Page 1

TITLE: MODBUS/J-BUS Protocol for SSi’s - AC20 ENG. 824E

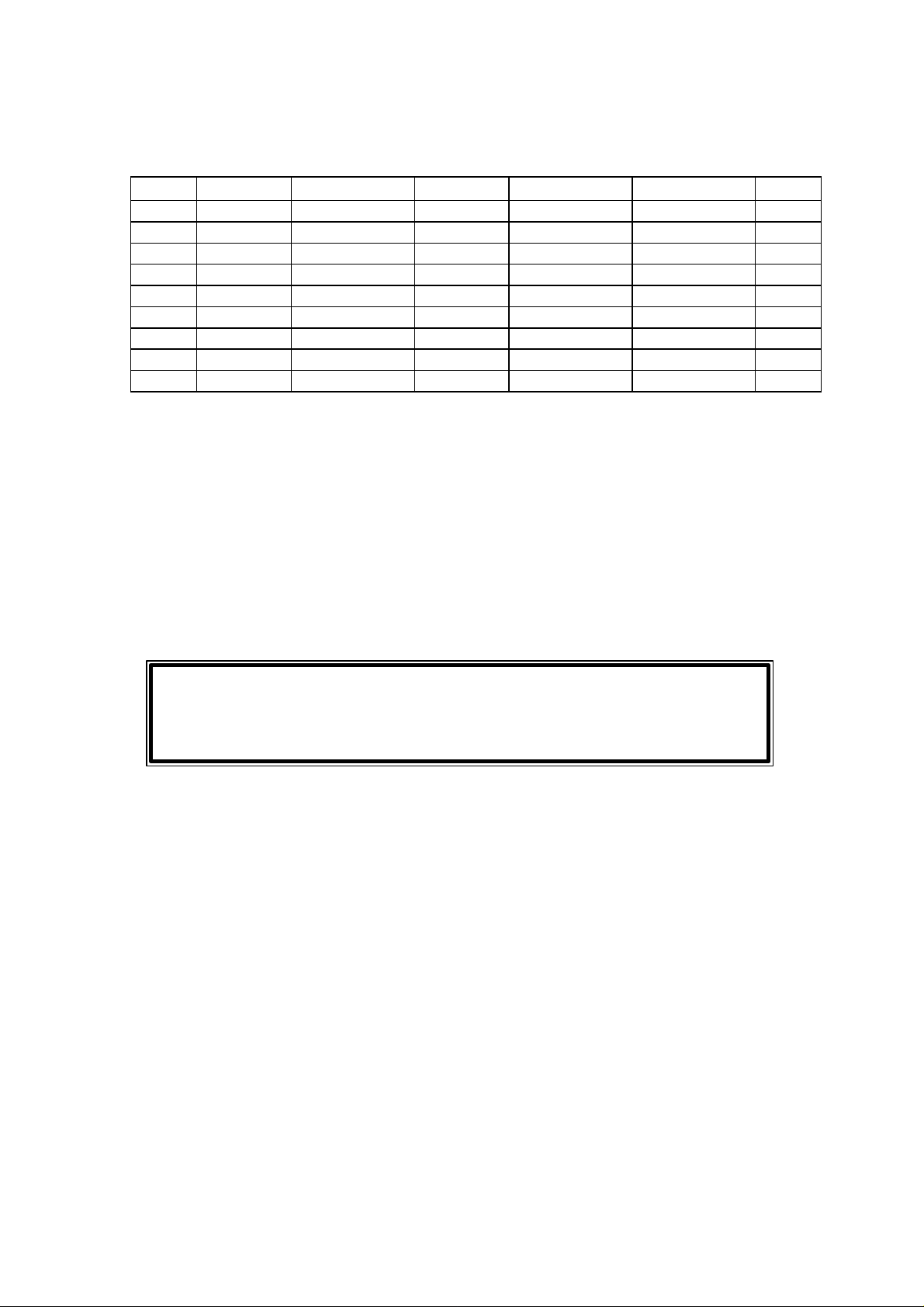

Rev. Date Description Written Verified Approved Prot.

0 04/30/98 First Issue

1 12/9/98

See shaded areas

98/144

MODBUS/J-BUS PROTOCOL FOR

SSi’s - AC20

All the information contained within this document are Company’s

confidential. Their content therefore cannot be divulged and/or

reproduced.

Page 2

Page 2/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

MODBUS/J-BUS PROTOCOL FOR

SSi’s - AC20

This document complies with ENG824E, Rev. 1 dated December 9, 1998.

The first page of this document is for R&D use only.

Headquarters: Factory:

Super Systems Inc

4250 Creek Road

Cincinnati, OH 45241

513-772-0060

www.supersystems.com

Page 3

Page 3/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

INDEX

Introduction Page 4

Function code 1 and 2: Bits reading Page 6

Function code 3 and 4: Words reading Page 7

Function code 5: Single bit writing Page 8

Function code 6: Single word writing Page 9

Function code 15: Multiple bits writing Page 10

Function code 16: Multiple words writing Page 11

Notes Page 12

Error reply Page 15

Words for device in control mode - Parameters Page 18

Words for device in control mode - Non parameters Page 26

Bits for device in control mode Page 31

Words for device in configuration mode - Parameters Page 37

Words for device in configuration mode - Non parameters Page 45

Words for device in security code mode Page 46

Index, divided in families and groups, of Modbus words Page 48

Index of Modbus bits Page 53

Index, in ascending order, of Modbus words Page 54

Index, in ascending order, of Modbus bits Page 58

Additional and specialized technical notes Page 59

Page 4

Page 4/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

INTRODUCTION

This half duplex protocol accepts one master and one or more slaves.

The physical interface should be of the RS-485 type.

A single multidrop link can take up to 128 devices having the same “High input impedance”

as the transceiver used..

The computer should be programmed to serve as a master controlling which slave has

access to the link. All other slaves are in waiting state. Each slave has a unique address

ranging from 1 to 255.

Address “0” is a broadcast one. When the master sends a message with address 0, all

slaves receive it and no one replies.

TRANSMISSION FORMAT

The protocol uses the RTU (Remote terminal unit) mode of transmission.

RTU is a binary method with byte format composed as follows:

1 start bit, 8 data bit, 1 parity bit (optional), 1 stop bit.

The communication speed is selectable among 600, 1200, 2400, 4800, 9600 and 19200

baud.

COMMUNICATION PROCEDURE

The communication can be initiated only by the master unit; the slave units can transmit

only after a query has been received from the master.

The general format for the transmission from master to slave is the following:

RANGE BYTE

Slave address 1

Function code 1

Data n

Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1

The slave detects the start of a query frame when the delay time between two characters

is greater than 3.5 T.U. (Time Unit = Time necessary to transmit one character).

ERROR CHECK(CRC-16 Cyclical Redundancy Check)

The CRC-16 value is calculated by the transmitting device. This value is appended to the

message. The receiving device recalculates a CRC-16 and compares the calculated value

to the received value. The two values must be equal.

Page 5

Page 5/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

The CRC-16 is started by first pre-loading a 16-bit register to all 1's. Then a process begins

of applying successive the bytes of the message to the current contents of the register.

Only the eight bits of data in each character are used for generating the CRC-16. Start and

stop bits, and the parity bit if one is used, do not apply to the CRC-16.

During generation of the CRC-16, each byte is exclusive ORed with the register contents.

Then the result is shifted to the right , with a zero filled into the most significant bit (MSB)

position. If the LSB was a 1, the register is then exclusive ORed with a preset, fixed value.

If the LSB was a 0, no exclusive OR takes place.

This process is repeated until eight shifts have been performed. After the last shift, the

next byte is exclusive ORed with the register's current value, and the process repeats for

eight more shifts as described above. The final contents of the register, after all the

characters of the message have been applied, is the CRC-16 value.

A procedure for generating a CRC-16 is:

1) Load a 16-bit register (CRC-16 register) with FFFFh (all 1's).

2) Exclusive OR the first byte of the message with the low byte of the CRC-16

register. Put the result in the CRC-16 register.

3) Shift the CRC-16 register one bit to the right (toward the LSB), zero-filling the

MSB. Extract and examine the LSB.

4) (If the LSB was 0): Repeat Step 3 (another shift).

(If the LSB was 1): Exclusive OR the CRC-16 register with the polynomial

value A001h (1010 0000 0000 0001b).

5) Repeat Steps 3 and 4 until 8 shifts have been performed. When this is done,

a complete byte will have been processed.

6) Repeat Steps 2 through 5 for the next byte of the message.

Continue doing this until all bytes have been processed.

7) The final contents of the CRC-16 register is the CRC-16 value.

When the CRC-16 (16 bytes) is transmitted in the message, the low byte

will be transmitted first, followed by the high byte

N.B. : the numerical value present in this text are expressed as:

binary value if they are followed by b

decimal value if they are not followed by any letter

hexadecimal value if they are followed by h

Page 6

Page 6/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

Function code 1 and 2: Bits reading

These function codes are used by the master unit to request the value of a consecutive

group of bits (max 24) which are representing the status of the slave unit.

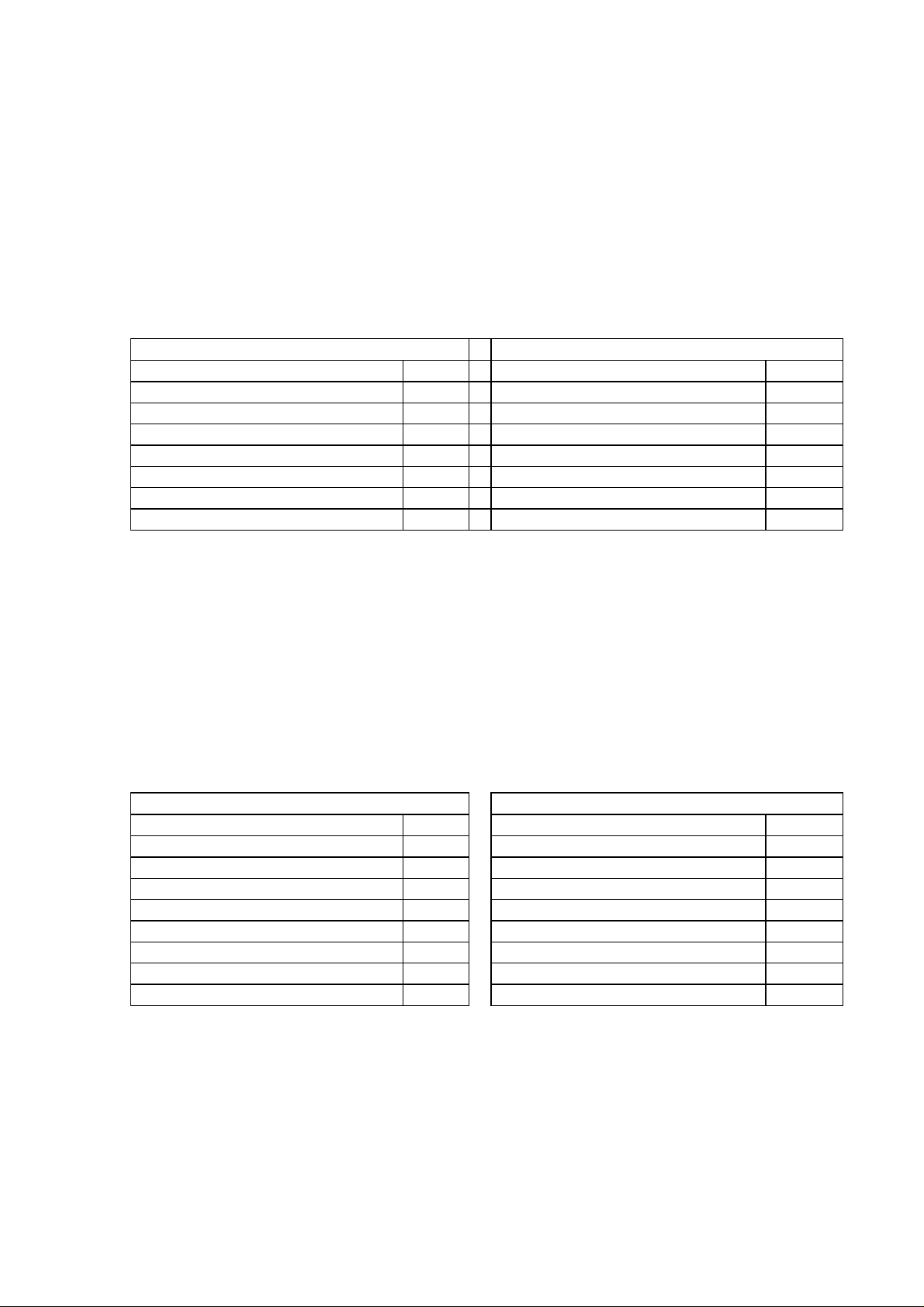

Request from master to slave Reply from slave to master

Range Byte Range Byte

Slave address (1-255) 1 Slave address (1-255) 1

Function code (01-02) 1 Function code (01-02) 1

Bit starting address (high byte) 1 Byte count (n) 1

Bit starting address (low byte) 1 Data n

Number of bits (high byte) 1 Error check (CRC-16) (low byte) 1

Number of bits (low byte) 1 Error check (CRC-16) (high byte) 1

Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1

The “Data” field indicates the bits requested: the bit with lower address is in the bit 0 of the

first byte, the next is in the bit 1, and so on.

The eventual don’t care bits necessary to complete the last byte are equal to 0.

Example:

Ask to slave at address 100 (64h) the status of 14 (Eh) bits starting from bit 201 (C9h).

Request from master to slave Reply from slave to master

Range Byte Range Byte

Slave address 64h Slave address 64h

Function code 01h Function code 01h

Bit starting address (high byte) 00h Byte count 02h

Bit starting address (low byte) C9h Data A7h

Number of bits (high byte) 00h Data 04h

Number of bits (low byte) 0Eh Error check (CRC-16) (low byte) 8Eh

Error check (CRC-16) (low byte) 64h Error check (CRC-16) (high byte) 07h

Error check (CRC-16) (high byte) 05h

The 2 bytes in “Data“ field (A7h=10100111b, 04h=00000100b) mean:

bit 201 status = 1 bit 209 status = 0

bit 202 status = 1 bit 210 status = 0

bit 203 status = 1 bit 211 status = 1

bit 204 status = 0 bit 212 status = 0

bit 205 status = 0 bit 213 status = 0

bit 206 status = 1 bit 214 status = 0

bit 207 status = 0 Don’t care = 0

bit 208 status = 1 Don’t care = 0

Page 7

Page 7/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

Function code 3 and 4: Words reading

These function codes are used by the master unit to read a consecutive group of words

(16 bit) which contain the value of the variable of the slave unit.

The master can require a maximum of 20 words at a time.

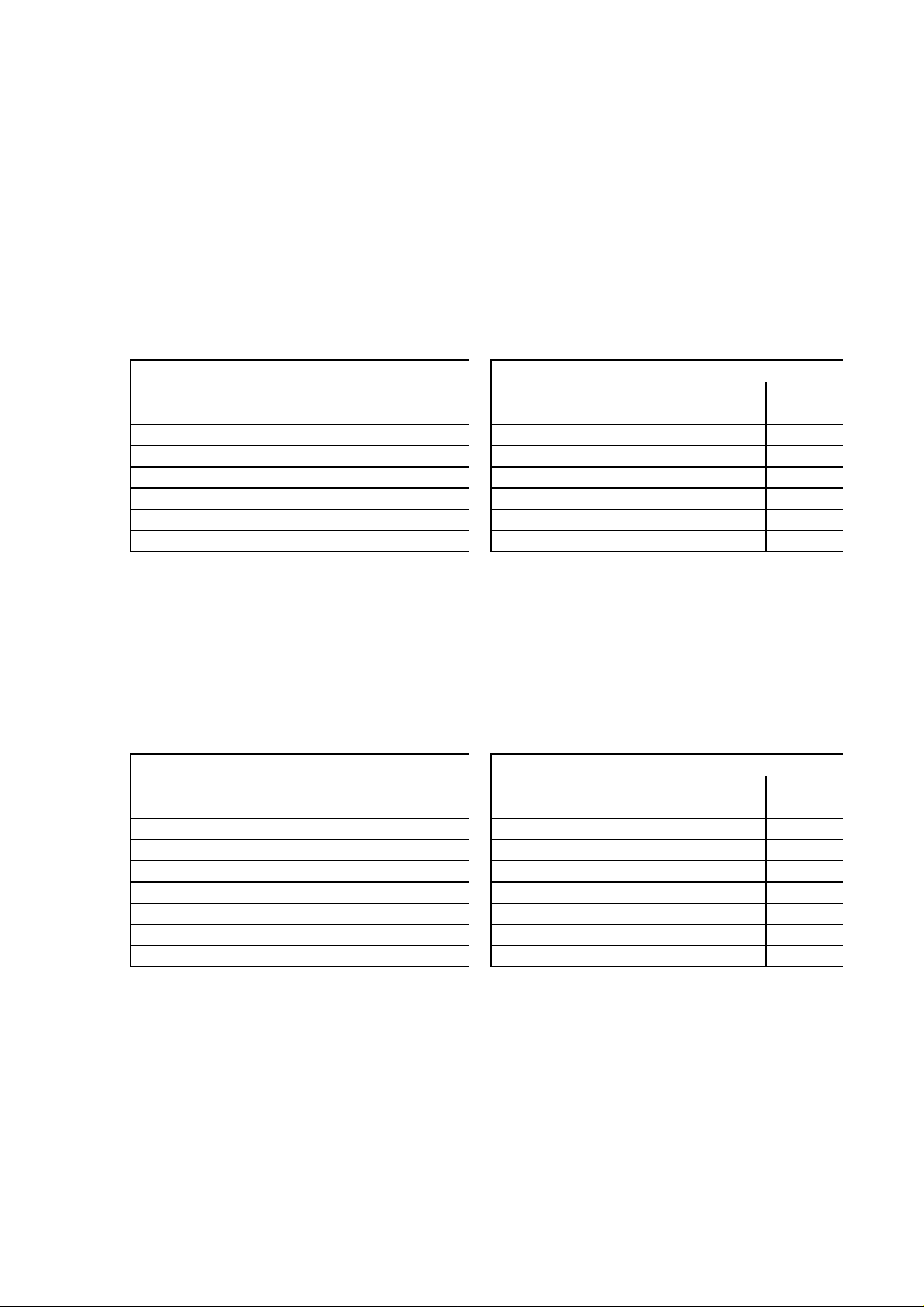

Request from master to slave Reply from slave to master

Range Byte Range Byte

Slave address (1-255) 1 Slave address (1-255) 1

Function code (03-04) 1 Function code (03-04) 1

Word starting address (high

1 Byte count (n) 1

byte)

Word starting address (low byte) 1 Data n

Number of word (high byte) 1 Error check (CRC-16) (low byte) 1

Number of word (low byte) 1 Error check (CRC-16) (high byte) 1

Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1

The “Data” field contains the requested words in the following format: high bytes of the first

word, low byte of the first word, high byte of the second word, and so on.

The “data” field contains 8000h for not implemented addresses or for information not

relevant in the actual device configuration.

Example:

Ask to slave at address 29 (1Dh) the value of 3 words (3h) starting from word 178 (B2h)

Request from master to slave Reply from slave to master

Range Byte Range Byte

Slave address 1Dh Slave address 1Dh

Function code 03h Function code 03h

Word starting address (high byte) 00h Byte count 06h

Word starting address (low byte) B2h Data FFh

Number of words (high byte) 00h Data 9Ch

Number of words (low byte) 03h Data 80h

Error check (CRC-16) (low byte) A7h Data 00h

Error check (CRC-16) (high byte) B0h Data 05h

Data 5Ah

Error check (CRC-16) (low byte) D7h

Error check (CRC-16) (high byte) 0Dh

The 6 bytes in “Data” field (FFh, 9Ch, 80h, 00h, 05h, 5Ah) are 3 words whose meaning is:

word 178 value = -100 (FF9Ch)

word 179 value = not implemented or not relevant (8000h)

word 180 value = 1370 (55Ah)

Page 8

Page 8/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

Function code 5: Single bit writing

By using this command, the master unit can change the state of one bit of the slave unit.

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address (0*-255) 1 Slave address (1-255) 1

Function code (05) 1 Function code (05) 1

Bit address (high byte) 1 Bit address (high byte) 1

Bit address (low byte) 1 Bit address (low byte) 1

Data 2 Data 2

Error check (CRC-16) (low byte) 1 Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1 Error check (CRC-16) (high byte) 1

* To use the address 0, see note 1 at page 12: “Broadcast address”.

“Data” field = 0h to reset the bit

= FF00h to set the bit

Example:

Set bit 219 (DBh) of slave at address 35 (23h)

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address 23h Slave address 23h

Function code 05h Function code 05h

Bit address (high byte) 00h Bit address (high byte) 00h

Bit address (low byte) DBh Bit address (low byte) DBh

Data FFh Data FFh

Data 00h Data 00h

Error check (CRC-16) (low byte) FAh Error check (CRC-16) (low byte) FAh

Error check (CRC-16) (high byte) 83h Error check (CRC-16) (high byte) 83h

Page 9

Page 9/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

Function code 6: Single word writing

By using this command, the master unit can change the value of one word (16 bit) of the

slave unit.

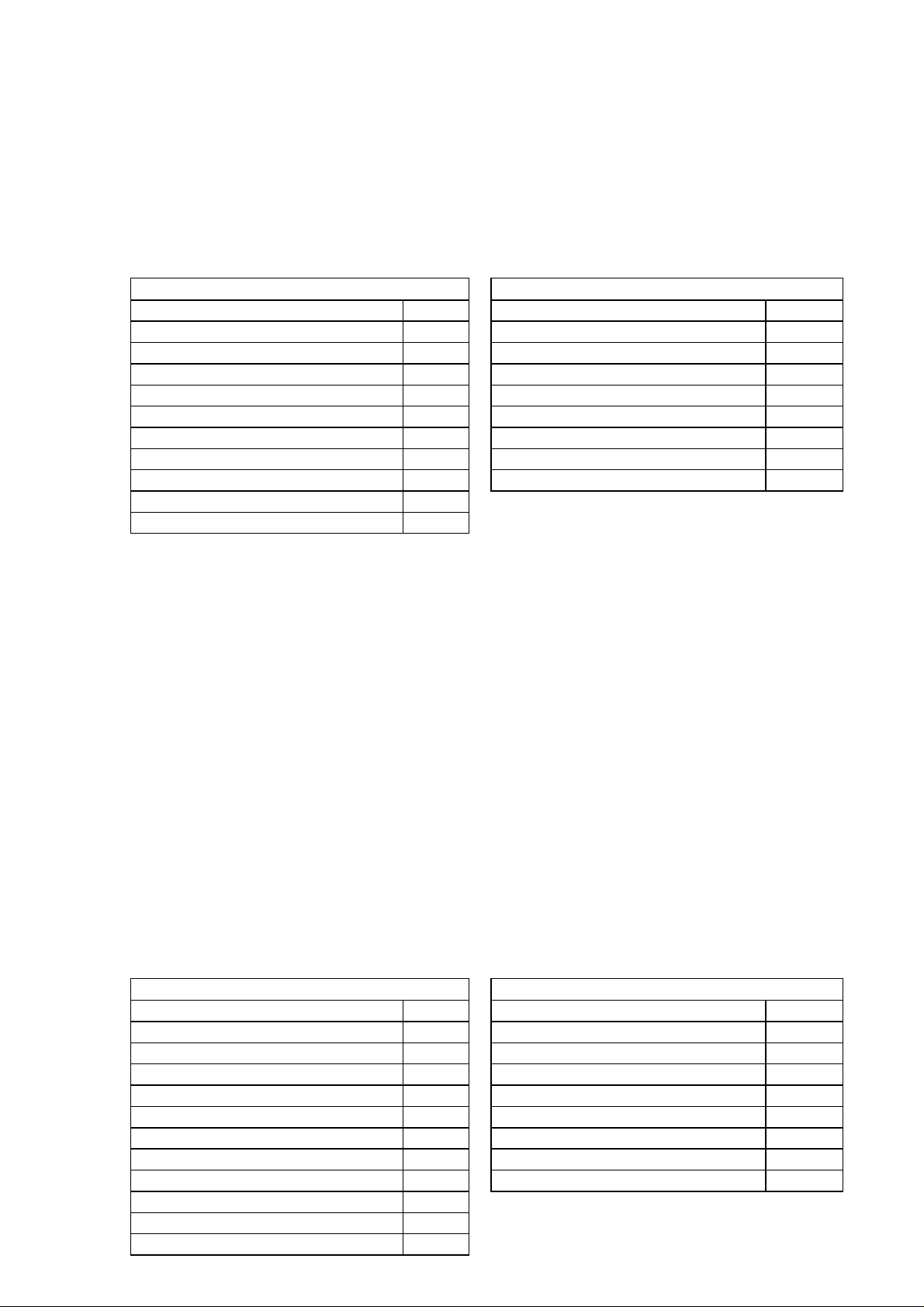

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address (0*-255) 1 Slave address (1-255) 1

Function code (06) 1 Function code (06) 1

Word address (high byte) 1 Word address (high byte) 1

Word address (low byte) 1 Word address (low byte) n

Data 2 Data 2

Error check (CRC-16) (low byte) 1 Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1 Error check (CRC-16) (high byte) 1

* To use the address 0, see note 1 at page 12: “Broadcast address”.

The 8000h value, present in the “data” field, should be considered as a don’t care value,

that is, the value present in the device at this address will not be modified.

Example:

Set word 2006 (7D6h) of slave at address 5 (5h) with value 1250 (4E2h)

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address 05h Slave address 05h

Function code 06h Function code 06h

Word address (high byte) 07h Word address (high byte) 07h

Word address (low byte) D6h Word address (low byte) D6h

Data 04h Data 04h

Data E2h Data E2h

Error check (CRC-16) (low byte) EAh Error check(CRC-16) (low byte) EAh

Error check (CRC-16) (high byte) 4Bh Error check (CRC-16) (high byte) 4Bh

Page 10

Page 10/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

Function code 15: Multiple bits writing

This function code is used by master unit to set/reset a consecutive group of bits (max 24).

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address (0*-255) 1 Slave address (1-255) 1

Function code (15) 1 Function code (15) 1

Bit starting address (high byte) 1 Bit starting address (high byte) 1

Bit starting address (low byte) 1 Bit starting address (low byte) 1

Number of bits (high byte) 1 Number of bits (high byte) 1

Number of bits (low byte) 1 Number of bits (low byte) 1

Byte counter (n) 1 Error check (CRC-16) (low byte) 1

Data n Error check (CRC-16) (high byte) 1

Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1

* To use the address 0, see note 1 at page 12: “Broadcast address”.

The desired status of each bit is packed in the DATA field (1 = ON, 0 = OFF).

The status imposed for read only bits will be ignored.

The command will be processed starting from the first bit and it will be executed or not

executed depending on the actual device status.

At the first error found, the command will be aborted and the slave will answer with an

error.

Example:

Send to slave, at address 2 (2h), the following set of 9 bits:

bit 224 status = 0 (bit 0) bit 232 status = 1 (bit 0)

bit 225 status = 1 (bit 1) Don’t care = 0 (bit 1)

bit 226 status = 1 (bit 2) Don’t care = 0 (bit 2)

bit 227 status = 0 (bit 3) Don’t care = 0 (bit 3)

bit 228 status = 1 (bit 4) Don’t care = 0 (bit 4)

bit 229 status = 0 (bit 5) Don’t care = 0 (bit 5)

bit 230 status = 1 (bit 6) Don’t care = 0 (bit 6)

bit 231 status = 1 (bit 7) Don’t care = 0 (bit 7)

NOTE: 2 bytes with 9 bits and 7 don’t care bits must be sent

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address 02h Slave address 02h

Function code 0Fh Function code 0Fh

Bit starting address (high byte) 00h Bit starting address (high byte) 00h

Bit starting address (low byte) E0h Bit starting address (low byte) E0h

Number of bits (high byte) 00h Number of bits (high byte) 00h

Number of bits (low byte) 09h Number of bits (low byte) 09h

Byte counter 02h Error check (CRC-16) (low byte) 94h

Data D6h Error check (CRC-16) (high byte) 08h

Data 01h

Error check (CRC-16) (low byte) 78h

Error check (CRC-16) (high byte) 4Ch

Page 11

Page 11/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

Function code 16: Multiple words writing

This function code is used by the master unit to write a consecutive group of words .

The master unit can change a maximum of 20 words at a time.

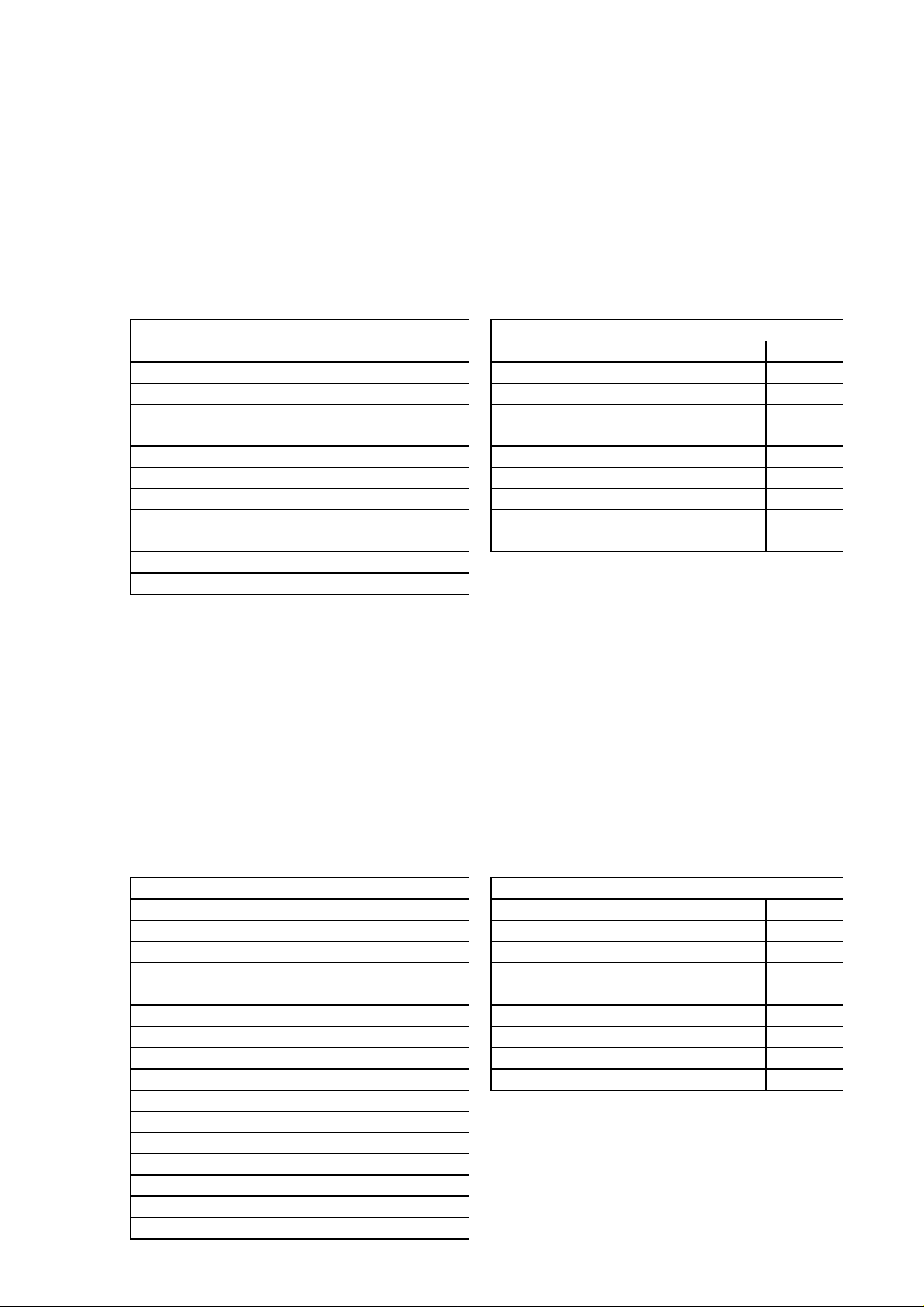

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address (0*-255) 1 Slave address (1-255) 1

Function code (16) 1 Function code (16) 1

Word starting address (high

1 Word starting address (high byte) 1

byte)

Word starting address (low byte) 1 Word starting address (low byte) 1

Number of words (high byte) 1 Number of words (high byte) 1

Number of words (low byte) 1 Number of words (low byte) 1

Byte counter (n) 1 Error check (CRC-16) (low byte) 1

Data n Error check (CRC-16) (high byte) 1

Error check (CRC-16) (low byte) 1

Error check (CRC-16) (high byte) 1

* To use the address 0, see note 1 at page 12: “Broadcast address”.

The data imposed for read only words will be ignored.

The command will be processed starting from the first word and it will be executed or not

executed depending on the actual device status.

At the first error found, the command will be aborted and the slave will answer with an

error.

The 8000h value, present in the “data” field, should be considered as a don’t care value,

this is, the value present in the device at this address will not be modified.

Example:

Set words 139 (8Bh), 140 (8Ch), 141 (8Dh) of slave at address 10 (Ah) with 300 (12Ch),

don’t care (8000h) and 700 (2BCh) values.

Command from master to slave Reply from slave to master

Range Byte Range Byte

Slave address 0Ah Slave address 0Ah

Function code 10h Function code 10h

Word starting address(high byte) 00h Word starting address (high byte) 00h

Word starting address (low byte) 8Bh Word starting address (low byte) 8Bh

Number of words (high byte) 00h Number of words (high byte) 00h

Number of words (low byte) 03h Number of words (low byte) 03h

Byte counter 06h Error check (CRC-16) (low byte) F1h

Data 01h Error check (CRC-16) (high byte) 59h

Data 2Ch

Data 80h

Data 00h

Data 02h

Data BCh

Error check (CRC-16) (low byte) 33h

Error check (CRC-16) (high byte) 00h

Page 12

Page 12/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

NOTES:

1. “Broadcast” address

When using the writing codes (5, 6, 15 and 16) the slave address 0 is permitted: in this

case all the slaves connected accept the command but do not give any reply.

2. Words format

Every time the information transfer is performed by using 2 bytes (1 word of 16 bits), the

first byte transmitted is the most significant one. For the negative numbers the “two

complement” format is used.

3. Reply time

The slave will start to send a reply from 2 ms to 250 ms after the end of the request

detected by counting the received bytes

4. Decimal digits

The decimal point that may be present in the value is ignored.

Example:

The value 204.6 is transmitted as 2046 (07FEh)

The value -12.50 is transmitted as -1250 (FB1Eh)

5. Local/remote status

At power up, the slave will be in local mode if it was in control mode at power off. In the

other cases, it will maintain the condition it was at the power off.

In order to enable a slave to be controlled from the master, it is necessary to set the

local/remote status bit (ModBus bit 218).

For a slave to remain in remote status, it is sufficient to detect line activity.

If there is no line activity for more than 3 sec. every slave will automatically return to

local mode.

Local mode: the communication between master and slave is limited to

transferring data from slave to master without possibility of modifying

any parameter from the master itself (with the exception of the

local/remote status bit). Therefore from the local keyboard,

parameters can be displayed and modified.

Remote mode: the instrument parameters can be modified by the master. Therefore,

from the local keyboard the parameters can be only displayed but not

modified.

Page 13

Page 13/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

6. Control mode

“Control mode” indicates the normal functioning status of the device

(indicator/controller).

In control mode they are parameters (menu groups), variables and status.

The parameters (Menu groups) are represented by words only.

Bits and words represent the variables and the status.

Reading:

The parameters (menu groups) are available only if they are meaningful in the present

contest.

The variables and the status are available only if the device is in control mode and if

they are meaningful in the present contest

Writing:

All the addresses are available only if the device is in control mode, in remote mode, in

unlock condition (see note 9) and if they are meaningful in the present contest

7. Configuration mode

The configuration parameters (Menu conf.) are represented by words only.

They are available as read only if they are meaningful in the present contest

They are available as writing only if the device is in configuration mode, and they are

meaningful in the present contest

At the end of the parameters programming of a configuration menu it is opportune to

send the “end of configuration menu” command (ModBus words 3000 ÷ 3005). The

congruence of the programmed data compared with the data of the other configuration

menus is checked. In case of non compatibility, the reply will include a 1xx error

message where xx represents the number of the menus whose closure has caused the

error.

The end of the group programming is anyway automatically sent if data of a different

menu are programmed or read and if the output of the configuration mode is imposed.

To modify the configuration parameters via serial link, it is necessary to set the slave in

remote (ModBus bit 218). Then, set the slave in configuration mode (send the safety

lock combination value for configuration mode to ModBus word 347 *).

The display will show:

SEr

COnF

To return in control mode condition, send 1 to Modbus word 3051. The slave will reset

and restart in control mode condition.

Page 14

Page 14/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

8. Security code mode

The security code parameters are represented by words only.

They are always available as read.

They are available as writing only if the device is in security code mode.

To modify the security code parameters via serial link, it is necessary to set the slave in

remote (ModBus bit 218). Then, set the slave in security code mode (send the safety

lock combination value for configuration mode to ModBus word 348 *).

The display will show:

Scrt

COnF

To return in control mode condition, send 1 to ModBus word 3051. The slave will reset

and restart in control mode condition.

* If the value of safety lock combination for configuration mode is 0, all values will be

accepted. If the value is 1, no value will be accepted.

The safety lock combination is the value set at ModBus word 4000.

9. Software key for lock/unlock

Software keys can protect the modification of the parameters.

There is a key to protect the access to configuration mode and security code mode.

There is a second key to protect the modification of control mode parameters.

Once the control mode key is programmed, it is possible to decide which menus will be

protected and which menus will not be protected.

Keys management via serial link

Set the slave in remote (ModBus bit 218).

Set the slave in security code mode (send the present safety lock combination value for

configuration mode at ModBus word 348).

Set the new safety lock combination value for configuration mode at ModBus word

4000.

Set the new safety lock combination value for control mode at ModBus word 4001.

To protect control mode menus with the key, write 1 (key protected) in Modbus words

4002÷4011. Write 0 (free) if no key protection is needed.

Page 15

Page 15/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

N.B.:

Safety lock combination = 0: No security code (all parameters can always be

modified)

If safety lock combination is for control mode, ModBus

word 4002÷4011 are forced to 0.

Safety lock combination = 1: No security code (all parameters cannot be modified).

If safety lock combination is for control mode, ModBus

word 4002÷4011 are forced to 1.

Safety lock combination=2÷250: Security code for parameter protection.

In order to remove the protection for the control mode

parameters, it is necessary to write the safety lock

combination value for control mode at ModBus word

349. It is sufficient to do this once only.

In order to protect the control mode parameters, it is

necessary to write a value different from the safety

lock combination value for control mode at ModBus

word 349.

In order to modify the configuration parameters, it is

necessary to set the configuration mode by writing the

safety lock combination value for configuration mode

at ModBus word 347.

In order to modify the security code parameters, it is

necessary to set security code mode by writing the

safety lock combination value for configuration mode

at ModBus word 348.

ERROR REPLY

If the “error check” is wrong or the function code is not implemented or a buffer over flows

has been received, the slave does not send any reply to the master.

If other errors are detected in the request or command frame, or the slave cannot reply

with the requested values or it cannot accept the requested sets because it is in error

condition, the slave replies by forcing at “1” the bit 7 of the “Function code” byte followed

by an error code.

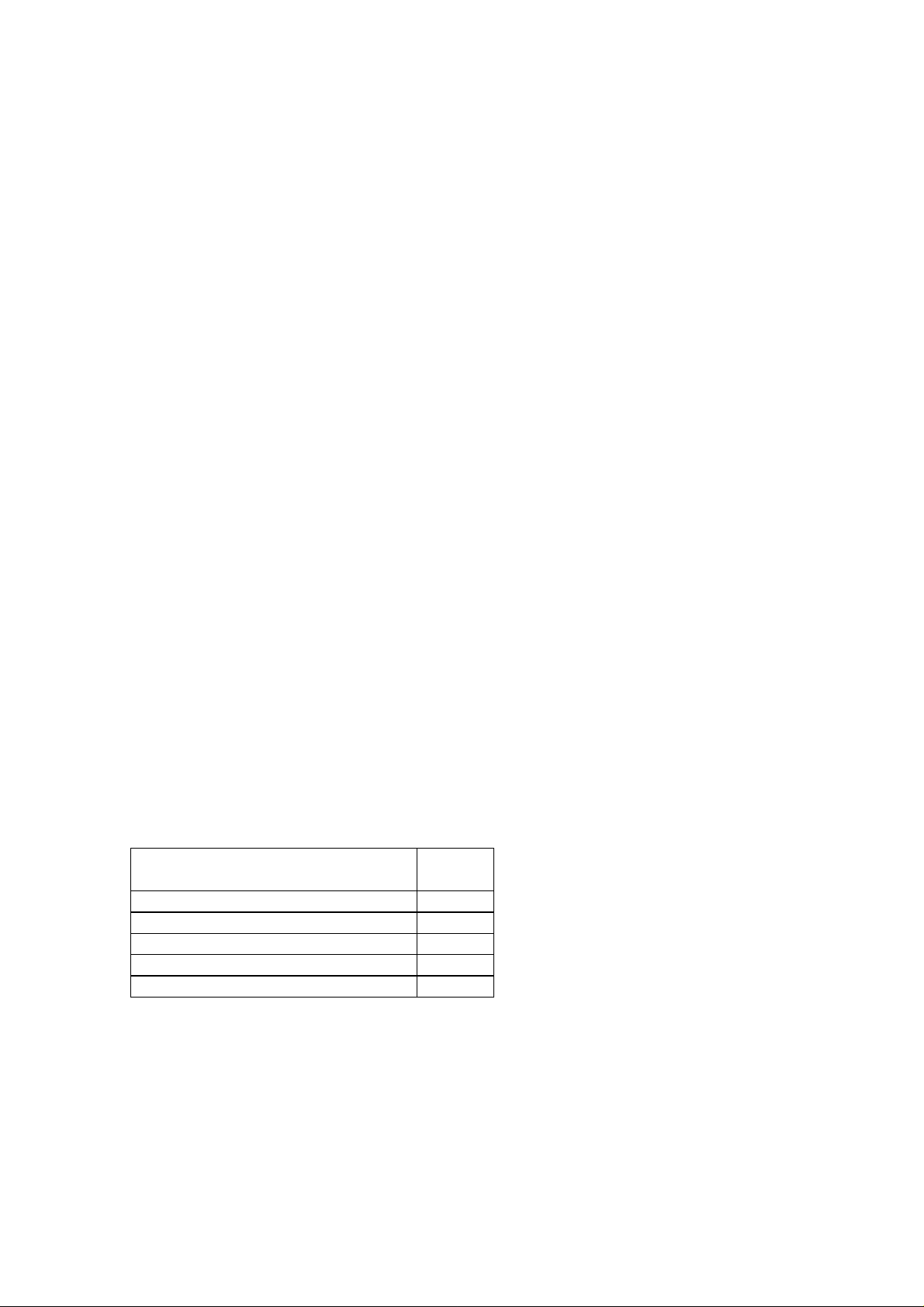

Error reply (from slave to master)

RANGE BYTE

Slave address 1

Function code (+80h) 1

Error code 1

Error check (CRC-16) 2

Page 16

Page 16/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

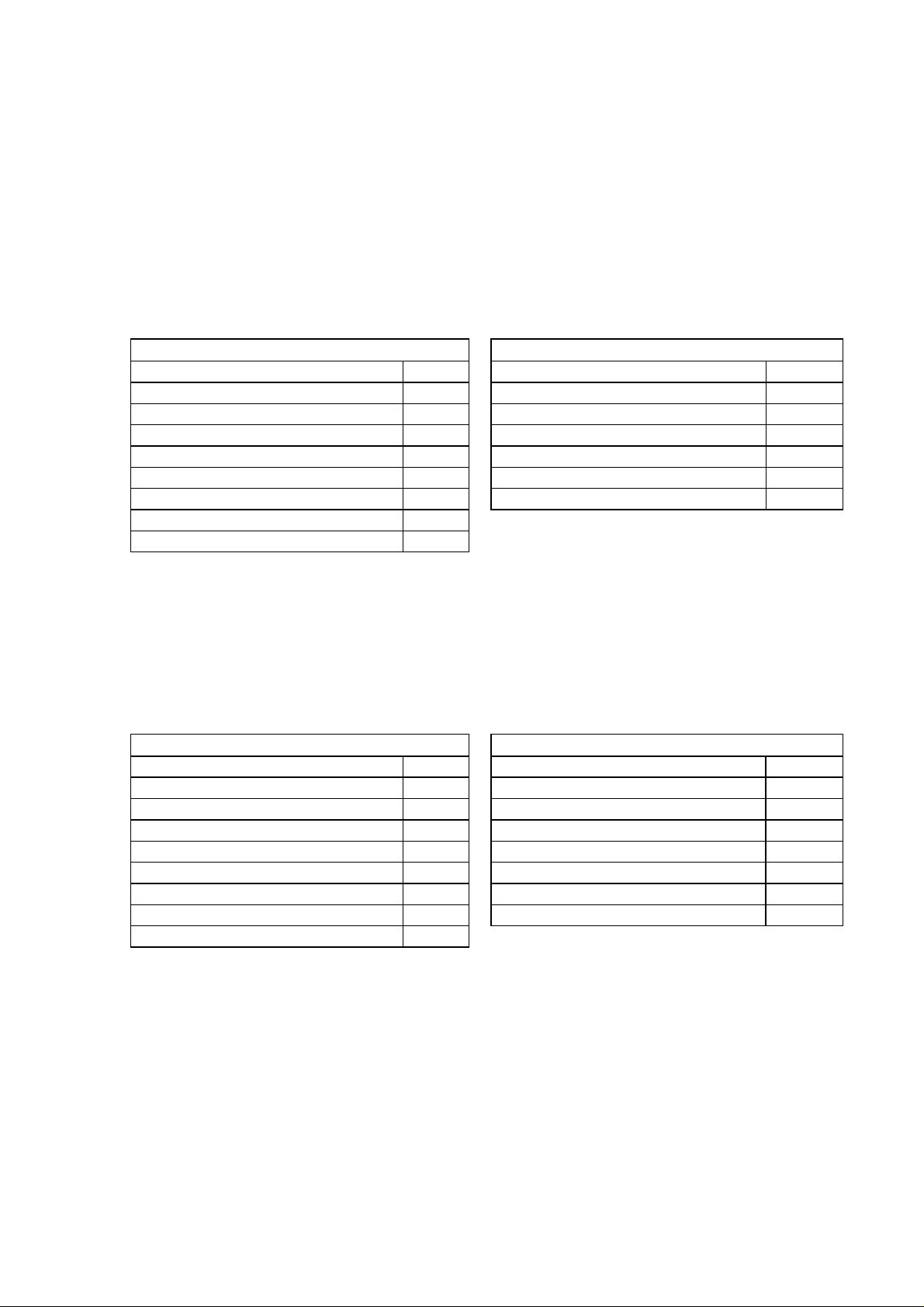

List of error codes

ERROR Nr. DESCRIPTION

2 Illegal data address

3 Illegal data value

9 Illegal number of data required

10 The bit or word indicated cannot be modified

50 The procedure cannot be initiated because another procedure is in pro-

gress

51 The procedure cannot be initiated because the first part of SMART

algorithm (TUNE) is in progress

52 The procedure cannot be initiated because it is not elapsed 5 minutes

from power on or from end of another procedure

53 The procedure cannot be initiated because the probe temperature is less

than 1000°F/538°

54 The procedure cannot be initiated because the probe output is less than

1000 mV

55 The procedure cannot be initiated because the probe output is unstable

(drift > 10 mV/minute)

101 Error on configuration group 1

102 Error on configuration group 2

103 Error on configuration group 3

104 Error on configuration group 4

105 Error on configuration group 5

106 Error on configuration group 6

151 Error on control mode group 1

152 Error on control mode group 2

153 Error on control mode group 3

154 Error on control mode group 4

155 Error on control mode group 5

156 Error on control mode group 6

157 Error on control mode group 7

158 Error on control mode group 8

159 Error on control mode group 9

160 Error on control mode group Hidden

200

201

202

Error on main probe input calibration (0÷1.5 V)

Error on main probe input calibration (1÷1.3 V)

Error on TC input calibration (0÷60 mV)

203 Error on CJ calibration

204

205

206

207

208

Error on auxiliary input current (0÷20 mA) calibration

Error on auxiliary input voltage (0÷5 V) calibration

Error on auxiliary input voltage (0÷10 V) calibration

Error on Out 6 (0÷20 mA output) calibration

Error on Out 7 (0÷20 mA output) calibration

Page 17

Page 17/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

On configuration error condition (101÷106), the device will replace the error message with

the requested value in the following cases:

• request of configuration mode menu addresses

• request of control mode menu addresses

• request of security code mode addresses

It will accept the following sets:

• set in remote (ModBus bit 218)

• set in configuration mode (ModBus word 347)

• set in security code mode (ModBus word 348)

• set of all of configuration addresses

• set of all of security code mode addresses

On control mode error condition (151÷160), the device will replace the error message with

the requested value in the following cases:

• request of configuration mode menu addresses

• request of control mode menu addresses

• request of security code mode addresses

It will accept the following sets:

• set in remote (ModBus bit 218)

• set in configuration mode (ModBus word 347)

• set in security code mode (ModBus word 348)

• set of all of configuration addresses

• set of all of control mode menu addresses

• load of control mode default parameters (ModBus bits 223÷232)

• set of all of security code mode addresses

On calibration error condition (200÷208), the device will replace the error message with the

requested value in the following cases:

• request of configuration mode menu addresses

• request of control mode menu addresses

• request of security code mode menu addresses

It will accept the following sets:

• set in remote (ModBus bit 218)

• set in configuration mode (ModBus word 347)

• set in security code mode (ModBus word 348)

• set of all of configuration mode addresses

• set of all of security code mode addresses

If a configuration or control mode or calibration error occurs at start up and no action is

taken, the device will reset after a 30 second time-out.

In configuration mode, the time-out will be disable.

Page 18

Page 18/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

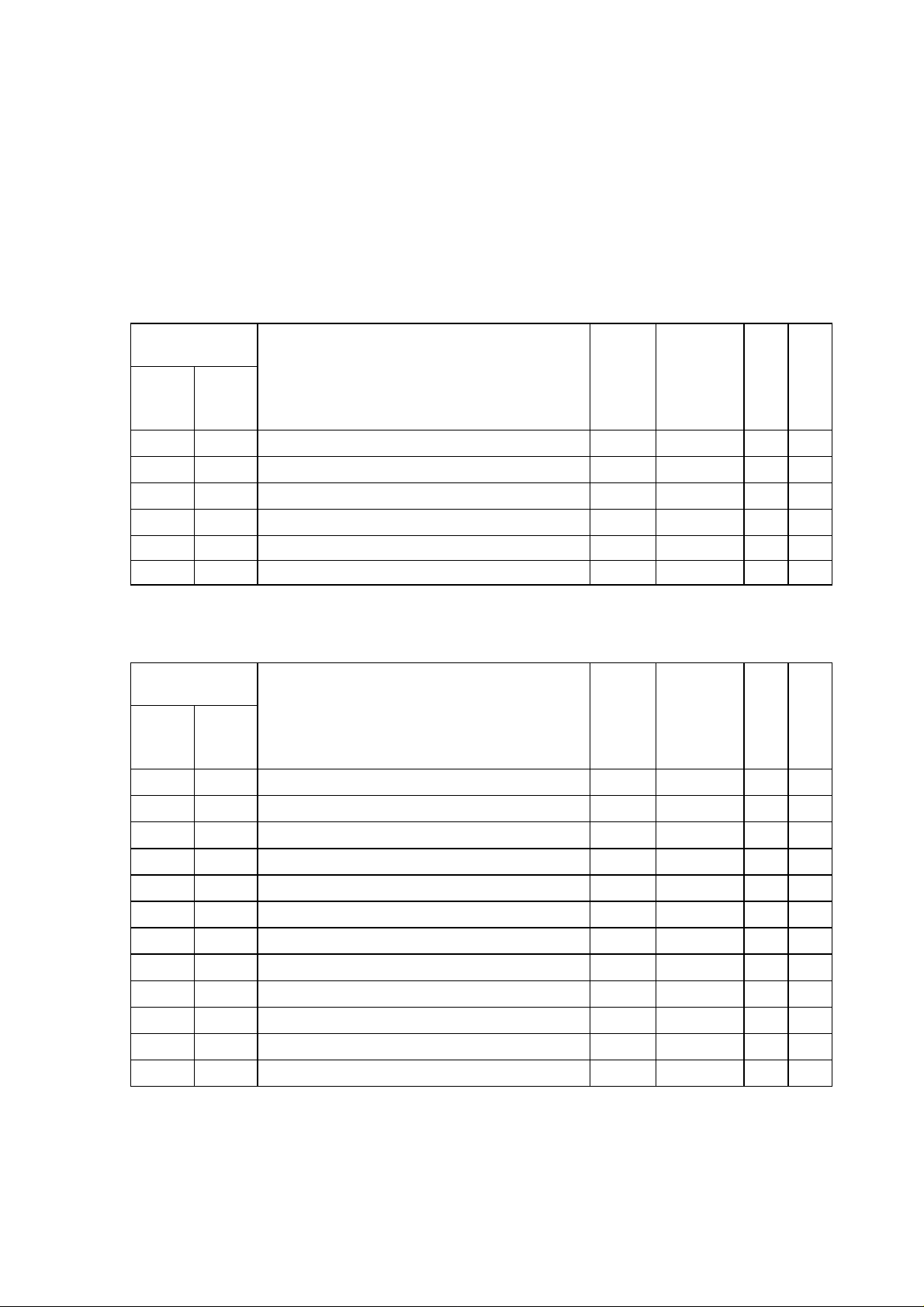

“St.Pn” - Menu group 1 - SET POINT VALUES

ADDRESS

(decimal) DEC. Display R

DESCRIPTION FIGU-

JBus Mod

Bus

139 138 Main set point

140 139 Auxiliary set point 2

141 140 Auxiliary set point 3

142 141 Auxiliary set point 4

RES

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

MNEM

CODE

E

A

D

(“SP”) x x

(“SP2”) x x

(“SP3”) x x

(“SP4”) x x

143 142 Carbon monoxide factor 0 (“COF”) x x

144 143 Hydrogen factor 0 (“H2F”) x x

“Alrñ” - Menu group 3 - ALARM THRESHOLD AND HYSTERESIS VALUE

ADDRESS

(decimal) DEC. Display R

DESCRIPTION FIGU-

JBus Mod

Bus

178 177 Alarm 1 threshold

179 178 Alarm 2 threshold

180 179 Alarm 3 threshold

182 181 Band alarm 1 threshold low

183 182 Band alarm 1 threshold high

184 183 Band alarm 2 threshold low

185 184 Band alarm 2 threshold high

186 185 Band alarm 3 threshold low

187 186 Band alarm 3 threshold high

192 191 Alarm 1 hysteresis

193 192 Alarm 2 hysteresis

194 193 Alarm 3 hysteresis

RES

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

MNEM

CODE

E

A

D

(“AL1”) x x

(“AL2”) x x

(“AL3”) x x

(“bA1.L”) x x

(“bA1.h”) x x

(“bA2.L”) x x

(“bA2.h”) x x

(“bA3.L”) x x

(“bA3.h”) x x

(“HSA1”) x x

(“HSA2”) x x

(“HSA3”) x x

W

R

I

T

E

W

R

I

T

E

Page 19

Page 19/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

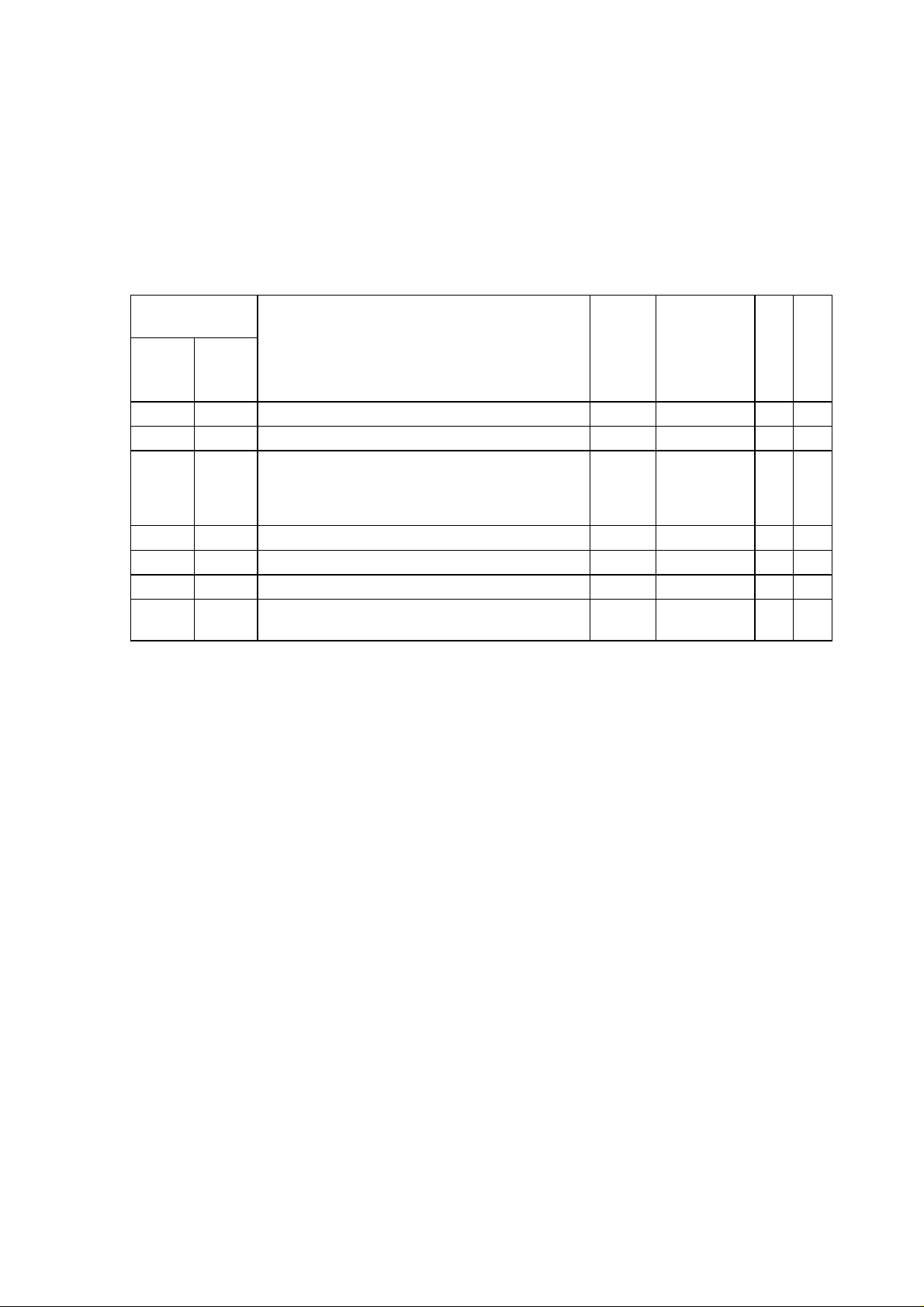

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“Cntr” - Menu group 4 - CONTROL PARAMETERS

ADDRESS

(decimal) DEC. Display RWR

JBus Mod

Bus

DESCRIPTION FIGU-

RES

MNEM

CODE

E

A

D

149 148 Proportional band 1 (“Pb”) x x

150 149 Hysteresis for on/off control mode 1 (“HYS”) x x

151 150 Integral time (in seconds)

Note:

The value 7FFFh means that the integral

action is excluded

0 (“ti”) x x

152 151 Derivative time (in seconds) 0 (“td”) x x

153 152 Integral pre-load 1 (“IP”) x x

154 153 Relative secondary output gain 2 (“r.Gn”) x x

155 154 Dead band/overlap between main/secon-

0 (“OLAP”) x x

dary output

I

T

E

Page 20

Page 20/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“A.Ctr” - Menu group 5 - AUXILIARY CONTROL PARAMETERS

ADDRESS

(decimal) DEC. Display RWR

JBus Mod

Bus

DESCRIPTION FIGU-

RES

MNEM

CODE

E

A

D

1001 1000 Anti-reset windup 0 (“ArU”) x x

1004 1003 Main control output low limit 1 (“ñ.OLL”) x x

1005 1004 Main control output high limit 1 (“ñ.OLH”) x x

1006 1005 Main control output max rate of rise

Note:

The value 7FFFh means that no ramp limitation is imposed.

1007 1006 Proportional cycle time on main control

1 (“ñ.rñP”) x x

0 (“ñC.CY”) x x

output (in seconds)

1008 1007 Secondary control output low limit 1 (“S.OLL”) x x

1009 1008 Secondary control output high limit 1 (“S.OLH”) x x

1010 1009 Secondary control output max rate of

1 (“S.rñP”) x x

rise

Note:

The value 7FFFh means that no ramp limitation is imposed

1011 1010 Proportional cycle time on secondary

0 (“SC.CY”) x x

control output (in seconds)

1012 1011 Set point low limit

1013 1012 Set point high limit

1014 1013 Rate of change for positive set point va-

See Mbus

Word 300

See Mbus

Word 300

See Mbus

Word 300

(“rL”) x x

(“rH”) x x

(“Grd1”) x x

riation

Note:

The value 7FFFh means that the transfer

is done as a step change.

1015 1014 Rate of change for negative set point va-

See Mbus

Word 300

(“Grd2”) x x

riation

Note:

The value 7FFFh means that the transfer

is done as a step change

1017 1016 External control of auto/man function

Range:

0 = Off

1 = On

N.A. (“E.Añ”) x x

I

T

E

Page 21

Page 21/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“A.SEt” - Menu group 6 - ALARM SETTING

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

1101 1100 Alarm 1 type

Range:

0 = Alarm on process variable

1 = Band alarm on process variable

2 = Deviation alarm on process variable

1102 1101 Alarm 1 configuration

Range:

0 = High alarm with automatic reset

1 = Low alarm with automatic reset

2 = High alarm with automatic reset and

acknowledge

3 = Low alarm with automatic reset and

acknowledge

4 = High alarm with manual reset

5 = Low alarm with manual reset

1103 1102 Alarm 1 action

Range:

0 = Rev

1 = Dir

1104 1103 Alarm 1 standby function

Range:

0 = Off

1 = On

1105 1104 Alarm 2 type

Note:

See “Alarm 1 type”

1106 1105 Alarm 2 configuration

Note:

See “Alarm 1 configuration”

1107 1106 Alarm 2 action

Range:

0 = Rev

1 = Dir

1108 1107 Alarm 2 standby function

Range:

0 = Off

1 = On

N.A. (“A1.tP”) x x

N.A. (“A1.Cn”) x x

N.A. (“A1.Ac”) x x

N.A. (“A1.St”) x x

N.A. (“A2.tP”) x x

N.A. (“A2.Cn”) x x

N.A. (“A2.Ac”) x x

N.A. (“A2.St”) x x

W

R

E

A

D

I

T

E

Page 22

Page 22/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“A.SEt” - Menu group 6 - ALARM SETTING

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

1109 1108 Alarm 3 type

Note:

See “Alarm 1 type”

1110 1109 Alarm 3 configuration

Note:

See “Alarm 1 configuration”

1111 1110 Alarm 3 action

Range:

0 = Rev

1 = Dir

1112 1111 Alarm 3 standby function

Range:

0 = Off

1 = On

N.A. (“A3.tP”) x x

N.A. (“A3.Cn”) x x

N.A. (“A3.Ac”) x x

N.A. (“A3.St”) x x

W

R

E

A

D

I

T

E

Page 23

Page 23/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“Sr.Ln” - Menu group 7 - SERIAL LINK PARAMETERS

ADDRESS

(decimal) DEC. Display RWR

DESCRIPTION FIGU-

JBus Mod

Bus

527 526 Serial interface protocol

Range:

0 = No serial interface

1 = Modbus

2 = Jbus

Note:

The new data will be activated after the

de-vice answer

528 527 Serial link device address

Note:

The new data will be activated after the

de-vice answer

529 528 Baud rate for serial link

Range:

0 = 600 Baud

1 = 1200 Baud

2 = 2400 Baud

3 = 4800 Baud

4 = 9600 Baud

5 = 19200 Baud

Note:

The new data will be activated after the

de-vice answer

530 529 Byte format for serial link

Range:

0 = 8 bits + even parity

1 = 8 bits + odd parity

2 = 8 bits without parity

Note:

The new data will be activated after the

de-vice answer

RES

N.A. (“S.L.Pr”) x x

N.A. (“S.L.Ad”) x x

N.A. (“S.L.bd”) x x

N.A. (“S.L.bF”) x x

MNEM

CODE

E

A

D

I

T

E

Page 24

Page 24/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“tiñE” - Menu group 8 - TIMERS SETTING

ADDRESS

(decimal) DEC. Display R

JBus Mod

Bus

DESCRIPTION FIGU-

RES

MNEM

CODE

E

A

D

1301 1300 Timer for burn-off (in seconds) 0 (“t.bOF”) x x

1302 1301 Timer for purge (in seconds) 0 (“t.PrG”) x x

1303 1302 Timer for automatic burn-off interval (in

0 (“bF.tr”) x x

minutes)

Note:

The value 7FFFh means that no time

interval is imposed

1304 1303 Timer for probe test interval (in minutes)

Note:

The value 7FFFh means that no time

interval is imposed

1305 1304 Time lasting to beginning of burn-off

0 (“Pb.tr”) x x

0 (“bF.ñn”) x

procedure (in minutes)

Note:

The value 7FFFh means that no time

interval is imposed

1306 1305 Time lasting to beginning of probe test

0 (“Pb.ñn”) x

procedure (in minutes)

Note:

The value 7FFFh means that no time

interval is imposed

W

R

I

T

E

Page 25

Page 25/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - PARAMETERS

“Hidn” - Menu group hidden - SMART LIMIT VALUE

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

1201 1200 Min value of proportional band calculated

1 (“Pb.Lo”) x x

by the smart algorithm

1202 1201 Max value of proportional band cal-

1 (“Pb.Hi”) x x

culated by the smart algorithm

1203 1202 Min value of integral time value cal-

0 (“ti.Lo”) x x

culated by the smart algorithm (in seconds)

1204 1203 Max value of integral time value cal-

0 (“ti.Hi”) x x

culated by the smart algorithm (in seconds)

1205 1204 Relative secondary output gain cal-

N.A. (“rG.CL”) x x

culated by the smart algorithm

Range:

0 = Off

1 = On

W

R

E

A

D

I

T

E

Page 26

Page 26/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - NON PARAMETERS

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

114 113 Status led alarm 1

Range:

0 = Off

1 = On

2 = Flashing (only for alarm)

115 114 Status led alarm 2

Range:

0 = Off

1 = On

2 = Flashing (only for alarm)

116 115 Status led alarm 3

Range:

0 = Off

1 = On

2 = Flashing (only for alarm)

120 119 Variation on alarm status

Note:

Alarm status information is on D8:

(1 for entrance, 0 for exit)

Number of alarm is on low byte (D2-D0)

121 120 Manufactured trade mark

Value:

50 (32h)

122 121 Device identification code

Note:

Nr. of software revision x 100 + identification code (43)

123 122 Probe sensor mV value

Note:

When an error is detected on measure,

the “Data field” contains one of these error

codes:

30004 (7534h) = Under-range

30005 (7535h) = Over-range

30050 (7562h) = Error on internal auto zero

30051 (7563h) = Error on internal zero integrator

124 123 Carbon potential value

Note:

When an error is detected on measure,

the “Data field” contains one of these error

codes:

30050 (7562h) = Error on internal auto zero

30051 (7563h) = Error on internal zero-

integrator

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

0 x

2 x

W

R

E

A

D

I

T

E

Page 27

Page 27/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - NON PARAMETERS

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

125 124 Dew point value (Value in Celsius or

0 x

Fahrenheit as configured at Mbus word

2003)

Note:

When an error is detected on measure,

the “Data field” contains one of these error

codes:

30050 (7562h) = Error on internal auto zero

30051 (7563h) = Error on internal zero-

integrator

126 125 Probe temperature value (Value in Cel-

0 x

sius or Fahrenheit as configured at Mbus

word 2003)

Note:

When an error is detected on measure,

the “Data field” contains one of these error

codes:

30002 (7532h) = Input open

30004 (7534h) = Under-range

30005 (7535h) = Over-range

30014 (753Eh) = Error on reference junc tion (t.a.<-25°C or

t.a. >75°C)

30050 (7562h) = Error on internal auto zero

30051 (7563h) = Error on internal zero-

integrator

127 126 Carbon monoxide measured value

Note:

When an error is detected on measure,

the “Data field” contains one of these error

codes:

30049 (7561h) = Out of range

30050 (7562h) = Error on internal auto zero

30051 (7563h) = Error on internal zero-

integrator

0 x

128 127 Probe resistor value (in Kilo Ohm) 2 x

129 128 Probe response time (in seconds) 1 x

130 129 Probe temperature at last probe test (Va-

0 x

lue in Celsius or Fahrenheit as configured at Mbus word 2003)

W

R

E

A

D

I

T

E

Page 28

Page 28/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - NON PARAMETERS

ADDRESS

(decimal) DEC. Display R

JBus Mod

Bus

DESCRIPTION FIGU-

RES

MNEM

CODE

E

A

D

131 130 Main control output value 1 x x

132 131 Secondary control output value 1 x x

133 132 Pid out value 1 x x

134 133 Main control output display value

135 134 Secondary control output display value

136 135 Device status mode

Range:

0 = Control mode

1 = Control mode with error E.130

2 = Control mode with error E.140

3 = Burn-off procedure in progress

4 = Purge procedure in progress

5 = Probe test procedure in progress

6 = Configuration mode

7 = Security code mode

Note:

For E.130/E.140 errors, see Technical

specifications Eng. 247E

The error is reset when read if device is in

remote state

137 136 Type of operative set point

Range:

0 = The set point utilized is a value set by

serial link (“Operative Set Point

Value”)

1 = Main set point

2 = Auxiliary set point 2

3 = Auxiliary set point 3

4 = Auxiliary set point 4

138 137 Operative set point value

Note:

It is utilized by the device for the PID as

well as for the SMART algorithms.

Any change will not be influenced by the

gradient mechanism. This set point value

is not going to be stored in Earom and it

will be lost at power down.

301 300 Decimal number relative to primary

See Mbus

word 301

See Mbus

word 302

(ñ.xxx) x

(S.xxx) x

N.A. x

N.A. x

See Mbus

word 300

N.A. x

x x

control variable

302 301 Decimal number relative to main control

N.A. x

output in engineering units

303 302 Decimal number relative to secondary

N.A. x

control output in engineering units

W

R

I

T

E

Page 29

Page 29/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - NON PARAMETERS

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

348 347 Code for enable configuration mode

Range :

Reading: 0 = Configuration mode

unlocked

1 = Configuration mode always

locked

2 = Configuration mode locked

by software key

Writing: 0-250

Note:

See Note 7 at page 13

349 348 Code for enable security code mode

Range :

Reading:0 = Security code mode unlocked

1 = Security code mode always

locked

2 = Security code mode locked

by software key

Writing: 0-250

Note:

See Note 8 at page 14

350 349 Code for lock/unlock control parameters

Range :

Reading: 0 = Parameters always

unlocked

1 = Parameters always locked

2 = Parameters can be locked

by software key:

Parameters locked

3 = Parameters can be locked

by software key:

Parameters unlocked.

Writing: 0-250

351 350 Lock/unlock status group hidden

Note:

See “Code For Lock/Unlock Control Para-

meters”

352 351 Lock/unlock status group 1

Note:

See “Code For Lock/Unlock Control Para-

meters”

353 352 Lock/unlock status group 2

Note:

See “Code For Lock/Unlock Control Para-

meters”

N.A. x x

N.A. x x

N.A. x x

N.A. x

N.A. x

N.A. x

W

R

E

A

D

I

T

E

Page 30

Page 30/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONTROL MODE - NON PARAMETERS

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

354 353 Lock/unlock status group 3

Note:

See “Code For Lock/Unlock Control Para-

meters”

355 354 Lock/unlock status group 4

Note:

See “Code For Lock/Unlock Control Para-

meters”

356 355 Lock/unlock status group 5

Note:

See “Code For Lock/Unlock Control Para-

meters”

357 356 Lock/unlock status group 6

Note:

See “Code For Lock/Unlock Control Para-

meters”

358 357 Lock/unlock status group 7

Note:

See “Code For Lock/Unlock Control Para-

meters”

359 358 Lock/unlock status group 8

Note:

See “Code For Lock/Unlock Control Para-

meters”

360 359 Lock/unlock status group 9

Note:

See “Code For Lock/Unlock Control Para-

meters”

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

W

R

E

A

D

I

T

E

Page 31

Page 31/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

BITS FOR DEVICE IN CONTROL MODE

ADDRESS

(decimal) Display R

DESCRIPTION MNEM

JBus Mod

CODE

Bus

201 200 Logic level of external contact Dig1

Range:

0 = Logic level 0

1 = Logic level 1

202 201 Logic level of external contact Dig2

Range:

0 = Logic level 0

1 = Logic level 1

203 202 Logic level of external contact Dig3

Range:

0 = Logic level 0

1 = Logic level 1

205 204 Status relay alarm 1

Range:

0 = Off

1 = On

206 205 Status relay alarm 2

Range:

0 = Off

1 = On

207 206 Status relay alarm 3

Range:

0 = Off

1 = On

211 210 Unsolicited request flag general

Range:

0 = No Parameters change is occurred

1 = Parameters change is occurred

Note:

The bit is set also to signal the start up.

Changes produced by serial link will not be

flaged

The bit resets after reading

W

R

E

A

D

I

T

E

x

x

x

x

x

x

x

Page 32

Page 32/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

BITS FOR DEVICE IN CONTROL MODE

ADDRESS

(decimal) Display R

DESCRIPTION MNEM

JBus Mod

Bus

212 211 Status tune

Range:

0 = No tune

1 = Tune

213 212 Status adaptive

Range:

0 = No adaptive

1 = Adaptive

214 213 Lock/unlock status

Range:

0 = Unlock device

1 = Lock device

Note:

See also ModBus word 349

CODE

E

A

D

x

x

x

217 216 Start probe test procedure x

218 217 Start burn-off procedure x

219 218 Local/remote device status

Range:

0 = Device in local

1 = Device in remote

220 219 Auto/manual function

Range:

0 = Auto

1 = Manual

222 221 Smart enable/disable

Range:

0 = Disable

1 = Enable

Note:

Reading, this bit is logical OR between Tune

(ModBus bit 211) and Adaptive status

(ModBus bit 212)

223 222 Manual reset/acknowledge of an alarm

(“Sñrt”) x x

(“ñ.Rst”) x

x x

x x

condition

Range:

0 = No operation

1 = Reset alarm

224 223 Load default control parameters value

Range:

0 = No operation

1 = Load default

Note:

The command is accepted only if “Smart”

(ModBus bit 221) is not active.

The default value of group 7 (Serial link parameters) are not loaded.

W

R

I

T

E

x

Page 33

Page 33/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

BITS FOR DEVICE IN CONTROL MODE

ADDRESS

(decimal) Display R

DESCRIPTION MNEM

JBus Mod

CODE

Bus

225 224 Load default data for group hidden

Range:

0 = No operation

1 = Load default

226 225 Load default data for group 1

Range:

0 = No operation

1 = Load default

228 227 Load default data for group 3

Range:

0 = No operation

1 = Load default

229 228 Load default data for group 4

Range:

0 = No operation

1 = Load default

Note:

The command is accepted only if “Smart”

(ModBus bit 221) is not active

230 229 Load default data for group 5

Range:

0 = No operation

1 = Load default

231 230 Load default data for group 6

Range:

0 = No operation

1 = Load default

232 231 Load default data for group 7

Range:

0 = No operation

1 = Load default

Note:

The new data will be activated after the device answer

233 232 Load default data for group 8

Range:

0 = No operation

1 = Load default

234 233 De-energized all 10 auxiliary outputs

Range:

0 = No operation

1 = De-energized relays

W

R

E

A

D

I

T

E

x

x

x

x

x

x

x

x

x

Page 34

Page 34/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

BITS FOR DEVICE IN CONTROL MODE

ADDRESS

(decimal) Display R

DESCRIPTION MNEM

JBus Mod

CODE

Bus

250 249 Unsolicited request flag for probe test data

Range:

0 = No change on probe test data

1 = The probe test is terminated and new

data are available

251 250 Unsolicited request flag group hidden

Range:

0 = No Parameters change is occurred

1 = Parameters change is occurred

Note:

Changes produced by serial link will not be

flaged. The bit resets after reading

252 251 Unsolicited request flag group 1

Note:

See “Unsolicited Request Flag Group Hidden”

253 252 Unsolicited request flag group 2

Range:

0 = No status change is occurred

1 = Status change is occurred

Note:

The information of group 2 are on Modbus

bits 211, 212, 221

254 253 Unsolicited request flag group 3

Note:

See “Unsolicited Request Flag Group Hidden”

255 254 Unsolicited request flag group 4

Note:

See “Unsolicited Request Flag Group Hidden”

256 255 Unsolicited request flag group 5

Note:

See “Unsolicited Request Flag Group Hidden”

257 256 Unsolicited request flag group 6

Note:

See “Unsolicited Request Flag Group Hidden”

258 257 Unsolicited request flag group 7

Note:

See “Unsolicited Request Flag Group Hidden”

259 258 Unsolicited request flag group 8

Note:

See “Unsolicited Request Flag Group Hidden”

260 259 Unsolicited request flag group 9

Range:

0 = No change on status of auxiliary output

10÷19

1 = One or more auxiliary output is changed

Note:

See “Unsolicited Request Flag Group Hidden”

W

R

E

A

D

I

T

E

x

x

x

x

x

x

x

x

x

x

x

Page 35

Page 35/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

BITS FOR DEVICE IN CONTROL MODE

ADDRESS

(decimal) LED R

DESCRIPTION MNEM

JBus Mod

CODE

Bus

301 300 Status auxiliary input 1

Range:

0 = Open

1 = Closed

302 301 Status auxiliary input 2

Range:

0 = Open

1 = Closed

303 302 Status auxiliary input 3

Range:

0 = Open

1 = Closed

304 303 Status auxiliary input 4

Range:

0 = Open

1 = Closed

305 304 Status auxiliary input 5

Range:

0 = Open

1 = Closed

306 305 Status auxiliary input 6

Range:

0 = Open

1 = Closed

307 306 Status auxiliary input 7

Range:

0 = Open

1 = Closed

308 307 Status auxiliary input 8

Range:

0 = Open

1 = Closed

(“IN1”) x

(“IN2”) x

(“IN3”) x

(“IN4”) x

(“IN5”) x

(“IN6”) x

(“IN7”) x

(“IN8”) x

W

R

E

A

D

I

T

E

Page 36

Page 36/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

BITS FOR DEVICE IN CONTROL MODE

ADDRESS

(decimal) Display R

DESCRIPTION MNEM

JBus Mod

CODE

Bus

311 310 Status auxiliary output 10

Range:

0 = OFF

1 = ON

312 311 Status auxiliary output 11

Range:

0 = OFF

1 = ON

313 312 Status auxiliary output 12

Range:

0 = OFF

1 = ON

314 313 Status auxiliary output 13

Range:

0 = OFF

1 = ON

315 314 Status auxiliary output 14

Range:

0 = OFF

1 = ON

316 315 Status auxiliary output 15

Range:

0 = OFF

1 = ON

317 316 Status auxiliary output 16

Range:

0 = OFF

1 = ON

318 317 Status auxiliary output 17

Range:

0 = OFF

1 = ON

319 318 Status auxiliary output 18

Range:

0 = OFF

1 = ON

320 319 Status auxiliary output 19

Range:

0 = OFF

1 = ON

(“OU.10”) x x

(“OU.11”) x x

(“OU.12”) x x

(“OU.13”) x x

(“OU.14”) x x

(“OU.15”) x x

(“OU.16”) x x

(“OU.17”) x x

(“OU.18”) x x

(“OU.19”) x x

W

R

E

A

D

I

T

E

Page 37

Page 37/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“Inpt.” - Menu Conf. 1 - MAIN/AUXILIARY INPUT CONFIGURATION

ADDRESS

(decimal) DEC. Display RWR

DESCRIPTION FIGU-

JBus Mod

Bus

2001 2000 Line frequency

Range:

0 = 50 Hz

1 = 60 Hz

2002 2001 Primary variable selection

Range:

0 = Carbon potential as primary control

variable (the span limits are 0.00

to 2.00)

1 = Dew point as primary control variable

(the span limits are -100 to 100°F or

-75 to 40°C)

2 = Sensor output in mV as primary

control variable (the span limits are 0

to 1500 mV)

2003 2002 Time constant for filter on probe sensor

RES

N.A. (“Ln.Fr”) x x

N.A. (“PV.SL”) x x

0 (“Pb.FL”) x x

MNEM

CODE

E

A

D

input (in seconds)

2004 2003 Input type and range value for

N.A. (“tP.In”) x x

temperature input

Range:

1 = TC K From -100 to 1370 °C

2 = TC S From - 50 to 1760 °C

3 = TC R From - 50 to 1760 °C

4 = TC K From -150 to 2500 °F

5 = TC S From - 60 to 3200 °F

6 = TC R From - 60 to 3200 °F

2005 2004 Temperature input offset adjustment

0 (“OFSt”) x x

(Value in Celsius or Fahrenheit as configured at Mbus word 2003)

2006 2005 Time constant for filter on temperature

0 (“tP.FL”) x x

value (in seconds)

2007 2006 Auxiliary input function for carbon mono-

N.A. (“CO.In”) x x

xide measurement

Range:

0 = Input not used

1 = Input used for CO measurement

2008 2007 Auxiliary input type

Range:

0 = 0÷20 mA

1 = 4÷20 mA

2 = 0÷5 V

3 = 1÷5 V

4 = 0÷10 V

5 = 2÷10 V

N.A. (“CO.tP”) x x

I

T

E

Page 38

Page 38/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“Out.” - Menu Conf. 2 - OUTPUT CONFIGURATION

ADDRESS

(Decimal) DEC. Display RWR

DESCRIPTION FIGU-

Jbus Mod

Bus

2101 2100 Out 1 function

Range:

0 = Output not used

1 = Time proportional main control output

2 = Time proportional secondary control

output

3 = Output used as alarm 1 output

2102 2101 Out 2 function

Range:

0 = Output not used

1 = Time proportional main control output

2 = Time proportional secondary control

output

3 = Output used as alarm 2 output

2103 2102 Out 3 function

Range:

0 = Output not used

1 = Time proportional main control output

2 = Time proportional secondary control

output

3 = Output used as alarm 3 output

2107 2106 Out 6 function

Range:

0 = Output not used

1 = Linear main control output

2 = Linear secondary control output

3 = Process variable retransmission

4 = Operative set point retransmission

2108 2107 Out 6 range

Range:

0 = 0 ÷ 20 mA

1 = 4 ÷ 20 mA

2109 2108 Retransmission low scale range value for

RES

N.A. ("O1.Fn") x x

N.A. ("O2.Fn") x x

N.A. ("O3.Fn") x x

N.A. ("O6.Fn") x x

N.A. ("O6.rn") x x

See Mbus

word 300

MNEM

CODE

E

A

D

(“O6.Lr”) x x

Out 6

2110 2109 Retransmission high scale range value

See Mbus

word 300

(“O6.Hr”) x x

for Out 6

2111 2110 Time constant for filter on Out 6 analog

0 (“O6.FL”) x x

retransmission value (in seconds)

I

T

E

Page 39

Page 39/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“Out.” - Menu Conf. 2 - OUTPUT CONFIGURATION

ADDRESS

(Decimal) DEC. Display RWR

DESCRIPTION FIGU-

Jbus Mod

Bus

2112 2111 Out 7 function

Range:

0 = Output not used

1 = Linear main control output

2 = Linear secondary control output

3 = Process variable retransmission

4 = Operative set point retransmission

2113 2112 Out 7 range

Range:

0 = 0 ÷ 20 mA

1 = 4 ÷ 20 mA

2114 2113 Retransmission low scale range value for

RES

N.A. (“O7.Fn”) x x

N.A. (“O7.rn”) x x

See Mbus

word 300

MNEM

CODE

E

A

D

(“O7.Lr”) x x

Out 7

2115 2114 Retransmission high scale range value

See Mbus

word 300

(“O7.Hr”) x x

for Out 7

2116 2115 Time constant for filter on Out 7 analog

0 (“O7.FL”) x x

retransmission value (in seconds)

I

T

E

Page 40

Page 40/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“C.Cn.” - Menu Conf. 3 - CONTROL OUTPUT CONFIGURATION

ADDRESS

(Decimal) DEC. Display RWR

DESCRIPTION FIGU-

Jbus Mod

Bus

2206 2205 Main control output conditioning

Range

0 = The control output is calculated by the

PID

1 = The control output is complemented

(100-PID calculated value)

2207 2206 Main control output scaleable for display

RES

N.A. (“ñC.Cn”) x x

N.A. (“ñ.SCL”) x x

MNEM

CODE

E

A

D

in eng. unit

Range:

0 = Scaleable is not required

1 = Scaleable is required

2208 2207 Decimal point position for main control

N.A. (“ñC.dP”) x x

output display in eng. unit

Range:

0 = No decimal figure

1 = One decimal figure

2 = Two decimal figure

2209 2208 Low scale range value for main control

output display in eng. unit

2210 2209 High scale range value for main control

output display in eng. unit

2211 2210 Main control output auxiliary conditioning

Range:

0 = The functions described in the note

are applied “Before” of the “Main

control output conditioning” stage

1 = The functions described in the note

are applied “After” of the “Main control

output conditioning” stage

Note:

a - Control output limiter

b - Control output max rate of rise

c - Control output display value

2212 2211 Secondary control output conditioning

Note:

See “Main control output conditioning”

2213 2212 Secondary control output scaleable for

See Mbus

word 301

or 2207

See Mbus

word 301

or 2207

N.A.

(“ñC.E.L.”)

(“ñC.E.H.”)

(“ñC.A.C.”)

x x

x x

x x

N.A. (“SC.Cn.”) x x

N.A. (“S.SCL”) x x

display in eng. unit

Range:

0 = Scaleable is not required

1 = Scaleable is required

I

T

E

Page 41

Page 41/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE – PARAMETERS

“C.Cn.” – Menu Conf. 3 – CONTROL OUTPUT CONFIGURATION

ADDRESS

(Decimal) DEC. Display RWR

DESCRIPTION FIGU-

Jbus Mod

Bus

2214 2213 Decimal point position for secondary

RES

N.A. (“SC.dP”) x x

MNEM

CODE

E

A

D

control output display in eng. Unit

Range:

0 = No decimal figure

1 = One decimal figure

2 = Two decimal figure

2215 2214 Low scale range value for secondary

control output display in eng. unit

2216 2215 High scale range value for secondary

control output display in eng. unit

2217 2216 Secondary control output auxiliary condi-

See Mbus

word 302

or 2213

See Mbus

word 302

or 2213

(“SC.E.L.”) x x

(“SC.E.H”) x x

N.A. (“SC.A.C”) x x

tioning

0 = The functions described in the note

are applied “Before” of the “Secondary

control output conditioning” stage

1 = The functions described in the note

are applied “After” of the “Secondary

control output conditioning” stage

Note:

a - Control output limiter

b - Control output max rate of rise

c - Control output display value

I

T

E

Page 42

Page 42/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“AC.Cn.” - Menu conf. 4 - AUXILIARY CONTROL OUTPUT CONFIGURATION

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

2301 2300 Smart function

Range

0 = Smart function disable

1 = Smart function may be enabled

2302 2301 Control action type

Range

0 = The process is controlled by PID

actions

1 = The process is controlled by PI actions

2303 2302 Manual function

Range

0 = Manual function disabled

1 = Manual function enabled

2304 2303 Output value for transfer from auto to

N.A. (“Sñ.Fn”) x x

N.A. (“Cn.tP”) x x

N.A. (“ñAn.F”) x x

1 (“Añ.UL”) x x

manual

Note:

The value 7FFFh means that the transfer

from auto to manual is bumpless

2305 2304 Manual/auto transfer type

Range

0 = Bumpless balance transfer

1 = Bumpless balanceless transfer

2306 2305 Device status at start up

Range

0 = It starts always in auto mode

1 = It starts always in manual mode with

power output set to 0

2 = It starts in the same way it was left

prior to power shut down (if in manual

mode the power output is set to 0)

3 = It starts in the same way it was left

prior to power shut down (if in manual

mode the power output will be the last

value prior to power shut down)

N.A. (“ñ.A.t.t”) x x

N.A. (“St.Fn”) x x

W

R

E

A

D

I

T

E

Page 43

Page 43/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“In.Ot.” - Menu conf. 5 - DIGITAL INPUT/OUTPUT CONFIGURATION

ADDRESS

(decimal) DEC. Display R

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

2401 2400 External contact “DIG1” function

Range:

0 = Input contact not used

1 = Input contact used for SP/SP2

auxiliary set point selection

2 = Input contact used for SP3/SP4

auxiliary set point selection

3 = Input contact used for Auto/Manual

selection

4 = Input contact used for output limiter

activation

5 = Input contact used to reset

(acknowledge) alarm

2402 2401 External contact “DIG1” logic level

Range:

0 = The input is at logic level “1” when

contact is open

1 = The input is at logic level “1” when

contact is closed

2403 2402 External contact “DIG2” function

Note:

See “External contact “DIG1” function”

2404 2403 External contact “DIG2” logic level

Note:

See “External contact “DIG1” logic level“

2406 2405 External contact “DIG3” logic level

Note:

See “External contact “DIG1” logic level“

N.A. (“d1.Fn”) x x

N.A. (“d1.St”) x x

N.A. (“d2.Fn”) x x

N.A. (“d2.St”) x x

N.A. (“d3.St”) x x

W

R

E

A

D

I

T

E

Page 44

Page 44/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - PARAMETERS

“Othr.” - Menu conf. 6 - OTHER CONFIGURATION PARAMETER

ADDRESS

(decimal) DEC. Display RWR

JBus Mod

DESCRIPTION FIGU-

RES

MNEM

CODE

Bus

2501 2500 Green bar-graph selection

Range:

0 = On bar-graph the process variable

value is shown

1 = On bar-graph the deviation error is

shown

2502 2501 Orange bar-graph selection

Range:

0 = On bar-graph the operative set-point

value is shown

1 = On bar-graph the process output value

is shown

2503 2502 Bar-graph low scale range value

2504 2503 Bar-graph high scale range value

2505 2504 Deviation bar-graph resolution

Range:

0 = 1 digit per segment

1 = 2 digits per segment

2 = 5 digits per segment

3 = 10 digits per segment

4 = 20 digits per segment

5 = 50 digits per segment

2507 2506 Set point display type

Range:

0 = the final set point will be shown

1 = the operative set point will be shown

2508 2507 Temperature threshold activation

Range:

0 = NO

1 = YES

2510 2509 Time-out selection

Range:

0 = 10 seconds time-out

1 = 30 seconds time-out

N.A. (“G.brG”) x x

N.A. (“O.brG”) x x

See Mbus

word 300

See Mbus

word 300

(“brG.L”) x x

(“brG.H”) x x

N.A. (“brG.d”) x x

N.A. (“SP.dS”) x x

N.A. (“t.t.Ac) x x

N.A. (“t.out”) x x

E

I

A

T

D

E

Page 45

Page 45/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN CONFIGURATION MODE - NON PARAMETERS

ADDRESS

(decimal) DEC. Display RWR

DESCRIPTION FIGU-

JBus Mod

Bus

3001 3000 The end of configuration menu 1

Range:

1 = end of configuration menu 1

3002 3001 The end of configuration menu 2

Range:

1 = end of configuration menu 2

3003 3002 The end of configuration menu 3

Range:

1 = end of configuration menu 3

3004 3003 The end of configuration menu 4

Range:

1 = end of configuration menu 4

3005 3004 The end of configuration menu 5

Range:

1 = end of configuration menu 5

3006 3005 The end of configuration menu 6

Range:

1 = end of configuration menu 6

3051 3050 Load default configuration value

Range:

1 = Load default TB1=European table

2 = Load default TB2=American table

3052 3051 Enable control mode

Range:

1 = Enable control mode

RES

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

N.A. x

N.A. (TB1/TB2) x

N.A. x

MNEM

CODE

E

A

D

I

T

E

Page 46

Page 46/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN SECURITY CODE MODE

ADDRESS

(decimal) DEC. Display RWR

DESCRIPTION FIGU-

JBus Mod

Bus

4001 4000 Safety lock combination for configuration

RES

MNEM

CODE

E

A

D

x x

mode

Range :

Reading: 0 = No parameters protection

1 = Parameters always

protected

2 = Parameters protected by

software key

Writing: 0-250

4002 4001 Safety lock combination for control mode

Range :

Reading: 0 = No parameters protection

1 = Parameters always

protected

2 = Parameters protected by

software key

Writing: 0-250

4003 4002 Group hidden protected

Range :

0 = Group non protected

1 = Group protected

4004 4003 Group 1 protected

Range :

0 = Group non protected

1 = Group protected

4005 4004 Group 2 protected

Range :

0 = Group non protected

1 = Group protected

4006 4005 Group 3 protected

Range :

0 = Group non protected

1 = Group protected

4007 4006 Group 4 protected

Range :

0 = Group non protected

1 = Group protected

4008 4007 Group 5 protected

Range :

0 = Group non protected

1 = Group protected

4009 4008 Group 6 protected

Range :

0 = Group non protected

1 = Group protected

4010 4009 Group 7 protected

Range :

0 = Group non protected

1 = Group protected

x x

x x

x x

x x

x x

x x

x x

x x

x x

I

T

E

Page 47

Page 47/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

WORDS FOR DEVICE IN SECURITY CODE MODE

ADDRESS

(decimal) DEC. Display RWR

DESCRIPTION FIGU-

JBus Mod

Bus

4011 4010 Group 8 protected

Range :

0 = Group non protected

1 = Group protected

4012 4011 Group 9 protected

Range :

0 = Group non protected

1 = Group protected

RES

MNEM

CODE

E

A

D

x x

x x

I

T

E

Page 48

Page 48/59

TITLE: MODBUS/J-BUS Protocol for SSi’s- AC20 ENG. 824E REV. 1

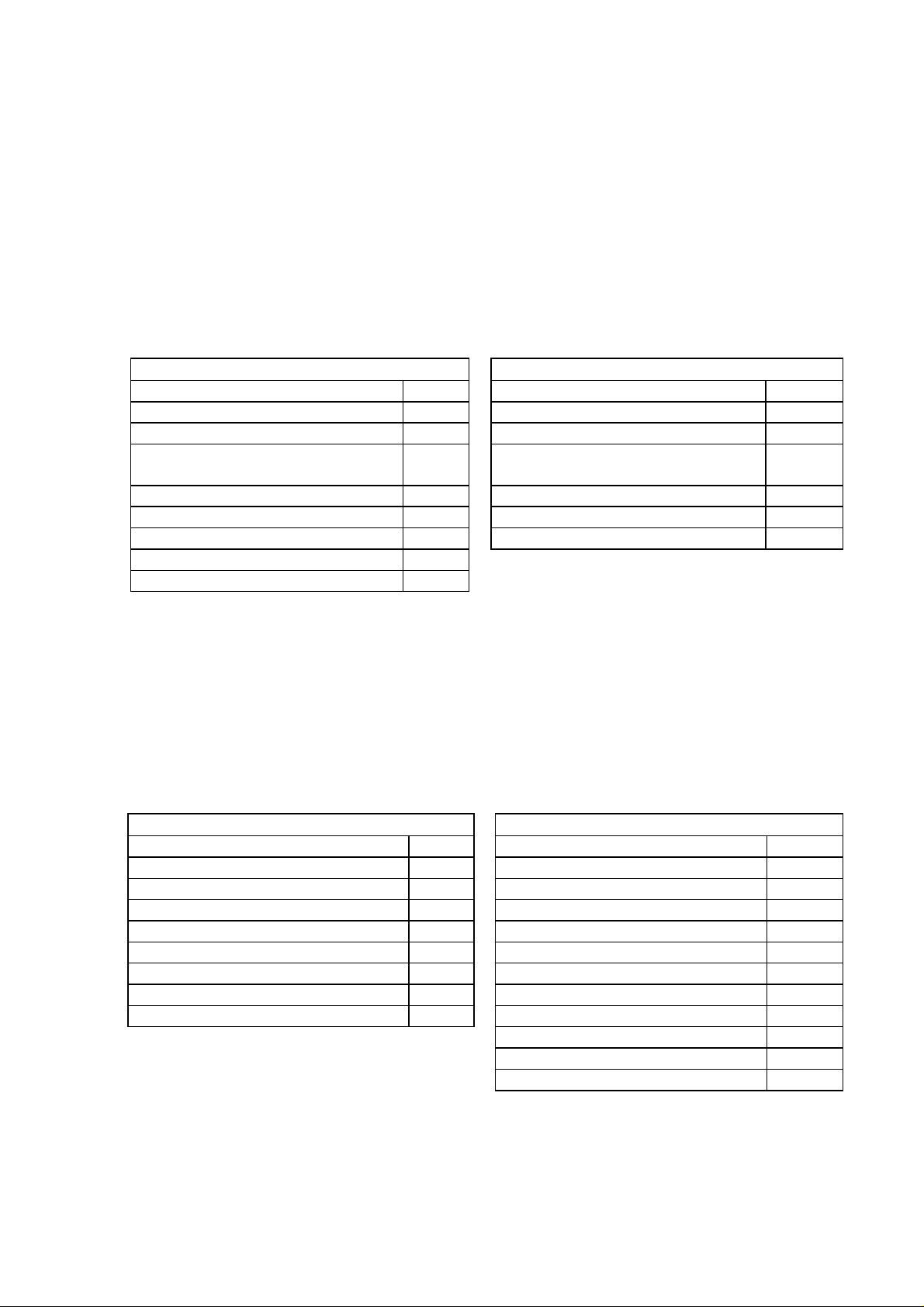

INDEX, DIVIDED IN FAMILIES AND GROUPS, OF MODBUS WORDS

Words For Device In Control Mode - Parameters

Menu group 1 – Set point values

138 - Main set point ("SP") page 18

139 - Auxiliary set point 2 (“SP2”) page 18

140 - Auxiliary set point 3 (“SP3”) page 18

141 - Auxiliary set point 4 (“SP4”) page 18

142 - Carbon monoxide factor ("COF") page 18

143 - Hydrogen factor ("H2F") page 18

Menu group 3 - Alarm threshold and hysteresis value

177 - Alarm 1 threshold ("AL1") page 18

178 - Alarm 2 threshold ("AL2") page 18

179 - Alarm 3 threshold ("AL3") page 18

181 - Band alarm 1 threshold low ("bA1.L") page 18

182 - Band alarm 1 threshold high ("bA1.h") page 18

183 - Band alarm 2 threshold low ("bA2.L") page 18

184 - Band alarm 2 threshold high ("bA2.h") page 18

185 - Band alarm 3 threshold low ("bA3.L") page 18

186 - Band alarm 3 threshold high ("bA3.h") page 18

191 - Alarm 1 hysteresis ("HSA1") page 18

192 - Alarm 2 hysteresis ("HSA2") page 18

193 - Alarm 3 hysteresis ("HSA3") page 18

Menu group 4 - Control parameters

148 - Proportional band ("Pb") page 19

149 - Hysteresis for on/off control mode ("HYS") page 19

150 - Integral time ("ti") page 19

151 - Derivative time ("td") page 19

152 - Integral pre-load ("IP") page 19

153 - Relative secondary output gain ("r.Gn") page 19

154 - Dead band/overlap between main/secondary output ("OLAP") page 19

Menu group 5 - Auxiliary control parameters

1000 - Anti-reset windup ("ArU") page 20

1003 - Main control output low limit ("ñ.OLL") page 20

1004 - Main control output high limit ("ñ.OLH") page 20

1005 - Main control output max rate of rise ("ñ.rñP") page 20

1006 - Proportional cycle time on main control output ("ñC.CY") page 20

1007 - Secondary control output low limit ("S.OLL") page 20

1008 - Secondary control output high limit ("S.OLH") page 20

1009 - Secondary control output max rate of rise ("S.rñP") page 20