Page 1

Operations Manual

HP15

Self-Heated Oxygen

Measurement and Control

System

Please read, understand, and follow these instructions before operating this equipment.

Super Systems, Inc. is not responsible for damages incurred due to a failure to comply with

these instructions. If at any time there are questions regarding the proper use of this product,

please contact us at (800) 666-4330 for assistance.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060 / 800-666-4330

Fax: 513-772-9466

www.supersystems.com

HP 15 Manual Rev A Page 1 of 1

Page 2

Table of Contents

Table of Contents................................................................................................................. 2

General Information .............................................................................................................3

Electrical Connections........................................................................................................... 4

Plumbing Connections .......................................................................................................... 7

HP 15 Screens ..................................................................................................................... 8

Initial Screen.................................................................................................................... 8

Main Menu .......................................................................................................................8

Set Points..................................................................................................................... 8

Temp Mode .................................................................................................................. 9

CO Factor ..................................................................................................................... 9

Hydrogen Factor ........................................................................................................... 9

Pump Control ............................................................................................................. 10

Auto / Manual............................................................................................................. 10

O2 View ..................................................................................................................... 10

Configuration Menu ........................................................................................................ 10

PVT Type ................................................................................................................... 10

Network Settings ........................................................................................................ 11

PID Settings ............................................................................................................... 11

Loop PID Settings – Page 1 ..................................................................................... 11

Loop PID Settings – Page 2 ..................................................................................... 12

Loop PID Settings – Page 3 ..................................................................................... 12

Loop PID Settings – Page 4 ..................................................................................... 12

Burn Off Setup............................................................................................................ 13

Analog Input Setup ..................................................................................................... 13

Analog Input Settings – Page 1 ................................................................................ 13

Analog Input Settings – Page 2 ................................................................................ 14

Analog Input Settings – Page 3 ................................................................................ 14

Analog Output Setup................................................................................................... 15

Analog Output Settings – Page 1.............................................................................. 15

Alarms ....................................................................................................................... 15

Alarm Settings - Page 1 ........................................................................................... 15

Alarm Settings – Page 2 .......................................................................................... 16

Alarm Settings – Page 3 .......................................................................................... 17

Over Temp Alarm........................................................................................................ 17

SSi Information Screen................................................................................................ 17

Spare Parts List.................................................................................................................. 18

Appendix 1 – Factory Defaults ............................................................................................ 19

Universal Defaults........................................................................................................... 19

Carbon PVT Defaults....................................................................................................... 20

Dewpoint PVT Defaults ................................................................................................... 20

Oxygen PVT Defaults ...................................................................................................... 20

Probe mV PVT Defaults ................................................................................................... 21

Probe Redundancy PVT Defaults...................................................................................... 21

Simple Nitrider PVT Defaults ........................................................................................... 22

Dual Loop PVT Defaults .................................................................................................. 22

Revision History ................................................................................................................. 23

HP 15 Manual Rev A Page 2 of 2

Page 3

General Information

The HP15 system includes two main enclosures. The first contains the heater and the Gold

Probe and is painted with a heat resistant black paint. The second is the blue electrical control

panel. Proper operation of this system requires that these two enclosures be wired to each

other to allow the heater to be controlled by the electrical enclosure. For detailed information

regarding the connections between the enclosures, please refer to the E

section of this manual.

lectrical Connections

HP 15 Manual Rev A Page 3 of 3

Page 4

Electrical Connections

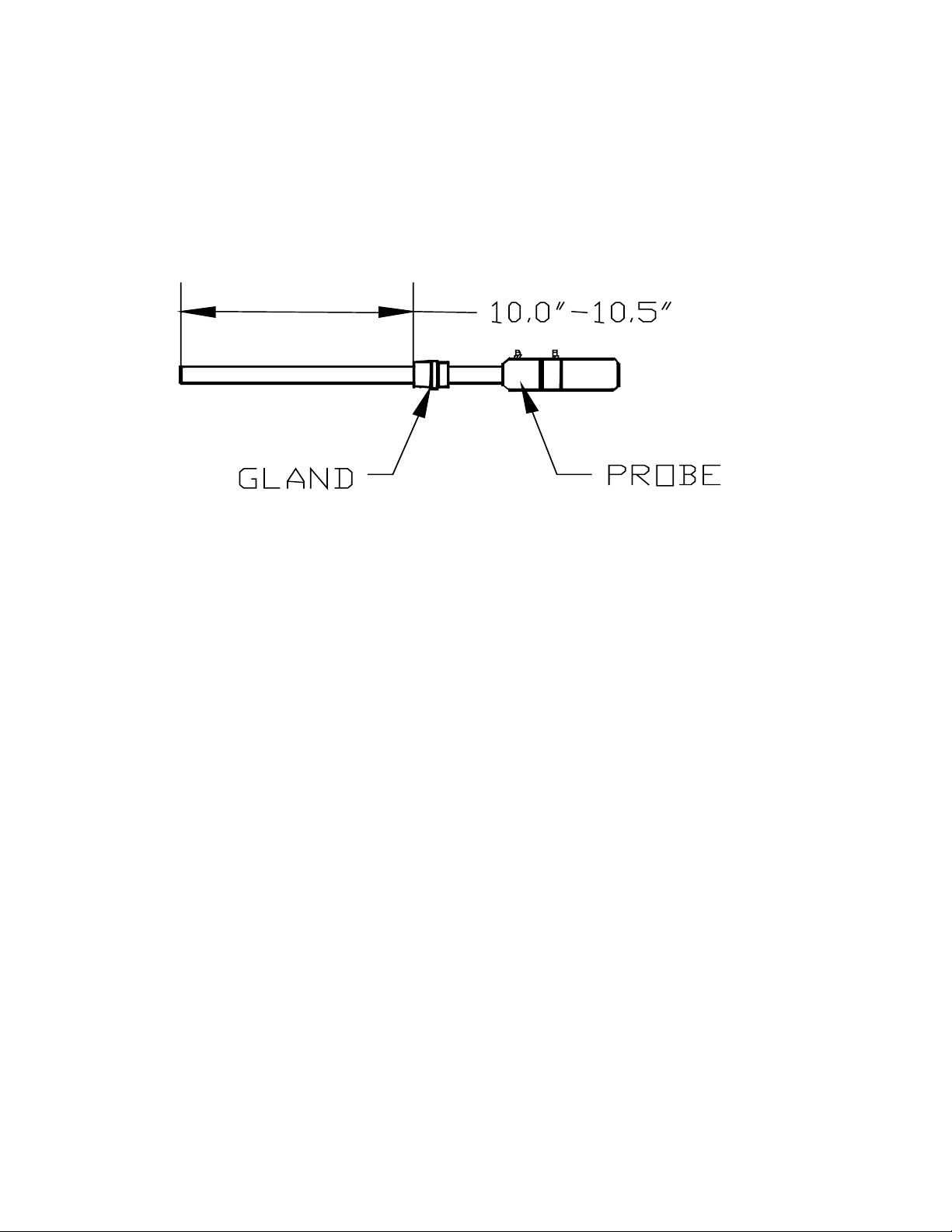

Insert the probe into the coupling at the base of the large box. It is important that the

probe is inserted at the correct depth to allow proper heating and prevent damage

to the ceramic well inside the unit. There should be between 10.0” and 10.5” between the

bottom of the adjustable 1” NPT gland and the end of the probe (see sketch below).

Once the probe has been inserted into the heater, make the necessary electrical connections at

the head of the probe. The green thermocouple wire from the electrical enclosure box should

be attached to the thermocouple connection at the head of the probe (Positive (+) = Black and

Negative (-) = Red). The sensor wire should also be attached to the probe (Positive (+) =

Black and Negative (-) = White).

This unit has been pre-configured and tested prior to shipment. To maximize the accuracy and

longevity of the Heated Probe, it is recommended that the unit be operated at 1500°F. It is

also possible to configure the HP to match the temperature of your furnace.

HP 15 Manual Rev A Page 4 of 4

Page 5

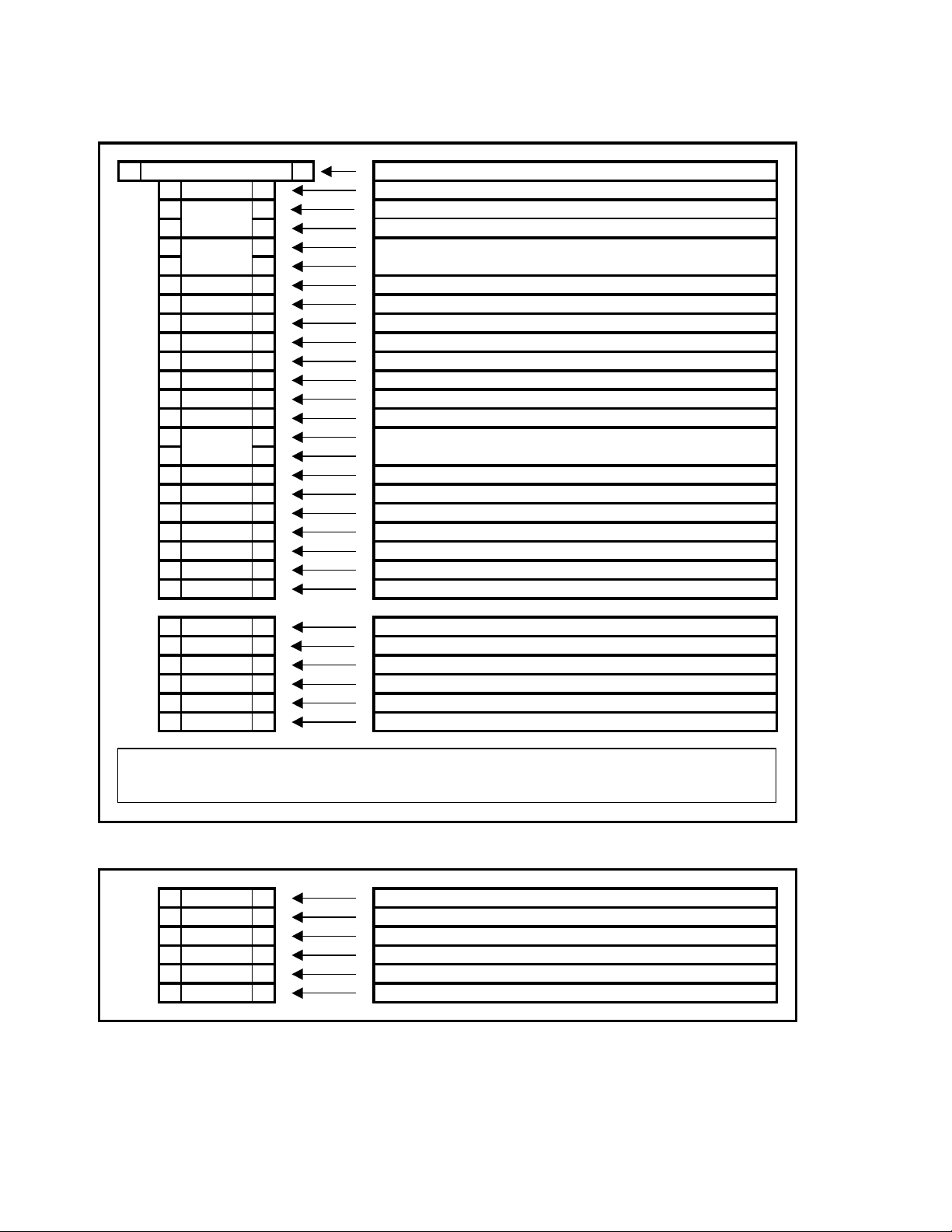

Inside Electrical Enclosure

r

A

A

;

6.0 AMP

;

1000

;;

1002

;;

;;

1003

;;

;

1103

;

1601

;

1602

;

1621

;

1622

;

1681

;

1682

;

1060

;;

1070

;;

;

1320

;

1330

;

1340

;

1641

;

1002

;

GND

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

6 Amp Circuit Breaker

Incoming Customer 110VAC (Line)

Incoming Customer 110VAC (Neutral)

110VAC (Neutral) To Heate

110VAC (Line) to Heater Enclosure

110VAC (Switched Line) to Heater Enclosure

Enriching Gas Contact #1

Enriching Gas Contact #2

Dilution Air Contact #1

Dilution Air Contact #2

Alarm Contact #1

Alarm Contact #2

24VDC (Negative)

24VDC (Positive)

Dry Contact for Sample Inhibit

Dry Contact for Probe Burn-Off

Dry Contact Common

Pump Terminal

110VAC (Neutral) - Spare

Incoming Customer 110VAC (Ground)

;

1021

;

1031

;

1041

;

1350

;

1360

;

1380

Host Communications connect to the Host Computer.

nalog Output #1 is the 4-20mA signal for Process Variable Retransmission.

nalog Output #2 is the 4-20mA signal for Temperature Control (Optional).

;

;

;

;

;

;

RS485 Host Communications Shield

RS485 Host Communications RT- (Negative)

RS485 Host Communications RT+ (Positive)

Analog Output Common (Positive)

Analog Output #1 (Negative)

Analog Output #2 (Negative)

Inside Heater Enclosure

;

1003

;

1002

;

1103

;;

;;

;;

;

;

;

Incoming 110VAC (Line) from Electrical Enclosure

Incoming 110VAC (Neutral) from Electrical Enclosure

Incoming 110VAC (Switched Line) from Electrical Enclosure

HP 15 Manual Rev A Page 5 of 5

Page 6

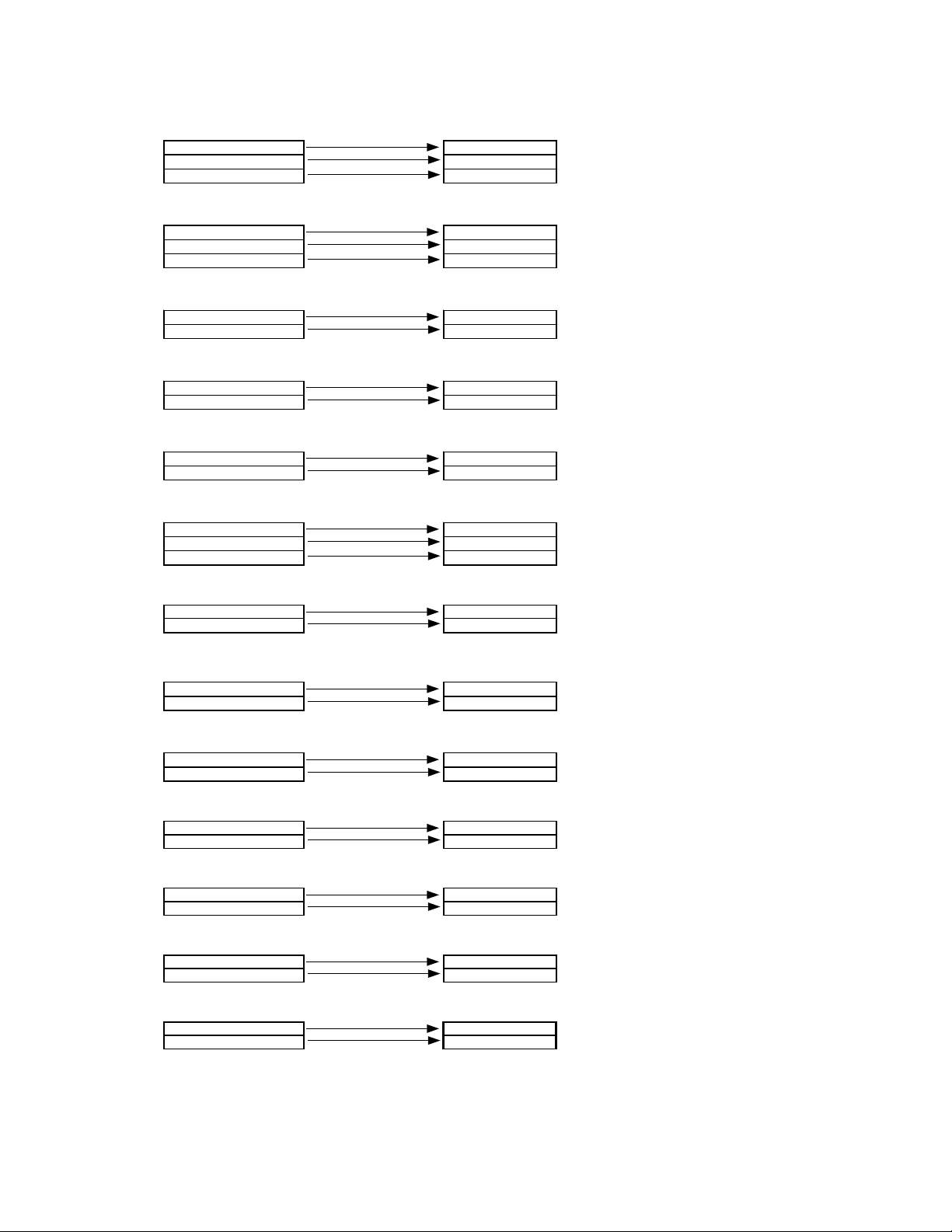

1. Connect incom ing 120VAC to the Electrical E nclosure:

110 VAC Line Terminal 1000

110 VAC N eutral Terminal 1002

110 VAC G round Terminal GN D

2. Connect Electrical Enclosure to Heater Enclosure:

3. Connect "S" Type Thermocouple wire from P robe to Model 9120 Controller in Electrical Enclosure

4. Connect Millivolt wire from P robe to M odel 9120 Controller in Electrical Enclosure

5.

(Optional)

6.

(Optional)

7.

(Optional)

Electrical Heater

Terminal 1003 Terminal 1003

Terminal 1002 Terminal 1002

Terminal 1103 Terminal 1103

Probe M odel 9120

+ T'CPLE (Black) Terminal 30

- T'CP LE (R ed ) Term ina l 29

Probe M odel 9120

+ SENSOR Terminal 32

- SE NS OR Terminal 31

Connect Furnace Thermocouple to Model 9120 Controller in Electrical Enclosure

Probe M odel 9120

+ T'CPLE Term inal 28

- T'CPLE Terminal 27

Connect RS485 Communications to H ost Com puter

Electrical Host Computer

Terminal 1021 Shield

Terminal 1031 RTTerminal 1041 RT+

Connect Enriching Gas Contact

Electrical (Custom er)

Terminal 1601 T.B.D

Terminal 1602 T.B.D

8.

(Optional)

9.

(Optional)

10.

(Optional)

11.

(Optional)

12.

(Optional)

13.

(Optional)

Connect Dilution A ir Contact

Electrical (Custom er)

Terminal 1621 T.B.D

Terminal 1622 T.B.D

Connect Dilution A ir Contact

Electrical (Custom er)

Terminal 1681 T.B.D

Terminal 1682 T.B.D

Connect Dry Contact for Sam ple Inhibit

Electrical (Custom er)

Terminal 1320 T.B.D

Terminal 1340 T.B.D

Connect Dry Contact for Probe Burnoff

Electrical (Custom er)

Terminal 1330 T.B.D

Terminal 1340 T.B.D

4-20m A O utput for Process Variable Retransm ission

Electrical (Custom er)

Terminal 1350 T.B.D +

Terminal 1360 T.B.D -

4-20m A O utput for Temperature Control

Electrical (Custom er)

Terminal 1350 T.B.D +

Terminal 1380 T.B.D -

HP 15 Manual Rev A Page 6 of 6

Page 7

Plumbing Connections

The sample gas can be transported from the sample port on the furnace to the bottom of the

external filter on the side of the electrical enclosure using silicone tubing. The sample flow

should be between 4.0 and 5.0 SCFH. Silicone tubing should also connect the ports on the side

of the electrical enclosure to the probe in the heater enclosure. Connect tubing from the fitting

on the electrical enclosure marked “To Probe Reference” to the “Ref. Air” port on the probe. A

connection should also be made between the “To Burnoff Port” fitting and the “B.O.” fitting on

the probe. There is a barb fitting on the stainless steel well on the heated probe. This is the

vent, which needs to be routed to an appropriately safe location.

HP 15 Manual Rev A Page 7 of 7

Page 8

HP 15 Screens

Initial Screen

The first screen to be displayed when the HP is powered up is the initial

screen, which will display a combination of: Oxygen, Carbon, millivolts, dew

point, temperature, setpoint, percent output, relay status, and pump status

depending on the selected process variable type.

The first section below the Super Systems Inc logo will display the process

variable type (PVT). The PVT can be: Oxygen, Carbon, Dewpoint, or

millivolts. See the section

information on how to change the PVT type.

The second section (Millivolts:) will display the probe’s current millivolt value.

The third section will display the probe’s current temperature, as well as the

current setpoint. See the section

change the setpoints.

The last section will display the Loop 1 and Loop 2 output percentages. An

A or an M will be displayed next to the output percentage to let the user know if Loop 1 or

Loop 2 is in automatic (A) or manual (M) mode. The “Pump” area will let the user know if the

pump status is on or off. The “Relays” area, which is directly above the Menu button, will

display the energized relays. The number corresponds to the relay in the panel. If a number is

displayed, then that specific relay in the panel is energized. If a number is not displayed, then

that specific relay in the panel is not energized. The Menu button will display the main menu.

Configuration Menu

Set Points

→

PVT Type

for more information on how to

for more

Main Menu

The main menu displays eight buttons, from which the user will be able to set

up the HP 15 instrument. The Exit button will return the user to the initial

screen.

Set Points

Two setpoints are initially displayed on the

screen: Loop 1 and Alarm. To change the

temperature setpoint or the alarm setpoint,

touch the setpoint value, which will display

the numeric keypad.

Enter the new setpoint value and press the

ENT button to set the setpoint. Press the

ESC button to cancel the change.

The Remote Setpoint Setup button will display the Remote Setpoint

screen, which will allow the user to set up a remote setpoint for Loop 2,

which is generally the temperature loop. There are six buttons to choose

from for a remote setpoint: None, Slave 1 PV, Slave 2 PV, Slave 1 SP,

Slave 2 SP, or Input 3 Value. Pressing the desired button will set the setpoint to the

specified source. When None is pressed, the setpoint that was set from the previous screen

HP 15 Manual Rev A Page 8 of 8

Page 9

will be used. To change the hysteresis, click on the Hysteresis button and

enter the new hysteresis value from the numeric keypad. The More >>>

button will allow the user to set the setpoint for the selected PVT (Dew point,

Carbon, Oxygen, or millivolts). The <<< More button will return the user to

the previous screen. The Menu button will return the user to the main menu.

Temp Mode

The temperature mode screen displays the current temperature mode

(Fahrenheit or Celsius) as well as the current setpoint. To

change the mode to Celsius, press the Switch to Celsius

button. To change the mode to Fahrenheit, press the

Switch to Fahrenheit button. When the temperature

mode is changed, the setpoint will be converted

automatically. This is a safety precaution to prevent setting

extremely high setpoints when switching to the Celsius scale. The setpoint

can always be changed from the

Set Points

menu.

CO Factor

The COF factor allows you to make adjustments that will

allow the controller to match the results obtained when

measuring shim stock. If the controller set point and the

process variable are the same, but you are not attaining the

desired surface Carbon, you can make the adjustment with

the CO Factor to increase the amount of surface Carbon available to the parts.

If you lower the CO factor, it immediately lowers the % Carbon process

variable. This will cause the controller to add more enriching gas--- raising the

process variable until once again the process variable and the set point match.

Conversely, raising the CO Factor will cause the process variable to read

higher, shutting down the enriching gas solenoid (possibly turning on the air

dilution solenoid) causing the % Carbon process variable to begin to lower (NOT ADDING

ENRICHING GAS) until the set point and process variable match. To change the CO Factor,

enter the new factor and press the ENT button. Pressing the ESC button will not set the new

CO Factor.

just for display purposes. The CO Factor will not be set to 0.

Note: when the ESC button is pressed, the display will show a 0; however, this is

Hydrogen Factor

The Hydrogen factor is very similar to the CO factor, as explained above.

The instrument will perform its calculations based on a theoretical amount of

carbon or hydrogen. However, the actual amounts of carbon or hydrogen

will probably be different from the theoretical amounts that the instrument is

using to perform the calculations. Changing the CO factor or the Hydrogen

factor will allow the instrument to make its calculations based on the actual

amount of carbon or hydrogen, which will make the calculations more

accurate. This screen has the same functionality as the CO Factor screen.

HP 15 Manual Rev A Page 9 of 9

Page 10

Pump Control

This screen will allow the user to manually turn the pump on or off. Press

the On button to turn the pump on. Press the Off button to turn the pump

off. The “Low Temperature Pump Cutoff” section will allow the user to set a

low temperature that will shut the pump off if the specified temperature is

reached. Press the value and enter the desired pump cutoff setpoint.

Auto / Manual

The “Loop 1 Out:” section displays the output percentage of

Loop 1, along with the current mode of the loop – Auto for

automatic, Man for manual. To switch the mode of the

loop to automatic, press the Automatic Control button.

To switch the mode of the loop to manual, press the

Manual Control button. When the loop is in manual

mode, the output percentage can be changed by pressing the output

percentage value and entering the new value from the numeric keypad that is

displayed.

The “Loop 2 Out:” section displays the output percentage of Loop 2, along

with the current mode of the loop – Auto for automatic, Man for manual. To

switch the mode of the loop to automatic, press the Automatic Control

button. To switch the mode of the loop to manual, press the Manual

Control button. When the loop is in manual mode, the output percentage can be changed by

pressing the output percentage value and entering the new value from the numeric keypad that

is displayed.

O2 View

This feature is not yet implemented.

Configuration Menu

The Config Menu button will display the configuration menu. The

Configuration menu displays six buttons that will allow the user to

configure the HP15. The Exit button will return the user to the main

menu.

PVT Type

This screen will allow the user to set the PVT type. The

currently selected PVT type will be listed at the top of the screen. Press the

Carbon button to set the PVT type to Carbon. Press the Dew Point button

to set the PVT type to Dew Point. Press the

Oxygen button to set the PVT type to Oxygen.

Press the Millivolts button to set the PVT type

to Millivolts. Press the Simple Nitrider button

to set the PVT type to Simple Nitriding. Press

the Dual Loop button to set the PVT type to

Dual Loop. Since changing the PVT type will set

HP 15 Manual Rev A Page 10 of 10

Page 11

default values for that type, certain settings may be lost. When the PVT type is changed, the

user will have to confirm the changes. Pressing the Yes button will change the PVT type, and

pressing the No button will not change the PVT type. The Menu button will return the user to

the configuration menu.

Network Settings

The Network Settings screen will allow the user to set up the network

addresses for the HP15. Each screen – IP Address, Netmask, and Gateway

– will function identically. The IP Address button will allow the user to

change the IP address of the device. The Netmask

button will allow the user to change the Netmask of the

device. The Gateway button will allow the user to

change the gateway of the device. To change a specific

section of an address, press the value and enter the new

value on the numeric keypad.

PID Settings

This menu screen will allow the user to select which loop to change the PID

settings for. Press the Loop 1 PID Settings button to change the PID

settings for Loop1, or press the Loop 2 PID Settings button to change the

PID settings for Loop 2. The Exit button will return the user to the

configuration menu screen. The screens for the Loop 1 PID settings and

Loop 2 PID settings function identically.

Loop PID Settings – Page 1

From this screen, the user can modify the proportional

band, reset, rate, and cycle time. To edit any of these

values, press the value and enter the new value from the

numeric keypad that is displayed. The More >>> button

will display Page 2 of the PID Settings menu. The Menu

button will display the

PID Settings

menu.

HP 15 Manual Rev A Page 11 of 11

Page 12

Loop PID Settings – Page 2

From this screen, the user can modify the control loop output, integral

preset, control low limit, control high limit, and the loop mode. To edit the

control loop output, integral preset, control low limit, or the control high

limit, press the value and enter the new value from the numeric keypad

that is displayed. The currently selected loop mode will be displayed in the

box. To change the loop mode, press the up arrow next to the displayed

mode. This will display the available modes in the form of buttons:

Dual Reverse (Gas/Air, Heat/Cool)

Single Reverse (Heat)

Dual Direct (Dew Point)

Dual Reverse (Cool)

Press the button for the desired mode. The <More

button will display Page 1 of the PID Settings menu. The

More> button will display Page 3 of the PID Settings

menu. The Menu button will display the

PID Settings

menu.

Loop PID Settings – Page 3

From this screen, the user can modify the auto PID setting, as well as whether

or not the high limit shuts down the control for each input. To turn the auto

PID on, press the On button. To turn the auto PID off, press the Off button.

The current status of the auto PID will be displayed. To modify whether the

high limit shuts down the control for Input 1, 2, or 3, press the Toggle button

for the desired input. For example, to have the high limit shut down control

for Input 1, press the top Toggle button; to have the high limit shut down

control for Input 3, press the bottom Toggle button. The <More button will

display Page 2 of the PID Settings menu. The More> button will display Page

4 of the PID Settings menu. The Menu button will display the

menu.

Loop PID Settings – Page 4

From this screen, the user can modify the zero setpoint shuts down control

value, as well as the set point change limit value. Whether or not a zero

setpoint shuts down control will be displayed above the Yes/No buttons.

To allow a zero setpoint to shut down control, press the

Yes button. To not allow a zero setpoint to shut down

control, press the No button. The current setpoint

change limit is displayed in the box. To change the

setpoint change limit, press the up arrow next to the

displayed value. This will display eight buttons that will

allow the user to change the setpoint change limit:

Off

80 %

70 %

PID Settings

HP 15 Manual Rev A Page 12 of 12

Page 13

60 %

50 %

40 %

30 %

20 %

Press the button for the desired setpoint change limit. The <<< More button will display Page

3 of the PID Settings menu. The Menu button will display the

PID Settings

menu.

Burn Off Setup

From this screen, the user can modify the burn off time in seconds,

recovery wait time in seconds, interval in minutes, minimum millivolts, and

the maximum temperature values. The user can also

start a manual burnoff from this screen. To modify the

burn off time, recovery wait time, interval, minimum

millivolts, or the maximum temperature value, press the

value and enter the new value from the numeric keypad

that is displayed. To start a manual burnoff, press the

Start Manual Burn Off button. While a burnoff is in

progress, the burnoff in progress screen will be displayed.

The current sequence number and the time remaining in

seconds will be displayed. The Close button will close

down the screen.

Note: While the burnoff in progress

screen may be closed, the burnoff will still be in progress, and another manual

burnoff may not be started until the current burnoff is finished

.

Analog Input Setup

This menu screen will allow the user to set up the analog input settings for

Input 1, 2, or 3. To change the analog inputs settings for Input 1, press

the Analog Input 1 Settings button. To change the analog inputs

settings for Input 2, press the Analog Input 2 Settings button. To

change the analog inputs settings for Input 3, press the Analog Input 3

Settings button. The screens for the analog input settings 1, 2, and 3

function identically. The Exit button will return the user

to the configuration menu.

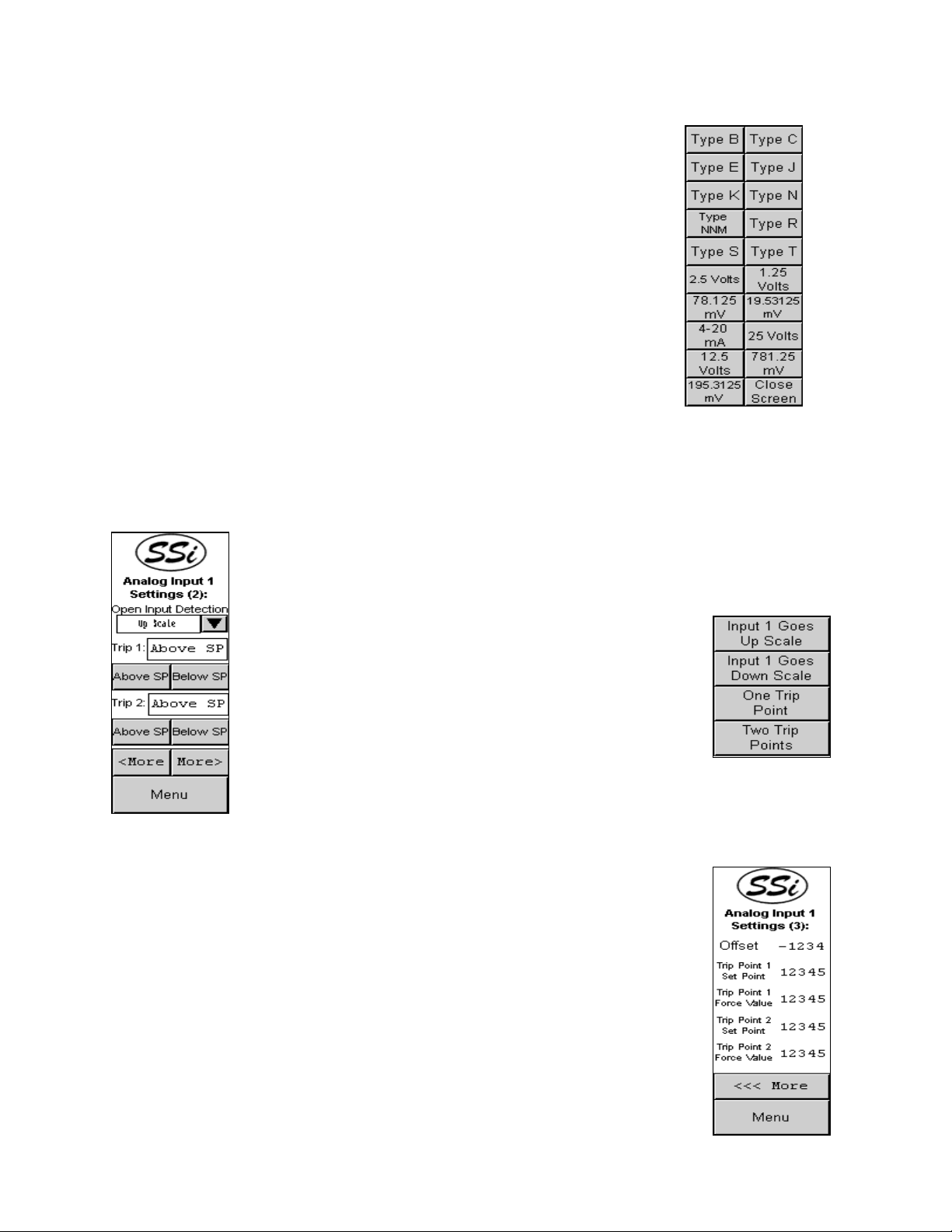

Analog Input Settings – Page 1

From this screen, the user can modify the input type,

filter, initial scale, full scale, and decimal point location.

The current input type is displayed in the box. To change

the input type, press the down arrow next to the displayed value. This action

will display twenty buttons that will allow the user to change the input type:

Type B

Type C

Type E

Type J

Type K

Type N

HP 15 Manual Rev A Page 13 of 13

Page 14

Type NNM

Type R

Type S

Type T

2.5 Volts

1.25 Volts

78.125 mV

19.53125 mV

4-20 mA

25 Volts

12.5 Volts

781.25 mV

195.3125 mV

Close Screen

Press the button for the desired input type. To change the filter, initial

scale, full scale, or decimal point location, press the value and enter the new value from the

numeric keypad that is displayed. The More >>> button will display Page 2 of the analog

input settings menu. The Menu button will display the

Analog Input Setup

menu.

Analog Input Settings – Page 2

From this screen, the user can modify the open input direction, trip 1 value,

and the trip 2 value. The current open input direction value is displayed in the

box. To modify the open input direction, press the down arrow next to the

displayed value. This will display four buttons that will allow the user to

change the open input direction:

Input X Goes Up Scale

Input X Goes Down Scale

One Trip Point

Two Trip Points

Press the button for the desired open input direction. To

set the Trip 1 value to Above Setpoint, press the Above SP

button under the Trip 1 value. To set the Trip 2 value to

Above Setpoint, press the Above SP button under the Trip 2 value. To set

the Trip 1 value to Below Setpoint, press the Below SP button under the Trip

1 value. To set the Trip 2 value to Below Setpoint, press the Below SP button under the Trip

2 value. Pressing the <More button will display Page 1 of the analog inputs settings menu.

Pressing the More> button will display Page 3 of the analog input settings

menu. The Menu button will display the

Analog Input Setup

menu.

Analog Input Settings – Page 3

From this screen, the user can modify the offset, trip point 1 set point, trip

point 1 force value, trip point 2 setpoint, and the trip point 2 force value. To

edit any of these values, press the value and enter the new value from the

numeric keypad that is displayed. Pressing the <<< More button will

display Page 2 of the analog input settings menu. The Menu button will

display the

Analog Input Setup

menu.

HP 15 Manual Rev A Page 14 of 14

Page 15

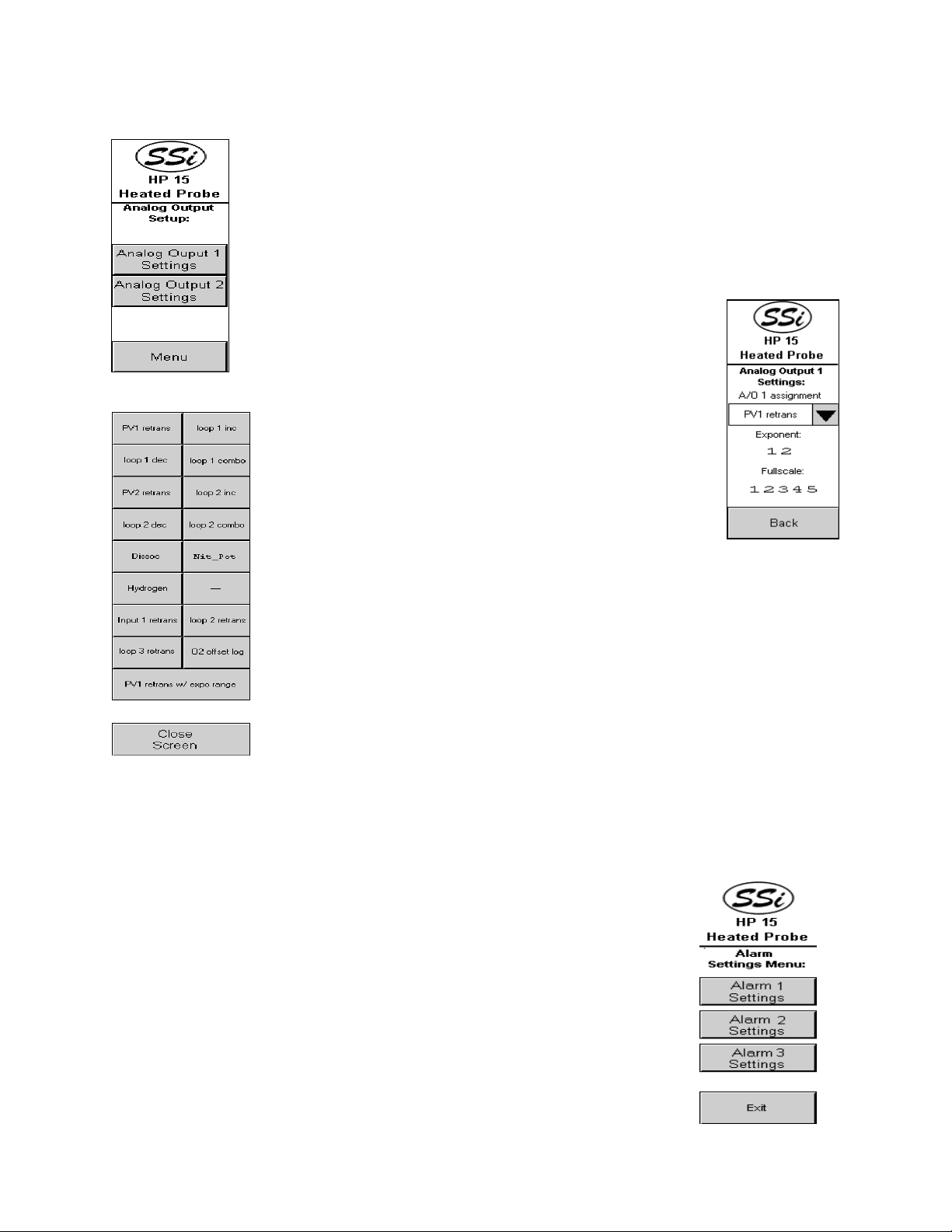

Analog Output Setup

This screen will allow the user to set up the analog output settings for output

1 or 2. To change the analog output settings for output 1, press the Analog

Output 1 Settings button. To change the analog output settings for output

2, press the Analog Output 2 Settings button. The screens for the analog

output settings function identically for outputs 1 and 2. The Menu button will

return the user to the configuration menu.

Analog Output Settings – Page 1

From this screen, the user can modify the analog output

assignment, the exponent, and the full-scale values. To

select a new analog output assignment, press the down

arrow next to the assignment. This will display a screen with

18 buttons to choose from:

PV 1 retrans

Loop 1 inc

Loop1 dec

Loop 1 combo

PV 2 retrans

Loop 2 inc

Loop 2 dec

Loop 2 combo

Disassociation

Nit_Pot

Hydrogen

- (Invalid Option)

Input 1 retrans

Loop 2 retrans

Loop 3 retrans

O2 offset log

PV 1 retrans w/ expo range

The Close Screen button will close the screen without selecting a new assignment. Press the

new assignment button to select it. To modify either the exponent or the full scale, press the

value and enter the new value from the numeric keypad that is displayed. The Back button

will display the analog output setup menu screen.

Alarms

This screen will allow the user to set up Alarm 1, Alarm 2, or Alarm 3. To

set up Alarm 1, press the Alarm 1 Settings button. To set up Alarm 2,

press the Alarm 2 Settings button. To set up Alarm 3, press the Alarm

3 Settings button. The screens for the alarms will function identically for

Alarms 1, 2, and 3.

The over temperature alarm will now read “Overtemp Alarm 1”

Note: Alarm 1 is a dedicated over temperature alarm.

.

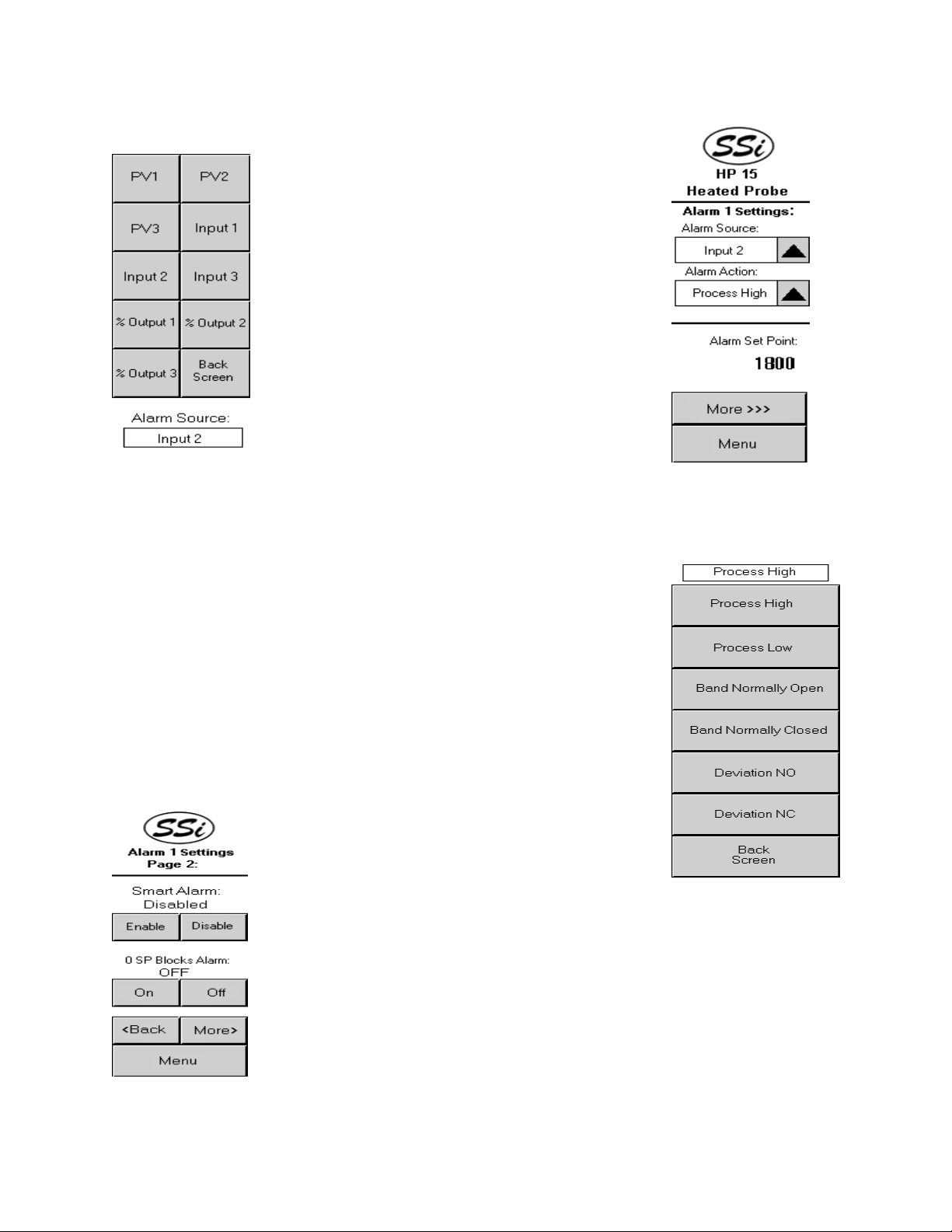

Alarm Settings - Page 1

This screen will allow the user to set the alarm source, alarm action, and

the alarm set point. To set the alarm source, press the up arrow next to

HP 15 Manual Rev A Page 15 of 15

Page 16

the source. This will display ten buttons from which the user can select

the alarm source:

PV1

PV2

PV3

Input 1

Input 2

Input 3

% Output 1

% Output 2

% Output 3

Back Screen

The current alarm source will be displayed at the

bottom of the screen. The Back Screen button

will display the Alarm Settings page 1 menu screen.

To set the alarm action, press the up arrow next to

the action. This will display a screen with seven

buttons from which the user can select the alarm action:

Process High

Process Low

Band Normally Open

Band Normally Closed

Deviation NO

Deviation NC

Back Screen

The current alarm action will be displayed at the top of the screen. The

Back Screen button will display the Alarm Settings page 1 menu

screen. To set the alarm setpoint, press the value and enter the new

setpoint on the keypad displayed. Pressing the More >>> button will

display page 2 of the Alarm Settings menu. Pressing the Menu button

will display the

Alarms

menu.

Alarm Settings – Page 2

This screen will allow the user to set the smart

alarm and whether or not a 0 setpoint blocks the

alarm. To enable the smart alarm, press the

Enable button under the smart alarm status. To

disable the smart alarm, press the Disable button under the smart alarm

status. To ensure that a 0 setpoint will block the alarm, press the On

button below the status. To ensure that a 0 setpoint will not block the

alarm, press the Off button below the status. Pressing the <Back button

will display the page 1 of the Alarm Settings menu. Pressing the More>

button will display page 3 of the Alarm Settings menu. Pressing the Menu

button will display the

Alarms

menu.

HP 15 Manual Rev A Page 16 of 16

Page 17

Alarm Settings – Page 3

This screen will allow the user to set the hysteresis and the on delay time

for the alarm. To set the hysteresis, press the value and enter the new

hysteresis value from the calculator. To set the On delay time, press the

value and enter the new On delay time from the calculator. Pressing the

<<<Back button will display page 2 of the Alarm Settings menu. Pressing

the Menu button will display the

Alarms

menu.

Over Temp Alarm

If at any time the alarm setpoint is exceeded, the over temp alarm screen will

be displayed on the screen. This screen will remain displayed until the

acknowledge button, ACK, is pressed.

SSi Information Screen

On any screen where the Super Systems Inc logo is visible, the user will be

able to display the information screen for the HP 15. Press the logo to

display the screen. The information screen will display the

Super Systems Inc address and contact information, as well

as the screen version and the firmware version of the 9120.

The user can close out the screen either by pressing the Super Systems Inc

logo again, or by pressing the Close button.

HP 15 Manual Rev A Page 17 of 17

Page 18

Spare Parts List

31125 24 Volt / 1.2 Amp Power Supply

13454 Series 9120 Controller

31292 Operator Interface - Touch Screen

37177 Pump - Sample and Burnoff Air

37020 Pump - Reference Air

20059 Filter with Media

37037 Replacement Filter Media (20 grams)

32074 Heater - 110V / 425 Watt

10138 Ceragold Probe 400 zirconia sensor w/ "S" T/C

HP 15 Manual Rev A Page 18 of 18

Page 19

Appendix 1 – Factory Defaults

Universal Defaults

• Temperature in °F

• All Baud Rates initially 19200 and set for Modbus

• Burnoff time is 90 seconds

• Burnoff recovery wait time is 2 minutes

• Burnoff interval is 12 hours

• Burnoff maximum temperature is 2000 °F

• CO Factor is 200

• Hydrogen factor for Dewpoint calculation is 40%

• Analog to Digital Converter filter time is 8 seconds for all 3 ADCs

• For analog input 1 initial scale is 0, and full scale is 1000

• For analog input 2 initial scale is 0, and full scale is 10000

• For analog input 3 initial scale is 0, and full scale is 10000

• First Process Control Setpoint is set to 0

• First Process Proportional Band is 20%

• First Process Reset for PID control is On

• First Process Rate for PID control is 0

• First Process Output Cycle Time for Control is 16 milliseconds

• First Process Auto/Manual set to Automatic

• First Process Control Load Line or Manual Reset (integral preset) set to 0

• Second Process Control Setpoint is set to 0

• Second Process Proportional Band is 4.4%

• Second Process Reset for PID control is 12

• Second Process Rate for PID control is 216

• Second Process Output Cycle Time for Control is 60 milliseconds

• Second Process Auto/Manual set to Automatic

• Second Process Control Load Line or Manual Reset (integral preset) set to 0

• Start PV for temporary tuning set to 0

• Temporary Proportional band for tuning set to 2%

• Temporary reset for tuning set to On

• Temporary rate for tuning set to 0

• Temporary integral preset for tuning set to 0

• Relay 1 set for loop 2 heat

• Relay 2 set for alarm 1

• Relay 3 set for loop 1 increment (gas)

• Relay 4 set for loop 1 decrement (air)

• Relay 5 fixed by PV type.

• Relay 6 set for Probe Burnoff

• Relay 7 set for Alarm 3

• Relay 8 set for all alarms.

• Alarm 1 setpoint set for 1800

• Alarm 1 is set for analog input 2

• Alarm 1 hysteresis is set for 1

• Alarm 2 setpoint set for 2000

• Alarm 2 is set for analog input 1

HP 15 Manual Rev A Page 19 of 19

Page 20

• Alarm 2 hysteresis is set for 1

• Alarm 3 setpoint set for 2000

• Alarm 3 is set for process variable 2

• Alarm 3 hysteresis is set for 1

• Digital to Analog converter 1 assignment is PV1 retransmit

• Digital to Analog converter 2 assignment is loop 2 increment

• Default IP is 192.168.0.200

Carbon PVT Defaults

• Process variable 1 is carbon

• Process variable 2 is temperature

• Process variable 3 is temperature

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• First process control low limit is –100

• First process control high limit is 100

• First process control mode is such that setpoint of 0 shuts down and it is in dual mode

• Second process control low limit is 0

• Second process control high limit is 100

• Second process control mode is such a high analog input 2 shuts down

• Analog input 1 full scale is 2500

• Analog input 1 type is 2.5 volts

• Analog input 2 type is S thermocouple

• Analog input 3 type is K thermocouple

Dewpoint PVT Defaults

• Process variable 1 is dewpoint

• Process variable 2 is temperature

• Process variable 3 is temperature

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• First process control low limit is –100

• First process control high limit is 100

• First process control mode is such that dual direct mode

• Second process control low limit is 0

• Second process control high limit is 100

• Second process control mode is such a high analog input 2 shuts down

• Analog input 1 full scale is 2500

• Analog input 1 type is 2.5 volts

• Analog input 2 type is S thermocouple

• Analog input 3 type is K thermocouple

Oxygen PVT Defaults

• Process variable 1 is carbon

HP 15 Manual Rev A Page 20 of 20

Page 21

• Process variable 2 is temperature

• Process variable 3 is temperature

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• First process control low limit is 0

• First process control high limit is 100

• First process control mode is such that it is in single reverse

• Second process control low limit is 0

• Second process control high limit is 100

• Second process control mode is such a high analog input 2 shuts down

• Analog input 1 full scale is 1250

• Analog input 1 type is1.25 volts

• Analog input 2 type is S thermocouple

• Analog input 3 type is S thermocouple

• Alarm 3 setpoint is 1.0%

• Alarm 3 type PV1 process low

• Open TC input1 goes down scale

• Relay 3 assignment is loop 1 decrement (gas)

• Relay 4 assignment is loop 1 increment (air)

Probe mV PVT Defaults

• Process variable 1 is Millivolts

• Process variable 2 is temperature

• Process variable 3 is temperature

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• Analog output 1 offset is 0

• Analog output 1 range is 2000

• First process control low limit is –100

• First process control high limit is 100

• First process control mode is such that setpoint of 0 shuts down and it is in dual mode

• Second process control low limit is 0

• Second process control high limit is 100

• Second process control mode is such a high analog input 2 shuts down

• Analog input 1 full scale is 2500

• Analog input 1 type is 2.5 volts

• Analog input 2 type is S thermocouple

• Analog input 3 type is K thermocouple

Probe Redundancy PVT Defaults

• Process variable 1 is probe 1

• Process variable 2 is probe 2

• Process variable 3 is temperature

• Analog output 1 offset is 0

• Analog output 1 range is 200

• Analog output 1 offset is 0

HP 15 Manual Rev A Page 21 of 21

Page 22

• Analog output 1 range is 200

• First process control low limit is –100

• First process control high limit is 100

• First process control mode is such that setpoint of 0 shuts down and it is in dual mode

• Second process control low limit is 0

• Second process control high limit is 100

• Second process control mode is such that it is in single reverse

• Analog input 1 full scale is 2500

• Analog input 2 full scale is 2500

• Analog input 1 type is 2.5 volts

• Analog input 2 type is 2.5 volts

• Analog input 3 type is K thermocouple

• 20 minutes delay time before alarm

• Band +/1 for alarm in millivolts is 10

• Modbus at 9600 baud

Simple Nitrider PVT Defaults

• Process variable 1 is carbon

• Process variable 2 is temperature

• Process variable 3 is temperature

• DAC 1 is set for Hydrogen

• DAC2 is set for Dissociation

• Analog output 1 offset is 0

• Analog output 1 range is 1000

• Analog output 1 offset is 0

• Analog output 1 range is 1000

• First process control low limit is –100

• First process control high limit is 100

• First process control mode is such that setpoint of 0 shuts down and it is in dual mode

• Second process control low limit is 0

• Second process control high limit is 100

• Second process control mode is such that it is in single reverse

• Analog input 1 full scale is 2500

• Analog input 1 type is 2.5 volts

• Analog input 2 type is S thermocouple

• Analog input 3 type is K thermocouple

• host RS232

• Hitech H2 cell at 9600 baud

Dual Loop PVT Defaults

• Alarm 2 setpoint is 2000

• Alarm 3 setpoint is 2000

• Alarm 2 type is input 1 process high

• Alarm 3 type is PV2 process high

HP 15 Manual Rev A Page 22 of 22

Page 23

Revision History

Rev. Description Date MCO #

- Initial Release 06/14/07 N/A

A Updated logo on title page; Changed screen

shots; Added “O2 View” (although this section

is not implemented); Added warning when PVT

type is changed; Added “Alarms” section of

Configuration Menu; Updated “Revision

History” section – Added “MCO #” block; Set

Alarm 1 as the dedicated over temperature

alarm; Added “Factory Defaults” appendix

12/21/07 2055

HP 15 Manual Rev A Page 23 of 23

Loading...

Loading...