Page 1

DEUTSCH

D

8217-3033-01

Silencium

Page 2

S

SVENSKA

1.

2.

2

Page 3

SVENSKA

S

3.

4.

3

Page 4

GB

GENERAL

ENGLISH

• Faulty or damaged parts in the device must be

replaced immediately.

Your garden shredder is a high-quality, efficient

machine.

Please read the following instructions carefully to

ensure a long life of your garden shredder.

Do not operate machine before having

read the operating instructions, understood all the notes and a ssembly the machine as described here.

PROPER USE

The garden shredders aresuitableforprivate use in

gardens and allotments.

Regarded as garden shredders for private gardens

and allotments are those units which are not employed in public grounds, parks, sports grounds,

andinagricultureandforestry.

SAFETY INSTRUCTIONS

Repairs on electrical parts of the machine and on the safety cut-out must be

done by the producer or by a company

designated by the producer.

Please read the following safety instructions carefully.

• Within his area of work the operator will be responsible to third parties.

• The machine may not be used by operators under the age of 16.

• Keepchildrenawayformmachine.

• Wear protective goggles, gloves and noise protection while working with the machine.

• The connecting lead to DIN 57 282 (H 07 RN-F)

should be equipped with a rubber plug. The lead

section should be a minimum of 3 x 1,5 mm².

• Never use faulty connecting lines.

• Connect the machine using a fault current protection switch.

• Always switch off motor before maintenance

and cleaning of shredder. Remove mains plug

from socket (also during transport and when

leaving machine unattended).

• Never reach into the filling or ejection opening

when the machine is running.

• Do not spray machine with water (this is hazardous due to live components).

• Wear safety gloves during assembly and cleaning work.

• Never modify the machine or parts thereof.

• Onlyusethemachinefor the purposes listedunder Section “Chopping”.

• Do not leave the machine standing in the rain or

use wh en raining. Store the machine in a dry

place.

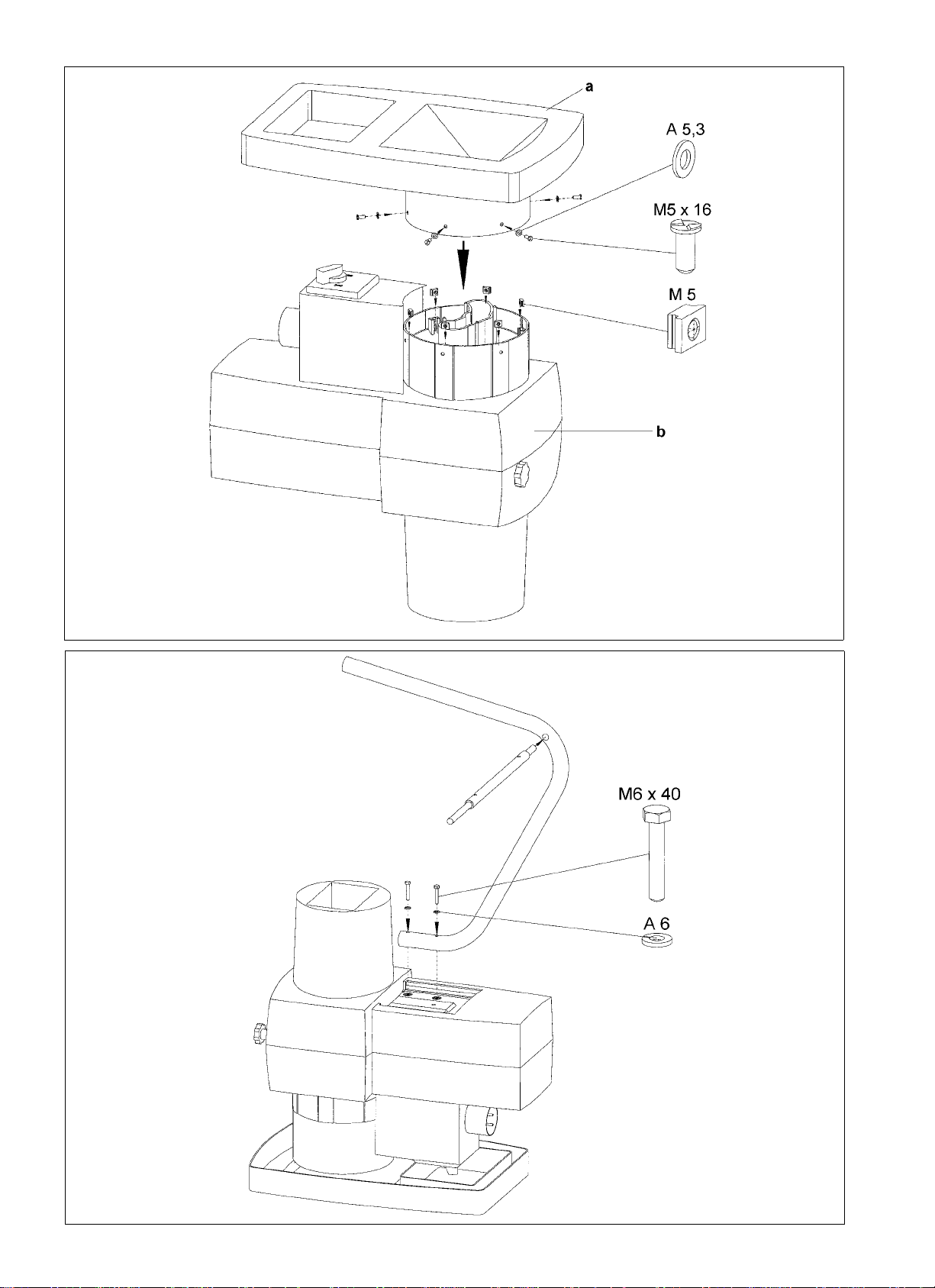

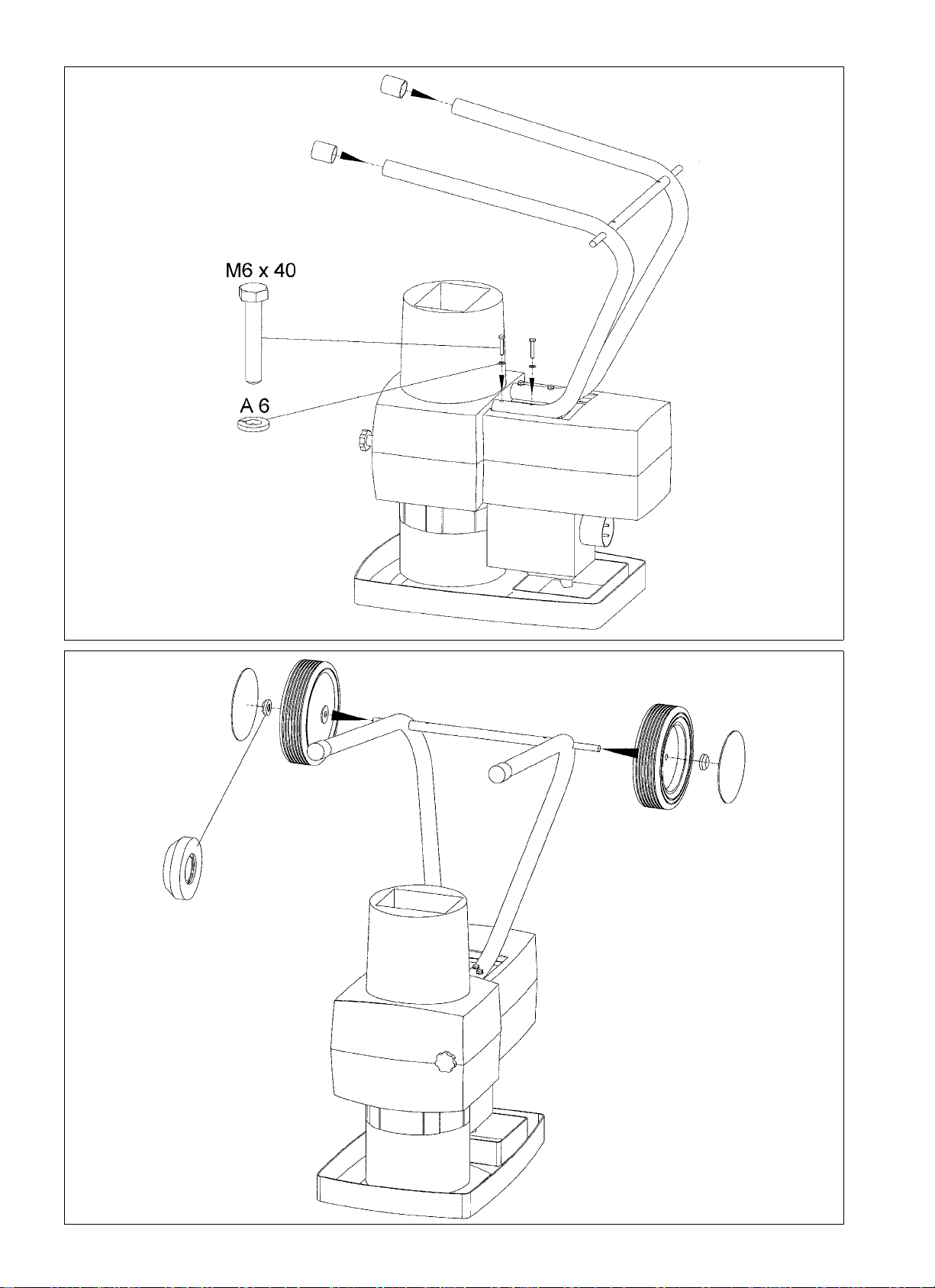

ASSEMBLY

See pages 4 - 5.

Use the enclosed disposable screws

(M5 x 16) to fit the funnel (a) to the preassembled machine (b). Otherwise no liability will be assumed!

START-UP

Checkthatthe machine is completelyandcorrectly

assembled.

To avoid toppling, place the chopper on a firm horizontal surface.

Connect the machine to an appropriate and correctly wired electric socket.

Only use extension leads with sufficient diameters:

- cable up to 25 metres: diameter at least 1,5

mm².

- cable over 25 metres:diameter at least 2,5 mm².

Fuse protection:

- for model 2000: 16 A inert

Before using the shredder, make sure each time

that:

- there are no faulty connections (tears, cuts, etc.)

-allscrewsaretight.

• Do not operate without the funnel.

4

Page 5

ENGLISH

GB

CHANGING THE DIRECTION OF

ROTATION

Alwaysswitchthedeviceoff,waituntilitcomesto

a standstill and shift the safety catch before changing the direction of rotation.

left position:

cutting rollers run backwardsand release blocked

shredding material

right position:

cutting rollers draw in and

cut shredding material

safety catch

Switch on:

Turn On-Off switch to “I”.

Switch off:

Turn On-Off switch to “0”.

CHOPPING

The cutter automatically draws the shredding materialintothe machinethroughthe slow rotationof

the cutting rollers.

If the machine is overloaded, a protective motor

switch ensures that the machine turns itself off automatically:

- turn the shredder on again after about 5

minutes.

- during those five minutes you cannot turn the

machine on. See “Operational faults”.

AUTOMATIC SWITCH-OVER IN THE DIRECTION OF ROTATION

If the unit suddenly clogs, the blades may start to

turn in the opposite direction and push the shredded material back out.

- switch off unit.

- wait until the blades come to a sta ndstill.

- switch unit back on and use material which is

easier to process.

ADJUSTING THE SHAVING PLATE

The cutting mechanism is adjusted in the works

and does not have to be set during initial commissioning.

What can I chop?

Yes:

- all types of branches.

- withered garden refuse which has lain a number of days. Only shred in alternation wi th

branches.

- hard wood, though only with sharp cutter.

No:

- glass, m etal, plastic, plastic bags, stones, cloth,

roots with soil.

- refuse which does not have a solid consistency,

e.g. kitchen waste.

SPECIAL TIPS ON CHOPPING

Pleasedo not exceed the maximum branch diameter specified for your appliance (see page 38).

Branches, twigs and wood should be broken down

immediately after they have been cut. Material of

this kinds gets very hard when itis dry,and it therefore makers sense to reduce the maximum branch

diameters, so that it is ready for chopping.

Remove any side shoots from branches with a

large number of twigs.

Switch on device (switch top right position)

Adjusting

knob

Turn adjusting knob in a clockwise direction with

the motor running until scraping noises are heard

and fine aluminium chips fall out o f the delivery

chute. Worn points on the shaving plate are optimally compensated.

This improves the cutting of the shredding

material.

MAINTENANCE AND CARE

Each time be fore starting maintenance work:

- switch off the motor and withdraw the mains

plug.

- wear protective gloves to prevent injury.

5

Page 6

GB

ENGLISH

Generally garden shredders require little maintenance. To maintain their efficiency and a long life,

observe the following:

- keep vent slits clean and freefrom obstructions.

- check the locking screws (tighten where necessary).

- clean the device after shredding.

- the shredder should not be cleaned with high

pressure cleaners or running water.

- treat the cutting roller after every use with a

biodegradable spray oil as protection against

corrosion.

- the cutting roller and shaving plate are expendable parts, though with normal use and

correct adjustment they have a service life of

many years.

SERVICE

Authorised service agents carry out repairs and

service. They use genuine spare parts.

Do you do basic repairs yourself? Then make sure

you use genuine spare parts. They fit immediately

and make your task easier.

When ordering spare parts please state the model,

part number and serial number.This information is

on the rating plate on the machine.

Do not fit any parts other than genuine

spare parts. This is a requirementof the

Testing Institute. The machine has been

tested and approved with these parts.

SPECIFICATION

Model 2000

Name of model AH 280

Motor AC-motor 230 V, 50 Hz,

S6 = 40% ED,

2800/40 min

Motor rating P1= 2000 W

On/Off switch With overload p rotection

With cutting and reverse

function

Weight 26 kg

Acoustic pressure

level at work L

(MeasuredtoRAL-UZ54,

DIN 45635Teil 1/05.84)

PA

79 dB (A)

Acousticcapacity

level L

(MeasuredtoRAL-UZ54,

DIN 45635Teil 1/05.84

WA

86 dB (A)

-1

The manufacturerreservesthe right to modify the product without prior notice.

GUARANTEE

This guarantee is valid for one year from the date

of purchase.

Any defects due to faulty materials or workmanship will be repaired free of charge at an authorised

service station.

Any machine returned by the purchaser for repair

must be in a clean condition.

Carriage costs to and from the service station are

the responsibility of the purchaser.

This guarantee does not apply to: Routine wear.

Careless use. Personal injury or damage to property. Machines that have been repaired at an unauthorised workshop.

Max. branch

diameter

fresh cut wood)

(only for

Safety class I

6

40 mm

Page 7

GB

ENGLISH

OPERATIONAL FAULTS

Problem Possible cause Remedy

Motor does not start. - No power supply.

- Mains cable defective.

- Machine overloaded.

Motor hums but does not

start.

Shredding material is not

drawn into the shredder.

- Cutting roller blocked.

- Capacitor faulty.

- Incorrect switch p osition.

- Shredding material caught in

funnel.

- Shredding material to soft or

wet.

- Cutting roller worn.

-Checkfuses.

- Have these checked (electrician).

- Overload protection triggered Turn OnOffswitchto“0”andletmachinecool

down.

- TurnOn-Offswitchtoleft,thenswitch

machine off and remove shredding material. If the blockage cannot be removed immediately switch the On-Off

switch between cutting and reverse a

number of times until the cutting roller

runs free.

- Bring machine to manufacturer or authorised workshop for repair.

- Turn On-Of switch to correct position.

- TurnOn-Offswitchtolefttorelease

shredding material, remove any dirt.

- Pushdownwithabranchandshred.

- Adjust shaving plate as described in

“Adjusting the shaving plate”, replace

cutting roller if heavily worn.

Shredding material not

cut cleanly.

Device starts but blocks

under as slight load and

switches off via protective

motor switch.

- Incorrect setting of shaving

plate.

- Extension cable too long or

cross-sectionto small Socket

too far from mains supply

and cross-section of mains

cable too small.

- Adjust shaving plate, if this cannot be

adjusted it has to be replaced by the

customer service department.

- Extension cable at least 1.5 mm², maximum 25 m long. If a longer cable is

used, minimum cross-section 2.5 mm².

8

Loading...

Loading...