Summers Hydraulic Fold Coil User Manual

HYDRAULIC

Operator’s

Manual

FOLD

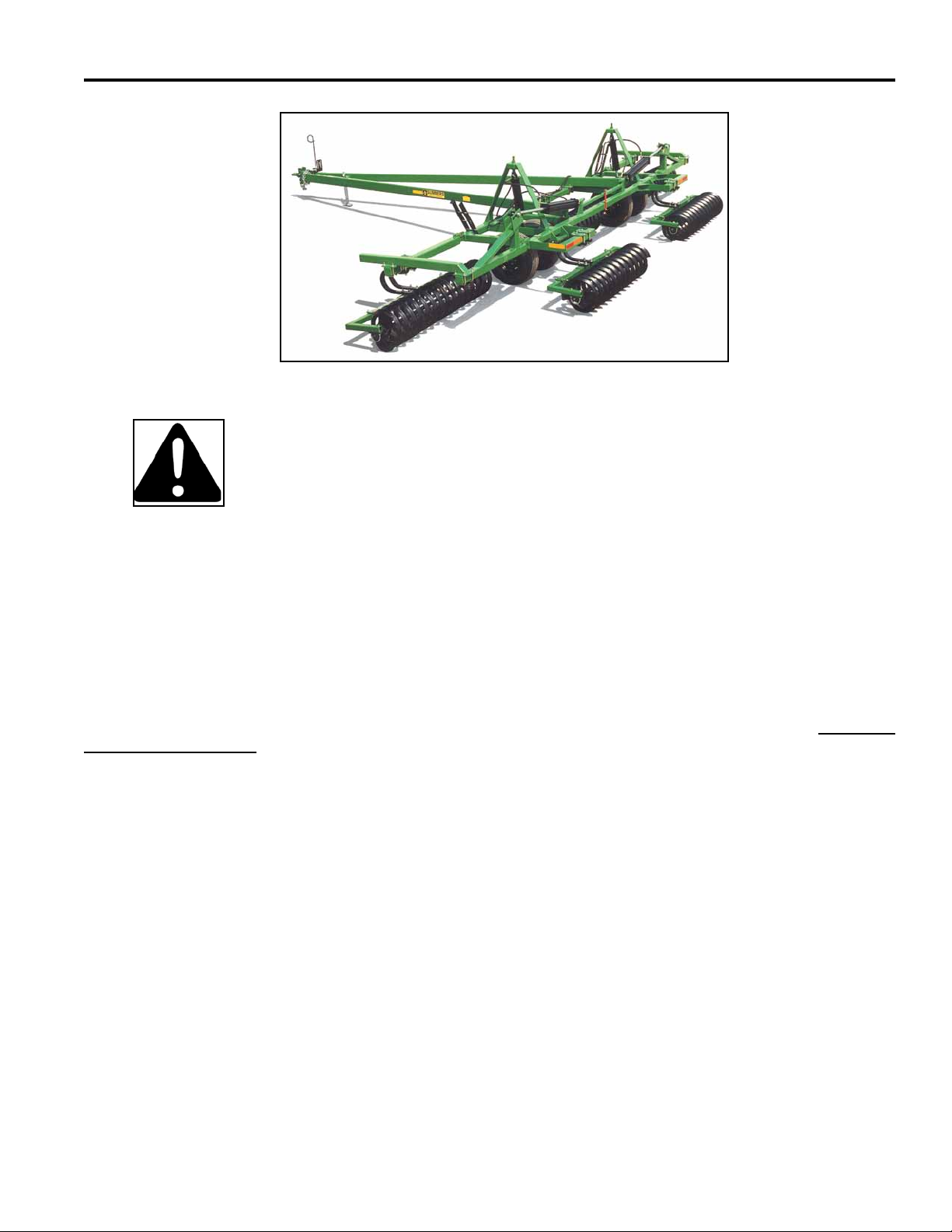

HF Coil Packer & Rolling Chopper

HYDRAULIC

HF Coil Packer & Rolling Chopper

FOLD

IMPORTANT

THE OPERATOR IS RESPONSIBLE FOR

ADJUSTING THE MACHINE SINCE MACHINE

DOES NOT COME “FIELD READY” FROM

FACTORY.

See www.summersmfg.com for the latest version of all Summers Operator’s Manuals.

ROLLING CHOPPER

15’ - 57’

COIL PACKER

14’ - 62’

CAUTION

READ & UNDERSTAND OPERATOR’S MANUAL

BEFORE USING MACHINE.

SUMMERS MANUFACTURING CO., INC.

WEB SITE: www.summersmfg.com

MADDOCK, NORTH DAKOTA 58348 ........................................................ (701) 438-2855

DEVILS LAKE, NORTH DAKOTA 58301 ................................................... (701) 662-5391

8Z1111 © Summers Mfg. Co., Inc. 2013 Printed in USA

Warranty

Summers warrants only products of its manufacture against operational failure caused by defective materials or workmanship which

occur during normal use within 12 months from the date of purchase by the end user from Summers’ dealer.

Summers’ obligation is to replace free of charge any part of any product that Summers inspection shows to be defective excluding

transportation charges to Maddock, ND or Devils Lake, ND and return and also excluding all transportation costs from Summers’ dealer to

the dealer’s customer and all other costs such as removal and installation expense.

Summers shall not be liable for loss of time, manufacturing costs, labor, material, loss of prots, consequential damages, direct or

indirect, because of defective products whether due to rights arising under the contract of sale or independently thereof, and whether or not

such claim is based on contract, tort or warranty.

Written permission for any warranty claim return must be rst obtained from authorized Summers’ personnel. All returns must be

accompanied with a complete written explanation of claimed defects and the circumstances of operational failure.

Written warranty for all component parts used in the manufacture of Summers products is available upon request. Warranty of such

component parts will be determined by said component manufacturer upon their inspection of the claimed defective part.

This express warranty is the sole warranty of Summers. There are no warranties, which extend beyond the warranty herein expressly

set forth. The sales for products of Summers under any other warranty or guarantee express or implied is not authorized. This warranty

voids all previous issues.

SUMMERS MANUFACTURING CO. INC.

MADDOCK, NORTH DAKOTA 58348

DEVILS LAKE, NORTH DAKOTA 58301

2/95

Mathison’s 9/12

INTRODUCTION

This manual provides information about Safety, Assembly, Operation and Parts for the Summers Hydraulic Fold Coil Packer

and Hydraulic Fold Rolling Chopper. Please refer to these sections before assembling or operating your machine.

Reference to “Right” and “Left” in this book is determined when the machine is viewed from the rear.

Parts are referenced in each drawing with the Summers Manufacturing Part Number. Use this Part Number when ordering replacement parts from your Summers dealer. See back section of manual for description of each Part Number.

It is the policy of this company to improve its products whenever possible and practical to do so. We reserve the right

to make changes or improvements in the design or construction of parts at any time without incurring the obligations to

install such changes on products previously delivered.

Summers Manufacturing Company, Inc. strongly recommends that each Operator READ and UNDERSTAND

the Operator’s Manual before using the machine. In addition, this Operator’s Manual should be REVIEWED at

least ANNUALLY thereafter.

NOTE: Operating Packer Coils or Rolling Choppers in wet conditions will cause:

1. Excessive packing with possible soil surface crusting.

2. Increased implement frame stress.

Discontinue use of packer coils or rolling choppers if mud build-up occurs.

SECTION CONTENTS

Section 1: SAFETY

Section 2: ASSEMBLY

Section 3: OPERATION and MAINTENANCE

Section 4: PARTS

Section 5: PART NUMBERS WITH DESCRIPTIONS

OWNER REGISTER

Name ________________________________ Size _____________________________________

Address ______________________________ Serial Number _____________________________

City __________________________________

(located by the hitch piece)

State/Prov. ____________________________ Date Purchased ____________________________

Mail Code _____________________________ Dealer ___________________________________

i

TABLE OF CONTENTS

SECTION 1: SAFETY

Safety-Alert Symbol & General Safety Practices ........................................................... 1-1, 1-2

SafetyDecals&Reectors ............................................................................................ 1-3 - 1-5

General Assembly Safety Practices ........................................................................................1-6

SECTION 2: ASSEMBLY

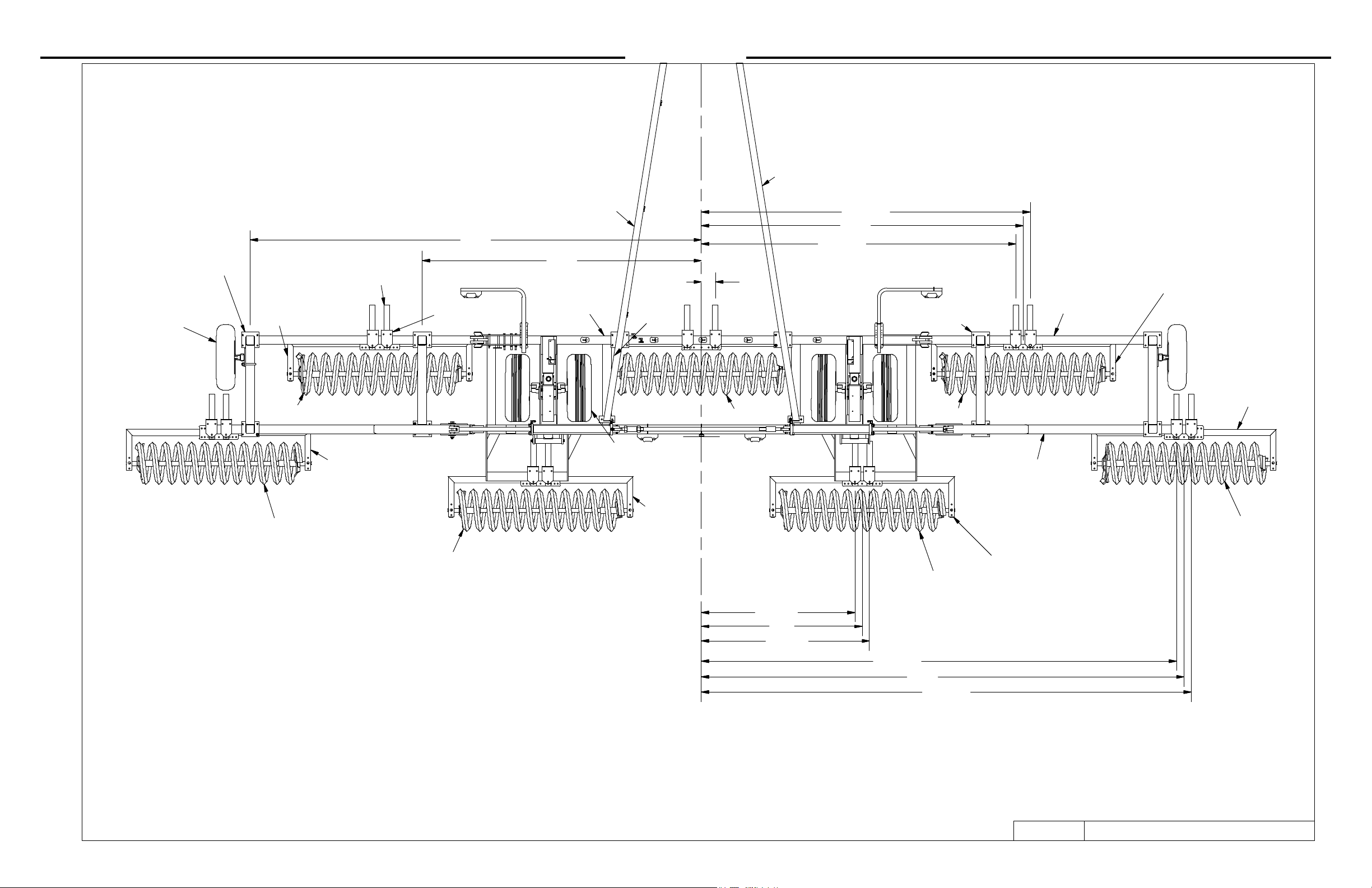

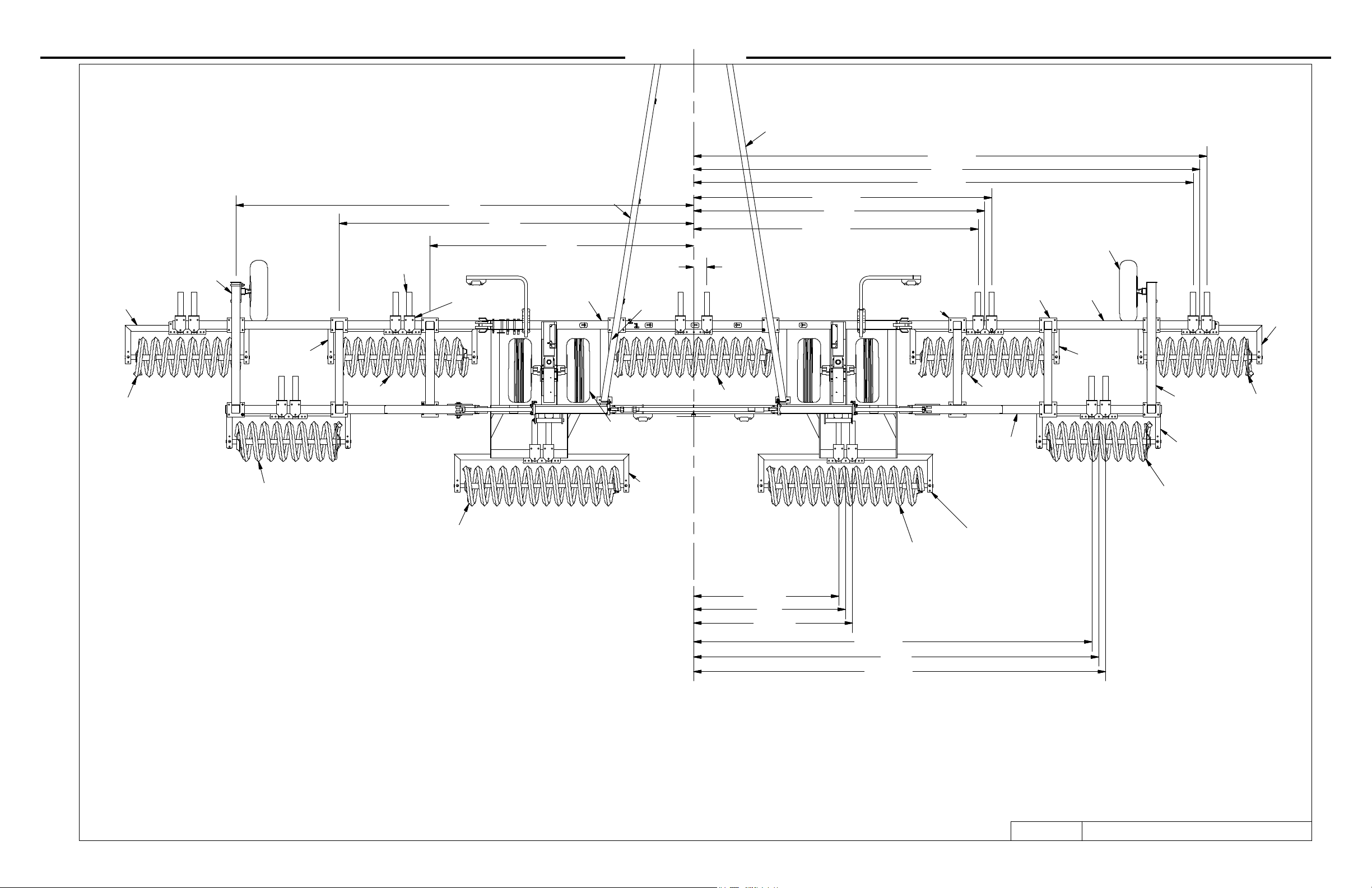

14’ to 44’ Set-Up Instructions ...................................................................................... 2-1 – 2-25

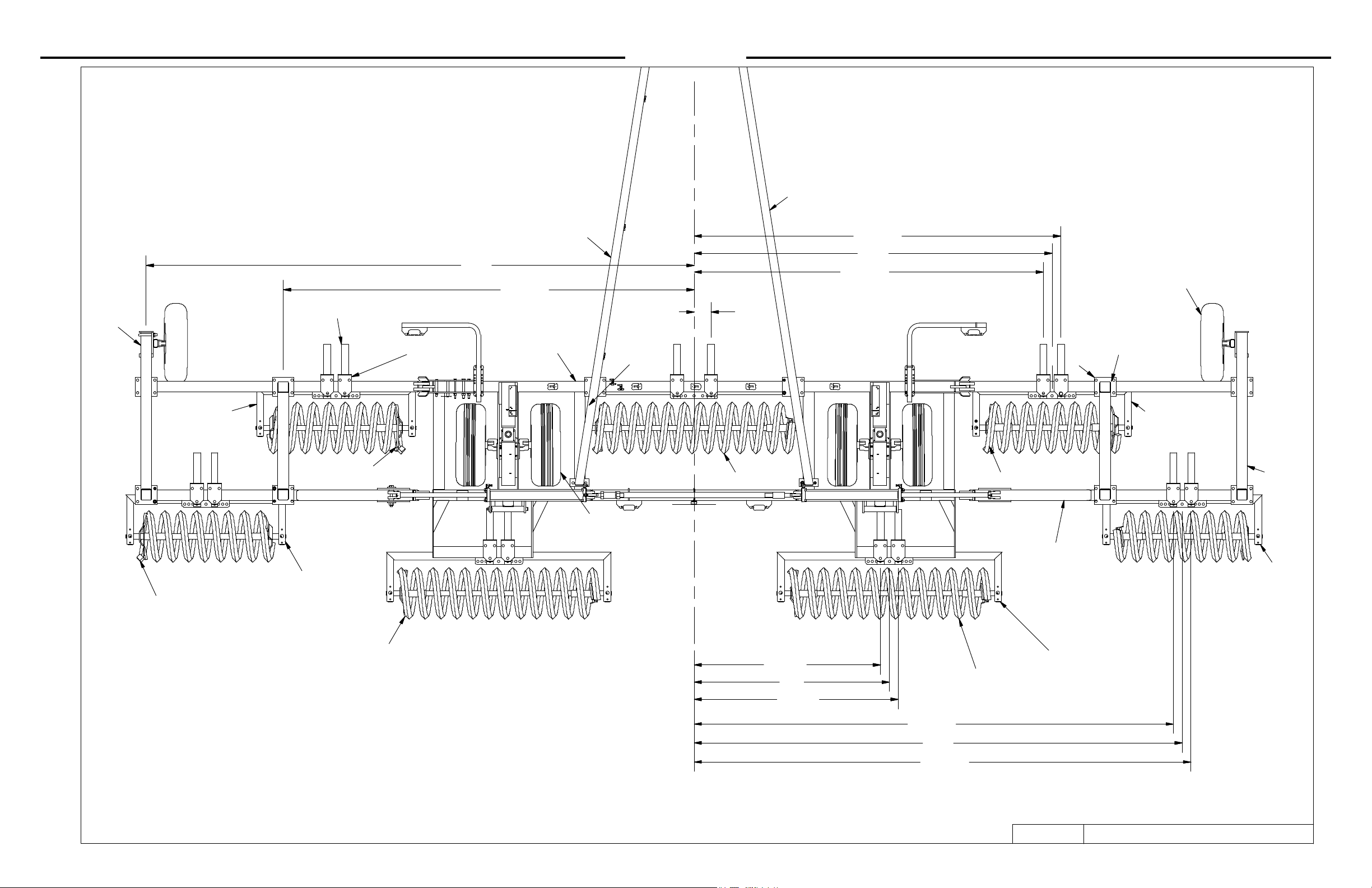

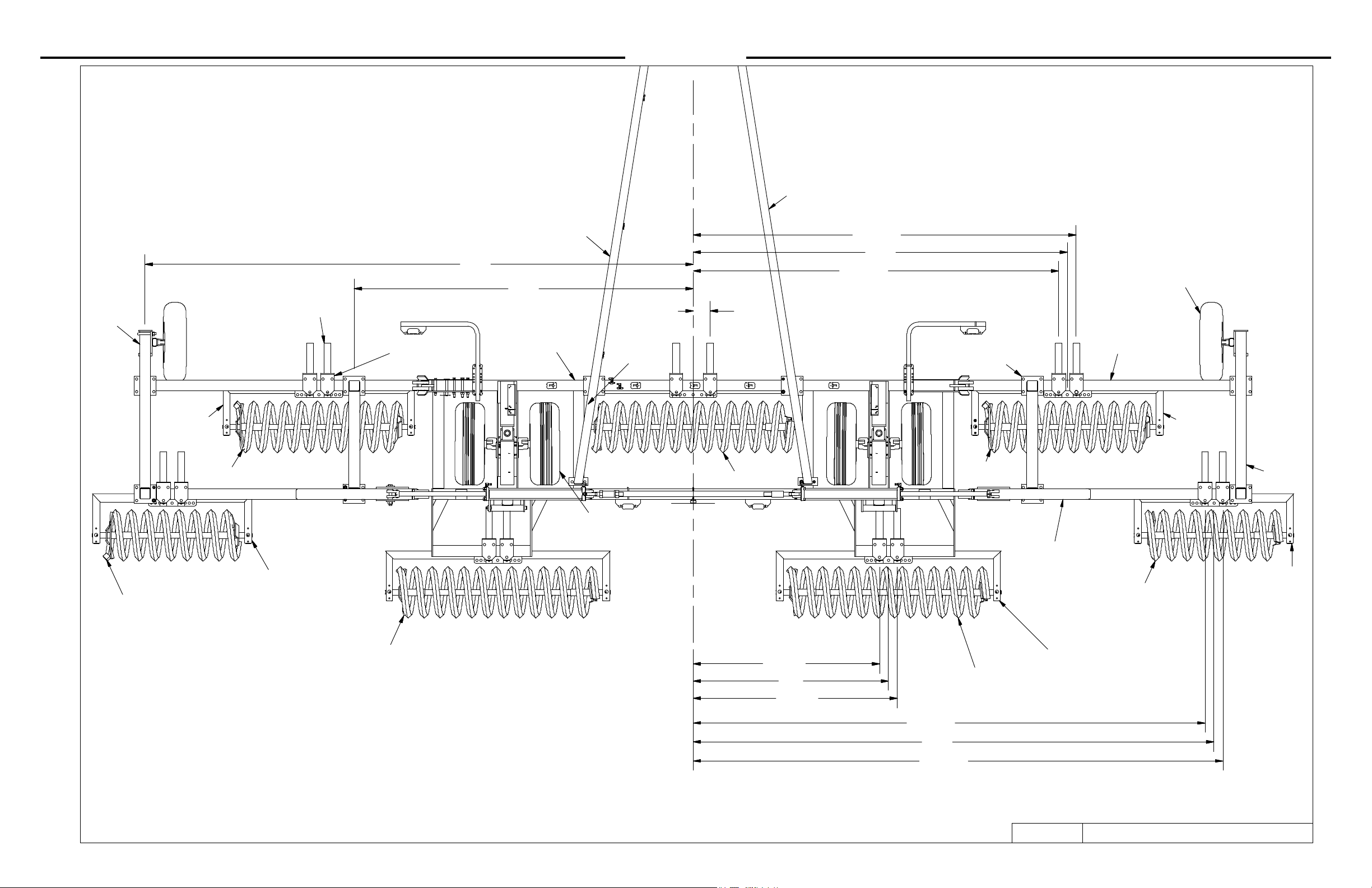

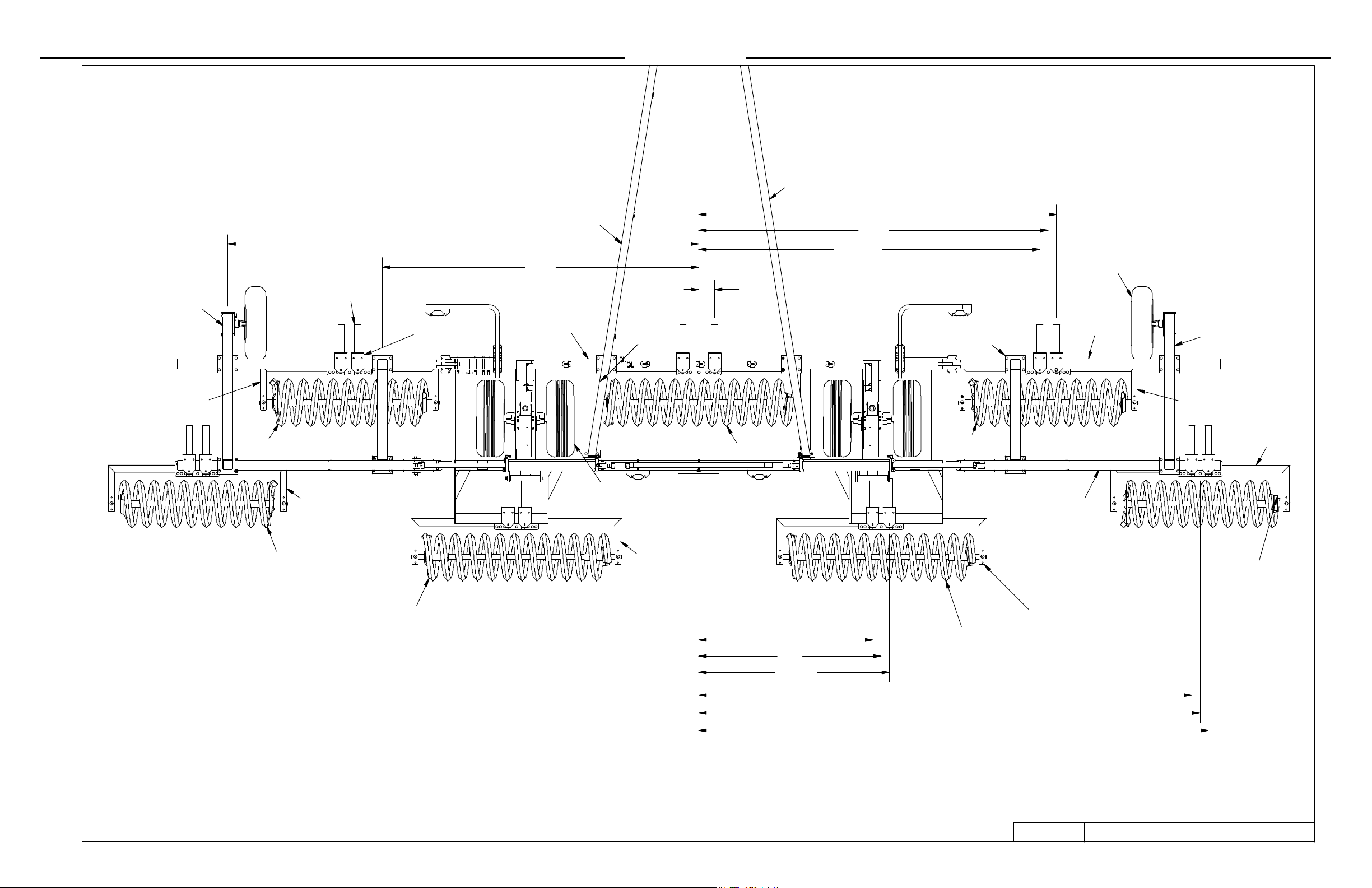

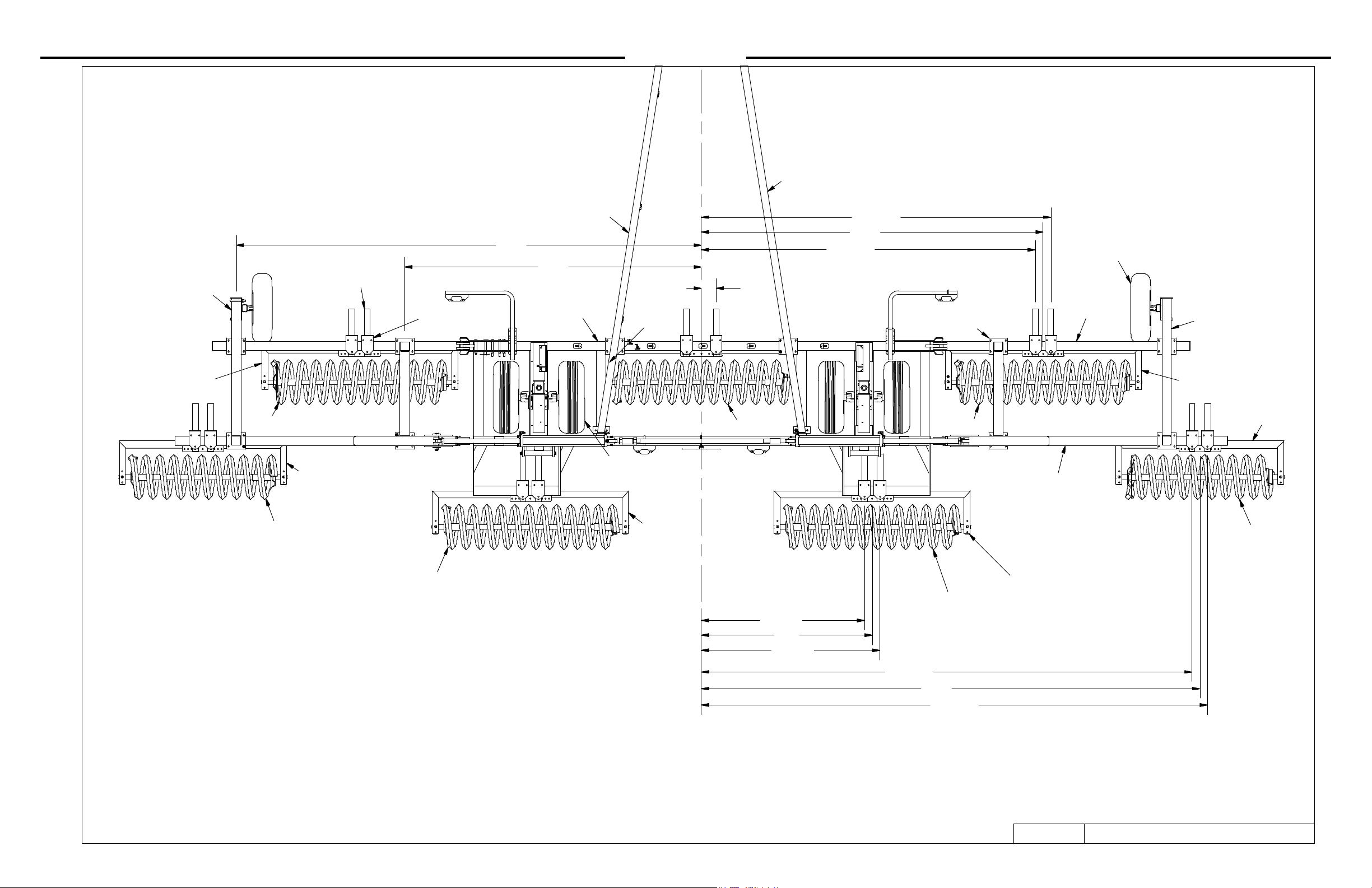

15’-42-1/2’ Hydraulic Fold Rolling Chopper Layouts ................................................. 2-35 – 2-56

46’ to 62’ Set-Up Instructions .................................................................................... 2-57 – 2-84

SECTION 3: OPERATION and MAINTENANCE

Operating Instructions ................................................................................................... 3-1 – 3-2

Maintenance and Service........................................................................................................3-2

SECTION 4: PARTS

Center Frame 14’-30’ Narrow Center .....................................................................................4-2

Center Frames 18’-50’ Standard Center ............................................................................... 4-3

Center Frames 52’-62’ Standard Center ................................................................................4-4

Wing 21’-44’ ........................................................................................................................... 4-5

Wing 46’-62’ ............................................................................................................................4-6

Packer Coil ..............................................................................................................................4-7

Hydraulic System 14’-21’ Standard Center .............................................................................4-8

Hydraulic System 21’-30’ Narrow Center ...............................................................................4-9

Hydraulic System 26’-44’ Standard Center .............................................................................4-9

Light Kit .................................................................................................................................4-10

Hydraulic System 46’-50’ ......................................................................................................4-11

Hydraulic System 51’-62’ ......................................................................................................4-12

Rolling Chopper Assembly .................................................................................................... 4-13

Hub and Axle Components ...................................................................................................4-14

Mounting Arm Assembly .......................................................................................................4-15

Mounted Harrow Assembly ..................................................................................................4-16

SECTION 5: PART NUMBERS WITH DESCRIPTIONS ................................................. 5-1 – 5-6

ii

SECTION 1 - SAFETY

SAFETY-ALERT SYMBOL

This symbol is used to denote possible danger and care

should be taken to prevent bodily injury. This symbol

means:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Denition of each Signal Word used in conjunction with the Safety-Alert symbol.

indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

DANGER

This signal word is to limited to the most extreme situations.

WARNING

CAUTION

1. READ AND UNDERSTAND Operator’s Manual before using machine. Review at least annually thereafter.

2. VERIFY all safety devices and shields are in place before using machine.

3. KEEP hands, feet, hair and clothing away from moving parts.

4. STOP engine, place all controls in neutral, set parking brake, remove ignition key and wait for all

moving parts to stop before servicing, adjusting, maintaining or unplugging.

5. BE CAREFUL when working around high pressure hydraulic system.

6. ALWAYS make sure that pressure is relieved from hydraulic circuits before servicing or disconnecting from

tractor..

7. DO NOT ALLOW RIDERS.

8. USE EXTREME CARE when making adjustments.

9. KEEP CHILDREN AWAY from machinery at all times.

10. NEVER ALLOW anyone to walk or work under a raised piece of equipment without installing transport

locks.

indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

GENERAL SAFETY PRACTICES

1-1

SECTION 1 - SAFETY

SAFETY DURING TRANSPORT

1. ONLY TOWatasafespeed.Usecautionwhenmakingcornersormeetingtrafc.

2. USE a safety chain between tractor drawbar and implement hitch when transporting on public

roads.

3. ALWAYS use transport locks when transporting on public roads.

4. COMPLY with local lighting, marking and maximum width regulations when transporting on

highways.

5.Frequentlycheckfortrafcefromrear,expeciallyduringturns.

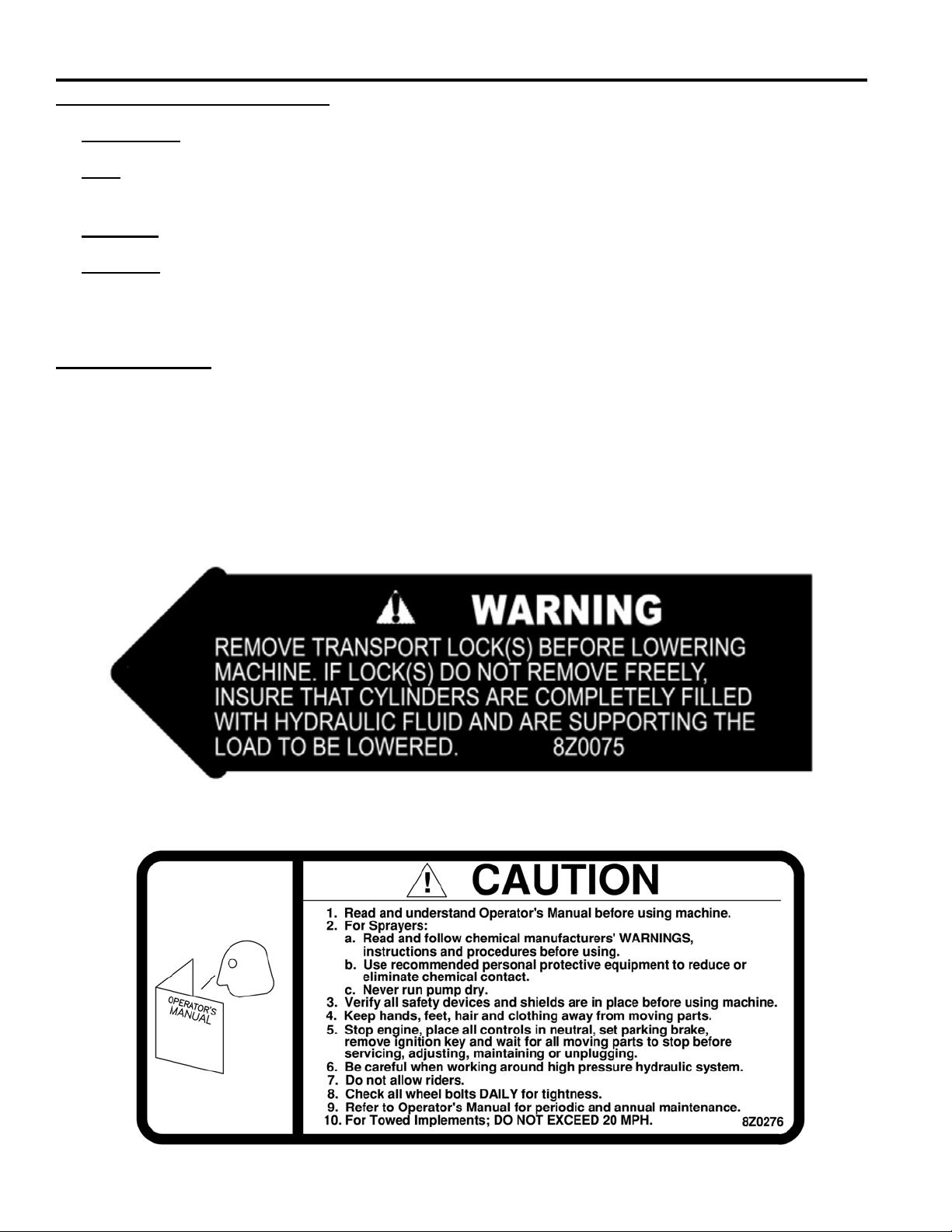

SAFETY DECALS

1. KEEP SAFETY DECALS AND REFLECTORS CLEAN.

2. REPLACE missing or unreadable decals. New decals are available from your Summers dealer

by stating correct part number (PN) located in lower right hand corner.

1. TRANSPORT LOCK DECAL (PN 8Z0075)

2. GENERAL CAUTION DECAL (PN 8Z0276)

1-2

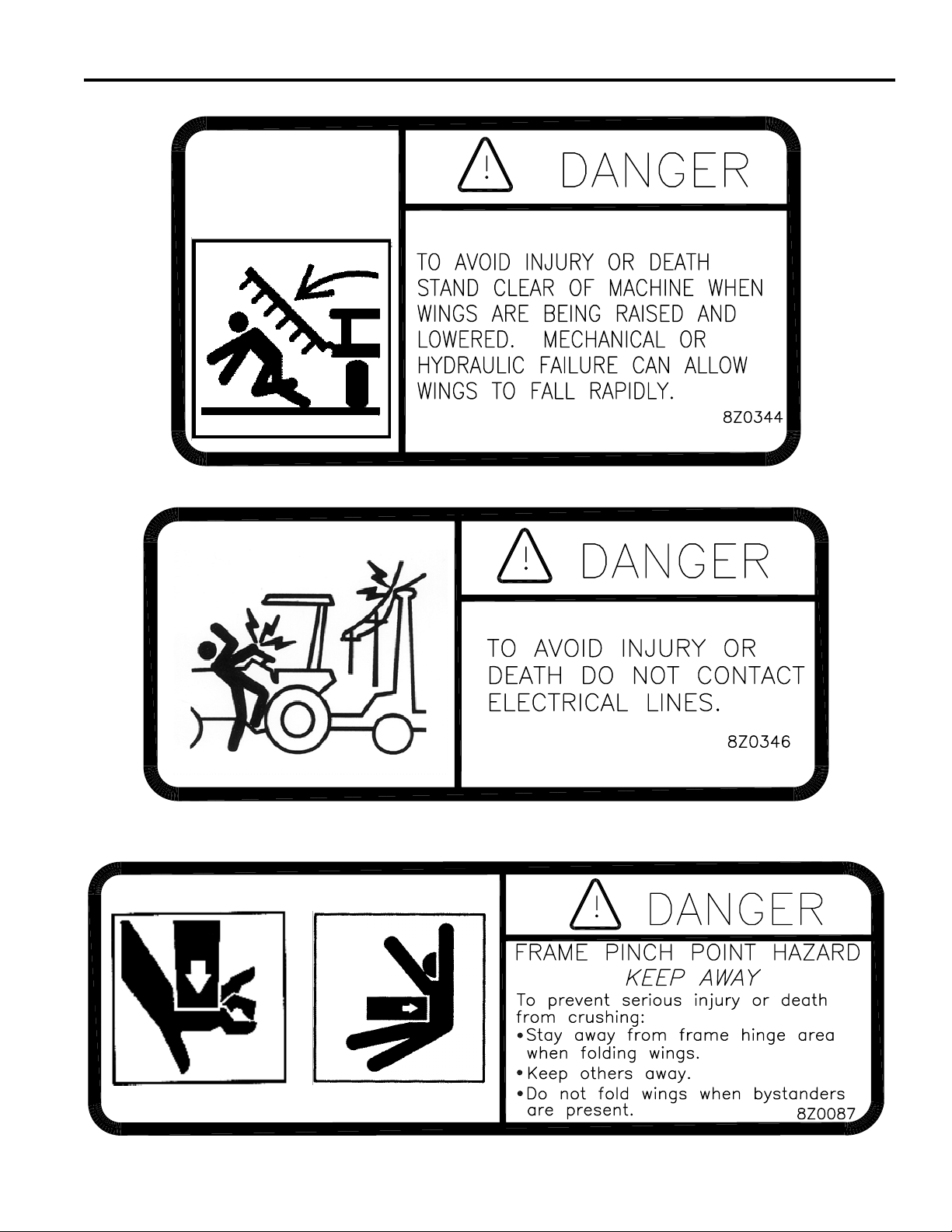

SECTION 1 - SAFETY

3. WING DANGER DECAL (PN 8Z0344)

4. ELECTROCUTION DANGER DECAL (PN 8Z0346)

5. PINCH POINT DECAL (PN 8Z0087)

1-3

6. AMBER REFLECTOR (PN 8Z0800)

7. RED-ORANGE REFLECTOR (PN 8Z0805)

SECTION 1 - SAFETY

8. RED REFLECTOR (PN 8Z0810)

SAFETY LIGHT OPERATION

The Summers Safety Light Kit is equipped with a 7 pin connector. To protect 7 pin connector,

store in dust cap (8K8067) when not attached to towing vehicle.

1-4

SECTION 1 - SAFETY

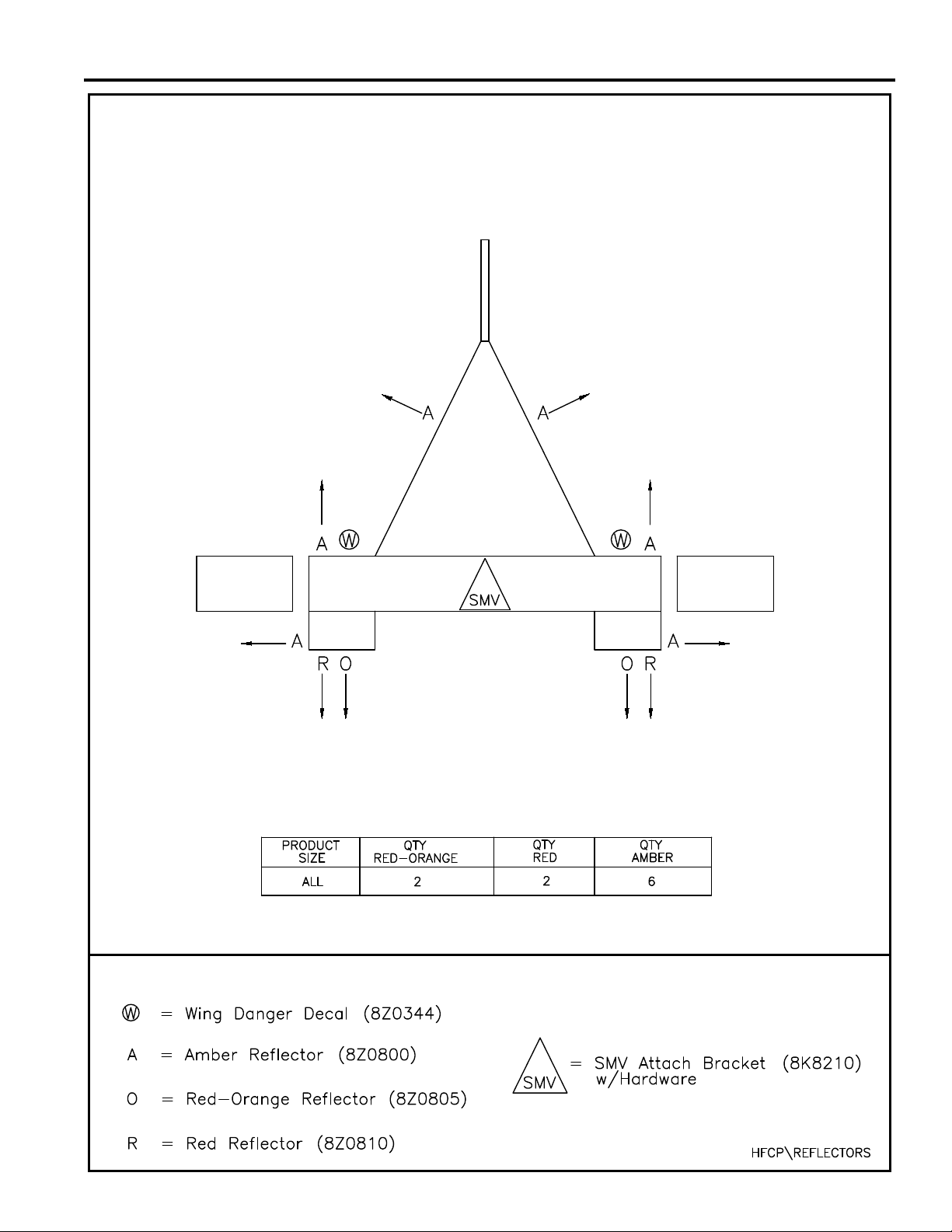

REFLECTOR LOCATIONS

Summers Mfg. Co., Inc.

HYDRAULIC FOLD IMPLEMENT

Legend

1-5

SECTION 1 - SAFETY

GENERAL ASSEMBLY SAFETY PRACTICES

YOU ARE RESPONSIBLE for the

safe assembly of the machine.

DO NOT ALLOW CHILDREN or

other unauthorized persons within

the assembly area.

WEAR PERSONAL PROTECTIVE

EQUIPMENT which includes a

hard hat, eye protection, work

gloves and steel toed boots with

slip resistant soles.

DO NOT MODIFY the equipment

or substitute parts in any way. Unauthorized modication may impair the function and/or safety of

the machine.

BLOCK UP ANY RAISED PART of

the machine. Be sure machine is

stable after blocking.

ALWAYS INSPECT LIFTING

CHAINS AND SLINGS for damage

or wear.

BE SURE LIFTING DEVICE

IS RATED TO HANDLE THE

WEIGHT.

STOP ENGINE, place all controls

in neutral, set parking brake, remove ignition key and wait for all

moving parts to stop before serving or adjusting.

USE SUITABLE LIFTING DEVICE

for components which could cause

personal injury.

GENERAL ASSEMBLY INSTRUCTIONS

1. READ AND UNDERSTAND Operator’s Manual before assembly of machine.

2. Reference to “RIGHT” and “LEFT” is determined when machine IS VIEWED FROM THE

REAR.

3. Reference to “FORWARD” means TOWARDS THE TRACTOR.

4. Reference to “REAR” means AWAY FROM THE TRACTOR.

BE SURE PRESSURE IS

RELIEVED from hydraulic circuits

before servicing or disconnecting

from tractor.

USE EXTREME CARE when

assembling, servicing or adjusting.

1-6

SECTION 2 - ASSEMBLY

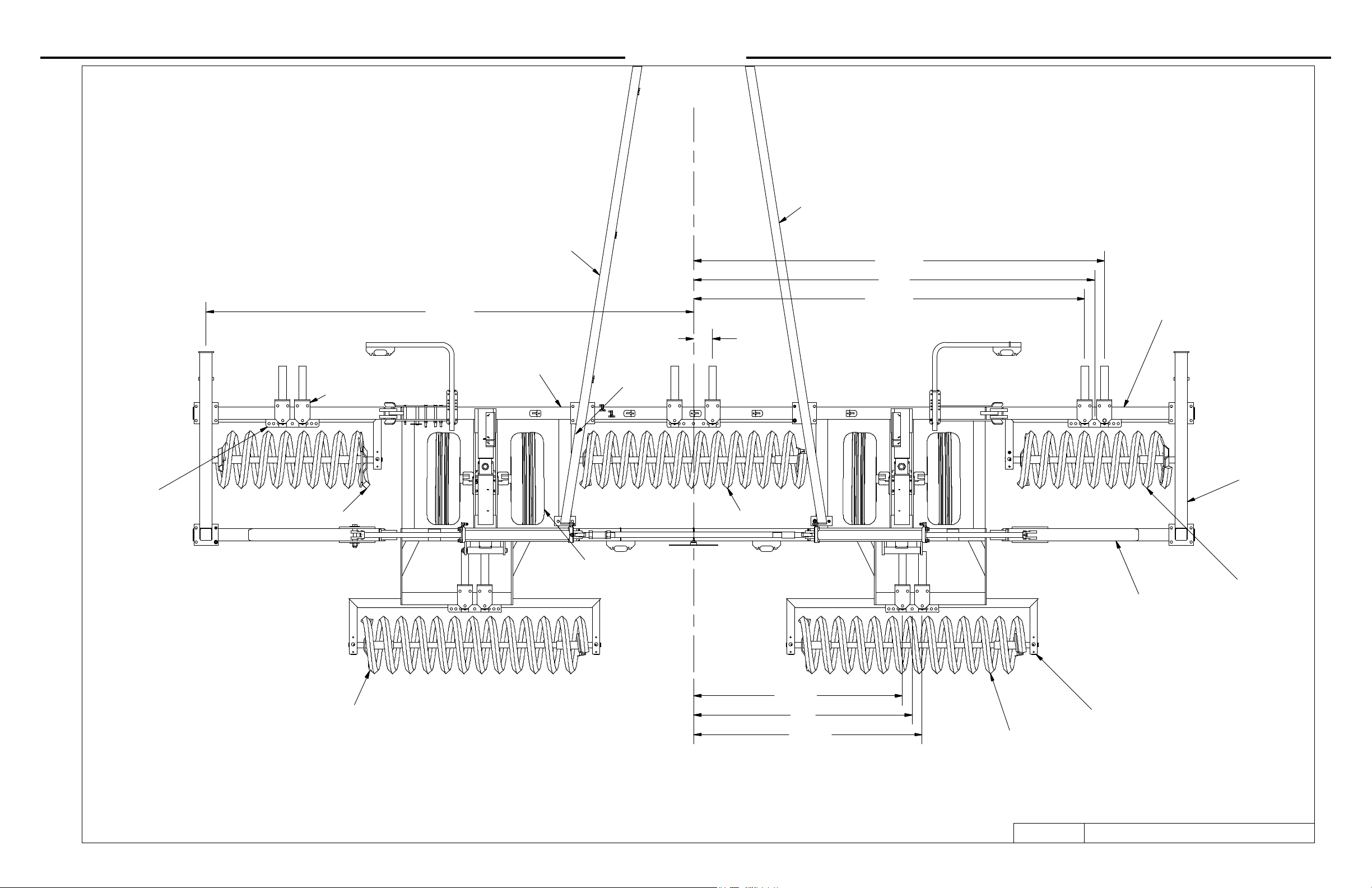

SET-UP INSTRUCTIONS – 14’ to 44’ HYDRAULIC FOLD IMPLEMENT

Refer to illustrations on following pages and follow these steps when assembling an 14’ to 44’ Summers Hydraulic Fold

CoilPackerorHydraulicFoldRollingChopper.Themachineshouldbeplacedinarm,levelareathatallowsample

roomforassemblyineldposition.

CAUTION: For safety purposes, block equipment while working on it.

CENTER ASSEMBLY

Placecentersectiononstablesupportsapproximately2-1/2ft.offoor.InstallcylinderattachEyeBolts.SetEyeBoltsin

middle of adjustment. Install hydraulic cylinders. Secure Main Lift Cylinders with 1” diameter pins and cotter pins. Secure

base end of Wing Lift Cylinders (8C0432) with 1” diameter pins and roll pins. Install center wheel lift arm assemblies

with 1-1/4” X 14” pins. Apply good quality Anti-Seize lubricant on pins prior to assembly. Secure with 1/2” X 1-3/4” cap

screws,locknutsandatwashers(overslottedhole).Pre-AssembleWalkingAxleassemblies(standardcenteronly).

Attach Walking Axle assemblies to lift arm assemblies with 3/4” bolts, lockwashers and nuts.

WING ASSEMBLY

Install left and right wings. Secure with 1-1/4” diameter pins and roll pins. Connect front and rear wing sections with

cross braces. Refer to layout drawings to determine brace locations. Secure cross braces with 3/4” u-bolts. Attach

wing axle assemblies to outside wing cross brace using 3/4” u-bolts. Wing axle and hub assemblies are optional on

single coil/chopper wings.

HYDRAULIC SYSTEM

Installcylinderhydraulicttingsandhydraulichosesbetweencylinders.

HITCH TUBES

Position hitch tube(s) on top of center section. Attach hitch tube(s) to center section with ¾” u-bolts, lockwashers and

nuts. Connect hitch tubes with hitch extension (8C5060, 8C5070 or 8C5100), hitch channel (8C5050) and hitch piece

(8D0720) at front of machine using hardware provided.

HYDRAULIC HOSES TO TRACTOR AND TIRES

Installhydraulichosesandttingstofrontofmachine.Securehoseswithclampsprovided.Donotovertighten,hydraulic hoses expand and shorten when pressurized. Install wheels and tires. Tighten wheel bolts to 170 ft-lb torque.

CHARGE HYDRAULIC SYSTEM

Block Wing Lift Hydraulic Cylinders (8C0432) so rods can fully extend without contacting wing (Photo 44a.). Connect

hydraulic tips to tractor hydraulic couplers. Extend and retract cylinders until air is purged from hydraulic system. At-

tachrodendofwingliftcylinderstowingliftslotswith1”X7”bolt,atwasher,bushingsandlocknut(Photo44b.).Do

not overtighten lock nuts as rod end of wing lift cylinder must slide freely in lift slot and bolt must rotate freely. Raise

and lower machine. Watch so hydraulic hoses do not tighten or get pinched, adjust hoses if necessary. Adjust wing

lift cylinder eye bolts so wings rest on center frame during transport. Tighten all Eye Bolts. Insure that cylinder attach

holes are aligned when eyebolts are tightened.

2-1

SECTION 2 - ASSEMBLY

C-SHANKS

Mark frame with coil /chopper locations shown in layout drawing. Install C-Shanks (8K4392) and secure with hardware

provided.

COIL/CHOPPER ASSEMBLIES

Pre-assemble Pull Frames. Secure pillow block to adjustment arm with 1/2” u-bolt and hardware. Secure bearing to coil

shaft with set screws and snap ring. Attach Coil and Pull Frame assemblies to C-Shanks using ¾” U-bolts (8C1720) and

hardware.Note:LeftandRighthandwoundcoilscanbeidentiedbycomparingtoLeftandRighthandboltthreads.

SMV sign, Wing Transport Locks, Main Transport Lock, ID & Safety Decals and Safety Lighting

Install SMV sign at rear center of machine. Install Wing and Main transport locks. Install decals. Install Safety Lighting

components. Where possible, run wiring harnesses next to hydraulic hoses. Secure with nylon ties.

2-2

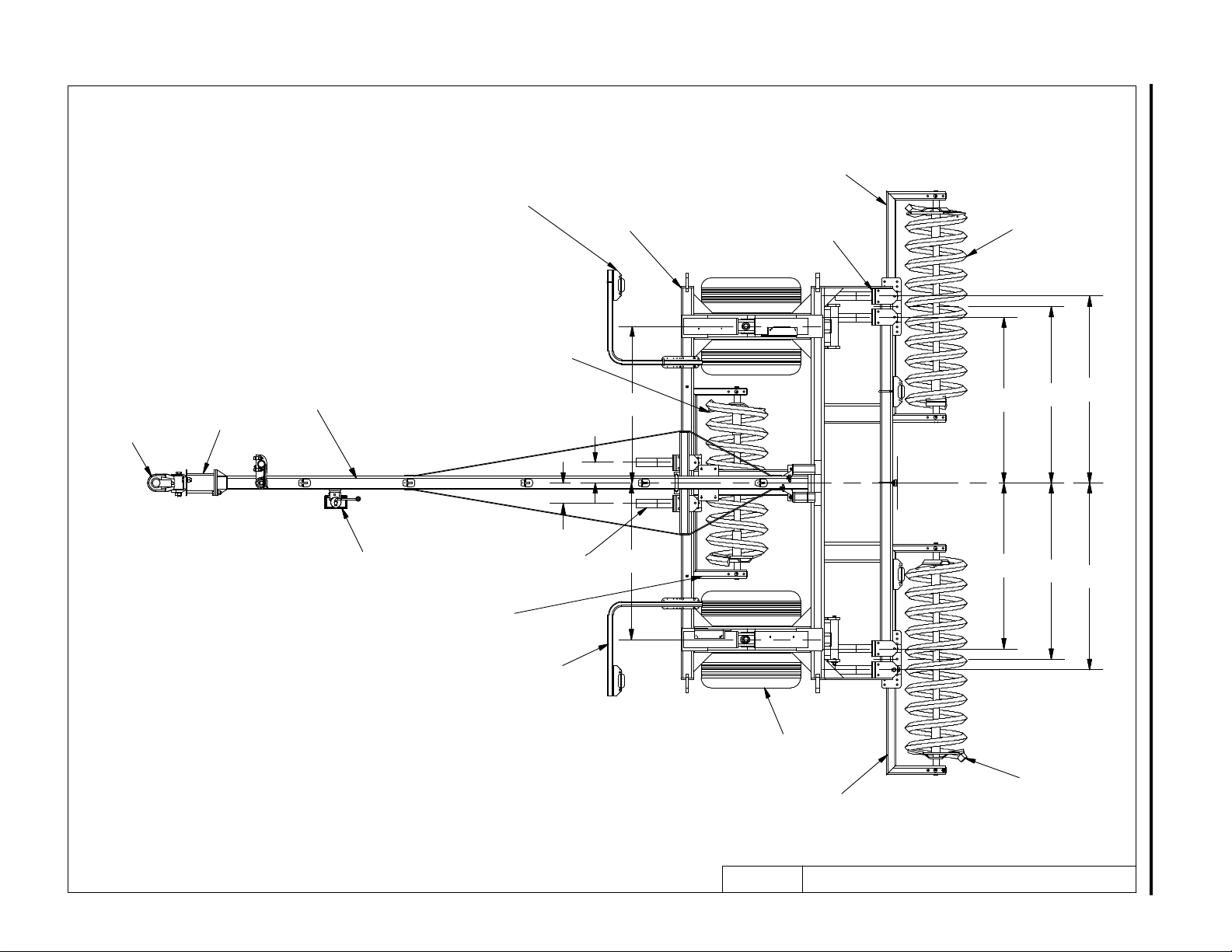

2-3

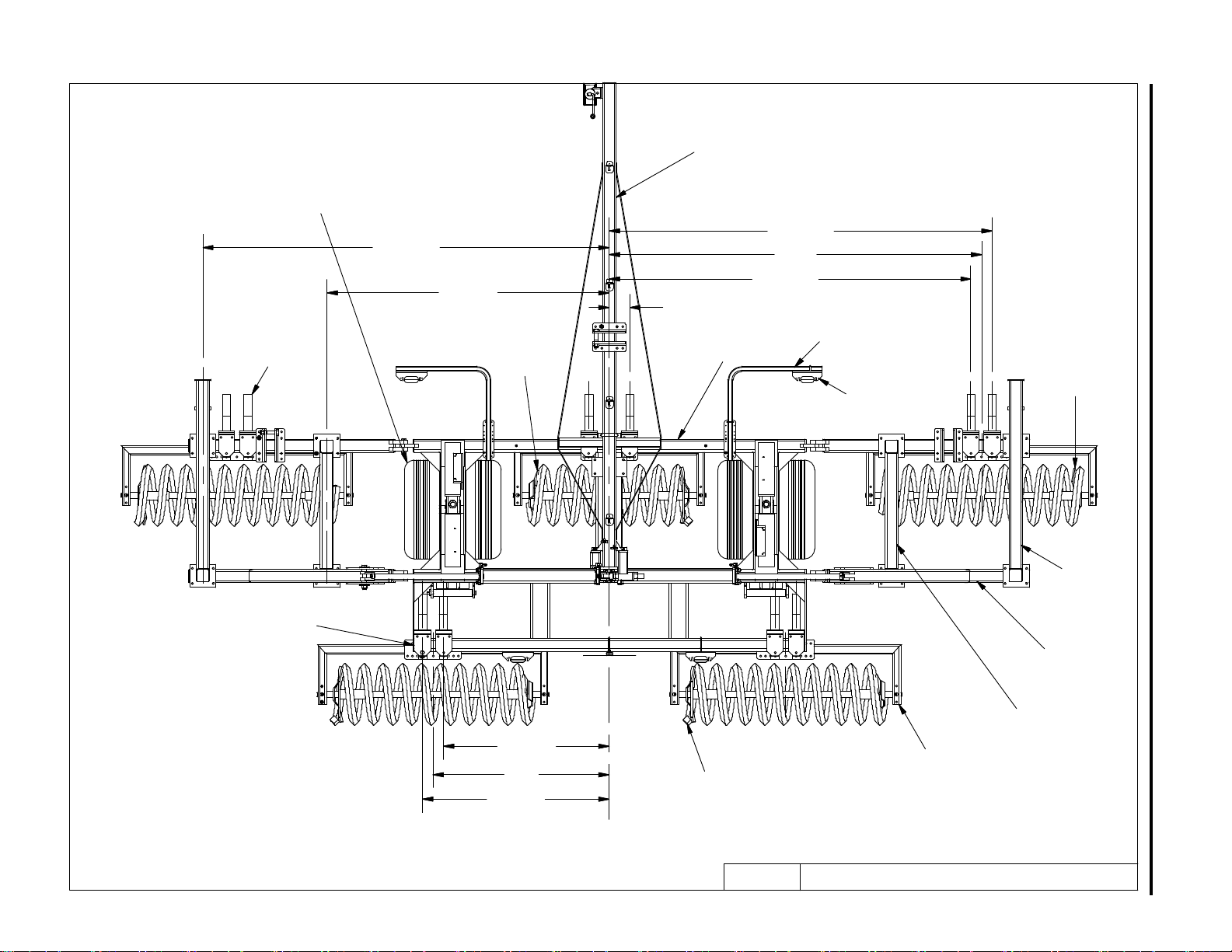

14’ Narrow Center

8C5075

8D0720

8C5060

8D8523

8K8020

8C4410

6 1/4"

8K4396

8C5145

6 1/4"

8C5850

8C5820

8C4515

SECTION 2 - ASSEMBLY

57 1/4"

48"

48"

50 3/4"

50 3/4"

54"

54"

57 1/4"

8C5840

8K8010

8K7033

8C5850

8C4515

HYD LIFT COIL PCKR N-CNTR 14'7/18/2012 9PD0140.iam/

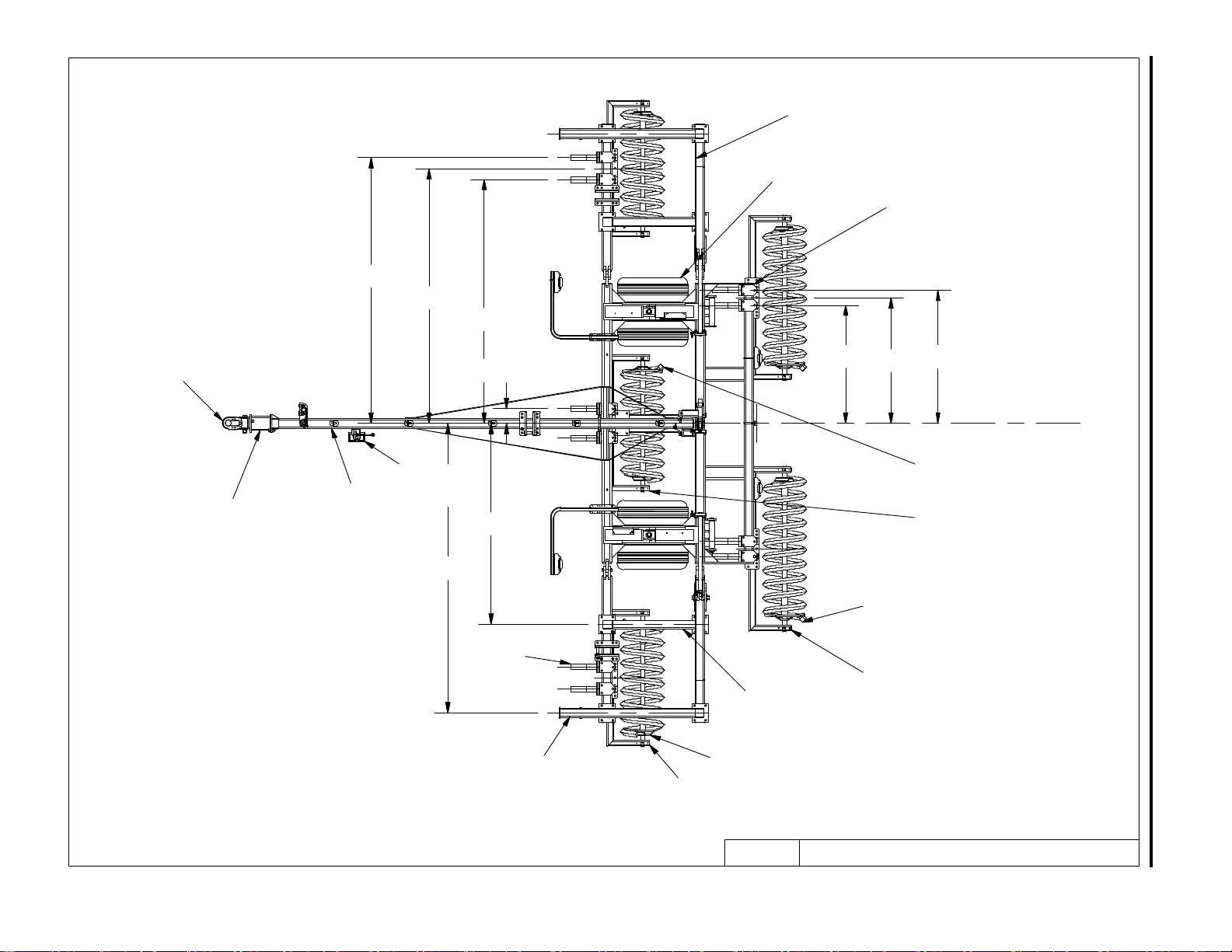

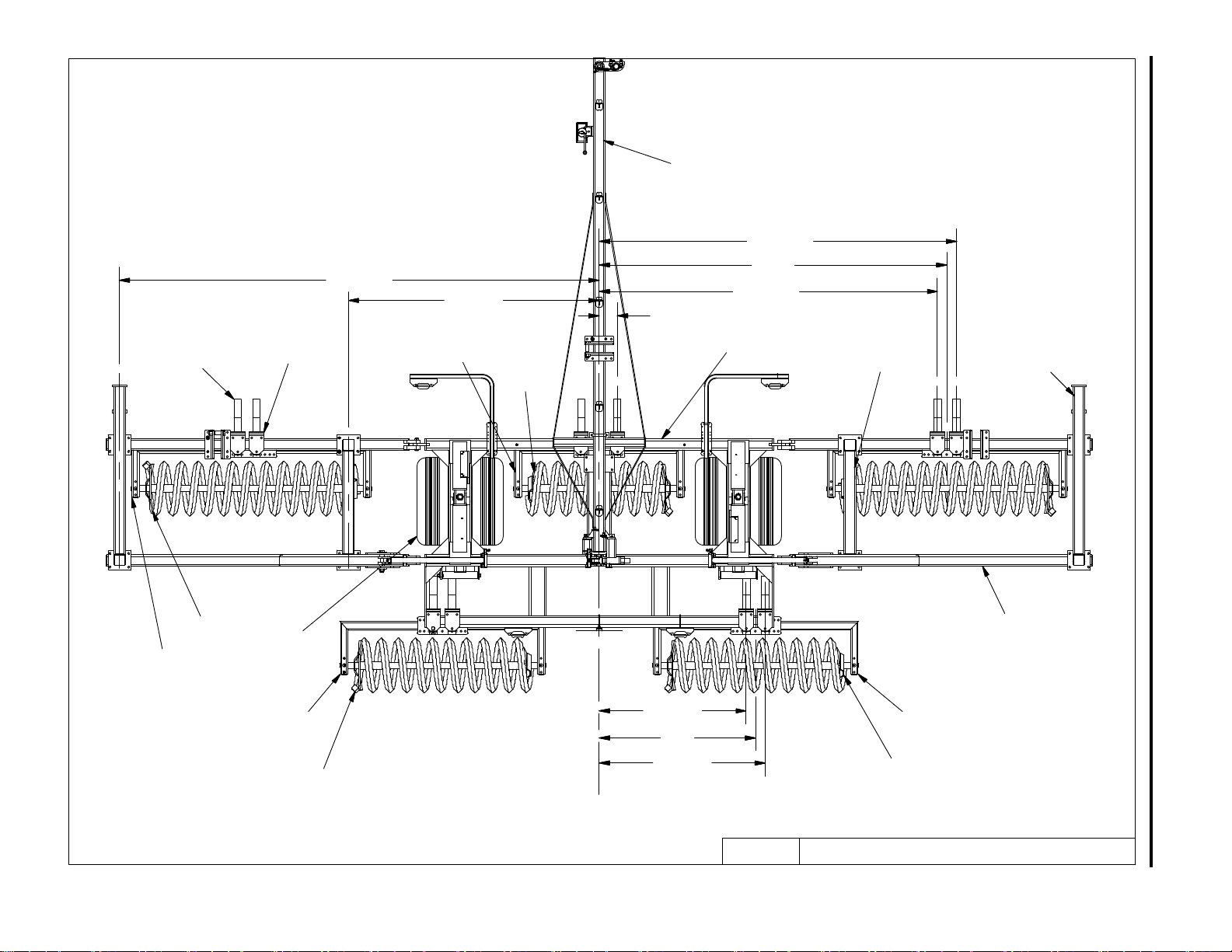

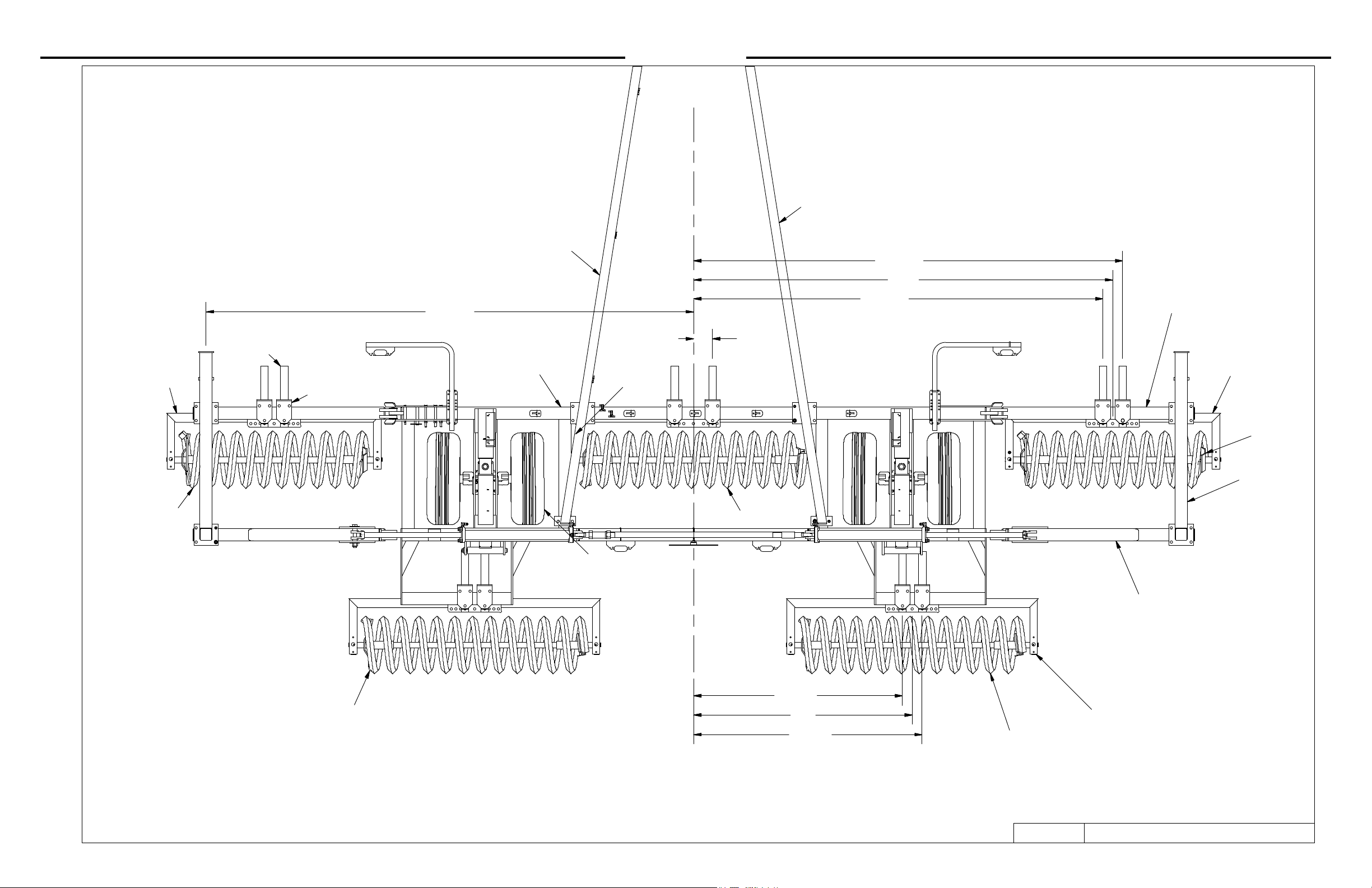

22’ Narrow Center

114 1/4"

109 1/2"

104 3/4"

8C5200

8K7033

8C5820

2-4

8D0720

8C5060

8C5075

8D8523

124 1/2"

6 1/4"

86 1/2"

8K4396

8C5170

50 3/4"

8C5180

8C4410

8C5840

54"

8C4515

8C5850

57 1/4"

8C4410

8C5840

SECTION 2 - ASSEMBLY

HYD FOLD COIL PCKR N-CNTR 22'7/18/2012 9PD0220.iam/

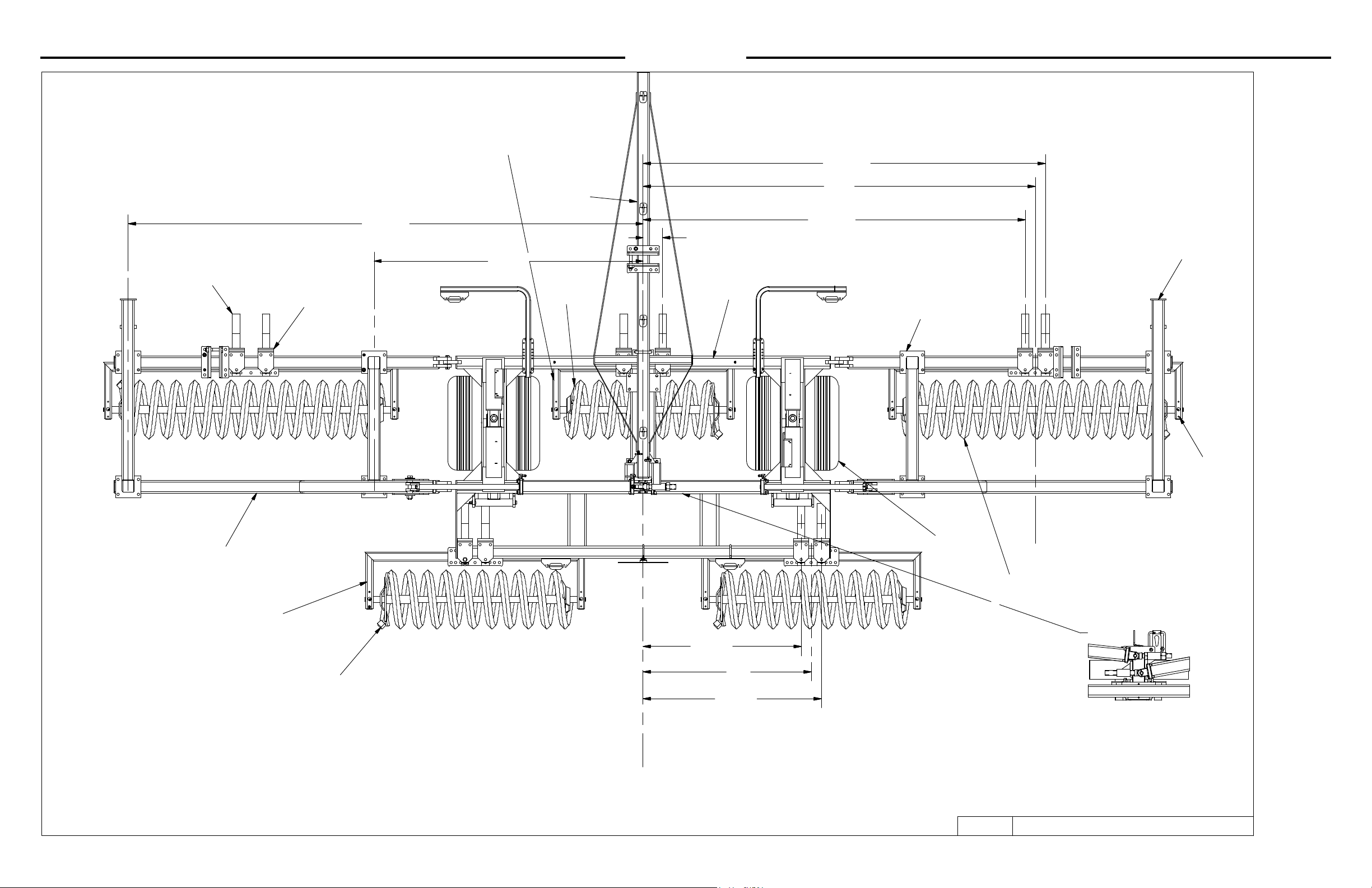

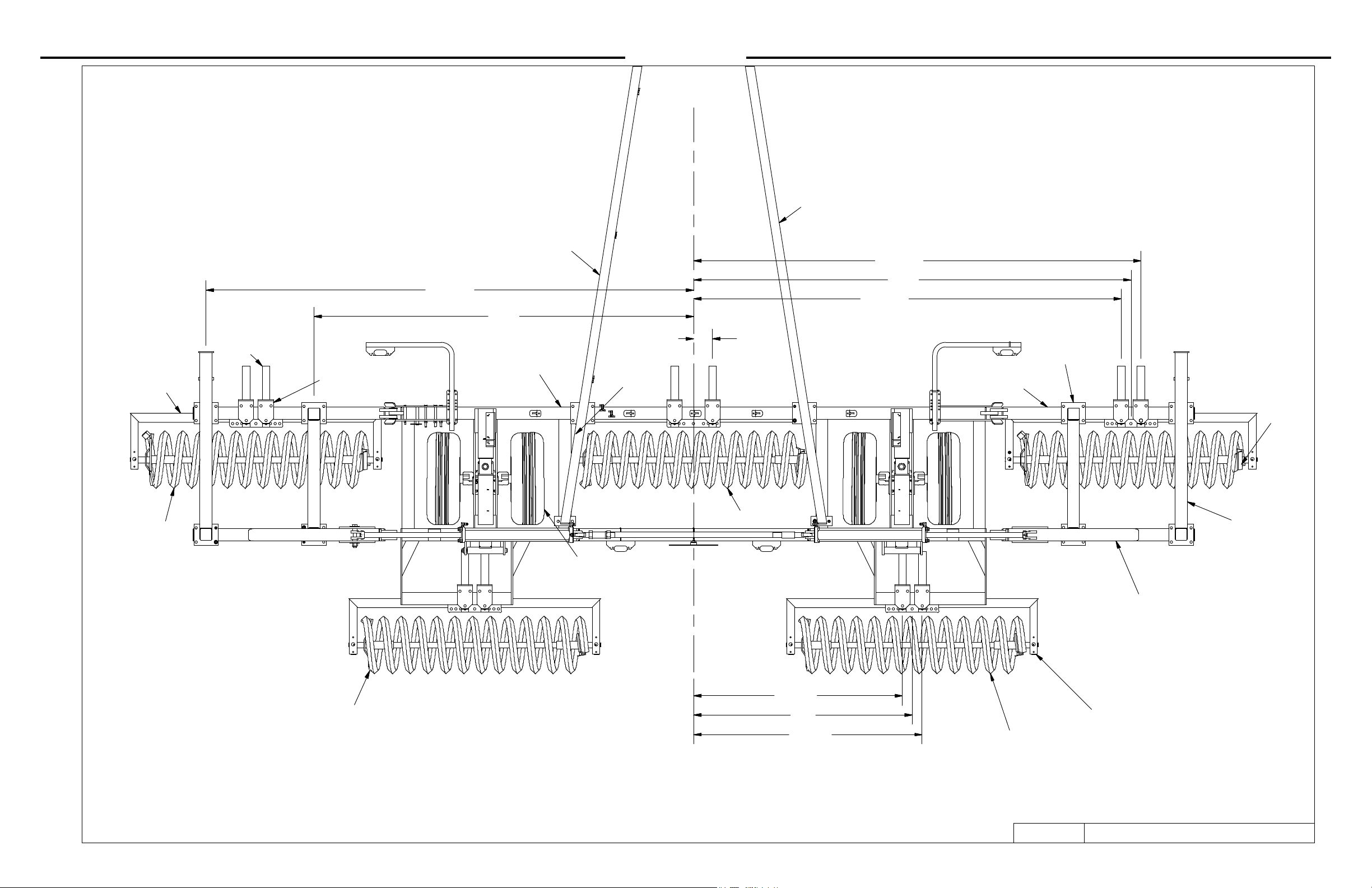

24’ Narrow Center

2-5

8K7033

8K4396

8C5075

117 1/4"

124 1/2"

86 1/2"

8C4410

6 1/4"

8C5145

114"

110 3/4"

8K8010

8K8020

8C4510

SECTION 2 - ASSEMBLY

8C5820

50 3/4"

54"

57 1/4"

8C4515

8C5170

8C5200

8C5180

8C5850

HYD FOLD COIL PCKR N-CNTR 24'7/18/2012 9PD0240.iam/

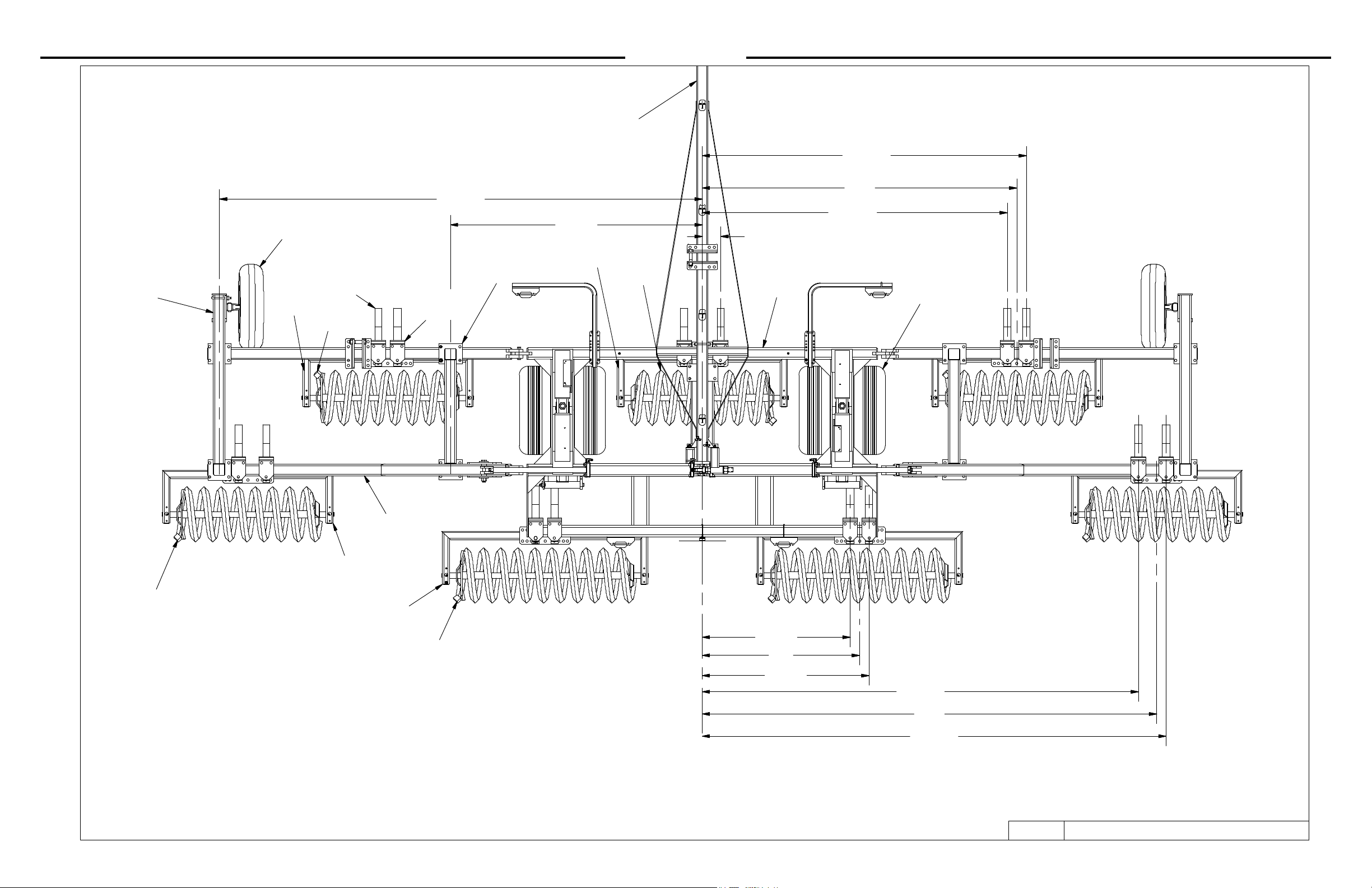

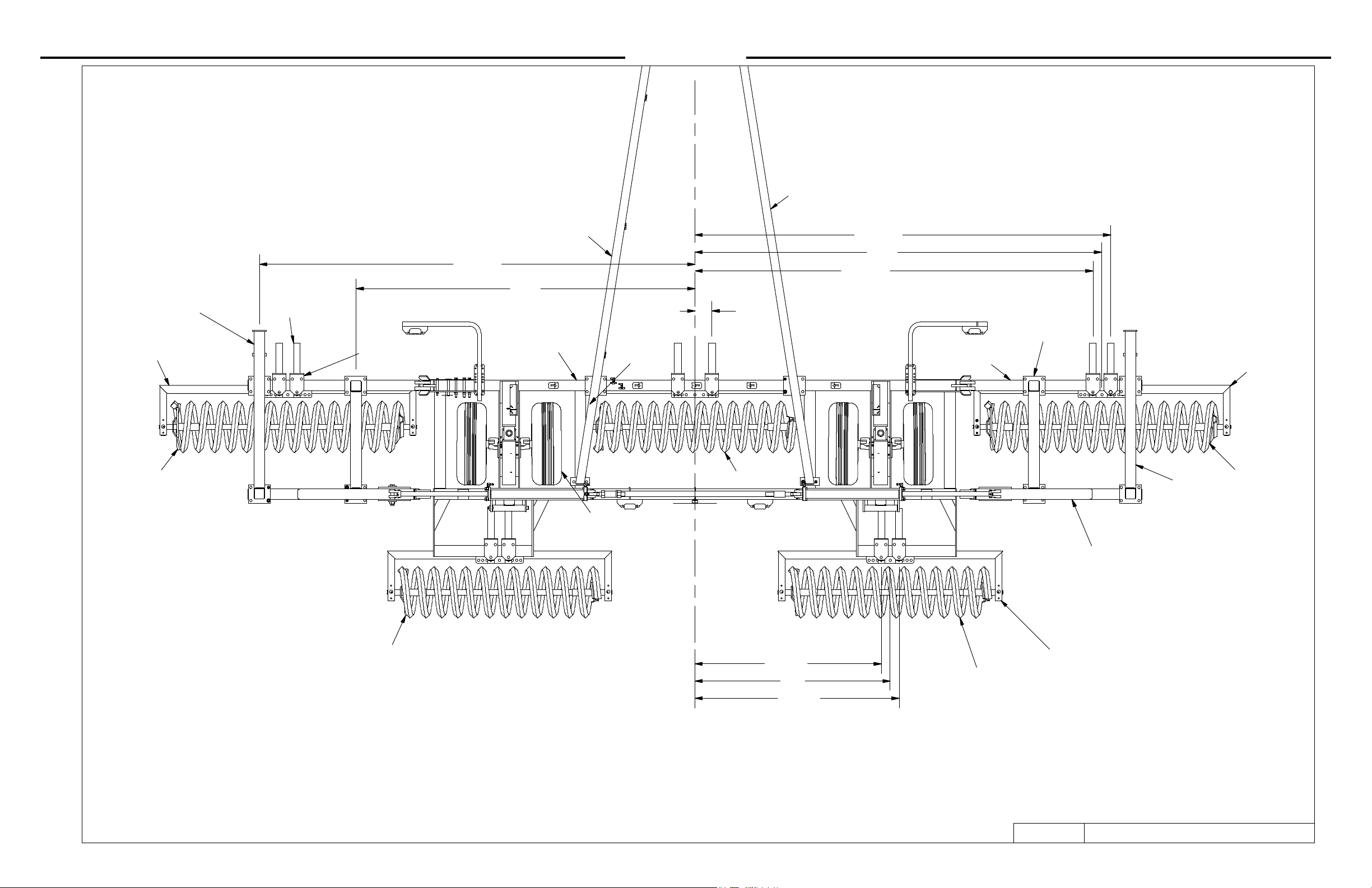

26’ Narrow Center

8K4396

2-6

8C5820

165 1/2"

86 1/2"

8C5840

8C4410

8C5075

6 1/4"

8C5145

123 1/4"

120"

116 3/4"

8C5180

8C5170

SECTION 2 - ASSEMBLY

8C5860

8C4610

8K7033

8C5850

8C4515

8C5250

50 3/4"

54"

57 1/4"

8C5850

8C4515

HYD FOLD COIL PCKR N-CNTR 26'7/18/2012 9PD0260.iam/

28’ Narrow Center

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

8C5840

129 1/4"

8K4396

8C5820

165 1/2"

86 1/2"

8C5075

8C4410

6 1/4"

8C5145

126"

122 3/4"

8C5170

8C5180

8C5870

8C5250

8C5850

8C4515

2-7

8K7033

8C4710

50 3/4"

54"

57 1/4"

HYD FOLD COIL PCKR N-CNTR 20'7/24/2012 9PD0280.iam/

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

30’ Narrow Center

8C5075

111 1/4"

8C5170

8D3031

8C5840

8K4396

8C4410

165 7/8"

8C5820

8C5180

86 1/2"

8C5840

108"

104 3/4"

6 1/4"

8C4410

8C5145

8K7033

8C4415

8C5840

8C5250

8C5850

8C4515

50 3/4"

54"

57 1/4"

149 3/4"

156"

159 1/4"

HYD FOLD COIL PCKR N-CNTR 30'7/24/2012 9PD0300.iam/

2-8

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

26’ Standard Center

8C5820

160 1/2"

8C5090

8C5080

135 1/4"

132"

128 3/4"

8C5210

6 1/4"

8C5150

8C5860

8C5840

8C4410

8C4615

8K7033

8C4610

68 3/4"

72"

75 1/4"

8C5170

8C4410

8C5200

8C5860

8C4615

2-9

HYD FOLD COIL PCKR 26'7/31/2012 9PD2675.iam/

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

28’ Standard Center

8C5090

8C5080

141 1/4"

138"

8C5850

8C4510

8K4396

8C5820

160 1/2"

8C5150

8K7033

8C5860

6 1/4"

8C4610

134 3/4"

8C5210

8C5850

8C4510

8C5170

8C5200

8C4615

68 3/4"

72"

75 1/4"

8C5860

8C4615

HYD FOLD COIL PCKR 28'8/8/2012 9PD2875.iam/

2-10

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

30’ Standard Center

8C5090

8C5080

147 1/4"

8C5860

8C4610

8K4396

8C5820

160 1/2"

125"

8C5150

8K7033

8C5860

144"

140 3/4"

6 1/4"

8C5180

8C5210

8C4610

8C4610

8C5170

8C5200

8C4615

2-11

68 3/4"

72"

75 1/4"

8C5860

8C4615

HYD FOLD COIL PCKR 30'8/8/2012 9PD3075.iam/

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

32’ Standard Center

8C5090

8C5870

8C4710

8C5170

8K4396

8C5820

160 1/2"

125"

8C5080

8C5150

8K7033

8C5860

6 1/4"

8C4610

153 1/4"

150"

146 3/4"

8C5210

8C5180

8C5870

8C4710

8C5170

8C4615

68 3/4"

72"

75 1/4"

8C5200

8C5860

8C4615

HYD FOLD COIL PCKR 32'8/8/2012 9PD3275.iam/

2-12

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

34’ Standard Center

8C5090

8C5170

8C5840

8K4396

8C4410

8C5820

202"

151 1/2"

8C5150

8C5080

8K7033

8C5860

6 1/4"

8C4610

135 1/4"

132"

128 3/4"

8C4410

8D3031

8C5260

8C5180

8C5840

8C5170

8C5250

8C4415

8C5840

2-13

8C4615

68 3/4"

72"

75 1/4"

8C5840

8C5860

8C4615

176 3/4"

180"

183 1/4"

HYD FOLD COIL PCKR 34'8/8/2012 9PD3475.iam/

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

36’ Standard Center

8C5090

8C5170

8C5850

8C4510

8K4396

8C5820

202"

125"

8C5080

8C5150

8K7033

8C5860

6 1/4"

8C4610

141 1/4"

138"

134 3/4"

8D3031

8C5260

8C5180

8C5850

8C4510

8C5170

8C5250

8C4415

8C5840

8C4615

68 3/4"

72"

75 1/4"

8C5840

8C4415

8C5860

8C4615

188 3/4"

192"

195 1/4"

HYD FOLD COIL PCKR 36'8/8/2012 9PD3675.iam/

2-14

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

38’ Standard Center

8C5090

8C5170

8C5850

8C4510

8C5850

8K4396

8C5820

186"

125"

8C5080

8C5150

8K7033

8C5860

6 1/4"

8C4610

141 1/4"

138"

134 3/4"

8C5180

8C4510

8C5260

8C5250

8D3031

8C5170

8C5850

8C5850

8C4515

2-15

8C4615

8C5860

68 3/4"

72"

75 1/4"

8C4515

8C5860

8C4615

194 3/4"

198"

201 1/4"

HYD FOLD COIL PCKR 38'8/8/2012 9PD3875.iam/

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

40’ Standard Center

8C5090

8C5170

8C5860

8C4610

8C4515

8C5850

8K4396

8C5820

196"

125"

8C5080

8C5150

8K7033

8C5860

8C5860

6 1/4"

8C4610

147 1/4"

144"

140 3/4"

8C5180

8C4610

8C5280

8D3031

8C5260

8C5170

8C5860

8C5850

8C4515

8C4615

8C5860

8C4615

68 3/4"

72"

75 1/4"

206 3/4"

210"

213 1/4"

HYD FOLD COIL PCKR 40'8/8/2012 9PD4075.iam/

2-16

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

42’ Standard Center

8C5090

8D3031

8C5180

8C5860

8C4610

8C4615

8C5860

8K4396

202"

8C5820

125"

8C5150

8C5080

8K7033

8C5860

8C5860

6 1/4"

8C4610

147 1/4"

144"

140 3/4"

8C5860

8C5260

8C5180

8C5860

8C4610

8C5280

8C4615

2-17

8C4615

8C5860

8C4615

68 3/4"

72"

75 1/4"

212 3/4"

216"

219 1/4"

HYD FOLD COIL PCKR 42'8/8/2012 9PD4275.iam/

SECTION 2 - ASSEMBLY SECTION 2 - ASSEMBLY

44’ Standard Center

217"

168"

125"

8C5080

8C5090

243 1/4"

240"

236 3/4"

141 1/4"

138"

134 3/4"

8D3031

8C5840

8C4410

8C5170

8C5850

8C4415

8C4510

8K4396

8C5820

8C4615

8C5150

8K7033

8C5860

8C5860

6 1/4"

8C4610

8C5180

8C4615

8C4510

8C5860

8C5180

8C5280

8C5270

8C5850

8C5170

8C5840

8C4415

8C5840

8C4410

68 3/4"

72"

75 1/4"

188 3/4"

192"

195 1/4"

HYD FOLD COIL PCKR 44'8/8/2012 9PD4475.iam/

2-18

SECTION 2 - ASSEMBLY

HYD. FOLD PACKER ASSEMBLY - PHOTO SUPPLEMENT – 42’ SHOWN

Center

1. Position Center Frame on supports.

2. Install main and wing lift cylinder eye bolts

(middle of adjustment).

3. Install main lift cylinders.

4. Attach wing lift cylinders.

2-19

SECTION 2 - ASSEMBLY

HYD. FOLD PACKER ASSEMBLY - PHOTO SUPPLEMENT – 42’ SHOWN

5. Install Center Lift Arms and secure Pivot Pin with bolt, washer and lock nut.

6. Assemble Walking Axles. 7. Walking Axle with Pivot Bolt.

8. Install pivot dampeners. 9. Tighten Walking Axle hardware.

2-20

Loading...

Loading...