Page 1

FS 25-4, 65-4

Contents

1. Safety Precautions 1

2. Introduction 2

3. Specifications 3

3.1 Engine 3

3.2 Fuel System 3

3.3 Ignition System 4

3.4 Gearhead 4

3.5 Special Accessories 4

3.5.1 For User 4

3.6 Dimensions and

Wear Limits 5

3.7 Tightening Torques 6

4. Troubleshooting 7

5. Clutch 10

5.1 Removing and

Disassembling 10

5.2 Assembling and

Installing 10

6. Engine 11

6.1 Checking/Adjusting

Valve Clearance 11

6.2 Checking Oil Level/

Changing Oil 13

6.3 Exhaust Muffler 14

6.4 Rocker Arms/Pushrods 14

6.5 Cam Followers 15

6.6 Cam Gear 15

6.7 Diaphragm 15

6.8 Crankcase,

Lower Half 16

6.9 Crankshaft 17

6.10 Valves/Valve Springs 18

6.11 Crankcase/Cylinder 18

9. Throttle Control 26

9.1 Throttle Trigger/Interlock

Lever (Bike Handle) 26

9.2 Contact Springs/Detent

Spring in Control Handle

(Bike Handle) 27

9.3 Throttle Trigger/Interlock

Lever (Loop Handle) 27

9.4 Slide Control

(Loop Handle) 28

9.5 Throttle Cable 29

9.5.1 Replacing 29

9.5.2 Adjusting 30

10. AV System 30

11. Fuel System 32

11.1 Air Filter 32

11.2 Carburetor 32

11.2.1 Leakage Test 32

11.2.2 Removing/Installing 33

11.2.3 Adjusting Idle Speed 34

11.3 Tank Vent 35

11.4 Pickup Body 35

11.5 Fuel Hoses 36

11.6 Fuel Tank 37

12. Shaft 38

12.1 Bike Handle 38

12.2 Loop Handle 38

12.3 Drive Shaft/

Flexible Liner 39

12.4 Drive Tube 40

13. Cutting Tool Drive 41

13.1 Gearhead 41

13.2 Clutch Drum 41

1. Safety Precautions

If the brushcutter is startedup

in the course of repairs or maintenance work, observe all local and

country-specific safety regulations

as well as the safety precautions

and warnings in the owner’s

manual.

Gasoline is an extremely flammable fuel and can be explosive in

certain conditions.

Improper handling may result in

burns or other serious injuries.

Warning! Do not smoke or bring

any fire or flame near the fuel. All

work with fuel must be performed

outdoors only. Spilled fuel must be

wiped up immediately.

Wash hands thoroughly after

every contact with waste oil.

Do not pour waste oil down the

drain or allow it to soak into the

ground.

Collect waste oil and take it to an

official disposal site for environment-friendly disposal.

7. Ignition System 19

14. Special Servicing

Tools and Aids 43

7.1 Ignition Module 19

7.1.1 Ignition Timing 20

7.1.2 Removing/Installing 20

14.1 Special Servicing Tools 43

14.2 Servicing Aids 44

7.2 Flywheel 21

15. Maintenance chart 45

8. Rewind Starter 22

8.1 General 22

8.2 Rope Rotor 22

8.3 Starter Rope 23

8.4 Starter Grip 23

8.5 Rewind Spring 24

8.5.1 Replacing 24

8.5.2 Tensioning 24

8.6 Starter Cup/Fanwheel 25

© 1998, Andreas Stihl AG & Co, Waiblingen

FS 25-4, 65-4 1

Page 2

2. Introduction

Thisservicemanualcontainsdetaileddescriptionsofalltherepair

andservicingproceduresspecific

tothispowertoolseries.

Thereareseparatehandbooksfor

servicingproceduresforstandardizedpartsandassembliesthat

areinstalledinseveralSTIHLpowertoolmodels.Referenceis

madetothesehandbooksinthe

appropriatechaptersinthis

manual.

Servicingthecarburetorisdescribedintheseparate"Carburetors"

manual.

Asthedesignconceptofmodels

FS25-4andFS65-4isalmost

identical,thedescriptionsand

servicingproceduresinthis

manualgenerallyapplytoboth

machines.Differencesare

describedindetail.

Youshouldmakeuseofthe

illustratedpartslistswhilecarrying

outrepairwork.Theyshowthe

installedpositionsoftheindividual

componentsandassemblies.

Refertothelatesteditionofthe

relevantpartslisttocheckthepart

numbersofanyreplacementparts

needed.

PartslistsonmicroficheandCDROMarealwaysmoreuptodate

thanprintedlists.

Thespecialservicingtoolsmentionedinthedescriptionsare

listedinthelastchapterofthismanual.

Usethepartnumberstoidentify

thetoolsinthe"STIHLSpecial

Tools"manual.

Themanuallistsallspecial

servicingtoolscurrentlyavailable

fromSTIHL.

Symbolsareincludedinthetext

andpicturesforgreaterclarity.

Themeaningsareasfollows:

Inthedescriptions:

•

=Actiontobetakenas

shownintheillustration

(abovethetext)

-=Actiontobetakenthat

isnotshowninthe

illustration

(abovethetext)

Intheillustrations:

=Pointer

=Directionofmovement

Servicemanualsandalltechnical

informationbulletinsdescribing

engineeringchangesareintended

exclusivelyfortheuseofSTIHL

servicingdealers.Theymustnot

bepassedtothirdparties.

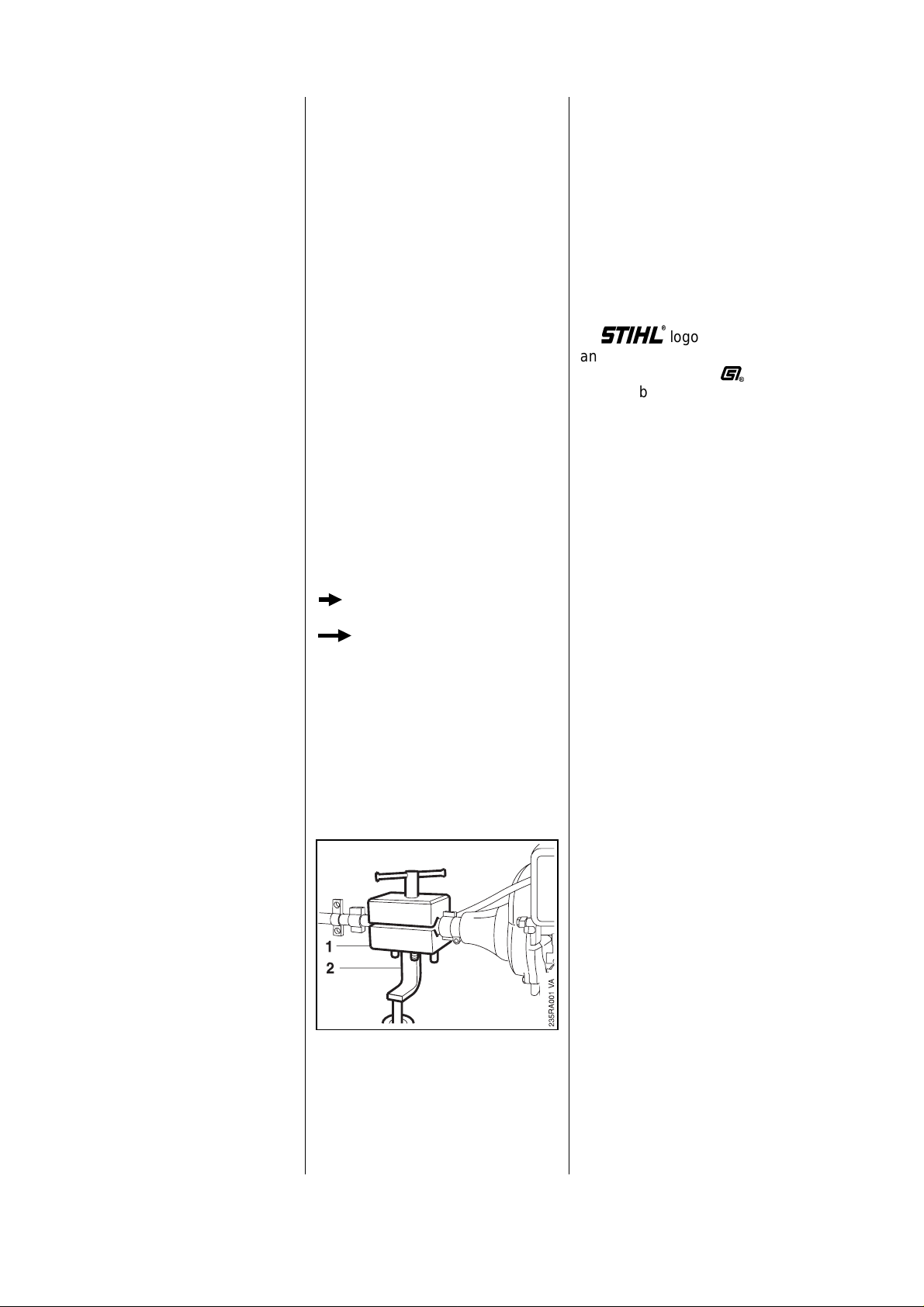

Securetheclamptotheassembly

standwithtwowashersandtwo

M8nuts.

Thecompletemachinecanthen

beswivelledtothebestposition

fortheongoingrepairandthisleavesbothhandsfree.

AlwaysuseoriginalSTIHL

replacementparts.

Theycanbeidentifiedbythe

STIHLpartnumber,

the

STIHL

andthe

STIHLpartssymbol

Thesymbolmayappearaloneon

smallparts.

logo

(

Afaultonthepowertoolmayhave

severalcauses.Apartfromthe

chapter"Troubleshooting"inthis

manual,alsoconsultthetroubleshootingchartsforallassembliesin

the"StandardRepairs,Troubleshooting"handbook.

Refertothe"TechnicalInformation"bulletinsforengineering

changeswhichhavebeenintroducedsincepublicationofthis

servicemanual.Technicalinformationbulletinsalsosupplementthe

partslistuntilarevisededitionis

issued.

2 FS25-4,65-4

Servicingandrepairsaremade

considerablyeasierifthemachine

ismountedonassemblystand(2)

59108903100withtheaidof

clamp(1)59108908800.

Page 3

3. Specifications

3.1 Engine

Singlecylinderfour-strokeoverheadvalveengine

FS25-4 FS65-4

Type: GX22 GX31

Displacement: 22cm

3

31cm

3

Bore: 33mm 39mm

Stroke: 26mm 26mm

PoweroutputtoISO8893: 0.6kW(0.8bhp) 0.85kW(1.2bhp)

at7,000rpm at7,000rpm

Max.enginespeed: Maximumrpmisdeterminedbymainjetandisnotadjustable

Idlespeed: 3,100±200rpm

Compressionpressure: 29-59kPa(2.9-5.9bar)

at1,200rpm

Pistonpindiameter: 8mm

Rewindstarter: Pawlengagement

Pawls: Singlepawlsystem

Reservepullonroperotor: min.1/2turn

Starterropediameter: 3mm

Clutch: Centrifugalclutchwithpress-fittedlinings

Clutchengagesat: 4,200±200rpm

Valveclearance

Inlet: 0.12±0.02mm

Exhaust: 0.15±0.02mm

Oilcapacity: 0.1l(100cm

3

)

Oilgrade: SAE15W-40

3.2 FuelSystem

Carburetor: Diaphragmcarburetor

Carburetorleakagetest

atgaugepressure: 8kPa(0.8bar)

Functionoftankvent

atgaugepressure: ≤3kPa(0.3bar)

undervacuum: ≤0.5kPa(0.05bar)

Fueltankcapacity: 0.45l(450cm

3

) 0.65l(650cm3)

Fuel: Regularbrandnamegasoline

Octanerating: min.90RON

Airfilter: Oilimpregnatedfoamfilter

FS25-4,65-4 3

Page 4

3.3 Ignition System Type: Electronic magneto

ignition (breakerless)

with integral trigger unit

Ignition timing: 27 degrees B.T.D.C.

Air gap: 0.35 - 0.5 mm

Spark plug (suppressed): NGK CR5HSB,

Denso U16FSR-UB

Electrode gap: 0.6 - 0.7 mm

3.4 Gearhead Type: Spiral-toothed bevel gear drive

Gear ratio: 1:1.4

Bearings: Deep groove ball bearings

Lubrication: STIHL gear lubricant

0781 120 1117, 1118

(capacity 7 g)

3.5 Special Accessories

3.5.1 For User Full harness

Safety glasses

Transport guard for

Metal cutting tools 4119 717 3005

STIHL gear lubricant (80 g tube) 0781 120 1109

STIHL gear lubricant (80 g tube) 0781 120 1117

4 FS 25-4, 65-4

Page 5

3.6 Dimen sionsandWear Limits

Description Standard Wear limit

Cylinder inside diameter 33.00 mm * 33.10 mm *

39.00 mm ** 39.10 mm **

Piston outside diameter 32.99 mm * 32.90 mm *

38.99 mm ** 38.90 mm **

Piston pin outside diameter 8.00 mm 7.95 mm

Cam lift 22.79 mm 22.49 mm

(inlet and exhaust)

Free length of valve springs 23.40 mm 22.50 mm

Valve stem outside diameter

Inlet: 3.985 mm 3.900 mm

Exhaust: 3.950 mm 3.880 mm

Valve guide inside diameter 4.000 mm 4.060 mm

Clearance between valve stem and guide

Inlet: 0.015 - 0.048 mm 0.098 mm

Exhaust: 0.050 - 0.083 mm 0.120 mm

Valve head diameter

Inlet: 12.5 mm *

13.5mm**

Exhaust: 12.0 mm

Clutch lining: 2.0 mm 1.0 mm

* FS 25-4

** FS 65-4

FS 25-4, 65-4 5

Page 6

3.7 Tightening Torques

DG and P screws (Plastoform) are used in polymer and lightmetal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often

as necessary without detrimentally affecting the strength of the screwed assembly, providing the specified

tightening torque is observed. For this reason it is essential to use a torque wrench.

Fastener Thread For component Torque Remarks

size Nm

Pan head screw M5x12 Valve cover 4.0

Pan head screw M5x22 Valve cover 4.0

Nut M5 Valve adjusting screw 5.0

Collar nut M8 Flywheel 15.0

M8 Starter cup 8.0

Nut M5 Carburetor 5.0

Pan head screw M6x28 Clutch shoes 10.0 1)

Pan head screw M8x28 Clutch shoes 15.0 2)

Pan head screw M4x16 Cam gear cover 3.0

Pan head screw M5x18 Crankcase 5.0

Pan head screw M5x55 Crankcase cover

1st stage 3.0

2nd stage 7.0

Spline screw IS-DG5x24 Gear housing/drive tube 8.5

Spline screw IS-M5x12 Clamp, control handle/

drive tube (loop handle) 2.0

Spline screw IS-M5x16 AV sleeve/drive tube (clamp screw) 5.5

Spline screw IS-M5x12 Clamp, control handle/drive tube 2.0

Spline screw IS-M5x16 Clamp/drive tube (harness) 4.5

Spline screw IS-M5x30 Control handle (bike handle) 2.0

Spline screw IS-M6x25 Clamp/loop handle 4.5

Screw plug M11x10 Gearhead 8.5

Plastoform screw IS-P4x16 Control handle/handle moldings 1.0

Collar screw IS-P3.5x10.6 Detent spring/slide control

(bike handle) 1.1

Nut M12x1.5 L Cutting tool 25.0

Spline screw IS-M5x16 Deflector/gearhead 4.3

All other screws M3 1.0

and nuts M5 5.0

M6 9.0

Use the following procedure to fit a DG or P screw in an existing thread:

– Place the DG or P screw in the hole and rotate it counterclockwise until it drops down slightly.

– Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread,

which would weaken the assembly.

1) FS 25-4

2) FS 65-4

Note: Power screwdriver speed settings for polymer: Plastoform screws max. 600 rpm

DG screws max. 500 rpm

6 FS 25-4, 65-4

Page 7

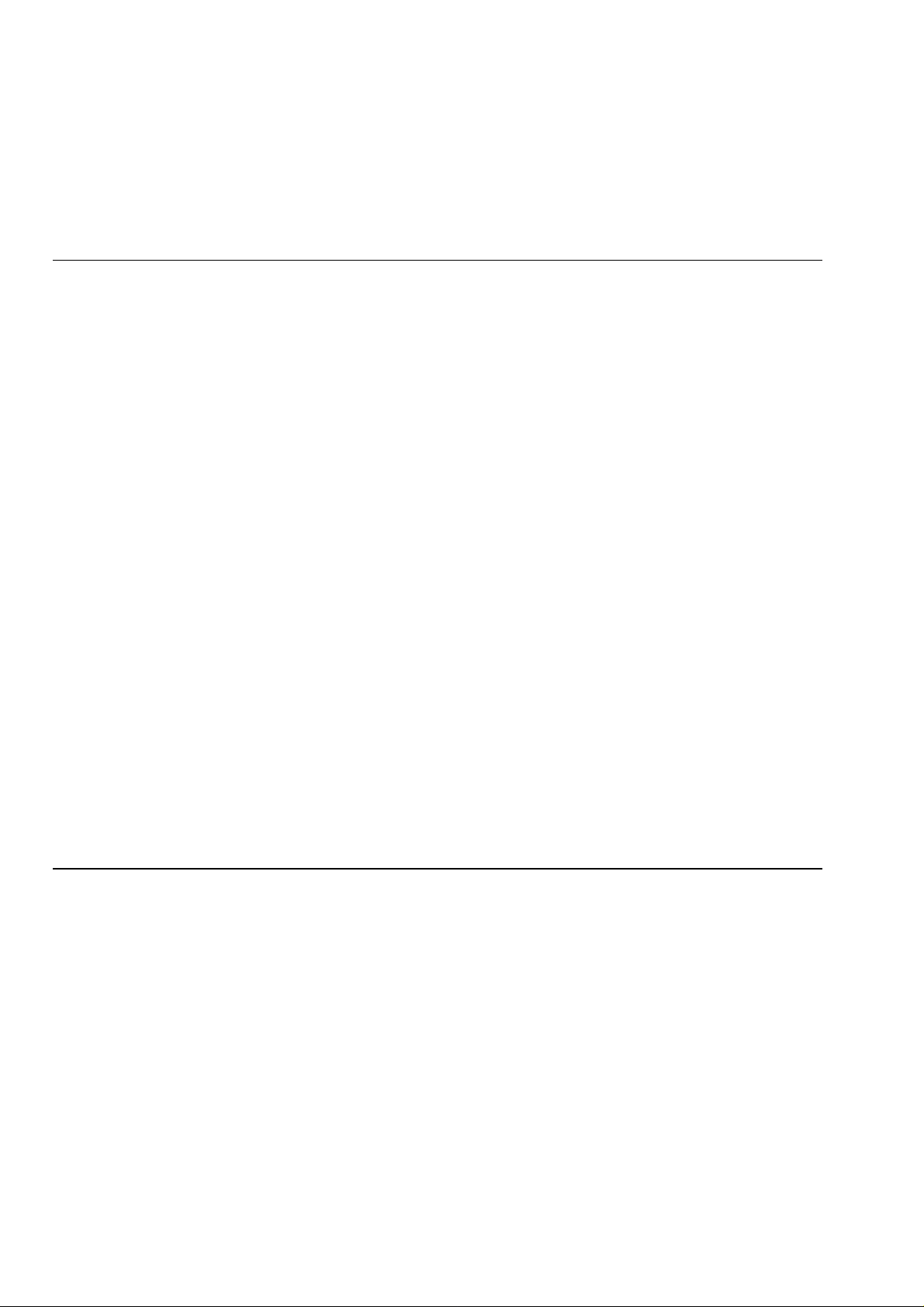

4. Troubleshooting

1. Engine difficult to start

Check fuel level in tank.

Adequate fuel in

tank

Operate manual fuel pump

and check that fuel is flowing to

carburetor.

Fuel flows to

carburetor

Remove spark plug and

check for damp or oily

electrodes.

Damp

No fuel

Fuel does not flow

to carburetor

Dry

Fill up with fuel and try starting

again.

– Check fuel line and fuel

filter for blockages.

– Faulty carburetor diaphragm

or float needle valve,

replace carburetor

Replace carburetor

Check spark plug

for spark.

Powerful spark

Check compression.

Adequate compression

Install spark plug and start

engine according to

instructions.

No spark or only a

weak spark

Compressioninorder

Compression too low

– Change spark plug and

repeat the spark test.

– Check ignition lead for

damaged insulation and

leakage current.

– Check ignition coil.

Check combustion chamber

for excessive build-up of

combustion deposits.

– Check, adjust valve

clearance.

– Valves must be in good

condition.

– Check piston, rings and

cylinder for wear.

FS 25-4, 65-4 7

Page 8

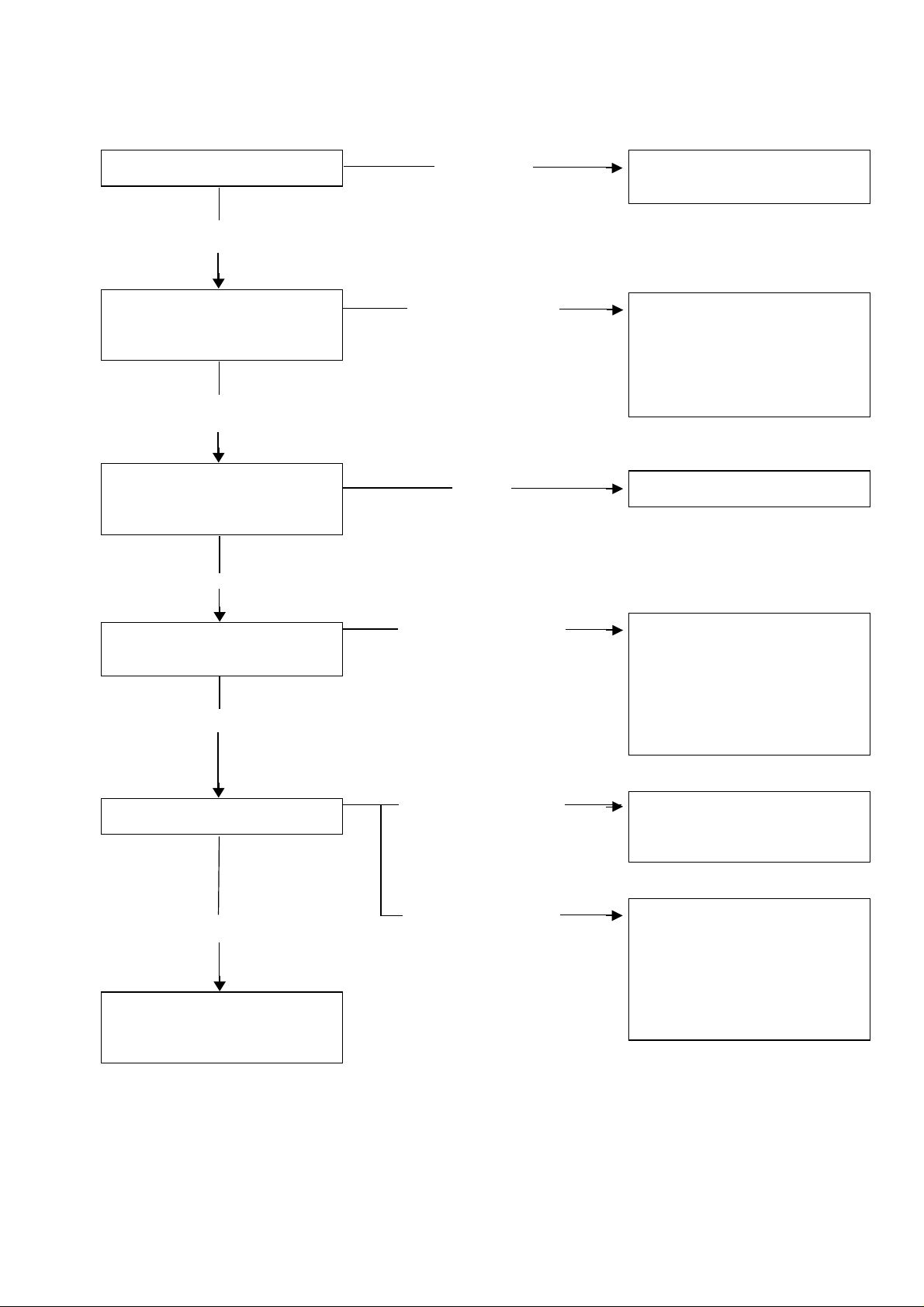

2. Erratic running behavior at low rpm

Inspect air filter element.

Not dirty

Remove spark plug and

check electrodes for coking,

check electrode gap.

Normal

Check to see if fuel line is kinked, pinched or cracked. Check

carburetor for looseness or air

entering through spacer flange.

Normal

Dirty

Abnormal

Abnormal

Clean, replace air filter

element.

– Clean spark plug and

adjust electrode gap.

– Replace spark plug.

– If fuel line is kinked

or pinched, fit a

new one.

– Tighten loose carburetor

nuts. Examine spacer

flange for damage and

install properly.

Check fuel filter.

Not dirty

Check correct function of

carburetor.

Normal

Check compression.

Normal

Start engine according to

instructions.

Dirty

Abnormal

Abnormal

Clean, replace filter.

Replace carburetor.

– Check, adjust valve

clearance.

– Check combustion chamber

for excessive build-up of

combustion deposits.

– Check valves for faults.

– Check piston, rings and

cylinder for wear.

8 FS 25-4, 65-4

Page 9

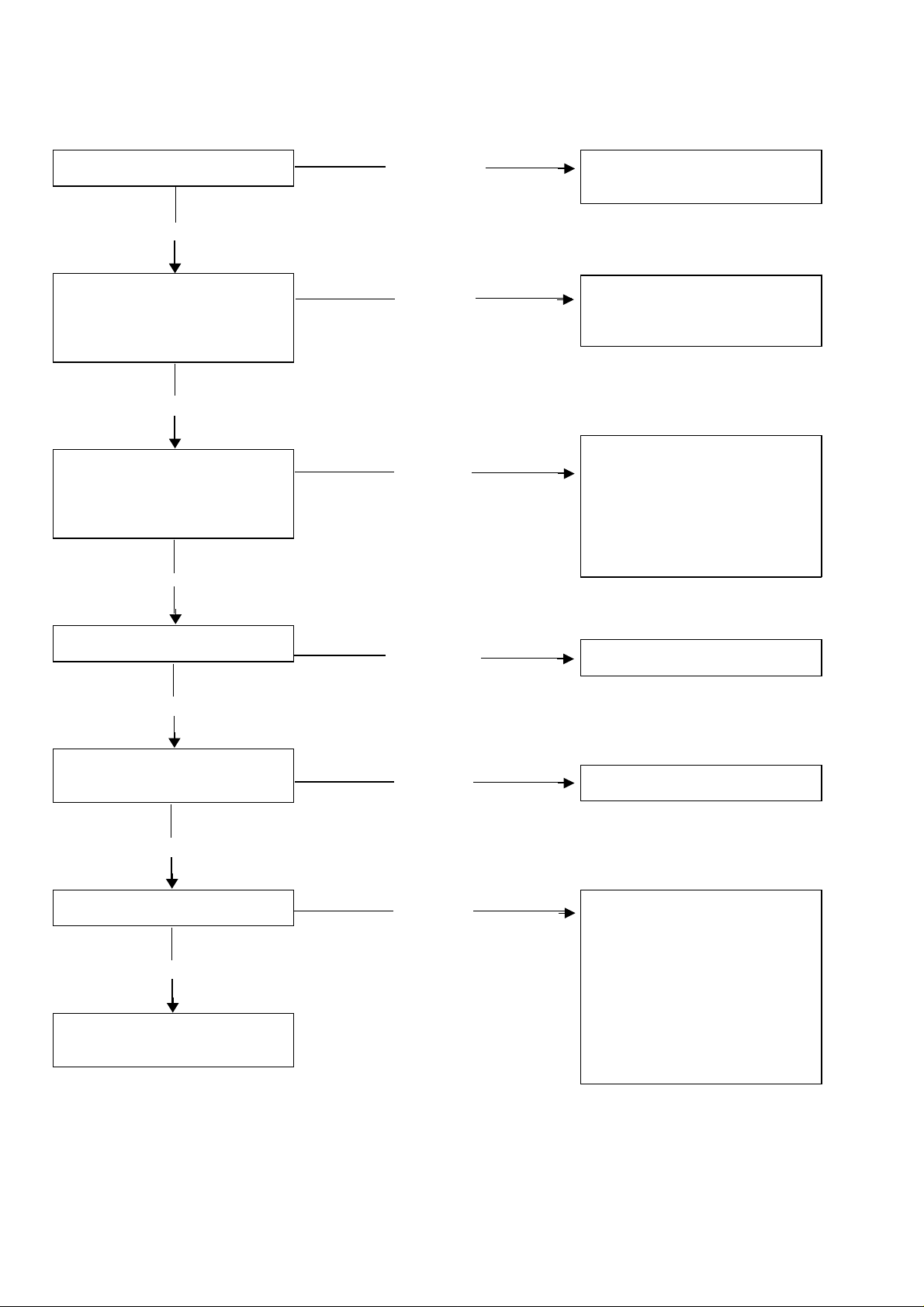

3. Erratic running behavior at high rpm

Inspect air filter element.

Not dirty

Remove spark plug and

check electrodes for coking,

check electrode gap.

Normal

Check to see if fuel line is kinked, pinched or cracked. Check

carburetor for looseness or air

entering through spacer flange.

Normal

Dirty

Abnormal

Abnormal

Clean, replace air filter

element.

– Clean spark plug and

adjust electrode gap.

– Replace spark plug.

– If fuel line is kinked

or pinched, fit a

new one.

– Tighten loose carburetor

nuts. Examine spacer

flange for damage and

install properly.

Check correct function of

carburetor.

Normal

Start engine according

to instructions.

Abnormal

Replace carburetor.

FS 25-4, 65-4 9

Page 10

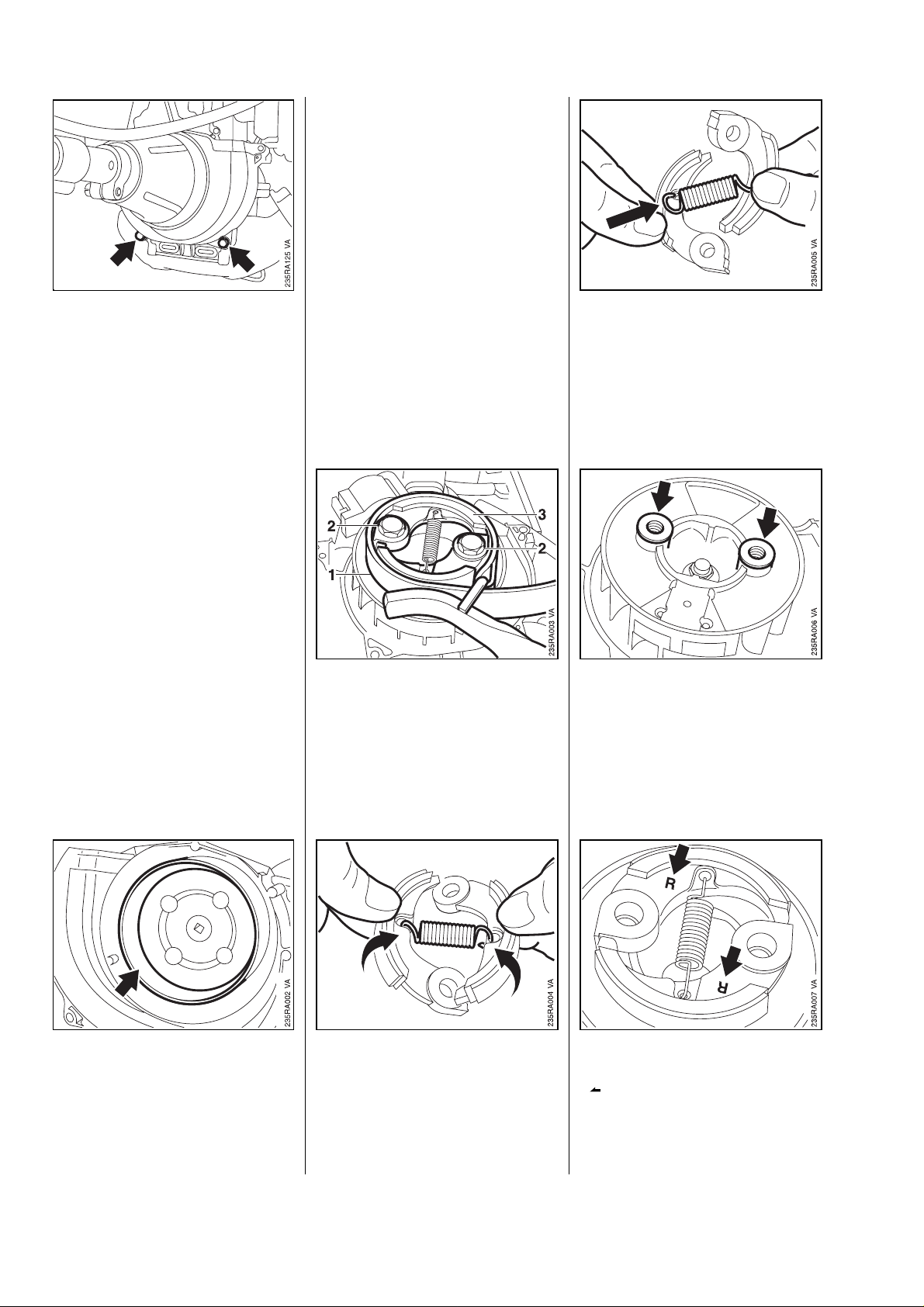

5. Clutch

5.1 RemovingandDisassembling 5.2 AssemblingandInstalling

Important:Iftherearesignsof

seriouswearontheinside

diameter,fitanewclutchdrum-

see13.2.

Troubleshootingchart-see

"StandardRepairs,Troubleshooting"handbook.

-Removetheshroud-see6.1.

-Removecontrolhandlefrombike

handle-see12.1.

-Onloophandlemachine,dis-

connectthrottlecablefrom

carburetor-see9.5.1.

•

Takeoutthescrews.

-Pulloffclutchhousingwithdrive

tube.

-Blockpistonwithlockingscrew-

see7.2.

•

Takeoutthecollarscrews(1).

•

Removetheclutchshoes(2).

•

Attachspringtoclutchshoes.

•

Fitthewashers.

•

Inspectclutchdrum.There

shouldbenoscoresorsigns

ofexcessivewear.

10 FS25-4,65-4

•

Twisttheclutchshoesand

detachthespring.

Important:Clutchshoesmust

alwaysbereplacedinpairs.

•

Fitclutchshoessothatthe

marksfaceoutwards.

" "=FS25-4

"R"=FS65-4

Page 11

•

Insertcollarscrews.

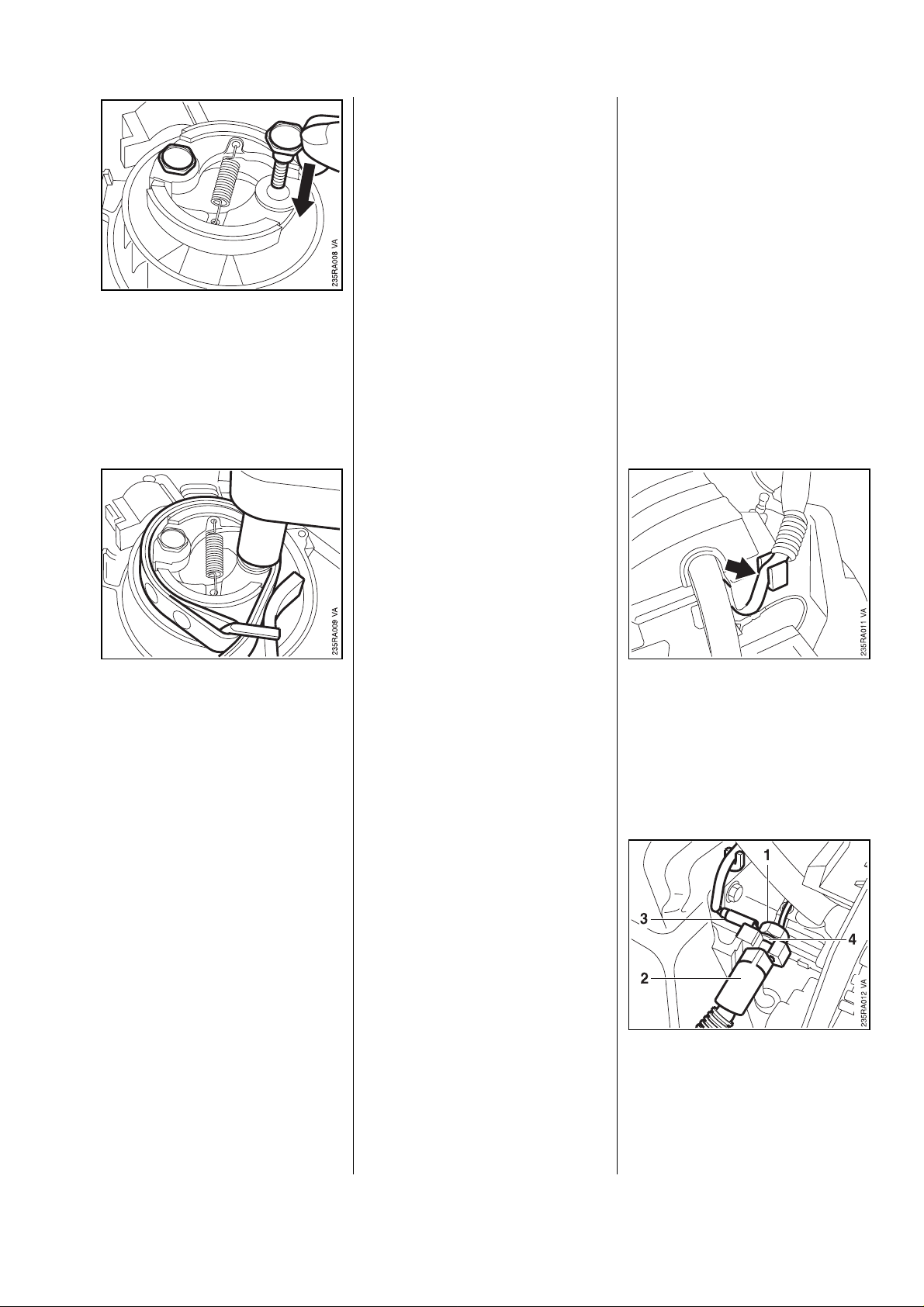

6. Engine 6.2 Checking/Adjusting

6.1 ValveClearance

Note:Checkandadjustvalveclea-

ranceonlywhenengineiscold.

-Removetherewindstarter.

-Removetheairfilter-see11.1.

•

Tightendowncollarscrewsto10

Nm(FS25-4)or15Nm(FS65-

4).

-Removelockingscrewfromcylinder.

-Installclutchhousingwithdrive

tube.

-Onloophandlemachine,attach

throttlecabletocarburetor.

-Onbikehandlemachine,install

thecontrolhandle.

-Fittheshroud.

-Pulloffthesparkplugboot.

•

Takeignitionleadoutofthe

retainer.

•

Slackenoffnut(1).

•

Pullthrottlecable(2)withshort

circuitwire(3)andwasher(4)

outofretainer.

FS25-4,65-4 11

Page 12

Note:Iftheexhaustvalveopens

whileyouareturningtheflywheel

toT.D.C.,rotateflywheelcounterclockwiseuntiltherecessand

projectionlineupagain.

•

Removeshroudfrombossesat

rewindstarterside.

•

Takeoutscrews(1)atclutch

side.

•

Removetheshroud(2).

•

Takeoutthescrews(1).

•

Removethevalvecover(2).

•

Removethegasket.

-Removeclutchhousingwithdrivetube-see12.4.

•

Insertfeelergauge(1)between

rockerarmandvalvestem.

Inletvalve(2):0.12±0.02mm

Exhaustvalve(3):0.15±0.02mm

Checking

•

Pullventhose(1)offthe

valvecover.

•

Pullignitionlead(2)andshort

circuitwire(3)outofthe

retainers.

12 FS25-4,65-4

•

Rotateflywheeluntilblade

recess(1)linesupwiththe

projection(2)onthecamgear

cover(pistonatT.D.C.).

Page 13

6.2 CheckingOilLevel/

ChangingOil

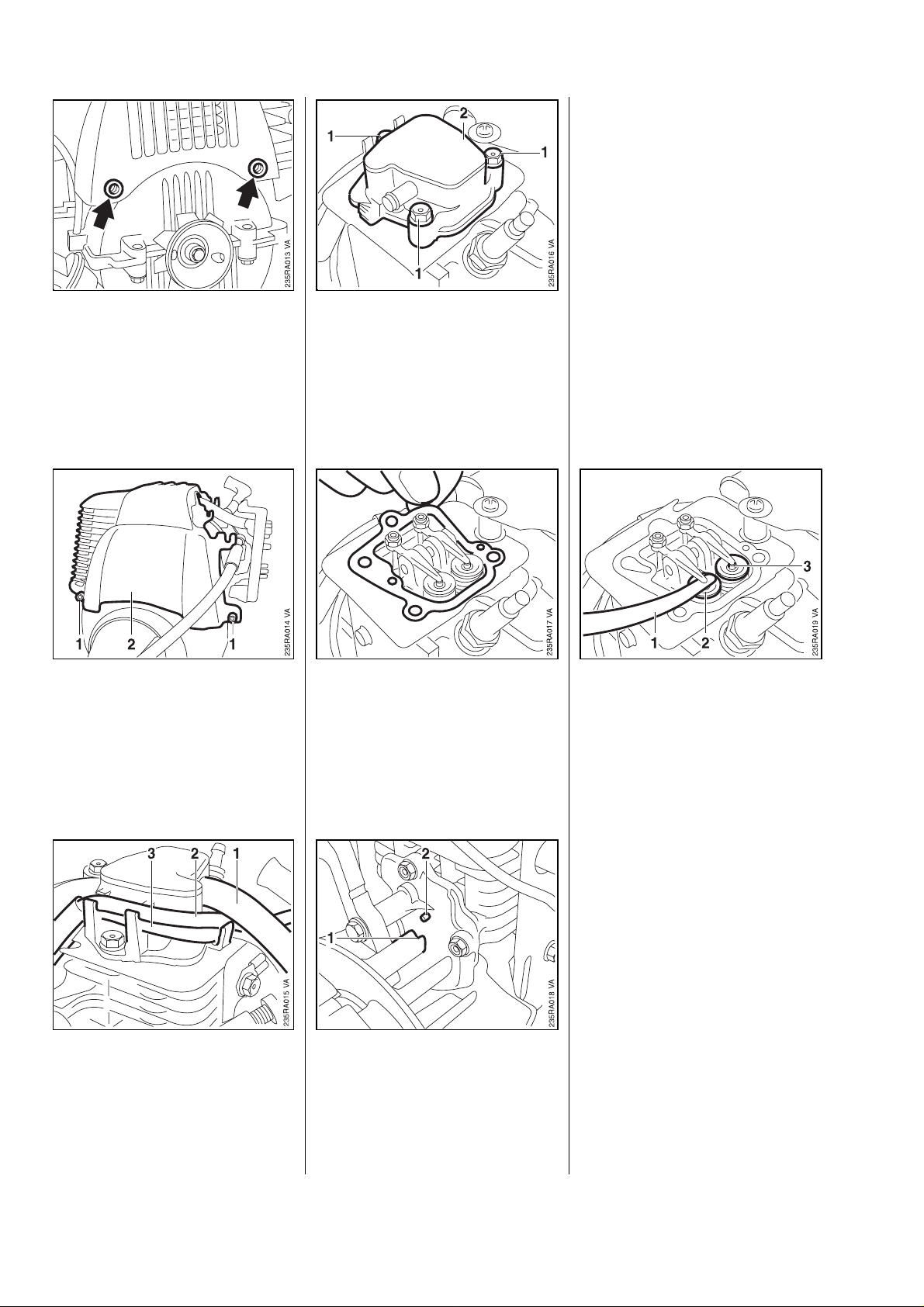

Adjusting

•

Slackenoffnut(1).Use2.5mm

Allenkeytorotateadjusting

screw(2).

Toincreasevalveclearance:

Turnscrewcounterclockwise.

Toreducevalveclearance:

Turnscrewclockwise.

-Holdadjustingscrewsteadyand

tightendownnutto5Nm.

Checking

-Putenginedownonalevel

surface.

-Unscrewthedipstickandwipeit

withacleancloth.

-Pushthedipstickintofillerneck

asfarasstopbutdonotscrewit

home.

-Putenginedownonalevel

surface.

-Fillupwithengineoiltoedgeof

fillerneck.

-Screwdipstickhomeandtighten

downfirmly.

-Checkvalveclearanceagain.

Assembleinthereversesequence.

-Usenewgasketforvalvecover.

-Tightendownvalvecover

screws

to4Nm.

•

Removethedipstickandcheck

theoillevel.

•

Ifoillevelislow,topupwith

freshengineoiltoedgeoffiller

neck.

-Screwdipstickhomeandtighten

downfirmly.

Changing

-Unscrewthedipstick.

-Tiptheenginetoonesideto

drainoilintoasuitablecontainer.

Note:Observesafetyprecautions-

see1.

FS25-4,65-4 13

Page 14

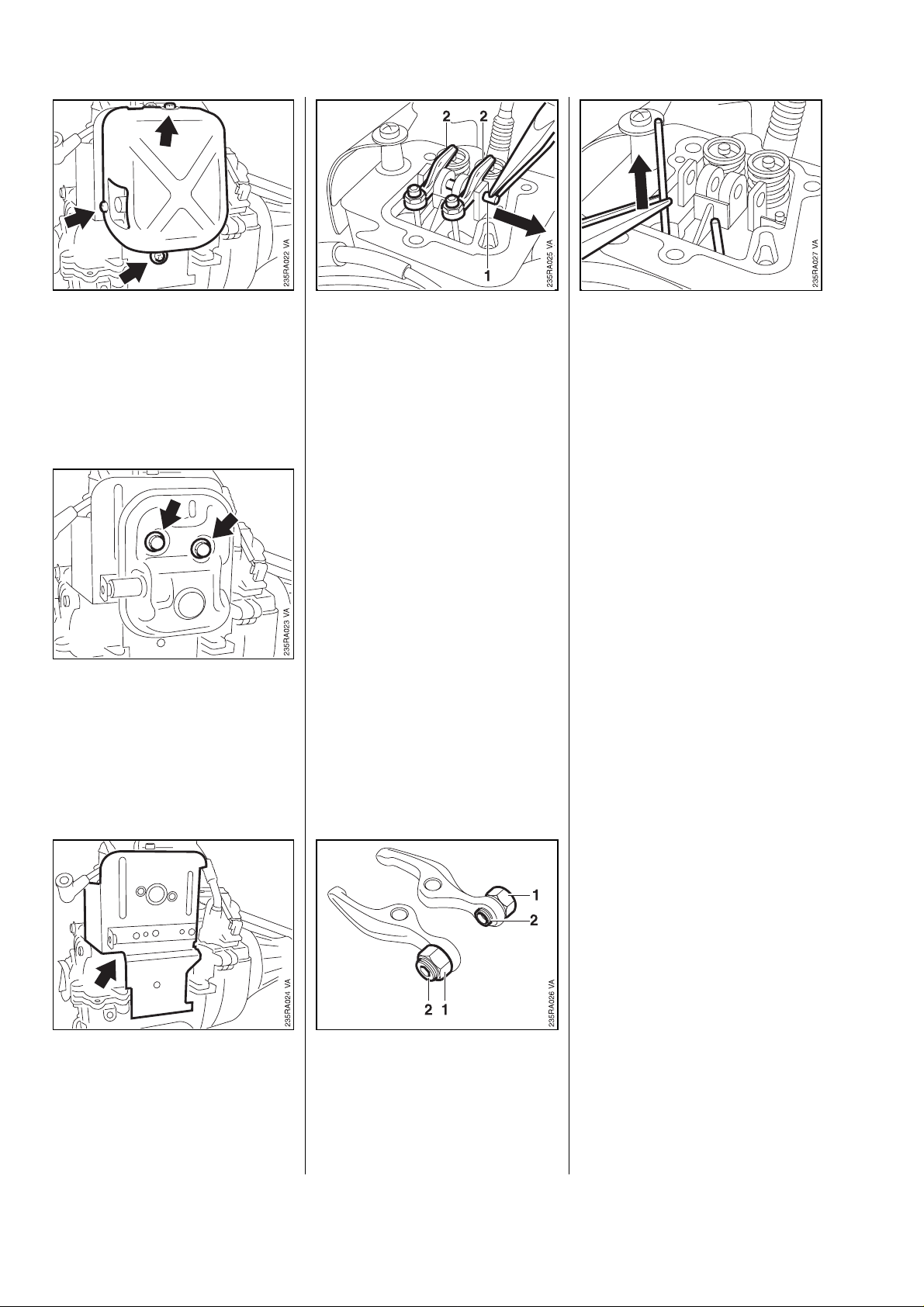

6.3 ExhaustMuffler 6.4 RockerArms/ Pushrod s

-Removetheshroud-see6.1.

•

Takeoutthescrews.

-Removetheguard.

•

Takeoutthescrews.

-Removethemuffler.

-Removethevalvecover-

see6.1.

-SetpistontoT.D.C.(bothrocker

armsrelieved).

•

Pulloutpin(1).

•

Removerockerarms(2).

•

Removethepushrods.

Assembleinthereverse

sequence.

-Pushrodsmustlocateproperly

intheadjustingscrews.

-Adjustvalves-see6.1.

•

Removecoverplate.

Assembleinthereverse

sequence.

Notedifferentlengthsofscrews.

14 FS25-4,65-4

•

Toreplace,slackenoffnut(1)

andtakeouttheadjusting

screw(2).

Page 15

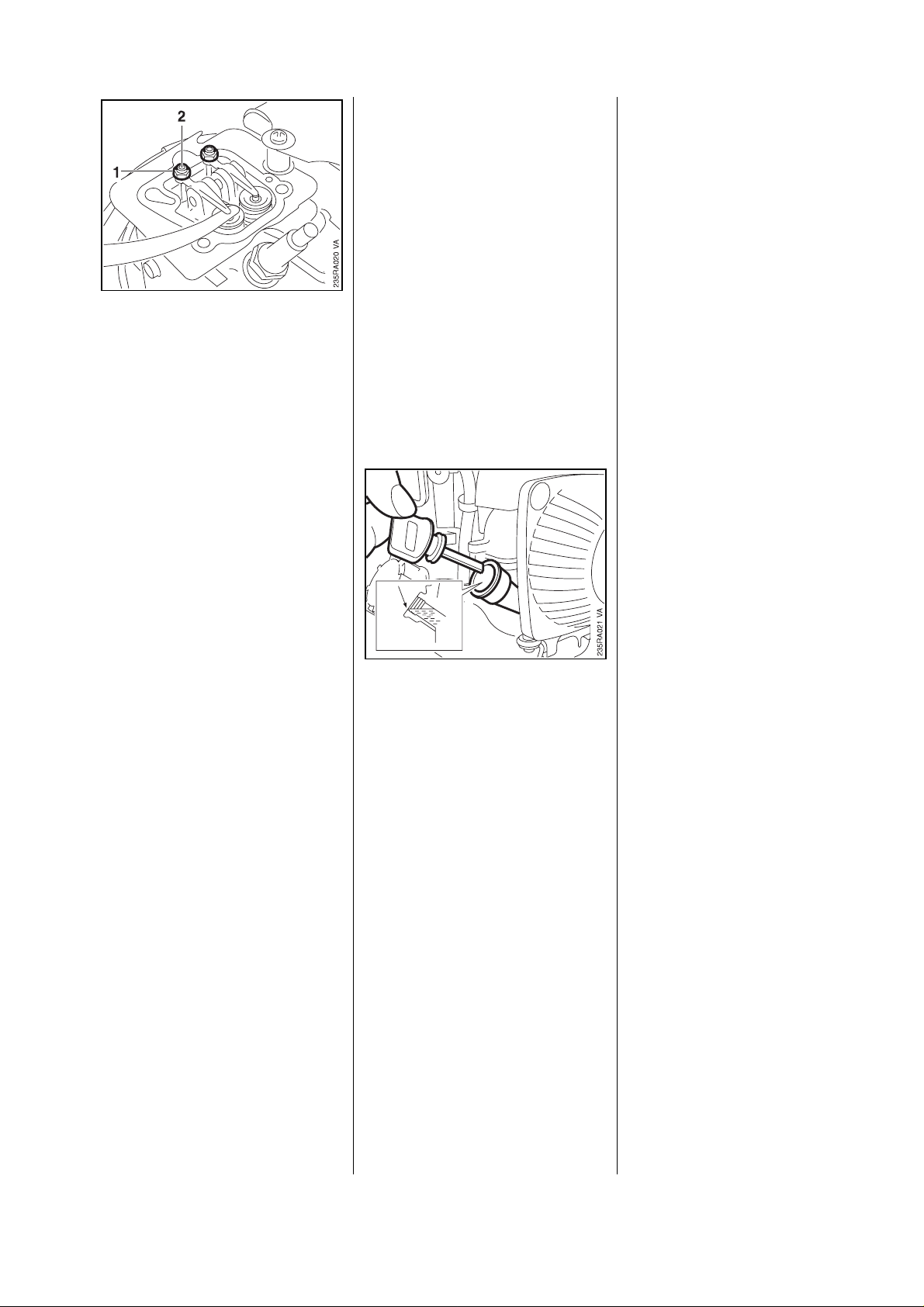

6.5 CamFollowers 6.6 CamGear 6.7 Diaphragm

-Removethepushrods-see6.4.

-Removetheflywheel

-see7.2.

•

Takeoutthescrews.

-Removethecover.

•

Pulloutpin(1).

•

Removethecamfollowers(2).

Installinthereversesequence.

-Thoroughlycleanthesealing

faceonthecylinderandcover.

-Applythincoatingofsealantto

cylinder-see14.2.

-Removethecamfollowers

-see6.5.

•

Pulloutpin(1).

•

Removethecamgear(2).

-SetpistontoT.D.C.:

Slot(1)incrankshaftpointsup.

•

Installcamgearsothatmarks

(2)lineupandthemarked

tooth(3)isinalignmentwith

theslotinthecrankshaft.

Important:Themarksmustnot

moveoutofpositionwhilecam

gearisbeingfitted.

-Drainengineoil-see6.2.

-Removethefueltank

-see11.6.

•

Takeoutthescrews.

-Removethecover.

•

Takeoutscrew(1).

•

Removethesupportplate(2).

•

Important:Followmanufacturer’s

instructions.

-Tightendownscrewsoncover

to3Nm.

-Installtheflywheel-see7.2.

-Installthepushrods

-see6.4.

FS25-4,65-4 15

Installthecamfollowers

-see6.5.

•

Removethediaphragm.

Page 16

6.8 Crankcase,

LowerHalf

•

Theangledcorneronthe

diaphragmandsupportplate

mustlineupwiththeanglein

thecrankcase(seearrows).

-Thoroughlycleanthesealingfacesonthecrankcaseandcover.

-Applythincoatingofsealantto

sealingfaceoncrankcase-

see14.2.

Important:Followmanufacturer’s

instructions.

-Fitthecover.

-Coatscrewthreadsandflanges

withengineoilandinsertscrews.

-Removecoveroverdiaphragm-

see6.7.

•

Takeoutthescrews.

-Takeawaythelowerhalfofthe

crankcase.

•

Unscrewdipstickifnecessary.

•

Checktoseeifoilreturnbores

areblocked.Blowclearwith

compressedairifnecessary.

-Thoroughlycleansealingfaces

onbothhalvesofcrankcase.

-Applythincoatingofsealantto

lowerhalfofcrankcase-

see14.2.

Important:Followmanufacturer’s

instructions.

-Tightendownscrewsto5Nm.

-Installcoveroverthediaphragm-

see6.7.

•

Initiallytightenscrewsin

sequenceshown(1to4)to

3Nm,thenfinallytightento

7Nminsamesequence.

16 FS25-4,65-4

•

Removegrommetsifnecessary.

Page 17

6.9 Crankshaft

-Removecamgearcover-

see6.5.

-Removethefanwheel-see8.6.

-Removelowerhalfofcrankcase

-see6.8.

-Ifoneofthesepartsisdamaged,

thecompletecrankshaftmustbe

replaced.

•

Rotatecamgearsothatthe

marks(1)areinalignment.

-Carefullypushthepistonintothe

cylinder.

Note:Thepistonringsandtheoil

scraperringarecompressedas

theyareeasedintothetapered

cylinder.

•

Turnthecrankshaftsothatthe

slot(2)pointstowardsthecam

gear.

•

Liftcrankshaftandpullpistonout

ofcylinderatthesametime.

-Inspectcylinderrunningface,

replacecylinderifnecessary-

see6.11.

•

Beforeinstallingthecrankshaft,

checkoilwayforblockages

andblowclearwithcompressed

airifnecessary.

-Coatpiston,pistonringsandoil

scraperringwithoil.

-Fitpistonringsothattheirgaps

areoffset120degrees.

Important:Ringgapsmustnotbe

inlinewithpistonpinbore.

•

Continuepushingpistoninto

cylinderandmakesurethatthe

markedtooth(3)linesupwith

theslot.

-Fitnewoilsealswiththeopen

sidefacingthecrankshaftand

pushcrankshaftfullyhome.

•

Removetheoilseals(1).

Note:Annularrib(1)mustengage

•

Inspectthepiston(2),ball

bearing(3)andoilsplash

plate(4).

FS25-4,65-4 17

groove(2).

Assembleallotherpartsin

thereversesequence.

Page 18

6.10 Valves/ValveSprings 6.11 Crankcasewith

Cylinder

-Removerockerarm/pushrods

-see6.4.

-Removethecrankshaft-see6.9.

•

Inspectseatsonexhaustvalve

(1),inletvalve(2)andcylinder

andreplacepartsasnecessary.

•

Checkfreelengthofvalve

springs(3),replacespringsifnecessary.

Assembleinthereverse

sequence.

Important:Donotmixupinlet

andexhaustvalves.

-Removethevalves-see6.10.

-Removethecamgear

-see6.6.

-Removethemuffler-see6.3.

-Removethecarburetor-

see11.2.2.

•

Pressvalvespringretainer(1)

downandmoveitsidewaysso

thatthevalvestemisinthelarge

hole.

•

Letgoofvalvespringretainer

andremoveittogetherwiththe

valvespring(2).

-Takevalvesoutofcylinder.

-Valvespringretainermust

engageproperlyingrooveon

valvestem.

•

Takeoutthescrews(1).

•

Removetheheatshield(2)and

spacerflange(3).

•

Takescrewsoutofspacerflange.

18 FS25-4,65-4

Page 19

7. Ignition System 7.1 Ignition Module

Warning! Exercise extreme

caution when carrying out

maintenance and repair work on

the ignition system. The high

voltages which occur can cause

serious or even fatal accidents!

Troubleshooting on the ignition system should always begin at

the spark plug. See "Standard Repairs, Troubleshooting" handbook.

•

Remove the gasket.

Assemble in the reverse

sequence.

- Use a new gasket.

•

Install spacer flange so that

recess (1) points down.

•

Secure connector tag (2) for

short circuit wire with the upper

screw.

Note: The electronic (breakerless)

ignition system basically consists

of an ignition module (1) and

flywheel (2).

The ignition module accommodates all the components required to

control ignition timing.

There are two electrical connections on the coil body:

1. the high voltage output with

ignition lead (1)

2. the connector tag (2) for the

short circuit wire

Accurate testing of the ignition

module is only possible with

sophisticated test equipment. For

this reason it is only necessary to

carry out a spark test in the workshop. A new ignition module must

be installed if no ignition spark is

obtained (after checking that

wiring and stop switch are in good

condition).

FS 25-4, 65-4 19

Page 20

7.1.1 IgnitionTiming 7.1.2 RemovingandInstalling

Ignitiontimingisnotadjustable.

Sincethereisnomechanicalwear

inthesesystems,ignitiontiming

cannotgetoutofadjustment.However,aninternalfaultinthecircuit

canaltertheswitchingpointin

suchawaythatasparktestwill

stillshowthesystemtobeinorder

althoughtimingisoutsidethe

permissibletolerance.Thiswill

impairenginestartingandrunning

behavior. -Removetheshroud-see6.1.

•

Takeoutthescrews.

-Removetheclutchhousingwith

drivetube-see12.4.

•

Disconnectshortcircuitwire

fromignitionmodule.

-Removetheignitionmodule.

•

Slipfeelergauge(0.4mm)

betweenthearmsoftheignition

moduleandtheflywheelmagnet

poles.

-Presstheignitionmodule

againstthefeelergaugeand

tightendownthemounting

screws.

Reassembleallotherpartsinthe

reversesequence.

•

Removeignitionleadfromthe

retainers.

20 FS25-4,65-4

Page 21

7.2 Flywheel

1

•

Usestrapwrenchtohold

flywheelsteadyandpullitoff.

VA

235RA138

Removingtheflywheel:

-Removetheclutch-see5.1.

•

Screwlockingscrew(1)4170

8931200intocylinderasfaras

stop.

•

Unscrewtheflywheelnut.

Inspecttheflywheel(1)and

magnetpoles(2)forcracksorotherdamage.Ifyoufindany

damage,installanewflywheel.

•

Checkcorrectpositionofkey.

•

Fitflywheelinposition,screw

onthenutandtightenitdown

to15Nm.

-Removelockingscrewfromcylinder.

Installingtheflywheel:

-Fitandtightendownthespark

plug.

Important:Cleanthestubofthe

crankshaftandtheflywheelhub

-Installtheclutch-see5.2.

borewithastandardcommercial,

solvent-baseddegreasantwhich

containsnochlorinatedor

halogenatedhydrocarbons

-see14.2.

•

Attachpuller(1)41198904501

toflywheelwithM6x25or

M8x25screws(2).

FS25-4,65-4 21

Page 22

8. RewindStarter

8.1 General 8.2 RopeRotor

Iftheactionofthestarterrope

becomesverystiffandtherope

rewindsveryslowlyornotcompletely,itcanbeassumedthat

thestartermechanismisinorder

butpluggedwithdirt.Atverylow

outsidetemperaturesthelubricatingoilontherewindspringmay

thickenandcausethespring

windingstosticktogether.This

hasadetrimentaleffectonthe

functionofthestartermechanism.

Insuchacaseitissufficientto

applyafewdropsofparaffin

(kerosine)totherewindspring.

Thencarefullypulloutthestarter

ropeseveraltimesandallowitto

rewinduntilitsnormalsmooth

actionisrestored.

Ifcloggedwithdirtorpitch,the

entirestartermechanism,includingtherewindspring,mustberemovedanddisassembled.Take

specialcarewhenremovingthe

spring.

Troubleshootingchart-see

"StandardRepairs,Troubleshooting"handbook.

-Removerewindstarterandtake

offthemachinesupport.

Relievetensionofrewindspring:

Note:Therewindspringwillnot

beundertensionifthestarterrope

isbroken.

-Pulloutthestarterropeabout

20cmandholdtheroperotor

steady.

•

Carefullypulltheroperotor(4)

offthestarterpost.

Caution:Therewindspringishousedintheroperotor.Itmaypop

outiftheroperotorispulledout

tooquickly.

-Removetherewindspring-

see8.5.1.

-Removestarterrope-see8.3.

-Lubricateboreinroperotorwith

STIHLspeciallubricant-

see14.2.

Washallpartsinparaffinorwhite

spirit.

Lubricatetherewindspringand

starterpostwithSTIHLspecial

lubricant,see14.2,before

installing.

-Locatestarterropeinthenotch

intheroperotor.

•

Usestarterropetoturnrotor

clockwiseuntilspringisnolongerundertension.

•

Fitroperotoronthestarterpost

sothattheinnerspringloop(1)

engagesthegroove(2)inthe

starterpost.

-Fitthecarrierwithspringsothat

thespringengagestheslotin

theroperotor.

Important:Donotturntherope

rotorclockwise.

-Insertscrewandtightenitdown

firmly.

-Tensiontherewindspring-

see8.5.2.

•

Takeoutscrew(1).

•

Removecarrier(2)with

spring(3).

22 FS25-4,65-4

Page 23

8.3 StarterRope 8.4 StarterGrip

-Removetherewindstarter.

-Pullstarterropeoutalittleand

holdtheroperotorsteady.

VA

362RA095

-Removetheroperotor-see8.2.

-Removethestartergrip-see8.4.

-Takeremainingropeoutofthe

roperotor.

•

Threadnewstarterropethrough

theholeinthesideoftherope

rotorandsecurewithoneofthe

specialknotsshown.

•

Pulltheropebacksothatthe

knotlocatesintherecessinthe

roperotor.

-Installtheroperotor-see8.2.

Standardgrip:

-Pullropeoutofstartergrip,untie

theknotandslipthegripoffthe

rope.

-Threadstarterropethroughthe

newgrip.

ElastoStart:

•

Prycapoutofstartergrip.

-Pullropeoutofstartergrip.

•

Threadendofnewstarterrope

throughtheundersideofthestartergrip.

-Secureendofropewithasimple

overhandknot.

VA

362RA096

•

Secureendofropewithoneof

thespecialknotsshown.

-Pullstarterropebacksothat

theknotissnuglyseatedinthe

startergrip.

•

Pulltheropebacktolocatethe

knotinthestartergrip.

-Pushcapintostartergrip.

FS25-4,65-4 23

VA

362RA097

Page 24

8.5 RewindSpring

8.5.1 Replacing 8.5.2 Tensioning

-Holdthestartergripfirmlyto

keeptheropetensioned.

-Letgooftheroperotorand

slowlyreleasethestarterrope

sothatitcanrewindproperly.

-Removetheroperotor-see8.2.

-Takeremainingpiecesofrewind

springoutofroperotorandstartercover.

•

Engagetheouterspringloopin

therecessandfittherewind

springcounterclockwiseinthe

roperotor,startingoutsideand

workinginwards.

-Lubricatedspringwithafew

dropsofSTIHLspeciallubricant-

see14.2.

-Installtheroperotor-see8.2.

-Tensiontherewindspring-

see8.5.2.

•

Locatestarterropeinnotchin

theroperotorandmakealoop.

•

Griptheropeclosetotherotor

anduseittoturntheroperotor

fivefullturnscounterclockwise.

Note:Therewindspringiscorrectlytensionedwhenthestartergrip

sitsfirmlyintheropeguidebush

withoutdroopingtooneside.If

thisisnotthecase,tensionthe

springbyoneadditionalturn.

Whenthestarterropeisfully

extended,itmuststillbepossible

torotatetheroperotoratleast

anotherhalfturnbeforemaximum

springtensionisreached.Ifthisis

notthecase,pulltheropeout,

holdtheroperotorsteadyand

takeoffoneturnoftherope.

Donotovertensiontherewind

springasthiswillcauseittobreak.

-Fitthesupportplate-see11.6.

•

Holdtheroperotorsteady.

•

Pullouttheropewiththestarter

gripandstraightenitout.

24 FS25-4,65-4

-Installtherewindstarter.

Page 25

8.6 StarterCup/Fanwheel

•

Slipascrewdriverbetweenthe

punchesandunscrewthestarter

cup.

-Removetherewindstarter.

-Removetheclutch-see5.1.

•

Fitclutchmountingscrews

intappedholesinflywheel.

•

Usescrewdrivertoblock

flywheelasshown.

•

Removefanwheelfromstubof

crankshaft.

Assembleinthereverse

sequence.

•

Tightendownstartercupto

8Nmviaflywheelnut.

•

Insertpunchinboresinstarter

cupandholdsteady.

FS25-4,65-4 25

•

Blockstartercupwithpunches

andscrewdriver.

Page 26

9. Throttle Control

9.1 Throttle Trigger/Interlock Lever (Bike Handle)

•

Take out screw and washer.

- Pull off the control handle.

Warning: To avoid risk of electric

shock, do not start the unit while

the control handle is open.

•

Remove screws with screwdriver

(1) 5910 890 2301.

•

Remove the torsion spring.

•

Take the throttle trigger (1) with

torsion spring (2) and throttle

cable (3) off the peg.

•

Attach the throttle cable, then

position torsion spring as shown

and push its long arm into the

slot.

•

The interlock lever must be

behind the throttle trigger.

- Separate two halves of handle.

•

Lift the interlock lever (1) slightly

and turn it to one side until the

torsion spring (2) is relaxed.

•

Pull the interlock lever off the

peg.

26 FS 25-4, 65-4

•

Disconnect throttle cable from

trigger.

Assemble in the reverse

sequence.

•

Check correct positions of

throttle cable (1), contact spring

(2), protective tube (3) and

insulator(4).

Page 27

9.2 ContactSprings/DetentSpringinControlHandle 9.3 ThrottleTrigger/Interlock

(BikeHandle) Lever(LoopHandle)

-Removethethrottletrigger

-see9.1.

•

Liftcontactspring(1)alittleand

removethethrottlecable(2).

•

Removespringfromseats(1)

andpeg(2).

•

Takeoutslidecontrol’scollar

screw(1).

•

Removedetentspring(2).

•

Pullslidecontroloutofhandle

molding.

Assembleinthereverse

sequence.

-Engagecontactspringcorrectly

ingrooveofcollarscrew.

•

Usescrewdriver(1)

59108902301toremovescrew.

•

Pushguard(2)forward.

Warning:Toavoidriskofelectric

shock,donotstarttheunitwhile

thecontrolhandleisopen.

•

Removescrewswithscrewdriver

(1)59108902301.

-Removehandlemolding.

•

Removecontactspringfrom

peg(1)andcollarscrew(2).

FS25-4,65-4 27

•

Removetorsionspring.

Page 28

9.4 SlideControl

(LoopHandle)

•

Pullthrottletrigger(1)with

throttlecable(2)offthepeg.

•

Disconnectthrottlecablefrom

trigger.

•

Pullinterlockleverwithcontact

springoffthepeg.

•

Removecontactspringfrom

interlocklever.

Assembleinthereverse

sequence.

-Removetheinterlocklever

-see9.3.

•

Pullslidecontroloffthehandle

molding.

•

Removescrewsfromclamps.

-Takehandlemoldingoffthedri-

vetube.

•

Liftcontactspring(1)alittleand

removethethrottlecable(2).

28 FS25-4,65-4

•

Checkpositionsofthrottlecable

(1),contactspring(2),protective

tube(3)andinsulator(4).

-Tightenscrewsto1.0Nm.

•

Removetorsionspringfrompeg.

Page 29

9.5 ThrottleCable

9.5.1 Replacing

-Removetheairfilter-see11.1.

-Takethrottlecableoffthecontactspring-see9.2.

Assembleinthereverse

sequence.

-Tightenclampscrewsto2.0Nm

•

Thegroove(1)intheslide

controlmustengageovertheouteredge(2)ofthehandlemolding.

•

Thetorsionspring(3)must

engagetherecess(4)intheslidecontrol.

•

Pullshortcircuitwireoffthe

connectortag.

•

Slackenoffnut(1).

•

Pullthrottlecable(2)outofholder.

•

Removeshortcircuitwire(3)

fromthethrottlecable.

•

Onbikehandle,takethrottle

cableoutofretainers.

Assembleinthereverse

sequence.

-Adjustthrottlecable-see9.5.2.

•

Disconnectthrottlecablenipple

(1)fromslottedpin(2)onthrottle

lever.

FS25-4,65-4 29

Page 30

9.5.2 Adjusting 10. AVSystem

Throttlelever(1)mustbuttagainst

housing(2)whenthrottletriggeris

squeezed(fullthrottle)andagainst

theidlespeedscrewwhenthe

triggerisintheidleposition.

Adjustmentiseffectedbymoving

thethrottlecableintheholder.

-Removetheairfilter-see11.1.

Rotatesleeveclockwiseto

moveleverclosertohousing.

Rotatesleevecounterclockwiseto

moveleverawayfromhousing.

-Lockadjustingsleevewithnut

(1)aftercompletingadjustment.

-Installtheairfilter-see11.1.

Theanti-vibration(AV)connection

betweentheengineanddrivetube

consistsofarubberelement

installedintheclutchhousing.

-Removethedrivetube

-see12.4.

-Removetheshroud-see6.1.

•

Slackenoffnut(1).

•

Rotateadjustingsleeve(2)as

required.

•

Takeoutthescrews.

-Removetheclutchhousing.

•

Usepliers(1)08116418380to

removeretainingringfromclutch

housing.

-Removeretainingringover

theAVsleeve.

30 FS25-4,65-4

Page 31

•

Push installing tool (1)

4126 893 4900 into AV sleeve

as far as stop.

•

Tighten down clamp screw (2).

•

Tighten the fixing screw (3)

moderately if necessary.

•

Release clamp screw (1) and

fixing screw (2) if necessary.

•

Pull the AV sleeve (3) off the

installing tool.

- Coat rubber element with a

lubricant (e.g. washing-up liquid).

•

Push the rubber element into

clutch housing as far as stop

so that slot (1) is opposite the

straight side (2) of the clutch housing.

- Apply a little lubricant (e.g.

washing-up liquid) between

the clutch housing and rubber

element.

•

Pull the rubber element off the

AV sleeve.

Assemble all other parts in the

reverse sequence.

- Retaining ring must locate

properly in the groove in the

clutch housing.

•

- Clamp installing tool in vice.

•

Pull clutch housing off the

rubber element.

FS 25-4, 65-4 31

Push the rubber element, larger

diameter (1) first, onto the AV

sleeve until the inner groove (2)

engages the annular rib (3).

Page 32

11. FuelSystem 11.2 Carburetor

11.1 AirFilter 11.2.1 LeakageTest

Dirtyandcloggedairfiltersreduce

enginepower,increasefuel

consumptionandmakestarting

moredifficult.

Theairfiltermustbecleaned

whenthereisanoticeableloss

ofenginepower.

-Closethechokeshutter.

-Cleanawayanyloosedirtfrom

aroundthefilterandfiltercover.

Washthefoamfilterinaclean,

non-flammablesolution(e.g.warm

soapywater)anddry.

Note:Replaceadamagedfoam

filterimmediately.

-Soakfoamfilterinfreshengine

oilandthensqueezeoutsurplus

oil.

-Installfoamfilter.

Troubleshootingchart-see

"StandardRepairs,Troubleshooting"handbook.

Important:Intheeventoftrouble

withthecarburetororthefuel

supplysystem,alwayscheckand

cleanthetankvent-see11.3.

Thecarburetorcanbetestedfor

leakswiththecarburetorand

crankcasetester11068502905.

-Removetheairfilter-see11.1.

•

Pressdownthetab.

•

Swingthefiltercoverdownwards

andliftitaway.

•

Removethefoamfilter.

•

Engagelugsonfiltercoverin

filterhousing.

-Swingfiltercoverupsothatit

snapsintoposition.

•

Pullfuelhoseoffcarburetor’s

elbowconnector.

2 1

•

Fitfuelhose(1)11101418600

onnipple(2)00008559200.

VA

143RA172

32 FS25-4,65-4

Page 33

•

Pushthefuelhosewithnipple

ontothecarburetorelbow

connector.

Ifthispressureremainsconstant,

thecarburetorisairtight.However,

ifitdrops,therearetwopossible

causes:

1.Theinletneedleisnotsealing

(foreignmatterinvalveseator

sealingconeofinletneedleis

damagedorinletcontrollever

sticking).

2.Themeteringdiaphragmis

damaged.

-Aftercompletingtest,openthe

ventscrewandpullthefuelhose

offtheelbowconnector.

-Pushthefuelhoseontothe

elbowconnector.

-Installtheairfilter-see11.1.

11.2.2 RemovingandInstalling

-Removetheairfilter-see11.1.

•

Pullbothfuelhosesofftheelbow

connectors.

•

Pushthenippleintothetester’s

pressurehose.

•

Closetheventscrew(1)onthe

rubberbulb(2)andpumpairinto

thecarburetoruntilthepressure

gauge(3)showsareadingof

approx.8kPa(0.8bar).

•

Disconnectthrottlecablenipple

(1)fromslottedpin(2)onthrottle

lever.

•

Pullventhoseoffthefilter

housing.

FS25-4,65-4 33

Page 34

11.2.3 AdjustingIdle

Speed

•

Unscrewnuts(1).

•

Removethesupportplate(2).

•

Pullthefilterhousing(3)away.

•

Takethesealingringoffthe

carburetor.

•

Removethegasket.

-Inspectspacerflangeand

replaceifnecessary-see6.11.

Assembleinthereversesequence.

-Installnewgasketandsealing

ring.

-Tightendownnutsto5.0Nm.

-Checktheairfilter,replaceif

necessary.

-Starttheengineandallowitto

warmup.

•

Adjustengineidlespeedwiththe

idlespeedscrew.

Turnclockwisetoincreaserpm.

Turncounterclockwiseto

reducerpm.

Note:Ifyouuseatachometer,

notethatthereisanignitionspark

oneachcrankshaftrevolution.

•

Pullcarburetoroffthestuds.

34 FS25-4,65-4

Page 35

11.3 Tank Vent 11.4 Pickup Body

Correct operation of the carburetor

is only possible if atmospheric

pressure and internal fuel tank

pressure are equal at all times.

This is ensured by the tank vent.

Important: If problems occur on

the carburetor or the fuel supply

system, always check and clean

the tank vent.

Check function by performing

pressure and vacuum tests on

the tank via the fuel hose.

Cleaning

- Unscrew the filler cap.

•

Ease the cap (1) off the valve

body (2).

•

Take the cap (3) out of the valve

body.

•

Remove sealing ring (4) from the

valve body.

- If the sealing ring is damaged, fit

a new fuel filler cap (5).

•

Wash valve body and valve (6)

in fresh gasoline.

The diaphragm pump draws fuel

out of the tank and into the

carburetor via the fuel hose. Any

impurities mixed with the fuel are

retained by the pickup body (filter).

The fine pores of the filter eventually become clogged with minute

particles of dirt. This restricts the

passage of fuel and results in fuel

starvation.

Important: In the event of trouble

with the fuel supply system,

always check the fuel tank and

the pickup body first. Clean the

fuel tank if necessary.

Cleaning the fuel tank

- Unscrew the filler cap and drain

the tank.

- Pour a small amount of clean

gasoline into the tank.

- Close the tank and shake the

unit vigorously.

- Open the tank again and drain it.

Equalization of pressure from the

outside inwards takes place via

the thread in the filler cap, the valve and holes in the cap.

Equalization of pressure from the

inside outwards takes place via

the holes in the cap, the slots in

the valve body and thread in the filler cap.

- If the valve is damaged, fit a new

fuel filler cap.

•

Insert cap (3) in the valve body.

•

Slip sealing ring (4) over the valve body.

•

Fit cap (1) on valve body and

push it home until it snaps into

position.

- Screw on the fuel filler cap.

Note: Dispose of fuel properly.

Pickup body

- Unscrew the filler cap and

remove it together with the

retainer.

FS 25-4, 65-4 35

Page 36

11.5 FuelHoses

•

Usehook(1)59108938800to

pullthepickupbodyoutofthe

fueltank.

•

Squeezeendsofhoseclip(1)

togetherandpushitdownthe

hose.

•

Pullthepickupbody(2)offthe

fuelhose.

-Pullfuelhosesoffthe

carburetor-see11.2.2.

•

Takefuelhosesoutof

theretainer.

•

Easethegrommetoutofthe

fueltank.

•

Squeezeendsofhoseclip(1)

togetherandpushitdownthe

hose.

•

Pullthepickupbody(2)offthe

fuelhose.

•

Pullthefuelhosesoutofthe

grommet.

Installinthereversesequence.

-Fitnewpickupbody.

Installinthereversesequence.

•

Pulloutfuelhoseswithpickup

body.

36 FS25-4,65-4

•

Pullfuelhosesintothe

grommetsothatthedistance

"a"is113-121mm,and

"b"is125-135mm.

Page 37

11.6 FuelTank

-Drainthefueltank.

-Pullfuelhosesoffthecarburetor,

see11.2.2,andoutofretainer.

-Removetherewindstarter.

-Removethetankguard.

•

Removethesupportplate.

•

Easethegrommet(1)outofthe

fueltank.

-Pulloutfuelhoseswithpickup

body.

•

Unscrewfillercap(2)with

removetogetherwithcap

retainer.

Assembleinthereverse

sequence.

•

Positionfueltanksothatthelugs

(1)engagethegrommets(2).

•

Inspectgrommetinsupportplate

andfitnewgrommetifnecessary

withthewiderflangefacingthe

fueltank.

•

Removethefueltank.

FS25-4,65-4 37

•

Inspectgrommetsincrankcase

andfitnewonesifnecessary.

Page 38

12. Shaft

12.1 Bike Handle 12.2 Loop Handle

- To replace left grip, carefully cut

it open and pull it off.

- Coat inside of new grip with a

little lubricant (e.g. washing-up

liquid).

Note: If too much lubricant is

used, the grip will twist on the

tube. Always leave it to dry for a

while after fitting.

•

Take out the screw.

Loop handle without barrier bar

- Pull off the control handle.

•

Unscrew the nuts (1).

•

Remove lower clamp (2),

support block (3), bike handle (4)

and upper clamp (5) with screws

(6).

•

Pushthegripintopositionso

that the longer ends (see arrows)

point toward the gearhead at an

angle of 7 - 15 degrees to the

shaft.

Assemble all parts in the reverse

sequence.

•

Unscrew the nuts (1).

•

Remove lower clamp (2).

•

Remove screws (1).

•

Remove the loop handle (2) and

upper clamp (3).

Reassemble in the reverse

sequence.

•

Use jaws (1) 5910 893 2700 to

clamp bike handle tube in vice.

38 FS 25-4, 65-4

•

Align the loop handle at

distance"A"=20cmfromthe

control handle and tighten down

firmly.

Page 39

12.3 DriveShaft/

FlexibleLiner

Thedriveshaftissupportedina

flexiblelinerinsidethedrivetube.

Theendsofthedrivetubearesealedwithplugs.

-Removethegearhead-see13.1.

A

VA

398RA179

Loophandlewithbarrierbar

•

Takeoutthescrews(1).

•

Removelowerclamp(2).

•

Removethebarrierbar(1),loop

handle(2)andupperclamp(3).

•

Takethesquarenuts(4)outof

thebarrierbar.

Driveshaft

•

Pullthedriveshaftoutofthe

drivetube.

Note:Iftheshafthasturnedblue,

fitanewone.

•

Pushthedriveshaftintothedrivetubeuntildimension"A"is23

mm.Ifnecessary,applyslight

pressuretotheshaftandrotateit

slowlyuntilitcanbepushedinto

thespecifieddimension.

-Fitthegearhead-see13.1.

Reassembleinthereverse

sequence.

-CoatthedriveshaftwithSTIHL

gearlubricant07811201109,

Flexibleliner

see14.2,beforeinstallation.

Important:Applythegrease

uniformlyandthinlytothewhole

driveshaft.Donotpumpgrease

directlyintothedrivetube.

-Pushthedriveshaftintothedri-

vetube.

•

Aligntheloophandleat

distance"A"=20cmfromthe

-Removethedrivetube

-see12.4.

controlhandleandtightendown

•

firmly.

Prytheplugoutofthedrivetube.

FS25-4,65-4 39

Page 40

12.4 DriveTube

-Removethedriveshaft

-see12.3.

-Removethebikeorloophandle

-see12.1or12.2.

•

Pullouttheflexibleliner.

•

Thehole(1)mustbebetween

thespokes(2).

-Insertplug,installthedrivetube

-see12.4.

•

Onmachineswithbikehandle,

takethrottlecableoutof

retainers.

•

Takethefixingscrew(1)outof

theAVsleeve.

•

Releasetheclampscrew(2).

-Pulloutthedrivetube.

•

Onmachineswithloophandle,

pullthedrivetube(1)outofthe

controlhandle(2)atthesame

time.

•

Onmachineswithloophandle,

releasescrewsoncontrolhandle

clamps.

40 FS25-4,65-4

•

Slipthethrottlecableretainer,if

fitted,offthedrivetube.

Page 41

13. CuttingToolDrive

13.1 Gearhead 13.2 ClutchDrum

-Takerubberelement(AV

system)outofclutchhousing

-see10.

•

Removescrewfromhoseclamp

forharness.

•

Pullthehoseclampapartand

takeitoffthedrivetube.

Reassembleinthereverse

sequence.

-Degreasetheclampmounting

area.

-Removedeflectororstop,iffitted.

•

Releaseclampscrews.

-Pullgearheadoffthedrivetube.

-Forfurtherdisassemblyand

assemblyproceduressee

"StandardRepairsandTroubleshooting"handbook.

-Degreaseclampmountingarea.

-Slidethegearheadontothedrivetube-turntheoutputshaft

backandforthatthesametime

sothatthesquareendofthedriveshaftengagesthesquaresokketinthedrivepinion.

-Pushthegearheadasfaras

stopandlineitup.

-Tightendownclampscrews

to8.5Nm.

-Refitthedeflectororstop.

•

Usepliers(1)08166101495to

removeretainingringfromthe

clutchdrumstub.

•

Pushthedrivetubehomesothat

theholeslineup.

-Tightendownfixingscrewto

2.5Nmandclampscrewto

5.5Nm.

FS25-4,65-4 41

•

Usedrift(1)11148934700to

pressclutchdrumoutofballbearing.

Page 42

•

Use pliers (1) 0811 641 8380 to

take retaining ring out of clutch

housing.

•

Use press arbor (1) 1118 893

7200 to remove ball bearing from

clutch housing.

Install in the reverse sequence.

•

Use drift (1) 1114 893 4700 to

press home clutch drum as far

as stop.

•

Use press arbor (1) 1118 893

7200 to press home ball bearing

as far as stop.

42 FS 25-4, 65-4

Page 43

14. Special Servicing Tools and Aids

14.1 Special Servicing Tools

No. Part Name Part No. Application Rem.

1 Puller 4119 890 4501 Removing flywheel

2 Crimping tool 5910 890 8210 Attaching connectors to

electrical wires

3 Carburetor and 1106 850 2905 Testing carburetor

crankcase tester for leaks

4 - Nipple 0000 855 9200

5 - Fuel hose 1110 141 8600

6 Torque wrench 5910 890 0301 0.5 to 18 Nm 1)

5910 890 0302 2)

7 Torque wrench 5910 890 0311 6 to 80 Nm 1)

5910 890 0312 2)

8 Spline screw socket T27x125 0812 542 2104 IS screws

9 Hook 5910 893 8800 Removing pickup body

10 Installing tool 4126 893 4900 Removing rubber element

from AV sleeve

11 Pliers 0816 610 1495 External retaining ring

on clutch drum

12 Pliers C19 0811 641 8380 Internal retaining ring

in clutch housing

13 T-handle screwdriver QI-T27x150 5910 890 2400 For all IS screws 3)

14 Screwdriver T20x100 5910 890 2301 Separating handle moldings

15 Assembly drift 1114 893 4700 Removing and installing

clutch drum

16 Vice jaws 5910 893 2700 Holding drive tube and bike

handle

17 Press arbor 1118 893 7200 Removing and installing ball

bearing in clutch housing

18 Assembly stand 5910 890 3100 Holding FS units

19 - Clamp 5910 890 8800 Holds drive tube of FS units

for repairs

(in conjunction with assembly stand)

20 Locking screw 4170 893 1200 Blocking crankshaft

Remarks:

1) Always use torque wrench to tighten DG/P screws.

2) Wrench has optical/acoustic signal.

3) On DG/P screws, use for releasing only.

FS 25-4, 65-4 43

Page 44

14.2 Servicing Aids

No. Part Name Part No. Application

1 Lubricating grease 0781 120 1111 Oil seals

(370 g tube)

2 Standard commercial, Cleaning crankshaft stub

solvent-based degreasant

containing no chlorinated or

halogenated hydrocarbons

3 STIHL special lubricant 0781 417 1315 Bearing bore in rope rotor,

rewind spring in rope rotor

4 Engine oil SAE 15W-40 Engine lubrication

5 Dirko sealant 0783 830 2120 Crankcase sealing faces

(100 g tube)

6 STIHL gear lubricant Drive shaft in drive tube

- 80 g tube: 0781 120 1109

- 225 g tube: 0781 120 1118

7 STIHL gear lubricant Gearhead lubrication

- 80 g tube: 0781 120 1117

- 225 g tube: 0781 120 1118

44 FS 25-4, 65-4

Page 45

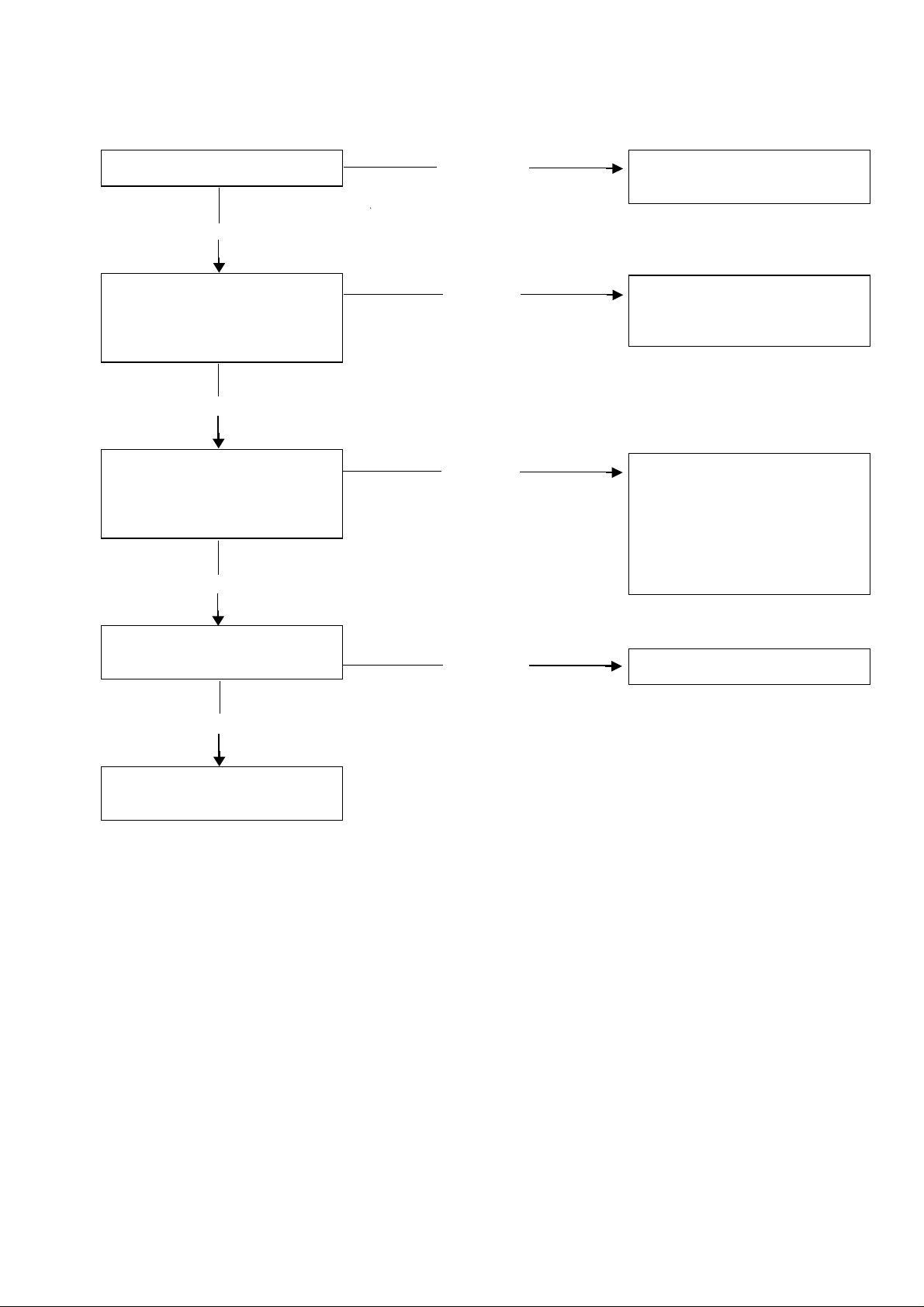

15.Maintenancechart

Pleasenotethatthefollowingmaintenanceintervalsapplyfornormal

operatingconditions

only.Ifyourdailyworkingtimeislongerthannormaloroperatingconditionsaredifficult

(verydustyworkareaetc.)shortenthespecif iedintervalsaccor dingly.

before starting work

and after each

refueling stop

or daily

after finishing work

in first month or

after 10 hours

every 3 months or

every 25 hours

every 6 months or

every 12 months or

every 50 hours

every 100 hours

if damaged

if faulty, if required

Engineoil

Completemachine

Checkoillevel

Change

Visualinspection(condition,leaks)

Clean

Controlhandle Checkoperation

Check

Airfilter

Clean

x

xx

xx

xx

xx

xx

Replace

Filterinfueltank

Check

Replace

xx

Fueltank Clean

Checkidlesetting-

Carburetor

cuttingtoolmustnotrotate

xx

Readjustidle

Sparkplug Readjustelectrodegap

Cylinderfins Clean

x

x

Allaccessiblescrewsandnuts

(notadjustingscrews) Retighten

Metalcuttingtools

Gearboxlubrication

Driveshaft

Visualinspection

Sharpen

Check

Topup

Check

Relubricate

Valveclearance Checkandadjustifnecessa ry

Fuellines Checkandreplaceifnecessary

xx

x

x

every2years

xx

xx

x

x

x

xx

x

FS25-4,65-4 45

Loading...

Loading...