Page 1

COMPACT HMI AND

COMPACT HMI EDITOR

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

www.supersystems.com

Page 2

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 2 of 60

Super Systems Inc.

Super Systems Europe

Super Systems Mexico

Super Systems China

USA Office

Corporate Headquarters

7205 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Sistemas Superiores Integrales S de RL de CV

Querétaro, QRO CP, MEXICO 76120

Phone: +52 (442) 410 9040

http://www.supersystems.com

Units 3 & 4, 17 Reddicap Trading Estate,

Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627

http://www.supersystemseurope.com

No. 335 XianXia Road

Room 308

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.com

Page 3

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 3 of 60

Table of Contents

Introduction ........................................................................................................................................ 5

Compact HMI Editor ........................................................................................................................... 7

Installation ...................................................................................................................................... 7

Prerequisites .............................................................................................................................. 7

Installation Procedure ............................................................................................................... 7

Solution Overview ........................................................................................................................... 9

Panels ............................................................................................................................................. 9

SSi Options ................................................................................................................................ 11

Tags (Tag Management) ............................................................................................................... 12

Expression Editor ......................................................................................................................... 17

Expression Operators, Constants, and Functions ................................................................... 17

Display Conditions ........................................................................................................................ 19

How Conditions are Prioritized ................................................................................................ 23

Controls ........................................................................................................................................ 26

Indicator Label .......................................................................................................................... 27

Control Button .......................................................................................................................... 29

Image Box ................................................................................................................................. 32

Exporting for the Touch Screen ................................................................................................... 33

Interacting with the Touch Screen .............................................................................................. 34

Using the Main Menu ................................................................................................................... 34

File ............................................................................................................................................ 34

Edit ............................................................................................................................................ 35

Format ...................................................................................................................................... 36

Tools .......................................................................................................................................... 36

Help ........................................................................................................................................... 37

Using the Design Environment Toolbar ...................................................................................... 40

Compact HMI (Use on SSi Touch Screen) ....................................................................................... 43

Prerequisites and Installation ..................................................................................................... 43

Use with Compatible Touch Screens ........................................................................................... 43

Example of Compact HMI Touch Screen Application Design and Rendering ............................ 43

Example Designs ...................................................................................................................... 43

Preparing Solution for Touch Screen ...................................................................................... 49

Page 4

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 4 of 60

Running the Compact HMI Solution......................................................................................... 51

Revision History ............................................................................................................................... 53

Appendix 1: Software Best Practices .............................................................................................. 54

When Configuring Connections and Tags in Compact HMI Editor ............................................. 54

Backing Up Touch Screen Files (.cfxml and .tdx) ....................................................................... 54

When Saving Multiple Solutions .................................................................................................. 54

Backing Up Development Files .................................................................................................... 55

Appendix 2: Font Measurement Units ............................................................................................. 56

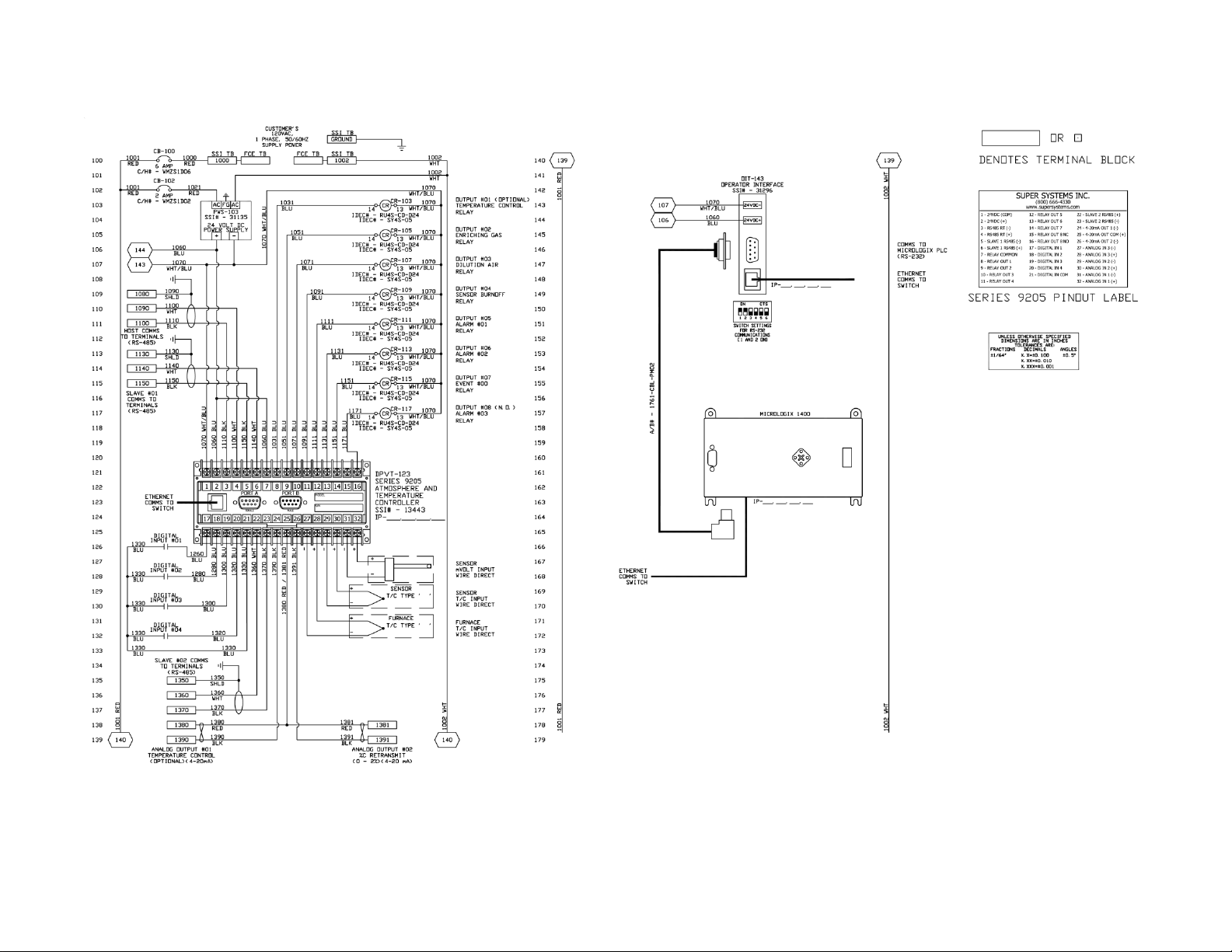

Appendix 3: Typical Wiring Diagrams ............................................................................................. 57

Page 5

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 5 of 60

Introduction

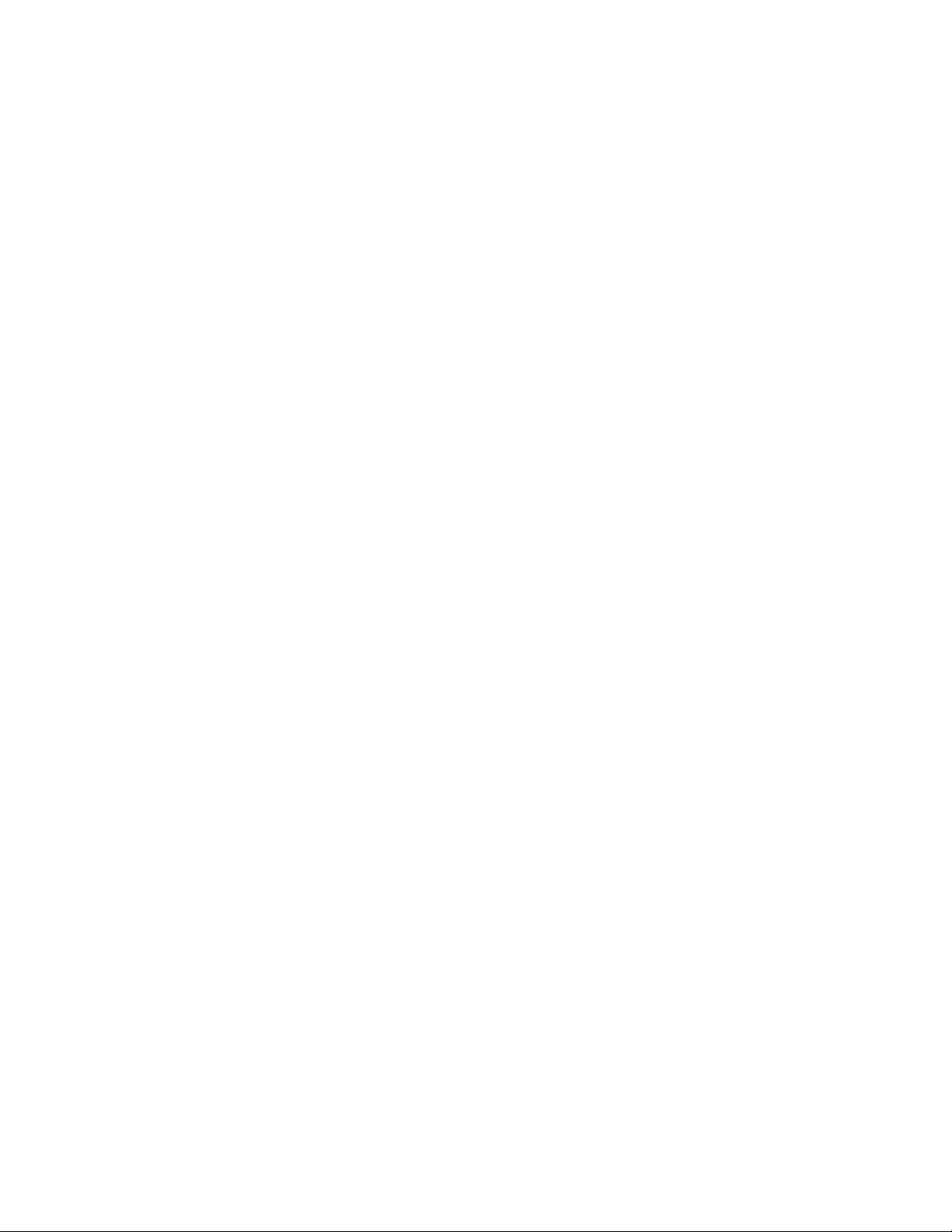

Compact HMI is a software platform that allows you to create customized HMI screens using an

application called

display of equipment, graphical display of process data, and objects used for interaction with

equipment. These screens can then be run on a compatible touch screen that works with Super

Systems Inc. (SSi) 9000 Series controllers. The touch screen application from SSi that provides

the framework for running customized HMI screens is

Compact HMI can handle communications via the Allen-Bradley DF1, Modbus TCP, and Modbus

RTU communication protocols. Using Allen-Bradley DF1, for example, with the touch screen

connected to a compatible data device (such as a MicroLogix 1400 PLC via an RS-232 serial

connection), Compact HMI can perform I/O operations with the data device and can access

register values within the data device. Design tools within Compact HMI Editor allow you to

program evaluations of register values and design multiple panels for use by the operator.

Figure 1 illustrates the components that make up a Compact HMI system.

Compact HMI Editor. A programmed HMI screen can contain a graphical

Compact HMI.

Page 6

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 6 of 60

Figure 1 - Compact HMI Platform components

Page 7

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 7 of 60

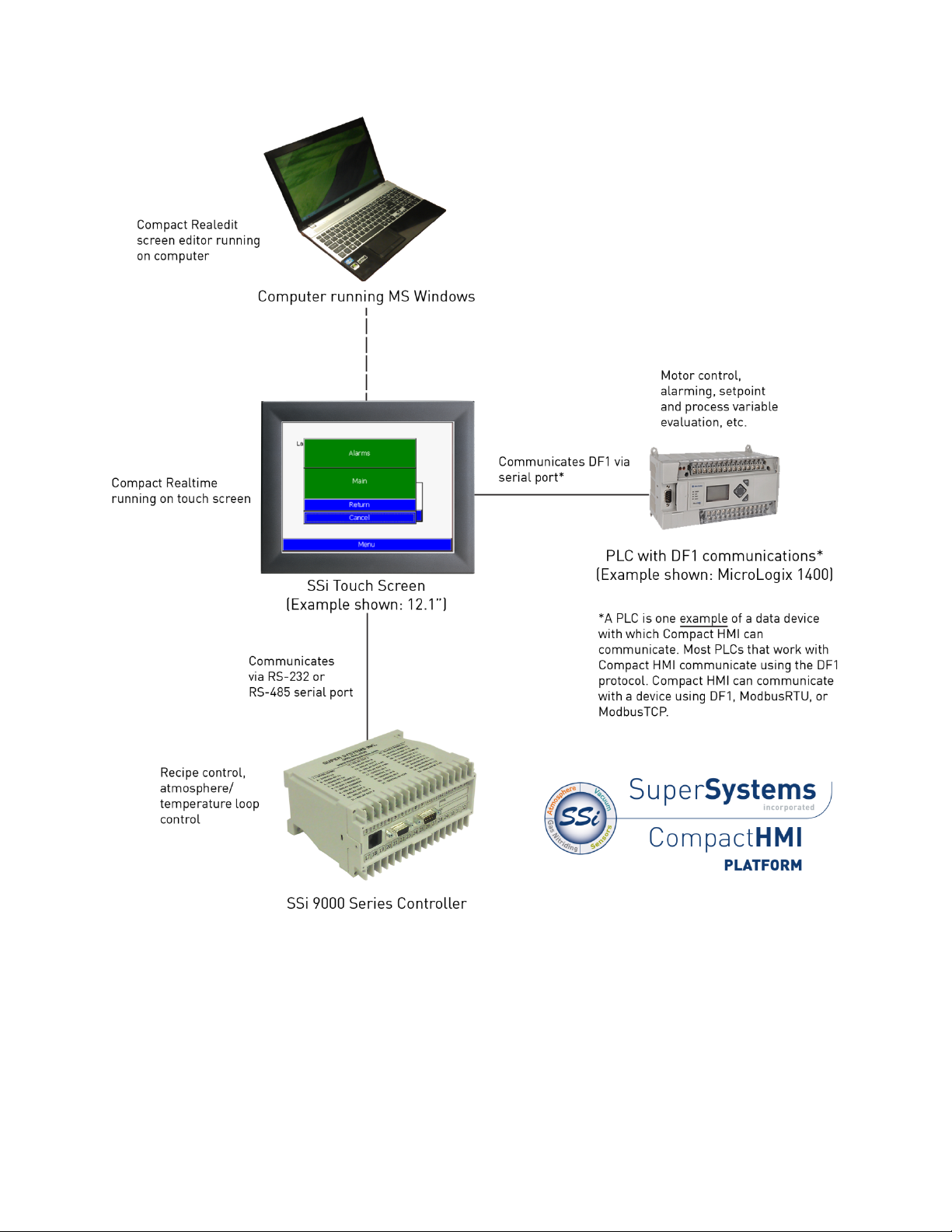

Insert the Compact HMI Editor installation media

those shown in Figure 2.

Figure 2 - Example Installation Files

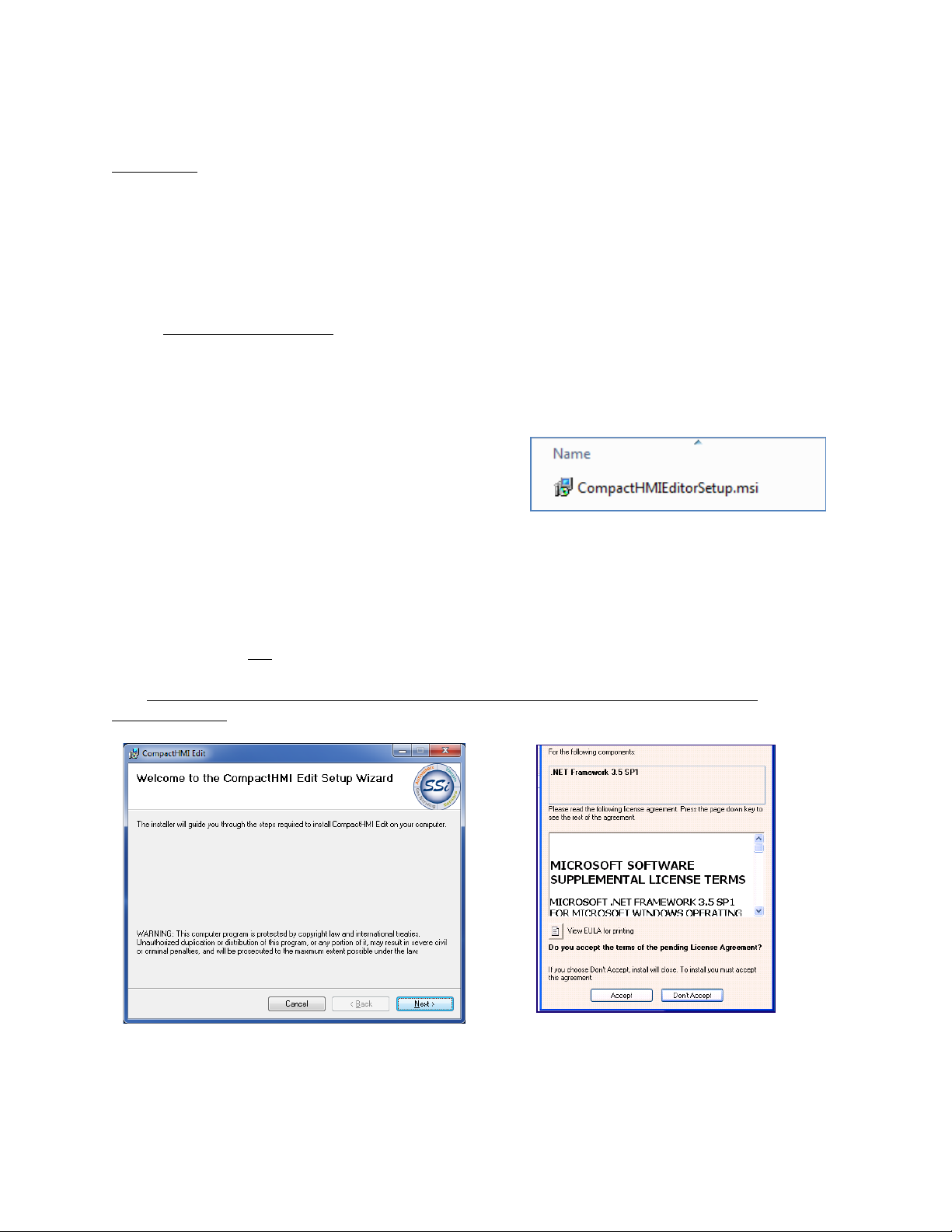

Figure 3 - Compact HMI Editor Setup Wizard screen

Figure 4 - .NET Framework 3.5 Setup Screen

(will appear if needed)

Compact HMI Editor

Installation

Prerequisites

Compact HMI Editor has prerequisites that must be fulfilled in order for the program to run

properly. These include:

• A computer with Windows XP, Vista, 7, or 8

• Microsoft .NET Framework 3.5. Compact HMI Editor setup will install this package if it is not

already present on the computer where Compact HMI Editor is being installed (see Figure

4

). Version 3.5 is required.

In order to use the screen you create with Compact HMI Editor, you need a Super Systems touch

screen with Compact HMI. Refer to the “Use with Compatible Touch Screens” section for more

details.

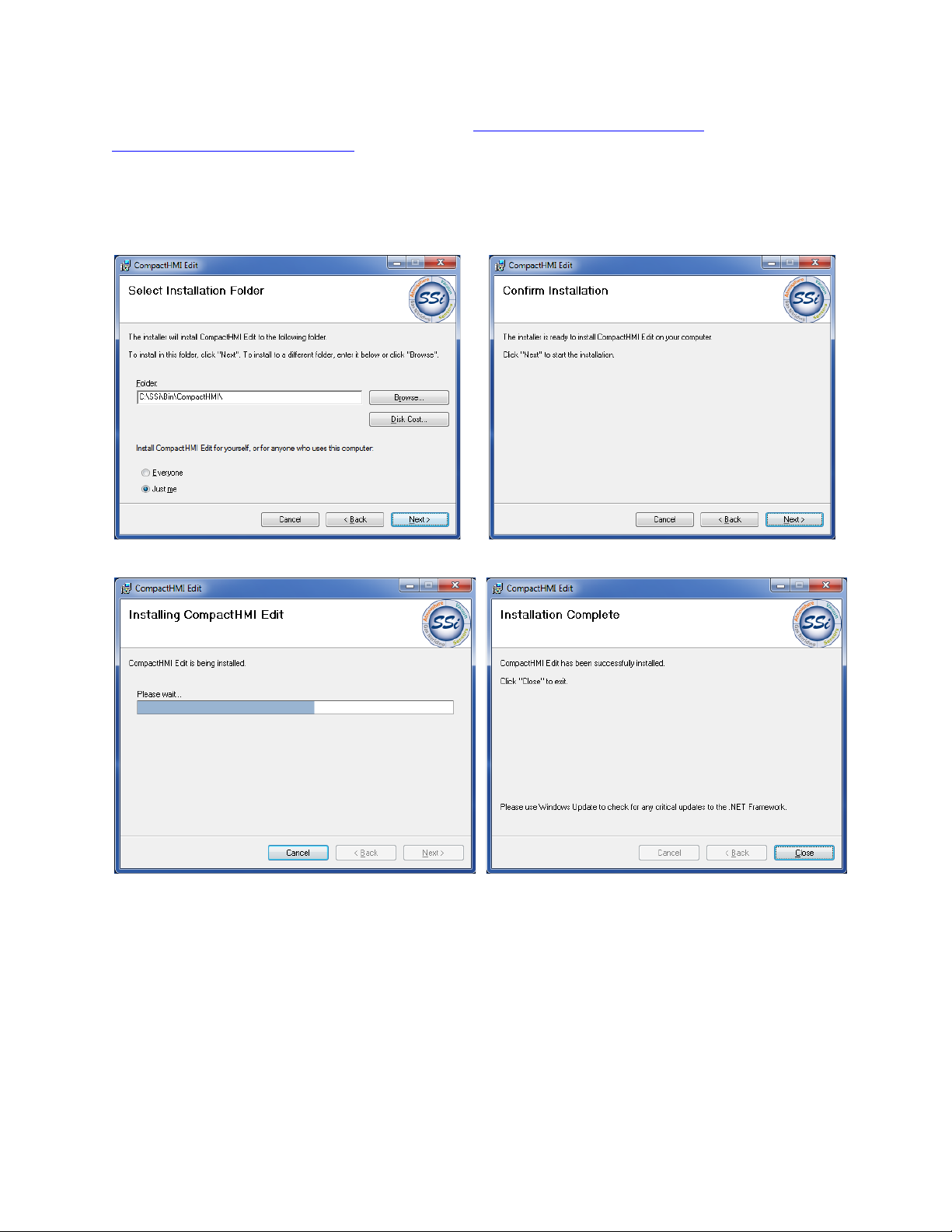

Installation Procedure

into the USB port, CD/DVD drive, or other proper

location. Open Windows Explorer and browse to

the folder containing the Compact HMI Editor

installation files. You will see installation files like

Double click on the “CompactHMIEditorSetup.msi” file.

If Microsoft .NET Framework 3.5 is installed, the Setup Wizard will appear (Figure 3

). If .NET

Framework 3.5 is not installed, the Setup Wizard will first prompt you to install .NET

Framework 3.5 (Figure 4). .NET Framework must be installed before Compact HMI Editor is

run. An Internet connection is needed in order to download the required files for .NET

Framework 3.5.

Page 8

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 8 of 60

The installation URL for .NET Framework 3.5 is http://www.microsoft.com/en-

Setup Wizard.

When ready to proceed with installation of Compact HMI Editor, click the Next button on the first

Compact HMI Editor installation (Figure 5).

us/download/details.aspx?id=21, if for some reason it cannot be installed properly using the

screen of the Setup Wizard. The screens below show typical screens that will appear in a

Figure 5 - Compact HMI Editor Setup Screens (in succession)

Once Compact HMI Editor is installed, you may begin using it.

Page 9

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 9 of 60

Solution Overview

A Solution is a collection of files that will be translated into a complete HMI during runtime.

Each screen within a solution is called a

accessible via the touch screen.

Therefore, a Solution can also be defined as a collection of HMI

Panel. Each Panel represents individual screens

Panels.

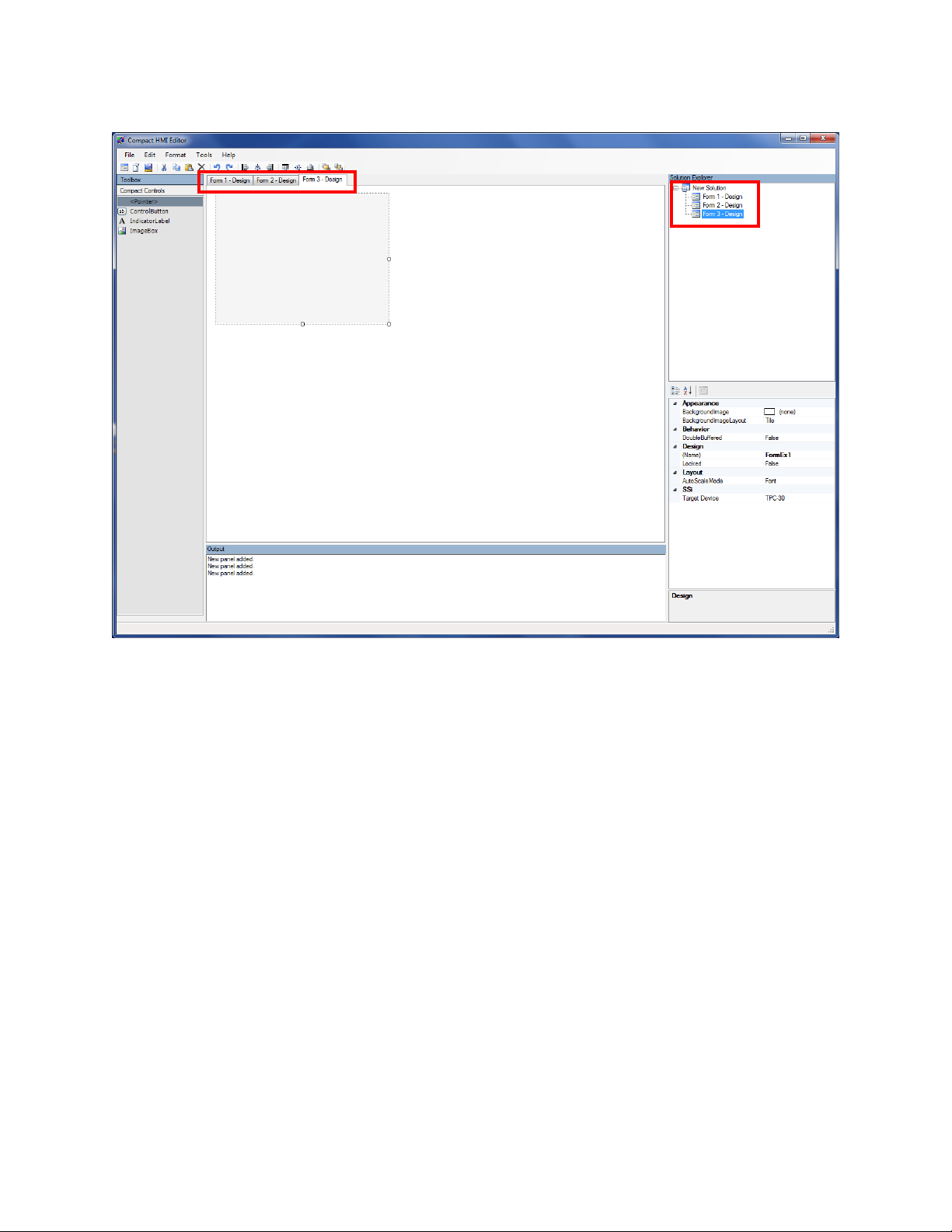

Compact HMI Editor creates display files for each Panel. When Compact HMI Editor is first

started, it will load a new Solution. You will be able to add Panels to the Solution.

Panels

You can add a Panel by using File New Panel or right clicking on the Solution name in the

Solution Explorer in the upper right part of the screen and selecting Panel. The Panel will serve

as a container for your display and command controls. Each Panel can have independent

communication setups and basic visual properties. Compact HMI communicates with a data

device using Allen-Bradley DF1, Modbus RTU, and Modbus TCP communications.

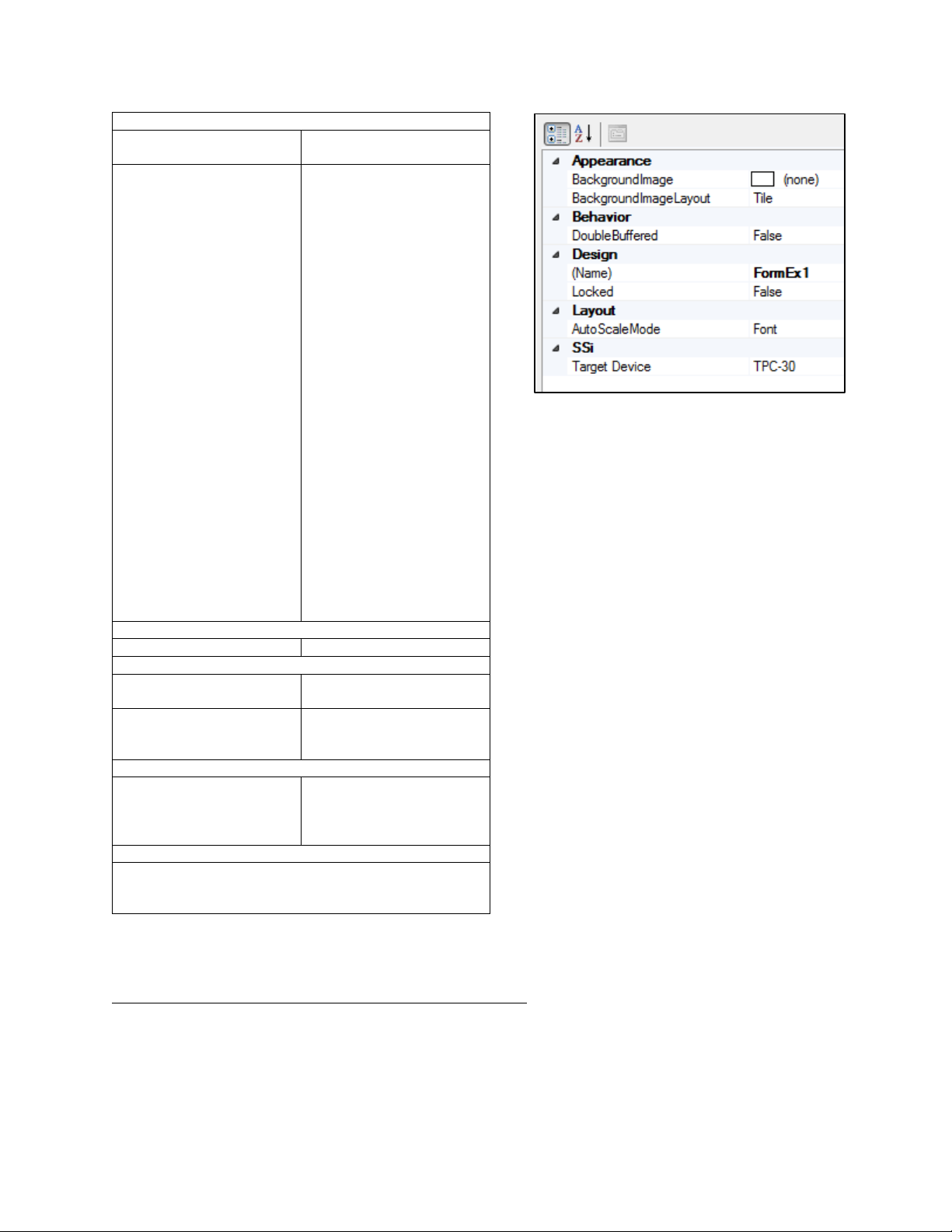

The most common settings to be modified on the Panel are the BackgroundImage (under

Appearance) and the Target Device (under the SSi grouping). The Target Device can be modified

at the Panel level. The Panel size should match the resolution of the target screen, which is

determined by the Target Device selection.

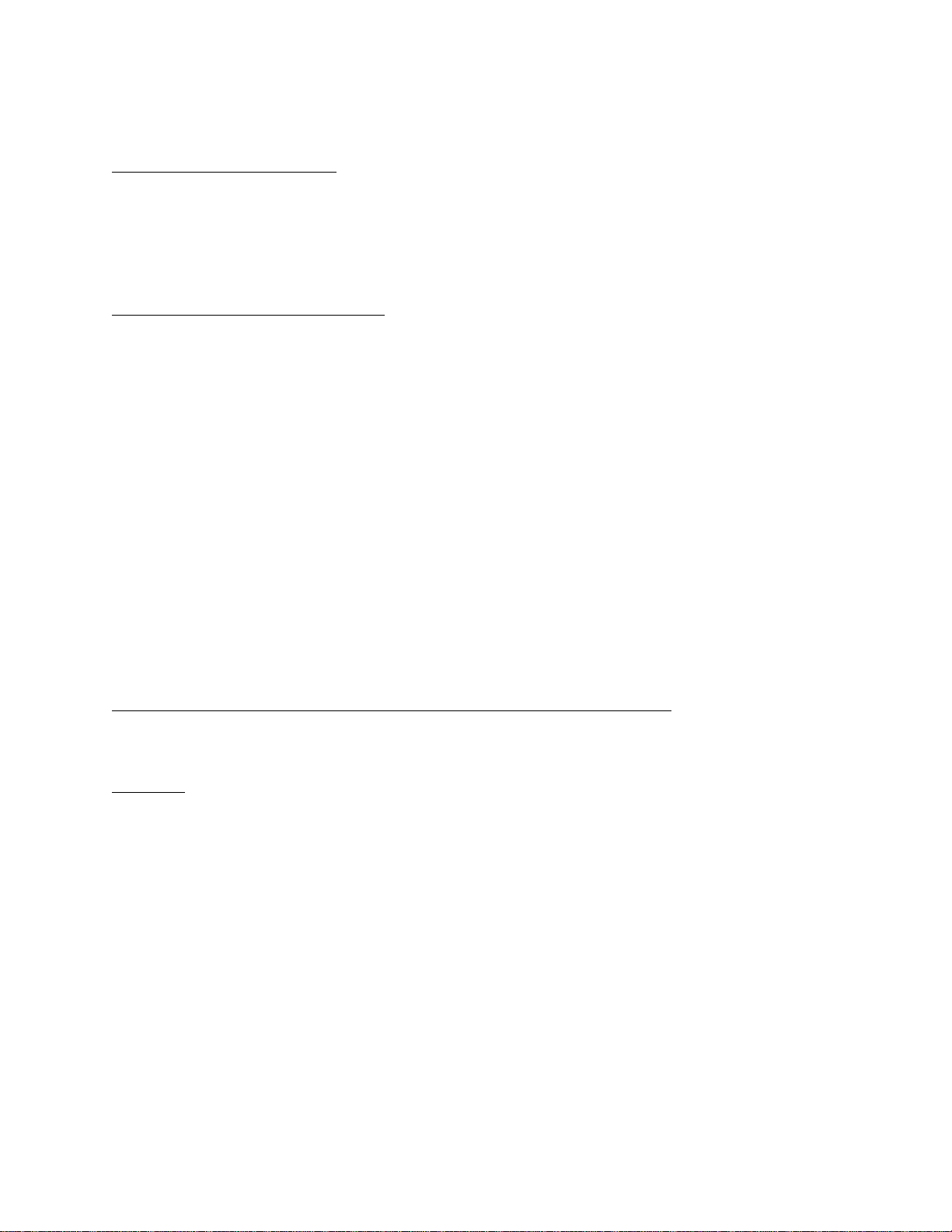

Figure 6 - Compact HMI Editor Design Environment

Page 10

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 10 of 60

Figure 7 - Design Environment with Panels Added

Figure 7 shows a Design Environment view with multiple Panels. On the bottom right is a view of

the Panel's properties.

NOTE: The first Panel created is called “Main” by default. You may change the name of this

Panel (or any others) as you wish. See

Table 1 for descriptions of Panel properties and an

example properties grid in Figure 8.

Remember that Panels can be arranged in the order in which you want them to appear in

Compact HMI on the touch screen. To reorder Panels, simply click and drag each tab into the

order in which you wish it to appear.

Page 11

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 11 of 60

Appearance

BackgroundImage

The background image

used for the Panel

BackgroundImageLayout

The layout used for the

otherwise would.

Behavior

DoubleBuffered

Do not change this setting.

Design

(Name)

Identifies the name used in

code to identify the object

Locked

Determines whether the

resized

Layout

AutoScaleMode

Determines how the form

change

SSi

See the “SSi Options” section below.

Table 1 - Panel properties

Figure 8 - Panel properties grid

background image.

Possible settings are:

• None: Image will be

applied with no

changes to its

appearance.

• Tile: Image will be tiled

multiple times in the

background (the

smaller the image's

dimensions, the more

frequently it will

appear)

• Center: The image will

be centered in the

background.

• Stretch: The image will

be stretched to fit the

background area.

• Zoom: The image will

be enlarged within the

background area. Note

that the visible part of

the image will appear

larger than it

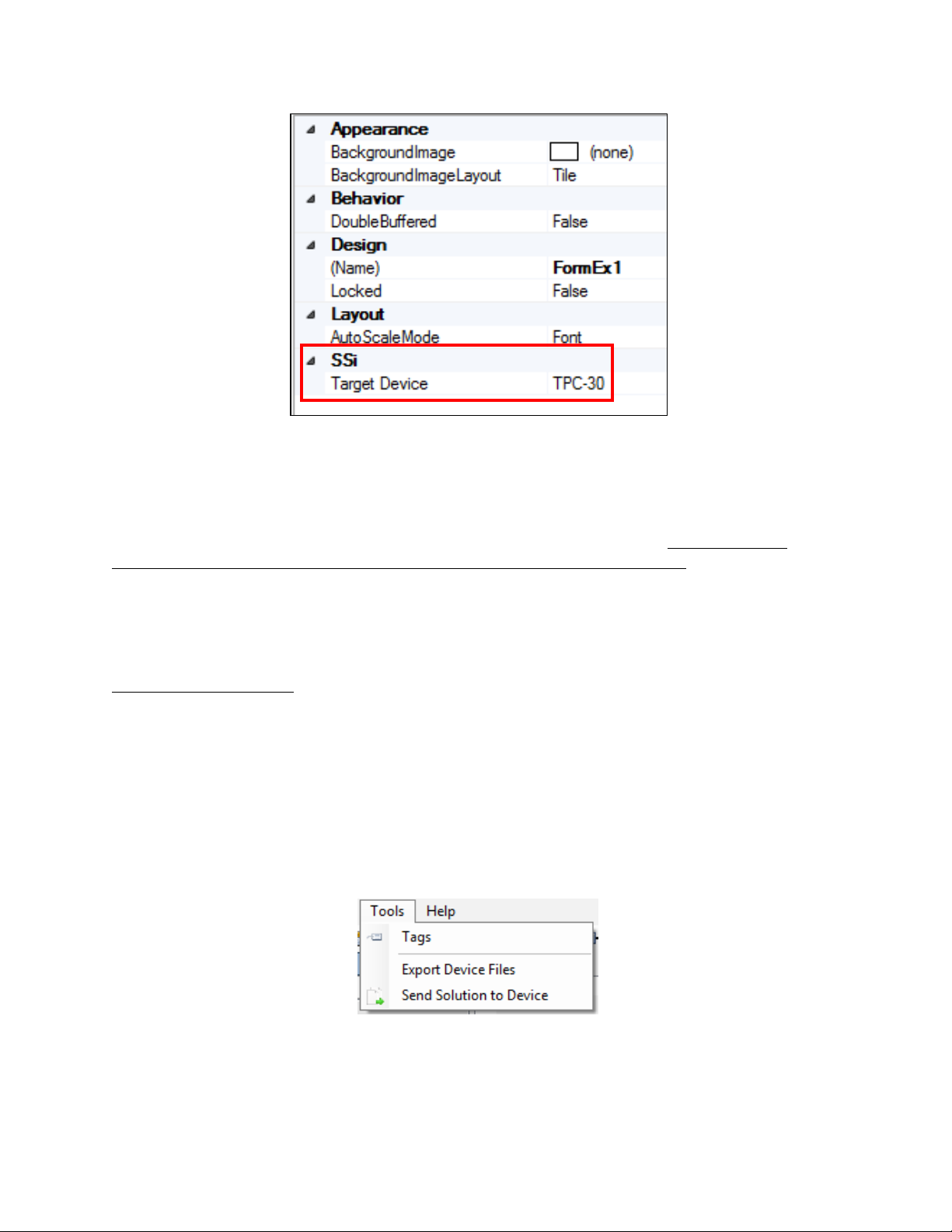

SSi Options

The active panel must be selected for this to be visible. If a control object is currently selected,

for example, the options will not be visible. Figure 9 shows what the options look like in the

Design View.

control can be moved or

or control will scale when

screen resolution or fonts

Page 12

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 12 of 60

Figure 9 - SSi Options

Target Device: The touch screen device model on which the Compact HMI will be running.

Models can be selected from a drop-down list. Typically, the models will start with “TPC-“ and

end in a number, sometimes followed by one or more letters. If the model starts with “TPC-3,”

the screen size is usually 3.5”. If the model starts with “TPC-6”, the screen size is usually 5.7”.

Finally, if the model starts with “TPC-12”, the screen size is usually 12.1”

This setting will

determine the size of each panel in the Solution and is extremely important. An incorrect

setting will result in the panels being rendered incorrectly—or not being rendered at all—on the

touch screen.

Contact SSi at (513) 772-0060for help with setting up these options.

Tags (Tag Management)

Compact HMI Editor includes a database framework that allows you to associate connections

with tags and tags with register locations. Each connection is identified by a user-defined name

along with relevant connection details. Each tag is associated with a 16-bit word register. All of

the connection, tag, and register data is contained in a “tags database” that Compact HMI

maintains. This approach allows you to configure Compact HMI to access data in a

straightforward and organized fashion.

To access the tags database, click on Tools Tags (Figure 10) in the Compact HMI Editor main

window.

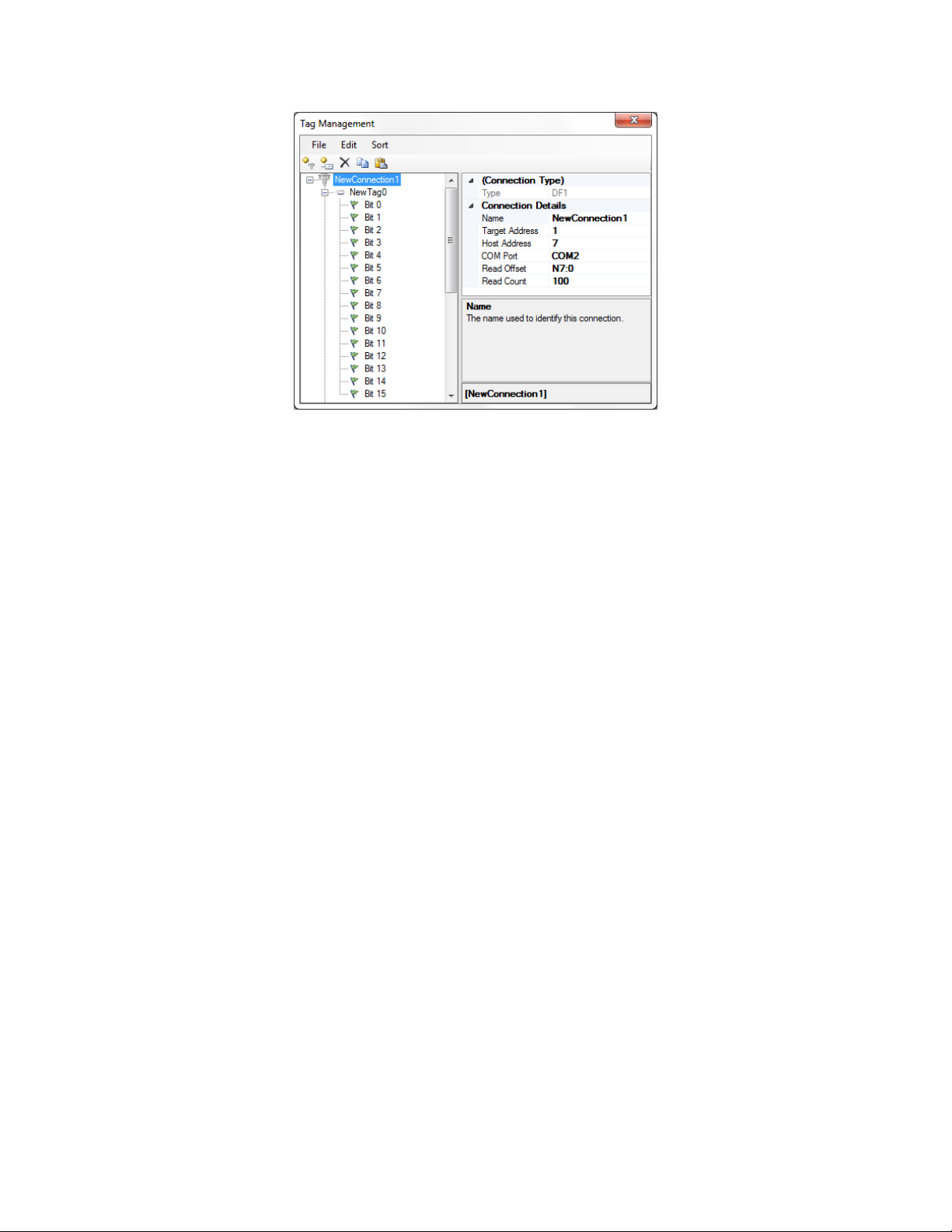

The Tag Management window will appear (Figure 11). In the example screen shot in Figure 11,

the window is populated with connection, tag, and bit data. More information is provided in this

section on how to configure connection, tag, and bit settings.

Figure 10 - Tag Management

Page 13

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 13 of 60

Figure 11 - Tag Management window

In the Tag Management window, you can perform several actions:

• Create a new connection name and define the connection parameters;

• Create a new tag under a connection name and associate it with a register location;

• Name tags and register bits associated with tags by using specific designations such as

Input, Output

, and

Alarm

;

• Identify bits that are associated with a bit alarm;

• Filter tags by search string (partial strings are okay); and

• Remove existing connections, tags, and bit definitions.

In the Tag Management window, the File menu provides these options: Add Connection, Add

Tag, and Close. Select Add Connection to add a new connection, Add Tag to add a new tag, and

Close to close the Tag Management window.

Page 14

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 14 of 60

For Allen-Bradley DF1 Connections

SSi 9000 Series controller.

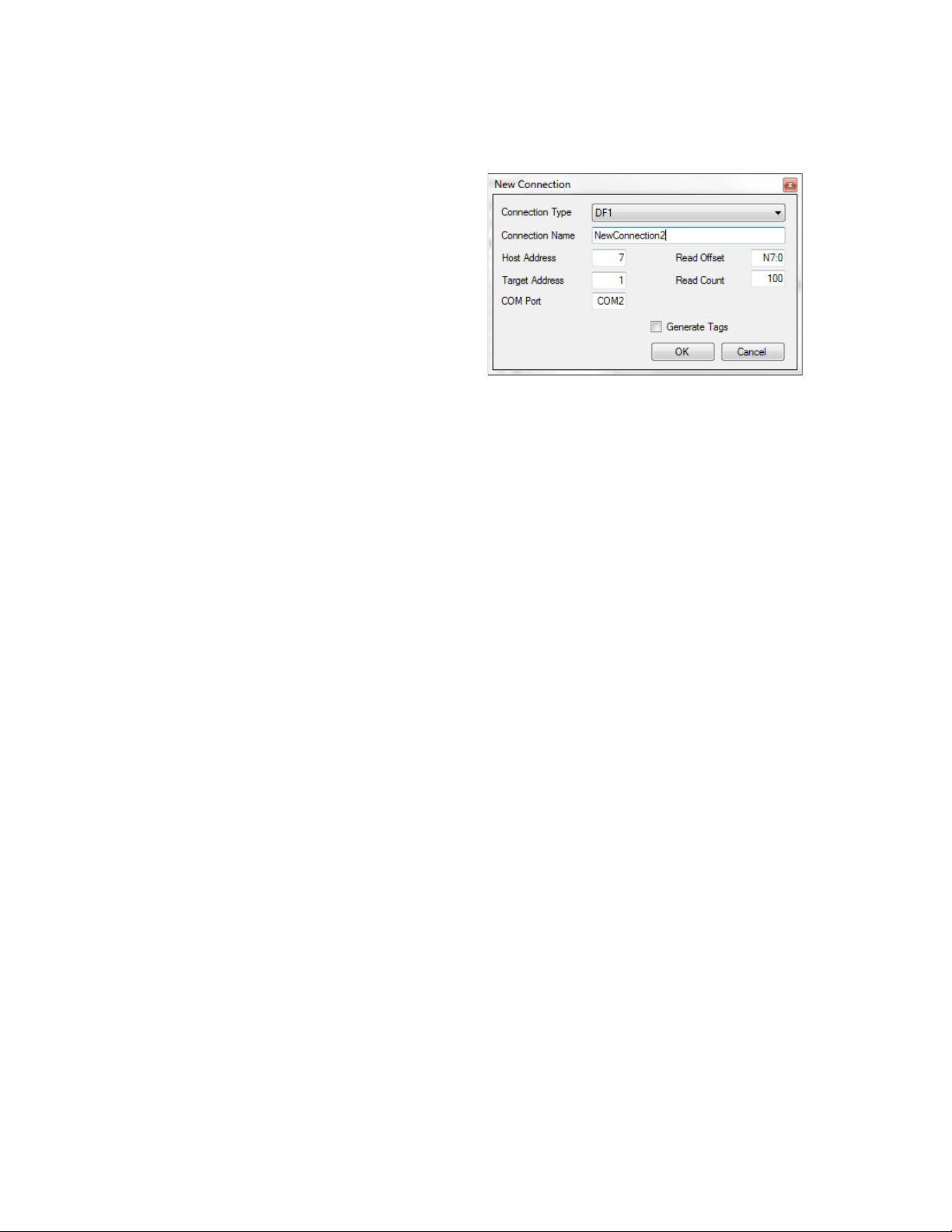

Figure 12 – New Connection window (DF1)

Connection properties are first defined in the New Connection window (Figure 12). The

parameters that must be set are as follows:

(Example: Figure 12)

• Connection Type: The protocol used

for communication between Compact

HMI and the data device. Available

settings are DF1, ModbusRTU, and

ModbusTCP.

• Connection Name: The user-defined

name for the Connection.

Recommended:

Use a Connection

Name that can be easily associated

with the data device and register

locations from which Compact HMI

will be reading and writing data.

• Host Address: The address of the

touch screen. Normally, this setting

can be kept as the default.

• Target Address: The address of the

data device. Normally, this setting can

be kept as the default.

• COM Port: The COM (serial) Port with

which the Compact HMI touch screen

will be connected to the data device.

This must match the actual COM Port

on which the serial cable is connected

to the touch screen.

The default COM Port is COM 2. Some

touch screens may have only one COM

Port. In such a case, COM 1 will need

to be used for the data device

connection, and an Ethernet

connection will need to be used for the

• Read Offset: The register address where

Compact HMI starts reading. This must be

defined to the word level within the data device.

• Read Count: The default number of registers,

starting with the Read Offset, that will be read.

The default is 100. This value must not exceed

the number of registers actually defined within

the data device.

Generate Tags checkbox: When checked, this

checkbox will cause tags to be generated. The tags

generated will be based on the Read Offset and

Read Count defined in this menu. For example,

with default settings, the tags generated will start

“N7:0” and end “N7:99”. Bits will be created for

each tag as well (Bit 0 through Bit 15).

Page 15

Super Systems Inc.

Page 15 of 60

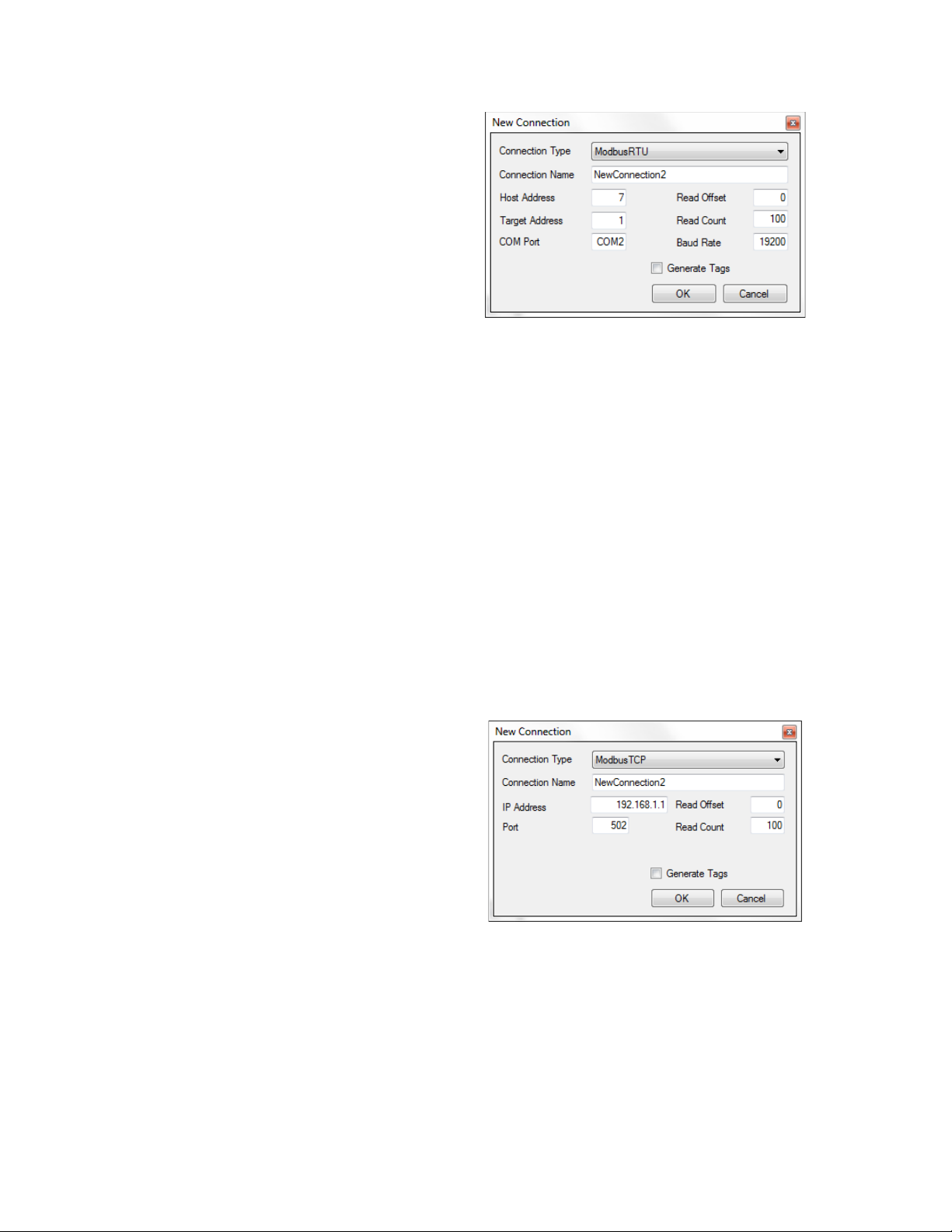

For ModbusRTU Connections

(Example: Figure 13)

Figure 13 – New Connection window (ModbusRTU)

For ModbusTCP Connections

Figure 14 – New Communications Window (ModbusTCP)

named Tag0, Tag1, and so on, through Tag99.

• Host Address: The address of the

touch screen. Normally, this setting

can be kept as the default.

• Target Address: The address of the

data device. Normally, this setting can

be kept as the default.

• COM Port: The COM (serial) Port with

which the Compact HMI touch screen

will be connected to the data device.

This must match the actual COM Port

on which the serial cable is connected

to the touch screen.

The default COM Port is COM 2. Some

touch screens may have only one COM

Port. In such a case, COM 1 will need

to be used for the data device

connection, and an Ethernet

connection will need to be used for the

SSi 9000 Series controller.

• Read Offset: The register address

where Compact HMI starts reading.

This must be defined to the word level

within the data device.

Compact HMI and Compact HMI Editor Operations Manual

• Read Count: The default number of registers,

starting with the Read Offset, that will be read.

The default is 100. This value must not exceed

the number of registers actually defined within

the data device.

• Baud Rate: The rate (in units per second) at

which communications bits are sent between

the touch screen and data device. The default is

19200.

Generate Tags checkbox: When checked, this

checkbox will cause tags to be generated. The tags

generated will be based on the Read Offset and

Read Count defined in this menu. For example, if

the Read Offset is 0 and the Read Count is 100, the

tags generated will be named Tag0, Tag1, and so

on, through Tag99.

(Example: Figure 14)

• IP Address: The IP address of the data

device.

• Port: The port number on the data

device through which the data device

will exchange data.

• Read Offset: The register address

where Compact HMI starts reading.

This must be defined to the word level

within the data device.

• Read Count: The default number of

registers, starting with the Read

Offset, that will be read. The default is

100. This value must not exceed the

number of registers actually defined

within the data device.

• Generate Tags checkbox: When checked, this

checkbox will cause tags to be generated. The

tags generated will be based on the Read

Offset and Read Count defined in this menu.

For example, if the Read Offset is 0 and the

Read Count is 100, the tags generated will be

Page 16

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 16 of 60

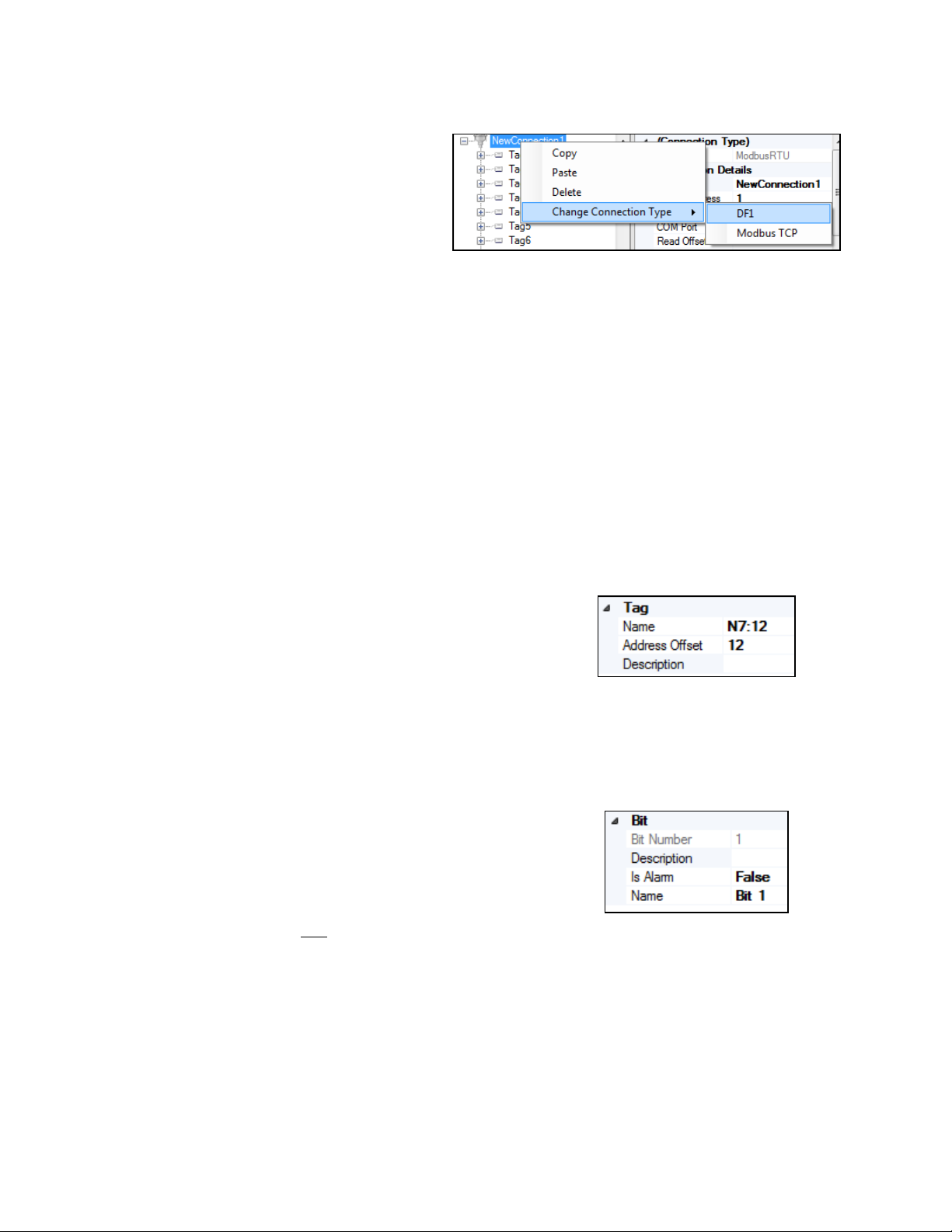

Connection types can be changed after a

Figure 15 - Change Connection Type option

Using the tag properties grid, you can name the tag set

Figure 16 - Tag "Data" fields

Each register is made up of 16 bits. The bits are

This feature is intended for future use.

Figure 17 - Bit fields

connection is defined. To do this, right

click on the Connection Name, select

“Change Connection Type”, and select the

Connection Type desired. See an example

in

Figure 15.

The Edit menu allows you to copy an existing connection or tag with all of its properties and bit

settings. Do this by first selecting the item you want to copy, then click

and then click

“

ItemName –

Finally, using the

Paste in the Edit menu. The new (copied) item will be added to the tags list as

Copy(

number

)”. Using the Edit menu’s Delete option, you can remove an item.

Find & Replace option, you can direct Compact HMI Editor to search for a

Copy in the Edit menu,

specific string of text in tag names and replace that text names with text that you enter.

The Sort menu allows you to order connection names and tags alphabetically (by name) or by

address (in the case of tags, that is the register address associated with the tag). Sorting can be

performed in ascending or descending order.

and address offset, and enter a brief description. See

Figure 16.

The default name of the tag will be “NewTag

x

is a sequential number. The Address Offset will be

applied to the Data Offset previously assigned to the

Panel. For example, referring to Figure 9 and Figure

16, if a Data Offset of N7:0 and Address Offset of 4 are

defined, the actual register being evaluated will be

N7:4.

numbered 0 through 15. Compact HMI Editor allows

you to name each bit, add a brief description, and

identify whether the bit is an alarm bit (see

If “Is Alarm Bit” is set to False, Compact HMI will not

identify the bit as an alarm bit; if “Is Alarm Bit” is set to

True, then Compact HMI will identify the bit as an

alarm bit. The default setting for this field is False.

Once configured, tags are used with Compact HMI’s control objects to help determine display

conditions and other characteristics of a control system.

x”,

where

Figure 17).

Page 17

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 17 of 60

Please refer to Appendix 1: Software Best Practices, “When Configuring Connections and Tags

in Compact HMI Editor,” for information on best practices for configuring connections and tags

in Compact HMI Editor.

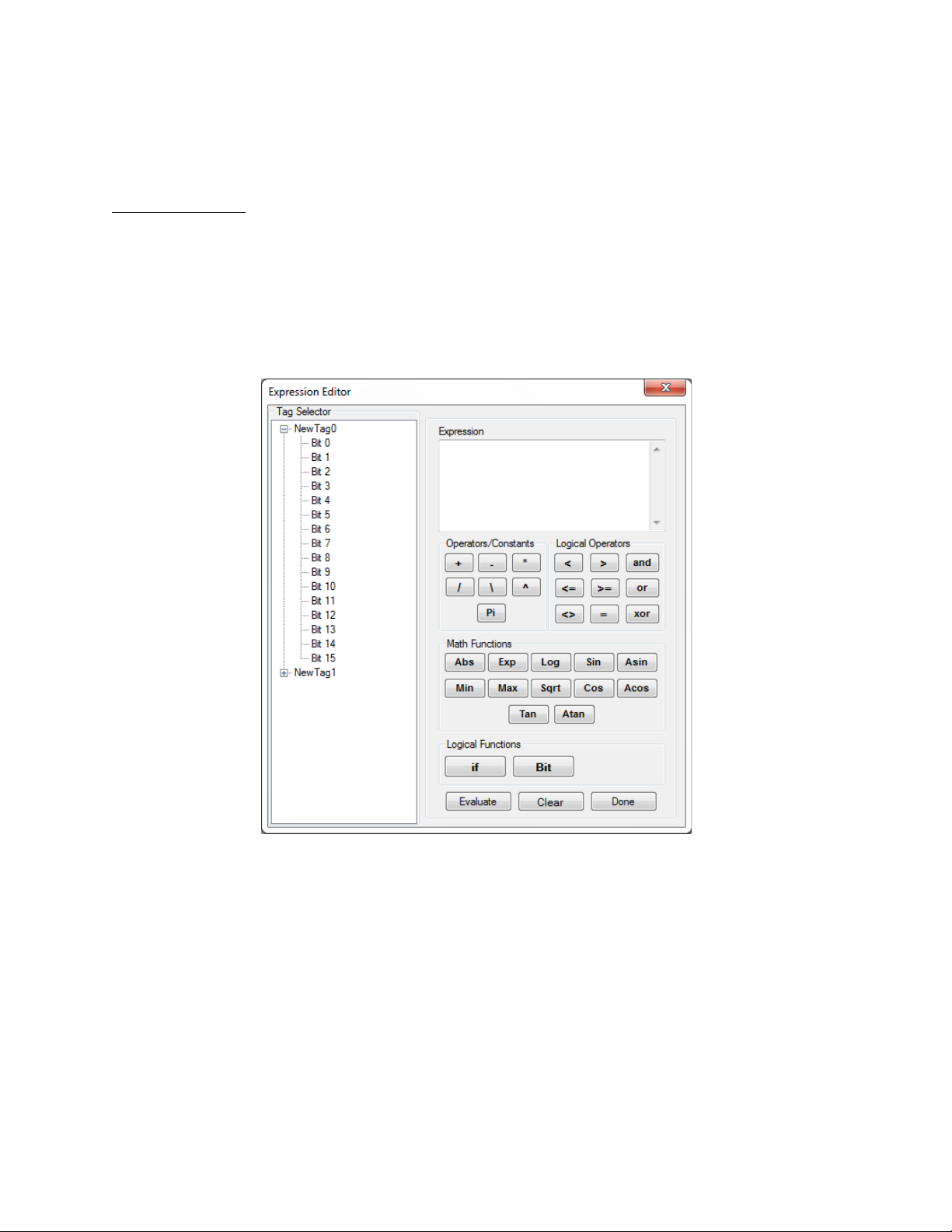

Expression Editor

The Expression Editor is used in conjunction with two Control properties: Display Expression

and Display Conditions. The Expression Editor will be displayed when Display Expression or

Display Conditions is selected (for example, from the Control Properties Grid).

NOTE: Some Display Conditions (described in more detail below) and the Expression Editor

utilize Tags.

Expression Operators, Constants, and Functions

Tag names identify register locations within a data device. Each register is constituted by a word

containing 16 bits. Compact HMI Editor provides ways of evaluating values contained within data

device registers against values defined by the user. In order to program valid expressions, it is

important to understand the expression syntax used in Compact HMI.

A Tag can be called using the following syntax:

Tag(“[ConnectionName]TagName”) where

connection and

A particular bit can be called according to one of the following two syntaxes:

TagName

Figure 18 - Expression Editor window

ConnectionName

is the name of a defined Tag within that connection.

is the name of a defined

Page 18

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 18 of 60

Operator/Constant/

Function

Purpose

Examples of Use in Valid Expression

Operators and Constants

+

Performs an addition

Tag(“[Connection1]N7:0”) + 15

- Performs a subtraction

Tag(“[Connection1]N7:0”) - 15

*

Performs a multiplication

Tag(“[Connection1]N7:0”) * 15

/

Performs a division and

(division)

Tag(“[Connection1]N7:0”) / 15

Note: 3/2 returns 1.5

\

Performs a division and

(modulus)

1 / Tag(“[Connection1]N7:1”)

Note: 3\2 returns 1

^

Performs an exponential

Tag(“[Connection1]N7:0”) ^ 3

Pi

Returns the value of Pi,

diameter

Pi + Tag(”[Connection]N7:0”)

Logical Operators

<

Less than

Tag(“[Connection1]N7:0”) < Tag(“[Connection1]N7:1”)

>

Greater than

Tag(“[Connection1]N7:0”) > 1

And

Inclusive of more than one

condition

(Tag(“[Connection1]N7:0”) < 10) and

(Tag(“[Connection1]N7:0”) > 5)

<=

Less than or equal to

Tag(“[Connection1]N7:0”) <= 3

>=

Greater than or equal to

Tag(“[Connection1]N7:0”) >= 3

Or

Inclusive of either/or

condition

(Tag(“[Connection1]N7:0”) < 1) or (Tag(“[Connection1]N7:3”) >

14)

<>

Not equal to

Tag(“[Connection1]N7:0”) <> Tag(“[Connection1]N7:1”)

=

Equal to

Tag(“[Connection1]N7:0.1”) = 0

1. Tag(“[ConnectionName]TagName.BitName”) where

name of a defined Connection,

connection, and

BitName

TagName

is the name of a defined Tag within that

is the name of a defined bit within the register represented by

ConnectionName

is the

TagName.

2. Bit(BitNumber,Tag(“[ConnectionName]TagName”)) where BitNumber is the

number of a bit (0 to 15) within the register represented by

connection

ConnectionName.

TagName

that is part of the

In most cases, Tags and bits will be called for the purpose of:

1. Calculating a value, which will typically be displayed and sometimes scaled before being

displayed; or

2. Evaluating a condition as True or False.

Table 2 provides details on the operators, constants, and functions that can be used in Compact

HMI Editor; the purpose of each; and examples of how they may be used in a valid expression.

keeps the decimal value

drops the decimal value

calculation (calculates a

number raised to a certain

power)

which is the ratio of the

circle’s circumference to its

3^3

Note: Pi by itself returns 3.14159265358979

Page 19

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 19 of 60

Operator/Constant/

Function

Purpose

Examples of Use in Valid Expression

Xor

Inclusive of one condition,

condition

(Tag(“[Connection1]N7:0”) <= 15) xor

Math Functions

Abs

Absolute value

Abs(Tag(“[Connection1]N7:0”))

Exp

Calculates base e raised to a

Exp(Tag(“[Connection1]N7:0”))

Note: Exp(3) calculates e to the power of 3

Log10

Base 10 logarithm

Log10(Tag(“[Connection1]N7:0”))

Log10(100) returns 2

Sin

Sine (trigonometric)

Sin(Tag(“[Connection1]N7:0”))

Asin

Arcsine or inverse sine

(trigonometric)

Asin(Tag(“[Connection1]N7:0”))

Min

Minimum

Min(Tag(“[Connection1]N7:0”),Tag(“[Connection1]N7:1”),

Tag(“[Connection1]N7:2”),Tag(“[Connection1]N7:3”))

Max

Maximum

Max(Tag(“[Connection1]N7:0”),Tag(“[Connection1]N7:1”),

Tag(“[Connection1]N7:2”),Tag(“[Connection1]N7:3”))

Sqrt

Square root

Sqrt(Tag(“[Connection1]N7:1”))

Cos

Cosine (trigonometric)

Cos(Tag(“[Connection1]N7:1”))

Acos

Arccosine or inverse cosine

(trigonometric)

Acos(Tag(“[Connection1]N7:1”))

Tan

Tangent (trigonometric)

Tan(Tag(“[Connection1]N7:1”))

Atan

Arctangent or inverse

tangent (trigonometric)

Atan(Tag(“[Connection1]N7:1”))

Logical Functions

If

Returns a value of TRUE or

condition is false)

If(Tag(“[Connection1]N7:0”)<Tag(“[Connection1]N7:1”),1,0)

exclusive of a second

specified power

FALSE

Syntax:

If(condition,return_if_true

,return_if_false)

condition is the condition

evaluated,

is the value returned if the

condition is true,

return_if_false is the

value returned if the

, where

return_if_true

(Tag(“[Connection1]N7:0”) = 5)

Note: If(2<3,1,0) returns 1

Table 2 - Expression Operators, Constants, and Functions in Expression Editor

Display Conditions

Display Conditions determine display elements for control objects by using the results of

evaluated expressions. The display conditions are found in the properties grid for controls. You

can also bring up the display conditions by double clicking on the control object for which you

want to set the display conditions.

NOTE: Some Display Conditions and the Expression Editor (described in more detail above)

utilize Tags.

Page 20

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 20 of 60

Figure 19 - Display Conditions window

Figure 19 shows the base window that appears when Display Conditions are opened. Note the

expanded list of options shown below the (

options from the

File Add Condition menu selection. Both show the categories of display

conditions that can be applied to a control based on evaluations described in “

Add Condition) button. You can also access these

Expression

Editor“. These categories are as follows:

• Background Color affects the background color of the control.

• Position affects the position of the control.

• Size affects the size of the control.

• Text affects the text displayed within the control.

• Text Color affects the color of the text displayed within the control.

• Visibility affects whether the control is visible (true) or not (false).

Once you have added a condition, Compact HMI Editor will create a category for the condition,

as shown in Figure 20. The number of conditions in each category will be the total number of

conditions that have been added to that category. Each condition will have the name of the

category to which the condition applies until you change the condition’s name, as described

below.

Page 21

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 21 of 60

Figure 20 - Conditions window with conditions added

To change the name of the condition, click on the name of the condition shown in the “Name”

field of the property grid (Figure 21).

Page 22

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 22 of 60

Figure 21 - Changing condition name

The “Text” field contains the text that will be displayed when the condition is applied.

The “Expression” field determines whether the condition is true or false, in this case. Setting up

an expression is described in “Expression Editor”.

To delete a condition, simply right click on the condition in the list on the left bar, and then click

Delete (Figure 22), or use the “X” ( ) button.

Figure 22 - Delete option

Page 23

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 23 of 60

How Conditions are Prioritized

Compact HMI will evaluate each condition in a linear order—from top to bottom as each

condition appears in the list of conditions in Compact HMI Editor. To change the priority of a

condition, simply use the arrow buttons ( and ) or right click on the condition whose

priority you want to change and click “Move Up” or “Move Down” as needed.

As conditions are evaluated as true or false, the following rules will be applied:

• When a condition is false, no action will be taken.

• When a condition is true, the action associated with that condition will be implemented.

• When more than one condition in a single category is true, the last condition that is true

will be the condition whose associated action is implemented.

• When all of the conditions in a single category are false, the setting associated with that

category will be set to the default.

Consider the following cases.

Page 24

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 24 of 60

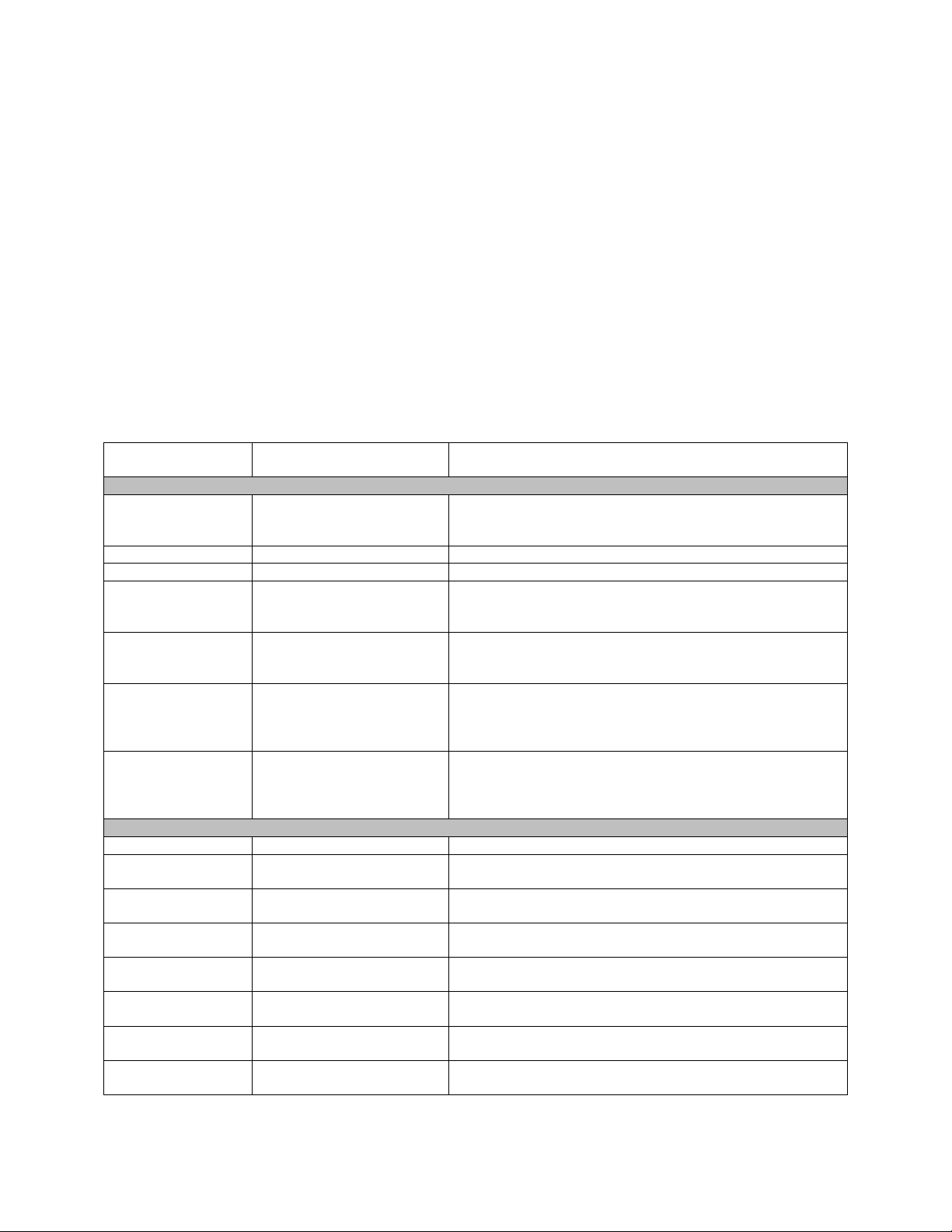

Case 1: All Conditions Are Evaluated as True

Category

Condition Name

Order of

Evaluation within

Category

Condition

True or False

Result

Background Color

RedBackgroundColor

First

Machine is in alarm

state

True

Background color

implemented

Background Color

BlueBackgroundColor

Second

Machine is running

True

Background color

implemented

Background Color

YellowBackgroundColor

Third

Machine is not

running

True

Background color

implemented

Table 3 - Example of Condition Evaluation (All True)

Case 2: At Least One Condition Is Evaluated as True, the Others as False

The examples below could apply to a number of scenarios. For illustration, assume that Compact HMI controls were developed for a

batch furnace. When designing the HMI, the interface designer wanted to make sure that the control clearly indicates conditions

such as running and alarm states so that the operator is aware of the those states. The following are programmed conditions that

were evaluated as true or false by Compact HMI and how those evaluations affect the actions taken within a condition category on the

control.

In the first example, a control’s background color is changed based on running conditions of the furnace. RedBackgroundColor,

BlueBackgroundColor, and YellowBackgroundColor are true. However, the YellowBackgroundColor action will be the one

implemented and seen by the user; the reason for this is that YellowBackgroundColor occurs after the other two in the list of

conditions. If RedBackgroundColor should take priority over BlueBackgroundColor and YellowBackgroundColor,

RedBackgroundColor should be moved so that it occurs after the other two in the list.

In this example, text displayed in a control changes based on whether an alarm state is present, the furnace is running normally with

no alarms, the furnace is shut down, or the furnace is starting up. In the case of the Text category, AlarmActiveText is true;

therefore, text programmed for the AlarmActiveText condition will be the text shown. Compact HMI Editor evaluated the remaining

Text conditions and found them to be false. Therefore, even though AlarmActiveText occurs first in the Text category, it will still be

Page 25

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 25 of 60

Category

Condition Name

Order of

Evaluation within

Category

Condition

True or False

Result

Text

AlarmActiveText

First

One or more alarms

are on

True

Alarm text displayed

Text

NormalOpText

Second

Machine is running

with no alarms

False

No change

Text

ShutdownText

Third

Machine is shut down

False

No change

Text

StartupText

Fourth

Machine is starting up

False

No change

Table 4 - Example of Condition Evaluation (At Least One True, Others False)

Case 3: All Conditions Are Evaluated as False

Category

Condition Name

Order of Evaluation

within Category

Condition

True or False

Result

Visibility

HeatModeOff

First

The heating cycle is

not running

False

No change

Visibility

AutoModeOn

Second

The machine is in

adjusted)

False

Control is displayed

Table 5 - Example of Condition Evaluation (All False)

the condition whose text is displayed on the control. This does not change until (A) AlarmActiveText is evaluated as false or (B) one of

the conditions following AlarmActiveText is evaluated as true.

The HMI programmer wants a control to be visible when a heating cycle is running and the user wants to manually control the cycle’s

output; this is the default setting for the control. The HMI programmer set up the control so that the control will not be visible when

either the heating cycle is not running or the furnace is in Auto (non-manual) mode. In this case, the heating cycle is running and the

machine is not in Auto mode. Both conditions in the Visibility category are evaluated as false; therefore, the default action (to display

the control) is taken.

Auto mode (output

cannot be manually

Page 26

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 26 of 60

Controls

Compact HMI includes multiple control objects available for use in designing Panels. All

controls will have customizable states that can be applied, allowing the user to conditionally

change many of the properties of the controls. These states are described in more detail in the

“Display Conditions” section.

• The Indicator Label is used for creating graphical displays of data. The user can specify

the format in which the data will be displayed.

• The Image Box is used to display an image on the Panel.

• The Control Button is used for controlling the process data. The control button supports

the following actions:

Value, and Open Menu.

Once the control is added to the Panel, you can select the control and edit its properties. All of

the controls use an offset from the base read defined in the Panel object.

Controls are in the Toolbox on the left side of the visual editor. These controls are what you will

use to display data or take action. Adding a Control is as simple as double-clicking the Control

you want to add.

Set Bit, Reset Bit, Toggle Bit, Send Value, Ask User and Send

Page 27

Super Systems Inc.

Page 27 of 60

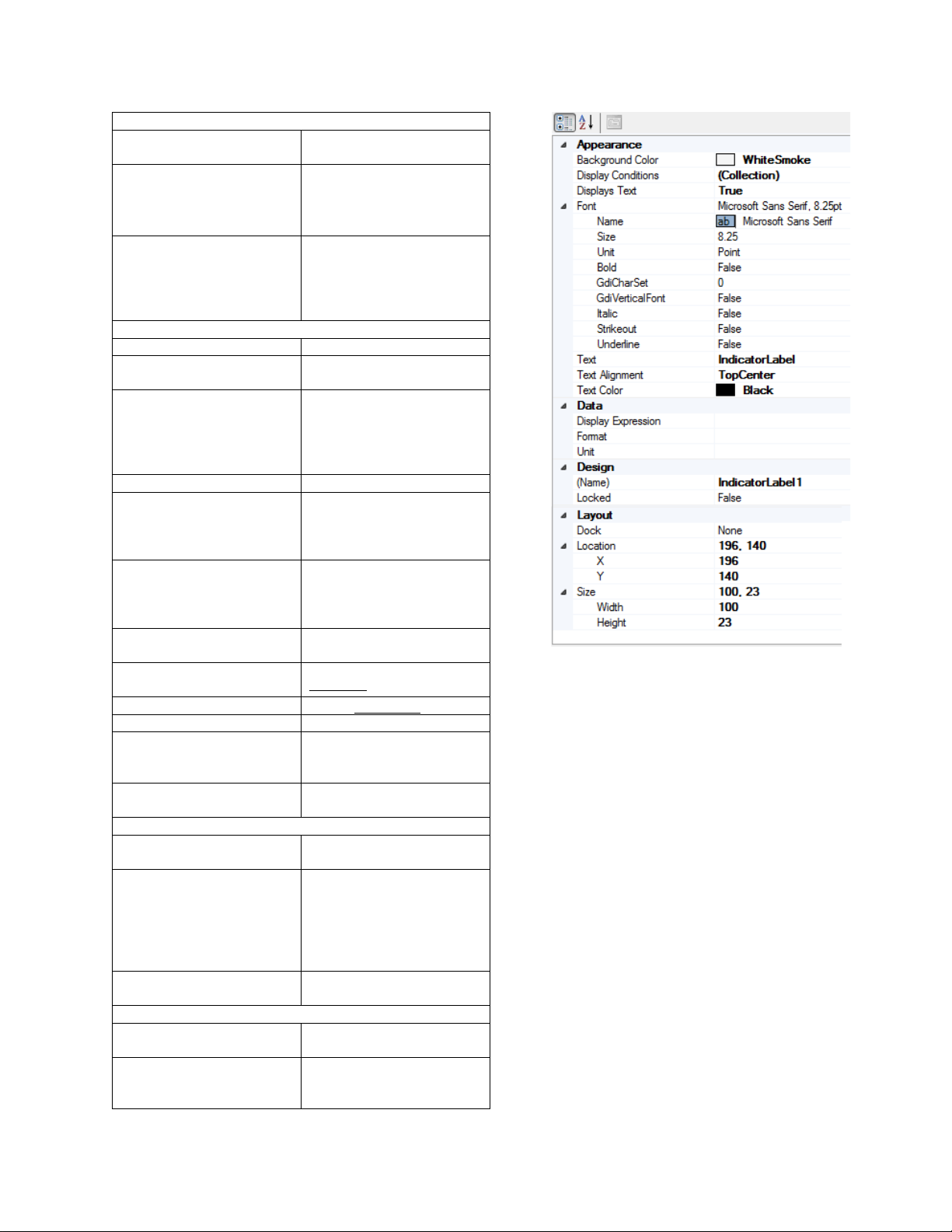

Indicator Label

Compact HMI and Compact HMI Editor Operations Manual

Figure 23 - Indicator Label

The Indicator Label provides a display of data or bit state information to the user. More

specifically, the

Indicator Label has the ability to display static text, conditional text based on an

expression, raw data, or data formatted from an expression. Select the data device tag in the

properties grid at right. Apply a tag from the tags database to the data device tag. See

Table 2

for descriptions of Indicator Label properties and an example properties grid in Figure 24.

Page 28

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 28 of 60

Appearance

Background Color

The color to display in the

background

Display Conditions

Conditions for changing the

Conditions” section.

Displays Text

If true, label will display the

in the Data group

Font

Name

Name of the font to use

Size

Size of the font, based on

the unit specified in Unit

Unit

The unit on which the size

more information.

Bold

If true, displays text in Bold

GdiCharSet

This setting should not be

Inc.

GdiVerticalFont

This setting should not be

Inc.

Italic

If true, displays text in

Italics

Strikeout

If true, displays text with

Strikeout

Underline

If true, underlines text

Text

The default text to display.

Text Alignment

Aligns text based on one of

settings

Text Color

The color of the displayed

text

Data

Display Expression

The expression that defines

what data is displayed

Format

The format in which to

places.

Units

The units of the displayed

data (°F, for example)

Design

(Name)

Indicates the name used in

code to identify the object

Locked

Determines whether the

resized

Figure 24 - Indicator Label properties grid

way data is displayed. More

details are in the “Display

text in the ‘Text’ field by

default; otherwise, it will

display a data value defined

of the font is based. See

Appendix 2: Font

Measurement Units for

changed without first

contacting Super Systems

changed without first

contacting Super Systems

nine available alignment

display the data. For

example, #.## would

format data with a ones

place and two decimal

control can be moved or

Page 29

Super Systems Inc.

Page 29 of 60

Layout

Dock

Defines which borders of

the container

Location

Coordinates of the upper

left corner of the control.

X

X coordinate of upper left

corner of control

Y

Y coordinate of upper left

corner of control

Size

The size of the control in

pixels.

Width

Width of the control in

pixels

Height

Height of the control in

pixels

Table 6 - Indicator Label properties

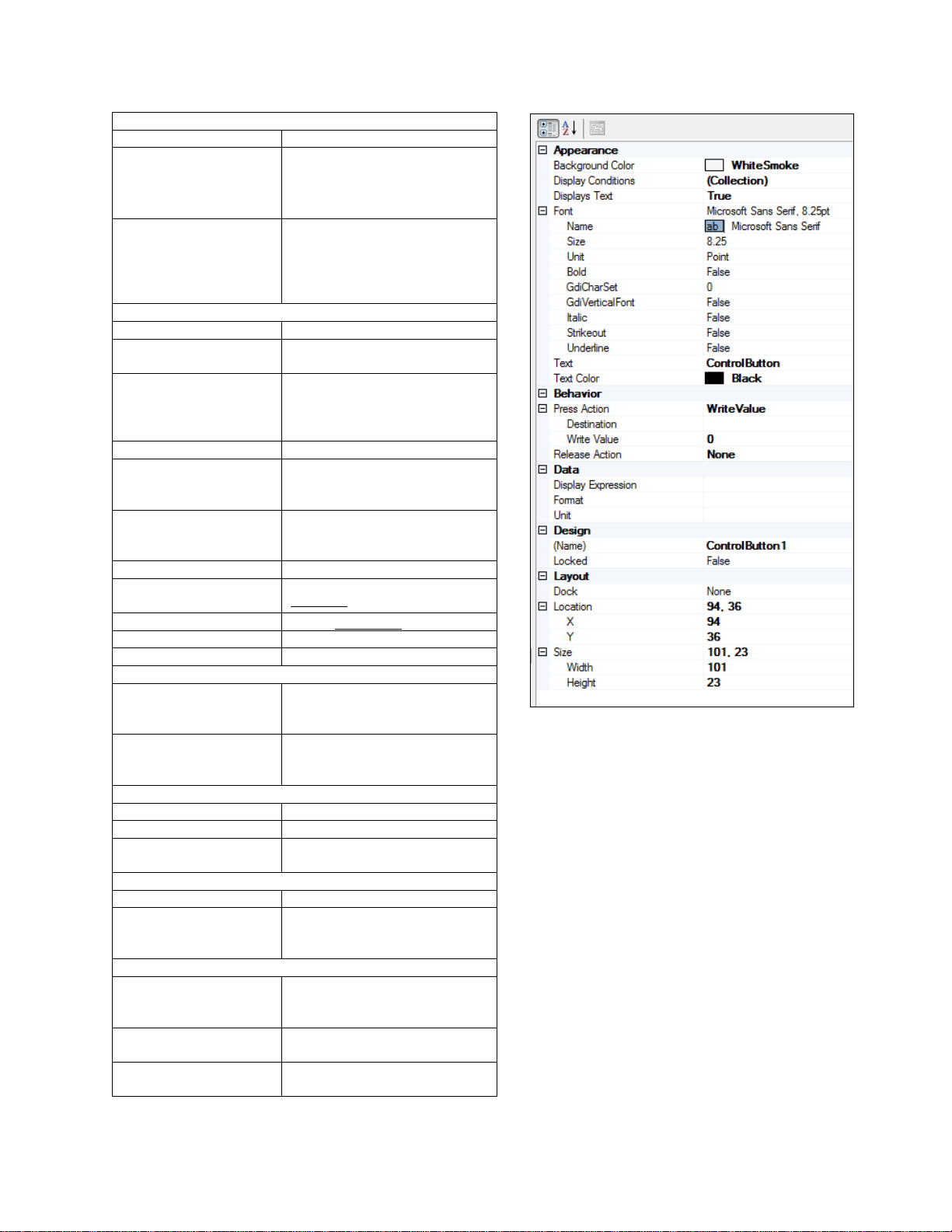

Control Button

Compact HMI and Compact HMI Editor Operations Manual

the control are bound to

The Control Button can display data in exactly the same way as the Indicator Label by

processing the display tag,

but it can also interact with the user and write Control data to the

Figure 25 - Control Button

Page 30

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 30 of 60

data device based on the Compact HMI configuration. To configure control action, define the

data device tag

controls the behavior of the button. The controls have the following options.

• None is no action.

• SetBit writes a value of “1” to the bit identified in the Target Bit of the Destination

register.

• ResetBit writes a value of “0” to the bit identified in the Target Bit of the Destination

register .

• ToggleBit toggles the bit identified in the Target Bit of the Destination register.

• WriteValue sends the value specified in Write Value to the Destination register.

• AskUserAndWriteValue will present the user with a numeric keypad and will write the

user-provided value to the

• OpenMenu will display a menu that allows the user to navigate between other Panels or

return to the 9000 Series controller screen. It is important that each Panel include a

Control Button with this Action; otherwise, there is no way to navigate away from this

Panel once selected.

• OpenScreen will open the Panel designated in the Screen property

Text in this control object will be centered at the top of the object.

Control Button properties are discussed in Table 7. An example properties grid is shown in

Figure 26.

to write to (also known as the Destination). The Press Action and Release Action

Destination register.

Page 31

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 31 of 60

Appearance

Background Color

The background color

Display Conditions

Conditions for changing the way

section.

Displays Text

If true, label will display the

the Data group

Font

Name

Name of the font to use

Size

Size of the font, based on the

unit specified in Unit

Unit

The unit on which the size of

more information.

Bold

If true, displays text in Bold

GdiCharSet

This setting should not be

contacting Super Systems Inc.

GdiVerticalFont

This setting should not be

contacting Super Systems Inc.

Italic

If true, displays text in

Italics

Strikeout

If true, displays text with

Strikeout

Underline

If true, underlines text

Text

The default text to display.

Text Color

The color of the displayed text

Behavior

Press Action

The action taken when the

description)

Release Action

The action taken when the

description)

Data

Display Expression

The display tag for the data

Format

The format for the data

Unit

The units of the displayed data

(°F, for example)

Design

(Name)

The name of the control.

Locked

Determines whether the

resized.

Layout

Dock

Defines which borders of the

container

Location

Coordinates of the upper left

corner of the control.

X

X coordinate of upper left

corner of control

Figure 26 - Control Button properties grid

data is displayed. More details

are in the “

text in the ‘Text’ field by

default; otherwise, it will

display a data value defined in

the font is based. See Appendix

2: Font Measurement Units for

changed without first

Display Conditions”

changed without first

button is pressed (see above

button is released (see above

control can be moved or

control are bound to the

Page 32

Super Systems Inc.

Page 32 of 60

Y

Y coordinate of upper left

corner of control

Size

The size of the control in pixels.

Width

Width of the control in pixels

Height

Height of the control in pixels

Table 7 - Control Button properties

Image Box

Compact HMI and Compact HMI Editor Operations Manual

The Image Box is used to display graphics on the panel. It will not be tied directly to data.

However, like all other controls, its properties can be modified through conditional formatting.

Image Box properties are described in

Figure 27 - Image Box

Table 8. An example properties grid is shown in Figure 28.

Page 33

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 33 of 60

Appearance

Display Conditions

Conditions under which

not displayed.

Image

The image the control

save the Solution.

Transparency Color

The color for the

user).

Design

Name

The name of the control.

Locked

Determines whether the

control can be moved.

Layout

Dock

Determines the position

(alignment) of the image

Location

Coordinates of the upper

left corner of the control.

Size

The size of the control in

pixels.

Table 8 - Image Box properties

Figure 28 - Image Box properties grid

When you are ready to export your Solution to the

Tools Export Device Files

but only use the appropriate Panels at runtime.

Figure 29 - Export Device Files window

the image is displayed or

will display. Compact

HMI Editor will convert

the selected image to a

format Compact HMI

understands and embed

the converted image in

the Solution when you

transparency behind the

image (if chosen by the

Exporting for the Touch Screen

touch screen, select

Figure 29). This option will create a folder containing

all of the Panel and Tag files needed for Compact HMI

on the touch screen. These files are saved to a folder

on your computer, allowing you to transfer the files to

the device manually (by using a flash drive, Compact

Flash card, or other compatible data transfer device),

back up the files, or perform other tasks with them as

necessary. Note that the files saved to the touch

screen device are not the Solution files saved on the

development computer.

The user has the option of saving certain Panels (and

not others) and the runtime executable files (which are

used on the touch screen) when exporting the device

files the specified path. This will allow the user to

create project templates with multiple screen layouts,

(see

Page 34

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 34 of 60

Please refer to Appendix 1: Software Best Practices, “Backing Up Touch Screen Files (.cfxml

and .tdx)”, for information on best practices for backing up touch screen files.

NOTE: The “Use with Compatible Touch Screens” section contains an example of how these

files are used.

Interacting with the Touch Screen

NOTE: These features have been tested only on the 5.7 inch touch screen using a USB

connection.

Compact HMI Editor can also write the Panels in your Solution directly to the touch screen using

Tools Send Solution to Device when the touch screen is connected via USB using Mobile

Device Center (Windows Vista, 7, & 8) or ActiveSync (Windows XP). Compact HMI Editor will

clear the .cfxml files from the touch screen's CompactRealtime folder and save the Panels in

the Solution to the touch screen.

Please refer to Appendix 1: Software Best Practices, “Backing Up Touch Screen Files (.cfxml

and .tdx)”, for information on best practices for backing up touch screen files.

Using the Main Menu

The Main Menu in Compact HMI Editor is comprised of five option headings, as shown in Figure

30. The option headings are File, Edit, Format, Tools, and Help. This section describes each of

the options under each option heading.

File

Figure 30 - Main Menu Bar

Figure 31 - File menu

Page 35

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 35 of 60

The File menu contains the following options:

• New is used to create a new Panel or a new Solution. New Panels can also be created in

the Solution Explorer. If a new Solution (a collection of Panels) is created and the

current Solution has not been saved, Compact HMI Editor will prompt the user with the

option to save the current Solution before opening a new one.

• Open Solution allows you to open a saved Solution (.cresln) file.

• Close Solution allows you to close the currently open Solution. If the Solution has not

been saved, you will be prompted with the option to save the current Solution.

• Save saves the current Solution.

• Save As saves the current Solution with a new file name.

• Recent Solutions will bring up a list of Solutions that were recently open in Compact HMI

Editor.

• Exit exits the program. If the current Solution has not been saved, Compact HMI Editor

will prompt the user with the option to save the current Solution before opening a new

one.

Please refer to Appendix 1: Software Best Practices, “When Saving Multiple Solutions” and

“Backing Up Development Files,” for information on best practices for saving and backing up

developments files in Compact HMI Editor.

Edit

Figure 32 - Edit menu

The Edit menu contains the standard Windows editing options.

• Undo will reverse the previous action performed in Compact HMI Editor.

• Redo will repeat a previously reversed action.

• Cut will remove a selected component and save it to the Clipboard.

• Copy will copy a selected component to the Clipboard so that it can be duplicated.

• Paste will place the content most recently copied to the Clipboard in the active window

or field.

• Delete will remove the selected component without copying it to the Clipboard.

• Select All will select all of the components that can be selected in the active window or

field.

Page 36

Super Systems Inc.

Page 36 of 60

Format

Compact HMI and Compact HMI Editor Operations Manual

Figure 33 - Format menu

The Format menu contains the following options:

• Align contains options to change the alignment of multiple objects.

o

Align Lefts

o

Align Centers

are aligned

o

Align Rights

o

Align Tops

o

Align Middles

aligned

o

Align Bottoms

aligned

• Make Same Size contains options to make the width, height, or both width and height of

multiple selected objects the same.

• Horizontal Spacing contains options to increase, decrease, or equalize the horizontal

spacing between multiple selected objects.

• Vertical Spacing contains options to increase, decrease, or equalize the vertical spacing

between multiple selected objects.

• Center in Form allows you to center the selected controls within the form horizontally or

vertically.

• Order allows you to arrange a selected object so that it appears in front of other objects

that overlap it (Bring to Front) or so that it appears behind other objects that overlap it

(Send to Back).

moves multiple selected objects so that their left edges are aligned

moves multiple selected objects so that their horizontal centers

moves multiple selected objects so that their right edges are aligned

moves multiple selected objects so that their top edges are aligned

moves multiple selected objects so that their vertical middles are

moves multiple selected objects so that their bottom edges are

Tools

Figure 34 - Tools menu

Page 37

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 37 of 60

The Tools menu contains the following options:

• Tags will bring up the Tags window. See Tags (Tag Management) for more information.

• Export Device Files exports the files that would normally be saved to the touch screen

device. See

Exporting for the Touch Screen for more details.

• Send Solution to Device will send the current Solution to a connected device so that the

device can utilize the programmed screens. See

Interacting with the Touch Screen for

more details.

Help

The Help menu (Figure 35) contains three options: About, Language, and Check for Updates….

Figure 35 - Help menu

Selecting About will bring up the “About” window, which will show version information on the

software. See

Figure 36 for an example.

Figure 36 - About screen (example)

Selecting Language allows you to set the language in which Compact HMI operates: English or

Spanish (Español). See

Figure 37.

Selecting Check for Updates… will direct CompactHMI Editor to check for updates to the

software and to the executable files that run on the touch screen. An Internet connection from

the PC is required in order to do this.

updates. Failure to do so will result in work being lost since the previous save.

Figure 37 - Language option

IMPORTANT: Save all open files before checking for

Page 38

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 38 of 60

If an update is found:

If no updates are found:

CompactHMI Editor will prompt you on whether

Figure 38 - Download Updates prompt

Figure 39 - Update status window

CompactHMI Editor will present a window

Figure 40 - "No Updates Available" window

you want to download the updates (Yes) or not

(No)—see

Figure 38.

If you click “Yes”, the software will close; updates

will be downloaded and then installed. A status

window will appear while the updates are being

downloaded and installed (Figure 39).

indicating that no updates are available

(

Figure 40).

Once the updates are installed, CompactHMI Editor will restart.

Touch Screen Files: Automatic Updates include files that will be needed for Compact HMI on the

touch screen. In order to copy updated touch screen files to the touch screen, follow the

procedure below.

1. Locate the TouchScreen subfolder in the folder where Compact HMI Editor is located. An

example is shown in

Figure 41 (where the subfolder is

“C:\SSi\Bin\CompactHMI\TouchScreen”).

Figure 41 - TouchScreen folder (for updated touch screen files)

Page 39

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 39 of 60

2. Insert a USB drive into a USB port on the computer.

3. Copy the files from the “TouchScreen” subfolder to the USB drive.

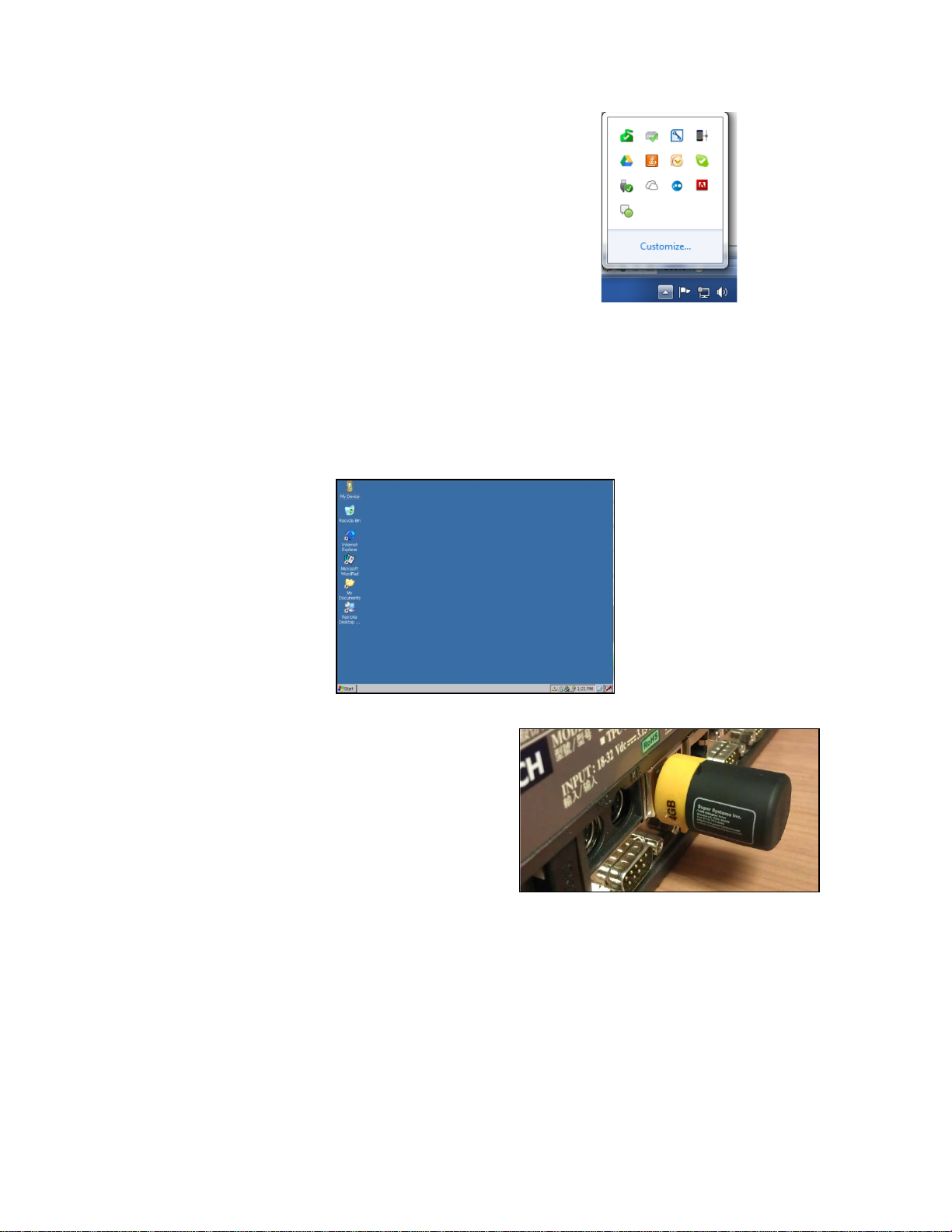

4. Remove the USB drive by selecting “Eject Mass Storage” from the System Tray options

(Figure 42) and then taking the flash drive out of the USB port. If an error appears, make

sure that all files have finished copying and that any windows showing the USB drive or

its contents have been closed.

Figure 42 - "Eject Mass Storage" option

5. With the touch screen on, exit the SSi controller application if it is open. (Refer to the

controller manual or contact SSi at (513) 772-0060 if you have questions about how to do

this.) The operating system screen will appear once the controller application is shut

down. It will look similar to the screen pictured in Figure 43.

Figure 43 - Touch Screen Operating System Screen

Page 40

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 40 of 60

6. Insert the storage medium into an

Figure 44 - Inserting USB Drive into USB Port on

Touch Screen Device

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

18

19

Tool Name

Description

1

New Panel

Opens a new panel for the current Solution, displaying the

2

Brings up a dialog box to open a saved Solution (a file saved by

Solution Overview)

3

Save

Saves the current Solution

4

Removes a block of text, a control object, or other editable

Clipboard so that it can be pasted elsewhere

available USB port on the touch screen.

Often, a port can be found on the back of

the touch screen, as shown in

Figure 44.

7. Double-tap on “My Device” on the touch screen desktop. Then copy the touch screen

files from the USB drive to the Compact HMI (destination) folder. The destination folder

will be the \CompactRealtime folder on the destination drive.

NOTE: A message will likely appear asking if you want to overwrite existing files. Simply choose

“Yes.”

Using the Design Environment Toolbar

The Design Environment contains a horizontal toolbar with icons representing many of the

common options used in Compact HMI Editor. See Figure 45.

The table describes the use of each tool in the toolbar.

Open Solution

Cut

Figure 45 – Toolbar

new panel in the Design Environment

Compact HMI Editor with the .cresln extension; described

further in

component of a Solution, and saves it to the Windows

Page 41

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 41 of 60

Tool Name

Description

5

Copies a block of text, a control object, or other editable

Clipboard so that it can be pasted elsewhere

6

Places a block of text, a control object, or other editable

Environment component (i.e., Panel)

7

Removes a block of text, a control object, or other editable

component to the Windows Clipboard

8

Undo

Reverses the previous action

9

Redo

Performs an action that was previously reversed

NOTE: All of the “align” options (10 through 15 below) align objects relative to a particular point

they are selected with a mouse.

10

Align Lefts

Moves multiple selected objects so that their left edges are

11

Moves multiple selected objects so that their horizontal

12

Align Rights

Moves multiple selected objects so that their right edges are

aligned

13

Align Tops

Moves multiple selected objects so that their top edges are

aligned

14

Moves multiple selected objects so that their vertical middles

are aligned

15

Moves multiple selected objects so that their bottom edges

are aligned

Copy

Paste

Delete

or axis. For example, Align Lefts will align selected objects so that they share the same left

alignment axis, while Align Middles will align selected objects so that they share the same

vertical middle. Multiple objects are selected by pressing Ctrl+Left Click or Shift+Left Click as

component of a Solution, and saves it to the Windows

component of a Solution in an active field or Design

component of a Solution, but does not save the removed

Align Centers

Align Middles

Align Bottoms

aligned

centers are aligned

Page 42

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 42 of 60

Tool Name

Description

16

Bring to Front

Arranges a selected object so that it appears in front of other

objects that overlap it

17

Send to Back

Arranges a selected object so that it appears behind other

objects that overlap it

Table 9 - Tools in the Toolbar and Their Use

Page 43

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 43 of 60

Compact HMI (Use on SSi Touch Screen)

Prerequisites and Installation

An SSi touch screen is required. In order to run Compact HMI Solutions, the SSi touch screen

must be Compact HMI-aware (programmed to recognize Compact HMI Solutions).

SSi designs, customizes, and implements Compact HMI for each touch screen.

Use with Compatible Touch Screens

Compact HMI runs on the touch screen in the \CompactRealtime folder. The \CompactRealtime

folder should have the following file types present:

• .cfxml. Each .cfxml file contains the data for a Panel within the Solution. There will be as

many .cfxml files as there are Panels in the Solution.

• .tdx. The .tdx file is the tags database file. This contains the data for the tags that have

been set up in the Solution.

• .dll. DLL files are required in order for Compact HMI to run properly on the touch

screen.

• .exe. The .exe file is an executable file that is run when Compact HMI is started.

There is no additional configuration necessary other than getting a copy of your primary touch

screen interface that supports Compact HMI; your primary touch screen interface will handle

starting, stopping and interacting with the Compact HMI application for you.

When your Compact HMI-aware interface is handling your Compact HMI Solution, the Menu

button will not take you directly to the Menu. Instead, it will give you the option of going to the

Menu or going to the Compact HMI Solution.

Example of Compact HMI Touch Screen Application Design and Rendering

Once a solution is designed in Compact HMI Editor and saved to a Compact HMI-aware SSi

touch screen, the interface can be accessed through Compact HMI. This section illustrates

examples of Panels that can be set up as part of a solution in Compact HMI in a furnace control

system and how those Panels can be saved from Compact HMI Editor and subsequently opened

in a Compact HMI-aware touch screen as a Compact HMI application.

Example Designs

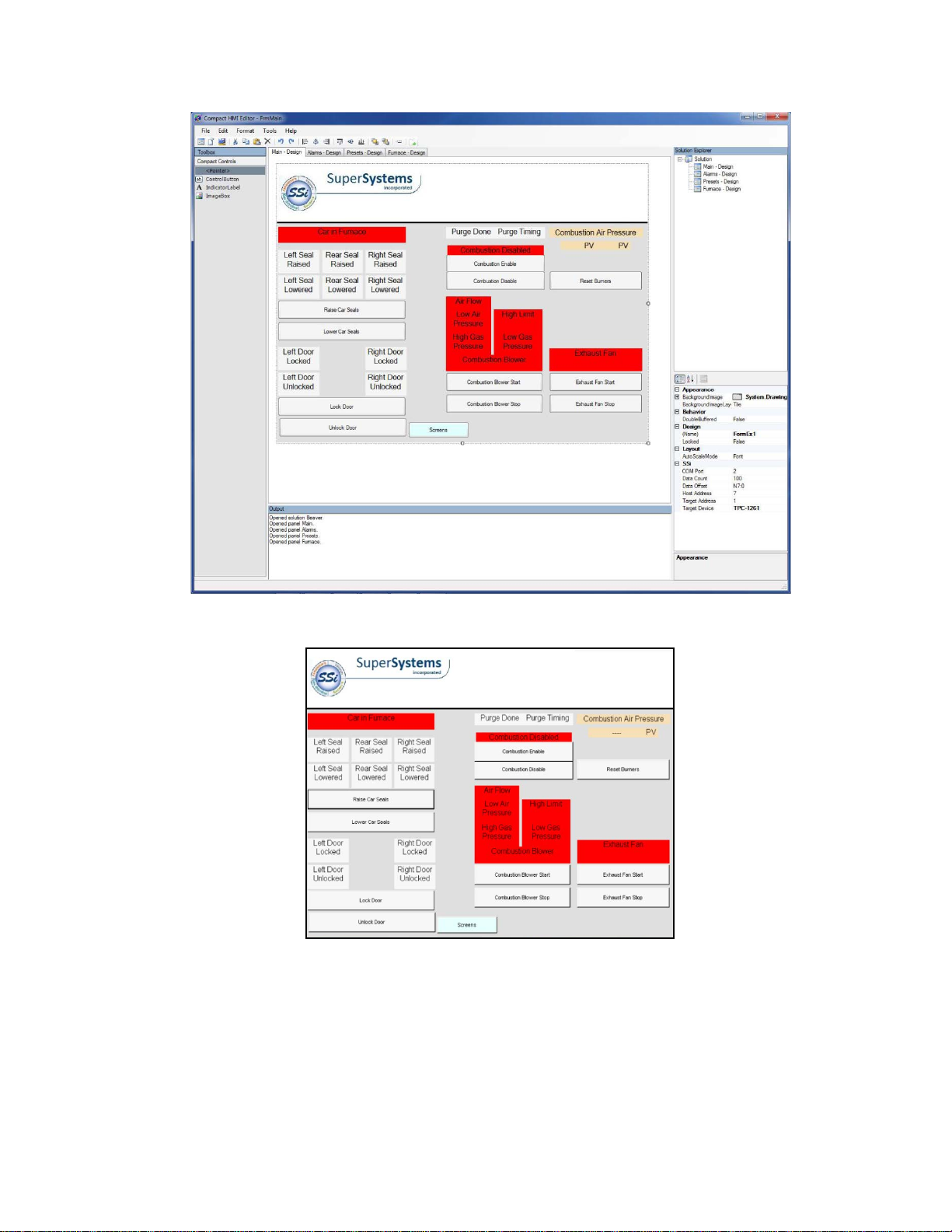

In this example, a designer has created four Panels for a furnace control system. These Panels

are as follows:

• Main Panel. The Main Panel provides an overview of essential furnace statuses (such as

combustion status and high/low gas pressure alarms) and allows for control of essential

furnace functions (such as locking and unlocking the furnace door). This is the Panel that

will appear when the Compact HMI application is first opened on a compatible touch screen.

The Compact HMI Editor view is shown in

is shown in Figure 47

.

Figure 46; the Compact HMI (Touch Screen) view

Page 44

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 44 of 60

Figure 46 - Main Panel (Compact HMI Editor)

Figure 47 - Main Panel (Compact HMI - Touch Screen)

Note the Screens button at the bottom of the Panel. Each Panel has one of these buttons. When

pressed, the button will bring up a menu allowing the user to select one of the other panels or

to open the controller touch screen main menu. See the example in

programmed into the panel using the

OpenMenu option as part of the Control Button in

Compact HMI Editor (more information on this can be found in the “

Figure 48. This menu is

Control Button” section).

Page 45

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 45 of 60

Remember that Panels can be arranged in the order in which you want them to appear in

Compact HMI on the touch screen. To reorder Panels, simply click and drag each tab into the

order in which you wish it to appear.

Figure 48 - Screens menu (Compact HMI - Touch Screen)

• Alarms Panel. The Alarms Panel shows alarms that have been configured in the system. If

an alarm is active, typically the attributes of the alarm display will be programmed to

change (for example, color and visibility). In the example, inactive alarms are displayed in

black text. If an alarm is active, the operator will be able to acknowledge it or take the

appropriate action to correct the alarm condition. The Compact HMI Editor view for the

Alarms Panel is shown in

Figure 49; the Compact HMI (Touch Screen) view is shown in

Figure 50.

Page 46

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 46 of 60

Figure 49 - Alarms Panel (Compact HMI Editor)

Figure 50 - Alarms Panel (Compact HMI - Touch Screen)

• Presets Panel. In the example, this Panel is used to enter furnace control presets. The

Panel also displays setpoints and process variables (PVs) for parameters such as

combustion air pressure. The Compact HMI Editor view for this Panel is shown in

Figure 51;

the Compact HMI (Touch Screen) view is shown in Figure 52.

Page 47

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 47 of 60

Figure 51 - Presets Panel (Compact HMI Editor)

Figure 52 - Presets Panel(Compact HMI - Touch Screen)

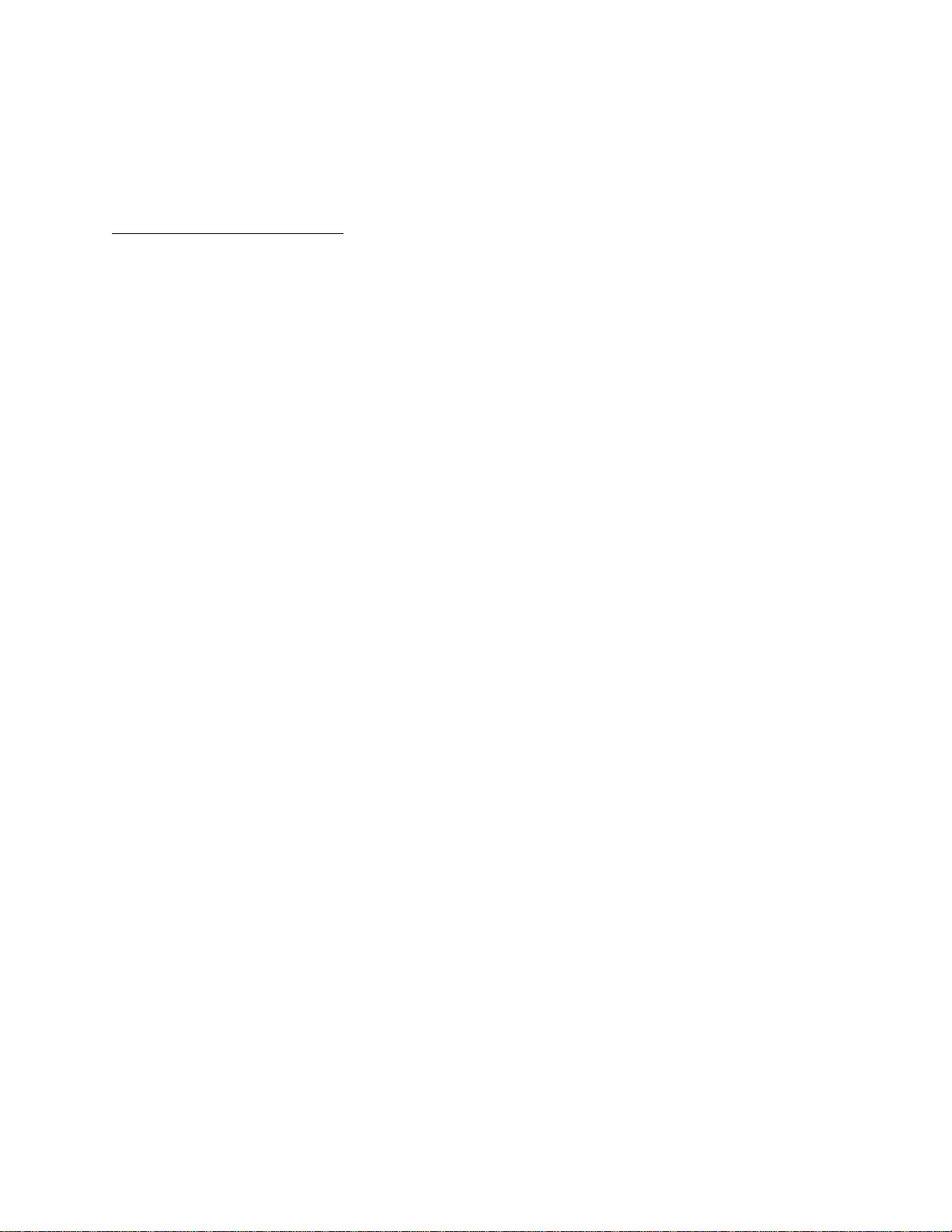

• Furnace Panel. The Furnace Panel provides furnace status information and allows the

operator to control operations such as starting fans, locking and unlocking doors, etc. A

visualization depicts the status of the furnace in real time. The Compact HMI Editor view for

Page 48

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 48 of 60

this Panel is shown in Figure 53; the Compact HMI (Touch Screen) view is shown in Figure

54.

Figure 53 - Furnace Panel (Compact HMI Editor)

Figure 54 - Furnace Panel (Compact HMI - Touch Screen)

Page 49

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 49 of 60

Preparing Solution for Touch Screen

There are two main ways to prepare the Solution to be run on the SSi touch screen:

1. Sending the Solution from Compact HMI Editor directly to the touch screen device; and

2. Exporting the device files to a storage device and copying the device files to the

CompactRealtime on the touch screen’s storage medium.

These methods are described in more detail in the Exporting for the Touch Screen and

Interacting with the Touch Screen sections.

Once the designer has verified that all of the Panels have been set up properly, the designer can

prepare the Solution for use on an SSi touch screen. (The Solution can also be implemented on

the touch screen for testing purposes, when needed.)

Suppose the designer decides to utilize method #2 (exporting and copying the device files to the

touch screen’s storage medium). The designer follows these steps:

1. Save Solution in Compact HMI Editor (using File Save or File Save As).

2. Using the Tools Export Device Files option, export the device files to a USB drive or

other storage medium. This process is depicted in

Figure 55.

Figure 55 - Exporting Device Files

Page 50

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 50 of 60

3. Once the files are successfully exported,

Figure 56 – “Safely Remove Hardware” icon

6. Insert the storage medium into an

Figure 58 - Inserting USB Drive into USB Port on

Touch Screen Device

eject the storage medium by using the

“Safely remove hardware” option in

Windows (typically found by expanding

the system tray and selecting the

“remove hardware” icon, an example of

which is shown in

Figure 56).

4. Turn on the touch screen.

5. Once the touch screen is on and the startup has completed, exit the SSi controller

application. (Refer to the controller manual or contact SSi at (513) 772-0060 if you have

questions about how to do this.) The operating system screen will appear once the

controller application is shut down. It will look similar to the screen pictured in Figure

57.

Figure 57 - Touch Screen Operating System Screen

available USB port on the touch screen.

Often, a port can be found on the back of

the touch screen, as shown in

NOTE: SSi recommends that you back up touch screen files onto a USB drive or other

storage medium before overwriting those files (which is part of the procedure described

in Step

7). Touch screen files are the .cfxml and .tdx files contained in the

\CompactRealtime folder. If your organization has a backup system in place, these files

should be backed up using that system.

Figure 58.

Page 51

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 51 of 60

7. Double-tap on My Device on the touch screen desktop. Remove any .cfxml and .tdx files

from the \CompactRealtime folder. Then copy the device files from the storage medium

to the drive from which the touch screen runs Compact HMI (this is typically the drive

from which the touch screen runs the SSi controller application). The destination folder

will be the \CompactRealtime folder on the destination drive. An example of this

procedure is depicted in

Figure 59.

The Solution should now be ready.

Running the Compact HMI Solution

Once the designer has set up the Solution to be run on the touch screen, the designer restarts

the touch screen to load the SSi controller application. When started, each SSi controller touch

screen has a standard screen that will first be displayed. As explained in the “Use with

Compatible Touch Screens” section, if the touch screen is Compact HMI-aware and has

Compact HMI screens saved to the proper location on the storage card, a menu like the one

shown in Figure 60 will be displayed on the standard screen.

Figure 59 - Copying Device Files to CompactRealtime Folder

Page 52

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 52 of 60

Figure 60 - Compact HMI Menu on Example Screen

Selecting Compact HMI will cause the touch screen software to open the Compact HMI

application.

Page 53

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 53 of 60

Rev.

Description

Date

MCO #

New

Initial release

10/22/2013

2127

A

Added Modbus communications capabilities

3.5” screen/Compact HMI wiring diagram

4/30/2014

2137

Revision History

as well as program menu changes; added

Page 54

Compact HMI and Compact HMI Editor Operations Manual

Super Systems Inc.

Page 54 of 60

Appendix 1: Software Best Practices

This appendix is intended to provide guidelines for setting up and using the Compact HMI

platform. SSi recommends observing these guidelines, as they have been found to enhance the

usability and functionality of the software.

When Configuring Connections and Tags in Compact HMI Editor

When configuring Connections and Tags, the following principles should be followed:

• Make sure that the Connection Type (DF1, ModbusRTU, or ModbusTCP) is configured

correctly, preferably before tags are added and named.

• Make sure that the Data Offsets are configured correctly. Remember that the Data

Offset must be set individually for each Tag.

• Make sure that the Connection Name is easily associated with the connection to the data

device.

• Make sure that each Tag Name allows for easy identification of a Tag’s register location.

However, avoid making a Tag Name so specific that it could create confusion. For

example, a tag name of “N7:1” would allow for easy identification of the Tag’s register

location (provided that the Data Offset and Address Offset are configured correctly). On

the other hand, a tag name of “Motor A On” could create confusion if the Data Offset

does not align with the correct register.

Relevant Section: “Tags (Tag Management)”, page 12

Backing Up Touch Screen Files (.cfxml and .tdx)

SSi recommends that you back up touch screen files onto a USB drive or other storage medium.

Touch screen files are the .cfxml and .tdx files contained in the \CompactRealtime folder. If your