Page 1

HIGH TECH SECURES YOUR FUTURE

DGA 2500

DGA 2500

DGA 2500DGA 2500

Diagnostic Gas Analyser

Operator’s Manual

Page 2

Page 3

Operator’s Manual

DGA 2500

DGA 2500

DGA 2500DGA 2500

Software Version V 2.1.0.14

Models: EEEA132

Diagnostic Gas Analyser

Copyright 2002 Snap-on UK Holdings Ltd.

All rights reserved

Part number : ZEEEAGB132A Rev.:C

PCN : 02 E 0293

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C i

Page 4

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C ii

Page 5

DISCLAIMER OF WARRANTIES AND

LIMITATIONS OF LIABILITIES

Whilst the authors have taken due care in the preparation of this manual,

nothing contained herein:

• modifies or alters in any way the standard terms and conditions of the

purchase, lease or rental agreement under the terms of which the

equipment to which this manual relates was acquired,

• increases in any way the liability to the customer or to third parties.

TO THE READER

Whilst every effort has been made to ensure that the information

contained in this manual is correct, complete and up-to date, the right to

change any part of this document at any time without prior notice is

reserved.

ä Before installing, maintaining or operating this unit, please read

this manual carefully, paying extra attention to the safety warnings

and precautions.

a

Copyright 2002 Snap-on UK Holdings Ltd

All Rights Reserved

Sun Electric Europe B.V.

Spaklerweg 69

1099 BB Amsterdam

The Netherlands

Tel: +31.20.5682.622

Fax: +31.20.6947.962

Web-site:

http://www.Sun-diagnostics.com

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C iii

Page 6

iv DGA 2500 2002 - 11

Page 7

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Notes on User Documentation . . . . . . . . . . . . . . . . . . . .5

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.1 Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1 Read all Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Product Specification . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Gas Bench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Propane Equivilance Factor . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 The DGA 2500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1 Platform Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Gas Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Common Program Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Gas Analyser Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 System and Gas Analyser General Screens . . . . . . . .21

5.1 Gas Analyser Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 The Gas Analyser System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Doc. No.: ZEEEAGB132A Operator’s Manual 1

Page 8

TABLE OF CONTENTS

5.3 Gas Analyser Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4 Gas Analyser System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.5 Gas Analyser System Information . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.6 Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6 Preparatory Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.1.1 Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.1.2 Data Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.1.3 Gas Module Pneumatic Connections . . . . . . . . . . . . . . . . .32

6.2 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.2.1 Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.2.2 Gas Analyser Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.2.3 Warm up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.2.4 Zero-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.3 Daily Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.4 HC Residue Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.5.1 Fuel Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.5.2 Speed Factor Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.5.3 Lambda/AFR Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.6 Vehicle Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.6.1 RPM Pick-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.6.2 Oil Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7 Operation — General . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Testing Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.2 Measurement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.3 Shut Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8 Operation – The Free Measurement Procedure . . . . .43

8.1 The Free Measurement Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

8.2 Free Measurement Vehicle Setup . . . . . . . . . . . . . . . . . . . . . . . . . .46

8.3 Saving and Loading Vehicle Setups . . . . . . . . . . . . . . . . . . . . . . . . .48

8.4 Editing Limit Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

8.5 Free Measurement Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . .50

8.6 Storing Data in the Data Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

8.7 The Print Preview Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2 DGA 2500 2002 - 11

Page 9

8.8 Printing Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9 Operation – The SUN EEC Test Procedure . . . . . . . . .57

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.2 SUN EEC Test Vehicle Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.3 Editing Limit Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.4 Saving and Loading Vehicle Set-ups . . . . . . . . . . . . . . . . . . . . . . . . 62

9.5 Test Procedure Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.6 Initialization Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.7 Fast Idle Preconditioning Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.8 Fast Idle Measurement Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.9 Normal Idle Preconditioning Phase . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.10 Normal Idle Measurement Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.11 Results Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.1 System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.2 Leak Check (Vacuum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.3 Leak Check (Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.4 Gas Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.5 Check and/or Install the O2 Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.6 Routine Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.6.1 Periodic Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.6.2 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.6.3 Sample Probe and Hose . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.6.4 Test Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.6.5 O2 Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.6.6 NO Cell (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.6.7 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.7 Error, Warning and System Status Messages . . . . . . . . . . . . . . . . . 95

10.7.1 Automatic Pop-up Windows . . . . . . . . . . . . . . . . . . . . . . . . 95

10.8 The Error/Warning Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.9 Maintenance Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 3

Page 10

TABLE OF CONTENTS

4 DGA 2500 2002 - 11

Page 11

Notes on User Documentation

The DGA 2500 user documentation contains instructions for the safe

operation and efficient use of the unit.

This important information is designed for the prevention of injury to the

operator and/or other persons and for the avoidance of damage to the

unit or vehicles connected thereto.

The user documentation comprises:

• The SUN

introduction to the SUN

safety and operating instructions that are common to all system

modules.

• The DGA 2500 Operator’s Manual describing the DGA 2500 module

in detail and providing instructions for carrying out complete Free

Measurement and SUN ECC vehicle test procedures.

• The appropriate Operator’s Manual or Manuals relating to any

jurisdiction specific test programs (e.g. MOT, AU etc.) that may be

installed.

Whilst no documentation is supplied in printed form, this documentation

is included on the CD-ROM and will be installed on the unit PC during

the installation of the software.

To access the documentation:

• press F1 on the keyboard or the F1 or help button on the remote

control.

or

• Click the “Help” button in the program toolbar.

® Diagnostic Platform Operator’s manual containing an

® Diagnostic Platform system together with

Doc. No.: ZEEEAGB132A Operator’s Manual 5

Page 12

C H A P T E R NOTES ON USER DOCUMENTATION

6 DGA 2500 2002 - 11

Page 13

1 Safety

All Safety Precautions relevant to the unit are described in the Safety

Precautions book, part number: EAZ0007E04A

Figure 1-1 part number: EAZ0007E04A

The Safety Precautions book should be fully understood by every

operator. We suggest that (a copy of) of the Safety Precautions book be

stored near the unit, in sight of the operator.

The Operator’s Manual will contain specific warnings and cautions when

possible dangerous situations may be encountered during the described

procedures.

1.1 Safety Notice

Read this manual thoroughly before operating the unit.

The unit is intended for use by properly trained, skilled professional

automotive technicians. The safety messages presented in the Safety

Precautions book and throughout this manual are reminders to the

operator to exercise extreme care when using this unit.

There are many variations in procedures, techniques, tools, and parts for

servicing vehicles, as well as in the skill of the individual doing the work.

Because of the vast number of test applications and variations in the

Doc. No.: ZEEEAGB132A Operator’s Manual 7

Page 14

C H A P T E R 1 SAFETY

products that can be tested with this instrument, we cannot possibly

anticipate or provide advice or safety messages to cover every situation.

It is the automotive technician’s responsibility to be knowledgeable of the

system being tested. It is essential to use proper service methods and

test procedures and to perform tests in an appropriate and acceptable

manner that does not endanger your safety, the safety of others in the

work area, or vehicle or equipment being tested.

It is assumed the operator has a thorough understanding of vehicle

systems before using the unit. Understanding of these system principles

and operating theories is necessary for competent, safe and accurate

use of this unit.

Before using the unit, always refer to and follow safety messages and

applicable test procedures provided by the manufacturer of the vehicle

or equipment being tested.

Warning:

Warning:

ä Use equipment only as described in the manual.

1.1.1 Read all Instructions

Read, understand and follow all safety messages and instructions in the

Safety Precautions book, this manual and on the unit.

1.2 Conventions

This manual contains text styles that ask you to pay extra attention:

Note:

p Suggestion or explaination.

Caution:

c Stresses that the following action may cause damage to the unit or

objects attached to it.

Warning:

Warning:

ä Stresses that the following action may cause (severe) injury to the

operator or others.

Warning:

Warning:

ä The operator must have full knowledge of all information stated in

the Operator’s Manual.

8 DGA 2500 2002 - 11

Page 15

2 Product Specification

2.1 General

Refer to the SUN® Diagnostic Platform Operator’s Manual for details of

the Power Supply (3.1: ‘Power Supply’) and Dimensions

(3.2: ‘Dimensions’) of the Diagnostic Platform and for the Minimum PC

Specifications (3.3: ‘Minimum PC Specifications’).

2.2 Gas Bench

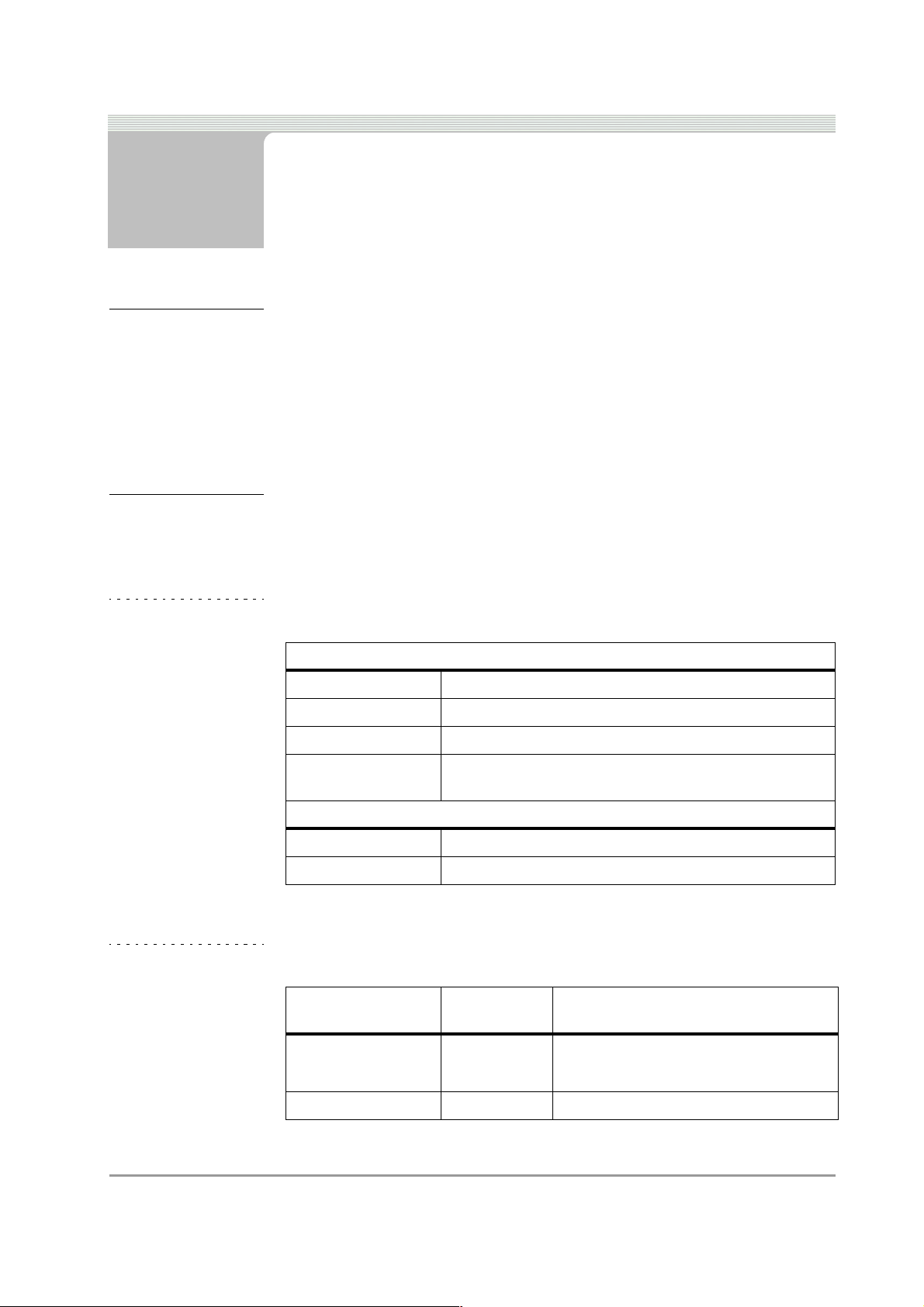

Table 2-1 Operation & Storage

Operating Conditions

Max. ambient temp. +40 °C

Min. ambient temp. +5 °C

Rel. humidity: up to 90%, non-condensing

Max atmospheric

pressure variation

Storage Conditions

Temperature: -20 to +55 °C

Rel. humidity: Up to 90%, non-condensing

Table 2-2 Measurements

Parameter Range/

%vol CO: 0.000 – 9.999

%vol CO

: 0.00 – 18.00 ±5%/±0.5%*

2

700 – 1100 mbar

Accuracy: Relative/Absolute

Resolution

±5%/±0.03*

10.00 –14.00

Doc. No.: ZEEEAGB132A Operator’s Manual 9

Page 16

C H A P T E R 2 PRODUCT SPECIFICATION

Table 2-2 Measurements

Parameter Range/

Resolution

ppmvol HC: 0 – 2000

2000 – 5000

5000 – 9000

%vol O

ppmvol NO (option): 0 – 5000 ±5%/25ppm (at room temperature)

rpm 0 – 9999 ±1.0%

°C: 0 – 120

°F: 14 –302

: 0 – 25.00 ±5%/±0.1*

2

Accuracy: Relative/Absolute

±5%/10ppm*

±5%/10ppm

±10%

Note:

p *accuracy according to OIML Class 0

2.2.1 Propane Equivilance Factor

The P.E.F. value is 0.530.

10 DGA 2500 2002 - 11

Page 17

3 Introduction

3.1 The DGA 2500

The SUN® DGA 2500 is a versatile, high-performance PC-based test

instrument for the analysis of motor vehicle exhaust gases. The unit is

designed to meet the performance requirements of OIML Class 1 and 0

and ISO 3930.

The basic configuration of the unit comprises:

- A gas analysis module containing a Siemens “Sibench” gas

bench.

- A rpm/oil temperature module (ROTI) for the measurement of

engine speed and oil temperature. The unit is supplied with a

Grey inductive pick-up (P/N EAX0048E03A; for use with

conventional HT ignition systems) as standard equipment.

- An exhaust probe and hose assembly, used for the collection of

the gas sample from the vehicle tailpipe.

The DGA 2500 forms part of the SUN

Refer to the SUN

Diagnostic Platform’) for an introduction to the system as a whole.

The addition of an optional USB to 4 x RS232 connector enables a

smoke module, for testing diesel emissions, and a Portable Data Link,

used to obtain information from the vehicle engine management system,

to be connected to the system via the Gas Analyser. This connector can

also be used for external communication with, for example, the

customer’s central computer system.

Specific software versions will be available for performing the emissions

tests specified by separate national or international jurisdictions.

Although this jurisdiction specific software may alter the DGA 2500

standard software described herein, this manual is also applicable to

these specific programs when used in conjunction with the specific

documentation relating to such programs.

® Diagnostic Platform Operator’s Manual (2: ‘The SUN

® Diagnostic Platform System.

Doc. No.: ZEEEAGB132A Operator’s Manual 11

Page 18

C H A P T E R 3 INTRODUCTION

With the standard software the unit is capable of measuring the

concentrations of up to five gases in vehicle exhaust emissions:

- Carbon Monoxide, Carbon Dioxide and Hydrocarbons (CO, CO

and HC) by infra red absorption.

- Oxygen (O

- Oxides of Nitrogen (NO) by electrochemical cell. The NO cell is

optional and is NOT operator changeable.

In addition to the gas measurements the unit also displays:

- Lambda (λ) according to Brettschneider.

- Engine speed (rpm) via the ROTI module. An inductive rpm pickup, to be placed on a secondary ignition cable, is supplied as

standard equipment. A capacitive pick-up, for use on a primary or

injector wire, and a primary ECU/RPM adapter, for connection to

a square wave from the engine management system, are

available as options, thus making the analyser suitable for

conventional, wasted spark and direct ignition systems.

- Oil temperature via the ROTI module by means of an oil

temperature probe substituted for the oil dipstick.

Note:

) by an operator changeable electrochemical cell.

2

p In cases where a Portable Data Link is connected to the analyser, rpm

and oil temperature data will be obtained via the PDL.

2

CO corrigé (CO

type.

c) may be displayed using a formula corrected for fuel

3.2 Maintenance

Details of the maintenance operations that should be carried out by the

operator are included in this manual together with a list of operator

service messages and a list of maintenance parts.

All maintenance operations, other than those specifically described in

this manual, must be carried out by trained service personnel authorised

by the manufacturer.

In particular, full gas calibrations must only be performed by a qualified

representative of the manufacturer.

12 DGA 2500 2002 - 11

Page 19

OPTIONS

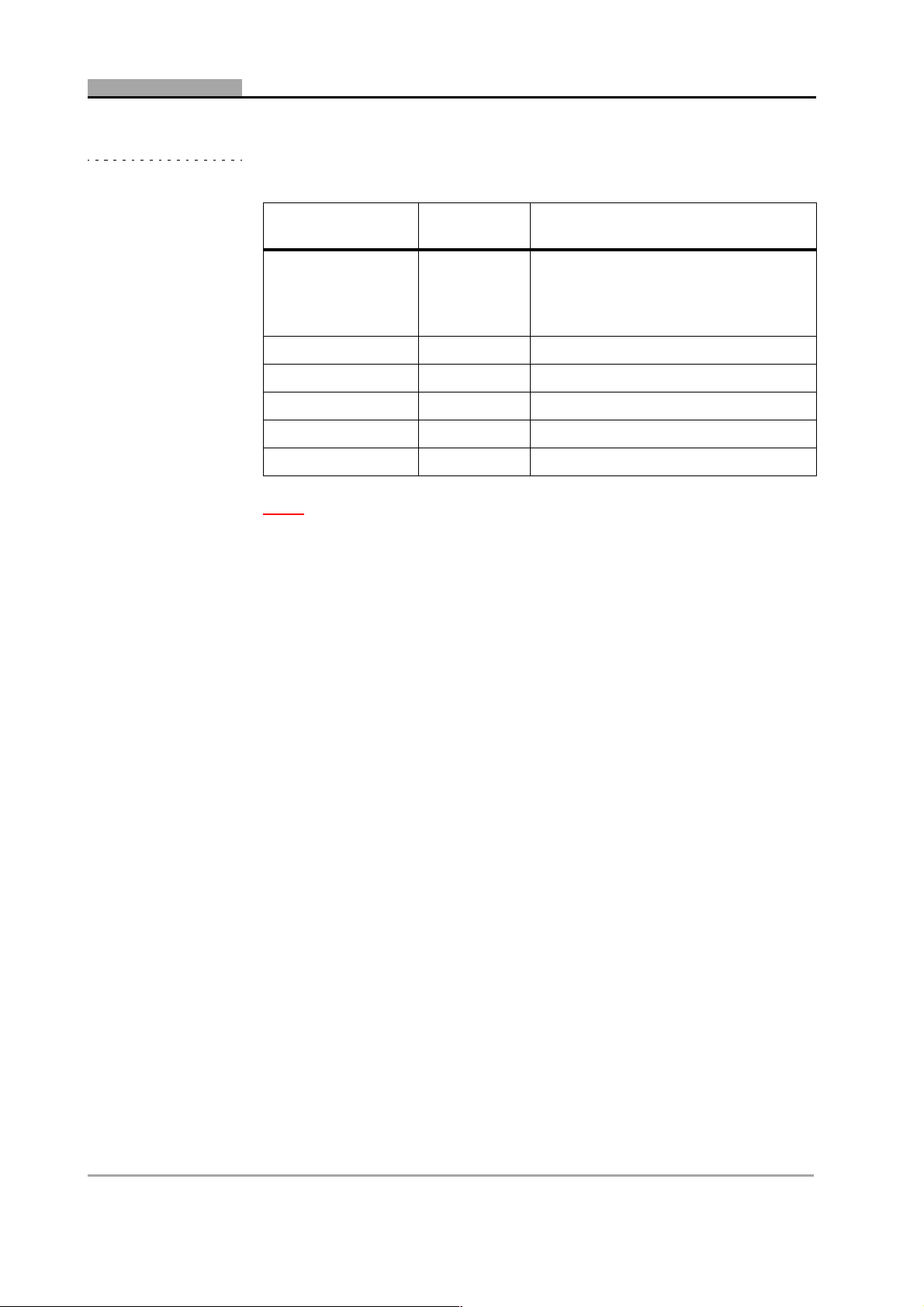

3.3 Options

The optional parts are available for the DGA 2500 are shown by the

table.

Table 3-1 Options

Part No. Description

EAK0245E01A Serial Interface Board Kit

EAK0245E02A NO Sensor Kit

EAK0245E04A PRIM/ECU rpm adaptor Kit

EAX0048E06A Capacitive rpm Pick-up Kit

7009E9322-69 Exhaust Probe Kit (High Temperature)

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 13

Page 20

C H A P T E R 3 INTRODUCTION

14 DGA 2500 2002 - 11

Page 21

4 Functional Description

4.1 Platform Layout

Refer to the SUN® Diagnostic Platform Operator’s Manual (4.1: ‘General

Layout’) for details of the Diagnostic Platform general layout .

4.2 Gas Module Layout

23 4 5 67891011 12

1

18

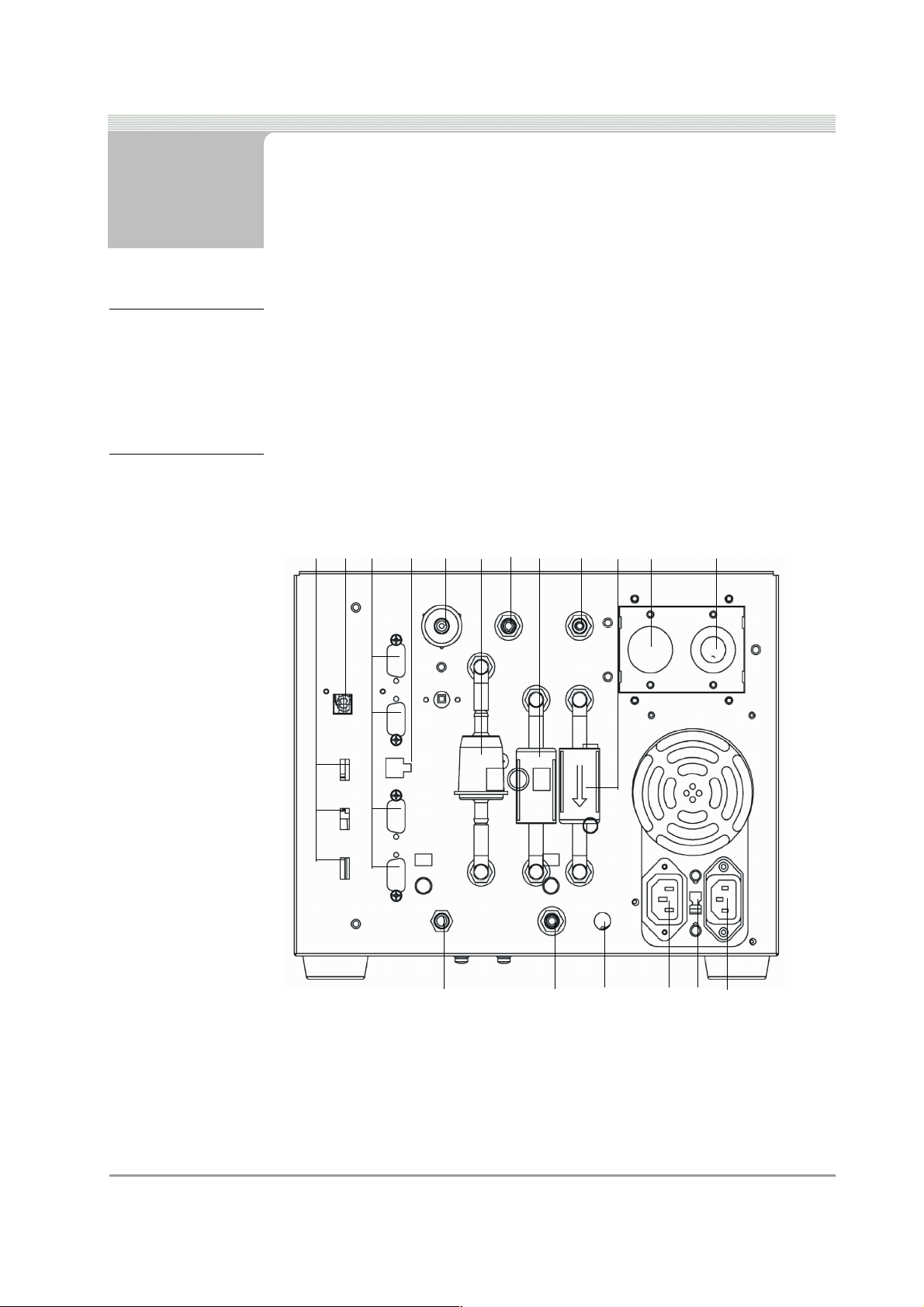

Figure 4-1 The Gas Module - Rear Panel

1. 3 x USB connections (used for connection to ROTI module,Infa red

reciever etc)

2. USB connection for PC interface

Doc. No.: ZEEEAGB132A Operator’s Manual 15

17

13141516

Page 22

C H A P T E R 4 FUNCTIONAL DESCRIPTION

3. 4 x RS232 connections (used for connection to Smoke Module,

Portable Data Link etc)

4. DC power output (for use with future options)

5. Clean air inlet (with charcoal filter (p/n 7096E9061-99) to filter

incoming air)

6. Primary filter (p/n 7096E9062-98)

7. Calibration gas inlet (used for the supply of calibration gas to the unit)

8. Gas Filter (white, p/n 7096E9061-03)

9. Gas sample inlet (connection point for exhaust probe/sample hose

assembly)

10. Water filter (blue, IDN-8G, p/n 7096E9061-02)

11. NO sensor (Behind cover plate; optional; p/n 7096E4060-20).

2 Sensor (behind cover plate; p/n 7096E4060-31)

12. O

13. 115/230 V~ in (115/230 V~ from cabinet power distribution system)

14. Voltage selector switch (selects 115 V~ or 230 V~)

15. 115/230 V~ out (may be used as power supply for optional or other

equipment)

16. NO outlet (gas sample outlet from NO sensor)

17. Water outlet (connect a tube to this outlet to drain water from the

water removal system)

18. Gas sample outlet (outlet for gas sample from gas bench)

16 DGA 2500 2002 - 11

Page 23

COMMON PROGRAM ELEMENTS

4.3 Common Program Elements

For details of program elements that are common across the SUN®

Diagnostic Platform system, refer to the following sections of the

Diagnostic Platform Operator’s Manual:

• For details of screen elements, refer to the Diagnotstic Platform

Manual 4.2: ‘Screen Elements’.

• For details of buttons together with an illustrated guide to icons used

in common by all system modules, refer to the Diagnostic Platform

Manual 4.3: ‘Buttons’.

• For details of the use of drop-down menus, refer to the Diagnostic

Platform Manual 4.4: ‘Drop-down Menus’.

• For details of Diagnostic Platform System Screens, refer to the

Diagnostic Platform Manual 5: ‘Diagnostic Platform System Screens’.

• For details of controls and navigation, refer to the Diagnostic Platform

Manual 6.1: ‘Navigation’.

4.4 Gas Analyser Icons

The toolbar and menu icons shown in the tables are specific to the Gas

Analyser.

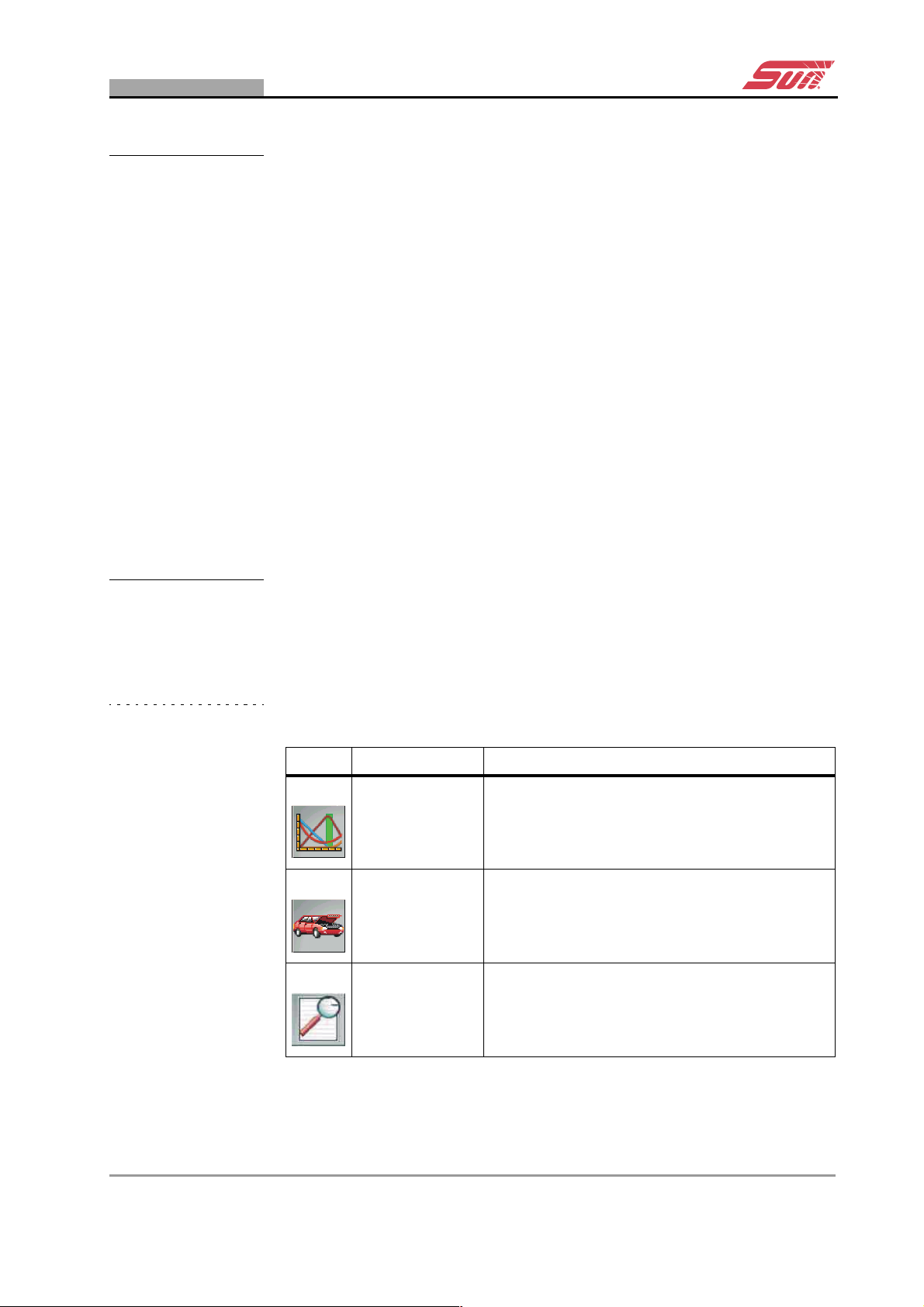

Table 4-1 Gas Analyser Toolbar Icons

Icon Name Desription

Gas Analyser

Vehicle Setup

Print Preview Use this button to preview the data to be printed.

Use this button to return to the Gas Analyser

Main Menu.

Use this button to access the vehicle setup

screens (see 8.2: ‘Free Measurement Vehicle

Setup’ and 9.2: ‘SUN EEC Test Vehicle Set-up’).

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 17

Page 24

C H A P T E R 4 FUNCTIONAL DESCRIPTION

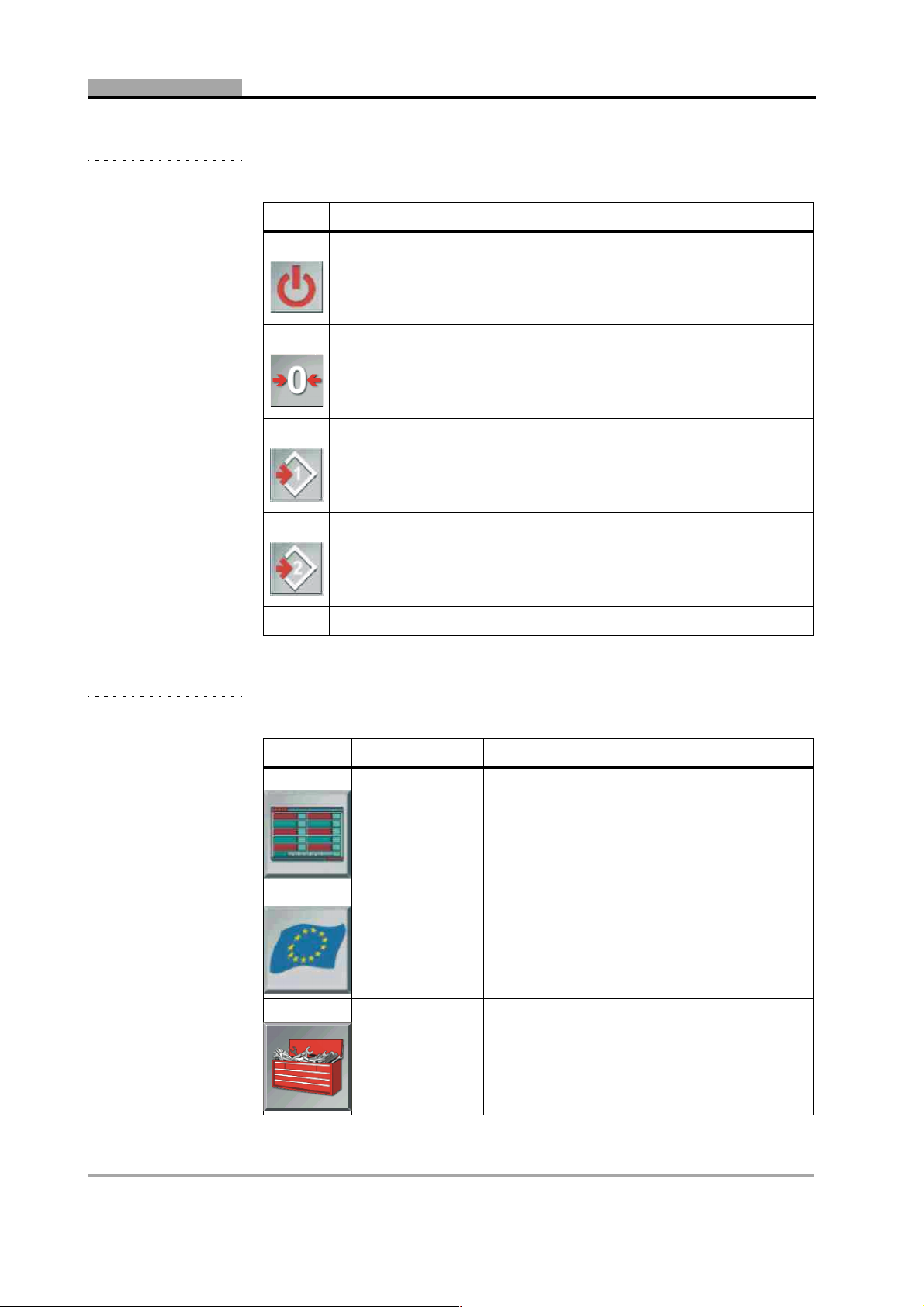

Table 4-1 Gas Analyser Toolbar Icons

Icon Name Desription

Standby

Zerocalibration

Toggle Limits 1

Toggle Limits 2

Table 4-2 Gas Analyser Menu Icons

Use this button to place the unit in standby

mode.

Use this button to manually initiate a zerocalibration (see 6.2: ‘Start-Up’).

Indicates that limit set 1 is currently applied; click

to toggle to limit set 2; (see 8.2: ‘Free

Measurement Vehicle Setup’ and 8.5: ‘Free

Measurement Test Procedure’).

Indicates that limit set 2 is currently applied: click

to toggle to limit set 1; (see 8.2: ‘Free

Measurement Vehicle Setup’ and 8.5: ‘Free

Measurement Test Procedure’).

Icon Name Description

Free

Measurement

Selects the Free Measurement Program (see

8: ‘Operation – The Free Measurement

Procedure’)

Selects the EU test procedure (see

EU

Gas Analyser

System Setup

9: ‘Operation – The SUN EEC Test

Procedure’)

1

Selects the The Gas Analyser System Menu

18 DGA 2500 2002 - 11

Page 25

GAS ANALYSER ICONS

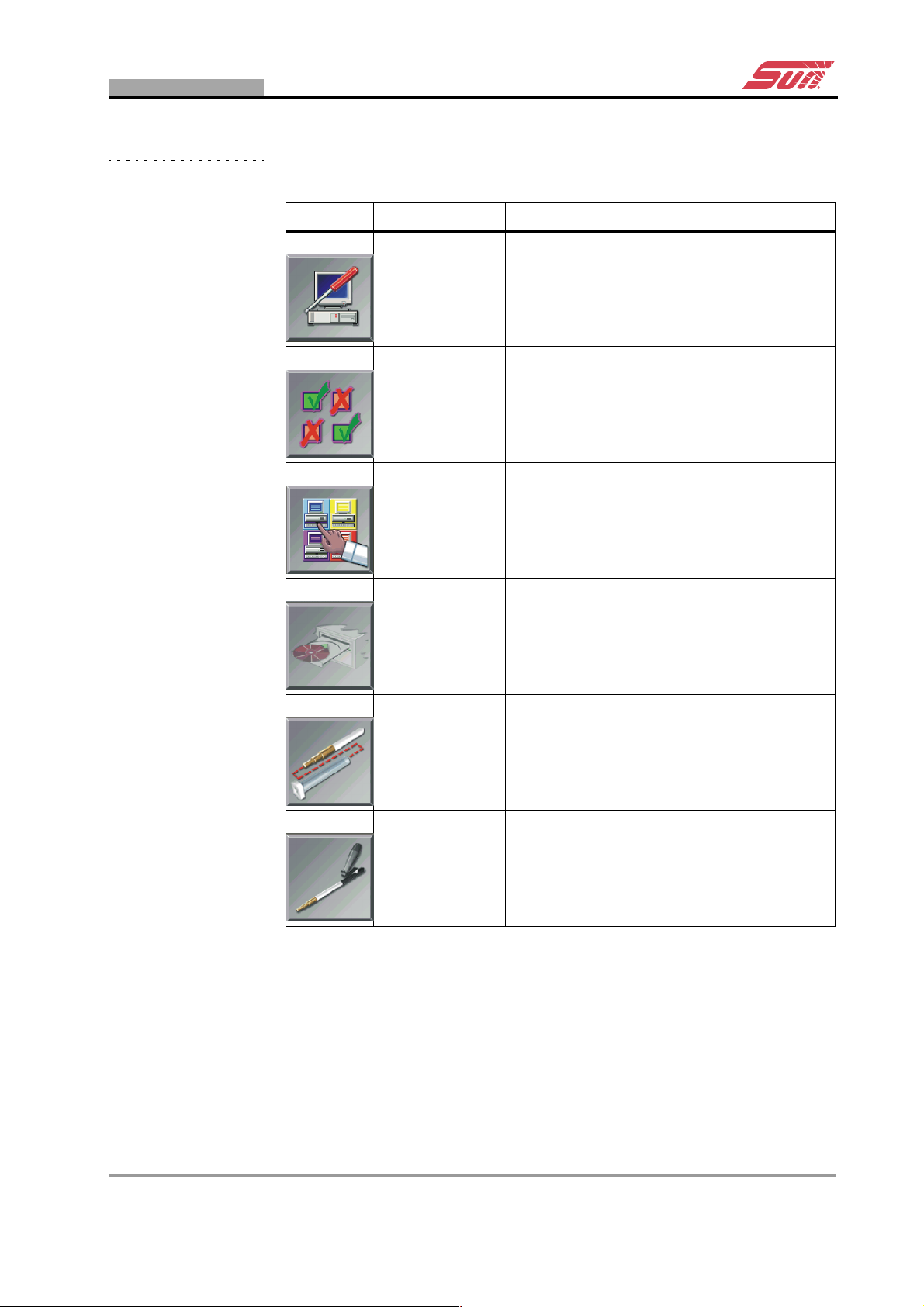

Table 4-2 Gas Analyser Menu Icons

Icon Name Description

Maintenance Selects the Gas Analyser Maintenance Menu

Setings Selects the Gas Analyser System Settings

Gas Analyser

System

Infomation

Selects Gas Analyser System Information

Gas analyser

Software

Update

Leak Check

(Vacuum)

Leak Check

(Gas)

Allows updated softwareto be loaded.

Currently disabled.

Initiates the Leak Check (Vacuum)

maintenance procedure.

Initiates the Leak Check (Gas) maintenance

procedure.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 19

Page 26

C H A P T E R 4 FUNCTIONAL DESCRIPTION

Table 4-2 Gas Analyser Menu Icons

Icon Name Description

Gas Calibration

Check

Check/install

O

Cell

2

1

If a specific national test procedure is installed on the unit, the EU icon button will

be replaced by the button relating to that procedure.

Initiates the Gas Calibration Check

maintenance procedure.

Initiates the Check and/or Install the O2 Cell

maintenance procedure.

20 DGA 2500 2002 - 11

Page 27

5 System and Gas Analyser

General Screens

This Chapter contains:

• A description of the DGA 2500 Gas Analyser System Screens. Gas

Analyser System Screens are defined as being screens shown by the

DGA 2500 that do not relate to a specific test procedure. These

Screens comprise:

- The Gas Analyser Main Menu (5.1: ‘Gas Analyser Menu’).

- The Gas Analyser System Menu (5.2: ‘The Gas Analyser System

Menu’).

- The Gas Analyser Maintenance Menu (5.3: ‘Gas Analyser

Maintenance Menu’).

- The Gas Analyser System Settings Screen (5.4: ‘Gas Analyser

System Settings’).

- The Gas Analyser System Information Window (5.5: ‘Gas

Analyser System Information’).

• Details of the procedure to be followed in order to obtain a printout of

the DGA 2500 gas analysis test results (5.6: ‘Print’).

Descriptions of the SUN

System Setup screens may be found in the Diagnostic Platform

Operator’s Manual (5.1: ‘The Diagnostic Platform Main Menu’ & 5.2: ‘The

General System Setup Screen’).

® Diagnostic Platfrom Startup and General

Doc. No.: ZEEEAGB132A Operator’s Manual 21

Page 28

C H A P T E R 5 SYSTEM AND GAS ANALYSER GENERAL SCREENS

5.1 Gas Analyser Menu

.

Figure 5-1 The Gas Analyser Menu

• To access the Gas Analyser Menu , select the “Gas Analyser” option

from The Diagnostic Platform Main Menu (see the SUN

Platform Operator’s Manual 5.1: ‘The Diagnostic Platform Main

Menu’).

The following options may be selected:

- Free Measurement Procedure.

- SUN EEC Test Procedure.

- The Gas Analyser System Setup Menu.

Note:

p If the DGA 2500 is configured to perform a country specific test

procedure, the SUN EEC test procedure will not be available. In this

case the “SUN EEC Test” button will be replaced by an icon button

corresponding to the country specific test in question.

• The “Free Measurement” procedure.

The Free Measurement procedure continuously measures and

displays the values for all available test parameters. Upper and lower

limits for any or all of these parameters may be introduced as

required. Refer to 8: ‘Operation – The Free Measurement

Procedure’for further information.

® Diagnostic

• The “SUN EEC Test” procedure.

22 DGA 2500 2002 - 11

Page 29

GAS ANALYSER MENU

The SUN EEC Procedure is based on the provisions of EU directives

which specify a procedure to be followed in testing motor vehicle

emissions and prescribes maximum default values for certain gas

emissions and related parameters. Refer to 9: ‘Operation – The SUN

EEC Test Procedure’.

• The “System Setup” option.

The The Gas Analyser System Menu allows operator maintenance

functions to be initiated, gas analyser system settings to be made,

gas analyser system information to be consulted and updates to the

gas analyser software to be loaded. Refer to 5.2: ‘The Gas Analyser

System Menu’ for further information.

• To return to the The Diagnostic Platform Main Menu, press the

“Home” icon button on the toolbar.

• To place the Gas Analyser in Standby Mode, press the “Standby” icon

button on the toolbar.

Once the Gas Analyser is switched on, it should remain on for the

whole working day, however, it is recommended that the unit should

be put into Standby Mode when tests are not being performed. This

will reduce waer and tear to the pump and increase the effecive life

of the filters.

The unit will return to the normal operating mode when:

- The “Standby” button is pressed once more, or

- One of the Gas Analyser Main Menu option buttons (“Free

Measurement”, “SUN EEC Test” “Country Specific Test”, or

“System Setup”) is pressed.

On leaving the Standby Mode, a Zero-calibration (see 6.2.4) and HC

Residue Check (see 6.4) will automatically be performed before the unit

returns to normal operation.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 23

Page 30

C H A P T E R 5 SYSTEM AND GAS ANALYSER GENERAL SCREENS

5.2 The Gas Analyser System Menu

Figure 5-2 The Gas Analyser System Menu

• To access the Gas Analyser System Menu , select the “System

Setup” option from the Gas Analyser Menu (see 5.1).

The Gas Analyser System Menu allows access to:

- The Gas Analyser Operator Maintenance Procedures.

- The Gas Analyser System Settings Screen.

- The Gas Analyser System Information Screen.

- The Gas Analyser Software Update Screen.

• To access the Gas Analyser Maintenance Menu, select the

“Maintenance” menu button.

The Gas Analyser Maintenance Menu Screen will be displayed, via

which leak checks, gas calibration checks and O

be initiated. Refer to 5.3 for a description of the Maintenance Menu

Screen and to Chapter 10: ‘Maintenance’for details of the available

maintenance procedures.

• To access the Gas Analyser System Settings Screen, select the

“System Settings” option.

The System Settings Screen allows settings to be made affecting the

operation of the gas Analyser. Refer to 5.4 for further information.

2 sensor checks can

• To reveal the Gas Analyser System Information window, select the

“System Information” option.

24 DGA 2500 2002 - 11

Page 31

GAS ANALYSER MAINTENANCE MENU

The System Information Pop-up Window provides details of gas

calibration dates, software versions etc. Refer to 5.5 for further

information.

• To access the Software Update Screen, select the “Update Software”

option.

Details of the software update procedure will be supplied with the

relevant software.

• Press “Back” or the “Gas Analyser” toolbar icon button to return to the

Gas Analyser Menu.

5.3 Gas Analyser Maintenance Menu

Figure 5-3 The Gas Analyser Maintenance Menu

• To access the Gas Analyser Maintenance Menu, select the

“Maintenance” option from the The Gas Analyser System Menu (see

5.2).

The Maintenance procedures that can be initiated from the Gas

Analyser Maintenance Menu are:

- Leak Check (Vacuum) (see 10.2).

- Leak Check (Gas) (see 10.3).

- Gas Calibration Check (see 10.4).

- Check and/or Install the O2 Cell (see 10.5).

• To initiate a Leak Check (Vacuum), select the “Leak Check (Vacuum)

option.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 25

Page 32

C H A P T E R 5 SYSTEM AND GAS ANALYSER GENERAL SCREENS

• To initiate Leak Check (Gas), select the Leak Check (Gas) option.

• To initiate a Gas Calibration Check, select the Gas Calibration Check

Option.

• To Check and/or Install the O2 Cell, select the O

Option.

Details of the procedures for these checks are to be found in

10: ‘Maintenance’.

5.4 Gas Analyser System Settings

.

2 Sensor Check

Figure 5-4 The Gas Analyser System Settings Screen

To access the Gas Analyser System Settings Screen, select the “System

Settings” option from the The Gas Analyser System Menu (see 5.2).

The Gas Analyser System Settings Screen comprises drop-down menus

for the selection of:

- Lambda/AFR.

- Summertime On/Off.

- LPG composition.

• Use the “Summertime On/Off” drop-down menu to switch between

Summertime/Wintertime.

The Summertime/Wintertime information is required by the gas

module for the calculation of daily leak check and gas calibration

intervals.

26 DGA 2500 2002 - 11

Page 33

GAS ANALYSER SYSTEM SETTINGS

• Use the Lambda/AFR drop down menu to select either Lambda or Air

Fuel Ratio (AFR).

Depending on the selection, the unit will calculate and display either

Lambda or Air Fuel Ratio.

• Use the LPG Composition drop-down menu to specify the appropriate

ratio of Butane (C

test vehicle.

The available range is from 100% Butane to 100% Propane in 10%

increments. This information is required for the determination of the

ratio of Hydrogen to Carbon present in the fuel, which information is,

in turn, used for the accurate determination of Lamdba.

Note:

4H10) to Propane (C3H8) in the LPG fuel used by the

p The composition of LPG fuel may vary from country to country. If the

composition of the LPG fuel is not known, set the Butane/Propane ratio

to 50%/50%. If the composition is known (e.g. LPG used in the United

Kingdom has a composition of 0% Butane/100% Propane), this ratio

should be selected.

• Press “OK” to apply the settings made in the Gas Analyser System

Settings Screen and return to the The Gas Analyser System Menu.

• Press “Cancel” to return to the The Gas Analyser System Menu

without applying any changes made in the Gas Analyser System

Settings Screen.

• Press the “Gas Analyser” toolbar button to return to the Gas Analyser

Menu.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 27

Page 34

C H A P T E R 5 SYSTEM AND GAS ANALYSER GENERAL SCREENS

5.5 Gas Analyser System Information

Figure 5-5 The Gas Analyser System Information Window

• To open the Gas Analyser System Information Window, select the

“System Information” option from the The Gas Analyser System Menu

(see 5.2).

The Gas Analyser System Information Window comprises six tabs:

- System Information (includes application versions, checksums

etc.).

- Gas Tag Values (displays the composition of the gases used for

gas calibration)

- Gas Settings (includes approval type, gas calibration interval,

summertime on/off setting, daily leak check requirement etc.).

- Service Dates (shows the last and next calibration dates, last leak

check date, date of sensor installation etc.)

- Factors (includes the applied PEF, NO gain and NO cell aging

factors).

- File Versions (Lists the version numbers of .dll and .exe files in

the DGA software)

28 DGA 2500 2002 - 11

Page 35

PRINT

5.6 Print

Figure 5-6 The “Notes” Dialog Box 1

Note:

p The DGA 2500 uses the same “Print” procedure to provide a printout of

all gas analyser test results. The following description is, therefore,

applicable irrespecive of whether the Free Measurement, SUN EEC or

Country Specific test procedure is employed.

• Open the “Notes” dialog box:

- By pressing the “Print” toolbar icon button, or

- By pressing the “Print” text button in the The Print Preview

Window (Free Measurement procedure only (see 8.7)).

The “Notes” dialog box will be displayed. The vehicle identification

information headings, entered via the “Printout Footer” box of the The

General System Setup Screen (see the Diagnostic Platform

Operator’s Manual 5.2: ‘The General System Setup Screen’), will be

shown in the left-hand text box.

• Enter the vehicle identification information for the test vehicle in the

right-hand text box, opposite the appropriate heading.

Figure 5-7 The “Notes” Dialog Box 2

• Press “OK” to make a printout of the test results.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 29

Page 36

C H A P T E R 5 SYSTEM AND GAS ANALYSER GENERAL SCREENS

A typical sample results printout is illustrated below..

• Press “Cancel” to abort the print instruction and return to the test

procedure.

Note:

p Calculated values will be shown for either Lambda or AFR depending on

the setting made in the Gas Analyser System Settings Screen (see 5.4).

Note:

p Although the printout format allows all test parameters to be shown,

numerical values will only be shown for the limit values applied and test

results obtained during the current test. Fields for which no data is

available will show a series of dashes.

Figure 5-8 Sample Printout

30 DGA 2500 2002 - 11

Page 37

6 Preparatory Steps

6.1 Connections

Warning:

ä For your own and other people’s safety the DGA 2500 must only be

used in a well ventilated clean air environment

6.1.1 Power Connections

Caution:

c Before making any power connections ensure that the mains power

switch is set to “off” and that the mains voltage selector switch is

set to correspond with the local mains supply voltage.

Power is supplied to the Gas analyser from the SUN

Platform electrical distribution block via an electrical input socket located

on the rear panel of the Gas Module (see 4.2: ‘Gas Module Layout’).

6.1.2 Data Connections

Communication between the PC. Gas Module, ROTI module and infra

red Remote Control Receiver takes place via the USB (Universal Serial

Bus) connectors located on the Gas Module rear panel (see 4.2: ‘Gas

Module Layout’).

An optional USB to 4 x RS232 connector may be installed in the Gas

Module allowing for communication with optional ancillary equipment

(Smoke Meter, Portable Data Link Etc.). Connection details for such

optional ancillary equipment will be found in the relevant documentation

that will be supplied together with the equipment.

• Connect the PC USB port to the Gas module via the USB P.C.

interface connector on the Gas Module rear panel.

The P.C. interface is marked with the letter “E” on the Gas Module

rear panel.

• Connect the ROTI Module and Remote Control Receiver to the USB

connectors on the Gas Module rear panel.

® Diagnostic

Doc. No.: ZEEEAGB132A Operator’s Manual 31

Page 38

C H A P T E R 6 PREPARATORY STEPS

The USB connectors are marked with the letters “F”, “G” and “H” on

the Gas Module rear panel. Connect the ROTI Module to “G” and the

Remote Control Receiver to “F”.

Note:

p If the DGA 2500 is used in conjunction with a Portable Data Link

(Scanner), the unit will derive rpm and oil temperature data direct from

the test vehicle engine management system via the PDL. In this case the

use of the ROTI Module is unnecessary.

• Connect the Printer, Mouse and Keyboard to the P.C. Printer, Mouse

and Keyboard ports.

6.1.3 Gas Module Pneumatic Connections

• Connect the Exhaust Sample Probe and Hose to the Gas Sample

Inlet on the Gas Module rear panel.

Note:

p Do not insert the Sample Probe into the vehicle exhaust tailpipe at this

stage.

6.2 Start-Up

6.2.1 Power Up

• Set the Main, PC and Gas Module power switches to “On”.

The PC will load the Windows Operating System. After a short

interval the Windows desk-top will be displayed.

Note:

p For normal operating purposes it is recommended that the PC and Gas

Module power switches be left permanently in the “On” position and that

the unit be turned on and off with the Diagnostic Platform main power

switch.

• Select the SUN

Windows start menu or the shortcut on the desk-top.

The operating system will load the software and the The Diagnostic

Platform Main Menu will be displayed (see the Diagnostic Platform

Operator’s Manual 5.1: ‘The Diagnostic Platform Main Menu’).

• Select the Gas Analyser option from the Main Menu.

Selecting the Gas Analyser mode will display the Gas Analyser Menu

(see 5.1: ‘Gas Analyser Menu’).

® Diagnostic Platform program using either the

32 DGA 2500 2002 - 11

Page 39

START-UP

Note:

p The body of this manual concerns the operation of the DGA 2500 in Gas

Analyser mode only. Information concerning the use of the unit in

conjunction with the Diesel Smoke Meter, Portable Data Link, and

Engine Diagnostics menu options will be provided as separate

documentation.

6.2.2 Gas Analyser Start-up

At start-up, the analyser will automatically perform the following functions

in sequence:

- Warm up.

- Zero-calibration.

- HC residue check.

While these functions are being performed, “pop-up” windows will be

automatically displayed showing the status of the unit. These windows

will automatically close when the function has been successfully

completed. They may be manually closed at any time to give full access

to the screen buttons.

Note:

p A manually closed pop-up window can reappear if a new screen is

selected which requires a change in the Gas Analyser mode, e.g. a popup screen can reappear if a leak check is selected but will not reappear

when moving to a different menu or set-up screen.

If the system is configured to require a Daily Leak Check (see 6.3), the

operator will be prompted to perform this during the initial start-up

sequence.

6.2.3 Warm up

The warm-up and stabilisation period normally lasts approximately 90

seconds. During this time:

- The pump will run continuously.

- The unit will check for condensation in the gas bench.

- The warm up pop-up screen will be displayed showing the

elapsed warm up time (unless manually closed).

If the gas bench and PC are switched on simultaneously (by use of the

main power switch), the warm-up period will proceed in the background

whilst the PC loads the Windows operating system. Since the time

needed to load the operating system is greater than the warm-up period,

the latter will not be apparent to the operator. Conversely, if the gas

bench is switched on after the operating system and Diagnostic Platform

software has been loaded by the PC, the warm-up period will be visible.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 33

Page 40

C H A P T E R 6 PREPARATORY STEPS

Note:

p The warm up period cannot be overridden by the operator.

At the end of the warm up period the unit will proceed to zero-calibration.

6.2.4 Zero-calibration

Zero-calibration, which allows the Gas Module to determine the correct

zero reference and gain settings, lasts approximately 30 seconds.

During this time:

- The pump will initially be off and will cut in after approximately 10

seconds.

- The zero-calibration pop-up screen will be displayed showing the

elapsed calibration time.

An zero-calibration may be triggered in three ways:

- As part of the start-up procedure or on return from standby mode

(initial zero-calibration).

- Automatically by the Gas Bench as required (automatic zerocalibration; see note below).

- Manually by the operator from The Free Measurement Screen

(see 8.1) (manual zero-calibration).

An initial or manual zero-calibration (but not an automatic zerocalibration) will be followed by a HC residue check (see below).

If the system is configured to require a Daily Leak Check, the unit will

prompt the operator to perform this at the end of the zero-calibration

period. Until a successful leak check has been preformed all

measurements will be blocked and it will not be possible to proceed

beyond the Gas Analyser Menu (see 6.3: ‘Daily Leak Check’ below for

further details).

Note:

p The gas bench automatically assesses the stability of the zero reference

and gain settings and will perform an zero-calibration as and when

required. The frequency with which an automatic zero-calibration is

performed will depend on the stability of the environment in which the

analyser is operated. If a CO

detected at the time the gas bench determines that an automatic zerocalibration is necessary, the software will assume that gas

measurements are currently being taken. In this case the zerocalibration will be delayed until the CO

0.5% vol. or for a maximum of 30 minutes. The Error/Warning toolbar

button will be displayed. If this button is pressed, error/warning code 06

will be seen, advising that a zero-calibration is pending

2 concentration of 0.5 % vol. or greater is

2 measurement has fallen below

34 DGA 2500 2002 - 11

Page 41

DAILY LEAK CHECK

Note:

p During zero-calibration the DGA 2500 derives the zero reference point

settings from the atmospheric conditions of the environment in which it is

operated. If the operating environment is poorly ventilated, or if sources

of atmospheric pollution (e.g. petrol soaked rags etc.) are present in

close proximity to the unit, this may lead to the zero reference points

being set too high. This may, in turn, lead to vehicle emission readings

that are below the zero reference settings of the analyser (“negative

indications”). To avoid this problem, the operating environment should be

well ventilated and possible sources of atmospheric pollution should be

removed.

6.3 Daily Leak Check

The accuracy of test measurements will be compromised if ambient air is

allowed to enter the analyser sampling and/or pneumatic systems. In

order to ensure the integrity of the system, the standard software

configuration requires that a leak check should be carried out prior to the

commencement of each day’s operation. The unit will not be capable of

normal operation unless a successful leak check has been carried out

within the preceding 24 hours. If the operator fails to carry out a daily

leak check, or if a leak check is failed, an error warning will appear in the

toolbar and all gas measurements will be blocked until a satisfactory leak

check has been performed.

Note:

p If the unit is left running continuously, the standard software configuration

will require a leak check to be performed within 24 hours of the previous

check. If the unit is switched off (e.g. overnight) the software will require

a leak check at the start of each operating day even if the previous leak

check was performed within the last 24 hours.

Note:

p The daily leak check requirement may be deactivated by Sun service

personnel unless the unit is configured for an approval type under which

such a check is mandatory

The leak check requirement may be satisfied by the successful

performance of either:

-A Leak Check (Vacuum) (see 10.2), or

-A Leak Check (Gas) (see 10.3).

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 35

Page 42

C H A P T E R 6 PREPARATORY STEPS

6.4 HC Residue Check

A HC residue check will follow every initial or manually triggered zerocalibration.

The HC residue check will be aborted or postponed if a maintenance

function is selected (e.g. in order to perform a leak check) The residue

check will be resumed when the maintenance function is exited.

The HC residue check lasts a minimum of 20 seconds with no upper

time limit. During the check the unit will:

- Display the HC Residue Check pop-up window.

- Determine the concentration of hydro-carbons present in the gas

circuit. If a concentration greater than 20 ppm is found the pop-up

window will continue to be displayed and all measurements will

be blocked until the concentration of HC present in the analyser

has fallen to within the acceptable limits.

Caution:

c The sample probe must not be allowed to remain in the vehicle

exhaust tailpipe during the HC residue check. A concentration of

more than 0.5 % vol. co

vehicle exhaust gases are being drawn into the unit. The program

will prompt the operator to remove the sample probe from the

tailpipe and all measurements will be blocked until this has been

done.

As ambient air is drawn through the gas circuit, the concentration of HC

should fall. If the residue has not fallen to within acceptable limits within

a reasonable time (1 – 2 minutes), the sample hose and probe should be

cleaned in accordance with the instructions contained in 10.6: ‘Routine

Maintenance Procedures’ and the zero-calibration procedure repeated.

If the concentration of HC does not fall to within acceptable limits after

the sample hose and probe have been cleaned the HC residue check

pop-up window will continue to be displayed. Switch the unit off and back

on in order to reset the machine. Repeat the calibration and HC residue

check procedure. If the concentration of HC is still too high, service is

required. Contact your SUN service centre or dealer.

2 detected during the check indicates that

36 DGA 2500 2002 - 11

Page 43

SETTINGS

6.5 Settings

The following settings must be made before the unit is ready for

operation:

6.5.1 Fuel Type Selection

The correct fuel type for the vehicle under test should be selected in the

Vehicle Setup screen.

• Select the vehicle fuel type (LPG, CNG or Petrol) from the fuel type

drop down menu as described in 8.2: ‘Free Measurement Vehicle

Setup’ and 9.2: ‘SUN EEC Test Vehicle Set-up’.

6.5.2 Speed Factor Setting

Refer to the SUN® Diagnostic Platform Operator’s Manual (6.2: ‘RPM

Measurement and Speed Factor Selection’) for details of factors

governing Speed Factor selection.

To set the Speed factor:

• Open the vehicle setup screen.

• Select and apply the Speed Factor as described in 8.2: ‘Free

Measurement Vehicle Setup’ or 9.2: ‘SUN EEC Test Vehicle Set-up’.

6.5.3 Lambda/AFR Selection

The DGA 2500 calculates and can display either Lambda (λ) or Air Fuel

Ratio (AFR).

To select Lambda or AFR:

• Open the Gas Analyser System Settings screen (see 5.4).

To reach the Gas Analyser System Settings screen select the

“System Settings” icon button in the Gas Analyser Menu (see 5.1).

The Gas Analyser System Menu (see 5.2) will be displayed. Select

the “Settings” Icon button in the The Gas Analyser System Menu, the

Gas Analyser System Settings page wll be shown.

• Select Lambda or AFR as required.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 37

Page 44

C H A P T E R 6 PREPARATORY STEPS

6.6 Vehicle Connections

Caution:

c Route the rpm pick-up lead and oil temperature probe clear of any

hot or moving engine parts.

6.6.1 RPM Pick-Up

Refer to the SUN® Diagnostic Platform Operator’s Manual (6.2.1: ‘RPM

Pick-up (Otto Engines)’) for details of rpm pick-up connection.

6.6.2 Oil Temperature Probe

Refer to the SUN® Diagnostic Platform Operator’s Manual (6.3: ‘Oil

Temperature Measurement’) for details of oil temperature measurement.

38 DGA 2500 2002 - 11

Page 45

7 Operation — General

The following sections contain general information applicable to all test

procedures. Specific information relating to the performance of tests

using the Free Measurement Procedure and the SUN EEC Test

Procedure may be found in 8: ‘Operation – The Free Measurement

Procedure’ and 9: ‘Operation – The SUN EEC Test Procedure’

respectively.

Information necessary to conduct country specific tests (MOT, AU, APK

etc.) will be provided in separate documentation.

7.1 Testing Tips

• Read and follow the procedures in this manual.

• Keep the probe tip openings clean and free from debris.

• Do not place the probe tip in liquids or allow liquids to be drawn into

the analyser sampling system. Contamination will affect the accuracy

of any future tests.

• Do not insert the probe into an exhaust pipe until the vehicle engine is

at normal operating temperature. This allows time for the exhaust

system to vaporize any residual moisture.

• Never move the analyser by pulling on the probe, sample hose or

power cord.

• Never drive over the probe, sample hose or power cord.

• Never place any liquids on the analyser that could spill and run into

the ventilation holes.

• Clean any spilt liquids (gasoline, brake fluid, cleaning solvents etc)

from the exterior of the analyser immediately in order to protect the

finish.

• In order to ensure accurate test results, perform a daily Leak Check

(Vacuum) as described in 10.2: ‘Leak Check (Vacuum)’ below. This

check should also be performed after probe changes or filter service.

• Prolonged use of the analyser in conjunction with a dynamometer and

a hot running vehicle under load may damage the sample probe and

affect readings. An alternative sample probe (P/N: 7009-1869-00) is

available for use in these circumstances.

Doc. No.: ZEEEAGB132A Operator’s Manual 39

Page 46

C H A P T E R 7 OPERATION — GENERAL

• The O2 Sensor is stated by the manufacturer to have life expectancy

of 24 months from the date of manufacture, irrespective of how often

the analyser is used.

• The (optional) NO sensor has a minimum life expectancy of 24

months after installation or until it undergoes a 20% signal strength

loss, whichever occurs sooner. It is powered by an internal battery.

The analyser must run at least 12 hours over a 30 day period to

maintain this battery at full charge.

7.2 Measurement Procedure

Caution:

cIn order to ensure representative measurements, The engine should

be at normal operating temperature.

Note:

p Under moderate loads and operating at moderate speeds a typical

nominal oil temperature is approximately 85 °C. Under these

circumstances a temperature of 65 °C is considered to be low and a

temperature of 105 °C is considered to be high. At idling speeds engine

oil temperature does not, generally, reach a nominal value. Proper oil

temperature depends on the engine operating conditions, but may be

considered acceptable if falling within the range mentioned above.

During testing, engine exhaust gas samples are continuously gathered

by means of the Exhaust Sample Probe inserted into the vehicle’s

exhaust tail pipe.

The DGA 2500 continuouslly determines the amount of CO, CO

and O

2 present in the exhaust sample. In the Free Measuring Procedure

these values are continuously displayed in the parameter windows

together with the values for CO corrigè, engine speed and oil

temperature. If the optional NO sensor is present the value for NO will

also be measured and displayed. Depending on the selection made (see

6.5.3: ‘Lambda/AFR Selection’), the value for Lambda or Air Fuel Ratio

will also be displayed. In the SUN EEC Procedure the values measured

are displayed in the Results Screen at the conclusion of the test.

Besides determining whether or not the vehicle exhaust emissions

comply with legal requirements, emissions tests may be performed at

various engine speeds and under various conditions, forming a valuable

diagnostic aid in the discovery of a variety of engine, ignition and fuel

system service requirements.

2, HC

40 DGA 2500 2002 - 11

Page 47

SHUT DOWN PROCEDURE

After all necessary settings and connections have been made, proceed

as follows:

• Start the vehicle engine and allow the oil temperature to come up to

normal operating temperature (see Note above).

• Insert the sample probe fully into the vehicle tailpipe.

Note:

p On exhaust systems having twin tail pipes that exit a common resonator

or muffler the exhaust gas sample may be diluted by ambient air

entering the system via the tail pipe that is not in use for sampling. To

prevent this, block off the tail pipe that is not in use for the sample probe.

Note:

p Do not block off a tail pipe if the vehicle is being operated on a chassis

dynamometer. Always be sure to unblock the tail pipe when testing is

complete.

Caution:

c Do not leave the sample probe in the tail pipe when measurements

are not being made, as this will shorten the life of the filter

elements.

• When testing has been completed and the test results have been

printed or noted, remove the sample probe from the tail pipe and

store it in a dust and water free environment until it is required again.

• Remove the Oil Temperature probe from the dipstick tube and reinsert

the oil dipstick.

• Disconnect the rpm pick-up.

Caution:

c If the dipstick is of an adjustable type, ensure that it is properly

adjusted before re-inserting it into the dipstick tube.

7.3 Shut Down Procedure

Refer to the SUN® Diagnostic Platform Operator’s Manual (6.4: ‘Shut

Down Procedure’) for details of the shut down procedure.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 41

Page 48

C H A P T E R 7 OPERATION — GENERAL

42 DGA 2500 2002 - 11

Page 49

8 Operation – The Free

Measurement Procedure

The Free Measurement program allows the DGA 2500 to be used as a

diagnostic tool for the investigation of the fuel, ignition and emission

control systems of a vehicle without applying the limits and procedures

specified in any local, national or international test. By operating the

vehicle under varying conditions (if neccessary on a chassis

dynanometer) it is possible to:

- Identify emission failure areas.

- Reduce emissions in general.

- Locate/correct driveability problems.

The driveability and emissions symptoms (or combinations of symptons)

that can be addressed include:

- Engine will not crank.

- Engine will crank but will not start.

- Engine is hard to start.

- Malfunction lamp is on.

- Engine stalls.

- Engine shows hesitation, sag, stumble and/or lack of power, is

sluggish or feels spongy.

- Engine surge.

- Engine misses or cuts out.

- Engine backfires.

- Excessive engine noise.

- Excessive emissions or a failed emission test.

- Poor fuel economy.

- Incorrect idle.

- Engine jumps or jerks.

- Excessive exhaust odour.

- Excessive exhaust smoke.

- Fuel odour and/or dieseling or run-on.

Doc. No.: ZEEEAGB132A Operator’s Manual 43

Page 50

C H A P T E R 8 OPERATION – THE FREE MEASUREMENT PROCEDURE

In testing emission control devices any of the following tests may be

performed as necessary, applicable or useful:

- Exhaust Gas Recirculation Valve.

- Positive Crankcase Ventilation (PCV) Valve.

-Air Pump

- Carburettor Adjustments for Vehicles Without Feedback Systems,

- Lean-misfire Adjustment.

- Lean-drop Adjustment.

- Accelerator Pump.

- Power Valve.

- High Fuel Level in Float Chamber.

- Testing the Cooling System for Combustion Gases.

- Fuel Leak.

- Exhaust Leak.

- Testing for Fumes in the Passenger Compartment.

- No-start Condition – Fuel.

The following section provides a brief description of the screens that will

be encountered during the Free Measurement Procedure

8.1 The Free Measurement Screen

Figure 8-1 The Free Measurement Screen

44 DGA 2500 2002 - 11

Page 51

THE FREE MEASUREMENT SCREEN

• To open the Free Measurement Screen, select the “Free

Measurement” option from the Gas Analyser Menu (see section 5.1).

The Free Measurement Screen displays the current values for the

test parameters that are continuously being analysed by the unit.

These values may be compared with two Limit Sets stored in the unit

memory. Limit Sets 1 and 2 are intended for use with measurements

at high and low engine speeds respectively.

Unlike the EU and country specific test procedures, available under

the DGA 2500 software, the Free Measurement Procedure does not

incorporate the requirements of any regulatory authority. The upper

and lower limits for each test parameter may be either edited by the

operator or disabled entirely.

Numerical values for the measured gas emissions, lambda/AFR, oil

temperature and engine speed are shown in the nine fields

comprising the bulk of the screen. The field background will be Green

so long as the measured value for a particular parameter falls within

the applied limits but will change to Red if the values fall outside

these limits.

An analog representation of the current test values, in relation to the

applied limits, is given by the coloured bars associated with each

parameter field. The Green section of these bars shows the range of

values falling within the limits whilst the Red sections indicate values

above and below the acceptable range. The relative proportions of

the Green and Red areas will reflect the limits applied. The value

currently measured for each parameter is represented by a thin

Yellow band.

If no limit sets are applied, or if no measurements are available, the

parameter field backgrounds and the analog bars will be Grey.

The current parameter values may be frozen, stored in the unit

memory or printed out at any time during normal operation.

• To specify the vehicle setup via the Free Measurement Vehicle Setup

Screen, press the “Vehicle Setup” toolbar button (see 8.2).

• To print test result data, press the Print button (see 5.6).

• To review or delete data stored in the data buffers, press the “Print

Preview” button to open the The Print Preview Window (see 8.7).

• To manually initiate an Zero-calibration, press the “Zero-calibration”

button (see 6.2.4).

• To toggle between limit sets, press the “Toggle Limit Sets” button (see

8.6: ‘Storing Data in the Data Buffers’).

• To freeze the current readings, press the “Freeze” button (see

8.6: ‘Storing Data in the Data Buffers’).

• To store the current readings, press the “Store” button.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 45

Page 52

C H A P T E R 8 OPERATION – THE FREE MEASUREMENT PROCEDURE

The “store” button is only available after the “Freeze” button has

been pressed (see 8.6: ‘Storing Data in the Data Buffers’).

• To unfreeze the frozen readings, press the “Unfreeze” button.

The unfreeze button is only available after the “Freeze” button has

been pressed (see 8.6: ‘Storing Data in the Data Buffers’).

• To return to the Gas Analyser Menu, press the “Gas Analyser” toolbar

button.

8.2 Free Measurement Vehicle Setup

Figure 8-2 The Free Measurement Vehicle Setup Screen

To access the Free Measurement Vehicle Setup Screen, press the

“Vehicle Setup” toolbar button in the The Free Measurement Screen

(see section 8.1).

In the Free Measurement Vehicle Setup Screen it is possible to:

- Specify the vehicle fuel type.

- Save the current set-up to file.

- Load a previous set-up from file

- Load the SUN default set-up.

- Enable/disable limit sets.

- Edit limit sets.

- Enter the speed factor.

46 DGA 2500 2002 - 11

Page 53

FREE MEASUREMENT VEHICLE SETUP

The vehicle fuel type, limit set values, limit sets On/Off setting and the

speed factor are collectively refered to as the “Vehicle Setup”.

8.3: ‘Saving and Loading Vehicle Setups’ and 8.4: ‘Editing Limit Sets’

provide information on saving, loading and editing Vehicle Setups.

• Use the Fuel Type Drop-down Menu to select the correct fuel type for

the vehicle under test (see 6.5.1: ‘Fuel Type Selection’).

The available alternatives are:

- Petrol (default).

- LPG (Liquified Petroleum Gas).

- CNG (Compressed Natural Gas).

Refer to the Diagnostic Platform Operator’s Manual (4.4: ‘Drop-down

Menus’) for details of the use of drop-down menus.

Note:

p In the event of the fuel type LPG being selected, ensure that the correct

Butane/Propane ratio is entered in Gas Analyser System Settings

Screen (see 5.4). Failure to set the correct ratio may result in inaccurate

lambda calculation.

• Select the appropriate Speed Factor.

• The Speed Factor is the factor that must be applied to the raw rpm

data received by the unit (e.g. from the inductive pick-up) in order to

arrive at a true engine speed reading. For further information

concerning Speed Factor selection refer to the Diagnostic Platform

Operator’s Manual (6.2.3: ‘Speed Factor Selection’). The Speed

Factor currently applied is highlighted in green in the Speed Factor

section of the Vehicle Setup Screen. To change the applied factor:

• Click with the mouse on the desired new Speed Factor, or

• Select the new Speed Factor using the keyboard or remote control left

and right cursor keys and press the “Enter” key to confirm the new

factor.

A thin yellow frame will move along the series of Speed Factor values

as the cursor keys are pressed. When the “Enter” key is pressed the

green highlight will move to the newly selected value.

• Use the “Limits” button to enable or disable the Limit Sets.

Pressing the “Limits” button will change the status of the limit sets

from ON to OFF and vice versa. The “Limits” button will be Green

when the limits are switched ON and Red when the limits are

switched OFF.

To toggle between “Limit Sets On” and “Limit Sets Off” or vice versa:

• Click with the mouse on the “Limits” button, or

• Select the “Limits” button with the cursor keys and press “Enter”.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 47

Page 54

C H A P T E R 8 OPERATION – THE FREE MEASUREMENT PROCEDURE

8.3 Saving and Loading Vehicle Setups

The vehicle setup currently displayed in the Vehicle Setup Screen can

be saved in the PC memory for future use.

The information stored will be:

-Fuel type

- Speed Factor

- Limits On/Off

- Limit set values.

To save the current vehicle setup:

• Press the “Save Setup” button.

The Save Limits File dialog box will be displayed .

Figure 8-3 The Save Limits Dialog Box

• Check the location to which the file is to be saved.

• Enter a name for the file in the File name box.

• To save the setup click “Save” or press the “Enter” key.

The file containing the vehicle setup will be saved and can be

recalled for future use using the “Load Setup” button.

• To cancel, click the “Cancel” button or press the”Esc” key.

The Save Limits File box will be closed without storing the setup.

To load a previously saved setup:

• Press the “Load Setup” button.

48 DGA 2500 2002 - 11

Page 55

EDITING LIMIT SETS

The Load Limits File dialog box will be displayed).

Figure 8-4 The Load Setup Dialog Box

• Select the file to be loaded with the mouse or enter the file name in

the file name box.

• Click “Open” in the dialog box or press the “Enter” key.

The loaded set-up will be applied in the Free Measurement Screen.

• To load the SUN default set-up, press the “Load Default” button.

• The software will warn that loading the default set-up will cause data

stored in the buffers to be lost and ask for confirmation before

continuing. Click “Yes” to proceed with loading the defaults or “No” to

continue using the current settings.

8.4 Editing Limit Sets

Figure 8-5 The Edit Limit Sets Window

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 49

Page 56

C H A P T E R 8 OPERATION – THE FREE MEASUREMENT PROCEDURE

To alter any or all of the limit values currently shown in the Vehicle Setup

Screen:

• Press the “Edit Limit Set” button corresponding to the Limit Set to be

edited.

The Edit Limit Set Window will be displayed.

• Use the keyboard to make the required alterations.

To alter a limit value:

• Select the value to be altered using the “Tab” key.

The selected field will be highlighted in Blue.

• Use the “Backspace” key to delete the current value.

• Enter the required new value.

• Repeat the procedure for all values that are to be altered.

• If required, repeat the procedure to edit the other limit set.

• To apply the new values, click “OK” or press the “Enter” key.

The new values will be applied and the window will be closed.

• To cancel the alterations and return to the Vehicle Setup Screen, click

“Cancel” or press the “Esc” key.

The window will be closed and the current limit values will continue to

be applied.

8.5 Free Measurement Test Procedure

Note:

p The following description of the Free Measurement Test Procedure

assumes that the Limit Sets are applied and that gas readings are

required at both high and low engine revolutions. This may not be the

case in all circumstances. Since the Free Measurement Procedure is

highly flexible and is suitable for a variety of diagnostic purposes, the

description below should be considered to be a guideline only. An

experienced operator may, for instance, consider that to perform both a

high speed and a low speed test is, in certain cases, unnecessary in

view of the diagnostic purpose of the test.

To make gas measurements using the Free Measuring procedure:

• Select the The Free Measurement Screen from the Gas Analyser

Menu (see 5.1 and 8.1).

• Make any necessary amendments to the vehicle setup in the Free

Measurement Vehicle Setup Screen (see 8.2).

• Allow the vehicle to come to normal operating temperature.

50 DGA 2500 2002 - 11

Page 57

STORING DATA IN THE DATA BUFFERS

• Insert the exhaust probe fully into the vehicle tail pipe.

Refer to the notes to 7.2: ‘Measurement Procedure’ if the test vehicle

is equipped with twin tail pipes.

• Select Limit Set 1 (see 8.1: ‘The Free Measurement Screen’)

• Accelerate the engine until the rpm reading falls within the Green

band of the Free Measurement Screen rpm indicator.

• Maintain a steady engine speed and allow the gas readings to

stabilize (approx. 30 seconds).

• Store the Limit Set 1 test results in data buffer 1 as described in

8.6: ‘Storing Data in the Data Buffers’.

After the test data for Limit Set 1 has been stored Limit Set 2 will be

automatically selected and the “Toggle Limit Sets” button will show

Limit Set 2. The Green and Red indicator bands will change to

represent the Limit Set 2 values. The fact that data is now stored in

data buffer 1 will be confirmed by the appearance of the figure “1” in

the Free Measurement Screen toolbar.

• Reduce the engine speed until the rpm indicator is between the upper

and lower limits specified for Limit Set 2, maintain a steady engine

speed and allow the gas readings to stabilize once more.

• Store the Limit Set 2 test results in data buffer 2.

After the test data for Limit Set 2 has been stored the “Toggle Limit

Sets” button will show that Limit Set 1 has been automatically

reselected and the indicator bands will change accordingly. A figure

“2” will appear in the toolbar, confirming that data is stored in data

buffer 2.

The data stored in the data buffers can be reviewed, printed or deleted

via the The Print Preview Window (see 8.7).

8.6 Storing Data in the Data Buffers

Current test readings to which a Limit Set has been applied may be

temporarily stored in one of the two data buffers. This temporary storage

allows the second Limit Set to be applied without the loss of the initial

test results. Data to which Limit Set 1 is applied will be stored in buffer 1

and data to which Limit Set 2 is applied will be stored in buffer 2.

Note:

p The following description assumes that the Free Measurement

Procedure is performed as outlined in 8.5: ‘Free Measurement Test

Procedure’ (i.e. the data to which Limit Set 1 has been applied is to be

stored before Limit Set 2 is applied). Although this will be the usual

procedure, it should be noted that it is possible to apply Limit Set 2

before Limit Set 1 or to apply either Limit Set independently.

Doc. No.: ZEEEAGB132A Operator’s Manual Rev.: C 51

Page 58

C H A P T E R 8 OPERATION – THE FREE MEASUREMENT PROCEDURE

To store data in data buffer 1:

• Apply Limit Set 1 using the “Toggle Limit Set” button .

Figure 8-6 Apply Limit Set 1

• Take the Limit Set 1 gas measurements as outlined in 8.5: ‘Free

Measurement Test Procedure’.

• Press the “Freeze” toolbar button.

Figure 8-7 Freeze Limit Set 1 Readings

The “Freeze” button will be replaced by the “Store” and “Undo”

buttons. The “Store” button will be automatically selected (indicated

by a Green background – see Figure 8-8).

• Press “Store” to store the data or “Undo” to unfreeze the data and

return to continuous measurement..

Figure 8-8 Store Limit Set 1 Readings

If the “Store” button is pressed:

- The “Store” and “Undo” buttons will be replaced by the “Freeze”

button.

- The “Freeze” button will be automatically selected.

- The number “1” (corresponding to the Limit Set and data buffer

selected) will appear in the toolbar indicating that the data is

stored in data buffer 1.

- Limit Set 2 will be applied automatically and the “Toggle Limit

Sets” button will change accordingly.

52 DGA 2500 2002 - 11

Page 59

STORING DATA IN THE DATA BUFFERS

Note:

p If the “Undo” button is pressed the “Store” and “Undo” buttons will be

replaced by the “Freeze” button. The “Freeze” button will be

automatically selected. Limit Set 1 will continue to be applied.

• Take the Limit Set 2 gas measurements as outlined in 8.5: ‘Free

Measurement Test Procedure’.

• Press the“Freeze” toolbar button.

Figure 8-9 Freeze Limit Set 2 Readings

The “Freeze” button will be replaced by the “Store” and “Undo”

buttons. The “Store” button will be automatically selected (indicated

by a Green background – see figure below).

• Press “Store” to store the Limit Set 2 data or “Undo” to unfreeze the

data and return to continuous measurement .

Figure 8-10 Store Limit Set 2 Readings

The number “2” will appear alongside the number “1” in the toolbar

indicating that data is now stored in both buffers.

Limit Set 1 will be automatically applied for the next set of

measurements and will be shown by the “Toggle Limit Sets” button.

The “Freeze” button will be automatically selected.

Figure 8-11 Limit Set 1 and 2 Readings Stored