Page 1

IMPORTANT INFORMATION: File this in your TPS records

Total Performance System Consoles

REF 5100-1 & 5100-1A Console

REF 5100-50 & 5100-50A Irrigation Console

User's Guide

••••••••••••••••••••••

Includes setup, safety, repair, and warranty information for the

Stryker Total Performance System.

For answers to questions about other equipment, see the

information supplied with that equipment.

V e r s i o n

4.x

US Patents D398,598; D415,134; 5,543,695; 5,689,159; 6,017,354; 6,025,683;

6,045,564; 6,329,778 and other patents pending

5100-001-709 Rev-F10/05

1

4100 E. Milham

Kalamazoo, Michigan

(USA) 49001

1-800-253-3210

1-269-323-7700

www.stryker.com

European Authorized Rep:

RA/QA Manager

Stryker France

ZAC Satolas Green Pusignan

Av. de Satolas Green

69881 MEYZIEU Cedex

France

Page 2

Contents

Software License Notice....................................................................................3

Where to Find Answers ..................................................................................... 4

Warning, Caution, Note Defined .........................................................................4

Important Safety Instructions ............................................................................. 5

System Overview

Symbol Definition ............................................................................................. 6

Operating Instructions

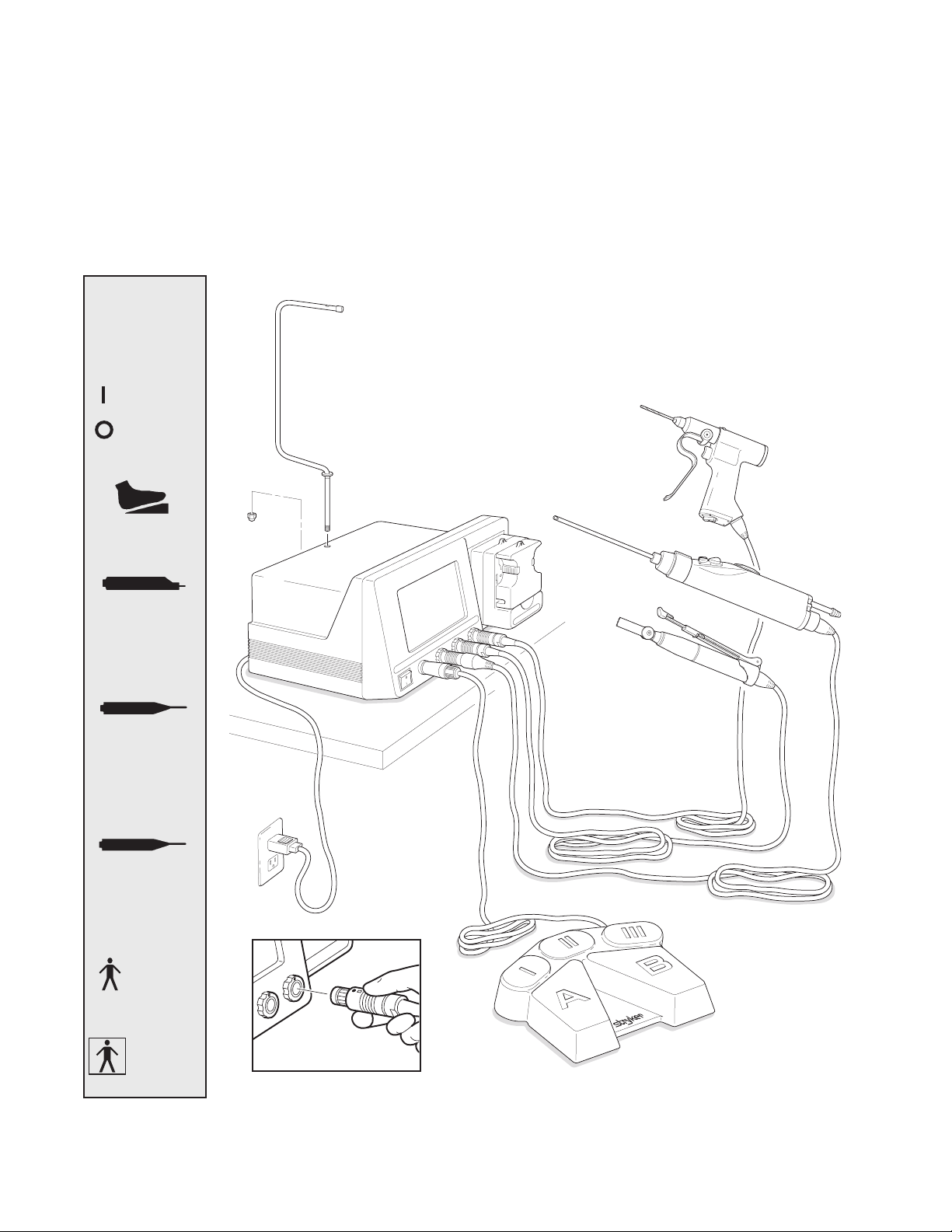

Connecting the Equipment ................................................................................7

The Control Screen

TPS Start-Up Screen

No Handpiece Detected Screen ..........................................................................8

Functions of the Control Screen

Elements of the Control Screen ..........................................................................9

Select Your System Settings

Standard Features ......................................................................................... 10

Quick Reference Guide (Icon Definition) ............................................................. 11

Handpiece Screens

Saw Handpiece Screen (TPS Oscillating and Sagittal Saws) ........................................... 12

Rotary Handpiece Screen

(TPS Universal and MicroDrills & TPS MicroDriver) ........................................................... 13

Stryker Endoscopy and Leibinger Handpiece Screen

(SE5 hand-controlled Endo Shaver, QuadraCut Shaver, QuadraCut Bone Plug,

and QuadraCut Small Joint, Hummer 4, Formula, 6K Micro, 12K Micro) .........................14

Other Screens

Main Option Screen ........................................................................................ 15

System Information Screen .............................................................................. 16

Handpiece Adjustment Screen ......................................................................... 17

Console Adjustment Screen ............................................................................. 18

Footswitch Adjustment Screen ......................................................................... 19

Footswitch Button Mapping Screen .................................................................. 20

Handpiece Button Mapping Screen................................................................... 21

Surgeon Preference Screen ............................................................................. 22

Messages and Error Messages ........................................................................ 23

Specifications................................................................................................ 24

Compliance Statements .................................................................................. 24

Declaration of Conformity ............................................................................... 25

Guidance and Manufacturer's Declarations .................................................... 26-28

Repair/Loaner Program

Limited Warranty ............................................................................................ 29

2

Page 3

Software License Notice

Stryker® TPS™ Surgical Tool System products contain software that is installed in the products by Stryker Corporation. Stryker Corporation owns

this software; this software is never sold. Each sale of a software containing product is not a sale of such software; it includes only a license to use

the software in the product in which the software was initially installed.

Any license granted by Stryker Corporation to use the software contained in its; products does not give the licensee the right to copy, alter,

disassemble, reverse engineer, create derivative works of such software or to use such software in either original or modified form in any product

other than the Stryker Corporation product in which the software was initially installed by Stryker Corporation.

© 2003, Stryker Corporation

3

Page 4

Where to Find Answers

When you have questions about your Stryker TPS products, there are several places to find the

answers.

In this book

Use this book to set up your system and select console options. This book also contains

information on system safety, repair, and component warranty.

............................................................................................................................................

In TPS component instructions

For answers to questions about any TPS handpiece, attachment, or component , see

the information supplied with that component. A copy of TPS Cleaning, Maintenance and

Sterilization Recommendations is also supplied with each component.

............................................................................................................................................

From your Stryker Sales Representative

If you can't find an answer in any of the materials provided or you have questions about

other Stryker Instruments products, call your Stryker Sales Representative.

............................................................................................................................................

From Stryker Customer Service

Please contact our Customer Service Department to order product information literature, a

cutting accessories guide, additional TPS maintenance manuals, and component instructions

by dialing 1-800-253-3210. Outside the U.S.A., contact your nearest Stryker subsidiary.

............................................................................................................................................

See the TPS Cleaning, Maintenance, and Sterilization Recommendations

booklet for care information.

Warning • Caution • Note

This symbol is used to alert the reader to important safety and precautionary information. When

displayed on the actual device, it refers the user to accompanying documents.

Please read this manual and follow all instructions carefully. The words WARNING, CAUTION and NOTE

carry special meanings and should be carefully reviewed.

WARNING: The personal safety of the patient and/or user may be involved. Disregarding this information

could result in injury to the patient and/or operating room staff.

CAUTION: These instructions point out special service procedures or precautions that must be followed

to avoid damaging the instrument.

NOTE: This provides special information to make maintenance easier or important instructions more

clear.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

WARNING: The personal safety of the patient and/or user may be involved. Disregarding this information could result in injury to

the patient and/or operating room staff. Read and understand the following warnings.

SYSTEM SAFETY

▪ Prior to each use, operate system components and inspect for

damage. DO NOT use if damage is apparent. Take special precautions regarding electromagnetic compatibility (EMC) when using

medical electrical equipment like the TPS Console. Install and

place the console into service according to the EMC information in

this manual. Portable and mobile RF communications equipment,

such as wireless phones, can affect the function of the console.

▪ Use only Stryker approved accessories. Other accessories may

result in increased emissions or decreased immunity of the system.

Contact your Stryker sales representative for a complete list of accessories. DO NOT modify any accessory. Failure to comply may

result in patient and/or operating room staff injury.

▪ DO NOT modify ground of power cord.

▪ Equipment not suitable for use in the presence of flammable anes-

thetic mixture with air or with oxygen or nitrous oxide.

▪ The Stryker Total Performance System is designed to be used by

persons familiar with surgical procedures. Misuse may cause injury

to both patient and system components. Prior to each use, system

components should be inspected for damage. DO NOT use if damage is apparent.

▪ Use only Stryker TPS components and accessories unless other-

wise specified.

▪ Clean and sterilize handpieces and accessories before first and

every use.

▪ Use of safety glasses by user and operating room staff is recom-

mended to prevent eye injuries.

HANDPIECE SAFETY

▪ Read this booklet and the information supplied with your TPS

components. Component instructions provide specific safety

information. Refer to the instructions supplied with Stryker

Endoscopy handpieces when using those handpieces in conjunction with the TPS console.

▪ DO NOT attempt to change a saw, bur, or drill while handpiece is

running.

▪ Stryker handpieces which fail due to long life and/or nose bearing

failure may allow foreign matter to migrate or emit from the distal

tip of the handpiece.

Fluid may leak into the surgical site, such that measures may be

required, per the physician's discretion, to protect the patient from

infection.

▪ Never rest handpiece on the patient. Improper handling of a hand-

piece could result in damage or burns to tissue.

▪ Do not place a TPS handpiece near or on a magnetic pad or tray.

The magnetic field can simulate a Universal Handswitch and may

cause the handpieces to run inadvertently.

▪ Burs and blades are intended for single use only.

▪ Excessive pressure, such as bending or prying, may cause acces-

sory to bend or break and cause tissue damage to patient and/or

operating room staff.

▪ Heavy sideloads and/or long operating periods occasionally will

cause overheating of the distal tip and the body of handpieces to

the point where the handpiece is uncomfortable to hold or causes

injury to the patient.

▪ If the recommended duty cycle is not followed, the handpiece may

overheat and cause injury to patient and/or operating room staff.

See the Duty Cycle information supplied with each handpiece.

▪ Excessive pressure, such as bending and/or prying with a bur, may

cause the bur to bend or fracture. If operated at a high speed, it is

possible that the bur will bend yet further. This could result in damage to tissue in the surgical site, handpiece vibration that causes

lost tactile control, or breakage of the bur such that the broken

piece would be ejected at a high velocity endangering the patient

and/or operating room staff. It is therefore recommended that

safety glasses be used.

▪ Excessive pressure, such as bending and prying with blade, may

cause the blade to bend or fracture and could result in damage to

tissue in the surgical site and/or loss of tactile control.

▪ If using a device with a safety lock, such as a MicroDriver or

Universal Handswitch, always place that device in the SAFE position

when not in use. IMPORTANT: Be aware that the TPS footswitch

will override the Universal Handswitch SAFE setting.

▪ Always use the appropriate accessory combination with a hand-

piece. Contact your Stryker sales representative for a complete

list of accessories. Failure to comply may result in patient and/or

operating room staff injury.

▪ Please note the handpiece starts with rapid acceleration when the

footswitch or handswitch is activated.

▪ During initial use of your TPS handpieces, monitor the heat

response in relation to the type of surgical procedure being

performed. Frequently check the distal tip and body until you are

familiar with its temperature rise characteristics. Failure to pay

close attention to handpiece temperature may cause burn injury to

patient.

▪ Operating a handpiece in the Window Jog mode may cause the

handpiece to overheat. If a handpiece overheats, the console

automatically turns off the handpiece. (The alarm does not sound

in this event.) Carefully monitor the operating time to prevent the

handpiece from overheating. Failure to comply may cause injury to

the patient and/or the operating room staff.

▪ DO NOT modify any bur to fit the handpieces. Use only Stryker

approved burs. Other burs may not fit properly in the handpiece.

During use they may come out of the handpiece or bend which

would result in damage to tissue in the surgical site due to loss of

control of the bur.

5

Page 6

System Overview

The Stryker Total Performance System is intended for use in the cutting, drilling, decorticating, and smoothing of bone and other

bone related tissue in a variety of surgical procedures. It is also used for the placement or cutting of screws, wires, pins, and other

fixation devices as it can be used to cut metal.

TPS console powers multiple handpieces while allowing the user to program a number of customized settings.

Symbol

Definition

Power ON

Power OFF

Footswitch

Connector

ENDO

Endoscopy

Handpiece Port

TPS1

TPS Handpiece

Port 1

TPS Handpiece

TPS Irrigation Console

Stryker Endoscopy

Handpiece

TPS Handpiece

with Universal

Handswitch

Handpiece

Cords

TPS2

TPS Handpiece

Port 2

Type B

Applied

Part

Type BF

Applied

Part

TPS Footswitch

Connection Detail

6

Page 7

Operating Instructions

WARNINGS:

▪ Before using this system read and understand the information in this manual and the instructions supplied with each TPS

component and Stryker Endoscopy handpieces. Pay close attention to the User/Patient Safety Information.

▪ Familiarization with the Total Performance System prior to use is important. If you have any questions, contact your Stryker

Instruments representative or Stryker Customer Service at 1-800-253-3210.

▪ Prior to use, system components should be operated and inspected for any damage. DO NOT use if damage is apparent.

Connecting the Equipment

This is a system overview. For specific instructions on each TPS component, refer to the

information supplied with the component.

1. Place your console on a sturdy, flat surface near a hospital grade outlet.

2. Plug the console's power cord into the recessed power socket on the back of the

console.

3. Plug the other end of the power cord into a hospital-grade wall outlet.

4. Turn on the console. The on/off switch is located on the front of the console.

NOTE: As you set up the system, the console's screen will change to indicate the various

components as they are plugged in.

5. If using a Footswitch, plug the footswitch cable into the console port marked

FOOTSWITCH. Align orientation marks and gently push connectors together.

CAUTION: All TPS Cords have push/pull connectors. Do not thread or twist for insertion or

removal.

6. Plug the handpiece cord(s) into the console port(s) identified for the handpiece. Align

connector orientation marks and gently push connectors together.

NOTE: Ports marked TPS1 and TPS2 are for Stryker TPS handpieces only.

The port marked ENDO is intended for the following list of Stryker Endoscopy handpieces:

SE5 Handpiece REF 272-704-100, SE5 Hand-controlled REF 272-704; QuadraCut Shaver

REF 275-701; QuadraCut Bone Plug REF 275-705; and QuadraCut small Joint REF 275-

601.

NOTE: If using a TPS Universal Handswitch, attach it to the handpiece before you plug the

cord into the handpiece.

WARNINGS:

▪ Portable and mobile RF communications

equipment can affect the TPS Console.

▪ The TPS Console should not be placed

adjacent to or stacked with other

equipment. If adjacent to or stacked, the

equipment must be observed to verify

normal operation.

7. Plug the other end of the handpiece cord(s) into the handpiece(s).

8. Attach cutting accessories to handpieces. Instructions supplied with each handpiece or

attachment provide details for cutting accessory assembly.

WARNING: Use only Stryker approved cutting accessories.

9. If using an Irrigation Console REF 5100-50, assemble Irrigation Pole REF 5100-50-28 to

the console as shown. Hang irrigation bag from pole. Install irrigation cassette into the

pump. Attach irrigation clips to handpieces and connect tubing.

10. Power the system and test the devices to ensure they are performing properly prior to

surgery.

7

Page 8

The Control Screen

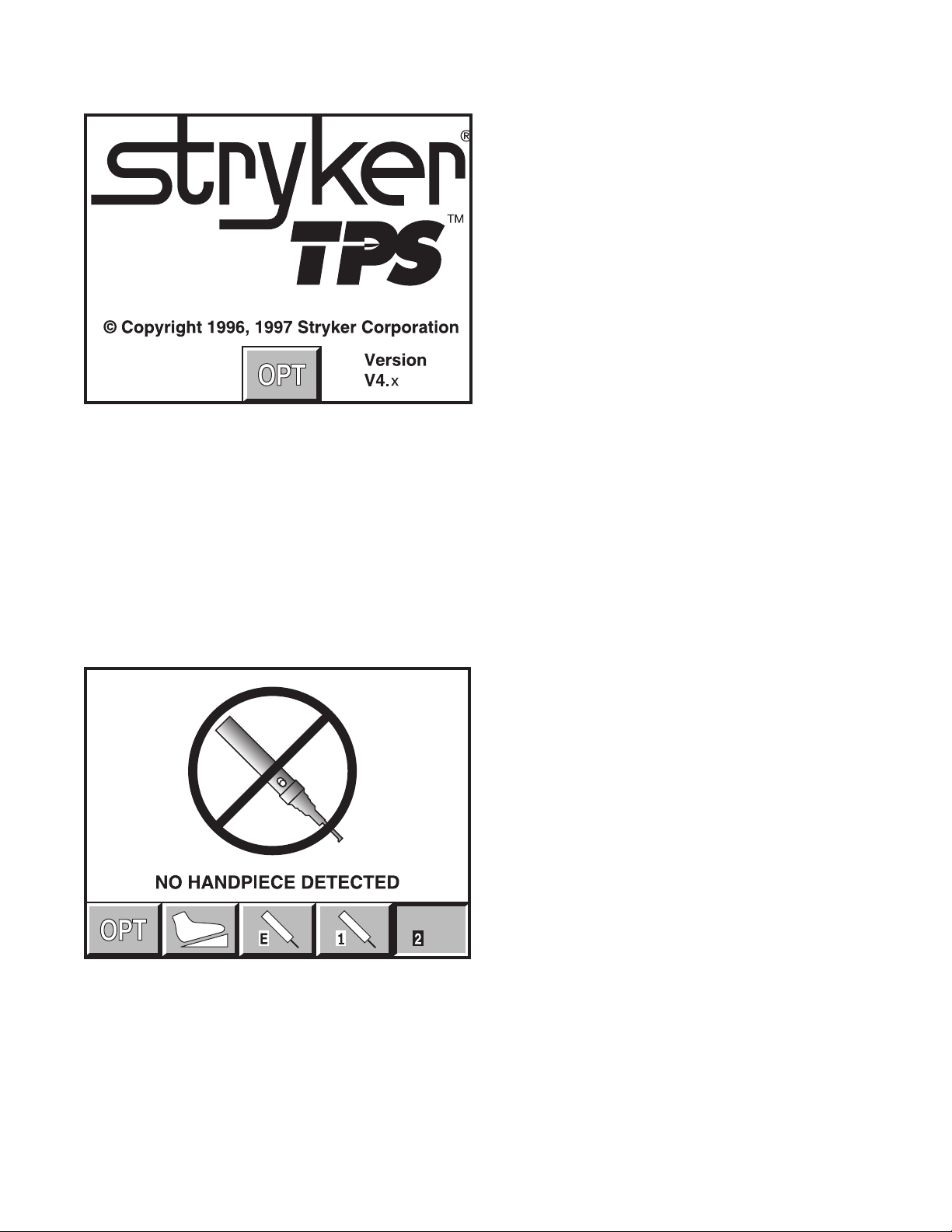

TPS Start-Up Screen

This display appears on the screen every time the

console is turned on.

This display remains on the screen until a cord is

plugged into one of the TPS handpiece ports or the

OPT button is depressed.

If a handpiece cord is plugged into a handpiece port

when the console is turned on, this display shows

momentarily before changing to either a no handpiece

detected screen or to the screen of the selected

handpiece.

This example shows that no handpiece is attached to the cord plugged into the

TPS2 port.

No Handpiece Detected Screen

This image indicates that no handpiece is attached to

the cord plugged into the selected port. The screen

will change to the handpiece screen when the missing

handpiece is connected to the cord.

NOTE: This screen will also appear if the console

is unable to recognize the handpiece. This could be

caused by a handpiece that is not compatible with the

TPS console, or a faulty or damaged handpiece or

cord.

8

Page 9

Functions of the Control Screen

The TPS console allows the user to select functions and settings such as handpiece selection, speed, and direction. Designed to

be easy to use and understand, the touch sensitive control screen allows you to set the system controls with the touch of a finger.

Interactive icons on the control panel represent system components and functions. The control screen also provides important

monitoring information for the selected handpiece.

Surgeon

Handpiece

identification

Attachment/

Blade

identification

preference

indicator

Handpiece

speed

Handpiece power

Indicator ramp

Select system

options screen

Footswitch

indicator and

options

Elements of the Control Screen

Control screen visually presents options which can be set for

the selected handpiece.

Icons represent elements of your TPS system. Icons are

functional buttons. Each function may be selected by pressing

the screen where the button is displayed. When you touch an

icon, the icon appears to be pressed down and the graphic

symbol highlights to indicate that it is activated. (See Icon

Definition).

NOTE: An audible signal indicates interface with icons.

NOTE: Buttons such as the adjust arrows or OPT button which

are temporary toggles or adjustment buttons only highlight while

depressed.

NOTE: Buttons with a white background are toggle buttons.

NOTE: Options vary among different handpieces. The console

will only display the options available for a given handpiece.

TPS handpiece

select buttons

Endo handpiece

select button

Handpiece identification displays the name of the active

handpiece. NOTE: Handpieces can be plugged into each of

the console's handpiece ports, but only one can be selected at

a time.

NOTE: When *CUSTOM* is displayed at the top of the screen,

the console's default settings are selected from Surgeon

Preferences. The console is able to capture the preferred

settings for several different users. When this feature is

activated, the preferred settings act as default settings. See

Surgeon Preference for further details.

Handpiece speed information displays the default speed for

each handpiece until you reset speed settings.

While the handpiece is running, the display shows the actual

handpiece speed. If the handpiece is not running the default or

selected speed is displayed.

NOTE: Incremental information displayed on the control screen is

accurate within +/-1%.

9

Page 10

Select Your System Settings

NOTE: When the console is turned on, its default setting

is factory default unless a Surgeon Preference setting is

selected as the start up default. See Surgeon Preference for

further details.

1. Handpiece select buttons enable you to activate the

handpiece plugged into one of the three ports on the

front of the console. To display the control screen for

the handpiece plugged into the TPS1 port, touch the

corresponding handpiece select icon. The icon highlights

and appears pressed down.

NOTE: Selecting a handpiece icon activates the

corresponding handpiece and displays its specific control

screen.

Standard Features

Main Option Icon

The option icon appears on all handpiece screens

and allows access to the MAIN OPTION screen. See

MAIN OPTION SCREEN for further details.

Footswitch Icon

2. Change the maximum handpiece speed. Press the

adjustment arrows to change the handpiece speed setting

incrementally until the desired speed is reached.

• Saws - The set point is displayed as a percentage of

maximum power and vertical line on the speed ramp. During

handpiece operation, the percentage reading and speed

ramp displays the power level.

• Rotary handpieces - The speed set point is displayed.

During handpiece operation, the current speed is displayed.

3. Select various settings as desired. Refer to the control

screens on the following pages for details for each

handpiece.

4. Select the OPT icon to access the MAIN OPTION screen.

This screen allows access to general console and user

settings as well as direct access to each handpiece option

screen.

NOTE: The screen returns to the active handpiece

adjustments screen when the handpiece name is touched.

5. Touch the EXIT icon to return to the active handpiece

control screen.

The footswitch icon only appears when a footswitch

is plugged into the console.

If using a footswitch with these graphics,

pedal functions can be reprogrammed.

See Footswitch Adjustments and Footswitch

Button Mapping.

A footswitch with these graphics

cannot be reprogrammed.

Handpiece Irrigation

Irrigation functions pertain only to Irrigation Console REF

5100-50.

Press the icon to start irrigation flow while the

handpiece is running.

If irrigation is desired while the handpiece is stopped, press and

hold the icon until the pump is activated. The pump can be turned

off by touching the icon again.

Irrigation flow rate can be adjusted from the HANDPIECE screen

or the HANDPIECE ADJUSTMENTS screen.

From the HANDPIECE screen, toggle the SPEED

icon to WATER before using the arrows to adjust

flow rate.

-OR-

From the HANDPIECE ADJUSTMENTS screen, select

the WATER icon and use the arrows to adjust flow

rate. Flow rate diminishes as the setting approaches

zero.

NOTE: Flow rate may vary among handpiece

models.

The pump can also be turned on and off with the footswitch.

10

Page 11

Quick Reference Guide

Icon Definition

Handpiece Select

This type of icon appears when

a cord (without a handpiece) is

plugged into the corresponding

Endo, TPS1 or TPS2 port.

It appears depressed when

selected.

The handpiece graphic appears

when a handpiece is attached to

the corresponding cord.

The handpiece graphic highlights

and the icon appears depressed

when selected.

System Options

Options: Gives access to

handpiece adjustments, system

information, console adjustments

and user preference.

Exit: Returns to previous screen.

Information: Displays system

information screen.

Console: Gives access to console adjustment screen.

Handpiece

option: Accesses

corresponding

handpiece adjustment

screens.

Footswitch Icon: Appears when

a footswitch is connected to the

console. Also gives access to

footswitch adjustments screen.

Adjustment Arrows: Use in conjunction with

other options to set handpiece speed or

power, braking, acceleration, irrigation flow,

screen contrast etc.

Increase

Decrease

Direction Arrows: Sets handpiece mode.

Forward (clockwise)

Reverse (counterclockwise)

Oscillate

Irrigation: Activates or de-

activates handpiece irrigation.

High: Enables handpiece to operate in a high speed mode.

Low: Enables handpiece to operate in a low speed mode.

Toggle Buttons

NOTE: For easy identification, only toggle buttons have a white background.

Speed: Use with the increase and

decrease icons to adjust rotary

handpiece speed.

Water: Use with the increase and

decrease icons to adjust irrigation

flow.

Power: Use with the increase

and decrease icons to adjust saw

power.

Variable: Handpiece speed

responds to varying degrees of

pressure on the footswitch or

handswitch.

Nonvariable: Handpiece operates

at constant set-point speed/power

level.

One touch: Handpiece is activated

by one touch of a trigger device

and continues to run when the trigger device is released. Handpiece

is deactivated by touching any

trigger device. In this mode, the

handpiece operates at constant

set-point speed/power level.

Allows access to the surgeon

preference screen.

NOTE: TPS Console REF 5100-1 does not display options related

to handpiece irrigation.

11

Advanced: - Accesses the

advanced footswitch mapping

screen.

Button: Access button mapping

screen.

Return to full screen: Return

from Big to full handpiece screen.

Page 12

Saw Handpiece Screen

TPS Oscillating and Sagittal Saws

POWER/WATER ADJUSTMENT

The power icon functions as a toggle switch

for power and water settings.

Power and irrigation adjustments are made

using the adjustment arrows.

As the power setting is reduced from 100%, a vertical bar

displays to correspond to the lower selected maximum

power.

This screen appears when a TPS saw is selected at the TPS1 port with the maximum

power set at 100%.

ENDO, TPS2 and the footswitch icons indicate other instruments are plugged into the

console.

The irrigation setting is not displayed on this screen.

However, it can be seen on the Handpiece Adjustments

screen.

METHOD OF OPERATION

Saws can be operated with the TPS Universal Handswitch

or TPS Footswitch.

Handswitch Handpiece selection can be made by

depressing the handswitch once. The handpiece select

icon changes to indicate the active handpiece. Depress

the handswitch again to run the handpiece.

Handpiece runs from start-up to the maximum selected

speed.

Footswitch Handpiece runs from start-up to the maximum

selected speed with either the forward or reverse pedal.

12

Page 13

Rotary Handpiece Screen

This screen appears when a TPS rotary handpiece is selected. The TPS Universal Drill is

plugged into the TPS2 port and the speed is set at 75,000 RPM.

ENDO, TPS1 and the footswitch icons indicate that other instruments are plugged into the

console.

SPEED/WATER ADJUSTMENT

The speed icon functions as a toggle switch

for speed and water settings.

Speed and irrigation adjustments are made

using the adjustment arrows.

DIRECTION OPTIONS

FORWARD Clockwise

REVERSE Counterclockwise

OSCILLATE

TPS Universal and Micro Drills

METHOD OF OPERATION

The Universal Drill can be operated with the TPS Universal

Handswitch or TPS Footswitch.

Handswitch Handpiece selection can be made by depressing the

handswitch once. The handpiece select icon changes to indicate

the active handpiece. Depress the handswitch again to run the

handpiece.

Handpiece runs from start-up to the maximum selected speed.

Speed and cutting direction corresponds to what is selected on the

screen.

Footswitch Handpiece runs from start-up to the maximum

selected speed.

Handpiece direction is controlled by selecting the forward or

reverse pedals. The direction icon on the screen changes when

the corresponding footswitch pedal is depressed.

TPS MicroDriver and Universal Driver

METHOD OF OPERATION

The TPS MicroDriver can be operated with its builtin trigger and rotary control switch or with the TPS

Footswitch.

NOTE: The handpiece will not run when the rotary switch

is in the SAFE position.

Trigger The built-in speed control trigger(s) runs the

handpiece from start-up to the maximum selected speed.

MicroDriver only: Select cutting direction with the rotary

switch on the handpiece. Direction icon will highlight to

match the rotary switch position.

Universal Driver only: Select cutting direction by

depressing either the forward trigger or the reverse

trigger. Squeezing both triggers simultaneously runs the

handpiece in the oscillate mode. The oscillate icon will

become highlighted.

Footswitch Handpiece runs from start-up to the

maximum selected speed.

The direction icon on the screen changes when the

corresponding footswitch pedal is depressed.

Footswitch operation overrides handpiece settings.

Example: If the footswitch reverse pedal is depressed

while the handpiece rotary switch is set in forward,

the handpiece operates in the reverse direction and

the reverse icon highlights. However, after the pedal is

released, the direction icon will revert to the direction set

on the rotary switch.

13

Page 14

The Stryker Endoscopy and Leibinger Handpiece Screen

This screen displays the cutter nomenclature only if the

handpiece and cutter being used contain cutter recognition

capabilities.

Depress the mode icon and set the maximum speed using

the adjustment arrows. Speed settings are individually

selected for each mode.

Default speed settings and incremental steps are specific to

each handpiece.

MODES

Operation in high speed mode.

This screen appears when a Formula handpiece with cutter recognition is selected. The

oscillate mode is selected and Set Speed is set at 1,800 RPM.

TPS1, TPS2 and the footswitch icons indicate that other instruments are plugged into the

console.

The Stryker Leibinger Hummer4 REF 5290-601-100 and Stryker

Endoscopy Formula REF 375-701-500 provide cutter recognition

capabilities.

WARNING: Read and understand the

Stryker Endoscopy handpiece instructions.

If instructions were not supplied with your

handpiece, refer to the appropriate Stryker

Endoscopy Operating and Maintenance Manual

listed below.

Handpiece Manual

272-704 1000-400-120

275-701 1000-400-034

275-705 1000-400-034

275-601 1000-400-034

290-601 1000-400-288

IMPORTANT INFORMATION

The hand-controlled Endo Shaver can be

controlled by the footswitch or by the hand-control

buttons built into the handpiece.

Operation in oscillate mode.

Operation in low speed mode.

When a cutting accessory with cutter recognition

capabilities is installed, the system may override selected

speed settings within each mode to more appropriate speed

settings for that particular cutting accessory.

The handpieces listed here do not have cutter

recognition capabilities.

14

Page 15

Main Option Screen

Select the OPT icon to access the MAIN OPTION screen.

This screen allows direct access to the handpieces attached

to the console, console and user settings, and system

information.

OPTION 1, 2, and E icons appear only when handpieces are

plugged into the corresponding console ports. A handpiece

must be plugged in to program its settings.

To go to the HANDPIECE ADJUSTMENT screen, touch the

option button that corresponds to the desired handpiece.

Refer to HANDPIECE ADJUSTMENT.

The MAIN OPTION screen also gives DIRECT access to:

Refer to SURGEON PREFERENCE.

Refer to CONSOLE ADJUSTMENT.

Refer to SYSTEM INFORMATION.

EXIT: Return to handpiece screen.

15

Page 16

System Information Screen

Selecting the INFO icon from the MAIN OPTION menu

displays the part numbers and revision levels of the

configured system components.

This information is used as a diagnostic aid only.

Return to the MAIN OPTION screen.

16

Page 17

Handpiece Adjustment Screen

Select a Handpiece Option icon from the MAIN OPTION

screen to access this screen.

NOTE: For quick access to this screen, touch the handpiece

title displayed at the top of any handpiece screen. And return

to the handpiece screen by touching the handpiece title displayed on this screen.

Depending on the type of handpiece, one or more of the

following options will be available.

Select BRAKE, ACCEL, TURNS or WATER then press the

arrow icons to change the setting.

Brake: At 100%, the handpiece stops abruptly.

Deceleration slows as the setting nears zero.

Accelerate: At 100%, handpiece speed accelerates

quickly. Acceleration slows as the setting

approaches zero.

Turns: Use to set the number of turns per direction

when running a handpiece in the oscillate mode.

The minimum setting will set the oscillate function

to operate in a TIME-BASED mode where the

number of turns are based on the speed of the

handpiece.

ATTACHMENT: Use the arrow icon on the left to scroll

through the list of attachments. Select the attachment that is

assembled to the handpiece by stopping on it.

Selecting the proper attachment will optimize the performance

of the handpiece for the attachment and display the appropriate

speed scale on the handpiece screen.

RUN MODE: Use the RUN MODE toggle button to scroll

through the options and stop on the desired setting.

Variable: Handpiece speed responds to the degree

of pressure applied to the handswitch.

Nonvariable: Handpiece speed runs at the

maximum setting only. Varying pressure on the

handswitch does not vary the handpiece speed.

One touch: Toggle the handpiece on and off with

a single touch of a trigger device. The trigger

device can be the handswitch or handpiece trigger

buttons.

BUTTON: See Handpiece Button Mapping.

Water: At 100%, irrigation volume is greatest.

Volume decreases as the setting approaches zero.

FOOTSWITCH: Activates FOOTSWITCH

ADJUSTMENTS. See Footswitch Adjustments.

17

Page 18

Console Adjustment Screen

Select the CONSOLE ADJUSTMENTS icon from the MAIN

OPTION screen to access this screen.

Select CONTRAST, BRIGHTNESS or VOLUME then press

the arrow icons to change the setting.

Contrast: Screen contrast lightens at

higher settings. The chosen setting

remains until reset.

Brightness: Screen brightness intensifies

at higher settings.

Volume: The audible signal is louder at

higher settings.

Use the BIG SCREEN toggle button to select one of the

following options.

Automatic: A big screen is displayed while the

handpiece is running and automatically returns

to the full screen when handpiece stops.

On: The big screen is continuously displayed.

It can be temporarily switched back to the

full screen by touching the Full Screen icon

which appears in the lower right corner of each

handpiece screen. See example of screens

below.

Off: The big screen option is turned off. Only a

full screen is displayed.

Example of full screen.

Example of big screen.

18

Page 19

Footswitch Adjustment Screen

This screen appears only when using a TPS Footswitch that is

Revision 3 or newer. See Standard Features.

NOTE: The Footswitch revision is displayed on the SYSTEM

INFORMATION screen.

Access this screen by selecting the Footswitch icon on the

HANDPIECE CONTROL SCREEN or HANDPIECE ADJUSTMENTS

screen.

NOTE: These footswitch settings function only for the handpiece

for which they were selected. The handpiece is identified at the top

of the screen.

From this screen, the default functions of footswitch pads A and B

can be reprogrammed to accommodate the surgeon's preferences.

The left and right toggle icons correspond respectively to

footswitch pads A and B. Press each icon to scroll through the

following function options and stop on the desired setting.

Off: Pedal is turned off.

Default: Footswitch defaults to the settings selected on

the handpiece screen.

Forward: Pedal setting default is overridden.

Pedal will provide handpiece rotation in the forward

(clockwise) direction.

Reverse: Pedal setting default is overridden.

Pedal will provide handpiece rotation in the reverse

(counterclockwise) direction.

Advanced: Use to access the Footswitch Button

Mapping screen. It will allow you to reprogram all the

footswitch pedals.

Return: Return to the previous screen.

19

Page 20

Footswitch Button Mapping Screen

Access this screen by selecting the ADVANCED icon on the

FOOTSWITCH ADJUSTMENTS screen. The default functions

of each footswitch pedal and button can be reprogrammed to

accommodate the surgeon's preferences.

Depending on the type of handpiece displayed at the top of the

screen, one or more of the following options will be available on

this screen.

The DIRECTION, OP MODE, and RUN MODE icons

correspond respectively to the two largest footswitch pedals.

Press each icon to scroll through the following function

options. And stop on the desired function setting.

DIRECTION

Pedal is turned off.

Footswitch defaults to the settings selected on the

handpiece screen.

Forward: Pedal setting default is overridden. Pedal

will provide handpiece rotation in the forward

(clockwise) direction.

Reverse: Pedal setting default is overridden. Pedal

will provide handpiece rotation in the reverse

(counterclockwise) direction.

OP MODE

Footswitch defaults to the settings selected on the

handpiece screen.

Handpiece operates in the high speed range.

Handpiece operates in the low speed range.

Handpiece operates in oscillate mode.

RUN MODE

Footswitch defaults to the settings selected on the

handpiece adjust screen.

Variable: Variable speed control. Speed responds

to varying degrees of pressure on the footswitch.

BUTTON FUNCTION

The I, II, and III icons correspond to the three small pads across

the top of the footswitch.

Button Function displays the active function of the

corresponding button.

Use the arrow icons to scroll through the functions and stop on

the desired setting.

See Button Functions listed on next page.

Reset all: Press to return all pedals and buttons

back to their default setting.

Reset: Press to return the selected footswitch

button back to its default setting.

Nonvariable: Handpiece operates at a constant

speed level determined by the maximum speed

selected from the handpiece screen.

One touch: The one touch function is similar to an

on/off toggle. Tap the footswitch to operate the

handpiece at the maximum speed selected from

the handpiece screen. Tap any trigger device

again to stop operation.

20

Page 21

Handpiece Button Mapping Screen

Access this screen from the Handpiece Adjustment screen.

Use it to change handpiece button functions.

Depending on the features of the handpiece, as many as

five buttons can be reprogrammed. Identify corresponding

button numbers by pressing the buttons on the handpiece.

When the handpiece button is selected, the corresponding

function is displayed on the screen. Use the arrow icons

to scroll through the function options. Stop on the desired

option. See the list below for a description of the options.

NOTE: Available options are handpiece specific.

BUTTON FUNCTIONS

Reset: Select to return a single button to its

default function.

Reset all: Select to return all buttons to their

default functions.

Return: Return to previous screen.

Button Function Description

Main trigger Starts handpiece in default direction

FWD trigger Starts handpiece in forward direction in

REV trigger Starts handpiece in reverse direction in

OSC trigger Starts handpiece in oscillate mode.

Speed increment Increments the set point speed.

Speed decrement Decrements the set point speed.

Water increment Increments the pump flow set point.

Water decrement Decrements the pump flow set point.

Water on/off Toggles the pump on/off button. If

and mode.

default mode.

default mode.

pressed and held, the pump can

be turned on without running the

handpiece. Once started, the pump

can be stopped by pressing the button

again or by starting the handpiece.

Button Functions List

Button Function Description

Osc <> High/low Toggles the run mode between oscillate and

high or low.

High <> Low Toggles the run mode between high and low.

Forward <> Reverse Toggles the running direction.

Change port Changes the active handpiece port.

Change attachment Scrolls through the attachment list for the

selected handpiece.

Pump flush Turns the pump on at the flush rate. Once

started the pump can be stopped by pressing

the button again or by starting the handpiece.

Make port active Makes the selected handpiece active.

Window jog Slowly rotates the inner cutter for positioning

within the outer cutter's window.

WARNING: Operating a handpiece in the Window Jog

mode may cause the handpiece to overheat. If a

handpiece overheats, the console automatically turns

off the handpiece. (The alarm does not sound in this

event.) Carefully monitor the operating time to prevent the

handpiece from overheating. Failure to comply may cause

injury to the patient and/or the operating room staff.

21

Page 22

Surgeon Preference Screen

Access the SURGEON PREFERENCE screen from the MAIN OPTIONS

screen.

The console is able to capture and store the preferred settings of

different surgeon's.

There are three options:

• Factory default settings

• Settings saved by a previous surgeon

• Collection and storage of new settings

Using factory settings

1. Use the arrows to obtain "Stryker" and "Factory Default."

NOTE: The EDIT, DELETE and padlock icons do not function while

factory default settings are selected.

Using the settings saved by a previous user

1. Use the arrows to select the surgeon and procedure.

2. Select LOAD. Screen returns to the MAIN OPTION screen.

3. Proceed with surgery.

Collect and store preferred settings

1. Select NEW. The editor screen will appear with the selected

surgeon's name.

2. To create a new procedure under this surgeons name, select

ENTER. Or if you wish to collect and store settings under a new

This is the key pad screen used to

enter the doctor's name and name of

procedure.

surgeon name, use the key pad to delete (DEL) the existing name

then key-in the new name. Upon completion, select ENTER.

3. Use the key pad to enter the procedure name.

4. Upon completion, select ENTER. The screen returns to the

SURGEON PREFERENCE screen.

5. Toggle padlock icon so that the padlock appears open.

6. Select LOAD.

7. Configure system settings.

8. Upon completion, return to the SURGEON PREFERENCE screen.

9. Toggle the padlock icon so that the padlock appears locked.

Padlock opened to gather preferences.

Padlock closed to store preferences.

NOTE: If the padlock icon remains in the unlocked position, the

selected settings will be continuously updated with current settings.

Select to add a surgeon name.

Select to change the doctor name and/or procedure.

NOTE: Toggle the UPPER/LOWERCASE pad on the editor

screen to select letter case.

Delete: Select to delete the currently displayed file.

Select and use with the open padlock to gather (load) new

preference settings.

Default: Using the arrows, scroll the SURGEON

PREFERENCE screen to the desired surgeon and

procedure settings before activating DEFLT. This selection

becomes the default power on setting for the system until

a different selection is made.

22

Page 23

Messages

Message If you select OK to this question:

Delete all the surgeon's procedures?

Change the name of all the surgeon's Procedures listed under the surgeon will be moved under

procedures?

Identical record found.

Maximum number of records exceeded. Please delete inactive records.

Initializing console hardware. Please wait.

Handpiece has reached recommended service interval. Please return for service at earliest convenience.

Handpiece does not support the selected preference. Default handpiece setting will be used.

Handpiece temperature has exceeded its nominal operating range and may cause burning.

Handpiece temperature has exceeded its operating range. Allow to cool before restarting.

Procedure name unspecified.

Ensure handpiece speed does not exceed specified attachment limitations. Failure to do so may result in user and/or patient injury.

Cutter/bur is not compatible with the current handpiece.

Cutter/bur has exceeded its life. Please replace with a new cutter/bur.

The surgeon ID and all procedures will be deleted.

the current surgeon's name.

Error Messages

Message Action to Take

Error 001. Console hardware fault detected. Return console to Stryker for repair.

Error 002. Console hardware fault detected. Turn unit off and on again. If problem persists, return

Contact your Stryker service representative. console to Stryker for repair.

Error 003. Console hardware fault detected. Turn console off and on again. If problem persists, return

Contact your Stryker service representative. console to Stryker for repair.

Error 004. Footswitch fault detected, right pedal will be disabled. Unplug Footswitch from console and plug in again.

Contact your Stryker service representative. If problem persists, return footswitch to Stryker for repair.

Error 005. Footswitch fault detected, left pedal will be disabled. Unplug Footswitch from console and plug in again.

Contact your Stryker service representative. If problem persists return footswitch to Stryker for repair.

Error 006. Footswitch unreadable. Unplug Footswitch from console and

Contact your Stryker service representative. plug in again. If problem persists,

return footswitch to Stryker for repair.

Error 007. Handpiece fault detected, handpiece triggers will be Unplug cord from handpiece and plug in again.

disabled. Contact your Stryker service representative. If problem persists, return handpiece to Stryker for repair.

Error 008. Handpiece unreadable. Unplug handpiece from console and plug in again.

Contact your Stryker service representative. If problem persists, return handpiece Stryker for repair.

Error 009. Handpiece requires additional console hardware. Call your Stryker Instruments sales representative.

Contact your Stryker service representative.

Error 010 Handpiece requires additional console hardware. Call your Stryker Instruments sales representative.

Contact your Stryker service representative.

Error 011 Handpiece requires additional console hardware. Call your Stryker Instruments sales representative.

Contact your Stryker service representative.

Error 012 Cutting accessory requires additional console hardware. See the instructions supplied with the cutting accessory.

The Total Performance System is not field repairable. In case of operating difficulties, Stryker products must be returned for maintenance or repair.

23

Page 24

Specifications

Models: 5100-1 & 5100-1A TPS Console

5100-50 & 5100-50A TPS Irrigation Console

Size: 11.8 in. [299 mm] width

7.0 in. [179 mm] height

9.0 in. [229 mm] depth

12.2 in. [310 mm] depth (units with irrigation pump)

Weight: 9 lbs. [4.1 Kg]

14.1 lbs. [6.4 Kg] (units with irrigation pump)

Electrical: 100-120VAC, 50-60Hz, 6.0A

220-240VAC, 50Hz, 3.0A

Approval:

CSA International

• UL 60601-1

• CAN/CSA-C22.2 No. 601.1 M90

• IEC 60601-1

Handling your console and equipment

• When setting up your console, place on a sturdy, flat surface, and

carefully follow all setup instructions.

• When connecting or disconnecting a cable, always hold the cable by

its connector (the plug, not the cord).

• Never force a connector into a port. If the connector and port do

not join with reasonable ease, they probably don't match. Make sure

that the connector matches the port and that you have positioned the

connector correctly in relation to the port.

• To ensure the longevity, performance, and safety of this equipment,

package in original package materials when storing or transporting.

If the console experiences sporadic electrical interference:

Class I

PORT TYPE SYMBOL

Endo B

TPS1 BF

TPS2 BF

IPX0 Ordinary Equipment

Protective Earth Ground

Duty Cycle: Continuous operation with

intermittent loading

Refer to cycle times defined in the

TPS handpiece instructions.

Environmental Conditions

These conditions apply to all components of the TPS system unless

otherwise specified in the information supplied with that device.

Environmental Conditions: Operation Storage and Transportation

Temperature:

Relative humidity:

Atmospheric Pressure:

• Turn off all electrical equipment not in use in the operating room.

• Relocate electrical equipment; increase spacial distance.

• Plug the TPS console and other operating room equipment into different

outlets.

Compliance Statements

Federal Communication Commission FCC ID: Q9R-5100

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference

that may cause undesired operation.

Note that FCC regulations provide that changes or modifications

not expressly approved by Stryker

Instruments could void your authority to operate this equipment.

24

Specifications listed are approximate and may vary slightly from unit to

unit or by power supply fluctuations.

IC: 4919A-5100

The term "IC:" before the radio certification

number only signifies that Industry Canada

technical specifications were met.

Page 25

R&TTE Declaration of Conformity (DoC)

We, Name of company: Stryker Instruments

Address:

Authorized Representative: Jean-Yves Carentz

Contact Detail of Authorized Representative: Stryker France, ZAC Satolas Green Pusignan,

Av. de Satolas Green, 69881 MEYZIEU Cedex, France

declare under our sole responsibility that the product:

Product Name: Total Performance System

Trade Name: Stryker Instruments

Type or Model:

Relevant supplementary information: EN/IEC 60601-1-2:2001 & EN 301-489-3:EN 300 330-2 v1.1.1

to which this declaration relates is in conformity with the essential requirements and other relevant requirements of the R&TTE

Directive (1999/5/EC).

The product is compliant with the following standards and/or other normative documents:

SAFETY (art 3.1.a): IEC 60601-1:1995 Medical Electrical Equipment

EMC (art 3.1.b): EN 301 489-3 v1.3.1 Specific Conditions for Short-Range Devices (SRD) operating on frequencies between 9 kHz

and 40 GHz.

SPECTRUM (art 3.2): EN 300 330-2 v1.1.1 Harmonized EN Covering Essential Requirements Under Article 3.2 of the R&TTE Directive

OTHER: ANSI C95.1 Safety Levels with Respect to Human Exposure to RF Electromagnetic Fields 300 kHz to 300 GHz

4100 East Milham Avenue, Kalamazoo, Michigan 49001-6197

5100-1 Console; 5100-50 Irrigation Console

Supplementary information: None

Notified Body involved: TUV Rheinland Product Safety (GmbH)

Technical file held by: Stryker Instruments

Place and date of issue (of this Doc): Kalamazoo, Michigan USA, January 2004

Signed by or for the manufacturer:

Name (printed): Paul Freestone

Title: Director, Regulatory Affairs, Quality Assurance

Hereby, Stryker Instruments, declares that this Short Range Device is in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

25

Page 26

Guidance and manufacturer's declaration - electromagnetic emissions

The TPS Console is intended for use in the electromagnetic environment specified below. The customer or the user of the TPS Console should

Emissions test

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/

flicker emissions

IEC 61000-3-3

Frequency of transmission: 13.56MHz Subcarrier: 423.75kHz

Manchester coding

Type of Frequency/

Characteristics of the modulation: 10% ASK Effective radiated power: 50µW

assure that it is used in such an environment.

Compliance

Group 1

Class B

Class A

Complies

The TPS Console uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely to cause

The TPS Console is suitable for use in all establishments, including

domestic establishments and those directly connected to the public

low-voltage power supply network that supplies buildings used for

Electromagnetic environment - guidance

any interference in nearby electronic equipment.

domestic purposes.

26

Page 27

Guidance and manufacturer's declaration - electromagnetic immunity

The TPS Console is intended for use in the electromagnetic environment specified below. The customer or the user of the TPS Console should

Immunity test

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

150 kHz to 80 MHz

80 MHz to 2.5 GHz

assure that it is used in such an environment.

IEC 60601

test level

3 Vrms

3 V/m

Compliance level

3 Vrms

Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to any part

of the TPS Console, including cables, than the

recommended separation distance calculated

from the equation applicable to the frequency of

the transmitter.

Recommended separation distance

d=1.67√P

d=1.67√P

80 MHz to 800 MHz

3 V/m

d=2.33√P

800 MHz to 2.5 GHz

Where P is the maximum output power rating

of the transmitter in watts (W) according to

the transmitter manufacturer and d is the

recommended separation distance in meters (m)

Interference may occur in the vicinity of equip-

ment marked with the following symbol:

NOTE 1: At 80 MHz and 800MHz the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures,

objects and people.

27

Page 28

Guidance and manufacturer's declaration - electromagnetic immunity

The TPS Console is intended for use in the electromagnetic environment specified below. The customer or the user of the TPS Console should

assure that it is used in such an environment.

Immunity test

IEC 60601

Compliance level

Electromagnetic environment - guidance

test level

Electrostatic discharge (ESD)

±6 kV contact

±6 kV contact

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic

IEC 61000-4-2

±8 kV air

±8 kV air

material, the relative humidity should be at

least 30%.

Electrical fast transient/burst

±2 kV for power supply lines

±2 kV for power supply lines

Mains power quality should be that of a

typical commercial or hospital environment.

IEC 61000-4-4

Surge

±1kV for input/output lines

±1 kV differential mode

±1 kV for input/output lines

±1 kV differential mode

Mains power quality should be that of a

typical commercial or hospital environment.

IEC 61000-4-5

Voltage dips, short

interruptions and voltage

variations on power supply

input lines

IEC 61000-4-11

±2 kV common mode

<5% U

(>95% dip in UT )

T

for 0,5 cycle

40% U

(60% dip in UT)

T

for 5 cycles

70% UT

±2 kV common mode

95% Reduction (10ms)

60% Reduction (100ms)

30% Reduction (500ms)

Mains power quality should be that of a

typical commercial or hospital environment.

If the user of the TPS Console requires

continued operation during power mains

interruptions, it is recommended that the TPS

Console be powered from an uninterruptible

power supply or a battery.

(30% dip in UT)

for 25 cycles

<5% U

(>95% dip in UT )

T

95% Reduction (5s)

for 5 sec

Power frequency

(50/60 Hz)

magnetic field

3 A/m

3 A/m

@ 50Hz

CRT 1A/m

Power frequency magnetic fields should be at

levels characteristics of a typical location in a

typical commercial or hospital environment.

IEC 61000-4-8

NOTE: UT is the a.c. mains voltage prior to application of the test level.

Recommended separation distances between portable and mobile RF communications equipment and the TPS Console

The TPS Console is intended for use in the electromagnetic environment in which radiated RF disturbances are controlled. The customer or

the user of the TPS Console can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile

RF communications equipment (transmitters) and the TPS Console as recommended below, according to the maximum output power of the

Separation distance according to frequency of transmitter

m

Rated maximum output power of

150 kHz to 80 MHz

80 MHz to 800 MHz

800 MHz to 2.5 GHz

transmitter

W

0.01

0.1

1

3.5

d = [ — ]√P

V

1

0.12

0.37

1.17

3.5

d = [ — ]√P

E

1

0.12

0.37

1.17

7

d = [ — ]√P

E

1

0.23

0.74

2.33

10

100

3.70

11.70

3.70

11.70

7.37

23.30

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using

the equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according

to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800MHz, the separation distance for the higher frequency range applies.

28

Page 29

Repair and Loaner Program

This service is available in the United States only. Outside the U.S.A., contact your Stryker sales representative or your nearest

subsidiary listed on the last page.

On request, Stryker Instruments will provide a loaner unit for your use while repairs are being made.

Please clean and sterilize all potentially contaminated products being sent in for repair, credit, or return of a loaner unit. The

policy of Stryker Instruments is not to accept or process potentially contaminated products which do not meet this requirement.

Also, please be aware that it is unlawful to transport bio-contaminated products through interstate commerce which are not

properly packaged and labeled as such.

1. Contact Stryker Customer Service at 1-800-253-3210 to request a loaner. Provide a name and address for shipping. Every

effort will be made to send a loaner unit immediately.

2. Send the inoperative unit to Stryker with a purchase order number of authorization for repair. The order should explain the

nature of the difficulty. Also, provide a name and address for shipping the repaired instruments.

Return the inoperative unit to: Stryker Instruments

Repair Department

4100 E. Milham

Kalamazoo, Michigan, 49001.

3. The repaired unit will be shipped back and the repair invoice will follow under separate cover. Under most conditions, repair

turnaround time will be approximately 2-3 weeks.

4. As soon as your repaired unit is returned, return the loaner to Stryker Instruments.

Limited Warranty

For all TPS products unless otherwise specified.

In the U.S.A. only, products of Stryker Instruments are warranted to the original purchaser for a period of one year from the date of purchase, with

exceptions noted below. Products are warranted to be free from defects in material and workmanship. Abnormal wear and tear or damage caused by

misuse or by failure to perform normal and routine maintenance as set out in the Maintenance Manual or Operating Instructions, or as demonstrated by

an authorized Stryker Instruments representative, is not covered by the warranty. Any effort at field repair or adjustment may invalidate your warranty.

The warranty extends to all purchasers and is limited to the repair or replacement of the product without charge when returned prepaid to Stryker

Instruments. There are no other expressed warranties. This warranty gives you specific legal rights and you may have other rights which vary by state

and municipality.

For selected products.

• Universal Handswitch is warranted for a period of 6 months from date of invoice.

• Handpiece cords are warranted for a period of 6 months from date of invoice.

• Cutting accessories are not warranted.

29

Page 30

303132

Page 31

Page 32

4100 E. Milham

Kalamazoo, Michigan

(USA) 49001

1-800-253-321

1-269-323-7700

European Authorized Rep:

RA/QA Manager

Stryker France

ZAC Satolas Green Pusignan

Av. de Satolas Green

69881 MEYZIEU Cedex

European equiv. 5100-001-712

Japanese equiv. 5100-001-720

N. European equiv. 5100-001-733

Polish/Greek Equiv. 5100-001-750

France

Loading...

Loading...