Page 1

45.80

50

Page 2

Page 3

3

Table of contents

TANDARD DISPLAY.......................................................................................page 57

Page 4

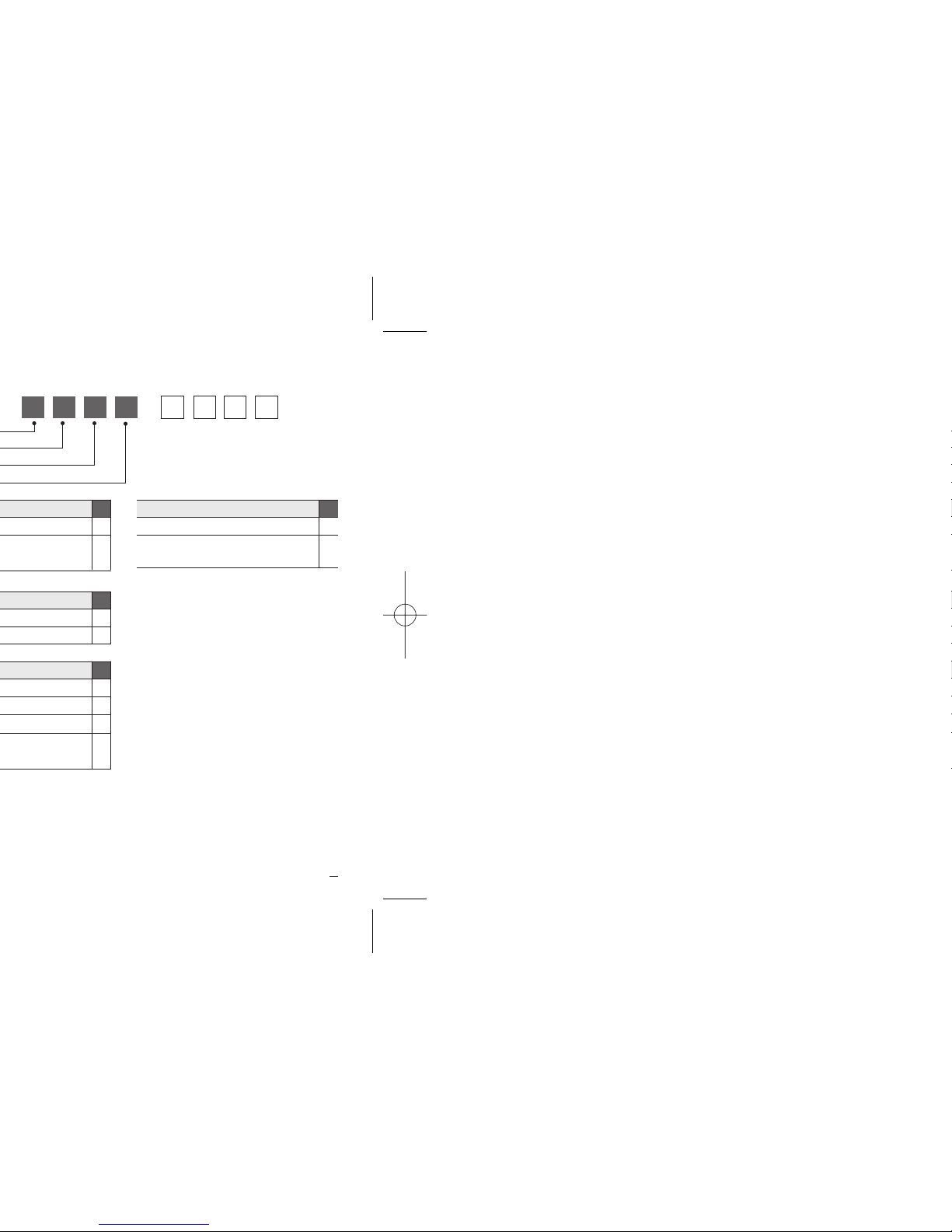

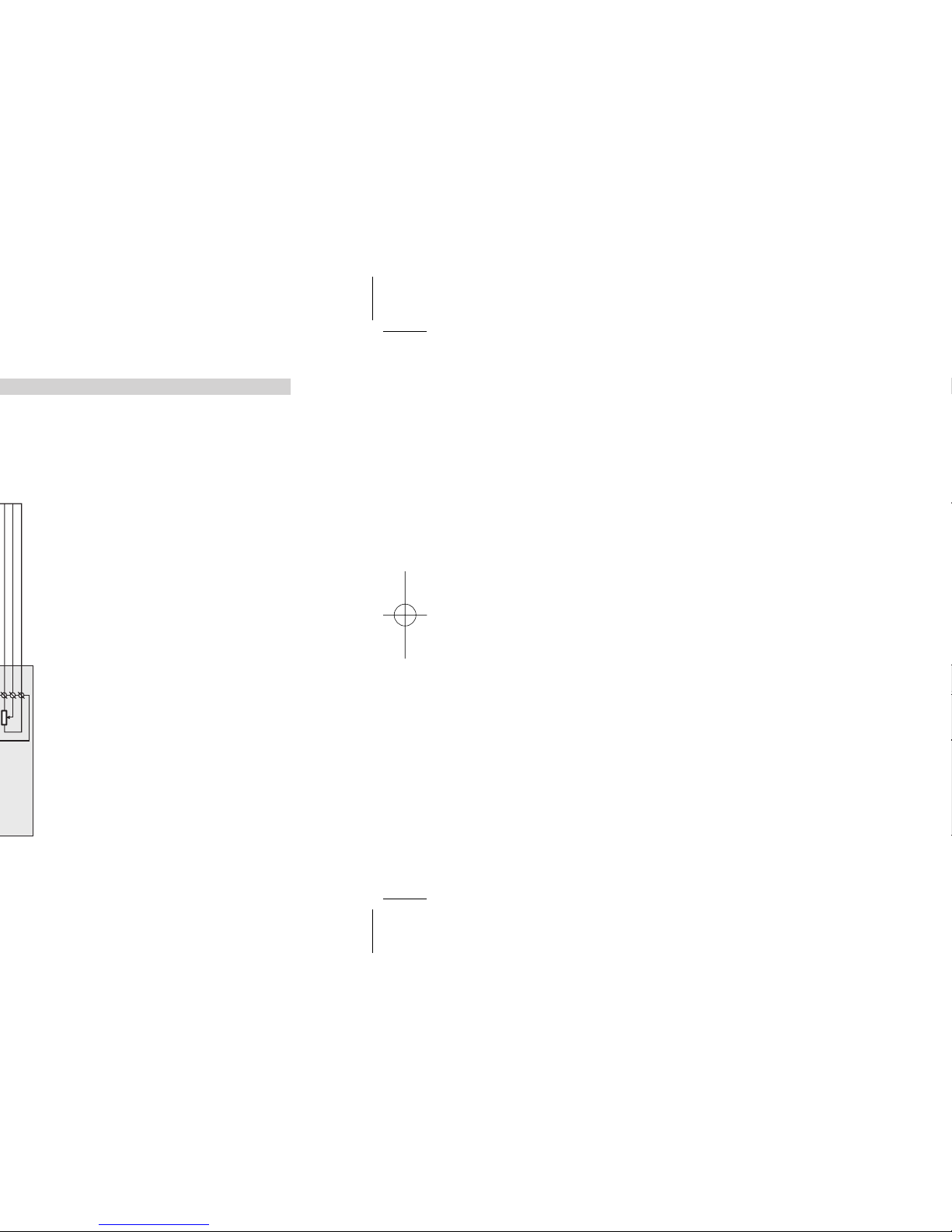

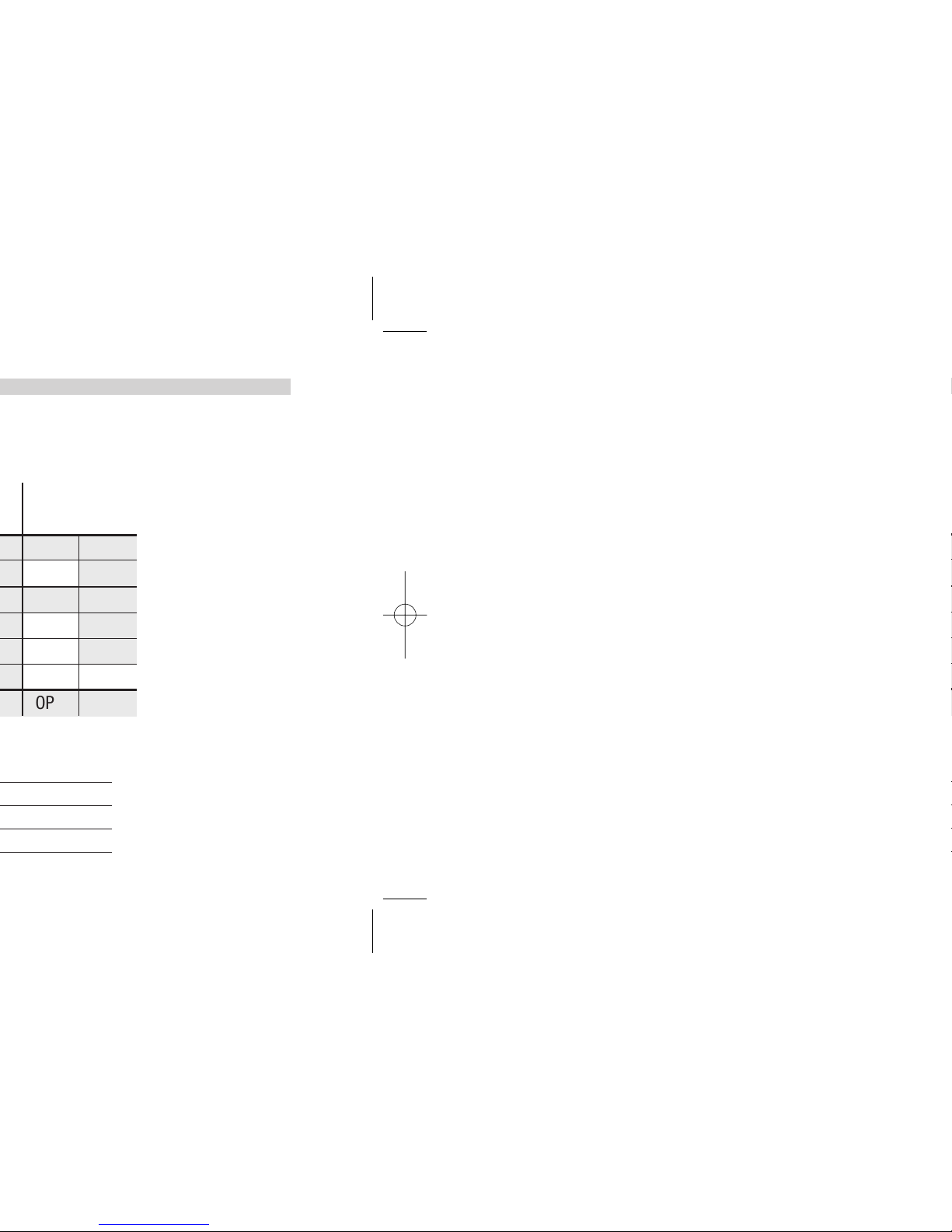

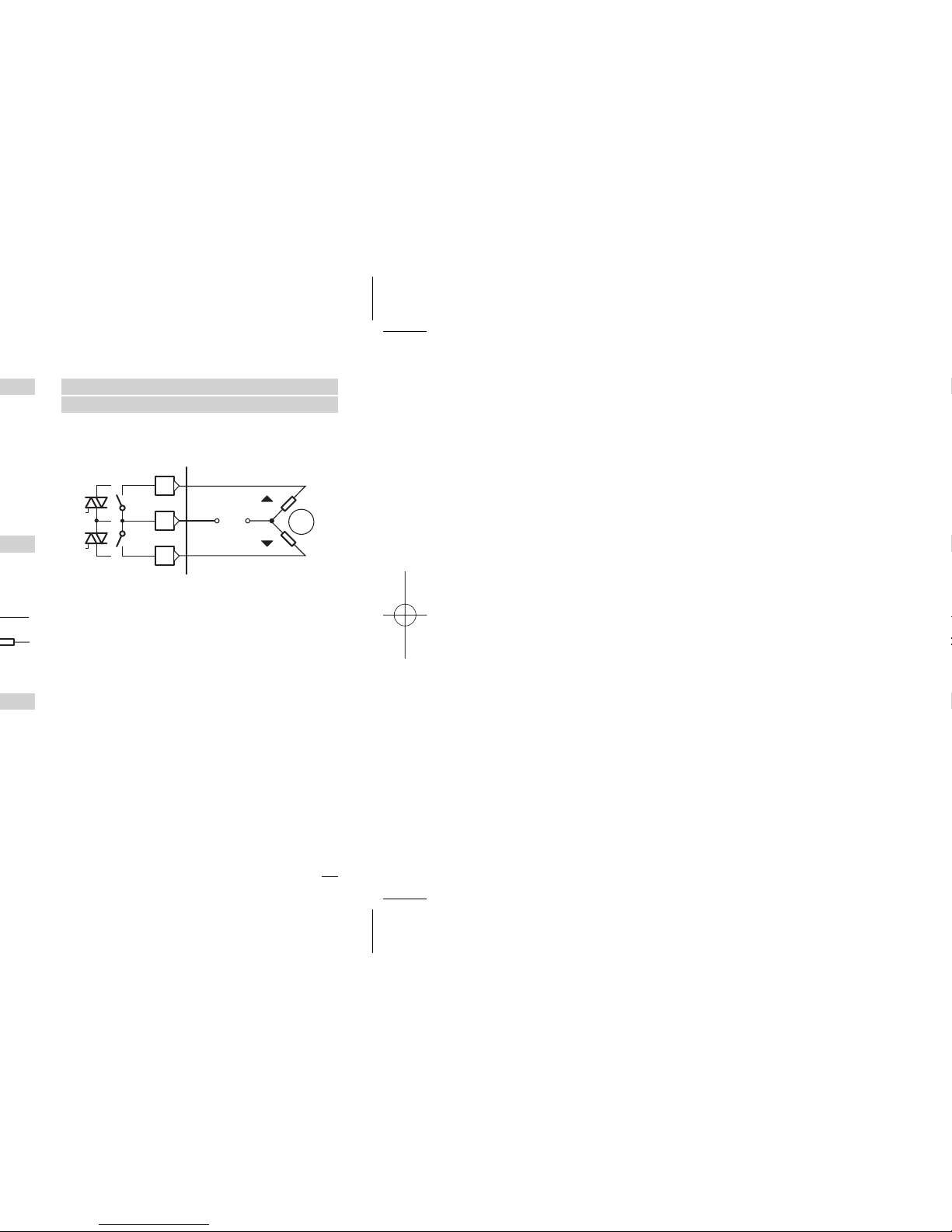

Control Alarms

Retransmission

OP1

OP2

OP3

OP4

OP5

OP6

(option)

Operating mode

2 OP5 OP1 OP2 OP3 OP4 OP6

3 OP1 OP2 OP3 OP4 OP5 OP6

4 OP1 OP5 OP2 OP3 OP4 OP6

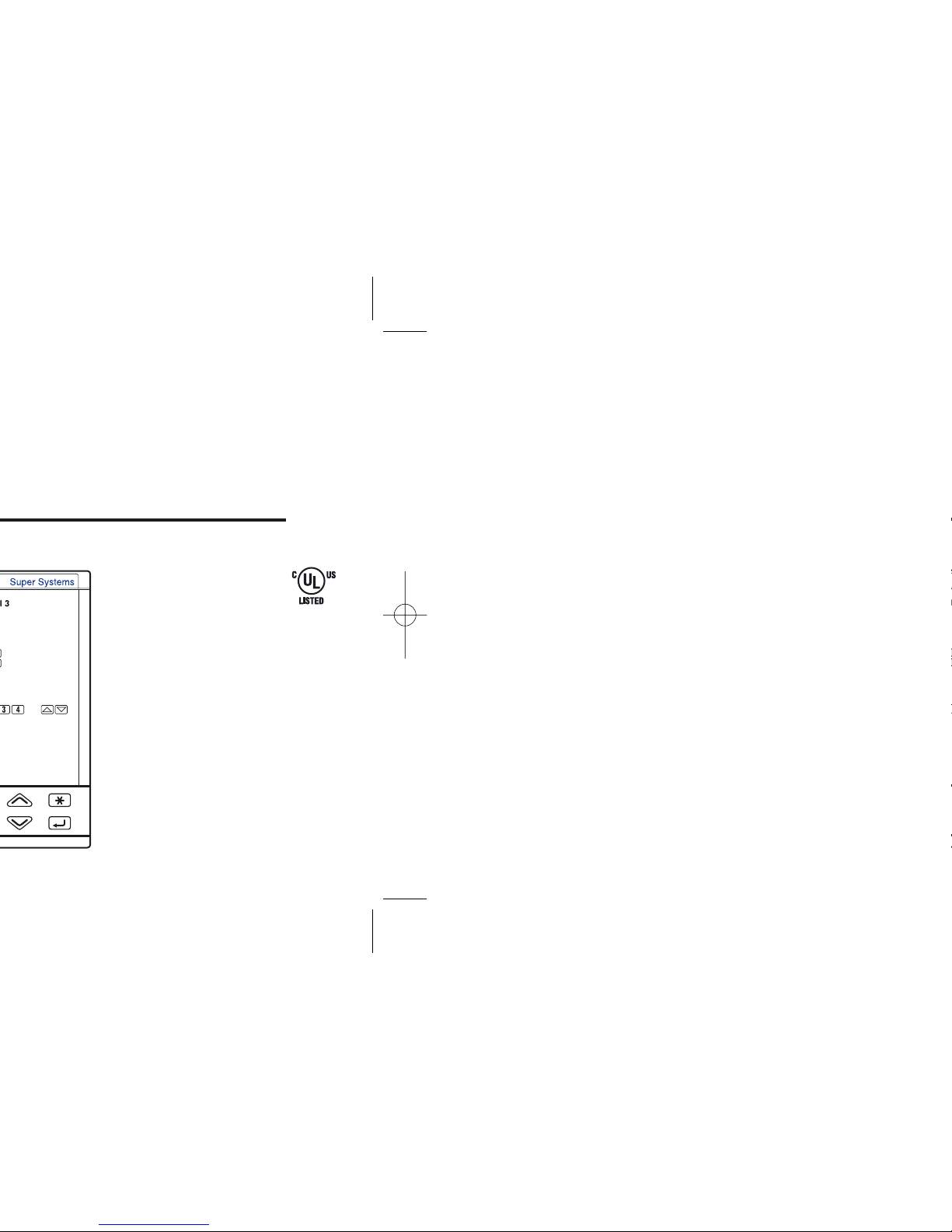

5 OP5 OP2 OP1 OP3 OP4 OP6

1 OP1 OP2 OP3 OP4 OP5 OP6

6 OP5 OP6 OP1 OP2 OP3 OP4

7

Valve

OP1 OP2 OP3 OP4 OP5 OP6

PV/SP/MV

Fuzzy tuning

with automatic selection

One shot

Auto tuning

One shot

Natural Frequency

(opt.)

Single

action

Double

action

Page 5

5

1 - Introduction

0

––

0X5 A B C D 3 0

3

5

5

1

5

0

2ndSSR drive/analog

output (OP6)

4

Options D

None

0

8

7

Page 6

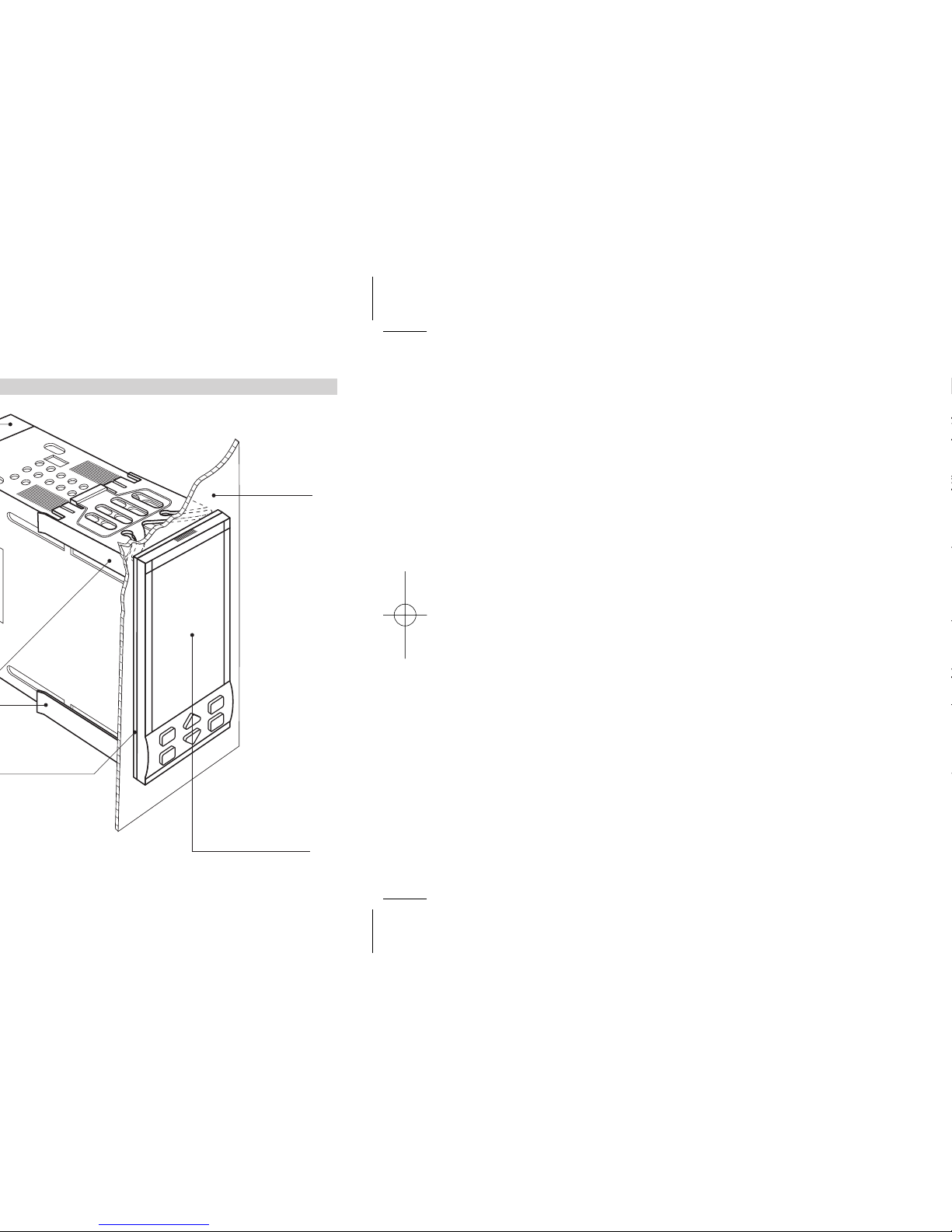

Front panel

IP65 protection

EN 650529 (IEC 529)

Panel

surface

Page 7

7

2 - Installation

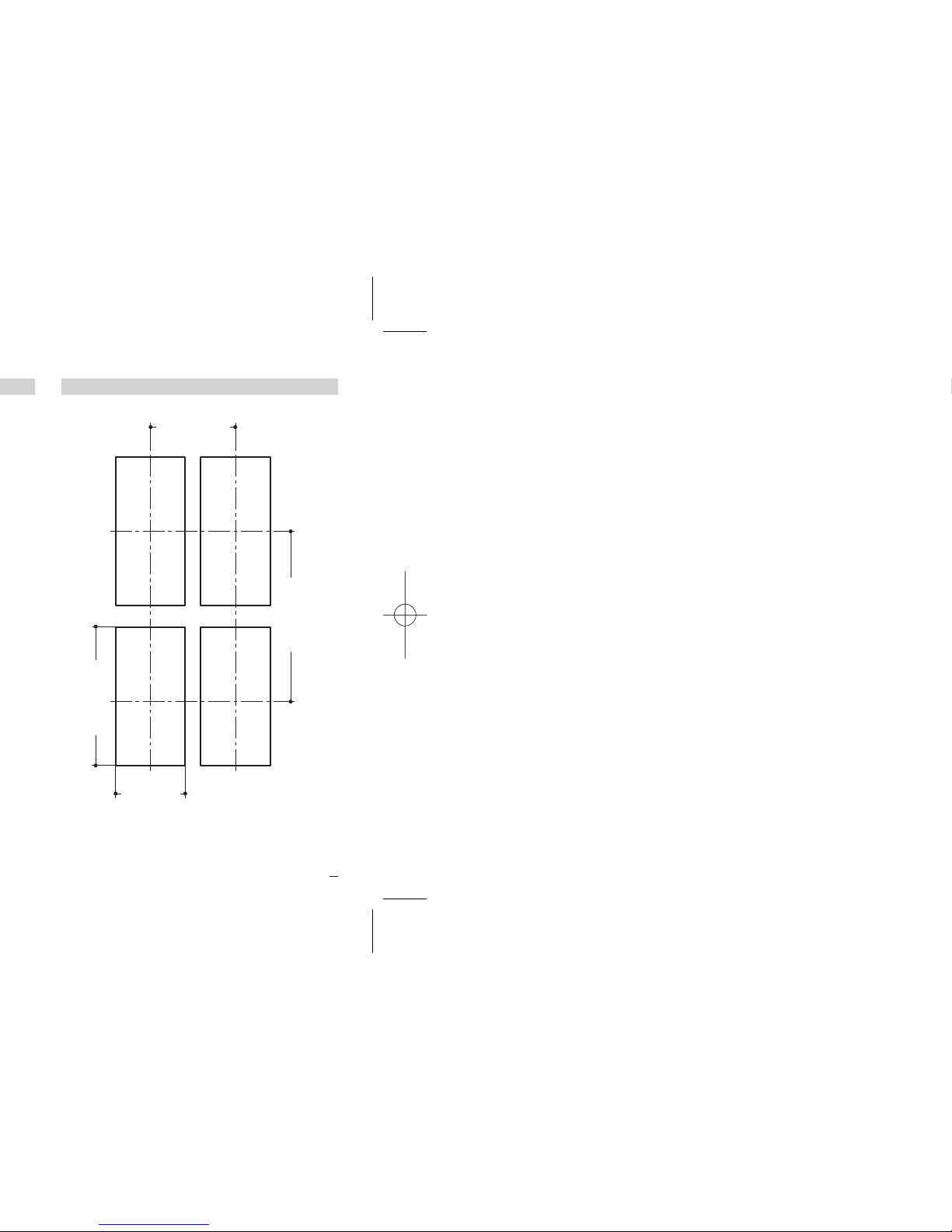

65 mm min

2.56 in min

45

+0.6

mm

1.78

+0.023

in

92

+0.8

mm

3.62

+0.031

in

113 mm min

4.45 in min

Page 8

B

Use filter

Warm up

Use forced air ventilation

Use 24Vac supply version

Suggestions

Page 9

9

2 - Installation

1

2

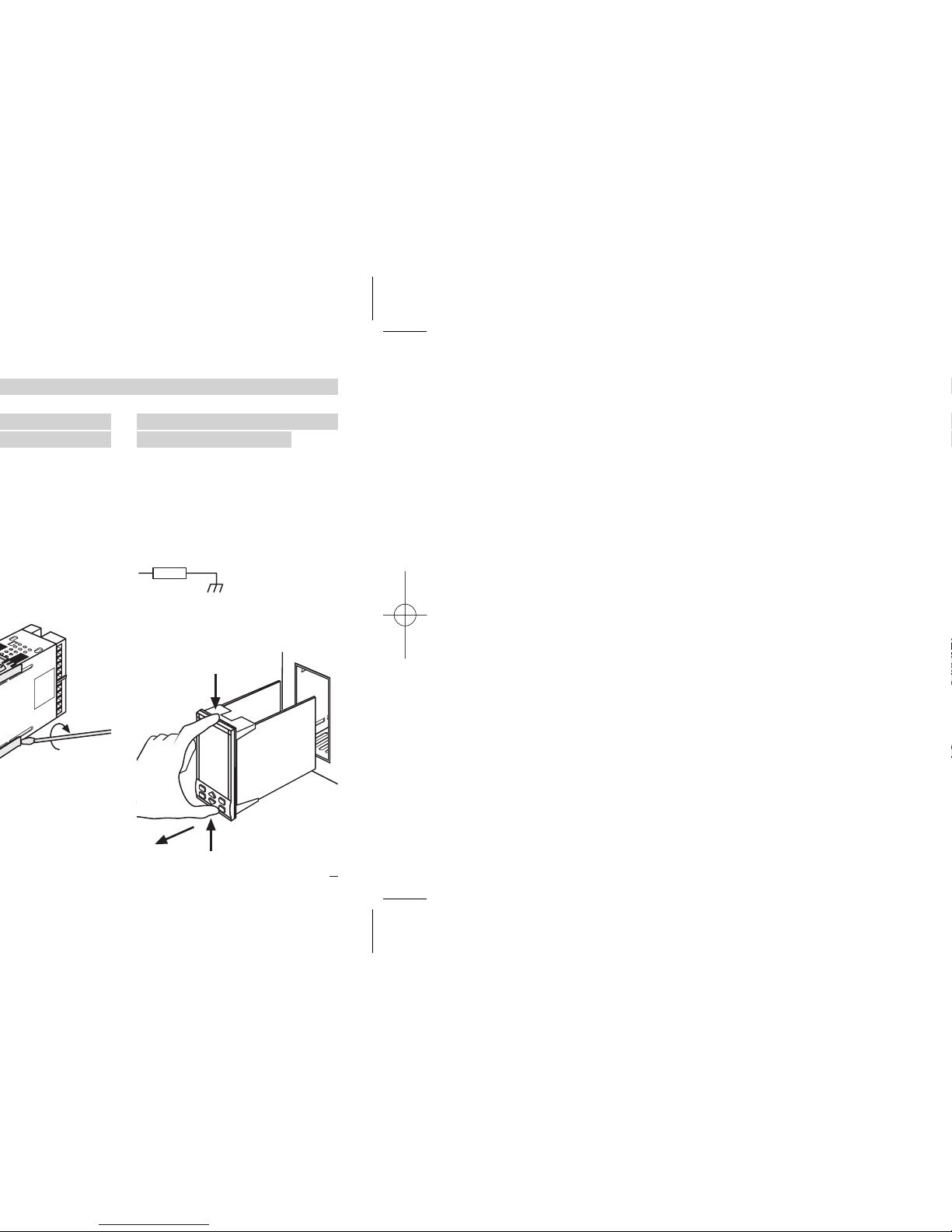

2.3.4 INSTRUMENT

REMOVAL

B

1 Push and

2 Pull to remove the instrument.

Electrostatic discharges can

damage the instrument.

Before removing the instrument

the operator must discharge

himself to ground.

1MΩ

2

1

1

Page 10

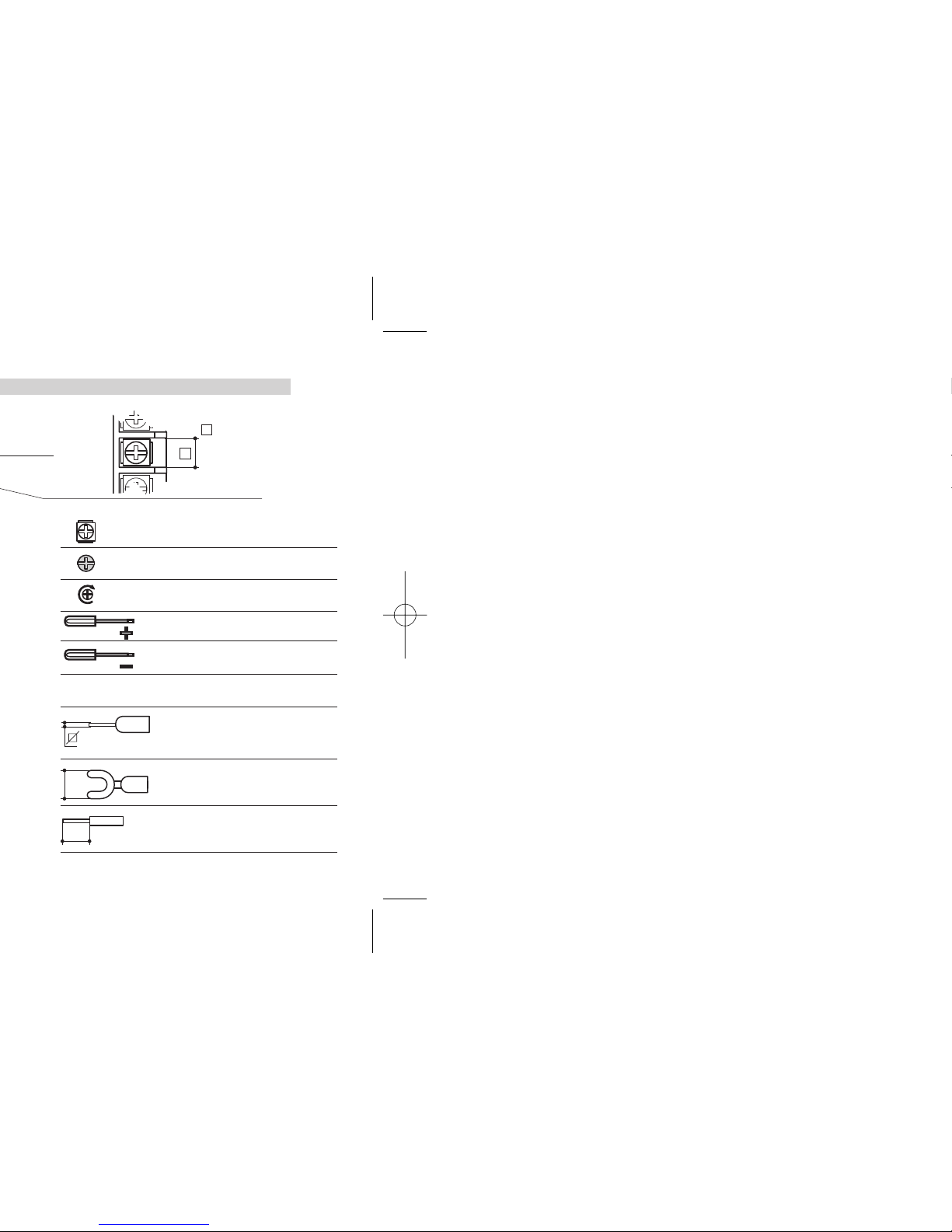

Terminals

Rear

terminal

cover

Cable size

1 mm

2

[2]

5.7 mm

0.22 in

B

35 screw terminals M3

Option terminals

Holding screw 0.5 Nm

Phillips screwdriver PH1

Flat blade screwdriver

0.8 x 4 mm

Pin connector

q 1.4 mm - 0.055 in max.

Ø

Fork-shape AMP 165004

Ø 5.5 mm - 0.21 in

L

Stripped wire

L 5.5 mm - 0.21 in

Page 11

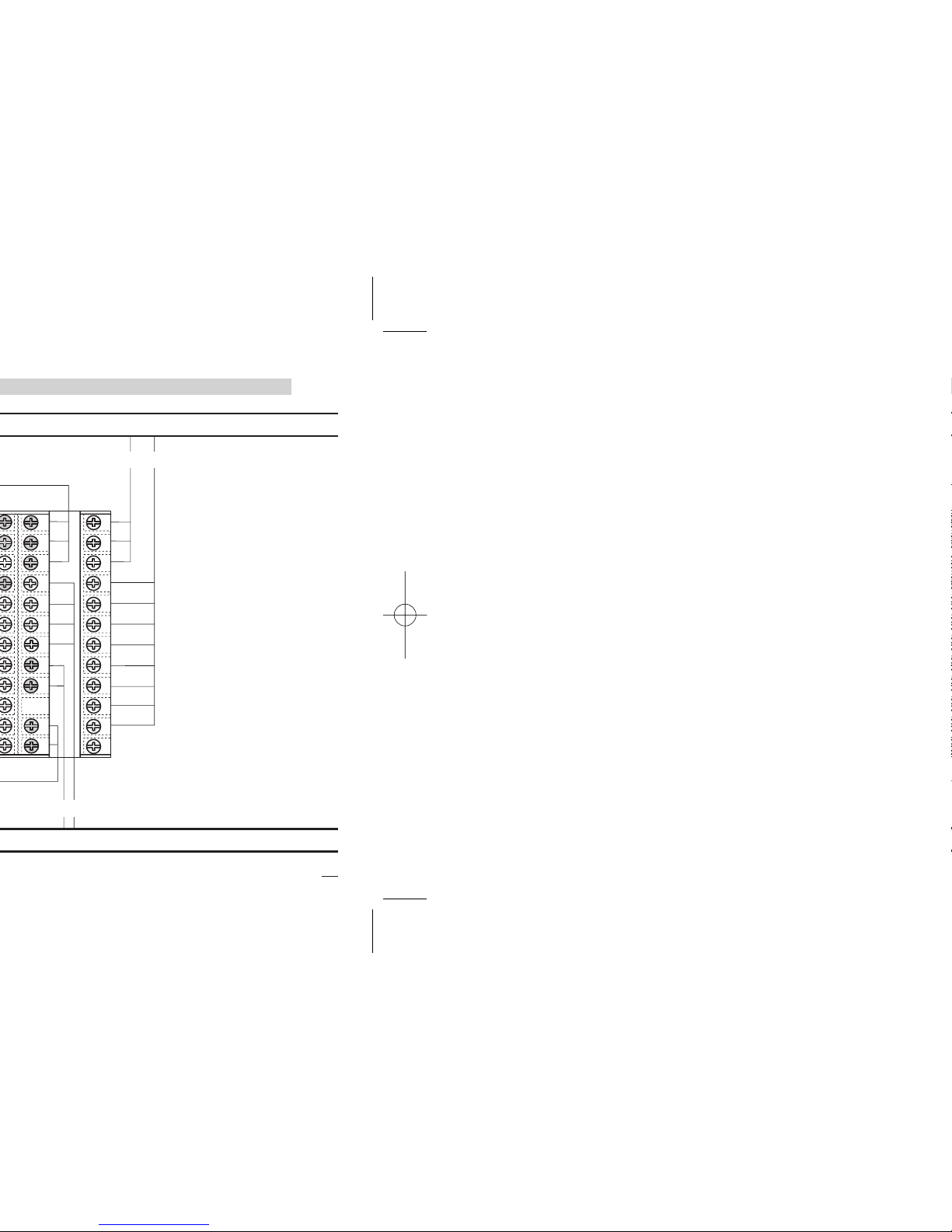

28

27

30

29

26

25

19

31

20

32

33

34

23

35

24

36

16

15

18

17

14

13

21

A B

11

3 - Electrical Connections

B

A = Supply

B = Outputs

C = Analog inputs

D = Analog output

E = Digital input

Serial Comm.s

Page 12

B

Notes:

1] Ensure that the power supply voltage is

the same as that on the instrument label.

2] Switch ON the power supply only after

all electrical connections have been

completed.

3] In accordance with electrical safety reg-

ulations, there must be an easly identifiable and accessable power disconnect.

4] The instrument is PTC protected.

In case of failure, return the instrument to

the manufacturer for repair.

5] To protect internal circuits use:

- 2 A

~ T fuse for Relay outputs (220 Vac)

- 4 A~ T fuse for Relay outputs (110 Vac)

- 1 A~ T fuse for Triac outputs

6] Relay contacts are protected with varis-

tors.

In case of 24 Vac inductive loads, use

model A51-065-30D7 varistors (on

request).

Page 13

13

3 - Electrical Connections

B

Wire resistance

150Ω max.

Only for two wires

system, put a

jumper between terminals 11 and 12.

Use wires of the

same length and 1.5

mm

2

size.

Maximum line resistance 20 Ω/line.

10

11

12

A

B

A

R2

R1

10

11

12

A

b

B

11

12

Page 14

Page 15

15

3 - Electrical Connections

B

3

7

6

TTL

o.c.

Isolated

contact

Com.

IL 3

IL 2

C2

C3

5

NPN

o.c.

IL 1

C1

Page 16

B

OP6

OP6

OP6

OP6

OP6

OP6

Page 17

17

3 - Electrical Connections

B

B

B

Fuse

Coil of the cool

load contactor

32

33

OP2

[1]

Cool

load

Static

Relay

8

9

OP5

8

9

OP5

Cool

load

mA mV,V

Page 18

Notes for pages 17 - 18 - 19

OP1 - OP2 Relay output

• SPST Relay N.O., 2A/250 Vac

(4A/120Vac)

for resistive load,

• Fuse 2A ac T at 250V, 4A ac T at 110V.

OP1 - OP2 Triac output

• N.O. contact for resistive load of up to

1A/250 Vac max.

• Fuse 1A ac T

Isolated digital outputs OP5-OP6

• 0…24Vdc, ±20%, 30 mA max.

Isolated analog outputs OP5-OP6

• 0/4…20mA, 750Ω / 15V max.

0/1…5V, 0…10V, 500Ω / 20mA max.

[1] Varistor for inductive load 24Vac only

Page 19

19

3 - Electrical Connections

3.3.6-G MOTOR POSITIONER OUTPUT

RELAY (TRIAC) / RELAY (TRIAC)

Valve drive PID without potentiometer 3 pole

output with N.O. contacts (raise, lower, stop)

OP1

33

32

31

OP2

V~

Lower

Raise

M

~

Page 20

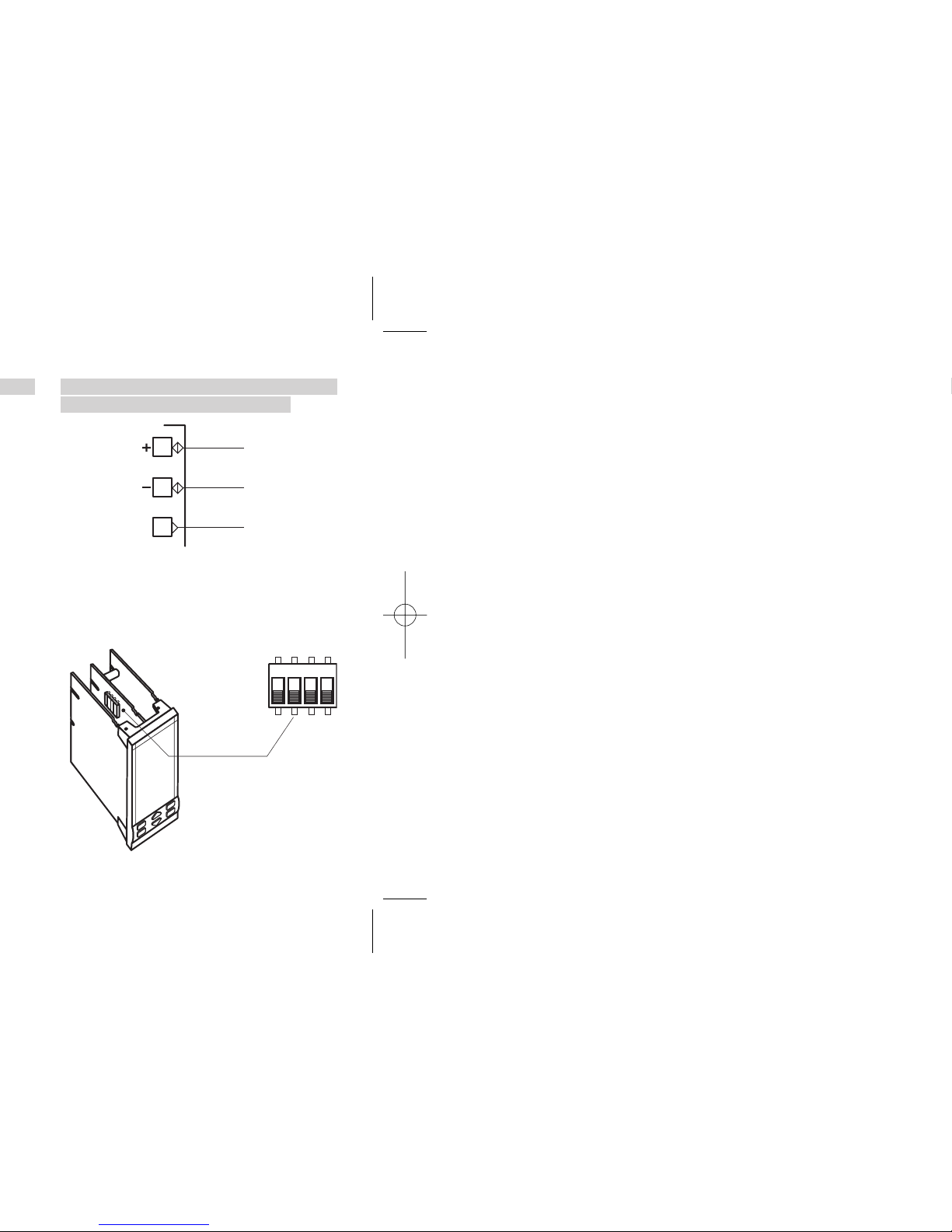

3.3.9 SERIAL COMMUNICATIONS

(OPTION) [2]

B

• Galvanic isolation 500Vac/1 min;

Compliance to the EIA RS485 standard

for Modbus/Jbus;

• Termination setting dip switches.

C

SLAVE

13

14

15

1234

SLAVE

Page 21

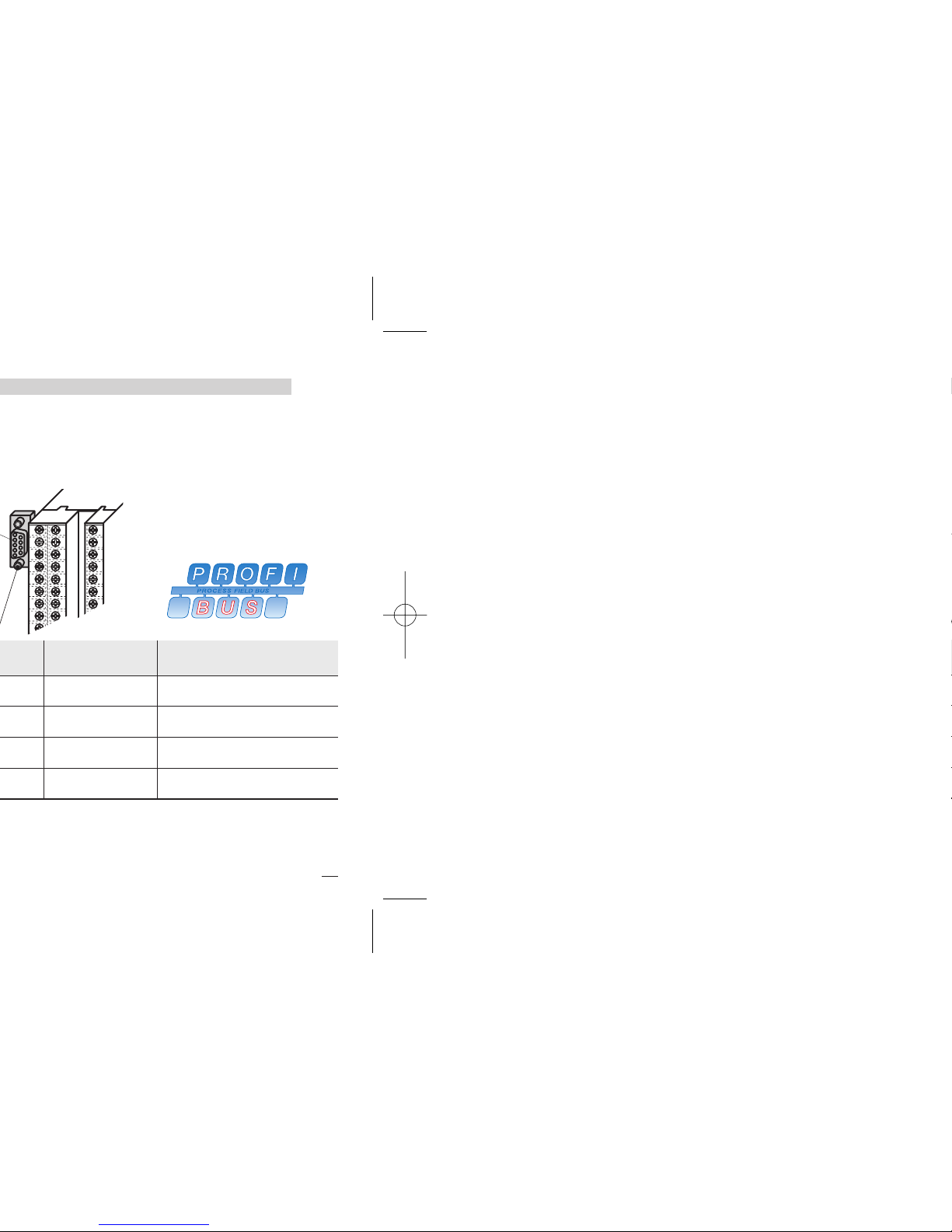

B

21

3 - Electrical Connections

33

Description according to

PROFIBUS specifications

Receive data/transmission

data plus

Receive data/transmission

data negative

VP (VP)

Data transmission potential

(ground to 5V)

Supply voltage of the terminating resistance-P, (P5V)

Page 22

SP operating Setpoint

(Local/Remote or Stored)

% Control output

or Program status (see page 64)

Control output LEDs (red)

å OP1/OP4 ON - ç OP2/OP4 OFF

Run/stop Timer or a program

Entry key for selection and value setting confirmation

Setpoint setting

Menu access

8888____ 8888----

PV control input in engineering units

Over range Under range

Page 23

23

4 - Operation

Parameter value

Value modification

Page 24

Unit

°f

Unit

none

Unit

ph

Engineering

Units

Celsius

Degree

Fahrenheit

Degree

Celsius

Degree

Fahrenheit

no units

defined

Ph

Page 25

25

4 - Operation

33

OK

EHit

Conf

ConfConf

tiMe

Conf

(see page 30... 33)

(see page 34)

NOYES

Back to the operator mode

Enter the configuration

password

Must be equal to the

value

of the parameter

C.Pas (see page.50)

from -999...9999

(33 default from factory)

Alarms

Timer

configuration

Exit the

Configuration

Page 26

Hertz

ph

Hz

PInp.

32…1112°F

Engineering

units

-58.0…122.0°F

-99.9…572.0°F

-328…1112°F

-328…752°F

32…2912°F

32…2912°F

32…2192°F

32…1112°F

Value Description

éUnit

Tab. 2 Engineering units

none

None

rh

°C

Degree centigrade

°f

Degree Fahrenheit

Rh

MA

mA

MU

mV

U

Volt

Ph

bar

bar

psI

PSI

Frequency

(option)

32…3272°F

32…2192°F

32…1112°F

32…3632°F

32…3632°F

éInP.

32…2012°F

Notes:

[1]

NiChroSil-NiSil thermocouple.

[2] Ni-Mo thermocouple.

[3] Factory default for the

custom range is: type K

(32... 2448°F).

Page 27

27

4 - Operation

Tab. 4 Rem. Setpoint

Value Description

0=5

0…5 Volt

1=5

1…5 Volt

0=20

0…20 mA

Tab. 3

4=20

4…20 mA

Setpoint type

0=10

reM.t

Remote - trim

0…10 Volt

érs.In

loc.t

Local - trim

l=r

Local/remote only

reM

Remote only

loc

Local only

Value Description

éS.P.ty

Page 28

rt. 2

énone

O.rt.2

é4=20

rt.L2

é 0

rt.H2

é9999

WITH OPTIONAL OP6 ANALOG

OUTPUT NOT USED AS COOL CON-

TROL OUTPUT

1

st

retransmitted

output selection

none/ P.U./S.P.

1stretransmission

output

see table 8

1

st

retransmission

low range

whole range

1

st

retransmission

high range

whole range

2

nd

retransmitted

output selection

none/P.U/S.P./M.U.

2ndretransmission

output

see table 8

2

nd

retransmission

low range

whole range

2

nd

retransmission

high range

whole range

Page 29

29

4 - Operation

Retransmitted

signal

none/P.U./S.P

/M.U.

Output

range

0=5 /1=5 /0=10

0=20 / 4=20

Retransmission

low

range

Retransmission

high

range

Example:

• T/C S: range 0…1600°C;

• Output range, 4…20 mA;

• Retransmitted signal PV on

800…1200°C range.

#rt.H1

#rt.H2

20

4

800 1200 1600

#retr = 4=20

#rt.H = P.U.

#rt.L1 = 800

#rt.H1 =1200

mA

°C

With rt.lI greater than

rt.H1 it is possible to obtain

a reverse scale.

Page 30

bloc

éno

Ltch

éno

A1.Ou

éOP1

AL. 1

éOFF

donb

éno

AL1 alarm type

see table 11

AL1 addressing

OP1 / OP2 [1]

OP3 / OP4

AL1 latching

no / yeS

AL1 start-up

disabling

no / yeS

Disables AL1 if a sensor break occurs

no / yeS

NOT AVAILABLE

OF

AL. 1 = OFF

Page 31

31

4 - Operation

AL4 alarm type

see table 11

AL4 addressing

OP1 / OP2 [1]

OP3 / OP4

AL4 latching

no / yeS

AL4 start-up

disabling

no / yeS

Disables AL4 if a sensor break occurs

no / yeS

Band

éAl 4

Description

Tab. 11 Alarm type

éAl 1

Value

Off

Not used or used by the

program (AL3/AL4)

fs.H

Active High

Absolute

fs.l

Active Low

deU.H

Active High

Deviation

deU.l

Active Low

bno

Active Out

bni

Active In

lba

Loop break alarm

(AL1 only)

éAl 3

éAl 2

tiMe

Alarm 3 active when

Timer ON

Page 32

Active high

é-fsH

On

Off

High rangeLow range

Active high

On

Off

+ range- range

é-deH

On

Off

SP

Alarm threshold

full scale

hyd hyu

∆SP ∆SP

[B] ALARM ACKNOWLEDGE

FUNCTION

The alarm, once occurred, is

presented on the display until

acknowledged. The acknowledge

operation consists in pressing any

key.

After this operation, the alarm

leaves the alarm state only when

the alarm condition is no longer

present.

Ltch

Yes

Page 33

mA

°C

OP1

275.0

A / M

1 2 3

Ilba

4

33

4 - Operation

LOOP BREAK ALARM (LBA)

When the controller connection to

the sensor is discontinued or

other faults are detected in the

control loop, AL1 alarm becomes

active after a predefined time of

1... 9999 s from the detection of

the failure (see page 37).

When a sensor failure occours,

the LBA interventrion is immediate. The alarm state ceases when

the fault condition is no longer

present.

eIn case of ON-OFF control, the

LBA alarm is not active.

#donb = no

#donb = yes

Page 34

Menu

AL

Menu

time

(see pages 37)

Operator

mode

(see page 41)

Alarm

menu

Time

menu

A

The parameter setting procedure

has a timeout. If no keys are

pressed for, at least, 30 seconds,

the controller switches back, automatically, to the operator mode.

Page 35

35

4 - Operation

Menu

Conf

Menu

AccS

(see page 54)

Access

menu

(see page 25)

Configuration

menu

menu

Page 36

SL. u

SL. d

éOFF

éOFF

S.P. H

éH.réange

S.P. L

éL.réange

Ratio Setpoint

-9.99…99.99

Remote

Setpoint bias

full scale

Setpoint

low limit

full scale

Setpoint

high limit

full scale

Slope up

0ff/1…9999 digit/

[1]

Slop down

0ff/1…9999

digit/..

0ff/1…9999

digit/ [1]

Page 37

37

4 - Operation

Timer

Action

Timer OP

function

std/eHpd

standard/extended

Standard: tdop = 0

OP3 is set to 1 at timer lauch

and reset 0 on time elapsing.

Extended: tdop = 1

OP3 is set to 1 at time

elapsing and set to 0 by reset

command.

P.I.D enable

yes/no

Yes:

PID is enabled when time

function is enabled.

Extended:

PID is disabled and output is

maintained at zero.

#Pid

#tdop

[1] OP3

status

Value

On

4

Off

5

On

6

Off

7

Page 38

C - Counting start time = timer launch

time, end in control mode.

The time counting starts when the timer is

launched. The control action is not affected

by the Timer function.

tdop = 1

tdop = 0

#tiMe

Timer

launch

SP

Process

variable PV

Output OP [2]

#t.Mod = 4

OP3

Reset

OP3

OP = 0

Page 39

39

4 - Operation

F - Control action with stand-by Setpoint

during the counting time.

The time counting starts when the timer is

launched and the control action use the

Stand-by Setpoint. At the end, the control

action use the working Setpoint.

tdop = 1

tdop = 0

#tiMe

Timer launch

#s.p. 2

#t.Mod =7

SP

Process

variable PV

Output OP [2]

OP3

Reset

OP3

OP = 0

Page 40

Page 41

41

4 - Operation

Alarm 3 hysteresis

asymmetric upper

0…5% Span

in engineering units

Alarm 3 hysteresis

asymmetric lower

0…5% Span

in engineering units

Alarm 3 delay

OFF/1...9999

Alarm 4 hysteresis

asymmetric upper

0…5% Span

in engineering units

Alarm 4 hysteresis

asymmetric lower

0…5% Span

in engineering units

Alarm 4 delay

OFF/1...9999

Type and value Mode

No. and

Param.

Absolute

full scale

Active high

-fs.H

Active low

-fs.l

Deviation

full scale

Active high

-de.H

Active low

-de.l

Band

full scale

L.B.A.

1…9999 s

Active high

-lba

Timer

ON on timer

signal

Alarm 3

active on

timer signal

-ton

[1] A code, specifying the No. and the

alarm type that has been configured (see page 31), is displayed. At

this point, the user must enter the

threshold value, according to the

following table.

Active out

-bno

Active in

-bni

Page 42

OK

t.d. C

é 12:0

t.i. C

é 60

P.b. C

é 5:0

Proportional band

Cool channel

0.5…999.9%c.s.

Cool

Integral time

0ff/1

…

9999 s

Cool

Derivative time

0ff/0.1

…

999.9 s

NO

YES

Page 43

43

4 - Operation

Menu

InP

T.SaM

é 0:11

In.Sh

é 0

t.FiL

éOFF

Filter time constant

(user enabled/disabled)

Off/0.2…99.9 seconds

Measure bias

-60…60 digit

Sampling time

0.1…10.0 seconds

Input

menu

Page 44

Op.rC

é Off

OP.C.H

t.c. C

é 10:0

é100:0

d.bnd

é 0:5

Motor travel time

15…600 seconds

Minimum

output step

0.1…5.0%

Dead band

0.0…5.0%

Cool cycle time

(time proportional only)

0.2…100.0 s

Cool control output

high limit

(PID only)

0.0…100.0%

Cool output rate limit

(user enabled/disabled)

0ff/0.01…99.99%s

Heat / Cool

Algorithm

Page 45

45

4 - Operation

Page 46

Target Setpoint

= 350°C

t = 10

#

sL. u = 10

digit/minute

1st stored

Setpoint

2nd stored

Setpoint

3th stored

Setpoint

Values of the three Setpoints,

that are activated by mean of

logic inputs, communication

parameters, and keyboard. The

Setpoint active is indicated by

the ú, ù or û green LED.

See page 56 for further explanation.

Remote Setpoint

Slope enable

To enable or disable slopes when

the remote Setpoint is active.

#rs.sl

#S.P. 3

#S.P. 2

#S.P. 1

Page 47

47

4 - Operation

bias = 20

ratio = 0.1

ratio = –0.1

Range

600

100

20

Remote

Setpoint span

bias = 100

a b

a´ b´

HR

´ ) b (a´ )

PV = Process Variable

LR = PV low limit

HR = PV high limit

SR = Remote Setpoint

a (a´) = SR starting point

b (b´) = SR ending point

Page 48

Asymmetric

upper alarm

hysteresis

Asymmetric

lower alarm

hysteresis

Alarm

delay

Delay time for alarm activation.

OFF: alarm activated immediately

1...9999 seconds: alarm activated only if the condition persists for the set time

#tF1

=

#hy-u

Page 49

49

4 - Operation

Manual

reset

Error

Dead Band

4.5.4 TUNING MENU

(not shown for ON-OFF

main control output)

See page also 57

Two tuning method are provided:

• Initial one shoot Fuzzy-Tuning

• Continuous, self learning

Adaptive Tuning

The Fuzzy-Tuning automatically

determines the best PID term with

behaviour respect to the process.

The controller provides 2 types

of “one shot” tuning algorithms,

that automatically are selected

according to the process conditions when the tune operation

is started.

STEP response

SP

End of the tuning

operating and

setting of the new

calculated terms

Start of autotune

operation

Setpoint change

PV variable

Control output

Page 50

4.5.5 INPUT MENU

Input

filter

Time constant, in seconds, of

the RC input filter on the PV

input. When this parameter is

Off the filter is bypassed.

Measure

Bias

This value is added to the measured PV input value. Its effect

is to shift the whole PV scale of

its value (±60 digits).

Sampling

Time

Sampling time, in seconds, of

the instrument. This parameter

is normally used when controlling slow process, increasing the

sampling time from 0.1... 10 s.

#t.SaM

#In.sh

0

PV

63.2%

Filter time

Time

#t.fil

Page 51

51

4 - Operation

Soft start

time

Travel

time

Minimum

step

#Op.r

Time

Speed in %/s

Heat/Cool

deadband

This parameter specifies the

width of the deadband between

the Cool and the Heat outputs.

#d.bnd

#OpC.H

#

Op.H.

0

100%

100%

0

SP

d.bnd

P.b. / CP.b.

eat / Cool Algorithm

Heat Cool

100%

Cool output

Heat output

Heat

Page 52

Page 53

53

4 - Operation

Page 54

Ac.le

C.pas

Oper

EHec

C.pas

33

Access

to all the levels

[1]

Execute

the following

operations

A/M enable

yes/nO

Operator

level Access

Change the

Configuration

password

Enter

the Configuration

password

Page 55

pot.H

EHec

C.pot

pot.l

O

255

55

4 - Operation

Calibrate

the potentiometer

(if present)

The valve

goes to low scale

The valve

goes to full scale

Download the data

to Memory chip

When the indication

(the valve) is stopped,

confirm the calibra-

tion value using

$ or %

Page 56

The parameters in the access

level

fast are recalled on the

front panel through the procedure of fast parameter

access illustrated in par. 5.2

page 57. The maximum number of fast parameters is 10.

At the end of the parameter list of

the selected group, the controller

exits from the Edit access level.

Therefore, the Edit level must

be selected for each group of

parameters

The access level of groups and

parameters is activated through:

Ac.le

Oper

Access

level operator

Confirm

Page 57

57

5 - Displays

Operator mode

Automatic mode

One shot

tune start

no/yes

Alarm 3 threshold

(high absolute

alarm)

full scale

Stored Setpoint

selection

none/s.LOC/

s.s.p.I/s.s.p.2/

s.s.p.3

5.2 FAST VIEW

(fast access to the parameters)

With this procedure, up to 10

parameters, selected through

the fast view (see par 4.6 page

56) are displayed and can be

modified by the operator

without requiring the standard

parameter setting procedure.

Press

$% in order to

modify the parameters.

The value is entered by

pressing è key.

On left side, please find a

sample list of parameters on

Fast view menu.

Page 58

6.3 SERIAL

COMMUNICATIONS

see the manual on this topic

Page 59

59

6 - Commands

275.0

274.8

63

275.0

274.8

35

275.0

274.8

63

A

Operator

mode

(automatic)

The bumpless action is present

switching between AUTO, MAN

and vice versa.

AUTO AUTO

SP = PV

OPMAN=OPAUTO

SP (PV)

O

Y

0

0

MAN

Op.r

SP

change OP

100%

Setpoint SP

with

100% output OP

OPAUTO=OPMAN

PV

OP

AIn case of power failure, the

AUTO/MAN status and the

output value remain stored in

the controller memory.

Page 60

s.sel

s.sel

S.LOC

s.sel

s.s.p.1

s.s.p.3

The selected Setpoint

becomes operating

pressing the

è key.

The three

ú ù û

leds flag the Setpoint

operating.

Page 61

tune

tune

no

tune

yes

no

61

6 - Commands

Confirm

yes

to start

Confirm

no

to stop

The command start/stop

is executed pressing the

è key.

When the controller is

calculating the PID

parameters, the green

Ä led is ON.

Fuzzy Tune

start-up

After the execution of the tuning, the

calculated values are automatically

presented in the PID menu.

Page 62

Notes

With the keypad locked the commands from digital

inputs and serial communications are still operating

The value of PV is “frozen” at the time the digital input

goes to the close state

The permanent closure forces the chosen stored value.

Setpoint modification is not possible.

The impulsive closure, selects the stored value. Setpoint

modification is allowed. If more than one digital input

is selecting a Setpoint, the last to be activated is the

operating one (see page 43)

When the input is in the on state, the Setpoint is changed

in steps

With ON command the output is equal to the forced

value (see page 28)

The blocking function is activated on closing the command from digital inputs

Page 63

63

8 - Technical Specifications

- the type and functionality of the alarms

- control parameter values

- access levels

Between 100…240Vac

the error is minimal

Max. wire Res: 20Ω max. (3 wires)

Input drift: 0.1°C/10° T

env

<0.1°C/10Ω Wire Res.

Line: 150Ω max.

Input drift: <2µV/°C. T

env.

<5µV/10Ω Wire Res.

—

Input drift: <0.1%/20°C T

env.

<5µV/10Ω Wire Res.

Page 64

Bias in engineering units and ± range

Ratio: -9.99… +99.99

Local + Remote Setpoint

OP2

OP3

Relay

OP4

Relay

OP5

Analog/Digital

OP6

Analog/Digital

OP2

OP3

Relay

OP4

Relay

OP6

Analog/Digital

OP3

Relay

OP4

Relay

OP5

Analog/Digital

OP6

Analog/Digital

OP2

OP3

Relay

OP4

Relay

OP6

Analog/Digital

OP3

Relay

OP4

Relay

OP6

Analog/Digital

OP2

OP3

Relay

OP4

Relay

OP3

Relay

OP4

Relay

OP5

Analog/Digital

OP6

Analog/Digital

Feedback valve position

Page 65

65

8 - Technical Specifications

Single action

PID algorithm

OFF = O

Double action

PID algorithm

(Heat / Cool)

OFF = O

Valve drive PID algorithm

Raise/Stop/Lower

OFF = O

OFF = O

Page 66

0/4... 20mA, 750Ω/15V max.

Page 67

67

8 - Technical Specifications

Power consumption 5W max.

Page 68

Factory default parameters

FACTORY DEFAULT PARAMETERS

Parameter Parameter Name Default value User settings Notes

S.SEL

Setpoint selection NONE

SP.1

1st stored Setpoint 0

SP.2

2nd stored Setpoint 0

S.P.L

Setpoint low limit PV.LO

S.P.H

Setpoint high limit PV.HI

Sl.u

Setpoint ramp up OFF

Sl.d

Setpoint ramp down OFF

rtio

Ratio remote Setpoint 1.00

biaS

Remote Setpoint Bias 0

1

AL1 alarm threshold 0

SSI.fm Page 68 Friday, December 12, 2008 5:04 PM

Page 69

Factory default parameters

tFl1

AL1 delay 1

Hy.2u

AL2 alarm hysteresis Up 1

Hy.2d

AL2 alarm hysteresis Down 1

tFl2

AL2 delay 1

Hy.3u

AL3 alarm hysteresis Up 1

Hy.3d

AL3 alarm hysteresis Down 1

tFl3

AL3 delay 1

Hy.4u

AL4 alarm hysteresis Up 1

Hy.4d

AL4 alarm hysteresis Down 1

tFl4

AL4 delay 1

t.Mod

Timer Operating Mode 0

t.act

Timer Action 4

t.dOP

Timer OP Function 1

Parameter Parameter Name Default value User settings Notes

SSI.fm Page 69 Friday, December 12, 2008 5:04 PM

Page 70

Factory default parameters

t.i.

Integral time 60

t.d.

Derivative time 12.0

d.Err

Error Dead Band OFF

O.C.

Overshoot Control 0.8

O.C.r.b.

Overshoot Control relative band 1.0

MreS

Manual Reset 50

P.b. C

Cool proportional band 3.0

t.i. C

Cool integral time 60

t.d. C

Cool derivative time 12.0

tune

Start/Stop One shot tuning (0=Stop 1=Run) NO

AdPt

Start/Stop Adaptive tuning (0=Stop 1=Run) NO

t.Fil

Input filter 2.0

In.Sh

Input shift OFF

Parameter Parameter Name Default value User settings Notes

SSI.fm Page 70 Friday, December 12, 2008 5:04 PM

Page 71

Factory default parameters

OP.r

Control output maximum speed OFF

St.OP

Soft start output high value OFF

St.tM

Soft start time 10

M.t

Output minimum step Servomotor 60

M.hy

Output minimum step Servomotor 0.5

d.bnd

Heat/Cool Dead band 0.5

tc.C

Cool cycle time 5.0

OP.C.H

Cool output maximum value 100.0

OP.rC

Cool output maximum speed OFF

Add.S

Communication SLAVE address 247

dr.S

SLAVE Baud rate 9600

Pro.S

SLAVE Communication protocol MBUS

Par.y

Parity NONE

Parameter Parameter Name Default value User settings Notes

SSI.fm Page 71 Friday, December 12, 2008 5:04 PM

Page 72

Factory default parameters

A.PAS

Access password 11

In

Input type selection 0 - 10

Unit

Engineering units NONE

SC.dd

Number of decimals (0... 3) 0

SC.lo

Low range 0

SC.Hi

High range 9999

Sqr

Square root (0 = OFF, 1 = ON) NO

Char

Linear input characterization NO

S.P.ty

Setpoint type LOC

S.P.tr

Stored Setpoint tracking NO

S.P.T

Time units and Setpoint slope P.SEC

.In

Remote Setpoint input 4 - 20

Parameter Parameter Name Default value User settings Notes

SSI.fm Page 72 Friday, December 12, 2008 5:04 PM

Page 73

73

Warranty

Page 74

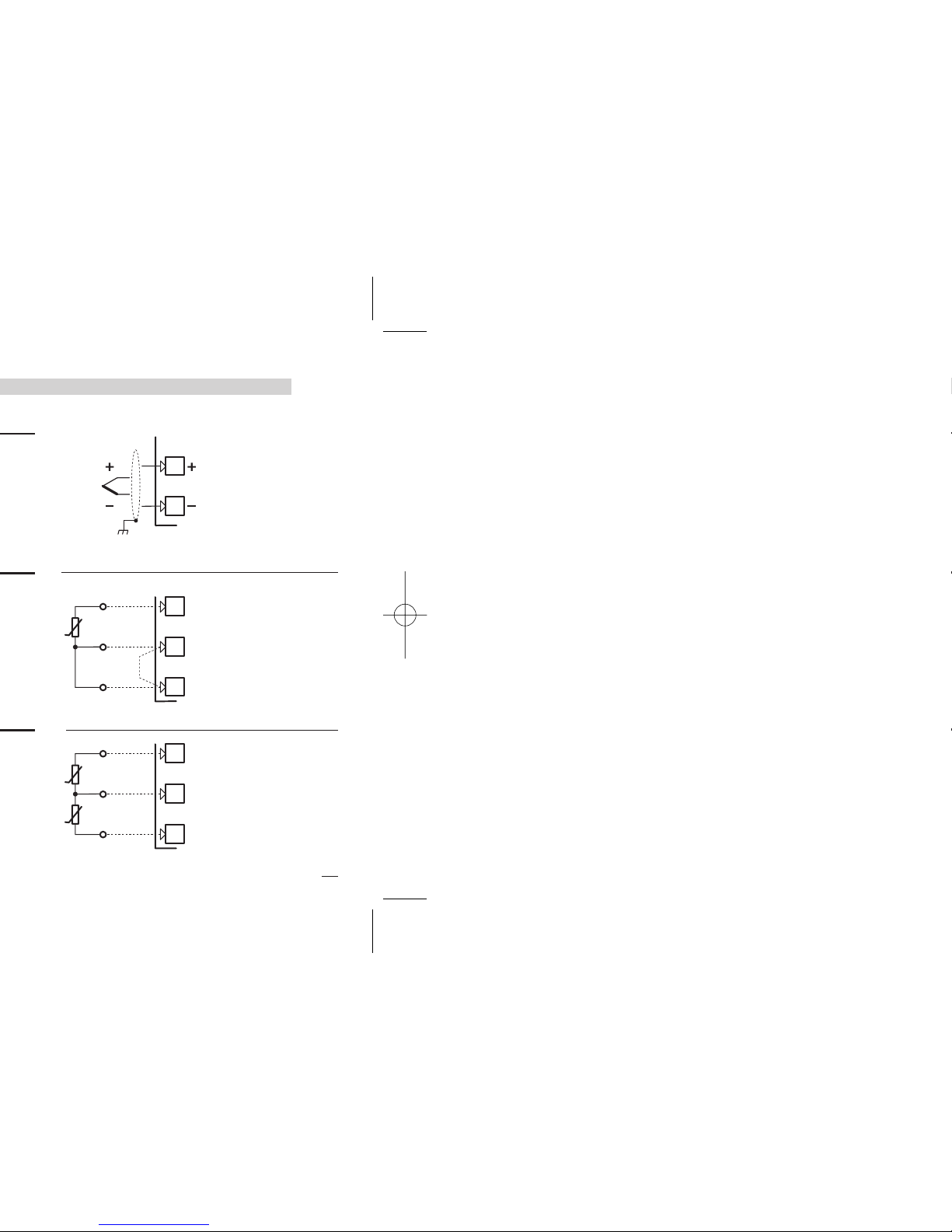

Logic

mA mV

mA

SPDT Relay

Triac

SPST Relay

Output

Setpoint slopes

inhibition

PV hold

Run, Hold, Reset and

program selection

Auto/Manual

Digital input

connected functions

Loading...

Loading...