Page 1

Configurator 2.0

Software

OPERATIONS

MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060 / 800-666-4330

Fax: 513-772-9466

www.supersystems.com

Super Systems Inc. Page 1 of 201 Configurator Manual #4562 Rev D

Page 2

Table of Contents

Table of Contents ................................................................................................................. 2

Main Menu ........................................................................................................................... 8

Toolbar Buttons ................................................................................................................... 9

1. The Connection button .......................................................................................... 9

2. The Login button .................................................................................................. 9

3. The Show Overview Display button ........................................................................ 9

4. The System Settings button ................................................................................... 9

Manage Controllers Tab ............................................................................................. 10

Backup/Restore Tab .................................................................................................. 13

Users Tab ................................................................................................................. 17

Configuration Tab ..................................................................................................... 19

R/W Data ................................................................................................................. 21

Set Factory Defaults .................................................................................................. 22

FD Preserve .............................................................................................................. 23

5. The Recipe Editor button ..................................................................................... 23

Recipe Editor Tab ...................................................................................................... 24

Recipe Management Tab ........................................................................................... 26

Configurator Main Form ...................................................................................................... 29

9200 Firmware Upgrade Procedure ..................................................................................... 35

Overview ..................................................................................................................... 35

Equipment Required ..................................................................................................... 35

Instructions ................................................................................................................. 35

Configurator – 8500 Drop-Down Menu ................................................................................ 43

Input Values ................................................................................................................... 43

Range Setups ................................................................................................................. 44

Calibration ...................................................................................................................... 45

TC Type mV Range Chart .......................................................................................... 46

Zero Calibration ........................................................................................................... 46

Span Calibration ........................................................................................................... 47

Cold Junction Calibration .............................................................................................. 47

Configurator-9005 Drop-Down Menu ................................................................................... 49

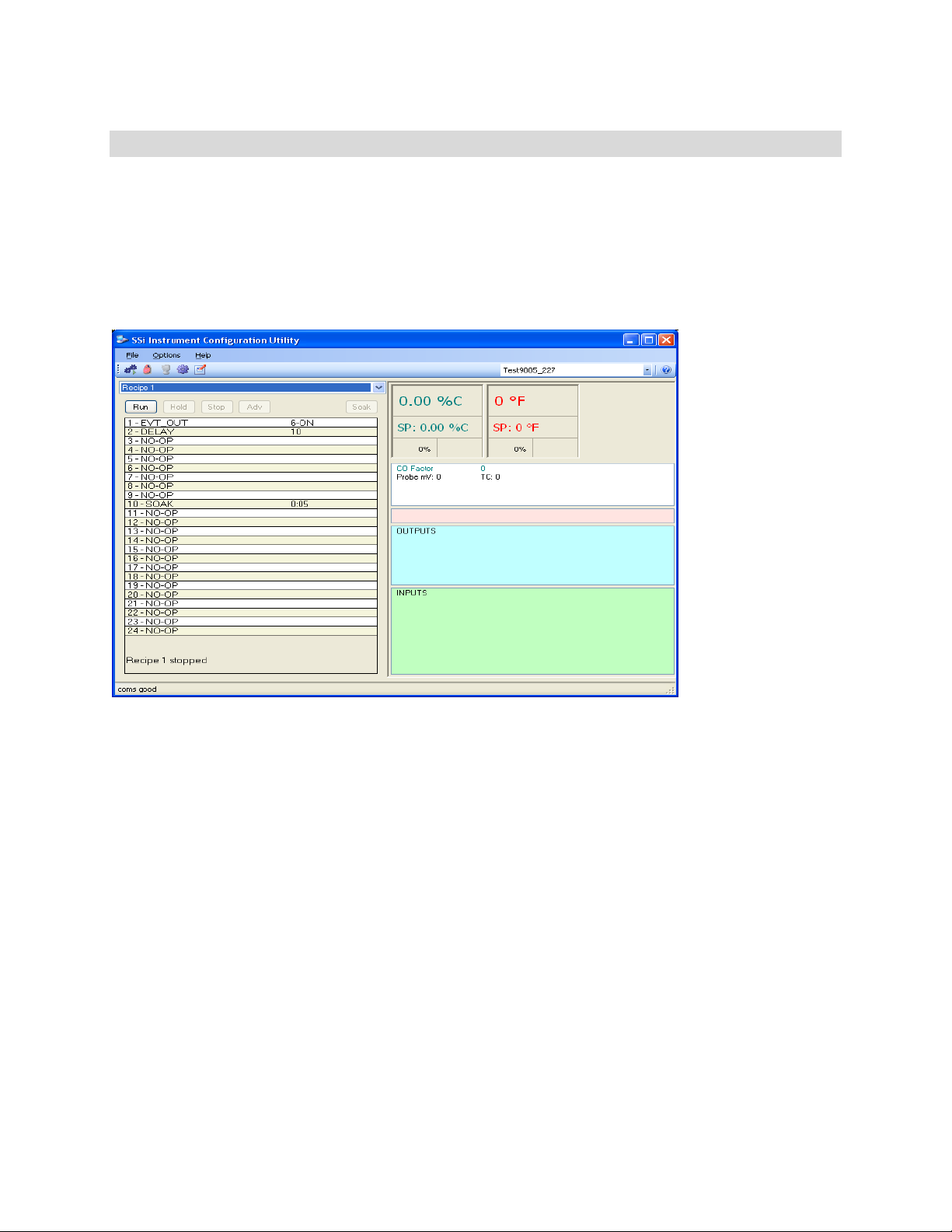

Recipe 1 – Recipe 4 ......................................................................................................... 49

Slave Instruments ........................................................................................................... 49

Auxiliary A/I .................................................................................................................... 49

Manual Event Control ...................................................................................................... 49

Event Run Program Setup ................................................................................................ 49

Port Setup ...................................................................................................................... 50

Slave Instrument Setup ................................................................................................... 50

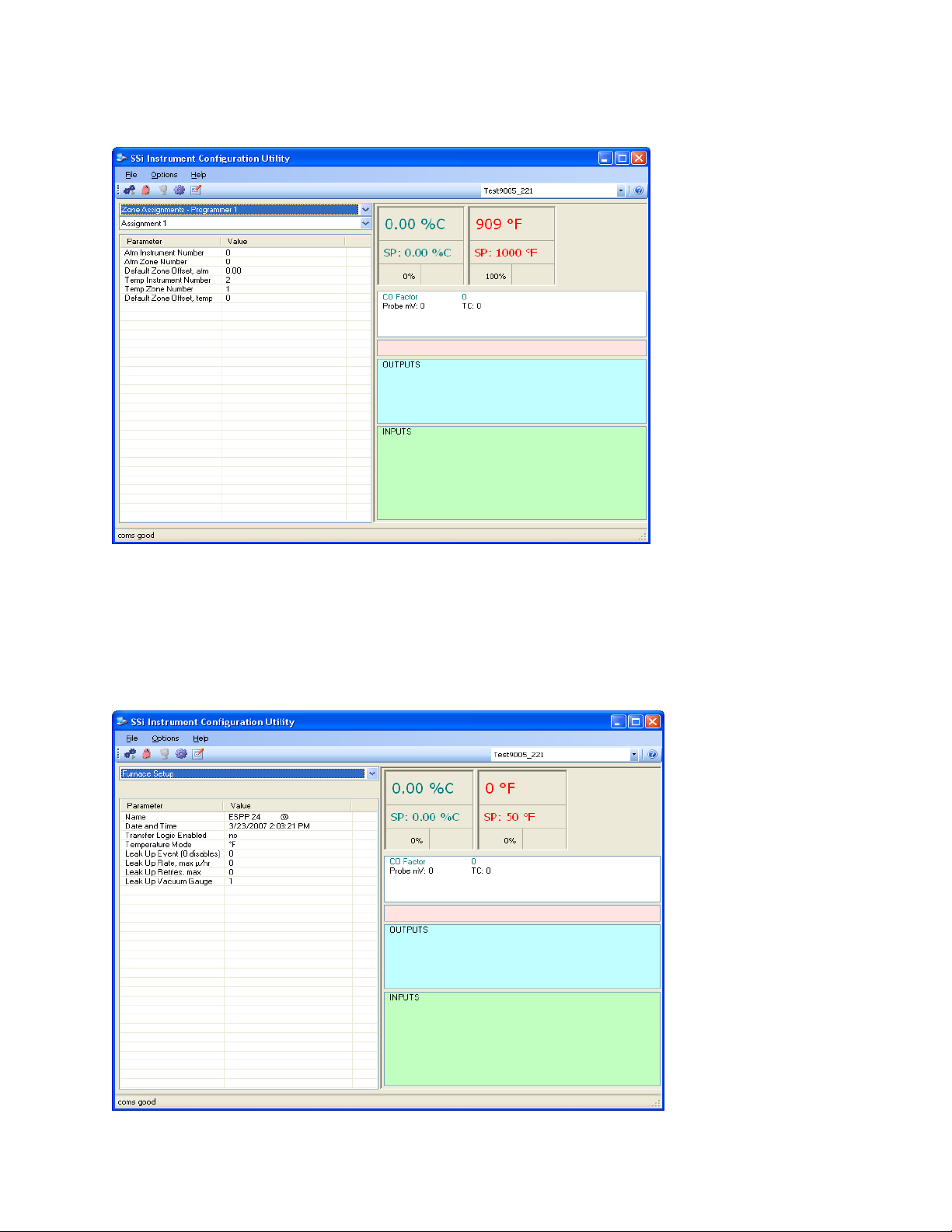

Zone Assignments – Programmer 1 – Zone Assignments - Programmer 4 ........................... 52

Furnace Setup ................................................................................................................ 52

Programmer Setup .......................................................................................................... 54

Passcode and Alarm ........................................................................................................ 55

IP Address ...................................................................................................................... 55

Zone/Load TC Setup ........................................................................................................ 55

Super Systems Inc. Page 2 of 201 Configurator Manual #4562 Rev D

Page 3

Event Control .................................................................................................................. 56

Set Menu Security ........................................................................................................... 57

SSi Analog Input Setup .................................................................................................... 57

Generic Mapping Setups .................................................................................................. 58

Communications and Mapping Table Section .................................................................. 58

Block Write Table Section ............................................................................................. 60

IP Address Table Section .............................................................................................. 61

DF1 Configuration ........................................................................................................... 62

Relay Assignments .......................................................................................................... 63

Vacuum Gauge Setup ...................................................................................................... 65

Relay Setpoints ............................................................................................................... 67

Configurator-9120 Drop-Down Menu ................................................................................... 68

Burnoff ........................................................................................................................... 68

Slave Instruments ........................................................................................................... 68

Aux Analog Inputs ........................................................................................................... 68

Burnoff Setup ................................................................................................................. 68

PID Loop Setup ............................................................................................................... 68

Furnace Setup ................................................................................................................ 68

Communications Setup .................................................................................................... 70

Slave Instrument Setup ................................................................................................... 70

Analog Input Setup ......................................................................................................... 70

Analog Output Setup ....................................................................................................... 71

Alarm Setup .................................................................................................................... 72

Calibration ...................................................................................................................... 72

Configurator-9200 Drop-Down Menu ................................................................................... 72

Burnoff ........................................................................................................................... 72

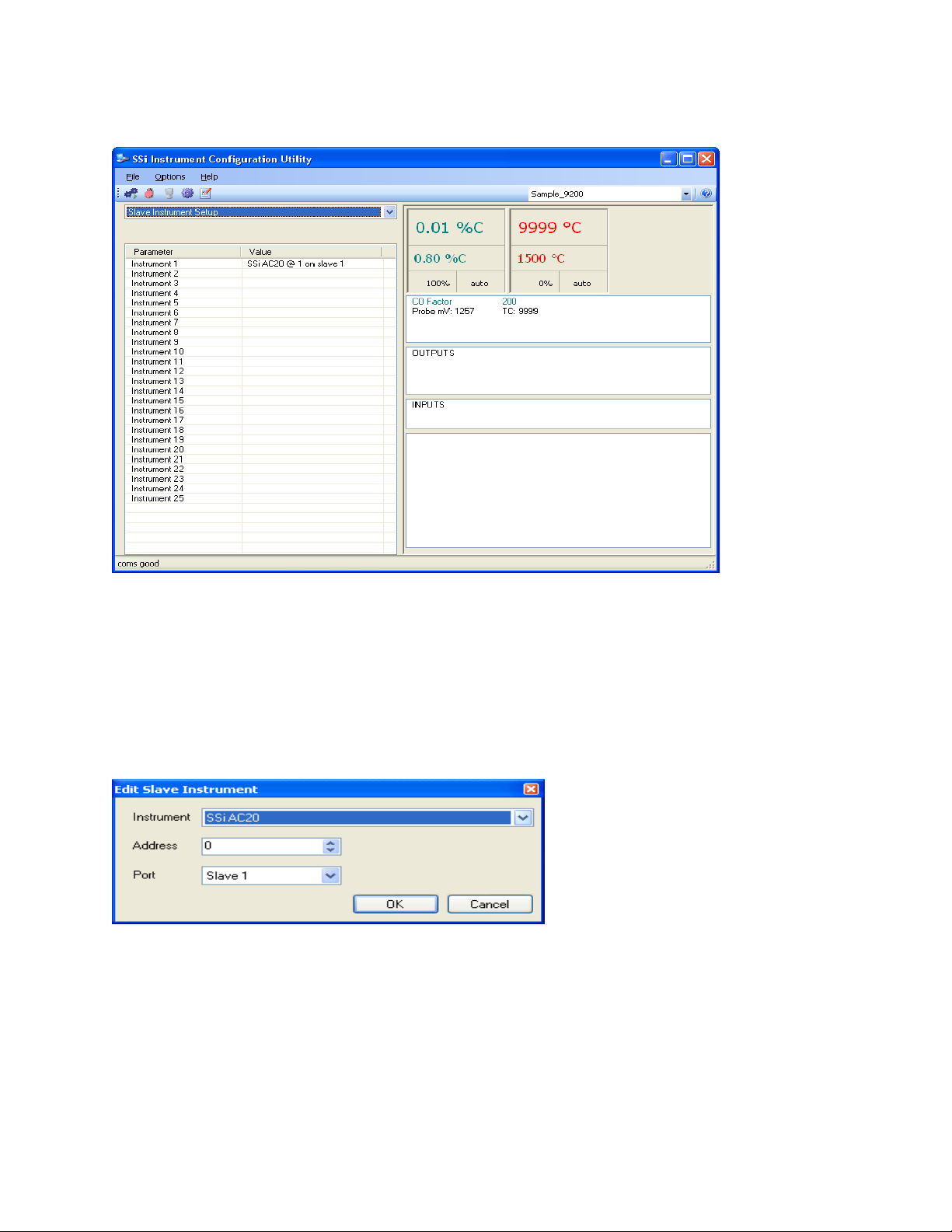

Slave Instruments ........................................................................................................... 74

Auxiliary Analog Input ..................................................................................................... 75

Manual Event Control ...................................................................................................... 76

Probe Burnoff Setup ........................................................................................................ 77

PID Loop Setup ............................................................................................................... 78

Event Run Program Setup ................................................................................................ 87

Zone/Load TC Setup ........................................................................................................ 88

Port Setup ...................................................................................................................... 89

Slave Instrument Setup ................................................................................................... 90

Zone Assignments ........................................................................................................... 92

Furnace Setup ................................................................................................................ 93

Default Wait Limits .......................................................................................................... 94

Furnace Name ................................................................................................................ 96

Alarm Setup .................................................................................................................... 97

Relay Assignments ......................................................................................................... 103

Relay Setpoints .............................................................................................................. 106

Analog Input Setup ........................................................................................................ 107

Analog Output setup ...................................................................................................... 112

Passcode and Alarm ....................................................................................................... 115

IP Address ..................................................................................................................... 117

Event Control ................................................................................................................. 118

Valve Setup ................................................................................................................... 119

Super Systems Inc. Page 3 of 201 Configurator Manual #4562 Rev D

Page 4

Valve Inputs .................................................................................................................. 120

Set Menu Security .......................................................................................................... 122

Curve Entry ................................................................................................................... 123

Alternate PID Setup ....................................................................................................... 124

SSI Analog Input Setup .................................................................................................. 125

SSi Configuration and Calibration .................................................................................... 126

Overview .................................................................................................................... 126

Equipment needed ...................................................................................................... 126

Notes ......................................................................................................................... 126

User Calibration .......................................................................................................... 127

Full Calibration ............................................................................................................ 129

ADAM Module Offset Correction ...................................................................................... 130

Aux Setpoint Configuration ............................................................................................. 131

TC Extension Correction Curves ...................................................................................... 132

Tuning Assistant ............................................................................................................ 133

Configurator – 9205 Drop-Down Menu ............................................................................... 136

Burnoff .......................................................................................................................... 136

Slave Instruments .......................................................................................................... 136

Auxiliary Analog Input .................................................................................................... 136

Manual Event Control ..................................................................................................... 136

Probe Burnoff Setup ....................................................................................................... 136

PID Loop Setup .............................................................................................................. 136

Event Run Program Setup ............................................................................................... 136

Zone/Load TC Setup ....................................................................................................... 136

Port Setup ..................................................................................................................... 136

Slave Instrument Setup .................................................................................................. 136

Zone Assignments .......................................................................................................... 136

Furnace Setup ............................................................................................................... 137

Default Wait Limits ......................................................................................................... 137

Furnace Name ............................................................................................................... 137

Alarm Setup ................................................................................................................... 137

Relay Assignments ......................................................................................................... 137

Relay Setpoints .............................................................................................................. 137

Analog Input Setup ........................................................................................................ 137

Analog Output Setup ...................................................................................................... 137

Passcode and Alarm ....................................................................................................... 137

IP Address ..................................................................................................................... 137

Event Control ................................................................................................................. 137

Set Menu Security .......................................................................................................... 138

Curve Entry ................................................................................................................... 138

Alternate PID Setup ....................................................................................................... 138

SSi Analog Input Setup ................................................................................................... 138

SSi Configuration and Calibration .................................................................................... 138

ADAM Module Offset Correction ...................................................................................... 138

Aux Setpoint Configuration ............................................................................................. 138

Configurator – 9210 Drop-Down Menu ............................................................................... 139

Slave Instruments .......................................................................................................... 139

Auxiliary Analog Input .................................................................................................... 139

Super Systems Inc. Page 4 of 201 Configurator Manual #4562 Rev D

Page 5

Manual Event Control ..................................................................................................... 139

PID Loop Setup .............................................................................................................. 139

Event Run Program Setup ............................................................................................... 139

Zone/Load TC Setup ....................................................................................................... 139

Port Setup ..................................................................................................................... 139

Slave Instrument Setup .................................................................................................. 139

Zone Assignments .......................................................................................................... 139

Furnace Setup ............................................................................................................... 139

Default Wait Limits ......................................................................................................... 139

Furnace Name ............................................................................................................... 140

Alarm Setup ................................................................................................................... 140

Relay Assignments ......................................................................................................... 140

Relay Setpoints .............................................................................................................. 140

Analog Input Setup ........................................................................................................ 140

Analog Output Setup ...................................................................................................... 140

Passcode and Alarm ....................................................................................................... 140

IP Address ..................................................................................................................... 140

Event Control ................................................................................................................. 140

Valve Configuration ........................................................................................................ 140

Valve Setup ................................................................................................................... 140

Set Menu Security .......................................................................................................... 141

Curve Entry ................................................................................................................... 141

Alternate PID Setup ....................................................................................................... 141

SSi Analog Input Setup ................................................................................................... 141

SSi Configuration and Calibration .................................................................................... 141

ADAM Module Offset Correction ...................................................................................... 141

Aux Setpoint Configuration ............................................................................................. 141

TC Extension Correction Curves ...................................................................................... 141

Tuning Assistant ............................................................................................................ 141

Configurator – 9215 Drop-Down Menu ............................................................................... 142

Slave Instruments .......................................................................................................... 142

Auxiliary A/I ................................................................................................................... 142

MGA .............................................................................................................................. 142

Manual Event Control ..................................................................................................... 142

PID Loop Setup .............................................................................................................. 142

Event Run Program Setup ............................................................................................... 143

Zone/Load TC Setup ....................................................................................................... 143

Port Setup ..................................................................................................................... 143

Slave Instrument Setup .................................................................................................. 143

Zone Assignments .......................................................................................................... 143

Furnace Setup ............................................................................................................... 143

Default Wait Limits ......................................................................................................... 145

Alarm Setup ................................................................................................................... 145

Relay Assignments ......................................................................................................... 145

Relay Setpoints .............................................................................................................. 145

Analog Input Setup ........................................................................................................ 145

Analog Output Setup ...................................................................................................... 146

Passcode and Alarm ....................................................................................................... 146

Super Systems Inc. Page 5 of 201 Configurator Manual #4562 Rev D

Page 6

Generic Mapping Setups ................................................................................................. 146

DF1 Configuration .......................................................................................................... 146

IP Address ..................................................................................................................... 146

Event Control ................................................................................................................. 146

Vacuum Gauge Setup ..................................................................................................... 146

Valve Configuration ........................................................................................................ 147

Valve Setup ................................................................................................................... 148

Custom Curves ............................................................................................................... 149

Alternate PID Setup ....................................................................................................... 149

SSi Analog Input Setup ................................................................................................... 149

SSi Configuration and Calibration .................................................................................... 149

ADAM Module Offset Correction ...................................................................................... 149

Aux Setpoint Configuration ............................................................................................. 149

TC Extension Correction Curves ...................................................................................... 149

MGA Setup .................................................................................................................... 150

Configurator-9220 Drop-Down Menu .................................................................................. 153

Slave Instruments .......................................................................................................... 153

Auxiliary Analog Input .................................................................................................... 153

Manual Event Control ..................................................................................................... 153

PID Loop Setup .............................................................................................................. 154

Event Run Program Setup ............................................................................................... 156

Zone/Load TC Setup ....................................................................................................... 156

Port Setup ..................................................................................................................... 157

Slave Instrument Setup .................................................................................................. 158

Zone Assignments .......................................................................................................... 159

Furnace Setup ............................................................................................................... 160

Default Wait Limits ......................................................................................................... 162

Furnace Name ............................................................................................................... 162

Alarm Setup ................................................................................................................... 162

Thermocouple Check ................................................................................................... 163

Relay Assignments ......................................................................................................... 164

Relay Setpoints .............................................................................................................. 166

Analog Input Setup ........................................................................................................ 167

Analog Output Setup ...................................................................................................... 169

Passcode and Alarm ....................................................................................................... 170

IP Address ..................................................................................................................... 170

Event Control ................................................................................................................. 170

Vacuum Gauge Setup ..................................................................................................... 170

Set Menu Security .......................................................................................................... 172

Custom Curves ............................................................................................................... 172

Alternate PID Setup ....................................................................................................... 172

SSi Analog Input Setup ................................................................................................... 173

SSi Configuration and Calibration .................................................................................... 173

ADAM Module Offset Correction ...................................................................................... 174

Aux Setpoint Configuration ............................................................................................. 174

TC Extension Correction Curves ...................................................................................... 174

Tuning Assistant ............................................................................................................ 174

Appendix A – Quench Control & Events .............................................................................. 175

Super Systems Inc. Page 6 of 201 Configurator Manual #4562 Rev D

Page 7

Appendix B – Opcodes ....................................................................................................... 176

Control Group ................................................................................................................ 176

Alarm Group .................................................................................................................. 176

Events Group ................................................................................................................. 176

Identity Group ............................................................................................................... 177

Temperature Group ........................................................................................................ 177

Time Group ................................................................................................................... 177

Vacuum Group ............................................................................................................... 178

SPP2 Group ................................................................................................................... 178

Notes About Opcodes ..................................................................................................... 179

BRANCH and LIMIT opcodes ........................................................................................ 180

Appendix C - Programmer Alarms ....................................................................................... 182

Appendix D - Flash Card Management ................................................................................ 183

Appendix E - SDRecorder Installation ................................................................................. 184

Appendix F – Slave Instrument Mapping ............................................................................. 186

Atmosphere Instruments ................................................................................................ 186

Temperature Instruments ............................................................................................... 190

Events Instruments ........................................................................................................ 196

Appendix G – Examples ..................................................................................................... 199

Example 1 – Cascade Setup for the 9205 ......................................................................... 199

Revision History ................................................................................................................ 201

Super Systems Inc. Page 7 of 201 Configurator Manual #4562 Rev D

Page 8

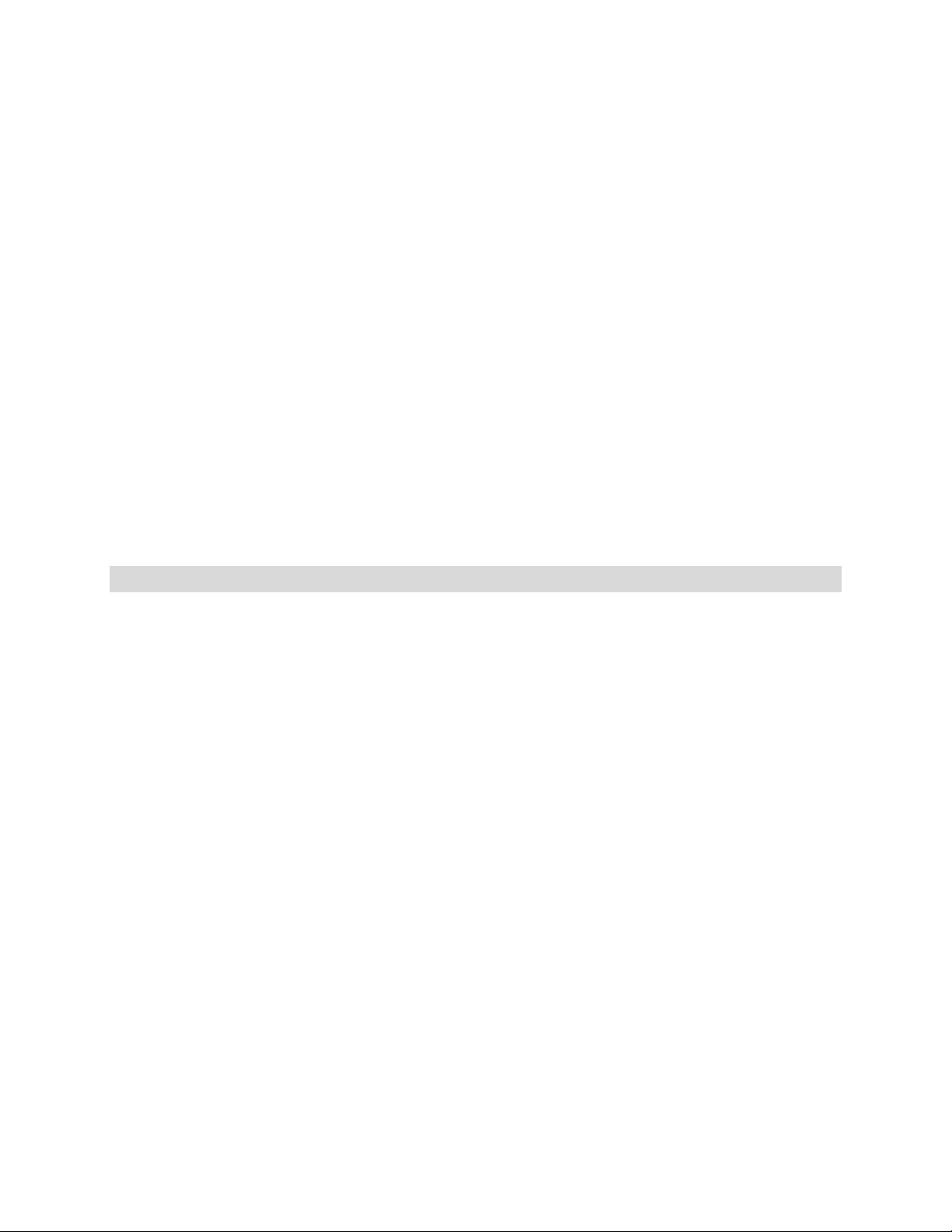

Main Menu

Configurator main display

The main menu consists of three sections: File, Options, and Help.

File

File Æ Close

This command will exit the Configurator application. This is the same as clicking on the close

button on the top right of the form,

.

Options

Options Æ Settings

This command will display the System Management form. This is the same as clicking on the

System Settings button,

.

Help

Help Æ About

This will display a small about screen.

Configurator – Help Screen

Super Systems Inc. Page 8 of 201 Configurator Manual #4562 Rev D

Page 9

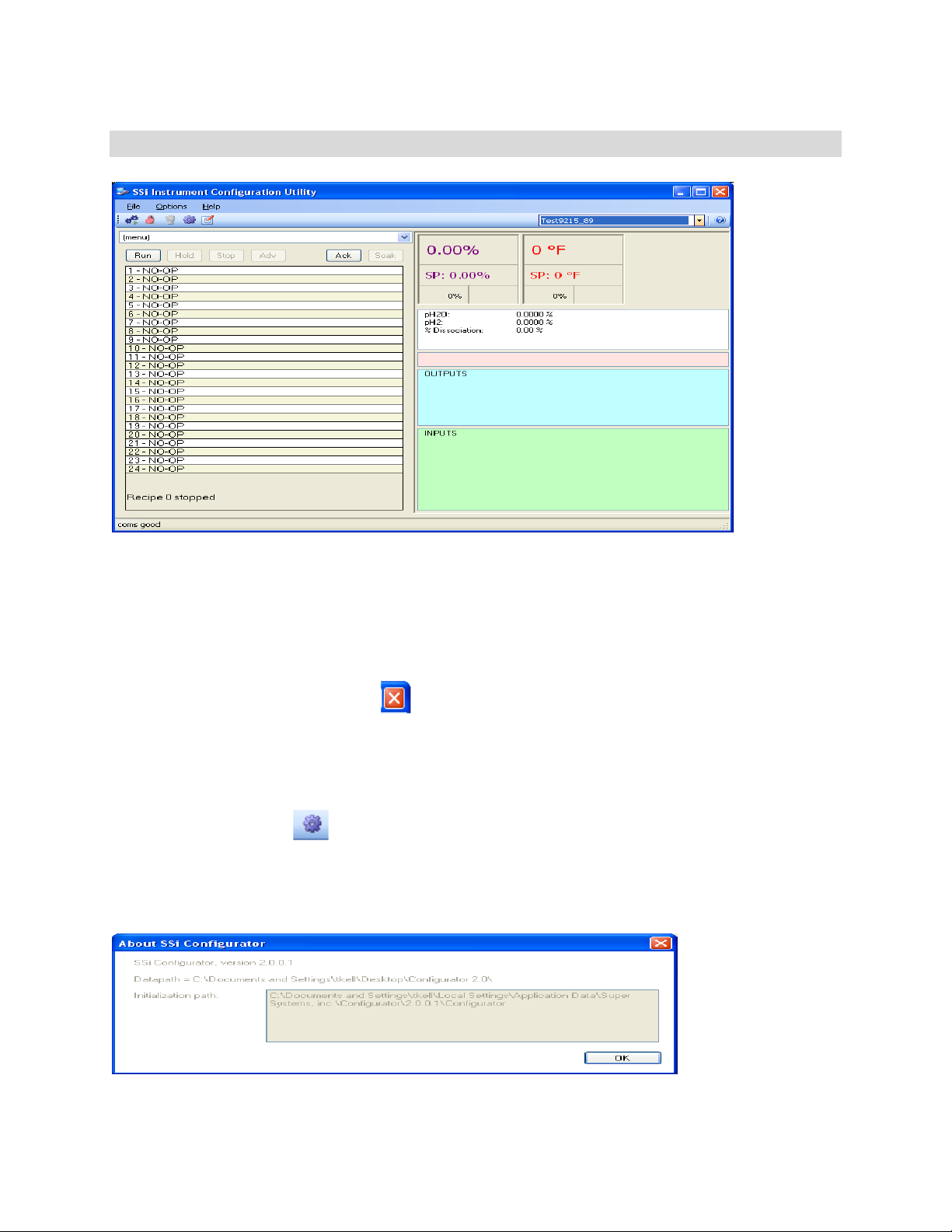

Toolbar Buttons

The toolbar across the top of the form, below the main menu, contains five icons:

1. The Connection button

When the program starts, the device is disconnected and the connect button will show

Also, the status bar in the bottom left corner will read “disconnected.” To connect to a device,

make sure that a device is selected from the drop-down list located on the top right of the form,

and click this button. While the Configurator is in the process of connecting, the connect button

will show

bar in the bottom left corner will read “coms good.” If the connection is not successful, the

connect button will remain

bad.” Clicking on this button again will disconnect the device.

2. The Login button

There are four levels of security with the Configurator – Operator, Supervisor, Administrator,

and SSi Special. Each level provides additional functionality with the Configurator software.

When the program starts, the device is logged in as Operator and the login button will show

(blue). The Operator level does not require any passcodes. To login at a higher level, click on

this button. A dialog box will pop up with a field for a user name and password.

login button will show

configuration of the device and the password can only be obtained from Super Systems. To

login as SSi Special, enter the pass code as the password.

SSi Special level

3. The Show Overview Display button

4. The System Settings button

. If a connection is successful, the connect button will show and the status

and the status bar in the bottom left corner will read “coms

To login as Supervisor, enter “Supervisor” as the

user name and enter the level 1 passcode as the

password. The user name is not case-sensitive. If

the login is successful, the login button will show

(gold). To login as Administrator, enter

“Administrator” as the user name and enter the

level 2 passcode as the password. The user name

is not case-sensitive. If the login is successful, the

(green). The SSi Special level is only used at Super Systems Inc for

No username is required for the

. If the login is successful, the login button will show (red).

.

The system settings button,

access or higher. The systems settings feature allows the user to manage any controller(s) and

also backup/restore any controller(s).

Super Systems Inc. Page 9 of 201 Configurator Manual #4562 Rev D

, is only available to those users who have a Supervisor level

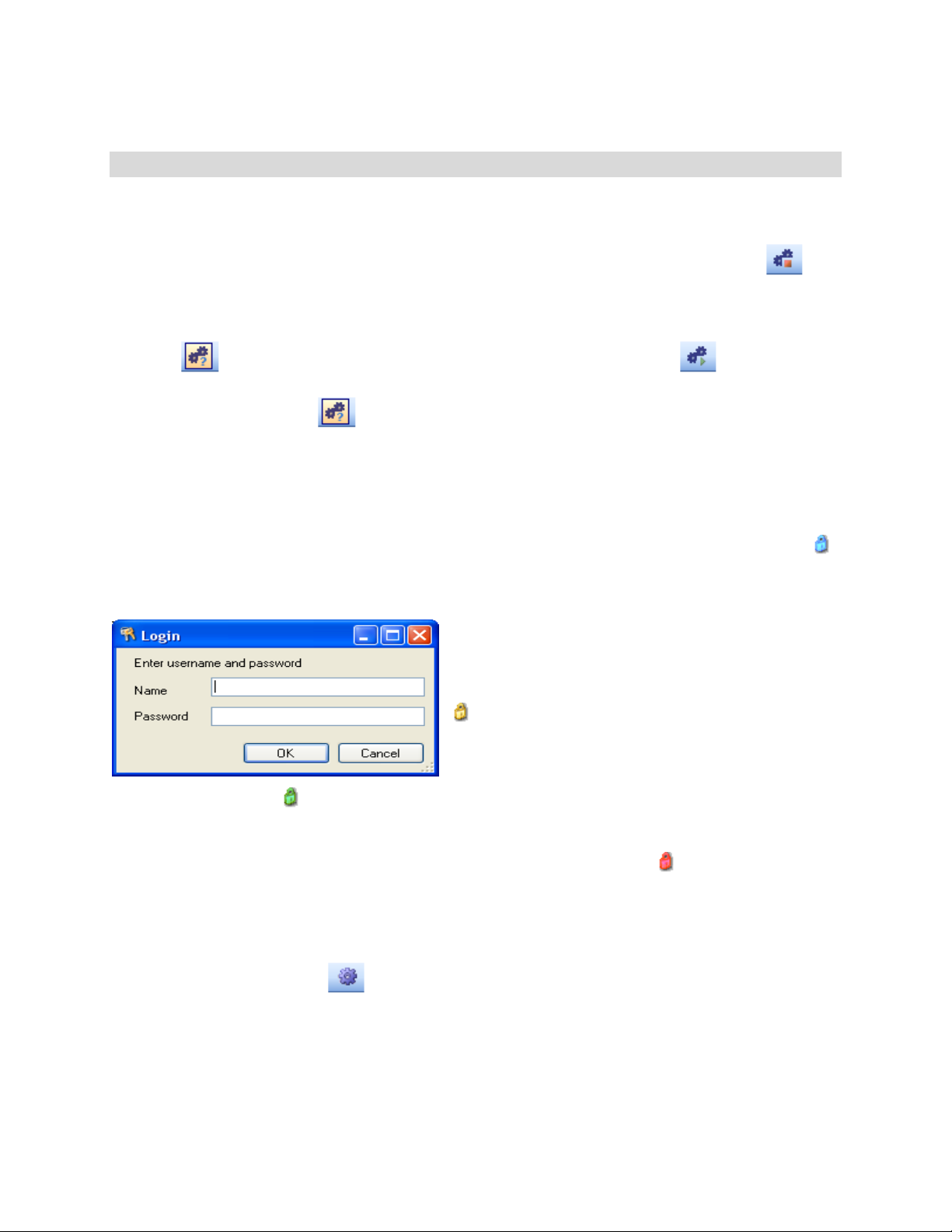

Page 10

Configurator Manage Controllers display

Manage Controllers Tab

The list box at the top of the form shows any controller setup that is currently stored in the

Configurator. The user can edit, add, or delete a controller setup from the Configurator.

Add a Controller

First, click on the “Add” button under the controller list.

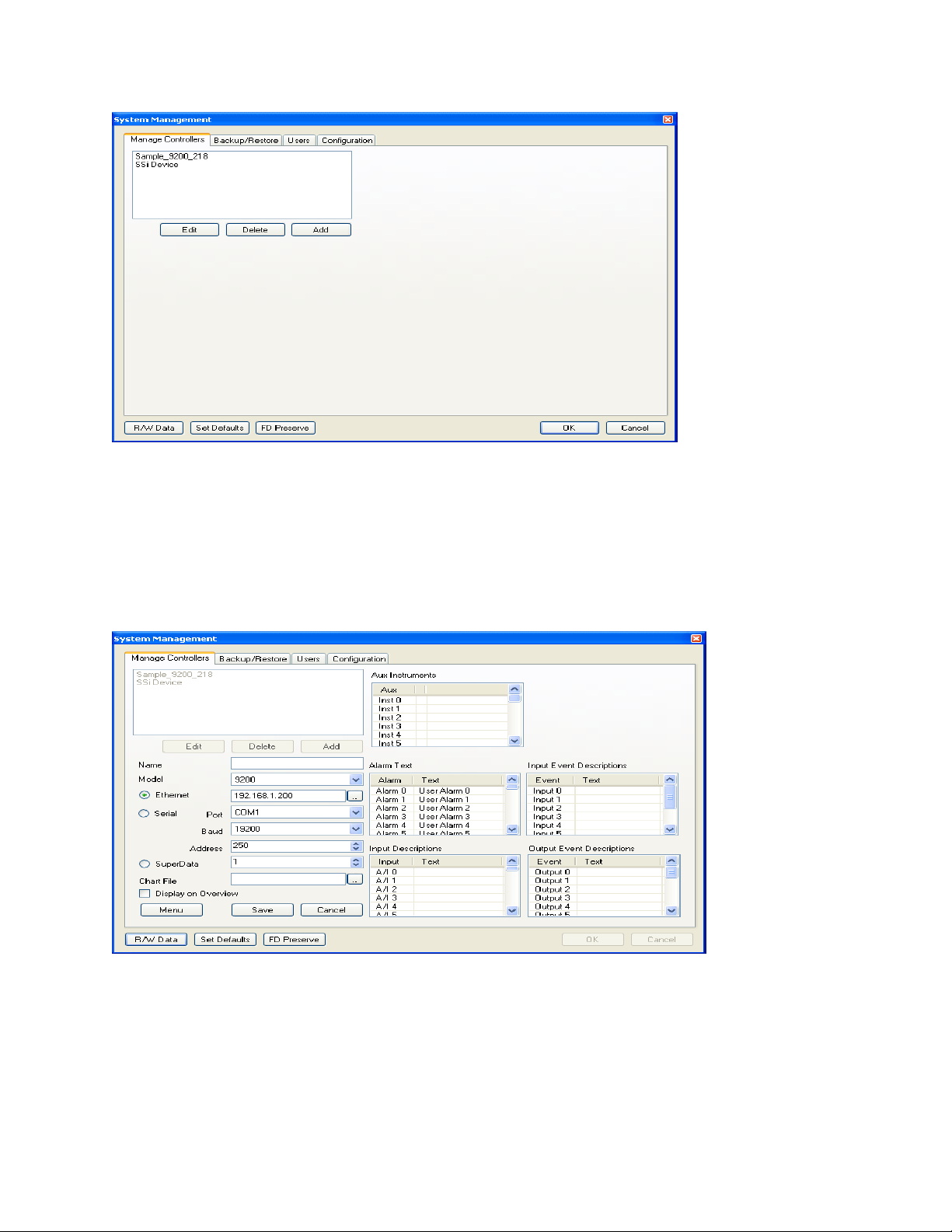

Configurator Add/Edit Controller section

The “Name” is the name the user wishes to give the controller. This is how the Configurator

will refer to this controller throughout.

The “Controller Type” is a drop-down list of all of the available controller types (9005, 9200,

9220, etc). This refers to what kind of controller you are adding.

Super Systems Inc. Page 10 of 201 Configurator Manual #4562 Rev D

Page 11

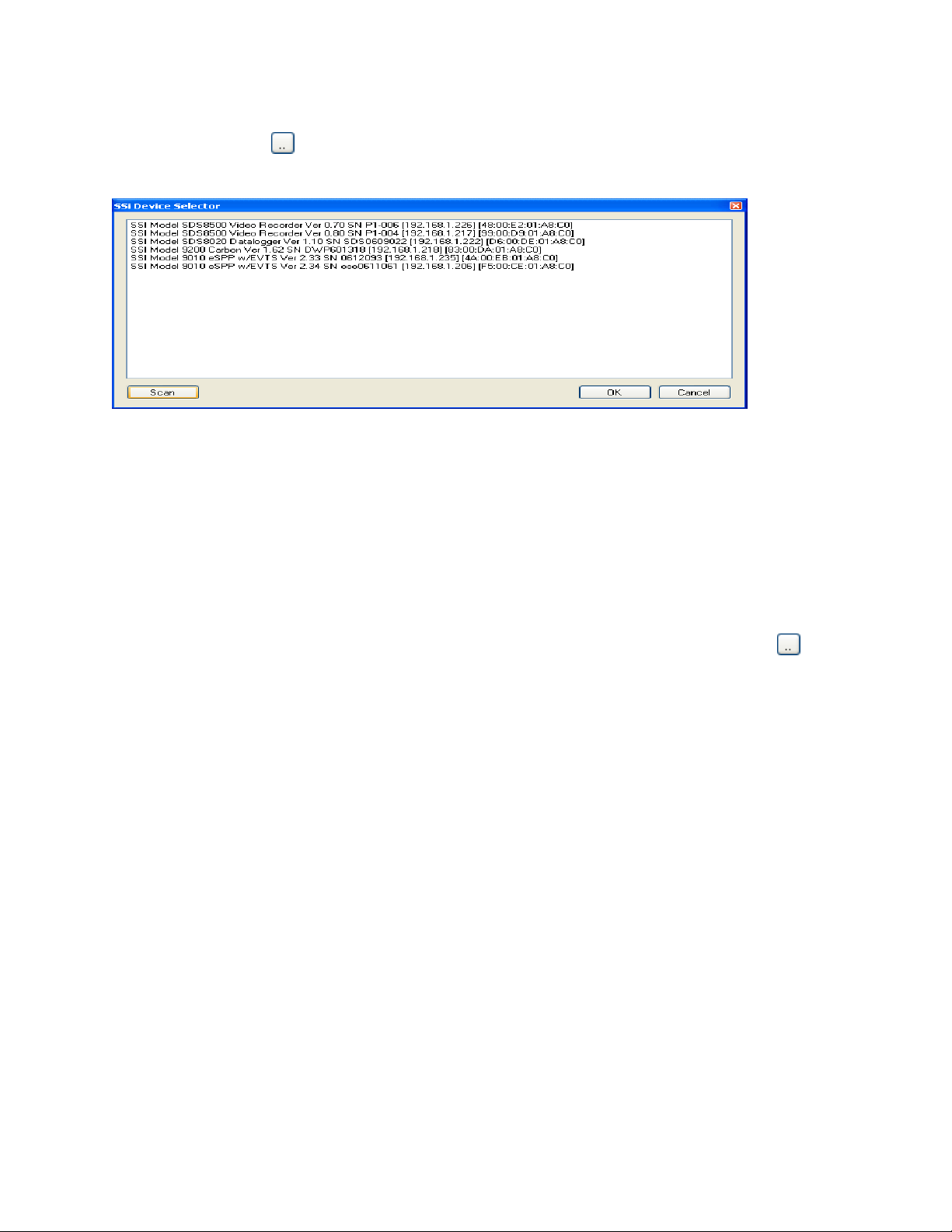

The “Ethernet” option specifies the IP Address of the controller. Clicking on the scan button

next to the text box,

the

SSi Device Selector

, will allow the user to scan the network for all available devices with

screen.

Configurator – SSi Device Selector

Clicking on the Scan button will initiate the scan procedure. Please note that this scan could

take a few minutes. Once the scan has completed, the list of available devices will be

displayed. Clicking on one of the devices will highlight that line in blue. Clicking on the OK

button once a device has been selected will set that device’s IP address in the Ethernet IP

address textbox. Clicking on the Cancel button will cancel the process and close down the

Device Selector

screen.

SSi

The “Serial” option specifies the “Com Port” (COM1 – COM20), the “Baud” rate (1200 –

115200), and the “Address” (0 – 250).

The “SuperData” option specifies the channel for SuperData (1 – 128).

The “Chart File” specifies the chart file (.ctm) to be used. Clicking on the open button,

, will

display a Windows open file dialog box that will allow the user to navigate to the proper

location, if necessary.

Check the checkbox next to “Display on overview” if you want to display this on the

Display

screen.

Overview

Clicking on the Menu button will allow the user to set up the menu options for each access

level.

Super Systems Inc. Page 11 of 201 Configurator Manual #4562 Rev D

Page 12

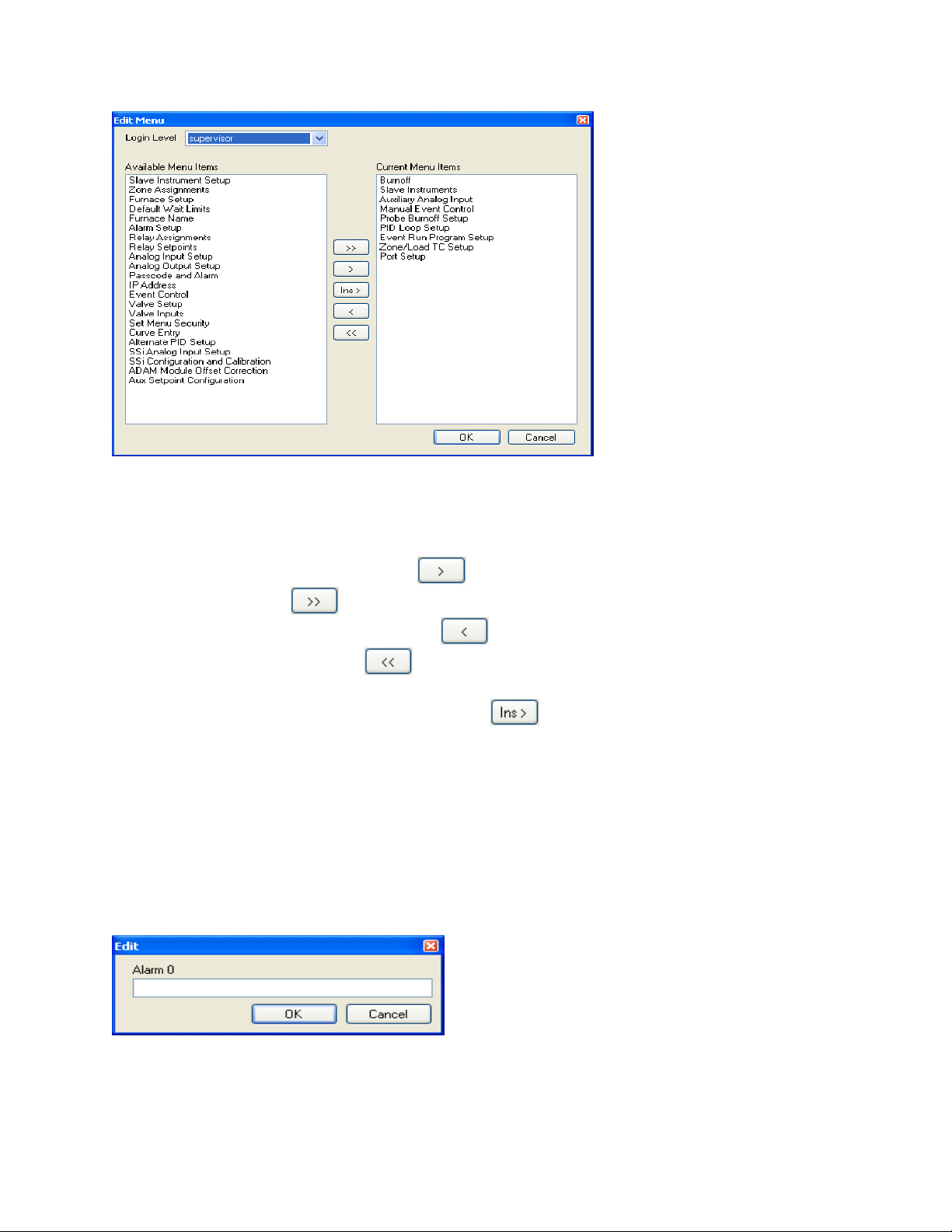

Configurator – Edit Menu screen

Use the drop-down list at the top of the form to select the access level to change. The list on

the right of the screen is the current menu list for the specific access level. The list on the left

of the screen lists the remaining items. To add a menu option, select the desired menu option

on the left and click on the Add button,

on the Add All button,

. To remove a menu option, select the desired menu option on

the right and click on the Remove button,

click on the Remove All button,

. To add a menu option to a specific position, click on

. To add all of the menu options at once, click

. To remove all of the menu options at once,

the menu option on the right where the new option will be inserted, click on the menu option

on the left to add and click on the Insert button,

. Click the OK button to accept the

changes or the Cancel button to close the form without accepting the changes.

Clicking on the Save button will save the changes, while clicking on the Cancel button will

cancel the action.

The right side of the form displays the Aux Instruments and the text for those instruments,

Alarms and the text for those alarms, Input Event Descriptions and the text for those

descriptions, Input Descriptions and the text for those descriptions, and the Output Event

Descriptions and the text for those descriptions. To change the text, double-click on the

specific item to change. The Configurator will display an input box that will allow the user to

change the current text value.

Configurator – Edit text input box

Clicking OK will change the text value, and clicking Cancel will not change the text value.

Super Systems Inc. Page 12 of 201 Configurator Manual #4562 Rev D

Page 13

To save these changes and add the controller, click the Save button. Click on the Cancel

button if this controller is not to be added. The bottom section of the form will become invisible

again.

Edit a Controller

Double-click on the specific controller that is to be modified, or single-click on the controller and

click the Edit button to begin editing. Change the necessary values, then click on the Save

button to save the changes or click on the Cancel button to cancel this operation. See the

above section

Add a Controller

for a description of the different fields.

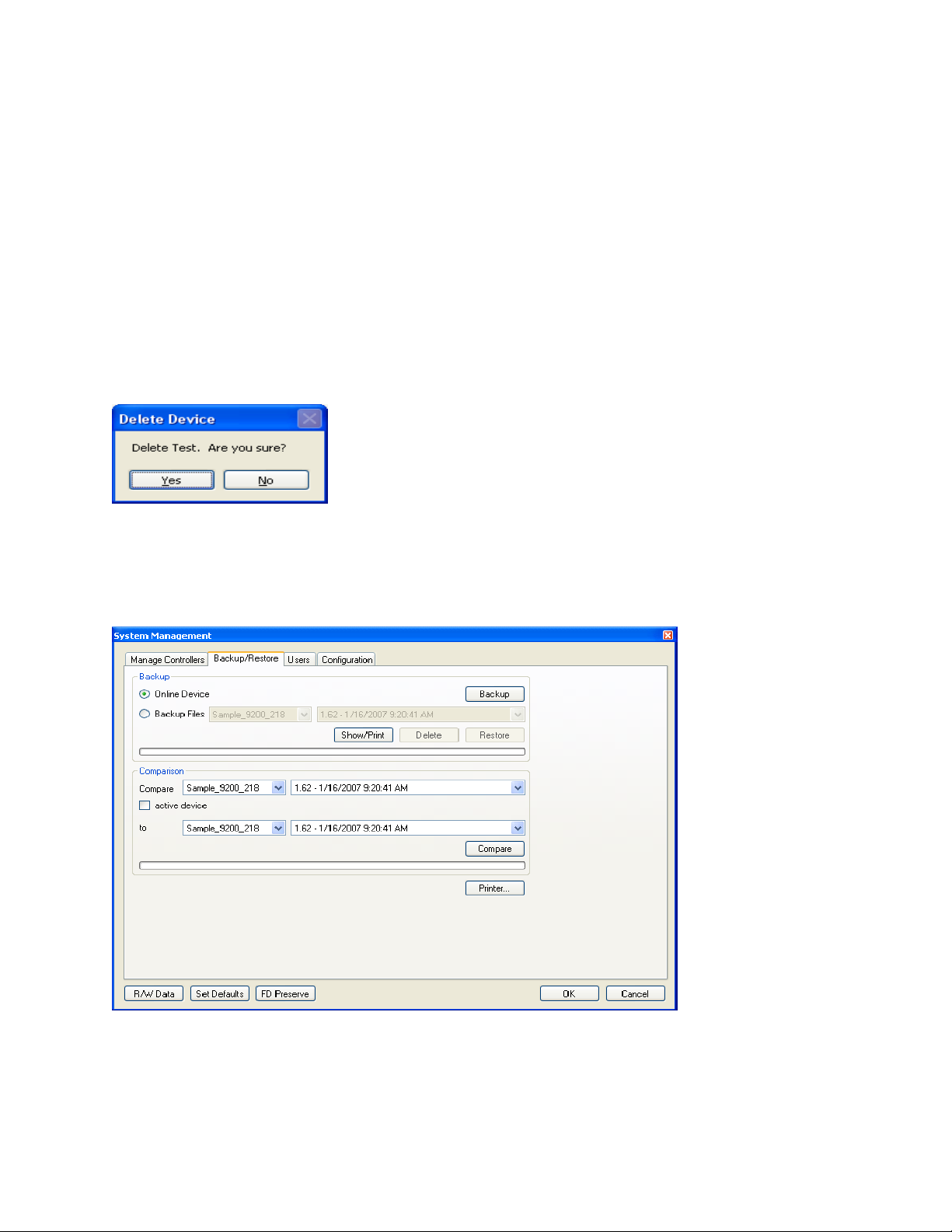

Delete a Controller

Click on the specific controller that is to be deleted. Click on the Delete button to delete this

controller. The Configurator will display a message box asking the user to confirm the delete.

Configurator – Confirm Delete Device

Clicking on the Yes button will delete the controller. Clicking on the No button will cancel the

delete.

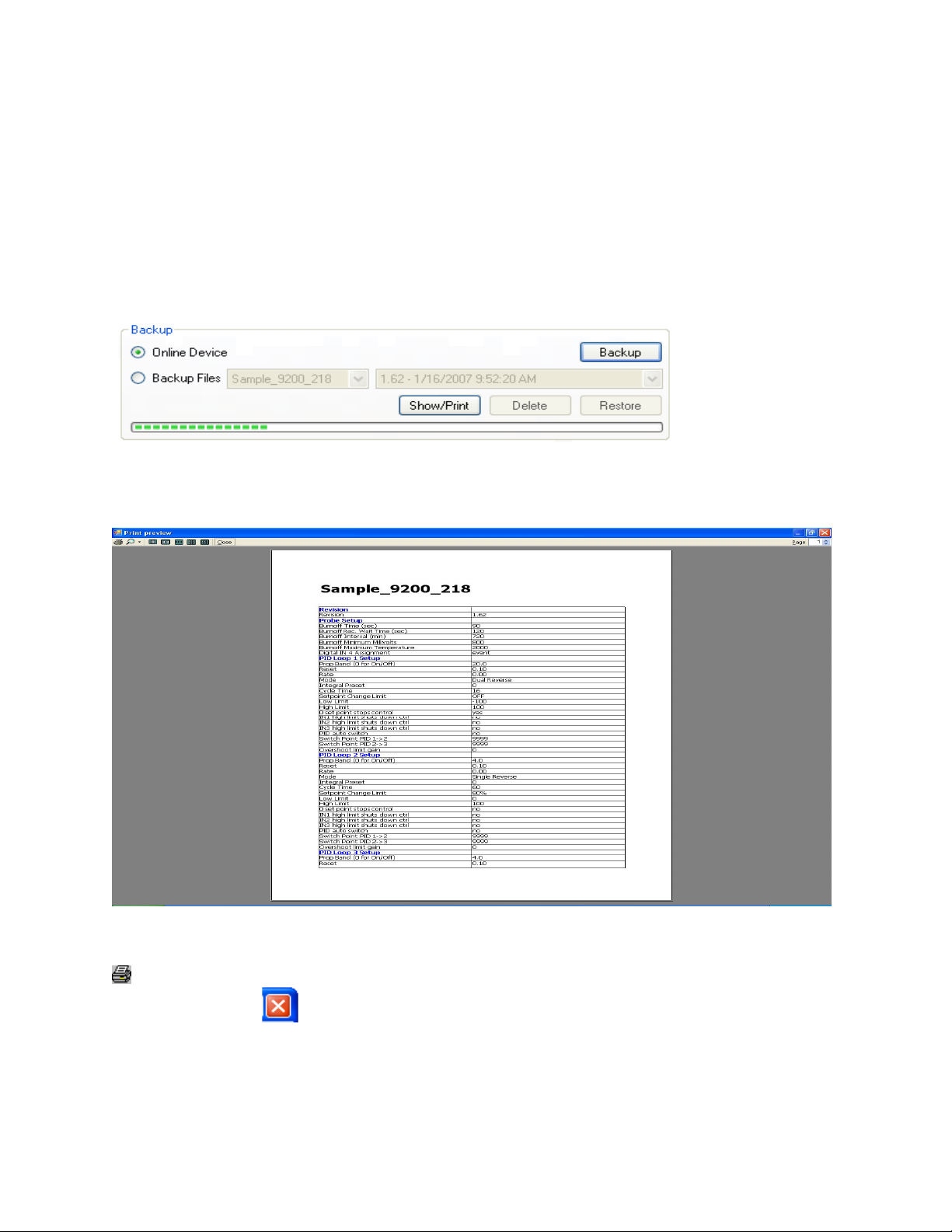

Backup/Restore Tab

Configurator Backup/Restore Display

The Backup/Restore display allows the user to create a backup of a controller configuration, or

restore a controller to a previous configuration.

Super Systems Inc. Page 13 of 201 Configurator Manual #4562 Rev D

Page 14

Backup Section

This area will allow the user to either backup the current controller, or restore the current

controller to a previous configuration.

before being able to backup or restore a configuration

option will allow the user to backup the controller. Once this section is selected, the Delete

and Restore buttons will become disabled, as well as the drop-down lists for the “Backup Files”

section, as they deal only with backed-up configuration files. Clicking on the Backup button

will backup the current configuration. The progress bar at the bottom of the section will update

the backup progress.

Configurator – Backup Section with progress

The Show/Print button will display a print preview with the current controller’s configuration.

Note: The user must be connected to a device

. Selecting the “Online Device”

Configurator – Print Preview screen

From this screen, the user can either print out the configuration by clicking on the printer icon,

, or close the print preview by clicking on the Close button or the close button on the top

right of the screen,

.

Selecting the “Backup Files” option will allow the user to manage the backup configurations on

the local computer. When this option is selected, the Backup button will become disabled.

The Delete button will delete the selected configuration. The user must confirm the delete

first.

Super Systems Inc. Page 14 of 201 Configurator Manual #4562 Rev D

Page 15

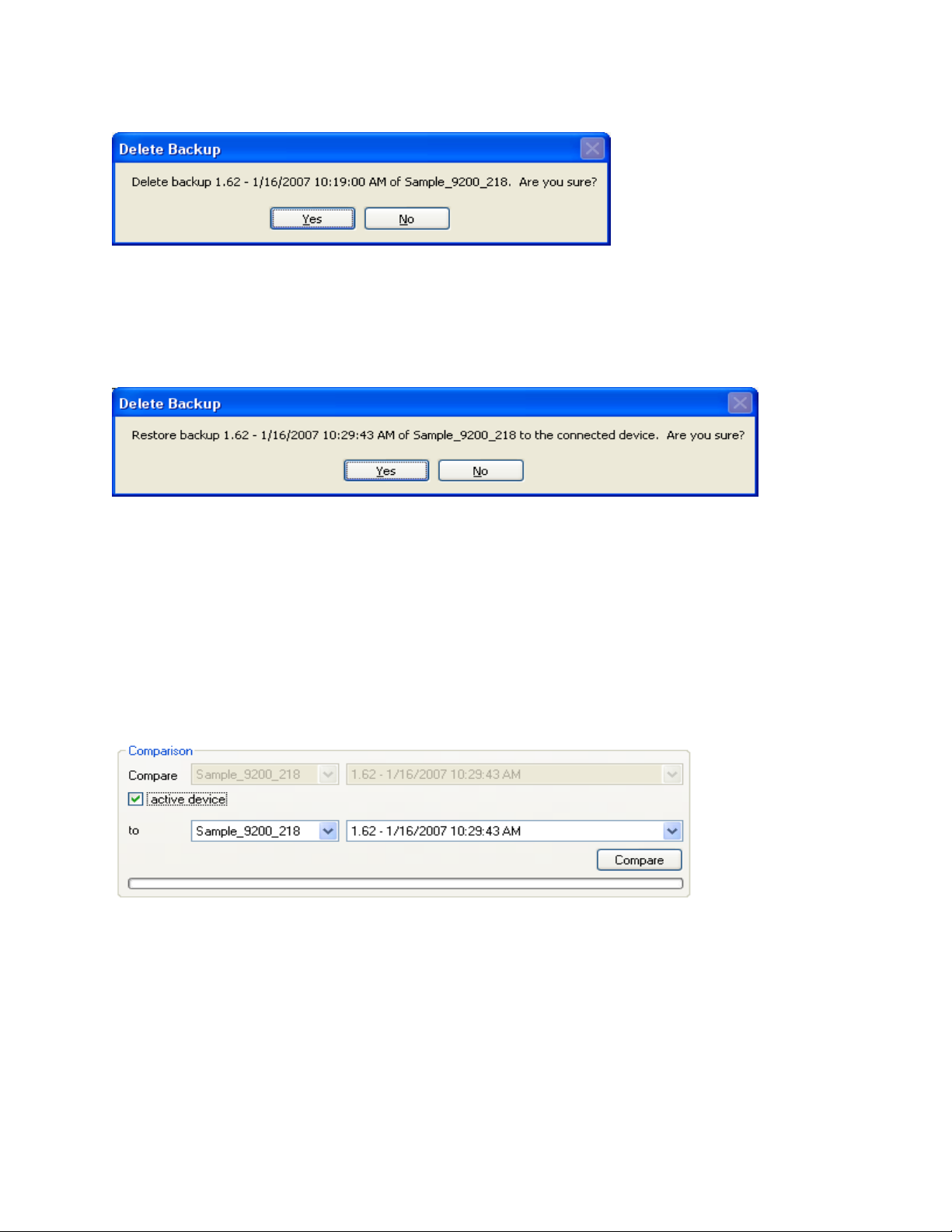

Configurator – Confirm Delete Backup file

Clicking on the Yes button will delete the configuration, but clicking on the No button will

cancel the delete.

Clicking on the Restore button will restore a backup configuration to the connected device.

The user must confirm the restoration.

Configurator – Confirm Restore backup

Clicking on the Yes button will restore the selected configuration file, but clicking on the No

button will cancel the restoration. The progress bar at the bottom of the section will update the

restore progress.

Comparison Section

The Comparison section allows the user to compare two backup files to each other.

Note: The

user must be connected to a controller if he/she wishes to use the active device for

comparison

. If the user wishes to use the device the Configurator is connected to, the user

can check the “Active Device” check box. This will disable the top two drop-down lists.

Configurator Compare section with “Active Device” checked

To compare a specific file with another, do not check the “Active Device” checkbox. If this

checkbox is not checked, then all four drop-down lists will be enabled. The user can then select

the device from the first drop-down list and the specific file for the comparison from the second

drop-down list. The user can select the device where the file to compare to is from the third

drop-down list, and the file to compare to can be selected from the fourth drop-down list. Once

all of the necessary information has been setup, the user can click the Compare button. The

progress bar at the bottom of the section will update the comparison. If the devices are

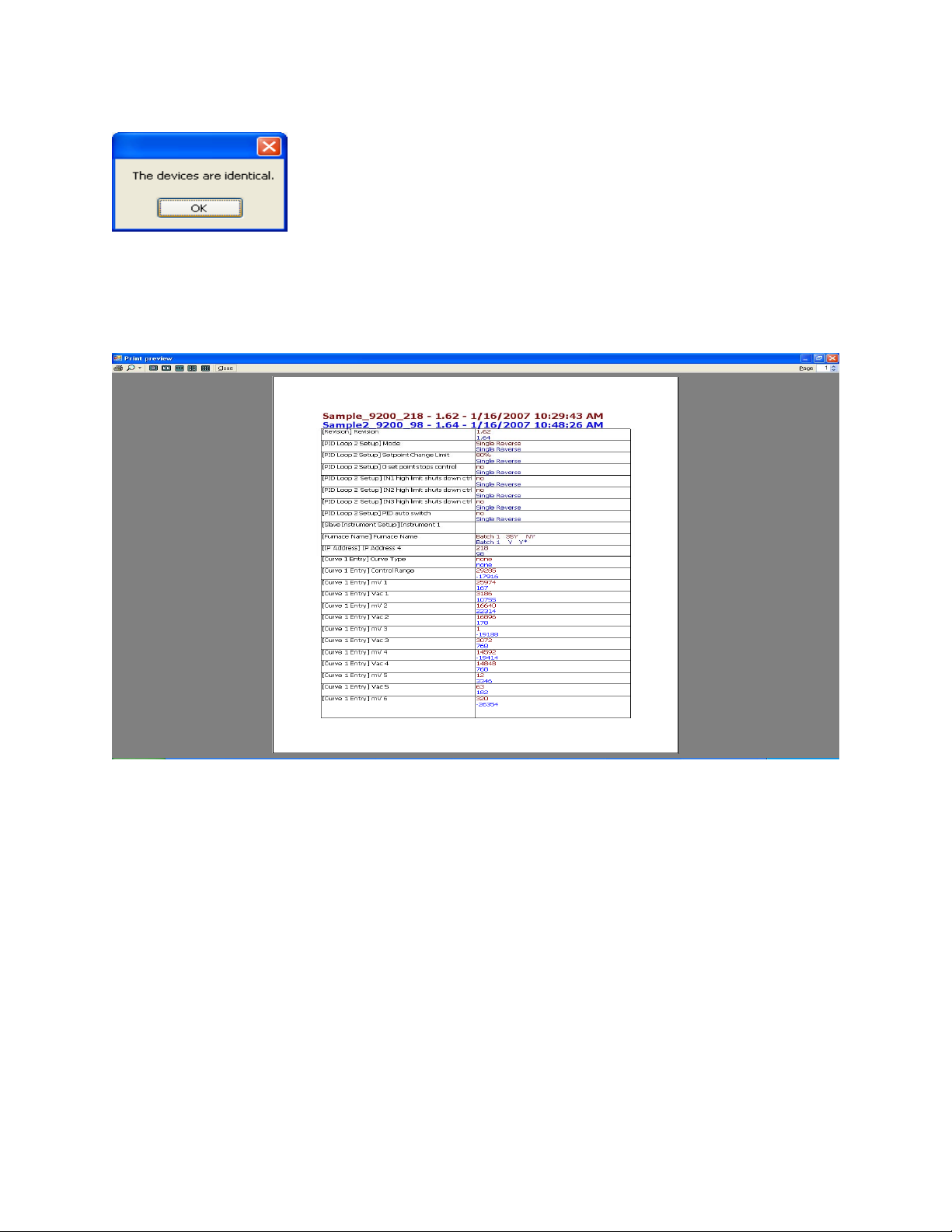

identical, the Configurator will display a message box.

Super Systems Inc. Page 15 of 201 Configurator Manual #4562 Rev D

Page 16

Configurator – Devices are identical message box

If the devices are different, the Configurator will display a print preview will the first device’s

values and properties printed in red, and the second device’s values and properties printed in

blue.

Configurator – Print Preview with different files

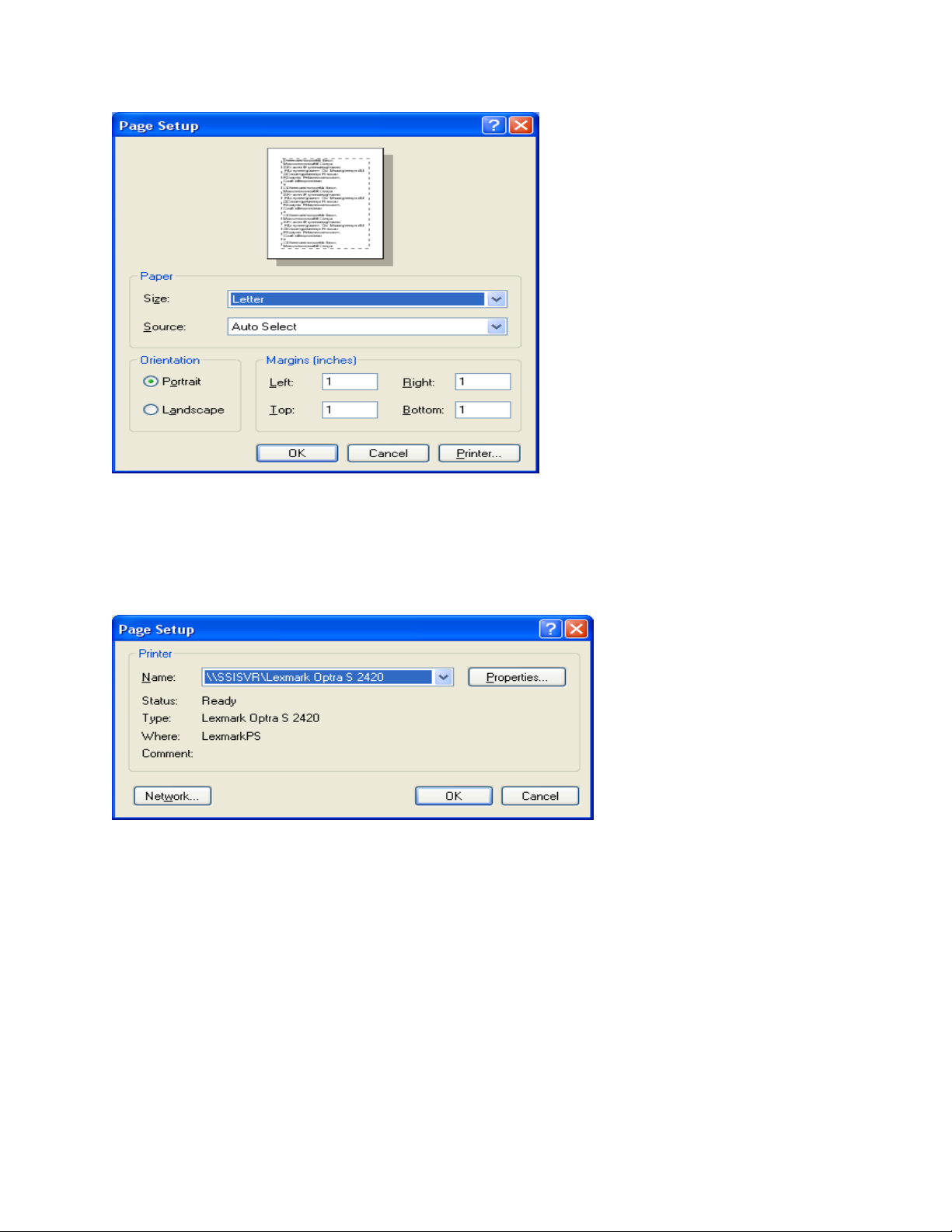

The Printer… button will allow the user to select page setup information for the printed

documents.

Note: The printer settings are set to their defaults whenever

Configurator loads. Any setting changes made through this button will not be

saved

.

Super Systems Inc. Page 16 of 201 Configurator Manual #4562 Rev D

Page 17

Configurator – Printer page setup screen

The user will be able to select the size and source of the paper, the orientation of the printed

material, and the margins for the printed material. Clicking on the OK button will set the page

settings. Clicking on the Cancel button will cancel the setup process. Clicking on the

Printer… button will allow the user to select the printer to send the information to.

Configurator – Select Printer screen

The user will be able to select the appropriate printer from the drop-down list. Clicking on the

Properties… button will display the properties for the selected printer. Clicking on the

Network button will allow the user to search through the local network for a printer. Clicking

the OK button will set the selected printer. Clicking the Cancel button will cancel the printer

selection.

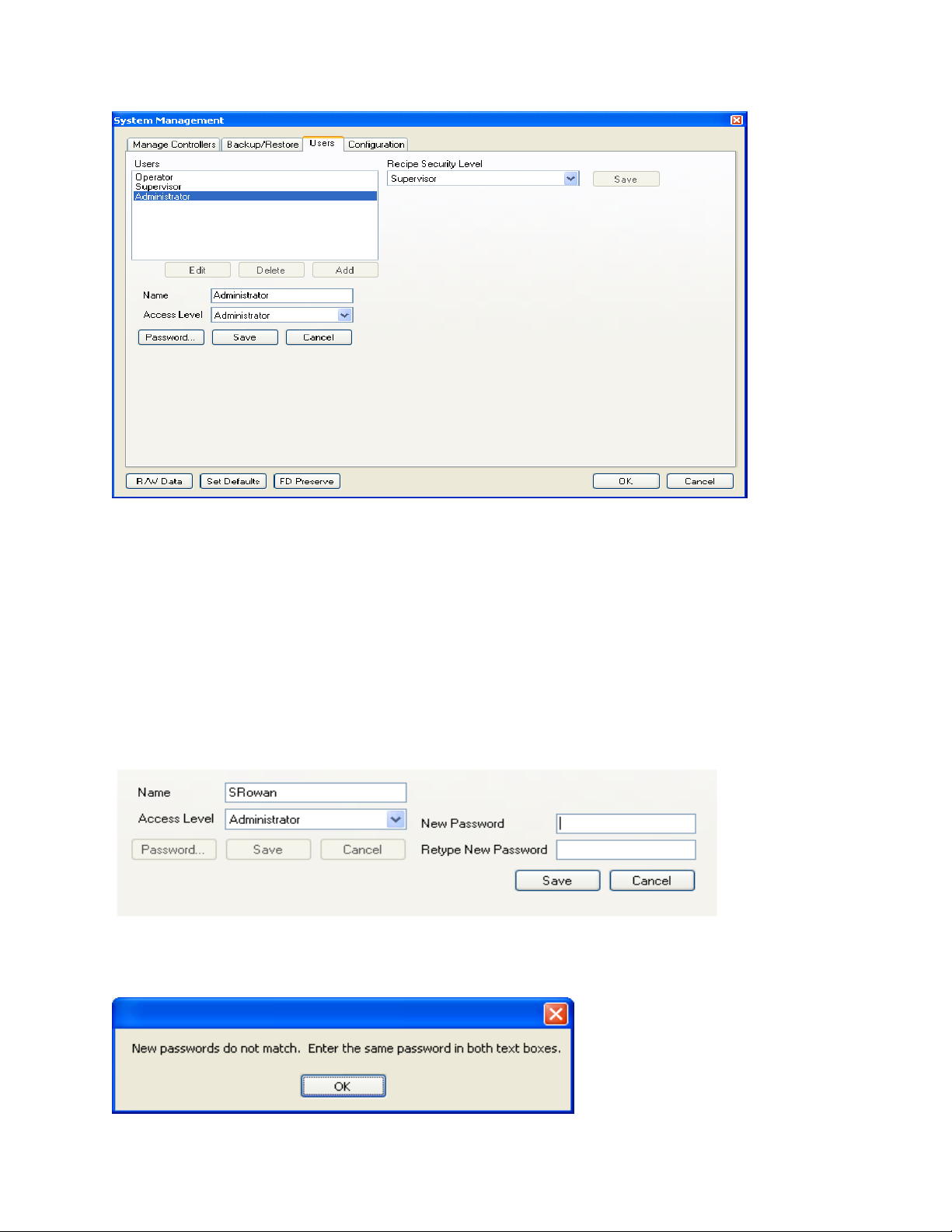

Users Tab

The Users tab allows the user to modify the user settings for any user on Configurator.

Super Systems Inc. Page 17 of 201 Configurator Manual #4562 Rev D

Page 18

Configurator – Users tab with Administrator User info

The default three users within Configurator are: Operator, Supervisor, and Administrator.

Add a User

To add a user, click on the Add button. This will display the user fields: Name, Access Level,

Password… button, Save button, and Cancel button. Enter the name of the user and select

the appropriate access level. To set a password, click on the Password… button. A password

does not have to be given to add a user. The password fields are displayed: New Password,

Retype New Password, Save button, and Cancel button. The user can type in the password in

the “New Password” and “Retype New Password” fields. Clicking on the Save button will save

the password, and clicking on the Cancel button will cancel the password add.

Configurator – Add User Password fields

If the passwords do not match, then Configurator will display an error message.

Super Systems Inc. Page 18 of 201 Configurator Manual #4562 Rev D

Page 19

Configurator – Passwords do not match error message

Clicking on the Save button will save the user and add the user name to the list. Clicking on

the Cancel button will cancel the add user process and hide the user fields.

Edit a User

To edit a user’s settings, select a user from the list and click on the Edit button, or double-click

on the user name in the list. This will display the user fields. The rules for adding a user apply

to editing a user as well. See the section

Add a User

for instructions.

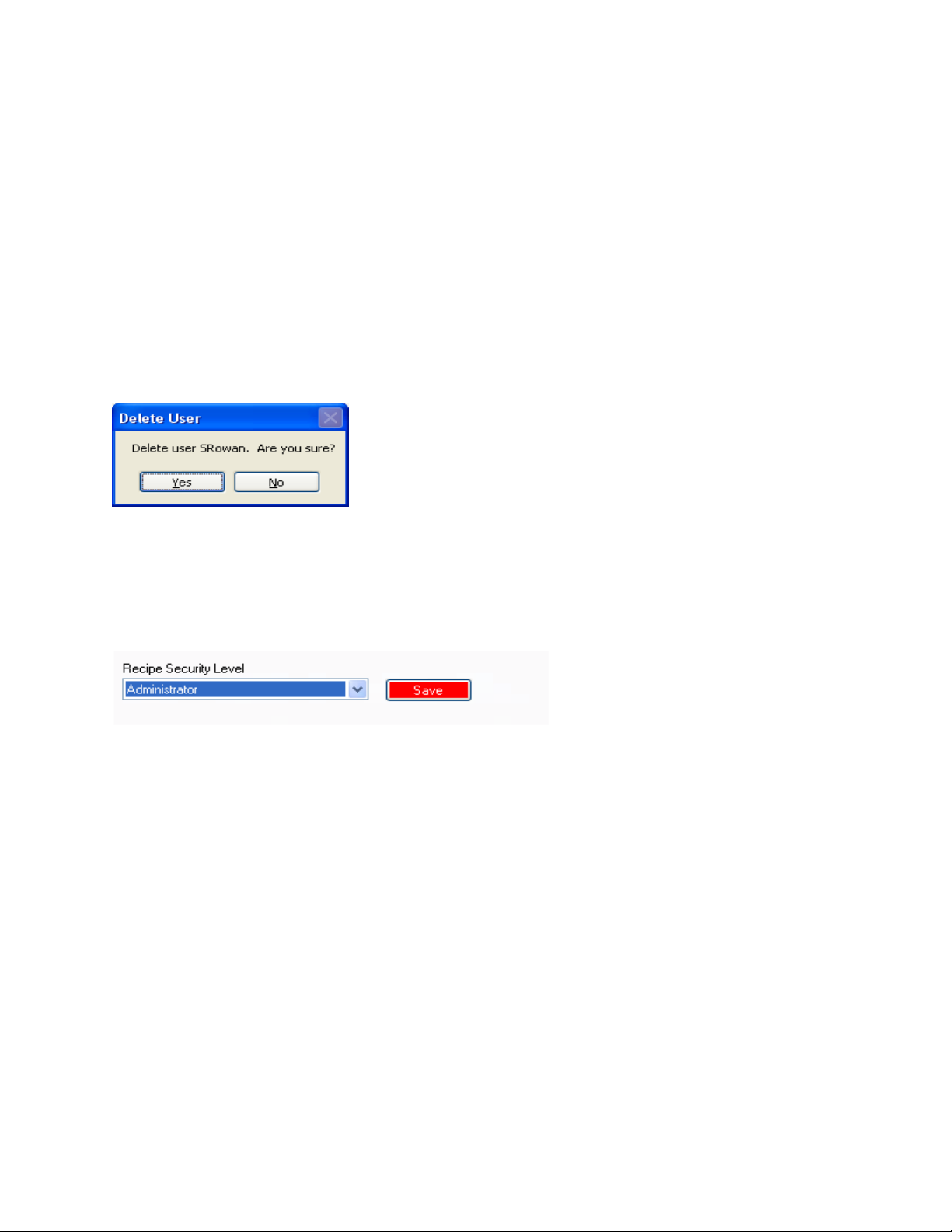

Delete a User

To delete a user, select a user from the list and click on the Delete button. The user will have

to confirm the deletion.

Configurator – Confirm delete user

Clicking on the Yes button will delete the user, and clicking on the No button will cancel the

delete process. Once a user has been deleted, the list of users will update.

The Recipe Security Level will determine what level of recipe security the users will have. Once

the user has selected a different level, the Save button will have a red background.

Configurator – Change User Recipe Security Level

Clicking on the Save button will save the new recipe security level.

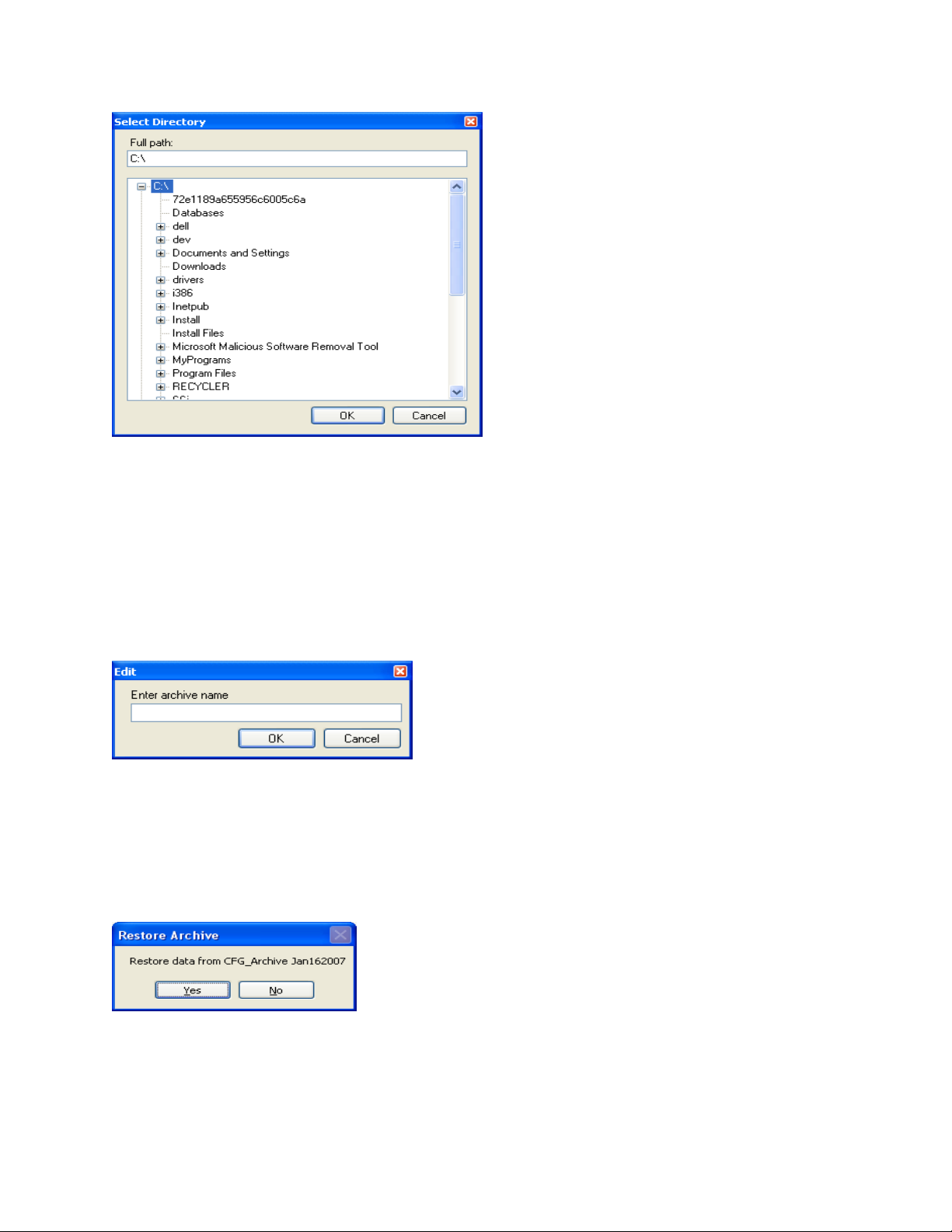

Configuration Tab

The Configuration tab will allow the user to change the configuration of Configurator. The

“Data Access” section displays the location for all of the data files that Configurator uses, such

as backup files, user configurations, etc. To change this location, click on the Change button.

This will display a dialog box that will allow the user to browse and select a new location.

Super Systems Inc. Page 19 of 201 Configurator Manual #4562 Rev D

Page 20

Configurator – Select Directory dialog box

The user can browse to a new location and click on the OK button to set that location as the

new location. Clicking on the Cancel button will cancel the change.

Note: The main

Configurator files (Configurator.exe, SSiLibrary.dll, etc) do not need to be in the

same directory as the data files

.

The “Configurator Settings” section deals with Configurator’s screen size. The Restore button

will restore Configurator’s screen size to the default size. The list below the Restore button

will display any archived configurations. To archive a configuration, click on the Archive

button. The user will have to give the archive a name.

Configurator – Archive Name input box

Clicking on the OK button after inputting a name will archive the configuration settings and

update the list. Clicking on the Cancel button will cancel the archival process. Clicking on the

OK button without giving an archive name will stop the archive process. To restore an archived

configuration, select the configuration from the list and click on the Restore button. The user

will have to confirm the restoration.

Configurator – Confirm restore archive

Clicking on the Yes button will restore the archive, while clicking on the No button will cancel

the restore process. The user will have the option to archive the current settings before

restoring the configuration settings.

Super Systems Inc. Page 20 of 201 Configurator Manual #4562 Rev D

Page 21

Configurator – Archive Settings message box

Clicking on the Defaults button will restore all default values to Configurator. Since some data

may be lost, the user will have to confirm the action.

Configurator – Restore defaults

Clicking on the Yes button will restore the defaults, but clicking on the No button will cancel

the restoration.

To remove a configuration from Configurator, select the configuration to remove and click on

the Remove button. The user will have to confirm the removal.

Configurator – Confirm Remove Archive

Clicking on the Yes button will continue with the removal, while clicking on the No button will

cancel the removal. Since removing the archived configuration will result in the loss of data,

the user will have to confirm the removal a second time.

Configurator – Second Confirm Removal

Clicking on the Yes button will remove the archived file, while clicking on the No button will

cancel the removal.

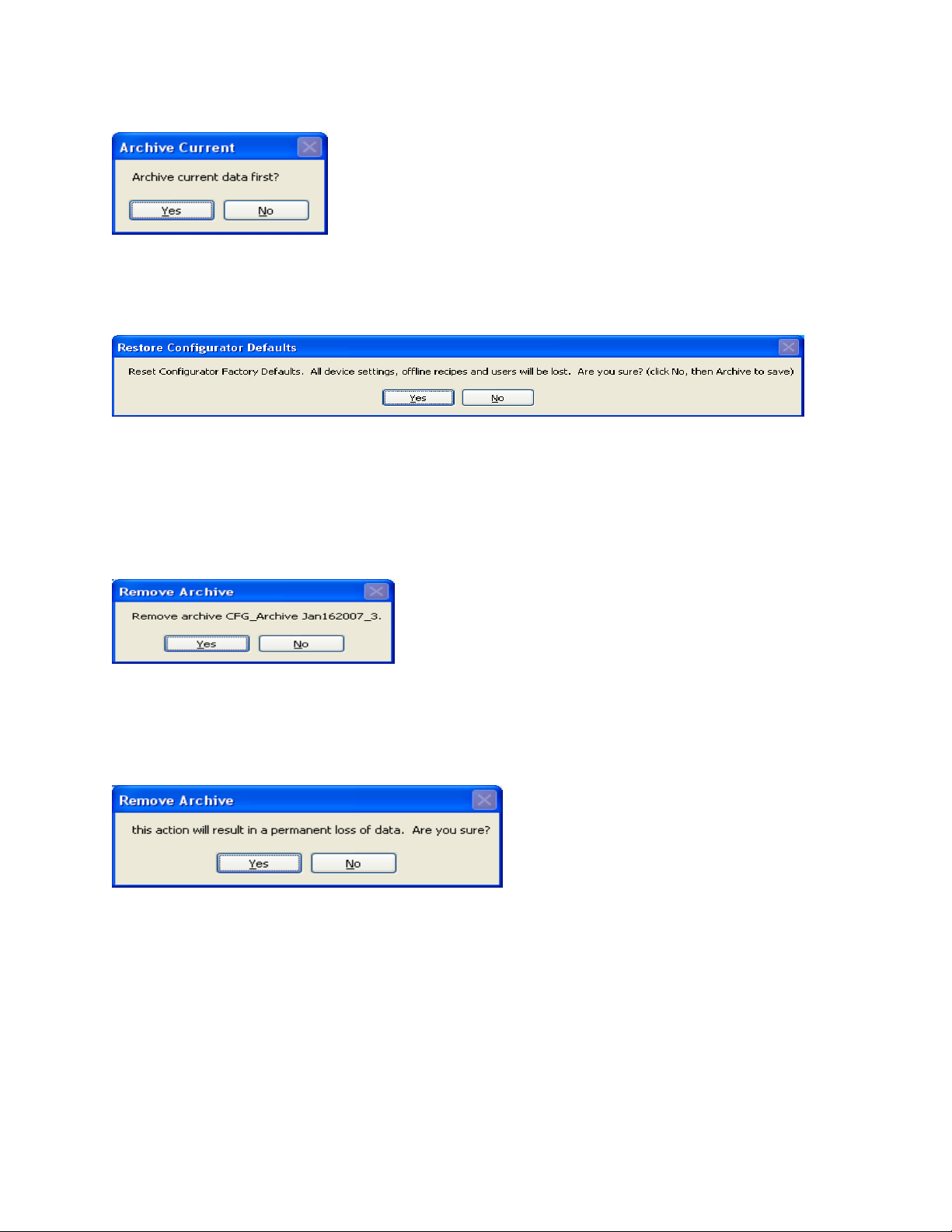

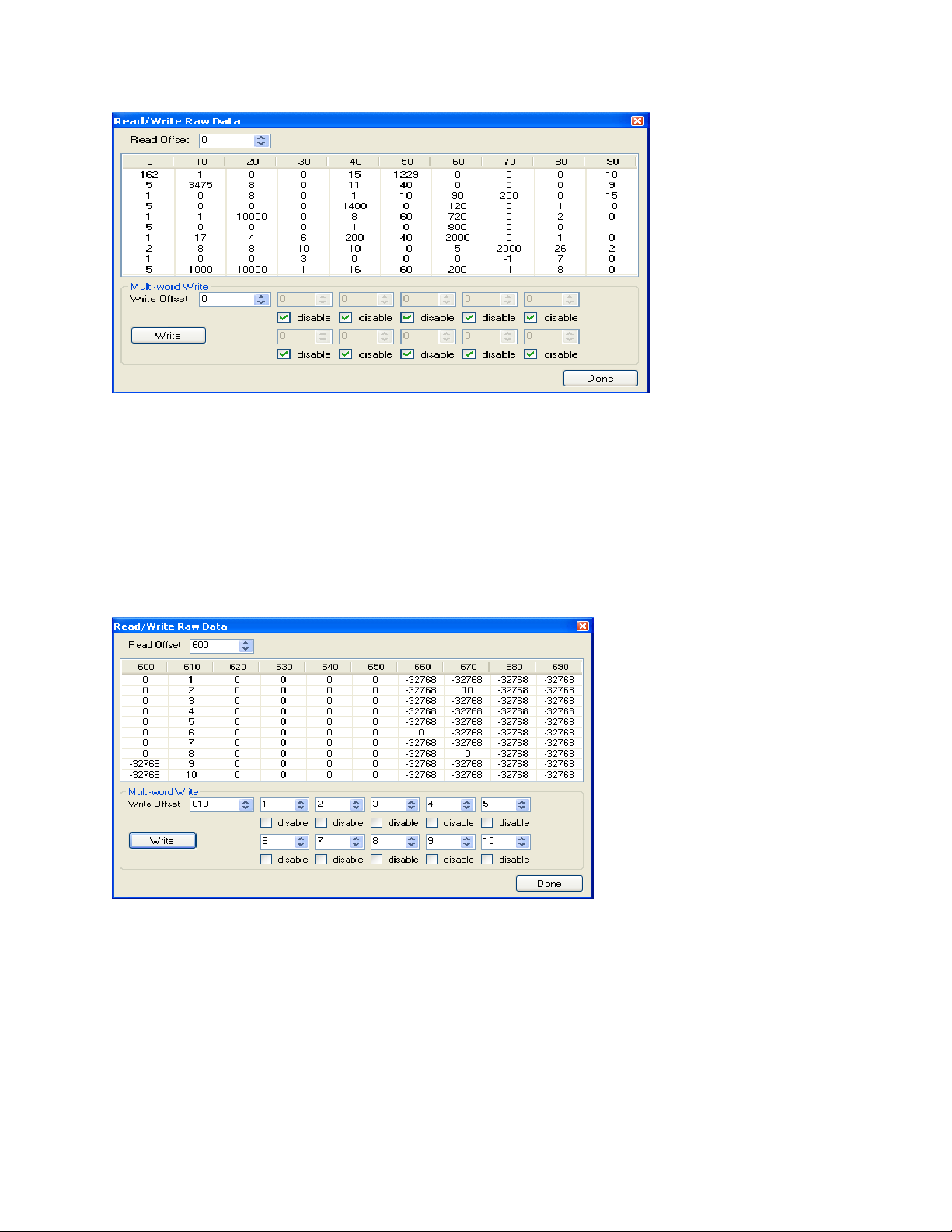

R/W Data

The R/W Data button will display the raw data from the selected controller.

Super Systems Inc. Page 21 of 201 Configurator Manual #4562 Rev D

Page 22

Configurator – Read/Write Raw Data screen

The user must use the SSi Special passcode to access the R/W Data screen. Values can be

written directly to the controller through this screen. Select the Modbus Read Offset value to

start reading data. Select the Modbus Write Offset write data to a specific Modbus register.

Configurator allows the user to write multiple words to sequential Modbus registers. Starting

from the Modbus register provided, any of the value boxes that do not have the “disable”

checkbox checked will write the value indicated to the sequential Modbus register. The top row

contains registers 1 through 5 and the bottom row contains registers 6 through 10. The screen

shot below shows how this process works.

Configurator – Write multi-word offsets

Since the “Write Offset” field was set to 610, this is the starting point for the write.

Clicking on the Done button will close out the Read/Write Raw Data screen.

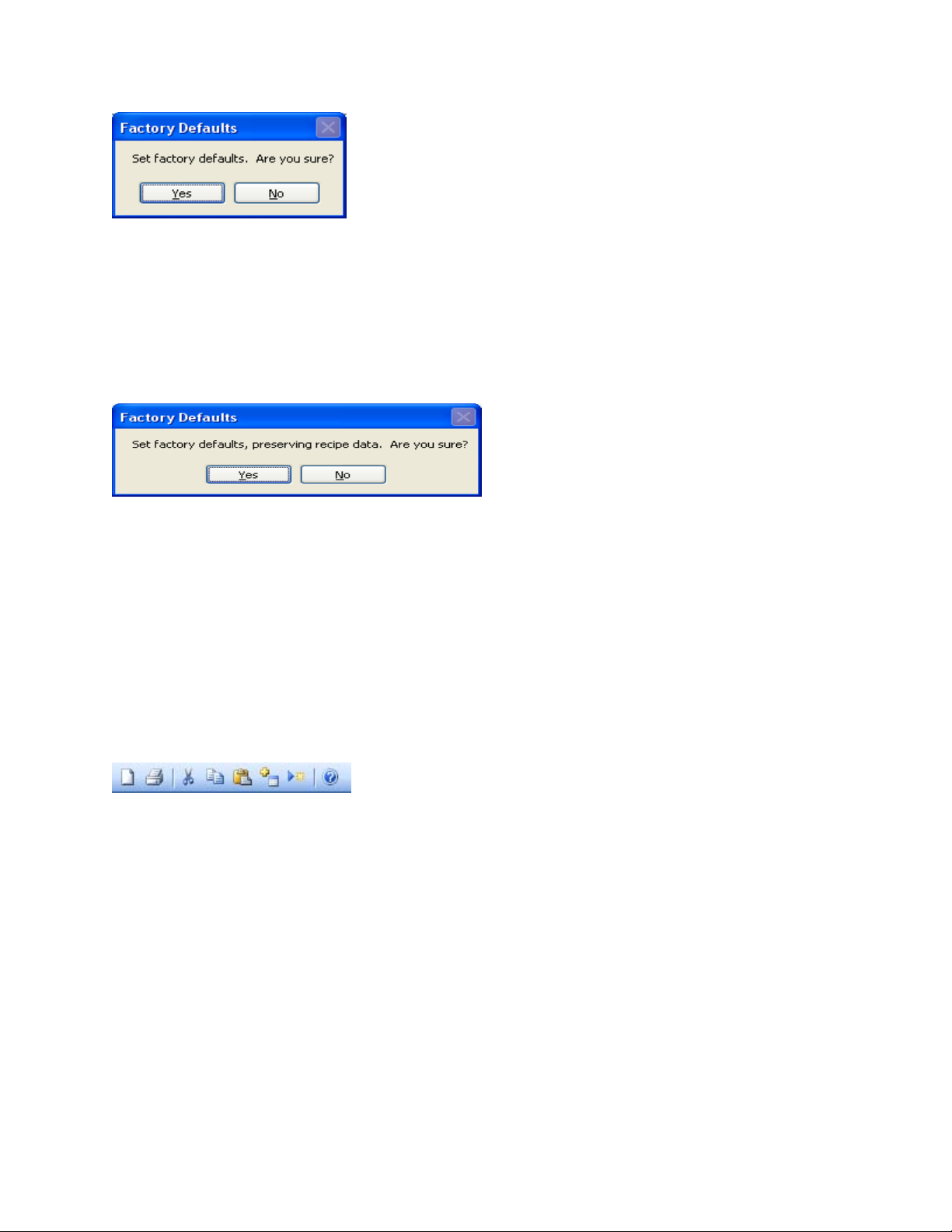

Set Factory Defaults

Clicking on the Set Defaults button will set the factory defaults for Configurator. The user will

have to confirm this action.

Super Systems Inc. Page 22 of 201 Configurator Manual #4562 Rev D

Page 23

Configurator – Set factory defaults confirmation

Clicking on the Yes button will set the factory defaults; clicking on the No button will cancel the

action.

FD Preserve

The FD Preserve button will set the factory defaults while also preserving the recipe

information. The user will have to confirm the action.

Configurator – Confirm set factory defaults with recipe preserve

Clicking on the Yes button will set the factory defaults and preserve the recipe information.

Clicking on the No button will cancel the action.

Clicking on the OK or Cancel button will close the

5. The Recipe Editor button

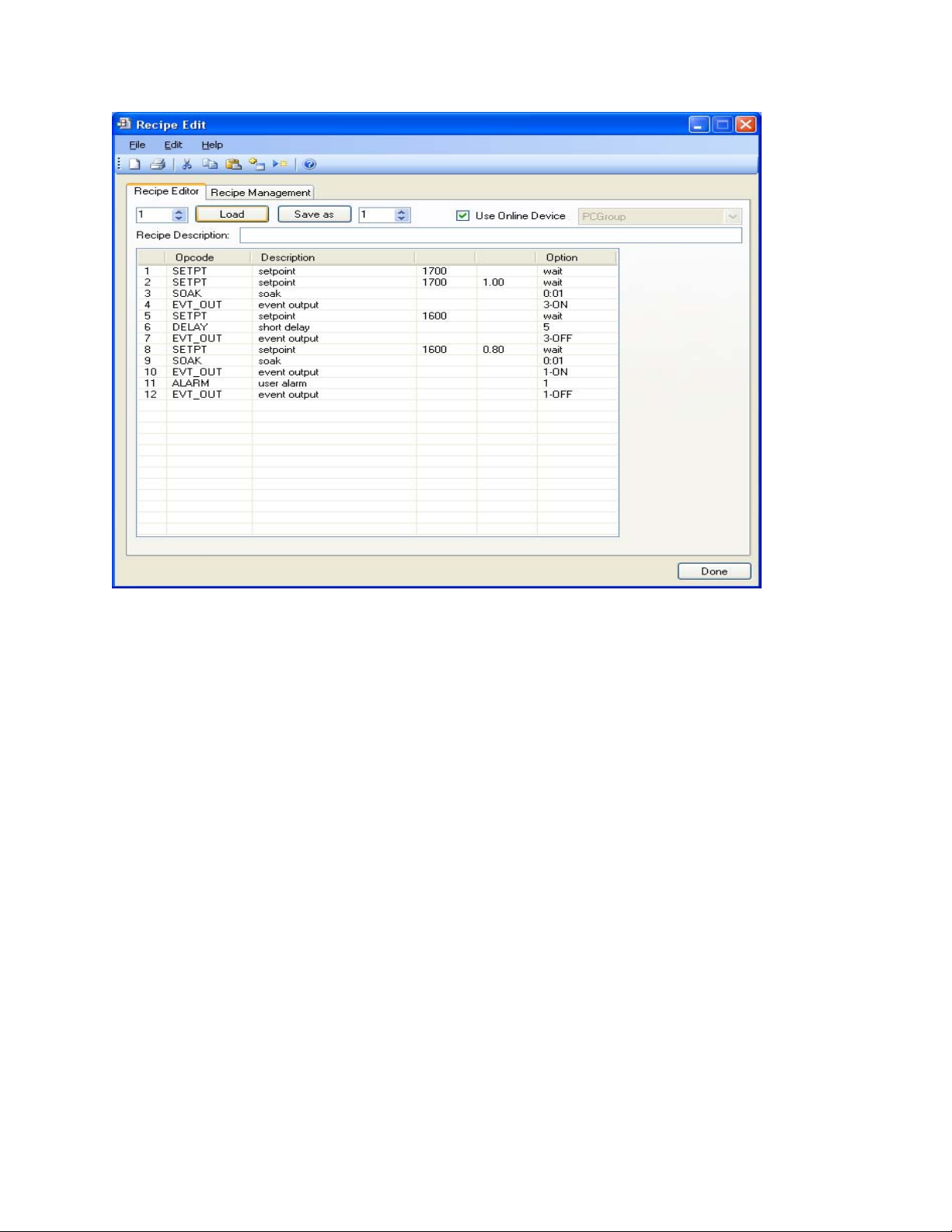

The Recipe Editor button is available to users of all access levels, however, users with Operatorlevel access cannot save recipes. This form allows users to manually edit a recipe.

The toolbar at the top of the form contains the basic Windows-type functions, new, cut, copy,

etc. The Windows-type shortcuts apply to most of the functions as well: Ctrl + C to copy, Ctrl +

X to cut, etc. The menu will list the shortcut next to each command.

System Management

screen.

Configurator – Recipe Edit toolbar

From left to right are: New (load a blank recipe), Print (print out the recipe steps), Cut (cut a

selected step), Copy (copy a selected step), Paste (paste the cut or copied step), Insert Step

(inserts a selected step into the program…all steps below the inserted step will move down),

Insert NO-OP Step (insert a NO-OP step into the program…all steps below the inserted step will

move down), and Help (display a help page).

Super Systems Inc. Page 23 of 201 Configurator Manual #4562 Rev D

Page 24

Configurator Recipe Editor screen

Recipe Editor Tab

Load/Save Recipes

The box in the top left of the form is where the user can select which recipe (0 – 300) to load.

Use the up or down arrows, or just type in the recipe number and click on the Load button.

The recipe steps will be filled in the white area on the form. Once the Load button has been

clicked, the box to the right of the Save As button will be filled with the recipe number

selected. By default, the Save As recipe will be the same as the Load recipe. To save the

loaded recipe as a different recipe number, use the up or down arrows, or just type in the new

number (0 – 300) in the box next to the Save As button and click this button.

Checking the “Use Online Device” check box will load and save the recipes on the currently

connected controller. Not checking this check box will load and save the recipes on the local

computer (PCGroup).

The “Recipe Description” line is a text description of the recipe.

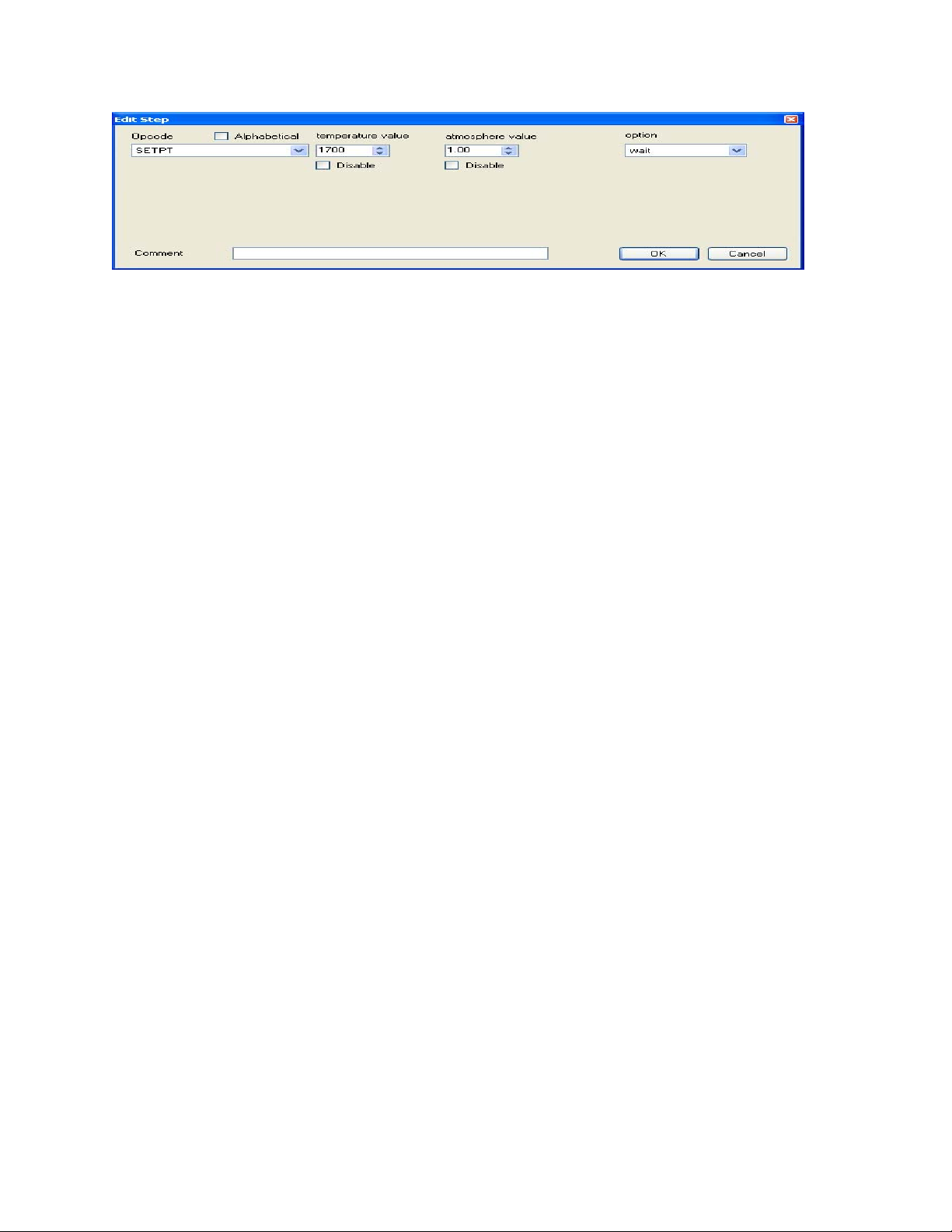

Modify Recipes

To modify any of the steps in the recipe, double-click on the row of the step that will be

modified. This will display the

Edit Step

form.

Super Systems Inc. Page 24 of 201 Configurator Manual #4562 Rev D

Page 25

Configurator Recipe Step Edit form

The drop-down list under “Opcode” allows the user to select the specific opcode that will be

used in the recipe step. Checking the “Alphabetical” checkbox will allow the user to alphabetize

the list. If a temperature value or an atmosphere value is needed, these can be set using the

up or down arrows, or by just typing in the value. If these are not needed, check the “Disable”

checkbox and the boxes will become unavailable. Note – for some opcodes, the display text will

change and the

Edit Step

screen will look slightly different to accommodate the different types

of values associated with each opcode, but the functionality of each item will remain the same.

The box(es) on the right side of the form is the action or value that should be taken. For

instance, with opcode “SetPt”, the box on the right is the “Option” and there is a drop-down list

of available options: wait, wait up, wait down. However, for opcode “soak”, the temperature

value and atmosphere value fields disappear and the boxes on the right of the form are “Soak

Time hoursminutes”, and there are two boxes that have values ranging from 0 to 1000 for the

hours and 0 to 59 for the minutes. These values can be adjusted by using the up or down

arrows, or by typing the new value in. The user can add an optional comment to the recipe

step in the “Comment” field, if desired. Once all of the changes have been made, the user can

click on OK to save these changes.

Super Systems Inc. Page 25 of 201 Configurator Manual #4562 Rev D

Page 26

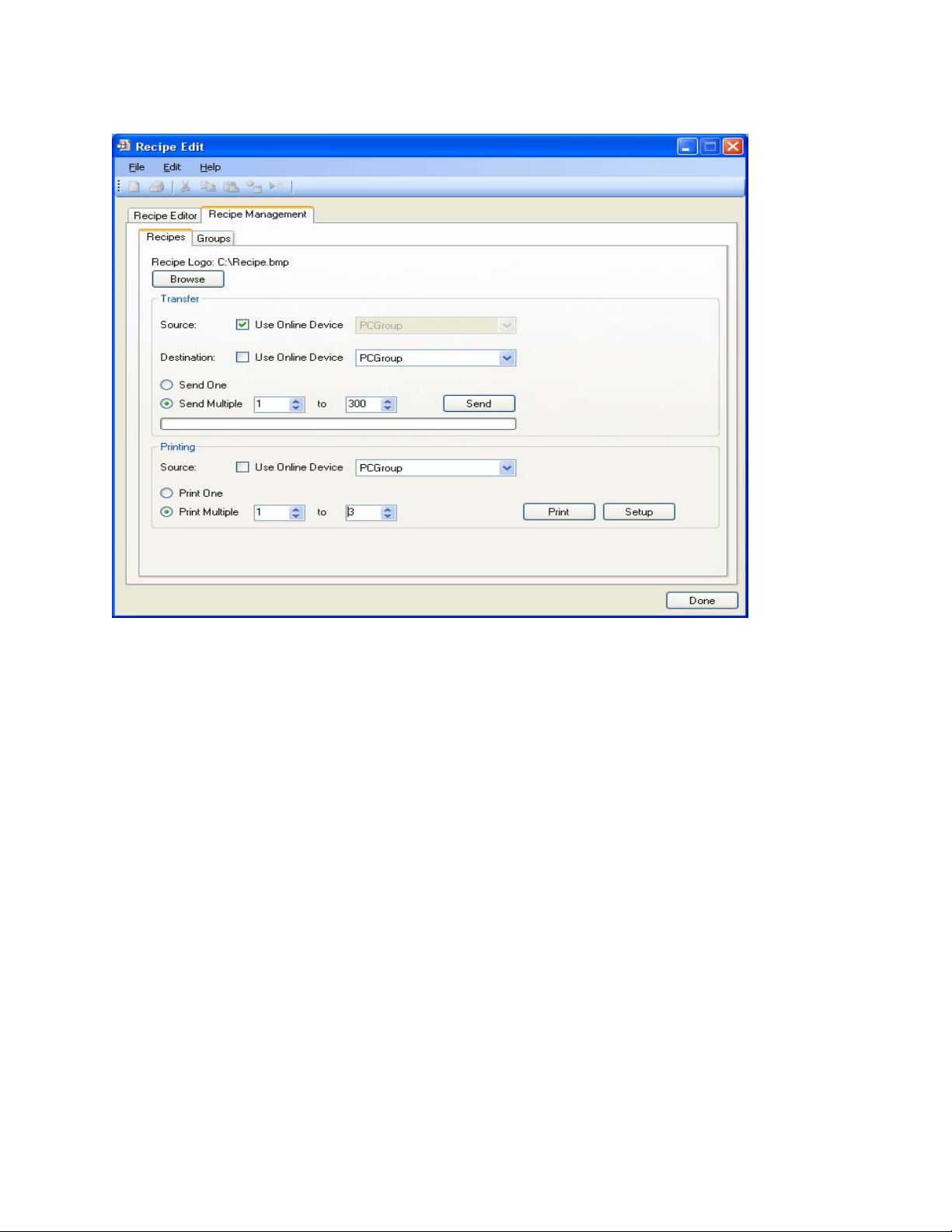

Recipe Management Tab

Configurator – Recipe Management tab with Recipes tab

Recipes Tab

The “Recipe Logo:” will allow the user to select a bitmap (.bmp) image to act as a logo for the

recipes. Clicking on the Browse button will open up a dialog box that will allow the user to

browse to the desired picture.

Transfer Section

The Transfer section will allow the user to transfer one or more recipes from one location to

another. The “Source” field could either be the currently connected device (“Use Online

Device”), or one of the offline groups (“PCGroup”). The “Destination” field could either be the

currently connected device (“Use Online Device”), or one of the offline groups (“PCGroup”).

The “Send One” option will send only one recipe from the source to the destination. The recipe

to send will be based upon the numeric value within the box next to the “Send Multiple” option.

The “Send Multiple” option will send any number of sequential recipes from the source to the

destination. When the “Send Multiple” option is selected, there will be another numeric value

box visible next to the first numeric value box. This second box will be invisible when the “Send

One” option is selected. Once all of the required information is present (source, destination,

recipe to send), clicking on the Send button will send the recipes. The progress bar at the

bottom of the section will update the send process.

a controller may take a few minutes

.

Note: Transferring recipes from or to

Super Systems Inc. Page 26 of 201 Configurator Manual #4562 Rev D

Page 27

Printing Section

The Printing section allows the user the ability to print out recipes. The “Source” field could

either be the currently connected device (“Use Online Device”), or one of the offline groups

(“PCGroup”). The “Print One” option will print only one recipe from the source. The recipe to

print will be based upon the numeric value within the box next to the “Print Multiple” option.

The “Print Multiple” option will print any number of sequential recipes from the source. When

the “Print Multiple” option is selected, there will be another numeric value box visible next to

the first numeric value box. This second box will be invisible when the “Print One” option is

selected. Clicking on the Print button will display a print preview dialog, where the user will be

able to view and/or print the recipes. Clicking on the Setup button will display a

Page Setup

screen, which will allow the user to set up the page settings for printing, as well as select the

printer.

Note: Printing recipes from a controller may take a few minutes

.

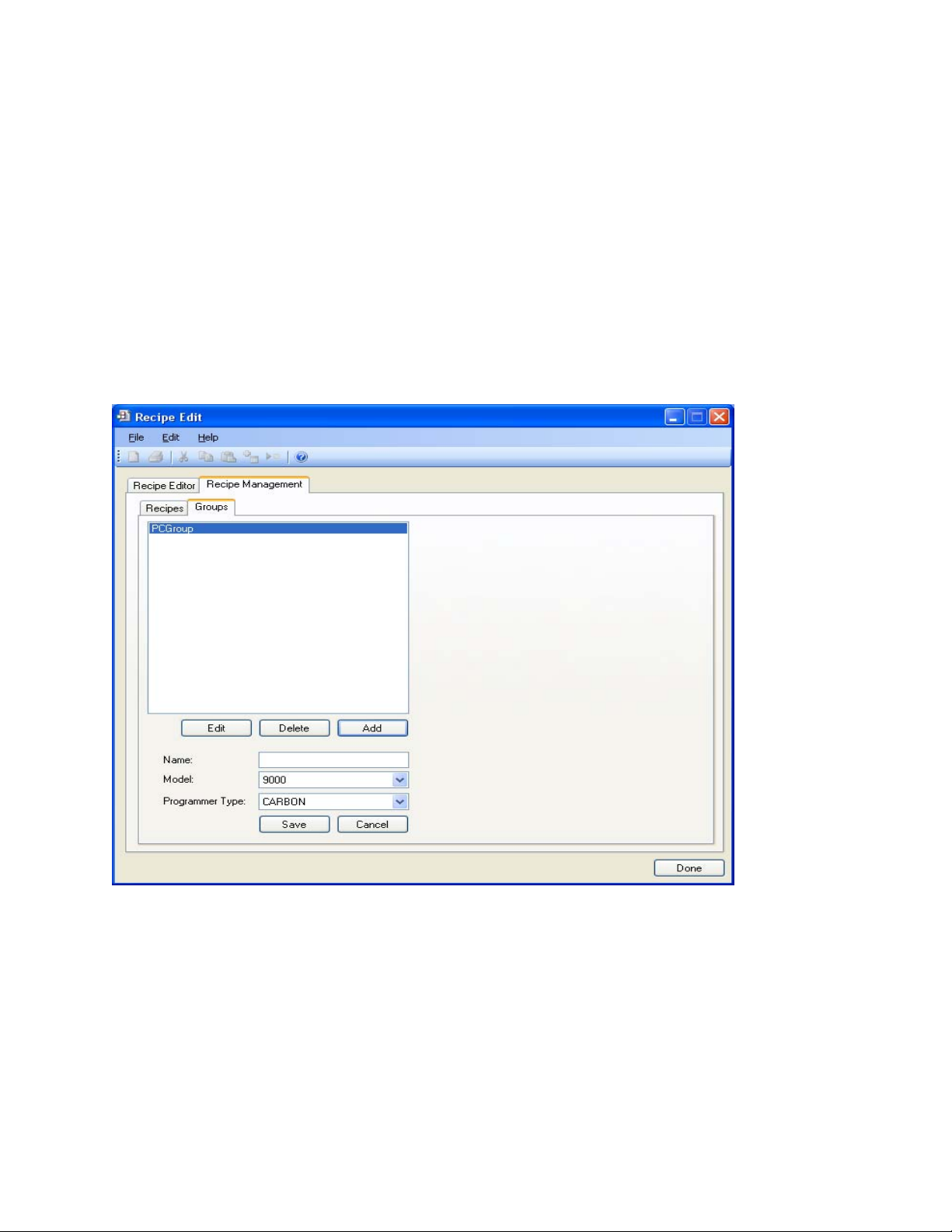

Groups Tab

Configurator – Recipe Management tab with Groups tab

The Groups tab will allow the user to add, modify, or delete the offline groups of recipes. The

offline recipe groups are used throughout the

Recipe Edit

screen, both on the Recipe Editor tab

and the Recipe Management tab.

To add a recipe group, click on the Add button. This will display the recipe group fields: Name,

Model, and Programmer Type. Enter or select the desired values and click the Save button to

save the new group, or click the Cancel button to cancel the add process.

To edit a recipe group, click on the group name to edit from the list and click on the Edit

buttons, or double-click the group name in the list. This will display the recipe group fields with

Super Systems Inc. Page 27 of 201 Configurator Manual #4562 Rev D

Page 28

the selected recipe group’s information loaded. Modify the desired values and then click the

Save button to save the changes, or click on the Cancel button to cancel the edit process.

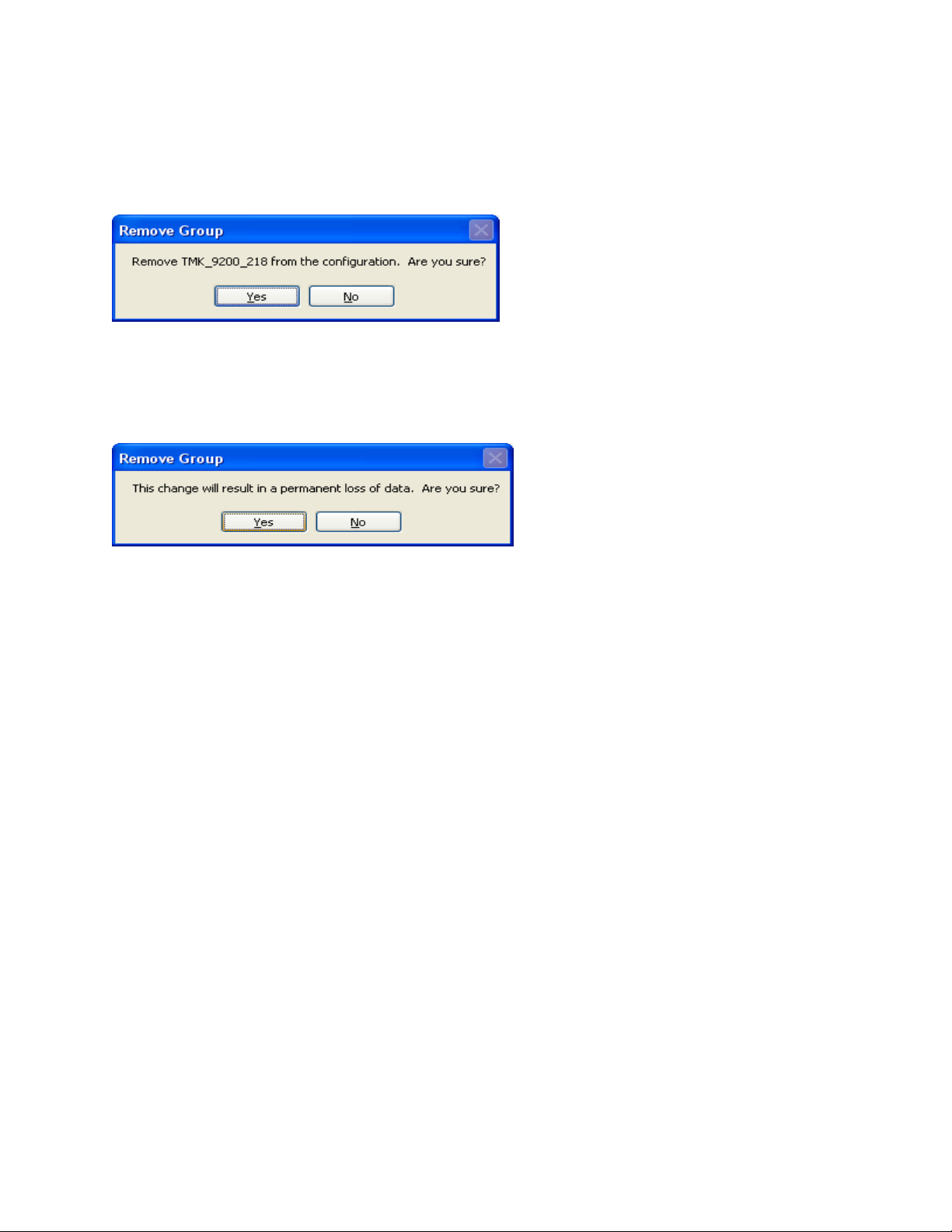

To delete a recipe group name, click on the group name to delete and click on the Delete

button. The user will have to confirm the delete.

Configurator – Confirm delete recipe group

Clicking on the Yes button will continue with the delete, while clicking on the No button will

cancel the delete process. Since deleting a recipe group will result in the loss of data, the user

will have to confirm the delete a second time.

Configurator – Second confirm delete recipe group

Clicking on the Yes button will delete the recipe group, while clicking on the No button will

cancel the delete process.

Clicking on the Done button will close the screen down.

Super Systems Inc. Page 28 of 201 Configurator Manual #4562 Rev D

Page 29

Configurator Main Form

The right side of the form contains a drop-down list that contains all of the devices configured

with the Configurator. To view a specific device, select it from the drop down list.

Configurator - Device drop-down list

The selected menu items on the left, and the values on the screen, will change to reflect the

new device’s values.

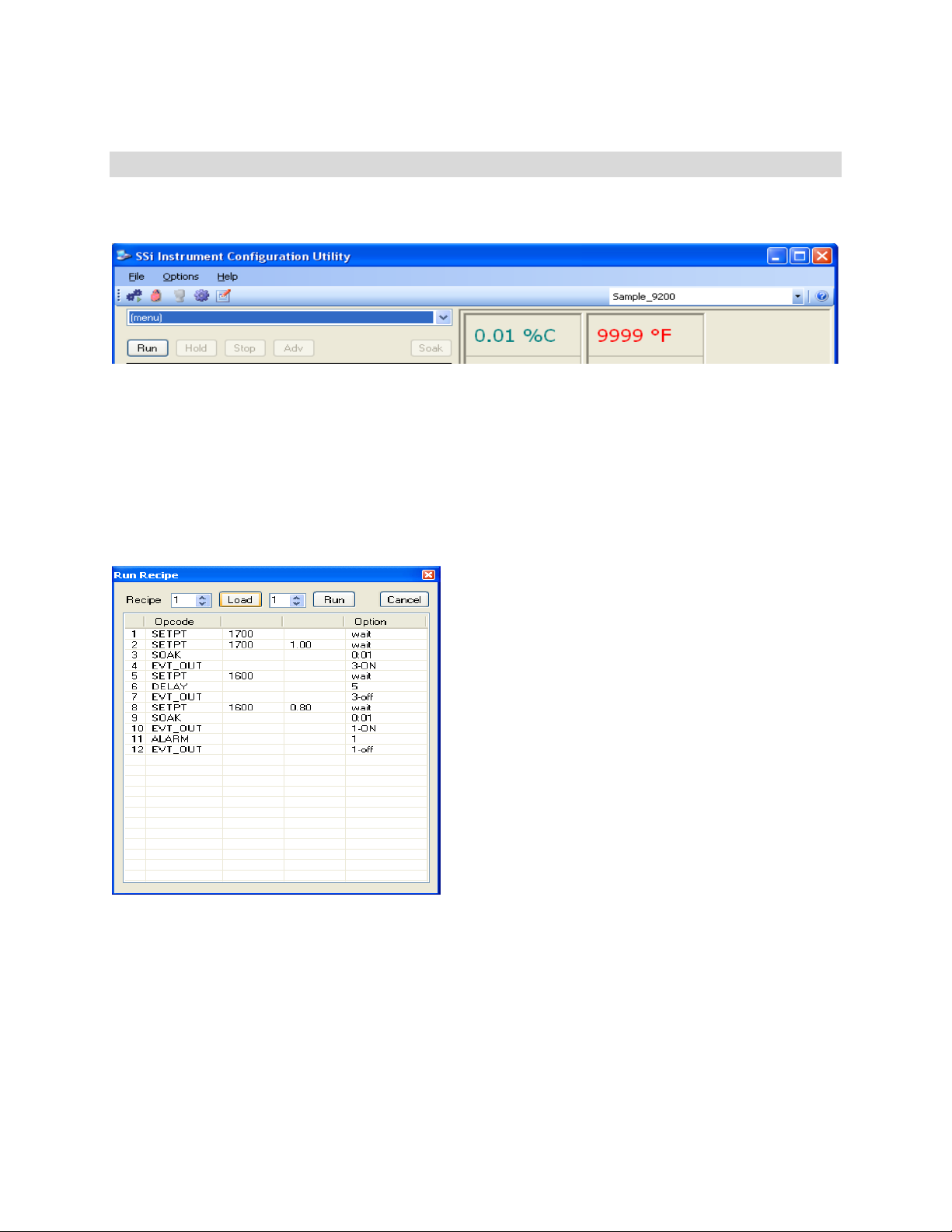

The area right below the drop-down menu list allows the user to start, stop, hold, or resume a

recipe.

Clicking on the Run button will display the

the recipe to run.

Run Recipe

screen, from which the user can select

Configurator – Run Recipe screen

Use the number box next to the “Recipe:” to select a recipe number from 1 to 300. Once the

recipe number has been selected, click on the Load button. This will display the steps in the

recipe in the white area. If the user wants the recipe to start from a step other than step 1, the

user can select which step from the number box to the right of the Load button. The user can

edit the steps in the recipe just like in the

Recipe Management

screen. Once the recipe number

and the starting step number have been chosen, the user can click on the Run button. This

will begin the recipe. If the user does not wish to run the recipe, clicking on the Cancel button

will close the form without starting the recipe.

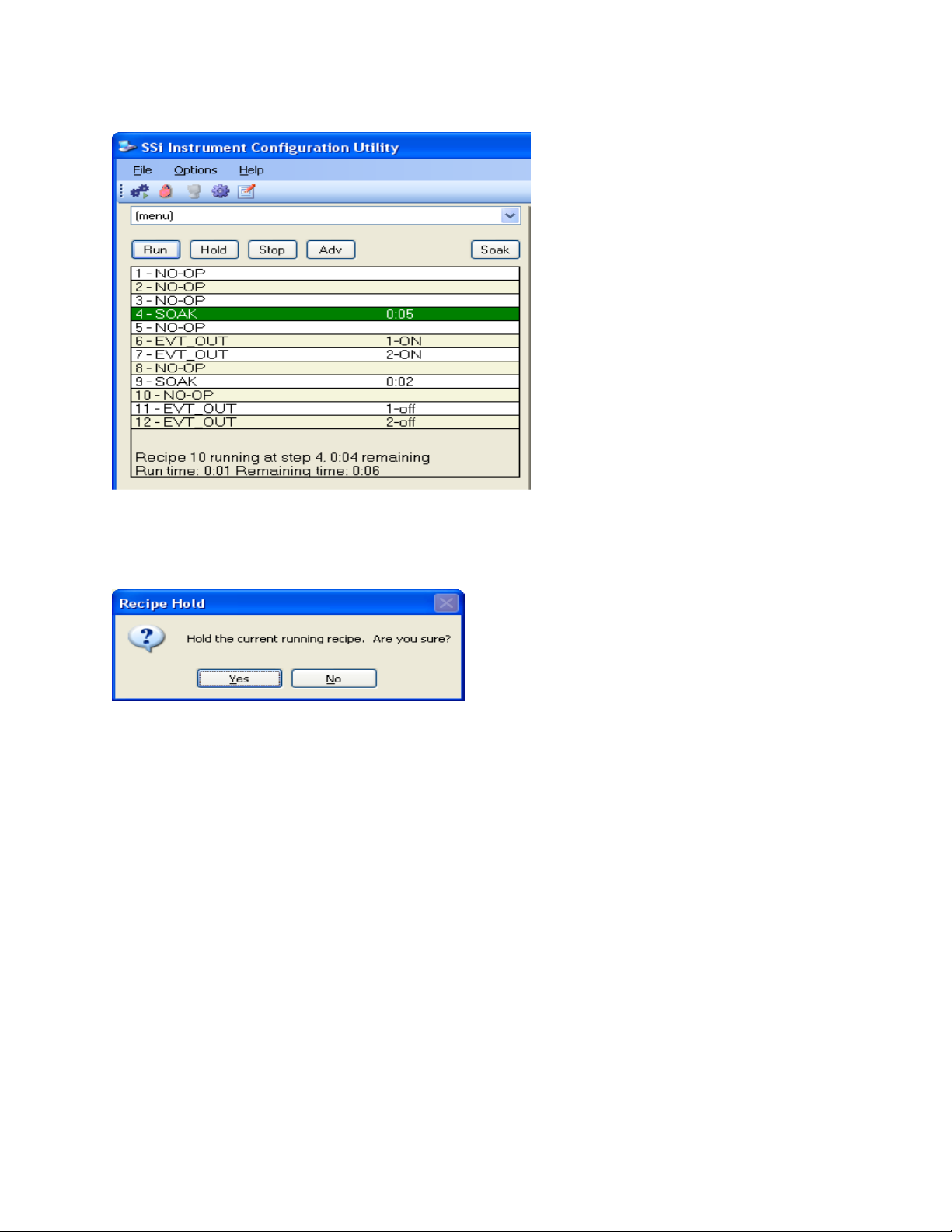

While a recipe is running, there will be a green highlight across the program display area.

Super Systems Inc. Page 29 of 201 Configurator Manual #4562 Rev D

Page 30

Configurator - Program running display

The Hold button will put the recipe on hold, but it will not stop the recipe. To hold a recipe,

click on the Hold button. The user will have to confirm the action.

Configurator – Confirm hold recipe

Clicking on Yes will hold the recipe, and clicking on No will not hold the recipe. Once the

program has been held, the Hold button will say Cont, there will be a yellow highlight across

the program display.

Super Systems Inc. Page 30 of 201 Configurator Manual #4562 Rev D

Page 31

Configurator – Program hold

To continue the recipe, click on the Cont button. The user will have to confirm the action

Configurator – Confirm continue recipe

Click the Yes button to continue the recipe. Click the No button to leave the recipe in hold.

Once the recipe has been continued, the green highlight will return and the Cont button will

say Hold.

To stop the recipe, click on Stop. This will display a message box confirming the action.

Configurator – Confirm stop recipe

Clicking on Yes will stop the program and clicking on No will cancel the action.

The ADV button will allow the user to advance to the next step in the recipe. The user will

have to confirm the action.

Super Systems Inc. Page 31 of 201 Configurator Manual #4562 Rev D

Page 32

Configurator – Confirm advance to the next step

Clicking on the Yes button will advance the recipe to the next step, while clicking on the No

button will cancel the advance.

If there is an alarm of any kind, the alarm text will be displayed at the bottom of the program

display area with a red highlight, and the Ack button will become visible.

Configurator – Program with alarm

Clicking on the Ack button will acknowledge the alarm. Once the alarm has been

acknowledged, the Ack button will disappear, and the alarm text will disappear as well.

The Soak button will allow the user to manually change the length of a soak time. To do this,

click on the Soak button.

enabled

. This will display the Soak Timer dialog box.

Note: The recipe must be in a soak step for this button to be

Configurator – Adjust soak time

The current soak time will be displayed initially. To set a new soak time, change the hours

and/or minutes to the desired values and click on the Set button.

Super Systems Inc. Page 32 of 201 Configurator Manual #4562 Rev D

Note – This change will

Page 33

only last for the current soak and will not be a permanent change

. To cancel the

change, click on the Cancel button.

The right side of the screen contains the controller data: atmosphere actual and setpoint,

temperature actual and setpoint, Probe information, Outputs, and Inputs.

Configurator – Main screen with a recipe running

The first part is the atmosphere values and the temperature values

Configurator – Atmosphere and Temperature values

The left side is the atmosphere values. The first box contains the actual value of the

atmosphere. The second box contains the atmosphere setpoint. Clicking on this box will allow

the user to alter the setpoint.

Configurator – Edit atmosphere setpoint

Enter the new value or use the up and down arrows to select the new value and click on the

OK button to set the new atmosphere setpoint. Clicking on the Cancel button will cancel the

Super Systems Inc. Page 33 of 201 Configurator Manual #4562 Rev D

Page 34

action. The bottom two boxes deal with the output values. Clicking on the bottom right box

will allow the user to change the value.

Configurator – Edit atmosphere value

Select the new value, either “auto” or “manual”, and click on the OK button to change the

value, or click on the Cancel button to cancel the action.

The right side is the temperature values. The first box contains the actual value of the

temperature. The second box contains the temperature setpoint. Clicking on this box will allow

the user to alter the setpoint.

Configurator – Edit temperature setpoint

Enter the new value or use the up and down arrows to select the new value and click on the

OK button to set the new temperature setpoint. Clicking on the Cancel button will cancel the

action. The bottom two boxes deal with the output values. Clicking on the bottom right box

will allow the user to change the value.

Configurator – Edit atmosphere value

Select the new value, either “auto” or “manual”, and click on the OK button to change the

value, or click on the Cancel button to cancel the action.

The next three boxes deal with the probe information, outputs and inputs, and these values

cannot be edited by the user.

Super Systems Inc. Page 34 of 201 Configurator Manual #4562 Rev D

Page 35

9200 Firmware Upgrade Procedure

Overview

The series 9200 firmware may require upgrades as determined by Super Systems Inc. These

upgrades can be performed at SSI or they may also be performed at your facility while in use.

The series 9200 will not maintain control of your system while this upgrade takes place and all

precautions must taken prior to beginning this procedure.

Equipment Required

• A PC with an Ethernet port and a cross over cable

• The Super Systems Configurator software e

• The LocateIP software

• The Serial Number Utility software

• The UDP Download software

• A PC with an Ethernet port and a crossover cable is required. The Super Systems

Configurator software, the LocateIP software, the Serial Number Utility software and the

UDP Download software are all required.

Instructions

1 – Go To, or start, the Configurator program on your PC.

2 - The Configurator has a toolbar menu in the upper left. From left to right the icons will be

referred to as:

A) Connect (

B) Login (

C) Show Overview Display (

D) System Settings (

E) Edit Recipes (

3 - Click the Login icon (

Enter the password obtained from Super Systems Inc. for that day into the “Password” text box

on the login form.

button. If the login was successful, the lock will change to a red lock (

NOTE: If you have only one (1) 9200 previously connected and running you can “SKIP” Steps

No. 4, 5, 6, 7, 8 & 9.

4 - Click the System Settings icon (

System Management form.

)

)

)

)

)

)

No username is required when logging in as SSi Special.

), then click the “Add” button. This will display the

Click on the “OK”

).

Super Systems Inc. Page 35 of 201 Configurator Manual #4562 Rev D

Page 36

Configurator - System Management form

5 - Use the drop-down menu next to “Model” to select “9200”

6 - Verify that the “Ethernet” address matches exactly the address of the controller being

upgraded, or click on the scan button -

- to find the device.

7 – Enter the name of the device next to “Name”, then click the Save button.

8 - Click the OK button. This will return the user back to the main form.

9 - On the upper right corner there will be a drop-down menu. Select the controller that needs

to be upgraded.

Controllers that were recently added will be at the bottom of the list

.

Configurator drop-down menu for the controllers

10 - Click the Connect icon (

) and verify after a few seconds that the communications

(COMS) link is “Good” by looking in the bottom left corner of the main screen. You cannot

proceed until the COMS are “Good”.

11 – Click the System Settings icon (

).

12 – Click on the “Backup/Restore” tab at the top of the screen

Super Systems Inc. Page 36 of 201 Configurator Manual #4562 Rev D

Page 37

Configurator Backup/Restore tab

13 – Make sure the “Online Device” option is selected, then click on the Backup button.

The

user must wait until the system finishes before attempting to navigate to another page or click

on any other item

. When finished, the user will notice that when selecting the current

controller in the “Backup” section, there will be a backup file with the firmware version and the

date and time the backup was completed.

14 – Click the OK button in the bottom right corner of the screen to close the screen out.

15 – On the main form, click on the Edit Recipes icon (

).

16 –Click on the “Recipe Management” tab, then click on the “Groups” tab.

Configurator – Recipe Management tab with Groups tab

17 – Click on the Add button

18 – Name the group with the same name of the controller used in step Number 7. Click the

Save button to save the changes.

Super Systems Inc. Page 37 of 201 Configurator Manual #4562 Rev D

Page 38

19 – Click on the Recipes tab.

Configurator – Recipe Management tab with Recipes tab

20 – In the “Transfer” section of the form, make sure the “Use Online Device” checkbox is

checked for the source, and use the drop-down menu to the right of “Destination:”

to select

the group that was created in the previous steps.

21 –Select the “Send Multiple” option, and set the left numeric value to 1 and the right numeric

value to 300. Click on the Send button to send the recipes. This will save all the recipes from

1 to 300. The user must wait until the send is complete before attempting to move on or click

on any items.

22 – Click the Done button to return to Configurator’s main screen. The configuration and

recipes have been saved.

23 – Go To, or start, the UDP Download software on your PC. All of the available instruments

will be populated in the list when the software loads up.

Note – To search for instruments

again, click on the Search menu option in the top right of the screen. This will start a new

search and display all of the available instruments

.

Super Systems Inc. Page 38 of 201 Configurator Manual #4562 Rev D

Page 39

UDP Download – Initial screen

24 – Click on the square box with the three periods marked on it ( ). This box is located to

the right of the drop-down menu near the top of the screen. This will open a Windows dialog

box that will allow the user to navigate the file system.

25 – Use the dialog to navigate to the firmware version stored on the local PC that you wish to

use, and click on the Open button to select that firmware. The user should see that firmware

name and version in the drop-down list to the right of “User Program”.

26 – Identify the Serial Number and IP address of the controller you wish to upgrade from the

list of items on your network (it will only be one unit if you are hooked up directly to the 9200

through its Ethernet port). Select the controller from this list with a single click. It should be

highlighted with a blue background.

***When you complete the next step the 9200 will not control your system***

27 – Click the Download menu option in the top right of the screen. The bottom part of the

screen will display the progress of the download, and a progress bar at the top of the screen

will also display the progress of the download. Once the progress bar finishes and the list of

instruments is reloaded, it is OK to close out the UDP software.

28 – Exit the UDP Download software by clicking on the Exit menu option on the top right of

the screen.

29 – Go To, or start, the LocateIP software on your PC. A list of available instruments will be

populated into the list when the software loads.

Super Systems Inc. Page 39 of 201 Configurator Manual #4562 Rev D

Page 40

Locate IP – Initial screen

30 – Identify the controller being upgraded by its serial number. The serial number will be the

last item on the “Response from” line.

31 – Click the Configure button on the upper left side of the screen. Use the drop-down menu

to identify the controller being upgraded. Click on the controller. Click on the OK button to the

right of the drop-down menu. Make a note of the IP Address.

Locate IP – Configure screen