Page 1

Operations Manual

PGA 3000

Portable 3-Gas IR Analyzer

Please read, understand, and follow these instructions before operating thi s equipment.

Super Systems, Inc. is not responsible for damages incurred due to a failure to comply with these

instructions. If at any time there are questions regarding the proper use of this analyzer, please

contact us at (800) 666-4330 for assistance.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060 800-666-4330

Fax: 513-772-9466

www.supersystems.com

SSi Manual 4549 Page 1 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 2

Table of Contents

PGA 3000 Operating Instructions...................................................................................................... 3

Introduction........................................................................................................................................... 3

Specifications........................................................................................................................................ 3

Basic Operating Theory ..................................................................................................................... 4

Analyzer Start-Up Procedure........................................................................................................... 4

Filters ....................................................................................................................................................... 5

Condensation / Moisture .................................................................................................................. 5

Battery..................................................................................................................................................... 5

Menu List................................................................................................................................................. 6

IR Status Display – Menu Page 1................................................................................................... 7

IR Overall Status Display – Menu Page 2 ................................................................................... 7

Combustion Display – Menu Page 3.............................................................................................. 8

Pump Control - Menu Page 4........................................................................................................... 8

Set Display Values – Menu Page 5................................................................................................. 8

Help Page - Menu Page 6.................................................................................................................. 9

Calibration Dates and Run Times - Menu Page 7..................................................................... 9

About/Sign-On – Menu Page 11................................................................................................... 10

Start logger – Menu Page 12......................................................................................................... 10

Logged Data File – Menu Page 13 ............................................................................................... 11

Zero Calibration – Menu Page 14................................................................................................. 11

O2 Cell Calibration – Menu Page 15............................................................................................ 12

Port Setup - Menu Page 21 ............................................................................................................ 12

Set The Date and Time - Menu Page 22..................................................................................... 12

Data Set Page - Menu Page 23 ..................................................................................................... 12

Span Calibration – Menu Page 24................................................................................................ 13

Set Pass Codes - Menu Page 25.................................................................................................... 13

Clear Logged File - Menu Page 26............................................................................................... 13

Typical diagnostic uses: .................................................................................................................. 14

Spare Parts........................................................................................................................................... 15

SSi Manual 4549 Page 2 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 3

PGA 3000 Operating Instructions

Introduction

The Model PGA3000 is a portable 3-Gas IR analyzer with an Oxygen (O2) cell onboard. It measures Carbon Monoxide (CO), Carbon Dioxide (CO2) and Natural

Gas (CH4) typically found in an endothermic atmosphere.

Specifications

The unit is designed and manufactured for the atmosphere heat-treating

industry.

CO range: 0.00 to 30.00 %

range: 0.000 to 2.000 %

CO

2

range: 0.00 to 15.00 %

CH

4

range: 0.01 to 25.00%.

O

2

Sampling method: Extraction by internal pump (when necessary)

Accuracy and repeatability: ± 1% of full scale

Flow Meter: Inside case lid and also on-screen

Pump Operation: On/Off/Automatic

Power: 115/230 VAC - 50/60 Hz – 60 Watts

(Rechargeable Battery Power)

Data Retrieval: Up to 4 gases - 10 Furnaces/Generators

500 minutes/furnace

Data collection review on PGA3000 screen or

Upload to Microsoft EXCEL

Operating Temperature: 32° to 122° F (0° to 50° C)

Dimensions: Approx. 16”H X 20”L X 8”D

Weight: Approx. 30 lbs.

SSi Manual 4549 Page 3 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 4

Basic Operating Theory

The Model PGA 3000 has been designed for the simultaneous analysis of CO,

CO2 and CH4 in heat-treat furnace atmosphere gases. It has a 16 line by 40character LCD display and a 4 x 4 keypad for the operator interface. Information

is presented to the operator on various screens. The operator selects the

appropriate page and enters the number using the keypad.

Numeric keypad key assignments.

0 – 9 are used to enter numeric data.

* is the escape key and clears all numbers previously entered.

# will display a specific menu, to select a specific page, press a numeric key (or

two numeric keys) and then the # key.

A is used as the ENTER key.

B moves the cursor up.

C moves the cursor down.

D adds a decimal point to the data being entered on a screen, also toggles from

one furnace to the next on the data collection page.

Analyzer Start-Up Procedure

Turn the power switch on and allow the instrument to warm up until numbers

appear on the default screen instead of ********. This process should take

approximately two minutes.

Accurate readings are only possible if the sample is taken from a clean (free of

excess carbon buildup) sample port. The current state-of-the-art technology

associated with IR sampling requires that a clean, soot free sample be available

for analysis. A clean sample port will also increase the life of the filter elements,

and reduce the possibility that soot will enter the unit and contaminate the

sensors.

On a furnace, the ideal port would be found on SSi’s Sample Port (Part Number

20263). If this is not available, the burnout port of a freshly burned-out Gold

Probe™ would be an alternative, although this would still contain a trace amount

of soot.

On a generator, a dedicated sample port should be available. This sample port

should be blown out before it is used, which will remove any soot that has

accumulated in the line. This is accomplished by opening the valve without

connecting the analyzer. Wait until the gas stream is clean before proceeding

and connect the sample line to the sample port.

SSi Manual 4549 Page 4 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 5

The ideal flow rate for sampling should be between 1.0 and 1.5 Standard Cubic

Feet per Hour (SCFH). A visual indication of flow rate can be obtained through

the mini flow meter located on the inside of the lid of the case, or by the digital

flow meter on the left side of the display. The flow meter on the inside of the

case also contains a dial that allows the user to restrict the flow if necessary to

maintain an appropriate flow rate. If the sample gas is not under pressure, the

internal pump can be used to extract it. The internal pump can be operated

manually, or it can be turned on or off automatically when it detects low sample

flow.

Filters

There are two filters that are intended to prevent soot or other contaminants

from entering the unit. The first is an in-line filter that is located at the end of

the sample tubing assembly. The second is a bowl filter located on the inside of

the lid. Periodic inspection of these filters will ensure smooth operation. When

new, the elements in both of these filters are white. Both are oriented in the

sample stream in a manner that causes any contaminants to collect on the

outside of the filter media, which allows for a visual inspection of filter status.

Condensation / Moisture

When a hot gas is cooled rapidly, moisture in the gas can condense and form

water. This water can collect in the sample tubing assembly, and eventually

enter the bowl filter. Care must be taken to ensure that no water enters the

unit, as this will cause permanent damage to the sensors. The unit should be

closely monitored during operation to determine if moisture is collecting in the

bowl filter. If this is the case, the bowl filter basin can be removed and emptied

by unscrewing it. Although water in the bowl filter will not cause damage to th e

unit, this filter is not intended to be used as a condensation receptacle. If

moisture has collected in the bowl filter, sampling should be stopped, and steps

should be taken to prevent this from occurring before operation is resumed.

Battery

The battery in the PGA3000 in intended to provide more than enough power to

operate the unit continuously for an eight-hour shift. When

Battery Low

is

displayed on the LCD screen, the unit is in need of a charge. To charge the

PGA3000, plug it into a 110 or 220VAC power source using the supplied power

cord. The LED above the power cord input is red while the unit is being charged,

and it will turn to green when charging is complete.

For maximum battery life, do not recharge the battery after each use unless the

Battery Low

message appears on the screen. Reducing the number of times that

the unit is charged will maintain the battery’s original storage capacity for a

longer period of time.

SSi Manual 4549 Page 5 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 6

Menu List

The menu list shows the available pages displayed six at a time. The cursor up

(B) and the cursor down (C) keys are used to scroll the list.

OPERATOR MENU

1. IR STATUS DISPLAY

2. IR OVERALL STATUS DISPLAY

3. COMBUSTION DISPLAY

4. PUMP CONTROL

5. SET LCD DISPLAY (CONTRAST/BRIGHTNESS) VALUES

6. HELP

7. CALIBRATION DATES

11. ABOUT/SIGN-ON

12. START LOGGER

13. LOGGED DATA FILE

14. ZERO CALIBRATION

15. O2 CELL CALIBRATION

CONFIGURATION MENU – Pass code required

21. PORT SETUP

22. SET THE DATE AND TIME

23. DATA SET PAGE

24. SPAN CALIBRATION

25. SET PASS CODES

26. CLEAR LOGGED FILE

Pages number 8, 9, 10, 16, 17, 18, 19, 20 do not exist. The Configuration Menu

pages require the entry of a pass code to access them. The menu list page

shows the date and time at the bottom of the screen.

Pressing the # key allows the user to review the menus at anytime.

Screens 1 through 20 do not require any security codes. Screens 21 and higher

are configuration screens, and a pass code is required. The default pass code is

1, however this can be changed to any number between 0 and 512 by accessing

Menu Page 25.

SSi Manual 4549 Page 6 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 7

IR Status Display – Menu Page 1

The IR Status Display

shows the current

readings of CO, CO2

and CH4. Also shown

is the relative flow rate

of the sample by a fuel

gauge on the left-hand

side of the screen.

The sample pump may

be turned on or off by

pressing the A key.

IR Overall Status Display – Menu Page 2

The IR Overall Status

Display shows measured

values and calculated

values, and allows entry

of data for the

calculations. The

operator can enter the

furnace temperature,

probe millivolts, probe

temperature, and either

the CO Factor or the

Process Factor. The probe calculations will be based on which value was entered

last (i.e. COF or PF). An * after the data values indicates which value is used in

the calculations. The equivalent value of the other value is computed and

displayed. For example if the probe millivolts is 1100, the probe temperature

1650 and the COF is 200, then the probe %C is calculated as 0.51% and the

equivalent PF is calculated as 143. From the three gases and the furnace

temperature the IR %C and equivalent millivolts is computed. The IR %C and

the probe %C are used to compute suggested COF and PF values. Data values

are changed by using the cursor keys (B and C) to highlight the value and then

entering the new value followed by the A key. Suggested COF or PF can be

entered in your control instrumentation so that the %C calculated from the

carbon probe readings will be the same as the %C calculated by the IR 3-Gas

readings.

WARNING – Large changes should be verified by shim stock analysis.

SSi Manual 4549 Page 7 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 8

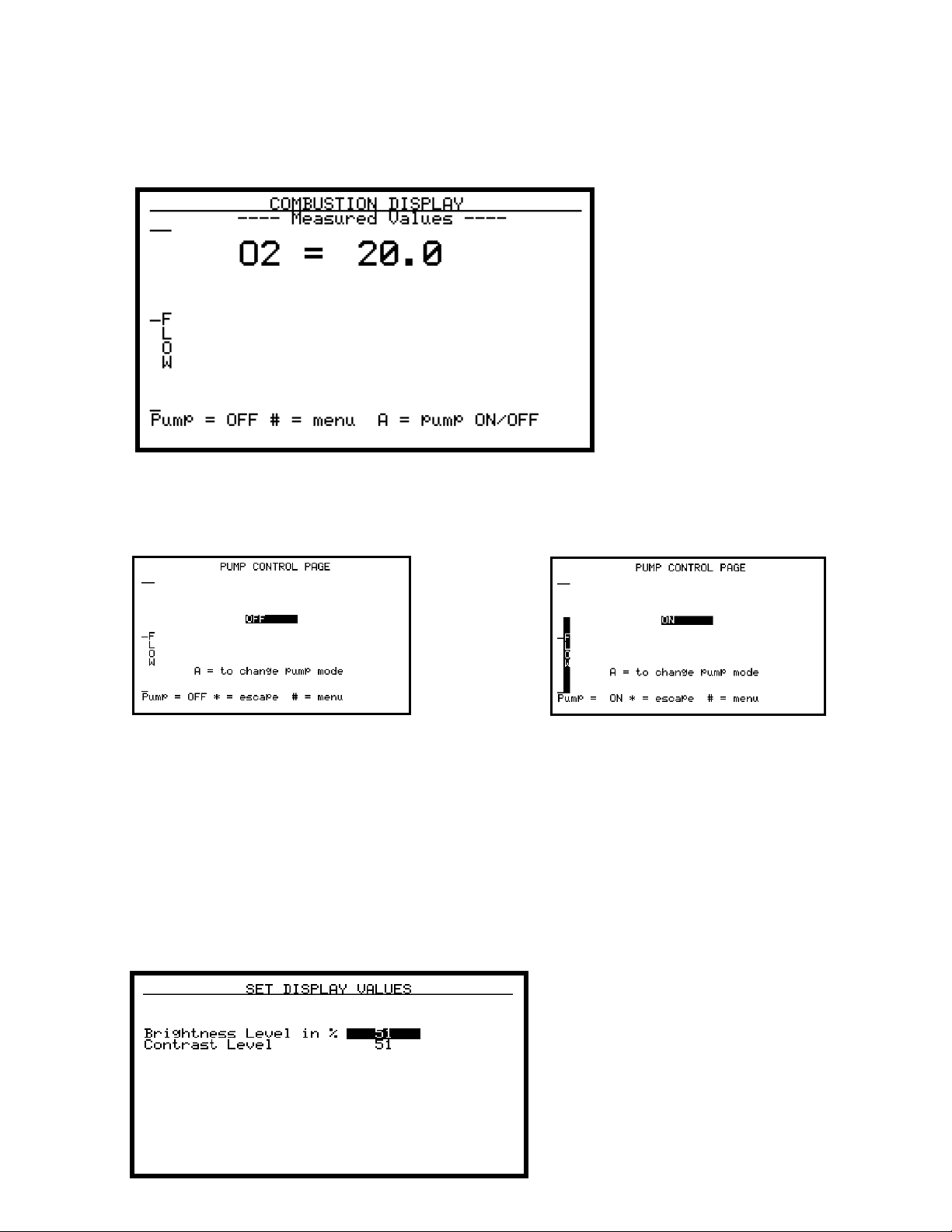

Combustion Display – Menu Page 3

Pump Control - Menu Page 4

The combustion display

shows the current reading

in % excess oxygen. Also

shown is the relative flow

rate of the sample by a

fuel gauge on the lefthand side of the screen.

The sample pump may be

turned on or off by

pressing the A key.

The pump control page is used to set the pump mode. The sample pump mode

can be changed from OFF to ON to AUTO by pressing the A key. Auto mode will

turn the pump on when the flow is below approximately 1.5 SCFH and off when

it is above approximately 1.5 SCFH. Also shown is the relative flow rate of the

sample by a fuel gauge on the left-hand side of the screen. There is also a

traditional flow meter located in the lid of the PGA. Although the flow indicator

on the screen has been calibrated at the factory, the most accurate flow

measurements should be taken with the flow meter inside the lid.

Set Display Values – Menu Page 5

This page is used to adjust the

display backlight brightness and

the contrast. The values

entered range from 0 to 100.

SSi Manual 4549 Page 8 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 9

Help Page - Menu Page 6

Calibration Dates and Run Times - Menu Page 7

This page can be used

as a reference to show

the functions of the

various buttons on the

keypad.

The same information

has also been included

on the laminated

reference sheet that has

been attached inside the

lid of the PGA.

This page shows the

most recent calibration

dates, as well as the

amount of time that has

elapsed since each

calibration. Time is

shown in hours and

minutes.

These dates do not need

to be set after calibration

since they will be set

automatically whenever

a calibration is

performed. NOTE: For the correct calibration dates to be entered, the internal

clock must be set correctly (see page 22).

SSi Manual 4549 Page 9 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 10

About/Sign-On – Menu Page 11

This page is the sign on

screen that shows the

SSi logo, address, and

phone number. Also

shown are the firmware

version number, the

unit serial number, and

the date of the last

factory calibration.

Some units will also

show the internal

temperature of the unit.

Start logger – Menu Page 12

This page is used to

name and store a data

log file. The PGA3000 is

capable of storing 10

tests (files) of 500

minutes each. To start

storing data, first select

a test number, 0 – 9.

This specifies the

storage location (file) of

the data. Then input a

name and then an ID number. The name selected from the list at the bottom of

the page by number (0 – 9). The ID number is any value from 0 to 999. Then

cursor down to the Stop/Run then select and press the A key to start or stop

storing data. STORING DATA will appear near the bottom of the screen

whenever the data logging is active. Only one test number can be active at a

time. If the test number is changed and started, then the previous one is

stopped. When a test is started, all previous data in that test is cleared. See

Basic Operating Theory (page 4 of 15) for keypad key assignments.

SSi Manual 4549 Page 10 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 11

Logged Data File – Menu Page 13

This page displays the

logged data ten points

at a time. When the

page is first entered, it

displays the most

recent test number and

the data point. The

starting number of the

data points displayed

can be changed either

by the cursor keys (B

= up. C = down) or

entering a point number and pressing the A key. Entering a number and pressing

the D key or simply pressing the D key to sequence through the tests can

change the test number displayed.

Zero Calibration – Menu Page 14

This page is used to zero the IR

cells. It is very important to be

sure that the sample gas is a

good zero especially for CO2.

Air has approximately 0.08%

CO2 and required a CO2

scrubber (See Spare Parts List).

WARNING: If using the CO2

scrubber, the source of air

should be from outside the

facility, not air from within

the facility.

the PGA3000. The sample gas flow rate should be between 1 and 1.5 SCFH.

Pressing the A key will start the zeroing process, which could take up to 4

minutes. If the flow rate is too low then an error page will appear and the cells

will not be zeroed. If any of the readings of the cells are greater than 10% of

nominal range, then a range error page will appear. This is a WARNING and it is

recommended that the zero gas be checked before proceeding. Pressing the A

key will bypass the range error and begin the zeroing process. If any of the

readings of the cells is greater than 20% of nominal range, then a FACTORY

CALIBRATION REQUIRED message will appear near the bottom of the screen

and the calibration is inhibited. A zero complete page will appear when zero

calibration is finished.

It is recommended that 99.9% pure nitrogen be used for zeroing

WARNING: Do not pressurize PGA3000 with

SSi Manual 4549 Page 11 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 12

compressed gas. Always start the flow of Nitrogen and regulate prior

to connecting to PGA3000 inlet.

O2 Cell Calibration – Menu Page 15

This page is used to

calibrate the oxygen

sensor. The oxygen

sensor is calibrated

using air (20.9% O2) as

the reference. If the

oxygen cell output is

outside of a 30% band

then the message

REPLACE O2 CELL! will

appear near the bottom

of the screen. When

calibrating the O2 sensor, turn on the pump and calibrate using air span only.

Pressing the A key will begin the calibration process. A calibration complete page

will appear when calibration is finished.

Port Setup - Menu Page 21

This page is used to set the parameters for the RS 232 port on the DB-9

connector. The baud rates are set by entering a number from 0 to 7 baud

rates of 1200 to 38400 (1200, 2400, 4800, 9600, 14400, 19200, 28800,

and 38400). Entering a number 0 to 2 can change the RS 232 mode. 0 is

the dump/minute mode, 1 is Modbus, and 2 is terminal mode.

The default setup is: 19200 Baud rate, MODBUS

Set The Date and Time - Menu Page 22

This page is used to set the internal clock/calendar. Select a number that

you would like to change by using the B and C buttons. Then type in the

number and press A to enter this number. No changes will take place

until the seconds are set, which starts the clock under the new settings.

Numbers 1 through 12 change the month. The days of the week are

entered using 0 for Sunday and 6 for Saturday. Hours are entered in 24hour format, i.e. 8 for 8AM and 14 for 2PM.

Data Set Page - Menu Page 23

This page allows for the entry of data that the operator should not

normally access. At this time the only data value is the IR shim factor

used in calculation the % carbon. Normally this value should be 150.

However furnace conditions, measured by shim stock tests, may require

changing this value.

SSi Manual 4549 Page 12 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 13

Span Calibration – Menu Page 24

This page is used to

span the IR cells. It is

very important to be

sure that the sample

gas is certified and

within the noted

specifications. Using the

B key, cursor up to the

value of each gas and

enter the value

displayed on the

certified tank. The

sample gas flow rate should be between 1.0 and 1.5 SCFH. Pressing the A key

will start the spanning process. Note that the spanning process could take up to

3 or 4 minutes. If the flow rate is too low, then an error page will appear and the

cells will not be calibrated. If any of the cell readings is greater than 10% of

nominal range, then a range error page will appear. This is a WARNING and it is

recommended that the span gas and entered values be checked before

proceeding. Pressing the A key will bypass the range error and begin the

calibrating process. If any of the readings of the cells is greater than 20% of

nominal range then a FACTORY CALIBRATION REQUIRED message will appear

near the bottom of the screen and the calibration is inhibited. A Span Complete

page will appear when calibration is finished.

For maximum accuracy, the values of the span gas should be approximately

20%CO, 1%CO2, and 5%CH4. The farther the gas value is from these nominal

values, the less accurate the calibration will be.

Set Pass Codes - Menu Page 25

This page is used to change the pass code for Menu Screens 21 and

higher. The default setting is 1, however this can be changed to any

number between 0 and 512.

Clear Logged File - Menu Page 26

This page is used to clear the data-logged data. Select the test number to

clear. Then cursor down and press the A key to clear the data. Since the

data log file is cleared whenever a test is started, it is usually not

necessary to use this page. The new data will over-write the existing

data.

SSi Manual 4549 Page 13 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 14

Typical diagnostic uses:

Why a 3-Gas IR Analyzer for atmosphere diagnostics?

The PGA3000 Analyzer measures CO, CO2, and CH4. Carbon potential can be

calculated using furnace temperature and the relationship of these 3-gases.

Oxygen probe real-time measurement of the furnace atmosphere can be verified

by 3-Gas analysis.

In addition to being an excellent diagnostic device, the PGA3000 will provide the

necessary data to fine-tune your atmosphere control.

Data retrieval: RS232, 9-Pin connector (included), Export to MS Excel via Upload

Utility Software (included)

Endothermic Generator Diagnostics

♦ The effectiveness of the catalyst is measured by the CH4 content. Less than

0.5% is an indication of properly functioning catalyst. Higher concentrations

indicate the necessity for either conditioning or replacement.

♦ Measuring the level of CO in the carrier gas allows correction of the % carbon

reading at the furnace.

Heat Treat Furnaces – Conventional Endo Gas

♦ Furnace atmosphere carbon potential (% C) can be verified with the

PGA3000.

♦ Measuring carbon monoxide (CO) and carbon dioxide (CO2) can show

possible problems (i.e. water leaks, air leaks, and radiant tube leaks).

♦ The PGA3000 measures the free methane (CH4) in the furnace atmosphere.

Heat Treat Furnaces – Nitrogen/Methanol Endo Gas

♦ The carbon monoxide (CO) level in the furnace atmosphere indicates the

effectiveness of the cracking of the methanol. Equilibrium of this reaction

CH3OH Æ CO + 2H2 is temperature dependent.

Heat Treat – Oxygen Sensor Control

♦ Periodic verification of the performance of oxygen probes.

SSi Manual 4549 Page 14 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 15

♦ COF and PFC adjustments can be made (based on the calculations of the 3

gases) to provide more precise control of the carbon in the furnace

atmosphere.

Combustion – Burner Balancing

♦ Measures excess O2 in the flue gas to allow burner adjustments.

Spare Parts

Bowl Filter Part Number 37048

Bowl Filter Media Replacement (10/Package) Part Number 31027

Sample Tubing Part Number 20104

In-Line Filter Part Number 31033

Flow Meter Part Number 36033

O2 Sensor Part Number 31409

CO2 Scrubber Part Number 13112

SSi Manual 4549 Page 15 of 16 3-Gas Analyzer PGA3000

Revision Level E

Page 16

Revision History

Rev. Description Date

Initial Release

-

A

B Modified per updated manufacturing procedure

C Updated Spare Parts List

D Added Additional Operation Instructions

E SSi Address Update, General Update

Added Revision History Page

04-27-2001

07-09-2001

08-10-2001

01-29-2002

06-19-2002

04-12-2005

SSi Manual 4549 Page 16 of 16 3-Gas Analyzer PGA3000

Revision Level E

Loading...

Loading...