Page 1

Super Systems

Instruction Manual

Model AC20

Part No. 31069 - Standard Atmosphere Controller

with expanded event capability

August 2004

Page 2

INDEXINDEX

INDEX

INDEXINDEX

MOUNTING REQUIREMENTS ..................................................... 1

OUTLINE AND CUT OUT DIMENSIONS ...................................... 2

CONNECTION DIAGRAMS ......................................................... 3

PRELIMINARY HARDWARE SETTINGS .................................... 14

SECURITY CODE SETTING MODE ........................................... 17

RUN TIME AND CONFIGURATION MODES .............................. 20

General notes about graphic symbols ............................. 20

Keyboard description ....................................................... 20

CONFIGURATIO N MODE.......................................................... 22

RUN TIME MODE ...................................................................... 44

Display function ................................................................ 44

Indicators.......................................................................... 46

Bargraph description ........................................................ 48

Direct access to the set point........................................... 49

Manual function ................................................................ 49

Special output features ..................................................... 50

Burn off procedure ............................................................51

Probe test procedure........................................................ 53

Serial link ......................................................................... 54

Lamp test ......................................................................... 55

SMART function................................................................ 55

COF and H2F adjustment diagram .................................... 57

Parameter protection ........................................................ 58

RUN TIME PARAMETER MODIFICATION ...................................58

ERROR MESSAGES ................................................................. 83

GENERAL INFORMATION ......................................................... 85

MAINTENANCE ......................................................................... 93

DEFAULT PARAMETERS ........................................................ A.1

ALGORITHMS........................................................................ B.1

CALIBRATION PROCEDURE................................................... B.1

Page 3

MOUNTING REQUIREMENTSMOUNTING REQUIREMENTS

MOUNTING REQUIREMENTS

MOUNTING REQUIREMENTSMOUNTING REQUIREMENTS

This instrument is intended for permanent installation, for indoor

use only, in an electrical panel which encloses the rear housing,

exposed terminals and wiring on the back.

Select a location, for instrument mounting, where minimum

vibrations are present and the ambient temperature is within 0

and 50 °C (32 and 122°F).

The instrument can be mounted on a panel up to 15 mm thick

with a cutout 92 x 92.

For outline and cutout dimensions refer to Fig. 2.

The surface texture of the panel must be better than 6,3 µm.

The instrument is shipped with rubber panel gasket (50 to

60 Sh).

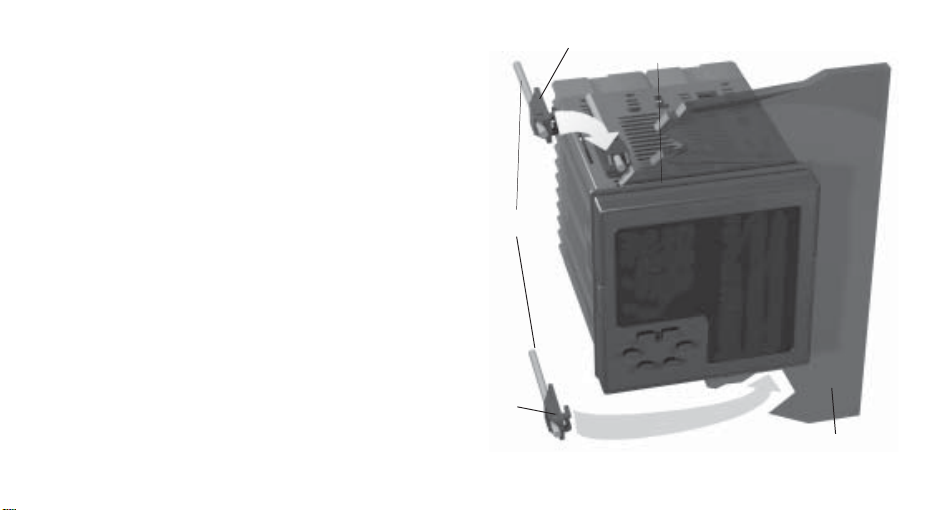

To assure the IP65 and NEMA 4X protection, insert the panel

gasket between the instrument and the panel as shown in

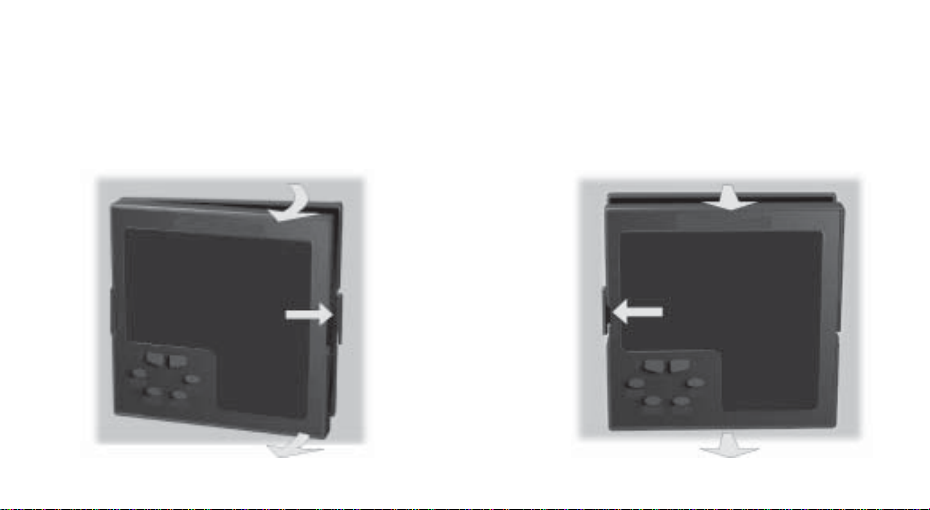

fig. 1.

While holding the instrument against the panel proceed as

follows:

1) insert the gasket in the instrument case;

2) insert the instrument in the panel cutout;

3) pushing the instrument against the panel;

4) insert the mounting brackets as shown in fig.1;

5) with a screwdriver, turn the screws with a torque between

0.3 and 0.4 Nm.

Screws

Bracket

Fig. 1

1

Bracket

Gasket

Panel

Page 4

OUTLINE AND CUT OUT DIMENSIONSOUTLINE AND CUT OUT DIMENSIONS

"

OUTLINE AND CUT OUT DIMENSIONS

OUTLINE AND CUT OUT DIMENSIONSOUTLINE AND CUT OUT DIMENSIONS

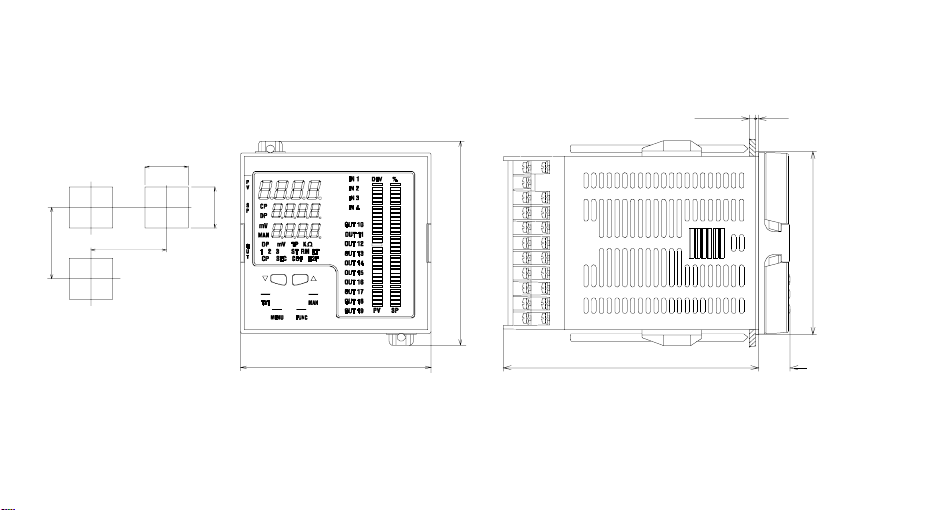

+0.03 +0.8

3.62" (92 mm )

+0.03

+0.8

3.62"

(92 mm )

(125 mm)

4.92"

(125 mm)

4.92

Fig. 2. OUTLINE AND CUT-OUT DIMENSIONS

3.78" (96 mm)

0.6" (15mm) max

4.17" (108.5 mm)

5" (128 mm)

0.06" (1.5 mm)

3.8" x 3.8" (97 x 97 mm) gasket

0.63"

(16 mm)

2

Page 5

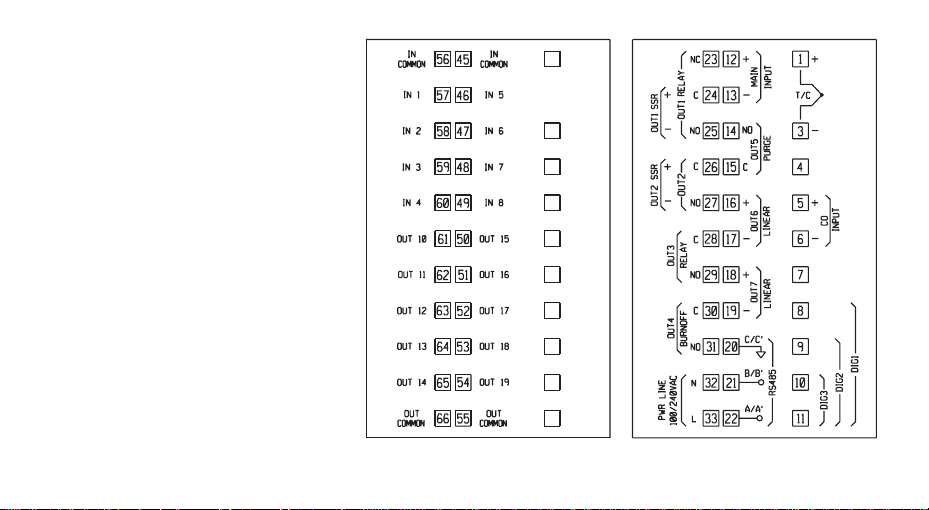

CONNECTION DIAGRAMSCONNECTION DIAGRAMS

CONNECTION DIAGRAMS

CONNECTION DIAGRAMSCONNECTION DIAGRAMS

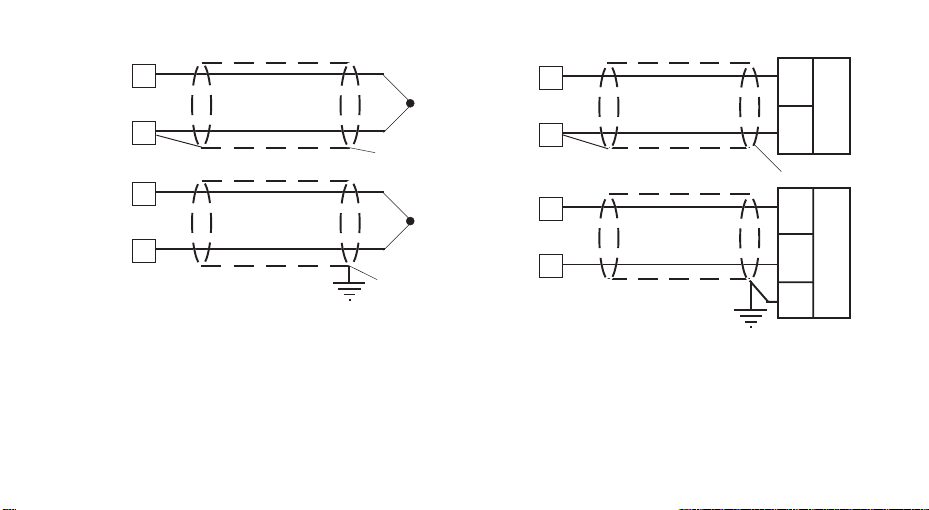

Fig. 3. REAR TERMINAL BLOCK

3

Page 6

CONNECTIONSCONNECTIONS

CONNECTIONS

CONNECTIONSCONNECTIONS

Connections are to be made when the instrument housing is

installed in its proper location.

A) PROBE SENSOR INPUT (MAIN INPUT)A) PROBE SENSOR INPUT (MAIN INPUT)

A) PROBE SENSOR INPUT (MAIN INPUT)

A) PROBE SENSOR INPUT (MAIN INPUT)A) PROBE SENSOR INPUT (MAIN INPUT)

12

13

+

_

Shield

Sensor

MEASURING INPUTSMEASURING INPUTS

MEASURING INPUTS

MEASURING INPUTSMEASURING INPUTS

NOTENOTE

NOTE: Any external component (like zener barriers etc.)

NOTENOTE

connected between sensor and input terminals may cause errors

in measurement due to excessive and/or not balanced line

resistance or possible leakage currents.

12

13

+

_

G

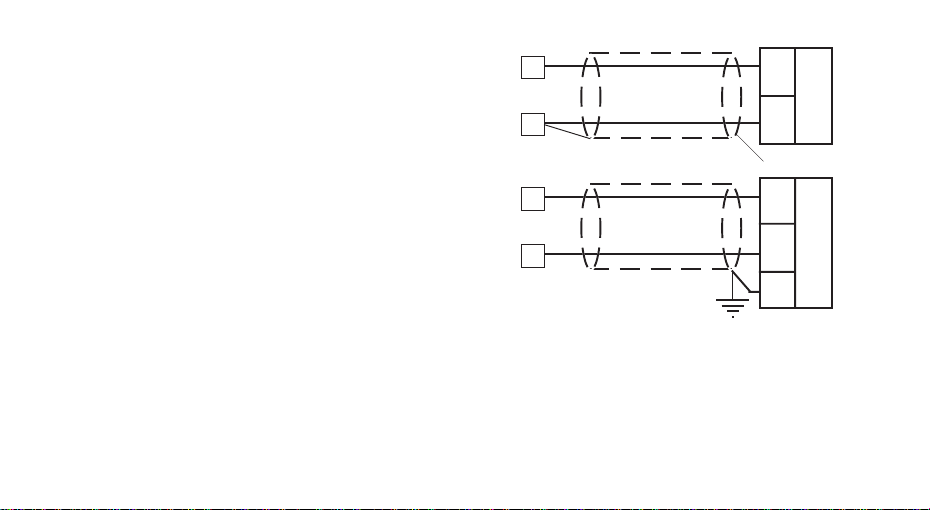

Fig. 4 MAIN INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is isolated from others measuring inputs

and digital inputs.

2) Don’t run input wires together with power cables.

3) When a shielded cable is used, it should be connected at

one point only.

4

Sensor

Page 7

A.1) TEMPERATURE (THERMOCOUPLE) INPUTA.1) TEMPERATURE (THERMOCOUPLE) INPUT

A.1) TEMPERATURE (THERMOCOUPLE) INPUT

A.1) TEMPERATURE (THERMOCOUPLE) INPUTA.1) TEMPERATURE (THERMOCOUPLE) INPUT

1

+

_

3

Shield

1

+

_

3

Shield

Fig. 5 TEMPERATURE INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is not isolated from others measuring inputs

and digital inputs.

2) Don’t run input wires together with power cables.

3) For TC wiring use proper compensating cable preferable

shielded.

4) When a shielded cable is used, it should be connected at

one point only.

A.2) AUXILIARY INPUT (CARBON MONOXIDE)A.2) AUXILIARY INPUT (CARBON MONOXIDE)

A.2) AUXILIARY INPUT (CARBON MONOXIDE)

A.2) AUXILIARY INPUT (CARBON MONOXIDE)A.2) AUXILIARY INPUT (CARBON MONOXIDE)

5

6

Shield

5

6

Fig. 6 AUXILIARY INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is not isolated from others measuring inputs

and digital inputs. A double or reinforced insulation between

instrument output and power supply must be assured by the

external instrument.

5

+

mA,

or

_

V

+

mA

or

_

V

G

Page 8

2) Don’t run input wires together with power cables.

3) Pay attention to the line resistance; a high line resistance

may cause measurement errors.

4) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

5) The input impedance is equal to:

< 5 Ω for 20 mA input

> 200 kΩ for 5 V input

> 400 kΩ for 10 V input

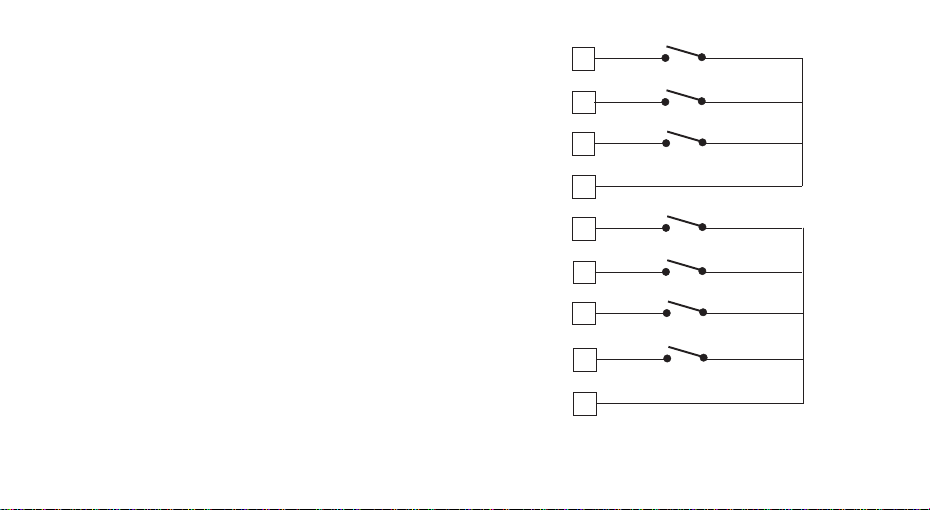

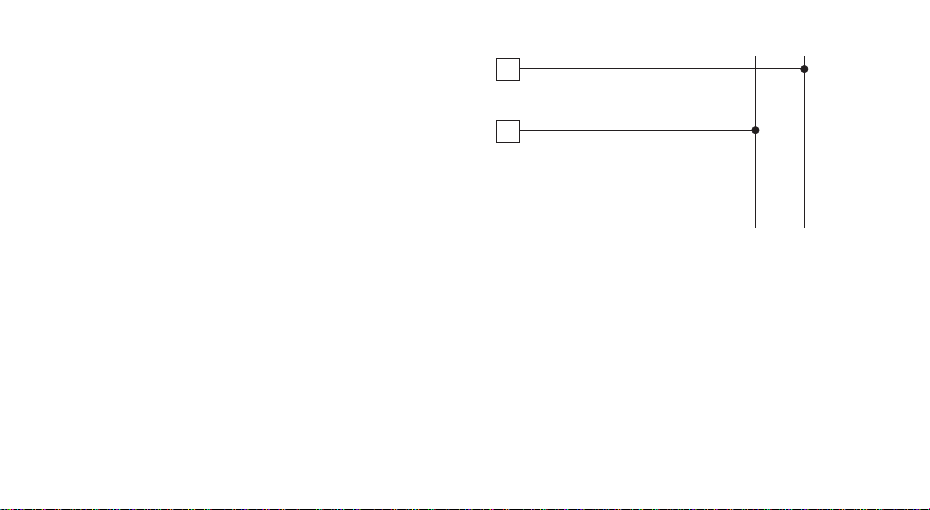

B) LOGIC INPUTSB) LOGIC INPUTS

B) LOGIC INPUTS

B) LOGIC INPUTSB) LOGIC INPUTS

DIG. 1

8

DIG. 2

9

DIG. 3

10

11

IN 1

57

IN 2

58

IN 3

59

IN 4

60

56

Fig. 7.A - LOGIC INPUTS DIG 1 TO DIG 3 AND IN1 TO IN4

WIRING

6

Page 9

IN 5

46

IN 6

47

IN 7

48

IN 8

49

45

Fig. 7.B - LOGIC INPUTS IN5 TO IN8 WIRING

Logic inputs from IN1 to In8 are optional.

NOTESNOTES

NOTES:

NOTESNOTES

1) Do not run logic input wiring together with power cables.

2) Use an external dry contact capable of switching 0.5 mA,

5 V DC.

3) The instrument needs 110 ms to recognize a contact status

variation.

4) The logic inputs are

NOT NOT

NOT isolated from measuring inputs.

NOT NOT

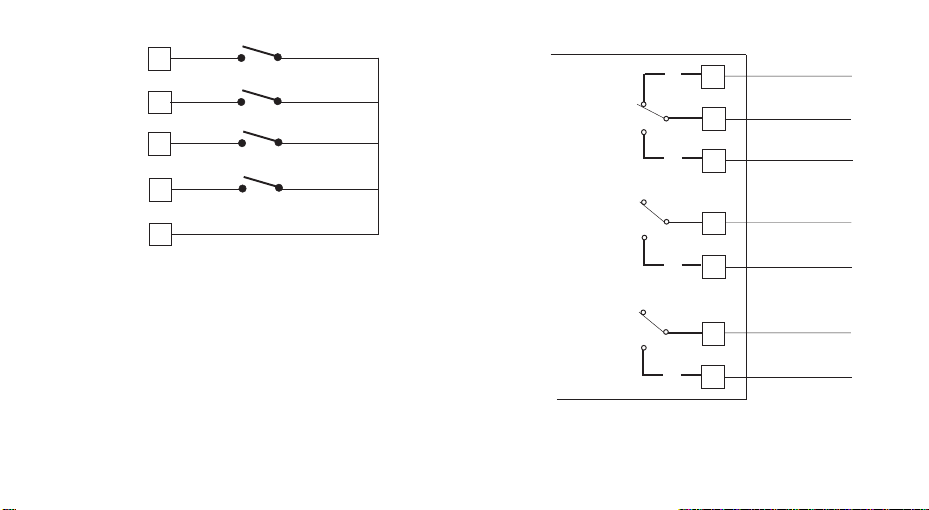

C.1) RELAY OUTPUTSC.1) RELAY OUTPUTS

C.1) RELAY OUTPUTS

C.1) RELAY OUTPUTSC.1) RELAY OUTPUTS

OUT 1

OUT 2

OUT 3

Fig. 8.A RELAY OUTPUTS 1, 2, 3 WIRING

7

23

24

25

26

27

28

29

NC

C

NO

C

NO

C

NO

Page 10

OUT 4

30

31

OUT 5

15

14

OUT 10

OUT 11

OUT 12

OUT 13

OUT 14

61

62

63

64

65

66

Fig. 8.B RELAY OUTPUTS 4, 5 and 10 TO 14 WIRING

C

NO

C

NO

NO - OUT 10

NO - OUT 11

NO - OUT 12

NO - OUT 13

NO - OUT 14

C - OUT 10 to 14

NO - OUT 15

OUT 15

OUT 16

OUT 17

OUT 18

OUT 19

Fig. 8.C RELAY OUTPUTS 15 TO 19 WIRING

Outputs from OUT 10 to OUT 19 are optional.

The contact rating from OUT 1 and OUT 2 is 3A/250V AC on

resistive load.

The contact rating from OUT 3 and OUT 4 is 2A/250V AC on

resistive load.

The contact rating of OUT 5 is 1A/250V AC on resistive load.

The contact rating from OUT 10 to OUT 19 is 0.5 A/250V AC on

resistive load.

The number of operations is 1 x 105 at specified rating.

8

50

NO - OUT 16

51

NO - OUT 17

52

NO - OUT 18

53

NO - OUT 19

54

C - OUT 15 to 19

55

Page 11

NOTES:NOTES:

NOTES: 1) To avoid electrical shock, connect

NOTES:NOTES:

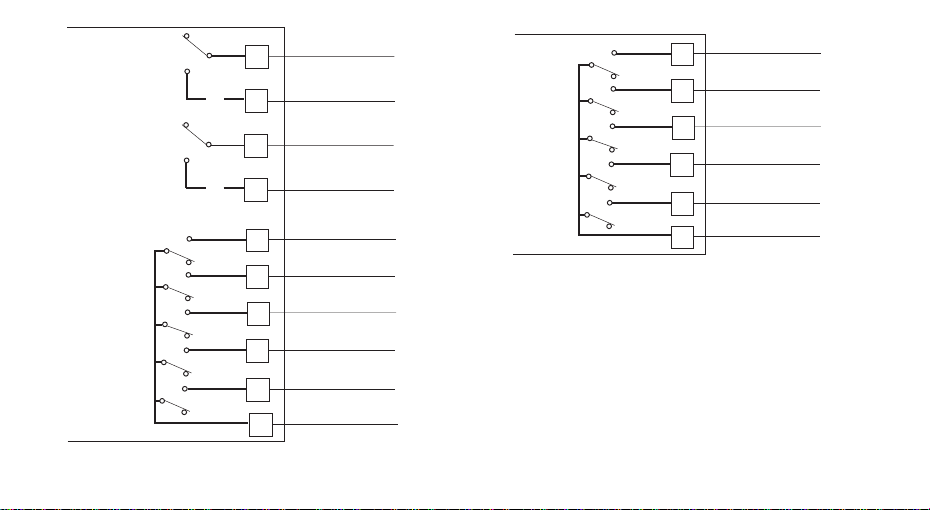

All relay contacts are protected by varistor against inductive load

with inductive component up to 0.5 A.

The following recommendations avoid serious problems which

may occur, when relay output drives inductive loads.

INDUCTIVE LOADSINDUCTIVE LOADS

INDUCTIVE LOADS

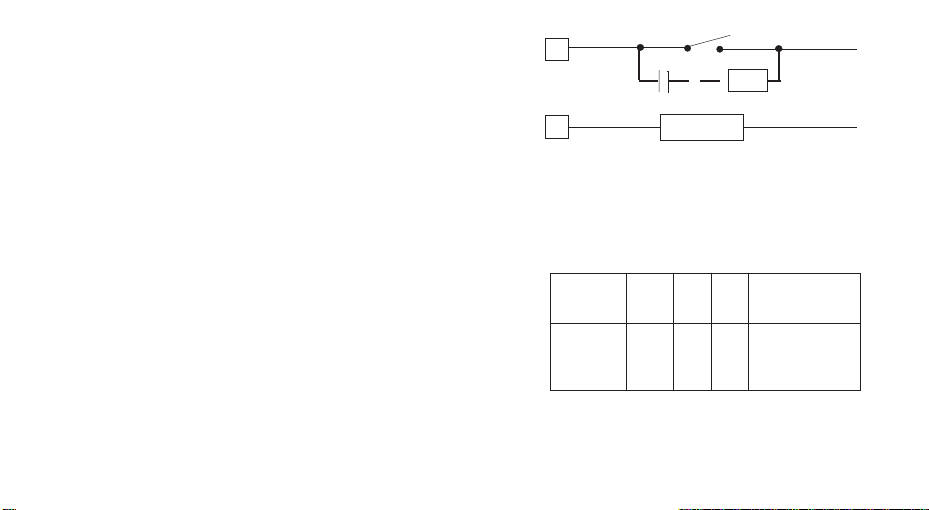

INDUCTIVE LOADSINDUCTIVE LOADS

High voltage transients may occur switching inductive loads.

Through the internal contacts these transients may introduce

disturbances which can affect the performance of the instrument.

For all the outputs, the internal protection (varistor) assures a

correct protection up to 0.5 A of inductive component.

The same problem may occur when a switch is used in series

with the internal contacts as shown in Fig. 9.

power line at the end of the wiring procedure.

2) For power connections use No 16 AWG or larger wires

rated for at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

5) When a relay output is used to drive a low power

signal (PLC input, alarm annunciator, etc..) it is

necessary to use an external relay with a gilded

contact.

C

R

LOAD

Fig. 9 EXTERNAL SWITCH IN SERIES WITH THE INTERNAL

CONTACT

In this case it is recommended to install an additional RC

network across the external contact as show in Fig. 9.

The value of capacitor (C) and resistor (R) are shown in the

following table.

LOAD

(mA)

<40 mA

<150 mA

<0.5 A

Anyway the cable involved in relay output wiring must be as far

away as possible from input or communication cables.

9

C

(µF)

0.047

0.1

0.33

(Ω)

100

22

47

R

P.

OPERATING

(W)

VOLTAGE

1/2

260 V AC

2

260 V AC

2

260 V AC

LINE

Page 12

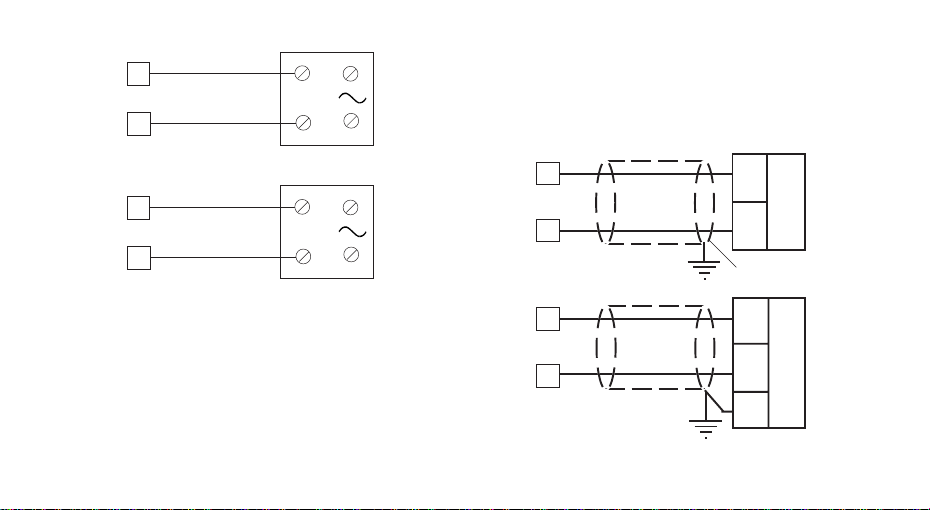

C.2) VOLTAGE OUTPUTS FOR SSR DRIVEC.2) VOLTAGE OUTPUTS FOR SSR DRIVE

C.2) VOLTAGE OUTPUTS FOR SSR DRIVE

C.2) VOLTAGE OUTPUTS FOR SSR DRIVEC.2) VOLTAGE OUTPUTS FOR SSR DRIVE

+

OUT 1

24

_

+

__

_

__

25

SOLID STATE

RELAY

+

OUT 2

26

_

+

__

_

__

27

SOLID STATE

RELAY

Fig. 10 SSR DRIVE OUTPUT WIRING

Logic level 0Logic level 0

Logic level 0: Vout < 0.5 V DC.

Logic level 0Logic level 0

Logic level 1Logic level 1

Logic level 1:

Logic level 1Logic level 1

- 14 V

+ 20 % @ 20 mA

- 24 V

+ 20 % @ 1 mA.

Maximum current = 20 mA

NOTENOTE

NOTE: These outputs are not insulated.

NOTENOTE

A double or reinforced insulation between instrument output and

power supply must be assured by the external solid state relay.

C.3) ANALOG OUTPUTSC.3) ANALOG OUTPUTS

C.3) ANALOG OUTPUTS

C.3) ANALOG OUTPUTSC.3) ANALOG OUTPUTS

+

OUT 6

16

_

17

+

20 mA

_

Shield

+

16

OUT 6

_

17

Fig. 11.A OUTPUT 6 WIRING

10

+

_

20 mA

G

Page 13

+

OUT 7

18

_

19

+

_

20 mA20 mA

Shield

+

18

OUT 7

_

19

Fig. 11.B OUTPUT 7 WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Do not run analog output wires together with AC power

cables.

2) Out 6 and 7 are isolated outputs.

3) The maximum load is equal to 600 Ω.

+

_

G

D) SERIAL INTERFACED) SERIAL INTERFACE

D) SERIAL INTERFACE

D) SERIAL INTERFACED) SERIAL INTERFACE

RS-485 interface allows you to connect up to 30 devices with

one remote master unit.

I

N

S

T

R

U

M

E

N

T

Fig. 12 - RS-485 WIRING

The cable length must not exceed 1.5 km at 9600 BAUD.

NOTESNOTES

NOTES:

NOTESNOTES

1) This is an isolated RS 485 serial interface.

2) The following report describes the signal sense of the voltage

appearing across the interconnection cable as defined by

EIA for RS-485.

a) The ” A ” terminal of the generator shall be negative with

respect to the ” B ” terminal for a binary 1 (MARK or OFF)

state.

11

22

21

20

A/A'

B/B'

COMMON

A'/A

B'/B

M

A

S

T

E

R

Page 14

b) The ” A ” terminal of the generator shall be positive with

respect to the ” B ” terminal for a binary 0 (SPACE or ON).

3) The EIA standard establishes that by RS-485 interface it is possible

to connect up to 30 devices with one remote master unit.

The serial interface of these instruments is based on “High

input impedance” transceivers; this solution allows you to

connect up to 127 devices (based on the same transceiver

type) with one remote master unit.

E) POWER LINE WIRINGE) POWER LINE WIRING

E) POWER LINE WIRING

E) POWER LINE WIRINGE) POWER LINE WIRING

N (L2)

32

POWER LINE 100 V to

240 V A.C (50/60Hz)

33

L (L1)

Line

Fig. 13 POWER LINE WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Before connecting the instrument to the power line, make

sure that line voltage corresponds to the description on the

identification label.

2) To avoid electrical shock, connect power line at the end of

the wiring procedure.

3) For supply connections use No 16 AWG or larger wires rated

for at last 75 °C.

12

Neutral

Page 15

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) The power supply input is fuse protected by a sub miniature

fuse rated T, 1A, 250 V.

When fuse is damaged, it is advisable to verify the power

supply circuit, so that it is necessary to send back the

instrument to your supplier.

7) The safety requirements for Permanently Connected

Equipment say:

- a switch or circuit-breaker shall be included in the building

installation;

- it shall be in close proximity to the equipment and within

easy reach of the operator;

- it shall be marked as the disconnecting device for the

equipment.

NOTENOTE

NOTE: a single switch or circuit-breaker can drive more than

NOTENOTE

one instrument.

8) When a neutral line is present please connect it to the 32

terminal.

13

Page 16

PRELIMINARY HARDWARE SETTINGSPRELIMINARY HARDWARE SETTINGS

PRELIMINARY HARDWARE SETTINGS

PRELIMINARY HARDWARE SETTINGSPRELIMINARY HARDWARE SETTINGS

How to remove the instrument from its caseHow to remove the instrument from its case

How to remove the instrument from its case

How to remove the instrument from its caseHow to remove the instrument from its case

1) Switch off the instrument.

2) Push gently the lock A on the right.

3) While the lock A is maintained out, slide out the right side of

the instrument (see fig. 14.a)

B

4) Push gently the lock C on the left.

5) While the lock C is maintained out, slide out the instrument

(see fig. 14.b)

D

Fig. 14.a

A

B

Fig. 14.b

14

C

D

Page 17

J103 SETTINGJ103 SETTING

J103 SETTING

J103 SETTINGJ103 SETTING

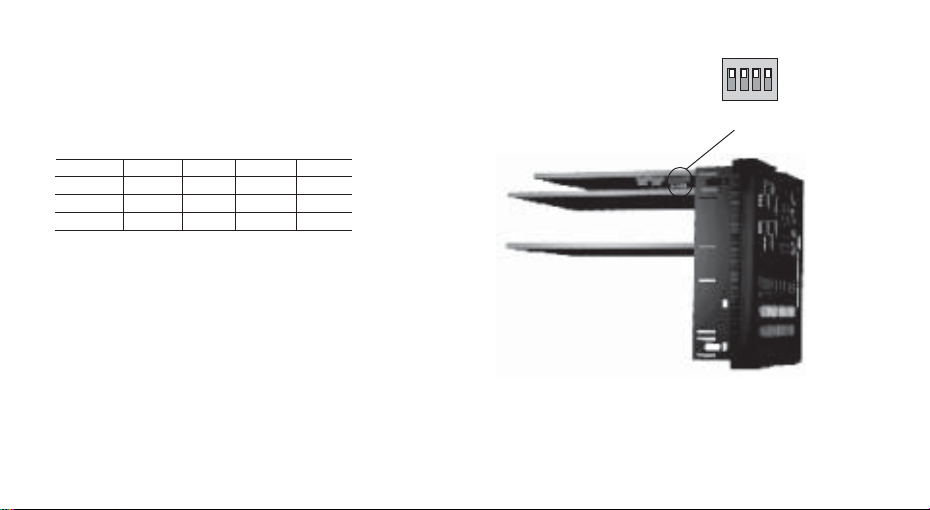

J103 (see fig. 15) must be set as follows:

J103

1-2 open

3-4 open

5-6 open

7-8 open

5-7 close

6-8 close

AUXILIARY INPUT SELECTIONAUXILIARY INPUT SELECTION

AUXILIARY INPUT SELECTION

AUXILIARY INPUT SELECTIONAUXILIARY INPUT SELECTION

Set J102 (see fig. 15) according to the desired input type as

shown in the following table.

J102 INPUT TYPE

5 V 10 V 20 mA

1-2 close open open

3-4 close close open

5-6 open open close

7-8 open open close

5-7 open close open

6-8 open open open

1 3 5 7

J102

2 4 6 8

1 3 5 7

J103

2 4 6 8

CPU

card

Fig.15

15

Page 18

Operative mode and Hardware lockOperative mode and Hardware lock

Operative mode and Hardware lock

Operative mode and Hardware lockOperative mode and Hardware lock

1) By V101 (see fig. 16) it is possible to select one of the

following operative modes:

a) run time mode without configuration mode

b) run time and configuration modes

c) security code setting mode

Set V101 according to the following table:

Modes V101.1 V101.2 V101.3 V101.4

a OFF ON ON ON

b OFF ON OFF ON

c OFF ON OFF OFF

2) When run time mode is selected (mode a or b), V101.3 allows

you to activate/deactivate the hardware lock for configuration

parameters.

If V101.3 is ON, the lock is activated.

If V101.3 is OFF, the lock is deactivated.

When the lock is activated, no one of the configuration

parameter can be modified.

3) All the others switch combinations are reserved.

ON DIP

1 2 3 4

V101

Fig. 16

16

Page 19

SECURITY CODE SETTING MODESECURITY CODE SETTING MODE

SECURITY CODE SETTING MODE

SECURITY CODE SETTING MODESECURITY CODE SETTING MODE

General notesGeneral notes

General notes

General notesGeneral notes

The instrument parameters are divided in two families and each

family is divided in groups.

- The first family encompasses all the run time parameters.

- The second family comprises all the configuration parameters.

A specific security code enables the parameter modification of

each family.

For run time parameters, it is possible to select which groups of

them will be protected by the security code and in this case it is

necessary to set the run time security code before to modify one

or more parameters of a protected group.

The configuration security code protects all configuration

parameters and it will be necessary to set the configuration

security code before to start the configuration parameters

modification.

For configuration parameters an hardware lock is also available.

Security code settingSecurity code setting

Security code setting:

Security code settingSecurity code setting

1) Remove the instrument from its case.

2) Set the internal dip switch V101 as follows:

- V101.1 = OFF - V101.2 = ON

- V101.3 = OFF - V101.4 = OFF

3) Re-insert the instrument.

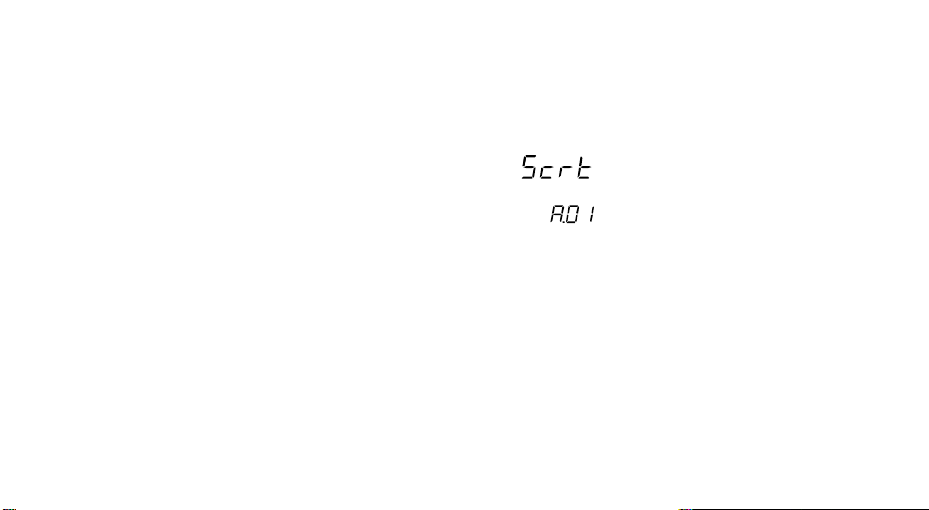

4) Switch on the instrument. The display will show:

The upper display shows that the security code setting mode

is selected while the lower display shows the firmware

version.

5) Push the FUNC pushbutton.

17

Page 20

Run time security codeRun time security code

Run time security code

Run time security codeRun time security code

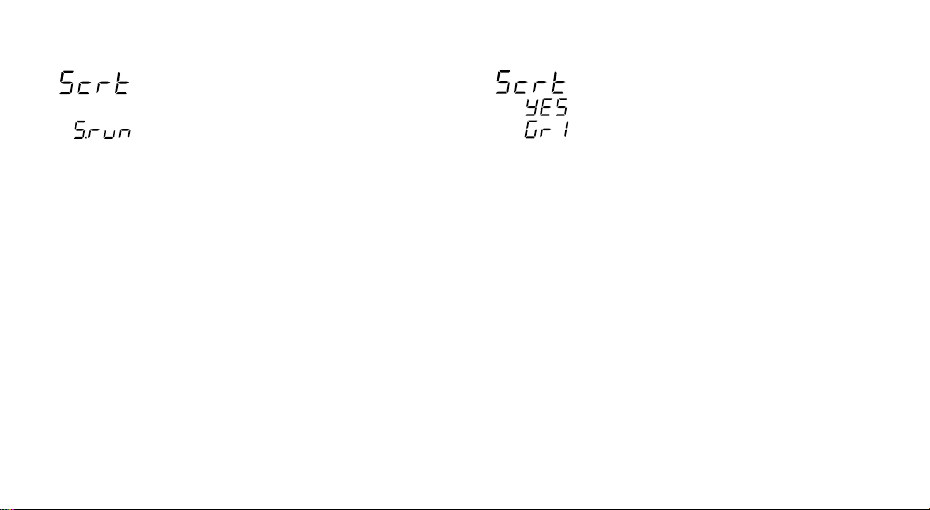

The display will show:

Run time groups protected by security codeRun time groups protected by security code

Run time groups protected by security code

Run time groups protected by security codeRun time groups protected by security code

The display will show:

NoteNote

Note: the middle display shows the current status of the run

NoteNote

time security code ("0", "1" or "On").

By and push-button, set "S.run" parameter as follows:

0 No protection (it is always possible to modify all run

time parameters);

1 always protected (it is never possible to modify a run

time parameter);

from 2 to 250 security code for run time parameter

protection.

NOTESNOTES

NOTES:

NOTESNOTES

1) The selected value of a security code cannot be displayed

anymore and, coming back to the "S.run" parameter, the display

will show "On" when "S.run" is different from 0 or 1, "0" when

"S.run" is equal to 0, "1" when "S.run" is equal to 1.

When the security code is forgotten, a new value can be set.

2) When "S.run" is different from 0 or 1, the "run time default "

and the "run time hidden" groups are always protected by

security code.

By this parameter it is possible to set if the run time group 1 will

be protected or not by the run time security code.

By and push-button, set "Gr1" parameter as follows:

nO No protection (it is always possible to modify run time

group 1 parameters).

Yes the run time group 1 parameter modification will be

protected by security code.

Push the FUNC push-button; the instrument memorizes the new

setting and goes to the next parameter.

NOTESNOTES

NOTES: 1) This selection may be performed only if a run time

NOTESNOTES

security code has been set (from 2 to 250).

2) The above described selection may be repeated for

all groups of the run time mode.

18

Page 21

Configuration security codeConfiguration security code

Configuration security code

Configuration security codeConfiguration security code

The display will show:

NoteNote

Note: the middle display shows the current status of the

NoteNote

configuration security code ("0", "1" or "On").

By and push-button, set "S.CnF" parameter as follows:

0 No protection (it is always possible to modify all

configuration parameters);

1 always protected (it is never possible to modify a

configuration parameter);

from 2 to 250 security code for configuration parameter

protection.

NOTESNOTES

NOTES:1) The selected value of a security code cannot be

NOTESNOTES

displayed anymore and, coming back to the "S.CnF"

parameter, the display will show "On" when "S.CnF"

is different from 0 or 1, "0" when "S.CnF" is equal to

0, "1" when "S.CnF" is equal to 1.

When the security code is forgotten, a new value can

be set.

2) At the end of the security code setting, set the V101

as described at page16.

RUN TIME AND CONFIGURATION MODESRUN TIME AND CONFIGURATION MODES

RUN TIME AND CONFIGURATION MODES

RUN TIME AND CONFIGURATION MODESRUN TIME AND CONFIGURATION MODES

The hardware selection described in "Operative mode and

hardware lock" paragraph allows you to start one of the two

following operative modes:

- run time mode

- configuration mode.

At power up, the instrument starts in the same mode it was prior

to the power OFF.

General note about graphic symbols used forGeneral note about graphic symbols used for

General note about graphic symbols used for

General note about graphic symbols used forGeneral note about graphic symbols used for

mnemonic code visualization.mnemonic code visualization.

mnemonic code visualization.

mnemonic code visualization.mnemonic code visualization.

The instrument displays some characters with special symbols.

The following table shows the correspondence between the

symbols and the characters.

19

symbol character

"

"k

" "m

" "V

" "W

" "Z

"J

"

Page 22

Keyboard descriptionKeyboard description

Keyboard description

Keyboard descriptionKeyboard description

MENU = is used to select a parameter group.

FUNC = When the instrument is in "normal display mode" it

changes the indication on the lower display (see

"display function").

During parameter modification, it allows you to

memorize the new value of the selected parameter

and go to the next parameter (increasing order).

MAN = When the instrument is in "normal display mode",

pushing MAN push-button for more than 1 s, it is

possible to enable or disable the manual function.

During parameter modification, it allows you to scroll

back the parameters and groups without memorizing

the new setting.

= During parameter modification, it allows you to

increase the value of the selected parameter.

During MANUAL mode, it allows you to increase the

output value.

TST + MAN = By pressing these keys it is possible to start the

BURNOFF function.

TST + FUNC = By pressing these keys it is possible to start the

PROBE TEST function.

+MENU = Are used to start the lamp test function (the

command is accepted when push-buttons are

kept depressed for more than 5 s and the

instrument is in normal display mode)

+FUNC or +FUNC

During parameter modification they allow you to

increase/decrease the value under modification with

higher rate.

+MAN or +MAN

During parameter modification they allow you to

jump to the max or min programmable value.

= During parameter modification, it allows you to

decrease the value of the selected parameter.

During MANUAL mode, it allows to decrease

the output value.

20

Page 23

NOTESNOTES

NOTES:

NOTESNOTES

1) All the actions explained above which requires two or more

push-buttons must follow exactly the push-button sequence

shown.

2) A 10 or 30 seconds time out (see "CnF.6 - t.out" [C.I08]) can

be selected for parameter modification during run time mode.

If, during parameter modification, no push-button is depressed

for more than 10 (30) seconds, the instrument goes

automatically to the “normal display mode” and the

modification (if carried out) of the last displayed parameter will

be lost.

CONFIGURATION MODECONFIGURATION MODE

CONFIGURATION MODE

CONFIGURATION MODECONFIGURATION MODE

Switch on the instrument.

The instrument will start in the same way it was prior to the

power down (configuration mode or run time mode).

If the instrument starts in configuration mode, push the MENU

pushbutton and go to the "Configuration group 1" (see page 25).

If the instrument starts in run time mode, by keeping depressed

the MENU push-button for more than 5 seconds the instrument

will show:

where:

- the upper display shows the selected parameter family;

- the middle display shows the selected action;

- the lower display shows the firmware version.

If no push-button is depressed for more than 10 s (or 30 s

according to "CnF.6 - "t.out" [time out selection" C.I08]

parameter setting), the instrument automatically returns to the

normal display mode.

21

Page 24

By or push-button it is possible to select between:

= (monitor) this selection allows you to monitor but

not to modify the value assigned to the

configuration parameters.

= (modify) this selection allows you to monitor and to

modify the value assigned to the configuration

parameters.

NOTESNOTES

NOTES:

NOTESNOTES

1) During monitor mode, the instrument continues to operate as

in run time mode.

2) When modify mode is started, the instrument stops the control

and:

- sets to OFF the control outputs;

- turns to OFF the bargraph displays;

- sets analog retransmissions to the retransmitted initial scale

value;

- sets to OFF the alarms;

- disables the serial link;

- the time out will be disabled.

3) When the modify mode is disabled by V101 (V101.3), the or

push-button pressure has no effect.

MONITOR MODEMONITOR MODE

MONITOR MODE

MONITOR MODEMONITOR MODE

During the run time mode, it is possible to monitor but not modify

all configuration parameters.

When it is desired to verify the instrument configuration, proceed

as follows:

1) By or push-button select the monitor mode.

2) Push the MENU push-button the display will show:

it shows that configuration group 1 is selected and it

encompasses all the input parameters.

The configuration parameter "Monitor mode" follows the "Modify

mode" sequence.

NOTESNOTES

NOTES:

NOTESNOTES

1) During monitor mode, the instrument continues to operate as

in run time mode.

2) During monitor mode, if no push-button is depressed for more

than 10 s (or 30 s according to "CnF.6 - t.out" [C.I08]

parameter setting), the instrument returns automatically to the

normal display mode.

22

Page 25

MODIFY MODEMODIFY MODE

MODIFY MODE

MODIFY MODEMODIFY MODE

1) By or push-button select the modify mode.

2) Push the MENU push-button.

If a security code is applied to the configuration parameter,

the instrument will show:

3) By and push-button set a value equal to the security

code assigned to the configuration mode (see "Configuration

security code " at page 19).

If the code is different from the security code, the instrument

automatically returns to the first configuration display

otherwise the display will show:

The modify mode is started.

This display allows you to load the default configuration

parameter (table 1 or table 2).

For more details see chapter "Default parameter" (see

Appendix A).

4) By or push-button select the OFF indication and push

the MENU push-button.

The display will show:

This is the starting display of the first group of configuration

parameters.

NOTESNOTES

NOTES:

NOTESNOTES

1) In the following pages we will describe all the parameters of

the instrument but the instrument will show only the

parameters related with the specific hardware and in

accordance with the specific instrument configuration [i.e.

setting OUT 6 as "nonE" (not used), all the parameters related

with this output will be automatically skipped].

23

Page 26

2) During configuration parameters modify mode, the upper

display shows the selected parameter group, the lower display

shows the mnemonic code of the selected parameter while

the central display shows the value or status assigned to the

selected parameter.

3) For an easy consultation of this manual, a sheet named

"Reference parameter guide" with all the parameter

visualizations is enclosed.

The groups of configuration parameters are identified by the

"C" letter followed by A, B etc.

The "code" formed by the group and the row (i.e. C.D01

where "C.D" is configuration group1 and "01" is the row 1) is

reported, in the user manual, before each parameter

description and allows you to quickly find out the respective

parameter.

CONFIGURATION GROUP 1 [C.Dxx]CONFIGURATION GROUP 1 [C.Dxx]

CONFIGURATION GROUP 1 [C.Dxx]

CONFIGURATION GROUP 1 [C.Dxx]CONFIGURATION GROUP 1 [C.Dxx]

INPUT CONFIGURATION

Push the FUNC push-button

C.D01- Line frequencyC.D01- Line frequency

C.D01- Line frequency

C.D01- Line frequencyC.D01- Line frequency

Upper display: CnF.1

Lower display: Ln.Fr

Range: 50 Hz

60 Hz

C.D02- Controlled variable selectionC.D02- Controlled variable selection

C.D02- Controlled variable selection

C.D02- Controlled variable selectionC.D02- Controlled variable selection

Upper display: CnF.1

Lower display: PV.SL

Ranges:

CP = Carbon potential (span limits within 0.00% to 2.00%).

dP = Dew point (span limits within -100 to 100 °F or -75 to 40°C).

ñV = Sensor output in mV (span limits within 0 to 1500 mV).

O2 = Oxygen value as primary control variable

( The span limits are 0.0 to 25.0)

24

Page 27

NOTES:NOTES:

NOTES:

NOTES:NOTES:

1) Changing the controlled variable, the following parameters:

"CnF.6 - brG.L" [C.I03] and "CnF.6 - brG.H" [C.I04] (Bargraph

initial and full scale values);

"CnF.2 - O6.Lr" [C.E06] and "CnF.2 - O6.Hr" [C.E07] (Out 6

retransmission initial and full scale values);

"CnF.2 - O7.Lr" [C.E11] and "CnF.2 - O7.Hr" [C.E12] (Out 7

retransmission initial and full scale values);

"Gr.5 - rL" [R.E10] and "Gr.5 - rH" [R.E11]

(set point low and high limits); will be forced to the span limits

of the new selected variable.

2) SP, SP2, SP3, SP4 values and alarm thresholds, if out of the

limits for the new selected variable, will be forced to the low

limit value.

C.D03- Filter on probe sensor input (Main input)C.D03- Filter on probe sensor input (Main input)

C.D03- Filter on probe sensor input (Main input)

C.D03- Filter on probe sensor input (Main input)C.D03- Filter on probe sensor input (Main input)

Upper display: CnF.1

Lower display: Pb.FL

Ranges: from 0 (no filter) to 8 seconds.

NOTES:NOTES:

NOTES:

NOTES:NOTES:

1) This is a first order digital filter applied on probe sensor input

value.

2) This filter can affect the control action, the alarms, the SMART

algorithm and the process variable retransmission.

C.D04 - Temperature input - TC type selectionC.D04 - Temperature input - TC type selection

C.D04 - Temperature input - TC type selection

C.D04 - Temperature input - TC type selectionC.D04 - Temperature input - TC type selection

Upper display: CnF.1

Lower display: tP.In

Ranges:

1 = TC K From -100 t o 1370 °C

2 = TC S From -50 to 17 6 0 °C

3 = TC R From -50 to 1760 °C

4 = TC K From -150 to 2500 °F

5 = TC S From -60 to 32 0 0 °F

6 = TC R From -60 to 3200 °F

7= TC B From 0 to 1820 °C

8= TC B From 32 to 3300 °F

NOTE:NOTE:

NOTE: When the controlled variable selected is dP, the span

NOTE:NOTE:

limits of the following parameters:

"CnF.6 - brG.L" [C.I03] and "CnF.6 - brG.H" [C.I04]

(Bargraph initial and full scale values);

"CnF.2 - O6.Lr" [C.E06] and "CnF.2 - O6.Hr" [C.E07] (Out

6 retransmission initial and full scale values);

"CnF.2 - O7.Lr" [C.E11] and "CnF.2 - O7.Hr" [C.E12] (Out

7 retransmission initial and full scale values);

"Gr.5 - rL" [R.E10] and "Gr.5 - rH" [R.E11]

(set point low and high limits); will be forced to:

-100 to 100 °F if the temperature input has been

changed from a °C to a °F type;

-75 to 40 °C if the temperature input has been

changed from a °F to a °C type.

25

Page 28

C.D05 - Temperature input offset adjustmentC.D05 - Temperature input offset adjustment

C.D05 - Temperature input offset adjustment

C.D05 - Temperature input offset adjustmentC.D05 - Temperature input offset adjustment

Upper display: CnF.1

Lower display: OFSt

Range: from -500 to 500

NOTENOTE

NOTE: The offset value is algebraically added to temperature

NOTENOTE

input value.

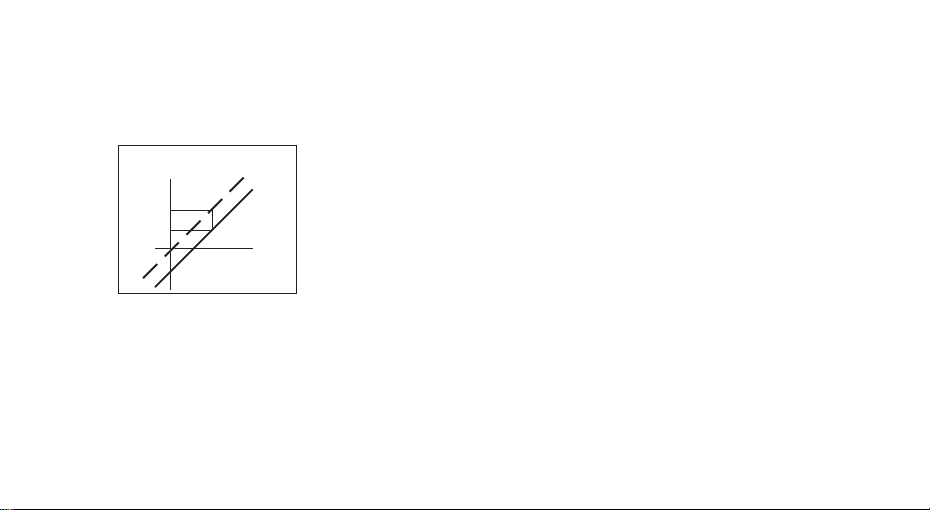

Read-out

OFSt

Real curve

Adjusted

curve

Input

C.D06 - Filter on temperature input valueC.D06 - Filter on temperature input value

C.D06 - Filter on temperature input value

C.D06 - Filter on temperature input valueC.D06 - Filter on temperature input value

Upper display: CnF.1

Lower display: tP.FL

Ranges: from 0 (no filter) to 8 seconds.

NOTES:NOTES:

NOTES:

NOTES:NOTES:

1) This is a first order digital filter applied to the temperature

input value.

2) When "dP" or "CP" or O2 are selected as the controlled

variable, this filter can affect the control action, the alarms,

the SMART algorithm and the process variable retransmission.

C.D07 - Auxiliary input functionC.D07 - Auxiliary input function

C.D07 - Auxiliary input function

C.D07 - Auxiliary input functionC.D07 - Auxiliary input function

Lower display: A.In.F

Range: nonE = Input not used

CO = Input used for CO measurement

rSP = Input used as remote set point

Available: Always

Note:The scalable for CO measurement is fixed from 000 to 100

When CO input is not used the CO value will be set to 20

The scalable for rSP measurement is fixed to:

0.00 / 2.00 if carbon potential is selected as primary control variable or

0 /100 °F (-18 / 40 °C) if dew point is selected as primary control variable or

0 / 1500 if sensor output in mV is selected as primary control variable

0.0/ 25.0 if oxygen value is selected as primary control variable

C.D08 - Auxiliary input type selectionC.D08 - Auxiliary input type selection

C.D08 - Auxiliary input type selection

C.D08 - Auxiliary input type selectionC.D08 - Auxiliary input type selection

Lower display: A.In.t

Range: 0-20 = 0÷20 mA

4-20 = 4÷20 mA

0- 5 = 0÷ 5 V

1- 5 = 1÷ 5 V

0-10 = 0÷10 V

2-10 = 2÷10 V

Available: When auxiliary input is used

26

Page 29

C.D09 - TIME CONSTANT FOR FILTER ON REMOTEC.D09 - TIME CONSTANT FOR FILTER ON REMOTE

C.D09 - TIME CONSTANT FOR FILTER ON REMOTE

C.D09 - TIME CONSTANT FOR FILTER ON REMOTEC.D09 - TIME CONSTANT FOR FILTER ON REMOTE

SETPOINT VALUE (CnF.1)SETPOINT VALUE (CnF.1)

SETPOINT VALUE (CnF.1)

SETPOINT VALUE (CnF.1)SETPOINT VALUE (CnF.1)

Lower display: A.I.FL

Range: From 0(filter OFF) to 8 s

Available: When auxiliary input is used as remote

set point

Note: First order filter with selected time constant

C.D10 - REMOTE SETPOINT ACTIVITY MODE (CnF.1)C.D10 - REMOTE SETPOINT ACTIVITY MODE (CnF.1)

C.D10 - REMOTE SETPOINT ACTIVITY MODE (CnF.1)

C.D10 - REMOTE SETPOINT ACTIVITY MODE (CnF.1)C.D10 - REMOTE SETPOINT ACTIVITY MODE (CnF.1)

Lower display: A.I.Añ

Range: norñ = The remote set point is

activated by external contact(or is always activated if none

contacts are configured for this feature) and the value is limited

at its min/max value when out of range

Cnd.A = The remote set point

activation is controlled by status of auxiliary input.

(The device works with local set point when auxiliary input is

out of range while it works with remote set point when auxiliary

input is in range)

Available: When auxiliary input is used as remote set point

C.D11 - LOCAL / REMOTE SETPOINT OPERATINGC.D11 - LOCAL / REMOTE SETPOINT OPERATING

C.D11 - LOCAL / REMOTE SETPOINT OPERATING

C.D11 - LOCAL / REMOTE SETPOINT OPERATINGC.D11 - LOCAL / REMOTE SETPOINT OPERATING

MODE (CnF.1)MODE (CnF.1)

MODE (CnF.1)

MODE (CnF.1)MODE (CnF.1)

Lower display: L.r.Oñ

Range: ALG = The local setpoint will be

aligned to last remote setpoint value when transfer from remote

to local setpoint action is performed through external contact

n.ALG = The local setpoint will be

not be changed when transfer from remote to local setpoint

action is performed (The programmed ramp (Grd1/Grd2) may be

activated)

Available: When auxiliary input is used as remote set point

and (“A.I.Añ = norñ)

Note :If transfer from remote to local setpoint is due to auxiliary

input status(“A.I.Añ = Cnd.A) the local setpoint

beenbeen

been aligned.

beenbeen

27

will neverwill never

will never

will neverwill never

Page 30

CONFIGURATION GROUP 2 [C.Exx]CONFIGURATION GROUP 2 [C.Exx]

CONFIGURATION GROUP 2 [C.Exx]

CONFIGURATION GROUP 2 [C.Exx]CONFIGURATION GROUP 2 [C.Exx]

OUTPUTS CONFIGURATION

C.E01 - OUT 1 functionC.E01 - OUT 1 function

C.E01 - OUT 1 function

C.E01 - OUT 1 functionC.E01 - OUT 1 function

Upper display: CnF.2

Lower display: O1.Fn

Range: nonE = Output not used

ñAin = Time proportional main control output

SECn = Time proportional secondary control output

ALr.1 = Alarm 1 output

C.E02 - OUT 2 functionC.E02 - OUT 2 function

C.E02 - OUT 2 function

C.E02 - OUT 2 functionC.E02 - OUT 2 function

Upper display: CnF.2

Lower display: O2.Fn

Range: nonE = Output not used

ñAin = Time proportional main control output

SECn = Time proportional secondary control output

ALr.2 = Alarm 2 output

C.E03 - OUT 3 functionC.E03 - OUT 3 function

C.E03 - OUT 3 function

C.E03 - OUT 3 functionC.E03 - OUT 3 function

Upper display: CnF.2

Lower display: O3.Fn

Range: nonE = Output not used

ñAin = Time proportional main control output

SECn = Time proportional secondary control output

ALr.3 = Alarm 3 output

C.E04 - OUT 6 functionC.E04 - OUT 6 function

C.E04 - OUT 6 function

C.E04 - OUT 6 functionC.E04 - OUT 6 function

Upper display: CnF.2

Lower display: O6.Fn

Range: nonE = Output not used

ñAin = Main control output (linear)

SECn = Secondary control output (linear)

PV.rt = Process variable retransmission

SP.rt = Operative set point retransmission

C.E05 - OUT 6 rangeC.E05 - OUT 6 range

C.E05 - OUT 6 range

C.E05 - OUT 6 rangeC.E05 - OUT 6 range

This parameter is available only when OUT 6 ("O6.Fn" [C.E04]) is

different from "nonE".

Upper display: CnF.2

Lower display: O6.rn

Range: 0-20 = 0-20 mA

4-20 = 4-20 mA

28

Page 31

C.E06 -C.E06 -

OUT 6 retransmission - initial scale valueOUT 6 retransmission - initial scale value

C.E06 -

OUT 6 retransmission - initial scale value

C.E06 -C.E06 -

OUT 6 retransmission - initial scale valueOUT 6 retransmission - initial scale value

This parameter is available only when Out 6 function [C.E04] is

configured as “PV.rt” or “SP.rt”

Upper display: CnF.2

Lower display: O6.Lr

Range: From -1999 to 9999

NOTENOTE

NOTE: The decimal point position will be the same as the

NOTENOTE

“CnF.1 - PV.SL” [C.D02] previously selected.

C.E07 -C.E07 -

OUT 6 retransmission - full scale valueOUT 6 retransmission - full scale value

C.E07 -

OUT 6 retransmission - full scale value

C.E07 -C.E07 -

OUT 6 retransmission - full scale valueOUT 6 retransmission - full scale value

This parameter is available only when Out 6 function [C.E04] is

configured as “PV.rt” or “SP.rt”

Upper display: CnF.2

Lower display: O6.Hr

Range: From -1999 to 9999

NOTENOTE

NOTE: The decimal point position will be the same as the

NOTENOTE

“CnF.1 - PV.SL” [C.D02] previously selected.

C.E08 -C.E08 -

OUT 6 filter on the retransmitted valueOUT 6 filter on the retransmitted value

C.E08 -

OUT 6 filter on the retransmitted value

C.E08 -C.E08 -

OUT 6 filter on the retransmitted valueOUT 6 filter on the retransmitted value

This parameter is available only when OUT 6 ("O6.Fn" [C.E04]) is

configured “PV.rt”.

Upper display: CnF.2

Lower display: O6.FL

Range: From 0 (no filter) to 8 seconds

NOTENOTE

NOTE: this is a first order digital filter applied to the retransmit-

NOTENOTE

ted output value.

C.E09 -C.E09 -

OUT 7 functionOUT 7 function

C.E09 -

OUT 7 function

C.E09 -C.E09 -

OUT 7 functionOUT 7 function

Upper display: CnF.2

Lower display: O7.Fn

Range: nonE = Output not used

ñAin = Main control output (linear)

SECn = Secondary control output (linear)

PV.rt = Process variable retransmission

SP.rt = Operative set point retransmission

C.E10 - OUT 7 rangeC.E10 - OUT 7 range

C.E10 - OUT 7 range

C.E10 - OUT 7 rangeC.E10 - OUT 7 range

This parameter is available only when Out 7 ("O7.Fn" [C.E09]) is

different from "nonE".

Upper display: CnF.2

Lower display: O7.rn

Range: 0-20 = 0 to 20 mA

4-20 = 4 to 20 mA

29

Page 32

C.E11 -C.E11 -

OUT 7 retransmission - initial scale valueOUT 7 retransmission - initial scale value

C.E11 -

OUT 7 retransmission - initial scale value

C.E11 -C.E11 -

OUT 7 retransmission - initial scale valueOUT 7 retransmission - initial scale value

This parameter is available only when Out 7 function [C.E09] is

configured as “PV.rt” or “SP.rt”

Upper display: CnF.2

Lower display: O7.Lr

Range: From -1999 to 9999

NOTENOTE

NOTE: The decimal point position will be the same as the

NOTENOTE

“CnF.1 - PV.SL” [C.D02] previously selected.

C.E12 -C.E12 -

OUT 7 retransmission - full scale valueOUT 7 retransmission - full scale value

C.E12 -

OUT 7 retransmission - full scale value

C.E12 -C.E12 -

OUT 7 retransmission - full scale valueOUT 7 retransmission - full scale value

This parameter is available only when Out 7 function [C.E09] is

configured as “PV.rt” or “SP.rt”

Upper display: CnF.2

Lower display: O7.Hr

Range: From -1999 to 9999

NOTENOTE

NOTE: The decimal point position will be the same as the

NOTENOTE

“CnF.1 - PV.SL” [C.D02] previously selected.

C.E13 -C.E13 -

OUT 7 filter on the retransmitted valueOUT 7 filter on the retransmitted value

C.E13 -

OUT 7 filter on the retransmitted value

C.E13 -C.E13 -

OUT 7 filter on the retransmitted valueOUT 7 filter on the retransmitted value

This parameter is available only when OUT 7 ("O7.Fn" [C.E09]) is

configured as “PV.rt”.

Upper display: CnF.2

Lower display: O7.FL

Range: From 0 (no filter) to 8 seconds

NOTENOTE

NOTE: this is a first order digital filter applied to the retransmit-

NOTENOTE

ted output value.

30

Page 33

General note on configuration group 2General note on configuration group 2

General note on configuration group 2

General note on configuration group 2General note on configuration group 2

Exiting from the configuration group 2 the instrument automatically verifies the congruence of all parameters.

If a wrong setting is detected, the device will show:

The parameter group 2 passes the congruence test when:

1) No one of the 5 outputs is configured as control output.

2) Only one of the 5 outputs is configured as main output (“ñAin”).

3) Only one of the 5 outputs is configured as secondary output

(“SECn”).

4) If only one control output is configured, it should be the main

control output (“ñAin”).

When changing menu, the following actions are performed:

1) The "CnF.4 - Añ.UL" [C.G04] parameter will be forced to "buñ"

if its value is less than zero and only one control output has

been configured.

2) The "Gr.4 - IP" [R.D05] parameter will be forced to 50.0 if only

one control output has been configured and its valueis < 0.

CONFIGURATION GROUP 3 [C.Fxx]CONFIGURATION GROUP 3 [C.Fxx]

CONFIGURATION GROUP 3 [C.Fxx]

CONFIGURATION GROUP 3 [C.Fxx]CONFIGURATION GROUP 3 [C.Fxx]

CONTROL OUTPUT CONFIGURATION

C.F01 - Main control output conditioningC.F01 - Main control output conditioning

C.F01 - Main control output conditioning

C.F01 - Main control output conditioningC.F01 - Main control output conditioning

This parameter is available only when main control output is

configured.

Upper display: CnF.3

Lower display: ñC.Cn

Range: norñ = The control output is as calculated by the PID.

CñPL = The control output is complemented (100-PID

calculated value).

C.F02 - Main control output in engineering unitC.F02 - Main control output in engineering unit

C.F02 - Main control output in engineering unit

C.F02 - Main control output in engineering unitC.F02 - Main control output in engineering unit

This parameter is available only when main control output is

configured.

Upper display: CnF.3

Lower display: ñ.SCL

Range: nO = Scalable is not required

YES = Scalable is required

31

Page 34

NOTENOTE

NOTE: This scaling allows you to display the output value in

NOTENOTE

engineering units instead of in percent.

C.F03 - Main output decimal point positionC.F03 - Main output decimal point position

C.F03 - Main output decimal point position

C.F03 - Main output decimal point positionC.F03 - Main output decimal point position

This parameter will be available only when "ñ.SCL" ("Main control

output in engineering units" [C.F02]) is set to "YES".

Upper display: CnF.3

Lower display: ñC.dP

Range:

---.

= No decimal figure

--.-

= One decimal figure

-.--

= Two decimal figures

C.F04 - Main control output initial scale valueC.F04 - Main control output initial scale value

C.F04 - Main control output initial scale value

C.F04 - Main control output initial scale valueC.F04 - Main control output initial scale value

This parameter is available only when "ñ.SCL" ("Main control

output in engineering units" [C.F02]) is set to "YES".

Upper display: CnF.3

Lower display: ñC.E.L

Range: from -199 to 999

C.F05 - Main control output full scale valueC.F05 - Main control output full scale value

C.F05 - Main control output full scale value

C.F05 - Main control output full scale valueC.F05 - Main control output full scale value

This parameter is available only when "ñ.SCL" ("Main control

output in engineering units" [C.F02]) is set to "YES".

Upper display: CnF.3

Lower display: ñC.E.H

Range: from -199 to 999

C.F06 - Main output auxiliary conditioningC.F06 - Main output auxiliary conditioning

C.F06 - Main output auxiliary conditioning

C.F06 - Main output auxiliary conditioningC.F06 - Main output auxiliary conditioning

This parameter is available only when main control output is

configured and “ñC.Cn” ("Main control output conditioning"

[C.F01]) is different from “norñ”.

Upper display: CnF.3

Lower display: ñC.A.C

Range: bEFr = The functions listed at Note (A) are calculated

before before

before to apply the action selected by “ñC.Cn”

before before

("Main control output conditioning" [C.F01])

parameter.

AFtr = The functions listed at Note (A) are calculated

after after

after to apply the action selected by “ñC.Cn”

after after

(“Main control output conditioning” [C.F01])

parameter.

Note (A)Note (A)

Note (A)

Note (A)Note (A)

- "Main control output limiters" - for more details see [r.E02] and

32

Page 35

[r.E03] parameters.

- "Main control output max rate of rise" (see [r.E04]).

- "Control output display value" - for more details see "Display

function" paragraph at pag. 43 and [C.F02], [C.F03], [C.F04],

[C.F05] parameters.

- The control output value displayed by bargraph.

C.F07 - Secondary control output conditioningC.F07 - Secondary control output conditioning

C.F07 - Secondary control output conditioning

C.F07 - Secondary control output conditioningC.F07 - Secondary control output conditioning

This parameter is available only when secondary control output is

configured.

Upper display: CnF.3

Lower display: SC.Cn

Range: norñ = The control output is as calculated by the PID.

CñPL = The control output is complemented (100-PID

calculated value).

C.F08 -C.F08 -

Secondary control output in engineering unitSecondary control output in engineering unit

C.F08 -

Secondary control output in engineering unit

C.F08 -C.F08 -

Secondary control output in engineering unitSecondary control output in engineering unit

This parameter is available only when secondary control output is

configured.

Upper display: CnF.3

Lower display: S.SCL

Range: nO = Scalable is not required

YES = Scalable is required

NOTENOTE

NOTE: This scaling allows to display the output value in

NOTENOTE

engineering units instead of in percent.

C.F09 -C.F09 -

Secondary control output decimal pointSecondary control output decimal point

C.F09 -

Secondary control output decimal point

C.F09 -C.F09 -

Secondary control output decimal pointSecondary control output decimal point

positionposition

position

positionposition

This parameter is available only when "S.SCL" ("Secondary

control output in engineering units" [C.F08]) is set to "YES".

Upper display: CnF.3

Lower display: SC.dP

Range:

---.

= No decimal figure

--.-

= One decimal figure

-.--

= Two decimal figures

C.F10 -C.F10 -

Secondary control output initial scale valueSecondary control output initial scale value

C.F10 -

Secondary control output initial scale value

C.F10 -C.F10 -

Secondary control output initial scale valueSecondary control output initial scale value

This parameter will be available only when "S.SCL" ("Secondary

control output in engineering units" [C.F08]) is set to "YES".

Upper display: CnF.3

Lower display: SC.E.L

Range: from -199 to 999

C.F11 -C.F11 -

Secondary control output full scale valueSecondary control output full scale value

C.F11 -

Secondary control output full scale value

C.F11 -C.F11 -

Secondary control output full scale valueSecondary control output full scale value

This parameter will be available only when "S.SCL" ("Secondary

control output in engineering units" [C.F08]) is set to "YES".

Upper display: CnF.3

Lower display: SC.E.H

Range: From -199 to 999

33

Page 36

C.F12 -C.F12 -

Secondary control output auxiliary condition-Secondary control output auxiliary condition-

C.F12 -

Secondary control output auxiliary condition-

C.F12 -C.F12 -

Secondary control output auxiliary condition-Secondary control output auxiliary condition-

inging

ing

inging

This parameter will be available only when secondary control

output is configured and “SC.Cn” ("Secondary control output

conditioning" [C.F07]) is different from “norñ”.

Upper display: CnF.3

Lower display: SC.A.C

Range: bEFr = The functions listed at Note (B) are calculated

before before

before to apply the action selected by “SC.Cn”

before before

("Secondary control output conditioning" [C.F07])

parameter.

AFtr = The functions listed at Note (B) are calculated

after after

after to apply the action selected by “SC.Cn”

after after

(“Secondary control output conditioning” [C.F07])

parameter.

Note (B)Note (B)

Note (B)

Note (B)Note (B)

- "Secondary control output limiters" - for more details see

[r.E06] and [r.E07] parameters.

- "Secondary control output max rate of rise" (see [r.E08]).

- "Control output display value" - for more details see "Display

function" paragraph at pag. 43 and [C.F08], [C.F09], [C.F10],

[C.F11] parameters.

- The control output value displayed by bargraph.

CONFIGURATION GROUP 4 [C.Gxx]CONFIGURATION GROUP 4 [C.Gxx]

CONFIGURATION GROUP 4 [C.Gxx]

CONFIGURATION GROUP 4 [C.Gxx]CONFIGURATION GROUP 4 [C.Gxx]

AUXILIARY CONTROL PARAMETER CONFIGURATION

C.G01 - Smart functionC.G01 - Smart function

C.G01 - Smart function

C.G01 - Smart functionC.G01 - Smart function

This parameter is available only when at least one control output

is configured

Upper display: CnF.4

Lower display: Sñ.Fn

Range: dIS = Smart function disabled

Enb = Smart function may be enabled

C.G02 - Control action typeC.G02 - Control action type

C.G02 - Control action type

C.G02 - Control action typeC.G02 - Control action type

This parameter will be available only when at least one control

output is configured.

Upper display: CnF.4

Lower display: Cn.tP

Range: Pid = The process is controlled by PID actions

Pi = The process is controlled by PI actions

34

Page 37

NOTENOTE

NOTE: if the control action type is changed, the control

NOTENOTE

parameter values (P, I, D) are updated with values

calculated by the last TUNE function (first part of SMART

algorithm).

If these values are wrong, they are not updated and the

E.120 error is displayed (for details see "Error messages"

at pag. 83).

When run time is activated, it will be necessary to enable

a new TUNE procedure.

C.G03 - Manual functionC.G03 - Manual function

C.G03 - Manual function

C.G03 - Manual functionC.G03 - Manual function

This parameter will be available only when at least one control

output is configured

Upper display: CnF.4

Lower display: ñAn.F

Range: dIS = Manual function disabled

Enb = Manual function may be enabled

C.G04 -C.G04 -

C.G04 -

C.G04 -C.G04 transfertransfer

transfer

transfertransfer

Output value for AUTO to MANOutput value for AUTO to MAN

Output value for AUTO to MAN

Output value for AUTO to MANOutput value for AUTO to MAN

This parameter will be available only when at least one control

output is configured and manual function is enabled (“ñAn.F”

[C.G03] = “Enb”)

Upper display: CnF.4

Lower display: Añ.UL

Range: - from 0.0 to 100.0 % of the output span if device is

configured with one control output only

- from -100.0 to 100.0 % of the output span if device is

configured with two control outputs.

Above the 100.0 % the display shows “buñ.” meaning that the

transfer from AUTO to MANUAL is bumpless (the instrument sets

for MANUAL mode the same power output used in AUTO mode)

C.G05 -C.G05 -

C.G05 -

C.G05 -C.G05 -

MANUAL to AUTO transfer typeMANUAL to AUTO transfer type

MANUAL to AUTO transfer type

MANUAL to AUTO transfer typeMANUAL to AUTO transfer type

This parameter is available only when at least one control output

is configured and manual function is enabled (“ñAn.F” [C.G03] =

“Enb”)

Upper display: CnF.4

Lower display: ñ.A.t.t

Range: buñ. = Bumpless balance transfer.

buñ.b =Bumpless balanceless transfer.

35

Page 38

NOTESNOTES

NOTES:

NOTESNOTES

1) During the manual to auto transfer, the instrument maintains

the same power output as in manual mode.

2) Selecting the "buñ.b", the operative set point will be aligned

to the measured value.

3) The “alignment” is not performed if measure is in error

condition.

4) The selected local set point will be changed even if it is

software protected.

Cnd.b = It starts in the same way it was left prior to

power shut down (if in manual mode the power

output will be equal to the last value prior to

power shut down).

C.G06 -C.G06 -

C.G06 -

C.G06 -C.G06 -

Device status at start upDevice status at start up

Device status at start up

Device status at start upDevice status at start up

This parameter will be available only when at least one control

output is configured and manual function is enabled (“ñAn.F”

[C.G03] = “Enb”).

Upper display: CnF.4

Lower display: St.Fn

Range: Auto = It starts always in auto mode

ñan =It starts always in manual mode with power

output set to 0

Cnd.A = It starts in the same way it was left prior to

power shut down (if in manual mode the power

output is set to 0)

36

Page 39

CONFIGURATION GROUP 5 [C.Hxx]CONFIGURATION GROUP 5 [C.Hxx]

CONFIGURATION GROUP 5 [C.Hxx]

CONFIGURATION GROUP 5 [C.Hxx]CONFIGURATION GROUP 5 [C.Hxx]

DIGITAL INPUT CONFIGURATION

C.H01 -C.H01 -

C.H01 -

C.H01 -C.H01 -

Digital input 1 functionDigital input 1 function

Digital input 1 function

Digital input 1 functionDigital input 1 function

Upper display: CnF.5

Lower display: d1.Fn

Range: nonE = Input contact not used

SP1.2 = Input contact used for SP /SP2 set point

selection.

SP3.4 = Input contact used for SP3/SP4 set point

selection.

Au.ñA = Input contact used for Auto/Manual selection

(Manual when logic level is “1”)

O.LIñ = Input contact used for output limiter activation

(Output limited when logic level is “1”).

ñ.rSt = Input contact used to reset (acknowledge) alarm

(Reset when logic level is “1”).

SP.L.r = Input contact used for Local/Remote set

point selection (Remote when logic level is “1”)

NOTENOTE

NOTE:

NOTENOTE

When one logic input is set to “SP.1.2” and no other logic

input is set to “SP.3.4”, the relation between the logic level

and the selected set point is the following:

Logic level 0 = SP

Logic level 1 = SP2

When one logic input is set to “SP.1.2” and a second logic

input is set to “SP.3.4”, the relation between the logic levels

and the selected set point is the following:

“SP.3.4” “SP.1.2” selected

level level set point

00SP

0 1 SP2

1 0 SP3

1 1 SP4

When one logic input is set to “SP.3.4” and no other logic

input is set to “SP.1.2”, the relation between the logic level

and the selected set point is the following:

Logic level 0 = SP

Logic level 1 = SP3

37

Page 40

C.H02 -C.H02 -

C.H02 -

C.H02 -C.H02 -

Digital input 1 contact statusDigital input 1 contact status

Digital input 1 contact status

Digital input 1 contact statusDigital input 1 contact status

This parameter is available only when "d1.Fn" [C.H01] is different

from “nonE”.

Upper display: CnF.5

Lower display: d1.St

Range: CLSd = The input is at logic level “1” when contact is

closed.

OPEn = The input is at logic level “1” when contact is

open.

C.H03 -C.H03 -

C.H03 -

C.H03 -C.H03 -

Digital input 2 functionDigital input 2 function

Digital input 2 function

Digital input 2 functionDigital input 2 function

Upper display: CnF.5

Lower display: d2.Fn

Range: nonE = Input contact not used.

SP1.2 = Input contact used for SP /SP2 set point

selection.

SP3.4 = Input contact used for SP3/SP4 set point

selection.

Au.ñA = Input contact used for Auto/Manual selection

(Manual when logic level is “1”).

O.LIñ = Input contact used for output limiter activation

(Output limited when logic level is “1”).

ñ.rSt = Input contact used to reset (acknowledge) alarm

(Reset when logic level is “1”).

SP.L.r = Input contact used for Local/Remote set

point selection (Remote when logic level is

“1”)

NOTENOTE

NOTE:

NOTENOTE

When one logic input is set to “SP.1.2” and no other logic

input is set to “SP.3.4”, the relation between the logic level

and the selected set point is the following:

Logic level 0 = SP

Logic level 1 = SP2

When one logic input is set to “SP.1.2” and a second logic

input is set to “SP.3.4”, the relation between the logic levels

and the selected set point is the following:

“SP.3.4” “SP.1.2” selected

level level set point

00SP

0 1 SP2

1 0 SP3

1 1 SP4

When one logic input is set to “SP.3.4” and no other logic

input is set to “SP.1.2”, the relation between the logic level

and the selected set point is the following:

Logic level 0 = SP

Logic level 1 = SP3

38

Page 41

C.H04 -C.H04 -

C.H04 -

C.H04 -C.H04 -

Digital input 2 contact statusDigital input 2 contact status

Digital input 2 contact status

Digital input 2 contact statusDigital input 2 contact status

This parameter will be available only when "d2.Fn" [C.H03] is

different from “nonE”.

Upper display: CnF.5

Lower display: d2.St

Range: CLSd = The input is at logic level “1” when contact is

closed.

OPEn = The input is at lo gic l evel “1” when contact is

open.

General notes on configuration group 5General notes on configuration group 5

General notes on configuration group 5

General notes on configuration group 5General notes on configuration group 5

1) Digital input function selection should be “consistent” with

other configuration parameters otherwise this digital input will

remain unused.

2) Changing menu the device will check that the same function

is not assigned to more than one digital input, otherwise the

display will show:

Upper display: CnF.5

Middle display: Err

Lower display: d.InP

C.H05 -C.H05 -

C.H05 -

C.H05 -C.H05 -

Digital input 3 contact statusDigital input 3 contact status

Digital input 3 contact status

Digital input 3 contact statusDigital input 3 contact status

Used to carry out the Burn Off procedure.

See on page 50 for details.

Upper display: CnF.5

Lower display: d3.St

Range: CLSd = The input is at logic level “1” when contact is

closed

OPEn = The input is at lo gic l evel “1” when contact is

open

39

Page 42

CONFIGURATION GROUP 6 [C.Ixx]CONFIGURATION GROUP 6 [C.Ixx]

CONFIGURATION GROUP 6 [C.Ixx]

CONFIGURATION GROUP 6 [C.Ixx]CONFIGURATION GROUP 6 [C.Ixx]

OTHERS CONFIGURATION PARAMETERS

C.I01 -C.I01 -

Green bargraph functionGreen bargraph function

C.I01 -

Green bargraph function

C.I01 -C.I01 -

Green bargraph functionGreen bargraph function

Upper display: CnF.6

Lower display: G.brG

Range: Pr.Ur = the green bargraph will show the process

variable value.

DEV. = the green bargraph will show the deviation

(process value minus set point).

C.I02 -C.I02 -

Orange bargraph functionOrange bargraph function

C.I02 -

Orange bargraph function

C.I02 -C.I02 -

Orange bargraph functionOrange bargraph function

Upper display: CnF.6

Lower display: O.brG

Range: OP.SP= The orange bargraph will show the operative set

point value.

P.Out. = The orange bargraph will show the process

output value.

C.I03 -C.I03 -

Bargraph initial scale valueBargraph initial scale value

C.I03 -

Bargraph initial scale value

C.I03 -C.I03 -

Bargraph initial scale valueBargraph initial scale value

This parameter is available when “G.brG” [C.I01] is equal to

“Pr.Ur” and/or “O.brG” [C.I02] is equal to “OP.SP”.

Upper display: CnF.6

Lower display: brG.L

Range: span limits of "CnF.1- PV.SL" [C.D02].

C.I04 -C.I04 -

Bargraph full scale valueBargraph full scale value

C.I04 -

Bargraph full scale value

C.I04 -C.I04 -

Bargraph full scale valueBargraph full scale value

This parameter is available when “G.brG” [C.I01] is equal to

“Pr.Ur” and/or “O.brG” [C.I02] is equal to “OP.SP”.

Upper display: CnF.6

Lower display: brG.H

Range: span limits of "CnF.1- PV.SL" [C.D02].

C.I05 -C.I05 -

Resolution of the deviation bargraphResolution of the deviation bargraph

C.I05 -

Resolution of the deviation bargraph

C.I05 -C.I05 -

Resolution of the deviation bargraphResolution of the deviation bargraph

This parameter is available when “G.brG” [C.I01] is equal to

“DEV.”.

Upper display: CnF.6

Lower display: brG.d

Range: 1-2-5-10-20 or 50 = Digits per segment

40

Page 43

C.I06 -C.I06 -

Set point display typeSet point display type

C.I06 -

Set point display type

C.I06 -C.I06 -

Set point display typeSet point display type

Upper display: CnF.6

Lower display: SP.dS

Range: Fn.SP = When device is in normal display mode and it is

performing a set point ramp, the middle display

will show the final set point value.

OP.SP= When device is in normal display mode and it is

performing a set point ramp, the middle display

will show the operative set point value.

C.I07 -C.I07 -

Burn Off and Purge activation thresholdBurn Off and Purge activation threshold

C.I07 -

Burn Off and Purge activation threshold

C.I07 -C.I07 -

Burn Off and Purge activation thresholdBurn Off and Purge activation threshold

Upper display: CnF.6

Lower display: t.t.Ac

Range: the instrument will start the Burn Off and the Purge

procedure according with the following selection:

No = without testing the temperature limit (1000 °F)

YES= if the temperature test is satisfy.

::

Available

: When mV is selected as primary control variable.

::

C.I08 -C.I08 -

Time out selectionTime out selection

C.I08 -

Time out selection

C.I08 -C.I08 -

Time out selectionTime out selection

Upper display: CnF.6

Lower display: t.out

Range: tñ.10 = 10 s time out

tñ.30 = 30 s time out

CONFIGURATION GROUP [C.Lxx]CONFIGURATION GROUP [C.Lxx]

CONFIGURATION GROUP [C.Lxx]

CONFIGURATION GROUP [C.Lxx]CONFIGURATION GROUP [C.Lxx]

INPUT/OUTPUT TEST

This group is displayed only when configuration modify mode is

enabled.

This group allows you to verify the correct working of:

- the relay outputs (OUT 1 up to OUT5),

- digital inputs (diG.1 up to diG.3),

- the inputs from In1 up to In8 and the relays of the outputs from

OUT10 up to OUT19, if the optional I/O card is fitted.

When an output is in "On" status, the related LED will light up

(for OUT 5 is used the "ST" LED)

C.L01 OUT 1 statusC.L01 OUT 1 status

C.L01 OUT 1 status

C.L01 OUT 1 statusC.L01 OUT 1 status

Upper display: VErF

Lower display: OU.1

Range: On = Output enabled (relay energized)

OFF = Output disabled (relay deenergized)

41

Page 44

NOTE:NOTE:

NOTE: By pushing the or key it is possible to change

NOTE:NOTE:

the output state. The setting above described is the

same for the remaining outputs.

C.L02 OUT 10 statusC.L02 OUT 10 status

C.L02 OUT 10 status

C.L02 OUT 10 statusC.L02 OUT 10 status

This parameter is available only if the optional card is fitted.

Upper display: VErF

Lower display: OU.10

Range: On = Output enabled (relay energized)

OFF = Output disabled (relay deenergized)

NOTE:NOTE:

NOTE: By pushing the or key it is possible to change

NOTE:NOTE:

the output state. The setting above described is the

same for the remaining outputs.

C.L04 Digital input In.1 statusC.L04 Digital input In.1 status

C.L04 Digital input In.1 status

C.L04 Digital input In.1 statusC.L04 Digital input In.1 status

This parameter is available only if the optional card is fitted.

Upper display: VErF

Lower display: In.1

Range: Open = Input open

CLSd = Input closed

NOTE:NOTE:

NOTE:The setting above described is the same for the

NOTE:NOTE:

remaining inputs.

General note for configuration group "VErF"General note for configuration group "VErF"

General note for configuration group "VErF"

General note for configuration group "VErF"General note for configuration group "VErF"

Returning in the "run time mode", the instrument restarts to

control the process, the settings performed into this group do not

affect the working settings.

C.L03 Digital input dIG.1C.L03 Digital input dIG.1

C.L03 Digital input dIG.1

C.L03 Digital input dIG.1C.L03 Digital input dIG.1

statusstatus

status

statusstatus

Upper display: VErF

Lower display: dIG.1

Range: Open = Input open

CLSd = Input closed

NOTE:NOTE:

NOTE:The setting above described is the same for the

NOTE:NOTE:

remaining inputs.

42

Page 45

CONFIGURATION GROUP END [C.Mxx]CONFIGURATION GROUP END [C.Mxx]

CONFIGURATION GROUP END [C.Mxx]

CONFIGURATION GROUP END [C.Mxx]CONFIGURATION GROUP END [C.Mxx]

END CONFIGURATION

This group is displayed only when configuration modify mode is

enabled.

Upper display: ConF

Lower display: End

Range: nO =with this selection the instrument comes back

to the first display of the configuration modify

mode.

YES =this selection ends the configuration modify

mode; the instrument preforms an automatic

reset and restarts in the run time mode.

Pushing ”” or “” push-button select the desired action and then

push “MENU” push-button.

RUN TIME MODERUN TIME MODE

RUN TIME MODE

RUN TIME MODERUN TIME MODE

If V101 is correctly set (see "Operative mode and hardware lock"

at page 16), and the configuration mode has been terminated,

the instrument will be in run time mode and in "normal display

mode" (see below).

During run time mode the instrument performs the loop control

and manages all the instrument functions (SMART, ALARMS,

etc.).

DISPLAY FUNCTIONDISPLAY FUNCTION

DISPLAY FUNCTION

DISPLAY FUNCTIONDISPLAY FUNCTION

When device is powered and it is operating in automatic mode,

the upper display shows the process variable, the middle display

shows the set point value (final or operative according to “SP.dS”

[C.I06] parameter setting).

We define the above condition as “normal display mode”.

The lower display will show:

a) the control output value.

NOTES:NOTES:

NOTES:

NOTES:NOTES:

1) If the instrument is configured with one control output

(linear or time proportional), the control output value is

displayed in the 0 to 100% range.

43

Page 46

2)if the device is configured with two control outputs; the

value of the MAIN output is shown on the two most

significant digits, while the value of the SECONDARY

output is shown on the two less significant digits.

The decimal point between the two values will be flashing.

The graphic symbol “ “ shows that the specific

control output is > 100%.

b) Pushing the FUNC push-button; it is possible to display the

sensor output in mV, the "mV" LED lights up.

NOTE:NOTE:

NOTE: this selection is available:

NOTE:NOTE:

- if "mV" is not selected as controlled variable,

- even if a measure error is shown on the upper

display,

- even if Burnoff or Probe test procedure are in

progress.

c) Pushing FUNC push-button again, it is possible to display the

sensor temperature, the "TP" LED lights up.

d)Pushing FUNC push-button again, it is possible to display the

Dew point value, the "DP" LED lights up.

NOTE:NOTE:

NOTE: this selection is available:

NOTE:NOTE:

- if Dew point or O2 are not selected as controlled

variable,