Page 1

Owner’s Manual

Serial No. __________________________

Patent No. 6,435,806

Stellar Industries, Inc.

190 State Street • PO Box 169 • Garner, IA 50438

800-321-3741 • 641-923-3741 • Fax: 641-923-2812

sales@stellar-industries.com • www.xtralift.com

®

Manual Part No. 26339

Updated: 11/16/07

XtraliftPRO

Page 2

If you have questions about your Stellar equipment, please contact one of

the individuals below.

Part Orders, Technical Questions, and Information:

Jeff Horstman Ext. 353 jhorstman@stellar-industries.com

Randy Milhan Ext. 224 rmilhan@stellar-industries.com

Brian Goll Ext. 357 bgoll@stellar-industries.com

Warranty and Returned Goods:

Lisa Piklapp Ext. 351 lpiklapp@stellar-industries.com

Customer Service Manager:

800-321-3741

800-321-3741

800-321-3741

Dave Schwichtenberg Ext. 227 ds@stellar-industries.com

Contact Lisa Piklapp before returning goods

to:

Stellar Industries, Inc.

Return Goods

190 Bush Ave

Garner, IA 50438

Page 3

Introduction

Stellar Industries, Inc. products are designed to

provide many years of safe, trouble-free,

dependable service when properly used and

maintained. This manual provides installation

and operating procedures to help you obtain

efficient and dependable use from your Stellar

X-Tra-Lift. This manual also contains maintenance information, safety suggestions, optional

items, and other general information.

It is specifically recommended that all operating

and service personnel consider this manual as

mandatory reading material before installing,

operating, or servicing the X-Tra-Lift. Keep this

manual with the X-Tra-Lift at all times for easy

reference. If at any time you have questions,

please contact your X-Tra-Lift dealer or the

Stellar Industries, Inc. Customer Service

Department.

This manual does not cover all maintenance,

operating, or repair instructions pertinent to all

possible situations. This manual is not intended

as a training manual for beginners or unskilled

operators. It offers guidelines for correct and

safe usage of the X-Tra-Lift, maintenance

guidelines, basic installation, and troubleshooting guidelines. If you require additional information, please contact Stellar Industries, Inc. at

800-321-3741.

Stellar Industries, Inc. reserves the right to

update this material without notice or obligation.

X-Tra-Lift Capacity: Not to

Exceed 1300 LBS (590 KG)

WARNING!

X-Tra-Lift is not rated for roll bar

application.

Page 4

Table of Contents

Chapter 1 - Operation & Safety 1-1

Chapter 2 - Maintenance 2-1

Chapter 3 - Installation 3-1

Chapter 4 - Wiring and Hydraulic Controls 4-1

Chapter 5 - Safety Decals 5-1

Chapter 6 - Assembly Drawings 6-1

Chapter 7 - Options 7-1

Chapter 8 - Troubleshooting 8-1

Mounting instructions specific to vehicle year, make,

and model will be found in mounting kit shipped with

each X-Tra-Lift.

Page 5

Chapter 1 - Operation & Safety

IMPORTANT SAFETY INFORMATION. DO

NOT OPERATE THIS UNIT WITHOUT

FIRST READING THIS MANUAL.

Congratulations on your purchase of this

exciting new X-Tra-Lift Pro. We are sure you

will enjoy many years of satisfying use from

this high quality product. This manual contains very important safety and maintenance

information. Failure to read and understand

the information contained in this manual will

expose you to unnecessary risk. This is a

safe and reliable product when used as

intended. As with any product, intentional

misuse or failure to operate in a safe and prescribed manner is potentially dangerous.

OPERATING THE LIFT:

1. Prior to operating the lift, park on flat and level

ground.

2. Set the parking brake.

3. Lower the tailgate.

4. Check for overhead obstructions (i.e. wires,

limbs, building overhangs, etc.).

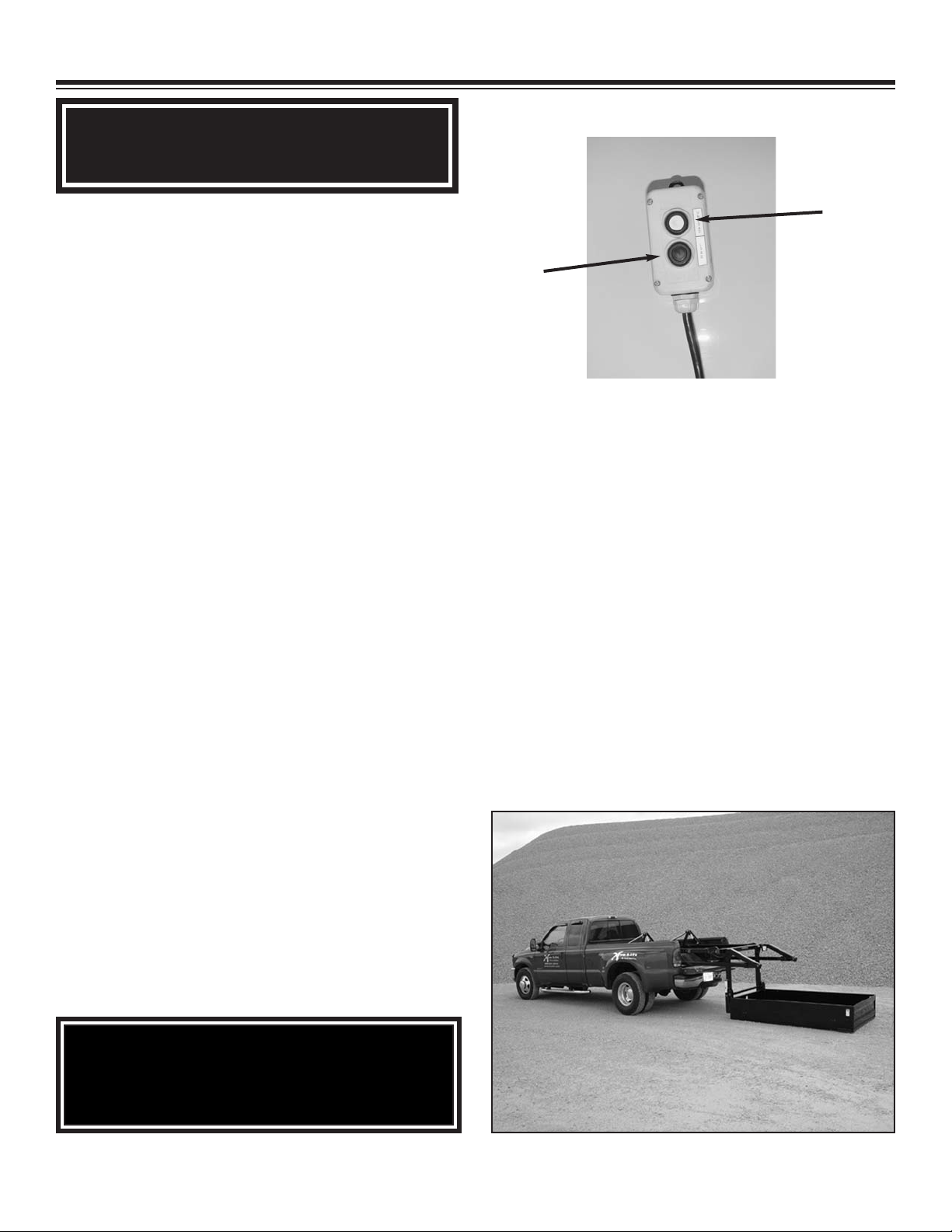

Unload

Load

Control Pendant

PN: 24387

8. Press and hold the “unload” button to cycle the

lift out of the truck. The lift is stable throughout

the load/unload cycle. It can be set on a higher

platform or truck bed safely for loading as long as

the lift is in complete contact with the mated surface. Continue through the “unload” cycle until

you have reached your desired loading surface.

The lift will not travel past its pre-set bottom point

but will stop travel at a designated level. Do not

continue to depress the “unload” button when the

lift “limits out” or makes contact with a solid surface. Release the “unload” button when the lift

makes complete contact with the ground, loading

dock, etc.

5. Check to make sure the area behind the truck

is clear, and free of people, pets or any other

obstructions.

6. Make sure control pendant wire is fully extended and not tangled or wrapped in the structure of

the lift in any way.

7. Make sure the container is free of obstructions,

and is clear to lift from the truck bed.

NOTICE!

Maintain good visual sight lines when

operating the lift.

Be aware of

potential conflicts during operation.

any

Chapter 1 - Operation

& Safety

1-1

Page 6

9. Load your cargo safely. Remember to bind

top-heavy loads with a minimum of two ratchet

straps, suitable chain-binders, or other appropriately rated cargo retention devices. Load heavy

items into the center of the container whenever

possible. It is much safer and will extend the life

of your lift. If the load extends beyond the length

of the container, you must secure it to the container by means of an appropriately rated ratchet-strap or chain binder.

10. To return the container to the truck bed, press

the “load” button on the pendant control. Again,

check to make sure there are no obstructions in

the path of the lift. Once the lift reaches its

stowed position, release the “load” button and

safely stow or remove the control pendant. Never

leave the pendant in a position for others to operate it without your control or consent.

NOTE:

Once the lift is in the stowed position, check

the load and any load binding devices to make

sure they have not shifted or loosened during

the lifting process.

When driving with a loaded container, be

aware that the bulk of the load may obscure

your vision from the cab. Also be aware that

the weight of the load will affect your vehicle’s

stopping distance and center of gravity. Stop

periodically to inspect and/or tighten any load

retaining devices as necessary.

WARNING!

Never use the lift to move people. It

is not designed as a personnel lift

and should never be used in this

manner.

Do not position any load over a person nor should any person be permitted to place hiself or herself under a

load.

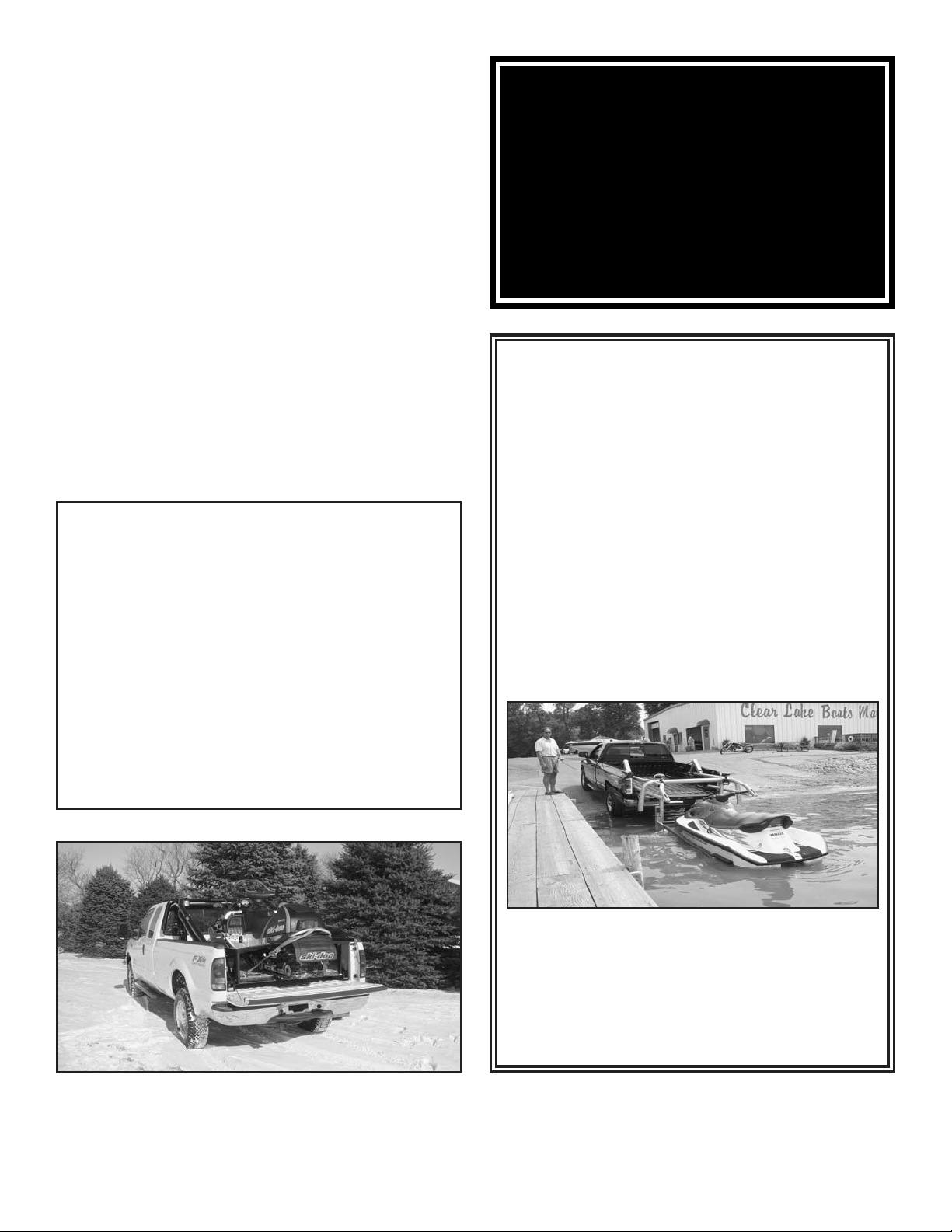

If you desire to load or unload small boats or

personal watercraft, it is permissible to submerge the X-Tra-Lift container in water.

Remember to set your parking brake fully

when using the lift adjacent to a body of

water. The lift and its container may become

slippery when their surfaces are wet. Use

caution during these circumstances to avoid

slips and falls. If you use the lift frequently in

this manner, you may want to attach “no-slip”

tape strips to various places around the lift to

increase wet operation safety. These can be

found at area hardware or building supply

stores.

Secure the load extending out the back

Chapter 1 - Operation

1-2

ra-Lift is submersible

X-T

NOTE: If you are submerging you X-Tra-Lift

and carrier into salt water, Stellar Industries

recommends you thoroughly wash the lift

and carrier after each submersion.

& Safety

Page 7

DETACHING THE CONTAINER:

Electrical Power Line

1. Park the truck on flat, level ground. This is

critical if you desire to remove the container.

2. Set the parking brake.

3. Lower the tailgate.

4. Check for obstructions, both on the ground

and above the lift.

5. Press and hold the “unload” button and cycle

the lift until it makes complete contact with the

ground.

6. Remove the two steel retaining pins (one per

side) at the forward end of the container retention blocks. Keep them in a safe place such as

the console or glove-box of the vehicle.

7. Press the “unload” button briefly until both

retention blocks drop free from the carrier.

Mark exactly where your vehicle is parked. To

reattach your carrier, it is necessary to be at the

correct distance from the carrier to mate the

retention blocks to the container.

8. Release the parking break. Drive ahead a

few inches. Re-depress parking brake fully.

9. Set the parking break.

9. Press “load” button on the control pendant,

until the lift structure, minus the carrier, is in the

fully retracted position.

Precautions

Death or serious injury can occur

when operating near power lines or

during electrical storms.

Allow extra space for swaying powerlines in

windy conditions.

Keep a minimum of ten feet between any portion of the X-Tra-Lift and an electrical line. Add

an additional 12" for every additional 30,000

Volts or less.

WARNING!

Never operate your vehicle unless

the lift is in the sto

with or without the container. The

only exception occurs during step

#8 of Detaching the Container.

Never use the lift for pulling against

fixed or imbedded objects. It is only

for movement of cargo and/or recreational vehicles.

Do not modify or alter the structure of the lift in any way. Limited

changes, additions, or modifications

to the container are acceptable.

(Examples include adding additional

tie-downs, no-slip tape, cycle

chocks, etc.)

wed position,

For further operating instructions, or for questions about operation, please contact your nearest X-Tra-Lift dealer or the manufacturer

Chapter 1 - Operation

1-3

Do not leave the X-Tra-Lift load suspended or unattended.

Do not walk under suspended loads.

.

& Safety

Page 8

Chapter 2 - Maintenance

Do not operate the lift if the fluid level is exces-

It is recommended to inspect and

service the X-Tra-Lift periodically.

Please use the following recommendations to ensure long and

trouble-free service from your XTra-Lift.

INSPECTION

sively low. This will risk introducing air into the

hydraulic system which requires a lengthy bleedout process and potential seal damage.

Inspect the lift structure and frame cross-member

bolts every six months. Re-torque any loose bolts

immediately. If bolts repeatedly require tightening, report this situation to the factory or a factory-approved distributor.

Every six months, inspect the joints and pivot

points of your lift. Be alert for any cracks, rust, or

chipped paint in these areas as they may indicate

structural failure. If cracks are found, take the lift

out of service immediately. This is a high-quality,

well-built product. Such failures are not anticipated, but should be checked for regardless. Also

inspect the carrier at this interval for similar

cracks.

factory-approved distributor immediately and

do not use the lift until repaired.

Inspect hydraulic hoses and fittings monthly for

signs of leakage. If leaks are found, call the factory for replacement hoses and/or appropriate fittings. Hoses are tightened to approximately 45

In-lbs. at the factory. If leaks are present, check

to make sure hoses are tightened to that specification with an appropriate torque wrench. Overtightening will only worsen a hydraulic leak. Do

not over-tighten fittings.

Inspect the fluid level of the hydraulic reservoir

weekly. It should be filled to the recommended

level. Do

approved hydraulic fluid. Stellar recommends

Mobil 13 fluid or equivalent.

Report any failure to the factory or a

not overfill the reservoir. Use only

Inspect all wires and control pendant for signs of

fraying or exposed wiring monthly.

Do not modify or alter the

structure of the lift in any way.

Limited changes, additions or

modifications to the container

are acceptable (Examples

include adding additional tiedowns, no-slip tape, cycle

chocks, etc.).

Chapter 2 - Maintenance

2-1

Page 9

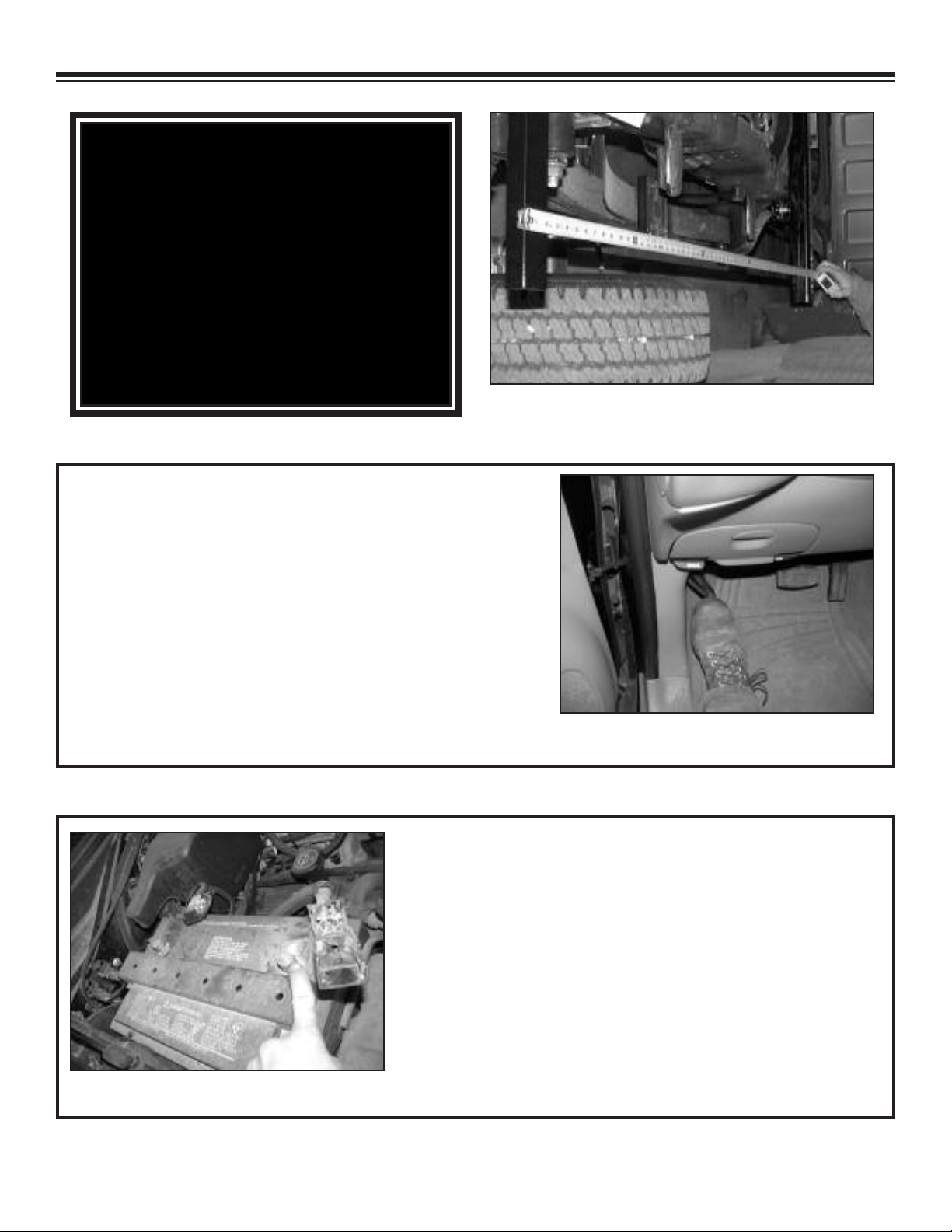

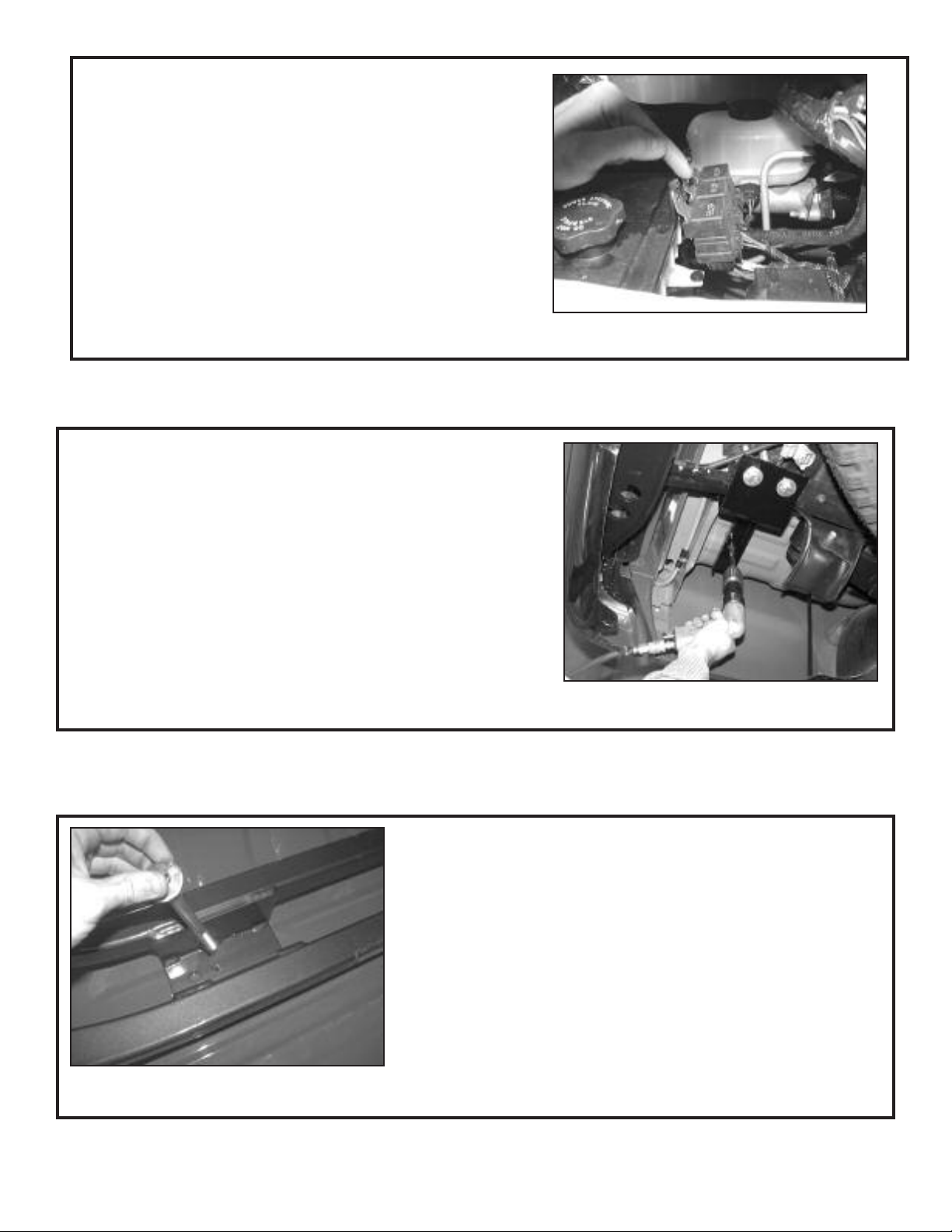

Chapter 3 - Installation

The following section is

set up to provide a basic

guide to the installation of

the X-Tra-Lift system. If

any questions occur during the installation

process, feel free to contact Stellar Customer

Service at 800-321-3741.

Plan the installation carefully.

1. Set parking brake on the truck and chock the wheels.

2. Disconnect the battery.

Parking Brake

Battery

Chapter 3 - Installation

3-1

Page 10

9. Run electrical wiring harnesses.

10. Place lift carefully inside the truck box.

11. Drill holes per mounting kit instructions. See

specific mounting kit diagrams on pages

3-4 (Chevy) and 3-5 (Ford) for details.

Wiring Harnesses

Drill Holes

Mounting Hardware

12. Put mounting hardware in place and tighten.

Chapter 3 - Installation

3-2

Page 11

*NOTE: On Ford F-Series trucks, installation requires partially extending the lift prior to placing

the forward two mount bolts.

14. Cycle the lift several times to insure everything is working properly.

Chapter 3 - Installation

3-3

Page 12

Chevy Mounting Kit

Chapter 3 - Installation

3-4

Page 13

Ford Mounting Kit

Chapter 3 - Installation

3-5

Page 14

The TR2P-PD

Installation and Programming

Instructions

In the picture above there are a series of numbers that will be referenced often in this installation process.

1. In the picture above, terminal #1 on the terminal strip will need to be wired to the positive side of a 12 to

24V DC battery.

2. In the picture above, terminal #2 on the terminal strip will need to be wired to the negative side of a 12 to

24V DC battery.

3. In the picture above, terminal #3 (Normally open output for channel one) on the terminal strip will need to

be wired to the power unit solenoid used for operating the power unit in the “up position.” In most cases,

this solenoid can be located on the solenoid valve block next to the “down position” solenoid. Once finding the solenoid, the connection of the wire is done by splicing the wire from the receiver unit into the wire

coming from the hand-held controller already being used for the “up” function.

4. Terminal #4 (normally open output for channel two) is not used in this procedure.

5. Terminal #5 on the terminal strip is the common input for channel one. This connector should be connected to a 12 to 24 volt positive source. The positive power that feeds the power unit is the preferred choice.

6. In the picture above terminal #6 (normally open output for channel two) on the terminal strip will need to

be wired to the power unit solenoid used for operating the power unit in the “down position.” In most

cases, this solenoid can be located on the solenoid valve bank next to the “up position” solenoid. Once

finding the solenoid, the connection of the wire is done by splicing the wire from the receiver unit to the

wire coming from the hand-held controller already being used for the down function.

7. Terminal #7 (solid state output) is to be connected to the motor solenoid (located on top of the motor in

most cases). The voltage of this output is determined by the voltage on both common terminals (#5 and

#8) and not to exceed 24V DC.

8. Terminal #8 on the terminal strip is the (common input) for channel two, this terminal should be connected

to a 12 to 24 volt positive source. The positive power that feeds the power unit is the preferred choice.

9. Connect the antenna provided to the red connector on the end of the black wire located next to terminal

#8.

10.Check over the unit to make sure it is wired correctly.

11.Take the wireless key chain remote and press button #1 and then button #2 making sure the up and down

positions work. If the unit doesn’t operate properly, it will need to be programmed, look at the provided

information for programming.

Chapter 3 - Installation

3-6

Page 15

Programming Instructions for the TR2P-PD

Mode Switch (one per channel):

Mode switch (one per channel):

Enter Programming Mode:

Learn Transmitter Code:

Clear Memory:

Press mode switch momentarily and release:

LED Indicator (on per channel):

Steady ON:

Press and hold mode switch S1 or S2 for 3

seconds. LED will flash fast.

Within 15 seconds of entering programming

mode press a transmitter button #1 or #2. LED

will flash 1 time when the button has been programmed. Do this for both buttons #1 to S1

and #2 to S2.

After entering programming mode, again press

and hold the switch for 3 seconds. LED will

flash twice to indicate memory clear.

The LED will flash the number of remotes that

have been programmed to that channel.

RF reception (receiver is receiving RF signal

from coded transmitter -- great for trouble

shooting).

Fast Flash:

One Flash:

Two Flashes:

In programming mode.

A transmitter code is programmed.

All programmed codes are cleared.

Notes to remember:

1. Terminals #1 and #2 have to be wired directly to the battery, or through a safety switch directly to

the battery. Do not wire terminals #1 and #2 into the power on the power unit itself.

2. Best location for the receiver unit is close to the battery under the hood.

3. Antenna needs to be outside of metal ground plane, i.e. not under the hood; outside in the open

is the best. Antenna needs to be at least on foot away from a power unit motor.

Chapter 3 - Installation

3-7

Page 16

Chapter 4 - Wiring and Hydraulic Controls

Chapter 4 - Wiring & Hydraulic Controls

4-1

Page 17

Hydraulic Controls

37143

Chapter 4 - Wiring & Hydraulic Controls

4-2

Page 18

Chapter 5 - Safety Decals

These decals are placed at various points on the X-Tra-Lift. Please read and follow all of them.

Replace decals if they are missing or illegible.

Chapter 5 - Safety Decals

5-1

Page 19

Decal Placement Drawing 1

Chapter 5 - Safety Decals

5-2

Page 20

Decal Placement Drawing 2

Chapter 5 - Safety Decals

5-3

Page 21

Chapter 6 - Assembly Drawings

Base Assembly

Chapter 6 - Assembly Drawings

6-1

Page 22

Link & Cylinder Assembly

Chapter 6 - Assembly Drawings

6-2

Page 23

Front Arm Assembly

Chapter 6 - Assembly Drawings

6-3

Page 24

Rear Arm Assembly

Chapter 6 - Assembly Drawings

6-4

Page 25

Lift Frame Assembly

Chapter 6 - Assembly Drawings

6-5

Page 26

Chapter 7 - Options

Appliance Container

Note: Capacity is de-rated to

1200 lbs with this container.

Chapter 7 - Options

7-1

Page 27

Steel Deck

Chapter 7 - Options

7-2

Page 28

Personal Water Craft Carrier

Chapter 7 - Options

7-3

Page 29

Casters Kit

Chapter 7 - Options

7-4

Page 30

Additional Options

Wireless Remote ControlVarious Light Configurations

Motorcycle Wheel Chock

Chapter 7 - Options

7-5

Page 31

Chapter 8 - Troubleshooting

This chapter will list a number of

possible problems that may occur

while operating the X-Tra-Lift Pro.

Most problems are easily solved

using the solutions portion of this

chapter. If problems persist,

please contact Customer Service

at Stellar Industries 1-800-321-3741

Problem: X-Tra-Lift will not operate.

Solutions:

• Make sure that the parking break is fully

engaged.

• Check for poor safety switch grounds or loose

ground connections. Thoroughly clean ground

connections and reattach.

Problem: X-Tra-Lift power unit operates, but

will not lift the rated load.

Solutions:

• Check the hydraulic fluid level. Add fluid if

necessary.

• Make sure that the pressure relief valve is

functioning properly. If it is faulty, call Stellar

Customer Service.

• Check the shaft and coupler between the

electric motor and hydraulic pump. If one has

broken, simply replace it.

• Make sure that the weight is evenly distributed across the carrier. Redistribute as necessary.

Problem: X-Tra-Lift cylinder drifts.

• Check to see if the electrical connections on

the battery or power unit are loose or corroded.

Clean corroded areas and tighten any loose

connections.

• Make sure that the tailgate is lowered.

• If the tailgate is lowered and the X-T

won’t operate, check the safety switch to make

sure it is functioning. If the switch is faulty,

simply replace it.

• Make sure the battery in the radio remote is

charged.

Problem: Brake light on lift is not illuminating.

Solutions:

• Check the bulb. If it is burned out, simply

replace it.

ra-Lift still

Solutions:

• Make sure the holding valves are operating

properly. If they are not, contact Stellar

Customer Service

• Check for bad or worn out cylinder piston

seals. Replace faulty seals with a seal kit.

• Check for scratches or dents inside the cylinder case wall. If such defects are found, simply replace the cylinder.

For problems not cov-

ered in this section,

please contact

Customer Service at

Stellar Industries

• Check for loose or broken wires.

replace wires as necessary.

Tighten or

Chapter 8 - Troubleshooting

1-800-321-3741

8-1

Page 32

Limited Warranty Statement

®®

Stellar Industries, Inc. (Stellar) warrants products designed and manufactured by Stellar to be free from defects in material and workmanship

under proper use and maintenance. Products must be installed and operated in accordance with Stellar’s written instructions and capacities. The

warranty period shall cover the following:

Twelve (12) month warranty on parts from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) months from

date of manufacture,

Twelve (12) month repair labor from the date recorded by Stellar as the in-service date, not to extend beyond twenty-four (24) month from date of

manufacture, and

Thirty-six (36) month warranty on all Stellar Crane and Hooklift structural parts from the date recorded by Stellar as the in-service date, not to

extend beyond forty-eight (48) months from date of manufacture.

The in-service date will be derived from the completed warranty registration card. In the event a warranty registration card is not received by

Stellar, the factory ship date will be used.

Stellar’s obligation under this warranty is limited to, and the sole remedy for any such defect shall be, the repair and/or replacement (at Stellar’s

option) of the unaltered part and/or component in question. Stellar after-sales service personnel must be notified by telephone, fax, or letter of

any warranty-applicable damage within fourteen (14) days of its occurrence. If at all possible, Stellar will ship the replacement part within 24hours of notification by the most economical, yet expedient, means possible. Expedited freight delivery will be at the expense of the owner.

Warranty claims must be submitted and shall be processed in accordance with Stellar’s established warranty claim procedure. Stellar after-sales

service personnel must be contacted prior to any warranty claim. A return materials authorization (RMA) account number must be issued to the

claiming party prior to the return of any warranty parts. Parts returned without prior authorization will not be recognized for warranty consideration.

All damaged parts must be returned to Stellar freight prepaid; freight collect returns will be refused. Freight reimbursement of returned parts will

be considered as part of the warranty claim.

Warranty service will be performed by any Stellar new equipment distributor, or by any Stellar-recognized service center authorized to service the

type of product involved, or by the Stellar factory in the event of a direct sale. At the time of requesting warranty service, the owner must present

evidence of date of delivery of the product. The owner shall be obligated to pay for any overtime labor requested of the servicing company by the

owner, any field service call charges, and any towing and/or transportation charges associated with moving the equipment to the designated

repair/service provider.

All obligations of Stellar and its authorized dealers and service providers shall be voided if someone other than an authorized Stellar dealer

provides other than routine maintenance service without prior written approval from Stellar. In the case repair work is performed on a Stellarmanufactured product, original Stellar parts must be used to keep the warranty in force. The warranty may also be voided if the product is

modified or altered in any way not approved, in writing, by Stellar.

The owner/operator is responsible for furnishing proof of the date of original purchase of the Stellar product in question. Warranty registration is

the ultimate responsibility of the owner and may be accomplished by the completion and return of the Stellar product registration card provided

with the product. If the owner is not sure of registration, he is encouraged to contact Stellar at the address below to confirm registration of the

product in question. This warranty covers only defective material and workmanship. It does not cover depreciation or damage caused by normal

wear and tear, accident, mishap, untrained operators, or improper or unintended use. The owner has the obligation of performing routine care

and maintenance duties as stated in Stellar’s written instructions, recommendations, and specifications. Any damage resulting from

owner/operator failure to perform such duties shall void the coverage of this warranty. The owner will pay the cost of labor and supplies

associated with routine maintenance.

The only remedies the owner has in connection with the breach or performance of any warranty on the Stellar product specified are those set

above. In no event will Stellar, the Stellar distributor/dealer, or any company affiliated with Stellar be liable for business interruptions, costs of

delay, or for any special, indirect, incidental, or consequential costs or damages. Such costs may include, but are not limited to, loss of time, loss

of revenue, loss of use, wages, salaries, commissions, lodging, meals, towing, hydraulic fluid, or any other incidental cost.

All products purchased by Stellar from outside vendors shall be covered by the warranty offered by that respective manufacturer only. Stellar

does not participate in, or obligate itself to, any such warranty.

Stellar reserves the right to make changes in design or improvement upon its products without imposing upon itself the same upon its products

theretofore manufactured.

This warranty will apply to all Stellar Hooklifts, Stellar Service Trucks, & Truck-mounted Cranes shipped from Stellar’s factory after July 1, 2005.

The warranty is for the use of the original owner only and is not transferable without prior written permission from Stellar.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. REMEDIES UNDER THIS WARRANTY ARE LIMITED TO THE

PROVISION OF MATERIAL AND SERVICES, AS SPECIFIED HEREIN. STELLAR INDUSTRIES, INC. IS NOT RESPONSIBLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Revision Date: February 2007 Document Number: 37040

Loading...

Loading...