Page 1

Operations Manual Series 3L

Series 3L Limit Alarm

OPERATIONS MANUAL

P/N 31334

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

Ph : 513-772-0060, 800-666-4330

Fax: 513-772-9466

www.supersystems.com

Series 3L Process Indicators and Alarm Units

Page 2

Operations Manual Series 3L

2

Contents

1. Installation and Basic Operation ............................................................................................ 4

1.1 Unpacking Your Indicator ...................................................................................................................... 4

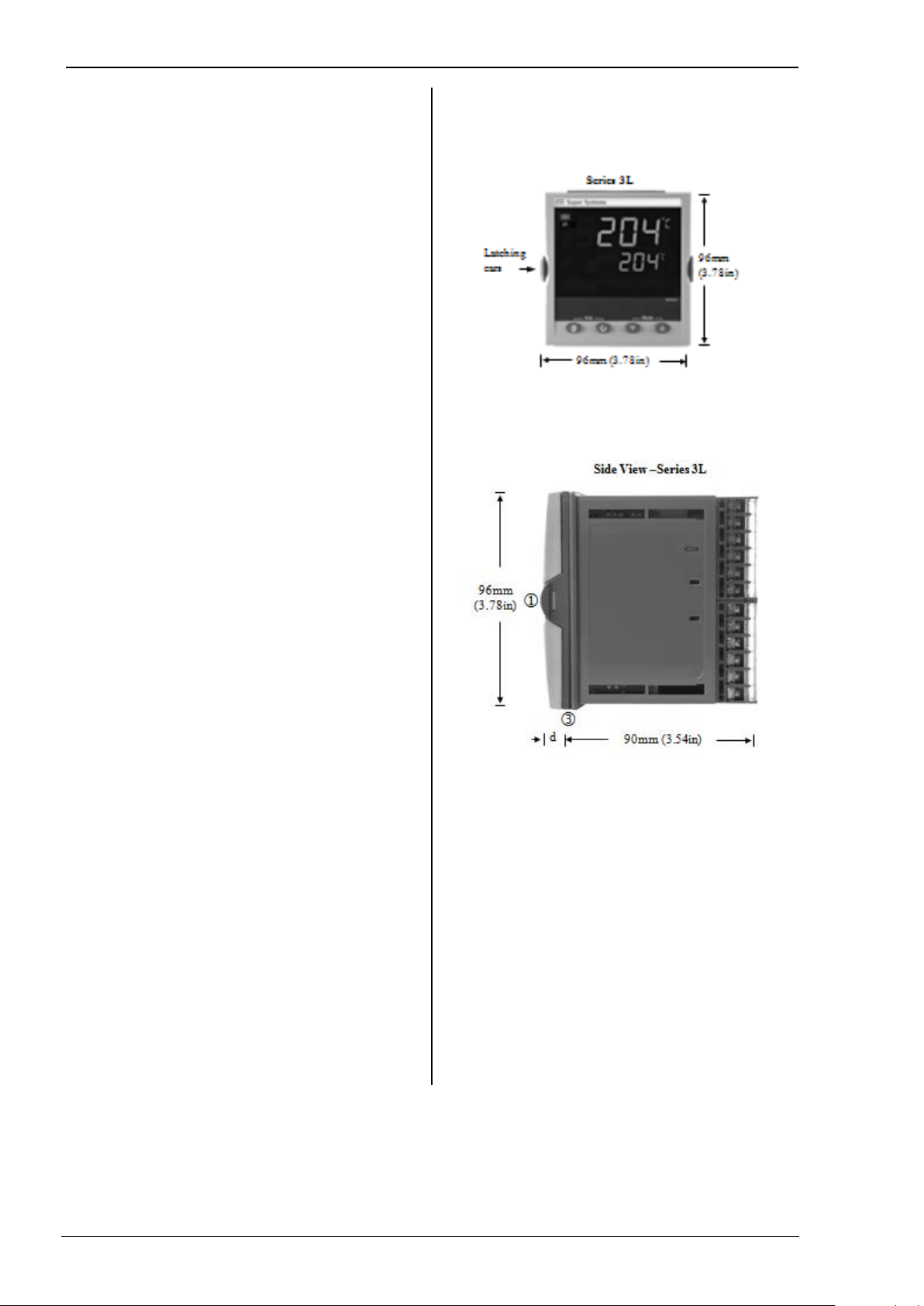

1.2 Dimensions Front Views ....................................................................................................................... 4

1.3 Dimensions – Side Views ....................................................................................................................... 4

1.4 Step 1: Installation ................................................................................................................................. 5

1.4.1 Panel Mounting the Indicator ....................................................................................................................................... 5

1.4.2 Panel Cut-out Sizes ..................................................................................................................................................... 5

1.4.3 Recommended Minimum Spacing of Indicators........................................................................................................... 5

1.4.4 To Remove the Indicator from its Sleeve ..................................................................................................................... 5

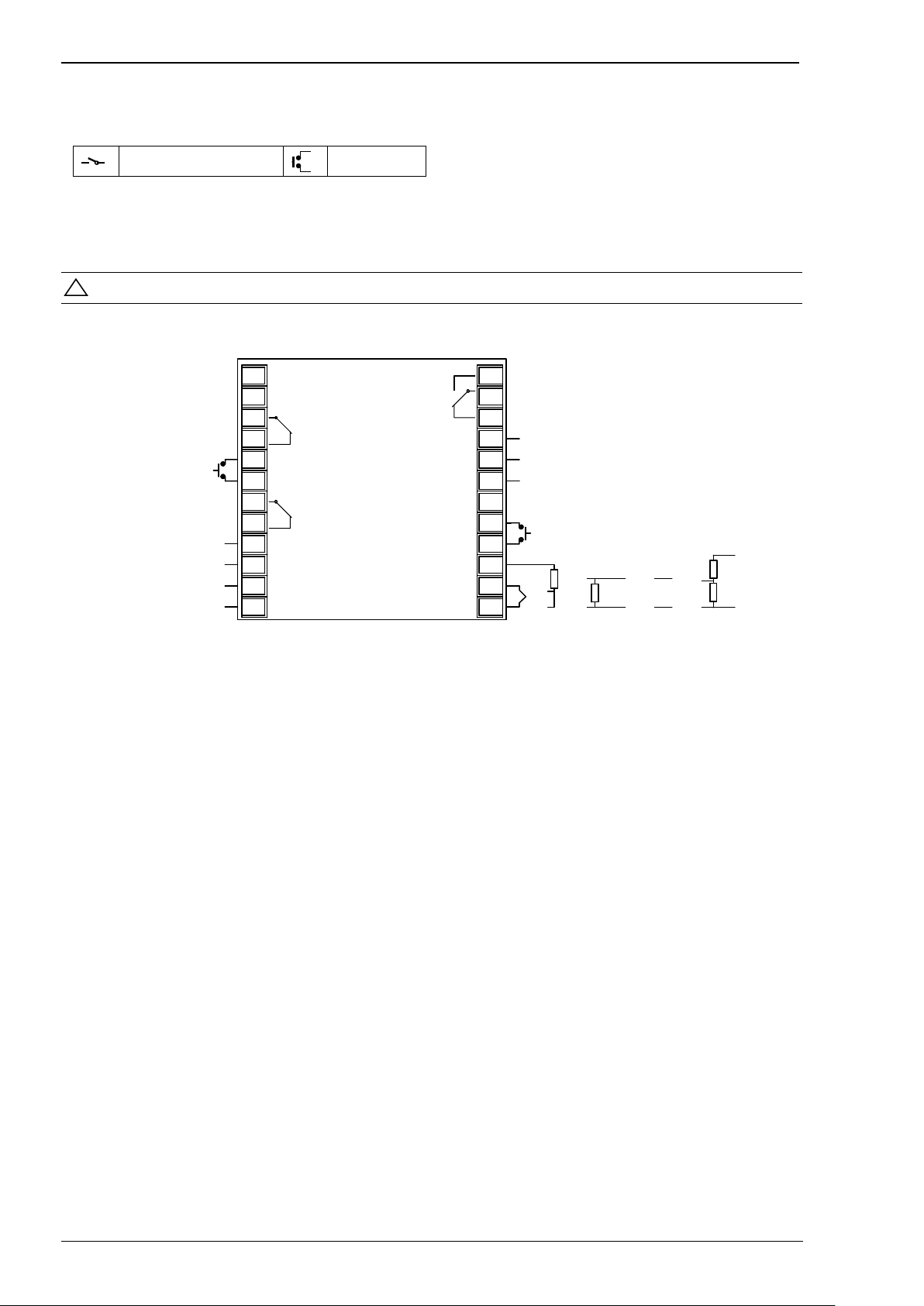

1.5 Step 2: Wiring ......................................................................................................................................... 6

1.6 Terminal Layout Series 3L Indicators ................................................................................................... 6

1.7 Wire Sizes ................................................................................................................................................ 7

1.8 Sensor Input (Measuring Input) ............................................................................................................. 7

1.9 Outputs .................................................................................................................................................... 7

1.9.1 Output 1 & Output 3 ..................................................................................................................................................... 7

1.9.2 AA Relay Form C (FM Approved) ................................................................................................................................ 7

1.9.3 Transmitter Supply ....................................................................................................................................................... 7

1.9.4 Digital Inputs A and B ................................................................................................................................................... 8

1.10 Indicator Power Supply .......................................................................................................................... 8

1.11 Digital Communications (Optional) ....................................................................................................... 8

2. Safety and EMC Information ................................................................................................... 9

2.1 Installation Safety Requirements .......................................................................................................... 9

3. Switch On .................................................................................................................................. 11

3.1 New Indicator .......................................................................................................................................... 11

3.1.1 To Re-Enter Quick Code Mode .................................................................................................................................. 13

3.2 Pre-Configured Indicator or Subsequent Starts ................................................................................... 13

3.3 Front panel layout ................................................................................................................................... 13

3.3.1 Alarm Indication ......................................................................................................................................................... 14

3.3.2 Out of Range Indication ............................................................................................................................................. 14

3.3.3 Sensor Break Indication ............................................................................................................................................. 14

3.4 Operator Parameters in Level 1 ............................................................................................................. 14

4. Operator Level 2 ....................................................................................................................... 15

4.1 To Enter Level 2 ...................................................................................................................................... 15

4.1.1 To Return to Level 1 ................................................................................................................................................... 15

4.2 Level 2 Parameters ................................................................................................................................. 15

4.3 FM and Alarm Units ................................................................................................................................ 17

4.4 Recipes .................................................................................................................................................... 17

5. Access to Further Parameters ................................................................................................ 18

5.1 Level 3 ...................................................................................................................................................... 18

5.2 Configuration Level ................................................................................................................................ 18

5.2.1 To Select Access Level 3 or Configuration Level ...................................................................................................... 19

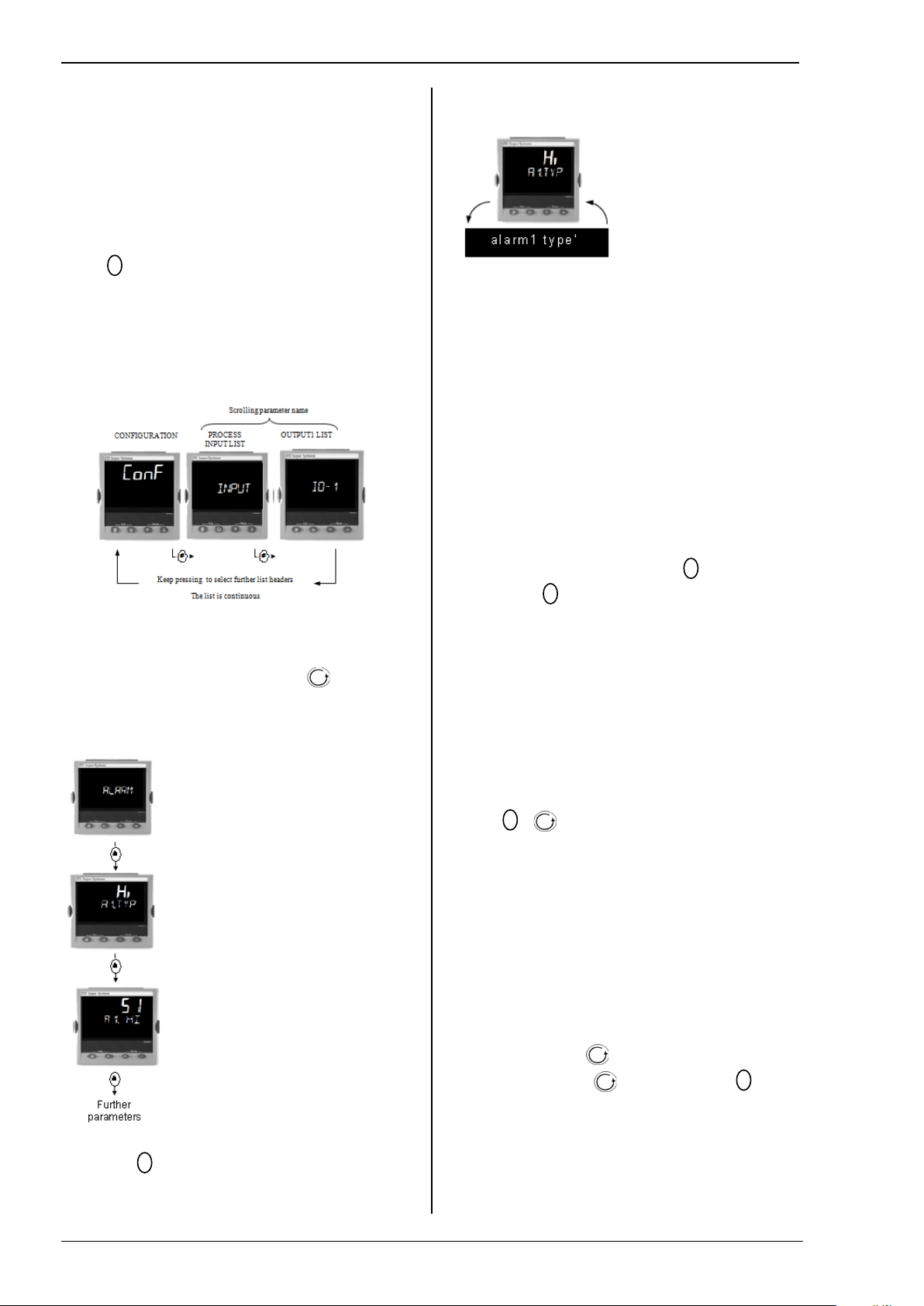

5.3 Parameter lists ........................................................................................................................................ 20

5.3.1 To Choose Parameter List Headers........................................................................................................................... 20

5.3.2 To Locate a Parameter .............................................................................................................................................. 20

5.3.3 How Parameters are Displayed ................................................................................................................................. 20

5.3.4 To Change a Parameter Value .................................................................................................................................. 20

5.3.5 To Return to the HOME Display ................................................................................................................................. 20

5.3.6 Time Out .................................................................................................................................................................... 20

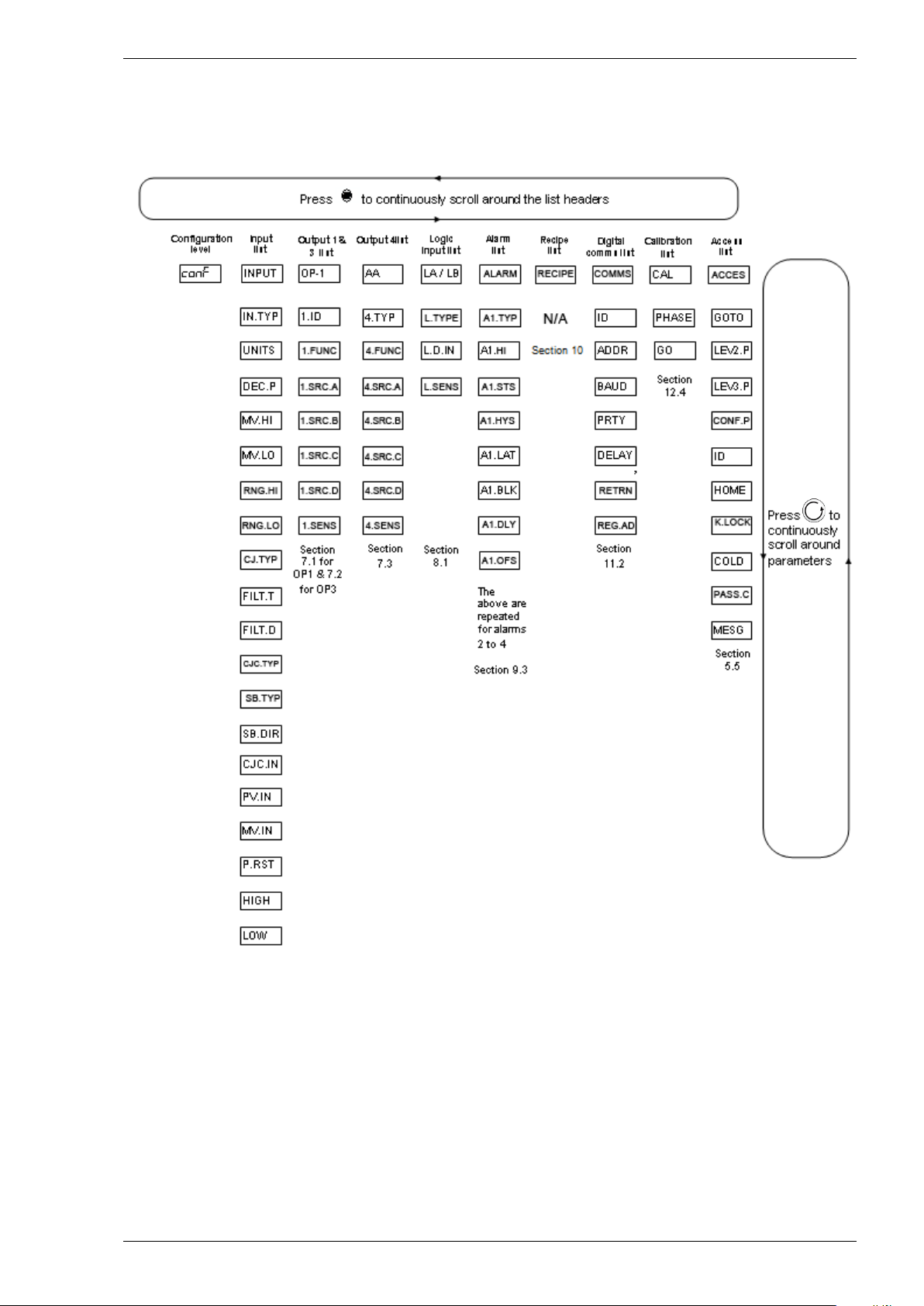

5.4 Navigation Diagram ................................................................................................................................ 21

5.5 Access Parameters ................................................................................................................................. 22

6. Process Input ............................................................................................................................ 23

6.1 Process Input Parameters ...................................................................................................................... 23

6.1.1 Input Types and Ranges ............................................................................................................................................ 24

6.1.2 Units ........................................................................................................................................................................... 24

6.1.3 PV Offset .................................................................................................................................................................... 25

6.1.4 PV Input Scaling ......................................................................................................................................................... 25

7. Input/Output Channels ............................................................................................................. 26

7.1 Output Channel 1 (OP-1) – Series 3L Indicators .................................................................................. 26

7.1.1 Sense ......................................................................................................................................................................... 27

7.1.2 Source ........................................................................................................................................................................ 27

7.1.3 Power Fail .................................................................................................................................................................. 27

7.1.4 Example: To Configure OP-1 Relay to Operate on Alarms 1 and 2:- ....................................................................... 27

7.2 Output Channel 3 (OP-3) – Series 3L Indicators .................................................................................. 28

7.2.1 Sense ......................................................................................................................................................................... 29

Page 3

Operations Manual Series 3L

3

7.2.2 Source ......................................................................................................................................................................... 29

7.2.3 Power Fail ................................................................................................................................................................... 29

7.2.4 Example: To Configure OP-3 Relay to Operate on Alarms 1 and 2:- ........................................................................ 29

7.3 AA Relay Channel (AA) (Output 4 FM Relay) ........................................................................................ 30

8. Digital Inputs ............................................................................................................................. 31

8.1 Digital Input Parameters ........................................................................................................................ 31

9. Alarms ........................................................................................................................................ 32

9.1 Types of Alarm ........................................................................................................................................ 32

9.1.1 Alarm Relay Output..................................................................................................................................................... 33

9.1.2 Alarm Indication .......................................................................................................................................................... 33

9.1.3 To Acknowledge An Alarm ......................................................................................................................................... 33

9.2 Behavior of Alar ms After a Pow er C ycle .............................................................................................. 34

9.2.1 Example 1 ................................................................................................................................................................... 34

9.2.2 Example 2 ................................................................................................................................................................... 34

9.2.3 Example 3 ................................................................................................................................................................... 34

9.3 Alarm Parameters ................................................................................................................................... 35

9.3.1 Example: To Configure Alarm 1 ................................................................................................................................. 36

9.4 Diagnostic Alarms .................................................................................................................................. 37

10. Recipe ........................................................................................................................................ 38

11. Digital Communications .......................................................................................................... 39

11.1 Digital Communications Wiring ............................................................................................................. 39

11.1.1 EIA 485 .................................................................................................................................................................. 39

11.2 Digital Commu nications Parameters .................................................................................................... 40

11.2.1 Broadcast Communications ................................................................................................................................... 41

11.2.2 Broadcast Master Communications ....................................................................................................................... 41

11.2.3 Wiring Connections ................................................................................................................................................ 41

11.3 Example: To Set Up Instrument Address ............................................................................................. 42

11.4 DATA ENCODING ................................................................................................................................... 42

11.5 Parameter Modbus Addresses .............................................................................................................. 43

12. Calibration ................................................................................................................................. 46

12.1 To Check Input Calibration .................................................................................................................... 46

12.1.1 Precautions ............................................................................................................................................................ 46

12.1.2 To Check mV Input Calibration .............................................................................................................................. 46

12.1.3 To Check Thermocouple Input Calibration ............................................................................................................ 46

12.1.4 To Check RTD Input Calibration ............................................................................................................................ 47

12.2 Offsets ..................................................................................................................................................... 47

12.2.1 Five Point Offset .................................................................................................................................................... 47

12.3 Input Calibration ..................................................................................................................................... 48

12.3.1 To Calibrate mV Range ......................................................................................................................................... 48

12.3.2 To Calibrate Thermocouple Ranges ...................................................................................................................... 48

12.3.3 To Calibrate RTD Ranges...................................................................................................................................... 49

12.4 Calibration P ar ameters .......................................................................................................................... 50

13. TECHNICAL SPECIFICATION .................................................................................................. 51

14. Parameter Index ........................................................................................................................ 53

15. Revision History ....................................................................................................................... 54

Page 4

Operations Manual Series 3L

4

1. Installation and Basic Operation

Thank you for choosing this Series 3L Process

Indicator.

This unit comes in a single 1/4DIN size with three relay

outputs.

Relay outputs can be configured for al ar m and events.

2-wire Modbus digital communications are available in

this unit.

The indicator may have been ordered to a hardware

code only or pre-configured using an opt ional ‘Quick

Start’ code. The label fitted to the side of the sleeve

shows the ordering code of the indicator. If the Quick

Code shows ***** the indicator will need to be

configured when it is first switched o n.

1.1 Unpacking Your Indicator

The following items are included in the box:

• Indicator mounted in its sleeve

• Two panel retaining clips

• AN IP65 sealing gasket mounted on the sleeve

• Component packet containing a s nubber for each

relay output and a 2.49Ω resistor for current inputs

(see section 2)

1.2 Dimensions Front Views

1.3 Dimensions – Side Views

Page 5

Series 3L Indicators

5

1.4 Step 1: Installation

10mm (0.4 inch)

This indicator is intended for permanent installation, for

indoor use only, and enclosed in an elect r i c al panel

Select a location which is subject to minimum

vibrations, the ambient temperatur e is within 0 and

o

C (32 - 131oF) and humidity 5 to 95% RH non

55

condensing.

The indicator can be mounted on a panel up to 15mm

thick

To ensure IP65 and NEMA 4 front sealing a gainst dust

and water, mount on a non-textured surface.

Please read the safety information in section 2 before

proceeding.

1.4.1 Panel Mounting the Indicator

1. Prepare a cut-out in the mo unting panel to the size

shown. If a number of instruments are t o be

mounted in the same panel, observe the minimum

spacing shown.

2. Fit the IP65 sealing gasket behind the front bezel of

the indicator.

3. Insert the indicator through the cut-out.

4. Spring the panel retaining clips into place. Secure

the indicator in position by holdin g i t level and

pushing both retaining clips forward.

5. Peel off the protective cover from the display

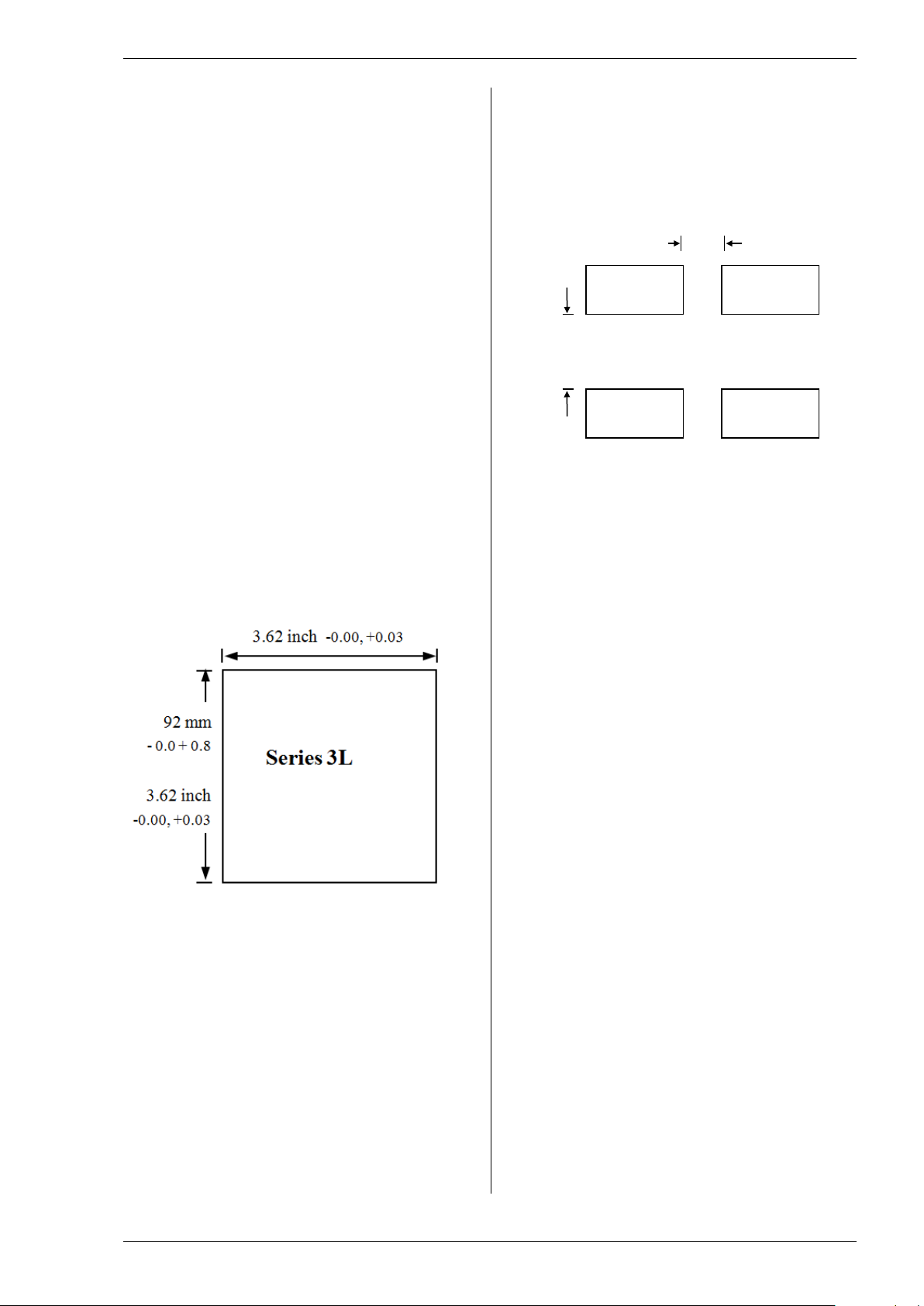

1.4.2 Panel Cut-out Sizes

1.4.3 Recommended Minimum Spacing of Indicators

Applies to all Model sizes

38mm (1.5 inch)

(Not to scale)

1.4.4 To Remove the Indicator from its Sl eeve

The indicator can be unplugged from its sleeve by

easing the latching ears outwards and pulling it forward

out of the sleeve. When plugging it back i nto its

sleeve, ensure that the latching ears click back into

place to maintain the IP65 sealing.

Page 6

Operations Manual Series 3L

6

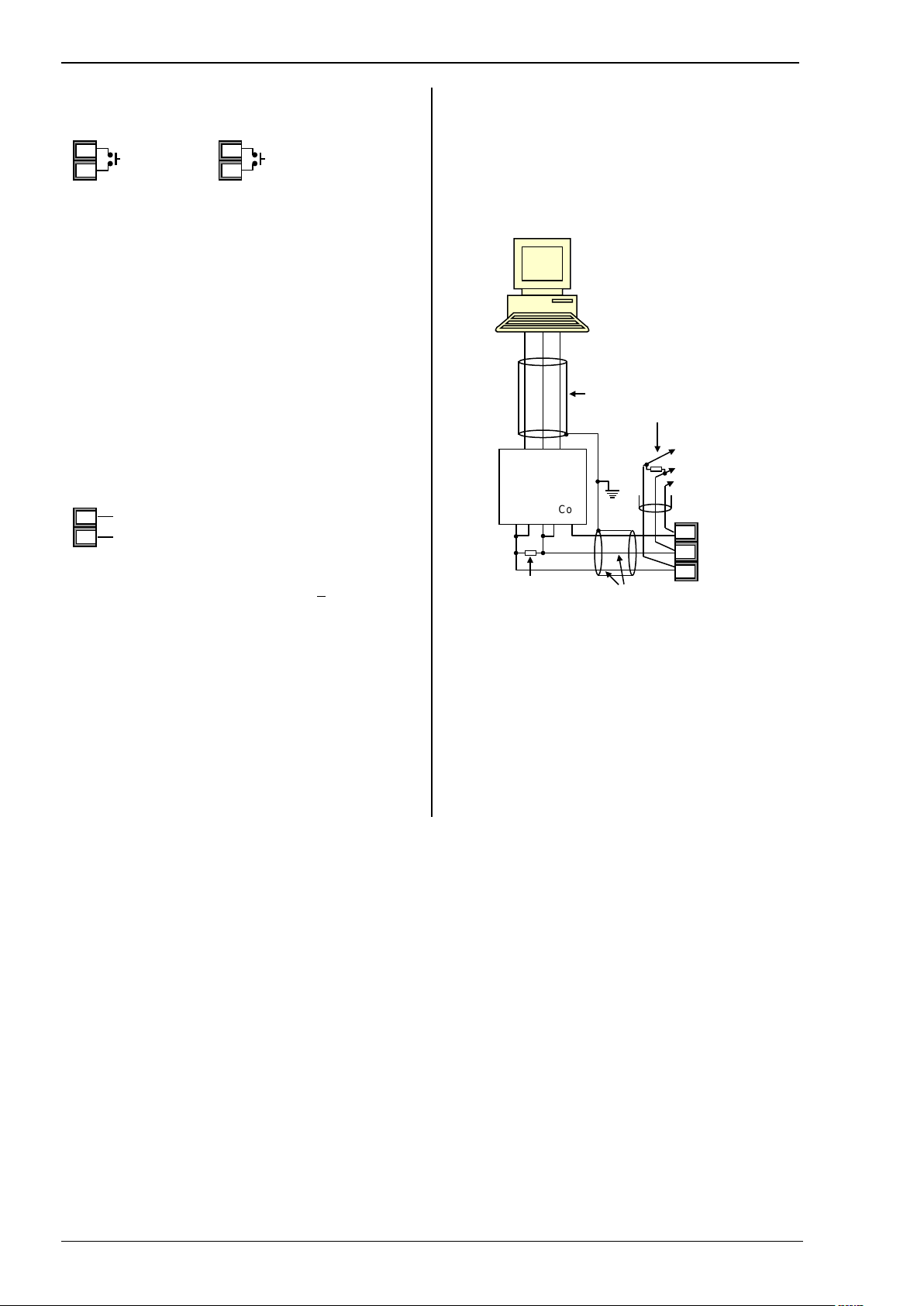

1.5 Step 2: Wiring

!

1A

1B

LB

LC

3A

3B

3C

3D

L

N

AA

AB

AC

HD

HE

HF

CT

C

LA

VI

V+

V-

Series 3L

+

24V

_

COM

A(+)

B(-)

Output 1 (OP1)

Digital Input B

Output 3 (OP3)

24V Transmitter Supply

Line Supply

100 to 230Vac ±15%

48 to 62 Hz

+

-

AA Relay (OP4)

FM RElay

Digital

Communications

EIA 485

Digital Input A

2.49

Ω

+

-

+

-

100K

Ω

806

Ω

+

-

10V Input

T/C Pt100 mA mV Vots

Sensor Input

Key to Symbols used in the wiring diagrams

Relay Output

Contact Input

1.6 Terminal Layout Series 3L Indicators

Ensure that you have the correct supply for your indicator. Check order code of the indicator supplied

Page 7

Series 3L Indicators

7

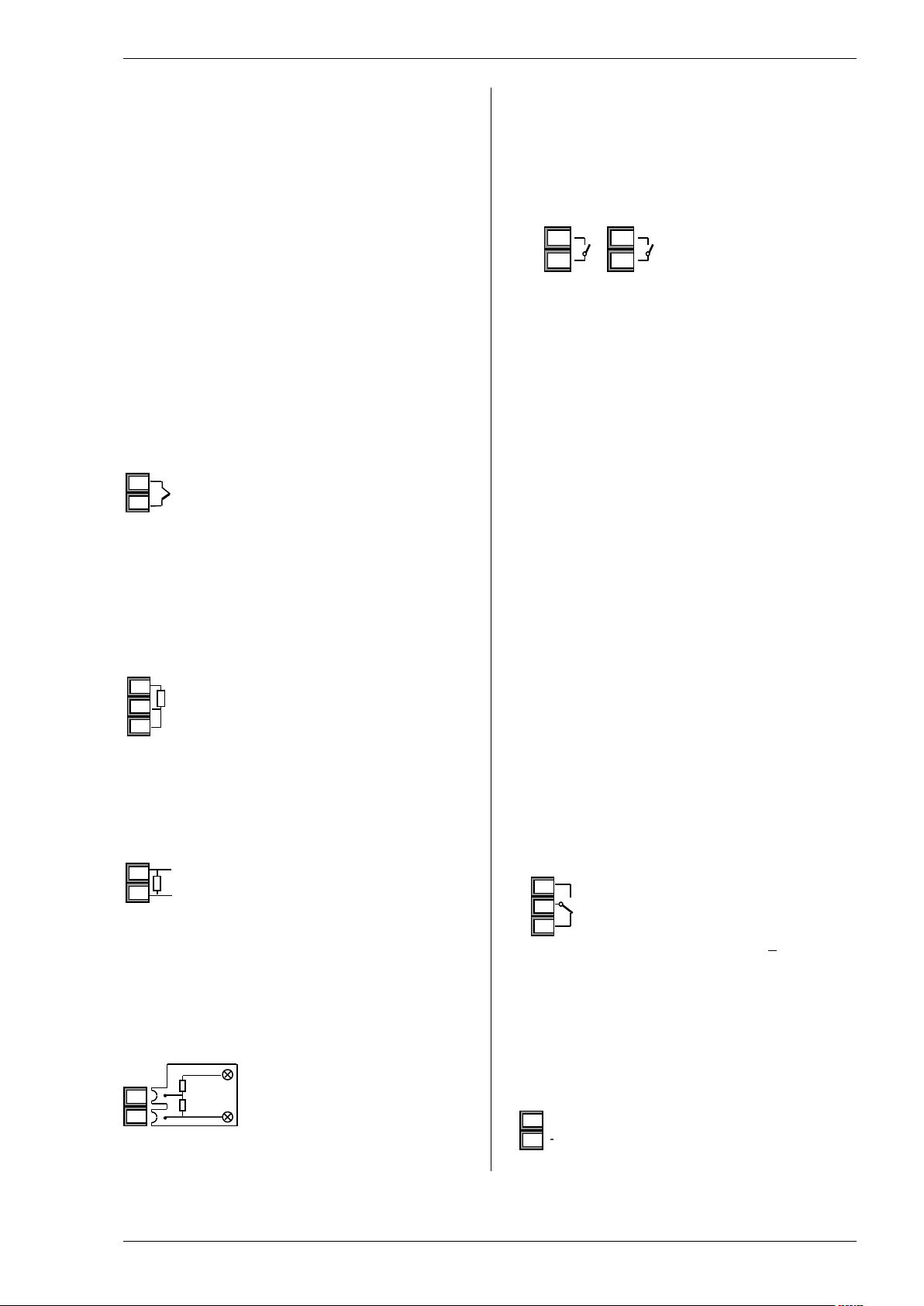

1.7 Wire Sizes

100KΩ

+

V+

+

-

3C

VI

V+

2.49Ω

-

V+

OP4

AA

OP1

OP3

1A

3A

The screw terminals accept wire siz es from 0.5 to 1.5

mm (16 to 22AWG). Hinged covers prevent hands or

metal making accidental contac t with live wires. The

rear terminal screws should be tight ened to 0.4Nm (3.5

in-lbs).

1.8 Sensor Input (Measuring Input)

• Do not run input wires with power cables

• When shielded cable is used, it should be

grounded at one point only

• Any external components (such as zener barriers)

connected between sensor and input terminals

may cause errors in measurement due to

excessive and/or un-balanced line r esistance, or

leakage currents.

• Not isolated from the logic outputs & digital inputs

Thermocouple Input

+

Positive

V-

-

Negative

• Use the correct compensating cable, preferably

shielded.

• It is not recommended to connect two or more

instruments to one thermocouple.

RTD Input

V+

V-

• The resistance of the three wires mus t be the

PRT

PRT

Lead compensation

same. The line resistance may cause err ors if it

exceeds 22Ω.

Linear mA, or mV Inputs

+

V-

Positive

Negative

• For a mA input, connect the 2.49Ω bur den resistor

supplied between the V+ and V- ter m i nals as

shown. For mV, omit this resistor.

Linear Voltage Inputs

An external potential

0-10V

V-

806Ω

Input

-

Sensor break alarm does not operate if this adaptor is

fitted.

divider is required for the

Series 3L

1.9 Outputs

The indicators are supplied as standard with two

changeover relay outputs as follows:.

1.9.1 Output 1 & Output 3

Relay (Form A)

1B

3B

• Isolated output 300Vac CATII

• Contact rating:: 2A 264Vac resis tive

• Output functions: Alarm/Event

* General Notes about Relays and Inductive Loads

High voltage transients may occur when switching

inductive loads such as some contact ors or solenoid

valves. Through the internal contact s , these transients

may introduce disturbances which could affect the

performance of the instrument.

For this type of load it is recommended that a ‘snubber’

be connected across the normally open contact of the

relay switching the load. The snub ber recommended

consists of a series connected resistor/capacitor

(typically 15nF/100Ω). A snubber will also prolong the

life of the relay contacts.

A snubber should also be connected acr oss the output

terminal of a triac output to prevent f alse triggering

under line transient conditions.

WARNING

When the relay contact is open, or it is connected

to a high impedance load, it passes a current

(typically 0.6mA at 110Vac and 1.2mA at 230Vac).

You must ensure that this current will not hold on

low power electrical loads. If the load is of this

type, the snubber should not be connected.

1.9.2 AA Rela y Form C (FM Approved)

o Isolated output 300Vac CATII

o Software configurable: 0-20mA or 4-

20mA plus 0-5V, 0-10V, 1-5V and 2-

AB

AC

1.9.3 Transmitter Supply

A fixed 24Vdc supply is available to power an external

transducer

• Isolated output 300Vac CATII

3D

10V.

o Max load resistance: 500Ω

o Calibr ation accuracy: +(<0.25% of

reading + <50µA

Page 8

Operations Manual Series 3L

8

1.9.4 Digital Inputs A and B

Dig In A

LA

Dig In B

LB

* EIA232/ EIA485 2-

Com

Twisted pairs

Tx Rx Com

Rx Tx Com

Screen

RxB/

RxA/

*

HD Common

Line

L

C

LC

• Not isolated from the sensor input

• Switching: 12Vdc at 40mA max

• Contact open > 500Ω. Contact closed < 200Ω

• Input functions: Please refer to the l ist in the quick

codes.

1.10 Indicator Power Supply

1. Before connecting the indicator to the power line,

make sure that the line voltage corresponds to the

description on the identification label.

2. Use copper conductors only.

3. The power supply input is not fuse pr otected. This

should be provided externally.

4. For 24V, the polarity is not important.

N

• High voltage supply: 100 to 230Vac, +15%,

• Recommended external fuse ratings are as

Neutral

48 to 62 Hz

follows:

For 100 - 230Vac, fuse type: T rated 2A

250V.

1.11 Digital Communications (Optional)

Digital communications uses the Modbus protocol.

The interface is EIA485 (2-wire).

• Isolated 300Vac CATII.

EIA 485 Connections

TxB

220Ω termination

resistor

TxA

wire communications

converter eg Type

KD485

220Ω termination

resistor on last

instrument in the line

Daisy Chain

to further

instruments

HE Rx

HF Tx

Page 9

Series 3L Indicators

9

2. Safety and EMC Information

!

Caution (refer to accompanying documents)

This indicator is intended for industrial temperature and

process applications when it will m eet the

requirements of the European Direct ives on Safety and

EMC. Use in other applications, or failure to observe

the installation instructions of this handbook, may

impair safety or EMC. The installer must ensure the

safety and EMC of any particular installation.

Safety

This indicator complies with the E uropean Low Voltage

Directive 2006/95/EC, by the application of the safety

standard EN 61010.

Electromagnetic compatibility

This indicator conforms with the es s ential protection

requirements of the EMC Directive 2004/108/EC by the

application of a Technical Constr uction File. This

instrument satisfies the general requirements of the

industrial environment defined in EN 61326. For more

information on product compliance, refer to the

Technical Construction File.

GENERAL

The information contained in this manual is subject to

change without notice. While every effor t has been

made to ensure the accuracy of the information, your

supplier shall not be held liable f or errors contained

herein.

Unpacking and storage

The packaging should contain an inst rument mounted

in its sleeve, two mounting brackets for panel

installation and an Installation & Operating guide.

Certain ranges are supplied with an input adapter.

If on receipt, the packaging or the instrument is

damaged, do not install the product but c ontact your

supplier. If the instrument is to be stor ed before use,

protect from humidity and dust in an ambient

temperature range of -10OC to +70OC.

Service and repair

This indicator has no user serviceable parts. Contact

your supplier for repair.

Caution: Charged capacitors

Before removing an instrument f rom its sleeve,

disconnect the supply and wait at least two minutes to

allow capacitors to discharge. I t may be convenient to

partially withdraw the instrument from the sleeve, then

pause before completing the removal. In any case,

avoid touching the exposed elect r oni c s of an

instrument when withdrawing it from the sleeve.

Failure to observe these precautions m ay cause

damage to components of the instrume nt or some

discomfort to the user.

Electrostatic discharge precautions

When the indicator is removed from it s sleeve, some of

the exposed electronic components are vulnerable to

damage by electrostatic discharge from someone

handling the indicator. To avoid this, before handling

the unplugged indicator, disch ar ge yourself to a

ground.

Cleaning

Do not use water or water based products to clean

labels, or they will become illegible. Isopropyl alcohol

may be used to clean labels. A mild soap solution may

be used to clean other exterior surfaces of the product.

2.1 Installation Safety Requirements

Safety Symbols

Various symbols may be used on the in dicator. They

have the following meaning:

Equipment protected throughout by DOUBLE

INSULATION

Helpful hints

Personnel

Installation must only be carried out by suitably

qualified personnel in accordance with the instructions

in this handbook.

Enclosure of Live Parts

To prevent hands or metal tools from touc hi ng parts

that may be electrically live, the indicator must be

enclosed in an enclosure.

Caution: Live sensors

The indicator is designed to operate if the temperature

sensor is connected directly to an el ec trical heating

element. However, you must ensure that service

personnel do not touch connections t o these inputs

while they are live. With a live sensor, al l cables,

connectors and switches for connec ting the sensor

must be mains rated for use in 230Vac +15% CATII.

Wiring

It is important to connect the indicator in accordance

with the wiring data given in this guide. Take particular

care not to connect AC supplies to the low voltage

sensor input or other low level inputs and outputs.

Only use copper conductors for conn ec tions (except

thermocouple inputs) and ensure that the wiring of

installations comply with all local wiring regulations.

For example, in the USA, use NEC Class 1 wi ring

methods. In the UK, use the latest vers ion of the IEE

wiring regulations (BS7671).

Power Isolation

The installation must include a power isolating switch

or circuit breaker. This device should be in close

proximity to the indicator, within easy reach of the

operator and marked as the disconnecting device for

the instrument.

Overcurrent protection

The power supply to the system should be f used

appropriately to protect the cabli ng to the units.

Page 10

Operations Manual Series 3L

10

Voltage rating

The maximum continuous voltage applied between any

of the following terminals must not exceed 230Vac:

• relay output to logic, dc or sensor connections;

• any connection to ground.

The indicator must not be wired to a three phase

supply with an unearthed star connec tion. Under fault

conditions, such a supply could ri s e above 240Vac

with respect to ground, and the produc t would not be

safe.

Conductive pollution

Electrically conductive pollut ion must be excluded from

the cabinet in which the indicator is mount ed. For

example, carbon dust is a form of elect rically

conductive pollution. To secure a suitable atmosphere

in conditions of conductive pollution, fit an air filter to

the air intake of the cabinet. Where con densation is

likely—for example, at low temperatures—include a

thermostatically controlled heater in the cabinet.

This product has been designed to conform to

BSEN61010 installation category II, pollution degree 2.

These are defined as follows:

Installation Category II (CAT II)

For equipment on nominal 230V supply, the maximum

rated impulse voltage is 2500V.

Pollution Degree 2

Normally only non-conductive pollution occurs.

Occasionally, however, a temporary conductivity caused

by condensation shall be expected.

Grounding of the temperature sensor shield

In some installations, it is common practice to replace

the temperature sensor while the indicator is still

powered up. Under these conditions, as additional

protection against electric shoc k, we recommend that

the shield of the temperature sensor be grounded. Do

not rely on grounding through the f ramework of the

machine.

Over-temperature protection

When designing any control system, it is essential to

consider what will happen if any part of the system

should fail. In temperature control applications, the

primary danger is that the heating will remain

constantly on. Apart from spoiling the product, this

could damage any process machinery being

controlled, or even cause a fire.

Reasons why the heating might remain c onstantly on

include:

• the temperature sensor becoming detac hed from

the process

• thermocouple wiring becoming short circuit

• the controller failing with its heating output

constantly on

• an external valve or contactor sticking in the

heating condition

• the controller setpoint being set too high.

Where damage or injury is possible, we recommend

fitting a separate over-temperature protection unit, with

an independent temperature sensor , which will isolate

the heating circuit.

This indicator can be used in addition t o a controller as

an over-temperature device. It is recommended that

the relay used to indicate the alarm condition should

be set to high alarm configured with sensor break and

inverse ‘Inv’ operation so that it relax es to the alarm

condition when power is removed.

Installation requirements for EMC

To ensure compliance with the Europea n E MC

directive certain installation precautions are necessary

as follows:

• When using relay outputs it may be necessary to

fit a filter suitable for suppressing the emissions.

The filter requirements will depend on the type of

load.

• If the unit is used in table top equipment which is

plugged into a standard power socket, then it is

likely that compliance to the commerc i al and light

industrial emissions standard i s required. In this

case to meet the conducted emissions

requirement, a suitable mains filter should be

installed.

Routing of wires

To minimize the pick-up of electrical noise, the low

voltage DC connections and the sensor input wiring

should be routed away from high-current power cables.

Where it is impractical to do this, us e s hi elded cables

with the shield grounded at both ends. In general,

keep cable lengths to a minimum.

Page 11

Series 3L Indicators

11

3. Switch On

!

K C H C 0

o

(1)

(1)

(1)

(1) Up to 2 decimal places on Series 3L

3.1 New Indicator

If the indicator is new and has not previously been

configured, or following a ‘Cold Start’ (section 5.5), it

will start up showing the ‘Quick Configuration’ codes.

This is a built in tool which enables you to configure

the input type and range, the output functions, and the

display format.

Incorrect configuration can result in damage

to the process and/or personal injury and must be

carried out by a competent person authorized to

do so. It is the responsibility of the person

commissioning the instrument to ensure the

configuration is correct.

The quick code consists of two ‘SETS’

of five characters.

The upper section of the display shows the set

selected. The lower section sho ws the fi v e digits which

make up the set.

Adjust these as follows:

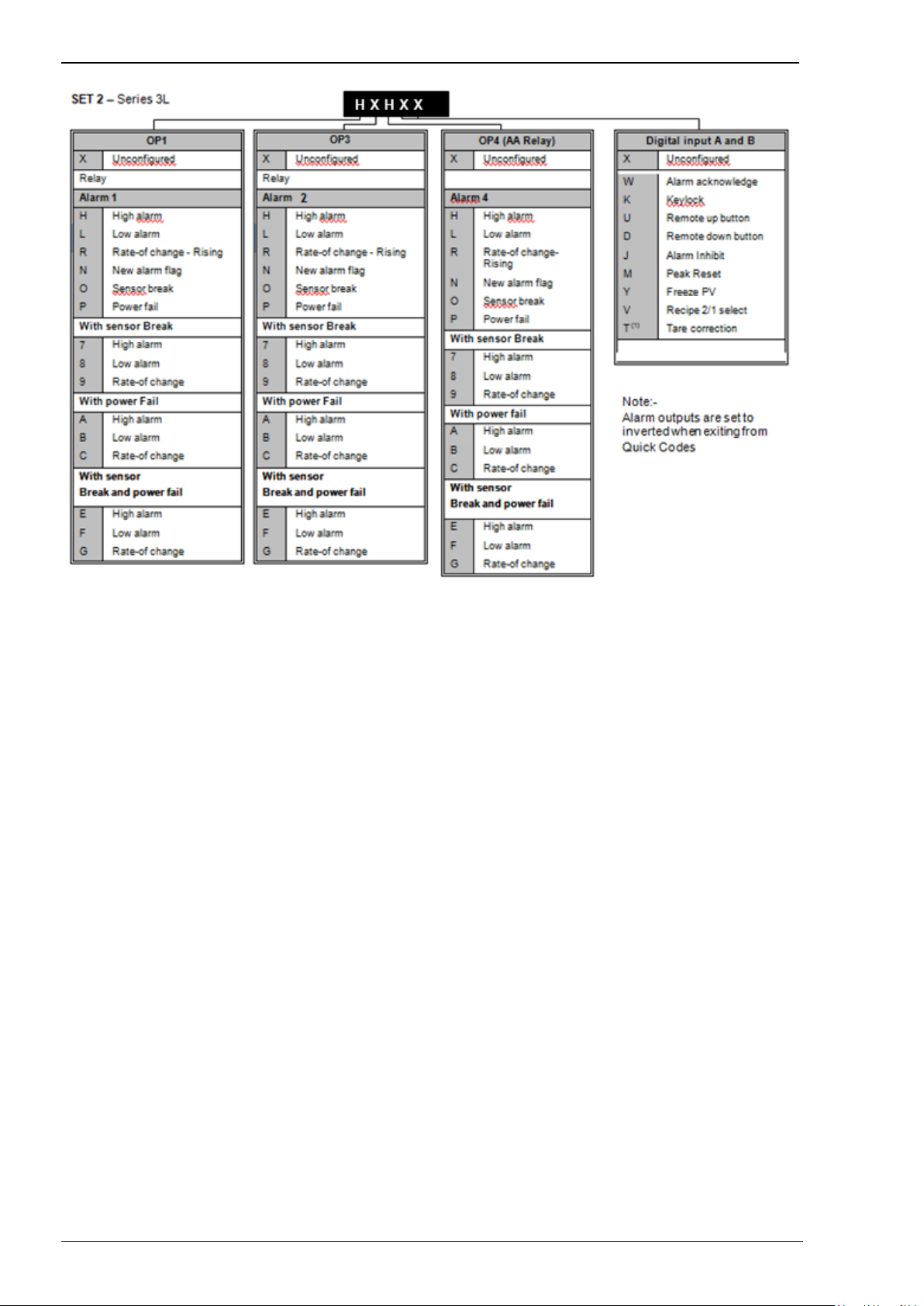

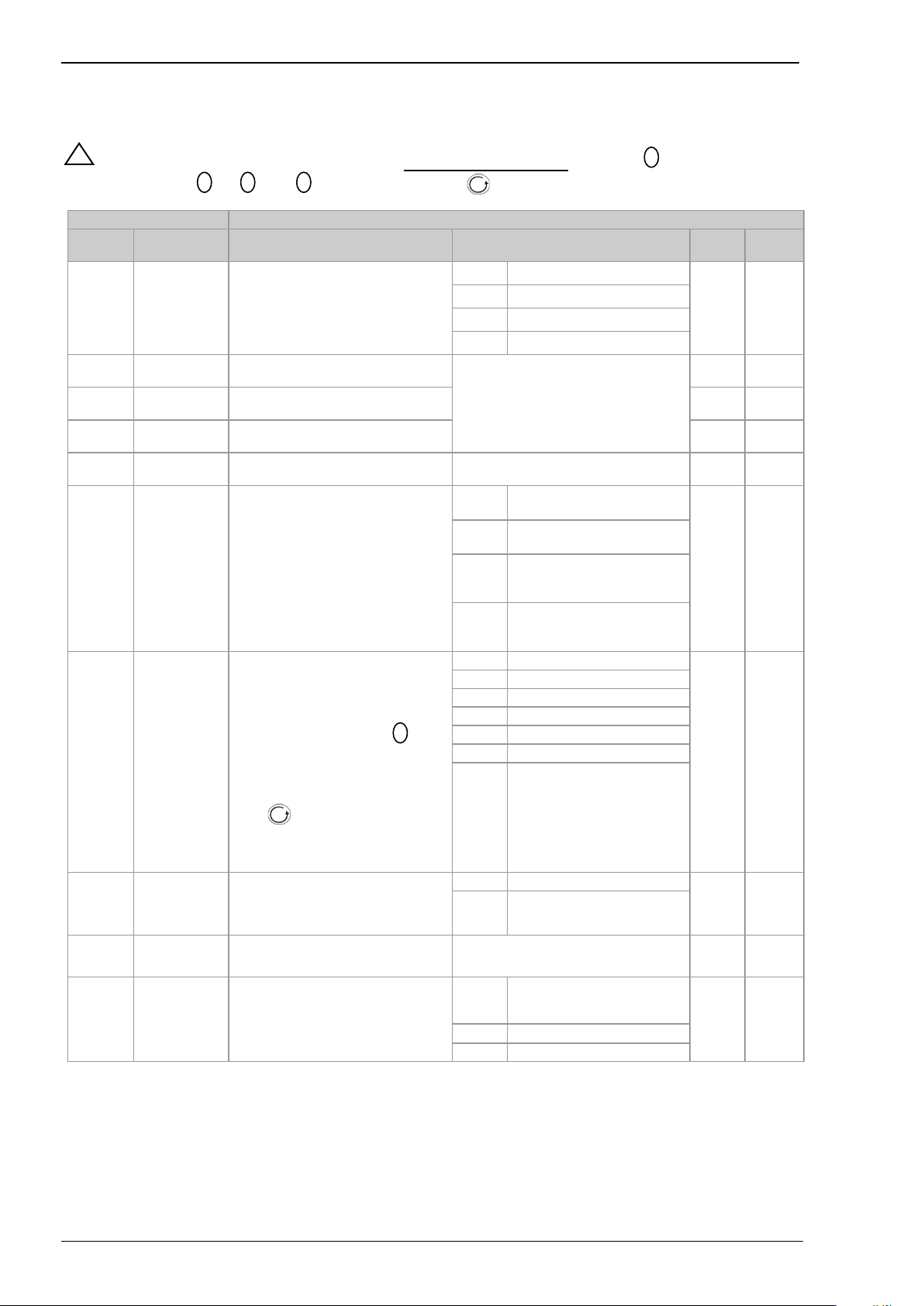

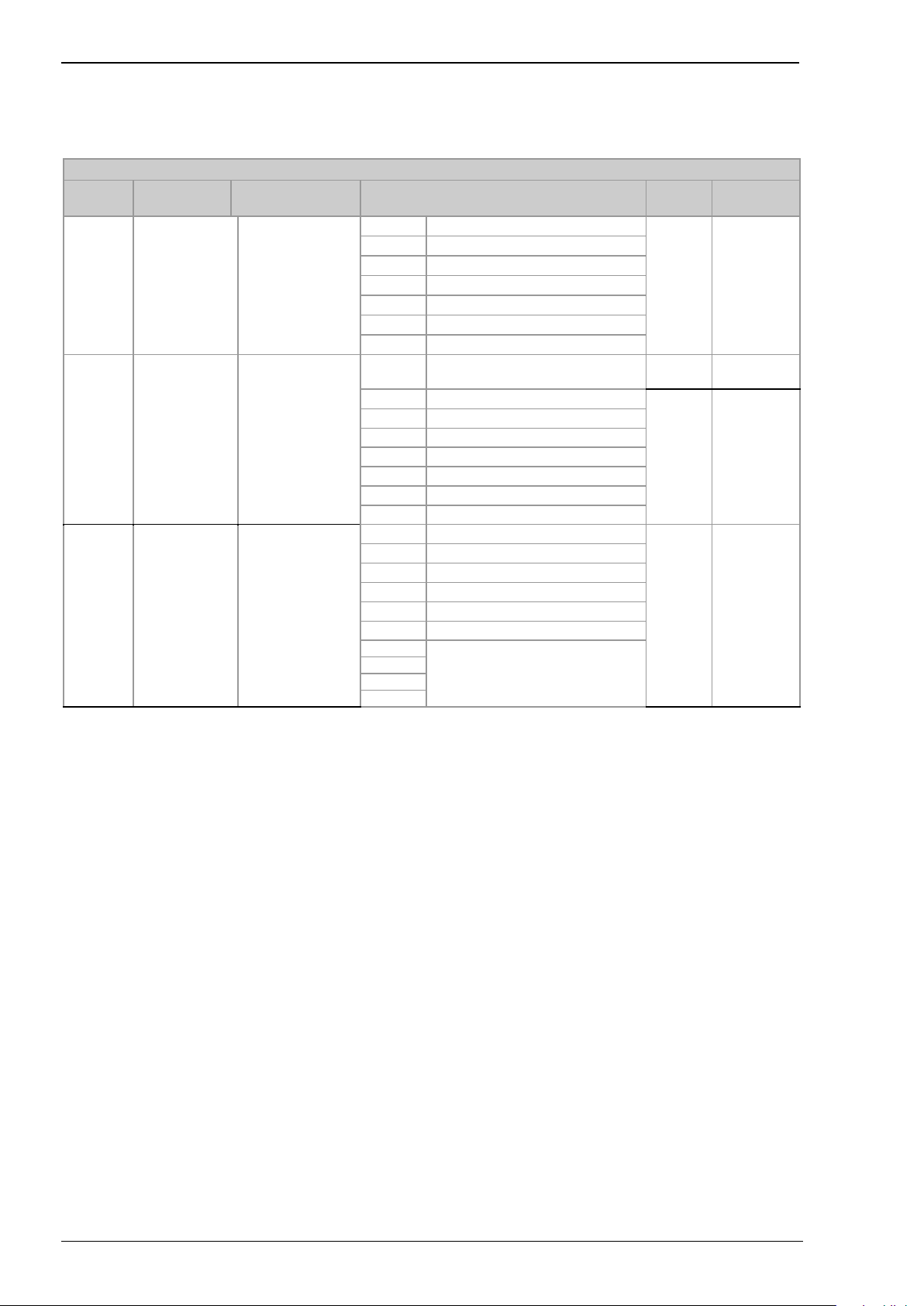

SET 1

Input Type

Thermocouple

B Type B

J Type J

K Type K

L Type L

N Type N

R Type R

S Type S

T Type T

C Custom C

RTD

P Pt100

Linear (all units)

M 0-80mV

2 0-20mA

4 4-20mA

Display

units

Temperature

X None 1 nnnn.n

C

F oF 3 nn.nnn

K K 4 n.nnnn

P %

Decimal point

0 nnnnn

C 2 nnn.nn

(1)

1. Press any button. The first charac ter will change

to a flashing ‘-‘.

2. Press

or

to change the flashing character

to the required code shown in the quick c ode

tables –see next page. Note: An

x indicates that

the option is not fitted.

3. Press to scroll to the next ch aracter.

You cannot scroll to the next character until the

current character is configured.

To return to the first character press

4. When all five characters have been conf i gured the

display will change to rng.hi followed by rng.lo

which allows range high and low limits to be set.

5. The next press of will select Set 2. Adjust

each character as described for Set 1.

6. When the last character has been entered press

again; the display will show . Continue

to press if you wish to repeat the above quick

or

codes or press

satisfied with the quick codes. The indicator will

then automatically go to the operator level

Not Applicable

(1)

X Not applicable

Set 1 is followed Set this for the maximum

with RNG.HI display range required

Then Set this for the minimum

RNG.Lo display range required

Set 2 follows these

parameters

to if you are

Home display

N PV only

A First Alarm SP only

1 PV + Alarm SP

2 PV + Alarm SP

See next page

.

(Read only)

Page 12

Operations Manual Series 3L

12

Page 13

Series 3L Indicators

13

3.1.1 To Re-Enter Quick Code Mode

If you need to re-enter the ‘Quick Configuration’ m ode

this can always be done as follows:

1. Power down the indicator.

3.3 Front panel layout

2. Hold

button down and power up the indicat or

again. Keep the button pressed until you are

requested to enter a passcode.

3. Enter a passcode using the

or

buttons. In

a new indicator the passcode defau l ts to 4. If an

incorrect passcode is entered, you must repeat

the whole procedure.

Parameters may also be configured using a

deeper level of access as described in subsequent

chapters of this manual. If this has been done and the

Quick Code Mode is re-entered as descri bed above,

then the quick codes are shown with full stops (e.g.

G.S.2.G.A.) to indicate that the conf iguration has been

changed.

3.2 Pre-Configured Indicator or Subsequent Starts

A brief start up sequence consists of a self test in

which all elements of the display are illuminated and

the software version number is shown.

The indicator will briefly displa y the quick codes during

start up and then proceed to Operator Level 1.

You will see the display shown below. It is called the

HOME display.

If the Quick Codes do not appear during start up,

this means that the indicator has been configured in a

deeper level of access, as stated opposite. The quick

codes may then not be valid and are therefore not

shown.

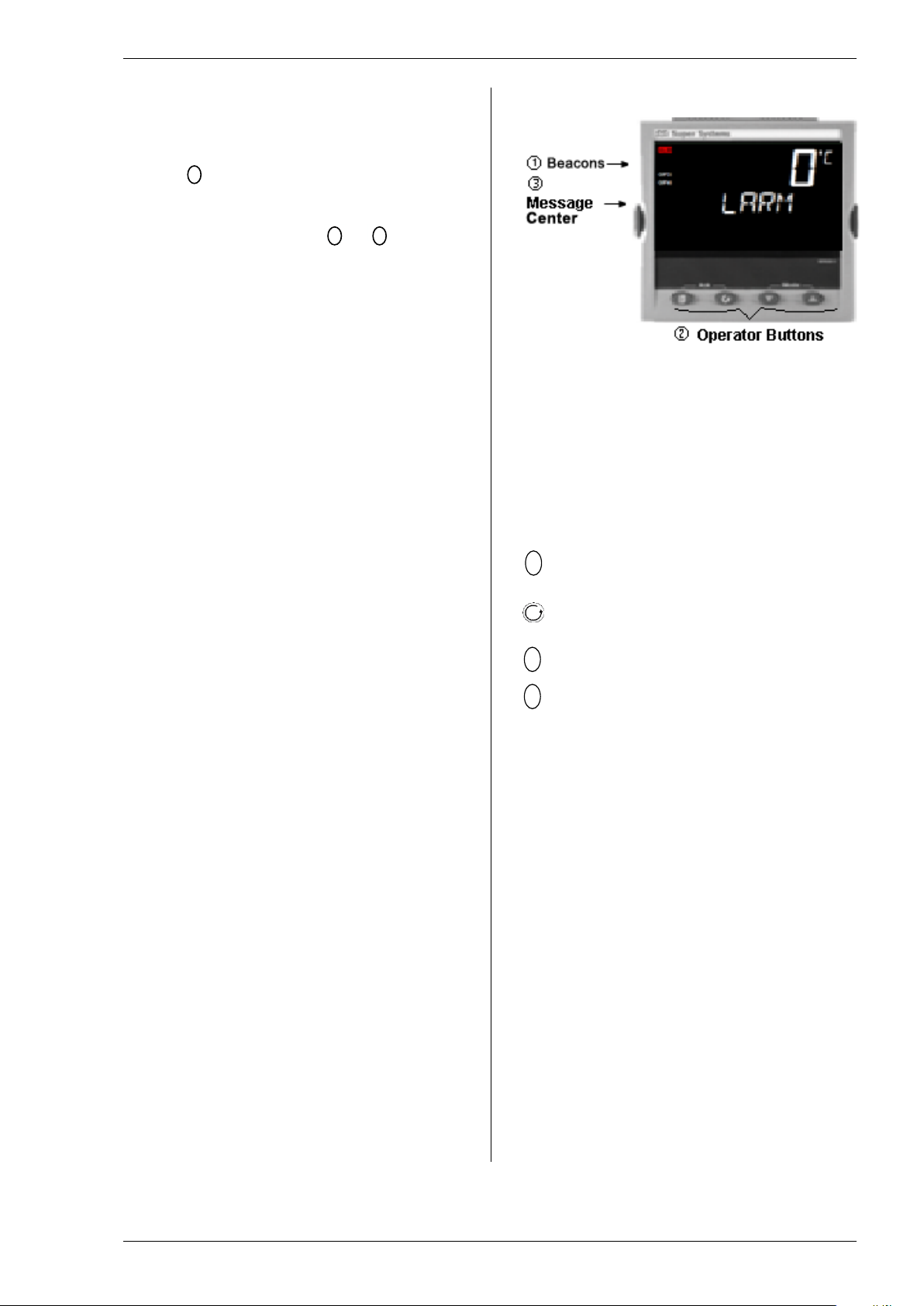

Beacons

ALM Alarm active (Red)

OP1 Lit when output 1 is ON

OP3 Lit when output 3 is ON

OP4 Lit when output 4 (AA relay) is ON

REM Communications active

Operator Buttons:

From any display - press to return to the HOME

display.

Press to select a new parameter. Hold down to

continuously scroll through parameters.

Press to change or decrease a value.

Press to change or increase a value.

Message Center

A scrolling message may appear in this section. For

example, if a high alarm is configured to operate output

1, and a low alarm is configured to operate output 4,

the scrolling messages ‘ALARM 1 HIGH’ and ‘ALARM

4 LOW’ are shown together with the beac ons ‘ALM’,

‘OP1’ and ‘OP4’. ‘ALM’ flashes if the alarm has not

been acknowledged.

If the input sensor is broken ‘S.br’ appear s in the top

display and the scrolling message ‘INPUT SENSOR

BROKEN’ appears in the message center.

Page 14

Operations Manual Series 3L

14

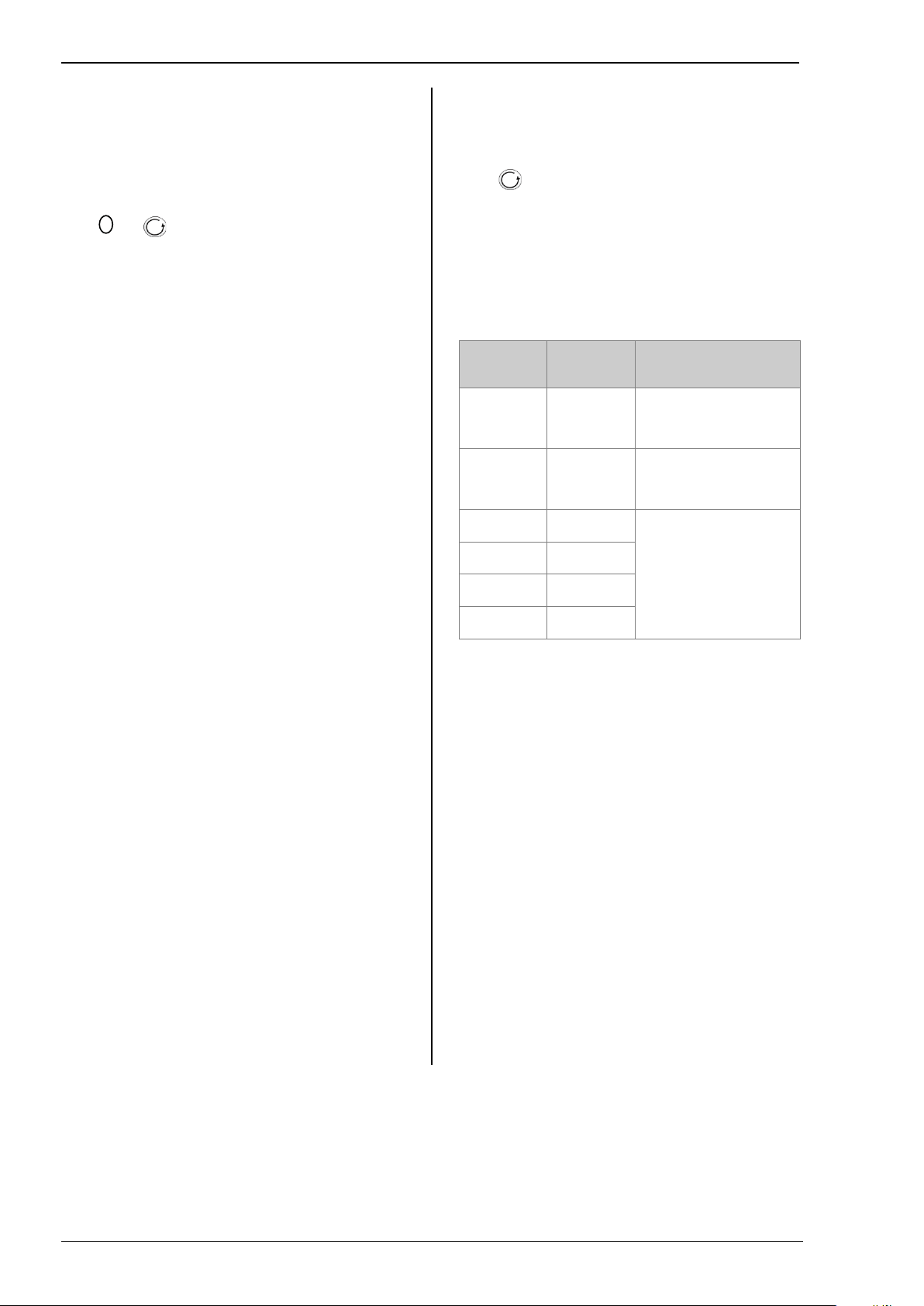

3.3.1 Alarm Indication

Parameter

Scrolling

Description

Availability

HIGH

PEAK HIGH

This is the highest reading

LOW

PEAK LOW

This is the lowest reading

or since it was reset

SETPOINT

SETPOINT

ALARM 3

SETPOINT

A4 (----)

ALARM 4

SETPOINT

Up to three alarms can be configured. If any alarm

occurs, the red ALM beacon will flas h. A scrolling text

message will describe the source of the alarm (for

example, ALARM 1 HIGH). Any output attached to the

alarm will operate.

Press

and (Ack) together to acknowledge the alarm

If the alarm is still present, the ALM beacon will light

continuously.

By default alarms are configured as non-latching, deenergized in alarm. If you require lat ched alarms,

please refer to the engineering handbook.

3.3.2 Out of Range Indication

If the input is too high, HHHHH will be displayed.

If the input is too low, LLLLL will be displayed.

3.3.3 Sensor Break Indication

An alarm condition (S.br) is indicated if the sensor or

the wiring between sensor and indicator becomes

open circuit.

For a PRT input, sensor break is indicated if any one of

the three wires is broken.

For mA input, sensor break will not be detected due to

the load resistor connected across the input terminals.

For Volts input, sensor break may not be detected due

to the potential divider network connec ted across the

input terminals.

3.4 Operator Parameters in Level 1

Operator level 1 is designed for day to day operation of

the indicator, and access to these parameters is not

protected by a pass code.

Press

to step through the list of parameters. The

mnemonic of the parameter is sho wn in t he lower

display. After five seconds, a scrolling text description

of the parameter appears.

The value of the parameter is shown in the u pper

display. In level 1 the value is read onl y.

The parameters that appear depend upon the

functions configured. They are:

Mnemonic

A1 (----) ALARM 1

A2 (----) ALARM 2

A3 (----)

text and

that the indicator has

recorded since switch on

or since it was reset

that the indicator has

recorded since switch on

(----) shows the type of

alarm configured. For

example: HI, LO, ROC.

This parameter sets the

alarm thresholds.

Page 15

Series 3L Indicators

15

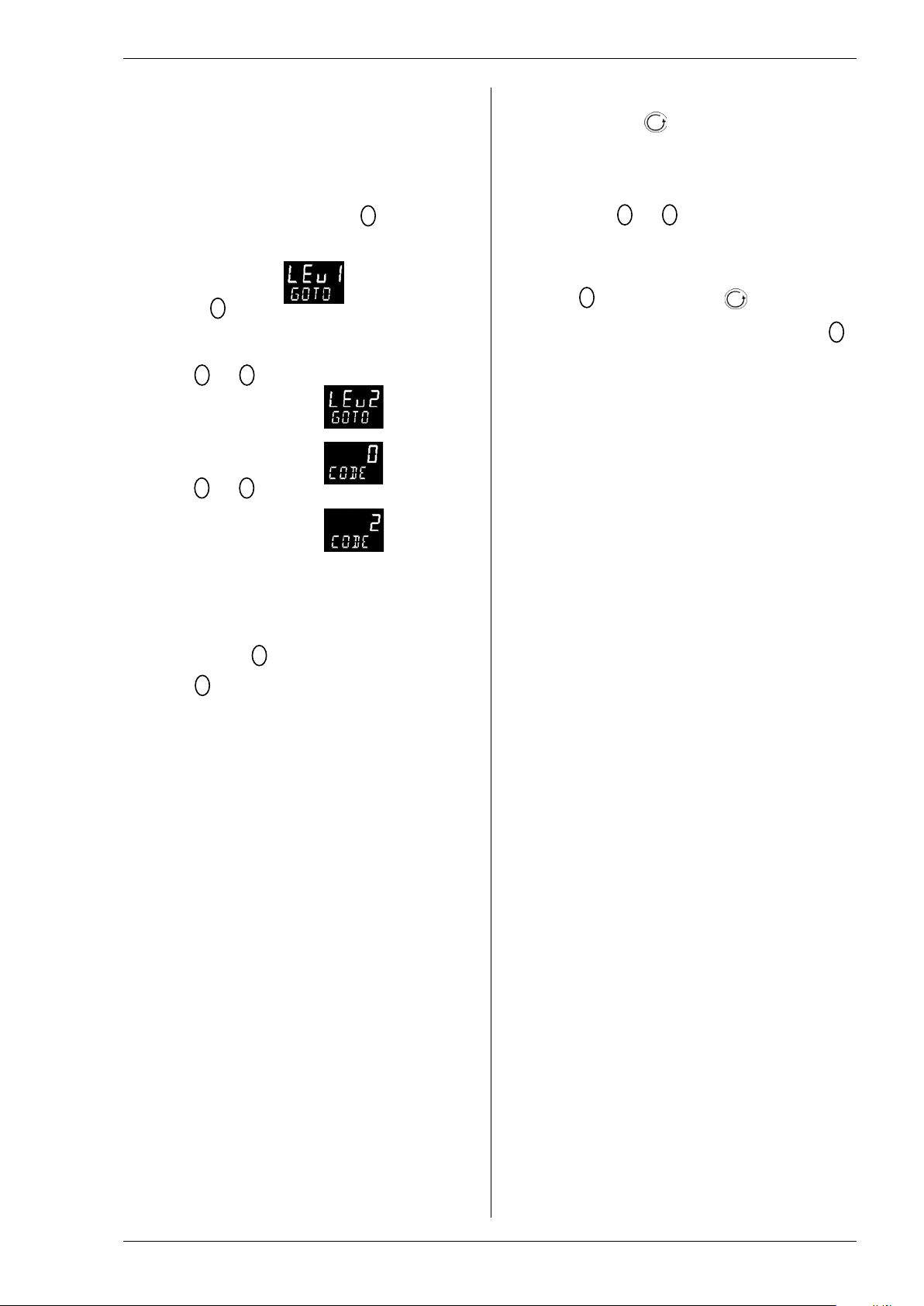

4. Operator Level 2

Level 2 provides access to additional parameters. It is

protected by a security code.

4.1 To Enter Level 2

1. From any display press and hold

2. After a few seconds the

display will show:-

3. Release

.

(If no button is pressed for 45 seconds the

display returns to the HOME display)

4. Press

or

to

choose Lev 2 (Level 2)

5. After 2 seconds the

dis play will show:-

6. Press

pass code. Default = ‘2’

or

to enter the

7. If an incorrect code is entered the indicator reverts

to Level 1.

4.1.1 To Return to Level 1

1. Press and hold

.

4.2 Level 2 Parameters

As in Level 1, press to step throu gh the list of

parameters.

in the message center. After five seconds, a scrolling

text description of the parameter appears.

The value of the parameter is shown in the upper

display. Press

If no key is pressed for 30 seconds, the indicator

returns to the HOME display.

Backscroll is achieved when you are in this list by

pressing

To return to the HOME display at any time, press

The following table shows a list of parameters

available in Level 2.

The mnemonic of the parameter is shown

or

to adjust this value.

while holding down .

.

2. Press

to select LEv 1

The indicator will return to the level 1 HOME display.

Note: A pass code is not required when goi ng from a

higher level to a lower level.

Page 16

Operations Manual Series 3L

16

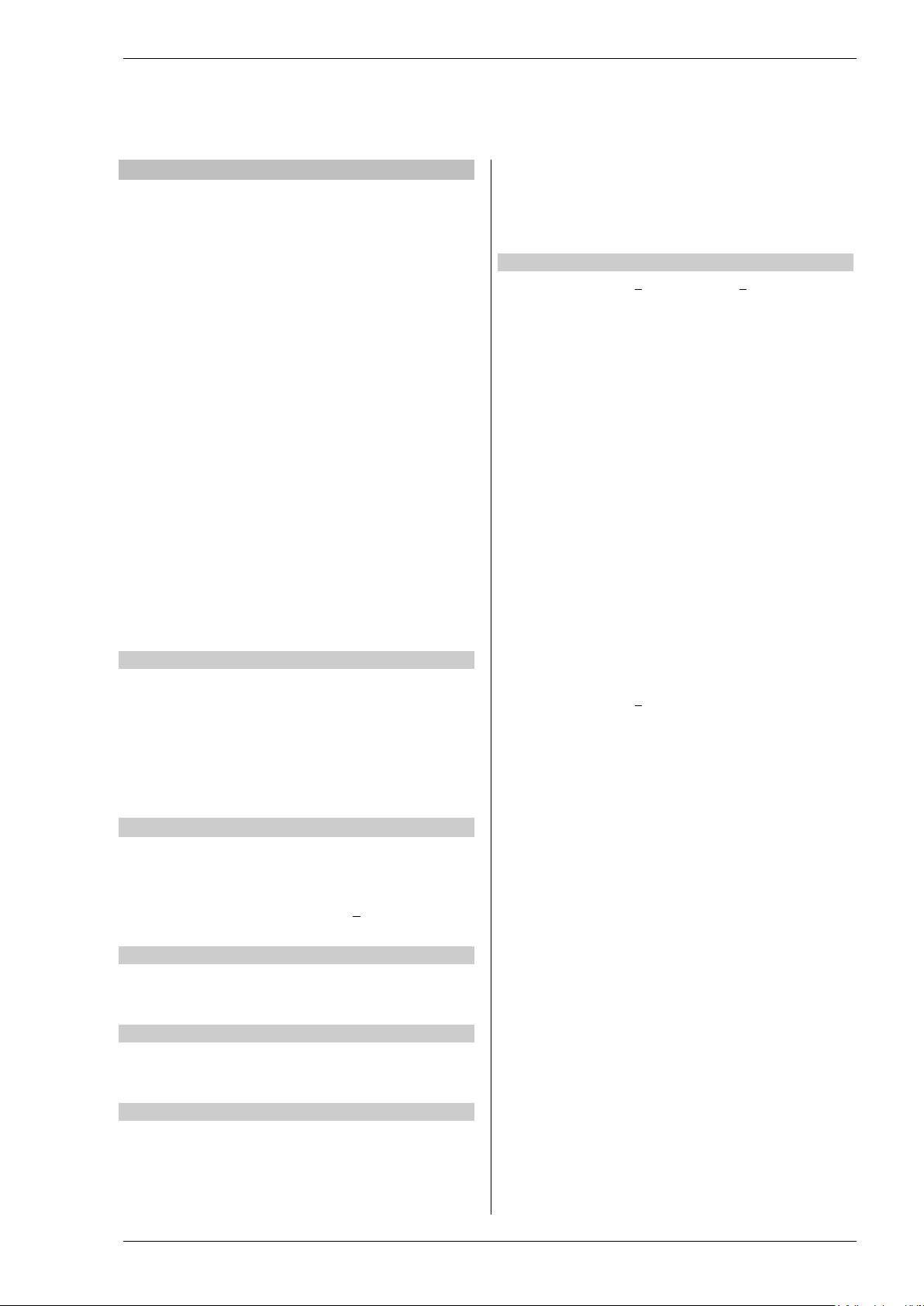

Mnemonic Scrolling Display and description Range

has recorded since switch on or since it was reset

Read only

has recorded since switch on or since it was reset

A1 (----)

ALARM 1 SETPOINT

(----) shows the type of alarm configured. For example

A2 (----)

ALARM 2 SETPOINT

ALARM 3 SETPOINT

A4 (----)

ALARM 4 SETPOINT

ADDR

ADDRESS Digital communications address for the

instrument (if digital communications fitted)

1 to 254

HOME

HOME DISPLAY This configures the parameter which

Process variable

PV + Alarm SP

PV + Alarm SP read only

number

O

O

O

PRST

PEAK RESET Select On to reset the HIGH and LOW peak

values. The display automatically returns to OFF

OFF

ON

HIGH PEAK HIGH This is the highest reading that the indicator

LOW

PEAK LOW This is the lowest reading that the indicator

Read only

HIGH, LOW,

A3 (----)

will be displayed in the HOME display in normal

operation

ALm

pv.aL

p.a.ro

PV

ID CUSTOMER ID Customized instrument identification

0 to 9999

UNITS DISPLAY UNITS The display units are shown in the top right hand

corner of the display in normal operation. Units available are:-

O

C

none

C

No units displayed

O

F

Perc

F

Percentage

Press

at any time to return immediately to the HOME screen at the top of the list.

Hold down to continuously scroll through the above list

Alarm setpoint

k

Kelvin

Page 17

Series 3L Indicators

17

4.3 FM and Alarm Units

!

Series 3L indicators supplied to Function code FM are

FM approved.

Series 3L indicators supplied to Function code DN are

approved to EN14597.

The instrument label is marked accordingly.

In these instruments, the alarm operating the AA relay

output is set to inverted and latching. This function

cannot be altered.

When the instrument is configured using the Quick

Start codes (section 3.1), Alarm 1 is used to operate

both Outputs 1 and 4 (AA relay). The Quick Start

configuration for the AA relay will enable and configure

Alarm 4 but Alarm 4 will not be used to operate Output

4.

If Quick Start is used to configure Alarm 1 as

a high alarm and Alarm 4 as a low alarm, then the

resulting configuration will be t hat the high alarm 1 is

used to drive both outputs 1 and 4. The low alarm 4

will not be connected to any output.

Further details on latching and blocking alarms can be

found in section 9.1.

4.4 Recipes

Not Applicable to this Instrument

Page 18

Operations Manual Series 3L

18

5. Access to Further Parameters

Parameters are available under different levels of

security and are defined as Level 1 (Lev1), Level 2

(Lev2), Level 3 (Lev 3) and Configuration (Conf).

Level 1 has no pass code since it contains a minimal

set of parameters generally sufficient to run the

process on a daily basis. Level 2 allows access t o

parameters which may used in commissioning an

indicator or settings between different products or

batches. This has been described in the previous

section.

Level 3 and Configuration level parameters are also

available as follows:

5.1 Level 3

Level 3 makes all operating parameters available and

alterable (if not read only). It is typically used when

commissioning an indicator.

Examples are:

Range limits, setting alarm levels, communications

address.

5.2 Configuration Level

This level makes available all par ameters including the

operation parameters so that there is no need to switch

between configuration and operati on levels during

commissioning. It is designed for those who may wish

to change the fundamental characteristics of t he

instrument to match the process.

Examples are:

Input (thermocouple type); Alarm type;

Communications type.

WARNING

Configuration level gives access to a wide range of

parameters which match the indicator to the

process. Incorrect configuration could result in

damage to the process and/or person al injury. It is

the responsibility of the person commissioning the

process to ensure that the configuration is correct.

In configuration level, the indicator is not providing

alarm indication.

Do not select configuration level on a live process.

Operating

Level

Level 1

Level 2

Level 3

Conf

Home

List

Full

Operator

Yes RW

Yes RO

Configuration Alarms

Yes

No

Page 19

Series 3L Indicators

19

5.2.1 To Select Access Level 3 or Configuration Level

Do This

The Display You Should See

Additional Notes

To Select Level 3

The default code is 3:

appear – see section 9.4 ‘Diagnostic Alarms’

3

Lev 3

0

Conf

0

Conf

4

Conf

Lev1

1. From any display press and

hold

seconds

2. Press

passcode for Level 3

3. When the LEV3 GOTO view is

shown, as in paragraph 1

above, press

‘Conf’

4. Press

passcode for Configuration

level

5. Press and hold

than 3 seconds

6. Press

required level—for example,

LEV 1

for more than 5

or

to enter the

to select

or

to enter the

to select the

for more

goto

code

To Select Configuration

code

level

goto

code

code

To Return to a Lower Level

goto

goto

The display will pass from the current operating

level, for example, Lev 1 to Lev 3 as the button

is held down.

(If no button is then pressed for about 50 seconds

the display returns to the HOME display)

If an incorrect code is entered the display reverts to

‘goto’.

If a correct code is entered the indicator is now in the

level 3 will then revert to the HOME display

Note:

indicator requests the code for level 3

The default code is 4:

If an incorrect code is entered the display reverts to

‘goto’.

If a correct code is entered the indicator is now in

Configuration level will now show Conf

The choices are:

LEv 1 Level 1

LEv 2 Level 2

LEv 3 Level 3

ConF Configuration

It is not necessary to enter a code when going from

a higher level to a lower level.

Alternatively, press

header, then press to select the required level.

The display will then flash ‘ConF’ for a few seconds

and the indicator will then go through its start up

sequence, starting in the level selected.

Do not power down while Conf is flashing. If a

power down does occur an error message will

must be pressed quickly before the

and scroll to the Acces list

A special case exists if a security code has been

configured as ‘0’ If this has been done i t is not

necessary to enter a code and the indicat or will enter

the chosen level immediately.

When the indicator is in configuration level the

ACCESS list header can be selected from any view by

holding down the

Then press

button for more than 3 seconds.

again to select ‘ACCES’

Page 20

Operations Manual Series 3L

20

5.3 Parameter lists

Parameters are organized in lists. The top of the list

shows the list header only. The name of the list

header describes the generic funct i on of the

parameters within the list. For example, the list header

‘ALARM’ contains parameters which enable you to set

up alarm conditions.

5.3.1 To Choose Parameter List Headers

Press

time this key is pressed.

The name of the list header appears in the lower

display, followed, after a few seconds, by a scrolling

longer description of the name.

The following example shows how to select the first

two list headers.

. Each list header is selected in turn every

5.3.3 How Parameters are Displayed

As shown above. Whenever a

parameter is selected it is displaye d as a mnemonic, of

four or five characters, for example ‘A1.TYP’.

After a few seconds this display is replaced by a

scrolling banner which gives a mor e detailed

description of the parameter. In thi s example ‘A1.TYP’

= ‘alarm 1 type’. The scrolling banner is onl y shown

once after the parameter is first acc essed.

The name of the list header is also displayed in this

way.

The upper part of the display shows the value of the

parameter.

The lower part shows its mnemonic foll owed by the

scrolling name of the parameter

5.3.4 To Change a Parameter Value

5.3.2 To Locate a Parameter

Choose the appropriate list, then press . Each

parameter in the list is selected in tur n each time this

button is pressed. The following example shows how

to select the first two parameters in t he ALARM List.

All parameters in all lists follow the same procedure.

With the parameter selected, press

value, press

held down the analogue value changes at an

to decrease the value. If either key is

to increase the

increasing rate.

The new value is entered after the key is released and

is indicated by the display blinking. The exception to

this is output ‘Power’ when in manual. In this case the

value is entered continuously.

The upper display shows the paramet er value the

lower display shows the parameter name.

5.3.5 To Return to the HOME Display

Press

+ .

On release of the keys the display returns to the

HOME list. The current operating level r emains

unchanged.

5.3.6 Time Out

A time out applies to the ‘Go To’ and ‘Control Mode’

parameters. If no key presses are detec ted within a

period of 5 seconds the display will rev ert back to the

HOME list.

Press and hold to scroll parameters forward

through the list. With depressed, press

scroll parameters backward.

Press

to jump back to the list header.

to

Page 21

Series 3L Indicators

21

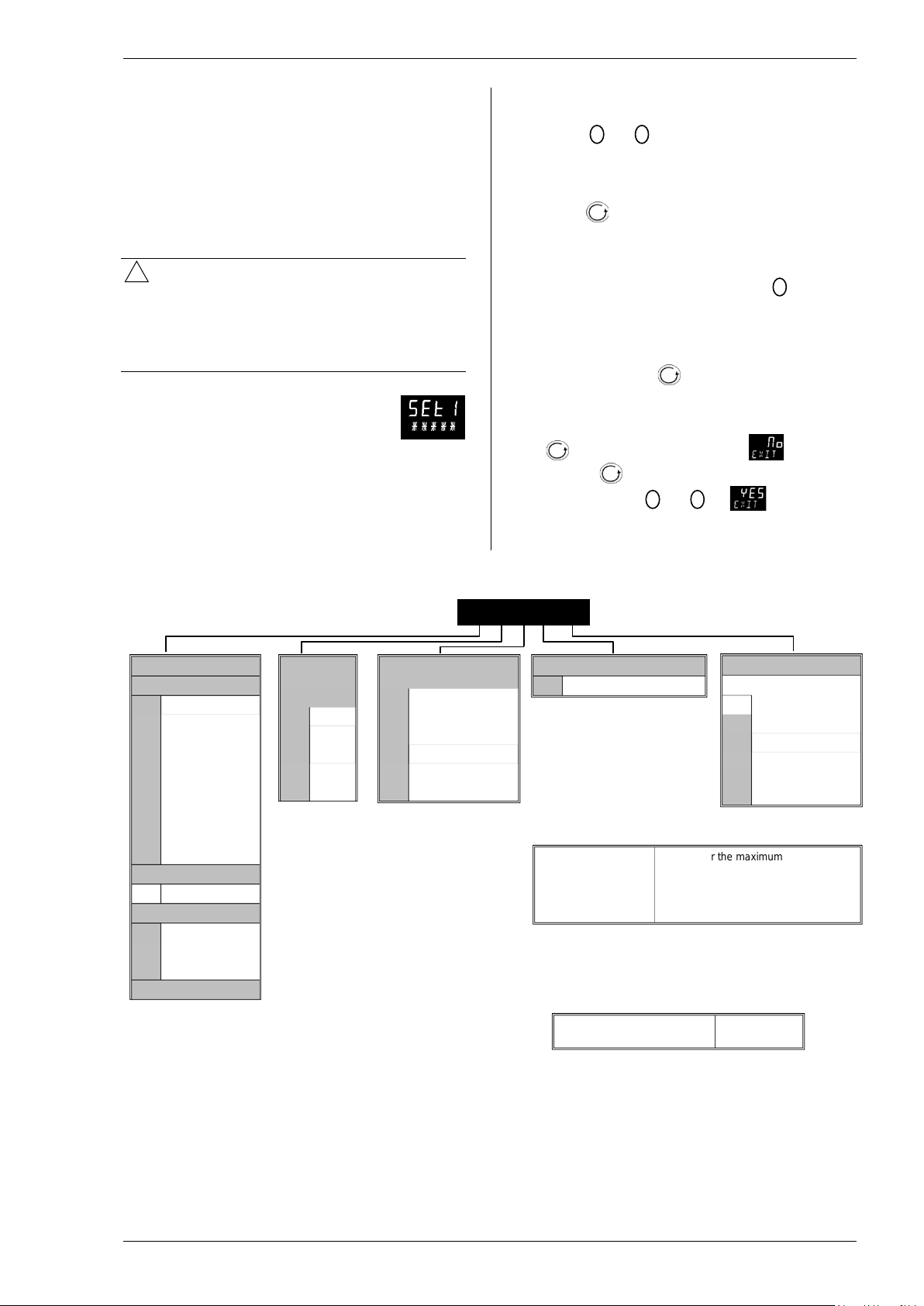

5.4 Navigation Diagram

The diagram below shows the all list h eadings available in configuration level for Series 3L indicator.

The parameters in a list are shown in t ables in the following sections of t his manual together with explanati ons of their

meanings and possible use.

Lists may vary depending on the type of input and options configured. For example CJC.TYP and CJC.IN only

appear if the Input Type is a thermocouple.

Page 22

Operations Manual Series 3L

22

5.5 Access Parameters

!

ACCESS LIST

‘ACCS’

Name

Scrolling

Display

Parameter Description

Values Allowed

Default

Access

Level

GOTO

GOTO

Allows you to change the access level

Operator level 1

Conf

Operator level 2

Operator level 3

Configuration level

LEV2.P

LEVEL 2

PASSCODE

The Level 2 passcode

Conf

LEV3.P

LEVEL 3

PASSCODE

The Level 3 passcode

Conf

CONF.P

CONFIG

PASSCODE

To set a Configuration level passcode

Conf

ID

CUSTOMER

ID

To set the identification of the indicator

Conf

HOME

HOME

To configure the parameters to be

Process Value – top display

Conf

section

PV - top display

only in lower section

K.LOCK

KEYBOARD

To limit operation of the front panel

normal.

Unlocked

Conf

All buttons locked

Edit keys locked

COLD

COLD START

Use this parameter with care.

power up

Disable

Conf

Enable

PASS.C

FEATURE

To enable chargeable options

Conf

MESG

STATIC HOME

Up to 15 messages can be configured.

The HOME display is

Conf

Message 15

The following table summarizes the par ameters available under the ACCESS list header

The Access List can be selected at any tim e when in configuration level by holding

seconds, then press

DISPLAY See

Note 1

or

with

still held down. Use the button to sc roll through the menu options.

of the indicator. Passwords prevent

unauthorized change

displayed in the HOME display

Lev.1

Lev.2

Lev.3

Conf

0-9999

0 = no passcode will be requested

0-9999

pV

Blank lower display

aLm

First configured alarm – top

Blank lower display

pV.aL

PV - top display

First configured alarm in lower

p.a.ro

First configured alarm read

key down for 3

Le

v.

1

2

3

4

St

d

LOCK

ENABLE/

DISABLE

PASSCODE

MESSAGE

The following sections in this handb ook describe the parameters associated with each subject. The general format of

these sections is a description of the subject, followed by the table of all parameters to be found in the list, followed by

an example of how to configure or set up parameters.

buttons when in operator levels.

If ALL has been selected, then to

restore access to the keyboard, cycle

power to High Limit with the

button held down and enter the

configuration level passcode as

described in section 3.1.1

take you to the Quick Code mode.

Press to scroll to the EXIT option

and select YES. The front panel

buttons can then be operated as

When set to yes the indicator will

return to factory settings on the next

This parameter calls up messages 1 to

15.

. This will

none

ALL

Edit

No

YES

OFF

1 to

15

none

Off

configured according to the

parameter HOME above

Message 1

Page 23

Series 3L Indicators

23

Input Type and

Thermocouple (TC) and 3-wire resistance thermometer (RTD) temperature detectors

See the table in section 6.1.1. for the list of input types available

Display units and

resolution

The change of display units and resolution will all the parameters related to the process

variable

Input filter

First order filter to provide dampin g of the input signal. This may be necessary to prevent

indication. More typically used with linear process inputs.

Fault detection

Sensor break is indicated by an alarm message ‘Sbr’. For thermocouple i t detects when

than 12Ω.

User calibration

Either by simple offset or by slope and gain. See section 12.2. for further details.

Over/Under range

When the input signal exceeds the input span by more than 5% the PV will flash

decimal point.

INPUT LIST

I NPUT

L3 R/O

UNITS

DISPLAY

Display units shown on the

No units - only for custom

linearisation

L3

For a full list of units see section 6.1.2.

DEC.P

DISPLAY

Decimal point position

Conf

INP.LO

LINEAR

INPUT LOW

Low limit for mV (mA) inputs

-10.00 to +80.00mV

Conf

RNG.HI

RANGE HIGH

Range high limit for

inputs

From the high limit of the selected input

minus one display unit.

Conf

RNG.LO

RANGE LOW

Range low limit for

From the low limit of the selected input

Conf

See section 6.1.3.

FILT.T

FILTER TIME

Input filter time constant

(first order digital filter)

OFF to 100.0 seconds

L3

FILT.D

DISPLAY

Provides a filter for the

No display filter

L3

Zero the least significant digit

Zero the two least significant digits

CJ.TYP

CJC TYPE

Configuration of the CJC

thermocouple inputs)

Automatic

Conf and if

Fixed at 50oC

No sensor break will be detected

Open circuit sensor will be

Latching

SB.DIR

SENSOR

BREAK

Defines the direction in

which the PV will range.

Up scale. Output goes to

maximum

Conf

6. Process Input

Parameters in the input list configure the input to match your sensor. These parameters provide the foll owing

features:-

linearization

Linear input (-10 to +80mV) through external shunt or voltage divider, m A assumes a

2.49Ω external shunt.

the effects of excessive process noise on the PV input from causing poor c ontrol and

the impedance is greater than pre-def ined levels; for RTD when the resistance is less

indicating under or over range. If the value is too high to fit the number of characters on

the display ‘HHHH’ or ‘LLLL’ will fl as h. The same indications apply when the display is

not able to show the PV, for example, when the input is greater than 999.9oC with one

6.1 Process Input Parameters

Name Scrolling

Display

IN.TYP INPUT TYPE Selects input linearization

UNITS

Parameter Description Value Default Access

and range

instrument

See section 6.1.1. for input types available

none

Level

o

C

Conf

POINTS

INP.HI LINEAR

INPUT HIGH

LIMIT

LIMIT

(1) See section 6.1.3 for an example of how to adjust the above four parameters.

PV.OFS PV OFFSET A simple offset applied to all

FILTER

SB.TYP SENSOR

BREAK TYPE

High limit for mV (mA) inputs

(1)

(1)

thermocouple RTD and mV

(1)

thermocouple RTD and mV

(1)

inputs

input values.

displayed value

type

(only shown for

Defines the action which is

applied to the output if the

sensor breaks (open circuit)

nnnnn - No decimal point to n.nnnn - four

decimal points

-10.00 to +80.00mV

type to the ‘Low Range Limit’ parameter

type to the ‘High Range Limit’ parameter

minus one display unit.

Generally one decimal point more than PV

Off

1

2

Auto

0oC

50oC

oFF

on

Lat

up

Fixed at 0oC

detected

nnnnn

80.00

-10.00

1.6

Off

Auto

on

up

L3 R/O

Conf

L3 R/O

L3 R/O

L3

T/C

L3 R/O

Conf

L3 R/O

Page 24

Operations Manual Series 3L

24

DIRECTION

Dwn

Down scale. Output goes to

minimum

CJC.IN

CJC

Temperature measured at

thermocouple inputs)

Read only

Conf

PV.IN

PV INPUT

VALUE

Current measured

temperature

Minimum display to maximum display range

Conf

MV.IN

MILLIVOLT

INPUT VALUE

Millivolts measured at the

rear PV Input terminals

xx.xx mV - read only

P.RST

PEAK RESET

Select ON to reset the HIGH

since it was reset

HIGH

PEAK HIGH

This is the highest reading

Read only

L1

o

o

o

o

o

o

o

o

o

o

o

C

o

F

Kelvin

No units displayed

Percentage

TEMPERATUR

E

the rear terminal block.

Used in the CJC calculation

(only shown for

and LOW peak values. The

display automatically returns

to OFF

LOW PEAK LOW This is the lowest reading

that the indicator has

recorded since switch on or

that the indicator has

recorded since switch on or

since it was reset

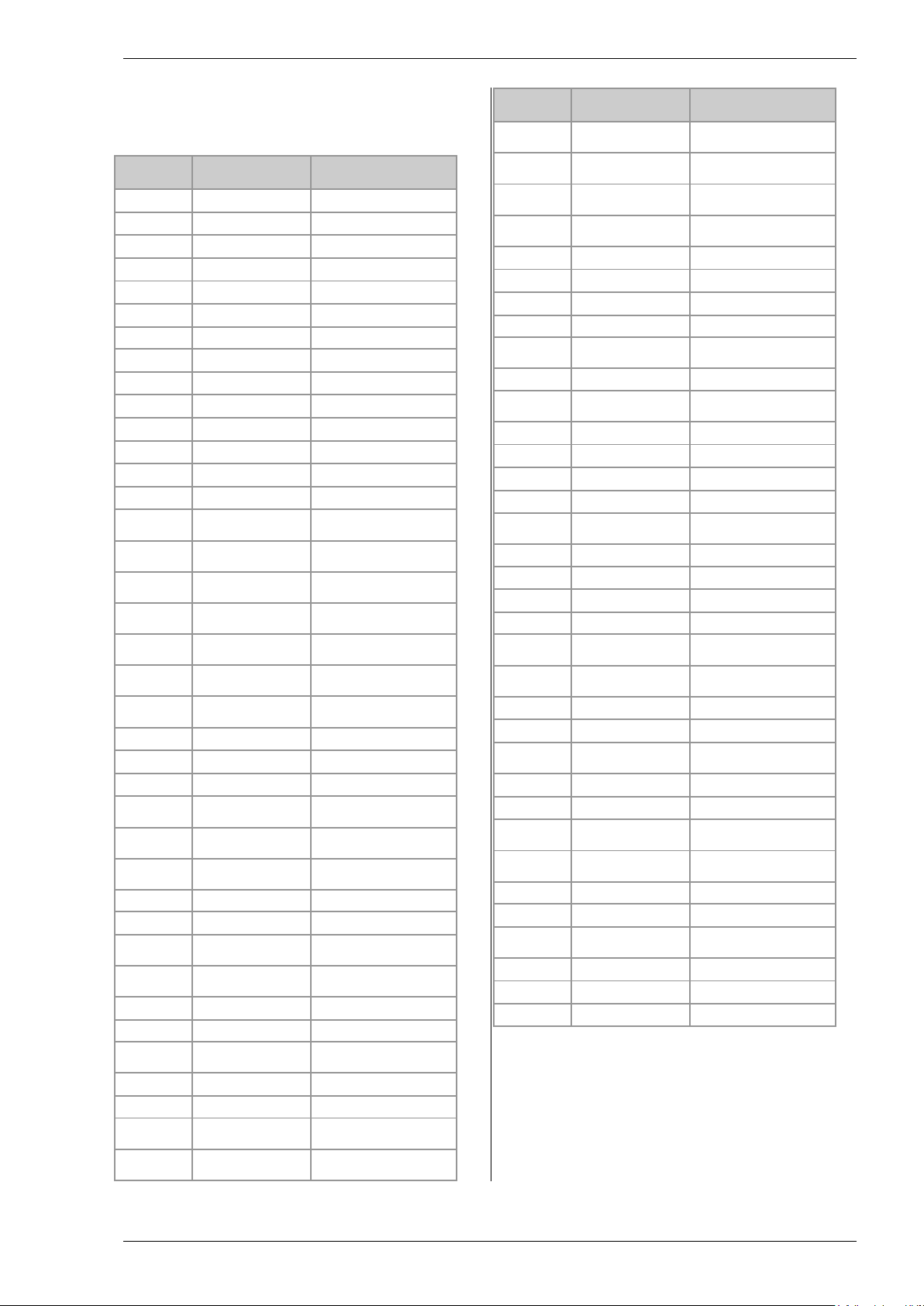

6.1.1 Input Types and Ranges

Input Type Min

J.tc

k.tc

L.tc

r.tc

b.tc

n.tc

t.tc

S.tc

rtd

mv

Cms

Thermocouple type J -210 1200

Thermocouple type K -200 1372

Thermocouple type L -200 900

Thermocouple type R -50 1700

Thermocouple type B 0 1820

Thermocouple type N -200 1300

Thermocouple type T -200 400

Thermocouple type S -50 1768

Pt100 resistance thermometer -200 850

mV or mA linear input -10.00 80.00

Value received over digital communications (modbus address 203).

This value must be updated every 5 seconds or the indicator will show sensor break

6.1.2 Units

O

C

none

O

F

Perc

OFF

On

Read only

Range

O

k

Max

Range

peak

Values

reset

Unit

s

o

C -238 2192

Min

Range

C -238 2498

C -238 1652

o

C -58 3124

o

C -32 3308

C -238 2372

C -238 752

o

C -58 3214

C -238 1562

Max

Range

L3 R/O

and if T/C

L3 R/O

OFF

L1

Unit

s

o

F

F

F

o

F

o

F

F

F

o

F

F

Page 25

Series 3L Indicators

25

Notes

Scrolling display

to ‘

Scrolling display

to ‘

Scrolling display

In operator level

to ‘

2.0

mv

500.0

2.0

For mA inputs

inp.lo eg

Electrical Input

Display

RNG.HI

Rng.lo

inp.hi

Electrical Input

Display

Fixed offset

Factory

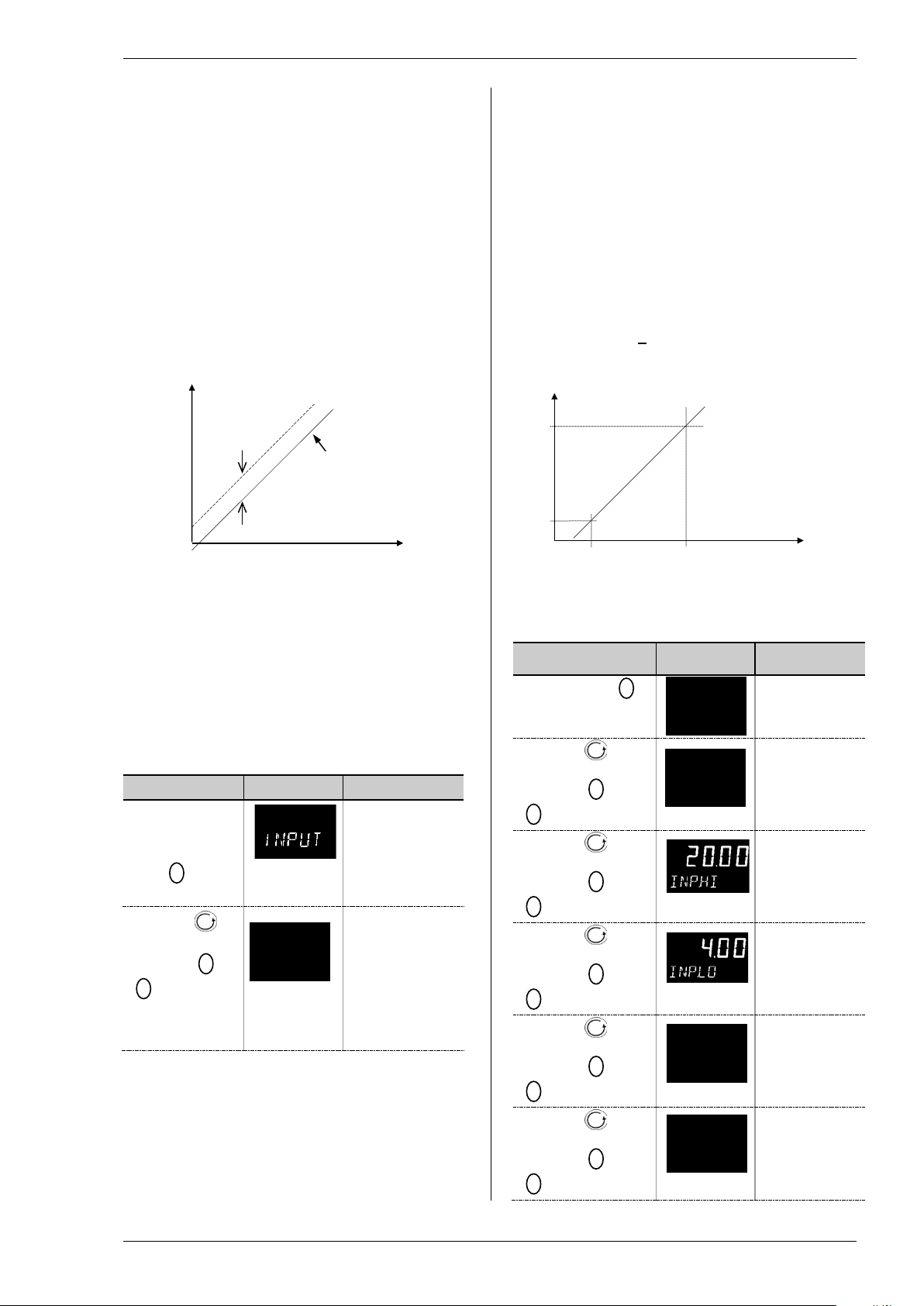

6.1.3 PV Offset

All ranges of the indicator have been calibrated against

traceable reference standards . This means that if the

input type is changed it is not necessary to calibrate the

indicator. There may be occasions, however, when you

wish to apply an offset to the standard calibration to

take account of known errors within th e pr ocess, for

example, a known sensor error or a known error due to

the positioning of the sensor. In these i ns tances it is

not advisable to change the referenc e ( factory)

calibration, but to apply a user defined offset.

PV Offset applies a single offset t o the temperature or

process value over the full display range of the indicator

and can be adjusted in Level 3. It has the effect of

moving the curve up a down about a central point as

shown in the example below:-

Reading

(e.g. 2)

calibration

6.1.3.1 Example: To Apply an Offset :-

Connect the input of the indicator t o the source device

which you wish to calibrate to

Set the source to the desired calibr ation value

The indicator will display the current measurement of

the value

If the display is correct, the indicator i s correctly

calibrated and no further action is necessary. If you

wish to offset the reading:-

Do This Display Additional Notes

1. Select Level

3 or Conf as

described in

Chapter 2. Then

press

select ‘INPUT’

2. Press to

scroll to ‘PV/OFS’

3. Press

offset to the

reading you

require

to

or

to adjust the

Scrolling display

pv.ofs

Scrolling display

‘process

input list’

‘pv offset’

In this case an

offset of 2.0 units

is applied

It is also possible to apply a five point offset which

adjusts both low and high points. T his is done in Level

3 using the CAL List, and the procedure is described in

the Calibration section 1212.2.1.

6.1.4 PV Input Scaling

Input scaling applies to the linear m V and volts input

ranges only. This is set by configuring the INPUT

TYPE parameter to mV or VoLt, mV has an input range

of –10 to 80mV. Using an external burden resistor of

2.49Ω, the indicator can be made to accept 4-20mA

from a current source. Scaling of the input will match

the displayed reading to the electri c al input levels from

the transducer. PV input scaling can only be adjusted

in Configuration level and is not pr ovided for direct

thermocouple or RTD inputs.

The graph below shows an example of input scaling,

where it is required to display 2.0 when the input is 4mV

and 500.0 when the input is 20mV .

If the input exceeds +5% of the inp.Lo or inp.Hi

settings, sensor break will be displayed.

Reading

eg 500.0

eg 2.0

4 mV

6.1.4.1 Example: To Scale a Linear Input

Select Configuration level as described in Chapter 2.

Then:-

Do This Display Additional

1. Then press

to select ‘input’

2. Press to

scroll to ‘in.typ’

3. Press

4. Press to

scroll to ‘inp.hi’

5. Press

to ’20.00’

6. Press to

scroll to ‘inp.lo’

7. Press

8. Press to

scroll to ‘rng.hi’

9. Press

to ‘500.0’

10. Press to

scroll to ‘rng.lo’

11. Press

or

mV’or VoLt

or

or

4.00’

or

or

2.0’

eg 20 mV

input

in.typ

rhg.hi

In operator level

rhg.lo

4-20mA = 9.96-49.8mV with

2.49Ω load resistor

0-20mA = 0-49.8mV with

2.49Ω load resistor

mA input will detect sensor

break if mA < 3mA

Use a current source to

remove shunt resistor errors

‘process

input list’

‘input type’

Scrolling display

‘linear input

high’

‘linear input

low’

the indicator will

read 500.0 for a

mV input of

20.00

the indicator will

read 2.0 for a

mV input of 4.00

Page 26

Operations Manual Series 3L

26

7. Input/Output Channels

OUTPUT LIST 1 ‘op-1 ’

Name

Scrolling Display

Parameter

Description

Value

Default

Access

Level

1.ID

I/O 1 TYPE

Displays the type of

output

Relay output

Read

only

1.FUNC

I/O 1 FUNCTION

The function may be

set to

Disabled. If disabled no further

parameters are shown

Conf

Digital output

output

Alarm 1

shown

Alarm 2

Alarm 3

1.SRC.D

I/O 1 SOURCE D

All alarms. Logical AND of

alarms 1 to 4.

Any new alarm

Power fail. See also section

7.1.3.

Output relay operates if the

indicator input is over range

Sensor break alarm

1.SENS

I/O 1 SENSE

To configure the

See also section 7.1.1

Normal

Conf

Indicators are ordered with two form A relays and one form C relay. These form A relays can be configured for a variety

of process applications and the form C relay is typically an FM approved high limit alarm output.

7.1 Output Channel 1 (OP-1) – Series 3L Indicators

Output 1 is always a form A relay in the indicator and is connected to terminals 1A and 1B. It is typically used to

provide external indication of alarms. OP1 beacon is operated from this out put.

Output 1 is configured using the parameters in the following table:-

turned off, otherwise

d.out

1.SRC.A I/O 1 SOURCE A Selects the source of

1.SRC.B I/O 1 SOURCE B

1.SRC.C I/O 1 SOURCE C

an event which will

operate the output

relay

The output status is

the result of an OR of

Src A, Src B, Src C,

and Src D

Up to four events can,

therefore, operate the

output

See section 7.1.2.

sense of the output

channel.

ReLy

none

d.out

none

1.---

2.---

3.---

4.---

ALL.A

nw.AL

Pwr.f

O.rng

sbr

nor

Inv

No event connected to the

The --- indicates the

alarm type. If the

alarm is not

Alarm4

Inverted

configured

AL.(Alarm no) is

ReLy

none

none

nor

Conf

Page 27

Series 3L Indicators

27

Do This

Display

Additional

Notes

S

reLy

d.out

SRC.A

SEnS

Output

Nor

Inv

Each source

OR

7.1.1 Sense

For an alarm output set this parameter t o ‘Inv’ so that

it de-energizes to the alarm state.

7.1.2 Source

The four parameters SOURCE A, SOURCE B,

SOURCE C, and SOURCE D appear when the output

is configured as a digital output i.e. ‘-.FUNC’ = ‘d.Out’

and provide the facility to connect up to four alarms to

operate a single relay output. If any one of the events

becomes true then the output relay will operate.

(SRC) may be

chosen from:-

Alarm 1

Alarm 2

Alarm 3

Alarm 4

All alarms

Any new alarm

Power Fail

SRC.B

SRC.C

SRC.D

7.1.3 Power Fail

An output, configured as a digital output, can be made

to operate following a power fail. It can be

acknowledged in the same manner as an alarm but no

alarm message is given.

7.1.4 Example: To Configure OP-1 Relay to Operate on Alarms 1 and 2:-

1. From any

display, press

as many times as

necessary to select

‘O p -1’

2. Press to

scroll to ‘1.id’

3. Press to

scroll to

‘1.FUNC’

4. Press

‘d.out’

5. Press to

scroll to ‘1.SRC.A’

6. Press

event which you

want to operate the

output

7. If a second

event is required to

operate the same

output, press to

select ‘1.SRC.B’

8. Press

second event which

you want to operate

the output, eg ‘AL.2’

9. Press

scroll to ‘1.sens’

10. Press

or

to select

or

to select the

or

to select the

to

or

to select ‘Inv’

1.id

1.func

Scrolling display

‘oP-1 list’

This is the

identification of

the hardware

fitted and cannot

be adjusted.

The output is

configured as a

digital output

function.

Scrolling display

‘op 1

function’

The output will

activate if either

alarm 1 is

triggered.

Note:- 1.

indicates the

alarm number,

Hi indicates the

alarm type.

Scrolling display

‘output 1

source a’

Scrolling display

‘output 1

source b’

Note:- ‘2’.

indicates the

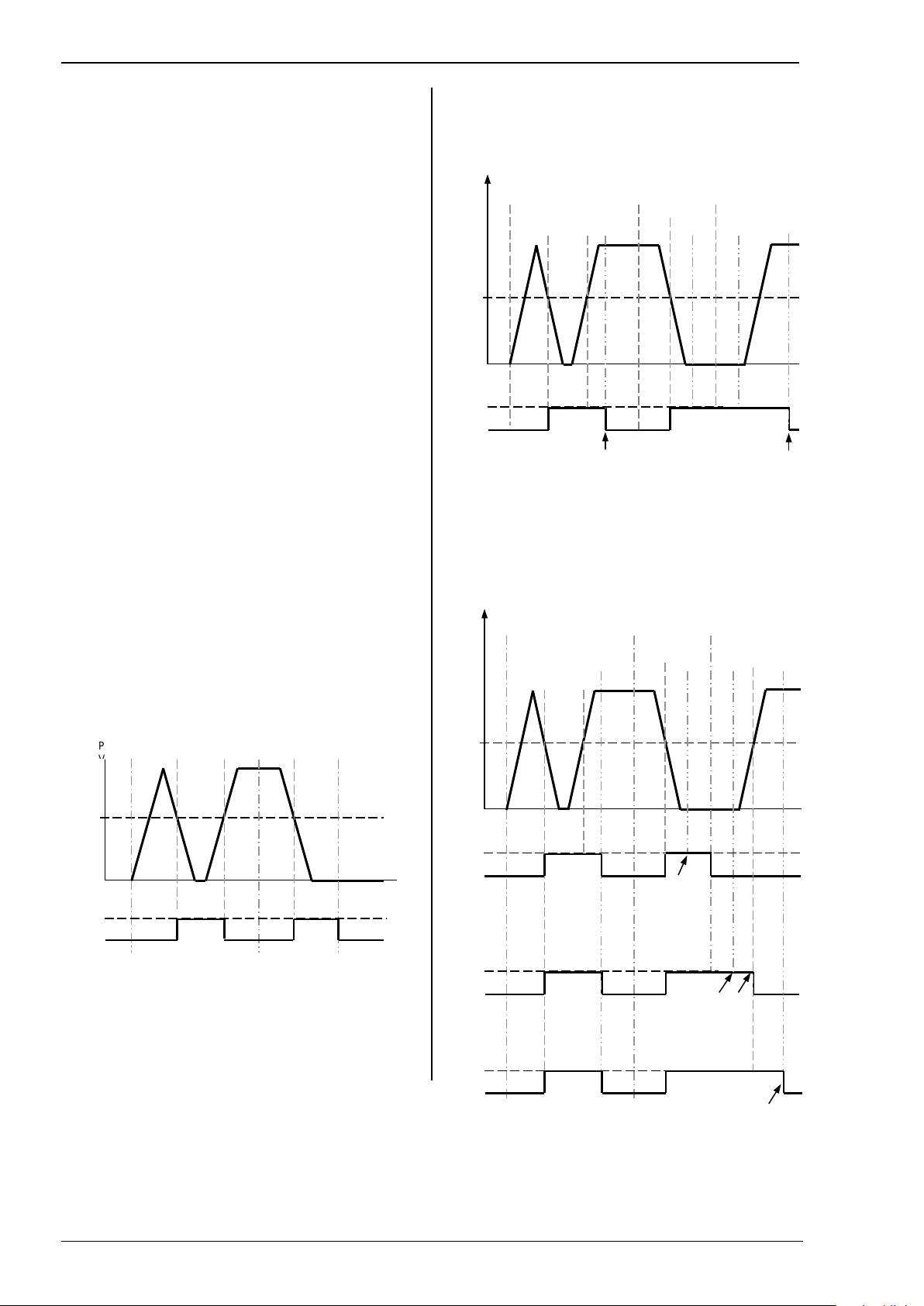

alarm number,