Page 1

LOAD ENTRY 3

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

www.supersystems.com

Page 2

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 2 of 35

Super Systems Inc.

USA Office

Corporate Headquarters:

7205 Edington Drive

Shipping Address:

7245 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Super Systems Europe

Unit E, Tyburn Trading Estate,

Ashold Farm Road, Birmingham

B24 9QG

UNITED KINGDOM

Phone: +44 (0) 121 306 5180

http://www.supersystemseurope.com

Super Systems México

Sistemas Superiores Integrales S de RL de CV

Acceso IV No. 31 Int. H Parque Industrial

Benito Juarez

C.P. 76120 Queretaro, Qro.

Phone: +52 442 210 2459

http://www.supersystems.com.mx

Super Systems China

No. 369 XianXia Road

Room 703

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.cn

Super Systems India Pvt. Ltd.

A-26 Mezzanine Floor, FIEE Complex,

Okhla Indl. Area, Phase – 2

New Delhi, India 110 020

Phone: +91 11 41050097

http://www.supersystemsindia.com

Page 3

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 3 of 35

Table of Contents

Introduction ..................................................................................................................................... 4

Prerequisites................................................................................................................................... 5

SQL Setup ........................................................................................................................................ 7

Installation ...................................................................................................................................... 7

Setup ............................................................................................................................................... 9

Management Window .....................................................................................................................10

User Editor .................................................................................................................................10

Options Editor .............................................................................................................................11

Operations Editor: ......................................................................................................................13

Assets (Furnace) Editor ..............................................................................................................14

Furnace Details Panel ............................................................................................................15

Overview Group Assignments.................................................................................................16

Recipe Editor ..............................................................................................................................16

Recipe Details Panel...............................................................................................................16

Recipe Panel ...........................................................................................................................16

Parts Editor (optional feature) ...................................................................................................17

Details Panel ..........................................................................................................................17

Fields Editor ...............................................................................................................................18

Fields Details Panel ................................................................................................................18

Gap Editor (Optional Feature) .....................................................................................................19

Shift Editor ..................................................................................................................................20

Sequence Editor .........................................................................................................................20

About ..........................................................................................................................................21

Overview Screen ............................................................................................................................21

Load Creation .............................................................................................................................24

Active Screen .................................................................................................................................25

Work Order Editor ......................................................................................................................26

History Screen................................................................................................................................27

Load Tracking Editor ..................................................................................................................29

Bulk Load Reports .........................................................................................................................30

Revision History .............................................................................................................................35

Page 4

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 4 of 35

Introduction

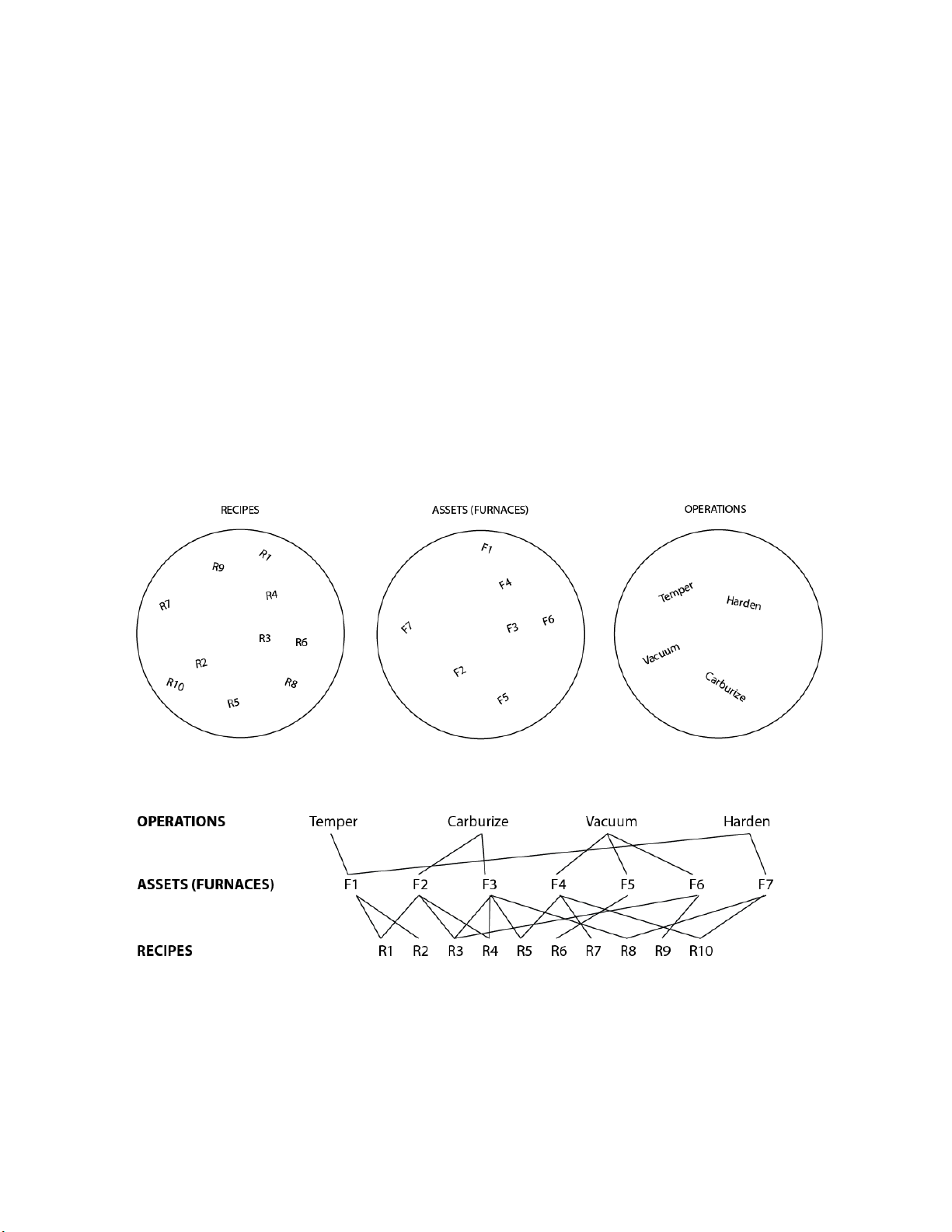

SSi’s Load Entry 3 software is part of the SSi SuperDATA suite of programs. Load Entry assists

with recipe management and tracking by providing a single, PC-based interface to control all

activities for a heat treat facility. Load Entry is accessible from any computer setup as a

SuperDATA workstation, allowing multiple access terminals throughout a facility. Load Entry

seamlessly integrates with existing SSi and Honeywell HC900 controllers for creating recipes

and starting and stopping recipes. Load Entry works with the SSI Configurator program to

import recipes that have already been created.

Load Entry allows you to enter various operations, furnaces, recipes, parts, and users, but also

enables you to “apply” these items to one another as required by your facility. This allows for

easy tracking, management, and information retrieval, saving you time and money.

Put another way, Load Entry manages the often complicated relationships and connections

between your facility’s recipes, furnaces, and operations:

With this complex web under control, you are free to more efficiently manage your resources

using the other tools included in LE3 software.

Page 5

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 5 of 35

If required, Load Entry allows controllers to extend past the previous limit of 300 recipes since

all recipes are stored in a database as part of the system.

Load Entry’s built-in Recipe Management features allow administrators to “lock” specific

recipes, preventing operators from making temporary changes, while providing flexibility by

allowing other recipes to remain “unlocked.” Recipe revisions are tracked, providing complete

visibility for actual recipes run in the equipment.

Load Entry also maintains historical data marking the beginning time, end time, and Operator ID

for each charged load. This data helps improve load traceability and increase operator

accountability. Historical data can be quickly accessed to generate reports and trend charts

(using SDRecorder II). Each report can store detailed part information (part number, quantity,

material, etc.) as well associate part images for a specific load.

We are constantly improving and updating this software. If you have questions about a feature

or functionality not covered in this manual, please contact SSi at 513-772-0060 for technical

support.

IMPORTANT!

Standard Load Entry will serve as a recipe manager as well as a load management system. It

is intended to replace your existing recipe management software. Attempting to use another

recipe manager in addition to Standard Load Entry on the same equipment is likely to result

in operational errors and should be avoided.

Prerequisites

.NET Framework 4.6.2+

Standard Load Entry requires Microsoft .NET Framework 4.6.2 or higher.

Super Systems API

Standard Load Entry requires access to the Super Systems Application Program Interface (API)

running on the server, which communicates to either SDIO or DataCenter (the SuperDATA

Communications engines), as well as SQL Server.

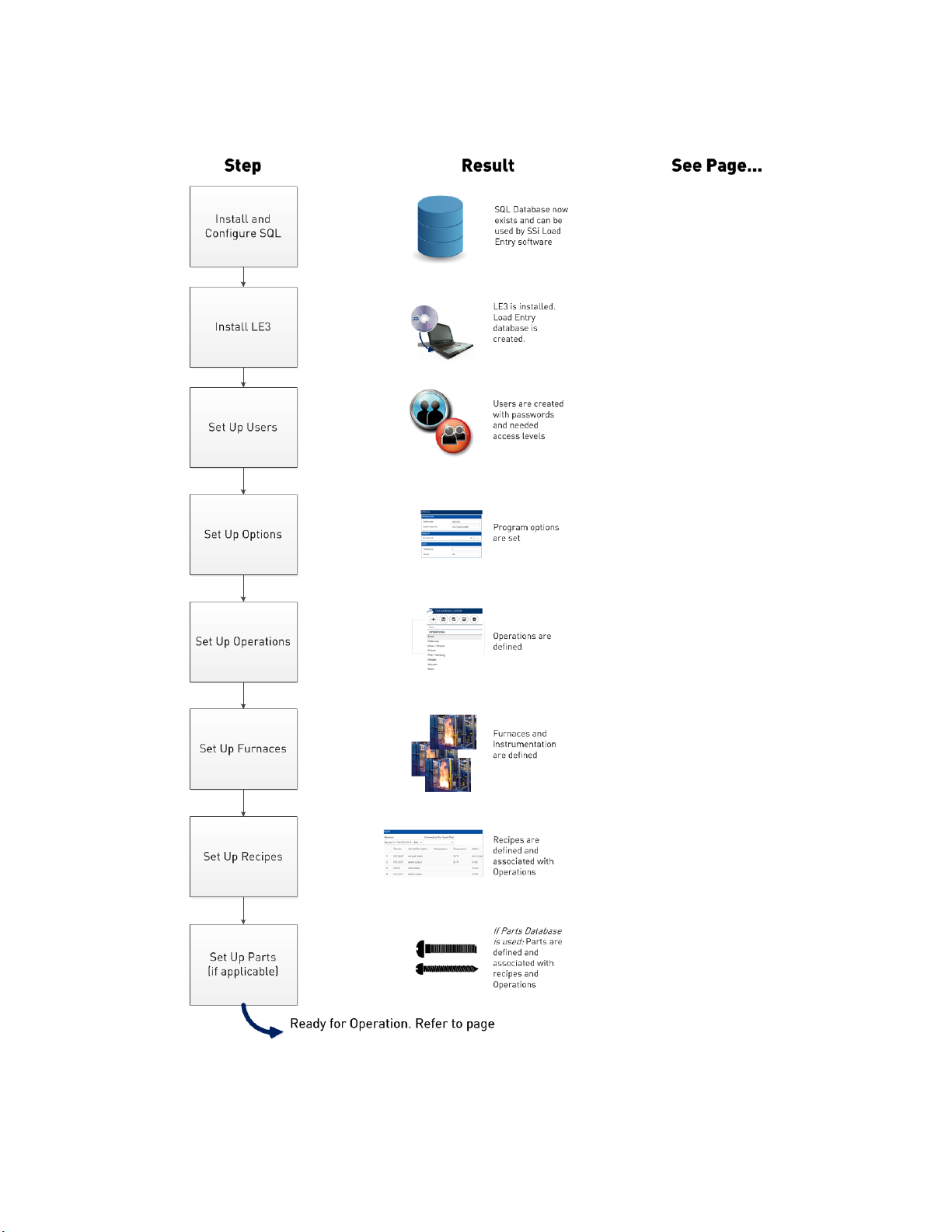

The Setup Flowchart below illustrates the recommended steps to follow when setting up and

installing Standard Load Entry, especially for the first time. These features will be used after

the initial setup as new loads are added, process requirements change, etc.

Page 6

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 6 of 35

Setup Flowchart

6

6 9 10

12

14

16

17

21.

Page 7

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 7 of 35

SQL Setup

Please refer to the

SQL Server Setup Guidelines for SSi Software Installations Reference Guide

found on the Manuals page of the Super Systems website: www.supersystems.com. In addition,

prior to installation, the Super Systems API must be installed and set up for SDIO or

DataCenter. If you have questions about your specific installation, please consult your IT

administrator or contact SSi at (513) 772-0060.

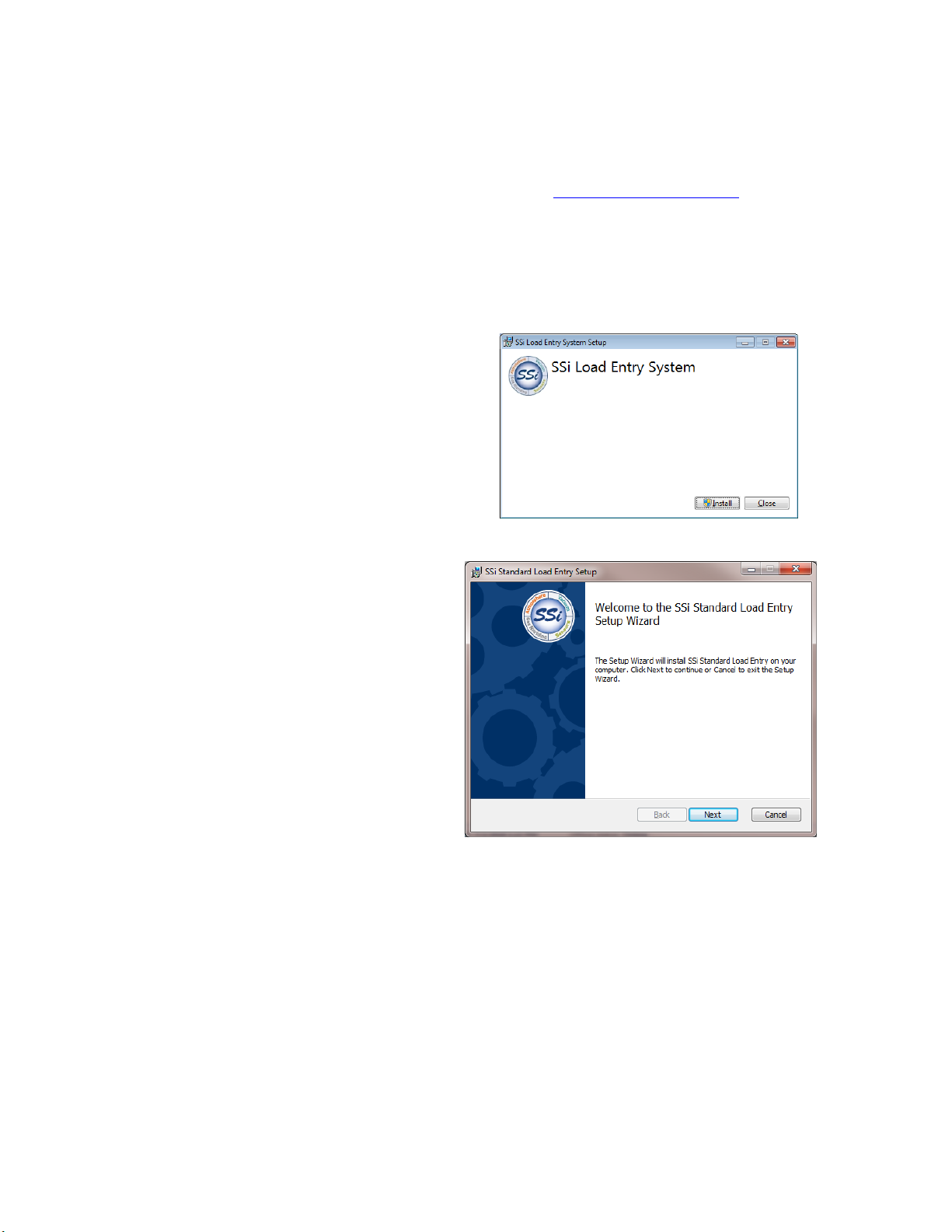

Installation

To install Standard Load Entry, first doubleclick on the

03_LoadEntry3_Client.msi

file

provided with the installation disc or

installation files you received. A screen

similar to the one at right will be shown.

Click the Install button to proceed.

When the Setup welcome screen appears,

click Next when ready to proceed.

Page 8

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 8 of 35

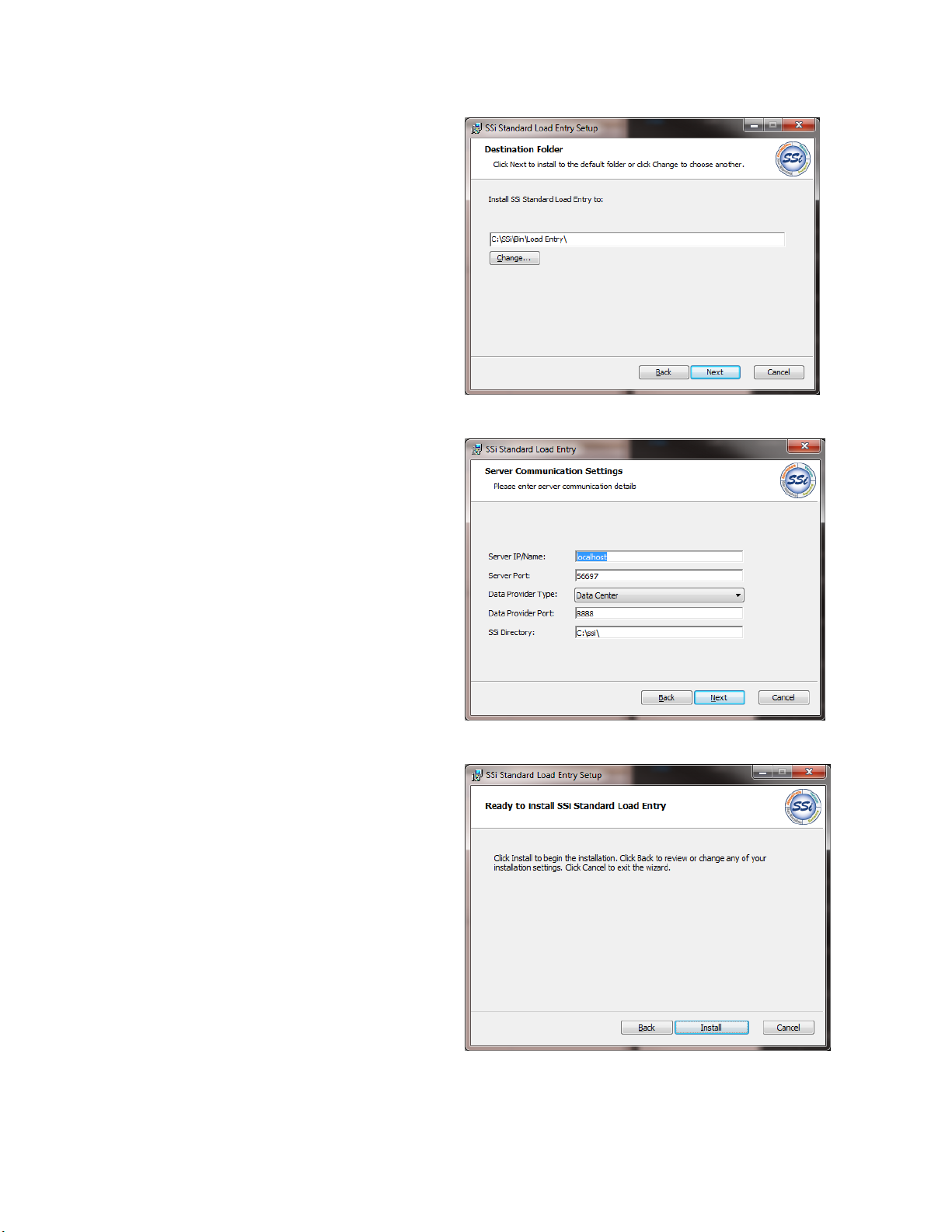

In the next window that appears, enter the

name of the folder where Load Entry should

be installed. The default will typically be

“C:\SSi\Bin\SSi Load Entry\”. If you want to

change the default, click the Change button.

When ready to proceed, click Next.

Load Entry will then ask for Server

Communication Settings.

If you are unsure of the correct settings and

information, please consult your IT

professional or contact SSi for assistance.

Click the Install button to proceed.

Page 9

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 9 of 35

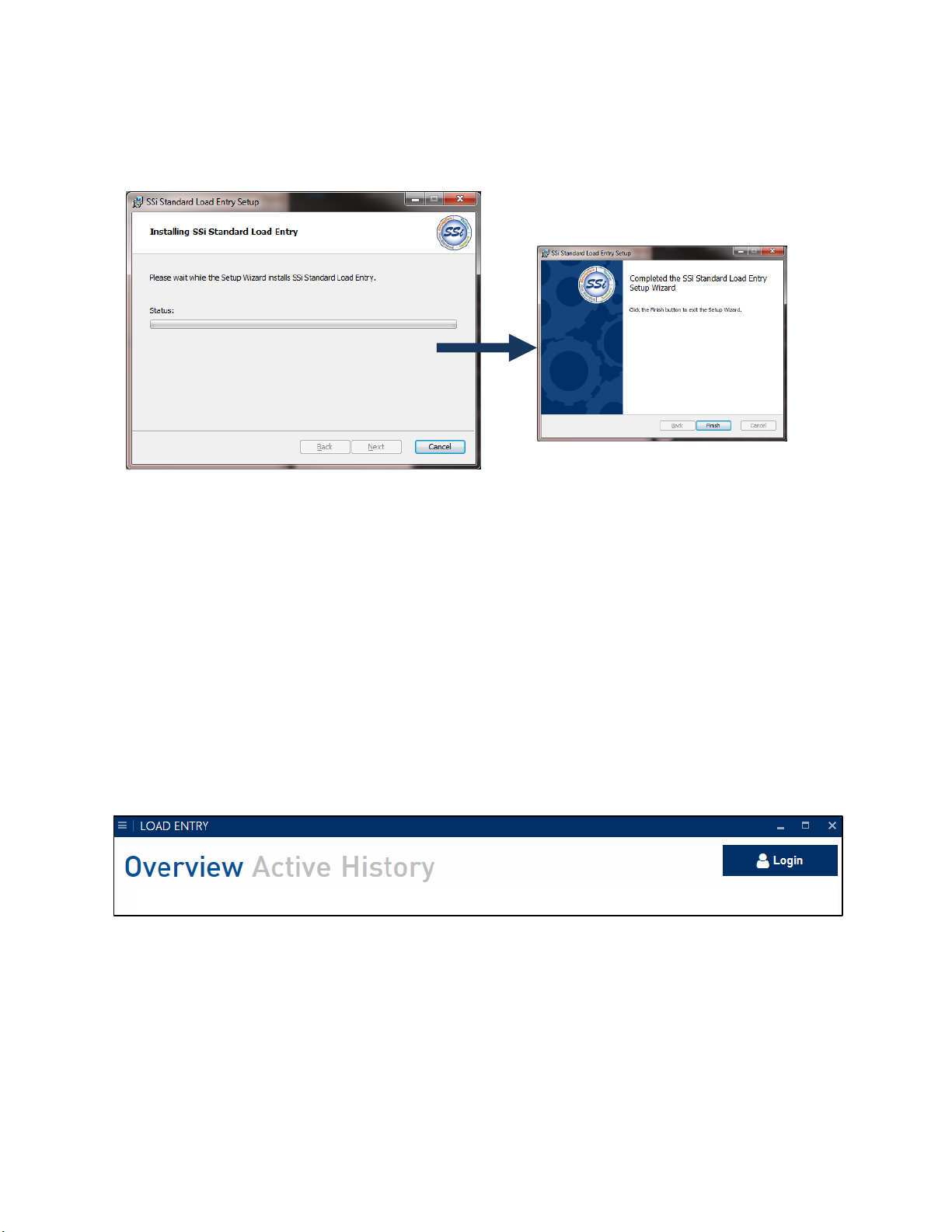

The software will install. The remaining

screens will confirm the installation.

Setup

When run for the first time, Load Entry users, furnaces, operations, recipes, and parts (if

applicable) must be created.

This manual is written with a suggested order of setting up items. SSi suggests this order based

on the most logical progression of steps for configuring LE3. The sections below detail setup of

the following components, in this order: users, options, operations, furnaces, recipes, and

parts.

To start Load Entry, open the LoadEntry.Windows program from the Start Menu. By default, this

program shortcut is located in the SuperSystems program group.

When first opened, the Overview screen will be displayed:

This screen will be explained in more detail on Page 21. Once logged in with administrator

access (by using the Login button at top right), you may continue with the setup.

Page 10

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 10 of 35

Management Window

Clicking the SSi button will bring up the Management Window which includes the

following options:

Operations

Furnaces

Recipes

Sequences

Parts

Fields

Users

Gaps

Shifts

Options

About

These options will allow you to input the information that Load Entry will use to control the

activity in your facility. Think of this as setting up the background processes that will allow you

to manage day-to-day operations elsewhere in the application. This manual is written with a

suggested order of setting up items. SSi suggests this order based on the most logical

progression of steps for configuring LE3. The sections below detail setup of the following

components, in this order: users, options, operations, furnaces, recipes, and parts.

User Editor

The User Editor allows you to add user information and set passwords and “Claims” for each

user. If any users have been created, you can click on the user’s name to view and change their

assigned claims. You can also use the “Filter” box to search for specific users.

“Claims” are simply permissions and determine what options the user will be able to access.

To change claims for an existing user, simply check or uncheck the desired boxes.

You can also change the User Name, Name, and update the user’s password information.

Click “Apply” to save the changes. To leave without saving changes, click “Cancel.”

To add a new user, click the “New” button. Enter the desired information in the boxes for

“User Name” and “Name” and then select desired Claims. Use the “Update Password” button

to enter password information for this user.

Available Claims are:

Admin Run Loads Manage Work Orders

Manage Parts Manage Recipe Manage Furnace

Page 11

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 11 of 35

Manage Users Manage Sequences Override Sequences

Override Work Order Manage Options Manage Operations

Manage Gaps Approve Work Edit Track

Edit Gap Manage Shift Overwrite Gaps

Add Historical Loads Check for Updates Delete Load Tracks

Force Load Out Add Rework

NOTE: The “Admin” Claim gives a user access to all options.

You will note that your new user appears in

italics

in the user list. This means that the user has

not been saved.

When completed, click “Apply” to save the User information. This user will now be added to

your list.

By right-clicking on a user name in the list, you can “Copy” and “Paste” a user (useful in

creating a new user with identical claims to an existing one). You can also “Delete” a user. The

option to set password information is also available via the right-click menu.

Click to close the User Editor.

Options Editor

The Options Editor window allows you to view and edit information about Language, Data

Provider, Defaults, Units, Logins, Visual Shop, Work Orders, and other optional features. This

will allow you to set up LE3 in the way that best fits the needs of your facility.

LANGUAGE:

Language: Select the language for LE3.

DATAPROVIDER:

DataProvider Hostname : Enter the hostname name of the Data Provider.

DEFAULTS:

Pick List Limit: Defines how far back the Pick List feature will go when creating a load

UNITS:

Temperature: Enter the desired temperature display unit.

Weight: Enter the desired weight display unit.

Page 12

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 12 of 35

LOGINS:

Login Limit Enabled: When checked, LE3 will log out users after a period of inactivity.

Login Limit Minutes: How long a user can remain inactive before being logged out by LE3.

VISUAL SHOP:

Connection String: This information is required to pull data from your Visual Shop database.

This feature can be set up from the Furnace Editor (see p. 14)

Custom Field: A label for a single piece of data that can be tracked with a Visual load.

WORK ORDERS:

Generate Work Order Names: Select whether LE3 will generate work order names

Use Part Serial Numbers: Select whether LE3 will use Part Serial Numbers for identification.

OPTIONAL FEATURES:

Use Parts Database: When checked, the Parts database options will be available.

Use Gap Time: When checked, the Gap options will be available.

Use Work Order Approval: When checked, LE3 will require approval of work orders.

Apply Default Offset to Trend: When checked, the report default offset will be applied to load

end and start after clicking “View Trend.”

Use Register Definitions: When checked, Register and Definition options will be available for

furnaces and recipes that use an HC900 controller.

Disable Weight: When checked, Weight options will

not

be available.

Display Furnace Run ID: When checked, a furnace ID will be displayed, based on the prefix

defined in the furnace and the number of loads that have been run in that furnace

Display Work Order Completed Steps: Displays the time in and time out of each completed step

on the Work Order Editor

Use External Database Mapping: When checked, allows you to connect to an external database

to pull data for custom fields. Use the “Edit Mappings” button to enter the desired settings.

Display status color: When checked, furnace status will be displayed by color in the Overview

screen. Use the “Edit Status Colors” button to customize the colors used for each status.

REPORT DEFAULTS:

Page 13

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 13 of 35

Start Offset: Enter a starting offset value. This defines the amount of time to wait before a load

begins when opening SDRecorder and running load reports.

End Offset: Enter an ending offset value. This defines the amount of time to wait after a load

ends when opening SDRecorder and running load reports.

Export to XML:

Custom Logo: Use to add your own custom logo to a Load Report Click the “…” button to

browse your computer for the desired file.

Click “Save” to save your Option settings.

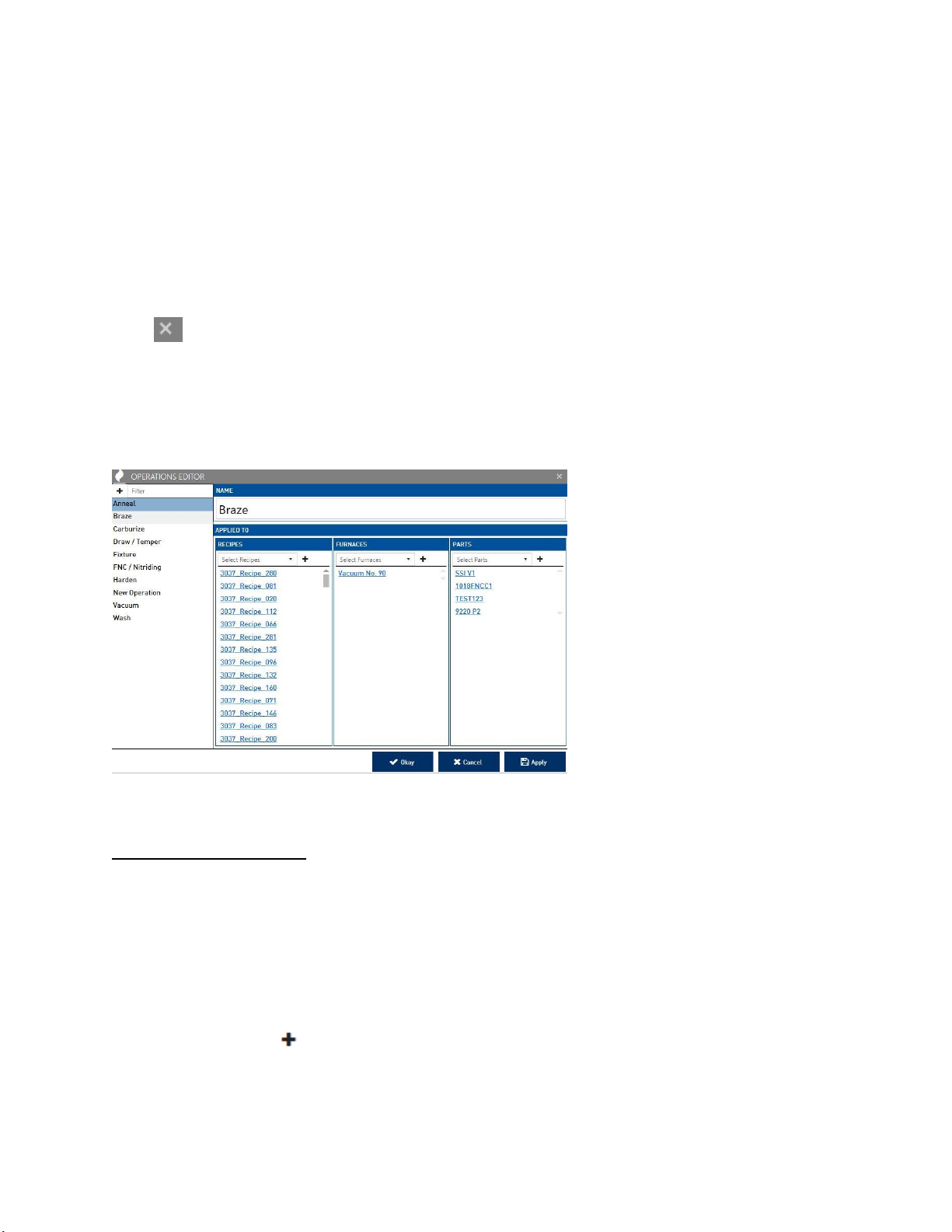

Operations Editor:

The Operations Editor Window allows you to enter information about the operations in your

facility that Load Entry will control. Specifically, you can choose to “Apply” an operation to any

Recipes, Furnaces, or Parts that you have already inputted into the software or imported from a

database.

On the left of the window you will see a list of Operations (empty if you have not yet created any)

and a “Filter…” input box which will allow you to filter/search the displayed Operations.

The main view area of the Operation Editor Window is where you will enter your Operations

information.

To begin, click the “Create New” button. Enter a name for your new Operation. You will

note that your new operation appears in

italics

in the operation list. This means that the

operation has not been saved.

If you have not yet created any Recipes, Furnaces, or Parts in the system, naming the Operation

will be your only option. If you

have

created any of this additional information, you will have the

option to apply your new operation to those items:

Page 14

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 14 of 35

Click “Apply” to save the current Operation. It will now be displayed on the list to the left

without italics.

To edit an existing Operation, simply select it in the list on the left and its information will

appear in the main view area.

By right-clicking on an operation in the list, you can “Copy” and “Paste” an operation (useful in

creating a new operation with applications to an existing one). You can also “Delete” an

operation.

Click to close the User Editor.

Click “Apply” to save the changes. To leave without saving changes, click “Cancel.”

After entering information for numerous Operations, as well as Recipes, Furnaces, and Parts

(all described later), your Operations Editor may look something like this:

Assets (Furnace) Editor

The Assets Editor Window allows you to enter information about the Furnaces and other

equipment in your facility that Load Entry will control or keep track of. You can then assign the

furnace to the desired Operations, Groups , and set Report Options.

Operations Tab

To assign a furnace to an existing operation, select the desired operation from the dropdown

menu, and then click .

Page 15

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 15 of 35

The operation will now be added to the operations list below the dropdown menu. The

operations list is clickable – clicking on an item in the list will bring up that operation’s

information.

To delete an operation from the list, right-click on it and select “Delete.”

Clicking the “Groups” tab will bring up options for Overview Groups Assignments. This will

allow you to assign your furnaces to various groups for easy viewing in your overview screen

(see p. 21)

The functionality of the Groups menu is identical to that of the “Operations” tab (see p. 13). In

addition, clicking “Manage Groups” will allow you to make changes to the groups seen in the

overview

Furnace Details Panel

The Details Panel allows you to choose a Name, Load Prefix, Connection, Model, SDRecorder

trend chart, set Min and Max Weights, enter a Programmer Number, and assign settings for

Visual Shop integration.

NOTE: If the furnace is Visual Shop integrated, the Visual Shop Equipment Id must match the

asset’s id in Visual Shop in order to use the tracking feature.

Page 16

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 16 of 35

Overview Group Assignments

The “Manage Overview Groups” button allows

you to organize the Furnaces displayed on the

Overview window into groups.

On the Overview Groups Editor window, simply

click the New button and enter a group name

in order to create a new group

When completed, click “Save.” You will now have

the option to assign furnaces to your new group by

using the “Overview Group Assignments” panel on

the Furnace Editor Window. (You will first need to

click Save on the main Furnace Editor, then close it

and restart.)

When you are finished assigning furnaces to

groups, the Overview Window will display your

Furnaces by groups. (NOTE: You may need to

restart the application for the new group to appear

in the Overview screen.l)

NOTE: If an Overview Group is displayed

in italics

within the list view,

this indicates that it contains unsaved changes.

Recipe Editor

The Recipe Editor Window allows you to enter information about the Recipes in your facility that

Load Entry will control.The basic functionality of the Recipe Editor is the same as the Operations

Editor (see p.12), but with the following additional options:

Recipe Details Panel

The Details Panel allows you to select the Controller Model, Recipe Number and, if desired, to

lock that selection or enable the current recipe to be used as a subroutine for the GOSUB and

JUMP opcodes . Depending on the selected recipe, you can also enter additional parameters

such as MaxTemp1 or Setpoint2.

Recipe Panel

The Recipe Panel allows you to select Opcodes to build a recipe.

NOTE: For explanations of Opcodes, refer to the manual for your controller.

Page 17

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 17 of 35

The “Revision” dropdown menu allows you to view and

select all the previous revisions of the currently selected

recipe. Each time a change is saved to the recipe, a new

revision is created along with a date and time stamp.

To edit a recipe, double-click on an Opcode to bring up the

step editor.

Use the Selected Opcode dropdown menu to select an

Opcode for this step and set all necessary parameters.

(Selecting the “Alphabetical” checkbox will display

available Opcodes alphabetically.) When finished, click

“OK.” Your new recipe step will be displayed in the recipe

editor (depending on the Opcode you entered, you may

need to scroll up and down or use the sorting tabs in order

to view the newly-entered step).

NOTE: If a Recipe is displayed

in italics

within the list view,

this indicates that it contains unsaved changes.

Parts Editor (optional feature)

In the Parts Editor, you can associate parts wtih the sequences and recipes that Load Entry will

control, allowing for quick selection of processes later. If you do not assign a part to a recipe in

the Parts Editor, it can only be run on manual loads or will require an override. The basic

functionality of the Parts Editor is the same as the Operations Editor (see p.12), but with the

following additional option:

Details Panel

The Details Panel allows you to enter the weight of a part, along with information for any

custom fields that have been created.

In addition, an image of the part can be assigned by clicking the button next to the part

Name and selecting a file from your computer.

NOTE: If a Part is displayed

in italics

within the list view,

this indicates that it contains unsaved changes.

Page 18

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 18 of 35

Fields Editor

The Fields Editor allows you to add additional field input options to the Details Panels of

Furnaces, Parts, Recipes, and Work Orders. The basic functionality of the Fields Editor is the

same as the Operations Editor (see p.12).

Fields Details Panel

The Details Panel will allow you to set a standard format for entries into the new Fields you will

create.

If “Normalized List” is checked, you may create a custom set of list items based on your own

needs. This can be useful to assign specific customers, priority levels, or other existing

terminology specific to your facility.

To add selections to your normalized list, click the Add button and enter the name of a list

selection. Repeat this process until you have created all the desired items in your list. These

items will appear as a dropdown menu for every Furnace, Part, Recipe, etc. that you apply it to.

If “Normalized List” is unchecked, you will see options that allow you to assign specific

formatting to fields. This is useful when using this feature for standard codes and numbering

systems in your facility.

The “Format” box allows you to set this format, as follows:

A = any alphabetical character

1 = any numerical character

Any other characters represent themselves literally.

Example 1:

You are creating a “Customer” field and your company uses a code of three numbers and three

letters to identify each customer (e.g.“FES027” or “MPS019”).

You would enter “AAA111” into the “Format” box to indicate three letters and three numbers.

Example 2:

You are creating a “Customer” field and your company uses a five-digit code followed by the

letter C to identify each customer (e.g.“45230C” or “18235C”).

You would enter “11111C” into the “Format” box to indicate five numbers followed by a “C.”

Page 19

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 19 of 35

Example 3:

You are creating a “Part Code” field and your company numbers parts using a numerical prefix

“007,” and a four-number numerical code, separated by a hyphen (e.g. “007-4129” or “0078173”).

You would enter “007-1111” into the “Format” box to indicate the numerals “007,” a hyphen, and

a four-digit number.

If a specific format is not required for the current field, simply leave the “Format” box blank.

If the “Format” box is not used, you can instead set a required length for entries into this field.

For example, if you have no standard format, but all entries must be exactly seven characters

long, you would enter “7” into the “Required Length” box.

NOTE: If using the “Format” box, you must enter “0” into the “Required Length” box.

Clicking the “Required” box will force all future users to match the indicated format before

saving entered information:

Clicking the “Export” box will cause this field to be included when using the export feature on

the History Tab (see p. 27).

Under the “Applied To” bar, select which Furnace, Part, Recipe, and Work Order you would like

to apply the selected Field to.

NOTE: If a Field is displayed

in italics

within the list view,

this indicates that it contains unsaved changes.

Gap Editor (Optional Feature)

The Gap Editor allows you to create names for gaps that exist in your facility’s processes. This

can be very useful in tracking downtime and improving efficiency in your facility.

On the Gap Editor window, simply click the New button and enter a Gap name in order to

create a new Gap. You can then assign a color to the selected gap if desired.

Page 20

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 20 of 35

When completed, click “Save.”

Shift Editor

The Shift Editor allows you to create and name shifts and set shift begin and end times. The

basic functionality of the Shift Editor is the same as the Operations Editor (see p.12). To set shift

start and shift end, either enter the time in the input box, or click the clock icon to set a time

using dropdowns.

NOTE: All shifts combined must add up to 24 hours with no overlap.

NOTE: If a Shift is displayed

in italics

within the list view,

this indicates that it contains unsaved changes.

Sequence Editor

The Sequence Editor window allows you to create a series of steps (called a Sequence) that can

control how a part or work order is processed through multiple operations, furnaces and

recipes. The basic functionality of the Sequence Editor is the same as the Operations Editor

(see p.12). The purpose of the sequence is to create consistency on the flow of a work order or

part through the heat treat operations. The interface makes it very easy to apply the steps to

achieve all operations. For example, if part xyz will always go through a wash, harden and

temper process, it would be beneficial to create a sequence that would follow these steps. This

does not have to be part specific, it can just be a consistent process used for a work order.

Once a new Sequence is created and named, use the New button to add steps to the

Sequence. Steps consist of Operation, Furnace, and Recipe assignments. Click “Save” to add

the step to the sequence.

Page 21

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 21 of 35

In the example above, the 1018 FNC CL1 sequence can be applied to a part or a work order to

ensure that these 2 steps are completed. The sequence can optionally assign the furnace and

recipe.

To edit a step, click the Edit button or double-click on the step in the Steps display area.

NOTE: If a Sequence is displayed

in italics

within the list view,

this indicates that it contains unsaved changes.

About

The About panel displays release notes and allows you to check for automatic updates.

Overview Screen

The Overview Screen displays all current furnace information in groups as assigned by the user.

This is also where you will assign gaps (if enabled), begin new loads and, if necessary, enter

historical loads.

NOTE: Instructions below assume that Gaps are enabled. If you are not using Gap options,

some functionality will differ slightly.

Page 22

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 22 of 35

Click on a group to display the furnaces in that group. “Overview” will display all furnaces

regardless of group.

Click on a furnace to display information on its current status. In addition, if a furnace is listed

as disconncted, you may have the option to add a manual load to the furnace.

Within active loads, you will have the ability to add Notes, access Work Order Details, and mark

times for “At Heat” and “Load End.”

In addition, Recipe information will be displayed. Depending on the recipe and its current

status, you will be able to control the steps in the recipe if you have the right user priveleges

(see user claims setup) using the “Hold,” “Cont,” “Stop,” “Adv,” and “Ack” buttons. For more

detailed information on recipes, see your controller manual.

Clicking on a furnace which is in a Gap state (assigned and defined in the Gap Editor) will bring

up a screen like this:

Page 23

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 23 of 35

From this screen, you can add notes to explain any changes in status. The purpose of the Gap

screen is to provide an interface for the user to assign a reason code of why the furnace was not

running a load. The Gap Reasons are user defined in the Gap Editor in the setup. If the furnace

is in the READY state, the time of the gap is from the time the gap went to ready to the current

time. If the Gap Reason is already assigned, then the time associated to this Gap continues until

another load is run or a new Gap is added using the Add New Gap button.

Click “Add New Gap” to begin a new gap if desired. Use the dropdown menu to assign a Gap

type from those created in the Gap Editor.

Click “Save” to close the current gap without assigning a new one.

Click “Save + Start” to close the gap and begin a new load for the furnace (See “Load Creation”

below.)

Right-clicking on furnaces brings up additional functionality:

Right-click on a furnace in a Gap state to bring up the following options:

Click “Add Historical Load” to open the NEW LOAD window. See “Load Creation” below for an

explanation of this window’s features.

Click “View Current Gaps” to view the gaps that are currently in effect for the furnace.

Clicking “View Trend” will bring up trend information from SDCrecorder/SDRecorder Pro. See

the associated manual for additional information on this functionality.

Page 24

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 24 of 35

Right-clicking on an active furnace will also provide the option to “Force Load Out.” Doing so

will return the furnace to a Gap state.

Clicking the button in the top right corner of each furnace is identical to clicking “View

Trend.” This will bring up trend information from SDRecorder Pro. See the SDRecorder Pro

manual for additional information on this functionality.

Load Creation

The Load Creation Editor can be accessed in several ways:

By clicking on a furnace in a gap state, then clicking “Save + Start.”

By right-clicking on a furnace, then clicking “Add Historical Load.”

By clicking on a furnace (if Gap options are turned off).

Use the “Operation” dropdown menu to select from the available Operations for this furnace.

Under “Work Orders” are the following buttons:

Clicking will bring up the Work Order Editor (see details on pg. 26).

Clicking will bring up the Pick List. This allows you to search for previous work orders.

Clicking will allow you to add an existing work order, either by scanning a barcode from a

traveler, or by entering the information manually. If entering manually, use the dropdown menu

to select the desired Work Order, then click”Add” to add it to the list to be added. When

finished, click “Add” at the bottom of the window to add to the Load Creation Editor.

Page 25

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 25 of 35

Clicking will allow you to select a traveler to assign to the current load. Functionality is

identical to the “Existing Work Order” window (see above).

Clicking will allow you to rework an existing work order selected from the Pick List.

Clicking will allow you to edit a selected Work Order (see details on pg. 26).

To Delete a Work Order, click it in the list to highlight, then click Delete .

Under the “Recipe” bar, use the dropdown menu to select from the recipes currently associated

with this Load. You can also choose to run the load manually using the corresponding

checkbox.

Notes can be added to the load as well.

Click “Start Load” to begin the load, and “Cancel” to exit without saving.

Active Screen

There is ways to create data in the Active Screen. 1) creating a load in the furnace from the

overview screen, 2) creating future work using the button.

The Active Screen displays all active Work Orders along with their associated Furnace, Current

Operation, Next Operation, and Estimated Completion. A color box is also displayed to indicate

if the Work Order is Ready, In Sequence, or In Process

To create a new Work Order in the Work Order Editor, click Add . (See Work Order Editor on

p.26 for explanation of this feature.)

To Edit a Work Order in the Work Order Editor, click it in the list to highlight, then click Edit .

(See Work Order Editor on p.26 for explanation of this feature.)

To Delete a Work Order, click it in the list to highlight, then click Delete .

To Refresh the display, click Refresh .

The various display columns are clickable to sort the list by that column.

Page 26

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 26 of 35

Work Order Editor

The Work Order Editor allows you to create and edit new work orders and assign the

appropriate details, operations, and parts. Other fields can be added for capture with the work

orders. This would be setup in the Fields setup screen and those fields would be assigned to

WorkOrder. In the above screen, Case Depth, Customer, Due Date, Material Type and Sales are

examples of this.

To assign Operations to a work order, click Add and select the desired Operation from the

dropdown menu. Once selected, available options (Furnace, Recipe, etc.) will auto-populate.

Click “Save” to add the Operation to the work order.

You can also assign entire Sequences directly, using the Sequence Template button.

To edit an existing Step, click on that row and click the Edit button (or, double click on the

Step in the list).

Page 27

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 27 of 35

To delete a Step, click on that row and click the Delete button.

To assign Parts to a work order, click Add and select the desired Part from the dropdown

menu. Once selected, available options will auto-populate. Click “Save” to add the Part to the

work order.

You can also access the Parts Database from this screen by using the Manage Parts button.

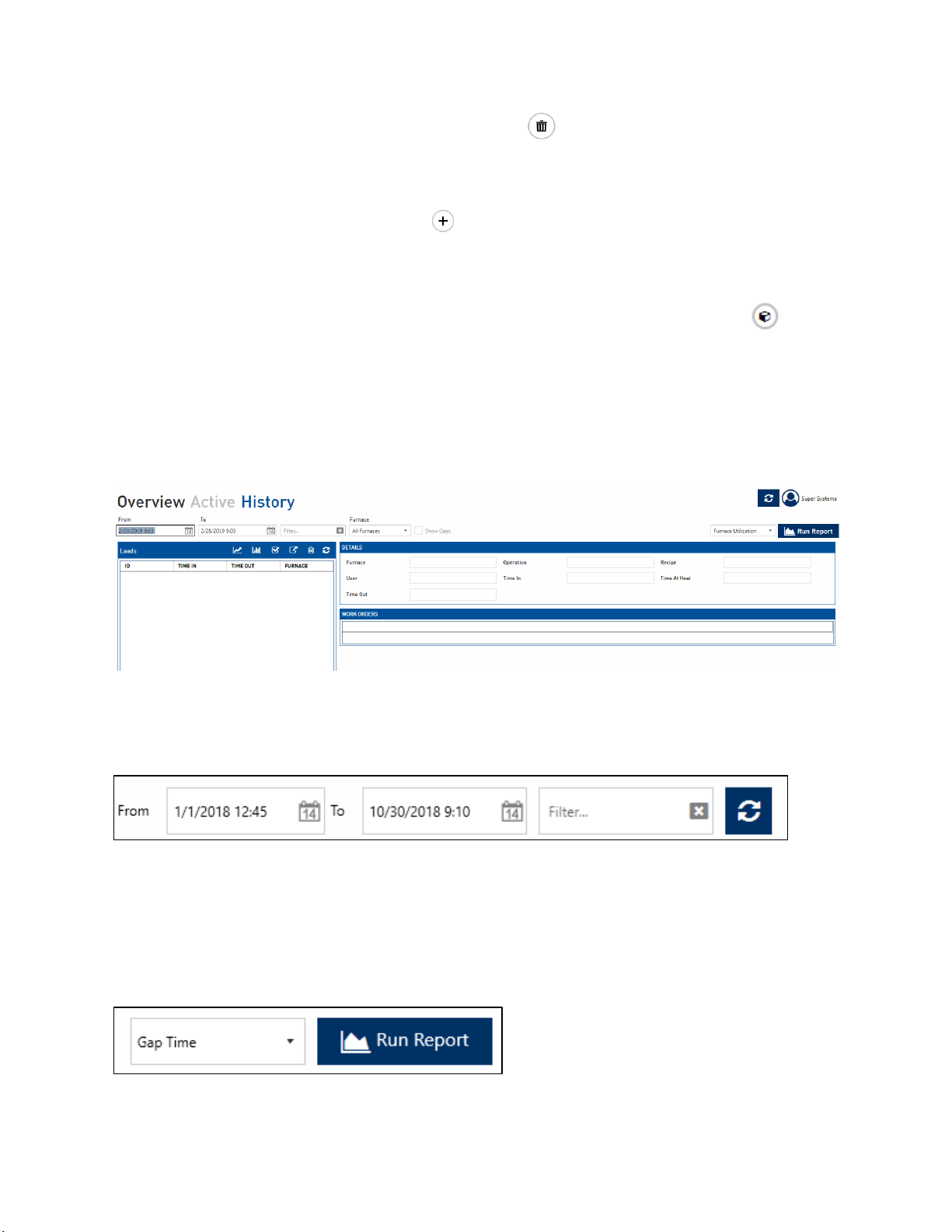

History Screen

The History Screen displays all completed loads, searchable by various timeframes and other

parameters.

Use the From/To Boxes and the filter input box to select a time range and/or text to search for

in the completed loads database.

The Filer field is a dynamic filter and will search all fields associated to the work orders.

Between the From and To date.

Use the Furnace dropdown menu to select which furnaces are currently visible.

Use the “Run Report” button to generate reports based on desired parameters.

Page 28

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 28 of 35

Use the report drop down menu to select a report on Furnace Utilization, Gap Time, Load

Tracking, or Work Order Tracking, then click “Run Report” to set parameters for the report.

NOTE: Depending on the type of report being run, the above screen may look different.

Click “OK” to generate the report.

To delete a Load, highlight the load and then click “Delete Load.”

The lower half of the History screen displays Work Orders associated with the highlighted load.

Clicking “View Trend” will bring up trend information from SDRecorder Pro. See the manual for

SDRecorder Pro for additional information on this functionality.

Clicking “Load Report” will generate a Load Report based on desired parameters and

information.

Clicking “Approval” allows you to add notes and attachments, then approve or reject the

information.

Clicking “Export” allows you to export information in various file formats to the desired location.

Page 29

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 29 of 35

Load Tracking Editor

Double click on a highlighted load to open the Load Tracking Editor for that load.

The Load Tracking Editor will display a unique load identifier, along with details about the

completed load; including Furnace, Operation, Recipe, User, Time In/Out, Time at Heat, and any

attachments. Any Work Orders associated with the load will be displayed as well, along with the

recipe used during the load. Notes can be added if desired.

Clicking “Edit” will make the information editable. Make any necessary changes, then click

“Save” to save those changes.

Clicking “View Trend” will bring up trend information from SDRecorder Pro. See the manual for

SDRecorder Pro for additional information on this functionality.

Clicking “Load Report” will generate a Load Report based on desired parameters and

information.

Clicking “Approval” allows you to add notes and attachments, then approve or reject the

information in the Load Tracking Editor.

Clicking “Close” returns you to the History screen.

Page 30

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 30 of 35

Bulk Load Reports

You can also generate multiple Load Reports at once from Load Entry 3. Multi-select load

histories (using Shift-click and Ctrl-click to select as you would in Windows) and click the Load

Report button to launch a process to produce Load Reports directly to PDF format.

Alternately, multi-select the desired load histories and click the Run Report button after

selecting Load Tracking from the accompanying dropdown.

The Bulk Report Parameters screen will then appear. Here you can choose for the reports to

include the trend image, the tabular data, or both. (This can be changed per report on a later

screen.)

Page 31

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 31 of 35

Next, on the Selected Historical Load Tracking screen, you will see the loads you selected, the

Run ID of that load, how many work orders that are associated with the load (and are auto

selected to run with the report) and an option to edit the load reports.

The Edit buttons will bring up the Report Parameters screen which allows you to deselect Work

Orders. Also, here you can set Trend, Data, or Both for each specific report.

Once everything is set as desired, click Export to begin the report generation process.

Page 32

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 32 of 35

The generation process goes through two main phases: Collecting Report Data and Generating

PDF Files.

Page 33

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 33 of 35

Once complete, you can click Open to view the file location of the reports.

Page 34

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 34 of 35

Windows Explorer will open to the BulkReports directory where you can find the export folder

and also a zip of that folder. The export folder is named with the full data and time of when the

reports were generated.

Within the folder the user will find the report PDFs.

Page 35

Standard Load Entry 3 Operations Manual

Super Systems Inc. Page 35 of 35

Revision History

Rev.

Description

Date

MCO #

-

Initial Release

2/28/2019

2259

A

Various interface and feature updates

11/23/2020

2303

Loading...

Loading...