Studer is a registered trade mark of Studer Professional Audio GmbH, Regensdorf

Prepared and edited by Copyright by Studer Professional Audio GmbH

Studer Professional Audio GmbH Printed in Switzerland

Technical Documentation Order no. 10.27.5180-1 (0608)

Althardstrasse 30

CH-8105 Regensdorf – Switzerland

http://www.studer.ch

Subject to change

I

A Safety Information

A1 First Aid

In Case of Electric Shock: Separate the person as quickly as possible from the electric power source:

• By switching the equipment off,

• By unplugging or disconnecting the mains cable, or

• By pushing the person away from the power source, using dry insulating

material (such as wood or plastic).

• After having suffered an electric shock, always consult a doctor.

Warning! Do not touch the person or his clothing before the power is turned off,

otherwise you stand the risk of suffering an electric shock as well!

If the Person is Unconscious: • Lay the person down

• Turn him to one side

• Check the pulse

• Reanimate the person if respiration is poor

• Call for a doctor immed iately.

Safety Information

To reduce the risk of electric shock, do not remove covers. No user-serviceable parts inside. Refer servicing to qualified service personnel (i.e.,

persons having appropriate technical training and experience necessary

to be aware of hazards to which they are exposed in performing a repair

action, and of measures to minimize the danger of themselves).

This symbol alerts the user to the presence of un-insulated dangerous volt-

age within the equipment that may be of sufficient magnitude to constitute

a risk of electric shock to a person.

This symbol alerts the user to important instructions for operating and

maintenance in this documentation.

Assemblies or sub-assemblies of this product can contain opto-electronic devices. As long as these devices comply with Class I of laser or

LED products according to EN 60825-1:1994, they will not be expressly

marked on the product. If a special design should be covered by a higher

class of this standard, the device concerned will be marked directly on the

assembly or sub-assembly in accordance with the above standard.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ACHTUNG

GEFAHR: ELEKTRISCHER SCHLAG

NICHT ÖFFNEN

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

CLASS 1

LASER PRODUCT

CLASS 1

LED PRODUCT

II

B General Installation Instructions

Please consider besides these general instructions also any product-specific

instructions in the “Installation” chapter of this manual.

B1 Unpacking

Check the equipment for any transport damage. If the unit is mechanically

damaged, if liquids have been spilled or if objects have fallen into the unit,

it must not be connected to the AC power outlet, or it must be immediately

disconnected by unplugging the power cable. Repair must only be performed

by trained personnel in accordance with the applicable regulations.

B2 Installation Site

Install the unit in a place where the following conditions are met:

• The temperature and the relative humidity of the environment must be

within the specified limits during operation of the unit. Relevant values

are the ones at the air inlets of the unit (refer to Appendix 1).

• Condensation must be avoided. If the unit is installed in a location with

large variation of ambient temperature (e.g. in an OB-van), appropriate

precautions must be taken before and after operation (refer to Appendix

1).

• Unobstructed air flow is essential for proper operation. Air vents of the

unit are a functional part of the design and must not be blocked in any

way during operation (e.g. by objects placed upon them, placement of the

unit on a soft surface, or installation of the unit within a rack or piece of

furniture).

• The unit must not be heated up by external sources of heat radiation (sunlight, spotlights).

B3 Earthing and Power Supply

Earthing of units with mains supply (class I equipment) is performed via

the protective earth (PE) conductor integrated in the mains cable. Units with

battery operation (< 60 V, class III equipment) must be earthed separately.

Earthing the unit is one of the measures for protection against electrical shock

hazard (dangerous body currents). Hazardous voltage may not only be caused

by a defective power supply insulation, but may also be introduced by the

connected audio or control cables.

If the unit is installed with one or several external connections, its earthing

must be provided during operation as well as while the unit is not operated.

If the earthing connection can be interrupted, for example, by unplugging

the mains plug of an external power supply unit, an additional, permanent

earthing connection must be installed using the provided earth terminal.

Avoid ground loops (hum loops) by keeping the loop surface as small as

possible (by consequently guiding the earth conductors in a narrow , parallel

way), and reduce the noise current flowing through the loop by inserting an

additional impedance (common-mode choke).

Installation

III

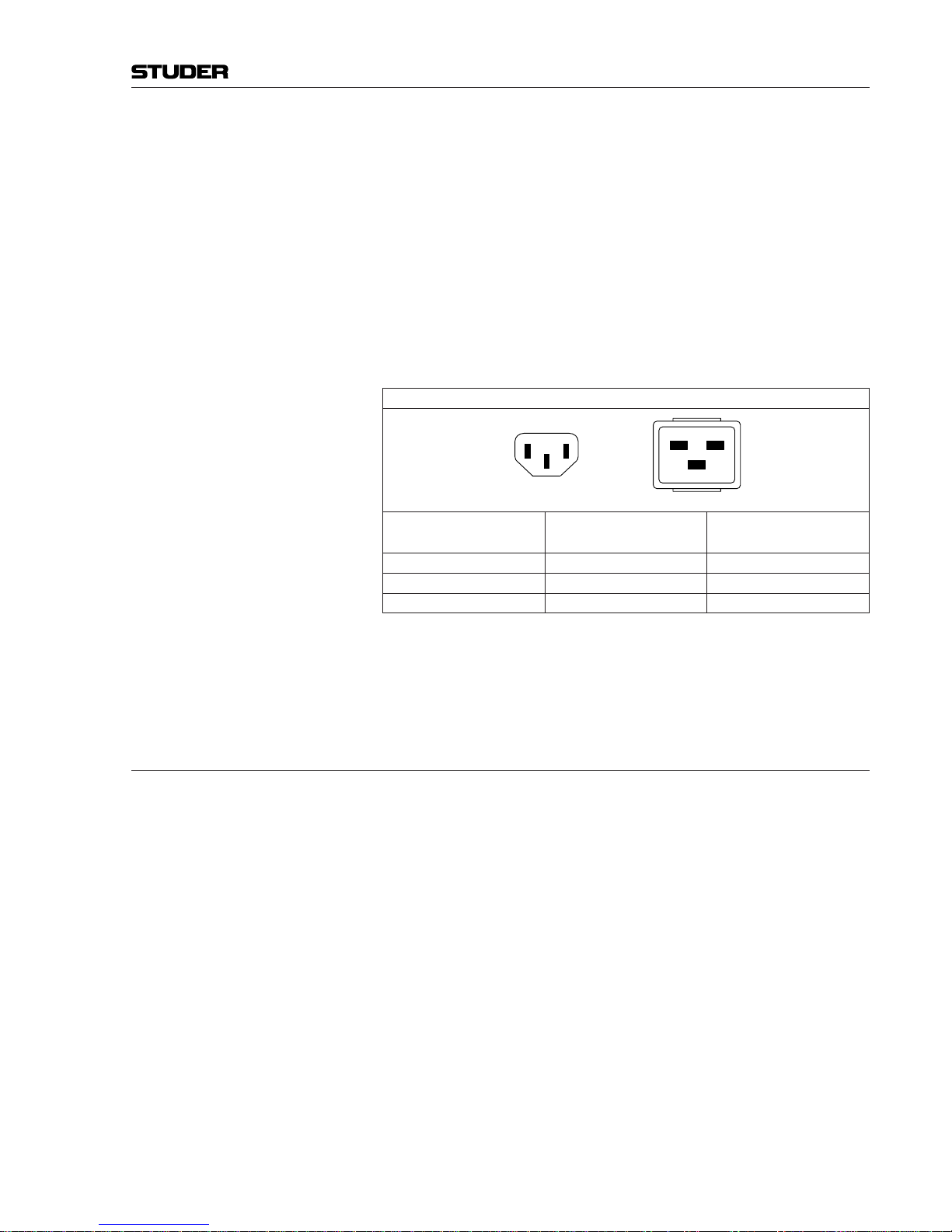

Class I Equipment (Mains Operation)

Should the equipment be delivered without a matching mains cable, the

latter has to be prepared by a trained person using the attached female plug

(IEC 320 / C13 or IEC 320 / C19) with respect to the applicable regulations

in your country.

Before connecting the equipment to the AC power outlet, check that the local

line voltage matches the equipment rating (voltage, frequency) within the

ad missible tolerance. The equipment fuses must be rated in accordance with

the specifications on the equipment.

Equipment supplied with a 3-pole appliance inlet (protection conforming to

class I equip ment) must be connect ed to a 3-pole AC power outlet in such a

way that the equipment ca binet is connected to the protective earth.

For information on mains cable strain relief, please refer to Appendix 2.

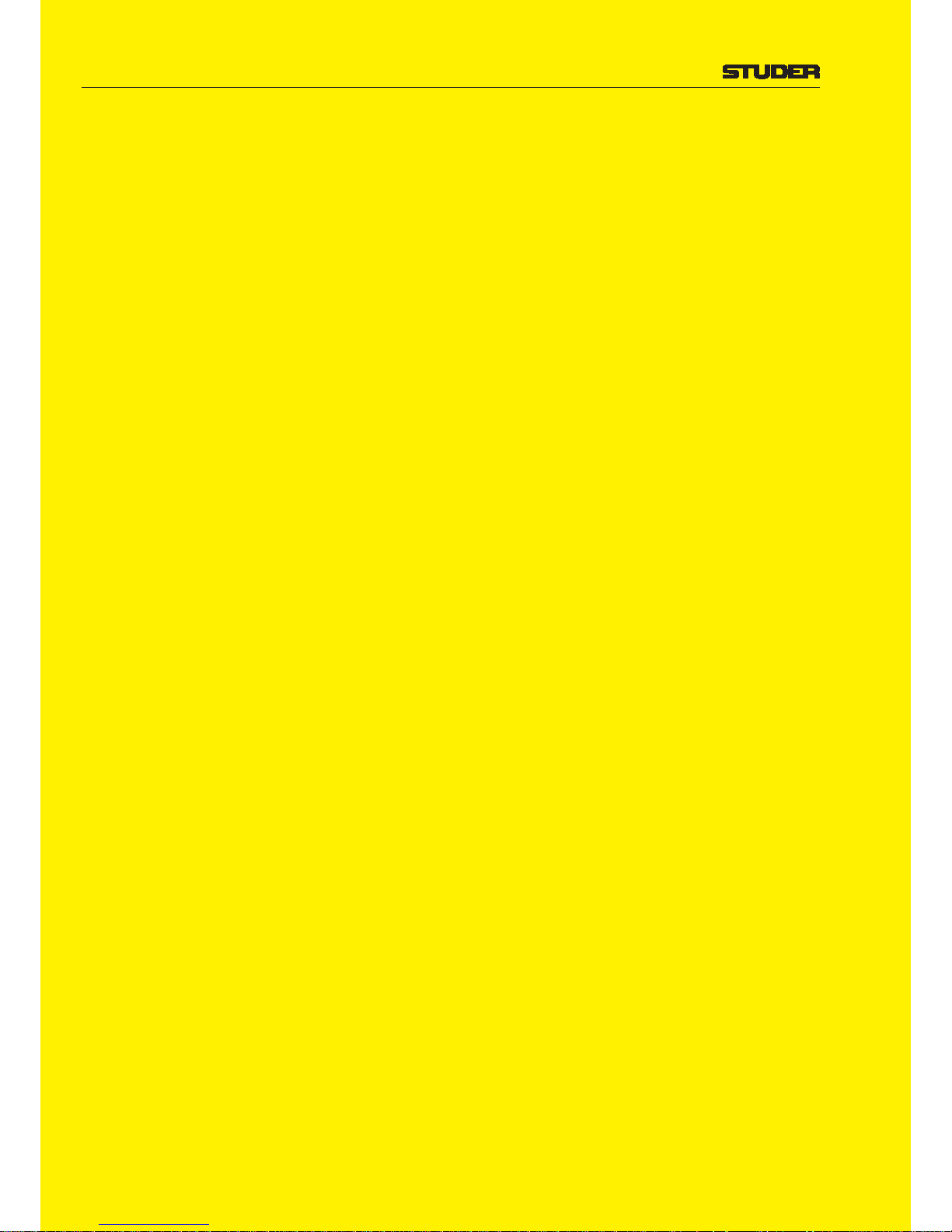

Female Plugs (IEC320), Front-Side View:

European Standard

(CENELEC)

North American Standard

(NAS)

Brown

L (Live)

Black

Blue

N (Neutral)

White

Green/Yellow

PE (Protective Earth)

Green (or Green/Yellow)

Class III Equipment (Battery Operation up to 60 VDC)

Equipment of this protection class must be earthed using the provided earth

terminal if one or more external signals are connected to the unit (see explanation at the beginning of this paragraph).

B4 Electromagnetic Compatibility (EMC)

The unit conforms to the protection requirements relevant to electromagnetic

phenomena that are listed in guidelines 89/336/EC and FCC, part 15.

• The electromagnetic interference generated by the unit is limited in such

a way that other equipment and systems can be operated normally.

• The unit is adequately protected against electromagnetic interference so

that it can operate properly.

The unit has been tested and conforms to the EMC standards of the speci-

fied electromagnetic environment, as listed in the following declaration.

The limits of these standards ensure protection of the environment and corresponding noise immunity of the equipment with appropriate probability.

However, a professional installation and integration within the system are

imperative prerequisites for operation without EMC problems.

For this purpose, the following measures must be followed:

• Install the equipment in accordance with the operating instructions. Use

the supplied accessories.

• In the system and in the vicinity where the equipment is installed, use only

components (systems, equipment) that also fulfill the EMC standards for

the given environment.

Installation / EMC

PE

LN

IEC 320 / C19IEC 320 / C13

PE

LN

IV

• Use a system grounding concept that satisfies the safety requirements

(class I equipment must be connected with a protective ground conductor) and that also takes into consideration the EMC require ments. When

deciding between radial, surface, or combined grounding, the advantages

and disadvantages should be carefully evaluated in each case.

• Use shielded cables where shielding is specified. The connection of the

shield to the corresponding connector terminal or housing should have a

large surface and be corrosion-proof. Please note that a cable shield connected only single-ended can act as a transmitting or receiving antenna

within the corresponding frequency range.

• Avoid ground loops or reduce their adverse effects by keeping the loop sur face as small as possible, and reduce the noise current flowing through the

loop by inserting an additional impedance (e.g. common-mode choke).

• Reduce electrostatic discharge (ESD) of persons by installing an appropriate floor covering (e.g. a carpet with permanent electrostatic filaments) and

by keeping the relative humidity above 30%. Further measures (e.g. conducting floor) are usually unnecessary and only effective if used together

with corresponding personal equipment.

• When using equipment with touch-sensitive operator controls, please take

care that the surrounding building structure allows for sufficient capacitive

coupling of the operator. This coupling can be improved by an additional,

conducting surface in the operator’s area, connected to the equipment

housing (e.g. metal foil underneath the floor covering, carpet with conductive backing).

C Maintenance

All air vents and openings for operating elements (faders, rotary knobs) must

be checked on a regular basis, and cleaned in case of dust accumulation. For

cleaning, a soft paint-brush or a vacuum cleaner is recommended.

Cleaning the surfaces of the unit is performed with a soft, dry cloth or a soft

brush.

Persistent contamination can be treated with a cloth that is slightly humidified

with a mild cleaning solution, such as dishwashing detergent.

For cleaning display windows, commercially available computer/TV screen

cleaners are suited. Use only a slightly damp (never wet) cloth.

Never use any solvents for cleaning the exterior of the unit! Liquids must

never be sprayed or poured on directly!

For equipment-specific maintenance information please refer to the corre-

sponding chapter in the operating and service manuals.

EMC / Maintenance

V

D Electrostatic Discharge during Maintenance and Repair

Caution: Observe the precautions for handling devices sensitive to electrostatic dis-

charge!

Many semiconductor components are sensitive to electrostatic discharge

(ESD). The lifespan of assemblies contain ing such components can be drastically reduced by improper handling during maintenance and repair. Please

observe the following rules when handling ESD sensitive components:

• ESD sensitive components should only be stored and transported in the

packing material specifically provided for this purpose.

• When performing a repair by replacing complete assemblies, the r emoved

assembly must be sent back to the supplier in the same packing material

in which the replacement assembly was shipped. If this should not be the

case, any claim for a possible refund will be null and void.

• Unpacked ESD sensitive components should only be handled in ESD protected areas (EPA, e.g. area for field service, repair or service bench) and

only be touched when wearing a wristlet connected to the ground potential

of the service bench by a series resistor. The equipment to be repaired or

serviced as well as all tools and electrically semi-conducting work, storage,

and floor mats should also be connected to this ground potential.

• The terminals of ESD sensitive components must not come in uncontrolled

contact with electro statically chargeable or metallic surfaces (voltage

puncture, discharge shock hazard).

• To prevent the components from undefined transient stress and possible

damage due to inadmissible voltages or compensation currents, electrical

connections should only be established or separated when the equipment

is switched off and after any capacitor charges have decayed.

E Repair

By removing housing parts or shields, energized parts may be exposed. For

this reason the following precautions must be observed:

• Maintenance may only be performed by trained personnel in accordance

with the applicable regulations.

• The equipment must be switched off and disconnected from the AC power

outlet before any housing parts are removed.

• Even if the equipment is disconnected from the power outlet, parts with

hazardous charges (e.g. capacitors, picture tubes) must not be touched until

they have been properly discharged. Do not touch hot components (power

semi con ductors, heat sinks, etc.) before they have cooled off.

• If a unit remains opened while being switched on, no un-insulated circuit com pon ents and metallic semiconductor housings must be touched,

neither with bare hands nor with un- insulated tools.

Certain components pose additional hazards:

• Explosion hazard from lithium batteries, electrolytic capacitors and power

semiconductors (Observe the component’s polarity. Do not short battery

terminals. Replace batteries only by the same type).

• Implosion hazard from evacuated display units.

• Radiation hazard from laser units (non-ionizing), CRTs (ionizing).

• Caustic effect of display units (LCD) and components containing liquid

electrolyte.

Such components should only be handled by trained personnel who ar e prop-

erly protected (e.g. protection glasses, gloves).

ESD / Repair

VI

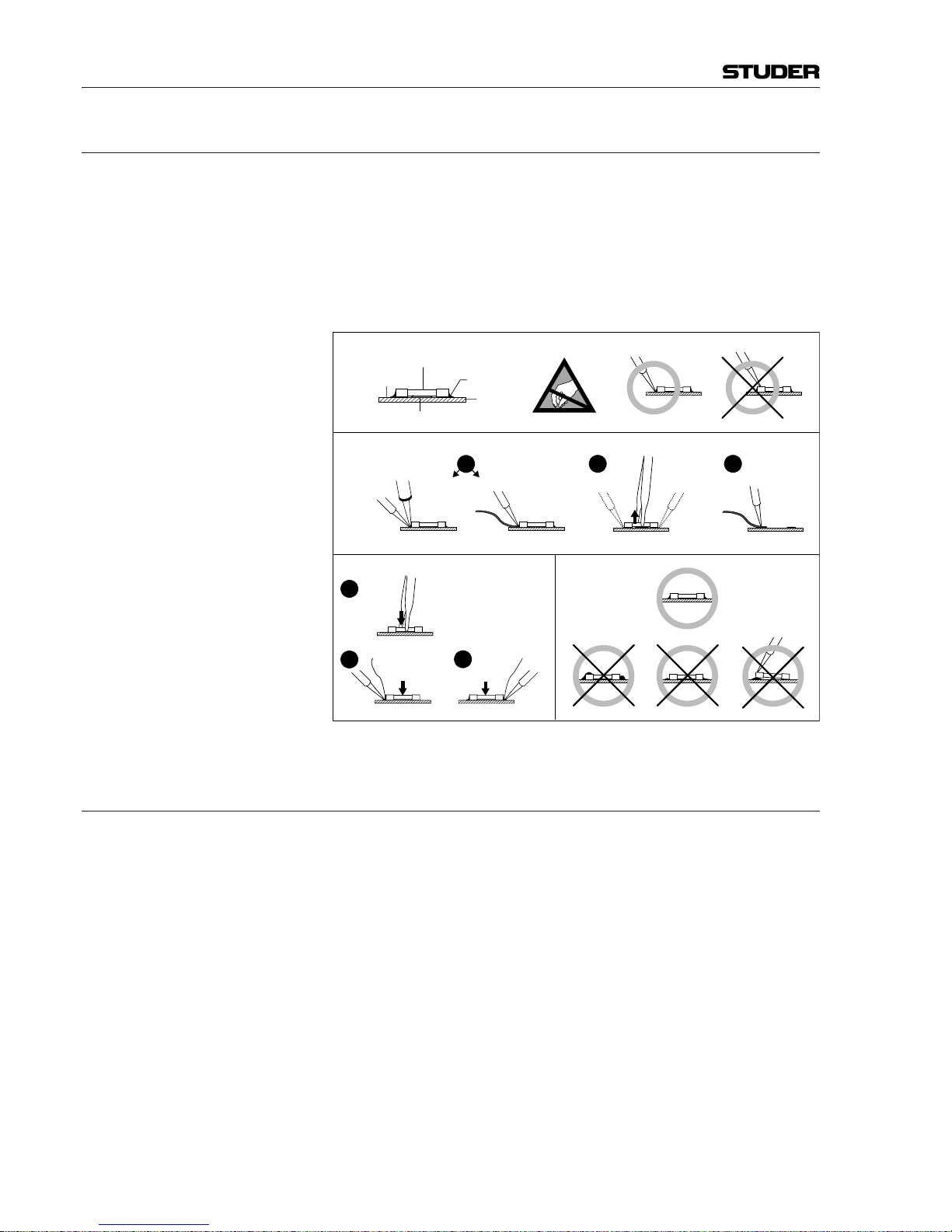

E1 SMD Components

Studer has no commercially available SMD components in stock for ser-

vice purposes. For repair, the corresponding devices have to be purchased

locally . The specifications of special components can be found in the service

manual.

SMD components should only be replaced by skilled specialists using appro-

priate tools. No warranty claims will be accepted for circuit boards that have

been damaged. Proper and improper SMD soldering joints are illustrated

below.

F Disposal

Packing Materials The packing materials have been selected with environmental and disposal

issues in mind. All packing material can be recycled. Recycling packing saves

raw materials and reduces the volume of waste.

If you need to dispose of the transport packing materials, please try to use

recyclable means.

Used Equipment Used equipment contains valuable raw materials as well as materials that

must be disposed of professionally . Please return your used equipment via an

authorized specialist dealer or via the public waste disposal system, ensuring

any material that can be recycled is.

Please take care that your used equipment cannot be abused. To avoid abuse,

delete sensitive data from any data storage media. After having disconnected

your used equipment from the mains supply, make sure that the mains connector and the mains cable are made useless.

Repair / Disposal

Dismounting

Mounting Examples

Solder

SMD

Component

Copper

Track

Adhesive

Soldering Iron

Desoldering

Iron

Desolder

Wick

Heat and Remove Cleaning

Solder

Ø 0.5...0.8 mm

Heating Time < 3 s per Side

Soldering

Iron

Desolder

Wick

PCB

3

2

1

3

2

1

VII

G Declarations of Conformity

G1 Class A Equipment - FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide a reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio com munications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

Caution: Any changes or modifications not expressly approved by the manufacturer

could void the user’ s authority to operate the equipment. Also r efer to relevant

information in this manual.

G2 CE Declaration of Conformity

We,

Studer Professional Audio GmbH,

CH-8105 Regensdorf,

declare under our sole responsibility that the product

Studer OnAir 2500, Digital Broadcast Mixing Console

(starting with serial no. 1001),

to which this declaration relates, according to following regulations of EU

directives and amendments

• Low Voltage (LVD):

73/23/EEC + 93/68/EEC

• Electro magnetic Compatibility (EMC):

89/336/EEC + 92/31/EEC + 93/68/EEC

is in conformity with the following standards or normative documents:

• Safety:

EN 60950:2001 (Class I equipment)

• Safety of laser products:

EN 60825-1:1994 + A11 + A2, EN 60825-2:2000

• EMC:

EN 55103-1/-2:1996, electromagnetic environments E2 and E4.

Regensdorf, May 21, 2008

B. Hochstrasser, President M. Lienert, Manager R&D

Conformity

VIII

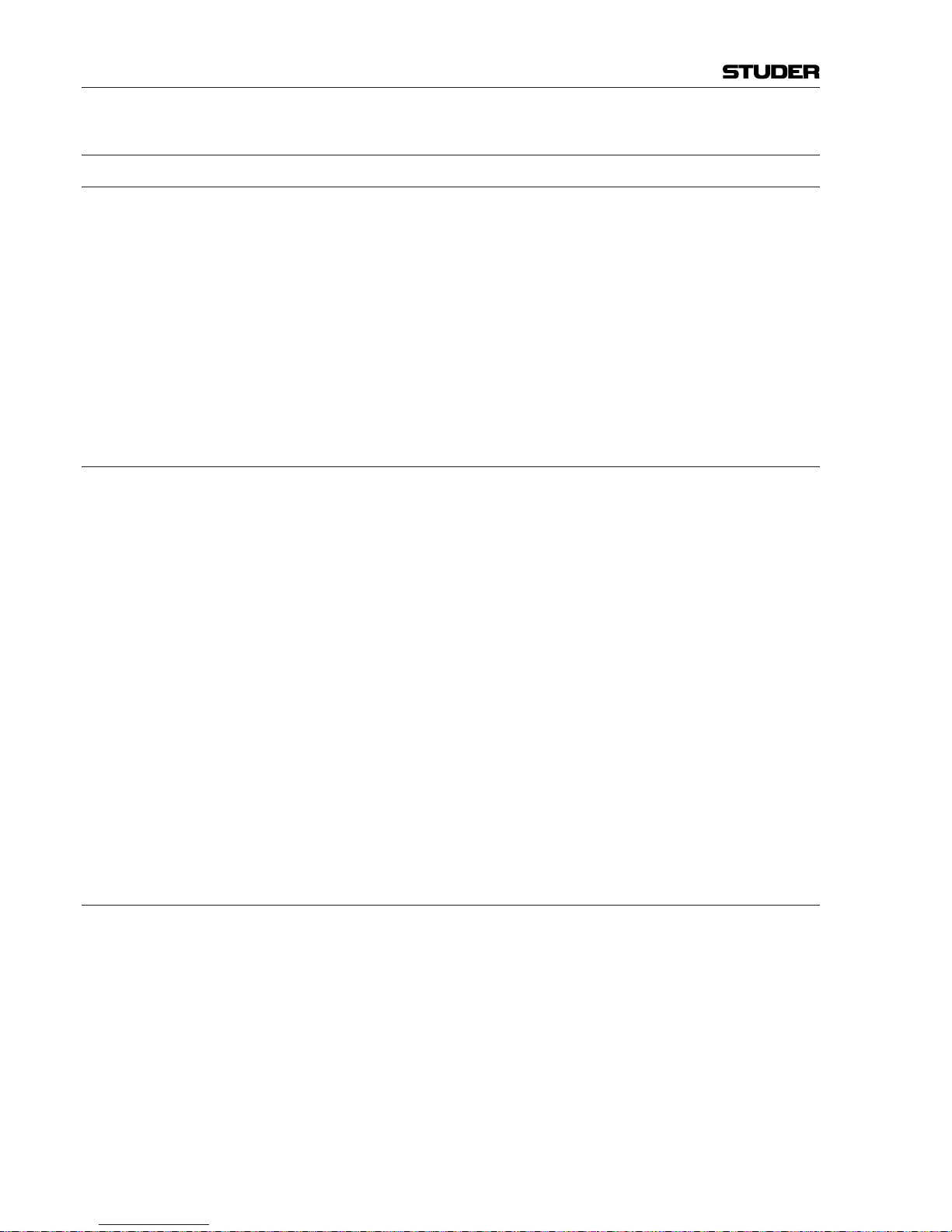

Appendix 1: Air Temperature and Humidity

General

Normal operation of the unit or system is warranted under the ambient condi-

tions defined by EN 60721-3-3, set IE32, value 3K3.

This standard consists of an extensive catalogue of parameters, the most

important of which are: Ambient temperature*, relative humidity 5...85%

(i.e., no formation of condensation or ice); absolute humidity 1...25 g/m³;

rate of temperature change < 0.5 °C/min. These parameters are dealt with in

the following paragraphs.

* Please Note: The ambient temperature range is restricted to +5...+35 °C, as opposed to the

standard mentioned above.

Under these conditions the unit or system starts and works without any prob-

lem. Beyond these specifications, possible problems are described below.

Ambient Temperature

Units and systems by Studer are generally designed for an ambient tempera-

ture range (i.e. temperature of the incoming air) of +5 °C to +40 °C. When

rack mounting the units, the intended air flow and herewith adequate cooling

must be provided. The following facts must be considered:

• The admissible ambient temperature range for operation of the semiconductor components is 0 °C to +70 °C (commercial temperature range for

operation).

• The air flow through the installation must provide that the outgoing air is

always cooler than 70 °C.

• Average heat increase of the cooling air shall be about 20 K, allowing for

an additional maximum 10 K increase at the hot components.

• In order to dissipate 1 kW with this admissible average heat increase, an

air flow of 2.65 m³/min is required.

Example: A rack dissipating P = 800 W requires an air flow of 0.8 * 2.65 m³/min which

corresponds to 2.12 m³/min.

• If the cooling function of the installation must be monitored (e.g. for fan

failure or illumination with spot lamps), the outgoing air temperature must

be measured directly above the modules at several places within the rack.

The trigger temperature of the sensors should be 65 °C to 70 °C.

Frost and Dew

The unsealed system parts (connector areas and semiconductor pins) allow

for a minute formation of ice or frost. However, formation of dew visible to

the naked eye will already lead to malfunctions. In practice, reliable operation can be expected in a temperature range above –15 °C, if the following

general rule is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it

reaches 100%, condensation will arise, usually in the boundary layer between

the air and a cooler surface, together with formation of ice or dew at sensitive areas of the system (contacts, IC pins, etc.). Once internal condensation

occurs, trouble-free operation cannot be guaranteed, independent of temperature.

Before putting into operation, the system must be checked for internal for-

mation of condensation or ice. Only with a minute formation of ice, direct

Appendix

IX

evaporation (sublimation) may be expected; otherwise the system must be

heated and dried while switched off.

A system without visible internal formation of ice or condensation should be

heated up with its own heat dissipation, as homogeneously (and subsequently

as slow) as possible; the ambient temperature should then always be lower

than the one of the outgoing air.

If it is absolutely necessary to operate the cold system immediately within

warm ambient air, this air must be dehydrated. In such a case, the absolute

humidity must be so low that the relative humidity, related to the coldest

system surface, always remains below 100%.

Ensure that the enclosed air is as dry as possible when powering off (i.e. before

switching off in winter, aerate the room with cold, dry air , and remove humid

objects such as clothes from the room).

These relationships are visible from the following climatogram. For a con-

trolled procedure, thermometer and hygrometer as well as a thermometer

within the system will be required.

Example 1: An OB-van having an internal temperature of 20 °C and a relative humidity of

40% is switched off in the evening. If the temperature falls below +5 °C, the

relative humidity will rise to 100% (7 g/m³); dew or ice will be forming.

Example 2: An OB-van is heated up in the morning with air of 20 °C and a relative

humidity of 40%. On all parts being cooler than +5 °C, dew or ice will be

forming.

Appendix

X

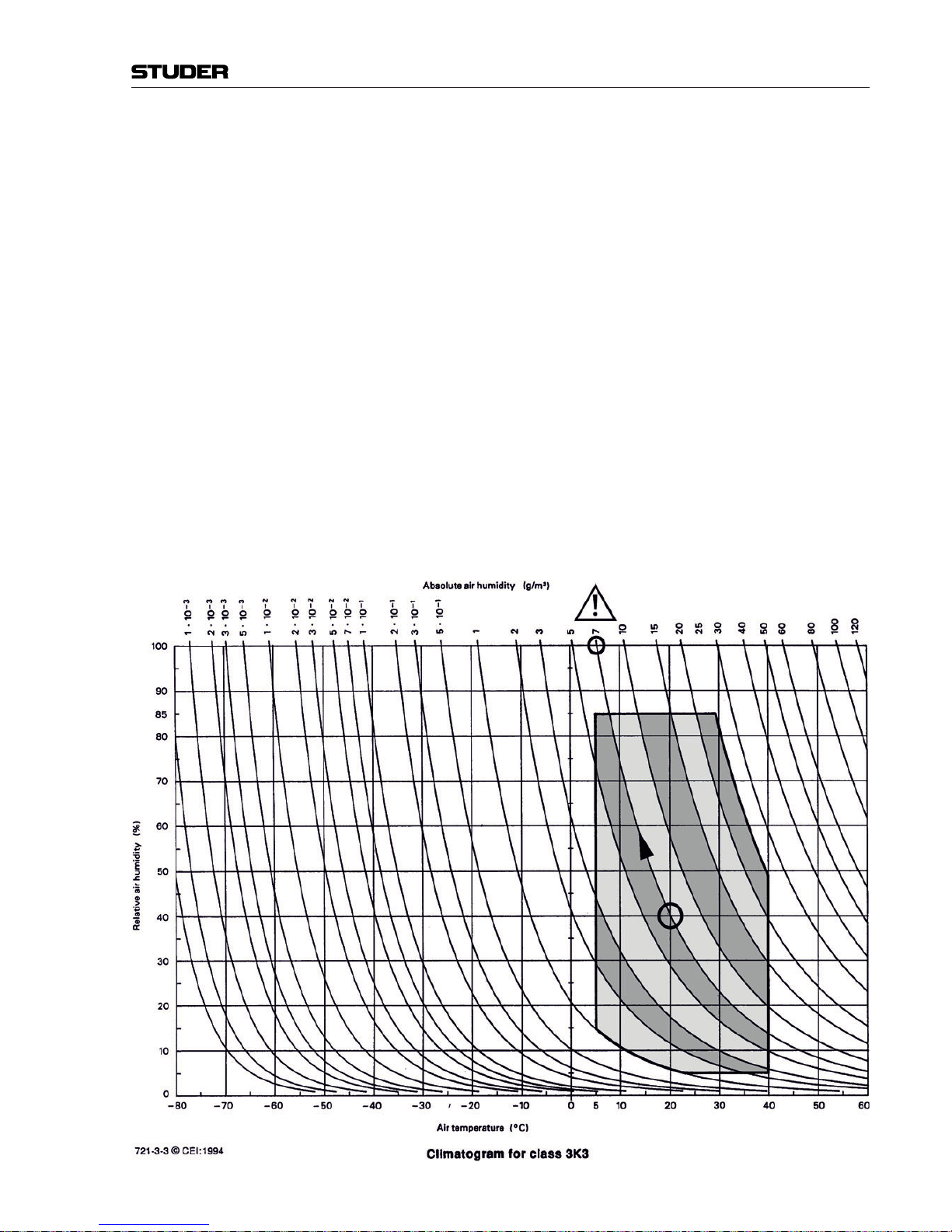

Appendix 2: Mains Connector Strain Relief

For anchoring connectors without a mechanical lock (e.g. IEC mains connec-

tors), we recommend the following arrangement:

Procedure: The cable clamp shipped with your unit is auto-adhesive. For mounting please

follow the rules below:

• The surface to be adhered to must be clean, dry , and free from grease, oil,

or other contaminants. Recommended application temperature range is

+20 °C to +40 °C.

• Remove the plastic protective backing from the rear side of the clamp

and apply it firmly to the surface at the desired position. Allow as much

time as possible for curing. The bond continues to develop for as long as

24 hours.

• For improved stability, the clamp should be fixed with a screw. For this

purpose, a self-tapping screw and an M4 bolt and nut are included.

• Place the cable into the clamp as shown in the illustration above and firmly

press down the internal top cover until the cable is fixed.

Appendix

XI

Appendix 3: Software License

Use of the software is subject to the Studer Professional Audio Software

License Agreement set forth below. Using the software indicates your acceptance of this license agreement. If you do not accept these license terms, you

are not authorized to use this software.

Under the condition and within the scope of the following Terms and Con-

ditions, Studer Professional Audio GmbH (hereinafter “Studer”) grants the

right to use programs developed by Studer as well as those of third parties

which have been installed by Studer on or within its products. References

to the license programs shall be references to the newest release of a license

program installed at the Customer’s site.

Programs Covered by the Agreement

License Programs of Studer The following Terms and Conditions grant the right to use all programs of

Studer that are part of the System and/or its options at the time of its delivery

to the Customer, as well as the installation software on the original data disk

and the accompanying documentation (“License Material”). In this Agreement the word “Programs” shall have the meaning of programs and data

written in machine code.

Using the software indicates your acceptance of this license agreement. If

you do not accept these license terms, you are not authorized to use this software.

Programs of Third Parties Programs of third parties are all programs which constitute part of the System

and/or its options at the time of delivery to the Customer but have not been

developed by Studer. The following conditions are applicable to programs of

third parties:

• The right to use third parties’ programs is governed by the License Agreement attached hereto (if applicable), which is an integral part of this Agreement. The Customer shall sign any and all License Agreements for all

further programs of third parties installed on the system. The Customer

shall be deemed to have received all License Agreements upon delivery

of the system and/or its options.

• Studer shall accept no responsibility or liability for, and gives no warranties (express or implied) as to the programs of third parties. The Customer

waives any and all claims versus Studer for any consequential damages,

which might occur due to defects of these programs.

Right of Use

Principle Studer grants the Customer the non-exclusive right to use the License Ma-

terial in one copy on the system and/or its options as laid down by the Sales

Agreement concluded between the parties and all Terms and Conditions

which shall be deemed to form and be read and construed as part of the

Sales Agreement. This right is assignable according to the “Assignability”

paragraph hereinafter.

Appendix

XII

Customized Configurations The Customer is not entitled to alter or develop further the License Material

except within the expressly permitted configuration possibilities given by the

software installed on the system or elsewhere. All altered programs, including but not limited to the products altered within the permitted configuration

possibilities, are covered by this License Agreement.

Reverse Engineering Reverse engineering is only permitted with the express consent of Studer.

The consent of Studer can be obtained but is not limited to the case in which

the interface software can not be provided by Studer. In any case Studer has

to be informed immediately upon complete or partial reverse engineering.

Copying the License Material The Customer is entitled to make one copy of all or parts of the License

Material as is necessary for the use according to this Agreement, namely for

backup purposes. The Customer shall apply the copyright of Studer found on

the License Material onto all copies made by him. Records shall be kept by

the Customer regarding the amount of copies made and their place of keeping.

The responsibility for the original program and all copies made lies with the

Customer. Studer is entitled to check these records on first request. Copies

not needed anymore have to be destroyed immediately.

Disclosure of License Material The License Material is a business secret of Studer. The Customer shall not

hand out or in any way give access to parts of or the complete License Material

to third parties nor to publish any part of the License Material without prior

written consent of Studer. The Customer shall protect the License Material

and any copies made according to the paragraph above by appropriate defense

measures against unauthorized access. This obligation of non-disclosure is a

perpetual obligation.

Third parties are entitled to have access to the License Material if they use the

License Material at the Customer’s site in compliance with this Agreement.

Under no circumstance are third parties entitled to have access to the instal-

lation software on the original data media. The Customer shall safeguard the

original data media accordingly.

Assignability The rights granted to the Customer according to this License Agreement shall

only be assignable to a third party together with the transfer of the system

and/or its options and after the prior written consent of Studer.

Rights to License Material

With the exception of the right of use granted by this License Agreement all

proprietary rights to the License Material, especially the ownership and the

intellectual property rights (such as but not limited to patents and copyright)

remain with Studer even if alterations, customized changes or amendments

have been made to the License Material.

Studer’s proprietary rights are acknowledged by the Customer. The Customer

shall undertake no infringements and make no claims of any patent, registered

design, copyright, trade mark or trade name, or other intellectual property

right.

Warranty, Disclaimer, and Liability

For all issues not covered herewithin, refer to the “General Terms and Condi-

tions of Sales and Delivery” being part of the sales contract.

Appendix

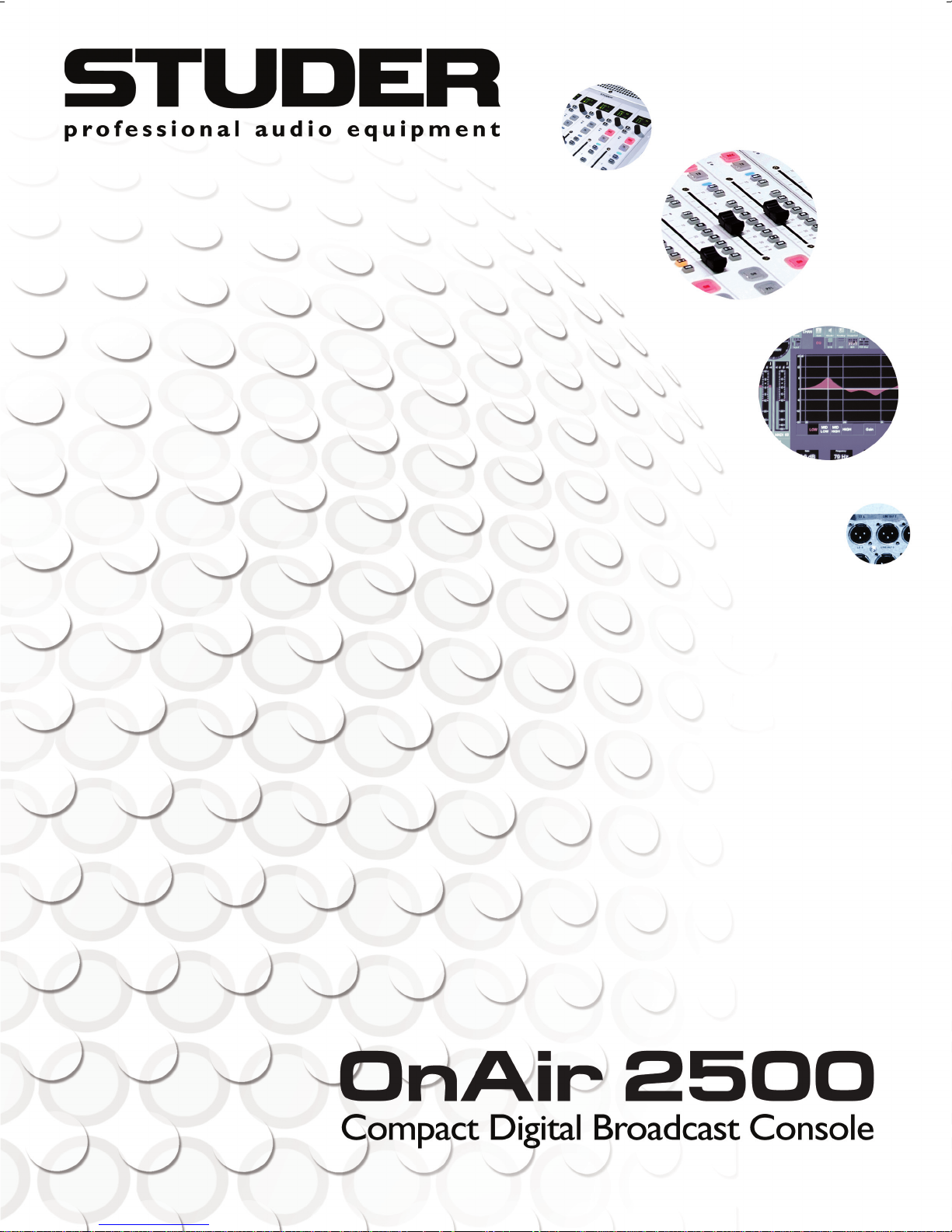

WIRING – IMPORTANT

The OnAir 2500 ST MON and LAN wiring must comply with the

following requirements:

Cable Type: Cat 5e, with shielded connectors on both ends.

Cable Dimensions:

Max. Length for

Monitoring/TB Module

Min.

AWG

Minimum

Sectional Area

100 m 24 0.21 mm

2

60 m 26 0.13 mm

2

Details: Cat(egory) 5e Cable is an enhanced version of Cat 5 that adds specifi cations for far-end cross-

talk. It replaced the specifi cation for Cat 5 with the 2001 introduction of the

TIA/EIA-568-B standard. Cat 5e cable performance characteristics and test

methods are defi ned in TIA/EIA-568-B.2-2001.

ST MON (RS422) Cables (both ends w. shielded connectors) from the ST MON socket to a monitoring/

TB module:

ST MON socket

Wire Color

Monitoring/TB Module

Signal Pin Pin Signal

+24 V *

1

2

wht/org

org

1

2

+24 V *

RX+ 3 wht/grn 3 TX+

TX+ 4 blu 4 RX+

TX– 5 wht/blu 5 RX–

RX– 6 grn 6 TX–

Gnd *

7

8

wht/brn

brn

7

8

Gnd *

* Caution: Connectors are identical on the ST MON and the LAN cables. Make sure not

to mix them up since the ST MON socket carries DC supply voltage!

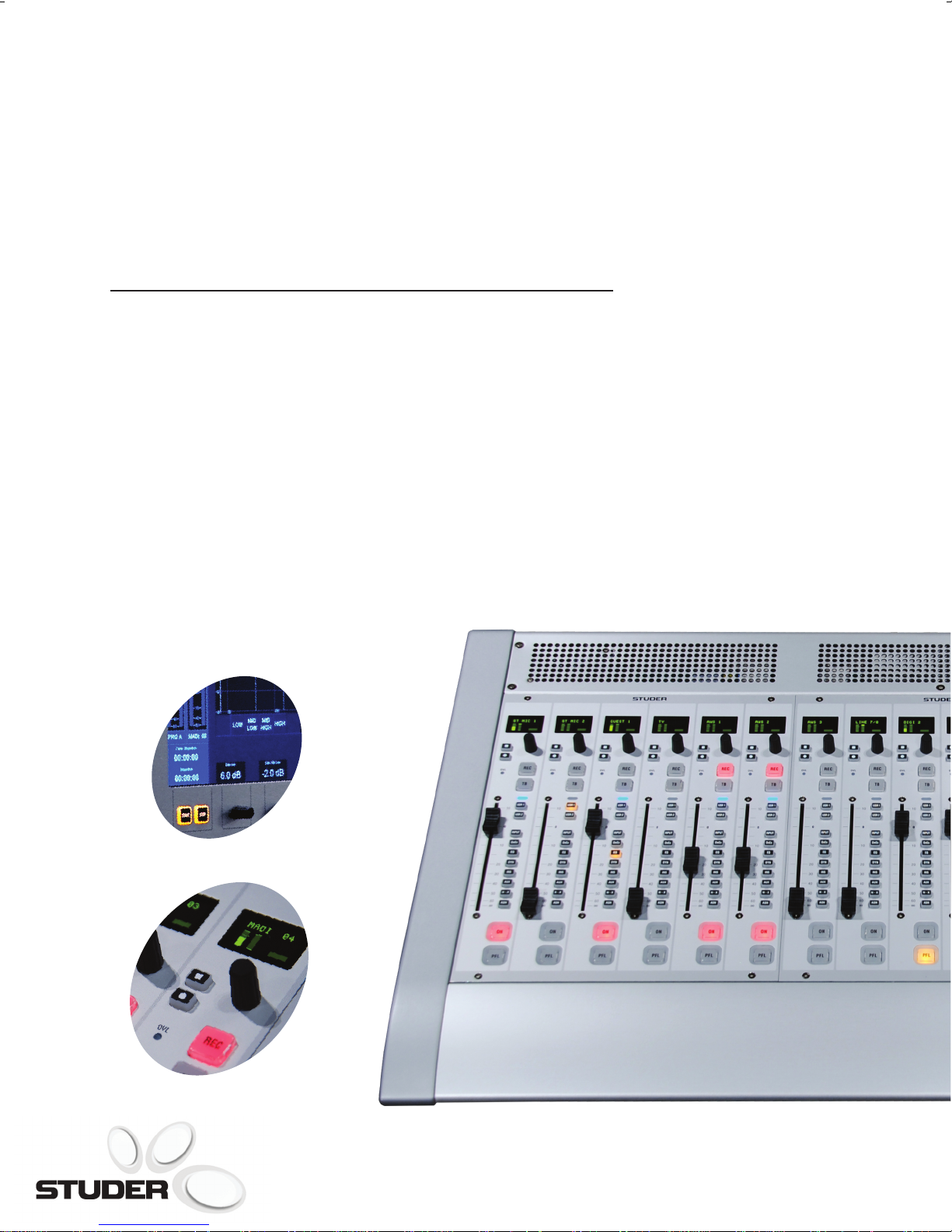

LAN (Ethernet) Cables (both ends w. shielded connectors) for connection of the console to e.g. a

router or an existing OnAir 3000 network. Since modern hubs and switches

have auto polarity selection, straight-through cables may be used in any

case.

Signal Pin

Wire Color

Pin Signal

TX+ 1 wht/org 1 TX+

TX– 2 org 2 TX–

RX+ 3 wht/grn 3 RX+

4 blu 4

5 wht/blu 5

RX– 6 grn 6 RX–

7 wht/brn 7

8 brn 8

Top (tab

down):

18

18

Front:

Top (tab

down):

18

18

Front:

Date printed: 09.06.08

SW V3.0

OnAir 2500 Digital Mixing Console

Important

Date printed: 09.06.08

SW V3.0

OnAir 2500 Digital Mixing Console

Important

1

2

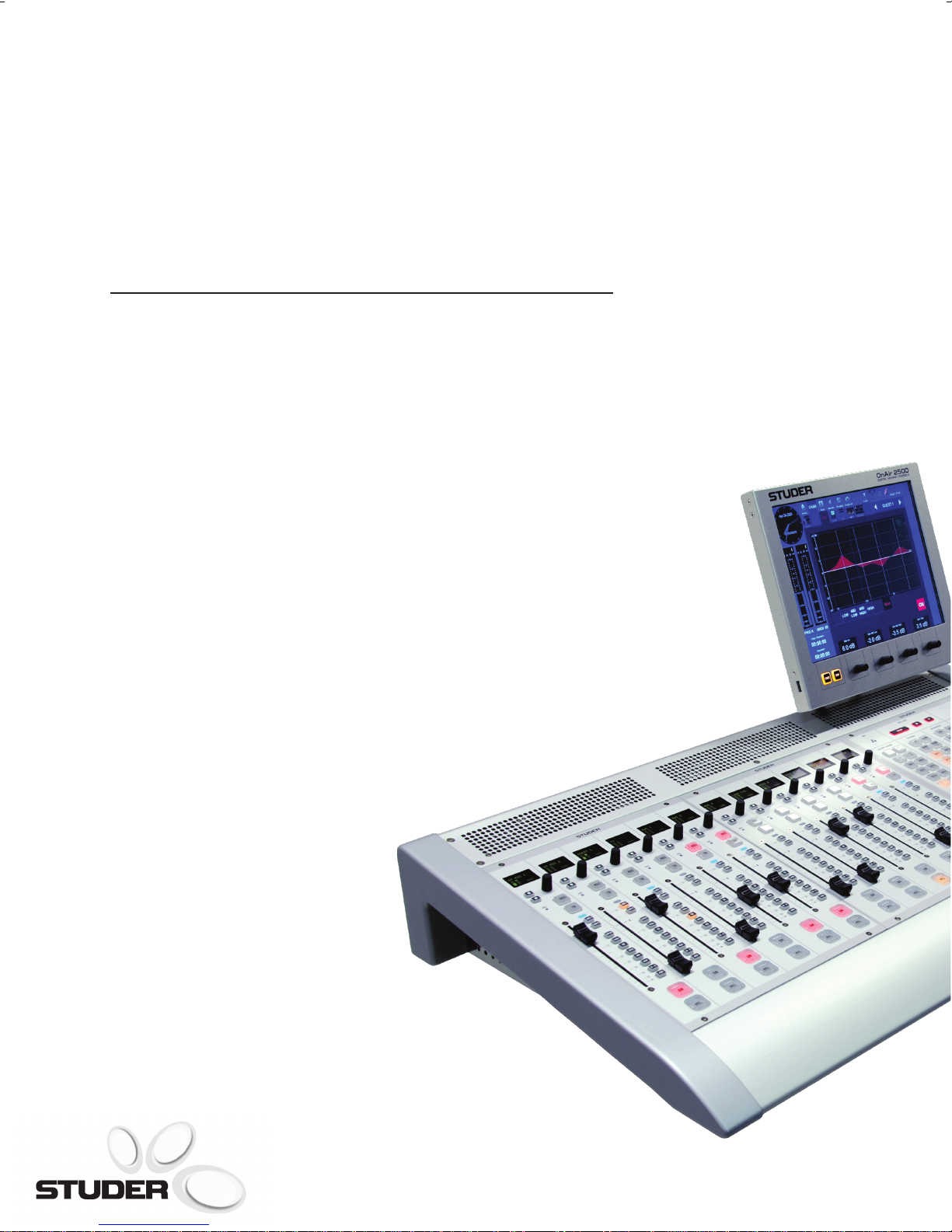

All-in-one Design

The Studer OnAir 2500 ensures a

new standard in ease-of-use for Radio

or TV Broadcast. Designed as

an integrated system – control

surface, I/O breakout, DSP and

controller boards, as well as power

supply, share the same chassis - it

addresses the medium segment of the

live broadcast market including both

private and public network stations.

Its self-contained architecture without

an external core reduces wiring

complexity and setup time to a

minimum. This makes the OnAir 2500

the OnAir 3000. Full compatibility

with other systems of the OnAir

family and a short learning curve

for operators with OnAir 3000

experience are only two of many

advantages.

the ideal audio mixing console for OB

applications, where robustness and

reliability are a must.

Studer’s OnAir 2500 user-interface

builds upon the highly acclaimed

operational concept of the OnAir

2000 and OnAir 3000. Having been

introduced to the market with the

very successful OnAir 2000, Studer’s

patented “Touch’n’Action” philosophy

is incorporated into the OnAir 2500.

The OnAir 2500 even runs the

same mature software platform as

3

OnAir 2500 Key Features:

• 12, 18 or 24 fader layout with

motorised or non-motorised

100mm faders

• Touch sensitive, central 12”

coloured screen with 4 encoders

for parameter adjustment

• OLED (Organic LED) in fader

and central module for clear

readability

• Ergonomic, easy to learn

Touch’n’Action user interface

• Complete integration with Radio

Automation Systems

• Integrated monitoring system

• 8 stereo N-1 busses

• Built-in full channel processesing

with 4-band parametric EQ

4

Ready For Broadcast – Whenever

And Wherever You Want

Like all other products in Studer’s

OnAir portfolio, the OnAir 2500

provides you and your operators with

a wide and well-balanced broadcast

feature set. Typical functions for

your every day work, like muting the

monitor speaker signal while

microphones are open, are already

integrated and need not be

configured, saving time and money.

Nonetheless, nearly all functions can

be easily activated, deactivated or

customised using the configuration

user interface on the main screen.

The ergonomic design and the

simple usability of the OnAir

2500 means that it’s ideally suited to

stressful live on-air operation. Being

under continuous time pressure, the

DJ can change from live presentation

to off air recording, from

pre-conferencing to OB connections.

operation have highest priority. The

OnAir 2500 is entirely geared to

let your talents do their job: making

radio.

The OnAir 2500 supports your daily

work even more. In most

installations, the console will be

operated in a multiuser environment.

Therefore, you can create

user accounts defined with individual

access restrictions on specified

console functions. This applies as

well for the system snapshots, which

are stored internally and contain

custom sets of signal parameters,

crosspoint settings and channel

assignment. According to the

configured rights, users may have

access to only a limited number of

snapshots. Independently, it is possible

to store snapshots externally on a

USB memory stick, connected to a

socket on the main screen.

With the OnAir 2500, Studer has

defined a new standard in ease-of use

for radio broadcast. Like no other

console, the OnAir 2500 with its

compact architecture is the ideal

solution for your mobile applications,

especially because it does not need

any external DSP core. Every signal

you need is connected directly to the

rear panel. No wasted time setting up

links to cores and networks, the

intuitive architecture ensures you’re

on-air fast!

This is where simple and intuitive

5

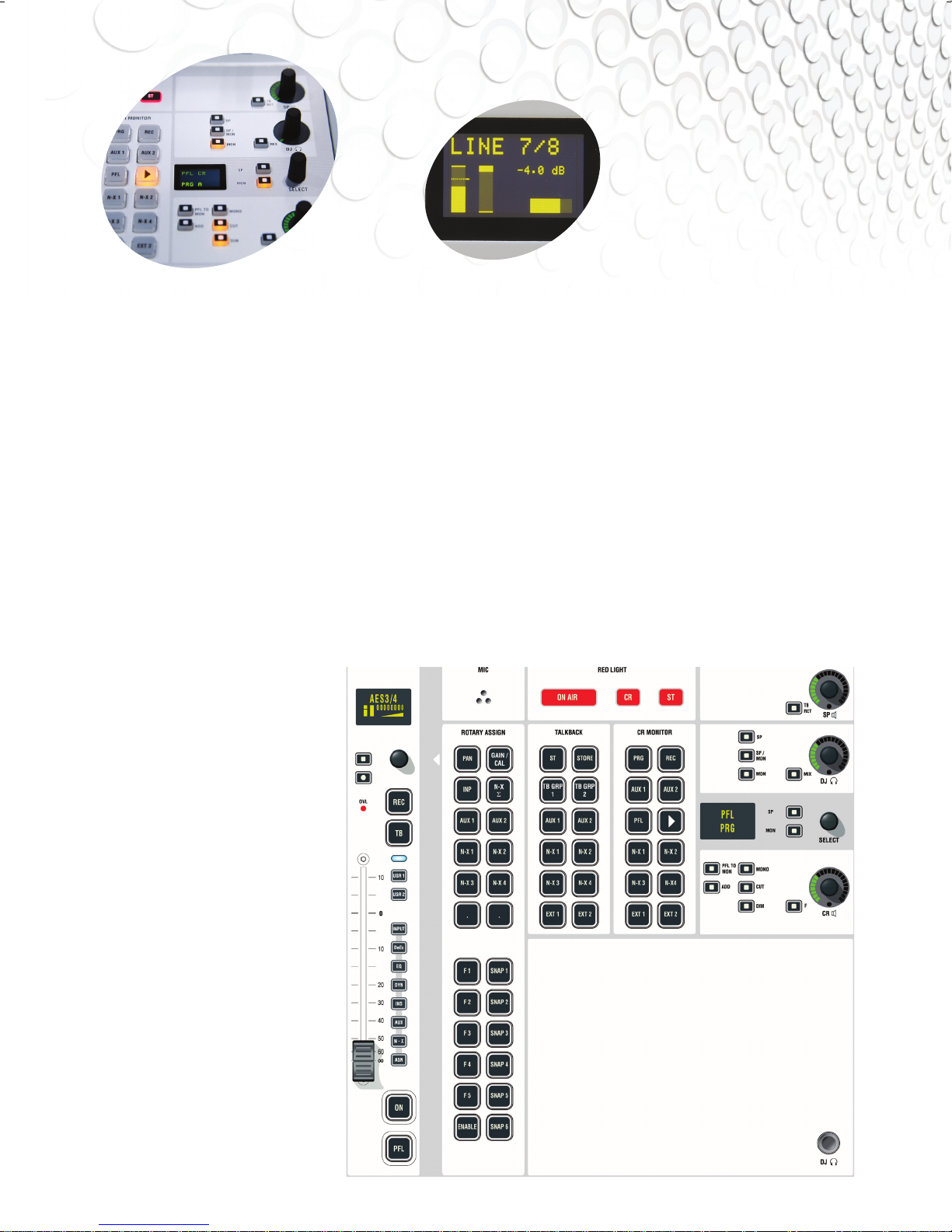

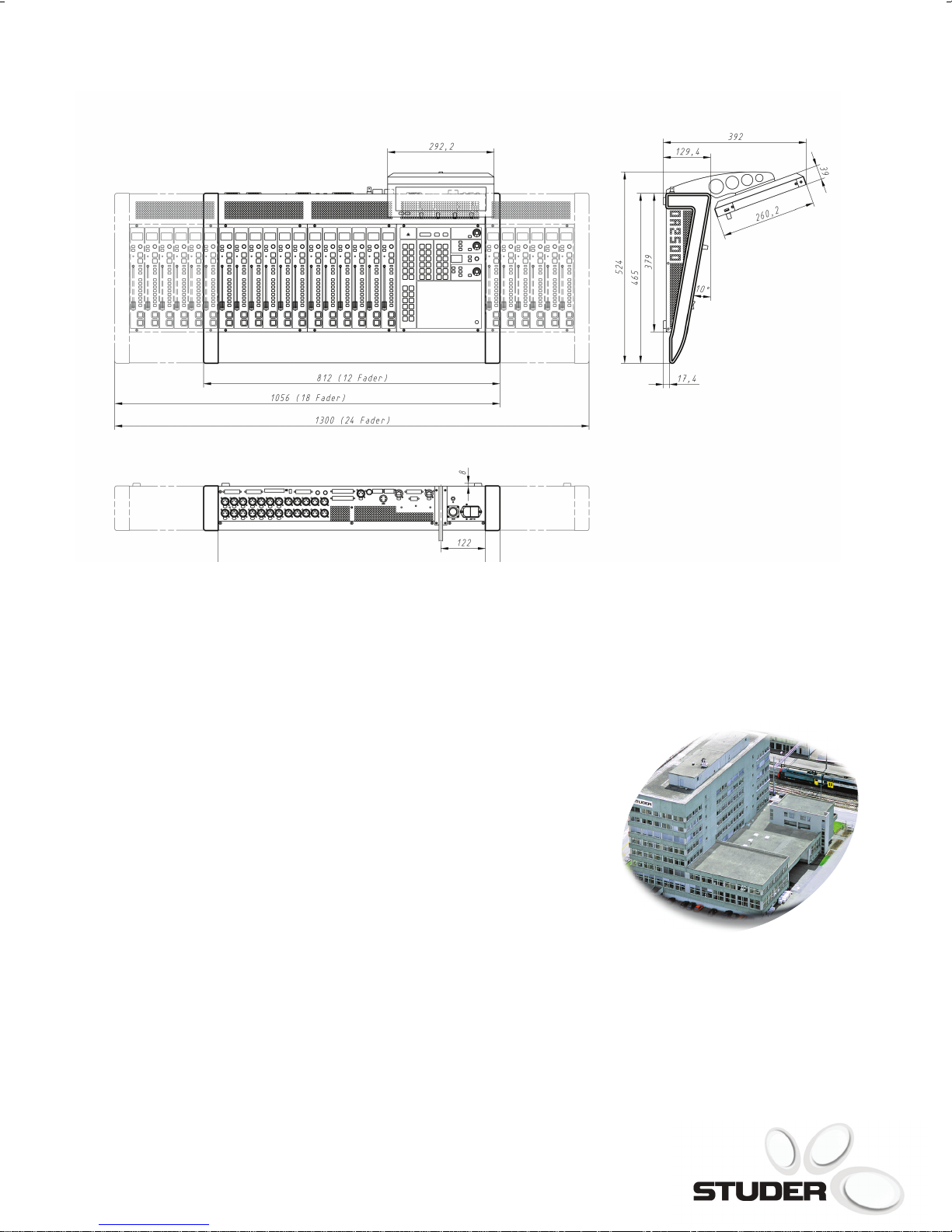

Studer’s OnAir 2500 is designed as an

integrated system – control surface,

I/O breakout, DSP and controller

boards, as well as power supply,

share the same chassis. Modules of

6 faders build the basis for the three

available consoles sizes with 12, 18 or

24 faders. A central module in every

console layout provides the operators

with a monitoring section, on air

indication, a talkback section and a

built-in talkback microphone.

further reinforces the mobile

capability.

Pushbuttons throughout the entire

console are made of silent rubber

pads, guaranteeing noiseless operation

and perfect tactile feedback.

Despite its compactness, the OnAir

2500 can be easily extended. When

installed in a control room and

connected to a voice booth, a

talkback and monitoring module

(1.943.444 or 1.943.447) can be

attached to enable communication

between engineer and journalist, or

even from the voice booth to any

other destination, e.g. the N-X

returns. Additonally, this extension

includes an independent studio

monitoring module with separate

The talkback and monitoring module

is connected directly to the OnAir

2500 via ADAT (audio) and CAT5

(control). The respective interfaces on

the rear panel are already

preconfigured for this purpose.

To allow fail-safe operation in case of

mains power loss, Studer offers an

external power supply for the OnAir

2500, in a smart 1RU 19” chassis. This

used as secondary feed providing

This all-in-one design is characterised

by a very small footprint. The

smallest version of the OnAir 2500

with 12 faders requires only 80x50

cm and the total weight of 17kgs

volume control for studio speakers

and headphones.

24V DC to the console.

6

Quick And Intuitive Operation

Like the OnAir 3000, the operation

of the desk is based on Studer’s well

proven and worldwide accepted

“Touch’n’Action” user interface

concept. Within minutes, your talent

is able to operate the console. If your

staff is already experienced with the

OnAir 3000, getting familiar with the

OnAir 2500 is simple. This is ensured

by the clear layout of the user

interface.

Within each single fader strip, an

OLED (Organic LED) ensures

clearest readability of the indicated

information. The display shows the

name of the assigned channel as well

as input level and gain reduction

meters. The level meter can be

alternatively switched to pre or

postfader signal indication or to the

corresponding N-X send level. The

lower right area of the display is

preserved for information about

the function assigned to the rotary

encoder below the display. During

operation, users can choose if the

rotary accesses the channels Gain

setting or the Aux 1 parameters or

any other of the assignable functions.

For immediate visual feedback, the

selected function is always indicated

by an individual graphic icon,

which is supported by text based

parameter indication, whenever the

encoder knob is touched. Two small

pushbuttons allow direct access to

switching parameters, like On/Off or

Pre/Post.

Each faderstrip includes an overload

indication LED which ashes

whenever the channel signal overloads

the input stage. Two large Pushbuttons

with replaceable labels on top of each

fader are precongured as ‘REC’ and

‘TB’. REC routes the channels signal

to the Record Bus, TB allows talkback

into the channel related return line

(available with N-X channel sources).

Below these buttons, a blue LED

indicates an open channel (faderstart

is active). The LED is followed by two

small pushbuttons, which can be

customised. Users can configure the

buttons, for example with a ‘Tally’

function.

On the right hand side of each fader,

a set of eight small pushbuttons with

fixed labels allows direct access to

fader related function pages shown

in the main screen. By pressing the

button at any time, the operator gets

immediate access to the channel

Input page, the DeEsser, EQ,

Dynamics pages, the Insert page or

the Aux, N-X, Bus Assign pages.

A simple touch on the

respective symbol of a channel

function, e.g. equalizer, dynamics,

AUX send, immediately opens the

corresponding page on the main

screen, allowing for quick and easy

adjustment. This can be done either

7

and Ext 1 and 2. The standard

configuration of the console dims the

main speakers whenever a talkback

button is pressed. The internal

microphone represents the default

source for the talkback.

The CR monitoring section provides

the user with a set of sources, which

can be monitored on the control

room speakers or the DJ headphone.

By default, all summing signals, like

Program bus, Record bus, Aux 1 or

2, are directly accessible while other

sources can be selected from a list

using the rotary encoder by the

OLED display. Pressing PFL in a

by the four rotary encoders below

the main screen or directly by

touching a selection list within the

main screen display. To prevent

accidential activation, pushbuttons

and other control elements can be

blocked according to user login rights.

At the bottom of each fader strip, two

large counter-sunk pushbuttons with

replaceable labels are preconfigured

as ‘ON’ and ‘PFL’. While PFL switches

the channels signal to the PFL bus,

ON activates the channel.

The large pushbuttons labelled REC,

TB, ON and PFL can be individually

customised on request. The central

module provides the user with 4

sets of 12 pushbuttons, a monitoring

control section, and an ‘On Air’ and

‘Mic On’ indication for the control

room and the connected studio.

Additionally, this module has an

integrated talkback microphone

and a socket for the DJ headphone

jack.

With the upper left array of 12

pushbuttons, the operator can assign

a function to the fader rotary. In the

standard console layout, the

preconfigured functions to be set are

Pan/Balance, Gain/Calibration,

Input Selection, N-X Send sum, Aux

1, Aux 2 and N-X 1..4 contribution.

In the talkback section, 12

pushbuttons allow communication

with the destination studio, talkback

group 1 and 2, Aux 1 and 2, N-X 1..4

fader strip activates the PFL listening

on the integrated speaker. Volume

for PFL speaker, control room

monitors and DJ headphone can be

controlled by rotary encoders with

value indication.

In the lower left part of the central

module, the fourth 12 pushbutton

array provides a set of user definable

functions. By default, SNAP 1..6 can

be assigned to internal snapshots for

immediate recall of console setups.

All large buttons are equipped with

replaceable key labels. On

request, labels and assigned

functionality can be customised.

8

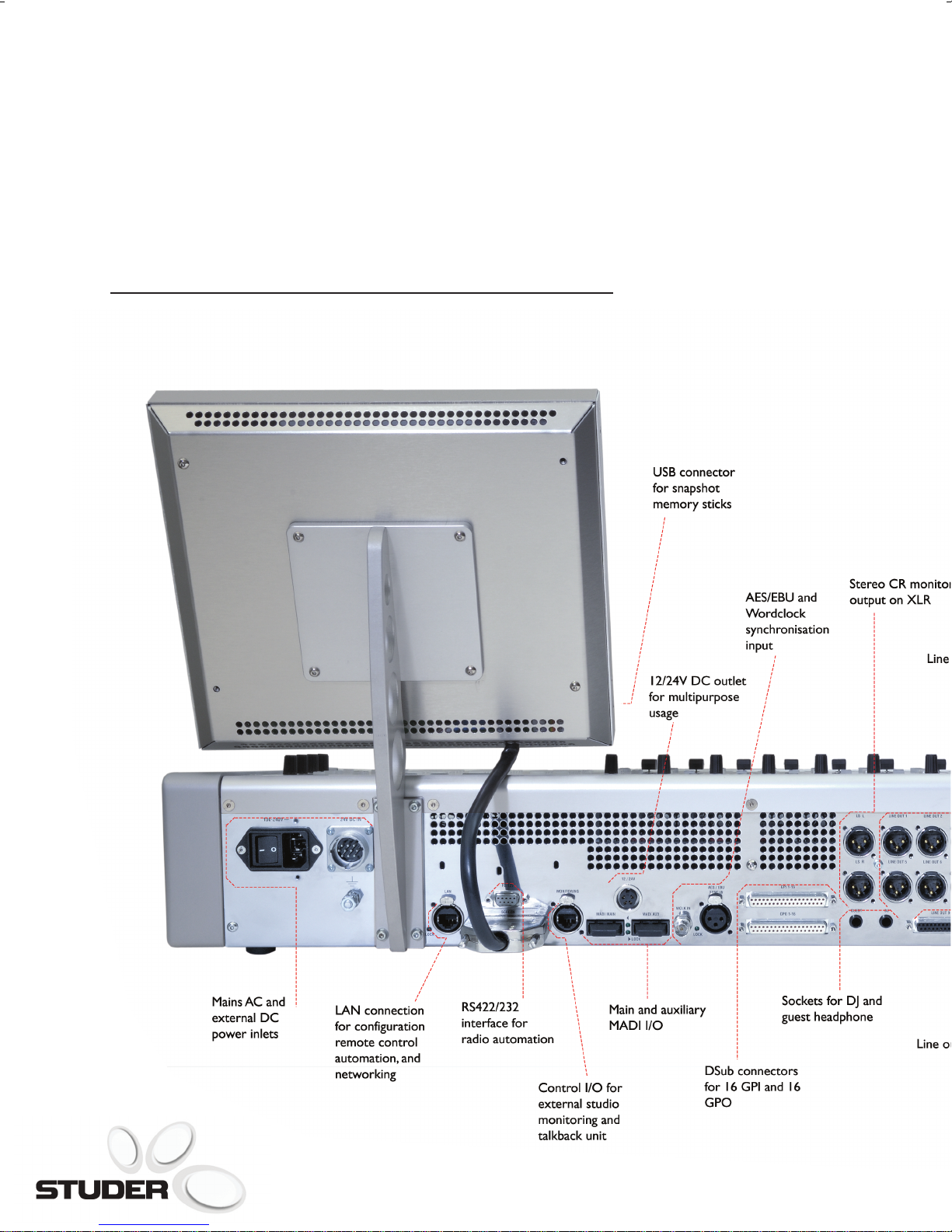

Connectivity

9

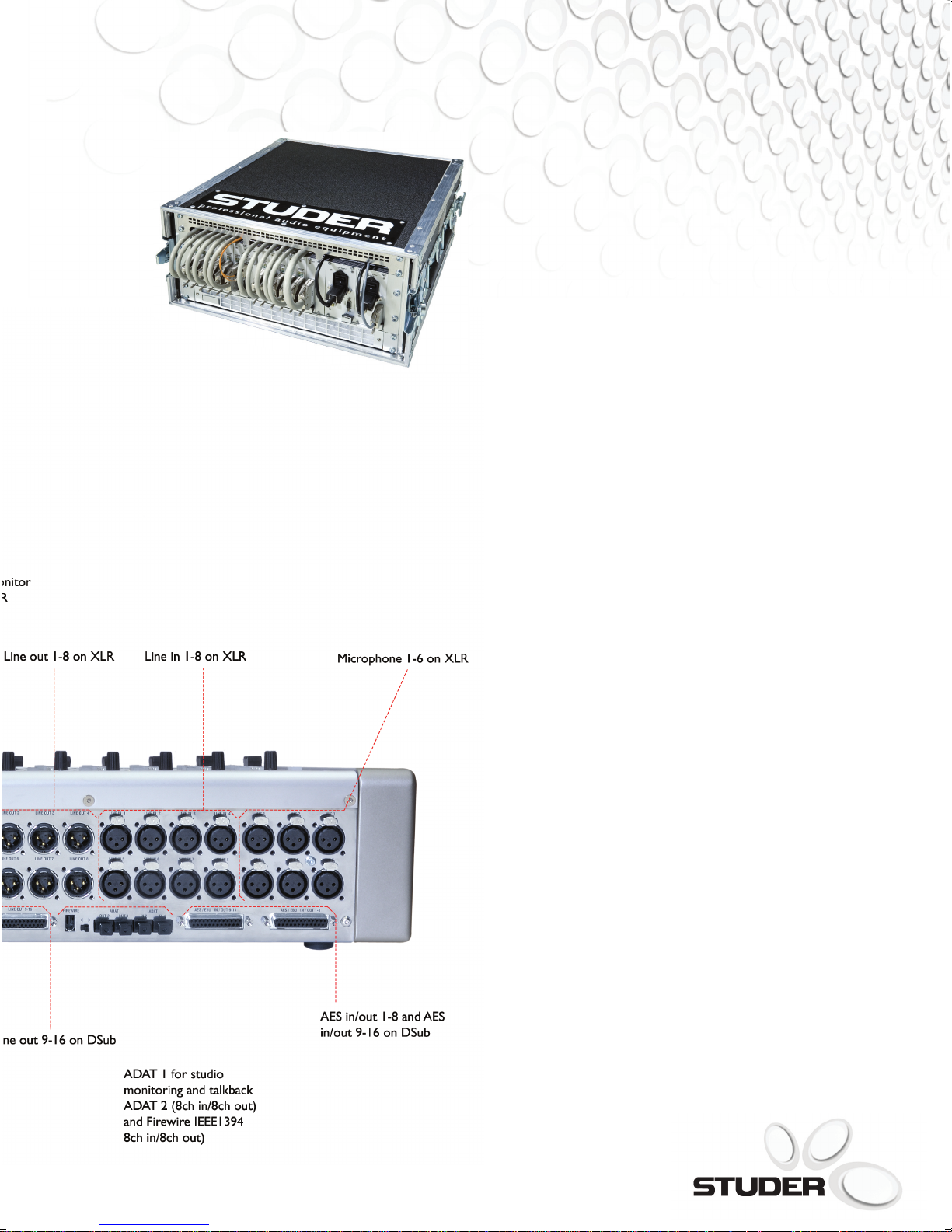

Input and output modules

The following D21m input and output cards

are available:

• Microphone / line card, 4

Channels

With analogue insert extension

connector

• Analogue Insert card

Provides 4 balanced insert send and

return paths

• Line In card, 8 channels

24 bit Delta-Sigma A/D converter

card

• Line Out card, 8 channels 24 bit

Delta- Sigma D/A converter card

• AES/EBU card, 8 channels AES/ EBU

in, 8 channels AES/EBU out

Available either with i/p SRC, with i/p

and o/p SRC, or without SRC

• ADAT card, 2 x 8 channels i/p and 2

x 8 channel o/p

With optical interfaces

• TDIF card

Provides 2 TDIF interfaces

• MADI card

Provides optical 64 ch MADI interface

• GPIO card

16 opto-coupler general purpose inputs

16 open collector general purpose

outputs, also available with relays.

The D21m system automatically detects

newly inserted cards in real time and sends

the appropriate information to the main

controller in the OnAir 2500. Additionally,

in the case of a card failure an error

message is transmitted and displayed on

the GUI.

The

OnAir 2500

provides you with an attractive

set of local inputs and outputs in multiple

formats. By connecting a Studer D21m I/O

Breakout box via MADI, the number and

format of the available I/Os can be extended.

10

Radio Integration

With the OnAir 2500, networking

and integration is easy.

Optional support of I/O Sharing

allows Studer’s sophisticated

technology to share signals with other

Studer devices regardless of model. In

a networked installation with multiple

OnAir 2500 and OnAir 3000, Route

6000 and Vista systems, operators

can use I/Os from these systems

and have full access to all parameters

of shared I/Os.

The OnAir 2500 allows integration

with radio automation systems.

Remote control in both directions

from the console to the automation

system and vice versa, is possible via

Monitora option. A single playout

session can be established via serial

interface, while multiple sessions are

possible via TCP/IP. In combination

with the audio connection over

IEEE1394 Firewire with 8ch I/O this

means an effective reduction of

wiring complexity and allows the user

to be on-air ready, fast.

Router control via ProBel is

optionally available. The console is

able to send crosspoint commands to

a Router using the comfortable main

screen as a controller, but it is also

possible to activate output patches in

the router. Patches are sets of

predefined crosspoints, which can be

activated by pressing a single button

on the console surface.

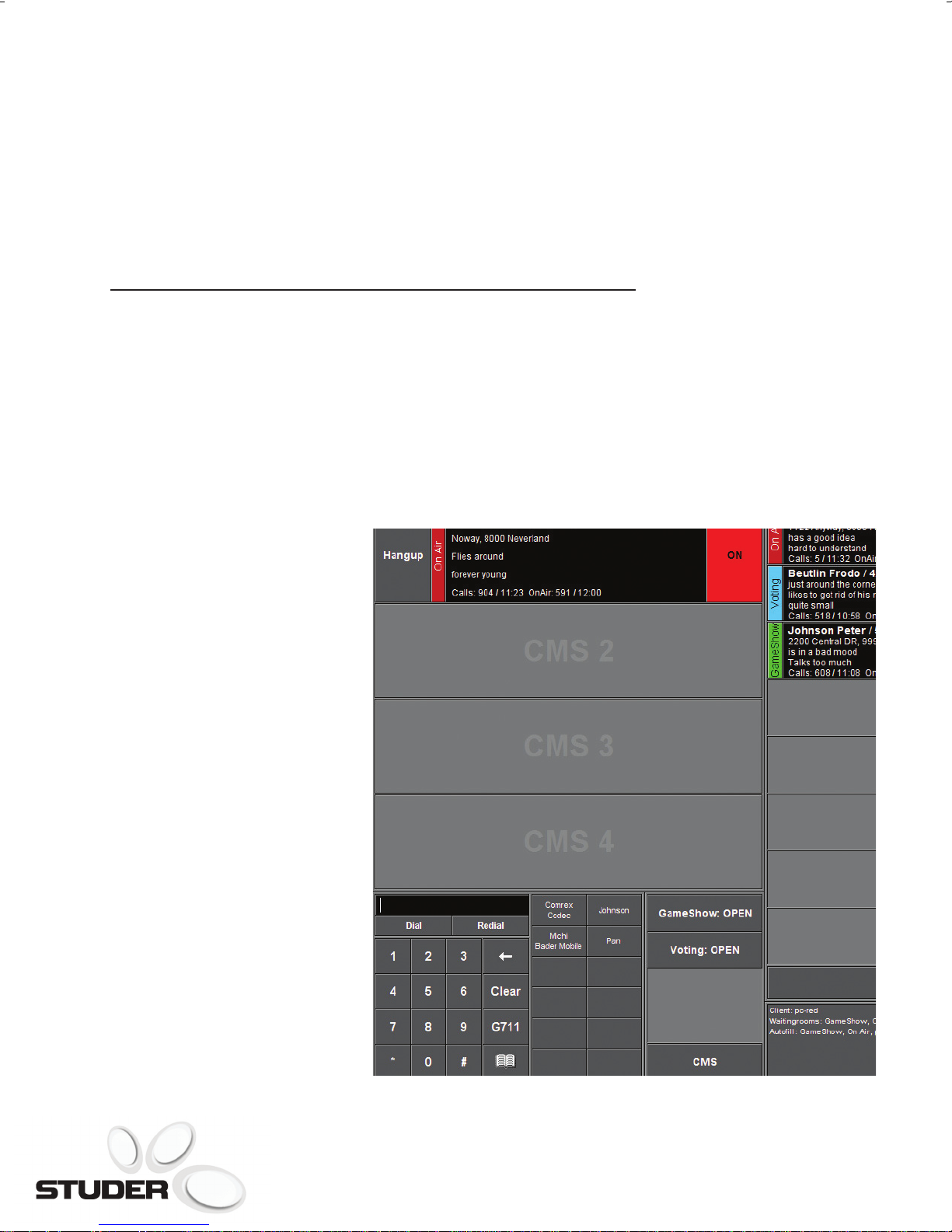

The OnAir 2500 can also be

integrated with Studer’s Call

Management System, CMS. This

system replaces the usual telephone

in a studio by software clients,

allowing sophisticated management

of incoming calls in a networked

environment. The CMS is able to

automatically route incoming callers

to pre-configured fader channels,

allowing caller names to be shown

dynamically as fader channel labels.

Finally, the optional SNMP

functionality enables the system to

send information into the network to

monitor the system’s health. Nearly

any parameter can be selected for

surveillance.

11

OnAir 2500 Main Features:

• Ergonomic, easy to learn “Touch’n’Action” user interface

• Complete system overview and fast parameter access via

fader screens

• 2 master buses PRG A, REC

• 8 weighted stereo mix-minus buses congurable as AUX

sends

• 2 AUX stereo buses

• 8 assignable inserts (stereo) plus analogue mic inserts

• Different audio I/O modules as option by D21m series

extension

• Congurable control signals (GPIOs)

• All buttons freely assignable

• Snapshots, user management, user logins

• Graphical user interface with colour TFT touch screen

• Interface to radio automation system(s)

• Remotely controllable via remote GUI or Probel

protocol

• Redundant power supplies

• Input and output router with graphical display

• Fixed Frame version for easy and fast installation

• Completely adaptable to customer needs

• I/O sharing of audio sources

Inputs

- 6x Mic XLR

- 4x Stereo line XLR

- 8x Stereo AES/EBU with Input SRC on D-Type

- ADAT1 (HCS 200/230μ) (for studio monitoring with 1.943.444 or

1.943.447)

- ADAT2 (POF 980/1000 μ Fiber Wire) or Firewire IEEE-1394

- 1x MADI with 56 IN optical. AUX connector for redundant wiring

- 1x TB mic on desk

Outputs

- 4x Stereo Line XLR

- 4x Stereo Line D-type

- 1x Stereo CR Loudspeaker

- 8x Stereo AES/EBU D-Type

- 1x DJ Headphone (2 connectors)

- 1x GUEST Headphone

- 1x PFL speaker on desk

- 1x ADAT1 (for Studio monitoring)

- 1x ADAT2 or Firewire (IEEE-1394)

- 1x MADI with 40 OUT, AUX connector for redundant wiring

• Each Channel with:

• 4 band parametric EQ

• Limiter, Compressor, Expander, Gate

• De-Esser

• Mic Inputs with High Pass Filter

• One PFL circuit

• Integrated PFL speaker in chassis

• External PFL function (e.g. for playout system)

• Audition bus

• CR monitoring with quick listening function on all inputs

and outputs

• One independent studio monitoring/talkback circuit

• Integrated talkback microphone

12

Technical Specifications

General

Level specs, digital, in dBFS: dB, referenced to full modulation (dBFS, dB Full

Scale)

Level specs, analogue, in dBu: 0 dB Ø 0.775 Vrms

Sampling rate: 48 kHz ±50 ppm (internally synchronized)

Headroom adjustable: 0 to 20 dB

Default setting: 9 dB

Output Level: 15 dBu @ 0 dBFS

All input faders set to their 0 dB position. External analogue sources:

source impedance < 200 Ω. Frequency range: 20 Hz to 20 kHz, if not

stated otherwise.

Microphone inputs

Input sensitivity: –60 dBu…26 dBu for 0 dBFS

Gain setting: in steps of 1dB

Frequency response: 30 Hz…20 kHz, –0.3 dB

High pass lter (12 dB/Octave): 75 Hz

Input impedance: 1.8 kOhm

Insert level (for 0 dBFS) +15 dBu

Dynamic range: 107 dB

THD+N (30 Hz … 20 kHz, –30 dBFS): –100 dBFS

THD+N (1 kHz, –1 dBFS): –95 dBFS

Equivalent input noise (200 Ω Ri, max gain): –124 dBu

Crosstalk, 1 kHz: –100 dB

Phantom power, switchable: 48 V

Line level inputs

Level (for full scale) 15 or 24 dBu xed (jumper), or 7...26 dBu adjustable

Input impedance min. 10 kΩ

Frequency response 20 Hz...20 kHz –0.2 dB

THD & N (35 Hz … 20 kHz, –30 dBFS), input level xed max. –108 dBFS

THD & N (1 kHz, –1 dBFS), input level xed max. –97 dBFS

Crosstalk 1 kHz max. –110 dB

Digital inputs/outputs

Input/Output impedance 110 Ω

Output level (into 110 Ω) 5V

Input Sampling rate with SRC 32 … 108 kHz

Analogue outputs

Level (for full scale) 15 or 24 dBu xed (jumper), or 7 … 26 dBu adjustable

Output Impedance 50 Ω

min. Load at +24 dBu 600 Ω

Frequency response 20 Hz … 20 kHz –0.2 dB

THD & N (20 Hz … 20 kHz, –30 dBFS), input level xed max. –104 dBFS

THD & N (1 kHz, –1 dBFS), input level xed max. –93 dBFS

Crosstalk 1 kHz max. –110 dBFS

Equalizer

4 Band, each band sweepable 20 Hz…20 kHz: ±18 dB

Q-factor 0.27 … 8.7

Dynamics

Dynamic level 0 dB … +24 dB

Dynamics ON/OFF

Limiter

Threshold -39 … + 9dB

Attack time 0.2 msec … 1 msec

Release time 10 msec … 10 sec

Compressor

Threshold -87 … +9 dB

Ratio 20:1 … 1:1

Attack time 0.2 msec … 20 msec

Release time 10 msec … 10 sec

Expander

Threshold -87 … +9 dB

Ratio 20:1 … 1:1

Attack time 0.2 msec … 1 msec

Release time 10 msec … 10 sec

Noise Gate

Threshold -87 … +9 dB

Attenuation -48 dB … 0 dB

Attack time 0.2 msec … 1 msec

Release time 10 msec … 10 sec

De-esser

Frequency range 4 kHz … 14 kHz

Q-factor 0.27 … 8.7

Threshold -87 dB … + 8 dB Auto Mode

Ratio 20:1 … 1:1

Power supply

Mains voltage: 100 to 240 V, 50/60 Hz (auto-ranging)

Power consumption Desk: typ. System 100 W

Weight

OnAir 2500 12 fader 17 kg

Note:

We reserve the right to change specifications as technological progress

may warrant. Data subject to change without notice

13

OnAir 2500 Fixed Frame

Service and Support

Studer has produced and delivered far more than a thousand time-tested and

proven digital OnAir mixing consoles throughout the world, many of which are

in use 24 hours a day, seven days a week. Due to the modular design and the

self-configuring software, individual hardware items can be easily and quickly

exchanged at the customer’s site. We at Studer know that reliability is vital to

our customers. Therefore Studer offers world wide service and support for

its products. Studer also offers operator training and service on-site or in the

factory. Please consult your local Studer representative.

INPUTS INPUT CHANNELS

STEREO INPUT

CHANNEL 1 to n

n = 12/18/24

AES

1/2

3/4

5/6

7/8

9/10

11/12

13/14

15/16

SFC

SFC

SFC

SFC

SFC

SFC

SFC

SFC

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

A

D

MIC

A

D

A

D

A

D

1

2

3

4

A

D

A

D

A

D

5

6

CR

ST

A

D

LINE

A

D

A

D

A

D

3

4

1

2

5

6

7

8

ADAT 2 / IEEE1394

ADAT

1394

D

D

8

d

D

D

8

d

ADAT 1

D

D

8

from

ST

MADI

D

D

56

56

d

d

Alt

GPIN

GPIO

(Optional, in D21m Frame)

16

GPOUT

16

GPIN

GPIO

16

GPOUT

16

#

CR SP SOURCE

CR MON SOURCE

CR MON ADD SOURCE

STUDIO SOURCE

EXT PFL 1

TB from EXT 1...4

TB from CR

TB from STUDIO

TB from EXTERN

EXT PFL 2

CUE

INS RET

CH INP

TEST GEN.

SINE WAVE

WHITE NOISE

PINK NOISE

PHASE

STEREO

CAL

DE-ESSER

INS

PP

PROCESSING

EQ

4-band

DYNAMICS

INS

AP

FADER BALANCE

CHANNEL

ON/OFF

AF

PF

CH METERGR METEROVL

DYNDe-S

PP

AP

4

4

CH

active

AF

PF

PF

AF

CUE

PFL

AF

PF

PF

AF

4

4

TB

TB to CR

TB to CR HP

TB to STUDIO

TB to STUDIO HP

TB to Extern

TB to Ext. 1...4

TB to Int.

1

12

12

AP

PP

CHANNEL OUT

PGM

AUDITION

AUX 1

AUX 2

PFL

REC

N–X 1

N–X

N–X 8

REC PF

INS SEND

+

+

+

+

+

+

+

+

+

+

+

+

CR TB RET

TB to STUDIO TB to STUDIO

TB to

STUDIO HP TB to STUDIO HP

TB to Ext. 1...4

TB to Extern

SLATE/TALK

STUDIO SRC

STUDIO SRC

MASTER / SEND AND MONITORING OUTPUTSS

AUDITION

AUX 1

REC

AUX 2

PFL

PGM

Master AUX Listen

N–X 1

N–X 8

N–X

CUE

N–X

N–X

CUE

CR SRC

CR SP SRC

CR SP SRC

TB to CR HP

CR ADD SRC

TB

TB

PFL

PFL

PFL

PFL

PFL

PFL

REC MASTER

PGM MASTER

AUX 1

AUX 2

SN–X 1

SN–X 8

FADER

FADER

FADER

FADER

FADER

FADER

ON

ON

ON

ON

TB

DIM

TB

DIM

TB

DIM

TB

DIM

TB

DIM

TB

DIM

TALK

TALK

TALK

SLATE

TALK

SLATE

M/S

M/S

INS LIM M/S

INS LIM M/S

M/S

M/S

1/2

3/4

5/6

7/8

9/10

11/12

13/14

15/16

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

AES

D

A

D

A

D

A

D

A

ADAT 2 / IEEE1394

D

D

d

8

D

D

d

8

ADAT 1

D

D

d

8

GUI Meter

MADI

D

D

40

d

4

d

40

Alt

Control

L (M)

R (M)

M

L (M)

R (M)

M

L (M)

R (M)

M

L (M)

R (M)

M

L (M)

R (M)

M

L (M)

R (M)

M

INS SEND

CHANNEL OUT

DIR OUT PP

DIR OUT AP

DJ HP

CR MON SP

GUEST HP

SP

TB to Ext. 1...4

TB to Extern

CR SP

PFL CR

GUEST HP

HP

Audition

#

TB

DIM

CUT

PFL CR

HP Src

CUT

Mono

DIM

TALK

TB

DIM

TB

DIM

CUT

STUDIO

DIM

TALK

TB

DIM

TB

DIM

DIM CUT

Mono

Mono

Mono

TALK

TALK

CR ADD MODE

NONE

SPLIT

MIX

CONTROL ROOM

SP

CR MON

CR/SP

Mono

MON to Left

Mono

with PFL SP

DJ HP MODE

TB

TB

TALK

3

4

2

1

5

6

7

8

D

A

D

A

D

A

D

A

11

12

10

9

13

14

15

16

D

A

D

A

D

A

D

A

DJ HP

CR SP

GUEST HP

SP

SP

HP

GUEST HP

ADAT

1394

LINE

0.9 1.031.05.07/HUR

OnAir 2500

Regensdorf

Switzerland

AUDIO BLOCK

DIAGRAM

SW V3.0

28.04.08/HUR

Configuration C3

Part No. Qt y. Type/Val. DescriptionPos.Idx. Part No. Qt y. Type/Val. DescriptionPos.Idx.

OnAir 2500

Page: 1 of 4

Fader Front PCB 1.943.611.21 ( 0)

C 1 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 2 59.60.3906 47u CER 6.3V, 121001 pce

C 3 not used 10u CER 25V, 121001 pce

C 4 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 5 59.60.3906 47u CER 6.3V, 121001 pce

C 6 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 7 59.60.3906 47u CER 6.3V, 121001 pce

C 8 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 9 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 10 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 11 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 12 59.60.2249 100p CER 50V, 5%, C0G, 060301 pce

C 13 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 14 59.60.3317 2n2 CER 50V, 10%, X7R, 080501 pce

C 15 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 16 59.60.2249 100p CER 50V, 5%, C0G, 060301 pce

C 17 59.60.3317 2n2 CER 50V, 10%, X7R, 080501 pce

C 18 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 19 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 20 59.60.3904 10u CER 6.3V, 080501 pce

C 21 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 22 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 23 59.60.3904 10u CER 6.3V, 080501 pce

C 24 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 25 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 26 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 27 59.60.3904 10u CER 6.3V, 080501 pce

C 28 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 29 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 30 59.60.3904 10u CER 6.3V, 080501 pce

C 31 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 32 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 33 59.60.3904 10u CER 6.3V, 080501 pce

C 34 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 35 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 36 59.60.3904 10u CER 6.3V, 080501 pce

C 37 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 38 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 39 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 40 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 41 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 42 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 43 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 44 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 45 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 46 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 47 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 48 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 49 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 50 59.60.2221 6p8 CER 50V, 5%, C0G, 060301 pce

C 51 59.60.2221 6p8 CER 50V, 5%, C0G, 0603

01 pce

C 52 59.60.2221 6p8 CER 50V, 5%, C0G, 060301 pce

C 53 59.60.2221 6p8 CER 50V, 5%, C0G, 060301 pce

C 54 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 55 59.60.2237 33p CER 50V, 5%, C0G, 060301 pce

C 56 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 57 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 58 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 59 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 60 59.60.2237 33p CER 50V, 5%, C0G, 060301 pce

C 61 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 62 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 63 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 64 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 65 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 66 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 67 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 68 59.60.3321 4n7 CER 50V, 10%, X7R, 080501 pce

C 69 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 70 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 71 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 72 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 73 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 74 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 75 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 76 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 77 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 78 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 79 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 80 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 81 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 82 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 83 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 84 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 85 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 86 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 87 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 88 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 89 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 90 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 91 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 92 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 93 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 94 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 95 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 96 59.60.3337 100n CER 50V, 10%, X7R, 080501 pce

C 97 59.60.3906 47u CER 6.3V, 121001 pce

C 98 59.60.3906 47u CER 6.3V, 121001 pce

D 1 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 2 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 3 50.60.8901 BAV99 250mA 70V dual SOT 2301 pce

D 4 50.60.8901 BAV99 250mA 70V dual SOT 2301 pce

D 5 50.60.8901 BAV99 250mA 70V dual SOT 2301 pce

D 6 50.60.8901 BAV99 250mA 70V dual SOT 2301 pce

D 7 50.60.8901 BAV99 250mA 70V dual SOT 2301 pce

D 8 50.60.8901 BAV99 250mA 70V dual SOT 2301 pce

D 9 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 10 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 11 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 12 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 13 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 14 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 15 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 16 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 17 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 18 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 19 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 20 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 21 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 22 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 23 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 24 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 25 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 26 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 27 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 28 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 29 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 30 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 31 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 32 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 33 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 34 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 35 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 36 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 37 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 38 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 39 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 40 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 41 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 42 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 43 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 44 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 45 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 46 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 47 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 48 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 49 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 50 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 51 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 52 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 53 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 54 50.60.8001 4448 200mA 75V 4ns SOD 80

01 pce

D 55 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 56 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 57 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 58 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 59 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 60 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 61 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 62 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 63 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 64 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 65 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 66 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 67 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 68 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 69 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 70 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 71 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 72 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 73 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 74 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 75 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 76 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 77 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 78 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 79 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 80 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 81 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 82 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 83 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 84 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 85 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 86 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 87 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 88 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 89 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 90 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 91 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 92 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 93 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 94 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 95 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 96 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 97 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 98 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 99 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 100 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 101 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 102 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 103 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 104 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 105 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 106 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 107 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

Date printed: 06.06.2008

Part No. Qt y. Type/Val. DescriptionPos.Idx. Part No. Qt y. Type/Val. DescriptionPos.Idx.

OnAir 2500

Page: 2 of 4

Fader Front PCB 1.943.611.21 ( 0)

D 108 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 109 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

D 110 50.60.8001 4448 200mA 75V 4ns SOD 8001 pce

DL 1 50.60.9402 yel SMD LED yellow01 pce

DL 2 50.60.9402 yel SMD LED yellow01 pce

DL 3 50.60.9402 yel SMD LED yellow01 pce

DL 4 50.60.9402 yel SMD LED yellow01 pce

DL 5 50.60.9402 yel SMD LED yellow01 pce

DL 6 50.60.9402 yel SMD LED yellow01 pce

DL 7 50.60.9402 yel SMD LED yellow01 pce

DL 8 50.60.9402 yel SMD LED yellow01 pce

DL 9 50.60.9402 yel SMD LED yellow01 pce

DL 10 50.60.9402 yel SMD LED yellow01 pce

DL 11 50.60.9402 yel SMD LED yellow01 pce

DL 12 50.60.9402 yel SMD LED yellow01 pce

DL 13 50.60.9402 yel SMD LED yellow01 pce

DL 14 50.60.9401 red SMD LED superred01 pce

DL 15 50.60.9402 yel SMD LED yellow01 pce

DL 16 50.60.9401 red SMD LED superred01 pce

DL 17 50.60.9402 yel SMD LED yellow01 pce

DL 18 50.60.9401 red SMD LED superred01 pce

DL 19 50.60.9402 yel SMD LED yellow01 pce

DL 20 50.60.9401 red SMD LED superred01 pce

DL 21 50.60.9402 yel SMD LED yellow01 pce

DL 22 50.60.9401 red SMD LED superred01 pce

DL 23 50.60.9402 yel SMD LED yellow01 pce

DL 24 50.60.9401 red SMD LED superred01 pce

DL 25 50.60.9401 red SMD LED superred01 pce

DL 26 50.60.9401 red SMD LED superred01 pce

DL 27 50.60.9401 red SMD LED superred01 pce

DL 28 50.60.9401 red SMD LED superred01 pce

DL 29 50.60.9401 red SMD LED superred01 pce

DL 30 50.60.9401 red SMD LED superred01 pce

DL 31 50.60.9402 yel SMD LED yellow01 pce

DL 32 50.60.9401 red SMD LED superred01 pce

DL 33 50.60.9402 yel SMD LED yellow01 pce

DL 34 50.60.9401 red SMD LED superred01 pce

DL 35 50.60.9402 yel SMD LED yellow01 pce

DL 36 50.60.9401 red SMD LED superred01 pce

DL 37 50.60.9402 yel SMD LED yellow01 pce

DL 38 50.60.9401 red SMD LED superred01 pce

DL 39 50.60.9402 yel SMD LED yellow01 pce

DL 40 50.60.9401 red SMD LED superred01 pce

DL 41 50.60.9402 yel SMD LED yellow01 pce

DL 42 50.60.9401 red SMD LED superred01 pce

DL 43 50.60.9418 blu SMD LED 1.25*2.001 pce

DL 44 50.60.9418 blu SMD LED 1.25*2.001 pce

DL 45 50.60.9418 blu SMD LED 1.25*2.001 pce

DL 46 50.60.9418 blu SMD LED 1.25*2.001 pce

DL 47 50.60.9418 blu SMD LED 1.25*2.001 pce

DL 48 50.60.9418 blu SMD LED 1.25*2.0

01 pce

DL 49 50.60.9402 yel SMD LED yellow01 pce

DL 50 50.60.9402 yel SMD LED yellow01 pce

DL 51 50.60.9402 yel SMD LED yellow01 pce

DL 52 50.60.9402 yel SMD LED yellow01 pce

DL 53 50.60.9402 yel SMD LED yellow01 pce

DL 54 50.60.9402 yel SMD LED yellow01 pce

DL 55 50.60.9402 yel SMD LED yellow01 pce

DL 56 50.60.9402 yel SMD LED yellow01 pce

DL 57 50.60.9402 yel SMD LED yellow01 pce

DL 58 50.60.9402 yel SMD LED yellow01 pce

DL 59 50.60.9402 yel SMD LED yellow01 pce

DL 60 50.60.9402 yel SMD LED yellow01 pce

DL 61 50.60.9402 yel SMD LED yellow01 pce

DL 62 50.60.9402 yel SMD LED yellow01 pce

DL 63 50.60.9402 yel SMD LED yellow01 pce

DL 64 50.60.9402 yel SMD LED yellow01 pce

DL 65 50.60.9402 yel SMD LED yellow01 pce

DL 66 50.60.9402 yel SMD LED yellow01 pce

DL 67 50.60.9402 yel SMD LED yellow01 pce

DL 68 50.60.9402 yel SMD LED yellow01 pce

DL 69 50.60.9402 yel SMD LED yellow01 pce

DL 70 50.60.9402 yel SMD LED yellow01 pce

DL 71 50.60.9402 yel SMD LED yellow01 pce

DL 72 50.60.9402 yel SMD LED yellow01 pce

DL 73 50.60.9402 yel SMD LED yellow01 pce

DL 74 50.60.9402 yel SMD LED yellow01 pce

DL 75 50.60.9402 yel SMD LED yellow01 pce

DL 76 50.60.9402 yel SMD LED yellow01 pce

DL 77 50.60.9402 yel SMD LED yellow01 pce

DL 78 50.60.9402 yel SMD LED yellow01 pce

DL 79 50.60.9402 yel SMD LED yellow01 pce

DL 80 50.60.9402 yel SMD LED yellow01 pce

DL 81 50.60.9402 yel SMD LED yellow01 pce

DL 82 50.60.9402 yel SMD LED yellow01 pce

DL 83 50.60.9402 yel SMD LED yellow01 pce

DL 84 50.60.9402 yel SMD LED yellow01 pce

DL 85 50.60.9402 yel SMD LED yellow01 pce

DL 86 50.60.9402 yel SMD LED yellow01 pce

DL 87 50.60.9402 yel SMD LED yellow01 pce

DL 88 50.60.9402 yel SMD LED yellow01 pce

DL 89 50.60.9402 yel SMD LED yellow01 pce

DL 90 50.60.9402 yel SMD LED yellow01 pce

DL 91 50.60.9402 yel SMD LED yellow01 pce

DL 92 50.60.9402 yel SMD LED yellow01 pce

DL 93 50.60.9402 yel SMD LED yellow01 pce

DL 94 50.60.9402 yel SMD LED yellow01 pce

DL 95 50.60.9402 yel SMD LED yellow01 pce

DL 96 50.60.9402 yel SMD LED yellow01 pce

DL 97 50.60.9402 yel SMD LED yellow01 pce

DL 98 50.60.9402 yel SMD LED yellow01 pce

DL 99 50.60.9402 yel SMD LED yellow01 pce

DL 100 50.60.9402 yel SMD LED yellow01 pce

DL 101 50.60.9402 yel SMD LED yellow01 pce

DL 102 50.60.9402 yel SMD LED yellow01 pce

DL 103 50.60.9402 yel SMD LED yellow01 pce

DL 104 50.60.9402 yel SMD LED yellow01 pce

DL 105 50.60.9402 yel SMD LED yellow01 pce

DL 106 50.60.9402 yel SMD LED yellow01 pce

DL 107 50.60.9402 yel SMD LED yellow01 pce

DL 108 50.60.9402 yel SMD LED yellow01 pce

DL 109 50.60.9402 yel SMD LED yellow01 pce

DL 110 50.60.9401 red SMD LED superred01 pce

DL 111 50.60.9402 yel SMD LED yellow01 pce

DL 112 50.60.9401 red SMD LED superred01 pce

DL 113 50.60.9402 yel SMD LED yellow01 pce

DL 114 50.60.9401 red SMD LED superred01 pce

DL 115 50.60.9402 yel SMD LED yellow01 pce

DL 116 50.60.9401 red SMD LED superred01 pce

DL 117 50.60.9402 yel SMD LED yellow01 pce

DL 118 50.60.9401 red SMD LED superred01 pce

DL 119 50.60.9402 yel SMD LED yellow01 pce

DL 120 50.60.9401 red SMD LED superred01 pce

DL 121 50.60.9402 yel SMD LED yellow01 pce

DL 122 50.60.9401 red SMD LED superred01 pce

DL 123 50.60.9402 yel SMD LED yellow01 pce

DL 124 50.60.9401 red SMD LED superred01 pce

DL 125 50.60.9402 yel SMD LED yellow01 pce

DL 126 50.60.9401 red SMD LED superred01 pce

DL 127 50.60.9402 yel SMD LED yellow01 pce

DL 128 50.60.9401 red SMD LED superred01 pce

DL 129 50.60.9402 yel SMD LED yellow01 pce

DL 130 50.60.9401 red SMD LED superred01 pce

DL 131 50.60.9402 yel SMD LED yellow01 pce

DL 132 50.60.9401 red SMD LED superred01 pce

IC 1 1.943.860.20 EPM240 SW611 Rotec8 (50.63.4218)01 pce

IC 2 50.65.0138 74LVC138 3 to 8 line decoder01 pce

IC 3 50.61.0201 TL062 Dual FET Op-Amp01 pce

IC 4 50.65.0244 74LVC244 Octal buffer/line driver 3.3V01 pce

IC 5 50.65.0244 74LVC244 Octal buffer/line driver 3.3V01 pce

IC 6 50.62.1595 74HC595 8bit shift/output register01 pce

IC 7 50.61.9001 LM393 Dual voltage comp. SO 801 pce

IC 8 50.62.1951 74HC4051 8ch analog mux/demux01 pce

IC 9 50.62.1014 74HC 14 Hex Schmitt trigger inverter01 pce

IC 10 50.62.1165 74HC165 8bit shift register01 pce

IC 11 50.62.1165 74HC165 8bit shift register01 pce

IC 12 50.62.1014 74HC 14 Hex Schmitt trigger inverter01 pce

IC 13 50.62.1904 74HCU04 Hex inverter unbuffered01 pce

IC 14 50.62.1595 74HC595 8bit shift/output register01 pce

IC 15 50.62.1595 74HC595 8bit shift/output register

01 pce

IC 16 50.62.1595 74HC595 8bit shift/output register01 pce