Page 1

CAT-100

ATMOSPHERIC CARBON

POTENTIAL ANALYZER

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

www.supersystems.com

Page 2

CAT-100 Operations Manual

Super Systems Inc.

Page 2 of 51

Super Systems Inc.

USA Office

Corporate Headquarters

7205 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

uper Systems Mexico

S

Sistemas Superiores Integrales S de RL de CV

Calle 3 Int.: 11.

Zona Ind. Benito Juarez

Querétaro, Qro. Méx.

C.P.: 76120

Phone: +52 (442) 210 2459

http://www.supersystems.com.mx

Super Systems Europe

Units 3 & 4, 17 Reddicap Trading Estate,

Sutton Coldfield, West Midlands

B75 7BU

UNITED KINGDOM

Phone: +44 (0) 121 329 2627

http://www.supersystemseurope.com

uper Systems China

S

No. 335 XianXia Road

Phone: +86 21 5206 5701/2

http://www.supersystems.com

Room 308

Shanghai, CHINA

200336

Page 3

CAT-100 Operations Manual

Super Systems Inc.

Page 3 of 51

Table of Contents

Introduction ........................................................................................................................................ 5

CAT-100 Specifications ...................................................................................................................... 6

Replacement Parts ............................................................................................................................ 6

Testing Procedure ............................................................................................................................. 8

Unpacking and Charging the CAT-100 .......................................................................................... 8

Entering the Coil Factor ................................................................................................................. 8

Preparing the Insertion Rod with Steel Wire Coil ....................................................................... 10

Using the Insertion Rod in the Testing Environment .................................................................. 12

Cooling Down and Removing the Insertion Rod .......................................................................... 14

Using the Emery Cloth on the Steel Wire Coil ............................................................................ 15

Attaching the Steel Wire Coil to the Binding Posts ..................................................................... 15

Storing Test Results ..................................................................................................................... 16

CAT-100 Menu Navigation ............................................................................................................... 19

Note about Battery Level Indicator .......................................................................................... 20

Main .............................................................................................................................................. 20

Detail............................................................................................................................................. 21

Coil Factor and Advanced Detail Display (Configuration Mode) ............................................. 21

Review Tests ................................................................................................................................. 22

About ............................................................................................................................................. 22

LOGIN ........................................................................................................................................... 23

Calibration .................................................................................................................................... 23

Coil TC Calibration ....................................................................................................................... 25

Comms Setup (Communications Setup) ..................................................................................... 25

Ethernet Setup ............................................................................................................................. 26

DHCP Button ............................................................................................................................. 27

Update .......................................................................................................................................... 28

View Updates ................................................................................................................................ 28

General Setups ............................................................................................................................. 29

Temperature Mode ................................................................................................................... 30

Date/Time Set ........................................................................................................................... 30

Display Theme .......................................................................................................................... 31

Factory Defaults ....................................................................................................................... 31

Clear Tests ................................................................................................................................ 31

Test Enables ................................................................................................................................. 31

Page 4

CAT-100 Operations Manual

Super Systems Inc.

Page 4 of 51

Touch Cal (Touch Screen Calibration) ......................................................................................... 32

Pass Code ..................................................................................................................................... 33

Language ...................................................................................................................................... 33

CAT-100 PC Software (CAT-100 View) ............................................................................................ 34

Installation .................................................................................................................................... 34

CAT-100 USB Driver ................................................................................................................. 35

Main Screen .................................................................................................................................. 35

Sorting Data in the Main Screen View ..................................................................................... 37

File Menu ...................................................................................................................................... 37

Show Graph .............................................................................................................................. 37

Export Tests to CSV .................................................................................................................. 38

Print Selected Tests ................................................................................................................. 40

Options Menu................................................................................................................................ 40

Manage CAT100s ...................................................................................................................... 41

Temperature Scale ................................................................................................................... 43

Data Menu .................................................................................................................................... 43

Sort ............................................................................................................................................ 43

Filter.......................................................................................................................................... 43

Users Menu .................................................................................................................................. 44

Log In ........................................................................................................................................ 44

Log Out ...................................................................................................................................... 45

Manage Users ........................................................................................................................... 45

Help Menu .................................................................................................................................... 45

Check for Updates .................................................................................................................... 46

About ......................................................................................................................................... 46

Troubleshooting ............................................................................................................................... 47

Warranty ........................................................................................................................................... 50

Revision History ............................................................................................................................... 51

Page 5

CAT-100 Operations Manual

Super Systems Inc.

Page 5 of 51

Introduction

The Super Systems Inc. (SSi) CAT-100 is an Atmospheric Carbon Potential Analyzer that

provides a measurement of Carbon Potential in a positive pressure atmosphere. This

measurement is determined by measuring specific properties of a steel wire coil that has been

inserted into an atmosphere with a carbon-bearing gas for a predefined amount of time. The

CAT-100 system is designed to provide accurate results in a cost-effective manner.

Figure 1 - CAT-100 Carbon Potential Analyzer

The concept behind the CAT-100 is similar to the concept behind the SSi Shim Port with Shim

Stock. The CAT-100 is designed to provide an on-site carbon measurement. More information

on this process can be found in the Testing Procedure section on page 8.

Page 6

CAT-100 Operations Manual

Super Systems Inc.

Page 6 of 51

CAT-100 Specifications

Carbon Potential Measurement Specifications

Range: 0.1% to 1.3% Carbon Potential

Read Time: 30 to 45 seconds per coil

Accuracy

Accurate to within ±0.03% Carbon Potential

Operating Temperature

50°F to 100°F (10°C to 377/9°C)

Power

Input Power Range: Universal, 85 – 264 VAC

Input Frequencies Supported: 50 Hz, 60 Hz

Batteries: NiMH (up to 6 hours of continuous operation)

Dimensions

Length of front and rear plates: 12.5 inches

Length of sides: 10.5 inches

Height: 5.5 inches

Weight

9.5 lbs. (approx. 4.31 kg)

Touch Screen

Type: Resistive, TFT LCD

Size: 4.3”

Insertion Rod

Maximum extension length: Approximately 41.4”. (NOTE: An extension to the rod is available

through SSi. The extension piece is approximately 24” in length.)

Replacement Parts

Contact SSi at (513) 772-0060 to order parts.

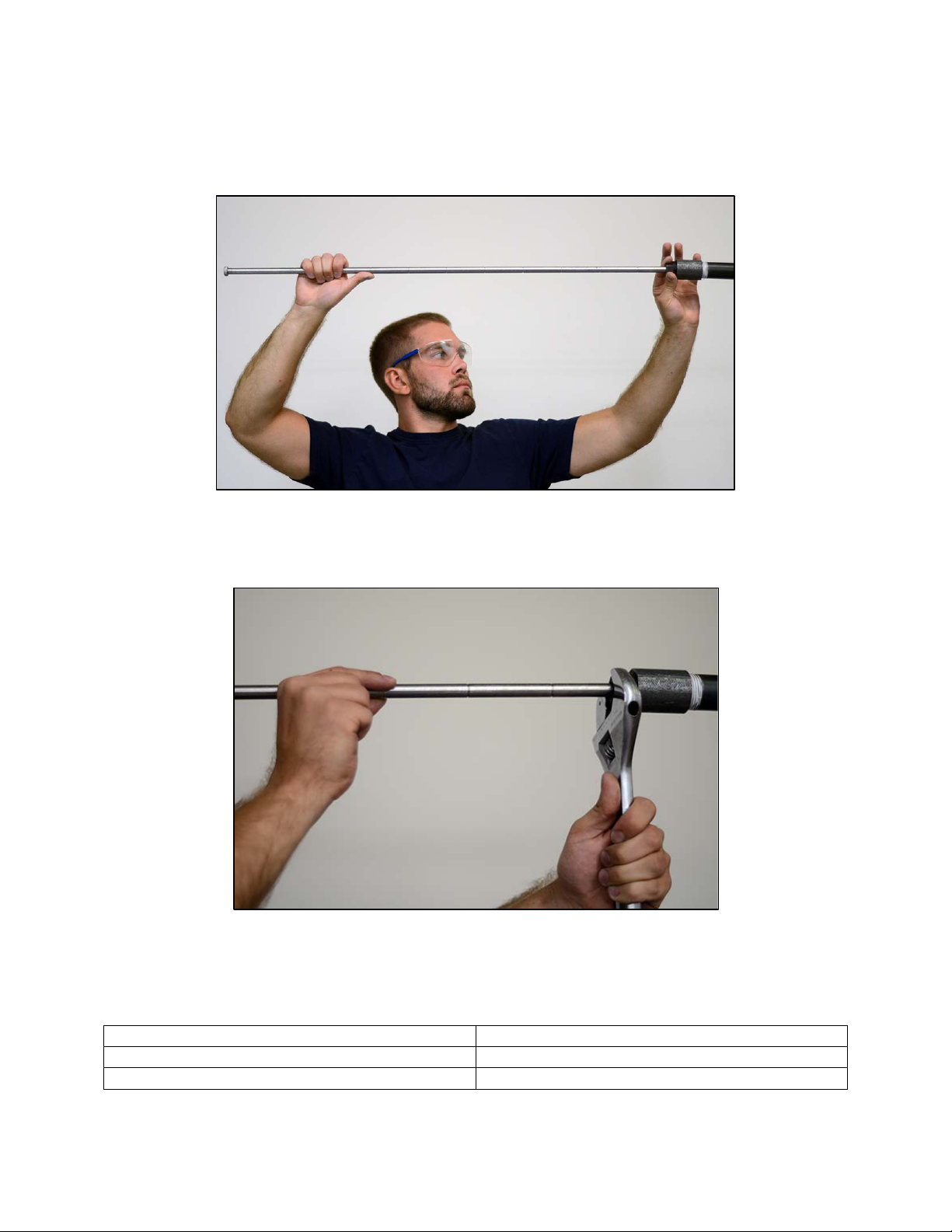

Figure 2 - Insertion rod

Page 7

CAT-100 Operations Manual

Super Systems Inc.

Page 7 of 51

Part

Number

Item

Explanation

13569

CAT-100 Complete Unit

CAT-100 retail unit. Includes all

components in an assembled unit.

13497

Insertion Rod

The rod used to properly insert the

equipment.

20616

Cage Assembly for Insertion Rod

The piece that attaches to the

steel wire coil

20767

Calibration Bridge

The module used to perform a circuit

Calibration section (page 23).

20753

Bag of 100 Coils

Steel wire coils that are inserted into

NOTE:

printed on the bag.

30058

Emery Cloth (Fine Grade, 150 Grit)

A cloth containing coarse material

carbon analysis.

13564

Carrying Case Assembly

Carrying case used to transport and

unit

34601

Hinged Standoff

The long, thin metal standoffs on the

front of the unit that support it

34557

CAT-100 Handle

Handle attached to the top of the

polycarbonate enclosure

32016

Battery

Replacement battery for CAT-100

33018

Power Cord

Power cord used with CAT-100

20759

Custom Foam Packaging

Specially designed packaging

storage

20756

Enclosure

The enclosure that covers the CAT100 unit

steel wire coils into a carboncontaining atmosphere. Typically,

the rod is inserted into the

atmosphere through an access port

on the furnace or other piece of

insertion rod and surrounds the

calibration on the CAT-100. See

a carbon-containing atmosphere for

testing purposes

The % Carbon content of the

untested coils will be imprinted on

this bag. The Coil Factor will also be

used with the steel wire coil prior to

provide protection for the CAT-100

material used to protect the CAT-100

from damage during transport or

Table 1 - Replacement Parts List

Page 8

CAT-100 Operations Manual

Super Systems Inc.

Page 8 of 51

First, note the recommended Coil Factor printed on the bag of coils that the coil you are using

Next, log in with Configuration Mode

Figure 3 – Entering Configuration pass code (default is ‘2’)

Open the Detail menu from the main

Figure 4 – Detail screen with Coil Factor box

Testing Procedure

Unpacking and Charging the CAT-100

Carefully remove the packing tape from the box in which the CAT-100 was shipped and remove

the CAT-100, right side up. Using proper lifting technique, place the CAT-100 on a level surface.

If you are going to use the CAT-100 without electrical outlet power, allow the unit to charge

overnight before use. Do this by simply plugging the unit into an AC electrical outlet and

allowing it to charge. Make sure that the unit is charging with the power turned OFF.

Entering the Coil Factor

The Coil Factor for the wire coil is used in calculating Carbon Potential and is based on

variations in coils in a batch. The recommended Coil Factor is printed on each bag of coils and is

the same for all coils in a batch. Before using the coil in the testing process, follow this

procedure for entering and verifying the Coil Factor.

It is essential that this procedure be

followed correctly.

came from. If you do not have the bag, assume a Coil Factor of 100.

on the CAT-100. This is done by

opening the “LOGIN” screen from the

main menu and entering the

Configuration pass code (which is ‘2’

by default).

menu. The Detail screen will be

shown, and the Coil Factor will be

displayed in a box labeled “Factor”.

Tap on that box.

Page 9

CAT-100 Operations Manual

Super Systems Inc.

Page 9 of 51

A numeric entry screen will appear.

Figure 5 – Entering a new Coil Factor

The Detail screen will now show the

Figure 6 – Detail screen with new Coil Factor shown

Return to the CAT-100 main status screen.

Enter the Coil Factor that you noted

earlier for the wire coil.

Coil Factor that you entered.

Attach the wire coil to the binding posts as illustrated in Figure 7. Make sure to tighten the

binding posts by turning each screw clockwise; do not overtighten. Also, do not allow the coil to

make contact with the external thermistor.

Page 10

CAT-100 Operations Manual

Super Systems Inc.

Page 10 of 51

Note location of

thermistor

Contact point

Contact point

external

Figure 7 - Attaching wire coil to binding posts

Once the coil is attached to the binding posts, note the %Carbon displayed on the CAT-100. The

% Carbon should be as close to

0.83 as possible, or within the range of .83 ±. 03. In order to

increase the %C, increase the Coil Factor. In order to decrease the %C, decrease the Coil

Factor.

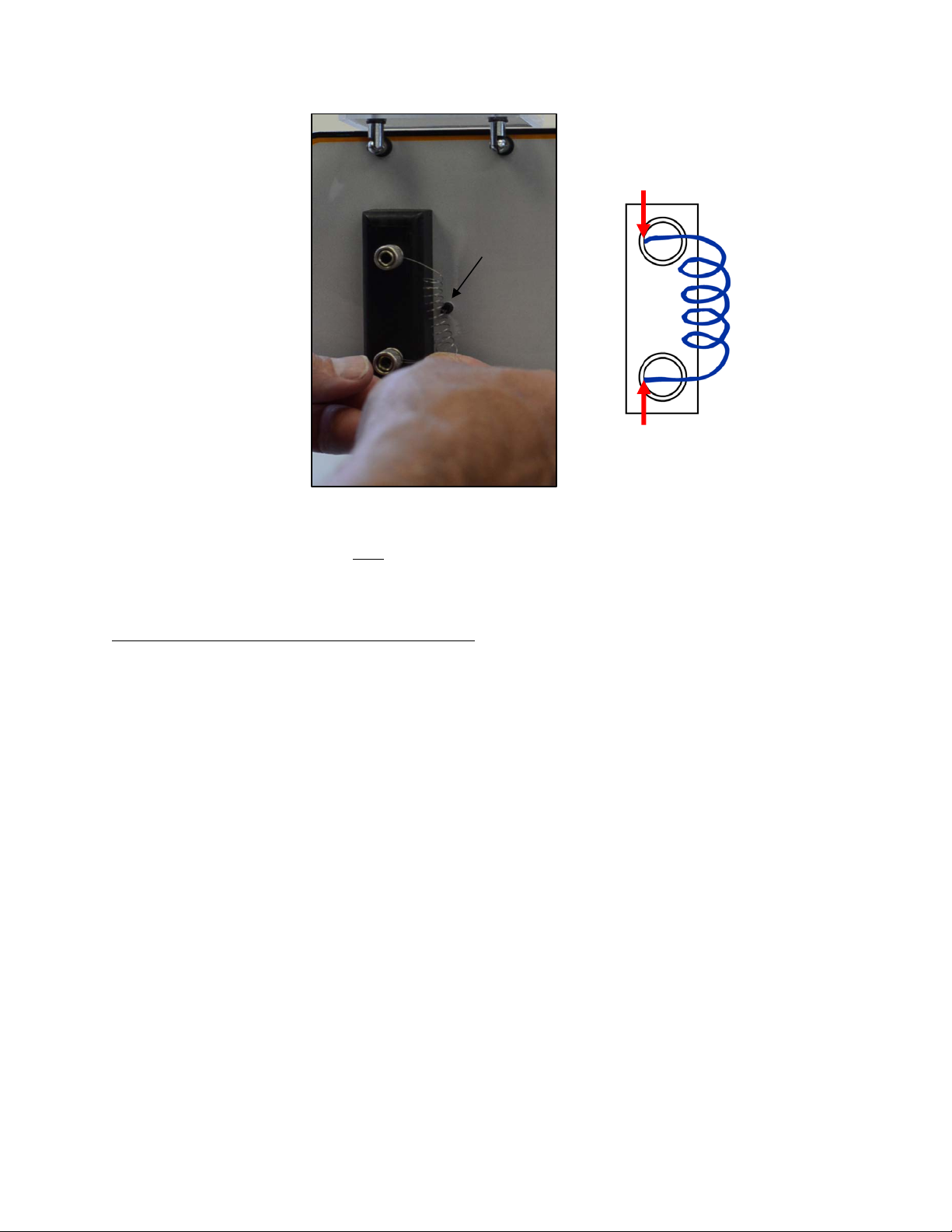

Preparing the Insertion Rod with Steel Wire Coil

The wire coil is designed to be placed in the testing atmosphere with the use of a metal

insertion rod that can be purchased from SSi. The parts of the insertion rod, shown in Figure 8,

are as follows:

• Shaft. A long metal shaft supports the working end of the insertion rod (where the wire

coil is housed) and allows the rod to span the length of a typical furnace access conduit.

• Threaded port connector. The port connector is designed to attach to, and provide a tight

connection with, the access port on a furnace.

• Protective cage. The protective cage provides housing for the wire coil when the coil is

attached to the insertion rod.

• Rod screw. The rod screw, which screws into the shaft through the protective cage,

helps keep the protective cage in place on the insertion rod.

Page 11

CAT-100 Operations Manual

Super Systems Inc.

Page 11 of 51

IMPORTANT!

Shaft

Protective cage

Rod screw

Threaded port connector

Figure 8 - Parts of metal insertion rod

NOTE: After repeated use, the insertion rod will gradually turn from its silver, “out of the box”

color to a charcoal black color. This is due to the rod’s placement in the furnace atmosphere

and does not affect its function.

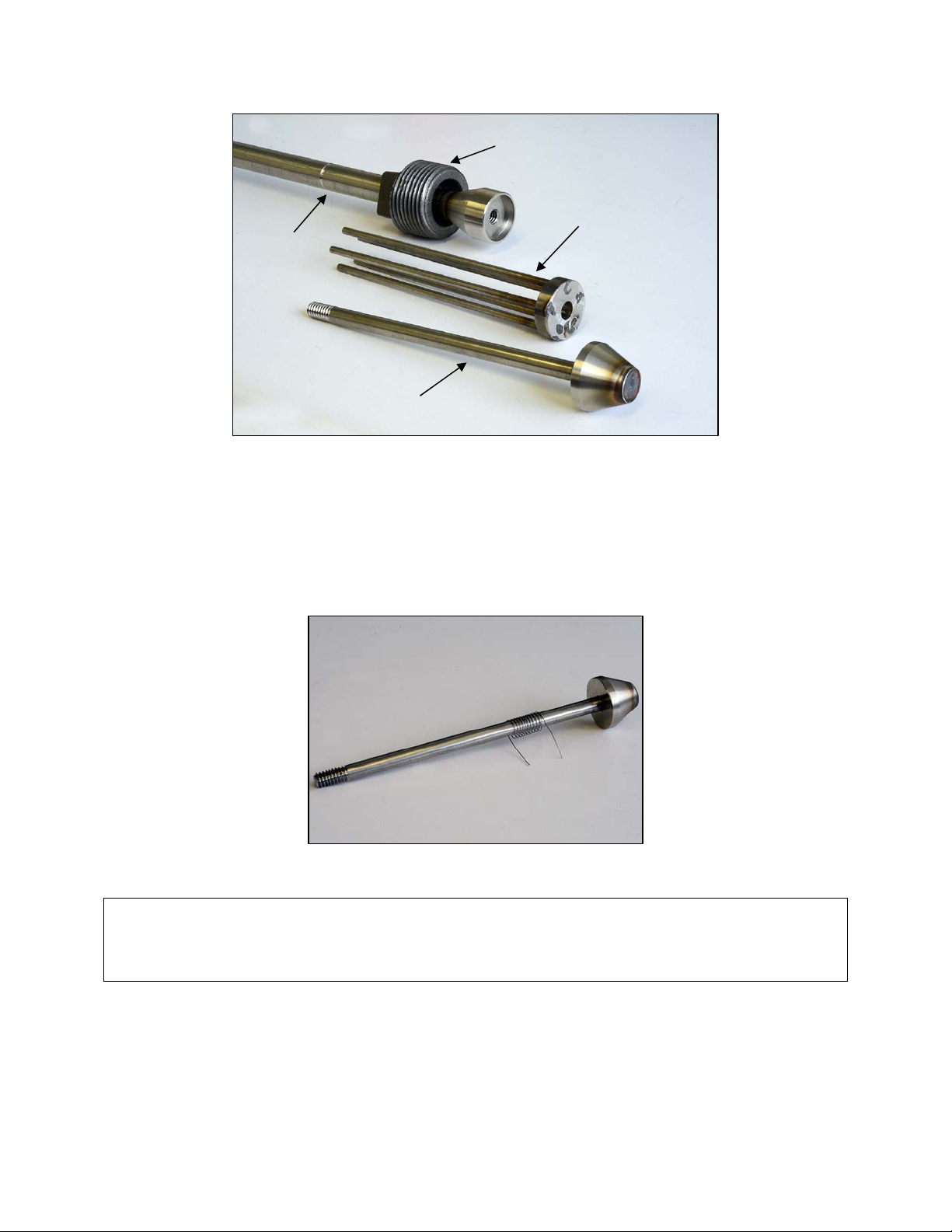

To prepare the insertion rod for placement in a testing atmosphere, first slide the “wound”

portion of the wire coil over the rod screw (Figure 9).

Figure 9 - Wire coil placed on rod screw

The wire coil must be placed on the rod screw, not on the protective cage.

Next, slide the rod screw through the opening in the protective cage (Figure 10).

Page 12

CAT-100 Operations Manual

Super Systems Inc.

Page 12 of 51

WARNING!

Use ANSI-approved eye protection at all times when working with the insertion rod in a plant or

other testing environment. Take any additional precautions necessary to lower the risk of injury

in the environment in which you are working.

IMPORTANT: Hand tighten rod screw until it

screws tightly in place on insertion rod.

Figure 10 – Rod screw inserted through opening in protective cage

Finally, insert the protective cage and rod screw into the insertion rod (Figure 11); hand tighten

the rod screw until it screws into place tightly on the insertion rod. Ensure that the “legs” of the

protective cage are inserted into the metal stopper on the insertion rod.

Figure 11 - Protective cage and rod screw attached to insertion rod

Using the Insertion Rod in the Testing Environment

The insertion rod is now ready to be placed in the testing atmosphere. Since the testing

atmosphere will be extremely hot, placement in the testing atmosphere is usually accomplished

by extending the insertion rod through an access port in the furnace.

Page 13

CAT-100 Operations Manual

Super Systems Inc.

Page 13 of 51

Temperature in Testing Atmosphere

Soak Time

1575°F and higher

30 minutes

1574°F and below

40 minutes

With the wire coil in place on the insertion rod, place the insertion rod through an access port or

other designated conduit. Begin hand-tightening the threaded port connector by turning the

connector clockwise. See Figure 12.

Figure 12 - Placing insertion rod in access port and tightening threaded port connector

Using a wrench, turn the port connector clockwise to finish tightening it (Figure 13). Take care

not to overtighten the connector.

Figure 13 - Tightening port connector with wrench

Push the insertion rod until the wire coil is present in the testing atmosphere. The wire must

now soak in the atmosphere; the amount of time to soak the wire is based on the temperature

in the testing atmosphere. Table 2 shows the appropriate soak times.

Table 2 - Soak times based on temperature in testing atmosphere

Page 14

CAT-100 Operations Manual

Super Systems Inc.

Page 14 of 51

NOTICE!

Exceeding indicated soak times by more than 5 minutes may result in adverse effects on carbon

potential readings when the wire coil is tested with the CAT-100.

WARNING!

Use ANSI-approved eye protection at all times when working with the insertion rod in a plant or

other testing environment. Use heat-resistant hand protection when removing the insertion rod

from the testing environment. Take any additional precautions necessary to lower the risk of

injury in the environment in which you are working.

NOTICE!

Do not immerse the insertion rod or wire coil in water or any other substance other than

ambient air or test environment air at any time. Doing so could damage equipment and will

invalidate the results of any carbon potential test.

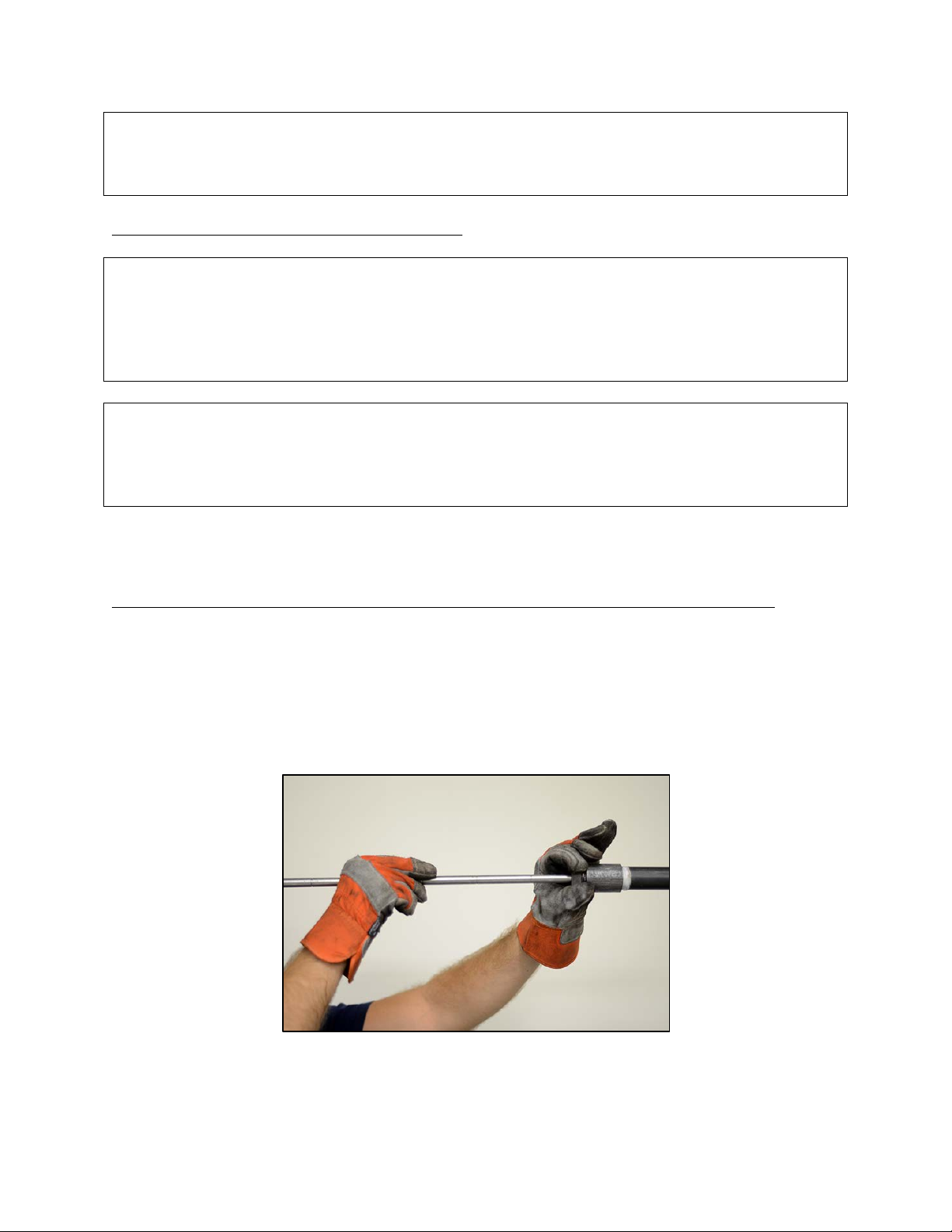

Cooling Down and Removing the Insertion Rod

Put on heat-resistant full hand protection (such as welding gloves) before proceeding.

Once the appropriate soak time has been achieved, the insertion rod is ready to be removed.

Proper removal of the insertion rod is essential for achieving accurate carbon readings. Follow

these steps for proper removal.

Recommended:

Measuring tape; stopwatch or watch with seconds indication.

1. Retract the first 6” (six inches) of the insertion rod length from the access port.

2. Pause for one minute.

3. Retract another 3” (three inches) of the insertion rod length from the access port. Pause

for another minute.

4. Repeat Step 3 as many times as needed until the protective cage makes contact with the

ball valve (Figure 14).

Figure 14 - Removing insertion rod from access port

5. Once the insertion rod is fully retracted, leave it in place for a minimum of three

minutes.

Page 15

CAT-100 Operations Manual

Super Systems Inc.

Page 15 of 51

NOTICE!

Do NOT quench in water; air cool only. If a method of cooling other than air cooling is utilized,

test results will be unreliable.

IMPORTANT!

IMPORTANT!

6. Close the access port valve.

7. Remove the insertion rod completely from the access port.

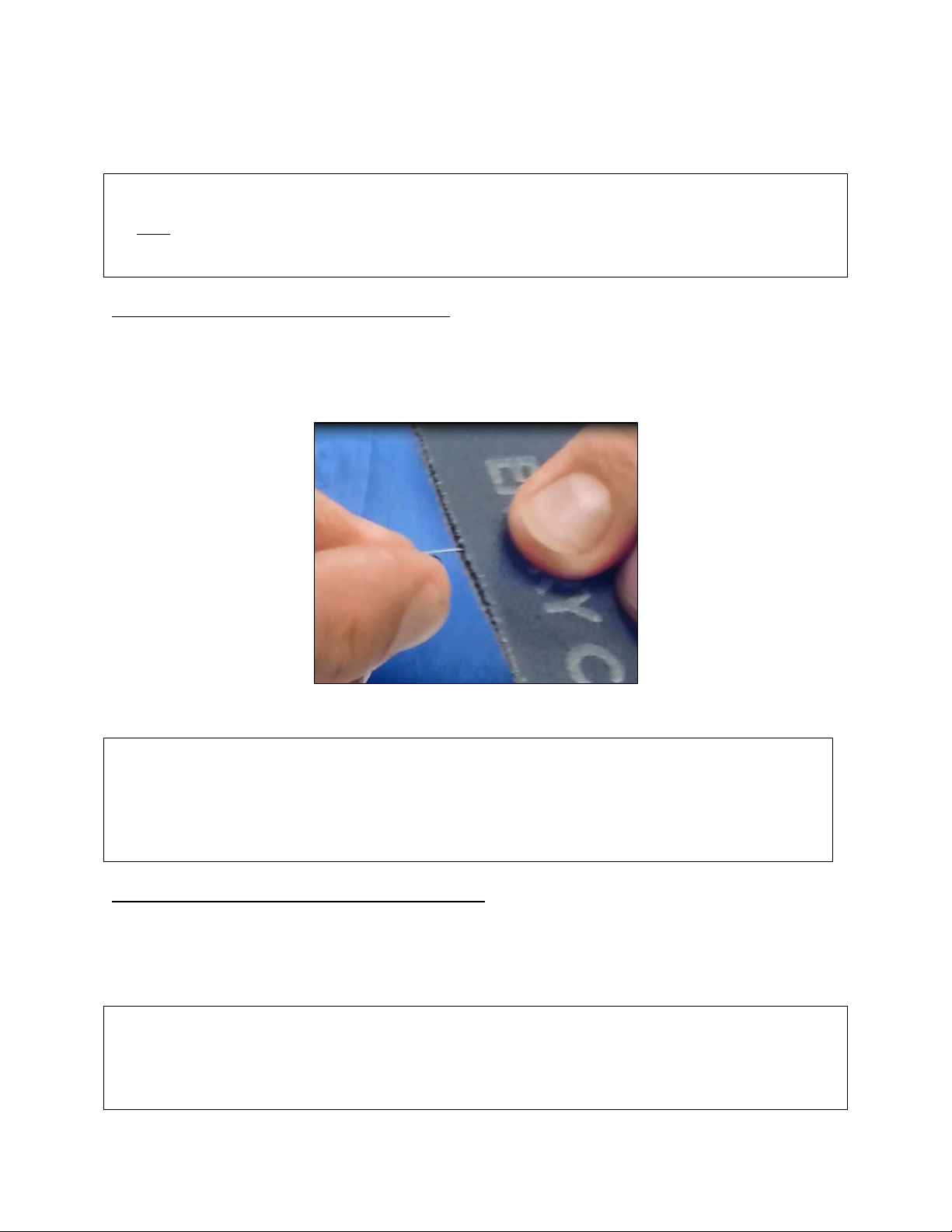

Using the Emery Cloth on the Steel Wire Coil

Before the wire coil is attached to the CAT-100 for analysis, the two ends of the wire should be

cleaned. An emery cloth is provided for this purpose. It is recommended that each wire end be

lightly cleaned with emery cloth, as pictured in Figure 15.

Figure 15 - Using emery cloth on wire coil

The correct type of emery cloth must be used for acceptable results. SSi sells a fine grade,

150 grit emery cloth for use in this process. See the Replacement Parts list (page 7) for more

information.

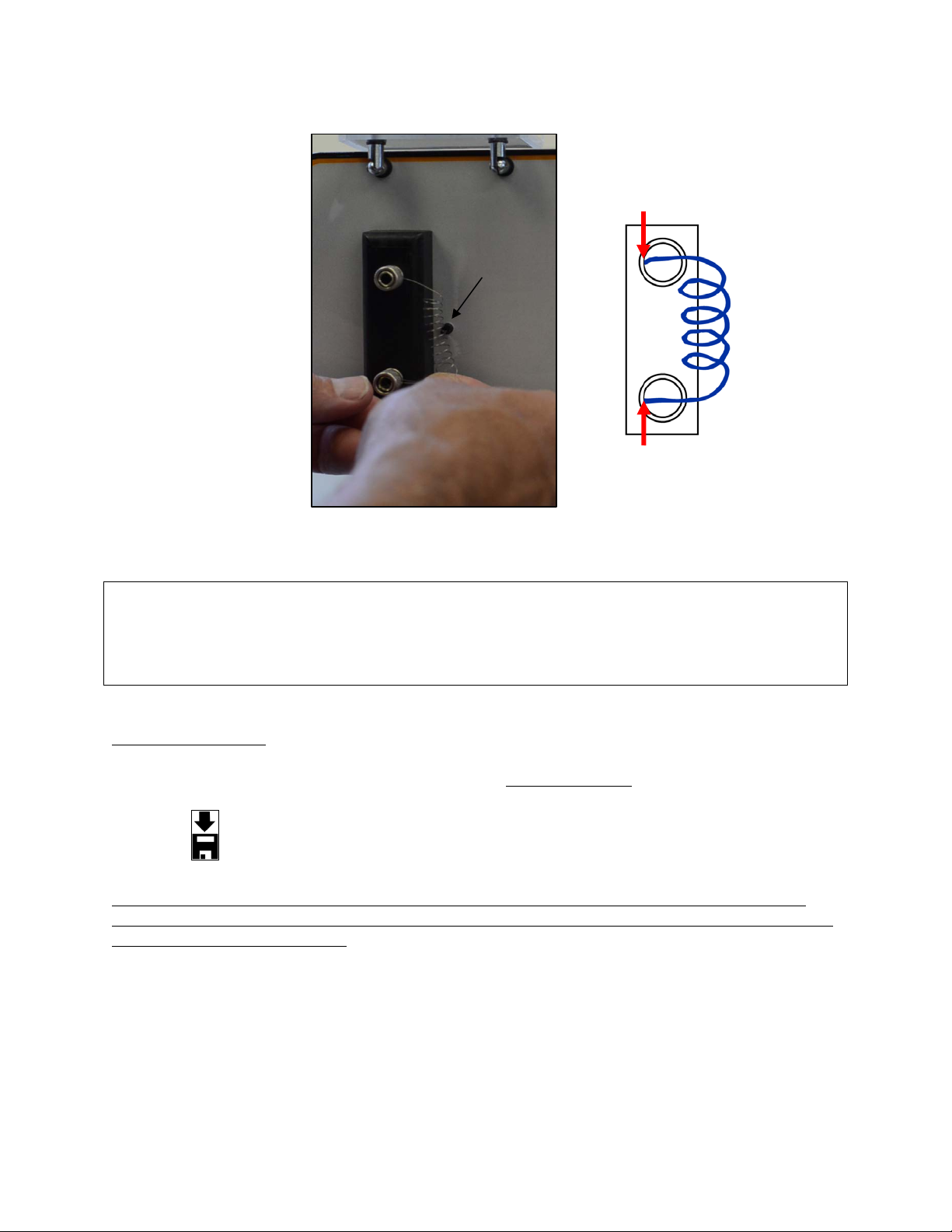

Attaching the Steel Wire Coil to the Binding Posts

Attach one of two wire coil leads to the hole on the right side of one of the two binding posts. Be

sure to insert the coil lead until it touches the back of the post (note the contact points in Figure

16). Then tighten the post to secure the lead. Repeat this procedure for the second lead.

Each lead must touch the back of the post to ensure the correct length of insertion. Note the red

arrows in Figure 16.

Page 16

CAT-100 Operations Manual

Super Systems Inc.

Page 16 of 51

IMPORTANT!

Note location of

thermistor

Contact point

Contact point

external

Figure 16 - Attaching wire coil to binding posts

Once the wire coil is secured to the binding posts, close the protective cover on the CAT-100.

Ensure that the wire coil does not make contact with the external thermistor once the wire is

attached to the binding posts. The location of the external thermistor is noted in Figure 16

.

Storing Test Results

Leave the wire coil attached to the binding posts for 30 to 45 seconds. During this time, the %

Carbon reading will likely fluctuate. This is expected and is not an error. After 30 to 45 seconds,

press the button to save the setting to the CAT-100’s internal storage.

Depending on which options are enabled in the Test Enables menu (see page 31

), a series of

screens will appear. If one or more of these options are NOT enabled in the Test Enables menu,

that screen(s) will NOT appear.

• Test ID Entry (Figure 17). This screen gives you the ability to enter an identification

number for the test data that you are saving. When finished, press

↵ to continue.

Page 17

CAT-100 Operations Manual

Super Systems Inc.

Page 17 of 51

Figure 17 - Test ID Entry

• Furnace # Selection (Figure 18). With this screen, you may select a furnace number to

associate with the saved test data. Furnace names may be edited in the CAT-100 PC

software; see the

number of furnace names is 16; the maximum number of characters for each name is 32.

Operator # Selection (Figure 19). With this screen, you may select an operator number to

associate with the saved test data. Operator names may be edited in the CAT-100 PC software;

see the

names is 16; the maximum number of characters for each name is 32.

View Operators section on page 42 for more details. The maximum number of operator

View Furnaces section on page 42 for more details. The maximum

Figure 18 - Furnace # Selection

• Enter probe data (Figure 20). Using this screen, probe data may be saved with the test

Figure 19 - Operator # Selection

data: % Carbon (“%C”), millivolts (“MV”), thermocouple number (“TC”), and CO Factor

(“COF”). Pressing each button associated with a field will bring up a numeric keypad that

will allow you to enter the appropriate value for that field. When finished entering

values, press

↵ to continue.

Page 18

CAT-100 Operations Manual

Super Systems Inc.

Page 18 of 51

Figure 22 - "Test Saved!" initial screen

Figure 23 - "Test Saved!" summary screen

Figure 20 - Probe data entry

• Enter date and time of test (Figure 21). This screen contains buttons allowing you to

enter the Year, Month, Day, Hour, and Minute of the test. You may also accept the default

values shown. When finished entering values, press

↵ to continue.

Figure 21 - Entry of date and time of test

The screen will read “Test Saved!” (see Figure 22) when the test data has been saved. A

summary of the data saved will then be shown (Figure 23) before the main menu is again

displayed.

Once the data has been saved appropriately, remove the wire coil from the binding posts.

Discard the wire coil in a proper manner.

reuse a coil that has already been used.

To prevent errors in test results, it is important not to

Page 19

CAT-100 Operations Manual

Super Systems Inc.

Page 19 of 51

Menu

CAT-100 Menu Navigation

Most of the CAT-100’s functional details and settings are accessed by using the CAT-100 menu.

To open the menu from the main screen, press the “Menu” ( ) button located in the upper

right hand corner of the touch screen, as shown in Figure 24.

button

Figure 24 - Main Screen with Menu button

A number of menu items will be visible.

User Level

• Main

• Detail

• Review Tests

• About

• LOGIN

Supervisor Level (Default Code: 1)

All of the above options and these:

• Calibration

• Coil TC Calibration

• Comms Setup (Communications Setup)

• Ethernet Setup

• Update

• View Updates

Configuration Level (Default Code: 2)

All of the above options and these:

• General Setups

o Temperature Mode

o Date/Time Set

o Display Theme

o Factory Defaults

o Clear Tests

• Test Enables

• Touch Cal (Touch Calibration)

• Pass Code Set

• Language

Page 20

CAT-100 Operations Manual

Super Systems Inc.

Page 20 of 51

Figure 25 shows an example of a CAT-100 menu list. The menu items are described in more

detail in the subsections below.

Figure 25 - CAT-100 Menu List

Note about Battery Level Indicator

The CAT-100 includes a battery level indicator which is displayed on the bottom of many

screens. The battery level indication will change as the battery discharges. When the battery is

nearly depleted of its charge, the indicator will change to a red color. Examples are shown in

Figure 26.

Figure 26 - Example Battery Level Indicators

Main

The Main menu option will open the main status screen (pictured in Figure 27). From this

screen, you can see Carbon Potential data and coil temperature for a properly attached wire

coil.

Figure 27 - Main Status Screen

If no coil is detected, or if the Carbon Potential cannot be calculated, the % Carbon will be

displayed as “NS” (“No Sample”).

The main status screen will be used during a typical coil testing procedure. Refer to the

Page 21

CAT-100 Operations Manual

Super Systems Inc.

Page 21 of 51

Testing Procedure section (page 8

) for further details on this process.

Detail

The Detail menu will open the Detail screen (Figure 28), which displays current values for %

Carbon, coil temperature (the temperature detected for the wire coil), and internal temperature

(the temperature detected inside the CAT-100).

Figure 28 - Detail Screen

Press the button to return to the menu list.

Coil Factor and Advanced Detail Display (Configuration Mode)

By logging in with configuration mode (see LOGIN section on page 23), you can:

• View and set the Coil Factor (shown as “Factor”) and

• View additional information on resistance, voltage, and current.

An example screen is shown in Figure 29.

Figure 29 - Coil Factor and Advanced Display on

Detail Screen (Configuration Mode Login Required)

Each wire coil has a Coil Factor associated with it. The Coil Factor is critical in accurate Carbon

Potential calculations and can be found printed on each bag of wire coils. More information on

how the Coil Factor is used and set can be found in the Entering the Coil Factor section on page

8.

Page 22

CAT-100 Operations Manual

Super Systems Inc.

Page 22 of 51

Review Tests

The Review Tests menu contains a record of recorded test results. When opened, the menu will

present a list of test results (Figure 30).

Figure 30 - Review Tests Screen

To view more detailed information on a specific test, use the and buttons to scroll to the

desired test result, and then press the ↵ button. A screen similar to the one pictured in Figure

31 will be shown.

Figure 31 - Detailed Test Results

Press to return to the list of recorded test results.

Once you are finished reviewing test results, press the button to return to the menu list.

About

Selecting the About menu option will bring up the About screen (similar to the screen shown in

Figure 32). This is the same screen that is shown when the CAT-100 first starts up.

Page 23

CAT-100 Operations Manual

Super Systems Inc.

Page 23 of 51

Figure 32 - About Screen

LOGIN

The purpose of the LOGIN option (Figure 33) is to allow the user to access Supervisor and

Configuration functions. Enter the Supervisor pass code (default is 1) to log in with the

Supervisor access level. Enter the Configuration pass code (default is 2) to log in with the

Configuration pass code. Functions available with each access level are shown in the CAT-100

Menu Navigation section on page 19.

Figure 33 - LOGIN Option

Calibration

A circuit calibration is required once per year and recommended every four months. The

required annual calibration is performed by SSi, and a certificate is issued for this calibration. A

circuit calibration can be performed by the end-user by using the Calibration Bridge provided by

SSi when the CAT-100 is first shipped.

An important guideline is as follows: A circuit calibration should be performed at any time the

“Error in %” found in this procedure is greater than 0.5 or less than -0.5.

NOTE: Information on ordering a replacement Calibration Bridge can be found in the

Replacement Parts section (page 6).

Page 24

CAT-100 Operations Manual

Super Systems Inc.

Page 24 of 51

Long end of

Calibration Bridge

(inserted first)

Short end of

Calibration Bridge

(inserted second)

The Calibration screen allows you to perform the circuit calibration. The procedure is as

follows.

1. Open the Calibration menu option. Doing this will require a Configuration level access code.

Figure 34 - Calibration menu screen

2. Connect the Calibration Bridge to the binding posts. Do this by first inserting the long end of

the Calibration Bridge into a binding post first, tightening that post, then inserting the short

end of the Calibration Bridge in the other binding post, and tightening that post. See

Figure 35.

Figure 35 - Calibration Bridge in CAT-100 Binding Posts

3. Wait five (5) minutes. This will allow “Error in %” readings to stabilize.

4. Press the ↵ button to calculate and store the calibration value. The “Error in %” should

now be equal to zero (0). If “Error in %” does not read zero (0) on the first attempt, press

to recalculate and store the calibration value.

↵

Page 25

CAT-100 Operations Manual

Super Systems Inc.

Page 25 of 51

IMPORTANT!

↵

Figure 36 - Location of external thermistor

Figure 37 – Coil TC Calibration screen

Thermistor

The maximum allowable “Error in %” range is ±05. If the “Error in %” is greater than 0.5 or less

than -0.5 after you have pressed the

for further assistance.

Press the button to return to the menu list.

Coil TC Calibration

The CAT-100 contains a thermistor used to measure ambient temperature in the area near the

binding posts to which the steel wire coil is attached for carbon analysis. This thermistor must

be calibrated annually.

To calibrate, first press the Coil TC Calibration button. Using a digital thermometer with

accuracy of ±0.1°C (±0.18°F), measure the ambient temperature within ¼” of the thermistor

(see Figure 36). Enter this value in the Coil TC Calibration screen (Figure 37). The “Coil Temp”

value will change to the value you entered.

button more than twice, contact SSi at (513) 772-0060

Press the button to return to the menu list.

Comms Setup (Communications Setup)

The Comms Setup screen allows you to change communications settings of the serial and USB

connections for the CAT-100. Use the

Press the ↵ button to change a setting. In most cases, these settings will not need to be

changed from their defaults.

and buttons to change which setting is selected.

Page 26

CAT-100 Operations Manual

Super Systems Inc.

Page 26 of 51

Figure 38 - Comms Setup Screen

The settings are as follows:

• RS-485 Baud: The baud rate (data transmission rate) of the RS-485 serial connection.

19200 is default.

• RS-485 Mode: The mode of the RS-485 serial connection. Master is default. Host may

also be selected.

• USB Baud: The baud rate (data transmission rate) of the USB connection. 115200 is

default.

To change the value for a selected setting, use the and buttons. When finished, press the

↵ button.

Press the button to return to the menu list.

Ethernet Setup

The Ethernet Setup menu (Figure 39) allows you to change settings for the network adapter on

the CAT-100. The following settings can be changed:

• Address (IP Address). The IP address of the CAT-100.

• Subnet Mask. The subnet mask for the CAT-100. If you intend to create an Ethernet

connection between the CAT-100 and a computer, all of these values must match the

subnet mask of the computer you are using to connect to the CAT-100.

• Gateway. The IP address of the router or network device that manages traffic on the

network.

Page 27

CAT-100 Operations Manual

Super Systems Inc.

Page 27 of 51

IMPORTANT!

If you are uncertain of the correct network settings for the CAT-100, first consult your network

administrator. Incorrect network settings may cause the CAT-100 to be unusable on the

network and may even cause network problems for other devices on the network (such as

computers and other connected instruments).

Figure 39 - Ethernet Setup Screen

Each of the numeric values may be changed by first tapping the numerical block and then using

the numeric keypad to enter a new value.

Press the button to return to the menu list.

DHCP Button

The DHCP button (Figure 40) turns on dynamic IP address assignment. When DHCP is on, the

CAT-100 will request an IP address from the network server. This IP address may change over

time.

Figure 40 – DHCP Button

If dynamic IP addressing is turned ON, a message will appear to the right of the “Address” text.

The message will read “DHCP ,” followed by an IP address. This is the dynamically assigned IP

address that the CAT-100 is using. When dynamic IP addressing is turned ON, the message

“DHCP” will also appear on the main screen.

Page 28

CAT-100 Operations Manual

Super Systems Inc.

Page 28 of 51

To turn dynamic IP addressing OFF, enter a static IP address. The CAT-100 will switch to

manual Ethernet settings.

In order to leave dynamic IP addressing ON, press the to exit the Ethernet Setup menu.

Update

The Update menu (Figure 41

In order for the update to work, the CAT-100 must be connected to an Ethernet network with

Internet access. Press the “START” button to begin downloading the calculation update.

) is used to perform an automatic update of operating parameters.

Figure 41 - Update Screen

NOTE: If the CAT-100 is connected to a network with Internet connectivity but fails to update

properly using this menu, turn on dynamic IP assignment (following the procedure described in

the

DHCP Button section on page 27) and try the update again. If you continue to have problems

after doing this, please call SSi at (513) 772-0060.

Press the button to return to the menu list.

View Updates

The View Updates screen (Figure 42

when they were applied. Pressing

100 will use that method to calculate % Carbon.

) allows you to view a log of calculation method changes and

↵ will load the highlighted calculation method, and the CAT-

Page 29

CAT-100 Operations Manual

Super Systems Inc.

Page 29 of 51

Figure 42 - View Updates Screen

Press the button to return to the menu list.

General Setups

The General Setups menu (Figure 43) contains five submenus used to control various settings,

reset the CAT-100 to factory default settings, and reset test numbering.

Figure 43 – General Setups screen

Page 30

CAT-100 Operations Manual

Super Systems Inc.

Page 30 of 51

Temperature Mode

The Temperature Mode menu (Figure 44) allows you to select one of two temperature modes for

displaying and recording data. These two modes are

Fahrenheit and Celsius.

Figure 44 – Temperature Mode selection

Date/Time Set

The Date/Time Set menu (Figure 45) allows you to set the current date (Year, Month, and Day)

and time (Hour, Minute, and Second) manually.

Figure 45 – Date/Time selection

Page 31

CAT-100 Operations Manual

Super Systems Inc.

Page 31 of 51

Display Theme

Using the Display Theme menu, you may choose one of three display modes: white text on black

background, black text on white background (default), or white text on gray background.

Figure 46 – Display Theme selection

Factory Defaults

Pressing this button will revert CAT-100 settings such as operating parameters, equipment

(furnace) numbers, and operator numbers to factory defaults. The static IP address (if assigned)

is not changed.

Use care when selecting this option, as any settings that were changed before factory defaults

are reset cannot be recovered.

Clear Tests

Pressing this button will erase the first character of each stored test and restart test numbering

at 0.

Test Enables

The Test Enables screen (Figure 47) allows you to toggle whether data for the following are

enabled or disabled:

• Test ID

• Equipment

• Operator

• Date/Time

• Probe Data

Page 32

CAT-100 Operations Manual

Super Systems Inc.

Page 32 of 51

Figure 47 – Test Enables screen

Touch Cal (Touch Screen Calibration)

Using the Touch Screen Calibration option (Figure 48), you will be able to set up the CAT-100

touch screen for optimal touch response. Using a stylus, press and hold the center of each

numerical block for a period of 10 seconds, as instructed on the screen. Once all of the blocks

have turned green, press the DONE button.

Figure 48 - Touch Calibration screen

Page 33

CAT-100 Operations Manual

Super Systems Inc.

Page 33 of 51

Pass Code

Use the Pass Code screen (Figure 49

codes. Simply press the pass code type you would like to set, enter the new code on the numeric

) to change the default Supervisor and Configuration pass

keypad, and then press

Press the button to return to the menu list.

Language

The CAT-100 provides several language options. Use the Language menu to change which

language the CAT-100 uses for operation.

Press the Language Update button to update the language definition file. An Internet connection

to the CAT-100 is required for this to work.

Press the button to return to the menu list.

↵ to save the newly entered pass code.

Figure 49 - Pass Code Screen

Page 34

CAT-100 Operations Manual

Super Systems Inc.

Page 34 of 51

Installation files for CAT-100 View are provided

Figure 50 - Example contents of installation CD

CAT-100 PC Software (CAT-100 View)

When purchased, the CAT-100 is provided with PC computer software, CAT-100 View, that can

be used to download and store data on the PC as well as display data in grid form and in a line

graph. CAT-100 View connects to the CAT-100 using a USB or Ethernet connection.

Installation

on a CD that is shipped with the CAT-100.

Insert the CD into a compatible disc reader to

begin the installation process. The installation

CD contents will look similar to what is shown

in

Figure 50. To install CAT-100 View, double

click on the “setup” or “setup.exe” file.

CAT-100 View Setup will run. Figure 51 shows an example of what the installation screens may

look like. The Setup procedure will ensure that all prerequisites for using CAT-100 View are

installed, in addition to the CAT-100 View software itself.

Page 35

CAT-100 Operations Manual

Super Systems Inc.

Page 35 of 51

Figure 51 - CAT-100 View installation screens

Once installed, CAT-100 View can be opened from the Windows Start menu.

CAT-100 USB Driver

The CAT-100 can be connected to a PC using an Ethernet connection or USB. In most cases,

Windows will detect the CAT-100 and install the USB driver that is needed for the computer to

access CAT-100 data via USB. In some cases, Windows will not be able to successfully install

the driver, in which case it will need to be installed manually. This can happen, for example, if

the computer to which the CAT-100 is connected does not have Internet access.

To install the USB driver manually, follow these steps:

1. Ensure that the CAT-100 is not connected to the computer. Remove any USB cables and

Ethernet cables from the CAT-100.

2. Insert the installation CD provided with the CAT-100 into the computer’s disc reader.

3. Open the installation CD in Windows Explorer. Find the file named

Certified.exe.

4. If using Windows XP, double click on the driver installation program. If using Windows

Vista, 7, or 8, right click on the driver installation program and select

administrator (you will need to confirm this action).

NOTE: The program must be run with administrator privileges in order to work

correctly.

5. Extract the driver installation files by clicking Extract. A driver installation window will

appear once all files are extracted.

6. Click Next to install the drivers.

Once the drivers are installed successfully, a window will appear showing the successful

installation.

7. Restart the computer.

If you encounter problems with this procedure, contact SSi by calling (513) 772-0060.

Main Screen

The main screen is what appears when CAT-100 View is first opened. In order to utilize most of

this screen, data must first be downloaded from a CAT-100 unit. This is performed with the

Manage CAT100s option described on page 41.

This is the driver installation program.

CDM v2.08.30 WHQL

Run as

Page 36

CAT-100 Operations Manual

Super Systems Inc.

Page 36 of 51

Main Screen Options

Label in Figure 52

Name

Description

A

Saved CAT100s drop-down list

Opens a list of CAT-100 units that have been accessed by the program

downloaded for that unit is displayed.

B

Test Info button

Opens a window containing information on a highlighted test

C

Edit Test button

Allows for the modification of highlighted test data (NOTE: This does

NOT change the data on the CAT-100 itself)

D

Delete Tests button

Deletes highlighted test data

E

Show Live Coil button

Displays coil data from a connected CAT-100

NOTE:

Main Screen Display Fields

Label in Figure 52

Name

Description

F

Test Number

The saved test number

G

Test ID

The test ID

(user-provided)

H

Time

The time of the test recorded by the CAT-100

I

Furnace

The saved furnace number

(user-provided)

J

Operator

The saved operator identifier

(user-provided)

K

Coil %C

The recorded carbon potential of the coil used in the selected test

L

SP %C

The carbon value of the process that is entered in the CAT-100 unit

during the soak of the coil

(user-provided)

M

SP °F

The temperature setpoint (may be displayed in °C or °F;

user-provided

)

N

Avg Coil %C

The average carbon potential for a particular Test ID

O

Deviation

The difference between the Coil %C and the SP %C

P

Notes

Test notes

(added in CAT-100 View)

Q

Probe mV

The probe millivolts

(user-provided)

R

COF

The CO factor

(user-provided)

S

Probe Temp °F

The probe temperature (may be displayed in °C or °F

; user-provided)

T

Coil Factor

The Coil Factor used in Carbon Potential calculation

(entered by user

during testing procedure)

Figure 52 shows the layout of the CAT-100 View main screen. Lettered labels in Figure 52

correspond to descriptions in Table 3 - Main Screen options and Table 4 - Main Screen display

fields.

Figure 52 - CAT-100 View main screen

previously. When a CAT-100 unit is selected, data that has been

If no CAT-100 data is loaded, the buttons (B, C, D, & E) will be grayed out.

Table 3 - Main Screen options

Table 4 - Main Screen display fields

With the exception of the Test Number, all of the fields can be changed by the user. When a field

is changed, it is changed in CAT-100 View, but not on the CAT-100 itself.

Page 37

CAT-100 Operations Manual

Super Systems Inc.

Page 37 of 51

The main screen provides a way to sort

Time

Figure 53 - Simple field sorting in CAT-100 View

The File menu (Figure 54) contains three options: Show

Graph, Export Tests to CSV,

Print Selected Tests.

Figure 54 - File Menu

Sorting Data in the Main Screen View

data based on one field by clicking on

that field’s column heading. For

example, if you want to sort test

results in order of time, simply click

on the

default, sorting will be performed in

ascending order. In the case of time,

this means that the least recent time

will be shown first. To change sorting

order to descending, click on the

column heading again. Again using the

example of time, a descending order

will display the most recent time first.

This example is depicted in

column heading. By

Figure 53.

For more advanced sorting options, see a description of the Sort menu on page 43.

File Menu

Show Graph

The Show Graph option displays CAT-100 data in line graph form. This is derived from the data

presented in the grid form displayed on the CAT-100 main screen. An example of a graph is

shown in

Figure 55.

and

Page 38

CAT-100 Operations Manual

Super Systems Inc.

Page 38 of 51

1. Save the CAT-100 data to a CSV file using

Export Tests to CSV

Figure 56 - Saving CSV file in CAT-100 View

2. Open Microsoft Excel (or a similar

File ->

Open

Open

Figure 57 - Opening CSV file in Microsoft Excel

Figure 55 - Example of Line Graph in CAT-100 View

Export Tests to CSV

This option allows you to save downloaded CAT-100 data in a comma-separated value (CSV) file

that can be opened with a program such as Microsoft Excel. To save a CSV file and use it in

Excel, follow these steps.

the

View (see example in

spreadsheet program). Open the

dialog box (Figure 57). Set the File

Type to include .csv files. Select the CSV

file you saved and click

option in CAT-100

Figure 56).

.

Page 39

CAT-100 Operations Manual

Super Systems Inc.

Page 39 of 51

The rest of this section pertains to Microsoft

Next

Figure 58 - Importing CSV file in Microsoft Excel

(Step 1 of 3)

4. Set the Delimiter type to “Comma” (Figure

Next.

Figure 59 - Importing CSV file in Microsoft Excel

(Step 2 of 3)

5. The “Column data format” can be

Finish

Figure 60 - Importing CSV file in Microsoft Excel

(Step 3 of 3)

Excel. However, other spreadsheet programs

will likely have similar functionality.

3. Choose “Delimited” for the “Original data

type” (Figure 58

). Click

.

59). Then click

configured for each column using the

options in Excel (

Figure 60). “General”

format should work well in most cases.

Click

when ready.

Page 40

CAT-100 Operations Manual

Super Systems Inc.

Page 40 of 51

6. Observe how the data is organized in Excel

Figure 61 - Example of formatted

CSV data in Microsoft Excel

The Options menu (Figure 63) provides the Manage

CAT100s

Temperature Scale

Figure 63 - Options Menu

(see an example in Figure 61). Make

changes to the formatting as needed.

Print Selected Tests

This option allows for the printing of selected CAT-100 data to a printer (see example Print

Options window in Figure 62).

Figure 62 - Example Print Options window

Options Menu

and

options.

Page 41

CAT-100 Operations Manual

Super Systems Inc.

Page 41 of 51

Download Options. This option (Figure 65) provides

Figure 65 - Download Options

Manage CAT100s

The Manage CAT100s menu is used to search for CAT-100 units via Ethernet or USB (see

example in

CAT-100, download data from it, and perform additional operations.

NOTE about USB connections: If you experience difficulty connecting the CAT-100 to the

computer using USB, refer to the CAT-100 USB Driver section on page 35

Figure 64). Once units are found, this option allows the PC to connect to a selected

Figure 64 - Finding and selecting CAT-100s for management options

NOTE: Once CAT-100 View connects to a CAT-100 via USB or Ethernet, that CAT-100 can be

connected to using the

Saved CAT100s drop-down menu in the CAT-100 View main screen.

The following options are available:

Download New Tests. When this button is clicked, CAT-100 View downloads all new test values

from the CAT-100 unit. New test values are those that have not been downloaded previously.

several parameters for downloading test results from

the CAT-100 unit.

The first parameter is Next Test Number To Download. This specifies the test number at which

CAT-100 View starts downloading test results. Any number less than that test number will not

be downloaded. If the number specified for the Next Test Number does not exist, nothing will be

downloaded.

Page 42

CAT-100 Operations Manual

Super Systems Inc.

Page 42 of 51

The third parameter is Download Range Tests

Figure 66 - Download Range Tests

"Input Range" option

View Furnaces (Figure 67). Selecting this

Edit Furnace Names

Figure 67 - View Furnaces option

View Operators (Figure 68). Similar to the View

Edit Operator

Names

Figure 68 - View Operators option

The second parameter is Current Download Group. This allows you to assign a group number to

the test data that will be downloaded when

Download New Tests is clicked. In the main screen,

the Test ID will display a value based on the following formula when a Group Number has been

assigned to downloaded results:

(Group Number * 10000) + Test Number.

(Figure 66). This option allows you to set a

range of tests that CAT-100 View will download

from the CAT-100 unit. The test number in the

“Start” field must exist in order for any values

to be downloaded in this range.

option will display the list of Furnace Names

that can be applied to a test result when the

test result is being saved on the CAT-100. The

option allows you to

change a selected Furnace Name. There is a

maximum of 16 furnace names, each with a

maximum of 32 characters in the name.

Furnaces option, this option, when selected,

displays the list of Operator Names that can be

applied to a test result when the test result is

being saved on the CAT-100. The

option allows you to change a selected

Operator Name. There is a maximum of 16

operator names, each with a maximum of 32

characters in the name.

Page 43

CAT-100 Operations Manual

Super Systems Inc.

Page 43 of 51

Using this option (Figure 69), you can toggle

Figure 69 - Temperature Scale option window

The Data menu (Figure 70) contains the Sort and

Filter

Figure 70 - Data Menu

Temperature Scale

the temperature units between degrees

Fahrenheit (°F) and degrees Celsius (°C).

Data Menu

options. These options are used to change

how data is displayed in CAT-100 View.

Sort

The Sort window (Figure 71) contains advanced options for arranging data. As explained in the

Sorting Data in the Main Screen View section on page 37

options. The

Sort menu provides additional functionality for sorting data, allowing for three

“layers” of sorting.

, the main screen provides sorting

As an example, if the settings in Figure 71 are applied, data will be sorted first by Test Number

in ascending order, second by Furnace Name also in ascending order, and third by Coil %C also

in ascending order.

Filter

The Filter window (Figure 72) is used to set conditions for determining what data is displayed on

the main screen and what data is not displayed.

Figure 71 - Sort options window

Page 44

CAT-100 Operations Manual

Super Systems Inc.

Page 44 of 51

Operator

Meaning

==

Is equal to

!=

Is NOT equal to

<

Is less than

>

Is greater than

<=

Is less than or equal to

>=

Is greater than or equal to

The Users menu (Figure 73) contains options for

Log In, Log Out,

Manage Users.

Figure 73 - Users Menu

Use this option (Figure 74) to log in with a

NOTE:

Figure 74 - Log In window

Figure 72 - Filter options window

The following operators are used in evaluating conditions:

Table 5 - Operators used in Filter window and their meanings

Users Menu

adding, removing, and modifying registered users

of CAT-100 View. It also provides the ability to log

in and log out users. The available options in this

menu are

and

Log In

registered user’s credentials. (

user, use the

Manage Users option.)

To set up a

Page 45

CAT-100 Operations Manual

Super Systems Inc.

Page 45 of 51

Once you’ve logged in a user successfully, that

Figure 75 - Message indicating

logged in user and access level

user and the user’s type will be displayed in

the upper left hand corner of the CAT-100 View

main screen (example in

Figure 75).

Log Out

Use this option to log out the currently logged in user.

Manage Users

This option allows you to add, remove, and modify registered users. The access levels possible

are Operator, Supervisor, and Administrator. Operator and Supervisor access levels allow for

the deletion of test results from CAT-100 View. Administrator access is required to add, remove,

and modify users. The exceptions to the Administrator access requirement are in two cases:

1. No users have been added. If no users have been added, one user may be added for the

first time.

adding any others.

2. Users have been added, but no Administrator level users have been added. If users have

been added, but none of the users have Administrator access privileges, then the

existing users have Administrator level access by default. Once an Administrator level

user has been added, only users with Administrator access privileges will be able to add,

remove, or modify other users.

Figure 76 illustrates an example of adding a user to CAT-100 View.

It is recommended to add at least one user with Administrator access before

Help Menu

The Help menu (Figure 77) provides the ability to check for (and, if available, download) updates

to the CAT-100 View software; it also provides information on the currently installed CAT-100

View version and software update history.

Figure 76 - Adding a user

Page 46

CAT-100 Operations Manual

Super Systems Inc.

Page 46 of 51

Figure 77 - Help Menu

Check for Updates

This option will check the Internet for updates to the software and, if an update is found, give

you the option to download and install it.

date and download updates when they are available.

It is recommended that you keep your software up-to-

About

The About screen provides information on the specific software version as well as a revision

history for the software.

Page 47

CAT-100 Operations Manual

Super Systems Inc.

Page 47 of 51

Troubleshooting

WARNING!

When troubleshooting, follow all proper safety precautions. Use proper eye protection and hand protection at all times.

Problem

Possible Causes

Possible Corrective Actions

Wire breaks at any point in the procedure

Coil cooled too quickly

Wire stretched beyond design limitations

When removing insertion rod, follow procedure

Avoid stretching wire excessively

% Carbon indicated by CAT-100 differs by more

Wire soaked too early in soak cycle

Instrumentation error

Insert wire coil into testing atmosphere during

Contact equipment manufacturer or distributor

The CAT-100 is designed to provide accurate results testing procedures and conditions are consistent with the product’s design. When

problems or discrepancies are encountered, they can often be corrected. The table below provides a list of potential problems that may be

encountered, possible causes, and corrective actions that may rectify the problem.

than 0.03% from Process Variable shown by

instrumentation at the time wire was exposed to

testing atmosphere

Emery cloth not applied to wire after soaking

Variability in % Carbon levels in testing

atmosphere

Testing procedure not followed correctly

exactly as shown in Cooling Down and Removing

the Insertion Rod

final one-third of soak cycle.

Perform a test of a new wire, closely following

the instructions in Using the Emery Cloth on the

Steel Wire Coil

Ensure that testing atmosphere remains

consistent during test. Temperatures, % Carbon,

and other parameters should not change

significantly while wire is exposed to testing

environment. Furnace should be in a soak state

for a minimum of one hour.

Calibrate CAT-100 and re-test using an unused

wire, following instructions exactly as indicated in

manual

section on page 14

page on 15

Page 48

CAT-100 Operations Manual

Super Systems Inc.

Page 48 of 51

Problem

Possible Causes

Possible Corrective Actions

% Carbon indicated by CAT-100 differs by more

testing atmosphere

(Continued)

Incorrect Coil Factor entered

Ensure that the correct Coil Factor is entered

Carbon Potential is not within the effective range

Actual Carbon Potential is not within the effective

% Carbon shown must be within the effective

times shown in Table 2 are applied as indicated.

Wire becomes detached from insertion rod

Unsecured attachment

Before inserting rod into testing atmosphere,

rod

Reading is not stored when “Store” is pressed on

Pressure on screen not hard enough

Increase pressure of contact with screen. Take

Call SSi Technical Support at (513) 772-0060

Test results not displaying correctly in Test

Results screen

Internal storage error

(513) 772-0060

than 0.03% from Process Variable shown by

instrumentation at the time wire was exposed to

of 0.1% to 1.3%

during soak in testing atmosphere

CAT-100 touch screen

range of the unit

Soak time too long or too short

Interference from protective film over screen

No reading to store

Internal storage error

during the testing procedure; see Entering the

Coil Factor section on page 8.

range in order to be reliable. A different method

of measuring Carbon Potential may be needed in

such a case.

Re-test using an unused wire. Ensure that soak

verify that wire coil is in place securely for

testing, that rod screw is securely tightened, and

that protective cage is securely in place on the

care not to cause damage to screen or protective

film.

Verify that spacing between protective film and

touch screen allows for contact with touch screen

Verify that a test result was generated when wire

coil was connected to binding posts on CAT-100.

If not, reconnect wire to binding posts and

observe reading again.

Call SSi Technical Support at

Page 49

CAT-100 Operations Manual

Super Systems Inc.

Page 49 of 51

Problem

Possible Causes

Possible Corrective Actions

CAT-100 View software cannot connect or access

(If connecting through Ethernet)

Ethernet

Ensure that the PC and the CAT-100 are

(513) 772-0060

Table 6 - Troubleshooting

data from CAT-100 unit

connection issue

(If connecting through USB)

issue

USB connection

connected to the same computer network and

that the needed computer network settings (such

as subnet mask and gateway) are correct. Ensure

that both the PC and the CAT-100 have network

connectivity. Consult with your IT/network

administrator if needed.

Ensure that the USB port on both the PC and

CAT-100 are working properly and that the USB

driver needed for use with the CAT-100 is

installed properly. If needed, contact your IT

administrator for assistance, or call SSi at

.

If you experience problems and cannot find the solution after troubleshooting, please call SSi Technical Support at (513) 772-0060.

Page 50

CAT-100 Operations Manual

Super Systems Inc

Page 50 of 51

Warranty

Limited Warranty for Super Systems Products:

The Limited Warranty applies to new Super Systems Inc. (SSI) products purchased direct from

SSI or from an authorized SSI dealer by the original purchaser for normal use. SSI warrants

that a covered product is free from defects in materials and workmanship, with the exceptions

stated below.

The limited warranty does not cover damage resulting from commercial use, misuse, accident,

modification or alteration to hardware or software, tampering, unsuitable physical or operating

environment beyond product specifications, improper maintenance, or failure caused by a

product for which SSI is not responsible. There is no warranty of uninterrupted or error-free

operation. There is no warranty for loss of data—you must regularly back up the data stored on

your product to a separate storage product. There is no warranty for product with removed or

altered identification labels. SSI DOES NOT PROVIDE ANY OTHER WARRANTIES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME JURISDICTIONS DO

NOT ALLOW THE LIMITATION OF IMPLIED WARRANTIES, SO THIS LIMITATION MAY NOT APPLY

TO YOU. SSI is not responsible for returning to you product which is not covered by this limited

warranty.

If you are having trouble with a product, before seeking limited warranty service, first follow the

troubleshooting procedures that SSI or your authorized SSI dealer provides.

SSI will replace the PRODUCT with a functionally equivalent replacement product,

transportation prepaid after PRODUCT has been returned to SSI for testing and evaluation. SSI

may replace your product with a product that was previously used, repaired and tested to meet

SSI specifications. You receive title to the replaced product at delivery to carrier at SSI shipping

point. You are responsible for importation of the replaced product, if applicable. SSI will not

return the original product to you; therefore, you are responsible for moving data to another

media before returning to SSI, if applicable. Data Recovery is not covered under this warranty

and is not part of the warranty returns process. SSI warrants that the replaced products are

covered for the remainder of the original product warranty or 90 days, whichever is greater.

Page 51

Super Systems Inc.

Page 51 of 51

Rev.

Description

Date

MCO #

-

Initial Release

11/25/2013

2131

A

Added PC software section; updated Calibration

section; updated specs and Parts List

3/7/2014

2136

B

Added Coil Factor and relevant procedures

4/4/2014

2139

C

Updated manual for redesigned insertion rod

5/21/2014

2149

Revision History

CAT-100 Operations Manual

Loading...

Loading...