Page 1

SuperData

Software

OPERATIONS MANUAL

COPYRIGHT

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or computer

language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual, or otherwise, without prior written permission

of Super Systems Inc., 7205 Edington Dr., Cincinnati, OH 45249 USA.

SuperData is a suite of software programs to be used by the Heat Treater. Super Systems Inc. is not responsible or liable for any product, process,

or damage or injury incurred as a result of using SuperData. Super Systems Inc. makes no representations or warranties with respect to the

contents hereof and specifically disclaims any implied warranties or merchantability or fitness for any particular purpose.

DISCLAIMER

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060 / 800-666-4330

Fax: 513-772-9466

www.supersystems.com

Super Systems Inc Page 1 of 172 Super Data Operations Manual

Page 2

Table Of Contents

TABLE OF CONTENTS ........................................................................................................................................ 2

SUPERDATA COMMUNICATIONS .................................................................. 8

SDIO INTRODUCTION ...................................................................................................................................... 8

STARTING SDIO ............................................................................................................................................. 8

MENU OPTIONS .............................................................................................................................................. 9

Action Menu ............................................................................................................................................ 9

Settings Menu. ......................................................................................................................................... 9

View Menu .............................................................................................................................................. 9

Comms View ................................................................................................................................................................. 10

Status View ................................................................................................................................................................... 11

Chan Data View ............................................................................................................................................................ 12

Help Menu ............................................................................................................................................. 13

SDIO INSTALLATION ...................................................................................................................................... 14

SDIO CONFIGURATION ................................................................................................................................... 18

Overview ............................................................................................................................................... 18

Protocols ............................................................................................................................................... 18

Instrument Types ................................................................................................................................... 19

Overview ...................................................................................................................................................................... 19

System Instruments ...................................................................................................................................................... 19

System Channels ....................................................................................................................................................... 19

Physical Instruments ..................................................................................................................................................... 19

Super Systems Instruments ....................................................................................................................................... 19

Eurotherm Instruments ............................................................................................................................................. 19

Honeywell Instruments ............................................................................................................................................ 20

Yokogawa Instruments .............................................................................................................................................. 20

Marathon Instruments ............................................................................................................................................... 21

Other Instruments .................................................................................................................................................... 22

TypeID Reference ......................................................................................................................................................... 22

Configuration File .......................................................................................................................................................... 23

RES Section .............................................................................................................................................................. 23

CONx Section ............................................................................................................................................................ 24

Instrument Section.................................................................................................................................................... 25

System Channels ............................................................................................................................................................................. 25

Super Systems Instruments .............................................................................................................................................................. 26

Generic MODBUS Instruments ....................................................................................................................................................... 27

MMI 10Pro and Barber Coleman 560 Instrument ........................................................................................................................... 28

MMI V3 and V3.5 Instruments ....................................................................................................................................................... 29

MMI V4 Instruments ....................................................................................................................................................................... 30

MMI CARB-PC Instruments ........................................................................................................................................................... 32

Honeywell CPL Instruments ........................................................................................................................................................... 32

Honeywell MODBUS Instruments .................................................................................................................................................. 33

Honeywell DPR3000 Instruments ................................................................................................................................................... 35

Yokogawa CPL Instruments ............................................................................................................................................................ 36

AllenBradley DF1 Instruments ........................................................................................................................................................ 37

Eurotherm Controllers ..................................................................................................................................................................... 38

Sample SCSPSYS.CFG File ......................................................................................................................................... 39

Alarm Block Configuration.............................................................................................................................................. 42

COMMUNICATIONS UTILITIES ............................................................................................................................ 44

Utilities .................................................................................................................................................. 44

SDCommSrv .......................................................................................................................................... 44

Super Systems Inc Page 2 of 172 Super Data Operations Manual

Page 3

ChStat ................................................................................................................................................... 44

SDIOConfig ............................................................................................................................................ 45

SDIOConfig Main Screen................................................................................................................................................ 47

SDIOConfig Connection Dialog ....................................................................................................................................... 48

SDIOConfig Instrument Configuration ............................................................................................................................ 48

ComRBridge ........................................................................................................................................... 50

ComRBridgeSrv ...................................................................................................................................... 53

Krunch .................................................................................................................................................. 53

CompDT ................................................................................................................................................ 54

ComSlots ............................................................................................................................................... 54

GetBuff ................................................................................................................................................. 55

PutBuff .................................................................................................................................................. 55

RWI ...................................................................................................................................................... 56

GetData ................................................................................................................................................ 56

GetStats ................................................................................................................................................ 57

SUPERDATA OPC COMMUNICATIONS ........................................................ 58

OPCBRIDGE ................................................................................................................................................ 58

OPCBridge Graphical Enviornment ............................................................................................................ 58

Starting OPCBridge ................................................................................................................................. 58

Menu Options ........................................................................................................................................ 58

File Menu. ..................................................................................................................................................................... 58

Chanel Menu. ................................................................................................................................................................ 58

OPC .............................................................................................................................................................................. 59

View ............................................................................................................................................................................. 59

Help .............................................................................................................................................................................. 60

SDOPC Installation ................................................................................................................................. 60

OPCBridgeSrv.exe................................................................................................................................... 65

OPCBridge Configuration ......................................................................................................................... 66

SUPERDATA DISPLAY AND INTERACTION ................................................. 71

REALEDIT.EXE .............................................................................................................................................. 71

RealEdit Graphical Environment ............................................................................................................... 71

Menus ........................................................................................................................................................................... 71

File ........................................................................................................................................................................... 71

Edit .......................................................................................................................................................................... 71

View ......................................................................................................................................................................... 72

Options ..................................................................................................................................................................... 72

Window .................................................................................................................................................................... 73

Help ......................................................................................................................................................................... 73

Toolbar ......................................................................................................................................................................... 74

Coolbar ......................................................................................................................................................................... 74

REALEDIT COMMON FORMS .............................................................................................................................. 74

Property Edit Sheet ................................................................................................................................. 74

Colors: .......................................................................................................................................................................... 75

Size and Position: .......................................................................................................................................................... 75

Lists:............................................................................................................................................................................. 75

Combo Box: .................................................................................................................................................................. 75

Color Dialog ........................................................................................................................................... 76

Caveats with the Color Dialog .................................................................................................................. 77

List Builder ............................................................................................................................................ 77

ODBC Edit Wizard ................................................................................................................................... 78

RealEdit Settings .................................................................................................................................... 79

Scale Factor ........................................................................................................................................... 80

REALEDIT OBJECTS ........................................................................................................................................ 81

Super Systems Inc Page 3 of 172 Super Data Operations Manual

Page 4

Communications ..................................................................................................................................... 82

Communications Channel Definitions.............................................................................................................................. 82

Properties ................................................................................................................................................................. 82

Communications Channel Source Parameter................................................................................................................... 82

Properties ................................................................................................................................................................. 82

Communications Channel Destination Parameter ............................................................................................................ 82

Properties ................................................................................................................................................................. 82

Fonts .................................................................................................................................................... 84

Constants .............................................................................................................................................. 86

Data Processes....................................................................................................................................... 86

Data Values ........................................................................................................................................... 88

Data Value Lists ..................................................................................................................................... 90

ODBC Connections.................................................................................................................................. 92

Pointers ................................................................................................................................................. 93

Trend Lines ........................................................................................................................................... 94

File References....................................................................................................................................... 96

Picture File References .................................................................................................................................................. 96

Application File References ............................................................................................................................................ 96

INI File References ........................................................................................................................................................ 96

Flat ASCII File References ............................................................................................................................................. 97

Link Screen File References ........................................................................................................................................... 98

Crystal Report File References ....................................................................................................................................... 98

Datalog File References ................................................................................................................................................. 98

Data Socket Sources ............................................................................................................................... 99

Data Socket Destinations ....................................................................................................................... 100

Function Sources .................................................................................................................................. 101

Image Boxes ........................................................................................................................................ 102

Simple Shapes ..................................................................................................................................... 103

Logic Boxes ......................................................................................................................................... 104

Portable Images ................................................................................................................................... 105

Simple Labels ....................................................................................................................................... 106

Auto Labels.......................................................................................................................................... 107

Edit Boxes ........................................................................................................................................... 108

Lookup Lists ........................................................................................................................................ 109

Spin Buttons ........................................................................................................................................ 110

Meters ................................................................................................................................................ 111

Simple Scales ....................................................................................................................................... 112

Recipe Boxes ....................................................................................................................................... 113

Alarm Lists .......................................................................................................................................... 114

Link Screen Buttons .............................................................................................................................. 116

RealTime Event Buttons ........................................................................................................................ 117

Data Grids ........................................................................................................................................... 118

Graphs ................................................................................................................................................ 118

Historical Graphs .................................................................................................................................. 120

Dials ................................................................................................................................................... 123

Toggle Buttons ..................................................................................................................................... 124

Numeric Edits ...................................................................................................................................... 127

Date Pickers ........................................................................................................................................ 127

iTools .................................................................................................................................................. 129

Animations .......................................................................................................................................... 130

Event Lists ........................................................................................................................................... 130

REALTIME EVENTS ....................................................................................................................................... 132

Copy Data Value X to Destination. .......................................................................................................... 132

Copy Pending Edit of Data Value X to Destination..................................................................................... 132

Append Blank Record. ........................................................................................................................... 132

Super Systems Inc Page 4 of 172 Super Data Operations Manual

Page 5

Show Hourglass Mouse Cursor. .............................................................................................................. 132

Clear Hourglass Mouse Cursor. ............................................................................................................... 132

Delete Database Record. ....................................................................................................................... 132

Send Pending Edit. ............................................................................................................................... 132

Cancel All Pending Edits. ....................................................................................................................... 133

Discard Current Screen. ........................................................................................................................ 133

Show Message with No Buttons. ............................................................................................................ 133

Show Message with Abort Button Only. ................................................................................................... 133

Show Message with Continue Button Only. .............................................................................................. 133

Show Message with Abort and Continue Buttons. ..................................................................................... 133

Wait For Continue Button. ..................................................................................................................... 133

Wait For Data Value X = Data Value Y. ................................................................................................... 133

Hide a Message. ................................................................................................................................... 134

Refresh All Files. ................................................................................................................................... 134

Reload All Lookup List. .......................................................................................................................... 134

Unconditional Screen Update. ................................................................................................................ 134

Discard All Other Screens. ..................................................................................................................... 134

Abort Button Branch Point. .................................................................................................................... 134

Append and Copy Value List to Destination. ............................................................................................. 134

Copy Value List to Destination. ............................................................................................................... 135

End RealTime....................................................................................................................................... 135

Exit Event if Data Value X = Data Value Y. .............................................................................................. 135

Update All Edit Boxes on the Screen. ...................................................................................................... 135

Clear Database Fields for Current Record. ............................................................................................... 135

Send a Report to the Screen. ................................................................................................................. 135

Send a Report to The Printer. ................................................................................................................ 135

Run an External Application File. ............................................................................................................ 135

End RealTime and Run an External Application File. ................................................................................. 136

Start New Screen. ................................................................................................................................ 136

Start v3.5 Recipe Program. .................................................................................................................... 136

Stop v3.5 Recipe Program. .................................................................................................................... 136

Search Datalog Data. ............................................................................................................................ 136

Erase a Destination File. ........................................................................................................................ 136

Print Current RealTime Screen. .............................................................................................................. 136

Minimize Current RealTime Screen. ........................................................................................................ 136

Maximize Current RealTime Screen. ........................................................................................................ 137

Normal Size Current RealTime Screen. .................................................................................................... 137

Set a Bit (Data Value X) in Destination. ................................................................................................... 137

Reset a Bit (Data Value X) in Destination. ................................................................................................ 137

Toggle a Bit (Data Value X) in Destination. .............................................................................................. 137

Refresh ODBC Specified in Destination. ................................................................................................... 137

Copy Data Value X to Pending Edit Value. ............................................................................................... 137

Move to First Record. ............................................................................................................................ 137

Move to Previous Record. ...................................................................................................................... 138

Move to Next Record. ........................................................................................................................... 138

Move to Last Record. ............................................................................................................................ 138

Copy pending edit value X to Destination ................................................................................................ 138

Append Value List to ODBC Destination as New Record............................................................................. 138

Exit to abort branch point if Data value X =Data Value Y .......................................................................... 138

Exit RTEvents....................................................................................................................................... 138

Jump to next Abort branch point ............................................................................................................ 138

Do while (data value X)<=(data value Y) ................................................................................................ 139

While end (must follow Do While Event) ................................................................................................. 139

Super Systems Inc Page 5 of 172 Super Data Operations Manual

Page 6

For 1 to (Data value X) ......................................................................................................................... 139

Next (must follow for loop) .................................................................................................................... 139

Suspend Execution for X milliseconds...................................................................................................... 139

Enable/Disable Screen Object ................................................................................................................ 139

Start SSI Recipe ................................................................................................................................... 139

Stop SSI Recipe ................................................................................................................................... 140

Hold SSI Recipe ................................................................................................................................... 140

Resume SSI Recipe ............................................................................................................................... 140

Advance SSI Recipe .............................................................................................................................. 140

Edit SSI Recipe .................................................................................................................................... 140

Run Edited SSI Recipe .......................................................................................................................... 140

Cancel SSI Recipe................................................................................................................................. 141

SUPERDATA RECORDER ........................................................................... 142

OVERVIEW ................................................................................................................................................ 142

DISPLAY ................................................................................................................................................... 143

Components of SDRecorder Display ........................................................................................................ 143

CHART VIEW .............................................................................................................................................. 144

CURSOR DATA AREA ..................................................................................................................................... 145

CHART CONTROL AREA ................................................................................................................................. 146

MENUS ..................................................................................................................................................... 148

File Menu ............................................................................................................................................ 148

Export Menu ........................................................................................................................................ 148

Points Menu ......................................................................................................................................... 148

Options Menu ...................................................................................................................................... 148

View Menu .......................................................................................................................................... 149

Loads Menu ......................................................................................................................................... 149

Notes Menu ......................................................................................................................................... 149

Help Menu ........................................................................................................................................... 149

TOOLBAR .................................................................................................................................................. 150

HOW TO ................................................................................................................................................... 151

Open a Chart ....................................................................................................................................... 151

Create a Chart ..................................................................................................................................... 151

Add a Chart Pen ................................................................................................................................... 151

Edit a Chart Pen ................................................................................................................................... 152

Delete a Chart Pen ............................................................................................................................... 153

Select a Process Scale ........................................................................................................................... 153

Set Chart Times ................................................................................................................................... 154

Use the Cursor ..................................................................................................................................... 155

Zoom .................................................................................................................................................. 156

Pan ..................................................................................................................................................... 157

Hide a Pen ........................................................................................................................................... 157

View a Pen's Statistics ........................................................................................................................... 158

Print a Chart ........................................................................................................................................ 160

View the Data Grid ............................................................................................................................... 161

Historical Load Chart ............................................................................................................................. 162

View an Alarm Report ........................................................................................................................... 164

Use Notes ............................................................................................................................................ 164

Viewing Notes .............................................................................................................................................................. 165

Adding Notes ............................................................................................................................................................... 167

FILES AND CONFIGURATION ............................................................................................................................ 168

SDRec Files .......................................................................................................................................... 168

SDRec Configuration ............................................................................................................................. 168

Super Systems Inc Page 6 of 172 Super Data Operations Manual

Page 7

Command Line ..................................................................................................................................... 171

Alternate Command Line: ............................................................................................................................................. 171

REVISION HISTORY ...................................................................................................................................... 172

Super Systems Inc Page 7 of 172 Super Data Operations Manual

Page 8

SuperData Communications

(SDIO.exe)

SDIO Introduction

The SuperData Comms application (SDIO.exe) is the communications program that provides up to 127 channels of

serial communications to configured instruments and builds shared data tables for other applications to access

instrument data. The communications program supports up to 8 serial ports and 120 Ethernet/TCP ports. Each port

may be configured with a different serial protocol (e.g. MMI, Modbus, CPL, DF1, etc.). This provides the flexibility to

connect to a wide variety of industrial controllers.

The following functions are provided by the SuperData Communications application:

1. Automatic polling for configured instruments.

2. Shared data tables for other applications to access instrument data.

3. Automatic data logging of all configured instruments on a minute-by-minute basis.

4. Real Time updates of process data.

5. Message handling system to allow other applications to read and write to configured instruments.

6. Provide communications statistics.

7. Provide communications error handling.

8. Periodic compression of logged data.

9. Provides an application event log for communications error and warning messages. The event log may be

viewed using the Windows event log viewer.

Starting SDIO

SDIO must be configured prior to running the application. Configuration consists of defining:

• File locations

• Serial Ports

• Instrument types, addresses and polling

Configuration is normally accomplished by Service personnel when SuperData is installed. The

section contains details on how to configure SDIO.

SDIO.exe is normally located in the \SSI\BIN directory and may be started manually from the directory by clicking on

the application file. However, SDIO is designed to run all of the time (24/7) and is normally started as a service.

When SDIO is run as a service, it will start automatically any time the computer is turned on (logon is not required).

To setup SDIO as a service, see the section

When SDIO is running, you will see the SDIO icon in the Quick Launch Toolbar portion of the Taskbar (normally on

the lower right portion of the desktop). When communications are normal, the dot above the "i" in the icon will blink

rapidly. Clicking the icon will bring the SDIO window to the foreground. Only one instance of SDIO is allowed to run

on a computer.

SDCommSrv

in the

Communications Utilities

section.

SDIO Configuration

Super Systems Inc Page 8 of 172 Super Data Operations Manual

Page 9

Menu Options

The following menu options are available on the

SuperData Communications

menu bar:

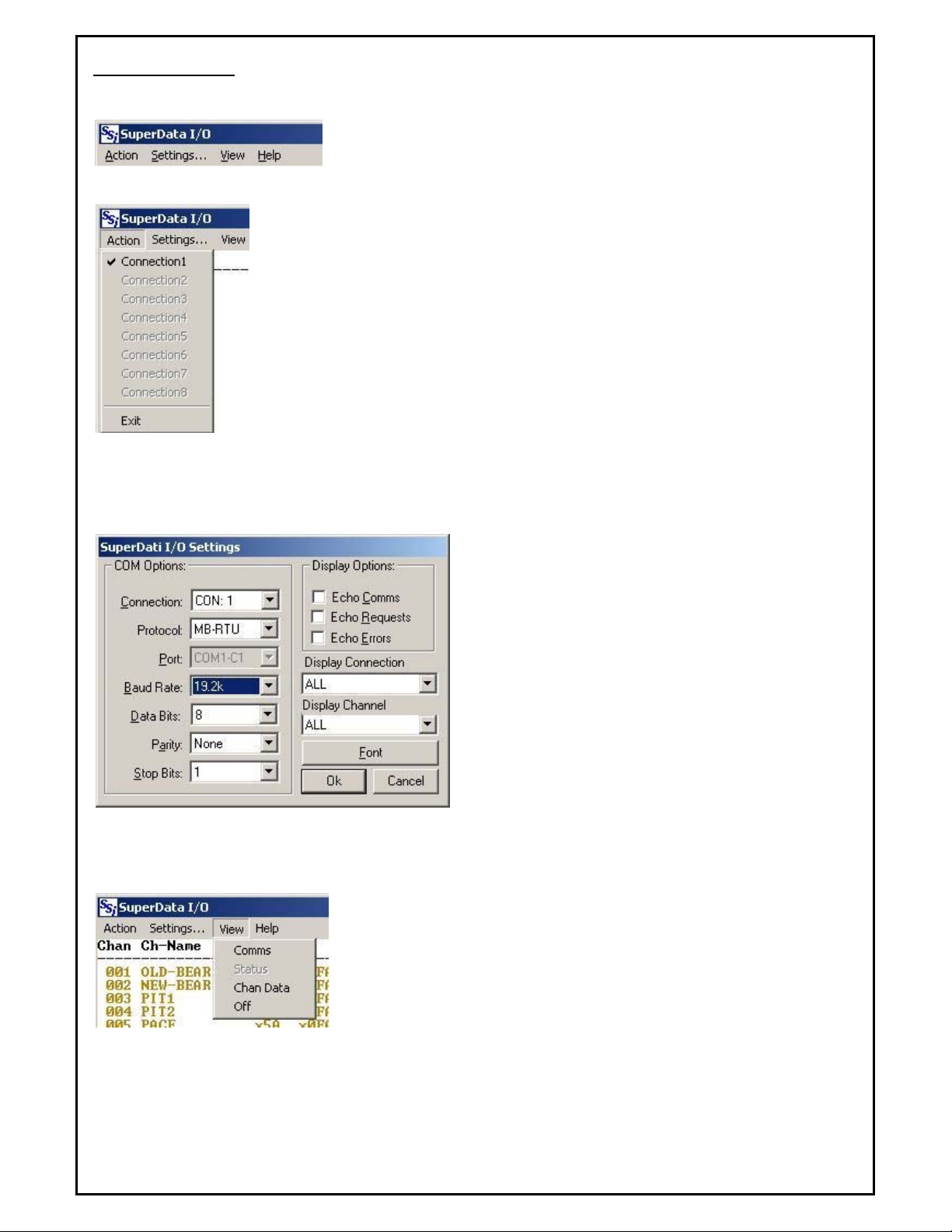

Action Menu

The Action menu dropdown shows the 8 serial connections. Configured connections are

in normal text. Connections that are not configured are shown in dimmed text. Clicking

on a connection will toggle between connect and disconnect. This is a useful tool to

reinitialize the communications port without having to shutdown and restart SDIO. A

connection with a checkmark is connected. A disconnected connection will only remain

disconnected for a max of 30 minutes. This is useful to re-initialize the communications

port without having to shut down and restart SDIO.

The Exit menu item stops the communications program.

Settings Menu.

The Settings menu item displays the following Settings dialog box:

The COM Options section of this dialog is used to view or

set the communications options for each connection.

Setting the communications options with this dialog is

temporary

revert to the settings in the configuration file

(SCSPSYS.CFG). To make settings

change the configuration file. To make temporary

communications changes, the associated connection must

first be disconnected. The PORT dropdown will display the

connection assigned to the port.

The Display options section is used to set the

information is to be displayed in the Comm view. The

Display Connection and Display Channel dropdowns

select which connections and channels are to be displayed

in the Comm. View. The Display Channel selection is

used to set the channel to view data in the Chan Data

view.

The Font button is used to open the Font selector dialog.

View Menu

The View Menu is used to select the Comms, Status or Chan Data view.

This menu may also be used to turn the view off. When the view is turned

off, the display will stop updating until the comm. or Status view is selected.

The Comms view displays messages and errors for selected channels as

configured in settings.

The status view displays an overall status of the communications.

The Chan Data view displays the polled data received from the instrument.

SDIO will normally be in the Status view.

. When the program restarts, the settings will

permanent

, you must

Super Systems Inc Page 9 of 172 Super Data Operations Manual

Page 10

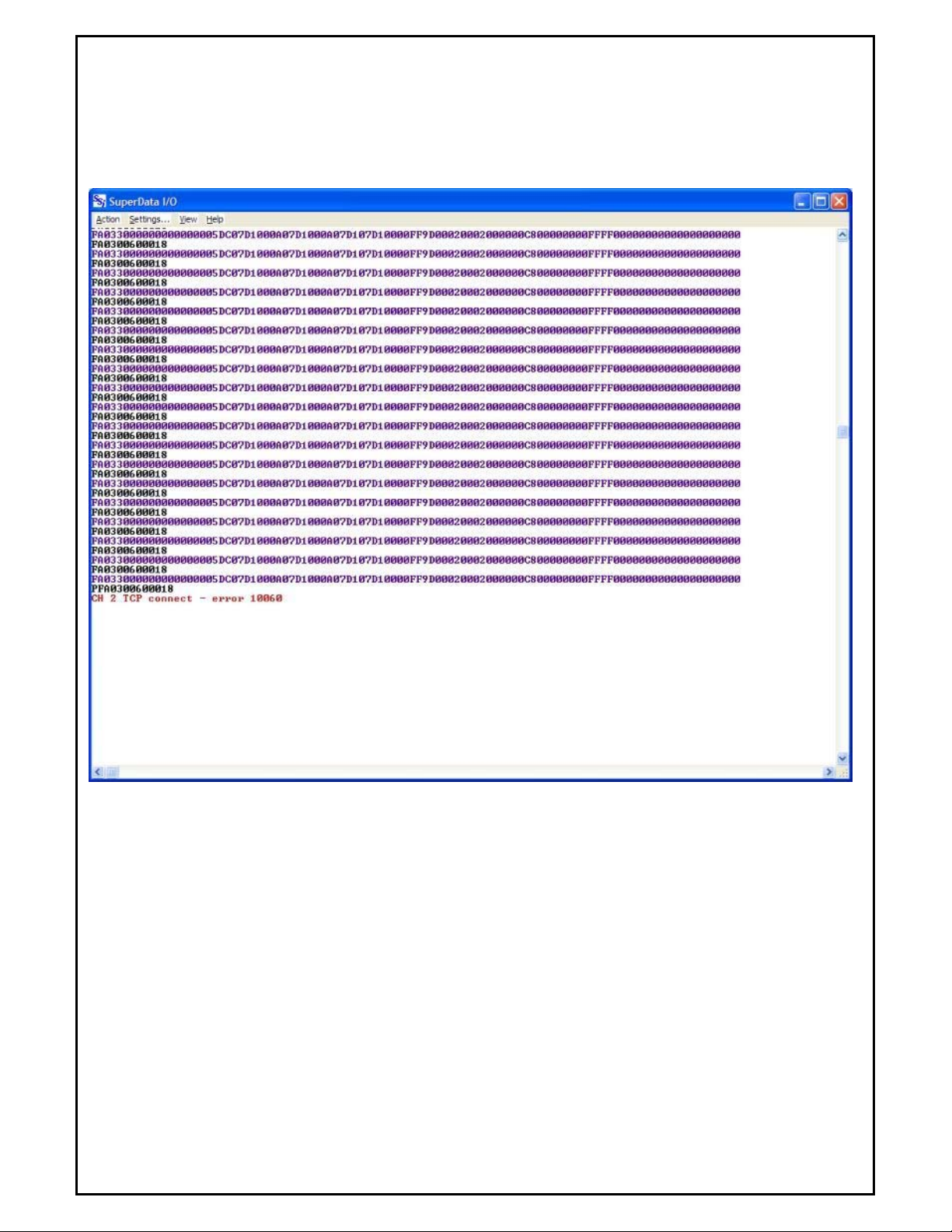

Comms View

The Comms view is normally used for trouble-shooting communications. Leaving the comm view open can slow

down communications throughput so it is best to return to the status view when not using the comms view.

Transmitted messages from the Comms program are displayed in BLACK, responses from the instrument are

displayed in PURPLE, and errors are displayed in RED. The screen scrolls as messages are transmitted and received.

To stop scrolling, use the "View Off" menu.

Super Systems Inc Page 10 of 172 Super Data Operations Manual

Page 11

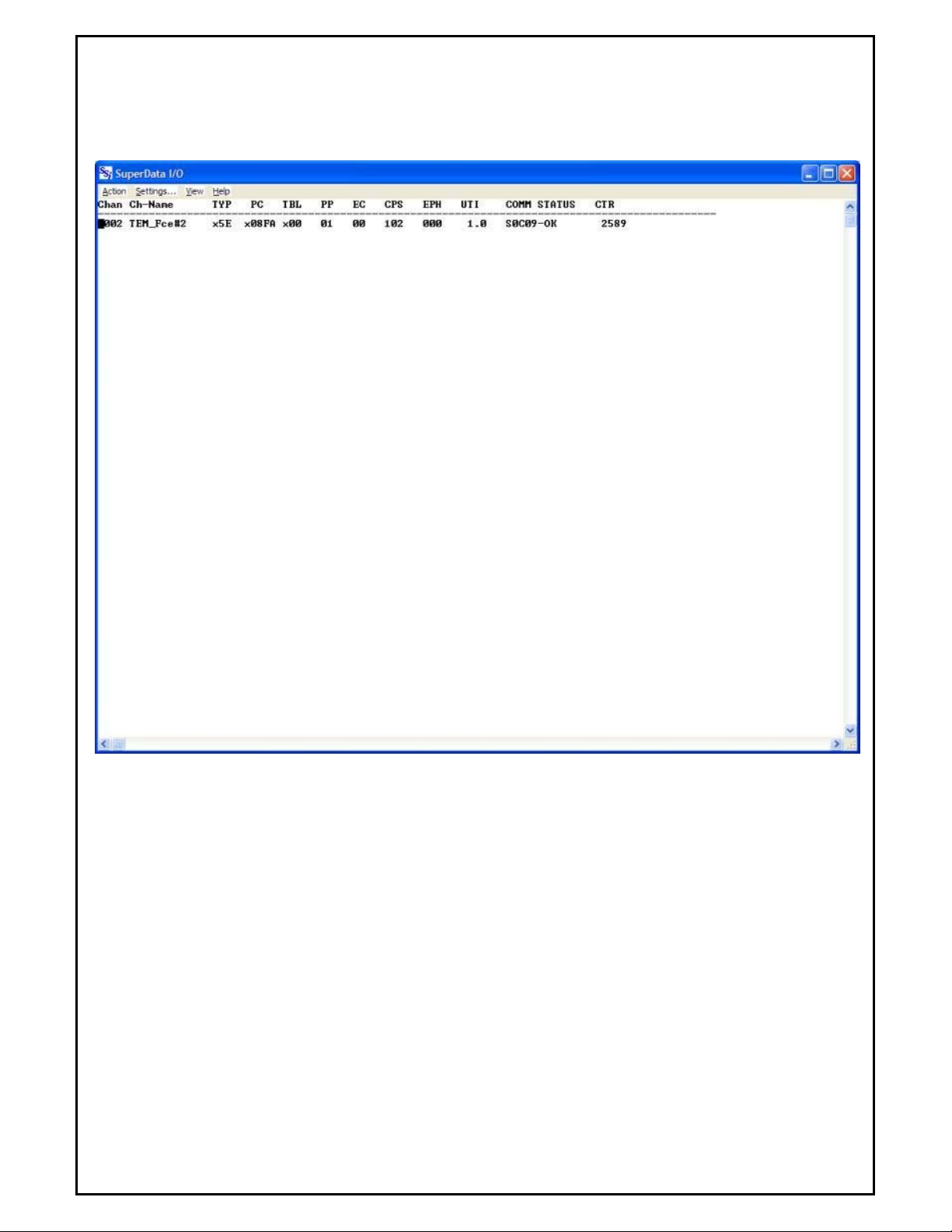

Status View

There will be one line for each configured instrument. Normally communicating instruments will be displayed in

BLACK, disconnected instruments will be displayed in dimmed text (GREY), invalid instruments (instruments that are

incompatible with the connection protocol) are displayed in RED, and instruments with errors (i.e. valid but not

communicating) are displayed in dark YELLOW

The following columns are displayed for each channel:

Chan – the logical channel number (1-127)

Ch-Name – the channel's name (up to 11 characters)

TYP – the channel's type identifier followed by L (logged channel) or N (not logged).

PC – the physical channel (in HEX). The first hex character is the connection (0-7 for serial connections 1-8; 8

– 127 for TCP connections), the remaining 2 hex characters identify the instrument's physical address.

TBL – an optional Table identifier.

PP – the current polling priority (1-3). If communications are good, polling priority will be 1. When the

instrument has 10 or more consecutive errors, polling priority will be set to 2 and the SDIO will only try to

reconnect to the instrument every 30 secs, when the consecutive error count exceeds 20 errors, priority will be

set to 3 and communications will attempt to reconnect every 2 minutes.

EC – the current consecutive error count.

Super Systems Inc Page 11 of 172 Super Data Operations Manual

Page 12

CPS – the estimated communications throughput in characters per second.

EPH – the estimated error rate in errors per hour.

UTI – the estimated update time interval in seconds (time between complete updates for the instrument).

COMM STATUS – identifies the instruments Station, Connection ID and current status. In most configurations

the Station will be zero.

CTR – update counter, counts the number of times the channel has been updated (rolls over at 9999 counts.)

Note

- System Channels (maintained by other applications) are a special case. SDIO does not know

their communications status. They will always contain the following column values

:

TYP - x14

PC – x000

TBL – x00

PP – 01

EC – 00

CPS – 001

EPH – 000

UTI – 999.9

COMM STATUS – SC01-OK

CTR – 0001

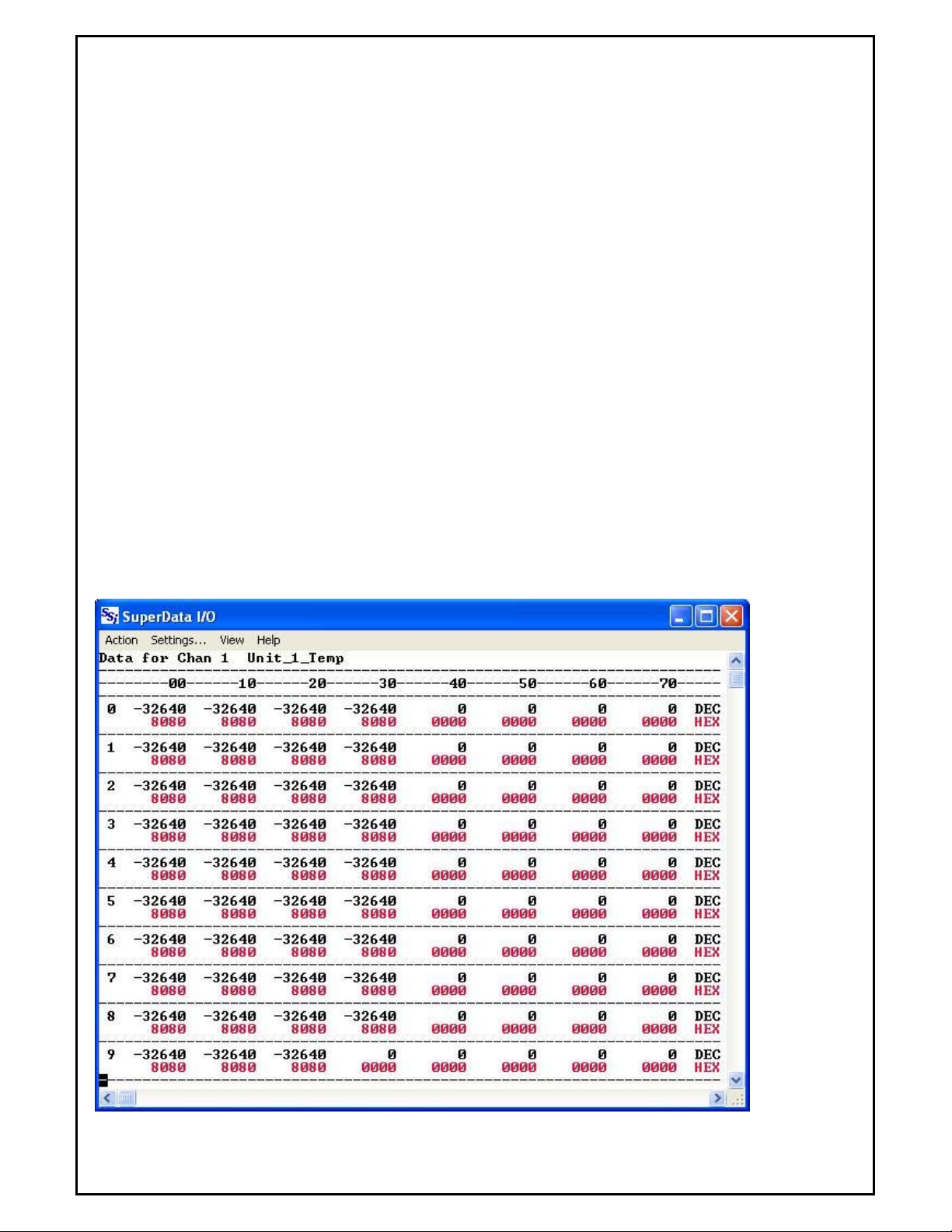

Chan Data View

This table displays the current value of all 80 slots of the Channel selected in the Settings Menu.

Super Systems Inc Page 12 of 172 Super Data Operations Manual

Page 13

The values displayed in black are decimal while the ones in red are in hexadecimal format.

are reserved for use by SDIO

. Slot 78 is used for CPS, and slot 79 is used for special alarm purposes (ABC

Note – Slots 78 and 79

configuration).

Help Menu

The Help Menu provides options to display the help file or to display the SuperData Communications about box.

Super Systems Inc Page 13 of 172 Super Data Operations Manual

Page 14

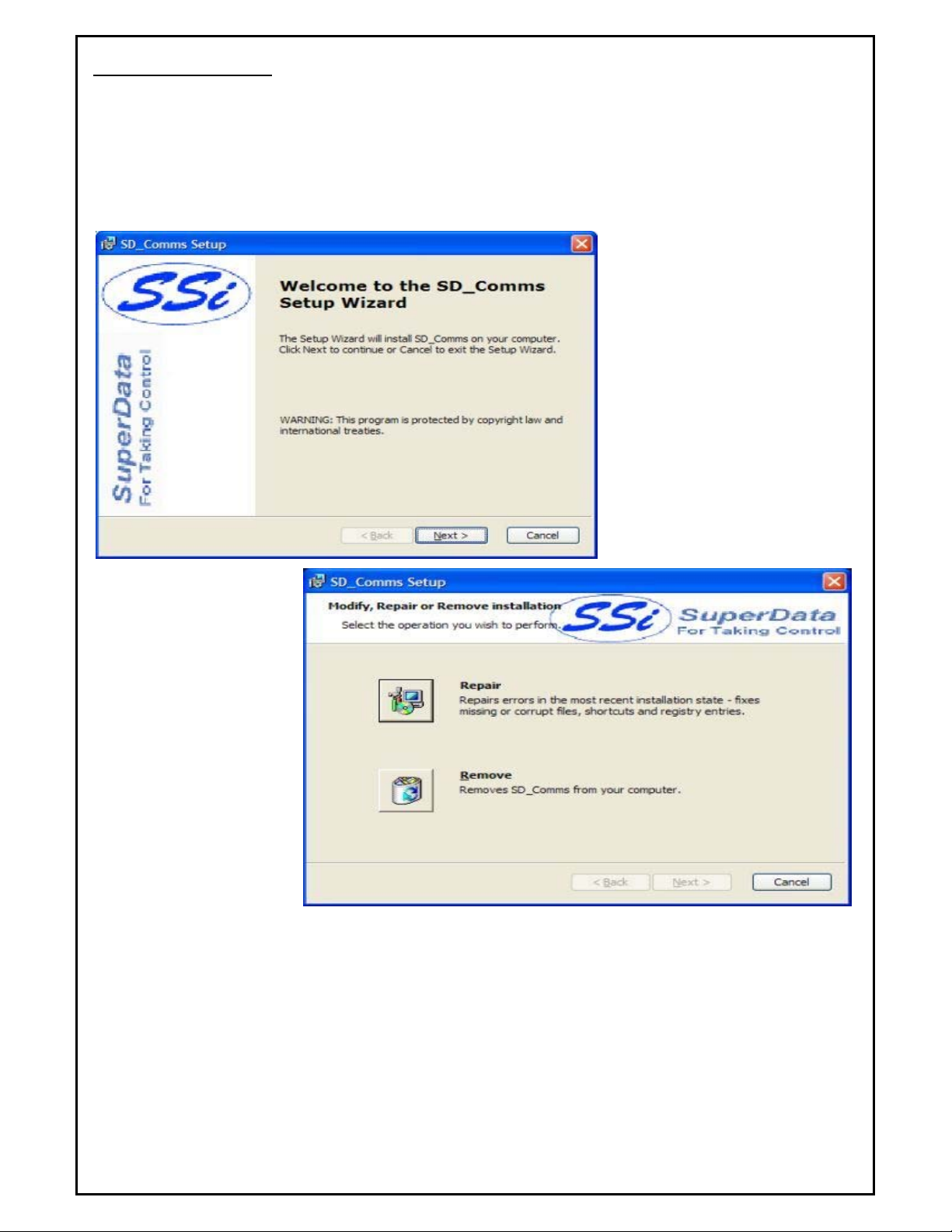

SDIO Installation

Note – The person installing the SD_Comms Software must have administrative rights on the

computer(s) where the installation is taking place for the installation to be successful

Insert the SuperData Installation CD into the computer’s optical drive and navigate to the SuperData folder. Doubleclick on the setup file - SDComms_Setup.msi - to start the auto-installation. If there is no version of the SD_Comms

running on the computer, the installation will display a splash screen.

Clicking the Next > button will

continue with the installation process.

Clicking on the Cancel button will

cancel the installation process. The

user will have to confirm the

cancellation.

.

If there is a version of the

SD_Comms already installed

on the computer, The

following screen will be

displayed:

The installer will either reinstall the software (Repair

button) or remove the

software from the computer

(Remove button). Clicking

on the Cancel button will

cancel the actions. The user

will have to confirm the

cancellation.

Note - the

installer does not

remove any subfolders in the main SSI folder. These files will have to be manually removed

. The

Repair option will allow the user to repair the installed files. This option is useful if the installation was interrupted in

some way and did not finish on its own.

The Remove option will remove the main executable file from the computer.

Super Systems Inc Page 14 of 172 Super Data Operations Manual

Page 15

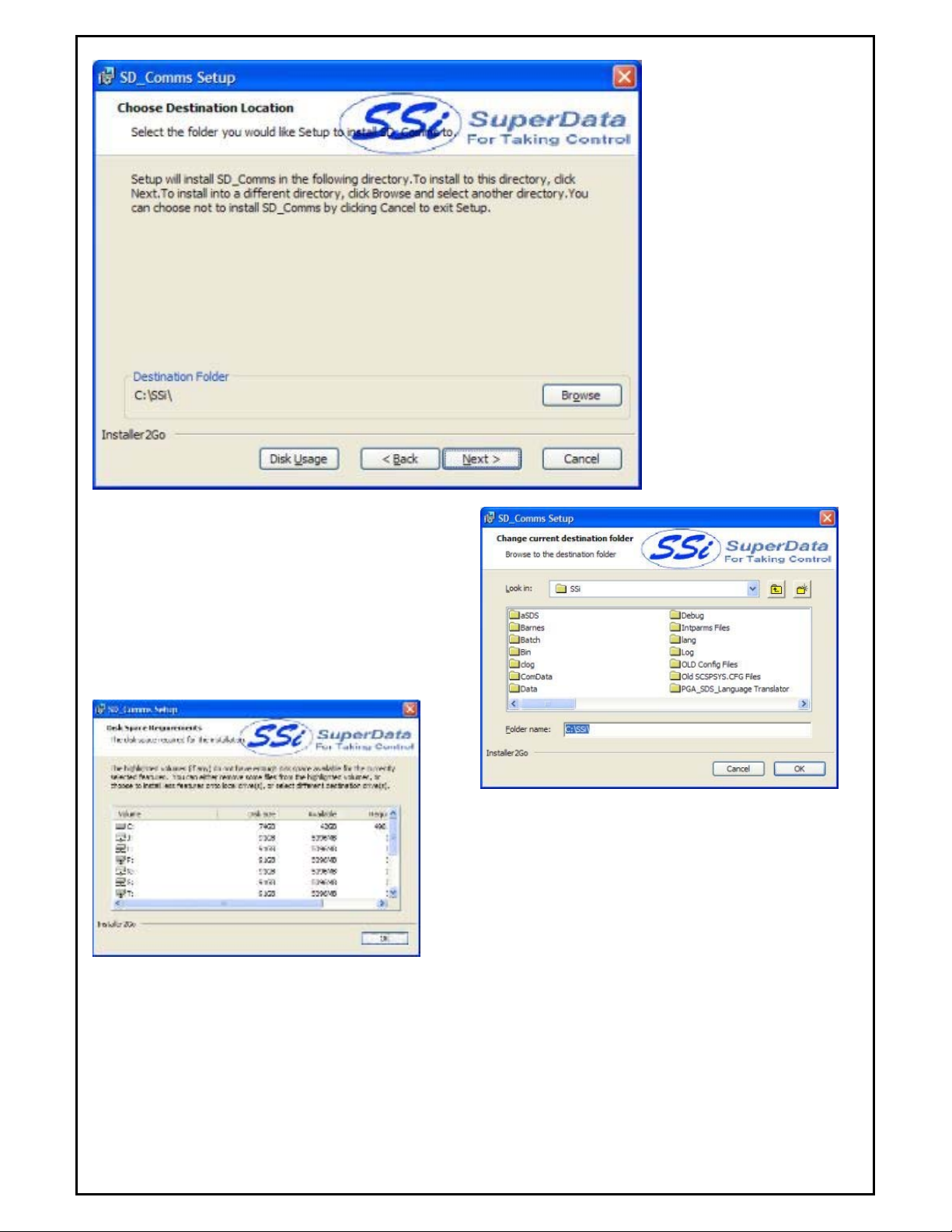

The next screen will prompt

the user for the download

location. The default location

is “C:\SSI\”.

Note: The

installer will automatically

create a “Bin” folder to install

the files to. For example, if

the default location, “C:\SSi\”

is used, then the files will be

installed to “C:\SSi\Bin”.

The user can click on the Browse button to select an

alternate location (right).

Clicking on the Disk Usage button will display the

available computer drives onto which the application can

be downloaded, as well as the total space, available

space and total space required (below). Clicking on the

OK button will close out the disk usage screen.

Clicking on the < Back button will display the previous screen.

Clicking the Next > button will continue with the installation

process.

Clicking on the Cancel button will cancel the installation process. The user will have to confirm the cancellation.

Super Systems Inc Page 15 of 172 Super Data Operations Manual

Page 16

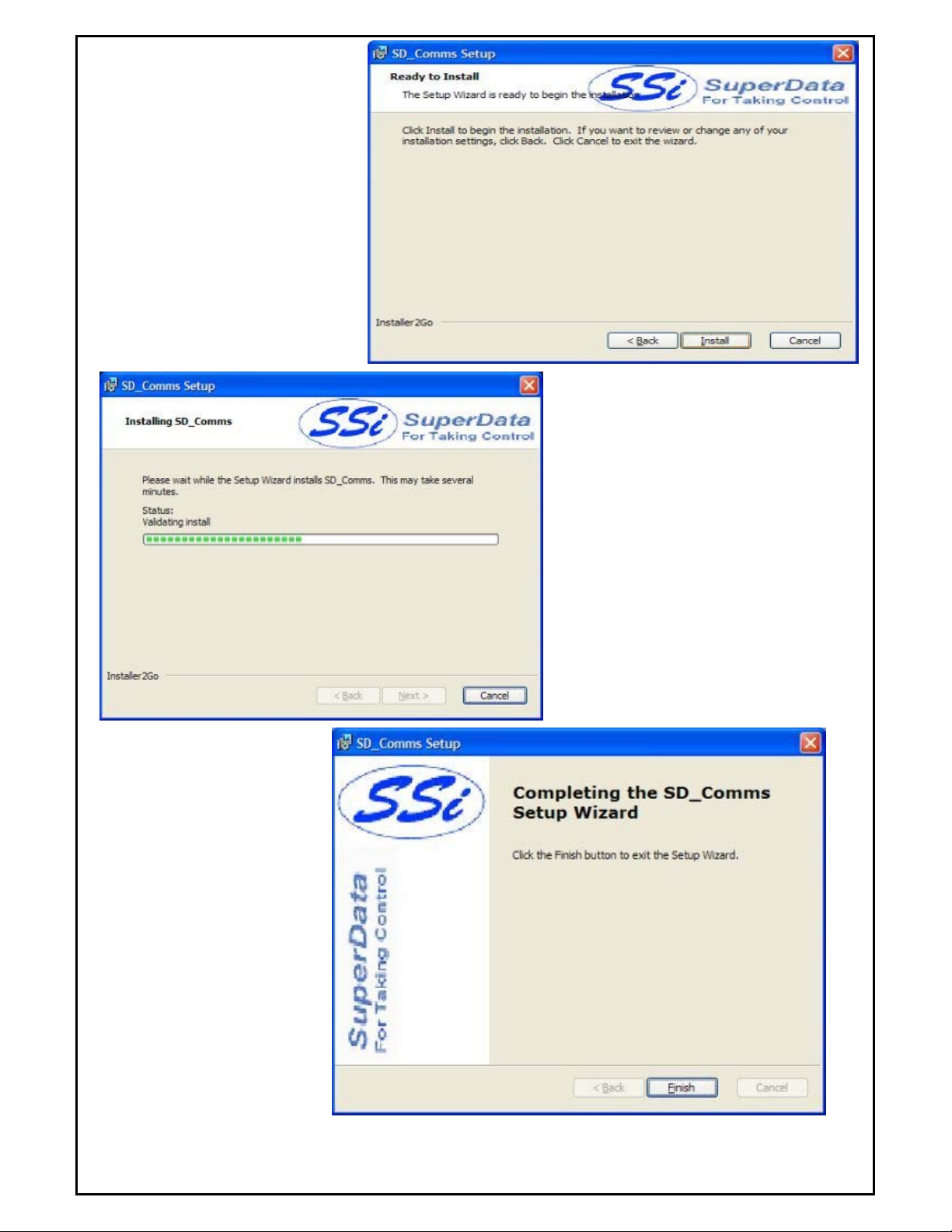

Clicking on the Cancel button will

cancel the installation process. The user

will have to confirm the cancellation.

Clicking on the < Back button will

display the previous page.

Clicking on the Install button will

install the software to the specified

location.

Click Finish to complete the

installation process.

Super Systems Inc Page 16 of 172 Super Data Operations Manual

Page 17

SD_Comms Minimum System Requirements

• Computer with a minimum of 600 MHz processor clock speed (Intel, AMD, etc).

• Operating System – Microsoft Windows 98/2000/XP/Vista

• Memory – 256 MB RAM or higher

• Disk Space - Minimum of 1 GB storage space

• CD-ROM drive or DVD-ROM drive

• Keyboard and mouse

• Monitor with 1024 x 768 resolution or higher and 256 colors

Super Systems Inc Page 17 of 172 Super Data Operations Manual

Page 18

SDIO Configuration

Overview

SuperData Comms Configuration File (SCSPSYS.CFG)

SuperData Comms is configured using a configuration file called SCSPSYS.CFG. This file is normally found in the

C:\SSi directory and may be edited using the configuration tool SDIOConfig.exe, (see Page 45), or any text editor

(e.g. Notepad, WordPad, TextPad, etc). When editing this file, always save this file as an ASCII text file. Anytime

the file is modified SuperData Comms will automatically reconfigure – there is no need to stop and restart SuperData

Comms (SDIO).

The configuration file consists the following sections:

RES– the basic communications parameters.

CONx– the communications configuration for each connection used (up to 8 sections)

INST – the instrument configuration parameters

ABC– optional section containing custom Alarm Block Configurations

Protocols

The following protocols are currently supported by SDIO:

MB-RTU Protocol is used for any instrument capable of Modbus RTU comms. This protocol is a binary protocol.

Modbus is capable of using integer or floating point data; However, SDIO converts all floating point data to integer

data for data logging and display. Modbus instruments may be connected using either RS485 2-wire or RS485 4wire. A wide variety of control instruments now use Modbus RTU comms including: Super Systems, Eurotherm,

Honeywell, Yokogawa etc.

ModbusTCP This protocol is Modbus over Ethernet used for any instrument capable of ModbusTCP or may be used

on Modbus RTU instruments with the addition of a Ethernet to Serial converter. Super Systems 9000 series

instruments directly support ModbusTCP.

HW-CPL Protocol is used with the Honeywell DCP550 controller. This protocol is a variation of PC Link. Data is

transmitted as a mix of binary and ASCII values. Instruments may be connected using either RS485 2-wire or

RS485 4-wire.

MMI-MSI Protocol is used for all Marathon Instruments. This protocol is an ASCII protocol and always uses 7 data

bits, EVEN parity and 1 stop bit. Baud rates depend on the instrument type. This is the only protocol that can be

used with the Marathon COMMUX board. Data is transmitted by WORDS (16 bit integers) or BLOCKs of 24 WORDS.

Instruments are always connected using RS485 2-wire. Note: SuperS ystems does not recommend using the

Marathon COMMUX board - it is no longer in production and no longer supported by Marathon Sensors.

YOK-CPL Protocol is used with Yokogawa UT series controllers. This protocol is a variation of PC Link. Data is

transmitted as a mix of binary and ASCII values. Instruments may be connected using either RS485 2-wire or

RS485 4-wire. Note: Most Yokogawa instruments now support Modbus RTU protocol and Modbus is the preferred

method of communications to those instruments.

AB-DF1 Protocol is used with AllenBradley PLC controllers. Typically, these controllers use RS232 ports. For long

distance, multidrop connections, each controller will require an RS232 to RS485 converter. Note: SDIO supports only

a limited subset of the DF1 protocol. The preferred method of talking to Allen Bradley PLCs is RSLinx (an OPC

Server) with Super Data's OPCBridge.

Note - If the instrument in use does not support one of the above protocols, SuperData may still

communicate with the instrument if there is an OPC Server available

supports numerous control instruments. If an OPC Server is available - Super Data's OPCBridge - see the

section to learn how to map data from the OPC Server to SDIO. This allows SuperData to communicate with nearly

all instruments used in the Heat Treat Industry.

. Software Toolbox's TOPServer

OPCBridge

Super Systems Inc Page 18 of 172 Super Data Operations Manual

Page 19

Instrument Types

Overview

Supported Instrument Types

SuperData Communications supports a variety of control instruments used in the Heat Treating industry. In the

following sections, the instrument ID (indicated in CAPS) is used to identify the instrument in the SCSPSYS.CFG file.

The instrument type code (numeric) follows each ID and is displayed in decimal and Hex. The Hex value is

displayed as the type on the SDIO status display and the ChStat display. Instruments that are not specifically

supported, may be supported by using an OPC Server in conjunction with SuperData's OPCBridge.

System Instruments

System Channels

SYS

System channels are SDIO channels that are maintained by an external application. SDIO does not provide

direct communications with these instruments. SDIO does log the data in these channels and makes the data

available for trending and screen display applications.

Examples of System channels:

OPCBridge channels

ComRBridge channels

Load Tracking applications

Dummy channels used for test/development

Physical Instruments

Super Systems Instruments

Super Systems Controllers

SSI_CON

MOD_SMPP

MOD_SSI

SSI-9000

SSI-9200

SSI-9205

SSI-9205V2

SSI-9210

SSI-9220

Note - For the 9000 Series instruments Slots 0 through 25 are predefined. Specific Modbus

blocks can be added starting at Slot 26

Generic MODBUS Instruments

MOD_PMC note 1

MMI_MOD note 2

Note 1. This protocol uses Modbus FN 03 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Note 2. This protocol uses Modbus FN 04 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Eurotherm Instruments

Eurotherm Controllers

MOD_ET2200 note 1.

MOD_ET2400 note 1.

Super Systems Inc Page 19 of 172 Super Data Operations Manual

.

Page 20

MOD_ET2600 note 1.

Note 1. Configured the same as Generic Modbus.

Generic MODBUS Instruments

MOD_PMC note 1

MMI_MOD note 2

Note 1. This protocol uses Modbus FN 03 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Note 2. This protocol uses Modbus FN 04 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Honeywell Instruments

Generic Honeywell CPL Instrument

CPL_HW note1.

Note 1. The only instrument tested using this protocol is the Honeywell DCP550. . Values to be polled are

specified in the instrument configuration line.

Honeywell Modbus Instruments

HWM_DPR3000 note 1

HWM_GEN note 2

HWM_DPR100 note 2

HWM_DPR180 note 2

HWM_DPR250 note 2

HWM_RSX note 2

HWM_VRX note 2

HWM_VPR note 2

HWM_DR4300 note 2

HWM_DR4500 note 2

HWM_UDC2300 note 2

HWM_UDC3300 note 2

HWM_UDC5300 note 2

Note 1. Supports READ only using Modbus FN 04. Data inputs are read in register pairs, one register for the

mantissa and one for the decimal indicator. Data inputs are converted to integer with implied decimal

location for SuperData. Inputs to be read are selected in the instrument configuration line.

Note 2. Generic Instrument for Honeywell Modbus using Modbus FN 03 For reading data . Data is read as

either Integer single registers or Floating-point as register pairs, each pair representing an IEEE floating

point number. Data inputs are converted to integer with implied decimal location for SuperData. Data to be

read are selected in the instrument configuration line.

Generic MODBUS Instruments

Honeywell instruments may be configured as Generic Modbus instruments. In this case, only integer data is

supported.

MOD_PMC note 1

MMI_MOD note 2

Note 1. This protocol uses Modbus FN 03 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Note 2. This protocol uses Modbus FN 04 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Yokogawa Instruments

Yokogawa CPL Instruments

CPL_YOK note 1

Super Systems Inc Page 20 of 172 Super Data Operations Manual

Page 21

Note 1. Testing was on a UT750. The following instruments use the same protocol and should communicate

with this protocol: UT550 series and UT350 series. These instruments are slower to respond than most.

Most Yokogawa instruments now support the Modbus RTU protocol.

Generic MODBUS Instruments

MOD_PMC note 1

MMI_MOD note 2

Note 1. This protocol uses Modbus FN 03 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Note 2. This protocol uses Modbus FN 04 to read registers and FN 6 or FN 16 to write registers. Values to

be polled are specified in the instrument configuration line.

Marathon Instruments

Marathon Instruments

MMI 10Pro Series and Barber Coleman 560 Instruments

BARBER-COLEMAN 560

10PRO note 1

Note 1. The 10Pro-E (series) may be configured as either a 10Pro or as an MMIGEN-V4.0 instrument.

Configure it as an MMIGEN-V4.0 to use the 10Pro-E's block transfer communications capability for faster

communication throughput.

MMI V3x Instruments

MCARB-V3.0

UCARB-V3.0

UCARB-V3.5

MCARB-IR note 1.

MCARB-IR-V3.5 note 1.

UNIPRO

UNIPRO-V3.5

Note 1. These are obsolete versions of the Multicarb-IR. New versions (with Siemens analyzers) support

block communications and must be configured as either DUALPRO-V4.0 or MMIGEN-V4.0.

MMI V4x Instruments

DUALPRO-V4.0 note 1,2.

CARBPRO-V4.0

UNIPRO-V4.0

MMIGEN-V4.0 note 1,3.

DPSTD-V4.0 note 1,4

Note 1. For communications purposes, the MMI Multipro is the same as a Dualpro and must be configured

as a DUALPRO-V4.0, MMIGEN-V4.0 or DPSTD-V4.0.

Note 2. Later model Dualpro and Multipro instruments are also capable of communicating with MODUS

protocol on either the Host or Aux port. For MODBUS comms these instruments must be configured as

MMI_MOD instruments.

Note 3. MMIGEN-V4.0 instrument type may be used for any instrument that uses the V4.0 communications

protocol. This includes, but is not limited to, 10Pro-E, 10Pro-L, AACC2000 (series), and DualPro/MultiPro

instruments. The user specifies the Blocks (up to 3) to be polled.

Note 4. This instrument definition should be used for a DualPro that is not running a BackGround program

to populate data collection parameters. This will collect most of the DualPro's useful data and populate it in

the integer table. Do not use this definition if the DualPro is running a standard Background program.

MMI CARB-PC Instruments

CARB-PC note 1.

Note 1. The CARB-PC supports both word and block communications and may be configured as either

10PRO or CARB-PC. When configures as CARB-PC, the block transfer mode is used.

Super Systems Inc Page 21 of 172 Super Data Operations Manual

Page 22

CARBPRO

-

V4.0 (x2F)

HWM_DR4300

(x4E)

Other Instruments

AllenBradley DF1 Instruments

AB_PLC

AB_SLC

Note 1. The SuperData support for DF1 is a very limited subset of the AllenBradley DF1 protocol.

Note 2: The preferred method for SuperData comms to an AB PLC is via RSLinx (an OPC server) and

SuperData's OPCBridge. This method brings much more flexibility to the overall application.

TypeID Reference

The "Type Name" is used in the Scspsys.cfg file to identify the instrument type. The "Type Number" is displayed in

the SDIO Status View "TYP" column.

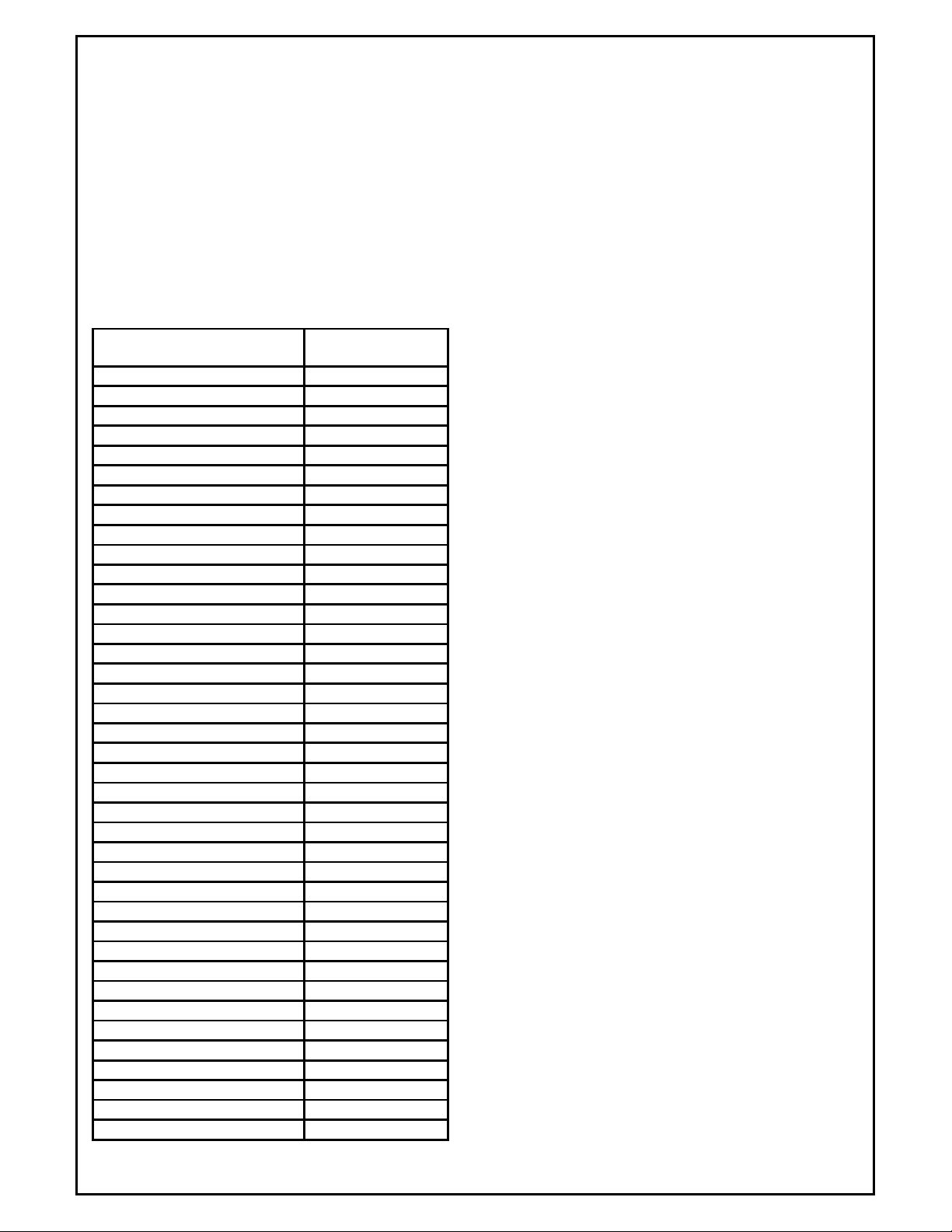

Type Name Type Number

(Hex)

CPL_HW (x01)

CPL_YOK (x02)

MOD_PMC (x10)

SSI_CON (x10)

MMI_MOD (x12)

SYS (x14)

BARBER-COLEMAN 560 (x18)

10PRO (x18)

MCARB-V3.0 (x21,x22)

UCARB-V3.0 (x23,x24)

UCARB-V3.5 (x25,x26)

MCARB-IR (x29,x2A)

MCARB-IR-V3.5 (x2B,x2C)

DPSTD-V4.0 (x2E)

DUALPRO-V4.0 (x2F)

MMIGEN-V4.0 (x30)

UNIPRO (x33,x34)

UNIPRO-V3.5 (x35,x36)

CARB-PC (x39)

UNIPRO-V4.0 (x3F)

HWM_GEN (x46)

HWM_DPR3000 (x47)

HWM_DPR100 (x48)

HWM_DPR180 (x49)

HWM_DPR250 (x4A)

HWM_RSX (x4B)

HWM_VRX (x4C)

HWM_VPR (x4D)

HWM_DR4500 (x4F)

HWM_UDC2300 (x50)

HWM_UDC3300 (x51)

HWM_UDC5300 (x52)

MOD_ET2200 (x55)

MOD_ET2400 (x56)

MOD_ET2600 (x57)

MOD_SMPP (x5A)

SSI_CON (x5B)

Super Systems Inc Page 22 of 172 Super Data Operations Manual

Page 23

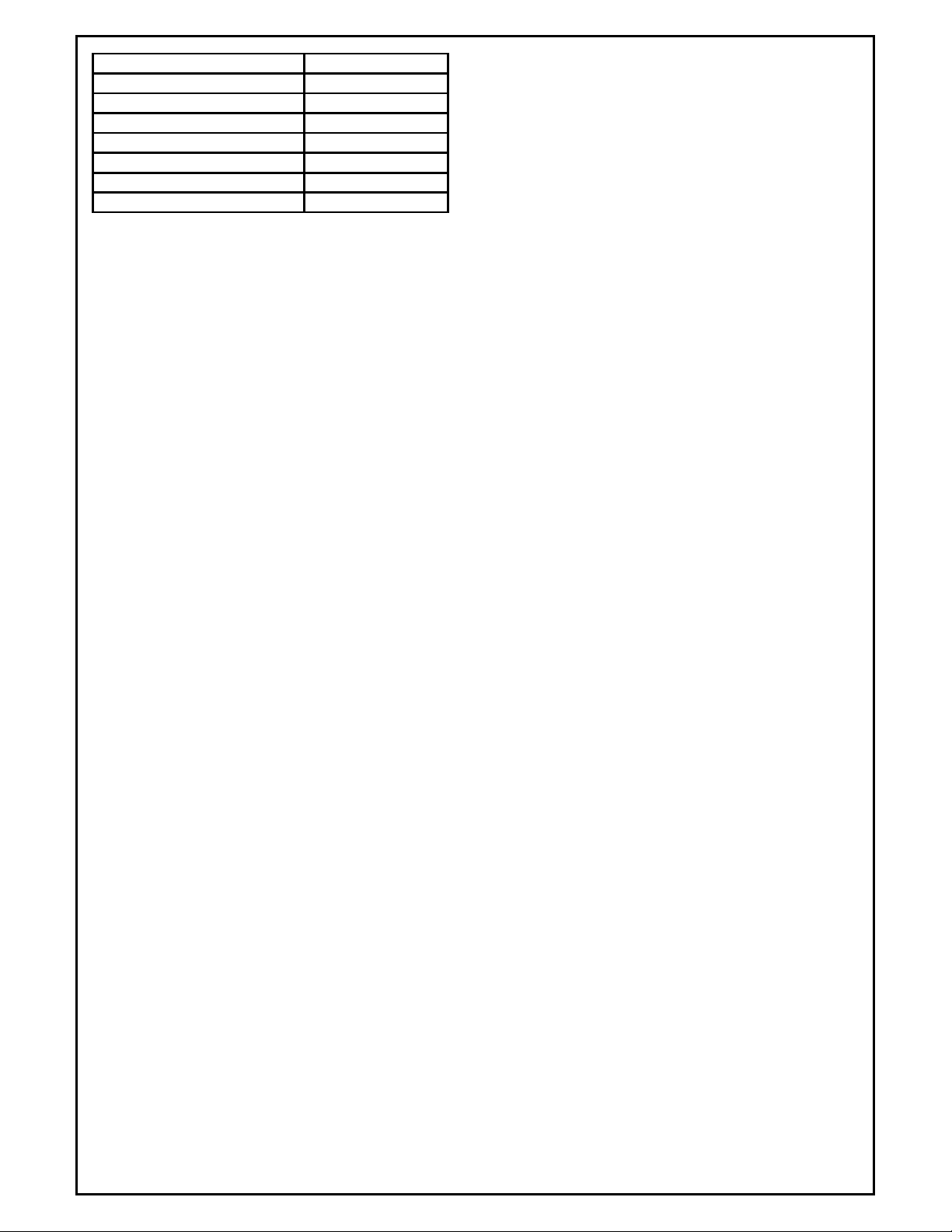

SSI_9000 (x5C)

SSI_9005 (x5D)

SSI_9010 (x5E)

SSI_9200 (x5F)

SSI_9205 (x60)

SSI_9210 (x61)

SSI_9215 (x62)

SSI_9220 (x63)

Configuration File

The configuration file, SCSPSYS.CFG consists the following sections:

RES– the basic communications parameters.

CONx– the comm configuration for each connection used (up to 8 sections)

INST – the instrument configuration parameters

ABC– optional section containing custom Alarm Block Configurations

RES Section

Serial communications is provided through one or more of the computer's comm ports or the Ethernet connection.

SDIO is capable of using up to 8 serial ports. These ports may be RS232 or RS485 ports. RS232 ports provide

point-to-point short distance comms, to use RS232 ports for long distance multidrop communications, they must be

routed through a RS232 to RS485 converter. Multiport RS485 cards may be installed in the computer and used

without a converter.

The RES section specifies general information for the communications program and may be used for the

Connection 1 setup information. This section is started by "{SRES}" and ends with "{ERES}". A sample RES

section follows:

{SRES}

COMMUX BOARD = "NO"

PORT = "COM1"

PROTOCOL="MB-RTU"

BAUD = "57600"

DBITS = "7"

PARITY = "NONE"

SBITS = "1"

STA = "0"

KRUNCH = "03:15AM"

{ERES}

Options:

COMMUX BOARD - "NO" if not using a COMMUX board "16" if using a COMMUX board.

PROTOCOL-The desired protocol for connection 1.

PORT-Computer's comm port "COM1", "COM2", etc. (ports 1-16 are supported)

BAUD-Baud rate "1200", "2400", "4800", "9600", "19200", "38400" or "57600"

DBITS-The number of Data bits. (7 or 8)

PARITY-The type of parity. (ODD, EVEN, or NONE)

SBITS-The number of stop bits. (1 or 2)

STA-The station number of the computer (Normally 0).

KRUNCH-Sets the time of day to automatically run the datalog compression program.

Note: It is generally best to use the highest reliable BAUD rate available. The port configuration must match the

instrument communication configuration for all instruments attached to the connection.

Super Systems Inc Page 23 of 172 Super Data Operations Manual

Page 24

CONx Section

Serial communications is provided through one or more of the computer's comm ports or the Ethernet port. SDIO is

capable of using up to 8 serial ports. These ports may be RS232 or RS485 ports. A serial Connection is a

communications link to one of the installed Comm Ports using a specific protocol. A port only supports one protocol.

You cannot have multiple protocols defined for one port. The characteristics of a connection are specified in the

CONx sections. There may be 8 (CON1 thru CON8) connections configured. The Ethernet connection is CON9 and

is not configurable. A sample CONx section follows:

{SCON2}

COMMUX BOARD = "NO"

PORT = "COM13"

PROTOCOL="AB-DF1"

BAUD = "9600"

DBITS = "8"

PARITY = "EVEN"

SBITS = "1"

NADDR = "7"

{ECON2}

Options:

COMMUX BOARD - "NO" if not using a COMMUX board "16" if using a COMMUX board.

PROTOCOL-The desired protocol for connection 1.

PORT-Computer's comm port "COM1", "COM2", etc. (ports 1-16 are supported). Use "none" to disable the

connection.

BAUD-Baud rate "1200", "2400", "4800", "9600", "19200", "38400" or "57600"

DBITS-The number of Data bits. (7 or 8)

PARITY-The type of parity. (ODD, EVEN, or NONE)

SBITS-The number of stop bits. (1 or 2)

NADDR-The Host computers Node Address (required only for AllenBradley DF1 Protocol).

Super Systems Inc Page 24 of 172 Super Data Operations Manual

Page 25

Instrument Section

system channels. Physical address is ignored.

Each line in the instrument configuration section specifies a logical channel attached to an instrument. The

following items apply to all types of instruments. For additional items see the configuration section for the specific

instrument type.

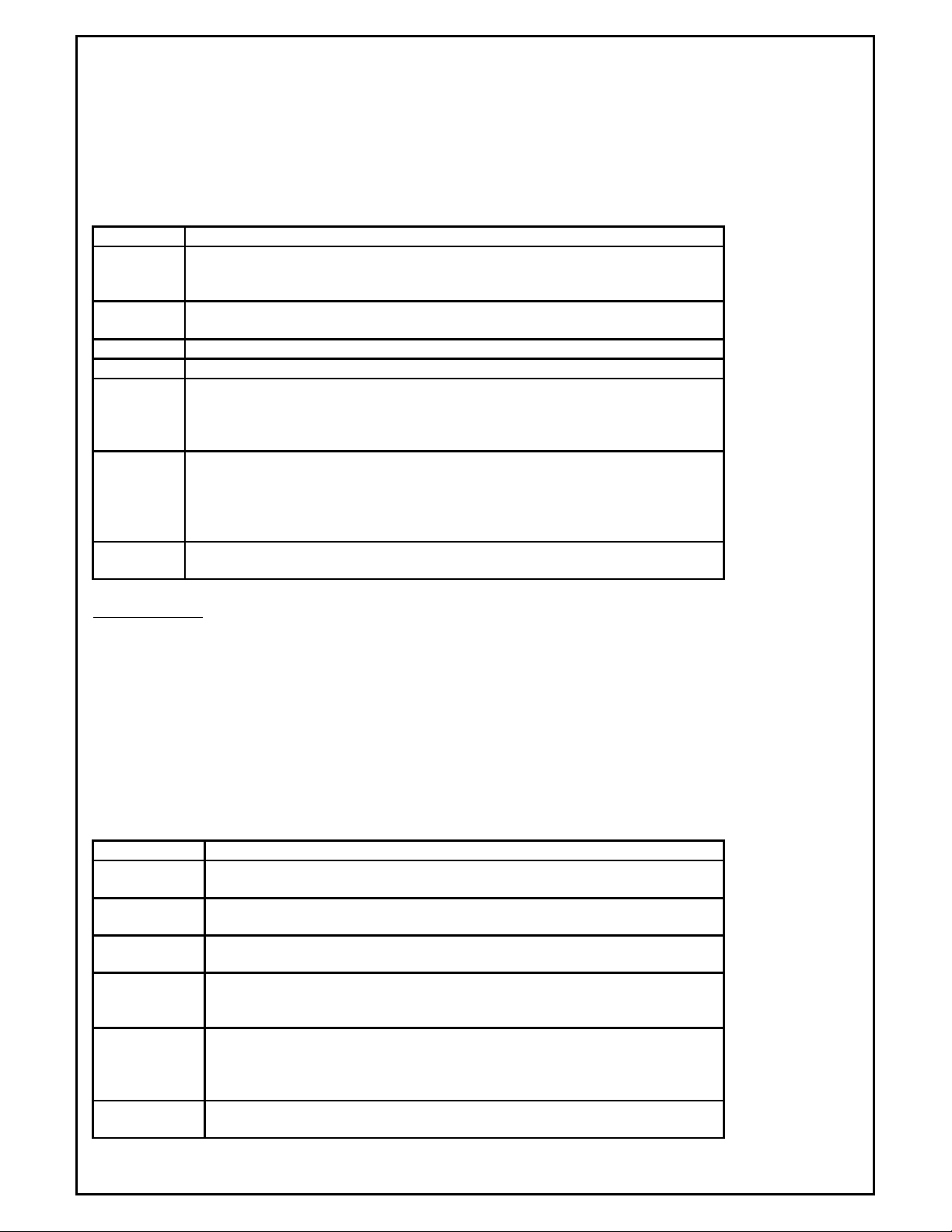

[C]CH#LLL(PPP ) = "ID,[…Instrument Specific Configuration…],[NOLOG ], [ABC] " = "tag "

Note: Items enclosed in brackets [ ] are optional but may be required for certain instrument types.

Item Definition

C Optional. Applies to ALL instruments. Specifies the Connection Identifier (1-8

for serial connections and 9 for Ethernet). The protocol for the connection must

match the protocol for the instrument. If not included, defaults to Connection 1.

LLL Required. Applies to ALL instruments. The logical channel number assigned (1-

128).

PPP Required. Applies to ALL instruments. The physical address of the instrument.

ID Required. Applies to ALL instruments. The instrument ID (e.g., SSI-CON)

NOLOG Optional. Applies to ALL instruments. Do not log data from this channel.

Include this when communications are required for real-time data but are not

required for historical data logging. If this is not included, the channel will be

data logged at one minute intervals.

ABC Optional. Applies to ALL instruments. Alarm Block Configuration . Caution: any

specified channel can use either ALM or ABC but not both.

Allows a custom

Alarm Block Bitmap (one word) to be setup for any instrument but generally used

only for non-programmable instruments that are not capable of maintaining

alarm bitmaps. See the section on Custom Alarm Block Configuration.

TAG Required. Applies to ALL instruments. Instrument name. Limited to 12

Characters with no spaces.

System Channels

[C]CH#LLL(PPP ) = "ID,[NOLOG],[ALM]" = "tag "

Examples:

1CH#12(0) = "SYS, ALM (0,800,66,0,12)" = "System"

Note: Items enclosed in brackets [ ] are optional but may be required for certain instrument types.

Note: When the system channel is an OPCBridge or ComRBridge channel, these applications will automatically add

the System channel to the SCSPSYS.cfg file.

Item Definition

C Optional. These are non-communications channels and may be used on any

Connection. Protocol is not important.

LLL Required. Applies to ALL instruments. The logical channel number assigned

(1-128).

PPP Required. Applies to ALL instruments. Always use physical address 0 for

ID Required. Applies to ALL instruments. The instrument ID: SYS. Note: Any

ID may be changed to a SYS channel by prefixing the ID with the letters

SYS, e.g. SYSSSI-CON

NOLOG Optional. Applies to ALL instruments. Do not log data from this channel.

Include this when communications are required for real-time data but are not

required for historical data logging. If this is not included, the channel will be

data logged at one minute intervals.

ALM Optional. Applies to Channels that contain bitmapped alarms. The ALARM

configuration setup.

Super Systems Inc Page 25 of 172 Super Data Operations Manual

ALM(PAL slot, Alarm offset, Alarm Bitmap Start Slot,

Page 26

Alarm ACK Bitmap Slot, Number of Bitmap Slots).

Normally this will be

configured by SSI personnel familiar with the application. If you are not sure,

do not include Bitmapped support. Invalid configurations may cause spurious

invalid alarms to be reported on RealTime and in AlarmReports.

ABC

Optional. Applies to ALL instruments. Alarm Block Configuration . Caution:

any specified channel can use either ALM or ABC but not both.

Allows a

custom Alarm Block Bitmap (one word) to be setup for any instrument but

generally used only for non-programmable instruments that are not capable of

maintaining alarm bitmaps. See the section on Custom Alarm Block

Configuration.

TAG

Required. Applies to ALL instruments. Instrument name. Limited to 12

Characters with no spaces.

Super Systems Instruments

[C]CH#LLL(PPP ) = "ID,[ALM],[ NOLOG],[ABC]" = "tag "

Examples:

SSi 7 series - may also be used for 20Q or 20PQ

2CH#5(1) = "SSI-CON,MB:122-2,MB:130-1,MB:137-2" = "SSIS7"

SSi AC20 series

2CH#6(2) = "SSI-CON,MB:122-9,MB:137-7" = "SSIAC20"

AC20 with events

2CH#7(2) = "SSI-CON,MB:122-9,MB:137-7,EB:300-8,EB:310-10" = "SSIAC20"

SSi SPP

2CH#7(3) = "MOD_PMC,MB:96-24,ALM(0,100,19,0,1)" = "SSISPP"

2CH#1(4) = "SSI-SPP,ALM(23,100,19,1)" = "9000"

SSi 9200 series

2CH#1(4) = "SSI-SPP,ALM(23,100,19,1)" = "9000"

2CH#1(4) = "MOD_PMC,IP:192.168.1.201,MB:100-78" = "SSi9200"

Same instrument over ethernet

9CH#1(250) = "SSI-SPP,IP:192.168.1.220,ALM(23,100,19,0,1)" = "9000"

9CH#1(250) = "MOD_PMC,IP:192.168.1.201,MB:100-78" = "SSi9200"

For the SSI9xxx instruments, a predefined , model specific ID may be used that automatically reads