Page 1

IMPORTANT

File in your

maintenance

records

Stryker Adelt Maternity Bed

Models 4700 & 5012

MAINTENANCE MANUAL

For Parts or Technical Assistance

1-800-327-0770 (option 2)

Page 2

Table of Contents

Introduction

Specifications 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning / Caution / Note Definition 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Tips And Guidelines 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking Instructions 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-Up Procedures 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bed Symbols and Illustration 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 13, 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventative Maintenance Checklist 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static Discharge Precautions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Information

Steer Wheel Cable Adjustment 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Motor Removal and Replacement 18, 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Motor Removal and Replacement 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler In/Out Motor Removal and Replacement 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Motor Removal and Replacement 20, 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Motor Removal and Replacement 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Board Replacement 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

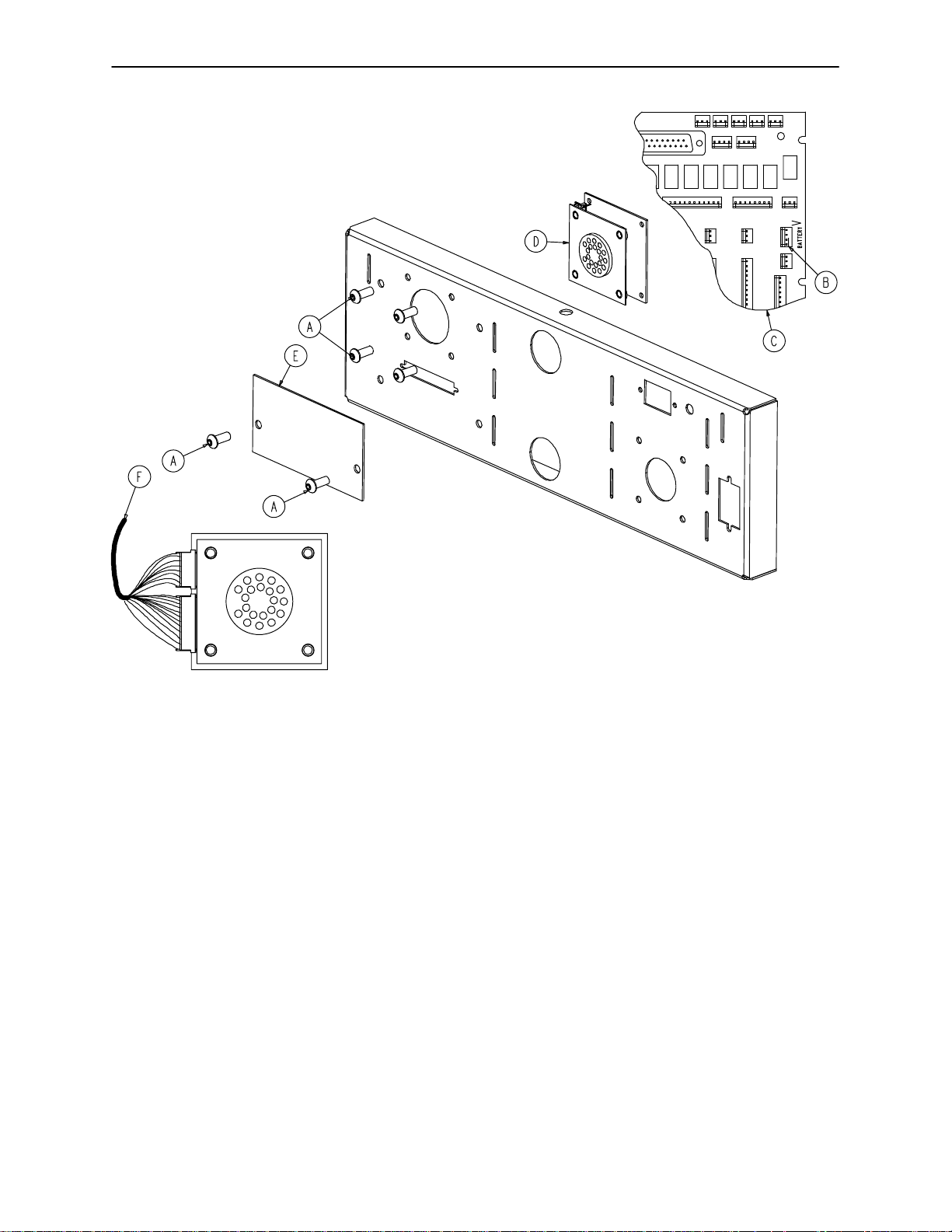

CPU Board Replacement 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Power Board Replacement 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift, Foot, And Fowler Calibration Procedure 23,24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smart TV Interface Burn-In Procedure 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Guide 26-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bed Circuit Boards 29-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Wall Output Configuration 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU/Headwall Jumper Configurations 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bed Communications Tester 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts List 38, 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly Drawings and Parts Lists

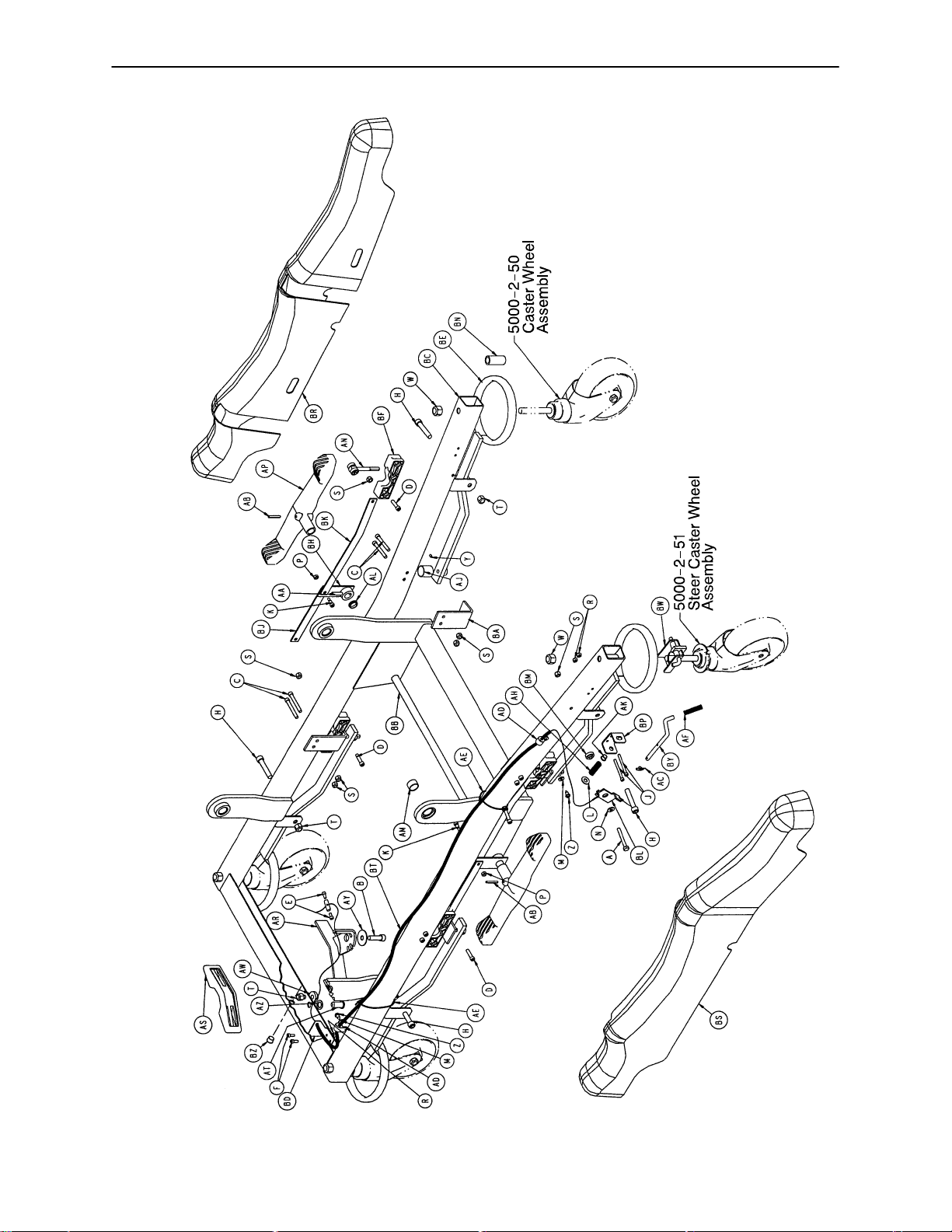

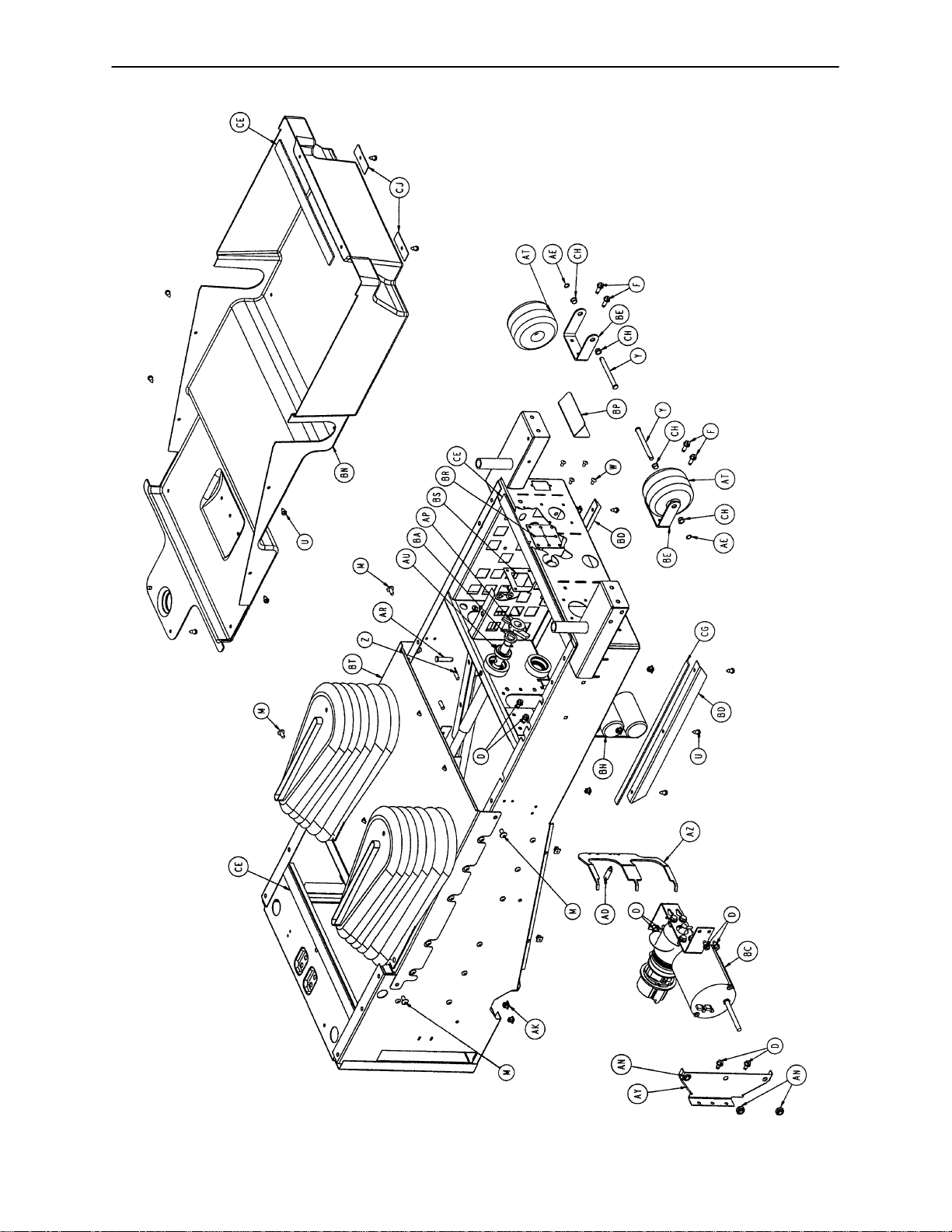

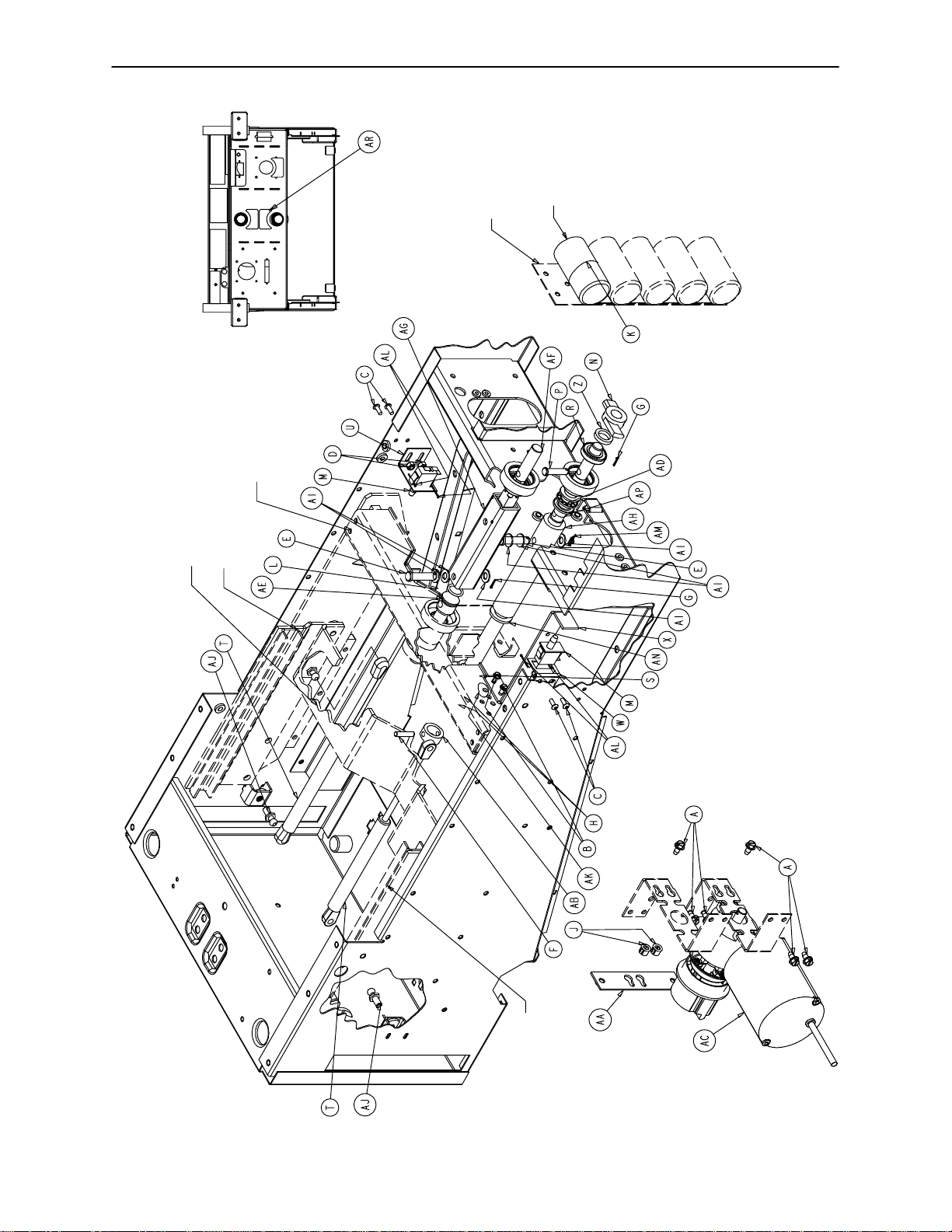

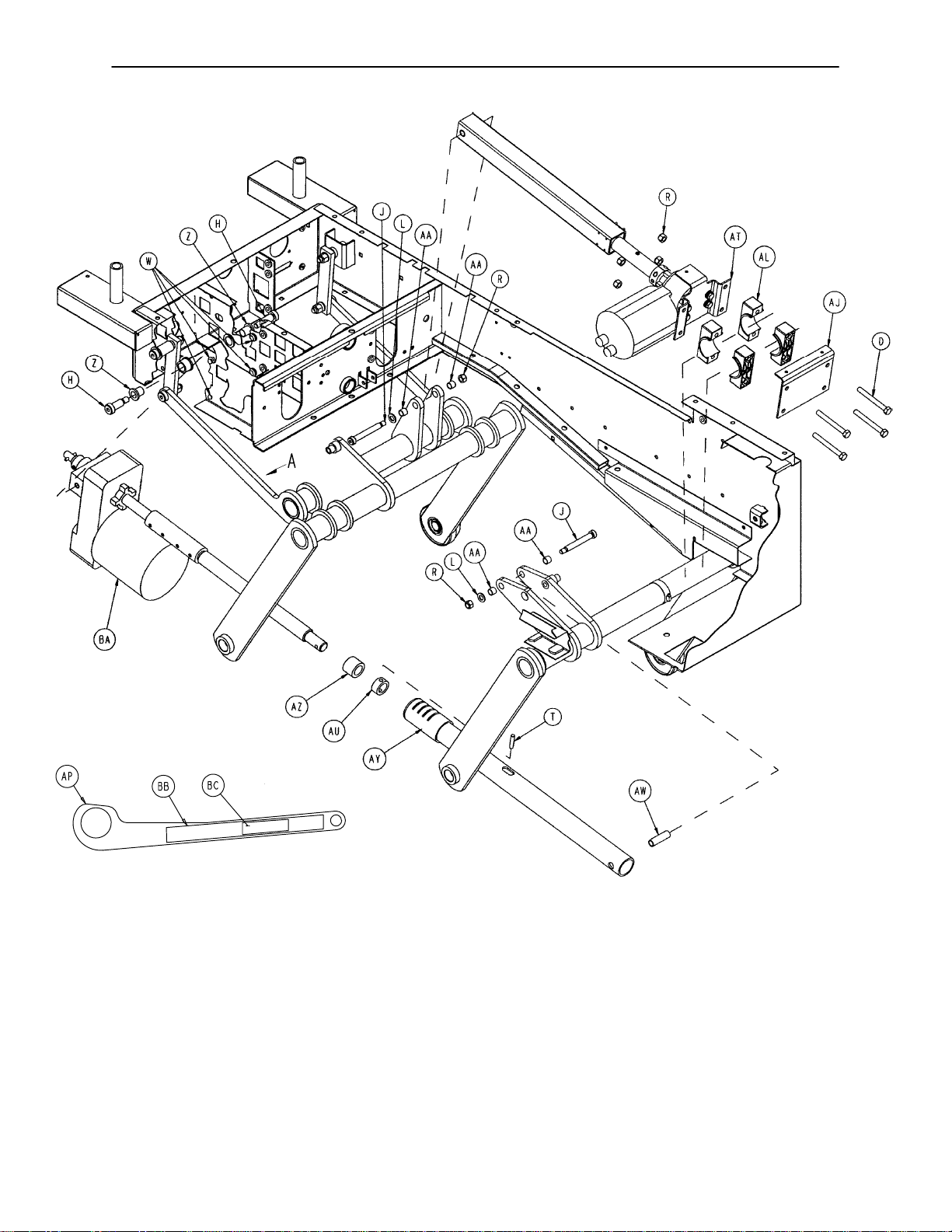

Base Assembly 40, 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

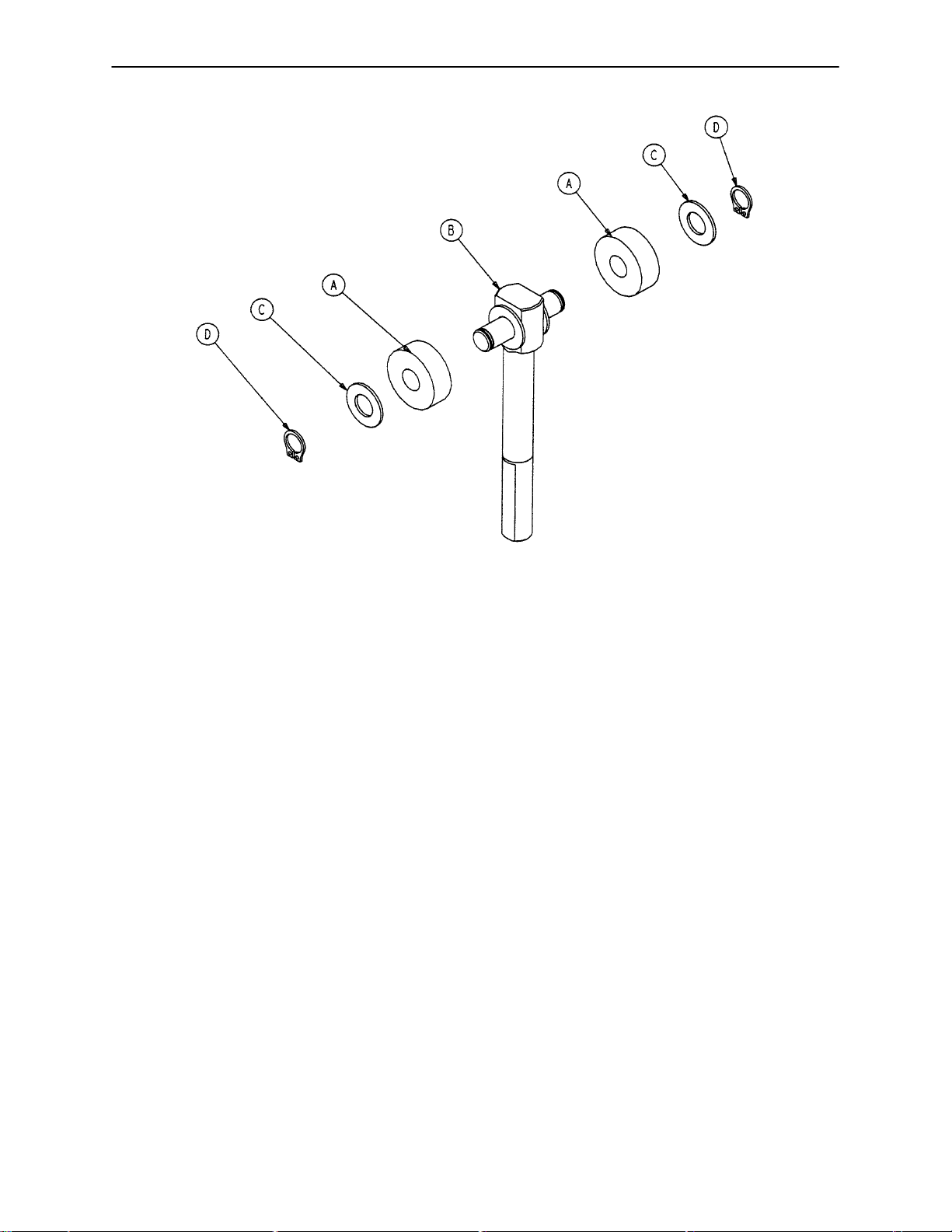

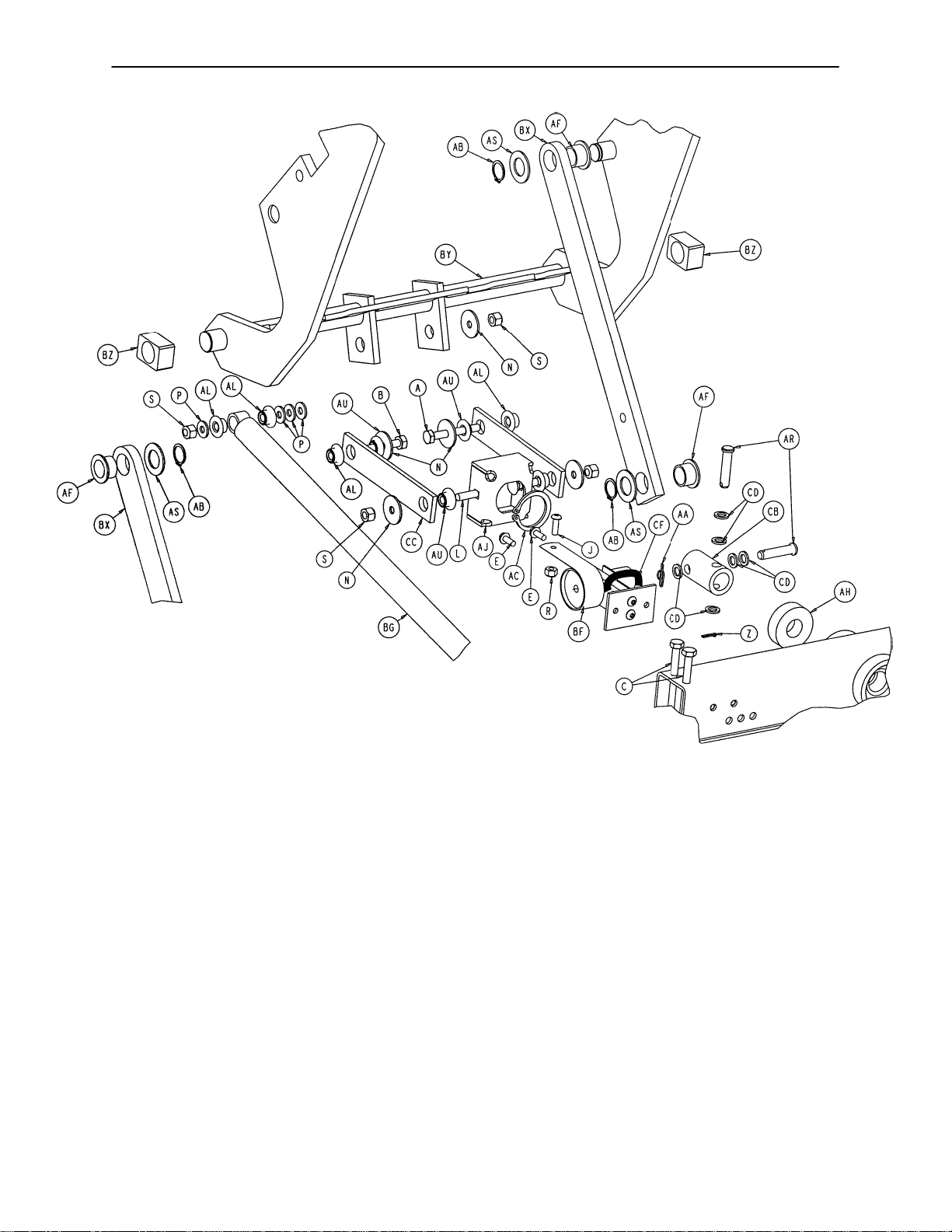

Brake Adjuster Assembly 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

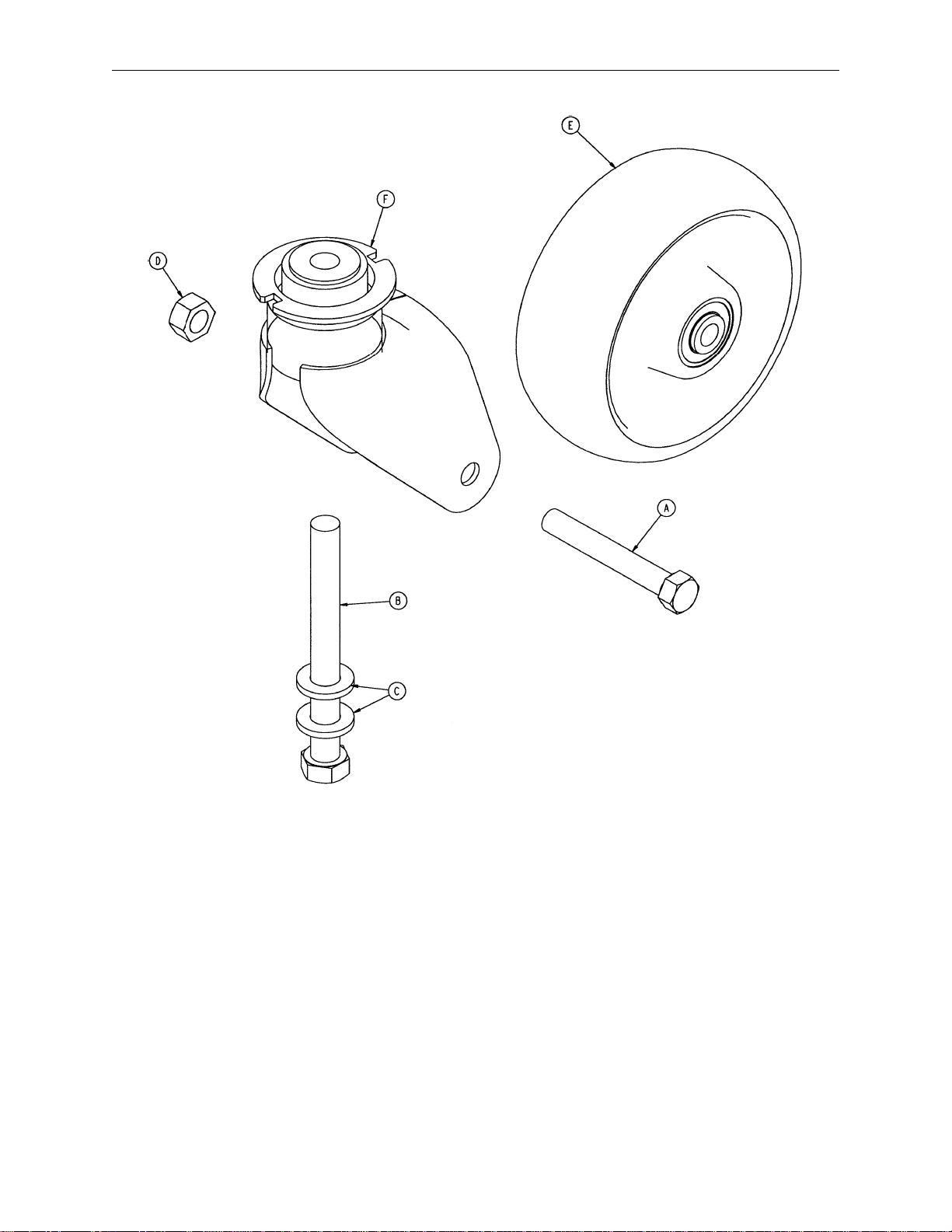

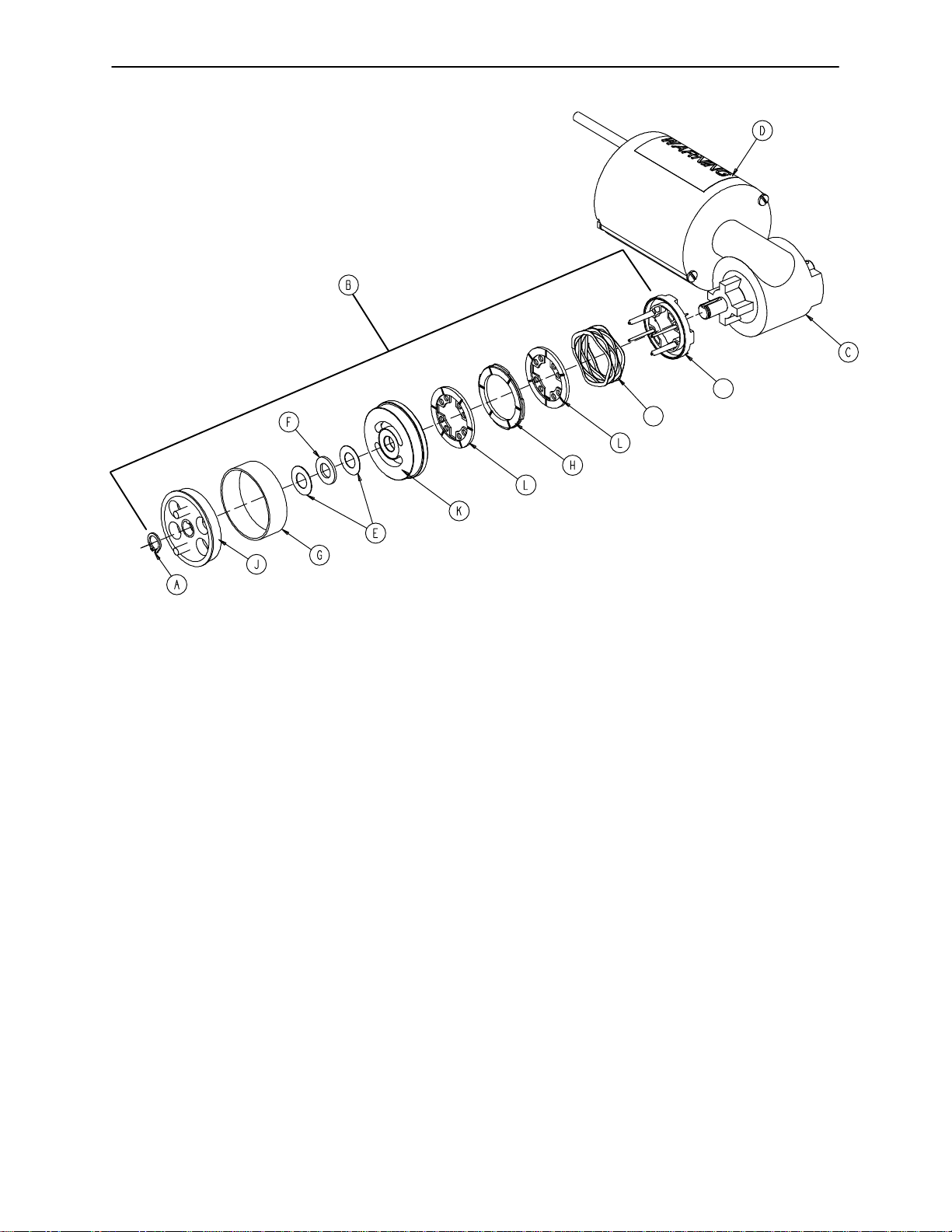

8” Casters Assembly 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8” Caster Assembly 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8” Steer Caster Assembly 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6” Caster Option Assembly 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6” Steer Caster Option Assembly 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6” Molded Wheel Assembly 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Assembly 49-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contents

Assembly Drawings and Parts Lists (Continued)

Fowler Motor Assembly 53, 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Potentiometer Assembly 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Cover Assembly 56, 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Capacitor Assembly 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-In/Out Fowler Assembly 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Skoocher Assembly 60, 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Assembly 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Square In/Out Fowler Tube Assembly 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

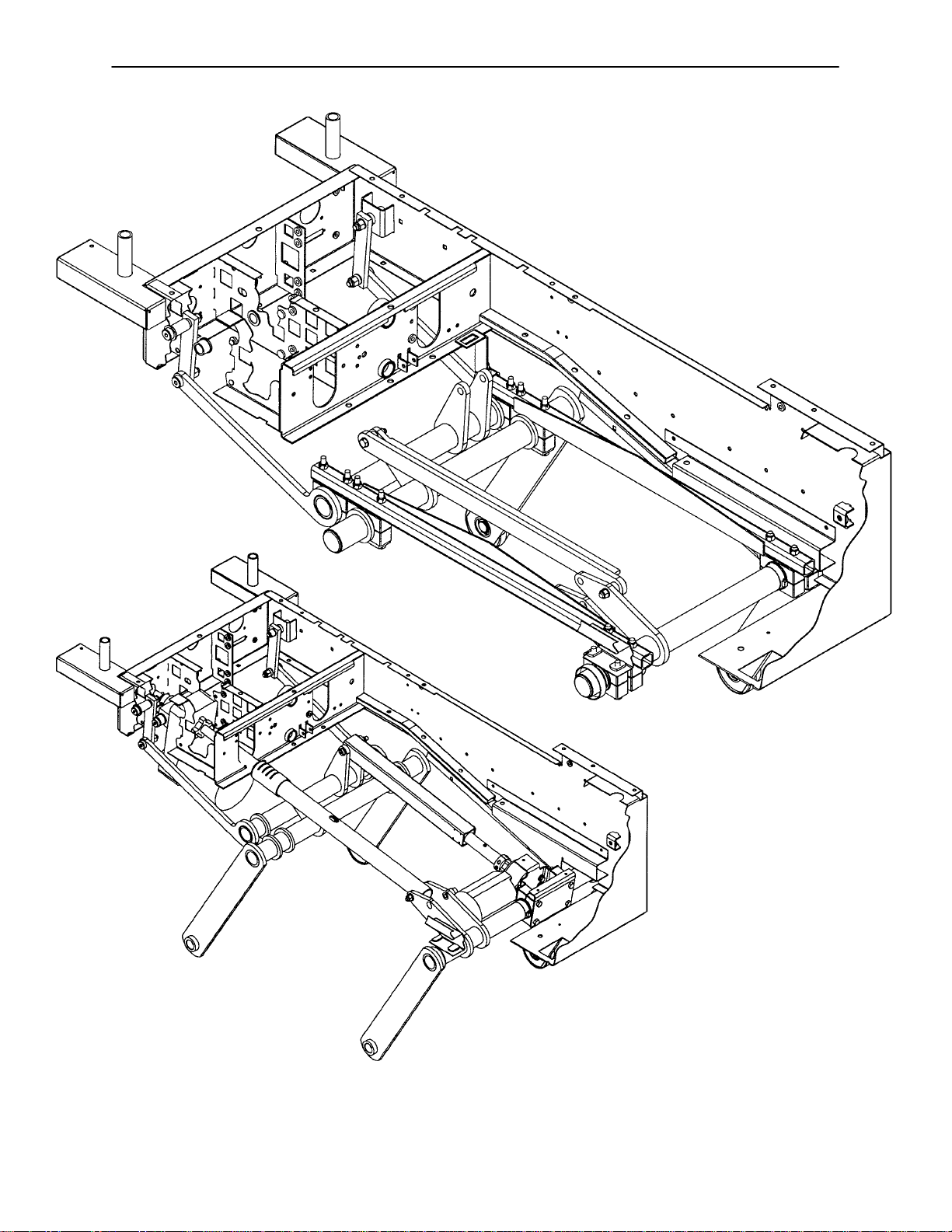

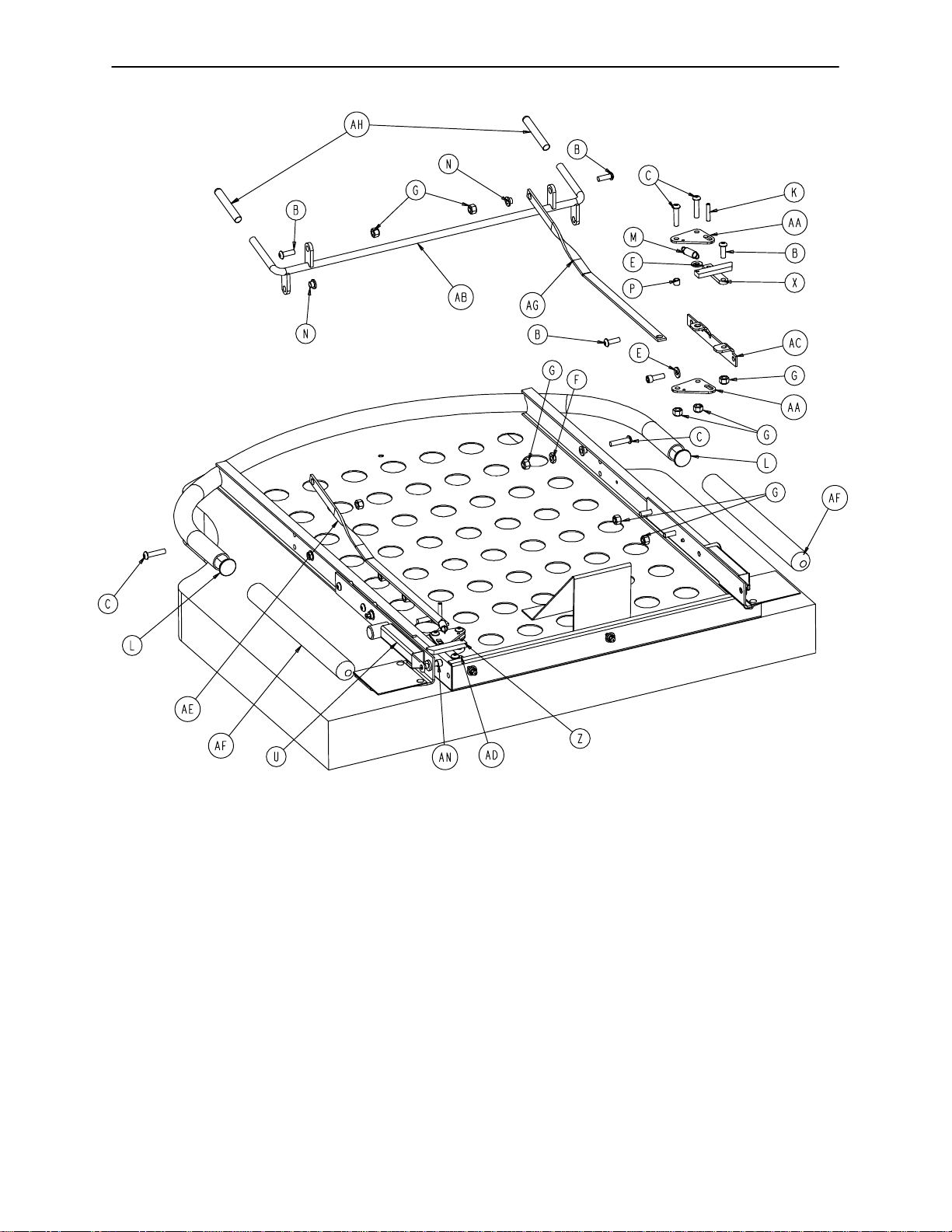

Litter Lift/Trend Assembly 64-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

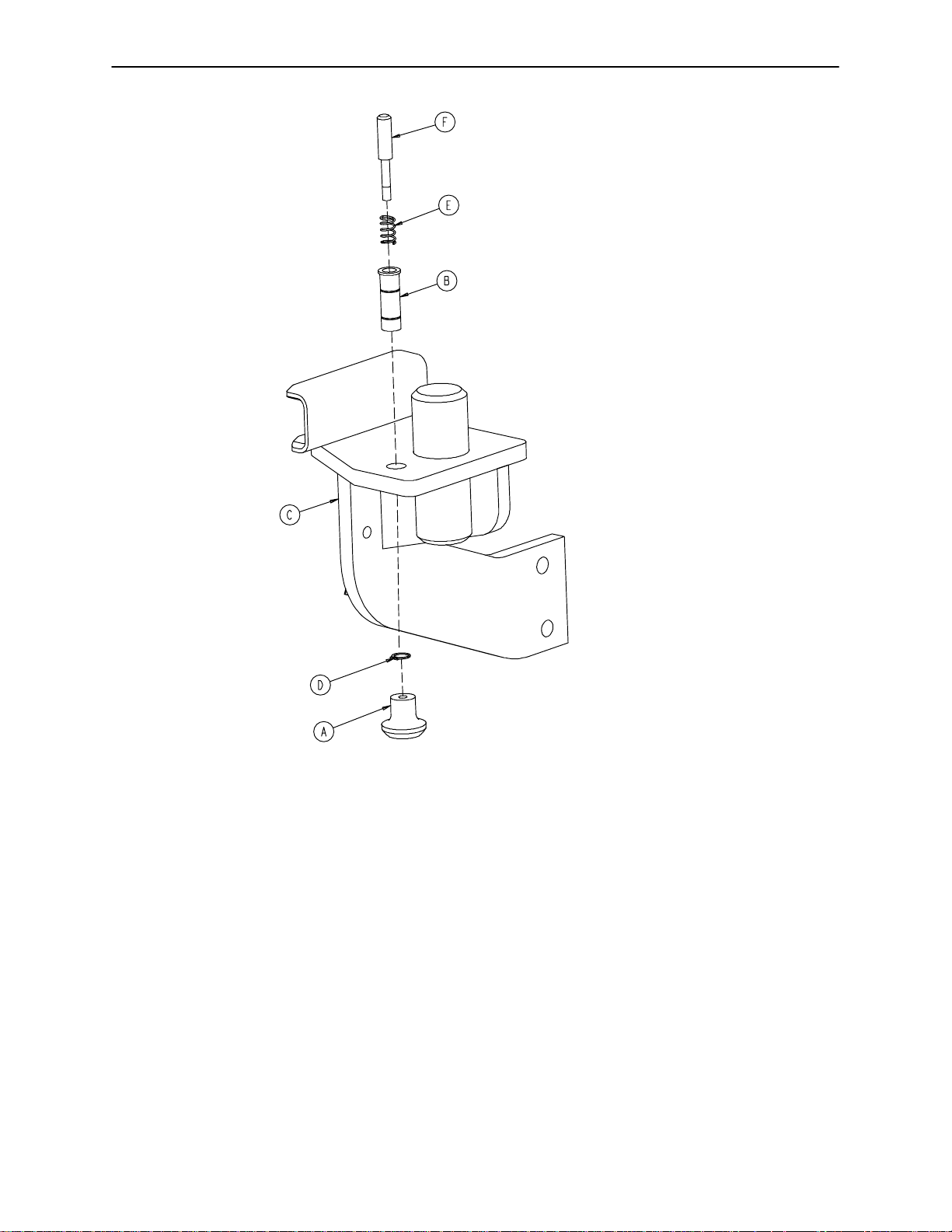

Trend Actuator Assembly 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

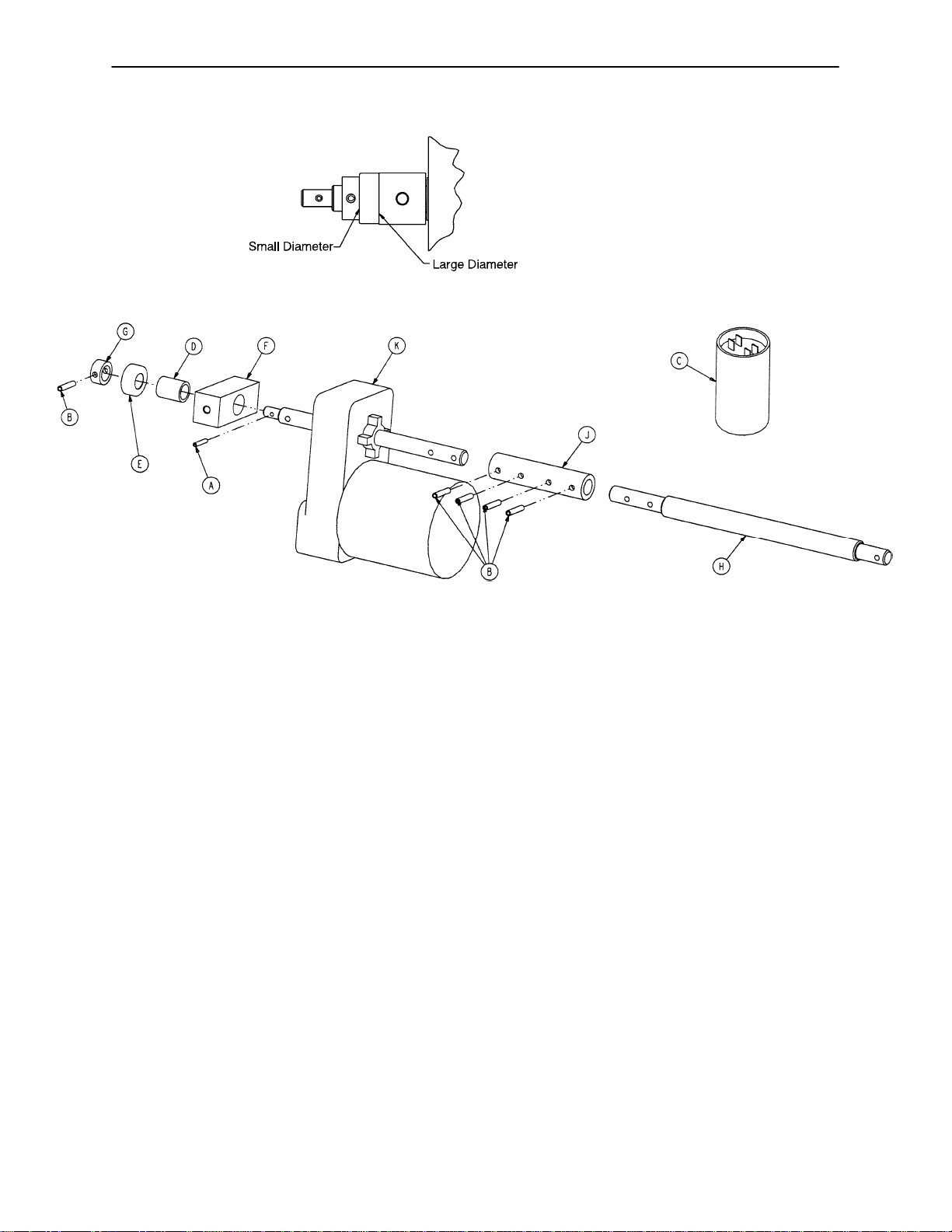

Lift Actuator Assembly 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

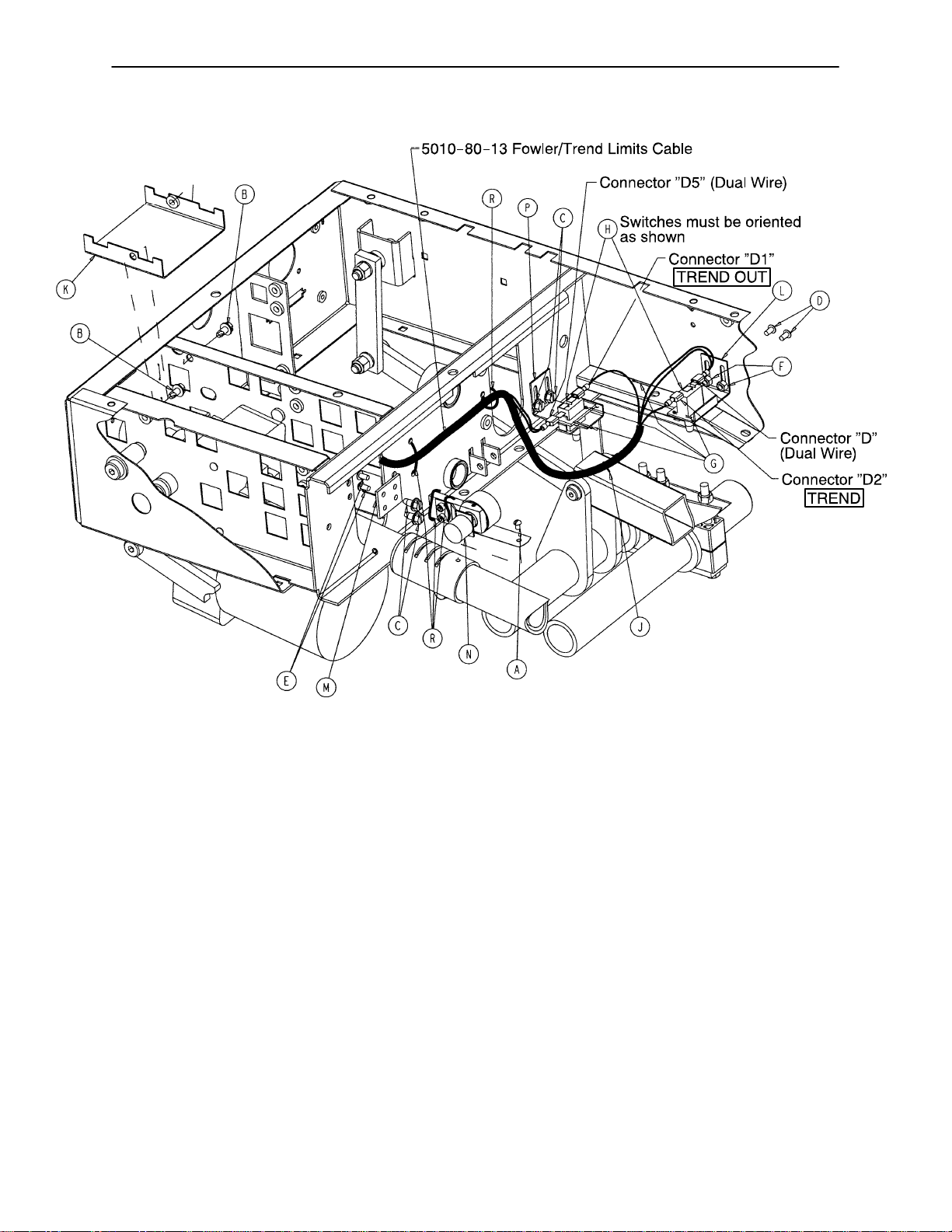

Bed Lift/Trend Limits Assembly 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

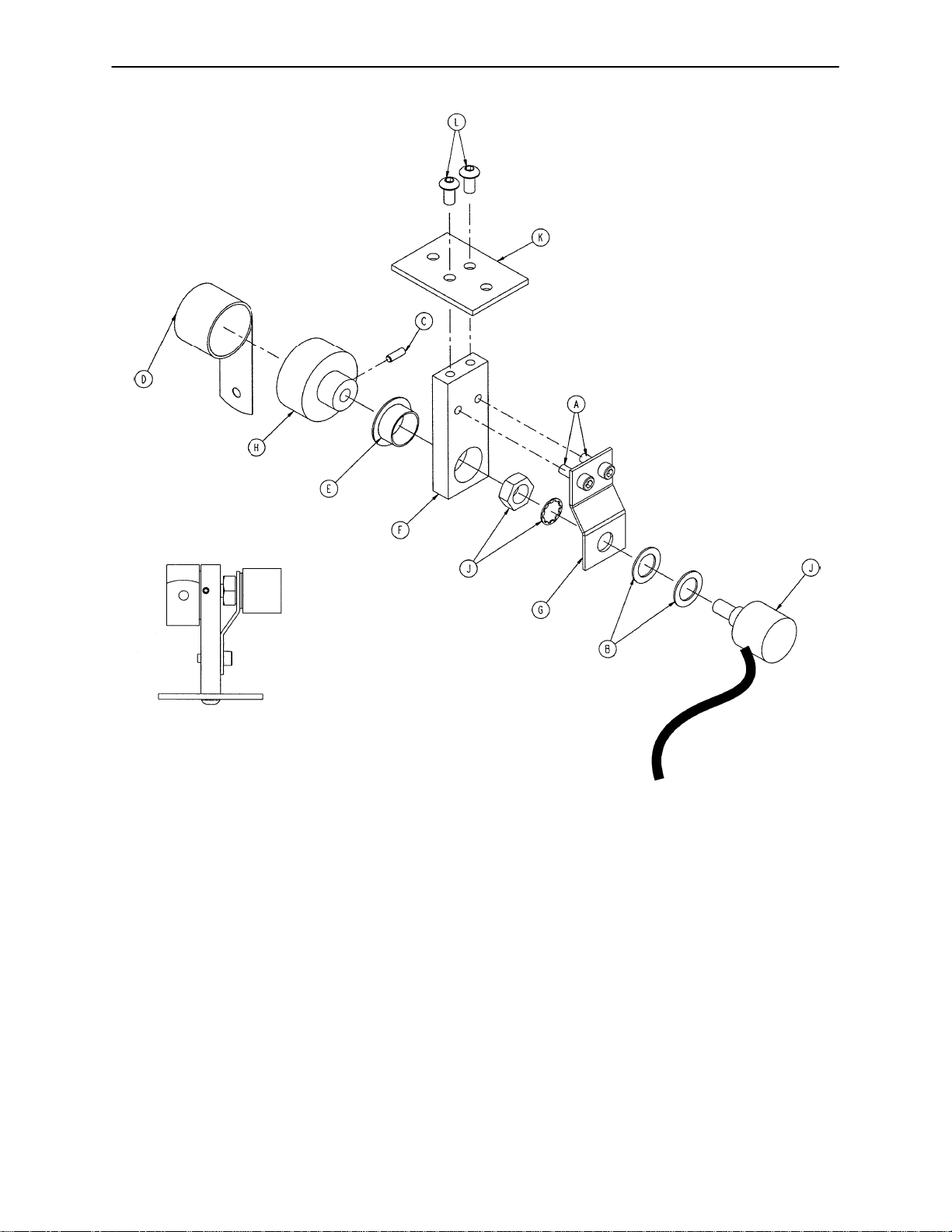

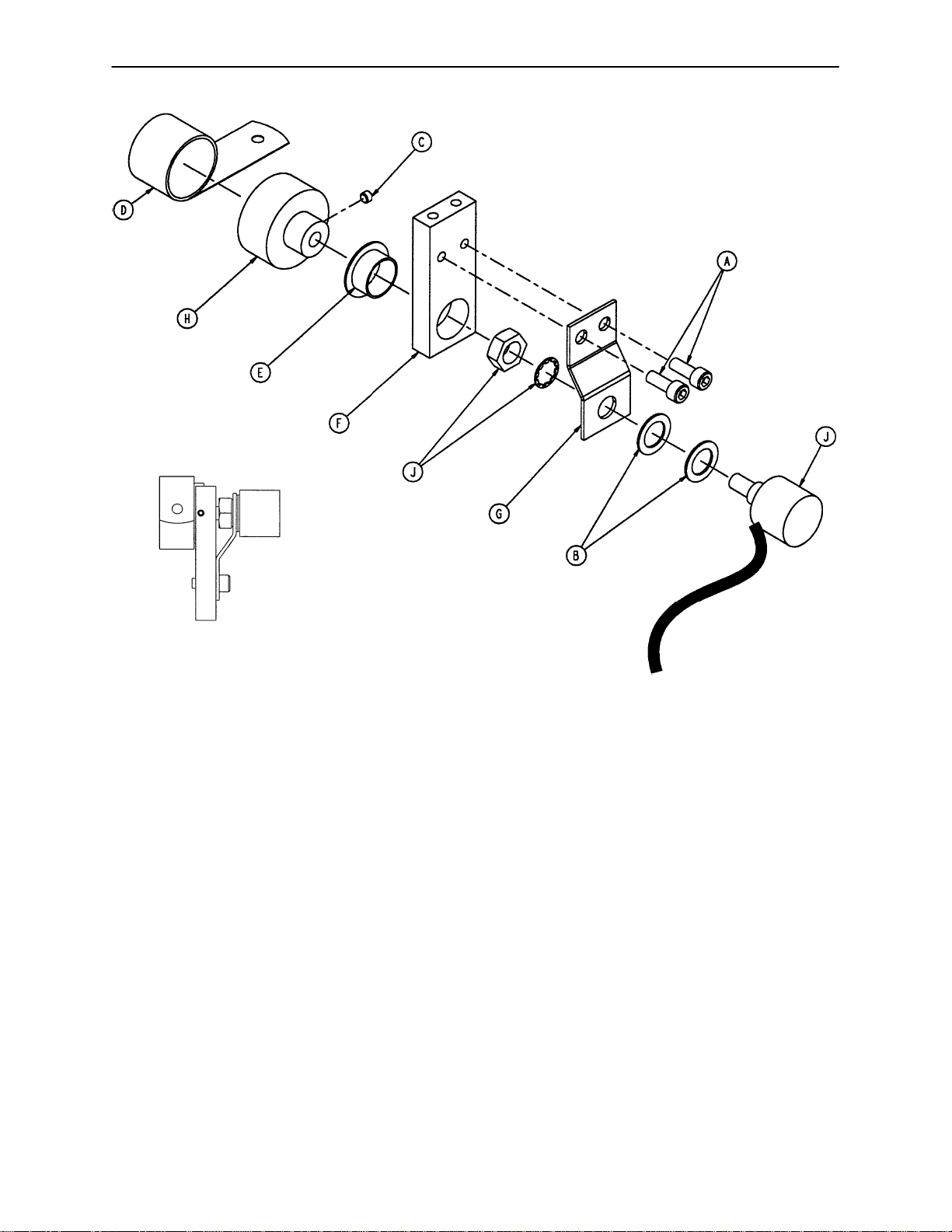

Bed Lift Potentiometer Assembly 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Lift Assembly 72, 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Potentiometer Assembly 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seat Assembly 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

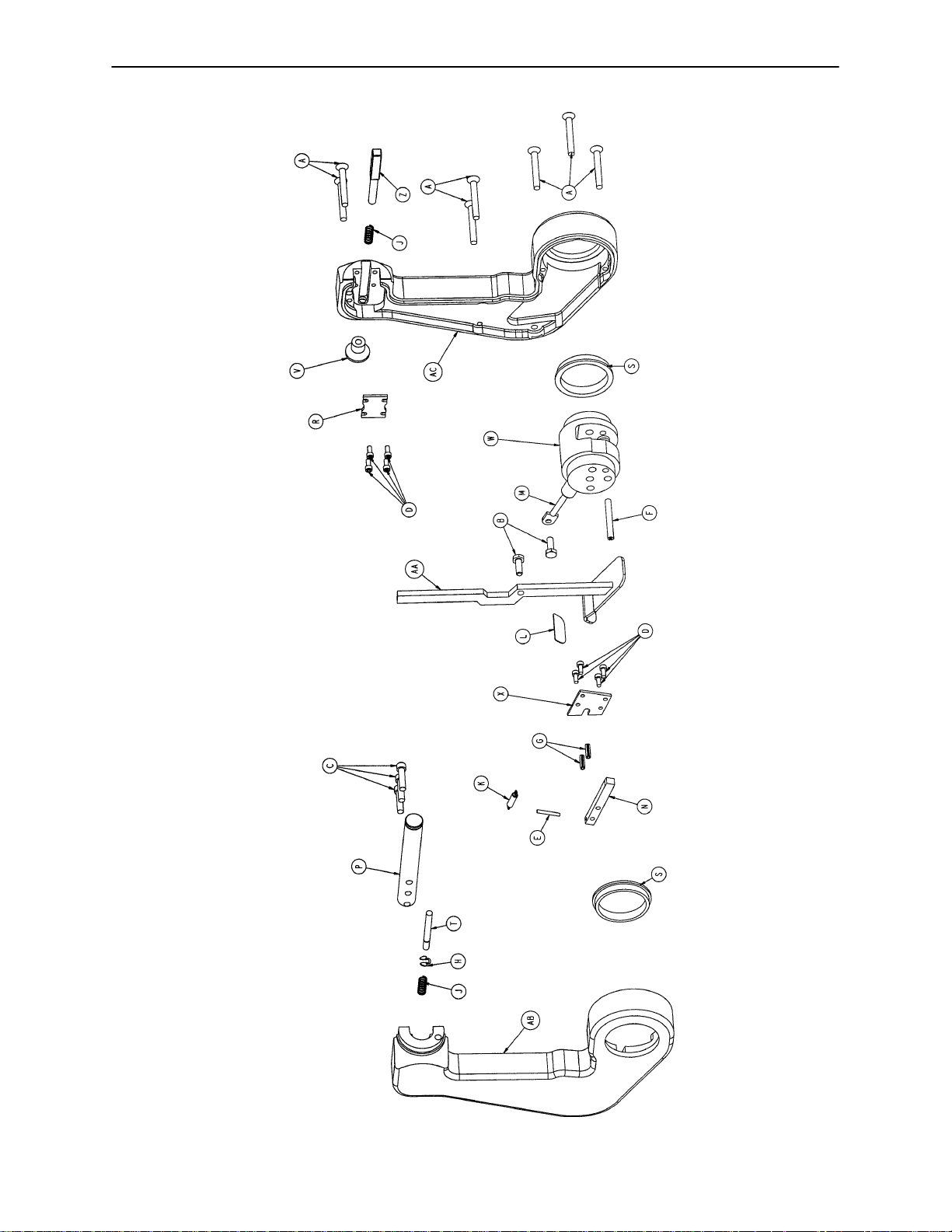

Hand Grip Assembly 76, 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glideaway Foot Support Assembly 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Mattress Assembly 80, 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Support Upright Assembly 82, 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glideaway Assembly 84, 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Pan Assembly, Left 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Pan Assembly, Right 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glideaway Link Assembly, Left 88, 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glideaway Link Assembly, Right 90, 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

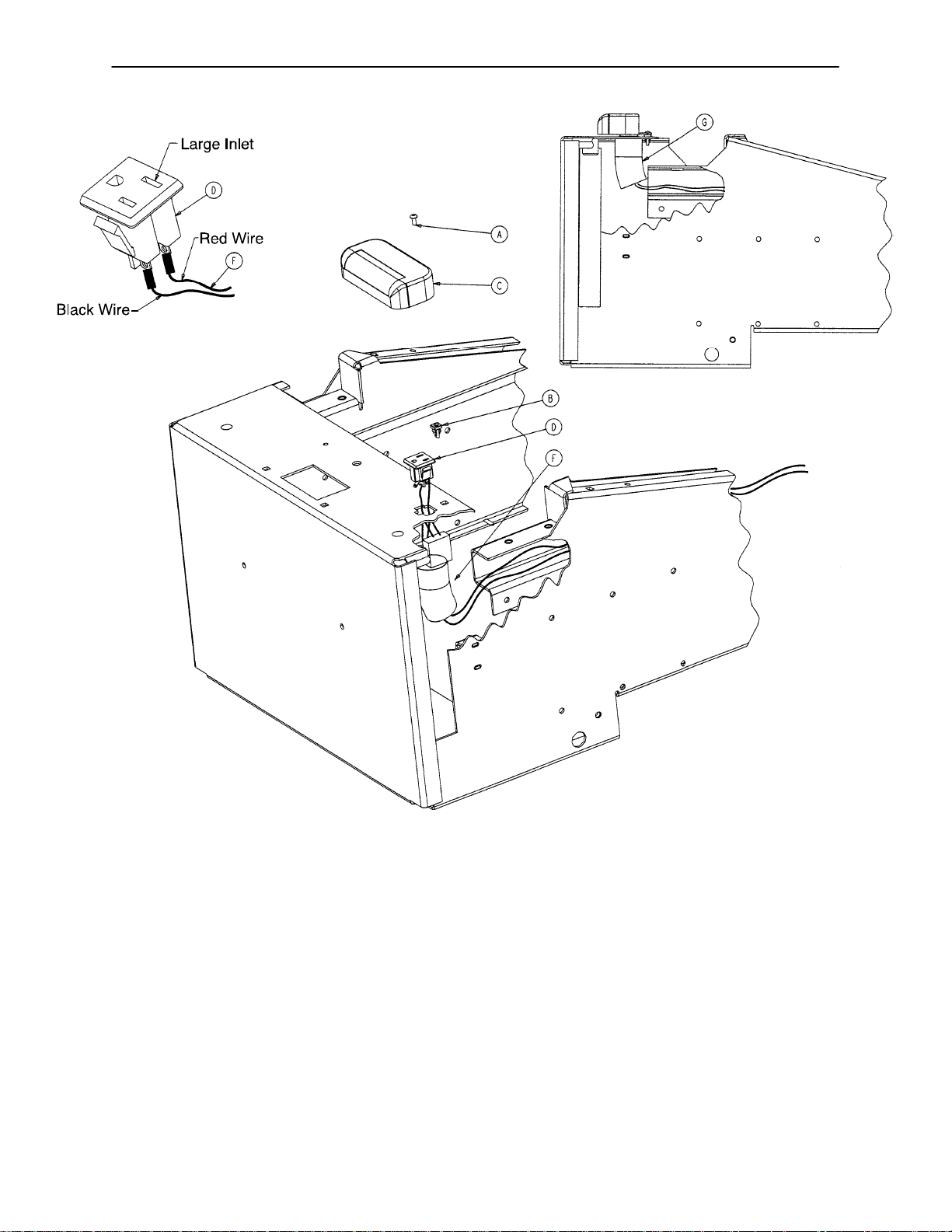

Electrical Assembly 92-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Night Light Assembly 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Head Wall Interface Assembly 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pendant Port Assembly with No Nurse Call 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Wall Interface Assembly with Nurse Call and No Port 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Wall Interface Nurse Call and Communication Assembly 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Mattress Assembly 100, 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Mattress Assembly 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perineal Pillow Assembly 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manifold Assembly 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Assembly 105-116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Latch Assembly 117, 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Bypass Detent Clip Assembly 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Timing Link Assembly 120, 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contents

Assembly Drawings and Parts Lists (Continued)

Siderail Release Lever Assembly 122, 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Outer Panel Assembly 124, 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Lumbar Module Assembly 126, 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Smart TV Module, No Lumbar 128, 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siderail Smart TV Module, With Lumbar 130, 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pendant Assembly 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wood Head Board Assembly 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crank Handle Assembly 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-Stage I.V. Mounting Pole Mounting Assembly 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-Stage I.V. Pole Assembly 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3rd Stage Assembly 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Pole Latch Assembly 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calf Rests 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attachable/Storable Calf Rest Assembly, Left 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attachable/Storable Calf Rest Assembly, Right 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Free Standing Calf Rest Assembly 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Labor Bar Assembly 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plastic Basin Assembly 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stainless Steel Basin Assembly 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arm Board Assembly 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-Purpose Shelf Assembly 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label Assembly 148, 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty

Obtaining Parts and Service 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Warranty Coverage 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Authorization 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freight Damage Claims 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Introduction

INTRODUCTION

This manual is designed to assist you with the maintenance of the Stryker Adel Maternity Bed. Read it thoroughly before beginning any maintenance on the equipment.

SPECIFICATIONS

Maximum Weight Capacity 500 pounds (227 kilograms)

Bed Length/Width 90” x 41” (with siderails up) - 37” (with siderails down)

229 cm x 104 cm (with siderails up) - 94 cm (with siderails down)

Bed Height (to top of seat) Low - 19” (49 cm), High - 37” (95 cm) (w/8” Casters)

Mattress Size Head - 49.5” (126 cm) x 33” (84 cm) x 5” (13 cm), Foot - 31” (79 cm) x

30” (77 cm) x 3” (8 cm), Patient Sleep Surface - 81” (206 cm)

Critical Angles Maximum Elevation - Head 70, Trendelenburg 8

Break-Away Point from Wall 60” (152 cm)

Electrical Standard 4 motor function: Head-Bed-Foot-Trendelenburg

120 VAC, 60 Hz, 6 Amp - 105 to 135 VAC operating range.

Optional: 230 VY, 50/60 Hz, 6 A - 220 to 240 VAC operating range

Current leakage less than 100 microamperes.

Hospital grade plug and 3-wire heavy duty cord.

Compatible with non-flammable anesthetic agents and oxygen by nasal

catheter or mask.

Caster Size 8” Standard; 6” Optional

Stryker reserves the right to change specifications without notice.

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury

to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

To ensure safe and proper use, the Stryker Adel Maternity Bed has the following caution and warning labels:

DANGER Explosion Hazard - do not use in the presence of flammable anesthetics.

CAUTION This unit is equipped with a hospital grade attachment plug. Grounding reliability can be

achieved only when equipment is connected to equivalent receptacle.

CAUTION Electrical shock hazard. Do not remove cover panels. Refer all servicing to qualified personnel.

CAUTION Disconnect power cord before using the back up hand crank. Remove hand crank from back

up outlet before connecting power cord.

4

Page 6

Introduction

SAFETY TIPS AND GUIDELINES

Before operating the Stryker Adel Maternity Bed, it is important to read and understand all information in this

manual. Carefully read and strictly follow the safety guidelines listed on this page.

It is important that all users have been trained and educated on the inherent hazards associated with the

usage of electric beds.

WARNING

The Stryker Adel Maternity Bed is equipped with a hospital grade plug for protection against shock haz-

ard. It must be plugged directly into a properly grounded three-prong receptacle. Grounding reliability

can be achieved only when a hospital grade receptacle is used.

Powered bed mechanisms can cause serious injury. Operate bed only when all persons are clear of the

mechanisms.

To help reduce the number and severity of falls by patients, always leave the bed in the lowest position

when the patient is unattended.

Leave the siderails fully up and locked when the patient is unattended. When raising the siderails, listen

for the ”click” that indicates the siderail has locked into the up position. Pull firmly on the siderail to ensure

it is locked into position. Siderails are not intended to be a patient restraint device. It is the responsibility

of the attending medical personnel to determine the degree of restraint necessary to ensure a patient will

remain safely in bed.

Always apply the caster brakes when a patient is getting on or off the bed. Always keep the caster brakes

applied when a patient is on the bed (except during transport). Serious injury could result if the bed moves

while a patient is getting in or out of bed. After the brake pedal is applied, push on the bed to ensure the

brakes are locked. When moving the bed, toggle the steer pedal to put the bed in the steer mode. This

locks the swivel motion of the right foot end caster and makes the bed easier to move.

The instant CPR release is for emergency use only. When activating the instant CPR, all persons and

equipment must be removed from the area below and around the Fowler (back rest) section of the bed

or serious personal injury or damage to the equipment could occur.

When large spills occur in the area of the circuit boards, 110 volt cables and motors, immediately unplug

the bed power cord from the wall socket. Remove the patient from the bed and clean up the fluid. Have

maintenance completely check the bed. Fluids can have an affect on operational capabilities of any electrical product. DO NOT put the bed back into service until it is completely dry and has been thoroughly

tested for safe operation.

Do not steam clean or hose off the bed. Do not immerse any part of the bed. The internal electric parts

may be damaged by exposure to water. Hand wash all surfaces of the bed with warm water and mild

detergent. Dry thoroughly. Inspect the mattress cover after each use. Discontinue use if any cracks or

rips are found in the cover which may allow fluids to enter the mattress. Exposure to fluids may cause

injury to patient and/or user.

Preventative maintenance should be performed at a minimum of annually to ensure all bed features are

functioning as designed. Close attention should be given to safety features including, but not limited to:

Safety side latching mechanisms

Frayed electrical cords and components

All electrical controls return to off or neutral position when released

Caster braking system

No controls or cabling entangled in bed mechanisms

Leakage current 100 MA max.

Always unplug bed during service or cleaning. When working under the bed with the bed in the high posi-

tion, always place blocks under the litter frame and set the brakes to prevent injury in case the Bed Down

switch is accidently pressed.

Unplug the bed power cord from the wall socket before using the hand crank. Remove the hand crank

before plugging the power cord into the wall socket or personal injury could result.

5

Page 7

Unpacking and Initial Set-Up Procedures

UNPACKING INSTRUCTIONS

Refer to unpacking instructions attached to the bed inside the crate.

SET-UP PROCEDURES

It is important that the Stryker Adel Maternity Bed is working properly before it is put into service. The following

list will help ensure that each part of the bed is tested.

Plug the bed into a properly grounded, hospital grade wall receptacle.

WARNING

The Stryker Adel Maternity Bed is equipped with a hospital grade plug for protection against shock hazard.

It must be plugged directly into a properly grounded three-prong receptacle. Grounding reliability can be

achieved only when a hospital grade receptacle is used.

Ensure the siderails raise and lower smoothly and lock in the up position.

Ensure that the brakes hold when the brake pedal is engaged.

Test each function on the (optional) hand pendant to ensure that each function is working properly.

Beds equipped with nurse communication siderail control option only:

Plug the interface cable into the 37 pin connector in the litter frame at the head end of the bed, and into

the ”Patient Station”, ”Head Wall”, ”Docker Station”, or equivalent (whichever applies).

Run through each function on the siderail control panels to ensure that each function is working properly.

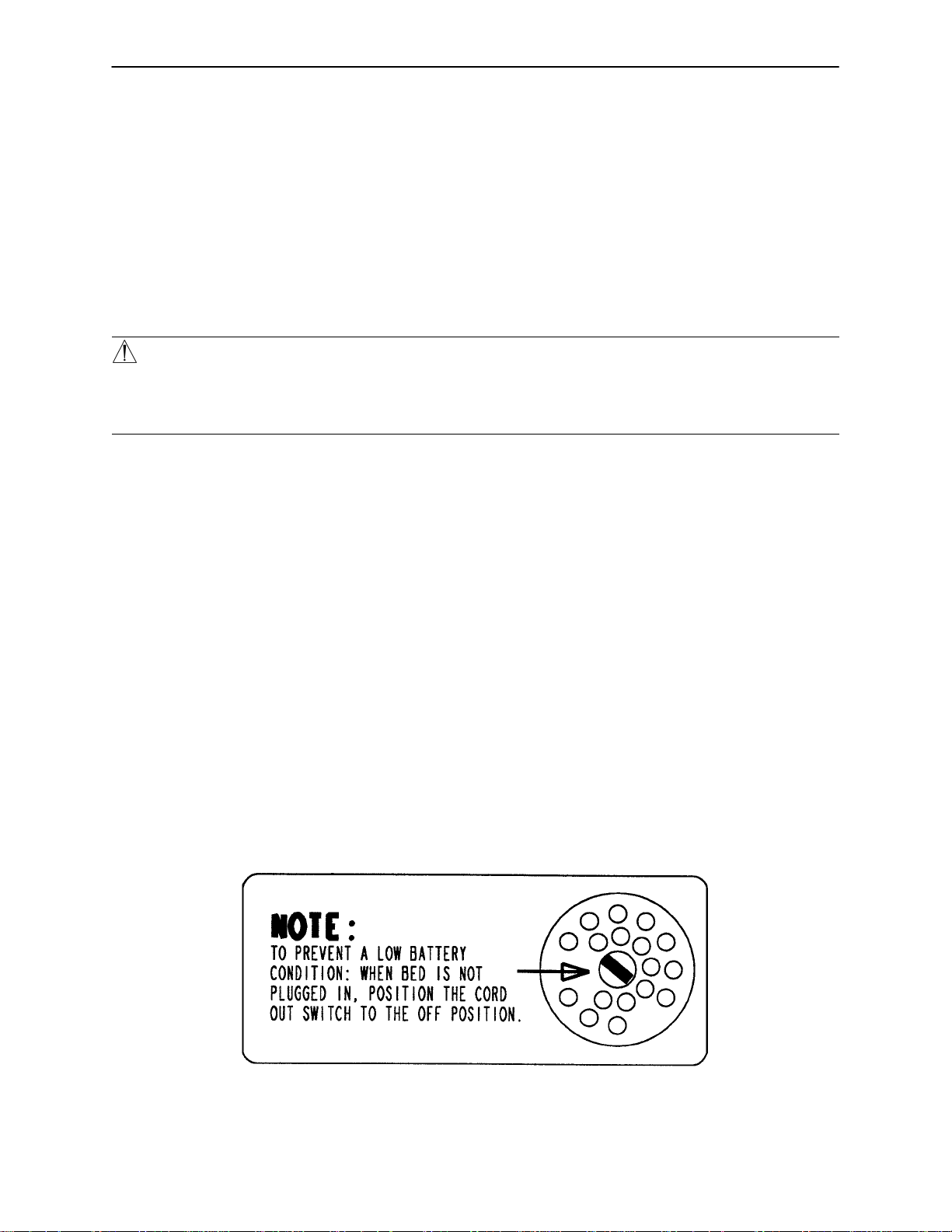

NOTE

To prevent a low battery condition when the bed is not plugged in, position the cord out switch at the head

end of the bed to the off position. The switch is identified by the label shown below. If the switch is not positioned as shown below and the bed power cord and pendant cord are unplugged, the life of the back-up battery will be significantly reduced.

If the siderail lights LED (located on the outside of both siderails) is flashing, the Nurse Call battery needs

to be replaced. The battery is located on the patient’s right side at the head end of the bed. No tools are

required to replace the battery. Unplug the bed power cord from the wall socket and replace the battery. After

replacing the battery, verify the siderail lights LED is no longer flashing and operates normally when the dif ferent light settings are selected.

6

Page 8

Bed Symbols

Warning, Refer to Service/Maintenance Manual

~

Alternating Current

Type B Equipment: equipment providing a particular degree of protection against electric shock, particularly regarding allowable leakage current and reliability of the protective earth connection.

Class 1 Equipment: equipment in which protection against electric shock does not rely

on BASIC INSULA TION only, but which includes an additional safety precaution in that

means are provided for the connection of the EQUIPMENT to the protective earth conductor in the fixed wiring of the installation in such a way that ACCESSIBLE METAL

PARTS cannot become live in the event of a failure of the BASIC INSULATION.

Mode of Operation: Continuous

IPX4: Protection from liquid splash

Dangerous Voltage Symbol

Protective Earth Terminal

Potential Equalization Symbol

Medical Equipment Classified by Underwriters Laboratories Inc. with Respect to Electric Shock, Fire, Mechanical and Other Specified Hazards Only in Accordance with UL

2601-1 and CAN/CSA C22.2 No. 601.1

7

Page 9

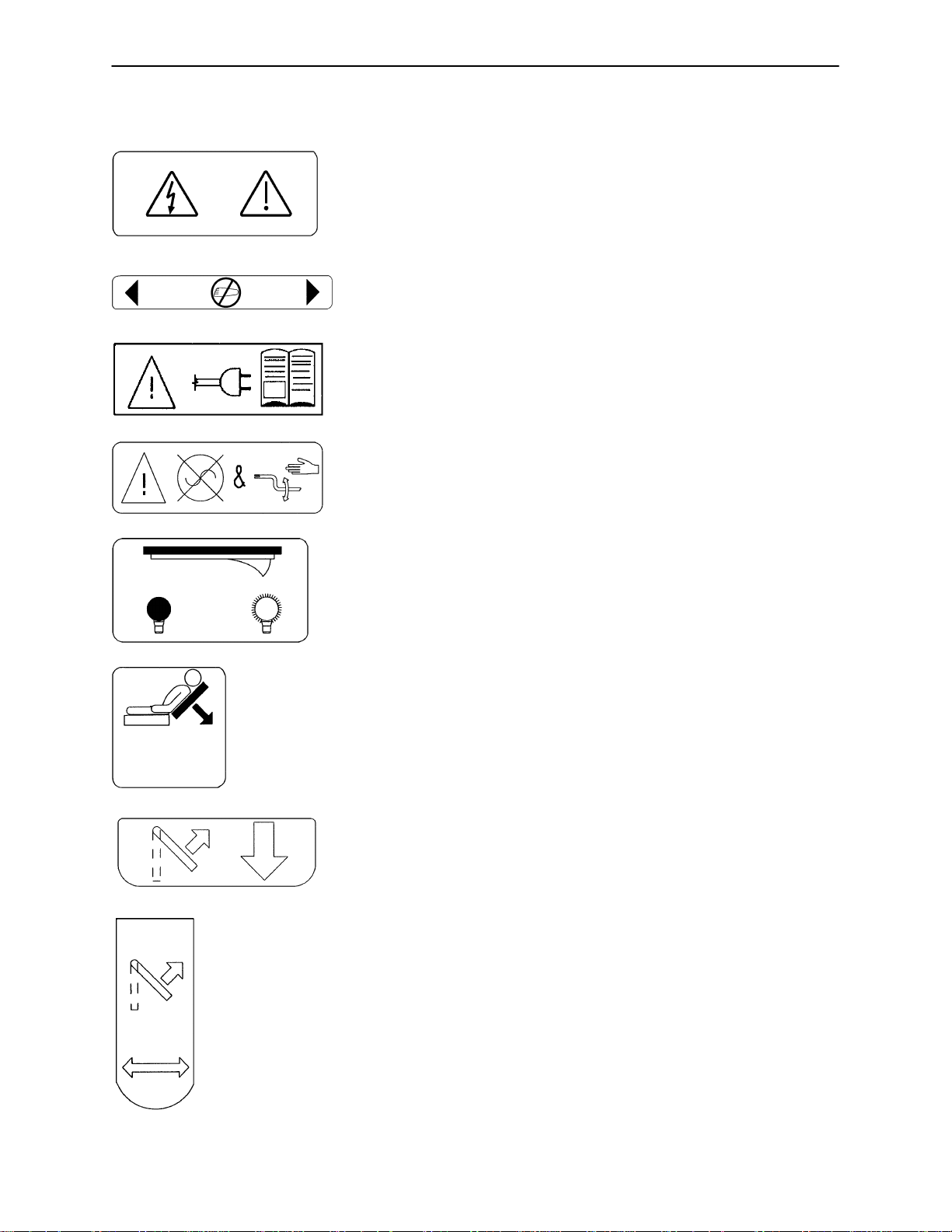

Bed Symbols

SYMBOL DESCRIPTION

Warning: Potential Electrical Shock if Cover is Removed.

Keep Feet Clear.

Warning: Read all Instructions Before Plugging in the Bed.

Warning: Unplug Bed Before Using the Hand Crank.

Night Light On/Off Switch

CPR Release

Lift to Lower

Lift to Move In or Out

8

Page 10

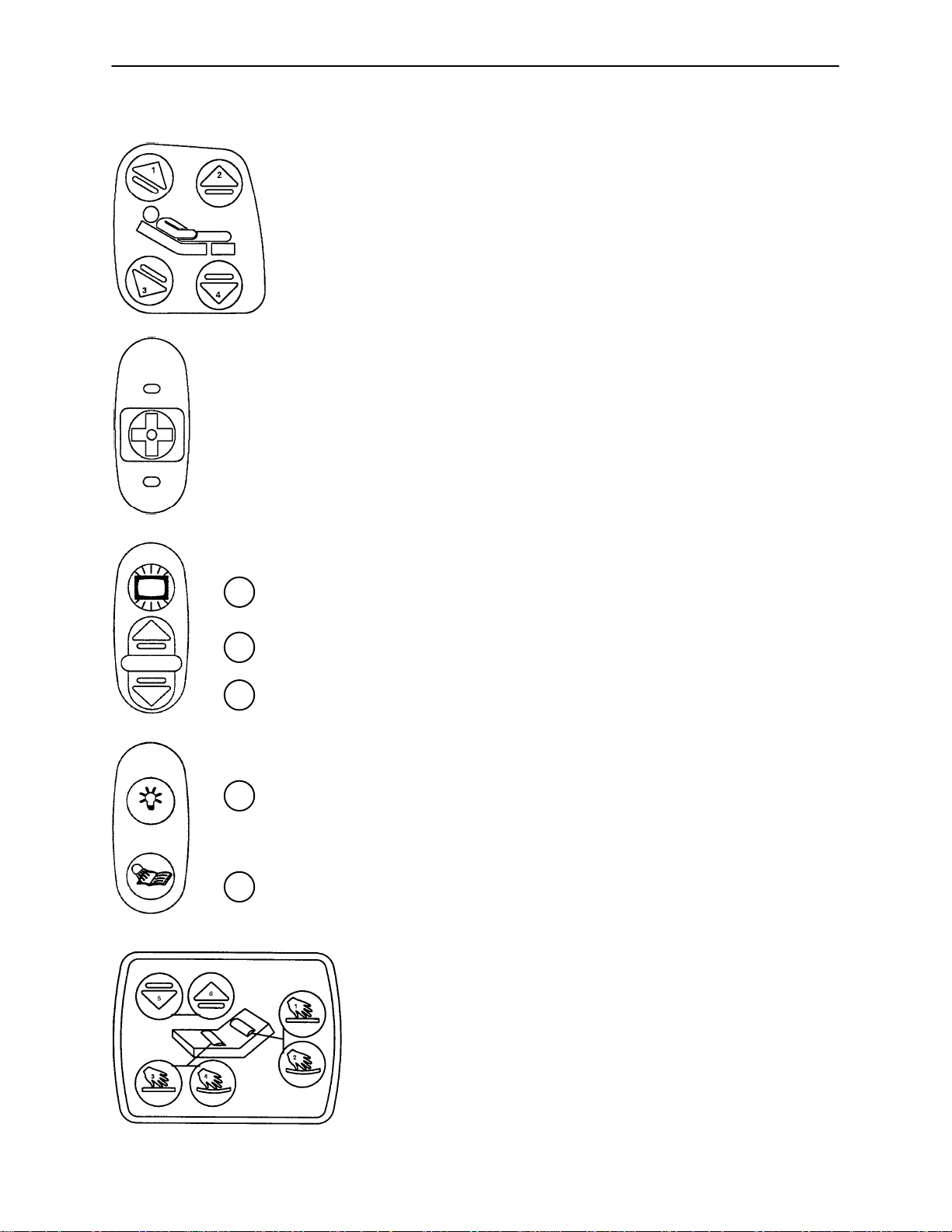

Bed Symbols

SYMBOL DESCRIPTION

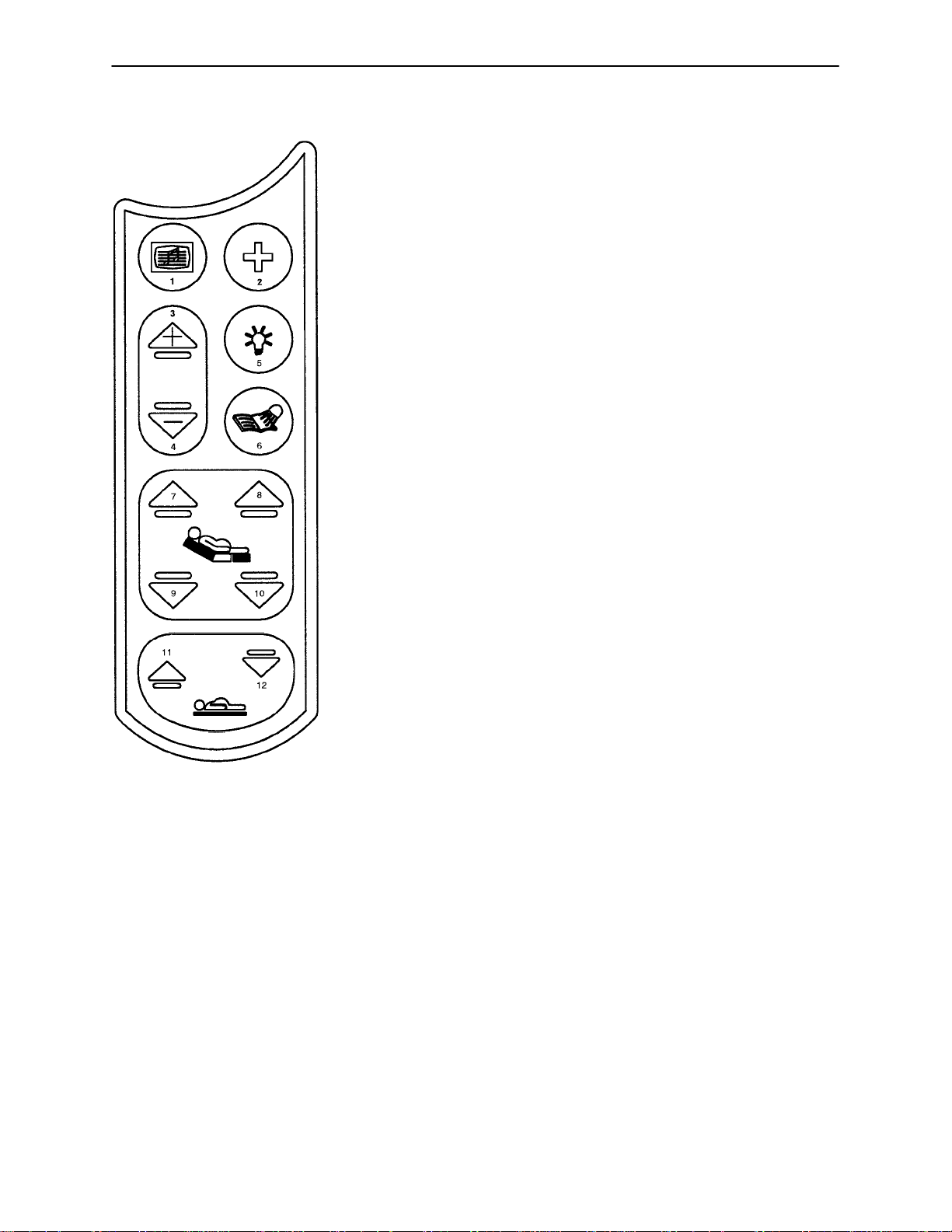

1. Raise Fowler (back rest).

2. Raise foot section.

3. Lower Fowler.

4. Lower foot section.

Activate Nurse Call

1.

2.

3.

1.

2.

1. Turn TV or radio on or select a channel.

2. Increase volume.

3. Decrease volume.

1. Turn the room light on or off.

2. Turn the bed overhead light on or off.

1. More support to the patient’s lower back.

2. Less support to the patient’s lower back.

3. More support to the patient’s seat section.

4. Less support to the patient’s seat section.

5. Lower the volume of the television.

6. Raise the volume of the television.

9

Page 11

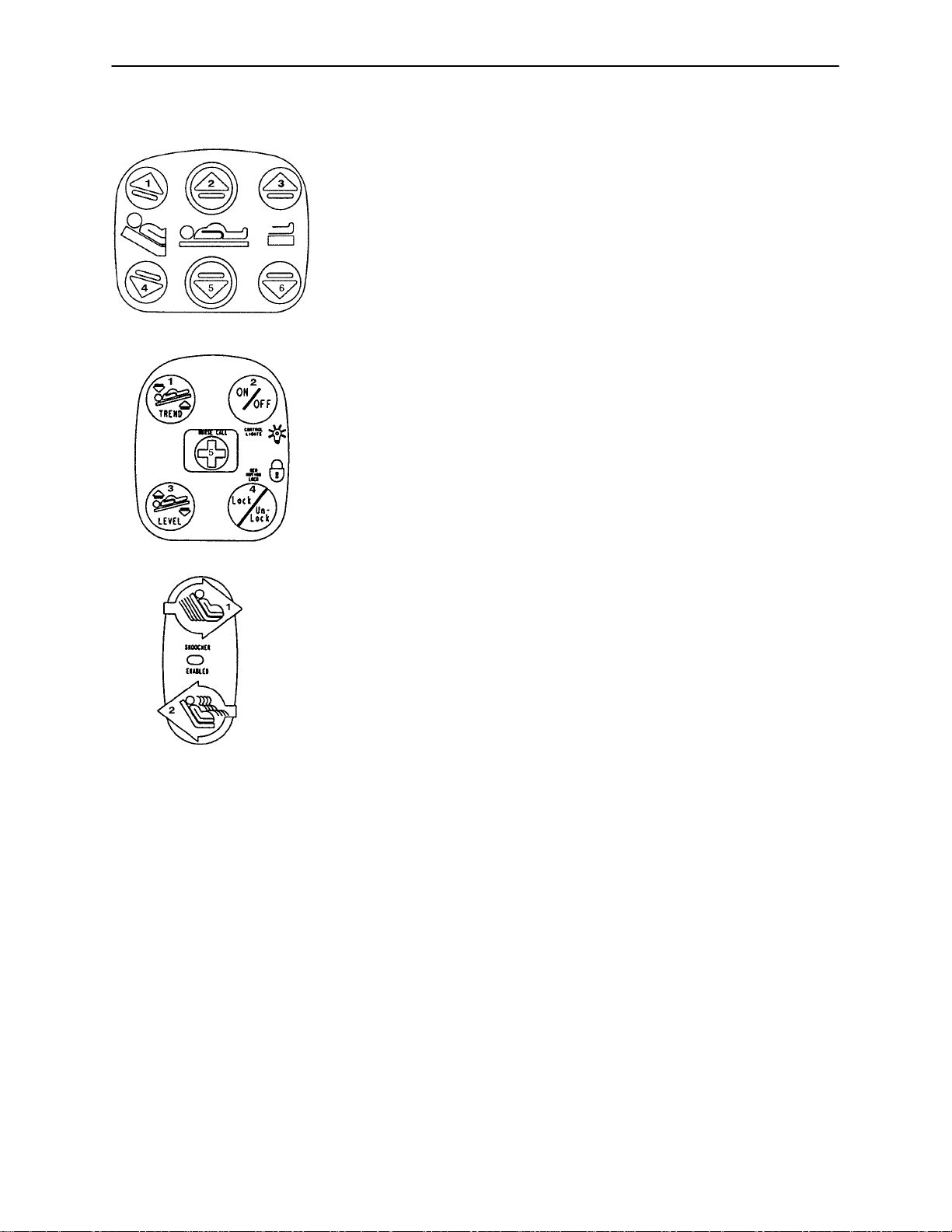

Bed Symbols

SYMBOL DESCRIPTION

1. Raise Fowler (back rest).

2. Raise bed height.

3. Raise foot section.

4. Lower Fowler (back rest).

5. Lower bed height.

6. Lower foot section.

1. Lower head end of bed.

2. Toggle siderail lights to different settings.

3. Raise head end of bed and/or return bed to level.

4. Lock/unlock all bed motion.

5. Activate Nurse Call.

1. Decrease seat depth.

2. Increase seat depth.

10

Page 12

Bed Symbols

SYMBOL DESCRIPTION

1. Turn TV or radio on or select a channel.

2. Activate Nurse Call.

3. Increase volume.

4. Decrease volume.

5. Turn the room light on or off.

6. Turn the bed overhead light on or off.

7. Raise Fowler.

8. Raise foot section.

9. Lower Fowler.

10. Lower foot section.

11. Raise bed height.

12. Lower bed height.

11

Page 13

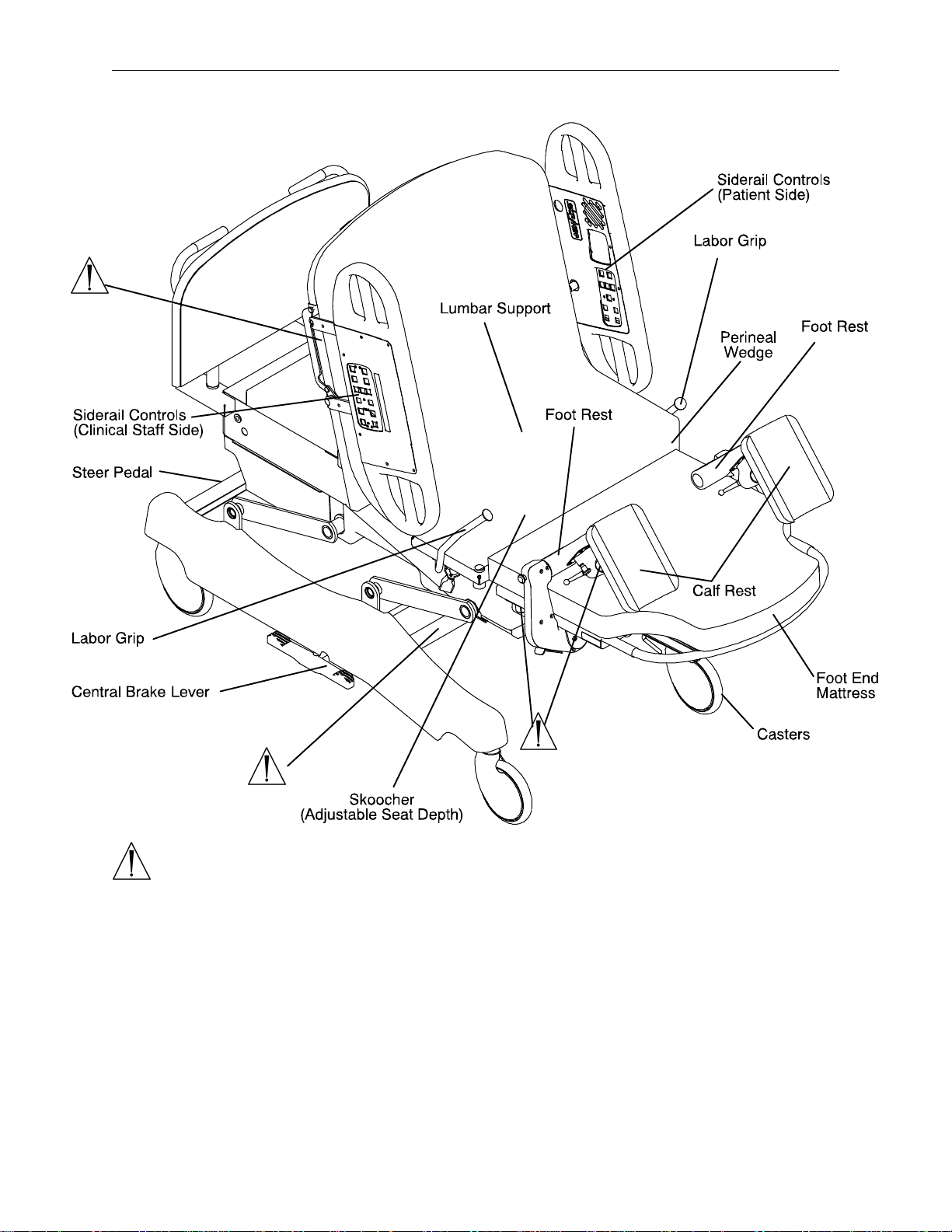

Bed Illustration

WARNING

Potential pinch points

12

Page 14

Cleaning

WARNING

Hand wash all surfaces of the bed with warm water and mild detergent. Dry thoroughly. DO NOT STEAM

CLEAN, PRESSURE WASH, HOSE OFF OR ULTRASONICALLY CLEAN. Using these methods of cleaning

is not recommended and may void this product’s warranty.

Inspect the mattress cover after each use. Discontinue use if any cracks or rips are found in the cover which

may allow fluids to enter the mattress. Exposure to fluids may cause injury to patient and/or user.

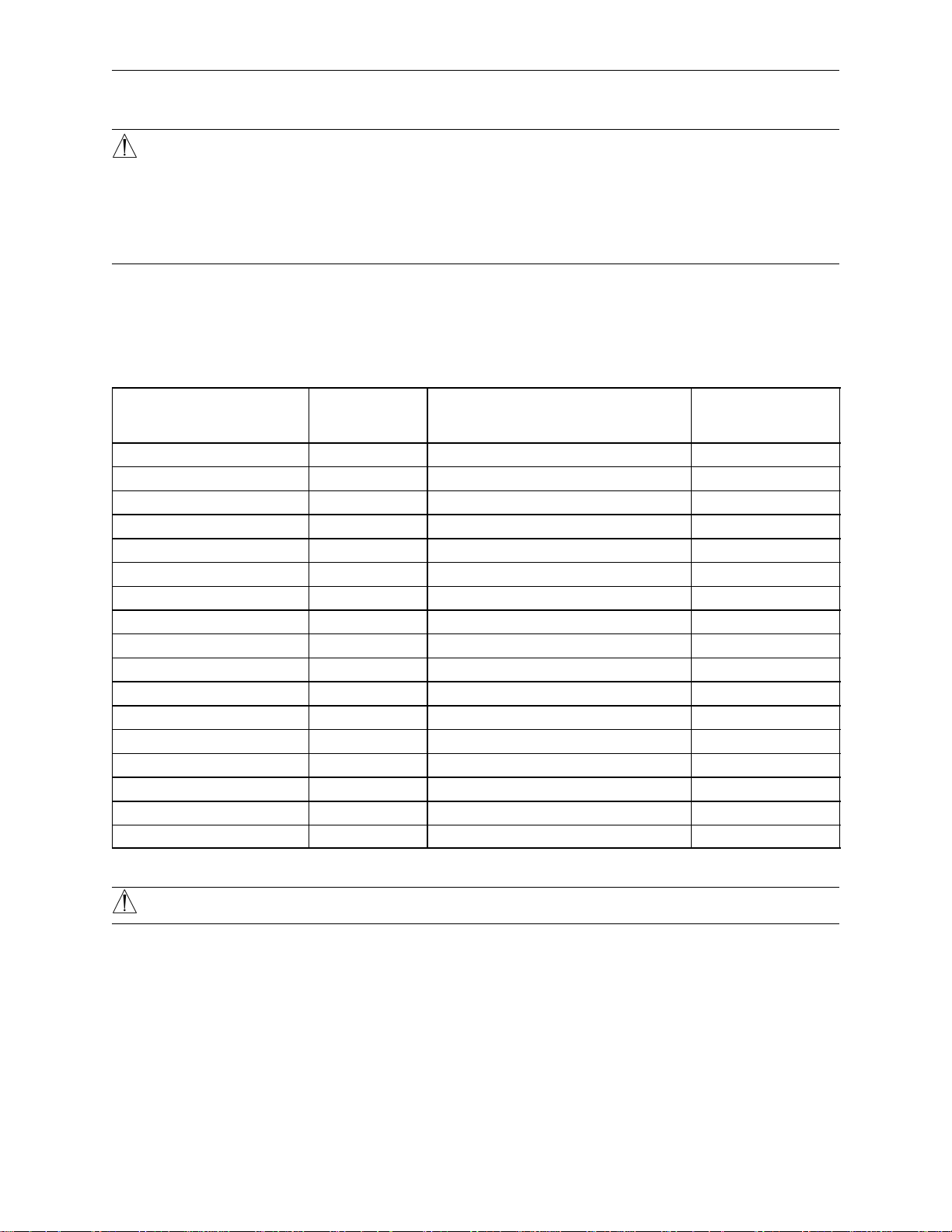

In general, when used in those concentrations recommended by the manufacturer, either phenolic type or

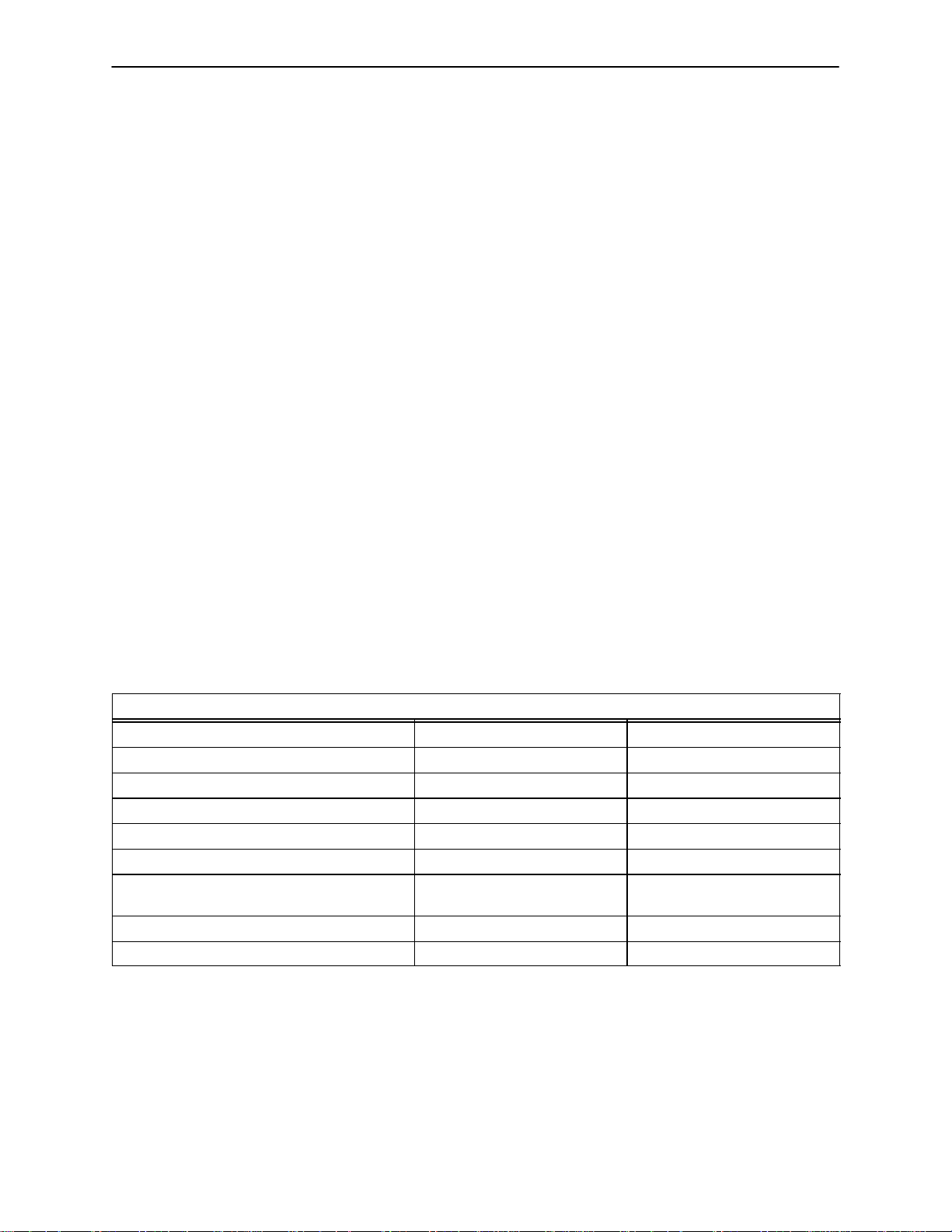

quaternary type disinfectants can be used. Iodophor type disinfectants are not recommended for use because staining may result. The following products have been tested and have been found not to have a harmful effect WHEN USED IN ACCORDANCE WITH MANUFACTURERS RECOMMENDED DILUTION.*

TRADE NAME

A33 Quaternary Airwick (Professional Products Division) 2 ounces/gallon

A33 (dry) Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Beaucoup Phenolic Huntington Laboratories 1 ounce/gallon

Blue Chip Quaternary S.C. Johnson 2 ounces/gallon

Elimstaph Quaternary Walter G. Legge 1 ounce/gallon

Franklin Phenomysan F2500 Phenolic Purex Corporation 1 1/4 ounce/gallon

Franklin Sentinel Quaternary Purex Corporation 2 ounces/gallon

Galahad Phenolic Puritan Churchill Chemical Company 1 ounce/gallon

Hi-Tor Quaternary Huntington Laboratories 1/2 ounce/gallon

LPH Phenolic Vestal Laboratories 1/2 ounce/gallon

Matar Phenolic Huntington Laboratories 1/2 ounce/gallon

Omega Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Quanto Quaternary Huntington Laboratories 1 ounce/gallon

Sanikleen Quaternary West Chemical Products 2 ounces/ gallon

Sanimaster II Quaternary Service Master 1 ounce/gallon

Vesphene Phenolic Vestal Laboratories 1 1/4 ounce/gallon

Wexcide Phenolic Wexford Labs 1/2 ounce/gallon

DISINFECTANT

TYPE

MANUFACTURER

*MANUFACTURER’S

RECOMMENDED

DILUTION

CAUTION

The recommended cleaning solutions for the optional wood head board are furniture polish or a 50% solution

of antibacterial hand soap and water. Any other cleaning solutions may damage the wood finish and should

not be used.

13

Page 15

Cleaning

Quaternary Germicidal Disinfectants, used as directed, and/or Chlorine Bleach products, typically 5.25% So dium Hypochlorite in dilutions ranging between 1 part bleach to 100 parts water, and 2 parts bleach

to 100 parts water are not considered mild detergents. These products are corrosive in nature and

may cause damage to your stretcher if used improperly. If these types of products are used to clean

Stryker equipment, measures must be taken to ensure the equipment is rinsed with clean water and thoroughly dried following cleaning. Failure to properly rinse and dry the equipment will leave a corrosive residue on

the surface, possibly causing premature corrosion of critical components.

NOTE

Failure to follow the above directions when using these types of cleaners may void this product’s warranty.

REMOVAL OF IODINE COMPOUNDS

This solution may be used to remove iodine stains from mattress cover surfaces.

1. Use a solution of 1-2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area.

Clean as soon as possible after staining occurs. If stains are not immediately removed, allow solution

to soak or stand on the surface.

2. Rinse surfaces which have been exposed to the solution in clear water before returning bed to service.

14

Page 16

Preventative Maintenance Checklist

All fasteners secure

All welds intact, not cracked or broken

No bent or broken tubing or sheet metal

No debris in casters

All casters secure and swivel properly

Engage brake pedal and push on the bed to ensure all casters lock securely

Steer caster latches properly

Siderails move and latch properly

Fowler operates properly

Fowler (back rest) Slide operates properly

Bed Up/Down operates properly

Foot operates properly

Trendelenburg operates properly

I.V. pole intact and operating properly

No rips or cracks in mattress cover

Lubricate where required

Replace Nurse Call 9V battery (annually)

Power cord not frayed

No cables worn or pinched

All electrical connections tight

All grounds secure to the frame

Ground impedance not more than 100 milliohms

Current leakage not more than 100 microamps

Serial No.

NOTE

Preventative maintenance should be performed at a minimum of annually. A preventative maintenance program should be established for all Stryker Medical equipment. Preventative maintenance may need to be

performed more frequently based on the usage level of the product.

15

Page 17

Static Discharge Precautions

The electronic circuits in the Stryker Adel Maternity Bed are completely protected from static electricity damage only while the bed is assembled. It is extremely important that all service personnel always use adequate

static protection when servicing the electronic systems of the bed. Whenever you are touching wires or circuit

boards, you should be using static protection.

Static Protection Equipment

The necessary equipment for proper static protection is:

1 static wrist strap; 3M part number 2214 or equivalent,

1 grounding plug; 3M part number 61038 or equivalent,

1 test lead with a banana plug on one end and an alligator clip on the other; Smith part number

N132B699 or equivalent.

Stryker has available the following equipment for proper static protection:

Complete static protection system - part number 3000-000-753

1 grounding plug - Stryker part number 3000-000-754

1 static wrist strap - Stryker part number 3000-000-755

1 test lead - Stryker part number 3000-000-756

CAUTION

All electronic service parts will be shipped in static shielding bags. Do not open the bags until you have completed steps 2 and 3 of the following procedure. All circuit boards must be returned to Stryker Medical. Return

circuit boards in the static shielding bags the new boards were shipped in.

Static Protection Procedure

1. Unplug the power cord from the wall receptacle.

2. Insert the grounding plug into a properly grounded hospital grade wall receptacle. Plug the banana plug

of the test lead into the receptacle on the grounding plug. Connect the alligator clip on the other end of

the test lead to a ground point on the bed.

3. Place the static control wrist strap on your wrist. Connect the alligator clip at the other end of the wrist strap

cord to a ground point on the bed.

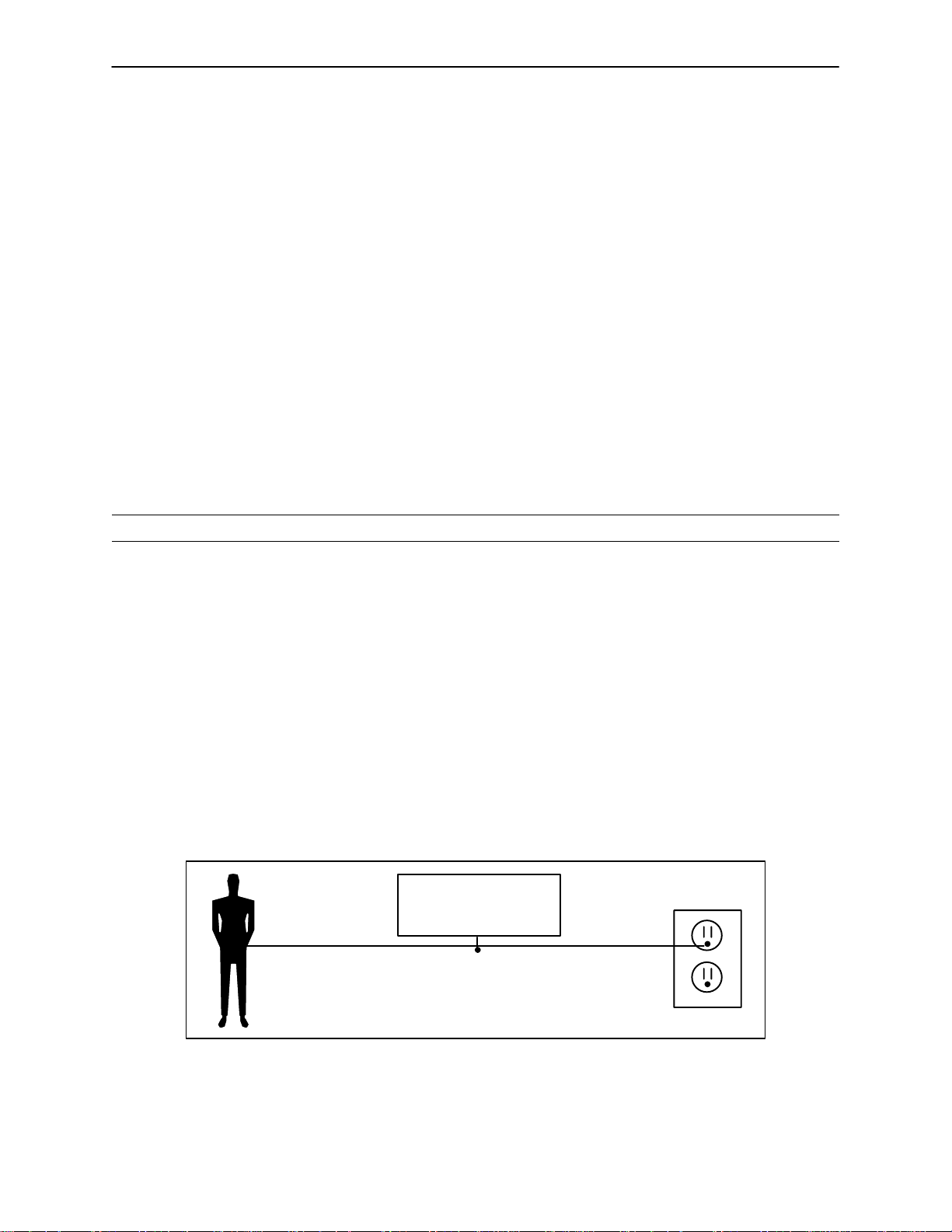

BED

GROUNDING DIAGRAM

16

Page 18

Service Information - Base

STEER WHEEL CABLE ADJUSTMENT

Required Tools:

(2) 10 mm Open End Wrenches

Adjustment Procedure:

1. Remove the base frame cover from the (patient) right side of the bed.

2. Position the steer pedal (located at the head end of the bed) in the off position.

3. Using two 10 mm open end wrenches, adjust the steer cable so the steer latch lever is approximately

3/16” away from the caster horn.

4. T est the steer wheel to ensure it engages when the steer pedal is in the on position and disengages when

the steer pedal is in the off position.

5. Reinstall the base cover.

BRAKE ADJUSTMENT

Required Tools:

3/32” Allen Wrench 6” C-Clamp

Adjustment Procedure:

1. Remove the base frame cover on the side of the bed needing service.

2. Put the brake pedal (located at the center of the base frame on both sides of the bed) in the neutral position.

3. Using a 6” C-clamp, clamp the brake bar to the frame to release the tension on the brake adjuster.

4. Using a 3/32” Allen wrench, loosen the set screw on the end of the brake bar.

5. Turn the brake adjuster clockwise to increase the brake tension and counterclockwise to decrease the

brake tension.

NOTE

All four wheel brakes should be set with equal brake tension.

6. Verify the brakes engage and disengage properly.

7. Using the 3/32” Allen wrench, tighten the set screw.

8. Reinstall the base frame cover.

17

Page 19

Service Information - Litter

LIFT MOTOR REMOVAL AND REPLACEMENT

Required Tools:

1/2” Wrench T27 Torx Wrench Hammer

Punch 3/8” Socket Wrench Standard Screwdriver

Snap Ring Pliers 5/16” Nut Driver 3/16” Allen Wrench

5/32” Allen Wrench 9/16” Wrench (2) 2x4’s

Removal Procedure:

1. Raise the bed to the full up position.

NOTE

If the bed will not raise electrically, crank the bed up manually.

2. Remove all accessories from the foot end of the bed (foot pan, mattress, basin, etc.).

3. Using a 5/16” nut driver, remove the 8 bolts holding the bottom cover to the litter.

4. Using a T27 Torx wrench, remove the six bolts holding the seat section to the frame and remove the

seat section.

5. Raise the Fowler to the full up position.

6. Run the Fowler to the full in position (toward the foot end of the bed).

7. Unplug the bed power cord from the wall socket.

8. Using a 3/8” socket wrench, remove the four bolts holding the electrical cover to the electrical pan.

9. Using a 3/8” socket wrench, remove the four bolts holding the electrical pan to the frame.

10. Using a 3/8” socket wrench, remove the two bolts holding the cover over the Fowler motor and remove

the cover.

11. Using a T27 Torx wrench, remove the four screws holding the front cover to the litter. Tilt and support it.

12. Slide the electrical panel toward the head end of the bed.

13. Using a standard screwdriver , remove the screw holding the potentiometer coil to the bed motor drive tube.

CAUTION

The potentiometer coil spring recoils very quickly. Before removing the screw, hold the spring securely to

avoid damaging the potentiometer.

14. Using (2) 2x4’s, support both ends of the bed between the base frame and the crank arms. Using the

manual crank, lower the bed until it is resting on the 2x4’s.

15. Using a hammer and punch, remove the 4 roll pins holding the lift coupler to the drive screw.

WARNING

It is very important to properly support the bed before removing the drive tube bolt or serious personal injury

could result.

16. Using a 3/16” Allen wrench and a 1/2” wrench, remove the bolt from the end of the bed lift drive tube.

17. Remove the drive tube and drive screw from the bed.

18. Disconnect the motor connectors from the CPU board and the capacitor.

19. Using a 1/4” Allen wrench and a 9/16” wrench, remove the trend. link shoulder bolt from the patient/right

side of the bed.

18

Page 20

Service Information - Litter

LIFT MOTOR REMOVAL AND REPLACEMENT (CONTINUED)

Removal Procedure (Continued):

20. Using a 1/4” Allen wrench, remove the two shoulder bolts holding the motor to the litter frame.

21. Move the lift motor assembly toward the head end of the bed.

22. Remove the motor by lowering it and moving it toward the head end of the bed.

23. Reverse the above procedure to reinstall the replacement lift motor. After the replacement lift motor is

installed, all the limits must be set and “burned in”. See page 23 & 24 for potentiometer replacement

and adjustment.

TREND MOTOR REMOVAL AND REPLACEMENT

Required Tools:

7/16” Socket Wrench 3/16” Allen Wrench 11/32” Open End Wrench

5/16” Socket Wrench 1/2” Open End Wrench 1/2” Socket Wrench

3/8” Socket Wrench

Removal Procedure:

1. Raise the bed to the full up position.

2. Remove all accessories from the foot end of the bed (foot pan, mattress, basin, etc.).

3. Using a 5/16” nut driver, remove the 8 bolts holding the bottom cover to the litter.

4. Support the head end of the bed from the head board mounting post to the floor.

WARNING

It is very important to properly support the bed before removing the drive tube bolt or serious personal injury

could result.

5. Unplug the bed power cord from the wall socket.

6. Using a 3/8” socket wrench or nut driver, remove the four 3/8” bolts from the electrical cover and remove

the cover.

7. Using a 3/8” socket wrench or nut driver, remove the two 3/8” bolts holding the holding the Fowler motor

access cover to the electrical pan.

8. Unplug the Trend motor from the litter CPU board.

9. Disconnect the motor to capacitor wires from the capacitor.

10. Using a 3/16“ Allen wrench and 1/2” open end wrench, reach under the bed and remove the bolt and nut

on the end of the drive tube.

11. Using a 11/32” open end wrench, remove the nut from the air compressor.

12. Using a 1/2” open end wrench and a 1/2” socket wrench, remove the four nuts and bolts from the motor

mounting bracket and remove the motor. (When installing the replacement motor, use Loctite 242 on the

bolts.)

13. Reverse the above procedure to install the new motor.

19

Page 21

Service Information - Litter

FOWLER IN-OUT MOTOR REMOVAL AND REPLACEMENT

Required Tools:

3/8” Socket Wrench 5/16” Socket Wrench

Removal Procedure:

1. Raise the bed and the Fowler to the full up position.

2. Run the Fowler to the full out position (toward the head end of the bed).

WARNING

If the Fowler slide will not run electrically, it must be manually cranked out (toward the head of the bed) to

prevent personal injury when the motor is removed. Remove the crank from the two clips at the head end

of the bed. Unplug the bed power cord from the wall socket. Insert the crank into the opening marked with

the Fowler Up/Down symbol. Center the notch in the end of the crank on the roll pin on the motor assembly

and crank to the desired height.

3. Raise the siderails to the full up position.

4. Unplug the bed power cord from the wall socket.

5. Using a 3/8” socket wrench, remove the four bolts holding the electrical cover to the electrical pan and

remove the cover.

6. Using the 3/8” socket wrench, remove the two bolts holding the Skoocher motor access cover to the electrical pan and remove the cover.

7. Using a 5/16” socket wrench, remove the 8 bolts holding the bottom cover to the litter frame and remove

the cover.

8. Disconnect the capacitor wires and the option power board connector for the Fowler slide motor.

9. Using a 3/8” socket wrench, remove the five bolts holding the motor mounting bracket to the frame and

remove the motor.

10. Reverse the above procedure to install the replacement motor.

FOWLER MOTOR REMOVAL AND REPLACEMENT

Required Tools:

3/8” Socket Wrench 5/16” Socket Wrench Tie-Down Straps

Removal Procedure:

1. Raise the bed and the Fowler to the full up position.

2. Raise the siderails to the full up position.

3. Unplug the bed power cord from the wall socket.

4. Using a 3/8” socket wrench, remove the four bolts holding the electrical cover to the electrical pan.

5. Using a 3/ 8 ” socket wrench, remove the two bolts holding the Fowler motor access cover to the electrical

pan and remove the cover.

6. Using a 3/8” socket wrench, remove the four bolts holding the electrical pan to the frame.

7. Unplug the Fowler motor from the main power board.

20

Page 22

Service Information - Litter

FOWLER MOTOR REMOVAL AND REPLACEMENT (CONTINUED)

8. Unplug the capacitor wires.

9. Lift the electrical pan up slightly and turn it sideways on an angle.

WARNING

It is important to properly support the Fowler before proceeding or personal injury could result.

10. Using a 3/8” inch socket wrench, remove the five 5/16” bolts holding the motor mounting bracket to the

litter frame.

11. Lift the motor up and out.

12. Reverse the above procedure to install the replacement Fowler motor.

FOOT MOTOR REMOVAL AND REPLACEMENT

Required Tools:

T27 Torx Driver Hammer Punch

7/16” Socket 9/16” Socket Ratchet

Removal Procedure:

1. Raise the bed to the full up position.

2. Remove all accessories from the foot end of the bed (foot pan, mattress, basin, etc.).

3. Using a 5/16” nut driver, remove the 8 screws holding the bottom cover to the litter.

4. Using a 9/16” socket, remove the bolts holding the left and right foot pan support brackets. (When replacing the brackets during re-assembly, use Loctite 242 on the bolts and torque them to 40 foot-pounds.)

5. Remove the head/seat section mattress.

6. Using a T27 Torx driver, remove the six bolts holding the seat section.

7. Run the foot motor half way up from the bottom stop.

8. Unplug the motor connector from the power board.

9. Unplug the connector from the foot motor capacitor.

10. While holding the motor to prevent it from falling, use a 7/16” wrench to remove the four bolts from the

seat section.

11. Using a hammer and punch, drive the roll pin out of the manual override nut.

12. With the motor and crosstube sitting on the seat frame, push down on the foot motor to force the Acme

nut out of the crosstube and remove the nut from the screw.

13. Unscrew the Acme nut from the motor shaft.

14. Tilt the motor toward the head end of the bed and carefully lift it up and remove it from the bed.

15. Reverse the above procedure to install the replacement foot motor. See page 24 for the potentiometer

adjustment procedure.

21

Page 23

Service Information - Litter

POWER SUPPLY BOARD REPLACEMENT

Required Tools:

3/8” Socket Ratchet Needle Nose Pliers

Procedure:

1. Properly ground yourself (see page 16 for static discharge precautions).

2. Raise the Fowler to the full up position.

3. Unplug the bed power cord from the wall socket.

4. Remove the four 3/8” bolts from the electrical service panel and remove the access cover.

5. Unplug all connectors from the power supply board.

6. Using needle nose pliers, squeeze the four stand-offs and pull up gently on the board to remove it.

7. Reverse the above procedure to install the replacement power supply.

CPU BOARD REPLACEMENT

Required Tools:

3/8” Socket Ratchet Needle Nose Pliers

Removal Procedure:

1. Properly ground yourself (see page 16 for static discharge precautions).

2. Raise the Fowler to the full up position.

3. Unplug the bed power cord from the wall socket.

4. Remove the four 3/8” bolts from the electrical service panel and remove the access cover.

5. Unplug all connectors from the CPU board. Note the location of the connectors so each will be attached

properly to the replacement CPU board. (Reference electrical assembly on pages 101-103).

6. Using needle nose pliers, squeeze the five stand-offs and pull up gently on the CPU board to remove it.

7. Install the replacement CPU board and plug all the connectors into the proper locations.

NOTE

All cables and board connections are lettered to aid with re-connection.

8. All replacement CPU boards must be calibrated. See page 23 & 24 for calibration procedures.

9. Reinstall the access cover.

22

Page 24

Service Information - Litter

OPTIONAL POWER BOARD REPLACEMENT

Required Tools:

3/8” Socket Ratchet 5/16” Nut Driver

Removal Procedure:

1. Properly ground yourself (see page 16 for static discharge precautions).

2. Raise the Fowler to the full up position.

3. Unplug the bed power cord from the wall socket.

4. Remove the four 3/8” bolts from the electrical service panel and remove the access cover.

5. Unplug all connectors from the optional power board.

6. Note the location of each connector so all will be attached properly to the replacement power board.

7. Remove the six 5/16” screws holding the optional power board to the electrical service panel.

8. Reverse the above procedure to install the replacement power board.

NOTE

All cables and board connections are lettered to aid with re-connection. (See electrical assembly on pages

101-103).

LIFT, FOOT, AND FOWLER CALIBRATION PROCEDURE

Required Tools:

Tape Measure Inclinometer Digital Volt Meter

Diagnostics Procedure:

1. Unplug the bed power cord from the wall socket.

2. Press and hold the “head up” and “head down” (Trendelenburg) buttons.

3. While continuing to hold down the “head up” and “head down” buttons, plug the bed power cord into a

properly grounded wall receptacle.

4. Release the “head up” and “head down” buttons. The motion Lock LED will flash, indicating the bed is

in diagnostics mode

Lift Calibration Procedure:

CAUTION

Raise the foot section of the bed to prevent the bed from being damaged when it is lowered.

1. Place the inclinometer on the seat section skin. Level the bed using the “head down” button.

2. Press the “bed down” button and lower the bed until the seat section skin is 19 3/8” above the floor (±1/8”).

3. To set the lift limit:

It is important to press the “head down” button first. The Motion Lock LED will light. Continue to hold

the buttons until the LED blinks on and off.

press first the “head down” (Trendelenburg) button, then the “bed down” button. Note:

23

Page 25

Service Information - Litter

LIFT, FOOT, AND FOWLER CALIBRATION PROCEDURE (CONTINUED)

Lift Calibration Procedure (Continued):

4. Press the “bed up” button and raise the bed until the seat section skin is 37 1/2” above the floor (±1/8”).

5. To set the lift limit:

It is important to press the “head down” button first. The Motion Lock LED will light. Continue to hold the

buttons until the LED blinks on and off.

6. If Fowler or foot section calibration is not necessary, end the calibration procedure by unplugging the bed

power cord from the wall socket.

7. Plug the power cord into the wall socket. Run the bed to full up, then full down to verify the bed limits.

Fowler Calibration Procedure:

1. Adjust the Fowler slide to the full out position. The Fowler down motion will not occur until this limit is met.

2. Press the Fowler down button until the Fowler is flat.

3. To set the Fowler limit:

Note: It is important to press the “head down” button first. The Fowler LED will light. Continue to hold

the buttons until the LED blinks on and off.

4. If lift or foot section calibration is not necessary, end the calibration procedure by unplugging the bed

power cord from the wall socket.

5. Plug the power cord back in to the wall socket. Run the Fowler to full up, then full down to verify the limits.

press first the “head down” (Trendelenburg) button, then the “bed up” button. Note:

press first the “head down” (T rendelenburg) button then the Fowler down button.

Foot Calibration Procedure:

CAUTION

Raise the bed high enough to allow the foot section to be lowered without damaging the bed.

1. Press the “foot down” button until the the foot section reaches full down or the bottom limit.

2. To set the foot limit:

Note: It is important to press the “head down” button first. The LED will light. Continue to hold the buttons

until the LED blinks on and off.

3. If lift or Fowler calibration is not necessary, end the calibration procedure by unplugging the bed power

cord from the wall socket.

4. Plug the power cord back in to the wall socket. Run the foot to full up, then full down to verify the limits.

Potentiometer Initial Settings for Lift, Fowler, and Foot:

Lift Potentiometer (reference page 71)

Looking at the stem of the potentiometer, turn potentiometer fully counterclockwise until it stops, then turn

it back (clockwise) two full turns.

Foot Potentiometer (reference page 74)

Looking at the stem of the potentiometer, turn potentiometer fully counterclockwise until it stops, then turn

it back (clockwise) six full turns.

Fowler Potentiometer (reference page 55)

Looking at the stem of the potentiometer, turn potentiometer fully clockwise until it stops, then turn it back

(counterclockwise) one full turn.

press first the “head down” (Trendelenburg) button, then the “foot down” button.

Upper Limit (35”) 5000 ohms $ 500 ohms 2.5 VDC " 0.2 VDC

HDR 23 + Lead Pin 3, - Lead Pin 2

Upper Limit 3300 ohms " 500 ohms 1.65 VDC " 0.2 VDC

HDR 28 + Lead Pin 3, - Lead Pin 2

Upper Limit (@68) 6750 ohms " 500 ohms 3.37 VDC " 0.2 VDC

HDR 3 + Lead Pin 3, - Lead Pin 4

24

Page 26

Service Information - Litter

SMART TV INTERFACE BURN-IN PROCEDURE

This procedure is used for selecting the style of TV interface desired for your bed. If traditional TV is desired,

no calibration is required. If optional Smart TV is available on the bed, select one of the TV manufacturers

listed in the table below.

SET-UP

Ensure the communication cable is connected between the bed and the Db37 wall port or the pillow

speaker port of the nurse call system. If available, a bed communication tester can be used instead of

the hospital wiring.

PROCEDURE

1. Place the bed in the lift potentiometer burn-in mode (see page 23).

2. Notice the Nurse Call LED (yellow) is flashing. Notice the Nurse Answer LED (green) is flashing on/off

slowly.

3. Press and release the TV ON/OFF switch on the bed’s siderail once. Notice the Nurse Call LED flashes

once. This is the first selection of TV manufacturers for the Smart TV mode. Notice the Nurse Answer

LED (green) is flashing on/off slowly. The Nurse Answer LED will only light when the Nurse Call LED

(yellow) is flashing.

4. Press and release the TV ON/OFF switch on the bed’s siderail to scroll to other TV manufacturers. Notice

the number of times the Nurse Call LED flashes matches the number listed in the table below and represents the TV manufacturer selected.

5. When the desired TV manufacturer has been selected, unplug the bed power cord from the wall socket

and plug it back in to complete the Smart TV burn-in procedure.

NOTE

If the bed is connected to a television during the burn-in procedure, the television will turn on when the correct

setting is selected.

TV MANUFACTURER SELECTION FOR SMART TV BURN-IN PROCEDURE

Press and release TV ON/OFF switch: Nurse Call LED (Yellow) TV Manufacturer

One time One flash RCA 1

Two times Two flashes RCA 2

Three times Three flashes Zenith 1

Four times Four flashes Zenith 2

Five times Five flashes Phillips/Magnavox

Six times Six flashes Magnavox

(models 9120, 9220, 9320)

Seven times Seven flashes Traditional TV

Eight times Eight flashes Traditional Plus

25

Page 27

Electrical Troubleshooting

TROUBLESHOOTING GUIDE

DEFINITIONS:

DMM = Digital Multi-Meter

PCB = Printed Circuit Board

CPU = Central Processing Unit

NOTE

See pages 29-33 for an outline of bed PCB’s and voltage test points. See pages 23 & 24 for potentiometer

calibration.

PROBLEM/FAILURE

No power to bed A. Unplug bed power cord and check continuity of fuses F1 and F2 with

DMM.

B. Check for 120 VAC power at J1 on the power supply, pin 1 and 2.

C. Check for DC voltages on J2 (pins 1,2,3 & 6) on power supply. See

page 32 for power supply voltage test points.

D. If no voltages at J2, unplug connector HDR2 on the CPU board and

recheck for DC voltages at J2 on the power supply.

E. Unplug all cables from the CPU board and recheck voltages.

No bed down motion. A. Enter diagnostics, (see page 23) and press bed down. If motion is

present, re-burn all limits.

B. Check for shunt on HDR3 on pin 1 and 2 on the CPU board.

C. Check for 5VDC on R135 positive lead, CPU ground test point nega-

tive lead while pushing the bed down button.

D. Check for 120 VAC on HDR29, pin 1 white and pin 2 red, of the CPU

board while pushing the bed down button.

No bed up motion. A. Enter diagnostics, (see page 23) and press bed up. If motion is pres-

ent, re-burn all limits.

B. Check for 5VDC on R139 positive lead, CPU ground test point negative lead on the CPU board while pushing the bed up button.

C. Check 120 VAC on HDR29, pin 1 white and pin 3 black, of the CPU

board while pushing the bed up button.

No foot down motion. A. Enter diagnostics, (see page 23) and press foot down. If motion is

present, re-burn all limits.

B. Check for shunt on HDR3 on pin 1 and 2 on the CPU board.

C. Check for 5VDC on R149 positive lead, CPU ground test point nega-

tive lead on the CPU board while pushing the foot down button.

D. If no down motion in diagnostics, check for 120 VAC on HDR34 pin 1

white and pin 3 red of the CPU board while pushing the foot down button.

No foot up motion. A. Enter diagnostics, (see page 23) and press foot up. If motion is pres-

ent, re-burn all limits.

B. Check for 5VDC on R147 positive lead, CPU ground test point negative lead on the CPU board while pushing the foot up button.

C. If no up motion in diagnostics, check for 120 VAC on HDR34, pin 1

white and pin 6 black of the CPU board while pushing the foot up button.

RECOMMENDED ACTION

26

Page 28

Electrical Troubleshooting

TROUBLESHOOTING GUIDE (CONTINUED)

PROBLEM/FAILURE RECOMMENDED ACTION

No Fowler down motion. A. Enter diagnostics, (see page 23) and check for Fowler down motion.

If motion is present, re-burn all limits.

B. If no Fowler down motion is present, check the Fowler Slide Out

switch for proper connection. See item M on page 60 for details.

C. Check for 5VDC on R137 positive lead, CPU ground test point negative lead of the CPU board while pushing the Fowler down button.

D. If no down motion in diagnostics,check for 120 VAC on HDR30 pin 2

red and pin 3 white of the CPU board while pushing the Fowler down

button.

No Fowler up motion. A. Enter diagnostics, (see page 23) and press Fowler up. If motion is

present, re-burn all limits.

B. Check for 5VDC on R141 positive lead, CPU ground test point negative lead of the CPU board while pushing the Fowler up button.

C. If no up motion in diagnostics, check for 120 VAC on HDR30, pin 1

black and pin 3 white of the CPU board while pushing the Fowler up button.

No Trend motion. A. Check for shunt on HDR3 of the CPU board pin 1 and 2.

B. Check for bed up and down limits. If no motion, reference bed motion troubleshooting.

C. Check for 5 VDC on R145 positive lead, CPU ground test point negative lead on the CPU board while pushing the Trend. button.

D. Check for 120 VAC on HDR33, pin 1 white and pin 3 red of the CPU

board while pushing the Trend button.

No Trend Out motion. A. Check for 5 VDC on R143 positive lead, CPU ground test point nega-

tive lead on the CPU board while pushing the Trend. button.

B. Check for 120 VAC on HDR33, pin 1 white and pin 6 black of the

CPU board while pushing the Trend. button.

No Skoocher In (Fowler

Slide In) motion.

No Skoocher Out (Fowler

Slide Out) motion.

A. Check for Fowler up and down limits. If no motion, reference Fowler

troubleshooting.

B. Check for 5 VDC at HDR2, pin 1 (Black) and 2 (White) of the option

power board.

C. Check for 12 VDC at HDR2 pin 1 (Black) and 3 (Red) of the option

power board.

D. Check for 5 VDC on HDR2 pin 1 (Green) and pin 4 (Black) of the option power board while pushing the Skoocher In button.

E. Check for 120 VAC on HDR6, pin 1 Black and pin 3 white of the option power board while pushing the Skoocher In button.

A. Check for Fowler up and down limits. If no motion, reference Fowler

troubleshooting.

B. Check for 5 VDC at HDR2, pin 1 (Black) and 2 (White) of the option

power board.

C. Check for 12 VDC at HDR2 pin 1 (Black) and 3 (Red) of the option

power board.

D. Check for 5 VDC on HDR2 pin 1 (Orange) and 5 (Black) of the option

power board while pushing the Skoocher Out button.

E. Check for 120 VAC on HDR6, pin 2 red and pin 3 white of the option

power board while pushing the Skoocher Out button.

27

Page 29

Electrical Troubleshooting

TROUBLESHOOTING GUIDE (CONTINUED)

PROBLEM/FAILURE RECOMMENDED ACTION

No Lumbar Firm. A. Check for 5VDC on HDR2 pin 1 white and pin 2 black of the option

power board.

B. Check for 12 VDC on HDR2 pin 1 red and pin 3 black of the option

power board.

C. Check for 5 VDC on HDR2 pin 8 red/black and pin 1 black of the option power board while pushing the lumbar firm button.

D. Check for 120 VAC on HDR 4 pin 1 and pin 3 of the option power

board while pushing the lumbar firm button.

No Lumbar Soft. A. Check for 5VDC on HDR2 pin 2 white and pin 1 black of the option

power board.

B. Check for 12 VDC on HDR2 pin 3 red and pin 1 black of the option

power board.

C. Check for 5 VDC on HDR2 pin 7 white/black and pin 1 black of the

option power board while pushing the lumbar soft button.

D. Check for 120 VAC on HDR4 pin 1 and pin 2 of the option power

board while pushing the lumbar soft button.

No Seat Firm. A. Check for 5VDC on HDR2 pin 2 white and pin 1 black of the option

power board.

B. Check for 12 VDC on HDR2 pin 3 red and pin 1 black of the option

power board.

C. Check for 5 VDC on HDR2 pin 10 orange/black and pin 1 black of the

option power board while pushing the seat firm button.

D. Check for 120 VAC on HDR3 pin 1 and pin 3 of the option power

board while pushing the seat firm button.

No Seat Soft A. Check for 5VDC on HDR2 pin 2 white and pin 1 black of the option

power board.

B. Check for 12 VDC on HDR2 pin 3 red and pin 1 black of the option

power board.

C. Check for 5 VDC on HDR2 pin 9 green/black and pin 1 black of the

option power board while pushing the seat soft button.

D. Check for 120 VAC on HDR3 pin 1 and pin 2 of the option power

board while pushing the seat soft button.

No compressor function. A. Check for 5VDC on HDR2 pin 2 white and pin 1 black of the option

power board.

B. Check for 12 VDC on HDR2 pin 3 red and pin 1 black of the option

power board.

C. Check for 5 VDC on HDR2 pin 6 blue and pin 1 black of the option

power board while pushing the lumbar firm or seat firm button.

D. Check for 120 VAC on HDR5 pin 1 and pin 3 of the option power

board while pushing the lumbar firm or seat firm button.

28

Page 30

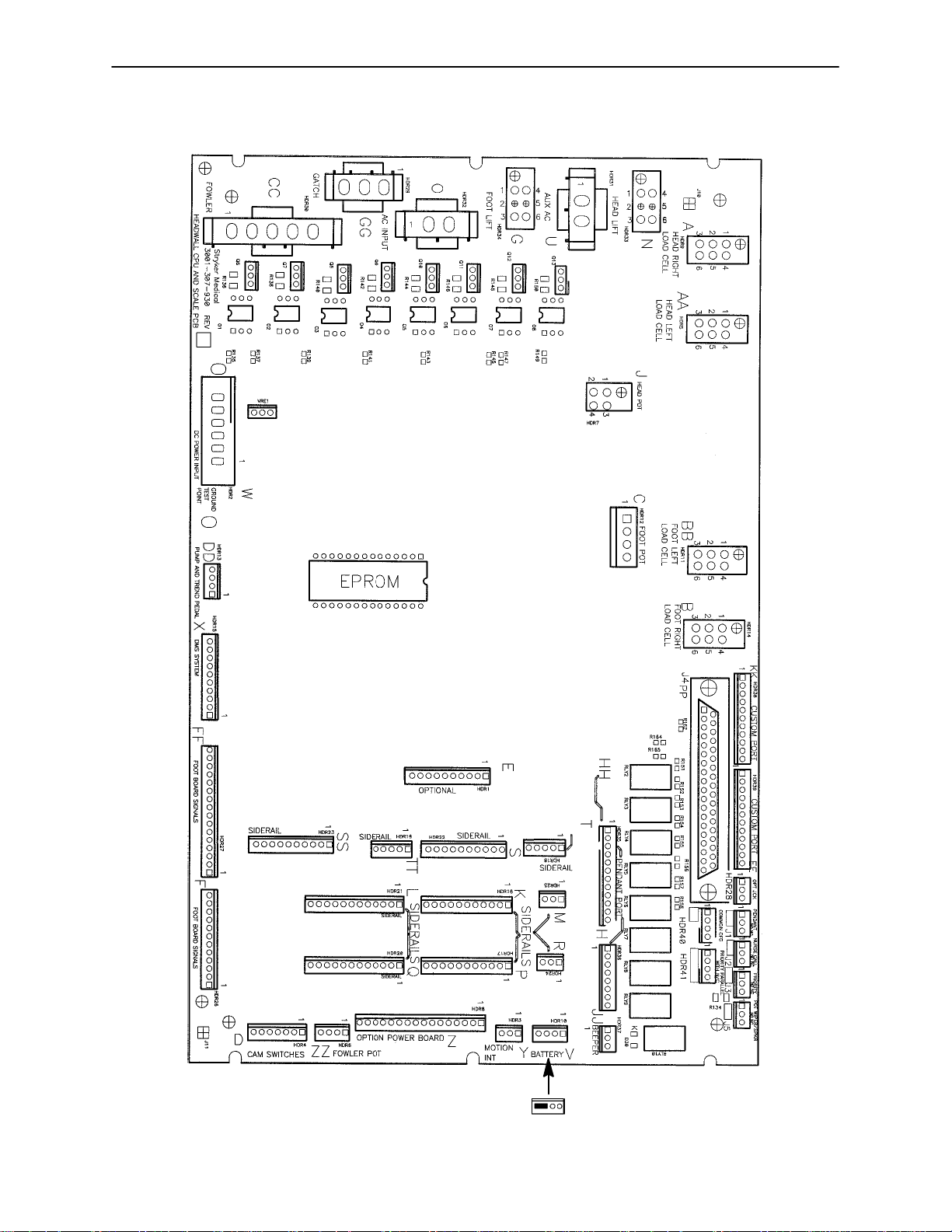

Bed Circuit Boards

CPU BOARD KIT WITH HEAD WALL INTERFACE - P/N 4700-700-4

CPU BOARD KIT WITHOUT HEAD WALL INTERFACE - P/N 4700-700-3

59-137

Shunt for

No Nurse Call

29

Page 31

Bed Circuit Boards

CPU BOARD KIT WITH HEAD WALL INTERFACE - P/N 4700-700-4

CPU BOARD KIT WITHOUT HEAD WALL INTERFACE - P/N 4700-700-3

CONNECTOR

LOCATION

HDR 2 W +12 VDC Pin 1 Pin 4 or 5 Relays & Siderails

HDR 2 W +5 VDC Pin 2 & 3 Pin 4 or 5 DC from Power Supply

HDR 2 W -12 VDC Pin 6 Pin 4 or 5 Relays & Siderails

HDR 6 ZZ +5 VDC Pin 1

HDR 6 ZZ 0 - 5 VDC

HDR 6 ZZ +5VDC Pin 1

HDR 7 J 0 - 5 VDC

HDR 7 J +5 VDC Pin 4

HDR 8 Z +5 VDC Pin 2

HDR 8 Z +12 VDC Pin 3

HDR 8 Z 0 VDC w/o Switch

HDR 8 Z 0 VDC w/o Switch

HDR 8 Z 0 VDC w/o Switch

HDR 8 Z 0 VDC w/o Switch

HDR 8 Z 0 VDC w/o Switch

HDR 8 Z 0 VDC w/o Switch

HDR 8 Z 0 VDC w/o Switch

HDR 12 C +5 VDC Pin 1

HDR 12 C 0 - 5 VDC

HDR 34 GG 0 VAC w/o Switch

HDR 34 GG 0 VAC w/o Switch

CABLE

LOCATION

VOLTAGE POSITIVE

while wipering

while wipering

+5 VDC w/Switch

+5 VDC w/Switch

+5 VDC w/Switch

+5 VDC w/Switch

+5 VDC w/Switch

+5 VDC w/Switch

+5 VDC w/Switch

while wipering

110 VAC w/Switch

110 VAC w/Switch

White/Black

Red/Black

Green/Black

Orange/Black

LEAD

Green

Pin 3

Red

Green

Pin 3

Red

Green

White

Red

Pin 5

Orange

Pin 4

Green

Pin 6

Blue

Pin 7

Pin 8

Pin 9

Pin 10

Black

Pin 3

Red

Pin 6

Black

Pin 3

Red

NEGATIVE

LEAD

Pin 4

Black

Pin 4

Black

Pin 4

Black

Pin 2

Black

Pin 2

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 1

Black

Pin 2

Green

Pin 2

Green

Neutral Pin

1 White

Neutral Pin

1 White

DESCRIPTION

Light Voltage

Light Voltage

DC for Fowler

Potentiometer

Fowler Potentiometer

Wiper

DC for Fowler

Potentiometer

Lift Potentiometer

Wiper

DC for Lift

Potentiometer

DC to Option Power

Board

DC to Option Power

Board

Fowler Slide Out

Fowler Slide In

Compressor

Lumbar Soft

Lumbar Firm

Seat Soft

Seat Firm

DC for Foot

Potentiometer

Foot Potentiometer

Wiper

Foot Up

Foot Down

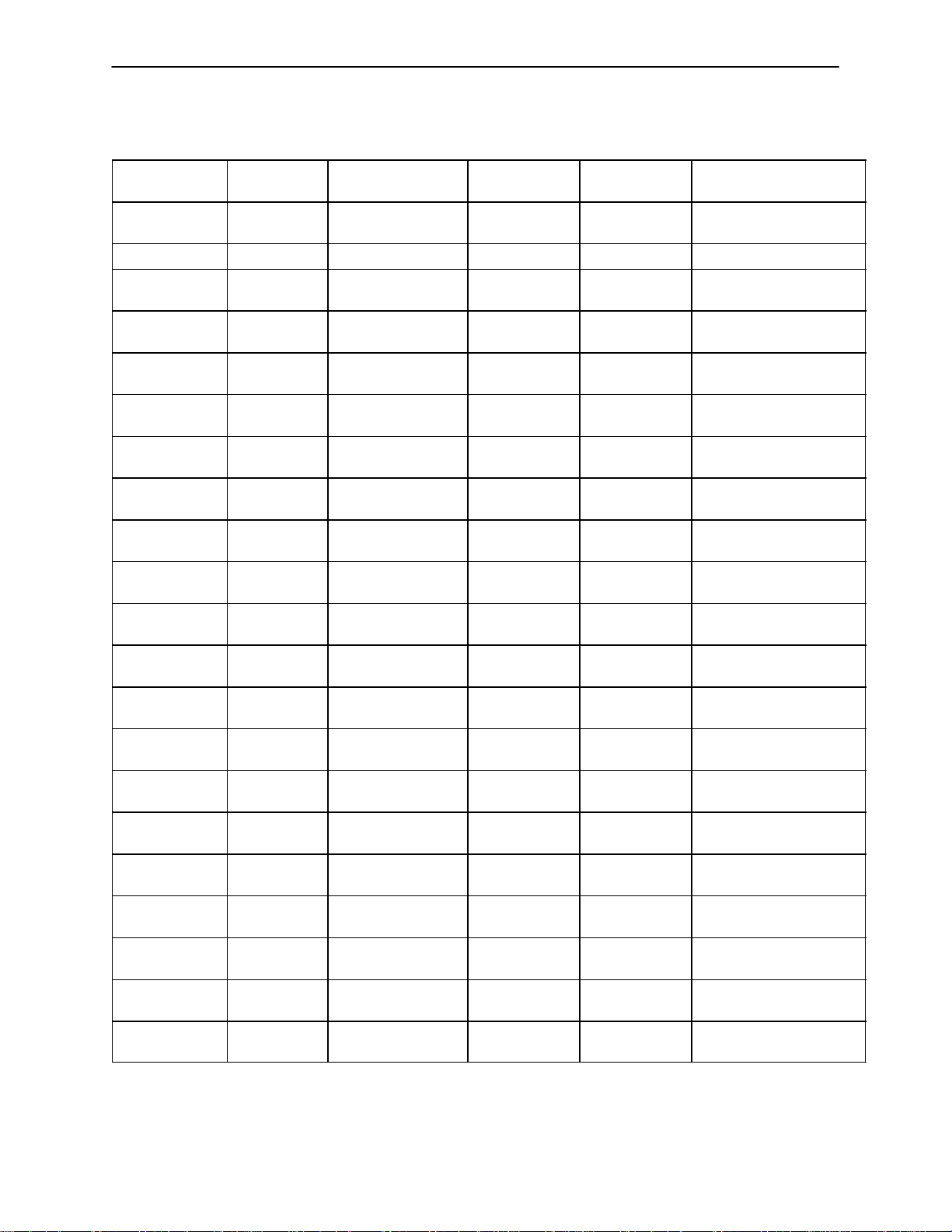

30

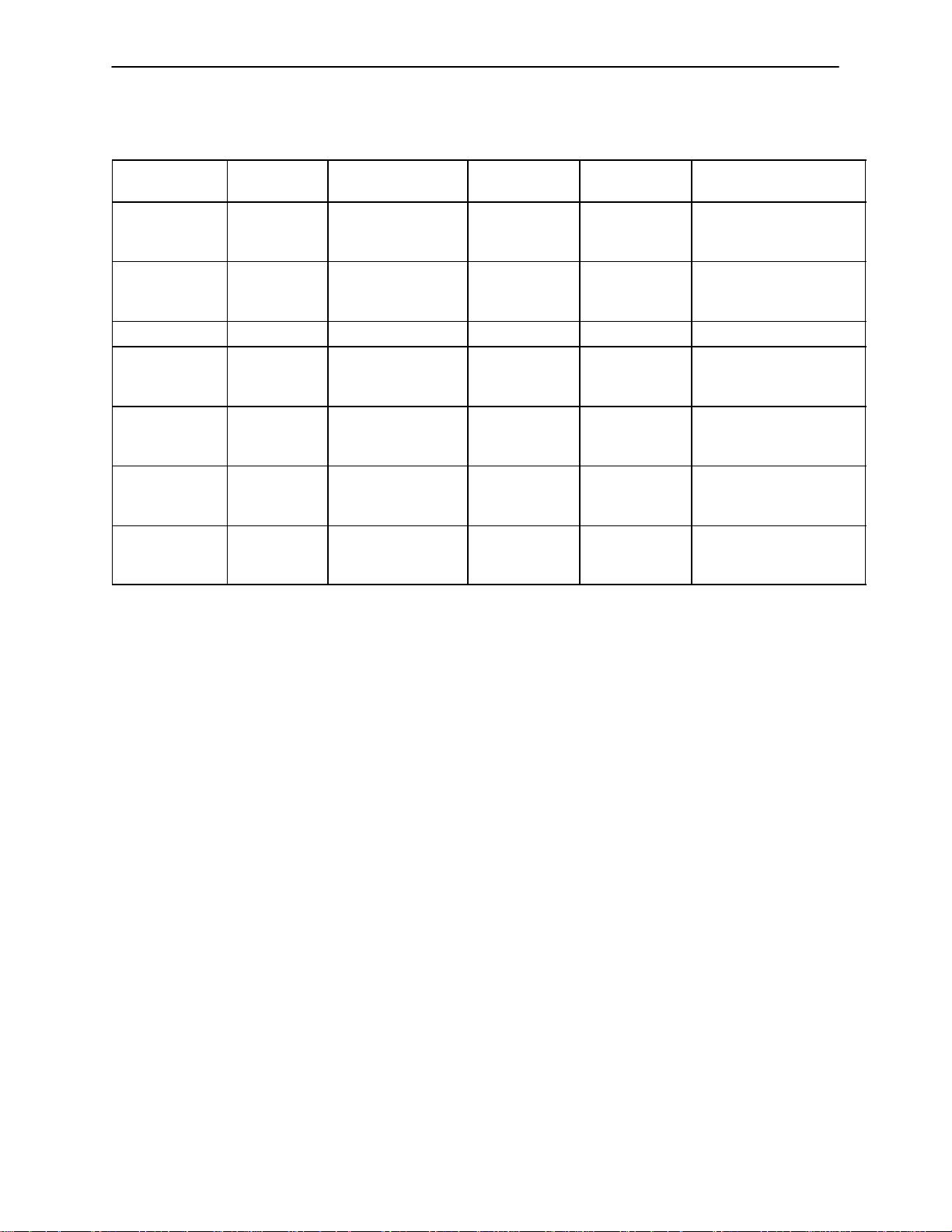

Page 32

Bed Circuit Boards

CPU BOARD KIT WITH HEAD WALL INTERFACE - P/N 4700-700-4

CPU BOARD KIT WITHOUT HEAD WALL INTERFACE - P/N 4700-700-3

CONNECTOR

LOCATION

HDR 30 CC 0 VAC w/o Switch

HDR 30 CC 0 VAC w/o Switch

HDR 32 O 110 VAC Pin 1 Pin 2 Line Voltage to Bed

HDR 29 N 0 VAC w/o Switch

HDR 29 N 0 VAC w/o Switch

HDR 33 G 0 VAC w/o Switch

HDR 33 G 0 VAC w/o Switch

CABLE

LOCATION

VOLTAGE POSITIVE

LEAD

Pin 2

120 VAC w/

Switch

120 VAC w/

Switch

120 VAC w/

Switch

120 VAC w/

Switch

120 VAC w/

Switch

120 VAC w/

Switch

Red

Pin 1

Black

Pin 2

Red

Pin 3

Black

Pin 3

Red

Pin 6

Black

NEGATIVE

LEAD

Neutral Pin 3

White

Neutral Pin 3

White

Neutral Pin 1

White

Neutral Pin 1

White

Neutral Pin 1

White

Neutral Pin 1

White

DESCRIPTION

Fowler Down

Fowler Up

Bed Down

Bed Up

Trend.

Trend. Out

31

Page 33

POWER SUPPLY - P/N 59-157

Bed Circuit Boards

CONNECTOR

LOCATION

J1 110V Pin 1 Pin 2

J2 12V Pin 1 Pin 4 or 5

J2 5V Pin 2 Pin 4 or 5

J2 5V Pin 3 Pin 4 or 5

J2 GND Pin 4 Pin 4 or 5

J2 GND Pin 5 Pin 4 or 5

J2 -12V Pin 6 Pin 4 or 5

VOLTAGE POSITIVE LEAD NEGATIVE LEAD

32

Page 34

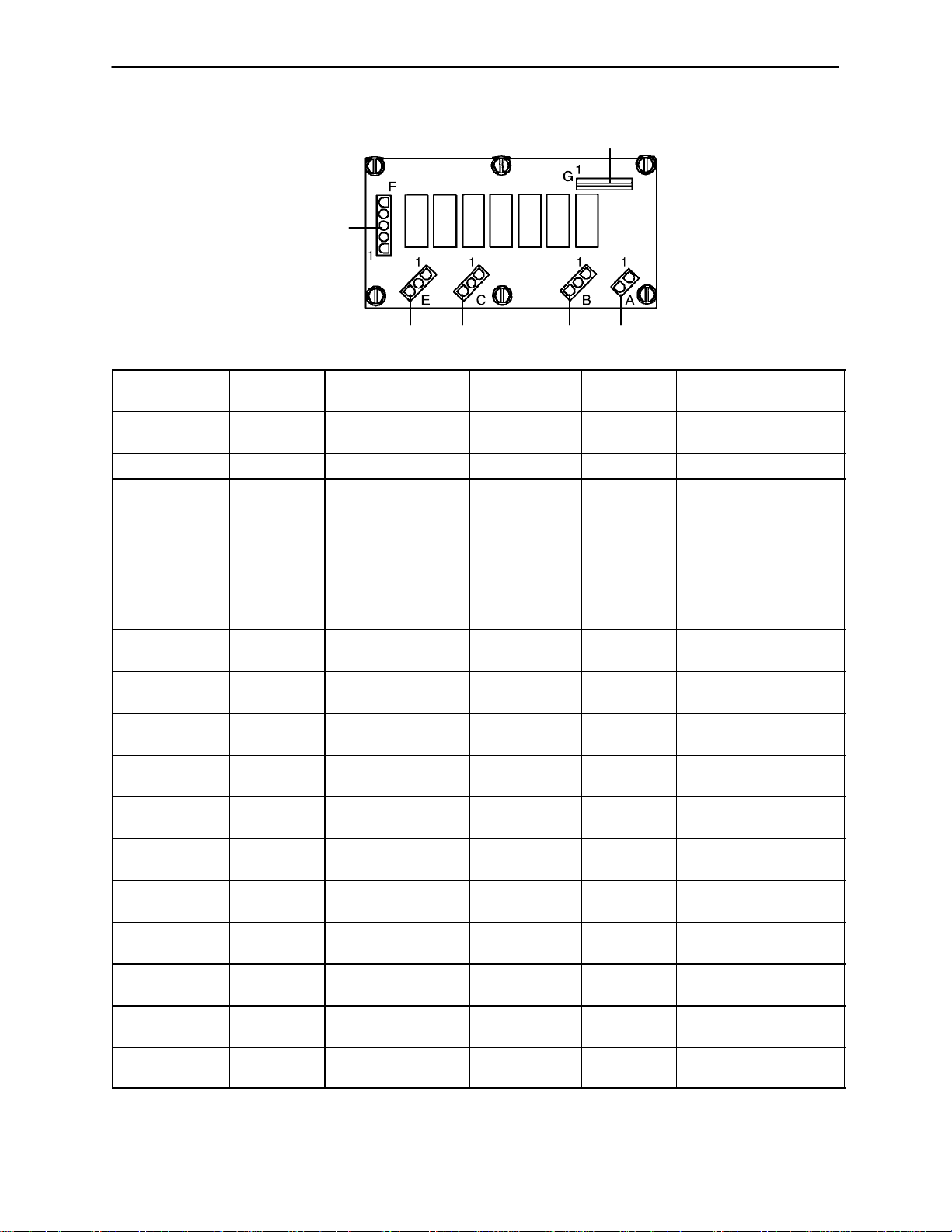

Bed Circuit Boards

OPTION POWER BOARD - P/N 5000-300-900

HDR 11

HDR 5 HDR 7 HDR 8 HDR 1

HDR 2

CONNECTOR

LOCATION

HDR 1 A 120 VAC* Pin 1 Pin 2 AC Line Voltage from

HDR 2 G +5 VDC Pin 2 White Pin 1 Black +5 VDC from CPU

HDR 2 G 12 VDC Pin 3 Pin 1 Black DC Voltage for Relays

HDR 2 G 0 VDC w/o Switch

HDR 2 G 0 VDC w/o Switch

HDR 2 G 0 VDC w/o Switch

HDR 2 G 0 VDC w/o Switch

HDR 2 G 0 VDC w/o Switch

HDR 2 G 0 VDC w/o Switch

HDR 5 E 0 VAC w/o Switch

HDR 5 E 0 VAC w/o Switch

HDR 5 E 0 VAC w/o Switch

HDR 7 C 0 VAC w/o Switch

HDR 7 C 0 VAC w/o Switch

HDR 8 B 0 VAC w/o Switch

HDR 11 F 0 VAC w/o Switch

HDR 11 F 0 VAC w/o Switch

CABLE

LOCATION

VOLTAGE POSITIVE

Pin 5 Orange Pin 1 Black Fowler Slide Out

5 VDC w/Switch

Pin 4 Green Pin 1 Black Fowler Slide In

5 VDC w/Switch

5 VDC w/Switch

Pin 7 White/

5 VDC w/Switch

5 VDC w/Switch

5 VDC w/Switch

120 VAC w/Switch

120 VAC w/Switch

120 VAC w/Switch

120 VAC w/Switch

120 VAC w/Switch

120 VAC w/Switch

120 VAC w/Switch

120 VAC w/Switch

Green/Black

Orange/Black

Pin 3 Black Pin 1 White Compressor

Pin 1 Black Pin 3 White Fowler Slide In

NEGATIVE

LEAD

Pin 6 Blue Pin 1 Black Compressor

Black

Pin 8

Red/Black

Pin 9

Pin 2 Pin 1 Black Seat Soft

Pin 3 Pin 1 Black Seat Firm

Pin 10

Pin 2 Pin 1 Black Lumbar Soft

Pin 3 Pin 1 Black Lumbar Firm

Pin 2 Red Pin 3 White Fowler Slide Out

LEAD

Pin 1 Black Lumbar Soft

Pin 1 Black Lumbar Firm

Pin 1 Black Seat Soft

Pin 1 Black Seat Firm

DESCRIPTION

CPU Board

* 120 VAC present when Fowler slide, lumbar, or seat button is pressed.

33

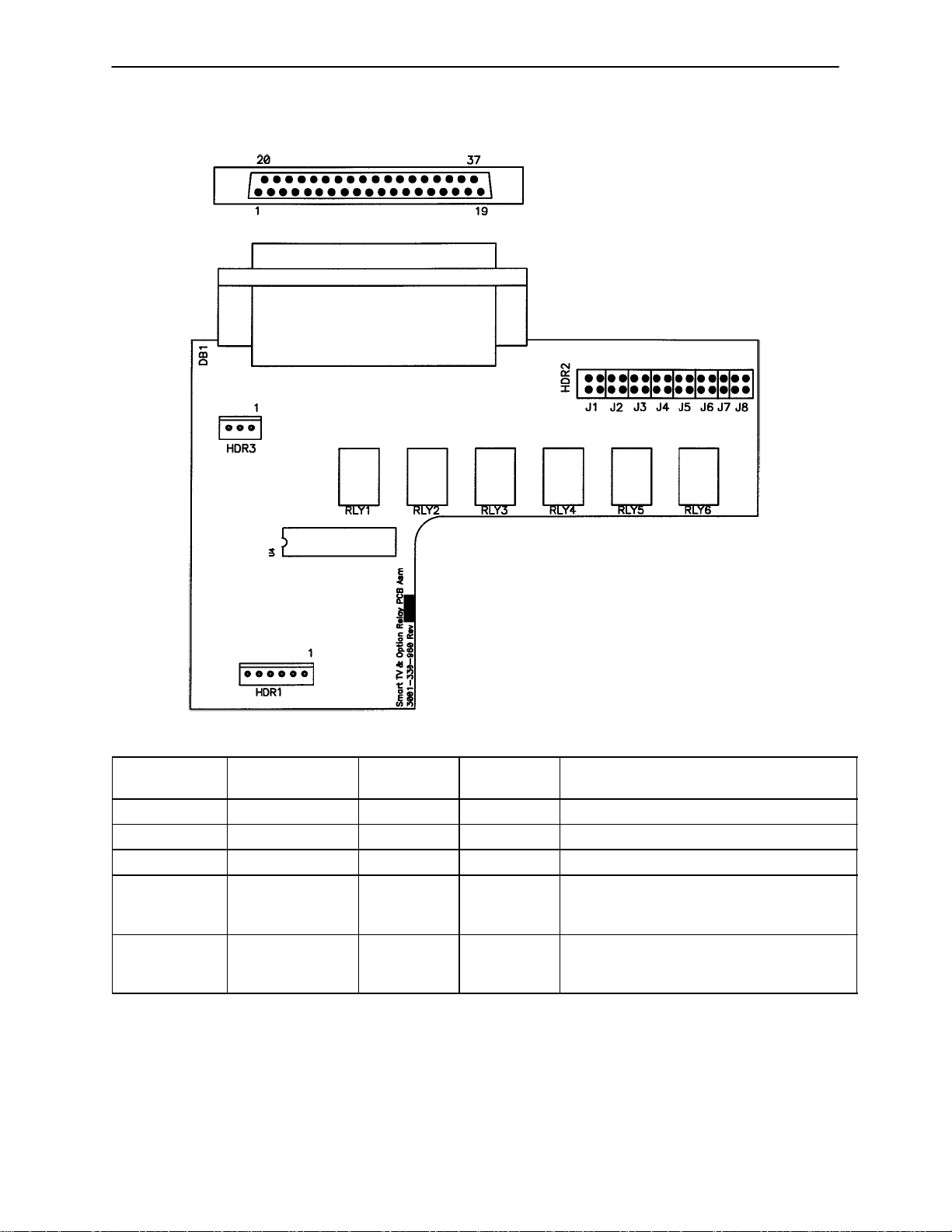

Page 35

Bed Circuit Boards

OPTIONAL SMART TV CIRCUIT BOARD WITH CUSTOM RELAYS - P/N 3001-330-960

CONNECTOR

LOCATION

HDR 1 5 VDC Pin 2 Pin 1 Regulated 5 VDC Power to the board

HDR 1 Digital Control Pin 3-5 Pin 1 Serial control lines

HDR 1 5 VDC Pin 6 Pin 1 5 VDC for option relay

HDR 3 +5 or +12 VDC 2 Pin 1 Power/control line from the TV

DB1 +5 or +12 VDC Pin 34 Pin 33 Power/Control line from the TV

VOLTAGE POSITIVE

LEAD

NEGATIVE

LEAD

34

DESCRIPTION

Note: This header provides TV control to

a non-Stryker pendant

Note: If this polarity is reversed, place

the shunts of J8 in the alternate position

Page 36

Head Wall Output Configuration

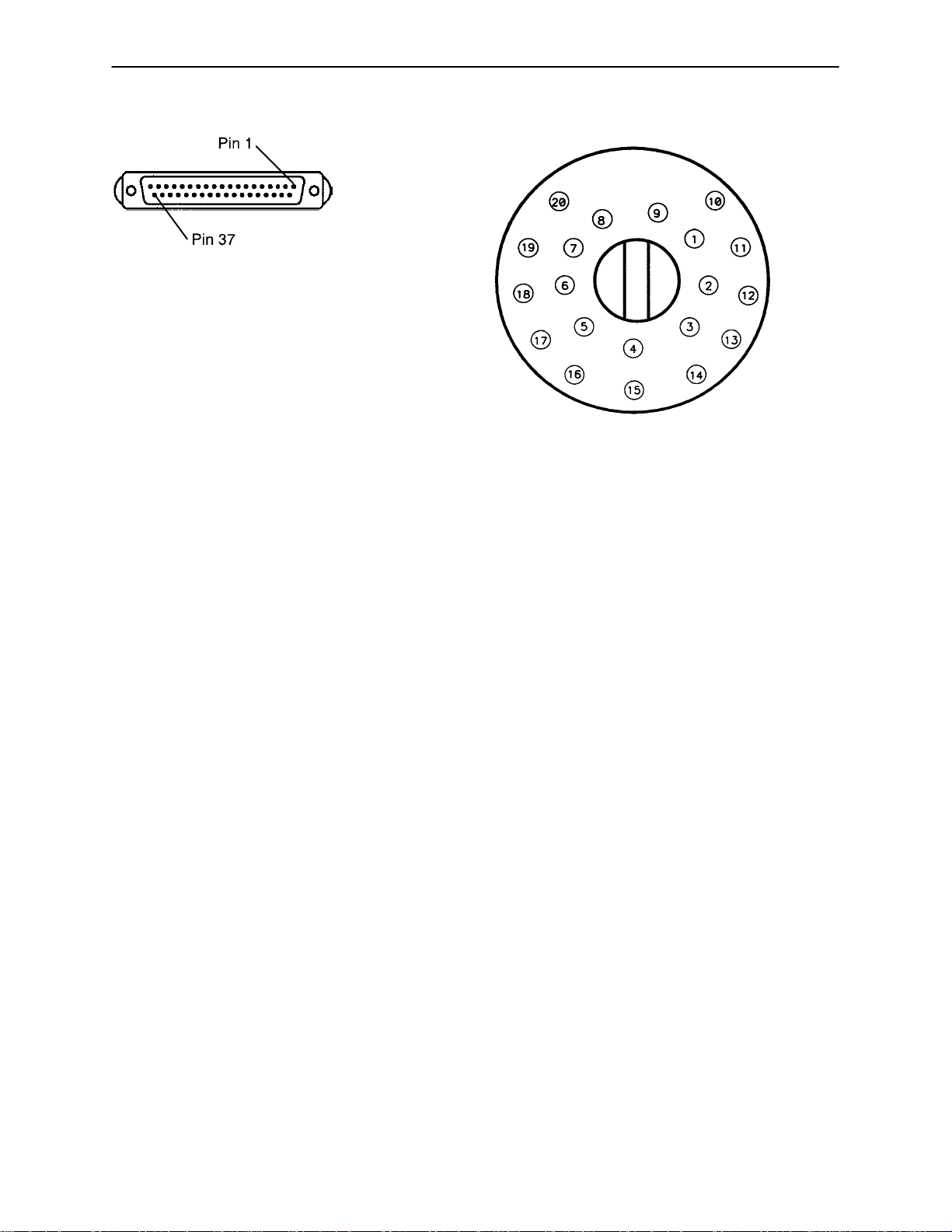

37-PIN CONNECTOR

Pin 1 Option 2 Common

Pin 2 Read Light

Pin 3 Room Light

Pin 4 Speaker High

Pin 5 Pot Wiper

Pin 6 Radio Common

Pin 7 Nurse Call Interlock

Pin 8 Audio Transfer Pin 9 Audio Transfer +

Pin 10 Interlock +

Pin 11 Interlock Pin 12 Spare

Pin 13 Options 3 Common

Pin 14 Pot Low Common

Pin 15 Pot High Common (Std.)/ Audio (STV)

Pin 16 Nurse Answer Light +

Pin 17 Option 1 NO/NC

Pin 18 Option 1 Common

Pin 19 Nurse Call Light +

Pin 20 Option 2 NO/NC

Pin 21 Option 3 NO/NC

Pin 22 Option 3A NO/NC

Pin 23 Option 2A Common

Pin 24 Option 2A NO/NC

Pin 25 Nurse Call +

Pin 26 Nurse Call NO/NC

Pin 27 Room/Read Light Common

Pin 28 Nurse Call Light Pin 29 Nurse Answer Light Pin 30 Priority NO/NC

Pin 31 Priority Common

Pin 32 Option 3A Common

Pin 33 TV - (Std.)/Data (STV)

Pin 34 TV + (Std.)/Common (STV)

Pin 35 Speaker Low Common

Pin 36 Audio Shield

Pin 37 Radio NO/NC

STRYKER PENDANT PORT

1 Scan Line

2 Audio (-)

3 Nurse Call (+)

4 +5 VDC

5 Scan Line

6 Scan Line

7 Nurse Call (-)

8 TV Channel Up

9 Backlight

10 Audio (+)

11 Gatch Up/Fowler In/Foot Up/DMS Firm

12 Gatch Down/Fowler Out/Foot Out/DMS

Soft

13 Fowler Up/Trend In

14 Fowler Down/Trend Out

15 Audio Shield

16 Not Used - Socket Filled

17 Bed Up

18 Ground

19 Read Light/Bed Down

20 Room Light

35

Page 37

CPU/Headwall Jumper Locations

Jumper Locations

J5 - Pot. Wiper/Speaker Pin 4 - Speaker High to Pin 5

Pot. Wiper

J3 - Priority Pin 30 - Priority No Nurse Call to

Pin 31 Priority Common

J2 - Nurse Call Pin 25 - Nurse Call

J1 - Pendant

HDR 41 - Priority Parallel with

Nurse Call

Pin 25 - Nurse Call+ to Pin 31

Priority Common & Pin 26 -

Nurse Call No Nurse Call to Pin

30 Priority No Nurse Call

Default Alternate

Double Shunt - Pin 33 - TV to

Pin 35 - Speaker Low Common

and Pin 14 - Pot Low Common

No Shunts - Separates Pin 33,

Pin 35 & Pin 14

36

Page 38

3001-303-160 Optional Bed Communications Tester

Item Part No. Part Name Qty.

A 3001-303-160 BCT Unit 1

B 3001-303-825 37-Pin Cable 1

C 3001-303-162 Instructions 1

D 3000-303-871 9V Battery 1

37

Page 39

Replacement Parts

PART NAME

Arm Board Assembly 5000-101-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjuster 715-201-150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Cam Actuator 5000-1-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Bed Motor 59-140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Bed Motor, 230V 59-155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Foot Motor 59-151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Foot Motor, 230V 59-153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Fowler Motor 59-151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Fowler Motor, 230V 59-153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Fowler Slide Motor 59-151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Fowler Slide Motor, 230V 59-153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Trendelenburg Motor 59-151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor, Trendelenburg Motor, 230V 59-153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Assembly, 8” 5000-2-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PART NUMBER

Caster Assembly, Steer, 8” 5000-2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Molded Wheel, 8” 715-2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Assembly, 6” 5000-2-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Assembly, Steer, 6” 5000-2-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Molded Wheel, 6” 5000-2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Tester 3001-303-160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Board Kit, with Head Wall Interface 4700-700-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Board Kit without Head Wall Interface 4700-700-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crank Handle Assembly 5000-230-320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Basin, Plastic 5000-30-297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Basin, Stainless Steel 5010-201-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Basin Liners 8813-320-000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse, 7Amp, 3AG, 250 VAC, Slo-Blo 59-150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Pole, 3-Stage 4700-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linens (Two Sets) 4700-45-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattress Assembly, Foot 4700-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattress Assembly, Head w/Electric Lumbar 4700-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattress Assembly, Standard, Enhanced Comfort 4700-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

Page 40

Replacement Parts

PART NAME

Motor, Bed Lift 5010-30-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .