Page 1

Model E111 & F111

SERVICE MANUAL

Manual No. 513531-2 Dec. 2005

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION 1 INTRODUCTION

1.1 Description .....................................................................................1

1.2 Specifications .................................................................................1

SECTION 2 INSTALLATION INSTRUCTIONS

2.1 Safety Precautions .........................................................................3

2.2 Shipment and Transit .....................................................................4

2.3 Freezer Installation .........................................................................4

2.4 Floor Stand Installation ...................................................................5

2.5 Installing Permanent Wiring............................................................5

SECTION 3 INITIAL SET-UP AND OPERATION

3.1 Operator’s Safety Precautions........................................................7

3.2 Operating Controls and Indicators ..................................................7

3.3 Sanitizing ........................................................................................8

3.4 Freeze Down and Operation...........................................................9

3.5 Mix Information...............................................................................10

3.6 Removing Mix Inlet Regulator.........................................................10

3.7 Cleaning the Freezer ......................................................................11

3.8 Disassembly of Freezer Parts.........................................................11

3.9 Cleaning the Freezer Parts.............................................................12

3.10 Sanitize Freezer & Freezer Parts....................................................12

3.11 Assembly of Freezer.......................................................................12

3.12 Routine Cleaning ............................................................................13

3.13 Preventive Maintenance .................................................................14

3.14 Extended Storage...........................................................................16

SECTION 4 REFRIGERATION SYSTEM

4.1 Refrigeration System ......................................................................17

4.2 Evaporators ....................................................................................18

4.3 Compressor Winding Test..............................................................18

4.4 Condensers ....................................................................................19

4.5 T.X.V. .............................................................................................20

4.6 T.X.V. Adjustment ..........................................................................20

4.7 T.X.V. Removal ..............................................................................20

4.8 T.X.V. Installation ...........................................................................21

4.9 Hopper............................................................................................22

4.10 E.P.R. Valve Adjustment ................................................................22

4.11 E.P.R. Removal ..............................................................................23

4.12 E.P.R. Valve Installation .................................................................23

4.13 Capillary Tubes...............................................................................24

4.14 Capillary Tube Removal .................................................................24

4.15 Capillary Tube Installation...............................................................24

4.16 Solenoid Valve................................................................................25

4.17 Solenoid Magnetic Coil Removal ....................................................25

4.18 Solenoid Magnetic Coil Installation .................................................26

Page 6

4.19 Solenoid Valve Removal.................................................................26

4.20 Solenoid Valve Installation..............................................................26

4.21 Refrigerant Charge (All Models) .....................................................26

SECTION 5 CONTROLS

5.1 Control System Type 4 ...................................................................27

5.2 Power Board...................................................................................27

5.3 Program Module.............................................................................27

5.4 Contactors ......................................................................................34

5.5 Spigot Switch..................................................................................34

5.6 Spigot Switch Removal...................................................................34

5.7 Spigot Switch Installation................................................................35

5.8 Front Door Interlock Switch ............................................................35

5.9 Front Door Interlock Removal.........................................................35

5.10 Front Door Interlock Switch Assembly ............................................36

5.11 Touch Pad Switch Module ..............................................................36

5.12 Touch Pad Switch Module Removal ...............................................36

5.13 Touch Pad Switch Module Assembly..............................................36

5.14 Sensor ............................................................................................37

5.15 Sensor Removal.............................................................................37

5.16 Sensor Installation ..........................................................................37

5.17 Preparation for Major Component Removal ...................................38

5.18 Condenser Fan Motor and Lubrication ...........................................38

5.19 Condenser Fan Motor Removal......................................................38

5.20 Condenser Fan Motor Installation...................................................39

5.21 Drive Motor.....................................................................................39

5.22 Drive Motor Removal......................................................................39

5.23 Drive Motor Installation ...................................................................40

5.24 Speed Reducer...............................................................................40

5.25 Speed Reducer Removal................................................................40

5.26 Speed Reducer Installation.............................................................41

5.27 Compressor....................................................................................41

5.28 Compressor Removal.....................................................................41

5.29 Compressor Installation..................................................................42

5.30 Final Assembly of Freezer ..............................................................43

SECTION 6 TROUBLESHOOTING

6.1 Dispensing, Servability, and Overrun..............................................46

6.2 Barrel and Hopper Mix Temperature Maintenance .........................47

6.3 Electro-Mechanical .........................................................................48

6.4 Control Displayed Error Conditions.................................................54

SECTION 7 REPLACEMENT PARTS

7.1 How To Order Parts........................................................................57

Page 7

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

1 Model Endura/Futura 111 Freezer..........................................................1

2 Specifications .........................................................................................1

3 Warning Label Locations ........................................................................3

4 Leveling the Freezer ...............................................................................4

5 Space and Ventilation Requirements......................................................4

6 Electrical Plug.........................................................................................4

7 Installing Tray and Cover........................................................................4

8 Floor Stand.............................................................................................5

9 Power Cord Connection..........................................................................5

10 Controls ..................................................................................................7

11 Mix Inlet Regulator..................................................................................9

12 Clean Control..........................................................................................9

13 Sanitizing Hopper ...................................................................................9

14 Draining Solution ....................................................................................9

15 Dispensing Product ................................................................................10

16 Removing Mix Inlet Regulator.................................................................10

17 Draining Mix ...........................................................................................10

18 Auger Flight Wear and Front Auger Support Bushing Wear ...................11

19 Removing Front Door .............................................................................11

20 Front Door Disassembly .........................................................................11

21 Removing Auger Support .......................................................................11

22 Auger Shaft Removal .............................................................................12

23 Removing “O” Ring.................................................................................12

24 Cleaning Freezer Barrel..........................................................................12

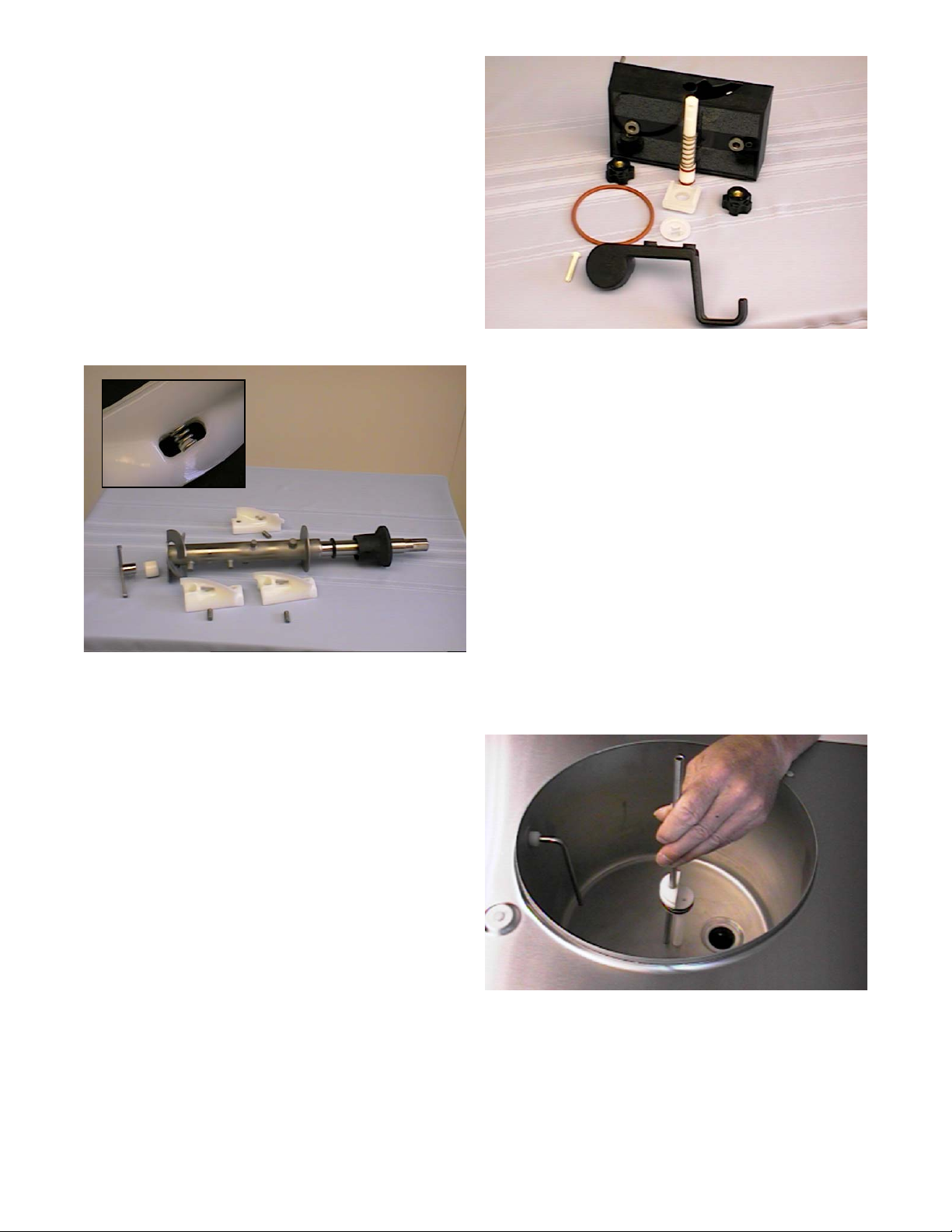

25 Exploded View of Auger .........................................................................13

26 Exploded View of Front Door..................................................................13

27 Mix Inlet Regulator..................................................................................13

28 Refrigeration System ..............................................................................17

29 Compressor Terminal Cover ..................................................................18

30 Compressor Connections .......................................................................18

31 Ohmmeter and Connections...................................................................18

32 Electrical Box..........................................................................................19

33 Condenser and Filter ..............................................................................19

34 Condenser Inspection.............................................................................20

Page 8

35 T.X.V. (Thermostatic Expansion Valve)..................................................20

36 Bulb Removal .........................................................................................21

37 T.X.V. Removal ......................................................................................21

38 Bulb Installation ......................................................................................22

39 Filter Drier...............................................................................................22

40 E.P.R. Schrader Access Fitting ..............................................................22

41 E.P.R. Valve Adjustment ........................................................................23

42 E.P.R. Valve and Lines...........................................................................23

43 Filter Drier...............................................................................................24

44 Capillary Tube and Drive Assembly ........................................................24

45 Filter Drier...............................................................................................24

46 Pressure Gauges ...................................................................................25

47 Power Cord ............................................................................................25

48 Solenoid Replacement............................................................................25

49 Solenoid Coil Removal ...........................................................................26

50 Power Board...........................................................................................28

51 Program Module.....................................................................................29

52 Membrane Switch Panel Display Board..................................................30

53 Spigot Switch Replacement....................................................................35

54 Interlock Switch Removal .......................................................................35

55 Interlock Switch Assembly......................................................................36

56 Switch Module Removal .........................................................................36

57 Cover Plate Removal..............................................................................37

58 Foam Insulation Removal .......................................................................37

59 Ty-raps Removal ....................................................................................37

60 Fan Motor Connections ..........................................................................38

61 Fan Bracket Removal .............................................................................39

62 Drive Belt Removal.................................................................................39

63 Drive Motor Wire Removal .....................................................................40

64 Motor Pulley Adjustment.........................................................................40

65 Belt Tension Adjustment.........................................................................40

66 Speed Reducer Removal........................................................................41

67 Speed Reducer Adjustment....................................................................41

68 Belt Tension Adjustment.........................................................................41

69 Compressor Cover Removal ..................................................................42

70 Compressor Connections .......................................................................42

71 Compressor Oil Test Kit .........................................................................42

72 Filter Drier...............................................................................................43

Page 9

SECTION 1

DESCRIPTION AND SPECIFICATIONS

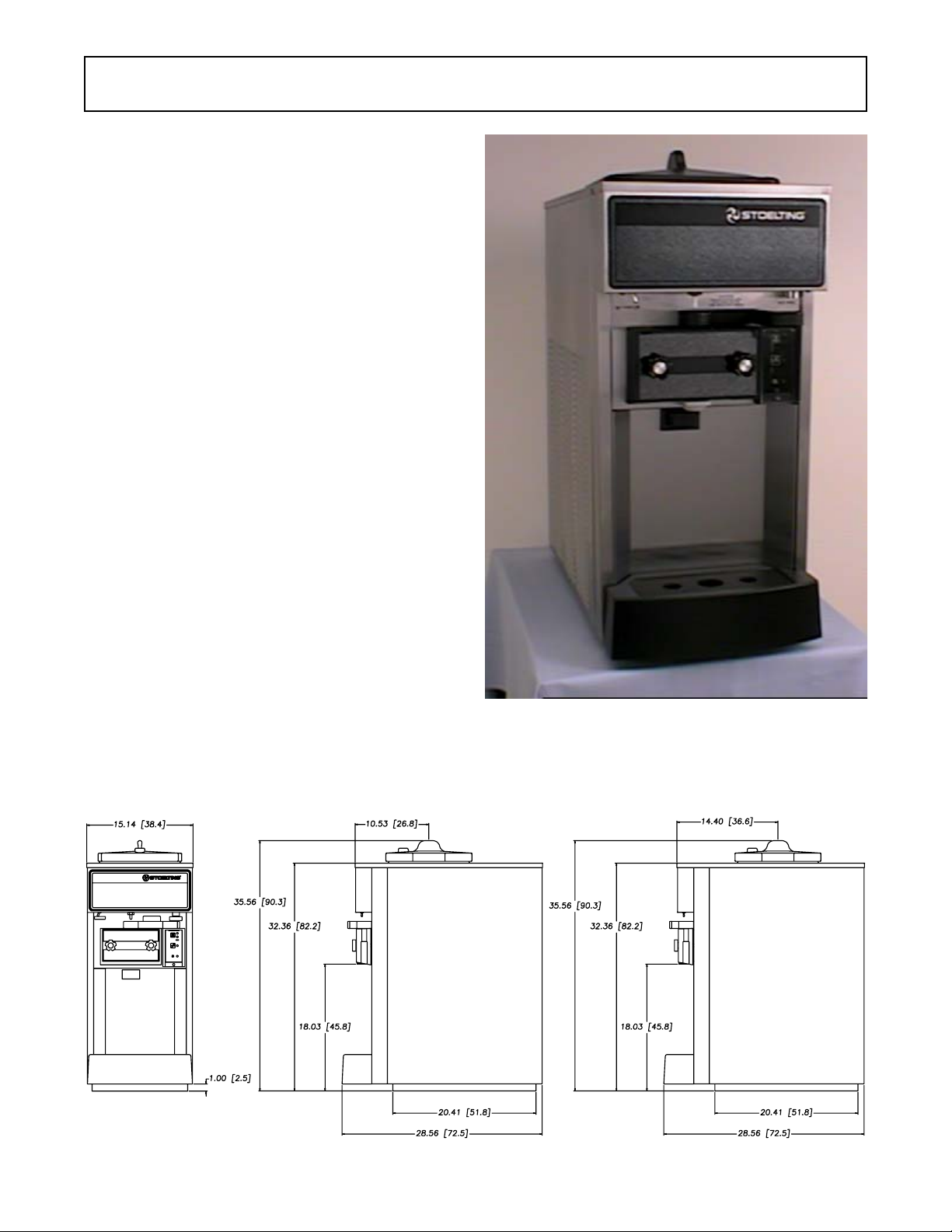

1.1 DESCRIPTION

The Stoelting Endura/Futura 11 1/1 12 counter freezers are

gravity fed. The freezers are equipped with fully automatic

controls to provide a uniform product. The freezers are

designed to operate with almost any type of commercial

soft serve or non-dairy mixer available, including ice milk,

ice cream, yogurt, and frozen dietary desserts. This

manual is designed to assist qualified service personnel

and operators in the installation, operation and maintenance of the Stoelting Model Endura 1 1 1/112 and Futura

1 1 1/1 12 gravity freezers.

1.2 SPECIFICATIONS

Model Endura/Futura

Front View

Figure 1. Model Endura/Futura 111/112 Freezer

Model Endura/Futura

Side Views

Figure 2. Specifications

1

Page 10

MODEL ENDURA/FUTURA 1 1 1/112

COUNTER MODEL

GRA VITY FREEZER

DIMENSIONS:

Freezer: 15" (38 cm) wide x 28.6" (72 cm) deep x 35.6" (90 cm) high

Crated: 19.5" (50 cm) wide x 33" (84 cm) deep x 40" (102 cm) high

WEIGHT:

Freezer: 230 lbs. (140 kg) Crated: 275 lbs. (125 kg)

ELECTRICAL:

Description Endura 11 1-37G Futura 11 1-38G

Voltage AC 1 PH 115V 1 PH 208/230

T ot al Run Amp s 12.00 10.00

Drive Motor 3/4 HP 3/4 HP

Use 20 amp HACR circuit breaker.

Automatic safeguard circuit built into electronic control-protects major

freezer components under abnormal operating conditions.

COOLING:

Air cooled requires minimum 3" (7.6 cm) air clearance on right and left hand side.

No clearance needed in the rear.

HOPPER:

3 Gallons (1 1.5 liters) refrigerated and insulated.

2

Page 11

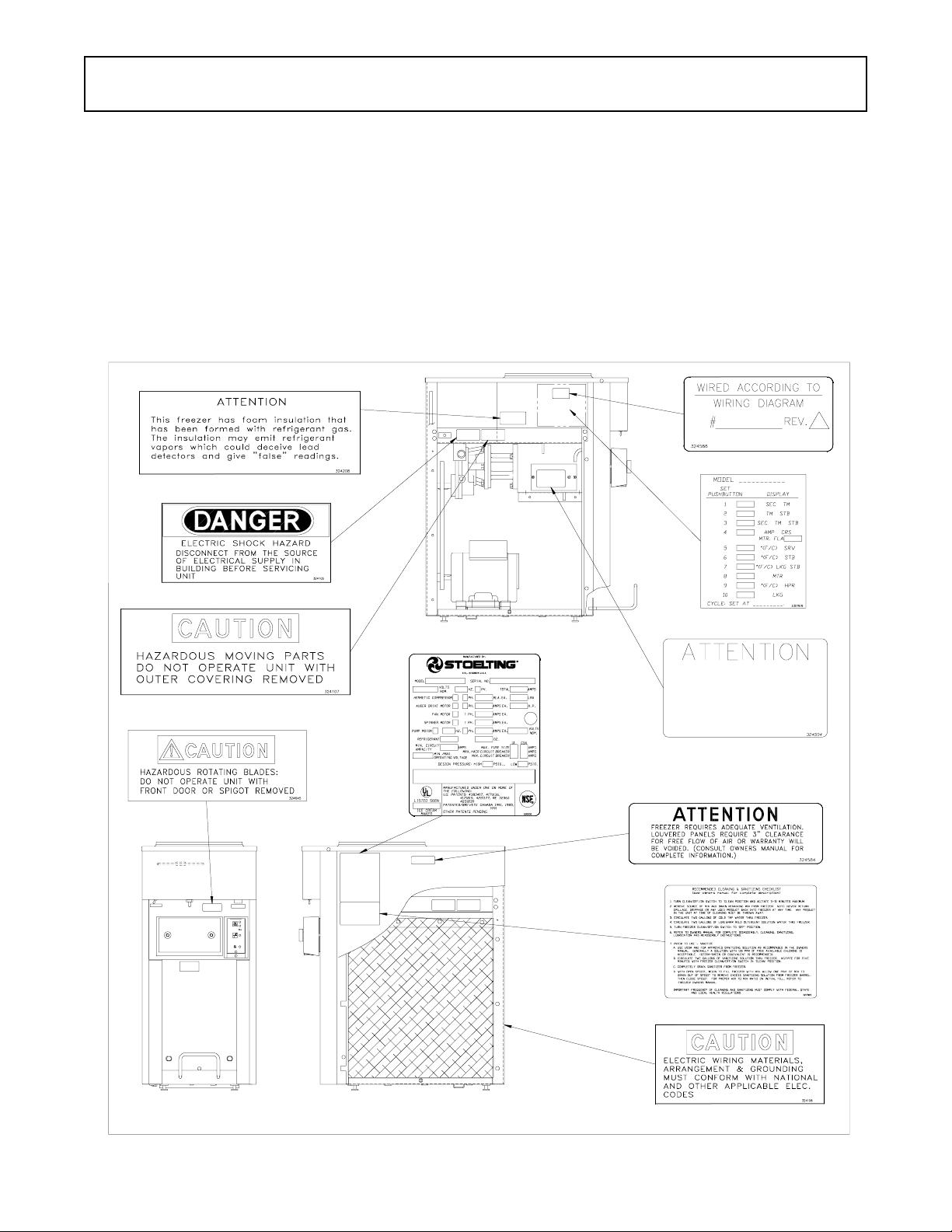

SECTION 2

THERMISTOR. HEAT SINK MUST BE

USED WHEN BRAZING ON EVAPORATOR

UNDER THIS COVER. TEMPERATURE

MUST NOT EXCEED 220°F NEAR

HEAT SENSITIVE THERMISTOR LOCATED

OUTLET. CHECK RESISTANCE BEFORE

SEE SERVICE MANUAL.

REMOVAL OF THERMISTOR.

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the freezer. The labels

have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the freezer. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, INC.

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

Figure 3. Warning Label Locations

3

Page 12

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and inspected

at the factory. Upon arrival at the final destination, the

complete freezer must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill until

the freezer has been checked for damage. Have the carrier

note any visible damage on the freight bill. If concealed

damage and/or shortage is found later, advise the carrier

within 10 days and request inspection. The customer must

place claim for damages and/or shortages in shipment

with the carrier. Stoelting, Inc. cannot make any claims

against the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

A. Uncrate the freezer.

B. Accurate leveling is necessary for correct drainage of

freezer barrel and to insure correct overrun. Place a

spirit level on top of the freezer at each corner to

check for level condition. If adjustment is necessary,

level the freezer by turning the bottom part of each leg

in or out. Then separate freezer base gasket and

install with seam to the back and angle to the top. (Fig.

4).

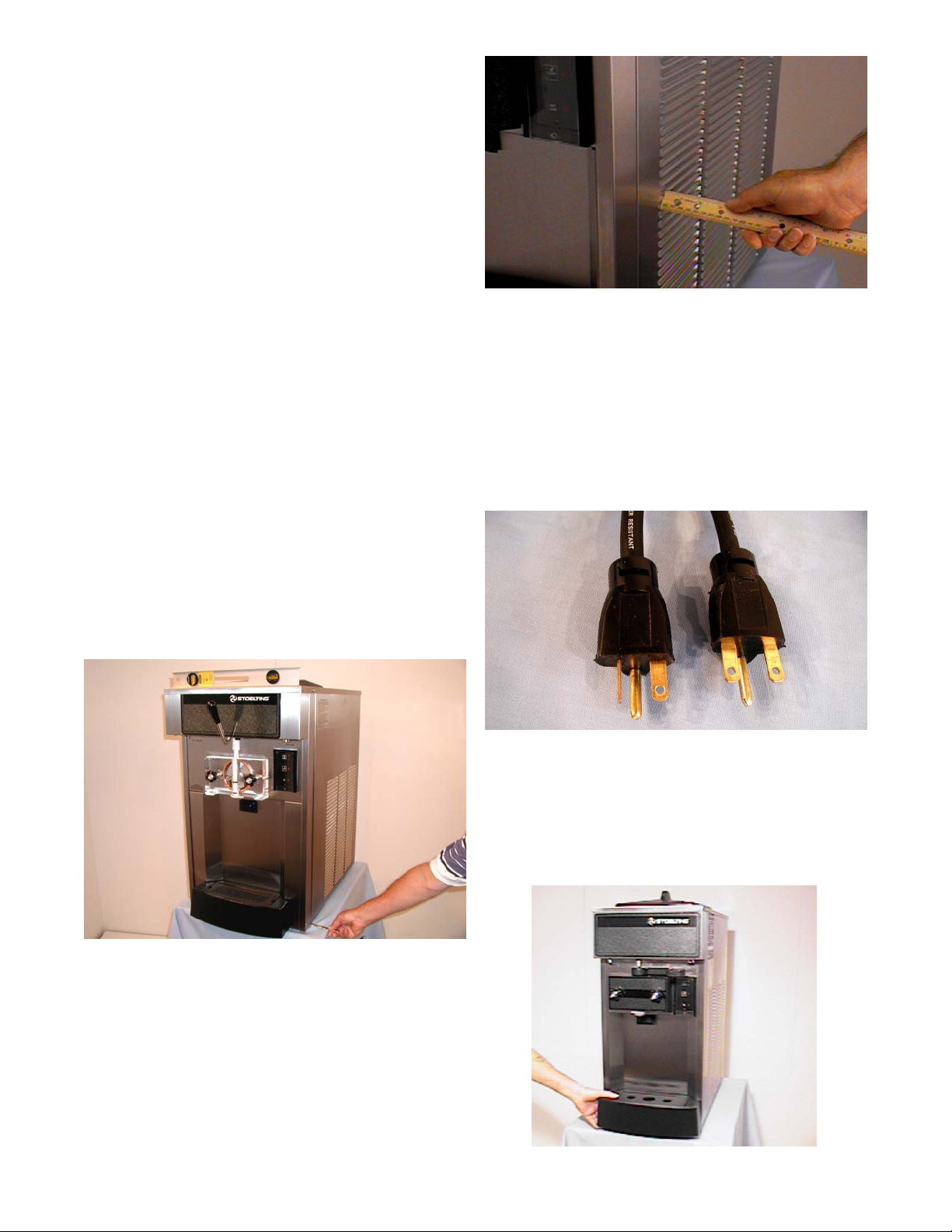

Figure 5. Space and Ventilation Requirements

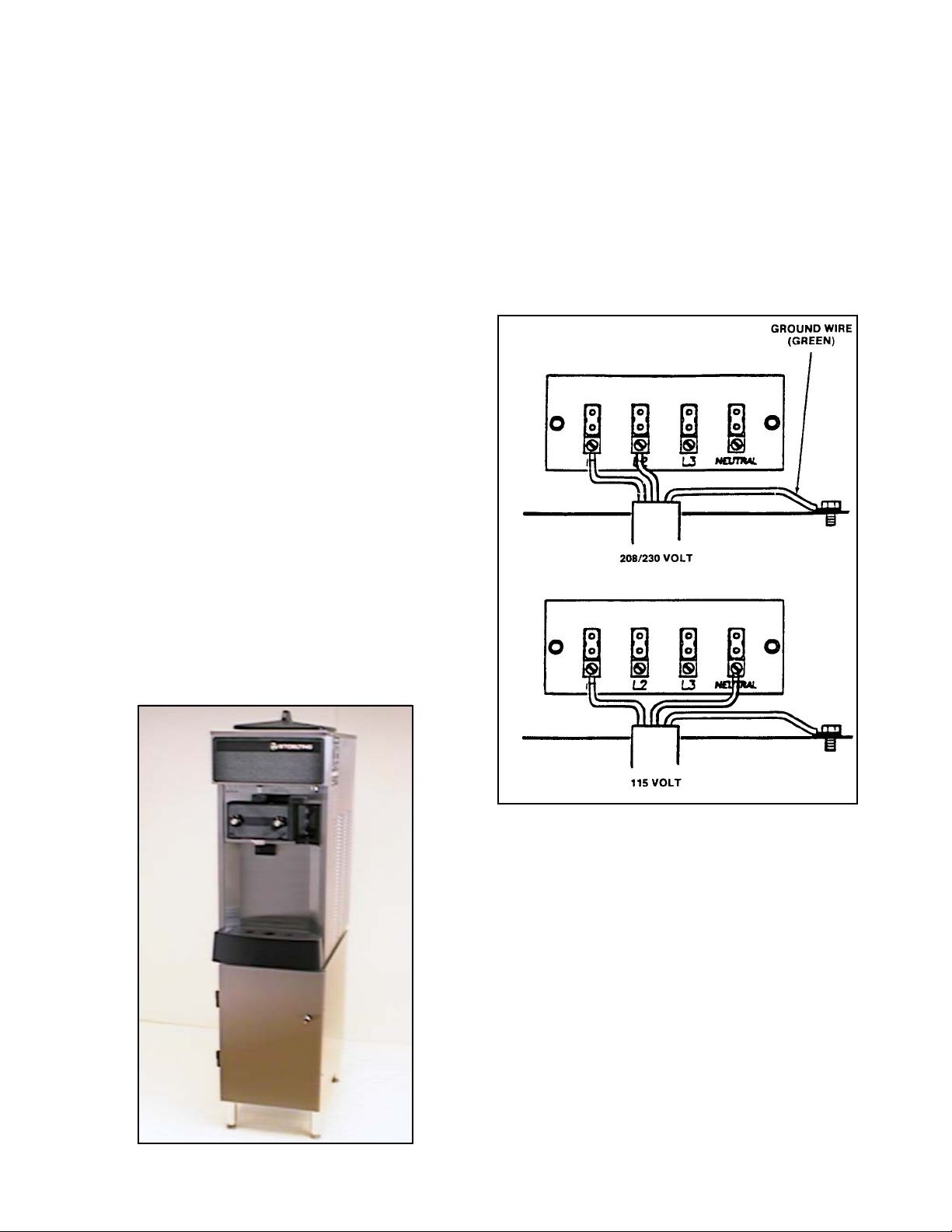

E. Connect the power cord. The plug is designed for 208

or 230 volt/20 amp duty. Check the nameplate on your

freezer for proper supply. The unit must be connected

to a properly grounded receptacle. The electrical cord

furnished as part of the freezer has a three prong

grounding type plug (Fig. 6). The use of an extension

cord is not recommended, if necessary use one with

a size 12 gauge or heavier with ground wire. Do not use

an adapter to get around grounding requirement.

115V

20 Amp

208/230V

20 Amp

Figure 4 - Leveling

C. The freezer is equipped with an air cooled condenser

and requires correct ventilation. The right side of the

freezer is the air intake and left side discharge. Both

sides must have 3" clearance the top requires 10" of

clearance. (Fig. 5).

CAUTION

FAILURE T O PROVIDE ADEQUA TE VENTILA TION

WILL VOID W ARRANTY!

D. Place the OFF-ON switch in the OFF position. (Fig.10).

Figure 6. Electrical Plug

CAUTION

DO NOT ALTER OR DEFORM PLUG IN ANY WAY!

F. Install the drip tray, drain tray, hopper cover and other

miscellaneous parts on the freezer. (Fig. 7).

Figure 7. Installing Tray and Cover

4

Page 13

2.4 FLOOR ST AND INST ALLA TION

2.5 INSTALLING PERMANENT WIRING

To install the E or F111/112 onto the floor stand, follow the

steps outlined below:

A. Uncrate the floor stand and place in an upright posi-

tion.

NOTE

Detailed instructions are included with each floor

stand.

B. Place a spirit level across the top of the stand to check

for level condition, side to side and front to back. If

adjustment is necessary , level the st and by turning

the bottom part of each leg in or out, then tighten the

lock nut.

WARNING

DO NOT INSTALL CASTERS ON THIS FLOOR

ST AND. THE ST AND IS UNST ABLE WITH CAST ERS AND COULD TIP CAUSING SERIOUS INJURY.

C. Place supports under freezer , then remove the 4 legs

and replace with the rubber stud/plate mounts provided. Mounts must be fully tightened to the freezer.

D. Place the freezer base gasket on the floor stand with

the connected seam to the back and angle side up.

Center the gasket side to side and 1-3/4 inches from

the rear of the floor stand.

If permanent wiring is required by local codes, the following procedure must be performed.

WARNING

DISCONNECT FREEZER FROM THE SOURCE

OF ELECTRICAL SUPPL Y BEFORE SERVICING.

A. Remove the back panel.

B. Disconnect the wires from the terminal

block. Disconnect the green ground wire from the

grounding stud. (Fig. 9).

E. Place the freezer on the floor stand with the front of

the freezer to the door end. All 4 stud/plate mounts

must engage the holes in the floor stand. Secure the

mounts with the nuts and washers provided. (Fig. 8).

Figure 9. Power Cord Connection

C. Remove the power cord.

D. Install permanent wiring according to local code.

E. Replace the back panel.

Figure 8 - Floor Stand

5

Page 14

6

Page 15

SECTION 3

INITIAL SETUP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

SAFE OPERA TION IS NO ACCIDENT; Observe these

rules:

A. Know the freezer . Read and underst and the

Operating Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting gar-

ments, and remove watches, rings or jewelry which

could cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect electrical cord for maintenance.

Never attempt to repair or perform maintenance on

the freezer until the main electrical power has been

disconnected.

High Pressure Cutout

Switch Located Back

of Freezer

(Some Models)

G. Do not operate under unsafe operating condi-

tions. Never operate the freezer if unusual or exces-

sive noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the

operator know the function of each operating control.

Refer to Figure 10 for the location of the operating

controls on the freezer. For the information regarding

flashing indicator lights, refer to the troubleshooting

section.

WARNING

THE OFF-ON SWITCH MUST BE PLACED IN THE OFF

POSITION WHEN DISASSEMBLING FOR CLEANING

OR SERVICING. THE FREEZER MUST BE DISCONNECTED FROM ELECTRICAL SUPPLY BEFORE REMOVING ANY ACCESS PANEL.

OFF-ON

POWER SWITCH

ÊÊ

Ê

ÊÊ

SPIGOT SWITCH

ÊÊ

Ê

ÊÊ

Figure 10. Controls

7

HOLD READY

SWITCH

ÈÈ

È

ÈÈ

ÇÇ

Ç

ÇÇ

ÅÅ

Å

ÅÅ

ÅÅ

Å

ÅÅ

ÅÅ

Å

ÅÅ

CONSISTENCY/TEMPERATURE

ADJUSTMENT

PUSH TO FREEZE

CLEAN

MIX LOW

Page 16

A. SPIGOT SWITCH

The SPIGOT switch will automatically actuate the

auger drive and refrigeration systems when the spigot

is opened to dispense product. When the spigot is

closed, the drive motor and compressor will remain

"on" until the product in the barrel reaches the proper

consistency, or temperature.

B. OFF-ON SWITCH

The OFF-ON switch is a two position toggle switch

used to supply power to the control circuit. When the

switch is in the OFF position, nothing will run. When

the switch is in the ON position the freezer will be in

the idle mode until a switch is activated.

C. PUSH TO FREEZE SWITCH

The PUSH TO FREEZE switch is a "snap" switch used

to start the freezing cycle. During initial freeze down,

the OFF-ON switch is placed in the ON position. Then

the PUSH TO FREEZE switch is pressed until the

drive motor and compressor come "ON".

NOTE

After the gearmotor starts, there is a 3 second delay before the compressor starts.

During the normal operation, the red PUSH TO FREEZE

switch light will illuminate after the freezer has been

idle for the preset cycles. Before drawing product,

press the PUSH TO FREEZE switch if it is illuminated.

Wait until the green light is illuminated before dispensing.

NOTE

If the freezer shuts off and the PUSH TO FREEZE

light flashes, you have an error condition. Turn the

OFF-ON swtich to the OFF position, correct the

problem and turn the freezer back on. (See Troubleshooting.)

D. GREEN LIGHT

The green light is used to indicate that the product has

reached the proper consistency or temperature and is

ready to be dispensed.

NOTE

If the PUSH TO FREEZE red light is illuminated,

push the PUSH TO FREEZE switch and wait until

the green light illuminates before dispensing.

F. DRIVE MOTOR OVERLOAD

The internal DRIVE MOTOR OVERLOAD will trip if the

drive motor is overloaded. It will reset after approximately 10-12 minutes. If the drive motor continues to

trip, refer to Troubleshooting (Sec. 4).

G. RED MIX LOW LENS

The red MIX LOW light is designed to alert the operator

to a low mix condition. The lens will illuminate with

approximately one gallon of mix in the hopper. When

the MIX LOW lens is lit, refill hopper immediately.

NOTE

Failure to refill hopper immediately may result in

operational problems.

H. HOLD READY SWITCH

The HOLD READY switch is a push button switch.

When pushed in and held for 5 seconds, the hold ready

mode will be activated. The product will remain ready

to serve and the freezer will not go to idle. To return to

normal operation push and hold for 5 seconds.

3.3 SANITIZING

Sanitizing must be done after the freezer is cleaned and

just before the hopper is filled with mix. Sanitizing the night

before is not effective. However, you should always clean

the freezer and parts after using it.

WARNING

THE UNITED ST ATES DEPARTMENT OF AGRICUL TURE AND THE FOOD AND DRUG ADMINISTRA TION REQUIRE THA T ALL CLEANING AND

SANITIZING SOLUTIONS USED WITH FOOD

PROCESSING EQUIPMENT BE CERTIFIED FOR

THIS USE.

When sanitizing the freezer, refer to local sanitary regulations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations. Mix sanitizer

according to manufacturer's instructions to provide a 100

parts per million strength solution. Mix sanitizer in quantities of no less than 2 gallons (7.5 liters) of 120°F water.

Allow sanitizer to contact the surfaces to be sanitized for

5 minutes. Any sanitizer must be used only in accordance

with the manufacturer's instructions.

E. CLEAN SWITCH

The CLEAN switch is a "snap" switch. When the

switch is pushed the refrigeration system will be OFF

and the auger will rotate for cleaning. When the switch

is pushed again, the auger will stop and the CLEAN

light will flash indicating the freezer is in the CLEAN

mode. To exit the CLEAN mode turn the OFF-ON

switch to the OFF position. If the freezer is left in

CLEAN for more than 30 minutes or is pushed three

times in ten seconds, it will go in error. To reset place

the CLEAN-OFF-ON switch in the ON position and

allow the error light to flash a minimum of 10 minutes.

Then turn to off, wait 5 seconds and turn on.

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning a

soft serve freezer. We therefore include a sample

with each new freezer. Other products may be as

effective. For further information refer to cleaning and

sanitizing information Section 3.13.

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MA Y CAUSE CORROSION OF ST AINLESS STEEL P ARTS.

8

Page 17

In general, sanitizing may be conducted as follows:

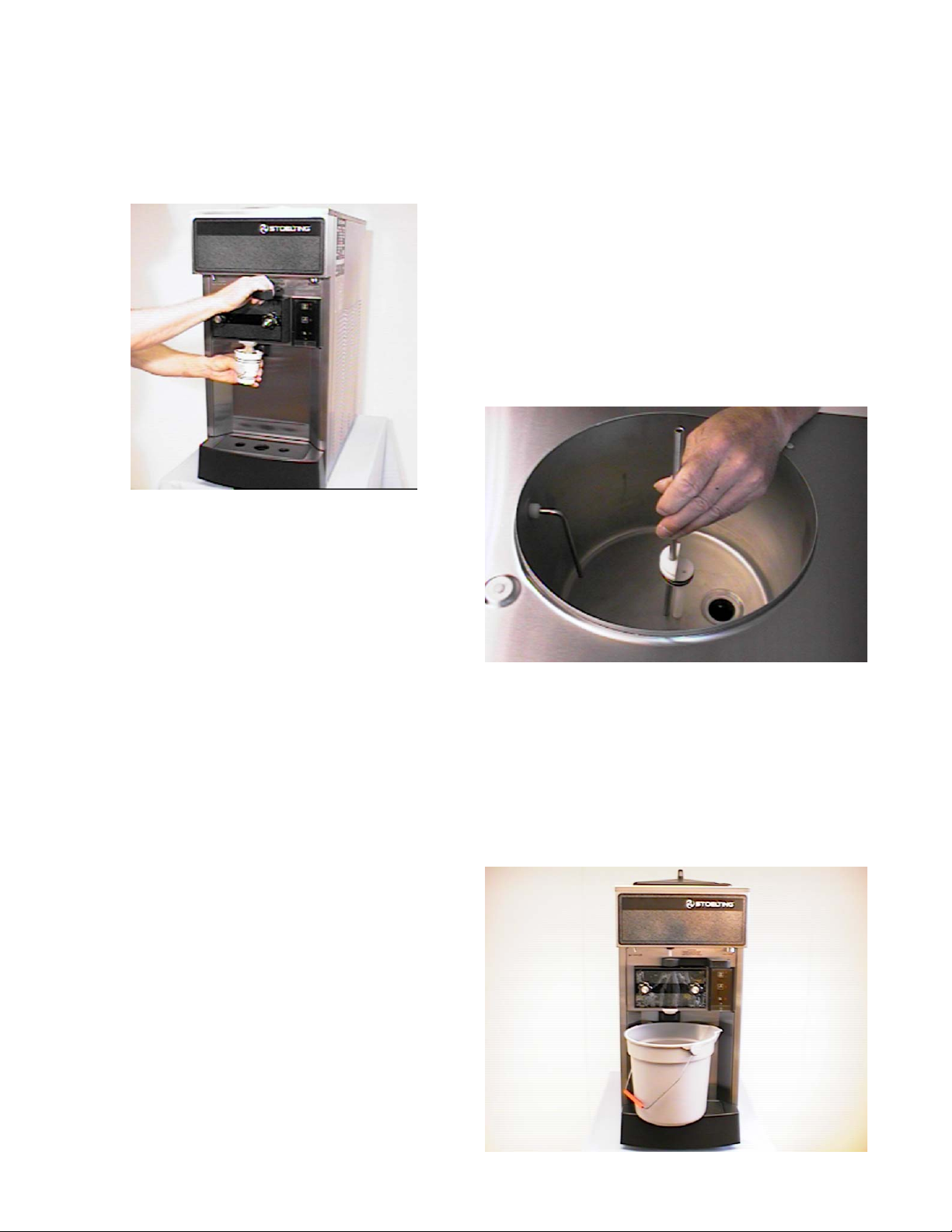

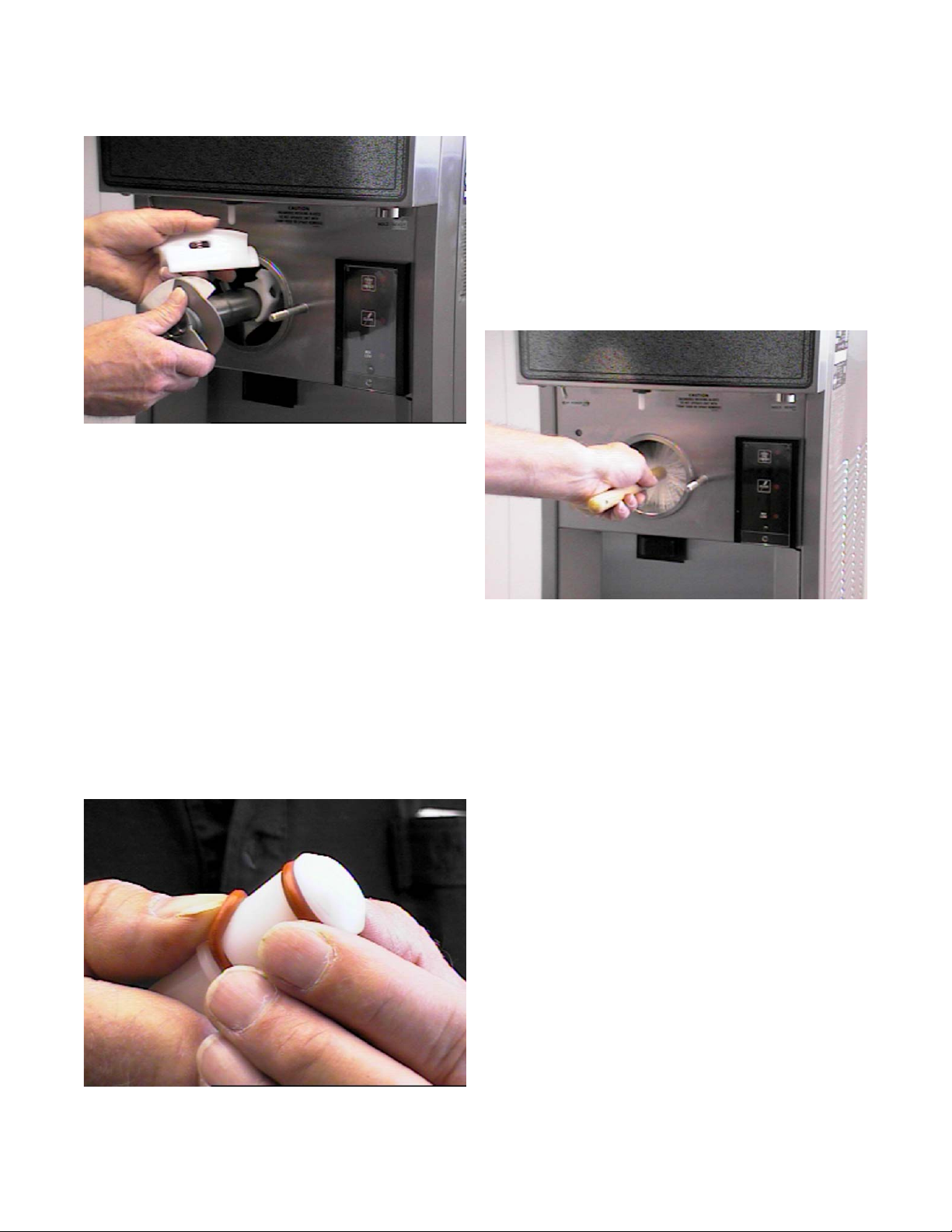

A. Push the mix inlet regulator into hopper with air

inlet (long) tube toward the front of the freezer

(Fig.11).

Figure 11. Mix Inlet Regulator

B. Prepare 2 gallons (7.5 liters) of sanitizing solution

following manufacturer's instructions. Pour into hopper with mix inlet regulator in place.

C. Place the OFF-ON toggle switch in the ON position

while pressing the CLEAN switch. Check for leaks.

(Fig. 12.)

E. After five minutes, place a bucket under the spigot and

open spigot to drain sanitizing solution. When solution

has drained, press the CLEAN snap switch to stop the

auger. Allow the freezer barrel to drain completely

(Fig. 14).

Figure 14. Draining Solution

3.4 FREEZE DOWN AND OPERATION

This section covers the recommended operating procedures to be followed for the safe operation of the freezer.

Figure 12. Clean Control

D. Clean sides of hopper, mix inlet regulator and under

side of hopper cover using a sanitized soft bristle brush

dipped in the sanitizing solution. (Fig. 13).

A. Sanitize just prior to use.

B. Place the OFF-ON switch in the OFF position.

C. With spigot open, pour approximately 1 gallon (3.8

liters) of mix into the hopper. Allow the mix to flush out

about 8 ounces (0.23 liters) of sanitizing solution and

liquid mix. Close the spigot.

D. Fill hopper with approximately 3 gallons (11.4 liters) of

pre-chilled (40°F or 4°C) mix.

CAUTION

DO NOT OVERFILL THE HOPPER. MIX LEVEL

MUST NOT BE HIGHER THAN THE AIR INLET

TUBE ON THE MIX INLET REGULA TOR.

E. The freezer barrel will automatically fill until it is about

1/2 full. If freezer barrel does not fill, check for obstruction in the mix inlet regulator. If freezer barrel fills over

1/2 full, indicated by low overrun, check for leaks at the

mix inlet regulator "O" Ring or check if the mix inlet

regulator was installed correctly or that the freezer is

level.

F. Place the OFF-ON switch in the ON position, then

press the PUSH TO FREEZE switch until the freezer

starts.

Figure 13. Sanitizing Hopper

NOTE

After the gearmotor starts, there is a 3 second delay before the compessor starts.

9

Page 18

G. After about 6 to 10 minutes the freezer will shut OFF

and the green lens will illuminate. The product is ready

to serve. Freeze down time may be longer for some

frozen diet dessert mixes. High ambient temperatures

may extend freeze down time.

H. For normal dispensing, move the spigot handle fully

open 60° (Fig. 15).

Figure 15. Dispensing Product

Mix does not improve with age. Old mix, or mix that has

been stored at too high temperature, can result in a

finished product that is less than satisfactory from the

appearance and taste standpoint. To retard bacteria growth

in dairy based mixes, the best storage temperature range

is between 36° to 40°F (2.2° to 4.4°C).

Some products tend to foam more than others. If excess

foam should occur, skim off with a sanitized utensil and

discard. Periodically, stir the mix in the hopper with a

sanitized utensil.

3.6 REMOVING MIX FROM FREEZER

To remove the mix from the freezer, refer to the following

steps:

A. Remove the mix inlet regulator from the hopper by

pulling straight up (Fig. 16).

CAUTION

REFRIGERATION IS AUTOMATICALLY ACTIV A TED WHEN THE SPIGOT IS OPENED. CLOSE

THE SPIGOT COMPLETELY AFTER DISPENSING.

I. The freezer is designed to dispense the product at a

reasonable draw rate. If the freezer is overdrawn, the

result is a soft product or a product that will not

dispense at all. If this should occur, allow the freezer

to run for approximately 30 seconds before dispensing

additional product. After a while the operator will sense

or feel when the freezer is beginning to fall behind, and

will slow down on the rate of draw so as not to exceed

the capacity.

J. Do not operate the freezer when the MIX LOW light is

on or with less than 1-3/4 inches (4.4 cm) of mix in the

hopper. Refill the hopper immediately.

3.5 MIX INFORMATION

Mix can vary considerably from one manufacturer to

another. Differences in the amount of butter-fat content and

quantity and quality of other ingredients have a direct

bearing on the finished frozen product. A change in freezer

performance that cannot be explained by a technical

problem may be related to the mix.

Figure 16. Removing Mix Inlet Regulator

B. Place the OFF-ON rocker switch in the ON position

and push the CLEAN switch to rotate the auger. Allow

the mix to agitate in freezer barrel until the mix has

become a liquid, about 5 minutes.

C. Drain the liquid mix by opening the spigot. A bucket or

container should be placed under the spigot to catch

the liquid mix. (Fig. 17).

D. Place the OFF-ON switch in the OFF position.

Proper product serving temperature varies from one

manufacturer's mix to another. Soft serve mixes should

provide a satisfactory product in the 18° to 20°F (-7° to

-6°C) range, shake mixes 24° to 28°F (-4° to -2°C).

When checking the temperature, stir the thermometer in

the frozen product to read the true temperature.

Figure 17. Draining Mix

10

Page 19

3.7 CLEANING THE FREEZER

To disassemble the freezer, refer to the following steps:

NOTE

The frequency of cleaning the freezer and freezer

parts must comply with local health regulations.

After the mix has been removed from the freezer, the

freezer must be cleaned. To clean the freezer, refer to the

following steps:

A. Close the spigot and fill the hopper with 2 gallons (7.5

liters) of cold tap water.

B. Place the OFF-ON switch in the ON position while

pushing the CLEAN switch to rotate the auger.

C. Allow the water to agitate for approximately 5 minutes.

NOTE

If freezer is left in CLEAN for more than 30 minutes,

it will go to error.

D. Open the spigot to drain the water. Remember to place

a bucket or container under the spigot to catch the

water. When the water has drained, turn the OFF-ON

switch to the OFF position. Allow the freezer barrel to

drain completely.

E. Repeat Steps A through D using a mild detergent

solution.

3.8 DISASSEMBLY OF FREEZER PARTS

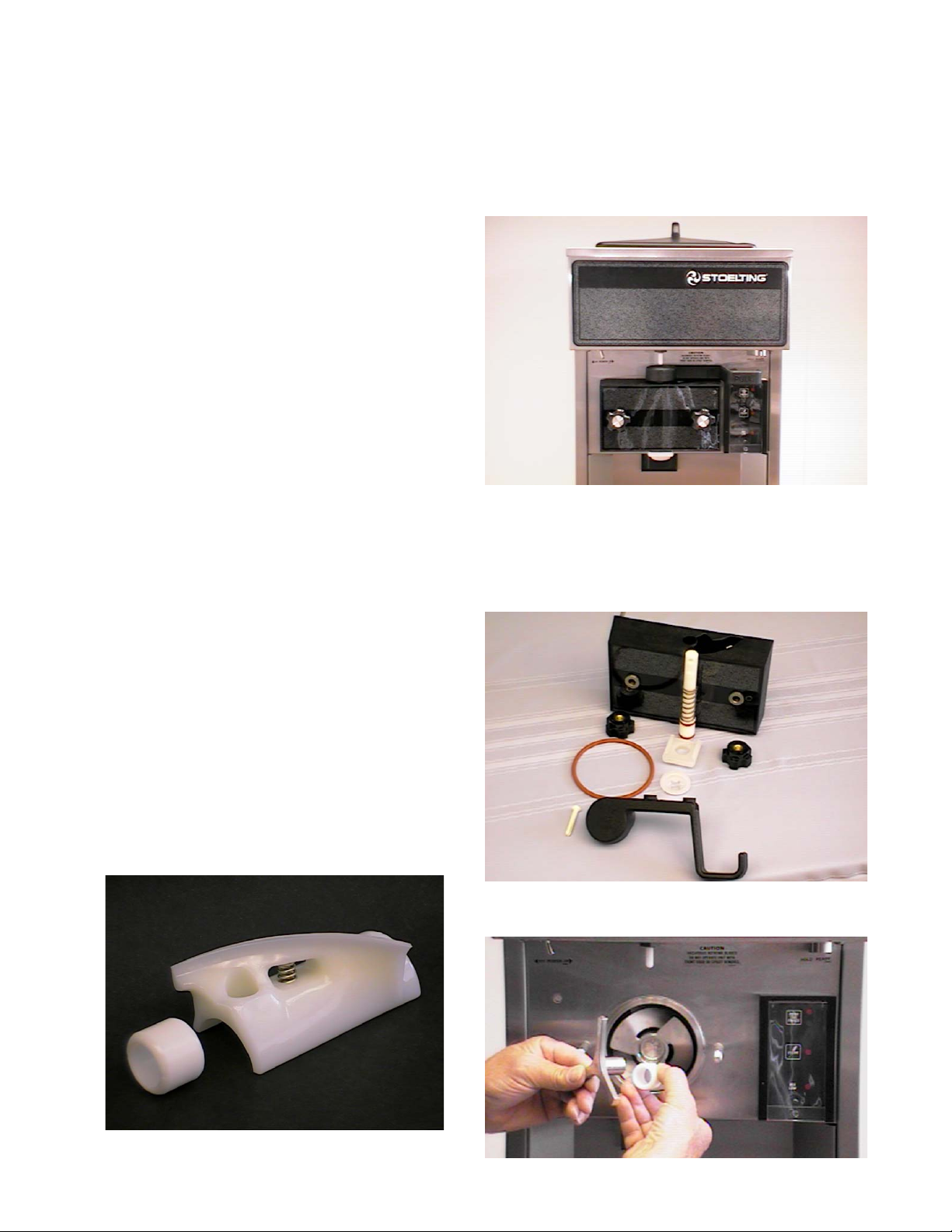

A. Remove hopper cover and drain tray (Fig. 19).

B. Remove the mix inlet regulator from the hopper by

pulling straight up.

C. Remove the front door by turning off the circular knobs

and then pulling the front door off the studs.

Hopper Cover

ËË

Ë

ËË

Drain Tray

D. Remove the rosette and adapter, then remove the

spigot body from the front door by pulling the clevis pin

out of the spigot handle. Push the spigot body through

the bottom of the front door (Fig. 20). Remove spigot

body and spring.

ÆÆ

Æ

ÆÆ

Figure 19. Removing Front Door

CAUTION

PLACE THE OFF-ON TOGGLE SWITCH IN THE

OFF POSITION BEFORE DISASSEMBLING FOR

CLEANING OR SERVICING.

Inspection for worn or broken parts should be made at

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced to

ensure safety to both the operator and the customer and

to maintain good freezer performance and a quality product. Two normal wear areas are the auger flights and front

auger support (Fig.18). Frequency of cleaning must comply with the local health regulations.

Figure 20. Front Door Disassembly

E. Remove the front auger support and bushing (Fig. 21).

Figure 18. Auger Flight Wear and Front Auger

Support Bushing Wear

Figure 21. Removing Auger Support

11

Page 20

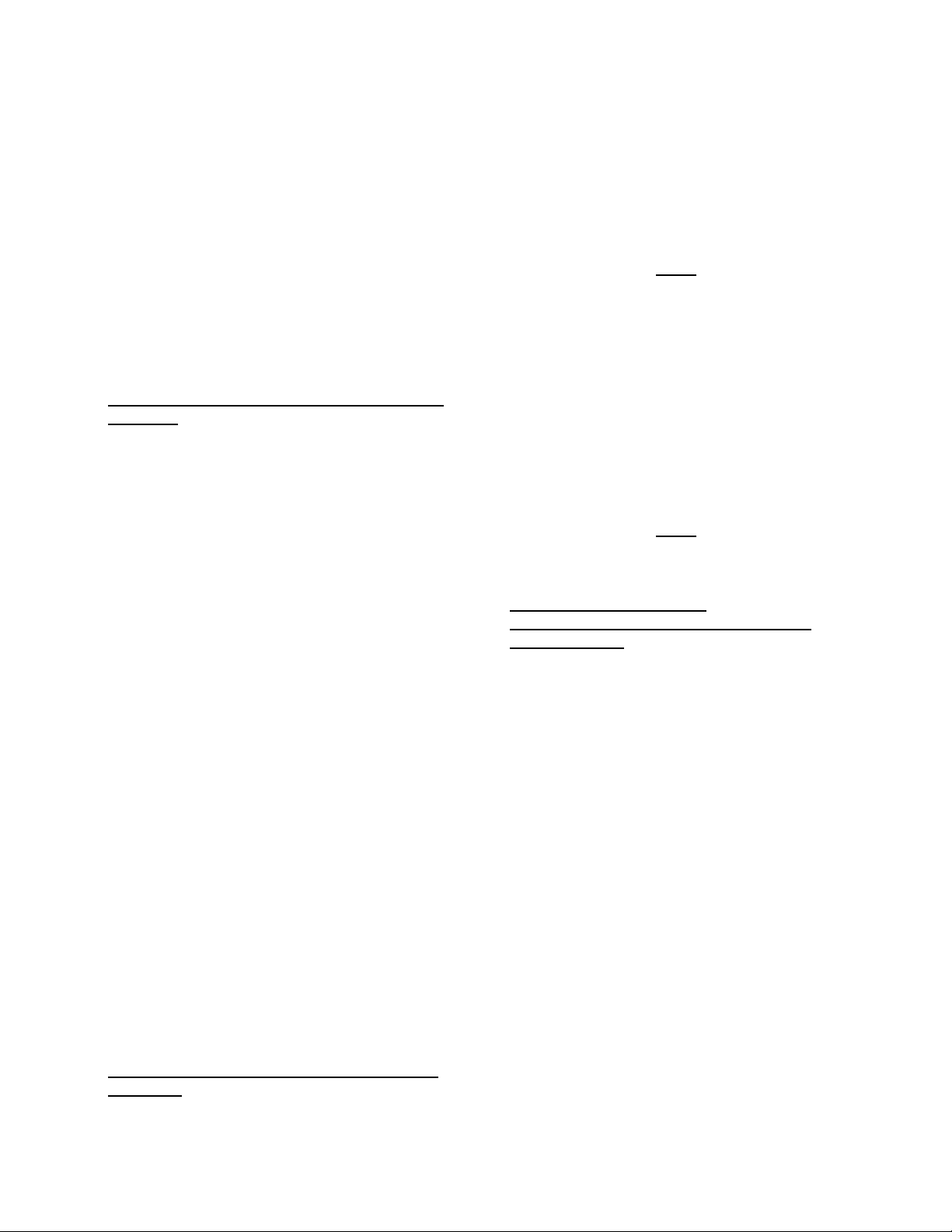

F. Remove the auger assembly from the freezer (Fig. 22).

Pull the auger out of the freezer barrel slowly. As the

auger is being pulled out, carefully remove each of the

plastic flights with springs.

Figure 22. Auger Shaft Removal

G. Keep the rear of the auger shaft tipped up once it is

clear of the freezer to avoid dropping rear seal.

3.9 CLEANING THE FREEZER PARTS

Place all loose parts in a pan or container and take to the

wash sink for cleaning. To clean freezer parts refer to the

following steps:

A. Place all parts in warm mild detergent water and clean

with brushes provided. Rinse all parts with clean hot

water.

CAUTION

DO NOT DAMAGE PARTS BY DROPPING OR

ROUGH HANDLING.

B. Wash the hopper and freezer barrel with warm deter-

gent water and brushes provided. (Fig. 24).

H. Remove the rear seal.

I. Wipe socket lubricant from the drive end (rear) of the

auger with a cloth or paper towel.

J. Remove all "O" Rings from parts by first wiping off the

lubricant using a clean paper towel. Then squeeze the

"O" Ring upward with a dry cloth (Fig. 23). When a loop

is formed, roll out of the "O" Ring groove.

WARNING

DO NOT USE ANY TYPE OF SHARP OBJECT TO

REMOVE THE "O" RINGS.

Figure 24. Cleaning Freezer Barrel

C. Clean the drip tray and insert with a soap solution.

Rinse with clean hot water.

3.10 SANITIZE FREEZER AND FREEZER PARTS

A. Use a sanitizing solution of 100 parts per million to

sanitize the parts before assembly.

B. Place all parts in the sanitizing solution, then remove

and let air dry.

C. Using this sanitizing solution and the large barrel

brush provided, sanitize the rear of the barrel by

dipping the brush in the sanitizing solution and

brushing.

3.11 ASSEMBLY OF FREEZER

To assemble the freezer parts, refer to the following steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

Figure 23. Removing "O" Ring

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubricants used on food processing equipment be certified for this use. Use lubricants only in accordance

with the manufacturer's instructions.

12

Page 21

A. Assemble all "O" Rings onto parts dry, without lubri-

cation. Then apply a thin film of sanitary lubrication to

exposed surfaces of the "O" Rings. Apply a thin film of

sanitary lubricant to metal part of rear seal. Also apply

a thin film of sanitary lubricant inside and outside of the

front auger support bushing.

B. Assemble the rear seal onto the auger with the large

end to the rear. Be sure the "O" Ring is in place before

installing the rear seal.

C. Lubricate the auger drive (rear) with a small amount of

white socket lubricant. A small container of socket

lubricant is shipped with the freezer.

D. Screw the springs onto the studs in plastic flights.

Springs must be screwed into the flights completely to provide proper compression (Fig. 25).

Figure 26. Exploded View of Front Door

NOTE

The spigot handle can only be installed one way .

I. Install the front door on the freezer. Shoulder on the

rear of the door must be inside of freezer barrel.

J. Install the circular knobs on the freezer studs.

Figure 25. Exploded View of Auger (E111 Shown)

CAUTION

DO NOT PLACE THE MIX INLET REGULATOR

INTO THE HOPPER BEFORE INST ALLING THE

AUGER.

E. Install the two plastic flights onto rear of the auger and

insert part way into freezer barrel.

F. Install the remaining plastic flights, push the auger into

the freezer barrel and rotate slowly until the auger

engages the drive shaft.

G. Install the bushing and auger support into the front of

the auger with one leg of the support pointing straight

up.

CAUTION

FINGER TIGHTEN THE CIRCULAR KNOBS

EVENL Y . DO NOT OVERTIGHTEN KNOBS.

Look for the proper seal between the freezer barrel, "O"

Ring, and front door.

K. Install the mix inlet regulator into the freezer with the

air tube to the front of the freezer (Fig. 27).

L. Install hopper cover and drain tray.

NOTE

Apply a small amount of Petro-Gel to the surface of

the cam on the spigot handle prior to assembly of

handle to the spigot body .

H. Install the spigot body with "O" Rings and spring into

the front door from bottom (Fig. 26). Push straight up

until the spigot is in place. Place the spigot handle on

top of the spigot and insert clevis pin, then install the

adapter and rosette.

Figure 27. Mix Inlet Regulator

3.12 ROUTINE CLEANING

To remove spilled or dried mix from the freezer exterior,

simply wash in the direction of the finish with warm soapy

water and wipe dry. Do not use highly abrasive materials

as they will mar the finish.

13

Page 22

3.13 PREVENTIVE MAINTENANCE

It is recommended that a maintenance schedule be followed to keep the freezer clean and operating properly.

A. Cleaning and Sanitizing Information

CLEANING vs. SANITIZING

It is important to distinguish between cleaning and

sanitizing. Although these terms may sound

synonymous, they are not. BOTH are required for

adequate food safety and proper machine

maintenance.

Soft serve freezers require special consideration

when it comes to food safety and proper cleaning

and sanitizing.

The following information has been compiled by

Purdy Products Company, makers of Stera-Sheen

Green Label Cleaner/Sanitizer and specifically

covers issues for cleaning and sanitizing frozen

dessert machines. This information is meant to

supplement a comprehensive food safety program.

Soil Materials Associated with Frozen Dessert

Machines

MILKFAT/BUTTERFAT – As components of icecream/frozen custard mix, these soils will

accumulate on the interior surfaces of the machine

and its parts. Fats are difficult to remove and help

attribute to milkstone build-up.

MILKSTONE – Is a white/gray film that forms on

equipment and utensils that come in contact with

dairy products. These films will accumulate slowly

on surfaces because of ineffective cleaning, use of

hard water, or both. Milkstone is usually a porous

deposit, which will harbor microbial

contaminants and eventually defy sanitizing

efforts.

Once milkstone has formed, it is very difficult to

remove. Without using the correct product and

procedure, it is nearly impossible to remove a thick

layer of milkstone.

(NOTE: general-purpose cleaners DO NOT remove

milkstone.) This can lead to high bacteria counts

and a food safety dilemma.

IT IS BEST TO CONTROL MILKSTONE ON A

DAILY BASIS BEFORE IT CAN BECOME A

SIGNIFICANT FOOD SAFETY PROBLEM.

In addition to food safety, milkstone can cause

premature wear to machine parts which can add to

costs for replacement parts or possibly more

expensive repairs if worn machine parts are not

replaced once they have become excessively worn.

Important Differences Between Cleaning and

Sanitizing

CLEANING

· Is the removal of soil materials from a surface.

· Is a prerequisite for effective sanitizing.

NOTE

An UNCLEAN surface will harbor

bacteria that can defy sanitizing efforts.

Bacteria can develop and resist sanitizing efforts

within a layer of soil material (milkstone). Thorough

cleaning procedures that involve milkstone

removal are critical for operators of frozen

dessert machines.

SANITIZING

· Kills bacteria.

· Can be effective on clean surfaces only.

NOTE

Using a SANTITIZER on an unclean surface will not

guarantee a clean and safe frozen dessert machine.

Proper Daily Maintenance:

The Only Way to Assure Food Safety and

Product Quality

Proper daily maintenance can involve a wide variety

of products and procedures. Overall, the products

and procedures fall into three separate categories.

(Please note that this is a brief overview intended for

informational purposes only.)

1. CLEANING – This involves draining mix from the

freezer barrel and rinsing the machine with

water. Next, a cleaner is run through the

machine. Then, the machine is disassembled

and removable parts are taken to the sink for

cleaning.

2. MILKSTONE REMOVAL – Since almost all

cleaners do not have the ability to remove

milkstone, the use of a delimer becomes

necessary. Although this procedure may not be

needed on a daily basis, it will usually follow the

cleaning procedure. It requires letting a delimer

solution soak in the machine for an extended

period of time. Individual parts are also soaked

in a deliming solution for an extended period of

time (more about delimers in Additional

Information).

14

Page 23

3. SANITIZING – After the machine has been

cleaned and contains no milkstone, the

machine is reassembled. Then a FDA-approved

sanitizing solution is run through the machine to

kill bacteria. The machine is then ready for food

preparation.

As a recommended cleaner and sanitizer for your

frozen dessert machine, STERA-SHEEN has proven

to be one of the best daily maintenance products for:

· CLEANING – Thorough removal of all solids

including butterfat and milk fat.

· MILKSTONE REMOVAL – Complete removal of

milkstone.

THE USE OF CHLORINE TEST STRIPS

“Test strips” are used to determine concentrations of

active chlorine in sanitizing solutions. To use the

strips, tear off a small portion and submerge it into

the sanitizing solution. Then, compare the color

change to the color key on the side of the test strip

dispenser to determine the approximate chlorine

concentration.

The ideal concentration of chlorine needs to be 100

ppm (as stated by the FDA).

NOTE

Follow the directions on the container for proper

concentration.

· SANITIZING – FDA-approved no rinse sanitizer

for food contact surfaces.

Additional Information

THE USE OF DELIMERS

A delimer is a strong acid that has the ability to

dissolve milkstone. This type of chemical may

become necessary once high levels of milkstone

have developed. While these products are very

effective for removing HIGH levels of milkstone, they

are not ideal for two reasons:

1. PRODUCT SAFETY – Strong acids are

dangerous chemicals and handling them

requires safety

2. MACHINE DAMAGE – Strong acids will attack

metal and rubber causing premature wear of

parts. The use of a delimer needs to be closely

monitored to avoid damage to machine surfaces

and parts.

With proper daily use of STERA-SHEEN or it’s

equivalent, there is no need for the use of a

DELIMER.

DO NOT USE BLEACH

· BLEACH HAS ABSOLUTELY NO CLEANING

PROPERTIES.

· BLEACH IS CORROSIVE. It can and will

damage components of the machine causing

premature wear and metal corrosion.

There are two main factors that contribute to falling

chlorine concentrations in a sanitizing solution.

1. PRODUCT USE – As the chlorine in the

solution is being used, chlorine concentrations

fall.

2. TIME – As time passes, small amounts of

chlorine “evaporate” from the solution. (That is

why you can smell it.)

Sanitizing solutions should not be allowed to fall

below 100 ppm chlorine. New solutions should be

mixed once old solutions become ineffective

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON FREEZER UNTIL THE MAIN

ELECTRICAL POWER HAS BEEN DISCONNECTED.

B. DAILY

1. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft

cloth or sponge to apply the cleaner.

CAUTION

DO NOT USE ACID CLEANERS, STRONG CAUSTIC COMPOUNDS OR ABRASIVE MA TERIALS TO

CLEAN ANY P ART OF THE FREEZER EXTERIOR

OR PLASTIC P ARTS.

GENERAL PURPOSE CLEANERS

General purpose cleaners do not have the ability to

remove milkstone. Milkstone will become a problem

if not remedied with additional products and

procedures.

C. WEEKLY

1. Check "O" Rings and rear seal for excessive

wear and replace if necessary.

2. Remove the drip tray by gently lifting up to

disengage from the support and pulling out.

Clean behind the drip tray and front of the

freezer with a soap solution.

15

Page 24

D. MONTHLY

CAUTION

THE FREEZER HAS AN AIR COOLED CONDENSER AND MUST HA VE PROPER AIR CIRCULATION. DO NOT PLACE RIGHT SIDE OF

FREEZER ANY CLOSER THAN 3 INCHES FROM

THE WALL. FAILURE TO CLEAN THE CONDENSER FILTER ON A REGULAR BASIS MAY

RESUL T IN SERIOUS FREEZER DAMAGE AND

COULD VOID FREEZER WARRANTY.

1. Remove the phillips head screws from the lower side

of the right side panel and pull the side panel down and

out.

2. Remove the condenser filter and clean in warm soapy

water. Rinse in clean water and squeeze dry, taking

care not to damage the filter in any way.

3. Replace the condenser filter and side panel.

E. SEMI-ANNUALLY

1. Check drive belt for proper tension. Push belt in with

one finger, belt should deflect about 3/8".

2. Lubricate condenser fan motor with S.A.E. 20 weight

oil. Three to six drops is required.

CAUTION

DO NOT OVER LUBRICA TE; RESUL TING DAMAGE COULD CAUSE MOTOR F AILURE.

3.14 EXTENDED STORAGE

Refer to the following steps for storage of the freezer over

any long period of shutdown time:

A. Turn the OFF-ON switch to the OFF position.

B. Disconnect (unplug) from the electrical supply source.

C. Clean thoroughly with a warm detergent all parts that

come in contact with the mix. Rinse in clean water and

dry parts. Do not sanitize.

NOTE

Do not let the cleaning solution stand in the hopper

or in the freezer barrel during the shutdown period.

D. Remove, disassemble and clean the front door, mix

inlet regulator and auger parts. Place the auger flights

and the front auger support bushing in a plastic bag

with a moist paper towel to prevent them from becoming brittle.

16

Page 25

SECTION 4

REFRIGERATION SYSTEM

WARNING

BOTH SUCTION SIDE SOLENOIDS MUST BE

ACTIVATED FOR PROPER PURGING OF

SYSTEM. USE POWER CORD P ART NUMBER

430119 OR EQUIVALENT FOR DIRECT

CONNECTION.

4.1 REFRIGERATION SYSTEM

The refrigeration system (Fig.28) is a dual-purpose

system.

Figure 28. Refrigeration System

17

Page 26

The system is designed to efficiently operate both the

hopper and evaporator simultaneously at different

temperatures. The proper charge is indicated on the

nameplate and on the compressor.

The compressor has an internal high-pressure bypass.

This bypass eliminates the need for a high-pressure

cutout switch. F111 models must have a high-pressure

cutout switch.

4.2 EVAPORATORS

The hopper and barrel evaporators are wrapped with

copper tubing and thermomastic, then insulated with

foam insulation.

4.3 COMPRESSOR WINDING TEST

To test the compressor motor windings for possible

problems, perform the following steps:

Warning

DISCONNECT FREEZER FROM ELECTRICAL

SUPPLY SOURCE BEFORE SERVICING.

Figure 30. Compressor Connections

NOTE

The following values are for the Copeland

compressor Model CRA1. For other models or

brands, consult the manufacturer’s service data

manual.

1. Remove the Phillips head screw from the bottom of

the left side panel and slide the side panel down and

out.

2. For the E1 1 1, remove the compressor terminal cover

by inserting a standard screwdriver between the

terminal cover and compressor cover frame: then,

gently pry off from the right side, then the left. For

the F1 11, insert a screwdriver between the retainer

clip and cover, then twist. (Figure 29).

3. Remove wires C, R, and S at compressor. Refer to

Figure 30 for compressor connections.

E111 F111

4. Connect an ohmmeter to terminals C and R.

Resistance through the run winding should be 3.12

to 3.60 ohms with the ohmmeter set at ohms x 1

(Figure 31).

Figure 31. Ohmmeter and Connections

Figure 29. Compressor Terminal Cover

18

Page 27

5. Connect the ohmmeter to terminals C and S.

Resistance through the start winding should be 7.77

to 8.93 ohms with the ohmmeter set at ohms x 1.

6. To check if windings are shorted to ground, connect

one ohmmeter lead to a bare metal part on the

compressor, such as any copper line leading to or

from the compressor and checking terminals C, R,

and S.

NOTE

The compressor for an E1 11 is equipped with an

internal overload protector, the F111 has an

external overload. If the compressor is warm and

ohmmeter readings indicate an open winding,

allow up to one hour for the overload to reset, if it

is an internal, if external up to 15 minutes.

To acces the compressor starting components, remove

the Phillips head screw from the bottom of the right side

panel and remove the panel by pulling down and out.

ventilation on the right and left sides of the unit for free flow

of air (Figure 33). Make sure the freezer is not pulling over

100° F (37° C) air from other equipment in the area.

Figure 32. Electrical Box

4.4 CONDENSERS

The air-cooled condenser is a copper tube and aluminum

fin type. Condensing is totally dependent upon airflow.

A plugged condenser filter, condenser, or restrictions in

the louvered panel will restrict airflow. This will lower the

capacity of the system and damage the compressor.

Figure 33. Condenser and Filter

The condenser and condenser filter require periodic

cleaning. To clean, refer to the following procedures.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPLY SOURCE BEFORE SERVICING.

1. Remove the Phillips head screw from the bottom of

the right side panel and back panel, then slide the

panels down and out.

2. To remove the condenser filter, grasp the top and

pull off. Visually inspect for dirt. If the filter is dirty,

shake or brush excess dirt off the filter and wash in

warm, soapy water. Once the filter is clean, rinse

thoroughly in warm, clear water and shake dry , taking

care not to damage the filter in any way .

3. Visually inspect the condenser for dirt by shining a

light through the coil from the back (inside) of the

condenser (Figure 34).

The condenser must be kept clean of dirt and grease.

The freezer must have a minimum of 3” (7.5 cm) of

19

Page 28

Figure 35. T.X.V. (Thermostatic Expansion Valve)

4.6 T.X.V. ADJUSTMENT

Figure 34. Condenser Inspection

4. If the condenser is dirty, place a wet towel over the

front (outside) of the condenser .

5. Using compressed air or a CO2 tank, blow out the

dirt from the back (inside) of the condenser. Most of

the dirt will cling to the wet towel.

NOTE

This procedure will result in a very loud noise.

6. An alternative method of cleaning the condenser is

to use a condenser brush and vacuum.

NOTE

If the condenser is not kept clean, loss of

refrigeration efficiency will result; causing

extended run time or soft product consistency.

4.5 T.X.V.

T.X.V. adjustment is not recommended. Any attempt

to adjust the T.X.V. will cause the freezer to be totally

out of calibration.

4.7 T.X.V. REMOVAL

CAUTION

IF A T.X.V. REPLACEMENT IS NEEDED, A

HEA TSINK (WET CLOTH) MUST BE USED TO

PREVENT DAMAGE TO THE V AL VE.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPLY SOURCE BEFORE SERVICING.

1. Remove the two Phillips head screws from the bottom

of the left side panel and slide the panels down and

out (Figure 36).

2. Remove the bulb from the suction line exiting from

the evaporator (Figure 36).

A T.X.V. (Thermostatic Expansion Valve) (Figure 35)

is used to meter the refrigerant to the evaporator. The

self-regulating T.X.V. is preset at the factory.

3. Recover the refrigerant charge, and then leave a port

open to prevent pressure buildup when applying heat.

20

Page 29

Figure 36. Bulb Removal

4.8 T.X.V. INSTALLATION

To replace the T.X.V., perform the following procedures:

CAUTION

WHEN PLACING THE T .X.V ., A HEATSINK (WET

CLOTH) MUST BE USED TO PREVENT

DAMAGE TO THE V AL VE.

1. Position the T.X.V . with heat sink so the liquid line and

suction line correspond with the proper valve ports.

2. Braze the liquid line and suction line to the T.X.V. by

using the appropriate brazing material.

3. Remove the heatsink from the T .X.V.

4. Remove any insulation from the T .X.V . and immediate

surrounding lines.

5. Remove or push back any foam insulation from

surrounding lines.

6. Apply a heatsink (wet cloth) to the valve dome (Figure

37).

7. Unsweat the suction line and liquid line from the T .X.V .

and remove.

4. Replace any foam insulation to the surrounding lines.

5. Replace any insulation to the T.X.V. and surrounding

areas.

NOTE

The liquid line from the condenser is bonded to

the suction line to provide a heat exchange to help

protect the compressor from liquid slugging. This

also assures that sub-cooled liquid is being

supplied to the expansion devices.

6. Install the bulb on the suction line exiting the

evaporator (Figure 38). The T.X.V . bulb should always

be mounted on the top of the horizontal line. Good

contact between the bulb and suction line is

necessary for proper operation of the valve. The bulb

must also be well insulated.

7. Replace filter drier using the appropriate brazing

material (Figure 39).

Figure 37. T.X.V. Removal

21

Page 30

Figure 38. Bulb Installation

4.10 E.P.R. VALVE ADJUSTMENT

To adjust the E.P.R. valve, refer to the following

procedures:

1. Remove the Phillips head screws from the bottom of

the front panel and remove the panel by sliding down

and out.

2. Remove the cap from the E.P.R. Schrader access

fitting (Figure 40).

3. Install a 0-100 P.S.I.G. gauge onto the E.P.R.

Schrader access fitting.

4. Start the refrigeration cycle and read the pressure.

NOTE

The ideal E.P .R. valve setting (50-52 P.S.I.G .) will

not allow mix to freeze to the walls of the hopper.

Figure 39. Filter Dryer

8. Once the T.X.V. and filter drier are installed, the

refrigeration system must be leaked checked, purged

and evacuated to 500 microns of mercury or less at

either barrel outlet access fitting proceeding suction

line solenoid valves.

4.9 HOPPER

A parallel refrigeration circuit feeds the hoppers. A

capillary tube is used to meter the refrigerant to each

hopper. An E.P.R. (Evaporator Pressure Regulating)

valve is used to control the refrigerant flow at the outlets.

The E.P.R. valve controls the hopper pressure so during

heavy dispensing periods, hopper temperatures will not

drop and freeze the mix in the hopper. The adjustable

E.P.R. valve is preset at the factory. If the hopper

temperature is too cold or too warm, an E.P.R. valve

adjustment may be necessary.

Figure 40. E.P.R. Schrader Access Fitting

5. If the pressure gauge reading does not fall between

the 50-52 P.S.I.G. parameters, proceed with the

following steps.

6. Remove the plastic cap and loosen the locknut on

the E.P.R. valve. Then, using a small screwdriver,

turn the valve stem one-forth (90°) turn

counterclockwise for more cooling or clockwise for

less cooling (Figure 41).

22

Page 31

3. Remove the foam insulation from the surrounding

lines.

4. Apply a heatsink (wet cloth) to the E.P .R. valve.

5. Unsweat the two refrigeration lines.

6. Remove the E.P.R. valve with the heat sink.

Figure 41. E.P.R. Valve Adjustment

7. Allow the system to level out for 3-5 minutes before

taking another pressure reading.

8. Should the readings not fall between 50-52 P.S.I.G.,

repeat steps 6 and 7 until the correct reading is

obtained.

9. Once the 50-52 P.S.I.G. reading is obt ained, tighten

the locknut snugly , remove the pressure gauge, and

replace the E.P.R. Schrader access fitting cap.

10.Replace all panels.

NOTE

The compressor ON and OFF times can also

affect the temperature of the hopper. Procedures

for adjusting compressor ON and OFF times will

be discussed in Section 5.

4.12 E.P.R. VALVE INSTALLATION

To replace the E.P.R. valve, perform the following

procedures:

CAUTION

WHEN REPLACING THE E.P.R. VALVE, A

HEA TSINK (WET CLOTH) MUST BE USED TO

PREVENT DAMAGE TO THE V AL VE.

1. Position the E.P.R. valve, with heatsink, so hopper

evaporator outlet line and the line leading to the low

side of the system correspond with the proper valve

ports (Figure 42).

4.11 E.P.R. REMOVAL

CAUTION

A HEATSINK (WET CLOTH) MUST BE USED

TO PREVENT DAMAGE TO THE V AL VE.

1. Assuming the necessary panels are removed for

adjusting the E.P.R. valve, perform the following

procedures for removing the E.P .R. valve.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPLY SOURCE BEFORE SERVICING.

2. Recover the refrigerant charge, then leave a port

open to prevent pressure buildup when applying heat.

Figure 42. E.P.R. Valve and Lines

2. Braze the lines to the E.P.R. valve using the

appropriate brazing material.

3. Remove the heatsink from the E.P .R. valve.

4. Replace any foam insulation to the surrounding lines.

5. Replace the filter drier using the appropriate brazing

material (Figure 43).

23

Page 32

Figure 43. Filter Drier

6. Once the E.P .R. valve and filter drier are inst alled, the

refrigeration system must be leaked checked, purged

and evacuated to 500 microns of mercury or less.

4.13 CAPILLARY TUBES

4. Remove the capillary tube drier assembly .

4.15 CAPILLARY TUBE INSTALLATION

1. Position the capillary tube drier assembly so the drier

inlet tube is in position to be brazed. Braze using the

appropriate material.

2. Position the capillary tube and braze the tube to the

hopper inlet using the appropriate material. (Figure

44)

Capillary tube replacement may be necessary if the

correct hopper cooling cannot be obtained. A plugged or

restricted capillary tube or drier will result in a warm

capillary tube at the end going to the hopper when the

freezer is running. Also, the pressure reading at the

E.P.R. valve will equal suction pressure at the

compressor if the tube is totally blocked.

4.14 CAPILLARY TUBE REMOVAL

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPLY SOURCE BEFORE SERVICING.

1. Remove the Phillips head screws from the left side

and front panels and pull the panels down and out.

2. Recover the refrigerant charge, then leave a port

open to prevent pressure buildup when applying heat.

3. Unsweat capillary tube drier assembly at the drier

inlet and at the hopper inlets.

Figure 44. Capillary Tube and Drier Assembly

3. Replace the foam insulation to the hopper inlet

connections.

4. Replace filter drier using the appropriate brazing

material (Figure 45).

NOTE

Before unsweating capillary tubes at the hopper

inlets, it will be necessary to remove the foam

insulation from the capillary at that connection.

Figure 45. Filter Drier

24

Page 33

5. Once the capillary tube drier assembly and filter drier

are installed, the refrigeration system must be leaked

checked, purged and evacuated to 500 microns of

mercury or less.

4.16 SOLENOID VALVE

To check for leaking valve seats, follow the procedure

outlined below.

NOTE

Freezer barrels must not contain frozen product

for this test.

1. T o check the liquid line solenoid valve seats, we must

disconnect one of the electrical lines from each of

the liquid line solenoids. Protect the terminal end of

the disconnected electrical line with a piece of

electrical tape. Then, connect the low side pressure

gauges to the access fittings. Force the freezer to

run by turning the OFF/ON switch to the ON position

and opening the spigot. The gauge should show

approximately 9” of vacuum after 1 minute. If the

gauge does not reach 1” of vacuum in 1 minute and

hold, you may have a leaking solenoid valve seat or

leaking valves in the compressor. (Figure 46)

Figure 47. Power Cord

4.17 SOLENOID MAGNETIC COIL

REMOVAL

1. Remove the Phillips head screw from the bottom of

the left side panel and remove the side panel by

sliding down and out.

2. Identify (mark) and disconnect the electrical wires

(Figure 48).

Figure 46. Pressure Gauges

2. To service the refrigeration system, connect power

cord, Part No. 4301 19. (Figure 47)

Figure 48. Solenoid Replacement

25

Page 34

3. Remove the retainer from the top of the solenoid and

pull the magnetic coil off.

5. Apply a heatsink (wet cloth) to the valve body and

unsweat the two joints. Remove the valve body .

NOTE

The retainer may be a screw , nut, or clip.

4.18 SOLENOID MAGNETIC COIL

INSTALLATION

To replace the magnetic coil, perform the following

procedures:

1. Push the magnetic coil on the solenoid body and

replace the retainer .

2. Connect the two electrical wires.

4.19 SOLENOID VALVE REMOVAL

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SUPPLY SOURCE BEFORE SERVICING.

4.20 SOLENOID VALVE INSTALLATION

1. Position the new valve with the arrow pointing toward

the direction or flow or expansion valve.

2. Apply a heatsink (wet cloth) to the valve body.

3. Braze the two joints using the appropriate brazing

material.

4. Replace the filter drier using the appropriate brazing

material.

5. Once the valve and filter drier are installed, the

refrigeration system must be leaked checked, purged

and evacuated to 500 microns of mercury or less.

6. Replace all panels.

4.21 REFRIGERANT CHARGE (ALL

MODELS)

The following symptoms will occur if there is a slow leak

in the system:

1. Remove the screw from the bottom of the left side

panel and pull the panel down and out.

2. Recover the refrigerant charge, then leave a port

open to prevent pressure buildup when applying heat.

3. Identify and disconnect the two wires from the

solenoid coil.

4. Remove the retainer holding the coil to the solenoid

body and remove the coil (Figure 49).

A. At first, the freezer will have a tendency to run longer

than usual.

B. As more refrigerant leaks out, the freezer will run

continuously and eventually the product will not

freeze down.

C. The hopper will not cool the product properly .

If a refrigerant leak is detected in the system, refer to the

following steps:

A. Determine the exact location of the leak.

B. Reclaim the entire charge.

C. Repair the leak.

D . Replace the drier.

E. Evacuate the system.

F. Charge by adding refrigerant to the system by weight.

Refer to the label on the freezer for refrigerant type

and total charge requirements.

Figure 49. Solenoid Coil Removal

G. Check for leaks.

26

Page 35

SECTION 5

CONTROLS

5.1 CONTROL SYSTEM TYPE 4

The control system is the brain of the freezer. To

understand how to service the freezer, it is essential to

understand how the control system operates. The Type

4 control is a consistency control and a temperature

control. To change functions, it is necessary to cut one

diode.

The control system when placed in the consistency

mode monitors the consistency (firmness) of the product

(mix) in the freezer evaporator. As the product freezes,

the drive motor develops a higher torque (resistance)

because of the freezing of the product in the evaporator.

The energy used to operate the drive motor is in direct

proportion to the torque. As the drive motor torque

increase, so does the energy required to operate the

motor. The program module senses the energy usage

and shuts off the drive motor when the preprogrammed

energy value is reached. The freezer will remain OFF

until the temperature rises to the preset looking

temperature (barrel temperature), then start.

The control system, when placed in the temperature

mode, monitors the product temperature in the freezer

evaporator. When the product temperature increases,

the temperature sensor probe sends an electronic signal

to the temperature control, which signals the compressor

and drive motor to switch ON. When the temperature

control is satisfied, the compressor will stop, and

approximately 10 seconds later, the gearmotor will stop.

The control also contains a hopper temperature control

(separate hopper refrigeration system only) and liquid

level indicator to monitor the mix temperature and level

in the hopper. When servicing a freezer in the consistency

mode, keep in mind the control system monitors product

consistency. To minimize the beating of product in the

evaporator, the program module will switch to the idle

mode after the preset number of consistency cycles are

complete. In the idle mode, the control is programmed to

maintain a preset hopper and barrel temperature. In this

idle mode, a servable consistency will not be held.

5.2 POWER BOARD

The power board is where the actual sensing of the drive

motor energy usage occurs. The power board also

supplies energy to the program module and sends

electronic signals associated with the drive motor