Page 1

DATA ACQUISITION (DAQ)

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Table of Contents

Introduction ..................................................................................................................................... 3

DAQ Wiring Diagram ....................................................................................................................... 3

DAQ Setup ....................................................................................................................................... 4

Step 1: Install Configurator 2.0 on the Local Computer ............................................................. 4

Step 2: Connect the DAQ to a Network or Local Computer ........................................................ 6

Step 3: Configure Configurator 2.0 on the local computer ......................................................... 8

Step 4: Complete Configurator Range Setups Menu Option ......................................................10

Step 5: Complete Configurator Input Offsets Menu Option .......................................................11

Analog Inputs .................................................................................................................................12

Adding a Jumper to an Input ......................................................................................................12

Thermocouple Connections .......................................................................................................13

Voltage Connections ...................................................................................................................13

4 – 20 mA Current Loop Connections ........................................................................................14

Setting the DIP Switches to Assign Board Numbers .................................................................14

Configurator Menu .........................................................................................................................15

Input Values ................................................................................................................................15

Aux Instruments .........................................................................................................................16

Communication Setup ................................................................................................................16

Device Configuration ..................................................................................................................18

Range Setups .............................................................................................................................19

Input Offsets ...............................................................................................................................20

Aux Instrument Setup ...............................................................................................................21

Custom Curves ...........................................................................................................................23

Calibration ..................................................................................................................................23

Zero/Span Calibration ............................................................................................................25

Cold Junction Offset ...............................................................................................................26

Satellite Boxes ...............................................................................................................................26

DAQ Data Sheets ............................................................................................................................28

Appendix 1: Input Number Table ...................................................................................................30

Appendix 2: Input Ranges ..............................................................................................................31

Appendix 3: SuperDATA (SDIO) Communication Setup .................................................................32

Appendix 4: Modbus Register Map ................................................................................................33

Revision History .............................................................................................................................34

Super Systems Inc. Page 2 of 34 DAQ Operations Manual

Page 3

Introduction

The SSi DAQ data acquisition module is a simple, powerful and expandable product for

measuring a vast array of signals in the process control environment. The DAQ can be used

with as few as 3 inputs and can be expanded to as many as 48 per DAQ depending upon your

needs. Each SSi fully-isolated 3 input analog module can be configured on an input-by-input

basis for a range of voltage inputs from as little as 20 mV to as much as 10V or for a 4 - 20 mA

current signal. Communications to the DAQ are available via Modbus serial protocol or through

the DAQ's Ethernet port via ModbusTCP. Calibration and configuration are available through

SSi's Configurator software (provided) and the DAQ also features a limited web server for

simple interfacing from any PC in your plant (Ethernet communications required).

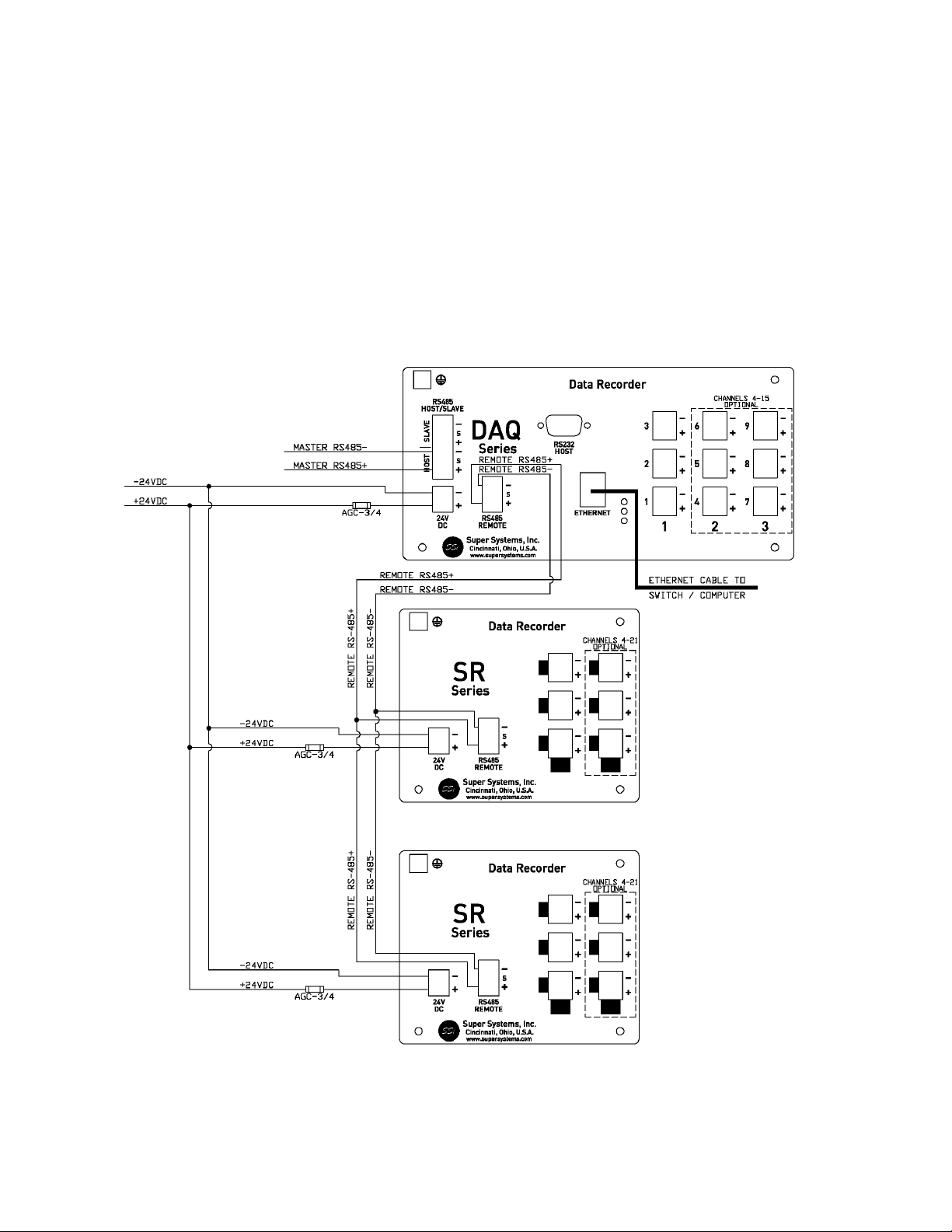

DAQ Wiring Diagram

Super Systems Inc. Page 3 of 34 DAQ Operations Manual

Page 4

DAQ Setup

Configurator 2.0 is a configuration utility

Next >

Cancel

The second page is a warning about

Next >

This section will explain how to set up the DAQ. The steps required to set up the DAQ through a

local computer are:

1. Install Configurator 2.0 on the local computer

2. Connect the DAQ to a network or local computer

3. Configure Configurator 2.0 on the local computer

4. Complete Configurator Range Setups menu option

5. Complete Configurator Input Offsets menu option

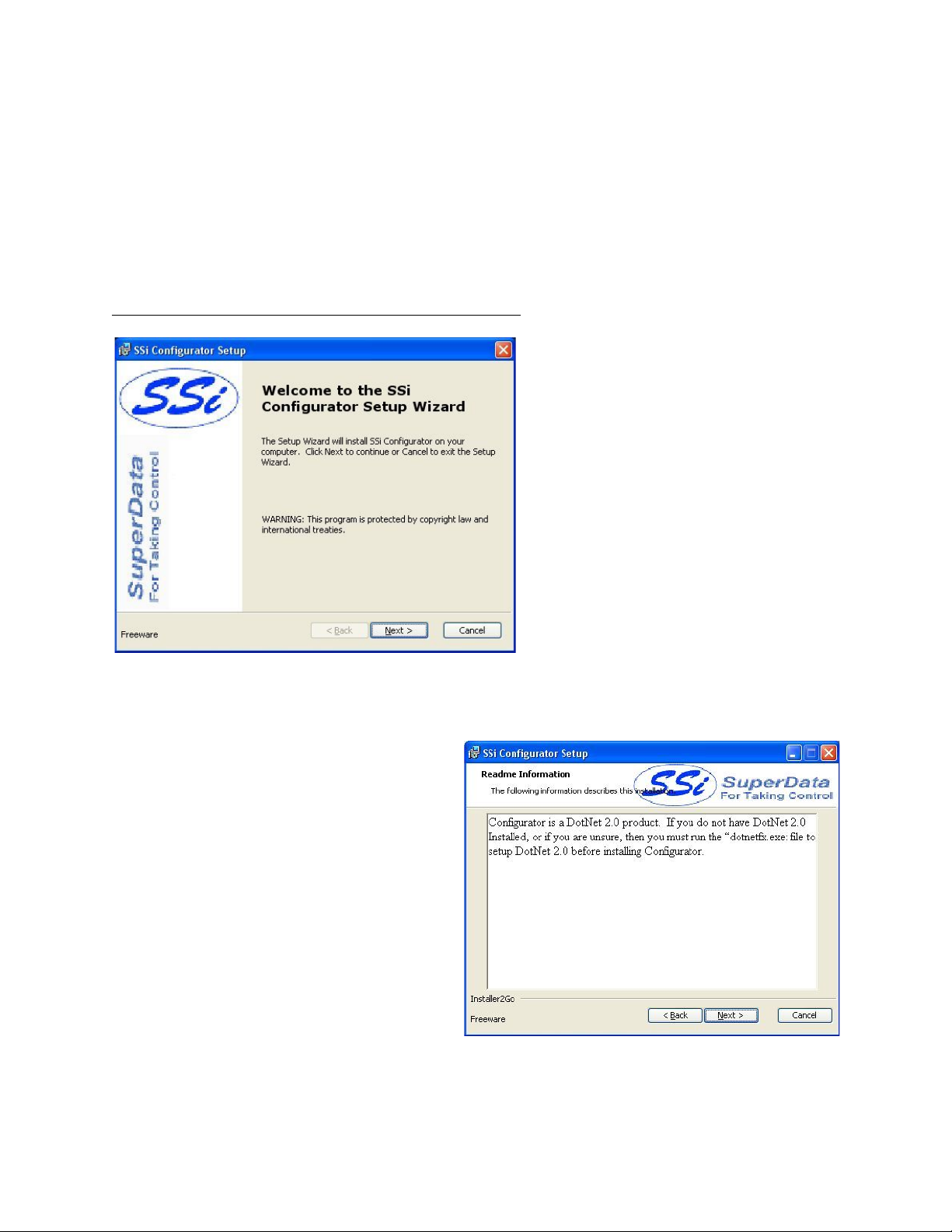

Step 1: Install Configurator 2.0 on the Local Computer

developed by SSi that will allow the user

to interface with an SSi instrument

directly or over a network. The

installation file, ConfiguratorSetup.msi,

should be included with the installation

CD provided by SSi. If this file is not on

the CD, contact Super Systems at 513772-0060.

Double-click on the installation file to

begin the installation process.

The first page displayed is just for

information purposes.

Click on the

next page, or press the

cancel the installation.

button to move to the

button to

Configurator 2.0. Since Configurator 2.0 is

a Microsoft .Net 2.0 product, the local

computer will have to have the .Net 2.0

framework installed before Configurator

2.0 can be used. Click on the

to continue or the Cancel button to cancel

the installation.

Super Systems Inc. Page 4 of 34 DAQ Operations Manual

button

Page 5

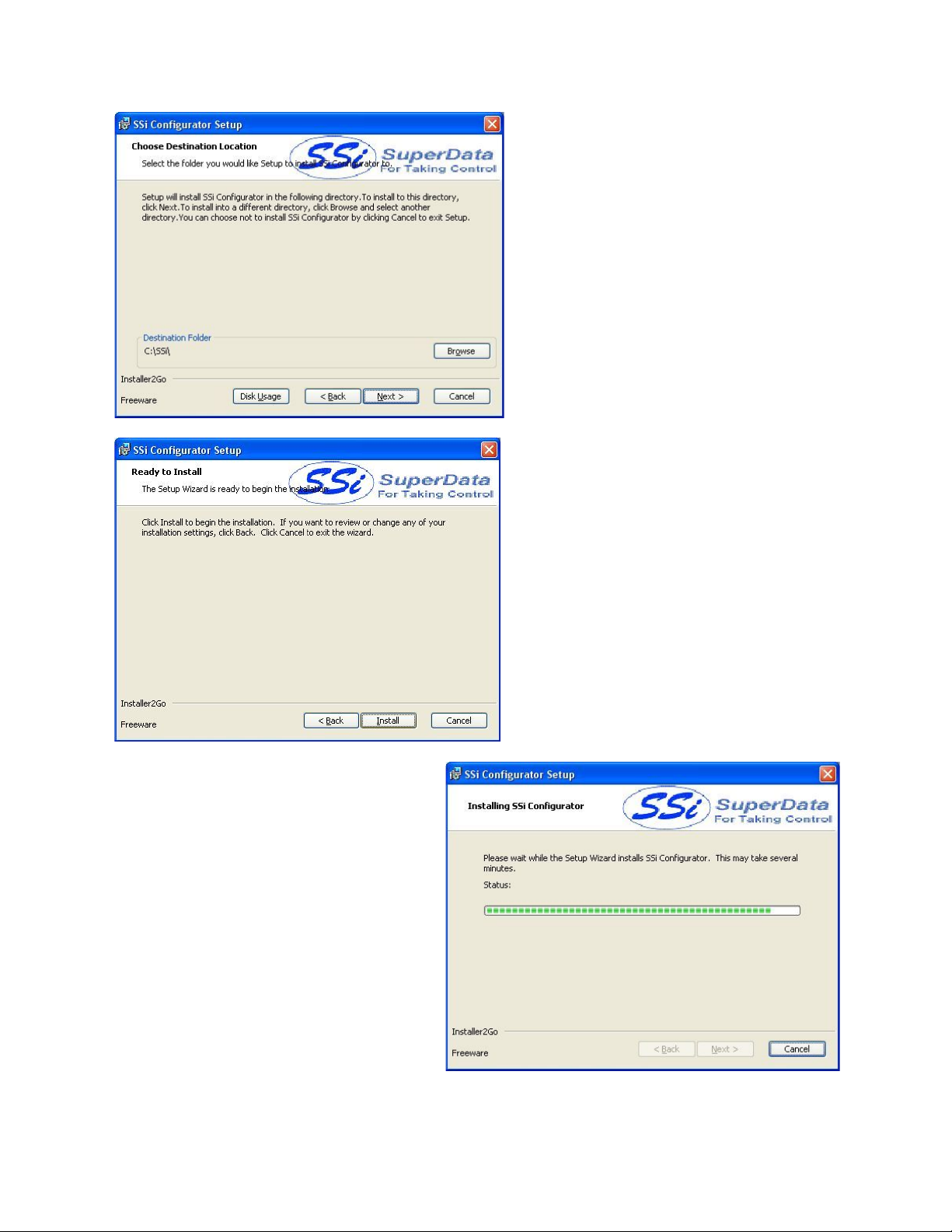

Page 3 will allow the user to select the

location of the installation. The default

Browse

Disk Usage

Next >

Page 4 will allow the user to review the

Page 5 will display a progress bar as the

Note:

location is “C:\SSi\”. To change this

location, click on the

button and

select a new location from the dialog box

that is displayed. The

button

is a utility that will display the available

hard drive space on the local computer.

Click on the

button to move to the

next page.

installation settings, if necessary. Click

on the Install button to install the

software.

installation proceeds.

The installation should only take a

few minutes.

Super Systems Inc. Page 5 of 34 DAQ Operations Manual

Page 6

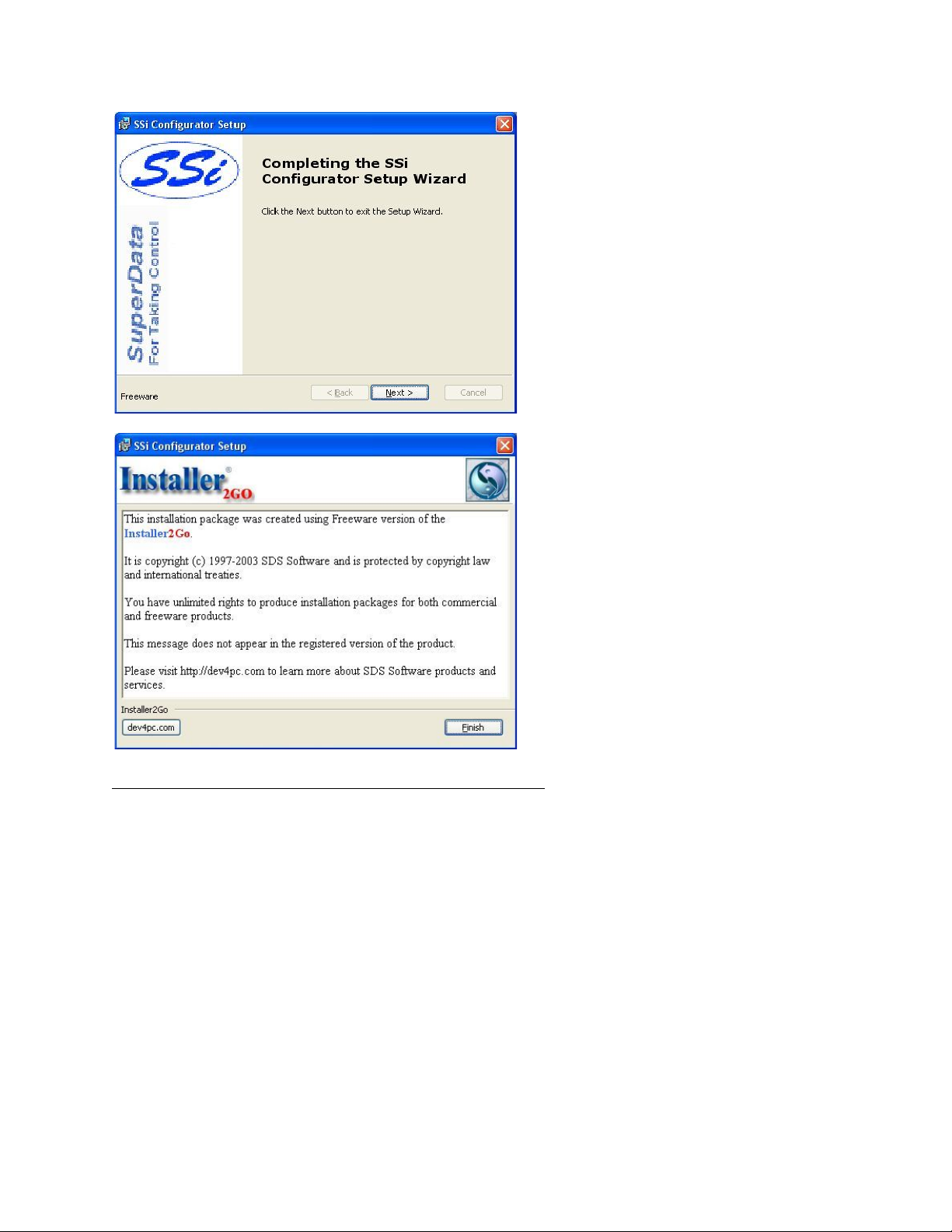

Page 6 is the finishing screen, which is

displayed after the software has been

Next >

Page 7 is the informational screen

installed. Click on the

continue.

about the makers of the installation

software. Click on the Finish button to

close out this screen.

button to

Step 2: Connect the DAQ to a Network or Local Computer

To connect the instrument to the network, through a wall port or switch, use a regular Ethernet

cable. To connect the instrument directly to a computer, use an Ethernet crossover cable.

Contact your IT Department for the necessary cables. Once the DAQ is connected to a network,

the Configurator 2.0 software will be able to find it during any searches. Connecting the

instrument to your network or directly to a PC is accomplished using the Ethernet port on the

instrument. If you are connecting the instrument to your network, you will need an Ethernet

cable. The cable is plugged into the instrument Ethernet plug and then other end should be

plugged into a network hub. If the IP Address of the instrument needs to be changed, this can be

done through the Configurator software (see

computer

Ethernet crossover cable. Ethernet crossover cables are most often used when connecting two

Ethernet computers without a hub. An Ethernet crossover cable has its send and receive wires

crossed. When using a hub or switch, this is automatically done for you. With a crossover cable,

you are forming a network between the computer that you are directly plugged into and the

DAQ. There will be some network settings on the computer that you will have to configure for

Super Systems Inc. Page 6 of 34 DAQ Operations Manual

below). If you are not putting the instrument on the network, you should use an

Step 3: Configure Configurator 2.0 on the local

Page 7

the 2 devices to communicate. The DAQ will have the network setting already setup with a

default IP address – normally supplied by the customer. This can be modified through the

Configurator software.

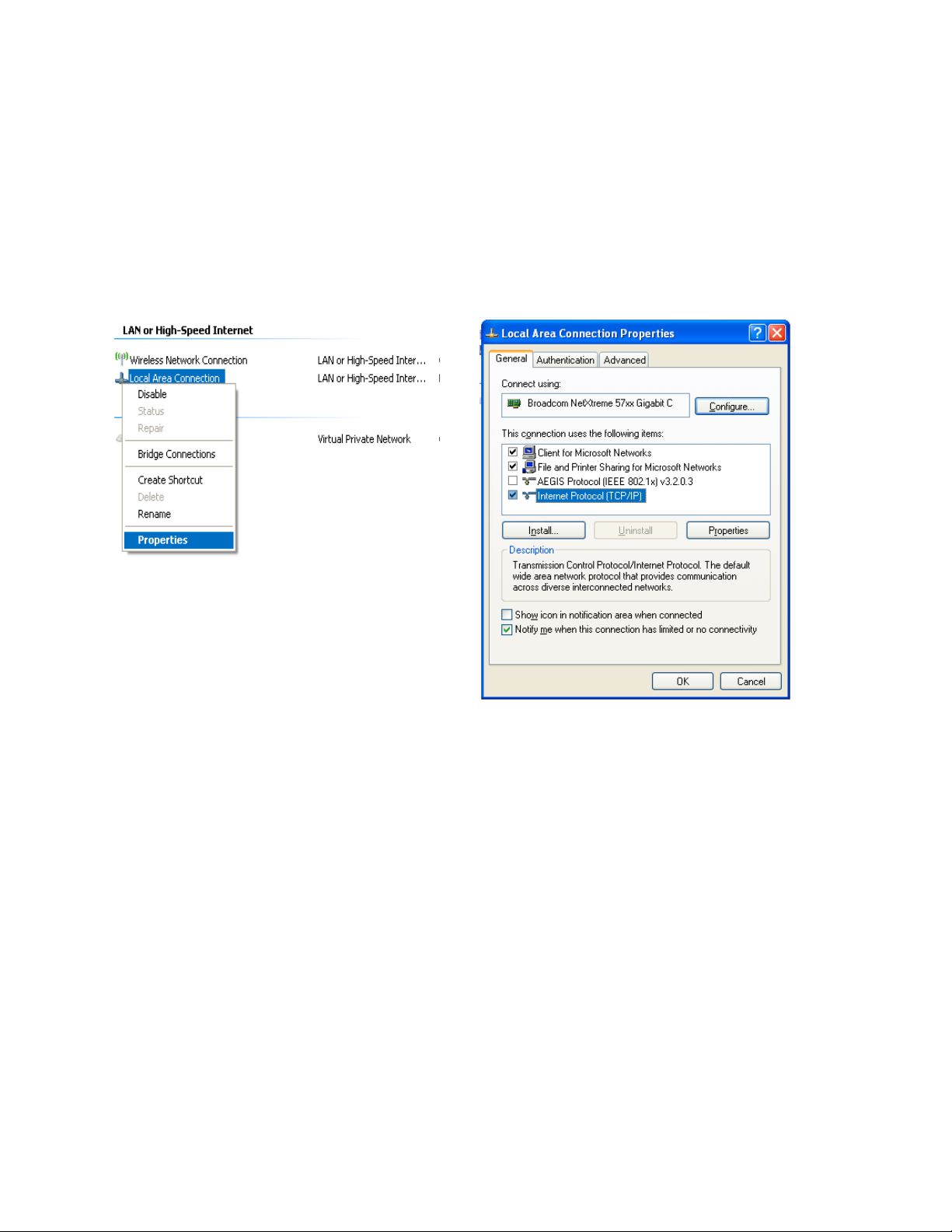

Network settings can be found through the

Network Setting

Using the crossover cable will require the “Local Area Connection” as seen in the diagram to be

modified.

, the operator will be given a list of the current available connection types.

Control Panel

in Microsoft Windows. By selecting

The Properties can be changed by highlighting the connection and using the right mouse button

to click and select the

setting of this connection. Once the

highlight the Internet Protocol (TCP/IP) option. Click the Properties button to display Internet

Protocol (TCP/IP) Properties. On the Internet Protocol (TCP/IP) Properties tab, you will need to

select the option for Use The Following IP Address.

Super Systems Inc. Page 7 of 34 DAQ Operations Manual

Properties

tab or by highlighting the connection and clicking on Change

Local Area Connection Properties

screen is displayed,

Page 8

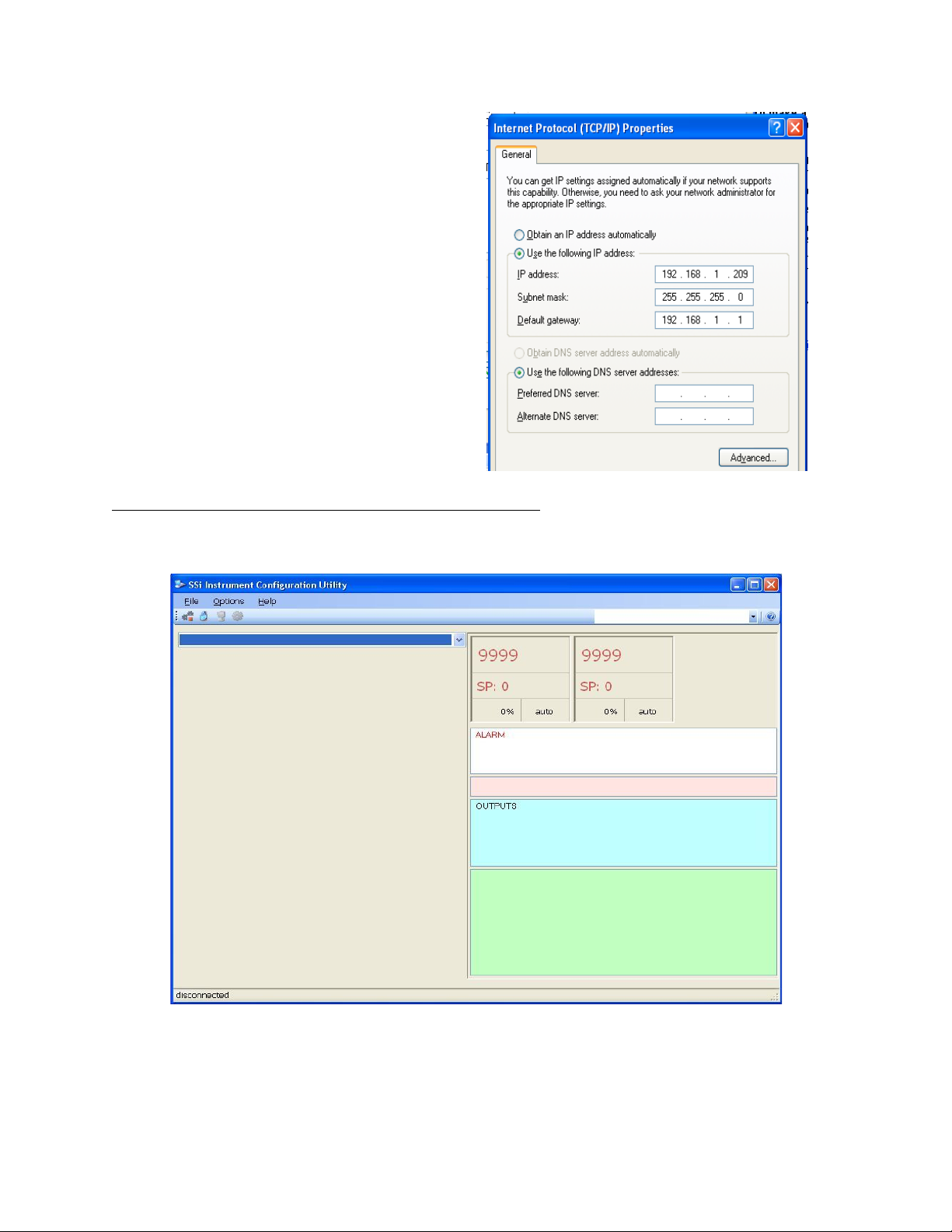

Enter the following in these fields:

IP Address: 192.168.0.209

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.1.1

Note: These fields are suggestions. Contact

your IT department to get a valid IP address,

Net Mask, and Gateway for the local computer.

To change the network settings on your

computer you may need addition information

so please refer to the computer manual.

Step 3: Configure Configurator 2.0 on the local computer

When Configurator starts up for the first time, the user will see the main screen, which will be

blank because no instruments have been set up yet. The first step is to set up an instrument in

Configurator.

First, the user will need to log in with administrative rights.

logged in with at least administrative rights; Supervisor rights will not allow the user to add an

instrument

The lock on the toolbar will let the user know what level is currently logged in. Operators are

Super Systems Inc. Page 8 of 34 DAQ Operations Manual

. The levels of rights in Configurator are operator, supervisor, and administrator.

Note: The user will need to be

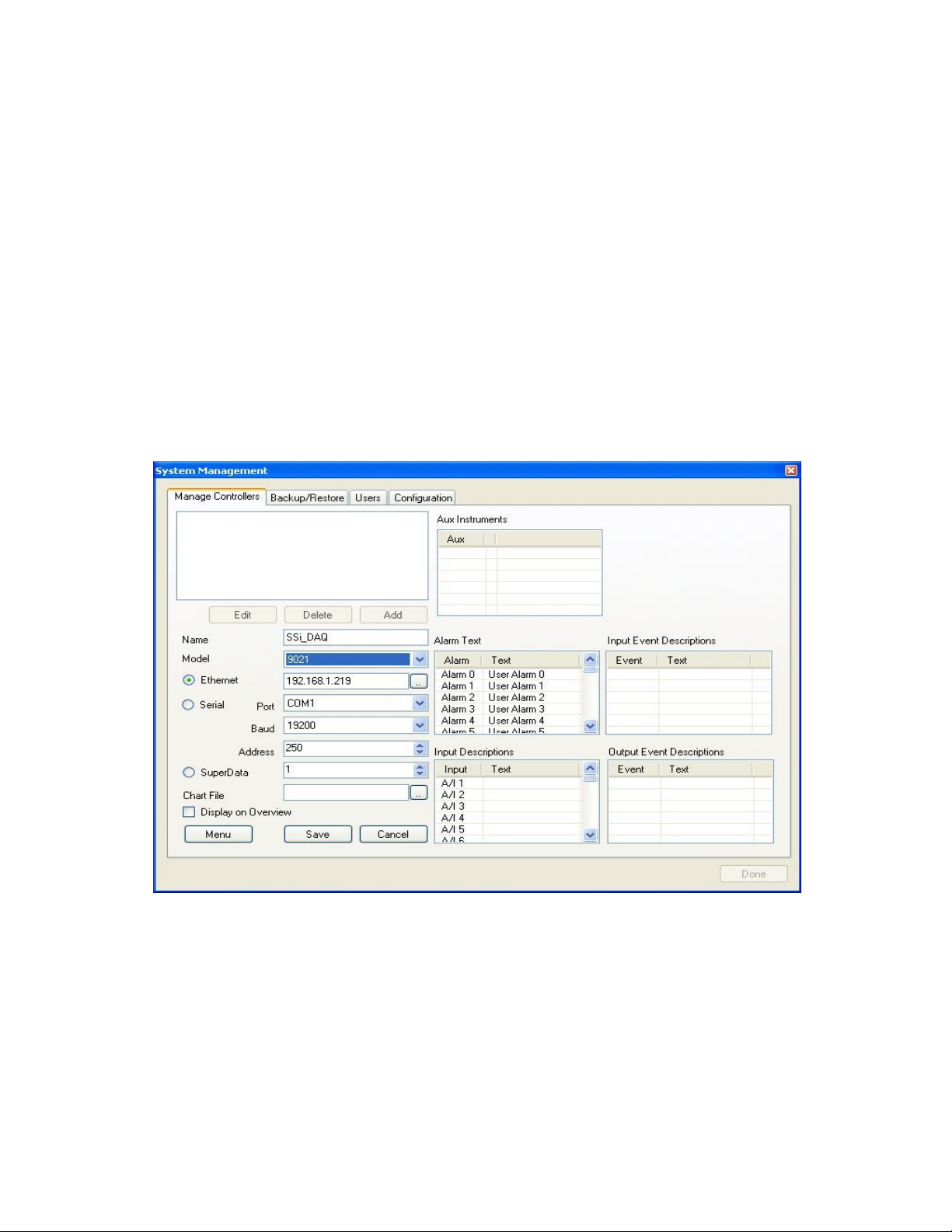

Page 9

blue, supervisors are gold, and administrators are green. Click on the lock and log in with the

following information: username = administrator, password = 2.

administrator passwords can be changed on the

now be green. Click on the

Management

Click on the Add button to display the rest of the screen. First, give the instrument a name. The

name can be anything the user wants, but it is suggested that the user makes the name

descriptive. Next, select the model from the drop-down list. For the DAQ, the model number is

“9021”. Next, enter the IP address in the “Ethernet” section and make sure the “Ethernet”

option is selected.

screen.

Note: The DAQ is shipped with an IP address supplied by the customer

Options

menu, then select

Furnace Setup

Settings

Note: The supervisor and

menu page

. This will display the

. The lock should

System

.

Note: even if the local computer is hooked up directly to the instrument through a crossover

cable, the IP address will still need to be correct

available SSi instruments by clicking on the search button next to the “Ethernet” IP address

box. This will set up Configurator for Ethernet communications. To set it up for serial or

SuperDATA communications, the proper option will need to be selected and filled out.

. The user can also scan the network to find all

The DAQ has RS-232 host communications and RS-485 host communications capability (shown

below). To set the DAQ up for serial communications, the user will need to know which COM

port will be used. Select that COM port (

left at the default –

communications, or if the DAQ is the only device on RS-485 communications, then the address

250 will be sufficient.

of

Super Systems Inc. Page 9 of 34 DAQ Operations Manual

19200. The address should be changed to 1. If the user is using RS-232

COM 1 – COM 20 is available). The Baud rate can be

Page 10

Click on the Save button to save the information. Click on the Done button to close down this

screen.

Step 4: Complete Configurator Range Setups Menu Option

Note: This menu item is also located later in the manual under the

Range Setups

The

each of the three inputs on a board. The user will also be able to view/modify the input

linearization for each input per board. There are a maximum of sixteen boards.

Super Systems Inc. Page 10 of 34 DAQ Operations Manual

menu option will allow the user to view/modify the selected input ranges for

Configurator Menu

section

.

Page 11

The Input Type can be one of the following:

B T

C 2.5 V

E 1.25 V

J 160 mV

K 80 mV

N 40 mV

NNM 20 mV

R 4-20 mA/124Ω

S 4-20 mA/62Ω

The Input Linearization can be one of the following:

Not Used

Curve 1

Curve 2

Curve 3

Curve 4

Curve 5

Curve 6

Curve 7

The “Input linearization” field is where the user can apply a specific curve, created with the

menu option

through 7, from the drop-down list for the selected input.

Step 5: Complete Configurator Input Offsets Menu Option

Custom Curves

Note: This menu item is also located later in the manual under the

Input Offsets

The

per board. There can be a maximum of sixteen boards. The offset can be within the range of

-32768 to 32767.

Range Setups

menu option will allow the user to enter an offset for each of the three inputs

Note: The decimal place will be dependent on the input type selected from the

menu

.

, to the input. To apply the curve, select the applicable curve, 1

Configurator Menu

section.

Super Systems Inc. Page 11 of 34 DAQ Operations Manual

Page 12

Analog Inputs

The Super Systems, Inc. Part Number 31611 Analog Board contains a group of three channels

isolated from the main DC power source. Each input is fully isolated. The board can be

connected to thermocouples, voltage sources from 20mV full scale to 1.28 Volts full scale,

voltage sources from 0 V full scale to 10 V DC full scale, or 4 – 20 mA current loops.

Adding a Jumper to an Input

When measuring a 4-20mA current signal or a voltage signal, such as a thermocouple, a jumper

must be placed on the corresponding two or three-position header. For example, Input 1 would

need to have a jumper placed between the pins labeled “I1” before connecting a 4-20mA signal.

Failure to add the jumper will result in damage to the circuit board.

present at each of the three headers, but unless it is attached across both pins (not just one) it

will not be connected.

The jumper may already be

Super Systems Inc. Page 12 of 34 DAQ Operations Manual

Page 13

Thermocouple Connections

Thermocouple wires can be connected directly to the terminal blocks. The thermocouple

junctions should not be grounded. If they do touch a ground reference, all thermocouples on a

board must have a common ground reference. If multiple thermocouples are connected to

different ground reference points, the accuracy of all thermocouples on the board cannot be

guaranteed to be accurate. When setting up a voltage input signal, such as a thermocouple

input or any voltage input signal up to 1.28 volts, the jumper must be placed on the pins in the

1:1 setup (left diagram).

Voltage Connections

Voltages from 0 mV to 10 Volts DC can be directly connected to the terminal blocks. When

measuring ground-referenced voltages, all references must share a common ground

reference. If the voltage sources are connected to different ground reference points, the

accuracy of all the voltage sources connected to the board need to be checked for accuracy.

Since higher voltages can damage the input board, any voltage input signals, such as a vacuum

gauge, must have the jumpers placed on the pins in the 10:1 setup (middle diagram).

ensure that any signal going into the board will be scaled down so it will not damage the input

board.

This will

Super Systems Inc. Page 13 of 34 DAQ Operations Manual

Page 14

4 – 20 mA Current Loop Connections Before connecting the current loop, insert the shorting jumper on the board for each channel used to measure current loops. This jumper inserts the 62-ohm shunt resistor across the input of the A/D. If multiple current loops are connected to one board, all must share the same power supply and ground reference points or the accuracy of all the current loops need to be checked for accuracy. When setting up a current input signal, such as a 4 – 20 mA signal, the jumper must be placed on the pins in the current setup (right diagram). Notice that there is also a jumper set up in the 1:1 setup only when inputting a current signal. This is because current signals also have a corresponding voltage signal.

Warning: Connecting a mA input without the Input Jumper will damage the input.

To add a jumper to an input:

1. Power down the unit.

2. Remove the thermocouple connector and the Ethernet cable from the DAQ.

3. Remove the top plate of the DAQ by unscrewing the screws around the top of the DAQ.

4. Grasping both sides of the input board, carefully pull the input board out of the DAQ and set

the jumper for the appropriate set of pins, i.e. “V1” for input 1, “V2” for input 2, etc. A jumper

will need to be set – placed on both pins – to be considered “on”. Slide the input board back

into the DAQ slot.

5. Replace the top plate of the DAQ by screwing in the screws around the top of the DAQ.

6. Re-connect the Ethernet cable and thermocouple connector.

Setting the DIP Switches to Assign Board Numbers

Each input board, whether directly connected in the DAQ or connected through a satellite box,

must have a unique address assigned by the DIP switches on each input board. A unique

address will ensure that the DAQ will correctly read all of the boards set up. If two or more

boards have the same address, multiple errors could occur such as: DAQ reading data from one

board one second, then reading data from another board the next second, no data being read

from the DAQ, etc.

four switches on it labeled: 1, 2, 3, and 4. These numbers follow a binary numbering system –

i.e. 1 = 1, 2 = 2, 3 = 4, and 4 = 8. There is an ON and an OFF position for each switch. OFF = 0

and ON = 1. Each board number can be assigned by setting the appropriate switches to ON. For

example, to set a board number to 1, set the “1” switch to ON and the “2”, “3”, and “4” switches

to OFF ((1*1) + (2*0) + (4*0) + (8*0) = 1). To set the board number to 10, set the “1” and “3”

switches to OFF and the “2” and “4” switches to ON ((1*0) + (2*1) + (4*0) + (8*1) = 10).

It is important that each board has a unique address

Turning all switches to the off position sets the board to address 16

. Each DIP switch has

NOTE:

.

Super Systems Inc. Page 14 of 34 DAQ Operations Manual

Page 15

Configurator Menu

Input Values

The

Input Values

sixteen boards, with three inputs per board. This screen is a read-only screen. See

Input Number Table

menu option will display the current values of the inputs for each board up to

for a description on the input numbering.

Appendix 1:

Super Systems Inc. Page 15 of 34 DAQ Operations Manual

Page 16

Aux Instruments

Aux Instruments

The

(if configured). This screen is a read-only screen. See the

information on setting up an auxiliary instrument.

menu option will display the auxiliary instruments and their current values

Aux Instrument Setup

section for

Communication Setup

Communication Setup

The

parameters for the DAQ.

menu option will allow the user to set up the communications

Super Systems Inc. Page 16 of 34 DAQ Operations Manual

Page 17

Host 232 Baud

This option will allow the user to set the Host 232 baud rate. The options are:

1200 2400 115200

4800 9600

14400 19200

28800 38400

57600 76800

Slave 232 Baud

This option will allow the user to set the Slave 232 baud rate. The options are:

1200 19200 115200

2400 28800

4800 38400

9600 57600

14400 76800

Host 485 Baud

This option will allow the user to set the Host 485 baud rate. The options are:

1200 19200 115200

2400 28800

4800 38400

9600 57600

14400 76800

Super Systems Inc. Page 17 of 34 DAQ Operations Manual

Page 18

Host 485 Address

This option will allow the user to set the Host 485 address. The range is 1 through 249.

Slave 1 (5,6) Baud

This option will allow the user to set the Slave 1 baud rate. The options are:

1200 19200 115200

2400 28800

4800 38400

9600 57600

14400 76800

IP Address/IP Mask/IP Gateway

These options will allow the user to change the various IP addresses of the DAQ. Contact Super

Systems Inc at 800-666-4330 or your IT department for help in changing any of these addresses.

Note: Once the IP address has been changed, communications with the DAQ will be lost until

the correct IP address is entered on the

Configurator 2.0 on the local computer

allow the user to change all of the options at once.

System Management

section above)

. Clicking on any of these options will

screen

(Step 3: Configure

Device Configuration

The

Device Configuration

options on the DAQ. Currently, the only option to change is the Temperature Mode option.

Temperature Mode

This option will allow the user to change the mode of the temperature. The options are °F or

°C.

menu option will allow the user to change certain configuration

Super Systems Inc. Page 18 of 34 DAQ Operations Manual

Page 19

Range Setups

The

Range Setups

each of the three inputs on a board. The user will also be able to view/modify the input

linearization for each input per board. There are a maximum of sixteen boards.

menu option will allow the user to view/modify the selected input ranges for

Super Systems Inc. Page 19 of 34 DAQ Operations Manual

Page 20

The Input Type can be one of the following:

B T

C 2.5 V

E 1.25 V

J 160 mV

K 80 mV

N 40 mV

NNM 20 mV

R 4-20 mA/124Ω

S 4-20 mA/62Ω

The Input Linearization can be one of the following:

Not Used

Curve 1

Curve 2

Curve 3

Curve 4

Curve 5

Curve 6

Curve 7

The “Input linearization” field is where the user can apply a specific curve, created with the

menu option

through 7, from the drop-down list for the selected input.

Input Offsets

The

Input Offsets

per board. There can be a maximum of sixteen boards. The offset can be within the range of

32768 to 32767.

Range Setups

the

Custom Curves

menu option will allow the user to enter an offset for each of the three inputs

NOTE: The decimal place will be dependent on the input type selected from

menu

, to the input. To apply the curve, select the applicable curve, 1

.

Super Systems Inc. Page 20 of 34 DAQ Operations Manual

Page 21

Aux Instrument Setup

The

Aux Instrument Setup

for the DAQ. This screen will list the instruments available for setup, and any configurations set

on the instruments.

menu option will allow the user to set up the auxiliary instruments

Super Systems Inc. Page 21 of 34 DAQ Operations Manual

Page 22

Instrument

SSi AC20/7EK/20Q/20PQ

SSi 7SL

9200 LP 1

9200 LP 2

9200 LP 3

AE Flow_Meter

Eur 2404, E2704 LP1

Eur 2500 LP 1

Eur 2500 LP 2, E2704 LP 2

E2704 LP3

UDC 3300

Yoko UT320, UT350

Yoko UP350

Yoko 550 LP 1, 750 LP 1

Yoko 550, 750 LP 2

The list of available instruments are:

Address

The address can be 0 to 249.

NOTE: There are 26 auxiliary instruments to set up on this menu screen, but only ten auxiliary

instruments listed on the

values for the aux instrument begin taking up the internal memory locations of the input boards,

starting with board 16: Aux instrument 11 replaces board 16; aux instrument 12 replaces board

15, etc.

Super Systems Inc. Page 22 of 34 DAQ Operations Manual

NOTE: An address of 0 disables the slave instrument on the DAQ

Aux Instruments

menu screen

. Starting with aux instrument 11, the

.

Page 23

Custom Curves

The

Custom Curves

Curves are applied when the user wants to use a non-linear compensation to the input, such as

in vacuum areas. There are a maximum of seven curves.

The Interpolation Type can be one of the following:

None

Linear

The mV 1 through mV 32 can be within the range of –32768 to 32767.

The Offset 1 through Offset 32 can be within the range of –32768 to 32767.

menu option will allow the user to set up the variables for the curves.

Note: This is where the user will create the custom curve that can be applied to the inputs

through the

to apply a curve to an input.

An example of a non-linear curve is for a 0 to 1V span (0 to 1000 mV). If the mV is 0, then the

offset is 0. If the mV is 200, then the offset if 400, etc.

Range Setups

menu option

. See the

Range Setups

section for information on how

Calibration

The

Calibration

click value to begin the calibration process.

Super Systems Inc. Page 23 of 34 DAQ Operations Manual

menu option will allow the user to calibrate the inputs on a board. Click on the

Page 24

The user will need a thermocouple calibrator capable of outputting a thermocouple signal to

calibrate the zero, span or cold junction value of the analog input board. The user will need to

connect the calibrator to one of the inputs on the board that will be calibrated. It is

recommended to let everything (calibrator and input board) sit for approximately thirty minutes

to allow the temperature to achieve equilibrium. Set up the calibrator for the specific

thermocouple type of the thermocouples in the analog input board, i.e. type K, type J, etc. Then,

source a specific temperature, like 1000 °F, or millivolt to the connected input. It is

recommended that the actual temperature used be similar to an appropriate process

temperature. For example, if your equipment normally operates at 1700 °F, then perform the

cold junction calibration using a 1700 °F signal. It is important to note that when performing a

zero or span calibration,

regular sensor wire, or even regular copper wire. To perform the calibrations, the user will

need a calibrator that is capable of outputting volts, millivolts, and temperature.

Below is a listing of the suggested ranges for the various TC types.

do not use

regular thermocouple wiring. Instead, use any kind of

TC Type mV Range Chart

TC Type Range in mV

B 20

C 40

E 80

J 80

K 80

N 80

NNM 80

R 40

S 20

T 20

Super Systems Inc. Page 24 of 34 DAQ Operations Manual

Page 25

NOTE: If the user is using a 10:1 jumper, the user will

Calibrate

Set Nominal

Zero/Span Calibration

The first step in the calibration process is the zero and span calibration. To select a board to

calibrate, click on the Select button. This will display a drop-down list that the user can select

the board to calibrate. This list will only display the available boards to calibrate. Once a board

is selected, the current values will be displayed along the right of the tab box. Select the input

range from the drop-down list. To perform a zero calibration, select the “Zero” option. To

perform a span calibration, select the “Span” option. The target value for a zero calibration is 0

millivolts. The target value for a span calibration is roughly ninety percent of the range

millivolts. The target value is displayed in the box and can be modified, if desired. If the

millivolt range is not known, the user can click on the help button next to the range drop-down

list. This will display a list of inputs. Selecting the correct input will set the correct millivolt

range.

Checking the check box next to the corresponding input will determine if that input will be

included in the calibration.

need to multiply the source signal by 10 to get the

correct span value

is set on a 1.25V range, the suggested source signal

will read 1000 mV. The supplied signal will need to

be 10000 mV to account for the 10:1 jumper.

For a zero calibration, a value of 0 mV will need to be

sourced to the input or inputs.

For a span calibration, a value of 90 % of the full

range will need to be sourced to the input or inputs.

Press the

process.

Press the

values to the inputs.

. For example, if the 10:1 jumper

button to begin the calibration

button to apply nominal

Super Systems Inc. Page 25 of 34 DAQ Operations Manual

Page 26

Cold Junction Offset

The second step in the calibration process is setting the cold junction offset. If necessary,

select a board to calibrate by clicking on the

that the user can select the board to calibrate. This list will only display the available boards to

calibrate. Select the board’s input to apply the cold junction offset to by using the up and down

arrows. Select the appropriate offset to use by using the up and down arrows. This can range

-25.00 to 25.00.

from

Note – To subtract a value from the current cold junction value, be sure to

set the offset value as a minus value by clicking on the plus/minus key on the keypad (+/-)

overall Cold Junction value is modified by adding or subtracting a value to the current value.

Press the Calibrate button to begin the calibration process.

Press the Done button to close out the screen.

Select button. This will display a drop-down list

.

The

Satellite Boxes

The satellite boxes represent expandable input slots for the Video Recorders which can be

mounted remotely and connected back to the main Video Recorder unit using the RS485 ports.

These satellite boxes will give customers the ability to add inputs to the Video Recorder.

The SR3 (pictured) contains three additional inputs for the Video Recorder. The satellite box SR6

contains six additional inputs, while the other satellite boxes contain the number of inputs

denoted by the number after the “SR”: SR9, SR12, SR15, SR18, and SR21.

To connect the satellite box back to the main Video Recorder unit, the “Remote RS485” on the

satellite box must be wired into the “RS485 Remote” on the main unit. 24VDC need to be

provided to the satellite box either by using a jumper from the main VR unit or from a separate

source.

Super Systems Inc. Page 26 of 34 DAQ Operations Manual

Page 27

Super Systems Inc. Page 27 of 34 DAQ Operations Manual

Page 28

DAQ Data Sheets

Serial Number

IP Address

Description

Number of Boards

Used

Notes

Board #

Input #

Input Type

Furnace Description

Curve

1

1 (1)

2 (2)

3 (3)

2

1 (4)

2 (5)

3 (6)

3

1 (7)

2 (8)

3 (9)

4

1 (10)

2 (11)

3 (12)

5

1 (13)

2 (14)

3 (15)

6

1 (16)

2 (17)

3 (18)

7

1 (19)

2 (20)

3 (21)

8

1 (22)

2 (23)

3 (24)

Super Systems Inc. Page 28 of 34 DAQ Operations Manual

Page 29

Serial Number

IP Address

Description

Board #

Input #

Input Type

Furnace Description

Curve

9

1 (25)

2 (26)

3 (27)

10

1 (28)

2 (29)

3 (30)

11

1 (31)

2 (32)

3 (33)

12

1 (34)

2 (35)

3 (36)

13

1 (37)

2 (38)

3 (39)

14

1 (40)

2 (41)

3 (42)

15

1 (43)

2 (44)

3 (45)

16

1 (46)

2 (47)

3 (48)

Super Systems Inc. Page 29 of 34 DAQ Operations Manual

Page 30

Appendix 1: Input Number Table

The

Input Values

menu screen (

Configurator Menu

section) displays the boards with the

absolute input number, rather than the board input number. For instance, Board 1 has input 1,

input 2, and input 3. Board 2 also has input 1, input 2, and input 3. However, each of the inputs

also has an absolute number that will range from 1 to 48. For instance, Board 1’s absolute

input numbers are input 1, input 2, and input 3. But, Board 2’s absolute input numbers are

input 4, input 5, and input 6. Below is a table listing the board numbers, input numbers, and

absolute input numbers.

Board # Input # Absolute Input # Board # Input # Absolute Input #

1 1 1 9 1 25

2 2 2 26

3 3 3 27

2 1 4 10 1 28

2 5 2 29

3 6 3 30

3 1 7 11 1 31

2 8 2 32

3 9 3 33

4 1 10 12 1 34

2 11 2 35

3 12 3 36

5 1 13 13 1 37

2 14 2 38

3 15 3 39

6 1 16 14 1 40

2 17 2 41

3 18 3 42

7 1 19 15 1 43

2 20 2 44

3 21 3 45

8 1 22 16 1 46

2 23 2 47

3 24 3 48

Super Systems Inc. Page 30 of 34 DAQ Operations Manual

Page 31

Appendix 2: Input Ranges

Input Type

Minimum

Maximum

B

32 °F

3308 °F C 32 °F

4208 °F

E

-328 °F

1832 °F

J

-346 °F

2192 °F

K

-328 °F

2502 °F

N

-328 °F

2372 °F

NNM

0 °F

1409 °F

R

-58 °F

3214 °F

S

-58 °F

3214 °F

T

-328 °F

752 °F

2.56 V

-25600

25600

1.28 V

-12800

12800

160 mV

-16000

16000

80 mV

-8000

8000

40 mV

-4000

4000

20 mV

-20000

20000

4 – 20 mA / 124Ω

Using 1:1 jumper

2000

10000

4 – 20 mA / 124Ω

Using 10:1 jumper

200

1000

4 – 20 mA / 62Ω

4000

20000

4 – 20 mA / 62Ω

Using 10:1 jumper

400

2000

Using 1:1 jumper

*** The 4 – 20 mA / 124Ω option is used mainly with the five input boards

*** The 4 – 20 mA / 62Ω option is used mainly with the three input boards

Super Systems Inc. Page 31 of 34 DAQ Operations Manual

Page 32

Appendix 3: SuperDATA (SDIO) Communication Setup

0

Analog Input #1, 1

24

Analog Input #1, 25

1

Analog Input #1, 2

25

Analog Input #1, 26

3

Analog Input #1, 4

27

Analog Input #1, 28

5

Analog Input #1, 6

29

Analog Input #1, 30

6

Analog Input #1, 7

30

Analog Input #1, 31

7

Analog Input #1, 8

31

Analog Input #1, 32

9

Analog Input #1, 10

33

Analog Input #1, 34

10

Analog Input #1, 11

34

Analog Input #1, 35

11

Analog Input #1, 12

35

Analog Input #1, 36

12

Analog Input #1, 13

36

Analog Input #1, 37

13

Analog Input #1, 14

37

Analog Input #1, 38

15

Analog Input #1, 16

39

Analog Input #1, 40

16

Analog Input #1, 17

40

Analog Input #1, 41

17

Analog Input #1, 18

41

Analog Input #1, 42

18

Analog Input #1, 19

42

Analog Input #1, 43

19

Analog Input #1, 20

43

Analog Input #1, 44

21

Analog Input #1, 22

45

Analog Input #1, 46

23

Analog Input #1, 24

47

Analog Input #1, 48

Serial 1CH#5(1) = "MOD_PMC,MB:1100-48" = "FCE 1"

Ethernet 9CH#17(250) = "MOD_PMC,IP:192.168.1.218,PI:1,MB:1100-48" = "FCE2"

Slot Parameter

Slot Parameter

2 Analog Input #1, 3

4 Analog Input #1, 5

8 Analog Input #1, 9

14 Analog Input #1, 15

20 Analog Input #1, 21

26 Analog Input #1, 27

28 Analog Input #1, 29

32 Analog Input #1, 33

38 Analog Input #1, 39

44 Analog Input #1, 45

Super Systems Inc. Page 32 of 34 DAQ Operations Manual

22 Analog Input #1, 23

46 Analog Input #1, 47

Page 33

Appendix 4: Modbus Register Map

1100

Analog Input #1, 1

1124

Analog Input #1, 25

1101

Analog Input #1, 2

1125

Analog Input #1, 26

1102

Analog Input #1, 3

1126

Analog Input #1, 27

1103

Analog Input #1, 4

1127

Analog Input #1, 28

1104

Analog Input #1, 5

1128

Analog Input #1, 29

1105

Analog Input #1, 6

1129

Analog Input #1, 30

1106

Analog Input #1, 7

1130

Analog Input #1, 31

1107

Analog Input #1, 8

1131

Analog Input #1, 32

1108

Analog Input #1, 9

1132

Analog Input #1, 33

1109

Analog Input #1, 10

1133

Analog Input #1, 34

1110

Analog Input #1, 11

1134

Analog Input #1, 35

1111

Analog Input #1, 12

1135

Analog Input #1, 36

1112

Analog Input #1, 13

1136

Analog Input #1, 37

1113

Analog Input #1, 14

1137

Analog Input #1, 38

1114

Analog Input #1, 15

1138

Analog Input #1, 39

1115

Analog Input #1, 16

1139

Analog Input #1, 40

1116

Analog Input #1, 17

1140

Analog Input #1, 41

1117

Analog Input #1, 18

1141

Analog Input #1, 42

1118

Analog Input #1, 19

1142

Analog Input #1, 43

1119

Analog Input #1, 20

1143

Analog Input #1, 44

1120

Analog Input #1, 21

1144

Analog Input #1, 45

1121

Analog Input #1, 22

1145

Analog Input #1, 46

1122

Analog Input #1, 23

1146

Analog Input #1, 47

1123

Analog Input #1, 24

1147

Analog Input #1, 48

Register Parameter Register Parameter

Super Systems Inc. Page 33 of 34 DAQ Operations Manual

Page 34

Rev.

Description

Date

MCO #

-

Initial Release

7/29/2008

N/A

A

Changed picture formatting to allow text to wrap

Added serial communications setup instructions

12/4/2008

2071

B

Changed manual to new format.

(SDIO) communications.

05/03/2013

2121

Revision History

around; Added “Aux Instruments”,

“Communication Setup”, “Device Configuration”,

“Aux Instrument Setup” Configurator menus;

Modified “Range Setups” Configurator menu;

Added sample curve in “Custom Curves” section;

Changed manual to reflect ability to use 6-pin

connection to RS232 port. This includes the

instrument picture as well as the wiring diagram.

Added new figure for Range Setups > Select New

Value.

Added Modbus register locations for SuperDATA

Super Systems Inc. Page 34 of 34 DAQ Operations Manual

Loading...

Loading...