Sunex Tools 7793C User Manual [en, es, fr]

MODEL 7793C

CAPACITY: 1/2 TON

TELESCOPIC TRANSMISSION JACK

OWNER'S MANUAL

CONTENTS:

Page 1 Specifications and Features

2Warning Information

3Setup and Operating

4Maintenance, Trouble Shooting

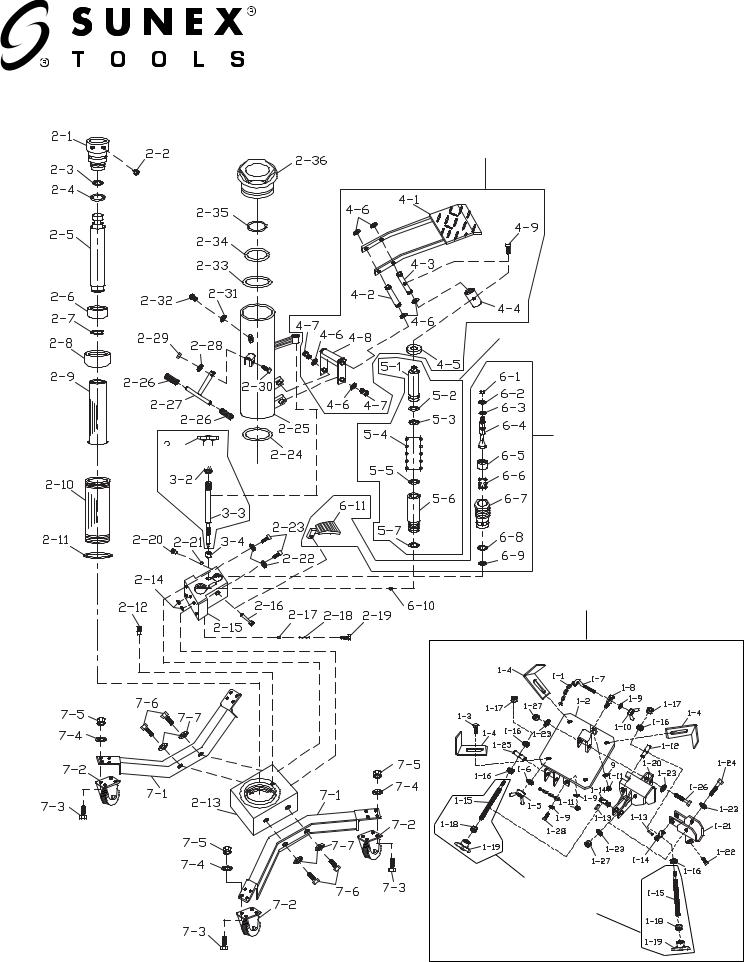

5Exploded View Drawing

6-7 Replacement Parts and Warranty Information

|

SPECIFICATIONS |

|

|

|

Capacity.......................................................................... |

1/2 Ton |

|

|

Low Height......................................................................... |

35.5" |

|

|

High Height............................................................................ |

75" |

|

|

Saddle Tilt................................. |

43° (forward) / 24° (backward) |

|

|

Saddle Tilt ............................................ |

+10°,-27° (side to side) |

|

|

Base Size................................................................ |

31.88" x 35" |

|

|

Saddle Adjustment............ |

14.75" x 14.75" to 23.25" x 23.25" |

|

|

Shipping Weight............................................................. |

171 Lbs |

|

|

|

|

© Copyright 2011, Sunex Tools® |

|

|

|

|

7793C |

1 |

rev. 04/13/11 |

|

Warning Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

|

WARNING: Indicates a hazardous situation |

|

WARNING |

||

which, if not avoided, could result in death |

||

|

or serious injury. |

IMPORTANT: READ THESE INSTRUCTIONS BEFORE OPERATING

IMPORTANT: READ THESE INSTRUCTIONS BEFORE OPERATING

BEFORE USING THIS DEVICE, READ THIS MANUAL COMPLETELY AND THOROUGHLY UNDERSTAND ITS OPERATING PROCEDURES, SAFETY WARNINGS AND MAINTENANCE REQUIREMENTS.

It is the responsibility of the owner to make sure all personnel read this manual prior to using the device. It is also the responsibility of the device owner to keep this manual intact and in a convenient location for all to see and read. If the manual or product labels are lost or not legible, contact Sunex for replacements. If the operator is not fluent in English, the product and safety instructions shall be read to and discussed with the operator in the operator's native language by the purchaser/owner or his designee, making sure that the operator comprehends its contents.

THE NATURE OF HAZARDOUS SITUATIONS

WARNING

WARNING

The use of portable automotive lifting devices is subject to certain hazards that cannot be prevented by mechanical means, but only by the exercise of intelligence, care, and common sense. It is therefore essential to have owners and personnel involved in the use and operation of the equipment who are careful, competent, trained, and qualified in the safe operation of the equipment and its proper use. Examples of hazards are dropping, tipping or slipping of loads caused primarily by improperly secured loads, overloading, off-centered loads, use on other than hard level surfaces, and using equipment for a purpose for which it was not designed.

METHODS TO AVOID HAZARDOUS SITUATIONS

WARNING

WARNING

•Read, study, understand and follow all instructions before operating this device.

•Inspect the jack before each use. Do not use jack if damaged, altered, modified, in poor condition, leaking hydraulic fluid, or unstable due to loose or missing components. Make corrections before using.

•Consult the vehicle manufacturer for the transmission's center of balance.

•Secure the transmission to the jack's saddle with the anchorage restraint system provided before raising or lowering the transmission.

•Center load on saddle. Be sure setup is stable before working on vehicle.

•Support the engine with a stand before unbolting the transmission from the engine.

•Wear eye protection that meets ANSI Z87.1 and OSHA standards.

•Do not use jack beyond its rated capacity.

•Use only on a hard level surface.

•Adequately support the vehicle before starting repairs.

•Use of this product is limited to the removal, installation and transportation in the lowered position, of transmissions, transfer cases and transaxles.

•Do not use any adapters unless approved or supplied by Sunex.

•Always lower the jack slowly and carefully.

•Failure to heed these markings may result in serious or fatal personal injury and/or property damage.

CONSEQUENCES OF NOT AVOIDING HAZARDOUS SITUATIONS

WARNING

WARNING

Failure to read this manual completely and thoroughly and failure to understand its OPERATING INSTRUCTIONS, SAFETY WARNINGS,

MAINTENANCE INSTRUCTIONS and comply with them, and neglecting the METHODS TO AVOID HAZARDOUS SITUATIONS could cause accidents resulting in serious or fatal personal injury and/or property damage.

7793C |

2 |

rev. 04/13/11 |

MODEL 7793C

CAPACITY: 1/2 TON

TELESCOPIC TRANSMISSION JACK

OWNER/USER RESPONSIBILITY

The owner and/or user must have a thorough understanding of the manufacturer’s operating instructions and warnings before using the transmission jack. Personnel involved in the use and operation of equipment shall be careful, competent, trained, and qualified in the safe operation of the equipment and its proper use when servicing motor vehicles and their components. Warning information should be emphasized and understood. If the operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed with the operator in the operator’s native language by the purchaser/owner, making sure that the operator comprehends its contents. Owner and/or user must study and maintain for future reference the manufacturer’s instructions and pertinent warning information Owner and/or user is responsible for keeping all warning labels and instruction manuals legible and intact. Replacement labels and literature are available from the manufacturer.

INSPECTION

Visual inspection should be made before each use of the transmission jack, checking for leaking hydraulic fluid and damaged, loose or missing parts. Each jack must be inspected by a manufacturer’s repair facility immediately if accidentally subjected to an abnormal load or shock. Any jack which appears to be damaged in any way, found to be badly worn, or operates abnormally MUST BE REMOVED FROM SERVICE until necessary repairs are made by a manufacturer’s authorized repair facility. It is recommended that an annual inspection of the jack be made by a manufacturer’s authorized repair facility and that any defective parts, decals or warning labels be replaced with manufacturer’s specified parts. A list of authorized repair facilities is available from the manufacturer

SETUP

PLEASE REFER TO THE EXPLODED VIEW DRAWING IN THIS MANUAL IN ORDER TO IDENTIFY PARTS.

1.Before using jack for the first time, some assembly is required. Place hydraulic unit in upright position and bolt legs to base using

(4) Index #7-6 hex bolts and (4) index #7-7 lock washers.

2.Assemble each caster to leg using (4) index #7-3 hex bolts, (4) index #7-4 washers, and (4) index #7-5 nuts.

3.Attach fingers to saddle using (4) index # 1-3 bolts, (4) index #1-6 washers, and (4) index #1-5 wingnuts.

IMPORTANT! BEFORE USING...

Open reservoir vent screw index #2-32 that is located on the reservoir and below the product label by turning the screw counterclockwise two

(2) full turns. NOTE: JACK WILL NOT OPERATE PROPERLY UNLESS THE VENT SCREW IS OPENED.

If the jack has been used without first opening the reservoir vent screw or the jack has been handled or shipped in different positions, air may be trapped in the hydraulic system. An air trapped system is identified by insufficient incremental pump strokes and failure to extend the telescopic rams to maximum height.

FOLLOW THESE INSTRUCTIONS TO PURGE AIR FROM THE SYSTEM:

1.Make sure the reservoir vent screw index #2-32 is opened two (2) full turns.

2.Open the release valve knob index #3-1 two (2) full turns.

3.Depress the release valve pedal index #6-11 while simultaneously operating the foot pump pedal index #4-1 fifteen (15) times.

4.Remove your feet from the pedals and close the release valve knob index # 3-1.

5.Pump the jack up. If the condition seems better, repeat steps (1 through 4) until all the air is purged from the system.

6.If air seems to be trapped in the secondary (smaller) ram, lower all rams to their collapsed position. Tighten the release valve knob index # 3-1. Insert an allen wrench in the allen socket set screw index #2-2 located in the side of the secondary hexagonal cylinder nut. Slightly turn the allen wrench in a counterclockwise direction while lightly depressing the pump pedal index #4-1. Continue to depress the pump pedal until the hydraulic fluid that escapes from the allen socket set screw hole has no air bubbles. Tighten the allen socket set screw.

OPERATING INSTRUCTIONS

This is the safety alert symbol used for the OPERATING INSTRUCTIONS section of this manual to alert you to potential personal injury hazards. Obey all instructions to avoid possible injury or death.

1.Lift the vehicle to the desired work height and support the vehicle in accordance with the lift manufacturer's recommended support procedure and all the instructions and warnings in this manual.

2.Use an under hoist stand rated greater than the weight of the engine to support the engine before unbolting the transmission from the engine or bolting the transmission to the engine.

3.Position the transmission jack directly under the transmission. Depress the large foot pedal up and down in order to raise the saddle to a height very close to the center of balance point of the transmission oil pan but do not touch the transmission.

4.Adjust the #1-4 fingers on the saddle so that the bent up section of the fingers will fit in the mounting flange around the perimeter of the transmission oil pan. Once the fingers are properly positioned tighten the wing nuts that secure the fingers to the saddle. Slowly and gently pump the jack so the connection is made and then secure the transmission to the jack's saddle with the safety chain provided. Sometimes it is necessary to turn the fore and aft and side to side tilt knobs so the saddle is in the proper alignment with the transmission pan before securing the load to the saddle.

7793C |

3 |

rev. 04/13/11 |

OPERATING INSTRUCTIONS

5.Make sure the safety chain is very tight when securing the transmission to the saddle and before raising or lowering the transmission.

6.Remove the transmission from the engine according to instructions in the vehicle service manual.

7.Once the transmission has been disconnected from the engine, very slowly depress the release pedal to make sure the jack's saddle and transmission do not hang up on any undercar components, wiring, fuel lines, etc. Continue to lower the jack all the way down.

8.When installing a transmission, follow the above instructions but in the applicable order and according to the vehicle manufacturer's installation procedure.

PREVENTATIVE MAINTENANCE

This is the safety alert symbol used for the PREVENTATIVE MAINTENANCE section of this manual to alert you to potential personal injury hazards. Obey all instructions to avoid possible injury or death.

1.Always store the transmission jack in a well protected area where it will not be exposed to inclement weather, corrosive vapors, abrasive dust, or any other harmful elements. The jack must be cleaned of water, snow, sand or grit before using.

2.Lubricate moving parts, excluding the telescopic rams, monthly with a general purpose grease. Periodic lubrication should be subject to a maintenance schedule based on frequency of use. A weekly lubrication inspection is suggested. Premature wearing of components due to lack of or inadequate lubrication is not eligible for warranty consideration.

3.Inspect the jack before each use. Do not use the jack if any component is cracked, broken, bent, shows sign of damage or leaks hydraulic fluid. Do not use the jack if it has loose or missing hardware or components, or is modified in any way. Take corrective action before using the jack again. Premature wearing or damage to components caused by loose or missing hardware is not eligible for warranty consideration.

4.It should not be necessary to refill or top off the reservoir with hydraulic fluid unless there is an external leak. An external leak requires immediate repair which must be performed in a dirt-free environment by qualified hydraulic repair personnel who are familiar with this equipment.

IMPORTANT: In order to prevent seal damage and jack failure, never use alcohol, hydraulic brake fluid or transmission oil in the jack. Use chevron Hydraulic Oil AW 150 32 or its equivalent Unocal Unax AW150. Any jack found to be defective as a result of foreign contaminants in the hydraulic system is not eligible for warranty consideration.

5.Every jack owner is responsible for keeping the jack labels clean and readable. Use a mild soap solution to wash external surfaces of the jack but not any moving hydraulic components. Contact Sunex for a replacement label if your jack's label is not readable.

6.Do not attempt to make any hydraulic repairs unless you are a qualified hydraulic repair person that is familiar with this equipment. Repairs must be performed by an authorized service center.

troubleshooting

Problem |

Action |

|

1. |

Unit will not lift load. |

Purge air from hydraulic system by following procedure under |

|

|

"Important before using" |

|

|

|

2. |

Unit will not sustain load or feels “spongy” |

Purge air from hydraulic system as above. |

|

under load. |

|

|

|

|

3. |

Unit will not lift to full height. |

Purge air from hydraulic system as above. |

|

|

|

4. |

Unit still does not operate. |

Contact Sunex authorized hydraulic service center. |

|

|

|

7793C |

4 |

rev. 04/13/11 |

MODEL 7793C CAPACITY: 1/2 TON TELESCOPIC TRANSMISSION JACK

Parts list and drawing

RS7793BRR

Release Rod

with Knob

with Knob

RS7793FPA

Foot Pedal Assembly

RS7793PA

Pump Assembly

RS7793BRV

Release Valve Assembly

RS6644A

Saddle Assembly

RS6644AR |

Saddle Adjustment |

Rod with Knob |

7793C |

5 |

rev. 04/13/11 |

MODEL 7793C

CAPACITY: 1/2 TON

TELESCOPIC TRANSMISSION JACK

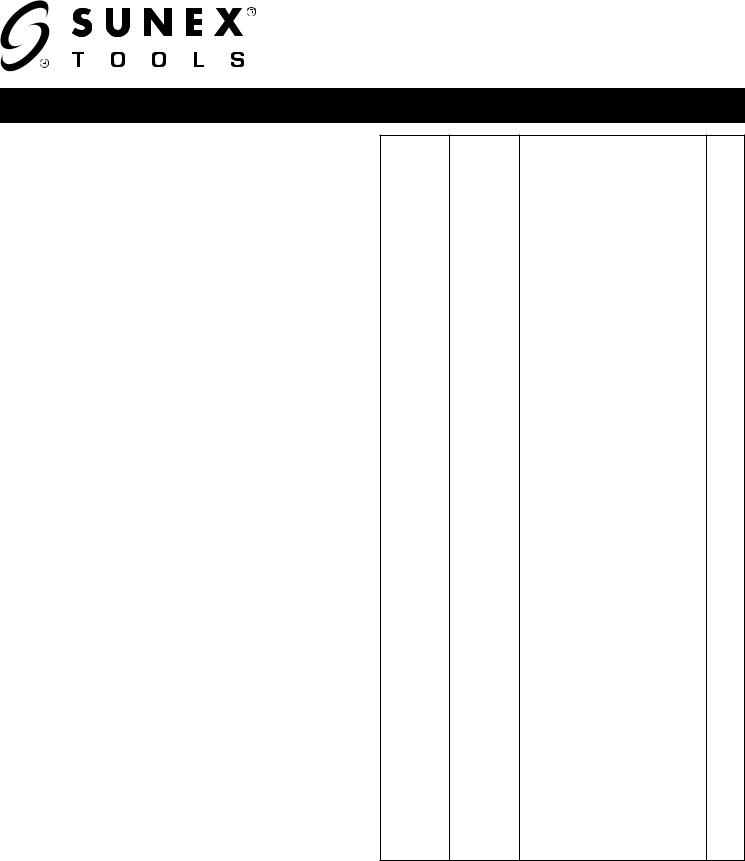

Parts list

Index No. |

Part No. |

Description |

Qty. |

|

Index No. |

Part No. |

Description |

Qty. |

|

2-1 |

|

Guide Bolt |

1 |

3-3 |

RS7793BRR |

Oil Return Valve Rod (incl. 3-1, 3-2, 3-3) |

1 |

||

2-2 |

|

Screw M8x10 |

1 |

|

|

|

|

|

|

|

3-4* |

|

Gasket |

1 |

|||||

|

|

|

|

|

|||||

2-3 |

|

O-Ring |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-1 |

RS7793FPA |

Pedal A ( incl. 4-1 to 4-9) |

1 |

|||||

|

|

|

|

||||||

2-4* |

|

O-Ring |

1 |

||||||

|

|

|

|

|

|

||||

|

4-2 |

|

Shaft |

1 |

|||||

|

|

|

|

|

|||||

2-5 |

|

Piston Rod A |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-3 |

|

Shaft |

1 |

|||||

|

|

|

|

|

|||||

2- |

|

Nut |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-4 |

|

Adapter Sleeve |

1 |

|||||

|

|

|

|

|

|||||

2-7 |

|

Retaining Ring 22 |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-5 |

|

Lock Washer |

1 |

|||||

|

|

|

|

|

|||||

2-8 |

|

Ram Bearing |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-6 |

|

Retaining Ring 14 |

6 |

|||||

|

|

|

|

|

|||||

2-9 |

|

Piston Rod B |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-7 |

|

Shaft |

2 |

|||||

|

|

|

|

|

|||||

2-10 |

|

Oil Cylinder |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-8 |

|

Link Rod |

1 |

|||||

|

|

|

|

|

|||||

2-11* |

|

Gasket |

1 |

|

|||||

|

|

|

|

|

|

||||

|

4-9 |

|

Allen Screw M6x30 |

1 |

|||||

|

|

|

|

|

|||||

2-12* |

|

Filter |

1 |

|

|||||

|

|

|

|

|

|

||||

|

5-1 |

|

Pump Plunger |

1 |

|||||

|

|

|

|

|

|||||

2-13 |

|

Ram Seat |

1 |

|

|||||

|

|

|

|

|

|

||||

|

5-2* |

|

Retaining Ring |

1 |

|||||

|

|

|

|

|

|||||

2-14* |

|

O-Ring |

2 |

|

|||||

|

|

|

|

|

|

||||

|

5-3* |

|

O-Ring |

1 |

|||||

|

|

|

|

|

|||||

2-15 |

|

Pump Seat |

1 |

|

|||||

|

|

|

|

|

|

||||

|

5-4 |

|

Spring |

1 |

|||||

|

|

|

|

|

|||||

2-16 |

|

Pin |

1 |

|

|||||

|

|

|

|

|

|

||||

|

5-5* |

|

O-ring |

1 |

|||||

|

|

|

|

|

|||||

2-17 |

|

Steel Ball 7 mm |

1 |

|

|||||

|

|

|

|

|

|

||||

|

5-6* |

RS7793PA |

Pump Cylinder Assembly |

1 |

|||||

|

|

|

|

||||||

2-18 |

|

Spring |

1 |

||||||

|

|

|

|

(incl. 5-1 to 5-7) |

|

||||

|

|

|

|

|

|

|

|

|

|

2-19 |

|

Screw |

1 |

5-7 |

|

Washer |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-20 |

|

Screw M8x8 |

1 |

6-1 |

|

Locking Nut M6 |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-21 |

|

Steel Ball 6 mm |

1 |

6-2 |

|

Washer 6 |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-22 |

|

Lock Washer 10 |

4 |

6-3 |

|

O-Ring |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-23 |

|

Allen Screw M10x45 |

4 |

6-4 |

|

Valve |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-24* |

|

Gasket |

1 |

6-5 |

|

Spring Sleeve |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-25 |

|

Oil Container |

1 |

6-6 |

|

Spring |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-26 |

|

Handle Sleeve |

2 |

6-7 |

|

Valve Sleeve |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-27 |

|

Handle |

1 |

6-8* |

|

O-Ring |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-28 |

|

Lock Washer 8 |

1 |

6-9* |

|

Gasket |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-29 |

|

Hex Nut M8 |

1 |

6-10 |

|

Steel Ball 8 mm |

1 |

||

|

|

|

|

|

|

|

|

|

|

2-30 |

|

Hex Bolt M8x45 |

1 |

6-11 |

RS7793BRV |

Pedal B Release Assembly |

1 |

||

|

|

|

|

|

|

|

(incl. 6-1 to 6-9, 6-11) |

|

|

2-31* |

|

Gasket |

1 |

|

|

|

|

||

|

|

|

|

|

|

||||

|

|

|

|

7-1 |

RS540062 |

Leg |

2 |

||

2-32 |

RS7793VS |

Reservoir Vent Screw (incl. 2-31) |

1 |

||||||

|

|

|

|

|

|||||

|

|

|

|

7-2 |

RSSC301A |

3" Swivel Caster |

4 |

||

2-33* |

|

O-Ring |

1 |

||||||

|

|

|

|

|

|

||||

|

|

|

|

7-3*** |

|

Hex bolt M8x25 |

16 |

||

2-34* |

|

O-Ring |

1 |

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

7-4*** |

|

Washer 8 |

16 |

||

2-35* |

|

O-Ring |

1 |

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

7-5*** |

|

Nylon Lock Nut M8 |

16 |

||

2-36* |

|

Piston Cap |

1 |

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

7-6** |

|

Hex Bolt M12x25 |

4 |

||

3-1 |

|

Release Knob |

1 |

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

7-7** |

|

Lock Washer 12 |

4 |

||

3-2 |

|

Hex Nut M12 |

1 |

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

|

Not Shown |

RS7793CLK |

Product Label Kit |

1 |

|

|

|

|

|

||||||

*Only available in seal kit, RS7793SK.

**Only available in bolt kit: RS7793BK.

***Only available in RS305004WK Wheel Kit ( hardware for 2 casters) Complete replacement hydraulic unit assembly: RS7793CHU (incl. 2-1 to 6-11). Only index numbers identified by Part Number are available separately.

7793C |

6 |

rev. 04/13/11 |

Loading...

Loading...