Super Systems 9205 User Manual

PROGRAMMABLE

ATMOSPHERE AND TEMPERATURE CONTROLLER

Series 9205

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive Cincinnati, OH 45249 513-772-0060

Fax: 513-772-9466 www.supersystems.com

Super Systems Inc.

USA Office

Corporate Headquarters

7205 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060 http://www.supersystems.com

Super Systems México

Sistemas Superiores Integrales S de RL de CV Calle 3 Int.: 11.

Zona Ind. Benito Juarez

Querétaro, Qro. Méx.

C.P.: 76120

Phone: +52 (442) 210 2459 http://www.supersystems.com.mx

Series 9205 Operations Manual Rev A |

1 |

Super Systems Europe

Units 3 & 4, 17 Reddicap Trading Estate, Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627 http://www.supersystemseurope.com

Super Systems China

No. 335 XianXia Road

Room 308

Shanghai, CHINA 200336

Phone: +86 21 5206 5701/2 http://www.supersystems.com

|

Table of Contents |

INSTALLATION SAFETY REQUIREMENTS ---------------------------------------------------------------------------------------------------- |

5 |

CHAPTER 1 - OVERVIEW ------------------------------------------------------------------------------------------------------------------------- |

8 |

MOUNTING ----------------------------------------------------------------------------------------------------------------------------------------- |

9 |

DIMENSIONAL DRAWINGS ----------------------------------------------------------------------------------------------------------------------- |

10 |

WIRING ------------------------------------------------------------------------------------------------------------------------------------------- |

12 |

ELECTRICAL INSTALLATION ----------------------------------------------------------------------------------------------------------------------- |

12 |

PIN OUT ------------------------------------------------------------------------------------------------------------------------------------------ |

13 |

ANCILLARY ITEMS--------------------------------------------------------------------------------------------------------------------------------- |

13 |

SETUP --------------------------------------------------------------------------------------------------------------------------------------------- |

14 |

ADDITIONAL FEATURES--------------------------------------------------------------------------------------------------------------------------- |

14 |

ETHERNET CONNECTIONS ------------------------------------------------------------------------------------------------------------------------ |

14 |

INSTRUMENT START-UP -------------------------------------------------------------------------------------------------------------------------- |

15 |

FLASH CARD & FLASH CARD READER------------------------------------------------------------------------------------------------------------ |

15 |

OPERATOR INTERFACE SCREEN SAVER----------------------------------------------------------------------------------------------------------- |

15 |

DEFAULT STATUS SCREEN ------------------------------------------------------------------------------------------------------------------------ |

15 |

MENU--------------------------------------------------------------------------------------------------------------------------------------------- |

16 |

CHART--------------------------------------------------------------------------------------------------------------------------------------------- |

16 |

CHART SUB MENU ------------------------------------------------------------------------------------------------------------------------------- |

18 |

RECIPE -------------------------------------------------------------------------------------------------------------------------------------------- |

19 |

LOOPS--------------------------------------------------------------------------------------------------------------------------------------------- |

20 |

ACK (ALARM ACKNOWLEDGE) ------------------------------------------------------------------------------------------------------------------- |

20 |

DATA LOGGING USING FLASH CARD ------------------------------------------------------------------------------------------------------------- |

21 |

CHAPTER 2 - CONFIGURATION--------------------------------------------------------------------------------------------------------------- |

22 |

MENU (CONFIGURATION) ----------------------------------------------------------------------------------------------------------------------- |

22 |

About----------------------------------------------------------------------------------------------------------------------------------------- |

24 |

Maintenance ------------------------------------------------------------------------------------------------------------------------------- |

24 |

Logs------------------------------------------------------------------------------------------------------------------------------------------- |

24 |

Probe Manager ---------------------------------------------------------------------------------------------------------------------------- |

25 |

Slave Communications Status ---------------------------------------------------------------------------------------------------------- |

26 |

Load TC/Auxiliary Analog Input-------------------------------------------------------------------------------------------------------- |

26 |

Manual Event Control -------------------------------------------------------------------------------------------------------------------- |

26 |

Shutdown------------------------------------------------------------------------------------------------------------------------------------ |

27 |

Probe Burnoff Setup ---------------------------------------------------------------------------------------------------------------------- |

27 |

PID Loop Setup ----------------------------------------------------------------------------------------------------------------------------- |

28 |

Recipe Edit ---------------------------------------------------------------------------------------------------------------------------------- |

33 |

Load T/C Configuration ------------------------------------------------------------------------------------------------------------------ |

34 |

Trend Chart Edit --------------------------------------------------------------------------------------------------------------------------- |

34 |

Communications Setup ------------------------------------------------------------------------------------------------------------------ |

36 |

Slave Instrument Setup ------------------------------------------------------------------------------------------------------------------ |

38 |

Zone Assignments ------------------------------------------------------------------------------------------------------------------------ |

41 |

Furnace Setup ------------------------------------------------------------------------------------------------------------------------------ |

42 |

Default Wait Limits ----------------------------------------------------------------------------------------------------------------------- |

46 |

Alarm Setup--------------------------------------------------------------------------------------------------------------------------------- |

46 |

Thermocouple Check --------------------------------------------------------------------------------------------------------------------- |

48 |

Relay Assignments ------------------------------------------------------------------------------------------------------------------------ |

48 |

Analog Input Setup------------------------------------------------------------------------------------------------------------------------ |

49 |

Analog Output Setup --------------------------------------------------------------------------------------------------------------------- |

51 |

Alarm Polarity ------------------------------------------------------------------------------------------------------------------------------ |

52 |

Redundant TC Setup ---------------------------------------------------------------------------------------------------------------------- |

53 |

Series 9205 Operations Manual Rev A |

2 |

Event Hold/Reset -------------------------------------------------------------------------------------------------------------------------- |

53 |

Security -------------------------------------------------------------------------------------------------------------------------------------- |

55 |

Curve Entry---------------------------------------------------------------------------------------------------------------------------------- |

56 |

Alternate PID Setup ----------------------------------------------------------------------------------------------------------------------- |

57 |

Aux Analog Input Setup------------------------------------------------------------------------------------------------------------------ |

58 |

TC Type mV Range Chart ---------------------------------------------------------------------------------------------------------------- |

59 |

Calibration ---------------------------------------------------------------------------------------------------------------------------------- |

59 |

Configuration------------------------------------------------------------------------------------------------------------------------------- |

61 |

A/I Module Offset Correction----------------------------------------------------------------------------------------------------------- |

71 |

Aux Setpoint Configuration ------------------------------------------------------------------------------------------------------------- |

71 |

T/C Extension Correction Curves------------------------------------------------------------------------------------------------------- |

71 |

Generic Instrument Setup --------------------------------------------------------------------------------------------------------------- |

72 |

DF1 Configuration------------------------------------------------------------------------------------------------------------------------- |

73 |

Tuning Assistant --------------------------------------------------------------------------------------------------------------------------- |

74 |

PLC Data Mapping ------------------------------------------------------------------------------------------------------------------------ |

75 |

Analog Input Correction Curves-------------------------------------------------------------------------------------------------------- |

76 |

Instrument Calculation------------------------------------------------------------------------------------------------------------------- |

76 |

CHAPTER 3 – CONFIGURATOR 2.0 MENUS ----------------------------------------------------------------------------------------------- |

79 |

BURNOFF ----------------------------------------------------------------------------------------------------------------------------------------- |

79 |

SLAVE INSTRUMENTS ----------------------------------------------------------------------------------------------------------------------------- |

81 |

AUXILIARY ANALOG INPUT ----------------------------------------------------------------------------------------------------------------------- |

81 |

MANUAL EVENT CONTROL----------------------------------------------------------------------------------------------------------------------- |

82 |

PROBE BURNOFF SETUP-------------------------------------------------------------------------------------------------------------------------- |

83 |

PID LOOP SETUP --------------------------------------------------------------------------------------------------------------------------------- |

85 |

EVENT RUN PROGRAM SETUP ------------------------------------------------------------------------------------------------------------------- |

90 |

LOAD T/C CONFIGURATION --------------------------------------------------------------------------------------------------------------------- |

90 |

PORT SETUP -------------------------------------------------------------------------------------------------------------------------------------- |

91 |

SLAVE INSTRUMENT SETUP ---------------------------------------------------------------------------------------------------------------------- |

94 |

ZONE ASSIGNMENTS ----------------------------------------------------------------------------------------------------------------------------- |

95 |

FURNACE SETUP ---------------------------------------------------------------------------------------------------------------------------------- |

97 |

DEFAULT WAIT LIMITS ------------------------------------------------------------------------------------------------------------------------- |

102 |

ALARM SETUP ---------------------------------------------------------------------------------------------------------------------------------- |

103 |

THERMOCOUPLE CHECK------------------------------------------------------------------------------------------------------------------------ |

104 |

RELAY ASSIGNMENTS--------------------------------------------------------------------------------------------------------------------------- |

105 |

RELAY SETPOINTS------------------------------------------------------------------------------------------------------------------------------- |

107 |

ANALOG INPUT SETUP ------------------------------------------------------------------------------------------------------------------------- |

108 |

ANALOG OUTPUT SETUP ----------------------------------------------------------------------------------------------------------------------- |

110 |

PASSCODE AND ALARM ------------------------------------------------------------------------------------------------------------------------ |

111 |

IP ADDRESS ------------------------------------------------------------------------------------------------------------------------------------- |

113 |

REDUNDANT TC SETUP ------------------------------------------------------------------------------------------------------------------------ |

113 |

EVENT CONTROL-------------------------------------------------------------------------------------------------------------------------------- |

114 |

SET MENU SECURITY --------------------------------------------------------------------------------------------------------------------------- |

115 |

CURVE ENTRY----------------------------------------------------------------------------------------------------------------------------------- |

115 |

ALTERNATE PID SETUP------------------------------------------------------------------------------------------------------------------------- |

116 |

SSI ANALOG INPUT SETUP --------------------------------------------------------------------------------------------------------------------- |

117 |

SSI CONFIGURATION AND CALIBRATION------------------------------------------------------------------------------------------------------- |

118 |

Overview ---------------------------------------------------------------------------------------------------------------------------------- |

118 |

Equipment needed ---------------------------------------------------------------------------------------------------------------------- |

118 |

Notes --------------------------------------------------------------------------------------------------------------------------------------- |

118 |

User Calibration ------------------------------------------------------------------------------------------------------------------------- |

118 |

Full Calibration--------------------------------------------------------------------------------------------------------------------------- |

120 |

TC Type mV Range Chart -------------------------------------------------------------------------------------------------------------- |

121 |

Series 9205 Operations Manual Rev A |

3 |

AUXILIARY INPUT OFFSET CORRECTION ------------------------------------------------------------------------------------------------------- |

122 |

AUX SETPOINT CONFIGURATION--------------------------------------------------------------------------------------------------------------- |

123 |

TC EXTENSION CORRECTION CURVES --------------------------------------------------------------------------------------------------------- |

123 |

GENERIC INSTRUMENT SETUPS ---------------------------------------------------------------------------------------------------------------- |

124 |

Configure Generic Instruments------------------------------------------------------------------------------------------------------- |

124 |

Configure IP Addresses----------------------------------------------------------------------------------------------------------------- |

125 |

Configure Block Writes----------------------------------------------------------------------------------------------------------------- |

125 |

DF1 CONFIGURATION-------------------------------------------------------------------------------------------------------------------------- |

125 |

TUNING ASSISTANT----------------------------------------------------------------------------------------------------------------------------- |

126 |

PLC DATA MAPPING --------------------------------------------------------------------------------------------------------------------------- |

128 |

ANALOG INPUT CORRECTION CURVES --------------------------------------------------------------------------------------------------------- |

128 |

INSTRUMENT CALCULATION-------------------------------------------------------------------------------------------------------------------- |

128 |

PROGRAMMER DESCRIPTION ------------------------------------------------------------------------------------------------------------------ |

131 |

WAIT-------------------------------------------------------------------------------------------------------------------------------------------- |

131 |

WAIT UP---------------------------------------------------------------------------------------------------------------------------------------- |

132 |

WAIT DOWN ----------------------------------------------------------------------------------------------------------------------------------- |

132 |

WAIT IN A GUARANTEED SOAK ---------------------------------------------------------------------------------------------------------------- |

134 |

GUARANTEE HIGH ASSIGNMENT--------------------------------------------------------------------------------------------------------------- |

135 |

SAMPLE EVENT ASSIGNMENTS----------------------------------------------------------------------------------------------------------------- |

136 |

FLASH CARD MANAGEMENT ------------------------------------------------------------------------------------------------------------------- |

136 |

SLAVE INSTRUMENT MAPPING----------------------------------------------------------------------------------------------------------------- |

140 |

Atmosphere Instruments -------------------------------------------------------------------------------------------------------------- |

140 |

Temperature Instruments ------------------------------------------------------------------------------------------------------------- |

143 |

Events Instruments---------------------------------------------------------------------------------------------------------------------- |

148 |

9205 ANALOG INPUT BOARD JUMPER SETTINGS--------------------------------------------------------------------------------------------- |

151 |

CHAPTER 4 – OPCODES ---------------------------------------------------------------------------------------------------------------------- |

153 |

WARRANTY ------------------------------------------------------------------------------------------------------------------------------------- |

168 |

APPENDIX A – WIRING DIAGRAM OF SERIES 9205----------------------------------------------------------------------------------- |

169 |

APPENDIX B – GUIDE TO BUILDING A RECIPE------------------------------------------------------------------------------------------ |

171 |

APPENDIX C – SETUP FOR CARBON / DUAL TEMPERATURE FOR QUENCH CONTROL -------------------------------------- |

179 |

APPENDIX D – 9205 INSTRUMENT ALARMS ------------------------------------------------------------------------------------------- |

181 |

APPENDIX E – FACTORY DEFAULT SETTINGS FOR THE 9205 CONTROLLER ---------------------------------------------------- |

183 |

REVISION HISTORY---------------------------------------------------------------------------------------------------------------------------- |

234 |

Series 9205 Operations Manual Rev A |

4 |

Installation Safety Requirements

Safety Symbols

Various symbols are used on the instrument; they have the following meaning:

!Caution, (refer to the accompanying documents)

Functional earth (ground) terminal!

The functional earth connection is required for safety purposes and to ground RFI filters.

Personnel

Installation must only be carried out by technically qualified personnel.

Enclosure of live parts

To prevent hands or metal tools from touching parts that may be electrically live (powered), the controller must be installed in an enclosure.

Caution: Live sensors

Do not connect live (powered) sensors to any signal input on the controller. Live

!sensors are sensors that must be connected to the main's supply. The controller has transient protection circuits connected between the inputs and the earth connection that might be damaged by live (powered) sensors.

Series 9205 Operations Manual Rev A |

5 |

Wiring

It is important to connect the controller in accordance with the wiring data given in this handbook. Take particular care not to connect AC supplies to the low voltage power supply input. Use copper wires for 24V DC power supply to the instrument. Ensure that the wiring of installations comply with all local wiring regulations. For example in the United Kingdom use the latest version of the IEE wiring regulations, (BS7671). In the USA use NEC Class 1 wiring methods.

Power Isolation

The installation must include a power isolating switch or circuit breaker. This device should be in close proximity to the controller, within easy reach of the operator and marked as the disconnecting device for the instrument.

Earth leakage current

Due to RFI Filtering there is an earth leakage current of less than 0.5mA. This may affect the design of an installation of multiple controllers protected by Residual Current Device, (RCD) or Ground Fault Detector, (GFD) type circuit breakers.

Over current protection

To protect the internal PCB tracking within the controller against excess currents, the AC power supply to the controller and power outputs must be wired through a fuse or circuit breaker specified in the technical specification.

Voltage rating

The maximum continuous voltage applied between any of the following terminals must not exceed 24V DC

•relay or triac output to logic, DC or sensor connections;

•any connection to ground.

The controller should not be wired to VAC. The 24V DC power supply voltage across the connections and between the power supply and ground must not exceed 2.5kV. Where occasional voltage over 2.5kV are expected or measured, the power installation to both the instrument supply and load circuits should include a transient limiting device.

These units will typically include gas discharge tubes and metal oxide varistors that limit and control voltage transients on the supply line due to lightning strikes or inductive load switching. Devices are available in a range of energy ratings and should be selected to suit conditions at the installation.

Series 9205 Operations Manual Rev A |

6 |

Conductive pollution

Electrically conductive pollution must be excluded from the cabinet in which the controller is mounted. For example, carbon dust is a form of electrically conductive pollution. To secure a suitable atmosphere in conditions of conductive pollution, fit an air filter to the air intake of the cabinet. Where condensation is likely, for example at low temperatures, include a thermostatically controlled heater in the cabinet.

Over-temperature protection

When designing any control system it is essential to consider what will happen if any part of the system should fail In temperature control applications the primary danger is that the heating will remain constantly on. Apart from spoiling the product, this could damage any process machinery being controlled, or even cause a fire. Reasons why the heating might remain constantly on include:

•the temperature sensor becoming detached from the process;

•thermocouple wiring becoming a short circuit;

•the controller failing with its heating output constantly on;

•an external valve or contactor sticking in the heating condition;

•the controller set point set too high.

Where damage or injury is possible, we recommend fitting a separate over temperature protection unit with an independent temperature sensor, which will isolate the heating circuit. Please note that the alarm relays within the controller will not give protection under all failure conditions.

Installation requirements for EMC

To ensure compliance with the European EMC directive certain installation precautions are necessary as follows:

•When using relay or triac outputs it may be necessary to fit a filter suitable for suppressing the emissions. The filter requirements will depend on the type of load. For typical applications we recommend Schaffner FN321 or FN612.

Routing of wires

To minimize the pick-up of electrical noise, the wiring for low voltage dc should be routed away from high-current power cables. Where it is impractical to do this, use shielded cables with the shield grounded at one end.

Series 9205 Operations Manual Rev A |

7 |

Chapter 1 - Overview

The 9205 is SSi’s versatile atmosphere programmable controller with Ethernet, RS485 Modbus, and DF1 communications to various slave devices such as temperature controllers, flow meters, and PLCs. This instrument can be used to address many thermal processing applications where temperature and carbon control along with event I/O management are necessary. The 9205 has math block capability allowing custom calculations and custom Modbus mapping for communications

The 9205 recipe programmer includes 24 independent steps per recipe with operational codes (opcodes) to enable effective process control. The 9205 also supports multiple user interface screens for more flexibility. Screen sizes include 3.5”, 5.7” and 12.1”. Functionality added to the screens include “stylus” notes entry, user defined data points and trend charts for paperless chart recording, zoom and pan touch screen control on the charting screen, and remote data retrieval through Ethernet.

Series 9205 Operations Manual Rev A |

8 |

Approximate Box Dimensions |

2.75" x 4" x 4.5" |

Power Requirements |

24VDC, 4 Watts |

Digital Output Rating |

300VAC / 1 AMP |

Analog Output Load Rating |

1000 Ohms (Total) |

Controller Enclosure Rating |

IP10 – hand protected |

Number of RS232 Ports |

Two (2) |

Number of Ethernet Ports |

One (1) |

Number of RS485 Host Ports |

One (1) |

Number of RS485 Slave Ports |

Two (2) |

Number of Internal Relays |

Eight (8) |

Number of Analog Inputs |

Three (3) |

Number of Analog Outputs |

Two (2) |

Number of Digital Inputs |

Four (4) |

Number of Control Loops |

Three (3) |

!The Model 9205 is powered by 24 VDC, not LINE Voltage. Please be careful when connecting power to this controller. Connecting anything other than 24 VDC will cause serious damage.

The variety of input and output combinations allows SSi to configure the Model 9205 to control temperature and atmosphere.

The product is available in three different screen sizes. 3.5”, 5.7” and 12”. Mounting

The Series 9205 Operator Interface mounts into a panel or on a plate by using the enclosed mounting brackets. A rectangular cutout is required; the size of the cutout is determined by the operator interface size. These units, along with an optional SSi SR3, 6, or 9 analog input board, will mount on a commercially available DIN rail. This can be mounted on the sub-panel on the side of an enclosure for the convenience of the control system.

Series 9205 Operations Manual Rev A |

9 |

Dimensional Drawings

Series 9205 Controller Dimensions

24V DC Power Supply Dimensions

Series 9205 Operations Manual Rev A |

10 |

3.5” Operator Interface Cutout dimensions

5.7” Operator Interface Cutout dimensions

12” Operator Interface Cutout dimensions

Series 9205 Operations Manual Rev A |

11 |

Wiring

Wiring to the Series 9205 operator interface can be done using 232 or 485 to two connectors, comm1 (232) or comm3 (485). The terminal strip on the lower right rear corner of the operator interface is used to connect 24VDC power. The DB-9 port A connection is used to connect the display via 232 to the Series 9205 PID controller. The controller is connected via RS485 communication to the single-loop controllers.

Electrical Installation

The Model 9205 requires 24VDC, 4 Watt, single-phase power. A 24 VDC power supply is required and is generally included as part of the Model 9205 system. This power supply has a universal input that can accept between 60 and 265VAC. Power should be applied in accordance with the electrical drawings that have been supplied. Since each installation is unique to the site, the customer is responsible for providing adequate power and making it available to the Model 9205 power supply.

SSi requirement:

MOV’s must be wired across the isolation relay coil terminals on all isolation relays that are connected to solenoids. Further… MOVs must be connected across the HOT and NEUTRAL wires when the solenoid is wired to them. IT IS AN ABSOLUTE MUST to have the MOVs at BOTH LOCATIONS.

Series 9205 Operations Manual Rev A |

12 |

Pin Out

9205 Pin Out

A wiring diagram of the Series 9205 controller can be found in Appendix B.

Ancillary Items

The following items can be included with the Series 9205: a flash card, a flash card reader, a touch screen, an RS232 cable, an RS485 cable, a 24V DC DIN rail mount power supply, and a software CD with Configurator, the Configurator manual, TS Manager, and .NET 2.0. The flash card is installed in the operator interface and the flash card reader connects to a Windows® based computer.

The operator interface includes a connection for a mouse and a keyboard. These may be connected to the operator interface via USB, allowing the operators to use a mouse and keyboard instead of the touch screen.

Series 9205 Operations Manual Rev A |

13 |

The following table shows the ancillary items and their part numbers.

Part |

Part Number |

|

|

|

|

3.5" Operator Interface |

31296 |

|

|

|

|

5.7" Operator Interface |

31297 |

|

|

|

|

12" Operator Interface |

31299 |

|

|

|

|

TS Manager/PC Configurator Software |

13339 |

|

|

|

|

RS485 comms cable for 12.1” and 5.7 “ |

20576 |

|

|

|

|

RS485 comms cable for 3.5” |

20635 |

|

|

|

|

Flash Card |

31604 |

|

|

|

|

Flash Card Reader |

13333 |

|

|

|

|

RS232 Cable |

33027 |

|

|

|

|

24V DC Din Rail Mounted Power Supply |

31135 or |

|

31137 |

||

|

||

9205 Controller |

13443 |

|

|

|

Setup

The Series 9205 setup consists of setting the local time if required. As shipped from the factory the communications ports are set at 19200 baud in Modbus mode.

Time will be set for local time in Cincinnati, Ohio (EST /EDT) or time zone of location of city and state on sales order. For instruction on adjusting these values, please see Chapter 3 - Configuration.

Additional Features

The Operator Interface (touch screen) contains a removable compact Flash or SD Card that can be used to transfer data from the Model 9205 to a computer. It is located on the back of the touch screen (see Flash Card & Flash Card Reader section for more details).

Also included is a Utility Software CD that includes SSi’s TS Manager. TS Manager is a utility program that can be loaded onto any Windows® based computer (operating Windows XP or higher). This software will allow the computer to read the data from the TS Flashcard, and allow it to be viewed in a manner that is similar to a strip chart recorder.

Ethernet Connections

The Ethernet connection has three distinct uses. First, should the Operator Interface fail, the Ethernet connection allows a laptop to be connected via a crossover cable to the Series 9205 DIN rail mounted unit using Internet Explorer Browser. This connection can act as a LIMITED

Series 9205 Operations Manual Rev A |

14 |

FUNCTION “operator interface” until the Operator Interface can be repaired or replaced. The laptop needs to be operating a Windows XP or higher with Internet Explorer. The default IP address is 192.168.0.200. If you are experiencing problems please call (513) 772-0060 and talk with our computer communications personnel. Secondly, the Ethernet port can be used for communications to a SCADA software package. Call us at (513) 772-0060 if you are interested in this option. The third use for the Ethernet Port is the primary communications connection for the Configurator 2.0 Software.

Instrument Start-up

On power-up, the Operator Interface will display a Microsoft Windows desktop screen for a few seconds and then switch to the default Status screen.

Flash Card & Flash Card Reader

!Never remove the flash card when the Operator Interface is “ON”.

To properly shut down the Operator Interface, press the Menu button on the default status screen. Once the menu has been displayed, select the Shutdown option. At the prompt, press Yes to shut down the Operator Interface. See the Chapter 2 - CONFIGURATION section for information on navigating and using the menu system. This will display a conventional Microsoft Windows screen. Sliding the black switch to the OFF position (located directly over the green power connector, on the back of the Operator Interface) or removing the 24VDC plug will turn off the power to the Operator Interface.

Once the Operator Interface is turned off, remove the compact flash card cover at the top or side of the display unit, exposing the card. Press the black release button or press card in to eject, and the card will pop out of the slot. To replace the flash card, simply return the card to the slot making sure that the release button is in its UP position, and replace the flash card cover to its proper position. To restore power to the unit, move the black switch to the right or ON position or connect plug.

Operator Interface Screen Saver

The Operator Interface has a default screen saver. It automatically “blanks” the screen after ten (10) minutes of non-activity. To disengage the screen saver, simply touch the screen and it will reappear.

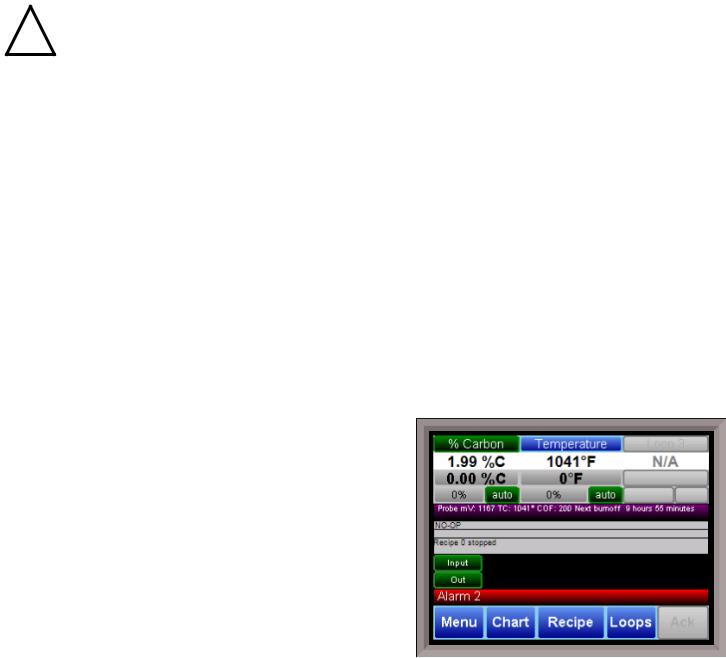

Default Status Screen

The Status Display shows the temperature controller information as well as any auxiliary analog inputs, the status of the timer, and an overview of the programmer. There are five active buttons on the Status Display: Menu, Chart, Recipe, Loops, and Ack.

•The Menu button will display the configuration menu.

Series 9205 Operations Manual Rev A |

15 |

•The Chart button will display the video recorder screen. Use of the Chart Display is explained below.

•The Recipe button will switch to the Program Display. This is a companion display to the status screen and is described below.

•The Loops button will display the main control loop, Temperature, as well as the timer status and any auxiliary analog inputs.

•The Ack (Alarm Acknowledge) button is used to acknowledge an alarm. The alarm message is displayed directly under the recipe display. Is this only present when an alarm is going off. This button only acknowledges 9205 alarms and does not acknowledge any PLC alarms.

When the quench timer is running, the ACK button is replaced with a quench button. This quench button is used to adjust the quench timer time remaining. In the purple status bar, the quench time remaining is displayed.

Menu

There are three levels of menus in the Series 9205.

•The first level is the operator level. These are functions or operations that are typically handled by the furnace operator. This menu is accessed without the need for a pass code.

•The second level is the supervisor level. This level requires the entry of a level 1 or a level 2-pass code.

•The third level is the administrator level. This requires the level 2-pass code ONLY.

As shipped, the supervisor and administrator

level codes are set as 1 and 2 respectively. The pass codes can be changed at the Passcode and Alarm Screen. Note: Any level can access a lower level screen. For instance, the Administrator level passcode can access all of the Supervisor and Operator level screens.

The menu items are explained in detail in Chapter 2 – Configuration.

Chart

The Chart Display shows between 1 hour and 24 hours of process variable data on the screen and can be scrolled back to view all of the data stored on the hard drive. The vertical timelines change as the time changes on the screen. Any trend charts that have been created through the Configuration menu are accessible here. See the Chapter 2 - CONFIGURATION section for more information on creating trend charts.

The function buttons run along the bottom of the screen.

Series 9205 Operations Manual Rev A |

16 |

The folder button -  -

-

The Trend Lines button -  - will allow the user to select or de-select the trend lines on the trend chart to display. If the checkbox next to each trend line is checked, then that trend line will be displayed.

- will allow the user to select or de-select the trend lines on the trend chart to display. If the checkbox next to each trend line is checked, then that trend line will be displayed.

`

The Datagrid View button -  - will display a screen with

- will display a screen with

the trend data in a grid format instead of with trend lines. The trend data is shown in 1-minute intervals. Clicking on the OK button on this screen will close the screen down and return to the Chart Display screen.

The Refresh button -  - will refresh the screen’s trend data if the screen is not in real-time mode.

- will refresh the screen’s trend data if the screen is not in real-time mode.

The left-pointing green arrow button -  - will move the chart’s view backward in time by the specified chart interval.

- will move the chart’s view backward in time by the specified chart interval.

The chart interval button -  - will determine the number of hours displayed on the trend chart. The options are: 1 Hour, 2 Hours, 4 Hours, 8 Hours, 12 Hours, or 24 Hours.

- will determine the number of hours displayed on the trend chart. The options are: 1 Hour, 2 Hours, 4 Hours, 8 Hours, 12 Hours, or 24 Hours.

The right-pointing green arrow button -  - will move the chart’s view forward in time by the specified chart interval.

- will move the chart’s view forward in time by the specified chart interval.

The right-pointing arrow with the vertical line next to it button -  - will put the chart into real-time mode if it is not in real-time mode, or take the chart out of real-time mode if it is. When in real-time mode, the chart will automatically be updated once a minute.

- will put the chart into real-time mode if it is not in real-time mode, or take the chart out of real-time mode if it is. When in real-time mode, the chart will automatically be updated once a minute.

Series 9205 Operations Manual Rev A |

17 |

Chart Sub Menu

There is a sub-menu available by putting a finger or a stylus anywhere on the chart and holding it there for a couple of seconds. The sub-menu will have the following options available: Zoom, Restore, Add Note, Data, and Exit.

to zoom in again.

The Zoom option will allow the user to zoom in on a particular part of the screen. Once this has been selected, the user can take a stylus or a finger and create a box around the desired data. Once the user releases the stylus or finger, a zoom is no longer possible, and the user will need to re-select the option from the sub-menu

The Restore option will back out of any zoom options that have been performed and display the chart screen as it initially was.

The Add Note option allows the operator to enter a note on the chart, similar to writing on a paper chart. The note shows up when the chart is printed out using the utility software included with the Series 9205 instrumentation. Pressing the Add Note option displays a screen where the operator can enter the operator ID or initials and a note. The user has the option to enter a note using the operator interface keyboard, where he or she will be able to type in the note; or the user can use the Signature mode, which will allow them to write a note using a stylus.

The Data option will show the trend data as a data grid instead of the trend lines on a chart. This

functionality is exactly the same as if the user pressed the Datagrid View button -  - from the chart screen.

- from the chart screen.

Exit will close out the sub-menu without selecting an item.

Pressing the red ‘X’ in the top right-hand corner of the screen will take the user back to the status screen.

Series 9205 Operations Manual Rev A |

18 |

Recipe

Pressing the Recipe button on the main status screen displays the recipe screen, which will allow the user to load up an existing recipe and start it, or see the currently running recipe.

The recipe screen shows the last program loaded into the program run buffer and its status. If the program is running, the active step number is highlighted green. When the step is highlighted green, then the recipe is running on that step. When a step is highlighted yellow, the recipe is in hold on that step. A red Acknowledge button in the bottom left corner of the screen displays an alarm condition. Note – the main status screen will also show the recipe running status, as well as run time and remaining time for the step as well as the entire recipe.

The recipe screen has a total of seven buttons that will allow the user to load up a recipe, as well as control the recipe and acknowledge an alarm.

•The Advance button will advance the recipe to the next step in the recipe. The user will need to confirm the advance command.

•The Hold button places the displayed recipe program in hold. Once a decision is made that affects the recipe, it may be continued by pressing the Resume button. Note – When a recipe is put into hold status, the text on the Hold button will change to “Resume”. When the step is started up again, the text on the button will change back to “Hold”. When a recipe step is in a hold status, the step will be highlighted yellow. The user will need to confirm the hold or resume command.

•The Stop button stops the recipe program that is currently running. Stop means exactly that! It stops the program. It is NOT a hold button. See the description for the hold button above. To restart the program if it has been stopped you must use the Load button, enter the recipe number, and then highlight the segment number of the recipe that you want to start with and start the recipe again. The user will need to confirm the stop command.

•The Soak button allows you to enter a new value for the time remaining in the current soak or ramp cycle only – future soak or ramp cycle times cannot be modified. The step must be a soak or ramp cycle for a change in soak/ramp time to be adjusted.

•The Acknowledge button will acknowledge the alarm. In most cases, it will be acknowledging end of soak. The alarm must be acknowledged to allow the program to go to the next step. Note – The Acknowledge button is only visible when an alarm condition is present. Once the condition is acknowledged, the Acknowledge button will become invisible again.

•The Load button allows the operator to enter the recipe number to be run and to view the recipe before pushing the Run button. Pushing the Run button starts the recipe.

If a recipe program is running and the operator enters a new recipe program it can be viewed and modified. The recipe does not become active until the Run button is pushed. Pressing Run places the program currently being viewed in the active memory and will begin to run the new

Series 9205 Operations Manual Rev A |

19 |

recipe. To select the recipe to view or edit, click on the recipe number button in the top left corner of the screen. This will display a screen where the user will be able to load up a valid recipe (range 1 – 300). The program can be started in any step by clicking on the step number button next to the “Step” text and entering the new step number (range 1 – 24), and then pressing the Run key.

While reviewing the program that is about to be run, each step can be modified. Highlight a step number and click on the Edit button. The opcode can be changed with the drop down list at the top. This list can be sorted alphabetically by click on the “Alphabetical” checkbox. The parameters of the opcode can be modified on this screen as well. See the Chapter 4 – OPCODES section for details about each opcode. Click on the OK button to accept the changes; click on the Cancel button to ignore the changes. Note – Any change to the recipe is a one-time edit, and will not affect the recipe that is saved on the 9205 controller. Click on the Cancel button on the Load Recipe screen to cancel loading a recipe and return to the main recipe screen.

•The Return button returns you to the main status

screen.

Loops

This screen will display the program loops for the 9205. Up to three loops can be displayed. The current process variable is displayed at the top, with each loop set point displayed beneath the process variable. The operator can change the process set point by touching the screen area below the large process variable numbers. When pressing the Temperature set point, a numeric keypad is displayed, showing the current value and allowing the operator to enter a new set point by simply pressing on the appropriate numeric keys. Once the correct set point has been entered, press the OK key to make the change. When the OK key is pressed the display returns to the Loops

Screen. Another active key within the Loops Screen is the Auto/Man (Auto/Manual) button. Pressing that button toggles the controller’s mode between Auto and Manual. In the manual mode, pressing the percent output button on the Loops Screen (next to the Auto/Man button) displays a numeric keypad, allowing a % output to control the “loop” in a manual mode to be entered. If a timer is running, the status will be displayed at the top right of the screen. Any load T/Cs that are actively communicating will be listed in the box to the right of the setpoint/percent output values. If an alarm condition is present, the alarm text will be displayed below the loop information. If the alarm needs acknowledging, then the Alarm Ack button will be displayed in the bottom left corner. If the alarm is part of a recipe step, the alarm will need to be acknowledged before the recipe can move to the next step.

The Loops Screen also allows you to move back to the default Status Screen by pressing the Return.

Ack (Alarm Acknowledge)

The Ack (Alarm Acknowledge) button will allow the user to acknowledge any alarms that have been configured, or that have been made part of the recipes that run on the Series 9205. If a recipe has an alarm as a step, the alarm must be acknowledged before the recipe will continue to the next step.

Series 9205 Operations Manual Rev A |

20 |

Data Logging using Flash Card

!NOTE: See Warnings with respect to removing the Flash Card.

The Advantech TPC-642S/642-SE touch screen Operator Interface utilizing a Compact Flash Card allows the unit to data log the parameters set up by a qualified SSi technician. Should a

customer not take the data offline in a timely manner, the data will be over-written, the oldest data being over-written first. Here is how it works:

1.When the Operator Interface detects that there is less than 5% disk space left on the compact flash card, an alarm will be displayed on the main interface screen stating "x% disk space remaining (overwrite at 3%)". In the upper right corner, an ALM is indicated, but because it is not a communications alarm or a 9205 device alarm, the background remains green. This alarm will remain active until more than 5% of disk space is available for writing data log files.

2.If the user does not copy the log data from the disk, it will eventually fall to 2% disk space. At this point, the touch screen will select the oldest compressed file and delete it. It then checks to see if 3% remains. It repeats this procedure until 3% disk space remains. At this point the alarm message changes to "Overwriting data log data!” Because this allows the system to seesaw between 2% and 3%, it will continue to display "Overwriting data log data!" until somebody offloads the files.

Technical concerns and details:

1.If there are not enough compressed files to bring the free space up to 3%, the system will hunt down and kill hourly files. This should only happen if compression would not be running for some reason.

2.If all compressed files and hourly files have been removed and there is still not enough disk space (perhaps a problem with the compact flash card), the data logger will not write to the disk until the condition is remedied. (Alarms continue to display).

3.The data log data alarm is the lowest priority. The alarm priorities are touch screen communications, then 9205 controller/programmer, then disk space.

See the Flash Card Management Section for more information.

Series 9205 Operations Manual Rev A |

21 |

Chapter 2 - CONFIGURATION

Menu (Configuration)

The Configuration Menu is entered through the Menu key that is part of the four buttons running along the bottom of the Default Display Screen. Pressing the Login key at the bottom of the screen will allow the user to enter a login user and password. Note – users can be set up through the Security menu option in this menu. User names and passwords are case sensitive. There are three levels of security for the menu system: Operator, Supervisor, and Administrator. Pressing the Login button will allow the user to enter a user name and password to log in. When the menu screen is first displayed, the operatorlevel menu options are visible.

The list of the operator-level menu options is:

•About

•Maintenance

•Logs

•Probe Manager

•Slave Communications Status

•Load TC/Auxiliary Analog Input

•Manual Event Control

•Shutdown

The list of supervisor-level menu options is:

•About

•Maintenance

•Logs

•Probe Manager

•Slave Communications Status

•Load TC/Auxiliary Analog Input

•Manual Event Control

•Shutdown

•Probe Burnoff Setup

•PID Loop Setup

•Recipe Edit

•Load T/C Configuration

•Trend Chart Edit

The list of administrator-level menu options is:

•About

•Maintenance

•Logs

•Probe Manager

•Slave Communications Status

•Load TC/Auxiliary Analog Input

•Manual Event Control

•Shutdown

Series 9205 Operations Manual Rev A |

22 |

•Probe Burnoff Setup

•PID Loop Setup

•Recipe Edit

•Load T/C Configuration

•Trend Chart Edit

•Communications Setup

•Slave Instrument Setup

•Zone Assignments

•Furnace Setup

•Default Wait Limits

•Alarm Setup

•Thermocouple Check

•Relay Assignments

•Analog Input Setup

•Analog Output Setup

•Alarm Polarity

•Redundant TC Setup

•Event Hold/Reset

•Security

•Curve Entry

•Alternate PID Setup

•Aux Analog Input Setup

•Calibration

•Configuration

•A/I Module Offset Correction

•Aux Setpoint Configuration

•T/C Extension Correction Curves

•Generic Instrument Setup

•DF1 Configuration

•Tuning Assistant

•PLC Data Matching

•Analog Input Correction Curves

•Instrument Calculation

The SSi code of the day can also be used to log in to the menu system. No user name will need to be entered when entering this code. Currently, the menu list is identical to the administrator-level list. The SSi code of the day is typically used for in-house configuration prior to shipment. The code can only be provided by Super Systems at (513) 772-0060.

To select any of the menu options, highlight that item by clicking on it, and click on the Detail button. The Return button will return the user to the default display screen.

Series 9205 Operations Manual Rev A |

23 |

About

The About screen displays important information on the 9205 controller that the touch screen is communicating with. The SSi 9205 field shows the firmware version of the controller itself. Serial Number shows the serial number of the controller. Interface Revision shows the current version of the touch screen interface.

The remaining fields show versions of various DLL (dynamic link library) files that the touch screen software uses to operate. These fields may be needed for troubleshooting if you need to contact SSi for technical support.

Maintenance

From the Maintenance Status menu, you can view a list of scheduled and completed maintenance items. Maintenance items are added from the Configuration -> Maintenance menu. See the Configuration section on page 61 for more information.

Logs

The Logs screen will allow the user to view three different types of logs – System, Alarms, and Cycle.

Clicking on the button that displays the log type (System Log, Alarm Log, or Cycle Log) will allow the user to select the type of log file to view.

The green directional arrows will display the previous items in the log or the next items in the log, if the log items are longer than one screen. The drop down list in between the directional arrows will allow the user to select the date of the log items to view.

The Return button will return the user to the menu screen.

Series 9205 Operations Manual Rev A |

24 |

Log Types

The System Log tracks the startup and shutdown activity of the touch screen as well as when communications to the controller are established.

The Alarm Log tracks all alarms—those that are internal to the controller and those that are generated by the PLC. This log tracks the alarm generated, its start time, and its end time. This log can be useful for helping build an alarm history.

The Cycle Log keeps track of charged loads and completed recipes. Specifically, it displays the start time and date, completed time and date, and recipe number executed. A Utilization button can be pressed to open a page with information on utilization based a selected date and on the amount of time that the 9205 controller has run a recipe compared to the amount of time it has not run a recipe.

Probe Manager

This option allows the user to register a probe within the 9205 by entering its serial number. Doing so starts a tracking history of probe burn-offs, impedance tests, recovery time, and other probe parameters. Trends can be monitored this way, and the impedance of the probe can be traced to help estimate its life expectancy.

To install a new probe, tap Install New Probe. You will be asked for the probe serial number. Enter it and tap OK.

When Burnoff Report is selected, a list showing

when a burnoff took place will appear, along with probe mV, temperature, and temperature change during the burnoff. When a burnoff event is selected, a chart will show temperature changes during the burnoff event.

When Probe Test Report is selected, a list will appear showing test parameters for the selected probe: time: Impedance kΩ, Recovery Time, Start Temperature, Test mV, and Test Temperature. When a test event is selected, a chart will show temperature changes during the test.

Tap Return to return to the main menu.

Series 9205 Operations Manual Rev A |

25 |

Slave Communications Status

This page is a display of the current process variables of each of the slave instruments communicating with the 9205 controller. These values are display-only, and cannot be modified from this screen.

There are five possible messages that can occur to describe the instrument communications status.

•N/A – No instrument is connected

•Bad – No communications exist

•??? – Communications exist, but there are frequent errors

•?OK – Communications exist, but there are occasional errors

•OK – Communication is established and working properly

For set-up of the auxiliary instruments go to the menu item “Slave Instrument Setup” The Return button will return the user to the menu screen.

Load TC/Auxiliary Analog Input

The Load TC/Auxiliary Analog Input screen will show the values for the load TCs and the auxiliary analog inputs. These values are display-only, and cannot be modified from this screen.

Manual Event Control

Events are assignable outputs, used in recipes/programs. Typically, they are used to signal the recipe is complete, to turn process gases off and on, and tell the equipment to do a variety of tasks. The Manual Event Control submenu allows the user to force the events off or on.

The Manual Event Control menu option shows the user all of the events (0 – 47) and their current status. It also allows the user to manually control the status of any event by clicking on the value. To change the status, highlight the specific event and click on the Edit button. The user will be able to select either an On value or an Off value.

Series 9205 Operations Manual Rev A |

26 |

WARNING!

Before assigning or changing events, be certain that you are familiar with the function of the event whose status you are going to change. Changing the status of an event without knowledge of the result can lead to hazardous situations.

Clicking on the OK button will set the value, while clicking on the Cancel button will cancel the action. The Return button will return the user to the menu screen.

Shutdown

The Shutdown selection will display a screen asking whether or not to shut down the interface of the Series 9205. When the operator interface is shutdown, the Series 9205 controller is still functioning. IT can be monitored by connecting the Ethernet connection to a laptop computer, using Internet Explorer, and assigning a legitimate IP address. Choosing Yes displays a typical computer desktop screen with the Start button in the bottom left-hand corner. The power to the operator interface can now be turned off without upsetting any of the settings. Choosing No displays the initial Status Screen. Note - Shutting down the Operator Interface does not shutdown the Series 9205 Controller.

Probe Burnoff Setup

When a probe is in a furnace, soot will collect in the end of the probe, which will have a negative effect on the performance of the probe. Burnoffs are used to clean out the built-up carbon by burning it off of the probe.

Burnoff Time: This is the duration of the burnoff measured in seconds. SSi recommends a 90 second burnoff, and this will be the default value. However, it can be adjusted by the operator. Click on the OK button to set the new value, or click on the Cancel button to cancel.

Rec Wait Time: The amount of time allotted to

allow the probe measurements to return to a stable, accurate range after the burnoff is complete. This is measured in seconds. The control output is held until this time is elapsed. Clicking on the value will allow the user to change the value.

Interval: This is the amount of time between the beginning of one burnoff and the beginning of the next scheduled burnoff, in minutes. Default time for the instrument is 720 minutes (12 hours). However, the amount of time between burnoffs should be determined by the application.

Minimum Millivolts: The minimum measured millivolt tolerance of the probe required to start a burnoff. Clicking on the value will allow the user to change the value. SSi recommends the millivolt value gets down to 200 mV.

Maximum Temperature: The maximum measured temperature allowed during a burnoff. If the temperature value is exceeded the burnoff will stop. This is done to help maintain the life and the accuracy of your probe. SSi recommends a value of 1800 degrees. Clicking on the value will allow the user to change the value.

Series 9205 Operations Manual Rev A |

27 |

Digital IN 4 Assignment: The value for the digital input 4 assignment. Clicking on the value will allow the user to change the value, which can be either event or Start Burnoff.

Burnoff Minimum Millivolts Alarm Setpoint: The minimum millivolt value that must be reached in order for the “Insufficient mV drop during BO” alarm not to be generated. If the millivolt value does not drop below the minimum, the alarm will be generated.

Burnoff Maximum Temperature Rise Limit: The maximum number of degrees that the temperature is allowed to increase before the “Excessive TC rise during BO” alarm is generated.

PID Loop Setup

PID is the tuning parameters entered for each Process

Variable loop.

Prop Band (0 for On/Off)

Proportional Band determines the response to the current error. The Proportional Band is the percent of the range of the process variable that will produce 100% output and is the inverse of the proportional gain. A low Proportional Band value results in a larger change in output for a given error. Conversely, a high Proportional Band value results in a smaller change in output for a given error. If the Proportional Band is too small, control may oscillate or be otherwise unstable.

If the Proportional Band is too large the control action may be too sluggish in response to changes within the system. Note: If the Proportional Band is set to 0.0, only on/off control is performed. The range 0 – 3276.0.

Reset

Reset determines the influence of past errors. The Reset, or integral action (expressed in repeats per minute), sums the error between the process variable and setpoint over time and adds this accumulated output to the proportional output. A “proportional only” controller generally operates with steady-state error because some error is required to produce control output. The goal of integral action is to drive the steady-state error to zero and eliminate this droop. The range 0 – 327.67.

Rate

Rate adjusts the response to future errors. The Rate, or derivative action (expressed in minutes), is used to predict system behavior and has a dampening effect. The more the controller tries to change the process variable the harder the derivative will work to counter that effort. This dampening effect can be valuable in reducing overshoot but is most often useful when trying to improve control on systems with significant and predicable lag. The range 0 – 327.67. NOTE: The rate is not typically used for carbon control.

Control Mode

This is the mode of the loop. The values are: Dual Reverse, Single Reverse, Dual Direct, or Single Direct. Dual – This has two output relays which can increase and decrease to achieve the SP.

Single – This has one relay which works in only one direction to achieve the SP.

Direct - If the PV - SP equals a positive number and the output would bring the PV down toward setpoint that is direct.

Reverse – If the PV - SP equals a negative number and the output would bring the PV up toward setpoint then that is reverse

Series 9205 Operations Manual Rev A |

28 |

Example: If a 12 mA output drives a 0 degree F temperature (PV) UP to a 1200 degree F temperature (SP), this would be REVERSE, and since this would take a SINGLE output from the controller, the Mode for the Temperature Loop is Single Reverse.

Integral Preset

This field provides an offset for the starting point for PID control, also referred to as “Load Line” or “Manual Reset”. The range is –100 to 100.

Cycle Time

This field is typically set to the valve travel time multiplied by 1.5. The range is 0 – 500.

Setpoint Change Limit

This is a smart time feature that allows Process Loop to use PB only without Reset until the Process Variable drops below the percent output set under this category.

It is used to eliminate overshoot.

The Output percentage selected under this category must be above the normal operating output percentage of the furnace at heat.

The options are: OFF, 80%, 70%, 60%, 50%, 40%, 30%, or 20%.

Example: If the furnace runs at 40% output at heat for the maximum load, the setpoint change limit should be set to 60%.

Control Low Limit

This is the low limit for the loop. The range is –100 to 100.

Control High Limit

This is the high limit for the loop. The range is –100 to 100.

0 Setpoint Stops Control

If the Setpoint is zero, then all outputs are turned off. The option is either Yes or No.

IN1 high limit shuts down ctrl

If input 1’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

IN2 high limit shuts down ctrl

If input 2’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

IN3 high limit shuts down ctrl

If input 3’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

PID Auto Switch

This is the PID auto switch field. The value can either be Yes or No.

PID auto switch is a feature within the instrument that allows multiple PID Loops to be used for various temperature ranges. This feature can be extremely helpful when a single PID Loop is not accurate across a wide temperature range. The most common indication that PID auto switching may improve furnace ability is failure to pass Temperature Uniformity Surveys (TUS). In many examples, a certain PID Loop may prevent underor over-shoot at normal operating temperatures; but produce unacceptable overshoot at lower temperature.

This feature allows the user to utilize (up to) three distinct loops to obtain more accurate heating curves. In most applications, it is helpful to use the built-in Tuning Assistant feature to determine appropriate PID

Series 9205 Operations Manual Rev A |

29 |

Loading...

Loading...