Page 1

COLOR TOUCH SCREEN

DATA LOGGER

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Table of Contents

Product Specifications ........................................................................................................................... 5

Software Installation .............................................................................................................................. 6

Changing the System Date and Time ................................................................................................... 6

Finding and Setting the IP Address of the Color SDS Data Logger ................................................. 7

Calibration ............................................................................................................................................... 9

Getting Started ........................................................................................................................................ 9

Analog Inputs ........................................................................................................................................ 10

Voltage connections............................................................................................................................ 11

4 – 20 mA Current Loop connections ................................................................................................. 11

Survey Templates ................................................................................................................................. 11

Installing the SDS Software ................................................................................................................ 13

Connecting the SDS Data Logger to a Network ............................................................................... 14

In Windows Vista and Windows 7 ...................................................................................................... 15

In Windows XP .................................................................................................................................... 16

Web Portal .............................................................................................................................................. 19

Home Screen ........................................................................................................................................... 19

Menu ....................................................................................................................................................... 20

Survey .................................................................................................................................................. 21

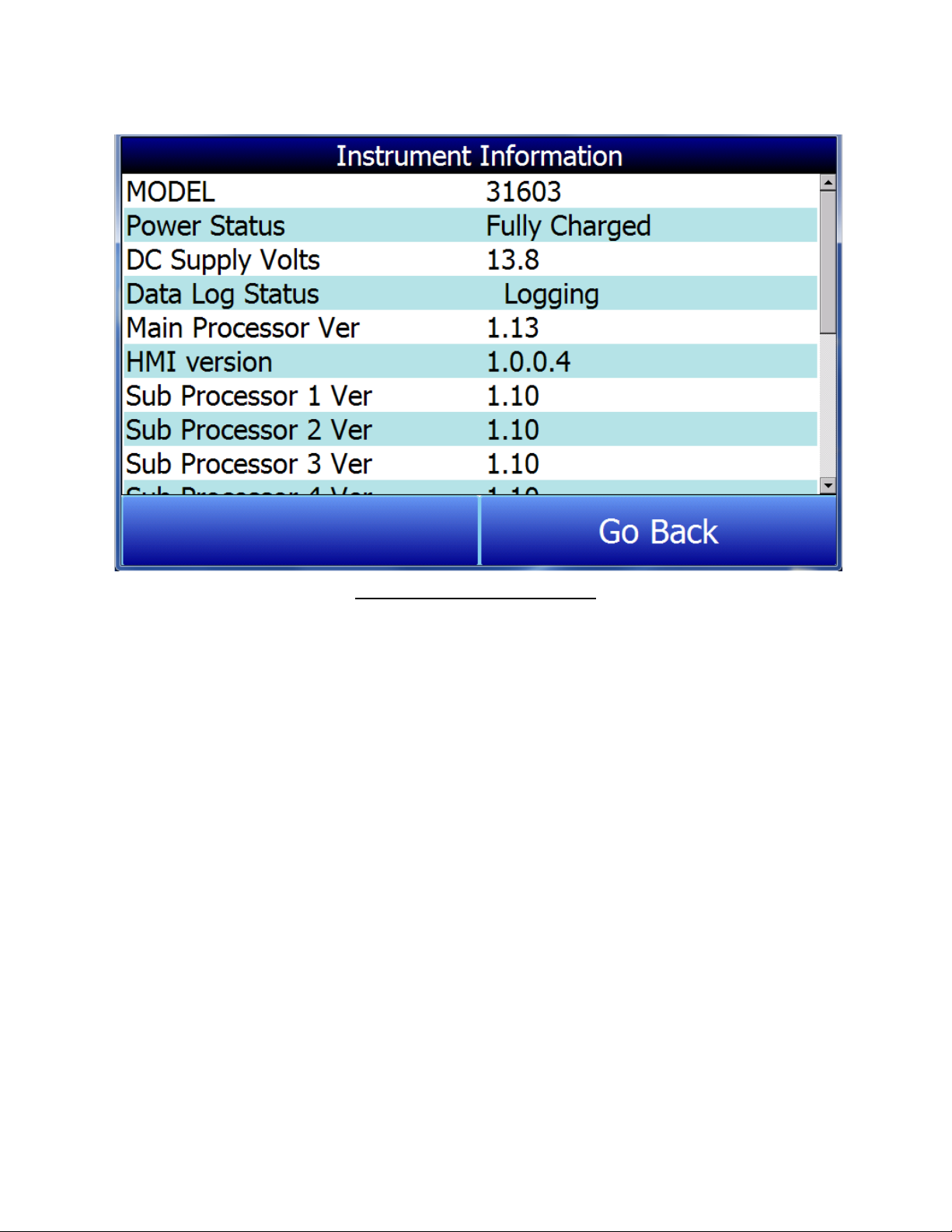

Instrument Information ...................................................................................................................... 23

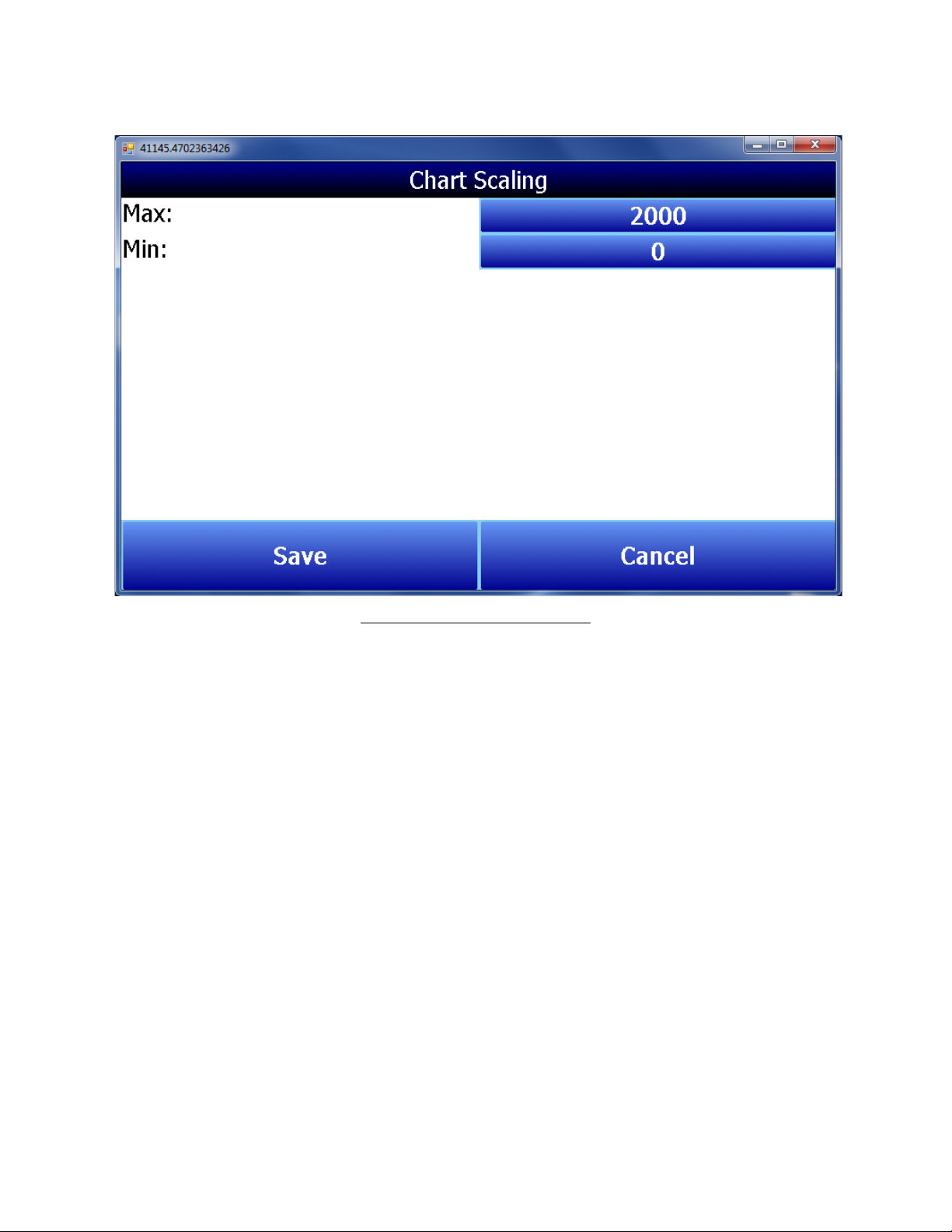

Chart Scaling ....................................................................................................................................... 24

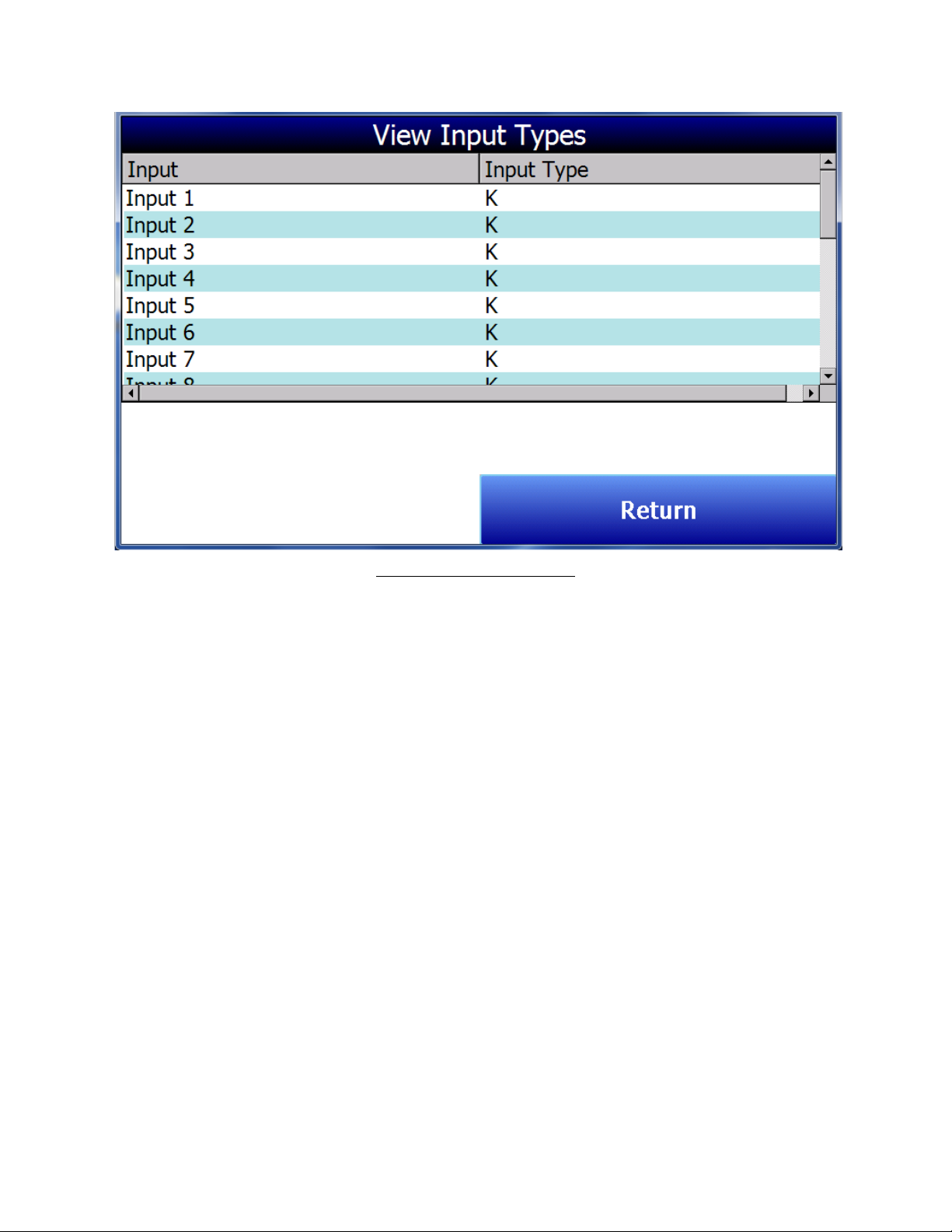

View Input Types ................................................................................................................................. 24

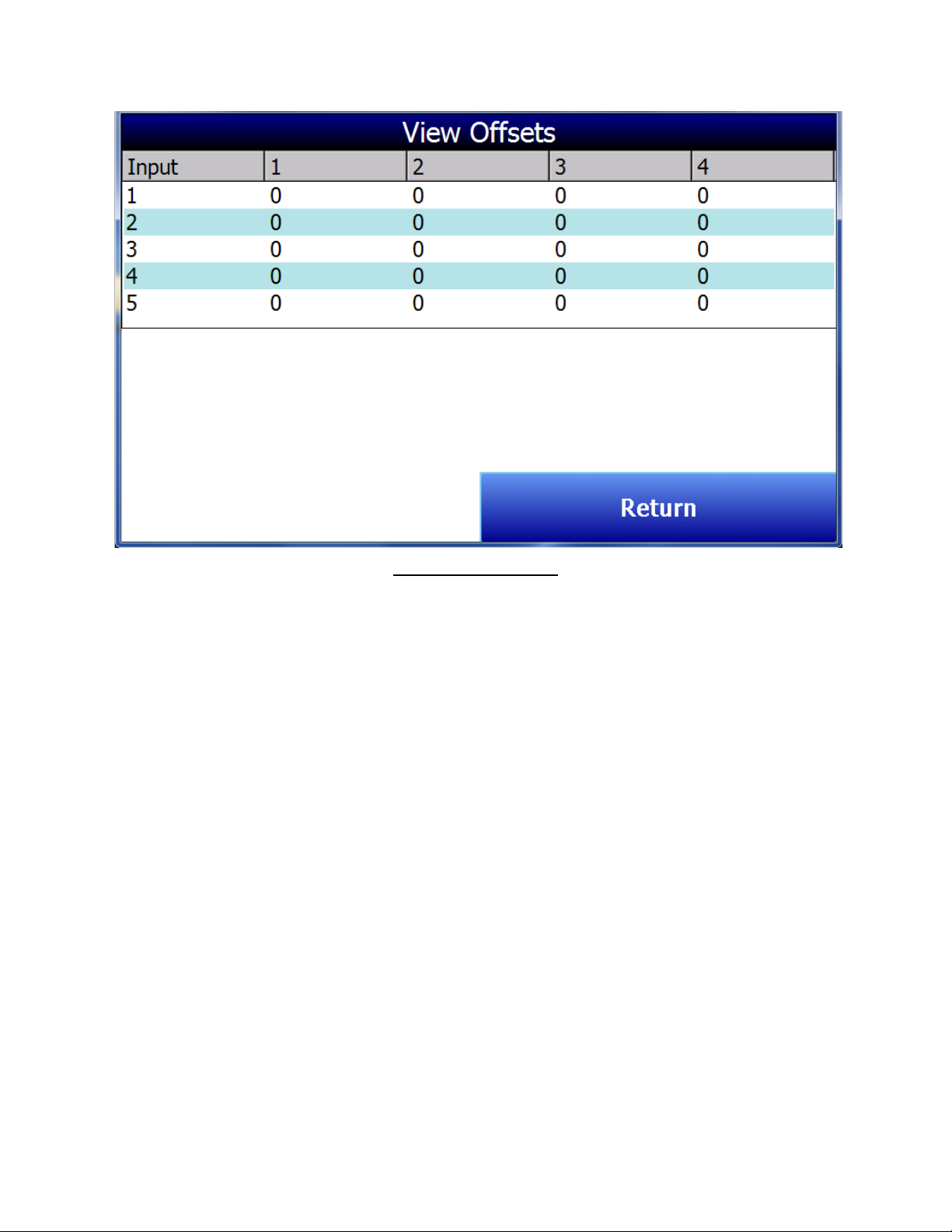

View Offsets ........................................................................................................................................ 25

Select Input Channels.......................................................................................................................... 26

Edit Input Types .................................................................................................................................. 28

Edit Offsets .......................................................................................................................................... 28

Spool Correction ................................................................................................................................. 29

About................................................................................................................................................... 30

Calibration ........................................................................................................................................... 31

Datalog Deletion ................................................................................................................................. 34

Passcodes ............................................................................................................................................ 35

Cold Junction Thermistor Calibration ................................................................................................. 36

Full Data Action ................................................................................................................................... 36

Exit Program ........................................................................................................................................ 37

Configuration ...................................................................................................................................... 37

Super Systems Inc. Page 2 of 104

Color Touch Screen Data Logger Operations Manual

Page 3

Reset Calibration Dates ....................................................................................................................... 38

Set Nominals ....................................................................................................................................... 39

Set K Factors ........................................................................................................................................ 41

SDX Control ......................................................................................................................................... 42

Modbus Control .................................................................................................................................. 43

SDS Reporter ........................................................................................................................................ 45

File Menu Options ................................................................................................................................. 45

File New / New Button .......................................................................................................... 45

File Open / Open Button .......................................................................................................... 46

Manually Creating a Survey Record .................................................................................................... 48

Comparison Check .............................................................................................................................. 57

File Save / File Save As / Save Button .................................................................................. 60

File Export....................................................................................................................................... 60

File Print ......................................................................................................................................... 60

Print Button ................................................................................................................................. 62

File Print Preview ........................................................................................................................... 63

File Exit ........................................................................................................................................... 63

SDS Menu Options ................................................................................................................................ 63

SDS Manage Survey Templates ...................................................................................................... 63

SDS Download Surveys and Data ................................................................................................... 63

SDS Launch Direct FTP .................................................................................................................... 65

SDS View Real-time Data ................................................................................................................ 66

SDS Manage Survey Records .......................................................................................................... 68

SDS Perform Comms Test ............................................................................................................... 70

Options Menu Options .......................................................................................................................... 72

Options Multiple SDS Mode ........................................................................................................... 72

Options Show Labels On Chart ....................................................................................................... 72

Options Color Screen Scanning ...................................................................................................... 72

Help Menu Options ............................................................................................................................... 72

Help Check for Updates .................................................................................................................. 72

Help About ..................................................................................................................................... 73

SDS Data Tags ...................................................................................................................................... 74

Creating a Personalized Template ...................................................................................................... 82

Super Systems Inc. Page 3 of 104

Color Touch Screen Data Logger Operations Manual

Page 4

SDS Template Manager ....................................................................................................................... 84

Description of Template Manager Screen Tabs ............................................................................... 87

Revision History ...................................................................................................................................... 91

Appendix 1: Quick Start Guide ................................................................................................................ 92

Unpacking the Color SDS Data Logger ................................................................................................ 92

Warming Up and Charging the Data Logger ....................................................................................... 93

Turning on the Data Logger ................................................................................................................ 94

Connecting the Thermocouple Wires and Setting the Input Type ..................................................... 94

Using Survey Templates ...................................................................................................................... 95

Starting a Survey ................................................................................................................................. 95

Stopping Survey .................................................................................................................................. 97

Installing SDS Reporter ....................................................................................................................... 97

Connecting the SDS Data Logger to a Local Computer via USB .......................................................... 98

Downloading Data with SDS Reporter ................................................................................................ 99

Generating a Report .......................................................................................................................... 101

Super Systems Inc. Page 4 of 104

Color Touch Screen Data Logger Operations Manual

Page 5

The Color SDS Touch Screen Data Logger (SDS8120 / SDS8140) provides the hardware

and software needed to meet industry standards for furnace temperature uniformity by

logging and generating temperature and data log reports.

It is easy to use and addresses the many industrial applications where data logging,

trending, and reporting are required. The product is available in either the 20- or 40channel version with user-defined inputs for each channel and comes with reporting

software to easily generate survey reports.

The easy to use Survey Template and Report Manager provide users with all of the tools

needed to generate uniformity reports. The Report Manager includes a report writer

that allows the user to set up reports to meet their specific requirements. The Template

Manager allows survey specific data to be created, updated and used during the

reporting process. All reports can be printed, saved electronically and emailed using

the software utilities. The SDS software tools, along with the data logger, combine to

create a powerful solution for data logging and reporting temperature uniformity

surveys.

Product Specifications

• User defined “logging” intervals as frequently as 10 seconds

• AC (90 – 240 V) and DC Power

• Rechargeable battery – Approximately 12 hours of “runtime”

• Dimensions: 16”D X 20”L X 8”H

• Password protected menu options

• Easy calibration

• Web-page enabled real-time view

• Ethernet and USB serial communications

• 16-Bit A/D converter

• 1 gigabyte of on-board storage

Super Systems Inc. Page 5 of 104

Color Touch Screen Data Logger Operations Manual

Page 6

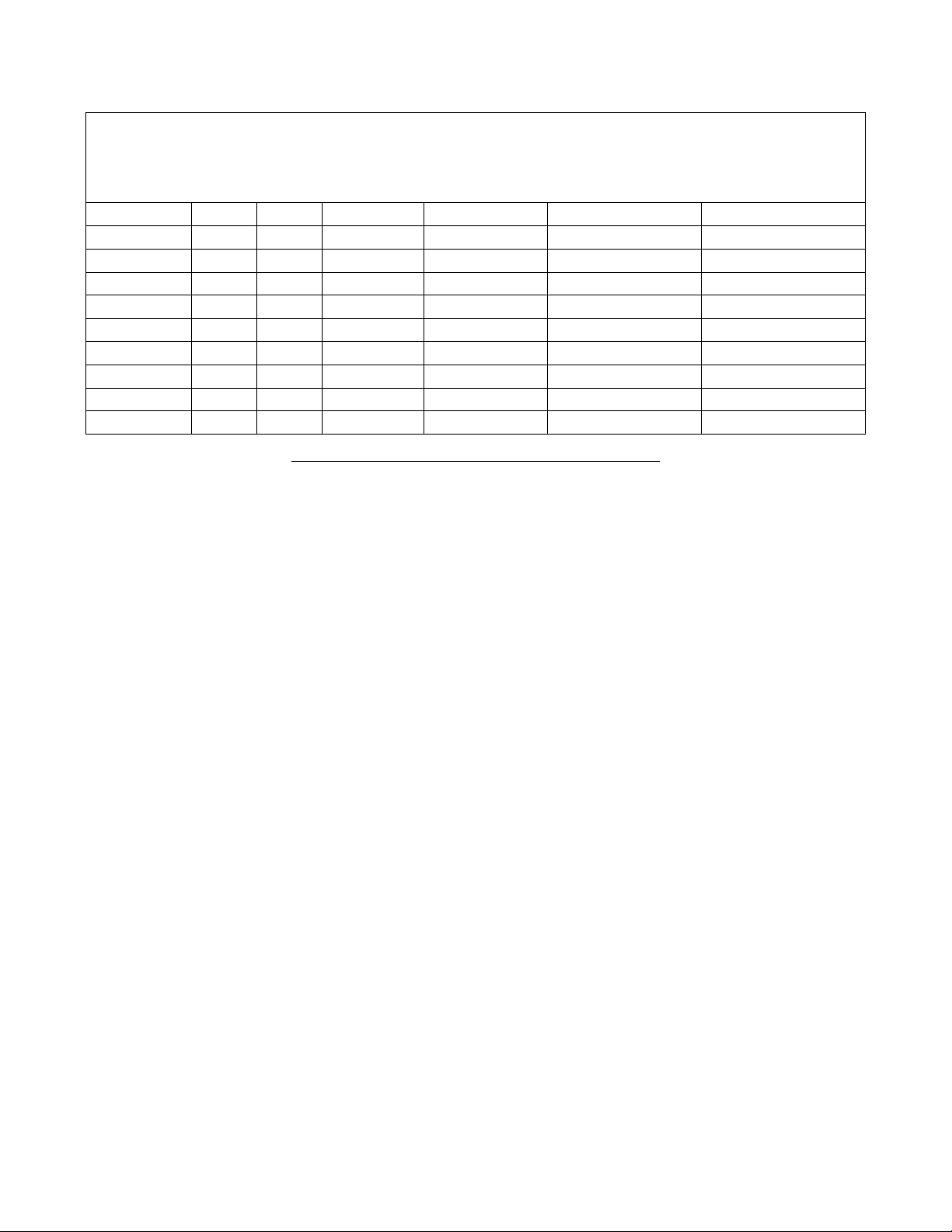

Degrees F.

A/D

Accuracy

Accuracy

Accuracy

TC Type

Min

Max

Full scale

Full Scale

At 1600 Degrees

F.

At 1600 Degrees F

with thermistor

error

B

32

3308

0.0124%

0.0179%

0.29

0.65

C

32

4208

0.0062%

0.0067%

0.11

0.47

E

-328

1832

0.0031%

0.0032%

0.05

0.41

J

-346

2192

0.0031%

0.0036%

0.06

0.42

K

-328

2502

0.0031%

0.0045%

0.07

0.43

N

-328

2372

0.0031%

0.0052%

0.08

0.44

NNM

0

1409

0.0031%

0.0033%

0.05

0.41

R

-58

3214

0.0062%

0.0118%

0.19

0.66

S

-58

3214

0.0124%

0.0133%

0.21

0.57

T

-328

752

0.0062%

0.0119%

0.19

0.55

Table 1 - Thermocouple Types, Scaling, and Accuracy

*** Note: Accuracy at 1600 Degrees F with thermistor error requires SDS firmware

level 1.10 or later ***

Software Installation

You will find the SDS Reporter software CD that ships with the unit includes all the

reporting and administrative utilities. Insert the CD into the optical drive on your

computer and click the setup.exe file. You will be given a step-by-step instruction for

completing the installation process. See Installing the SDS Software section for more

details.

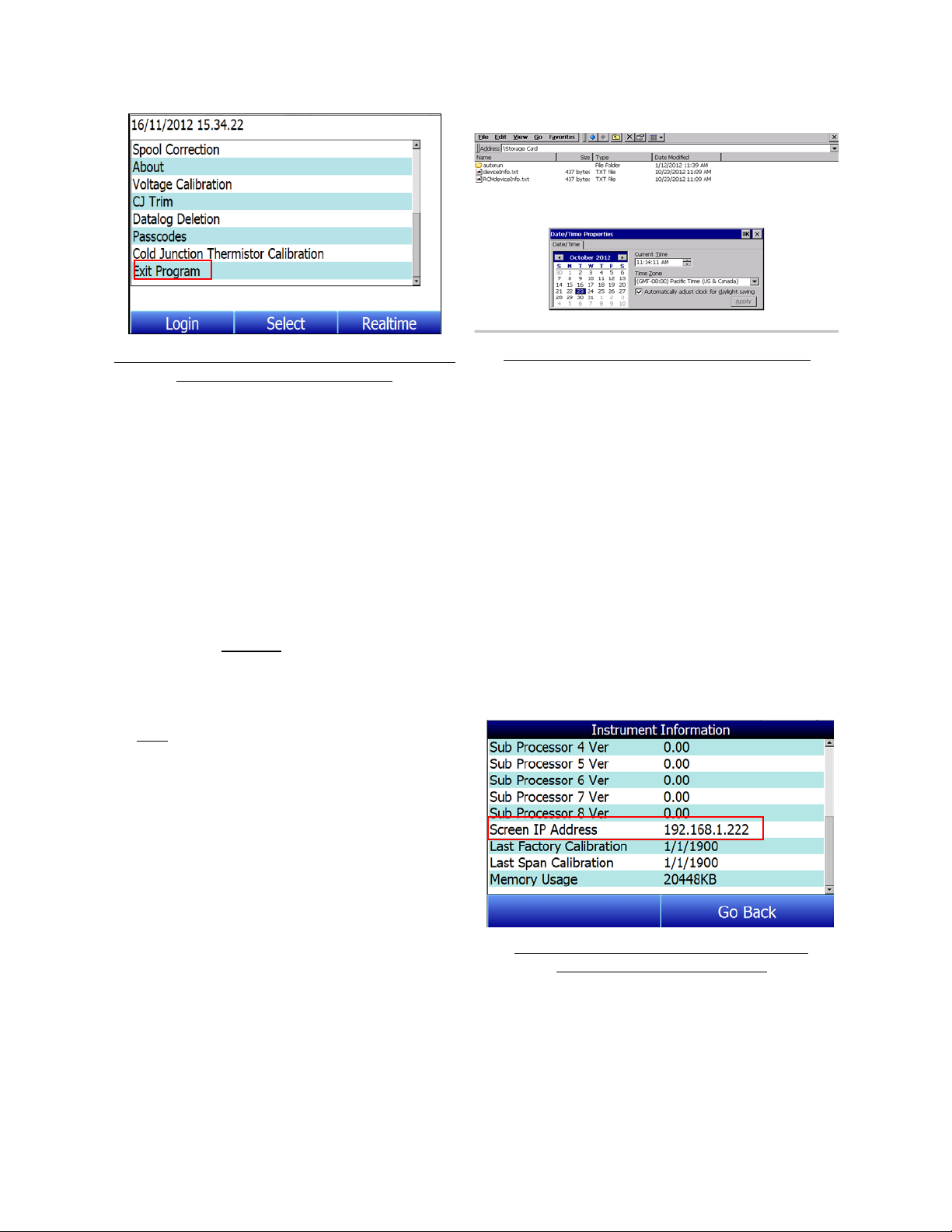

Changing the System Date and Time

The time and date that SDS uses are based on the time and date of the touch screen

operating system. To change the time and date, first shut down the SDS software

(Figure 1); note that this requires administrator access. Once the software is shut down,

double tap on the time shown in the task bar at the bottom of the screen on the

operating system desktop (Figure 2). Change the date and time in the dialog box that

appears.

Super Systems Inc. Page 6 of 104

Color Touch Screen Data Logger Operations Manual

Page 7

To find the current IP address of the data

Figure 1 - Option to Shut Down the SDS Software

(Administrator Access required)

Figure 2 - Date and Time Change Dialog Box

Once you have changed the date and time, you will need to save the changes to the

operating system registry. This is done using the “SaveRegs” application. In most cases,

the “SaveRegs” shortcut will be installed on the operating system desktop. Double tap

on the shortcut and save the registry settings. Then close the “SaveRegs” window.

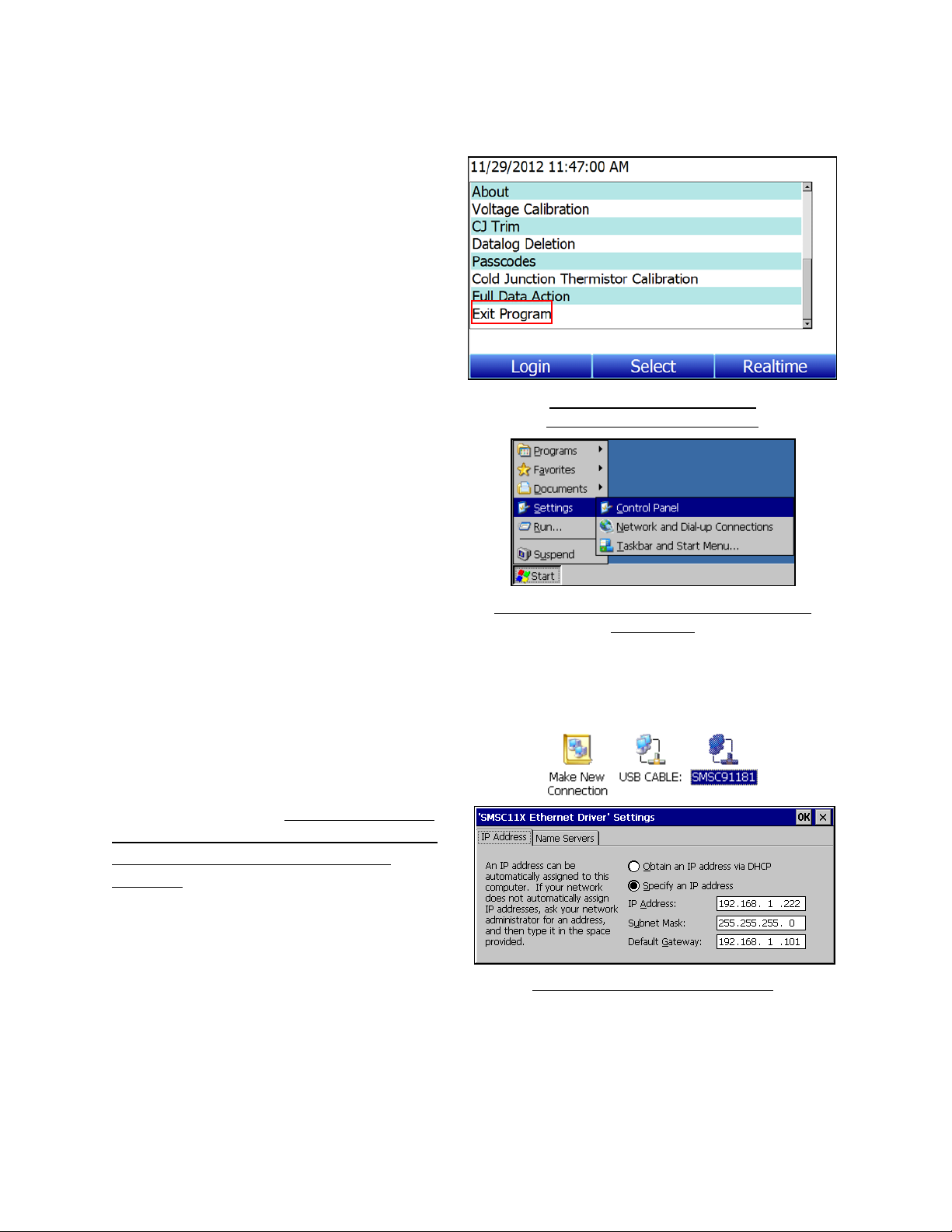

Finding and Setting the IP Address of the Color SDS Data Logger

For certain functions, it may be necessary to find the IP address (the address that

identifies the device on a network) of the Color SDS Data Logger. A possible example of

this could be Connecting the SDS Data Logger to a Network. Less frequently, it may be

necessary to change the IP address of the data logger, or to change it from a dynamic IP

address assigned by the local network to a static IP address that does not change

(unless you change it or set the IP address back to dynamic).

logger, simply open the Instrument

Information screen and scroll down to the

Screen IP Address (Figure 3)

By default, the Windows CE operating system on which the data logger software runs

obtains IP addresses dynamically. This means that the IP address may change

depending on a number of factors. In order to change IP assignment or the IP address

itself, you will need to shut down the SDS software and access the operating system

Control Panel. This procedure is described below.

Super Systems Inc. Page 7 of 104

Color Touch Screen Data Logger Operations Manual

Figure 3 - Location of Screen IP Address in

Instrument Information screen

Page 8

To change the IP address of the Color

Next, click Start, Settings, and Network

Double tap on the connection for the Color

Make sure that the

IP address does not conflict with another

IP address already assigned on the

network.

responsible for routing network traffic.

SDS Data Logger, first shut down the

SDS software. This requires

administrator access.

and Dial-up Connections (Figure 5).

Figure 4 - Exit Program option

(requires administrator access)

SDS touch screen device (in the example,

it is called “SMSC91181”). An Ethernet

Driver settings window will appear, giving

you the ability to specify an IP address. To

do so, click the “Specify an IP address”

radio button (see Figure 6). Then enter an

IP address manually.

You will also need to add a Subnet Mask

and a Default Gateway. The subnet mask

is usually already determined for the

network. A common subnet mask is

255.255.255.0; however, check with the

network administrator to be sure. The

default gateway is usually the address of

the network router or other device that is

Figure 5 - Accessing the Network and Dial-Up

Connections

Figure 6 - Specifying an IP Address

Super Systems Inc. Page 8 of 104

Color Touch Screen Data Logger Operations Manual

Page 9

Calibration

The SDS data logger is calibrated prior to shipment. The calibration process is

available through the touch screen Menu on the data logger. Instructions for calibration

are included in this manual. Super Systems calibrates the SDS data logger using NIST

traceable instruments that are listed on the calibration certificate included with the

device. The default calibration is performed using a zero and span routine for the

millivolt range of 0 – 80mV unless otherwise specified on the purchase order. Ranges

and thermocouple types will be listed on the certification provided with the SDS data

logger. Each range that is being used should be calibrated. For a list of suggested mV

ranges by thermocouple types, please refer to Table 1 - Thermocouple Types, Scaling,

and Accuracy. Other calibration ranges are available upon request.

An input device will be used to input a specific type K thermocouple value and the data

logger value will be recorded. This will be performed at different temperatures and

printed with the certificate.

Getting Started

IMPORTANT:

When using SDS Reporter with the Color SDS Data Logger, Options >

Color Screen Scanning must be selected. Refer to the section Options Color Screen

Scanning for more details.

When logging data, the operator will use the on-board display to start and stop the data

logging / survey process. The first steps related to data logging are connecting the

inputs to the terminal strips on the data logger. Each terminal strip represents a single

analog board with 5 inputs. You can remove these terminal strips by pulling up on both

ends of the terminal strip.

Depending on the model number, you have either 20 or 40 input channels for data

logging. For each channel there will be a positive and negative connection which must

be attached to the appropriate input.

The operator defines an input type for each channel.

Once the inputs have been connected, the operator selects which inputs will be included

in the survey. This is done in two ways:

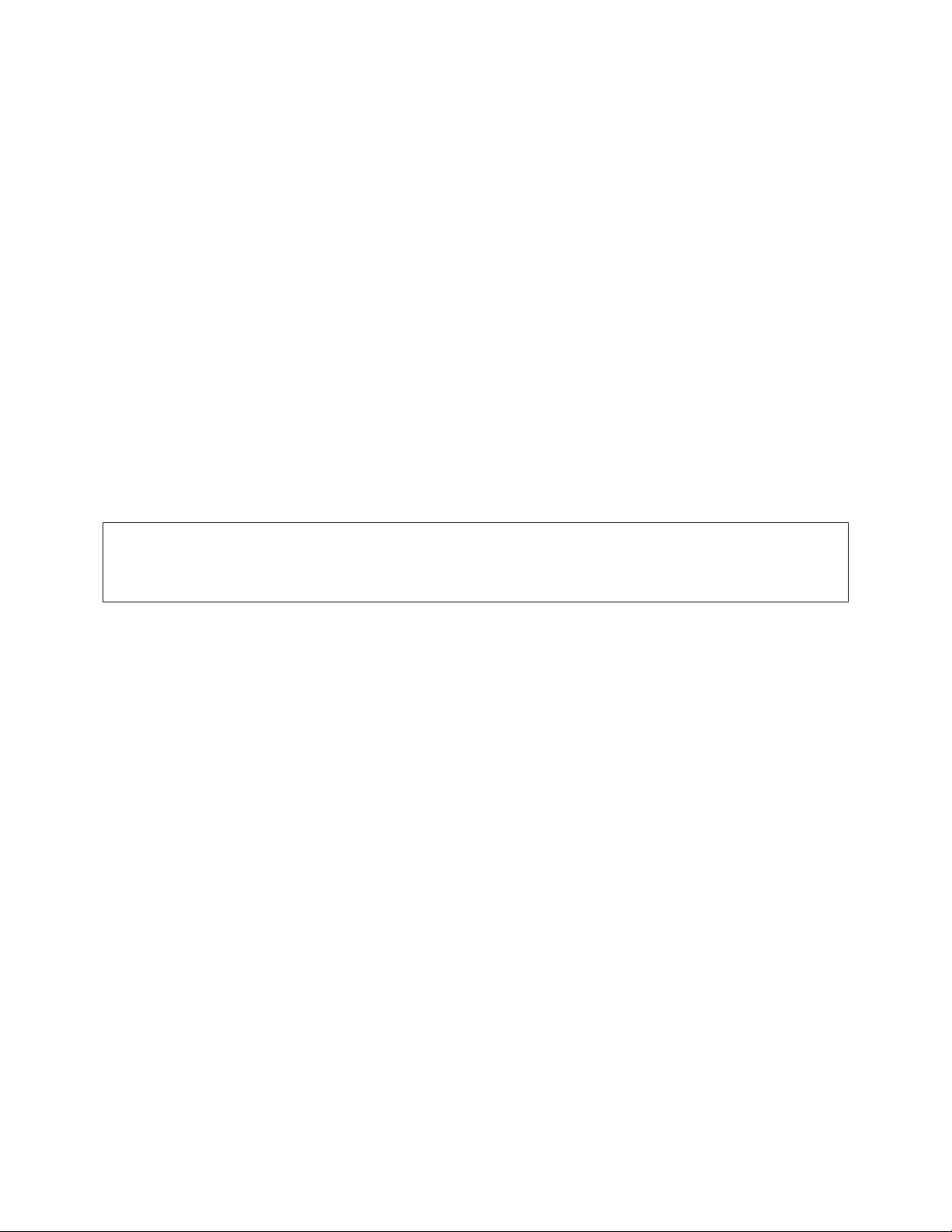

1. When a template has been selected, the input channels setup for the template,

as defined in the Template Manager, will be the selected channels for the survey.

It is strongly suggested that you select a template prior to running a survey. If

you want to create new templates, please see the section

Manager

. Survey Control and input selection screens are shown in Figure 7.

SDS Template

Super Systems Inc. Page 9 of 104

Color Touch Screen Data Logger Operations Manual

Page 10

Figure 7 - Survey Control and Input Selection screens

IMPORTANT: Input channels defined in the Survey Template will override the settings in

the

Select Input Channel

option once the survey is started. All channels are being data

logged at all times. The active inputs provide real time information on the display and

evaluation for stabilization, hottest TC and coldest TC. In the event that a TC is not

selected, it can be selected when using SDS Reporter for inclusion in the final survey

report.

2. Once a survey is started, the input selection can be updated on the data logger

using the

Select Input Channels

option.

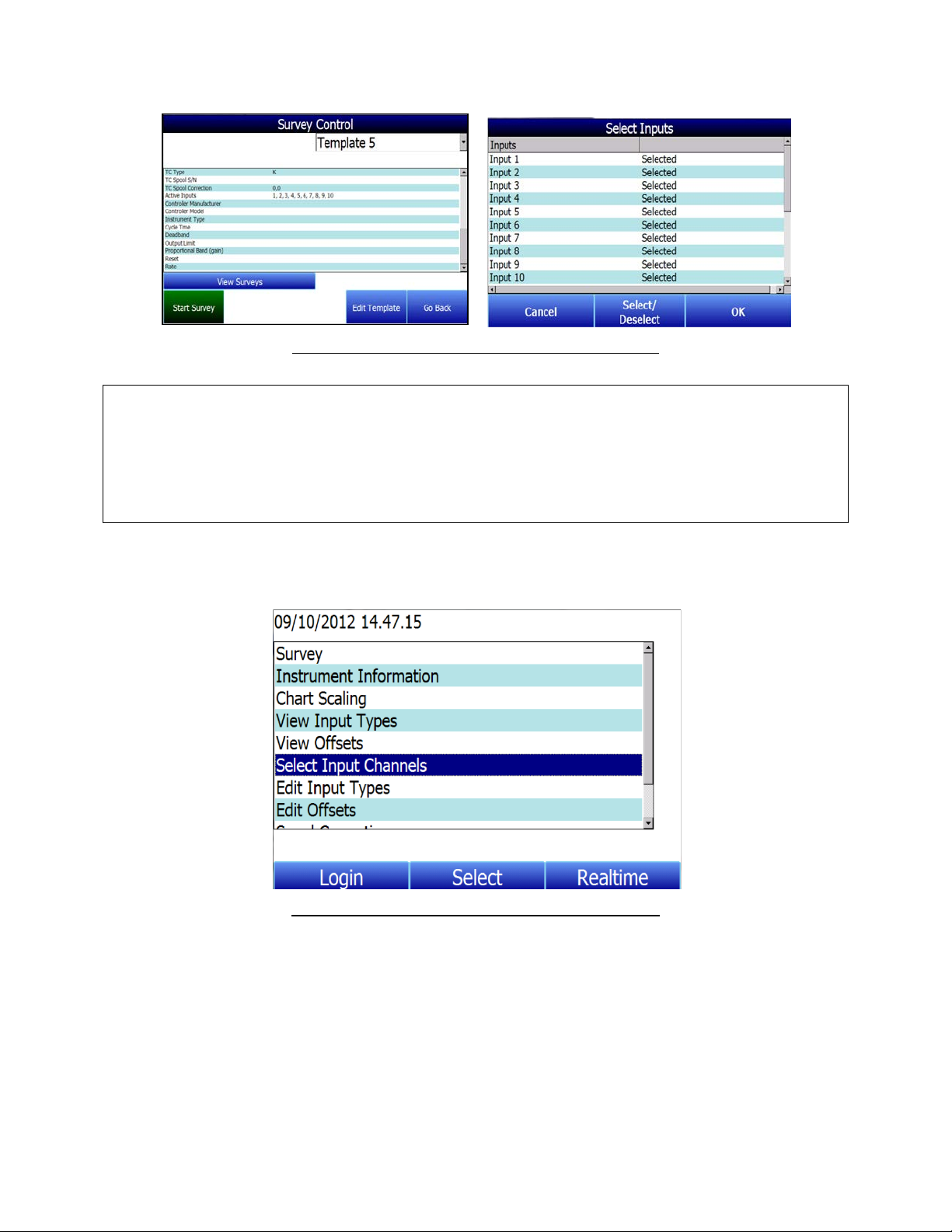

Figure 8 - Select Input Channels Option in Main Menu

Analog Inputs

The Super Systems, Inc. 31631 Analog Board contains a group of five channels isolated from the

main DC power source. The board can be connected to thermocouples, voltage sources from

20mV full scale to 1.28 Volts full scale, or 4 – 20 mA current loops.

current loops to avoid damaging the input (see 4 – 20 mA Current Loop connections).

Thermocouple wires can be connected directly to the terminal blocks. The thermocouple

junctions should not be grounded. If they do touch a ground reference, all thermocouples on a

Super Systems Inc. Page 10 of 104

Color Touch Screen Data Logger Operations Manual

Take caution when using

Page 11

board must have a common ground reference. If multiple thermocouples are connected to

different ground reference points, the accuracy of all thermocouples on the board cannot be

guaranteed to be accurate.

Voltage connections

Voltages from 0 mV to 1.28 Volts can be directly connected to the terminal blocks. When

measuring ground-referenced voltages, all references must share a common ground

reference. If the voltage sources are connected to different ground reference points, the

accuracy of all the voltage sources connected to the board need to be checked for accuracy.

4 – 20 mA Current Loop connections

Before connecting the current loop, insert the shorting jumper on the board for each channel

used to measure current loops. This jumper inserts the 62-ohm shunt resistor across the input

of the A/D. If multiple current loops are connected to one board, all must share the same power

supply and ground reference points or the accuracy of all the current loops need to be checked

for accuracy.

Survey Templates

The data logger will default to the last survey template used. To modify the template being

used, the operator can go to the

Survey

menu option. This data will be carried over for the

reporting process to make the reporting quick and easy. On the Survey Template screen there

are parameters, such as setpoint, that can be modified for a specific survey. After setting the

required parameters, the start survey process can be selected. This will timestamp the

selection and the data logger will log all channels that have been selected for logging.

The operator may receive deviation alarms depending on the current input and setpoint as well

as the alarm settings. The alarm will notify the operator when an input is outside the

plus/minus tolerance for the setpoint. The alarm information will display on the data logger

and show the number of channels above tolerance and below the tolerance. The survey

continues to run. It is simply providing the operator with the information on the display.

The operator can view the input channel data on a number of different screens. The

display

will display all channels on the device.

overview

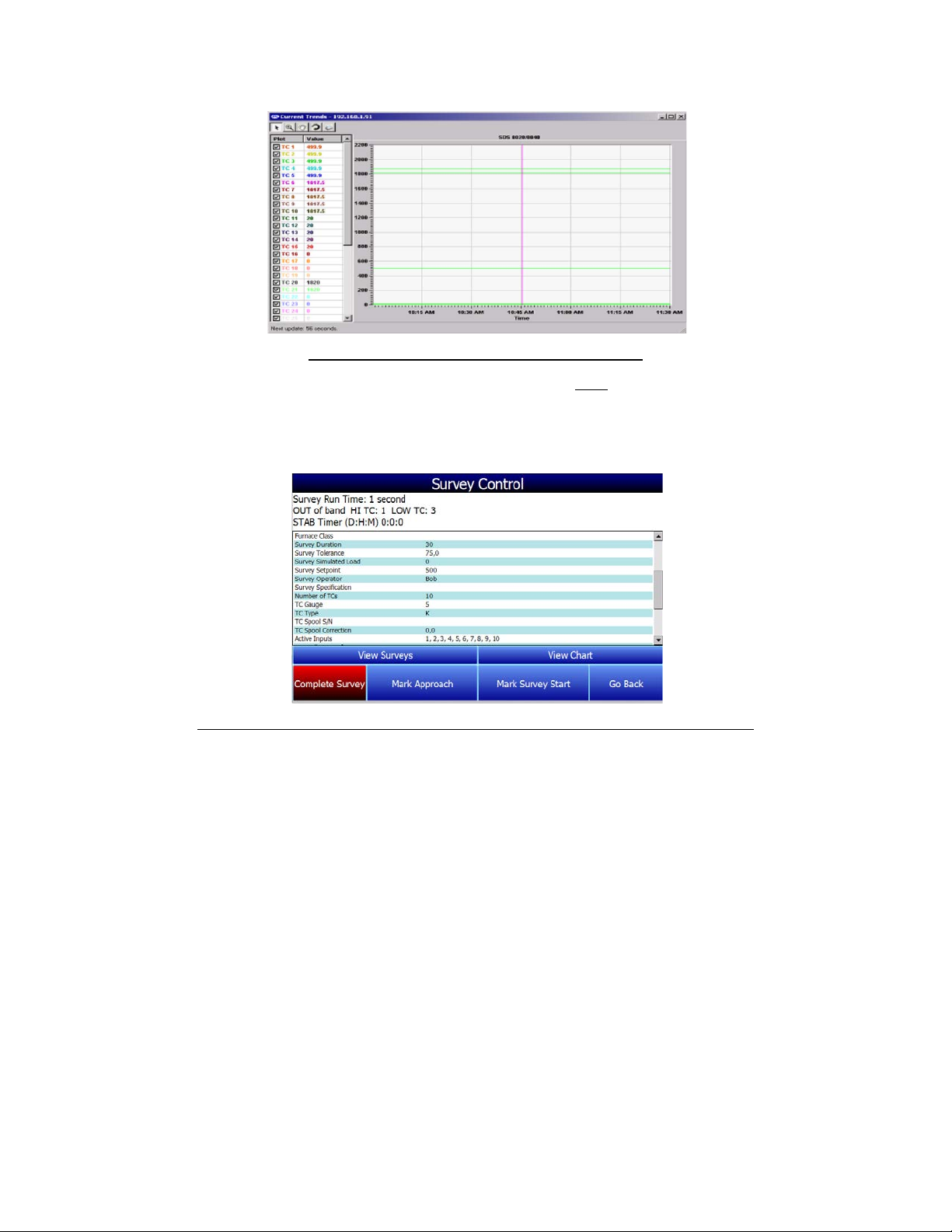

At any time, the operator can view the data in real time from the computer using the SDS

Reporter software. When selected, the real time data option displays data every 10 seconds.

The system will update the data in 10 second intervals every minute. Follow instructions for

connecting the data logger to the PC.

Super Systems Inc. Page 11 of 104

Color Touch Screen Data Logger Operations Manual

Page 12

Figure 9 - Current Trends Screen (SDS Reporter)

While the survey is running, several options are available: To stop the survey, select

Survey

main menu). Use

heating up to its target temperature. Use

Click

data being logged.

After stopping the survey, other surveys can be taken by repeating the above steps. At any time,

all survey data can be downloaded to the PC using the Download Surveys and Data option on

SDS Reporter. Follow instructions for connecting the data logger to the PC.

Once the data has been downloaded, it is available for reporting. By clicking on the File > Open

menu option, the operator will be given the Report dialog to generate a survey report. Reports

use logged data and the user specified interval in the report. The report template that is

selected will form the final report view with all of the template data, survey data and additional

report parameters that are entered. The report templates are user-defined and should be

configured to meet your needs. All reports can be saved and displayed at a later date.

from the Survey Control screen (which can be opened using the Survey option from the

Mark Approach

Figure 10 - Survey Control Window (visible from the data logger during a survey)

View Surveys

to view data on past surveys. Click

to add a timestamp to the survey on when the furnace was

Mark Survey Start

View Chart

to mark when the survey began.

to view the current chart of

Complete

Super Systems Inc. Page 12 of 104

Color Touch Screen Data Logger Operations Manual

Page 13

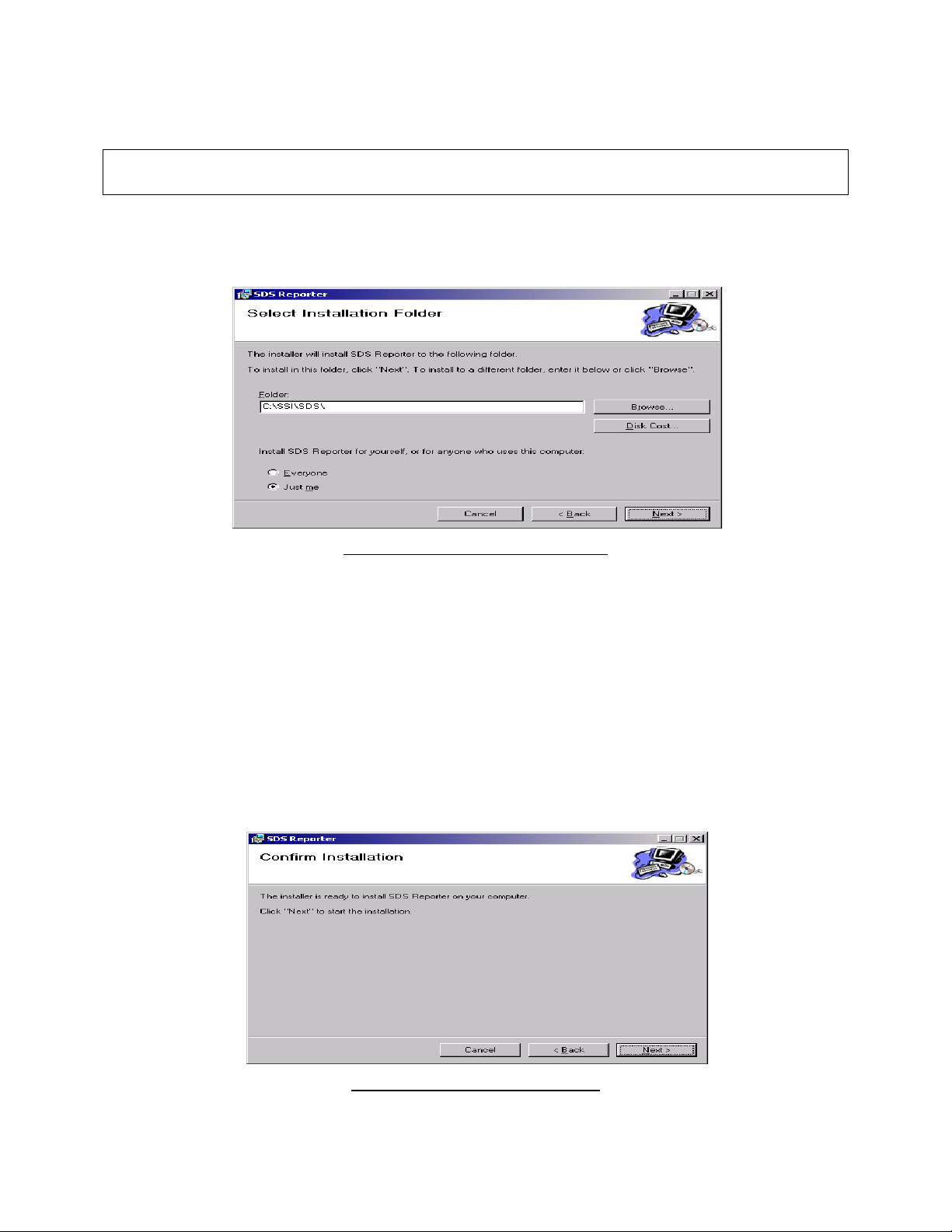

Installing the SDS Software

IMPORTANT: The person installing the SDS Software must have administrative rights on the

computer(s) where the installation is taking place for the installation to be successful.

Double-click on the setup file, setup.exe, to start the auto-installation. (Avoid installing from

SDSSetup.msi, as this will not install prerequisites if necessary.) If there is no version of the

SDS Reporter running on the computer, the installation will prompt the user for the download

location (Figure 11).

Figure 11 - SDS Reporter setup screen

Prerequisites for installing SDS Reporter include .NET Framework 2.0, SQL CE 3.5, and either

ActiveSync or Windows Mobile Device Center. The setup.exe program will check to make sure

that these prerequisites are installed and, if necessary, install them.

The default location is “C:\SSI\SDS”. Click on the “Browse” button to select an alternate

location. Clicking on the “Disk Cost…” button will display the available computer drives onto

which the SDS Reporter can be downloaded, as well as the total space, available space, and

required space for each drive. Selecting the “Everyone” option will install the SDS Reporter for

all users on the computer, while selecting the “Just me” option will only install the

SDSReporter for the current user. Clicking on the “Cancel” button will prompt the user to

confirm exiting the setup without continuing. Clicking on the “< Back” button will display the

previous screen, which is the introduction screen for the installer. Clicking the “Next >” button

will continue with the installation process (Figure 12).

Figure 12 - Installation ready screen

Super Systems Inc. Page 13 of 104

Color Touch Screen Data Logger Operations Manual

Page 14

Clicking on the “Cancel” button will prompt the user to confirm exiting the setup without

continuing. Clicking on the “< Back” button will display the previous page, which is the

installation setup page (Figure 11). Clicking on the “Next >” button will install the software to

the specified location. Once the software has been installed, the installer can be closed. The

SDS Reporter software will now be ready to use.

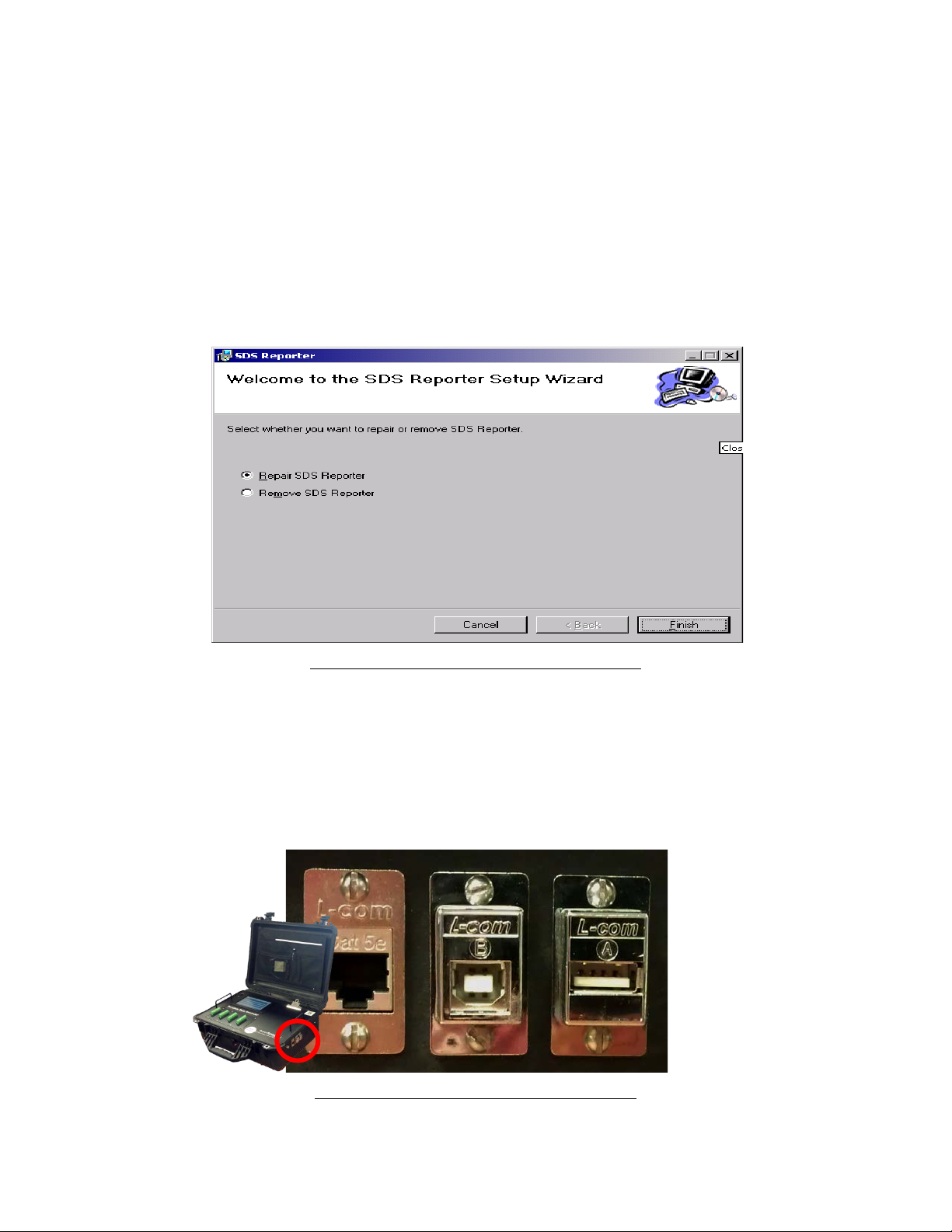

If there is a version of the SDS Reporter already installed on the computer, the installer will

either re-install the software (Repair SDS Reporter option) or remove the software from the

computer (Remove SDS Reporter option) (Figure 13). Clicking on the “Finish” button will

proceed with the selected action. Note: The installer does not remove any subfolders in the

main SDS folder. These files will have to be manually removed.

Figure 13 - Repair/Remove SDS Reporter screen

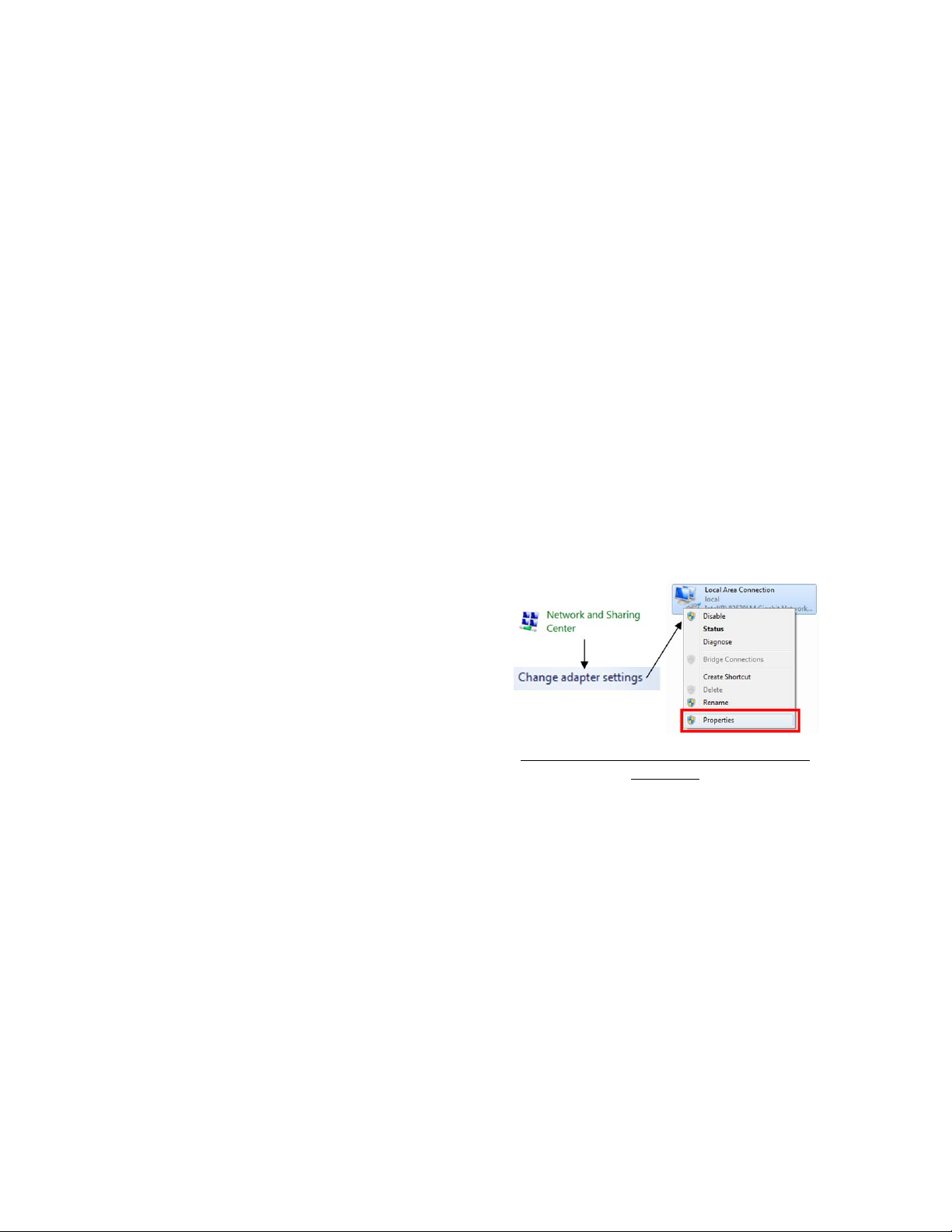

Connecting the SDS Data Logger to a Network

Every SDS Data Logger shipped includes an Ethernet crossover cable that will connect the data

logger to a network. Once the data logger is connected to a network, the SDS Reporter

software will be able to find it during any searches.

Connecting the data logger to your network or directly to a PC can be accomplished using the

Ethernet port on your data logger.

Figure 14 - Location of Ethernet and USB ports

Super Systems Inc. Page 14 of 104

Color Touch Screen Data Logger Operations Manual

Page 15

If you are connecting the data logger to your network, you will need an Ethernet cable (the cable

In Windows Vista and Windows 7, open the

provided is a crossover cable for direct connections to a PC). The cable is plugged into the data

logger Ethernet plug; the other end should be plugged into a network hub. If the IP Address of

the data logger needs to be changed, this can be done on the data logger through the Set IP

Address menu option.

If you are not putting the data logger on the network, you should use the Ethernet crossover

cable that has been provided with the device. Ethernet crossover cables are most often

used when connecting two Ethernet computers without a hub. An Ethernet crossover cable has

its send and receive wires crossed. When using a hub or switch, this is automatically done for

you.

With a crossover cable, you are forming a network between the computer that you are directly

plugged into and the data logger. There will be some network settings on the data logger and

on the computer that you will have to configure for the two devices to communicate.

Setting an IP address in the data logger is described in Finding and Setting the IP Address of the

Color SDS Data Logger above.

Network settings can be found through the

Control Panel

in Microsoft Windows.

Using the crossover cable will require the Local Area Connection to be modified.

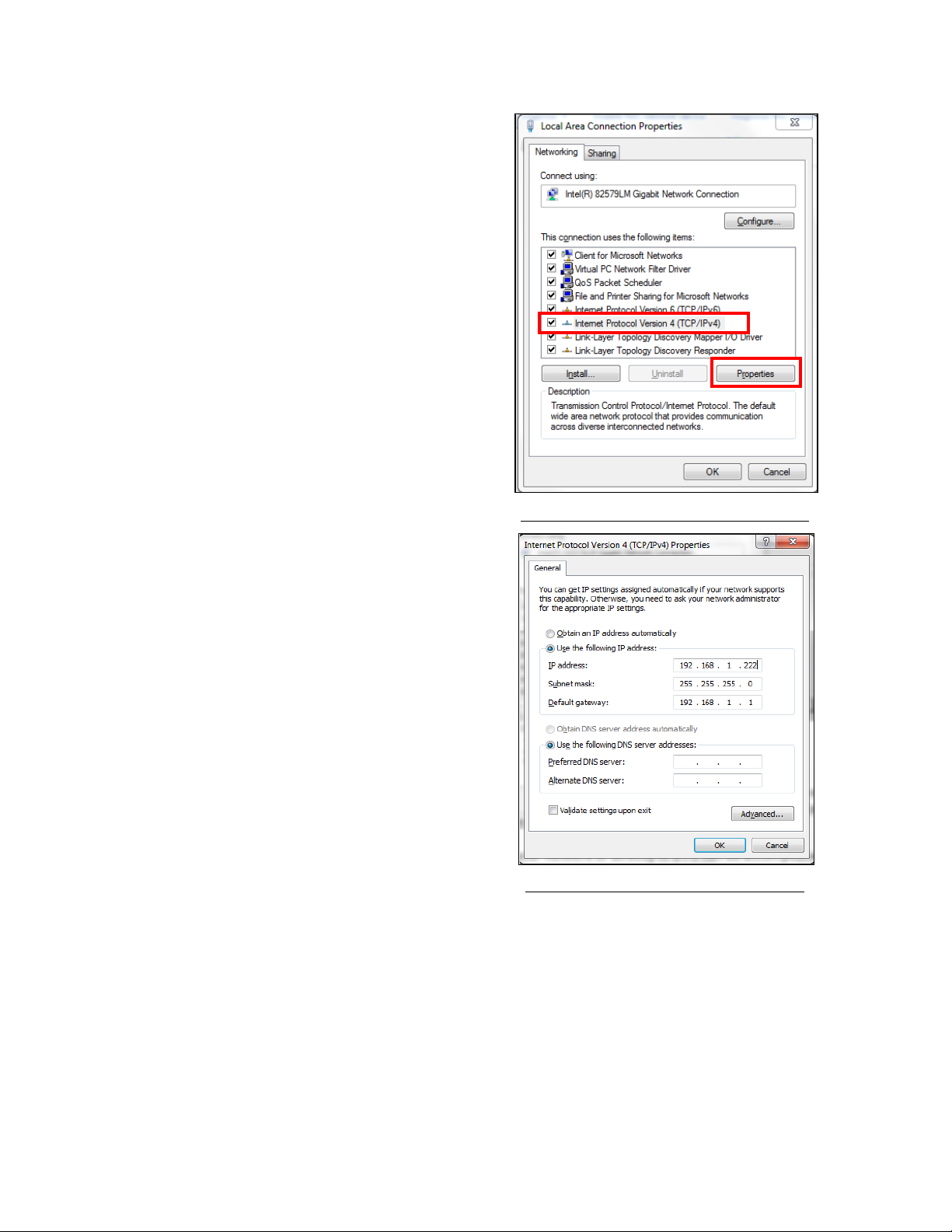

In Windows Vista and Windows 7

Network and Sharing Center menu within

Control Panel. Click “Change adapter settings”.

This will bring up a list of network connections,

including active and inactive ones. Right click

on the name of the network to which the Color

SDS Data Logger is or will be connected, and

then click Properties.

Figure 15 - Accessing Network Connection

properties

Super Systems Inc. Page 15 of 104

Color Touch Screen Data Logger Operations Manual

Page 16

The network properties window will appear.

In the Internet Protocol Version 4 (TCP/IPv4)

Click on the line that reads “Internet Protocol

Version 4 (TCP/IPv4)” and then click Properties.

Properties window, you will need to select the

option for Use The Following IP Address. These

settings should match the settings on the Color

SDS Data Logger.

To change the network settings on your

computer you may need additional information.

If needed, please refer to the computer manual.

Figure 16 - Accessing TCP/IPv4 Properties

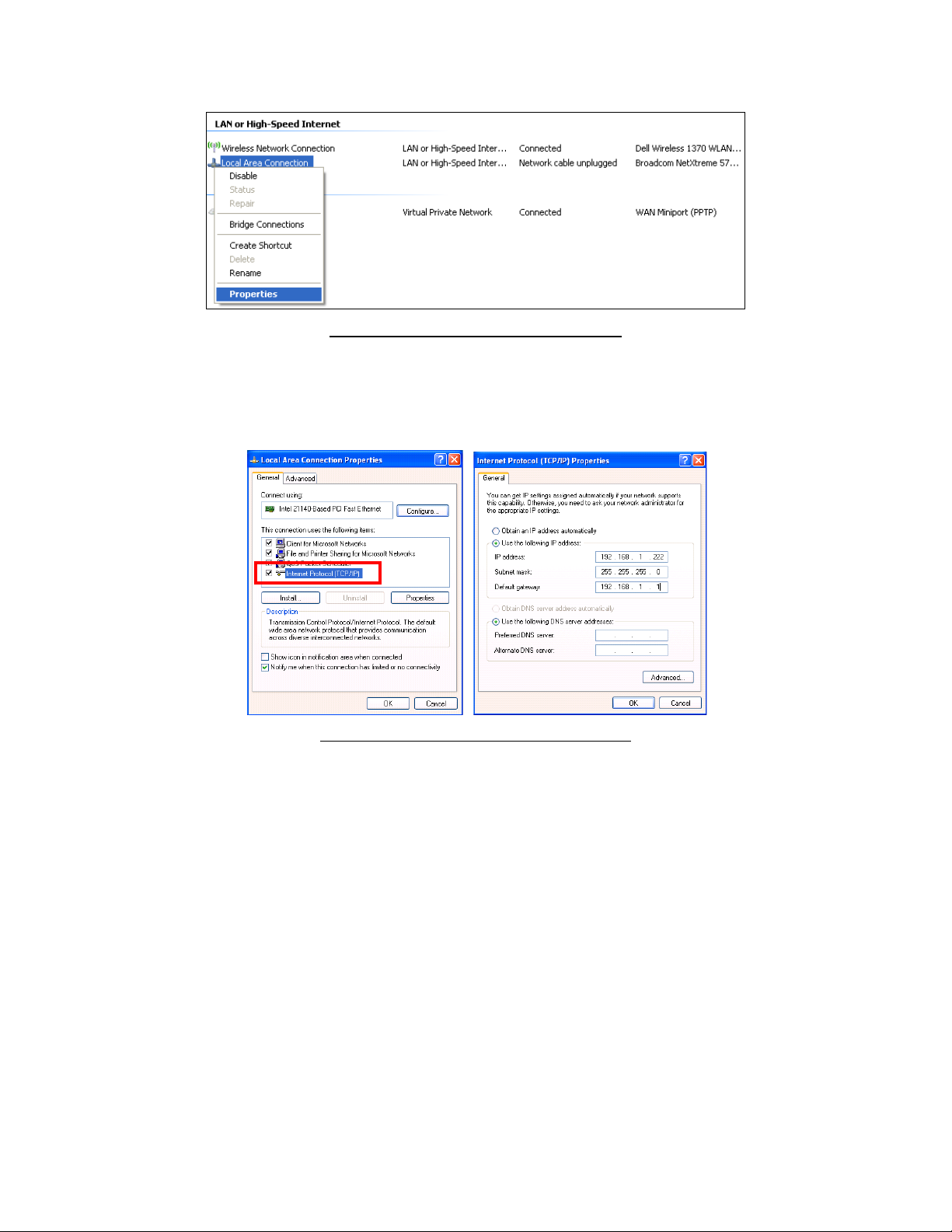

In Windows XP

The Properties can be changed by highlighting the connection and using the right mouse button

to click and select the Properties tab or by highlighting the connection and clicking on Change

setting of this connection.

Super Systems Inc. Page 16 of 104

Color Touch Screen Data Logger Operations Manual

Figure 17 - Changing IP address settings

Page 17

Figure 18 - Network Connection Properties

Once the Local Area Connection Properties screen is displayed, the Local Area Connection

Properties tab should be highlighted. Click on Internet Protocol (TCP/IP) and then click the

Properties button to display Internet Protocol (TCP/IP) Properties.

Figure 19 - Network Connection Dialog Boxes

In the Internet Protocol (TCP/IP) Properties window, you will need to select the option for Use

The Following IP Address. These settings should match the settings on the Color SDS Data

Logger.

To change the network settings on your computer you may need additional information. If

needed, please refer to the computer manual.

Connecting the SDS Data Logger to a Local Computer via USB

The data logger can be connected directly to a local computer using a USB cable and SDS

Reporter. Windows uses special software to transfer files and information between the data

logger and the local computer when connected via USB. If you are using Windows XP, this

software is called ActiveSync. If you are using Windows Vista or Windows 7, the software is

called Mobile Device Center. If the required software was not installed prior to installing

SDSReporter, the SDSReporter Setup utility (run from setup.exe) would have installed the

required software.

Super Systems Inc. Page 17 of 104

Color Touch Screen Data Logger Operations Manual

Page 18

Windows XP requires a driver for it to properly

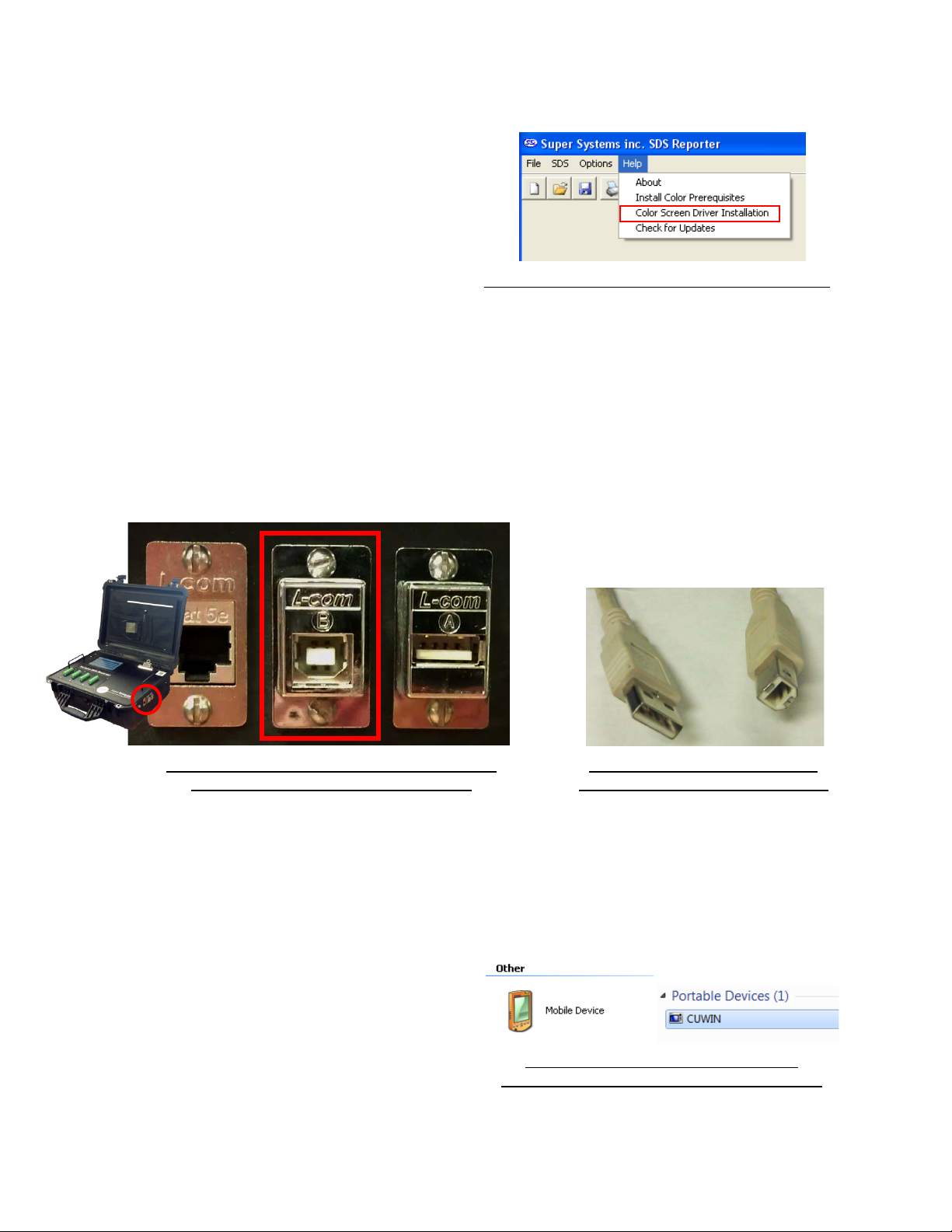

Help

NOTE: If there is any question as to whether

shown in Figure 23. Other devices, such as

connect to the data logger’s color touch

screen operating system. Install this driver, if

necessary, by selecting the “Check Screen

Driver Installation” option under the

menu in SDSReporter (

Figure 20), and then

clicking “Start Driver Installation” on the next

screen.

Figure 20 - Color Screen Driver Installation option

If you are using an older version of SDSReporter, be sure to update it by clicking “Check for

Updates”, also in the

Help menu, and then downloading the update when prompted.

To connect the SDS Data Logger to a local computer with USB, first make sure that the data

logger is turned on and that the SDS software is running on the touch screen. Next, identify the

USB connection point used to connect the data logger to the local computer (shown in Figure

21). To connect the data logger to the computer, you will need a USB cable with cable ends that

look like those in Figure 22.

Figure 21 - Location of USB connection point for

connecting data logger to local computer

Connect the SDS Data Logger to the local computer via USB. If you are connecting the data

logger to the computer via USB for the first time, you may see a message on the screen saying

that Windows is installing drivers, especially on Windows Vista and 7. Windows may also ask you

if you want to set up the device. If this happens, allow Windows to install the drivers, but close

the device setup window from ActiveSync or Mobile Device Center.

the computer is detecting the data logger and

connecting to it properly, check the “My

Computer” window in Windows XP or the

“Computer” window in Windows Vista and 7.

The data logger should appear in this window

with a mobile or portable device icon, as

Super Systems Inc. Page 18 of 104

Color Touch Screen Data Logger Operations Manual

Figure 22 - USB connection types

Figure 23 - Data Logger Device Icons in

Windows XP (left) and Windows 7/Vista (right)

Standard-A (left), Standard-B (right)

Page 19

smartphones, may also appear as part of the

same list.

To access the web portal, first open a web

Once the SDS Data Logger is connected to the computer via USB, start SDS Reporter.

Web Portal

The Color SDS Data Logger features a web-based portal that can be accessed by web browser,

using Ethernet, from any computer that is connected to the same network as the data logger.

The web portal displays current temperature readings for each thermocouple input.

browser (such as Internet Explorer or Firefox).

Next, in the location bar, type

http://

followed

by the IP address of the data logger. One way

of finding this IP address is to obtain it from

the Instrument Information window, as shown

in

Figure 24.

Figure 24 – Instrument Information screen and IP

address

Once you’ve entered the needed web address, you will see a screen that looks like the following

one.

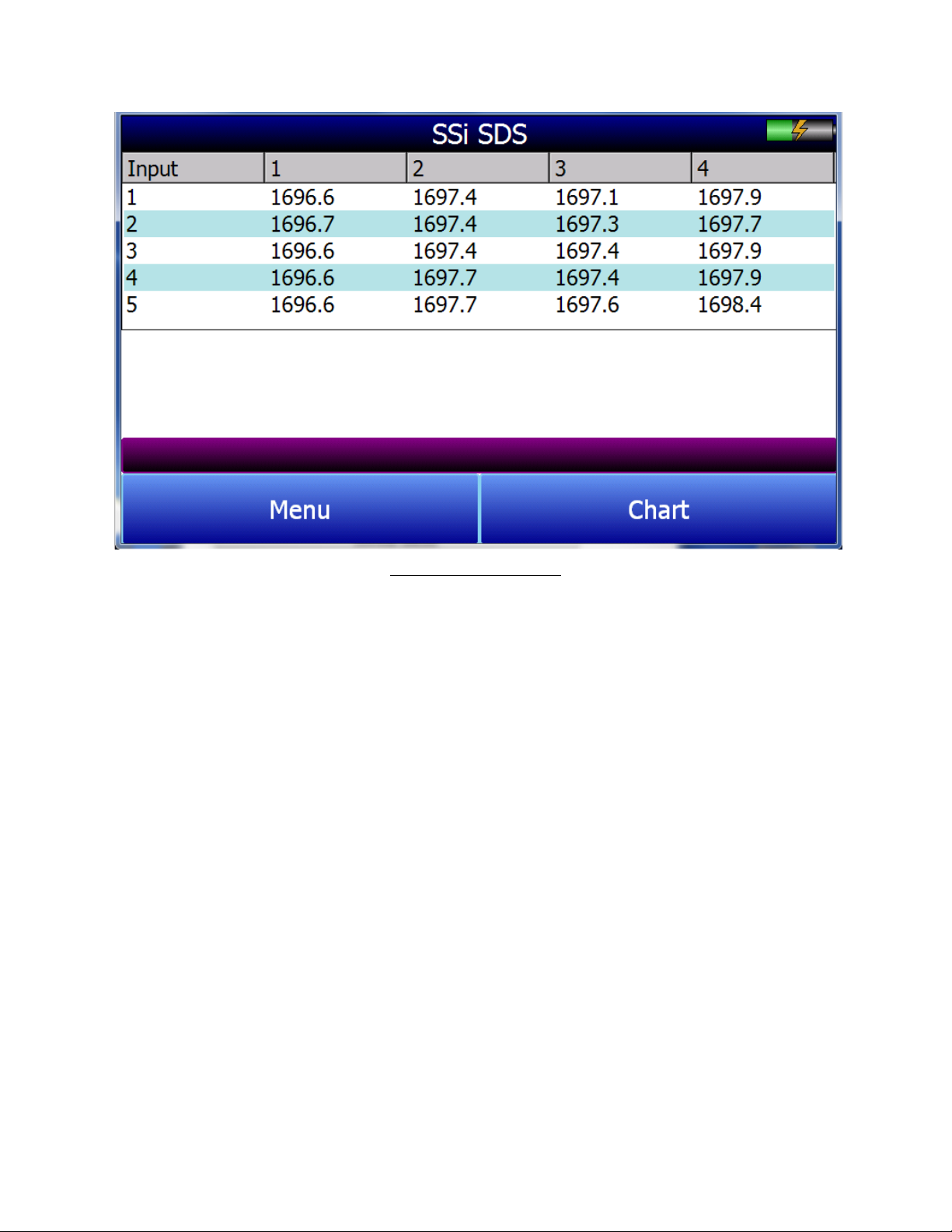

Home Screen

The default Home Screen for the SDS will display the temperature at each channel. The grey

bar along the top represents the 4 analog boards and the numbers along the left-hand side

represent the 5 channels for each board.

Super Systems Inc. Page 19 of 104

Color Touch Screen Data Logger Operations Manual

Figure 25 - Web Portal Screen

Page 20

Figure 26 - Home Screen

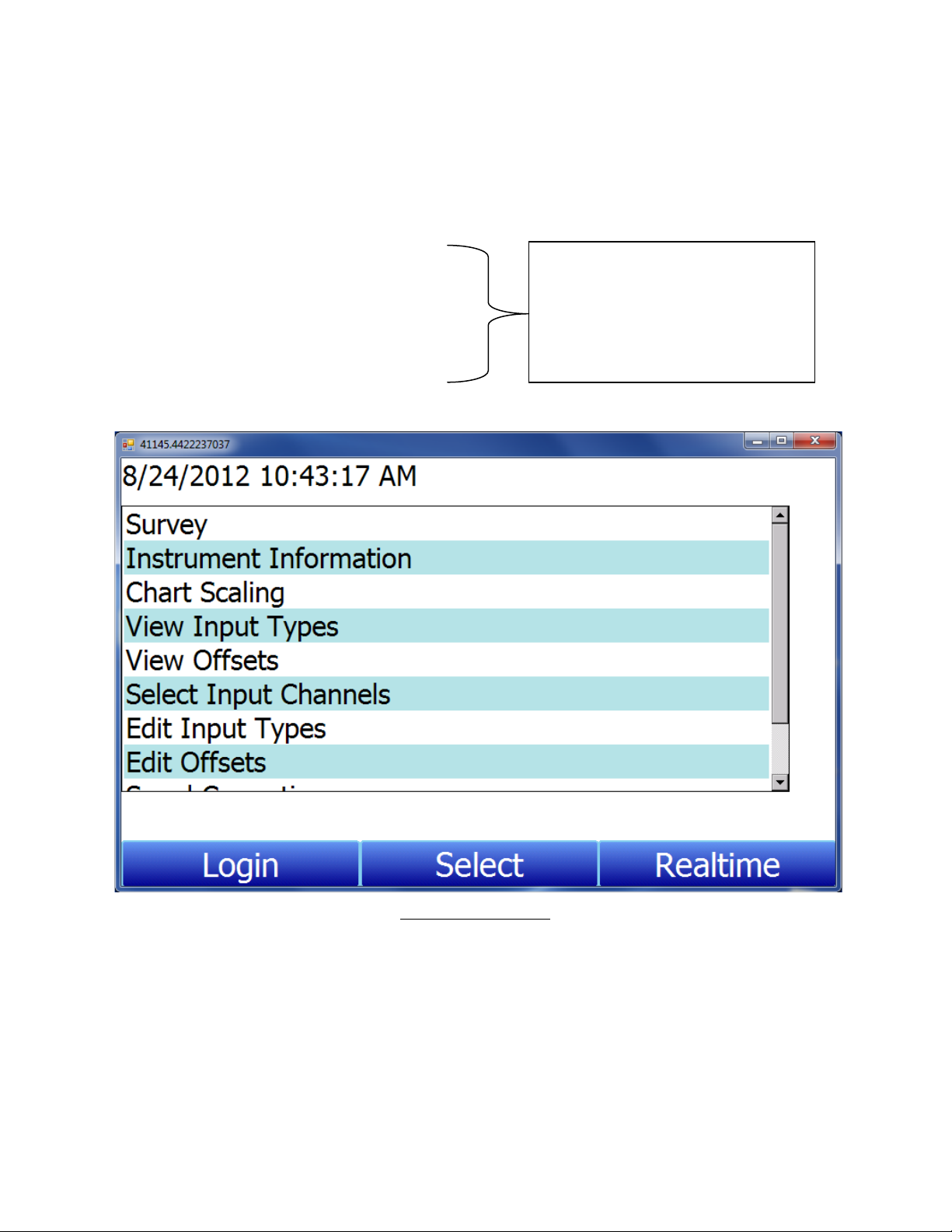

Menu

Menu contains the list of operations that the SDS performs as well as other information about the unit.

The viewable Menu items change depending on the login value. The complete list of Menu items

includes:

User-Level Access (or Higher) Required:

• Survey

• Instrument Information

• Chart Scaling

• View Input Types

• View Offsets

• Select Input Channels

• Edit Input Types

• Edit Offsets

• Spool Correction

• About

Supervisor Access (or Higher) Required:

• Voltage Calibration

• CJ Trim

• Datalog Deletion

Super Systems Inc. Page 20 of 104

Color Touch Screen Data Logger Operations Manual

Page 21

Please call Super Systems Inc.

Control, or Modbus Control.

Administrator Access (or Higher) Required:

• Passcodes

• Cold Junction Thermistor Calibration

• Full Data Action

• Exit Program

Highest Level Security Access Required:

• Configuration

• Reset Calibration Dates

• Set Nominals

• Set K Factors

• SDX Control

• Modbus Control

Technical Support (800-666-4330)

before attempting to access any of

these Menu items: Configuration,

Reset Calibration Dates, Set

Nominals, Set K Factors, SDX

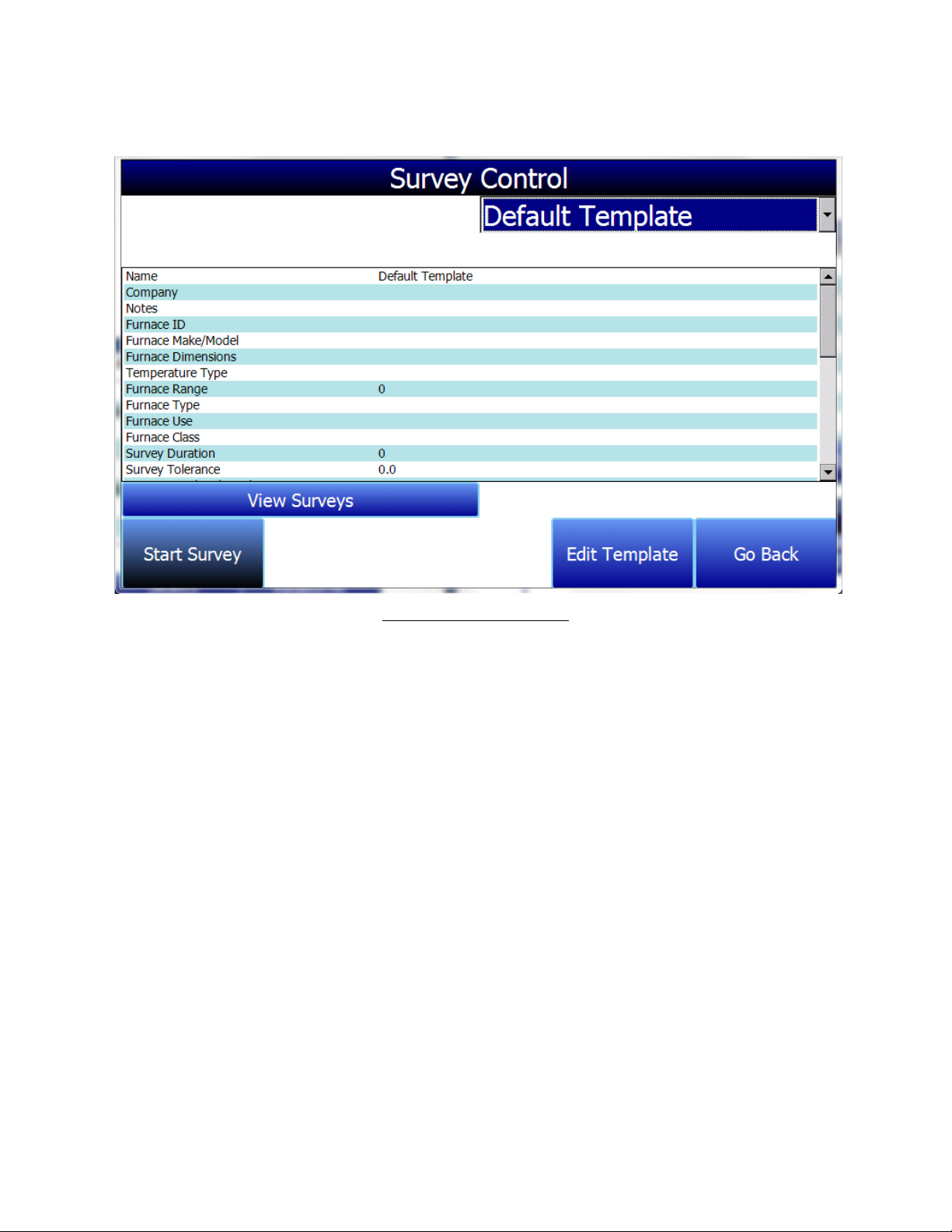

Survey

This option contains the survey information and the controls to perform a survey. The

appropriate template can be chosen from the dropdown menu in the top right-hand

corner. The Edit Template button allows for changes to be made to the selected survey.

When editing a survey, pressing OK will make changes only for that particular survey,

while pressing Save will permanently change the template. The View Surveys button

will display a list of previous surveys from the selected time range. Once the template

Super Systems Inc. Page 21 of 104

Figure 27 - SDS Menu

Color Touch Screen Data Logger Operations Manual

Page 22

has been selected and any necessary edits have been made, press Start Survey to

begin.

Figure 28 - Survey Window

Super Systems Inc. Page 22 of 104

Color Touch Screen Data Logger Operations Manual

Page 23

Instrument Information

Figure 29 - Instrument Information

Instrument Information displays the condition of several parameters for the SDS, and no

changes can be made to this screen.

Super Systems Inc. Page 23 of 104

Color Touch Screen Data Logger Operations Manual

Page 24

Chart Scaling

Figure 30 - Chart Scaling Window

Chart scaling allows the user to adjust the maximum and minimum degrees displayed

on the chart. To change, press the blue button with the max or min number, press OK,

then press Save.

View Input Types

This menu option displays the thermocouple type for each of the 20 channels. No

changes can be made to this screen.

Super Systems Inc. Page 24 of 104

Color Touch Screen Data Logger Operations Manual

Page 25

Figure 31 - View Input Types

View Offsets

View Offsets displays the offset values for each thermocouple channel on the SDS. No

changes can be made to this screen.

Super Systems Inc. Page 25 of 104

Color Touch Screen Data Logger Operations Manual

Page 26

Figure 32 - View Offsets

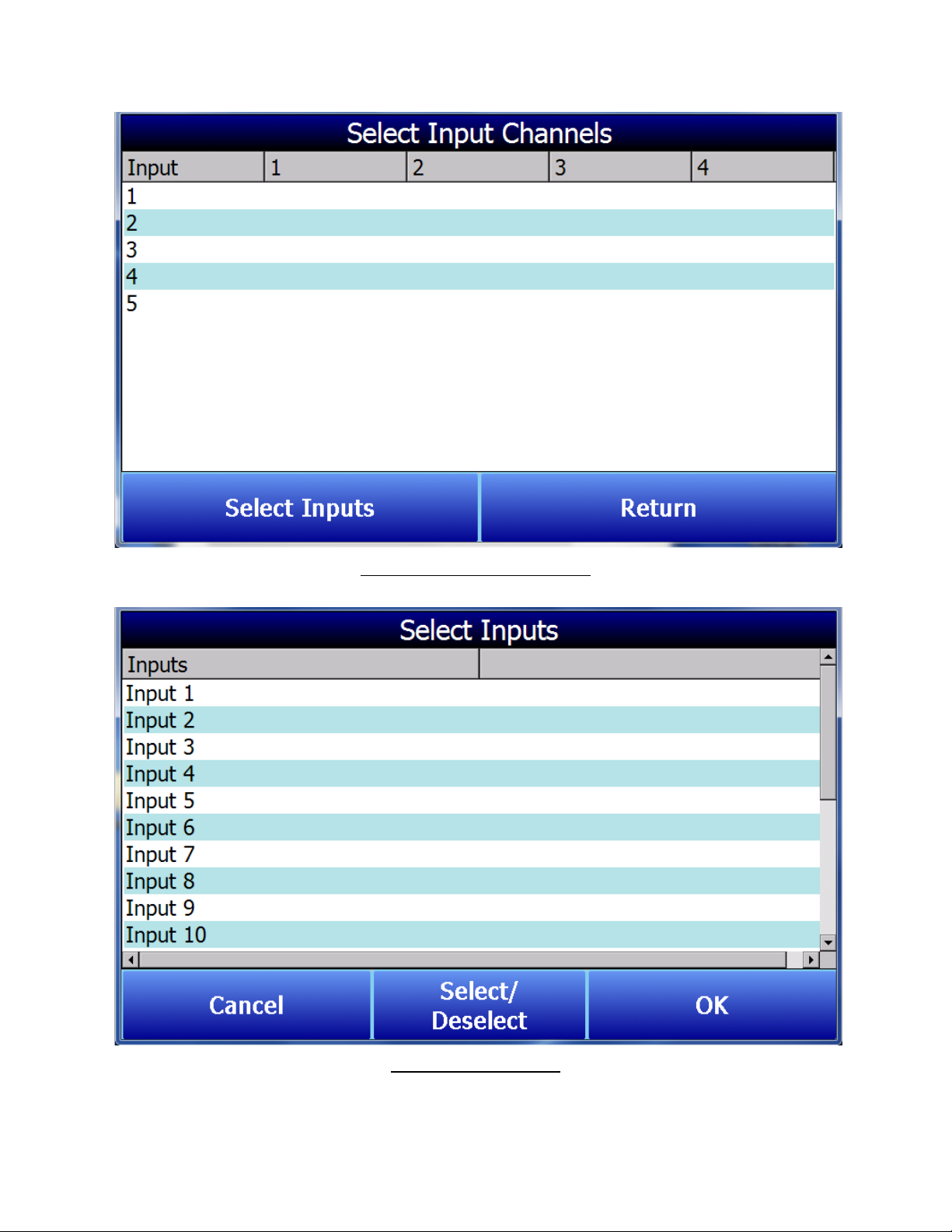

Select Input Channels

Select Input Channels allows the user to manually determine whether a thermocouple

is included in a survey or not while the survey is running. First press Select Inputs.

Then, highlight the Input # to toggle between Select/Deselect. To save changes, press

OK.

Super Systems Inc. Page 26 of 104

Color Touch Screen Data Logger Operations Manual

Page 27

Figure 33 - Select Input Channels

Figure 34 - Select Inputs

Super Systems Inc. Page 27 of 104

Color Touch Screen Data Logger Operations Manual

Page 28

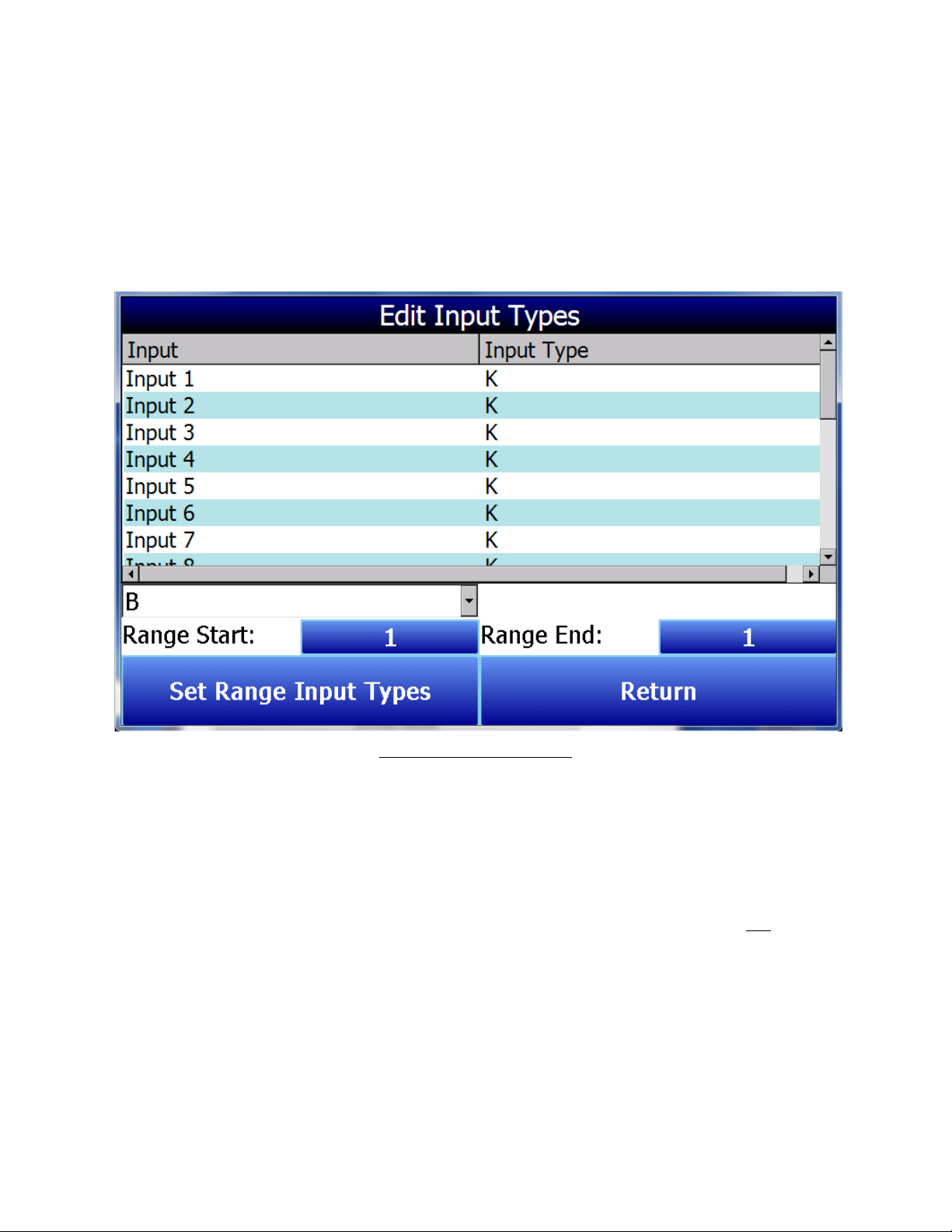

Edit Input Types

Edit Input Types allows the type of thermocouple to be changed for any channel. The

drop-down bar contains a list of thermocouple types. Select the appropriate

thermocouple types. The Range Start and Range End correspond to the channels of the

SDS that will be changed. To change only one channel, set the Range Start and Range

End both to that number. To change all channels, the Range Start will be 1 and the

Range End will be 20. Any interval in between can also be used. Press Set Range Input

Types to save.

Figure 35 - Edit Input Types

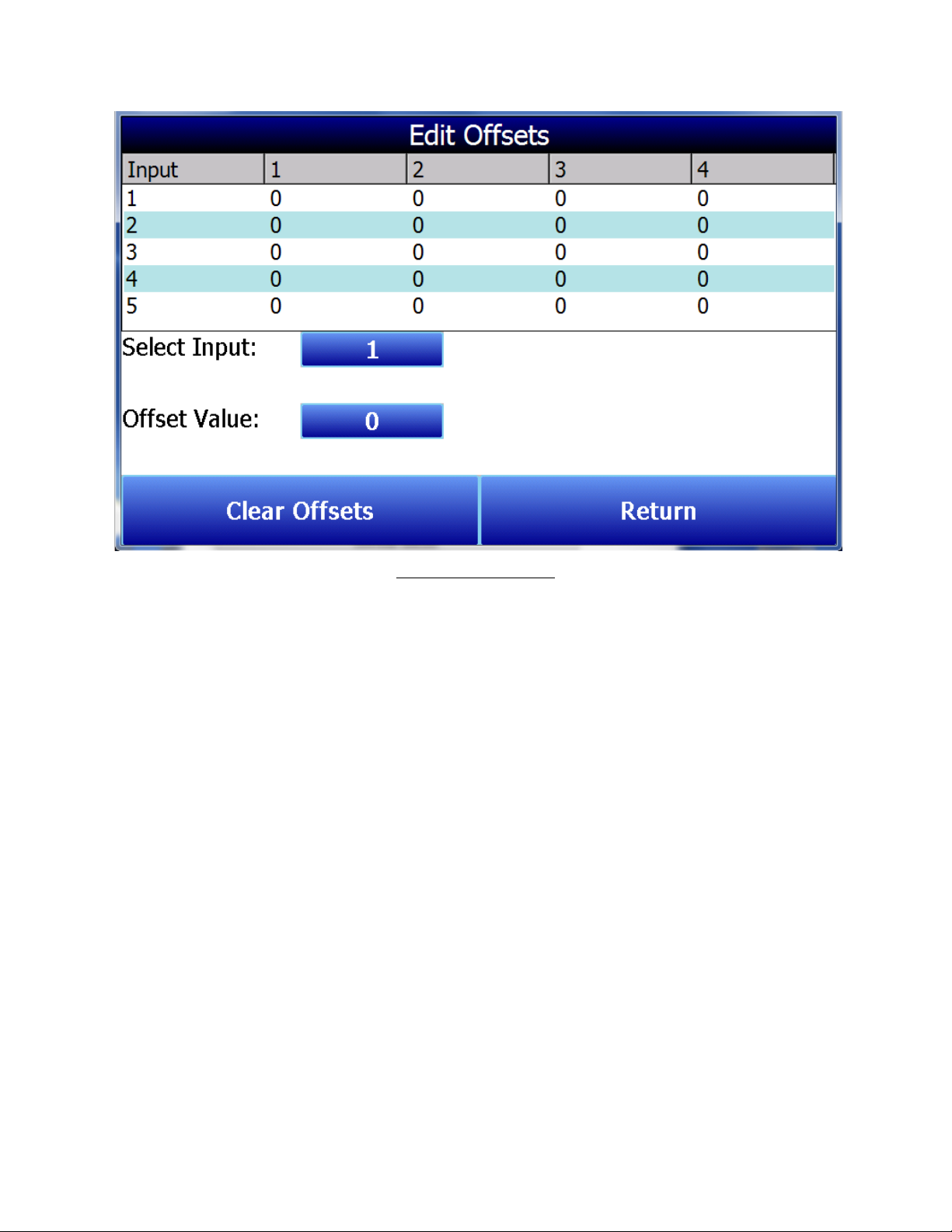

Edit Offsets

The Edit Offsets option will change the offset for each thermocouple. Press the blue

number button next to Select Input and enter the appropriate channel number. Press

OK. Then enter the Offset Value and press OK.

NOTE: These offsets should be used to address the calibration report parameters to

correct for a known deviation by individual channel at a specific temperature OR to

compensate for an individual thermocouple wire for each channel. All offsets that are

used can be displayed on the final report using the reporting tags.

Super Systems Inc. Page 28 of 104

Color Touch Screen Data Logger Operations Manual

Page 29

Figure 36 - Edit Offsets

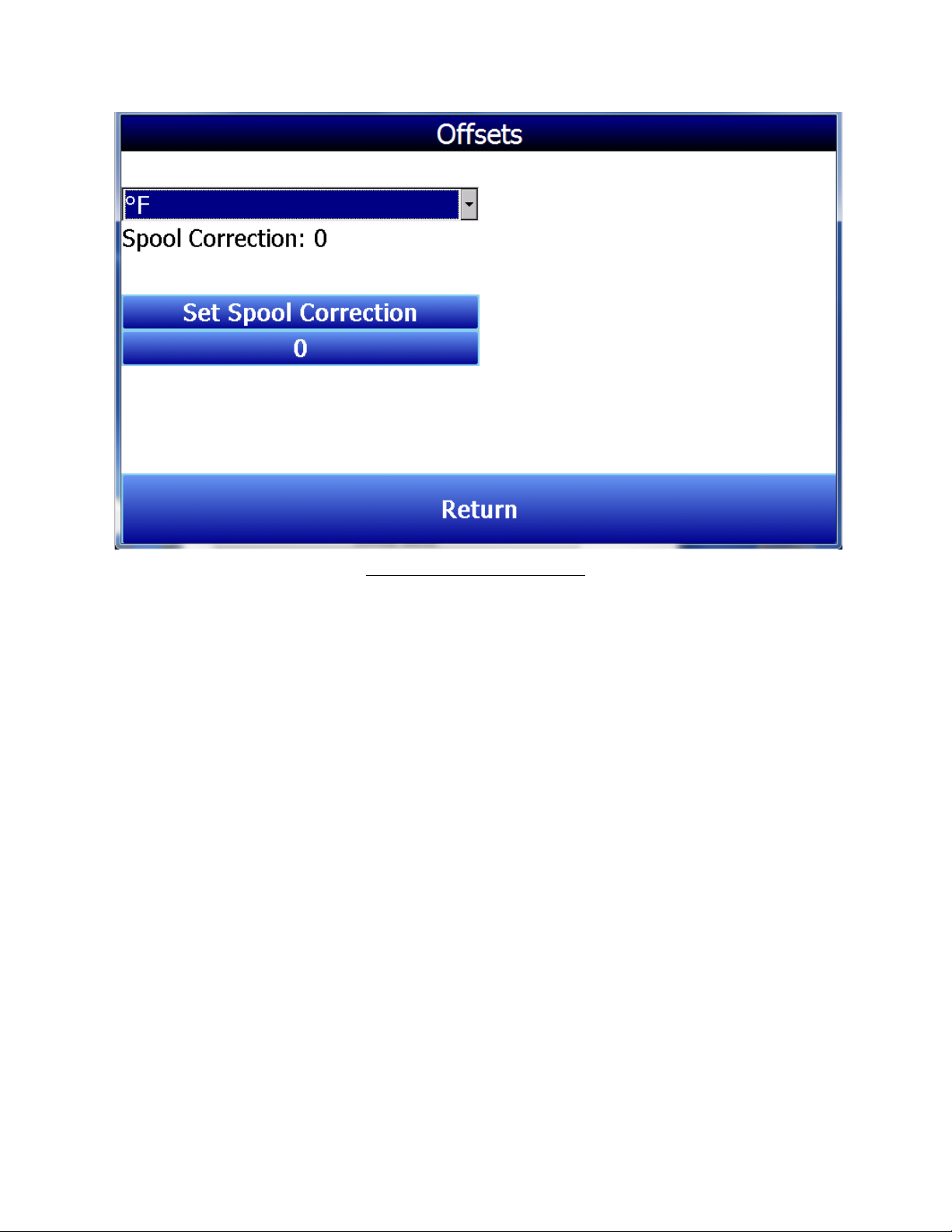

Spool Correction

This menu item allows the thermocouple Spool Correction to be modified. First select

the temperature type from the drop down menu, then enter the spool correction value

and press Set Spool Correction to save. Press return to go back to the Menu list. The

thermocouple spool correction can be used to before a survey is run so that the data

displayed is corrected. You can also enter the TC offset in after the survey is completed

using the SDS Reporter software.

Super Systems Inc. Page 29 of 104

Color Touch Screen Data Logger Operations Manual

Page 30

Figure 37 - Set Spool Correction

About

This screen will display basic information about the SDS including the version and the

serial number. Nothing on this screen can be changed.

Super Systems Inc. Page 30 of 104

Color Touch Screen Data Logger Operations Manual

Page 31

Figure 38 - The About Screen

IMPORTANT:

Do not perform any of these calibrations without a sourcing device that is properly

additional calibration steps.

Calibration

Before using the SDS Data Logger in surveys, it is essential to ensure that the unit is properly

calibrated. This means that

are converted (scaled) to values that accurately reflect the

the user will typically need to perform (before using the data logger in surveys) are the Voltage

Calibration and Cold Junction Trim Calibration (also called CJ Trim). First, the Voltage

Calibration will be performed to ensure that the voltages measured by the leads connected to

each thermocouple are scaled correctly. Second, the CJ Trim will be performed to ensure that

the temperature measured at each data logger terminal (where the cold junction is created) is

correctly scaled. Both types of calibration require a sourcing device and thermocouple wire. The

sourcing device should be calibrated and certified to generate accurate voltages before these

calibrations are performed.

connected and sourcing voltage into the proper inputs on the Color SDS Data Logger. Running a

calibration without a sourcing device that is providing voltage into the unit may require

raw

voltages

measured

by instruments connected to the data logger

actual

voltages. The calibrations that

Voltage Calibration

The leads that connect to each input thermocouple measure the voltage generated by that

thermocouple. In most cases, the voltage that the data logger detects (the raw voltage) is

slightly different from the actual voltage generated by the thermocouple. When properly

performed, a Voltage Calibration (also called an Input Calibration) ensures that the SDS Data

Super Systems Inc. Page 31 of 104

Color Touch Screen Data Logger Operations Manual

Page 32

Logger software properly scales the raw voltage so that an accurate temperature can be

calculated. The Voltage Calibration consists of two parts: a Zero Calibration and a Span

Calibration. A Zero Calibration ensures that the raw voltage is scaled properly when the actual

voltage at a thermocouple is zero volts. A Span Calibration ensures that the raw voltage is

scaled properly when the actual voltage is 90% of the upper limit of the desired range (for

example, 72 mV when the upper limit of the range is 80 mV).

Figure 39 shows what the Voltage Calibration screen looks like.

Figure 39 - Voltage Calibration screen

The horizontal row of numbers represents each circuit board containing five inputs. The

vertical column of numbers represents each individual input. A 20-input SDS Data

Logger will feature four circuit boards depicted on this screen, while a 40-input unit will

feature eight circuit boards. Since each board has five inputs, a Voltage Calibration

usually involves five inputs on the same board at one time. A single input can be

calibrated if it is suspected that the temperature reading associated with one input is

incorrect.

Range Value: The mV value shown in the drop-down box represents the range value for

the particular kind of thermocouple wire that you are using in the calibration. Pressing

the question mark (“?”) will bring up a window that shows the range value specific to

various kinds of thermocouple wire.

Zero or Span: Check “Zero” to perform a Zero Calibration. Check “Span” to perform a

Span Calibration.

All or Use Selected: Check “All” to calibrate all inputs. Check “Use Selected” to

calibrate a group of inputs selected by pressing the Select Inputs button and choosing

the inputs that you want to calibrate.

Super Systems Inc. Page 32 of 104

Color Touch Screen Data Logger Operations Manual

Page 33

Set up your calibration device as needed. When ready to begin calibrating, press

Calibrate.

Figure 40 - Setting Up A Voltage Calibration

Figure 41 - Voltage Calibration (Span)

Ready to Begin

Use the results of the calibration to set up offsets for the SDS Data Logger. Editing

offsets is described in the “Edit Offsets” section above.

CJ Trim

For the Trim calibration, TC wire should be used. The trim calibration is performed by

connecting a thermocouple calibration device to each input and outputting a trim

temperature that should be equal to the expected operating temperature. For example,

the calibration could be completed using an output temperature of 1700°F. After the

zero calibration and span calibration, the temperature may read 1701.5°F instead. This

type of calibration should be used instead of the regular cold junction thermistor

calibration unless the cold junction temperatures are reading a temperature that is

much too high for what the ambient temperature could possibly be. A cold junction

thermistor calibration can be used in this instance when need be, but the Trim

Calibration is preferred.

IMPORTANT:

1. Ensure that a sourcing device is properly connected and sourcing voltage into the proper

inputs on the Color SDS Data Logger.

2. Ensure that the input types are set up correctly. See View Input Types and, if necessary,

Edit Input Types.

3. If the data logger has been brought inside from a cold environment, wait 30 minutes

before performing the Cold Junction Trim Calibration. This will provide enough time for

the data logger to reach a stable temperature.

Before performing this calibration:

To perform a cold junction trim, first select the thermocouple type from the dropdown

list. Select the inputs that will be included by pressing the Select Inputs button. Enter

the Target Value and press Calibrate.

Super Systems Inc. Page 33 of 104

Color Touch Screen Data Logger Operations Manual

Page 34

Figure 42 - CJ Trim Screen

Cold Junction Thermistor Calibration

This procedure is performed by Super Systems Inc. before the SDS Data Logger is

shipped. In most cases, the procedure will not need to be performed in the field. If a

situation should arise where a cold junction calibration may need to be performed in the

field, please contact Super Systems Inc. Technical Support at 800-666-4330.

Datalog Deletion

The Color SDS Data Logger includes an option to delete log data files and survey data

files. This option is useful when these data files are no longer needed or when removing

them would free up space on a storage card nearing its full capacity. The Datalog

Deletion screen (Figure 43) allows you to change the date and time range of the files

that will be deleted (Start Date and End Date). The Delete Log Data button will cause

only the log data files to be removed, while the Delete Survey and Log Data button will

delete both the survey data and log data files.

Super Systems Inc. Page 34 of 104

Color Touch Screen Data Logger Operations Manual

Page 35

Figure 43 - Datalog Deletion Screen

Passcodes

This screen allows the user to set the passcodes to access the higher-level functions on the

SDS. To change either passcode, press the corresponding button, enter the new code, and

press OK.

Super Systems Inc. Page 35 of 104

Color Touch Screen Data Logger Operations Manual

Page 36

Figure 44 - Passcode Change Screen

Cold Junction Thermistor Calibration

Please refer to the Calibration section above for more details.

Full Data Action

Full Data Action allows you to configure the way in which the SDS software handles data logging

and data log files as the storage card nears its full capacity. This can happen as data log files

are continually added to the storage card, eventually leading to the card running out of storage

space. As shown in Figure 45, there are two choices in this menu: Automatic Deletion and Stop

Datalogging.

Automatic Deletion causes the SDS software to delete data log files (starting with the oldest)

automatically as the storage card nears its full capacity; it will not delete data log files that have

been written less than 30 days before the current system date and time. For this reason, it is

important that the system date and time be set correctly when this setting is used and the

storage card is nearing its full capacity. For more information on setting the system date and

time, refer to Changing the System Date and Time.

Stop Datalogging causes the SDS software to stop logging data to the storage card when the

storage card is nearing its full capacity. When this occurs, a message box will appear indicating

that data logging has stopped. Click OK to close the window. In order to resume data logging,

you will need to restart the Color SDS Data Logger. For more information on deleting data log

files, see the section on Datalog Deletion.

Super Systems Inc. Page 36 of 104

Color Touch Screen Data Logger Operations Manual

Page 37

Figure 45 - Full Data Action options

Exit Program

Selecting this option allows you to exit the Color SDS Touch Screen program. A confirmation box will

appear when you select this option (Figure 46). There are very few situations where this action would

need to be performed.

Figure 46 - Shut Down Interface confirmation

Configuration

The Configuration Menu contains the following items:

• Communications Setup. This menu item allows you to change the COM port

number, address, and baud rate of the communications port used to connect the

touch screen interface to the SDS mainboard.

• Compact Database. When clicked, Compact Database optimizes and reduces the

size of the database contained on the storage card.

• Read/Write Data. Using this feature, you can view the raw data on the underlying

hardware and also write data to the underlying hardware. This feature should not

be used in most circumstances.

• About. This option simply shows the About screen for Super Systems SDS, as

shown in Figure 38.

• Shut Down Software. This option shuts down the SDS touch screen.

• Set Serial Number. This feature allows you to change the serial number of the

touch screen software. This setting should not be changed.

• Degree Type. This feature allows you to change the unit of measurement used for

temperature—degrees Fahrenheit or degrees Celsius.

• Product Type. This feature allows you to change the SDS product type as it is

known to the touch screen software.

Super Systems Inc. Page 37 of 104

Color Touch Screen Data Logger Operations Manual

Page 38

• Thermistor Calibration. This feature

allows for calibration of the ambient

thermistor (pictured in Figure 47)

and internal thermistor.

Figure 47 - Location of Ambient

(External) Thermistor

IMPORTANT:

Before attempting to access Configuration features, please contact Super

Systems Inc. Technical Support (800-666-4330).

Reset Calibration Dates

To change either of these dates, press the corresponding button and enter the new

date. Press OK to save.

Super Systems Inc. Page 38 of 104

Color Touch Screen Data Logger Operations Manual

Figure 48 - Configuration Menu

Page 39

Figure 49 - Reset Calibration Dates

IMPORTANT:

Avoid resetting calibration dates without first contacting Super Systems

Inc. Technical Support (800-666-4330).

Set Nominals

Nominals are calibration constants used in the process of converting raw analog data to

voltage values. The

Set Nominals menu provides the ability to reset calibration

constants for all inputs, or for a specified set of inputs, to default values.

A user may decide to use this feature if, for example, temperature readings from the

SDS are deemed to be outside a certain acceptable range and subsequent calibrations

are not successful. When the calibration constants are reset, the device is placed in an

uncalibrated state and will require recalibration. If recalibration does not result in

temperature readings that are within an acceptable range, it is likely that the SDS has

experienced hardware damage and will need to be shipped to Super Systems Inc. for

repair.

The Set Nominals screen is shown in Figure 50. To reset all nominals, simply select the

checkbox labeled “All” and then press the Set Nominals button.

Super Systems Inc. Page 39 of 104

Color Touch Screen Data Logger Operations Manual

Page 40

Figure 50 - Set Nominals

To reset nominals for specific inputs, first select the checkbox labeled “Use Selected”

and then press the Select Inputs button. The Select Inputs screen will appear. Select

each input for which you would like to reset the nominals, and then press Select

Highlighted for each one. Note that you may enter a range of inputs using the “Select

Range” feature. These screens are shown in

Figure 51. Once you have selected the

specific inputs for which you want to reset nominals, press Return and then press Set

Nominals on the

Set Nominals screen.

Super Systems Inc. Page 40 of 104

Color Touch Screen Data Logger Operations Manual

Page 41

Figure 51 - Use Selected Inputs in Set Nominals Screen

IMPORTANT:

Avoid setting nominals without first contacting Super Systems Inc.

Technical Support (800-666-4330).

Set K Factors

K Factors are mathematical coefficients that help correct for changes in outside

temperature. When correctly programmed, K Factors help minimize the effect of

outside temperature variations on thermocouple temperature readings. It is possible to

adjust K Factor settings from the Set K Factors menu, but doing so is not recommended

without first contacting Super Systems Inc. Technical Support. See the notice below.

IMPORTANT:

Avoid adjusting K Factors on any channel without first contacting Super

Systems Inc. Technical Support (800-666-4330). Incorrect adjustment of K Factors will

likely result in incorrect temperature readings.

Super Systems Inc. Page 41 of 104

Color Touch Screen Data Logger Operations Manual

Page 42

Figure 52 - Set K Factors

SDX Control

By selecting Run for SDX Control, the SDS will run a program called SDX that monitors

thermocouples to ensure they are calibrated properly using the SDX software module.

SDX is available through SSi.

Super Systems Inc. Page 42 of 104

Color Touch Screen Data Logger Operations Manual

Page 43

Figure 53 - SDX Control

IMPORTANT:

Avoid running SDX without first contacting Super Systems Inc. Technical

Support (800-666-4330).

Modbus Control

Running Modbus Control will enable the Modbus protocol to read and write registers.

To set this up, press

monitored. Press

Run, then determine the range of Modbus registers that will be

OK to save.

Super Systems Inc. Page 43 of 104

Color Touch Screen Data Logger Operations Manual

Page 44

Figure 54 - Modbus Control Not Running Screen

Figure 55 - Run Modbus Control Window

Super Systems Inc. Page 44 of 104

Color Touch Screen Data Logger Operations Manual

Page 45

IMPORTANT:

Avoid running Modbus control without first contacting Super Systems Inc.

Technical Support (800-666-4330).

SDS Reporter

IMPORTANT:

When using SDS Reporter with the Color SDS Data Logger, Options >

Color Screen Scanning must be selected. Refer to the section Options Color Screen

Scanning for more details.

Figure 56 - SDS Reporter initial screen

When the SDS Reporter software is started up, the user sees the above screen (Figure 56). The

four menu options to choose from are:

choose from: New , Open , Save , and Print .

File Menu Options

File New / New Button

The New option allows the user to create a new report that will include the report properties,

the trend chart, and the TC data (Figure 57). Note: the selected tab will be in Red when it is

active only for the three main tabs – Report Properties, Chart, and Data.

Super Systems Inc. Page 45 of 104

Color Touch Screen Data Logger Operations Manual

File, SDS, Options

and

Help

. There are four buttons to

Page 46

Figure 57 - Report Properties Tab

File Open / Open Button

The Open menu option will allow the user to choose an existing report from a common Windows

Open dialog box. The software will open the dialog box in the “SDSReports” folder (typically,

C:\SSi\SDS\SDSReports) for existing reports (.SDSReport) to open.

The Report Properties tab contains several tabs, which in turn contain the information that

makes up the report. The first tab is the Report tab (Figure 57), which contains the data to use

for the report, the report template to use, the report heading or title, the survey results, and any

notes about the report.

Super Systems Inc. Page 46 of 104

Color Touch Screen Data Logger Operations Manual

Page 47

Figure 58 - Report Properties Report Tab

Clicking on the open box, , next to the “Data” field will display a screen from which the

user can select the interval time (ten seconds, twenty seconds, thirty seconds, one minute, two

minutes, or five minutes) and also the specific survey to use (Figure 58). This screen will only

display survey data that has already been downloaded (SDS → Download Surveys and Data).

Figure 59 - Load Survey Data screen

The default interval is one minute. Select the survey to use and click on the “Use” button.

Information included with the data sources is: Template Name, [Company Name - Furnace Id],

(Survey box Serial number), and the date/time range of the survey data. Any manual entries will

have [Manual Entry] at the beginning. See the section

Manually Creating a Survey Record

for

information on how to add a survey record manually. Clicking on the open box next to the

“Report Template” field will open a dialog box from which the user can select the specific report

template to use for the report. The software will open the dialog box in the

“SDSReportTemplates” folder (typically C:\SSi\SDS\ReportTemplates) for existing report

templates to use. The “Report Heading / Title” field is for the heading or title of the report and

Super Systems Inc. Page 47 of 104

Color Touch Screen Data Logger Operations Manual

Page 48

the “Survey Results (Pass/Fail)” field is for the results of the survey. The “Notes” field is for any

general notes for the report.

Manually Creating a Survey Record

Clicking on the “Advanced: Manually Create Survey Record” link from the Load Survey Data

screen will allow the user to create a survey record to use. Clicking on this link will display the

“Manually Create Survey Record” form (Figure 60). Five pieces of data are required to manually

create a record: the SDS model, serial number, the start time and date of the survey, the end

time and date of the survey, and the TC Spool Offset. All data will need to be downloaded from

the SDS either before or after this process in order to get data. To download all data, please

refer to section SDS Download Surveys and Data.

Figure 60 - Manually Create Survey Record form

The drop-down list next to “Survey Box Model” contains a list of the available models. Make

sure to select the appropriate Color SDS Data Logger. Select the model type (the Color SDS

Data Logger is referred to as “SDS Touch Screen”). Enter the SDS serial number on the next

line, “Survey Box Serial Number”. The serial number can be found in the About window, as

discussed in the About section. The process for selecting the start date/time and the end

date/time is the same. To select a date, click on the down arrow next to the time listed. This

will bring up a calendar from which the user can select a new date (Figure 61). Select the new

date by clicking on it.

Super Systems Inc. Page 48 of 104

Color Touch Screen Data Logger Operations Manual

Page 49

Figure 61 - Select new date

The date of the survey start /end is listed to the right of the drop-down list. To select a time,

click on the hours, minutes, seconds or “AM/PM”. The selected field will be highlighted. Each

field can be changed by using the up or down arrows on the keyboard. If the survey start date is

later than the survey end date, a message will be displayed to the user and the record will not

be added (Figure 62).

Figure 62 - Survey start/end date error message

Enter the TC spool offset and click on the “Add Record” button to add the record. Clicking on

the “Cancel” button will cancel the add process and bring the user back to the “Load Survey

Data” dialog box. If the add was successful, a message box will be displayed (Figure 63).

Figure 63 - Record Add successful message

The added record will be displayed chronologically in the top of the list. Any record manually

added will begin with “[Manual Entry]” (Figure 64). If the manually created survey is less than

one second, it will not be displayed in the list.

Super Systems Inc. Page 49 of 104

Color Touch Screen Data Logger Operations Manual

Page 50

Figure 64 - Manual entry on Load Survey Data form

NOTE: Most of the “Report Properties” tabs (Report, Furnace, Survey Box) will need to be filled

out manually as well.

The next tab is the Thermocouples tab (Figure 65). This tab contains the information about the

thermocouple settings and it also lists the active thermocouples. The information in the

thermocouple settings includes: the temperature type (F or C), the number of thermocouples,

the number of TCs used in the report, the thermocouple type, the thermocouple gauge, the

thermocouple spool number, whom the thermocouple was calibrated by, the date the

thermocouple was calibrated, and the thermocouple spool correction factor. Clicking on the

“Change” button will allow the user to change the spool correction (Figure 66).

Figure 65 - Report Properties Thermocouples Tab

Super Systems Inc. Page 50 of 104

Color Touch Screen Data Logger Operations Manual

Page 51

Figure 66 - Spool Correction screen

All values displayed to the users are corrected

TC Spool and a channel offset, the user would be shown the net result of those offsets into the

value displayed.

. That means if there is a defined offset for the

There are checkboxes for a possible forty thermocouples, but only the active thermocouples will

have checks in the checkboxes. Clicking on the “Define Control TC” link will allow the user to

select the TC or TCs that will be the control TC(s) (Figure 67). The operator can select any of the

thermocouples to be the control TC(s) and provide an optional description for that TC.

Figure 67 - Define Control TC screen

Clicking on the Accept button will set the selected control TC(s). Once a control TC(s) has been

selected, the TC’s number will be in Red on the “Active Thermocouples” section of the

Thermocouples tab.

The thermocouple(s) that is identified as the control TC will not be used for

the TC summary when identifying hottest and coldest channels.

Clicking on the “View Offsets used in Survey” link will display a list of the offsets that were used

on the survey (Figure 68

means the Offset defined for these TCs have already been incorporated into the value the

operator would see. IF there is a value for the TC Spool Correction Factor, that value will also

be incorporated providing a corrected view for the user.

Super Systems Inc. Page 51 of 104

).

All values that are displayed to the users are corrected values.

Color Touch Screen Data Logger Operations Manual

That

Page 52

Figure 68 - TCOffsets screen

Note: Checking or unchecking TCs on the Thermocouples Tab will affect the TCs plotted on the

Chart Tab.

The Thermocouples tab also includes an option to view and edit individual TC correction factors

(see Figure 69). Once these correction factors are in place, they will be applied to TC values

from survey data. These corrections will be reflected in the report generated by SDS Reporter.

Super Systems Inc. Page 52 of 104

Color Touch Screen Data Logger Operations Manual

Page 53

Figure 69 - Viewing and Editing Individual TC Correction Factors

The TC correction factors are passcode protected in the

SDS Reporter installation folder (typically, the “C:\SSi\SDS” folder). The default passcode is 2.

To change it, open the

file:

PASSCODE=

SDSReporter.ini

x

file and add this line in the [SETTINGS] block of the .ini

SDSReporter.ini

file contained in the

Where x is zero or a positive integer.

The next tab is the Furnace tab (Figure 70), which contains the furnace ID, the make and model

of the furnace, the furnace type, the furnace use, the furnace’s operating range, the furnace

dimensions, the furnace class (newer versions only), and an optional image of the furnace.

Super Systems Inc. Page 53 of 104

Color Touch Screen Data Logger Operations Manual

Page 54

Figure 70 - Report Properties Furnace Tab

Clicking on the open box next the image frame will open a dialog box where the user can search

for an image of the furnace to use.

The next tab is the Survey Box tab, which contains information about the survey box itself, such

as the make and model, the serial number, whom the survey box was calibrated by, and the

calibration date (Figure 71).

Figure 71 - Report Properties Survey Box Tab

The next tab is the Survey Details Tab (Figure 72). The Survey Details tab contains the company

name, the survey start date, the survey duration, the actual duration of the survey, the survey

Super Systems Inc. Page 54 of 104

Color Touch Screen Data Logger Operations Manual

Page 55

specification(s), whom the survey was performed by, whom the survey was approved by, the

date range for the survey, and the due date of the next survey.

Figure 72 – Report Properties Survey Details Tab

The next tab is the Survey Parameters Tab (Figure 73). The Survey Parameters tab contains: the

survey tolerance, the survey setpoint, the overtemp setpoint, the simulated load in pounds, and

the microns.

The Cooling/Heating combo box affects tags:

• <SDS:OV>

• <SDS:OD>

• <SDS:OVT>

Heating is default. If Cooling is selected, values below the tolerance range are thought to be

overshot instead of above the tolerance range (as they are thought to be for Heating).

Super Systems Inc. Page 55 of 104

Color Touch Screen Data Logger Operations Manual

Page 56

Figure 73 - Report Properties Survey Parameters Tab

The next tab is the Controller Tab (Figure 74). This tab contains the Controller manufacturer,

the controller model, and the instrument type (newer versions only) in the “Temperature

Controller Settings” area and this tab also contains the PID Settings: cycle time, dead band,

output limit, PB (Gain), rate, and reset.

Figure 74 - Report Properties Controller Tab

The User Defined tab contains twenty fields that can be defined by the user and included in the

report. To create a user defined field, click on the “Modify User Defined Fields”. This will

display a screen that will allow the user to edit the fields (Figure 75). The user can type in the

name or description of the field and click the “Save” button.

Super Systems Inc. Page 56 of 104

Color Touch Screen Data Logger Operations Manual

Page 57

Figure 75 - User Defined Fields screen

Comparison Check

SDS Reporter includes two Comparison Check tabs, as shown in Figure 76. The two Comparison Check

tabs perform the same function with different defined data sets.

Figure 76 - Report Properties Comparison Check window

Super Systems Inc. Page 57 of 104

Color Touch Screen Data Logger Operations Manual

Page 58

The information for the comparison check is generated from several of the Report Properties

Report Field

Location in Tabs

Comparison

Factor

Thermocouples, click View

Offsets Used in Survey

button*

Thermocouples, click View

Offsets Used in Survey

button

fields.

Time Chart Start Time

Comparison Test T/C

Spool Number

Middle Left of Comparison

Check

Comparison T/C

Number

Comparison T/C Wire

Correction Factor

Instrument Correction

Comparison T/C

Temperature Readings

Adjacent T/C Number

for Comparison Check

Adjacent T/C Wire

Correction

Adjacent Instrument

Correction Factor

Adjacent T/C

Temperature Readings

for Comparison Check

CC Difference

Top Right of Comparison

Check

Top Right of Comparison

Check

Thermocouples

Records the temperature

of the Comparison T/C

Top Right of Comparison

Check

Records the temperature

of Adjacent T/C

Difference Between

Comparison T/C and

Adjacent T/C temperatures

*The offsets for the T/C Wire Correction can be adjusted solely for the purpose of the

comparison by checking the box on the Comparison Check page labeled

Corrections.

A header text and a body text can be put in the report. There are Preview Report and Print

Report buttons in the top left hand corner of the Comparison Check page.

Super Systems Inc. Page 58 of 104

Accept/Reject Criteria =

Tolerance of Furnace

Set on Comparison Check

Page, Middle Right

Accept/Reject Dependent on A/R Criteria

Table 2 - Location of Report Fields

Color Touch Screen Data Logger Operations Manual

Use Custom Wire

Page 59

The Chart Tab (Figure 77) contains the charted information from the time specified on the

survey. This tab is similar in design and function to the Real-Time chart (Figure 89

). When the

chart tab is active, the chart toolbar buttons also appear and these buttons can be used to zoom

in on a section of the chart, pan the chart up, down, left or right, and refresh the chart back to

its original values. The screen will display 2 horizontal lines that represent the high and low

temperature tolerance levels based on the setpoint. This display will change based on the

tolerance level and setpoint defined in the Report Parameters. For more information about the

function of this screen, see the section “

SDS View Real-time Data.”

Figure 77 - Chart Tab

Note: checking or unchecking TCs on the Chart Tab will affect the Active TCs on the Report

Properties – Thermocouples tab.

The Data Tab (Figure 78) contains the data from each thermocouple for the each interval

selected from the Load Survey Data screen (Figure 59).

Figure 78 - Data Tab

Clicking on the “Round this data off to the nearest degree” link will pop up a message box

confirming the action (Figure 79). The rounding only affects imported data. The data in the

Super Systems Inc. Page 59 of 104

Color Touch Screen Data Logger Operations Manual