Page 1

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

P/N 31091P/N 31091

P/N 31091

P/N 31091P/N 31091

170.IU0.20Q.SA0

mkc_0_ssi.pmd 05/07/2004, 11.121

20 Q20 Q

20 Q

20 Q20 Q

ControllerController

Controller

ControllerController

Page 2

mkc_0_ssi.pmd 05/07/2004, 11.122

Page 3

INDEXINDEX

INDEX

INDEXINDEX

MOUNTING REQUIREMENTS................................................. 1

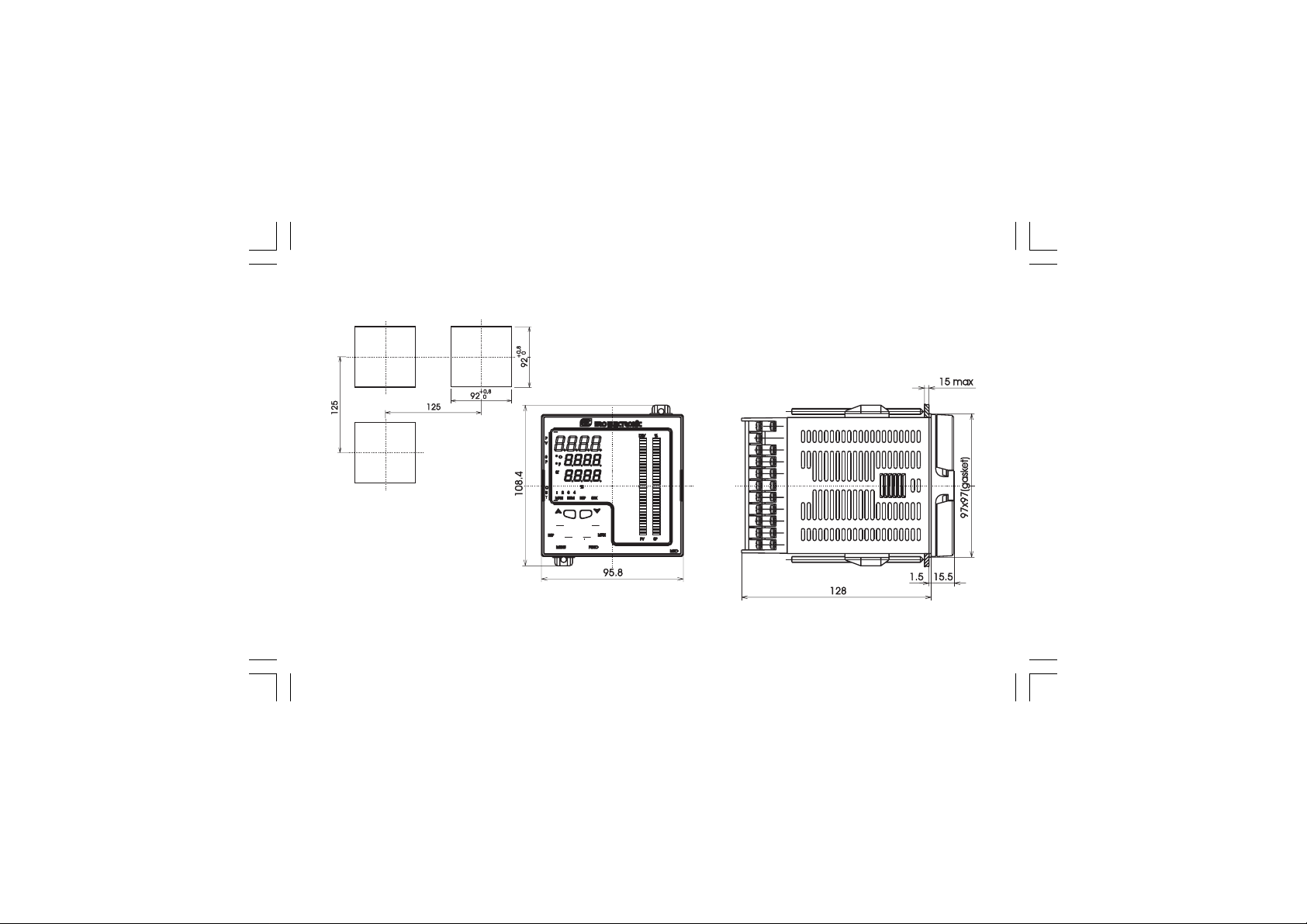

OUTLINE AND CUT OUT DIMENSIONS ................................. 2

CONNECTION DIAGRAMS.......................................................... 3

PRELIMINARY HARDWARE SETTINGS ..................................... 18

SECURITY CODE SETTING MODE ............................................ 22

RUN TIME AND CONFIGURATION MODE ................................. 25

General notes about graphic symbols ............................... 2 5

Keyboard description ........................................................ 2 6

CONFIGURATION MODE .......................................................... 27

RUN TIME MODE ...................................................................... 62

Display function ................................................................ 62

Indicators.......................................................................... 64

Bargraph description ........................................................ 65

OUT failure detection function (OFD) ............................... 66

Direct access to the set point........................................... 65

Manual function ................................................................66

Serial link ......................................................................... 68

Lamp test ......................................................................... 68

SMART function ................................................................ 69

Hold function .................................................................... 69

Parameter protection ........................................................ 70

RUN TIME PARAMETER MODIFICATION ................................... 70

mkc_0_ssi.pmd 05/07/2004, 11.123

ERROR MESSAGES ................................................................. 95

GENERAL INFORMATIONS .................................................... 100

MAINTENANCE ....................................................................... 109

DEFAULT PARAMETERS ........................................................ A.1

ALPHANUMERIC INDEX OF THE

DISPLAY INDICATION ......................................................... B.1

CODING................................................................................ B.7

Page 4

mkc_0_ssi.pmd 05/07/2004, 11.124

Page 5

MOUNTING REQUIREMENTSMOUNTING REQUIREMENTS

MOUNTING REQUIREMENTS

MOUNTING REQUIREMENTSMOUNTING REQUIREMENTS

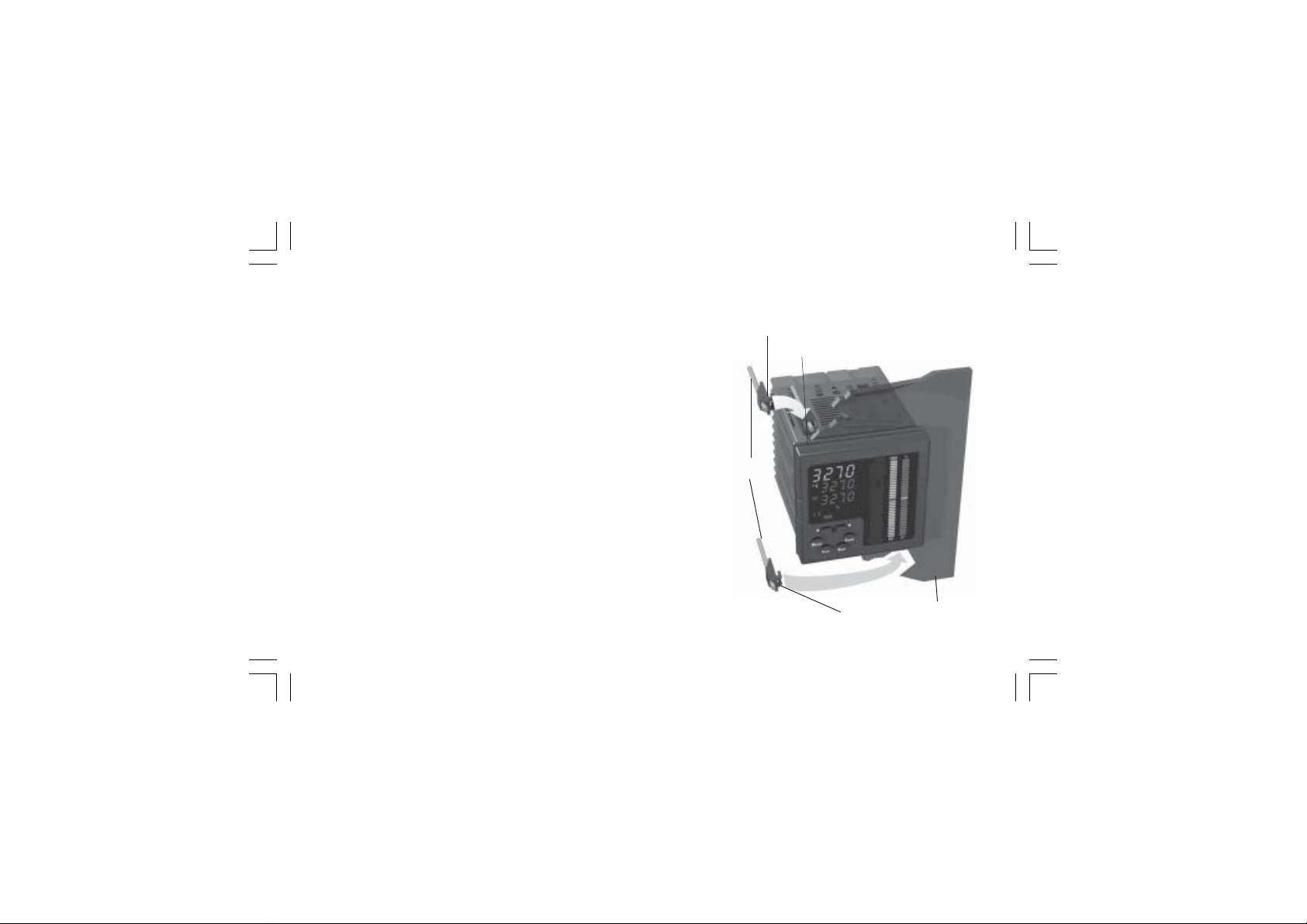

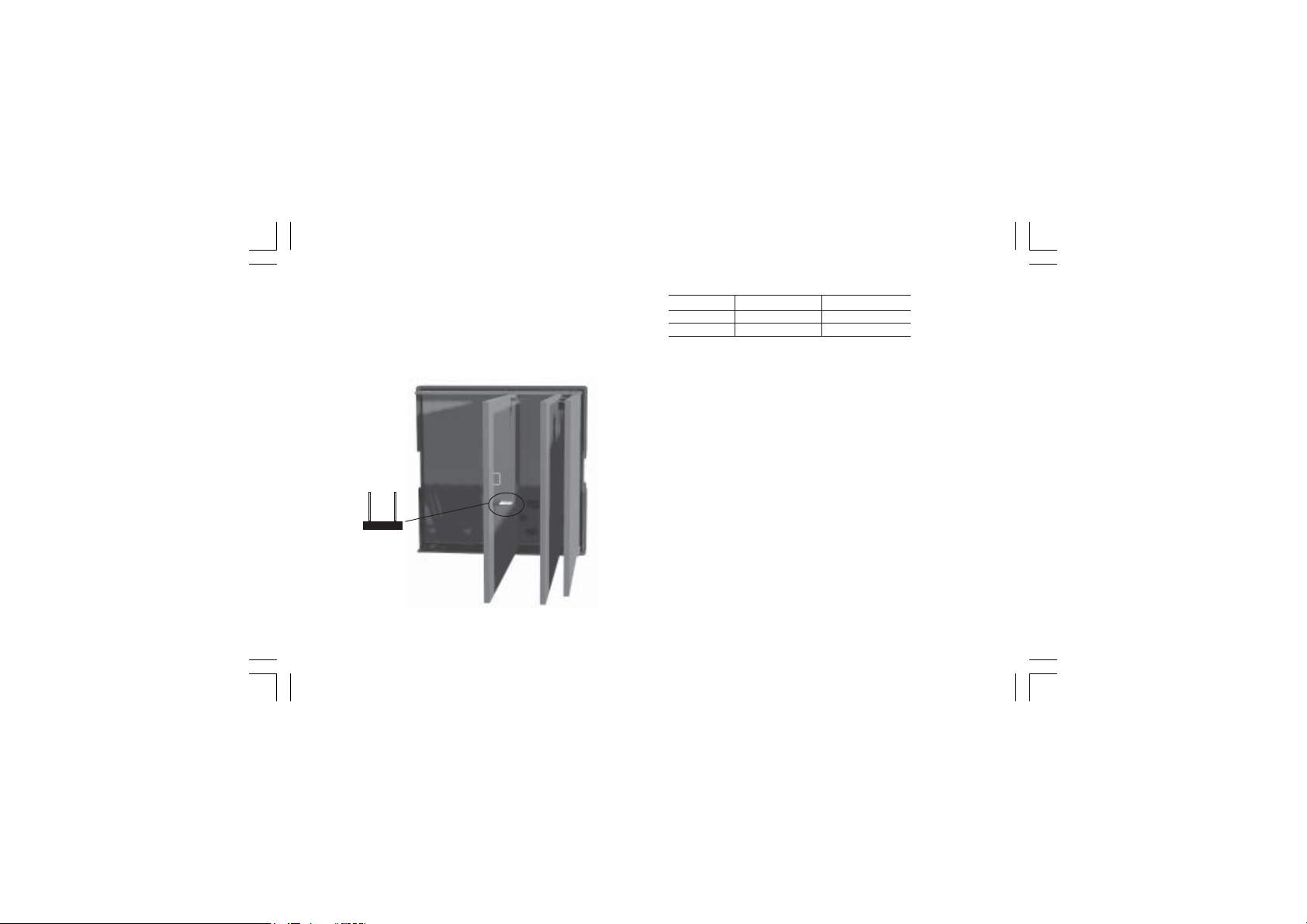

Select a location, for instrument mounting, where minimum

vibrations are present and the ambient temperature is within 0

and 50 °C (32 and 122 °F).

The instrument can be mounted on a panel up to 15 mm thick

with a cutout of 92 x 45 mm (PKC) or 92 x 92 (MKC).

For outline and cutout dimensions refer to Fig. 2.

The surface texture of the panel must be better than 6,3 µmm.

The instrument is shipped with rubber panel gasket (50 to 60

Sh).

To assure the IP65 and NEMA 4 protection, insert the panel

gasket between the instrument and the panel as shown in fig. 1.

While holding the instrument against the panel proceed as

follows:

1) insert the gasket in the instrument case;

2) insert the instrument in the panel cutout;

3) pushing the instrument against the panel;

4) insert the mounting brackets as shown in fig.1;

5) with a screwdriver, turn the screws with a torque between

0.3 and 0.4 Nm.

mkc-ssi.pmd 06/07/2004, 12.191

bracket

Gasket

Screws

Fig. 1

1

bracket

Panel

Page 6

OUTLINE AND CUT OUTOUTLINE AND CUT OUT

OUTLINE AND CUT OUT

OUTLINE AND CUT OUTOUTLINE AND CUT OUT

DIMENSIONSDIMENSIONS

DIMENSIONS

DIMENSIONSDIMENSIONS

Fig. 2 OUTLINE AND CUT-OUT DIMENSIONS

mkc-ssi.pmd 06/07/2004, 12.192

2

Page 7

CONNECTION DIAGRAMSCONNECTION DIAGRAMS

CONNECTION DIAGRAMS

CONNECTION DIAGRAMSCONNECTION DIAGRAMS

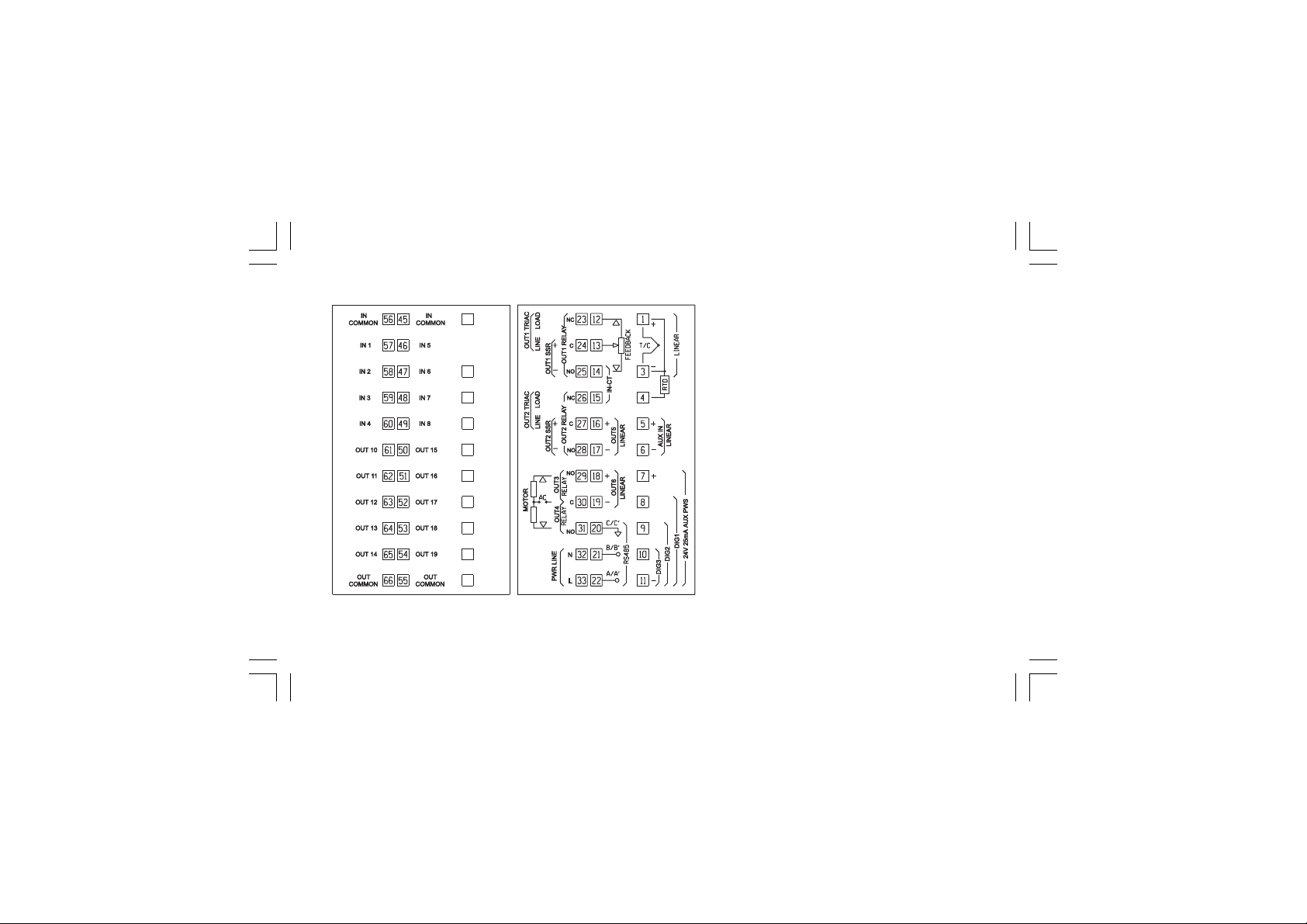

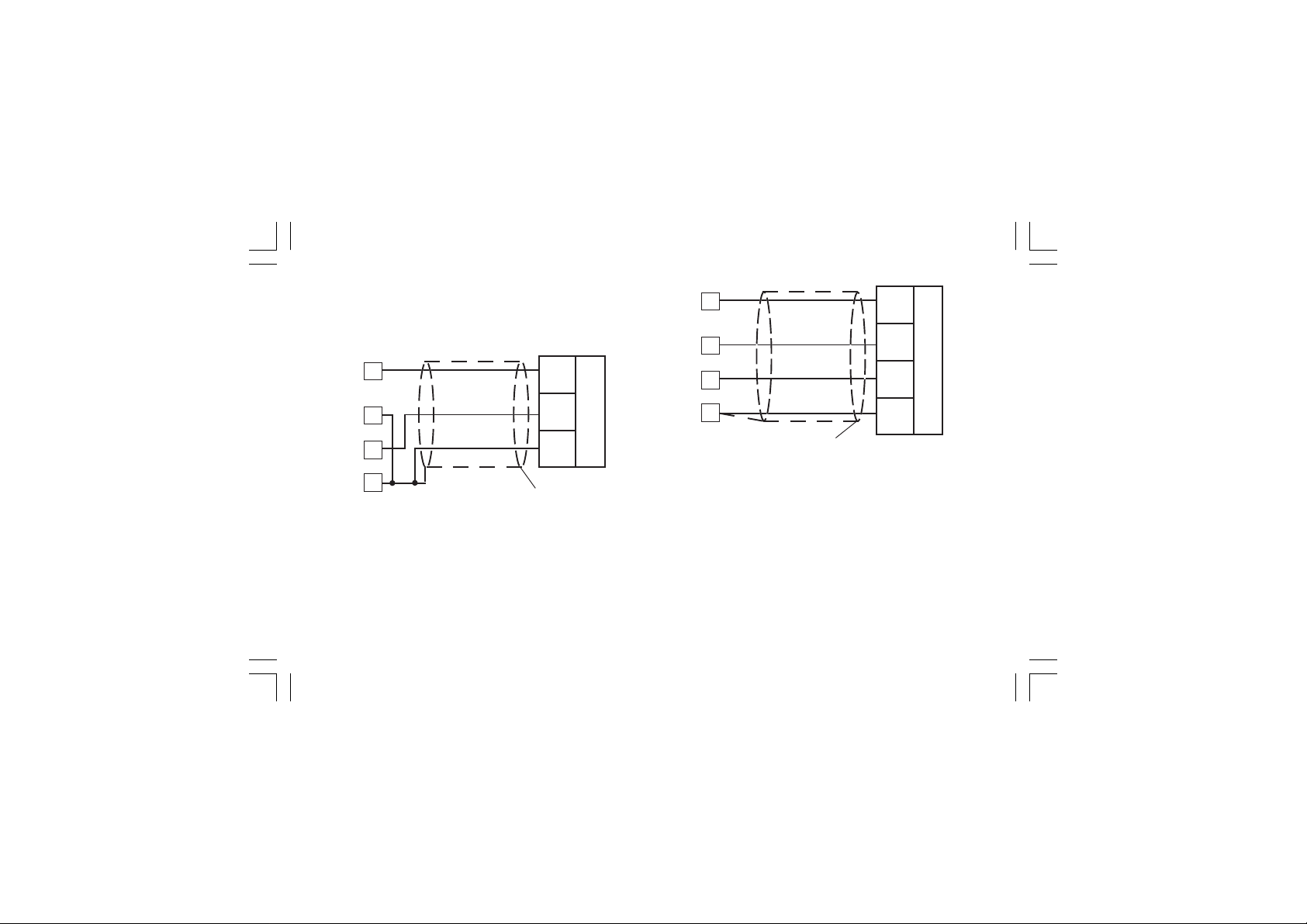

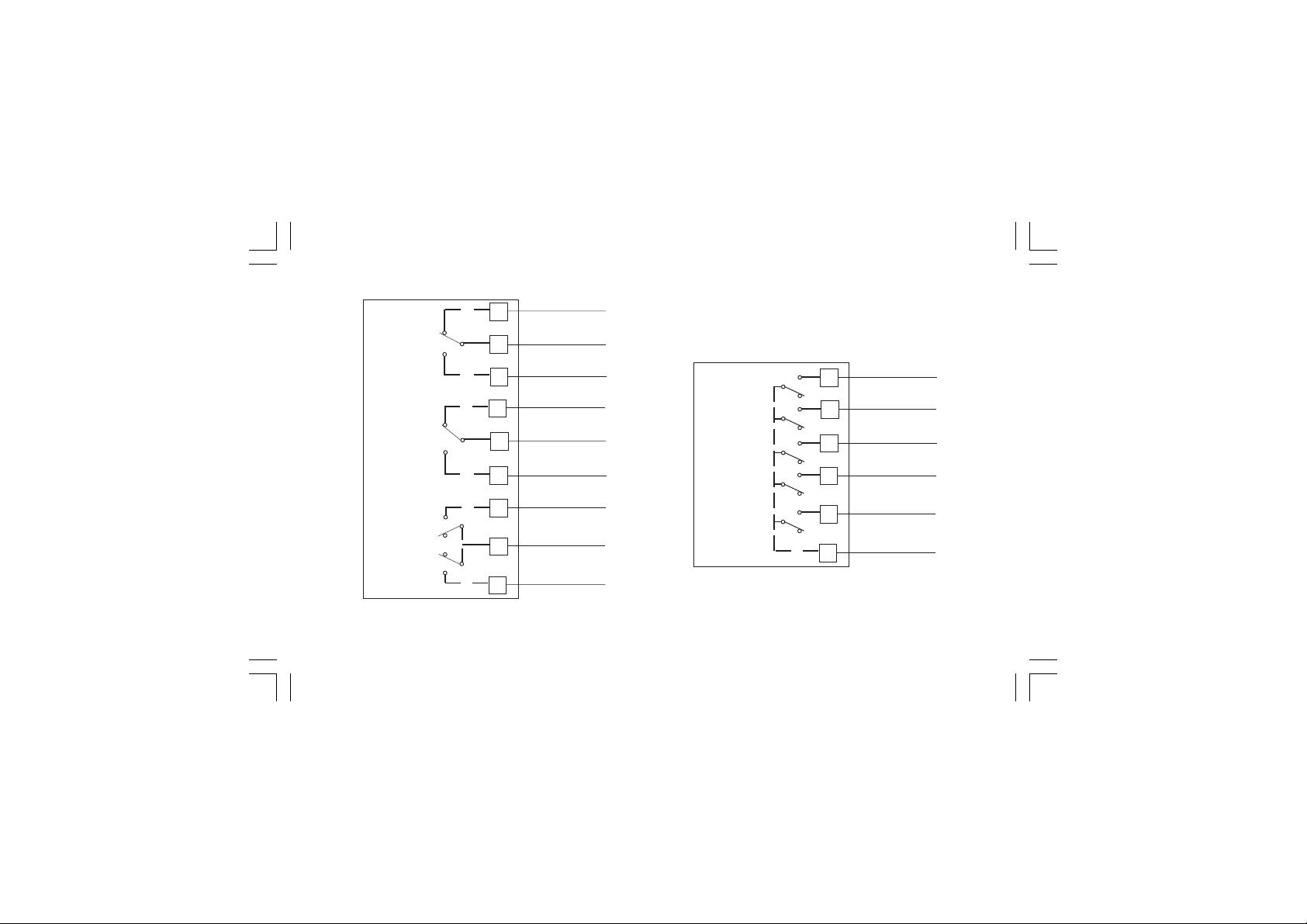

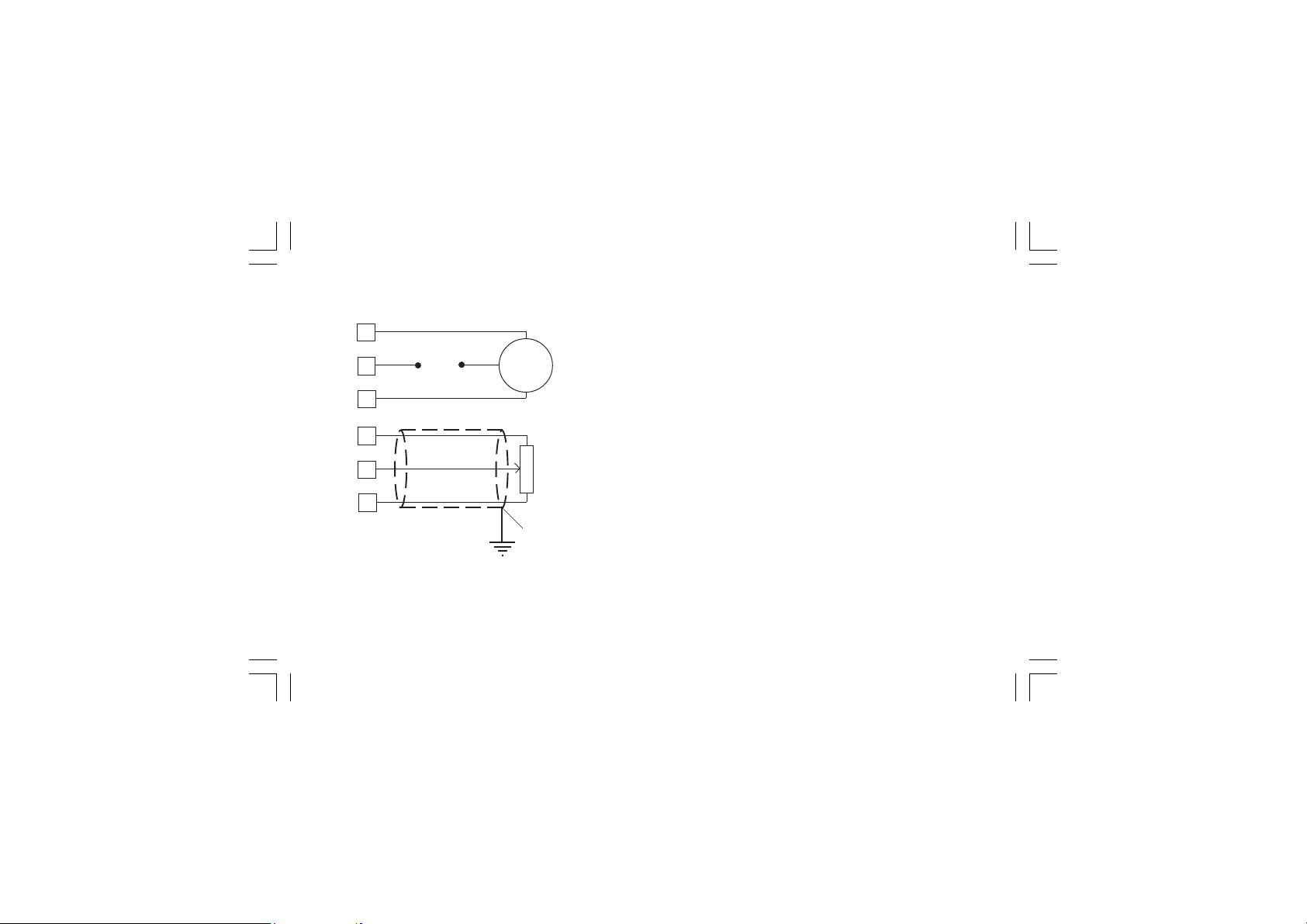

Fig. 3 REAR TERMINAL BLOCK

mkc-ssi.pmd 06/07/2004, 12.193

Connections are to be made with the instrument housing

installed in its proper location.

A) MEASURING INPUTSA) MEASURING INPUTS

A) MEASURING INPUTS

A) MEASURING INPUTSA) MEASURING INPUTS

NOTENOTE

NOTE: Any external component (like zener barriers etc.)

NOTENOTE

connected between sensor and input terminals may

cause errors in measurement due to excessive and/or not

balanced line resistance or possible leakage currents.

3

Page 8

A.1) TC INPUTA.1) TC INPUT

A.1) TC INPUT

A.1) TC INPUTA.1) TC INPUT

1

+

_

3

1

+

_

3

Shield

Shield

A.2) RTD INPUTA.2) RTD INPUT

A.2) RTD INPUT

A.2) RTD INPUTA.2) RTD INPUT

RTD

4

3 4

RTD

1

3

1

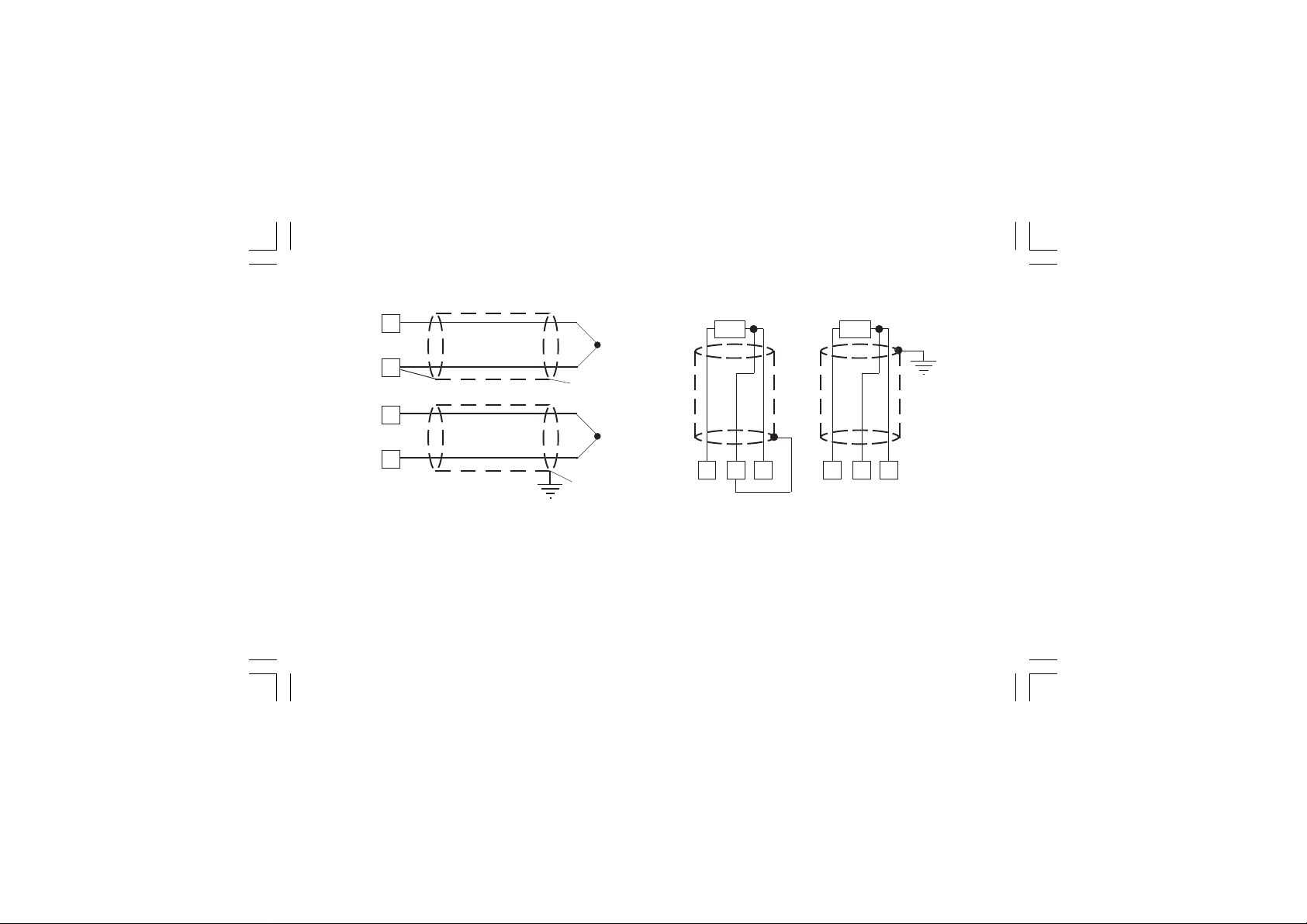

Fig. 4 THERMOCOUPLE INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) For TC wiring use proper compensating cable preferable

shielded.

3) When a shielded cable is used, it should be connected at

one point only.

mkc-ssi.pmd 06/07/2004, 12.194

Fig. 5 RTD INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The resistance of the 3 wires must be the same.

4

Page 9

A.3) LINEAR INPUTA.3) LINEAR INPUT

A.3) LINEAR INPUT

A.3) LINEAR INPUTA.3) LINEAR INPUT

1

3

1

3

+

_

Shield

+

_

G

mA,

mV

or

V

mA

mV

or

V

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The input impedance is equal to:

< 5 Ω for 20 mA input

> 1 MΩ for 60 mV input

> 200 kΩ for 5 V input

> 400 kΩ for 10 V input

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUTA.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUTA.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

1

3

_

TX

+

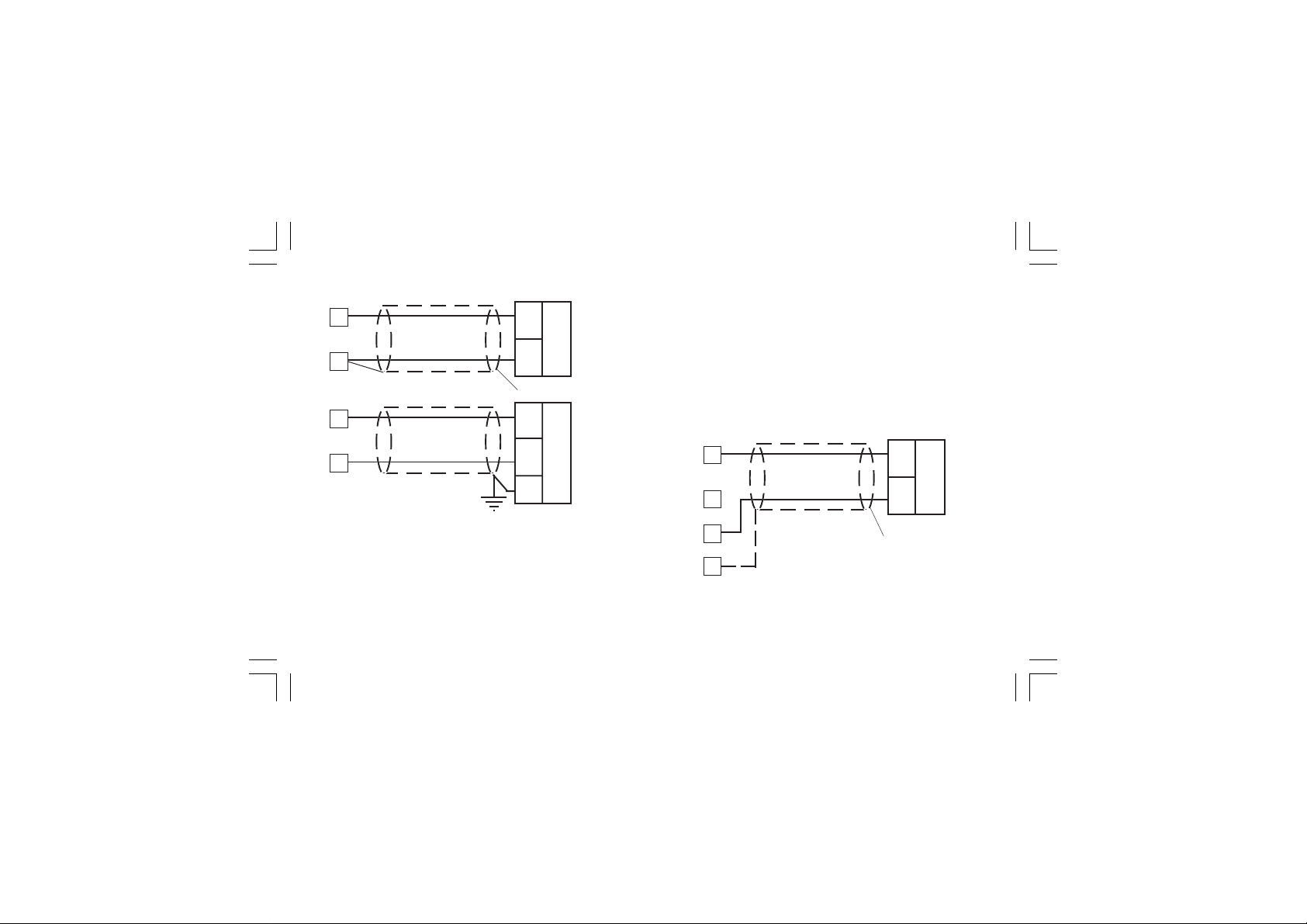

Fig. 6 mA, mV AND V INPUTS WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

mkc-ssi.pmd 06/07/2004, 12.195

7

Shield

11

Fig. 7.A INPUTS WIRING FOR 2-WIRE TRANSMITTER

5

Page 10

1

Out

+

Out

3

1

3

7

Out

PWR

+

GND

TX

7

11

Shield

_

PWR

+

PWR

_

TX

11

Fig. 7.B INPUTS WIRING FOR 3-WIRE TRANSMITTER

mkc-ssi.pmd 06/07/2004, 12.196

Shield

Fig. 7.C INPUTS WIRING FOR 4-WIRE TRANSMITTER

NOTESNOTES

NOTES:

NOTESNOTES

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The input impedance is lower than 5 Ω (20 mA input)

6

Page 11

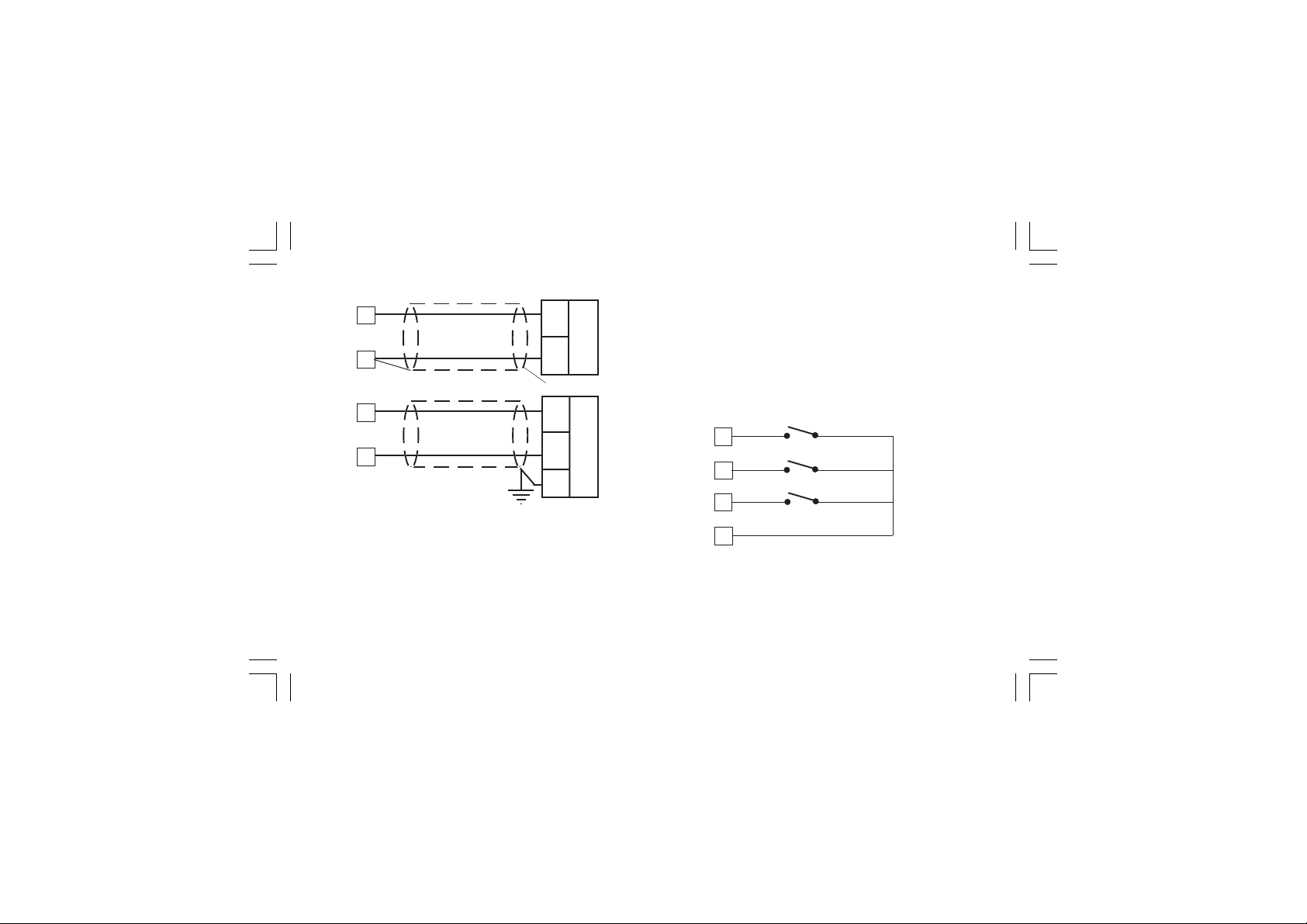

B) AUXILIARY INPUTB) AUXILIARY INPUT

B) AUXILIARY INPUT

B) AUXILIARY INPUTB) AUXILIARY INPUT

5

6

+

mA

or

_

V

Shield

5

6

+

mA

_

or

V

G

Fig. 8 AUXILIARY INPUT WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is

reinforced insulation between instrument output and power

supply must be assured by the external instrument.

2) Don’t run input wires together with power cables.

3) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

mkc-ssi.pmd 06/07/2004, 12.197

not isolated not isolated

not isolated from measuring input. A double or

not isolated not isolated

4) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

5) The input impedance is equal to:

< 5 Ω for 20 mA input

> 200 kΩ for 5 V input

> 400 kΩ for 10 V input

C) LOGIC INPUTC) LOGIC INPUT

C) LOGIC INPUT

C) LOGIC INPUTC) LOGIC INPUT

DIG. 1

8

DIG. 2

9

DIG. 3

10

11

Fig. 9 - LOGIC INPUTS WIRING

7

Page 12

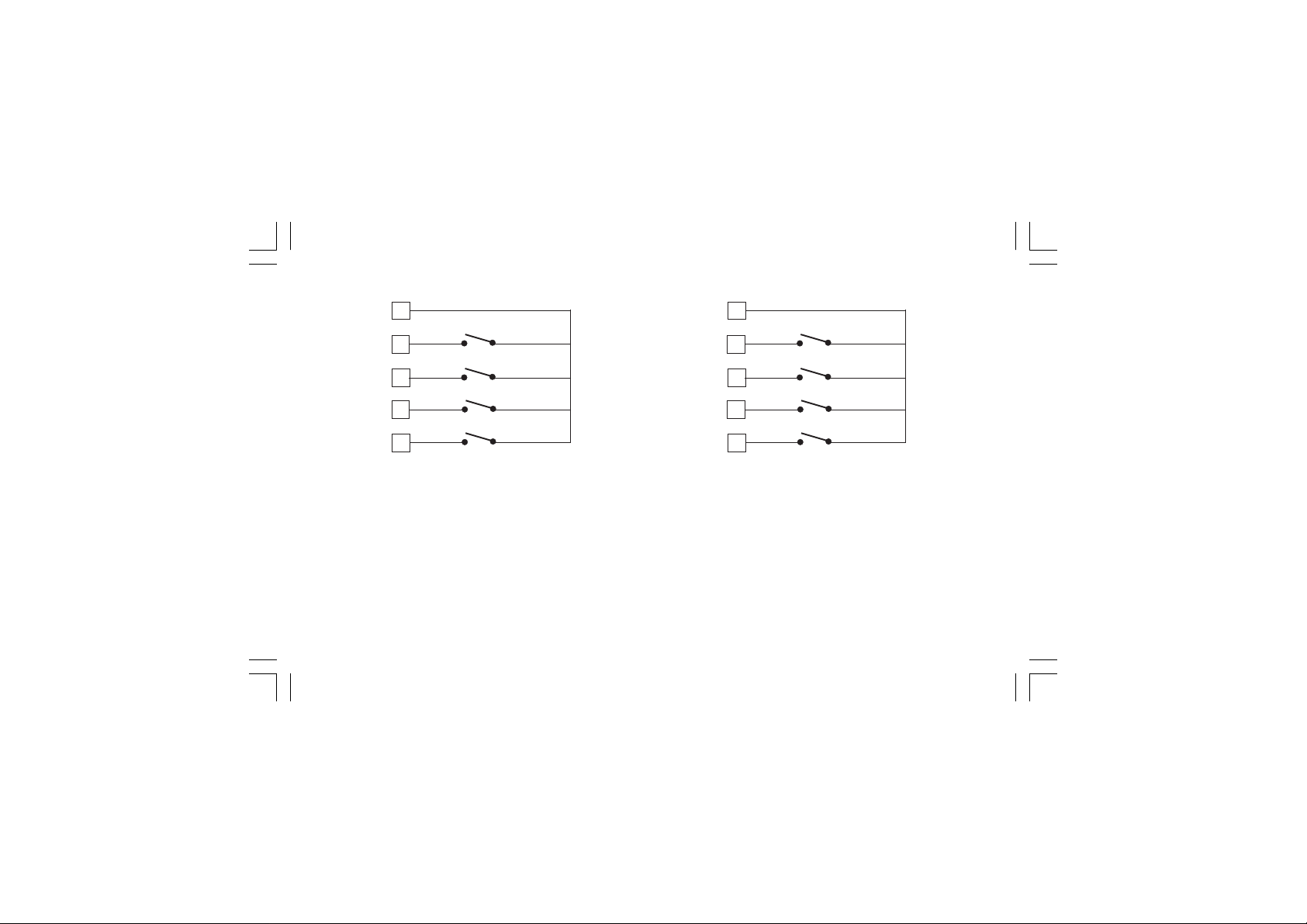

56

IN 1

57

IN 2

58

IN 3

59

IN 4

60

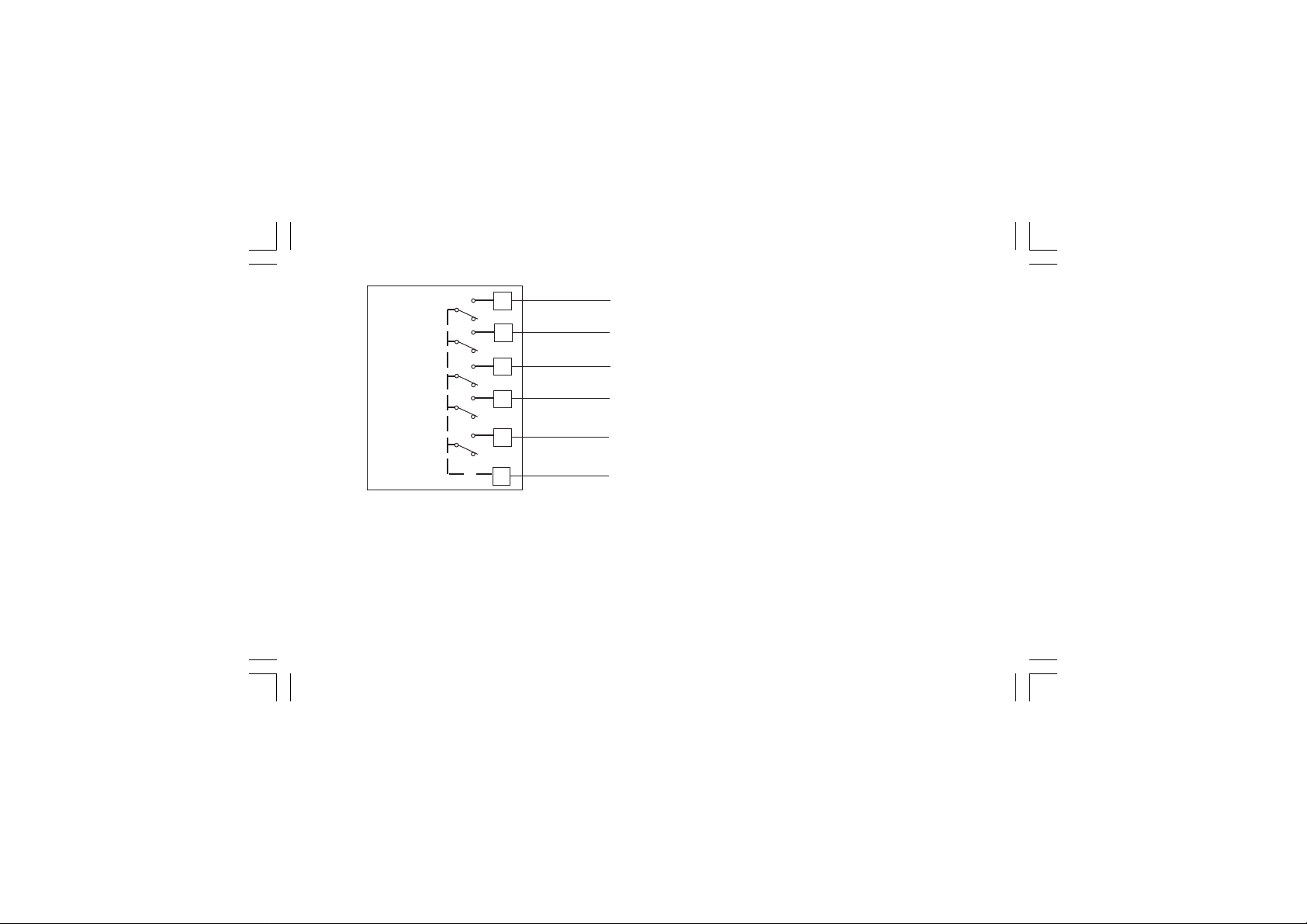

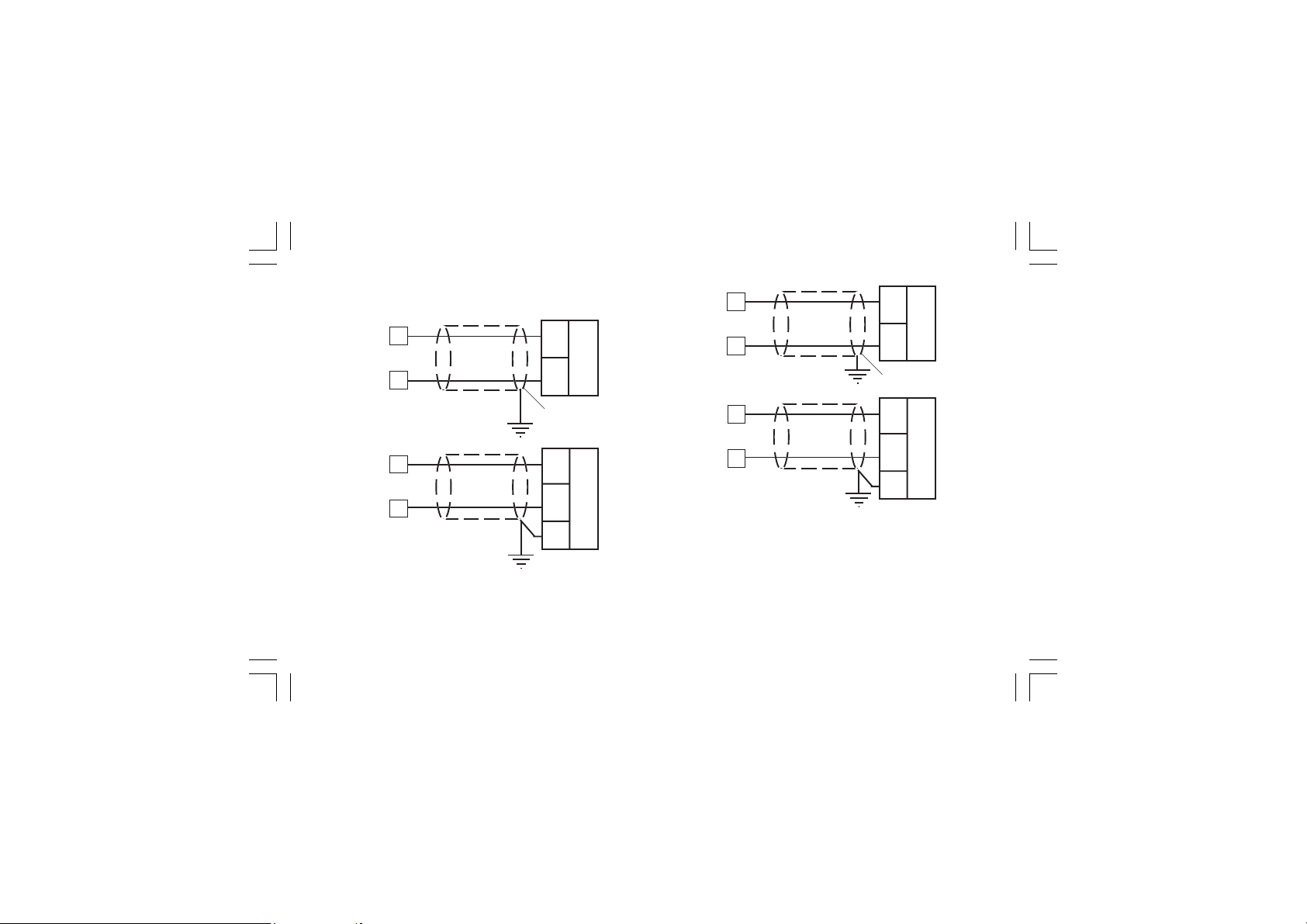

Fig. 9.B - LOGIC INPUTS IN 1, 2, 3 and 4 WIRING

mkc-ssi.pmd 06/07/2004, 12.198

56

IN 5

57

IN 6

58

IN 7

59

IN 8

60

Fig. 9.C - LOGIC INPUTS IN 5, 6, 7 and 8 WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Do not run logic input wiring together with power cables.

2) Use an external dry contact capable of switching 0.5 mA,

5 V DC.

3) The instrument needs 110 ms to recognize a contact status

variation.

4) The logic inputs are

A double or reinforced insulation between instrument input

and power line must be assured by the external element.

8

NOT NOT

NOT isolated by the measuring input.

NOT NOT

Page 13

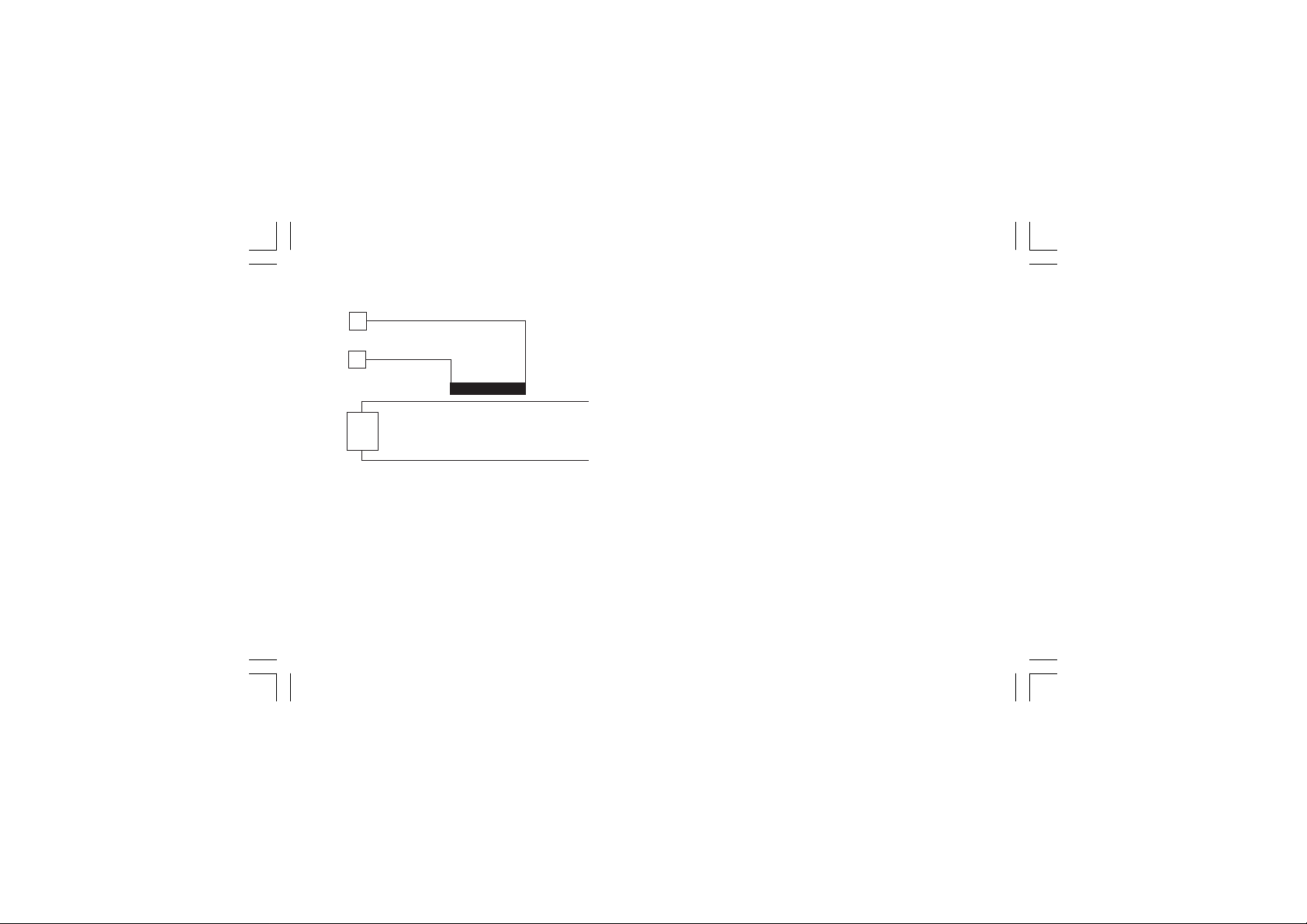

D) CURRENT TRANSFORMER INPUTD) CURRENT TRANSFORMER INPUT

D) CURRENT TRANSFORMER INPUT

D) CURRENT TRANSFORMER INPUTD) CURRENT TRANSFORMER INPUT

14

Current

15

Load

Fig. 10 CURRENT TRANSFORMER INPUT WIRING

This input allows you to measure and display the current running

in the load, driven by a time proportional control output, during

the ON and OFF periods of the output cycle time. By this feature

it is also available the "Output failure detection" function (see

page 66).

mkc-ssi.pmd 06/07/2004, 12.199

transformer

NOTESNOTES

NOTES:

NOTESNOTES

1) This input is

reinforced insulation between instrument output and power

supply must be assured by the external element.

2) Do not run current transformer input wiring together with AC

power cables.

3) The minimum active period to perform this measurement is

equal to 120 ms.

4) The input impedance is equal to 20 Ω.

9

not isolated not isolated

not isolated from measuring input. A double or

not isolated not isolated

Page 14

E.1) RELAY OUTPUTSE.1) RELAY OUTPUTS

E.1) RELAY OUTPUTS

E.1) RELAY OUTPUTSE.1) RELAY OUTPUTS

23

OUT 1

24

25

26

OUT 2

27

28

29

OUT 3

30

OUT 4

31

Fig. 11.A RELAY OUTPUTS 1,2,3 and 4 WIRING

mkc-ssi.pmd 06/07/2004, 12.1910

NC

C

NO

NC

C

NO

NO - OUT 3

C - OUT 3/4

NO - OUT 4

The outputs from OUT 1 to OUT 4 are equipped with relays

having contact rating equal to 3A/250V AC on resistive load.

WARNINGWARNING

WARNING: When OUT 3 and 4 are used as independent relay

WARNINGWARNING

outputs the addition of the two currents must not exceed 3 A.

NO OUT 10

OUT 10

OUT 11

OUT 12

OUT 13

OUT 14

COMMON

Fig. 11.B RELAY OUTPUTS 10 to 14 WIRING

10

61

62

63

64

65

66

NO OUT 11

NO OUT 12

NO OUT 13

NO OUT 14

COMMON

Page 15

OUT 15

OUT 16

OUT 17

OUT 18

OUT 19

COMMON

50

51

52

53

54

55

NO OUT 15

NO OUT 16

NO OUT 17

NO OUT 18

NO OUT 19

COMMON

GENERAL NOTES ABOUT RELAY OUTPUT WIRINGGENERAL NOTES ABOUT RELAY OUTPUT WIRING

GENERAL NOTES ABOUT RELAY OUTPUT WIRING

GENERAL NOTES ABOUT RELAY OUTPUT WIRINGGENERAL NOTES ABOUT RELAY OUTPUT WIRING

1) To avoid electrical shock, connect power line at the end of

the wiring procedure.

2) For power connections use No 16 AWG or larger wires rated for

at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

For all relay outputs, the number of operations is 1 x 105 at

specified rating.

All relay contacts are protected by varistor against inductive load

with inductive component up to 0.5 A.

The following recommendations avoid serious problems which

may occur, when using relay output for driving inductive loads.

Fig. 11.C RELAY OUTPUTS 15 to 19 WIRING

The outputs from OUT 10 to 19 are equipped with relays having

contact rating equal to 0.5A/250V AC on resistive load.

mkc-ssi.pmd 06/07/2004, 12.1911

INDUCTIVE LOADSINDUCTIVE LOADS

INDUCTIVE LOADS

INDUCTIVE LOADSINDUCTIVE LOADS

High voltage transients may occur switching inductive loads.

Through the internal contacts these transients may introduce

disturbances which can affect the performance of the instrument.

For all the outputs, the internal protection (varistor) assures a

correct protection up to 0.5 A of inductive component.

The same problem may occur when a switch is used in series

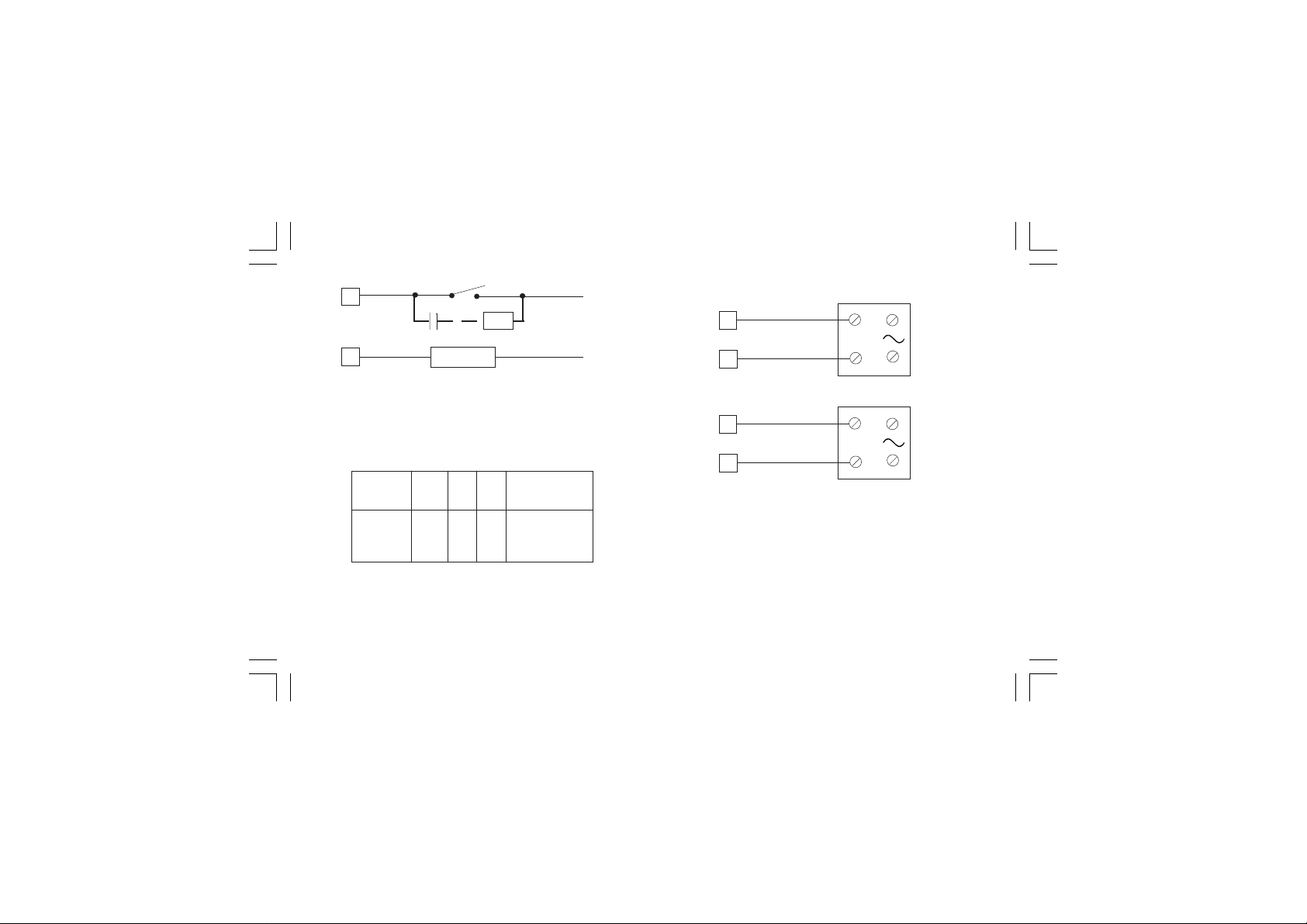

with the internal contacts as shown in Fig. 12.

11

Page 16

C

R

LINE

LOAD

Fig. 12 EXTERNAL SWITCH IN SERIES WITH THE INTERNAL

CONTACT

In this case it is recommended to install an additional RC

network across the external contact as show in Fig. 12

The value of capacitor (C) and resistor (R) are shown in the

following table.

LOAD

(mA)

<40 mA

<150 mA

<0.5 A

Anyway the cable involved in relay output wiring must be as far

away as possible from input or communication cables.

mkc-ssi.pmd 06/07/2004, 12.1912

C

(µF)

0.047

0.1

0.33

(Ω)

100

22

47

R

P.

OPERATING

(W)

VOLTAGE

1/2

260 V AC

2

260 V AC

2

260 V AC

E.2) VOLTAGE OUTPUTS FOR SSR DRIVEE.2) VOLTAGE OUTPUTS FOR SSR DRIVE

E.2) VOLTAGE OUTPUTS FOR SSR DRIVE

E.2) VOLTAGE OUTPUTS FOR SSR DRIVEE.2) VOLTAGE OUTPUTS FOR SSR DRIVE

+

OUT 1

24

_

+

__

_

__

25

SOLID STATE

RELAY

+

OUT 2

27

_

+

__

_

__

28

SOLID STATE

Fig. 13 SSR DRIVE OUTPUT WIRING

Logic level 0Logic level 0

Logic level 0: Vout < 0.5 V DC.

Logic level 0Logic level 0

Logic level 1Logic level 1

Logic level 1:

Logic level 1Logic level 1

- 14 V

+ 20 % @ 20 mA

- 24 V

+ 20 % @ 1 mA.

Maximum current = 20 mA.

NOTENOTE

NOTE: This output is not isolated.

NOTENOTE

A double or reinforced insulation between instrument output and

power supply must be assured by the external solid state relay.

12

RELAY

Page 17

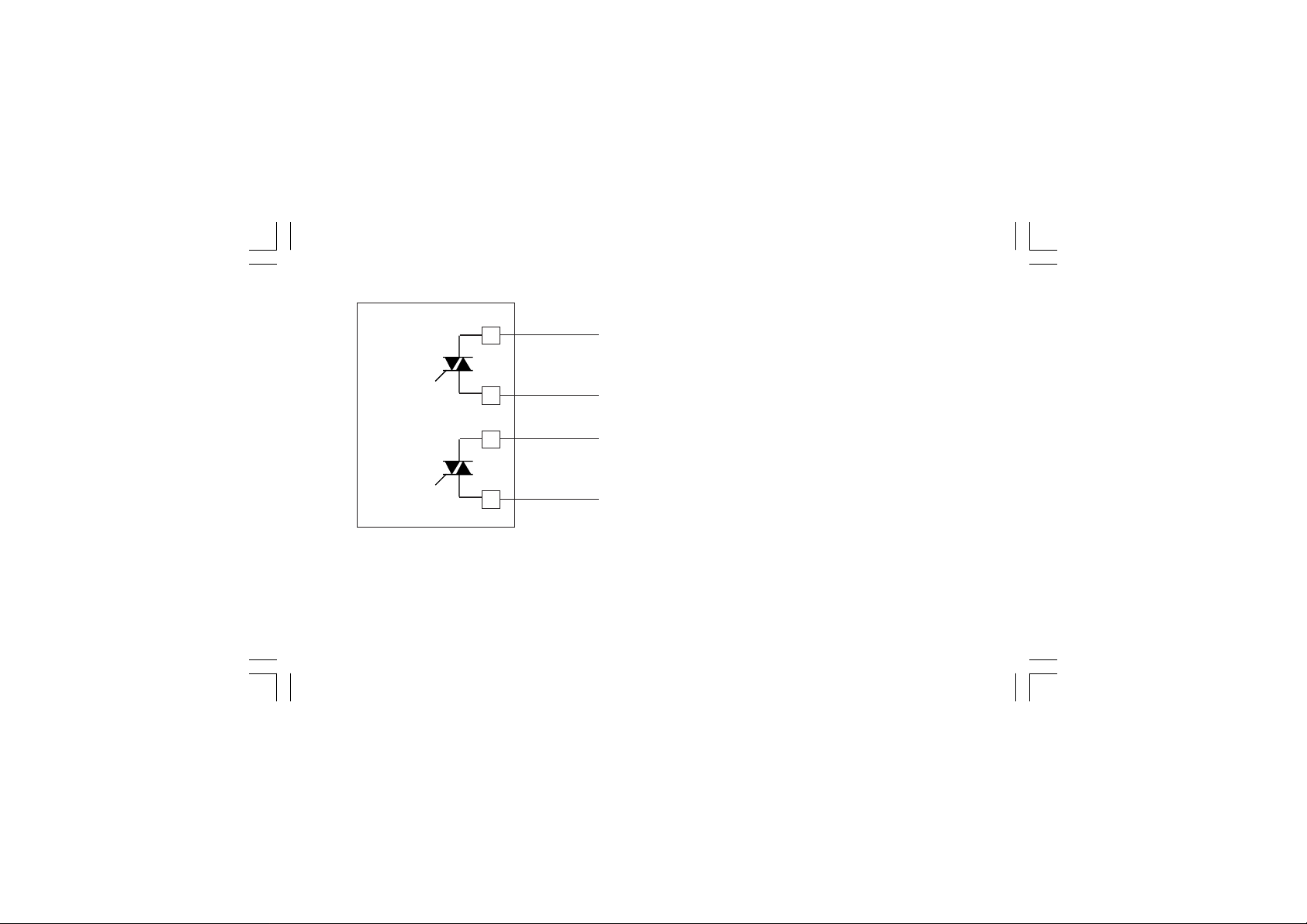

E.3) TRIAC OUTPUTSE.3) TRIAC OUTPUTS

E.3) TRIAC OUTPUTS

E.3) TRIAC OUTPUTSE.3) TRIAC OUTPUTS

OUT 1

24

23

Line

Load

NOTESNOTES

NOTES 1) To avoid electrical shock, connect power line at

NOTESNOTES

the end of the wiring procedure.

2) For power connections use No 16 AWG or larger wires

rated for at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

5) This output is not fuse protected. Please, provide it

externally using a fuse with a I2t equal to128.

27

OUT 2

26

Fig. 14 TRIAC OUTPUT WIRING

Switching modeSwitching mode

Switching mode: isolated zero crossing type.

Switching modeSwitching mode

Rated currentRated current

Rated current: from 50 mA to 1 A.

Rated currentRated current

Rated voltageRated voltage

Rated voltage: from 24 V

Rated voltageRated voltage

Load typeLoad type

Load type: resistive load only

Load typeLoad type

mkc-ssi.pmd 06/07/2004, 12.1913

to 240 V

RMS

RMS

Line

Load

-10 % +15 % (50/60Hz)

13

Page 18

E.4) SERVOMOTOR OUTPUTE.4) SERVOMOTOR OUTPUT

E.4) SERVOMOTOR OUTPUT

E.4) SERVOMOTOR OUTPUTE.4) SERVOMOTOR OUTPUT

(Open the valve)

29

30

31

Power

line

(Close the valve)

12

13

14

Fig. 15 SERVOMOTOR OUTPUT WIRING

mkc-ssi.pmd 06/07/2004, 12.1914

Servo-

motor

(Open)

(Close)

Shield

Feedback

potentiometer

The two relay output must be interlocked (see chapter

"Preliminary hardware setting" paragraph "Out 3 and 4

selection").

NOTESNOTES

NOTES:

NOTESNOTES

1) Before connecting the instrument to the power line, make sure

that line voltage and the load current are in accordance with the

contact rating (3A/250V AC on resistive load).

2) To avoid electric shock, connect power line at the end of the

wiring procedure.

3) For servomotor connections use No 16 AWG or larger wires rated

for at last 75 °C.

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) For feedback potentiometer, use shielded cable with the shield

connected to the earth at one point only.

7) The relay outputs are protected by varistor against inductive

load with inductive component up to 0.5 A.

14

Page 19

E.5) ANALOG OUTPUTSE.5) ANALOG OUTPUTS

E.5) ANALOG OUTPUTS

E.5) ANALOG OUTPUTSE.5) ANALOG OUTPUTS

+

16

OUT 5

_

17

+

16

OUT 5

_

17

Fig. 16.A OUTPUT 5 WIRING

mkc-ssi.pmd 06/07/2004, 12.1915

+

_

Shield

+

_

G

20 mA20 mA

+

OUT 6

18

_

19

+

_

Shield

OUT 6

18

19

+

_

+

_

G

Fig. 16.B OUTPUT 6 WIRING

NOTENOTE

NOTE:

NOTENOTE

1) Do not run analog output wirings together with AC power

cables.

2) Out 5 and 6 are isolated outputs.

3) The maximum load is equal to 600 Ω.

15

20 mA

20 mA

Page 20

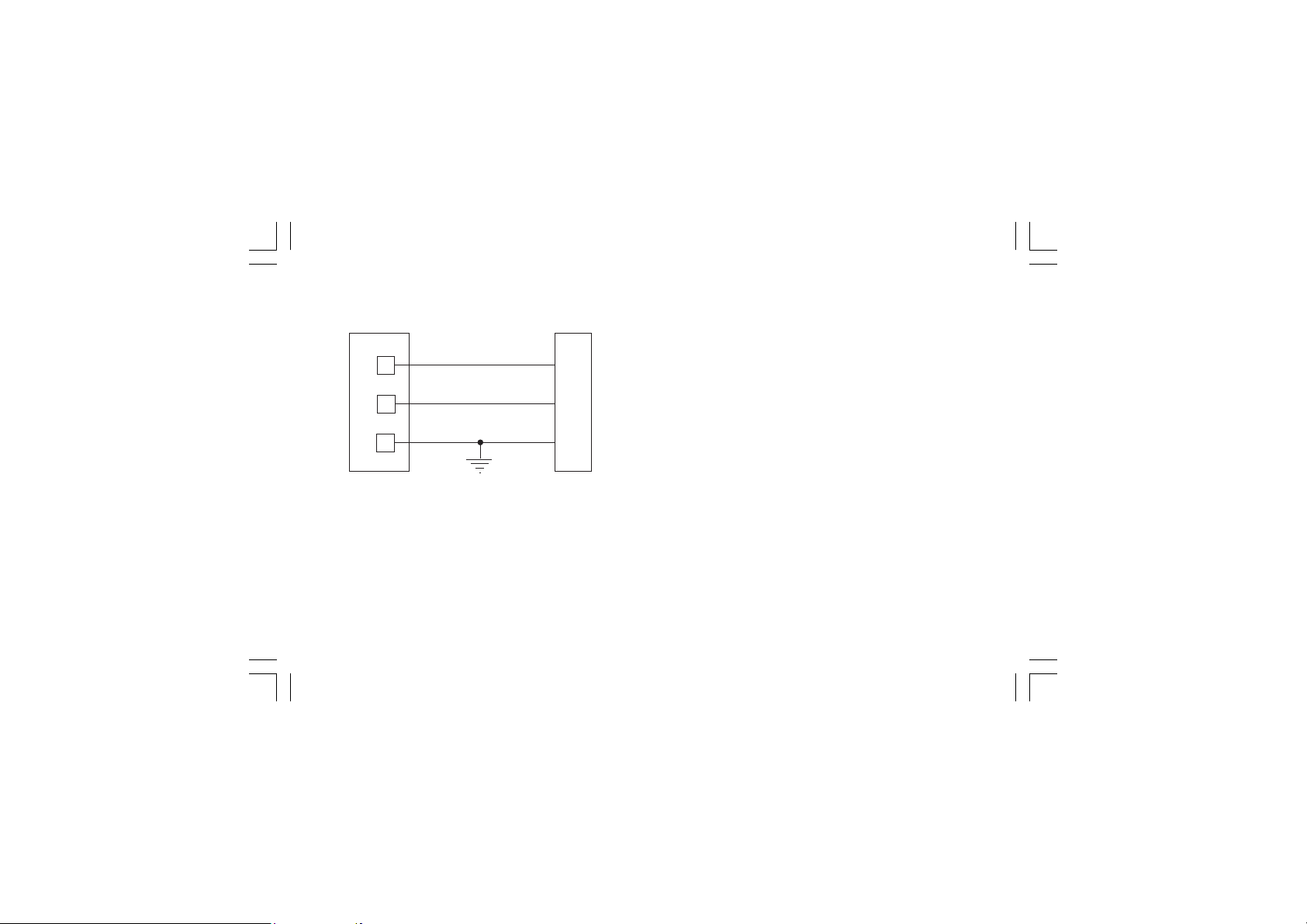

F) SERIAL INTERFACEF) SERIAL INTERFACE

F) SERIAL INTERFACE

F) SERIAL INTERFACEF) SERIAL INTERFACE

RS-485 interface allows you to connect up to 30 devices with

one remote master unit.

I

N

S

T

R

U

M

E

N

T

Fig. 17 - RS-485 WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) The cable length must not exceed 1.5 km at 9600 BAUD.

2) This serial interface is isolated.

3) The following report describes the signal sense of the voltage

appearing across the interconnection cable as defined by

EIA for RS-485.

a) The ” A ” terminal of the generator shall be negative with respect

to the ” B ” terminal for a binary 1 (MARK or OFF) state.

b) The ” A ” terminal of the generator shall be positive with respect

mkc-ssi.pmd 06/07/2004, 12.1916

22

21

20

A/A'

B/B'

COMMON

A'/A

B'/B

M

A

S

T

E

R

to the ” B ” terminal for a binary 0 (SPACE or ON).

4) The EIA standard establishes that by RS-485 interface it is possible

to connect up to 30 devices with one remote master unit.

The serial interface of these instruments is based on “High

input impedance” transceivers; this solution allows you to

connect up to 127 devices (based on the same transceiver

type) with one remote master unit.

16

Page 21

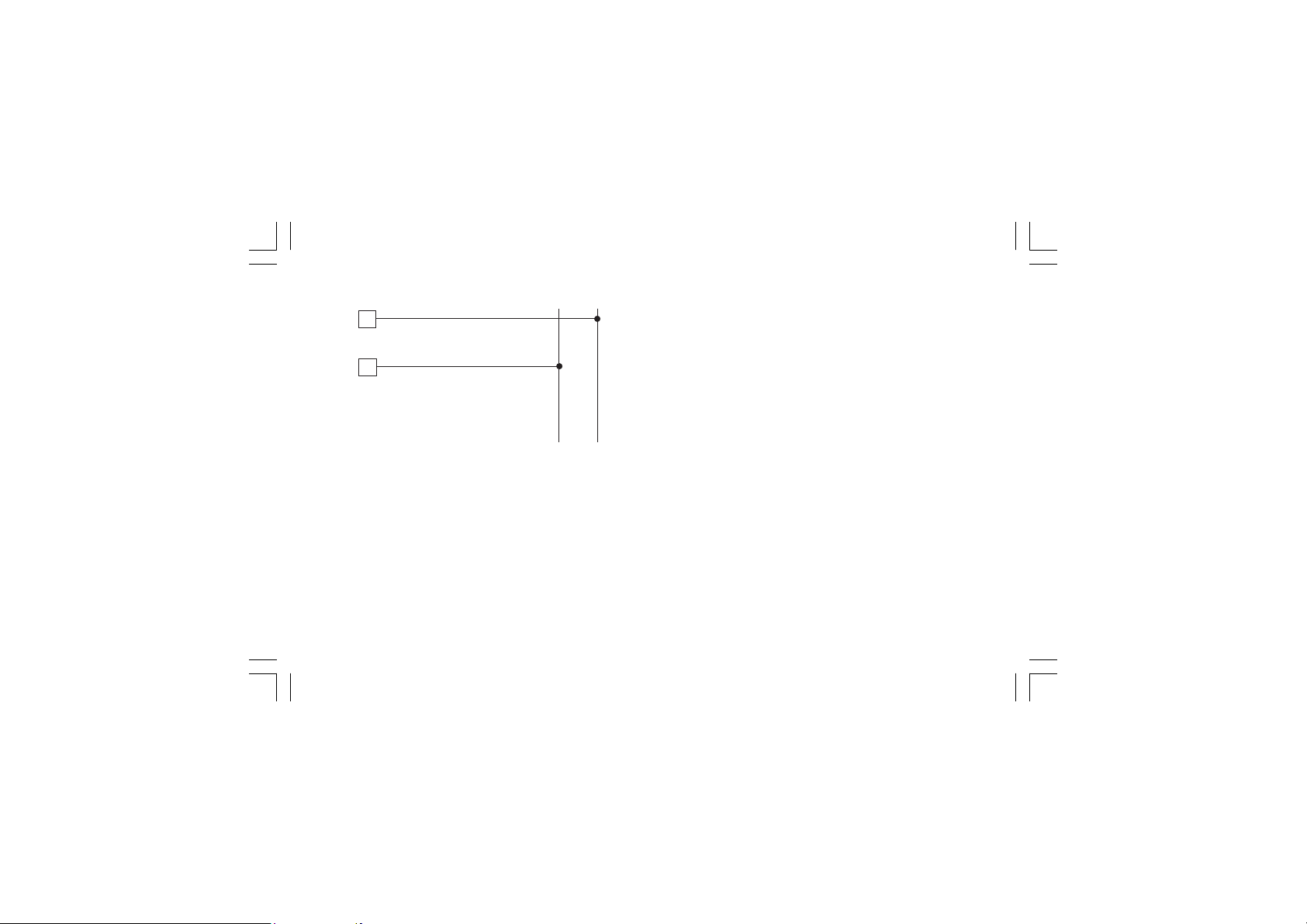

G) POWER LINE WIRINGG) POWER LINE WIRING

G) POWER LINE WIRING

G) POWER LINE WIRINGG) POWER LINE WIRING

N (L2)

32

POWER LINE 100 V to

240 V A.C (50/60Hz)

33

Fig. 18 POWER LINE WIRING

NOTESNOTES

NOTES:

NOTESNOTES

1) Before connecting the instrument to the power line, make sure

that line voltage corresponds to the description on the identification label.

2) To avoid electrical shock, connect power line at the end of the

wiring procedure.

3) For supply connections use No 16 AWG or larger wires rated for

at least 75 °C.

mkc-ssi.pmd 06/07/2004, 12.1917

or 24 V AC/DC

L (L1)

Line

Neutral

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) For 24 V DC the polarity is a not care condition.

7) The power supply input is fuse protected by a sub miniature fuse

rated T, 1A, 250 V.

When fuse is damaged, it is advisable to verify the power supply

circuit, so that it is necessary to send back the instrument to your

supplier.

8) The safety requirements for Permanently Connected

Equipment say:

- a switch or circuit-breaker shall be included in the building

installation;

- it shall be in close proximity to the equipment and within

easy reach of the operator;

- it shall be marked as the disconnecting device for the

equipment.

NOTENOTE

NOTE: a single switch or circuit-breaker can drive more than one

NOTENOTE

instrument.

9) When a neutral line is present please connect it to the 32 terminal.

17

Page 22

PRELIMINARY HARDWARE SETTINGSPRELIMINARY HARDWARE SETTINGS

PRELIMINARY HARDWARE SETTINGS

PRELIMINARY HARDWARE SETTINGSPRELIMINARY HARDWARE SETTINGS

How to remove the instrument from its caseHow to remove the instrument from its case

How to remove the instrument from its case

How to remove the instrument from its caseHow to remove the instrument from its case

1) Switch off the instrument.

2) Push gently the lock A on the right.

3) While the lock A is maintained out, slide out the right side of

the instrument (see fig. 19.a)

B

A

4) Push gently the lock C on the left.

5) While the lock C is maintained out, slide out the instrument

(see fig. 19.b)

D

C

D

Fig. 19.a

mkc-ssi.pmd 06/07/2004, 12.1918

B

Fig. 19.b

18

Page 23

MAIN INPUT SELECTIONMAIN INPUT SELECTION

MAIN INPUT SELECTION

MAIN INPUT SELECTIONMAIN INPUT SELECTION

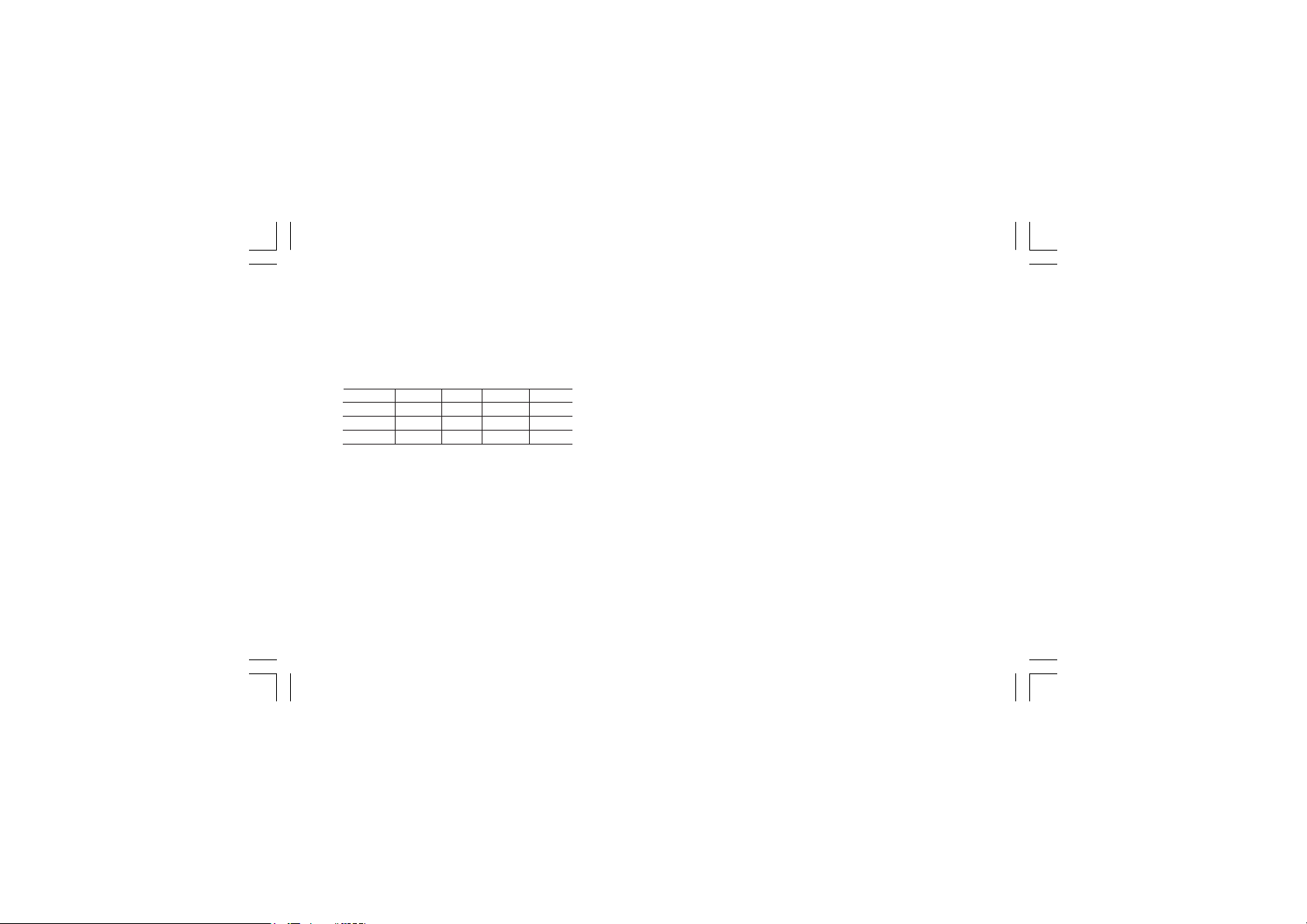

Set J103 (see fig. 20) according to the desired input type as

shown in the following table.

1 3 5 7

J102

2 4 6 8

1 3 5 7

J103

2 4 6 8

J205

ON DIP

Fig. 20

mkc-ssi.pmd 06/07/2004, 12.1919

V301

1 2 3 4

CPU

card

J103 INPUT TYPE

T/C, RTD 60 mV 5 V 10 V 20 mA

1-2 open open close open open

3-4 open open close close open

5-6 open open open open close

7-8 open open open open close

5-7 close close open close open

6-8 close close open open open

AUXILIARY INPUT SELECTION (option)AUXILIARY INPUT SELECTION (option)

AUXILIARY INPUT SELECTION (option)

AUXILIARY INPUT SELECTION (option)AUXILIARY INPUT SELECTION (option)

Set J102 (see fig. 20) according to the desired input type as

shown in the following table.

J102 INPUT TYPE

5 V 10 V 20 mA

1-2 close open open

3-4 close close open

5-6 open open close

7-8 open open close

5-7 open close open

6-8 open open open

19

Page 24

OUTPUT 3 AND 4 SELECTIONOUTPUT 3 AND 4 SELECTION

OUTPUT 3 AND 4 SELECTION

OUTPUT 3 AND 4 SELECTIONOUTPUT 3 AND 4 SELECTION

Output 3 and 4 can be set as:

- 2 independent relay outputs

- 1 servomotor output with interlocked contact.

Set J204 (see fig. 21) and J205 (see fig. 20) according to the

desired output type as shown in the following table.

J204

Fig.21

mkc-ssi.pmd 06/07/2004, 12.1920

Output J 204 J 205

Relay close open

Servo open close

NOTENOTE

NOTE: when the servomotor close loop or the servomotor open

NOTENOTE

loop with valve position indication outputs is required, it will be

necessary to set also V301 (see "IN CT/Feedback selection"

paragraph)

IN CT / FEEDBACK SELECTIONIN CT / FEEDBACK SELECTION

IN CT / FEEDBACK SELECTION

IN CT / FEEDBACK SELECTIONIN CT / FEEDBACK SELECTION

This instrument can use the "IN CT" input or the "Feedback"

input; the two inputs are not contemporarily.

The current transformer input allows you to measure and display

the current running in a load driven by a time proportional

control output during the ON and OFF periods of the output

cycle time. By this feature it is also available the "Out failure

detection" function (see page 111).

The feedback input is used when the servomotor close loop or

the servomotor open loop with valve position indication outputs is

required.

20

Page 25

To select the desired input type, set V301 (see fig. 20) as

detailed in the following table:

Input V301.1 V301.2 V301.3 V301.4

IN CT ON OFF ON ON

Feedback OFF ON OFF ON

OPTION CHECKOPTION CHECK

OPTION CHECK

OPTION CHECKOPTION CHECK

This instrument can be supplied with several options.

Two integrated circuits (KY101 and KY103), located as shown in

fig. 22 and inserted in a socket, give you the possibility to verify

if your instrument is equipped with the desired option.

When KY101 is present the auxiliary input and the digital inputs

are present.

When KY103 is present the auxiliary power supply option is

present.

mkc-ssi.pmd 06/07/2004, 12.1921

ON DIP

KY101

KY103

1 2 3 4

V101

Fig. 22

21

Page 26

Operative mode and Hardware lockOperative mode and Hardware lock

Operative mode and Hardware lock

Operative mode and Hardware lockOperative mode and Hardware lock

By V101 (see fig 22) it is possible to select one of the following

operative modes:

a) run time mode without configuration mode

b) run time and configuration modes

c) security code setting mode

Set V101 according to the following table:

Modes V101.1 V101.2 V101.3 V101.4

a OFF ON ON ON

b OFF ON OFF ON

c OFF ON OFF OFF

All the others switch combinations are reserved.

mkc-ssi.pmd 06/07/2004, 12.1922

SECURITY CODE SETTING MODESECURITY CODE SETTING MODE

SECURITY CODE SETTING MODE

SECURITY CODE SETTING MODESECURITY CODE SETTING MODE

General notesGeneral notes

General notes

General notesGeneral notes

The instrument parameters are divided in two families and each

family is divided in groups.

- The first family encompasses all the run time parameters.

- The second family comprises all the configuration parameters.

A specific security code enables the parameter modification of

each family.

For run time parameters, it is possible to select which groups of

them will be protected by the security code and in this case, it is

necessary to set the run time security code before to modify one

or more parameters of a protected group.

The configuration security code protects all configuration

parameters and it will be necessary to set the configuration

security code before to start the configuration parameters

modification.

For configuration parameters an hardware lock is also available.

22

Page 27

Security code settingSecurity code setting

Security code setting:

Security code settingSecurity code setting

1) Remove the instrument from its case.

2) Set the internal dip switch V101 as follows:

- V101.1 = OFF - V101.2 = ON

- V101.3 = OFF - V101.4 = OFF

3) Re-insert the instrument.

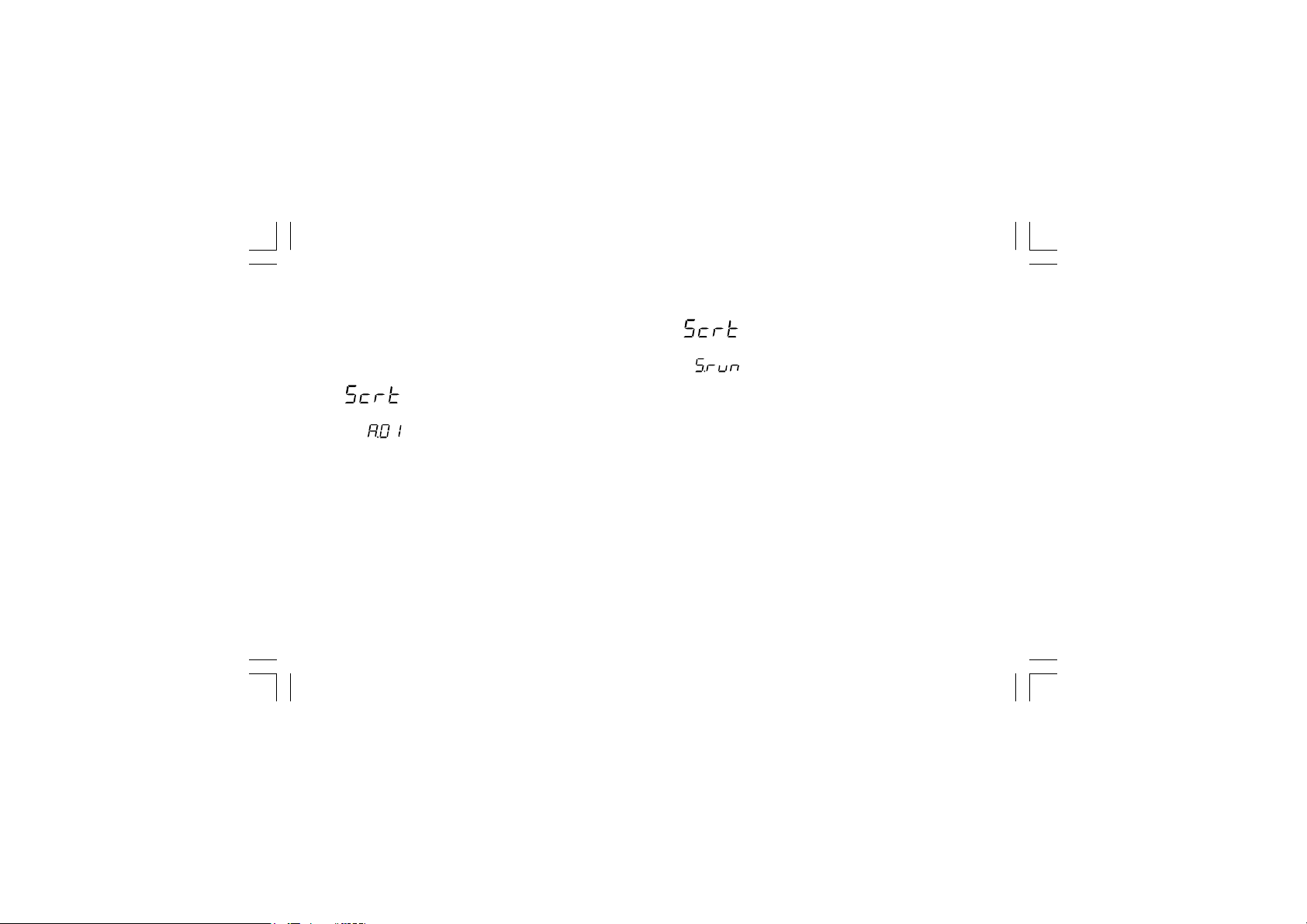

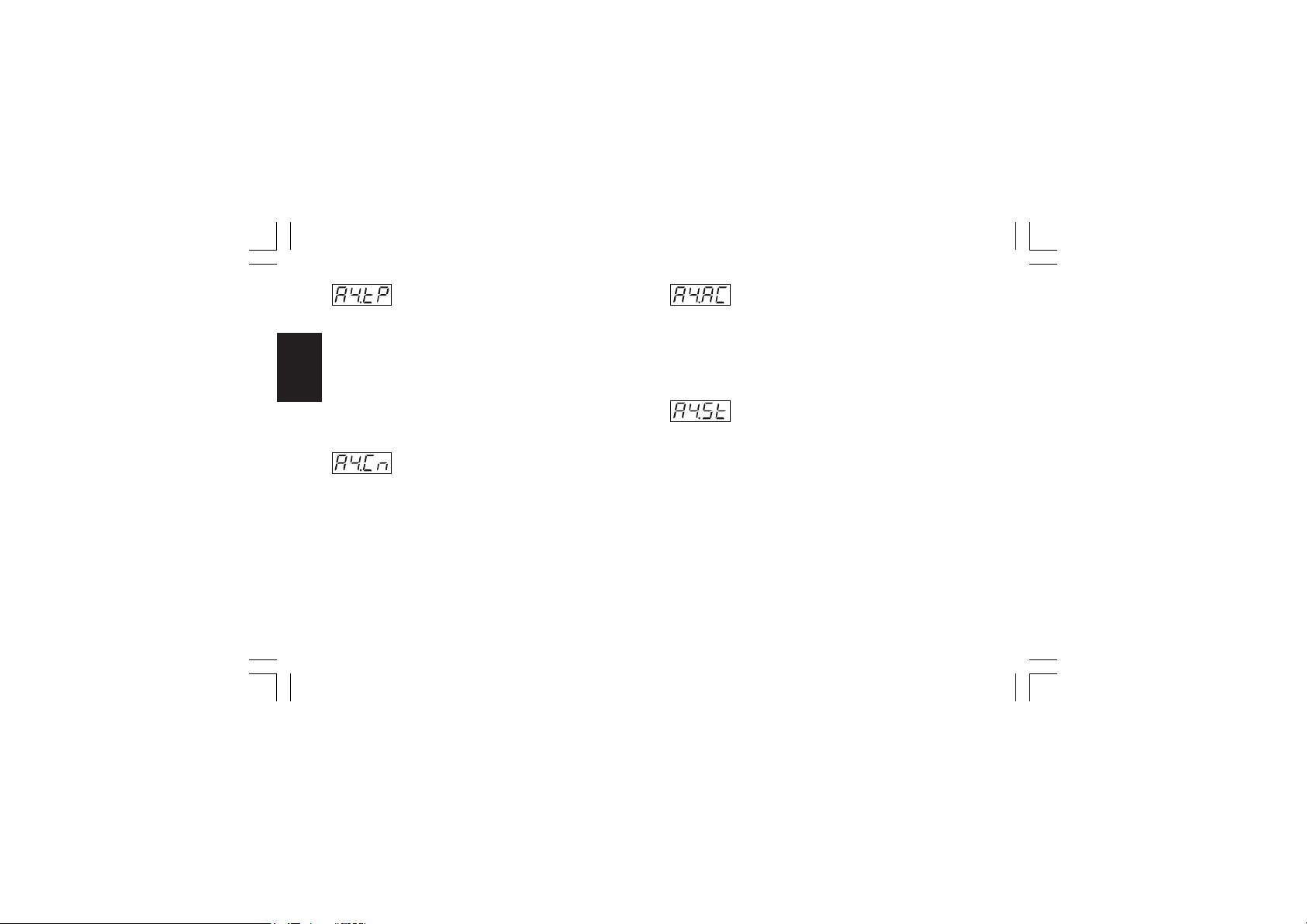

4) Switch on the instrument. The display will show:

The upper display shows that the security code setting mode

is selected while the lower display shows the firmware version.

5) Push the FUNC pushbutton.

mkc-ssi.pmd 06/07/2004, 12.1923

Run time security codeRun time security code

Run time security code

Run time security codeRun time security code

The display will show:

NoteNote

Note: the middle display shows the current status of the run

NoteNote

time security code ("0", "1" or "On").

By and push-button, set "S.run" parameter as follows:

0 No protection (it is ever possible to modify all run time

parameters);

1 ever protected (it is never possible to modify a run time

parameter);

from 2 to 250 security code for run time parameter protection.

NOTESNOTES

NOTES:

NOTESNOTES

1) The selected value of a security code cannot be displayed anymore

and, coming back to the "S.run" parameter, the display will show

:

- "On" when "S.run" is different from 0 or 1

- "0" when "S.run" is equal to 0

- "1" when "S.run" is equal to 1.

When the security code is forgotten, a new value can be set.

2) When "S.run" is different from 0 or 1, the "run time default "

and the "run time hidden" groups are ever protected by security

code.

23

Page 28

Run time groups protected by security codeRun time groups protected by security code

Run time groups protected by security code

Run time groups protected by security codeRun time groups protected by security code

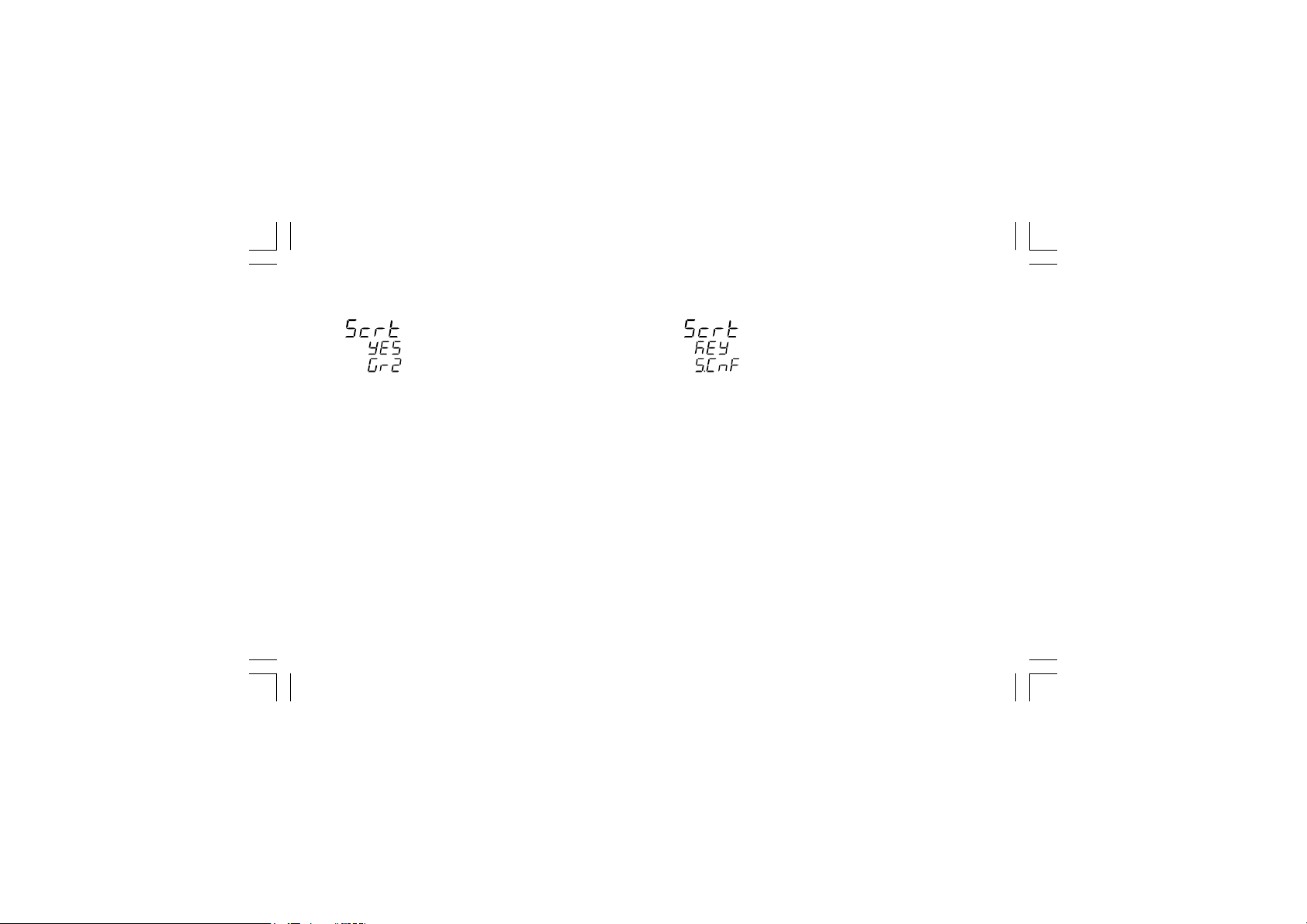

The display will show:

Configuration security codeConfiguration security code

Configuration security code

Configuration security codeConfiguration security code

The display will show:

By this parameter it is possible to set if the run time group 2 will

be protected or not by the run time security code.

By and push-button, set "Gr2" parameter as follows:

nO No protection (it is always possible to modify run time

group 2 parameters)

Yes the run time group 1 parameter modification will be

protected by security code.

Push the FUNC push-button; the instrument memorizes the new

setting and goes to the next parameter.

NOTESNOTES

NOTES:1) This selection may be carried out only if a run

NOTESNOTES

time security code has been set (from 2 to 250).

2) The above described selection may be repeated for all

groups of the run time mode.

mkc-ssi.pmd 06/07/2004, 12.1924

NoteNote

Note: the middle display shows the current status of the

NoteNote

configuration security code ("0", "1" or "On").

By and push-button, set "S.CnF" parameter as follows:

0 No protection (it is ever possible to modify all

configuration parameters);

1 ever protected (it is never possible to modify a

configuration parameter);

from 2 to 250 security code for configuration parameter

protection.

NOTENOTE

NOTE: the selected value of a security code cannot be

NOTENOTE

displayed anymore and, coming back on the "S.CnF"

parameter, the display will show "On" when "S.CnF" is

different from 0 or 1, "0" when "S.CnF" is equal to 0, "1"

when "S.CnF" is equal to 1.

When the security code is forgotten, a new value can

be set.

24

Page 29

NOTENOTE

NOTE: at the end of the security code setting procedure, set

NOTENOTE

V101 according to the desired operative mode (see

"Operative mode and hardware lock" paragraph).

mkc-ssi.pmd 06/07/2004, 12.1925

RUN TIME AND CONFIGURATION MODESRUN TIME AND CONFIGURATION MODES

RUN TIME AND CONFIGURATION MODES

RUN TIME AND CONFIGURATION MODESRUN TIME AND CONFIGURATION MODES

The hardware selection described in "Operative mode and

hardware lock" paragraph allows you to start one of the following

operative modes:

- configuration mode.

- run time mode

The run time mode can be divided as follows:

- Run time mode as controller

- Run time mode as programmer

At power up, the instrument starts in the same mode (configuration or run time) it was prior to the power OFF.

General note about graphic symbols used forGeneral note about graphic symbols used for

General note about graphic symbols used for

General note about graphic symbols used forGeneral note about graphic symbols used for

mnemonic code visualization.mnemonic code visualization.

mnemonic code visualization.

mnemonic code visualization.mnemonic code visualization.

The instrument displays some characters with special symbols.

The following table shows the correspondence between the

symbols and the characters

symbol character symbol character

"

"k ""W

"m ""Z

"

" "V ""J

25

Page 30

Keyboard descriptionKeyboard description

Keyboard description

Keyboard descriptionKeyboard description

MENU = is used to select a parameter group

FUNC = when the instrument is in "normal display mode" it

changes the indication on the lower display (see

"display function").

During parameter modification, it allows you to

memorize the new value of the selected parameter

and go to the next parameter (increasing order).

MAN = when the instrument is in "normal display mode",

pushing MAN push-button for more than 1 s, it is

possible to enable or disable the manual function.

During parameter modification, it allows you to scroll

back the parameters and groups without memorizing

the new setting.

= During parameter modification, it allows you to

increase the value of the selected parameter

During MANUAL mode, it allows you to increase the

output value.

mkc-ssi.pmd 06/07/2004, 12.1926

= During parameter modification, it allows you to

decrease the value of the selected parameter

During MANUAL mode, it allows to decrease the

output value.

RSP = allows to toggle from Local set point to Remote set

point or viceversa when depressed for more than 1

sec.

+MENU= are used to start the lamp test function (the

command is accepted when push-button are kept

depressed for more than 5 s and device is in normal

display mode)

+FUNC or +FUNC

During parameter modification they allow you to

increase/decrease the value under modification with

higher rate.

+MAN or +MAN

During parameter modification they allow you to

jump to the max or min programmable value.

26

Page 31

NOTESNOTES

NOTES:

NOTESNOTES

1) All the actions explained above which requires two or more

push-buttons must follow exactly the push-button sequence

shown.

2) A 10 or 30 seconds time out (see "t.out" [C.I10]) can be

selected for parameter modification during run time mode.

If, during parameter modification, no push-button is depressed

for more than 10 (30) seconds, the instrument goes

automatically to the “normal display mode” and the eventual

modification of the last parameter will be lost.

mkc-ssi.pmd 06/07/2004, 12.1927

CONFIGURATION MODECONFIGURATION MODE

CONFIGURATION MODE

CONFIGURATION MODECONFIGURATION MODE

Switch on the instrument.

The instrument will start in the same way it was prior to the

power down (configuration mode or run time mode)

If the instrument starts in configuration mode, push the MENU

pushbutton and go to the "Configuration group 1" (see page 31).

If the instrument starts in run time mode, by keeping depressed

the MENU push-button for more than 5 seconds the instrument

will show:

NOTESNOTES

NOTES:

NOTESNOTES

1) The upper display shows the selected parameter family.

2) The middle display shows the selected action.

3) The lower display shows the firmware version.

4) If no push-button is depressed for more than 10 s (or 30 s

according to "CnF.6" "t.out" [time out selection" C.I10]

parameter setting), the instrument returns automatically to the

normal display mode.

27

Page 32

By or push-button it is possible to select between:

= (monitor) this selection allows you to monitor but

not to modify the value assigned to the configuration parameters

= (modify) this selection allows you to monitor and to

modify the value assigned to the configuration

parameters.

NOTESNOTES

NOTES:

NOTESNOTES

1) During monitor mode, the instrument continues to operate as

in run time mode.

2) When modify mode is started, the instrument stops the control

and:

- sets to OFF the control outputs;

- turns to OFF the bargraph displays (25Q only);

- sets analog retransmissions to the retransmitted initial scale

value;

- sets alarms in no alarm condition;

- sets to OFF the events;

- disables the serial link;

- the time out will be removed.

3) When the modify mode is disabled by V101 (V101.3), the or

push-button pressure has no effect.

mkc-ssi.pmd 06/07/2004, 12.1928

MONITOR MODEMONITOR MODE

MONITOR MODE

MONITOR MODEMONITOR MODE

During the run time mode, it is possible to monitor but not modify

all configuration parameters.

When it is desired to verify the instrument configuration, proceed

as follows:

1) Push the MENU push-button for more than 5 seconds: the

display will show:

.

2) Push the MENU push-button the display will show:

it shows that configuration group 1 is selected and it

encompasses all the input parameters.

The configuration parameter "Monitor mode" follows the "Modify

mode" sequence.

28

Page 33

NOTESNOTES

NOTES:

NOTESNOTES

1) During monitor mode, the instrument continues to operate as

in run time mode.

2) During monitor mode, if no push-button is depressed for more

than 10 s (or 30 s according to "t.out" [C.I10] parameter

setting), the instrument returns automatically to the normal

display mode.

mkc-ssi.pmd 06/07/2004, 12.1929

MODIFY MODEMODIFY MODE

MODIFY MODE

MODIFY MODEMODIFY MODE

1) By or push-button select the modify mode.

2) Push the MENU push-button.

If a security code is applied to the configuration parameter,

the instrument will show:

3) By and push-button set a value equal to the security

code assigned to the configuration mode (see "Configuration

security code " at page 25).

If the code is different from the security code, the instrument

automatically returns to the first configuration display

otherwise the display will show:

The modify mode is started.

This display allows you to load the default configuration

parameter.

For more details see chapter "Default parameter" (see

Appendix A).

29

Page 34

4) By or push-button select the OFF indication and push

the MENU push-button.

The display will show:

visualizations is enclosed.

The group (column) of configuration parameters are identified

by the "C" letter followed by A, b, etc.

The "code" formed by the column and row (example [C.d03]) is

reported, in the user manual, before each parameter

description and allows you to quickly find out the respective

parameter.

This is the starting display of the first group of configuration

parameters.

NOTESNOTES

NOTES:

NOTESNOTES

1) In the following pages we will describe all the parameters.

The instrument, however, will show only the parameters

related to the specific hardware and in accordance with the

specific instrument configuration (i.e. setting OUT 3 different

from servo, all the parameters related to servomotor output

will be skipped).

2) During configuration parameters modify mode, the upper

display shows the selected parameter group, the lower display

shows the mnemonic code of the selected parameter while

the central display shows the value or status assigned to the

selected parameter.

3) For an easy consultation of this manual, a sheet named

"Reference parameter guide" with all the parameter

mkc-ssi.pmd 06/07/2004, 12.1930

When it is desired to exit from configuration modify mode proceed

as follows:

a) Push "MENU" push-button until the "Configuration group END is

displayed.

b) Pushing ”” or “” push-button select the "YES" indication.

c) Push “MENU” push-button. The instrument terminates the

configuration modify mode, it preforms an automatic reset and

restarts in the run time mode.

30

Page 35

CONFIGURATION GROUP 1 [C.dxx]CONFIGURATION GROUP 1 [C.dxx]

CONFIGURATION GROUP 1 [C.dxx]

CONFIGURATION GROUP 1 [C.dxx]CONFIGURATION GROUP 1 [C.dxx]

MAIN AND AUXILIARY INPUT CONFIGURATION

Push the FUNC push-button

- Line frequency - [C.d01]- Line frequency - [C.d01]

- Line frequency - [C.d01]

- Line frequency - [C.d01]- Line frequency - [C.d01]

Range: 50 Hz

60 Hz

- Main input type and range - [C.d02] - Main input type and range - [C.d02]

- Main input type and range - [C.d02]

- Main input type and range - [C.d02] - Main input type and range - [C.d02]

Ranges:

* 1= TC L From -100 to 900 °C

* 2= TC J From -100 to 1000 °C

* 3= TC K From -100 to 1370 °C

* 4= TC T From -200 to 400 °C

* 5= TC U From -200 to 600 °C

* 6= TC E From -100 to 800 °C

mkc-ssi.pmd 06/07/2004, 12.1931

7 = TC N From -100 to 1400 °C

8 = TC S From - 50 to 176 0 °C

9 = TC R From - 50 to 1760 °C

10 = TC B From 0 to 1820 °C

11= TC G (or W) From 0 to 2300 °C

12 = TC D (or W3) From 0 to 2300 °C

13= TC C (or W5) From 0 to 2300 °C

14 = TC Ni-Ni18%Mo From 0 to 1100 °C

* 15= RTD Pt100 From -200 to 850 °C

16 = T C L From -150 to 1650 °F

17 = T C J From -150 to 1830 °F

18 = T C K From -150 to 2500 °F

19 = TC T From -330 to 750 °F

20 = TC U From -330 to 1110 °F

21 = TC E From -150 to 1470 °F

22 = TC N From -150 to 2550 °F

23 = TC S From - 60 to 3200 °F

24 = TC R From - 60 to 3200 °F

25 = TC B From 32 to 3300 °F

26 = TC G ( or W) From 0 to 4170 °F

27 = TC D (or W3) From 0 to 4170 °F

28= TC C (or W5) From 0 to 4170 °F

29 = TC Ni-Ni18%Mo From 0 to 2000 °F

* 30= RTD Pt100 From -330 to 1560 °F

31= Linear From 0 to 20 mA

32= Linear From 4 to 20 mA

31

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

Page 36

33= Linear From 0 to 5 V

34= Linear From 1 to 5 V

35= Linear From 0 to 10 V

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

36= Linear From 2 to 10 V

37= Linear From 0 to 60 mV

38= Linear From 12 to 60 mV

* For these ranges it is possible to select a read-out with one

decimal figure but the instrument could not display a measure

lower than -199.9 or higher than 999.9 and the input range

will be limited by it.

NOTESNOTES

NOTES:

NOTESNOTES

1) When a linear input is selected, the instrument set automatically the "readout initial scale value" [C.d05] equal to 0 and

the "readout final scale value" [C.d06] equal to 4000

2) When input type has been changed, the instrument

automatically forces:

- the "ñ.In.L" [C.d05], "SS.th" [C.I09] and "brG.L" [C.I03]

parameters to the new initial scale value,

- the "ñ.In.H" [C.d06] and "brG.H" [C.I04] parameter to the new

final scale value and

- the "ñ.In.d" [C.d03] parameter to "no decimal figure".

mkc-ssi.pmd 06/07/2004, 12.1932

- Decimal point position - [C.d03]- Decimal point position - [C.d03]

- Decimal point position - [C.d03]

- Decimal point position - [C.d03]- Decimal point position - [C.d03]

----. = no decimal figure

Ranges:

---.- = one decimal figure

--.-- = two decimal figures

-.--- = three decimal figures

NOTESNOTES

NOTES:

NOTESNOTES

1) For main input type 1 to 6, 15 and 30 only the "no decimal

figure" and "one decimal figure" are selectable, the input

range is limited within -199.9 and 999.9 and it acts as an

input type changement.

2) For main input type 7 to 14 and 16 to 29 this parameter is not

available.

3) For linear input types (from 31 to 38) all positions are available.

- Square root extraction for main input- Square root extraction for main input

- Square root extraction for main input

- Square root extraction for main input- Square root extraction for main input

- [C.d04]- [C.d04]

- [C.d04]

- [C.d04]- [C.d04]

Ranges: dIS = square root extraction disabled

Enb = square root extraction enabled

NOTESNOTES

NOTES:

NOTESNOTES

1) This parameter is available only for main input type 31 to 38.

32

Page 37

2) When the square root extraction is enabled the "ñ.In.L" (readout - initial scale value [C.d05]), "ñ.In.H" (read-out - full scale

value [C.d06]), "brG.L" (bargraph - initial scale value [C.I03]),

"brG.H" (bargraph - full scale value [C.I04]) and "SS.th"

(threshold to enable the soft start [C.I09]) parameter values

must be positive or equal to zero.

Enabling the square root extraction the instrument verify the

actual value of the "ñ.In.L", "ñ.In.H", "brG.L", "brG.H" and

"SS.th" parameters and force to zero the eventual negative

values.

Read-out- initial scale value - [C.d05]Read-out- initial scale value - [C.d05]

-

Read-out- initial scale value - [C.d05]

Read-out- initial scale value - [C.d05]Read-out- initial scale value - [C.d05]

Ranges: - from -1999 to 9999 for linear input (Input range 31 to

38),

- from 0 to 9999 for linear input with square root

extraction,

- from initial range value to "ñ.In.H" (read-out- full scale

value C.d06]) for TC/RTD input

NOTENOTE

NOTE: Changing the value of this parameter, the "brG.L"

NOTENOTE

(bargraph - initial scale value [C.I03]) and "rL" (set point low limit

[r.E12]) parameters will be realigned to it.

If a linear input is selected, also the “SS.th” (threshold for soft

start [C.I09]) will be realigned to it.

mkc-ssi.pmd 06/07/2004, 12.1933

- Read-out- full scale value - [C.d06]- Read-out- full scale value - [C.d06]

- Read-out- full scale value - [C.d06]

- Read-out- full scale value - [C.d06]- Read-out- full scale value - [C.d06]

Ranges: - from -1999 to 9999 for linear input (Input range 31 to

38),

- from 0 to 9999 for linear input with square root

extraction,

- from "ñ.In.L" (read-out- initial scale value [C.d05]) to full

range value for TC/RTD input.

NOTESNOTES

NOTES:

NOTESNOTES

1) Changing the value of this parameter, the "brG.H" (bargraph full scale value [C.I04]) and "rH" (set point high limit [r.E13])

parameters will be realigned to it.

2) The programmed input span, in absolute value, must be

greater than:

300 °C or 550 °F for TC inputs

100°C or 200 °F for RTD inputs

100 digits for linear inputs.

33

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

Page 38

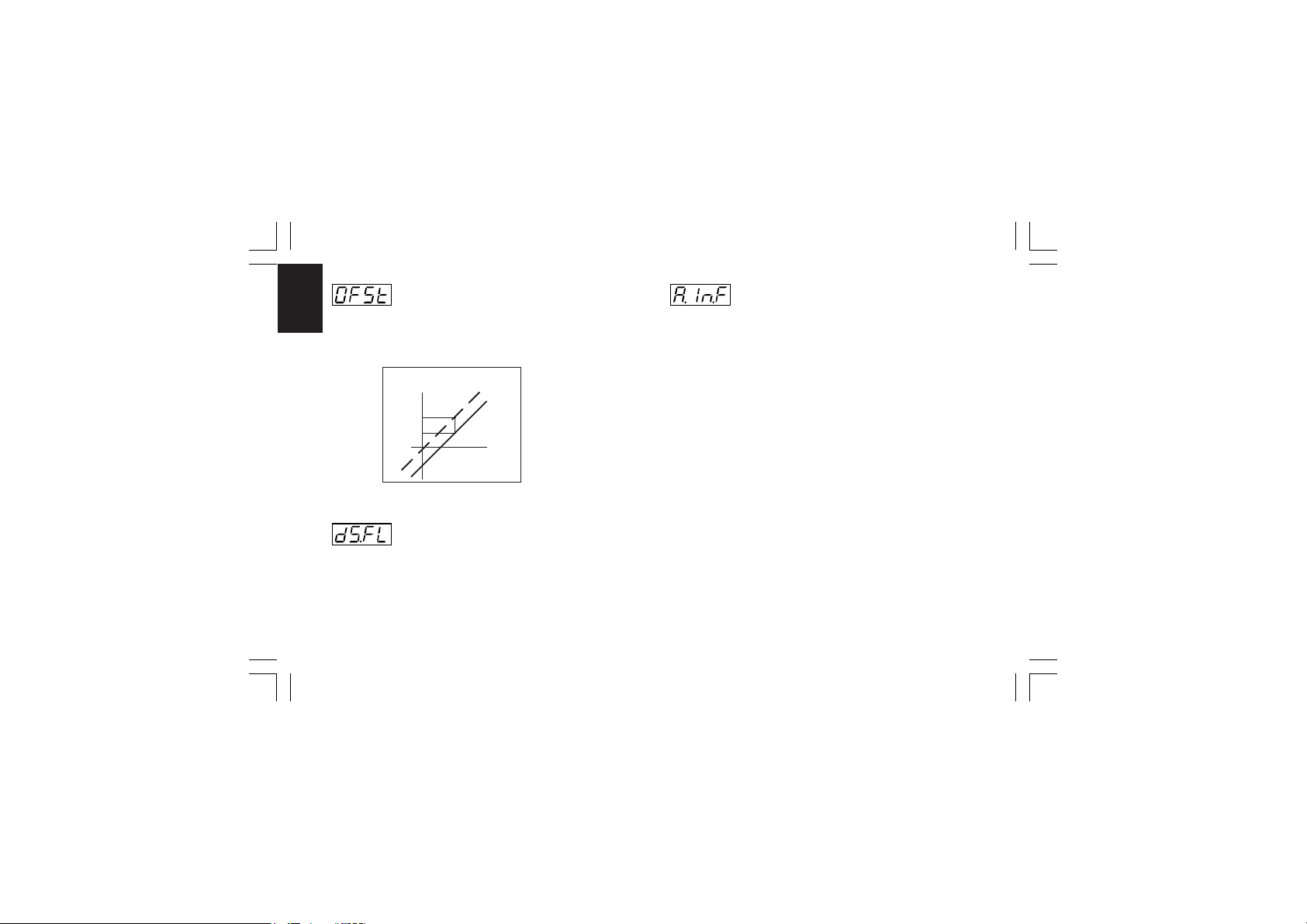

- Offset on the main input - [C.d07]- Offset on the main input - [C.d07]

- Offset on the main input - [C.d07]

- Offset on the main input - [C.d07]- Offset on the main input - [C.d07]

Ranges: from -500 to 500.

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

NOTENOTE

NOTE: the decimal point will be automatically positioned as

NOTENOTE

selected for the main input.

Read-out

OFSt

Real curve

Adjusted

curve

Input

- Filter on the displayed value - [C.d08]- Filter on the displayed value - [C.d08]

- Filter on the displayed value - [C.d08]

- Filter on the displayed value - [C.d08]- Filter on the displayed value - [C.d08]

Ranges: from 0 (no filter) to 8 seconds.

NOTENOTE

NOTE: this is a first order digital filter applied to the read-out of

NOTENOTE

the main input.

mkc-ssi.pmd 06/07/2004, 12.1934

- Auxiliary input function - [C.d09]- Auxiliary input function - [C.d09]

- Auxiliary input function - [C.d09]

- Auxiliary input function - [C.d09]- Auxiliary input function - [C.d09]

Range: nonE = Input not used

rSP = Input used as remote set point input

bIAS = Input used as bias for local set point

NOTESNOTES

NOTES:

NOTESNOTES

1) When auxiliary input option is not mounted the middle display

will show “no.Pr” (not present).

2) The parameter “L.r.O.ñ” [C.d16] will be forced to “n.ALG” if

“A.In.F” [C.d09]= “bIAS” and “A.I.Añ” [C.d14]= “Cnd.A”.

3) When "bIAS" is selected, the instrument uses as operative set

point the sum of the local set point with the value measured

by the auxiliary input scaled by "A.In.L" [C.D11] and "A.In.H"

[C.d12] parameters.

34

Page 39

- Auxiliary input type- Auxiliary input type

- Auxiliary input type

- Auxiliary input type- Auxiliary input type

- [C.d10]- [C.d10]

- [C.d10]

- [C.d10]- [C.d10]

This parameter will be skipped when the auxiliary input option is

not mounted or "A.In.F" (auxiliary input function [C.d09]) is equal

to "nonE".

Range: 0-20 = 0−20 mA

4-20 = 4−20 mA

0- 5 = 0− 5 V

1- 5 = 1− 5 V

0-10 = 0−10 V

2-10 = 2−10 V

- Initial scale read-out of the auxiliary- Initial scale read-out of the auxiliary

- Initial scale read-out of the auxiliary

- Initial scale read-out of the auxiliary- Initial scale read-out of the auxiliary

inputinput

input

This parameter is available only when auxiliary input is configured

inputinput

- [C.d11]- [C.d11]

- [C.d11]

- [C.d11]- [C.d11]

Range: from -1999 to 9999

NOTENOTE

NOTE: the decimal point will be automatically positioned as

NOTENOTE

selected for the main input.

mkc-ssi.pmd 06/07/2004, 12.1935

- Full scale read-out of the auxiliary- Full scale read-out of the auxiliary

- Full scale read-out of the auxiliary

- Full scale read-out of the auxiliary- Full scale read-out of the auxiliary

inputinput

input

inputinput

- [C.d12]- [C.d12]

- [C.d12]

- [C.d12]- [C.d12]

This parameter is available only when auxiliary input is configured

Range: from -1999 to 9999

NOTENOTE

NOTE: the decimal point will be automatically positioned as

NOTENOTE

selected for the main input.

- Filter on auxiliary input - [C.d13]- Filter on auxiliary input - [C.d13]

- Filter on auxiliary input - [C.d13]

- Filter on auxiliary input - [C.d13]- Filter on auxiliary input - [C.d13]

This parameter is available only when auxiliary input is configured

Ranges: from 0 (no filter) to 8 seconds.

NOTENOTE

NOTE: this is a first order digital filter applied to the measured

NOTENOTE

value made by the auxiliary input.

- Auxiliary input activation mode -- Auxiliary input activation mode -

- Auxiliary input activation mode -

- Auxiliary input activation mode -- Auxiliary input activation mode [C.d14][C.d14]

[C.d14]

[C.d14][C.d14]

This parameter is available only when auxiliary input is configured

Range: norñ =The auxiliary input activation is controlled by

external contact, front key or serial link

Cnd.A= The auxiliary input activation is controlled by its

status (The device works with local set point

when auxiliary input is out of range, while it

works with remote set point (or bias) when it is

35

within range)

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

Page 40

NOTENOTE

NOTE: The parameter “L.r.O.ñ” (local/remote set point operative

NOTENOTE

mode [C.d16]) will be forced to “n.ALG” if “A.In.F” (auxiliary input

function [C.d09]) is equal to “bIAS” and “A.I.Añ” (auxiliary input

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

activation mode [C.d14]) is equal to “Cnd.A”.

- Auxiliary input safety condition -- Auxiliary input safety condition -

- Auxiliary input safety condition -

- Auxiliary input safety condition -- Auxiliary input safety condition [C.d15][C.d15]

[C.d15]

[C.d15][C.d15]

This parameter is available only when auxiliary input is configured

and "A.i.Añ" [C.d14] is equal to "norñ".

Range: nonE = when the auxiliary input is out of range, the

instrument operates as in presence of the min or

max auxiliary input value.

Cnd.A = when the auxiliary input is out of range, the

control output goes to safety value “SF.UL”

(output safety value [C.G08]).

If servomotor open loop control drive is

configured the “Safety value” "SF.UL" [C.G08]

has no effect and the instrument operates in

accordance with “SF.Cn” (Output safety

condition [C.G07]) parameter setting.

NOTE: NOTE:

NOTE: The “SF.Cn” (Output safety condition” [C.G07]) has the

NOTE: NOTE:

priority on “A.I.Sc” (auxiliary input safety condition [C.d15]).

mkc-ssi.pmd 06/07/2004, 12.1936

- Local/remote set point operative mode- Local/remote set point operative mode

- Local/remote set point operative mode

- Local/remote set point operative mode- Local/remote set point operative mode

- [C.d16]- [C.d16]

- [C.d16]

- [C.d16]- [C.d16]

This parameter is available only when auxiliary input is configured

Range: ALG = when the transfer from remote to local set point

is performed, the local set point value will be

aligned to last remote set point value.

n.ALG = when the transfer from remote to local set point

is performed, the local set point value will not

be changed (The programmed ramps Grd1

[r.E14] and Grd2 [r.E15] may be activated).

NOTESNOTES

NOTES:

NOTESNOTES

1) The selected local set point will be changed even if it is

software protected.

2) The parameter is forced to “n.ALG” if “A.In.F” (auxiliary input

function [C.d09]) is equal to “bIAS” and “A.I.Añ” (auxiliary input

activation mode [C.d14]) is equal to “Cnd.A”

General note on configuration group 1General note on configuration group 1

General note on configuration group 1

General note on configuration group 1General note on configuration group 1

Exiting from the configuration group 1 the instrument verifies

automatically the programmed span for the linear input.

If it is wrong, the device will show:

36

Page 41

CONFIGURATION GROUP 2 [C.Exx]CONFIGURATION GROUP 2 [C.Exx]

CONFIGURATION GROUP 2 [C.Exx]

CONFIGURATION GROUP 2 [C.Exx]CONFIGURATION GROUP 2 [C.Exx]

OUTPUTS CONFIGURATION

- OUT 1 function - [C.E01]- OUT 1 function - [C.E01]

- OUT 1 function - [C.E01]

- OUT 1 function - [C.E01]- OUT 1 function - [C.E01]

Range: nonE = Output not used

ñAin =Time proportional main control output

SECn = Time proportional secondary control output

ALr.1 =Alarm 1 output

Eun.1 = Event 1 output

mkc-ssi.pmd 06/07/2004, 12.1937

- OUT 2 function - [C.E02]- OUT 2 function - [C.E02]

- OUT 2 function - [C.E02]

- OUT 2 function - [C.E02]- OUT 2 function - [C.E02]

Range: nonE = Output not used

ñAin = Time proportional main control output

SECn = Time proportional secondary control output

ALr.2 = Alarm 2 output

Eun.2 = Event 2 output

- OUT 3 function - [C.E03]- OUT 3 function - [C.E03]

- OUT 3 function - [C.E03]

- OUT 3 function - [C.E03]- OUT 3 function - [C.E03]

When the option is not mounted the middle display will show

“no.Pr” (not present).

Range: nonE = Output not used

ñAin =Time proportional main control output

SECn = Time proportional secondary control output

ALr.3 = Alarm 3 output

Eun.3 =Event 3 output

ñC.Sñ =Servomotor control drive as main control output

SC.Sñ = Servomotor control drive as secondary control

output

37

CnF. 1CnF. 1

CnF. 1CnF. 1

CnF. 1

CnF.2CnF.2

CnF.2CnF.2

CnF.2

Page 42

- OUT 4 function - [C.E04]- OUT 4 function - [C.E04]

- OUT 4 function - [C.E04]

- OUT 4 function - [C.E04]- OUT 4 function - [C.E04]

Range: nonE = Output not used

CnF. 2CnF. 2

CnF. 2CnF. 2

CnF. 2

ñAin = Time proportional main control output

SECn = Time proportional secondary control output

ALr.4 = Alarm 4 output

Eun.4 = Event 4 output

NOTESNOTES

NOTES:

NOTESNOTES

1) When option is not mounted the middle display will show

“no.Pr” (not present).

2) When servomotor control drive is hardware selected (see

"Output 3 and 4 selection" at pag. 20), the OUT 4 can be

used only as servomotor drive.

- Servomotor type - [C.E05]- Servomotor type - [C.E05]

- Servomotor type - [C.E05]

- Servomotor type - [C.E05]- Servomotor type - [C.E05]

This parameter will be available only when servomotor control

drive is configured (“CnF.2 - O3.Fn” [C.E03]= “ñC.Sñ” or “SC.Sñ”).

Range: CLSd = Close loop type

NOTENOTE

NOTE: this selection is available only if

NOTENOTE

feedback circuitry is mounted and selected.

OPEn = Open loop type

mkc-ssi.pmd 06/07/2004, 12.1938

- Valve position indication - [C.E06]- Valve position indication - [C.E06]

- Valve position indication - [C.E06]

- Valve position indication - [C.E06]- Valve position indication - [C.E06]

This parameter will be displayed only when open loop servomotor

control drive output is confi-gured.

Range: Fb = The valve position is measured and displayed

no.Fb = The valve position is not measured

NOTENOTE

NOTE: If the feedback option is not mounted, this parameter will

NOTENOTE

be forced to “no.Fb” (no feedback).

- OUT 5 function - [C.E07]- OUT 5 function - [C.E07]

- OUT 5 function - [C.E07]

- OUT 5 function - [C.E07]- OUT 5 function - [C.E07]

Range: nonE = Output not used

ñAin =Main control output (linear)

SECn = Secondary control output (linear)

PV.rt = Process variable retransmission

SP.rt = Operative set point retransmission

NOTENOTE

NOTE: When the option circuitry is not mounted the middle

NOTENOTE

display will show “no.Pr” (not present).

38

Page 43

- OUT 5 range - [C.E08]- OUT 5 range - [C.E08]

- OUT 5 range - [C.E08]

- OUT 5 range - [C.E08]- OUT 5 range - [C.E08]

This parameter will be available only when Out 5 is configured

("O5.Fn" [C.E07] different from "nonE")

Range: 0-20 = 0÷20 mA

4-20 = 4÷20 mA

- OUT 5 retransmission initial scale value- OUT 5 retransmission initial scale value

- OUT 5 retransmission initial scale value

- OUT 5 retransmission initial scale value- OUT 5 retransmission initial scale value

- [C.E09]- [C.E09]

- [C.E09]

This parameter will be available only when Out 5 function [C.E07]

- [C.E09]- [C.E09]

is configured as “PV.rt” or “SP.rt”

Range: From -1999 to 9999

NOTENOTE

NOTE: Decimal point is positioned as previously selected at

NOTENOTE

“CnF.1 - ñ.In.d” [C.d03])

- OUT 5 retransmission full scale value- OUT 5 retransmission full scale value

- OUT 5 retransmission full scale value

- OUT 5 retransmission full scale value- OUT 5 retransmission full scale value

- [C.E10]- [C.E10]

- [C.E10]

This parameter will be available only when Out 5 function [C.E07]

- [C.E10]- [C.E10]

is configured as “PV.rt” or “SP.rt”

Range: From -1999 to 9999

NOTENOTE

NOTE: Decimal point is positioned as previously selected at

NOTENOTE

“CnF.1 - ñ.In.d” [C.d03])

mkc-ssi.pmd 06/07/2004, 12.1939

- OUT 5 filter on the retransmitted value- OUT 5 filter on the retransmitted value

- OUT 5 filter on the retransmitted value

- OUT 5 filter on the retransmitted value- OUT 5 filter on the retransmitted value

- [C.E11]- [C.E11]

- [C.E11]

- [C.E11]- [C.E11]

This parameter will be available only when OUT 5 is configured

as process variable retransmission ("O5.Fn" [C.E07] is equal to

“PV.rt”).

Range: From 0 (no filter) to 8 seconds

NOTENOTE

NOTE: this is a first order digital filter applied to the retransmit-

NOTENOTE

ted output value.

- OUT 6 function - [C.E12]- OUT 6 function - [C.E12]

- OUT 6 function - [C.E12]

- OUT 6 function - [C.E12]- OUT 6 function - [C.E12]

Range: nonE = Output not used

ñAin = Main control output (linear)

SECn = Secondary control output (linear)

PV.rt = Process variable retransmission

SP.rt = Operative set point retransmission

NOTENOTE

NOTE: When the option circuitry is not mounted the middle

NOTENOTE

display will show “no.Pr” (not present).

39

CnF. 2CnF. 2

CnF. 2CnF. 2

CnF. 2

Page 44

- OUT 6 range - [C.E13]- OUT 6 range - [C.E13]

- OUT 6 range - [C.E13]

- OUT 6 range - [C.E13]- OUT 6 range - [C.E13]

This parameter will be available only when Out 6 is configured

CnF. 2CnF. 2

CnF. 2CnF. 2

CnF. 2

("O6.Fn" [C.E12] different from "nonE")

Range: 0-20 = 0÷20 mA

4-20 = 4÷20 mA

- OUT 6 retransmission initial scale value- OUT 6 retransmission initial scale value

- OUT 6 retransmission initial scale value

- OUT 6 retransmission initial scale value- OUT 6 retransmission initial scale value

- [C.E14]- [C.E14]

- [C.E14]

This parameter will be available only when Out 6 function [C.E12]

- [C.E14]- [C.E14]

is configured as “PV.rt” or “SP.rt”

Range: From -1999 to 9999

NOTENOTE

NOTE: Decimal point is positioned as previously selected at

NOTENOTE

“CnF.1 - ñ.In.d” [C.d03].

mkc-ssi.pmd 06/07/2004, 12.1940

- OUT 6 retransmission full scale value- OUT 6 retransmission full scale value

- OUT 6 retransmission full scale value

- OUT 6 retransmission full scale value- OUT 6 retransmission full scale value

- [C.E15]- [C.E15]

- [C.E15]

This parameter will be available only when Out 6 function [C.E12]

- [C.E15]- [C.E15]

is configured as “PV.rt” or “SP.rt”

Range: From -1999 to 9999

NOTENOTE

NOTE: Decimal point is positioned as previously selected at

NOTENOTE

“CnF.1 - ñ.In.d” [C.d03])

- OUT 6 filter on the retransmitted value- OUT 6 filter on the retransmitted value

- OUT 6 filter on the retransmitted value

- OUT 6 filter on the retransmitted value- OUT 6 filter on the retransmitted value

- [C.E16]- [C.E16]

- [C.E16]

This parameter will be available only when OUT 6 is configured

- [C.E16]- [C.E16]

as process variable retransmission ("O6.Fn" [C.E12] is equal to

“PV.rt”).

Range: From 0 (no filter) to 8 seconds

NOTENOTE

NOTE: this is a first order digital filter applied to the retransmit-

NOTENOTE

ted output value.

40

Page 45

General notes on configuration group 2General notes on configuration group 2

General notes on configuration group 2

General notes on configuration group 2General notes on configuration group 2

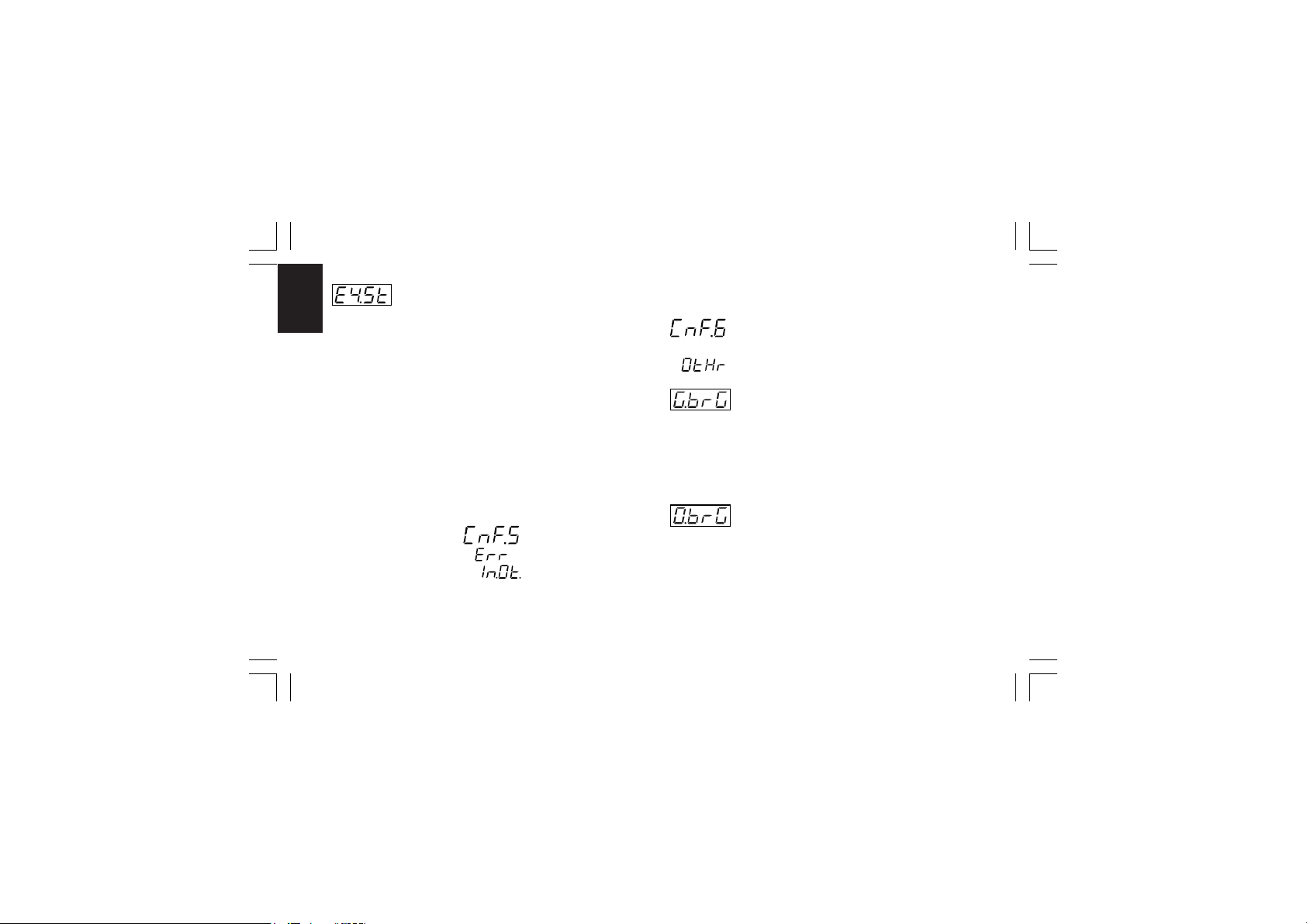

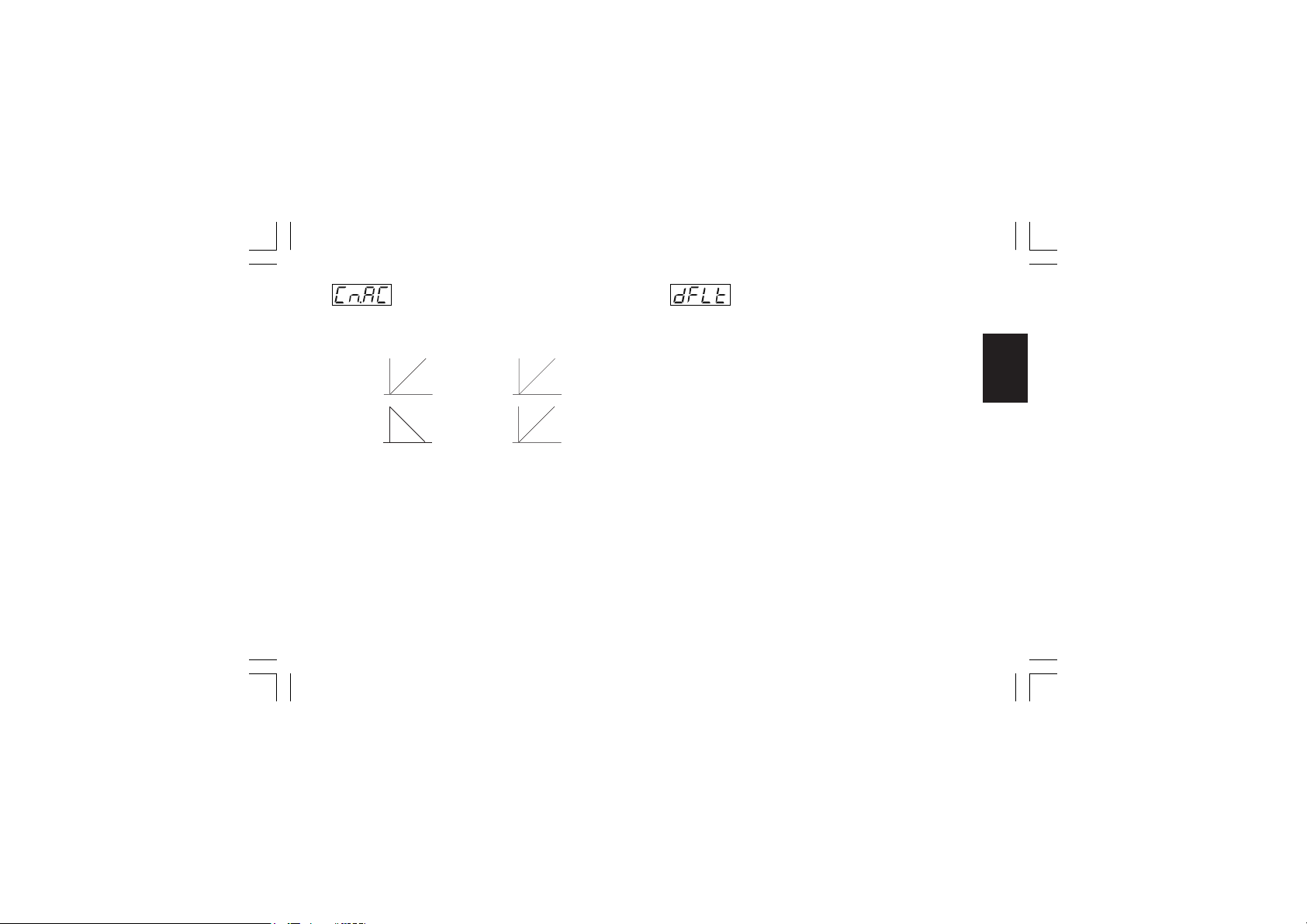

I) Exiting from the configuration group 2 the instrument verifies

automatically the congruence of all parameters. If a wrong

setting is detected, the device will show:

The group 2 parameter passes the congruence test when:

1) Only one of the 6 outputs is configured as main output

(“ñAin”)

2) Only one of the 6 outputs is configured as secondary

output (“SECn”)

3) If only one control output is configured, it should be the

main control output (“ñAin”)

4) The servomotor must be “close loop” type if it is one of two

control outputs.

NOTENOTE

NOTE: The instrument may be used as an indicator, so that this

NOTENOTE

test is satisfied even if no output is configured as control output

mkc-ssi.pmd 06/07/2004, 12.1941

II) Exiting from the configuration group 2 also the following

actions are automatically performed:

A) The "Añ.UL” parameter ("Output value for auto to manual

transfer" [C.G04]) will be forced to "bumpless" (“buñ”) if:

1) its value is < 0 and only one control output is configured;

2) servomotor open loop without feedback is configured.

B) The parameter “SF.Cn” ("Condition for output safety value"

[C.G07]) will be forced to "standard" (“Std.”) if it is not complied

with configured control output type

C) The parameter “SF.UL” ("Output safety value" [C.G08]) will be

forced to 0 if only one control output is configured and its value

is < 0.

D) The parameter “Fd.Fn” ("Out failure detection current

measurement" [C.I11]) will be forced to “nonE” if it is

assigned to a control output different from a time

proportional output.

E) The parameter “Fd.Ou” ("Out failure detection output

assignment" [C.I13]) will be forced to “nonE” if it is assigned

to an output configured as control output

F) The parameter “IP” ("Integral pre-load" [r.d05]) will be forced to

50.0 if only one control output is configured and its value

is < 0

41

CnF. 2CnF. 2

CnF. 2CnF. 2

CnF. 2

Page 46

CONFIGURATION GROUP 3 [C.Fxx]CONFIGURATION GROUP 3 [C.Fxx]

CONFIGURATION GROUP 3 [C.Fxx]

CONFIGURATION GROUP 3 [C.Fxx]CONFIGURATION GROUP 3 [C.Fxx]

CONTROL OUTPUT CONFIGURATION

CnF. 2CnF. 2

CnF. 2CnF. 2

CnF. 2

CnF.3CnF.3

CnF.3CnF.3

CnF.3

- Split range - [C.F01]- Split range - [C.F01]

- Split range - [C.F01]

- Split range - [C.F01]- Split range - [C.F01]

This parameter will be available only when two control outputs

are configured.

Range: dIS = Split range feature is not required

Enb = Split range feature is required

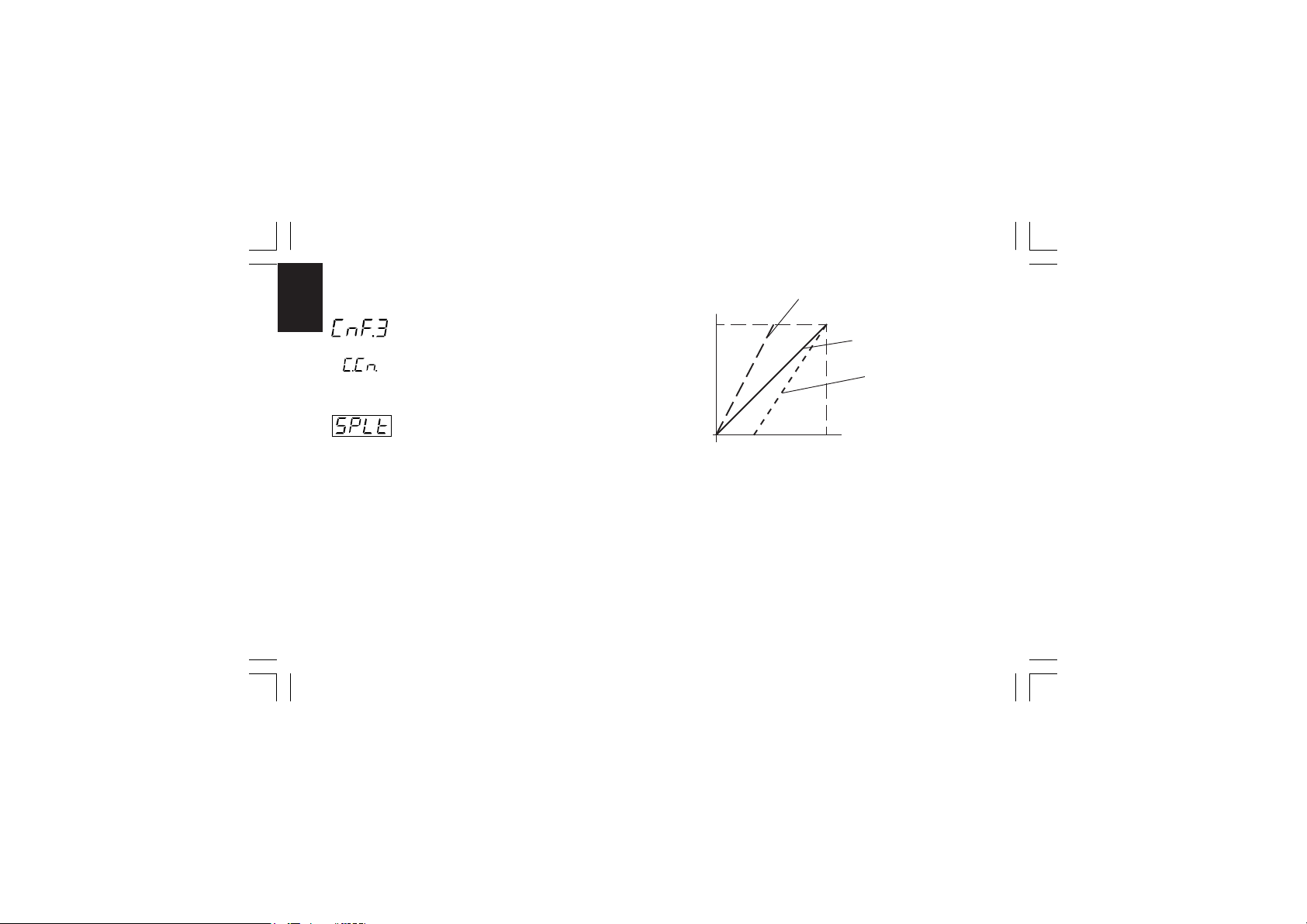

NOTE about the split rangeNOTE about the split range

NOTE about the split range.

NOTE about the split rangeNOTE about the split range

This function allows you to drive by the same control action, two

physical outputs (two actuators) with different bias and gain.

The relation between the Calculated Power Output and the

resulting real outputs are shown below:

mkc-ssi.pmd 06/07/2004, 12.1942

Real PWR

Output

First split

output (MAIN)

100 %

Standard curve

Second split

output

(Secondary)

0 %

ABCD

where:

100 %

Calculated

PWR Output

- for the first split output (MAIN)

Bias 1 = -A

Gain 1 = 100 / (B - A)

- For the second split output (SECONDARY)

Bias 2 = -C

Gain 2 = 100 / (D - C)

FOR EXAMPLEFOR EXAMPLE

FOR EXAMPLE:

FOR EXAMPLEFOR EXAMPLE

Let's suppose that the first split output operates from 0 % to

33.3 % of the calculated output while the second one operates

from 33.3 % to the 100 % of the calculated output.

42

Page 47

100 %

Real PWR

Output

First split

output (MAIN)

Standard curve

The bias and gain of the two split outputs are the following:

“ñC.bS” [C.F03] is the Bias 1 applied to the main output

“ñC.Gn” [C.F02] is the Gain 1 applied to the main output

“SC.bS” [C.F05] is the Bias 2 applied to the secondary output

“SC.Gn” [C.F04] is the Gain 2 applied to the secondary output

CnF. 2CnF. 2

CnF. 2CnF. 2

CnF. 2

CnF.3CnF.3

CnF.3CnF.3

CnF.3

0 %

100 %

33.3 %

Where: A = 0 %

B = C = 33.3 %

D = 100 %

We will set:

Bias 1 = 0

Gain 1 = 100 / (33.3 - 0) = 3

Bias 2 = - 33.3

Gain 2 = 100 / (100 - 33.3) = 1,5

mkc-ssi.pmd 06/07/2004, 12.1943

Second split

output

(Secondary)

Calculated

PWR Output

- Main control output gain - [C.F02]- Main control output gain - [C.F02]

- Main control output gain - [C.F02]

- Main control output gain - [C.F02]- Main control output gain - [C.F02]

This parameter will be available only when the split range is

enabled ("SPLt." [C.F01] = "Enb").

Range: from 0.50 to 5.00.

- Main control output bias - [C.F03]- Main control output bias - [C.F03]

- Main control output bias - [C.F03]

- Main control output bias - [C.F03]- Main control output bias - [C.F03]

This parameter will be available only when the split range is

enabled ("SPLt." [C.F01] = "Enb").

Range: from -100.0 to 100.0 % of the output span.

- Secondary control output gain - [C.F04]- Secondary control output gain - [C.F04]

- Secondary control output gain - [C.F04]

- Secondary control output gain - [C.F04]- Secondary control output gain - [C.F04]

This parameter will be available only when the split range is

enabled ("SPLt." [C.F01] = "Enb").

Range: from 0.50 to 5.00

43

Page 48

- Secondary control output bias - [C.F05]- Secondary control output bias - [C.F05]

- Secondary control output bias - [C.F05]

- Secondary control output bias - [C.F05]- Secondary control output bias - [C.F05]

This parameter will be available only when the split range is

CnF. 3CnF. 3

CnF. 3CnF. 3

CnF. 3

enabled ("SPLt." [C.F01] = "Enb").

Range: from -100.0 to 100.0 % of the output span.

- Main control output conditioning -- Main control output conditioning -

- Main control output conditioning -

- Main control output conditioning -- Main control output conditioning [C.F06][C.F06]

[C.F06]

[C.F06][C.F06]

This parameter will be available only when main control output is

configured.

Range: norñ = The control output is calculated by the PID

CñPL = The control output is complemented (100-PID

calculated value)

Ouic = The control output is conditioned to match a

“QUICK OPENING” flow characteristic

Eou = The control output is conditioned to match an

“EQUAL PERCENTAGE” flow characteristic

NOTE about output conditioningNOTE about output conditioning

NOTE about output conditioning

NOTE about output conditioningNOTE about output conditioning

Sometimes non linear valves are used where a linear valve is

suitable.

In these cases, it is advisable to linearize the ratio between flow

rate and valve travel in order to obtain a better control of the

process.

mkc-ssi.pmd 06/07/2004, 12.1944

This instrument allows you to select an output linearization in

accordance with the two most common valve flow characteristics:

- Quick opening

- Equal percentage.

44

Page 49

- Main control output in engineering unit- Main control output in engineering unit

- Main control output in engineering unit

- Main control output in engineering unit- Main control output in engineering unit

- [C.F07]- [C.F07]

- [C.F07]

This parameter will be available only when main control output is

configured.

Range: nO = Scalable is not required

NOTENOTE

NOTE: This scaling allows you to display the output value in

NOTENOTE

engineering units instead of in percent.

This parameter will be available only when "ñ.SCL" ("Main control

output in engineering units" [C.F07]) is set to "yES".

Range:

- [C.F07]- [C.F07]

YES = Scalable is required

- Main output decimal point position -- Main output decimal point position -

- Main output decimal point position -

- Main output decimal point position -- Main output decimal point position -

[C.F08][C.F08]

[C.F08]

[C.F08][C.F08]

----. = No decimal figure

---.- = One decimal figure.

--.-- = Two decimal figures.

mkc-ssi.pmd 06/07/2004, 12.1945

- Main output initial scale readout -- Main output initial scale readout -

- Main output initial scale readout -

- Main output initial scale readout -- Main output initial scale readout [C.F09][C.F09]

[C.F09]

[C.F09][C.F09]

This parameter will be available only when "ñ.SCL" ("Main control

output in engineering units" [C.F07]) is set to "YES".

Range: from -199 to 999

- Main output full scale readout - [C.F10]- Main output full scale readout - [C.F10]

- Main output full scale readout - [C.F10]

- Main output full scale readout - [C.F10]- Main output full scale readout - [C.F10]

This parameter will be available only when "ñ.SCL" ("Main control

output in engineering units" [C.F07]) is set to "YES".

Range: from -199 to 999

- Main output auxiliary conditioning -- Main output auxiliary conditioning -

- Main output auxiliary conditioning -

- Main output auxiliary conditioning -- Main output auxiliary conditioning [C.F11][C.F11]

[C.F11]

[C.F11][C.F11]

This parameter will be available only when main control output is

configured and “ñC.Cn” ("Main control output conditioning"

[C.F06]) is different from “norñ”.

Range: bEFr = The functions listed at Note (**) are calculated

45

before before

before to apply the action selected by “ñC.Cn”

before before

("Main control output conditioning" [C.F06])

parameter.

CnF. 3CnF. 3

CnF. 3CnF. 3

CnF. 3

Page 50

AFtr = The functions listed at Note (**) are calculated

after after

after to apply the action selected by “ñC.Cn”

after after

CnF. 3CnF. 3

CnF. 3CnF. 3

CnF. 3

Note (**)Note (**)

Note (**)

Note (**)Note (**)

- "Main control output limiters" - for more details see [r.E04] and

[r.E05] parameters.

- "Main control output max rate of rise" (see [r.E06]).

- "Control output display value" - for more details see "Display

function" paragraph at pag. 62 and [C.F07], [C.F08], [C.F09]

and [C.F10] parameters.

- "Threshold for alarm on control output value" - for more details

see [r.F01], [r.F05] [r.F09] and [r.F13] parameters.

- The control output value displayed by bargraph.

This parameter will be available only when secondary control

output is configured.

Range: norñ = The control output is calculated by the PID

mkc-ssi.pmd 06/07/2004, 12.1946

(“Main control output conditioning” [C.F06])

parameter.

- Secondary control output conditioning- Secondary control output conditioning

- Secondary control output conditioning

- Secondary control output conditioning- Secondary control output conditioning

- [C.F12]- [C.F12]

- [C.F12]

- [C.F12]- [C.F12]

CñPL = The control output is complemented (100-PID

calculated value)

Ouic = The control output is conditioned to match a

“QUICK OPENING” flow characteristic

Eou = The control output is conditioned to match an

For more details see also

at page 43.

This parameter will be available only when secondary control

output is configured.

Range: nO = Scalable is not required

NOTENOTE

NOTE: This scaling allows to display the output value in

NOTENOTE

engineering units instead of in percent.

This parameter will be available only when "S.SCL" ("Secondary

control output in engineering units" [C.F13]) is set to "YES".

Range:

“EQUAL PERCENTAGE” flow characteristic

- Secondary control output in engineer-- Secondary control output in engineer-

- Secondary control output in engineer-

- Secondary control output in engineer-- Secondary control output in engineering unit - [C.F13]ing unit - [C.F13]

ing unit - [C.F13]

ing unit - [C.F13]ing unit - [C.F13]