Page 1

eFLO

ELECTRONIC GAS

FLOW METER

OPERATIONS MANUAL

Super Systems Inc.

www.supersystems.com

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

Page 2

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 2 of 25

Super Systems Inc.

Super Systems Europe

Super Systems Mexico

Super Systems China

USA Office

Corporate Headquarters

7205 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Sistemas Superiores Integrales S de RL de CV

Querétaro, QRO CP, MEXICO 76120

Phone: +52 (442) 410 9040

http://www.supersystems.com

Units 3 & 4, 17 Reddicap Trading Estate,

Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627

http://www.supersystemseurope.com

No. 335 XianXia Road

Room 308

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.com

Page 3

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 3 of 25

Table of Contents

Introduction ..................................................................................................................................... 4

Safety Information ....................................................................................................................... 4

Specifications .................................................................................................................................. 4

Replacement Parts ......................................................................................................................... 5

Installation Procedure .................................................................................................................... 6

Mechanical Installation ............................................................................................................... 6

Electrical Connections ................................................................................................................ 7

Modbus Registers ........................................................................................................................... 8

Operating Procedure....................................................................................................................... 9

Valve Control Mode ....................................................................................................................11

Setpoint Control and Adjustment ...............................................................................................11

Flow Limit Control (Automatic Mode) ........................................................................................12

Flow Alarm .................................................................................................................................13

Flow Rate Totalizer ....................................................................................................................14

Setup ..........................................................................................................................................14

Maintenance ...................................................................................................................................14

Zero Calibration .............................................................................................................................15

Flow Rate Calibration ....................................................................................................................15

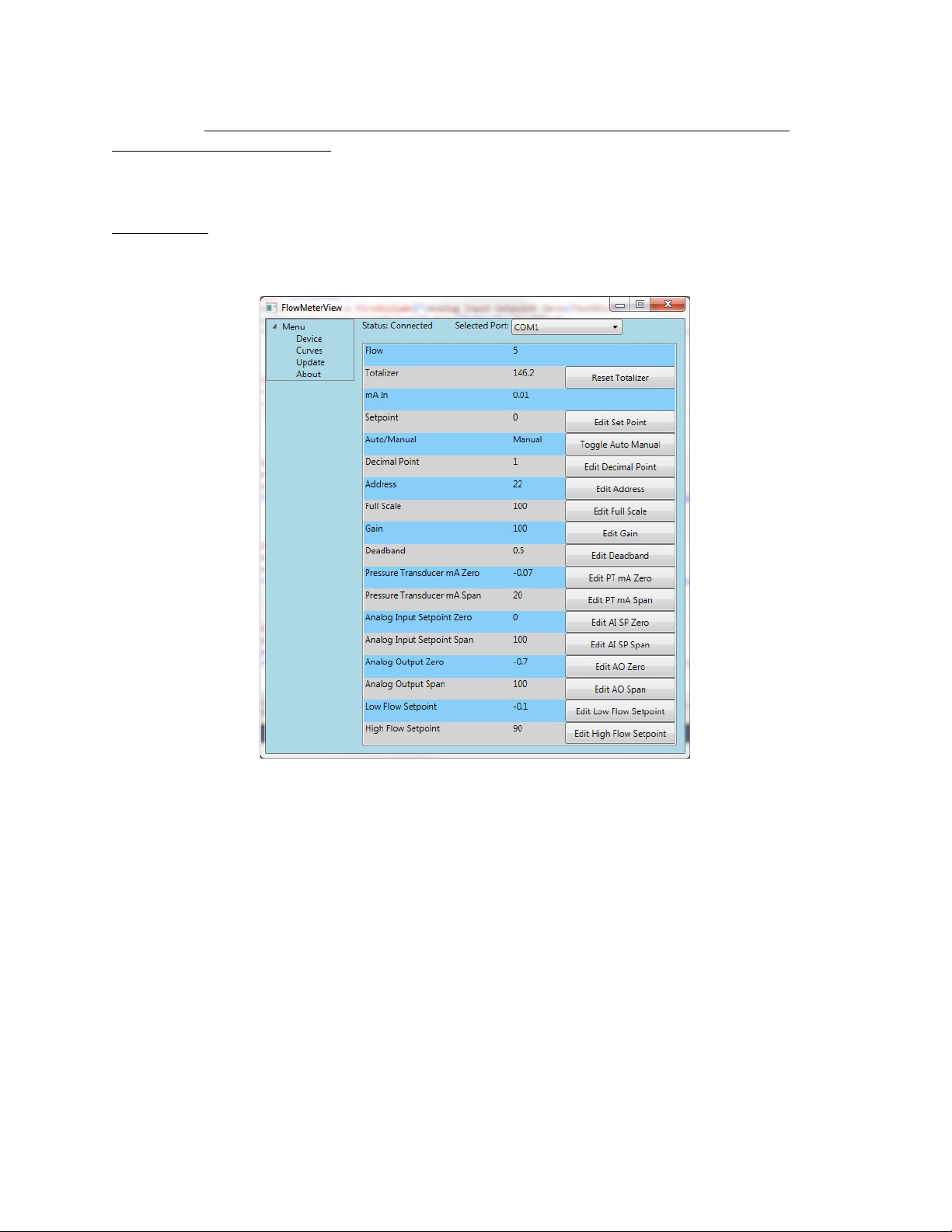

Configuration and Control Software: FlowMeterView ...................................................................17

Prerequisites and Installation ....................................................................................................17

Operation ....................................................................................................................................17

Device Menu ...............................................................................................................................18

Curves Menu...............................................................................................................................19

Update Menu ..............................................................................................................................20

About Menu ................................................................................................................................20

Troubleshooting .............................................................................................................................21

Warranty.........................................................................................................................................23

Revision History .............................................................................................................................24

Appendix 1: Electrical/Wiring Diagram .........................................................................................25

Page 4

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 4 of 25

Introduction

eFlo

FlowMeterView

WARNING!

manual. Exceeding specified values could result in hazardous conditions.

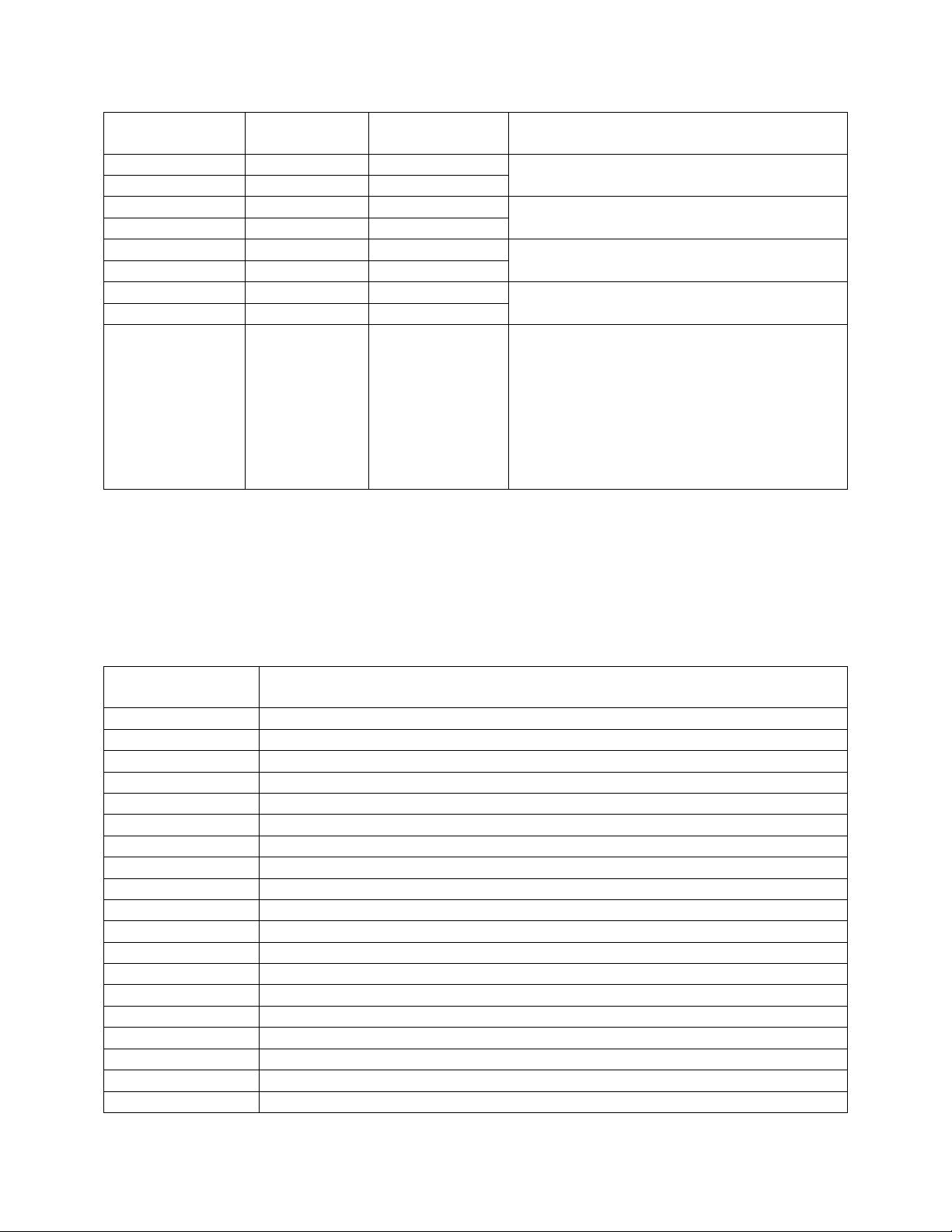

Specifications

Power Required

24 VDC @ 400 mA

Accuracy

4%

Repeatability

2%

Turndown Ratio

6:1

Medium Temperature Limits

-10°F to 150°F (-20°C to 65°C)

Figure 1 - eFlo 3-

dimensional angled

view

The

instrument is Super Systems Inc.’s electronic flow meter. eFlo

works by measuring the differential pressure (the difference in pressure

of a gas at two points) of a gas flowing through a specially designed

opening in the gas flow assembly. Based on properties of the flowed gas,

the differential pressure can then be used to calculate the flow rate of

the gas.

The eFlo features built-in high and low flow rate alarms and a flow rate

totalizer. The gas flow valve can be operated in manual mode or

automatic mode. Automatic mode allows the eFlo to use a flow rate

setpoint as a basis for adjusting the valve (and thus the gas flow) using a

built-in valve motor. The setpoint can be programmed manually by the

user or obtained by the instrument from a 4-20mA analog signal or

digital signal over RS485.

eFlo is part of SSi’s Flow Meter lineup, which also includes the FLO-

®

SCOPE

manual flow meter.

This manual also covers the configuration and control software provided

with the eFlo meter: SSi

.

Safety Information

Observe the following safety requirements when configuring, operating,

servicing, or maintaining the eFlo instrumentation.

The eFlo instrument is NOT guaranteed to provide gas shutoff, nor is it designed to do so. For

reliable gas shutoff, incorporate a valve that provides positive gas shutoff. Ensure that all gas

flow equipment is in compliance with National Fire Protection Agency (NFPA) requirements,

including those found in NFPA 86. Failure to follow these requirements could result in

flammable gas leaks into the unit.

Ensure that the air and gas mixture ratio settings are within the specifications provided in this

The specifications for the eFlo instrument are as follows.

Page 5

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 5 of 25

Ambient Temperature Limits

-10°F to 150°F (-20°C to 65°C)

Flow Output Signal (Linear)

4-20mA

Maximum Output Signal Load

500Ω

Input Control Signal (Linear)

4-20mA

Response Time

1 – 10 seconds

Communications

RS232, RS485

Communication Protocol

Modbus RTU

Pressure Drop @ 100% Capacity

drop.

5” wcg (Standard Model)

Flow Meter Pressure Limits

Report for more details.

5 psig – maximum allowable

Table 1 - eFlo Specifications

Replacement Parts

Part Number

Item

Explanation

33149

Motor and Shaft

Drives the Valve Needle open and

flow.

34224

O-Ring, eFlo Body & Plate

O-ring that seals the three

Bottom Plate, and Motor Plate.

37315

O-Ring, eFlo Valve Needle Shaft

O-ring that seals the Valve

Plate.

37321

Gasket, eFlo Motor Plate

Gasket that seals the eFlo Motor

and Motor.

34603

Grommet, Cylinder Adjustment

Grommet on top of the Electronic

Housing.

34692

Calibration Test Ports

Two pressure ports located on

meter.

10” wcg (Standard Model)

See Calibration Report for specific pressure

The pressure will be calibrated to userspecified requirements. See the Calibration

Replacement parts can be ordered for the eFlo unit when and if needed. Contact SSi at (513)

772-0060 to order parts.

closed to maintain the correct gas

components of the eFlo Body

(upper, lower, and middle),

Needle Shaft against the Motor

Plate to the Motor Spacer Block

the side of the Body of the meter.

These ports allow the pressure

drop to be measured for

calibration verification of the

Page 6

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 6 of 25

Part Number

Item

Explanation

31182

Pressure Transducer

Measures the pressure drop

flow.

31542

Flow Board

The primary electronics board

input and output pins.

31657

Motor Control Board

The electronics board that

motor.

20823

Cable

6 foot pigtail for RS485, 4-20mA

if desired.

Table 2 - Replacement Parts List

Installation Procedure

through the Element and provides

that signal to the electronic

boards for calculation of the gas

containing all of the circuitry and

controls the operation of the

input, 4-20mA output and 24VDC

power. Note that use of the cable

is not mandatory: connections

can be made directly to terminals

Installing the eFlo unit consists of a mechanical installation and an electrical installation. The

mechanical installation includes mounting as well as inlet and outlet piping. The eFlo unit will

be assembled prior to shipment. Before beginning installation:

• Ensure that all fittings and connections are tightly secured prior to beginning

installation.

• Ensure that all expected components are present. Contact SSi at (513) 772-0060 if you

have questions.

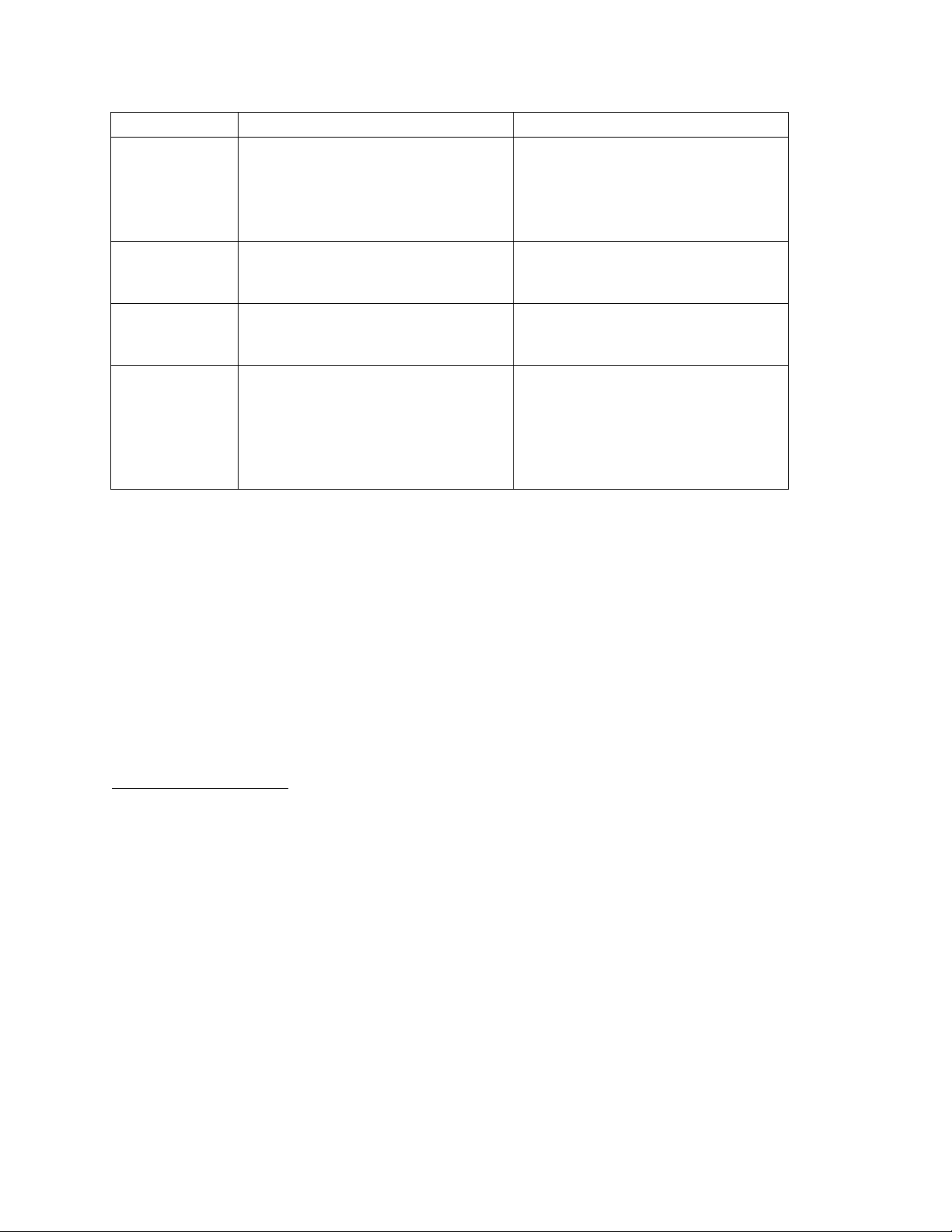

Mechanical Installation

Secure mounting is achieved by correctly and securely installing the required piping in the inlet

and outlet connections of the eFlo unit. Note the distance between the centers of inlet and

outlet openings is 8.3” (21.1cm). The outlet openings themselves measure 1.25” NPT. The

locations of these connections are shown in Figure 2. Use of bushings or reducers at these

connections is okay as long as the maximum flow rate can still be achieved. Contact SSi at (513)

772-0060 for questions about pipe sizing.

Page 7

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 7 of 25

Figure 2 - Flow Outlet and Inlet Connections

IMPORTANT!

board can be found in Appendix 1: Electrical/Wiring Diagram.)

8.30

5.00

1.40

Outlet Connection

Inlet Connection

(Opening: 1.25” NPT)

Ensure that the inlet pressure is within specified parameters for your eFlo unit.

Electrical Connections

The eFlo unit uses a male 9-pin D-Sub connector for electrical connections. The electrical

connections are defined in Table 3

(Opening: 1.25” NPT)

below. (An electrical/wiring diagram for the flow control

Page 8

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 8 of 25

9-Pin D-Sub Pin

Number

Wire-In Color

Signal Type

Description

1

Red

+ VDC

Power Supply 24 VDC (250 mA)

2

Black

- VDC

3

Green

+ mA

Output Flow Signal (4 – 20 mA)

4

White

- mA

5

Orange

+ mA

Input Setpoint Signal (4 – 20 mA)

6

Blue

- mA

7

Brown

+ RS485

Communications Signal provided by

8

Yellow

- RS485

9

Purple

24V Sinking

Flow Alarm Output

NOTE: The alarm current should have a

maximum current rating of 100mA. An

back diode should

be used if the output is driving an

inductive load (such as a contactor or

horn).

Table 3 - Electrical Connections

NOTE:

Modbus Registers

Modbus Register

Number

Description

16

Actual Flow

17

Flow Sensor mA Input Value

18

Flow Setpoint

19

Decimal Place for Display of Flow and Setpoint

20

Instrument Modbus Address

21

Flow Meter Full Scale Value

22

Control Gain

23

mA Zero Value

24

mA Span Value

25

Deadband for Control

26

Setpoint Zero

27

Setpoint Span

28

Not Used

29

Analog Output Zero in Flow Units

30

Analog Output Span in Flow Units

31

Not Used

32

Low Flow Alarm Setpoint

33

High Flow Alarm Setpoint

34

Alarms

Modbus over serial.

Output

If RS-232 is needed, an additional 9-pin D-Sub connector can be set up on the eFlo unit

prior to shipment.

The eFlo Modbus registers are as follows.

isolation relay with fly-

Page 9

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 9 of 25

Modbus Register

Number

Description

35

Auto (1) / Manual (0) for Control

36

(Not Used)

37

Reset Totalizer Values to Zero

38

(Not Used)

39

Totalizer Units (0 to 9999)

40

Totalizer in 10,000s (0 to 9999 -> 0 to 99,990,000)

41

Totalizer in 10,000,000s (0 to 9999 -> 0 to 999,900,000,000)

Table 4 - Modbus Registers and Descriptions

Operating Procedure

IMPORTANT!

The eFlo system is equipped with a flow rate alarm (high and low), flow rate totalizer, and

integrated valve control. The unit can be operated in either manual or automatic mode for flow

rate control. This section of the manual provides an explanation of how the unit is operated:

valve control modes, flow limit control, flow alarming, flow totalizing, and programming of the

unit.

For best long term results, it is recommended that pressure be maintained on the flow meter at

all times. Pressure can be maintained when the shut off solenoid/valve is downstream from the

outlet of the meter. This will ensure long term calibration and accuracy.

Figure 3 shows the layout of the flow control panel on the eFlo unit. An explanation of the

panel’s components is provided as well. The panel layout will be referenced further in this

section.

Page 10

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 10 of 25

Figure 3 - eFlo Flow Control Panel Layout

A – LED display

B – Status indicators

C – Totalizer button

D – Up button

E – Setpoint button

F – Reset button

By default, the LED display is used to display the

current flow. With different button combinations,

the LED display can also be used to show the

totalizer value, current setpoint, and Setup menu

options with associated settings. Alarm status

messages may also be displayed.

These are four lights that come on in various

situations.

Auto – When lit, the eFlo is in Auto valve control

mode. When not lit, the unit is in Manual valve

control mode.

Alarm – When lit, an alarm is active. This will be

a Low Flow Rate Alarm, a High Flow Rate Alarm,

or a Limit Switch Alarm.

Open – When lit, the valve is driving open.

Drive – When lit, the valve is driving. If this light is

illuminated, but the Open light is not, the valve is

driving closed.

When pressed and held, the Up button will increase the flow rate through the inlet connection

by opening the valve. This button can also be used in conjunction with other items, such as

Setpoint and Setup menu options.

When pressed and held, this button will show the current flow setpoint. By default, the setpoint

can be changed manually by pressing the up or down arrow to increase or decrease the setpoint

while the Setpoint button is being held. It is important to note that the setpoint cannot be

manually changed when the eFlo unit is obtaining a remote setpoint from another instrument.

The remote setpoint can be obtained using an analog or digital signal; it will overwrite any

manual input from the user. See the Setpoint Control and Adjustment on page 11 for more

details.

When pressed and held for five seconds, the Reset button will erase the current totalized flow

value and change it to zero.

When pressed and held, the totalized flow value

is shown. After being held for a few seconds, the

value will begin to scroll to the left to show the

full totalized numeric value.

Page 11

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 11 of 25

G – Down button

H – Auto/Manual button

I – Setup button

When pressed and held, the Down button will decrease the flow rate through the inlet

connection by closing the valve. This button can also be used in conjunction with other items,

such as Setpoint and Setup menu options.

This button toggles the Valve Control Mode between Auto and Manual. To change the current

mode, hold the button in for five seconds.

In Auto Valve Control Mode, the eFlo unit will automatically change the position of the valve. It

will drive the valve open or closed depending on the flow needed at any given time (for example,

in order to maintain setpoint).

In Manual Valve Control Mode, the position of the valve is determined by the operator using the

Up and Down arrows.

The Setup button will open the Setup menu when the button is held for five seconds. The options

are displayed on the LED screen. Scroll through the options by pressing the Setup button.

Change the values by pressing the Up and Down buttons. Change the values by pressing the Up

and Down buttons.

Refer to the Setup section below for more information.

Valve Control Mode

The Valve Control Mode can be either Auto or Manual. In Auto mode, the motorized valve will be

automatically adjusted. If the currently measured flow rate is lower than setpoint, the valve will

be driven open. If the currently measured flow rate is higher than setpoint, the valve will be

driven closed.

To change Valve Control Mode, hold the Auto / Manual button down for five seconds. The Auto

light will show which control mode is active. If the Auto light is illuminated, Auto mode is active.

If the light is not illuminated, Manual mode is active.

Setpoint Control and Adjustment

The setpoint can be controlled and adjusted using one of four methods:

1. Manually, by using the Setpoint button

2. By using a remote analog signal (4-20mA)

3. By using a remote digital signal with Modbus serial communications over RS485

4. By using the FlowMeterView software (refer to the Device Menu on page 18).

It is important to note that the remote setpoint setting overwrites any manual setting.

Therefore, if manual control of setpoint is desired, ensure that there is no external signal

overwriting the manual setting.

Page 12

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 12 of 25

IMPORTANT!

Flow Limit Control (Automatic Mode)

Adjusting the flow limit setting can result in erratic operation if the adjustment is performed

improperly. For this reason, it is recommended that the adjustment be performed by an SSi

technician or with technical support. For more information, contact SSi at (513) 772-0060.

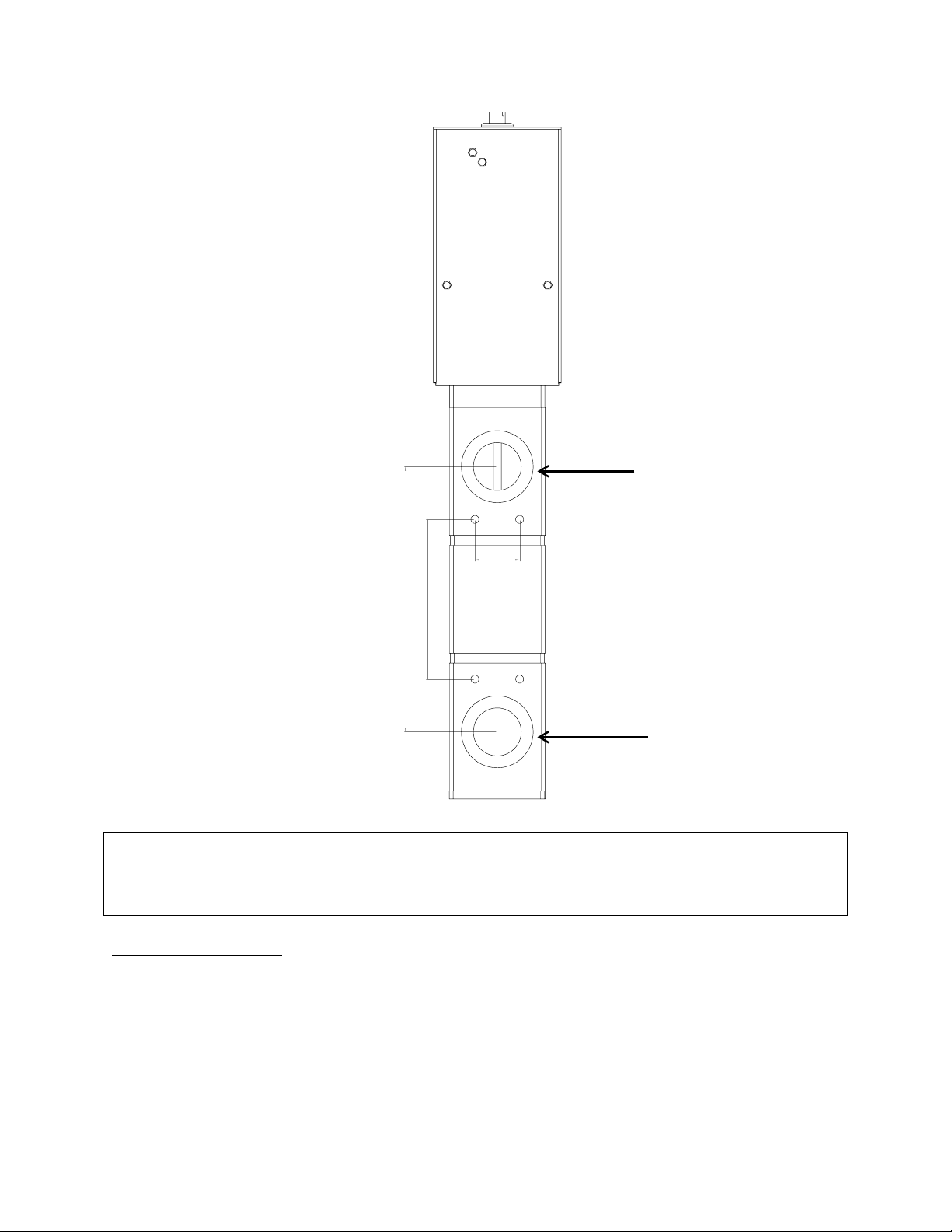

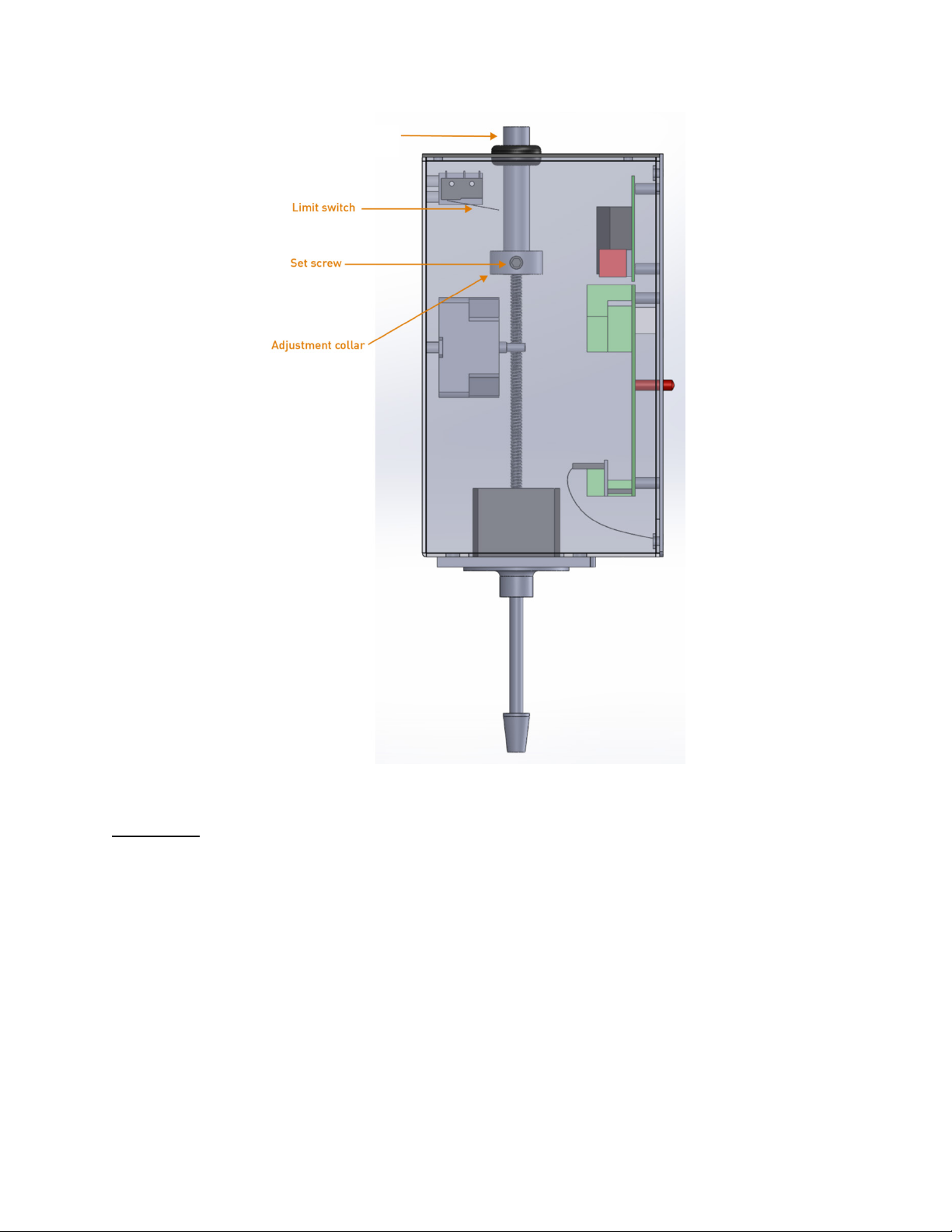

In Automatic Valve Control Mode, a mechanism is needed to prevent the control valve from

opening too far (if the value opens too far, damage to the motor could result). A limit switch on

the eFlo unit provides this mechanism (see Figure 4). This adjustment was completed during

calibration of the eFlo instrument. In the event that the adjustment collar was moved from its

factory set position, the steps below describe how to reset this collar to the proper position. To

set the limit switch to a proper setting for your application:

1. In the Automatic Valve Control Mode, set the eFlo control valve to allow for full flow

capacity as specified when the instrument was purchased. Allow the valve to reach the

maximum flow so that the motor stops moving.

2. Using a 1/8” hex wrench, loosen the adjustment collar and move it so that it is located

approximately 1/8” below the limit switch.

3. Tighten the set screw on the adjustment color to lock its position on the adjustment

cylinder.

4. Set the eFlo instrument to zero flow so that the adjustment lowers and the valve closes.

5. Again, set the eFlo instrument to full flow capacity. Observe the adjustment collar’s

location relative to the limit switch.

6. Verify that the adjustment collar has traveled to the same location (approximately 1/8”

from the limit switch), indicating the correct position of the collar.

7. Ensure that the set screw is tightened properly.

The limit switch should now be properly set.

Page 13

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 13 of 25

Figure 4 - Location of Manual Adjustment Cylinder, Set Screw, and Adjustment Collar

Adjustment cylinder

Flow Alarm

The eFlo meter incorporates a High Flow Alarm and Low Flow Alarm. Setpoints for these

alarms are set through a Modbus interface or by using SSi’s FlowMeterView software (provided

free of charge to eFlo users).

When the alarm is active, the Alarm light will turn on. A warning message will be displayed on

the LED screen.

In order to function properly, the flow alarm setpoints must be set prior to use of the eFlo unit,

and the alarm must be wired properly. The alarm current should have a maximum current

rating of 100mA. An isolation relay with fly-back diode should be used if the output is driving an

inductive load (such as a contactor or horn). See Appendix 1: Electrical/Wiring Diagram for

more information on wiring.

Page 14

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 14 of 25

GAIN:

DEAD

ADDR

ZERO

BAUD:

Maintenance

Do not apply pressure to the pressure transducer.

Flow Rate Totalizer

The eFlo meter’s flow rate totalizer records cumulative flow rates measured by the meter. The

totalizer is active at all times. The maximum totalized value is 999,999,999,999 (the unit of

measurement is any unit of flow measurement). To show the totalized value, press and hold the

Totalizer button. The totalized value will begin scrolling across the LED screen if the value is

greater than what the screen can display.

To reset the totalizer to zero, press and hold the Reset button for five seconds.

Setup

The Setup button will open the Setup menu when the button is held for five seconds. The options

are displayed on the LED screen. Scroll through the options by pressing the Auto/Manual

button. Change the values by pressing the Up and Down buttons.

The available options are as follows.

Gain is used to control the speed of valve response for automatic control. The higher the

value, the more quickly the valve will open and close. The lower the value, the more slowly it

opens and closes. The range for this value is 10 to 500.

(Deadband): Deadband is used to determine the area above and below the setpoint where

no control action will occur. If the deadband is too small, the control may oscillate around

setpoint. If the deadband is too high, the flow will not reach setpoint. The range for this value is

1 to the full scale flow value.

(Address): The Address is the RS485 Modbus address of the eFlo unit. The range for this

value is 1 to 249.

: The Zero value is the adjusted mA input from the pressure transducer. This value allows

the user to adjust the pressure transducer, which transmits a 4-20mA signal to indicate flow.

When no flow is present, the ideal value for the Zero value is 4.00mA (although the value will not

always be exactly 4.00). To change the Zero value, use the Up and Down buttons. To reset the

Zero value and remove any previous adjustments, press the Up and Down buttons

simultaneously. For more information, refer to the

The Baud is the serial baud rate. This value can be 9600 or 19200 (1920 represents

Zero Calibration section on page 15.

19200).

SSi recommends the following maintenance guidelines for the eFlo meter.

Clean any carbon or water from pressure transducer gas lines as needed. To do this:

1. Remove the rubber tubing from one side of the pressure transducer located in the

electronics enclosure. (Note that the two tubes plumbed to the pressure transducer

must not be switched; otherwise, the meter will not read properly.) The other end of the

tubing should be connected to the stainless steel tubing plumbed vertically along the

right side of the meter.

2. Apply air to the tubing to “flush” out any carbon and/or moisture, which may have

developed.

3. Reassemble the tubing to the pressure transducer port and repeat the procedure for the

other side of the pressure transducer.

Page 15

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 15 of 25

Zero Calibration

zero drift.

zero value

.

zero calibration

zero offset

Setup

Auto/Manual

first mA value

Down

first mA value

first mA value.

Down

Flow Rate Calibration

IMPORTANT!

have any questions, please contact SSi at (513) 772-0060.

4. Verify gas flow with manometer.

When the flow rate is set to zero, it is possible that drift can occur due to a pressure difference

on the inlet as compared to the factory calibration pressure setting This is called

One

way to avoid zero drift is to position the shutoff valve or isolation solenoid downstream of the

flow meter so that gas flows through the shutoff or isolation solenoid after entering the eFlo

inlet. This is the preferred shutoff/isolation method.

In the eFlo meter, there is an adjusted mA input based on the pressure transducer

measurement when the flow rate is zero. This mA value is known as the

zero value will be 4.00mA

present, a

the

to account for the pressure applied to the inlet at zero gas flow. The procedure is

In a situation where pressure is applied to the inlet but no flow is

in the field will often be required. Zero calibration involves changing

; ideally, the

as follows:

1. Press and hold the

2. Press the

button until the LED screen displays Configuration mode.

button to cycle through options until “ZERO” flashes on the

screen.

3. Note the

4. Using the Up and

value below the

NOTE: To remove any previous adjustments, press the Up and

shown on the factory Calibration Report.

buttons, change the displayed value to the

or a

buttons at the same

time.

The zero offset is now adjusted.

The following procedure is used for calibration of flow rate for the purpose of eFlo certification.

To ensure consistency and quality, it is recommended that this procedure be performed by SSi

personnel. SSi takes no responsibility for calibrations performed by non-SSi personnel. If you

For this procedure, you will need a calibrated manometer, a small standard screwdriver, and

the original Calibration Report for the eFlo unit.

1. On the left side of the unit (when facing it), you will notice two barb fittings. One is a high

pressure port and a low pressure port used for calibration. The high pressure port is the

lower port; the low pressure port is located above the high pressure port.

2. Using a small standard screwdriver, turn the small valve located in each pressure port

counterclockwise one full turn.

3. Connect a calibrated manometer to the test ports. Remember that the high pressure

port is the lower port; the low pressure port is located above the high pressure port.

4. Set the actual flow rate to a value tested on the original Calibration Report.

Page 16

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 16 of 25

NOTE:

5. Using the manometer, measure the actual differential pressure at the selected flow

rate. Compare the differential pressure to the differential pressure shown on the

Calibration Report.

6. If the actual differential pressure is within acceptable limits (±4% of the full scale value),

no action is necessary. If the actual differential pressure is not within acceptable limits,

adjust the zero/span potentiometers inside the differential pressure transducer. The

pressure transducer is located inside the black enclosure on top of the unit.

Typically, a 0.5”wc deviation equates to 5% flow error.

Page 17

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 17 of 25

Configuration and Control Software: FlowMeterView

IMPORTANT!

Before running FlowMeterView, ensure that the eFlo unit is connected to the computer using an

Device, Curves, Updates,

About.

Device;

Curves

Update

About

Status

Selected Port,

SSi’s FlowMeterView software is used to configure and control the eFlo meter via a serial

connection (RS232 or RS485). This software is provided free of charge to eFlo customers. If you

have an eFlo meter and need to obtain FlowMeterView, please contact SSi at (513) 772-0060.

Prerequisites and Installation

To run properly, FlowMeterView must be run on a computer with Windows XP or higher.

Windows 7 or higher is recommended. The computer on which FlowMeterView is running must

have a working serial port (either RS232 or RS485) for communication with the eFlo meter.

Finally, the eFlo meter must be configured for the serial communications standard that is being

used: RS232 or RS485.

To use FlowMeterView with the eFlo unit, you first need to install the software. To do this, run

the file

shipped with the eFlo unit. When you run the program, you will be prompted with a series of

steps. Administrator access may be required for proper installation of the program. Contact

your IT system administrator with system-related questions or SSi at (513) 772-0060 if you have

questions about the installation procedure.

Operation

setup.exe

. This is an installation and setup program and is usually supplied on a CD

RS232 or RS485 connection. Take note of the COM port number that the eFlo unit is connected

to on the computer.

To run the software, open FlowMeterView from the Windows Start menu. The shortcut for

FlowMeterView is typically found in the SuperSystems program group.

Once the software is running, you will see a window similar to the one pictured in Figure 5

FlowMeterView interface is designed to be straightforward. On the left-hand side of the window,

you will see menu options:

double-click on it. The default menu is

and values on the eFlo meter. The

save curves to the local computer, download the active curve from the meter, and upload a

curve to the meter. The

software updates and, if available, give you the option to download and install any updates. The

menu shows version information for the software as well as a change log.

At the top of the FlowMeterView window, you will see a connection

down menu,

menu, when selected, will cause the software to check for

that allows you to select the COM port for communication with the

menu allows you to adjust Calibration Curve points,

and

this menu is used to view and change settings

To select a menu option,

as well as a drop-

. The

Page 18

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 18 of 25

The correct COM port must be selected in order for the software to be able to

communicate with the meter

Device

Figure 5 - FlowMeterView Device Menu

Flow.

Totalizer.

Reset Totalizer

mA In.

Setpoint.

Edit Set Point

Auto/Manual.

Toggle Auto

Manual

Decimal Point.

Edit Decimal

Point

Address.

Edit Address

Full Scale.

Edit Full Scale

eFlo meter.

The menus are described in more detail in the following sections.

Device Menu

Using the

.

menu, you can view and change settings and values on the eFlo meter.

The settings and values that can be accessed in this menu are as follows:

•

The current flow rate read from the eFlo unit.

•

•

•

value.

•

•

•

that value.

•

you to change this value.

The current totalized flow.

The current milliamp value of the analog input signal.

The current flow setpoint.

The current setting for valve control mode: Auto or Manual.

changes the mode between Auto and Manual.

The number of decimal places used in the flow display.

allows you to change this value.

The RS485 Modbus address of the eFlo unit.

The maximum flow value to be measured by the meter.

resets the value to zero.

allows you to change the setpoint

allows you to change

allows

Page 19

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 19 of 25

Gain.

Edit Gain

Deadband.

Edit Deadband

Pressure Transducer mA Zero.

Edit PT mA Zero

NOTE:

Pressure Transducer mA Span.

Edit PT mA Span

Analog Input Setpoint Zero.

Edit AI SP Zero

Analog Input Setpoint Span.

Edit AI SP Span

Edit SP Zero

Analog Output Zero.

Edit AO Zero

Analog Output Span.

Edit AO Span

Low Flow Setpoint.

Edit Low Flow Setpoint

High Flow Setpoint.

Edit High Flow

Setpoint

Curves

•

The current gain. This value controls the speed of valve response for automatic

control. The higher the value, the more quickly the valve will open and close. The lower

the value, the more slowly it opens and closes.

•

action will occur. If the deadband is too small, the control may oscillate around setpoint.

If the deadband is too high, the flow will not reach setpoint. The range for this value is 1

to the full scale flow value.)

•

This value allows the user to adjust the pressure transducer, which transmits a 4-20mA

signal to indicate flow. When no flow is present, the ideal value for the Zero value is

4.00mA (although the value will not always be exactly 4.00).

to adjust the zero value.

to change the zero value—a procedure described in more detail in the

section on page 15.

•

transducer. For instance, if 20mA is the highest value that the transducer will send, the

mA span value is 20.

•

value will correspond to approximately 4mA.

value.

•

This value will correspond to approximately 20mA.

this value.

•

signal from the eFlo meter. This value will correspond to approximately 4mA. If the flow

range is 0 to 100, the Analog Output Zero value will be 0.

change this value.

•

signal from the eFlo meter. This value will correspond to approximately 20mA. If the

flow range is 0 to 100, the Analog Output Span value will be 100.

to change this value.

•

active as long as the flow rate is less than or equal to this value.

allows you to change this value.

•

active as long as the flow rate is greater than or equal to this value.

Curves Menu

The

local computer, download the active curve from the meter, and upload a curve to the meter.

menu (Figure 6) allows you to adjust Calibration Curve points, save curves to the

The value defining the area above and below the setpoint where no control

The adjusted mA input from the pressure transducer.

allows you to change this value.

allows you to change this value.

The lowest flow rate that will be transmitted by an analog output

The highest flow rate that will be transmitted by an analog output

The value that will trigger a Low Flow Rate Alarm. The alarm will be

The value that will trigger a High Flow Rate Alarm. The alarm will be

This achieves the same result as using the eFlo keypad

The highest value of the mA range sent by the pressure

allows you to change this value.

The lowest flow rate value for a remote setpoint of 0. This

The highest flow rate value for the remote setpoint flow.

allows you to change the deadband value.

allows you to change the value.

Zero Calibration

allows you to change this

allows you to change

allows you to

allows you

allows you

Page 20

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 20 of 25

Figure 6 - Curves Menu

Saved Curves

Selected Curve

Curve Points

Saved Curves

Selected Curve

Saved Curves

Curve Points

Update

Figure 7 – Update Menu

About

The window has three sections related to the Calibration Curve:

Figure 6),

(Section “B” in Figure 6), and

These sections are described in more detail below.

•

(“A”). This section of the window displays a list of saved Calibration

Curves. It also allows you to begin work on a new curve (by clicking on “New Curve”) and

to delete a selected curve (by clicking on “Delete Curve”). To select a curve, single-click

on the name of the curve.

•

(“B”). This section displays the name of the curve selected from the

area. It also provides the ability to save the current curve to a file on the

local computer (“Save Curve” button), upload the current curve to the eFlo unit (“Upload

Curve To Device”), and download the curve that is currently loaded in the eFlo unit

(“Download Curve From Device”).

•

(“C”). This section allows you to define new points on the currently selected

Calibration Curve and to delete existing points on that curve. Flow values correspond

with milliamp signal values produced by the eFlo unit; each point denotes where these

values coincide on the Calibration Curve. New points are defined with the “New Point”

button. Selected points are deleted with the “Delete Point” button.

Update Menu

The

menu (Figure 7) will cause the software to check for software updates and, if

available, give you the option to download and install any updates.

(Section “A” in

(Section “C” in Figure 6).

About Menu

When selected, the

(Application Version) and a change log (Revision Notes).

menu will bring up a window showing the software version

Page 21

Super Systems Inc.

Page 21 of 25

Troubleshooting

WARNING!

When troubleshooting, follow all proper safety precautions. Use proper eye protection and hand protection at all times.

Problem

Possible Causes

Possible Corrective Actions

Unit is not reaching higher flow setpoint

Pressure may be less than pressure specified on

Adjust regulator using a manometer to set

maximum flow required through the meter.

Unit is indicating that there is gas flow when no

Zero value is not set on the meter (if gas supply is

Verify that the hand valve for gas supply is closed.

on page 15 for more details.

eFlo Electronic Flow Meter Operations Manual

flow should be present

order

Meter may not be the correct size

Meter may not be calibrated for correct gas

Gas piping may be too small for required flow

shut off)

The shutoff valve may be located upstream of the

flow meter. This causes a zero drift condition

since there is no pressure on the meter.

correct pressure while gas is flowing and meter

is open

Call SSi at (513) 772-0060 to discuss a different

size (model) of flow meter

Verify Calibration Report for gas calibration. If the

gas is different than the gas you are flowing

through the meter, contact SSi at (513) 772-0060

to discuss a recalibration.

Verify that the plumbing is adequate for the

If flow is still showing, perform the zero

calibration procedure as shown in the manual.

• SSi recommends that the shutoff valve be

moved downstream of the meter so that gas

pressure on the meter is always available.

The error will correct itself when gas

pressure is supplied to the meter.

• Another option is to perform a Zero

Calibration. See the Zero Calibration

section

Page 22

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 22 of 25

Problem

Possible Causes

Possible Corrective Actions

Unit is indicating that there is no gas flow when

Hand valve for gas supply may be closed

gas supply

Open hand valve.

restriction, and correct any problems.

Unit is not communicating

Communications may not be configured correctly

Verify RS485 wire polarity

the RS485 loop

Unit is not reaching setpoint

There may be insufficient gain

Verify gain is high enough; adjust bias as needed

Setpoint cannot be changed directly from the

An analog setpoint signal may be wired and

overwriting manual setpoint

Ensure that an analog input signal to the eFlo is

setpoint via communications

Table 5 - Troubleshooting

calling for a flow setpoint

eFlo control panel

If a solenoid is used, solenoid may not be

energized

Restrictions may be present downstream in the

overwriting manual setpoint

A master device wired to the eFlo may be

Ensure that solenoid is energized.

Check for issues such as exhaust gas outlet

Verify address and baud rate

Verify that only one meter has address set to 1 on

not wired and overwriting manual setpoint

Ensure that no device is actively writing the

If you experience problems and cannot find the solution after troubleshooting, please call SSi Technical Support at (513) 772-0060.

Page 23

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 23 of 25

Warranty

Limited Warranty for Super Systems Products:

The Limited Warranty applies to new Super Systems Inc. (SSI) products purchased direct from

SSI or from an authorized SSI dealer by the original purchaser for normal use. SSI warrants

that a covered product is free from defects in materials and workmanship, with the exceptions

stated below.

The limited warranty does not cover damage resulting from commercial use, misuse, accident,

modification or alteration to hardware or software, tampering, unsuitable physical or operating

environment beyond product specifications, improper maintenance, or failure caused by a

product for which SSI is not responsible. There is no warranty of uninterrupted or error-free

operation. There is no warranty for loss of data—you must regularly back up the data stored on

your product to a separate storage product. There is no warranty for product with removed or

altered identification labels. SSI DOES NOT PROVIDE ANY OTHER WARRANTIES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME JURISDICTIONS DO

NOT ALLOW THE LIMITATION OF IMPLIED WARRANTIES, SO THIS LIMITATION MAY NOT APPLY

TO YOU. SSI is not responsible for returning to you product which is not covered by this limited

warranty.

If you are having trouble with a product, before seeking limited warranty service, first follow the

troubleshooting procedures that SSI or your authorized SSI dealer provides.

SSI will replace the PRODUCT with a functionally equivalent replacement product,

transportation prepaid after PRODUCT has been returned to SSI for testing and evaluation. SSI

may replace your product with a product that was previously used, repaired and tested to meet

SSI specifications. You receive title to the replaced product at delivery to carrier at SSI shipping

point. You are responsible for importation of the replaced product, if applicable. SSI will not

return the original product to you; therefore, you are responsible for moving data to another

media before returning to SSI, if applicable. Data Recovery is not covered under this warranty

and is not part of the warranty returns process. SSI warrants that the replaced products are

covered for the remainder of the original product warranty or 90 days, whichever is greater.

Page 24

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 24 of 25

Revision History

Rev.

Description

Date

MCO #

-

First release

3/23/2015

4621

Page 25

eFlo Electronic Flow Meter Operations Manual

Super Systems Inc.

Page 25 of 25

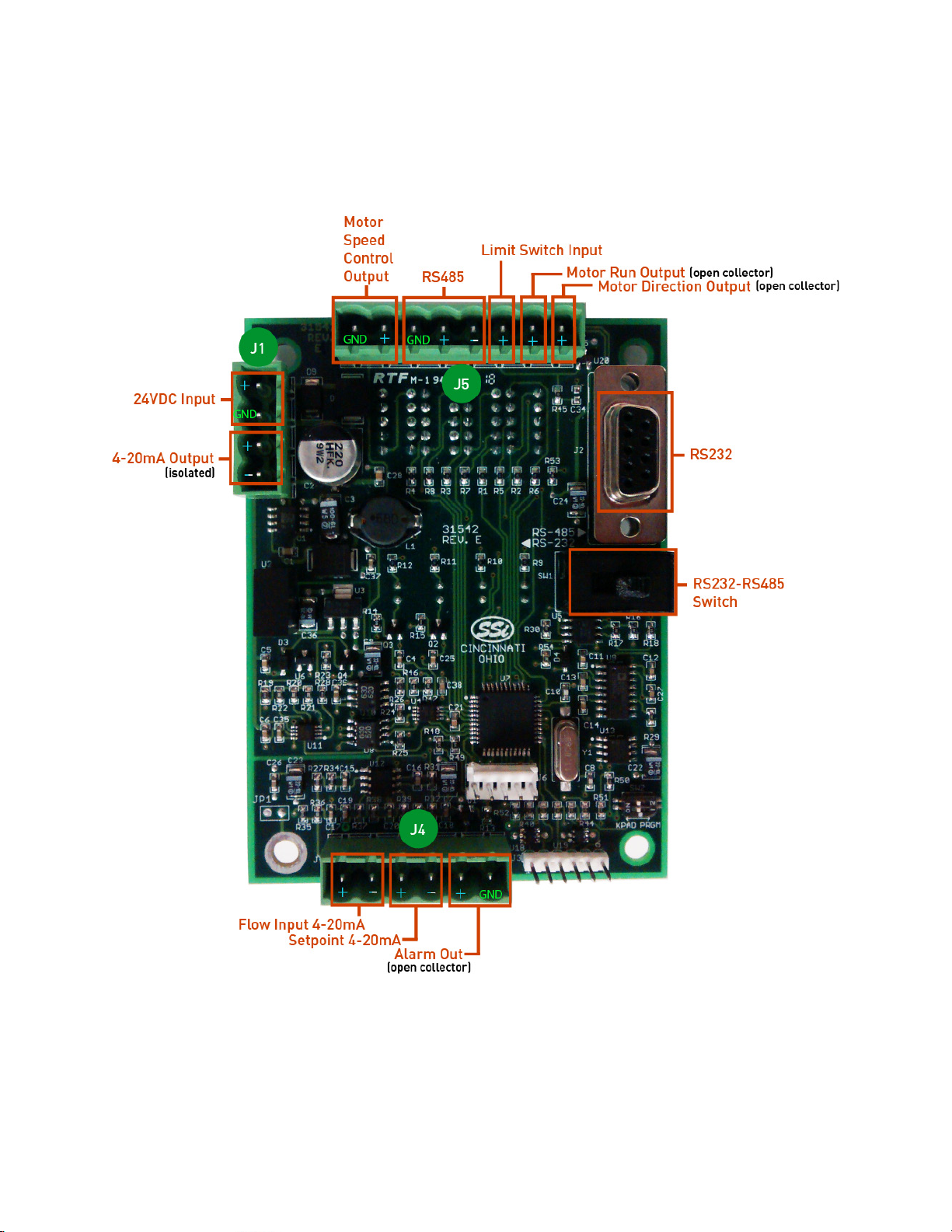

Appendix 1: Electrical/Wiring Diagram

Flow Board: Connection Diagram

Loading...

Loading...