Page 1

HYDROGEN (H2) SENSOR

(PART NUMBER 20624)

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 2 of 17

Table of Contents

Introduction ........................................................................................................................................ 3

Features ............................................................................................................................................. 3

Specifications ..................................................................................................................................... 3

Switch Settings, Jumper Settings, and Connector Assignments .................................................... 5

Location of RS-485, DC Input, and Analog Output Terminals ...................................................... 5

Dip Switch Settings ........................................................................................................................ 5

Jumper Positions – Modbus RTU/ASCII ........................................................................................ 6

9-Pin Connector ............................................................................................................................. 7

Analog Output Jumpers ................................................................................................................. 7

Plumbing Connections ................................................................................................................... 8

Analog Output Assignments .......................................................................................................... 8

Calibrating and Configuring the Sensor using the H

Configuration Utility Software ..................... 9

2

Minimum Computer Requirements ............................................................................................... 9

Configuring Communications ........................................................................................................ 9

Overview Screen ............................................................................................................................. 9

Sensor Output Configuration ....................................................................................................... 10

Sensor Output Calibration ........................................................................................................... 10

Sensor Calibration ....................................................................................................................... 11

About ............................................................................................................................................. 12

Modifying Modbus Registers ....................................................................................................... 12

Calibrating the Sensor using Modbus Registers ........................................................................ 13

Performing a Zero Calibration ................................................................................................. 13

Performing a Span Calibration ................................................................................................ 13

Changing the 4-20mA Assignments using Modbus Registers ................................................... 13

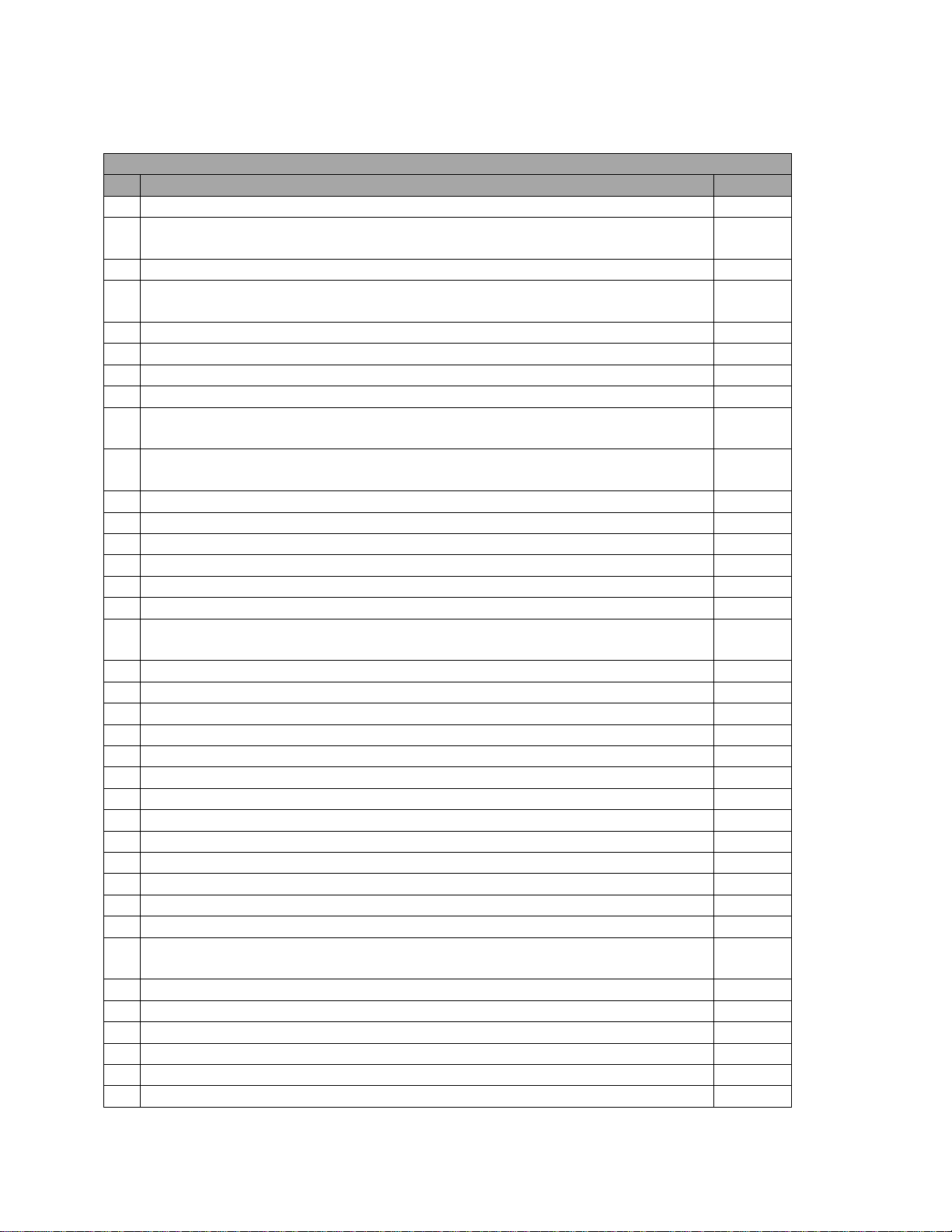

Appendix 1: Modbus Register Map .................................................................................................. 14

Warranty ........................................................................................................................................... 16

Revision History ............................................................................................................................... 17

Page 3

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 3 of 17

Introduction

This sensor is designed to accurately measure Hydrogen through thermal conductivity

technology. It is capable of providing additional computations based on the Hydrogen

measurement, and it has multiple methods of digital and analog communications capabilities.

Features

• Measures H

• Calculates NH

from 0 to 100% with 0.01% resolution

2

, DA, and KN for nitrider applications

3

• Two isolated analog outputs capable of outputting current (4-20 mA or 0-20 mA) as well as

voltage (2-10 VDC, 0-10 VDC, 1-5 VDC, or 0-5 VDC)

• One RS-232 port with Modbus RTU or a simple ASCII protocol

• One RS-485 port with Modbus RTU protocol

• Wide power supply input range (9 to 30VDC)

• Small physical size

Specifications

Hydrogen measurement

• Range: 0 to 100%

• Accuracy: ±0.01%

• Repeatability: ±0.01%

• Resolution: ±0.01%

Calculated Variables for simple nitrider applications

• %NH

0 to 100%

3

• %DA (dissociated ammonia) 0 to 100%

nitriding potential

• K

N

Analog Outputs

• Two isolated analog outputs with common supply; capable of outputting current (4-20 mA or

0-20 mA) as well as voltage (2-10 VDC, 0-10 VDC, 1-5 VDC, or 0-5 VDC)

• Output variables: %H

, %NH3, %DA, and KN on either output

2

• Adjustable range of PV: zero and span

• Resolution: 0.005 mA

• Accuracy: ±0.01% of range

• Linearity: ±0.01%

• Minimum load resistance: 0 Ohms

• Maximum load resistance: 500 Ohms

Sample flow rate

• 1.5 to 2 cfh

RS-232 Serial Communications

• Protocols: Modbus RTU or a simple ASCII

• Baud rates: 9600, 19200, or 38400

• Format: 8 bits No parity, 1 stop bit, No handshaking

• Connection: DB-9F

Page 4

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 4 of 17

RS-485 Serial Communications:

• Protocol: Modbus RTU

• Baud rates: 9600, 19200, or 38400.

• Format: 8 bits No parity, 1 stop bit, No handshaking

Power requirement

• 9 to 30 volts DC @ 2 watts

Temperature and Humidity

• Electronics Operating: 0 to 50 °C, RH 0 to 90% non-condensing

• Sample gas: 0 to 70 °C, RH 0 to 90% non-condensing

• Storage: -20 to 70 °C, RH 0 to 90% non-condensing

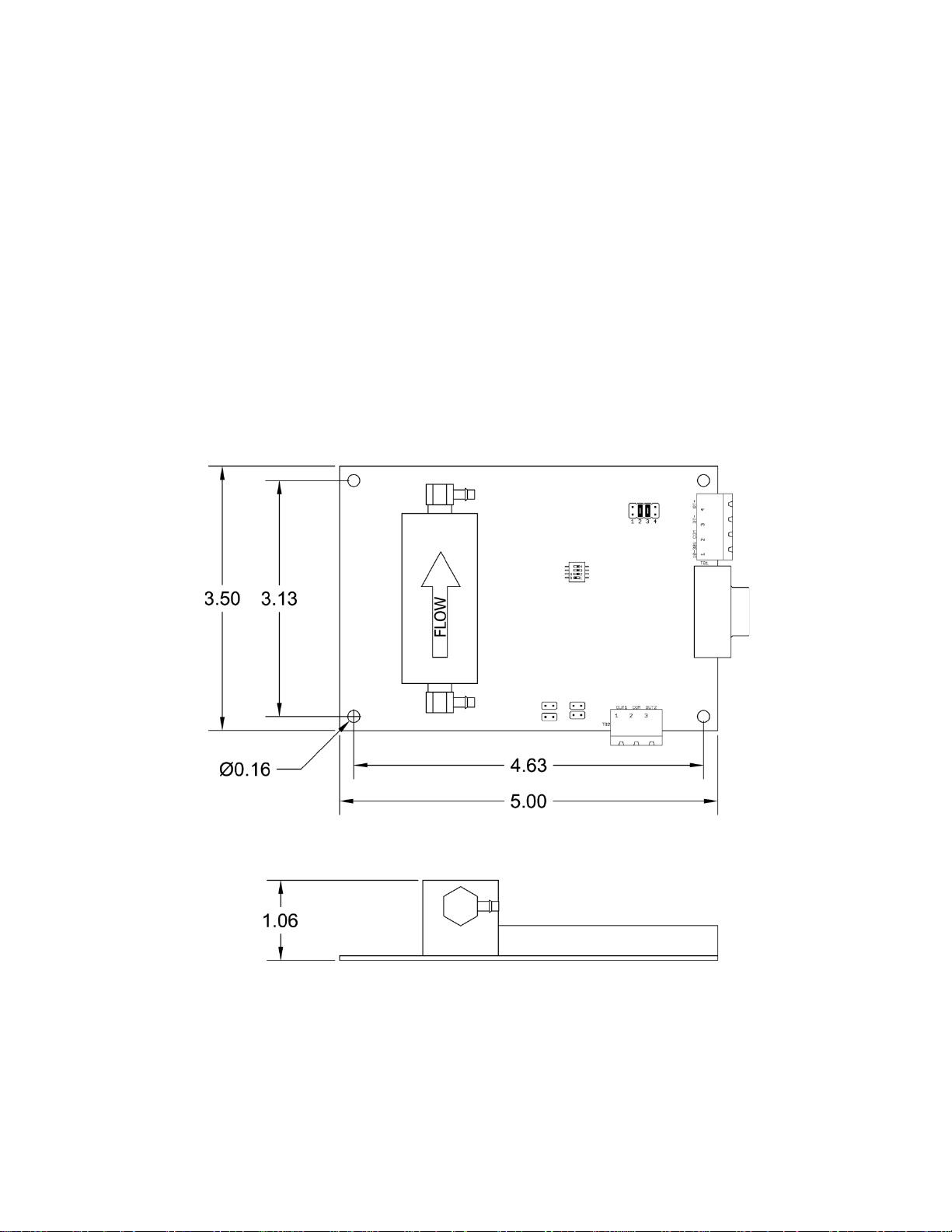

Dimensions:

See Figure 1.

Weight:

Material:

Figure 1 - H2 Sensor Dimensions

350 g

Stainless steel sensor housing

Page 5

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 5 of 17

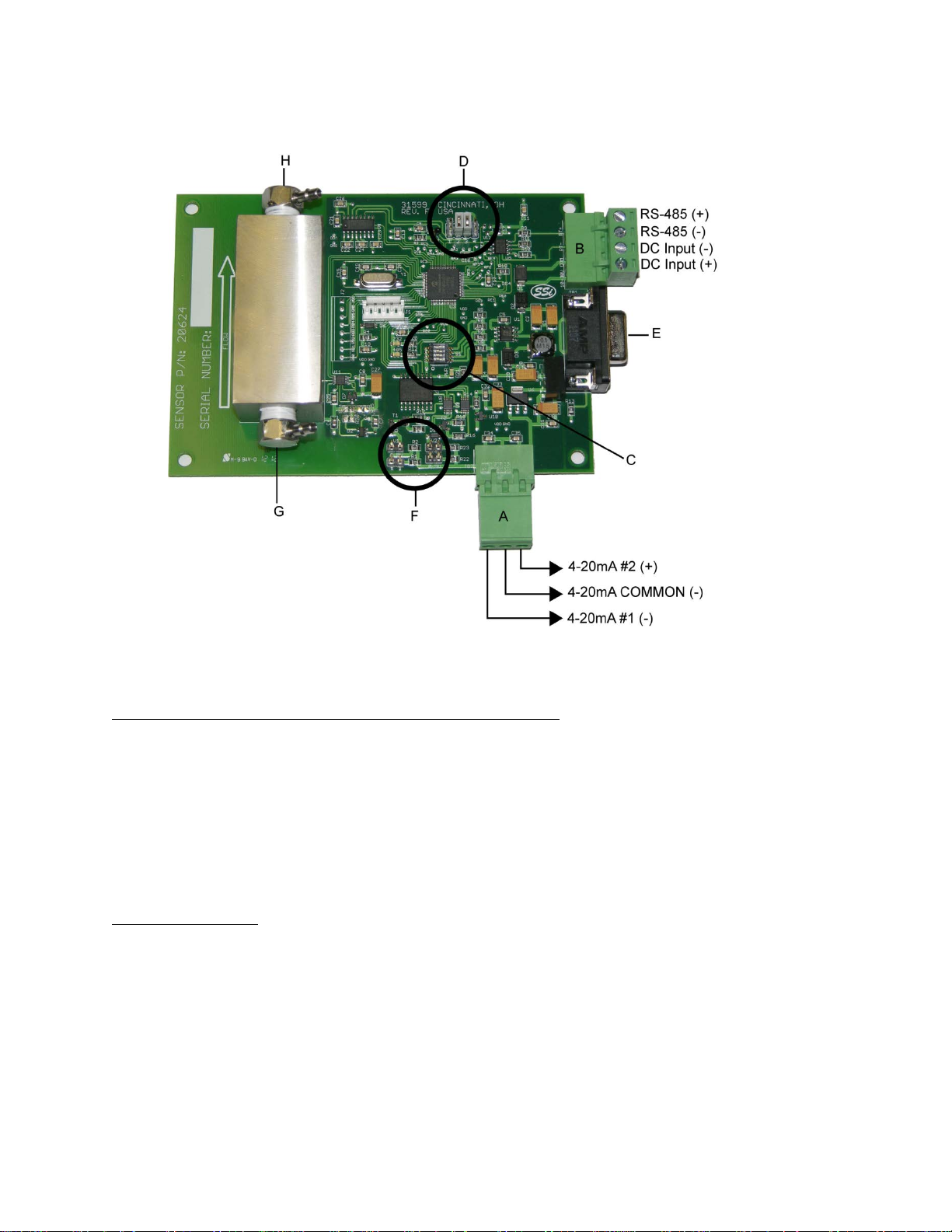

Wiring:

See Figure 2.

Figure 2 - H2 Sensor Wiring

Switch Settings, Jumper Settings, and Connector Assignments

Location of RS-485, DC Input, and Analog Output Terminals

(Items “A” and “B” in Figure 2)

There are two terminal blocks on the H2 cell circuit board. Figure 2 shows their locations.

One block (“A”) contains the analog output terminals. Jumper settings on the circuit board are

used to change whether resistance or voltage is generated. These jumper settings can be found

in “Analog Output Jumpers” below.

Another block (“B”) contains the digital communications (RS-485) and power (DC) terminals.

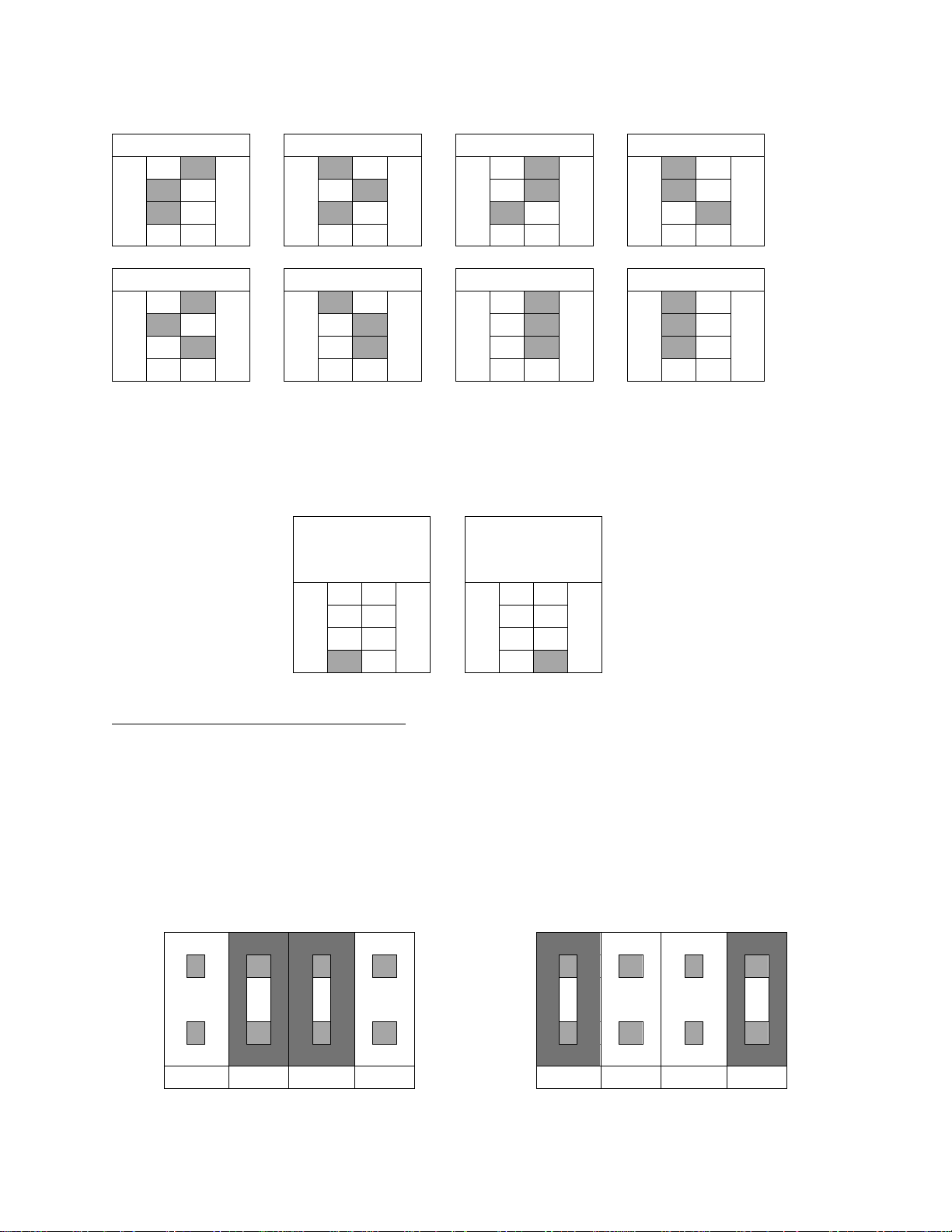

Dip Switch Settings

(Item “C” in Figure 2)

The first three dip switches determine the Modbus address. The address can be set for any

number between 1 and 8 using a binary numbering system where Bit #1 is the least significant

bit and Bit #3 is the most significant bit. The diagram below describes the switch position for

each possible address. The shaded area indicates the location of the switch.

Page 6

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 6 of 17

ADDRESS 1

ADDRESS 2

ADDRESS 3

ADDRESS 4

1 O 1 O 1 O 1 O

2 N 2 N 2 N 2 N 3 3 3 3

4 4 4 4 ADDRESS 5

ADDRESS 6

ADDRESS 7

ADDRESS 8

1 O 1 O 1 O 1 O 2 N 2 N 2 N 2

N

3 3 3 3 4 4 4 4

Protocol

1 O 1 O

2 N 2 N

3 3 4 4

1 2 3

4

1 2 3

4

Figure 3 - Dip Switch Settings (#1, #2, #3)

The last dip switch (#4) indicates the communication protocol. The ‘Off’ position is Modbus RTU

mode, and the ‘On’ position emulates the simple ASCII protocol of the previous version of the

SSI Hydrogen Sensor. The diagram below describes the switch position for each protocol. The

shaded area indicates the location of the switch.

Modbus RTU

Protocol

Previous SSI

Sensor

Figure 4 - Dip Switch Positions (#4)

Jumper Positions – Modbus RTU/ASCII

(Item “D” in Figure 2)

Four jumper terminals can be found on the board approximately 1.5” (3.81cm) to the left of the

RS-485 connections (specifically, when looking at the board in the orientation shown in Figure

2). These jumpers determine the pins that transmit and receive data via RS-232 communication.

The jumpers should be on Pins 2 and 3 for normal Modbus RTU operation (pin 2 is receiving and

pin 3 is transmitting). The jumpers should be on Pins 1 and 4 if the sensor is being used to

communicate via the simple ASCII protocol used on the previous version of the SSI Hydrogen

Sensor (pin 2 is transmitting and pin 3 is receiving).

Modbus RTU Protocol

Simple ASCII Protocol

Figure 5 - Jumper Positions (Modbus RTU/ASCII)

Page 7

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 7 of 17

JP2

JP4

JP3

JP5

Note the location of terminals #1 and #2, as well as the

Figure 7 – Analog Output

Terminal Block

#1

C

#2

9-Pin Connector

(Item “E” in Figure 2)

The sensor has a female 9-pin connector used for RS-232 communication. Only three of the

nine pins are used, and their assignments are:

Pin #2: Transmit or Receive (Depends on jumper positioning)

Pin #3: Transmit or Receive (Depends on jumper positioning)

Pin #5: Ground

Analog Output Jumpers

(Item “F” in Figure 2)

Jumpers near the analog output terminal block are used to determine whether a current or a

voltage is produced. Figure 6 shows the locations of the four jumpers: JP2, JP3, JP4, and JP5.

V1

0-5V

Figure 6 - Layout of Analog Output Jumpers

0-5V

If all jumpers are OPEN, a 4-20mA signal is produced.

COMMON terminal, in Figure 7. #1 and COMMON, in

combination, constitute loop 1, or the “left side” of the block.

#2 and COMMON, in combination, constitute loop 2, or the

“right side” of the block.

JP2 and JP3 are used for loop 1. JP4 and JP5 are used for

loop 2.

V2

O

M

M

O

N

The following table shows how the jumpers are used to change settings for the analog outputs.

Page 8

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 8 of 17

Applies to Loop 1 (#1 and COMMON)

Applies to Loop 2 (#2 and COMMON)

JP2

JP3

Resulting

Output

JP4

JP5

Resulting

Output

Open

Open

4-20mA

(current)

Open

Open

4-20mA

(current)

Closed

Open

2-10 VDC

Closed

Open

2-10 VDC

Open

Closed

4-20mA

(current)

Open

Closed

4-20mA

(current)

Closed

Closed

1-5 VDC

Closed

Closed

1-5 VDC

IMPORTANT: If Modbus register 43 is set to 0,

• 1-5 VDC becomes 0-5 VDC.

IMPORTANT: If Modbus register 44 is set to 0,

• 1-5 VDC becomes 0-5 VDC.

the above conditions are true. If Modbus register

43 is set to 1, the following changes take place

(depending on jumper settings):

• 4-20mA becomes 0-20mA

• 2-10 VDC becomes 0-10 VDC

Table 1 - Analog Output Jumper Settings

the above conditions are true. If Modbus register

44 is set to 1, the following changes take place

(depending on jumper settings):

• 4-20mA becomes 0-20mA

• 2-10 VDC becomes 0-10 VDC

Plumbing Connections

(Items “G” and “H” in Figure 2)

The sensor is provided with barb fittings (Items “G” and “H”) that are intended for use with 1/8”

ID flexible tubing. Flow goes into “G” and out through “H”. The barb fittings can be removed at

the user’s discretion, and any fitting with a 1/8” male pipe thread can be used in their place. If

the fittings are going to be replaced with different fittings, they must be replaced while the

stainless steel sensor block is still attached to the circuit board. Do not remove the sensor

block since its alignment with the sensors is a critical function that should only be performed by

a trained technician.

Analog Output Assignments

There are two analog outputs on the sensor. The default settings result in Output 1 being set

for Percent H2 (0-100%) and Output 2 being set for Percent Dissociation (0-100%). Both of

these outputs can be configured for any of the following parameters:

Percent Hydrogen (H

)

2

Percent Dissociation (DA)

Percent Ammonia (NH

Nitriding Potential (K

)

3

)

N

External

In “External” output mode, no calculation is performed, and the output is set to match a specific

value. Modifications to the Analog Output Assignments can be performed with the SSI H

Cell

2

Configuration Utility Software, which is described in the next section of this manual.

Page 9

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 9 of 17

Calibrating and Configuring the Sensor using the H2 Configuration Utility Software

The simplest way to set up the analog outputs, calibrate the analog outputs, and calibrate the

Hydrogen sensor is to use the SSi H

Configuration Utility software. This software provides a

2

simple to use graphical interface for performing the setup and calibration functions. It

communicates via Modbus (either RS-232 or RS-485). This is set by moving dip switch #4 to the

off position. To communicate via RS-232, use the 9-pin connector with the jumpers in positions

2 and 3. To communicate via RS-485, use the RT+ and RT- terminals on the 8 pin terminal strip.

Minimum Computer Requirements

• Microsoft Windows XP/Vista/7

• 500 MHz CPU

• 128MB RAM

• 2MB hard disk storage space

• 1 RS-232 or RS-485 Serial Port

Configuring Communications

Open the H2 Configurator and click Options Settings to open the dialog that allows you to set

the serial port, baud rate and target address of the H2 cell. (See

Figure 8.)

Figure 8 - Settings window

When using the RS-232 port, the baud rate should be set to 9600 and the address should be set

to 250. 250 is an SSi broadcast address and any H

cell that sees the message will answer, so

2

while the 250 address should be used for RS-232 it should not be used for RS-485 if there are

multiple SSi instruments on the same serial port. The Port setting may need to be adjusted to

match the port on your PC that is connected to the H

cell. RS-232 communications use a

2

simple straight through cable to the DB9 connector.

Overview Screen

The Overview screen (Figure 9) displays the current % H2 and the three buttons used to

configure or calibrate the H2 cell.

Page 10

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 10 of 17

Figure 9 - Overview screen

Sensor Output Configuration

The Configuration screen (Figure 10) allows basic configuration of the H2 cell.

Figure 10 - Configuration screen

The Instrument Mode is the primary PV (Process Variable) setup. This is mainly used by the

touch screen and normally does not need to be changed as the % H

is always available. The

2

output sources are the PVs that will be retransmitted via the selected output. The Output Zero

is the PV value that will result in a 4 mA output and the output span value is the PV value that

will result in a 20 mA output.

Sensor Output Calibration

Output calibration calibrates the outputs. Each output can be zeroed and spanned. To perform

this calibration a reliable measurement device capable of accurately measuring a 4-20mA

signal will be required. An example screen is shown in Figure 11; a screen showing the success

of an output calibration can be seen in Figure 12.

Page 11

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 11 of 17

Figure 11 - Output Calibration screen

Figure 12 - Successful Output Calibration

The steps to performing an output cal are as follows:

• Select an output and whether you are going to do a zero or a span.

• Click Prep for Cal. The H

• Measure the output current at the H

cell will set the output appropriately for measurement.

2

cell’s terminals and input that value into the box next

2

to ‘Measured Output mA’. For example, if you are performing a zero calibration and your

measurement device is indicating 4.03mA, you would enter the value of 4.03 in the

“Measured Output mA” box.

• Click the Calibrate button to perform the calibration.

• When the calibration is complete, the measurement device should display the target value.

For a zero calibration that would be 4.00mA, and for a span calibration that would be 20mA.

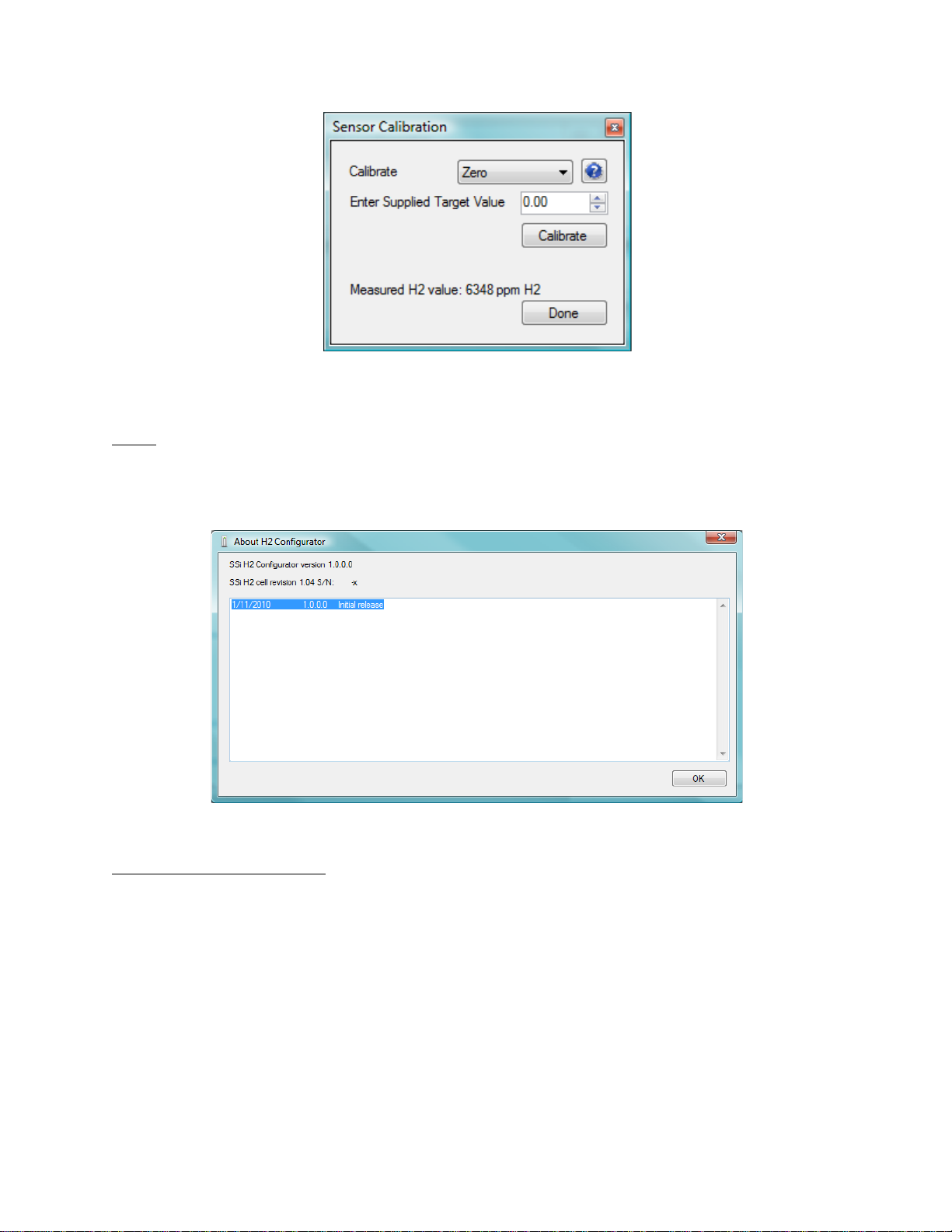

Sensor Calibration

The sensor can be zeroed or spanned via Sensor Calibration (Figure 13). The gas should flow at

a rate of 1.5 SCFH and the detected H

value needs to be steady before a calibration is

2

performed. To perform a Zero cal select Zero in the drop down box next to Calibrate. Enter the

% H

of the supplied gas (for zero this will be 0.00%). Wait for the readings to come to

2

equilibrium and click Calibrate. To perform a Span cal select Span in the drop down list and

repeat the process.

Page 12

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 12 of 17

Figure 13 - Sensor Calibration screen

About

The About screen (Figure 14) is access from the overview screen by clicking Help…About. The

About screen provides release information about the H

the firmware in the SSi H

cell.

2

Configuration utility and the revision of

2

Modifying Modbus Registers

The setup parameters of the H2 sensor can also be modified by adjusting the Modbus registers.

A list of all Modbus registers can be found in “Appendix 1: Modbus Register Map”. To make

modifications, you must connect the sensor to a computer that uses SSI’s “Configurator”

software. When communicating with Configurator, use a straight-through serial extension

cable connecting the computer to the sensor. Set the baud rate in Configurator to 9600. On the

sensor, set DIP Switch #4 to Off for Modbus communication, and be sure that the jumpers are

on pins 2 and 3.

Figure 14 - "About" Screen

Page 13

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 13 of 17

Calibrating the Sensor using Modbus Registers

Performing a Zero Calibration

1. Begin the flow of Zero gas (Nitrogen or Argon) at a rate of 1.5 SCFH.

2. Allow the readings from the sensor to stabilize.

3. Set Register #13 to 0 (equal to 0% H

).

2

4. Set Register 12 to 1.

Performing a Span Calibration

1. Begin the flow of Span gas (with a known %H

2. Allow the readings from the sensor to stabilize.

3. Set Register #13 to the H

value in the span gas. Multiply the gas value by 100 before

2

entering the number (i.e. if the gas has 40.13%H

enter a 997 into Register 13).

4. Set Register 12 to 2.

Changing the 4-20mA Assignments using Modbus Registers

Register 19 denotes the assignment for 4-20mA #1, and register 23 denotes the assignment of

4-20mA #2. The default value for #1 is %H

2

number into either register according to the following list:

• 0 = %H

2

• 1 = %DA

• 2 = %NH

3

• 3 = %Kn

• 4 = External Source

) at a rate of 1.5 SCFH.

2

, enter a 4013 or if the gas has 9.97% H2

2

, and #2 is #DA. To change the assignment, enter a

Page 14

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 14 of 17

Register Functions and Default Values

#

Function

Default

0

Current firmware revision level

Varies

1

RS-232 communication mode (0=Modbus slave, 1=ASCII /Previous SSI

Sensor)

DIP Sw.

2

RS-232 baud rate (0=9600, 1=19200, 2=38400)

0

3

RS-485 communication mode (0=Modbus slave, 1=Modbus master [NOT

USED])

0

4

RS-485 baud rate (0=9600, 1=19200, 2=38400)

1

5

Temperature trim for thermistor 1 / ambient temperature

200

6

A/d counts for thermistor 1

Varies

7

Thermistor 1 temperature

Varies

8

%H2 A/D counts – High (Right justified: 0x00 byte, high byte, mid byte,

low byte)

Varies

9

%H2 A/D counts – Low (Right justified: 0x00 byte, high byte, mid byte, low

byte)

Varies

10

%H2 measured voltage

Varies

11

%H2 as found from a polynomial

Varies

12

%H2 sensor calibration (0=none, 1=zero cal, 2=span cal)

0

13

%H2 gas composition (value/100 = %H2/N2 balance)

0

14

Sensor Modbus address (important for slave communications only)

DIP Sw.

15

Model Number

4100

16

Set Factory Defaults (23205=Full, 23206=%H2, 23207=Loop 1, 23208 =

Loop 2)

0

17

4-20mA #1 DAC output counts

Varies

18

4-20mA #2 DAC output counts

Varies

19

4-20mA #1 Source (0=%H2, 1=%DA, 2=%NH3, 3=Kn, 4= External)

0

20

4-20mA #1 Zero value

Varies

21

4-20mA #1 Span Value

10000

22

4-20mA #1 External current loop (Used only if register 19 = 4)

0

23

4-20mA #2 Source (0=%H2, 1=%DA, 2=%NH3, 3=Kn, 4= External)

1

24

4-20mA #2 Zero value

0

25

4-20mA #2 Span Value

1000

26

4-20mA #2 External current loop (Used only if register 23 = 4)

0

27

Enable Calibration of 4-20ma output (0=disable, 1=enable)

0

28

Calibrate 4-20mA output (1=#1 zero, 2=#1 span, 3=#2 zero, 4=#2 span)

0

29

4-20mA calibration value (4000 to 20000 for 4-20mA)

0

30

Calibration result codes (9-12=successes, 13-16=failures, 20=no cal

specified)

0

31

Percent DA value

Varies

32

Percent NH3 value

Varies

33

Super Kn value

Varies

34

%N2 flow

0

35

%NH3 flow

0

36

%DA flow

0

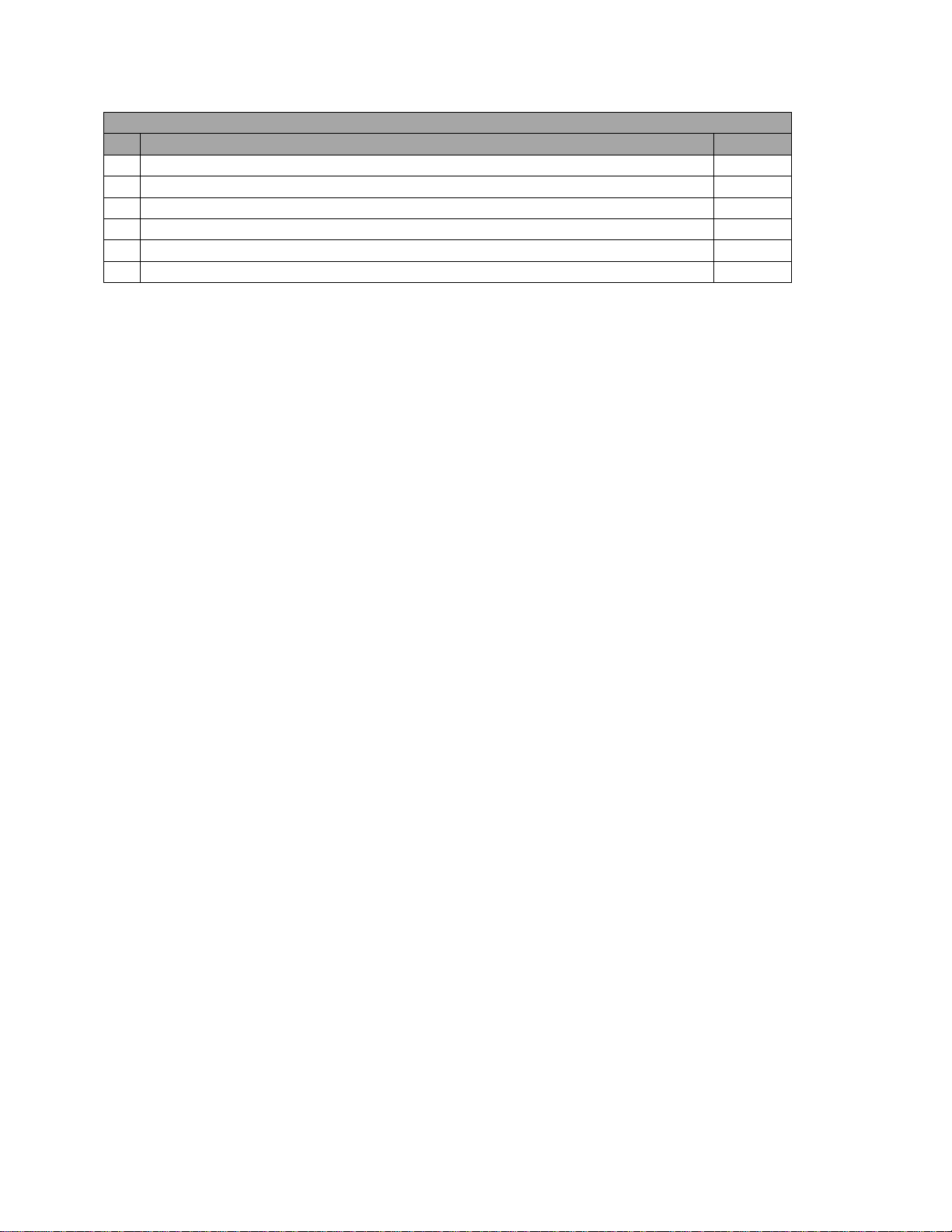

Appendix 1: Modbus Register Map

Page 15

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 15 of 17

Register Functions and Default Values

#

Function

Default

37

Process variable mode (0=H2, 1=DA, 2=NH3, 3=KN)

0

38

Process variable value

Varies

39

%H2 mantissa

Varies

40

%H2 exponent

Varies

41

Force theoretical current loop values

0

42

Minimum H2 value

0

Page 16

Hydrogen (H2) Sensor Operations Manual

Super Systems Inc.

Page 16 of 17

Warranty

Limited Warranty for Super Systems Products:

The Limited Warranty applies to new Super Systems Inc. (SSI) products purchased direct from

SSI or from an authorized SSI dealer by the original purchaser for normal use. SSI warrants

that a covered product is free from defects in materials and workmanship, with the exceptions

stated below.

The limited warranty does not cover damage resulting from commercial use, misuse, accident,

modification or alteration to hardware or software, tampering, unsuitable physical or operating

environment beyond product specifications, improper maintenance, or failure caused by a

product for which SSI is not responsible. There is no warranty of uninterrupted or error-free

operation. There is no warranty for loss of data—you must regularly back up the data stored on

your product to a separate storage product. There is no warranty for product with removed or

altered identification labels. SSI DOES NOT PROVIDE ANY OTHER WARRANTIES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME JURISDICTIONS DO

NOT ALLOW THE LIMITATION OF IMPLIED WARRANTIES, SO THIS LIMITATION MAY NOT APPLY

TO YOU. SSI is not responsible for returning to you product which is not covered by this limited

warranty.

If you are having trouble with a product, before seeking limited warranty service, first follow the

troubleshooting procedures that SSI or your authorized SSI dealer provides.

SSI will replace the PRODUCT with a functionally equivalent replacement product,

transportation prepaid after PRODUCT has been returned to SSI for testing and evaluation. SSI

may replace your product with a product that was previously used, repaired and tested to meet

SSI specifications. You receive title to the replaced product at delivery to carrier at SSI shipping

point. You are responsible for importation of the replaced product, if applicable. SSI will not

return the original product to you; therefore, you are responsible for moving data to another

media before returning to SSI, if applicable. Data Recovery is not covered under this warranty

and is not part of the warranty returns process. SSI warrants that the replaced products are

covered for the remainder of the original product warranty or 90 days, whichever is greater.

Page 17

Super Systems Inc.

Page 17 of 17

Rev.

Description

Date

MCO #

A

Previous Release

B

Changes made to reflect changes in board

setting analog outputs to volts.

11/1/2013

2132

Revision History

Hydrogen (H2) Sensor Operations Manual

design. Changed pinout. Added content for

Loading...

Loading...