Page 1

Series 3 PID Temperature

Controller

OPERATIONS MANUAL

P/N 31333

Super Systems Inc.

72 05 Edington Drive

Cincinnati, OH 45249

Ph : 513-772-0060, 800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Operations Manual Series 3

Series 3 PID Temperature Controller

Operations Manual

Series 3 Controller

Contents

Installation and Basic Operation What Instrument Do I Have? ...................................................................................... 6

1.1 Unpacking Your Controller ...................................................................................................................................................6

1.2

Dimensions ...........................................................................................................................................................................6

1.3

Step 1: Installation ...............................................................................................................................................................7

1.3.1

Panel Mounting t he Controller ...............................................................................................................................................7

1.3.2

Panel Cut Out Sizes ................................................................................................................................................................7

1.3.3

Recommended minimum spacing of c ontrollers .....................................................................................................................7

1.3.4

To Remove the Controller from its Sleeve ...............................................................................................................................7

2. Step 2: Wiring ............................................................................................................................................ 8

2.1 Terminal Layout Series 3 Controller .....................................................................................................................................8

2.2

Wire Sizes .............................................................................................................................................................................9

2.3

Precautions ...........................................................................................................................................................................9

2.4

Sensor Input (Measuring Input) .............................................................................................................................................9

2.4.1

Thermocoup le Input ..............................................................................................................................................................9

2.4.2

RTD Input ..............................................................................................................................................................................9

2.4.3

Linear Input (mA or mV) .........................................................................................................................................................9

2.4.4

Two-Wire Transmitter Inputs ..................................................................................................................................................9

2.5

Input/Output 1 & Output 2 ....................................................................................................................................................10

2.5.1

Relay Output (Form A, normally open) ...................................................................................................................................10

2.5.2

Logic (SSR drive) Output ........................................................................................................................................................10

2.5.3

DC Out put .............................................................................................................................................................................10

2.5.4

Triac Output ..........................................................................................................................................................................10

2.5.5

Logic Co ntact Closure Inp ut (I/O 1 only) ..................................................................................................................................10

2.6

Remote Setpoint Input .........................................................................................................................................................10

2.7

Output 3 ...............................................................................................................................................................................10

2.8

Summary of DC Outputs .......................................................................................................................................................10

2.9

Output 4 (AA Relay) ..............................................................................................................................................................11

2.10

General Note About Relays and Inductive Loads ..................................................................................................................11

2.11

Digital Inputs A & B ...............................................................................................................................................................11

2.12

Transmitter Power Supply ....................................................................................................................................................11

2.13

Digital Communications ........................................................................................................................................................12

2.14

Controller Power Supply .......................................................................................................................................................13

2.15

Example Heat/Cool Wiring Diagram .....................................................................................................................................13

3. Safety and EMC Information ...................................................................................................................... 14

3.1 Installation Safety Requirements ..........................................................................................................................................14

4. Switch On .................................................................................................................................................. 16

4.1 New Controller .....................................................................................................................................................................16

4.1.1

Quick Start Code ...................................................................................................................................................................16

4.2

To Re-Enter Quick Code mode ..............................................................................................................................................17

4.3

Pre-Configured Controller or Subsequent Starts ...................................................................................................................17

4.4

Front Panel Layout ...............................................................................................................................................................18

4.4.1

To Set The Target Temperature. .............................................................................................................................................18

4.4.2

Alarms ...................................................................................................................................................................................18

4.4.3

Alarm Indication ....................................................................................................................................................................18

4.4.4

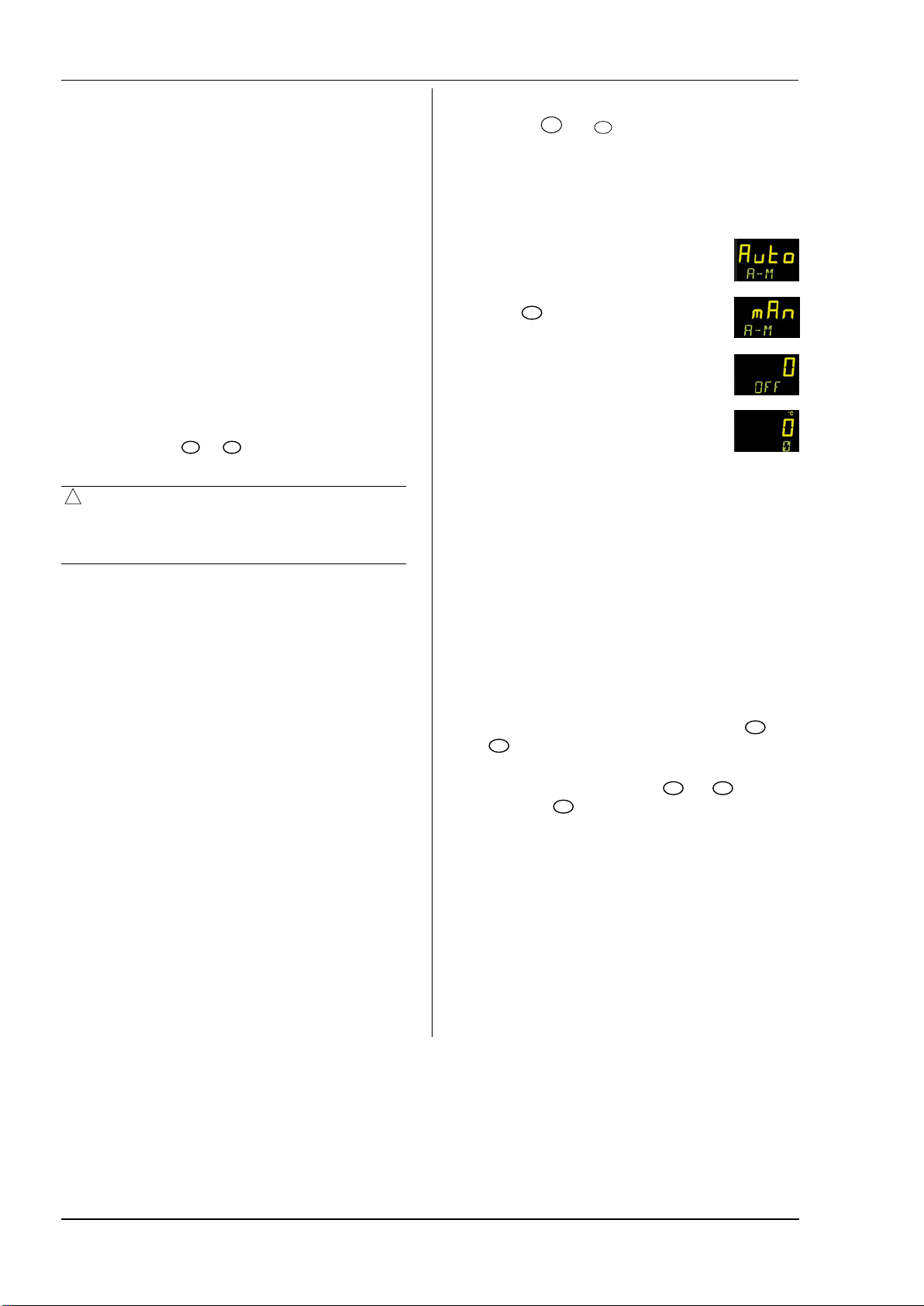

Auto, Manual and Off Mode ...................................................................................................................................................20

4.4.5

To Select Auto, Manual or Off Mode .......................................................................................................................................20

4.4.6

Level 1 Operator Parameters ..................................................................................................................................................21

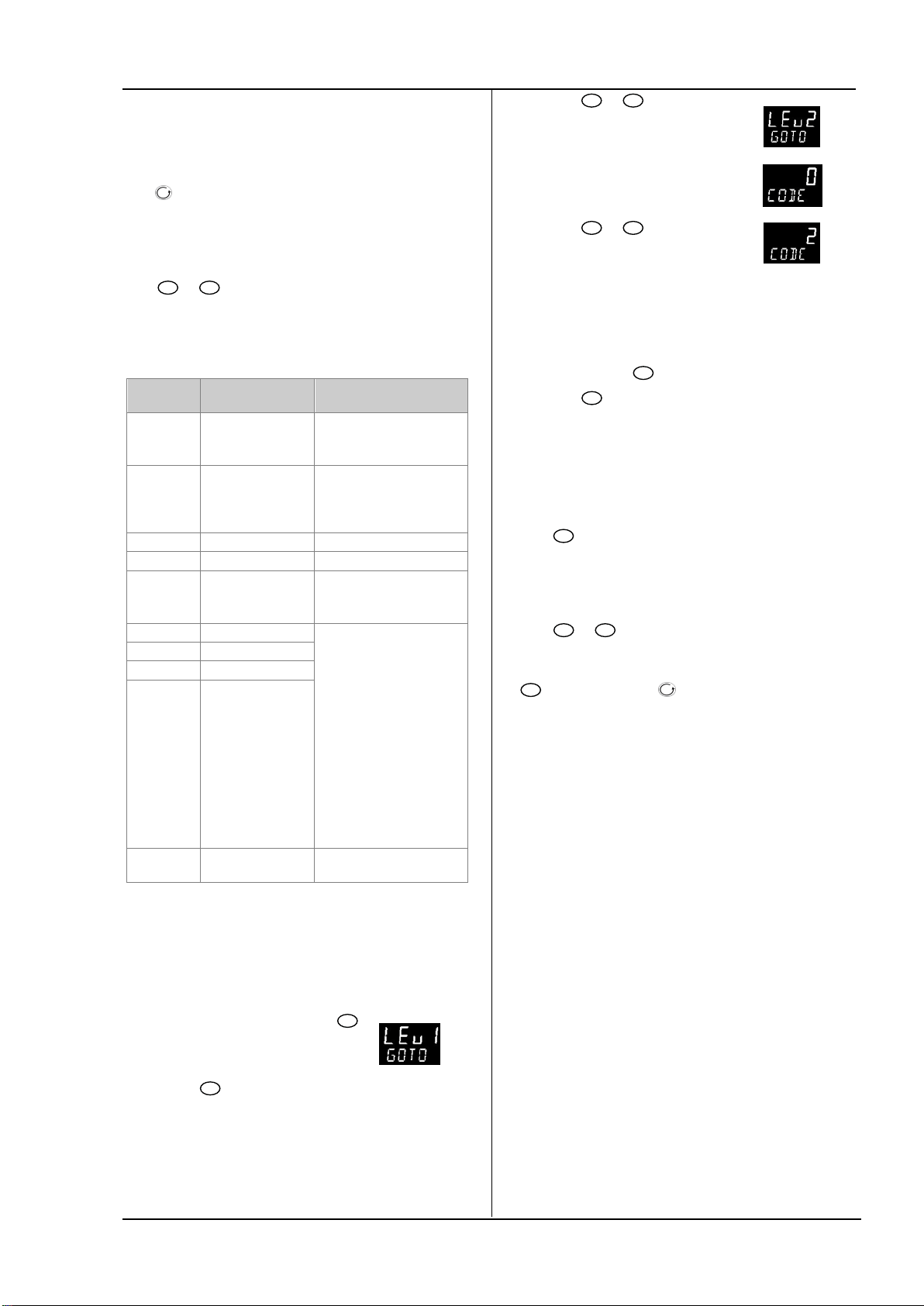

5. Operator Level 2 ........................................................................................................................................ 21

5.1 To Enter Level 2 ....................................................................................................................................................................21

5.2

To Return to Level 1 .............................................................................................................................................................21

5.3

Level 2 Parameters ...............................................................................................................................................................21

6. Access to Further Parameters .................................................................................................................... 25

6.1.1 Level 3 ...................................................................................................................................................................................25

6.1.2

Configuration Level ...............................................................................................................................................................25

6.1.3

To Select Access Level 3 or Configuration Level .......................................................................................................................26

6.2

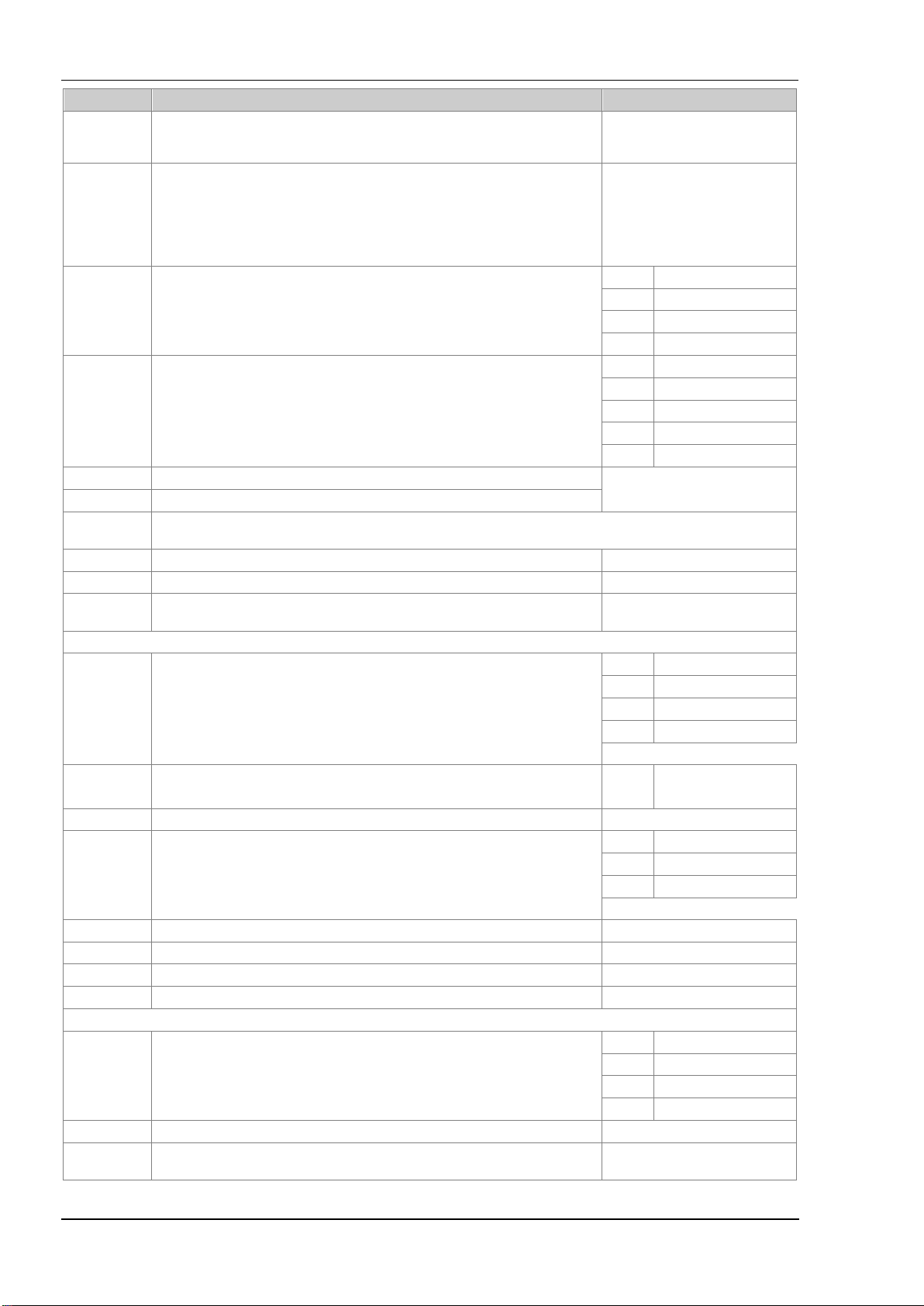

Parameter lists ......................................................................................................................................................................27

6.2.1

To Choose Parameter List Headers .........................................................................................................................................27

6.2.2

To Locate a Parameter ...........................................................................................................................................................27

6.2.3

How P arameters are Displayed ..............................................................................................................................................27

6.2.4

To Change a Parameter Value ................................................................................................................................................27

6.2.5

To Return to the HOME Display ..............................................................................................................................................27

6.2.6

Time Out ...............................................................................................................................................................................27

6.3

Navigation Diagram ..............................................................................................................................................................28

2

Page 3

Series 3 Operations Manual

6.4 Access Parameters ............................................................................................................................................................... 29

7. Controller Block Diagram ........................................................................................................................... 31

8.

Temperature (or Process) Input ................................................................................................................. 32

8.1 Process Input Parameters .................................................................................................................................................... 32

8.1.1

Input Types and Ranges ........................................................................................................................................................ 33

8.1.2

Operation of Sensor Break .................................................................................................................................................... 34

8.2

PV Offset ............................................................................................................................................................................. 35

8.2.1

Example: To Apply an Offset: ............................................................................................................................................... 35

8.3

PV Input Scaling .................................................................................................................................................................. 35

8.3.1

Example: To Scale a Linear Input ........................................................................................................................................... 35

9. Input/Output ............................................................................................................................................. 36

9.1 Input/Output Parameters ..................................................................................................................................................... 37

9.1.1

Input /Output 1 List (IO-1) ...................................................................................................................................................... 37

9.1.2

Remote Digital Setpoint Select and Remote Fail .................................................................................................................... 38

9.1.3

Sense ................................................................................................................................................................................... 38

9.1.4

Source .................................................................................................................................................................................. 38

9.1.5

Po wer Fail ............................................................................................................................................................................. 38

9.1.6

Example: To Configure IO-1 Relay to Operate on Alarms 1 and 2: ........................................................................................... 38

9.1.7 Output List 2 (OP-2) ............................................................................................................................................................. 39

9.1.8

Output List 3 (OP-3) .............................................................................................................................................................. 39

9.1.9

AA Relay (AA) (Output 4) ...................................................................................................................................................... 40

9.1.10

Digital Inp ut Parameters .................................................................................................................................................. 41

9.2

Current Transformer Input Parameters (Current Transformer is not available) .................................................................... 42

10. Setpoint Generator .................................................................................................................................... 43

10.1 Setpoint Parameters ............................................................................................................................................................ 43

10.2

Example: To Set Ramp Rate ............................................................................................................................................... 44

11. Control ...................................................................................................................................................... 45

11.1 Types of Control .................................................................................................................................................................. 45

11.1.1

On/Off Control ................................................................................................................................................................ 45

11.1.2

PID Control ...................................................................................................................................................................... 45

11.2

Control Parameters .............................................................................................................................................................. 46

11.2.1

Proportional Band ‘PB’ ..................................................................................................................................................... 48

11.2.2

Integral Term ‘TI’ .............................................................................................................................................................. 48

11.2.3

Derivative Term ‘TD’ ........................................................................................................................................................ 49

11.2.4

Relative Cool Gain ‘R2G’ ................................................................................................................................................... 49

11.2.5

High and Low Cutback ..................................................................................................................................................... 50

11.2.6

Manual Reset ................................................................................................................................................................... 50

11.2.7

Control Action ................................................................................................................................................................. 50

11.2.8

Loop Break ...................................................................................................................................................................... 50

11.2.9

Cooling Algorithm ........................................................................................................................................................... 50

11.3

Tuning ................................................................................................................................................................................. 50

11.3.1

Loop Response ................................................................................................................................................................ 51

11.3.2

Initial Settings ................................................................................................................................................................. 51

11.3.3

Automa tic Tuning ............................................................................................................................................................ 53

11.3.4

To Start Autotune ............................................................................................................................................................ 53

11.3.5

Autotune from Below SP – Heat/Cool ............................................................................................................................... 54

11.3.6

Autotune From Below SP – Heat Only .............................................................................................................................. 55

11.3.7

Autotune at Setpoint – Heat/Cool ......................................................................................................................................... 56

11.3.8

Manual Tuning ................................................................................................................................................................. 56

11.3.9

Manually Setting Relative Cool Gain ................................................................................................................................. 57

11.3.10

Manually Setting the Cutback Values ............................................................................................................................... 58

11.4

Auto-tune Configures R2G ................................................................................................................................................... 59

11.5

Example: To Configure Heating and Cooling ....................................................................................................................... 60

11.5.1

Effect of Control Action, Hysteresis and Deadband ........................................................................................................... 61

12. Alarms ....................................................................................................................................................... 62

12.1 Types of Alarm ..................................................................................................................................................................... 62

12.1.1

Alarm Rela y Output ......................................................................................................................................................... 64

12.1.2

Alarm Indication .............................................................................................................................................................. 64

12.1.3

To Acknowledge An Alarm ............................................................................................................................................... 64

12.2

Behaviour of Alarms After a Power Cycle ............................................................................................................................. 65

12.2.1

Examp le 1 ........................................................................................................................................................................ 65

12.2.2

Example 2 ........................................................................................................................................................................ 65

12.2.3

Examp le 3 ........................................................................................................................................................................ 65

12.3

Alarm Parameters ................................................................................................................................................................ 66

12.3.1

Example: To Co nfigure Alarm 1 ........................................................................................................................................ 67

12.4

Diagnostic Alarms ................................................................................................................................................................ 68

12.4.1

Out of Range Indication ................................................................................................................................................... 68

13. Digital Communications ............................................................................................................................. 69

13.1 Digital Communications Wiring ............................................................................................................................................ 69

13.1.1

EIA485 ( 2-wire) ................................................................................................................................................................ 69

3

Page 4

Operations Manual Series 3

13.2 Digital Communications Parameters .....................................................................................................................................70

13.3

Example: To Set Up Instrument Address ..............................................................................................................................71

13.4

DATA ENCODING .................................................................................................................................................................71

13.5

Parameter Modbus Addresses ...............................................................................................................................................71

14. Calibration ................................................................................................................................................. 81

14.1 To Check Input Calibration ....................................................................................................................................................81

14.1.1

Precautions ......................................................................................................................................................................81

14.1.2

To Check mV Input Calibratio n ..........................................................................................................................................81

14.1.3

To Check Thermocouple Input Calibration .........................................................................................................................81

14.1.4

To Check RTD Input Calibration ........................................................................................................................................81

14.2

Offsets ..................................................................................................................................................................................82

14.2.1

Two Point Offset ..............................................................................................................................................................82

14.2.2

To Apply a Two Point Offset .............................................................................................................................................83

14.2.3

To Remove the Two Point Offset ......................................................................................................................................83

14.3

Input Calibration ...................................................................................................................................................................84

14.3.1

To Calibrate mV Input .......................................................................................................................................................84

14.3.2

To Calibrate Thermocouple Input ......................................................................................................................................85

14.3.3

To Calibrate RTD Input ......................................................................................................................................................86

14.3.4

To Calibrate mA Outputs ..................................................................................................................................................87

14.3.5 To Calibrate Remote Setpoint Input ..................................................................................................................................88

14.3.6

To Return to Factory Calibration .......................................................................................................................................89

14.4

Calibration Parameters .........................................................................................................................................................90

15. Appendix A TECHNICAL SPECIFICATION .................................................................................................. 91

4

Page 5

Series 3 Operations Manual

Issue Status of this Manual

Issue 5 of this Handbook applies to software versions 2.09 and above for PID controller and 2.29 and above for Valve Position

controllers and includes:

• Remote Setpoint Input Option RCL

• Triac output

It also applies to firmware versions 2.11 and includes new parameters:

Inverted status word

Rate of change alarms

Setpoint retransmission limits

Input filter

Issue 6 includes parameter ‘AT.R2G’

Issue 7 corrects range limits. Change to definition of LOC.T. Correct description of enumerations for parameter IM.

Issue 8 includes the following changes:

A more detailed description of loop tuning.

Updates to Appendix A, Technical Specification.

5

Page 6

Operations Manual Series 3

Installation and Basic Operation What Instrument Do I Have?

Thank you for choosing this Series 3 Temperature Controller.

The Series 3 provides precise temperature control of

industrial processes and is available in one standard DIN size:

• 1/4 DIN

A universal input accepts various thermocouples, RTDs or

process inputs. Up to four outputs can be configured for

control, alarm or re-transmission purposes. 485

communication is also available.

The controller may have been ordered pre-configured or

setup with defualt configuration..

If the display shows SET 1 the controller was supplied

without parameters and will need to be configured when it

is first switched on.

This Manual takes you through all aspects of installation,

wiring, configuration and use of the controller.

1.1 Unpacking Your Controller

The controller is supplied with

• Sleeve (with the controller fitted in the sleeve)

• Two panel retaining clips and sealing gasket mounted

on the sleeve

• Component packet containing a snubber for relay

output and a 2.49Ω resistor for current inputs.

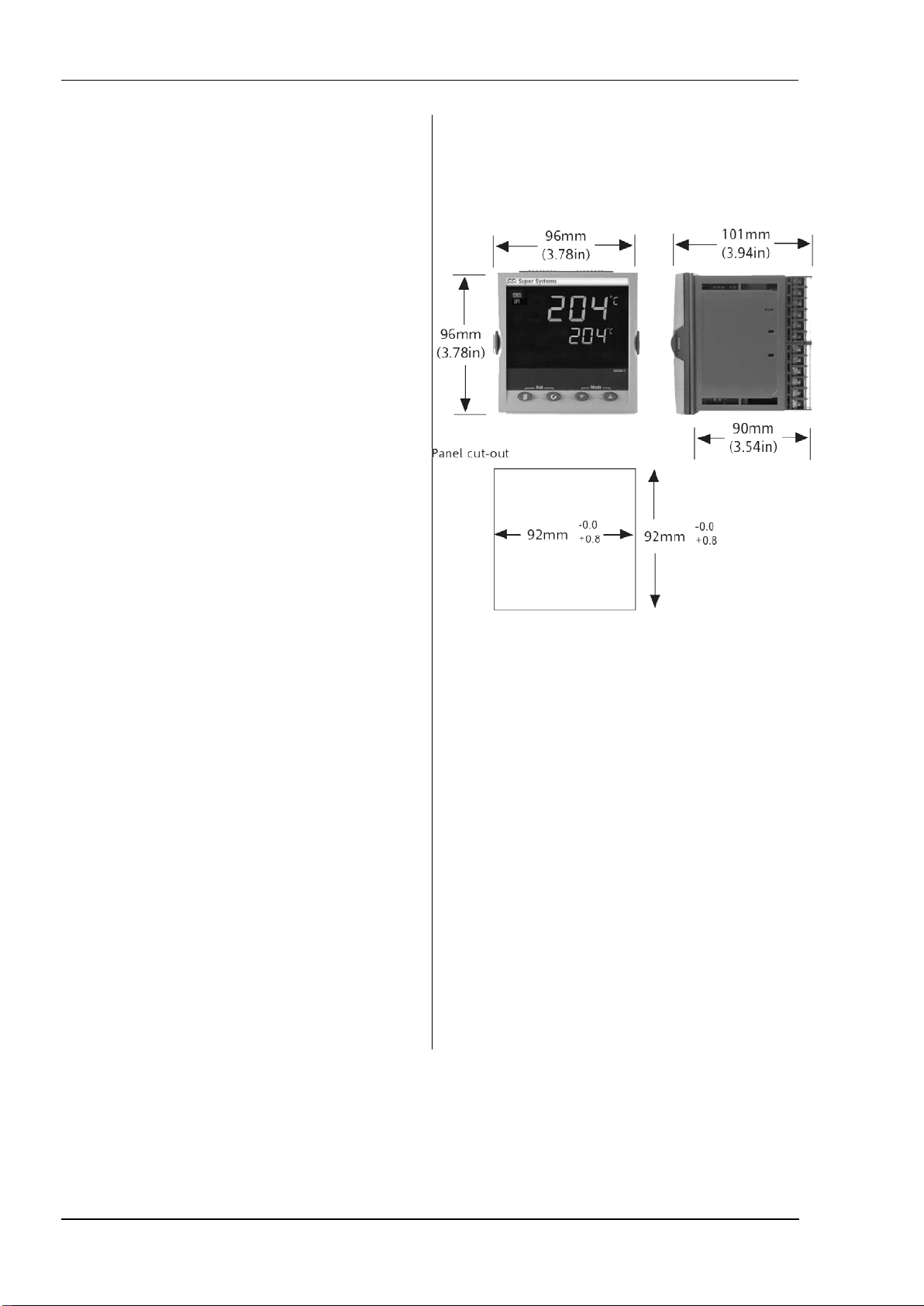

1.2 Dimensions

General views of the controller are shown below together

with overall dimensions.

6

Page 7

Series 3 Operations Manual

1.3 Step 1: Installation

This instrument is intended for permanent installation, for

indoor use only, and to be enclosed in an electrical panel

Select a location which is subject to minimum vibrations the

ambient temperature is within 0 and 55oC (32 - 131

humidity 5 to 95% RH non condensing.

The instrument can be mounted on a panel up to 15mm

thick.

To ensure IP65 and NEMA 4 front protection, mount on a

non-textured surface.

Please read the safety information in section 3 before

proceeding.

1.3.1 Panel Mounting the Controller

1. Prepare a cut-out in the mounting panel to the size

shown. If a number of controllers are to be mounted in

the same panel observe the minimum spacing shown.

2. Fit the sealing gasket behind the front bezel of the

controller

3. Insert the controller through the cut-out

4. Spring the panel retaining clips into place. Secure the

controller in position by holding it level and pushing both

retaining clips forward.

5. Peel off the protective cover from the display.

o

F) and

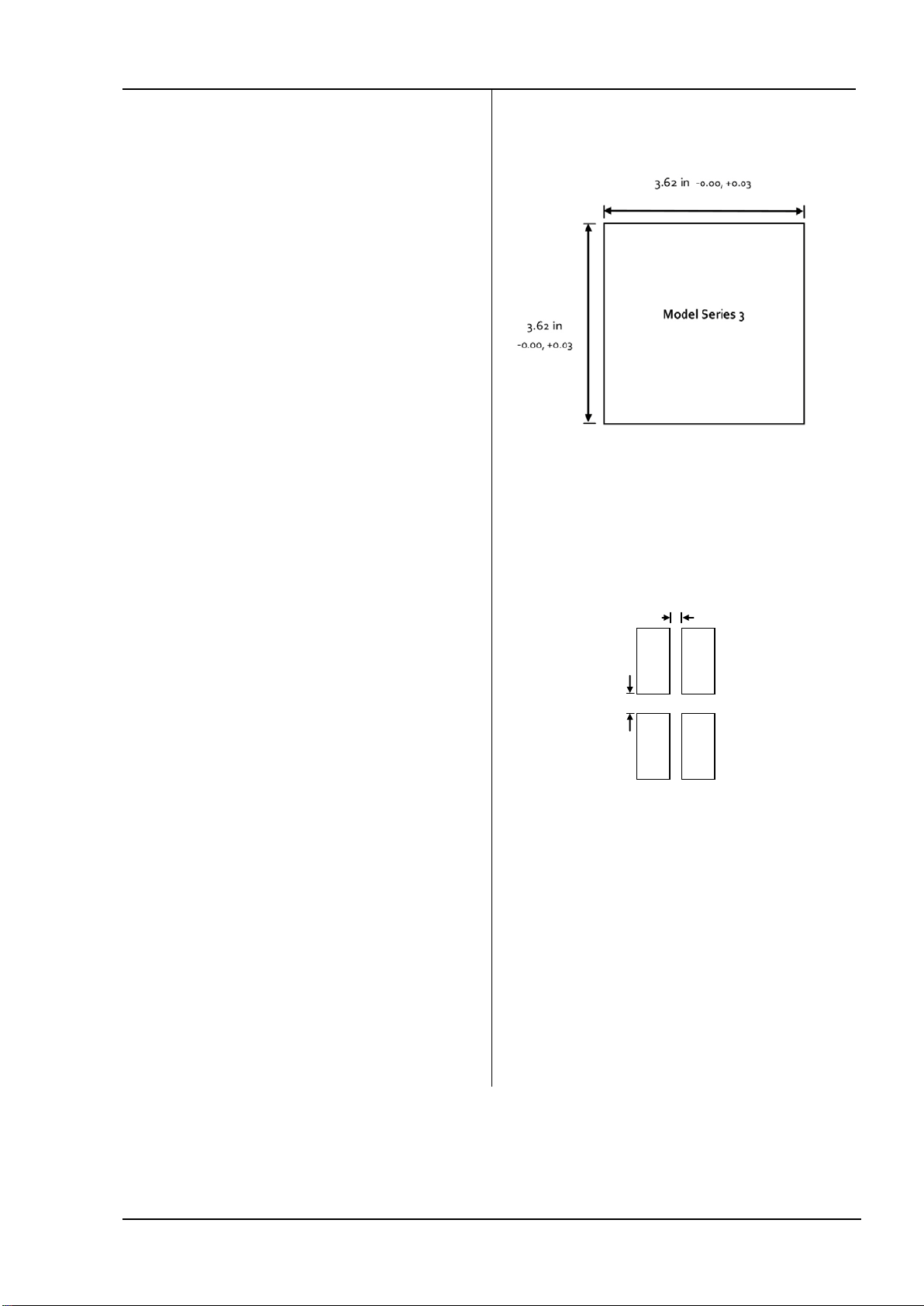

1.3.2 Panel Cut Out Sizes

1.3.3 Recommended minimum spacing of

controllers

10mm (0.4 in)

38mm (1.5 in)

(Not to scal e)

1.3.4 To Remove the Controller from its Sleeve

The controller can be unplugged from its sleeve by easing

the latching ears outwards and pulling it forward out of the

sleeve. When plugging it back into its sleeve, ensure that

the latching ears click back into place to maintain the sealing

7

Page 8

Operations Manual Series 3

!

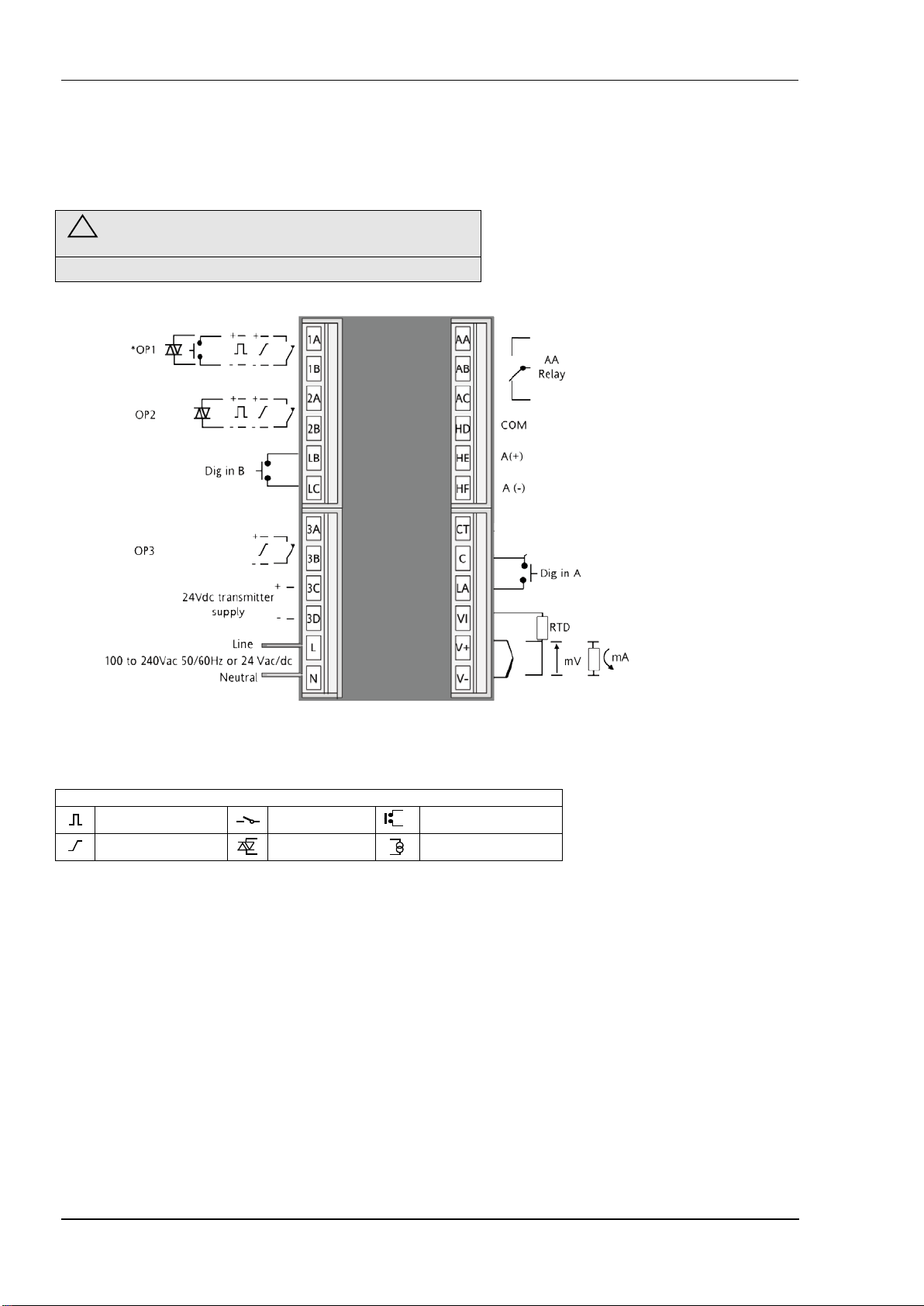

2. Step 2: Wiring

2.1 Terminal Layout Series 3 Controller

Ensure that you have the correct supply for your indicator

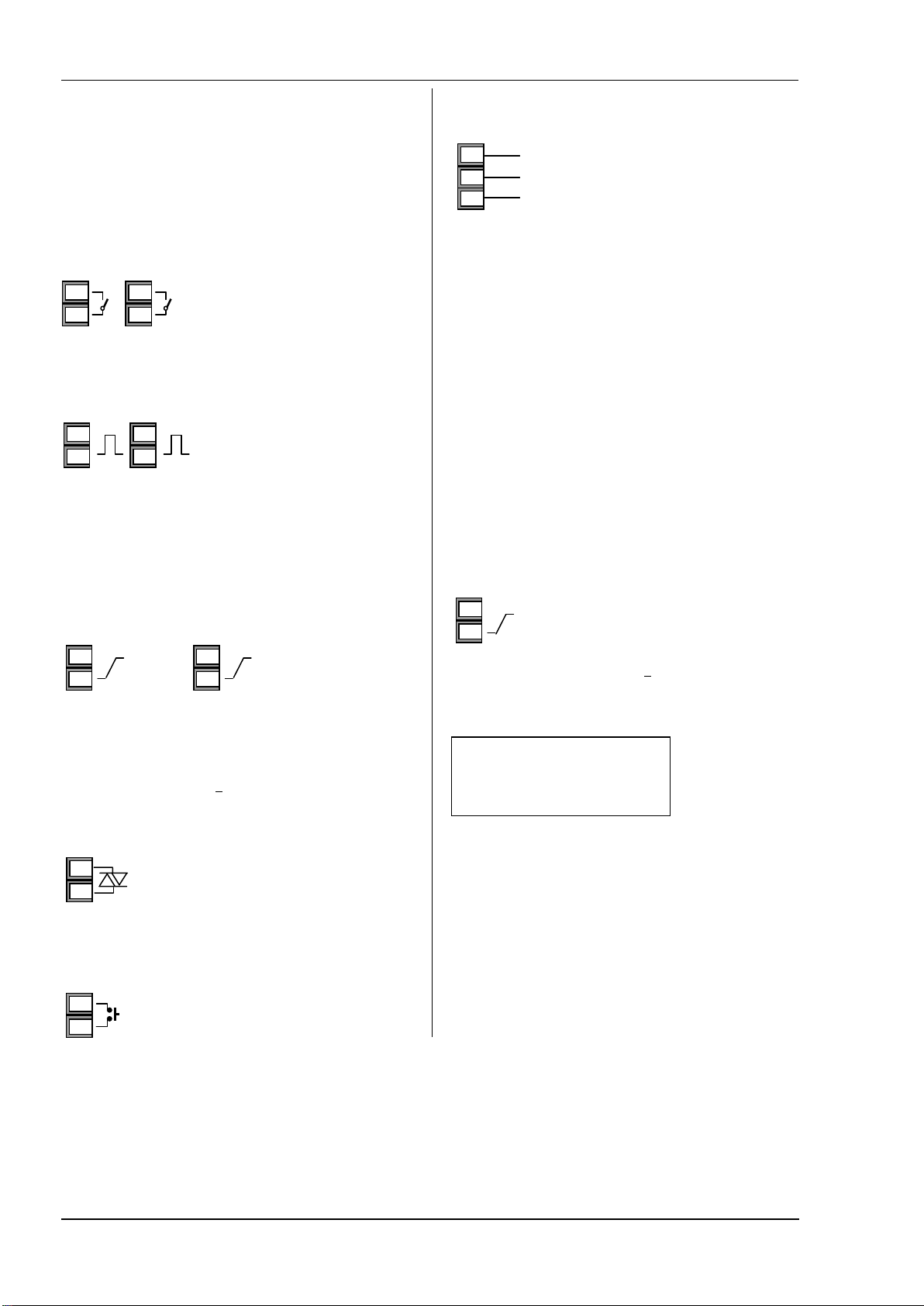

Key to symbols used in wiring diagrams

Logic ( SSR drive) out put

mA analogue output

Relay output

Triac output

Contact input

Current t ransformer input

8

Page 9

Series 3 Operations Manual

-

2.2 Wire Sizes

The screw terminals accept wire sizes from 0.5 to 1.5 mm (16

to 22AWG). Hinged covers prevent hands or metal making

accidental contact with live wires. The rear terminal screws

should be tightened to 0.4Nm (3.5lb in).

2.3 Precautions

• Do not run input wires together with power cables

• When shielded cable is used, it should be grounded at

one point only

• Any external components (such as zener barriers, etc)

connected between sensor and input terminals may

cause errors in measurement due to excessive and/or

un-balanced line resistance or possible leakage currents

• Not isolated from the logic outputs & digital inputs

• Pay attention to line resistance; a high line resistance

may cause measurement errors

2.4 Sensor Input (Measuring Input)

2.4.1 Thermocouple Input

+

Positive

V+

V-

Negative

-

• Use the correct compensating cable preferably shielded

2.4.2 RTD Input

VI

PRT

V+

PRT

V-

Lead compensation

• The resistance of the three wires must be the same.

The line resistance may cause errors if it is greater than

22Ω

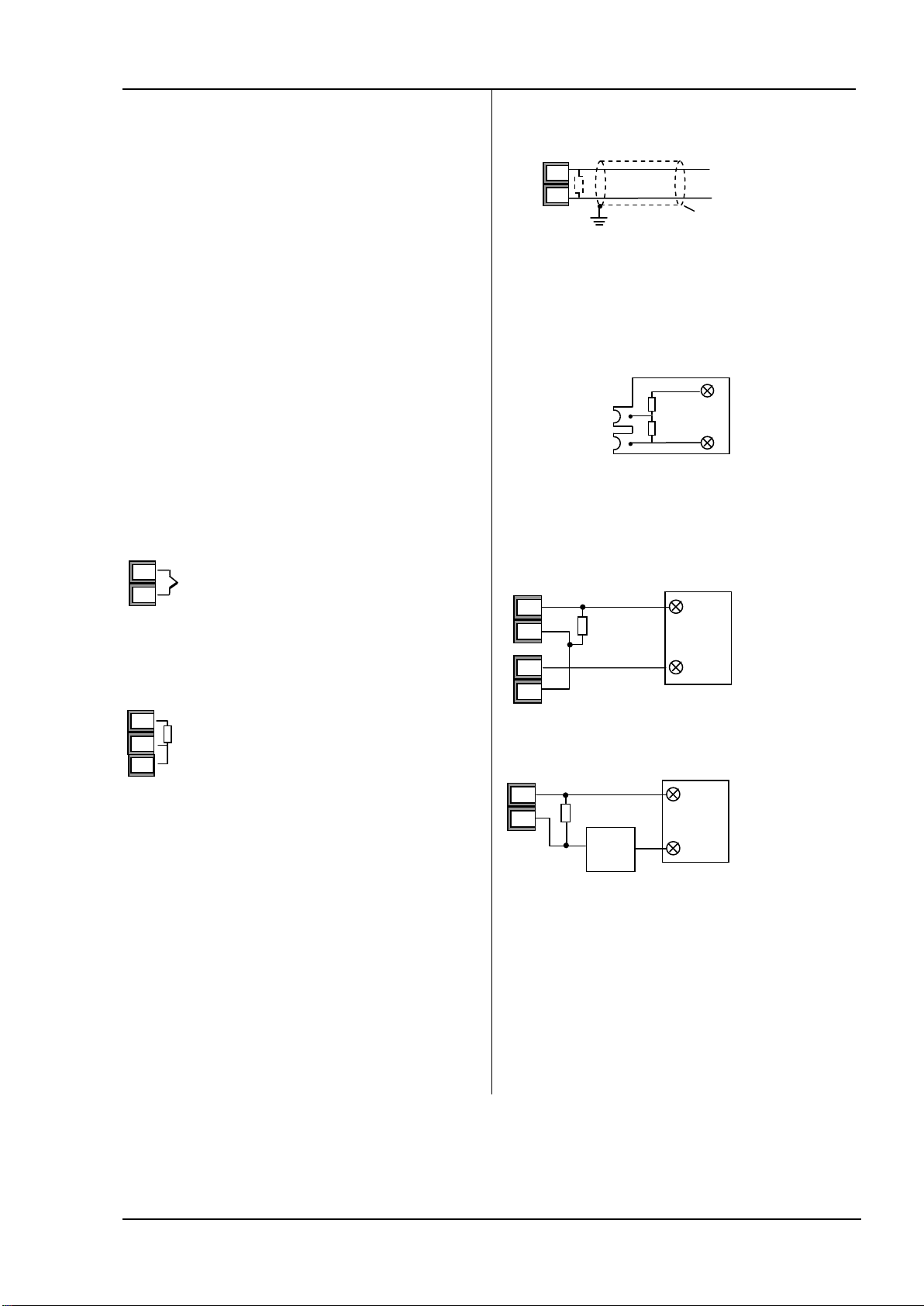

2.4.3 Linear Input (mA or mV)

V+

V-

2.49Ω

+

+

mA / mV input

-

Shield

• If shielded cable is used it should be grounded in one

place only as shown

• For a mA input connect the 2.49Ω burden resistor

supplied between the V+ and V- terminals as shown

• For a 0-10Vdc input an external input adapter is required

(not supplied).

+

-

100KΩ

806Ω

+

0-10V

Input

-

Sensor break alarm does not operate with this adaptor

fitted.

2.4.4 Two-Wire Transmitter Inputs

Using internal 2 4V power supply ( Series 3)

+

V+

-

V-

3C

3D

2.49Ω

+

-

Using external pow er supply

+

V+

-

V-

2.49Ω

-

Extern al power

supply

+

-

2-Wire

Transmitter

+

-

2-Wire

Transmitter

+

9

Page 10

Operations Manual Series 3

2.5 Input/Output 1 & Output 2

OP3

Non-isolated

OP4

Non-isolated

1A

2A

+

-

+

-

1A

+

-

+

-

+

-

These outputs can be logic (SSR drive), or relay, or mA dc. In

addition the logic output 1 can be used as a contact closure

input.

For input/output functions, see Quick Start Code in section

4.1.1.

2.5.1 Relay Output (Form A, normally open)

Isolated output 240Vac CAT II

OP1 OP2

1B

2B

2.5.2 Logic (SSR drive) Output

OP1

1A

1B

OP2

2A

2B

• The output switching rate must be set to prevent

damage to the output device in use. See parameter

1.PLS or 2.PLS in section 5.

2.5.3 DC Output

OP1

1A

1B

• Not isolated from the sensor input

• Software configurable: 0-20mA or 4-20mA.

• Max load resistance: 500Ω

• Calibration accuracy: +(<1% of reading + <100µA)

2.5.4 Triac Output

•

Isolated output 240Vac CATII

1(2) A

• Rating: 0.75A rms, 30 to 264Vac resistive

1(2)B

•

• Contact rating: 2A 264Vac

resistive

Not isolated from the sensor

•

input

• Output ON state: 12Vdc at

40mA max

• Output OFF state: <300mV,

<100µA

OP2

2A

2B

2.6 Remote Setpoint Input

• There are two inputs; 4-20mA and 0-10 Volts which can be

HD

HE

HF

0-10 Volts

4-20 mA

Common

fitted in place of digital

communications

• It is not necessary to fit an

external burden resistor to the

4-20mA input

• If the 4-20mA remote setpoint input is connected and

valid (>3.5mA; < 22mA) it will be used as the main

setpoint. If it is not valid or not connected the controller

will try to use the Volts input. Volts sensor break occurs at

<-1; >+11V. The two inputs are not isolated from each

other

• If neither remote input is valid the controller will fall back

to the internal setpoint, SP1 or SP2 and flash the alarm

beacon. The alarm can also be configured to activate a

relay or read over digital communications.

• To calibrate the remote setpoint, if required, see section

15.3.5

• A local SP trim value is available in access level 3.

2.7 Output 3

Output 3 will be a mA output.

DC Output

OP3

3A

3B

• Isolated output 240Vac CAT II

• Software configurable: 0-20mA or 4-

20mA

• Max load resistance: 500Ω

• Calibration accuracy: 0.5%, +100µA

2.8 Summary of DC Outputs

OP1 Non-isolated

OP2 Non-isolated

2.5.5 Logic Contact Closure Input (I/O 1 only)

Not isolated from the sensor input

•

OP1

• Switching: 12Vdc at 40mA max

• Contact open > 500Ω. Contact closed <

1B

10

150Ω

Page 11

Series 3 Operations Manual

2.9 Output 4 (AA Relay)

Output 4 is a relay..

For output functions, see Quick Start Code in section 4.1.1.

OP4

AA

AB

AC

Relay Output (Fo rm C)

• Contact rating: 2A 264Vac resistive

2.10 General Note About Relays and

Inductive Loads

High voltage transients may occur when switching inductive

loads such as some contactors or solenoid valves. Through

the internal contacts, these transients may introduce

disturbances which could affect the performance of the

instrument.

For this type of load it is recommended that a ‘snubber’ is

connected across the normally open contact of the relay

switching the load. The snubber recommended consists of a

series connected resistor/capacitor (typically 15nF/100Ω). A

snubber will also prolong the life of the relay contacts.

A snubber should also be connected across the output

terminal of a triac output to prevent false triggering under

line transient conditions.

WARNING

When the relay contact is open or it is connected to a high

impedance load, the snubber passes a current (typically

0.6mA at 110Vac and 1.2mA at 240Vac). You must ensure

that this current will not hold on low power electrical

loads. If the load is of this type the snubber should not be

connected.

• Isolated output 240Vac CAT II

• Output: 24Vdc, +/- 10%. 28mA max.

• inside the controller

2.11 Digital Inputs A & B

Digital input A is an optional input in model Series 3. Digital

input B is always fitted in model Series 3.

Dig in A

C

LA

Dig in B

LB

LC

• Not isolated from the current transformer input or the

sensor input

• Switching: 12Vdc at 40mA max

• Contact open > 500Ω. Contact closed < 200Ω

• Input functions: Please refer to the list in the quick

codes.

2.12 Transmitter Power Supply

The Transmitter is fitted as standard in model Series 3.

Transmi tter Supply

3C

3D

24Vdc

11

Page 12

Operations Manual Series 3

2.13 Digital Communications

Optional.

Digital communications uses the Modbus protocol. The

interface comes standard as EIA485 (2-wire).

Digital communications is not available if Remote

Setpoint is fitted

Cable screen should be grounded at one point only to

prevent earth loops.

• Isolated 240Vac CAT II.

EIA485 Connections

Rx Tx Com

Tx Rx Com

RxB/

TxB

*

RxA/

TxA

220Ω termination

resist or

Com

* EIA2 32/EIA485 2-wire

communicat ions convert er eg

Type K D485

Screen

220Ω termination

resistor on last

controller in the line

Twis ted pair

Daisy Chain to

further

controllers

HD

Common

HE

Rx A(+)

HF

Tx B(-)

12

Page 13

Series 3 Operations Manual

AA

2.14 Controller Power Supply

1. Before connecting the instrument to the power line,

make sure that the line voltage corresponds to the

description on the identification label.

2. Use copper conductors only.

3. For 24V the polarity is not important

4. The power supply input is not fuse protected. This

should be provided externally

Power Supply

L

Line

N

• High voltage supply: 100 to 240Vac, -15%, +10%, 48 to

• Recommended external fuse ratings are as follows:

Neutral

62 Hz

For 100-240Vac, fuse type: T rated 2A 250V.

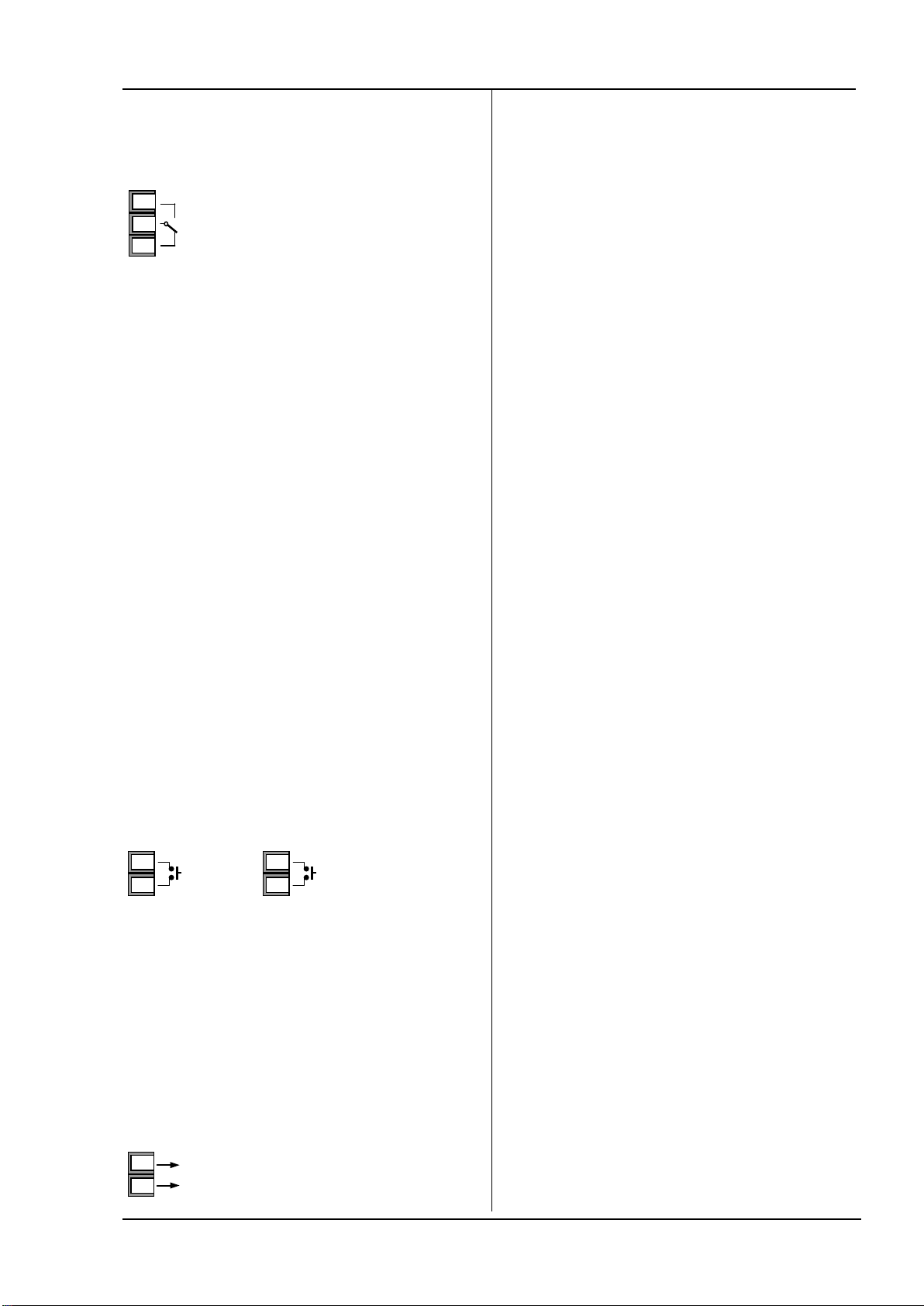

2.15 Example Heat/Cool Wiring Diagram

This example shows a heat/cool temperature controller

where the heater control uses a SSR and the cooling control

uses a relay.

L

Heater

fuse

Solid State Relay

(e.g. TE10)

N

Heater

Controller fuse

1A

1B

2A

2B

L

N

J

CT

AB

C

AC

LA

VI

HD

V+

HE

V-

HF

J

+

-

T/C

Relay

output

fuse

Snubber*

Cooling or

alarm relay

Safety requirements for permanently connected equipment

state:

• A switch or circuit breaker shall be included in the

building installation

• It shall be in close proximity to the equipment and

within easy reach of the operator

• It shall be marked as the disconnecting device for the

equipment

A single switch or circuit breaker can drive more than

one instrument

13

Page 14

Operations Manual Series 3

3. Safety and EMC Information

This controller is intended for industrial temperature and

process control applications when it will meet the

requirements of the European Directives on Safety and

EMC. Use in other applications, or failure to observe the

installation instructions of this handbook may impair safety

or EMC. The installer must ensure the safety and EMC of

any particular installation.

Safety

This controller complies with the European Low Voltage

Directive 73/23/EEC, by the application of the safety

standard EN 61010.

Electromagnetic compatibility

This controller conforms with the essential protection

requirements of the EMC Directive 89/336/EEC, by the

application of a Technical Construction File. This instrument

satisfies the general requirements of the industrial

environment defined in EN 61326. For more information on

product compliance refer to the Technical Construction File.

GENERAL

The information contained in this manual is subject to

change without notice. While every effort has been made to

ensure the accuracy of the information, your supplier shall

not be held liable for errors contained herein.

Unpacking and storage

The packaging should contain an instrument mounted in its

sleeve, two mounting brackets for panel installation and an

Installation & Operating guide.

If on receipt, the packaging or the instrument are damaged,

do not install the product but contact Super Systems, Inc. If

the instrument is to be stored before use, protect from

humidity and dust in an ambient temperature range of -30oC

o

to +75

C.

SERVICE AND REPAIR

This controller has no user serviceable parts. Contact Super

Systems, Inc. for repair.

Caution: Charged capacitors

Before removing an instrument from its sleeve, disconnect

the supply and wait at least two minutes to allow capacitors

to discharge. It may be convenient to partially withdraw the

instrument from the sleeve, then pause before completing

the removal. In any case, avoid touching the exposed

electronics of an instrument when withdrawing it from the

sleeve.

Failure to observe these precautions may cause damage to

components of the instrument or some discomfort to the

user.

Electrostatic discharge precautions

When the controller is removed from its sleeve, some of the

exposed electronic components are vulnerable to damage by

electrostatic discharge from someone handling the

controller. To avoid this, before handling the unplugged

controller discharge yourself to ground.

Cleaning

Do not use water or water based products to clean labels or

they will become illegible. Isopropyl alcohol may be used to

clean labels. A mild soap solution may be used to clean

other exterior surfaces of the product.

3.1 Installation Safety Requirements

Safety Symbols

Various symbols may be used on the controller. They have

the following meaning:

Caution, (refer to

!

accompanying documents )

Equipm ent protect ed

throughout by DOU BLE

INSULATION

Helpful hints

Personnel

Installation must only be carried out by suitably qualified

personnel in accordance with the instructions in this

handbook.

Enclosure of Live Parts

To prevent hands or metal tools touching parts that may be

electrically live, the controller must be enclosed in an

enclosure.

Caution: Live sensors

The controller is designed to operate if the temperature

sensor is connected directly to an electrical heating element.

However you must ensure that service personnel do not

touch connections to these inputs while they are live. With a

live sensor, all cables, connectors and switches for

connecting the sensor must be mains rated.

Wiring

It is important to connect the controller in accordance with

the wiring data given in this guide. Take particular care not

to connect AC supplies to the low voltage sensor input or

other low level inputs and outputs. Only use copper

conductors for connections (except thermocouple inputs)

and ensure that the wiring of installations comply with all

local wiring regulations. For example in the UK use the

latest version of the IEE wiring regulations, (BS7671). In the

USA use NEC Class 1 wiring methods.

Power Isolation

The installation must include a power isolating switch or

circuit breaker. This device should be in close proximity to

the controller, within easy reach of the operator and marked

as the disconnecting device for the instrument.

Overcurrent protection

The power supply to the system should be fused

appropriately to protect the cabling to the units.

14

Page 15

Series 3 Operations Manual

Voltage rating

The maximum continuous voltage applied between any of

the following terminals must not exceed 264Vac:

• relay output to logic, dc or sensor connections;

• any connection to ground.

The controller must not be wired to a three phase supply

with an unearthed star connection. Under fault conditions

such a supply could rise above 264Vac with respect to

ground and the product would not be safe.

Conductive pollution

Electrically conductive pollution must be excluded from the

cabinet in which the controller is mounted. For example,

carbon dust is a form of electrically conductive pollution. To

secure a suitable atmosphere in conditions of conductive

pollution, fit an air filter to the air intake of the cabinet.

Where condensation is likely, for example at low

temperatures, include a thermostatically controlled heater in

the cabinet.

This produ ct has been designed to conform to BS EN61010

installat ion category II, pol lution degree 2 . These are defined as

follows:

Installation Category II (CAT II)

The rated impulse voltage for equipment on nominal 230V supply

is 2500V.

Pollution Degree 2

Normally only non conductive pollution occurs. Occasionally,

independent temperature sensor, which will isolate the

heating circuit.

Please note that the alarm relays within the controller will

not give protection under all failure conditions.

Routing of wires

To minimise the pick-up of electrical noise, the low voltage

DC connections and the sensor input wiring should be routed

away from high-current power cables. Where it is

impractical to do this, use shielded cables with the shield

grounded at both ends. In general keep cable lengths to a

minimum.

however, a temporary conductivity caused by condensation shall

be expected.

Grounding of the temperature sensor shield

In some installations it is common practice to replace the

temperature sensor while the controller is still powered up.

Under these conditions, as additional protection against

electric shock, we recommend that the shield of the

temperature sensor is grounded. Do not rely on grounding

through the framework of the machine.

Over-temperature protection

When designing any control system it is essential to consider

what will happen if any part of the system should fail. In

temperature control applications the primary danger is that

the heating will remain constantly on. Apart from spoiling

the product, this could damage any process machinery being

controlled, or even cause a fire.

Reasons why the heating might remain constantly on

include:

• the temperature sensor becoming detached from the

process

• thermocouple wiring becoming short circuit;

• the controller failing with its heating output constantly

on

• an external valve or contactor sticking in the heating

condition

• the controller setpoint set too high.

Where damage or injury is possible, we recommend fitting a

separate over-temperature protection unit, with an

15

Page 16

Operations Manual Series 3

4. Switch On

!

The way in which the controller starts up depends on factors

described below in sections 4.1, 4.2 and 4.3.

4.1 New Controller

If the controller is new AND has not previously been

configured it will start up showing the ‘Quick Configuration’

codes. This is a built in tool which enables you to configure

the input type and range, the output functions and the

display format.

Adjust these as follows:.

1. Press any button. The characters will change to ‘-‘, the

first one flashing.

or

2. Press

to change the flashing character to the

required code shown in the quick code tables – see

below. Note: An

x indicates that the option is not

fitted.

3. Press to scroll to the next character.

You cannot scroll to the next character until the current

character is configured.

Incorrect configuration can result in damage to the

process and/or personal injury and must be carried out by a

competent person authorised to do so. It is the

responsibility of the person commissioning the controller to

ensure the configuration is correct

To return to the first character press

4. When all five characters have been configured the

display will go to Set 2.

5. When the last digit has been entered press

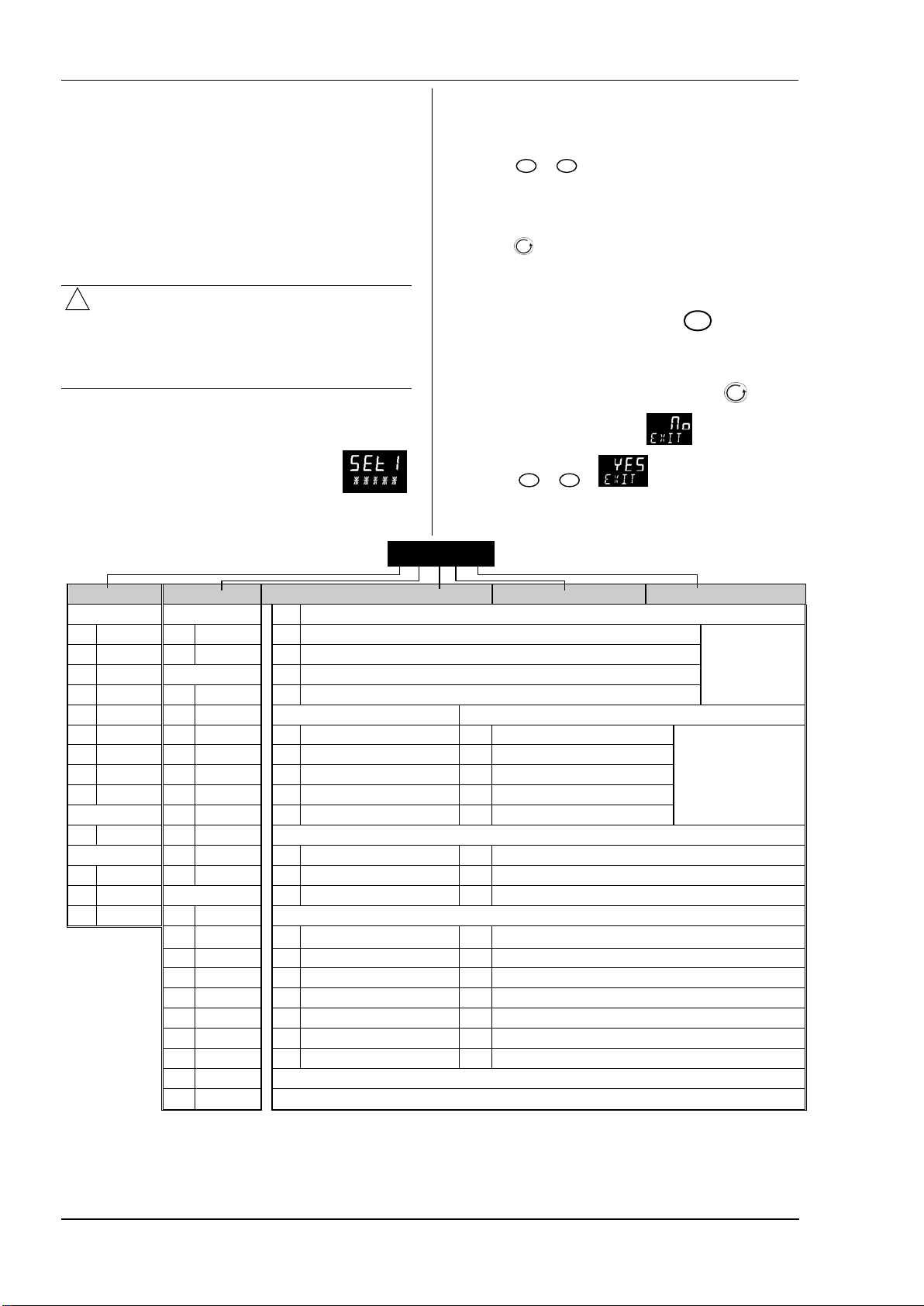

4.1.1 Quick Start Code

The quick start code consists of two ‘SETS’ of

five characters. The upper section of the

display shows the set selected, the lower

section shows the five digits which make up

the set.

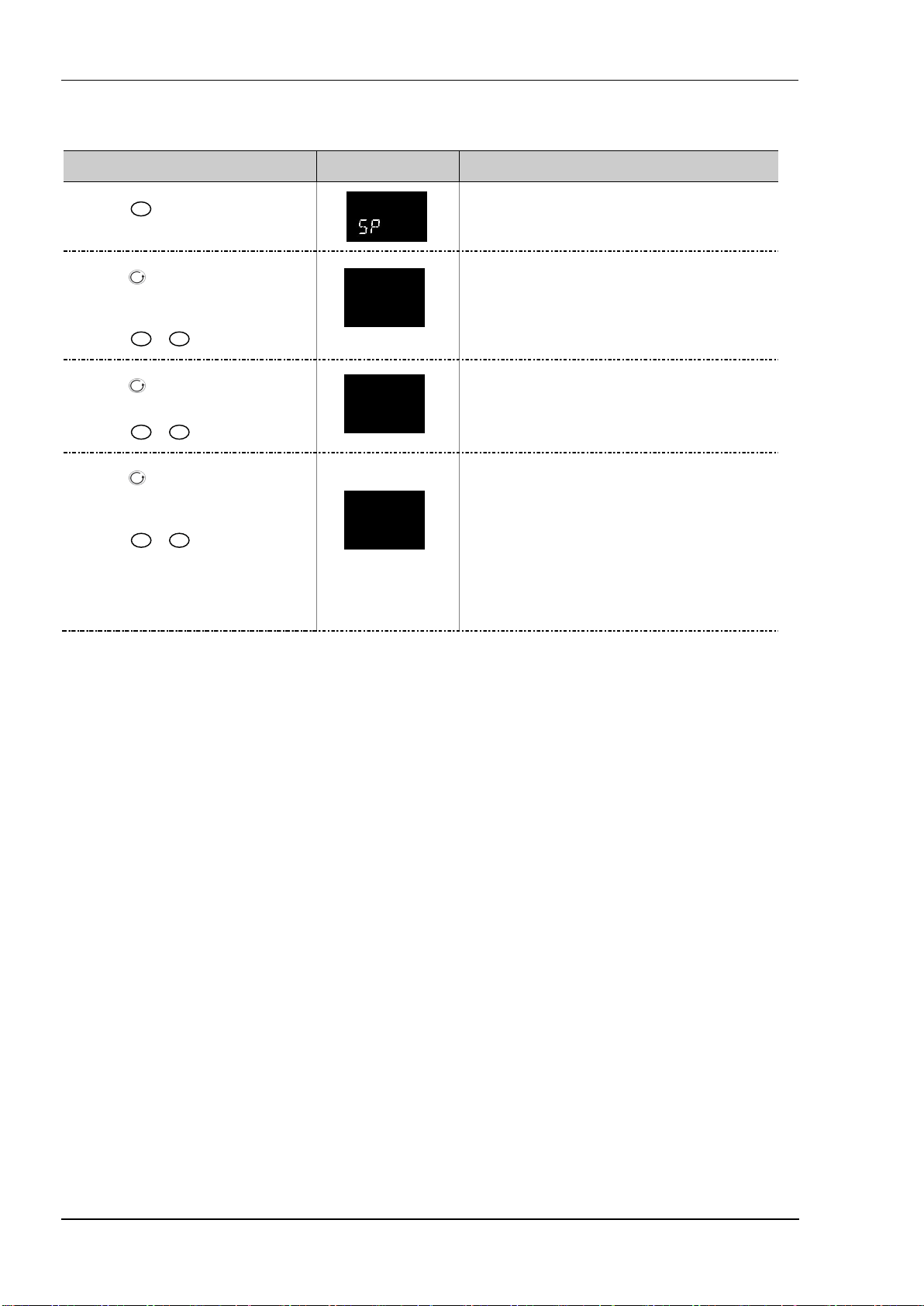

SET 1

Input ty pe Range Input/O utput 1 Output 2 Output 4

Thermocouple Full range X Unconfigured

B Ty pe B C

J Type J F

K Type K Centigra de J ON/OF F Heating [logic or relay (1)], or PI D 0-20mA heating

L Type L 0 0-100 K ON/OF F Cooling [logic or relay (1)], or P ID 0-20mA cooling

N Type N 1 0-200 Alarm (2): energised in alarm Alar m (2): de-energised in alarm

R Type R 2 0 -400 0 High alarm 5 High alarm Note (2)

S Type S 3 0-600 1 Low alarm 6 Low alarm

T T ype T 4 0-800 2 Deviation high 7 Dev iation high

C Custom 5 0-1000 3 Deviation low 8 Deviat ion low

RTD 6 0-1200 4 D eviation band 9 Deviat ion band

P Pt100 7 0-1400 DC Retransmission (no t O/P4)

Linear 8 0-1600 D 4-20mA Setpoint N 0-20mA Setpoint

M 0-80mV 9 0-1800 E 4-20mA Temperature Y 0-20m A Temperatu re

2 0-20mA Fahrenheit F 4-20mA output Z 0 -20mA output

4 4-20mA G 32-212 Logic input functions ( Input/Output 1 only)

H 32-392 W Alarm acknowledge V Recipe 2/1 select

J 32-752 M Manual select A Remote UP button

K 32-1112 R FEATURE UNAVAILABLE B Remote DOWN button

L 32-1472 L K eylock G FEATURE UNAVAILABLE

M 32-1832 P Setpoint 2 s elect I FEATURE UNAVAILABLE

o

o

N 32-21 92 T FEATURE UNAVAILABLE Q Standby select

P 32-2552 U Remot e SP enable

R 32-2912

T 32-3272

C H PID H eating [ logic, relay (1) or 4-20mA] or motor valve open [VC and VP only] Note (1) O/P4 is relay

F C PID Cooling [logic, relay (1) or 4-20mA] or motor valve close [VC and VP only]

KCHC0

again, the display will show

6. Press

The controller will then automatically go to the operator

level.

or

to .

OP1 = alarm 1

OP2 = alarm 2

OP3 = alarm 3

OP4 = alarm 4

only.

16

Page 17

Series 3 Operations Manual

SET 2

1 WRDT

Input CT Scaling Digital In put A Digita l Input B (2) Output 3 (2) Lo wer Display

Unconfigured

X

10 Amps

1

25 Amps

2

50 Amps

5

100 Amps

6

Note (1)

X

W Alarm acknowledg e H PI D heating or motor valve open (3) P Output

M M anual select C PID cooling or motor valve close (3) R Time remaining

R FEATURE UNAVAILABLE J ON/OFF heating (not show n if VC or VP) E Elapsed time

L Keylock K ON/OFF cooling (not shown if VC or VP) 1 Alarm setpoint

P Setpoint 2 select Alarm Outputs (1) A Load Amps

T FEATURE UNAVAILABLE Energised in alarm De-energised in alarm D D well/Ramp

OP1 = alarm 1 (I/O1)

OP2 = alarm 2

V Recipe 2 /1 select 1 Low alarm 6 Low alarm N None

OP3 = alarm 3

B Remote DOWN button 3 Dev L ow 8 Dev L ow Output meter (2)

OP4 = alarm 4 (AA)

Note (3)

VP, VC o nly

G FEATURE UNAVAILABLE 4 D ev Band 9 Dev Band M Setpoint with

I FEATURE UNAVAILABLE DC outputs Am meter (2)

Q St andby select H 4-20mA heating

C 4-20mA cooling

K 0-20mA cooling

Retransmission output

D 4-20 Setp oint

E 4-20 Measured Temperat ure

F 4-20mA output

N 0-20 Setpoint

Y 0-20 M easured Temp erature

Z 0-20mA output

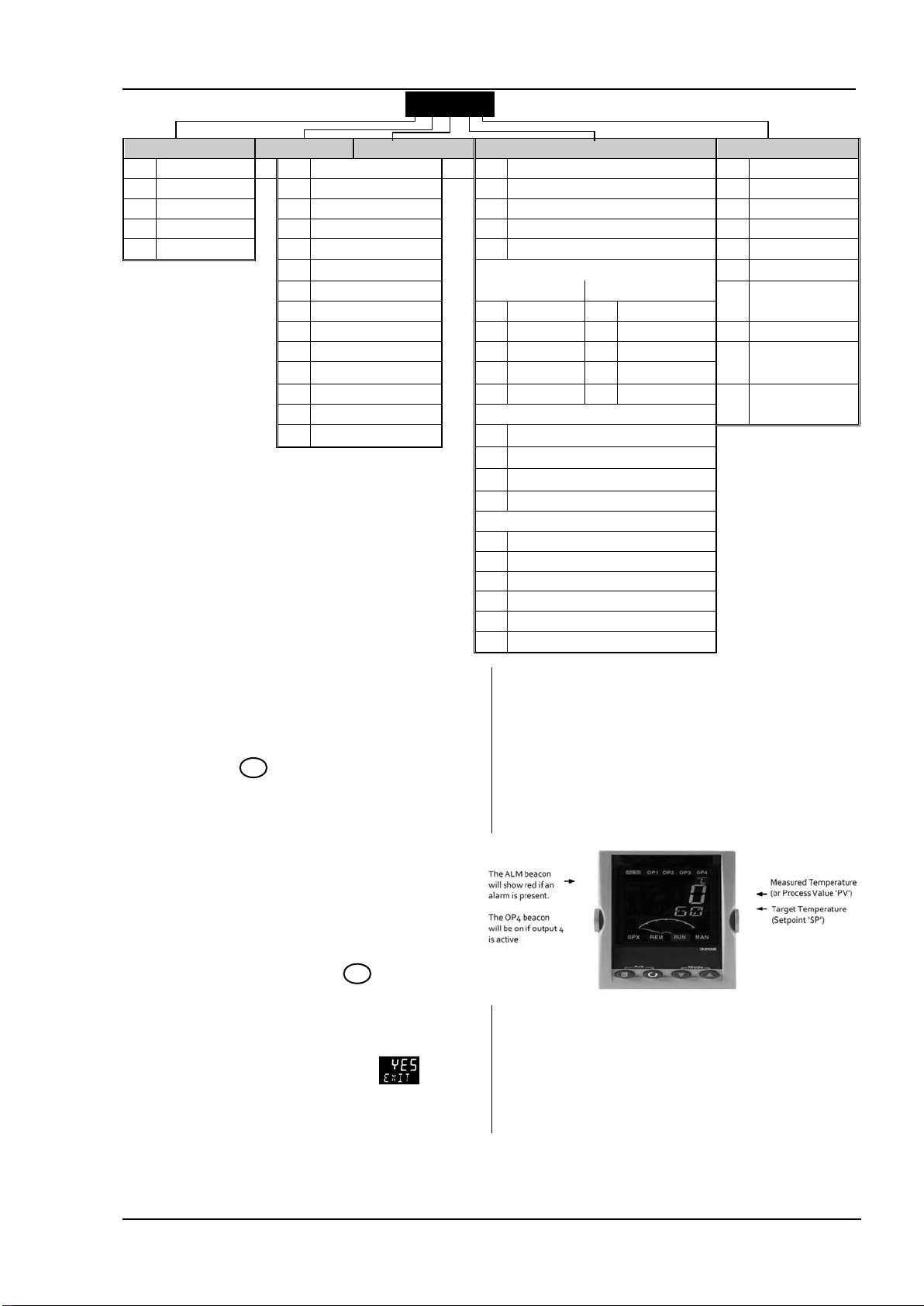

4.2 To Re-Enter Quick Code mode

If you need to re-enter the ‘Quick Configuration’ mode this

can always be done as follows:

1. Power down the controller

Unconfigured

U Rem ote SP enable 0 High alarm 5 High alarm T ime/Target

A Remote UP button 2 Dev High 7 Dev High C Setpoint with

X Unconfigured T Setpoint (std)

J 0-20mA heating

4.3 Pre-Configured Controller or

Subsequent Starts

A brief start up sequence consists of a self test during which

the software version number is shown followed briefly by the

quick start codes.

2. Hold down the

controller again.

3. Keep the button pressed until code is displayed.

4. Enter the configuration code (this is defaulted to 4 in a

new controller)

5. The quick start codes may then be set as described

previously

Parameters may also be configured using a deeper level

of access. This is described in later chapters of this

handbook.

If the controller is started with the

down, as described above, and the quick start codes are

shown with dots (e.g. J.C.X.X.X), this indicates that the

controller has been re-configured in a deeper level of access

and, therefore, the quick start codes may not be valid. If the

quick start codes are accepted by scrolling to then

the quick start codes are reinstated.

button, and power up the

button held

It will then proceed to Operator Level 1..

You will see the display shown below. It is called the HOME

display.

If the quick start codes do not appear during this start up,

it means that the controller has been configured in a deeper

level of access, see the note in section 4.2. The quick start

codes may then not be valid and are therefore not shown.

17

Page 18

Operations Manual Series 3

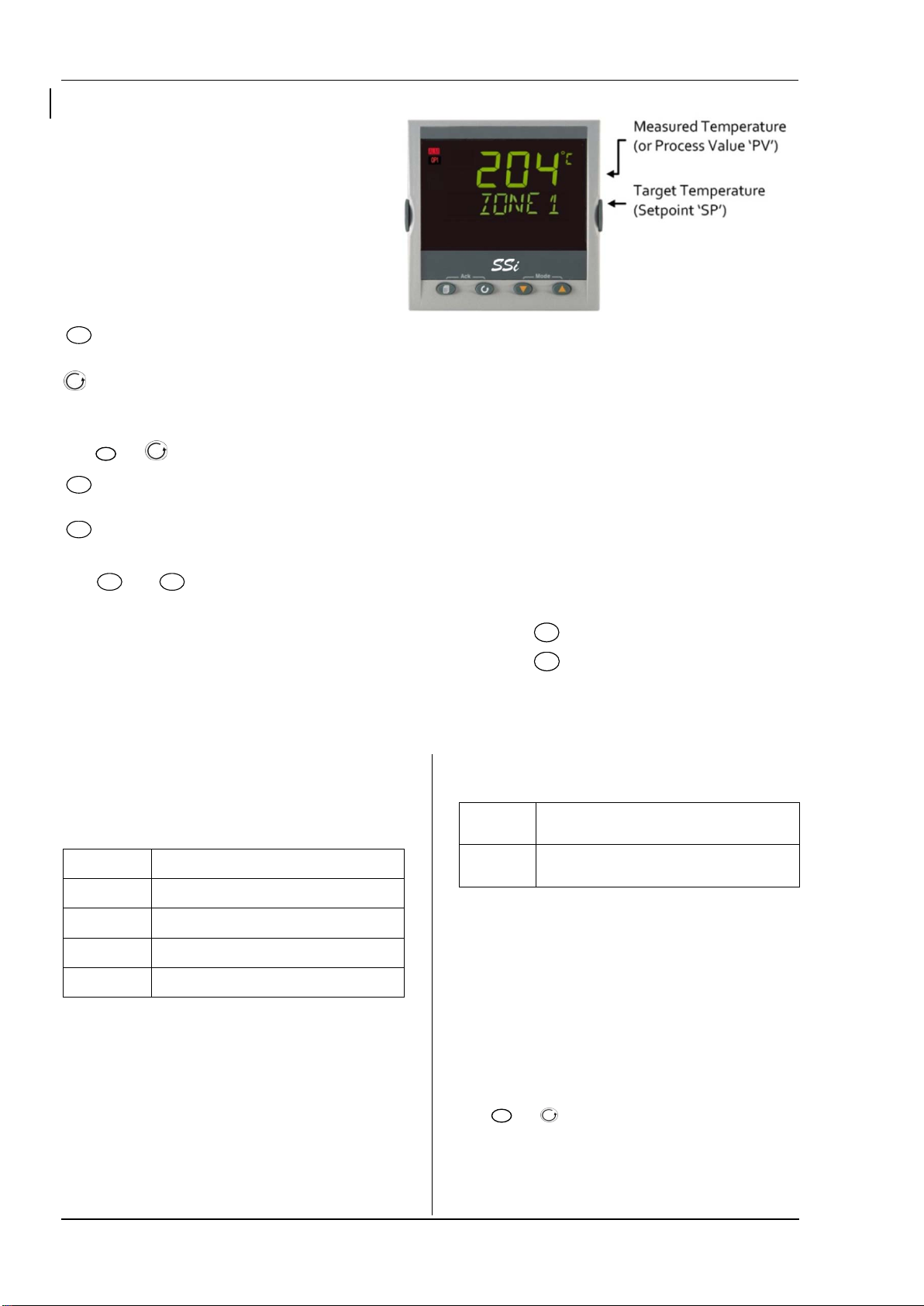

4.4 Front Panel Layout

ALM Alarm active (Red)

OP1 lit when output 1 is ON

OP2 lit when output 2 is ON

OP3 lit when output 3 is ON

OP4 lit when output 4 relay is ON

SPX Alternative setpoint in use (e.g. setpoint 2)

REM Remote digital setpoint. Also flashes when digital

communications active

MAN Manual mode selected

Operator Buttons:

Referred to as the ‘page’ button. From any view -

press to return to the HOME display

Referred to as the ‘scroll’ button. Press to select a new

parameter. If held down it will continuously scroll through

parameters.

Press

decrease a value

a value

Press

and Manual mode.

and (ACK) together to acknowledge an alarm.

Referred to as the ‘arrow down’ button. Press to

Referred to as the ‘arrow up’ button. Press to increase

and

(MODE) together to toggle between Auto

4.4.1 To Set The Target Temperature.

From the HOME display:

Press

Press

The new setpoint is entered when the button is released

and is indicated by a brief flash of display.

to raise the setpoint

to lower the setpoint

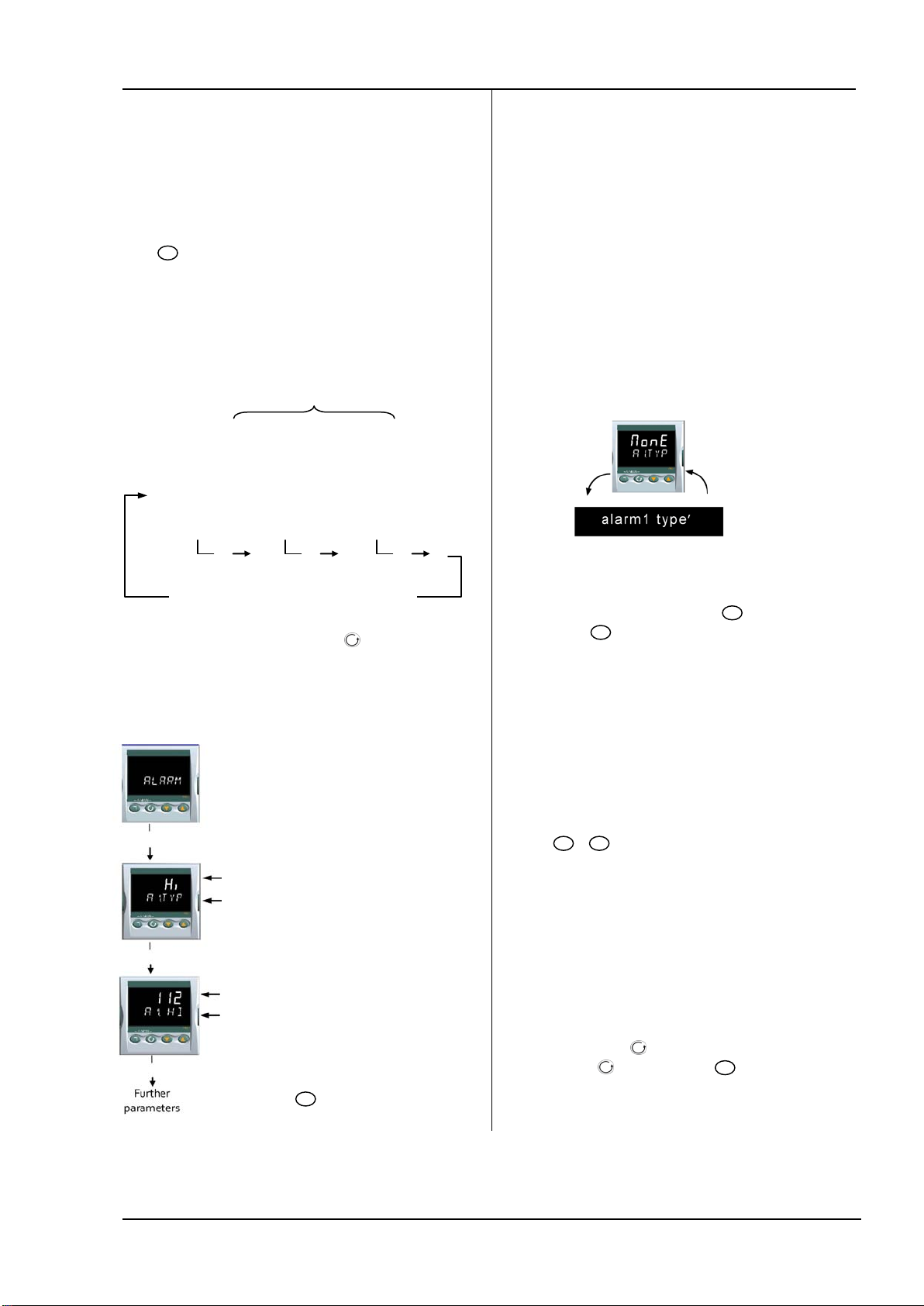

4.4.2 Alarms

Process alarms may be configured using the Quick Start

Codes. Each alarm can be configured for:

Full Scale Low The alarm is shown if the proces s value falls below a

set t hreshold

Full Scale High The alarm is shown if t he process value rises above a

set t hreshold

Deviation Low The alarm is shown if the process value deviates below

the setpoint by a set threshold

Deviation High The alarm is s hown if the process valu e deviates above

the setpoint by a set threshold

Deviation Band The alarm is s hown if the process value deviates abov e

or below t he setpoint by a set threshold

If an alarm is not configured it is not shown in the list of

level 2 parameters.

Additional alarm messages may be shown such as

CONTROL LOOP BROKEN. This occurs if the controller

does not detect a change in process value following a

From firmware version 2.11 two further alarm types

have been made available. These are:

Rising rat e of

change

Falling rat e of

change

These alarms cannot be configured by the Quick Start Code

– they can only be configured in Configuration Mode..

4.4.3 Alarm Indication

If an alarm occurs, the red ALM beacon will flash. A

scrolling text message will describe the source of the alarm.

Any output (usually a relay) attached to the alarm will

operate. An alarm relay can be configured using the Quick

Start Codes to be energised or de-energised in the alarm

condition. It is normal to configure the relay to be deenergised in alarm so that an alarm is indicated if power to

the controller fails.

An alarm will be det ected if the rat e of change

(unit s/minute) in a positive direct ion exceeds the alarm

threshold

An alarm will be det ected if the rat e of change

(units/m inute) in a negativ e direction exceeds the alarm

threshold

change in output demand after a suitable delay time.

Another alarm message may be INPUT SENSOR BROKEN

(SBr). This occurs if the sensor becomes open circuit; the

output level will adopt a ‘SAFE’ value which can be set up in

Operator Level 3..

Press

If the alarm is still present the ALM beacon will light

continuously otherwise it will go off.

The action which takes place depends on the type of alarm

and (ACK) together to acknowledge an alarm.

configured:

18

Page 19

Series 3 Operations Manual

Non

latching

A non latching alarm will reset itself when

the alarm condition is removed. By default

alarms are configured as non-latching, deenergised in alarm.

Auto

Latching

An auto latching alarm requires

acknowledgement before it is reset. The

acknowledgement can occur BEFORE the

condition causing the alarm is removed.

Manual

Latching

The alarm continues to be active until both

the alarm condition is removed AND the

alarm is acknowledged. The

acknowledgement can only occur AFTER

the condition causing the alarm is

removed.

By default alarms are configured as non-latching, deenergised in alarm. To configure latched alarms, refer to

section 12.3.1.

19

Page 20

Operations Manual Series 3

4.4.4 Auto, Manual and Off Mode

!

The controller can be put into Auto, Manual or Off mode –

see next section.

Auto mode is the normal operation where the output is

adjusted automatically by the controller in response to

changes in the measured temperature.

In Auto mode all the alarms and the special functions (auto

tuning, soft start) are operative

Manual mode means that the controller output power is

manually set by the operator. The input sensor is still

connected and reading the temperature but the control

loop is ‘open’.

In manual mode the MAN beacon will be lit, Band and

deviation alarm are masked

The power output can be continuously increased or

decreased using the

Manual mode must be used with care. The power

level must not be set and left at a value that can damage

the process or cause over-heating. The use of a separate

‘over-temperature’ controller is recommended.

Off mode means that the heating and cooling outputs are

turned off. The process alarm and analogue retransmission

outputs will, however, still be active while Band and

deviation alarm will be OFF.

or

buttons.

4.4.5 To Select Auto, Manual or Off Mode

Press and hold

second.

This can only be accessed from the HOME display.

1. Auto’ is shown in the upper display.

After 5 seconds the lower display will

scroll the longer description of this

parameter. ie ’ loop mode – auto

manual off’

2. Press

to select ‘OFF’. This is shown in the

upper display.

3. When the desired Mode is selected, do

not push any other button. After 2

seconds the controller will return to the

HOME display.

4. If OFF has been selected, OFF will be

shown in the lower display and the heating and cooling

outputs will be off

5. If manual mode has been selected, the MAN beacon

will light. The upper display shows the measured

temperature and the lower display the demanded

output power.

and

(Mode) together for more than 1

to select ‘mAn’. Press again

+

+

The transfer from Auto to manual mode is ‘bumpless’.

This means the output will remain at the current value

at the point of transfer. Similarly when transferring

from Manual to Auto mode, the current value will be

used. This will then slowly change to the value

demanded automatically by the controller.

6. To manually change the power output, press

to lower or raise the output. The output power is

continuously updated when these buttons are pressed

7. To return to Auto mode, press

Then press

to select ‘Auto’.

and

or

together.

20

Page 21

Series 3 Operations Manual

4.4.6 Level 1 Operator Parameters

A minimal list of parameters are available in operator Level

1 which is designed for day to day operation. Access to

these parameters is not protected by a pass code.

Press to step through the list of parameters. The

4. Press

choose Lev 2 (Level 2)

5. After 2 seconds the

display will show

or

to

mnemonic of the parameter is shown in the lower display.

After five seconds a scrolling text description of the

parameter appears.

The value of the parameter is shown in the upper display.

Press

for 30 seconds the controller returns to the HOME display

or

to adjust this value. If no key is pressed

The parameters that appear depend upon the functions

configured. They are:

Parameter

Mnemonic

WRK.OP WORKING OU TPUT

WKG.SP WORKING

SP1 SETPOINT 1 Alterable

SP2 SETPOINT 2 Alterable

T.REMN TIME REM AINING

A1.xxx ALARM 1 SETPOINT Read only.

A2.xxx ALARM 2 SETPOINT

A3.xxx ALARM 3 SETPOINT

A4.xxx ALARM 3 SETPOINT

LD.AMP LOAD CURRENT Read only. On ly shown if CT

Scrolling Display

and Description

The active output

value

SETPOINT

The active setpoint

value.

Time to end of set

period

Alterability

Read only.

Appears when the controller

is in AUTO or OFF mode.

Read only.

Only shown when the

controller is in MAN or OFF

mode.

Read only

0:00 to 9 9.59 hh:mm or

mm:ss

Only shown if the alarm is

configured.

xxx = alarm type as follows:

HI = High alarm

LO = Low alarm

d.HI = Deviatio n high

d.LO = Deviation low

d.HI = Deviatio n high

rrc = Rising ra te of change

(unit s/minute)

Frc = Falling rate of chan ge

(unit s/minute)

is configured

6. Press

or

to enter the

pass code. Default = ‘2’

• If an incorrect code is entered the controller reverts to

Level 1.

5.2 To Return to Level 1

1. Press and hold

2. Press

to select LEv 1

The controller will return to the level 1 HOME display.

Note: A security code is not required when going from a

higher level to a lower level.

5.3 Level 2 Parameters

Press

mnemonic of the parameter is shown in the lower display.

After five seconds a scrolling text description of the

parameter appears.

The value of the parameter is shown in the upper display.

Press

for 30 seconds the controller returns to the HOME display

Backscroll is achieved when you are in this list by pressing

The following table shows a list of parameters available in

Level 2.

to step through the list of parameters. The

or

to adjust this value. If no key is pressed

while holding down .

5. Operator Level 2

Level 2 provides access to additional parameters. Access to

these is protected by a security code.

5.1 To Enter Level 2

1. From any display press and hold

2. After a few seconds the display will

show

3. Release

.

(If no button is pressed for about 45 seconds the display

returns to the HOME display)

21

.

Page 22

Operations Manual Series 3

Mnemonic Scrolling Display and description Range

WKG.SP

WORKING SETPOINT is the active setpoint value and appears when the controller is

SP.HI to SP.LO

in Manual mode. It may be derived from SP1 o r SP2, or, if t he cont roller is ramp ing

(see SP.RAT), it is the current ramp value.

WRK.OP WORKING OUTPUT is the output from the controller expressed as a percentage of

full output. It ap pears when the controller is in Auto mode.

For a time proportioning output, 50% = relay or logic output on or off for equal

lengths of time.

For On/Off control: OFF = <1%. ON = >1 %

Read only value

0 to 100% for heatin g

0 to –100% for cooling

-100 (max c ooling) to 100% (max

heating

T.STAT FEATURE UNAVAILABLE Reset rES

Running run

Hold hoLd

End Timed out

UNITS DISPLAY UNITS Temperature display units. ‘Percentage’ is provided for linear

input s

O

C Degrees C

O

F Degrees F

O

k Degrees K

nonE

PErc

None

Percentage

SP.HI SETPOINT HIGH High set point limit applied to SP1 and SP2. Alterable between range limits

SP.LO SETPOINT LOW Low setpoint limit applied to SP1 and SP2

By default the remote setpoint is scaled between SP.HI and SP.LO. Two further parameters (REM.HI and REM.LO) are

available in access level 3 to limit the Remote SP range if req uired.

SP1 SETPOINT 1 allows control setpoint 1 value to be adjusted Alterable: SP.HI to SP.LO

SP2 SETPOINT 2 allows cont rol setpoint 2 value to be adjusted

Alterable: SP.HI to SP.LO

SP.RAT SETPOINT RATE LIMIT Rate of change of setpoint value. OFF to 3000 display units per

minute

The next section applies to the Timer only.

TM.CFG FEATURE UNAVAILABLE none None

Dwel

DeLy

sfst

Dwell

Delayed switch on

Soft start

TM.RES FEATURE UNAVAILABLE Hour

min

THRES FEATURE UNAVAILABLE

OFF or 1 to 3000

END.T FEATURE UNAVAILABLE OFF

Dwel

SP2

Hours

Minutes

Control OP goes to zero

Control continues at SP1

Go to SP2

SS.PWR FEATURE UNAVAILABLE -100 to 100%

SS.SP FEATURE UNAVAILABLE

DWELL FEATURE UNAVAILABLE

T.REMN FEATURE UNAVAILABLE

Between SP.HI and SP.LO

0:00 to 9 9.59 hh :mm: or mm:ss

0:00 to 99.59 hh:mm: or mm:ss

The following parameters are available when the timer is configured as a programmer.

SERVO FEATURE UNAVAILABLE SP

PV

SP.rb

PV.rb

Setpoint

Process variable

Ramp back to SP

Ramp back to PV

TSP.1 TARGET SETPOINT 1. To set the target value for the first setpoint

RMP.1 FEAT URE UNAVAILABLE OFF, 0:01 to 3000 units per min or

hour as set by

TM.RES

22

Page 23

Series 3 Operations Manual

!

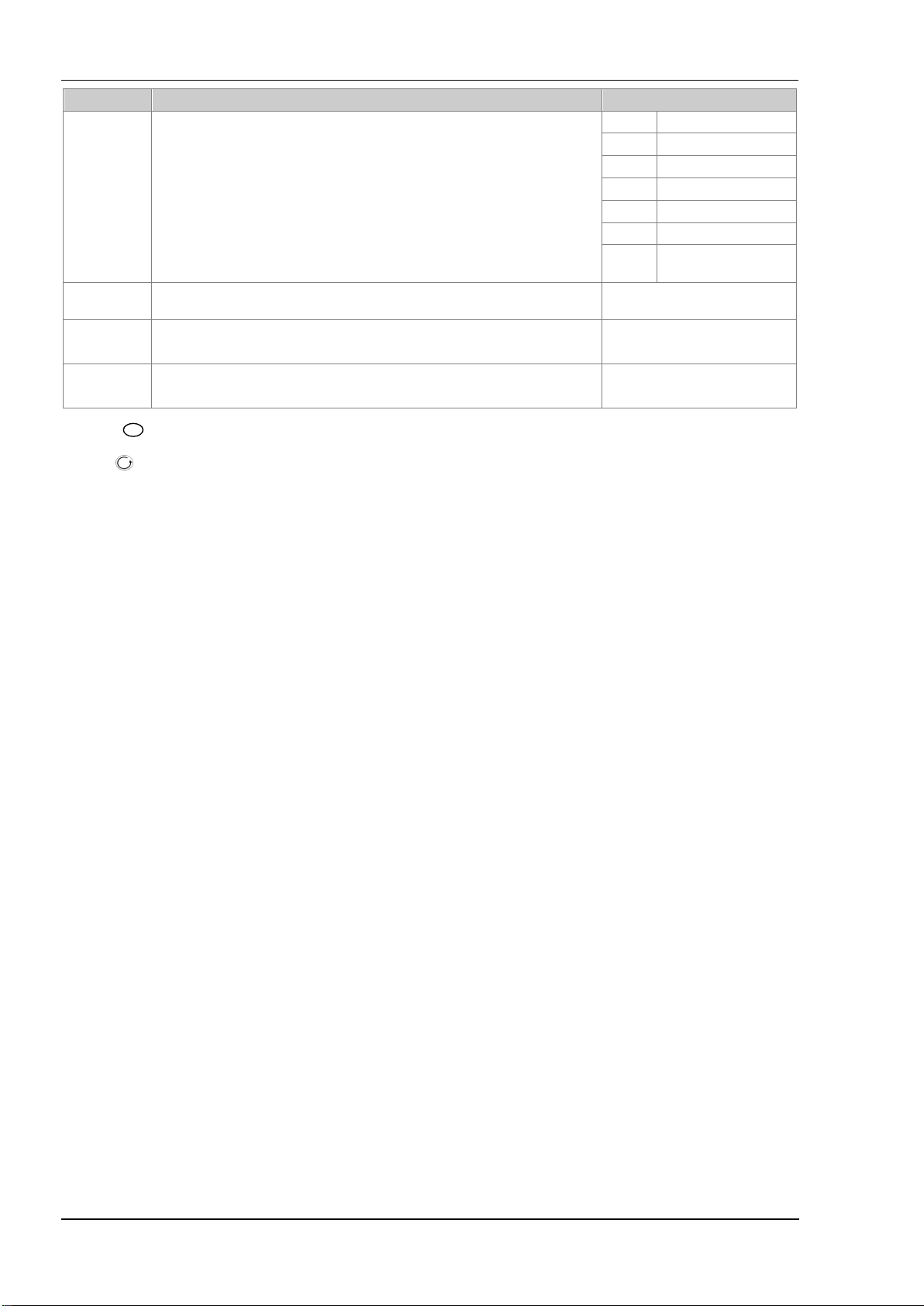

Mnemonic Scrolling Display and description Range

DWEL.1 FEATURE UNAVAILABLE OFF, 0:01 to 99:59 hh:mm or

The above three parameters are repeated for the next three program segments, i.e. TSP.2 (3 & 4), RMP.2 (3 & 4), DWEL.2 (3 & 4)

This section applies to Alarms only If an alarm is not configured the parameters do not appear

A1.--- - to A4.-

--

A.TUNE AUTOTUNE automatically sets the control parameters to match the process

PB PROPORTIONAL BAND sets an output which is proportional to the size of the error

TI INTEGRAL TIME removes steady state control offsets by ramping the output up or

TD DERIVATIVE TIME determines how strongly the controller will reac t to the rate of

MR MANUAL RESET applies to a PD on ly controller i.e. the integral term is turned off.

R2G RELATIVE COOL GAIN adjusts the cooling proportional band relative to the heating

HYST.H HEATING HYSTERESIS Sets the difference in temperature units between heating

HYST.C COOLING HYSTERESIS Sets the difference in temperature units between cooling

D.BAND CHANNEL 2 DEADBAND adjusts a zone between heating and cooling outputs when

OP.HI OUTPUT HIGH limits the maximum heating power applied to the process or a

1. (2, 3 or 4)

PLS.

LD.AMP LOAD CURRENT is the measured load current when the power demand is on CT Range

LK.AMP LEAK CURRENT is the measured leakage current when the power demand is off.

LD.ALM LOAD CURRENT THRESHOLD Sets a low alarm on the load current measured by

LK.ALM LEAK CURRENT THRESHOLD sets a high alarm on the leakage current measured by

HC.ALM OVERCURRENT THRESHOLD Sets a high alarm on the load current measured by

ADDR ADDRESS - communications address of the controller. 1 to 254

HOME HOME DISPLAY Defines the parameter which appears in the lower section of the STD Standard

ALARM 1 (2, 3 or 4) SETPOINT sets the threshold value at which an alarm occurs.

Up to four alarms are available and are only shown if configured.

The last three characters in the mnemonic specify the alarm type:

Lo Full Scale Low Hi Full Scale High

dHi Deviation H igh dLo Deviation Low Bnd Deviation Band

rrc Rising rate of

change

This section applies to control the parameters. A further description of theses parameters is given in section 11

characteristics.

signal. Units may be % or display units.

down in proportion to the amplitude and duration of the error signal.

change in the process value. It is used to prevent overshoot and undershoot and to

restore the PV rapidly if there is a sudden change in demand.

Set this to a value of power output (from +100% heat, to -100% cool which removes

any steady state error between SP and PV.

proportional band. Particularly necessary if the rate of heating and rate of cooling are

very different. (Heat/Cool only)

turning off and turning on when ON’OFF control is used. Only appears if channel

1(heating) control action is On/Off

turning off and turning on when ON/OFF control is used. Only appears if channel 2

(cooling) control action is On/Off

neither output is on. Off = no deadband. 100 = heating and cooling off.

Only appears if On/Off control configured.

minimum cooling output.

OUTPUT 1 (2, 3 or 4) MINIMUM PULSE TIME Sets the minimum on an d off time for

the control output.

Ensure this parameter is set to a value that is suitable for the output

switching device in use. For example, if a logic output is used to switch a small

relay, set the value to 5.0 seconds or greater to prevent damage to the device due

to rapid switching.

This section applies to current transformer input only. The CT option is not available on the Series 3.

the CT. Used to detect partial load failure.

the CT.

the CT

Frc Falling rate of

change

mm:ss as set by

SP.HI to SP.LO

1 to 9999 units/minute

Off

On

1 to 9999 display units

Default 20

Off to 9999 seconds

Default 36 0

Off to 9999 seconds

Default 60 for PID control

Default 0 for VP control

-100 to 100%

Default 0

0.1 to 10. 0

Default 1. 0

0.1 to 200.0 d isplay units

0.2 D efault 1.0

0.1 to 200.0 d isplay units

Default 1. 0

OFF or 0.1 to 100.0% of the

cooling proportional band

+100% to OP.LO

Relay outputs 0.1 to 150.0 seconds

– default 5.0.

Logic outputs Auto to 150.0 -

Default

CT Range

CT Range

CT Range

CT Range

1 to 25 4

TM.RES

Disable

Enable

Auto = 55ms

23

Page 24

Operations Manual Series 3

Mnemonic Scrolling Display and description Range

HOME display .

ID CUSTOMER ID Sets a number from 0 to 9999 used as a custom defined identification

number for th e contro ller.

REC.NO FE ATURE UNAVAILABLE none or 1 to 5 or

STORE FEATURE UNAVAILABLE none or 1 to 5

OP Output power

Tr Time remaining

ELAP Time elapsed

AL First alarm setpoint

CT Load c urrent

CLr Clear (blank)

TMr Combined setpoint and

time display

0 to 9999

FaiL if no recipe set stored

done when stored

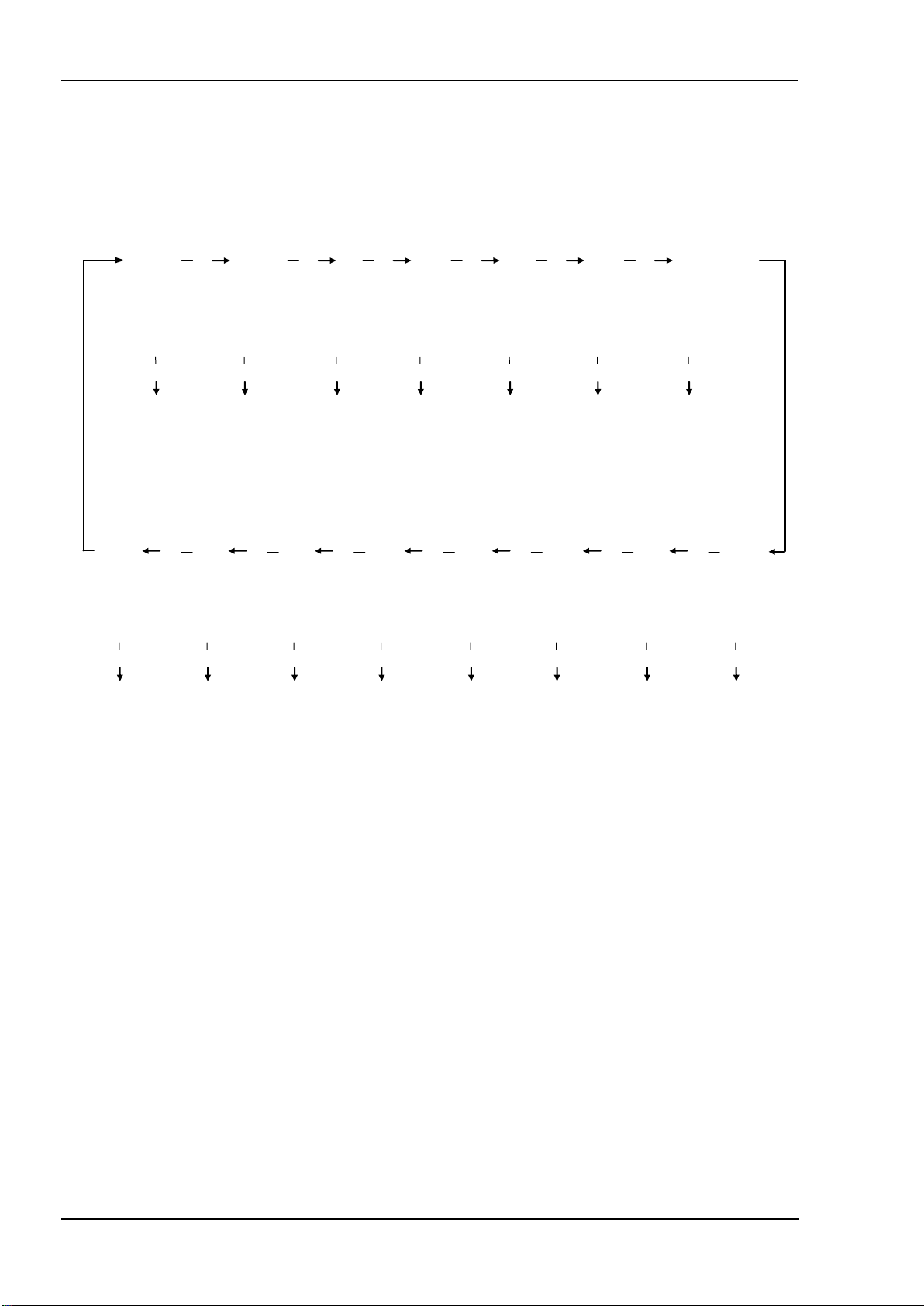

Press