Page 1

PAPERLESS VIDEO RECORDER

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Table of Contents

Product Overview _____________________________________________________________________________ 3

Product Description ________________________________________________________________________ 3

Product Specifications _____________________________________________________________________ 3

Environmental Specifications _______________________________________________________________ 3

Software Installation ______________________________________________________________________ 4

Calibration ______________________________________________________________________________ 4

Components ____________________________________________________________________________ 4

Analog Inputs _____________________________________________________________________________ 5

Adding a Jumper to an Input ________________________________________________________________ 5

Thermocouple connections _________________________________________________________________ 6

Voltage connections ______________________________________________________________________ 6

4 – 20 mA. Current Loop connections ________________________________________________________ 6

Setting the DIP switches to Assign Board Numbers ______________________________________________ 7

Getting Started ____________________________________________________________________________ 7

Physical Installation ________________________________________________________________________ 8

Connecting the Video Recorder to the Touch Screen _____________________________________________ 8

Wiring Diagram – Network Connection _______________________________________________________ 9

Wiring Diagram – Direct Connection ________________________________________________________ 10

Change the IP Address of the Touch Screen ___________________________________________________ 11

Touch Screen Interface _______________________________________________________________________ 12

Configuration Menu _________________________________________________________________________ 21

Status _________________________________________________________________________________ 21

Template Edit __________________________________________________________________________ 21

Communications ________________________________________________________________________ 23

Calibration _____________________________________________________________________________ 24

Target VR IP Address ____________________________________________________________________ 24

Video Recorder IP ________________________________ _______________________________________ 24

Analog Input Type Setup _________________________________________________________________ 24

Analog Input Offsets _____________________________________________________________________ 25

Synchronize Clocks ______________________________________________________________________ 25

Exit the program ________________________________________________________________________ 25

Full Disk Options ________________________________ _______________________________________ 25

Manage Curves _________________________________________________________________________ 26

Totalizers ______________________________________________________________________________ 27

Averagers _____________________________________________________________________________ 27

Function Based Timers ___________________________________________________________________ 28

Alarm Text ________________________________________________________________ ____________ 28

Alarm Setup ___________________________________________________________________________ 29

Purge Data _____________________________________________________________________________ 29

Slave Instrument Setup ___________________________________________________________________ 32

Notes Search ___________________________________________________________________________ 33

Loads _________________________________________________________________________________ 34

Date Time Settings ______________________________________________________________________ 35

User Fields ____________________________________________________________________________ 35

Passcodes _____________________________________________________________________________ 36

Menu Configuration _____________________________________________________________________ 36

Input Calibration – Screen Version 1.47 and Below _____________________________________________ 37

Input Calibration – Screen Version 1.49 and Above _____________________________________________ 39

Changing the Date/Time of the Touch Screen display ___________________________________________ 42

Super Systems Inc. Page 1 Video Recorder Manual Version 2 Rev. B

Page 3

Remote Trend Web Page___________________________________________________________________ 43

Video Recorder Web Page _________________________________________________________________ 48

VR Manager Software ________________________________________________________________________ 49

Installing the VR Manager Software _________________________________________________________ 49

VR Manager Minimum System Requirements _________________________________________________ 52

VR Manager Overview ____________________________________________________________________ 52

VR Manager Screen _______________________________________________________________________ 53

Operating the VR Manage Screen ___________________________________________________________ 54

VR Manager Menu Options ________________________________________________________________ 55

File New / New Button_________________________________________________________________ 55

File Open / Open Button _______________________________________________________________ 55

File Save / File Save As / Save Button __________________________________________________ 56

File Print Chart ____________________________________________________________________ 56

File Print Notes ____________________________________________________________________ 56

Print Button ____________________________________________________________________________ 56

File Print Preview Chart _____________________________________________________________ 56

File Print Preview Notes _____________________________________________________________ 57

File Exit ____________________________________________________________________________ 57

Tools Customize Chart Interval________________________________________________________ 57

Tools Communications Setup _________________________________________________________ 57

Tools Communications Advanced Download & Maintenance ________________________________ 59

Tools Export _________________________________________________________________________ 61

Tools Export Notes to SDRecorder _____________________________________________________ 61

Tools Data Backup ____________________________________________________________________ 62

Tools Alarms Report __________________________________________________________________ 62

Help Check for Updates ________________________________________________________________ 63

Help About __________________________________________________________________________ 63

Totalizers and Function Based Timers Logs ___________________________________________________ 64

Edit Custom Curves _______________________________________________________________________ 64

Tabular Data ____________________________________________________________________________ 66

Editing a Chart in VR Manager _____________________________________________________________ 66

VR Manager Batch Mode (Version 1.0.1.11 & up) ______________________________________________ 67

Adding The VR Manager Location to the System Path __________________________________________ 67

Running the VR Manager Software in batch mode______________________________________________ 68

Error logging ___________________________________________________________________________ 69

List of Batch Mode Parameters _____________________________________________________________ 69

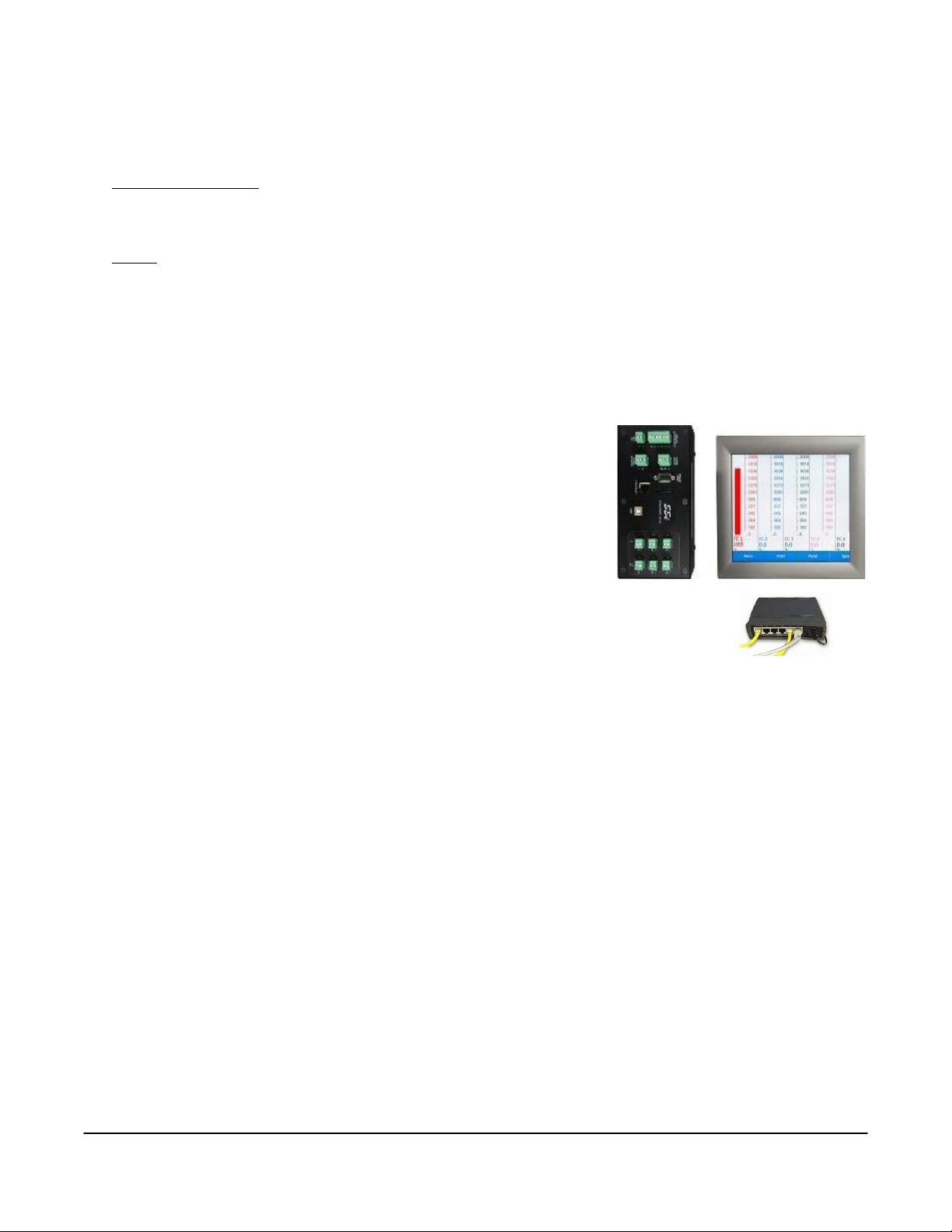

Satellite Boxes – SR3, SR6 ________________________________________________________________ ____ 70

Running Applications Over A Network ________________________________ __________________________ 71

Purpose _________________________________________________________________________________ 72

Cutout Dimensions for Touch Screens ___________________________________________________________ 73

Parts List __________________________________________________________________________________ 75

Revision History _____________________________________________________________________________ 76

Super Systems Inc. Page 2 Video Recorder Manual Version 2 Rev. B

Page 4

Product Overview

Product Description

You’ll find all the necessary information related to how to use the product in this manual. The product is

broken up into two parts; the software and hardware components. This user guide is also written in this

manner.

The video recorder provides the hardware and software needed to meet industry standard digital chart

recording.

It is easy to use and addresses the many industrial applications where data logging, trending, and

reporting is required. The product is available with three different screen sizes and up to 48 inputs with

user-defined inputs for each channel.

The easy-to-use VR Manager provides users with all the necessary tools to generate trend chards from a

remote computer. Data is stored on a flash card on the touch screen display where data can be extracted

through a network connection OR by removing the flash card and extracting the files to the computer

using the VR Manager software. All data can be printed or stored electronically in an un-modifiable

format.

Product Specifications

User defined logging intervals as frequently as one second

Optically Isolated inputs

DC Power Supply: +24 VDC, 9 watts max, fused at ¾ A

Password protected menu options

Easy calibration

Web-page enabled real-time view

ETHERNET, RS485 and RS232 serial communications

16-Bit A/D converter

Redundant data storage

Environmental Specifications

Storage Temperature → -4° F to 158° F (-20° C to 70° C)

Ambient operating temperature → 32° F to 131° F (0° C to 55° C)

Ambient humidity → 5% to 95% relative humidity (non-condensing)

Super Systems Inc. Page 3 Video Recorder Manual Version 2 Rev. B

Page 5

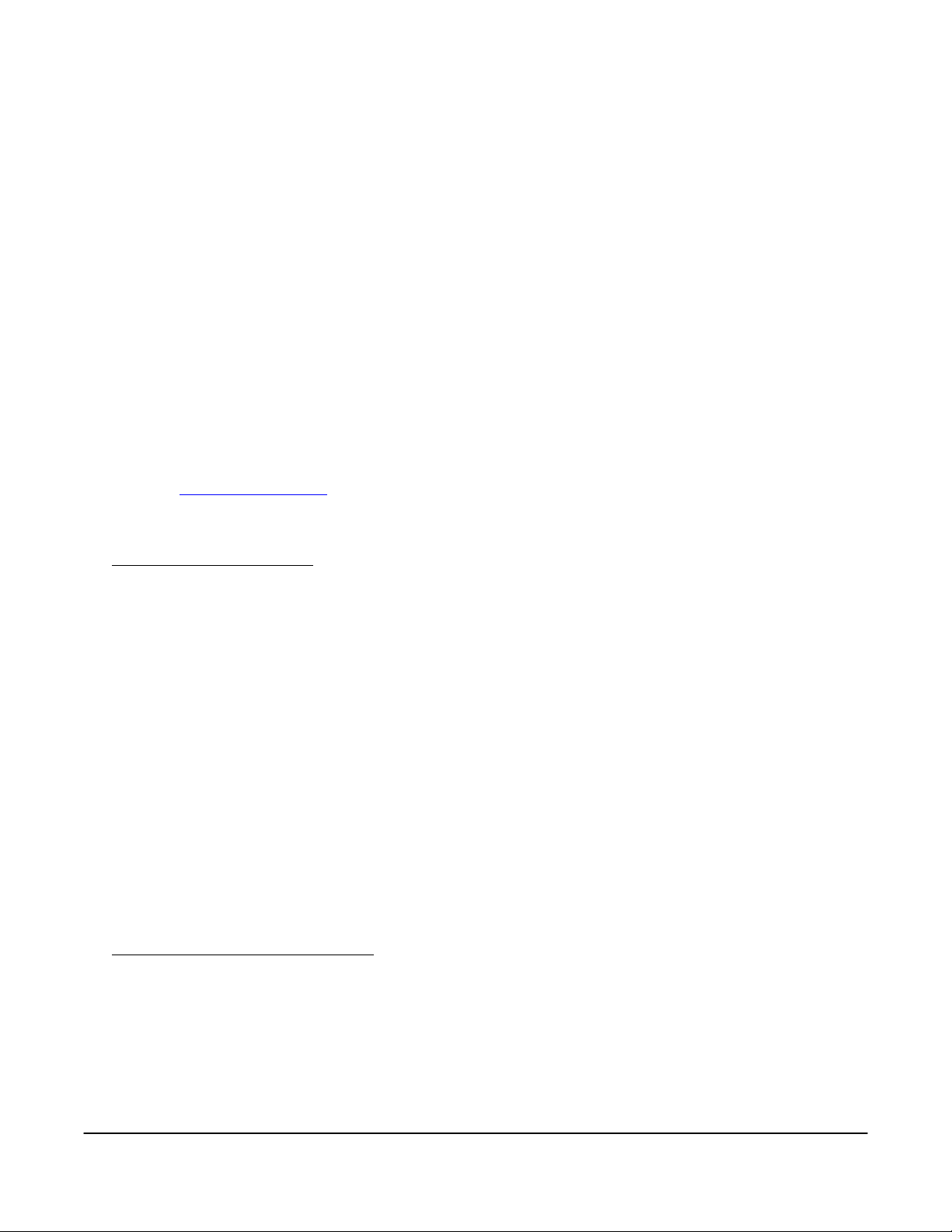

Degrees F.

TC Type

Min

Max B 32

3308 C 32

4208

E

-328

1832

J

-346

2192

K

-328

2502

N

-328

2372

NNM

0

1409

R

-58

3214

S

-58

3214

T

-328

752

Thermocouple range listed by thermocouple

Software Installation

You will find the VR Manager software CD that ships with the unit includes all the reporting and data

management utilities. Insert the CD into the CD ROM device on your computer and click the setup.exe

file. You will be given step-by-step instructions for completing the installation process. See the section

Installing the VR Manager Software

for more details.

Calibration

The Video Recorder is calibrated prior to shipment, although the calibration process is also available

through the touch screen. Instructions for calibration are included in this manual. Super Systems

calibrates the Video Recorder using NIST traceable instruments that are listed on the calibration

certificate included with the device. The default calibration is performed using a zero and span routine

for the millivolt range of 0 – 80mV. Each range that is being used should be calibrated. For a list of

suggested mV ranges by thermocouple types, please refer to the

Input Calibration

section of this manual.

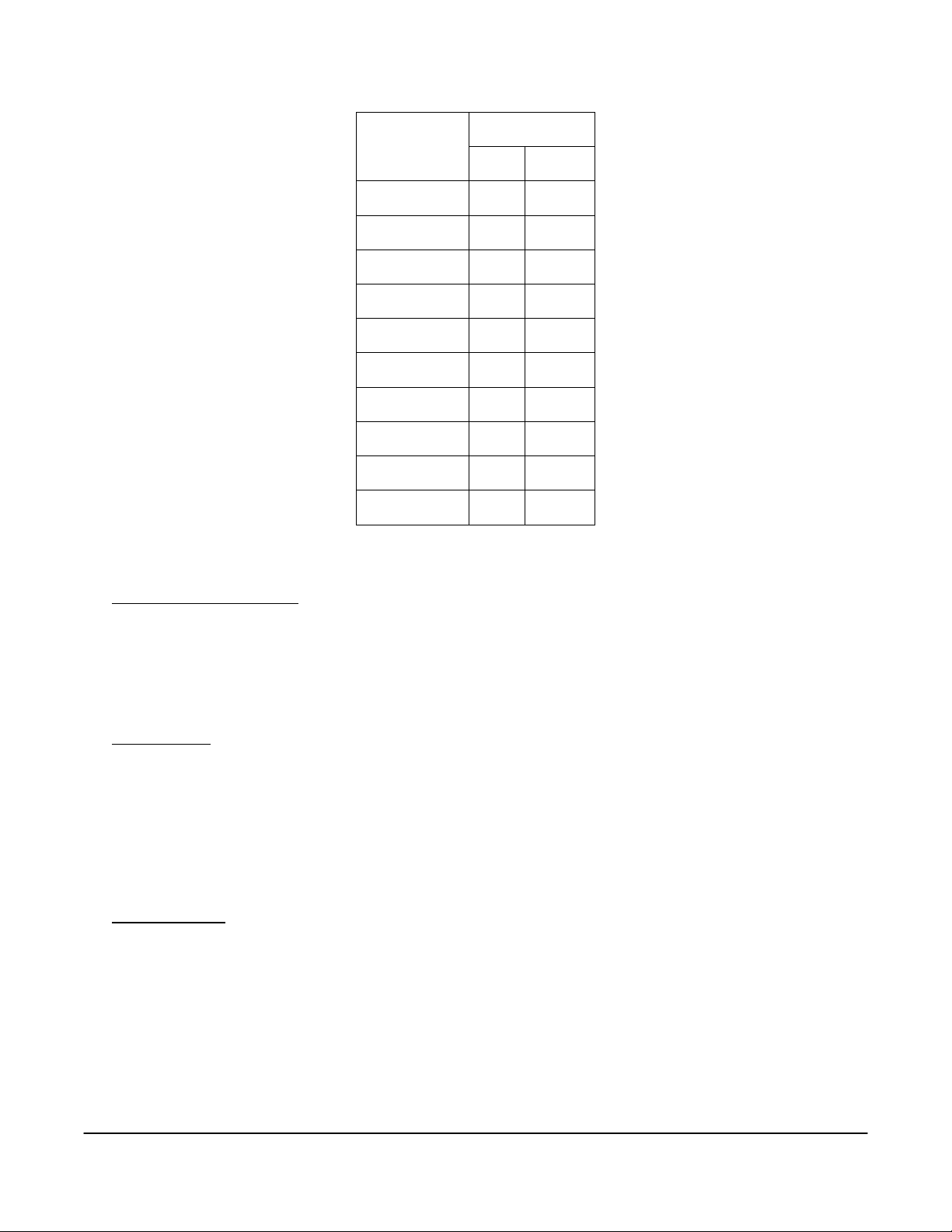

Components

The Video Recorder consists of the Touch Screen Interface, Data Logging Device, and VR Manager

Software. The Data Logging device is made up of five user-defined analog inputs per boards. Each input

is configurable using the Touch Screen Interface and allows for different math functions to be performed

on the input. Each input is fully isolated.

Super Systems Inc. Page 4 Video Recorder Manual Version 2 Rev. B

Page 6

Analog Inputs

The Super Systems, Inc. Part Number 31575 Analog Board contains a group of three channels isolated

from the main DC power source. Each input is fully isolated. The board can be connected to

thermocouples, voltage sources from 20mV full scale to 1.28 Volts full scale, voltage sources from 0 V full

scale to 10 V DC full scale, or 4 – 20 mA current loops.

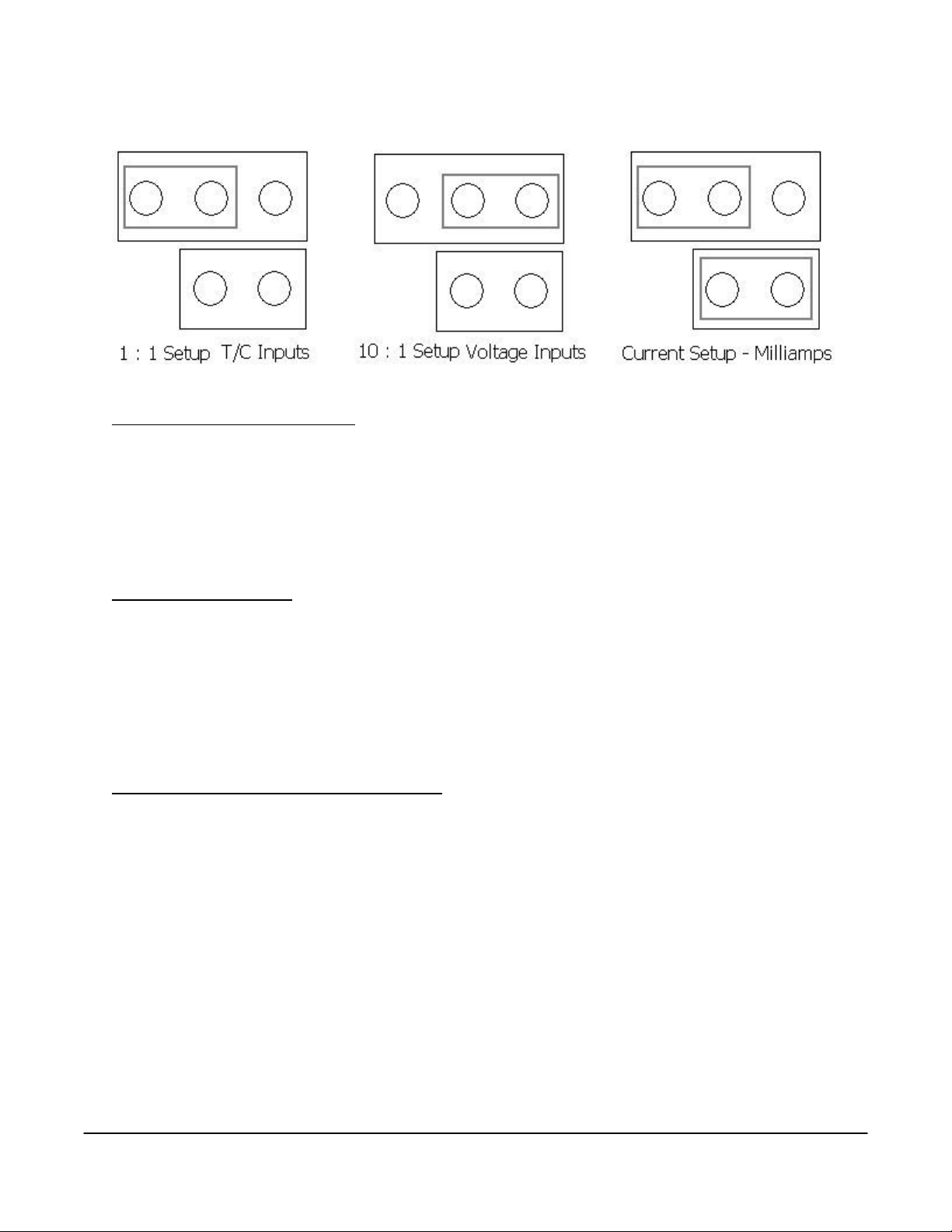

Adding a Jumper to an

Input

When measuring a 4-20mA

current signal or a voltage

signal, such as a

thermocouple, a jumper must

be placed on the

corresponding two or threeposition header. For example,

Input 1 would need to have a

jumper placed between the

pins labeled “I1” before

connecting a 4-20mA signal.

Failure to add the jumper will

result in damage to the circuit

board. The jumper may

already be present at each of

the three headers, but unless

Super Systems Inc. Page 5 Video Recorder Manual Version 2 Rev. B

Page 7

it is attached across both pins (not just one) it will not be connected.

Thermocouple connections

Thermocouple wires can be connected directly to the terminal blocks. The thermocouple junctions should

not be grounded. If they do touch a ground reference, all thermocouples on a board must have a common

ground reference. If multiple thermocouples are connected to different ground reference points, the

accuracy of all thermocouples on the board cannot be guaranteed to be accurate. When setting up a

voltage input signal, such as a thermocouple input or any voltage input signal up to 1.28 volts, the jumper

must be placed on the pins in the 1:1 setup (left diagram).

Voltage connections

Voltages from 0 mV to 10 Volts DC can be directly connected to the terminal blocks. When measuring

ground-referenced voltages, all references must share a common ground reference. If the voltage

sources are connected to different ground reference points, the accuracy of all the voltage sources

connected to the board need to be checked for accuracy. Since higher voltages can damage the input

board, any voltage input signals, such as a vacuum gauge, must have the jumpers placed on the pins in

the 10:1 setup (middle diagram). This will insure that any signal going into the board will be scaled down

so it will not damage the input board.

4 – 20 mA. Current Loop connections

Before connecting the current loop, insert the shorting jumper on the board for each channel used to

measure current loops. This jumper inserts the 62-ohm shunt resistor across the input of the A/D. If

multiple current loops are connected to one board, all must share the same power supply and ground

reference points or the accuracy of all the current loops need to be checked for accuracy. When setting

up a current input signal, such as a 4 – 20 mA signal, the jumper must be placed on the pins in the

current setup (right diagram). Notice that there is also a jumper set up in the 1:1 setup only when

inputting a current signal. This is because current signals also have a corresponding voltage signal.

Warning: Connecting a mA input without the Input Jumper will damage the

input.

1. To add a jumper to an input:

2. Power down the unit.

3. Remove the thermocouple connector and the Ethernet cable from the video recorder.

4. Remove the top plate of the video recorder by unscrewing the six (6) screws around the top of the

video recorder.

Super Systems Inc. Page 6 Video Recorder Manual Version 2 Rev. B

Page 8

5. Grasping both sides of the input board, carefully pull the input board out of the video recorder and set

the jumper for the appropriate set of pins, i.e. “V1” for input 1, “V2” for input 2, etc. A jumper will need

to be set – placed on both pins – to be considered “on”. Slide the input board back into the video

recorder slot.

6. Replace the top plate of the video recorder by screwing in the six (6) screws around the top of the

video recorder.

7. Re-connect the Ethernet cable and thermocouple connector.

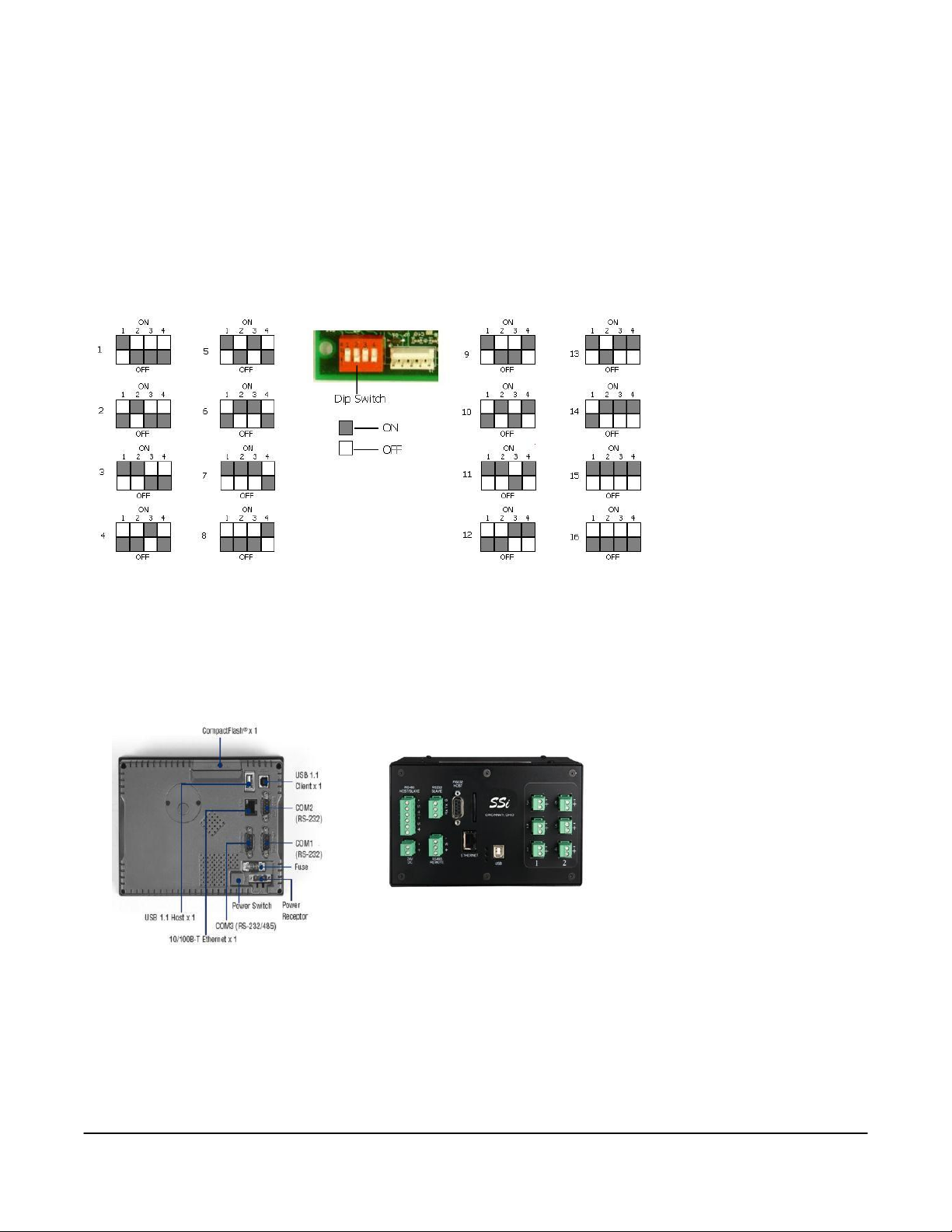

Setting the DIP switches to Assign Board Numbers

Each input board, whether

directly connected in the

Video Recorder or

connected through a

satellite box, must have a

unique address assigned

by the DIP switches on

each input board. A

unique address will

ensure that the Video

Recorder will correctly

read all of the boards set

up. If two or more boards

have the same address,

multiple errors could occur such as: VR reading data from one board one second, then reading data from

another board the next second, no data being read from the VR, etc.

unique address

binary numbering system – i.e. 1 = 1, 2 = 2, 3 = 4, and 4 = 8. There is an ON and an OFF position for each

switch. OFF = 0 and ON = 1. Each board number can be assigned by setting the appropriate switches to

ON. For example, to set a board number to 1, set the “1” switch to ON and the “2”, “3”, and “4” switches

to OFF ((1*1) + (2*0) + (4*0) + (8*0) = 1). To set the board number to 10, set the “1” and “3” switches to

OFF and the “2” and “4” switches to ON ((1*0) + (2*1) + (4*0) + (8*1) = 10).

. Each DIP switch has four switches on it labeled: 1, 2, 3, and 4. These numbers follow a

It is important that each board has a

The exception to the rule is

setting a board number to 16 – all

switches are off

.

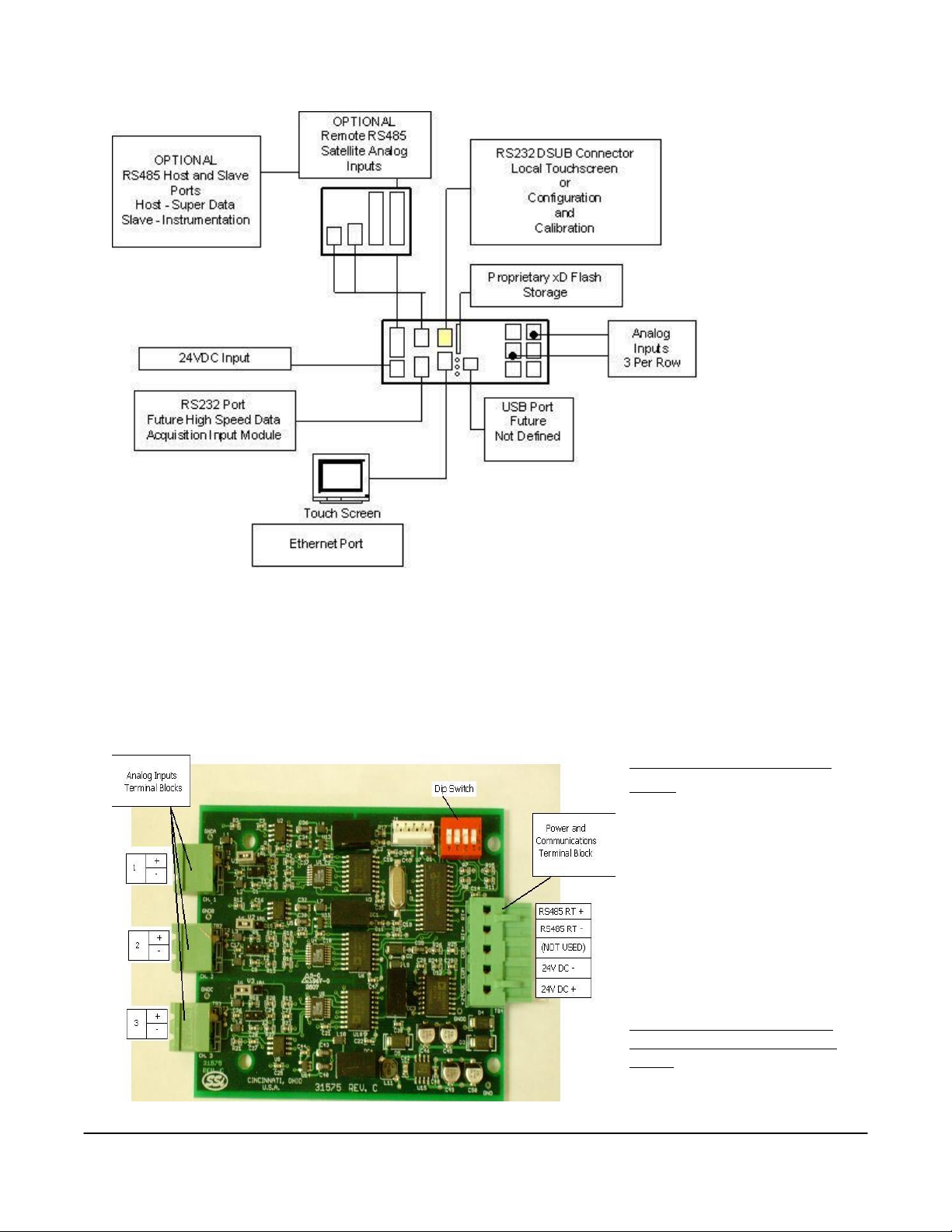

Getting Started

The data logging device and the

touch screen have a unique IP

address. The communications

between the screen and the data

logger is performed through the

Ethernet ports. Both the screen

and data logger require separate and unique fixed IP addresses.

Super Systems Inc. Page 7 Video Recorder Manual Version 2 Rev. B

Page 9

Physical Installation

Mechanical Mounting

The 3 foot din rail (Allen-Bradley P/N 1492-N22) is mounted to the enclosure panel. Snap the video

recorder enclosure onto the DIN-rail.

Wiring

Connect power with 18 or 20 AWG wire and inline fuse holder as shown in either the

Network Connection

to the panel connector as shown in either the

Wiring Diagram – Direct Connection

diagram or the

Wiring Diagram – Direct Connection

Wiring Diagram – Network Connection

diagram.

diagram. Connect earth ground

Wiring Diagram –

diagram or the

Connecting the Video Recorder to the Touch Screen

Every Video Recorder shipped includes a red Ethernet crossover cable

that will connect the Video Recorder to the screen. The screen and the

data logging device communicate either through the crossover cable

OR using an existing network.

If you are connecting the video recorder to your network, you will need

a straight-through Ethernet cable (the cable provided is a crossover

cable for direct connections to a PC) to be connected from the data

logging device to an Ethernet hub and the Touch Screen to an Ethernet

hub. The cable is plugged into the data logger Ethernet plug and then

other end should be plugged into a network hub. The IP address of the data logging

device will be provided with shipment.

If you are not putting the data logger on the network, you should use the red Ethernet

crossover cable that has been provided with the device. Ethernet crossover cables are most often

used when connecting two Ethernet computers without a hub. An Ethernet crossover cable has its send

and receive wires crossed. When using a hub or switch, this is automatically done for you.

With a crossover cable, you are forming a network between the computer that you are directly plugged

into and the touch screen. See the below section

diagram for a connection on a network, or

direct connection using the crossover cable.

Wiring Diagram – Direct Connection

Wiring Diagram – Network Connection

for a wiring diagram for a

for a wiring

Super Systems Inc. Page 8 Video Recorder Manual Version 2 Rev. B

Page 10

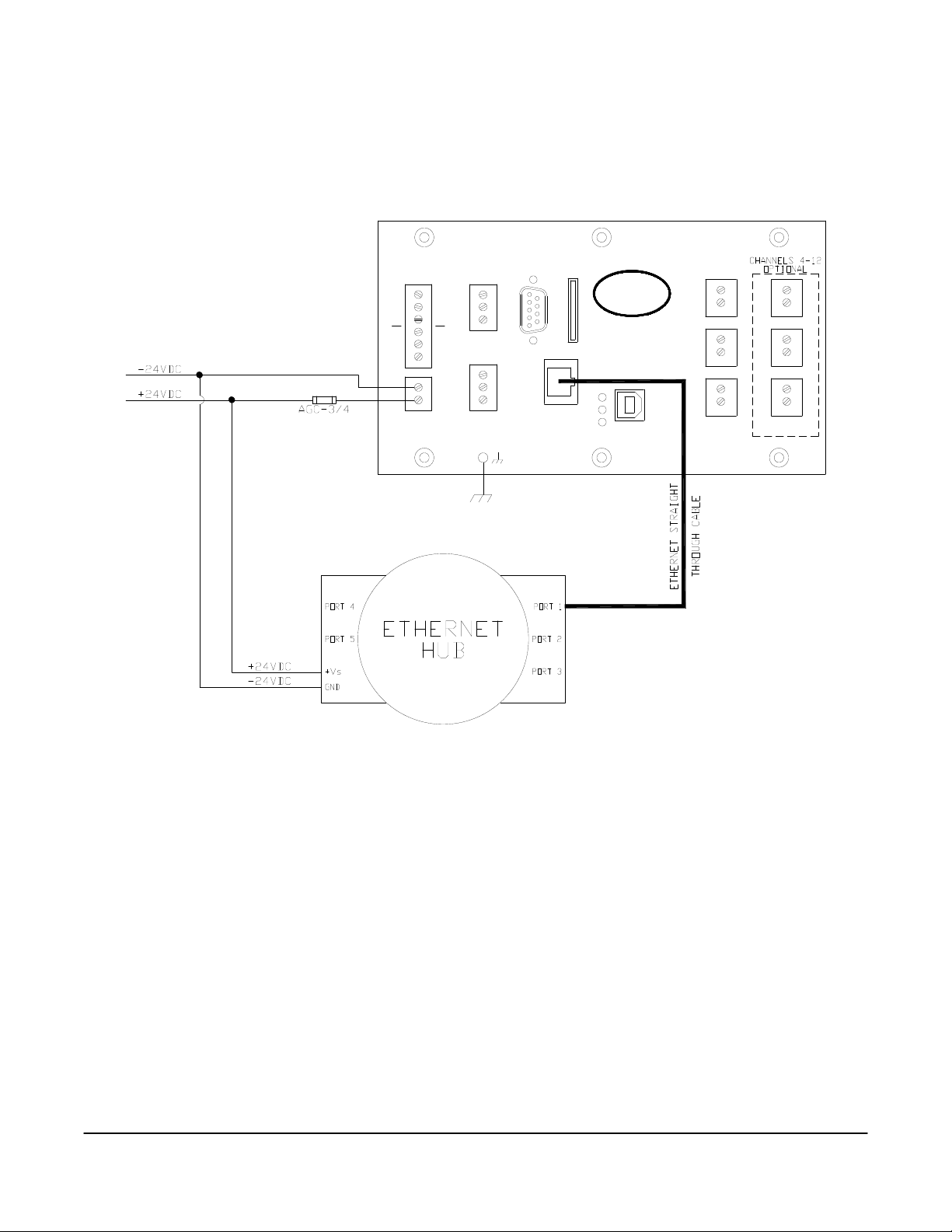

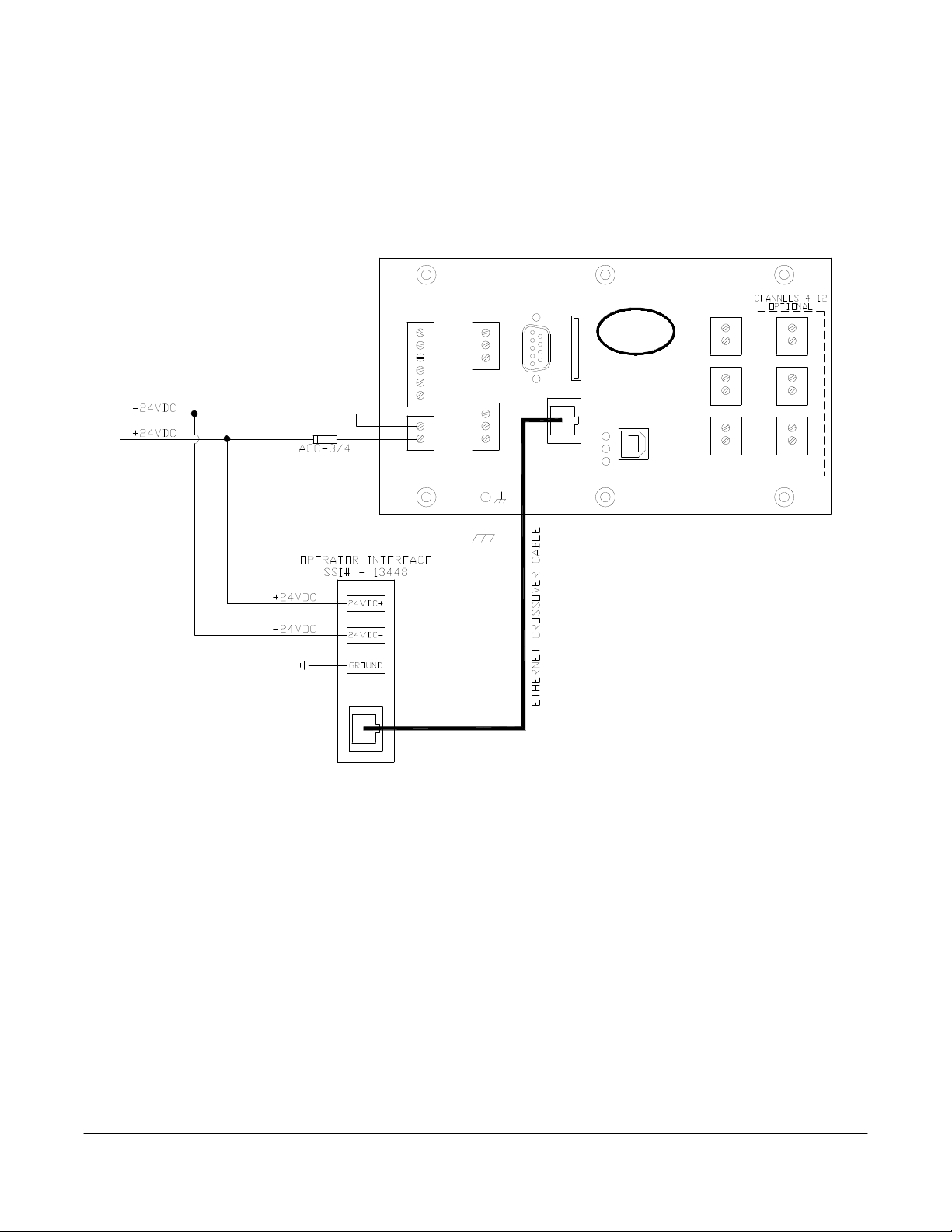

Wiring Diagram – Network Connection

-

DC

24V

HOST

REMOTE

USB

ETHERNET

RS485

+

+

S

+

S

-

21

1

+

-

4

+

-

+

2

+

5

-

RS485

HOST/SLAVE

SLAVE

S

+

-

TxRx

G

SLAVE

RS232

HOST

RS232

SSi

CINCINNATI, OHIO

+

3

+

6

-

Below is a wiring diagram for a network connection:

Super Systems Inc. Page 9 Video Recorder Manual Version 2 Rev. B

Page 11

Wiring Diagram – Direct Connection

-

DC

24V

HOST

REMOTE

USB

ETHERNET

RS485

+

+

S

+

S

-

21

1

+

-

4

+

-

+

2

+

5

-

RS485

HOST/SLAVE

SLAVE

S

+

-

TxRx

G

SLAVE

RS232

HOST

RS232

SSi

CINCINNATI, OHIO

+

3

+

6

-

Below is a wiring diagram for a direct connection:

Super Systems Inc. Page 10 Video Recorder Manual Version 2 Rev. B

Page 12

Each screen and Video Logging device is configured and setup with a fixed IP address. The screen is

configured to communicate with a specific device. This is done through the

Address

Menu Option.

Configuration

Target VR IP

Change the IP Address of the Touch Screen

It is important to obtain an available IP address and correct Net Mask and Default Gateway from an

administrator or IT associate before changing any of the IP settings. In order to change the IP address of

the touch screen, the program must be shut down. Click on Start Menu Settings Network and Dialup Connections. This will display the Network settings screen. Double-Click on the existing connection

to display the properties. To specify an IP address, select the “Specify an IP address” option and fill in the

sections for the IP Address, Subnet Mask, and Default Gateway using the on-screen keyboard, which can

be started by clicking on the Pen/Paper icon in the lower right corner and then clicking on “Keyboard”

from the menu option. Move the keyboard to a position where you will still be able to see the IP address

section and the keyboard at the same time. Highlight the first section of the IP address and enter the IP

address.

two or one-digit section of the address, begin the section with zeroes, i.e., 001 instead of 1. Repeat for the

Subnet Mask and Default Gateway.

To have the IP address assigned by the network, select the “Obtain an IP address via DHCP” option. This

option will disable the text boxes for entering the IP address, since the IP address will be given by the

network. Click on the OK or X button on the top of the screen to close the screen.

address of the touch screen is changed, then the corresponding profile in the VR Manager will have to be

updated as well

Note – The cursor will move to the next section once three digits have been entered

Note – If the IP

.

. To enter a

Super Systems Inc. Page 11 Video Recorder Manual Version 2 Rev. B

Page 13

Touch Screen Interface

The VR Series recorder can be equipped with a touch screen operator interface, which is used to view the

different variables that are being recorded. When the screen is powered up with the 24 VDC supply and

connected to the VR series analog input base module, the Main screen appears.

The three options available are Display,

Configuration, and Template. Clicking on

the Display option will load the chart.

On the Chart screen, there are several variables displayed.

1. Template – the chart view with the chosen process variable.

2. Date/Time – the current date and time in real time or historical mode.

3. Decimal Values – actual value of trend variable.

4. Greeen arrows – Move the displayed information either forward or backward in time.

5. Chart Menu – More choices for displayed features.

Super Systems Inc. Page 12 Video Recorder Manual Version 2 Rev. B

Page 14

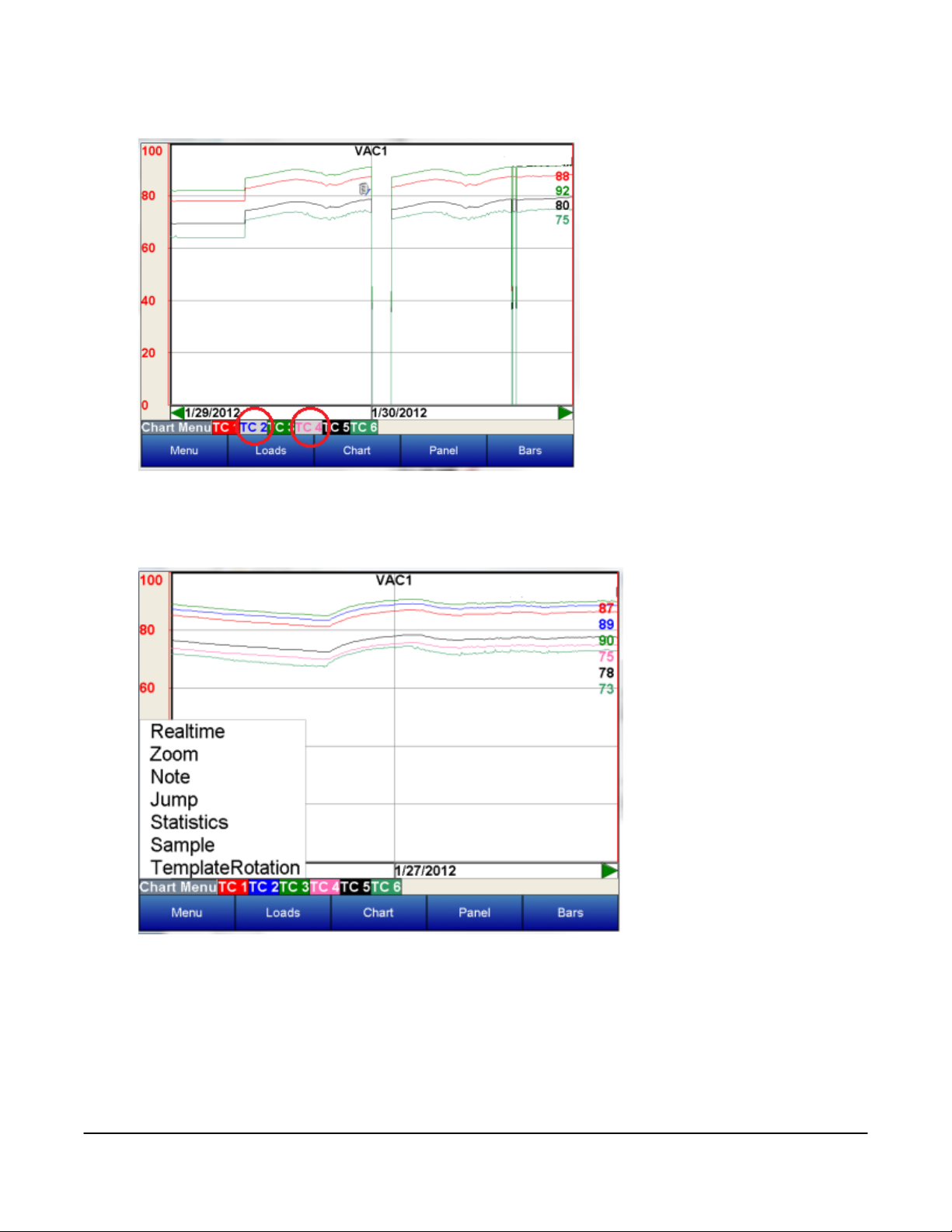

Selecting the Chart Menu provides more options for the display.

The inputs that appear on the chart

can be toggled between being

displayed or being left off simply by

tapping on the name of the input

along the bottom of the chart. The

box with the input number will turn

gray.

In this example, TC2 and TC4 are

left off of the chart display and are

in gray boxes.

Super Systems Inc. Page 13 Video Recorder Manual Version 2 Rev. B

Page 15

Realtime – Choosing this option sets the displayed values to the present date and time.

Zoom – This selection allows you to move your stylus or finger on the screen to a specific point creating a

box. The zoom box will also display decimal values for the low and high variables inside the box. It will

display the start and end time for

the zoom box itself. The zoom

feature can be used as often as

desired allowing the user to drill

down on the variable to show a

specific value displayed on the

screen.

Note – the Note feature

available on VR series

recorders allows the operator

to add notes in the chart

display. Notes can be added

using either a stylus or the

keyboard displayed on the

screen. Choose the Add Note

option from the Chart Menu

then select keyboard or stylus

to add a note.

Note on

keyboard functionality –

pressing the “caps” button or

the “shift” button will display

more keys for data entry. Also,

the “del” key works more like

the “Backspace” key on a

regular keyboard – i.e. it will

delete the character to the left

of the cursor

If a note requires editing select clear to retype or scribe the note or cancel to go back to the chart display.

.

Super Systems Inc. Page 14 Video Recorder Manual Version 2 Rev. B

Page 16

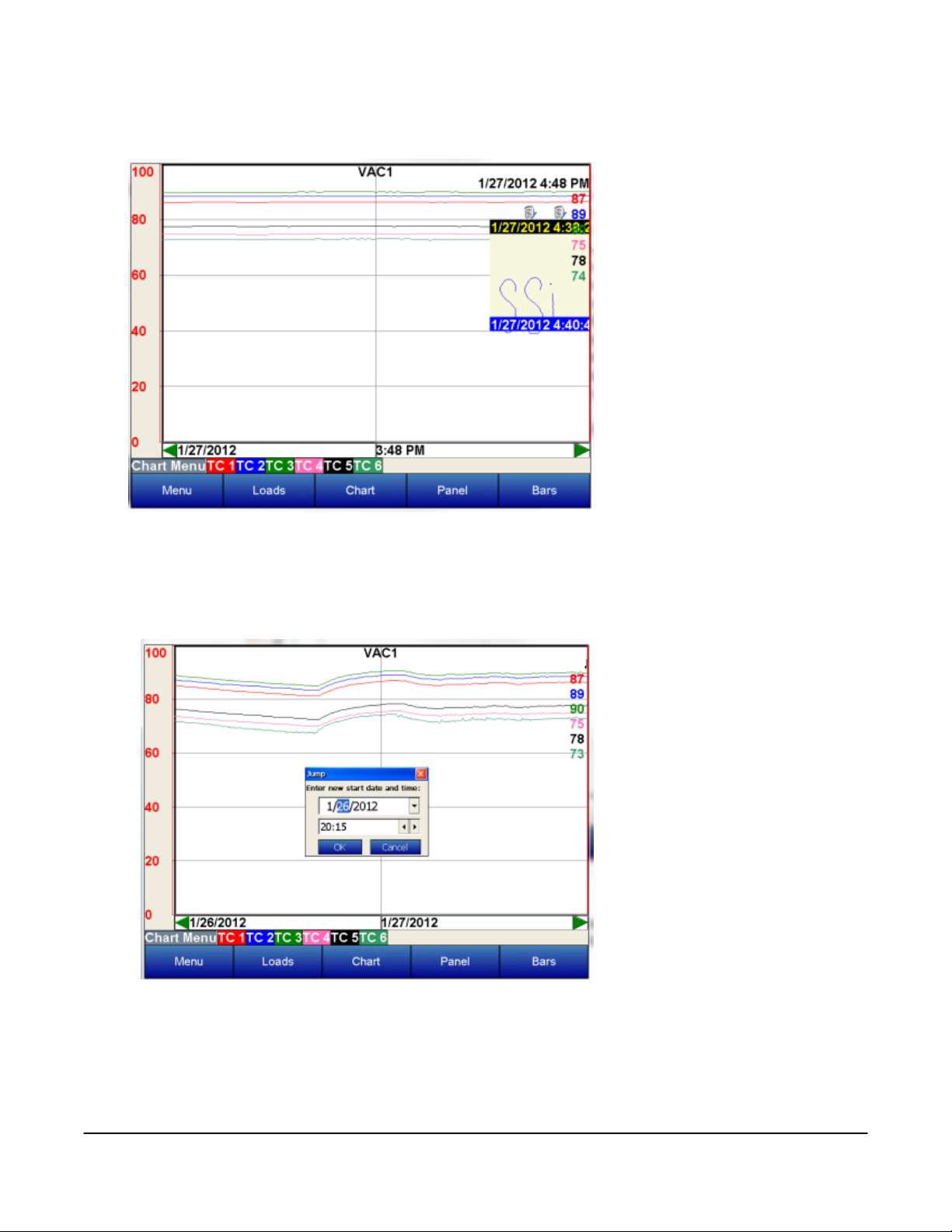

The note is displayed on the chart menu with a small icon. If the icon is touched it will expand to show the

information either scribed or typed onto the recorder.

Jump – This option allows the user to input the date and time to be displayed. The chart will jump to this

time.

Super Systems Inc. Page 15 Video Recorder Manual Version 2 Rev. B

Page 17

Statistics – The statistics option is also available on the chart menu. Choosing this option allows the

operator to view statistics on any

variable displayed on the operator

interface. The statistics are based

on the screen image displayed

whether looking at seven days of

data or zoomed in on a few

minutes.

The statistics parameters include

the trend name, the number of data

points available for calculating

statistics, the Minimum value, the

Maximum value, the Average value,

and the standard deviation.

Sample – Pre selected time frame formats change the displayed values on the screen to this duration.

Note: When the sample rate is

“15 minutes @ 1 sec”, the

averagers will not be displayed

on the trend chart (Touch

screen Versions 3.00 and

above).

Super Systems Inc. Page 16 Video Recorder Manual Version 2 Rev. B

Page 18

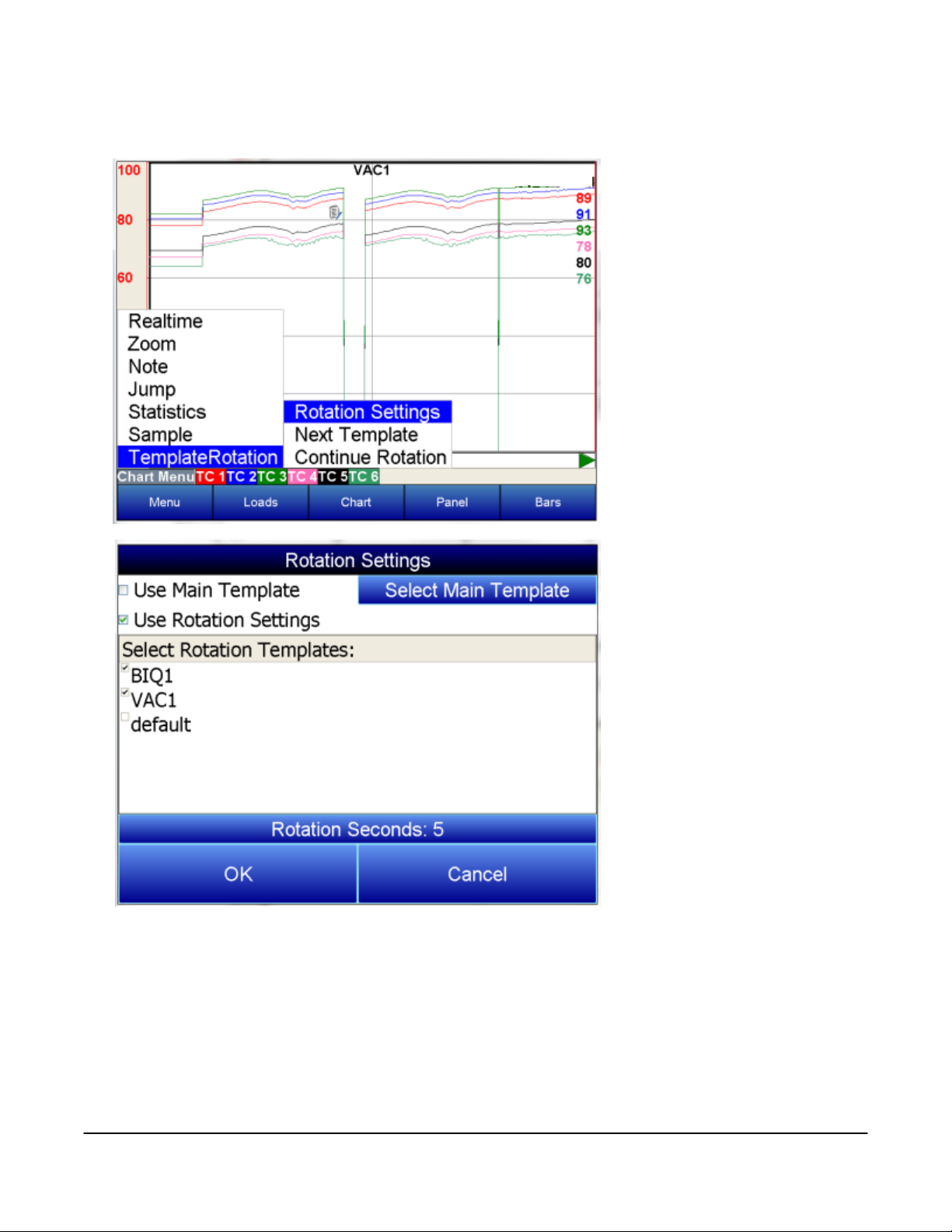

Template Roatation – This option enables the display to cycle through the different templates that have

been saved.

Selecting Rotation Settings

brings up a list of available

options for the display settings.

Checking the Use Main

Template box will keep the

display on one template. Select

Main Template allows the user

to decide which template to

display permanently if Use Main

Template is chosen. Checking

the Use Rotation Settings box

will enable the templates to

cycle. The templates to be

displayed can be customized by

checking or unchecking the box

next to each name under Select

Rotation Templates. The

amount of time each template is

displayed can be adjusted using

the Rotation Settings button.

Super Systems Inc. Page 17 Video Recorder Manual Version 2 Rev. B

Page 19

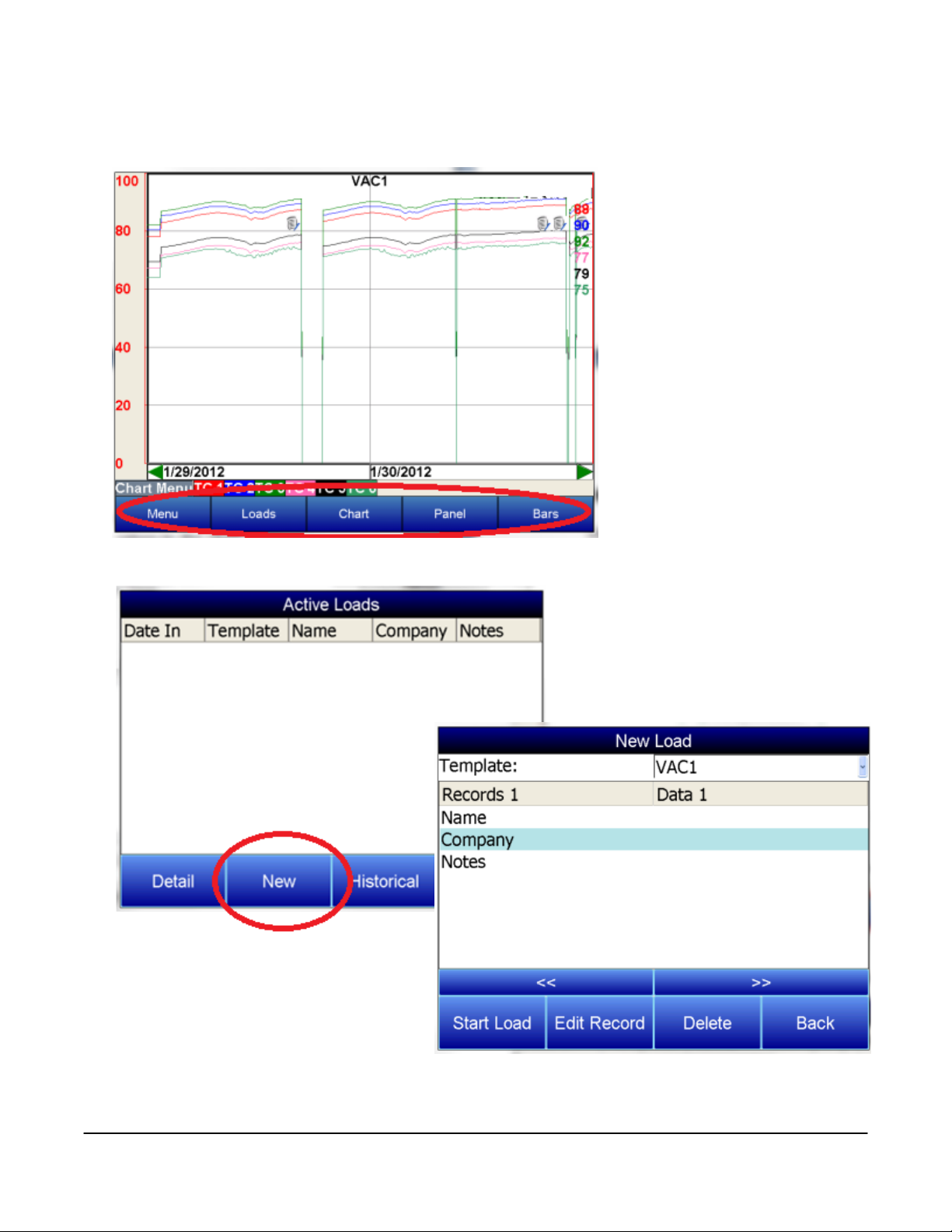

Along the bottom of the Display screen, there are other options for the way the template information is

presented.

The Loads button helps keep track of Active and Historical load data.

Pressing New will bring up the screen

for a New Load.

To input information about the new load, highlight any field, Name, Company, or Notes, and press Edit

Record. A keypad will display. Press enter on the keypad to save information, delete to backspace a

letter, and esc to leave the keypad without saving changes. Choose the corresponding template from the

Super Systems Inc. Page 18 Video Recorder Manual Version 2 Rev. B

Page 20

drop down menu along the top of the screen. When the load begins, press the Start Load button. When

the load finishes, choose End Load on the same screen.

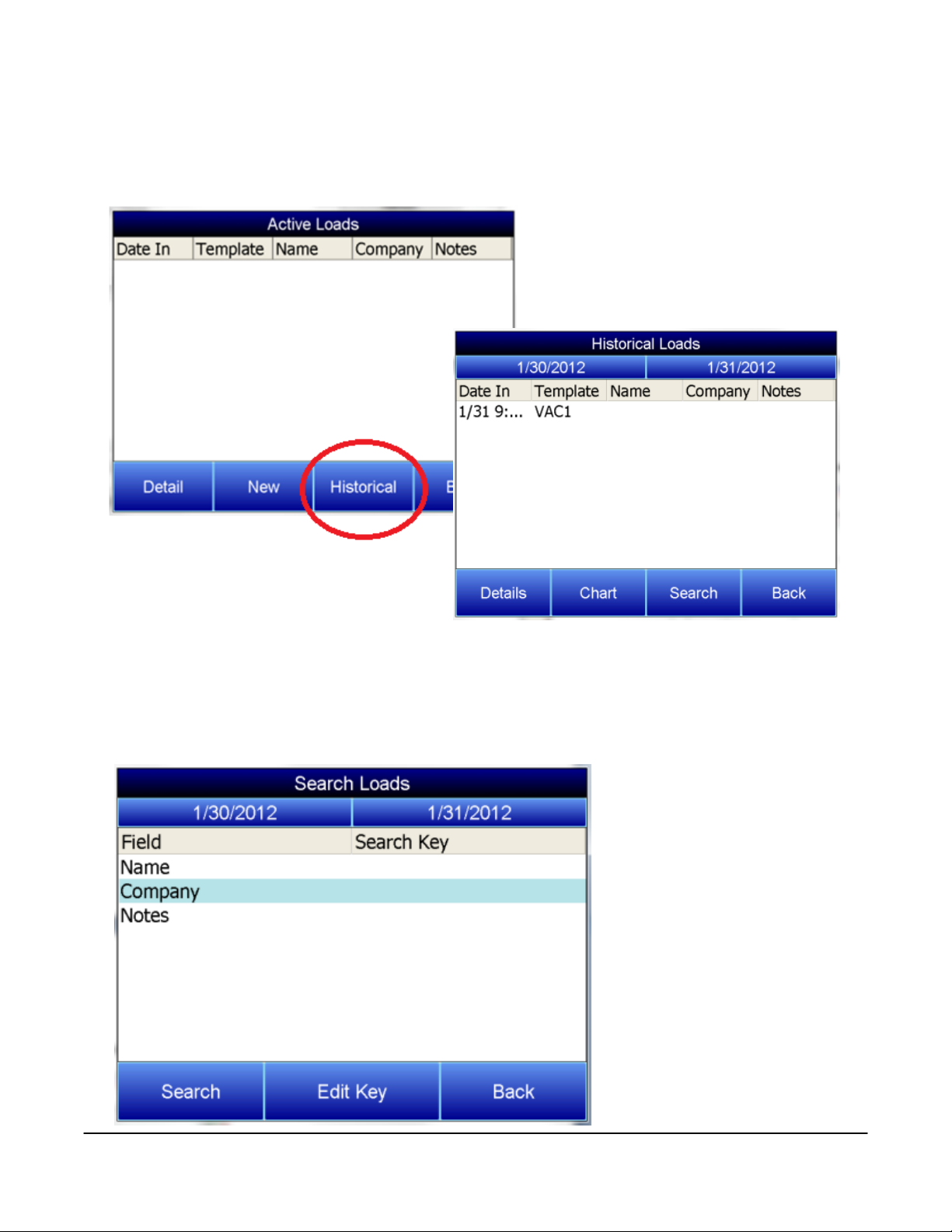

By pressing the Historical button on the loads screen, the historical load data will be displayed.

The Details button will display the information that has been stored about each load. The Search key

allows all historical load data to be searched through according to either the Name, Company, or within

the Notes. Only notes that have been entered with the keypad can be searched. Notes written the stylus

will not be included in searches.

To search historical loads, press the Search key.

Highlight the appropriate field

and press Edit Key. A keypad will

display. Press enter on the

keypad to save information,

delete to backspace a letter, and

esc to leave the keypad without

saving changes. Once the search

key(s) have been entered, press

the Search button, and a list of

matching results will be

displayed.

Super Systems Inc. Page 19 Video Recorder Manual Version 2 Rev. B

Page 21

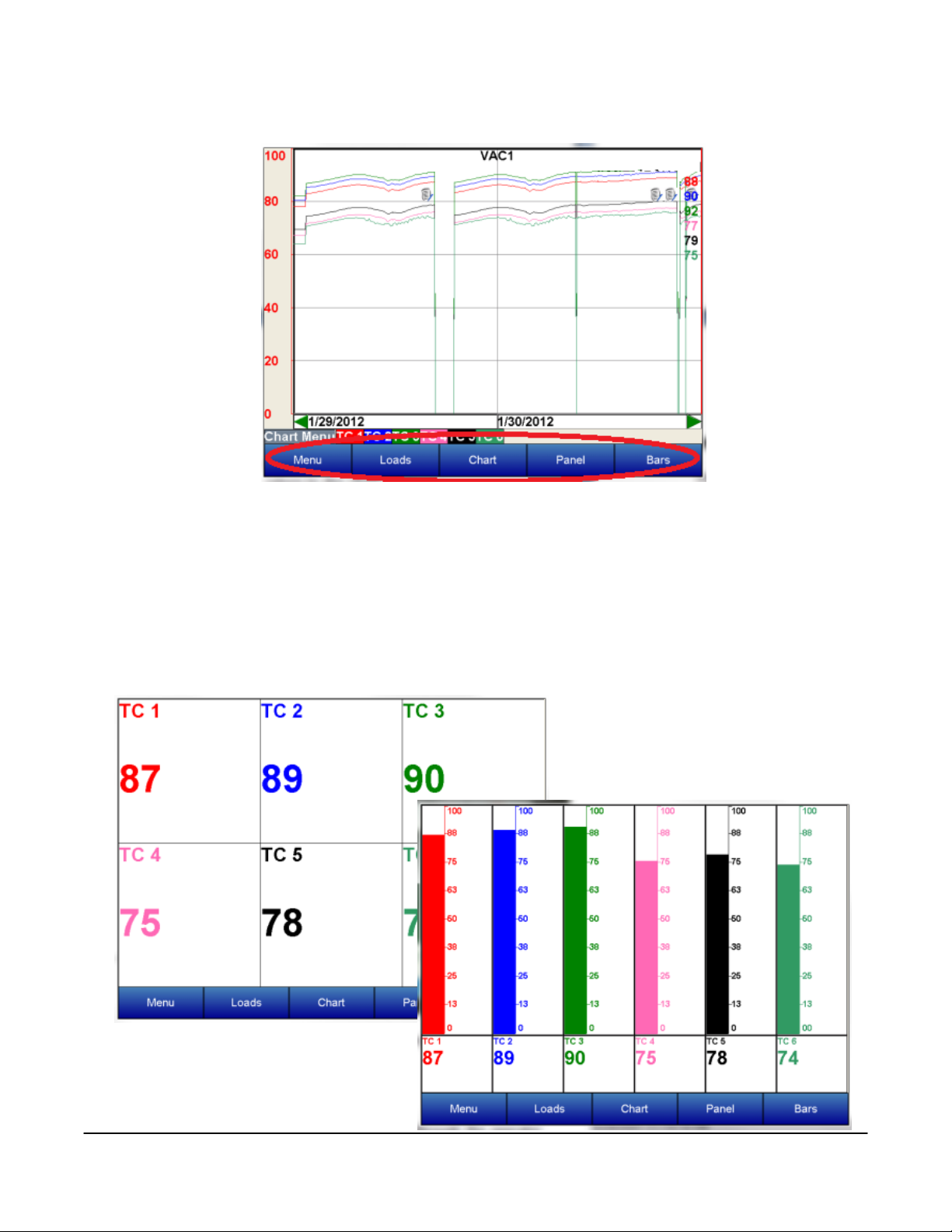

Returning to the main display screen, the data can also be displayed in a panel or bar format.

To select the panel view, view touch the Panel button on the bottom of the screen. In this mode,e decimal

values chosen for this template are displayed. Only realtime data can be displayed in the panel view.

Starting with version 3.12 of the screen software, it will be possible to send a setpoint down to a slave

instrument. The slave instrument’s setpoint must be included as a trend line. From the panel view

screen, touch the slave instrument’s setpoint panel and a menu will pop up that will allow the user to

send the setpoint down to the instrument. Select this option and enter the new setpoint.

A third choice for viewing variables on the VR operator interface is the Bars view. To select this view touch

the Bars button on the bottom of the screen. In this mode, the decimal values chosen for this template

are displayed as well as a vertical bar

chart for each variable with the

appropriate scaling for each. Only

realtime data can be displayed in the

Bars view.

Super Systems Inc. Page 20 Video Recorder Manual Version 2 Rev. B

Page 22

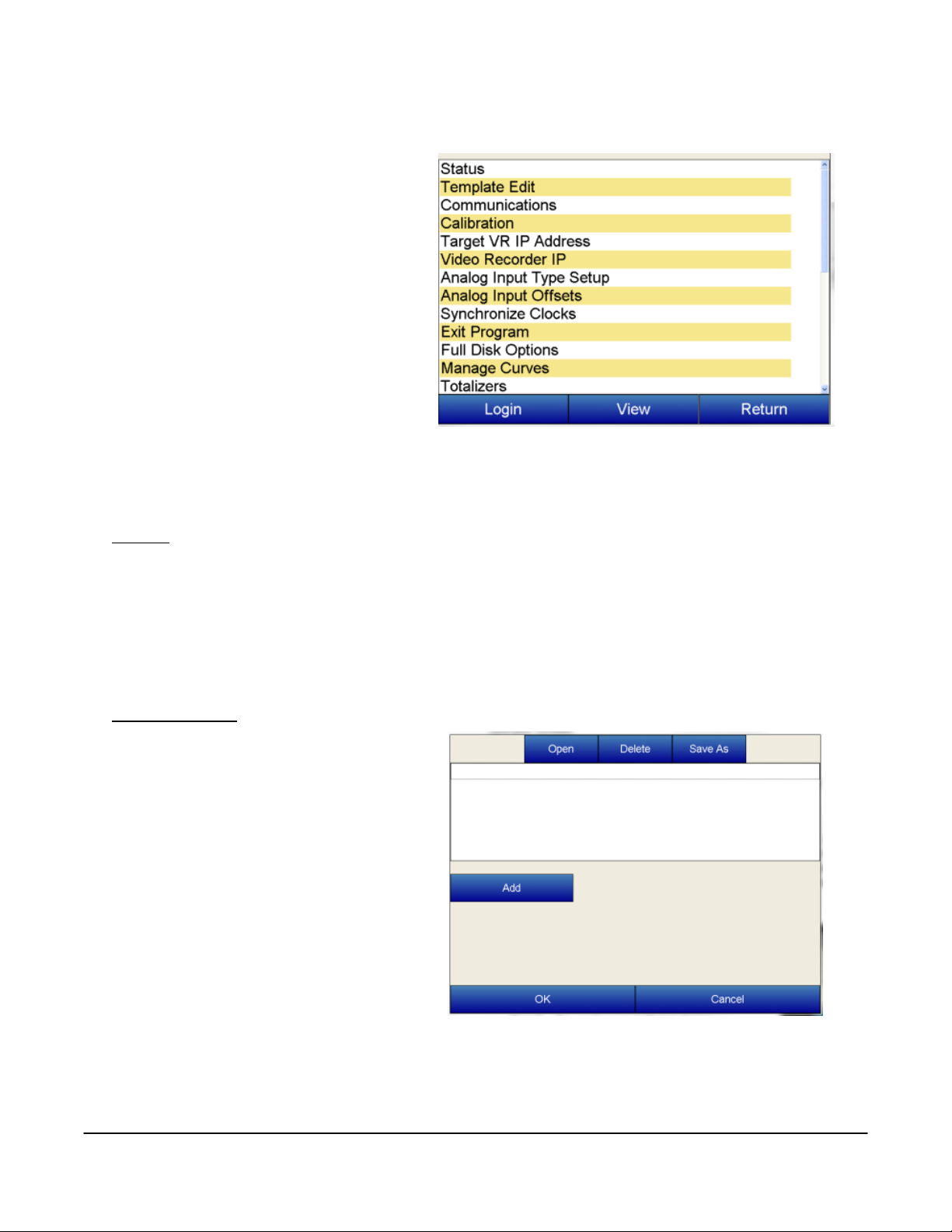

Configuration Menu

The VR recorder is configured through the

operator screen. The user must first select

the configuration button from the main

menu. Then choose the login button located

on the lower left of the next screen.

Login – Allows the operator to enter

a password to enter the

configuration of variables. The

password for logging in is “2”.

View – Allows the operator to view a

configuration parameter that has

been highlighted.

Return – pressing this button returns the operator interface to the previous viewing screen.

Press Login, type the password and press enter for configuration.

Status

Status – Includes the VR firmware revision, touch screen software revision, communication status,

remaining disk space, and estimated storage space remaining, which is displayed in number of days.

The communication status shows the status of communications from the VR base unit to the operator

touch screen. This will show either OK or BAD if communications have failed between the base and the

operator screen.

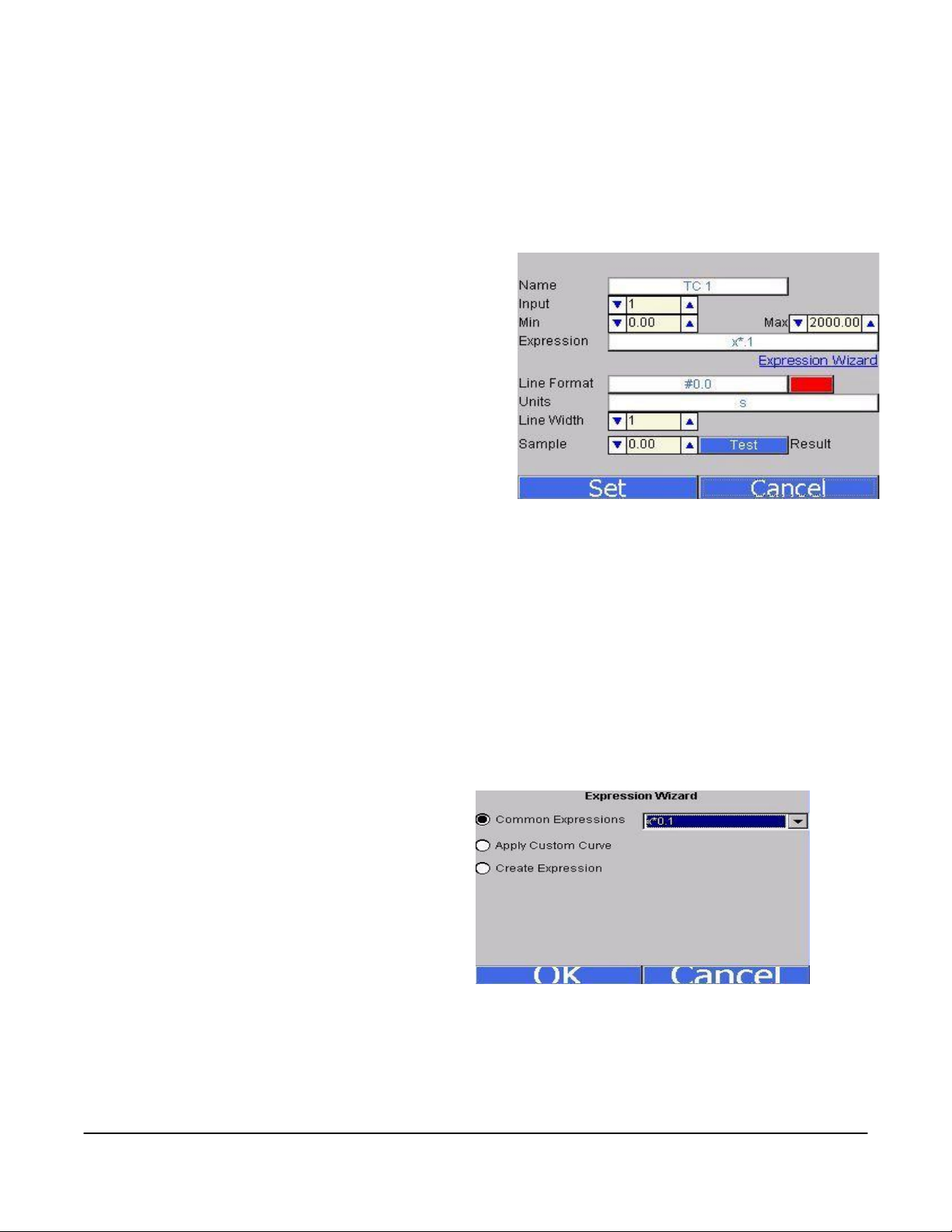

Template Edit

Template Edit allows the operator to edit an

existing template, or create a new template.

A template is the number of variables

displayed on one screen. For example this

could be a control, overtemp, or load

thermocouple on a batch furnace. Or it could

be one thermocouple from eight temper

furnaces. There is not a maximum for

template selections, but the number of

variables displayed on one screen must be a

consideration in this process.

To create a template the Add key is pressed

which allows the operator to configure the

following parameters.

Name – the name of the input, for example “Control T/C” which should be changed to the least

amount of understood characters “Ctl T/C”

Super Systems Inc. Page 21 Video Recorder Manual Version 2 Rev. B

Page 23

Input - the analog input that is being configured, for example on a VR5 this could be a channel from

one through five. The list of options is: TC 1 – TC 40, Averager Group 1 – Averager Group 3, Totalizer

1 – Totalizer 10, and Function Based Timer 1 – Function Based Timer 5. Plus, with version 3.11+ of

the screen software, Slave 1 Process Variable, Slave 1 Setpoint, Slave 1 % Output – Slave 10 Process

Variable, Slave 10 Setpoint, Slave 10 % Output are available for versions 2.01+ on the VR Brick.

Min – the minimum displayed scale value on a chart

Max – the maximum displayed scale value on a chart

Expression – every input requires an expression to

be calculated and displayed correctly. For example

an expression for thermocouple inputs would be x

*.1. Use the onscreen keyboard to enter an

expression.

Expression Wizard – This feature will allow the

operator to build an expression using either a

custom curve or a regular expression. See the

“Note About Expression Wizard” below for more

information about this feature.

Line Format – the value displayed on the chart display of the operator interface. A short custom

description can be added here. For example, to display one (1) decimal point, enter a value of “#0.0”.

For carbon values, enter a value of “#0.00” for 2 decimals. This would display a value like “0.81”.

Entering “#.00” would display a value of “.81”.

Units – The type of units used for the trend.

Line Width – a numeric value for the thickness of the trend line. A 1 is a thin line; A higher value =

thicker line width.

Sample – a number is entered here to test the expression.

Test – Press the test button to calculate the expression with the value entered in the sample

parameter. For example with and expression of x*.1 and a value of 250 entered in the sample

parameter will display a 25.0

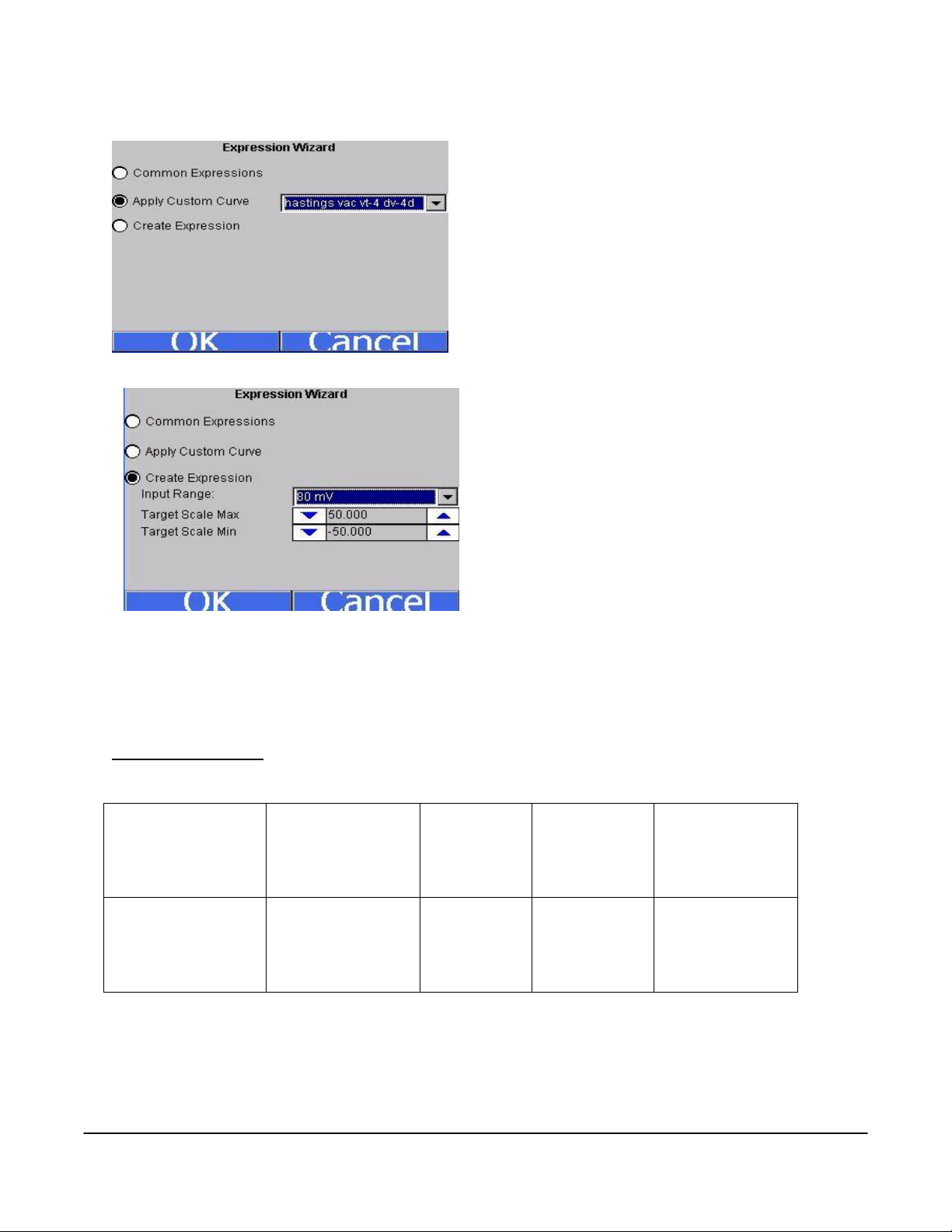

Note About Expression Wizard

This option will allow the user to select either a

common expression, such as “x*.01”, a custom

curve created with the

Manage Curves

menu

option, or to create an expression.

Super Systems Inc. Page 22 Video Recorder Manual Version 2 Rev. B

Page 24

To use a common expression, select the “Common Expressions” menu option and select the desired

RS232 Modbus Host

Baud Rate

RS232 Modbus

Slave Baud Rate

RS485 Host

Mode

RS485 Host

Baud Rate

RS485 Slave

Mode

RS485 Slave Baud

Rate

Serial Address

expression from the drop-down list. Clicking on the

OK button will set the expression to the trend, but

clicking on the Cancel button will not set the

expression to the trend.

To use a custom curve, select the “Apply Custom

Curve” menu option and select the desired curve from

the drop-down list. Clicking on the OK button will set

the curve to the trend, but clicking on the Cancel

button will not set the curve to the trend. If a custom

curve is used, the “Expression” line will read “curve:

<Custom Curve>” where <Custom Curve> is the name

of the curve used.

To create an expression, select the “Create

Expression” menu option. Select the input range for

the trend from the drop-down list, and then select

the scale minimum and maximum. Clicking the OK

button will set the expression for the trend, but

clicking on the Cancel button will not set the

expression for the trend. The “Expression” line will

contain the new expression, if an expression was

created using the wizard.

Note – Expressions can

still be entered in the text box manually, as

described above

.

The “Open”, “Delete”, “Save As”, and “Save” buttons along the top of the screen will allow the user to

work with different templates, while the “Add”, “Edit”, and “Delete” buttons in the middle of the screen

allow the user to work with specific trend lines in a template.

Communications

Communications allows the operator to change the baud rate, or mode of these parameters:

The IP Address, IP Netmask, and the IP Gateway are also displayed on this screen, but they cannot be

configured from this screen. Starting with Version 3.12, this screen also contains the communications

status for any slave instruments that have been configured.

Super Systems Inc. Page 23 Video Recorder Manual Version 2 Rev. B

Page 25

Calibration

B C E J K N

NNM

R S T

0 – 2.56

0 – 1.28

160 mV

80 mV

40 mV

20 mV

4-20mA 124 ohms *Future Use

4-20mA 62 ohms

This menu option allows the operator to calibrate each input on the VR recorder. This will be covered in

detail in the

Input Calibration

section.

Target VR IP Address

Target VR IP address is the address of the operator screen or computer attached directly to the VR series

recorder. This address has to match the IP Address setup on the data logging device to display and store

data. Changing the IP address on this screen will point the screen to a different video recorder data

logger.

Video Recorder IP

This feature will display the IP address of the instrument that the VR is currently talking to and allow this

IP address to be changed. Changing this IP address will change the IP address of the instrument that the

VR is currently talking to. The VR will continue talking to the same instrument, however the IP address

for that instrument will have changed.

Analog Input Type Setup

For information about ensuring that the jumper is set up properly on a 4-20mA input, please

see the Analog Inputs section starting on page 6.

Analog Input Type – allows the operator to choose from the following parameters for each input of the VR

recorder:

Thermocouple Input Types

Voltage Input Types

Current Input Types

Super Systems Inc. Page 24 Video Recorder Manual Version 2 Rev. B

Page 26

Note – The 4-20 mA 124 ohms option is currently reserved for future use. Currently, when using a 4-20

mA input, be sure to select the 4-20 mA 62 ohms option

. For information about ensuring that the

jumper is set up properly on a 4-20mA input, please see the Analog Inputs section starting on

page 6.

Analog Input Offsets

Allows the operator to offset the input by a value entered for this parameter. For example if

thermocouple input is chosen as an input type, a value of 5 will increase the displayed value 5°. Scaling

of the input should be considered when entering an offset value for any input.

Synchronize Clocks

Choose this parameter to synchronize the clock in the operator interface with the clock in the analog

input base unit of the VR series recorder. This should only be performed when there has been a loss of

power or other data logging issues.

Exit the program

Clicking on this menu item will exit the program and display the Windows screen. The user will have to

confirm this action.

Full Disk Options

As the disk space on the flash card nears its capacity, the operator will have to decide how to handle the

data logging capabilities if there is not enough free space to continue data logging. There are two

options: “Overwrite Old Data”, or “Stop Datalogging”.

The first option, “Overwrite Old Data”, will begin to overwrite the oldest files when the free space goes

under 10 MB. The software will look for the oldest

compressed files and it will begin to delete those

files first. The software will delete around 5 MB and

then resume normal data logging. Once the disk

space gets below 10 MB again, these steps will be

repeated.

The second option, “Stop Datalogging”, will stop all

data logging and inform the user that data logging

has stopped. When this option is selected, the

software will not log data until the disk space has

been cleaned up.

Super Systems Inc. Page 25 Video Recorder Manual Version 2 Rev. B

Page 27

Manage Curves

decimal location: 0, 1, 2, 3, or 4. The “Value

Units” text box will allow the operator to

define the value units for the curve using the

onscreen keyboard. The Add Plot button will

allow the user to add a plot point to the

custom curve.

When the

down list will load with all of the custom curves that

have been set up, if any.

Clicking on the New button will allow the operator to add

a custom curve.

The operator will have to name the curve before being

able to edit a curve. The “Interpolation” drop-down list

contains two options: Polynomial or Linear. The “Input

Dec.” drop-down list has five options for the input

Manage Curves

screen loads up, the drop-

Use the up and down arrows to enter the desired input

and value. Clicking on the value will display the numeric

keypad, which will allow the user to enter the value that

way as well. Click on the OK button to set the values, or

click on the Cancel button to cancel the process.

The Edit Plot button will allow the operator to edit a

selected plot point, while the Delete Plot button will allow

the operator to delete a selected plot point. The operator will have to confirm the delete.

The Delete button will delete a selected curve. The operator will have to confirm the delete.

The Save As button will allow the operator to save the curve as another curve, while the Save button will

save the changes made to the current curve.

The Done button at the top of the screen will close the

Manage Curves

screen.

Super Systems Inc. Page 26 Video Recorder Manual Version 2 Rev. B

Page 28

Totalizers

This menu option will allow the user to add or

modify up to ten totalizers. If the totalizer selected

is already set up, then the user will be able to see

the type, the active inputs, and the date of the last

reset, which is where the totalizer is set back to

zero. If the totalizer is not already set up, the user

will only see the type and active inputs, which will be

blank. To select the type, click on the “Type” line

and then click the Edit button. The type can be one

of the following: Off, Seconds, Minutes, or Hours.

Select the desired type and click on the OK button to

set the type, or the Cancel button to cancel the

action.

To select the active inputs, click on the “Active

Inputs” line and then click on the Edit button.

This will display the screen where the user can

select the active inputs for the totalizer. To

select an input, the user can click on the desired

input, which will place a check mark next to the

input. The available inputs are Input 1 – Input 32.

After selecting the input(s), click on the OK

button to set the active inputs, or click on the

Cancel button to cancel the action.

screen may take a few seconds to update the

active inputs and display them

set to something other than Off, then the date of

the last reset will be displayed. If the “Type” is

changed from a value to Off, then the date of the

last reset will become invisible.

totalizer will be reset every time a value is given for the type

force a reset for the totalizer. The user will have to confirm the reset first. To reset a totalizer, click on

the “RESET” line and then click on the Edit button. A message box will pop up confirming the reset. Click

on the Yes button to confirm and reset the totalizer, or click on the No or Cancel button to cancel the

action.

. The “RESET” line will allow the user to

Note: The

. If the “Type” is

Note: The

Averagers

Averagers allow the user to get an average value from

one or more inputs and display that average on the

graph.

Select the averager group to work with from the dropdown list at the top of the screen. The options are:

Averager Group 1 – Averager Group 3. The first line,

“Enabled”, lets the user know if the selected averager

is enabled or not. Clicking on this line and then clicking

on the Edit button will allow the user to enable/disable

all three averager groups at once, instead of doing it

Super Systems Inc. Page 27 Video Recorder Manual Version 2 Rev. B

Page 29

one at a time.

Click on the averager group to enable/disable that group.

Click on the OK button to set the changes, or click on the

Cancel button to cancel the action. Clicking on the “Active

Inputs” line then clicking on the Edit button will allow the

user to select the active inputs for the averager. The

process is identical to selecting the active inputs for a

totalizer. Once the active inputs have been set, the

“Min|Avg|Max” line will populate with the appropriate data.

Function Based Timers

The function based timers will allow the user to monitor whether a specific input goes above a certain

setpoint and for how long the input is over the setpoint. Select the timer to work with from the drop-down

list. The options are: Timer 1 – Timer 5.

The function will determine what input to base the

timer off of. To select the function, click on the

“Function” line and then click on the Edit button.

This will bring up a list of functions to use. The

choices are: DISABLED (No timer function), or

Input 1 > Setpoint – Input 40 > Setpoint. Select the

desired option and click on the OK button to set

the function, or click on the Cancel button to

cancel the action.

function will reset the timer to zero

setpoint, click on the “Setpoint” line and then click

on the Edit button. This will bring up the numeric

keypad so the user can enter the desired setpoint.

Note: Setting a different setpoint will reset the timer to zero

entered, the timer will begin to count if the function’s condition exists. The value of the function is listed

on the “Value” line, which shows the timer in terms of days, hours, and minutes. The “Last Reset” line

will display the most recent date the timer was reset to zero. The “RESET” line will allow the user to

force a reset for the timer. The user will have to confirm the reset first. To reset a timer, click on the

“RESET” line and then click on the Edit button. A message box will pop up confirming the reset. Click on

the Yes button to confirm and reset the timer, or click on the No or Cancel button to cancel the action.

. Once a function and setpoint have been

Note: Function based timers can be added as an input on a template, but they will not be displayed on the

graph

.

Note: Selecting a different

. To set the

Alarm Text

This option will allow the alarm text displayed to be customized. Select the appropriate alarm number,

and press the Edit button. A keypad will display. Press enter on the keypad to save information, delete to

backspace a letter, and esc to leave the keypad without saving changes.

Super Systems Inc. Page 28 Video Recorder Manual Version 2 Rev. B

Page 30

Alarm Setup

This menu option allows the user to set up the

alarms for the screen. The user can set up to

twelve alarms per screen. Select the alarm to

edit from the drop down list at the top of the

screen. Once selected, the alarm’s settings will

be displayed.

The “Type” field will define what type of alarm

this alarm will be set up as.

The options are:

Off (No alarm)

Process (High)

Process (Low)

Band (In)

Band (Out)

Deviation (High)

Deviation (Low)

The “Setpoint” field will allow the user to set the setpoint for the alarm. This will bring up the numeric

keypad where the user can enter the setpoint.

The “Hysteresis” field will allow the user to set the hysteresis for the alarm. This will bring up the

numeric keypad where the user can enter the setpoint.

The “Input Source” field will allow the user to select the input or inputs to focus the alarm on. The

process is identical to selecting the active inputs for a totalizer.

The “Delay (sec)” field will allow the user to set the delay time, in seconds, for the alarm. This will bring

up the numeric keypad where the user can enter the setpoint.

The “Base” field will allow the user to set the base for the alarm. This will bring up the numeric keypad

where the user can enter the setpoint.

The two “State” fields are non-editable, and will display the state of the alarm.

The “Alarm Text” field will allow the user to give a text description that will be displayed on the screen

when the alarm is activated. The text of the alarm will also be referenced on the alarms report in the VR

Manager.

Purge Data

This menu option will allow the user to delete data in one of four ways. This menu option will be useful if

any of the following conditions apply:

There is a “Low disk space” alarm on the screen

Communication with the video recorder data logger has been down for a few hours and the user

needs to get that data from the data logger

The user believes that data is missing or is incorrect for the past week and would like to

synchronize just those hours and/or days

Super Systems Inc. Page 29 Video Recorder Manual Version 2 Rev. B

Page 31

The user wants to delete all data and completely resynchronize with the video recorder data

logger

Before, this would have been accomplished by shutting down the screen program and manually deleting

the files from the storage card. With this menu

option, the user can perform these operations

without shutting the screen program down. There is

a drop down list on the

allow the user to select what data is to be deleted.

The first option, “Recent Data”, will allow the user to delete the most recent data from the screen. Each

option will have a brief description listed on the screen that the user can scroll through and read. These

descriptions will also be listed in this manual.

Description – This option is useful if you have had an interruption in communications between the VR

screen and the VR brick (data logger). After purging recent data and restarting the screen, the screen

will download the data from the brick during the synchronization procedure. Assuming continuous

operation, data from the past 7 days is available for download from the VR brick.

Purge Data

screen that will

It may take up to 1 hour for the screen to download and compress the week of data.

The user will have the option to delete between 0 and 7 days, and 0 and 24 hours from the VR screen.

Clicking on the Purge button will delete the files. Clicking on the Cancel button will cancel the purge and

close out the screen. The user will have to confirm the purge.

Clicking on the Yes button will begin the file deletion. Clicking on the No button will cancel the delete

process. Since this process involves deleting data logged data, the user will have a second chance to

confirm the deletion.

Clicking on the Yes button will begin the file deletion. Clicking

on the No button will cancel the delete.

Since the VR screen will need to be restarted in order to

resynchronize with the data logger, the user will have the

option to restart the screen from the

Purge Data

menu.

Super Systems Inc. Page 30 Video Recorder Manual Version 2 Rev. B

Page 32

The second option, “All Data”, will allow users

the ability to delete all of the logged data from

the VR screen. This option can be used if the

user wishes to completely resynchronize the

VR screen with the VR data logger.

Description – This option deletes all log data

stored on the screen. After rebooting the

screen is rebooted, recent data will be

downloaded from the VR brick (data logger)

and compressed. This will take up to 1 hour to

complete.

The user will have to confirm the deletion

twice in order for the files to be deleted.

Since the VR screen will need to be restarted in order to resynchronize with the data logger, the user will

have the option to restart the screen from the

Purge Data

menu.

The third option, “Old Data”, will allow the users

the ability to delete older data from the VR

screen. The option can be used if the user

wishes to free up space on the storage card.

Description – This option is useful for freeing up

space on the flash card. Be sure that the data

you are deleting has been backed up, or is no

longer needed.

The user can select the start date from the list

box on the screen. The program will delete any

datalog files that are older than the selected

date.

To ensure that the datalog files are backed up before purging the data, it is recommended that the user

run the download option from the VR Manager (Download Data button on the main screen, or

Communications

The user will have to confirm the deletion twice in order for the files to be deleted.

Since there is no need to resynchronize the data on the screen with the data on the VR data logger, the

user will not have to restart the screen.

Advanced Download & Maintenance

menu option).

Tools

Super Systems Inc. Page 31 Video Recorder Manual Version 2 Rev. B

Page 33

The fourth option, “Advanced”, will allow the

users the ability to delete datalog data from

specific time frames. This option can be used to

free up space on the flash card, or to cause a

resynchronization between the VR screen and

data logger.

Description – This option deletes data between

two specific dates. If these dates fall within the

past week, you may choose to restart the screen

to synchronize that data.

The user can select the starting date and time

from the “Between:” section and the ending time from the “and” section.

The user will have to confirm the deletion twice in order for the files to be deleted.

Since the VR screen may need to be restarted in order to resynchronize with the data logger, the user will

have the option to restart the screen from the

Purge Data

menu.

Slave Instrument Setup

This menu option is only available with versions 2.01+ on

the VR Brick and with version 3.11+ of the screen software.

The Slave Instrument Setup menu option will allow the

user to set up to ten slave instruments off of the Video

Recorder. To set the slave type, select the appropriate

slave instrument type and press the Edit button.

slave instrument must be wired to the RS485 Slave

terminals on the Video Recorder brick

.

Note: Any

The list of possible slave types is:

SSi AC20/7EK/20Q/20PQ

SSi 7SL

9200 LP 1

9200 LP 2

9200 LP 3

AE Flow_Meter

Eur 2404, E2704 LP 1

Eur 2500 LP 1

Eur 2500 LP 2, E2704 LP 2

E2704 LP 3

Super Systems Inc. Page 32 Video Recorder Manual Version 2 Rev. B

Page 34

UDC 3300

Yoko UT320, UT350

Yoko UP350

Yoko 550 LP 1, 750 LP 1

Yoko 550, 750 LP 2

The slave address can be an integer ranging from 1 to 250. A value of 0 will disable the slave instrument,

and the address will be displayed as disabled.

Notes Search

To search for a certain word or phrase in the notes, press the click to input search phase button. A

keypad will be displayed.

Note on keyboard functionality – pressing the “caps” button or the “shift”

button will display more keys for data entry. Also, the “del” key works more like the “Backspace” key on

a regular keyboard – i.e. it will delete the character to the left of the cursor

saving, or enter to save the search criteria. A list of notes with this phrase will then be displayed. Only

notes written with the keypad can be searched. Notes written with the stylus will not be included in the

search.

Super Systems Inc. Page 33 Video Recorder Manual Version 2 Rev. B

. Press esc to go back without

Page 35

Loads

The Loads option keeps track of Active and Historical load data.

Pressing New will bring up the

screen for a New Load.

To input information about the new load, highlight any field, Name, Company, or Notes, and press Edit

Record. A keypad will display. Press enter on the keypad to save information, delete to backspace a

letter, and esc to leave the keypad without saving changes. Choose the corresponding template from the

drop down menu along the top of the screen. When the load begins, press the Start Load button. When

the load finishes, choose End Load on the same screen.

By pressing the Historical button on the

loads screen, the historical load data will

be displayed.

Super Systems Inc. Page 34 Video Recorder Manual Version 2 Rev. B

Page 36

The Details button will display the information that has been stored about each load. The Search key

allows all historical load data to be searched

through according to either the Name, Company, or

within the Notes. Only notes that have been entered

with the keypad can be searched. Notes written the

stylus will not be included in searches.

To search historical loads, press the Search key.

Highlight the appropriate field and press Edit Key. A

keypad will display. Press enter on the keypad to

save information, delete to backspace a letter, and

esc to leave the keypad without saving changes.

Once the search key(s) have been entered, press the

Search button, and a list of matching results will be

displayed.

Date Time Settings

The Date Time Settings option lets the user change

the current date and time from this menu.

Furthermore, the Date and Time settings can be

changed to 24 hour instead of AM/PM. For changes to

take effect, the screen must be shut down and

rebooted (See the Exit Program configuration menu

option).

User Fields

The User Fields feature allows for the Name, Company, and Notes asscotiated with a load to be either

displayed or hidden. To toggle between, select the appropriate field name and press the Show/Don’t

Show button.

Super Systems Inc. Page 35 Video Recorder Manual Version 2 Rev. B

Page 37

Passcodes

Passcodes allows the login numbers for the supervisor or administrator passcodes to be customized.

The administrator is the only login with access to this menu. To change the passcode, press the

corresponding box. A numerical keypad will be displayed. Select the new number and press Enter.

Menu Configuration

Menu configuration allows the Configuration Menu to be customized in terms of what is displayed

depedending on the login level. The Administrator is the only login with access to this menu. To adjust

whether or not the Menu Item is displayed, highlight the appropriate item and press either the Toggle

Operator or Toggle Supervisor button. If the status reads True, the item will be accessable in the

Super Systems Inc. Page 36 Video Recorder Manual Version 2 Rev. B

Page 38

configuration menu. If the status reads False, it will not appear in the configuration menu list. Press

Save to save changes.

Input Calibration – Screen Version 1.47 and Below

Note: To check the screen version number, click on

the

Status

menu option from the

The screen’s revision number will be listed next to the

“Touchscreen Revision” line

information to setup the calibration of the inputs.

Calibration can be performed 1 channel at a time or

from 1 – 5 inputs per board. The user can select board

one through sixteen from the selector box on the

bottom left of the screen. Clicking on the yellow area

will display the onscreen keyboard, which will allow

the operator to enter in the number of the board to

calibrate. Once a board has been selected, press the

Enter Cal Mode button to start the calibration process.

If the module is not communicating, the software will display an error message.

The user will need a thermocouple calibrator capable of outputting a thermocouple signal to calibrate the

zero, span or cold junction value of the video recorder data logger. The user will need to connect the

calibrator to one of the inputs on the data logger for the channel that will be calibrated. It is

recommended to let everything (calibrator and datalogger) sit for approximately thirty minutes to allow

the temperature to achieve equilibrium. Set up the calibrator for the specific thermocouple type of the

thermocouples in the video recorder datalogger, i.e. type K, type J, etc. Then, source a specific

temperature, like 1000 F, or millivolt to the connected input. It is recommended that the actual

temperature used be similar to an appropriate process temperature. For example, if your equipment

normally operates at 1700 F, then perform the cold junction calibration using a 1700 F signal. It is

important to note that when performing a zero or span calibration,

wiring. Instead, use any kind of regular sensor wire, or even regular copper wire. To perform the

calibrations, the user will need a calibrator that is capable of outputting volts, millivolts, and

temperature.

do not use

Configuration

. This screen displays

regular thermocouple

menu.

Below is a listing of the suggested ranges for the various TC types.

TC Type mV Range Chart

TC Type Range in mV

B 20

C 40

E 80

J 80

K 80

N 80

NNM 80

Super Systems Inc. Page 37 Video Recorder Manual Version 2 Rev. B

Page 39

Zero Calibration

R 40

S 20

T 20

To perform a zero calibration, click on the “Zero”

option. The circle will be filled in for the selected

option. The drop down list under “Range” will

allow the user to select the millivolt range of the

inputs being calibrated. When a range is

selected, the recommended value will also be

populated. For a zero calibration, the

recommended value is 0. The list of ranges is:

20 mV

40 mV

80 mV

160 mV

1.28 Volt

2.56 Volt

The recommended value can be changed either by using the up and down arrows to adjust the value, or

by clicking on the value, which will display the numeric keypad. The user can enter the new value in that

way. The user can also individually select each input (one through five) to calibrate, where Check = yes

(calibrate) and No Check = no (do not calibrate). Once an input is checked, its current value will be

displayed.

For a zero calibration, a value of 0 mV will need to be sourced to the input or inputs.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

Span Calibration

To perform a span calibration, click on the

“Span” option. The circle will be filled in for the

selected option. The drop down list under

“Range” will allow the user to select the

millivolt range of the inputs being calibrated.

When a range is selected, the recommended

value will also be populated. For a span

calibration, the recommended value is 90 % of

the full range. For example, if the range is 80

mV, then the span should be 75. The

recommended value can be changed either by

using the up and down arrows to adjust the

value, or by clicking on the value, which will

display the numeric keypad. The user can enter

the new value in that way.

Note: If the user is

Super Systems Inc. Page 38 Video Recorder Manual Version 2 Rev. B

Page 40

using a 10:1 jumper (see the

will need to multiply the source signal by 10 to get the correct span value

jumper is set on a 1.25V range, the suggested source signal will read 1000 mV. The supplied signal will

need to be 10000 mV to account for the 10:1 jumper. The user can also individually select each input (one

through five) to calibrate, where Check = yes (calibrate) and No Check = no (do not calibrate). Once an

input is checked, its current value will be displayed.

For a span calibration, a value of 90 % of the full range will need to be sourced to the input or inputs.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

Adding a Jumper to an Input

section in the

Analog Inputs

. For example, if the 10:1

section), the user

Cold Junction Adjust

To perform a cold junction adjust, click on the

“CJ Adjust” option. The circle will be filled in for

the selected option. The cold junction offset can

be entered by using the up and down arrows to

modify the “Enter Cold Junction Offset” value.

The user could also click on the value, which will

display the numeric keypad, which will allow the

user to enter the new value in that way. The cold

junction adjust will adjust all of the inputs on one

board simultaneously.

Note – To subtract a

value from the current cold junction value, be

sure to set the offset value as a minus value by

clicking on the plus/minus key on the keypad (+/)

.

The overall Cold Junction value is modified by

adding or subtracting a value to the current

value.

Click on the Calibrate button to begin the calibration.

A progress bar will be displayed along the bottom of the screen giving the progress of the calibration.

Press the Exit Cal Mode to return to the previous

screen and select a different board. Pressing

the Done button from that screen will exit the

calibration menu item.

Input Calibration – Screen Version

1.49 and Above

The user will need a thermocouple calibrator

capable of outputting a thermocouple signal to

calibrate the zero, span or cold junction value of

the video recorder data logger. The user will

need to connect the calibrator to one of the

inputs on the data logger for the channel that

will be calibrated. It is recommended to let

everything (calibrator and datalogger) sit for approximately thirty minutes to allow the temperature to

achieve equilibrium. Set up the calibrator for the specific thermocouple type of the thermocouples in the

Super Systems Inc. Page 39 Video Recorder Manual Version 2 Rev. B

Page 41

video recorder datalogger, i.e. type K, type J, etc. Then, source a specific temperature, like 1000 F, or

millivolt to the connected input. It is recommended that the actual temperature used be similar to an

appropriate process temperature. For example, if your equipment normally operates at 1700 F, then

perform the cold junction calibration using a 1700 F signal. It is important to note that when performing

a zero or span calibration,

sensor wire, or even regular copper wire. To perform the calibrations, the user will need a calibrator that

is capable of outputting volts, millivolts, and temperature.

do not use

regular thermocouple wiring. Instead, use any kind of regular

Note: To check the screen version number, click on the

menu. The screen’s revision number will be listed next to the “Touchscreen Revision” line

Calibration

settings. When the settings have been loaded, the Calibration tab will be displayed.

If an existing input board is selected in the “Analog Input Card” section, then that input board’s firmware

revision number will be displayed next to the input board number and the inputs to be calibrated will be

enabled (see the figure on the left above). If a non-existing board is selected, there will be no firmware

revision number shown and the inputs to be calibrated will be disabled (see the figure on the right above).

menu is first selected, the screen software must first load up the screen’s configuration

The user will be able to select boards 1 through 8. Select

the inputs to calibrate by checking the checkbox next to each

input where: check = Yes (calibrate) and no check = No (do

not calibrate). Once the inputs to calibrate have been

chosen, press the Enter Cal Mode button to begin the

calibration process.

Status

menu option from the

Configuration

. When the

Once the calibration screen is displayed, the drop-down list

on the left of the screen will allow the user to select either

Zero Cal or Span Cal, depending on which calibration is

desired.

The “Input Values (mV)” section will display the selected

inputs and the associated values for those inputs. If an input has not been selected from the previous

screen, that input’s value will be dashes “---”. The “Calibration Range” drop-down list will allow the user

to select the appropriate range for the thermocouples. See the

range is not known for a specific thermocouple type.

Super Systems Inc. Page 40 Video Recorder Manual Version 2 Rev. B

TC Type mV Range Chart

on page 35 if the

Page 42

For a zero calibration, a value of 0 mV will need to be sourced to the input or inputs, and the “Enter

Source:” field should be set to 0.00. A recommended value will be displayed next to the “Recommended

Value:” field.

For a span calibration, a value of 90 % of the full range will need to be sourced to the input or inputs, and

the “Enter Source:” field should be set to 90% of the full mV range. A recommended value will be

displayed next to the “Recommended Value:” field.

Note: If the user is using a 10:1 jumper (see the

Adding a Jumper to an Input

section in the

Analog Inputs

section), the user will need to multiply the source signal

by 10 to get the correct span value

10:1 jumper is set on a 1.25V range, the suggested

source signal will read 1000 mV. The supplied signal

will need to be 10000 mV to account for the 10:1 jumper.

Press the Calibrate button to begin the calibration.

Press the Cancel button to cancel the calibration and

return to the previous screen.

The Cold Junction tab will allow the user to set the cold

junction offset for a specific input on a specific board.

The board being calibrated will be listed in the “Board #x, Input:” line, where x is the board selected from

the Calibration tab. The drop-down list will allow the user to select the input to set a cold junction offset

for. The “Current Input Value” line will display the selected input’s current value. The “Apply Offset:” box

will allow the user to select the cold junction offset to set.

Press the Apply Cold Junction Offset button to apply the selected offset.

. For example, if the

Super Systems Inc. Page 41 Video Recorder Manual Version 2 Rev. B

Page 43

The “Exit” link at the top right of the screen will exit the

Calibration

menu option.

Changing the Date/Time of the Touch Screen display

If the date or time needs to be changed on the Touch Screen display unit, use the following steps:

1. Exit the Video Recorder display by selecting the “Exit Program” menu option from the

“Configuration” menu.

a. Click on the View button along the bottom of the screen to select the menu option.

b. Click on the Yes button to confirm the program close.

2. Once the Video Recorder display has closed, double-click on the time in the taskbar in the lower

left corner. This will bring up the dialog to change the date or time.

OR

3. Go to Start Menu Settings Control Panel

a. Click on “Date/Time” once and select File Open or

b. Double-click the “Date/Time” icon to open the Date/Time dialog

4. If necessary, select the new date from the calendar by clicking on the date. Months can be

changed by using the left or right arrow buttons next to the month/year on the calendar.

5. If portions of the dialog are not visible due to the screen size, click and hold the title bar and move

the dialog by dragging the dialog.

6. If necessary, select the new time zone from the drop-down list.

7. Check the “Automatically adjust clock for daylight saving” checkbox if desired.

8. If necessary, adjust the time:

a. Highlight the hours, minutes, or seconds by clicking on the desired section. When

selected section will be highlighted in blue.

b. Use the up or down arrows to change the selected section

9. Click on the Apply button or the OK button at the top of the dialog to save the changes

10. If no changes were made, click on the X button in the top right of the dialog to close the dialog

11. Cycle the power to the Video Recorder Touch Screen to bring up the Video Recorder display.

Super Systems Inc. Page 42 Video Recorder Manual Version 2 Rev. B

Page 44

Remote Trend Web Page

Each touch screen will also contain a simple web page that will display the trend information for all of the

templates. However, before anyone can view this web page, the web server may need to be configured.

Open a web browser such as Internet Explorer or Mozilla Firefox, and enter the following into the address

bar: http://<

Touch Screen IP >

where < Touch

Screen IP > is the

IP address of the

touch screen

the video

recorder box).

This will display

the web page.

The templates are

listed in the dropdown list next to

“Trend

Template:”. Once

a template has

been selected,

the trends will be

displayed

underneath. The

current date and time of the touch screen will be displayed beneath the trends.

(not

If the above web page is not displayed, then the web server on the touch screen will need to be

configured. First, enter the following address into a web browser’s address bar:

http://< Touch Screen IP

>/remoteadmin where

< Touch Screen IP > is

the IP address of the

touch screen.

This will display the

remote administration

page for the touch

screen

Enter a password in the

“Password:” and

“Verification:” fields and

then click on the Apply

button. Clicking on the