Page 1

Operating

Instructions

®

OPERATING INSTRUCTIONS FOR RECHARGEABLE STREAMLIGHT SYCLONE

®

Safety

A. Use only Streamlight battery #13057. Dispose of worn out or damaged batteries

properly. Do not attempt to incinerate the battery as it may explode in a fire and never

allow it to short circuit.

B. A small leakage of liquid from the battery cells may occur under extreme usage or tempera-

ture. This does not necessarily indicate a failure. However, if the outer case seal is broken

and liquid gets on your skin: Wash the affected area promptly with soap and water.

Neutralize with a mild acid, such as lemon juice or vinegar. If battery liquid gets into your

eyes flush them with clear water for a minimum of ten (10) minutes and seek immediate

medical attention. (Medical note: The liquid is 25%-35% solution of potassium hydroxide.)

C. It is important to keep the two (2) holes on either side of the flashlight head/body and

pivot area/body clean and clear of debris.

OPERATION

The Syclone is designed for multiple applications, waterproof to 100 feet and quickly

becomes a hands-free light with its snap-on helmet attachment or optional elastic head strap.

The 360 degrees rotating clip fastens to belt, harness or pocket. Attachment points on the tilting head and clip accept hooks or lanyards. It features two (2) separate bulbs selectable by

swinging the switch to the right or left and adjustable focus. The light accepts either the

rechargeable nickel-metal hydride battery pack or, if needed, the 4 "AA" alkaline battery clip,

P/N 13056.

GENERAL

The on-off switch is located on the back of the tilting head. The center position is “OFF”. Flip

the switch to the left for the LED backup light; to the right for the high intensity Krypton beam.

CHARGING

The charge is designed to hold the Syclone in virtually any position and charge without disassembly. Two (2) self-tapping #8 x 2" screws are included to mount the charger; use 1/8"

holes. The charger can use four (4) interchangeable power cords; P/N: 22051 12V DC

cord with cigarette lighter plug (DC 1); P/N: 22050 12V DC Direct Wire cord (DC 2); P/N

22311 120V AC cord; P/N: 21725 230V AC cord.

Fully charge your Syclone before the first use. Several charge/discharge cycles may be necessary to achieve full battery capacity. To charge the Syclone, turn it off and insert it into the

charger tailcap down until it snaps into place. The LED should light, indicating that the charge

current is flowing. A full charge is achieved in ten (10) hours. Normally, the Syclone can be

left on charge continuously. However, if the surrounding temperature is below 10 degrees F,

continuous charging is not recommended. Remove the Syclone from the charger by depressing

the pushbutton on the side of the charger holder. A fully charged Syclone should operate a

Krypton lamp for two (2) hours and an LED for over twenty four (24) hours.

VEHICLE INSTALLATION

WARNING: A shorted auto batter y can easily star t a fire. Use the proper insulated connectors

and be sure that your installation is fused with a 1 amp slow blow fuse. If you are not skilled

in this type of work have a skilled professional install the Syclone charger.

S

YCLONE

®

Page 2

A Syclone, when charging, draws 100 milliamperes from the vehicle battery. We recommend

that the charger be connected directly to the battery or an unswitched terminal on the vehicle

fuse block. A permanent installation is made by using the DC 2 direct wire cord. Route the

wires from the mounted charger base to the 12 volt power source. The positive lead is striped

and should be connected to the side of a fuseholder which is dead when the fuse is removed.

The unstriped lead is negative and may be connected to any convenient chassis ground.

CARE AND USE OF NICKEL-METAL HYDRIDE BATTERIES

NOTE: Leaving the light running once the lamp becomes dim can reduce the useful life of the

rechargeable battery system.

Do not periodically "condition" or "exercise" your flashlight battery, despite what you may have

been told about nickel-metal hydride"memory". Streamlight specifically discourages a regular

ritual of deep discharging, which is not only unnecessary, but will greatly shorten lamp and

battery life. If a nickel-metal hydride battery is subjected to repeated and extensive overdeep

discharges, such as an aggressive conditioning procedure to eliminate "memory" which runs

the battery down completely on a regular basis, it can experience a voltage reversal of one

(1) of the individual cells. This may cause a build up of pressure within the cell, which can

lead to venting the electrolyte, cell damage and early battery failure. In addition, should the

pressure relief vent on top of the battery become damaged, this pressure increase could cause

the cell to burst, causing damage to the Syclone and possible personal injury.

BULB REPLACEMENT

The Syclone utilizes a high pressure Krypton bulb with a life expectancy of 25 hours in a primary center position. An off center back-up reflector features either an amber super-bright LED

or a second Krypton bulb. The flashlight must be in the "Off" position to change either bulb.

Never touch a hot bulb and wear eye protection.

To access the bulbs unscrew the facecap/lens assembly and remove the reflector and focus

spring. Pull the old bulb straight out from the head. Fit the primary (central) bulb socket with a

Krypton bulb (P/N 13048). Do not handle bulbs with bare fingers. Align the pins at the base

of the new bulb with the holes in the bulb socket. Carefully slide the bulb into the socket until it

seats. Do not force. The secondary (off-center) bulb socket fits either a Kr ypton bulb or an LED

(P/N 13043). Both bulbs are keyed to fit only one (1) way or " in this position".

To reassemble place the focus spring around the primary bulb socket and make sure that it is

fully seated on the ledge. Grasp the reflector by the edges only and align the holes with the

two (2) bulbs. The keys on he outside of the reflector must align with the slots on the interior of

the head of the flashlight. Check and make sure that the "O" Ring on the outside of the head of

the flashlight is in place and lubricated with silicone grease. Replace the facecap over the head

of the flashlight, being careful not to crossthread. Rotate the facecap to adjust the focus pattern.

WATERPROOFNESS

"O" Rings in the facecap and tailcap ensure that Syclone is waterproof to 100 feet. To maintain waterproofness lubricate both "O" Rings with silicone grease and keep tailcap tight.

SYCLONE HANDS-FREE MOUNTING SYSTEM

Every Syclone comes complete with a unique mounting clip that can be permanently attached

to helmets, as well as bulkheads, dashboards and other structures for hands-free use or convenient access. You can use either a pair of #8 threaded fasteners or the special VHB adhesive

pad included with the mounting clip (P/N 13050 or P/N 13150 or P/N 13650).

Additionally, an optical elastic head strap assembly (P/N 13070) is available as an accessory to convert the Syclone to a headlight.

ATTACHING THE MOUNTING CLIP WITH THE ADHESIVE PAD

The enclosed adhesive pad uses a super durable, very high bond acrylic glue. If you follow

these directions carefully the mounting clip will not come off. It is important to get the best fit

between the mounting clip and helmet to maximize the adhesive area.

1. Determine location for the mounting clip and the desired orientation of the flashlight

on the helmet.

2. Wearing gloves, carefully heat the mounting clip by using a heat gun or placing it in boiling water for thirty (30) seconds until it is pliable.

3. Press the mounting clip against the mounting location on the helmet and hold until it conforms to the shape of the surface and cools.

4. Lightly wipe the mounting surfaces with alcohol. After the surfaces have dried, remove the

backing from one (1) side of the adhesive and affix the adhesive pad to the mounting clip.

5. Remove the remaining protective backing, align the mounting clip with the surface and

press firmly into place with the hooks facing up. Allow the mounting to cure for 24 hours

before using.

Page 3

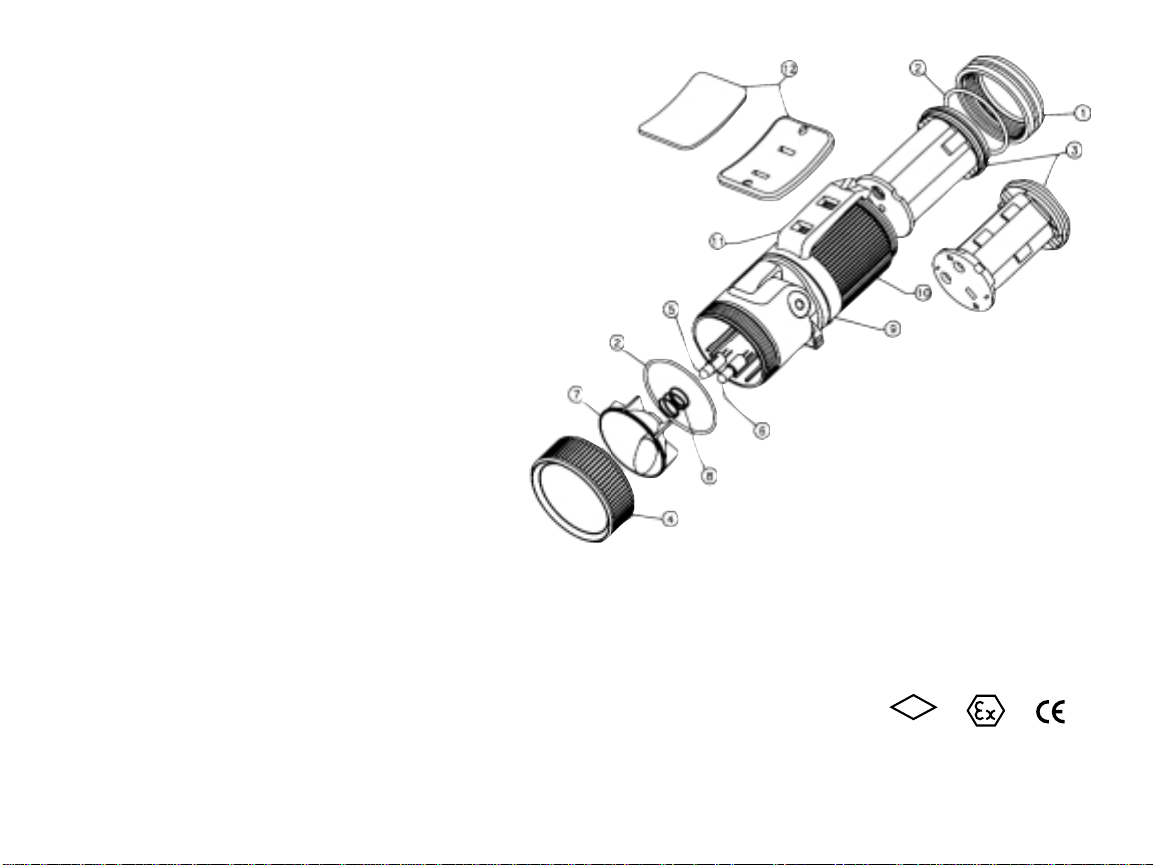

Replacement Parts

Item Quantity Part No. Description

1 1 130006-1 Tail Cap, Orange

130006-2 Tail Cap, Y ellow

130006-6 Tail Cap, Green

2 2 130015 O-Ring; Battery Pack, Head

3 1 13057 Rechargeable Battery Pack Assy.

13056 Battery Clip Assy., Alkaline

(Batteries not included)

4 1 13053 Face Cap/Lens w/Sleeve

5 1 13048 Bulb, Main Krypton

6 1 13048 Bulb, Backup Krypton

13043 LED, Backup

7 1 130004 Reflector

8 1 130028 Spring, Focus

9 1 130071 Body Assy., Replacement Yellow

130071-1 Body Assy., Replacement Orange

130071-6 Body Assy., Replacement Green

10 1 130099 Sleeve, Body

11 1 130005-1 Belt Clip, Orange

130005-2 Belt Clip, Yellow

130005-6 Belt Clip, Green

12 1 13050 Mounting Clip w/ Adh. Pad Y ell.

13150 Mounting Clip w/ Adh. Pad Org.

13650 Mounting Clip w/ Adh. Pad Grn.

Not Shown

22311 120V AC Charge Cord

21725 230V AC Charge Cord

22050 12V DC DIirect Wire Charge Cord

22051 12V DC Charge Cord

w/ Lighter Adapter

13100 Charger/ Holder

FM

APPROVED

Page 4

WARRANTY STREAMLIGHT SYCLONE

®

Streamlight makes no express warranties other than those expressly provided herein.

Streamlight does not make, and hereby expressly disclaims, any implied warranties, including

warranties of merchantability or fitness for a particular purpose, except to the extent that

implied warranties may not be disclaimed under applicable law. To the extent any such

implied warranties may not be disclaimed under applicable law, the duration of such implied

warranties shall be limited to the minimum period required by applicable law. Streamlight's

responsibility under all warranties, both expressed and implied, shall be limited to the repair,

replacement or refund of the purchase price of any products covered by such warranty.

Streamlight shall, in no event, be liable for any other damages, including consequential or

incidental damages. Some jurisdictions my not allow the waiver of or limitations on the scope

or duration of implied or expressed warranties or on the exclusion of consequential or incidental damages, in which case the above waivers, limitations or exclusion may not apply to you.

Money Back Guarantee

Your Streamlight is unconditionally guaranteed to perform to your satisfaction or your money

will be refunded, provided you return your Streamlight to the seller (shipping charges prepaid)

within ten (10) days of purchase, along with receipt or any proof of purchase for full refund.

Warranty Registration Card

Complete and return Warranty Registration Card within ten (10) days of purchase to register

your warranty. Retain your receipt or any proof of purchase. Failure to return the Warranty Card

as required will invalidate the warranty and service coverages described herein.

Warranty

Your Streamlight, including case and all internal components, but excluding lamp, battery, and

charger holder, has a Limited Lifetime Warranty from date of purchase. In any country or jurisdiction where specific limitations are placed on limited lifetime warranties, Streamlight will

honor a 10-Year Limited Warranty. Should your Streamlight fail to operate, return it (shipping

charges prepaid) to the factory or Authorized Service Center at the address listed with these

instructions, along with your proof of purchase and, if you have owned your Streamlight for

more than (1) year, $5.00 for handling. Streamlight will repair or replace the warranted

defective parts without cost and return the unit to you (shipping charges prepaid within the

Continental USA) or, at Streamlight's option, if permitted by law, Streamlight will refund your

purchase price.

Limitations on Warranty and Service Coverage

1. Warranty is invalid if, in Streamlight's sole opinion, there has been tampering, alteration,

abuse, misuse, or failure to follow proper care and maintenance procedures.

2. This warranty shall not extend to repairs by anyone other than Streamlight or other than service facilities designated by Streamlight.

3. This warranty is limited to the original user-purchaser as such appears on the Warranty

Registration Card.

Battery Stick and Charger Holder Warranty

The Battery Stick and Charger Holder are warranted for a period of one (1) year in accordance with the above terms.

Date of Purchase ______________________________________________

This warranty gives you specific legal rights and you may also have other rights.

©2001 11/01

MANUFACTURER

Streamlight, Inc.

30 Eagleville Road / Eagleville, PA USA 19403-3996

(610) 631-0600 / (800) 523-7488 / Fax (610) 631-0712 / Fax (800) 220-7007 /

www.streamlight.com

IMPORTANT – Be sure to use genuine Streamlight replacement parts.

WARRANTY REGISTRATION: To register the warranty on your Streamlight, complete the card

enclosed and mail to Streamlight, Inc., within ten (10) days of purchase. When returning product for warranty repairs, please provide receipt or other proof of purchase.

PRODUCT USE: The Streamlights are intended for use as high intensity, heavy duty, rechargeable, portable light sources. Use of the Streamlights for any purpose other than light sources is

specifically discouraged by the manufacturer.

The rechargeable battery contained in this product is recyclable. At the end of its useful life, under

various country and state laws, it may be illegal to dispose of this battery in the municipal solid

waste stream. Check with your local solid waste officials for details in your area for recycling options

or proper disposal.

®

Loading...

Loading...