Page 1

Oxygen Sensor

Operations Manual

TM

SuperOX

U.S. Patent No. 5,635,044

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Table of Contents

Introduction ..................................................................................................................................... 3

Specifications .................................................................................................................................. 3

Characteristics ................................................................................................................................ 3

Operating Theory ............................................................................................................................ 4

Installation ...................................................................................................................................... 5

Troubleshooting .............................................................................................................................. 7

Glass Tank/Glass Furnace Installation ........................................................................................... 9

Warranty.........................................................................................................................................12

Notes ..............................................................................................................................................13

Revision History .............................................................................................................................14

Super Systems Inc. Page 2 of 14 SuperOXTM Operations Manual

Page 3

Introduction

-20

F

• Overall length: 26.5” (67.31 cm), 35.5”

NPT female

Sheath diameter: 1.00" (25.4 mm)

Thank you for selecting the Super Systems Inc. (SSi) SuperOXTM Sensor for your combustion

control application.

TM

SuperOX

represents "state of the art" in oxygen sensor technology. It has been designed for

use in combustion control systems for glass, power, steel reheat, chemical process and

incineration applications.

TM

SuperOX

, with its patented measuring electrode construction, is the product of a team of

design and application engineers, each with over twenty years of atmosphere control

experience. The SSi engineering team has long recognized that the sensor is the most critical

component in a control system and has traditionally been the weakest link. Now, reliability,

TM

repeatability and accuracy are assured with the use of SSi’s SuperOX

high temperature, in situ

sensor in your system.

Specifications

• Useful O

• Temperature range: 1200

• Stability: within +/- 1 mvdc

• Impedance: less than 5 kohms @ 1700

• Useful output: -50 to 1250 mvdc

Range: 10

2

to 100%

o

F to 2900

o

o

F

(90.17 cm), and 44.5” (113.03 cm)

• Weight: 3.0 lbs.

• Insertion to 18” (45.72 cm), 27” (68.58 cm),

and 36” (91.44 cm)

• Mounting: into 1" (25.4 mm)

•

Characteristics

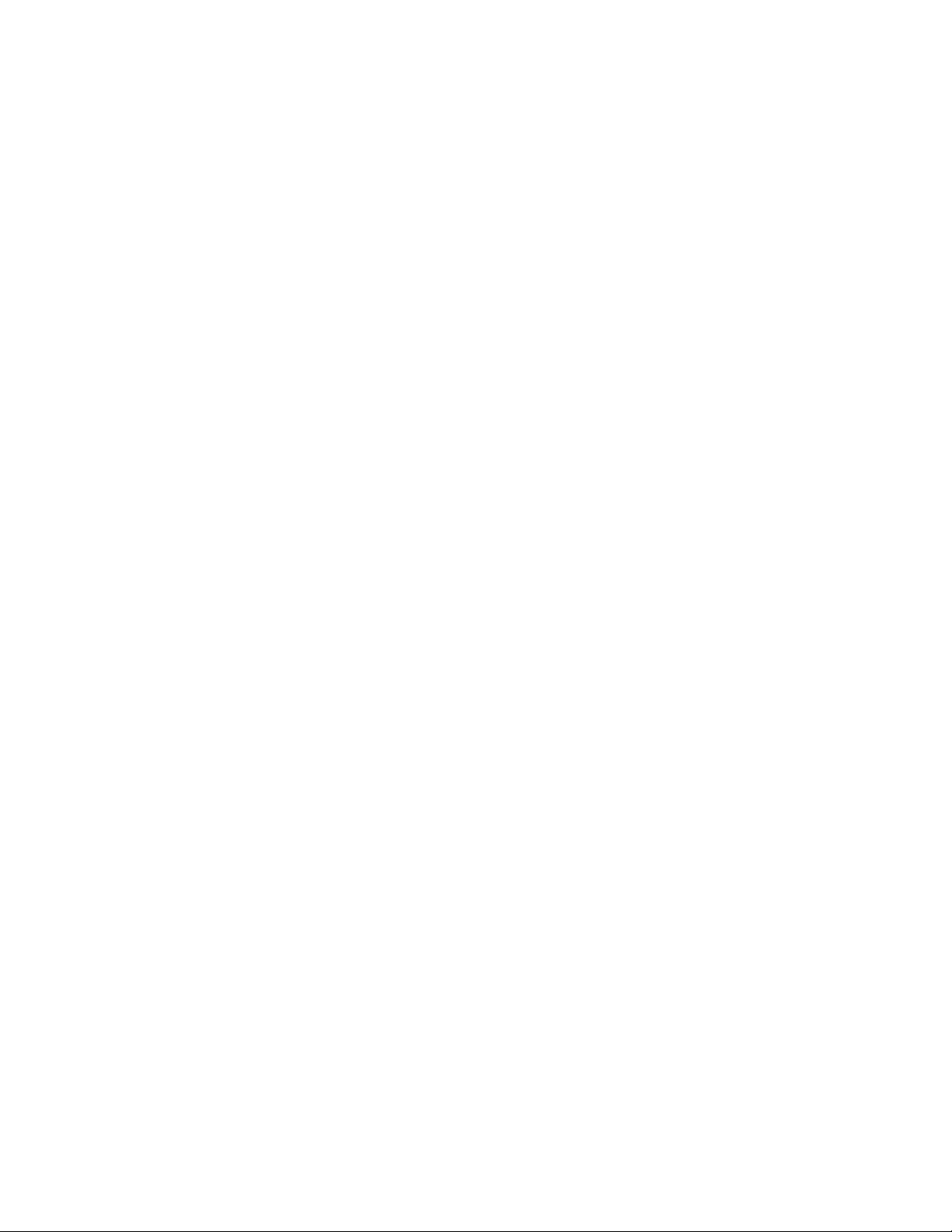

The typical zirconia oxygen sensor consists of a closed end tube with the sensing portion at the

tip. The tube operates on the principle of yttria-stabilized zirconia. Figure 1 illustrates the

SuperOX

TM

Sensor design with details omitted for clarity. The tip of the tube is spring loaded into

contact with the outer, negative platinum electrode, which is in contact with the ceramic sheath.

The inner, positive electrode is spring loaded into contact with the inner zirconia surface. A

thermocouple is positioned close to the inner electrode surface and reference air bathes the

sensing surface.

Super Systems Inc. Page 3 of 14 SuperOXTM Operations Manual

Figure 1

Page 4

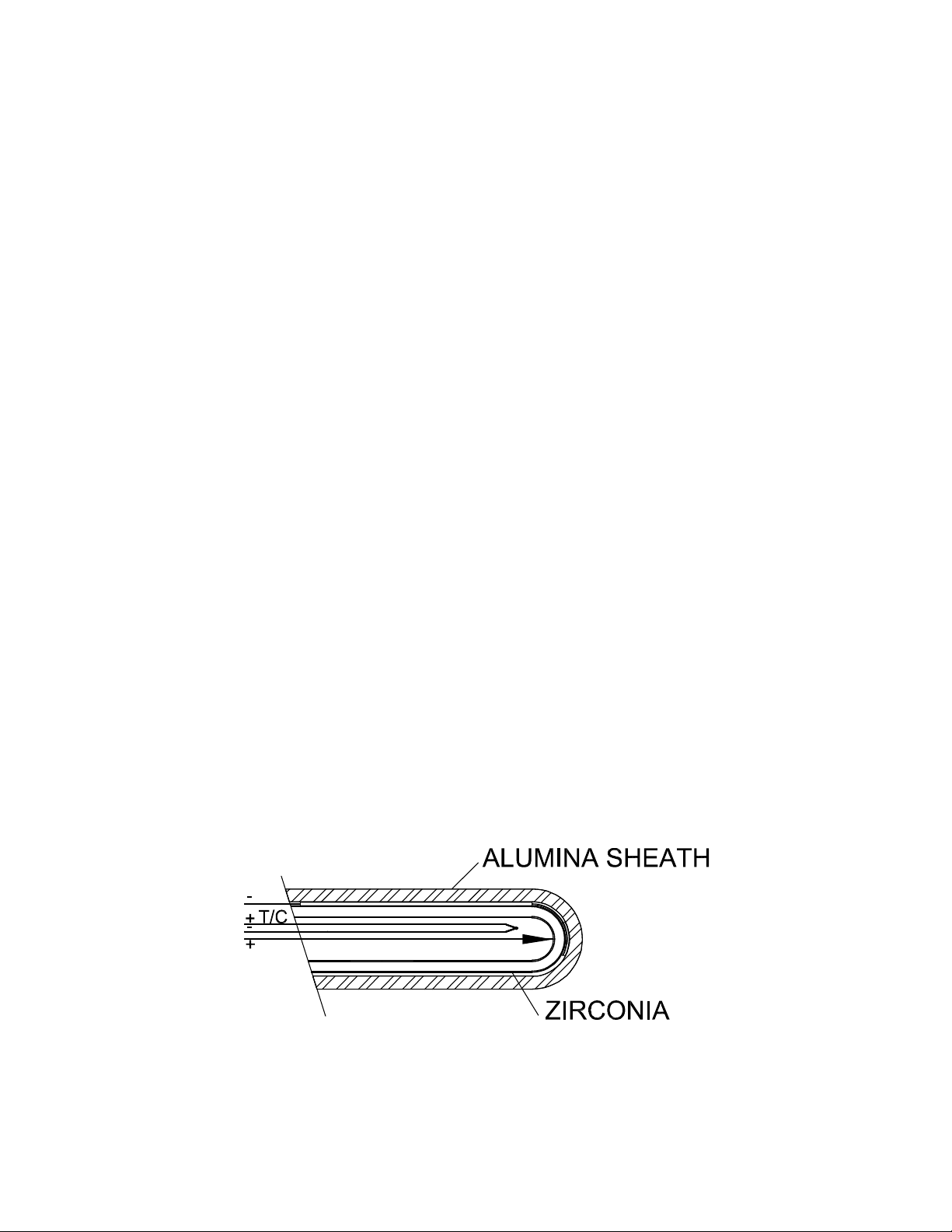

To the instrument technician, the sensor looks like a battery (see Figure 2). It displays a voltage,

EC, from which the carbon potential can be calculated. The probe thermocouple is shown next

to the sensing electrode.

Figure 2

The value of the internal resistance can be measured, as shown in Figure 3, by connecting a

shunt resistor across the sensor terminals, measuring the resultant voltage, Em, and carrying

out the simple calculation shown.

Figure 3

Operating Theory

Oxygen concentration of a conventional combustion atmosphere is measured by an in situ

zirconia sensor, which responds to oxygen according to the Nernst equation shown here.

Because the equation is logarithmic (to the base 10), the coefficient 0.0496TR is the number of

millivolts accompanying a tenfold change in concentration:

Ec= -0.02756TR log (PR /PF) millivolts

where TR is the temp in degrees Rankine and PF and PR are the % oxygen (O2) in the furnace

and the reference gas.

Super Systems Inc. Page 4 of 14 SuperOXTM Operations Manual

Page 5

Installation

If your new sensor is to be installed in an existing entry port, be advised that the sensor is 100%

interchangeable with your current sensor.

For new installations in furnaces, an

entry fitting

must be provided at the furnace wall to permit

the sensor to extend into the furnace chamber. The furnace is prepared by drilling (ideally) a 3”

(76.2 mm) diameter hole through the wall and the insulation. A 1" (25.4 mm) coupling may then

be welded to the wall to provide the gas-tight entry. As the SuperOX

TM

has a 1" (25.4 mm) NPT

hub; use of conventional 1" (25.4 mm) fittings allows for appropriate installation. A combination

of 1" (25.4 mm) nipples and couplings allows for appropriate insertion depth.

Your SuperOXTM Sensor has been shipped with TeflonTM pipe tape applied to the gland, so you

may insert it directly into the furnace. When installing in a hot furnace, insert the first two

inches (50.8 mm) directly, then at a rate of no faster than 4" (101.6 mm) per 5 minutes

in order

to avoid thermal shock fracture. Support the cover end of the sensor during installation.

The sensor requires a reference air supply. In addition, the SuperOX

TM

Sensor has been

designed with an optional cooling port that may require an additional air supply. SSi provides a

custom system, P/N 13017, that supplies both requirements.

It is imperative to emphasize that the reference air must be

dry, clean, and oil free.

Any

combustibles in the reference air will cause the sensor to read high in oxygen. Avoid the use of

lubricated compressed plant air. The air connection at the sensor should be made of silicone

rubber tubing to avoid problems related to the high temperatures normally encountered at the

sensor connection block. Reference air flow should be in the range of 0.2 to 2 CFH at no more

than 2 psi. Cooling air flow should be in the range of 1 to 10 CFH at no more than 2 psi.

Figure 4 and Figure 5 show installations in furnaces and glass tank regenerators.

These views show the installation of SuperOXTM probes in the walls of two different furnaces

furnace, utilizing a silicon protection tube which requires a 1 ½” (38.1 mm) coupling (or half

coupling) entry. This arrangement is typically used for extremely high temperature applications.

The wall is typically 13 ½” (342.9 mm) thick. Correct location of the sensor in the protection tube

may be accomplished by inserting a 1” (25.4 mm) coupling and appropriate length 1” (25.4 mm)

nipple between the sensor and the protection tube. There are three lengths of protection tubes

for use with sensors of 18” (45.72 cm), 27” (68.58 cm) and 36” (91.44 cm) lengths. When using

the unprotected sensor

NOTE: A protection tube is not required for use of the SuperOX

, a 1” (25.4 mm) coupling (or half coupling) can be used for direct entry.

TM

Sensor.

Super Systems Inc. Page 5 of 14 SuperOXTM Operations Manual

Page 6

Protection Tube

1 1/2” (38.1 mm) Coupling,

Gas Tight Weld

Hot Face

Furnace Wall

SuperOX

TM

1 3/4” (44.45 mm) Diameter Hole

Protection Tube

1 1/2” (38.1 mm) Coupling,

Gas Tight Weld

Hot Face

Furnace Wall

1 3/4” (44.45 mm) Diameter Hole

SuperOX

TM

1” to 2” (25.4 mm to 50.8 mm) Recess

Standard Installation

Figure 4

Glass Tank Installation

Figure 5

The standard SuperOXTM, Ver. 2.0, is provided with a 5 foot long high-temperature cable, as

illustrated in Figure 6, so that a plug may be mounted for interconnection with the customer’s

measurement and control instrumentation. Alternatively (and preferably), the customer may

feed his instrument interconnection cable through the cord connector, and make connections

directly to the internal connector.

Super Systems Inc. Page 6 of 14 SuperOXTM Operations Manual

Page 7

Figure 6

Wire designation:

R

e

fe

ren

c

e

Air

C

ooling

Air

C

able

E

nt

r

y

White (Sensor +)

Black (Sensor -)

Green (Thermocouple +)

Red (Thermocouple - )

Troubleshooting

When trouble arises with an oxygen control system, it is important to establish where the

problem is located: the sensor, signal transmission lines, the control instrument, or the

combustion chamber itself. Several simple tests can help to isolate the problem quickly. It is

most important to first understand the nature of the fault. Aside from erratic behavior like

cycling, or failure to stabilize at the setpoint, the most common symptom is non-conformity of

the work pieces to quality assurance specifications.

To evaluate most faults, the recommended tools are:

1. A 3 1/2-digit millivoltmeter with at least 10 MΩ input impedance and 0 to 1999 mV range;

2. A temperature calibrator; and

3. A simulator to output 0 to 200 millivolts at less than 50 MΩ output impedance.

Sensor troubleshooting: In order to establish the source of problems in your installation, first

avoid removing the SuperOXTMSensor from the furnace.

questions must be answered while your sensor is at temperature and is exposed to a normal

atmosphere under

1. Are the connections from the T/C extension wire and sensor cable clean and firmly

attached at the correct sensor and control instrument terminals? Note that the shield

wire in the sensor cable should be connected to ground at the control instrument end

only!

2. Is the sensor impedance less than 50 KΩ at temperatures above 1550

test shown in Figure 3 using a shunt resistor of about 100 KΩ. Measure the voltage EC

before shunting, then EM with the shunt in place. Calculate RP. If it exceeds 50 KΩ,

proceed to step 6 below.

3. How quickly does the sensor react to a change in O

millivolts with the controller or the digital meter. Short the sensor for 5 seconds,

remove the short and measure the time required to return to within 1% of the original

reading. If it exceeds 60 seconds, proceed to step 6, below.

manual control:

All of the following meaningful

°

F? Conduct the

concentration? Read the sensor

2

Super Systems Inc. Page 7 of 14 SuperOXTM Operations Manual

Page 8

4. Is there a leak in the zirconia substrate? To test this property, turn off the reference air

for one minute. Measure the sensor mV as indicated by the controller or a digital

voltmeter. Turn the air back on and measure the mV again. If there is a difference

greater than 5 mV, replace the sensor.

5. Should it be necessary to remove your SuperOX

carefully.

UNDER NO CIRCUMSTANCES should it be removed faster than 4" (101.6 mm)

TM

Sensor from a hot furnace, do so

per 5 minutes.

6. If your atmosphere control problem cannot be resolved, our technical support staff is

available Monday through Friday, 7:00 a.m. to 6:00 p.m. Eastern Standard Time. You may

call us at (800) 666-4330.

Super Systems Inc. Page 8 of 14 SuperOXTM Operations Manual

Page 9

Glass Tank/Glass Furnace Installation

Figure 7 shows a diagram of a typical installation of a SuperOX

furnace.

TM

Sensor into a glass tank/glass

Figure 7

Safety Guidelines

WARNING: You must follow operational safety guidelines when drilling and installing a sensor

in an operating glass furnace. It may be possible to use existing furnace openings. When

repairing a furnace, or planning for new construction, you should consider drilling the holes for

oxygen sensors.

The SuperOX

TM

Sensor contains a significant number of ceramic parts. It is therefore subject to

thermal shock. The sensor must be installed in an area that provides an adequate, turbulent,

and consistent gas stream representative of the atmosphere in the process. The sensor must

be located so that the “hot” end can measure the oxygen level of the flue gas, at a temperature

Super Systems Inc. Page 9 of 14 SuperOXTM Operations Manual

Page 10

greater than 1200°F (650°C), but less than 3000°F (1650°C) in a slightly positive pressure

situation to prevent air in-leakage.

The sensor cannot be exposed in an area with excessive turbulence or high gas velocity,

especially when there is particulate in the atmosphere. In order to comply with these

requirements, SSI recommends that, for glass tanks with regenerative heating, the sensor be

installed vertically in the center of the regenerator crown or horizontally on the regenerator

“target” wall. Please note that target wall life will be significantly less when compared with a

vertical, crown installation.

For glass tanks with recuperative heating, SSI recommends installation in a vertical position in

the flue gas collector, behind the branch off, but in front of the gate valve. Please remember

the temperature constraints when looking for this location.

You must drill 2 ¾ to 3 inch (19.05 to 76.2 mm) holes through the refractory brick. This will allow

easy installation and removal of the SuperOX

TM

Sensor.

Vertical installation

Sensor should be recessed 1 to 2 inches (25.4 to 50.8 mm) into the refractory away from furnace

atmosphere. When installing the probe, it is best to insure this length of insertion. From the hot

face, one will recess the sensor until the readings begin to change. Once a change has been

observed, lower the sensor approximately ½ inch (12.7 mm) and secure the sensor in place.

Horizontal Installation

SSI recommends that the “hot” end of the sensor extend approximately 3 to 5 ½ inches (76.2 to

139.7 mm) beyond the hot face of the refractory. If there is an excessive amount of batch carryover, or if the gas stream has a very high velocity, it is recommended that the sensor be

recessed. Batch carry-over and high velocity gas will erode the sensor and significantly reduce

life.

Sensor Preparation before installation

When using the SSI oxygen mounting assembly, place the sensor at the maximum height

possible and lower it toward the furnace 2 to 4 inches (50.8 to 101.6 mm) every five minutes. If

you do not have an SSI Mounting Assembly, note that approximately 2 hours before installing

the sensor, you should lay the sensor on top of the regenerator (for pre-warming), taking care

to protect the sensor head and wiring assembly.

Sensor installation (insertion) rate

WARNING: You must follow operational safety guidelines when drilling, and installing a sensor

in an operating glass furnace. It may be possible to use existing furnace openings. When

repairing a furnace, or planning for new construction, you should consider drilling the holes for

oxygen sensors.

Insertion of the sensor should be no greater than 4 inches (101.6 mm) every 5 minutes.

Super Systems Inc. Page 10 of 14 SuperOXTM Operations Manual

Page 11

Installation Hints:

The sensor will need to be supported while being installed. The installation process will take 1

to 4 hours depending upon sensor length and rate of insertion. When the sensor is in its final

position, it is recommended that the opening be covered or filled with fiber blanket around the

protection tube.

NOTE: The sensor is warranted against workmanship defects, but not against damage caused

by installing the sensor incorrectly.

1. SuperOx

TM

- Maintenance

It is important to check the sensor’s position every one to two months. If the fiber placed

around the protection tube and the bored hole has shrunk, add fiber into the area between the

protection tube and the bored hole. Use wooden sticks or dowels. Touching the HOT ceramic

tube with a metal screw driver is

NOT recommended.

The sensor head should be observed for any excessive temperature. The internal workings of

the sensor head will ideally be exposed to temperatures no greater than 150 to 200°F (65 to

93°C).

During troubleshooting, it may be necessary to read the sensor millivolts from the sensor. If

you are asked to supply this information, please remove the electrical connection from the head

of the sensor and, using a digital voltmeter, measure the sensor millivolts by touching pins “1”

and “2,” and then observing the number reading. The number should be between 30 and 125

millivolts during a firing cycle. Check the reading against a millivolt vs temperature Oxygen

Chart. You can check the temperature by measuring the millivolts across pins “3” and “4”.

These values can be correlated using a “B-Type” thermocouple chart.

2. Reference Air System - Installation

The reference air system should be installed in an area protected from excessive heat and dust.

It is recommended that it be installed on a column or wall, at a height easily accessible for

maintenance of the air pump. The system should be installed with respect to local electrical

regulations. The reference airline needs to be run from the reference air system to the head of

the sensor. The line can be run using ¼ inch (6.35 mm) tubing (stainless or copper). Terminate

the tubing approximately 6 inches (152.4 mm) from the sensor head and finish the connection

with flexible tubing included in the sensor carton.

3. Reference Air System - Maintenance

The reference air system requires little maintenance. Changing the filter (dependent on the

dust level) 4 - 6 times per year ensures that the sensor receives a quality source of reference

air for proper function. The amount of reference air supplied to the sensor should be

maintained at 0.5 – 1.5 SCFH. The reference air pump needs to be checked periodically to

ensure proper operation.

Super Systems Inc. Page 11 of 14 SuperOXTM Operations Manual

Page 12

Warranty

• Super Systems Inc. (SSi), as manufacturer of the SuperOX

TM

Sensor, warrants it to be

free from defects in material and workmanship for a period of twelve (12) months under

normal use and service. SSi’s obligation under this warranty is limited to repairing or

replacing, at its option, the sensor described herein, should failure occur within the

warranty period. The warranty period shall commence on installation of the sensor. If

premature failure occurs, the sensor must be returned in the complete, original

packaging to SSi. Upon receipt, SSi will conduct an examination as to the cause of

failure, at which time appropriate action will be taken. See more information on

arranging for shipment of the sensor below.

• There are no warranties, expressed or implied, by the distributors or representatives for

the SuperOX

TM

Sensor, except the expressed warranty against defects described above.

There will be no applicable warranty in the event of breakage resulting from thermal or

mechanical shock. Additionally there will be no applicable warranty for a sensor that has

been subjected to misuse or negligence, or was damaged in an accident. SSi shall in no

way be liable for special or consequential damages related to the use of this sensor.

• In the case of failure or malfunction, the user must call SSi at (800) 666-4330 to arrange

for shipment of the SuperOX

TM

Sensor to SSi. As part of arranging shipment, SSi will

issue a Return Materials Authorization (RMA) number. The product must be returned in

the original packaging. It is also recommended that the user fill out the Warranty Claim

Report that is sent with the new SuperOX

TM

Sensor.

Super Systems Inc. Page 12 of 14 SuperOXTM Operations Manual

Page 13

Notes

We suggest that you use this space to keep a record of installation date, test data and

experiences with your

SuperOX

TM

Sensor.

Super Systems Inc. Page 13 of 14 SuperOXTM Operations Manual

Page 14

Rev.

Description

Date

MCO #

-

Initial Release

03/21/2001

N/A

A

Added Revision History

07/11/2001

N/A

B

Revised Fig 5 Drawing, changed Step 8 to read

Step 6

02/19/2002

2024

C

Changed “eight inches” to “two inches” Page 2

Installation Instructions

06/04/2003

2029

D

Changed company address

05/15/2005

N/A

E

Corrected air flow parameters under Installation

06/23/2011

2082

F

Changed manual to new format; implemented

05/22/2013

2123

Revision History

updated artwork to increase clarity; added Glass

Tank/Glass Furnace Installation; revised

contents as needed to match product

parameters.

Super Systems Inc. Page 14 of 14 SuperOXTM Operations Manual

Loading...

Loading...