Page 1

STIH)

Technical Information

New STIHL BR 500, BR 550 and BR 600 backpack blowers – Series 4282

Contents

1. Technical description

2. Specifications

3. Accessories

4. Service accessories and special tools

5. Service notes

08.2005

TI_08_2005_11_01_02.fm

englisch / English

Page 2

Page 2 Technical Information 08.2005

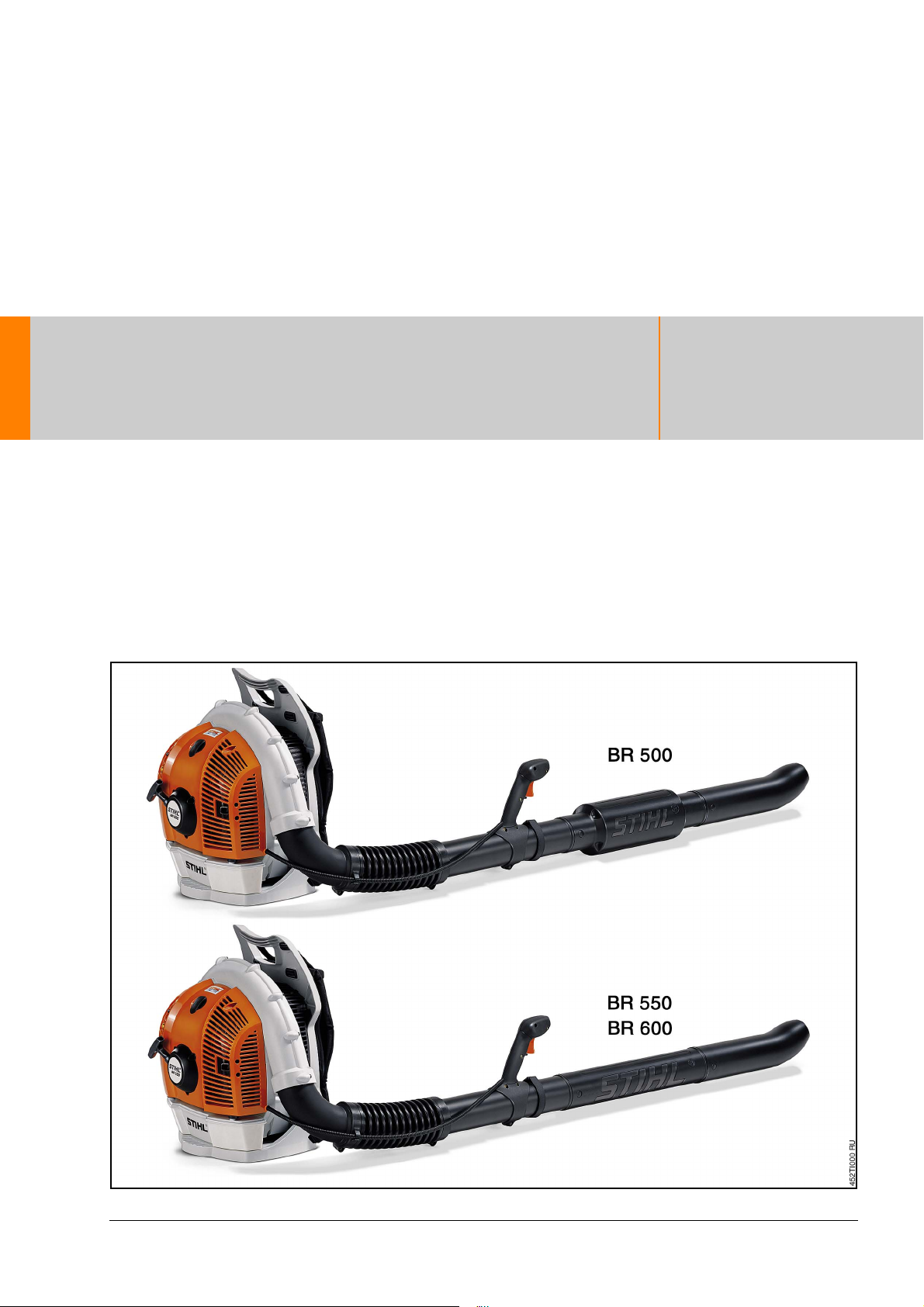

The new STIHL BR 500, BR 550 and BR 600

backpack blowers are three ideal models for

demanding, professional users.

The BR 500 is especially low-noise yet highly

powerful for use in noise-sensitive areas.

The BR 550 has an attractive price with far aboveaverage blowing strength.

The BR 600 is particularly powerful - one of the

strongest blowers in the world.

The STIHL 4-MIX engine of the new blowers sets

benchmarks in blowing strength, economy and

environmental friendliness.

Comfort is increased with the simplified starting

procedure. This is realised with the newly designed

control handle and central control section that holds

all operating elements required for starting.

Another innovation is the electrostatic arrester in the

blowing system that protects the user from

electrostatic shock.

The devices are equipped with an adjustable

carrying system with breathing padding for superior

wearing comfort.

The holder for the blowing system makes the

devices easier to transport and saves space in

storage.

1. Technical description

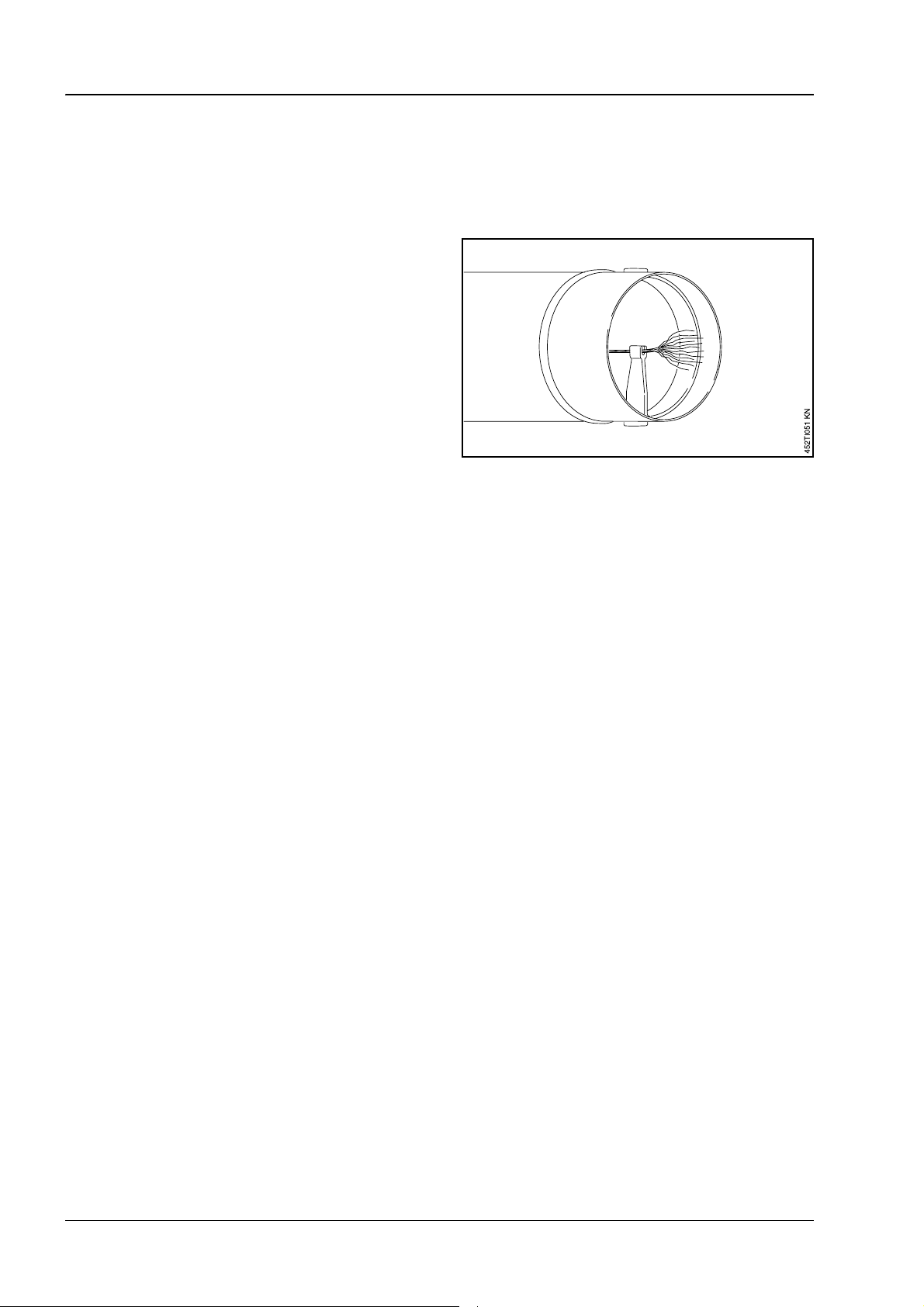

1.1 Blowing system with electrostatic arrester

The extremely high flow of air from the new blowers

generates friction in the blower tubes. The friction

can build up an electrostatic charge.

The arrester in the blower tube creates a conductive

link to the engine block to prevent the build up of

electrostatic charges that can lead to sparkover.

. Before starting the blower, check to see if it is

intact and seated correctly. If the arrester is

damaged, replace it (see 5.6).

. Never operate the machine without an arrester.

TI_08_2005_11_01_02.fm

Page 3

Technical Information 08.2005 Page 3

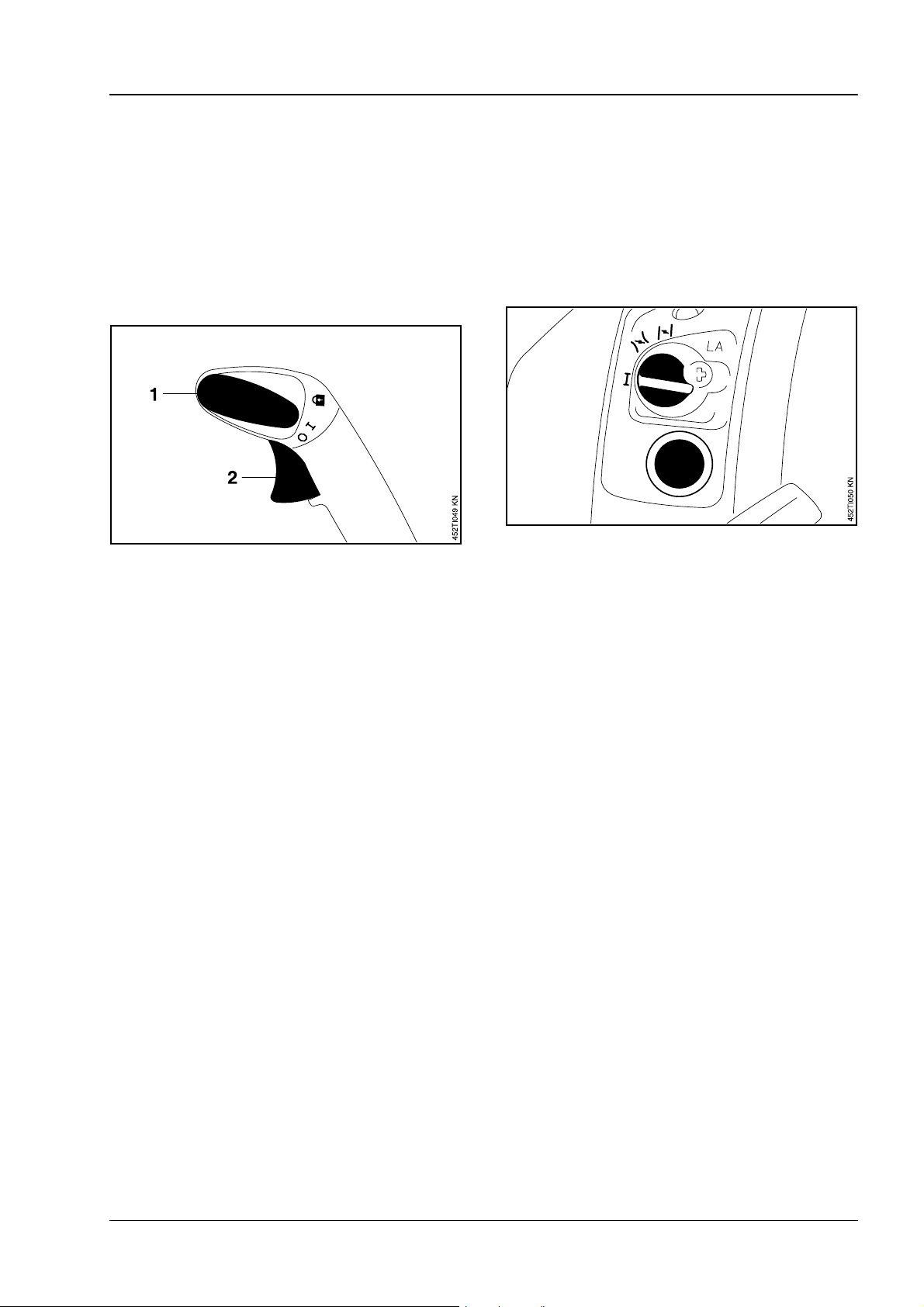

1.2 Control handle

For simplified starting, the choke does not have to

be set on the control handle.

Since the setting lever does not lock at

"Engine Stop" (0), the ignition system is

continuously ready to operate, and the blower can

be started at any time.

1

2

. Setting lever (1)

. Throttle trigger (2)

Engine stop (0)

. The ignition system is sent a stop pulse to shut

off the blower.

. The setting lever does not lock but rather

springs back – the ignition system is

automatically ready to operate.

1.3 Simplified starting

All operating elements for starting are on a central

control area. Set the starting throttle position with

the choke knob. The choke knob automatically

springs back into operating position after the throttle

trigger is actuated.

. Press the fuel pump bulb at least five times.

. Setting the choke knob:

When the engine is cold l

When the engine is hot n

. Pull the cord until the engine starts; at the latest,

set the choke knob to starting throttle position

n after the third time the cord is pulled.

. Set the choke knob to the starting throttle

position n

. Continue cranking until the engine runs.

Operating position (#)

. The engine is running or can start – the throttle

trigger can be smoothly actuated.

Set locked position (C)

. The throttle trigger can be locked at three levels:

1/3 gas, 2/3 gas and full throttle.

. To release the locked position, set the setting

lever to #.

To switch to idle:

. Pull the throttle trigger - the choke knob

automatically jumps to operating position #

or

. Set the choke knob manually to #

TI_08_2005_11_01_02.fm

Page 4

Page 4 Technical Information 08.2005

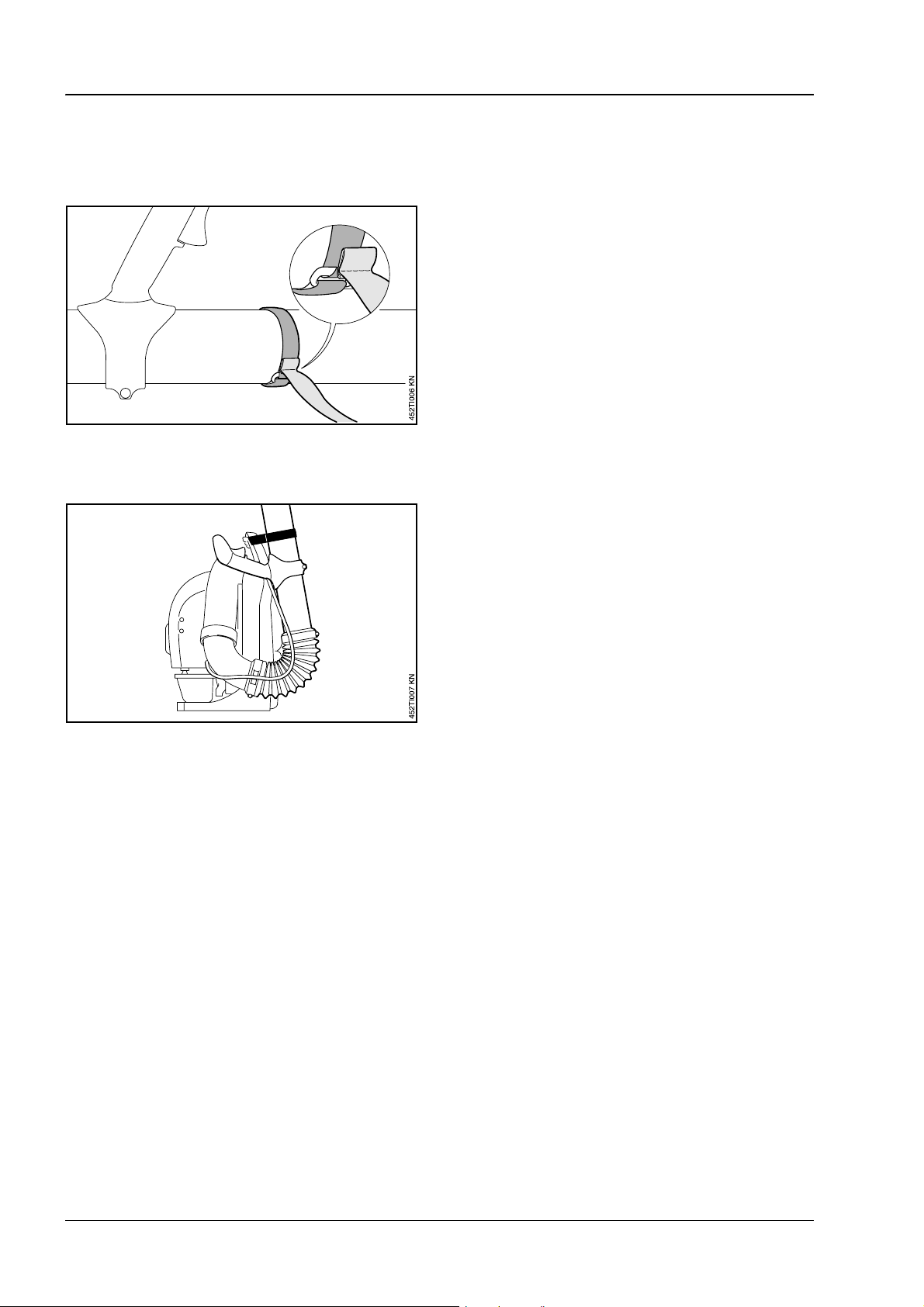

1.4 Blower holder

For storage and transport:

. Affix the Velcro tape to the blower tube, pull the

tab through the cinch.

1.5 STIHL 4-MIX engine

The 4-MIX engine works with mixed lubrication.

Unlike a conventional four-stroke engine, the 4-MIX

engine does not have any supply of oil in the

crankcase. The engine is lubricated entirely with a

mixture of petrol and engine oil.

This design yields the following advantages:

. Same fuel

. Lower fuel consumption

. Can be operated in all positions

. Fewer emissions

. Good acceleration

. Compact size – attractive design

. Advantageous power-to-weight ratio

. Easy maintenance – easy to service

. Pleasanter sound – lower noise level

. Fewer vibrations

. Lower starting force

. Affix the blower tube to the handle opening of

the back plate.

TI_08_2005_11_01_02.fm

Page 5

Technical Information 08.2005 Page 5

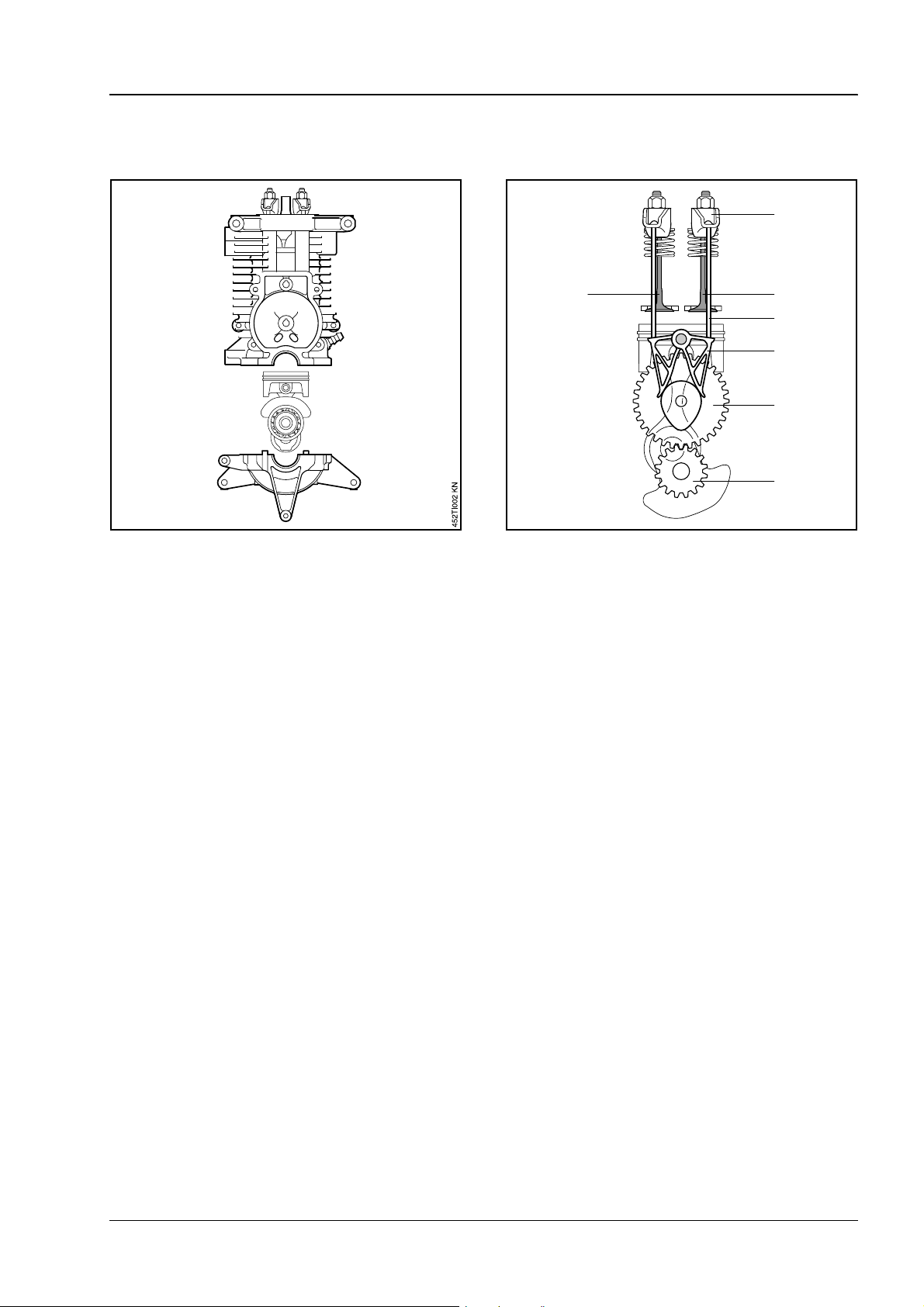

1.5.1 Engine design

Single-cylinder engine with overhead valves.

Cylinder head, cylinder and upper half of crankcase

have been combined into a single unit.

The crankcase is horizontally split along the

crankshaft.

1.5.2 Engine control

7

1

2

6

5

4

3

. Overhead valves (OHV), one exhaust valve (1)

and one inlet valve (2)

. Valve control via crankshaft gear (3),

cam disk (4), lever (5), pushrod (6) and

rocker arm (7)

254TI011 KN

. Crossflow scavenging

(= inlet and exhaust on opposite sides)

TI_08_2005_11_01_02.fm

Page 6

Page 6 Technical Information 08.2005

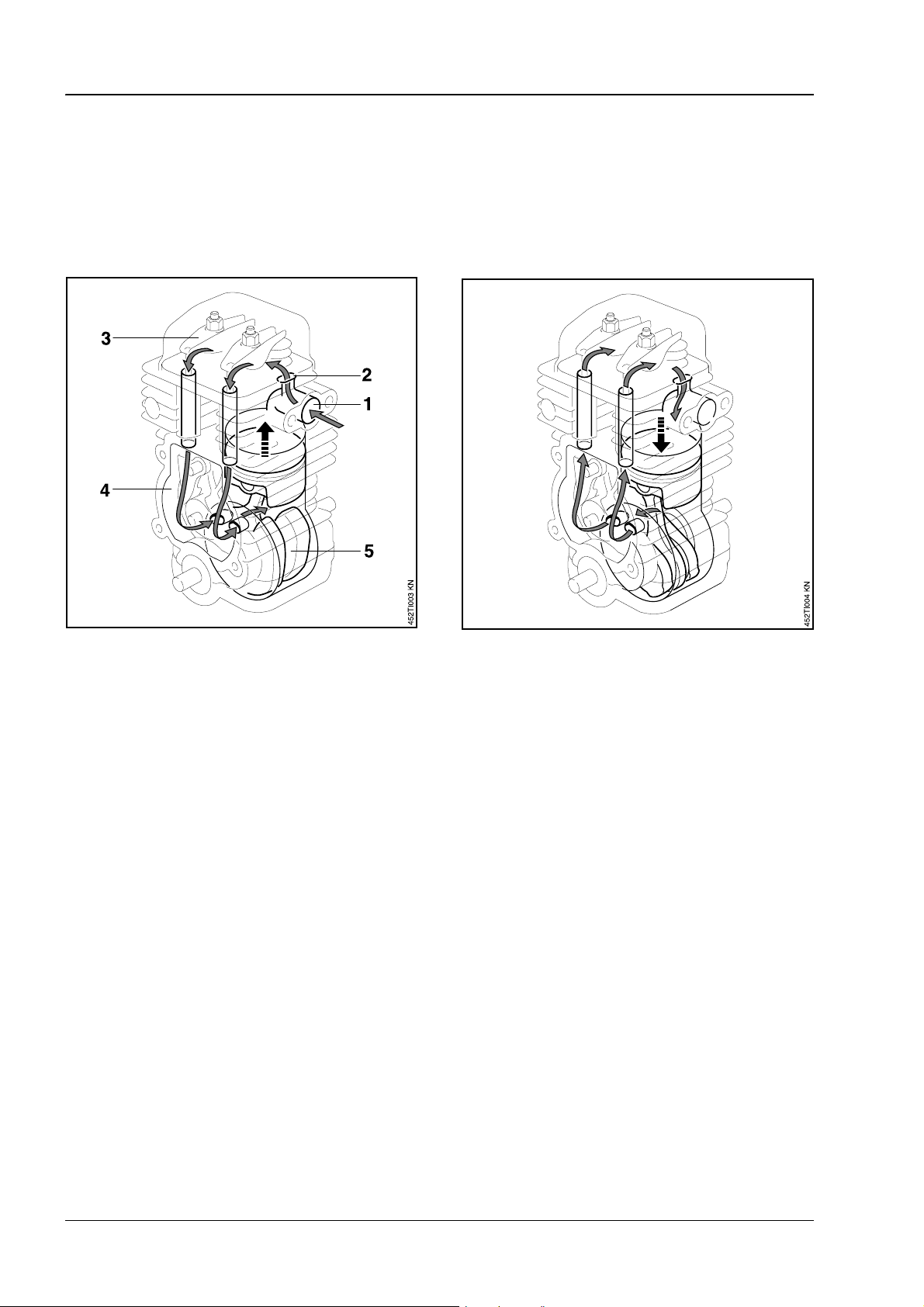

1.5.3 Engine lubrication

The engine is lubricated in two phases during each

revolution of the crankshaft.

Phase 1

The piston rises to the top dead centre.

Phase 2

The piston descends to the bottom dead centre.

The increase in volume in the crankcase produces

a vacuum. From the intake duct (1), the air-fuel-oil

mixture is drawn through the bypass port (2), valve

train (3) and timing gear (4) into the crankcase (5).

The oil contained in this mixture lubricates the

crankgear, timing gear, valve train and cylinder wall.

Excess pressure builds up in the crankcase due to

the decrease in volume.

The mixture of air, fuel and oil in the crankcase is

returned to the intake duct via the timing gear, valve

train and bypass bore. This rewets the lubrication

points.

TI_08_2005_11_01_02.fm

Page 7

Technical Information 08.2005 Page 7

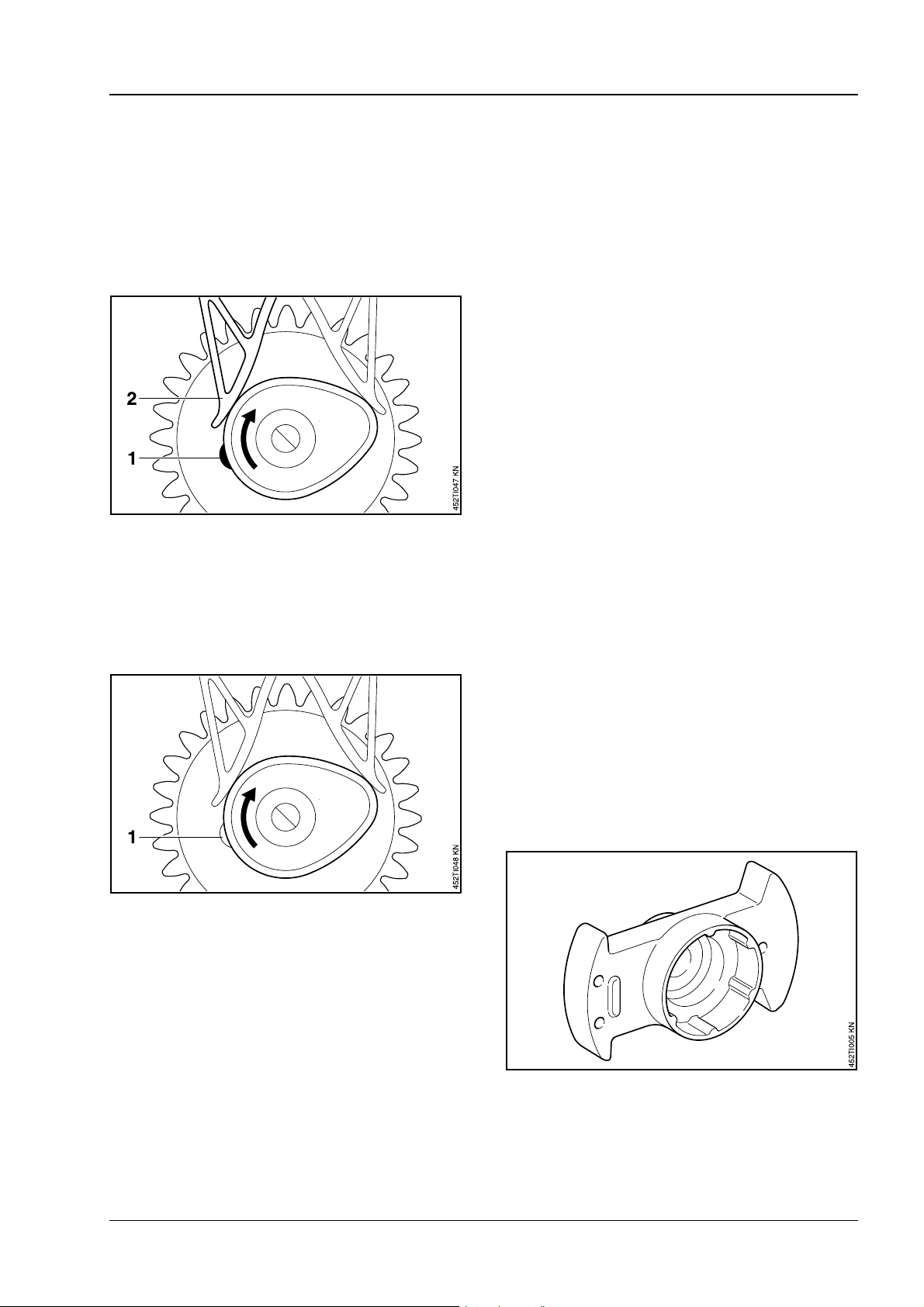

1.6 Decompression system

The automatic decompression system reduces the

compression upon starting and hence the required

pull on the starter rope.

Cam disk at low speed (starting):

. Decompression cam (1) projects and actuates

the lever (2)

. This lengthens the valve opening time, which

reduces the compression

Cam disk when the engine has started:

1.7 Carburetor

. All-position diaphragm carburetor with

independent idle

. The range of the high-speed adjusting screw (H)

and the low-speed adjusting screw (L) is limited

by limiter caps (approx. 3/4 turn). This limitation

ensures greater operating safety and

maintenance of future exhaust emission levels

. Accelerator pump for faster and spontaneous

acceleration (see 5.3).

. Choke knob with integrated starting throttle

position

1.8 Ignition system

. Microprocessor-controlled with ignition timing

adjustment

. Low power-up threshold

1.9 Air filter

. Large-area paper air filter for long filter service

life

. Easily accessible

. The centrifugal mechanism retracts the

decompression cam (1) – this cancels the effect

of the decompression cam

1.10 Muffler

. Two-chamber muffler with spark arresting

screen, depending on the market concerned.

1.11 Flywheel

. Weight-optimised geometry

TI_08_2005_11_01_02.fm

Page 8

Page 8 Technical Information 08.2005

2. Specifications

2.1 Engine

BR 500 BR 550 BR 600

Displacement 64.8 cm

Cylinder bore 50 mm

Piston stroke 33 mm

Idle speed 2,500 rpm

Operating speed with nozzle 5,500 rpm 6,100 rpm 7,200 rpm

Maximum air flow 1,380 m³/h 1,490 m³/h 1,720 m³/h

Air flow with nozzle 810 m³/h 900 m³/h 1,210 m³/h

Air velocity 81m/s 89 m/s 90 m/s

3

Sound pressure level L

to EN ISO 11201

Sound power level L

to ISO 3744

1)

1)

Vibration acceleration a

to ISO 8662

1)

Idle speed 1.7 m/s

at max. RPM 1.4 m/s

peq

according

weq

eq

according

86 dB(A) 92 dB(A) 96 dB(A)

95 dB(A) 103 dB(A) 105 dB(A)

2

2

1.5 m/s

1.6 m/s

2

2

1.7 m/s

1.8 m/s

Weight 9.9 kg 9.7 kg 9.5 kg

1

) Weighted equivalent level includes idling, full load and racing with the same duration of exposure

2.2 Fuel system

Carburetor

All-position diaphragm carburetor with limiter caps

Fuel tank capacity

1.4 l (1400 cm³)

on the high-speed adjusting screw (H) and the lowspeed adjusting screw (L) and integrated fuel pump.

Standard setting with limiter caps

Low-speed adjusting screw L: 3/4 turn open

(max. to stop)

2.3 Ignition system

Ignition module: Microprocessor-

controlled with

adjustment of the

High-speed adjusting screw H: 3/4 turn open

(max. to stop)

Spark plug (suppressed): NGK CMR 6 H

ignition timing

Electrode gap: 0.7 mm

2

2

Basic setting without limiter caps

Low-speed adjusting screw L: 2 turn open

High-speed adjusting screw H: 3 1/2 turn open

TI_08_2005_11_01_02.fm

Page 9

Technical Information 08.2005 Page 9

3. Accessories

Part name Part number Use

Nozzle 4282 708 6300 Straight nozzle for BR 500, BR 550

Nozzle 4282 708 6310 Straight nozzle for BR 600

Nozzle 4282 708 6320 Bent nozzle for BR 500, BR 550

Nozzle 4282 708 6330 Bent nozzle for BR 600

Hip belt 4282 710 9100 BR 500, BR 550, BR 600

4. Service accessories and special tools

4.1 Service accessories

Part name Part number Use

Grease (2 2 5 g tube) 0781 120 1111 Oil s e a l s, oil pum p d rive, sp r o c ket beari n g s , chain t e n s ioner

Bearing and sliding surfaces for throttle trigger, brake lever

and trigger interlock

STIHL special lubricant 0781 417 1315 Bearing bore in rope rotor, rewind spring in fan housing

STIHL Press Fluid OH 723 0781 957 9000 Rubber elements

Standard commercially

available CFC and HFC-free

solvent-based degreasing

agent

Sealing compound

Dirko HT red sealant

Set of parts for adjusting

valve clearance

Set of gaskets 4282 007 1010

0783 830 2000 Engine pan, oil seals (outside diameter)

4282 007 1001

Cleaning crankshaft stub and cone on flywheel

TI_08_2005_11_01_02.fm

Page 10

Page 10 Technical Information 08.2005

4.2 Special servicing tools

To be procured for the first time for the STIHL

BR 500, 550, 600:

Part name Part number Use

Stop screw 4282 890 2700 Block crankshaft

Sleeve 5910 893 1704 Fit hookless snap rings in piston

The available special tools are listed in the repair

instructions for the STIHL BR 500, 550, 600.

4.2.1 Stop screw

When servicing, always use stop screw

4282 890 2700.

Stop screw 4180 890 2700 can cause damage to

the piston and crankgear with the 4282.

In the future, stop screw 4180 890 2700 will be

replaced by stop screw 4282 890 2700. Stop screw

4282 890 2700 can also be used for the 4180.

4.2.2 Assembly tool

Use assembly tool 5910 890 2212 for inserting the

snap ring between the piston and piston pin.

The assembly tool must be combined with the new

sleeve 5910 893 1704 for the 4282.

TI_08_2005_11_01_02.fm

Page 11

Technical Information 08.2005 Page 11

5. Service notes

5.1 Carburetor adjustment

270°270°

With this carburetor, the high-speed adjusting

screw (H) and low-speed adjusting screw (L) can

only be adjusted by the user within a range of 270°

(3/4 turn).

The carburetor has been adjusted for optimum

performance and fuel efficiency in all operating

states.

Fine adjustments are still possible to adapt to

changed conditions of work and use such as

changes in elevation (mountains, sea-level).

The limiter caps are fitted over the knurled head of

the adjusting screws. The stop on the carburetor

housing serves as a limiter.

5.1.2 Maintenance / repair

249TI004 KN

When servicing, the limiter caps must be removed

when exchanging damaged adjusting screws or to

clean the carburetor.

. Remove limiter caps (2) with puller

5910 890 4501 (1).

Used caps may not be reused, as they are damaged

when pulled off.

5.1.1 Mechanical design

. Low-speed adjusting screw with sealing ring (1)

. Limiter cap for low-speed adjusting screw (2)

. High-speed adjusting screw with sealing ring (3)

. Limiter cap for high-speed adjusting screw (4)

. Stop (5)

. Idle speed adjusting screw (6)

Adjustment after maintenance / repair

. Check air filter and replace it if necessary.

. Check spark arresting screen (if installed) –

clean or replace if necessary.

. Check the throttle cable

TI_08_2005_11_01_02.fm

Page 12

Page 12 Technical Information 08.2005

5.1.3 Basic setting without limiter cap

. Starting from the tight position of the adjusting

screws:

Open H = 2 turns

Open L = 3 1/2 turns

Set the specified speeds within the tolerance range

of +/– 200 rpm.

1. Set speed to 3,300 rpm with idle speed

adjusting screw (LA).

2. Turn the low-speed adjusting screw (L)

clockwise or anticlockwise to set the highest

speed.

5.1.4 Securing the limiter caps

H

Used caps may not be reused, as they are damaged

when pulled off.

. Align the new limiter caps for the adjusting

screws on the stop knob (arrow) and press on

to the 2nd clearly locked position.

L

249TI007 KN

If this speed is greater than 3,700 rpm, stop and

start again with step 1.

3. Set the speed to 3,300 rpm again with idle

speed adjusting screw (LA).

4. Set the speed to 2,500 rpm with low-speed

adjusting screw (L).

5. Set the maximum speed with the high-speed

adjusting screw (H):

BR 500: 5,500 rpm

BR 550: 6,100 rpm

BR 600: 7,200 rpm

If you make the setting too lean it will increase the

risk of engine damage through lack of lubrication

and overheating.

6. Continue with "securing the limiter caps".

Do not press on the limiter caps until they contact

the carburetor housing since they would become

damaged:

Minimum distance a=1mm

TI_08_2005_11_01_02.fm

Page 13

Technical Information 08.2005 Page 13

5.2 Standard setting with limiter caps

The limiter caps must not be removed when making

the standard setting.

. Turn the high-speed adjusting screw (H) and

low-speed adjusting screw (L) anticlockwise as

far as possible (max. 3/4 turn).

See instructions for use, "Setting the carburetor," to

set the carburetor for users.

5.4 Valve clearance

The valve clearance must be checked once after

approx. 139 hours of operation and adjusted if

necessary.

The valve clearance may only be checked and

adjusted when the engine is cold. Kit 4282 007 1001

"Parts for adjusting valve clearance" must be used

for this purpose. The kit comprises a setting gauge,

O-ring and gasket.

5.4.1 Preparatory steps

. Remove the shroud with rewind starter

. Remove the lines from the ignition module

. Remove the air guide shroud.

. Unscrew spark plug

5.3 Accelerator pump

The carburetor is equipped with an accelerator

pump.

The pump piston (1) is located in the cylinder bore

(a) behind the throttle shaft (2) and is held in the idle

position by a compression spring (3).

When opening the throttle shutter, fuel is also sent

through the main nozzle into the the air cone

(Venturi valve) providing fast and spontaneous

acceleration.

. Clean area around valve cover

. Remove screw (1)

. Remove O-ring (2), valve cover (3) and

gasket (4)

. Determine top dead centre

TI_08_2005_11_01_02.fm

Page 14

Page 14 Technical Information 08.2005

5.4.2 Top dead centre

The top dead centre (TDC) is defined as the point at

which the piston ends its upward stroke and starts

its downward stroke. In a 4-MIX engine, the power

stroke is executed once in every two revolutions of

the crankshaft. The piston consequently passes

through the top dead centre twice in order to

execute one power stroke. Refer to the STIHL

Service Training System "Carburetor", under the

heading four-stroke principle.

Top dead centre, valve overlap

Top dead centre, ignition

2

3

1

Cam (1) points upwards.

The rocker arms (2) and valve stems (3) move up

and down (see arrows above) when the crankshaft

is turned back and forth a few degrees.

This represents the change of cycle between intake

and delivery.

254TI010 KN

2

3

1

254TI009 KN

Cam (1) points downward.

The rocker arms (2) and valve stems (3) do not

move up and down when the crankshaft is turned

back and forth a few degrees.

This represents the change of cycle between

compression and power stroke.

The valve clearance must be set at the top dead

centre for ignition. The inlet and exhaust valves

are only closed simultaneously in this position.

TI_08_2005_11_01_02.fm

Page 15

Technical Information 08.2005 Page 15

5.4.3 Determine top dead centre

. Rotate the crankshaft until the tip of the flywheel

(arrow) is flush with the ignition coil as shown

The piston is now at the top dead centre, valve

overlap, or in top dead centre, ignition.

5.4.4 Check valve clearance

The cam disk cover must be installed to "Check the

valve clearance“ and "Set the valve clearance“.

. Insert setting gauge (1) between rocker arm (2)

and valve stem (3) – the setting gauge must

produce a slight suction effect when it is pulled

through

. Turn the crankshaft back and forth a few

degrees – if the rocker arms and valve stems

move up and down (see arrows), the piston is in

the top dead centre for valve overlap

. Rotate the crankshaft once more until the tip of

the flywheel is flush with the ignition coil.

Rocker arms and valve stems do not move and the

piston is now in the top dead centre for ignition.

. Turn the crankshaft back anticlockwise

approx.1/4 turn and then slowly turn it clockwise

again until the tip of the flywheel is lined up with

the ignition coil.

The crankshaft must be turned backwards in order

to eliminate the flank backlash from the timing gear.

The valve clearance must be adjusted if it is found

to be too large or too small.

TI_08_2005_11_01_02.fm

Page 16

Page 16 Technical Information 08.2005

5.4.5 Set valve clearance

. Insert setting gauge (1) between rocker arm and

valve stem

Depending on the momentary valve clearance:

. Turn nut (2) clockwise to reduce the valve

clearance or anticlockwise to increase it – the

setting gauge must produce a slight suction

effect when it is pulled through

. Rotate the crankshaft twice until the tip of the

flywheel is flush with the ignition coil.

. Check the valve clearance again and re-adjust if

necessary

5.4.6 Assembly

Use the gaskets in kit 4282 007 1001 "Parts for

adjusting valve clearance".

. Fit gasket (1) in position (arrows)

. Fit valve cover and tighten screw with a torque

of 6 Nm

. Mount the air guide shroud

. Screw in spark plug, fit shroud, and plug in spark

plug boot

. Fit starter cover and tighten down screws

. Start engine and let it warm up

. Switch off engine

. Check engine does not leak

TI_08_2005_11_01_02.fm

Page 17

Technical Information 08.2005 Page 17

5.5 Test the compression pressure

In order to discharge the ignition voltage,

the ZAT 3 5910 850 4520 ignition system tester

must be mounted – high voltage shock hazard!

. Remove the ignition system tester from the

spark plug, and screw out the spark plug.

While using the ZAT 3, hold it only by the handle (4)

or position it in a safe place. Fingers and other body

parts must be at least 1 cm away from the spark

window, high-voltage terminal, ground connection

and ground terminal.

. Pull the rewind starter quickly and forcefully

(min. 1,000 rpm) as when starting.

. Read the compression –

the target is 7.5 ... 8.5 bar

If the compression is under 7.5 bar

. Check valve clearance, set if necessary and

recheck the compression

If the compression is still under 7.5 bar

. Check the cylinder, valve seat, piston and piston

rings for scoring and damage.

. Screw in compression tester 5910 850 2000 (1)

into the sparkplug hole.

. Connect the spark plug boot to the high voltage

terminal (1).

. Affix the ground terminal (2) to the muffler.

. Set the knob (3) for the spark gap to

approx. 2 mm.

TI_08_2005_11_01_02.fm

Page 18

Page 18 Technical Information 08.2005

5.6 Mounting the blower tube and arrester

. Clip the sleeve on the arrester into the holder

(arrow).

. Run the arrester (1) through the blower tube (2).

. Run the arrester (1) through the sliding ring (5).

. With its wide lip facing left, shove the sliding

ring (5) onto the blower tube end section (2).

. Run the arrester (1) through the hose clip (6)

(hose clip without the retention groove for the

throttle cable) – screw head facing forward.

. Run the arrester (1) through the pleated

hose (7).

. Shove blower tube (3) onto blower tube (2), and

lock the buttons (4)

. Shove the blower tube (2) into the pleated

hose (7).

. Tighten the hose clip (6) with the screw (8).

TI_08_2005_11_01_02.fm

Page 19

Technical Information 08.2005 Page 19

. Run the arrester (1) through the pleated hose

(7) and hose clip (9) (hose clip with the retention

groove for the throttle cable) – screw head and

retention groove facing forward.

. Shove the hose clip (9) onto the pleated

hose (7).

. Hook the discharge wire hook (1) in the

loop (10).

. Shove nozzle (13) (depending on the market

region) onto blower tube (2), and lock the

buttons (14).

Only operate the device when the arrester is

correctly mounted.

Check the following:

. The hook on the arrester is always in the loop

(arrow)

. Shove the pleated hose (7) with the hose clip (9)

in the shown position over the manifold (11).

. Tighten down the screw (12).

TI_08_2005_11_01_02.fm

. The sleeve on the arrester is always clipped in

the holder (arrow)

Page 20

Page 20 Technical Information 08.2005

5.7 Adjusting the throttle cable

After assembling the blower or after it has been

operated for a long time, the throttle cable may have

to be readjusted.

The throttle cable may only be adjusted when the

blower is completely assembled.

. Pull the throttle trigger all the way back.

. Carefully turn the screw in the throttle trigger

until it starts to encounter resistance.

5.8 Install tank vent

Tank vents must not be reused.

. Moisten the O-ring and bead with STIHL press

fluid.

. Centre the tank vent in the hole.

. Press in the tank vent until it locks; it must

audibly snap in.

TI_08_2005_11_01_02.fm

Page 21

Technical Information 08.2005 Page 21

5.9 Replace the pick-up body

Removal

Installation

. Remove the shroud with rewind starter

. Clean the connecting element (1) and

surrounding area.

. Carefully pry out the connecting element (1) with

the hoses and pick-up body.

. Replace the pick-up body.

Do not confuse the hose for the fuel return (2) and

suction hose (3):

The suction hose (3) has a larger inner diameter and

is connected to the hose for the pick-up body (4).

. Always use a new seal (5).

. Coat the entire seal with STIHL press fluid.

. The removal tab on the connecting element

(arrow) must lie in the recess of the fuel tank.

. Press in the connecting element until it locks; it

must audibly snap in.

TI_08_2005_11_01_02.fm

Page 22

Page 22 Technical Information 08.2005

5.10 Repair times

The repair times are specified for trained specialist

personnel and a fully equipped customer service

repair shop.

The repair times are specified in minutes.

Repair procedure

1 Removing and refitting the engine 60

BR 500

BR 550

BR 600

2 Crankcase, pressure test* 100

5.11 Location of the serial number

3 Pressure testing the crankshaft,

bearings*

4 Pressure testing the O-rings* –

5 Testing the crankcase for leaks,

100

40

trial run

6 Cylinder, piston, pressure test * –

7 Ignition system, contact 15

8 Fuel supply, tank vent, test run 15

9 Manifold or flange, pressure test 10

10 Carburetor, testing* 30

11 Blower tube and throttle control 10

12 Starter with trial run 10

13 Clutch, trial run –

14 Muffler 10

The serial number is on the cylinder below the valve

cover.

15 Air filter 5

16 Stop switch with trial run 10

17 Clutch housing –

18 Drive tube –

19 Replace gearhead or bearing

–

housing

20 Limit stop or deflector –

21 Drive shaft –

22 Fuel tank 10

23 Test the compression pressure 10

24 Set valve clearance 10

25 Replace crankcase, bottom half 150

26 Replace crankshaft 160

27 Replace cylinder, piston 180

28 Oil supply –

29 Oil pump, trial run –

30 Back plate 5

31 Strap 5

32 Fan housing 50

33 Fanwheel 30

34 Pleated hose with nozzle and

30

control handle

35 Arrester 30

* Trial run under load

© ANDREAS STIHL AG & Co. KG, 2005 Technical Documentation

D1/MTK-ru

TI_08_2005_11_01_02.fm

Loading...

Loading...