Subaru Baja 2004 User Manual

FOREWORD

FOREWORD

1. Foreword

A: FOREWORD

These manuals are used when performing maintenance, repair, or diagnosis of the Subaru FORESTER.

Applied model: SG***** from 2004MY

The manuals contain the latest information at the

time of publication. Changes in specifications,

methods, etc. may be made without notice.

FW-2

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

1. How to Use This Manual

A: HOW TO USE THIS MANUAL

1. STRUCTURE

Each section consists of SCT that are broken down

into SC that are divided into sections for each component. The specification, maintenance and other

information for the components are included, and

diagnosis information has also been added where

necessary.

2. INDEX

The first page has an index with tabs.

HU-2

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

3. COMPONENTS

Illustrations are listed for each component. The information necessary for repair work (tightening torque,

grease up points, etc.) is described on these illustrations. Information is described using symbol. To order the

parts, refer to parts catalogue.

Example:

T2

(6)

(12)

(17)

(32)

T5

(37)

(14)

(19)

(3)

(4)

(22)

(34)

(5)

(33)

(20)

(16)

(18)

(7)

(8)

(21)

(23)

T1

(35)

T5

T3

T3

T3

T3

T3

(36)

(8)

T2

T2

(7)

T5

T1

T6

(10)

(16)

T3

(10)

(14)

(3)

(15)

T11

(4)

T10

(23)

T7

(18)

(1)

T6

(17)

(4)

T8

(2)

T1

T2

(22)

(10)

T6

(13)

(9)

(21)

(4)

(4)

(3)

(5)

T2

(3)

(24)

(25)

T2

(12)

(24)

(28)

T4

T2

T4

(10)

(29)

(25)

(6)

(11)

(26)

(30)

T1

(2)

(1)

(9)

(10)

(11)

T2

T4

T5

(27)

(31)

:Selective part

:Replacement part

:Sealing point

T3

(13)

(15)

T4

T9

(19)

(20)

HU-3

T1

:Should be lubricated with oil.

:Should be lubricated with grease.

,

T2

....

:Tightening torque

HU-00001

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

4. SPECIFICATIONS

If necessary, specifications are also included.

5. INSPECTION

Inspections are included to be carried out before and after maintenance.

6. MAINTENANCE

• Maintenance instructions for serviceable parts describes work area and detailed steps with illustration. It

also describes the use of special tool, tightening torque, cautions for each procedure.

• If many serviceable parts are included in one service procedure, appropriate reference are provided for

each part.

Example:

15.Main Shaft Assembly for Single-Range

A: REMOVAL

1) Remove the manual transmission assembly

from vehicie. <Ref. to MT-33, REMOVAL, Manual

Transmission Assembly.>

11) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

NOTE:

Secure the lock nuts in two Places affer tightening.

ST2 499987003 SOCKET WRENCH

ST1 498937000 TRANSMISSION HOLDER

Tightening torque:

118 N m (12.0 kgf-m, 86.8 ft-lb)

(E) (F)

(A)

(B)

(C)

(D)

(G)

(H)

ST2

(A) Component (D) Caution (G) Tightening torque

(B) Process (E) Tool number of special tool (H) Illustration

(C) Reference (F) Name of special tool

ST1

HU-4

HU-00002

HOW TO USE THIS MANUAL

7. DIAGNOSIS

Tables showing a step-by-step process make it

easy to conduct diagnosis.

8. SI UNITS

Measurements in these manuals are according to

the SI units. Metric and yard/pound measurements

are also included.

Example:

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

HOW TO USE THIS MANUAL

HU-5

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

HU-6

IDENTIFICATION

IDENTIFICATION

1. Identification

A: IDENTIFICATION

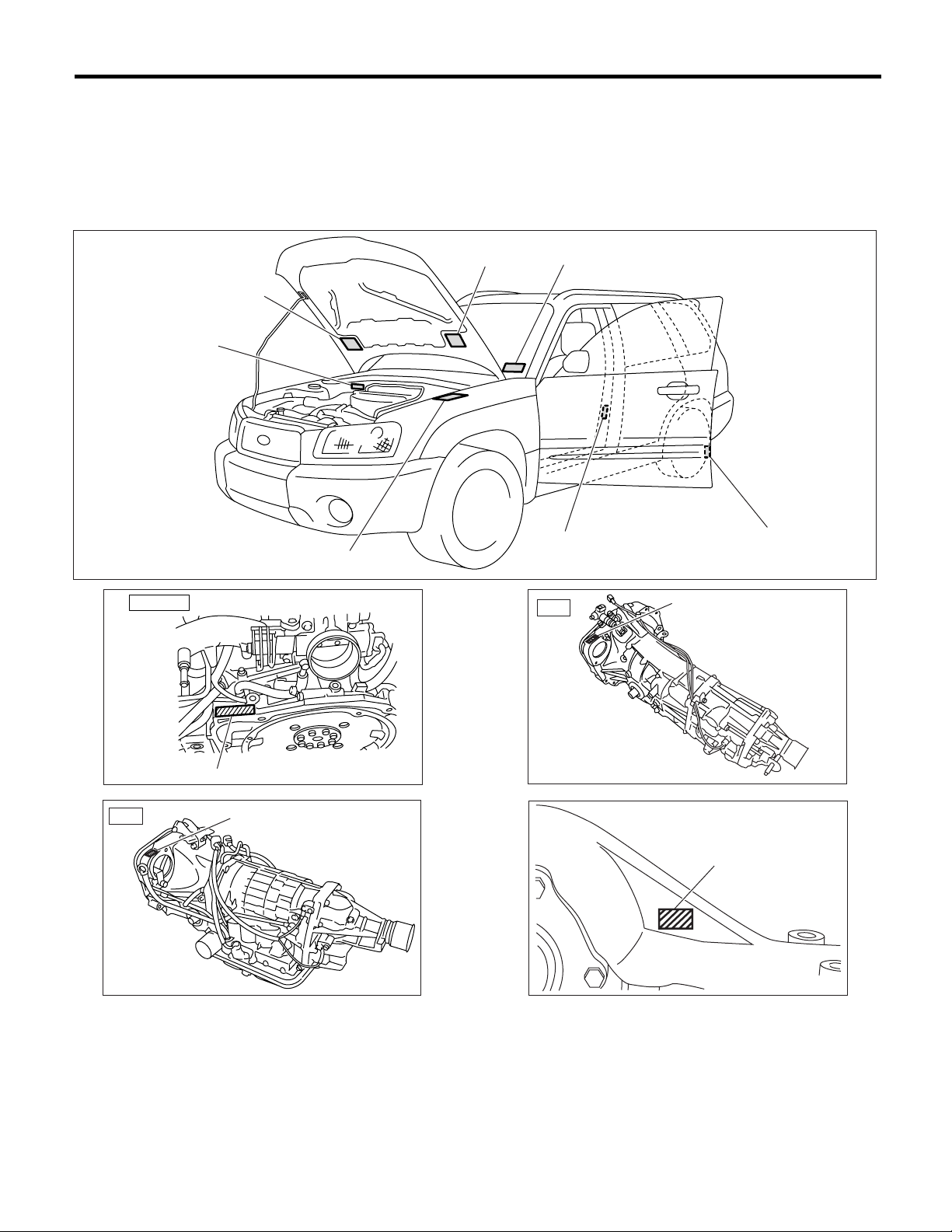

1. IDENTIFICATION NUMBER AND LABEL LOCATIONS

The VIN (Vehicle Identification Numbers) is used to classify the vehicle.

Positioning of the plate label for identification

Vacuum hose

piping label

Emission control label

Vehicle identification

number

Vehicle identification number plate

ENGINE

4AT

Engine serial number

Transmission serial number

Model number plate

ID-00011

Tire inflation

pressure label

5MT

Bar cord label

(America spec. vehicles only)

ID-00010

Transmission serial number

ID-00013

Stamp location

ID-00012

ID-00014

ID-2

IDENTIFICATION

Model number plate

trim code

Color code

2. MEANING OF V.I.N.

The meaning of the VIN is as follows:

]JF1SG636X4G700001[

The starting and ending brackets ( ][ ) are stop marks.

FUJI HEAVY INDUSTRIES LTD.

1SG

VIN

applied model

41

23

J

F

S

G

0

0

transmission type

63

9AY7J

engine type

G

5X3

option code

EJ251BWUAA

55

T

Y7

70000

0

E

VC3A

IDENTIFICATION

1

A

ID-00006

Digits Code Meaning Details

1 to 3 JF1 Manufacturer body area JF1: Passenger car, FHI made

4 S Car line S: Forester

5 G Body type G: Wagon

6 6 Displacement 6: 2.5L AWD

7 3 Grade 3: 2.5X

5: 2.5XS

9: 2.5XT

8 6 Restraint 6: Manual belts, dual airbag, side airbag

9 X Check digit X or 0 — 9

10 4 Model year 4: 2004MY

5: 2005MY

6: 2006MY

11 G Transmission type G: Full-time AWD 5-speed MT

H: Full-time AWD 4-speed AT

12 to 17 700001 Serial number —

ID-3

IDENTIFICATION

IDENTIFICATION

3. MODEL NUMBER PLATE

The model number plate indicates: the applied model, the option code, the trim code, the engine type, the

transmission type, and the exterior color code. This information is helpful when placing orders for parts.

SG9BY7J

Digits Code Meaning Details

1 S Series S: Forester

2 G Body type G: Wagon

3 9 Engine displacement

Drive system

Suspension system

4 B Model year B: 2004MY

5 Y Destination Y: U.S.A., Canada

6 7 Grade 7: 2.5X

7 J Transmission, fuel feed

system

The engine and transmission type are as follows:

• Engine

9: 2.5L AWD

8: 2.5XS

B: 2.5XT

J: SOHC MFI 5-speed MT

R: SOHC MFI 4-speed AT

D: DOHC Turbo MFI 5-speed MT

P: DOHC Turbo MFI 4-speed AT

EJ251BWTAA

Digits Code Meaning Details

1 and 2 EJ Engine type EJ: 4 cylinders

3 and 4 25 Displacement 25: 2.5L

5 1 Fuel feed system 1: D-MFI SOHC-A

5: MFI DOHC Turbo

6 B Exhaust regulations B: US Federal & California

7 W Transmission W: MT

X: AT

8 to 10 TAA Detailed specifications Used when ordering parts. See the parts catalog for details.

• Transmission

TY755VC4AA

Digits Code Meaning Details

1 T Transmission T: Transmission

2 Y Transmission type Y: Full-time AWD MT center differential

Z: Full-time AWD AT MPT

3 and 4 75 Classification 75: MT

1A: AT

1B: AT (Turbo)

55 Series 3: AT

5: MT, AT (Turbo)

6 V Transmission specifica-

tions

7 C Mounted body C: US 2.5L SOHC

8 to 10 4AA Detailed specifications Used when ordering parts. See the parts catalog for details.

V: Full-time AWD 5-speed MT with viscous coupling center differential single range

Z: Full-time AWD 4-speed AT with MPT

L: Full-time AWD 4-speed AT with MPT (Turbo)

H: 2.5L DOHC Turbo

ID-4

IDENTIFICATION

• Rear differential

T2

Code Reduction gear ratio LSD

T2 4.111 No

JP 4.111 Viscous

TP 4.444 No

CF 4.444 Viscous

• Option code

U4QW

Digits Code Meaning Details

1 to 2 U4 Destination U4: U.S.A.

CO: Canada

3 to 4 QW Main option of vehicle —

IDENTIFICATION

ID-5

IDENTIFICATION

IDENTIFICATION

ID-6

NOTE

1. Note

A: NOTE

This is information that can improve efficiency of

maintenance and assure sound work.

1. FASTENER NOTICE

Fasteners are used to prevent parts from damage

and dislocation due to looseness. Fasteners must

be tightened to the specified torque.

Do not apply paint, lubricant, rust retardant, or other substances to the surface around bolts, fasteners, etc. Doing so will make it difficult to obtain the

correct torque and result in looseness and other

problems.

2. STATIC ELECTRICITY DAMAGE

Do not touch the control unit, connectors, logic

boards, and other such parts when there is a risk of

static electricity. Always use a static electricity prevention cord or touch grounded metal before conducting work.

NOTE

3. BATTERY

When removing the battery cables, always be sure

to turn the ignition off to prevent electrical damage

to the control unit from rush current.

4. SERVICE PARTS

Use authentic service parts for maximum performance and maintenance, when conducting repairs.

Subaru/FHI will not be responsible for poor performance resulting from the use of parts not specified

by a genuine dealer.

5. PROTECTING VEHICLE UNDER MAINTENANCE

Make sure to attach the fender cover, seat covers,

etc. before work.

6. ENSURING SAFETY DURING WORK

When working in a group of two or more, perform

the work with calling each other to ensure mutual

safety.

NT-2

NOTE

NOTE

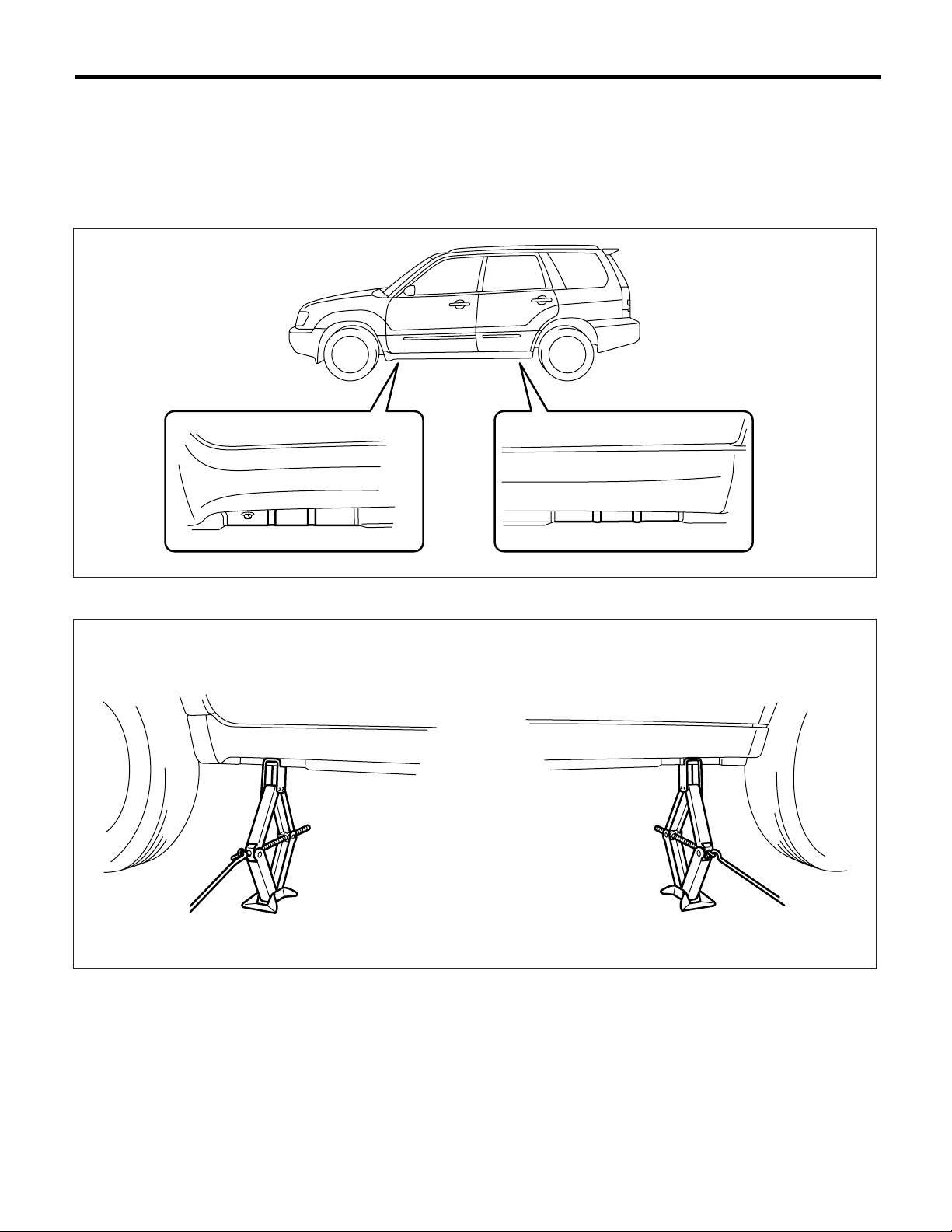

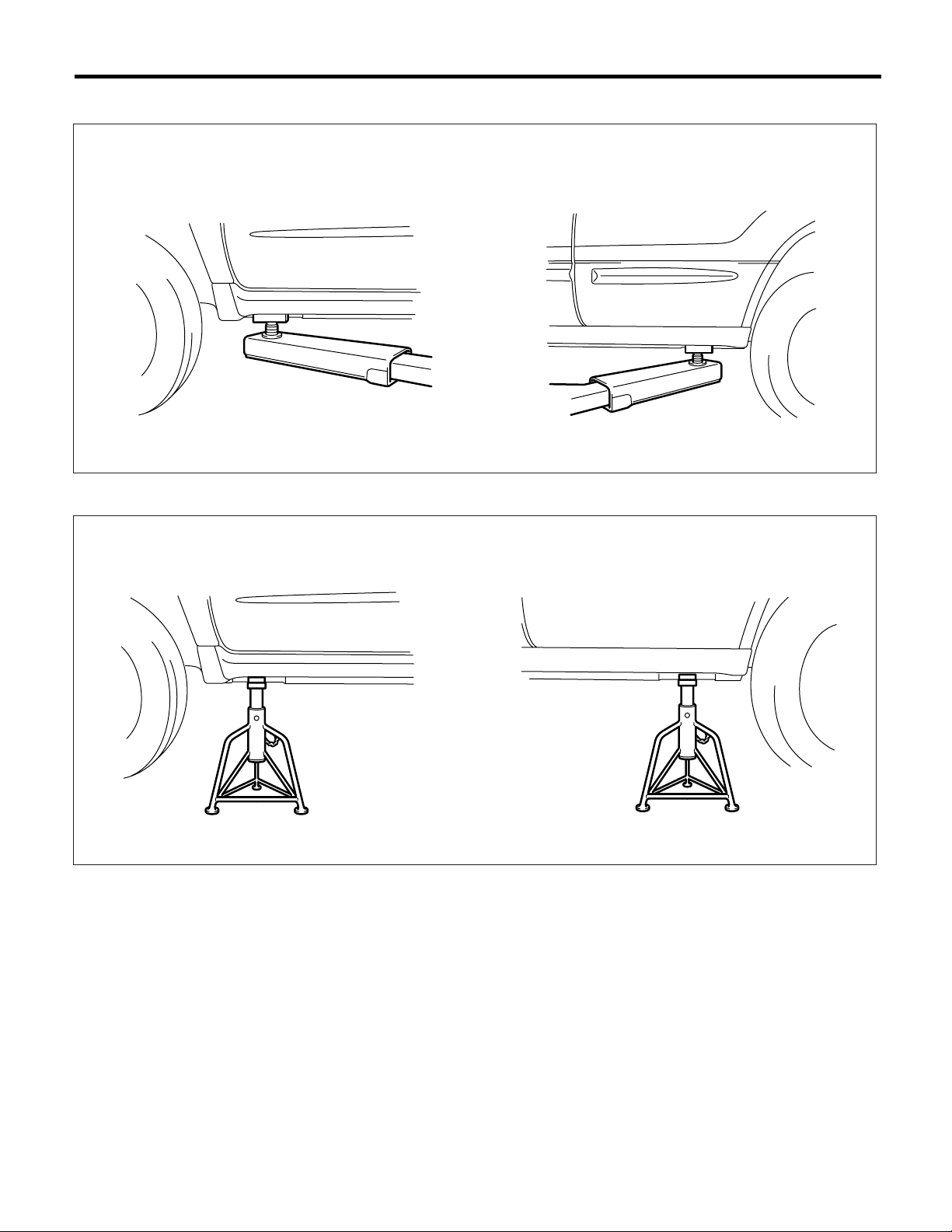

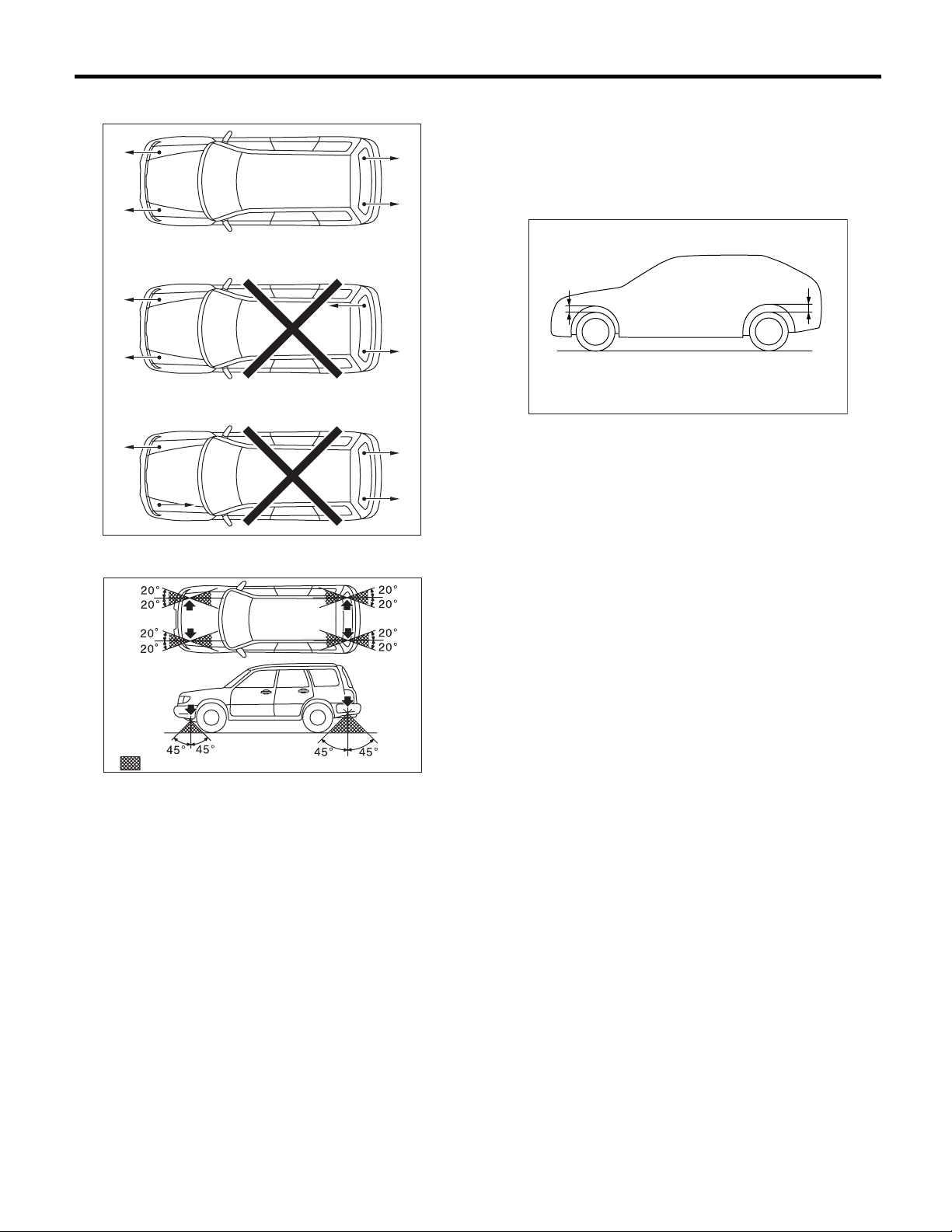

7. LIFTS AND JACKS

When using a lift or jack to raise a vehicle, always follow instructions concerning jack-up points and weight

limits to prevent the vehicle from falling, which could result in injury. Be especially careful to make sure the

vehicle is balanced before raising it.

Be sure to set the wheel stoppers when jacking-up only the front or rear of the vehicle.

• Support Locations

• Pantograph jack

NT-00001

NT-00002

NT-3

NOTE

• Lift

• Safety stand

NOTE

NT-00003

NT-4

NT-00004

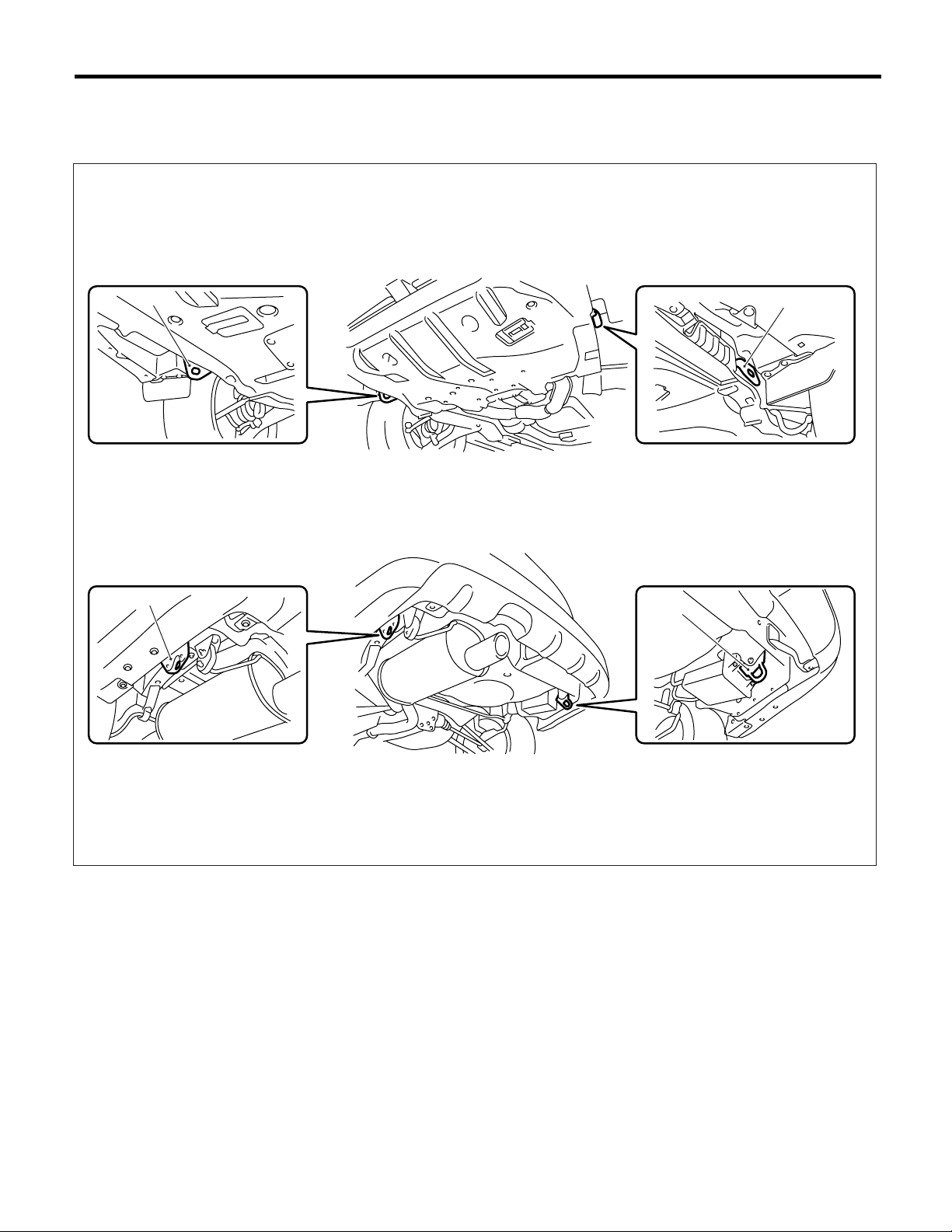

• Jack-up point

(A)

(B)

NOTE

NOTE

(A) Front

(B) Rear

NT-00005

NT-5

NOTE

NOTE

8. TIE-DOWNS

Tie-downs are used when transporting vehicles and when using the chassis dynamo. Attach tie-downs only

to the specified points on the vehicle.

(A)

(D)

(C)

(B)

(C)

(B)

(A) Front

(B) Hook for towing and tie-down

(C) Hook for tie-down

(D) Rear

NT-00006

NT-6

NOTE

NOTE

• Chain direction at tie-down condition

NT-00007

• Chain pulling range at tie-down condition

• Vehicle sinking volume at tie-down condition

Measure the distance L between tire highest point

to arch highest point before tie-down and after tiedown. Difference of measurement value (drop

height) shall be within 50 mm (1.97 in). Make sure

to fix the vehicle securely.

L

L

NT-00082

: (A)

(A) Chain pulling range at tie-down condition

NT-00008

9. TOWING

Avoid towing vehicles except when the vehicle cannot be driven. For models with AWD or AT use a loader

instead of towing. When towing other vehicles, to prevent excessive weight from damaging the hook or vehicle:

• Do not tow other vehicles with a front hook for tie-down.

• Make sure the vehicle towing is heavier that the vehicle being towed.

NT-7

NOTE

10.FRONT HOOD STAY INSTALLATION

• At the check and general maintenance

NOTE

NT-00009

• When wider hood opening is necessary

Set stay into the hole of hood inner as shown in the figure below.

NOTE:

Before setting the front hood in this position, remove the windshield washer hose attaching clip from the front

hood.

NT-00010

11.TRAINING

For information about training, contact a dealer or

agent.

12.GENERAL SCAN TOOL

Using general scan tools will greatly improve efficiency of repairing engine electronic controls. The

SUBARU Select Monitor can be used to diagnose

the engine and also the ABS, the air conditioner,

and other parts.

NT-8

PERIODIC MAINTENANCE SERVICES

COOLING SYSTEM

11.Cooling System

A: INSPECTION

1) Check the radiator for leakage, filling it with coolant and attach the radiator cap tester (A) to filler

neck.

PRESSURE:

157 kPa (1.6 kg/cm

Check the following points.

• Each portion of radiator for leakage

• Hose joints and other connections for leakage

CAUTION:

• For turbo model, be sure to install tester to

filler tank side.

• When attaching or detaching tester and when

operating tester, use special care not to deform

radiator filler neck.

• When performing this check, be sure to keep

the engine stationary and fill the radiator with

coolant.

• Wipe off check points before applying pressure.

• Use care not to spill coolant when detaching

the tester from radiator.

• Non-turbo model

2

, 23 psi)

CAUTION:

Rust or dirt on the cap may prevent the valve

from functioning normally: be sure to clean the

cap before testing.

Radiator cap valve open pressure

Standard value:

2

93 — 123 kPa (0.95 — 1.25 kg/cm

, 14 — 18

psi)

Service limit:

2

83 kPa (0.85 kg/cm

, 12 psi)

PM-00023

(A)

CO-00042

• Turbo model

(A)

CO-00043

2) Check the radiator cap valve open pressure using radiator cap tester.

Raise the pressure until the needle of gauge stops

and see if the pressure can be retained for 5 to 6

seconds. The radiator cap is normal if a pressure

above the service limit value has been maintained

for this period.

(A)

(A)

(A) Deformation

(B) Deformation, damage, rust

(B)

PM-00089

3) Start the engine, and then check if it does not

over heat or it is cooled excessively. If it overheats

or it is cooled excessively, check the cooling system. <Ref. to CO(H4SO)-19, Water Pump.> <Ref.

to CO(H4SO)-24, Thermostat.> <Ref. to

CO(H4SO)-26, Radiator.> <Ref. to CO(H4SO)-32,

Radiator Cap.>

4) Check the radiator fan operates using SUBARU

Select Monitor, when the coolant temperature exceeds 95°C (203°F). If not operate, check the radiator fan system. <Ref. to CO(H4SO)-11, Radiator

Fan System.>

PM-18

DISC BRAKE PADS AND DISCS

PERIODIC MAINTENANCE SERVICES

20.Disc Brake Pads and Discs

A: INSPECTION

1. DISC BRAKE PAD AND DISC

1) Lift-up the vehicle. Then remove the wheels.

2) Visually check the pad thickness through inspection hole of disc brake assembly. Replace the pad if

necessary.

CAUTION:

When replacing a pad, always replace the pads

for both the right and left wheels at the same

time. Also replace the pad clips if they are twisted or worn.

(A)

3) Check the disc rotor, and correct or replace if it is

damaged or worn.

Brake disc thickness mm (in)

Front Rear

Standard 24 (0.94) 10 (0.39)

Wear limit 22 (0.87) 8.5 (0.335)

4) Remove the caliper body. <Ref. to BR-18, Front

Disc Brake Assembly.> <Ref. to BR-24, Rear Disc

Brake Assembly.>

5) Tighten the wheel nuts to secure disk rotor.

6) Set a dial gauge at a point less than 10 mm (0.39

in) from outer periphery of rotor, and then measure

the disk rotor runout.

Disc rotor runout limit:

Front: 0.075 mm (0.0030 in)

Rear: 0.070 mm (0.0028 in)

PM-00049

(A) Inspection hole

Pad thickness including back metal mm (in)

Front Rear

Standard 17 (0.67) 14 (0.55)

Wear limit 7.5 (0.295) 6.5 (0.256)

(A)

(C)

(B)

PM-00050

(A) Thickness of pad

(B) Back metal

(C) Lining

PM-00051

PM-31

ENGINE OIL FILTER

PERIODIC MAINTENANCE SERVICES

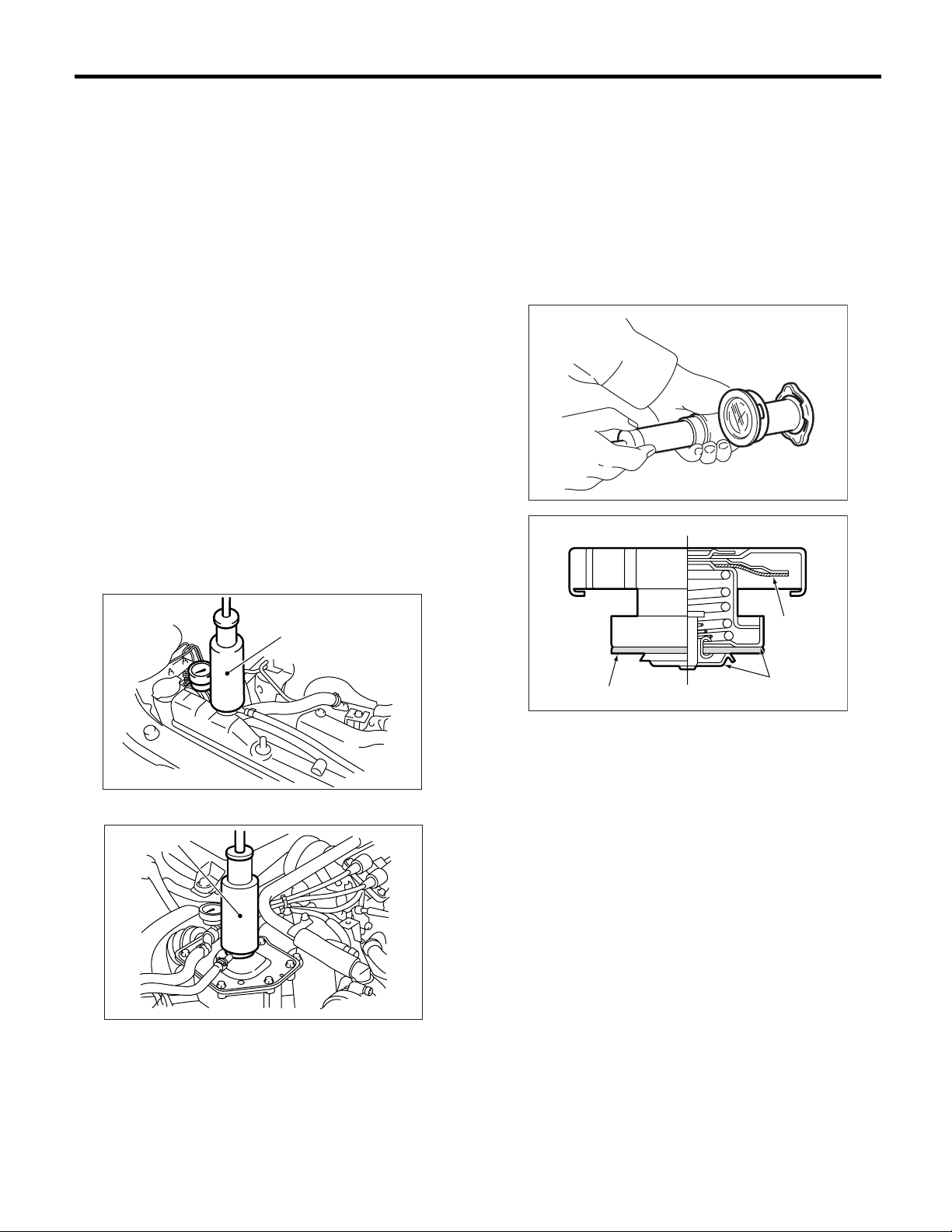

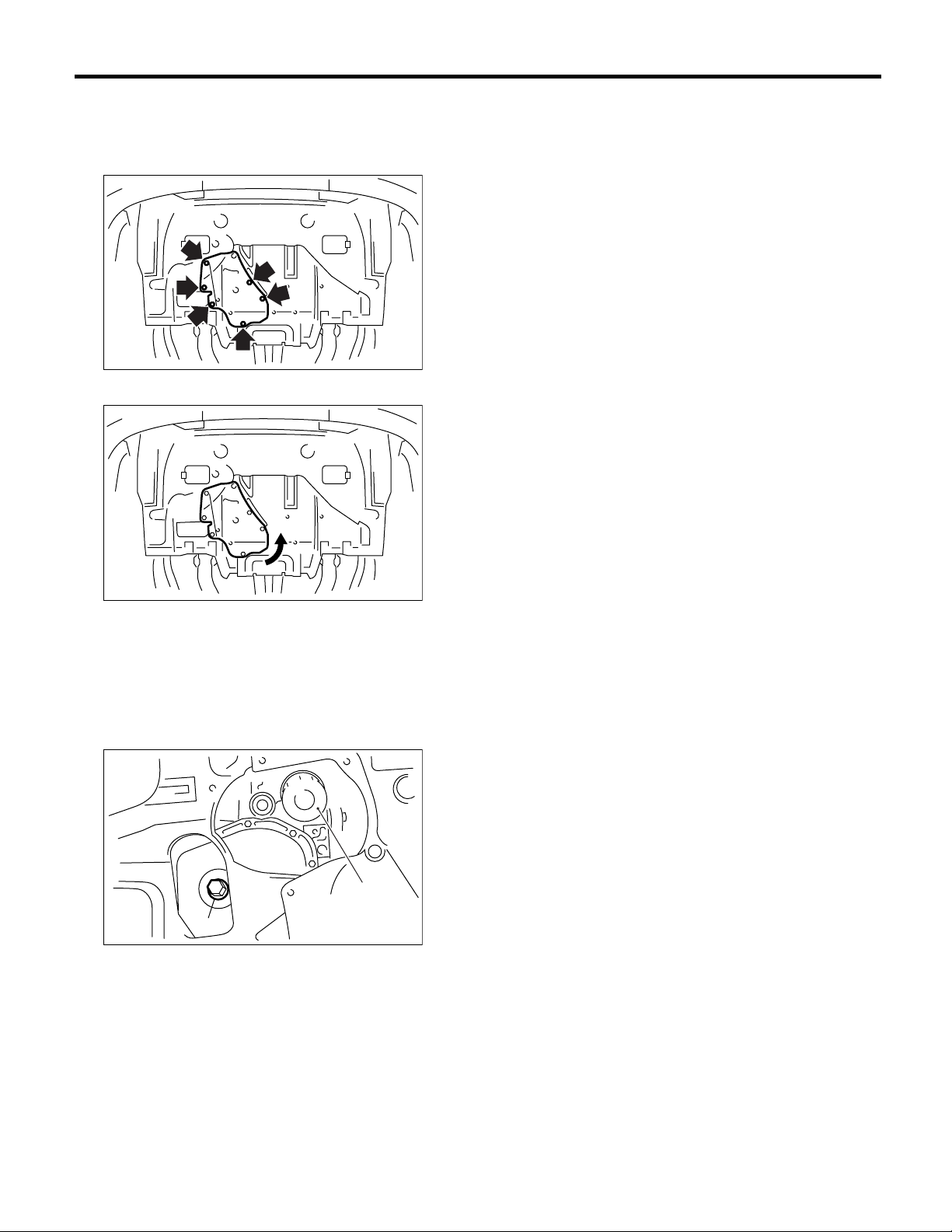

4. Engine Oil Filter

A: REPLACEMENT

1) Remove six clips securing service hole cover.

LU-00005

2) Turn the service hole cover counterclockwise.

6) Install the oil filter by turning it by hand, being

careful not to damage the seal rubber.

• Tighten the oil filter 80 mm (3.15 in) in diameter

by approx. 2/3 - 3/4 rotation more after the seal rubber of oil filter comes in contact with cylinder block

or oil cooler.

• Tighten the oil filter 68 mm (2.68 in) or 65 mm

(2.56 in) in diameter by approx. 1 rotation more after the seal rubber of oil filter comes in contact with

cylinder block or oil cooler.

CAUTION:

Do not tighten excessively, or oil may leak.

7) After installing the oil filter, run the engine and

make sure that no oil is leaking around seal rubber.

NOTE:

The filter element and filter case are permanently

joined; therefore, interior cleaning is not necessary.

8) Check the engine oil level. <Ref. to PI-3, PDI

PROCEDURE, Pre-delivery Inspection.>

LU-00006

3) Remove the oil filter with ST.

ST 498547000 OIL FILTER WRENCH (Outer

diameter: 80 mm (3.15 in))

ST 18332AA000 OIL FILTER WRENCH (Outer

diameter: 68 mm (2.68 in))

ST 18332AA010 OIL FILTER WRENCH (Outer

diameter: 65 mm (2.56 in))

(B)

(A)

(A) Engine oil drain plug

(B) Engine oil filter

LU-00007

4) Wipe clean the oil filter matching surface on cylinder block or oil cooler.

5) Get a new engine oil filter and apply a thin coat of

engine oil to the seal rubber.

CAUTION:

Be careful not to use the oil filter 80 mm (3.15 in)

in diameter to turbo model.

PM-7

Loading...

Loading...