back to the

operator mode.

After selecting the parameter or

the code, press $ and %

to display or modify the value.

The value is entered when the

next parameter is entered, by

pressing the è key.

The changes are not saved if

either the back key ê is

pressed or if the instrument is

left alone for 30 seconds.

From every parameter, pressing

the

í key, the controller

switches to the operator mode.

Parameter value

Parameter mnemonic

Back to the previous parameter

Entry key for selection

and value setting confirmation

Value modification

Access to the menu for:

- Parameter setting

- Configuration

- Access selection

23

Page 24

4 - Operation

275.0

274.8

275.0

274.8

230.0

274.8

240.0

274.8

240.0

°C

Unit

°C

Unit

°f

Unit

°C

Unit

°f

Unit

none

Unit

ph

4.2 PARAMETER SETTING

4.2.1 NUMERIC ENTRY

(i.e. the modification of the Setpoint

value from 275.0 to 240.0 )

Press $ or % momentarily

to change the value by 1 unit

every push.

Hold $ or % to change

the value at rate that doubles

every second.

The rate of change decreases

when the button is released.

The change of the value stops

when it has reached the max./

min limit set for the parameter.

In case of Setpoint modification:

press

$ or % once to

display the local Setpoint

instead of working Setpoint.

To evidence this change the

display flashes once. Then the

Setpoint can be modified

24

Operator

mode

working Setpoint

displayed

Local

Setpoint display

————Decrease

Setpoint

modification

————Increase

after 2 s

Setpoint entry.

The operation is

acknowledged by

one flash of the

display.

4.2.2 MNEMONIC CODE SETTING

(e.g. configuration see page 26)

Press the

for the selected parameter.

Continued pressing of $ or % will display further mnemonics

at a rate of one mnemonic every 0.5 s. The mnemonic displayed

at the time the next parameter is selected is the one stored and used.

$ or % to display the next or previous mnemonic

Engineering

Units

Celsius

Degree

Fahrenheit

Degree

Celsius

Degree

Fahrenheit

no units

defined

Ph

Page 25

4.3 CONFIGURATION PROCEDURE

Conf

275.8 Menu C.pas

33

OK

Conf

EHit

274.8

InP.

S.P. Out L.inP ALM

Conf Conf

Conf

ConfConf

tiMe

Conf

Operator

Mode

Configuration

menu

Press the key until

4 - Operation

Enter the configuration

password

from -999...9999

(33 default from factory)

Must be equal to the

value

of the parameter

C.Pas (see page.50)

Configuration

Inputs

Setpoint

Configuration

Output

Configuration

Digital inputs

configuration

(see page 26) (see page 27) (see pages 28 and 29) (see page 30)

Alarms

configuration

(see page 30... 33)

NOYES

Timer

configuration

Back to the operator mode

(see page 34)

Exit the

Configuration

25

Page 26

4 - Operation

Conf

InP.

Inp.

Unit

sc.dd

sc.lo

é 0

é 0

sc.Hi

é9999

Sqr

éno

CHar

éno

é0=10

énone

4.3.1 INPUTS CONFIGURATION

26

Input type

see table 1

Engineering

Units

see table 2

LINEAR INPUT

ONLY

No. of decimals

0 / 1 / 2 / 3

Low range

from min. range

Sc.Hi

up to

High range

Sc.Lo

from

to max. range

Square root

no / yes

Linear inputs

characterization

no / yes

Tab. 1 Input type

Value Description

0…600°C

tc. j

0…1200°C

tc. k

0…600°C

tc. l

0…1600°C

tc. s

0…1600°C

tc. r

-200…400°C

tc. t

0…1800°C

tc. b

0…1200°C [1]

tc. n

0…1100°C [2]

tc.ni

0…2000°C

tc.U3

0…2000°C

tc.U5

0…600°C

tc. E

Custom range on request [3]

cuSt

-200…600°C

rtd1

-99.9...300.0°C

rtd2

-50.0…50.0°C

del.t

0…50 mV

M.50

0…300 mV

M.300

0…5 Volt

0=5

1…5 Volt

1=5

0…10 Volt

0=10

0…20 mA

0=20

4…20 mA

4=20

0…2.000 Hz

Frq.L

0…20.000 Hz

Frq.H

PInp.

éInP.

32…1112°F

32…2192°F

32…1112°F

32…2912°F

32…2912°F

-328…752°F

32…3272°F

32…2192°F

32…2012°F

32…3632°F

32…3632°F

32…1112°F

-328…1112°F

-99.9…572.0°F

-58.0…122.0°F

Engineering

units

Frequency

(option)

Tab. 2 Engineering units

Value Description

Notes:

[1]

[2] Ni-Mo thermocouple.

[3] Factory default for the

None

none

Degree centigrade

°C

Degree Fahrenheit

°f

mA

MA

mV

MU

Volt

U

bar

bar

PSI

psI

Rh

rh

Ph

ph

Hertz

Hz

NiChroSil-NiSil thermocouple.

custom range is: type K

(32... 2448°F).

éUnit

Page 27

Conf

S.P.

S.P.ty

S.P.tr

éLoc

éno

S.P.tM

éP.Sec

éNo

rS.sl

REMOTE

INPUT ONLY

rS.In

é4=20

4.3.2 SETPOINT CONFIGURATION

Tab. 3

Setpoint type

Value Description

Local only

loc

Remote only

reM

Local/remote only

l=r

Local - trim

loc.t

Remote - trim

reM.t

4 - Operation

éS.P.ty

Setpoint

type

see table 3

Stored

Setpoint Tracking

see page 43

no/ yes

Time units and

Setpoint slope

P.Sec/P.Min/

P.Hr

Remote Setpoint input

see table 4

not displayed if the

frequency input is present

Remote Setpoint

Slope enable [1]

no / yes

[1] Not available with Setpoint

Programmer option

Tab. 4 Rem. Setpoint

Value Description

0…5 Volt

0=5

1…5 Volt

1=5

0…10 Volt

0=10

0…20 mA

0=20

4…20 mA

4=20

érs.In

27

Page 28

4 - Operation

Conf

Out

Cn.ty

M.C.OP

rt. 2

énone

O.rt.2

é4=20

rt.L2

é 0

rt.H2

é9999

éPid:r

éOFF

rt.H1

é9999

rt.L1

é 0

O.rt.1

é4=20

rt. 1

énone

F.Out

éOFF

S.Out

éOFF

C.OP.5

éno

S.C.OP

éOFF

4.3.3 OUTPUT CONFIGURATION

28

Control

type

see table 5

Main output

(Heat)

see table 6

Secondary output

(Cool)

(Heat/Cool only)

see table 7

Cool output on OP5

(Heat/Cool only)

no/yes

Main output

safety value

OFF/-100…+100%

Main output

forcing value

OFF/-100…+100%

Split range %

(split range only)

0.0…+100%

WITH OP5 ANALOG OUTPUT NOT

USED AS CONTROL OUTPUT

st

1

retransmitted

output selection

none/ P.U./S.P.

1stretransmission

output

see table 8

st

retransmission

1

low range

whole range

st

retransmission

1

high range

whole range

WITH OPTIONAL OP6 ANALOG

OUTPUT NOT USED AS COOL CON-

TROL OUTPUT

nd

retransmitted

2

output selection

none/P.U/S.P./M.U.

2ndretransmission

output

see table 8

nd

2

retransmission

low range

whole range

nd

2

retransmission

high range

whole range

Page 29

20

4

800 1200 1600

#retr = 4=20

#rt.H = P.U.

#rt.L1 = 800

#rt.H1 =1200

mA

°C

Tab. 5

Value Description

Of.re

Of.di

pid.d

pid.r

U.dir

U.reU

H.C.ln

H.C.Ol

H.C.H2

Tab. 6

Value Description

Off

OP 1

log

0=5

1=5

0=10

0=20

4=20

Control mode

Reverse action

Direct action

Direct action

Reverse action

Direct action

Reverse action

Linear

Oil charac.

Water charac.

Main Output (Heat)

Not used

Relay / Triac

Digital

0…5 Volt

1…5 Volt

0…10 Volt

0…20 mA

4…20 mA

On - Off

PID

Modul.

valves

Heat/

Cool

Digital

signal

DC

signal

éCn.ty

éM.C.OP

Tab. 7

Secondary output (Cool)

Value Description

Not used

Off

Relay / Triac

OP 2

Digital

log

0…5 Volt

0=5

1…5 Volt

1=5

0…10 Volt

0=10

0…20 mA

0=20

4…20 mA

4=20

Tab. 8

Retransmission outputs

Value Description

0…5 Volt

0=5

1…5 Volt

1=5

0…10 Volt

0=10

0…20 mA

0=20

4…20 mA

4=20

éS.C.OP

Digital

signal

DC

signal

éO.rt.1

éO.rt.2

RETRANSMISSION

When OP5 and OP6 outputs

are not configured as control

output, they can retransmit the

PV, SP or MV linearized value.

#rt. 1

Retransmitted

signal

none/P.U./ S.P

#rt. 2

#O.rt.I

#O.rt.2

The following parameters define

the low and high range.

#rt.L1

#rt.L2

/M.U.

Output

range

0=5 /1=5 /0=10

0=20 / 4=20

Retransmission

low

range

4 - Operation

#rt.H1

Retransmission

high

range

#rt.H2

Example:

• T/C S: range 0…1600°C;

• Output range, 4…20 mA;

• Retransmitted signal PV on

800…1200°C range.

With rt.lI greater than

rt.H1 it is possible to obtain

a reverse scale.

29

Page 30

Conf

L.inp

IL1

IL2

éOFF

éOFF

IL3

éOFF

4 - Operation

Conf

ALM

bloc

éno

Ltch

éno

A1.Ou

éOP1

AL. 1

éOFF

donb

éno

4.3.4 DIGITAL INPUT CONFIGURATION 4.3.5 ALARM CONFIGURATION

30

IL1 digital input

function

see table 10

IL2 digital input

function

see table 10

IL3 digital input

function

see table 10

Tab. 10 Digital Inputs

Value

Off

l=r

A.Man

s.p. 1

s.p. 2

s.p. 3

keb.I

slo.1

H.pU

F.Out

blck

strt

tres

end

functions

Description

Not used

Local/Remote

Auto/Man

1ststored Setpoint

2ndstored Setpoint

3rdstored Setpoint

Keyboard lock

s.p. slope disable

Measure hold

Output forcing mode

Reset blocking

Start-Hold timer

Reset out timer

Quit timer

éIl1

éIl2

éIl3

[1] OP1 and OP2 outputs

can be used as alarm

outputs if they are not

used as control outputs.

NOT AVAILABLE

OF

AL. 1 = OFF

AL1 alarm type

see table 11

AL1 addressing

OP1 / OP2 [1]

OP3 / OP4

AL1 latching

no / yeS

AL1 start-up

disabling

no / yeS

Disables AL1 if a sensor break occurs

no / yeS

Page 31

4 - Operation

AL. 4

éOFF

A4.Ou

éOP4

Ltch

éno

bloc

éno

bloc

éno

Ltch

éno

A3.Ou

éOP3

AL. 3

éOFF

bloc

éno

Ltch

éno

A2.Ou

éOP2

AL. 2

éOFF

donb

éno

donb

éno

donb

éno

OF

NOT AVAILABLE

AL. 2 = OFF

AL2 alarm type

see table 11

AL2 addressing

OP1 / OP2 [1]

OP3 / OP4

AL21 latching

no / yeS

AL2 start-up

disabling

no / yeS

Disables AL2 if a sensor break occurs

no / yeS

OF

NOT AVAILABLE

AL. 3 = OFF

AL3 alarm type

see table 11

AL3 addressing

OP1 / OP2 [1]

OP3 / OP4

AL3 latching

no / yeS

AL3 start-up

disabling

no / yeS

Disables AL3 if a sensor break occurs

no / yeS

OF

AL4 alarm type

see table 11

NOT AVAILABLE

AL. 4 = OFF

AL4 addressing

OP1 / OP2 [1]

OP3 / OP4

AL4 latching

no / yeS

AL4 start-up

disabling

no / yeS

Disables AL4 if a sensor break occurs

no / yeS

Tab. 11 Alarm type

Description

Value

Not used or used by the

Off

program (AL3/AL4)

Active High

fs.H

Active Low

fs.l

Active High

deU.H

Active Low

deU.l

Active Out

bno

Active In

bni

Loop break alarm

lba

(AL1 only)

Alarm 3 active when

tiMe

Timer ON

éAl 1

éAl 2

éAl 3

éAl 4

Absolute

Deviation

Band

31

Page 32

4 - Operation

Absolute alarm

Active high

é-fsH

Active low

é-fsl

hyd hyu

On

Off

On

Off

Alarm threshold

High rangeLow range

Deviation alarm

Active high

Active low

é-del

hyd hyu

On

Off

On

Off

SP

Alarm threshold

+ range- range

é-deH

Band alarm

Active out

é-bnd

hyd hyu

On

Off

SP

Alarm threshold

full scale

full scale

hyd hyu

∆SP

∆SP ∆SP

Ltch

Yes

275.0

3deH

The type of alarm is presented

flashing, on the front panel in

alternation with the PV value.

The red led of the activated

alarm output is on.

4.3.6 AL1, AL2, AL3, AL4 ALARM CONFIGURATION [A] OPERATING CONDITIONS

Up to four alarms can be configured: AL1, AL2, AL3 and AL4 (see

page 31).

For each alarm the following selections can be mode:

A the type and the operating condi-

B the functionality of the alarm

C the start-up disabling (blocking)

D alarm inhibition on sensor break

E the physical output of the alarm

The outputs can be used for

alarms if they are not used as

control outputs (see par.

page 20).

It is possible to route up to 4 alarm

to a single output (OR of the alarms).

32

tion of the alarm (table 11 page 31)

acknowledge (latching)

#bloc

#OpI #Op2 #Op3 #Op4

#ltch

3.3.7

Alarm occurrence display

This function can be enabled by the

configuration software.

Please, read the user manual:

“Serial communication and configuration software”.

[B] ALARM ACKNOWLEDGE

FUNCTION

The alarm, once occurred, is

presented on the display until

acknowledged. The acknowledge

operation consists in pressing any

key.

After this operation, the alarm

leaves the alarm state only when

the alarm condition is no longer

present.

Page 33

mA

°C

OP1

275.0

A / M

1 2 3

Ilba

4

[C] START-UP DISABLING

∆SP

Disable

SP

On

Off

Start-up

ramp

down

ramp

up

∆SP

threshold

=

SP± range

Disable

SP

∆SP

On

Off

Start-up

Bloc

Yes

PV

Process

variable PV

AL1

#donb = no

#-FS.H = 300°C

Sensor

break

Sensor

replacement

AL1

#donb = yes

#Sc.Hi = 500°C

[D] ALARM DISABLING AT SENSOR BREAK

For those alarms that are configured to be different than LBA, it is possible

to set the parameter

Set:

#donb

(disable on break).

no To maintain the alarm status when a sensor break is detected.

yes To disable the alarm intervention when a sensor break is detected. Once

the sensor has been changed, the alarms that were active before the

sensor break are activated again

.

4 - Operation

LOOP BREAK ALARM (LBA)

When the controller connection to

the sensor is discontinued or

other faults are detected in the

control loop, AL1 alarm becomes

active after a predefined time of

1... 9999 s from the detection of

the failure (see page 37).

When a sensor failure occours,

the LBA interventrion is immediate. The alarm state ceases when

the fault condition is no longer

present.

eIn case of ON-OFF control, the

LBA alarm is not active.

33

Page 34

4 - Operation

Menu

S.P.

Menu

AL

275.0

274.8

Menu

time

t.dop

t.Act

pid

s.p.s.U

t.h.s.U

Op.Hs

tiMe

cont

é Off

éEHpd

t.Mod

é 0:5

é Off

é 0:5

é 0:5

START-UP FUNCTION

(only if t.Mod = 1)

TIMER FUNCTION

(only with AL3 enabled)

4.3.7 TIMER CONFIGURATION

Timer and

Start-up

Menu

Timer Action

t.Modnot

(only if

Offor to 1)

equal to

(see table 2 page 37)

Timer OP function

std

34

Back to

EHpd

Enable/disble PID

t.Mod= 7)

(with

0= disble

1 = enable

t.Mod parameter

Timer/Start-up

operating mode

(see table 1 page 37)

Hold time

0…500 min.

Start-up Setpoint

S.P. L…S.P. H

Output high limit

during

Start-up

5.0…100.0%

4.4 PARAMETERIZATION - MAIN MENU

Operator

mode

The parameter setting procedure

has a timeout. If no keys are

pressed for, at least, 30 seconds,

the controller switches back, automatically, to the operator mode.

Setpoint

menu

(see page 36)

Time

menu

(see pages 37)

A

Alarm

menu

(see page 41)

Page 35

Menu

Tune

Menu

PId

Menu

InP

Menu

Conf

Menu

AccS

Menu

CoMM

Menu

Out

After having selected the parameter or the code,

press $ or % to modify the value (see page

24) The value is entered when the next parameter

is selected, by pressing the è key.

Pressing í go back to the Operator mode

4 - Operation

PID

menu

(see page 42)

Tuning

menu

(see page 43)

Input

menu

(see page 43)

Output

menu

(see page 44)

Communication

menu

(see page 45)

Access

menu

(see page 54)

Configuration

menu

(see page 25)

35

Page 36

4 - Operation

Menu

S.P.

L=r

éLoc

SL. u

SL. d

éOFF

éOFF

S.P. H

éH.réange

S.P. L

éL.réange

Bias

é 0

rtio

é 1:00

S.P. 2

S.P. 3

é 0

é 0

S.P. 1

é 0

S.Sel

énone

Setpoint menu

LOCAL ONLY

#Loc

INDEX

LOCAL/REMOTE,

REMOTE OR PROGRAMMED

#L=r #reM #Prog

INDEX

4.4.1 PARAMETERIZATION - SETPOINT MENU

Setpoint selection

local/remote

Loc / reM

Depending on the configuration index shown on page 27,

the following parameters may or may not be present.

[1] The units of the slope parameters are Digit/s, digit/min digit/h

LOCAL WITH TRIM OR

REMOTE WITH TRIM

#Loc.t #reM.t

INDEX

36

Stored Setpoint

selection

none/ S.LOC/

S.S.P1 / S.S.P2/

S.S.P3

1st stored

Setpoint

full scale

2nd stored

Setpoint

full scale

3th stored

Setpoint

full scale

Ratio Setpoint

-9.99…99.99

Remote

Setpoint bias

full scale

Setpoint

low limit

full scale

Setpoint

high limit

full scale

Slope up

0ff/1…9999 digit/

[1]

Slop down

0ff/1…9999

0ff/1…9999

digit/..

digit/ [1]

Page 37

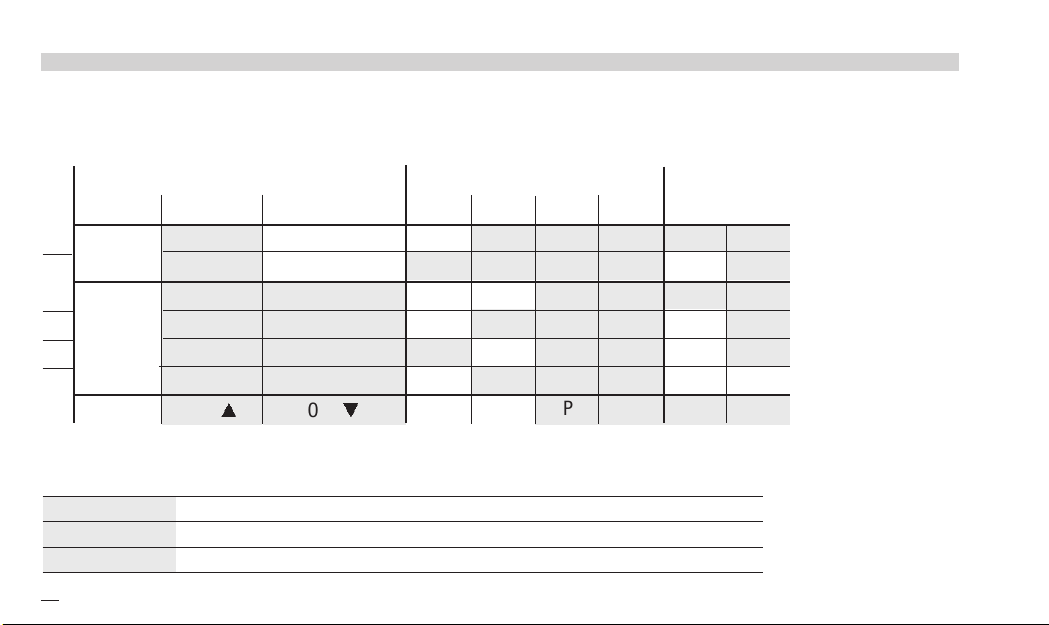

4.4.4.2 TIMER FUNCTION

AThe Timer cannot be

enabled with Heat/Cool

control.

To enable this function, perform

the following:

1 In order to use this AL3 func-

tion, index qmust be set to

0 in configuration (see page 22)

2 To select one of the 6 possible

functioning modes of the

Timer, set the value of the following 2 parameters in parameterization (see p. 29).

Timer/Start-up

#t.Mod

This parameter can be defined:

(see table 1)

- counting start time

- control output status at the

end of the counting

table 1

Timer/Start-up counting mode Value

Disabled

Start-up function

Counting

start time

When inside

the band

When launched

When launched.

Control disabled

When launched

stand-by Setpoint

Now the other parameter values

can be entered:

operating mode

OFF

End mode

Control mode

Output to 0

Control mode

Output to 0

Control mode

Control mode

1

2

3

4

5

6

7

#t.Act

This parameter can be defined:

(see table 2)

- time units

- starting mode

- OP3 status when the timer is

running.

When the timer is not running,

the OP3 takes the opposite

status.

table 2

Time

units

Minutes

[1] If used by Timer

[2] Using this selection, manual

starting mode is also possible.

Timer

Action

Starting

mode

Manual by

keypad

Auto at

Power ON [2]

[1] OP3

status

On

Off

On

Off

Value

4

5

6

7

4 - Operation

#tdop

standard/extended

Standard: tdop = 0

OP3 is set to 1 at timer lauch

and reset 0 on time elapsing.

Extended: tdop = 1

OP3 is set to 1 at time

elapsing and set to 0 by reset

command.

#Pid

Yes:

PID is enabled when time

function is enabled.

Extended:

PID is disabled and output is

maintained at zero.

Timer OP

function

std/eHpd

P.I.D enable

yes/no

37

Page 38

4 - Operation

tdop = 1

tdop = 0

Timer start

counting

Time

elapsed

#tiMe

Timer

launch

Process

variable PV

Output OP [2]

OP3

±tbs

band

#t.Mod = 2

Reset

±tbr band

SP

OP3

Timer start

counting

Time

elapsed

tdop = 1

tdop = 0

#tiMe

Timer

launch

Setpoint

OP3

#t.Mod =3

Process

variable PV

Output OP [2]

±tbs

band

Reset

±tbr band

SP

OP3

OP = 0

tdop = 1

tdop = 0

#tiMe

Timer

launch

SP

Process

variable PV

Output OP [2]

#t.Mod = 4

OP3

Reset

OP3

OP = 0

4.4.4.2 TIMER FUNCTION

TIMER COUNTING MODES

A - Counting start time inside the band,

end in control mode.

The time counting starts only when the error

is inside a ±1 digit band. The control action

is not affected by the Timer function.

B - Counting start time inside the band,

end with control output forced to zero.

The time counting starts only when the error

is inside a ±1 digit band. At the end, the control output is forced to zero [1].

C - Counting start time = timer launch

time, end in control mode.

The time counting starts when the timer is

launched. The control action is not affected

by the Timer function.

Notes

[1] When the Timer is not running the control output is forced to zero.

[2] When the PID enable parameter is set to “0” (PID disabled) the OP output is set to “0”.

38

Page 39

TIMER COUNTING MODES

tdop = 1

tdop = 0

#tiMe

Timer launch

#t.Mod = 5

Process

variable PV

Output OP [2]

OP3

Reset

OP3

OP = 0

tdop = 1

tdop = 0

#tiMe

Timer launch

SP

#t.Mod = 6

Process

variable PV

Output OP [2]

OP3

Reset

OP3

OP = 0

tdop = 1

tdop = 0

#tiMe

Timer launch

#s.p. 2

#t.Mod =7

SP

Process

variable PV

Output OP [2]

OP3

Reset

OP3

OP = 0

D - Counting start time = timer launch time,

end with control output forced to zero.

The time counting starts when the timer is

launched. At the end, the control output is

forced to zero [1].

E - No control action during

the counting time.

The time counting starts when the timer is

launched and the control output is forced to

zero. At the end, the control action starts.

4 - Operation

F - Control action with stand-by Setpoint

during the counting time.

The time counting starts when the timer is

launched and the control action use the

Stand-by Setpoint. At the end, the control

action use the working Setpoint.

Notes

[1] When the Timer is not running the control output is forced to zero.

[2] When the PID enable parameter is set to “0” (PID disabled) the OP output is set to “0”.

39

Page 40

4 - Operation

End

850

850

850

RUN

4.4.4.2 TIMER FUNCTION (OPTION)

POWER FAILURE

If there is a power failure during the Timer execution, the

value of the elapsed time is lost.

Depending on Timer action

#t.act selection, when the

controller restarts you can have

two different situations:

• with automatic mode

(

#t.act = 6,7), the Timer

function starts again and the

counting time is re-initialized.

• with manual mode

(

#t.act = 4,5), the control

output is forced to zero, if

#tMod = 3 e 5; otherwise

the control action restarts

using the working Setpoint

40

TIMER START

See the Timer starting procedure

on page 50 (chapter 6.2.2)

DISPLAY

When the Timer is running, the

Ö LED is on.

TIMER REMAINING TIME

When the timer is running it is

possible to see the remaining

time and to modify it.

To change the value of Time

Remaining, it is necessary to

put (from the time menu) the

parameter t.sts in HOLD.

When the user exits the menu,

it is possible through the up

(S) and down (G) keys to

change the Time Remaining.

To restart the timer, select the

t.sts parameter in Time Menu

and set it to RUN.

Page 41

4.4.2 PARAMETERIZATION - ALARMS MENU

Menu

AL

hy.3u

é 1

hy.3d

é 1

hy.4u

é 1

hy.4d

é 1

hy.2d

é 1

hy.2u

é 1

hy.Iu

é 1

4---

é 0

3---

é 0

2---

é 0

1---

é 0

tf1-

é 1

hy.Id

é 1

tf3-

é 1

tf2-

é 1

tf4-

é 1

4 - Operation

Alarms

menu

Alarm threshold 1

[1] see table

Alarm threshold 2

[1] see table

Alarm threshold 3

[1] see table

Alarm threshold 4

[1] see table

Alarm 1 hysteresis

asymmetric upper

0…5% Span

in engineering units

Alarm 1 hysteresis

asymmetric lower

0…5% Span

in engineering units

Alarm 1 delay

OFF/1...9999

Alarm 2 hysteresis

asymmetric upper

0…5% Span

in engineering units

Alarm 2 hysteresis

asymmetric lower

0…5% Span

in engineering units

Alarm 2 delay

OFF/1...9999

Alarm 3 hysteresis

asymmetric upper

0…5% Span

in engineering units

Alarm 3 hysteresis

asymmetric lower

0…5% Span

in engineering units

Alarm 3 delay

OFF/1...9999

Alarm 4 hysteresis

asymmetric upper

0…5% Span

in engineering units

Alarm 4 hysteresis

asymmetric lower

0…5% Span

in engineering units

Alarm 4 delay

OFF/1...9999

[1] A code, specifying the No. and the

alarm type that has been configured (see page 31), is displayed. At

this point, the user must enter the

threshold value, according to the

following table.

Type and value Mode

Absolute

full scale

Deviation

full scale

Band

full scale

L.B.A.

1…9999 s

Timer

ON on timer

signal

Active high

Active low

Active high

Active low

Active out

Active in

Active high

Alarm 3

active on

timer signal

No. and

Param.

-fs.H

-fs.l

-de.H

-de.l

-bno

-bni

-lba

-ton

41

Page 42

4 - Operation

Menu

PID

OK

t.d. C

é 12:0

t.i. C

é 60

P.b. C

é 5:0

M.reS

é 50:0

O.C.

é 1:00

d.Err

ééOFF

t.d.

é 12:0

t.i.

é 60

P.b.

é 5:0

4.4.3 PARAMETERIZATION - PID MENU (not shown for ON-OFF control action)

Menu

PID

42

Proportional

band

0.5…999.9%c.s.

Integral

time

0ff/1

…

9999 s

Derivative

time

0ff/0.1

…

999.9 s

Error

dead band

0ff/0.1...10.0 digits

Overshoot control

0.01…1.00

(not displayed if

Heat/Cool)

Manual reset

0ff/1…100% output

(not displayed if

Heat/Cool)

Heat / Cool

Algorithm

NO

YES

Proportional band

Cool channel

0.5…999.9%c.s.

Cool

Integral time

0ff/1

…

9999 s

Cool

Derivative time

0ff/0.1

…

999.9 s

Page 43

Menu

Tune

Yes

No

t.d.

t.i.

p.b.

tune

éno

for AT

OK

4.4.4 PARAMETERIZATION

Menu

InP

T.SaM

é 0:11

In.Sh

é 0

t.FiL

éOFF

TUNING MENU (not shown for ON-OFF control action)

4 - Operation

4.4.5 PARAMETERIZATION

INPUT MENU

Tuning

menu

Initial

[1] These values are not automatically stored on the PID

menu parameters

tune start

(One shot tune)

no/yes

P.b.,t.i.,t.d.

Calculated Proportional

band [1] (display only)

(available when adaptive tune is selected)

Calculated Integral

time [1] (display only)

(available when adaptive tune is selected)

Calculated derivative

time [1] (display only)

(available when adaptive tune is selected)

Input

menu

Filter time constant

(user enabled/disabled)

Off/0.2…99.9 seconds

Measure bias

-60…60 digit

Sampling time

0.1…10.0 seconds

43

Page 44

4 - Operation

Menu

Out

Op.hy

é 1

ST.tM

St.OP

é Off

é 10

OP.r

é Off

OP. H

é100:0

OP. L

é 0:0

MU.hy

MU.tM

é 0:5

é 60

Op.rC

é Off

OP.C.H

t.c. C

é 10:0

é100:0

d.bnd

é 0:5

t.c.

é 10:0

4.4.6 PARAMETERIZATION - OUTPUT MENU

On-Off

Algorithm

44

Output

menu

PID

Algorithm

Output hysteresis

0…5% Span

in engineering units

Cycle time

(time proportional only)

0.2…100.0 s

Control Output low limit

(not available in

Heat/Cool configuration)

0…100%

Control output

high limit

0…100%

Control output

rate limit

(user enabled/disabled)

0ff/0.01…99.99%s

Control Output

soft start value

(user enabled/disabled)

0ff/1…100%

Soft start function

activation time

1…9999 s

Valve drive

algorithm

Motor travel time

15…600 seconds

Minimum

output step

0.1…5.0%

Heat / Cool

Algorithm

Dead band

0.0…5.0%

Cool cycle time

(time proportional only)

0.2…100.0 s

Cool control output

high limit

(PID only)

0.0…100.0%

Cool output rate limit

(user enabled/disabled)

0ff/0.01…99.99%s

Page 45

PAr.y

bdr.S

é9600

énone

Add.S

é 1

PAr.y

é 3

Pro.S

bdr.S

é9600

éJbuS

Add.S

é 1

Pro.S

éJbuS

Add.P

é 3

Menu

CoMM

Serial

communication

menu

4.4.7 PARAMETERIZATION - SERIAL COMMUNICATION MENU

Depending on serial communication choosen (see model code

on page 5), there are the following parameters:

RS485 Modbus/Jbus

SLAVE + PROFIBUS DP

Index

c= 7-8

4 - Operation

RS485 Modbus/Jbus

SLAVE

SLAVE address

communication

(if option installed)

0ff / 1…247

SLAVE baud rate

1200/2400

/9600/19200

4800

SLAVE

communication protocol

MbuS / jbuS / SSIM

Parity

none/EVEn/odd

Index

c= 5

SLAVE address

communication

(if option installed)

0ff / 1…247

SLAVE baud rate

1200/2400

/9600/19200

4800

Communication

protocol

MbuS / jbuS

Parity

none/EVEn/odd

PROFIBUS DP

address

3…124

45

Page 46

4 - Operation

Setpoint

change

Target Setpoint

= 350°C

t

t = 10

#

sL. u = 10

digit/minute

Example

Initial

Setpoint

= 250°C

4.5 PARAMETERS

For a simpler use of the controller, the parameters have been

organized in menus, according

to their functional area.

46

4.5.1 SETPOINT MENU

#s.P. L

#s.P. H

High and low limit of the SP.

The minimum span (S.P.L - S.P.H)

must be greater than 100 digit.

#sl. u

#sl. d

This parameter specifies the

maximum rate of change of the

Setpoint.

Adjustable in digit/s,digit/min

and digit/hour (see page 27)

When the parameter is

this function is disabled and

the new Setpoint is reached

immediately after being

entered.

Setpoint

low limit

Setpoint

high limit

Setpoint

ramp up

Setpoint

ramp down

OFF,

Otherwise, the Setpoint value is

obtained according to the configured rate of change.

The new Setpoint value is called

"Target Setpoint". It can be displayed by means the parameter

#t.S.P.

(see procedure at page 53).

When Remote Setpoint is configured, we suggest to disable

#sl. u and #sl. d parameters

Off.

#S.P. 1

#S.P. 2

#S.P. 3

Values of the three Setpoints,

that are activated by mean of

logic inputs, communication

parameters, and keyboard. The

Setpoint active is indicated by

the ú, ù or û green LED.

See page 56 for further explanation.

#rs.sl

To enable or disable slopes when

the remote Setpoint is active.

1st stored

Setpoint

2nd stored

Setpoint

3th stored

Setpoint

Remote Setpoint

Slope enable

Page 47

4 - Operation

bias = 20

ratio = 0.1

ratio = –0.1

Remote

signal

Range

600

100

20

0

Remote

Setpoint span

10V

bias = 100

a b

a´ b´

-200 °C

HR

a (b

´ ) b (a´ )

LR

#S.P.tr

Stored Setpoint

Tracking

(see chapter 4.3.2 at page 27)

Two different operation mode

can be set:

A Stand-by mode

The selection of any memorized

SP (SP1, SP2, SP3) does not

overwrite the previous local

Setpoint when the memorized

SP is no longer active. The pre-

# no

vious local SP in unchanged.

B- Tracking mode #yeS

The use of any memorized SP

(SP1, SP2, SP3) overwrites the

local SP value.

The previous Local Setpoint

value will be lost.

#rtio

Remote

Setpoint Ratio

Ratio is the coefficient which

defines the remote Setpoint

span with respect to the input

span.

#bias

Remote

Setpoint

Bias defines the starting point of

analog Remote Setpoint in engineering units corresponding to

the low limit (current or voltage)

of the remote signal.

PV = Process Variable

LR = PV low limit

HR = PV high limit

SR = Remote Setpoint

a (a´) = SR starting point

b (b´) = SR ending point

47

Page 48

4 - Operation

biaS = starting point = a

rtio =

E.g.: biaS= 20

rtio =

b - a

HR - LR

100 - 20

600 - (-200)80800

= 0.1=

biaS = starting point = a´

rtio =

E.g.: biaS= 100

rtio =

b´ - a´

HR - LR

20 - 100

600 - (-200)

-80

800

= -0.1=

4.5.1 SETPOINT MENU

If SR starting point is lower

than the ending point, both

expressed in engineering units:

If SR starting point is higher

than the ending point, both

expressed in engineering units

Working Setpoint (SP) as combination of Local Setpoint (SL)

and remote signal

Loc.t (table 3, page 27)

Setpoint

SP = SL + (rtio • REM) + biaS

48

4.5.2 ALARM MENU

Setpoint reM.t (table 3, page 27)

SP = REM + (rtio • SL) + bias

SIGN = Remote signal %

SPAN = HR-LR

SIGN * SPAN

REM =

E.g.:Local Setpoint (SL) with an

Setpoint type = Loc.t

rtio

Remote Setpoint (SR) with an

internal Trim with multiplying

coefficient of 1/5:

Setpoint type =

rtio

Remote Setpoint range equal to

the Input range:

Setpoint type =

rtio

100

external Trim with multiplying coefficient of 1/10:

= 0.1; biaS=0

reM.t

= 0.2; biaS=0

Loc.t

= 1; biaS=LR

SL =0

(see also pages 32 and 33)

#hy-u

#hy-d

Example with high absolute alarm

On

Off

The parameter can be set

between 0 and 5% of the configured Span and set in

Engineering units. e.g.

Range = -200…600°C

Span = 800°C

Max. Hysteresis = 5% 800°= 40°C

For symmetrical hysteresis set

Asymmetric

upper alarm

hysteresis

Asymmetric

lower alarm

hysteresis

Alarm threshold

#hy-d

=

#hy-u

Alarm

#tF1

Delay time for alarm activation.

delay

OFF: alarm activated immediately

1...9999 seconds: alarm activated only if the condition persists for the set time

#hy-d = #hy-u

Page 49

4.5.3 PID MENU

STEP response

SP

End of the tuning

operating and

setting of the new

calculated terms

Start of autotune

operation

Setpoint change

PV variable

Control output

Not present with On-Off main

output or Timer PID = 0.

Proportional

Band

Cool Proportional

Band

Integral

Time

Cool integral

Time

#p.b.

#p.b. C

This parameter specifies the

proportional band coefficient

that multiplies the error (SP - PV)

#t.i.

#t.i. C

This is the integral time value that

specifies the time required by the

integral term to generate an output

equivalent to the proportional term.

When Off, the integral term is not

included in the control algorithm.

#t.d.

#t.d. C

This is the time required by the

proportional term P to reach the

level of D. When Off it is not

included in the control algorithm.

#O.C.

(Automatically disabled when the

adaptive tune is running)

This parameter specifies the

span of action of the overshoot

control. Setting lower values

(1.00—>0.01) the overshoot

generated by a Setpoint change

is reduced. The overshoot control doesn’t affect the effectiveness of the PID algorithm.

Setting 1, the overshoot control

is disabled.

Derivative

Time

Cool Derivative

Time

Overshoot

control

#M.res

This term specifies the value of

the control output when PV = SP,

in a PD only algorithm (lack of

the Integral term).

#d.err

Inside this band for (PV - SP),

the control output does not

change to protect the actuator

(output Stand-by).

Manual

reset

Error

Dead Band

4 - Operation

4.5.4 TUNING MENU

(not shown for ON-OFF

main control output)

See page also 57

Two tuning method are provided:

• Initial one shoot Fuzzy-Tuning

• Continuous, self learning

Adaptive Tuning

The Fuzzy-Tuning automatically

determines the best PID term with

behaviour respect to the process.

The controller provides 2 types

of “one shot” tuning algorithms,

that automatically are selected

according to the process conditions when the tune operation

is started.

49

Page 50

4 - Operation

0

PV

63.2%

Filter time

Time

Fuzzy-Tuning is selected when,

at the start of the autotune

operation, the PV is far from

the Setpoint (more than 5% of

the span). This method has the

advantage of fast calculation

with a reasonable accuracy in

the term calculated.

Natural frequency

tuning start

PV variable

Control output

Natural frequency is selected

when the PV is close to the SP.

This method has the advantage

of better accuracy in the terms

calculated with reasonable speed.

The Fuzzy Tuning automatically determines the best

method to use to calculate

the PID term, according the

50

End of the tuning

operating and

setting of the new

calculated terms

process conditions.

The self-learning adaptive autotune is not intrusive. It does not

affect the process during the

phase of calculation.

Continuous adaptive tune

Perturbation

New

parameters

Continuous adaptive tune is

particularly suitable for controlling process whose control

characteristics change with

time or are not linear in relation to the Setpoint values.

It does not require any operation

by the user. It continuously samples the process response to the

various perturbations, determining the frequency and the amplitude of the signals. On the basis

of this data and their statistical

values stored in the instrument,

it modifies the PID term parameters.

It is the ideal for all applications

where it is required to continuously change the PID terms

parameters in order to adjust the

PID to the changes of the

process dynamic conditions.

In case of power OFF with the

Adaptive Tune enabled, the values of the PID terms parameters are stored, in order to be

reused at the next power ON.

At power on the Adaptive Tune

starts automatically.

4.5.5 INPUT MENU

Input

#t.fil

Time constant, in seconds, of

the RC input filter on the PV

input. When this parameter is

filter

Off the filter is bypassed.

#In.sh

This value is added to the measured PV input value. Its effect

is to shift the whole PV scale of

its value (±60 digits).

#t.SaM

Sampling time, in seconds, of

the instrument. This parameter

is normally used when controlling slow process, increasing the

sampling time from 0.1... 10 s.

Measure

Bias

Sampling

Time

Page 51

4.5.6 OUTPUT MENU

SP On

hy

#

#Op.hy

The parameter can be set

between zero and 5% of the

configured Span and set in

Engineering units.

e.g. Range = -200…600°C

Span = 800°C

Max. Hyst. = 5% 800° = 40°C

#t.c.

#t.c. C

This is the cycle time of the logic

control output. The PID control

output is provided by the pulse

width modulation of the waveform.

#Op. l

It specifies the minimum value of

the control output signal.

It is also applied in manual mode.

Control output

hysteresis

Control output

cycle time

Cool

cycle time

Control Output

low limit

#Op. H

#Op.C.H

This specifies the maximum

value the control output. It is also

applied in manual mode.

#Op.r

#Op.rC

This value, specified in %/seconds, with a range from 0.01 to

99.99%/s provides the maximum rate of change of the output. When set to Off this function is disabled.

#st.Op

This specifies the value at which

the control output is set during

the soft start phase.

Control output

high limit

Cool output

high limit

Heat output

maximum rate

Cool output

maximum rate

Soft start of the

control output

Soft-Start

phase

#st.Op

Soft start

time

#Op.r

Speed in %/s

Time

Travel

time

Minimum

step

#st.tM

This value specifies the time the

soft start phase lasts. The start

up phase starts at power up of

the controller.

OP

100%

tart-up

#MU.tM

Provides the time required for

the motor positioner to go from

the 0% position to 100%

#MU.hy

This specifies the minimum

allowed time activation of the

output to a motor positioner that

produces a sensible effect. It is

related to the deadband of the

positioner.

4 - Operation

#d.bnd

This parameter specifies the

width of the deadband between

the Cool and the Heat outputs.

eat / Cool Algorithm

Heat

100%

Op.H.

100%

Heat output

Heat/Cool

deadband

Heat Cool

SP

d.bnd

P.b. / CP.b.

0

0

#OpC.H

100%

Cool output

51

Page 52

4 - Operation

4.5.7 SERIAL COMMUNICATION MENU (OPTION)

RS485 address

#Add.S

#Add.P

All instruments connected to the

same supervisor must have different addresses. If set

serial comm.s is not active.

communication

- 1…247

SLAVE

Profibus DP

address

- 3…124

Off the

#Prot

Two serial communication

options are available:

A - Modbus/Jbus SLAVE

The parameters value can be read

and when possible modified.

Protocol

selection

Mbus Modbus

Jbus Jbus

sSi Modbus SSI

• The list of data transfer (profile

file) is user configurable.

It can be set by means the

configuration software [1]

Notes:

A Please, read the user

[1]

manual:

“Serial communications

and configuration software”.

#bdr.S

This provides the baud rate in

the range 1200... 19200 bit/s.

#PAr.y

May be set even (

odd). If None is set, parity will

(

be excluded.

52

SLAVE

Baud rate

Parity

EVEn) or odd

B - PROFIBUS DP SLAVE

(Process Field bus protocol)

Industrial standard for peripheral devices connection to a

machine in a plant.