Page 1

Model E122 & F122

SERVICE MANUAL

Manual No. 513668 Rev.0

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

White Glove Service Network

Phone: 888.319.9549

© 2017 Stoelting

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF

CONTENTS

Section Description Page

1 Description and Specifi cations

1.1 Description .................................................................................................. 1

1.2 Specifi cations ............................................................................................. 2

1.3 Component Settings ................................................................................... 4

1.4 Modes of Normal Operation .......................................................................5

1.5 Operation During an Error Mode ................................................................ 6

2 Maintenance and Adjustments

2.1 Accessing Control Readings and Settings .................................................9

2.2 Navigation and Modifying Settings ............................................................. 9

2.3 User Interface Screens ............................................................................... 9

2.4 Performance Screens ................................................................................. 10

2.5 Settings Screens ........................................................................................10

2.6 Utilities Screens .......................................................................................... 12

2.7 Errors and Statistics Screens ..................................................................... 14

2.8 Product Consistency Adjustment ................................................................ 17

2.9 Drive Belt Tension Adjustment .................................................................... 17

2.10 Preventative Maintenance .......................................................................... 17

2.11 Extended Storage ....................................................................................... 18

3 Refrigeration and Wiring Diagrams

3.1 Refrigeration Diagram ................................................................................19

3.2 Wiring Diagrams ......................................................................................... 20

4 Replacement Parts

4.1 Decals and Lubrications ............................................................................. 29

4.2 Auger Shaft and Faceplate Parts ...............................................................30

4.3 Hopper Parts ..............................................................................................31

4.4 Motor Components ..................................................................................... 32

4.5 Spigot Assembly ......................................................................................... 32

4.6 Panels and Screws ..................................................................................... 33

4.7 Kits and Miscellaneous ............................................................................... 33

4.8 Electrical Components ................................................................................ 34

4.9 Refrigeration ............................................................................................... 36

4.10 Auto Fill Parts ............................................................................................. 38

Page 6

Page 7

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1.1 DESCRIPTION

The Stoelting E122 & F122 countertop machines are gravity fed. The machines are equipped with fully automatic

controls to provide a uniform product. This manual is

designed to help qualifi ed service personnel and opera-

tors with the installation, operation and maintenance of

the Stoelting E122 & F122 gravity machines.

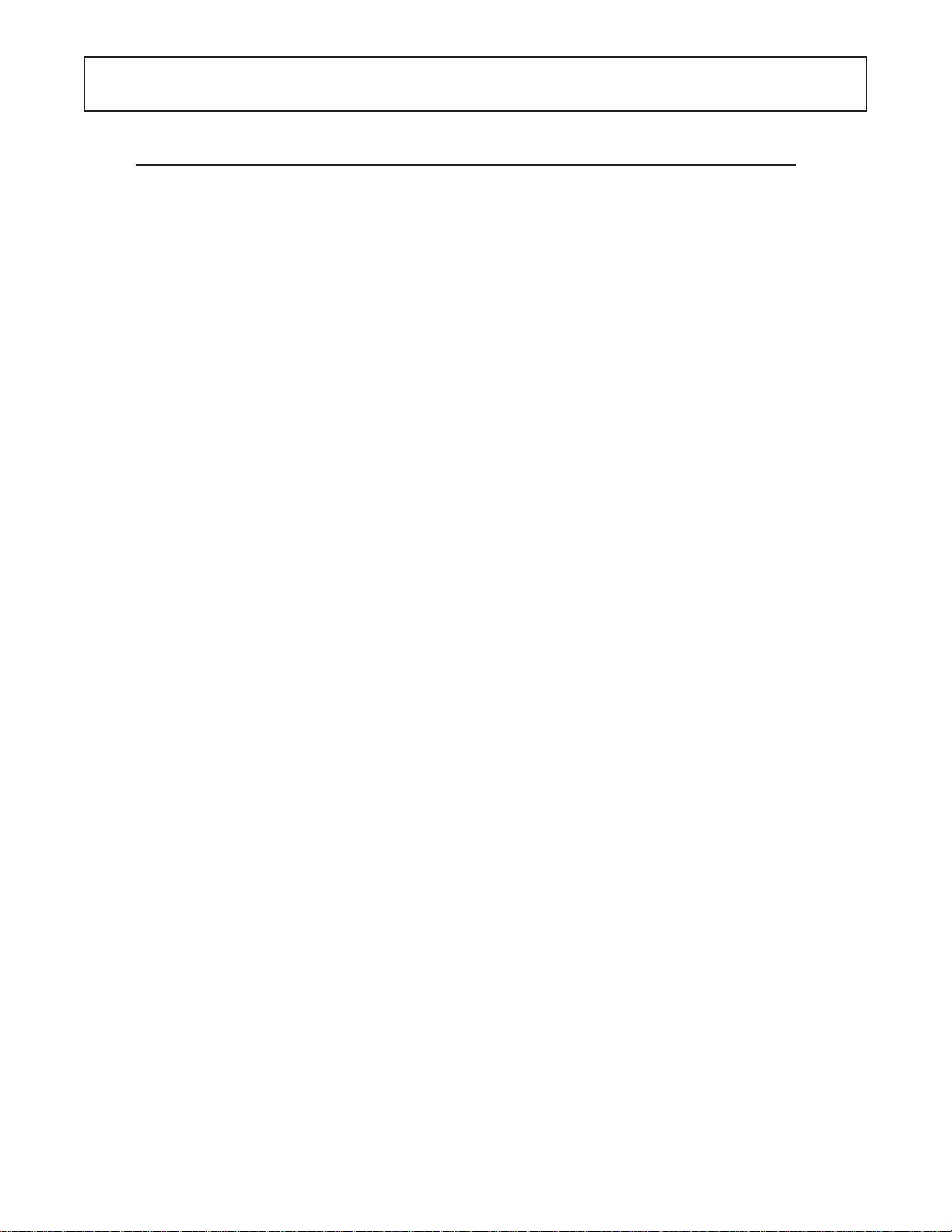

Figure 1-1 Model E122

Figure 1-2 Model F122

Service Manual #513668 1 E122 & F122 Model Machines

Page 8

1.2 SPECIFICATIONS

Model E122

Dimensions Machine with crate

width 19-5/8’’ (49,8 cm) 28-1/2’’ (72,4 cm)

height 35-1/2’’ (90,2 cm) 44’’ (111,8 cm)

depth 30-1/4’’ (76,8 cm) 36’’ (91,4 cm)

Weight 275 lbs (124,7 kg) 278 lbs (126,0 kg)

Electrical 1 Phase, 208-240 VAC, 60Hz

running amps 10.6A

connection type NEMA6-15P power cord provided

Compressor 5,500 Btu/hr

Drive Motor Two - 1/3 hp

Air Flow Air cooled units require 4” (10,2 cm) air space in back

Water cooled units require 3/8” N.P.T. water and drain fi ttings. Maximum

Plumbing Fittings

water pressure of 130 psi. Minimum water fl ow rate of 3 GPM per barrel.

Ideal EWT of 50°-70°F.

Hopper Volume Two - 3 gallon (11,36 liters)

Freezing Cylinder

Volume

Two - 2.125 gallon (8,04 liters)

E122

Refrigerant R-404A

Charge 30 oz

Suction Pressure

(at 80-85°F)

23-26 psig

Discharge Pressure 270 psig

Hot Gas Bypass

Pressure

EPR Valve 68-70 psig

Service Manual #513668 2 E122 & F122 Model Machines

18 psig

Page 9

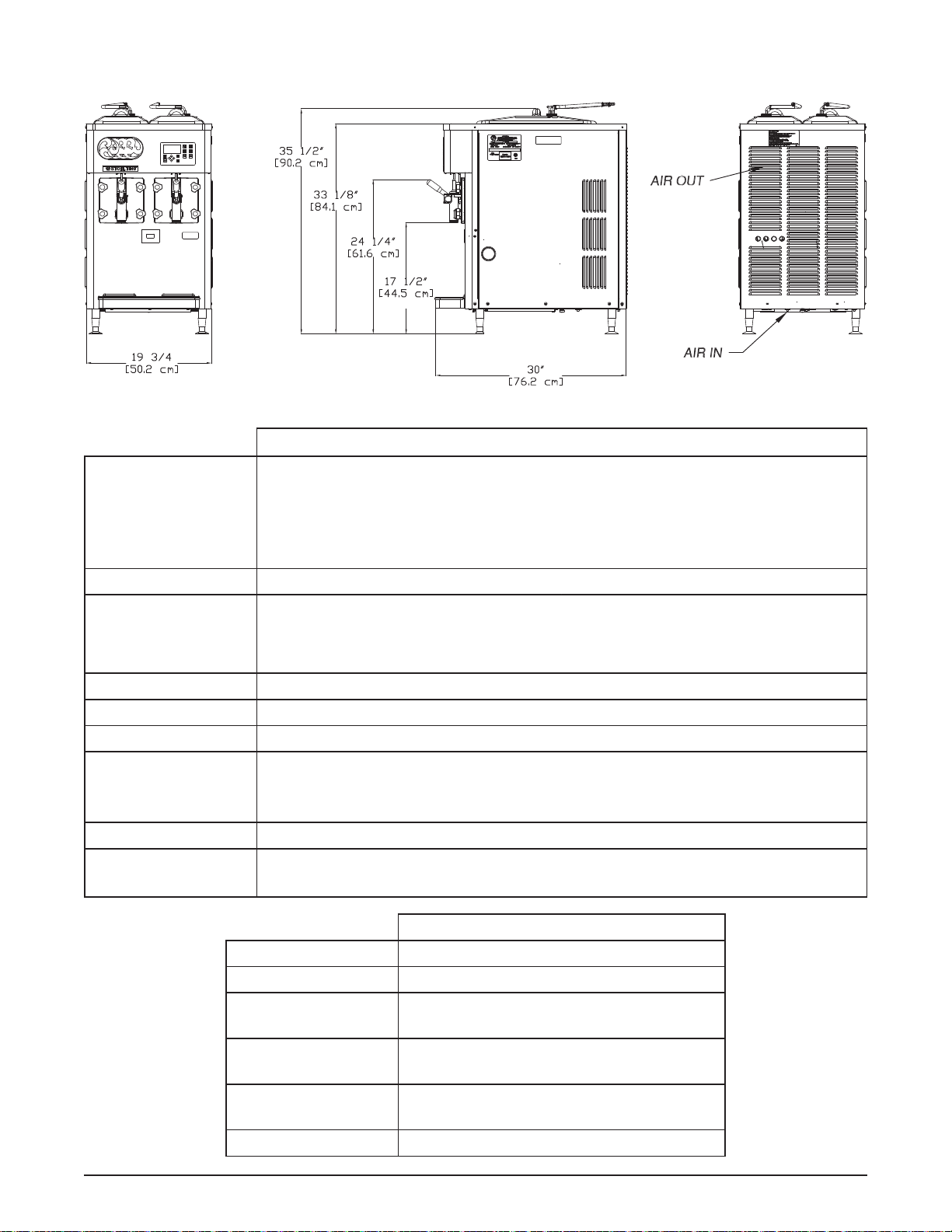

Model F122

Dimensions Machine with crate

width 25-7/8’’ (65,7 cm) 31-3/4’’ (80,6 cm)

height 38-1/4’’ (97,2 cm) 47-3/8’’ (120,3 cm)

depth 33-3/8’’ (84,8 cm) 41-1/4’’ (104,8 cm)

Weight 390 lbs (176,9 kg) 458 lbs (207,7 kg)

Electrical 1 Phase, 208-240 VAC, 60Hz

running amps 14.5A

connection type NEMA6-20P power cord provided

Compressor 12,000 Btu/hr

Drive Motor Two - 1/2 hp

Air Flow Air cooled units require 6” (15,24 cm) air space on both sides

Water cooled units require 3/8” N.P.T. water and drain fi ttings. Maximum

Plumbing Fittings

Hopper Volume Two - 3 gallon (11,36 liters)

Freezing Cylinder

Volume

water pressure of 130 psi. Minimum water fl ow rate of 3 GPM per barrel.

Ideal EWT of 50°-70°F.

Two - 2.125 gallon (8,04 liters)

F122

Refrigerant R-404A

Charge 40 oz

Suction Pressure

(at 72°F)

Discharge Pressure 225-235 psig

Hot Gas Bypass

Pressure

EPR Valve 68-70 psig

Service Manual #513668 3 E122 & F122 Model Machines

34 psig

14 psig

Page 10

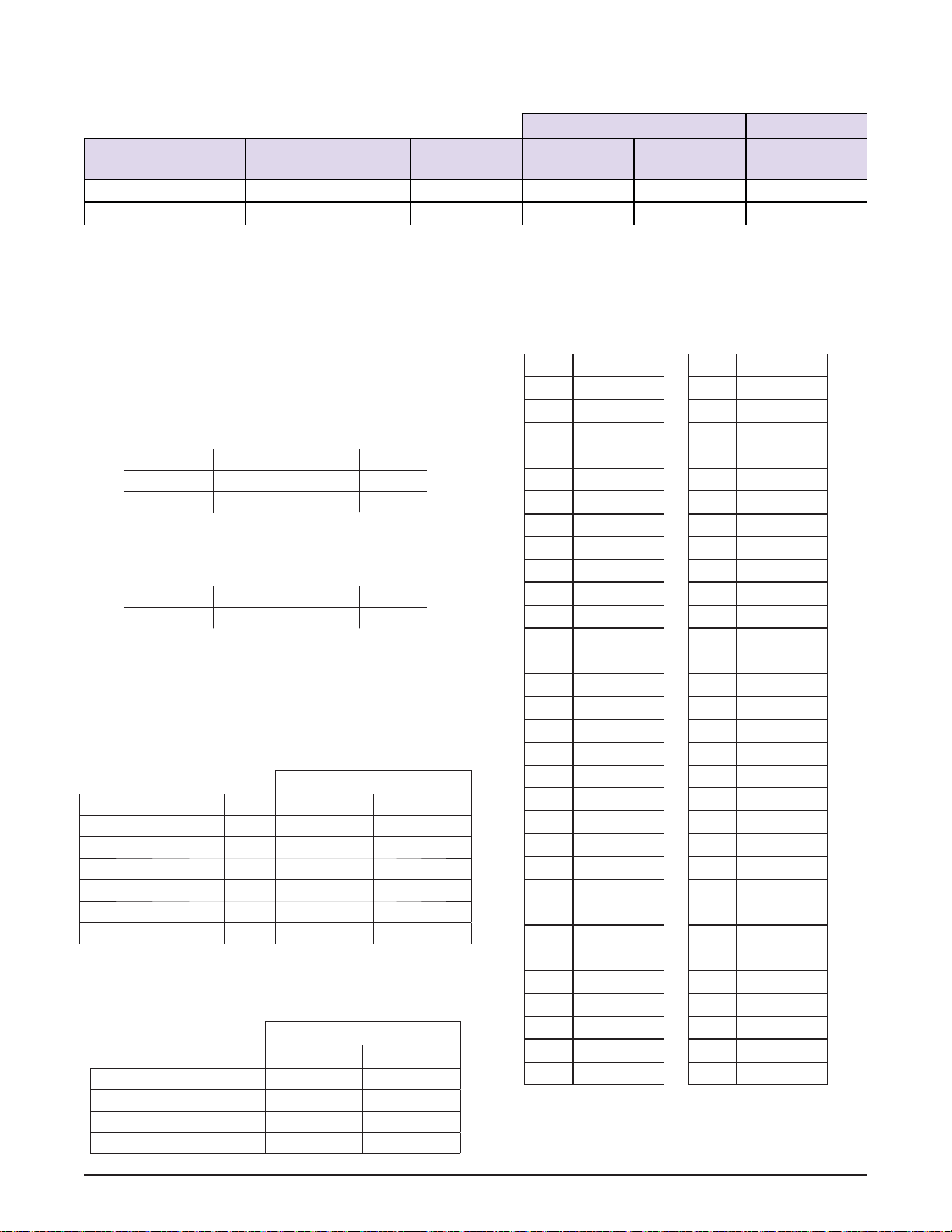

1.2 SPECIFICATIONS (CONTINUED)

PEAK HEAT OF REJECTION

Water Cooled Only Air Cooled Only

Model Electrical

Peak Heat of

Rejection

Peak Water

Usage

Estimated Wa-

ter Usage

AC Load Rating

E122 1 PH, 60Hz 11,511 BTU/hr 2.3 GPM 1.4 GPM 8,850 BTU/hr

F122 1 PH, 50Hz 14,947 BTU/hr 3.0 GPM 1.9 GPM 11,721 BTU/hr

1.3 COMPONENT SETTINGS

Following are the settings for the components in the

E122 & F122 machines.

C. TEMPERATURE CONTROL SENSOR

The following table shows the relationship between the

thermistor resistance and the suction line temperature.

A. COMPRESSOR WINDINGS

When testing the compressor windings the resistance

through the windings should be as follows:

F122

Compressor Electrical S to C R to C

282032-SV 1 PH 60Hz 3.10Ω 1.16Ω

282050 1 PH 50Hz 3.79Ω 1.39Ω

E122

Compressor Electrical S to C R to C

282094 1 PH 60Hz 5.94Ω 1.18Ω

B. CAPACITORS

Refer to the following table for the capacitance of all the

capacitors in the machine:

F122

Rating

Capacitor Part MFD VAC

Comp - Run (50/60 Hz) 231084 30 MFD 370 VAC

Comp - Start (60 Hz) 231079 145-174 MFD 220 VAC

Comp - Start (50 Hz) 230649 130-156 MFD 250 VAC

Drive Motor - Run 230687 30 MFD 370 VAC

Drive Motor - Start 230685 645-774 MFD 125 VAC

Fan Motor 230654 5 MFD 400 VAC

E122

Rating

Part MFD VAC

Compressor - Run 230666 20 MFD 440 VAC

Compressor - Start 230632 72-86 MFD 330 VAC

Drive Motor - Start 230447 189-227 MFD 165 VAC

Fan Motor 230665 88-106 MFD 330 VAC

°F Resistance °F Resistance

-22 176950 40 26100

-20 165200 42 24725

-18 154300 44 23400

-16 144200 46 22175

-14 134825 48 21000

-12 126125 50 19900

-10 118050 52 18875

-8 110550 54 17900

-6 103550 56 17000

-4 97075 58 16125

-2 91025 60 15325

0 85400 62 14550

2 80150 64 13825

4 75275 66 13150

6 70725 68 12500

8 66475 70 11875

10 62500 72 11300

12 58800 74 10750

14 55325 76 10250

16 52100 78 9750

18 49075 80 9300

20 46250 82 8850

22 43600 84 8450

24 41125 86 8050

26 38800 88 7675

28 36625 90 7325

30 34575 92 7000

32 32675 94 6675

34 30875 96 6375

36 29175 98 6100

38 27600 100 5825

Service Manual #513668 4 E122 & F122 Model Machines

Page 11

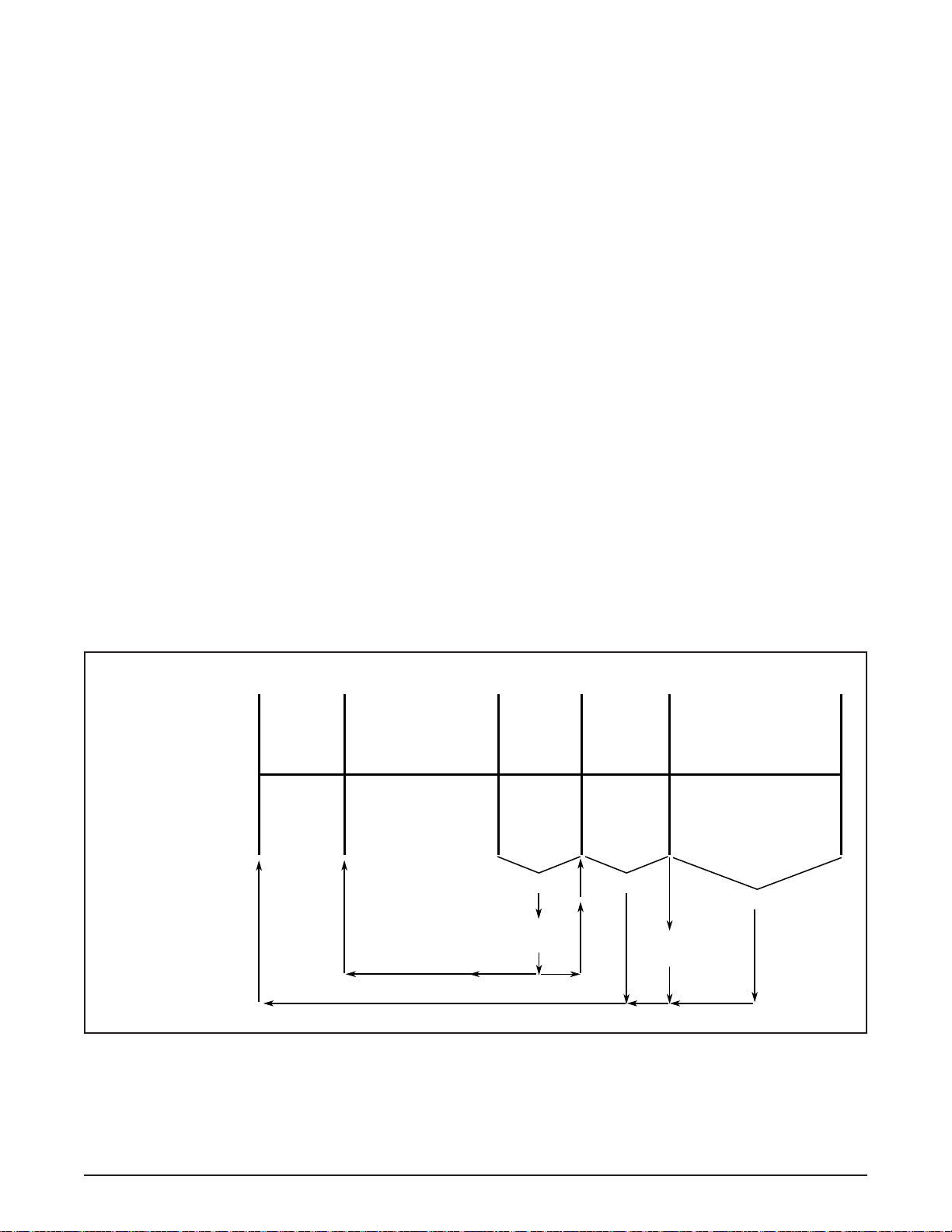

1.4 MODES OF NORMAL OPERATION

Following is an explanation of the normal operation modes

on the E122 and F122 (Refer to Figure 1-3).

NOTE

The machine uses the torque switch to maintain

product consistency. The IntelliTec2™ controls

the timers which include Pre Stir, Post Stir and Off

Time (standby).

A. PRE STIR

When the Push To Freeze button is pressed or when

the spigot is opened, the drive motor starts a 5-second

pre stir. The torque switch determines if a freezing cycle

begins. If the consistency of the product holds the torque

switch closed for 3 seconds the machine goes to Standby.

Otherwise a freezing cycle begins.

B. FREEZING CYCLE

The freezing cycle runs until the torque rod closes the

torque switch and keeps the switch closed for 3 seconds.

If product consistency is not met within 20 minutes, the

machine operates in the compressor time out mode (See

Section 1.5).

NOTE

If the spigot is pulled during a freezing cycle, the

20-minute timer restarts.

C. POST STIR

After the freezing cycle ends, the drive motor continues

to run for a 12 second post stir. The post stir ensures the

product does not freeze to the cylinder. If the spigot is

opened during the post stir, the machine checks consistency. If the product is at consistency, the machine goes to

standby. If the product is not at consistency, the machine

starts a freezing cycle.

D. STANDBY

The machine remains in Standby for 5 minutes or until

the spigot is pulled. At the end of Standby the machine

goes to Pre Stir if the cycle count has not been met. If the

cycle count has been met it goes to Refrigerate Mode.

E. REFRIGERATE MODE

After the cycle count is met without a spigot pull, the

machine is in Refrigerate Mode. It remains in refrigerate

mode until the spigot is pulled.

F. CLEAN MODE

When the Clean button is pressed, the drive motor starts

and runs for 20 minutes. After the 20 minutes expire, the

drive motor stops and a Clean alert will be displayed on

the IntelliTec2™. To clear the alert, press the On/Off button

for the cylinder to turn it off then press it again to turn it on.

CLEAN-OFF-ON

Switch Moved to ON

Pre Stir Post Stir

Drive

Motor

5

Seconds

Consistency

check.

Freezing Cycle

will not start if

the product is

at consistency.

Freezing Cycle

Drive Motor &

Cylinder Refrigeration

Until Consistency

Setting is Met

If this time exceeds 20

minutes, the Compressor

Time Out mode is initiated

Drive

Motor

12

Seconds

Spigot Pull

Product at

Consistency?

No Yes

Figure 1-3 Modes of Normal Operation

Standby

5

Minutes

Spigot Pull

cycle count is

Refrigerate

Drive Motor &

Cylinder Refrigeration

12 Minutes Off

5 Second Pre Stir

7 Second Refrigeration

5 Second Post Stir

Spigot Pull

To Pre Stir if

not met.

Service Manual #513668 5 E122 & F122 Model Machines

Page 12

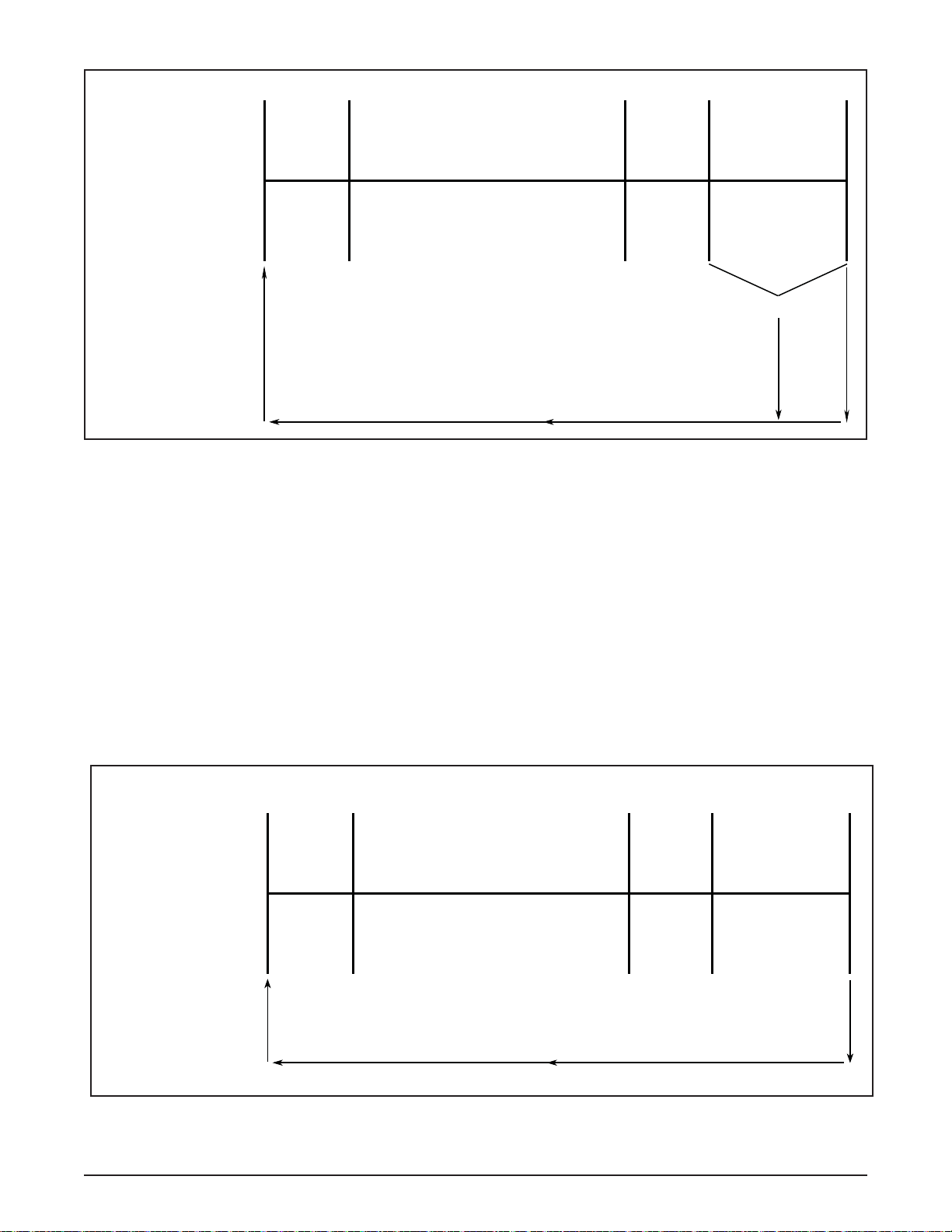

Pre Stir Post Stir

Freezing Cycle

Standby

Drive

Motor

Drive Motor &

Cylinder Refrigeration

Compressor Run Time

Exceeds 20 Minutes

5

Seconds

Consistency

check.

Freezing Cycle

will not start if

the product is

at consistency.

Continues to operate until the cylinder is turned

off then on again using the On/Off button.

90 Seconds or

Until Consistency

Setting is Met

Figure 1-4 Compressor Time Out Mode

1.5 OPERATION DURING AN ERROR MODE

A. COMPRESSOR TIME OUT MODE

If the freezing cycle exceeds 20 minutes, the machine

operates on timers (Refer to Figure 1-4).

Drive

Motor

12

Seconds

7

Minutes

Spigot Pull

B. LOW MIX MODE

If the mix level falls below the sensor probe, the machine

operates on timers. The machine continues to operate

on timers until the mix level in the hopper is above the

sensor probe (Refer to Figure 1-5).

Pre Stir Post Stir

Drive

Motor

Freezing Cycle

Drive Motor &

Cylinder Refrigeration

Drive

Motor

Standby

Mix Level Falls

Below Sensor Probe

5

Seconds

10

Seconds

The freezer will return to normal operation

after mix level is above the sensor probe

12

Seconds

12

Minutes

Figure 1-5 Low Mix Mode

Service Manual #513668 6 E122 & F122 Model Machines

Page 13

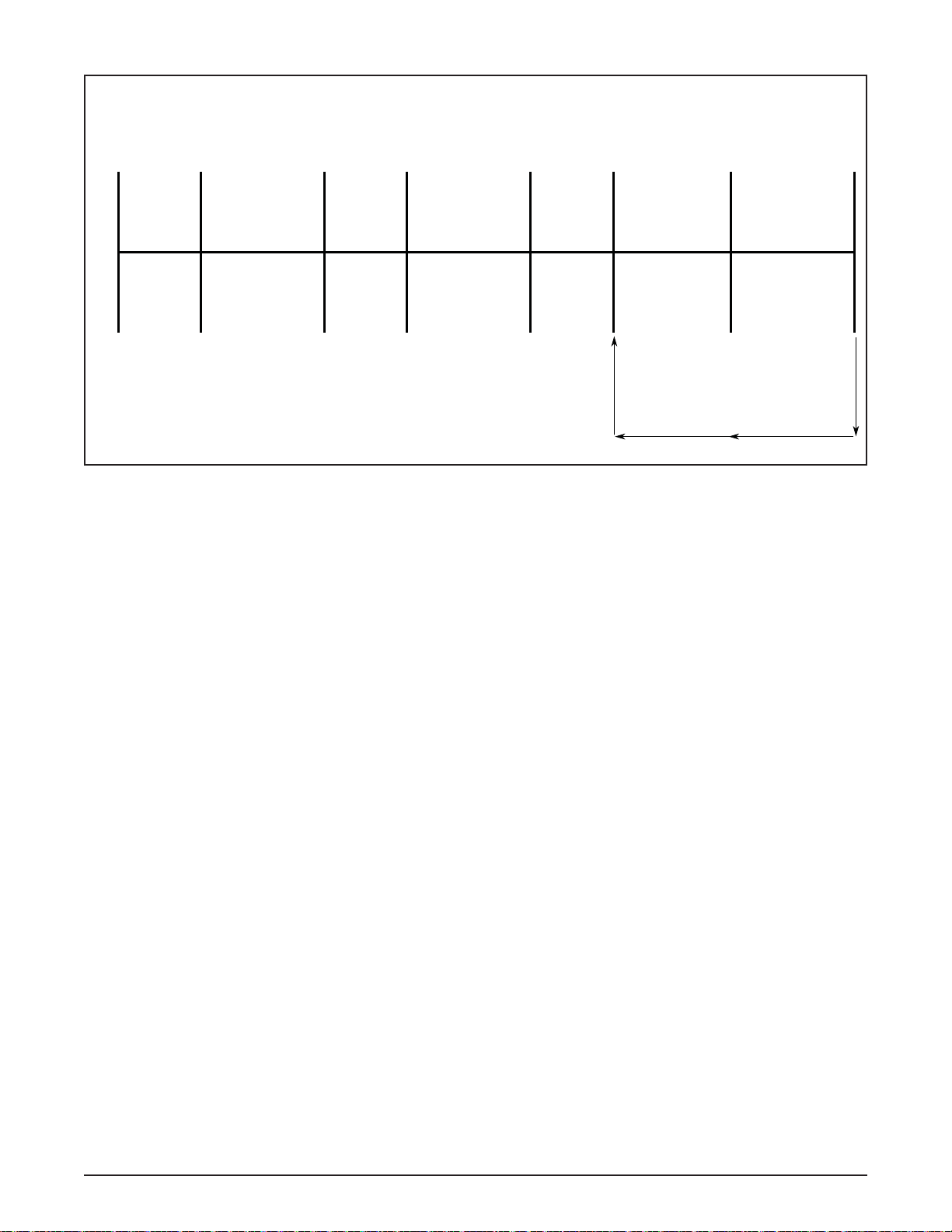

First

Attempt

Pre Stir

Standby

Second

Attempt

Pre Stir

Standby

Third

Attempt

Pre Stir

Refrigeration

Cycle

Standby

Drive

Motor

5

Seconds

12

Minutes

Drive

Motor

5

Seconds

Minutes

Figure 1-6 Drive Motor Error Mode

C. DRIVE MOTOR ERROR MODE

If the control does not sense current from the drive motor

during a pre stir, the machine goes into standby mode for

12 minutes. After standby, the control repeats the pre stir

and attempts to sense drive motor current. After the third

pre stir without sensing drive motor current, the machine

operates on timers. If the spigot is pulled during standby,

the machine immediately attempts to sense drive motor

current.

12

Drive

Motor

5

Seconds

Cylinder

Refrigeration

7

Seconds

Continues to operate until the

cylinder is turned off then on again

using the On/Off button.

12

Minutes

Service Manual #513668 7 E122 & F122 Model Machines

Page 14

Service Manual #513668 8 E122 & F122 Model Machines

Page 15

SECTION 2

MAINTENANCE AND ADJUSTMENTS

This section is intended to provide maintenance personnel

with a general understanding of the machine adjustments.

It is recommended that any adjustments be made by a

qualifi ed person.

NOTE

There are many settings in the IntelliT ec2™ control

that do not affect the operation of the E122 or F122.

These settings will not be covered in this manual

and should not be changed.

2.1 ACCESSING CONTROL READINGS AND

SETTINGS

The readings and settings on the IntelliTec2™ control are

accessed by using a keypad sequence. Press the left arrow button from the Current Status screen to access the

passcode input screen.

The specifi c readings and parameters available depend

on the keypad sequence entered. The lowest level is Associate and has limited access. The Manager level has

access to the majority of screens except Utilities (2 of 2).

The Technician and Factory levels have full access to the

control including the Associate and Manager level options.

The Factory level has an additional factory settings menu.

Following are the keypad sequences for the three levels

available.

Associate Press the right arrow then the SEL button.

Manager Press the right arrow, up arrow then the

SEL button

Technician Press the right arrow, SET, then the SEL

button

Factory Press the right arrow, down arrow, SET,

up arrow then the SEL button.

2.2 NAVIGATION AND MODIFYING SETTINGS

Navigating through the IntelliTec2™ screens is done with

the arrow keys on the touchpad. After positioning the cursor on a desired menu, press the SEL button to select

that option. To change a setting, press the SET button.

Use the arrow keys to change the value. Press the SET

button to save the changes.

The SEL button changes the cylinder selection on screens

that show the cylinder.

Pressing the left arrow button from any menu will go back

one screen. Pressing the left arrow button at the Main

Menu screen goes to the Current Status screen.

2.3 USER INTERFACE SCREENS

A. CURRENT STATUS

Current Status 01/01/01

12:34:56

Left Off

Right Off

Storage Hoppers Off

Left Hopper Autofill On

Right Hopper Autofill On

_ Service Company

The Current Status screen gives an overview of the

machine's operation. It shows the mode of the freezing

cylinders, the storage refrigeration, and the status of the

autofi ll system. If there is an error, the error text descrip-

tion replaces the status information.

The Service Contact Information screen is accessed from

the Current Status screen. Move the cursor to the Service

Contact Information option and press the SEL button.

B. SERVICE CONTACT INFORMATION

Service Contact Information

Name

Stoelting

Telephone Number

800 - 319 - 9549

Unit Serial Number

1234567AA

Version 00.00/00.00

The Service Contact Information screen provides the

name and telephone number for service. The default is

Stoelting White Glove Service. The default can be changed

by selecting the Modify Contact Information option or by

uploading the info.txt fi le.

C. MAIN MENU

Main Menu

- Technician Level Access

_ Fine Consistency Adjustment

_ Performance

_ Modify Settings

_ Utilities

_ Errors and Statistics

The Main Menu screen provides access to all the readings and settings on the IntelliTec2™ control. To access

the Main Menu, use one of the keypad sequences from

Section 2.1. The example above shows the options available when entering the Manager, Technician or Factory

keypad sequence. The Associate will only see the Fine

Consistency Adjustment option.

Service Manual #513668 9 E122 & F122 Model Machines

Page 16

D. FINE CONSISTENCY ADJUSTMENT

The Fine Consistency Adjustment screen has no effect

on machine operation.

2.5 SETTINGS SCREENS

A. MODIFY OPERATING SETTINGS

2.4 PERFORMANCE SCREENS

A. PERFORMANCE (1 OF 2)

Performance (1 of 2)

Cylinder Right

Consistency 000.00

Cylinder Temp -000.0°F

Motor Amps 00.000A

Input Voltage 000.0V

The Performance screens display the current status of the

machine. These screens are available to the Manager,

Technician, and Factory levels. Press the right arrow to

go to the second screen.

Cylinder

The performance information displayed is for the selected

cylinder. To change cylinders press the SEL button.

Consistency

Disregard this value. Product consistency is regulated by

the torque switch (See Section 2.8)

Cylinder Temperature

This is the current suction line temperature of the selected

cylinder.

Motor Amps *

This is the motor amps of the selected cylinder. Note

that the Motor Amps are not used to determine product

consistency.

Input Voltage *

This is the voltage of the selected cylinder.

* Only shown when the drive motor is running.

B. PERFORMANCE (2 OF 2)

Performance (2 of 2)

Cylinder Right

Ambient Temp -000.0°F

Storage Temp -000.0°F

Number of Cycles 000

Modify Operating Settings

Reset Serve Amount

_ Basic Settings

_ Advanced Settings

_ Storage Settings

_ User Preferences

_ Time and Date

_ Factory Settings

This menu provides access to view and change the different

operating settings on the machine. The Manager, Technician, and Factory levels have access to these screens.

B. BASIC SETTINGS

Basic Settings

Cylinder Right

_ CutOut Consist Offset 000

_ CutIn Consist Offset 000

_ Cycles In Serve Mode 000

_ CutIn Refrig Temp 00.0°F

_ CutOut Refrig Temp 00.0°F

This menu contains settings for the CutIn and CutOut,

cycles in serve mode and auger cycle times. This screen

is available to the Technician and Factory levels.

Cylinder can be changed by pressing the SEL button.

CutOut Consistency Offset has no effect on machine

operation.

CutIn Consistency Offset has no effect on machine

operation.

Cycles In Serve Mode is a count of the number of freez-

ing cycles.

CutIn Refrig T emp is the suction line temperature in the

cylinder when a freezing cycle will start during Refrigerate

Mode. Decreasing this value lowers product temperature.

CutOut Refrig T emp is the suction line temperature in the

cylinder when a freezing cycle will stop during Refrigerate

Mode. Decreasing this value lowers product temperature.

Error Status No Error

The Performance screens display the current status of

the machine. This screen shows the current ambient temperature, storage temperature, and number of cycles since

the Push to Freeze button was pressed or the spigot was

pulled. Press the left arrow to go back to the fi rst screen.

Service Manual #513668 10 E122 & F122 Model Machines

Page 17

C. ADV ANCED SETTINGS

The Advanced Settings options have no effect on machine

operation.

E. STORAGE SETTINGS (1 OF 2)

Storage Settings (1 of 2)

_ Storage Refirgeration Active

_ Storage CutIn -00.0°F

_ Storage CutOut -00.0°F

_ Storage Degree Offset 00°F

_ Storage Off Time 00 min

_ Storage On Time 0000 sec

The Temperature Units setting changes the units dis-

played to Fahrenheit or Celsius.

The Service Contact Information option is used to change

the service contact details including service company

name and number and machine serial number.

The Contact Information USB Update option is used for

uploading the info.txt fi le. The info.txt fi le is available from

Stoelting White Glove Service and contains the service

company name and telephone number. Select this option

after connecting a USB drive to the port on the machine.

H. TIME AND DATE

Time and Date

This Storage Settings menu contains storage refrigeration

parameters and is available to the Technician and Factory

level. Press the right arrow to go to the second screen.

Storage Refrigeration can be set to Active or Suspend.

Active is the normal setting. Suspend is used only for

troubleshooting and setting an expansion valve. Never set

storage refrigeration to Suspend during normal operation.

Storage CutIn has no effect on machine operation.

Storage CutOut has no effect on machine operation.

The Storage Degree Offset value is added to the storage

temperature reading to determine if storage refrigeration

starts with a freezing cycle. This setting is used in conjunction with the Storage Off Time and Storage On Time

during an error.

The Storage Off Time setting determines the time be-

tween storage refrigeration cycles during a sensor failure.

The Storage On T ime setting determines the length of a

storage refrigeration cycle during a sensor failure.

F. STORAGE SETTINGS (2 OF 2)

This Storage Settings options have no effect on machine

operation.

G. USER PREFERENCES

User Preferences

_ Language English

_ Temp Units Farenheit(°F)

_ Service Contact Information

_ Contact Information USB Update

The User Preferences menu contains language options,

temperature units, and service contact information. The

screen is available to the Manager, Technician, and Factory levels.

The Language setting changes the language displayed.

English is the only language currently available.

Time 00:00:00 AM

Date 00/00/00

Daylight Savings Off

Clock Type 12 HR

Date Format

_ Modify Time and Date

The Time and Date menu shows the time and date settings. The Manager, Technician, and Factory levels can

change the time and date by using the Modify Time and

Date option.

I. FACTORY SETTINGS (1 OF 6)

Factory Settings (1 of 6)

Cylinder Right

_ Pre Stir 00 sec

_ Post Stir 00 sec

_ Off Time 0000 sec

_ Consistency Sensing Switch

The Factory Settings screen 1 of 6 contains timer settings.

The screen is available only to the Factory level.

The Pre Stir setting is the amount of time the machine

will perform a consistency check before a freezing cycle

begins. During the pre stir the drive motor will run and

the machine will monitor the torque switch.

The Post Stir setting is the amount of time the drive mo-

tor will operate after a freezing cycle ends. The post stir

ensures product does not freeze to the cylinder.

The Off Time setting is the standby time. It is the period

between the end of the Post Stir and start of the Pre Stir

(without opening the spigot).

Consistency Sensing has no effect on machine operation.

J. FACTORY SETTINGS (2 OF 6) THROUGH (6 OF 6)

The remaining factory settings screens do not affect machine operation and should not be changed.

Service Manual #513668 11 E122 & F122 Model Machines

Page 18

2.6 UTILITIES SCREENS

B. TOUCHPAD LOCKUP

Utilities (1 of 2)

_ Adjust LCD Contrast

_ Touchpad Lockup

_ Export Machine Stats

_ Clean Options

Next Utilities Menu

Utilities (2 of 2)

_ Testing and Manual Operation

_ Unit Calibration

_ Clear Log Data

_ Restore Factory Defaults

_ Reset Unit Configuration

The Utilities menu gives access to various settings and

operations in the control. The Utilities menu is available to

the Manager, Technician, and Factory levels. The Manager

level will only have access to the fi rst screen. The Tech-

nician and Factory levels have access to both screens.

NOTE

Entering the Utilities (2 of 2) screen automatically

shuts off the freezing cylinders (refrigeration and

drive motors).

A. ADJUST LCD CONTRAST

Touchpad Lockup

Touchpad Status: Unlocked

Do you want to lock keys

_ No Unlock Touchpad

_ Yes Lock Touchpad

The Touchpad Lockup is used to lock and unlock the

keypad for self service locations.

C. EXPORT MACHINE STATS

Export Machine Stats

This will export statistics

data to stats.txt file

Please insert USB flash memory

Are you sure you want to do that

_ No

_ Yes

The Export Machine Stats screen allows you to export

all the data and statistics stored in the control. Connect a

USB fl ash drive (1 MB minimum) to the port on the side

of the machine and select the yes option.

D. CLEAN OPTIONS

Clean Options

Adjust LCD Contrast

0123456789

ABCDEFGHIJKLMNOPQRSTUVWXYZ

ź to change

Press

Ÿ

The Adjust LCD Contrast screen adjusts the contrast between the background lighting and the text on the screen.

Clean History Log

Clean Warning

Clean Lockout

The Clean Options Menu gives access to the Clean History Log and Clean Lockout options.

The Clean History Log screen shows the date, time and

duration of the last 32 clean cycles.

Clean History Log (32 of 32)

Cylinder Right

Clean Log ID 0: 00/00/00

00:00:00

Clean Total Time 000 min

Service Manual #513668 12 E122 & F122 Model Machines

Page 19

The Clean Warning and Clean Lockout screens are

used to enable the clean warning mode or the clean

lockout mode. When one of the modes is enabled and

the machine is not cleaned within a specifi ed period, the

machine will either display a warning (for warning mode)

or remain in sleep mode and not go into serve mode (for

lockout mode).

Clean Warning

Clean Warning Enabled

This option will

require cylinder cleaning

Are you sure you want to do that

_ No - Cancel Clean Warning

_ Yes - Enable Clean Warning

Clean Lockout

Clean Lockout Disabled

This option will

enforce cylinder cleaning

Are you sure you want to do that

_ No - Cancel Clean Lockout

_ Yes - Enable Clean Lockout

F. TESTING AND MANUAL OPERATION

The Testing and Manual Operation menu provides access

for individual components to be energized to assist with

troubleshooting. There are also test monitoring screens

that provide details of the machine status during testing.

Any energized component will deenergize after leaving

the Testing and Manual Operations menu.

Testing and Manual Operation

Select below for testing

_ Left Output Control

_ Right Output Control

_ Left / Right Monitoring

Selecting Left or Right Output Control goes to a screen

that allows motors, solenoids, or the compressor to be

individually activated. Activate by moving the cursor to the

desired component and pressing the SET button.

Testing and Manual Ops, Left

_ Drive Motor Off

_ Fan Motor Off

_ Liquid Solenoid Off

_ Compressor Off

_ Refer Solenoid Off

_ Aux Solenoid Off

_ Pump Motor Off

Selecting Left/Right Monitoring goes to screens that show

current statistics of the selected cylinder.

The Test Monitoring screens can be used for immediate

feedback when troubleshooting. For example the spigot

switch can be tested by opening the spigot and observing

if the status text changes from "Closed" to "Open".

Test Monitoring (1 of 3)

Cylinder Right

CRC Errors Dis/IO 0/6791

Motor Voltage 0.0 V

Motor Current 0.000

I/V Phase Angle 0.0°

Frequency 0.0 Hz

Consistency 0.0

Test Monitoring (2 of 3)

Cylinder Right

CRC Errors Dis/IO 0/12

Ambient Temp +00.0°F

Cylinder Temp +00.0°F

Storage Temp +00.0°F

Liquid Level OK

Test Monitoring (3 of 3)

Cylinder Right

CRC Errors Dis/IO 0/12

Spigot Closed

Door Closed

Hi Pressure No

Torque Switch Input Off

Service Manual #513668 13 E122 & F122 Model Machines

Page 20

G. UNIT CALIBRATION

The Unit Calibration screens have no effect on machine

operation.

H. MOTOR CALIBRATION

The Motor Calibration screen has no effect on machine

operation.

H. CLEAR LOG DATA

Clear Log Data

This will clear the error log

and the statistics.

Are you sure

you want to do that

_ No

_ Yes

The Clear Log Data screen will clear all the errors and

statistics in memory.

I. RESTORE FACTORY DEFAULTS

Restore Factory Defaults

2.7 ERRORS & STATISTICS SCREENS

The Errors & Statistics menu gives the Technician and Factory levels access to machine statistics and error history.

Errors and Statistics

_ Machine Statistics

_ Error History

A. MACHINE STATISTICS (1 OF 10)

Machine Statistics (1 of 10)

Cylinder Right

Time in Serve Mode 0000 hr

Last 24hrs 0000 min

Last 7days 0000 hr

Time in Off Mode 0000 hr

Last 24hrs 0000 min

Last 7days 0000 hr

This will reset all machine

settins to the original

factory configurations. Are

you sure you want to do that

_ No

_ Yes

The Restore Factory Defaults screen is used to restore

the control to the original factory confi guration.

J. RESTORE UNIT CONFIGURATION

Reset Unit Configuration

This will reset the unit type

and motor types.

Are you sure you want to do that

_ No

_ Yes

The Restore Unit Confi guration screen allows you to

change the motor type default. The E122 unit confi gura-

tion is 0, and the F122 unit confi guration is 1.

The Machine Statistics screen 1 of 10 shows the time in

serve mode and time in sleep mode. The screen shows a

running total, the total for the previous day, and the total

for the previous week for both statistics.

B. MACHINE STATISTICS (2 OF 10)

Machine Statistics (2 of 10)

Cylinder Right

Total Low Mix Time 0000 hr

Last 24hrs 0000 min

Last 7days 0000 hr

The Machine Statistics screen 2 of 10 shows the low mix

running time. This is the total time, including serve mode

and sleep mode, that the freezing cylinder was operating

with a low mix error. The screen shows a running total,

the total for the previous day, and the total for the previous week.

Service Manual #513668 14 E122 & F122 Model Machines

Page 21

C. MACHINE STATISTICS (3 OF 10)

F. MACHINE STATISTICS (6 OF 10)

Machine Statistics (3 of 10)

Cylinder Right

Last Clean Cycle 00/00/00

00:00:00 AM

Last Clean Time 0000 min

The Machine Statistics screen 3 of 10 provides the time

and date that the freezing cylinder was last cleaned. This

value is recorded when the Clean button is pressed on

the touchpad. The screen also shows how long the most

recent clean mode lasted.

D. MACHINE STATISTICS (4 OF 10)

Machine Statistics (4 of 10)

Cylinder Right

Spigot Open Total 0000 min

Last 24hrs 0000 min

Last 7days 0000 min

Spigot Total Cycles 0000

Average Spigot Open 0000 sec

Machine Statistics (6 of 10)

Cylinder Right

Compressor Run Time 0000 hr

Compressor Cycles 0000

Last Compressor Reset 00/00/00

00:00:00

_ Reset Compressor Time

The Machine Statistics screen 6 of 10 shows the total run

time for the compressor and counts the total cycles. There

is an option to reset the timer and the screen shows when

the last reset was done. Only reset the compressor time

if the compressor is changed.

G. MACHINE STATISTICS (7 OF 10)

Machine Statistics (7 of 10)

Cylinder Right

Motor Run Time 0000 hr

Motor Cycles 0000

Last Motor Reset 00/00/00

00:00:00 AM

_ Reset Motor Time

The Machine Statistics screen 4 of 10 shows the total time

that the spigot has been open during serve mode. The

screen shows a running total, the total for the previous

day, and the total for the previous week. The screen also

shows the total times that the spigot has been opened.

E. MACHINE STATISTICS (5 OF 10)

Machine Statistics (5 of 10)

Cylinder Right

Estimated Serve Amount 0000 gal

Last Reset Amount

00/00/00

00:00:00 AM

The Machine Statistics screen 5 of 10 gives the estimated

serve amount of the freezing cylinder based on the time

the spigot is open during serve mode. The estimation is

also calculated for the previous day and the previous week.

The screen gives an option to reset the serve amount and

shows when the last reset was done.

The Machine Statistics screen 7 of 10 shows the total run

time for the drive motor and counts the total cycles. There

is an option to reset the timer and the screen shows when

the last reset was done. Only reset the motor time if the

drive motor is changed.

H. MACHINE STATISTICS (8 OF 10)

Machine Statistics (8 of 10)

Cylinder Right

Pump Run Time 0000 hr

Pump Cycles 0000

Last Pump Reset 00/00/00

00:00:00 AM

_ Reset Pump Time

The Machine Statistics screen 8 of 10 does not apply to

this machine.

Service Manual #513668 15 E122 & F122 Model Machines

Page 22

I. MACHINE STATISTICS (9 OF 10)

L. STATUS AT TIME OF ERROR

Machine Statistics (9 of 10)

Cylinder Right

Current Hose Usage 0000 hr

Hose Service Limit 100 hr

Last Hose Reposition 00/00/00

00:00:00 AM

_ Reset Hose Service Time

The Machine Statistics screen 9 of 10 does not apply to

this machine.

J. MACHINE STATISTICS (10 OF 10)

Machine Statistics (10 of 10)

Last Unit Power Up 00/00/00

00:00:00

Avg Power KWH/Day 0 Watts

Status at Time of Error

Operating Mode Off

Mix Levels Full Level

Consistency 000.00

Input V/A/P 000.0V 00 00

Outputs Status 0 0 0 0 0 0 0

Inputs Status 0 0 0 0 0 0

Amb/Cyl Temp -000.0°F -000.0°F

The Status at Time of Error screen gives data for the time

the error occurred.

The Machine Statistics screen 10 of 10 shows when the

machine was last powered on. The screen also gives an

average power consumption per day.

K. ERROR HISTORY

Error History 25 of 25

Type Cylinder Sensor

Date 00/00/00 00:00:00 AM

Cylinder Right

_ Status At Time of Error

_ Help

The Error History screen shows the last error that occurred.

The screen shows the type of error, the time and date and

the cylinder that had the error. Up to 25 errors are stored.

Press the up or down arrow to scroll through the errors.

Select the Status at Time of Error option to view data for

the time the error occurred. The Help option explains the

error and provides quick troubleshooting tips.

Service Manual #513668 16 E122 & F122 Model Machines

Page 23

2.8 PRODUCT CONSISTENCY ADJUSTMENT

The Consistency Adjustment Screw increases or decreases product consistency by changing the amount of

torque needed to complete a refrigeration cycle. Turn the

knob clockwise to increase consistency.

Consistency Adjustment ScrewConsistency Adjustment Screw

TENSION SPRINGS

An optional spring is included with the machine and is

for use with shake mixes only. It is located behind the

header panel. To change springs, remove the header

panel, unhook the original spring from the torque switch

assembly and hook the new spring into place.

E122 - The standard spring is green. The optional

spring is yellow. The yellow spring is thicker.

F122 - The standard spring is yellow. The optional

spring is red. The red spring is thicker.

2.9 DRIVE BELT TENSION ADJUSTMENT

To check belt tension, follow the steps below:

A. Remove the side panels and back panel.

B. Use a Burroughs Belt Tension Gauge to check

the drive belt tension. The belt tension should be

50-55 lbs.

C. If an adjustment is necessary, loosen the four

motor plate retaining nuts, adjust belt tension

bolt then retighten the four nuts.

D. Using a straightedge, check that the drive motor

pulley is aligned with the speed reducer pulley.

Align the pulley if necessary.

NOTE

Belt life will be increased if new drive belts are

tightened after two or three weeks of operation.

2.10 PREVENTIVE MAINTENANCE

Stoelting recommends that a maintenance schedule be

followed to keep the machine clean and operating properly.

A. DAILY

1. The exterior should be kept clean at all times to

preserve the luster of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth

or sponge to apply the cleaner.

2. Make sure nothing is blocking airfl ow around the

machine.

B. WEEKLY

1. Check o-rings and rear seal for excessive wear

and replace if necessary.

2. Remove the drip tray by gently lifting up to

disengage from the support and pulling out. Clean

behind the drip tray and front of the machine.

C. QUARTERLY

The air-cooled condenser is a copper tube and aluminum

fi n type. Condensing is totally dependent upon airfl ow.

A plugged condenser fi lter, condenser, or restrictions in

the louvered panel will restrict airfl ow. This will lower the

capacity of the system and damage the compressor.

The condenser must be kept clean of dirt and grease. The

E122 must have a minimum of 4" (10.2 cm) of ventilation at

the back. The F122 must have a minimum of 6” (15.2 cm)

of ventilation on both sides of the unit for free fl ow of air.

The condenser and condenser fi lter require periodic clean-

ing. To clean, refer to the following procedures.

F122 Air Cooled Condenser Cleaning

A. Disconnect power to the machine

B. Remove the Phillips head screws from the right

side panel, and remove the panel.

C. To remove a condenser fi lter, grasp the top and

pull off. Visually inspect the fi lters for dirt. If a

fi lter is dirty, shake or brush excess dirt off the

fi lter and wash it in warm, soapy water. Once it

is clean, rinse it thoroughly in warm, clear water

and shake dry, taking care not to damage the

fi lter in any way.

E122 Air Cooled Condenser Cleaning

A. Unscrew the knob located on the underside of

the machine.

B. Remove the fi lter bracket and remove the fi lter.

C. Visually inspect the condenser fi lter for dirt.

D. If the fi lter is dirty, vacuum or brush clean, rinse

with clean water and allow to dry before replacing

on the machine.

Service Manual #513668 17 E122 & F122 Model Machines

Page 24

D. SEMI-ANNUALLY

1. Disconnect the machine from the power source.

2. Check drive belt for proper tension.

3. Lubricate condenser fan motor with S.A.E. 20

weight oil. Three to six drops is required.

4. Sanitize the autofi ll system (if applicable) following

the steps below:

AUTOFILL SANITIZING

A. If necessary, disassemble, clean and sanitize the

machine.

NOTE

If the machine does not require cleaning and sanitizing, press the Pump On/Off button to turn off the

pump. Then dispense enough product so that the

mix level in the hopper is below the long probe. If

the mix level is above the long probe, the solenoid

will not activate and the pump will not operate.

B. Prepare Stera-Sheen Green Label Sanitizer

or equivalent according to manufacturer’s

instructions to provide a 100ppm strength solution.

Mix the sanitizer in quantities of no less than 2

gallons of 90° to 110°F (32° to 43°C) water. Any

sanitizer must be used only in accordance with

the manufacturer’s instructions.

C. Cut an adapter from an empty bag of syrup.

Connect the adapter to the Bag-In-Box (BIB)

connector of the syrup line. Put the BIB connector

into the bucket of sanitizer.

NOTE

If you do not have an empty bag of syrup, remove

the plug from the top of the BIB connector. Do not

lose the plug; it is needed for proper operation of

the BIB.

H. The pump is now ready to operate. Place the

hopper cover on the hopper.

2.11 EXTENDED STORAGE

Refer to the following steps for storage of the machine

over any long period of shutdown time:

A. Follow the cleaning and sanitizing procedures

for the machine and follow the semi-annual

instructions to sanitize the autofi ll system.

B. Press the Main Power On/Off button so that power

to the machine is off.

C. Disconnect (unplug) from the electrical supply

source.

D. Thoroughly clean all parts that come in contact

with mix. Rinse in clean water and dry parts. Do

not sanitize.

NOTE

Do not leave cleaning solution in the hopper or in

the freezing cylinder during the shutdown period.

E. Remove, disassemble and clean the front door,

mix inlet regulator and auger parts.

D. Make sure the display screen shows that the

main power is on. Hold the hopper cover over a

bucket and press the Pump On/Off button. The

solenoid will activate and the brix pump will pump

sanitizer into the bucket.

NOTE

The solenoid will only activate when there is not any

liquid touching the longer mix probe in the hopper.

E. After all the sanitizer has run through the pump,

press the Pump On/Off button to turn off the pump.

F. Disconnect the bag adapter from the BIB connector

(or reinsert the plug into the connector). Connect

the BIB connector to the syrup BIB.

G. Hold the hopper cover over a bucket and press the

Pump On/Off button. This will fl ush the sanitizer

out of the pump and tubing. Once the sanitizer

is fl ushed out, press the Pump On/Off button.

Service Manual #513668 18 E122 & F122 Model Machines

Page 25

SECTION 3

!"#!

#

$%&

+&*

),/4.5

)*

0

#

$'

0

2#

0

2#

0#

#

0#

#

$

'

!"#!

#

$%&'

(#

)*

!

#

$

'

!"#!

#

$%&'

(#

)*

!

#

$%&

+&*

REFRIGERATION & WIRING DIAGRAMS

Service Manual #513668 19 E122 & F122 Model Machines

Page 26

E122-38I2AF

Service Manual #513668 20 E122 & F122 Model Machines

Page 27

E122-38I2AF

Service Manual #513668 21 E122 & F122 Model Machines

Page 28

E122-38I2 & E122-38I2P

Service Manual #513668 22 E122 & F122 Model Machines

Page 29

E122-38I2 & E122-38I2P

Service Manual #513668 23 E122 & F122 Model Machines

Page 30

F122-38I2-AF & F122-38I2AF

Service Manual #513668 24 E122 & F122 Model Machines

Page 31

F122-38I2 & F122-38I2P

Service Manual #513668 25 E122 & F122 Model Machines

Page 32

F122X-302I2

Service Manual #513668 26 E122 & F122 Model Machines

Page 33

F122-38I2 & F122-38I2P

Service Manual #513668 27 E122 & F122 Model Machines

Page 34

Service Manual #513668 28 E122 & F122 Model Machines

Page 35

SECTION 4

REPLACEMENT PARTS

4.1 DECALS AND LUBRICATION

Quantity

Part Description E122 F122

C-1000-26C Decal - Made In USA 1 1

208135 Brush - 4” X 8” X 16” (Barrel) 1 1

208380 Brush - 1/4” X 3” X 14” 1 1

208401 Brush - 1” X 3” X 10” 1 1

232091 Cap - Protective (Gray) - #490716 Leg 1

236054 Card - Cleaning Instructions - Brix Pump (Auto Fill) 1 1

236065 Card - Cleaning Instruction - E122 & F122 1 1

324065 Decal - Water Inlet 1

324105 Decal - Caution Electrical Shock 4 3

324106 Decal - Caution Electrical Wiring Materials 1 1

324107 Decal - Caution Hazardous Moving Parts 2 2

324141 Decal - Caution Rotating Blades 1 1

324208 Decal - Attention Refrigerant Leak Check 2 2

324509 Decal - Cleaning Instructions 1 1

324548 Decal - Adequate Ventilation 6” 2 2

324594 Decal - Attention Heat Sensitive 2 2

324686 Decal - Danger Automatic Start 2

324804 Decal - Domed Stoelting Swirl (Header Panel) 1 1

324888 Decal - Fan Motor Reset 1

324901 Decal - Transformer Switch 1

324909 Decal - USB Port 1 1

324921 Decal - Arctic Quake 1

324922 Decal - Assembly Check 1

324938 Decal - 4” Ventilation 1

325023 Decal - Stoelting (Black) (Large) 1 1

325024 Decal - Stoelting (Black) (Small) 1 1

325032 Decal - White Glove Service 1 1

396245 Gasket - Freezer Base 1

490716 Leg 4

490749 Leg - Front 2

490750 Leg - Rear (w/Suction Cup) 2

508053 Lubricant - Total Blend (50 Packets) 1 1

513667 Manual - Operators 1 1

1183955 O-Ring Kit -

2183636 Spacer - Leg 4

2203790 Sensor Probe Kit - -

Service Manual #513668 29 E122 & F122 Model Machines

Page 36

4.2 AUGER SHAFT AND FACEPLATE PARTS

630053

630053

336551

336551

2183447

2183447

2183099

2183099

570197

570197

482019

482019

624645

2203370

2203370

624644

624644

624645

2202068

2202068

2202181

2202181

2183444

2183444

2183751

2183751

2204226

2204226

666786

666786

624678

624678

2203224

2203224

2203555

624515

624515

624545

624545

2183449

2183449

Quantity

Part Description E122 F122

336551 Door - Front 2 2

482019 Knob - Front Door (Black) 8 8

570197 Pin - Cotterless Clevis (Front Door) 2 2

624515-5 O-Ring - Stator Bar Rear (5 Pack) 2 2

624545-5 O-Ring - Stator Bar Front (5 Pack) 2 2

624644-5 O-Ring - Spigot Body (Bottom) (5 Pack) 2 2

624645-5 O-Ring - Spigot Body (Top) (5 Pack) 2 2

624678-5 O-Ring - Rear Seal - Black (5 Pack) 2 2

625310 Quad-Ring - Front Door - Black 2 2

630053 Rod - Torque Actuator 2 2

666786 Seal - Rear Auger - Black 2 2

2183099 Breaker Bar - Spigot Body 2 2

2183444 Bushing - Stator Support (Rear) 2 2

2183447 Handle Only - Spigot 2 2

2183449 Bushing - Front Auger Support 2 2

2183751 Blade - Scraper 2

2202068 Stator Bar 2

2202181 Stator Bar 2

2203224 Auger Shaft 2

2203370 Spigot Body 2 2

2203555 Auger Shaft 2

2204226 Blade - Scraper 2

625310

625310

2203555

Service Manual #513668 30 E122 & F122 Model Machines

Page 37

4.3 HOPPER PARTS

2187918

2187918

2187919

2187919

314453

314453

2203078

2203078

744252

744252

744281

744281

2187058

2187058

2203090

2203090

2203206

2203206

624607

624607

417006

417006

417031

417031

744273

744273

744609

744609

Quantity

Part Description E122 F122

314453 Cover - Hopper 2 2

417006 Grid - Drip Tray (Vinyl Coated Metal) 1

417031 Grid - Drip Tray 1

624607-5 O-Ring - Mix Inlet (5 Pack) 4 4

744252 Tray - Drain 1

744273 Tray - Drip 1

744281 Tray - Drain (Front) 1

744609 Tray - Drip 1

2187058 Mix Inlet Regulator 2

2187918 Mix Inlet Adapter (Auto Fill) 2 2

2187919 Clip - Retaining (Mix Inlet Adapter) (Auto Fill) 2 2

2203090 Mix Inlet Regulator 2

2203078 Cover - Hopper (Auto Fill) 2 2

2203206 Mix Inlet Regulator (Auto Fill) 2

Service Manual #513668 31 E122 & F122 Model Machines

Page 38

4.4 MOTOR COMPONENTS

614222

614222

614232

614232

598155

598155

598296

598296

152207

152207

152340

152340

230441

598026

598026

598039

598039

522720

522720

522302-SV

522302-SV

522304-SV

522304-SV

Quantity

Part Description E122 F122

152207 Belt - Gripnotch (AX29) (Each) 2

152340 Belt - Gripnotch (AX41) (Each) 2

230441 Capacitor Start (#522235 Motor) 2

230447 Capacitor (#522720 Drive Motor) 2

230685 Capacitor - Start (#522302-SV Motor) 2

230687 Capacitor - Run (#522302-SV Motor) 2

522720 Motor - Drive - 1/3 HP (60 Hz) 2

522302-SV Motor - Drive w/Mounting Base - 1PH - 60Hz 2

522304-SV Motor - Drive w/Mounting Base - 1PH - 50Hz 2

598026 Pulley - Drive Motor 2

598039 Pulley - Drive Motor 2

598155 Pulley - Speed Reducer 2

598296 Pulley - Speed Reducer 2

614222 Speed Reducer 2

614232 Speed Reducer 2

4.5 SPIGOT ASSEMBLY

718773

718773

694334

694334

230441

230447

230447

718013

718013

Quantity

Part Description E122 F122

694334 Spring - Compression (Spigot Switch) (2.25”) 2 2

694336 Spring - Compression (Spigot Switch) (2.75”) 2

695706 Spring - Consistency Adjustment (Green) 2

695707 Spring - Consistency Adjustment (Yellow) 2 2

695714 Spring - Consistency Adjustment (Red) 2 2

718013 Switch - Roller (Spigot) 2 2

718773 Switch - Limit (Torque Consistency) 2 2

Service Manual #513668 32 E122 & F122 Model Machines

Page 39

4.6 PANELS & SCREWS

Quantity

Part Description E122 F122

644734 Screw - Panel (Sides & Rear) - 647653 Screw - Panel (Header) 647886 Screw - Drip Tray Support Bracket 647899 Screw - Panel (Front) 649114 Screw - Panel (Rear Air Plenum) 2202679 Panel - Header 1

2202681 Drip Tray Support Bracket 1

2202884 Panel - Front 1

2202885 Panel - L.H. Side 1

2202886 Panel - R.H. Side 1

2202887 Panel - Rear 1

2202896 Panel - Header 1

2203051 Panel - Drip Tray 1

2203584 Panel - L.H. Side 1

2203589 Panel - Front 1

2203590 Panel - R.H. Side 1

2202776-1 Panel - Rear 1

2206167 Plenum Assembly (L.H. Side) 1

2206173 Panel - Rear Air Plenum 1

4.7 KITS & MISCELLANEOUS

Quantity

Part Description E122 F122

396245 Gasket - Freezer Base 1

513667 Manual - Owner's 1 1

1183955 O-Ring Kit -

2203790 Sensor Probe Kit - -

Service Manual #513668 33 E122 & F122 Model Machines

Page 40

4.8 ELECTRICAL COMPONENTS

Quantity

Part Description E122 F122

202245 Circuit Breaker (Air-Cooled Only) 1

229148 Cable - IntelliTec2 (Control Board to Display Board) 1 1

229158 USB Cable Extension 1 1

230632 Capacitor - Start (Compressor) 1

230649 Capacitor - Start (#282050 Compressor) 1

230654 Capacitor (Fan Motor) 2

230665 Capacitor - Fan Motor 2

230666 Capacitor - Run (Compressor) 1

231079 Capacitor - Start (#282032 Compressor) 1

231084 Capacitor - Run (#282032 & #282050 Compressors) 1

232452 Plug - USB 1 1

292353 Connector - 9 Pin Phoenix (#521513 Board) 1

292354 Connector - 8 Pin Phoenix (#521514 Board) 1

292355 Connector - 9 Pin Phoenix (#521514 Board) 1

292356 Connector - 6 Pin Phoenix (#521514 Board) 1

292357 Connector - 6 Pin Phoenix (Low Mix) (#521513 Board) 1

292358 Connector - 6 Pin Molex (Thermistor) (#521513 Board) 1

292359 Connector - 8 Pin Molex (Switch Input) (#521513 Board) 1

295017 Contactor (45CG20AG) (Compressor & Drive) 3 3

332563 Board - Display Module 1 1

430119 Cord - Power (60 Hz) 1

430172 Cord - Power 1

430608 Cord - Power (50 Hz) (Cord Only - No Plug) 1

521511 Board - Program - IntelliTec2 1

521512 Board - Control - Mix Level (Auto Fill) 1

521513 Board - Program / Power (IntelliTec2) 1

521514 Board - Relay (IntelliTec2) 1

521516 Board - Program / Relay (IntelliTec2) 1

610038 Diode (IntelliTec2) 1

618157 Relay - Start (#282032 & #282050 Compressors) 1

618363 Relay - Compressor (60 Hz) 1

694200 Spring - Door Interlock 2 2

718539 Switch - Toggle (Transformer Voltage Selector)

(208/230V) (Air-Cooled Only) 1

719111 Switch - Limit (Door Interlock) 1 1

719127-SV Switch - Membrane Strip (Touchpad & Ribbon) 1 1

719128-SV Switch - Membrane Strip (Touchpad & Ribbon) 1

743654 Transformer - Booster (Air-Cooled Only) 1

2177301 Probe Assembly - Hopper (5”) 2 2

2177302 Probe Assembly - Hopper (3.25”) 2 2

2183006 Probe Assembly - Hopper Liquid Level (Long) (Non Autofi ll Units)) 1

Service Manual #513668 34 E122 & F122 Model Machines

Page 41

4.8 ELECTRICAL COMPONENTS (CONTINUED)

2177302

2177302

332563

332563

719127-SV

719127-SV

719128-SV

719128-SV

F122

295017

295017

231079

231079

2177301

2177301

2183006

2183006

618363

618363

694200

694200

719111

719111

F122

521512

521512

231084

231084

229158

229158

743654

743654

521513

521513

230654

230654

521516

521516

521514

521514

618157

618157

E122

230666

230666

521511

521511

295017295017

202245

202245

718539

718539

230665

230632

230632

F122

Service Manual #513668 35 E122 & F122 Model Machines

230665

Page 42

4.9 REFRIGERATION

Quantity

Part Description E122 F122

231107 Cap Tube Only 1

231107-SV Cap Tube & Drier Assembly 1

282032-SV Compressor - Copeland 1 PH - 60 Hz - R404A (No Capacitors) 1

282050 Compressor - 1 PH (50 Hz) (No Capacitors) 1

282094 Compressor - Copeland 1 PH (No Capacitors) 1

284000 Condenser - Air Cooled 1

284084 Condenser (Air-Cooled) 1

284104 Condenser (Water-Cooled) 1

342006 Drier 1

342008 Drier 1

357102 Motor - Fan (Air-Cooled Condenser) (Includes Blade & Guard) 1

357105 Fan - Axial (Includes Blade & Grill) 1

368140 Filter - Air 1

368466 Filter - Condenser 1

458003 Sight Glass 1

458009 Sight Glass 1

482004 Knob - Rear Filter Support 1

718794 Switch - High Pressure Reset 1

762275 Valve - Magna Check 1

762277 Valve - Magna Check 1

762455 Valve - Expansion (R404A) 2

762482 Valve - Expansion 2

762604 Valve - Solenoid (3/8”) (Liquid Line) 2

762978 Valve - EPR 1 1

763002 Valve - Solenoid (1/2”) (Suction) 2

763012 Valve - Hot Gas Bypass 1 1

763181 Valve - Water 1

763422 Valve - Solenoid (1/4”) (Liquid Line) 3 1

763482 Valve Coil - Solenoid (#763422) 3 1

763674 Valve - Solenoid (1/2”) (Suction Line) 2

763674B Valve Coil - Solenoid (#763674) 2

2202669 Evaporator Assembly 1

2202880 Evaporator 1

Service Manual #513668 36 E122 & F122 Model Machines

Page 43

4.9 REFRIGERATION (CONTINUED)

2202669

2202669

762482

284000

284000

762482

763422

763422

763482

763482

762978

762978

718794

718794

763012

763012

231107-SV

231107-SV

282094

282094

NOTE E112 shown

357105

357105

458003

458003

763674

763674

763674B

763674B

342006

342006

Service Manual #513668 37 E122 & F122 Model Machines

Page 44

4.10 AUTO FILL PARTS

763596763596

Quantity

Part Description E122 F122

264096 Clamp - Oetiker (Tubing to Hopper Cover) 18

264235 Clamp - Metal (Tubing to Solenoid) 4

376086 Hose Adapter (1/4” x 3/8”) 4 4

756067 Tubing - 1/4” ID - Clear (Mix Inlet to Solenoid) (Per Inch) 192” 120”

756187 Tubing - 1/4” ID - Braided (Syrup Solenoid) (Per Inch) 96” 192”

763596 Valve - Solenoid 2 2

Service Manual #513668 38 E122 & F122 Model Machines

Loading...

Loading...