Page 1

STIHL TS 440

WARNING

Read Instruction Manual thoroughly

before use and follow all safety

precautions – improper use can

cause serious or fatal injury.

ADVERTENCIA

Antes de usar la máquina lea y siga

todas las precauciones de

seguridad dadas en el manual de

instrucciones – el uso incorrecto

puede causar lesiones graves o

mortales.

{

Instruction Manual

Manual de instrucciones

Page 2

Instruction Manual

1 - 56

Manual de instrucciones

57 - 116

Page 3

Contents

English

Guide to Using this Manual 2

Safety Precautions and Working

Techniques 2

Sample Applications 20

Abrasive Cutting Wheels 26

Composite Cutting Wheels 27

Diamond Cutting Wheels 27

Wheel Brake System 31

Original Instruction ManualPrinted on chlorine-free paper

Electronic Water Control 33

Mounting an Abrasive Cutting

Wheel 34

Fuel 36

Fueling 37

Starting / Stopping the Engine 38

Air Filter System 41

Engine Management 42

Adjusting the Carburetor 43

Spark Arresting Screen in Muffler 44

Spark Plug 44

Storing the Machine 46

Maintenance and Care 47

Main Parts 49

Printing inks contain vegetable oils, paper can be recycled.

Specifications 51

Maintenance and Repairs 52

Disposal 52

Limited Warranty 53

STIHL Incorporated Federal

Emission Control Warranty

Statement for Emission-Related

Parts 53

Trademarks 55

Allow only persons who fully understand

this manual to operate your cut-off

machine.

To receive maximum performance and

satisfaction from your STIHL Cutquik

cut-off machine, it is important that you

read, understand and follow the safety

precautions and the operating and

maintenance instructions in the chapter

"Safety Precautions and Working

Techniques" before using it. For further

information you can go to

www.stihlusa.com

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

WARNING

Because a cut-off machine is a powerful

cutting tool, some special safety

precautions must be observed to reduce

the risk of personal injury. Careless or

improper use may cause serious or even

fatal injury.

{

© ANDREAS STIHL AG & Co. KG, 2017

0458-520-8621-A. VA1.H17.

0000007253_002_GB

TS 440

This instruction manual is protected by copyright. All rights reserved, especially the rights to reproduce, translate and process

with electronic systems.

1

Page 4

English

Guide to Using this Manual

Pictograms

The meanings of the pictograms

attached to or embossed on the

machine are explained in this manual.

The following pictograms are on your

machine.

Fuel tank for gasoline

and engine oil mixture

Press to operate manual

fuel pump

Pull brake lever toward

the front handle to

release the wheel brake

Symbols in Text

Many operating and safety instructions

are supported by illustrations.

The individual steps or procedures

described in the manual may be marked

in different ways:

N A bullet marks a step or procedure.

A description of a step or procedure that

refers directly to an illustration may

contain item numbers that appear in the

illustration. For example:

N Loosen the screw (1).

N Lever (2) ...

In addition to the operating instructions,

this manual may contain paragraphs

that require your special attention. Such

paragraphs are marked with the

symbols and signal words described

below:

DANGER

Indicates a hazardous situation that, if

not avoided, will result in death or

serious injury.

WARNING

Indicates a hazardous situation that, if

not avoided, could result in death or

serious injury.

NOTICE

Indicates a risk of property damage,

including damage to the machine or its

individual components.

Engineering Improvements

STIHL’s philosophy is to continually

improve all of its products. As a result,

engineering changes and improvements

are made from time to time. Therefore,

some changes, modifications and

improvements may not be covered in

this manual. If the operating

characteristics or the appearance of

your machine differs from those

described in this manual, please contact

your STIHL dealer or the STIHL

distributor for your area for assistance.

Safety Precautions and

Working Techniques

The use of any cut-off

machine may be hazardous. Because a cut-off

machine is a powerful

cutting tool that often creates sparks during the

cutting process, special

safety precautions must

be observed to reduce

the risk of personal injury

and fire.

It is important that you

read, fully understand

and observe the following

safety precautions and

warnings. Read the

instruction manual and

the safety precautions

periodically.

WARNING

Careless or improper use of any cut-off

machine may cause serious or fatal

injury.

Have your STIHL dealer show you how

to operate your cut-off machine.

Observe all applicable national, state

and local laws, safety regulations,

standards and ordinances.

WARNING

Your cut-off machine is for professional

use only. Do not lend or rent your cut-off

machine without the instruction manual.

Be sure that anyone using it

understands the information contained

in this manual.

2

TS 440

Page 5

English

A first-time operator should obtain

practical instruction before using the

machine. Employers should establish a

training program for operators of

gasoline-powered, hand-held, portable

cut-off machines to assure safe

operation of these machines and proper

choice of cutting attachments.

WARNING

Use your cut-off machine only for

authorized uses. For instance, it is not

suitable for cutting wood or plastic or

wooden or plastic objects. Unauthorized

uses may result in death, serious

personal injury or property damage,

including damage to the machine.

WARNING

Minors should never be allowed to use a

cut-off machine. Bystanders, especially

children, and animals should not be

allowed in the area where a cut-off

machine is in use. Never let the cut-off

machine run unattended.

See the appropriate section of your

instruction manual for a description of

the controls and function of the parts of

your cut-off machine.

Safe use of a cut-off machine involves

1. the operator

2. the power tool

3. the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate a

cut-off machine when you are fatigued.

Be alert – if you get tired while operating

your cut-off machine, take a break;

fatigue may result in loss of control.

Working with any cut-off machine can be

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating

a cut-off machine.

WARNING

Prolonged use of cut-off machines (or

other machines) exposing the operator

to vibration may produce whitefinger

disease (Raynaud's phenomenon) or

carpal tunnel syndrome. These

conditions reduce the hand's ability to

feel and regulate temperature, produce

numbness and burning sensations and

can cause nerve and circulation damage

and tissue necrosis. All factors which

contribute to whitefinger disease are not

known, but cold weather, smoking and

diseases or physical conditions that

affect blood vessels and blood transport,

as well as high vibration levels and long

periods of exposure to vibration, are

frequently cited as factors in the

development of whitefinger disease. In

order to reduce the risk of whitefinger

disease and carpal tunnel syndrome,

please observe the following

precautions:

– The TS 440 is equipped with an

anti-vibration ("AV") system

designed to reduce the

transmission of vibration created by

the machine to the operator's

hands.

– Keep the AV system well

maintained and in good condition. A

cut-off machine with loose

components or with damaged or

worn AV elements will tend to have

higher vibration levels. Replace

immediately any part of the system

that is damaged or worn.

– Wear gloves and keep your hands

warm.

– Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure. Take

frequent breaks.

These precautions do not guarantee

that you will not sustain whitefinger

disease or carpal tunnel syndrome.

Therefore, continual and regular users

should monitor closely the condition of

their hands and fingers. If any of the

above symptoms appear, seek medical

advice immediately.

WARNING

The ignition system of your cut-off

machine produces a low intensity

magnetic field. This field may interfere

with some pacemakers. To reduce the

risk of serious or fatal injury, persons

with a pacemaker should consult their

physician and the pacemaker

manufacturer before operating this tool.

TS 440

3

Page 6

English

Proper Clothing

WARNING

To reduce the risk of injury, the operator

should wear proper protective apparel.

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Avoid loosefitting jackets, scarfs,

neckties, jewelry, flared

or cuffed pants, unconfined long hair or

anything that could

become caught on any

obstacles or moving parts

of the machine. Wear

overalls or long pants to

protect your legs. Do not

wear shorts.

WARNING

When cutting metal, including rebar and

other metals embedded in concrete or

other materials, a cut-off machine

generates sparks that can ignite clothing

and other flammable materials. Most

fabrics used in clothing are flammable –

even flame-retardant fabrics will ignite at

higher temperatures. To reduce the risk

of burn injury, STIHL recommends

wearing clothing made of leather, wool,

flame-retardant-treated cotton or a

tightly woven, heavier cotton such as

denim. Some flame-retardant synthetic

fabrics may also be suitable, but others,

such as polyester, nylon, rayon and

acetate, can melt during a fire into a tarlike matter that burns into the skin.

Check the clothing manufacturer's

instructions. Keep clothing free of oil,

fuel, grease and other flammable

substances.

Always wear heavy-duty

work gloves (e.g. made of

leather or other wear

resistant material) when

handling the cut-off

machine. Heavy-duty,

non-slip gloves improve

your grip and help to

protect your hands.

Good footing is important

in cut-off machine work.

Wear sturdy boots with

non-slip soles. Steel-toed

safety boots are

recommended.

WARNING

Loose objects may be thrown toward the

operator by the cutting wheel.

To reduce the risk of

injury to your eyes never

operate a cut-off machine

unless wearing goggles

or properly fitted safety

glasses with adequate

top and side protection

and that comply with

ANSI Z87 "+". Proper eye

protection is a must.

Wear an approved safety hard hat to

protect your head.

Cut-off machine noise may damage your

hearing. Always wear sound barriers

(ear plugs or ear muffs) to help protect

your hearing. Regular users should have

their hearing checked regularly.

WARNING

When wet cutting at the

flow rate recommended

in this instruction manual

is not utilized or cannot

be confirmed, to reduce

the risk of serious or fatal

respiratory illness or cancer the operator and any

bystanders should

always wear a respirator

approved by NIOSH for

the material being cut

and with an Assigned

Protection Factor sufficient to provide the level

of respiratory protection

needed for worksite-specific conditions.

Consult your employer for information

relating to the respirator needed for your

worksite-specific conditions. Your

employer is likely to have in place an

OSHA-required respiratory protection

program and can provide information

regarding the type and level of

respiratory protection needed for your

worksite conditions. Information also is

available from OSHA at

www.OSHA.gov. Even if wet cutting at

the recommended flow rate, an operator

who is working with the machine for

more than two hours in one day should

wear a NIOSH-approved respirator that

is rated for the material being cut. For

additional details and warnings on this

subject, see information under "Working

Conditions" in this instruction manual.

4

TS 440

Page 7

English

WARNING

Use only diamond cutting wheels for wet

cutting with the TS 440. Wet cutting with

a composite cutting wheel may increase

the risk of wheel breakage, resulting in

severe or fatal injury.

THE POWER TOOL

For illustrations and definitions of the

parts of the cut-off machine, see the

chapter "Main Parts."

WARNING

Never modify a cut-off machine in any

way. Only STIHL branded parts and

cutting attachments expressly approved

by STIHL for use with the specific STIHL

cut-off machine models are

recommended. Although certain other

parts or attachments may be useable,

their use may be extremely dangerous.

Abrasive Cutting Wheels

WARNING

Before mounting the cutting wheel,

make sure that the maximum operating

wheel speed is above or equal to the

spindle speed of your cut-off machine as

provided in the specifications of this

manual. A wheel that is not so rated may

shatter or break and poses a threat of

serious or fatal injury to the operator and

other nearby persons.

WARNING

Never use a reducer bushing inserted

into the wheel to reduce the diameter of

the arbor hole. It may slip out of place,

causing out-of-roundness, vibration,

wheel breakage or loss of control,

resulting in the possibility of severe or

fatal injury.

WARNING

Wheels that are not STIHL branded may

be more likely to shatter, break or create

other hazards, such as increased

reactive forces. Use only wheels with

approved RPM ratings. Read and follow

any addional safety precautions that

accompany the wheel.

WARNING

Never use circular saw

blades, carbide tipped

blades, rescue blades,

wood-cutting blades or

toothed blades of any

nature on your cut-off

machine. They can cause

severe personal injury

from blade contact,

thrown objects and/or

reactive forces, including

kickback. See the section

"Reactive Forces" in this

instruction manual. Your

STIHL dealer stocks

STIHL branded abrasive

cutting wheels suitable

for the many authorized

applications of this cut-off

machine.

WARNING

Using the wrong abrasive cutting wheel

or cutting material for which the wheel

was not designed may cause the wheel

to wobble, shatter, break or increase

reactive forces, causing serious or fatal

injury. See below and the section

"Reactive Forces" in this instruction

manual.

Cutting unauthorized materials, such as

wood or plastic, or using wheels that are

not rated for the material being cut, can

result in severe personal injury or death

from wheel breakage, reactive forces or

loss of control.

WARNING

Use only diamond cutting wheels for wet

cutting with the TS 440. Wet cutting with

a composite cutting wheel may increase

the risk of wheel breakage, resulting in

severe or fatal injury.

Composite Cutting Wheels

Free-hand cutting with composite

cutting wheels can subject the wheels to

particularly high bending and

compression stress, which can increase

the possibility of wheel breakage. Avoid

side loading the cutting wheel and

always use proper working technique.

See the chapter "Sample Applications"

in this instruction manual.

TS 440

5

Page 8

English

WARNING

Inspect the composite

cutting wheel frequently

and replace immediately

if it is cracked or warped.

Cracked or warped

wheels may shatter or

break and cause serious

or fatal personal injury.

Out-of-round or

unbalanced wheels

increase vibration,

reduce the service life of

the cut-off machine and

may result in loss of

control.

Composite cutting wheels are heat

sensitive. Always store your cut-off

machine in a place where a composite

cutting wheel is not exposed to direct

sunlight or other sources of heat. Store

spare composite cutting wheels flat on a

level surface in a dry place where there

is no risk of frost damage. Failure to

follow these directions may cause the

wheel to shatter or crack in use, causing

serious or fatal injury.

STIHL has only developed one

composite cutting wheel suitable for use

on the TS 440. It is rated for dry cutting

metal only. Composite cutting wheels

designed for use on traditional, highspeed cut-off machines should not be

used on the TS 440. They are not

designed for the slower cutting speeds

and higher torque of the TS 440 and will

wear prematurely and perform poorly.

Never use a composite wheel not rated

for the material to be cut.

Diamond Cutting Wheels

WARNING

Some diamond cutting wheels that are

not STIHL branded utilize poor quality

steel cores, are not properly hardened or

tensioned, or have other design or

manufacturing defects that can result in

wheel breakage, thrown segments and

other safety issues, including wheel

wobble. Wheels that wobble during use

can result in reactive forces and present

other safety issues that could result in

loss of control and severe personal

injury or death. Wobbling, for example,

can lead to a severe binding of the wheel

in the cut, that, under certain

circumstances, can then result in

serious or fatal injury from kickback or

other reactive forces. See the section

"Reactive Forces including Kickback" in

this instruction manual. Never use a

wheel that wobbles or that has ever

wobbled. Even though such a wheel

may temporarily cease to wobble, e.g., if

run without load, it will always be prone

to wobble again under certain

conditions. Replace it immediately

before further use of the cut-off machine.

Diamond cutting wheels generally have

a better cutting performance than

composite cutting wheels. Diamond

cutting wheels have steel cores and

cutting segments embedded with

diamonds attached to their outer edges.

Properly rated diamond cutting wheels

can be used for cutting concrete,

asphalt, natural stone, clay pipe, brick

and the like. STIHL also offers diamond

cutting wheels for cutting ductile iron and

some structural steel. They are not,

however, suitable for cutting all metals

or other materials, including wood or

plastic. See the chapter "Diamond

Cutting Wheels" in this instruction

manual for more details regarding the

type of materials that can be cut with

properly rated STIHL diamond cutting

wheels.

WARNING

Wet or dry cutting is possible with the

appropriate diamond cutting wheel. A

water attachment kit is mounted on your

STIHL cut-off machine. Wet cutting

reduces dust and reactive forces and is

recommended whenever possible. See

the chapter "Sample Applications" in this

instruction manual.

WARNING

Do not remount a used diamond cutting

wheel without first inspecting it for

under-cutting, flatness, core fatigue or

damage, segment damage or loss, signs

of overheating (discoloration) and

possible arbor hole damage. See the

chapter "Diamond Cutting Wheels."

Check the wheel for cracks and make

sure that no pieces have broken off the

wheel before use. Never use any wheel,

diamond or composite, that has been

damaged.

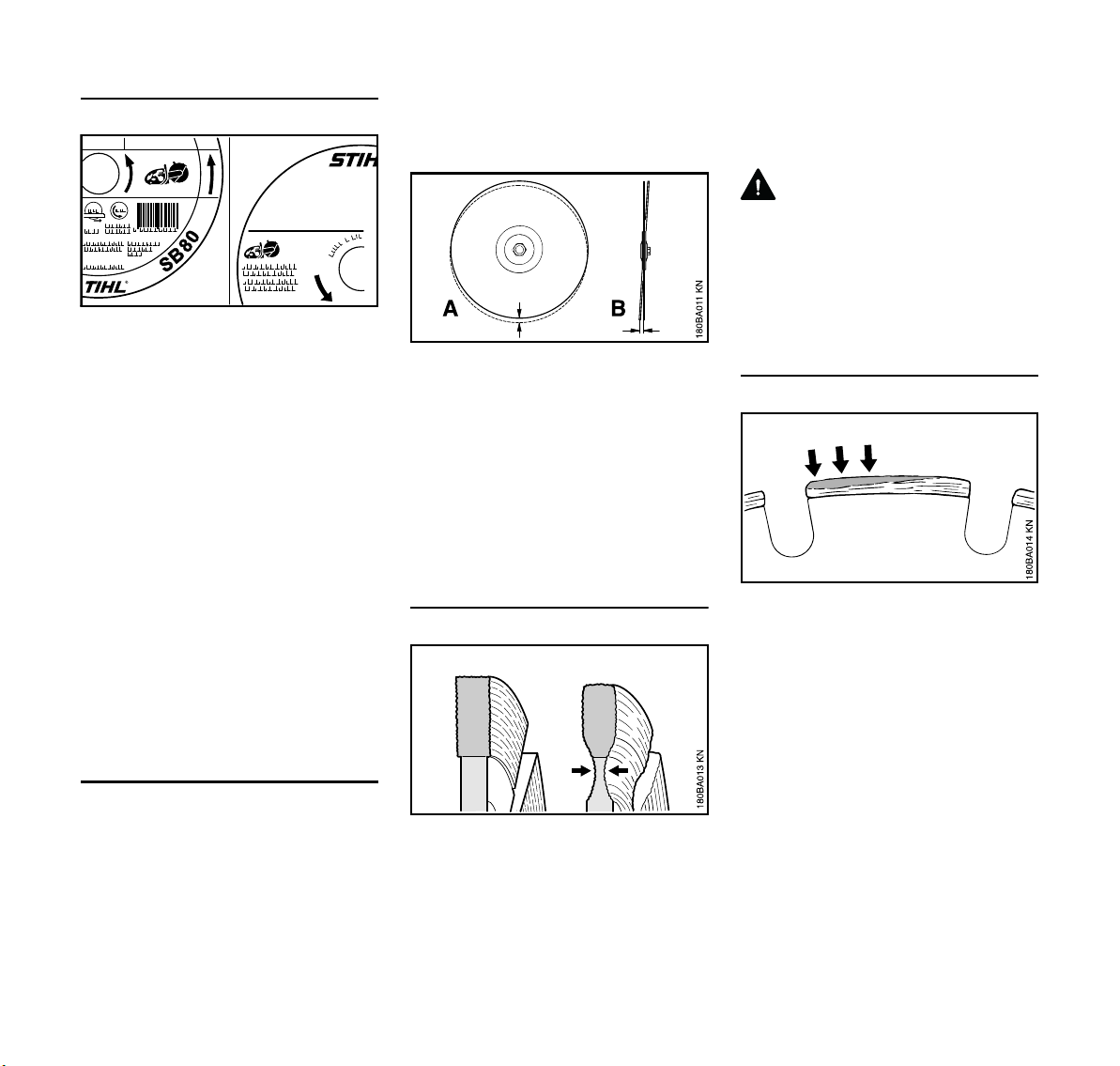

Always mount the diamond cutting

wheel so that the arrow on the wheel

points in the direction of the rotation of

the spindle.

6

TS 440

Page 9

English

THE USE OF THE POWER TOOL

Transporting the STIHL Cutquik

WARNING

To reduce the risk of injury from

unintended activation and/or contact

with a moving wheel, always shut off the

engine before putting the machine down

or carrying it. The abrasive cutting wheel

continues to rotate (coast down) for a

few seconds after the throttle trigger is

released and before the brake engages.

If faster stoppage time is required, bring

the wheel to a stop by lightly contacting

the bottom of the wheel with a hard

surface. Carrying a cut-off machine with

the wheel turning or the engine running

is extremely dangerous. Contact with a

moving wheel, even if the engine is

turned off, can result in severe personal

injury or death, and accidental

acceleration of the engine can cause the

wheel to rotate if the engine is still

running. Avoid touching the hot muffler

or allowing it to touch you.

WARNING

Always protect the cutting wheel from

accidentally hitting the ground or any

other objects, which can increase the

risk of serious personal injury or death

from a shattered composite cutting

wheel, from loss of diamond cutting

wheel segments or from loss of control.

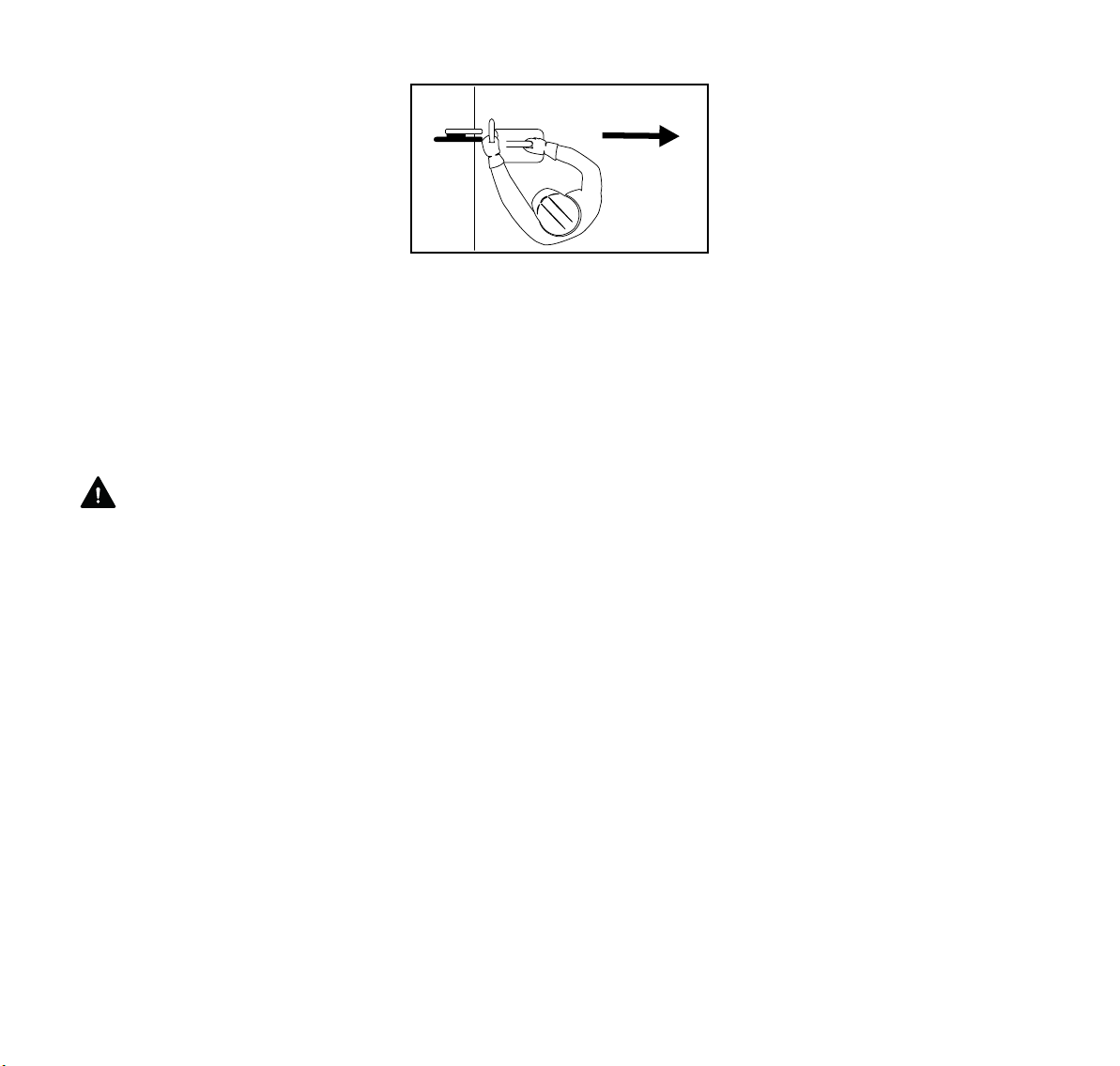

Transporting by hand: When carrying

your cut-off machine by hand, the

engine must be shut off and the rotating

wheel stopped, and the cut-off machine

must be correctly positioned. Grip the

front handle and place the muffler at the

side away from the body with the cutting

attachment to the rear.

Transporting by vehicle: Properly secure

your cut-off machine to prevent turnover,

fuel spillage and damage to the cut-off

machine. Never transport your cut-off

machine with a cutting wheel mounted.

A wheel damaged during transportation

can cause serious personal injury or

death.

Fuel

Your STIHL cut-off machine uses an oil-

gasoline mixture for fuel. See the

chapter "Fuel" in this instruction manual.

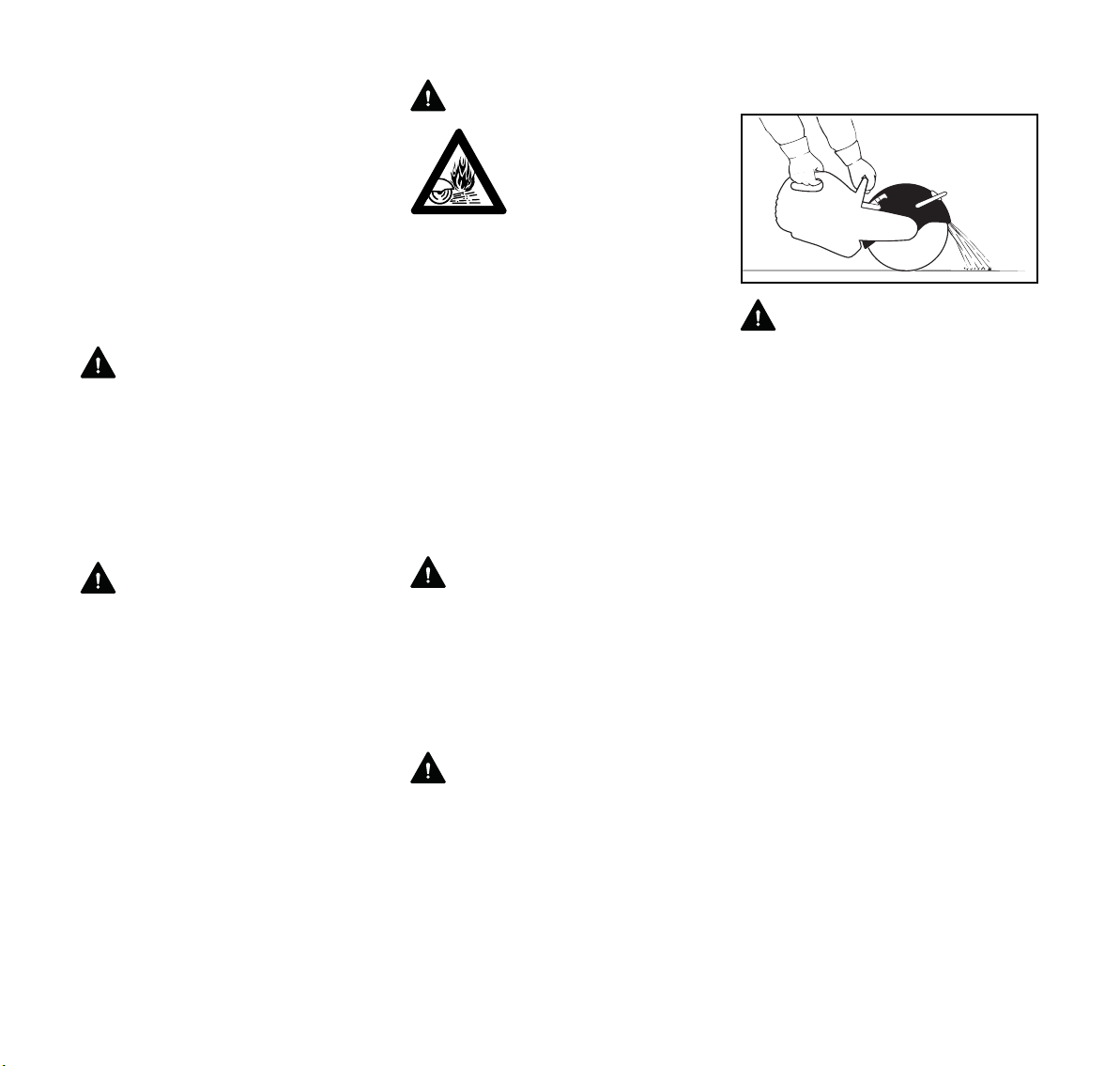

WARNING

Gasoline is an extremely

flammable fuel. If spilled

and ignited by a spark or

other ignition source, it

can cause fire and serious burn injury or

property damage. Use

extreme caution when

handling gasoline or a oilgasoline fuel mix. Do not

smoke or bring any fire or

flame near the fuel or the

power tool. Do not refuel

near any ignition source.

Note that combustible

fuel vapor may escape

from the fuel system or

gas can during fueling

operations.

WARNING

Dust or other debris may collect on the

powerhead, especially around the

carburetor, and may absorb gasoline,

resulting in a risk of fire. Clean dust and

debris from the powerhead regularly.

Fueling Instructions

WARNING

To reduce the risk of personal injury and

property damage, fuel your cut-off

machine in well-ventilated areas,

outdoors. Always shut off the engine and

allow the machine to cool before

refueling. Never remove the fuel cap

near any ignition source.

Under certain conditions, gasoline vapor

pressure may build up inside the fuel

tank depending on the fuel used,

weather conditions and the condition of

the tank venting system. In order to

reduce the risk of burns and other

personal injury from escaping gas vapor

and fumes, allow the machine to cool

adequately before opening the cap. Do

not smoke. Remove the fuel filler cap

slowly and as described in this

instruction manual to allow any residual

pressure in the tank to release gradually.

Never remove the fuel filler cap while the

engine is still running.

Select bare ground for fueling and move

at least 10 feet (3 m) from the fueling

spot before starting the engine. Wipe off

any spilled fuel before starting your

machine. If gasoline has spilled or

contaminated your clothing, change

clothes before starting the power tool,

resuming work or approaching an

ignition source.

TS 440

7

Page 10

English

Always use fuels blended for the season

and conditions in which you are cutting.

Avoid the use of winter blend fuels in

summer weather conditions. Use fresh

fuel of good quality and at least

89 octane. STIHL MotoMix, available

from your authorized STIHL servicing

dealer, is recommended for best

performance.

WARNING

Check for fuel leakage

while refueling and during

operation. If fuel leakage

is found, do not start or

run the machine until the

leak is fixed and any

leaked fuel has been

wiped away. Take care

not to get fuel on your

clothing. If this happens,

change your clothing

immediately. Always

move at least 10 feet

(3 m) from the fueling

spot before starting the

engine.

WARNING

If fuel is spilled on clothes, especially

trousers, it is very important to change

clothes immediately. Do not rely upon

evaporation. Flammable quantities of

fuel may remain on clothes after a spill

for longer than expected. Cutting metal

or other materials capable of creating

sparks with a cut-off machine when

clothes are contaminated with fuel or

gasoline is extremely dangerous, as the

operator's clothes might catch fire and

cause serious or fatal injury. Do not

approach any ignition source with

clothes contaminated by fuel.

WARNING

An improperly installed fuel cap can

come off and spill quantities of fuel.

Fuel Filler Cap

Never use a tool to open or close the fuel

filler cap, as this could damage the cap

and cause fuel leakage or spillage.

The fuel filler cap must be securely

closed after refuelling.

WARNING

Never attempt to force the fuel cap open

by using a tool. It may damage the cap

and allow fuel to leak.

WARNING

Before use, make sure that the fuel cap

has been securely and properly installed

and any spilled fuel wiped away. Check

for fuel leakage while refueling and

during operation. If a fuel leak is

suspected, do not start or run the

machine until the leak is fixed and all

leaked fuel has been wiped away.

Before Starting

For wheel installation, follow the

procedure described in the chapter

"Mounting an Abrasive Wheel" in this

instruction manual.

WARNING

Check the fuel system for leaks,

especially the visible parts, e.g., fuel

tank, filler cap, hose connections and

manual fuel pump. To reduce the risk of

personal injury or property damage from

fire, do not start the engine if there are

fuel leaks or damage to the fuel system.

Have the machine repaired by an

authorized STIHL servicing dealer

before using it.

WARNING

Never operate a cut-off machine if it is

damaged, improperly adjusted or

maintained, or not completely or

properly assembled. Check that the

machine is ready for safe operation.

Keep the handles dry, clean and free of

oil and fuel.

WARNING

Before operation of your cut-off

machine, be sure the controls (e.g.

throttle trigger, throttle trigger lockout,

stop switch), brake and the other safety

devices are working properly, the

carburetor idle and maximum speed

settings are correctly adjusted, the

wheel is properly mounted, and the

wheel guard is properly positioned and

securely fastened to your unit. All

wheels should be carefully inspected for

8

TS 440

Page 11

English

002BA058 KN

damage before mounting. Never mount

or use an abrasive cutting wheel that is

cracked or otherwise damaged.

Adjust the wheel guard

so that sparks, dust and

cut material are deflected

away from the operator,

and cannot reach flammable surroundings or

materials. See the section "Operating

Instructions" in this

instruction manual. Never

direct sparks or cutting

debris toward flammable

materials or toward the

operator.

When it is necessary to open the guard

to access the underside of an in-ground

pipe or other structure (see "Sample

Applications"), always be aware of your

surroundings. Make sure sparks and

other debris are not directed toward

flammable materials or the operator.

Always wear appropriate eye protection

and protective apparel. Return the guard

to cover the top of the cutting wheel as

soon as it is possible to continue the

work with the guard in that position.

STIHL recommends always guarding as

much of the top of the wheel as possible

and not opening the guard any further

than necessary to make or complete a

cut.

WARNING

Check that the spark plug boot is

securely mounted on the spark plug – a

loose boot may cause arcing that could

ignite combustible fumes or spilled fuel

and cause a fire.

Starting

WARNING

Your cut-off machine is a one-person

tool. Do not allow other persons to be

near a running cut-off machine. Start

and operate your cut-off machine

without assistance. Check the wheel

brake system before starting and follow

the specific starting instructions, found in

the chapter "Starting/Stopping the

Engine" in this instruction manual.

Do not drop start the cut-off machine.

Drop starting means pushing the

machine away from the operator, or

allowing it to drop toward the ground,

while pulling on the starter grip. This

method is very dangerous because you

may lose control of the cut-off machine.

Instead, to start the cut-off machine

place it on firm ground or other solid

surface in an open area and hold it

securely to the ground or surface.

Maintain good balance and secure

footing. Be absolutely sure that the

cutting wheel is clear of you and all other

obstructions and objects, including the

ground or surface on which the machine

is being started. Never attempt to start

the cut-off machine when the abrasive

cutting wheel is in a cut.

Once the engine has started,

immediately blip the throttle trigger,

which should release the slide control to

the run position and allow the engine to

slow down to idle. After the choke lever

is set to e, pull the brake lever toward

the front handle and release the wheel

brake. The abrasive cutting wheel

should not rotate when the engine is

idling and the wheel brake is released. If

the wheel does turn, adjust the

carburetor to set the proper idle speed.

See the chapter "Adjusting the

Carburetor" in this instruction manual. If

you cannot adjust the carburetor to the

proper idle speed, shut the machine off

and take it to an authorized STIHL

servicing dealer for repair before using

the TS 440. For complete starting

information, see the chapter

"Starting/Stopping the Engine" in this

instruction manual.

WARNING

When you pull the starter grip, do not

wrap the starter rope around your hand.

Do not allow the grip to snap back, but

guide the starter rope slowly back to

permit the rope to rewind properly.

Failure to follow this procedure may

result in injuries to hand or fingers and

may damage the starter mechanism.

TS 440

9

Page 12

English

Important Adjustments

At correct idle speed, the wheel should

not turn, even when the wheel brake is

released. For directions on adjusting idle

speed, see the chapter "Adjusting the

Carburetor" in this manual.

WARNING

Do not use a cut-off machine with the

idle speed incorrectly adjusted. The

rotating wheel may cause injury. If you

cannot obtain the correct setting, have

your STIHL dealer check your cut-off

machine and make proper adjustments

or repairs.

Working Conditions

Operate the cut-off machine under good

visibility and daylight conditions only.

Wearing hearing protection reduces

sound perception. Be alert not to miss

voice or other audible signals from coworkers or supervisors. Keep within

calling distance to other persons who

may assist in case of emergency.

WARNING

As soon as the engine is

running, this machine

generates toxic exhaust

fumes containing chemicals, such as unburned

hydrocarbons (including

benzene) and carbon

monoxide, that are

known to cause respiratory problems, cancer,

birth defects, or other

reproductive harm, and

other injuries. Some of

the gases (e.g. carbon

monoxide) may be colorless and odorless and

can cause asphyxiation

and death very quickly.

To reduce the risk of serious or fatal injury/illness

from inhaling toxic fumes,

never run the machine

indoors or in poorly ventilated locations. Ensure

proper ventilation when

working in trenches or

other confined areas.

WARNING

Use of this product to cut masonry,

concrete, metal and other materials can

generate dust and fumes containing

chemicals known to cause serious or

fatal injury or illness, such as respiratory

disease, cancer, birth defects or other

reproductive harm, and other injuries. If

you are unfamiliar with the risks

associated with the material being cut,

review the applicable material safety

data sheet and/or consult your

employer, the material

manufacturer/supplier, governmental

agencies such as OSHA and NIOSH

and other sources on hazardous

materials. California and some other

authorities, for instance, have published

lists of substances known to cause

cancer, reproductive toxicity, and other

injuries. Control dust and fumes at the

source where possible.

In this regard, use engineering controls,

good work practices and follow the

recommendations of the material

manufacturer/supplier, OSHA/NIOSH,

and occupational and trade

associations.

A water attachment kit is

provided with your cut-off

machine and should be

used to reduce dust

whenever wet cutting is

feasible. For dust suppression purposes, the

flow rate should be at

least 20 fl. oz. (0.6 liters)

of water per minute. If

wet cutting at the recommended flow rate is not

utilized or cannot be confirmed, to reduce the risk

of serious or fatal respiratory illness or cancer the

operator and any

bystanders should

always wear a respirator

approved by NIOSH for

the material being cut

and with an Assigned

Protection Factor sufficient to provide the

necessary level of respiratory protection for

worksite- specific

conditions.

10

TS 440

Page 13

English

Consult your employer for information

regarding worksite conditions. Your

employer is likely to have in place an

OSHA-required respiratory protection

program and can provide information

regarding the required type and level of

respiratory protection needed for your

worksite. Alternatively, information is

available from OSHA at www.osha.gov.

See the section on “Respiratory

Protection” in the chapter “Sample

Applications” in this instruction manual.

Even if wet cutting at the recommended

flow rate, to reduce the risk of serious or

fatal respiratory illness or cancer an

operator who is working with the

machine for more than two hours in one

day should wear a NIOSH-approved

respirator rated for the material being cut

and with an Assigned Protection Factor

sufficient to provide the level of

respiratory protection needed for

worksite-specific conditions. Consult

your employer for information relating to

the respirator needed for your worksitespecific conditions. Your employer is

likely to have in place an OSHA-required

respiratory protection program and can

provide information regarding the type

and level of respiratory protection

needed for your worksite conditions.

Information also is available from OSHA

at www.OSHA.gov. Consult and follow

any federal, state or local laws or

regulations with respect to dry and wet

cutting, including any requirements for

engineering controls, work practices and

respiratory protection to reduce

exposure to respirable crystalline silica

or other potentially harmful substances.

WARNING

Cutting masonry, concrete and other

materials with silica in their composition

may produce dust containing crystalline

silica. Silica is a basic component of

sand, quartz, brick clay, granite and

numerous other minerals and rocks.

Inhalation of airborne crystalline silica

can cause serious or fatal respiratory

diseases, including silicosis. California

and some other authorities have listed

respirable crystalline silica as a

substance known to cause cancer.

OSHA has established a maximum

permissible exposure limit for crystalline

silica. When cutting materials that may

contain crystalline silica, always follow

the respiratory precautions described in

this instruction manual.

WARNING

Breathing asbestos dust is dangerous

and can cause severe or fatal injury,

respiratory illness or cancer, including

mesothelioma. The use and disposal of

asbestos-containing products are strictly

regulated by OSHA and the

Environmental Protection Agency. Do

not use your cut-off machine to cut or

disturb asbestos, asbestos-containing

products, or products such as pipes

which are wrapped or covered with

asbestos-containing insulation or

material. If you have any reason to

believe that you might be cutting

asbestos containing-material, or if you

cannot be sure, stop work and

immediately contact your employer or a

local OSHA or EPA representative.

002BA549 AM

WARNING

The STIHL TS 440 is designed for handheld use only. It should not be used on a

cart, as the added torque delivered by

the TS 440 will cause the drive belt

system to wear prematurely.

WARNING

Cutting with your cut-off machine resting

on the ground or other surface can

cause excessive wear to the bracket

designed to protect the bottom of the

tank housing. Loss of fuel and property

damage or severe personal injury or

death from fire may result. Replace

damaged or badly worn brackets

immediately.

WARNING

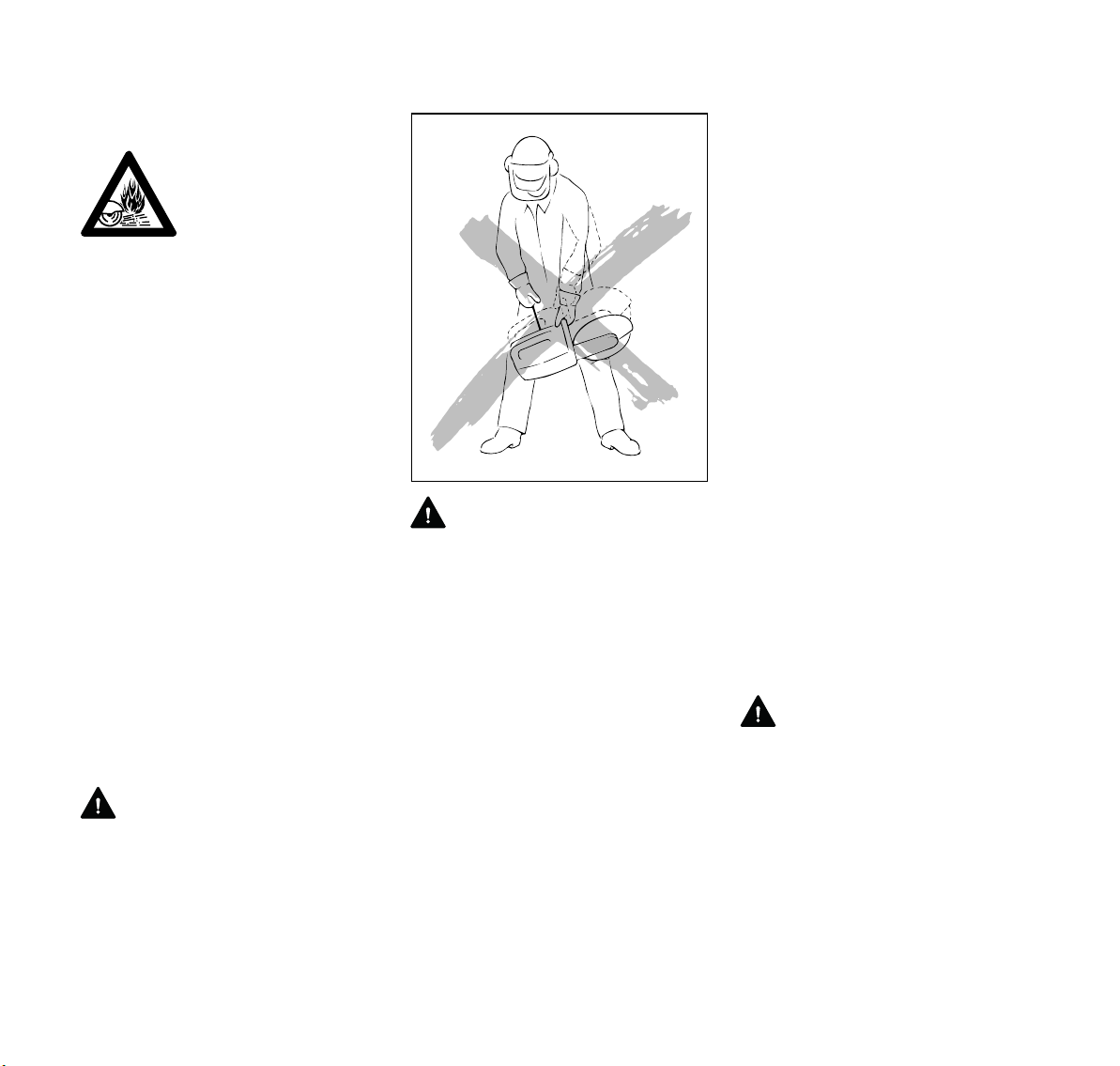

Grip: Never use the cut-off machine with

one hand. Always hold the cut-off

machine firmly with both hands when the

engine is running. Place your left hand

on the front handle and your right hand

on the rear handle and throttle trigger.

Left-handed users also must follow this

instruction in order to reduce the risk of

severe or fatal personal injury from

kickback and/or loss of control. Using

the machine "left-handed" positions your

body in the plane of the abrasive cutting

TS 440

11

Page 14

English

wheel and increases the risk that you will

be struck by the moving wheel if

kickback occurs.

Wrap your fingers tightly around the

handles, keeping the handles cradled

between your thumbs and forefingers.

Make sure the cut-off machine’s handles

and grip are in good condition and free

of moisture, pitch, oil, fuel mix or grease.

Never touch a rotating wheel with your

hand or any part of your body or allow it

to touch you.

WARNING

Clear the area where you are working.

Avoid stumbling on obstacles and be

alert for ditches or other irregularities

and impediments. Be extremely

cautious when working on slopes or

rocky or uneven ground. Take extreme

care in wet and freezing weather (rain,

snow, ice).

WARNING

Never operate the cut-off machine with

the starting-throttle lock engaged as this

does not permit proper control of the

speed of the unit and may lead to

serious injury.

WARNING

Sparks from cutting metal

can burn the operator or

cause clothing or other

objects or materials to

catch fire. Direct sparks

away from the operator

and any flammable surroundings. Never cut

metal while standing on a

flammable surface, such

as wood or tar paper.

Where there is a risk of

fire, work with a fire

watch and have appropriate fire extinguishing

equipment readily available. Do not use the cut-off

machine if you cannot

direct sparks away from

flammable substances or

the operator.

WARNING

To reduce the risk of severe personal

injury or death from fire, exlosion or

other event, do not cut into any pipe,

drum or other container without first

ensuring that it does not contain a

volatile or flammable substance and is

not pressurized.

WARNING

When cutting into existing walls, floors or

similar structures, be alert for hidden

hazards such as electrical cables, water

and gas pipes and flammable or

pressurized materials, substances and

structures. Make sure that power, water

and gas have been shut off and pipes

drained before starting to cut.

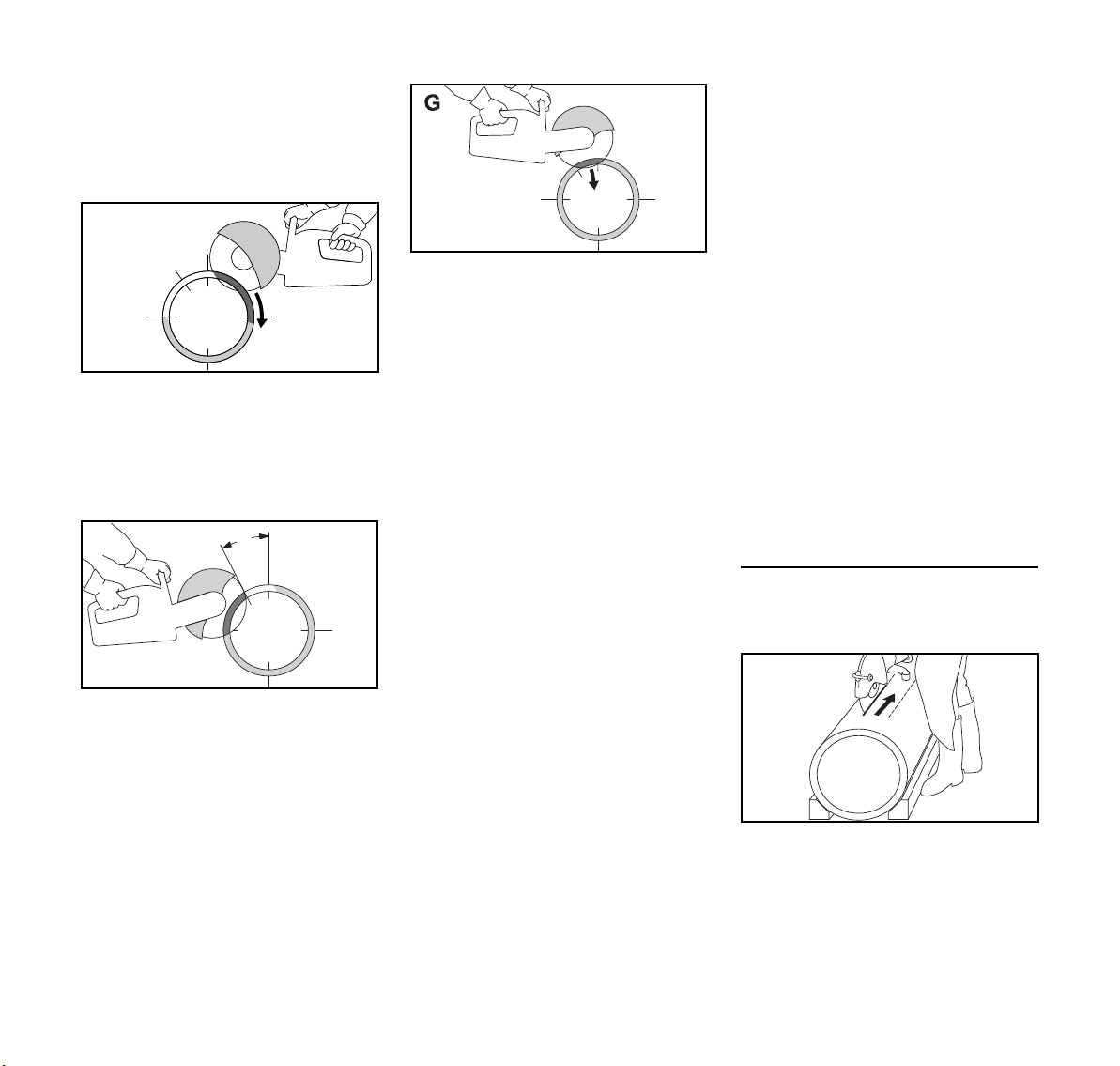

Operating Instructions

0000-GXX-5154-A0

WARNING

The wheel guard on the TS 440 is

adjustable. It is extremely important that

the wheel guard is in place and adjusted

properly for the type of work you are

doing, your stance and your work

position. The guard should always be

adjusted so that the user is not

endangered by particles of the material

being cut, sparks or pieces of damaged

wheels, either directly or by ricochet.

Failure to follow this instruction could

result in serious or fatal injury.

Particular care must be taken when the

guard is adjusted to expose the top of

the wheel. The guard should only be

adjusted to this position when necessary

to access the underside of a pipe or

other structure or to finish cuts requiring

use of the top portion of the wheel.

When cutting the underside of a pipe or

other structure, the pipe or other

structure itself should provide protection

against debris, but if the operator is

endangered by debris, the guard must

be adjusted to protect the operator. That

may mean, in some circumstances, the

TS 440 cannot be used to complete a

cut. The guard always should be

adjusted forward to cover the top of the

wheel immediately upon completion of

12

TS 440

Page 15

English

any cut requiring the top of the wheel to

be exposed. STIHL recommends

always guarding as much of the top of

the wheel as possible and not opening

the guard any further than necessary to

make or complete a cut.

The recommended guard position for

use of the TS 440, whenever possible, is

fully forward to the forward stop position,

which will then cover the top of the

abrasive cutting wheel down to the point

roughly midway between 9:00 and 12:00

(when viewing the wheel from the fan

wheel housing side of the machine).

WARNING

To reduce the risk of severe injury or

death, always shut off the machine and

allow the wheel to stop before

attempting to adjust the guard. After

shutting off the machine, the wheel will

continue to rotate for a few seconds

before the brake engages. Never

attempt to adjust the guard while the

engine is running or the wheel is still

rotating.

WARNING

Always check the wheel before use and

after unintentionally striking any object;

check it frequently during use when the

engine is turned off. Look for cracks and

other damage, such as cracked, missing

or broken segments on a diamond

cutting wheel. Make sure that the wheel

is undamaged and in good condition,

that it is not cracked, that no pieces have

broken off and that no segments are

loose, missing or damaged. See the

sections "Abrasive Cutting Wheels" and

"Reactive Forces" in this manual. Check

the wheel guard for cracks or other

damage. If you discover any breaks,

cracks or other damage, mount a new

guard before further use.

WARNING

It is essential to determine the exact

direction of the cut before applying the

abrasive cutting wheel to the workpiece.

Wheels are constructed for radial

pressure only. To reduce the risk of

wheel breakage and severe personal

injury or death, avoid putting lateral

pressure (side loading) on the wheel.

Hold the cut-off machine steady. Work

along a straight cutting line. Do not

attempt to correct the position or

direction of a cut by tilting or twisting the

machine or cutting wheel. If corrections

are necessary, always lift the machine

and reposition the cutting wheel, taking

care to ensure that it is not wedged,

tilted, twisted or side loaded. Attempting

to change the position or direction of a

cut while the wheel is in the cut can bind

the wheel. This can lead to kickback,

other reactive forces or a shattered

composite cutting wheel, which could

result in severe or fatal personal injury.

See the section "Reactive Forces" in this

manual.

WARNING

Use your cut-off machine for cutting

only. It is not designed for prying,

shoveling or moving any objects.

Do not use abrasive cutting wheels for

rough grinding using the sides of the

wheel. Large bending stresses occur

during such work, which may result in

reactive forces, including kickback, or

cause the wheel to shatter or break,

resulting in serious or fatal injury.

WARNING

To reduce the risk of injury from

damaged abrasive cutting wheels:

1. Do not use a wheel on your machine

that has a rated operating speed

lower than the maximum operating

speed of you machine's spindle, as

specified in this instruction manual.

2. Do not use a wheel that has been

dropped or damaged.

3. Run each new wheel immediately

after installation for approximately

one minute at maximum speed

without cutting, making sure to keep

bystanders away. If the wheel

wobbles or otherwise shows

operational problems, do not use it.

4. Do not cut any material for which the

wheel is not authorized.

5. Do not grind using the sides of the

wheel.

6. Do not twist, thrust, knock or drop

the machine. This can cause

damage to the wheel.

7. Do not transport the cut-off machine

with the cutting wheel mounted.

To achieve a clean and efficient cut,

maintain a firm grip and apply the cutting

wheel to workpiece, allowing the cutting

wheel to engage the material naturally.

Don't force or jam the cutting wheel into

the workpiece. The machine will have a

natural tendency to move away from the

operator. Slowly pulling the machine

back through the cut or kerf toward the

operator and then allowing it to move

forward again will improve cutting

performance.

TS 440

13

Page 16

English

Insert the wheel into the material only as

deep as necessary to make the cut. To

reduce the amount of dust created, do

not cut all the way through stone,

concrete and similar materials – leave a

thin layer of material uncut. This layer

can be easily broken afterwards using a

hammer or other appropriate tool.

Always wear properly rated eye

protection when breaking any uncut

piece or layer. Do not cock, jam or

wedge the wheel in the cut, as this may

result in reactive forces or a damaged or

broken wheel and the possibility of

severe or fatal personal injury.

Release the pressure on the cut-off

machine as you reach the end of the cut.

Too much pressure may cause the

operator to lose control of the cut-off

machine when the abrasive cutting

wheel completes the cut. The abrasive

cutting wheel may contact the operator

or strike some foreign object and break

or shatter.

Always shut off the engine and be sure

the wheel has stopped rotating before

setting the cut-off machine down.

WARNING

When the engine is shut off, the wheel

brake will engage within a few seconds.

If the cut-off machine is on the ground, it

may tip forward when the wheel brake

engages. The abrasive cutting wheel

can touch the ground and may shatter,

break or sustain damage. It also may

cause damage to the surface it contacts.

STIHL Quickstop Wheel Brake System

The STIHL Quickstop wheel brake

system is designed to stop the rotation

of the cutting wheel during kickback if

the kickback energy is sufficiently high.

WARNING

The Quickstop does not prevent

kickback. It is designed to reduce the

risk of kickback injury, if activated, when

the guard on the TS 440 has been

"opened," exposing the top of the cutting

wheel. In order for the Quickstop to

reduce the risk of kickback injury, it must

be properly maintained and in good

working order. An improperly

maintained wheel brake may increase

the time needed to stop the abrasive

cutting wheel after activation, or it may

not activate at all. See the chapter

entitled "Wheel Brake System" in this

instruction manual.

WARNING

The brake is intended to substitute for

the wheel guard when the guard has

been "opened," i.e., pulled back toward

the operator, exposing the top of the

wheel, by stopping the rotation of the

wheel if kickback occurs and kickback

energies are sufficiently high. Like all

safety devices, the brake cannot protect

the operator in all circumstances. There

must be enough distance between the

top of the wheel and the operator to

ensure that the Quickstop has sufficient

time to activate and stop the abrasive

cutting wheel before potential contact

with the operator. Always stand outside

of the plane of the cutting wheel when

using a cut-off machine, including the

TS 440, and do not crouch over the

wheel.

Always maintain at least a 45° angle

between the top of the wheel and the

operator’s head, neck and body to

reduce the risk of severe personal injury

or death in the event of a kickback,

particulary when the guard has been

opened to expose the top of the wheel.

WARNING

The primary device intended to reduce

the risk of injury from kickback on the

TS 440 is the wheel guard. The wheel

guard also reduces the risk of injury from

shattered wheels, thrown segments,

sparks and cutting debris. The brake is

intended to substitute for the wheel

guard in kickback situations when the

guard has been "opened," exposing the

top of the wheel. The TS 440 should be

used with the guard in this position only

when necessary to make a cut as, for

example, when accessing the underside

of a pipe in a trench. The guard should

be returned to the forward stop position

(covering the top of the wheel down to

the point on the cutting wheel roughly

midway between 9:00 and 12:00 when

viewing the wheel from the fan wheel

housing side of the machine) as soon as

the cut requiring a more open guard

position has been completed. Make this

adjustment sooner if it is necessary to

protect the operator from thrown debris

generated during cutting.

The guard should not be opened to

expose the top portion of the wheel if

doing so means that cutting debris or

14

TS 440

Page 17

English

sparks will be directed toward the

operator, or if sparks or debris would be

directed into flammable surroundings.

WARNING

If you experience kickback of sufficient

magnitude to activate the Quickstop,

please review the operating instructions

and safety precautions in this chapter

before resuming work. Kickback

situations can and always should be

avoided. Pinching or binding of the

wheel can be prevented by proper

support of the workpiece (see below),

proper working technique (e.g., not side

loading the wheel and standing outside

the plane of the wheel), and by the use

of properly designed, manufactured and

maintained abrasive cutting wheels that

do not wobble and that do not have

friction-generating abrasive material on

their sides.

WARNING

To reduce the risk of injury from reactive

forces, shattered wheels, thrown

segments, sparks and cutting debris, the

guard should be pushed fully forward to

the forward stop position (covering the

top of the wheel, down to the point on

the cutting wheel roughly midway

between 9:00 and 12:00 when viewing

the wheel from the fan wheel housing

side of the machine) whenever a more

"open" guard position is not needed to

make a cut. Make this adjustment

sooner if it is necessary to protect the

operator and surroundings from thrown

debris generated during cutting.

The guard always should be positioned

to cover as much of the top of the wheel

as possible consistent with the type of

cut being made and the proper direction

and containment of sparks and other

debris. The recommended guard

position is fully forward to the front stop

position whenever possible.

WARNING

Check the wheel brake system before

starting work as described in the chapter

"Starting/Stopping the Engine" in this

instruction manual. Do not work with the

TS 440 if the wheel brake system is not

functioning properly. Have the wheel

brake system repaired by an authorized

servicing dealer before using the

machine.

WARNING

The wheel brake should be engaged

when starting your machine. If the

abrasive cutting wheel turns at startup

without the brake first being disengaged,

do not use the cut-off machine and have

the wheel brake system repaired by an

authorized servicing dealer before using

it.

Reactive Forces Including Kickback

WARNING

Reactive forces may

occur at any time the cutting wheel on a cut-off

machine is rotating.

The powerful forces used to cut through

a workpiece can be reversed and work

against the operator. If the wheel is

slowed or stopped sufficiently by

frictional contact with any solid object or

by a pinch or binding, reactive forces

can occur instantly and may result in the

operator losing control of the cut-off

machine, which, in turn, may result in

serious or fatal injury. An understanding

of the causes of these reactive forces

will help you avoid them and loss of

control.

Reactive forces are exerted in a

direction opposite to the direction in

which the wheel is moving at the point of

contact or of the pinching/binding. If the

wheel is slowed by frictional contact with

a solid object, the resulting reactive

forces are normally moderate and

readily controllable by an operator who

is holding the machine properly. If,

however, the wheel is abruptly slowed or

stopped by a severe pinch or bind, the

reactive forces may be substantially

greater. The greater the force

generated, the more difficult it will be for

the operator to control the cut-off

machine. Loss of control can result in

severe personal injury or death.

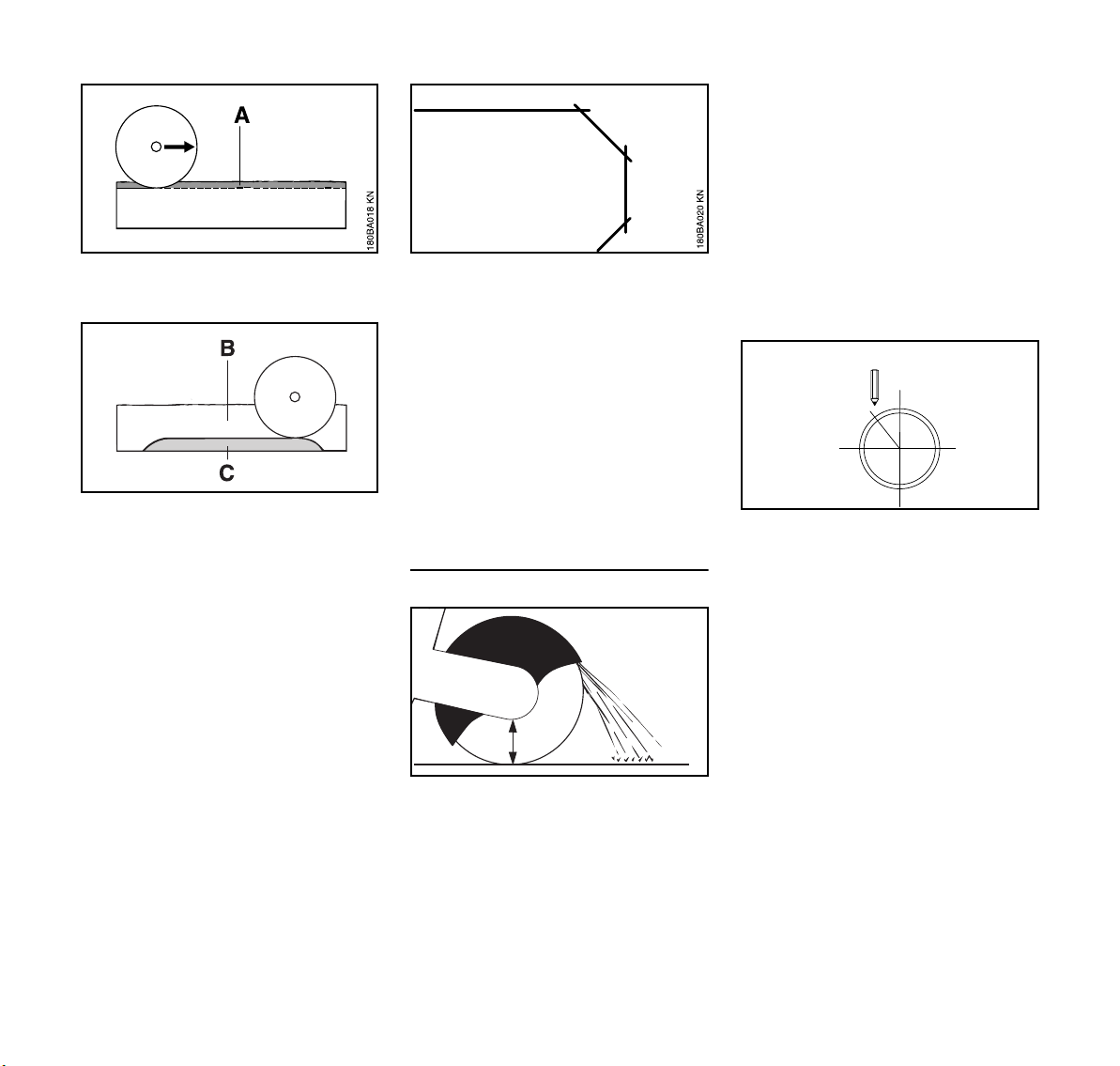

Pull-away, Climbing, Pinching and

Rotational Kickback Forces

002BA553 AM

The most common reactive forces are

pull-away and climbing. If the contact is

at the bottom of the wheel, a cut-off

machine will try to pull away from the

operator (pull-away). If the contact is at

the front of the wheel, the wheel may

attempt to climb the object being cut

TS 440

15

Page 18

English

002BA146 KN

(climbing). When the guard is opened on

the TS 440 to expose the top portion of

the wheel, contact in this top portion of

the wheel can cause the machine to

move linearly toward the operator (push

back). Any of these reactions can result

in loss of control and severe personal

injury or death.

Pinching occurs when the piece being

cut closes on the wheel. A severe

binding may also occur if the wheel is

substantially sideloaded in the cut or if

an improper or damaged diamond

cutting wheel begins or ceases to

wobble in the kerf. The location of the

pinch or bind on the wheel will determine

the direction the machine will move in

response to any reactive force that is

generated – push back from the top of

the wheel, pull away from areas below

the upper quadrant of the wheel.

However, if the wheel is severely

pinched or bound in the upper quadrant

at the front of the wheel, the wheel may

be instantly thrown up and back towards

the operator with significant force in a

rotational kickback motion. Such

kickback situations can and always

should be avoided.

Pinching or binding of the wheel can be

prevented by proper support of the

workpiece (see below), proper working

technique (e.g., not side loading the

wheel and standing outside the plane of

the wheel) and by the use of properly

designed, manufactured and maintained

wheels that do not wobble or have

friction-generating abrasive material on

their sides.

Reducing the Risk of Kickback Injury

WARNING

To reduce the risk of kickback injury,

avoid cutting with the upper quadrant of

the wheel (illustrated above) whenever

possible. Be especially cautious for a

pinching or binding of the wheel in this

area, which can cause severe reactive

forces in a rotational kickback motion.

Avoid wedging action. The severed part

of a workpiece must fall free and not

wedge, bind or clamp the abrasive

cutting wheel.

Be alert to potential movement of the

workpiece or anything else that could

cause the cut to close and pinch, bind or

clamp the wheel. In order to reduce the

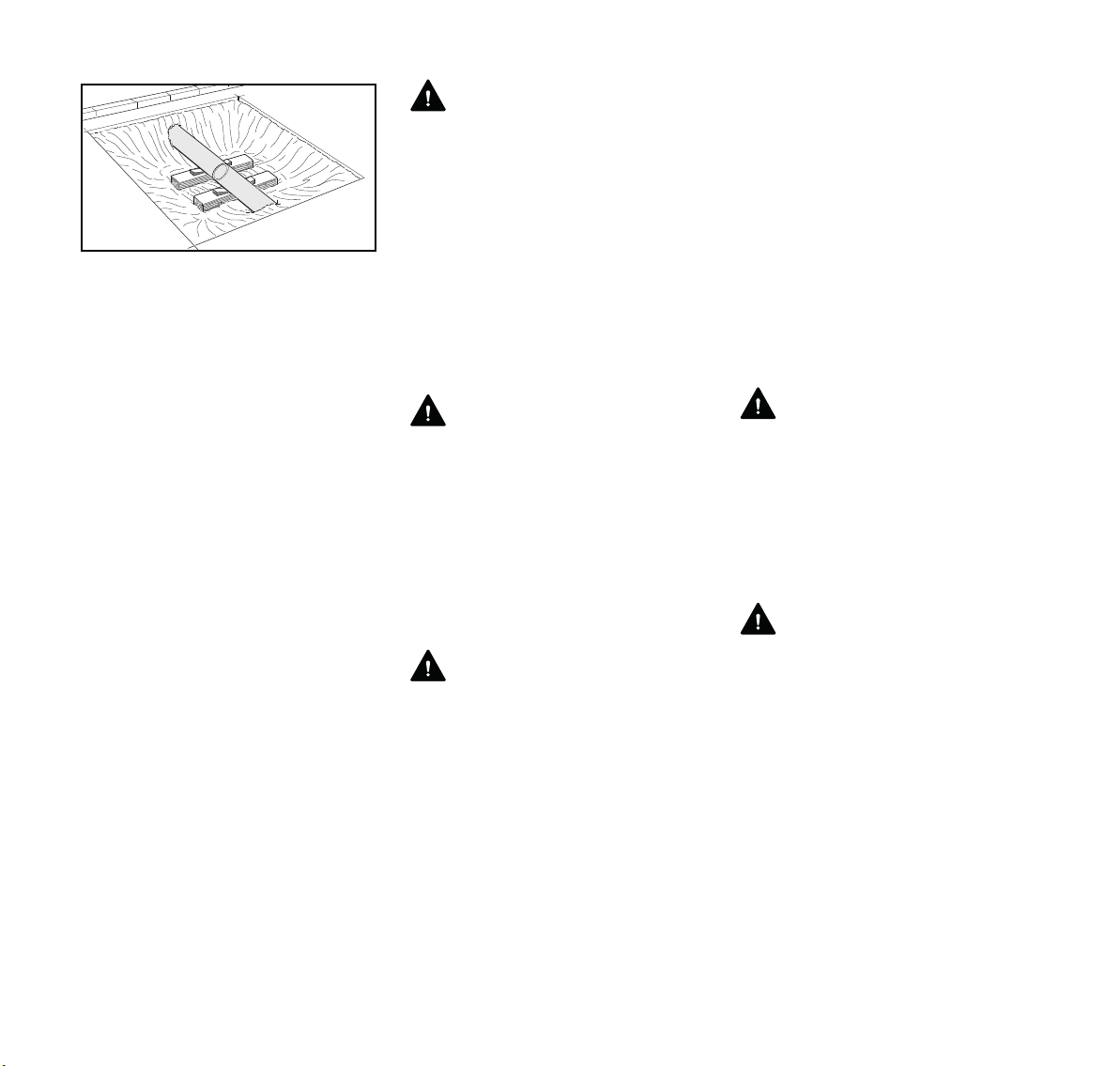

risk of pinching, binding or clamping,

support the workpiece in such a way that

the cut remains open during the cutting

process and when the cut is finished

(see illustration). Never make a cut that

results in a binding of the wheel. If you

cannot properly support the workpiece,

do not use a cutting-off machine to make

the cut; select another tool or method.

Where there is a possibility of a pinch,

you should leave an uncut portion of the

workpiece that prevents the cut from

closing and pinching the wheel, which

can later be broken manually using a

hammer or other appropriate tool. If you

002BA582 ST

are making a complete cut, make sure

that the final, separating cut is made at

the top of the workpiece using the

bottom of the wheel, with the guard of

the machine pushed fully forward to the

forward stop position. In this way, if there

is any residual pinching, it will be at the

bottom of the wheel, where it may result

in pull-away, but not in kickback. Be alert

for pull-away.

Objects to be cut always must be

properly supported and must be secured

against pinching, rolling away, slipping

or vibration.

16

TS 440

Page 19

English

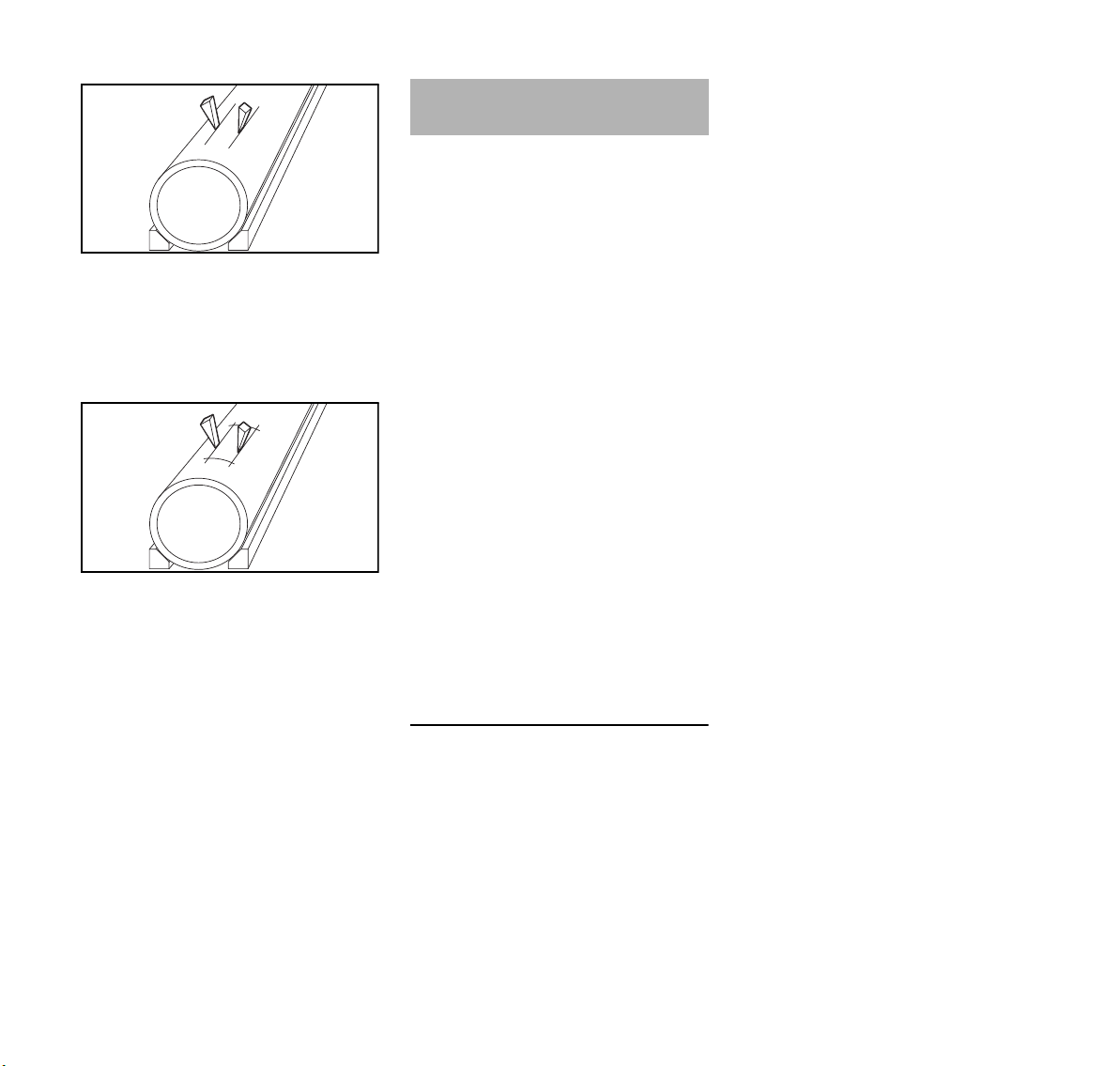

Support an exposed pipe in a trench so

that it is stable and will not "sag" or

"drop". If the ends of the pipe are firmly

in the ground, the ground may act as a

support where the pipe emerges into the

open. Additional support will be needed

closer to the cut, however, to prevent

sagging (see illustration). Be alert for

pipe that is under stress that may cause

it to shift when cut; pipe in the ground

may be under stress because of uneven

pipe bed surfaces. The release of stress

or tension in the pipe can propel the cutoff machine, causing loss of control and

resulting in severe personal injury or

death. It also can cause a binding or

pinching of the abrasive cutting wheel,

which could result in reactive forces,

including kickback

Make sure any section of pipe to be

removed is also properly supported and

will not shift. After the first cut, you may

need to move the supports or add

additional support for the second cut so

that both sides of that cut are fully

supported, including the section to be

removed.

Always pay attention in

subgrade/subsurface work areas –

supporting material can crumble or slide

away, causing the pipe to sag and pinch

the wheel.

WARNING

Be particularly alert when cutting a

workpiece such as a pipe with a bell end

or when cutting out a section of pipe in a

trench that, if not properly supported,

can sag or drop upon completion of the

cut, creating a pinch or bind. Without

0000-GXX-4256-A0

proper support, a pipe with a bell end

laying on the ground will tend to create a

ramp effect that will cause the pipe to

sag or drop as the pipe is cut. If the pinch

or bind occurs in the upper quadrant of

the abrasive cutting wheel, kickback can

result.

WARNING

Use wet-cutting whenever feasible.

Water can act as a lubricant in a pinch

situation and can reduce both the

likelihood of reactive forces occurring

and the energy of any such forces if they

do occur, making it easier to maintain

control of the machine. Please note,

however, that wet cutting should not be

used with composite wheels on the

TS 440.

WARNING

Only STIHL branded cutting

attachments are recommended. Use of

certain non-STIHL branded wheels may

be extremely dangerous. Many

substandard diamond cutting wheels

are available in the market. If they are

not manufactured with the proper quality

materials in their core, if they are not

properly hardened or tensioned, or if

other design or manufacturing problems

exist, they may begin to wobble during

use, lose segments or exhibit other

operational problems that can

substantially increase the risk of

personal injury or death from reactive

forces, thrown segments or loss of

control. If a diamond cutting wheel

begins or ceases to wobble within the

cut, the change in the behavior of the

wheel may cause a severe binding that

can lead to loss of control and/or

kickback. If the wheel you are using

begins to wobble or has ever wobbled,

discard it immediately. Although such a

wheel may temporarily cease to wobble,

e.g., if run without load, it will always be

prone to wobble again. A wheel that

wobbles is extremely dangerous.

WARNING

Some non-STIHL branded diamond

cutting wheels are manufactured with

abrasive material on their sides. Do not

use such wheels, since the abrasive

material increases frictional forces and

will lead to substantially increased

reactive forces in a pinch or side loading

situation.

WARNING

Never use chipped abrasive cutting

wheels, wheels with missing or

damaged segments, or circular saw

blades, carbide-tipped blades, rescue

blades or wood-cutting or toothed

blades of any nature on a cut-off

machine. The use of such wheels or

blades will greatly increase the risk of

loss of control and severe personal

injury or death from reactive forces,

since the chipped or damaged section of

an abrasive cutting wheel or the teeth of

a saw blade may catch in the material

TS 440

17

Page 20

English

being cut and generate substantially

greater reactive forces, including

rotational kickback.

Cut-off machines are designed for use

with abrasive cutting wheels in good

condition only. Machines designed for

use with wood-cutting or other toothed

blades use different types of guarding

systems that provide the protection

necessary for those types of blades.

Machines, such as a cut-off machine,

that are designed for use with abrasive

cutting wheels require a different

guarding system, which is not designed

to provide protection against all dangers

presented by circular saw blades,

carbide-tipped blades, rescue blades or

wood-cutting or toothed blades of any

nature.

WARNING

To reduce the risk of injury from loss of

control from reactive forces, including

kickback, when cutting:

1. Hold the cut-off machine firmly with

both hands, left hand on the front

handle, right hand on the rear

handle.

2. Maintain good balance and footing

at all times. Never cut while

standing on a ladder or other

unsecure platform.

3. Position the cut-off machine in such

a way that your body is clear of the

cutting attachment and outside the

plane of the cutting attachment.

That means the operator must avoid

standing in direct line with the wheel

(see illustration). Never bend over

the cutting attachment or position

your head and upper body forward

of the front handle, especially when

the guard is pulled back exposing

the top of the wheel. Always

maintain at least a 45° angle

between the top of an exposed

wheel and the operator’s head,

neck and body. Ensure sufficient

freedom of movement, especially in

trenches. Make sure there is

sufficient space for the user and the

fall of the severed portion of the

workpiece.

4. STIHL recommends using only

STIHL branded abrasive cutting

wheels properly rated for the

material to be cut.

5. Never work with a diamond cutting

wheel that wobbles or that has ever

wobbled or that is manufactured

with abrasive material on its sides.

6. Do not cut wood, plastic or any other

material for which the abrasive

cutting wheel is not authorized.

7. Begin cutting and continue cutting

at full throttle. Do not overreach.

Never cut above shoulder height.

8. Never sideload, jam or twist a wheel

in the cut.

9. Be especially alert for reactive

forces, including kickback, when

002BA554 AM

cutting with the front and upper

quadrant of the wheel.

10. Be alert to shifting of the workpiece

or anything that could cause the cut

to close and pinch the wheel,

especially in the upper quadrant.

Support the workpiece in such a

way that the cut remains open.

Never make a cut that results in a

binding, pinching or clamping of the

wheel. Finish a separating cut in the

top portion of the workpiece using

the bottom section of the wheel and

the guard adjusted fully forward

covering the top of the wheel.

11. Use wet-cutting whenever feasible.

In a pinch situation the water can act

as a lubricant and reduce the

energy of reactive forces. It also

helps control dust. Do not wet cut

when using a composite wheel on

the TS 440.

12. Use extreme caution when

reentering a cut and do not twist the

wheel in the cut, turn it at an angle

or jam it into the cut as this may

result in a binding or pinching of the

wheel.

Gyroscopic Forces

Be alert for gyroscopic forces that are

caused by the rapid spinning of the cutoff wheel. These forces result in

opposition to directional change, e.g.,

18

TS 440

Page 21

English

when the operator attempts to move the

machine in a sideways direction, and

can result in loss of control.

Maintenance, Repair and Storing of the

Cut-Off Machine

Never operate a cut-off machine that is

damaged, improperly adjusted or not

completely or properly assembled.

Follow the maintenance and repair

instructions in the appropriate sections

of this instruction manual.

WARNING

STIHL recommends the use of only

STIHL replacement parts for

maintenance and repair. Use of parts

manufactured by others may be

extremely dangerous and could result in

serious or fatal injury.

WARNING

Always shut off the machine and make

sure that the wheel is stopped before

doing any maintenance or repair work or

cleaning the cut-off machine. When the

machine is shut off, the wheel continues

to rotate for a few seconds before the

brake engages. Do not attempt any

maintenance or repair work not

described in this manual as appropriate

for users. STIHL recommends that you

have all other work performed at your

authorized STIHL servicing dealer.

Clean off dust and other cutting debris

after finishing work. Check and, if

necessary, tighten all nuts, bolts and

screws except the carburetor

adjustment screws after each use.

Do not clean your machine with a

pressure washer. The solid jet of water

may damage the machine or its

components.

WARNING

Never test the ignition system with the

spark plug boot removed from the spark

plug or with an unseated spark plug,

since uncontained sparking may cause

a fire.

WARNING

To reduce the risk of fire and burn injury

or property damage, use only spark

plugs authorized by STIHL. Always

press the spark plug boot snugly onto

the spark plug terminal of the proper

size. A loose connection between the

spark plug terminal and the ignition wire

connector in the boot may create arcing

that could ignite combustible fumes and

cause a fire. Keep the spark plug clean,

and make sure the ignition lead is in

good condition. Do not use a spark plug

with a detachable SAE adapter terminal.

Arcing may occur that could ignite

combustible fumes and cause a fire.

This can result in serious injuries or

damage to property.

WARNING

Do not operate your cut-off machine if

the muffler is damaged, missing or

modified. An improperly maintained

muffler will increase the risk of fire and

hearing loss. Never touch a hot muffler

or spill fuel or other flammable liquid

over it. Your muffler is equipped with a

spark-arresting screen to reduce the risk

of fire. Never operate your cut-off

machine if the screen is missing or

damaged.

WARNING

Operation of this equipment may create

sparks that can start fires around dry

vegetation. A spark arrester is required.

The operator should contact local fire

agencies for laws or regulations relating

to fire prevention requirements.

In California, it is a violation of § 4442 or

§ 4443 of the Public Resources Code to

use or operate gasoline-powered tools

on forest-covered, brush-covered or

grass-covered land unless the engine’s

exhaust system is equipped with a

complying spark arrester that is

maintained in effective working order.

The owner/operator of this product is

responsible for properly maintaining the

spark arrester. Other states or

governmental entities/agencies, such as

the U.S. Forest Service, may have

similar or additional requirements.

Contact your local fire agency or forest

service for the laws or regulations

relating to fire protection requirements.

Even if the spark arrester is in place, it

may not be advisable to use gasolinepowered equipment, including cut-off

machines, in hot, dry conditions or

around dry vegetation or brush. Contact

your local fire authorities or the U.S.

Forest Service if you have any question

about whether conditions are suitable for

the use of a cut-off machine.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of this manual.

TS 440

19

Page 22

English

Do not store a cut-off machine with a

wheel mounted on the machine. Store

the cut-off machine in a high or locked

place, out of reach and inaccessible to

children.

Empty the fuel tank before storing your

cut-off machine for longer than a few

days. Store fuel only in correctly labeled

and approved containers. Avoid direct

skin contact and do not inhale the gas

vapors. Dispose of fuel in accordance

with all applicable laws and regulations.

WARNING

Check the wheel brake system as

described in this manual before starting

work. Do not work with the cut-off

machine if the wheel brake system is not

functioning properly. If the brake is not

operating properly, have it repaired by

an authorized STIHL servicing dealer

before using the machine.

Sample Applications

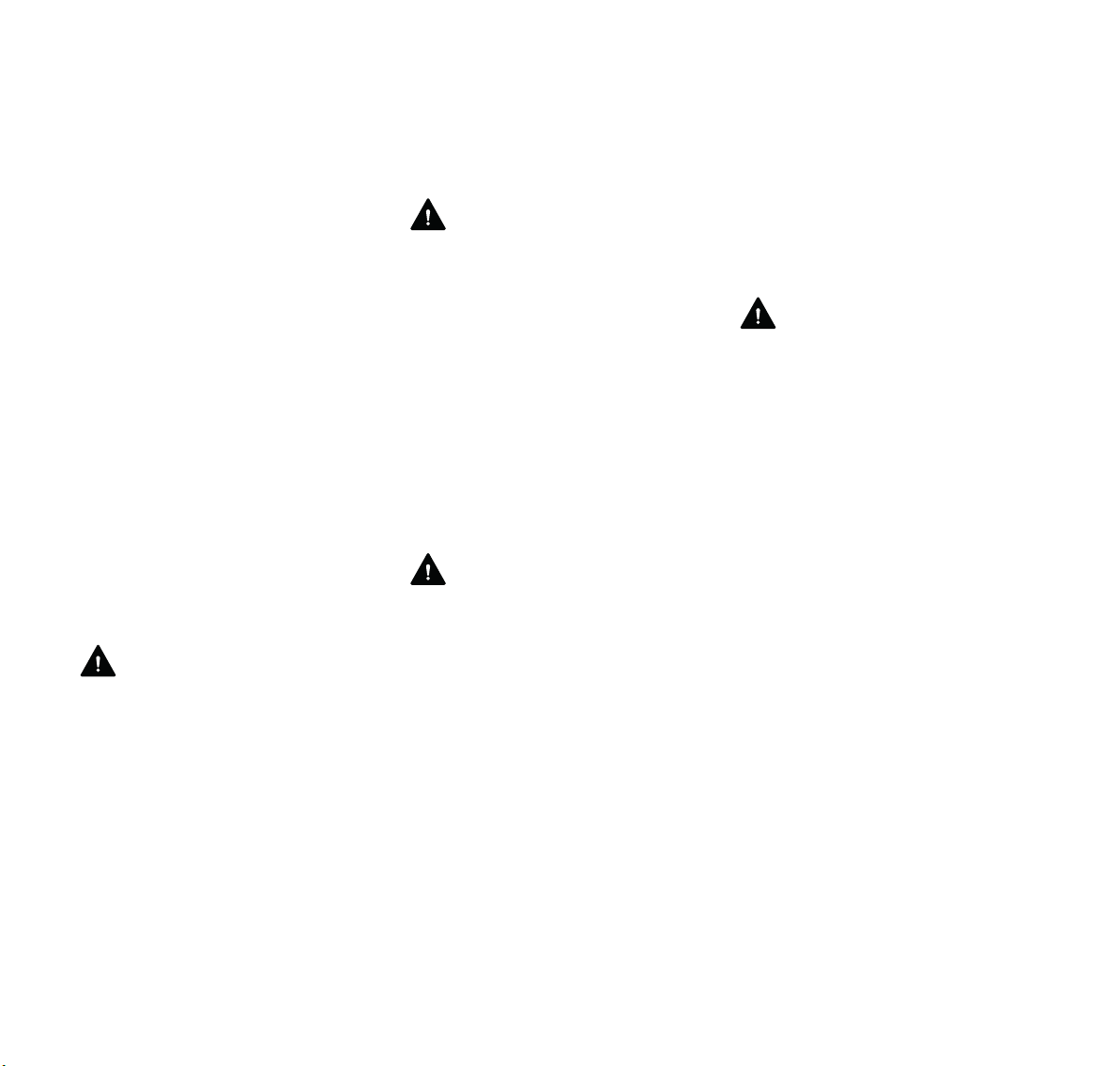

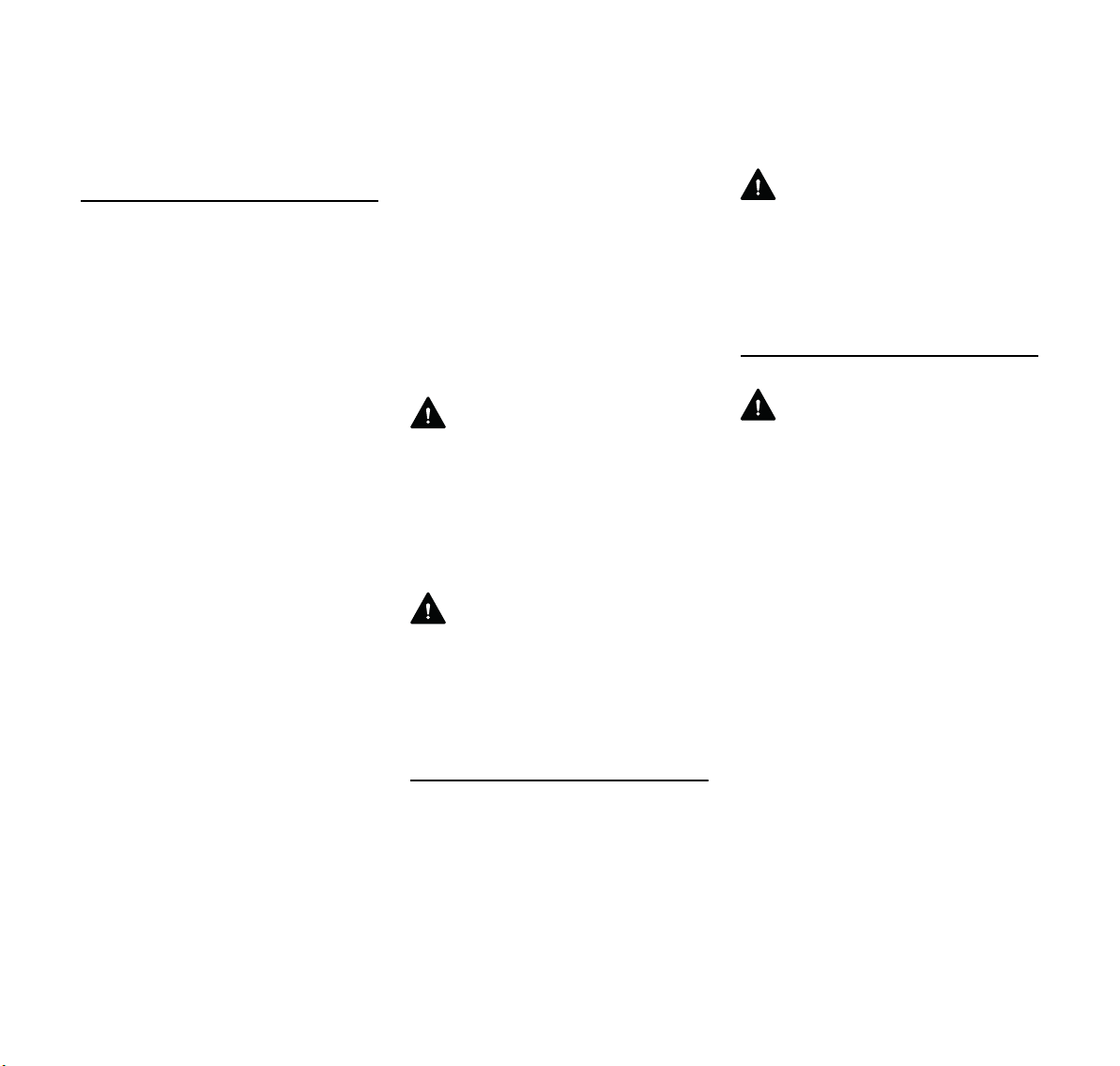

Water connection

– A water attachment kit is mounted

on the machine for use with all types

of water supply.

– A pressurized 2.6 gallon (10 liter)

water tank also is available from

STIHL for wet cutting.

For proper dust suppression, always

ensure that you have sufficient water

pressure to produce the recommended