Page 1

Basic Nitriding Sampling System

Operations Manual

Hydrogen Analyzer with Calculated % DA,

% NH

and K

3,

Values

N

Please read, understand, and follow these instructions before operating this equipment.

Super Systems, Inc. is not responsible for damages incurred due to a failure to comply with these

instructions. If at any time there are questions regarding the proper use of this analyzer, please contact

us at 513-772-0060 for assistance.

Page 2

Basic Nitriding Sampling System – Hydrogen Analyzer

Super Systems Inc.

Super Systems Europe

Super Systems México

Super Systems China

USA Office

Corporate Headquarters

7205 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Sistemas Superiores Integrales S de RL de CV

Calle 3 Int.: 11.

Zona Ind. Benito Juarez

Querétaro, Qro. Méx.

C.P.: 76120

Phone: +52 (442) 210 2459

http://www.supersystems.com.mx

Units 3 & 4, 17 Reddicap Trading Estate,

Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627

http://www.supersystemseurope.com

No. 335 XianXia Road

Room 308

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.com

Super Systems Inc. Page 2 of 12

Page 3

Basic Nitriding Sampling System – Hydrogen Analyzer

Table of Contents

Introduction ................................................................................................................................................... 4

Specifications ................................................................................................................................................ 4

Electrical Connections / Terminal Assignments ........................................................................................... 4

Getting Started .............................................................................................................................................. 4

Default Settings ............................................................................................................................................. 5

Modifying the Default Settings ...................................................................................................................... 5

Description of Menu Items ............................................................................................................................ 5

Parts List and Internal Components ............................................................................................................. 7

Warranty ........................................................................................................................................................ 9

Revision History .......................................................................................................................................... 10

Appendix A: Drawings (Electrical, Plumbing, and Mounting) ...................................................................... 11

Exit Program ................................................................................................................................................... 5

Instrument Information .................................................................................................................................. 5

Communication Setup ..................................................................................................................................... 5

Instrument Configuration ............................................................................................................................... 5

Percent Hydrogen ....................................................................................................................................... 5

Percent Dissociation................................................................................................................................... 6

Percent Ammonia ....................................................................................................................................... 6

Nitriding Potential ...................................................................................................................................... 6

Output Configuration ....................................................................................................................................... 6

Output Calibration ........................................................................................................................................... 6

Sensor Calibration .......................................................................................................................................... 6

Performing a Zero Calibration ................................................................................................................... 7

Performing a Span Calibration .................................................................................................................. 7

Super Systems Inc. Page 3 of 12

Page 4

Basic Nitriding Sampling System – Hydrogen Analyzer

Introduction

Specifications

Electrical Connections / Terminal Assignments

Wire Number

Function

1000

AC Line Power (100-240VAC)

1002

AC Neutral Power

Ground

AC Ground

1121

Analog Output Common (+)

1111

Analog Output #1 (-)

1121

Analog Output Common (+)

1131

Analog Output #2 (-)

1081

RS485 (-)

1091

RS485 (+)

Getting Started

This instrument uses the measurement of Hydrogen to display % Hydrogen (H2), % Dissociation (DA), and

% Ammonia (NH

entered, the instrument can also calculate Nitriding Potential (K

). When the flow rates of Nitrogen, Ammonia, and Dissociated Ammonia are manually

3

).

N

• Power Requirements: 100-240 VAC

• Current Draw: Max. 0.2 Amps

• Sensor Technology: Thermal Conductivity

• User Interface: 3.5” Color QVGA TFT LCD Touch Screen

• Measurement Range: 0-100% H

• Hydrogen Measurement Accuracy: +/- 0.01%

• Hydrogen Measurement Repeatability: +/- 0.01%

• Hydrogen Measurement Resolution: 0.01%

• Analog Outputs: Two Isolated 4-20mA (User Configurable)

• Analog Output Resolution: 0.005mA

• Analog Output Accuracy: +/- 0.01% of Range

• Analog Output Linearity: +/- 0.01%

• Analog Output Load Resistance: Minimum 0 Ohm, Maximum 500 Ohm

• Digital Communications: RS485 Modbus, Ethernet

• Enclosure Size (Without Filter): Approx. 13”L x 13”W x 6”D / 330mmL x 330mmW x 142mmD

• Enclosure Weight: 22.5 lbs. / 10.2 kg.

• Enclosure Ventilation: Continuous Purge Fan, Dual Vents

• Recommended Flow Rate: 1.5 to 2.0 SCFH / 0.71 to 0.94 lpm

• Process Gas Fittings: Stainless Steel Compression for ¼” OD Tubing

• Calibration Gas Fitting: 1/8” Barb (can be removed for 1/8” Female NPT Port)

• Operating Environment: 10-90 %RH (Non-Condensing)

• Operating Temperature: 32 to 122°F / 0 to 50°C

• Sample Gas Temperature: 32 to 158°F / 0 to 70°C

2

Please refer to the enclosed drawing for instructions regarding the proper electrical and mechanical

installation of this instrument. The flow meter on the door of the enclosure should be adjusted to

maintain 1.5 SCFH of process gas flow.

Super Systems Inc. Page 4 of 12

Page 5

Basic Nitriding Sampling System – Hydrogen Analyzer

Default Settings

Modifying the Default Settings

Description of Menu Items

Exit Program

Instrument Information

Communication Setup

Instrument Configuration

When the instrument is turned on, it will display % H2 on the screen. To display additional values (% DA,

, or KN), see the “Instrument Setup” screen. The first 4-20mA output will be set up to retransmit

% NH

3

the %H

Any changes to these default parameters will be stored so they will not need to be re-entered when the

power is shut off to the instrument

value scaled for 0 to 100%, and the second output will be set up for %DA also scaled for 0-100%.

2

To access the operational and setup parameters, press the “menu” button at the lower left section of the

screen. This will allow you to select only two options, Exit Program and Instrument Information. To

prevent unwanted modification to the operation of the instrument, these are the only options available

unless the user logs in. To access the other menu options, press the “Login” button and enter “2”. This

will give the operator access to the setup and operational parameters.

Each individual menu option is described in detail below:

The touch screen display is constantly writing data to its flash card for storage, and it is important that

the instrument not be shut down during this process. Before removing power from the enclosure, select

“Exit Program”. It will ask is you are sure that you want to shut down the interface. By answering yes, it

closes the operating program in an orderly manner. Once the standard Microsoft Windows screen

appears it is safe to remove power from the instrument. If this procedure is not followed, there is a

chance that there could be an error writing to the flash card that could cause problems with the operation

of the instrument.

This screen provides information on any applicable revision levels and serial numbers. It also shows if

the instrument is logging data. There are no functions that can be performed on this screen; it is for

informational purposes only.

The communication methods shown on this screen are for display only and cannot be modified. The baud

rates can be adjusted but they have been optimized for this instrument and modification is not

recommended.

This instrument is capable of displaying four different parameters. These include:

• Percent Hydrogen (H

• Percent Dissociation (DA)

• Percent Ammonia (NH

• Nitriding Potential (K

The Percent Hydrogen is displayed on the main screen at all times. One additional parameter can be

displayed along with Hydrogen by highlighting it and pressing the “OK” button. A clearer description of

each of these parameters can be found in Appendix “A”, Gas Nitriding Technical paper.

)

2

)

3

)

N

Percent Hydrogen

The percent hydrogen is the amount of Hydrogen that is being detected by the thermal conductivity

sensor inside the instrument. There are no additional calculations being performed to this value.

Super Systems Inc. Page 5 of 12

Page 6

Basic Nitriding Sampling System – Hydrogen Analyzer

Output Configuration

Output Calibration

Sensor Calibration

Percent Dissociation

Dissociation is derived from the amount of Hydrogen in the sample gas.

Percent Ammonia

The amount of Ammonia can also be inferred from the Hydrogen value.

Nitriding Potential

The accurate calculation of Nitriding Potential (KN) requires the flow rates of other gases that are being

introduced into the process. These flow rates are measured in SCFH (Standard Cubic Feet per Hour). K

can only be calculated by entering the flow of Nitrogen (N

(%DA). These values are entered at the bottom of the main screen when K

), Ammonia (NH3) and % Dissociated Ammonia

2

is selected.

N

N

There are two 4-20mA outputs that can be configured for any of the four parameters. For each input, the

operator can select the Source (H

, DA, NH3, KN), the zero value (the value to be represented by 4mA) and

2

the span value (the value to be represented by 20mA).

• Output 1 can be measured from Terminal #1121(+) and 1111 (-).

• Output 2 can be measured from Terminal #1121(+) and 1131 (-).

Accurate retransmission of the selected parameters can only be obtained through calibrating both of the

analog outputs. This is done at the factory prior to shipment, however it is a relatively simple procedure

that can be performed in the field if desired. To perform a calibration, a multimeter with a current input

is required. Please keep in mind that the accuracy of the instrument used to calibrate the outputs is

directly related to the accuracy of the outputs after calibration, so a meter calibrated against NIST

(National Institute of Standards and Technology) standards is preferred. Before performing any

calibrations, all other devices must be disconnected from the analog outputs. Multiple devices on the

outputs will cause inaccurate measurement of current.

Attach the leads of the multimeter to the terminals for Output 1. The positive lead should be attached to

Terminal #1121 and the negative lead to Terminal 1111. Select “Zero Output 1” and press the “Prep for

Cal” button. The low limit of the output is 4mA, so 4.000 is shown as the default measured value. Ideally

the meter connected to the outputs will also show 4.000. If the two values are not close enough to obtain

the desired level of accuracy, a calibration should be performed.

If, for example, the meter connected to the outputs reads 4.216mA, then the value “4.216” should be

entered on the screen as the Measured Value. Once the value has been entered, press the “calibrate”

button. This will offset the mA output of the instrument in an amount that results in an exact output of

4.000mA. When the calibration is complete, the multimeter should be reading 4.000mA (+/- .005).

The procedure can be repeated for the Span of Output 1. When “Span Output 1” is selected and “Prep for

Cal” is pressed, the instrument will output the high output limit, which is 20mA. The multimeter will

display the actual output from the instrument, and if it is not within the desired tolerance it can be

calibrated using the same procedure as above.

To calibrate Output 2, attach the leads of the multimeter to Terminal #1121 (+) and the negative lead to

Terminal 1131 (-) and follow the same procedure that was used for the first output.

A proper calibration of the sensor requires two gases. The first gas should be pure Nitrogen or Argon.

This contains no Hydrogen, and is therefore referred to as the Zero Gas. The second gas is the Span Gas.

The Span Gas should ideally contain a quantity of Hydrogen similar to the amount of Hydrogen in the

process gas. The Span Gas should also include any other gases that are present in the process gas in

Super Systems Inc. Page 6 of 12

Page 7

Basic Nitriding Sampling System – Hydrogen Analyzer

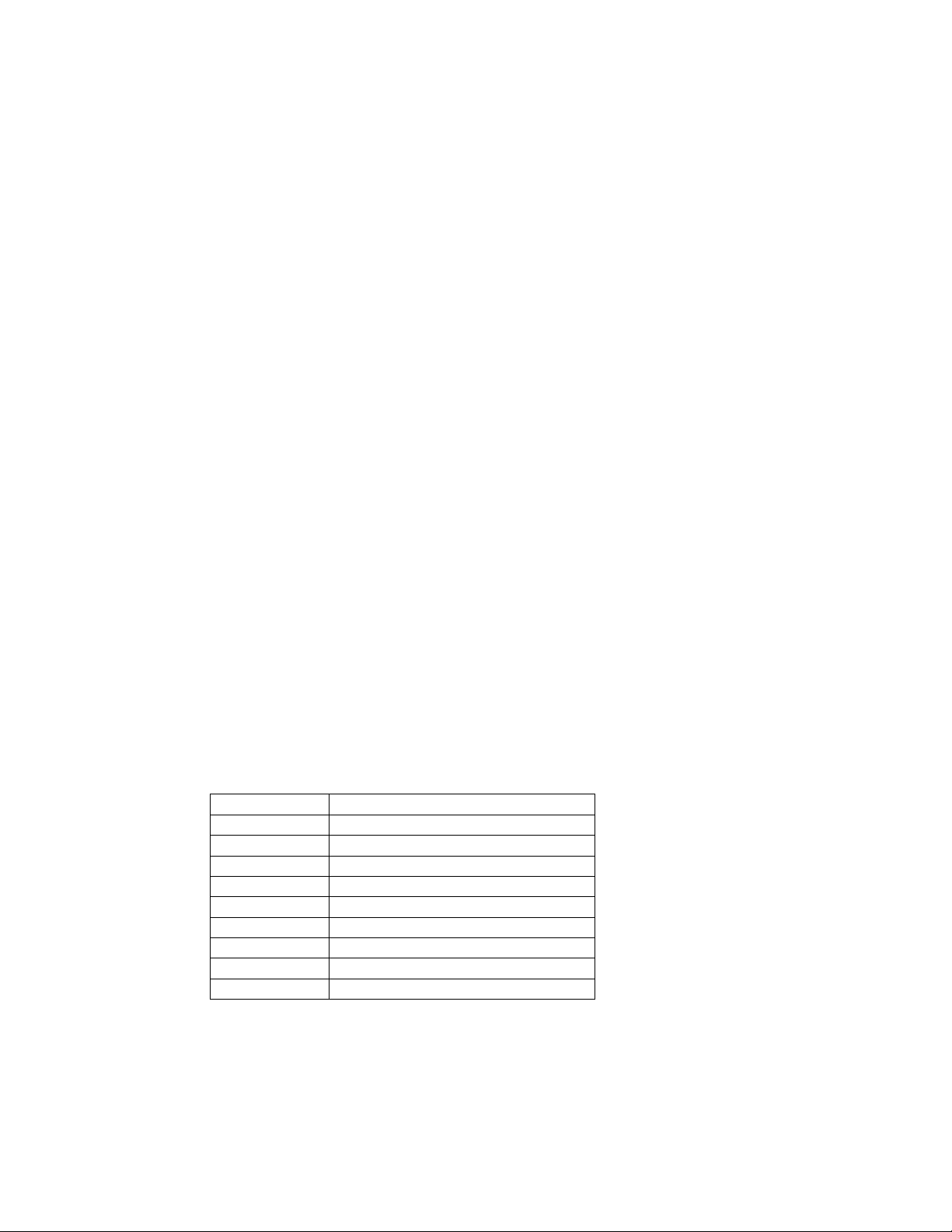

Parts List and Internal Components

Part Number

Description

Full Unit

their respective percentages. The more similar to the process gas the calibration gas is, the more

accurate the calibration will be.

Performing a Zero Calibration

On the Sensor Calibration page, select “Zero Hydrogen”. Turn the valve on the side of the enclosure to

the “Calibration Gas” position, and attach the Zero gas to the “Calibration Gas Inlet” port. Begin the flow

of gas at a rate of 1.5 to 2.0 SCFH as measured on the flow meter on the door of the enclosure. The gas

should not be under any pressure other than the amount required to maintain the appropriate flow

amount. The target Value is shown on the screen. For a Zero Calibration, this will be 0.00 (the amount of

Hydrogen in the Zero Gas). The Measured H

value comes to equilibrium, it will not be showing any upward or downward trends, only the slight

oscillation of the readings. This usually occurs in approximately 30 seconds. When the sensor is at

equilibrium, press the green “Calibrate” button to perform the zero calibration. After the Zero

Calibration is complete, turn off the flow of gas and disconnect it from the enclosure.

Value can be seen at the bottom of the screen. When this

2

Performing a Span Calibration

To perform a span calibration, select “Span Hydrogen”, attach the Span Gas to the Calibration Gas Inlet

port, and begin the flow of gas at 1.5 to 2.0 SCFH. The Target Value should be set to the exact amount of

Hydrogen that is in the Span Gas cylinder. Then the same procedure should be followed as the Zero

calibration, with the “Calibrate” button being pressed after the readings reach equilibrium. After the

Span Gas calibration is complete, turn off the flow of gas, disconnect the cylinder from the enclosure, and

restore the valve on the side of the instrument to the “Sample Gas” position. This will re-connect the

sensor to the process gas stream.

The following items can be purchased as needed for the Hydrogen Nitrider Analyzer.

31604 2 GB SD card

37026 Fan (24VDC, 60mm)

37029 Fan filter assembly

37150 3-way ball valve

37050 High capacity bowl filter

37051 High capacity filter element

34444 Tubing

33097 Circuit breaker

31135 Power supply

A20624 Hydrogen sensor

31296 3.5” touch screen

15357 Hydrogen Nitrider Analyzer

Super Systems Inc. Page 7 of 12

Page 8

Basic Nitriding Sampling System – Hydrogen Analyzer

The following diagram illustrates the location of important internal components of the Hydrogen Nitrider

Analyzer, along with relevant part numbers.

Super Systems Inc. Page 8 of 12

Page 9

Basic Nitriding Sampling System – Hydrogen Analyzer

Warranty

Limited Warranty for Super Systems Products:

The Limited Warranty applies to new Super Systems Inc. (SSI) products purchased direct from SSI or

from an authorized SSI dealer by the original purchaser for normal use. SSI warrants that a covered

product is free from defects in materials and workmanship, with the exceptions stated below.

The limited warranty does not cover damage resulting from commercial use, misuse, accident,

modification or alteration to hardware or software, tampering, unsuitable physical or operating

environment beyond product specifications, improper maintenance, or failure caused by a product for

which SSI is not responsible. There is no warranty of uninterrupted or error-free operation. There is no

warranty for loss of data—you must regularly back up the data stored on your product to a separate

storage product. There is no warranty for product with removed or altered identification labels. SSI DOES

NOT PROVIDE ANY OTHER WARRANTIES OF ANY KIND, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

SOME JURISDICTIONS DO NOT ALLOW THE LIMITATION OF IMPLIED WARRANTIES, SO THIS LIMITATION

MAY NOT APPLY TO YOU. SSI is not responsible for returning to you product which is not covered by this

limited warranty.

If you are having trouble with a product, before seeking limited warranty service, first follow the

troubleshooting procedures that SSI or your authorized SSI dealer provides.

SSI will replace the PRODUCT with a functionally equivalent replacement product, transportation prepaid

after PRODUCT has been returned to SSI for testing and evaluation. SSI may replace your product with a

product that was previously used, repaired and tested to meet SSI specifications. You receive title to the

replaced product at delivery to carrier at SSI shipping point. You are responsible for importation of the

replaced product, if applicable. SSI will not return the original product to you; therefore, you are

responsible for moving data to another media before returning to SSI, if applicable. Data Recovery is not

covered under this warranty and is not part of the warranty returns process. SSI warrants that the

replaced products are covered for the remainder of the original product warranty or 90 days, whichever is

greater.

Super Systems Inc. Page 9 of 12

Page 10

Revision History

Rev.

Description

Date

MCO#

NEW

First release

N/A

A

Revised terminal numbers; added product diagrams;

added part numbers; updated format of document.

11/7/2014

2155

Basic Nitriding Sampling System – Hydrogen Analyzer

Super Systems Inc. Page 10 of 12

Page 11

Basic Nitriding Sampling System – Hydrogen Analyzer

Appendix A: Drawings (Electrical, Plumbing, and Mounting)

Super Systems Inc. Page 11 of 12

Page 12

Basic Nitriding Sampling System – Hydrogen Analyzer

Super Systems Inc. Page 12 of 12

Loading...

Loading...