Page 1

Operating Instructions • Warning Information • Parts Breakdown

Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equip

ment, such as those dust masks that are specially designed to filter out

microscopic particles.

SPECIFICATIONS

Free Speed .......................... 2,500 RPM

Air Inlet Thread ....................... 1/4" NPT

Hose Size ..................................

Avg. Air Consumption ...................4 cfm

3/8" I.D.

Rec. Air Pressure ..........90 psig (6.2bar)

Sound Level ............................... 82 dBA

Length .............................................8.5"

Shipping Weight .......................3.3 Lbs.

ALWAYS READ INSTRUCTIONS

BEFORE USING POWER TOOLS

ALWAYS WEAR

SAFETY GOGGLES

WEAR HEARING

PROTECTION

-

AVOID PROLONGED

EXPOSURE TO VIBRATION

SX227B

METAL

SHEAR

Page 2

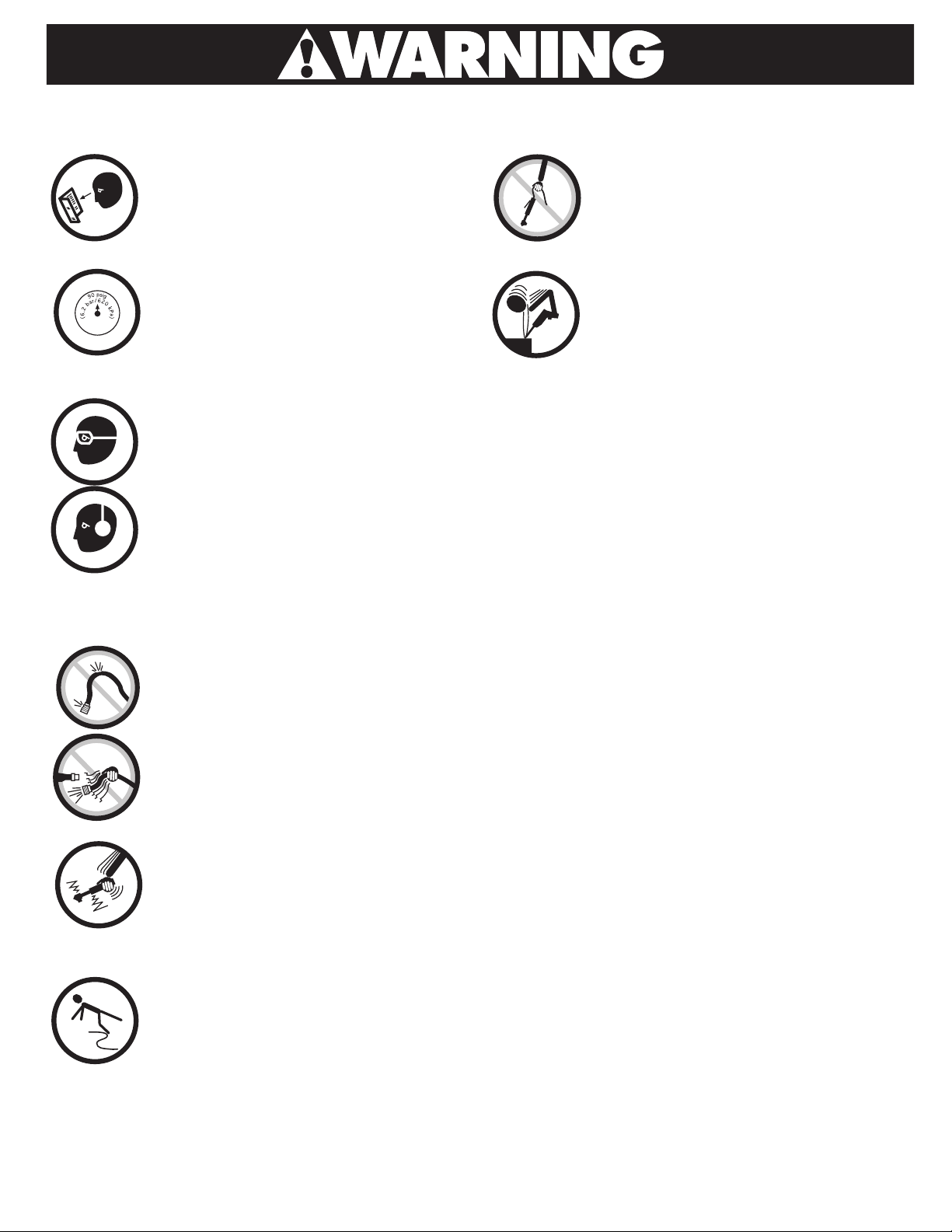

FAILURE TO OBSERVE THESE WARNINGS

COULD RESULT IN INJURY

THIS INSTRUCTION MANUAL CONTAINS

IMPORTANT SAFETY INFORMATION.

READ THIS INSTRUCTION MANUAL CAREFULLY

AND UNDERSTAND ALL INFORMATION BEFORE

OPERATING THIS TOOL.

• Always operate, inspect and maintain this tool in accor

dance with American National Standards Institute

Safety Code of Portable Air Tools (ANSI B186.1) and any

other applicable safety codes and regulations.

• For safety, top performance and maximum durability of

parts, operate this tool at 90 psig 6.2 bar max air pres

sure with 3/8” diameter air supply hose.

• Always wear impact-resistant eye and face protection

when operating or performing maintenance on this tool.

Always wear hearing protection when using

this tool.

• High sound levels can cause permanent

hearing loss. Use hearing protection as

recommended by your employer or OSHA

regulation.

• Keep the tool in efficient operating condition.

• Operators and maintenance personnel must

be physically able to handle the bulk, weight

and power of this tool.

• Air under pressure can cause severe injury. Never

direct air at yourself or others. Always turn off the air

supply, drain hose of air pressure and detach tool from

air supply before installing, removing or adjusting any

accessory on this tool, or before performing any main

tenance on this tool. Failure to do so could result in

injury. Whip hoses can cause serious injury. Always

check for damaged, frayed or loose hoses and fittings,

and replace immediately. Do not use quick detach cou

plings at tool. See instructions for correct set-up.

• Air powered tools can vibrate in use. Vibration, repet

tive motions or uncomfortable positions over extended

periods of time may be harmful to your hands and

arms. Discontinue use of tool if discomfort, tingling

feeling or pain occurs. Seek medical advice before

resuming use.

• Place the tool on the work before starting the tool. Do

not point or indulge in any horseplay with this tool.

• Slipping, tripping and/or falling while operating air tools

can be a major cause of serious injury or death. Be

aware of excess hose left on the walking or work sur

face.

• Keep body working stance balanced and firm. Do not

overreach when operating the tool.

• Anticipate and be alert for sudden changes in motion

during start up and operation of any power tool.

• Do not carry tool by the hose. Protect the hose from

sharp objects and heat.

• Tool shaft may continue to rotate briefly after throttle is

released. Avoid direct contact with accessories during

and after use. Gloves will reduce the risk of cuts or

burns.

• Keep away from rotating end of tool. Do not wear

jewelry or loose clothing. Secure long hair. Scalping can

occur if hair is not kept away from tool and accessories.

Choking can occur if neckwear is not kept away from

tool and accessories.

• Do not lubricate tools with flammable or volatile liquids

such as kerosene, diesel or jet fuel.

• Do not force tool beyond its rated capacity.

• Do not remove any labels. Replace any damaged

labels.

• Use accessories recommended by Sunex Tools.

SX227B: Parts Breakdown & Operating Manual 2 rev. 02/09/07

Page 3

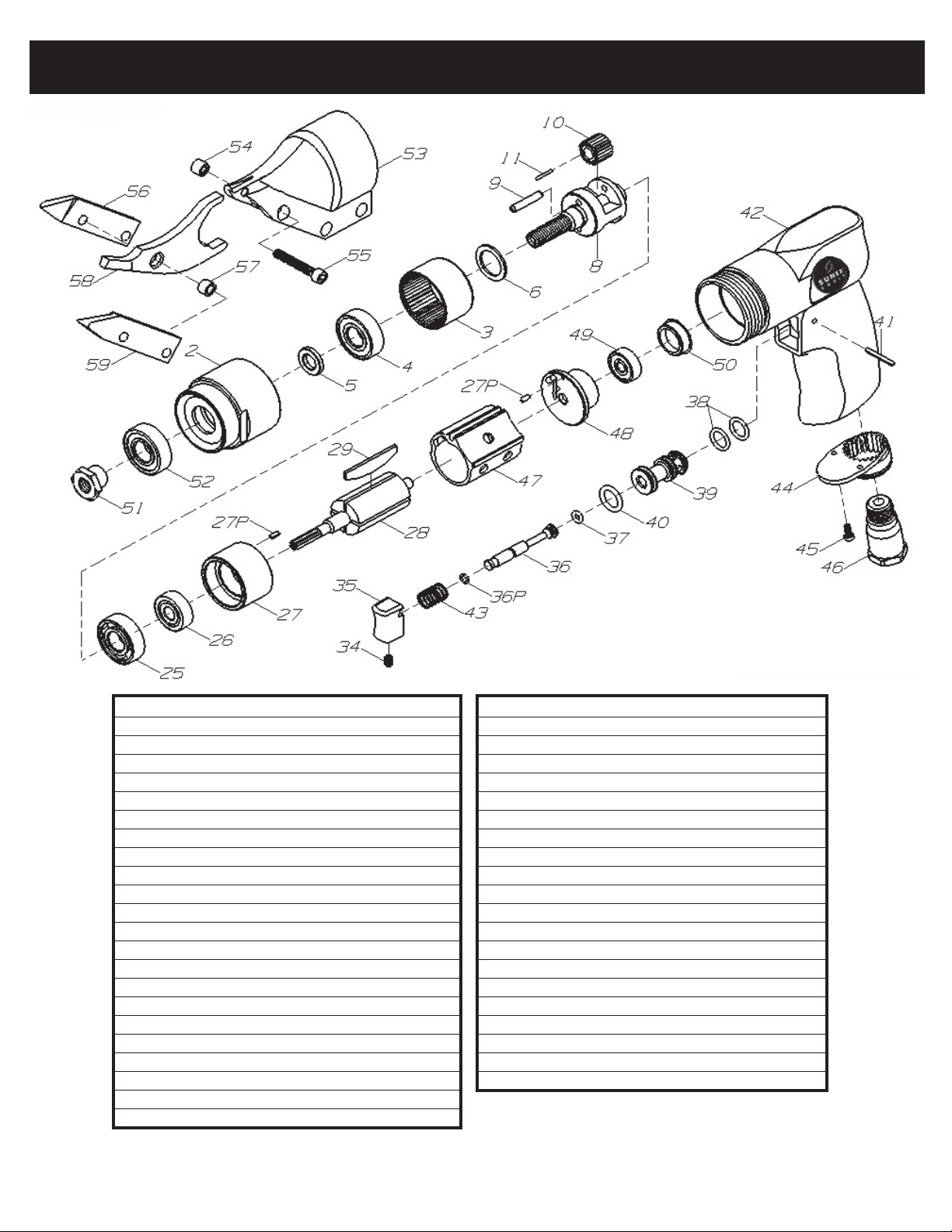

SX227B PARTS BREAKDOWN & PARTS LIST

Ref#

2

3

4

5

6

8

9

10

11

25

26

27

27P

28

29

34

35

36

36P

37

38

39

Part #

RS227B02

RS227B03

RS227B25

RS227B05

RS227B06

RS227B08

RS227B09

RS227B10

RS227B11

RS227B25

RS30524

RS227B27

RS227B47

RS227B28

RS227B29

RS227B34

RS227B35

RS227B36

RS227B36P

RS227B37

RS227B38

RS227B39

Description

Gear Cover

Internal Gear

Ball Bearing

Spacer

Fiber Washer

Gear Plate

Pin

Gear

Gear Needles

Ball Bearing

Ball Bearing

Front End Plate

Pin

Rotor

Rotor Blade

Set Screw

Trigger

Valve

O-Ring

O-Ring

O-Ring

Valve Bushing

Qty.

1

1

1

1

1

1

2

2

22

1

1

1

2

1

4

1

1

1

1

1

2

1

Ref #

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

Part #

RS227B40

RS227B41

RS227B42

RS227B43

RS227B44

RS227B45

RS227B46

RS227B30

RS227B48

RS21114

RS227B50

RS227B12

RS227B13

RS227B14

RS227B16

RS227B15

RS227B17

RS227B18

RS227B19

RS227B20

Description

O-Ring

Pin

Motor Housing

Spring

Exhaust Deflector

Screw

Inlet Bushing

Cylinder

Rear End Plate

Ball Bearing

Bearing Cap

Hex Nut

Ball Bearing

Cutter Housing

Lock Nut

Lock Screw

Left Blade

Spacer

Center Blade

Right Blade

Qty

1

1

1

1

1

2

1

1

1

1

1

1

1

1

3

3

1

2

1

1

SX227B: Parts Breakdown & Operating Manual 3 rev. 02/09/07

Page 4

Operating Instructions • Warning Information • Parts Breakdown

Nipple

Air Supply

Tools of this class operate on a wide range of air pressures. It is

recommended that air pressure of these tools measures 90 PSI at the

tool while running free. Higher pressure (over 90 psig; 6.2 bar) raises

performance beyond the rated capacity of the tool which will shorten the

tool’s life because of faster wear and could cause injury.

Always use clean, dry air. Dust, corrosive fumes and/or water in the air

line will cause damage to the tool. Drain the air tank daily. Clean the

air inlet filter screen on at least a weekly schedule. The recommended

hookup procedure can be viewed in the above figure.

The air inlet used for connecting air supply, has standard 1/4" NPT. Line

pressure should be increased to compensate for unusually long air hoses

(over 25 feet). Minimum hose diameter should be 3/8" I.D. and fittings

should have the same inside dimensions and be tightly secured.

Lubrication

Lubricate the air motor daily with air tool oil. If no air line oiler is used,

run 1/2 oz. of oil through the tool. The oil can be squirted into the tool air

inlet or into the hose at the nearest connection to the air supply, then run

the tool. Overfilling will cause a reduction in the power of the tool.

Operation

The rotation of the shearing head can be changed by loosening

the allen head screw. Then turn cutter housing to desired position and tighten allen head screw securely.

NEVER use this air shear on material with a gauge greater than

18 as this will result in breakage of the center blade.

Cutting with this tool will create sharp edges. Wear gloves to

protect hands.

Cutting edges and saw blades can become hot during use.

Do not touch.

Never force the tool to cut faster or through heavier gauge

material than rated capacity.

Limited Warranty

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS® BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective

workmanship or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product.

This product carries a ONE YEAR warranty. During this warranty period, Sunex Tools will repair or replace at our option any part or unit which

proves to be defective in material or workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or

replacement made by anyone other than Sunex Tools or its authorized warranty service centers. The foregoing obligation is Sunex Tools’ sole

liability under this or any implied warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. Please contact your local Sunex distributor for proper warranty handling procedures.

If you have any questions about warranty service, please write to Sunex Tools. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools products regardless

of whether or not the product is still covered by a warranty plan.

Shipping Address: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Mailing Address: Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

SX227B: Parts Breakdown & Operating Manual 4 rev. 02/09/07

Page 5

Instrucciones de operación • Información de advertencia • Desglose de partes

Lijar, cortar, esmerilar, taladrar y otras actividades propias de las obras en

construcción, con equipo neumático pudieran crearse ciertos polvos

identificados como causantes de cáncer, defectos en el nacimiento u otras

lesiones en los órganos reproductores. Entre algunos de los ejemplos de

estos productos químicos están:

• El plomo en las pinturas con base de plomo,

• Sílice cristalina en los ladrillos y cemento así como

en otros productos de albañilería,

• Arsénico y cromio proveniente de la madera tratada

con productos químicos.

Los peligros al exponerse a estos productos varía, dependiendo de qué

tanfrecuentemente se hagan esos tipos de trabajos. Si desea disminuir

su exposición a estos productos químicos: trabaje en un lugar con buena

ventilación y hágalo con el equipo de seguridad aprobado, como lo son las

mascarillas cubrepolvo que fueron diseñadas especialmente para filtrar las

partículas microscópicas.

ESPECIFICACIONES

Velocidad libre ..................... 2,500 RPM

Entrada de aire .......................

Tamaño mín.

de manguera ................

Presión de aire

recomendada ................90 psig (6.2bar)

1/4" NPT

3/8" Diám. Int.

Consumo promedio de aire ..........4 cfm

Nivel sonoro ............................... 82 dBA

Longitud .......................................... 8.5"

Peso de embarque .................... 3.3 Lbs.

LEA SIEMPRE LAS

INSTRUCCIONES ANTES DE

USAR HERRAMIENTAS

NEUMÁTICAS.

USE SIEMPRE

GAFAS DE

SEGURIDAD.

USE

PROTECCIÓN

PARA LOS OÍDOS.

EVITE EXPONERSE

PROLONGADAMENTE

A LAS VIBRACIONES

SX227B

CIZALLA DE

METAL

SX227B: Desglose de Partes & Manual de Operación 5 rev. 02/09/07

Page 6

OMITIR RESPETAR ESTAS ADVERTENCIAS PUDIERA

DAR COMO RESULTADO LESIONARSE.

ESTE MANUAL INSTRUCTIVO CONTIENE INFORMACIÓN

IMPORTANTE RELACIONADA CON SU SEGURIDAD.

LEA CUIDA DOSAMEN TE ESTE MANUA L

INSTRUCTIVO Y ENTIENDA TODA LA INFORMACIÓN

ANTES DE OPERARATION ESTA HERRAMIENTA

• En todo momento, opere, revise y mantenga

esta herramienta según lo establece el Código

de Nacional de Normas del Instituto Americano de

Seguridad en las Herramientas Portátiles Neumáticas

(ANSI B186.1) y cualquiera otros códigos y

reglamentación de seguridad pertinentes

• Por su seguridad, el rendimiento operativo

óptimo y durabilidad máxima de los

componentes, opere esta herramienta a una

presión máxima neumática de 90 psig/6.2 barios

y una manguera de abasto con un diámetro

de 3/8”.

• Protéjase siempre con gafas y caretas

resistentes a los impactos mientras opera o

hace labores de mantenimiento a esta

herramienta. Cuando utilice esta herramienta, use

en todo momento protección para los oídos.

• Los elevados niveles de ruido pudieran

provocarla la pérdida del oído. Use la protección

para los oídos según lo recomiende su empleador o la

normatividad de OSHA.

• Mantenga la herramienta en condiciones

operativas eficientes

• Los operarios y personal de mantenimiento

deberán estar físicament aptos para manejar las

dimensiones, peso y potencia de esta herramienta.

• El aire comprimido puede causa le lesiones graves.

Nunca dirija la descarga del aire hacia usted

o los demás. Interrumpa siempre el abasto de aire,

descargue la presión neumática en la manguera y

desconecte la herramienta del abasto de aire, antes

de instalar, desmontar o ajustar cualquier accesorio de

esta herramienta, o antes de ejecutar labores

de mantenimiento a esta herramienta. Omitir

hacerlo así pudiera dar como resultado una lesión.

Los latigazos de las mangueras podrán causarle una

lesión grave. Revise siempre que las mangueras y sus

accesorios no estén dañados, raídos ni flojos y

cámbielos inmediatamente. No use coples de

desconexión rápida en esta herramienta. Consulte en

las instrucciones los preparativos correctivos.

• Las herramientas neumáticas vibran durante su

uso. La vibración, los movimientos repetitivos o

las posiciones incómodas durante extensos

periodos de tiempo pudieran serles nocivos a

sus manos y brazos. Suspenda el uso de esta

herramienta si sufre de alguna molestia, siente

hormigueo dolor Acuda al consejo de un médico

antes de reanudar el uso de la herramienta.

• Coloque la herramienta sobre la superficie de

trabajo antes de hacerla funcionar. Los resbalones,

tropiezos y/o caídas durante la operación de

herramienta pueden ser la causa de una lesión

grave o la muerte. Manténgase alerta con el

exceso de manguera sobre las superficies donde

transita o del producto.

• Mantenga su postura de trabajo equilibrada

y firme. No pretenda extender su capacidad

alcance mientras opera esta herramienta.

• Anticipe y manténgase alerta de los cambios

súbitos en el movimie to al hacer funcionar y

operar cualquier herramienta neumática.

• No transporte la herramienta sosteniéndola

con la manguera. Proteja la manguera contra

los objetos filosos y el calor.

• Al liberar el acelerador de la herramienta, el eje

impulsor pudiera seguir girando brevemente.

Evite el contacto directo con los accesorios

durante y despuees de usarlos. Los guantes

disminuirá el riesgo de cortaduras y

quemaduras.

• Mantenga alejado el extremo giratorio

de la herramienta. No vista con alhajas ni ropa

holgada. Sostenga el cabello largo. El pelo largo

pudiera perderse si no se mantiene sostenido

fuera del alcance de la herramienta y sus accesorios.

Pudiera ocurrir una estrangulación si los collares no

se mantienen fuera del alcance de la herramienta y sus

accesorios.

• No lubrique las herramientas con líquidos flamables

o volátiles como lo es el queroseno, diesel o combustible

aeronáutico.

• No force la herramienta más allá de su capacidad

calculada.

• No le extraiga ninguna de las etiquetas. Cambie

cualquier etiqueta dañada.

• Utilice los accesorios recomendadas por Sunex Tools.

SX227B: Desglose de Partes & Manual de Operación 6 rev. 02/09/07

Page 7

Instrucciones de operación • Información de advertencia • Desglose de partes

Abasto de aire

Las herramientas de esta clase operan en una amplia gama de presiones

neumáticas. Se recomienda que la presión neumática para esta clase de

herramientas mida 90 psig en la herramienta mientras la herramienta

funciona sin carga. La presión neumática más elevada (más de 90 psig,

6.2 barios) eleva su rendimiento operativo más allá de la capacidad

calculada de la herramienta y esto acortará la vida útil de la herramienta

debido al desgaste más rápido, además de la posibilidad de sufrir una

lesión.Utilice siempre aire comprimido limpio y seco. El polvo, los humos

corrosivos y/o el agua en la tuberÌa del aire pueden causarle daños a la

herramienta. Vacía diariamente el tanque del aire comprimido. Limpie

la malla a la entrada del purificador de aire por lo menos dentro de un

programa semanal. El procedimiento recomendado para su conexión

podrá verse en la ilustración arriba indicada. La entrada del aire para

conectar el abasto de aire es de 1/4" NPT estándar. La presión en la

tubería deberá incrementarse como medio de compensación cuando

se utilicen mangueras largas más allá de lo común (más de 25 pies).

El diámetro interior mínimo de la manguera deberá ser de 3/8" y sus

accesorios deberán tener las mismas dimensiones interiores y además

estar firmemente apretados.

Lubricación

Lubrique diariamente el motor neumático con aceite para herramientas

neumáticas. Si no se usa aceite de aerolínea, deje correr una 1/2 oz.

de aceite por la herramienta. Se puede lanzar un chorro de aceite por

la ventila de admisión de aire de la herramienta, o por la

manguera en la conexión más cercana al abastecimiento de

aire, luego ponga en marcha la herramienta. El sobrellenado

reducirá la potencia de la herramienta.

Operación:

La rotación del cabezal de corte puede ser cambiada al

aflojar el tornillo de cabeza Allen. Luego gire la carcasa de la

cortadora a la posición deseada y apriete fijamente el tornillo

Allen.

NUNCA use esta cizalla neumática con algún material de un

calibre mayor a 18, ya que esto traerá como consecuencia la

rotura de la navaja central.

Hacer corte con esta herramienta creará bordes afilados. Lleve

puesto guantes para proteger sus manos.

Los bordes de corte y las navajas de la sierra pueden

calentarse durante el uso.

No los toque.

Nunca ejerce fuerza adicional para que la herramienta corte

más rápidamente, o por material de un calibre más allá de su

capacidad nominal.

Garantía Limitada

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS CON

LA MARCA DE LA EMPRESA SUNEX TOOLS NO CONTIENEN DEFECTOS EN SU MANO DE OBRA NI MATERIAS

PRIMAS.

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio debido a que la

mano de obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de garantía descritos a continuación y

asignados a ese producto específico. Este producto tiene una garantía de UN AñO. Durante ese periodo de garantía, Sunex Tools reparará o sustituirá, como

así opte por hacerlo, cualquier componente o unidad que se compruebe tener decectos en su materia prima o mano de obra.

Otra importante información de la garantía...

Esta garantía no cubre ningún daño al equipo o herramientas, si este surge como resultado de su alteración, abuso, o mal uso o daños ni tampoco cubre

las reparaciones o reposiciones hechas por cualquier persona ajena a los centros de servicio de garantía autorizados y que no sean de Sunex Tools. La

obligación antes mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o de cualquier garantía implícita y bajo ninguna

circunstancia quedará bajo su responsabilidad cualquier garantía implícita ya bajo ninguna circunstancia quedará bajo su responsabilidad cualquier daño

incidental o consecuencial.

Note: Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo tanto la limitación o exclusión arriba

mencionada quizá no pudiera serle pertinente a usted. Devuelva el equipo o componentes a Sunex Tools, un centro de servicio de garantía autorizado, con

elflete pagado. Asegúres haber incluido su nimbre y dirección, la evidencia de la fecha de adquisición y la descripción del defecto que se sospeche tener. Si

tiene alguna duda relacionada con elservicio de garantía, por favor escríbale a Sunex Tools. Esta garantía le concede derechos jurídicos específicos y quizá

otros derechos que varían de un estado a otro, Sunex Tools tiene a su disposición los juegos de reparación y refacciones de repuesto para muchos de sus

productos, sin importar si el producto continúe o no bajo el plan de la garantía.

DIRECCIóN A EMBARCARSE: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, South Carolina 29690

DIRECCIóN DE CORREOS: Sunex Tools • P.O. Box 4215 • Greenville, South Carolina 29608

SX227B: Desglose de Partes & Manual de Operación 7 rev. 02/09/07

Page 8

Instructions d'utilisation • Avertissements • Liste des pièces

Certains types de poussières produites par le sablage, le sciage, le meulage

et d'autres activités de construction contiennent des produits chimiques

cancérigènes, qui causent des anomalies congénitales ou d'autres dangers

pour la reproduction. Parmi ces produits chimiques on compte :

• le plomb des peintures à base de plomb,

• la silice cristalline des briques et du ciment

et d'autres

produits de maçonnerie, et

• l'arsenic et le chrome du bois traité

chimiquement.

Les risques associés à ces expositions varient selon la fréquence et le

type de travail. Afin de réduire votre exposition à ces produits chimiques

travailler dans un endroit bien ventilé, avec de l'équipement de sécuri

té approuvé, comme des masques antipoussières conçus spécialement

pour filtrer les particules microscopiques.

SPÉCIFICATIONS

Vitesse libre .................................... 2,500 RPM

Entrée d’air .........................................

Dimension min. du boyau .....................

Pression d’air recommandée

..........90 psig (6.2bar)

1/4" NPT

3/8" D.I

Moy. de consommation d’air ..........4 cfm

Niveau sonore ...............................82 dBA

Longueur .......................................... 8.5"

Poids à l’expédition .....................3.3 Lbs.

-

LEA SIEMPRE LAS INSTRUCCIONES

ANTES DE USAR HERRAMIENTAS

NEUMÁTICAS.

USE SIEMPRE GAFAS

DE SEGURIDAD.

USE PROTECCIÓN

PARA LOS OÍDOS.

EVITE EXPONERSE

PROLONGADAMENTE

A LAS VIBRACIONES

SX227B

CISAILLE À

MÉTAUX

SX227B: Vue éclatée des pièces et mode d’emploi 8 rev. 02/09/07

Page 9

NÉGLIGER D'OBSERVER CES AVERTISSEMENTS

PEUT ENTRAŒNER DES BLESSURES

CE MANUEL D'INSTRUCTIONS CONTIENT DES

INFORMATIONS IMPORTANTES SUR LA SÉCURITÉ.

LIRE CE MANUEL D'INSTRUCTIONS AVEC ATTENTION ET

COMPRENDRE L'INT…GRALIT… DES INFORMATIONS

AVANT D'UTILISER CET OUTIL.

• Toujours utiliser, inspecter et entretenir cet outil selon

le code du American National Standards Institute

Safety » pour les outils pneumatiques portatifs

Portable Air Tools) (ANSI B186.1) de méme que tout

autre code de sécurité et règlement applicable.

• Pour des raisons de sécurité, de performance et de

durabilité maximale des pièces, utiliser cet outil à une

pression díair maximale de 6,2 bars / 90 psig, avec un

flexible d'alimentation díair de 3/8 po de diamètre.

• Lors de l'utilisation ou de l'entretien de cet outil,

toujours porter une protection pour les yeux et le

visage qui résiste aux chocs Toujours porter un

dispositif de protection antibruit lors de l'utilisation de

cet outil.

• Des niveaux de bruit élevés peuvent entraîner une

perte permanente de l'ouîe Utiliser une protection

antibruit recommandée par votre employeur ou par la

réglementation OSHA.

• Garder l'outil en bon état de fonctionnement.

• Le personnel qui utilise et entretient cet outil doit Ítre en

mesure de manipuler physiquement le volume, le poids

et la puissance de cet outil.

• De l'air sous pression peut entraîner des blessures

graves. Ne jamais diriger l'air vers soi ou vers les autres.

Toujours couper l'alimentation díair, purger le flexible

de toute pression d'air et détacher l'outil de l'alimentation

en air avant d'installer, de dé poser ou díajuster un

quelconque accessoir sur cet outil, ou avant d'effectuer

l'entretien de cet outil. Négliger ces directives peut

entraîner des blessures. Les flexibles qui

claquent peuvent entraîner de graves

blessures. Toujours vérifier si les flexibles ou les

raccords ne sont pas endommagés, effilochés ou

desserrés et les remplacer immédiatement le cas

échéant. Ne pas utiliser de raccords à dégagement

rapide au niveau de líoutil. Voir les instructions pour

l'installation correcte.

• Les outils pneumatiques peuvent vibrer

pendant leur utilisation. Les vibrations, les

mouvements répétitifs ou les positions inconfortables

pendant des périodes prolongées peuvent nuire à vos

mains ou à vos bras. Cesser d'utiliser l'outil lorsqu'un

sensation díinconfort, de fourmillement ou de douleur

survient. Consulter un médecin avant de reprendre

líutilisation.

• Placer l'outil sur la pièce à travailler avant de le mettre

en marche.

• Un glissement, un trébuchement et /ou

une chute lors de l'utilisation de l'outil

peuvent être des causes importantes de

blessures graves ou mortelles. Être conscient

de la longueur excessive du flexible laissée

sur le plancher ou sur la surface de travail.

• Le corps doit garder une position de travail

équilibrée et ferme. Ne pas dépasser la

portée de l'outil pendant son utilisation.

• Anticiper et surveiller les changements de

mouvement brusques à la mise en marche et

pendant l'utilisation de n'importe quel outil

électrique.

• Ne pas transporter l'outil par son flexible.

Protéger le flexible contre les objets pointus

et la chaleur.

• L'arbre de l'outil peut continuer å tourner

quelques instants après le relâchement

de la commande de puissance. Éviter un

contact direct avec les accessoires pendant

et après l'utilisation. Le port de gants réduit

les risques de coupures et de brûlures.

• Rester à bonne distance de l'extrémité

rotative de l'outil. Ne pas porter de bijoux

ou de v'tements lêches. Attacher les cheveux

longs. Les cheveux peuvent être arrachés s'ils

ne sont pas gardés loin de l'outil et des

accessoires.

• Ne pas forcer l'outil au-delà de sa capacité nominale.

• N'enlever aucune étiquette. Remplacer toute étiquette

endommagée.

• Utilice los accesorios recomendadas por Sunex Tools.

SX227B: Vue éclatée des pièces et mode d’emploi 9 rev. 02/09/07

Page 10

Alimentation en air

Les outils de cette catégorie fonctionnent sur une grande plage de pressions

d'air. Il est recommandé que la pression d'air de ces outils mesure 6,2 bars (90

PSI) lorsque l'outil fonctionne en régime libre. Une pression supérieure à 6,2 bars

(90 psig) accroît la performance au-delà de la capacité nominale de l'outil, ce

qui réduit sa durée de vie utile étant donné que les pièces s'usent plus rapide

ment, et ce qui peut entraîner des blessures. Toujours utiliser de l'air propre et

sec. La poussière, les fumées corrosives et / ou de l'eau dans la conduite d'air

endommage l'outil. Purger le réservoir d'air quotidiennement. Nettoyer la crépine

d'entrée d'air en suivant au moins un calendrier hebdomadaire. La procédure de

raccord recommandée est illustrée dans la figure ci-dessus. L'entrée d'air utili

sée pour connecter l'alimentation en air est munie d'un élément standard de 1/4

NPT. Augmenter la pression de la conduite pour compenser une longueur de flex

ible supérieure à 7,6 m (25 pi). Le diamètre intérieur minimal du flexible doit être

de 3/8 po et le raccord doit être de mêmes dimensions et être fixé fermement.

Lubrification

Lubrifiez le moteur pneumatique chaque jour avec de l'huile à outil pneumatique. Si vous n'utilisez pas de burette à conduite d'air, injectez. 1/2 oz d'huile

dans l'outil. Vous pouvez injecter l'huile dans l'entrée d'air de l'outil ou dans le

boyau par l'entremise du raccord le plus près de la source d'alimentation en air.

Ensuite, faites fonctionner l'outil. Un excès d'huile réduira la puissance de

l'outil.

Opération

La rotation de la tête de cisaillement peut être changée en desserrant la tête de la vis Allen. Tournez alors

le logement du couteau à la position désirée et serrez

la tête de vis Allen solidement.

-

N’utilisez JAMAIS cette cisaille pneumatique sur du

matériel ayant un calibre supérieur à 18, car ceci aura

comme conséquence la rupture de la lame centrale.

La coupe avec cet outil produira des rebords tran

chants. Portez des gants pour protéger vos mains.

Les rebords tranchants et les lames de scie peuvent

-

devenir chauds pendant l’utilisation. Ne touchez pas.

Ne forcez jamais l’outil à couper plus rapidement ou

dans un matériel plus épais que la capacité nominale.

-

Garantie limitée

SUNEX INTERNATIONAL, INC. GARANTIT À SES CLIENTS QUE LES OUTILS DE MARQUE SUNEX TOOLS SONT

EXEMPTS DE DÉFAUTS DE MAIN D'(UVRE ET DE MATÉRIAU

Sunex International, Inc. réparera ou remplacera ses outils de marque Sunex Tools qui ne donnent pas un service satisfaisant à cause d'un défaut de main

d'œuvre ou de matériau, selon les termes et conditions décrits ci-dessous dans les plans de garantie correspondant à ce produit spècifique. Ce produit a

une garantie de UN AN. Pendant la période de garantie, Sunex Tools réparera ou remplacera, à sa seule discrétion, toute pièce ou tout appareil dont il a été

déterminé qu'il comporte un défaut de matériau ou de main d'œuvre.

Autres informations importantes sur la garantie...

Cette garantie ne couvre pas les dommages à de l'équipement ou à des outils modifiés, sujets à des abus ou à une utilisation incorrecte,

ou encore endommagés; elle ne couvre pas les réparations ou le remplacement effectué par quiconque autre que Sunex Tools ou ses cen

tres de services de garantie autorisés. L'obligation qui précède constitue la seule responsabilité de Sunex Tools en vertu de cette garan

tie ou de toute garantie implicite; et en aucun cas Sunex Tools ne pourra être responsable pour des dommages indirects ou consécutifs.

Remarque : Certaines juridictions ne permettent pas l'exclusion ou la limitation des dommages indirects ou consécutifs; la limitation ou l'exclusion

ci-dessus pourrait donc ne pas s'appliquer à votre cas. Retourner l'équipement ou les pièces à Sunex Tools, ou à un centre de service de garantie autorisé,

port prépayé. S'assurer d'inclure votre nom, votre adresse, une preuve de la date d'achat et la description de la défaillance présumée. Veuillez adresser par

écrit toutes vos questions sur le service de garantie à Sunex Tools. Cette garantie donne à l'acheteur des droits juridiques spécifiques ainsi que certains

autres droits qui peuvent varier selon la juridiction. Les trousses de réparation et de remplacement sont disponibles pour plusieurs produits Sunex Tools,

peu importe si le produit est encore sous garantie.

Adresse d'expédition : Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Adresse postale : Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

SX227B: Vue éclatée des pièces et mode d’emploi 10 rev. 02/09/07

-

-

Loading...

Loading...