Page 1

e-TRIM

OPERATIONS MANUAL

Super Systems Inc.

www.supersystems.com

7205 Edington Drive

Shipping Address: 7245 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

Page 2

Super Systems Inc.

Super Systems Europe

Super Systems México

Super Systems China

USA Office

Corporate Headquarters:

7205 Edington Drive

Shipping Address:

7245 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Units 3 & 4, 17 Reddicap Trading Estate,

Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627

http://www.supersystemseurope.com

Sistemas Superiores Integrales S de RL de CV

Calle 3 Int.: 11.

Zona Ind. Benito Juarez

Querétaro, Qro. Méx.

C.P.: 76120

Phone: +52 (442) 210 2459

http://www.supersystems.com.mx

Super Systems Inc. Page 2 of 27 e-TRIM Operations Manual

No. 335 XianXia Road

Room 308

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.com

Page 3

Table of Contents

E-TRIM OVERVIEW ................................................................................................................................................. 4

E-TRIM TOUCHSCREEN INTERFACE......................................................................................................................... 5

MAIN SCREEN ............................................................................................................................................................... 5

DETAILS ........................................................................................................................................................................ 6

MENU.......................................................................................................................................................................... 6

e-TRIM Menu ........................................................................................................................................................ 7

Offset .................................................................................................................................................................... 7

Status .................................................................................................................................................................... 8

System Setup ......................................................................................................................................................... 9

Board Setup ......................................................................................................................................................... 10

Burner Zones ....................................................................................................................................................... 12

Shutdown ............................................................................................................................................................ 13

Close .................................................................................................................................................................... 13

CHART ....................................................................................................................................................................... 14

CHART SUB MENU ....................................................................................................................................................... 17

WARRANTY .......................................................................................................................................................... 18

APPENDIX A – E-TRIM MODBUS REGISTERS ......................................................................................................... 19

APPENDIX B – SPARE PARTS LIST ......................................................................................................................... 21

APPENDIX C – ELECTRICAL DRAWINGS (FOR REFERENCE ONLY) ........................................................................... 22

APPENDIX D – TYPICAL INSTALLATIONS BASED ON APPLICATION ........................................................................ 24

TYPICAL SET UP OF E-TRIM WITH BIQ FURNACE ................................................................................................................ 24

TYPICAL SET UP OF E-TRIM WITH CONTINUOUS FURNACE .................................................................................................... 25

EXAMPLE SETUP OF E -TRIM IN A CUSTOM INSTALLATION .................................................................................................... 26

REVISION HISTORY ............................................................................................................................................... 27

Super Systems Inc. Page 3 of 27 e-TRIM Operations Manual

Page 4

e-TRIM Overview

WARNING:

772-0060 for questions about mounting and cooling.

IMPORTANT: When first warming up, the 02 percentage for each burner will read 99.99%. This is

sensor. Call Super Systems Inc. technical support at 513-772-0060 for assistance.

e-TRIM is designed to be installed on indirect fired burners. With e-TRIM, the operator will be

able to monitor and alarm based on a desired oxygen percentage during high fire. The system

will provide continuous indication of oxygen and will warn the operator when the burner is

outside of the desired oxygen band.

Additionally, e-TRIM is equipped with a critical alarm. This alarm is designed to provide an

audible and visual indication when a burner is either not lit or running extremely lean.

Typical settings are as follows:

Desired percent on high fire is 2% per the DOE, which would provide 10% excess air. The band

alarm should be set to 1%. When on high-fire, if the reading is below 1% or above 3%, the

screen will show an out-of-band condition. Additionally, SSi recommends the critical alarm be

set to 8%. When on high fire, if the reading goes above 8% and the trim delay expires, the horn

will sound. This is notification that a burner that is not lit or is extremely lean.

It is recommended that the desired oxygen percentage be verified with the burner manufacturer

prior to adjusting. It is important to make sure that the Carbon Monoxide PPM limit is not

increased when adjusting the burner.

e-TRIM electronics enclosure must not be exposed to temperatures above 120°F (49°C). It

should not be mounted on the furnace unless proper cooling is installed. Contact SSi at 513-

Sensor installation:

The sensor should be mounted on the exhaust leg of the burner prior to any gaps or possible air

drafts. The sensor should be installed in a location that will not exceed 1000° F on high fire.

Sensor Mounting:

The thread for the e-TRIM O

sensor is M18 x 1.5. It is a metric thread.

2

Please refer to the electrical print provided with the panel for all wire terminations.

expected, and the value will change to an appropriate value within 30 to 60 seconds. If the 02

percentage should read 99.99% at any time other than during the warm-up period or if it

remains 99.99% after the first two minutes of operation, there may be a problem with the

Examples of e-TRIM installations are shown in Appendix D – Typical Installations Based on

Application.

Super Systems Inc. Page 4 of 27 e-TRIM Operations Manual

Page 5

e-TRIM Touchscreen Interface

NOTE:

OK

**coms**

Alarm Pending

**Out of Band**

**Critical Alarm**

Critical Alarm Ack’d

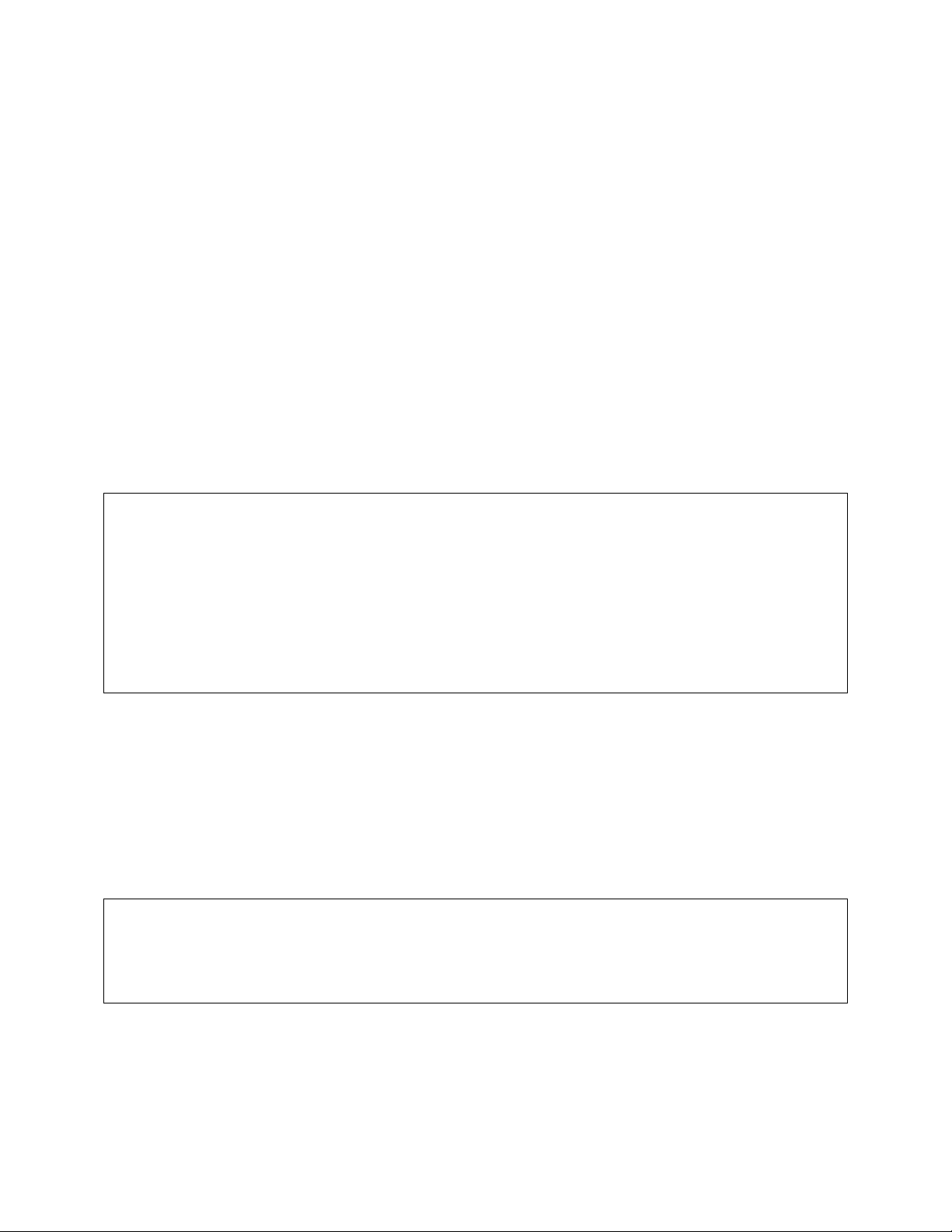

Main Screen

This manual was written with oxygen readings from the ambient air, not in a valid run-

time environment.

This is the main screen for the e-TRIM Touchscreen software. Once the software has booted up,

this screen will be displayed. This screen will list the Burners, along with the % Oxygen

reading, the Status of each burner, and the status of high fire or low fire. The possible

messages are:

•

– everything (coms, burner conditions, etc.) is ok.

•

•

- there is bad communication to the sensor board.

– there is an out of band condition, and the system is waiting for the

delay timer to expire.

•

- The burner is out of band. Status Disabled – The board has been

disabled.

•

•

- There is a critical alarm active.

– The critical alarm is active, but the alarm has been acknowledged.

The yellow icon signals that the burner is on high fire.

Super Systems Inc. Page 5 of 27 e-TRIM Operations Manual

Page 6

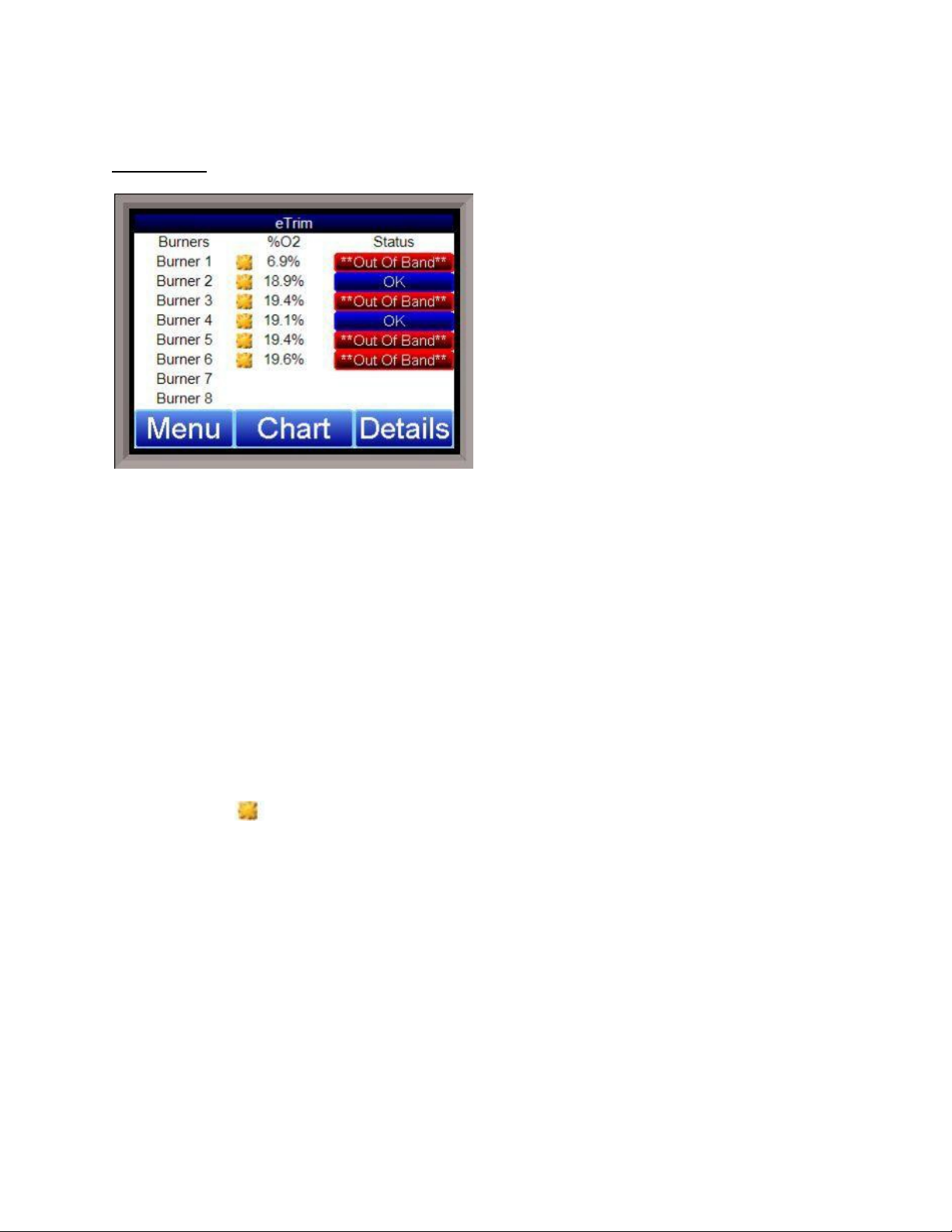

Details

NOTE:

Toggle

Close

time environment.

This will display a details screen for the e-TRIM system.

The

on the screen at one time, and each burner will have its oxygen reading and status displayed on

the screen. Clicking on the

Clicking on the

Clicking on the burner number will display some details about the specific burner: The board

address, baud rate, board version, TC type, TC temperature, Cold Junction temperature,

diagnostic, and percent oxygen.

Menu

This will display the menu, which will allow the user to configure the e-TRIM system. See the

section e-TRIM Menu for instructions on using the menu.

This manual was written with oxygen readings from the ambient air, not in a valid run-

Details

screen is basically an expanded version of the main screen. Four burners are shown

button will close the

button will display the next four burners, etc.

Details

screen.

Super Systems Inc. Page 6 of 27 e-TRIM Operations Manual

Page 7

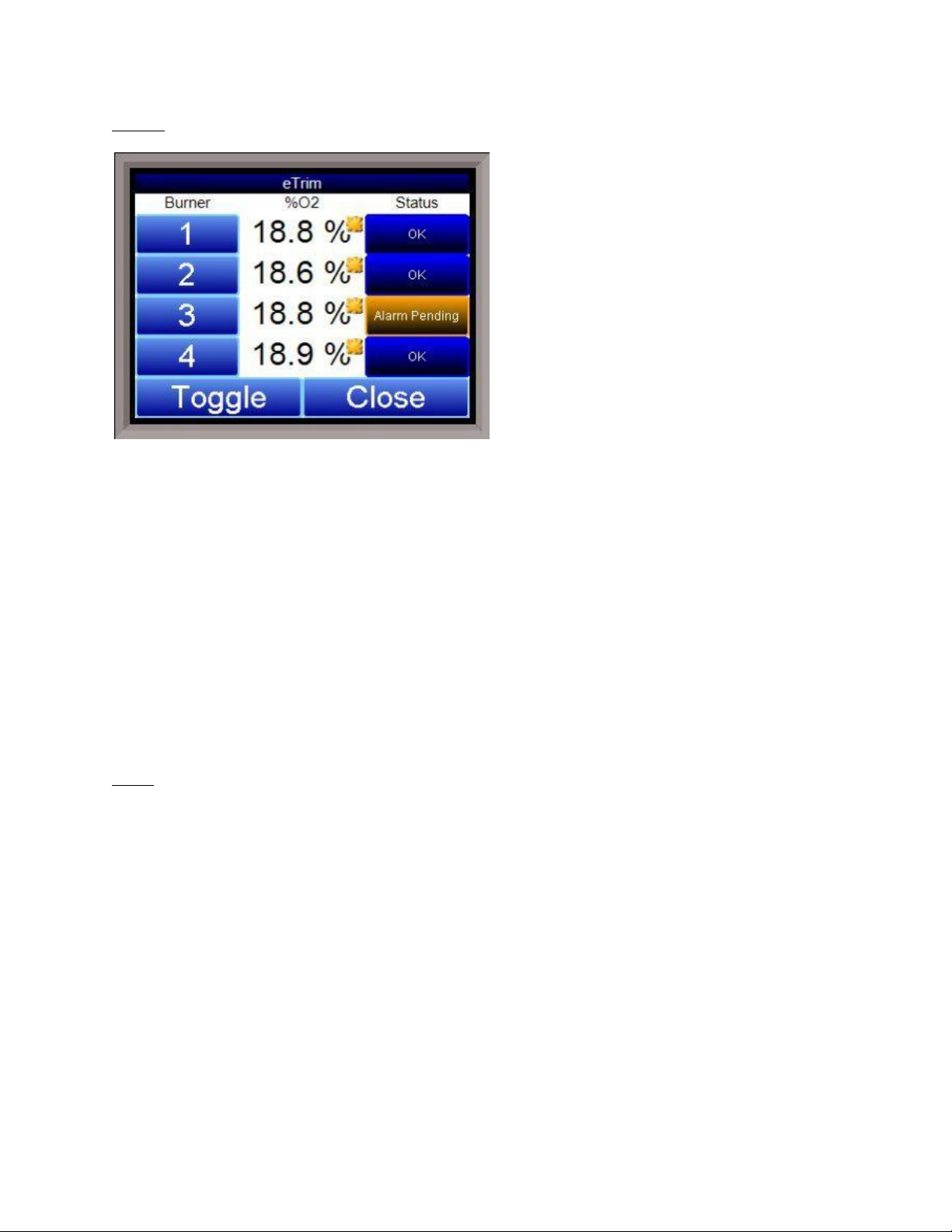

e-TRIM Menu

NOTE:

Toggle

Set

time environment.

This screen is the main menu for the e- TRIM system. Currently, there are seven options:

This manual was written with oxygen readings from the ambient air, not in a valid run-

• Offset

• Status

• System Setup

• Board Setup

• Burner Zones

• Shutdown

• Close

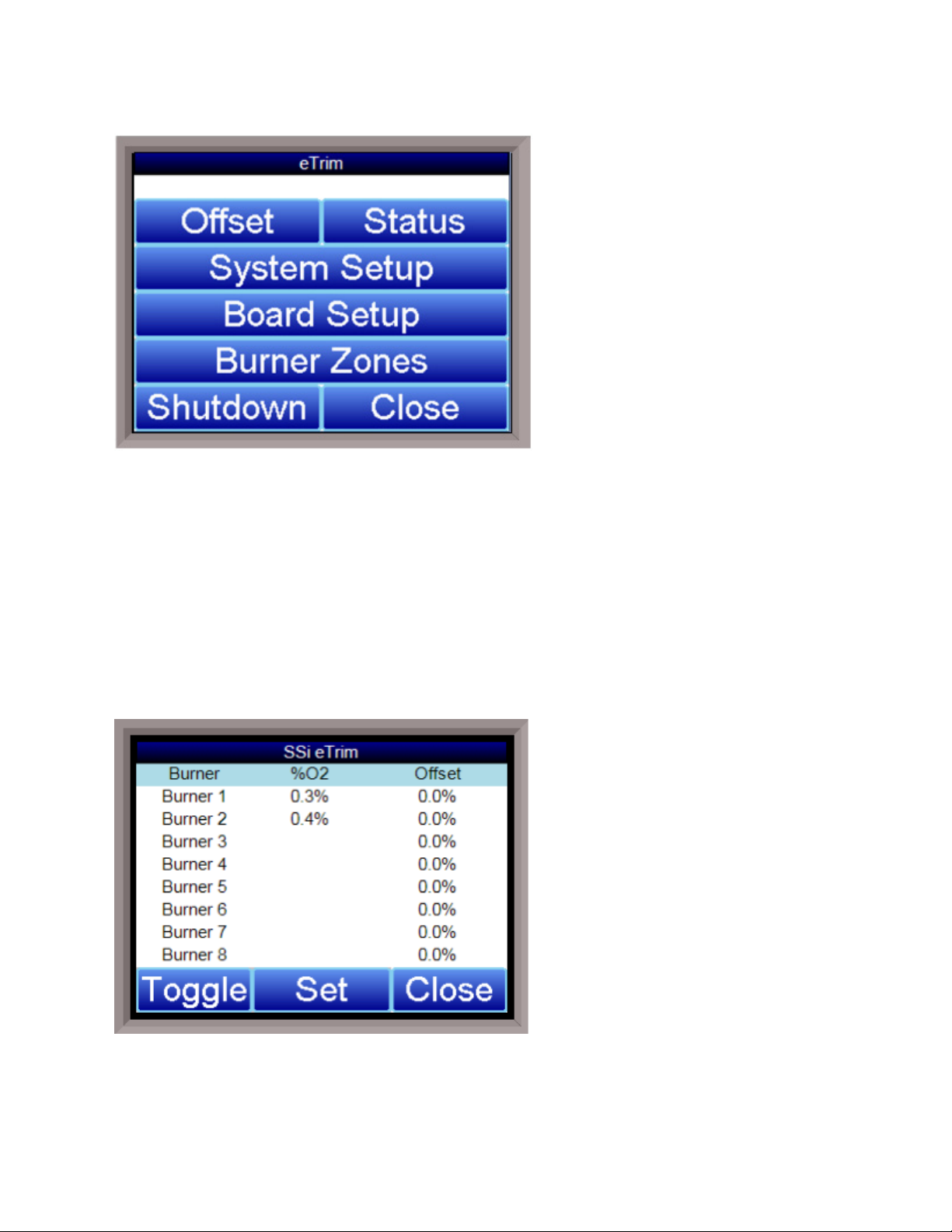

Offset

The offset screen displays the %O2 and Offset percentage for eight burners at a time. Pressing

the

press the

Super Systems Inc. Page 7 of 27 e-TRIM Operations Manual

button will show the other eight burners. To change the offset of one of the burners,

button and select the burner number.

Page 8

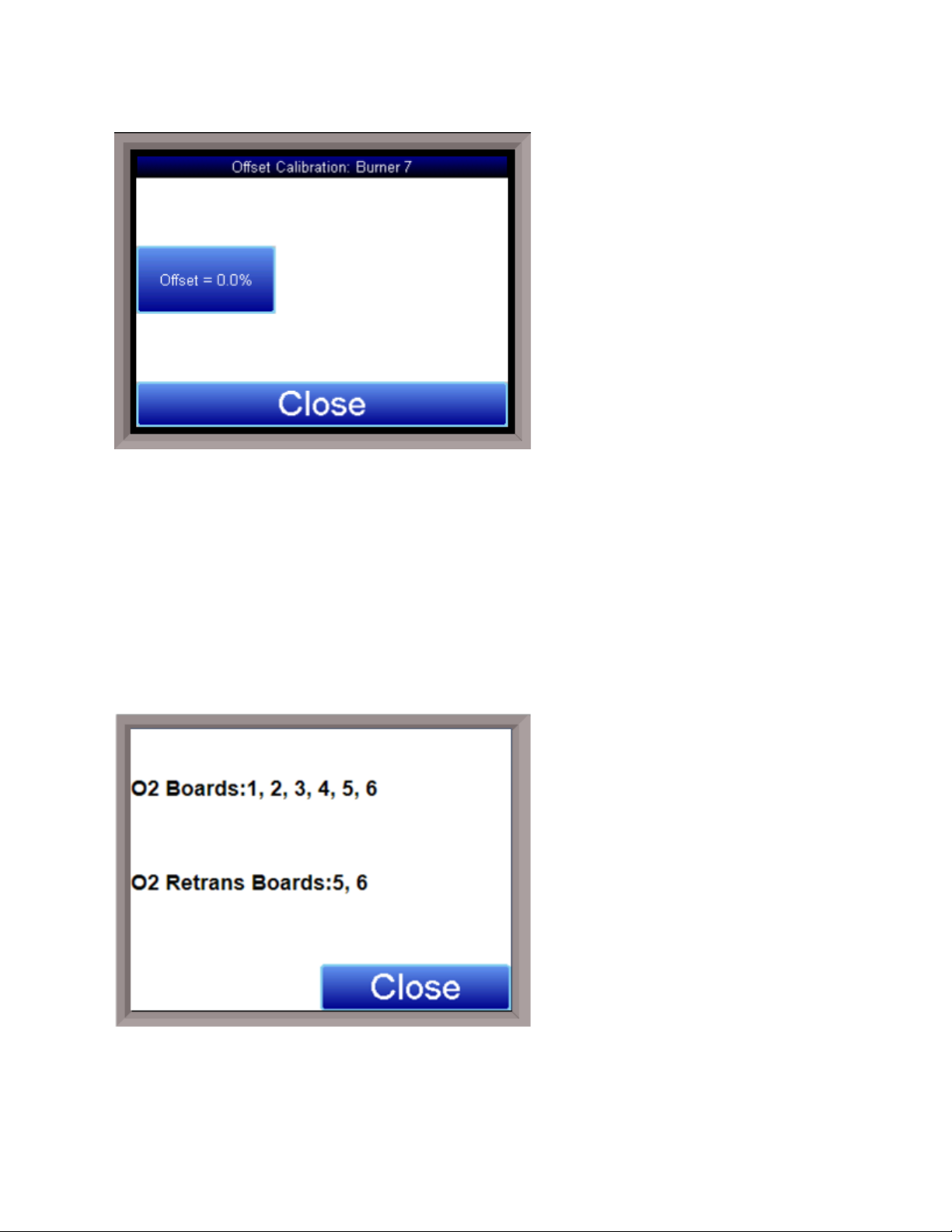

This screen will display:

Offset=

-20.9%

20.9%

Click the

This option will allow the user to enter an offset for each specific burner to match an external

calibration source such as a hand held oxygen monitor. Adjustments should only be made when

on high fire for more than 120 seconds.

To change an offset for a specific burner, select the burner from the drop-down list. The button

below the list will show the current offset. Click on this button to change the offset. The range

is

to

button to enter the offset percentage. Click OK to save it.

.

Status

Status

The

the controller.

Super Systems Inc. Page 8 of 27 e-TRIM Operations Manual

screen shows the addresses of the connected boards that are communicating with

Page 9

The O

0 to

60,000 seconds (0 minutes to 1,000 minutes)

NOTE:

Master High Fire, Individual High Fire,

Editable

Zones

Boards are the active circuit boards that are obtaining the oxygen measurement from

2

each sensor.

The O

Retransmission Boards (optional) are the circuit boards that provide an analog output (4-

2

20mA) of the oxygen measurement from each sensor. The electrical connections should be

made in accordance with the electrical schematic located at the back of this manual, with 4 to

20mA corresponding proportionally to 0 to 25% oxygen. The ability to retransmit the oxygen

signal requires circuit boards that are not part of the standard system. For additional

information regarding this feature, please contact Super Systems Inc. (513-772-0060).

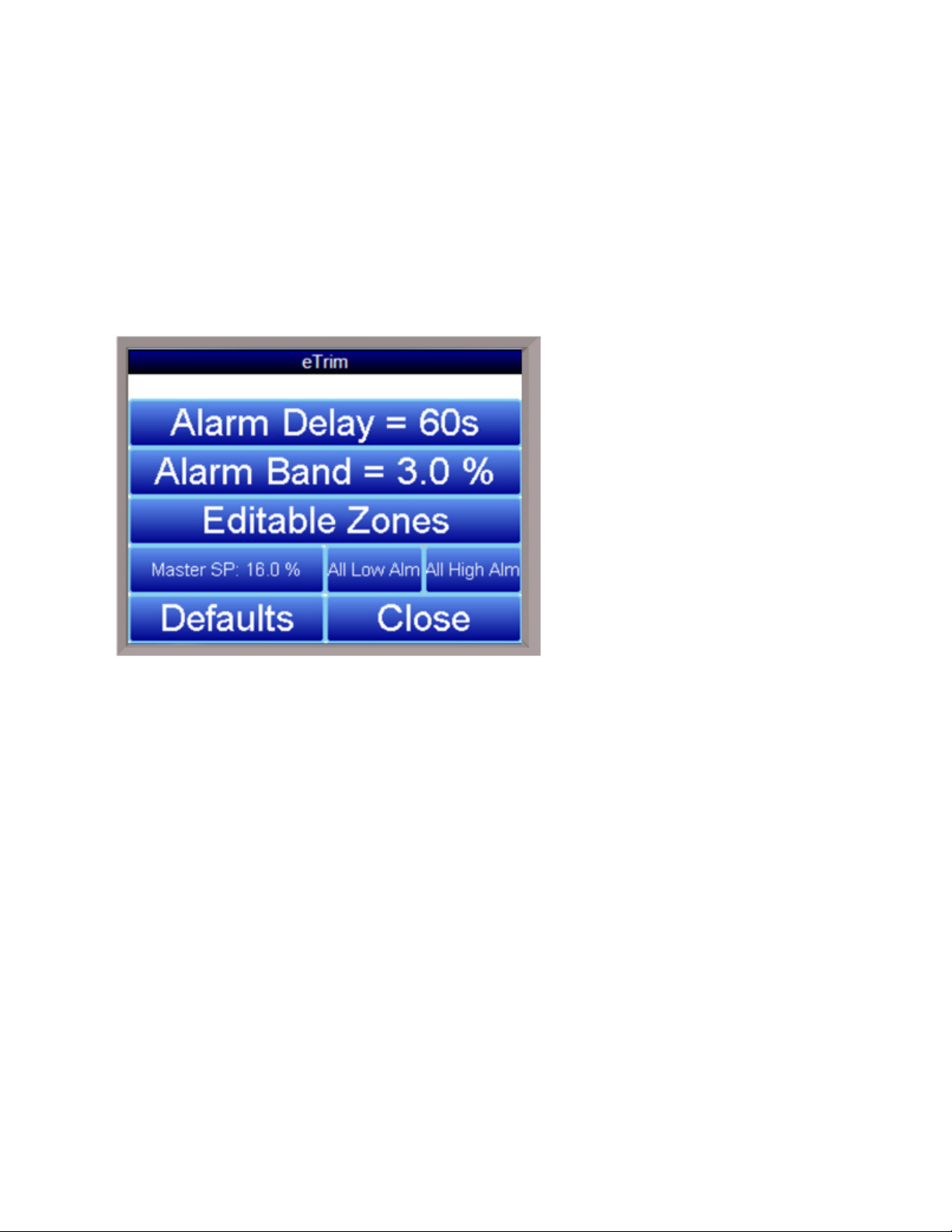

System Setup

This option will allow the user to make changes to the current system settings. Currently, there

are six options to modify.

Alarm Delay

This setting is the number of seconds that the system will wait before showing an out of band

alarm condition, if an alarm condition is present. This is entered in seconds. The range is

.

Alarm Band

This setting is the band for the boards’ setpoint. If the setpoint is 3%, and the band is 2%, then

an alarm indication condition will not be present until the reading goes under 1% or above 5%.

This is entered in percentages. The range is 0% to 20.9%.

The alarm band will not

sound the horn and is for indication only. Output 7 can be wired to an external horn or light if

needed (see the electrical prints for termination details).

Master High Fire/Individual High Fire/Editable Zones

Clicking on this button will toggle between

. The Master High Fire setting will allow the controller to see the one digital input signal

and

as a high fire signal for all burners. Individual high fire will put the burners in groups of 4, each

group being a separate zone. Editable Zones will allow the user to determine the burner and

zone configuration. The high fire digital input is required for the e-TRIM system to provide band

Super Systems Inc. Page 9 of 27 e-TRIM Operations Manual

Page 10

alarm and critical alarm information. The default setting is master high fire. The master high

0%

20.9%

IMPORTANT:

Low Alarm

High Alarm

Active anytime, not just during high fire

Only active during high fire

A 0 (zero) setpoint blocks the alarm; alarm

disable does not block the alarm

Alarm disable blocks the alarm

fire contact is terminal 1270 to terminal 1340, as shown in the electrical drawing in “Appendix C

– Electrical Drawings (For Reference ONLY)”. See the electrical prints for more termination

details.

Master SP: 3.0%

This setting will control the master setpoint for the burners. This setting will set the desired

setpoint for all of the burners at once. This is entered in percentages. The range is

. A setpoint of 0% will disable the master setpoint and allow the individual burners to use

their setpoints.

All Low Alarms (All Low Alm)

This allows the controller to edit the low alarms for all 16 burners at once. They can be

changed individually through the Board Setup option. See IMPORTANT note below.

All High Alarms (All High Alm)

This allows the controller to edit the high alarms for all 16 burners at once. They can be

changed individually through the Board Setup option. See IMPORTANT note below.

Note the following about Low Alarm and High Alarm characteristics:

to

Note that the default critical high alarm value is 8%. The default critical low alarm value is 0%

(disabled).

Defaults

This will return all of the settings to the factory default settings. The user will have to confirm

this action before the defaults are set.

Close

This will close the

System Startup

screen.

Board Setup

This option will allow the user to make changes to each of the boards and their setup

parameters.

Super Systems Inc. Page 10 of 27 e-TRIM Operations Manual

Page 11

Board 1 – Board 16

0%

20.9%

0

10,000 seconds

Burner Active

Burner Inactive

The user will have to select the board to modify from the “Select Burner” list that appears after

Board Setup is selected (see screen shot above). The options are

.

Once the burner is selected, the screen above appears, allowing the user to change

configuration on that board.

Setpoint

This will modify the individual setpoint for control (not currently available). This setting is the

desired amount of oxygen for the burners. This is entered in percentages. The range is

.

to

Trim Delay

This setting will affect how long the system waits before activating any alarms, if necessary, or

the control trim. Since it takes a few seconds for the burner combustion gasses to reach the

sensor, the trim delay holds off any action until the sensor is truly seeing the gasses. This is

entered in seconds. The range is

.

to

Burner Active/Burner Inactive

This setting will modify whether the selected burner is active or inactive. Clicking on this option

will toggle between

and

.

Super Systems Inc. Page 11 of 27 e-TRIM Operations Manual

Page 12

Alarm Enabled

Alarm Disabled

0

100

0

100

Edit

Alarm Enabled

This setting will modify whether the selected burner’s Band alarm is active or inactive. An

inactive alarm will not sound if an alarm condition is present. Clicking on this option will toggle

between

Low Alm

This will modify the low alarm setpoint. This alarm will sound when the amount of oxygen is

lower than the value indicated when the high fire input is wired to the external high fire contact.

The low alarm will sound when there is a low amount of oxygen being read, which could mean

that too much fuel is being consumed or there is an extremely rich environment. This is entered

in percentages. The range is

High Alm

This will modify the critical alarm setpoint. This alarm will sound when the amount of oxygen

exceeds the value when the high fire input is wired to the external high fire contact. The critical

alarm will sound when there is a high amount of oxygen being read, which could mean that a

burner is not lit, or there is an extremely lean environment. This is entered in percentages. The

range is

to

.

and

to

.

.

Close

This will close down the

Board Setup

menu.

Burner Zones

This option will allow the user to view all the burners and their corresponding zones. To change

the zones, press the

button, and choose the proper burner number. Enter the new zone

Super Systems Inc. Page 12 of 27 e-TRIM Operations Manual

Page 13

and press OK. Note that Editable Zones must be configured in the System Setup menu in order

to edit the burner and zone settings.

Edit

This option will allow the user to select the burner and set the zone.

Close

This will close down the Burner Zones menu.

Shutdown

This option will show the e-TRIM Touchscreen software down and display the Windows CE©

desktop. This option is useful if the user needs to make any changes to the Touchscreen itself,

or if the user is removing the memory card from the Touchscreen for data transfer.

Close

This option will close the menu screen and return the user to the main screen.

Super Systems Inc. Page 13 of 27 e-TRIM Operations Manual

Page 14

NOTE:

Chart

time environment.

This will display a chart of the data points for the e-TRIM system. Currently, the data points that

are logged are the Oxygen readings for up to sixteen burners. Each oxygen reading will be a

separate line and color on the graph.

The red line on the graph will act as a cursor. Holding down the stylus on the red line and

moving to the left or the right will modify the time on the bottom of the chart and update the

oxygen values displayed.

The red “X” in the top right corner will close the

The date for display can be changed by clicking on the down arrow next to the date in the top left

corner.

The beginning time for the display range will be listed in the bottom left corner of the chart. The

middle of the display range will be listed in the center of the chart. The chart will always use

the current system time as the starting point for the display range. If the range is 8 Hours, then

the time in the left corner of the chart will be 8 hours ago, and the time in the middle of the

chart will be 4 hours ago. If the range is 12 Hours, then the time in the left corner of the chart

will be 12 hours ago, and the time in the middle of the chart will be 6 hours ago.

If the user holds the stylus or their finger down on the white area of the chart for three (3)

seconds, a sub chart menu will be displayed.

This manual was written with oxygen readings from the ambient air, not in a valid run-

Chart

screen.

Super Systems Inc. Page 14 of 27 e-TRIM Operations Manual

Page 15

fx

Cancel

The button on the left - - is the Trend Lines button. This button will allow the user to

select which trend lines (data points) to display on the chart, as well as view statistics for each

data point. Note – Removing a trend line from display does not stop logging the data for that

point. If the checkbox is checked, that data point will be displayed on the chart. If the checkbox

is unchecked, the data point will not be

displayed. Clicking on the check box will

toggle between checked and unchecked.

The “

” button will display the statistics for

the selected data point. The statistics that

are displayed are: the name of the data

point, the minimum value for the date/time

range, the maximum value for the

date/time range, the number of data points

in the date/time range, the average value

for the date/time range, and the standard

deviation for the date/time range.

The OK button will save any changes made and close down the Trend Lines screen. The

button will simply close down the Trend Lines screen and not save any changes that have been

made.

- is the datagrid button. This will

display all of the data points for the trend

lines in a column format. The date/time

range for the display will be the same as

the date/time range for the chart.

- is the undo button. This will

undo any zooming on the chart and return it to the original aspect.

Super Systems Inc. Page 15 of 27 e-TRIM Operations Manual

Page 16

- will move the chart display back in the past by half of the display range. For example, if

the display range is 12 Hours, then clicking on this button will display six more previous hours.

- will allow the user to change the display time range for the chart. The options are:

1 hour

2 hours

4 hours

8 hours

12 hours

24 hours

- will move the chart display forward in the future (up to the current time) by half of the

display range. For example, if the display range is 12 Hours, then clicking on this button will

display the next six hours.

- will put the chart into real-time mode. When in realtime mode, the chart cursor (red

line) will move to the far right of the chart and display those values. Once a minute, these values

will be updated as the time refreshes.

Super Systems Inc. Page 16 of 27 e-TRIM Operations Manual

Page 17

Chart Sub Menu

Zoom,

Restore, Add Note, Data,

Exit

Zoom

Restore

Add Note

Add Note

Data

Exit

There is a sub-menu available by putting a finger or a stylus anywhere on the chart and holding

it there for a couple of seconds. The sub-menu will have the following options available:

and

.

The

option will allow the user

to zoom in on a particular part of

the screen. Once this has been

selected, the user can take a stylus

or a finger and create a box around

the desired data. Once the user

releases the stylus or finger, a

zoom is no longer possible, and the

user will need to re-select the

option from the sub-menu to zoom

in again.

The

option will back out of any zoom

options that have been performed and display

the chart screen as it initially was.

The

option allows the operator to

enter a note on the chart, similar to writing on

a paper chart. The note shows up when the

chart is printed out using the utility software

included with the SERIES 9130

instrumentation. Pressing the

option

displays a screen where the operator can

enter the operator ID or initials and a note.

The user has the option to enter a note using the operator interface keyboard, where he or she

will be able to type in the note; or the user can use the Signature mode, which will allow them to

write a note using a stylus.

The

option will show the trend data as a data grid instead of the trend lines on a chart. This

functionality is exactly the same as if the user pressed the Datagrid View button - - from

the chart screen.

will close out the sub-menu without selecting an item.

Super Systems Inc. Page 17 of 27 e-TRIM Operations Manual

Page 18

Warranty

Limited Warranty for Super Systems Products:

The Limited Warranty applies to new Super Systems Inc. (SSI) products purchased direct from

SSI or from an authorized SSI dealer by the original purchaser for normal use. SSI warrants

that a covered product is free from defects in materials and workmanship, with the exceptions

stated below.

The limited warranty does not cover damage resulting from commercial use, misuse, accident,

modification or alteration to hardware or software, tampering, unsuitable physical or operating

environment beyond product specifications, improper maintenance, or failure caused by a

product for which SSI is not responsible. There is no warranty of uninterrupted or error-free

operation. There is no warranty for loss of data—you must regularly back up the data stored on

your product to a separate storage product. There is no warranty for product with removed or

altered identification labels. SSI DOES NOT PROVIDE ANY OTHER WARRANTIES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME JURISDICTIONS DO

NOT ALLOW THE LIMITATION OF IMPLIED WARRANTIES, SO THIS LIMITATION MAY NOT APPLY

TO YOU. SSI is not responsible for returning to you product which is not covered by this limited

warranty.

If you are having trouble with a product, before seeking limited warranty service, first follow the

troubleshooting procedures that SSI or your authorized SSI dealer provides.

SSI will replace the PRODUCT with a functionally equivalent replacement product,

transportation prepaid after PRODUCT has been returned to SSI for testing and evaluation. SSI

may replace your product with a product that was previously used, repaired and tested to meet

SSI specifications. You receive title to the replaced product at delivery to carrier at SSI shipping

point. You are responsible for importation of the replaced product, if applicable. SSI will not

return the original product to you; therefore, you are responsible for moving data to another

media before returning to SSI, if applicable. Data Recovery is not covered under this warranty

and is not part of the warranty returns process. SSI warrants that the replaced products are

covered for the remainder of the original product warranty or 90 days, whichever is greater.

Super Systems Inc. Page 18 of 27 e-TRIM Operations Manual

Page 19

Appendix A – e-TRIM Modbus Registers

11

Active burner bitmap

15

Master Setpoint (2 decimal places)

16

Deviation alarm band setpoint (2 decimal places)

17

Out of band alarm delay time

18

Alarm disable bitmap

19

Alarm bitmap, burners 1 - 16.

20 - 35

O2 readings, sensors 1 - 16, 2 decimal places.

68 - 83

High Fire ON, sensors 1 - 16.

116 - 131

O2 trim delay, sensors 1 - 16.

132 - 147

O2 trim interval time, sensors 1 - 16.

148 - 163

O2 alarm state, sensors 1 - 16.

0 = normal, 1 = bad communications, 2 = out of and pending, 3 = out

164 - 179

Alarm delay timer (sec), sensors 1 = 16.

180 - 195

O2 offset, sensors 1 - 16.

220 - 235

Slave communications status, boards 1 - 16. 0 = bad

communications, 4 = OK.

460

Critical alarm bitmap

477 - 492

Critical alarm set point, sensors 1 - 16.

493

Critical alarm acknowledge. 1 = acknowledged.

600

High fire total time (sec), sensor 1

601

High fire total time (hr), sensor 1

602

Low fire total time (sec), sensor 1

603

Low fire total time (hr), sensor 1

604

High fire timer, sensor 1

605

Low fire timer sensor 1

606 - 611

Timers for Sensor 2

612 - 617

Timers for sensor 3

618 - 623

Timers for sensor 4

624 - 629

Timers for sensor 5

630 - 635

Timers for sensor 6

636 - 641

Timers for sensor 7

The following list is a description of the relevant Modbus registers in the e-TRIM system. For

communications, the e-TRIM supports Modbus on the Host 485 port and ModbusTCP through

Ethernet.

14 Modbus address

of band.

461 - 476 Critical alarm, sensors 1 - 16.

642 - 647 Timers for sensor 8

Super Systems Inc. Page 19 of 27 e-TRIM Operations Manual

Page 20

648 - 653

Timers for sensor 9

654 - 659 Timers for sensor 10

660 - 665

Timers for sensor 11

666 - 671

Timers for sensor 12

678 - 683

Timers for sensor 14

690 - 695

Timers for sensor 16

672 - 677 Timers for sensor 13

684 - 689 Timers for sensor 15

Super Systems Inc. Page 20 of 27 e-TRIM Operations Manual

Page 21

Appendix B – Spare Parts List

31296

3.5" Touch Screen

13562

e-TRIM Controller

13584

e-TRIM Sensor Cable

31430

Oxygen Sensor

31594

Oxygen Sensor Control Circuit Board

31621

4-20 mA Output Board

The following is a list of spare parts, with SSi part numbers, for the e-TRIM system.

Super Systems Inc. Page 21 of 27 e-TRIM Operations Manual

Page 22

Appendix C – Electrical Drawings (For Reference ONLY)

Super Systems Inc. Page 22 of 27 e-TRIM Operations Manual

Page 23

Super Systems Inc. Page 23 of 27 e-TRIM Operations Manual

Page 24

Appendix D – Typical Installations Based on Application

The following pictures show typical installations based on common e-TRIM applications. Your

installation requirements may vary; the pictures in this section provide examples only and

should not be used as instructional pictures.

Typical Setup of e-TRIM with BIQ Furnace

Typical BIQ Furnace Installation

Close-Up of BIQ Sensor Installation with Top Exhaust

Super Systems Inc. Page 24 of 27 e-TRIM Operations Manual

Page 25

Typical Setup of e-TRIM with Continuous Furnace

Typical Continuous Furnace Installation

Close-Up of Continuous Furnace Sensor Installation

Super Systems Inc. Page 25 of 27 e-TRIM Operations Manual

Page 26

Example Setup of e-TRIM in a Custom Installation

Example Custom Installation

Super Systems Inc. Page 26 of 27 e-TRIM Operations Manual

Page 27

Revision History

Rev.

Description

Date

MCO #

-

Initial Release

6/11/2010

N/A

A

Changed the “alarm delay” to “trim delay” in the

registers (Appendix A)

6/23/2010

2076

B

Updated Screen Shots & descriptions, added new

info

10/31/11

2086

C

Updated specification to include the Quad board

Changed screen shots as needed

1/18/2013

2108

D

Added warning related to exposure of electronics

warranty information.

05/20/2015

2162

overview section; Changed the “Trim Delay”

description; Changed the “Alarm Enabled”

description; Modified some of the Modbus

photo, added electrical drawings, added high fire

for the 4-20mA retransmission and/or control

Updated the wiring diagram to identify which

digital input is for the master high fire

Updated manual text to cover new screen options

enclosure to high temperatures, as well as

electronic enclosure mounting. Added default

values for critical low alarm and critical high

alarm. Added example installation pictures for

typical applications. Updated parts list. Added

Super Systems Inc. Page 27 of 27 e-TRIM Operations Manual

Loading...

Loading...