Page 1

26_03_01_0106

270783

FEK

Control module

Operating and installation instructions

Page 2

Index

1. Operating instructions 2

for users and contractors

1.1 Equipment description 2

1.2 Equipment overview 2

1.3 Important information 2

1.4 Operation 3

1.5 Settings 3

2. Installation instructions 12

for contractors

2.1 Standard delivery 12

2.2 General 12

2.3 Installation 12

2.4 Specification 13

2.5 Commissioning 13

2

Page 3

1 Operating instructions for users and contractors

1.1 Equipment description

The FEK control module only works in

conjunction with the weather-compensated

WPMi control unit. It enables the convenient

entry and display of system parameters, e.g.

outside temperature, relative humidity and

heating circuit parameters (e.g. heating times

and required room temperature) for the

heating system from the user’s living room.

This allows the constant monitoring and

optimising of the heating system, both in

heating and in cooling mode.

In addition, hooking up a room temperature

enables the correction of the weathercompensated WPMi control unit.

1.2 Equipment overview

1.2.1 With closed control flap and standard

display

Relative humidity

Heating times

Time

Room temperature

Day

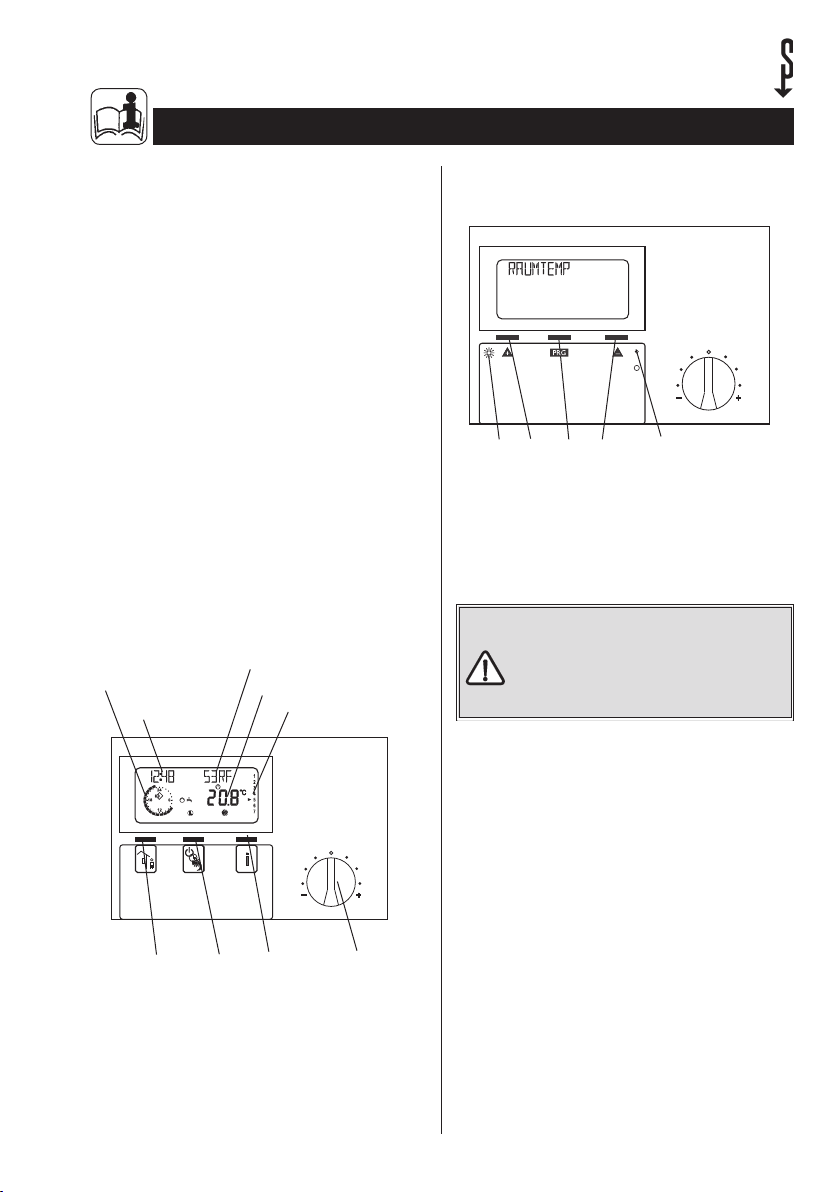

1.2.2 With the control flap open and with all

indicator elements on display

2

1

1 Programming indicator

2 + key

3 PRG key

4 - key

5 Reset

1.3 Important information

3 4

The control module must only be

installed and maintained by qualified

contractors.

5

C26_21_01_0011

1 2

1 Away key

2 Operating mode key

3 Help key

4 Rotary selector for changing the set

room temperature ± 5 K

3 4

1.4 Operation

The operation is split over three control levels.

Control levels

and contractors alike. Control level 3 is only

designed for qualified contractors:

Control level 1

This enables the adjustment of operating

modes, such as standby mode, programmed

C26_21_01_0010

operation, constant day or setback mode (for

this, see section 1.5.1).

Control level 2

This enables parameters, such as room

temperature, heating programs, etc. to be

adjusted (for this, see section 1.5.5).

1 and 2 are accessible to users

(control flap closed)

(control flap open)

3

Page 4

Control level 3 (for contractors only)

This level is protected by a code and should

only be used by contractors. At this level,

heat pump and system-specific details are

determined (for this, see section 2.5).

1.5 Adjustments (control level 1)

With the flap closed, the display shows the

operating mode, time and day, as well as

the current room temperature and relative

humidity.

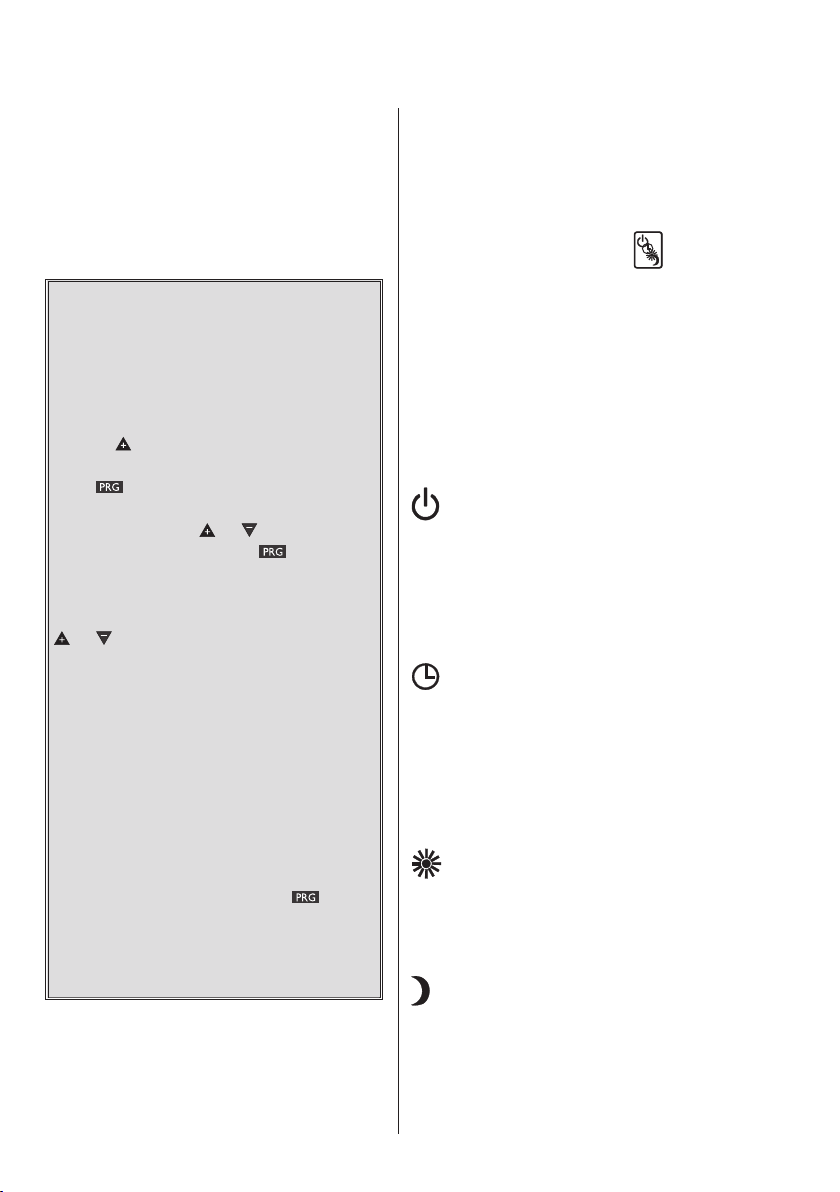

1.5.1 Operating mode key

Vital facts in brief

Settings

All adjustments follow the same pattern:

Opening the control flap toggles the FEK

to control level 2. The display shows the

parameter “room temp.”.

Pressing enables you to adjust the

parameter you want to change.

Press to change the value of the

parameter. You can change the currently

displayed value with

indicator is illuminated. Press again, the

indicator then extinguishes and the new

set value has been saved. You can modify

further values for this parameter by pressing

or , if the red indicator has not been

extinguished after saving.

The programming step can only be

terminated when the red indicator has

extinguished.

Terminating programming

You can terminate the programming process

after entering and saving the required

parameter changes by closing the control

flap. However, if you want to make further

changes, press one of the keys until the

display shows BACK, then press

will return you to the previous level. Closing

the control flap with illuminated indicator

returns the FEK into its original position. The

modified value will then not be saved.

or , when the red

. This

When connecting a FEK, only the operating

modes for the pre-selected heating circuit are

adopted by the WPMi.

You can select the required operating mode

by pressing this key several times with the

flap closed. The selected operating mode is

indicated by a symbol in the display. It becomes

effective if the setting was not changed for five

seconds.

Standby mode

Frost protection for the heating operation

is active. The standby symbol flashes, when

the heat pump manager is in standby

mode, and the operating mode cannot be

adjusted.

Application: During holidays.

Automatic mode

Heating according to time switch program.

Changeover between day temperature

and setback temperature. With this

operating mode, an additional symbol (sun

or moon) indicates in the display, whether

the heating circuit is currently in day or in

setback mode.

Constant day mode

The heating circuit is held at constant day

temperature.

Application: In low energy houses without

setback mode.

Constant setback mode

The heating circuit is held at constant

setback temperature.

Application: During weekends away.

4

Page 5

1.5.2 Away key

This key activates the eco mode (away).

Press twice: The heating circuit switches to

setback mode for one hour. The selected

heating interruption is briefly displayed in

hours.

Press this key several times: the heating circuit

switches for the respective number of hours

to setback mode. If no key is then pressed for

approx. three seconds, the display returns to

the standard display and the active heating

interruption is displayed by the flashing moon

symbol.

You can scan the selected heating interruption

by pressing the “Away” key once at any time.

Pressing the operating mode key deactivates

the “Away” period and the moon symbol will

extinguish.

1.5.3 Help key

Pressing this key allows you to scan

sensor

temperatures of the heat pump or heat

pump system, such as outside temperature,

actual DHW temperature, actual return

temperature, actual room temperature and

the relative humidity.

After you press this key, the first display is

the outside temperature. Continuing to

press displays, in sequence, the actual DHW

temperature, the actual return temperature,

the maximum and minimum room

temperatures and the maximum and minimum

relative humidity. The standard display returns

after five seconds.

The MIN/MAX values for room temperature

and relative humidity are constantly updated

and stored.

If you hold down the key for four seconds, the

top of the display shows DELETE VALUES. All

MIN/MAX values will then be deleted.

Any fault in the heat pump causes an arrow

above the help key and the attention symbol

to flash. Pressing the help key displays that

fault. Three seconds later, the fault display

extinguishes and the standard display returns

again.

1.5.4 Room temperature

You can adjust the room temperature by

+/- 5K with the rotary selector. This set value

adjustment applies to the then current heating

time, not to the setback time.

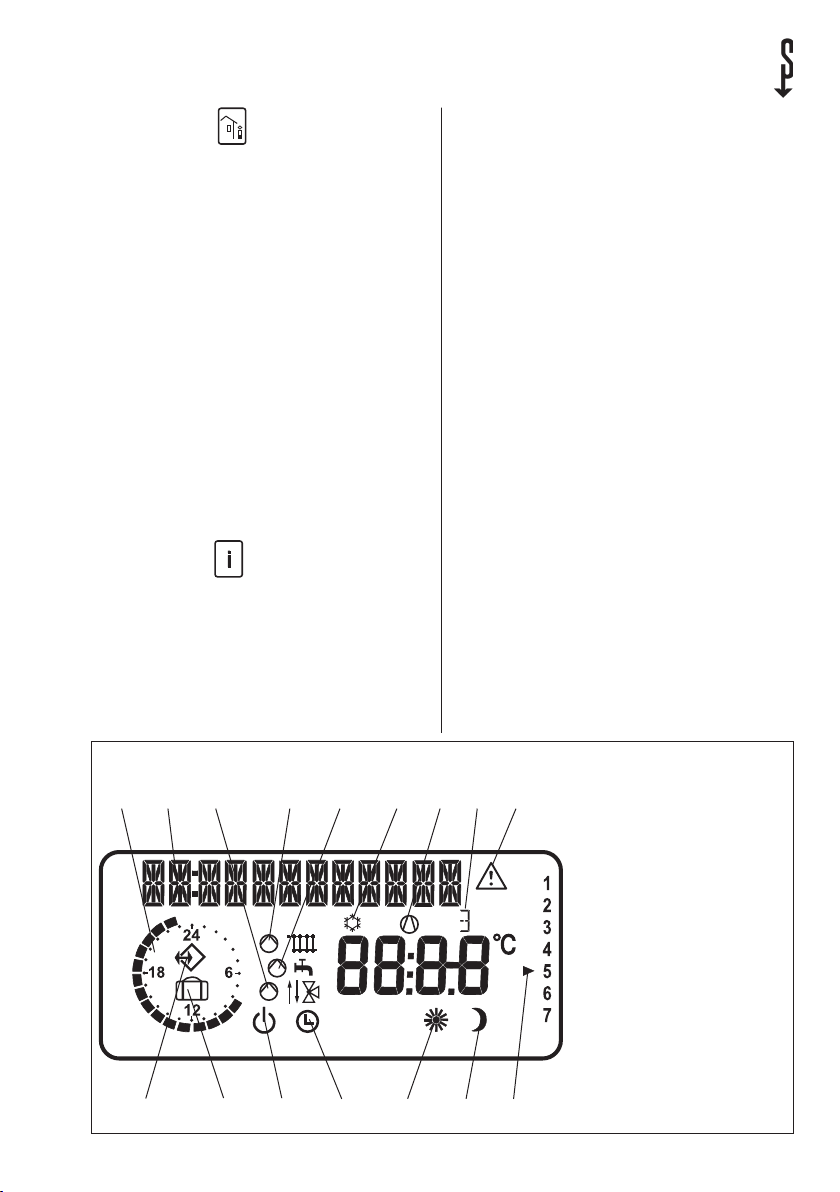

Display (including all elements)

1 2 3

10

11

4

5

6

12 13 14915 16

7 8

1 Heating times for central

heating and DHW (black)

2 12-digit plain text display

3 Mixer mode

4 Heating mode

5

DHW mode

6 Cooling mode

7 Compressor runs

8 Booster in operation

Stage 1, 2 or 3

9 Fault message (flashing)

10 ‘BUS connection to the

WPMi established

11 WPMI in away mode

12 Standby mode

13 Automatic mode

14 Constant day mode

15 Constant setback mode

16 Day

C26_21_01_0012

5

Page 6

1.5.5 Overview of system parameter (control level 2)

Select the required parameter with the rotary selector.

For adjustments to parameters, turn to page 6.

With the Room temp. parameter you can adjust the set

ROOM T

room temperature of the heating circuit for the day and

setback mode.

TEMPERATURES

HTG PROG

HTG CURVE

CONTRACTOR

The Temperatures parameter enables you to scan the

sensor temperatures of the heat pump or heat pump

system, comparing the actual with the set temperatures,

the relative humidity, etc.

In the Heating program parameter, you can adjust the

heating program.

In the Heating curve parameter, you can adjust the

heating curve. The room temperature will only remain

constant, irrespective of the outside temperature, if the

correct heating curve has been selected for the relevant

type of building. Selecting the correct heating curve is

therefore vitally important.

commissioning, you need to not only determine

During

the settings of control level 2, but also the system-specific

parameters. These parameters are adjusted at control

level 3 by your heating contractor, access to which is

protected by code.

.

6

Page 7

Adjustments at control level 2 for users and contractors

The heating curve, room temperature

and heating program parameters are

not shown at the WPMi heat pump manager,

if the FEK is pre-selected for a specific

heating circuit.

Room temperature

With the Room temp. parameters you can

adjust the set room temperature for the day

and setback mode. Changing these parameters

results in a parallel offset of the heating curve.

Open the control flap

ROOM T

SET DAY

SET HIGHT

SET HIGHT

ROOM T

BACK

Temperatures

SET DAY

SET DAY

SET HIGHT

The Temperatures parameter enables you to

scan the following sensor temperatures of the

heat pump or heat pump system, comparing

the actual with the set temperatures,

relative humidity, etc.

– Outside temperature

– Actual room temperature

– Set room temperature

– Relative humidity

– Actual DHW temperature

– Set DHW temperature

– Actual heat pump return temperature

– System frost protection temperature

Note

No display, if the corresponding temperature

sensor is not connected.

.

the

7

Page 8

Open the control flap

TEMPERATURES

OUTDOOR TEMP

BACK

At all other times, the heat pump operates

in setback mode. You will already have

selected the corresponding set values for day

and setback mode under the Room temp.

parameter.

Example:

Your heating system should operate daily

from Monday to Friday at two different times,

i.e. from 05:30 h until 08:30 h and from 14:00

h until 22:00 h. For the weekend, your heating

system should provide heat from 08:30 h until

21:00 h.

Open the control flap

HTG PROG

MON-FRI

TEMPERATURES

Heating program

Under this parameter you have the option of

setting up a heating program, i.e:

– for every day of the week (Mo, ..., Su

–

Monday to Friday (Mo - Fr)

– Saturday and Sunday (Sa - Su)

– the whole week (Mo - Su)

You can adjust three switching time pairs (I, II,

III) for each of these options.This determines

when and how often the heat pump system

should heat in day mode.

8

)

ON

OFF

ON

Page 9

OFF

ON

SAT - SUN

ON

OFF

Heating curve

The Heating curve parameter allows you to

select a heating curve for heating circuit 1 or

2. Selecting the correct heating curve is vitally

important.

Note: Your contractor will have set up a

building and system-specific optimum heating

curve for the heating circuit. It relates to the

heat pump return temperature for heating

circuit 1 and to the mixer flow temperature for

heating circuit 2.

When adjusting the heating curve, the

calculated set return or flow temperature,

which is subject to the outside temperature

and the set room temperature, will be shown

at the top of the display.

Relative to +20 °C

Outside temperature

Relative to 0 °C

Outside temperature

Relative to -20 °C

Outside temperature

ON

ON

BACK

Relative to +20 °C

Outside temperature

Relative to 0 °C

Outside temperature

Relative to -20 °C

Outside temperature

26_21_01_0013

9

Page 10

Open the control flap

1,5

2

1,2

1

0,6

0,4

0,2

2,5

3

2018161412

10

8

6

4

2

0

-2-4-6

-8

-10

-12

-14

-16

-18

-20

100

80

60

40

20

Außentemperatur [°C]

Heizkreis 2 WP-Vorlauftemperatur [°C]

Heizkreis 1 WP-Rücklauftemperatur [°C]

0,8

HTG CURVE

BACK

Heating curve diagram

One heating curve respectively can be adjusted for heating circuit 1 and heating circuit 2.

At the factory, heating curve 0.6 is set up for heating circuit 1 and heating curve 0.2 for

heating circuit 2. These heating curves relate to a set room temperature of 20 °C.

Heating circuit 1, HP return temperature [°C]

Heating circuit 2, HP flow temperature [°C]

10

Outside temperature [°C]

26_03_01_0077

Page 11

2018161412

10

8

6

4

2

0

-2

-4

-6

-8

-10

-12

-14

-16

-18

-20

Außentemperatur [°C]

70

60

50

40

30

20

Tag-Betrieb

Absenk-Betrieb

Rücklauf- / Vorlauftemperatur [°C]

Adjustment of programmed changeover between day/setback mode

2018161412

10

8

6

4

2

0

-2

-4

-6

-8

-10

-12

-14

-16

-18

-20

Außentemperatur [°C]

Rücklauf- / Vorlauftemperatur [°C]

70

60

50

40

30

20

geänderte Heizkurve

The figure shows a standard heating curve with a slope of 0.8, relative to a set room

temperature for day mode of 20 °C. The lower curve represents the setback curve. For this,

a set room temperature for setback mode of 15 °C is used, in other words the heating curve

is subjected to a parallel offset.

Day operation

Setback operation

HP return temp. / flow temp. [°C]

Matching a heating curve to actual conditions

Example: During spring and autumn, the return or flow temperature of a heating system is

too low at an outside temperature between 5 and 15 °C, but is OK at outside temperatures

of ≤ 0 °C. This problem can be remedied by a parallel offset and a simultaneous reduction of

the heating curve. Prior to this adjustment, heating curve 1.0 was adjusted, relative to a set

room temperature of 20 °C. The dotted line indicates the modified heating curve at 0.83 and

a modified set room temperature at 23.2 °C.

HP return temp. / flow temp. [°C]

Modified heating curve

Outside temperature [°C]

26_03_01_0078

Outside temperature [°C]

26_03_01_0079

11

Page 12

2 Installation instructions for contractors

2.1 Standard delivery

FEK Part no: 22 01 93

Dimensions: 147 x 97 x 33 (mm)

2.2 General information

The FEK is vitally important for area cooling,

e.g. underfloor heating systems, area heating

etc. Apart from the room temperature, it also

determines the relative humidity to prevent

condensation.

2.3 Installation

The correct function of the control module can

only be assured if the following are observed:

– Fitting on an internal wall (not in a recess)

– No cover through curtains or similar

– External heat influence is prevented

(e.g. sun, heating system, TV set)

– Prevention of direct draughts

(next to windows and doors)

For fitting, remove

the top part of the

casing by levering a

screwdriver above

the opening in the

bottom part.

Secure the bottom part on the wall and

connect the BUS cable.

A Fixing holes

B Cable entry (knock-out)

C Terminals

Position the top part

of the casing centrally

at the upper edge,

hook into place and

then pivot down onto

the base, using only

26_21_01_0018

light pressure, and

push home.

26_21_01_0017

12

26_21_01_0016

Page 13

2.4 Specification

Supply voltage 12 V DC ± 15 %

Power consumption

EN 60529 IP 40

EN 60730 Protection class II

Clock backup > 10 hours

Permiss. ambient temp. during operation

Permiss. ambient temp. during storage

Room temperature sensor resistance

Tolerance in Ohm

Temperature tolerance

~ 25 mA

0 to 50 °C

- 20 to 60 °C

Test resistance NTC 5 k

± 1 % at 25 °C

± 0.2 K at 25 °C

Ω

2.5 FEK commissioning

Only approved contractors may commission

this control module and instruct the owner

in its use.

Not only the adjustments at control level 2

but also the system-specific parameters must

be determined as part of commissioning the

FEK. These parameters are adjusted at control

level 3, access to which is protected by code.

To reach this point, press

“Contractor” parameter, then

press . Check all parameters in sequence,

Note: Not all adjustments take immediate

effect. Some adjustments only become effective

in certain situations or after a delay.

Code 1 0 0 0

Enter the correct four-digit code to change

parameters at control level 3.

The factory-set code is 1 0 0 0.

After pressing (indicator illuminates),

by pressing

Pressing again confirms the value, then

the second digit of the code begins to flash.

you can adjust the first digit.

, until you reach the

Pressing enables the adjustment of the

second digit of the code, etc. The display

shows CODE OK when all four digits have

been entered correctly. This enables access

to control level 3. Closing and re-opening the

flap requires that the code is entered again.

Checking settings does not require the code to

be entered.

Language

Press and select the required language

with . Then confirm your selection by pressing

.

Contrast

Press

SELECT REM CON

You can predetermine with parameter

selection, to which heating circuit the remote

control applies.

As standard, HC1 is pre-selected. Accordingly,

the parameters room temp., heating curve and

heating program for heating circuit 1 are not

displayed at the WPMi.

and adjust the contrast with

or .

FE

13

Page 14

FE Correction

This parameter enables the calibration of the

actual room temperature.

Room influence for FEK

Standard setting 5; adjustable from ----via

“0 to 20” dashes (----) in the display:

When the FEK control module is connected,

the room temperature sensor only serves

to capture and display the actual room

temperature; it has no influence on the actual

control. With any setting, you can adjust the

set room temperature for the heating circuit at

the FEK control module by ±5 K. This set value

adjustment applies for the then current heating

time, not for the setback time.

At the same time, setting “0 to 20” serves to

control the room temperature-dependent night

setback. This means, the heating circuit pump

is switched OFF at the point of changeover

from the heating into the setback phase. It

remains OFF, until the actual room temperature

first drops below the set room temperature.

Afterwards the system regulates in weathercompensated mode.

If you want the room temperature to be taken

into account, set the room temperature sensor

influence to > 0. The room sensor influence

has the same effect as the outside temperature

sensor has on the return temperature. Only

this effect is 1 to 20 times greater than the set

factor.

Room temperature-dependent return

temperature with weather compensation

With this type of control, a control cascade is

formed from weather-compensated and room

temperature-dependent return temperature

control. In other words, the weathercompensated return temperature control

pre-selects the return temperature, which is

corrected by the overlaid return temperature

control in accordance with the following

formula:

Because a substantial proportion of control

is already taken care of by the weathercompensated control, the room temperature

sensor influence K can be set lower than with a

purely room temperature control (

figure on page 15 indicates the control method

with the set factor K = 10 (room influence)

and a heating curve S = 1.2.

Room temperature control with weathercompensation

This type of control offers two substantial

benefits:

Incorrectly set heating curves are corrected

by the room temperature sensor influence

K, whilst the smaller factor K provides more

stable control.

However, observe the following for all control

units with room temperature sensor influence:

– The room temperature sensor must capture

the room temperature accurately.

– Open doors and windows severely

influence the control result.

– All radiator valves in the lead room must

always be fully open.

– The temperature inside the lead room is

decisive for the entire heating circuit.

Set the room temperature sensor influence to

> 0, if you want the room temperature to be

taken into account.

LCD test

Pressing once initiates a LCD test. All

display elements are displayed in sequence.

FEK software

Display of the current software issue.

K = 20). The

∆ϑR = (ϑ

14

Rset

− ϑ

Ractual

) * S * K

Page 15

20

30

40

20

50

60

70

80

90

Vorlauftemperatur [°C]

15 16 1917 18 21 22 23 24 25

Raumtemperatur [°C]

0

10

20

30

40

0

50

60

70

80

90

Vorlauftemperatur [°C]

20

-20

Außentemperatur [°C]

0

10

15

10

5

-5

-10

-15

Heizkurve

S = 1,2

= S K (

- )

witterungsabhängiger Vorlaufsollwert bei

A

= -10°C

witterungsabhängiger Vorlaufsollwert bei

A

= 0°C

witterungsabhängiger Vorlaufsollwert bei

A

= 10°C

Raumfühlereinfluss bei K = 10 und S = 1,2

und Regelabweichung +/- 2 K

R

R soll R ist

26_03_01_0098

S = 1.2

Heating curve

Outside temp. [°C]

Flow temp. [°C]

Weather-compensated set flow temperature ϑ = 0 °C

Weather-compensated set flow temperature ϑ = -10 °C

Weather-compensated set flow temperature ϑ = 10 °C

Room temp. [°C]

and control deviation ± 2 K

Room influence at K = 10 and S = 1.2

∆ϑRoom = S * K * (ϑSet Room - ϑSet Room )

Room influence

Flow temp. [°C]

15

Page 16

www.stiebel-eltron.com

Stiebel Eltron International GmbH

Dr.-Stiebel-Str. 37603 Holzminden

Telefon 0 55 31/702

-0

Fax

055 31/702 - 479

E-Mail info@stiebel-eltron.com

Internet www.stiebel-eltron.com

Austria

Stiebel Eltron Ges.m.b.H.

Eferdinger Str. 73 A-4600 Wels

072 42-47367-0 Fax 07242-47367-42

E-Mail info@stiebel-eltron.at

Internet www.stiebel-eltron.at

Belgique

Stiebel Eltron S.p.r.l./ b.v.b.a.

Rue Mitoyenne 897 B-4840 Welkenraedt

087-88 1465 Fax 087-881597

E-Mail info@stiebel-eltron.be

Internet www.stiebel-eltron.be

Stiebel Eltron spol. s r.o.

K Háju

o

m 946 C�Z-15500 Praha 5-Stodulky

235 512 122 / 6111 Fax 251 116 111

E-Mail info@stiebel-eltron.cz

Internet www.stiebel-eltron.cz

France

Stiebel Eltron SAS

7-9, rue des Selliers

BP 85107 F-57073 Metz-Cédex 3

03-87-74 3888 Fax 03-87-746826

E-Mail info@stiebel-eltron.fr

Internet www.stiebel-eltron.fr

Great Britain

Exclusive Distributor:

Applied Energy Products Ltd.

Morley Way GB-Peterborough PE2 9JJ

08709 000420 Fax 01733-319610

E-Mail sales@applied-energy.com

Internet www.applied-energy.com

Magyarország

Stiebel Eltron Kft.

Pacsirtamezo´´ u. 41 H-1036 Budapest

012 50-6055 Fax 013 68-8097

E-Mail info@stiebel-eltron.hu

Internet www.stiebel-eltron.hu

Nederland

Stiebel Eltron Nederland B.V.

Daviottenweg 36

Postbus 2020 NL-5202 CA‘s-Her togenbosch

073-6 2300 00 Fax 073-6 231141

E-Mail stiebel@stiebel-eltron.nl

Internet www.stiebel-eltron.nl

Polska

Stiebel Eltron sp.z. o.o

ul. Instalatorów 9 PL-02-237 Warszawa

022-8 4648 20 Fax 022-8 466703

E-Mail stiebel@stiebel-eltron.com.pl

Internet www.stiebel-eltron.com.pl

Sverige

Stiebel Eltron AB

Friggagatan 5 SE-641 37 Katrineholm

0150-487900 Fax 0150-487901

E-Mail info@stiebel-eltron.se

Internet www.stiebel-eltron.se

Switzerland

Stiebel Eltron AG

Netzibodenstr. 23 c CH-4133 Pratteln

061-8 169333 Fax 061-8 169344

E-Mail info@stiebel-eltron.ch

Internet www.stiebel-eltron.com

Thailand

Stiebel Eltron Asia Ltd.

469 Moo 2, Tambol Klong-Jik

Amphur Bangpa-In Ayutthaya 13160

035-220088 Fax 035-221188

E-Mail stiebel@loxinfo.co.th

Internet www.stiebeleltronasia.com

USA

Stiebel Eltron Inc.

17 West Street West Hatfield MA 01088

04 13-247-3380 Fax 0413-247-3369

E-Mail info@stiebel-eltron-usa.com

Internet www.stiebel-eltron-usa.com

Irrtum und technische Änderungenvorbehalten · Subject to errors

and technical changes! · Sous réserve d‘erreurs et de modifications

techniques!

· Onder voorbehoud vanvergissingen en technische

wijzigingen! · Salvo error o modificación técnica! · Rätt till misstag och

tekniska ändringar förbehålls! · Excepto erro ou alteração técnica ·

· Omyly a

technické změny jsou vyhrazeny!

·

· Возможность неточностей и

технических изменений не исключается

CAP 270783/34075/1/8043 · HD · Subject to modifications. · 6.6701.394-00

Loading...

Loading...