Page 1

SIMPLE DEW

DIGITAL DEW POINT

ANALYZER

OPERATIONS MANUAL

Super Systems Inc.

www.supersystems.com

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

Page 2

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 2 of 18

Super Systems Inc.

Super Systems Europe

Super Systems México

Super Systems China

USA Office

Corporate Headquarters

7205 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Sistemas Superiores Integrales S de RL de CV

Calle 3 Int.: 11.

Zona Ind. Benito Juarez

Querétaro, Qro. Méx.

C.P.: 76120

Phone: +52 (442) 210 2459

http://www.supersystems.com.mx

Units 3 & 4, 17 Reddicap Trading Estate,

Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627

http://www.supersystemseurope.com

No. 335 XianXia Road

Room 308

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.com

Page 3

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 3 of 18

Table of Contents

Introduction ..................................................................................................................................... 4

Specifications .................................................................................................................................. 4

Warnings ......................................................................................................................................... 4

Startup ............................................................................................................................................ 4

Operation ......................................................................................................................................... 5

Instrument Damage ........................................................................................................................ 5

What Is Dew Point? ......................................................................................................................... 6

How It Works ................................................................................................................................... 6

Maintenance/Safety Issues ............................................................................................................. 7

Factory Calibration.......................................................................................................................... 7

Field Calibration .............................................................................................................................. 7

Replacement Parts ........................................................................................................................11

Returning the Unit to SSi ...............................................................................................................11

Warranty.........................................................................................................................................13

Revision History .............................................................................................................................14

Appendix A: Determining the Sensor Temperature in °F ..............................................................15

Appendix B: Determining the Sensor Temperature in °C .............................................................16

Appendix C: Determining the Dew Point in °F ...............................................................................17

Appendix D: Determining the Dew Point in °C ...............................................................................18

Page 4

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 4 of 18

Introduction

Specifications

Warnings

Startup

Thank you for selecting Super Systems Inc. and the Simple Dew as your source for accurate

dew point measurements. The Simple Dew unit is a digital dew point analyzer for standard

range (greater than 0°F or -18°C) measurement. Typical uses of the Simple Dew include

measurement of endothermic atmospheres (with endothermic generators) and

nitrogen/methanol atmospheres, as well as use with plant air systems.

Carefully unpack the Simple Dew - Dew Point Analyzer. If there are any signs of shipping

damage, notify SSi and the shipper immediately.

Measurement Range: 0 to +80°F (-18 to +27°C)

Temperature Range: 0 to +120°F (-18 to +49°C)

Power Supply: 115 to 230 VAC (universal input)—for Part No. 13134

24VDC input—for Part No. 13136

Retransmission Output: 0-1 Volt (range is –50 to +80°F)

Size (Closed Case): 15.25” x 9” x 6.25” (approximately)

Weight: 8.2 lbs (3.7 kg)

Although it is intended for use in an industrial environment, the Simple Dew is a sensitive piece

of analysis equipment. Care should be taken not to drop the analyzer or to operate it in a

manner inconsistent with its intended use.

• Open all sample ports and remove all soot and/or moisture from the lines prior to attaching

the sample tubing for the first time.

• The analyzer should be stored at ambient temperature (65-80°F or 18-27°C) for at least two

hours prior to operation.

• If the unit is to be returned to SSi for service or any other reason, protect the instrument

with at least four inches of foam or other impact-absorbing material on all sides and place it

in an appropriately sized cardboard box.

• This unit is not designed to measure the dew points in corrosive gases, such as Ammonia,

, Chlorine, and HCL.

S0

3

• Please read and understand this Product Manual before operating the unit.

Failure to comply with these conditions may cause damage to the unit that will not be covered

under the warranty. Super Systems Inc. is not responsible for damage to this unit caused by

disregard of these warnings, neglect, or misuse.

The Simple Dew unit was calibrated before it was shipped from Super Systems Inc. You can

begin typical operation as soon as the unit has been allowed to stabilize in a temperature

similar to the temperature in the heat treating department. This stabilization is particularly

important for units that may have been sitting overnight in a delivery vehicle in freezing

Page 5

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 5 of 18

Operation

.

NOTE: Allow the sample port to blow out any soot and / or water before connecting the sample

tube

Instrument Damage

weather. Rapid temperature change can cause condensation on the sensor which will cause the

unit to temporarily display inaccurate readings.

The use of the Simple Dew is somewhat dependent upon the application. For connection to an

endothermic generator, no pump is required since the sample gas is under positive pressure. If

this instrument is to be used on a furnace or other non-positive pressure application, an

external sample pump will be required to deliver the gas to the sensor.

Be sure that the filter (mounted to the bottom of the instrument) is clean and functional, since

high accumulations of soot can hold moisture and influence the dew point measurement. It will

also prevent soot and other contaminants from entering the unit and damaging the sensor.

The optimum flow rate of the sample gas should be between 1.5 and 2.0 Standard Cubic Feet

per Hour (SCFH), although a flow rate as low as 1.0 SCFH is acceptable. If the unit is reading

less than 1.0 SCFH, verify that there are no obstructions to the flow such as a clogged sample

line or filter, or a poorly adjusted knob on the Simple Dew’s flow meter.

Heat Treat Furnace Sampling:

external pump. The sample tube from which the sample is taken out of the furnace should

extend into the furnace past the HOT face of the refractory. For accurate results, a designated

sample port should be used to extract the sample. SSi offers two versions of sample port

assemblies (part numbers 20263 and 20264) which are ideal for this purpose. If a designated

sample port is not available, then a clean “burn-off” port on a Gold Probe, an industry leading

oxygen sensor for atmosphere control, can be used. Readings taken from the burn-off port on a

probe may be artificially high due to the presence of soot in the probe sheath.

Endothermic Generator Sampling:

small restriction valve on the flow meter. A flow rate between 1.5 and 2.0 SCFH is ideal. The

sample should be taken from the endothermic gas manifold after the gas has been cooled

. Failure to do so will result in inaccurate readings and expose the sensor to potential

damage.

The main causes of damage to the Simple Dew are the ingestion of soot and the ingestion of

water. Both of these contaminants will cause erroneous readings in the short term, and cause

long-term damage to the sensor and internal components.

A gas sample must be extracted from the process using an

For applications under pressure, the flow is controlled by the

Soot / Particulate Contaminants

When taking a sample from a furnace or a generator, care should be taken to reduce the

amount of soot that enters the instrument. The filter will trap these particles, but cleaning the

sample line before attaching the Simple Dew will increase the life of the filter. Furnace ports

can be burned off by pumping air through them while hot, or by removing them from the heat

and mechanically cleaning them. Generator ports should be opened before the instrument is

attached to allow any particulate buildup to be blown out. It is also helpful to tap on the port

while it is being blown out to eject any loose particles before the instrument is attached.

If soot is allowed to collect on the dew point sensor in the instrument, it could result in higher

readings. This soot will also retain moisture than can corrode the sensor over time. The sensor

Page 6

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 6 of 18

What Is Dew Point?

How It Works

tip can be cleaned by carefully removing it from the sample block (see Section 2.0 of the Field

Calibration instructions) and rinsing it in isopropyl alcohol. The power should be off while this is

done, and the power should remain off for at least 30 minutes after this procedure to allow all of

the alcohol to completely evaporate.

Water / Moisture Contamination

When a furnace or generator is being started up or cooled down, the resulting gases will

contain unusually high amounts of CO

. When these gases cool, moisture will precipitate out

2

and become condensation inside the sample tubing assembly. Even if the furnace or generator

is operating normally, residual moisture may still be present in the sample tube or plumbing

system. In the same way that the ports are checked for soot (see above) they should be checked

for moisture before attaching the instrument. This is especially important when taking a

sample from a generator, since the sample port is usually preceded by a significant amount of

plumbing. All traces of moisture should be eliminated before attaching the instrument. Failure

to do so will result in erroneous measurements and could result in damage to the analyzer.

The first signs of moisture in the instrument will be visible condensation collecting in the bowl

filter and an unusually high dew point. The upper range of the sensor is +80°F, so if that value

is displayed on the instrument it is probably due to the presence of moisture. If this moisture is

not removed, it will cause the sensor tip to corrode and will eventually require the sensor to be

replaced.

To remove moisture from the instrument, the filter should be removed from the instrument

(since it will probably be wet) and an inert gas such as Nitrogen or Argon should then be flowed

through the instrument for as much time as it takes to dry out. This dry-out time will depend on

the amount of moisture present in the instrument. The condition of the sensor can be

monitored by periodically reading the dew point from the display and watching the value

decrease over time. To test if it is operating properly, verify the ambient dew point against a

web-based weather station that will report the ambient dew point for your area. If the displayed

reading is within three degrees of the reported dew point when the instrument is taken outside,

then all of the moisture has probably been successfully removed. The wet filter and sample

tubing can be re-attached after they have been completely dried out. The filter element will

regain all of its original filtering properties after it has dried out.

To prevent the possibility of moisture damaging the instrument, be sure that the measured dew

point is below ambient levels before it is stored. If necessary, Nitrogen or Argon can be used to

purge the instrument after use.

Dew point can be defined as the temperature at which the water vapor pressure of the gas

equals the saturated water vapor pressure. In other words, it is the temperature at which

condensation will just begin to occur as the gas is cooled. Dew point and relative humidity are

not the same measurement. Relative humidity is the amount of water vapor in the air compared

to the amount the air could hold if it was totally saturated, and it is expressed as a percentage,

not a temperature. To determine dew point, two main variables are required: Relative Humidity

and Temperature. The Simple Dew measures both variables to compute the dew point.

Page 7

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 7 of 18

Maintenance/Safety Issues

Factory Calibration

Field Calibration

microprocessor board

The dew point sensor is a “dielectric ceramic” that varies its electrical capacitance with

changes in relative humidity. The sensor is mounted in a short probe, which is installed in a Tfitting that allows the sample gas to flow past the sensor. The tip of this probe contains the

dielectric ceramic relative humidity (RH) sensor, as well as a built in temperature sensor to

determine its dry bulb temperature. Information from both of these sensors is used to compute

the resultant dew point.

Maintaining proper sensor temperature will prevent the premature failure of the sensor. The

operating temperature of the sensor should remain below 130° F (54°C) at all times. To

determine the sensor temperature, measure the voltage between pins 5(+) and 9(-) on the

microprocessor board. The voltage will be between 0 and 1VDC. Use the chart in Appendix A to

determine the temperature in °F, or use Appendix B to determine the temperature in °C. If this

temperature shows in excess of 130°F (54°C), the length of sample tubing should be increased

to allow for adequate cooling of the sample before it passes the sensor tip.

Calibration of the sensor is recommended annually. SSi’s initial calibration is performed in our

ISO/IEC 17025 certified laboratory, and includes an NIST traceable “Certificate of Calibration”.

Any calibration performed at SSi will be NIST traceable and will have documentation of ISO/IEC

17025 certification. The certificate also indicates the accuracy of the analyzer before and after

calibration. Please contact Super Systems, Inc. at (513) 772-0060 for more information

regarding this service.

It is also possible to calibrate the Simple Dew in the field, which will require one of two optional

calibration kits. One calibration kit is NIST traceable (Part No. 31425); one kit is non-traceable

(Part No. 31030). To perform this calibration, you will need a calibration kit and a voltmeter that

will allow you to measure between 0 and 1 volt DC. Since there is no display on the instrument

itself, the voltages from the sensor circuit board will have to be translated into temperature and

dew point measurements for the purpose of verifying the calibration. The instructions for doing

this are contained in this document along with reference charts to aid in the interpretation of

the voltages.

The calibration kit consists of two bottles of saturated salt solution in which each bottle

generates a precise relative humidity percentage (R.H.%) value. One bottle is 11.3% R.H., and

the other is 75.3% R.H. These two specific calibration points are already pre-programmed into

the microprocessor board.

1.0 Locate the key components within the unit

1.1 The

contains three very small buttons that are used for

calibration. Two are next to one another, and they are marked “75.3%” and “11.3%”,

while the other has no label. The unmarked button is the “Calibrate” button. The

approximate locations of each button are shown on this diagram:

Page 8

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 8 of 18

sensor-sampling chamber

sensor probe

SPAN

BUTTON

(75.3)

ZERO

BUTTON

(11.3)

CAL

BUTTON

Dew Point Microprocessor Board

1.2 The

is the gray rectangular box with brass barb fittings

on either side with a black plastic gland protruding from the center.

1.3 The

is positioned in the sensor-sampling chamber. It is held in

place by the nut on the black plastic gland.

2.0 Remove the sensor probe from the sensor sampling chamber.

2.1 Loosen the black plastic gland nut and slowly slide the sensor probe out through

the airtight seal. Care must be taken when removing this sensor probe, since the tip

is very delicate and can be easily damaged if it is mishandled. Note that the probe

has white mark at the wire entry point, which must be aligned with corresponding

white mark in plastic gland when it is re-inserted in the sampling chamber.

3.0 Install the sensor probe into the 75.3% salt solution.

3.1 Slip the black sensor gland (supplied in the calibration kit) over the sensor probe

with the sensor tip protruding from the threaded end of the gland and the sensor

wires being flush with the top of the rubber o-ring in the gland. Tighten the gland

around the sensor. This does not need to be done with a wrench or other tools, but it

does need to be tight enough to prevent ambient air from contaminating the humidity

level of the sampling chamber.

3.2 Remove the cap of the 75.3% salt solution and install the sensor gland (with the

sensor) into the salt solution. To increase the life of the calibration salts, an effort

should be made to minimize the amount of time that the salt solution is exposed to

the ambient air.

4.0 Allow the sensor to reach equilibrium with the calibration salt.

Page 9

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 9 of 18

4.1 Leave the sensor in the calibration salt for a minimum of eighteen (18) hours. It is

acceptable to leave the sensor in the salt solution for a longer period of time, even a

few days, if desired.

5.0 Begin the 75.3% (Span) calibration process.

5.1 After leaving the sensor in the salt for at least eighteen (18) hours, turn the unit

on (if it isn’t on already).

5.2 Simultaneously press the “75.3%” and “Calibration” buttons on the

microprocessor board.

6.0 Verify the 75.3% (Span) calibration.

6.1 Leave the sensor in the 75.3%RH calibration salt.

6.2 Record the temperature and the dew point of the sensor. Since there is no display

on the instrument, you will need to measure the voltage from the microprocessor

board and translate that into the appropriate measurement.

6.2.1 To determine the sensor temperature, measure the voltage between pins

5(+) and 9(-) on the microprocessor board. The voltage will be between 0

and 1VDC. Use the chart in Appendix A to determine the temperature in

°F, or use Appendix B to determine the temperature in °C.

6.2.2 Temporarily record the sensor temperature.

6.3 Look up this temperature in Appendix “C” (Determining the Dew Point in °F) or

Appendix “D” (Determining the Dew Point in °C). Appendix C will show the

temperature values in Fahrenheit, and Appendix D will show the temperature values

in Celsius.

6.4 Next to the appropriate sensor temperature, note the number in the

corresponding column titled “75.3%”. This will match the measured dew point,

which can be verified wherever the dew point is displayed.

7.0 After the 75.3% (Span) calibration has been completed, remove the sensor from the

calibration salt and replace the cap on the salt.

7.1 Leave the sensor probe in the gland and while the unit is still on, allow it to

achieve equilibrium at the ambient atmosphere in the room. This is accomplished by

simply leaving the sensor exposed to ambient air for between two and three minutes.

You will know when this has been accomplished when the numbers on the display

begin to stabilize.

8.0 Install the sensor probe into the 11.3% salt solution.

Page 10

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 10 of 18

8.1 Remove the cap of the 11.3% salt solution and install the sensor gland (with the

sensor) into the salt solution. To increase the life of the calibration salts, an effort

should be made to minimize the amount of time that the salt solution is exposed to

the ambient air.

9.0 Allow the sensor to reach equilibrium with the calibration salt.

9.1 Leave the sensor in the calibration salt for a minimum of 24 hours. It is acceptable

to leave the sensor in the salt solution for a longer period of time, even a few days, if

desired.

10.0 Begin the 11.3% (Zero) calibration process

10.1 After leaving the sensor in the salt for at least twenty-four (24) hours, turn the

unit on (if it isn’t on already).

10.2 Simultaneously press the “11.3%” and “Calibration” buttons on the

microprocessor board.

11.0 Verify the 11.3% (Zero) calibration

11.1 Leave the sensor in the 11.3%RH calibration salt

11.2 Record the temperature and the dew point of the sensor. Since there is no

display on the instrument, you will need to measure the voltage from the

microprocessor board and translate that into the appropriate measurement.

11.2.1 To determine the sensor temperature, measure the voltage between pins

5(+) and 9(-) on the microprocessor board. The voltage will be between 0

and 1VDC. Use the chart in Appendix A to determine the temperature in

°F, or use Appendix B to determine the temperature in °C.

11.2.2 Temporarily record the sensor temperature.

11.3 Look up this temperature in Appendix “C” (Determining the Dew Point in °F) or

Appendix “D” (Determining the Dew Point in °C). Appendix C will show the

temperature values in Fahrenheit, and Appendix D will show the temperature values

in Celsius.

11.4 Next to the appropriate temperature, note the number in the corresponding

column titled “11.3%”. This will match the measured dew point, which can be

verified wherever the dew point is displayed.

12.0 After the 11.3% (Zero) calibration has been completed, remove the sensor from the

calibration salt and replace the cap on the salt.

Page 11

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 11 of 18

Replacement Parts

Description

Part Number

Factory Calibration

65010

Calibration Kit (non-traceable)

31030

Calibration Kit (NIST traceable)

31425

Bowl Filter

37048

Bowl Filter Element

31027

Dew Point Sensor

31038

Sensor Sampling Block

20192

Sample Tube

20263

Sample Tube (With High-Temp Filter)

20264

Complete Units

Simple Dew Unit (with Power Supply)

13134

Simple Dew Unit (without Power Supply)

13136

Returning the Unit to SSi

12.1 After the 11.3% (Zero) calibration has been completed, remove the sensor from

the calibration salt and replace the cap.

13.0 Re-assemble the unit

13.1 After the calibration process has been completed, remove the sensor probe from

the gland and return it to the sensor-sampling chamber, taking care to position it

properly. The white mark on the sensor probe should face towards the inlet tubing.

If the white mark is not visible, then it should be placed so the sample flow directly

strikes the face of the mirror on the sensor tip. In other words, the mirror should

face the incoming gas stream.

13.2 Hand-tighten the black sensor gland to prevent air from leaking out of the

sampling chamber.

14.0 Make sure that all caps are replaced on the calibration salts, and return the instrument

to service.

This analyzer contains some components that may require periodic replacement based on the

amount of use that the unit experiences and the methods in which it is used. If service on the

unit is necessary, it should be sent back to Super Systems, Inc. in the original packaging for

repair. If the original packaging is not available, the analyzer should be surrounded by impactabsorbing materials and placed in a box. It is the responsibility of the shipper to ensure that the

Simple Dew arrives at SSi undamaged.

Page 12

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 12 of 18

Super Systems, Inc.

ATTN: RMA #XXXX

7205 Edington Drive

Cincinnati, OH 45249

Before shipping the analyzer, please call (513) 772-0060 to receive a Return Materials

Authorization (RMA) number. The shipping address that should be used for returns is:

Page 13

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 13 of 18

Warranty

Limited Warranty for Super Systems Products:

The Limited Warranty applies to new Super Systems Inc. (SSI) products purchased direct from

SSI or from an authorized SSI dealer by the original purchaser for normal use. SSI warrants

that a covered product is free from defects in materials and workmanship, with the exceptions

stated below.

The limited warranty does not cover damage resulting from commercial use, misuse, accident,

modification or alteration to hardware or software, tampering, unsuitable physical or operating

environment beyond product specifications, improper maintenance, or failure caused by a

product for which SSI is not responsible. There is no warranty of uninterrupted or error-free

operation. There is no warranty for loss of data—you must regularly back up the data stored on

your product to a separate storage product. There is no warranty for product with removed or

altered identification labels. SSI DOES NOT PROVIDE ANY OTHER WARRANTIES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME JURISDICTIONS DO

NOT ALLOW THE LIMITATION OF IMPLIED WARRANTIES, SO THIS LIMITATION MAY NOT APPLY

TO YOU. SSI is not responsible for returning to you product which is not covered by this limited

warranty.

If you are having trouble with a product, before seeking limited warranty service, first follow the

troubleshooting procedures that SSI or your authorized SSI dealer provides.

SSI will replace the PRODUCT with a functionally equivalent replacement product,

transportation prepaid after PRODUCT has been returned to SSI for testing and evaluation. SSI

may replace your product with a product that was previously used, repaired and tested to meet

SSI specifications. You receive title to the replaced product at delivery to carrier at SSI shipping

point. You are responsible for importation of the replaced product, if applicable. SSI will not

return the original product to you; therefore, you are responsible for moving data to another

media before returning to SSI, if applicable. Data Recovery is not covered under this warranty

and is not part of the warranty returns process. SSI warrants that the replaced products are

covered for the remainder of the original product warranty or 90 days, whichever is greater.

Page 14

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 14 of 18

Revision History

Rev.

Description

Date

MCO#

-

First Release

03-06-2009

N/A

A

Manual updated to current standard format.

units.

04-13-2015

2158

Introduction updated. Specifications updated to

include power requirements specified based on

Simple Dew unit. Calibration instructions updated

to include two calibration kit options.

Replacement parts list updated, including the

addition of two calibration kits and two complete

Page 15

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 15 of 18

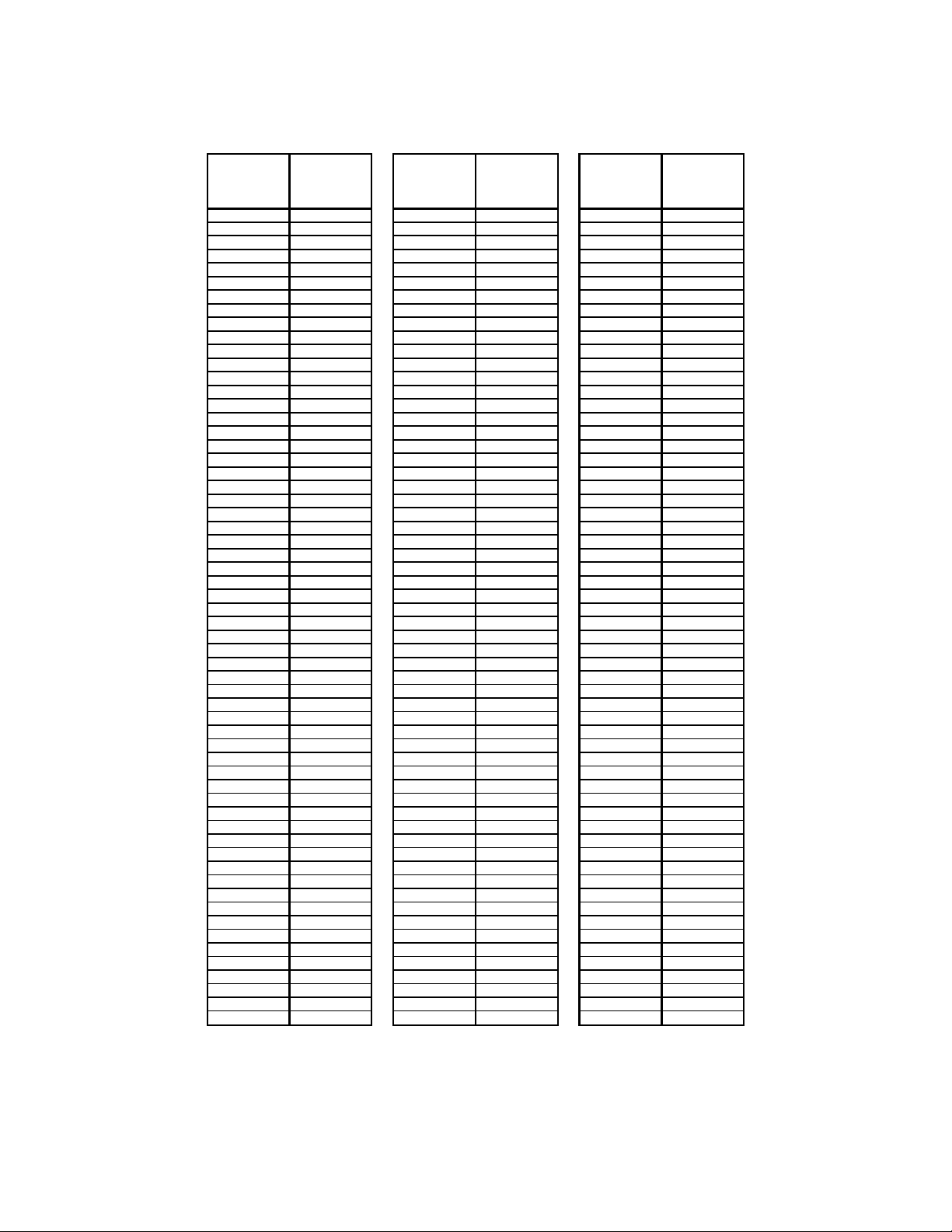

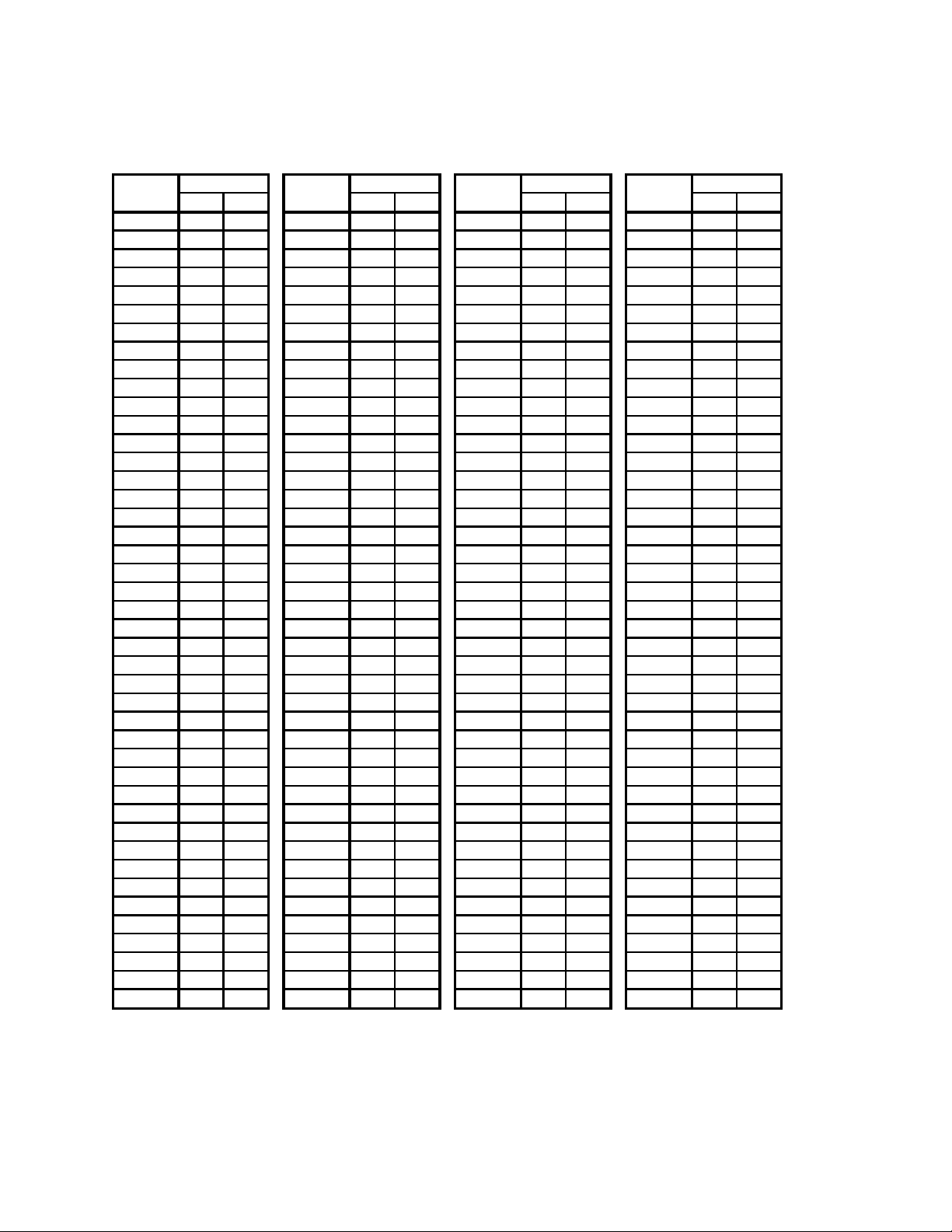

Appendix A: Determining the Sensor Temperature in °F

When the DC

voltage

between 5(+)

and 8(-) is:

Then the

sensor

temperature

(°F) is:

When the DC

voltage

between 5(+)

and 8(-) is:

Then the

sensor

temperature

(°F) is:

When the DC

voltage

between 5(+)

and 8(-) is:

Then the

sensor

temperature

(°F) is:

0.3472 67.0 0.3806 79.0 0.4139 91.0

0.3478 67.2 0.3811 79.2 0.4144 91.2

0.3483 67.4 0.3817 79.4 0.4150 91.4

0.3489

67.6

0.3822

79.6

0.4156

91.6

0.3494 67.8 0.3828 79.8 0.4161 91.8

0.3500 68.0 0.3833 80.0 0.4167 92.0

0.3506

68.2

0.3839

80.2

0.4172

92.2

0.3511

68.4

0.3844

80.4

0.4178

92.4

0.3517

68.6

0.3850

80.6

0.4183

92.6

0.3522 68.8 0.3856 80.8 0.4189 92.8

0.3528 69.0 0.3861 81.0 0.4194 93.0

0.3533 69.2 0.3867 81.2 0.4200 93.2

0.3539 69.4 0.3872 81.4 0.4206 93.4

0.3544 69.6 0.3878 81.6 0.4211 93.6

0.3550 69.8 0.3883 81.8 0.4217 93.8

0.3556

70.0

0.3889

82.0

0.4222

94.0

0.3561 70.2 0.3894 82.2 0.4228 94.2

0.3567 70.4

0.3900

82.4 0.4233 94.4

0.3572 70.6

0.3906

82.6 0.4239 94.6

0.3578 70.8 0.3911 82.8 0.4244 94.8

0.3583 71.0 0.3917 83.0 0.4250 95.0

0.3589 71.2 0.3922 83.2

0.4256 95.2

0.3594 71.4 0.3928 83.4 0.4261 95.4

0.3600 71.6 0.3933 83.6 0.4267 95.6

0.3606 71.8 0.3939

83.8

0.4272 95.8

0.3611 72.0 0.3944 84.0 0.4278 96.0

0.3617

72.2 0.3950 84.2

0.4283

96.2

0.3622

72.4 0.3956 84.4 0.4289 96.4

0.3628 72.6 0.3961

84.6

0.4294 96.6

0.3633 72.8 0.3967 84.8 0.4300 96.8

0.3639 73.0 0.3972 85.0

0.4306 97.0

0.3644 73.2 0.3978 85.2 0.4311 97.2

0.3650

73.4 0.3983 85.4 0.4317 97.4

0.3656 73.6 0.3989 85.6 0.4322 97.6

0.3661 73.8 0.3994

85.8 0.4328 97.8

0.3667 74.0 0.4000 86.0 0.4333 98.0

0.3672 74.2 0.4006 86.2 0.4339 98.2

0.3678 74.4 0.4011 86.4 0.4344 98.4

0.3683 74.6 0.4017 86.6 0.4350 98.6

0.3689 74.8 0.4022 86.8 0.4356 98.8

0.3694 75.0 0.4028 87.0 0.4361 99.0

0.3700 75.2 0.4033 87.2 0.4367 99.2

0.3706 75.4 0.4039 87.4 0.4372 99.4

0.3711 75.6 0.4044 87.6 0.4378 99.6

0.3717 75.8 0.4050 87.8 0.4383 99.8

0.3722 76.0 0.4056 88.0 0.4389 100.0

0.3728

76.2 0.4061 88.2 0.4394 100.2

0.3733 76.4 0.4067 88.4 0.4400 100.4

0.3739 76.6 0.4072 88.6 0.4406

100.6

0.3744 76.8 0.4078 88.8 0.4411 100.8

0.3750 77.0 0.4083 89.0 0.4417 101.0

0.3756 77.2 0.4089 89.2 0.4422 101.2

0.3761

77.4

0.4094

89.4

0.4428

101.4

0.3767 77.6 0.4100 89.6 0.4433 101.6

0.3772 77.8 0.4106 89.8 0.4439 101.8

0.3778 78.0 0.4111 90.0 0.4444 102.0

0.3783 78.2 0.4117 90.2 0.4450 102.2

0.3789 78.4 0.4122 90.4 0.4456 102.4

0.3794

78.6

0.4128

90.6

0.4461

102.6

0.3800 78.8 0.4133 90.8 0.4467 102.8

Page 16

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 16 of 18

Appendix B: Determining the Sensor Temperature in °C

When the DC

voltage

between 5(+)

and 8(-) is:

Then the

sensor

temperature

(°C) is:

When the DC

voltage

between 5(+)

and 8(-) is:

Then the

sensor

temperature

(°C) is:

When the DC

voltage

between 5(+)

and 8(-) is:

Then the

sensor

temperature

(°C) is:

0.3472 19.4

0.3806 26.1

0.4139 32.8

0.3478 19.6 0.3811

26.2 0.4144

32.9

0.3483

19.7 0.3817

26.3 0.4150

33.0

0.3489 19.8 0.3822

26.4

0.4156 33.1

0.3494

19.9 0.3828

26.6 0.4161

33.2

0.3500

20.0 0.3833 26.7 0.4167

33.3

0.3506 20.1

0.3839 26.8

0.4172 33.4

0.3511 20.2 0.3844

26.9 0.4178

33.6

0.3517

20.3 0.3850

27.0 0.4183

33.7

0.3522 20.4 0.3856

27.1 0.4189 33.8

0.3528

20.6 0.3861

27.2 0.4194

33.9

0.3533

20.7 0.3867 27.3 0.4200

34.0

0.3539 20.8

0.3872 27.4

0.4206 34.1

0.3544 20.9

0.3878 27.6 0.4211

34.2

0.3550

21.0 0.3883 27.7 0.4217

34.3

0.3556

21.1 0.3889 27.8

0.4222 34.4

0.3561 21.2

0.3894 27.9 0.4228

34.6

0.3567

21.3 0.3900

28.0 0.4233

34.7

0.3572

21.4 0.3906 28.1

0.4239 34.8

0.3578 21.6 0.3911 28.2 0.4244 34.9

0.3583 21.7 0.3917 28.3

0.4250 35.0

0.3589

21.8

0.3922 28.4 0.4256 35.1

0.3594

21.9 0.3928 28.6 0.4261 35.2

0.3600 22.0 0.3933 28.7

0.4267 35.3

0.3606 22.1 0.3939 28.8 0.4272 35.4

0.3611 22.2 0.3944 28.9 0.4278

35.6

0.3617 22.3

0.3950 29.0 0.4283 35.7

0.3622 22.4 0.3956 29.1

0.4289

35.8

0.3628 22.6 0.3961

29.2 0.4294 35.9

0.3633 22.7 0.3967 29.3 0.4300 36.0

0.3639 22.8

0.3972 29.4 0.4306 36.1

0.3644

22.9 0.3978 29.6 0.4311 36.2

0.3650 23.0 0.3983 29.7 0.4317 36.3

0.3656 23.1 0.3989 29.8 0.4322 36.4

0.3661 23.2 0.3994

29.9 0.4328 36.6

0.3667

23.3 0.4000 30.0

0.4333 36.7

0.3672

23.4 0.4006 30.1 0.4339

36.8

0.3678

23.6 0.4011 30.2

0.4344 36.9

0.3683 23.7 0.4017 30.3

0.4350 37.0

0.3689

23.8 0.4022 30.4

0.4356 37.1

0.3694

23.9 0.4028 30.6

0.4361 37.2

0.3700 24.0 0.4033 30.7

0.4367 37.3

0.3706

24.1 0.4039 30.8

0.4372 37.4

0.3711

24.2 0.4044 30.9

0.4378 37.6

0.3717 24.3 0.4050 31.0

0.4383 37.7

0.3722

24.4 0.4056 31.1 0.4389 37.8

0.3728 24.6 0.4061 31.2 0.4394 37.9

0.3733 24.7 0.4067 31.3 0.4400

38.0

0.3739 24.8 0.4072 31.4 0.4406 38.1

0.3744 24.9 0.4078 31.6 0.4411 38.2

0.3750 25.0 0.4083 31.7

0.4417 38.3

0.3756 25.1

0.4089

31.8

0.4422 38.4

0.3761 25.2 0.4094 31.9 0.4428 38.6

0.3767 25.3 0.4100 32.0 0.4433 38.7

0.3772 25.4 0.4106 32.1

0.4439

38.8

0.3778 25.6 0.4111 32.2

0.4444 38.9

0.3783 25.7 0.4117 32.3

0.4450 39.0

0.3789 25.8 0.4122 32.4

0.4456 39.1

0.3794 25.9

0.4128 32.6 0.4461 39.2

0.3800 26.0 0.4133 32.7 0.4467 39.3

Page 17

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 17 of 18

Appendix C: Determining the Dew Point in °F

Sensor Sensor

Sensor Sensor

Temp (°F) 11.3% 75.3%

Temp (°F) 11.3% 75.3% Temp (°F) 11.3% 75.3% Temp (°F) 11.3% 75.3%

67.0

11.38 58.94

75.6

18.06

67.24

84.1 24.70 75.53 92.8 31.31 83.82

67.2

11.54 59.13

75.8

18.21

67.43

84.2 24.85 75.73 93.0 31.46 84.01

67.4

11.69 59.32

76.0

18.37 67.62

84.3

25.01 75.92

93.2

31.61 84.21

67.6 11.85 59.52 76.2 18.52 67.82 84.4 25.16 76.11 93.4 31.77 84.40

67.8

12.00 59.71

76.4

18.68 68.01

84.5 25.32 76.30

93.6

31.92 84.59

68.0 12.16 59.90 76.6 18.83 68.20 85.2 25.47

76.50

93.8

32.07 84.78

68.2

12.31 60.09

76.8

18.99 68.40

85.4 25.63

76.69 94.0 32.23 84.98

68.4

12.47 60.29

77.0

19.14 68.59

85.6

25.78

76.88

94.2 32.38 85.17

68.6

12.63 60.48

77.2

19.30 68.78

85.8

25.94 77.07

94.4

32.53 85.36

68.8 12.78 60.67 77.4 19.45 68.97 86.0 26.09 77.27

94.6

32.69 85.55

69.0

12.94 60.86 77.6 19.61 69.17 86.2 26.24 77.46 94.8 32.84 85.75

69.2

13.09 61.06 77.8 19.76 69.36 86.4 26.40 77.65 95.0 32.99 85.94

69.4

13.25

61.25 78.0

19.91 69.55 86.6 26.55 77.85 95.2 33.14 86.13

69.6

13.40 61.45 78.2 20.07 69.75 86.8 26.70

78.04

95.4

33.30 86.32

69.8 13.56

61.64 78.4 20.22 69.94 87.0

26.86 78.23 95.6

33.45 86.52

70.0 13.71 61.83 78.6 20.38

70.13

87.2

27.01 78.42 95.8 33.60 86.71

70.2

13.87 62.03 78.8 20.53 70.33 87.4 27.17 78.62 96.0

33.76 86.90

70.4

14.02 62.22 79.0 20.69 70.52 87.6 27.32 78.81 96.2

33.91 87.09

70.6 14.18

62.41

79.2

20.84 70.71 87.8 27.47 79.00 96.4 34.06 87.29

70.8 14.33 62.60 79.4 21.00 70.90 88.0 27.63 79.19 96.6 34.21

87.48

71.0 14.49 62.80 79.6 21.15 71.10 88.2

27.78 79.39 96.8 34.37 87.67

71.2 14.65 62.99 79.8 21.31 71.29 88.4 27.93 79.58 97.0 34.52 87.87

71.4 14.80 63.18 80.0 21.46 71.48 88.6 28.09

79.77 97.2 34.67 88.06

71.6 14.96 63.38 80.2 21.61 71.68 88.8 28.24 79.97 97.4 34.82 88.25

71.8 15.11 63.57 80.4 21.77 71.87 89.0 28.39 80.16 97.6 34.98 88.44

72.0 15.27 63.76 80.6 21.92 72.06 89.2 28.55 80.35 97.8 35.13 88.64

72.2 15.42 63.96 80.8 22.08 72.25 89.4 28.70 80.54 98.0

35.28 88.83

72.4

15.58 64.15

81.0

22.23 72.44

89.6

28.85 80.74 98.2 35.44 89.02

72.6 15.73 64.34 81.2 22.39 72.64 89.8 29.01 80.93 98.4 35.59 89.21

72.8 15.89

64.54 81.4 22.54 72.83 90.0 29.16 81.12 98.6 35.74 89.41

73.0 16.04 64.73 81.6 22.70 73.03

90.2 29.32 81.31 98.8 35.89 89.60

73.2 16.20 64.92 81.8 22.85 73.22 90.4 29.47 81.51 99.0 36.05 89.79

73.4 16.35 65.11 82.0 23.00 73.41 90.6 29.62 81.70 99.2 36.20 89.98

73.6 16.51 65.31 82.2 23.16 73.60 90.8 29.78

81.89 99.4 36.35 90.18

73.8 16.66 65.50 82.4 23.31 73.80 91.0 29.93

82.09 99.6 36.50 90.37

74.0 16.82 65.69 82.6 23.47 73.99

91.2 30.08 82.28 99.8 36.66 90.56

74.2 16.97 65.89

82.8 23.62 74.18 91.4 30.24 82.47 100.0 36.81 90.75

74.4 17.13 66.08 83.0 23.77 74.38 91.6 30.39 82.66 100.2 36.96 90.95

74.6 17.28

66.27 83.2 23.93 74.57 91.8 30.54 82.86 100.4 37.11 91.14

74.8 17.44 66.47 83.4 24.08 74.76 92.0 30.69 83.05 100.6 37.27 91.33

75.0 17.59 66.66 83.6 24.24 74.95 92.2 30.85 83.24 100.8 37.42 91.52

75.2 17.75 66.85 83.8 24.39 75.15 92.4 31.00 83.43 101.0 37.57 91.72

75.4 17.90 67.04 84.0

24.55 75.34 92.6 31.15 83.63 101.2 37.72 91.91

Percent RH

Percent RH

Percent RH

Percent RH

Page 18

Simple Dew Digital Dew Point Analyzer Operations Manual

Super Systems Inc.

Page 18 of 18

Appendix D: Determining the Dew Point in °C

Sensor Sensor

Sensor Sensor

Temp (°F) 11.3% 75.3%

Temp (°F) 11.3% 75.3% Temp (°F) 11.3% 75.3% Temp (°F) 11.3% 75.3%

19.4

-11.46 14.97

24.2

-7.74

19.58

28.9 -4.06 24.18 33.8 -0.38 28.79

19.6

-11.37 15.07

24.3

-7.66

19.68

29.0 -3.97 24.29 33.9 -0.30 28.89

19.7

-11.28 15.18

24.4

-7.57 19.79

29.1

-3.88 24.40

34.0

-0.22 29.01

19.8 -11.19 15.29 24.6 -7.49 19.90 29.1 -3.80 24.51 34.1 -0.13 29.11

19.9

-11.11 15.39

24.7

-7.40 20.01

29.2 -3.71 24.61

34.2

-0.04 29.22

20.0 -11.02 15.50 24.8 -7.32 20.11 29.6 -3.63

24.72

34.3

0.04 29.32

20.1

-10.94 15.61

24.9

-7.23 20.22

29.7 -3.54

24.83 34.4 0.13 29.43

20.2

-10.85 15.72

25.0

-7.14 20.33

29.8

-3.46

24.93

34.6 0.21 29.54

20.3

-10.76 15.82

25.1

-7.06 20.43

29.9

-3.37 25.04

34.7

0.29 29.64

20.4 -10.68 15.93 25.2 -6.97 20.54 30.0 -3.28 25.15

34.8

0.38 29.75

20.6

-10.59 16.03 25.3 -6.88 20.65 30.1 -3.20 25.26 34.9 0.47 29.86

20.7

-10.51 16.14 25.4 -6.80 20.76 30.2 -3.11 25.36 35.0 0.55 29.97

20.8

-10.42

16.25 25.6

-6.72 20.86 30.3 -3.03 25.47 35.1 0.63 30.07

20.9

-10.33 16.36 25.7 -6.63 20.97 30.4 -2.94

25.58

35.2

0.72 30.18

21.0 -10.24

16.47 25.8 -6.54 21.08 30.6

-2.86 25.68 35.3

0.81 30.29

21.1

-10.16 16.57 25.9 -6.46 21.18 30.7 -2.77 25.79 35.4

0.89 30.39

21.2

-10.07 16.68

26.0

-6.37 21.29 30.8 -2.68 25.90 35.6

0.98 30.50

21.3

-9.99 16.79 26.1 -6.28 21.40 30.9 -2.60 26.01 35.7 1.06 30.61

21.4 -9.90 16.89 26.2 -6.20 21.51 31.0

-2.52 26.11

35.8

1.14 30.72

21.6 -9.82

17.00 26.3 -6.11 21.61 31.1 -2.43 26.22 35.9 1.23 30.82

21.7 -9.73 17.11 26.4 -6.03 21.72 31.2 -2.34 26.33 36.0 1.32

30.93

21.8 -9.64 17.22

26.6 -5.94 21.83 31.3 -2.26 26.43 36.1 1.40 31.04

21.9 -9.56 17.32 26.7 -5.86 21.93 31.4 -2.17 26.54 36.2 1.48 31.14

22.0 -9.47 17.43 26.8

-5.77 22.04 31.6 -2.09 26.65 36.3 1.57 31.25

22.1

-9.38 17.54

26.9

-5.68 22.15 31.7 -2.01 26.76 36.4 1.66 31.36

22.2

-9.29 17.64

27.0

-5.60 22.26 31.8 -1.92 26.86 36.6 1.74 31.47

22.3

-9.21 17.76

27.1

-5.51 22.36 31.9 -1.83 26.97 36.7 1.82 31.57

22.4 -9.12 17.86 27.2 -5.43 22.47 32.0 -1.75 27.08 36.8

1.91 31.68

22.6 -9.04 17.97 27.3 -5.34 22.58 32.1 -1.66 27.18 36.9 1.99 31.78

22.7 -8.95 18.08 27.4 -5.26 22.68

32.2 -1.58 27.29 37.0 2.08 31.89

22.8 -8.87 18.18 27.6 -5.17 22.79 32.3 -1.49 27.39 37.1 2.16

32.00

22.9 -8.78 18.29 27.7 -5.08 22.90 32.4

-1.41 27.51 37.2 2.25 32.11

23.0 -8.69 18.39

27.8 -5.00 23.01 32.6 -1.32 27.61 37.3 2.33 32.21

23.1 -8.61 18.51 27.9 -4.91 23.11 32.7 -1.23 27.72 37.4 2.42 32.32

23.2 -8.52 18.61 28.0 -4.83 23.22 32.8 -1.15 27.83 37.6 2.50 32.43

23.3 -8.43 18.72 28.1 -4.74 23.33 32.9 -1.07 27.93 37.7 2.59 32.53

23.4 -8.35 18.83 28.2 -4.66 23.43 33.0 -0.98 28.04 37.8

2.67 32.64

23.6 -8.26 18.93 28.3 -4.57 23.54

33.1 -0.89 28.14 37.9 2.76 32.75

23.7 -8.18 19.04 28.4

-4.48 23.65 33.2 -0.81 28.26 38.0 2.84 32.86

23.8 -8.09 19.15 28.6 -4.40 23.76 33.3 -0.73 28.36 38.1 2.93 32.96

23.9 -8.01 19.26 28.7 -4.31

23.86 33.4 -0.64 28.47 38.2 3.01 33.07

24.0 -7.92 19.36 28.8 -4.23 23.97 33.6 -0.56 28.57 38.3 3.09 33.18

24.1 -7.83 19.47 28.9

-4.14 24.08 33.7 -0.47 28.68 38.4 3.18 33.28

Percent RH

Percent RH

Percent RH

Percent RH

Loading...

Loading...