Page 1

CarbCalc II

Carbon Diffusion Model for

Atmosphere Furnaces

Copyright

Super Systems Inc

7205 Edington Drive

Cincinnati,OH 45249

Page 2

CarbCalc III

Table of Contents

Part I

Part II

Introduction

................................................................................................................................... 31 Welcome to SuperSystems

................................................................................................................................... 42 CarbCalcII Introduction

CarbCalcII

................................................................................................................................... 71 Overview

................................................................................................................................... 82 Typical Uses

................................................................................................................................... 93 Menu and Toolbar

................................................................................................................................... 104 Displays

.......................................................................................................................................................... 10Atmosphere Display Area

.......................................................................................................................................................... 11Model Segment Display Area

.......................................................................................................................................................... 12Segment Properties Dialog

.......................................................................................................................................................... 13Temperature and Carbon Chart

.......................................................................................................................................................... 14Carbon Profile Chart

................................................................................................................................... 155 Users and Security

.......................................................................................................................................................... 15Login

.......................................................................................................................................................... 16Manage Users

................................................................................................................................... 176 Parts and Loads

.......................................................................................................................................................... 17Loads

.......................................................................................................................................................... 17Control Mode

.......................................................................................................................................................... 20Monitor Mode

.......................................................................................................................................................... 21BatchMaster Mode

................................................................................................................................... 237 Model and Furnace Settings

.......................................................................................................................................................... 23Settings Overview

.......................................................................................................................................................... 23Model Settings

.......................................................................................................................................................... 24Furnace Settings

.......................................................................................................................................................... 26Furnace RealTime Setup

................................................................................................................................... 288 Material Selection

.......................................................................................................................................................... 28Material Dtabase

.......................................................................................................................................................... 29Initial Carbon Profile

................................................................................................................................... 319 Target Profile

.......................................................................................................................................................... 31Specifying a Target Profile

.......................................................................................................................................................... 32Recommended Profile

................................................................................................................................... 3310 Carbobn Profiles

.......................................................................................................................................................... 33Carbobn Profile Dialog

................................................................................................................................... 3611 SuperCalc

.......................................................................................................................................................... 36The SuperCalc Application

................................................................................................................................... 3712 Simulation Mode

.......................................................................................................................................................... 37Typical Uses

3

7

......................................................................................................................................................... 18Entering a Load

......................................................................................................................................................... 19Load History in Control Mode

......................................................................................................................................................... 19Parts in Control Mode

© 2005,2006,2007 Super Systems Inc.

Page 3

.......................................................................................................................................................... 37Report

................................................................................................................................... 3913 RealTime Control Mode

.......................................................................................................................................................... 39Typical Uses

.......................................................................................................................................................... 39Report

................................................................................................................................... 4114 Replay Monitor Mode

.......................................................................................................................................................... 41Typical Uses

.......................................................................................................................................................... 43Report

IIContents

Part III

CarbCalcII Configuration

44

Index 0

© 2005,2006,2007 Super Systems Inc.

II

Page 4

1 Introduction

1.1 Welcome to SuperSystems

Super Systems Inc.

Super Systems Introduces

Load Tracking and RealTime Control

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language or computer language, in any form or by any means, electronic,

mechanical, magnetic, optical, chemical, manual, or otherwise, without prior written permission of

Super Systems Inc., 7205 Edington Dr., Cincinnati, OH 45249 USA.

CARBCALCII is a software program to be used by the Heat Treater. Super Systems Inc. is not

responsible or liable for any product, process, or damage or injury incurred as a result of using

CARBCALCII. Super Systems Inc. makes no representations or warranties with respect to the

contents hereof and specifically disclaims any implied warranties or merchantability or fitness for any

particular purpose.

IntroductionCarbCalc II3

CarbCalcII

with

COPYRIGHT

DISCLAIMER

© 2005,2006,2007 Super Systems Inc.

Page 5

1.2 CarbCalcII Introduction

CarbCalcII is a Carbon Diffusion Model for use with Batch Furnace Gas Carburizing.

IntroductionCarbCalc II 4

Gas Carburizing

low-carbon steel part at a temperature sufficient to render the steel austenitic, followed by quenching

and tempering to form a martensitic microstructure. The resulting gradient in carbon content below the

surface of the part causes a gradient in hardness, producing a strong, wear-resistant surface layer on

a material, usually low-carbon steel, which is readily fabricated into parts. In gas carburizing the source

of carbon is a carbon-rich furnace atmosphere produced either from gaseous hydrocarbons, for

example, methane (CH4), propane (C3H3), and butane (C4H10), or from vaporized hydrocarbon

liquids.

Carbon Sources

Low-carbon steel parts exposed to carbon-rich atmospheres will carburize at temperatures of 850°C

(1560°F) and above. If the carbon source is so rich that the solubility limit of carbon in austenite is

reached at the surface of the steel some carbides may form at the surface. At these "above saturation"

atmospheres soot will deposit on surfaces within the furnace, including the parts. The goal of modern

gas carburizing practice is to control the carbon content of furnace atmospheres such that: The final

carbon concentration at the surface of the parts is below the solubility limit in austenite and Sooting of

the furnace atmosphere is minimized. Endothermic gas (Endogas) is a blend of carbon monoxide,

hydrogen, and nitrogen (with smaller amounts of carbon dioxide water vapor, and methane) produced

by reacting a hydrocarbon gas such as natural, gas (primarily methane), propane or butane with air. A

© 2005,2006,2007 Super Systems Inc.

is a case-hardening process in which carbon is dissolved in the surface layers of a

Page 6

IntroductionCarbCalc II5

carrier gas similar in composition to Endogas may be produced from methane can be formed from a

nitrogen-methanol blend.

Carburizing Process Variables

The gas carburizing process depends on the control of three principal variables:

·

Temperature

·

Time

·

Atmosphere composition.

Other variables that affect the amount of carbon transferred to parts include the degree of atmosphere

circulation and the alloy content of the parts.

Temperature

. The maximum rate at which carbon can be added to steel is limited by the rate of

diffusion of carbon in austenite. This diffusion rate increases greatly with increasing temperature; the

rate of carbon addition at 925°C (1700°F) is about 40% greater than at 870°C (1600°F). The

temperature most commonly used for carburizing is 925°C (1700°F). This temperature permits a

reasonably rapid carburizing rate without excessively rapid deterioration of furnace equipment. The

carburizing temperature is sometimes raised to 955°C (1750°F) or 980°C (1800°F) to shorten the time

of carburizing for parts requiring deep cases. Conversely, shallow case carburizing is frequently done

at lower temperatures because case depth can be controlled more accurately with the slower rate of

carburizing obtained at lower temperatures. For best results, the workload should be heated to the

carburizing temperature in a near-neutral furnace atmosphere. In batch furnaces, parts can be heated

in Endogas until they reach the furnace temperature; then carburizing can commence with the addition

of the enriching gas.

Time.

The effect of time and temperature on the Carbon vs Depth profile shows that the carburizing

time decreases with increasing carburizing temperature. In addition to the time at the carburizing

temperature, several hours may be required to bring large work pieces or heavy loads of smaller parts

to operating temperature. For a work piece quenched directly from the carburizing furnace, the cycle

may be lengthened further by allowing time for the work piece to cool from the carburizing temperature

to about 843°C (1550°F) prior to quenching. Similarly, additional diffusion and interchange of carbon

with the atmosphere will occur during cooling prior to quenching.

Carbon Potential.

The carbon potential of the furnace atmosphere must be greater than the carbon

potential at the surface of the work piece in order for carburizing to occur. It is the difference in carbon

potential that provides the driving force for carbon transfer into the parts.

Carbon Diffusion.

The combined effects of time, temperature, and carbon concentration on the

diffusion of carbon in austenite can be expressed by Fick's laws of diffusion.

Alloy Effects.

The various alloying elements found in carburizing steels have an influence on the

activity of carbon dissolved in austenite.

Chromium

·

Nickel

·

tends to decrease the activity of carbon

tends to raise the activity of carbon

The primary effect of alloys on the diffusion of carbon is their effect on the driving force at the surface

reaction.

The CarbCalcII Model

CARBCALCII is a carbon difussion model for simulation and analysis of gas carburizing process for

low-alloy steels. The interactions of the gas carburizing process cannot be modeled by simple

one-dimensional analysis. In order to accurately predict how a low-alloy steel will react in a controlled

atmosphere process, many factors must be taken into account, including:

·

Alloy steel composition

·

Equilibrium and non-equilibrium gas composition

·

Temperature

·

Atmosphere agitation

·

Surface radius of curvature, concave or convex

© 2005,2006,2007 Super Systems Inc.

Page 7

IntroductionCarbCalc II 6

·

Initial carbon profile

CARBCALCII takes as many factors as possible into account for the accurate prediction of (1) transfer

of carbon between gas and steel surface, and (2) diffusion of carbon within the steel.

Possible uses for CARBCALCII include:

·

Computer-aided design of heat treatment processes

·

Optimization of existing cycles

·

"What if" analysis when a change in an existing process or material is contemplated

·

Reconstruction of the effects that an out-of-control process may have had on a load

·

Education of personnel in the intricacies of atmosphere processing

·

Real-Time control with an on-line process

CARBCALCII can pay for itself quickly because process development experiments can be carried out

quickly on the computer instead of weeks in a furnace. When a trial is finally made in the furnace, the

results will be reasonably close to those predicted by the software.

CARBCALCII has thee main operating modes:

1. Simulation

2. RealTime Control

3. Monitor/Replay

The object in all cases is to accurately predict the diffusion gradient that carbon establishes in a given

material from a given set of processing parameters.

SIMULATION

allows construction of a diffusion gradient from complex a set of processing

parameters. For example, in a batch integral quench furnace, one might be interested in the following

sequence:

·

Come to Heat

·

Boost Carburize

·

Diffuse Carburize

·

Equalize for Quench

·

Brief Exposure to Vestibule Atmosphere

REALTIME CONTROL

- CarbCalcII is able to connect to "dumb controllers" via SuperData

communications. In this mode, CarbCalcII becomes the "Recipe Programmer" and sends setpoints to

the Temperature and Carbon Controllers.

MONITOR/REPLAY

running and logged in SuperData. This mode can be integrated with BatchMaster furnace control

systems.

© 2005,2006,2007 Super Systems Inc.

is used to view the Carbon Profile for load cycles previously run or currently

Page 8

2 CarbCalcII

2.1 Overview

CarbCalcIICarbCalc II7

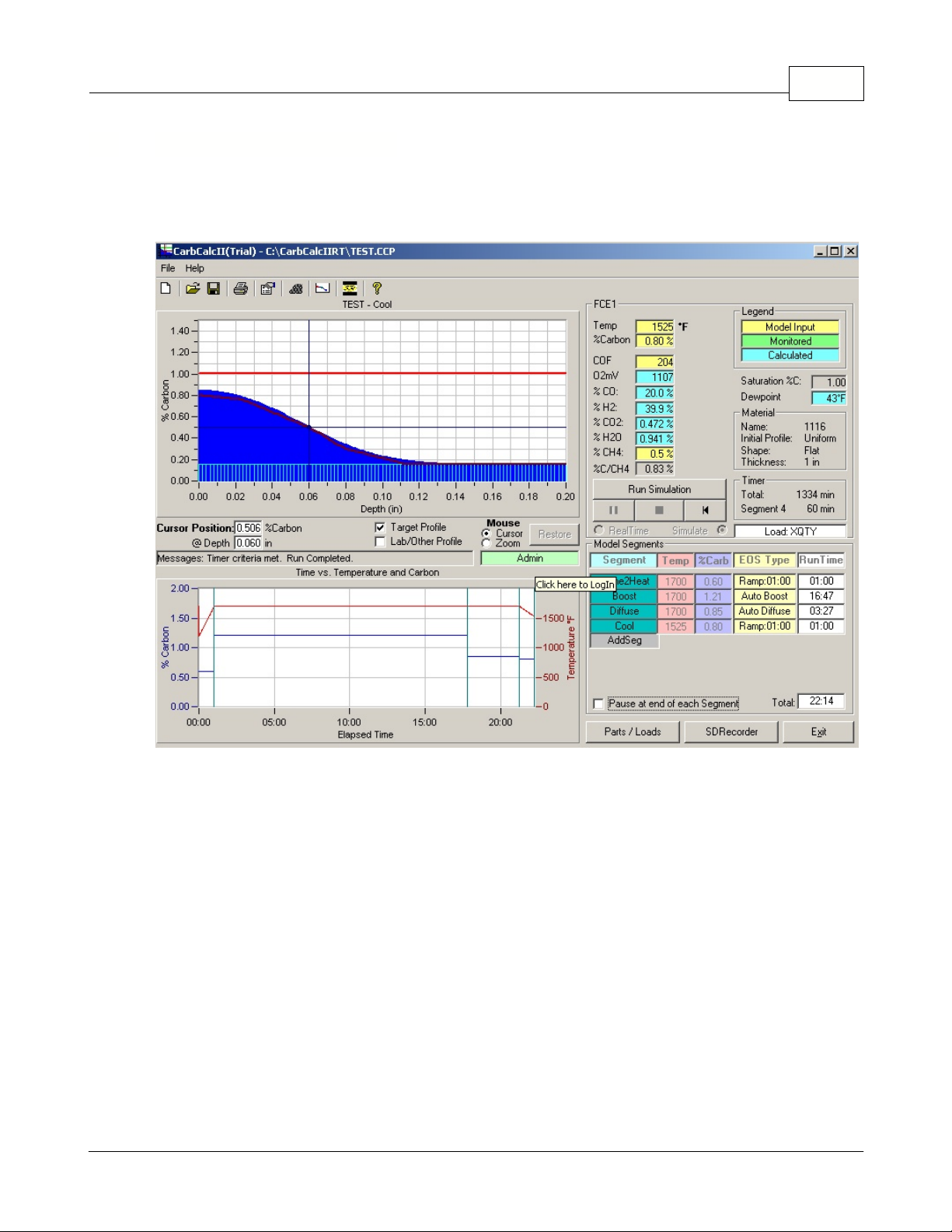

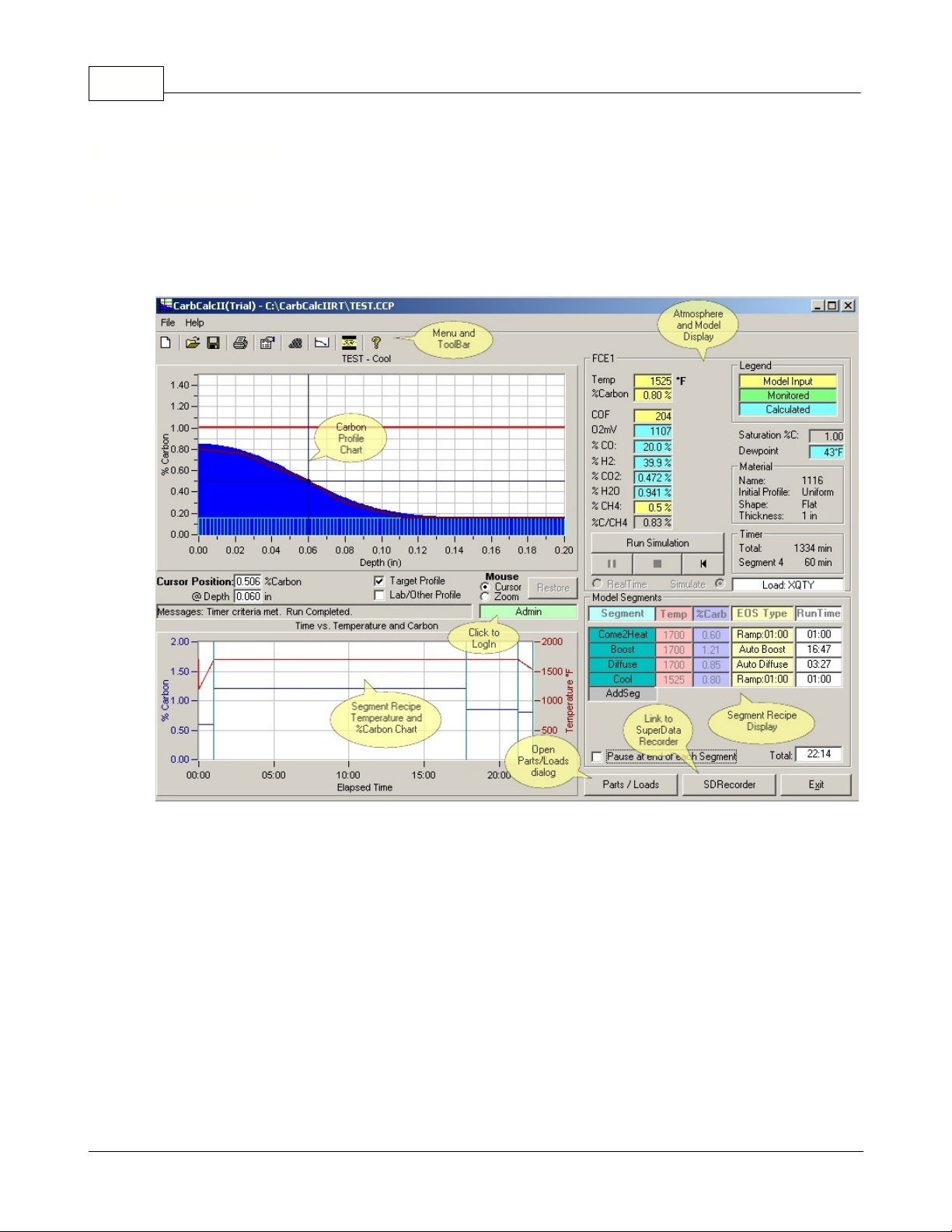

The Main Screen.

Menu and ToolBar:

·

Furnace Atmosphere Display:

·

material information and timers.

Recipe Segment Display:

·

Recipe Temperature and Carbon Chart:

·

displays segment markers.

Carbon Profile Chart:

·

Saturation Carbon line.

Provides access to Files, Printer and Model settings.

Displays Temperature, %Carbon and Gas values. Also displays

Displays the Recipe segments in the current model, (Max 8 segments).

Displays Initial Carbon, Carbon Diffusion profile, Target profile and

Displays theTemperature and Carbon vs Time. Also

© 2005,2006,2007 Super Systems Inc.

Page 9

2.2 Typical Uses

Simulation mode

In

·

Up to 8 segments may be modeled.

·

For each segment, define the Segment Name, Temperature, Carbon and End-Of-Segment (EOS)

type.

·

EOS types are:

1. Timed - ends after a specified time.

2. Match Surface Carbon - ends when Surface Carbon matches the Target Surface Carbon.

3. Match Carbon at a specified depth - ends when Diffused Carbon matches Carbon at a

specified depth.

4. Auto Boost - ends when the amount of excess carbon near the surface exceeds the deficient

carbon at depth.

5. Auto Diffuse - ends when the deviation between the diffused profile and the target profile is

minimized (curve matching).

·

Model Temperature units may be displayed in Celsius of Fahrenheit and Measurement units in

inches or mm.

·

Probe Factors may use either the CO Factor or the Process Factor (typical to Marathon

Instruments) .

·

The Type of Material may be selected from a Material Database.

·

The Initial Carbon Profile is based on the material selected and is assumed to be uniform.

·

The Initial Carbon Profile may be customized based on 10 points - useful for modeling "Rework"

recipes.

·

The Target Profile (up to 10 points) may be specified or you can request a recommended profile

based on Surface Carbon, Carbon at Effective Case Depth and Carbon at total Case Depth.

·

After starting the simulation, it may be paused at any time. You can also set it to "AutoPause" at the

end of each segment.

CarbCalcIICarbCalc II 8

, CabcalcII is used to develop Batch Carburizing Segment recipes.

RealTime Control mode

In

Controller and is used to Control a running Batch Furnace Carb Cycle.

·

A simple Load Entry system is used

·

The Segment display represents the Carb Cycle Recipe.

·

The Time vs Temperature and Carbon chart displays both the Setpoints and Actual values for

Temperature and Carbon.

·

The Carbon Profile is based on actual data from the instruments.

·

Instrument communication data sources are easily configured from within the application and saved

in a "Furnace" file.

Monitor/Replay mode

In

data logged by the SuperSystems communications datalogger. This mode is useful in analyzing a

comparing a cycle profile with the actual Profile from Lab results.· Display is similar to RealTime mode

but the data source is from the historical logged data.

·

Model runs at high speed similar to simulation mode.

·

Model may be paused, stopped or restarted at any time.

·

Target profile may be used to compare actual Lab measured profile for comparison with the model

results.

·

Analysis may be helpful in "Tuning" the recipe to achieve more precise results.

, CarbCalcII is connected to a Carbon Controller and a Temperature

, CarbCalcII is used to reproduce a cycle based on a Furnace Load and the

© 2005,2006,2007 Super Systems Inc.

Page 10

2.3 Menu and Toolbar

Menu Items

·

File

·

·

ToolBar Items

·

- Provides standard file open, save and close routines for CarbCalcII Model Files.

Help

- Opens Help file and About box.

CarbCalcIICarbCalc II9

New Model - Opens the default New Model

Save Model - saves the current model.· Print - prints the Carbon Profile report.

Model and Furnace Settings - Opens the

Model and Furnace settings dialog.

Carbon Profiles - Opens the Carbon Profiles

dialog.

Help - Opens this help file.

Open Model - displays the File Open

dialog for CarbCalcII Model Files

(report depends on model mode and settings see Reports in this help file)

Material - Opens the Material selection

dialog.

SuperCalc - Opens the SuperCalc

program.

© 2005,2006,2007 Super Systems Inc.

Page 11

2.4 Displays

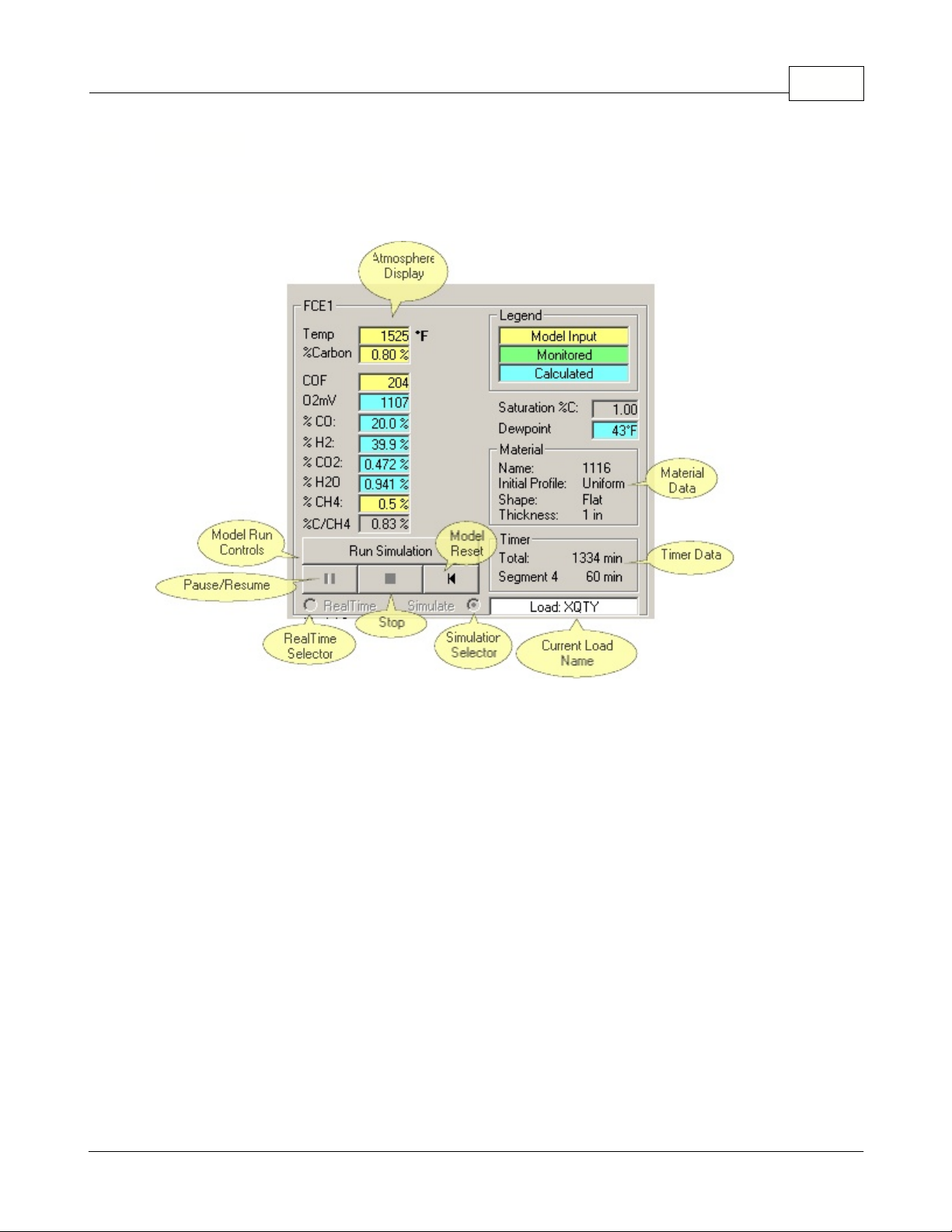

2.4.1 Atmosphere Display Area

CarbCalcIICarbCalc II 10

Atmosphere

·

All atmosphere values are displayed. Model Inputs (yellow background) are "given" or "assumed"

values. Monitored values (green background) are used only in the RealTime and Replay modes.

Calculated values (blue background) are calculated based on Model Inputs and the assumption that

the atmosphere is in equilibrium.

In simulation mode, the inputs will always be Temperature, %Carbon, Probe Factor and CH4. In

Realtime and Replay modes the model inputs are selectable. In these modes, data that is available

but not selected as a model input may be monitored - in this case, a monitored value will be displayed

next to the model value.

Temperature

·

%Carbon

·

PF or COF

·

O2mV

·

·

·

·

·

·

·

·

dependent on Temperature. When designing recipes, a good rule of thumb is to keep the %C

setpoint below about 90% of the Saturation Carbon.

- Oxygen Probe millivolts

%CO

- %Carbon Monoxide in the furnace atmosphere

%H2

- %Hydrogen Monoxide in the furnace atmosphere

%CO2

- %Carbon Dioxide in the furnace atmosphere

%H2O

- %Water in the furnace atmosphere

%CH4

%C/CH4

Saturation Carbon

- units may be in Fahrenheit or Celsius.

- Carbon Potential (based on water-gas equations)

- Process Factor or CO Factor (depends on type of controller)

- %Hydrocarbon in the furnace atmosphere

- Efective%Carbon with CH4 taken into consideration

- the level at witch free carbon (soot) precipitates in the atmosphere. Primarily

© 2005,2006,2007 Super Systems Inc.

Page 12

Dewpoint

·

Material

·

material toolbar icon.

Timers

·

Model Run Controls

·

- displays the calculated Dewpoint for the given atmosphere.

- displays the material selected, may be changed by opening the material dialog with the

-Displays the Total elapsed time and segment elapsed time in minutes.

- Used to start, stop, pause and reset the simulation.

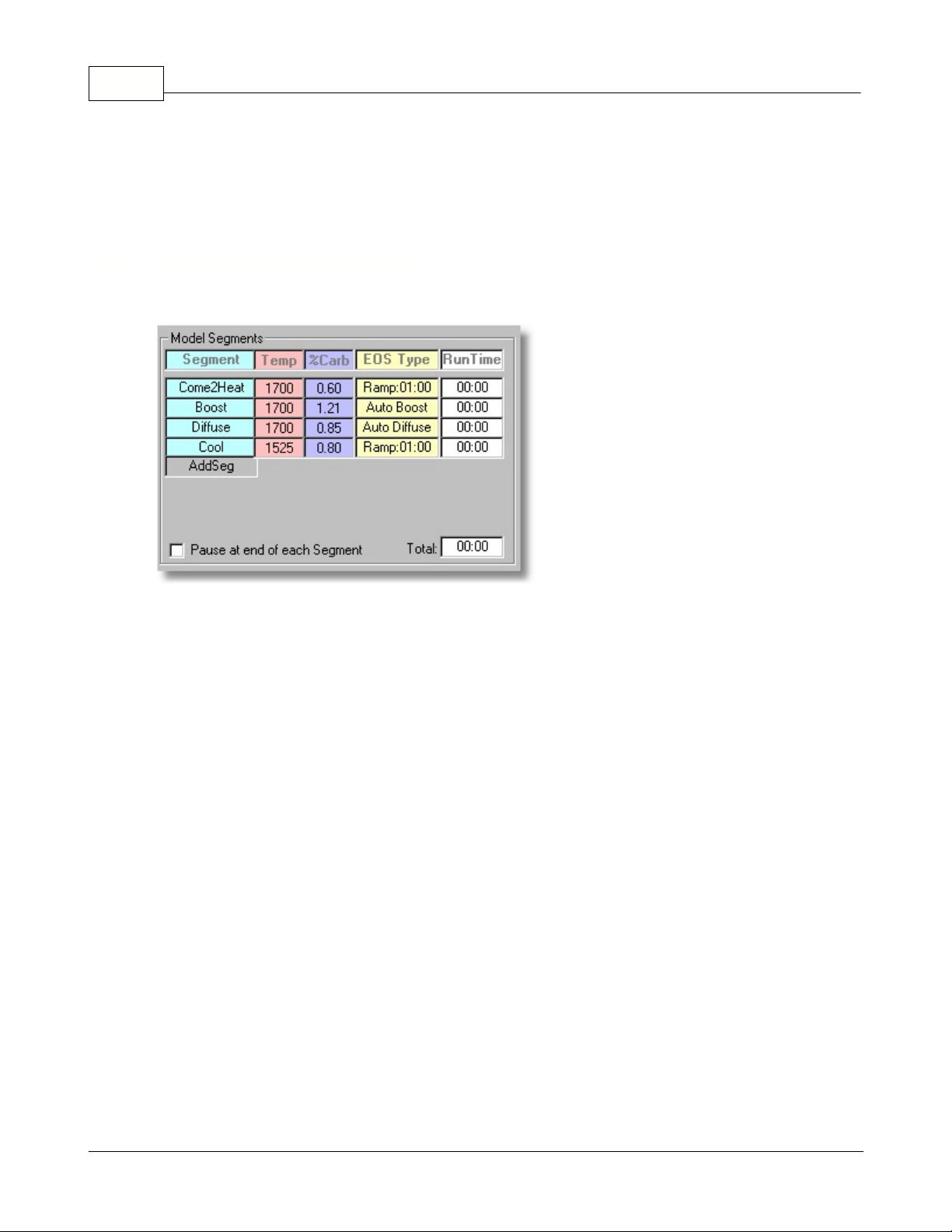

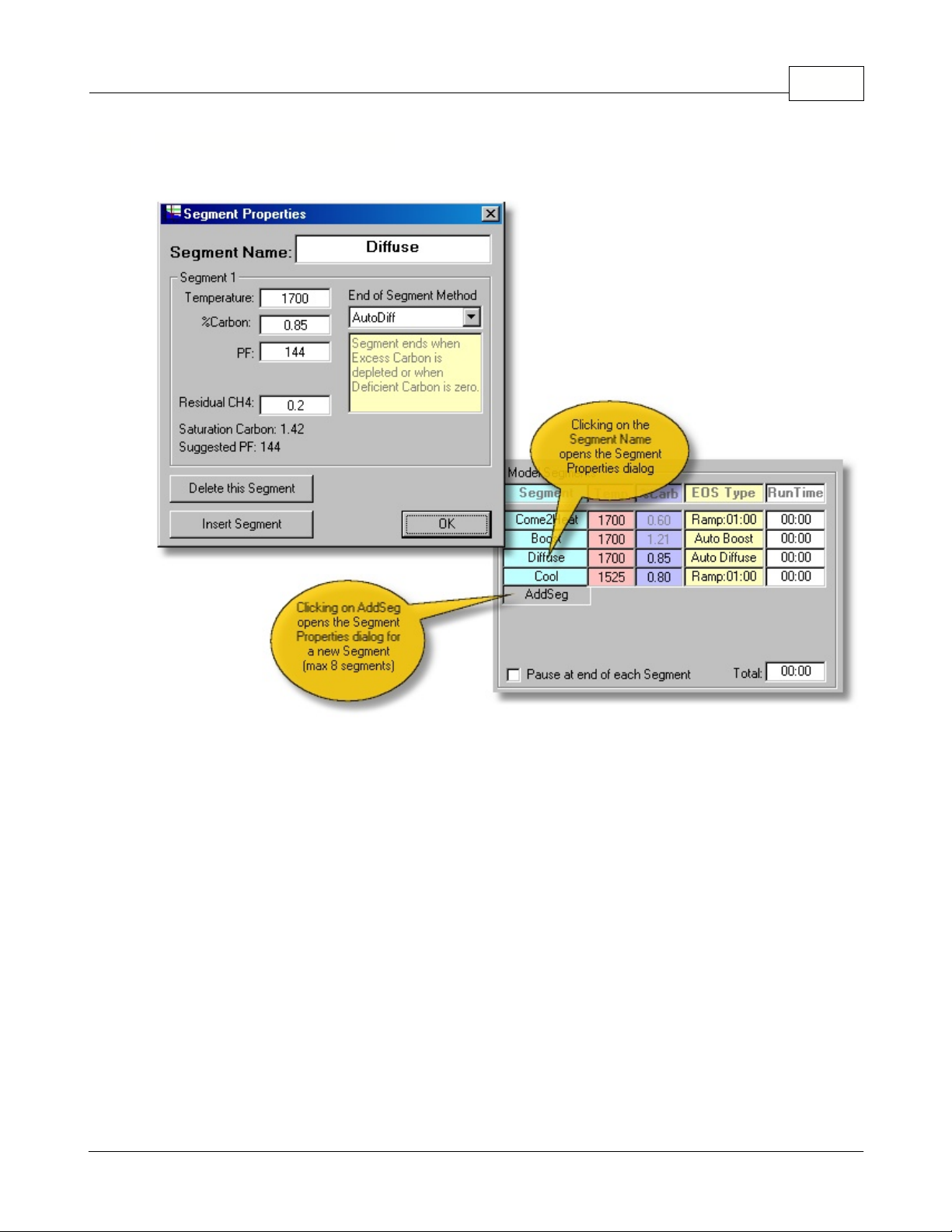

2.4.2 Model Segment Display Area

CarbCalcIICarbCalc II11

Model Recipe

A

Segment

·

paused or stopped, you may click on the segment name to open the segment properties dialog and

edit the segment.

Temp

·

·

·

·

·

·

·

·

- The temperature for the segment. You may edit the temperature for segments that have not

yet executed.

%Carb

executed.

EOS Type

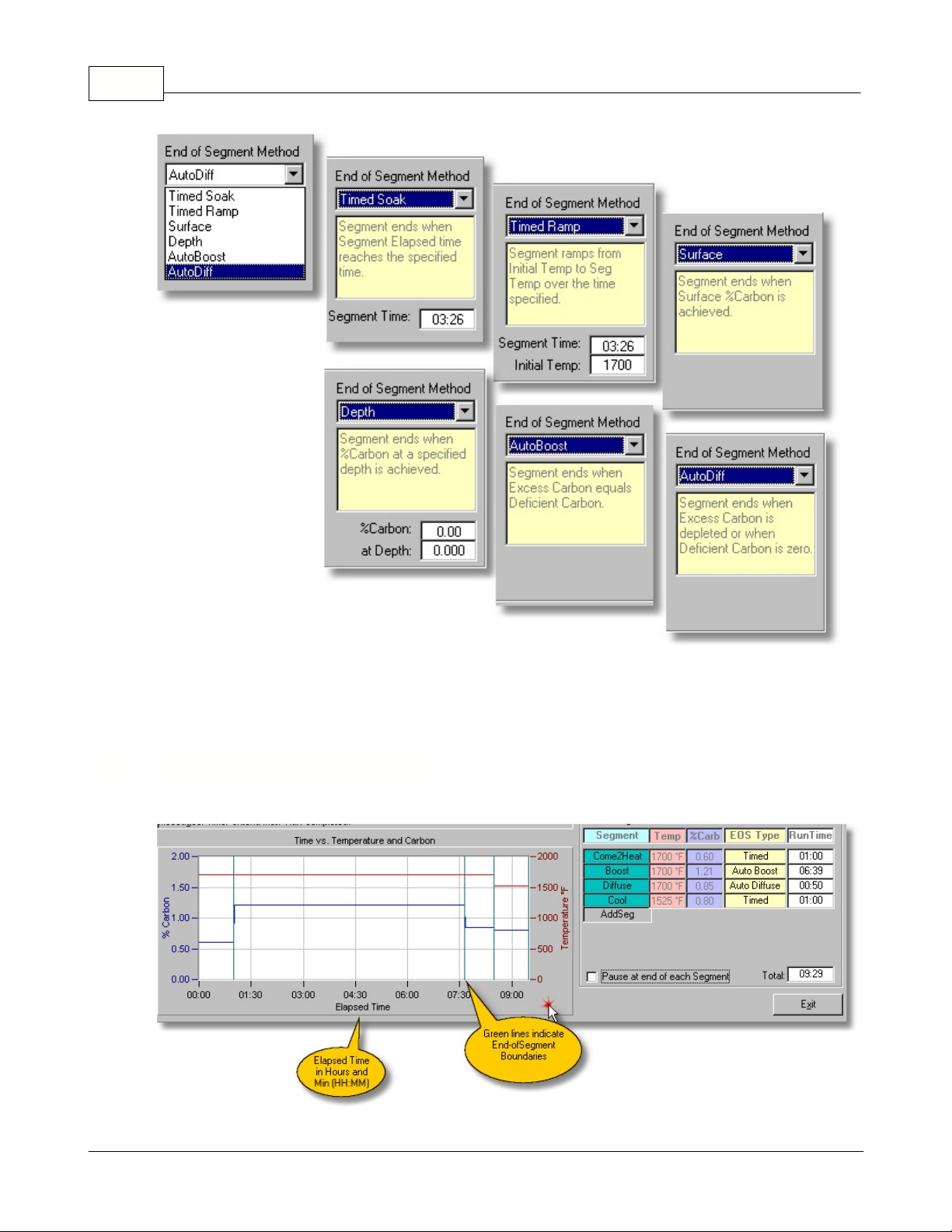

available:

RunTime

Pause Checkbox

end of each segment.

Total Timer

Note:

It is not normally not displayed during Monitor and Replay modes.

- The %Carbon for the segment. You may edit the %Carbon for segments that have not yet

Timed Soak

1.

Timed Ramp

2.

Surface

3.

Depth

4.

AutoBoost

5.

"Excess" carbon is the carbon above the "target" profile and "deficient" carbon is carbon below

the target profile.

AutoDiffuse

6.

The Model Segment Display Area is always used in Simulation and Realtime Control Modes.

may have up to 8 Segments.

- the name given to the segment (defaults to Seg1, Seg2, etc). When the simulation is

- The End-Of-Segment type determines how the segment terminates. There are 6 types

- ends after a given time is reached.

- ramps temperature ends after a given time is reached.

- ends when the Carbon profile "matches" a specified Surface Carbon.

- ends when the Carbon profile "matches" a specified carbon at a specified depth.

- ends when the "excess" carbon is sufficient to satisfy the "deficient" carbon.

- ends when the Carbon Profile matches the Target Profile ("best fit") .

- displays the segment time in days, hours and minutes (D:HH:MM).

- (simulation and replay only) check this box to make the simulation pause at the

- displays the total time in days, hours and minutes (D:HH:MM).

© 2005,2006,2007 Super Systems Inc.

Page 13

2.4.3 Segment Properties Dialog

CarbCalcIICarbCalc II 12

Segment Name

·

Temperature

·

%Carbon

·

Probe Factor

·

to the Suggested PF and may be edited.

Residual CH4

·

Saturation Carbon

·

this amount.

Suggested Probe Factor

·

selected.

End of Segment Method

·

below.

© 2005,2006,2007 Super Systems Inc.

- Enter or Edit the Segment Name.

- Enter or Edit the Segment Temperature

- Enter or Edit the Segment %Carbon.

(PF or COF) - Enter or Edit the Probe Factor. Note: for new segments this will default

- Enter or Edit the CH4 (normally 0.0 to 5.0 depending on your furnace).

- displays saturation carbon level, %Carbon should be set to a value less than

(PF or COF) - Theoretical value of the Probe Factor based on Material

- select the End of Segment type and supply required data as indicated

Page 14

CarbCalcIICarbCalc II13

Delete Button

·

Insert Button

·

OK Button

·

- clicking on this button will delete this segment from the model.

- clicking this button inserts the segment as a new segment.

- exits the dialog and saves changes to the segment.

2.4.4 Temperature and Carbon Chart

© 2005,2006,2007 Super Systems Inc.

Page 15

Simulation mode

In

executed.

RealTime

In

process variables and setpoints are displayed and times are displayed as actual clock times rather

than elapsed times.

and

, the Temperature and Carbon Chart displays a profile of the recipe as it is

Replay modes

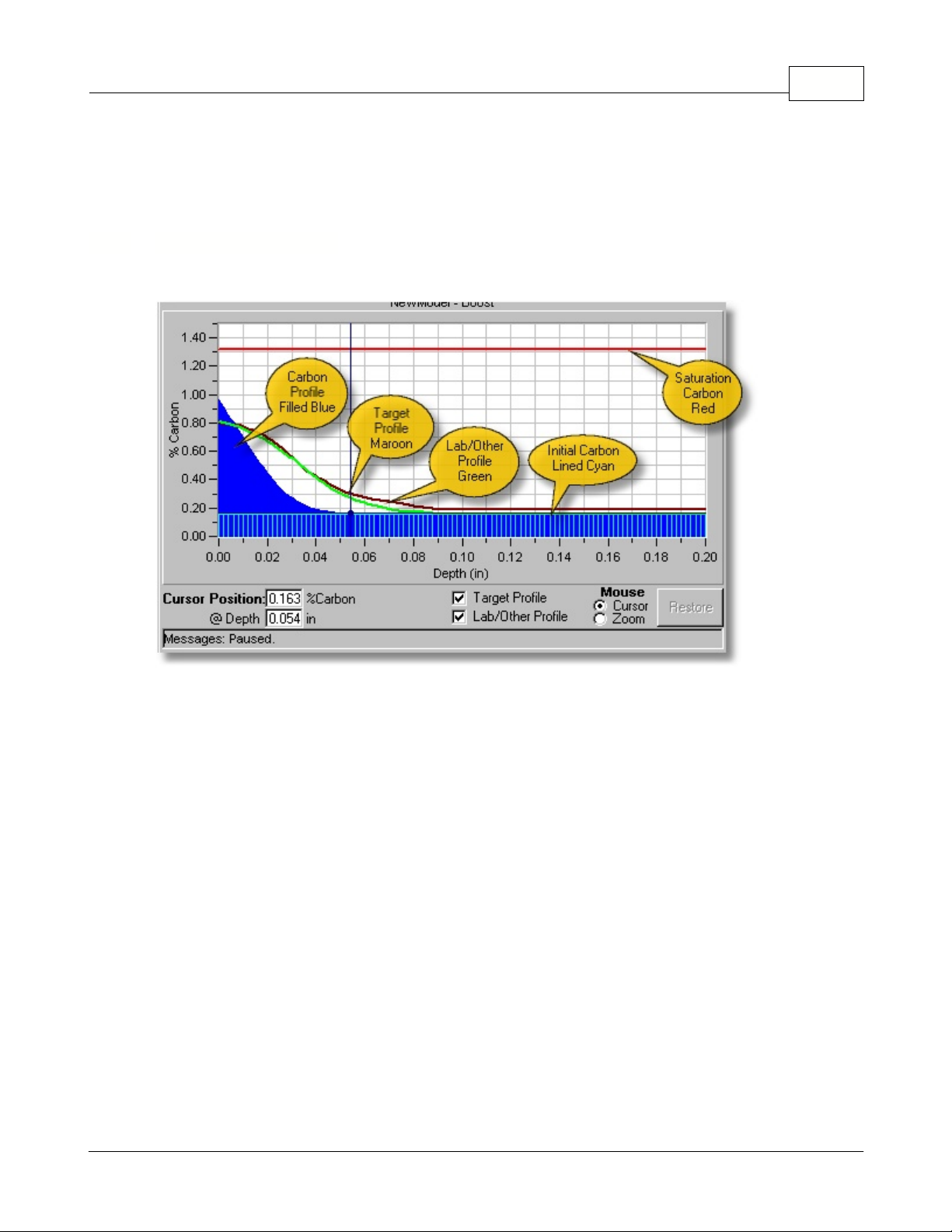

2.4.5 Carbon Profile Chart

CarbCalcIICarbCalc II 14

, the Actual monitored values of the Temperature and Carbon

The Carbon Profile Chart displays %Carbon (Y axis) vs Depth (X axis).

Title

·

In RealTime and Replay Modes, displays Load Name and Model Name.

·

·

·

·

·

·

·

·

·

·

·

·

·

- In Simulation mode, displays "Model Name - Segment Name"

Y Axis

X Axis

Cursor Position

Target Profile

Lab/Other Profile

Mouse Mode

Restore Button

Message box

Carbon Profile

Initial Carbon Profile

Target Profile

Lab/Other Profile

Saturation Carbon

- %Carbon

- Depth (in inches or mm depending on model settings)

- displays the %Carbon at Depth corresponding to the cursor crosshair position.

- check to display the target profile.

- check to display the Lab or other imported profile.

- places mouse in either cursor or zoom mode (default is cursor).

- used to restore the chart after using the zoom mode.

- message display.

- primary display (filled Blue) Carbon vs Depth

- Uniform or Custom Initial Carbon Profile (Lined Cyan)

- Maroon line indicating the "spec" or Target Profile

- Green line indicating the imported Lab or other imported Profile.

- Red Line indicating the "saturation" carbon for the given furnace temperature.

© 2005,2006,2007 Super Systems Inc.

Page 16

2.5 Users and Security

2.5.1 Login

Previous versions of CarbCalcII did not require Login or passwords. This version may be used to

control furnace cycles in a production environment and therefore requires some protection. For each

authorized user a User Name, Password and Access Level are maintained. When a user successfully

logs in, he is granted access to program features depending on Access Level, Run Mode and Run

Status.

A Login remains valid until 1) User Logs out or 2) In RealTime Control with program running Login is

valid for 15 minutes.

There are 6 Access Levels (0 through 5):

·

Level 0 - Guest

·

access to simulation modes

·

cannot save or create models, parts, or loads

·

Note: This is the default User Level

·

Level 1 - Basic Operator

·

Access level 0 plus

·

can start and stop realtime loads

·

Level 2 - Advanced Operator

·

Access level 1 plus

·

can save and create loads, parts and models

·

Level 3 - Supervisor

·

Access Level 2 plus

·

can add and edit Material in the Material database

·

Note: This is the default User Level for BatchMaster Integration

·

Level 4 - Advanced Supervisor

·

Access level 3 plus

·

Level 5 - Administrator

·

Access level 4 plus

·

Manage User accounts

·

Unrestricted access to all features

CarbCalcIICarbCalc II15

To Login, click on the User Name Display/Login button. The Login dialog will open as shown above.

·

Enter User Name (not case sensitive)

·

Enter Password (this is case sensitive)

·

Click Enter

·

Successful Login - User name will be displayed in the User Name Display with a green

background.

·

Unsuccessful login - message and Guest will be displayed as user name.

·

Click Cancel to logout (reverts to Guest)

© 2005,2006,2007 Super Systems Inc.

Page 17

Password restrictions:

·

Password cannot be blank

·

Password must be 3 or more characters or numbers

·

Password cannot be the same as user name (indicates reset)

Setting or changing a password. Only the Administrator can "reset" your password. When it is

reset, the password is set to the User Name. When you logon, you will be prompted to enter a new

password. If you forget your password, the Administrator can access it.

2.5.2 Manage Users

Only the Administrator (Access Level 5) can access the User's screen.

CarbCalcIICarbCalc II 16

When you login as Administrator, the buttons at the bottom of the login dialog will change to "Manage

Users" and "Continue". Click continue to complete the login normally. Click "Manage Users" to show

the Users Dialog.

·

Personnel Grid - Use the grid to Add, Edit or Delete Users.

·

Show Password - click and hold to display password for selected user.

·

Reset Password - click to reset the selected user's password. When reset, the password becomes

the User Name and must be changed on next login.

© 2005,2006,2007 Super Systems Inc.

Page 18

2.6 Parts and Loads

2.6.1 Loads

CarbCalcII comes with a Part and Load database. The user interface with the database varies

depending on the operating mode,

·

CarbCalcII in Control Mode - Loads and Parts integrated with Load Entry System.

·

CarbCalcII in Monitor Mode - Loadfs and Parts for display and replay of data.

·

CarbCalcII integrated with BatchMaster - BatchMaster Load database used for display and replay of

data.

2.6.2 Control Mode

The Parts and Loads dialog contains 3 tabs: New Loads, Completed Loads and Parts.

CarbCalcIICarbCalc II17

New Loads

select a load to run.

(Note: Yous must be logged in with access level 2 or higher to use this screen)

- This tab is used to build loads and add them to the Loads database. It is also used to

Load Name

·

load or type in a new name for a new load. The drop list will only display loads that have not been

completed.

Load Part

·

associated with that part.

Qty

·

- enter the quantity of parts in this load.

Operator

·

Load Remarks

·

Model

·

changed using the droplist)

- A unique name to identify the Load. You may use the drop list to select an existing

- Select a part for the load (when a part is selected, the Model will change to the model

- (optional) enter an identifier for the operator

- Optional remarks

- Select the model to use for this load (model is selected when you select a part, but may be

© 2005,2006,2007 Super Systems Inc.

Page 19

Save Load

·

Select Load

·

- Click to save the Load in the database (does not select the load for execution)

- Click to select the load for execution (also saves the load to the database)

2.6.2.1 Entering a Load

In the Control Mode, you may enter a new load and either "Save" it for later use or "Select" it for

current operations.

CarbCalcIICarbCalc II 18

Steps to Enter and execute a Load in Realtime Control Mode

1. Select Realtime Mode (the run button changes to 'Load Entry")

2. Click on "Load Entry" to open the New Loads dialog

3. Select a Load and click on the Select Load button

4. The button changes from "Load Entry" to Start Recipe.

5. At this point you should verify the recipe, profile, material etc. You may switch to "Simulation"

and make simulation runs before starting the recipe in RealTime control.

6. Make sure the furnace is physically loaded.

7. Start the recipe. When the recipe is running, the computer is sending setpoints to the Carbon

and Temperature controllers. Ath this point, CarbCalcII and the CarbCalc computer are

dedicated to controlling the recipe. If you attempt to stop CarbCalcII you will get a warning

message.

© 2005,2006,2007 Super Systems Inc.

Page 20

2.6.2.2 Load History in Control Mode

The Completed Loads Tab may be used to select loads for "Replay". Note: This tab is not available

when a load is active in control mode.

CarbCalcIICarbCalc II19

The Completed Load Tab is displays a grid of loads, most recently completed on top.

The "Time In" is stamped when the "Start Recipe" button is pressed and the "Time Out" is stamped

when the load is completed ("unloaded"). These times may be edited on this screen with the

appropriate access level. With appropriate access level, Loads may be edited, added or deleted from

the database using the grid view.

To replay a load, select the load with the arrow indicator and click on the "Set Selected Load" button.

2.6.2.3 Parts in Control Mode

The Parts Tab is used to associate parts with models.

© 2005,2006,2007 Super Systems Inc.

Page 21

CarbCalcIICarbCalc II 20

Select/Enter Part

·

Description

·

Select Model

·

Save

·

Note: A Model is a set containing the "Material", "Target Profile" and "Recipe". Models are normally

developed using CarbCalcII in the Simulation Mode.

- save changes

- enter/edit a part description.

2.6.3 Monitor Mode

The Parts and Loads dialog contains 3 tabs: New Loads, Completed Loads and Parts. In the Monitor

Mode, there is no control of the process. However, Loads may be manually added to the loads

database and replayed using SuperData's logged process data.

New Loads

(Note: Yous must be logged in with access level 2 or higher to use this screen)

- This tab is used to create loads and add them to the Loads database.

- Select an existing part or enter a new part name.

- Select the model to use when loading this part.

© 2005,2006,2007 Super Systems Inc.

Page 22

CarbCalcIICarbCalc II21

Load Name

·

Load Part

·

associated with that part.

Qty

·

- enter the quantity of parts in this load.

Operator

·

Load Remarks

·

Model

·

changed using the droplist)

Select Furnace

·

logged process data).

Start Date and Time

·

End Date and Time

·

date and time initializes to the start date and time)

Save Load

·

Select Load

·

In the Monitor Mode, the

Mode.

- A unique name to identify the Load.

- Select a part for the load (when a part is selected, the Model will change to the model

- (optional) enter an identifier for the operator

- Optional remarks

- Select the model to use for this load (model is selected when you select a part, but may be

- Select the furnace that ran this load (CarbCalcII must know where to get the

- Click to save the Load in the database (does not select the load for replay)

- Click to select the load for replay (also saves the load to the database)

2.6.4 BatchMaster Mode

BatchMaster Integration

The

BatchMaster Mode, the Loads database is provided and maintained by an external application

(normally AFC-Holcroft's BatchMaster system). In the BatchMaster Mode, CarbCalcII provides

simulation for modelling and Load Replay for monitoring cycles. Since the external application provides

the load information, parts, times, etc. the "

Completed Loads

" tab is provided in the BatcfhMaster" mode.

- Enter the estimated Load Start date and time (may be edited later)

- Enter the estimated load end date and time (may be edited later). (Note: End

Completed Loads

mode is a special case of CarbCalcII's Monitor Mode. In the

Parts

and

New Loads

Tabs operate the same as in the Control

Parts

" and "

" tabs are not provided. Only the "

© 2005,2006,2007 Super Systems Inc.

Page 23

CarbCalcIICarbCalc II 22

See the "Configuration" section for setting up the BatchMaster Integration mode.

© 2005,2006,2007 Super Systems Inc.

Page 24

2.7 Model and Furnace Settings

2.7.1 Settings Overview

CarbCalcIICarbCalc II23

Settings dialog

·

The

model

·

The

·

The

·

Any model may be used with any furnace.

contains the "recipe segments", the material, the target profile, etc.

Furnace

contains data specific to a furnace.

2.7.2 Model Settings

is used to select the Model and the Furnace.

© 2005,2006,2007 Super Systems Inc.

Page 25

CarbCalcIICarbCalc II 24

Select Mode

·

Model Units

·

Measurement

·

Carbon Profile Chart

·

X Axis

·

Y Axis

·

Add New Model

·

will be saved with the current model settings. The settings may be subsequently changed and

saved as desired.

Delete Mode

·

Save Model

·

model was last saved.

l - use this dropdown to select the desired model.

·Temperature - select Celsius or Fahrenheit

- select English or Metric

setting (Depth Axis) - Auto is recommended.

setting (Carbon Axis) - Auto is recommended.

- Clicking this button will prompt you to enter a name for the new model, the model

l - clicking this button will delete the current model.

- will save the current model and all changes that may have been made since the

2.7.3 Furnace Settings

© 2005,2006,2007 Super Systems Inc.

Page 26

CarbCalcIICarbCalc II25

Select Furnace

·

Default Atmosphere Settings

·

·

Set Use Standard H2 to CO ratio 2:1

·

or Specify Custom H2 to CO ratio

·

Specify a Furnace Factor ( range 0.0 to 2.5 with normal value of 1.0 )

Probe Factor

·

PF

·

- used by Marathon Instruments

COF

·

or

Furnace RealTime Setup

·

- use this dropdown to select the desired furnace.

- used by most instruments

- Clicking this button opens the RealTime setup dialog for the selected

furnace.

Add New Furnace

·

- Clicking this button will prompt you to enter a name for the new Furnace, the

furnace will be saved with the current furnace settings. The settings may be subsequently changed

and saved as desired.

Delete Furnace

·

Save Furnace

·

- clicking this button will delete the current furnace.

- will save the current furnace and all changes that may have been made since the

furnace was last saved.

© 2005,2006,2007 Super Systems Inc.

Page 27

2.7.4 Furnace RealTime Setup

CarbCalcIICarbCalc II 26

Furnace RealTime Settings

·

monitor/replay modes, they are not required for simulation mode. The realtime settings describe

what information is available from the furnace instrumentation and where it can be accessed from

SuperData. The realtime modes require SuperData communications and datalog system.

Installed Atmosphere control

·

Carbon Probe Controller

·

IR Analyze

·

Carbon Potential Determination

·

Temperature and %CH4 are always assumed to be model inputs.

Carbon and Probe Factor

·

Probe Millivolts and Probe Factor

·

Probe Millivolts and %CO

·

Analyzer).

%CO and %CO2

·

Data Sources

·

Data Name

·

Background color

·

·

Yellow - model input

·

Green - monitored but not used as model input

·

Blue - calculated value

·

Red - not used

Data Source

·

Select Data Source Dialog

·

r - select type installed or none.

- Uses %CO and %CO2 as model inputs (requires IR Analyzer).

- Displays the data source (SuperData channel and slot) for the models data values.

- name of the data value, Clicking on the Data Name opens the Data Source Dialog.

- displays the Channel, Slot and Multiplier location for the data value.

- The realtime settings are required for the realtime control and

- select yes or no.

- Select data values to be used as model inputs.·Note:

- Uses Carbon and Probe Factor as model inputs.

- Uses Probe millivolts and Probe Factor as model inputs.

- Uses Probe Millivolts and %CO as model inputs (requires IR

- the dialog is opened when you click on the Data Name. The dialog is

© 2005,2006,2007 Super Systems Inc.

Page 28

CarbCalcIICarbCalc II27

used to specify the data source values.

Chan

·

·

·

. - select the SuperData channel from the dropdown.

Slot

. - select the SuperData slot from the dropdown.

Default/Manual

- enter a default value - this value is used in the model when communications is

lost, the value is also used as a manual input value when the data is not available and the channel

is set to "(None)".

Multiplier

·

- SuperData data is always stored as integer with implied decimal points. e.g. 1.05 %C

would be stored as 105, For this reason, it is necessary to provide a multiplier to retrieve the

correct value. In the case of %Carbon, the multiplier is 0.01.

OK Button

·

- saves the changes for the current furnace (you must save the furnace settings to

make these changes permanent)

Cancel Button

·

- ignores any changes and exits the dialog.

·

Note: When in Control mode, you will also be prompted to supply the Setpoint Write

·

Locations.

© 2005,2006,2007 Super Systems Inc.

Page 29

2.8 Material Selection

2.8.1 Material Dtabase

Material database

The

Additional material may be added to the database. The Probe Factor calculated by the model takes

into account the composition of the steel. The %Carbon in the steel is used to set the initial Carbon

Profile for the model (uniform).

dialog allows selection of most standard material for the given model.

CarbCalcIICarbCalc II 28

Material grid

·

Material Shape

·

Material Thickness

·

Set Custom Profile

·

normally used for modeling re-work where the Initial Carbon Profile is no longer uniform as in new

steel.

Add New Material

·

OK Button

·

- Use the row selector to select the desired steel.

- select from Flat, Concave or Convex (not implemented - Flat is always used) .

- enter value, ( max value for the model is 1.0 inch or 25.4 mm )

- clicking this button opens the Custom Profile dialog. The custom profile is

- clicking this button opens the "Add New Material" dialog.

- applies changes to the current model and closes the material dialog.

© 2005,2006,2007 Super Systems Inc.

Page 30

CarbCalcIICarbCalc II29

The Add New Material dialog permits adding material to the database. You must specify a material

name and composition.

2.8.2 Initial Carbon Profile

The Initial Carbon Profile is assumed to be uniform based on the %Carbon in the steel. This is the

normal case for new product. In special circumstances, e.g. product to be re-worked, the Initial

Carbon Profile may be substantially different.

Chart Area

·

Depth and %Carbon Columns

·

- displays the initial %Carbon vs Depth.

- Values in yellow background have been entered, values between

© 2005,2006,2007 Super Systems Inc.

Page 31

CarbCalcIICarbCalc II 30

entered values are interpolated and displayed with a white background. Surface and Max Model

depth values are fixed.

Clear Set

·

Import Profile

·

- this button clears the yellow background for the Depth and %Carbon values respectively.

- permits importing (from a .tsv or .csv file) a carbon profile to be used as the initial

carbon.

Export Profile

·

OK

·

- accepts changes and applies them to the current model. Note changes are not saved with the

- permits exporting the initial carbon profile to an excell compatible .tsv or .csv file.

model, the next time the model is loaded it will revert to uniform carbon for the selected material.

© 2005,2006,2007 Super Systems Inc.

Page 32

2.9 Target Profile

2.9.1 Specifying a Target Profile

The Target Profile is normally the specified goal for the simulation. The Target Profile is used to

calculate excess and deficient Carbon during the "Auto Boost" segment and is used for curve

matching in the "Auto Diffuse" segment.

Note: The Boost Diffuse Carbon cycle normally results in a profile that is "S" shaped. The principal

points in describing the curve are:

·

Surface - surface %Carbon

·

Plateau - %Carbon at half of the effective case depth to produce an "s" shape curve.

·

Effective Case - Depth/Carbon for the effective case depth.

·

Total Case - Depth/Carbon for the total case depth (Carbon defaults to the %Carbon in the

material).

·

Max Model - Always 1 inch (25.4 mm) with carbon the same as the material initial carbon.

CarbCalcIICarbCalc II31

Chart Area

·

Depth and %Carbon Columns

·

entered values are interpolated and displayed with a white background. Surface and Max Model

depth values are fixed.

Clear Set

·

Import Profile

·

Profile.

Export Profile

·

Recommend Profile

·

OK

·

- accepts changes and applies them to the current model.

- displays the Target Profile as %Carbon vs Depth.

- Values in yellow background have been entered, values between

- this button clears the yellow background for the %Carbon values.

- permits importing (from a .tsv or .csv file) a carbon profile to be used as the Target

- permits exporting the Target carbon profile to an excell compatible .tsv or .csv file.

- opens the "Recommend Profile" Dialog.

© 2005,2006,2007 Super Systems Inc.

Page 33

2.9.2 Recommended Profile

The Recommended Profile dialog permits easy entry of the target profile based on Surface

Carbon,Carbon at the Effective Case Depth and Carbon at Total Case Depth.

CarbCalcIICarbCalc II 32

·

Edit Carbon and Depth values as desired

·

Cancel - ignores any changes and closes the dialog.

·

OK - Applies changes and closed the dialog.

© 2005,2006,2007 Super Systems Inc.

Page 34

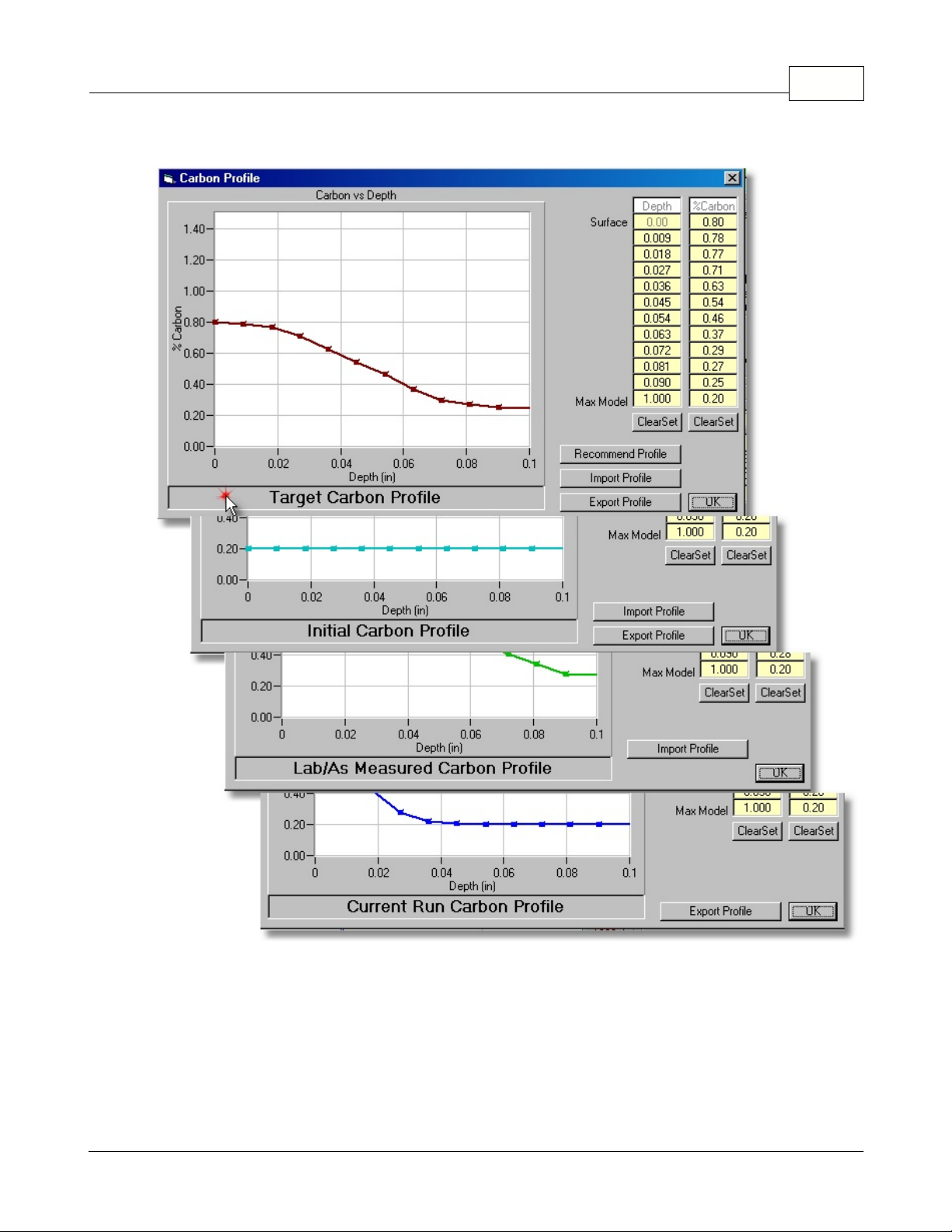

2.10 Carbobn Profiles

2.10.1 Carbobn Profile Dialog

CarbCalcIICarbCalc II33

There may be up to 4 simultaneously displayed on CarbCalcII's Carbon profile chart:

·

Current Predicted Carbon - The model's current predicted carbon profile

·

Initial Carbon - The material's initial carbon profile

·

Target Carbon - The target or specification carbon profile

·

Lab/Other Carbon - An imported Carbon profile, may be from lab data or other source.

Clicking on the Carbon Profiles toolbar icon opens the Carbon Profile dialogue with the Target Profile

active.

© 2005,2006,2007 Super Systems Inc.

Page 35

Clicking on the Active Profile Title box will switch the dialog to the next profile.

CarbCalcIICarbCalc II 34

Chart Area

·

Depth and %Carbon Columns

·

- displays the Active Profile as %Carbon vs Depth.

entered values are interpolated and displayed with a white background. Surface and Max Model

depth values are fixed.

Clear Set

·

Import Profile

·

- this button clears the yellow background for the Depth or %Carbon values respectively.

- permits importing (from a .tsv or .csv file) a carbon profile to be used as the

selected Active Profile (Target, Initial or Lab).

Export Profile

·

Recommend Profile

·

© 2005,2006,2007 Super Systems Inc.

- permits exporting the Active carbon profile to an excell compatible .tsv or .csv file.

- Values in yellow background have been "set", values between

- opens the "Recommend Profile" Dialog (Target Profile only).

Page 36

OK

·

- accepts changes and applies them to the current model.

CarbCalcIICarbCalc II35

© 2005,2006,2007 Super Systems Inc.

Page 37

2.11 SuperCalc

2.11.1 The SuperCalc Application

SuperCalc is an SSi Utility that aids in determining Carbon and Dewpoint based on Oxygen Probe or

3Gas IR analyzer. This utility is included with CarbCalcII and is also available on the web at

SuperSystems.com

CarbCalcIICarbCalc II 36

© 2005,2006,2007 Super Systems Inc.

Page 38

2.12 Simulation Mode

2.12.1 Typical Uses

The Simulation mode provides a method for developing Carb Cycle recipes for Batch Furnaces.

Typical uses include:

·

·Developing recipes for new product.

·

·Developing re-work recipes.

·

·Modifying existing recipes to potentially shorten furnace time.

In the Simulation mode, model inputs are always Temperature, %Carbon, Probe Factor and %CH4.

The Simulation Mode features various methods to model the End of Segment.

·

Timed segments

·

Match Surface Carbon

·

Match Carbon at a specified depth

·

Auto Boost

·

Auto Diffuse

CarbCalcIICarbCalc II37

Typical Steps in developing a Boost-Diffuse Carburizing Recipe

1.

Select the Furnace

2.

Select the Material

3

. Generate a Target Profile (Use recommended profile and modify as desired)

4

. Generate recipe segments

·

Usually 4 segments will be adequate (Come2Heat, Boost, Diffuse, Equalize)

·

Come2Heat - Soak for specified time

·

Boost - Use "AutoBoost" to end segment. %Carb should be just less than saturation for the

given temperature.

·

Diffuse - Use "AutoDiff" to end segment. %Carb should be at or slightly above the Target

Profile Surface Carbon.

·

Equalize/Cool - Timed Soak

5

. Run Simulation and evaluate results.

6

. Modify model (steps 2,3 and 4 above) and repeat simulation.

7

. When satisfied with simulation results, make a product test run,

8

. Compare test run lab results with simulation results (may use "Lab Profile" to aid in comparison).

9

. May be necessary to adjust the "Furnace Factor" to correct for differences in Lab Profile and

Simulation Profile.

Note 1:

Note 2:

When developing a "re-work" recipe, you will need to modify the "Initial Profile", all other

steps remain the same.

When modifying an existing recipe, replace the 4 segment cysle in step 4 with your existing

recipe.

2.12.2 Report

In the simulation mode, clicking on the print icon will print the following report. The report is a

snapshot of the current model status and can be printed at any time during the simulation.

© 2005,2006,2007 Super Systems Inc.

Page 39

CarbCalcIICarbCalc II 38

© 2005,2006,2007 Super Systems Inc.

Page 40

2.13 RealTime Control Mode

2.13.1 Typical Uses

In the RealTime Control Mode, a Carb Cycle may be controlled via SuperData Communications.

Typical uses include:

Controlling a Carbon Cycle Recipe and monitoring the Carbon Profile in RealTime

In the RealTime mode, Model inputs include Temperature and %CH4 and either Probe Data or IR

Analyzer Data for Carbon Potential determination.

2.13.2 Report

In the RealTime Control mode, clicking on the print icon will print the following report. The report is a

snapshot of the current model status and can be printed at any time during the run.

CarbCalcIICarbCalc II39

© 2005,2006,2007 Super Systems Inc.

Page 41

CarbCalcIICarbCalc II 40

© 2005,2006,2007 Super Systems Inc.

Page 42

2.14 Replay Monitor Mode

2.14.1 Typical Uses

The Replay/Monitor mode may be used to review potential probelms with a load and as an aid in

determining what may have gone wrong. The Replay/Monitor mode may be used in conjunction with

the RealTime control Mode or with Superdata Datalog and a manually maintained Loads Database, or

with BatchMaster Integration using an external Loads database.

Replay Monitor in conjunction with the RealTime Control Mode.

The Replay mode is similar to the RealTime Control Mode. When a Carb Cycle is run in Control

Mode, the following data is saved:

·

Load Information - in the CCLoads Database

·

Model as run - an "as run" model file is saved under the name "L-xxx-model.ccp" (where xxx=load id

number and model=model name)

·

Logged Process data - SuperData Communications historically logged data.

Using this data, the Cycle can be selected from the CCLoads database and may be replayed.

CarbCalcIICarbCalc II41

Replay Monitor With SuperData and a Manual Database.

This method is used when the Control Mode is not used. This method requires that the RealTime

Data Sources be configured for each furnace supported. This method also requires that a Load be

© 2005,2006,2007 Super Systems Inc.

Page 43

CarbCalcIICarbCalc II 42

manually entered using the Load Entry Screen. Load Entry must include a Load Start and Load End

time.

·

Load Information - manually entered in the CCLoads Database

·

Model as run - after the first replay, an "as run" model file is saved under the name

"L-xxx-model.ccp" (where xxx=load id number and model=model name)

·

Logged Process data - SuperData Communications historically logged data.

Using this data, the Cycle can be selected from the CCLoads database and may be replayed. During

replay, the recipe will be displayed, but only the total time (not segment times) will be displayed. This

is becaause the actual recipe used in the control instrument is unknown to CarbCalcII; only the logged

data and start/ent times are known.

Replay Monitor With BatchMaster Integration and an External Database.

This method is used when an external Load Entry system and Database are used (e.g with

BatchMaster or other Load Tracking systems). This method requires that the RealTime Data Sources

be configured for each furnace supported. This method also requires that the External Database must

be available through an ODBC DSN and that the carbcalc.ini file be configured for Load Database

access (see configuration section).

·

Load Information - obrtained from an external Load Tracking Database

·

Model as run - initial replay uses default settings, saving the load settings saves an "as-run" model

file for the load the name "BML-xxx-model.ccp" (where xxx=load id number and model=model

name)

© 2005,2006,2007 Super Systems Inc.

Page 44

CarbCalcIICarbCalc II43

·

Logged Process data - SuperData Communications historically logged data.

Using this data, the Cycle can selected from the CCLoads database and may be replayed. During

replay, the recipe will not be displayed; only the total time will be displayed. This is becaause the

actual recipe used in the control instrument is unknown to CarbCalcII; only the logged data and

start/ent times are known.

2.14.2 Report

n the Replay mode, clicking on the print icon will print the following report. The report is a snapshot of

the current model status and can be printed at any time during the replay.

© 2005,2006,2007 Super Systems Inc.

Page 45

CarbCalcIICarbCalc II 44

3 CarbCalcII Configuration

CarbCalcII is supplied in a fully functional 30 day "Trial" version. To continue using CarbCalcII beyond

the 30 day time limit, it must be registered and purchased from Super Systems Inc. Instructions for

registering ar contained in the Help/About screen.

CarbCalcII will require some configuration at time of installation.

CarbCalc

·

No configuration required

CarbCalc

·

Communications Data Sources must be configured for each furnace. (part of furnace settings)

© 2005,2006,2007 Super Systems Inc.

Simulation

RealTime Control, Replay and Monitoring

mode

modes

Page 46

CarbCalcII ConfigurationCarbCalc II45

CarbCalc.ini file :

This file will be located in the same directory that contains CarbCalcII.exe (the

application directory). This file is used to configure some operating modes, and database locations

and external database structure.

General

The

·

TID = xxxx (where xxxx = a 4 digit TrialID number. Do not remove this number, you may lose your

section

registration.)

·

RTMONITOR=x (where x=0 or 1. When set to 1, puts CarbCalc in a Replay/Monitor mode using

CCLoads Database)

·

BMIntegration=x (where x=0 or 1. When set to 1, puts CarbCalc in a BatchMaster Monitor mode

using and external Database)

Databases

The

·

Material=<name>.mdb (where <name> is the name of the material access database (default

carbcalc.mdb

·

CCLoads=<name>.mdb (where <name> is the name of the CarbCalc Load access database

(default

section

if not specified)

CCLoads.mdb

if not specified)

Note: the database names may be filename only (assumes file is in the application directory) or full

path and filename.

BMLoads

The

·

DSN=<name> (where <name> is the ODBC DSN)

·

T_LOAD=<name> (where <name> is the table name for the table containing the load information)

·

F_ID=<name> (where <name> is the field name for the numeric field containing the load ID)

·

F_LNAME=<name> (where <name> is the field name for the character field containing the load

section (only required when BMIntegration=1, ignored otherwise)

Name)

·

F_FCE=<name> (where <name> is the field name for the character field containing the Furnace

Name)

·

F_TIMEIN=<name> (where <name> is the field name for the datetime field containing the Load Start

time)

·

F_TIMEOUT=<name> (where <name> is the field name for the datetime field containing the Load

End time)

·

F_LINFO=<name> (where <name> is the field name for a character field containing additional Load

Information)

·

F_COMMENTS=<name> (where <name> is the field name for a character field containing additional

LoadComments)

Sample Carbcalc.ini file

[General]

*trial ID

TID= 9638

RTMONITOR=0

BMIntegration=1

[DataBases]

Material=carbcalc.mdb

CCLoads=C:\ssi\data\CCLoads.mdb

[BMLoads]

DSN=BM1

T_LOAD=Loads

© 2005,2006,2007 Super Systems Inc.

Page 47

F_ID=LID

F_LNAME=LoadNo

F_FCE=FceName

F_TIMEIN=StartDT

F_TIMEOUT=EndDT

F_LINFO=Recipe

F_COMMENTS=Part

CarbCalcII ConfigurationCarbCalc II 46

© 2005,2006,2007 Super Systems Inc.

Loading...

Loading...