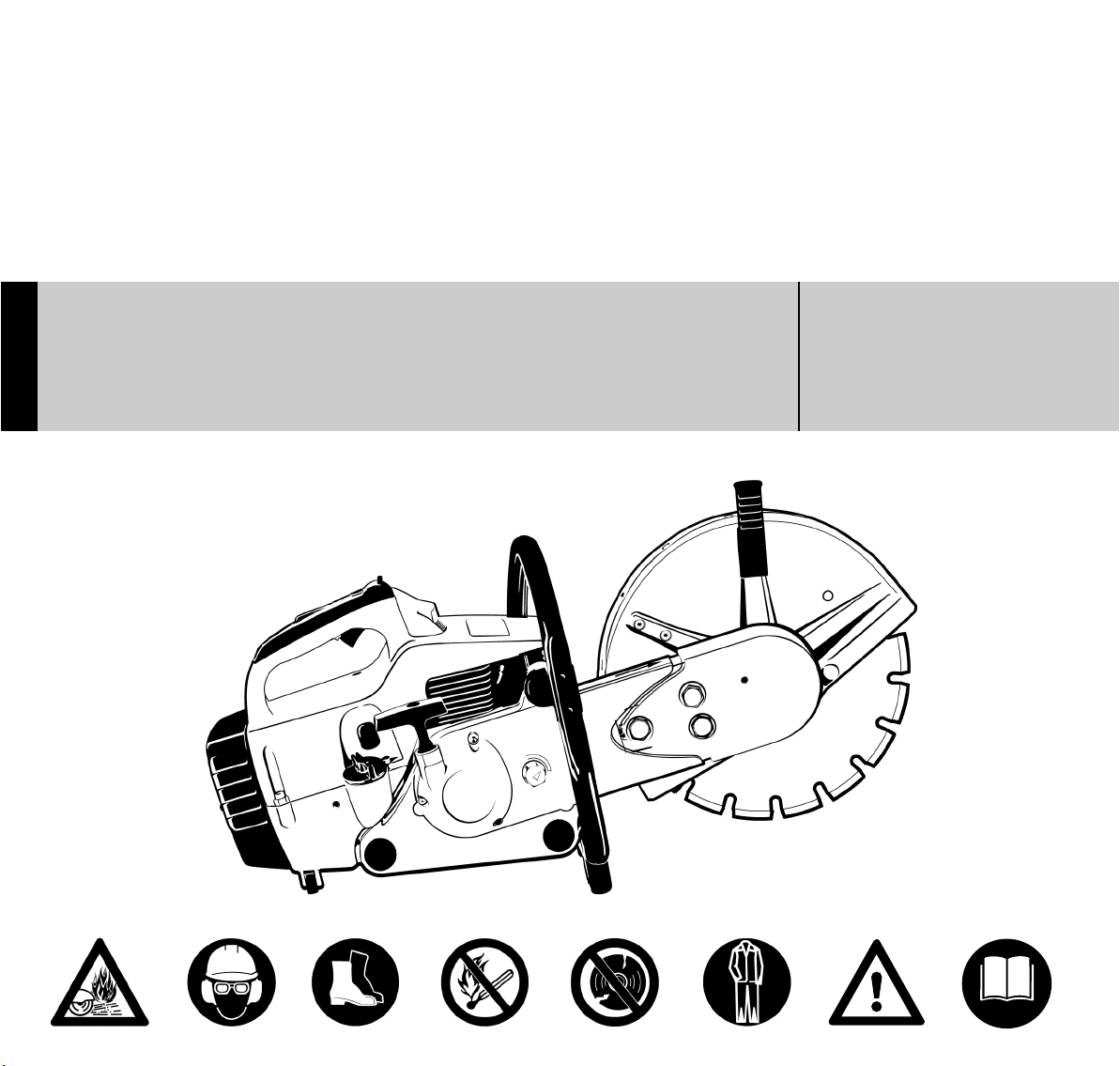

Page 1

Working safely with cut-off machines

{

Warning!

Read and follow all safety precautions in

Instruction Manual – improper use can cause

serious or fatal injury.

Page 2

Page 3

Contents

English

Safety Precautions and Working

Techniques 2

Sample applications 15

Cutting wheels 18

Composite resin cutting wheels 18

Diamond cutting wheels 18

Maintenance and Care 22

Main Parts 24

Original Instruction ManualPrinted on chlorine-free paper

Printing inks contain vegetable oils, paper can be recycled.

This manual contains the safety

precautions and recommended cutting

techniques outlined in STIHL instruction

manuals for gasoline-powered cut-off

machines. Even if you are an

experienced cut-off machine user, it is in

your own interest to familiarize yourself

with the latest instructions and safety

precautions regarding your cut-off

machine.

Please note that the illustrations in the

chapter "Main Parts of the Machine" in

this manual show the cut-off machine

STIHL Cutquik

®

TS 420.

Other cut-off machine models may have

different parts and controls. You should

therefore always refer to the instruction

manual of your particular cut-off

machine model.

Contact your STIHL dealer or the STIHL

distributor for your area if you do not

understand any of the instructions in this

manual.

{

© ANDREAS STIHL AG & Co. KG, 2010

0457-186-3021. M0.B10.xxx.

0000000552_001_GB

Working safely with cut-off machines

1

Page 4

English

Safety Precautions and

Working Techniques

The use of any cut-off

machine may be hazardous. Because a cut-off

machine is a high-speed,

fast-cutting power tool,

special safety precautions must be observed to

reduce the risk of personal injury and fire.

It is important that you

read, fully understand

and observe the following

safety precautions and

warnings. Read the

instruction manual and

the safety precautions

periodically.

Warning!

Careless or improper use of any cut-off

machine may cause serious or fatal

injury.

Have your STIHL dealer show you how

to operate your cut-off machine.

Observe all applicable national, state

and local safety regulations, standards

and ordinances.

Warning!

Your cut-off machine is for professional

use only. Do not lend or rent your cut-off

machine without the instruction manual.

Be sure that anyone using it understands the information contained in this

manual.

A first-time operator should obtain

practical instruction before using the

machine. Employers should establish a

training program for operators of

gasoline-powered, hand-held portable

cut-off machines to assure safe

operation of these machines. These

safety precautions and warnings apply

to the use of all current STIHL Cutquiks.

Warning!

Use your cut-off machine only for

authorized uses. For instance, it is not

suitable for cutting wood or wooden

objects. Misuse may result in personal

injury or property damage, including

damage to the machine.

Warning!

Minors should never be allowed to use a

cut-off machine. Bystanders, especially

children, and animals should not be

allowed in the area where a cut-off

machine is in use. Never let the cut-off

machine run unattended.

Different models may have different

parts and controls. See the appropriate

section of your instruction manual for a

description of the controls and function

of the parts of your model cut-off

machine.

Safe use of a cut-off machine involves

1. the operator

2. the power tool

3. the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition

and mental health and not under the

influence of any substance (drugs,

alcohol, etc.) which might impair vision,

dexterity or judgment. Do not operate a

cut-off machine when you are fatigued.

Be alert – if you get tired while operating

your cut-off machine, take a break;

tiredness may result in loss of control.

Working with any cut-off machine can be

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating

a cut-off machine.

Warning!

Prolonged use of cut-off machines (or

other machines) exposing the operator

to vibrations may produce whitefinger

disease (Raynaud's phenomenon) or

carpal tunnel syndrome. These conditions reduce the hand's ability to feel

and regulate temperature, produce

numbness and burning sensations and

cause nerve and circulation damage

and tissue necrosis. All factors which

contribute to whitefinger disease are not

known, but cold weather, smoking and

diseases or physical conditions that

affect blood vessels and blood transport, as well as high vibration levels and

long periods of exposure to vibration are

mentioned as factors in the development of whitefinger disease. In order to

reduce the risk of whitefinger disease

and carpal tunnel syndrome, please

note the following:

2

Working safely with cut-off machines

Page 5

English

– STIHL cut-off machines are

equipped with an anti-vibration

("AV") system designed to reduce

the transmission of vibrations

created by the machine to the

operator's hands. An AV system is

recommended for those persons

using cut-off machines on a regular

or sustained basis.

– Wear gloves and keep your hands

warm.

– Keep the AV system well

maintained. A cut-off machine with

loose components or with damaged

or worn AV elements will tend to

have higher vibration levels.

– Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure. Take

frequent breaks.

All the above-mentioned precautions do

not guarantee that you will not sustain

whitefinger disease or carpal tunnel

syndrome. Therefore, continual and

regular users should monitor closely the

condition of their hands and fingers. If

any of the above symptoms appear,

seek medical advice immediately.

Warning!

The ignition system of your unit produces an electromagnetic field of a very

low intensity. This field may interfere

with some pacemakers. To reduce the

risk of serious or fatal injury, persons

with a pacemaker should consult their

physician and the pacemaker manufacturer before operating this tool.

Proper Clothing

Warning!

To reduce the risk of

injury, the operator

should wear proper protective apparel.

Clothing must be sturdy and snug-fitting,

but allow complete freedom of

movement. Avoid loose-fitting jackets,

scarfs, neckties, jewelry, flared or cuffed

pants, unconfined long hair or anything

that could become caught on any

obstacles or moving parts of the unit.

Wear overalls or long pants to protect

your legs. Do not wear shorts.

Warning!

When cutting metal, a cut-off machine

generates sparks that can ignite clothing. Most fabrics used in clothing are

flammable – even flame-retardant fabrics will ignite at higher temperatures.

To reduce the risk of burn injury STIHL

recommends wearing clothing made of

leather, wool, flame-retardant-treated

cotton or a tightly woven, heavier cotton

such as denim. Some flame-retardant

synthetic fabrics are also suitable, but

others such as polyester, nylon, rayon

and acetate can melt during a fire into a

tar-like matter that burns into the skin.

Check the clothing manufacturer's

instructions. Keep clothing free of oil,

fuel, grease and other flammable

substances.

Always wear gloves

when handling the cut-off

machine. Heavy-duty,

nonslip gloves improve

your grip and help to protect your hands.

Good footing is important

in cut-off machine work.

Wear sturdy boots with

nonslip soles. Steel-toed

safety boots are

recommended.

Warning!

Loose objects may be thrown toward

the operator by the cutting tool.

To reduce the risk of

injury to your eyes never

operate a cut-off machine

unless wearing goggles

or properly fitted safety

glasses with adequate

top and side protection

complying with

ANSI Z 87.1. Proper eye

protection is a must.

Wear an approved safety hard hat to

protect your head. Cut-off machine

noise may damage your hearing. Always

wear sound barriers (ear plugs or ear

mufflers) to help protect your hearing.

Regular users should have their hearing

checked regularly.

Working safely with cut-off machines

3

Page 6

English

Warning!

When wet cutting at the

recommended flow rate

is not utilized, the operator should always wear

a respirator approved

by NIOSH / MSHA for

the material being cut to reduce the risk

of serious or fatal respiratory illness. For

additional details and warnings on this

subject, see information under "Working

Conditions" in this instruction manual.

THE POWER TOOL

For illustrations and definitions of the

parts of the cut-off machine, see the

chapter "Main Parts."

Warning!

Never modify a cut-off machine in any

way. Only attachments supplied by

STIHL or expressly approved by STIHL

for use with the specific STIHL cut-off

machine models are authorized.

Although certain unauthorized attachments are useable with the STIHL

powerhead, their use may, in fact, be

extremely dangerous.

Abrasive Wheels

Warning!

Before mounting the cutting wheel,

make sure that the maximum operating

wheel speed is above or equal to the

spindle speed of your cut-off machine

as provided in the specifications of this

manual. A wheel that is not so rated

may shatter or break and poses a threat

of serious or fatal injury to the operator

and other nearby persons.

Abrasive wheels for free-hand cutting

are subjected to particularly high

bending and compression stresses.

Warning!

Unauthorized wheels may be more

likely to shatter or break. Use only

STIHL wheels or other authorized

wheels with approved RPM ratings.

Read and follow any addional safety

precautions that accompany the wheel.

Warning!

Inspect the abrasive

wheel frequently and

replace immediately if

the abrasive wheel is

cracked or warped.

Cracked or warped

wheels may shatter or break and cause

serious or fatal personal injury. Out-ofround or unbalanced abrasive wheels

increase vibration and reduce the service life of the cut-off machine.

Unauthorized diamond abrasive wheels

that utilize poor quality steel cores, that

are not properly tensioned, or that have

other design or manufacturing defects

may begin to wobble during use, which

can cause wheel breakage. Such

wobbling can also lead to a severe

binding of the wheel in the kerf, that,

under certain circumstances, can then

result in serious or fatal injury from

reactive forces. See the section entitled

"Reactive Forces including Kickback."

Never use a wheel that wobbles or that

has ever wobbled. Even though such a

wheel may temporarily cease to wobble,

e.g., if run without load, it will always be

prone to wobble again under certain

conditions. Replace it immediately

before further use.

Composite abrasive wheels are heat

sensitive. Always store your cut-off

machine in a place where a composite

wheel is not exposed to direct sunlight or

other sources of heat. Store spare

composite wheels in a dry place where

there is no risk of frost damage. Failure

to follow these directions may cause the

wheel to shatter or crack in use causing

serious or fatal injury.

Warning!

Never use circular saw

blades, carbide tipped

blades, rescue blades,

wood-cutting blades or

toothed blades of any

nature. They can cause

severe personal injury from blade contact, thrown objects and / or reactive

forces, including kickback. See section

on "Reactive Forces." Your STIHL

dealer stocks a range of special abrasive wheels for the many applications of

the cut-off machine.

4

Working safely with cut-off machines

Page 7

English

Warning!

Use of the wrong abrasive wheel or the

cutting of material for which the wheel

was not designed may cause the wheel

to shatter causing serious or fatal injury.

Only use the abrasive wheel approved

for the type of material to be cut. There

are different types of abrasive wheels,

each specially marked. With respect to

composite wheels, for example:

1. Stone

Also can be used for concrete,

masonry, reinforced concrete and

brick cutting.

2. Steel

Can be used for all ferrous metal

cutting.

3. Asphalt

Also can be used for aggregate

concrete cutting.

4. Ductile iron

Also can be used for certain grades

of cast iron (SG 17-24), bronze and

copper cutting.

For cutting composite materials please

ask your STIHL dealer.

They are not normally suitable for cutting

metal or other materials.

Wet or dry cutting is possible. Water

attachments are included with your

STIHL cut-off machine. See the

appropriate section of your instruction

manual.

Warning!

Do not remount a used diamond abrasive wheel without first inspecting for

under-cutting, flatness, core fatigue,

segment damage or loss, signs of overheating (discoloration) and possible

arbor hole damage. See the chapter

"Diamond Cutting Wheels." Check the

wheel for cracks and make sure that no

pieces have broken off the wheel before

use.

Always fit the wheel so that the arrow on

the wheel points in the direction of the

rotation of the spindle.

THE USE OF THE POWER TOOL

Transporting the STIHL Cutquik

Warning!

To reduce the risk of injury from unintended activation and / or contact with a

moving wheel, always stop the engine

before putting a cut-off machine down or

carrying it. The abrasive wheel continues to rotate (coast down) for a short

while after the throttle trigger is released

(flywheel effect). Bring the wheel to a

stop by lightly contacting the bottom of

the wheel with a hard surface or wait

until the wheel comes to a complete

stop on its own. Carrying a cut-off

machine with the engine running is

extremely dangerous. Accidental acceleration of the engine can cause the

wheel to rotate. Avoid touching the hot

muffler.

By hand: When carrying your cut-off

machine by hand, the engine must be

stopped and the cut-off machine must

be in the proper position. Grip the front

handle and place the muffler at the side

away from the body.

Diamond Abrasive Wheels

Diamond abrasive wheels have a much

better cutting performance than

composite abrasive wheels. The

diamond wheels are steel centered, and

diamond particles are imbedded in their

cutting edges.

They can be used for concrete, asphalt,

natural stone, clay pipe, brick and the

like.

Working safely with cut-off machines

Warning!

Always protect the cutting wheel from

hitting the ground or any other objects.

Damaged wheels may shatter and

cause serious or fatal injury.

By vehicle: Properly secure your cut-off

machine to prevent turnover, fuel

spillage and damage to the cut-off

machine. Never transport with cutting

wheel mounted. A wheel damaged

5

Page 8

English

during transportation may shatter during

operation and cause serious personal

injury.

Fuel

Your STIHL power tool uses an oilgasoline mixture for fuel (see the

chapter on "Fuel" of your instruction

manual.)

Warning!

Gasoline is an extremely

flammable fuel. If spilled

and ignited by a spark or

other ignition source, it

can cause fire and seri-

ous burn injury or

property damage. Use extreme caution

when handling gasoline or fuel mix. Do

not smoke or bring any fire or flame near

the fuel or the power tool. Note that

combustible fuel vapor may escape

from the fuel system.

Warning!

Dust may collect on the powerhead,

especially around the carburetor, and

may absorb gasoline resulting in danger

of fire. Clean dust from the powerhead

regularly.

Fueling Instructions

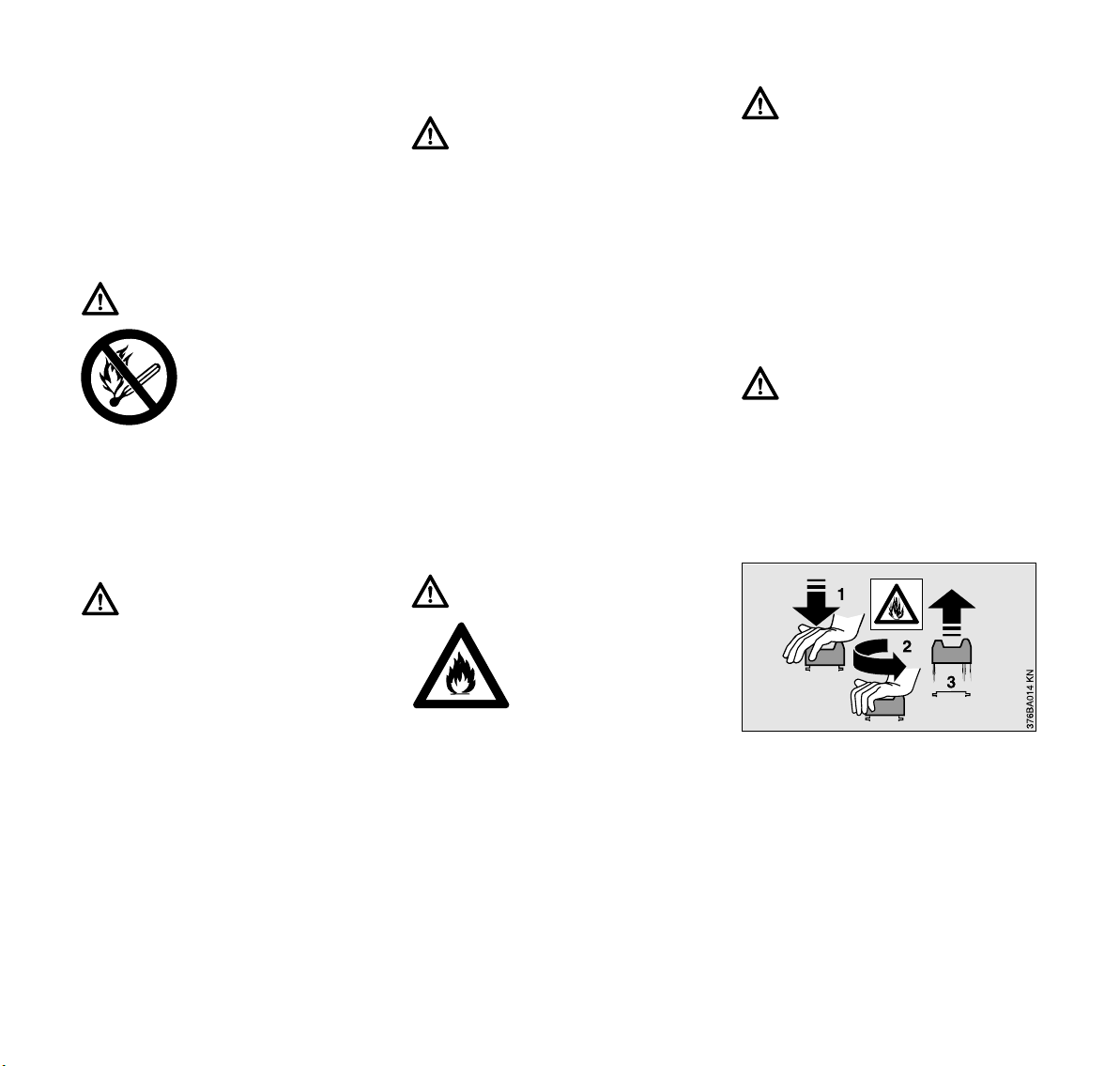

Warning!

Fuel your power tool in well-ventilated

areas, outdoors. Always shut off the

engine and allow it to cool before refueling. Gasoline vapor pressure may

build up inside the fuel tank depending

on the fuel used, the weather conditions

and the tank venting system.

In order to reduce the risk of burns and

other personal injury from escaping gas

vapor and fumes, remove the fuel filler

cap on your power tool carefully so as to

allow any pressure build-up in the tank

to release slowly. Never remove the fuel

filler cap while the engine is running.

Select bare ground for fueling and move

at least 10 feet (3 m) from the fueling

spot before starting the engine. Wipe off

any spilled fuel before starting your

machine.

Warning!

Check for fuel leakage

while refueling and during operation. If fuel

leakage is found, do not

start or run the engine

until the leak is fixed and

any spilled fuel has been wiped away.

Take care not to get fuel on your clothing. If this happens, change your

clothing immediately.

Warning!

If fuel gets spilled on clothes, especially

trousers, it is very important to change

clothes immediately. Do not rely upon

evaporation. Flammable quantities of

fuel may remain on clothes after a spill

for longer than expected. Cutting metal

with a cut-off machine when clothes are

wet or damp from gasoline is extremely

dangerous, as the operator's clothes

might catch fire and cause serious or

fatal injury.

Warning!

An improperly tightened fuel cap can

loosen or come off and spill quantities of

fuel.

Different cut-off machines may be

equipped with different fuel filler caps:

Bayonet Fuel Filler Cap

Never use a tool to open or close the

bayonet fuel filler cap, as this could

damage the cap and cause fuel to leak

out.

The bayonet fuel filler cap must be

closed with care after refuelling.

6

Working safely with cut-off machines

Page 9

English

Fuel Filler Cap with Screw Thread

Tighten the fuel filler cap

as securely as possible

after refuelling.

This reduces the risk of the cap working

loose due to engine vibrations and fuel

leaking out.

Warning!

Never attempt to force the cap open by

using a tool. It may damage the cap and

allow fuel to leak.

Before use, make sure that the fuel cap

has been properly tightened and any

spilled fuel wiped away. Check for fuel

leakage while refueling and during

operation. If a fuel leak is suspected, do

not start or run the engine until the leak

is fixed and spilled fuel has been wiped

away.

Before Starting

For assembly, follow the procedure

described in the appropriate section of

your instruction manual.

Never operate a cut-off machine that is

damaged, improperly adjusted or not

completely and securely assembled.

Check machine that it is ready for proper

operation.

Keep the handles dry, clean and free of

oil and fuel.

Warning!

Before operation of your cut-off

machine, be sure the controls (e.g.

throttle trigger, throttle trigger lockout,

stop switch) and the safety devices are

working properly, the carburetor idle

and maximum speed are correctly

adjusted, the wheel is properly

mounted, and the wheel guard is in

place and securely fastened to your

unit. All wheels should be carefully

inspected for good condition before

mounting.

Adjust the wheel guard

so that sparks, dust and

cut material are deflected

away from the operator,

and cannot reach flammable surroundings. See

section "Operating

Instructions" of your

instruction manual.

Warning!

Check that the spark plug boot is

securely mounted on the spark plug – a

loose boot may cause arcing that could

ignite combustible fumes and cause a

fire.

Proper tensioning of the ribbed V-belt is

important. In order to avoid an incorrect

setting, the tensioning procedure must

be followed as described in your

manual. Always make sure the

hexagonal collar nuts for the cast arm

are tightened securely.

Check ribbed belt tension after one hour

of operation and correct if necessary.

Starting

002BA058 KN

Warning!

Your cut-off machine is a one-person

tool. Do not allow other persons to be

near a running cut-off machine. Start

and operate your cut-off machine without assistance. For specific starting

instructions, see the appropriate section

of your instruction manual.

Do not drop start. This method is very

dangerous because you may lose

control of the cut-off machine. Place the

cut-off machine on firm ground or other

solid surface in an open area. Maintain

good balance and secure footing. Be

absolutely sure that the cutting wheel is

clear of you and all other obstructions

and objects, including the ground. When

the engine starts at starting-throttle,

engine speed will be fast enough for the

clutch to engage the belt pulley and turn

Working safely with cut-off machines

7

Page 10

English

the wheel. Never attempt to start the cutoff machine when the abrasive wheel is

in a cut.

Once the engine has started,

immediately blip the throttle trigger,

which should release the starting throttle

lock and allow the engine to slow down

to idle.

Warning!

When you pull the starter grip, do not

wrap the starter rope around your hand.

Do not allow the grip to snap back, but

guide the starter rope slowly back to

permit the rope to rewind properly. Failure to follow this procedure may result in

injuries to hand or fingers and may damage the starter mechanism.

Important Adjustments

At correct idle speed, the wheel should

not turn. For directions to adjust idle

speed, see the appropriate section of

your instruction manual.

Warning!

Do not use a cut-off machine with incorrect idle speed adjustment. The rotating

wheel may cause injury. If you cannot

obtain the correct setting, have your

STIHL dealer check your cut-off

machine and make proper adjustments

or repairs.

Working Conditions

Operate the cut-off machine under good

visibility and daylight conditions only.

Wearing of hearing protection reduces

sound perception. Be alert not to miss

voice signals from co-workers. Keep

within calling distance to other persons

who may assist in case of emergency.

Warning!

As soon as the engine is

running, this product generates toxic exhaust

fumes containing chemicals, such as unburned

hydrocarbons (including

benzene) and carbon monoxide, that

are known to cause respiratory problems, cancer, birth defects, or other

reproductive harm. Some of the gases

(e.g. carbon monoxide) may be colorless and odorless. To reduce the risk of

serious or fatal injury / illness from inhaling toxic fumes, never run the machine

indoors or in poorly ventilated locations.

Ensure proper ventilation when working

in trenches or other confined areas.

Warning!

Use of this product to cut masonry, concrete, metal and other materials can

generate dust and fumes containing

chemicals known to cause serious or

fatal injury or illness, such as respiratory

disease, cancer, birth defects or other

reproductive harm. If you are unfamiliar

with the risks associated with the particular material being cut, review the

material safety data sheet and / or consult your employer, the material

manufacturer / supplier, governmental

agencies such as OSHA and NIOSH

and other sources on hazardous materials. California and some other

authorities, for instance, have published

lists of substances known to cause cancer, reproductive toxicity, etc. Control

dust and fumes at the source where

possible.

In this regard use good work practices

and follow the recommendations of the

manufacturer / supplier, OSHA / NIOSH,

and occupational and trade

associations. A water attachment kit is

provided with your cut-off machine and

should be used to reduce dust whenever

wet cutting is feasible. For dust

suppression purposes, the flow rate

should be at least 0.6 liters (20 fl.oz) of

water per minute. If wet cutting at the

recommended flow rate is not utilized,

the operator and any bystanders should

always wear a respirator approved by

NIOSH / MSHA for the material being

cut. See the section on "Respiratory

Protection" in the chapter "Sample

Applications" in the instruction manual.

Even if wet cutting at the recommended

flow rate, an operator who is actively

cutting for more than two hours in one

8

Working safely with cut-off machines

Page 11

English

day should wear at least a NIOSHapproved disposable respirator. Consult

and follow any federal, state or local

laws or regulations with respect to dry

and wet cutting.

Warning!

Cutting masonry, concrete and other

materials with silica in their composition

may give off dust containing crystalline

silica. Silica is a basic component of

sand, quartz, brick clay, granite and

numerous other minerals and rocks.

Repeated and / or substantial inhalation

of airborne crystalline silica can cause

serious or fatal respiratory diseases,

including silicosis. In addition, California

and some other authorities have listed

respirable crystalline silica as a substance known to cause cancer. When

cutting such materials, always follow the

respiratory precautions mentioned

above.

Warning!

Breathing asbestos dust is dangerous

and can cause severe or fatal injury,

respiratory illness or cancer. The use

and disposal of asbestos-containing

products have been strictly regulated by

OSHA and the Environmental Protection Agency. Do not use your cut-off

machine to cut or disturb asbestos,

asbestos-containing products, or products such as pipes which are wrapped

or covered with asbestos insulation. If

you have any reason to believe that you

might be cutting asbestos, immediately

contact your employer or a local OSHA

representative.

Warning!

Your STIHL cut-off machine is designed

for hand-held use or operation on a cutoff machine cart. Cutting with your cutoff machine resting on the ground or

other surface can cause excessive wear

to the bracket designed to protect the

bottom of the tank housing. Loss of fuel

and personal injury from fire may result.

Replace damaged or badly worn brackets immediately.

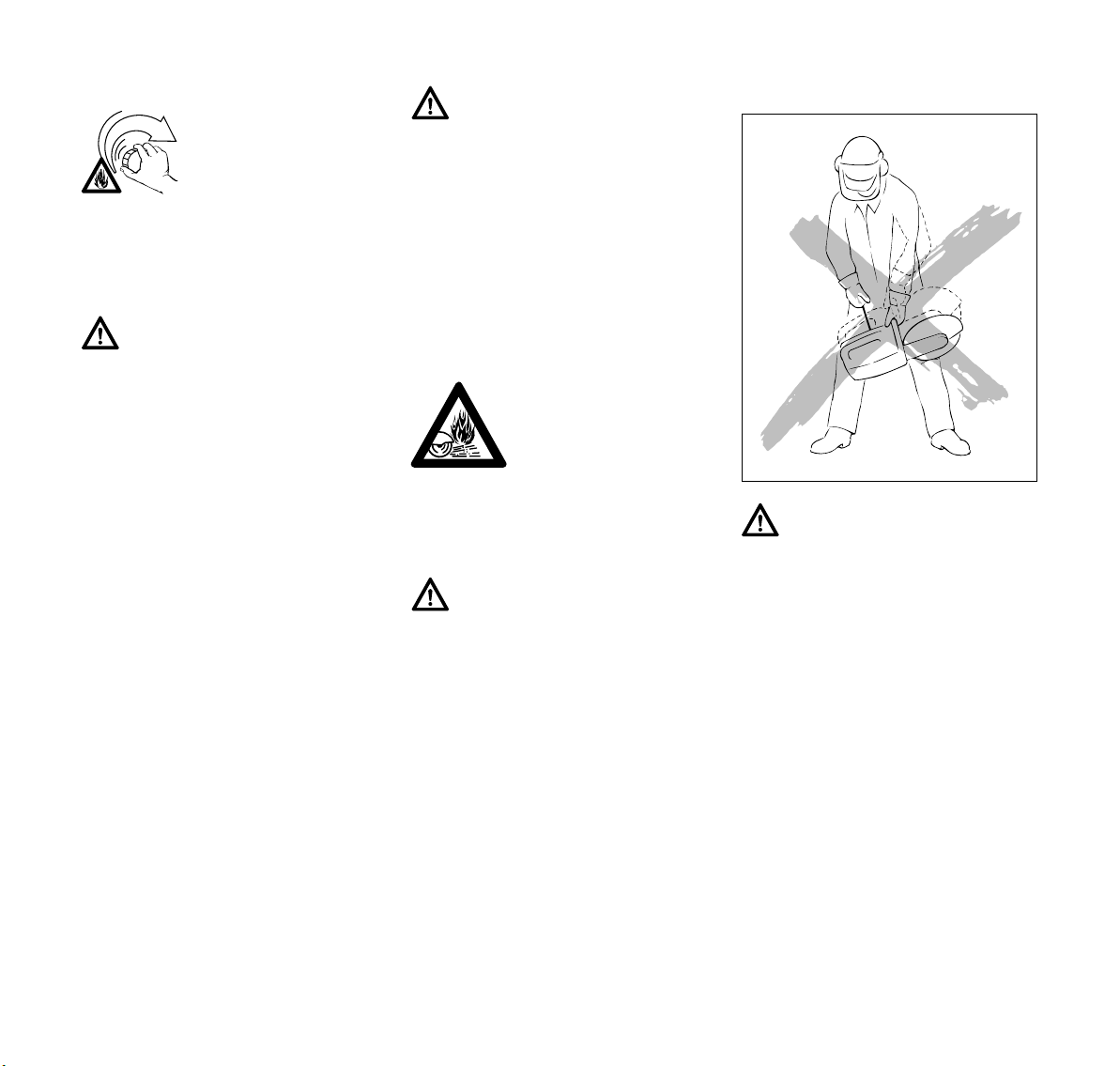

Grip: Never use the cut-off machine with

one hand. Always hold the cut-off

machine firmly with both hands when the

engine is running. Place your left hand

on front handle bar and your right hand

on rear handle and throttle trigger. Lefthanded users should follow this

instruction too.

Wrap your fingers tightly around the

handles, keeping the handles cradled

between your thumbs and forefingers.

Make sure your cut-off machine handles

and grip are in good condition and free

of moisture, pitch, oil, fuel mix or grease.

Never touch a rotating wheel with your

hand or any part of your body.

002BA060 KN

Warning!

Clear the area where you are working.

Avoid stumbling on obstacles and watch

out for holes or ditches. Be extremely

cautious when working on slopes or

uneven ground. Take extreme care in

wet and freezing weather (rain, snow,

ice.)

Warning!

Never operate the cut-off machine with

the starting-throttle lock engaged as this

does not permit proper control of the

speed of the unit and may lead to serious injury.

Warning!

Sparks from cutting

metal can burn or cause

clothing to catch fire.

Always direct sparks

away from the operator

or any flammable surroundings. Never cut metal while

standing on a flammable surface, such

as wood or tar paper. Where there is a

risk of fire, have appropriate fire extinguishing equipment readily available.

002BA061 KN

Working safely with cut-off machines

9

Page 12

English

Warning!

To reduce the risk of injury from fire, do

not cut into any pipe, drum or other container without first ensuring that it does

not contain a volatile or flammable

substance.

Warning!

When cutting into existing walls, floors

or similar structures, be alert for hidden

hazards such as electrical cables, water

and gas pipes and flammable substances. Make sure that power, water

and gas have been shut off and pipes

drained before starting to cut.

Operating Instructions

Warning!

The wheel guard is adjustable. It is

extremely important that the wheel

guard is in place and set to suit the type

of work and your stance. The guard

should always be adjusted so that the

user is not endangered by particles of

the material being cut, sparks or pieces

of damaged wheels either directly or by

ricochet. Failure to follow this instruction

could result in serious or fatal injury.

Warning!

Your cut-off machine is equipped with a

wheel guard limit stop that restricts the

opening of the wheel guard. To reduce

the risk of injury from wheel contact and

/ or reactive forces and to avoid damaging the guarding system, never attempt

to pull the adjusting lever past the limit

stop.

Warning!

Always check the wheel before use and

after unintentionally striking any object;

frequently check it during use when it is

stopped. Look for cracks and make sure

that it is undamaged and in good condition and that no pieces have broken off.

See sections on "Abrasive Wheels" and

"Reactive Forces" in this manual. Check

the wheel guard for cracks. If you discover any breaks or cracks, fit a new

guard before further use.

Warning!

It is essential to determine the exact

direction of the cut before applying the

abrasive wheel to the work. Wheels are

constructed for radial pressure only.

Lateral pressure must be avoided. Hold

the cut-off machine steady. To reduce

the risk of serious or fatal injury, do not

change the direction of the cut during

the cut as this may produce a high torsional load on the abrasive wheel and

may cause it to break or shatter.

Warning!

Do not use abrasive wheels for rough

grinding. Large bending stresses occur

during such work, which may cause

abrasive wheels to shatter or break and

result in serious or fatal injury.

Warning!

To reduce the risk of injury from shattered abrasive wheels:

1. Do not exceed the maximum

operating speed marked on the

wheel.

2. Do not use a wheel that has been

dropped.

3. Test each new wheel immediately

after installation for approximately

one minute at maximum speed

without cutting, making sure to keep

bystanders away.

4. Do not cut any material for which the

abrasive wheel is not authorized.

5. Do not grind on the side of the

abrasive wheel.

6. Do not twist, thrust, knock or drop

the machine. This can cause

damage to the wheel.

To achieve a clean and efficient cut, pull

the abrasive wheel across the work or

move it "to and fro" in the cutting

direction. Do not use force to push the

abrasive wheel into the work.

Insert the wheel into the material only as

deep as necessary to make the cut. To

reduce the amount of dust created, do

not cut all the way through stone and

concrete materials – leave a thin piece

uncut. For most such materials, this

piece can be easily broken afterwards.

Do not cock, jam or wedge the wheel in

the cut.

Always stop the engine and be sure the

wheel has stopped rotating before

setting down the cut-off machine.

If a cut-off machine cart is used, sweep

debris from the path of the wheels, as

debris under one of the cart’s wheels

may cause flexing of the abrasive wheel.

This could result in high frictional forces

and thus greatly reduce the engine

10

Working safely with cut-off machines

Page 13

English

power available for the actual cutting

work. It could also damage the abrasive

wheel.

STIHL recommends the use of the cart

for longer cuts in a straight line.

Wet Cutting with Abrasive Wheels

Before wet cutting, make sure water will

not damage the floor or building.

Warning!

To reduce the risk of electrocution to

you or bystanders, do not allow water or

sludge to contact live electric wires.

Warning!

To reduce the risk of injury from wheel

breakage when wet cutting with any

composite wheel:

1. Make certain water does not flow on

a wheel that is not running, since the

wheel will absorb water, which will

affect wheel balance.

2. Be certain water is applied to both

sides of wheel, since uneven

distribution can cause "one sided"

wear.

3. After finishing work, run the cutting

wheel at normal operating speed for

about 3 to 6 seconds without water

so that the remaining water is flung

off.

Warning!

To reduce the risk of injury from wheel

breakage when wet cutting with a composite wheel that is not specifically

designed for wet cutting, never store

and reuse such a wheel that has been

used with water. Use these wheels up

the same day.

Reactive Forces including Kickback

Warning!

Reactive forces may

occur at any time the cutting wheel on a cut-off

machine is rotating. The

powerful force used to

cut through a workpiece

can be reversed and work against the

operator. If the wheel is slowed or

stopped by frictional contact with any

solid object or by a pinch or binding,

reactive forces can occur instantly and

may result in the operator losing control

of the cut-off machine, which, in turn,

may result in serious or fatal injury.

An understanding of the causes of these

reactive forces may help you avoid loss

of control. Reactive forces are exerted in

a direction opposite to the direction in

which the wheel is moving at the point of

contact or of pinching / binding. If the

wheel is slowed solely by frictional

contact with a solid object, such as the

workpiece, the resulting reactive forces

are normally moderate and readily

controllable by an operator who is

holding the machine properly. If,

however, the wheel is abruptly slowed or

stopped by a pinch or severe bind, the

reactive forces may be substantially

greater. The greater the force

generated, the more difficult it will be for

the operator to control the cut-off

machine. Loss of control can result in

severe personal injury or death.

Pull-away, Climbing, Pinching and

Rotational Kickback Forces

The most common reactive forces are

pull-away and climbing. If the contact is

at the bottom of the wheel, a cut-off

machine will try to pull away from the

operator (pull-away.) If the contact is at

the front of the wheel, the wheel may

attempt to climb the object being cut

(climbing.)

Pinching occurs when the piece being

cut closes on the wheel. A severe

binding may also occur if the wheel is

substantially sideloaded in the kerf or if

an improper or damaged diamond wheel

begins or ceases to wobble in the kerf. If

the wheel is severely pinched or bound

in the upper quadrant, the wheel may be

instantly thrown up and back towards

the operator with great force in a

rotational kickback motion. Such

kickback situations can and should

always be avoided. Pinching of the

wheel can be prevented by proper

support of the workpiece. (See below.)

Severe binding of the wheel can be

prevented by proper cutting techniques,

e.g., not sideloading the wheel, and by

the use of properly designed,

manufactured and maintained wheels.

Working safely with cut-off machines

11

Page 14

English

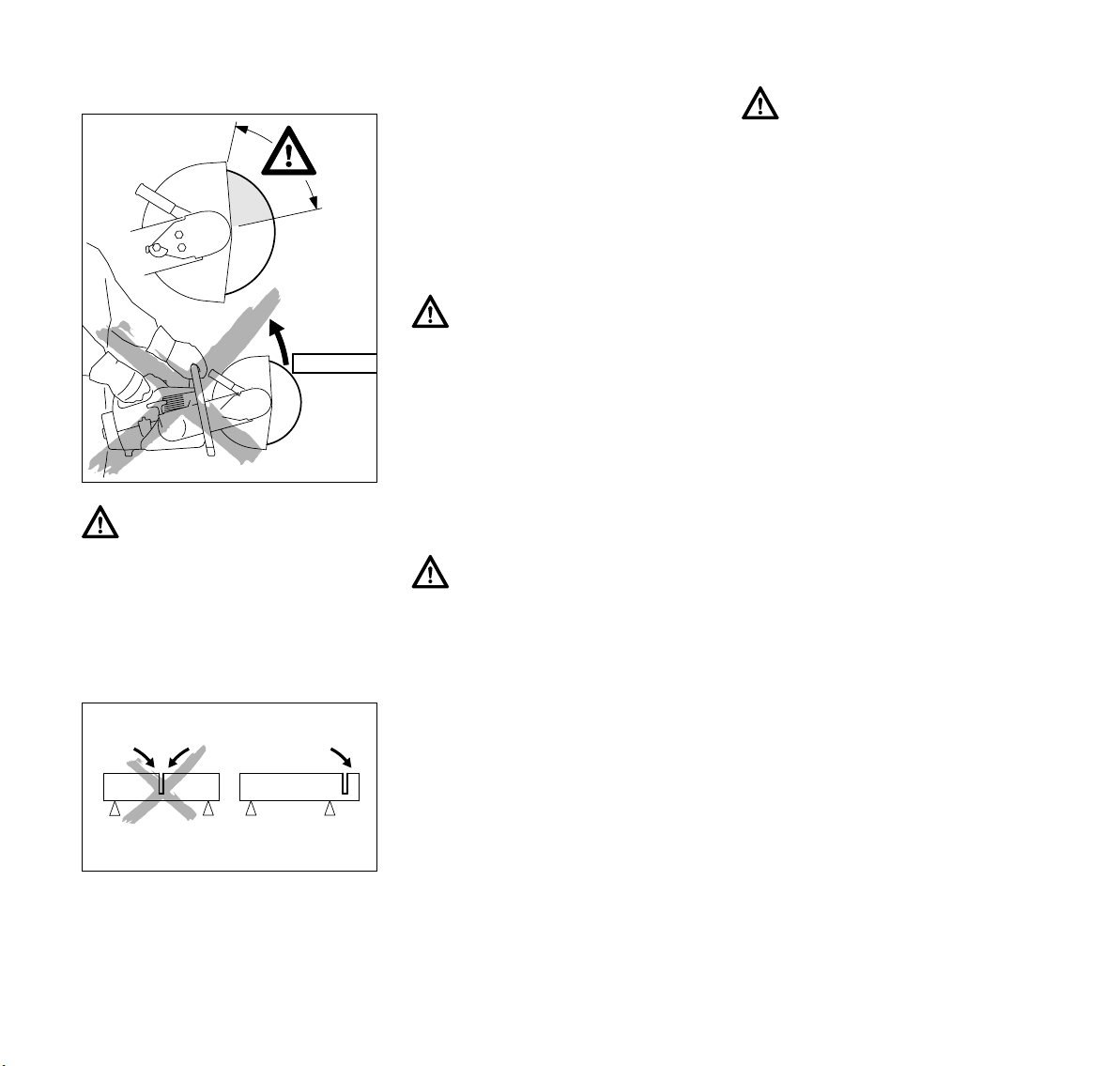

Reducing the Risk of Kickback Injury

Warning!

To reduce the risk of kickback injury,

avoid cutting with the upper quadrant of

the wheel where possible. Be especially

cautious for a pinching or binding of the

wheel in this area, which can cause

severe reactive forces in a rotational

kickback motion.

pinching, support the workpiece in such

a way that the cut remains open during

the cutting process and when the cut is

finished (see illustration.) Never make a

cut that results in a binding of the wheel.

If you cannot properly support the

workpiece, do not use a cutting-off

machine to make the cut; select another

tool or cutting technique that is not

subject to kickback.

Warning!

Be particularly alert when cutting a

workpiece such as a pipe with a belled

end or a pipe in a trench that, if not properly supported, can sag upon

completion of the cut, creating a pinch

not where you are actually cutting but,

rather, at or near the top of the work-

002BA242 KN

piece. If the pinch is in the upper

quadrant of the abrasive wheel, kickback can result.

Warning!

Use wet-cutting whenever feasible,

since the water can act as a lubricant in

a pinch situation and thus reduce the

likelihood of reactive forces occurring

and the energy of any such forces that

do occur, making it easier to maintain

control of the machine.

Warning!

Use only cutting attachments authorized by STIHL. Use of non-STIHLauthorized wheels may be extremely

dangerous. Many substandard diamond

wheels, for instance, are available in the

market. If they are not manufactured

with the proper quality steel in their core,

if they are not properly tensioned, or if

other design or manufacturing defects

exist, they may, e.g., begin to wobble

during use. If a diamond wheel begins

or ceases to wobble within the kerf, the

change in the behavior of the wheel may

cause a severe binding that can lead to

loss of control and / or kickback. If the

wheel you are using begins to wobble or

has ever wobbled, discard it immediately. Although such a wheel may

temporarily cease to wobble, e.g., if run

without load, it will always be prone to

wobble again under certain conditions.

Some other unauthorized diamond

wheels are manufactured with abrasive

material on their sides. Do not use such

wheels, since the abrasive material may

lead to increased reactive forces in a

pinch situation.

Be alert to potential movement of the

workpiece or anything else that could

cause the cut to close and pinch the

wheel. In order to reduce the risk of

12

002BA146 KN

Working safely with cut-off machines

Page 15

Warning!

Never use chipped abrasive wheels or

circular saw blades, carbide-tipped

blades, rescue blades or wood-cutting

or toothed blades of any nature on a cutoff machine. The use of such wheels or

blades will greatly increase the risk of

loss of control and severe personal

injury or death from reactive forces,

since the chipped section of an abrasive

wheel or the teeth of a saw blade may

catch in the material being cut and generate substantially greater reactive

forces, including rotational kickback.

Cut-off machines are designed for use

with abrasive wheels in good condition

only. Machines designed for use with

wood-cutting or other toothed blades

use different types of guarding systems

that provide the protection necessary for

those types of blades. Machines, such

as a cut-off machine, that are designed

for use with abrasive wheels require a

different guarding system, which is not

designed to provide protection against

all dangers presented by circular saw

blades, carbide-tipped blades, rescue

blades or wood-cutting or toothed

blades of any nature.

Warning!

To reduce the risk of injury from loss of

control from reactive forces, including

kickback:

1. Hold the cut-off machine firmly with

both hands.

2. Maintain good balance and footing

at all times. Never cut while

standing on a ladder.

3. Position the cut-off machine in such

a way that your body is clear of the

cutting attachment. Avoid standing

in direct line with the wheel. Never

bend over the cutting attachment,

especially when the guard is pulled

back towards the top and there is a

risk of reactive forces. (See

illustration.)

4. Do not cut above shoulder height.

5. Use only STIHL-branded diamond

and composite abrasive wheels.

Never work with a diamond wheel

that wobbles or that has ever

wobbled or that is manufactured

with abrasive material on its sides.

6. Do not cut wood or any other

material for which the abrasive

wheel is not authorized.

7. Never use circular saw blades,

carbide-tipped blades, rescue

blades, wood-cutting blades or

toothed blades of any nature. Their

use increases the risk of injury from

blade contact, thrown tips and

reactive forces, including kickback.

8. Begin cutting and continue at full

throttle.

9. Do not overreach.

10. Never sideload a wheel in the kerf.

11. Use your cut-off machine for cutting

only. It is not designed for prying or

shoveling away any objects.

12. Be especially alert for reactive

forces, including kickback, when

cutting with the front and upper

quadrant of the wheel. Never pull

002BA059 KN

the top of the wheel guard back

beyond the limit stop.

13. Be alert to shifting of the workpiece

or anything that could cause the cut

to close and pinch the wheel,

especially in the upper quadrant.

Support the workpiece in such a

way that the cut remains open.

Never make a cut that results in a

binding of the wheel.

14. Use wet-cutting whenever feasible.

In a pinch situation the water can act

as a lubricant and reduce the

energy of reactive forces.

15. Release the pressure on the cut-off

machine as you reach the end of the

cut. Too much pressure may cause

the operator to lose control of the

cut-off machine when the abrasive

wheel completes the cut. The

abrasive wheel may contact the

operator or strike some foreign

object and shatter.

16. Use extreme caution when

reentering a cut and do not turn the

wheel at an angle or push the wheel

into the cut as this may result in a

binding of the wheel.

Gyroscopic Forces

Be alert for gyroscopic forces that are

caused by the rapid spinning of the cutoff wheel. These forces result in

English

Working safely with cut-off machines

13

Page 16

English

opposition to directional change, e.g.,

when the operator attempts to move the

machine in a sideways direction.

Maintenance, Repair and Storing of

the Cut-Off Machine

Maintenance, replacement, or repair

of the emission control devices and

systems may be performed by any

nonroad engine repair establishment

or individual. However, if you make a

warranty claim for a component that

has not been serviced or maintained

properly or if nonapproved

replacement parts were used, STIHL

may deny warranty coverage.

Never operate a cut-off machine that is

damaged, improperly adjusted or not

completely or securely assembled.

Follow the maintenance and repair

instructions in the appropriate sections

of your instruction manual.

Warning!

Use only STIHL replacement parts for

maintenance and repair. Use of parts

manufactured by others may cause serious or fatal injury.

Warning!

Always stop the machine, make sure

that the wheel is stopped, and remove

the spark plug boot from the spark plug

before doing any maintenance or repair

work or cleaning the cut-off machine. Do

not attempt any maintenance or repair

work not described in your instruction

manual. Have such work performed

only at your STIHL servicing dealer.

Clean off grinding dust after finishing

work. Tighten all nuts, bolts and screws

except the carburetor adjustment

screws after each use.

Do not clean your machine with a

pressure washer. The solid jet of water

may damage parts of the machine.

Warning!

Never test the ignition system with spark

plug boot removed from spark plug or

with unseated spark plug, since uncontained sparking may cause a fire.

Warning!

To reduce the risk of fire and burn injury,

use only spark plugs authorized by

STIHL. Always press spark plug boot

snugly onto spark plug terminal of the

proper size. (Note: If terminal has a

detachable SAE adapter nut, it must be

attached.) A loose connection between

spark plug terminal and ignition wire

connector in the boot may create arcing

that could ignite combustible fumes and

cause a fire. Keep spark plug clean, and

make sure ignition lead is in good

condition.

Warning!

Do not operate your cut-off machine if

the muffler is damaged, missing or modified. An improperly maintained muffler

will increase the risk of fire and hearing

loss. Never touch a hot muffler or spill

fuel or other flammable liquid over it.

Burn injuries or fire will result. If your

muffler was equipped with a sparkarresting screen to reduce the risk of fire

(e. g. in the USA, Canada and Australia), never operate your cut-off

machine if the screen is missing or

damaged.

For any maintenance please refer to the

maintenance chart and to the warranty

statement near the end of the instruction

manual.

Store wheels on a flat surface in a dry

place, preferably at a constant

temperature, where there is not a risk of

frost. Do not store a cut-off machine with

a wheel mounted on the machine. Store

cut-off machine in a high or locked

place, away from children.

Empty the fuel tank before storing for

longer than a few days. Store fuel only in

correctly labeled and approved

containers. Avoid direct skin contact and

do not inhale the gas vapors.

14

Working safely with cut-off machines

Page 17

English

Sample applications

Most diamond cutting wheels are

suitable for wet cutting

Wet cut whenever feasible. It

increases the service life and cutting

speed of diamond cutting wheels.

Ensure that the cutting wheel is

generously supplied with water.

Wet cutting helps to suppress dust.

The water binds the dust.

The cutting wheel must be supplied with

at least 0.6 liters water per minute.

Wet cutting can reduce the energy of

reactive forces. In a pinch situation, the

water can act as a lubricant.

Water connection

– A water attachment kit is mounted

on the machine for use with all types

of water supply.

– A pressurized 10 liter water tank is

available from STIHL for dust

suppression.

– A water tank for mounting on the

Cutquik cart is also available for

dust suppression.

Composite resin wheels can be used

for dry cutting of metals or for wet or

dry cutting of concrete, stone or

masonry.

Composite resin wheels designed for

dry cutting

Special procedures must be followed

when wet cutting with a composite nondiamond wheel designed for dry cutting.

See the section entitled "Wet Cutting

with Abrasive Wheels" in the safety

precautions of this manual. Wet cutting

is generally not suitable for cutting

metals.

Composite resin wheels designed for

wet cutting

Adjust water flow rate

during cutting so it is sufficient to bind all the dust

that occurs (at least

0.6 L/min).

If the water flow rate is too high, the

cutting wheel may skim on the water

surface in the cut and greatly reduce

cutting performance. To avoid this, do

not exceed a water flow rate of about

4L/min.

Use water properly:

1. Be certain water is applied to both

sides of wheel, since uneven

distribution can cause one sided

wear with possible wheel breakage.

2. Make certain water does not flow on

wheel that is not running, since the

wheel will absorb water and that will

affect wheel balance.

3. After finishing work, run the cutting

wheel at normal operating speed for

about 3 to 6 seconds without water

so that the remaining water is flung

off.

Water connection

– A water attachment kit is mounted

on the machine for use with all types

of water supply.

– A pressurized 10 liter water tank is

available from STIHL for dust

suppression.

– A water tank for mounting on the

Cutquik cart is also available for

dust suppression.

Respiratory protection

Warning!

When wet cutting at the recommended

flow rate is not utilized, the operator and

any bystanders should always wear a

respirator approved by NIOSH/MSHA

for the material being cut. Even if wet

cutting, an operator who is actively cutting for more than two hours a day

should wear at least a NIOSH-approved

disposable respirator.

Working safely with cut-off machines

15

Page 18

English

Points to be noted with diamond and

composite resin cutting wheels

Object to be cut

– Must be fully supported

– Must be secured so that it cannot

roll or slip away

– Must be protected against vibration

The cutting sequence

The cutting sequence is important when

cutting openings and recesses, etc. The

last cut must always be made in such a

way that the cutting wheel cannot

become bound and so that the user is

not at risk of being injured by the part

that has been cut off or out.

If applicable, leave small ridges of uncut

material to hold the severed part in

position. These ridges can subsequently

be broken through.

A number of points must be decided

before the part is finally severed:

– How heavy is the part?

– In which direction can it move after

being severed?

– Is it under tension?

Helpers must not be put at risk of injury

when the part is broken off or out.

Cutting in several passes

N Mark cutting line (A).

N Work along the cutting line. If

corrections are necessary, always

reposition the cutting wheel, taking

care to ensure that it is not wedged.

The cutting depth per pass should

not exceed 5 to 6 cm (2“ to 2 1/2“).

Thicker material must be cut in

several passes.

Cutting slabs

N Place the slab securely on a non-

slip surface.

N Cut a guiding groove (A) along the

marked line.

N Cut deeper into the parting cut (B)

with uniform back-and-forth

movements.

N Leave a ridge (C) of uncut material.

N Cut through the slab at the ends so

the material does not chip.

N Then break the slab.

16

N Thick-walled workpieces should be

cut with a uniform swinging

movement, back and forth.

Working safely with cut-off machines

Page 19

severed part in position. These

ridges can subsequently be broken

through.

Cutting shapes on pipes

English

N Curves must be cut in several

straight passes, taking care to

ensure that the cutting wheel does

not become wedged.

Cutting round and hollow workpieces

N Pipes and round objects, etc. must

be secured so that they cannot roll.

N Avoid reinforcing elements,

especially in the direction of the cut,

when deciding on the cutting line.

N Cut a guiding groove along the

marked line.

N Cut deeper into the parting cut with

uniform back-and-forth movements.

Advance the cutting wheel along the

guiding groove at full cutting depth.

Always reposition the cutting wheel,

taking care not to wedge it, if the

cutting direction has to be corrected

slightly. If necessary, leave small

ridges of uncut material to hold the

N Mark the cutting line.

Warning!

Particular care and precision are

required for free-hand cutting along

such cutting lines. Avoid side-loading

the wheel or causing it to bind.

N Cut a guiding groove along the

marked cutting line, starting at the

top and moving out towards both

sides.

N Cut into the pipe or round object,

etc. at the ends of the cutting line so

that the material does not chip.

N Cut deeper into the parting cut with

uniform back-and-forth movements,

starting at the top and moving out

towards the sides. Advance the

cutting wheel along the guiding

groove at full cutting depth. Always

reposition the cutting wheel afresh,

taking care not to wedge it if the

cutting direction has to be corrected

slightly. If necessary, leave small

ridges of uncut material to hold the

severed part in position. These

ridges can subsequently be broken

through.

Working safely with cut-off machines

17

Page 20

English

Cutting wheels Composite resin cutting

wheels

Cutting wheels are exposed to

extremely high loads especially during

freehand cutting.

The cutting wheels, which have been

developed by STIHL in cooperation with

renowned manufacturers of abrasive

wheels, are of high quality and tailored

precisely to the respective intended use

as well as the engine performance of the

cut-off machine.

They are of consistently outstanding

quality.

Transport and storage

– Do not expose cutting wheels to

direct sunshine or other thermal

stresses during transport and

storage

– Avoid jolting and impacts

– Stack cutting wheels flat on a level

surface in the original packaging in

a dry place where the temperature

is as constant as possible

– Do not store cutting wheels in the

vicinity of aggressive fluids

– Store cutting wheels in a frost-free

place

Economic benefit is improved and

premature wear can be avoided by

choosing and using the correct

composite resin cutting wheel. The short

name (e.g. “asphalt“, “concrete“)

– on the label and

– on the packaging (table with

recommended uses)

can help to ensure the correct choice.

STIHL composite resin cutting wheels

are suitable, depending on the version,

for cutting the following materials:

– Asphalt

– Concrete

– Stone

– Ductile cast pipes

– Steel

STIHL composite resin cutting wheels

cannot be used to cut railway tracks.

Diamond cutting wheels

Economic benefit is improved and

premature wear can be avoided by

choosing and using the correct diamond

cutting wheel. The short name (see

following explanation)

– on the label and

– on the packaging (table with

recommended uses)

can help to ensure the correct choice.

STIHL diamond cutting wheels are

suitable, depending on the version, for

cutting the following materials:

– Asphalt

– Concrete

– Stone (hard rock)

– Abrasive concrete

– Green concrete

– Clay bricks

– Clay pipes

Diamond abrasive wheels cannot be

used to cut metal.

18

Working safely with cut-off machines

Page 21

Short names

The short name is a combination of

letters and numerals with up to four

digits:

– The letters indicate the main area of

use for the cutting wheel.

Letter Main area of use

A Asphalt

B Concrete

BA Concrete, Asphalt

S Stone (rock)

SB Rock, Concrete

– The numerals indicate the

performance class of the STIHL

diamond cutting wheel.

English

Excessive radial run-out (A) causes

individual diamond segments to be

overloaded and to overheat. This can in

turn lead to stress cracking in the wheel

core or to softening of individual

segments.

Axial run-out or wobble (B) results in

higher thermal stress and wider cuts.

Radial and axial run-out

A correctly mounted spindle bearing on

the cut-off machine is essential for a

long service life and efficient operation

of the diamond cutting wheel.

Using a cutting wheel on a cut-off

machine with defective spindle bearing

can lead to axial and radial run-out.

Working safely with cut-off machines

19

Page 22

English

Troubleshooting

Cutting wheel

Problem Cause Remedy

Frayed edges or tears, cut wanders out

Radial or axial run-out Consult a dealer

of line, increased wear at the sides of the

segments

Cutting wheel wobbles Use a new cutting wheel

Frayed edges, cut wanders out of line, lit-

tle or no cutting performance, sparking

Cutting wheel is blunt; built-up edges on cut-

ting wheels for stone

Dress the cutting wheel for stone by

briefly cutting in abrasive material; use a

new cutting wheel for cutting asphalt

Poor cutting performance, high level of

segment wear

Chipping or cracking in the wheel core

and segments

Undercutting Cutting in a material for which the wheel is

1)

STIHL recommends that a STIHL servicing dealer be consulted.

Cutting wheel rotates in the wrong direction Mount the cutting wheel with correct

direction of rotation

Overload Replace immediately with a new cutting

wheel

Use a new cutting wheel; note the differ-

not rated

ent cutting layers in different materials

1)

20

Working safely with cut-off machines

Page 23

English

Undercut

Undercutting is a wearing away of the

steel core at or just below the diamond

segments. When cutting road surfaces,

do not cut through into the more

abrasive ballast (gravel, crushed rock)

below, as indicated by a light colored

dust. This can cause excessive

undercutting, resulting in wheel

breakage and/or thrown segments.

Warning!

Immediately replace a diamond wheel if

the core has been severely undercut.

Built-up edges, dressing

– when cutting extremely hard

material, such as granite,

– as a result of incorrect handling,

such as applying excessive feed

force,

– if extremely large sections are cut

without a pendulum movement

(back and forth in the cutting plane).

Built-up edges increase vibrations,

reduce cutting performance and cause

sparking.

Diamond cutting wheels must be

"dressed" at the first sign of built-up

edges. For this purpose, briefly cut a

more abrasive material, such as

sandstone, aerated concrete or asphalt.

Wet cutting helps to prevent the

formation of built-up edges.

Warning!

Such cutting wheels may break apart or

throw off segments during use, causing

serious or fatal injury. Replace them

immediately.

Built-up edges are identified by a pale

grey deposit on the top of the diamond

segments that clogs and blunts the

segments.

Built-up edges can form:

Working safely with cut-off machines

If you continue to use a cutting wheel

with blunt segments, the segments may

soften as a result of excessive heat built

up. The wheel core will also overheat

and lose its mechanical strength. This

can lead to considerable stress, as

clearly indicated by stress cracks and/or

a wobbling movement of the cutting

wheel.

21

Page 24

English

Maintenance and Care

The following maintenance intervals apply in normal operating conditions. The

specified intervals must be shortened accordingly when working for longer than

normal or under difficult cutting conditions (extensive dust, etc.).

before starting work

at the end of work and/or

daily

Whenever tank is refilled

Weekly

Monthly

Yearly

If faulty

Complete machine

Operating elements Check operation XX

Fuel pick-up body in fuel tank

Fuel tank Clean X

Ribbed V-belt

Air filter (all filter components) Replace Only if there is a noticeable loss of engine power

Cooling air intake slits Clean X

Cylinder fins

Spark arresting screen

Water attachment

Carburetor

Spark plug

All accessible screws, nuts and bolts (not

adjusting screws)

2)

in muffler

Visual inspection (condition, leaks) XX

Clean X

test, check X

Replace XXX

Clean / retension XX

Replace XX

Have them cleaned by a specialist

1)

dealer

test, check X

Clean or replace X

test, check xx

Have them maintained by a specialist

1)

dealer

Check idle adjustment – abrasive

wheel must not rotate

Readjust idle speed X

Adjust electrode gap X

Replace after 100 hours’ operation

Retighten XX

XX

X

If damaged

As required

x

22

Working safely with cut-off machines

Page 25

The following maintenance intervals apply in normal operating conditions. The

specified intervals must be shortened accordingly when working for longer than

normal or under difficult cutting conditions (extensive dust, etc.).

before starting work

at the end of work and/or

daily

Whenever tank is refilled

Weekly

Monthly

Yearly

If faulty

test, check XXX

Antivibration elements

Abrasive wheel

Supports/rubber buffers (underneath the

machine)

Safety information sticker Replace X

1)

STIHL recommends STIHL servicing dealers

2)

present only in some countries

Have them replaced by a specialist

1)

dealer

test, check XX

Replace XX

test, check X

Replace XX

If damaged

X

English

As required

Working safely with cut-off machines

23

Page 26

English

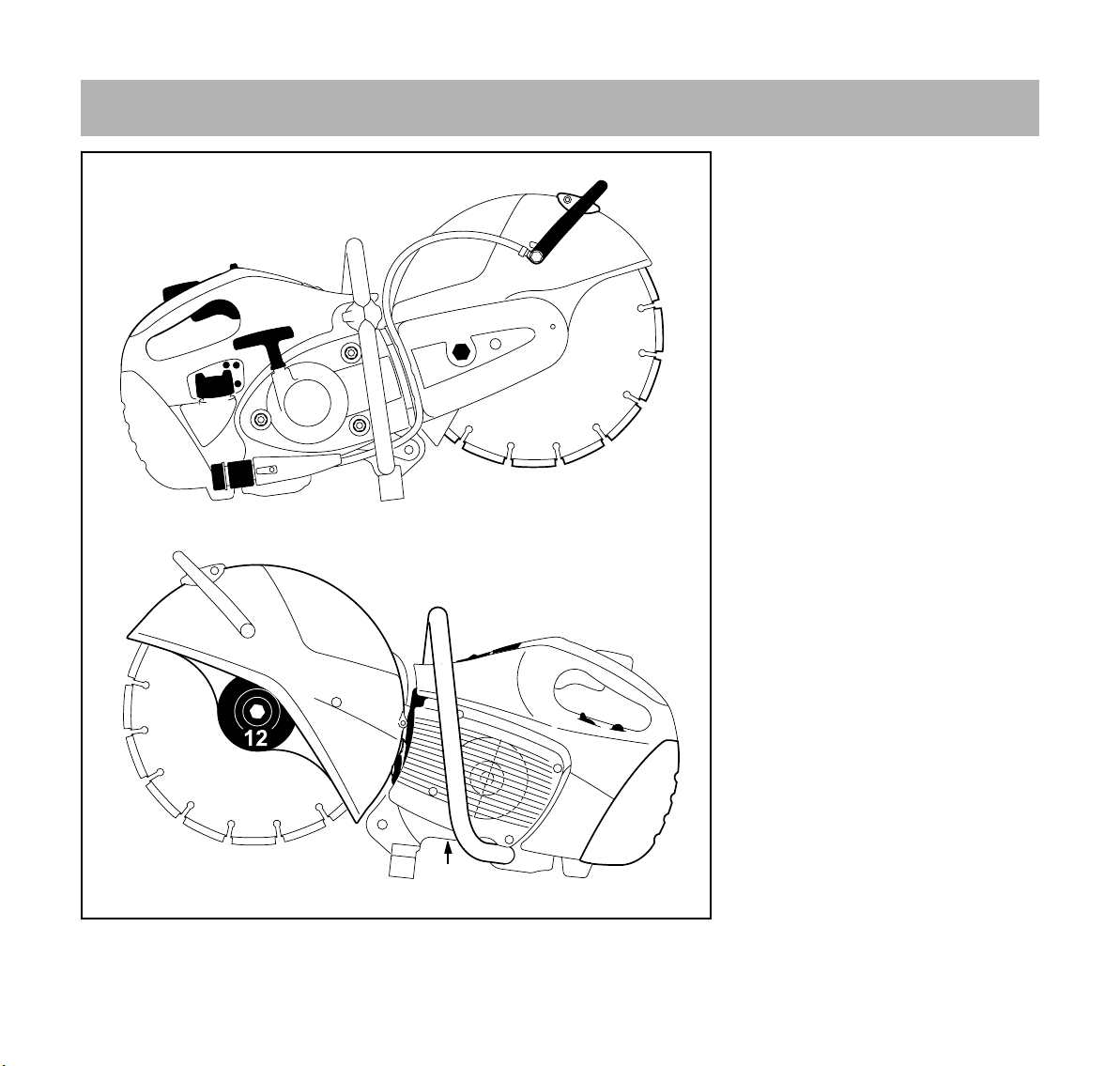

Main Parts

1

1 Rear Handle

2 Throttle Trigger Lockout

10

4

2

5

3

9

6

11

7

8

16

13

17

18

3 Throttle Trigger

4 Slide Control

5 Starter Grip

6 Carburetor Adjusting Screws

7 Fuel Filler Cap

8 Water Attachment

9 Tensioning Nut

10 Adjusting Lever

11 Abrasive Wheel

12 Front Thrust Washer

13 Guard

14 Muffler

15 Spark Arresting Screen

16 Front Handle

17 Decompression Valve

18 Cap for Spark Plug Boot

19 Choke Lever

20 Fuel Pump

21 Filter Cover

# Serial Number

24

14

15

19

20

21

#

370BA046 KN

Working safely with cut-off machines

Page 27

English

Definitions

1Rear Handle

The support handle for the right

hand.

2 Throttle Trigger Lockout

Must be depressed before the

throttle trigger can be activated.

3 Throttle Trigger

Controls the speed of the engine.

4 Slide Control

For starting throttle, run and stop.

Keeps the throttle partially open

during starting and switches off the

ignition to stop the engine.

5 Starter Grip

The grip of the pull starter, for

starting the engine.

6 Carburetor Adjusting Screws

For tuning the carburetor.

7 Fuel Filler Cap

For closing the fuel tank.

8 Water Attachment

For connection of water supply for

wet cutting.

9 Tensioning Nut

For tensioning the ribbed belt.

10 Adjusting Lever

To adjust the wheel guard in a way

that sparks, dust, cutting debris or

wheel fragments are directed away

from the operator.

11 Abrasive Wheel

Can either be a composite abrasive

wheel or a diamond abrasive wheel.

12 Front Thrust Washer

Distributes clamping pressure of

mounting nut evenly over cutting

wheel.

13 Guard

Guards the wheel and deflects

sparks, dust, cutting debris or wheel

fragments.

14 Muffler

Reduces engine exhaust noises

and diverts exhaust gases away

from operator.

15 Spark Arresting Screen

Designed to reduce the risk of fire.

16 Front Handle

Handlebar for the left hand of the

power tool.

17 Decompression Valve

Releases compression pressure to

make engine starting easier - when

activated.

18 Cap for Spark Plug Boot

The spark plug boot connects the

spark plug with the ignition lead.

19 Choke Lever

Eases engine starting by enriching

mixture.

20 Fuel Pump

Provides additional fuel feed for a

cold start.

21 Filter Cover

Covers and protects the air filter

element.

Clutch

Couples engine to the belt pulley

when engine is accelerated beyond

idle speed. (Not illustrated)

Belt Pulley

The wheel that drives the ribbed belt

and the abrasive wheel. (Not

illustrated)

Anti-Vibration System

The anti-vibration system includes a

number of anti-vibration elements

designed to reduce the

transmission of vibrations created

by the engine to the operator's

hands. (Not illustrated)

Working safely with cut-off machines

25

Page 28

! WARNING!

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

! WARNING!

Some dust created by power grinding and

other construction activities contains

chemicals known to the State of California

to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints, and

• crystalline silica from bricks and

cement and other masonry products.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals : work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

0457-186-3021

englisch USA

englisch

U

G

www.stihl.com

*04571863021*

0457-186-3021

Loading...

Loading...