Page 1

Page 2

Contents

English

Guide to Using this Manual .............. 2

Safety Precautions ........................... 3

Applications ...................................... 4

Mounting the Tool ............................. 4

Selecting the Grinding Wheel ........... 6

Mounting the Grinding Wheel ........... 7

Test Run ........................................... 8

BA_SE_025_002_01_06.fmPrinted on chlorine-free paper.

Dressing the Grinding Wheel ............ 8

Scales ............................................... 8

Setup for Sharpening Saw Chain ..... 9

Sharpening Procedure ................... 15

Lowering Depth Gauges ................. 17

Setup for Sharpening

Hedge Trimmer Blades ................... 19

Sharpening

Hedge Trimmer Blades ................... 24

Preparations for Sharpening

Circular Saw Blade ......................... 27

Sharpening Circular Saw Blade ...... 31

Maintenance Chart ......................... 32

Minimize Wear and

Avoid Damage ................................ 33

Main Parts of Sharpener ................. 34

Specifications ................................. 35

Special Accessories ....................... 35

Maintenance and Repairs ............... 35

Printing inks contain vegetable oils; paper can be recycled.

Certificate of Conformity ................. 36

Quality Certification ........................ 36

Dear Customer,

Thank you for choosing a quality

engineered STIHL product.

This machine has been built using

modern production techniques and

comprehensive quality assurance.

Every effort has been made to ensure

your satisfaction and troublefree use

of the machine.

Please contact your dealer or our

sales company if you have any

queries concerning your machine.

Hans Peter Stihl

STIHl

© ANDREAS STIHL AG & Co. KG, 2004

0458 523 0121. M0,5. C4. T. Printed in Germany

1USG

Page 3

English

Guide to Using this Manual

Pictograms

All the pictograms attached to the

machine are shown and explained in

this manual.

The operating and handling instructions

are supported by illustrations.

Symbols in text

The individual steps or procedures

described in the manual may be marked

in different ways:

: Step or procedure without direct

reference to an illustration.

Description of step or procedure that

refers directly to the illustration and

contains item numbers that appear in

the illustration.

Example:

Loosen the screw (1)

Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols described below:

Warning where there is a risk of an

accident or personal injury or

serious damage to property.

Caution where there is a risk of

damaging the machine or individual

components.

Note or hint which is not essential

for using the machine, but may

improve the operator’s understanding of the situation and result

in better use of the machine.

Note or hint on correct procedure in

order to avoid damage to the

environment.

Equipment and features

This instruction manual refers to

several models with different

features. Components that are not

installed in all models and related

applications are marked with an

asterisk (*). Such components may

be available as special accessories

from your STIHL dealer.

Engineering improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. If the

operating characteristics or the

appearance of your machine differ from

those described in this manual, please

contact your STIHL dealer for

assistance.

Therefore, we cannot be responsible for

changes, modifications or

improvements not covered in this

manual.

2

USG

Page 4

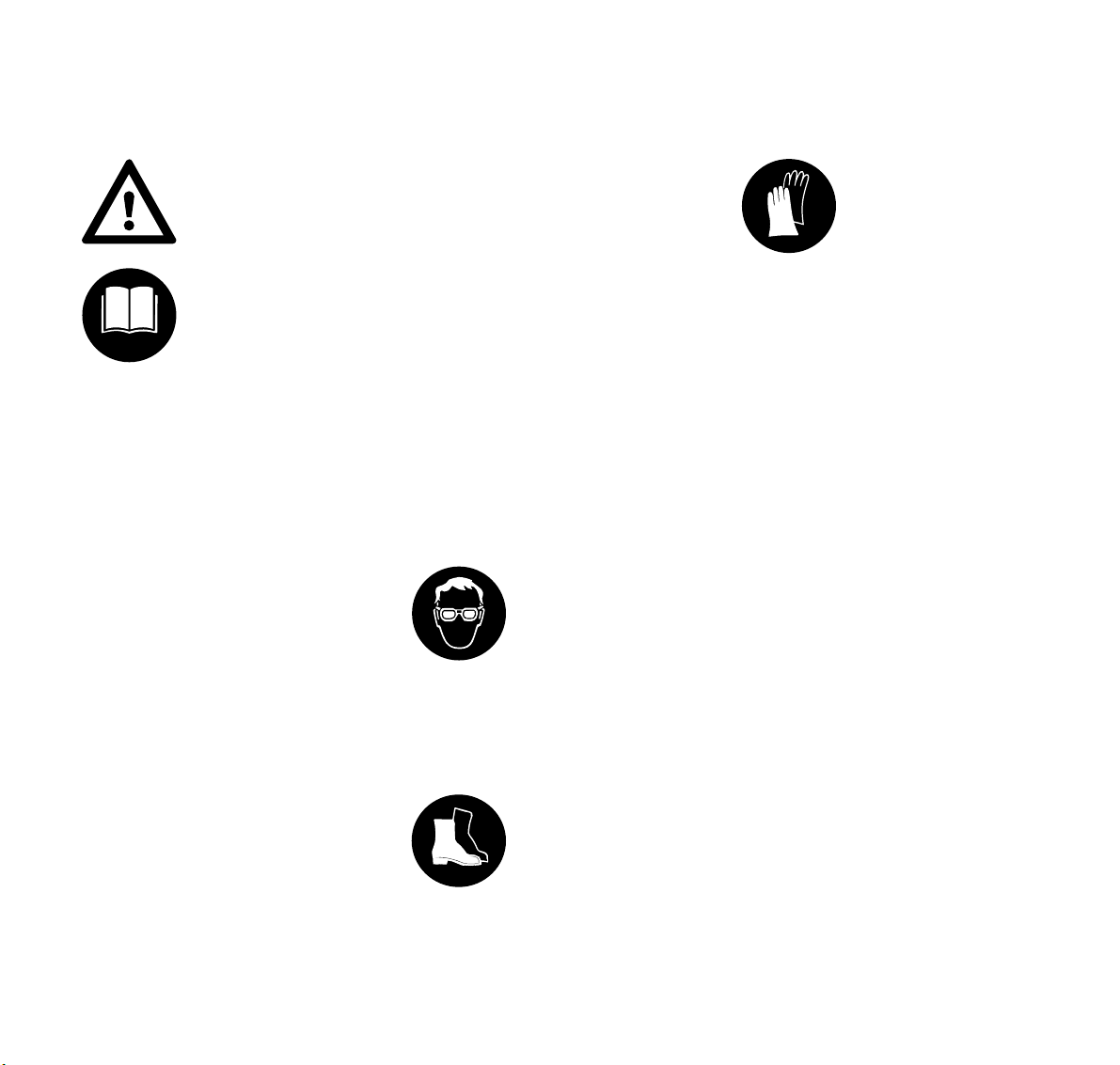

Safety Precautions

English

Additional safety

precautions have to be

observed when operating

the universal sharpener.

It is important that you

read and understand the

owner’s manual before

using your tool for the first

time. Keep it in a safe

place for later reference.

Non-observance of the following safety

precautions may cause serious or even

fatal injury.

Always observe local safety regulations,

standards and ordinances.

If you have never used this sharpener

model before:

Have your dealer or a trained expert

show you how to operate it properly and

safely.

Minors should never be allowed to use

an electric sharpener.

Keep children, bystanders and animals

well clear of the work area.

Only use the grinding wheels supplied

by STIHL or expressly approved by

STIHL for use with your specific model.

Do not use any other grinding wheels

since they will increase the risk of injury.

Switch on the motor only if its operating

voltage agrees with the voltage of your

power supply.

Clothing and Equipment

Wear proper protective clothing and

equipment.

The grinding dust produced when using

this sharpener may cause health

problems. Always use a dust extractor

or wear a suitable respirator.

The sparks created during sharpening

may cause eye injuries.

Always wear safety

glasses.

Clothing must be sturdy and snug-fitting,

but allow complete freedom of

movement.

Wear overalls – avoid loose-fitting

jackets.

Wear steel-toed safety

boots with non-slip soles.

Wear heavy-duty, non-

slip gloves, preferably

made of leather.

Before Starting Work

Check that your sharpener is properly

assembled and in good condition. Do

not operate your sharpener with a

damaged connecting cord or grinding

wheel.

Maintenance and Repairs

Always disconnect the unit from the

power supply before carrying out any

maintenance work. Only perform the

adjustments and maintenance

operations described in this manual.

All other maintenance and repairs

should be carried out by your STIHL

dealer.

Only use original STIHL replacement

parts.

In the interests of your own safety, never

modify your electric sharpener in any

way.

3USG

Page 5

English

Applications Mounting the Tool

The STIHL USG sharpens all STIHL

Oilomatic saw chains, hedge trimmer

blades and circular saw blades.

Optional swivelling tool rests are

required for sharpening scratcher tooth

chain, hedge trimmer blades and

circular saw blades.

The unit may be mounted on a wall or

workbench.

If you mount the unit on a bench, note

that the unit must overhang the bench by

at least 120 mm.

If you use the special attachment for

hedge trimmer blades:

If you mount the unit on a wall, note that

a clearance of at least 450 mm is

required between the wall and the unit

for sharpening hedge trimmer blades.

Recommendation: Mount the unit on a

bench for such work.

A

B

523BA045 KN

Secure the unit with screws

A = For wall mounting, use three

suitable 8 mm dia. screws (e.g.

8 mm x 100 mm wood screws,

DIN 571-St), 8.4 mm dia. washers

and suitable wall plugs (e.g.

10x50 mm plastic wall plugs)

B = For bench mounting, use two

suitable 8 mm dia. screws (e.g.

8 mm x 100 mm wood screws,

DIN 571-St), 8.4 mm dia. washers

4

USG

Page 6

English

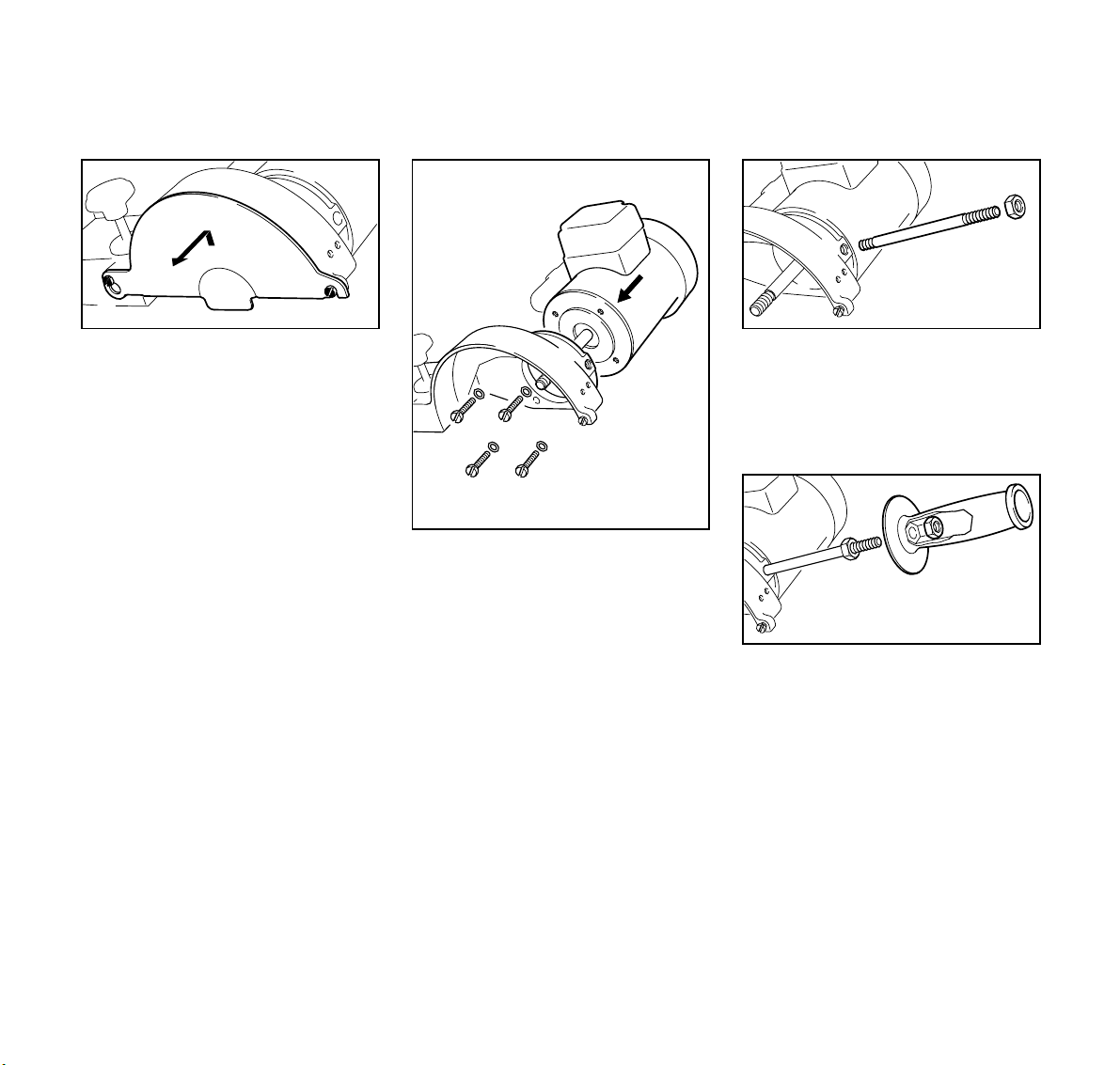

2

1

: Loosen the M5x10 screws (1)

and then lift and remove the guard

plate (2).

5

78

9

3

1

523BA046 KN

4

6

: Fit motor (3) on motor arm (4). The

switchbox (5) must face up.

: Insert the four M5x22 pan head

screws (6) and tighten them down

firmly in a diagonal pattern.

: Screw the short thread of M10x145

stud (7) into the housing bore (8).

: Screw the M10 nut (9) onto the stud

as far as stop.

523BA047 KN

: Place the M10 nut (10) in the

hexagon recess in the handle (11)

and screw the handle firmly into

position.

10

11

523BA048 KN

523BA049 KN

5USG

Page 7

English

Selecting the Grinding Wheel

13

14

: Place the eye shield (12) against the

guard and line up the holes.

: Insert the M4x12 screws (13) in the

holes and fit the nuts (14).

: Tighten down the screws firmly.

: Refit the guard plate.

12

523BA050 KN

Work Light (Special Accessory)

: Use a punch to pierce the casting

skin.

: Clean up the edges with a round file.

: Position lamp socket in opening

from outside and secure it with the

screw ring.

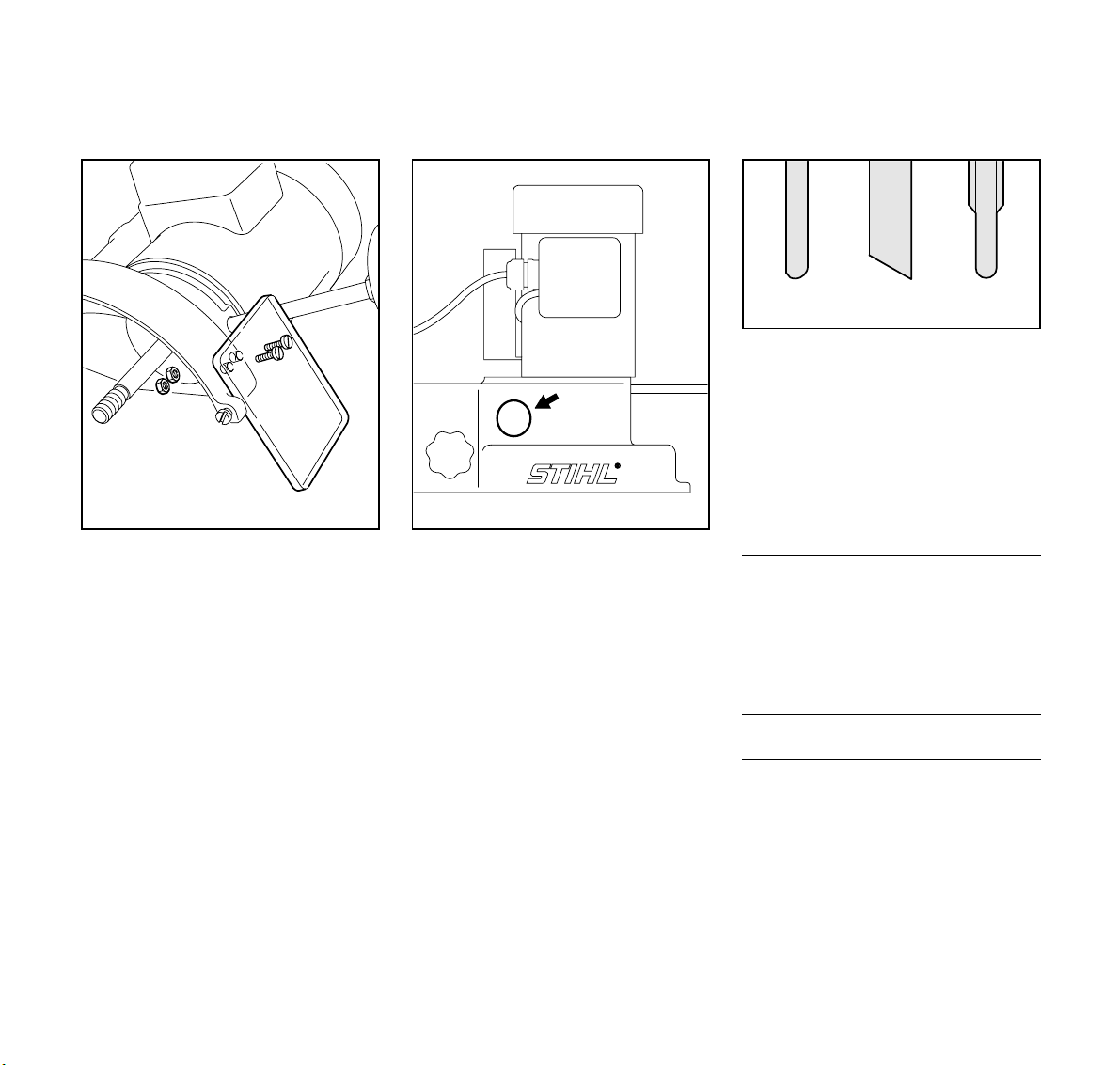

A/B C D

A = Grinding wheel 5203 750 7010

(2.4 mm radius at one side)

B = Grinding wheel 5203 750 7013

(2.0 mm radius at one side)

C = Grinding wheel 5203 750 7015

D = Diamond grinding wheel

5203 757 0901

523BA051 KN

Grinding

wheel

Application

A . Circular saw blades

. Hedge trimmer blades

. Oilomatic chain,

pitch: 3/8“, 0.404“, 0.325“

B . Oilomatic chain,

pitch:

1/4“, 3/8“ P, 3/8“ PMN

C . Oilomatic chain,

depth gauges

DCarbide:

. Oilomatic chain

Rapid Duro

Rapid Duro S

. Carbide tipped circular

saw blade

523BA091 KN

6

USG

Page 8

Mounting the Grinding Wheel

English

2

1

Always check condition of grinding

wheels by performing ringing test

before mounting. Never use

damaged grinding wheels.

: Loosen the M5x10 screws (1), then

lift and remove the guard plate (2).

1

6

523BA046 KN

4

5

7

3

: Fit the O-ring (3) in the groove in the

spacer (4) and then push the spacer

onto the motor shaft (5) (spacer

flange must face away from motor).

: Fit the required grinding wheel (6).

: Fit the thrust washer (7) on the shaft

with its raised side facing away from

motor.

523BA092 KN

Grinding

wheel

A/B

A/B Radius facing motor

C Large outside diameter

D Either way round

C

Installed position

(pointing to the right)

facing motor (pointing to the

right)

D

523BA093 KN

7USG

Page 9

English

Test Run Dressing the

Grinding Wheel

Every time you mount a grinding wheel:

: Cordon off the general work area

(danger zone).

: Run grinding wheel at maximum

permissible speed for at least one

minute.

The profile of the grinding wheel is

subject to wear.

Switch off the motor.

: Use dressing gauge (special

accessory) to check the profile of

the grinding wheel.

: Set scale C on swivelling tool

rest to "0".

: Use dressing stone (special

accessory) to correct the profile of

the grinding wheel.

Scales

+

A

1

-

B

-

2

523BA030 KN

Scale A

: Loosen the nut (1), adjust angle,

tighten down the nut firmly.

Scale B

: Loosen the wingnut (2) on the

underside of the base, adjust to

required value, tighten down the

wingnut firmly.

Scale C

: Loosen the wingnut (3), adjust

angle, tighten down the wingnut

firmly.

C

+

-

+

3

523BA138 KN

8

USG

Page 10

A

English

Setup for Sharpening Saw Chain

Inspect the chain.

Replace damaged or worn parts of

the chain. Grind the new parts back

to the shape and size of the other

parts.

: Select the grinding wheel – see

+

1

-

+

-

4

C

B

-

+

2

instruction sheet 0457 716 0000.

: Mount the grinding wheel – see

"Mounting the Grinding Wheel".

: Test run the grinding wheel – see

"Test Run".

: Check profile of grinding wheel and

dress if necessary – see "Dressing

the Grinding Wheel".

1

2

3

4

5

Scale C (attachment for

circular saw blades)

: Loosen the wingnut (4), adjust

angle, tighten down the wingnut

firmly.

523BA094 KN

6

Mounting Attachment for Saw

Chain

: Engage pin (1) in hole (2) in base.

: Insert bolt (3) in slot (4).

: Fit the washer (5) and wingnut (6)

and tighten down moderately.

523BA054 KN

9USG

Page 11

English

a

Determining Drive Link Gauge

The clamp must be adjusted to suit the

drive link gauge.

Drive link gauge:

: Use slide caliper to measure

dimension "a"

or

: note the digit (arrow)

Digit Drive link gauge in mm

11.1

31.3

51.5

61.6

02.0

523BA135 KN

2

1

Adjusting the Clamp

: Unscrew the clamping lever (1).

: Remove the thrust plate (2) and nut.

3

4

523BA095 KN

: Take out the screws (3).

: Take out the screws (4).

3

4

523BA057 KN

10

USG

Page 12

English

3

3

5

6

4

Chain with 1.1/1.3 mm drive link

gauge

: Fit the shim (5).

: Fit the screws (3).

: Install a 1.6 mm washer (6)

between the guide rail and clamping

rail (at each end).

: Fit the screws (4).

6

4

3

5

6

4

523BA096 KN

Chain with 1.5/1.6 mm drive link

gauge

: Remove the shim (5) (if fitted).

: Fit the screws (3).

: Install two 0.9 mm washers (6)

between the guide rail and clamping

rail (at each end).

: Fit the screws (4).

3

3

3

5

6

4

523BA097 KN

Chain with 2.0 mm drive link

gauge

: Remove the shim (5) (if fitted).

: Fit the screws (3).

: Install one 0.9 mm and one

: Fit the screws (4).

6

4

1.6 mm washer (6) between the

guide rail and clamping rail (at each

end).

6

4

523BA097 KN

11USG

Page 13

English

2

3

1

: Fit the clamping lever.

12

523BA137 KN

Finding the Master Cutter

The shortest cutter is used as the master

cutter.

The master cutter is sharpened first. All

other cutters are then ground to the

same length as the master cutter.

: Use a slide caliper to find the

shortest cutter and mark it, e.g. with

chalk.

523BA012 KN

Fitting the Saw Chain

: Release the clamping lever (1).

: Place the chain in position, drive link

tangs (2) between the rails (3) –

cutting edges must point to the left.

523BA061 KN

USG

Page 14

English

+

5

4

-

-

B

A

+

-

+

C

523BA077 KN

Setting the scales

: Set the scales to the values

specified in the instruction sheet

0457 716 0000.

: Pull the master cutter back against

the stop (4).

523BA062 KN

: The pivot pin (5) moves backward

and forward so that the stop can be

properly located against the back of

the cutter.

: To sharpen the left-hand row of

cutters: Pull the stop in the direction

of the arrow.

: To sharpen the right-hand row of

cutters: Push the stop in the other

direction.

523BA063 KN

13USG

Page 15

English

1

2

3

Adjusting Lateral Stop

: Back off the travel limiting screw (1).

: Use the handle to bring the grinding

wheel down to the chain.

14

523BA098 KN

: Move the stop (2) with the adjusting

screw (3) so that the master cutter's

side plate butts against the grinding

wheel.

: Clamp the chain firmly in position.

523BA099 KN

: Tighten down the knurled nut on the

adjusting screw.

523BA066 KN

USG

Page 16

English

Sharpening Procedure

Wear safety glasses.

Sharpening the Master Cutter

: Switch on the motor.

1

3

2

: Bring motor arm slowly downward.

Check sharpening process. Do not

remove too much material.

: If necessary, switch off motor and

readjust.

: Sharpen the side plate by applying

the wheel several times – do not

sharpen in a single pass.

: When result is satisfactory, check

the grinding depth.

Adjusting Grinding Depth

: Swing the motor arm down until

grinding wheel touches the gullet of

the cutter – hold it in this position.

523BA100 KN

: Screw the travel limiting screw (1)

down as far as the stop lug (2).

: Tighten down the knurled nut (3)

firmly.

: Swing the motor arm up again.

523BA101 KN

15USG

Page 17

English

1

The travel limiting screw must now butt

against the stop lug and the side plate

angle (1) should be as specified.

Chain type Angle in

degrees

Rapid-Standard 85

Rapid-Micro 85

Rapid-Super 60

Picco-Micro 85

Picco-Micro-Mini 85

Rapid-Duro 65

RCX, RMX, PMX 80

: Check angle with a filing gauge.

If side plate angle is too obtuse (wide):

: Use travel limiting screw to set

motor arm lower.

Avoid touching the drive links or tie

523BA022 KN

straps with the grinding wheel. This

could cause the chain to break.

If side plate angle is too acute (narrow):

: Use travel limiting screw to set

motor arm higher.

: Lock the adjusting and travel

limiting screws with their knurled

nuts.

523BA070 KN

523BA071 KN

Sharpening Row of Cutters

Use the setting for the master cutter to

sharpen all the other cutters in the row.

: Release clamping lever. Pull the

chain to the left until the stop is

behind the next cutter but one.

16

USG

Page 18

English

Lowering Depth Gauges

: Pull the chain to the right until the

back of the cutter butts against the

stop.

: Clamp the chain in position.

: Sharpen the side plate.

: Repeat procedure until all side

plates on one side have been

sharpened.

Sharpening the Second Row of

Cutters

: Set scale B to the same sharpening

angle on the other side of the chain.

: Set scale C to the specified angle on

the other side of the chain.

: Move the stop with the pivot pin –

the stop must locate properly

against the back of the cutter.

: After sharpening first cutter in the

second row, check its length against

that of the other row and adjust the

stop if necessary.

: Now sharpen the second row of

cutters.

523BA072 KN

Checking Depth Gauge Setting

: Select the filing gauge (special

accessory) that matches the chain

pitch.

Chain pitch Filing gauge

inch mm Part No.

1

/

4

3

/8 PMN 9.32 0000 893 4000

3

/8 P 9.32 1110 893 4000

0.325 8.25 1110 893 4000

3

/

8

0.404 10.26 1106 893 4000

: Place the filing gauge on the saw

6.35 1110 893 4000

9.32 1110 893 4000

chain. If the depth gauge projects

beyond the filing gauge it has to be

lowered.

564BA017 KN

17USG

Page 19

English

If the depth gauges have to be lowered:

: Select the correct grinding wheel

– see instruction sheet

0457 716 0000

: Mount the grinding wheel – see

"Mounting the Grinding Wheel".

: Test run the grinding wheel – see

"Test Run".

: Check profile of grinding wheel and

dress if necessary – see "Dressing

the Grinding Wheel".

Setting the Scales

1

1

3

2

2

+

A

-

-

+

B

: Set scale A to 40°

: Set scales B and C to 0°

18

523BA102 KN

+

-

C

Adjusting the Lateral Stop

: Swing the motor arm down.

: Slide the chain along the guide rail

523BA077 KN

until the profile (1) of the grinding

wheel is centered above the depth

gauge.

: Clamp the chain in position.

: Turn the adjusting screw (2) until the

back of the cutter butts against the

stop.

Adjusting Grinding Wheel

: Swing the motor arm down until the

grinding wheel touches the depth

gauge.

: Screw home the travel limiting

screw (1) until it butts against the

stop lug (2).

: Put on safety glasses.

: Switch on the motor.

: Carefully bring the motor arm down

as far as the stop.

523BA101 KN

USG

Page 20

4

5

: Switch off the motor.

: Place the filing gauge (5) on the

chain.

: If the depth gauge (4) still projects

above the filing gauge, make

appropriate adjustment with the

travel limiting screw (1).

: Remove the filing gauge (5).

: Switch on the motor.

: Carefully bring the motor arm down.

: Switch off the motor.

: Repeat the procedure until the

depth gauge is level with the filing

gauge.

: Tighten down the knurled nut (3)

firmly.

: Use this setting to lower all the other

depth gauges.

The kickback tendency of the saw is

increased if the depth gauges are

too low.

523BA103 KN

On PM1 and RM2 chains the rear

hump of the tie strap (with service

mark) is lowered at the same time

as the depth gauge. The other parts

of the triple-humped tie strap must

not be ground because this may

increase the kickback tendency of

the saw.

English

Setup for Sharpening Hedge Trimmer Blades

: Select the correct grinding wheel

– see "Selecting Grinding Wheel".

3

: Mount the grinding wheel – see

"Mounting the Grinding Wheel".

: Test run the grinding wheel – see

"Test Run".

: Check profile of grinding wheel and

523BA139 KN

dress if necessary – see "Dressing

the Grinding Wheel".

19USG

Page 21

English

+

A

-

-

+

-

+

C

2

3

B

523BA077 KN

1

4

2

5

6

Mounting the Attachment for

Hedge Trimmer Blades

: Engage pin (1) in hole (2) in base.

: Insert bolt (3) in slot (4).

: Fit the washer (5) and wingnut (6)

and tighten down moderately.

Setting the Scales

HL 45, HL 75,

HLR 85, HS 61

HS 75, 80, 85

HL 100,

HS 246 HS 45

Scale A - 10° - 6°

523BA054 KN

Scale B 00

Scale C

left

Scale C

right

+ 45° + 55°

- 45° - 55°

3

1

523BA104 KN

Principle of Clamp

: Turn the star knob (1) to open and

close the clamp.

The stop (2) is automatically

engaged and disengaged by the

spring (3).

20

USG

Page 22

4

English

3

2

1

Fitting Cutting Blade

: Turn the star knob (1) until the

spring (2) is in the positon shown.

: The clamp is open in this position –

the cutting blade may be fitted.

523BA106 KN

Fitting one-sided cutting blade

: Fit the angle iron rail (5).

: Fit the cutting blade (6) in position

so that the cutting edges point to the

rear.

6

523BA107 KN

5

Fitting double-sided cutting blade

: Fit the cutting blade (4) in position

so that the cutting edges point to the

rear.

523BA108 KN

21USG

Page 23

English

5

4

2

1

6

Adjusting the Stop

Adjusting the lateral stop

: Swing the motor arm down until the

grinding wheel is above the gullet of

the tooth – hold it in this position.

: Pull the cutting blade (1) to the left

until the first tooth (2) in the row

butts against the grinding wheel.

3

523BA110 KN

: Swing the motor arm up again.

: Turn the star knob (1) clockwise

until the spring is in the position

shown – the clamp is closed.

7

523BA111 KN

: Swing the stop (4) into position by

hand.

: Turn the adjusting screw (5) until the

stop butts against the tooth (6).

: If range of adjustment is insufficient,

loosen the screws (7) on the stop.

: Move the stop (4) until it butts

against the tooth and then tighten

down the screws (7) firmly.

523BA112 KN

22

USG

Page 24

English

1

3

3

2

If stop is now correctly positioned:

: Continue turning the star knob (3)

clockwise until the stop swings

back.

523BA113 KN

Adjusting sharpening depth

: Swing the motor arm down until the

grinding wheel touches the gullet of

the tooth – hold it in this position.

523BA109 KN

: Screw the travel limiting screw (1)

down as far as the stop lug (2).

: Tighten down the knurled nut (3)

firmly.

523BA101 KN

23USG

Page 25

English

Sharpening Hedge Trimmer Blades

Wear safety glasses to protect your

eyes.

Observe the following points when

sharpening:

: The cutting blade must be correctly

clamped in position and the stop

must swing back out of the way.

: Bring the motor arm slowly

downward. Check sharpening

process. Do not remove too much

material. If necessary, switch off the

motor and readjust.

: Sharpen the cutting edges by

applying the wheel several times –

do not sharpen in a single pass.

3

2

1

1

24

Sharpening Row of Teeth

: Switch on the motor.

: Sharpen the first tooth.

: Turn the star knob (1) counter-

clockwise to loosen the clamp.

: Move cutting blade (2) one tooth to

the left.

: Continue turning the star knob (1)

until the stop swings forward

automatically. The left tooth flank

must butt against the stop.

523BA114 KN

: Turn the star knob (1) clockwise

until the stop swings back – the

cutting blade is now clamped in

position.

: Sharpen the tooth.

Repeat the above procedure until all the

teeth in the row have been sharpened.

Now follow the separate descriptions for

sharpening one-sided and double-sided

cutting blades.

523BA115 KN

USG

Page 26

180°

English

180°

Sharpening Double-Sided Hedge

Trimmer Blades

: Sharpen the first row of teeth –

cutting edges point to the rear.

523BA131 KN

: Take the cutting blade out of the

clamp and turn it 180° lengthwise –

cutting edges point to the rear.

: Sharpen the teeth.

523BA116 KN

: Take the cutting blade out of the

clamp and turn it over (180°) –

cutting edges point forwards.

: Set scale C to opposite angle.

: Sharpen the teeth.

523BA117 KN

25USG

Page 27

English

180°

523BA120 KN

180°

: Take the cutting blade out of the

clamp and turn it over (180°) –

cutting edges point forwards.

: Set scale C to opposite angle.

: Sharpen the teeth.

: Take the cutting blade out of the

clamp and turn it 180° lengthwise –

cutting edges point forwards.

: Sharpen the teeth.

26

523BA118 KN

Sharpening One-Sided Hedge

Trimmer Blades

: Sharpen the first row of teeth –

cutting edges point to the rear.

523BA119 KN

USG

Page 28

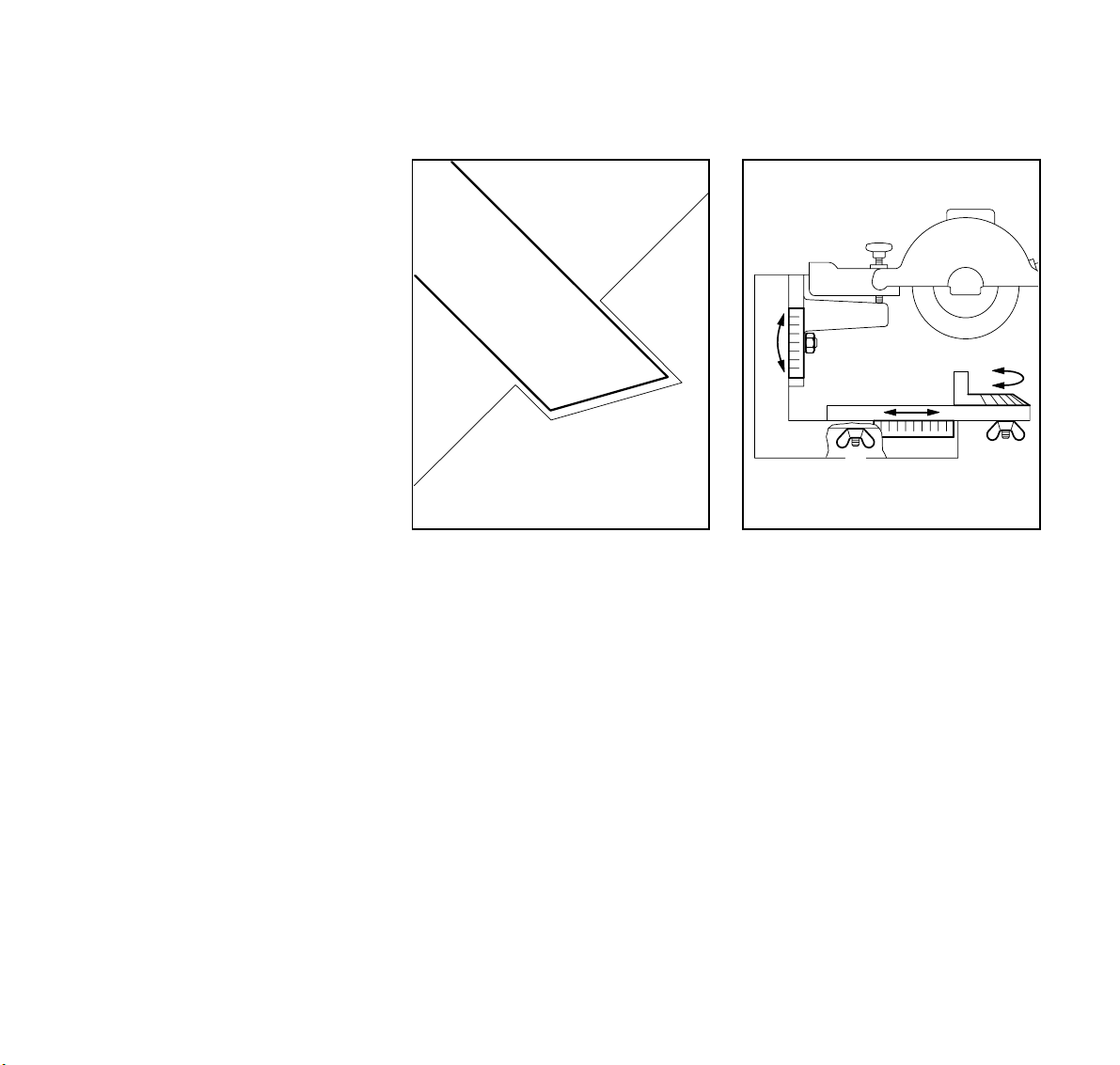

Preparations for Sharpening Circular Saw Blade

Check the blade. Always perfom a

ringing test.

Do not continue to use warped or

cracked blades since they may

shatter.

: Select the correct grinding wheel –

see "Selecting the Grinding Wheel".

: Mount the grinding wheel – see

"Mounting the Grinding Wheel".

: Test run the grinding wheel – see

"Test Run".

: Check profile of grinding wheel and

dress if necessary – see "Dressing

the Grinding Wheel".

1

0

2

Mounting the Special Attachment

: Fit the attachment (1) so that the

arrow points to "0" on the scale.

: Tighten down the wingnut (2) firmly.

a

b

c

Clamping the Circular Saw Blade

: Use the tapped hole specified for

the saw blade diameter:

a = for 200 mm blade

b = for 225 mm blade

c = for 250 mm blade

523BA121 KN

If necessary, change the position of

the shoulder stud (1).

English

1

523BA122 KN

27USG

Page 29

English

5

4

: Position the saw blade (2) on the

shoulder stud (1) so that the cutting

edges point to the left (counterclockwise).

: Fit the locator (4) over the shoulder

stud and push it home – this centers

the saw blade.

: Tighten down the clamp lever (5)

firmly.

The saw blade must now locate against

the retaining plate free from play, but it

must still be possible to turn the blade by

hand.

2

1

1

2

523BA123 KN

3

4

Setting the Scales

The settings depend on the type of saw

blade:

Chisel tooth, standard (1)

Chisel tooth, special (2)

Scratcher tooth (3)

Carbide tipped blade (4)

There are saw blades with

square ground teeth (5)

(scale C = 0) and

bevel ground teeth (6)

523BA124 KN

In the case of bevel ground teeth,

mark the teeth that have the same

sharpening angle (every second

tooth). Marking them helps avoid

accidentally sharpening a tooth on

the other side of the blade.

5

6

523BA125 KN

28

USG

Page 30

English

+

A

-

: Set angles as specified in the

following table.

Type of tooth Scale

Chisel tooth,

standard +5°...+15°

Chisel tooth,

special +5°...+15°1)+15°/ -15°

Scratcher

2)

tooth

Carbide

tipped blade

1)

Depending on type of wood, set

between +5° (for hardwood) and

+15° (for soft wood)

2)

Scratcher tooth saw blade with 80

teeth cannot be sharpened with the

USG

+

-

C

Scale

A

1)

0° 0°

7° +5°/-5°

C

+15°/ -15°

3

1

2

523BA126 KN

Adjusting the Stop

Adjusting the lateral stop

: Swing the motor arm down.

: Use the adjusting screw (1) to move

the stop (2) so that the side plate of

the tooth to be sharpened butts

against the grinding wheel – make

sure the stop locates firmly against

the back of one tooth.

: The stop can be moved in the

slot (3) to suit the saw blade.

523BA127 KN

Adjusting sharpening depth

: Swing the motor arm down until the

required sharpening depth is

reached – see "Sharpening

profiles".

: Screw home the travel limiting

screw (1) until it butts against the

stop lug (2).

: Tighten down the knurled nut (3)

firmly.

1

3

2

523BA101 KN

29USG

Page 31

English

1

2

3

4

Sharpening profiles

Chisel tooth, standard (1)

Chisel tooth, special (2)

Scratcher tooth (3)

Carbide tipped blade (4)

Sharpening Limits

Chisel tooth:

– Sharpening depth: max. 5 mm

– Top plate must not be sharpened

back to more than half its length.

– Tooth set must not be less than

1mm.

Scratcher tooth

– Sharpening depth: no more than

diameter of blade body.

– Do not reduce tooth height by more

than 1/3.

– Do not touch back of next tooth with

523BA128 KN

grinding wheel.

Carbide tipped blade

– Sharpen carbide tip only – do not

sharpen material of blade body.

a

523BA136 KN

Checking Tooth Set

After sharpening chisel tooth saw

blades:

: Use saw set (special accessory) to

check tooth set (a) and correct if

necessary.

30

USG

Page 32

Sharpening Circular Saw Blade

2

3

1

Wear safety glasses and work

gloves.

Sharpening the First Tooth

: Push the saw blade clockwise

against the stop (1) with your left

hand.

: With the motor running, carefully

swing the motor arm down.

: Only remove sufficient material to

obtain a "clean" cutting edge. If

necessary, use adjusting screw (2)

to correct position of stop.

Sharpening Remaining Teeth

The sharpening process now depends

on how the teeth are ground.

Saw blade without bevel ground teeth

(scale C = 0°):

: Rotate the saw blade counter-

523BA129 KN

clockwise to the next tooth.

: Sharpen all teeth with the same

setting.

Saw blade with bevel ground teeth:

: Rotate the saw blade counter-

clockwise to the next tooth but

one.

: Sharpen all the teeth in one row that

have the same sharpening angle

(every second tooth).

: Then set scale C to the angle for the

opposite row of teeth – all other

settings are left unchanged, do not

turn the saw blade over.

: Now sharpen all the teeth in the

second row.

English

31USG

Page 33

English

Maintenance Chart

Please note that the following maintenance intervals apply for normal operating conditions. If your

daily working time is longer than normal or conditions are difficult, shorten the specified intervals

accordingly.

Complete machine

Machine mounting

Switch

Power supply cord

Grinding wheel

Cooling air inlets Clean

Accessible screws and nuts Retighten

Shield

Clamp and guide rail

Stop and lock

Visual inspection condition)

Clean

Check

Retighten

Check operation

1)

Replace

Check

Replace

Check (wear)

Check profile

Dress

Replace

Check

Replace

Check

Replace

Check

Replace

1)

before

starting work

after finishing

work or daily

weekly

monthly

if problem

if damaged

as required

X

X

X

X

X

XX

X

XX

X

X

XX

XX

X

X

X

XX

X

X

X

X

1)

Have work performed by qualified

electrician

32

USG

Page 34

Minimize Wear and Avoid Damage

English

Observing the instructions in this manual

helps reduce the risk of unnecessary

wear and damage to the unit.

The unit must be operated, maintained

and stored with the due care and

attention described in this owner’s

manual.

The user is responsible for all damage

caused by non-observance of the safety

precautions, operating and maintenance

instructions in this manual. This includes

in particular:

– Alterations or modifications to the

product not approved by STIHL.

– Using attachments or sharpening

tools not approved by STIHL.

– Using the product for purposes for

which it was not designed.

– Consequential damage caused by

continuing to use the product with

defective components.

Maintenance Work

All the operations described in the

“Maintenance Chart” must be performed

on a regular basis. If these maintenance

operations cannot be performed by the

owner, they should be performed by an

authorized STIHL servicing dealer.

If these operations are not carried out

as specified, the user assumes

responsibility for any damage that may

occur.

Among other things, this includes:

– Damage to the unit due to neglect

or deficient maintenance.

– Corrosion and other consequential

damage resulting from improper

storage.

– Damage and consequential

damage resulting from the use of

parts other than original STIHL

replacement parts.

– Damage resulting from

maintenance or repair work not

performed by authorized STIHL

servicing dealers.

Parts Subject to Wear and Tear

Some parts of the unit are subject to

normal wear and tear even during

regular operation in accordance with

instructions and, depending on the type

and duration of use, have to be replaced

in good time.

Among other parts, this includes:

– Grinding wheels

– Carbon brushes

– Transparent shield

– Clamping lever and thrust pad

– Clamping and guide rails

–Stop

33USG

Page 35

English

Main Parts of Sharpener

1

2

4

10

678

11

35

9

3

Attachment for

hedge trimmer blades

1 Star knob

2 Spring

3 Stop

4 Adjusting screw

5 Clamp

6 Angle iron rail

523BA133 KN

4

4

2

1

5

6

523BA132 KN

5

3

1

2

523BA134 KN

USG with attachment for

Oilomatic saw chain

1 Motor

2 Switchbox

3 Attachment

4 Motor arm

5 Clamping lever

6 Thrust plate

7 Travel limiting screw

8 Stop

9 Adjusting screw

10 Grinding wheel

11 Stop lug

34

Attachment for

circular saw blades

1 Locator

2 Shoulder stud

3 Clamping lever

4 Adjusting screw

5 Stop

USG

Page 36

English

Specifications Special Accessories Maintenance and Repairs

Motor

Type: Single-phase

AC, squirrel-cage

motor

Operating

voltage: 230 V

Frequency: 50 Hz

Rated current: 1.3 A

Power rating: 0.18 kW

Motor speed: 2,800 RPM

Equivalent sound

pressure level

Lpeq 75 dB (A)

1)

Work light

Foot-operated clamping attachment

Diamond dressing attachment

Filing gauge

Diamond grinding wheel for carbide

tipped saw chain and carbide tipped

circular saw blades

Attachment (tool rest) for scratcher tooth

chain

Attachment (tool rest) for hedge trimmer

blades

Attachment (tool rest) for circular saw

blades

Saw set for checking and correcting

tooth set

Contact your STIHL dealer for the latest

information on these and other special

accessories.

The user of this unit should carry out

only the maintenance operations

described in this manual. Other repair

work may be performed only by an

authorized STIHL dealer.

Warranty claims following repairs can be

accepted only if the repair has been

performed by an authorized STIHL

dealer using original STIHL replacement

parts.

Original STlHL parts can be identified by

the STIHL part number, the

STIHl

logo and the STlHL parts symbol (.

The symbol may appear alone on small

parts.

1)

according to EN ISO 11204,

measured at operator’s ear while

sharpening a saw chain

35USG

Page 37

English

Certificate of Conformity Quality Certification

Andreas Stihl AG & Co. KG

Badstr. 115

71336 Waiblingen

certify that the new machine described

below

Category: Universal

sharpener

Make: STIHL

Model: USG

Serial identification: 5203

conforms to the specifications of

Directives 73/23/EEC, 98/37/EG and

89/336/EEC.

The product has been developed and

manufactured in compliance with the

following standards:

EN 60335-1, EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3 and

EN 60204-1

Technical documents deposited at:

Andreas Stihl AG & Co. KG

Product Licensing

Done at Waiblingen,

September 1, 2003

Andreas Stihl AG & Co. KG

Steinhauser

Director

Group Product Management/

Engineering Services

000BA026

All STIHL products comply with the

highest quality standards.

An independent organization has

certified that all products manufactured

by STIHL meet the strict requirements of

the ISO 9001 standard for quality

management systems in terms of

product development, materials

purchasing, production, assembly,

documentation and customer service.

36

USG

Page 38

Loading...

Loading...